Patents

Literature

58results about How to "Good technical and economic indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite

InactiveCN101862703ASimple processGood technical and economic indicatorsMagnetic separationCombined methodSlurry

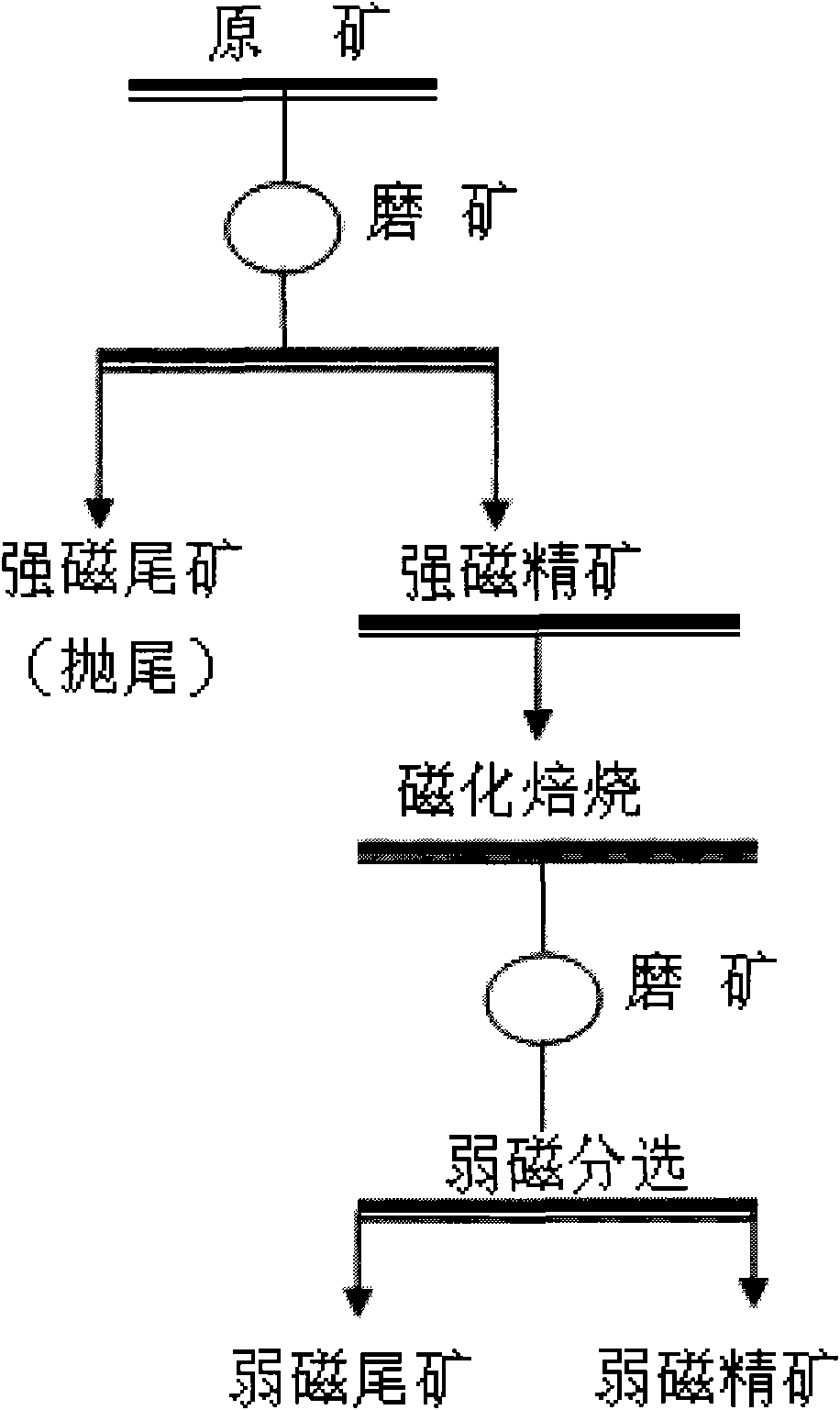

The invention relates to a separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite. The technical scheme first comminutes oolitic lean hematite containing 30 to 40 percent of iron, the comminuted mineral slurry enters a high-intensity magnetic separator and preseparated, weak-magnetic mineral is turned into strong-magnetic concentrate, and tailings are removed in advance; the strong-magnetic concentrate is mixed with pulverized coal, the weight of which accounts for 10 to 30 percent of the weight of the concentrate, and the mixture is heated to 900 DEG C to 1100 DEG C in a muffle furnace, and is magnetically roasted as the temperature is kept for 1 to 3 hours; after being cooled, the magnetically roasted mineral sample is wet-milled, and is then fed into a low-intensity magnetic separator and separated under low-intensity magnetism, magnetic mineral is turned into weak-magnetic concentrate, and thereby high-quality iron concentrate is produced. The grade of the obtained iron concentrate is higher than 64 percent, the phosphor content is less than 0.15 percent, and the sulfur content is less than 0.10 percent. The invention is characterized by simple process flow, good technical and economic indexes and high product quality.

Owner:KUNMING UNIV OF SCI & TECH

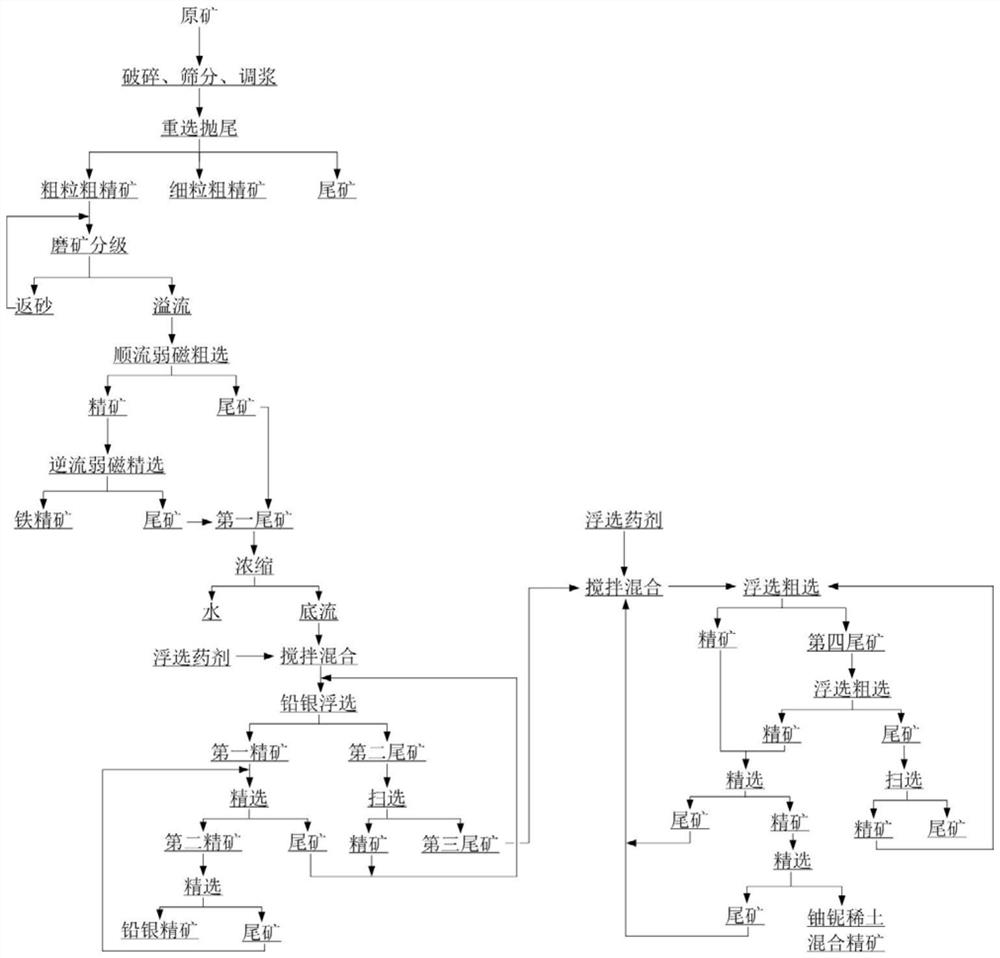

Comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore

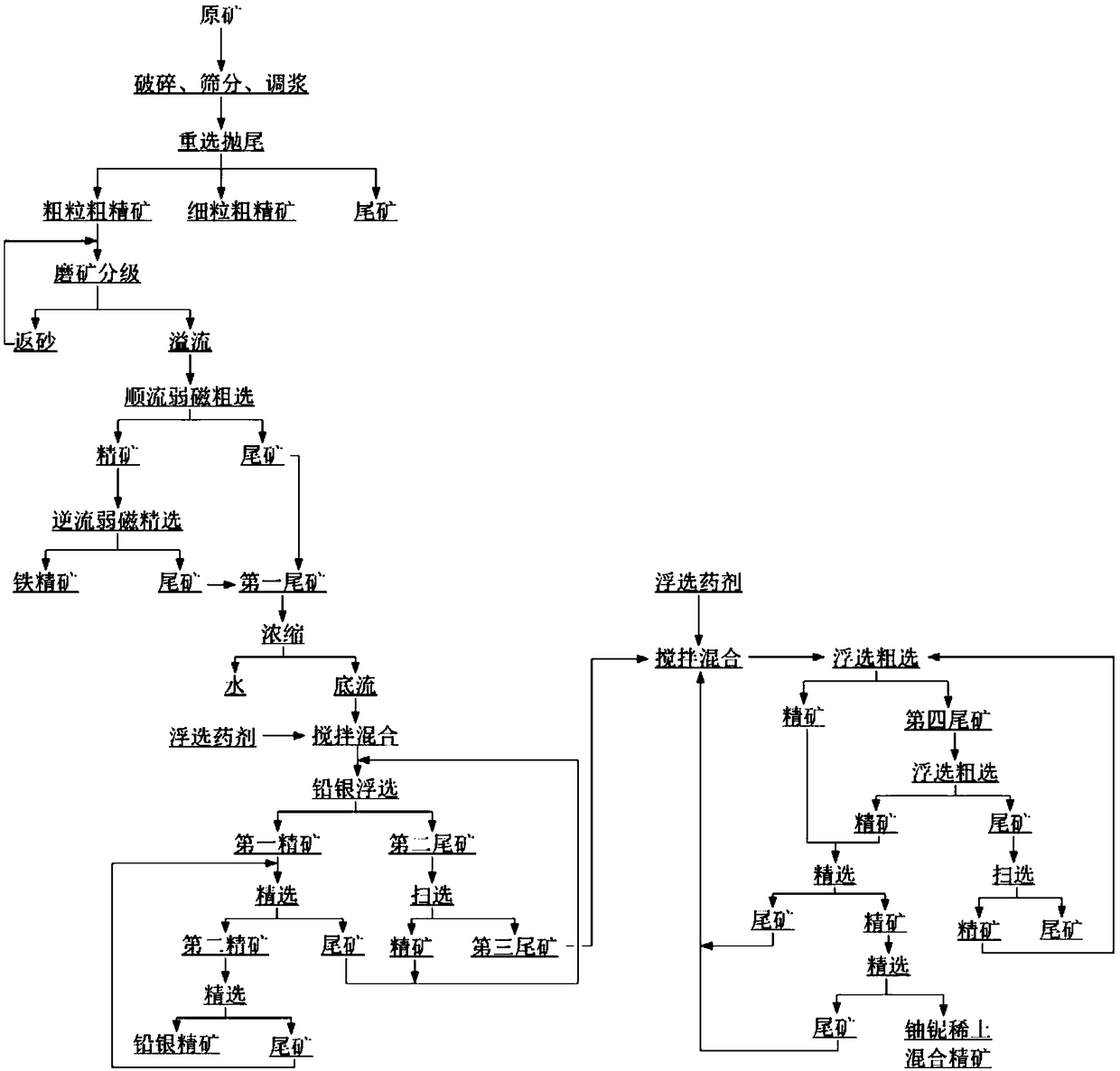

The invention provides a comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore. The comprehensive recovery and beneficiation method comprises the followingsteps that (1) overflow products obtained by grinding the uranium-containing polymetallic ore are subjected to direct flow magnetic separation roughing operation and reverse flow magnetic separation concentration operation in sequence, and iron concentrate and first tailings are obtained; (2) the tailings are subjected to condensation and flotation to obtain first concentrate and second tailings,the first concentrate is subjected to concentration to obtain lead silver concentrate, and the second tailings are subjected to scavenging to obtain third tailings; and (3) the third tailings are subjected to flotation roughing and condensation, and then uranium, niobium and rare earth mixed concentrate is obtained. The beneficiation index is good, the purpose of fully recovering all useful components in coarse-grain coarse concentrate subjected to tailing discarding through gravity concentration under the coarse grinding condition is achieved, an efficient beneficiation separation and enrichment technology is provided for large-scale development and utilization of the low-grade complex polymetallic hard rock uranium ore in China, and the subsequent cost of extracting uranium, niobium andrare earth in the uranium ore through hydrometallurgy is greatly lowered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

