Patents

Literature

57results about How to "Process control stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

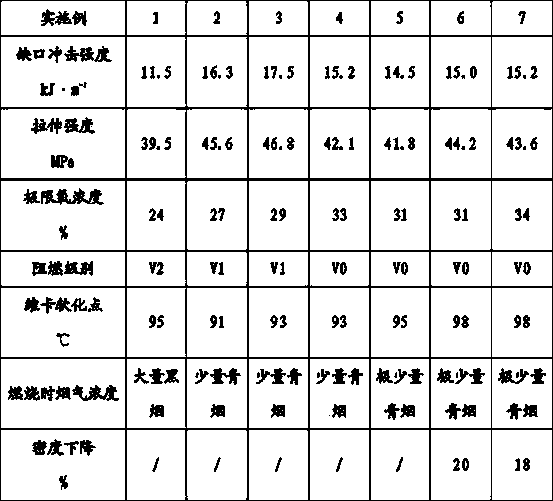

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

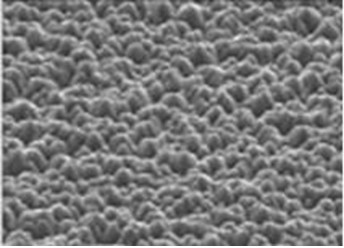

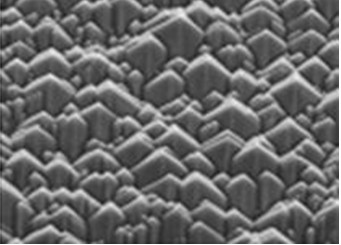

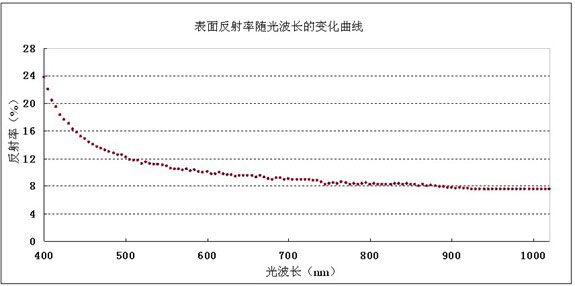

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

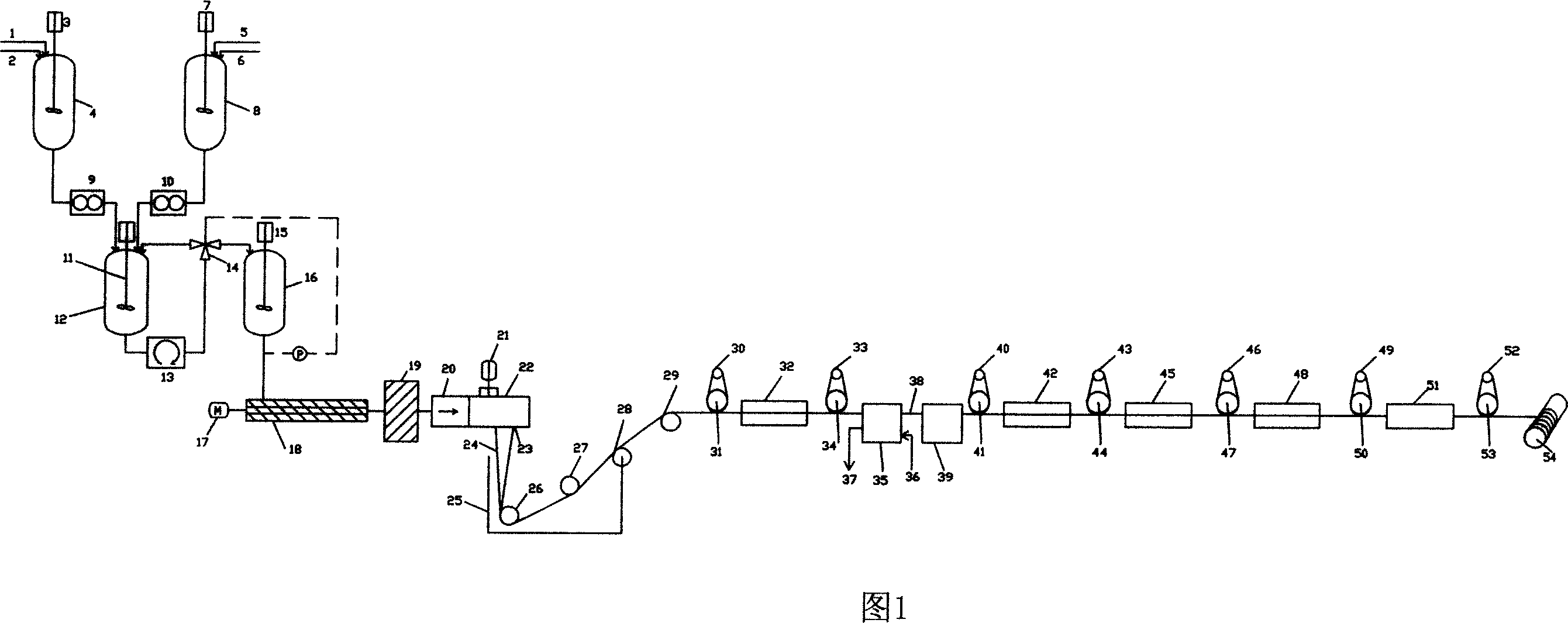

Super high molecular weight polyethylene gel method for continuous producing direct spinning fine denier filament

InactiveCN1995496AUniform and stable qualityGuaranteed accurate feedingWet spinning methodsMonocomponent polyolefin artificial filamentFiberState of art

The invention relates to a manufacturing method for continuous direct spinning fine denier yarn by uhmwpe jelly method, belonging to the spinning area and solving the problem that the single yarn or yarn beam generated by prior technology is on the high side and bad uniformity so that the difficulty for stability of manufacturing and quality of subsequent product is enhanced and the applicable range is limited. The method is provided with reasonable and compact process flow, stable process control, skillful operation and improving the quality and uniformity of product. By the method continuous stable spinning in line is realized in process parameters and the production efficiency is improved. The labor cost and intensity are lessened. Because there is less turnover link in the middle of process it is favor of decreasing producing consumption and uncontrollable factors. Under the stable running, uhmwpe fine denier yarn or yarn beam with even and stable quality, and good performance is provided.

Owner:SINOTEX INVESTMENT & DEV CO LTD

Process for water-phase suspension ultraviolet preparing chlorinated polyvinyl chloride

InactiveCN1401672ANo pollutionProcess control stabilityOrganic solventChlorinated polyvinyl chloride

A process for preparing chlorinated polyvinyl chloride by water-phase suspension method and ultraviolet radiation includes adding polyvinyl chloride resin and disperser to water, introducing C1 gas, copolymerizing reaction at 70-100 deg.C and 0.2-0.4 MPa under ultraviolet radiation for 4-6 hr, washing with water, neutralizing, centrifugal separation and drying. Its advantages are stable process, low cost, and high stability of products.

Owner:刘旭思

Preparation method of fluorine-silicon surfactant

ActiveCN102070662ARaw materials are easy to getSmooth responseGroup 4/14 element organic compoundsTransportation and packagingSolventMethanol

The invention discloses a preparation method of a fluorine-silicon surfactant. The method comprises the following steps of: continually dripping 13 to 18 weight parts of trichlorosilane into 44 to 65 weight parts of perfluor alkyl ethylene or perfluor alkyl ethyl iodide serving as a raw material in the presence of 0.1 to 1.0 weight part of noble metal catalyst so as to obtain an intermediate product; and adding 14.8 to 20 weight parts of high-boiling-point solvent into the intermediate product, continuously dripping 10 to 16.35 weight parts of methanol or ethanol for reacting, decompressing and rectifying so as to obtain a target product. In the method, raw materials are readily available, byproduct is not produced, a reaction in an entire synthesis process is stable, process control is stable, safety, low cost and easy separation are realized, the yield of a final fluorine-silicon surfactant is over 95 percent, and the purity of the surfactant is over 98 percent. Due to the presence of a siloxane active group, the fluorine-silicon surfactant can react with and be tightly combined with substances with a hydroxy functional group, such as glass and the like, so that the surface of the fluorine-silicon surfactant has high waterproofness, oil resistance and soil resistance, surface tension is less than 17.6 dynes per meter, and light transmittance is over 99.9 percent.

