Patents

Literature

760 results about "Chlorinated polyvinyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin, which is significantly more flexible and can withstand higher temperatures than standard PVC. Uses include hot and cold water delivery pipes and industrial liquid handling. CPVC, as PVC, is deemed safe for the transport and use of potable water, potable meaning water used for drinking, cooking, and bathing.

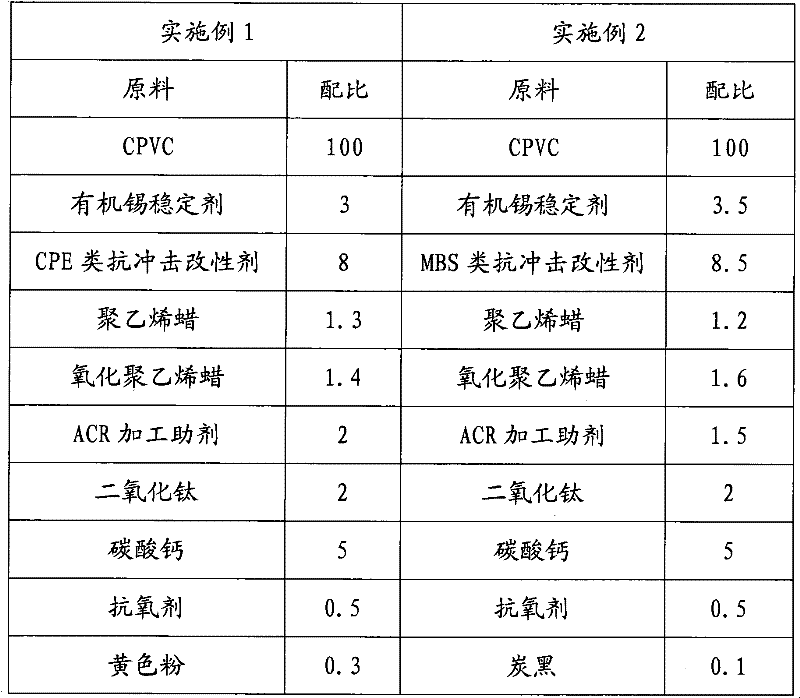

Chlorinated polrvinyl chloride modified material as well as preparation method and application thereof

ActiveCN102532763AGood physical and mechanical propertiesImprove brittlenessInsulated cablesInsulated conductorsAntioxidantShock resistance

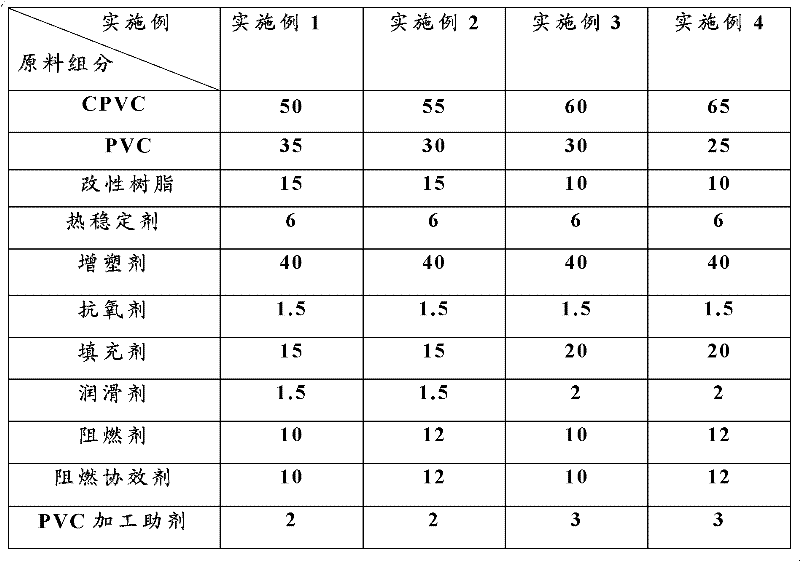

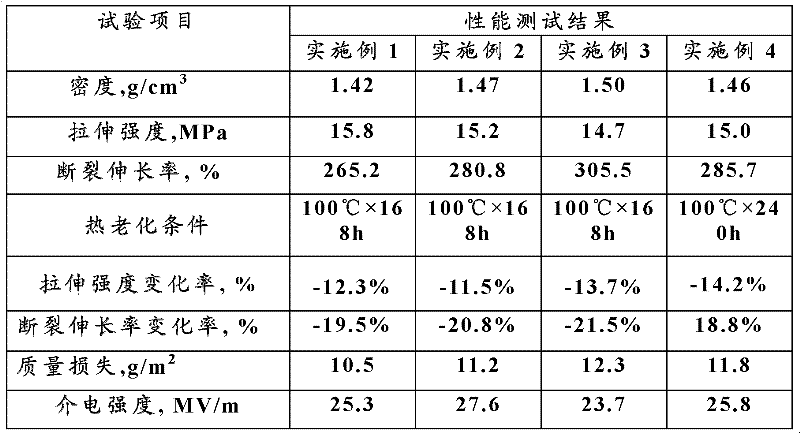

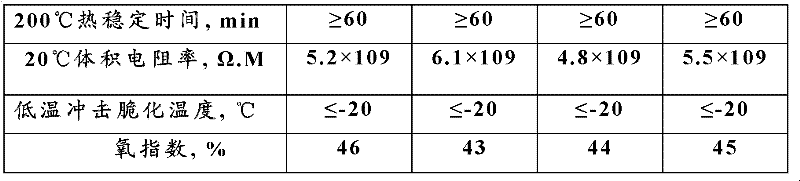

The invention relates to a chlorinated polrvinyl chloride modified material as well as a preparation method and application thereof. The raw material formula of the chlorinated polrvinyl chloride modified material comprises the following components in parts by weight: 40-90 parts of chlorinated polrvinyl chloride, 20-70 parts of polrvinyl chloride, 5-30 parts of modified resin, 1.5-10 parts of heat stabilizing agent, 20-60 parts of plasticizer, 1-10 parts of antioxidant, 1-10 parts of lubricating agent, 5-40 parts of filling agent, 8-40 parts of fire retardant, 8-40 parts of flame retardant synergist and 1-20 parts of polrvinyl chloride processing aid. Compared with the known CPVC (chlorinated polrvinyl chloride) modified plastic, the CPVC modified plastic disclosed by the invention is more excellent in physical and mechanical properties and is relatively reduced in cost; and compared with the known CPVC modified plastic, the CPVC modified material disclosed by the invention is obviously improved in heat resistance and flame retardant property (oxygen index can reach about 45%, and simple root of CPVC modified material can be vertically burnt) besides more excellent processabilityand obviously improved material brittleness and shock resistance. Thus, the CPVC modified material disclosed by the invention is suitable for being used as a wire and cable sheath material.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes

ActiveCN102134360ADoes not show brittlenessExcellent low temperature toughnessRigid pipesPolymer scienceChlorinated polyvinyl chloride

The invention discloses a preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes, which is characterized in that the tubes are made by the following steps: 75 to 100 portions of chlorinated polyvinyl chloride resin, 0 to 25 portions of vinyl chloride resin, 3 to 10 portions of ABS, 1 to 8 portions of acrylic acid resin, 3 to 8 portions of bismaleimides, 1 to 5 portions of plasticizing accelerator, 1 to 5 portions of compatibilizer, 10 to 25 portions of engineering plastics, 1 to 3 portions of lubricant, 1 to 5 portions of nanometer materials, 4 to 8 portions of stabilizing agent, 2 to 15 portions of filler, 0 to 1 portion of cross-linking agent, 1 to 5 portions of processing modifier and 3 to 10 portions of impact modifier are mixed and blended according to weight proportion, and then extruded by a mould. Compared with the prior art, the super-strong high temperature-resistant chlorinated polyvinyl chloride tubes has the advantages of being high in vicat softening point, being capable of meeting the high-temperature requirement of more than 120 DEG C, and having good anti-aging performance, antiflaming and insulation performance, and compression resistance, and long service life.