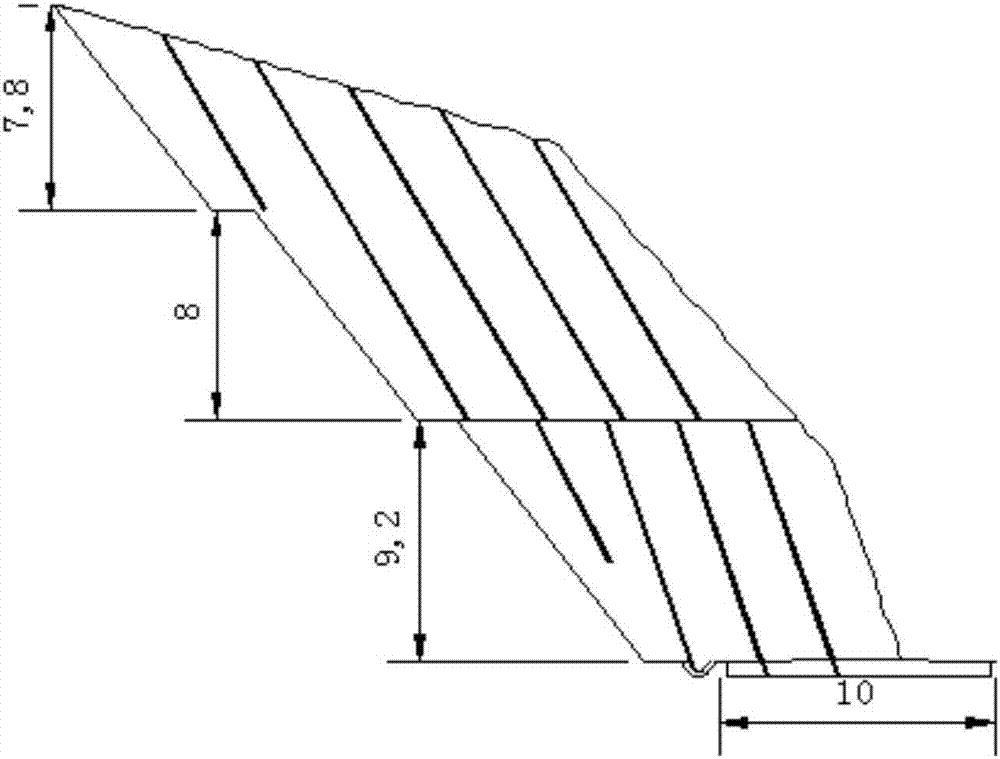

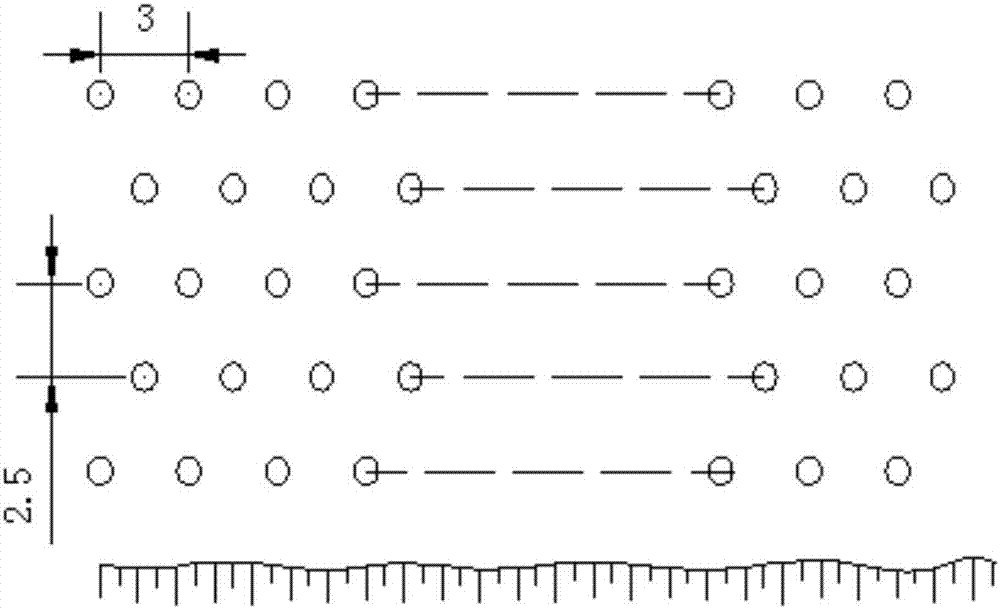

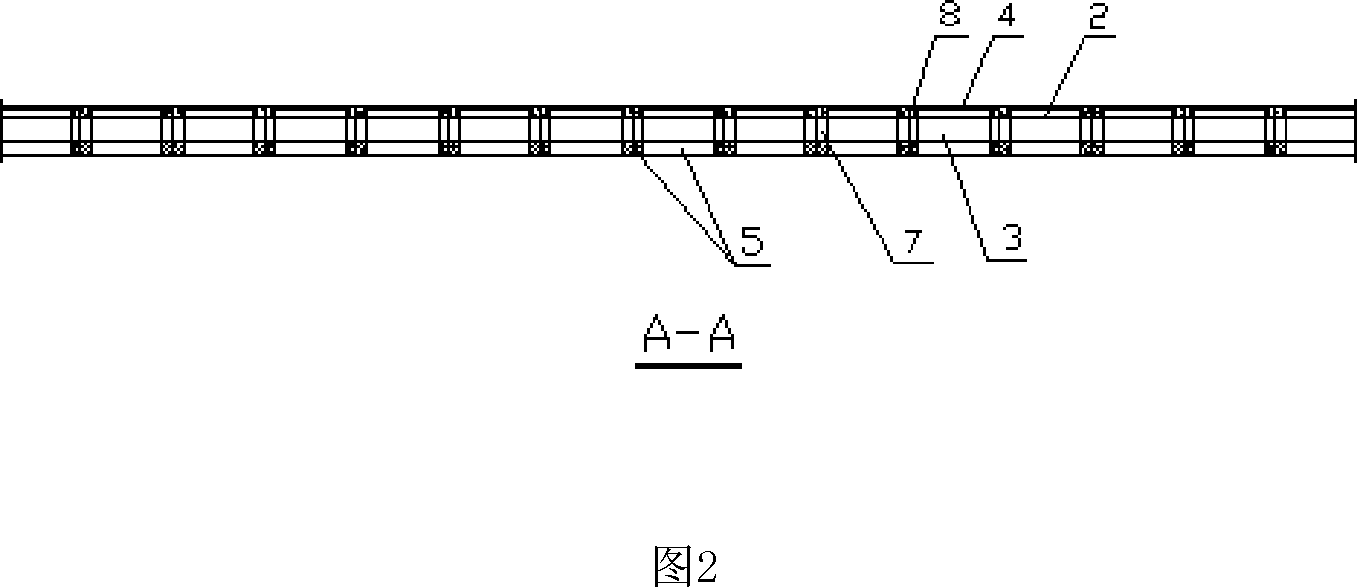

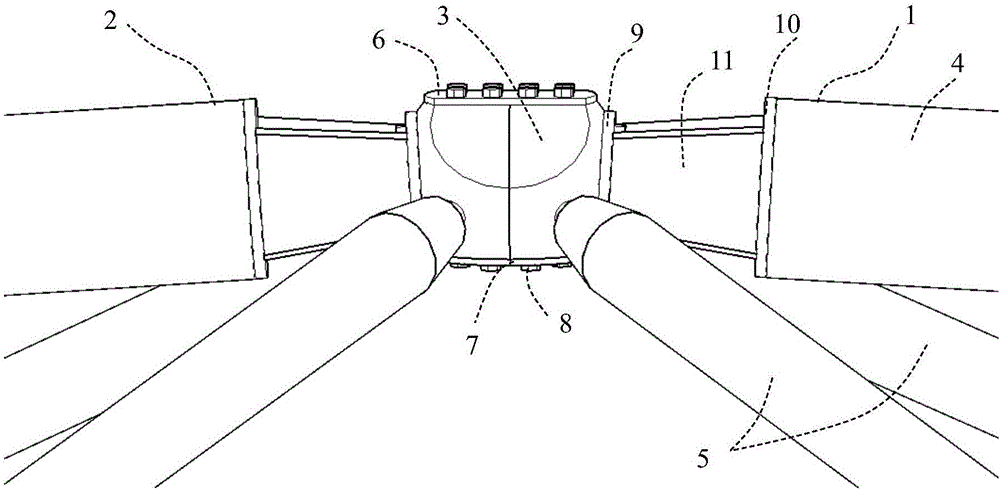

Hollow floor system filled with an air-filling bag and construction method thereof

InactiveCN101793070AGood technical and economic indicatorsReasonable forceFloorsEngineeringSteel bar

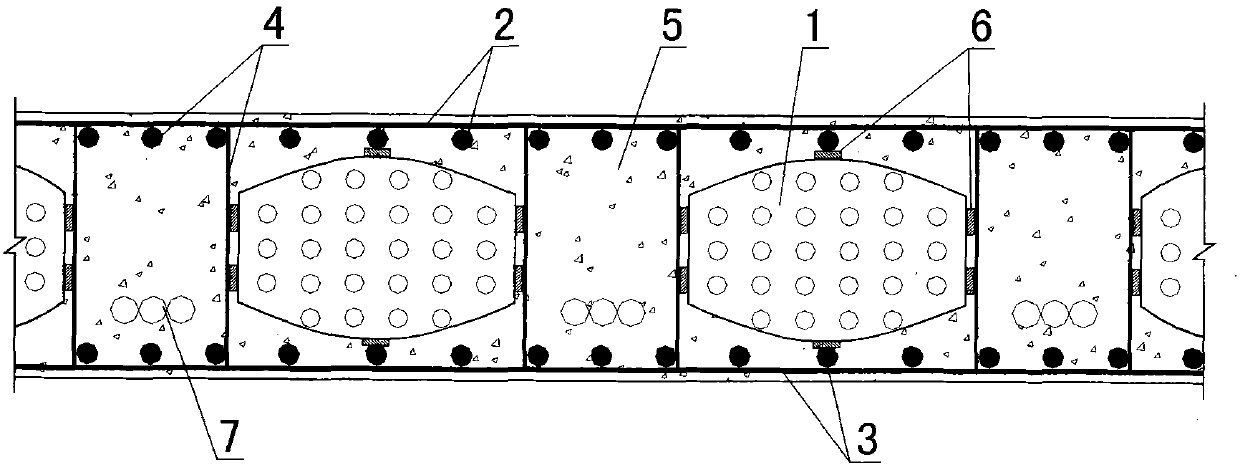

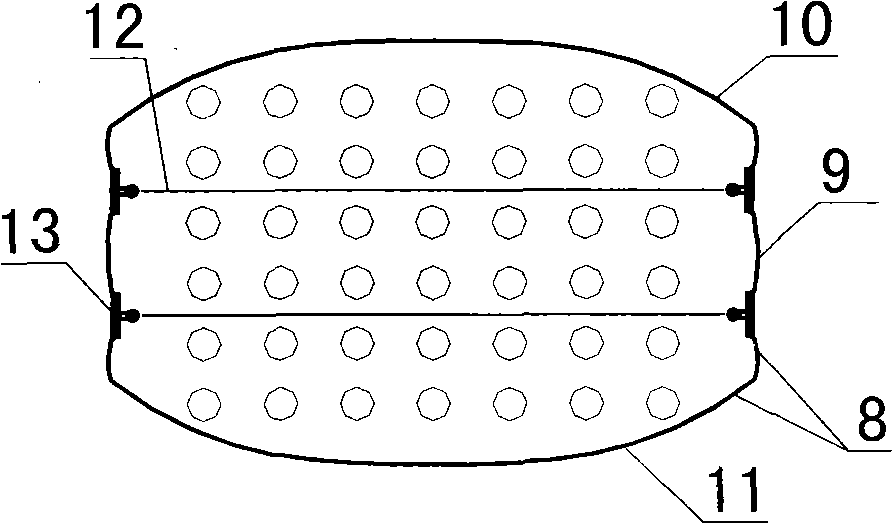

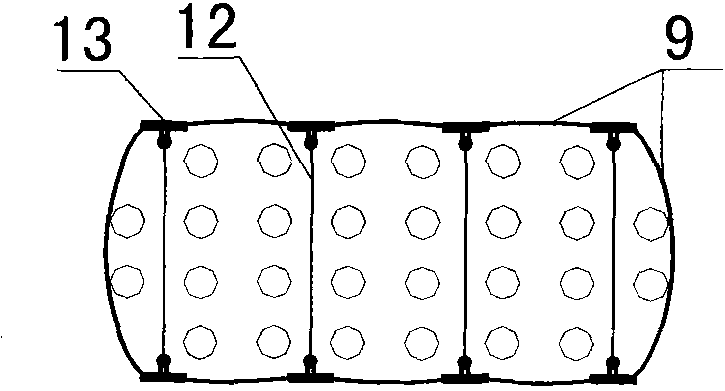

The invention relates to a hollow floor system filled with an air-filling bag and a construction method thereof, belonging to the field of the structure of the common building. The hollow floor system consists of the air-filling bag (1), upper steel bars (2), lower steel bars (3), hidden girder steel bars (4) and concrete (5), wherein the air-filling bag (1) is positioned among the upper steel bars (2), the lower steel bars (3) and the hidden girder steel bars (4); a bag wall (8) of the air-filling bag (1) consists of four side walls (9), an upper wall (10) and a lower wall (11); the shapes of at least two side walls (9) adjacent to the hidden girder steel bars (4) in the air-filling bag (1) are planes; the shapes of the upper wall (10) and the lower wall (11) are heaved-outward arc surfaces; and positioning pieces (12) are arranged among the inner sides of the side walls (9) so as to ensure that the two side walls (9) are parallel mutually. The hollow floor system has large span, better reliability, earthquake resistance and crack resistance, and good economy and applicability.