Owner:JINZHOU DPF TH CHEM CO LTD

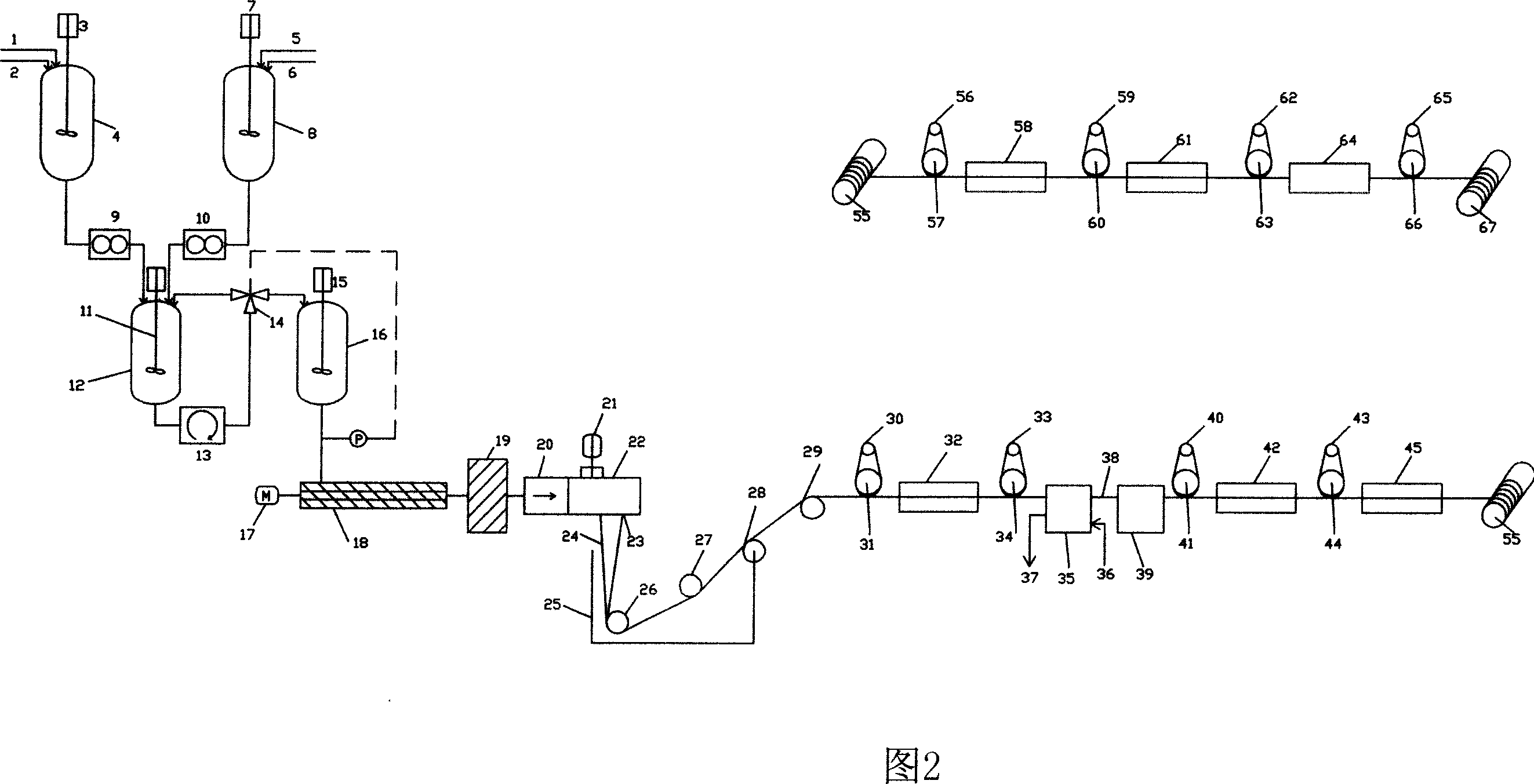

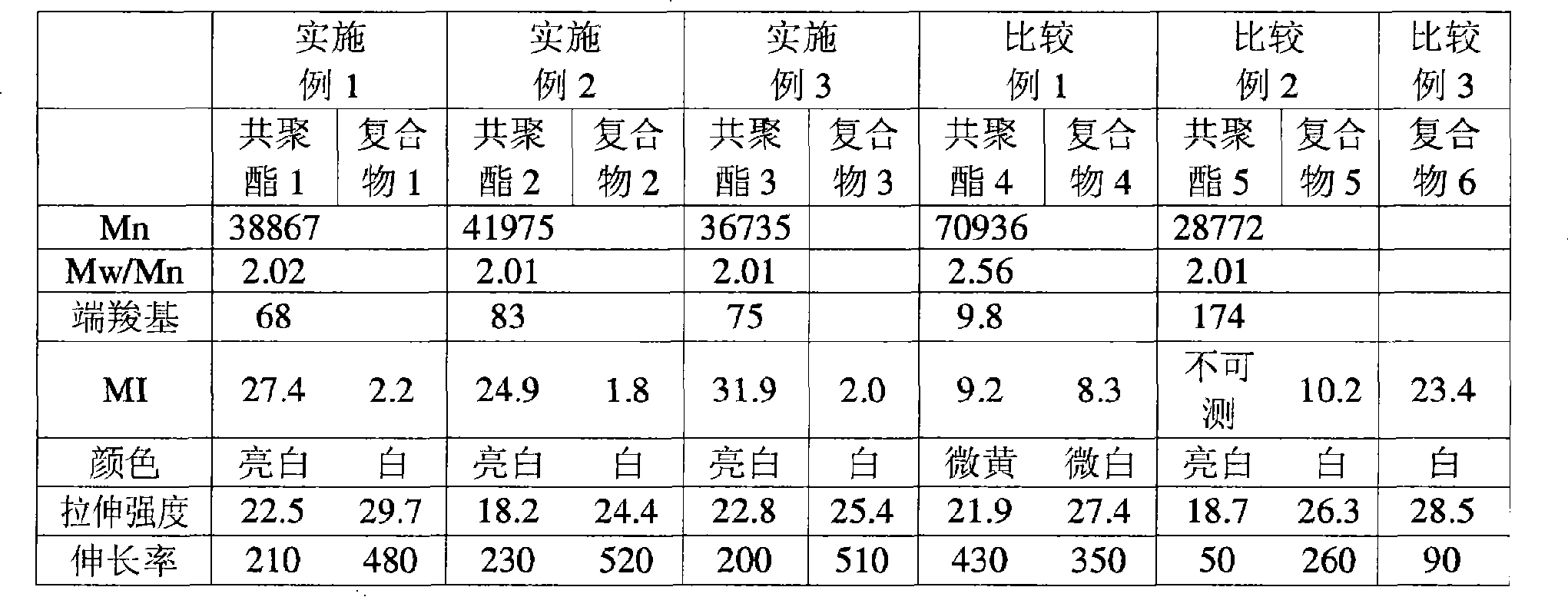

Aliphatic polyester complexes and method of preparing the same

The invention discloses a fatty polyester compound and a preparation method thereof, including the following steps: (1) synthesis of condensation fatty co-polyester: the react between two, three or four fatty dicarboxylic acids or the esters thereof and fatty dibastic alcohol is conducted to achieve condensation fatty co-polyester; (2) the condensation fatty co-polyester reacts with poly lactic acid under the existence of double functional-group chain-extension agent and the extruded out, the achieved fatty polyester compound is the blend of high molecular weight fatty co-polymer, high molecular weight fatty block copolymer and high molecular weight poly lactic acid. The weight percents of condensation fatty co-polyester and poly lactic acid drop is 5:95-95:5. The preparation method has the advantages that the condensation duration is short, the process control is stable and simple, and the method can be directly applied to various processing techniques such as film inflation, extrusion, vacuum molding, blow molding, foaming, and the like; the achieved products have high purity and nice color; the performance adjustment is flexible and convenient, and the cost is low.