Owner:SHANGHAI YUANZHOU PIPE

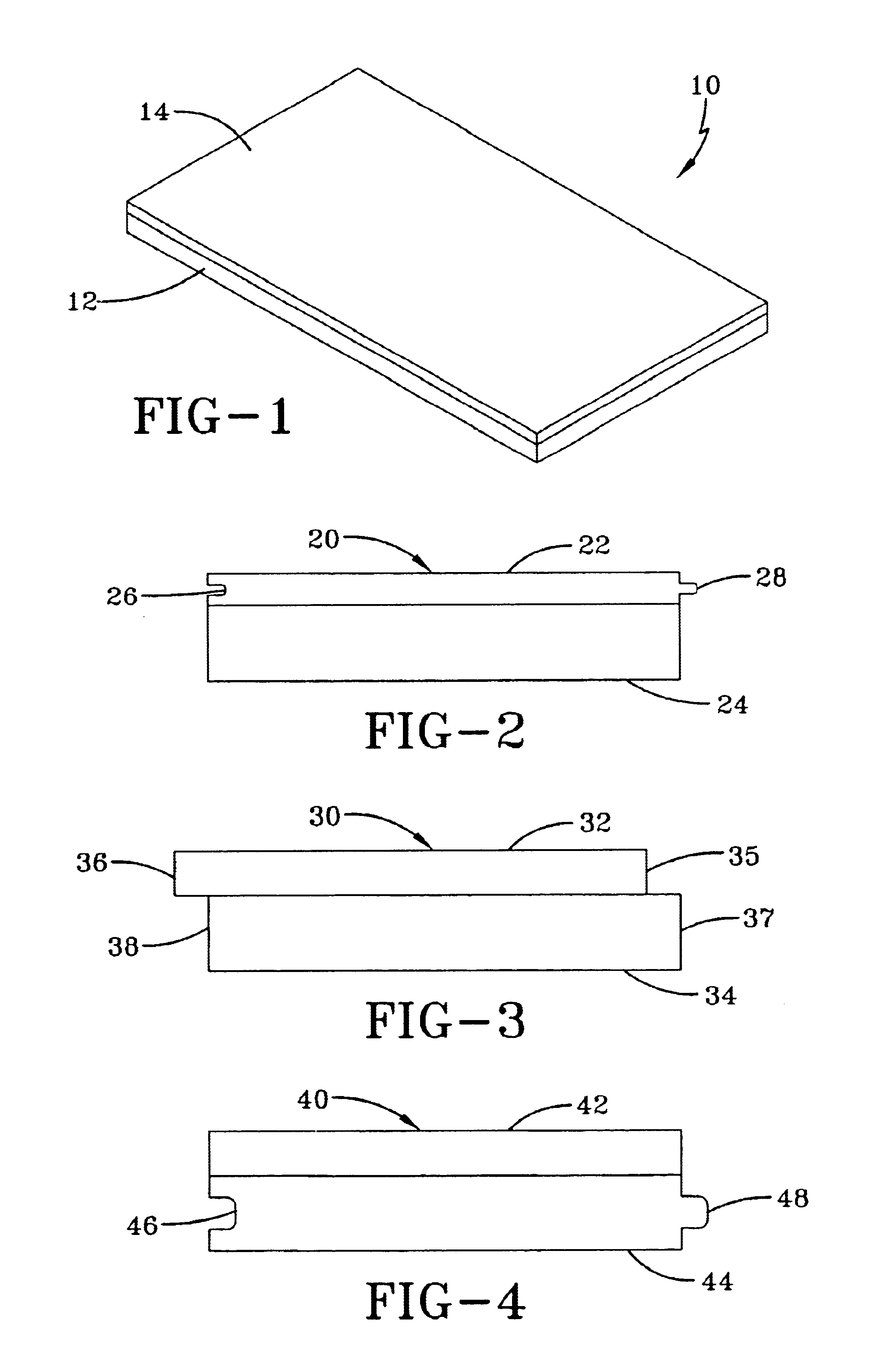

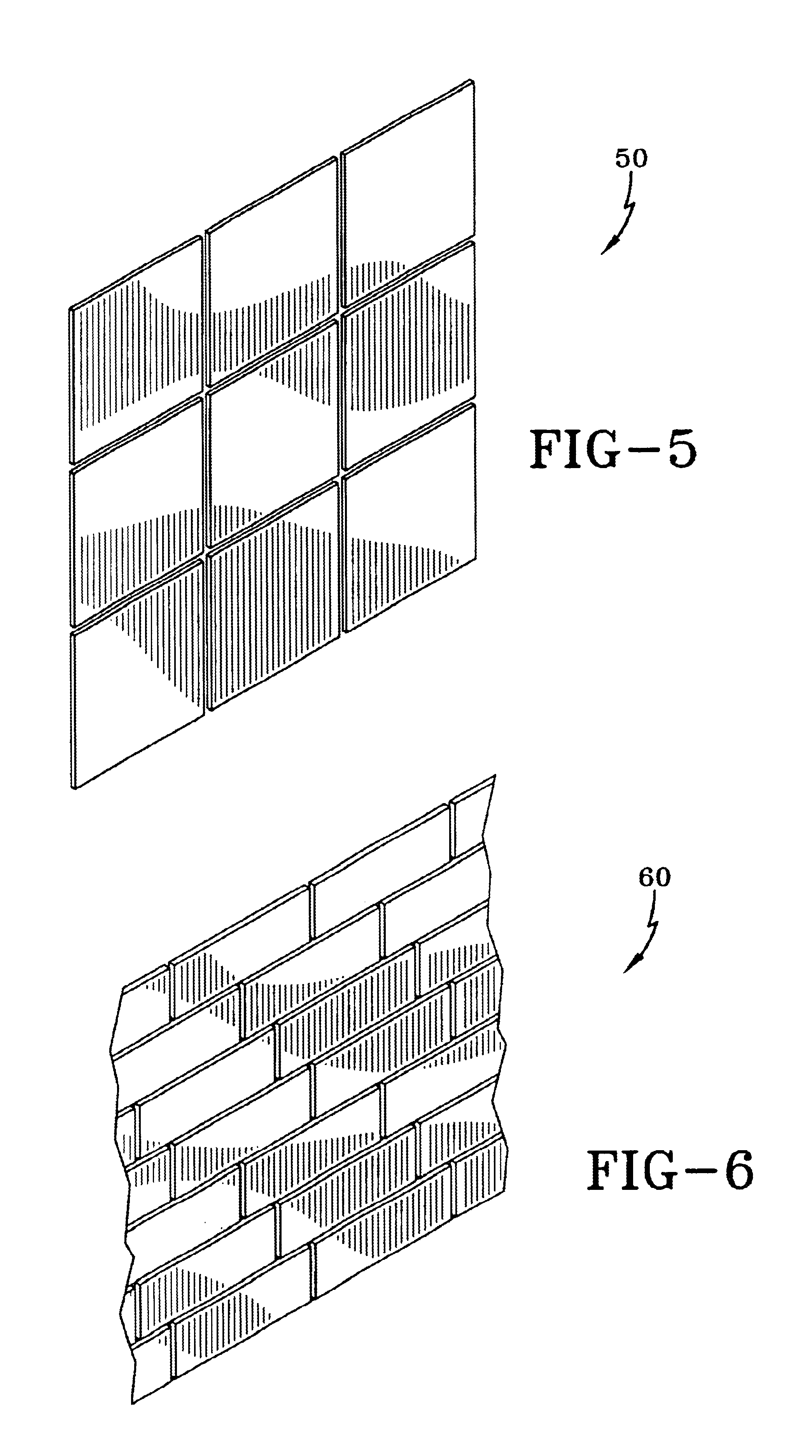

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

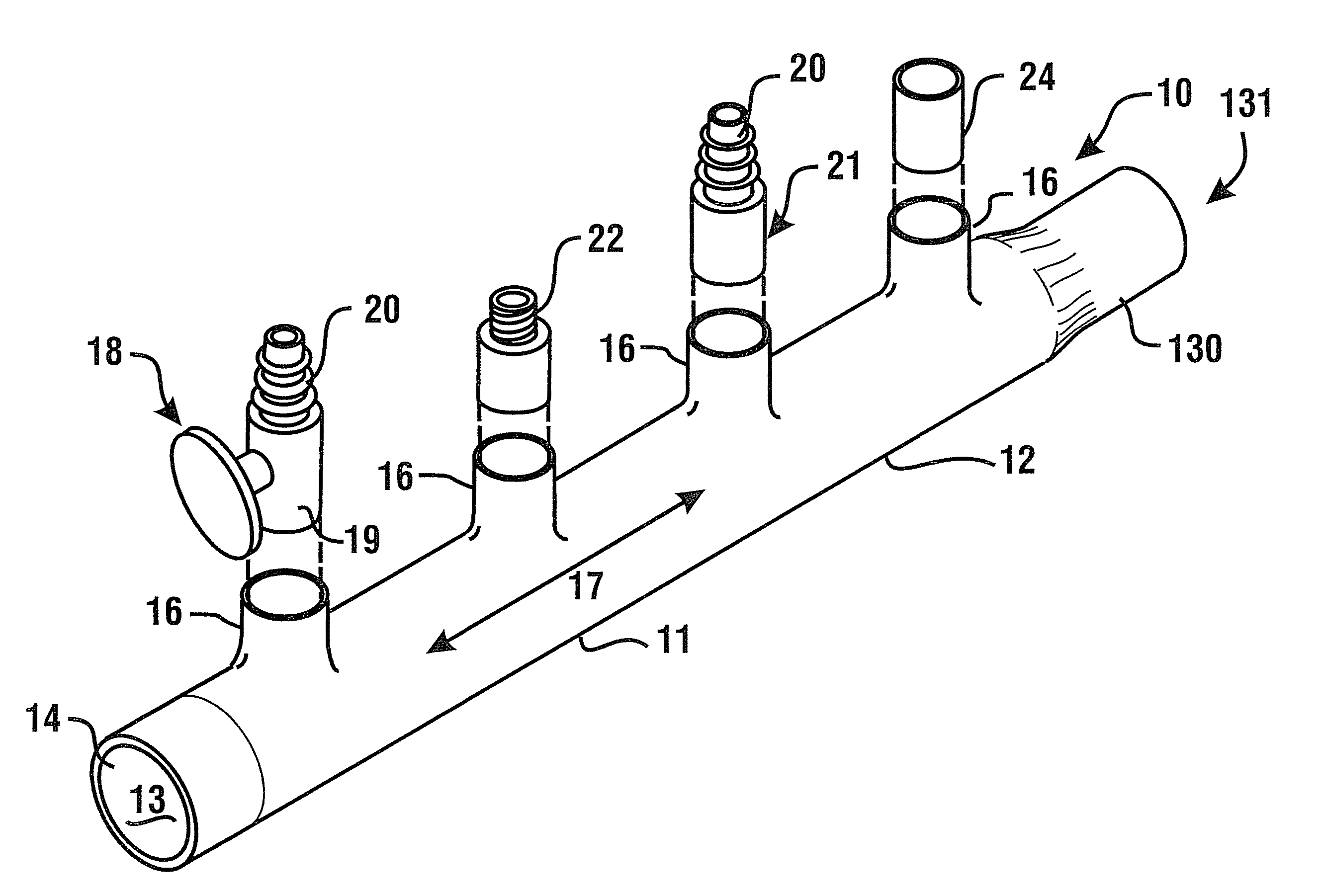

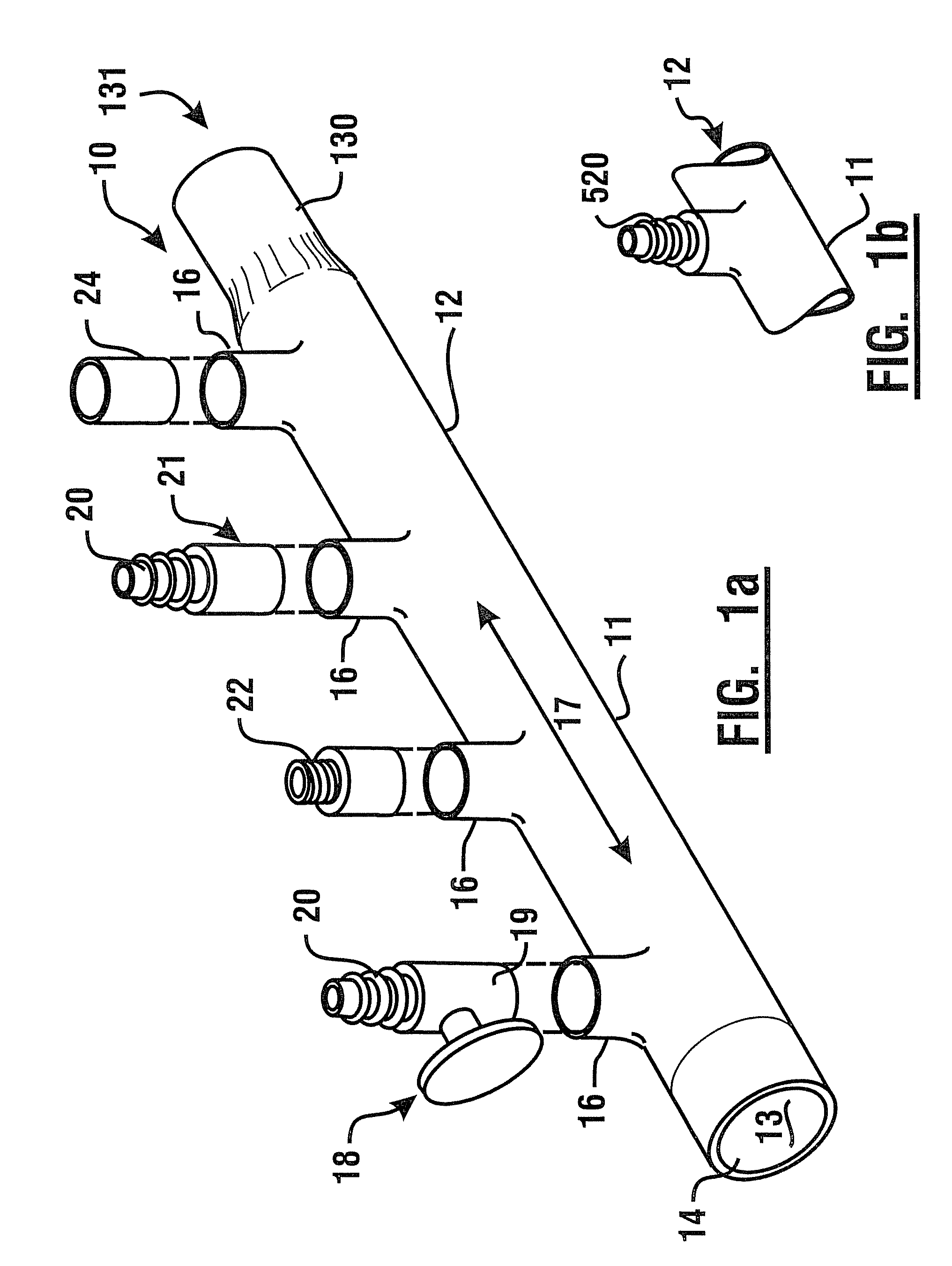

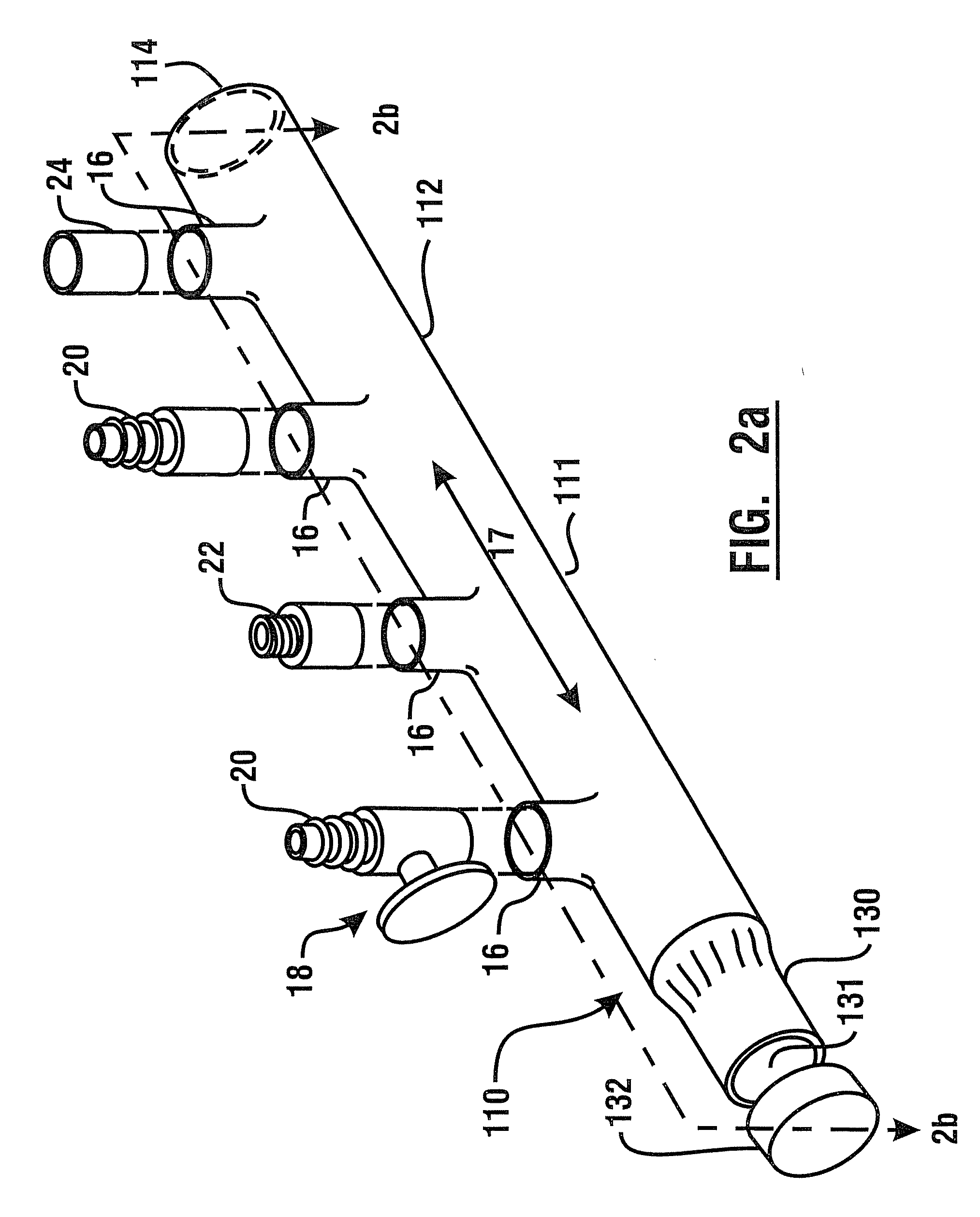

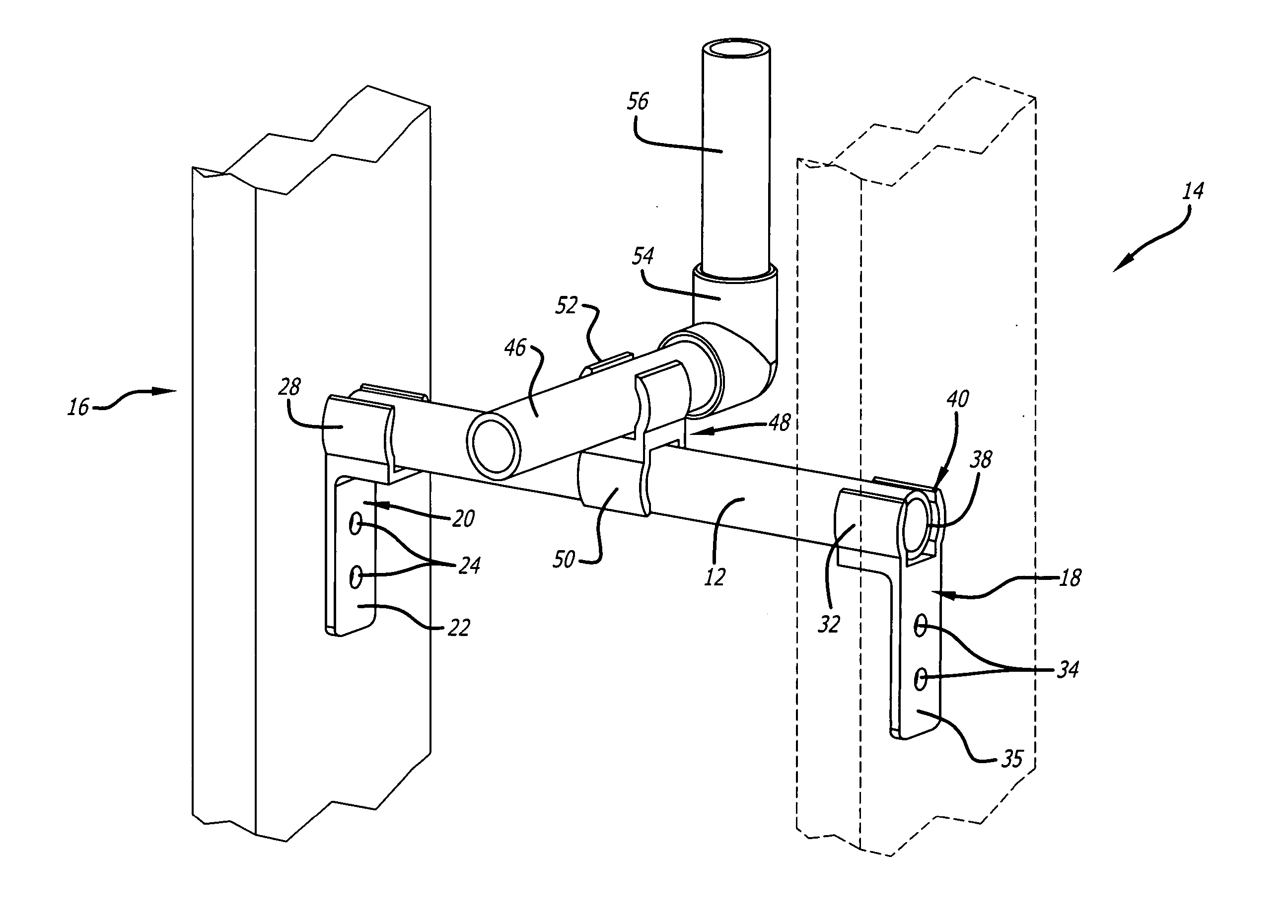

Water Manifold System And Method

InactiveUS20080276998A1Easily in buildingImprove scalabilityLighting and heating apparatusDomestic plumbingChlorinated polyvinyl chlorideEngineering

A system for distributing water within a building operates to distribute water from a pressurized water supply source to devices that receive water, such as faucets, toilets, showers, sprinklers, and hot water heating devices. The system includes at least one manifold which may be of unitary molded plastic construction and comprised of chlorinated polyvinyl chloride (CPVC). The manifold includes an entry port and a plurality of outlet ports which are also referred to as sockets. The sockets are configured to receive fitting inserts of various types that include water line connectors. The sockets are also configured to accept standard plastic water conduits therein in cemented relation. The water line connectors may include metallic connectors such as barbed fittings, which can be used to connect the manifold and crosslinked polyethylene (PEX) pipe in nonthreaded relation. Manifolds may be connected together to provide suitable distribution arrangements.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Heat-resistant wear-resistant PVC pipe

ActiveCN101696306AHigh strengthHigh corrosion resistance propertiesRigid pipesChlorinated polyvinyl chlorideWear resistant

The invention relates to a heat-resistant wear-resistant PVC pipe, which is characterized in that the PVC pipe comprises chlorinated polyvinyl chloride resin (CPVC). The invention makes full use of the principle that CPVC has the same chemical polarity with PVC resin and adds the CPVC to the PVC resin, utilizes the characteristics of the CPVC in high temperature resistance and wear resistance on the one hand, and utilizes the characteristics of the PVC resin in easy processing, low price and high pipe pressure-bearing capability so as to produce the heat-resistant wear-resistant PVC pipe low in price.