Owner:徐焱

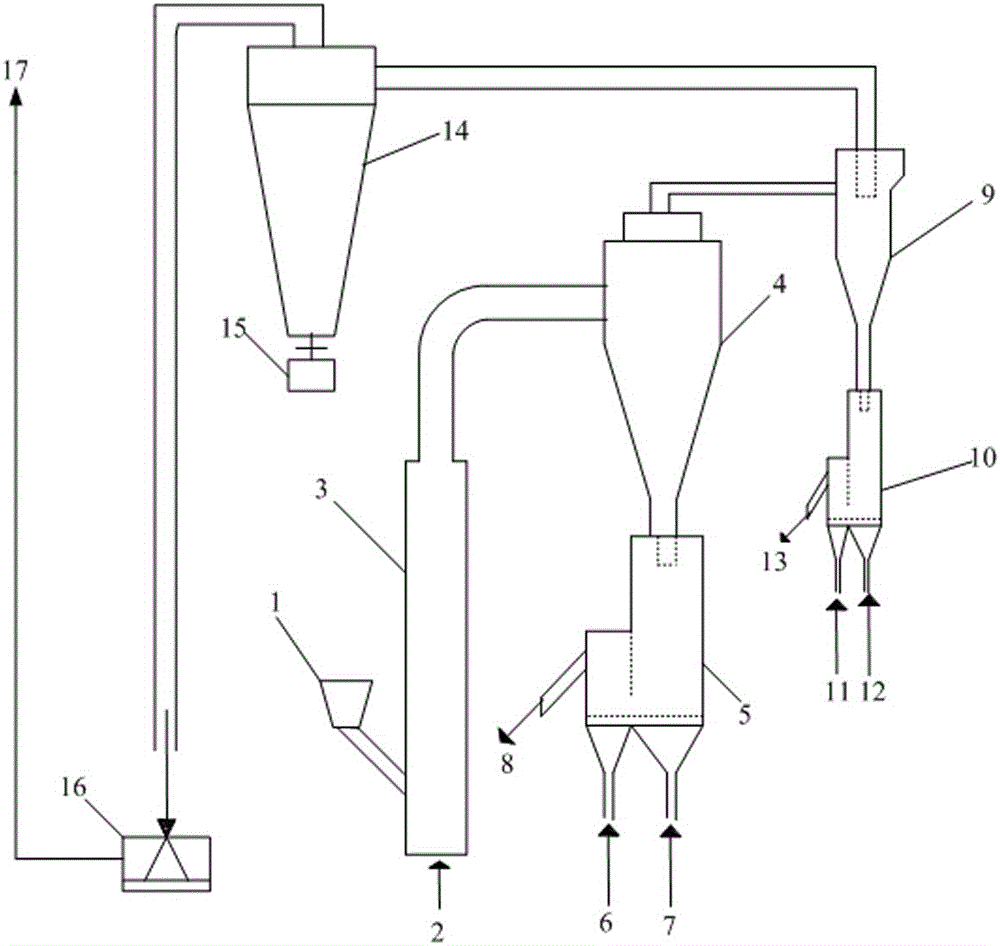

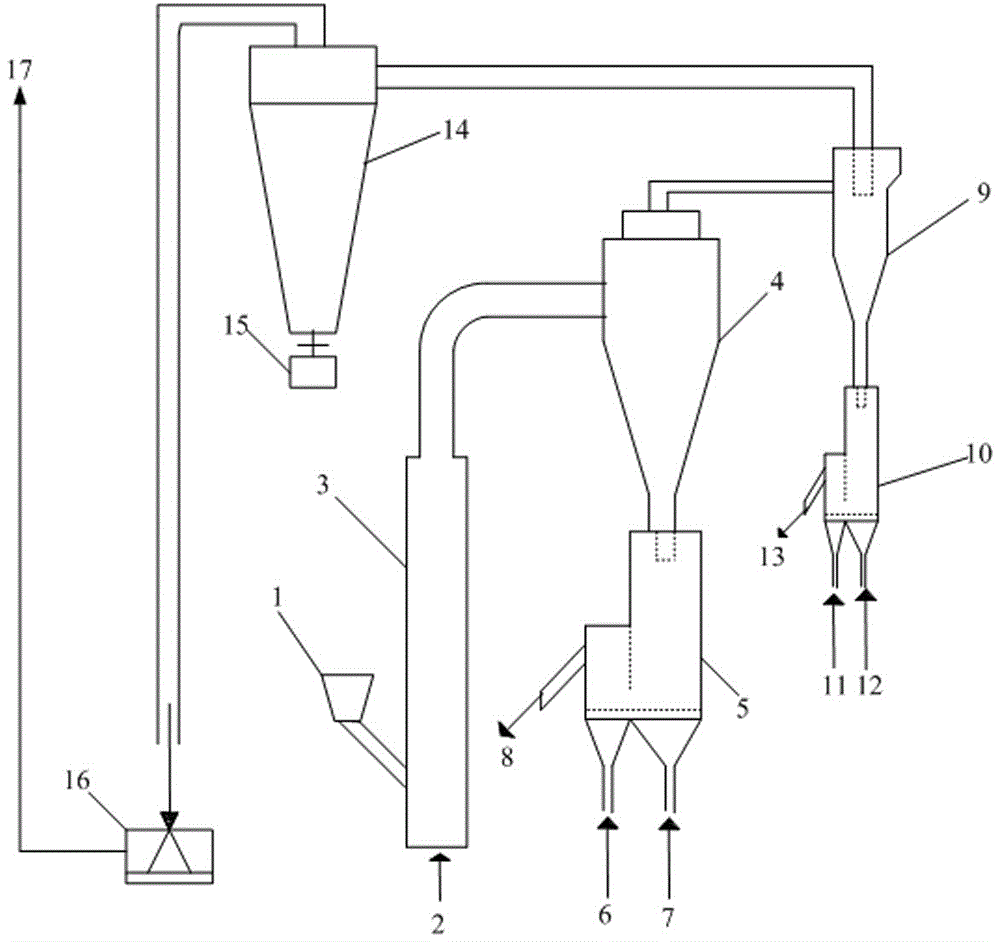

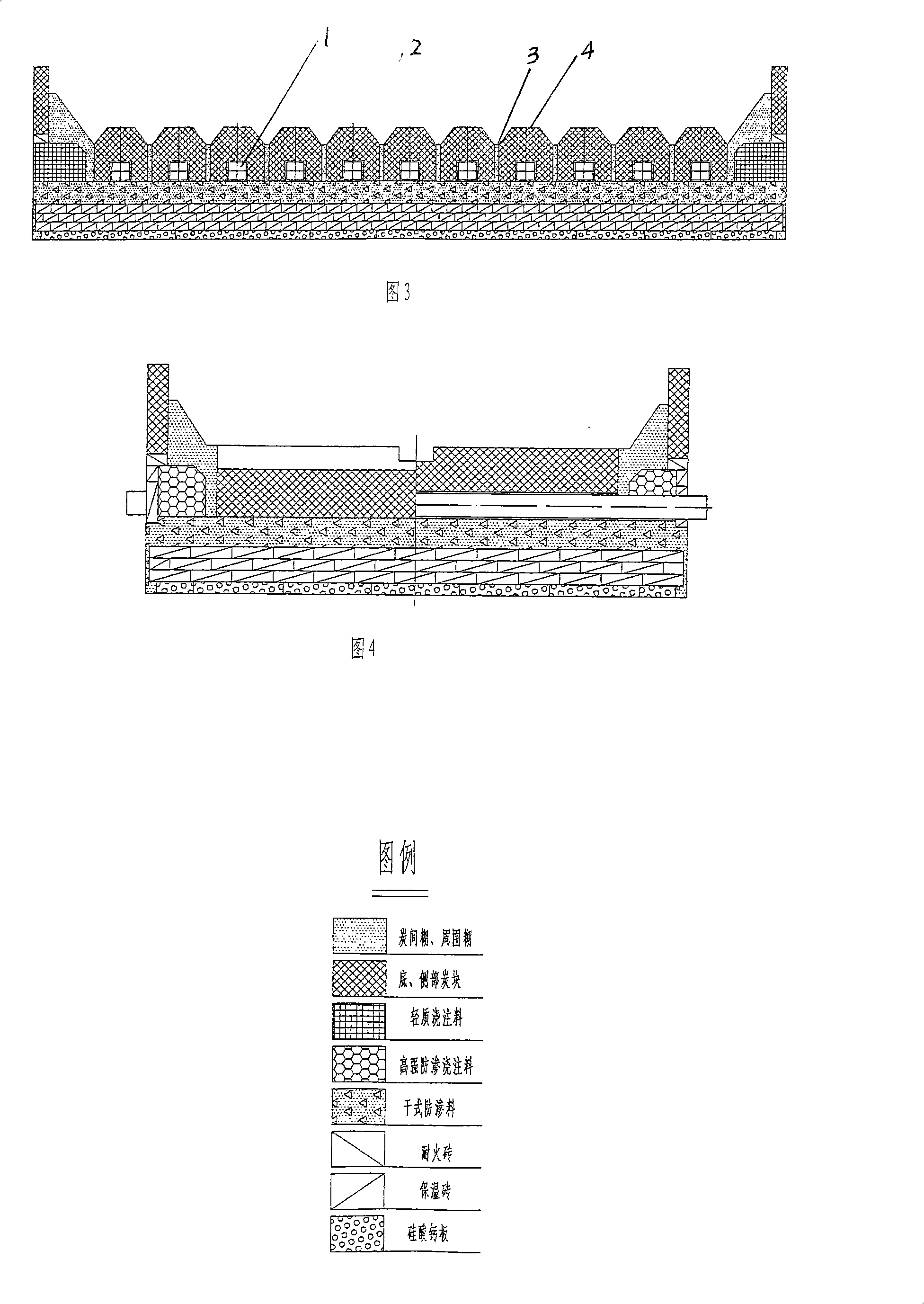

Classifying suspension roasting device for complex refractory iron ore

The invention provides a classifying suspension roasting device for complex refractory iron ore. The device comprises a suspension preheating oxidizing device, two-stage cyclone classifiers, two-stage suspension reducers, a cyclone separator and a draught fan, wherein the suspension preheating oxidizing device communicates with the first-stage cyclone classifier, and the first-stage cyclone classifier communicates with the second-stage cyclone classifier; the second-stage cyclone classifier communicates with the cyclone separator, and the cyclone separator communicates with the draught fan; discharging ports of the first-stage classifier and the second-stage classifier are correspondingly inserted into the first-stage suspension reducer and the second-stage suspension reducer. With the adoption of the device, coarse and fine materials can be classified, magnetized and roasted, and thus the reduction conditions of the materials at different classes can be controlled; in addition, the energy consumption can be greatly reduced, and the optimal technical-economic indicator can be obtained.

Owner:SHANGHAI MILESTONE TECH CO LTD

Method for judging position of cohesive zone of blast furnace and position of cohesive zone of blast furnace

InactiveCN104915556APromote rational distributionGood technical and economic indicatorsBlast furnace componentsBlast furnace detailsEngineeringMechanical engineering

The invention relates to a method for judging a position of a cohesive zone of a blast furnace and the position of the cohesive zone of the blast furnace. The method is used for judging the position of the cohesive zone of the large-scale blast furnace of which the volume is 4000 to 5000 m<3>; a flat cold plate structure is adopted by a furnace body of the blast furnace; the furnace body totally comprises 53 layers of flat cold plates; a furnace bosh of the blast furnace is in 14th to 20th layers; the method comprises the judging steps of (I) measuring a thermal load valve of each part, and measuring a thermal load valve of the upper part of the furnace body; (II) comparing a ratio of the thermal load values of all parts according to the thermal load values of all the parts, wherein the thermal load value of a furnace bosh area during normal production of the large-scale blast furnace is (450 to 550)*10MJ / h, the ratio of the thermal load value of the furnace bosh area occupies 4.5% to 5,5% of the thermal load of the whole blast furnace, and the thermal load ratio of each flat cold plate layer is lowest; (III) judging that the position of the cohesive zone is in the furnace bosh. According to the method for judging the position of the cohesive zone of the blast furnace, disclosed by the invention, the position of the cohesive zone of the blast furnace during normal production can be clearly found; the temperature of the cohesive zone is controlled to be 50 to 60 DEG C after the position of the cohesive zone is determined, and a furnace wall can be prevented from getting thick.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Fault real-time detection method for aluminum cell supplying system

InactiveCN101275246AGrasp the running status in timeIncreased level of controlElectrical resistance and conductanceState parameter

A malfunction real-time detecting method for an aluminum electrobath discharging system relates to an online monitoring method of the electrobath discharging system operating state and discharging system malfunction in the process of an aluminum electrolysis production. The detecting process is real-time judging the discharging system operating state and discharging system malfunction by a bath-control machine according to the discharging interval, the discharging period and the changing rate of the electrobath resistance as the time, the aluminum oxide concentration changing state parameter; then displaying the malfunction state on the monitoring system and processing broadcast via the workshop vocal broadcast. The method of this invention processes the real-time detection for the discharging system to timely find the discharging system malfunctions so that the discharging system malfunctions can be timely maintained and detected to reduce the influence for the operation of the entire electrobath system caused by the discharging system malfunctions, which enhances the electrobath control effect and achieves the purposes of saving energy and reducing the consumption.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

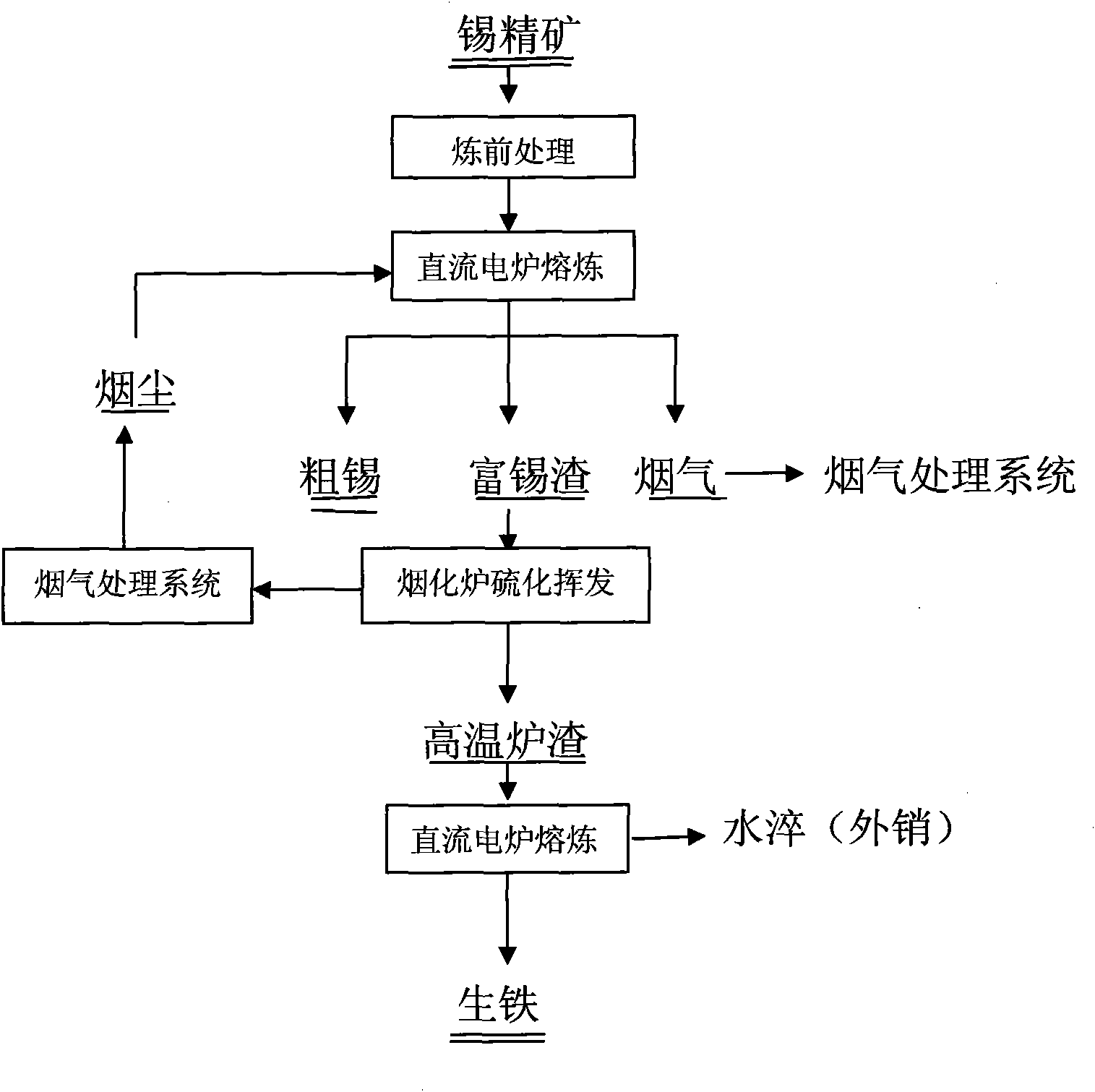

DC electric furnace-fuming furnace combined tin-smelting method

InactiveCN101787445AIncrease production capacityFast meltingProcess efficiency improvementElectric arc furnaceLiquid state

