Process for producing cathode copper through electrolytic refining of low-grade copper anode plate

A copper anode plate, electrolytic refining technology, applied in the direction of photography process, photography auxiliary process, improvement of process efficiency, etc., can solve the problem of inability to meet the electrolytic refining treatment of high arsenic and low copper content anode plate, and achieve excellent technical and economic indicators , The effect of high quality product, high product rate and stable process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A process for producing cathode copper by electrolytic refining of low-grade copper anode plates, the composition of the electrolytic solution used in the electrolytic refining is: H 2 SO 4 : 190g / L; Ni 2+ : 10g / L; As: 10g / L; Cu 2+ : 42g / L; Additives are ADT, gelatin, thiourea and hydrochloric acid, the amount of ADT added is 10g / t.Cu, the amount of 12 degree gelatin added is 20g / t.Cu; the amount of thiourea added is 60g / t.Cu, The amount of hydrochloric acid added is 200ml / t.Cu, and the ratio of thiourea to 12-degree gelatin is 2.5:1.

[0020] Electrolyte temperature is 62°C, current density: 270A / m 2 , The cell pressure of the electrolytic cell: 0.28V, the center distance of the same pole: 105mm, and the cycle volume of a single cell is 30L / min cell.

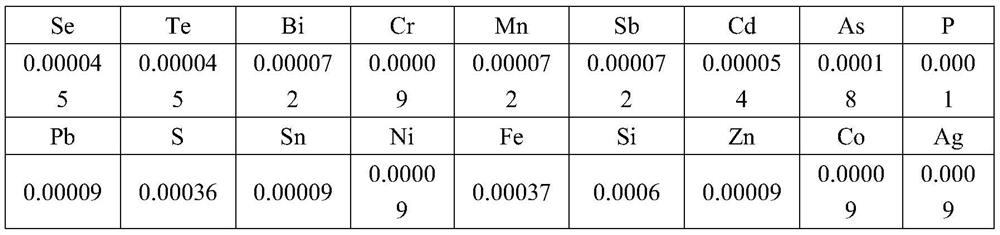

[0021] The specifications of high arsenic, high nickel and low copper anode plates are 1000×960×48mm, the weight is 375kg / piece, and the chemical composition (see Table 1).

[0022] Table 1 Anode Plate Chemical Comp...

Embodiment 2

[0028] A process for producing cathode copper by electrolytic refining of low-grade copper anode plates, the composition of the electrolytic solution used in the electrolytic refining is: H 2 SO 4 : 195g / L; Ni 2+ : 12g / L; As: 13g / L; Cu 2+ : 44g / L; the additives are ADT, gelatin, thiourea and hydrochloric acid, the amount of ADT added is 12g / t.Cu, the amount of 12 degree gelatin added is 30g / t.Cu; the amount of thiourea added is 50g / t.Cu, The added amount of hydrochloric acid is 250ml / t.Cu, and the ratio of added amount of thiourea to 12 degree gelatin is 1.67:1.

[0029] Electrolyte temperature is 63°C, current density: 275A / m 2 , The tank voltage of the electrolyzer: 0.30V, the center distance of the same pole: 105mm, and the circulation volume of a single tank is 30L / min.

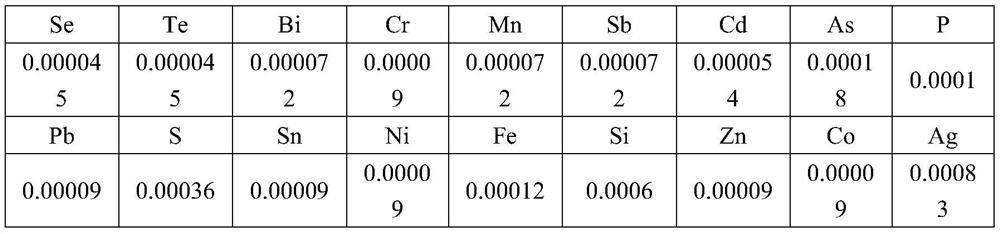

[0030] The specifications of high arsenic, high nickel and low copper anode plates are 1000×960×48mm, the weight is 375kg / piece, and the chemical composition (see Table 3).

[0031] Table 3 Anode Pla...

Embodiment 3

[0037] A process for producing cathode copper by electrolytic refining of low-grade copper anode plates, the composition of the electrolytic solution used in the electrolytic refining is: H 2 SO 4 : 200g / L; Ni 2+ : 14g / L; As: 14g / L; Cu 2+ : 46g / L; Additives are ADT, gelatin, thiourea and hydrochloric acid, the amount of ADT added is 15g / t.Cu, the amount of 12 degree gelatin added is 25g / t.Cu; the amount of thiourea added is 55g / t.Cu, The added amount of hydrochloric acid is 300ml / t.Cu, and the ratio of added amount of thiourea to 12 degree gelatin is 2.2:1.

[0038] Electrolyte temperature is 64°C, current density: 300A / m 2 , The cell voltage of the electrolytic cell: 0.31V, the center distance of the same pole: 105mm, and the circulation volume of a single cell is 35L / min. cell.

[0039] The specifications of the high arsenic, high nickel and low copper anode plates are 1000×960×48mm, the weight is 375kg / piece, and the chemical composition (see Table 5).

[0040] Table 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com