Owner:宁夏青龙塑料管材有限公司

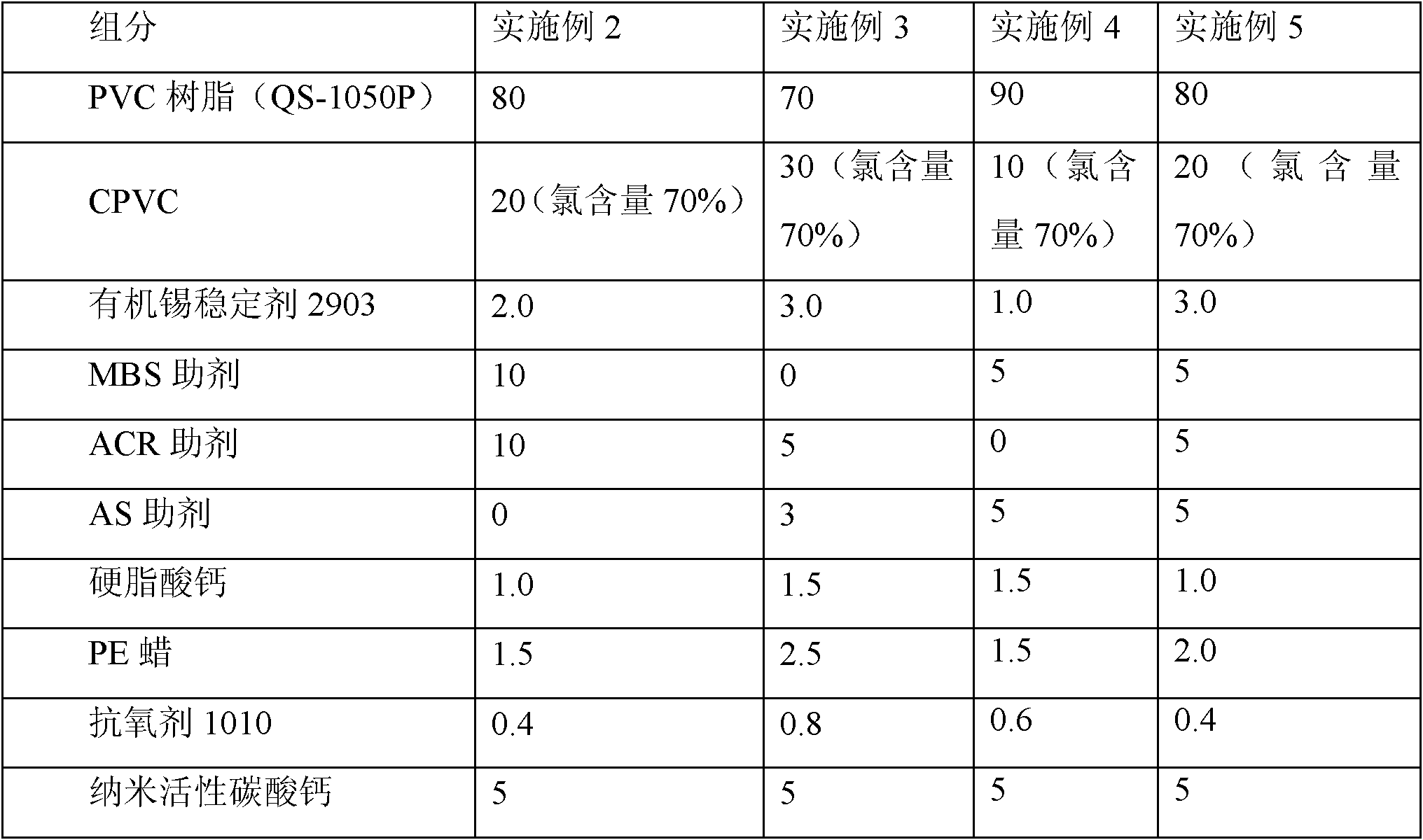

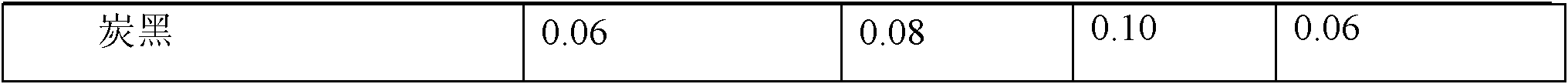

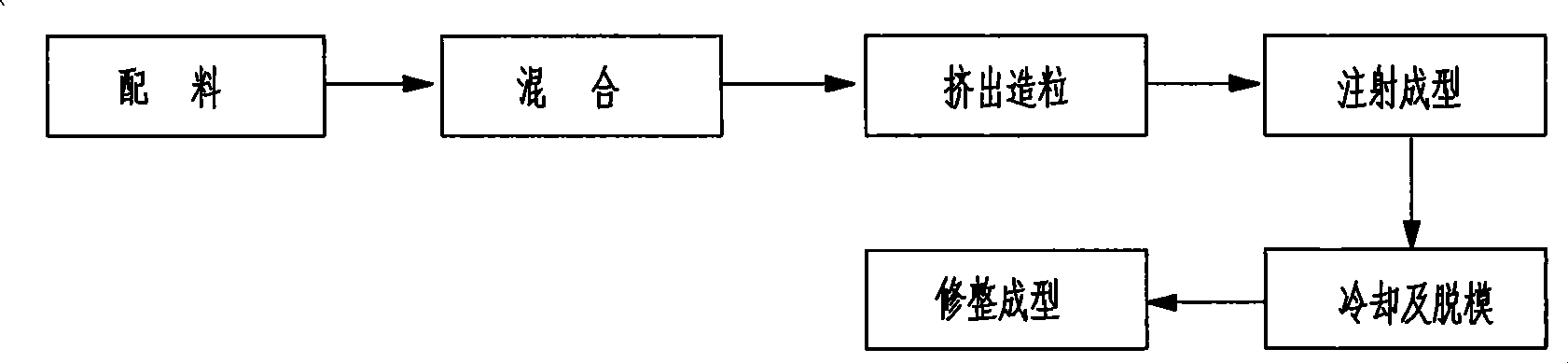

Heat-resisting PVC high impact-resisting tubular product and preparation method thereof

ActiveCN102863711AHigh impact resistanceRaise the Vicat softening temperatureRigid pipesChlorinated polyvinyl chlorideAntioxidant

The invention discloses a heat-resisting PVC high impact-resisting tubular product and a preparation method thereof, belonging to the field of polymer materials. The tubular product disclosed herein comprises the following ingredients: 70-90 weight parts of PVC resin, 10-30 weight parts of chlorinated polyvinyl chloride (CPVC), 1-3 weight parts of stabilizer, 8-20 weight parts of impact modifier, 1.5-4.0 weight parts of lubricant, 0.2-0.8 weight parts of antioxidant, 0.01-0.10 weight parts of coloring agent, and 1-5 weight parts of filler. According to the invention, by using the heat-resisting modified resin CPVC and the heat-resisting impact modifier, the tubular product disclosed herein is guaranteed to have high impact resistance and simultaneously have high vicat softening temperature; and by using the two-step method of firstly granulation and then extrusion molding, the extrusion speed of the tubular product is greatly raised, the raise of the production efficiency is benefited, and the production cost is low.

Owner:CHINA PETROLEUM & CHEM CORP

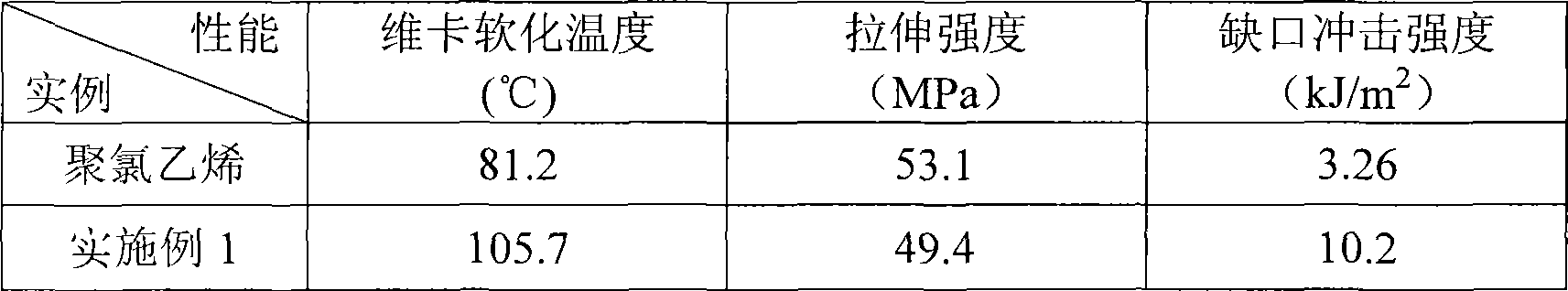

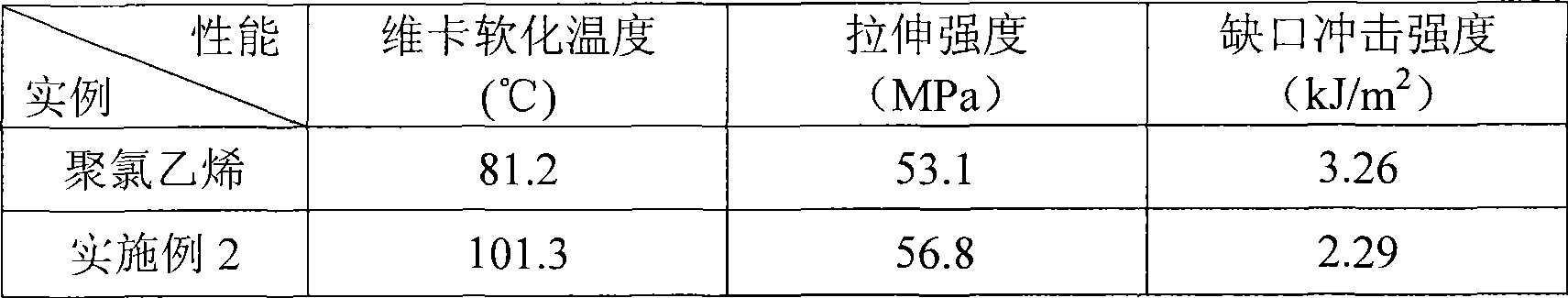

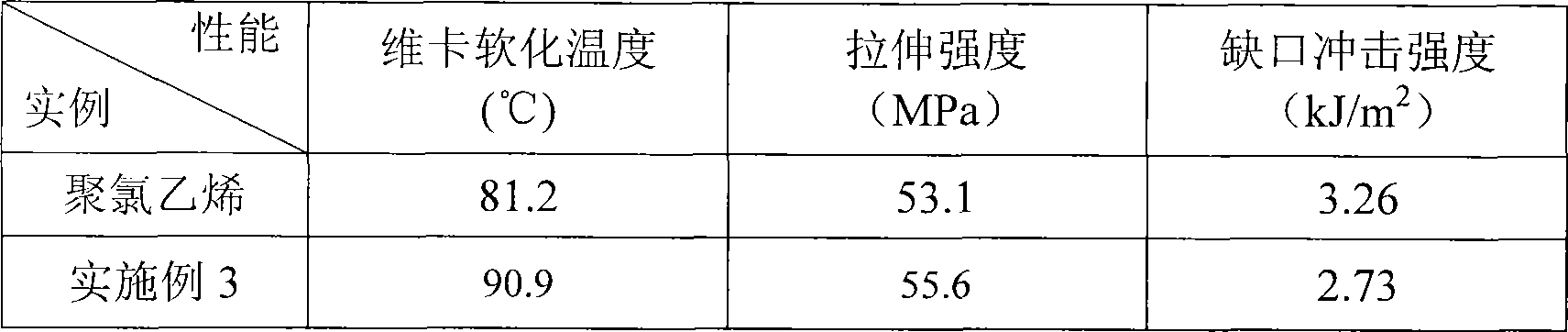

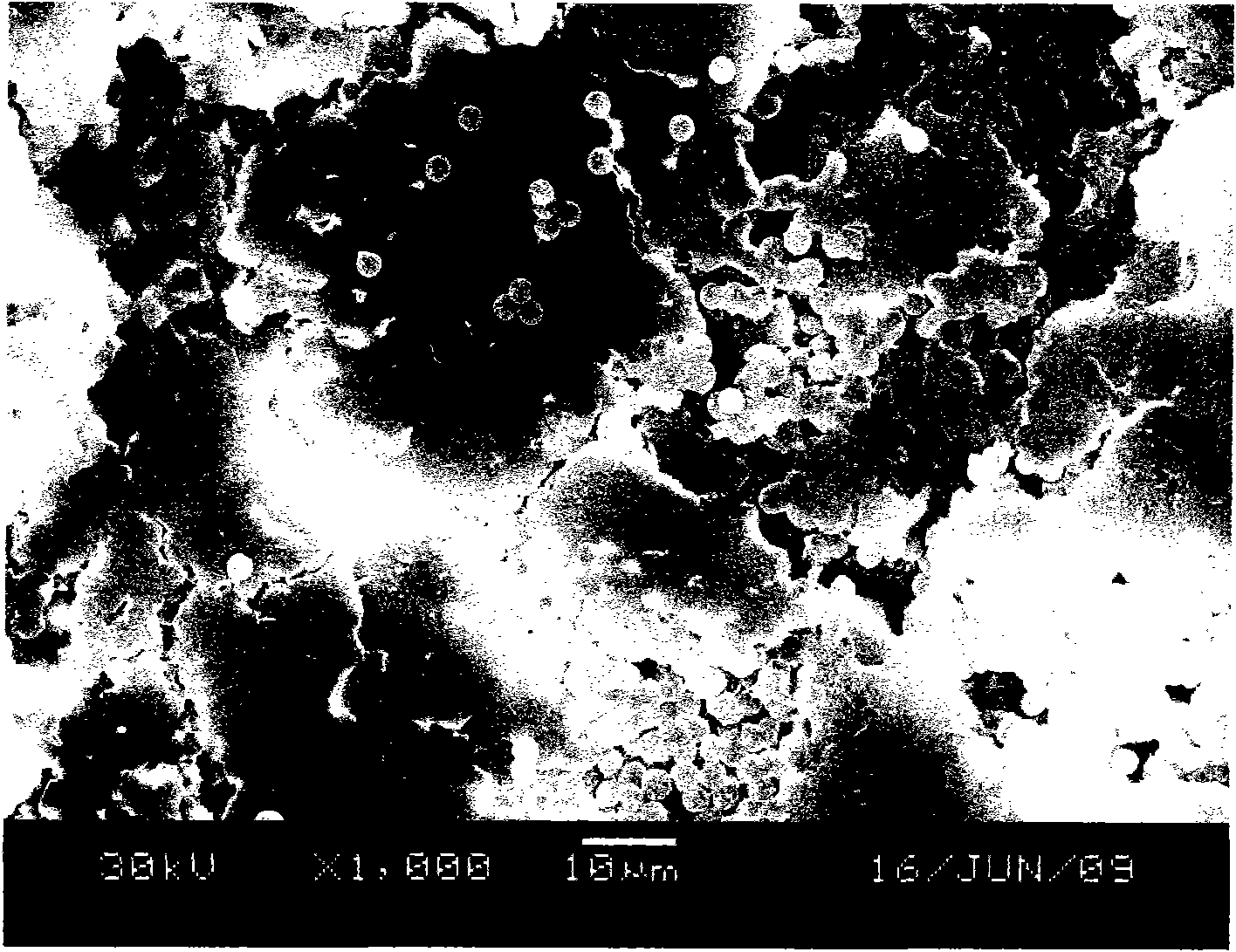

Heat-resistant polyvinyl chloride alloy material and preparation method thereof

The invention provides a heat-resistant polyvinyl chloride alloy material and a preparation method thereof. The alloy material mainly comprises the components of a polyvinyl chloride matrix, a heat-resistant modifying agent, a thermal stabilizer, a lubricating agent, a filler, a shock-resistant modifying agent and a processing agent. The components of the processing agent and the filler in the invention are the processing agent modified by a new method and the organically processed filler, and self plasticisation, toughening and reinforcement of PVC are organically combined by a mechanical chemical reaction, so as to improve the compatibility between the polyvinyl chloride and a heat-resistant resin, to solve the conflict among the increment of heat-resistant quality, the working quality, the strength and the ductility of the polyvinyl chloride, to overcome the problems that the polyvinyl chloride has a low heat-resistant temperature and the working quality of the polyvinyl chloride is poor even though the heat-resistant temperature of the polyvinyl chloride is high, and to prepare the polyvinyl chloride engineering plastic with high heat resistance, high strength, high ductility and excellent working quality. The preparation method of the heat-resistant polyvinyl chloride alloy material in the invention has simple technology, stable quality and high production efficiency, and is easily operated and controlled.