The invention relates to a tin-smelting process, in particular to a method for tin smelting by combining a DC electric furnace and a fuming furnace and for comprehensively recycling iron. The steps of the invention are as follows: reducing agent is added according to the components of tin concentrate, and then, the mixture is put in the DC electric furnace for reduction and smelting to generate metallic tin; and vulcanizing agent and slagging flux are added to liquid slag according to components of the liquid slag, and then, the mixture is put in the fuming furnace to be vulcanized to volatilize the tin in the slag; meanwhile, the mixture is recycled in the form of tin oxide fume; the fumed slag is put in the DC electric furnace in the liquid state, and then, the reducing agent and the flux are added to the fumed slag to be smelted to generate pig iron; meanwhile, the residual sulphur contained in the slag is utilized to continually volatilize the residual tin, and the water-quenched slag can be used as the raw material for building. The method is suitable for processing various tin-containing materials; compared with the traditional tin-smelting method, the tin-smelting method provided by the invention has the advantages of less investment and high tin recovery rate and can comprehensively recycle iron and other valuable metals.

Owner:YUNNAN TIN GROUP HLDG

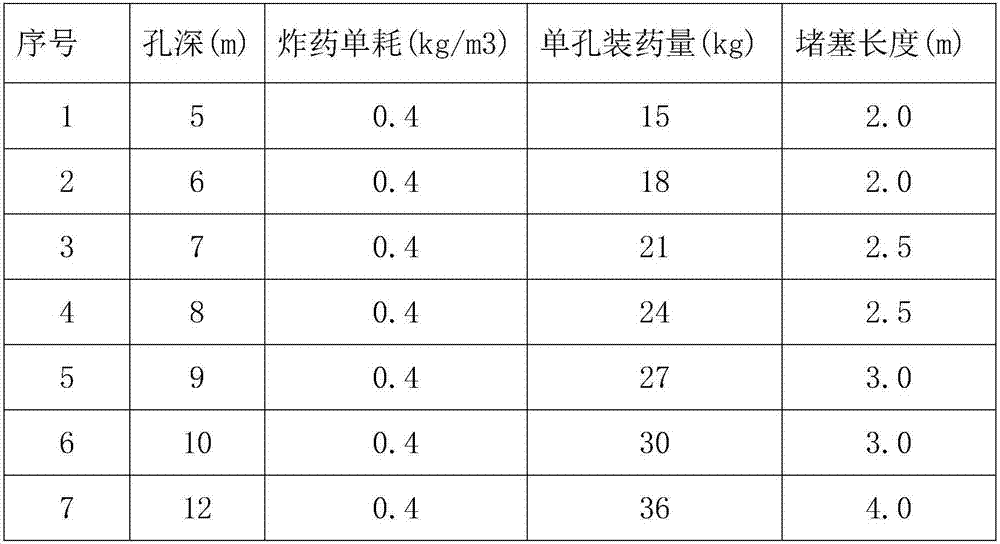

Medium-deep hole blasting calculation method

The invention discloses a medium-deep hole blasting calculation method. The medium-deep hole blasting calculation method comprises the following steps that S1, explosive unit consumption is calculated; S2, a blast hole diameter is calculated; S3, the hole drilling depth is calculated; S4, the over-drilling depth deltah excess drilling is calculated; S5, the chassis resistance line W bottom is calculated; S6, the hole distance a and the row distance b are calculated; S7, the blockage length is calculated; and S8, the single hole explosive payload Q is calculated. According to the calculation method, theoretical calculation and site situations are combined, rock can be effectively blasted, the construction cost is reduced, and safety is high; and an in-hole subsection interval charging structure is adopted, in-hole and out-hole millisecond delay blasting is carried out, and the blasting rock breaking effect and the blasting vibration harm are well controlled.

Owner:中交一公局第五工程有限公司

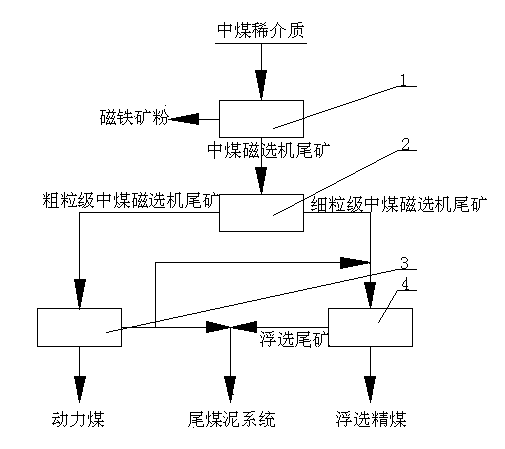

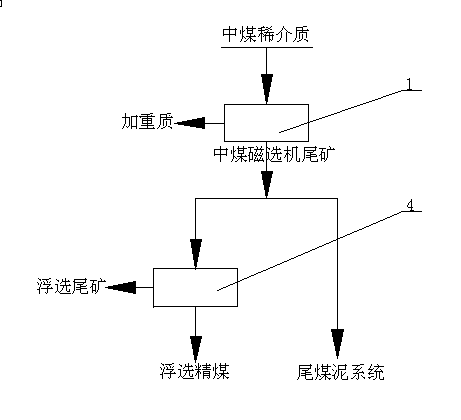

Middings magnetic separator tailings classifying separation recovery system and middings magnetic separatortailings classifying separation recovery technology for dense medium coal preparation plant

InactiveCN103639077AHigh recovery rateReduce the number of flotation devicesVortex flow apparatusMagnetic separatorEngineering

The invention relates to a middings magnetic separator tailings classifying separation recovery system and a middings magnetic separatortailings classifying separation recovery technology for a dense medium coal preparation plant. The system comprises a middings magnetic separator, a coal slime classifying device, a flotation unit and a coarse coal slime dewatering and recycling device, wherein the middings magnetic separator is connected with the coal slime classifying device; the coal slime classifying device is respectively connected with the flotation unit and the coarse coal slime dewatering and recycling device. The method comprises the steps of firstly, feeding dilute middings medium into the middings magnetic separator to carry out magnetic separation; feeding the middings magnetic separator tailings into the coal slime classifying device, and classifying according to the particle sizes of the middings magnetic separator tailings; after that, dividing the middings magnetic separator tailings into coarse fraction and fine fraction; feeding the middings magnetic separator tailings in the coarse fraction into the coarse coal slime dewatering and recycling device, feeding the middings magnetic separator tailings in the fine fraction into the flotation unit, and sorting and recovering fine-particle clean coal. After the system and the technology are adopted, under the condition of same quality indexes of the clean coal, the recovery rate of the clean coal can be improved, or the number of flotation units and the consumption of flotation reagent can be reduced, and the floatability of flotation fed material can be improved.

Owner:TANGSHAN SENPU ENG DESIGN

Washing device and washing method for marine exhaust flue gases

ActiveCN102112207BEfficient washingLow running costGas treatmentUsing liquid separation agentFlue gasEnvironmental engineering

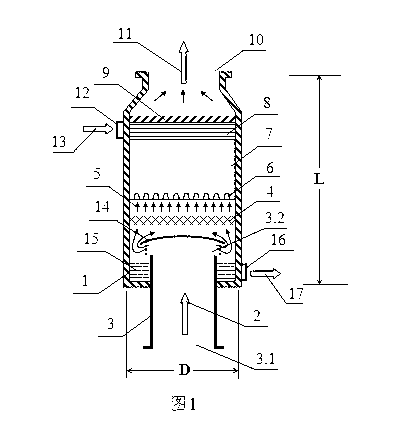

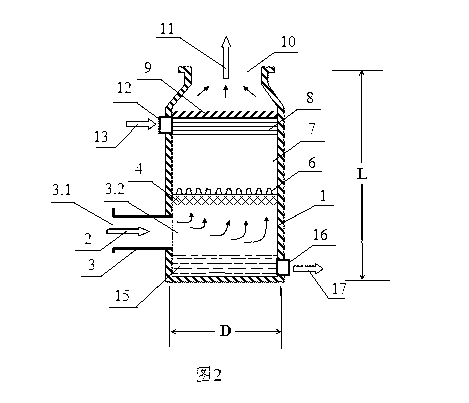

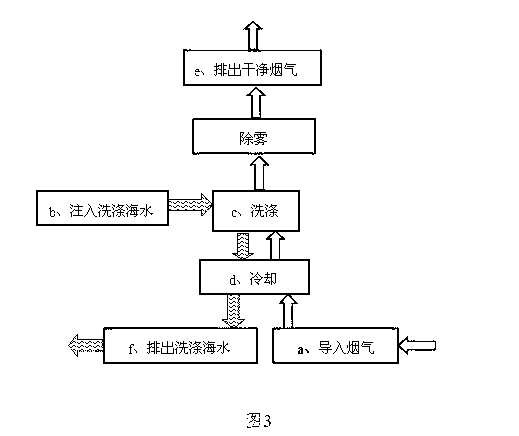

This invention relates to a ship flue gas scrubbing apparatus and scrubbing method. The apparatus includes a housing (1), an upper scrubbing layer (7) at the upper side inside the housing (I), and a liquid collecting pool (15) in the lower side inside the housing (1), a flue gas leading-in port (3.2) between the scrubbing layer (7) and the liquid collecting pool (15), a scrubbing seawater inlet (12) above the scrubbing layer (7), and a cooler (4) located at a flue gas passage between the flue gas inlet (3.1) outside the housing and the scrubbing layer (7). The method includes leading flue gas, cooling, injecting scrubbing seawater, scrubbing and other steps.

Owner:CLEAN ENERGY PROJECT TECH INC

Method for maintenance and fettling of blast furnace by using low titanium pellet

The present invention belongs to the field of iron smelting blast furnace protecting technology in metallurgical industry, and is blast furnace protecting and repairing method with low-titanium pellet. The low-titanium pellet is produced in rotary kiln or vertical kiln through adding titania sand into the concentrate powder less than 30 % to result in titania content of 1-4 %. By means of controlling titania content in the low-titanium pellet, the burden has simplified structure and consists of sintered ore 60-80 wt%, low-titanium pellet 0-20 wt% and raw ore 5-20 wt% and relatively high grade over 60 %. While protecting or repairing furnace, the present invention obtain high technological indexes and high production efficiency.

Owner:SHOUGANG CORPORATION

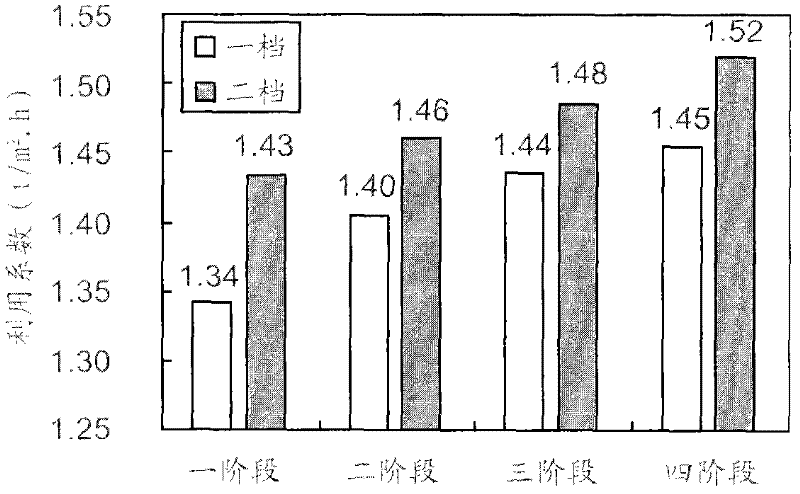

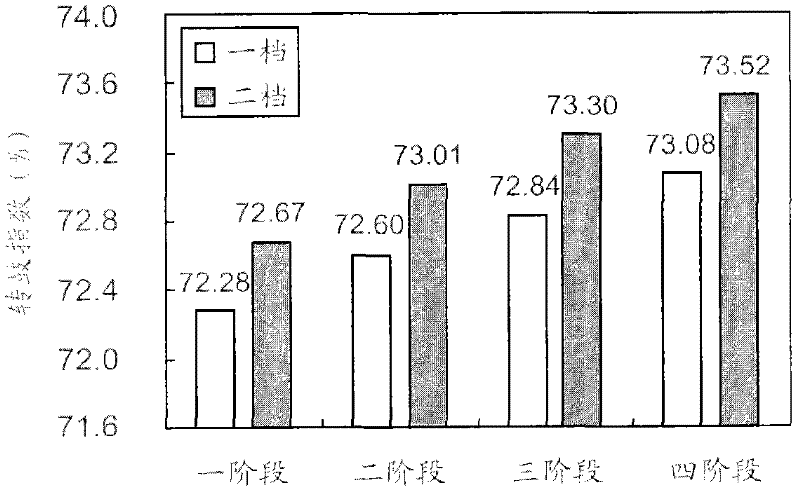

Process optimization method for sintering vanadium-titanium magnetite concentrate by large-scale sintering machine