Owner:KINGFA SCI & TECH CO LTD +1

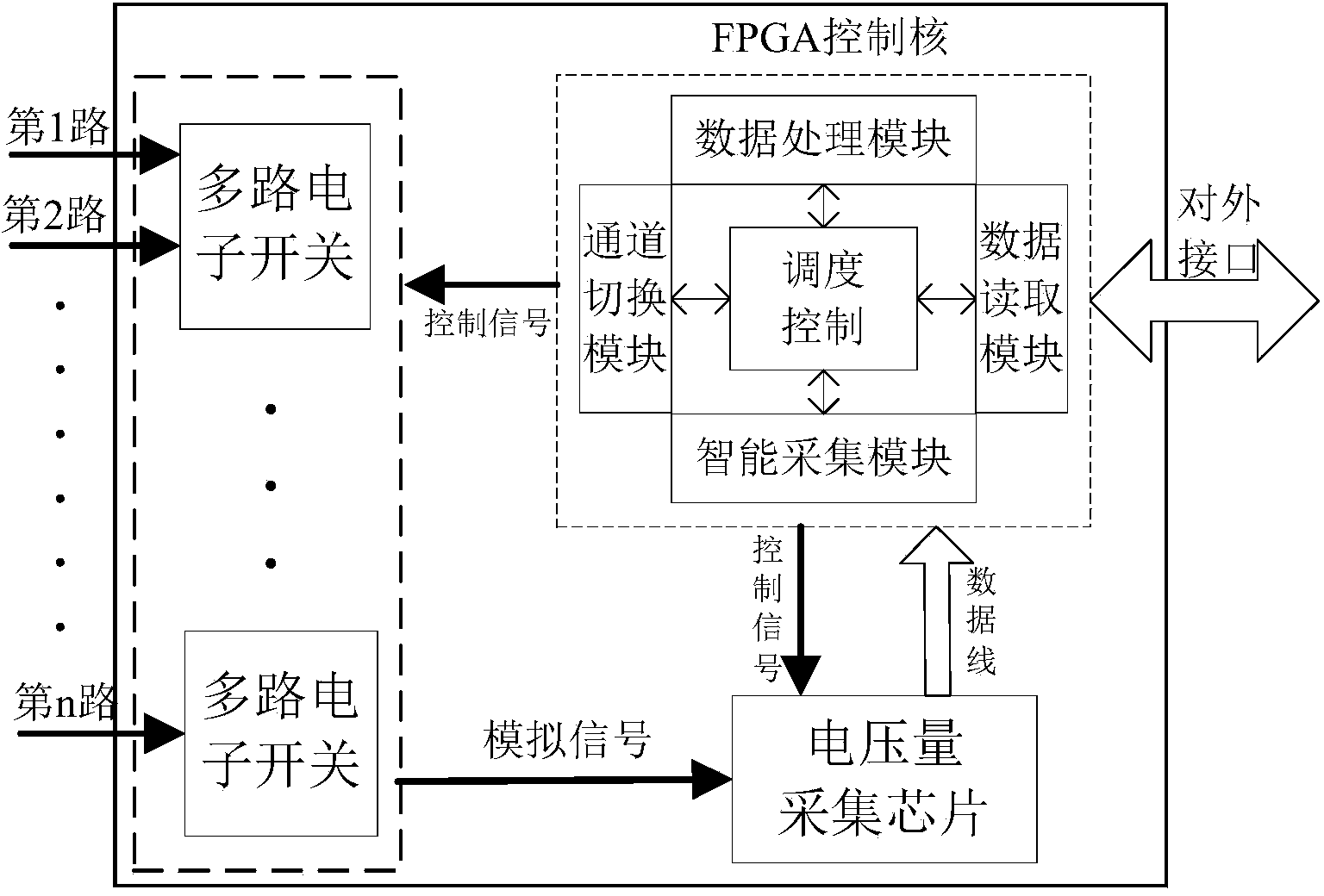

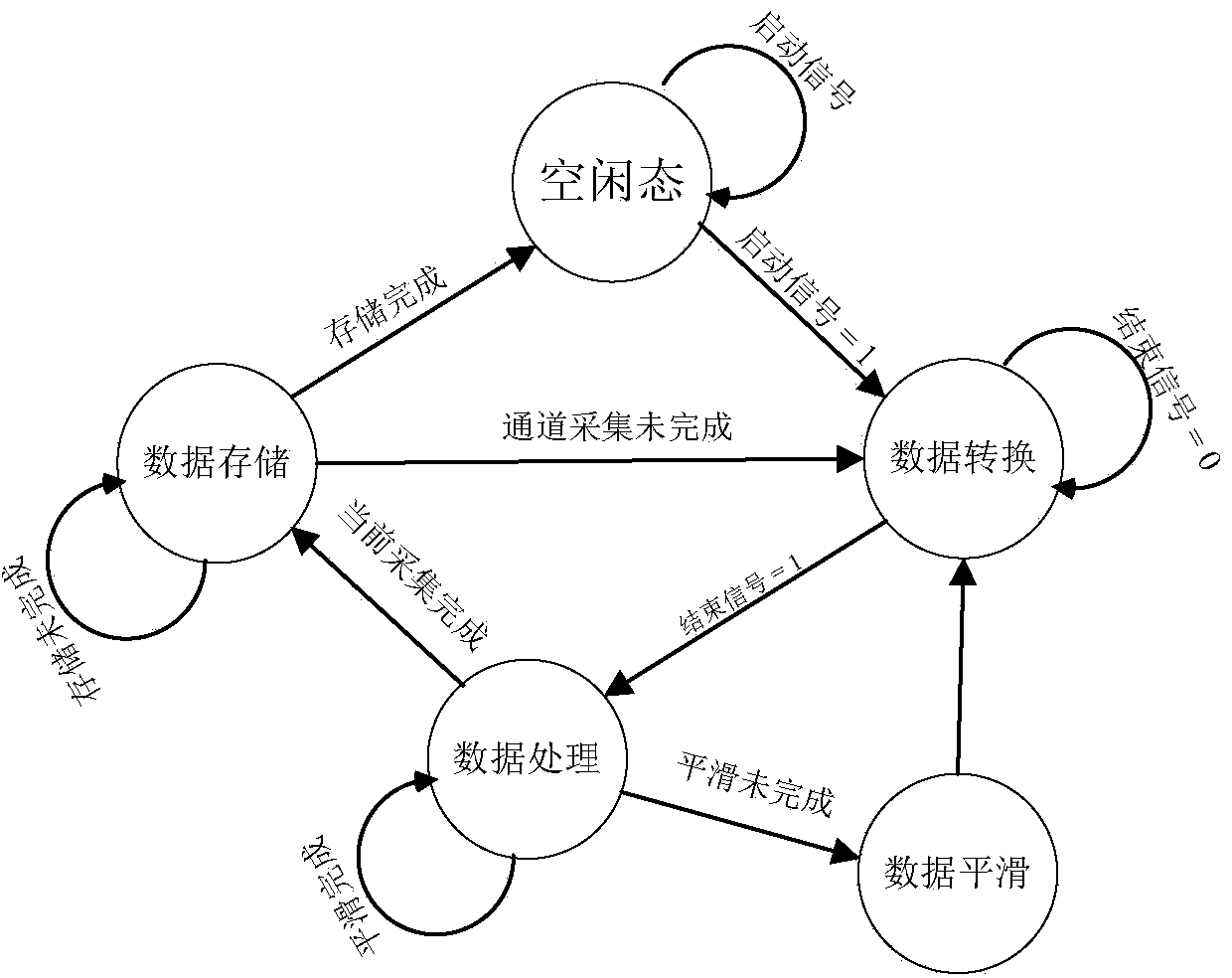

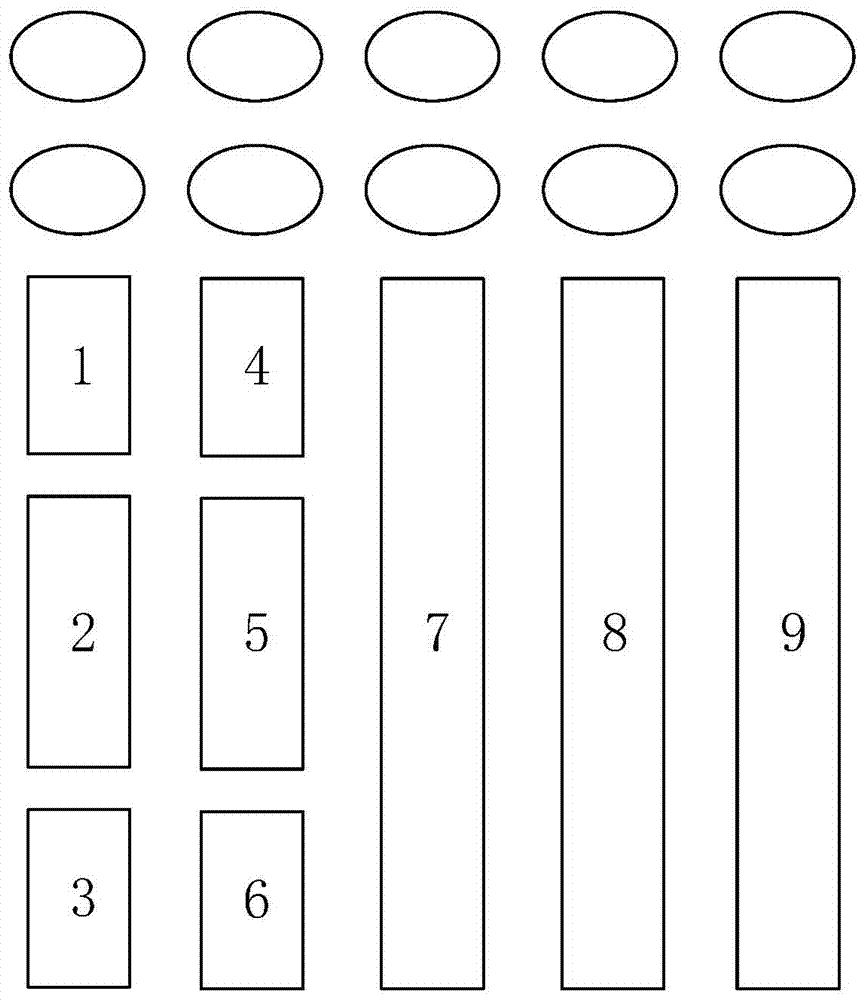

Multi-channel data collection control circuit and method for satellite

InactiveCN104166353AReduce acquisition timeProcess control stabilityProgramme control in sequence/logic controllersModularityEmbedded system

The invention discloses a multi-channel data collection control circuit and method for a satellite. The multi-channel data collection control circuit comprises multi-channel electronic switches, a voltage collection chip and an FPGA control module, and the FPGA control module is used for achieving switching of channels of the multi-channel electronic switches, control over the voltage collection time sequence work, data smoothing operation and the data storage and reading function. The hardware circuit formed by the FPGA control module, the multi-channel electronic switches and the voltage collection chip is used for replacing the complex software function, the collection function and the data processing and storage function can get rid of control of a processor, the resources of a CPU are effectively released, collection time is saved, and process control is more stable. An independent system for achieving collection modularization and control process intellectualization is achieved, and the far-reaching significance in satellite-borne integration of a satellite system is achieved.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

Preparation method of non-close packed inverse opal photonic crystal

ActiveCN102345167AComplete arrangementClosely arrangedPolycrystalline material growthSingle crystal growth detailsPhotonic crystalPhysical chemistry

A preparation method of non-close packed inverse opal photonic crystals comprises the following steps: preparing SiO2 spherical particles with ethyl orthosilicate as a raw material, performing ultrasonic treatment and vertical deposition of small-size SiO2 spherical particles and large-size organic particles to obtain a dual-size colloidal crystal structure, calcining the obtained heterogeneous dual-size colloidal crystal structure at a combustion decomposition temperature of the organic particles to remove organic matter so as to obtain non-close packed inverse opal photonic crystals; the method of the invention has simple equipment, simple operations, a short preparation period, and high yield.