Owner:SICHUAN UNIV

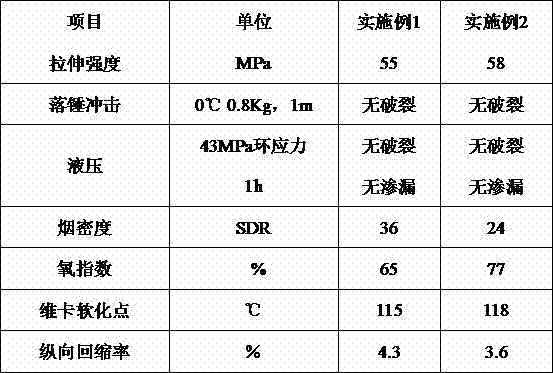

High-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material and preparation method thereof

The invention relates to a high-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material which comprises the following raw materials in weight parts: 100 parts of chlorinated polyvinyl chloride, 1-50 parts of impact modifier, 1.5-10 parts of thermal stabilizer, 0.1-10 parts of lubricant, 0.5-15 parts of PVC processing aid, 0.1-0.5 part of antioxidant and 0-40 parts of filler. The invention solves the problems of low heat resistance and aging resistance while improving the tenacity of CPVC in the prior art; and the Vicat softening point can vary within the range of 104 to 119 DEG C, the tensile strength can reach 45-64 MPa, and the notch impact strength can be increased by more than 200 percent.

Owner:LIAOCHENG UNIV

Acrylic copolymer for use in highly filled composites

ActiveUS20090111915A1Film/foil adhesivesConductive materialChlorinated polyvinyl chloridePolymer chemistry

The invention relates to an acrylic copolymer additive useful as a process aid in highly filled polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) composites. The acrylic additive is especially useful in highly filled PVC flooring tiles, rolled flooring, pipe and siding. The acrylic copolymer additive contains from 50 to 79 weight percent of methyl methacrylate monomer units, and has a Tg of less than 90° C.

Owner:ARKEMA INC

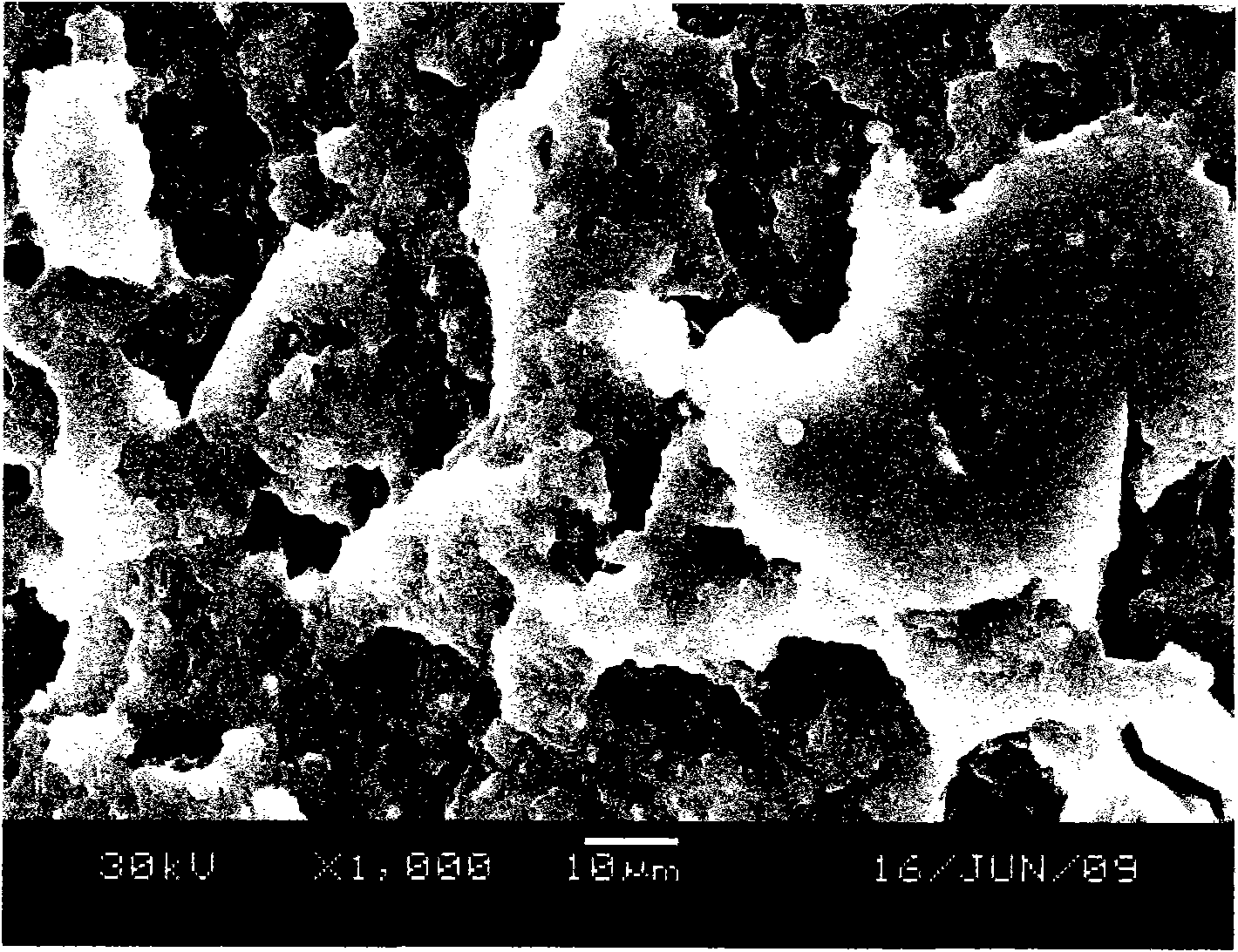

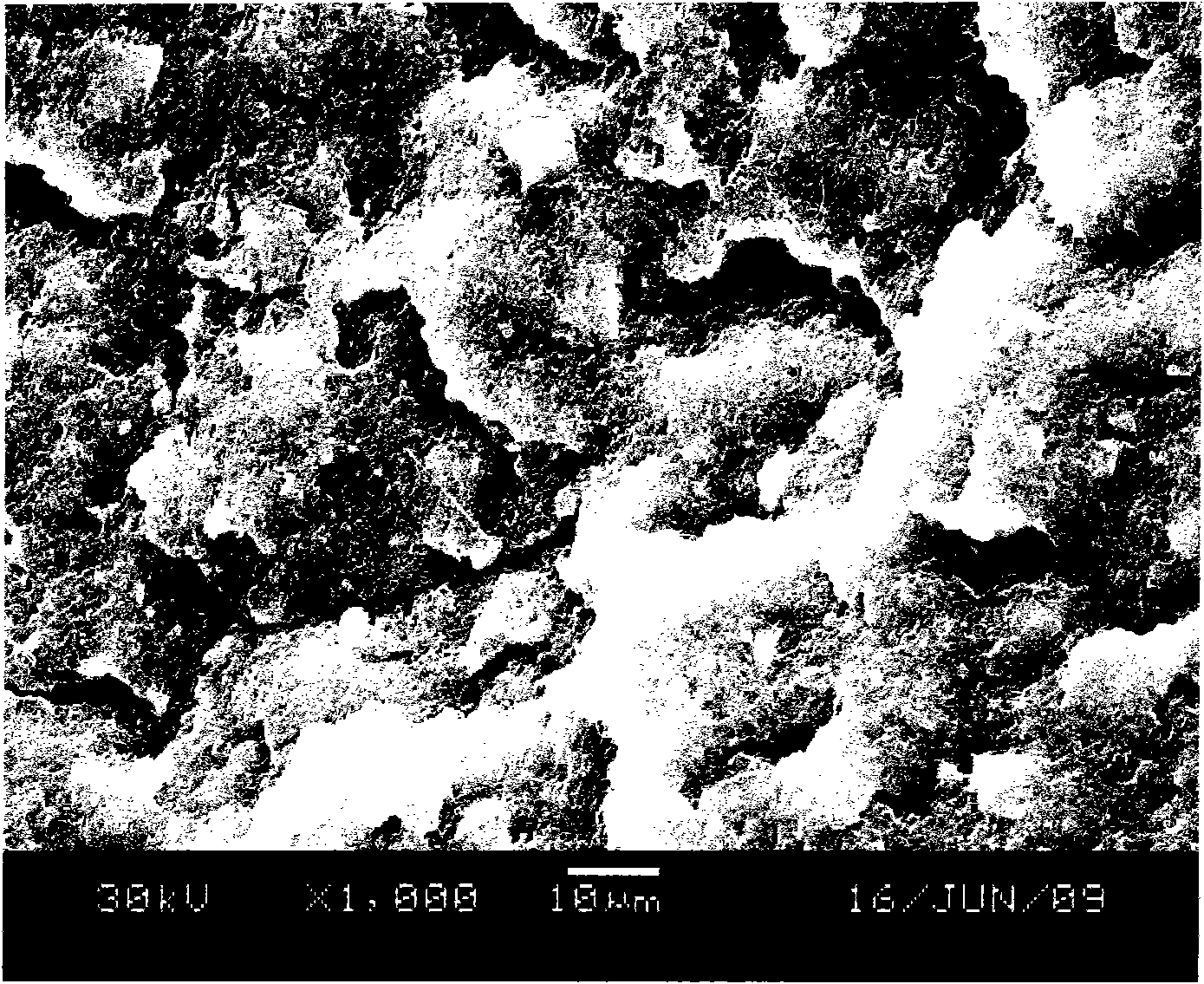

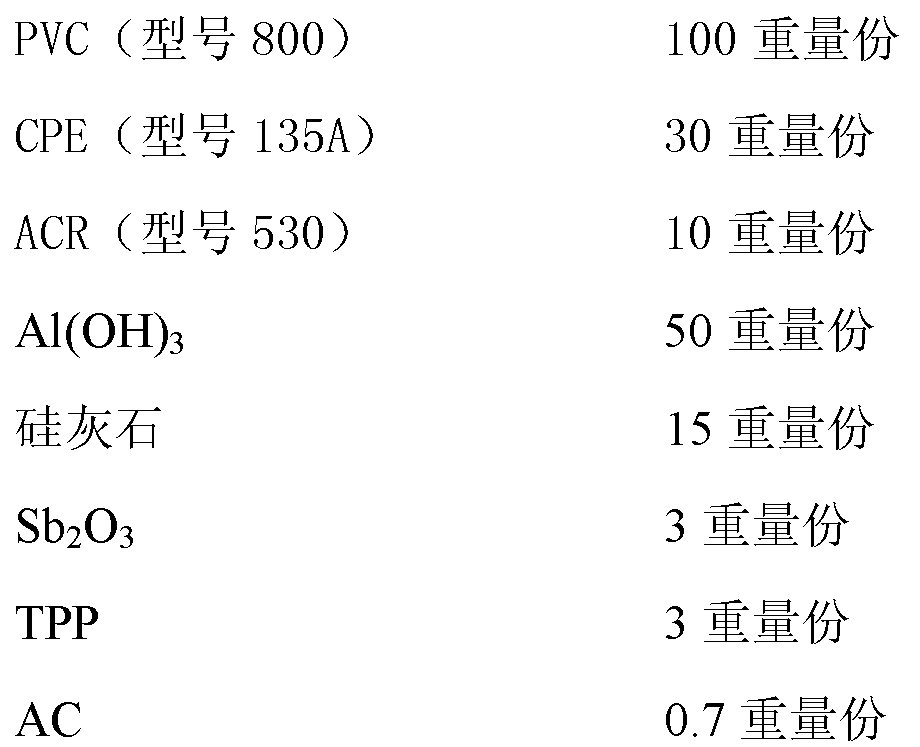

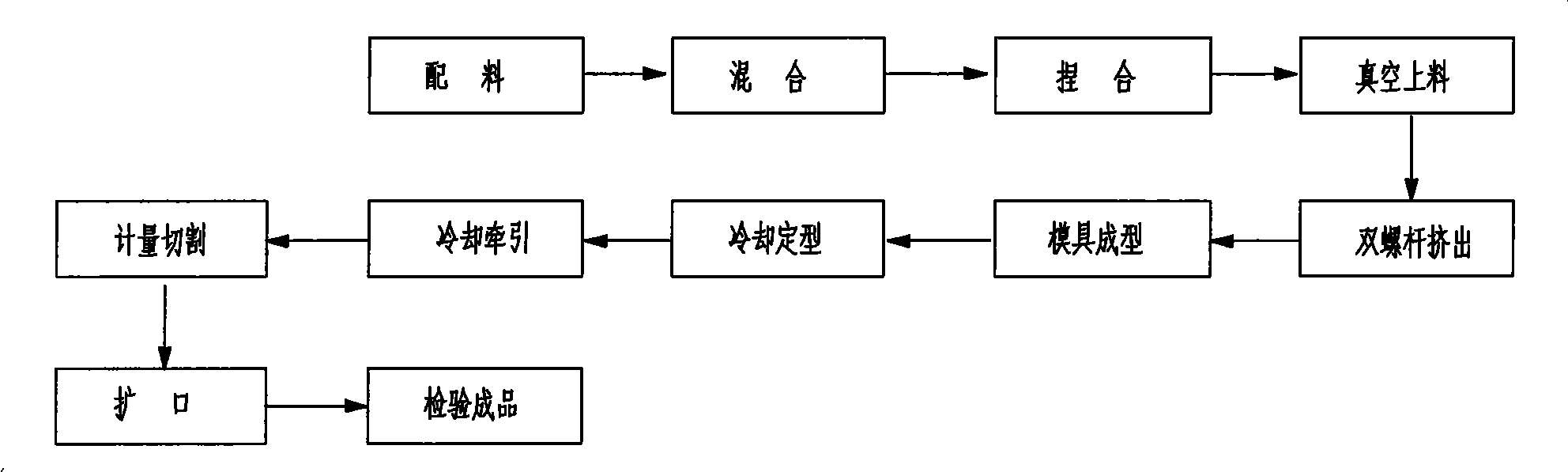

Composition for flame-retardant polyvinyl chloride (PVC) plastic foam board, product prepared from same, and preparation method thereof

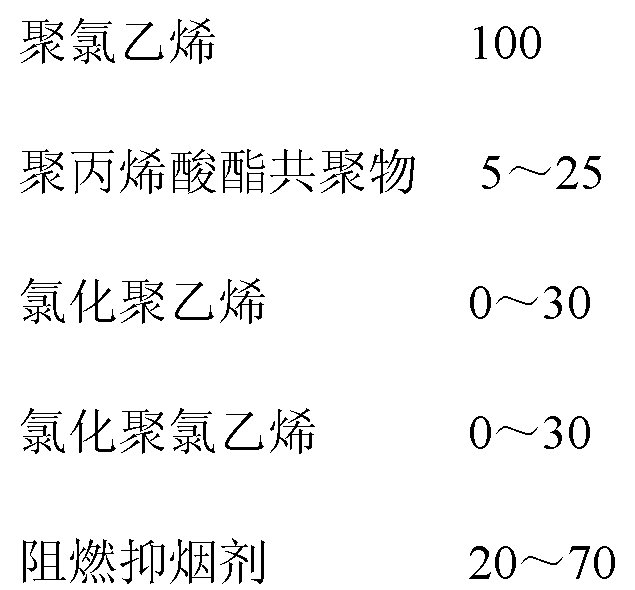

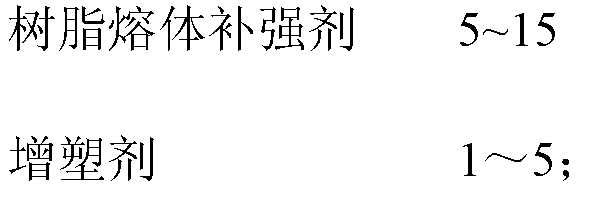

The invention relates to a composition for a flame-retardant polyvinyl chloride (PVC) plastic foam board, and the flame-retardant PVC plastic foam board produced by a double screw extrusion method. The composition comprises the following components in part by weight: 100 parts of polyvinyl chloride, 5 to 25 parts of polyacrylate copolymer, 0 to 30 parts of chlorinated polyethylene, 0 to 30 parts of chlorinated polyvinyl chloride, 20 to 70 parts of flame retardant and smoke suppression agent, and 0 to 5 part of plasticizer, and also comprises a resin melt reinforcing agent and additives such as a foaming agent, a lubricating agent and a stabilizing agent and the like. After the produced flame-retardant PVC plastic foam board is detected by Shanghai Building Material and Component Quality Surveillance Office and State Laboratory of Fire Science (University of Science and Technology of China, Hefei), the oxygen index is more than or equal to 32, the smoke density grade is less than or equal to 75, the average combustion time is less than or equal to 30 seconds, the heat release rate is less than 250W / g, the heat conductivity is 0.047W / m.K, and the flame-retardant PVC plastic foam board meets the B1 requirement of GB / T8624-1997, and meets the V-0 standard of UL-94.