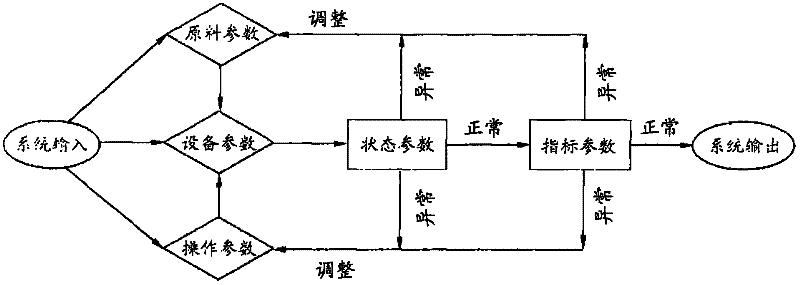

ActiveCN102269993AGood technical and economic indicatorsImprove technical and economic indicatorsTotal factory controlProgramme total factory controlProcess optimizationSolid fuel

The invention provides a process optimization method for sintering a vanadium-titanium magnetite concentrate by a large-scale sintering machine. According to the invention, the method comprises the following steps that: a sintering process is constructed into a sintering system that includes input, an intermediate link and output; ore return quantity, feeding quantity, material layer thickness, machine speed, and material temperature and the like are selected and are taken as adjustable parameters; index parameters of a sintering system are improved by a plurality of phases that are connectedsequentially, wherein each phase among the plurality of phases comprises multi-group records that record adjustable parameters and the index parameters that are corresponding to the adjustable parameters during sintering production and a record in which index parameters satisfy a target range of the present phase is selected from the multi-group records; adjustable parameters at the next phase are controlled on the basis of a mean value of adjustable parameters of the last phase among the plurality phases, wherein the adjustable parameters of the last phase are in a record and satisfy a target range of the last phase and the target range of the next phase is not inferior to that of the last phase. According to the invention, index parameters including a utilization coefficient, a drum index and low solid fuel consumption and the like in the sintering process are improved.

Owner:PANZHIHUA IRON AND STEEL +1

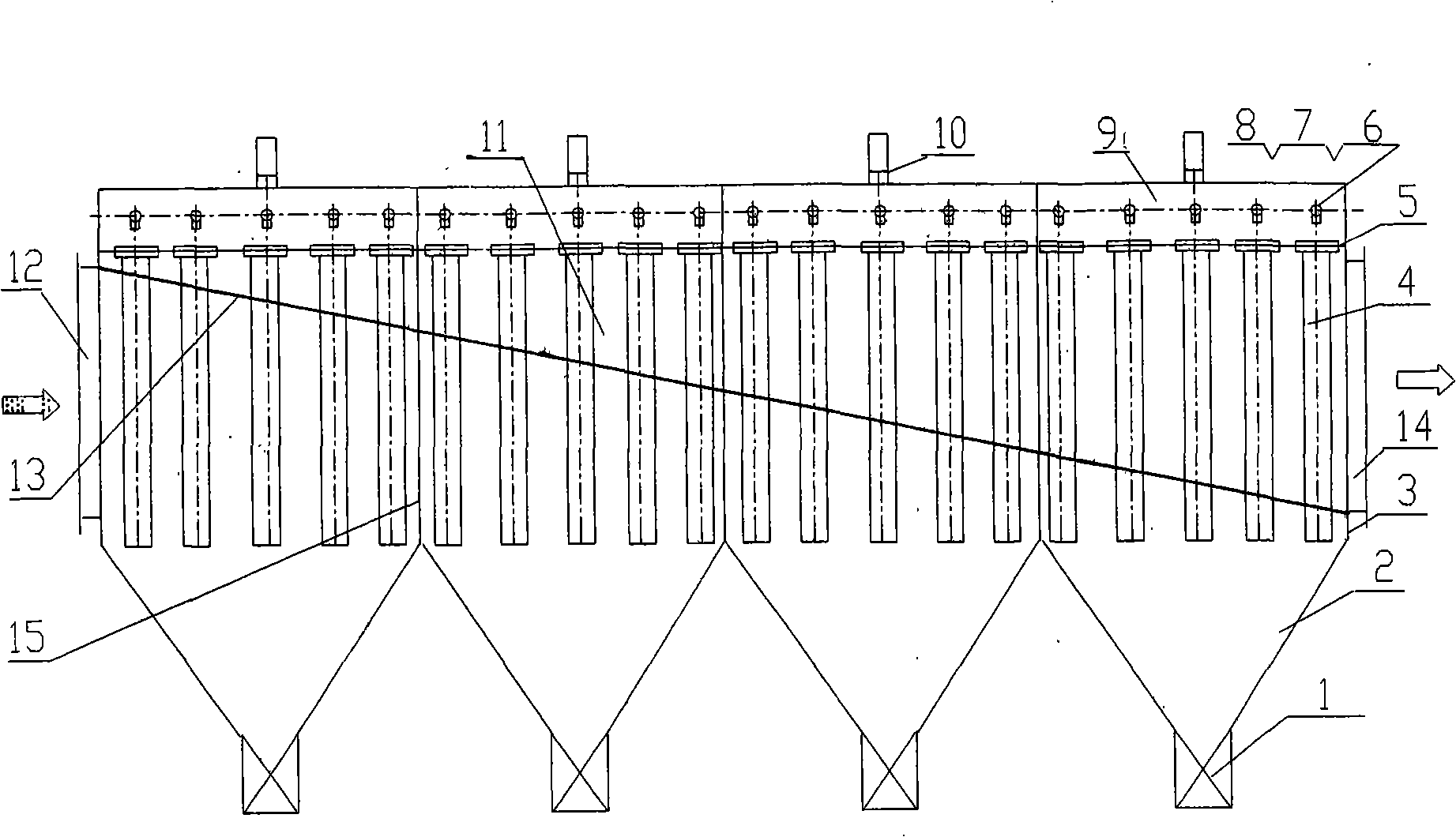

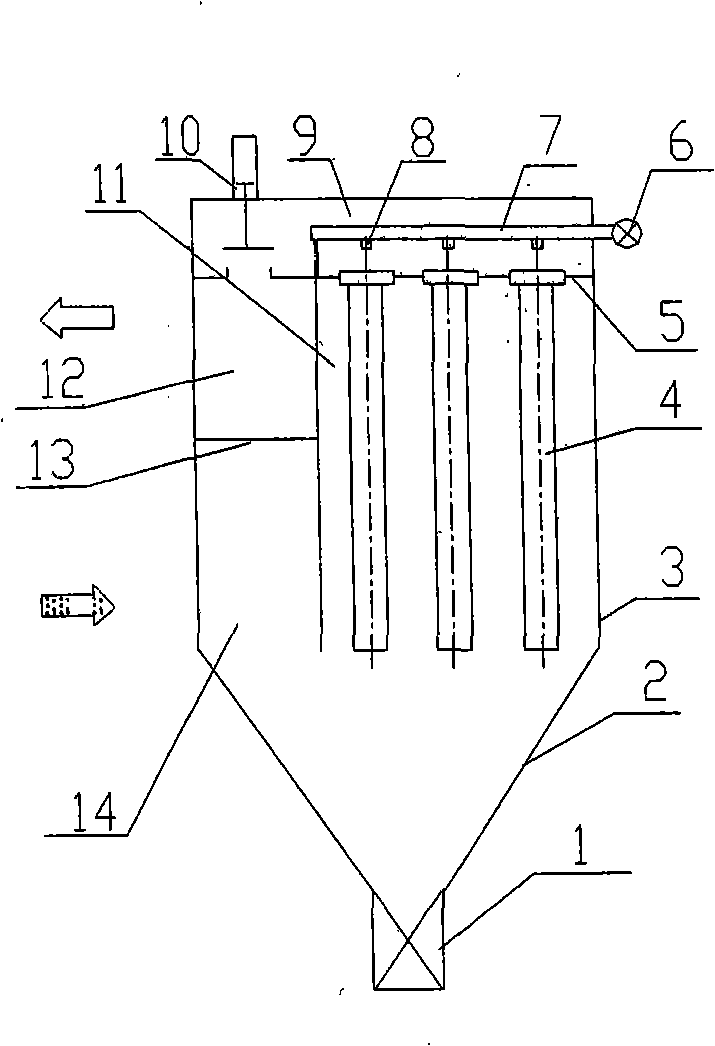

Semi-off-line deash bag dust-cleaning equipment

InactiveCN101254386ASmall filter resistanceExtended service lifeCombination devicesDispersed particle filtrationAir velocityFiltration

The invention discloses a half off-line bag filter, which belongs to the technology field of a dust remover. The invention aims to provide a half off-line bag filter which can improve the dust-cleaning efficiency, reduce the resistance of the dust remover, and avoid the damage to the dust remover body caused by the excessive negative pressure in an air cleaning room which is arranged at the upper part of a tubesheet when dust is cleaned. The invention is characterized in that an air cleaning room (9) arranged at the upper side of each row of filter bags of each bag chamber is internally provided with jet pipes (7) corresponding to each row of filter bags (4) in parallel, and the inlet ends of the jet pipes are connected with the outlets of pulse valves (6); nozzles (8) which are parallel with the jet pipes, have the same quantity as the filter bags the same centers with the filter bag mouths are arranged on the jet pipes; and a poppet valve (10) which has two working states of full open and semi close is arranged on a box body arranged on one side of the upper side of each bag chamber. Compared with the off-line dust cleaning, the half off-line bag filter cannot increase the filtration load of other bag chambers; compared with the on-line dust cleaning, the filtration velocity of the bag chambers and the velocity among the bag chambers are reduced by 1 / 2 to 2 / 3, thereby being more beneficial to the deposition of the discharged dust.