Owner:JIANGSU GUOJIAO CHEM TECH

Cleaning and wool making technology for monocrystal silicon chip

InactiveCN103774239AStrong decontaminationEasy to cleanAfter-treatment detailsCleaning using liquidsPotassium hydroxideReaction temperature

The invention relates to a cleaning and wool making technology for a monocrystal silicon chip, and belongs to the technical field of chemical engineering. The technology particularly comprises the following step: (1) adopting a self-made silicon chip cleaning agent to perform precleaning on the silicon chip; (2) putting the pre-cleaned silicon chip into a wool making trough; preparing a wool making liquid in the wool making trough, and adding 0.1 to 5% of sodium hydroxide, 0.1 to 3% of potassium hydroxide, 1 to 5% of isopropyl alcohol and 0.02 to 5% of a self-made wool making additive in percentage by weight into the wool making liquid; rising temperature until the reaction temperature is 70 DEG C to 90 DEG C to make wool; turning on ultrasonic equipment during the wool making process; (3) when the wool is prepared, closing the trough body; before the chip is cast, stirring by adopting a stirring device, wherein the wool making reaction time is 15 to 40 min. According to the invention, through the adoption of the cleaning agent and the wool making additive, the technology is controlled to be simple and stable, the energy consumption is reduced, and the capability of process control is enhanced, so that the control quality of the product in various aspects is greatly improved, the production cost in various aspects is reduced, and the comprehensive economic benefit is increased.