Owner:SHANGHAI YUANQI ENERGY TECH DEV

Chlorinated polyvinyl chloride pipe material and preparation method thereof

ActiveCN102516693ATo achieve the double effect of toughening and strengtheningLarge specific surface areaRigid pipesHeat resistanceChlorinated polyvinyl chloride

The invention discloses a chlorinated polyvinyl chloride pipe material and a preparation method thereof. The chlorinated polyvinyl chloride pipe material disclosed by the invention comprises the following components in parts by weight of: 100 parts of chlorinated polyvinyl chloride resin, 0.3-5 parts of stabilizer, 1-4 parts of lubricant, 1-3 parts of processing modification addition agent, 3-10 parts of anti-impact modification additive, 3-10 parts of fire retardant and 0.1-4 parts of paint. Compared with the ordinary chlorinated polyvinyl chloride pipe material, the high temperature resistance, the toughness and the anti-flaming and smoke abatement property of the chlorinated polyvinyl chloride pipe material disclosed by the invention can be greatly improved. The chlorinated polyvinyl chloride pipe material can be widely applicable to various fields with requirements on the high temperature resistance and the anti-flaming and smoke abatement property, such as industrial or civil architectures and municipal engineering.

Owner:GUANGDONG LIANSU TECH INDAL

Preparation method of high-performance chlorinated polyvinyl chloride injection aggregate

The invention discloses a preparation method of chlorinated polyvinyl chloride (CPVC) injection aggregate which is characterized by high strength, high-temperature resistance, corrosion resistance and combustion supporting and a product of smooth surface. The chlorinated polyvinyl chloride injection aggregate comprises by weight: 100 parts of CPVC resin; 3-5 parts of stabilizer; 2-5 parts of lubricant and 5-12 parts of impact modifier; 0.5-5 parts of processing agent; 1-10 parts of filler; 0.1-2 parts of antioxidant. The invention also provides a preparation method of the chlorinated polyvinyl chloride injection aggregate. Specifically, each ingredient is subjected to a high-speed mixture to reach a temperature of 100-140 DEG C and dispersed well. Then the mixed ingredients are cooled to 40-60 DEG C. After extrusion and granulating, the chlorinated polyvinyl chloride injection aggregate can be obtained. With a Vicat softening temperature not below 103 DEG C, the high-performance chlorinated polyvinyl chloride injection aggregate provided in the invention has the advantages of high mechanical strength and toughness, excellent corrosion resistance and fire resistance. Thus, the injection aggregate can be widely used in manufacturing valves and parts for conveying high temperature soda acid in chemical industry and daily domestic hot water, and manufacturing other injection products with high intensity and high temperature resistance.

Owner:SHANGHAI DEWIN PLASTIC TECH

Nontoxic chlorinated polyvinyl chloride pipe and preparation thereof

ActiveCN101486821AImprove corrosion resistanceImprove aging resistanceRigid pipesTubular articlesStrong acidsPolymer chemistry

The invention discloses a novel nontoxic chlorinated polyvinyl chloride tube that has high strength, high temperature resistance, corrosion resistance and flame retardance and is applied to drinking water or hot water delivery. The tube consists of the following ingredients according to parts by weight: 100 parts of CPVC resin, 3-8 parts of stabilizer, 1-3 parts of lubricant, 1-4 parts of processing modified additive, 5-12 parts of impact modifier and 5-20 parts of filling agent. The invention also provides a method for preparing the chlorinated polyvinyl chloride tube, which comprises the steps of: kneading all the ingredients and uniformly dispersing the ingredient into a mixture, and implementing extrusion, plasticization and molding to obtain the tube. The tube has the vicat softening temperature not lower than 110 DEG C, good corrosion resistance, ageing resistance and flame retardance, not only resists the corrosion of strong acid, strong alkali and salt water, but also has higher mechanical strength and tenacity and is not chloridized and corroded by remaining chlorine in water. The novel nontoxic chlorinated polyvinyl chloride tube is widely applicable to chemical corrosion resistance and hot water or drinking water delivery in daily life and has wide application prospect.

Owner:GUANGDONG LIANSU TECH INDAL

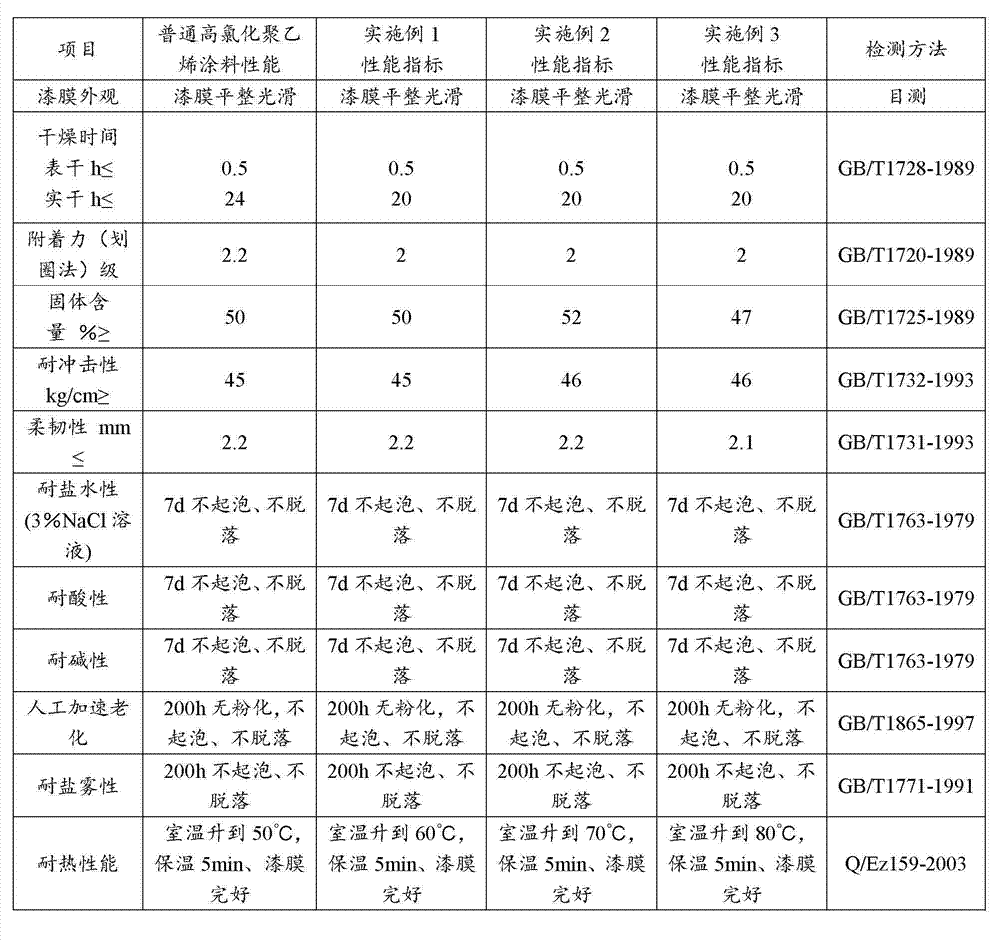

High chlorinated potyethlene anti-corrosive paint and preparation method thereof

ActiveCN102863854AImprove heat resistanceHigh bonding strengthAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to heat-resistant high chlorinated potyethlene anti-corrosive paint and a preparation method thereof and belongs to the field of anti-corrosive paint. The paint comprises, by weight, 10-40 parts of high chlorinated polyvinyl chloride, 5-35 parts of epoxide resin, 5-25 parts of acrylic resin containing fluorine, 10-30 parts of fillers, 0.1-1 part of pigment, 0.05-0.5 part of dispersant, 0.05-0.5 part of plasticizer, 0.1-0.5 part of defoaming agent and 20-60 parts of solvent. The paint can be used at the temperature of 50-80 DEG C. The paint has the advantages of being good in heat resistance, corrosion resistance, coating and processability.

Owner:SHANDONG LIAOCHENG QILU SPECIAL PAINT

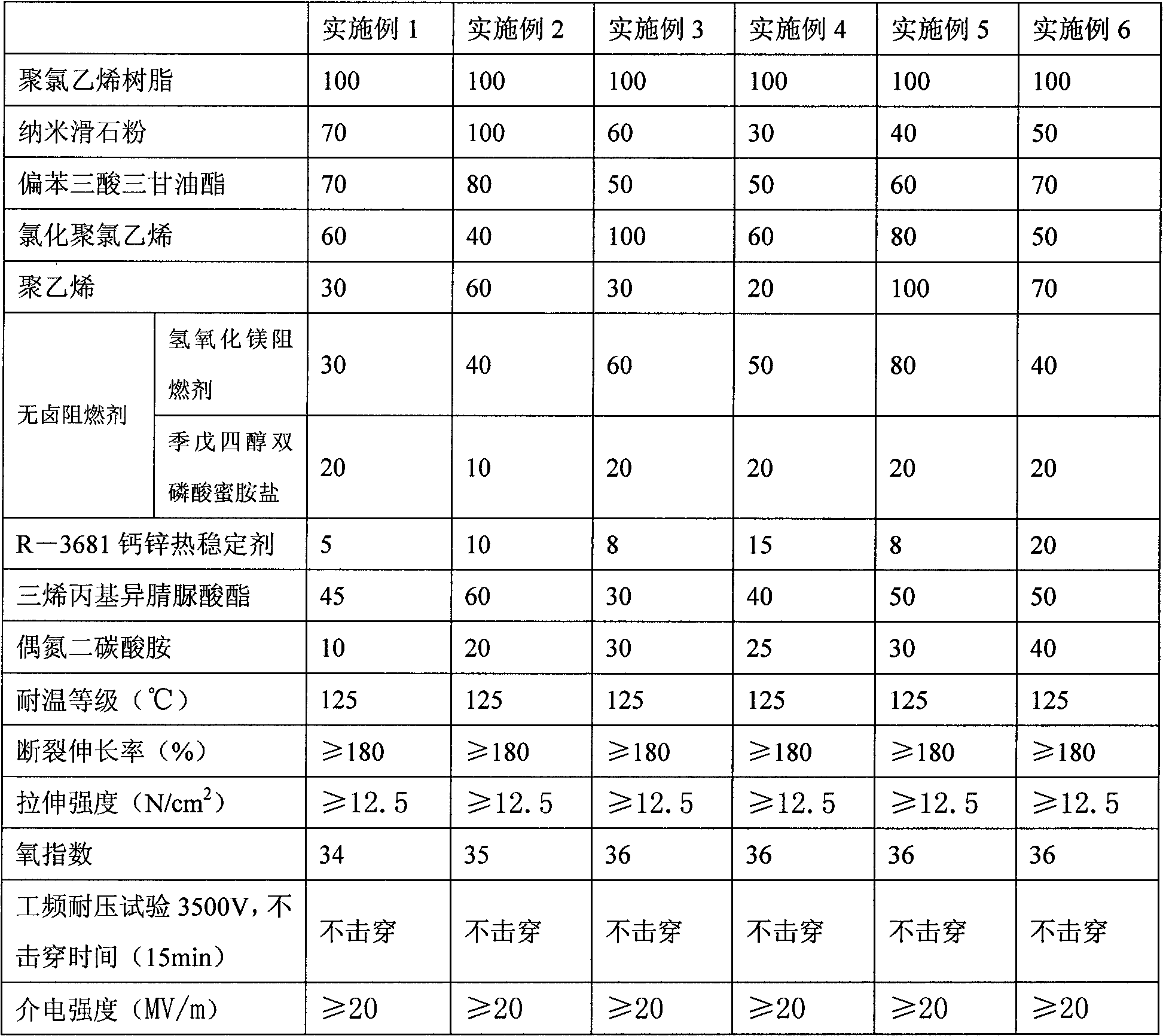

Crosslinked high flame-retardant foamed polyvinyl chloride modified material

InactiveCN102181108AImprove high temperature resistanceImprove electrical performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterCross linker

The invention discloses a crosslinked high flame-retardant foamed polyvinyl chloride modified material. The material comprises the following components in part by weight: 100 parts of polyvinyl chloride resin, 30 to 100 parts of nano talcpowder, 50 to 80 parts of high-temperature resistant polyester plasticizer, 20 to 100 parts of chlorinated polyvinyl chloride resin, 20 to 100 parts of polyethylene, 30 to 100 parts of halogen-free flame retardant, 5 to 20 parts of calcium zinc thermal stabilizer, 20 to 60 parts of cross linker and 10 to 40 parts of foaming agent. The material has excellent high-temperature resistance, high flame-retardant performance and excellent high-voltage electric resistance, and is particularly suitable to be used as a cable material with high flame-retardant requirement and used for a product shell.