Owner:HEFEI CEMENT RES DESIGN INST

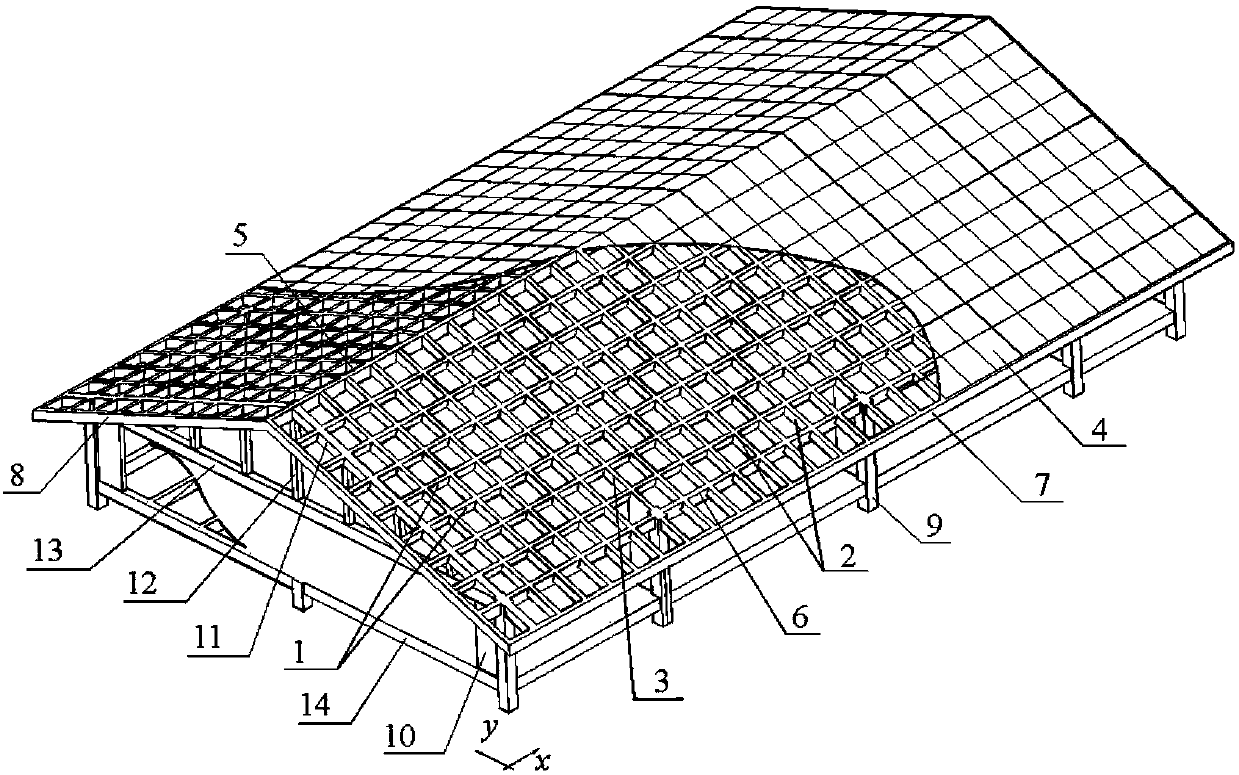

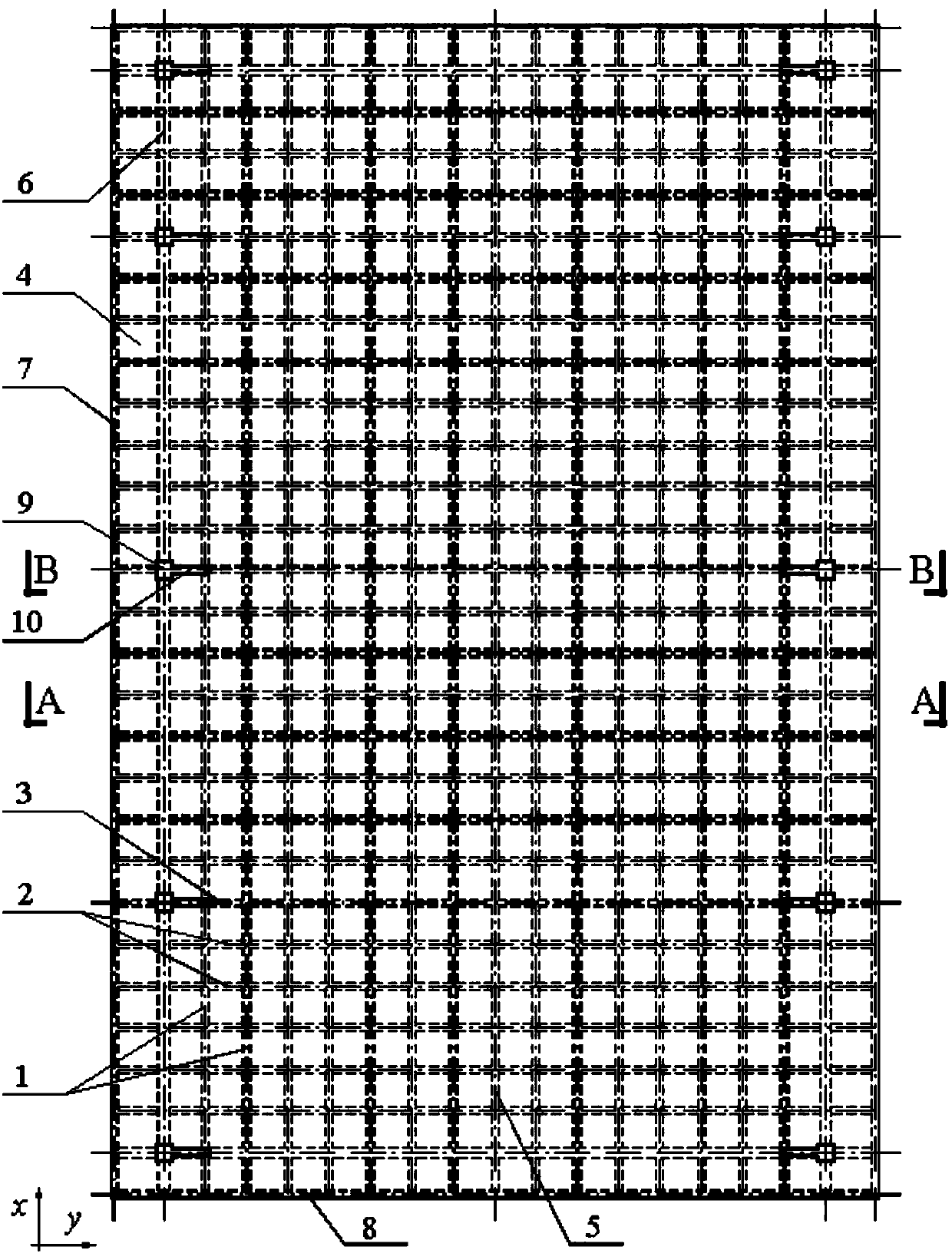

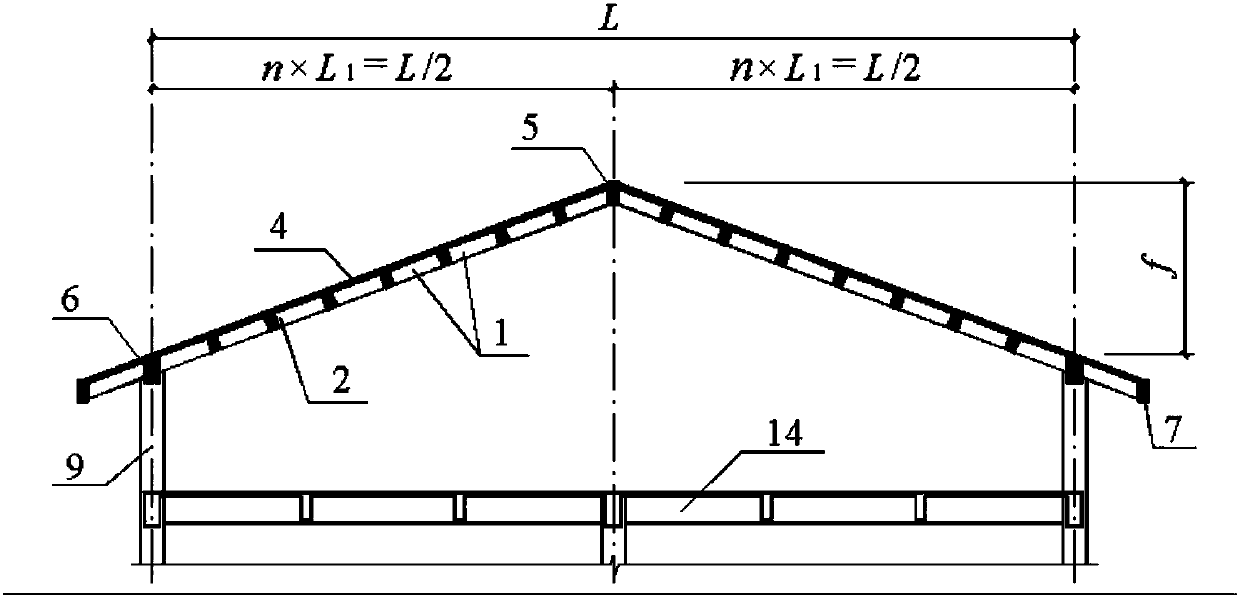

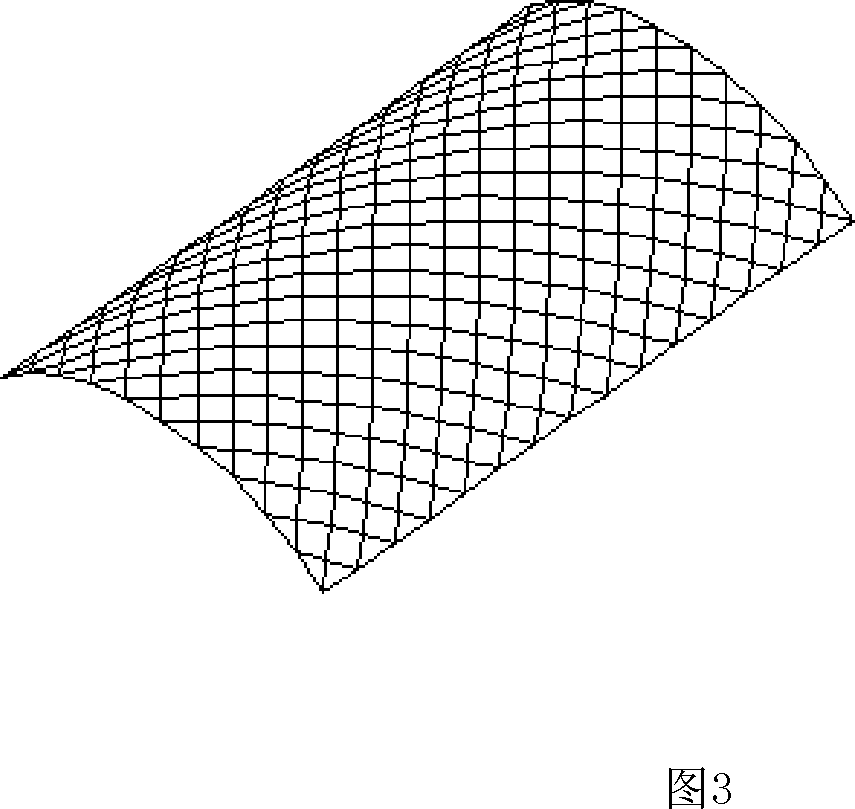

Fabricated longspan concrete double-slope net shell roof framework and manufacturing method thereof

PendingCN107916740AGood space performanceMeet styling needsBuilding roofsBuilding material handlingFalseworkArchitectural engineering

The invention discloses a fabricated longspan concrete double-slope net shell roof framework and a manufacturing method thereof. The framework is formed by obliquely placed multi-ribbed slabs converged at a ridge beam, the two ends are supported on gable end partitions, slope bases supported on longitudinal frame beams vertically intersected with anti-pushing frameworks, and no supporting frame isinstalled under the ridge beam. The gable end partitions are triangle vierendeel trusses composed of upper chords, lower chords and vertical web members, the anti-pushing frameworks are composed of framework columns and short-leg shears supported under lower part floor beams. The framework manufacture adopts a fabricated method, roof boards and ribs are prefabricated and all-round scaffolds, prefabricated parts are connected into an entirety through cast-in-place of connecting blocks and pouring of the boards and the ribs connecting concrete, the use ratio of the large space under the roof isimproved, the problem of flowing during the cast-in-place of obliquely placed concrete in a large area is overcame, the template consumption is reduced, and the construction period is shortened.