Owner:HENAN INST OF SCI & TECH

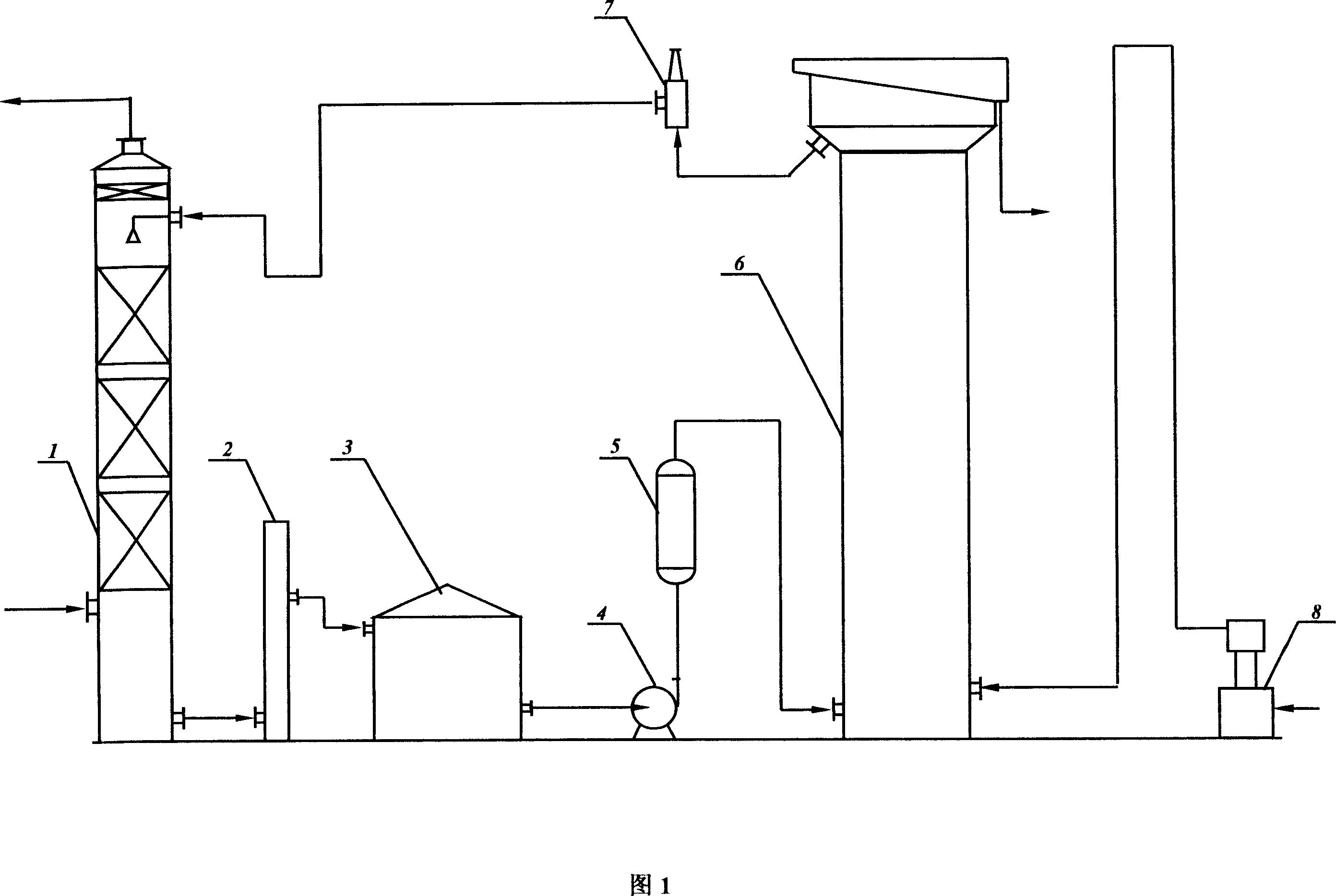

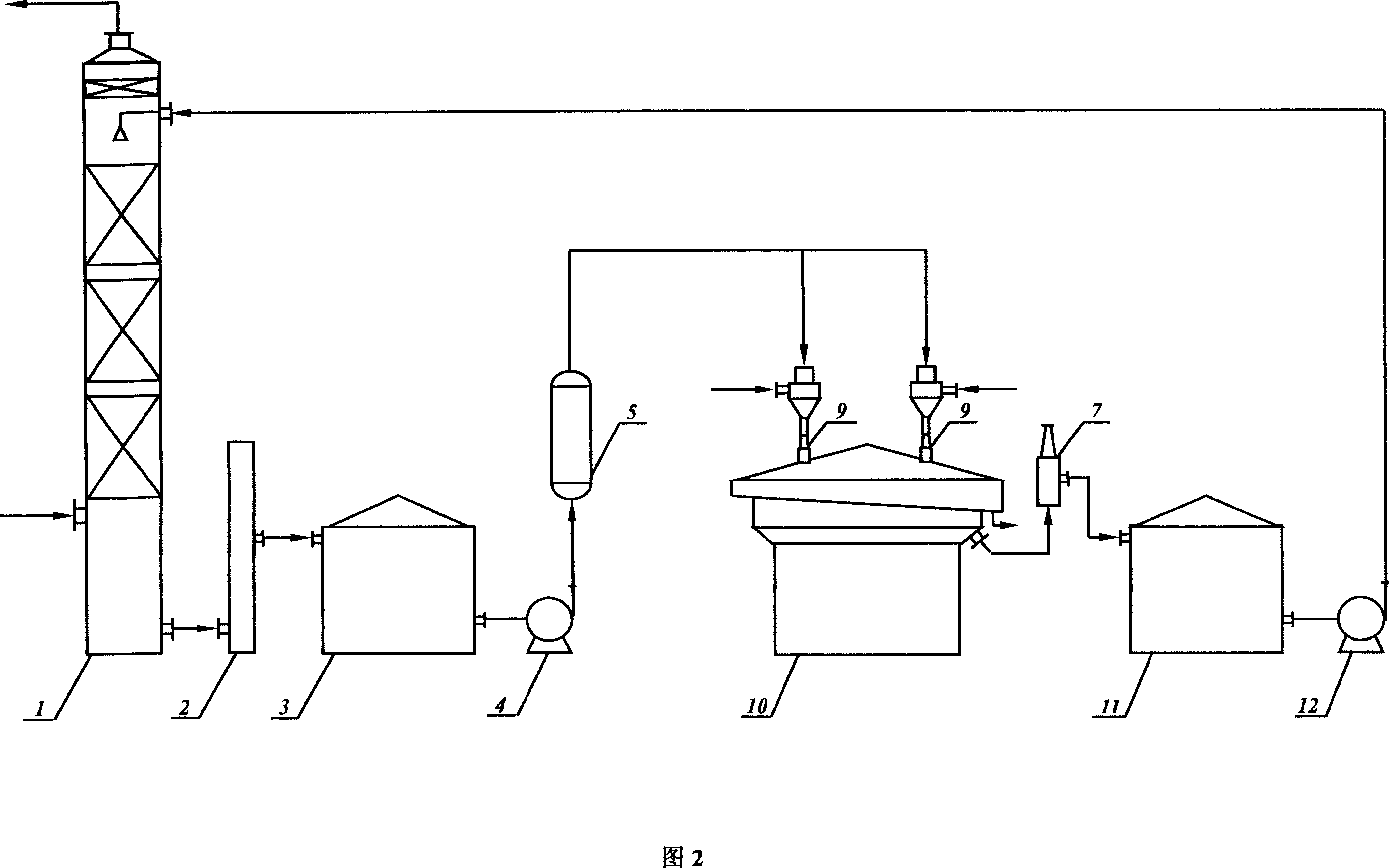

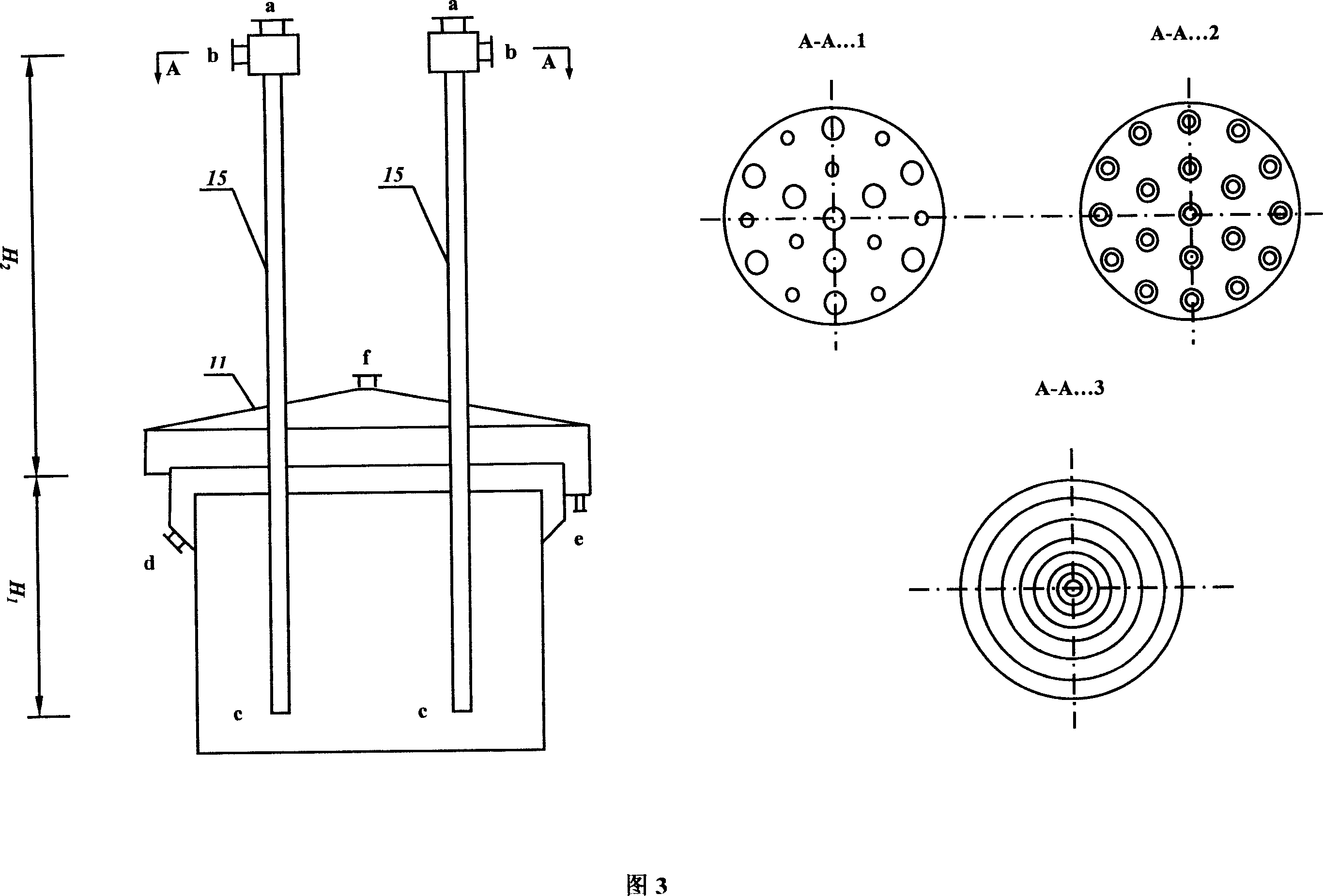

Gas desulfurizing-regenerating technological method and equipment with remarkable energy-saving effect by liquid-phase catalyzed oxidation

InactiveCN1935334ASave energyLess investmentDispersed particle separationCatalytic oxidationProduct gas

The present invention relates to a liquid-phase catalytic oxidation method gas sweetening regeneration process and its equipment, belonging to the field of sweetening technology. It is characterized by that said invention adopts a new-type low-pressure double-jet regenerator. Its rich mother liquor working pressure difference is low pressure (0.03-0.08 MPa), the desulfurizing tower and reaction tank are combined into one body, and its rich mother liquor outlet is set in the upper portion of said reaction tank, and the desulfurizing tower, reaction tank, low-pressure double-jet regenerator and regeneration tank are arranged according to ladder form. Said invention also can obtain obvious energy-saving effect.

Owner:山西源辉节能科技有限公司

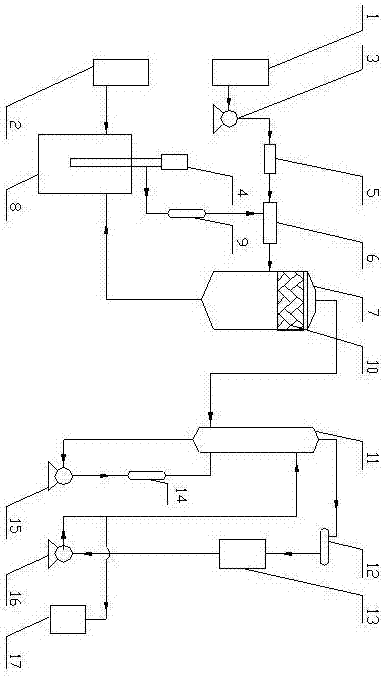

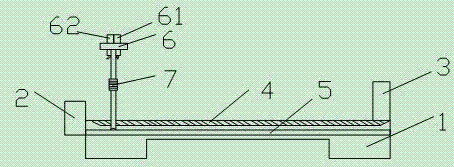

Chemical reaction apparatus and chemical reaction method for removing vanadium from crude TiCl4

InactiveCN106946286AHigh vanadium removal efficiencyProcess control stabilityTitanium tetrachlorideChemical reactionDouble tube

The invention discloses a chemical reaction apparatus for removing vanadium from crude TiCl4. The chemical reaction apparatus comprises, in a successively connected manner, a mixing reactor (6), a flash tank (7), a float valve column (11), a cooler (12), and a reflux tank (13), and also includes a crude TiCl4 storage tank (2), a secondary reactor (8), a double tube-sheet heat exchanger (9), a white oil storage tank (1), a metering pump (3), a flow meter (5), and a vanadium-removed TiCl4 storage tank (17). The invention is direct at a conventional technology of using mineral oil to remove the vanadium from crude TiCl4, wherein the crude TiCl4 heated by the double tube-sheet heat exchanger and precisely metered white oil are uniformly mixed according to ratio in the mixer, so that the two components are rapidly reacted in the mixer to remove the vanadium; the mixture then is fed into the flash tank to perform flash; and the TiCl4, with a VOCl3 impurity being removed, is fed into the high-boiling-point impurity removing float valve column in the form of vapor to further remove high-boiling-point impurities in the TiCl4; and the TiCl4 is cooled to produce a TiCl4 inter-product. The method solves the problems of poor quality stability and high energy consumption in a conventional TiCl4 vanadium removal process, has simple device arrangement and stable process control, and is high in vanadium removal efficiency.