Owner:宁波西尼尔新材料有限公司

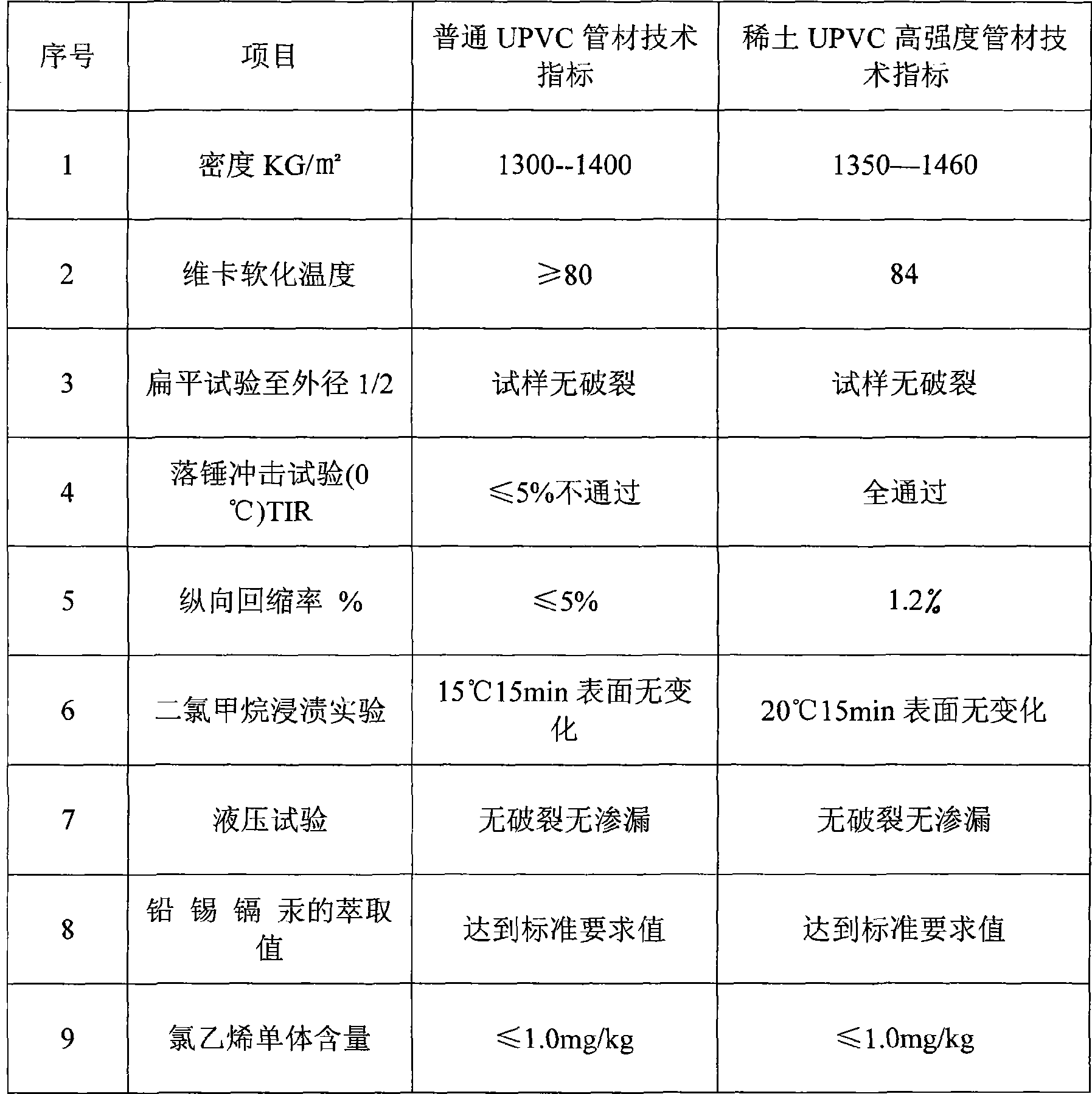

UPVC pipe material/element and preparation method thereof

InactiveCN101532591AReduce wall thicknessImprove mechanical propertiesRigid pipesChlorinated polyvinyl chlorideHeat resistance

The invention discloses a UPVC pipe material / element and preparation method thereof; the UPVC pipe material / element contains polyvinyl chloride (PVC) resin of 50-100 parts, hard lead of 0.75-1.4 parts, hard calcium carbonate of 0.85-1.7 parts, chlorinated polyvinyl chloride of 4-9.4 parts, PVC resin processing modifier of 2-5 parts, paraffin of 0.28-0.6 parts, stearic acid of 0.23-0.6 parts, light calcium carbonate of 4.5-10 parts, and rare-earth composite complex stabilizer of 0.15-0.5 parts by weight. Compared with existing product, this pipe material / element enhances mechanics performance by 20%, improves pressure resistance by 15%, reduces wall thickness of pipe material by 15%, and greatly enhances heat resistance as well as corrosion resistance. Correspondingly, this invention further claims a UPVC pipe material and a preparation method thereof.

Owner:内蒙古桂华塑料有限公司

Plastic-wooden composite tray and preparation method thereof

The invention discloses a plastic-wooden composite tray which is prepared from the raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of copolymerization polypropylene, 30-40 parts of modified wood meal, 40-50 parts of plastic renewable material, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of n-butyl methacrylate, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of triethoxyvinylsilane, 0.3-0.4 part of antioxidant 1010, 0.4-0.6 part of anti-aging agent MB, 8-10 parts of foaming modifier, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of TPE (Thermoplastic Polyurethane Elastomer), 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of glass fiber and 3-4 parts of semi-reinforced carbon black. The plastic-wooden composite tray produced by using the preparation method has the advantages of excellent mechanical property, capability of being sawed, planed and nailed, good durability, high repeated usage rate, capability of being recycled, resistance to insect biting, acid and alkaline resistance, aging resistance, and low water absorption and low deformation rate.

Owner:芜湖太平洋塑胶有限公司

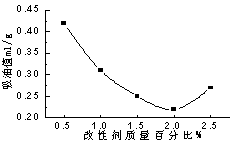

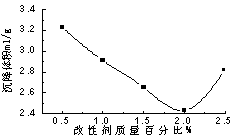

Ground calcium carbonate powder surface modification method

InactiveCN103421142AExcellent performance indexImprove application featuresPigment treatment with macromolecular organic compoundsPolymer scienceIn situ polymerization

The invention discloses a modification method for ground calcium carbonate powder (referred to as coarse whiting powder, the same below). The modifying agent of the coarse whiting powder is the composite compatilizer which comprises the components of polymer maleic anhydride-acrylamide-n-butyl methacrylate and stearic acid. Two-time modification is performed, the first modification adopts a wet method about in-situ polymerization with the modifying agent of polymer maleic anhydride-acrylamide-n-butyl methacrylate, and the second modification adopts a dry method with the modifying agent of stearic acid; the brief method comprises the steps as follows: fully mixing the coarse whiting powder, the polymer maleic anhydride-acrylamide-n-butyl methacrylate and the stearic acid, and dissolving the mixture into the mixed liquor formed by liquid paraffin and swill-cooked dirty oil, wherein the total organic matters account for 1 to 3 percent of the coarse whiting powder (mass fraction); the volume ratio of liquid paraffin to swill-cooked dirty oil is 1:1, and mass ratio of the polymer maleic anhydride-acrylamide-n-butyl methacrylate to the stearic acid is 2:1. According to the invention, the active coarse whiting powder can be used as filler of chlorinated polyvinyl chloride, polyvinyl chloride and polyethylene. The active coarse whiting powder is good in dispersion uniformity in the resin, and low in cost, and oriented towards industrialized production.

Owner:HEZHOU UNIV +1

Catalyst for tert-butyl alcohol cleavage reaction and preparation method thereof

ActiveCN103611572AIncreased intermolecular attractionNot easy to fall offOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsChlorinated polyvinyl chloridePolystyrene

The invention provides a catalyst for tert-butyl alcohol cleavage reaction, which is prepared by the following steps: by using a melt granulation process, blending and melting polystyrene, chlorinated polyvinyl chloride, polytrifluorochloroethylene and polyvinylidene fluoride, and granulating; and carrying out sulfonation reaction on the granulation product in the fixed bed and sulfur trioxide to obtain the catalyst. When being used for tert-butyl alcohol cleavage reaction, the catalyst has the advantages of high selectivity for technique reaction, fewer side reactions and low shedding tendency of sulfo-group under high-temperature conditions. The invention also provides a preparation method of the catalyst.

Owner:南通灵润医用新材料有限公司

Process for water-phase suspension ultraviolet preparing chlorinated polyvinyl chloride

InactiveCN1401672ANo pollutionProcess control stabilityOrganic solventChlorinated polyvinyl chloride

A process for preparing chlorinated polyvinyl chloride by water-phase suspension method and ultraviolet radiation includes adding polyvinyl chloride resin and disperser to water, introducing C1 gas, copolymerizing reaction at 70-100 deg.C and 0.2-0.4 MPa under ultraviolet radiation for 4-6 hr, washing with water, neutralizing, centrifugal separation and drying. Its advantages are stable process, low cost, and high stability of products.

Owner:刘旭思

Method for producing chlorinated polyvinyl chloride with high chlorinity by one-step method

The present invention discloses a method for producing chlorinated polyvinyl chloride with a high chlorinity by a one-step method, namely, in a CPVC synthetic process of an aqueous phase method, an industry alcaine with 20% of water or mass concentration is used as a reaction medium, by means of improving the reaction pressure suitably and adding the dissolvability of chlorine gas in water, the reaction speed and the product chloridization uniformity degree are all improved, thereby a CPVC resin with good processability and high chlorinity will be synthesizing by one step.

Owner:WUHU RONGHUI CHEM IND

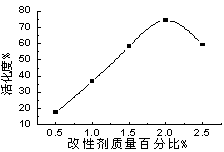

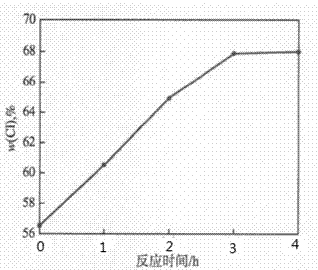

Method for synthesizing CPVC resin by gas-solid phase method

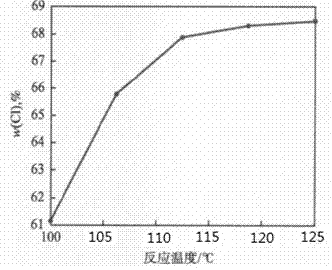

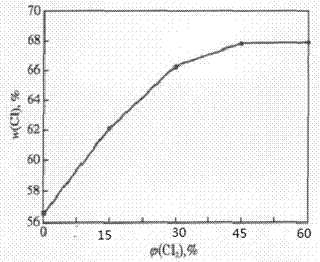

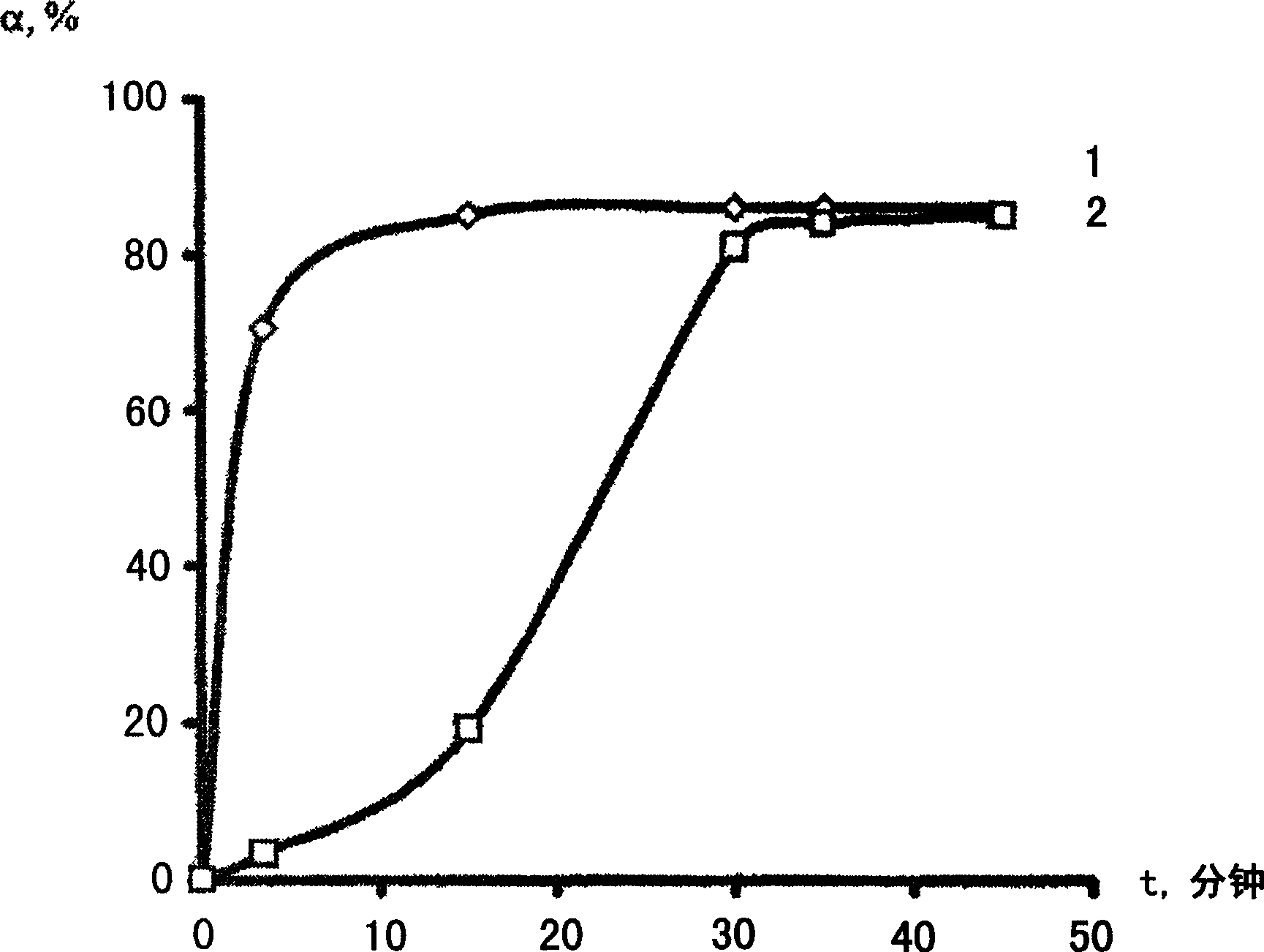

The invention provides a method for synthesizing CPVC resin by gas-solid phase method. According to the invention, in a fluidized bed reactor, the synthetic process of the CPVC resin initiated by ultraviolet lights is studied, and the reaction time, reaction temperature, and Phi (C12) in the raw material gas and the influence of the ultraviolet light intensity to a product Omega (C1) are investigated.

Owner:苏州宝津塑业有限公司

Super-tough and super-flexible high-temperature-resistance polyvinyl chloride pipe and manufacturing technology thereof

InactiveCN103304914ASuper strong and super toughSuper toughRigid pipesChlorinated polyvinyl chloridePlasticizer

The invention relates to the technical field of plastic pipes, and in particular relates to a super-tough and super-flexible high-temperature-resistance polyvinyl chloride pipe and a manufacturing technology thereof. The super-tough and super-flexible high-temperature-resistance polyvinyl chloride pipe comprises the following components in parts by weight: 50-65 parts of polyvinyl chloride, 25-38 parts of chlorinated polyvinyl chloride, 12-18 parts of shock resistance agent, 4-10 parts of filler, 3-8 parts of stabilizing agent, 2-5 parts of plasticizer, 0.1-0.6 part of external lubricating agent, 0.1-0.6 part of internal lubricating agent and 3-7 parts of modifying agent. The pipe has the advantages of high intensity, high super-flexibility, high-temperature resistance, shock resistance, corrosion resistance and lower cost and can meet a construction requirement on an electronic pipe.