Owner:GUIZHOU UNIV

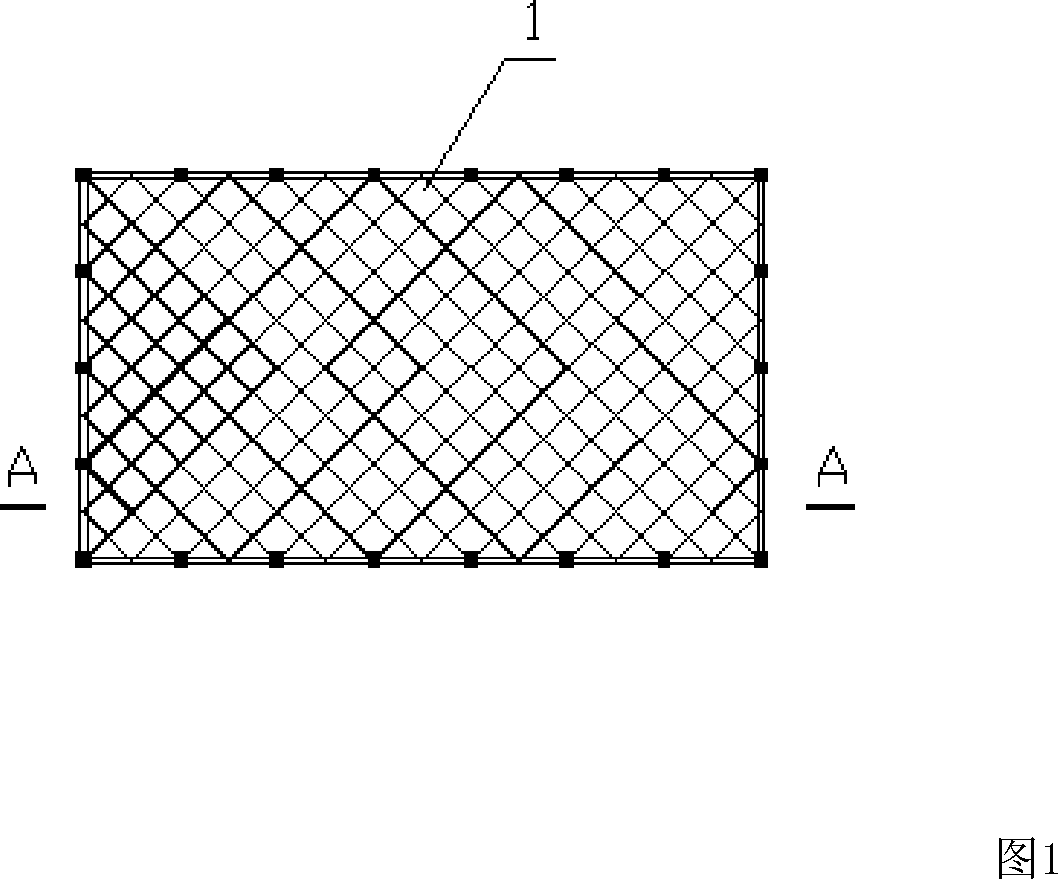

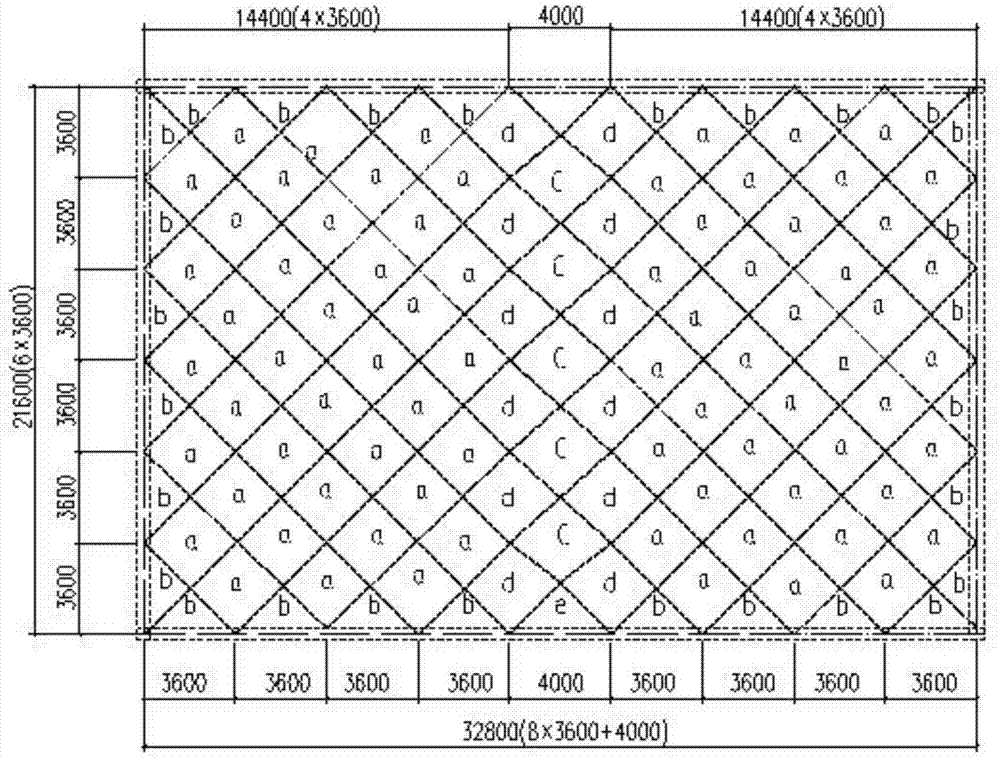

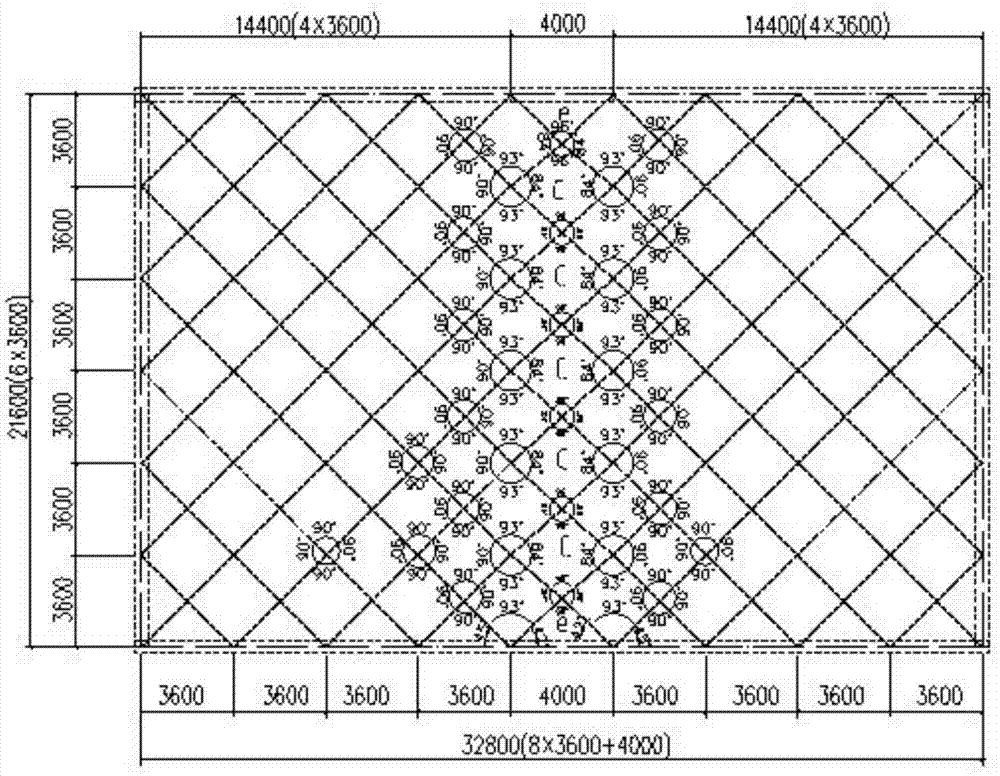

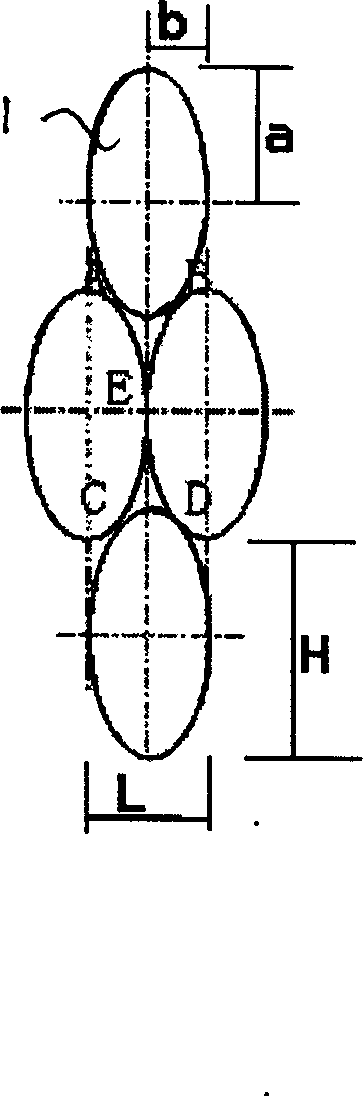

Oblique crossing inclined grid steel-concrete hollow sandwich mesh-like wagon shell and arched roof structure

PendingCN1975059ALow production costEasy to installBuilding roofsArched structuresMesh gridSelf weight

The present invention discloses a kind of obliquely-crossed obliquely-placed grid reinforcement-concrete open-web sandwich reticulated barrel shell and barrel vault roof structure. It is made up by utilizing reinforcement-concrete crossed, obliquely-placed and combined open-web sandwich plate and bending it along span direction according to the curved or parabolic form. As compared with existent technique the invented concrete reduced thickness can be reduced by 30%-50%, its structure self weight can be reduced by 30%-50% and its reinforcement consumption can be reduced by 25%-30%, so that its construction cost also is reduced.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD +1

Method of microorganism induction bauxite flotation desilicication

A method of microorganism induction bauxite flotation desilicication relates to the technical field of bauxite flotation, by adding microorganism into ore pulp of bauxite, the microorganism carries out surface modification to the mineral in the ore pulp, accordingly, the hydrophilia of the mineral per se is changed, and thus the mineral is more easily subjected to flotation separation. Compared with a conventional flotation technology in the prior art, the method has the advantages of high bauxite recovery rate, good desilicication effect, less energy consumption and reagent consumption, and the like, and furthermore, the method does not cause pollution to the environment; simultaneously, the microorganism treatment time is short, so that the method can be applied to industrialization flotation on a large scale.

Owner:平顶山市华兴浮选工程技术服务有限公司

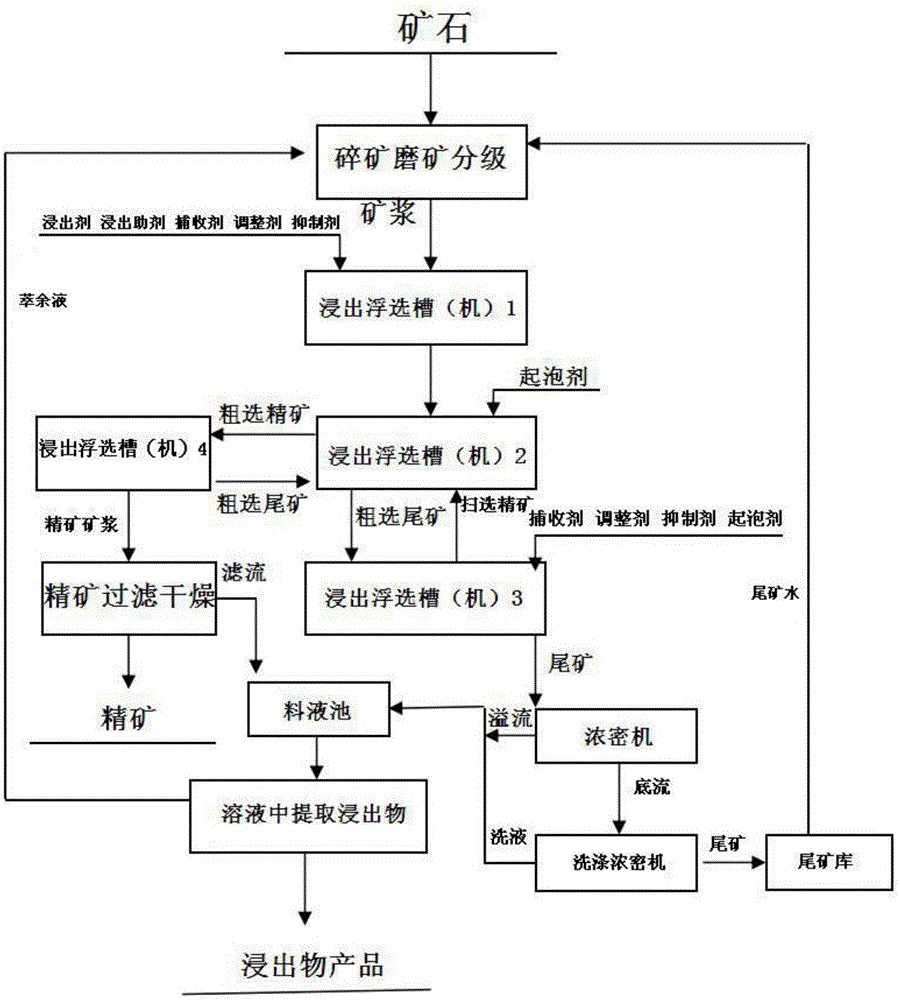

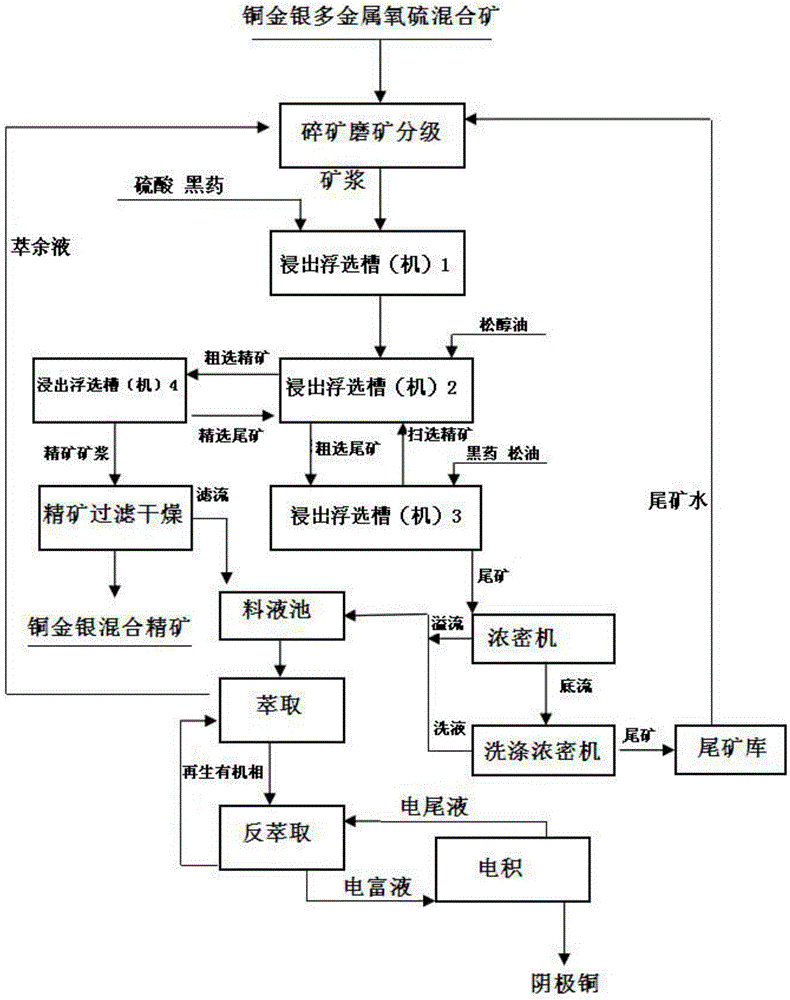

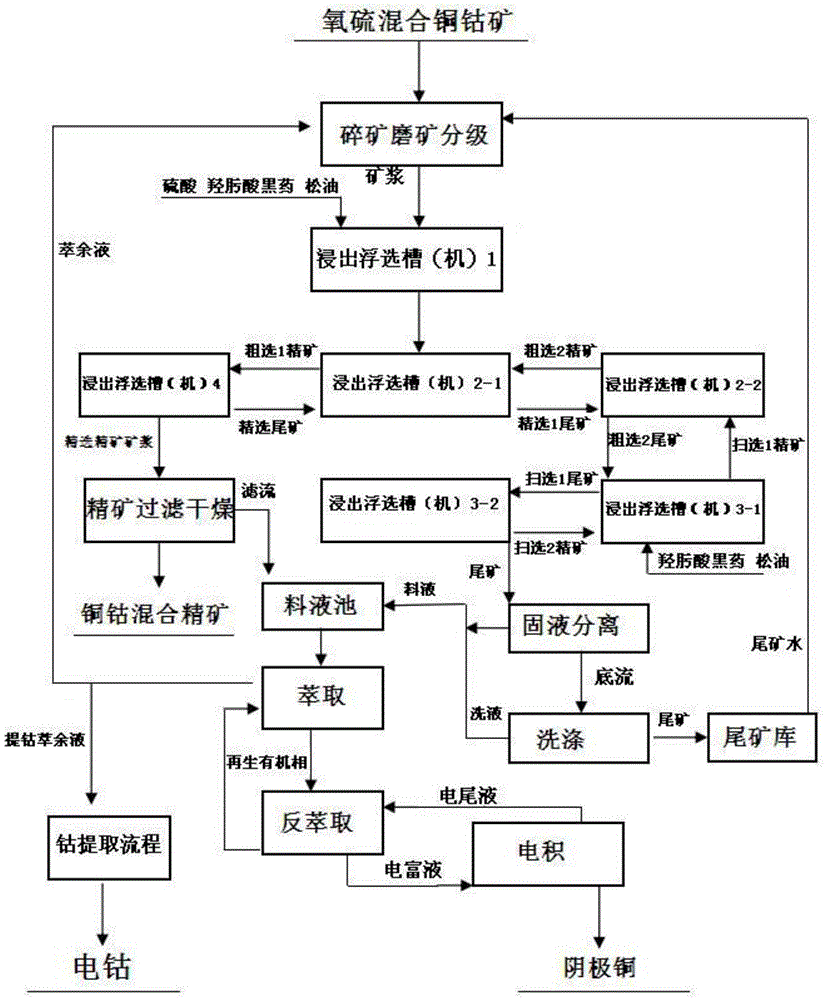

Method for conducting leaching and flotation on ores in same leaching and flotation cells

ActiveCN105483374AOptimum drug conditionSimple process conditionsFlotationEnergy consumptionMaterials science

The invention provides a method for conducting leaching and flotation on ores in the same leaching and flotation cells. The method is characterized in that the ores are leached and floated in the same leaching and flotation cells; and the leaching and flotation cells are divided into two or more sections according to the chemical mixing, roughing, scavenging and fine selecting functions required by the flotation procedure in the procedure, and each section is provided with at least one leaching and flotation cell. The method has the beneficial effects that leaching and flotation are performed in the same cells, so that the leaching process, the flotation process, a leaching system, a flotation system, a leaching agent, a floating agent and leaching liquid are coordinated, and the recovery rate index and the concentrate quality index are increased. The leaching process and the flotation process are better combined. The procedure of the method is shorter than the procedure in which the ores are leached firstly and then floated or floated firstly and then leached in the prior art, equipment investment is saved, energy consumption is low, used labor is small, and production cost is low.