Owner:JINCHUAN GROUP LIMITED

Recycled-ABS toughened foam material and preparation method thereof

The invention discloses a recycled-ABS (acrylonitrile-butadiene-styrene) toughened foam material. The recycled-ABS toughened foam material is prepared from the following components in parts by weight: 100 parts of recycled ABS, 5-50 parts of polyvinyl chloride, 0.5-15 parts of hollow glass microsphere, 0.5-20 parts of plasticizer, 0.5-20 parts of lubricant, 0.1-20 parts of fire retardant, 0.1-10 parts of smoke suppression agent, and 0.1-5 parts of antioxidant. The invention further discloses a preparation method of the recycled-ABS toughened foam material. The method fully utilizes the recycled ABS, toughens with polyvinyl chloride and improves the flame retardant property, and uses the hollow glass microsphere to fill and foam, so as to avoid the disadvantages that the product is heavy in smell, and the injection molding process is strictly controlled while performing the chemical foaming method; during the production process, the water gap leftover material can be repeatedly processed and utilized for many times. The recycled-ABS toughened foam material prepared from the preparation method is particularly suitable for production of injection products with requirements for high recycled-ABS utilization rate, low production price, good material toughness, light product dead load and flame retardant property.

Owner:HUBEI SUPERE ELECTRIC

Technology of improving and stabilizing titanium recorery rate in titanium micro-alloyed high strength weether resistant sinelting and continuous casting process

The invention discloses a improving and stabilizing titanium recovery technique in titanium micro-alloying high intensity weathering steel smelting and continuous casting process. The technique includes the following steps: adopting modern electric furnace to smelt; adjusting the component and adding titanium to do titanium micro-alloying in ladle refining furnace; and adopting protection casting. This can smelt out low carbon titanium micro-alloying high intensity weathering steel molten steel whose carbon content is less than 0.08%. And titanium recover is more than 70%. To adjust titanium percentage by weight can produce yield strength 450MPa-700MPa titanium micro-alloying high intensity weathering steel.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

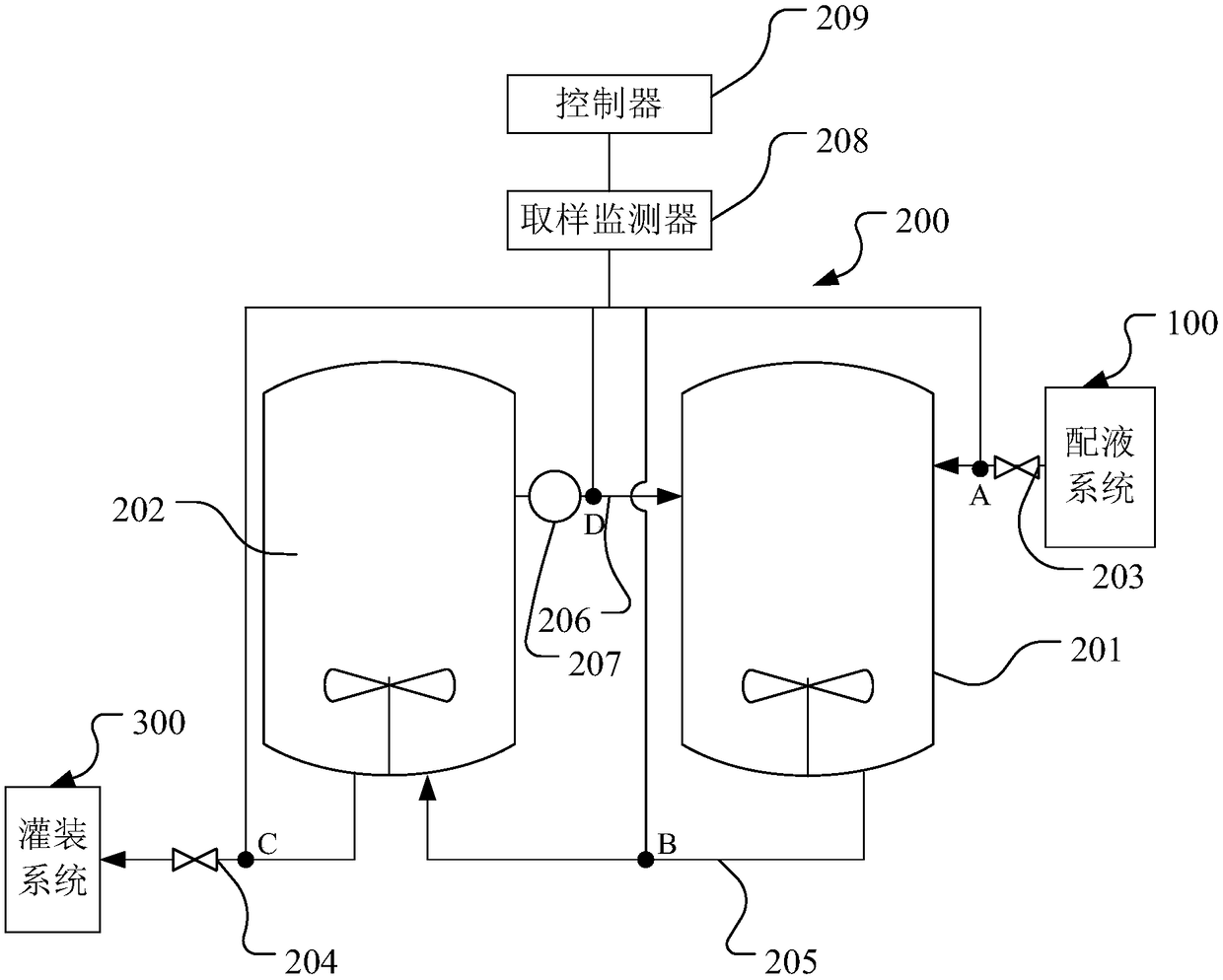

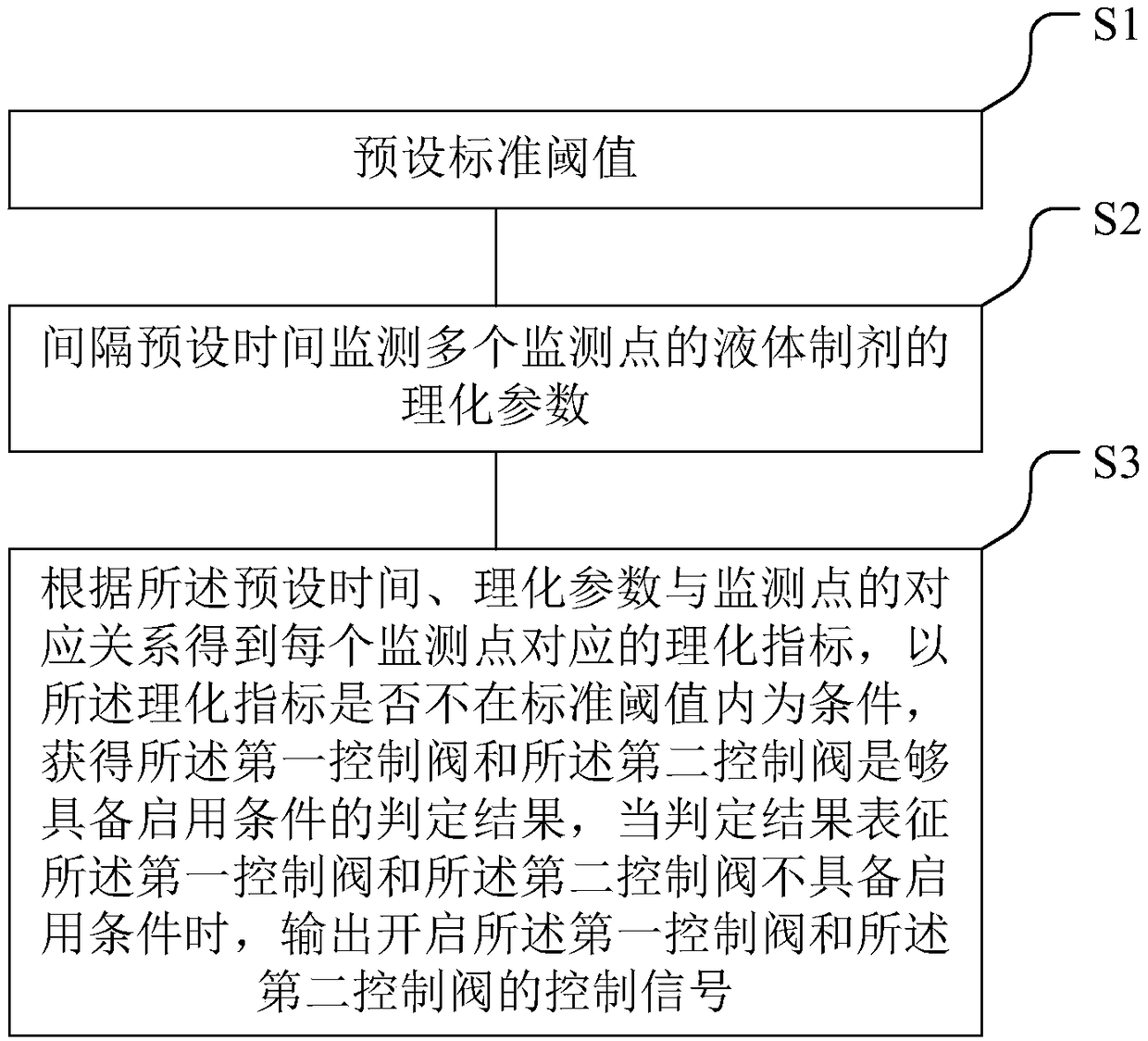

Device and method for continuously mixing liquid preparations

InactiveCN108786633AIncrease profitEnsure uniformity of outputTransportation and packagingMixing methodsEngineeringControl valves

The invention discloses a device and a method for continuously mixing liquid preparations. The device for continuously mixing the liquid preparations can realize the simultaneous and continuous implementation of feeding, mixing and discharging under the control effect of a first control valve and a second control valve, and monitors the physical and chemical parameters of multiple monitoring points at predetermined time intervals under the action of a sampling monitor, thus enabling the liquid preparations to meet the requirements, and further guaranteeing the uniformity of discharge. Since the device for continuously mixing the liquid preparations can realize continuous production, so that the production batches can be divided according to time periods. Compared with the prior art, the production efficiency can be increased by using the device occupying a smaller area, so that the utilization rate of a plant is increased.