Owner:杭州联通管业有限公司

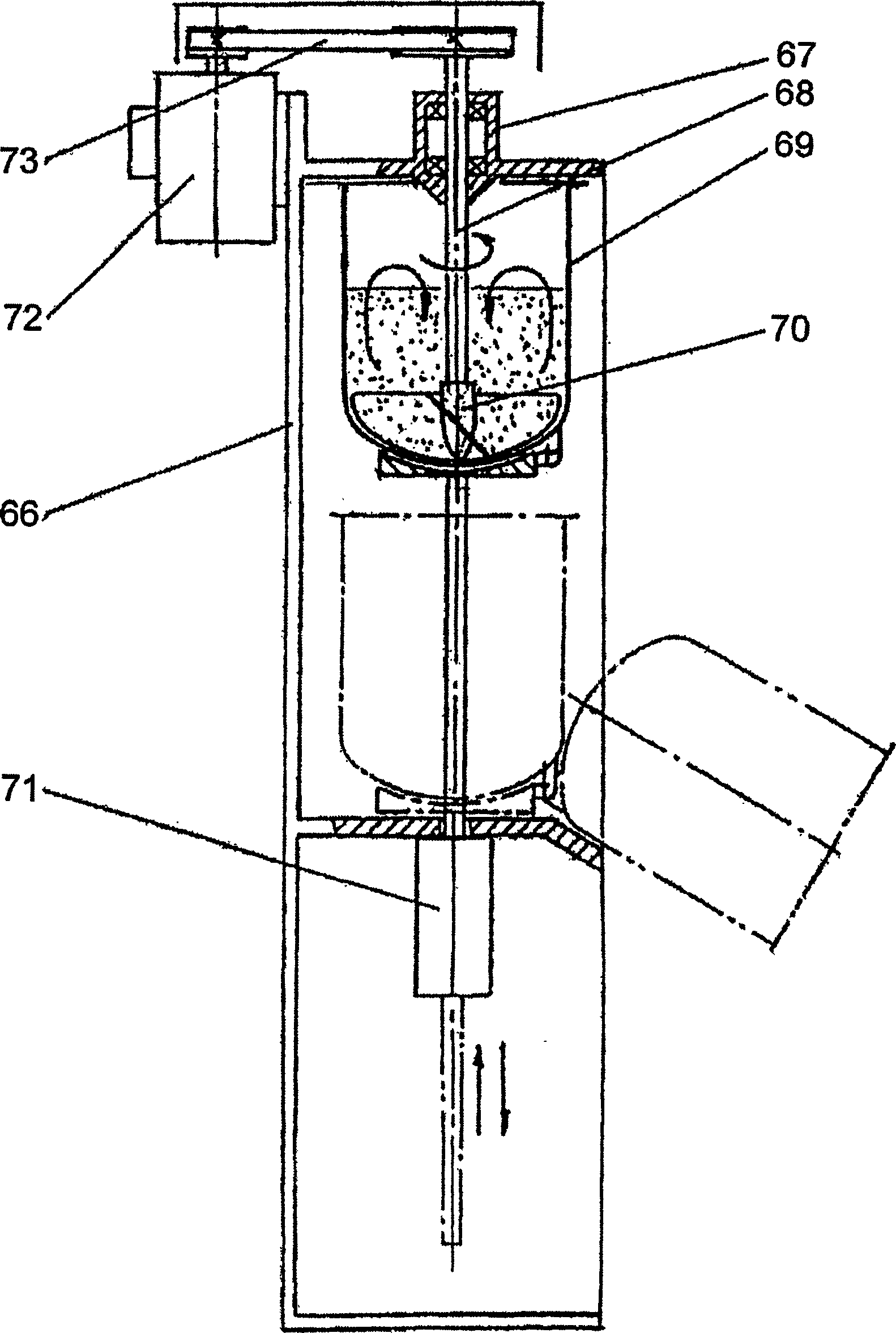

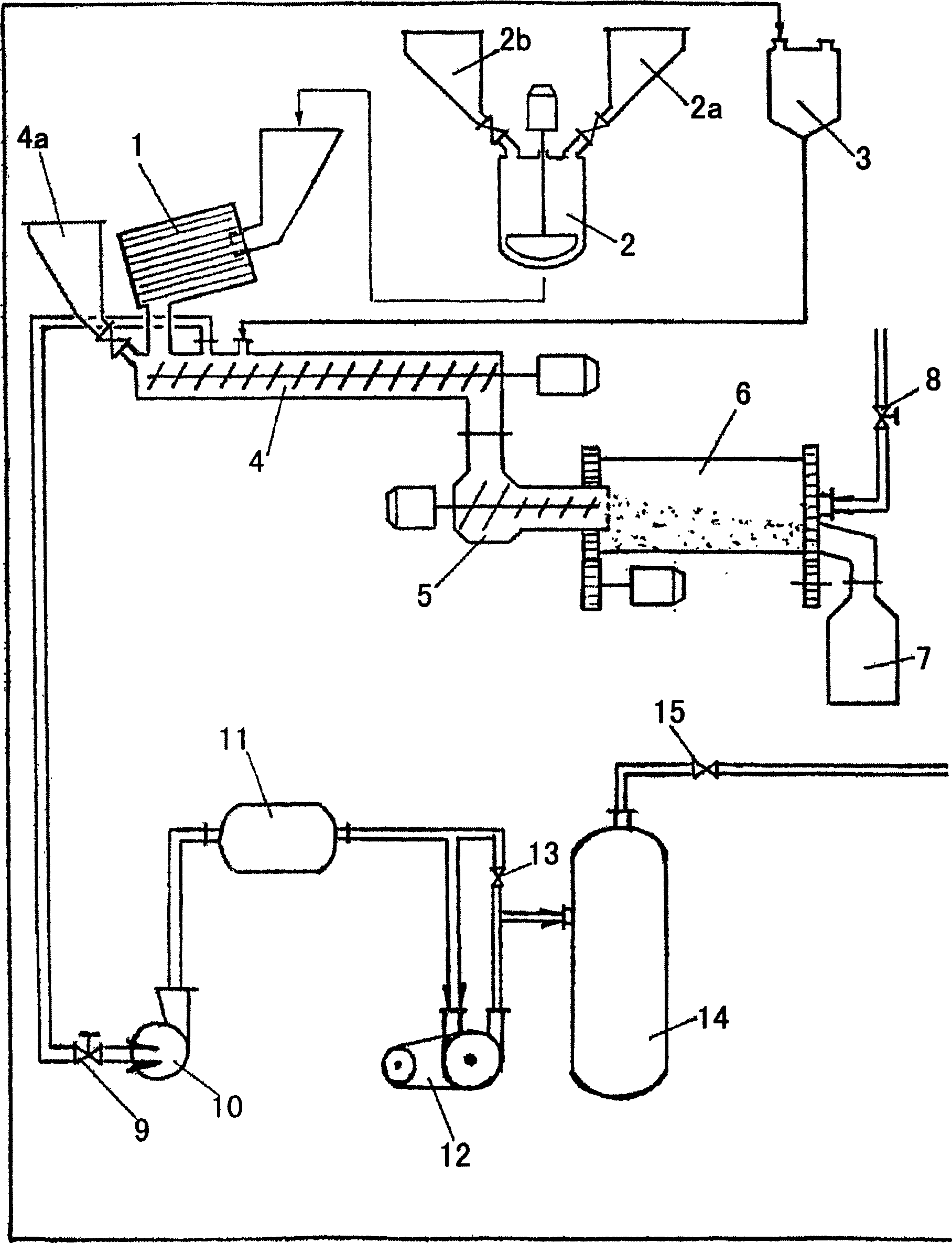

Method for producing granulated sorbents and installation for carrying out the method

The invention relates to a method for producing granulated sorbents, and to an installation for carrying out the method. The aim of the invention is to obtain the chloride form of the double hydroxide of aluminium and lithium as LiCL2AI / OH)3 nH2O (DHAL-CL) in a waste-free solid phase of aluminium hydroxide and lithium salts in a mixer, with subsequent continuous activation of crystalline DHAL-CI in a centrifugal mill activator in order to obtain a defectuous material structure. The product obtained is mixed with chlorinated polyvinyl chloride as a binding agent and with liquid methylene chloride. The granulation is carried out by extruding the paste produced and refining the same in the granulator. The methylene chloride produced is collected by an organic liquid absorbent having a high boiling point. The methylene chloride steam is guided out of the material flow in the carrier gas flow in the manner of an ideal displacement in the counter-current of the contact phases. The methylene chloride recuperation is carried out in two steps according to the thermal method, during the heating of the absorbent used. The inventive method is characterised by essentially reduced environmental impact in relation to prior art, due to the closed material circuits used. The granulated sorbent is especially suitable for the selective extraction of lithium from chloride salt lye of any mineralization, with an extraction degree of 95 %.

Owner:青海盐湖蓝科锂业股份有限公司

Convex rib winding reinforced polyvinyl chloride hose for sand transportation and preparation method thereof

ActiveCN102190836AGood performance of elastomerIncrease elasticityFlexible pipesChlorinated polyvinyl chloridePlasticizer

The invention discloses a convex rib winding reinforced polyvinyl chloride hose for sand transportation and a preparation method thereof. The convex rib winding reinforced polyvinyl chloride hose for sand transportation is prepared from a polyvinyl chloride soft mixture and a polyvinyl chloride hard mixture, wherein the polyvinyl chloride soft mixture is prepared from suspension-process polyvinylchloride, high-molecular-weight polyvinyl chloride, plasticizer, anti-shock modifier, toughener, processing modifier, organotin stabilizer, calcium-zinc composite stabilizer, rare-earth stabilizer, lubricant, light stabilizer, filler and other assistants; and the polyvinyl chloride hard mixture is prepared from suspension-process polyvinyl chloride, chlorinated polyvinyl chloride, anti-shock modifier, toughener, processing modifier, organotin stabilizer, calcium-zinc composite stabilizer, lubricant, light stabilizer, filler and other assistants. The product prepared by the technical scheme ofthe invention has the advantages of favorable wear resistance, heat resistance, freezing resistance, fatigue resistance, bending resistance, energy saving and low cost, and is a new product expected in sand transportation industry.

Owner:漯河科莱堡科技有限公司

Glass fiber mesh and PVC compound enhanced film and production method thereof

InactiveCN101693419ASimple processRealize industrial applicationSynthetic resin layered productsGlass/slag layered productsFiberglass meshGlass fiber

The invention relates to a glass fiber mesh and PVC compound enhanced film and a production method thereof. The traditional film has very low shock resistance. The compound enhanced film is in a three-layer structure, wherein an upper layer and a lower layer are PVC films, and a middle layer is a glass fiber mesh. The production method of the glass fiber mesh and PVC compound enhanced film comprises the following concrete steps: knitting high-strength glass fiber yarn into a meshed glass fiber mesh; processing the surface of the glass fiber mesh by using chlorinated polyvinyl chloride (CPVC) resin; and compounding the PVC resin and the glass fiber mesh. The compound enhanced film has superior shock resistance; and meanwhile, the production method of the enhanced film has simple technology, the used equipment is common film producing equipment, and the industrial application can be realized.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

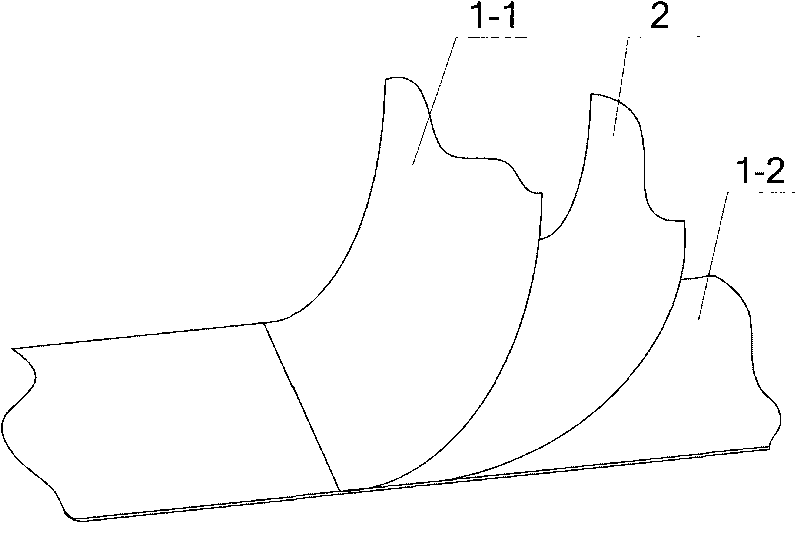

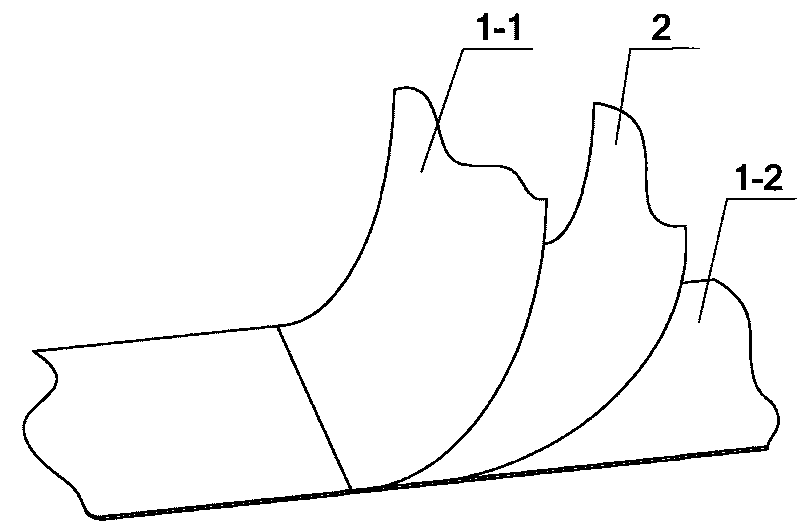

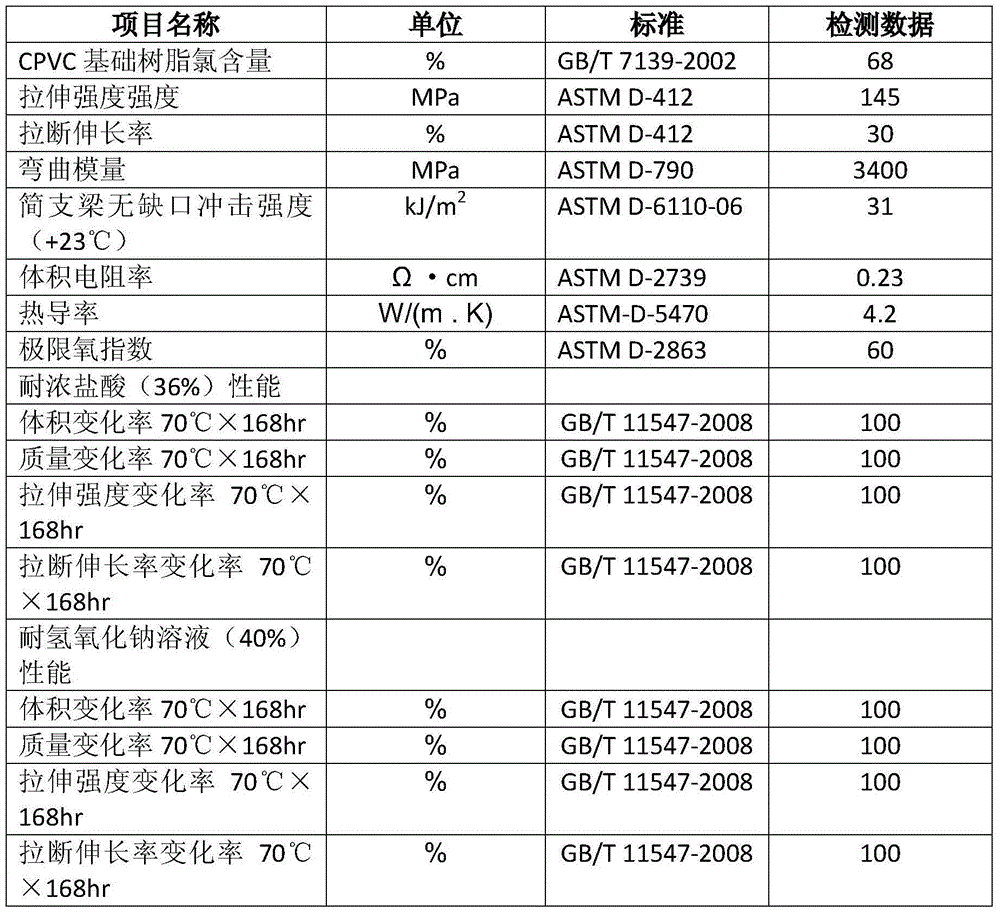

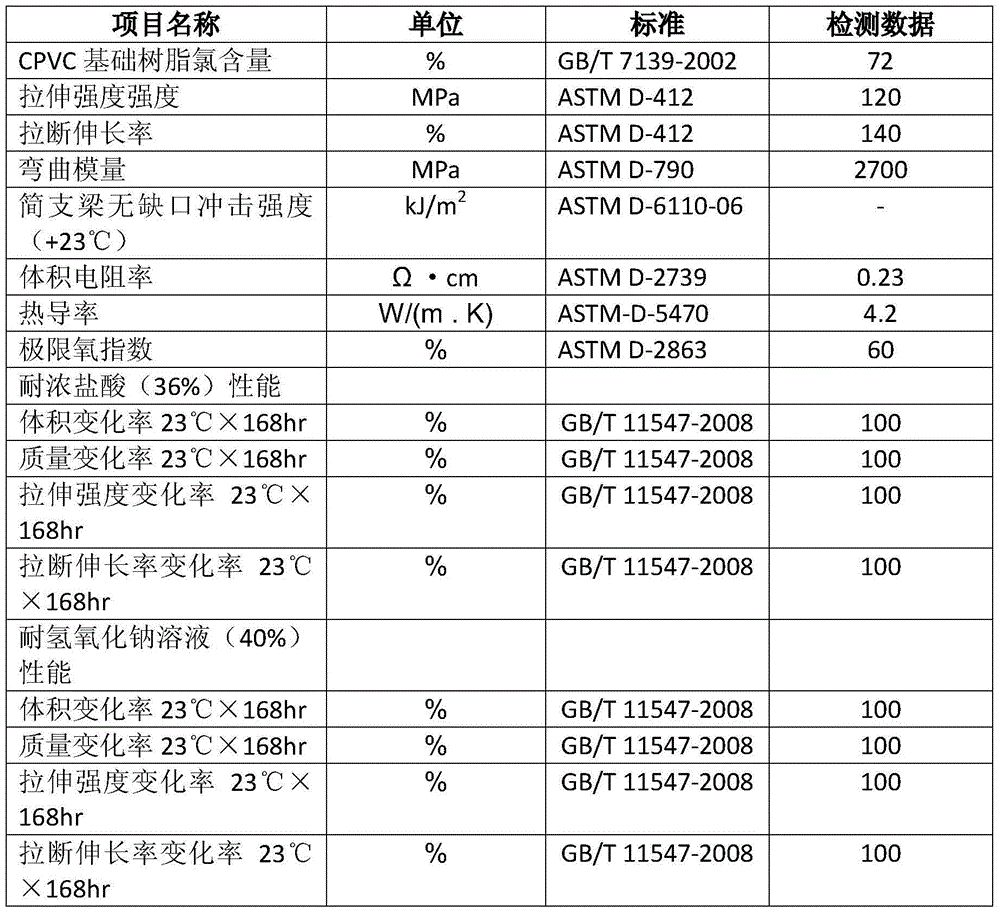

Corrosion-resistant electric conduction and heat conduction chlorinated polyvinyl chloride resin material and preparation method and application thereof