Owner:无限极(营口)有限公司

Method for preparing high-temperature resistant zinc stearate

InactiveCN101914007AImprove long-term high temperature performanceNo pollution in the processCarboxylic acid salt preparationProcedure AgentsAntioxidant

The invention relates to the technical field of plastic processing aids, in particular to a method for preparing high-temperature resistant zinc stearate. An obtained product is mainly taken as a lubricating mold release agent in the plastic industry for processing at the high temperature. The method comprises the following steps of: putting stearic acid into a reaction kettle under normal pressure to heat the stearic acid to 130 to 180 DEG C; adding zinc oxide and a catalyst in two steps; reacting, adding an antioxidant, stirring and discharging the reaction product, wherein temperature is kept between 130 and 180 DEG C in an entire reaction process; and smashing to obtain a zinc stearate product. The acid value of free stearic acid in the high-temperature resistant zinc stearate prepared by the method is less than 0.5 percent and the whiteness of the product is enhanced greatly after heat is preserved at the temperature of 220 DEG C for 2 hours. Moreover, the zinc stearate has the advantages of stable process control, stable product quality, small fluctuation, no pollution of the used catalyst and the antioxidant on the environment and capability of meeting the environmental protection requirements of energy conservation and emission reduction; and the process has the advantages of simpleness, easy implementation, contribution to expanding the application field of the zinc stearate and very high economic benefit and social benefit.

Owner:DONGGUAN CHNV TECH CO LTD

High-strength normalized container steel with yield strength at 415 MPa level and thermal treatment method thereof

The invention provides high-strength normalized container steel with the yield strength at the 415 MPa level and a thermal treatment method of the high-strength normalized container steel with the yield strength at the 415 MPa level and belongs to the technical field of steel for pressure containers. When the thickness of the high-strength normalized container steel with the yield strength at the 415 MPa level is 6-29 mm, the high-strength normalized container steel with the yield strength at the 415 MPa level comprises, by weight, not larger than 0.2% of C, 0.1%-0.5% of Si, 1.0%-1.3% of Mn, not larger than 0.035% of P, not larger than 0.035% of S, 0.1%-0.18% of V, 0.4%-0.7% of Ni and the balance Fe and inevitable impurities; when the thickness of the high-strength normalized container steel with the yield strength at the 415 MPa level is 30-55 mm, the high-strength normalized container steel with the yield strength at the 415 MPa level comprises, by weight, not larger than 0.2% of C, 0.1%-0.5% of Si, 1.31%-1.6% of Mn, not larger than 0.035% of P, not larger than 0.035% of S, 0.1%-0.18% of V, 0.4%-0.7% of Ni and the balance Fe and inevitable impurities; and when the thickness of the high-strength normalized container steel with the yield strength at the 415 MPa level is 56-75 mm, the high-strength normalized container steel with the yield strength at the 415 MPa level comprises, by weight, not larger than 0.2% of C, 0.1%-0.5% of Si, 1.61%-1.7% of Mn, not larger than 0.035% of P, not larger than 0.035% of S, 0.1%-0.18% of V, 0.4%-0.7% of Ni and the balance Fe and inevitable impurities. The high-strength normalized container steel with the yield strength at the 415 MPa level and the thermal treatment method of the high-strength normalized container steel with the yield strength at the 415 MPa level have the advantages that the mechanical properties of a steel plate can all meet standard requirements, it can be guaranteed that the steel plate has good tenacity, the technology cost is low, and the technology is easy to implement.

Owner:SHOUGANG CORPORATION

Filter material for self-antibacterial and self-disinfecting mask and manufacturing method thereof

PendingCN111841149ADoes not change filterabilityNo change in physical propertiesBiochemical fibre treatmentMembrane filtersFiberMicroorganism

The invention belongs to the technical field of daily protection products, in particular to a filter cloth material for a mask with self-antibacterial and self-disinfecting functions and a manufacturing method thereof. The specific implementation process comprises the steps of discharging, degreasing, washing, acid pickling, sensitizing, washing, activating, pre-silvering, silvering, washing, surface modifying, drying, collecting and the like, and proper nano-silver particles can be deposited on the fiber surface after a conventional mask filter material is treated by the method, so that the killing effect on microorganisms such as bacteria or viruses is realized. According to the technology, the defect that an existing mask filter material can only filter particulate matter or droplets but cannot exterminate bacteria or viruses can be overcome; meanwhile, the nano-silver particles and the filter material fibers are firmly combined and are only distributed on the surfaces of the filtermaterial fibers, and compared with other silver-containing filter materials, the nano-silver filter material has the advantages of continuous industrial production, high effective utilization rate ofsilver, strong binding force of the silver particles and the filter material fibers, low manufacturing cost and the like.

Owner:常州微度化工新材料科技有限公司

Continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation

ActiveCN100463934CSimple recipeSimple process controlLong-fiber-reinforced thermoplasticFire retardant

Owner:KINGFA SCI & TECH CO LTD +1

Continuous flame quenching heat treatment method and device for roll necks

InactiveCN107058713AMeet the working conditionsImprove quenching uniformityFurnace typesHeat treatment furnacesHardnessService condition

The invention discloses a continuous flame quenching heat treatment method for roll necks. The method comprises the following steps: carrying out displacement type quenching on a roll neck when a roll rotates; and after quenching on one side of the roll neck is finished, turning the roll and quenching the roll in the same mode. Meanwhile, the invention further discloses a continuous flame quenching heat treatment device for roll necks. The roll neck with the surface hardness of 40-55 HSc can be obtained, service conditions of a roll bearing are met, the roll rotates in a quenching process, a quenching device continuously moves from one side to the other side at constant speed, quenching uniformity is good, quenching operation is simple, and a process is controlled stably.

Owner:安徽宝昌联合轧辊有限公司

Method for improving wash resistance of organic silicon nitrogen fire resistant fibers

InactiveCN105970328AGood alkali washing resistanceReduce loss rateArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentCross-linkLoss rate

The invention discloses a method for improving the wash resistance of organic silicon nitrogen fire resistant fibers. The method is characterized in that in the immobilization cross-linking procedure in the production process of organic silicon nitrogen fire resistant fibers, the PH value of an immobilization cross-linking bath is maintained to be 6.0-8.0. The method is used for further reducing the loss rate of a fire retardant of organic silicon nitrogen fire resistant regenerated cellulose fibers in high-temperature alkali wash. The method overcomes the defect that the concentration of an immobilization cross-linking agent needs to be improved to ensure the effect of an immobilization cross-linking reaction under the acid condition, and is easy to implement and stable in process control. Obtained fire resistant fibers are good in alkali-wash resistance, and the loss rate of the fire retardant in alkali wash is low.

Owner:SOL FLAME RETARDANT FIBER

Steel plate cooling method

ActiveCN104498674AReduce manufacturing costGuaranteed stabilityFurnace typesHeat treatment furnacesQuenchingSteel plates

The invention discloses a steel plate cooling method. After a steel plate is normalized, cooling in a quenching stage is carried out at a speed of 40-60m / min, and speed of a roller cooled by the quenching stage is 30-40m / min. The steel plate cooling method has the advantages that the steel plate is quickly cooled after being normalized, phase-transition temperature can be reduced while cooling speed of the steel plate is increased, nucleation rate of ferrite is increased, ferrite grains are refined, a phase transformation structure is thinned, carbide growth of microalloy elements can also be inhibited, and the microalloy elements are dispersed and separated out at low temperature, and thus strength of a steel plate is improved, and toughness of the steel plate is not reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for producing carotenoid through solid fermentation of blakeslea trispora

InactiveCN110982867AEasy to prepareBig cost advantageFood processingAnimal feeding stuffLiquid wasteOil and grease

The invention relates to a method for producing carotenoid through solid fermentation of blakeslea trispora, a solid fermentation extract and animal feed. The method comprises the following steps: inoculating blakeslea trispora on a fermentation culture medium and carrying out fermentation culture; and to be specific, the fermentation culture medium contains kitchen solid waste accounting for 5-30% of the total weight of the culture medium and kitchen waste grease accounting for 5-15% of the total weight of the culture medium. The preparation method of the kitchen waste solid waste and the kitchen waste grease comprises the following steps: (1), roughly selecting the kitchen waste; (2), filtering or centrifugally separating the roughly selected kitchen waste to obtain the kitchen solid waste and the kitchen liquid waste; and (3) further carrying out oil-water separation on the kitchen liquid waste to obtain the kitchen waste grease and the kitchen waste swill. Kitchen waste is used asa fermentation medium, so that the cost is low; the kitchen waste is used as a main raw material and carotenoid is generated through biotransformation, so that kitchen waste pollution is reduced whilethe feed application requirement is met.

Owner:CABIO BIOTECH WUHAN CO LTD

Complex electron donor for drag reducer polymerization

ActiveCN101735366ASignificantly increased activityUniform heat releasePipeline systemsChemical industryElectron donor

The invention relates to an organic polymer synthesis technique, in particular to a complex electron donor for drag reducer polymerization, belonging to the technical field of chemical industry. The complex electron donor is characterized in that polymerization monomers are added into an anhydrous oxygen-free reaction system, wherein the mixture ratio of laurylene to styrene is 10:1-1:10, or the mixture ratio of laurylene to octylene is 10:1-1:10; the cocatalyst is 0.1%-3% and is obtained by diluting triisobutylaluminum with a refined solvent, wherein the triisobutylaluminum is 20%, the normal heptane is 20%-50%, the rubber solvent oil is 20%-50%, the main catalyst is 0.005%-0.1%, and the complex electron donor is 0.01%-0.5%; and the reaction temperature of the system is -40-10 DEG C, the stirring process is carried out continuously, the reaction time is 24-188 hours, thus a sticky super high molecular weight polymer is obtained. The invention has the advantages of obviously improving the activity of the catalyst system, reducing the consumption of the main catalyst, reducing the consumption of other additives, and the like. In the process of production, the heat release of the catalysis system is uniform, and the process control is stable. By applying the complex electron donor of the invention to long-distance oil transmission pipelines, the pipeline transmission capacity is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for smelting hydrogen crack resisting container steel with yield level being 245 MPa

The invention belongs to the technical field of steelmaking, and relates to a method for smelting hydrogen crack resisting container steel with the yield level being 245 MPa. The method comprises the steps that desulfuration pretreatment is carried out through magnesium injection and lime adding of molten iron, the magnesium injection amount is 0.25 kg / t-0.5 kg / t of steel, the lime adding amount is 3 kg / t-7 kg / t of steel, and the slagging-off time ranges from 7 min to 10 min; converter smelting is carried out, the tapping temperature ranges from 1,570 DEG C to 1,600 DEG C, and the phosphorus content during tapping ranges from 0.003 wt% to 0.005 wt%; LF refining is carried out, and the final sulfur content ranges from 0.0006 wt% to 0.001 wt%; RH vacuum treatment is carried out, and the hydrogen content is smaller than 1.5 ppm at the end; and the slab continuous casting process is completed. The method has the beneficial effects that cost is low, implementation is easy, process control is stable, and popularization is easy.

Owner:SHOUGANG CORPORATION

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479BHeat-resistant and anti-yellowingLattice stabilizationPigment treatment with organosilicon compoundsPigment physical treatmentSlurryRutile

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

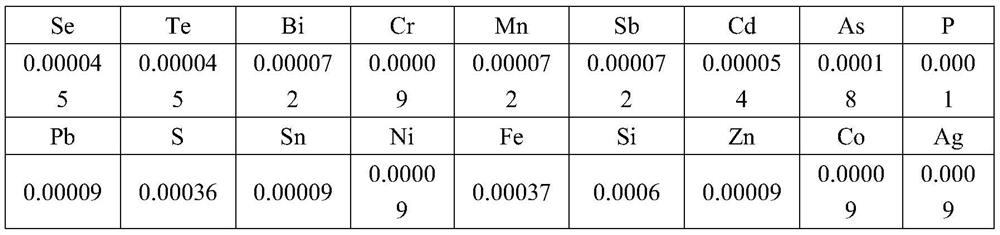

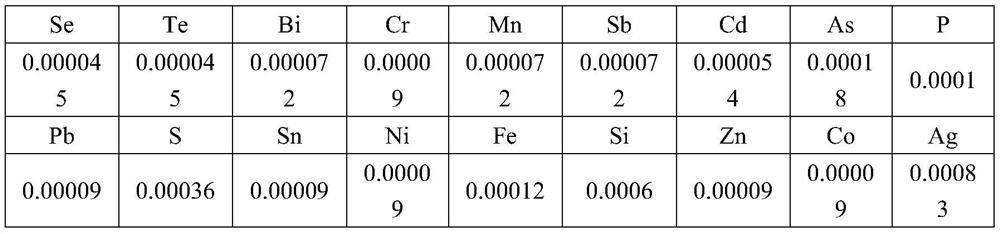

Process for producing cathode copper through electrolytic refining of low-grade copper anode plate

PendingCN113564639AImprove the quality rateProcess control stabilityPhotography auxillary processesProcess efficiency improvementElectrolytic agentMetallurgy

The invention discloses a process for producing cathode copper by electrolytic refining of a low-grade copper anode plate. The process is as follows: electrolyte adopted by electrolytic refining comprises the following components: 190-200g / L of H2SO4, less than or equal to 15g / L of Ni<2+>, less than or equal to 15g / L of As, and 42-46 g / L of Cu<2+>; the additives are ADT, gelatin, thiourea and hydrochloric acid, the addition amount of the ADT is 10-15 g / t.Cu, and the addition amount of the gelatin is 20-30 g / t.Cu; and the addition amount of the thiourea is 50-60 g / t.Cu, the addition amount of the hydrochloric acid is 200-300 ml / t.Cu, the temperature of the electrolyte is 62-64 DEG C, and the circulation amount of a single tank is 30-35 L / min. The process is stable in process control and high in high-quality product rate of products, the purpose that the process adapts to raw materials is achieved, and good conditions are created for widening copper raw material purchasing channels and reducing cost and increasing benefits of enterprises.

Owner:JINCHUAN GROUP LIMITED

One-bath dyeing method for spandex and viscose

InactiveCN103643548ASimple production processProcess control stabilityDyeing processVegetal fibresYarnMethyl cellulose

The invention discloses a one-bath dyeing method for spandex and viscose. The method comprises the following steps: (1) knitting 2 parts by mass of viscose and 3 parts by mass of spandex blended yarns into a knitted fabric; (2) putting the knitted fabric into an overflow dyeing machine, adding water, adding a chelating agent and isopropanolamine in sequence, adjusting the pH to 4-5, heating to 60 DEG C, running for 20 minutes, adding an active dye, running for 30 minutes, adding a cation dye, running for 30 minutes, adding anhydrous sodium sulphate, running for 25 minutes, heating to 90 DEG C, running for 1 hour, cooling to 35 DEG C, draining water, and washing with hot water of 75 DEG C for 30 minutes; (3) putting the dyed knitted fabric into water of 35 DEG C, adding an acid soaping agent and hydroxypropyl methyl cellulose in sequence, heating to 90 DEG C, running for 40 minutes, adding cold water, overflowing, cooling to 15 DEG C, draining water, adding cold water, and washing for 20 minutes. The one-bath dyeing method for the spandex and the viscose provided by the invention has the advantages of simple production process, stability in process control and energy conservation.

Owner:JIANGSU JINTAI KNITTING

A method for improving the washing resistance of organosilicon nitrogen flame-retardant fiber

InactiveCN105970328BGood alkali washing resistanceReduce loss rateArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentCross-linkNitrogen

The invention discloses a method for improving the wash resistance of organic silicon nitrogen fire resistant fibers. The method is characterized in that in the immobilization cross-linking procedure in the production process of organic silicon nitrogen fire resistant fibers, the PH value of an immobilization cross-linking bath is maintained to be 6.0-8.0. The method is used for further reducing the loss rate of a fire retardant of organic silicon nitrogen fire resistant regenerated cellulose fibers in high-temperature alkali wash. The method overcomes the defect that the concentration of an immobilization cross-linking agent needs to be improved to ensure the effect of an immobilization cross-linking reaction under the acid condition, and is easy to implement and stable in process control. Obtained fire resistant fibers are good in alkali-wash resistance, and the loss rate of the fire retardant in alkali wash is low.

Owner:SOL FLAME RETARDANT FIBER

Technology of improving and stabilizing titanium recorery rate in titanium micro-alloyed high strength weether resistant sinelting and continuous casting process

The invention discloses a improving and stabilizing titanium recovery technique in titanium micro-alloying high intensity weathering steel smelting and continuous casting process. The technique includes the following steps: adopting modern electric furnace to smelt; adjusting the component and adding titanium to do titanium micro-alloying in ladle refining furnace; and adopting protection casting. This can smelt out low carbon titanium micro-alloying high intensity weathering steel molten steel whose carbon content is less than 0.08%. And titanium recover is more than 70%. To adjust titanium percentage by weight can produce yield strength 450MPa-700MPa titanium micro-alloying high intensity weathering steel.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com