ActiveCN104927261AImprove conductivityGood chemical resistanceDielectricChlorinated polyvinyl chloride

The invention relates to a corrosion-resistant electric conduction and heat conduction chlorinated polyvinyl chloride resin material, which is prepared from the following components by weight percentage: 100 parts of modified chlorinated polyvinyl chloride resin of which the chlorine content is 68 to 72 percent, 40 to 60 parts of electric conduction and heat conduction dielectric material, 5 to 15 parts of filler, 8 to 15 parts of anti-impact modifier, 8 to 10 parts of stabilizer, 0 to 15 parts of plasticizer, 3 to 5 parts of antioxygen, 0.2 to 0.5 parts of ultraviolet light absorber, 0.5 to 1.5 parts of chelating agent and 0.5 to 2.5 parts of lubricant. According to the corrosion-resistant electric conduction and heat conduction chlorinated polyvinyl chloride resin material disclosed by the invention, the high electric conduction and heat conduction chlorinated polyvinyl chloride resin prepared by adding the electric conduction and heat conduction dielectric material specially treated to the modified polyvinyl chloride base resin obtained through a special polymerization process and modified chlorinated polyvinyl chloride obtained through chlorination has excellent electric conductivity (mass resistivity is about 10<-1>) and heat conductivity [more than 4W / (m.K)], meanwhile, also has excellent chemical medium resistance, and has very extensive application; the corrosion-resistant electric conduction and heat conduction chlorinated polyvinyl chloride resin material disclosed by the invention is simple in process, high in production efficiency and has no polluting waste.

Owner:青岛科凯达橡塑有限公司

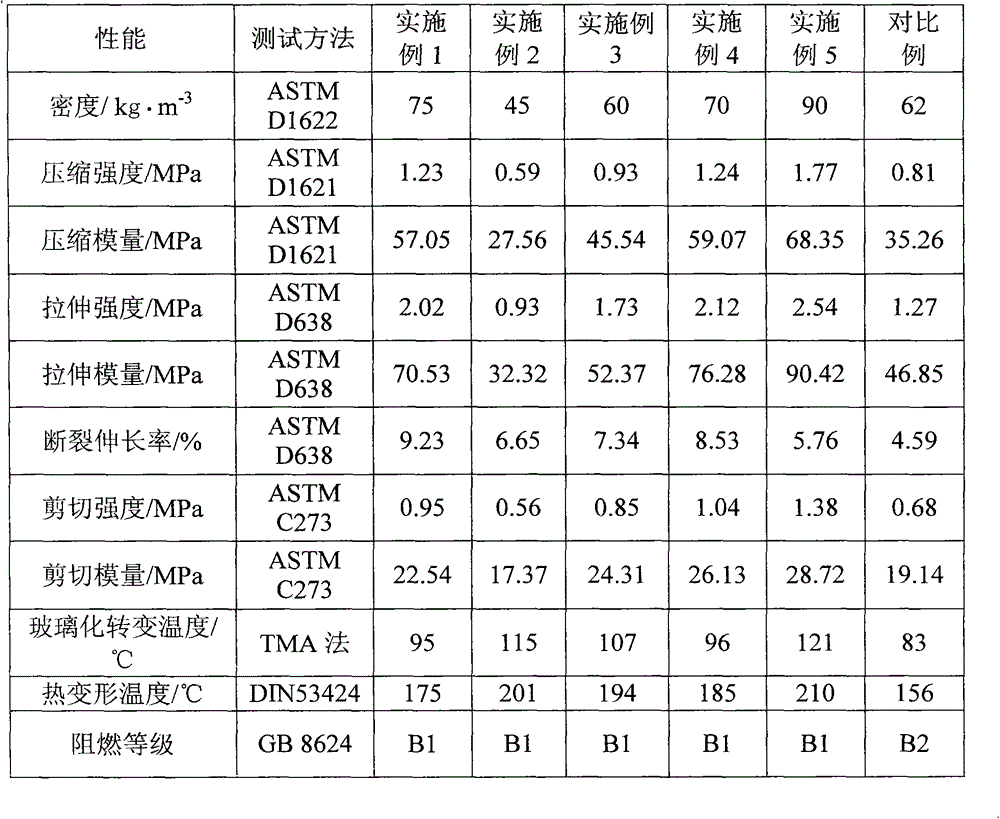

Modified hard crosslinked polyvinyl chloride flame-retardant foam and preparation method thereof

ActiveCN104031326AImprove propertiesImprove flame retardant performanceFoaming agentChlorinated polyvinyl chloride

The invention discloses modified hard crosslinked polyvinyl chloride flame-retardant foam and a preparation method thereof. The modified hard crosslinked polyvinyl chloride flame-retardant foam is prepared from 90-99 parts by weight of polyvinyl chloride paste resin, 1-10 parts by weight of chlorinated polyvinyl chloride resin, 3-15 parts by weight of a cross-linking agent, 30-70 parts by weight of isocyanate, 9-24 parts by weight of anhydride, 4-8 parts by weight of an azo foaming agent, 2-15 parts by weight of epoxy soybean oil, 2-6 parts by weight of a filling material and 5-30 parts by weight of a fire retardant. Through formula optimization, the modified hard crosslinked polyvinyl chloride flame-retardant foam having a B1 flame-retardant level is prepared. The modified hard crosslinked polyvinyl chloride flame-retardant foam has original excellent properties of the modified hard crosslinked polyvinyl chloride foam and has good flame resistance.

Owner:维赛(江苏)复合材料科技有限公司

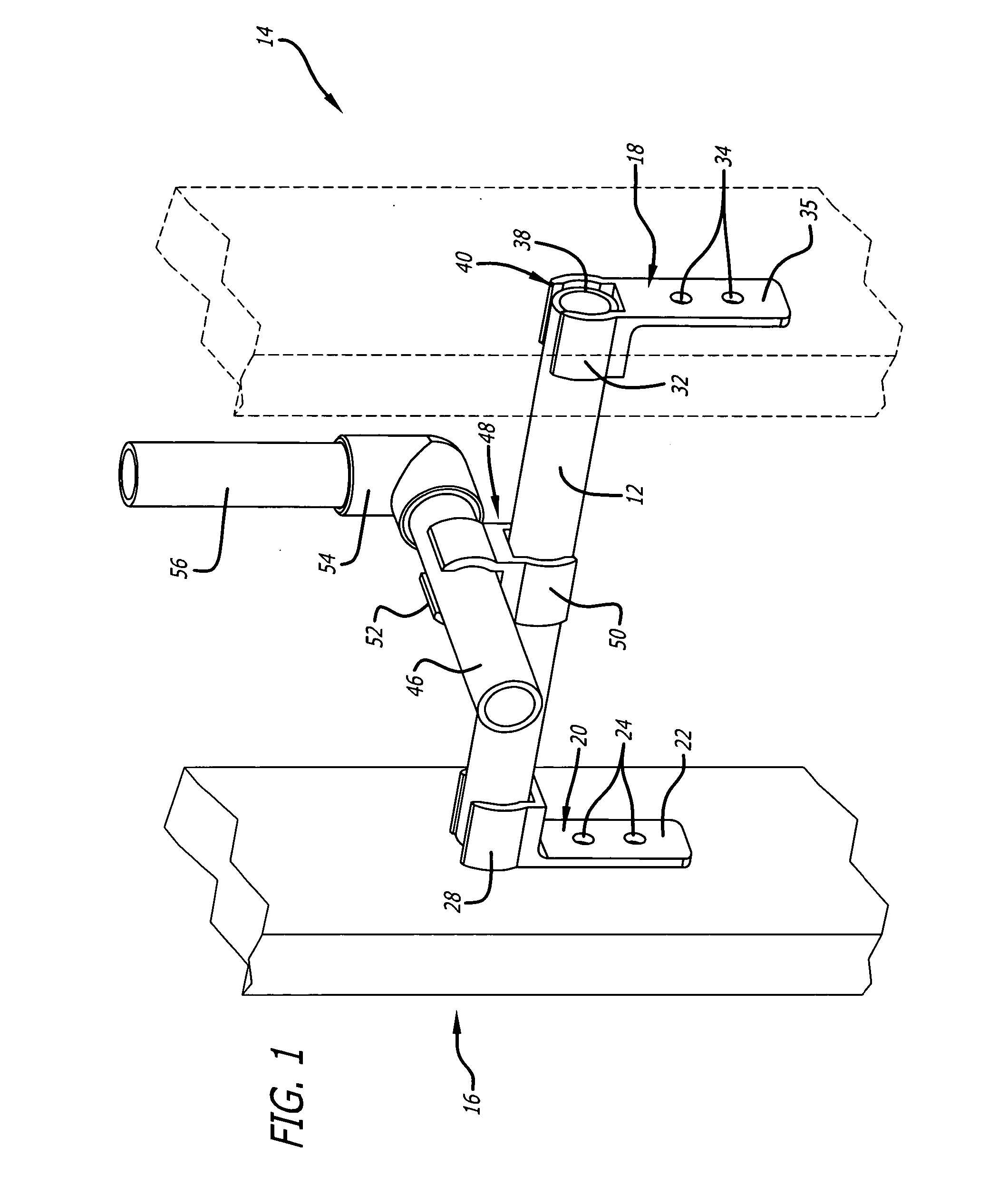

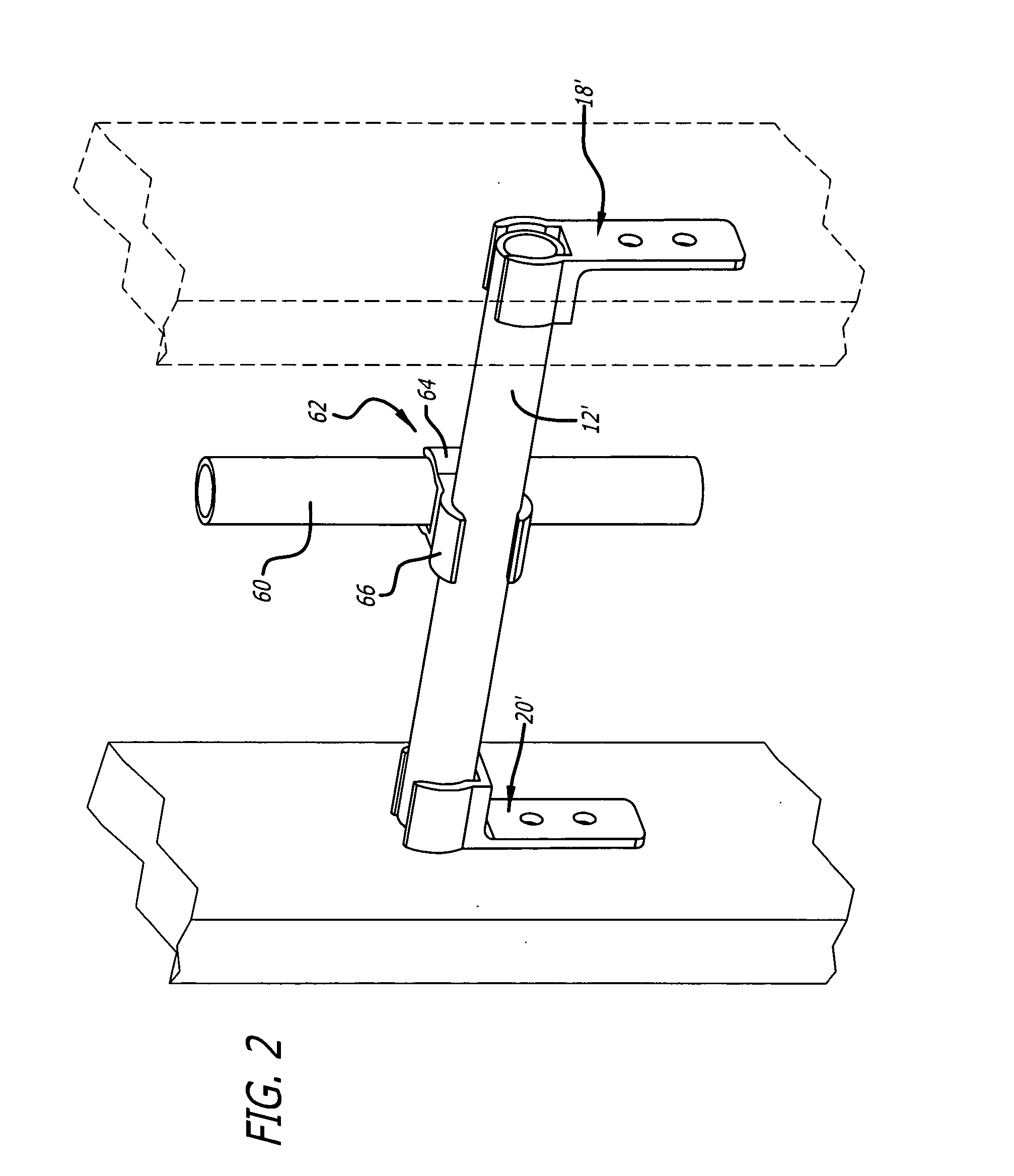

Simplified pipe support assembly

InactiveUS20050121559A1Unsnapped easilyEasy to cutPipe supportsStands/trestlesChlorinated polyvinyl chlorideOperating energy

A plastic pipe support assembly includes a pair of snap-on wall brackets or fittings with each bracket or fitting including a base portion and a snap-on, pipe receiving portion. The base portion includes holes for receiving nails or screws for mounting to studs in a building, for example; and the snap-on pipe receiving portion includes a pair of jaws for extending around a support pipe, with the opening between the jaws having a spacing which is less than the diameter of the support pipe so that the support pipe may be snapped into the jaws, and held firmly in place. One or more pipe-to-pipe fittings may be provided with each fitting having a pair of pipe receiving jaws, for mounting water pipes to the support pipe. The support pipe and the brackets or fittings may be all formed of the same type of plastic as the water pipe, such as polyvinyl chloride, or chlorinated polyvinyl chloride. Plastic solvent may be employed to bond the pipes and fittings together.

Owner:KING ROBERT W

Resin anti-corrosive paint

InactiveCN101525514AEasy to get formulaLow priceAnti-corrosive paintsTetrafluoroethyleneKetone solvents

The invention discloses a resin anti-corrosive paint which is prepared from 10-35 of resin composition, 5-15 of plasticiser, 45-70 of solvent, and 1-5 of assistant according to the weight percent, wherein the resin composition is prepared from 30-60 of polyvinyl chloride, 20-50 of chlorinated polyvinyl chloride and 0-20 of polyfluortetraethylene according to the weight percent; the plasticiser is phthalic acid esters; the solvent is one or more of a ketone solvent, a benzene solvent or an ester solvent; the assistant is antioxidant or age inhibitor; and the polyvinyl chloride uses powder as the raw material. The anti-corrosive paint has the advantages of corrosion resistance, long service life, simple and convenient coating and mending, little pollution and cheap price, can be widely used for flue gas purification and surface corrosion of chemical equipment, engineering construction, ships, and the like, and has a good market prospect.

Owner:沈福昌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com