Owner:罗光臣

Method for recycling byproducts generated in aluminum electrolysis

InactiveCN102140651AImprove technical and economic indicatorsGood technical and economic indicatorsProgramme control in sequence/logic controllersZero emissionAluminium

The invention discloses a method for recycling byproducts generated in aluminum electrolysis, and relates to a method for recycling byproducts such as shell surface materials, recycled aluminum dirty materials, aluminum ash and the like in the aluminum electrolysis production process. The method is characterized by comprising the following steps of: collecting the byproducts generated in the process of electrolyzing aluminum, screening, mixing and crushing, and gathering in a storage silo; and when an anode is replaced during aluminum electrolysis, lifting materials in the silo on the ground, conveying into a feeding bin of an electrolyzer through a pipe, and automatically feeding to cover the surface of the anode. In the method for recycling the byproducts generated in aluminum electrolysis, the byproducts such as the shell surface materials, recycled aluminum dirty materials, aluminum ash and the like generated in the aluminum electrolysis process are all recycled, and problems of high cost, high labor intensity, long working hours, high thermal loss of the electrolyzer, low environmental sanitation and the like in the adding process are solved. The technical economical indexes of the system are obviously improved, and the aims of zero emission of the byproducts of the aluminum electrolysis and energy conservation and consumption reduction are fulfilled.

Owner:陕西铜川铝业有限公司

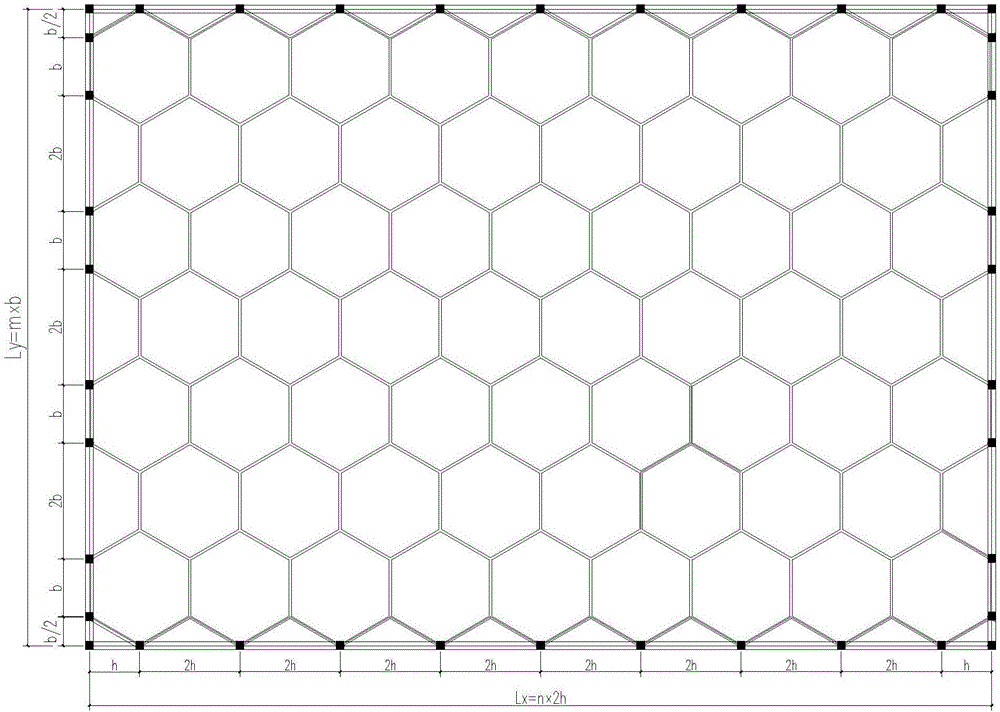

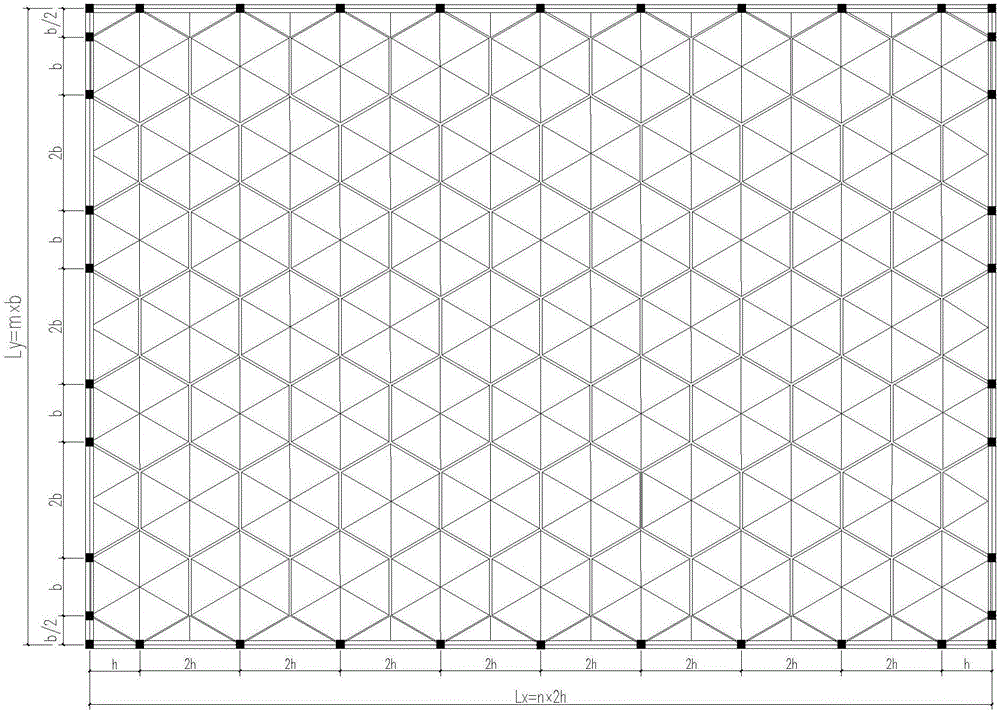

Long-span long-narrow concrete honeycomb open-web sandwich floor covering and manufacturing method

InactiveCN106121110ASimple structureThere will be no defects such as structural reinforcementFloorsReinforced concreteHoneycomb

The invention discloses a long-span long-narrow concrete honeycomb open-web sandwich floor covering which comprises an upper chord layer and a lower chord layer. The lower chord layer comprises a plurality of orthohexagonal grids formed by open web girders in a crossed mode, each short edge is formed by edges and diagonal lines of regular hexagons alternately, and each support on the short edges of the covering is connected with one corresponding open web girder, wherein the included angle between each short edge and the corresponding open web girder is 60 degrees; and each support on the long edges of the covering is connected with two corresponding symmetrically arranged open web girders, wherein the included angle between each long edge and the corresponding open web girder is 30 degrees. The upper chord layer is a regular triangular prefabricated slab fixedly connected with the lower chord layer, so that a reinforced concrete floor plate with regular triangular grids is formed, and a concrete layer is poured on an orthohexagonal prefabricated slab. By improving the structure of the honeycomb open-web sandwich floor covering, the effect that the covering is prevented from being overreinforced, and constructional reinforcement defects are avoided is guaranteed, ideal technical and economical indexes can be met, and the construction policy that the covering is applicable, economical, environmentally friendly and attractive is met.

Owner:SOUTHEAST UNIV +4

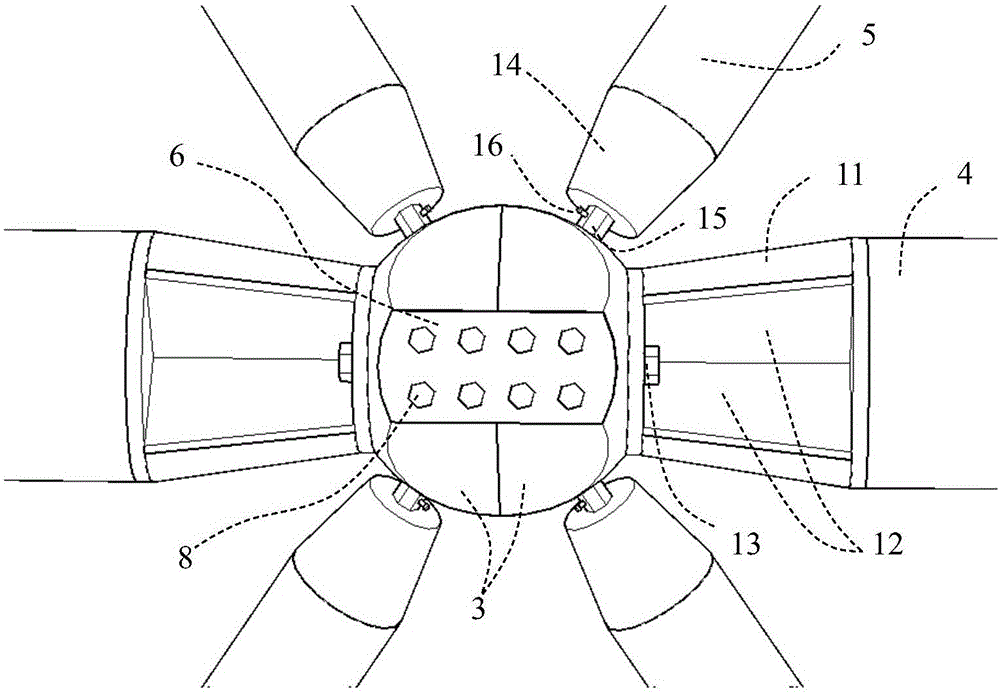

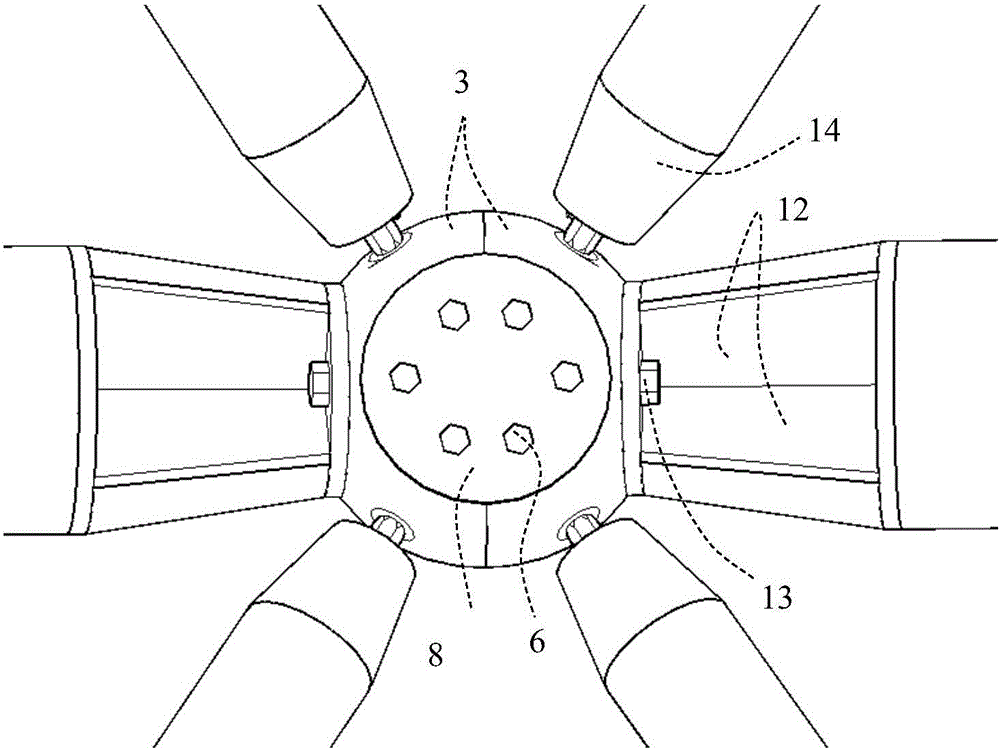

Six-rod-tetrahedral-module-unit assembled cover-plate-and-bolt-connected sphere joint and assembling method thereof

The invention relates to an assembled cover-plate-and-bolt-connected sphere joint, in particular to a six-rod-tetrahedral-module-unit assembled cover-plate-and-bolt-connected sphere joint and an assembling method thereof, and belongs to the field of steel structures. The six-rod-tetrahedral-module-unit assembled cover-plate-and-bolt-connected sphere joint comprises a left connecting body and a right connecting body, and the left connecting body and the right connecting body are jointed in an end-to-end mode. The six-rod-tetrahedral-module-unit assembled cover-plate-and-bolt-connected sphere joint and the assembling method thereof are compact in structure, excellent in using performance and high in adaptability.

Owner:浙江东南网架股份有限公司

Environment-friendly vegetable protein based efficient water and fertilizer slow/controlled-release material

InactiveCN104003800AEnvironmentally friendlyExcellent slow and controlled release characteristicsFertilizer mixturesSoil scienceFoaming agent

The invention provides an environment-friendly vegetable protein based efficient water and fertilizer slow / controlled-release material. The slow / controlled-release material is prepared from the following components in parts by mass: 30-80 parts of thermoplastic vegetable proteins, 20-60 parts of resin, 5-7 parts of graft modification substances, 1-5 parts of initiator, 2-5 parts of foaming agent and 2-5 parts of lubricating agent. A slow / controlled-release fertilizer prepared on the basis of the slow / controlled-release material provided by the invention has the initial nutrient release rate of less than 13.0% after being soaked in 25-DEG C static water for 24h, the accumulated nutrient release rate of less than 78.0% within 28d and the accumulated release rate of more than 92.6% within the nutrient release period. The effective utilization ratio of nutrients in the fertilizer is increased by more than 35.9%, so that the usage amount and fertilization times of the fertilizer can be greatly reduced, the effective utilization rate of the fertilizer can be increased, and the ecological environment destruction caused by the fertilizer can be effectively relieved.

Owner:XINJIANG HUIER AGRI GRP CO LTD

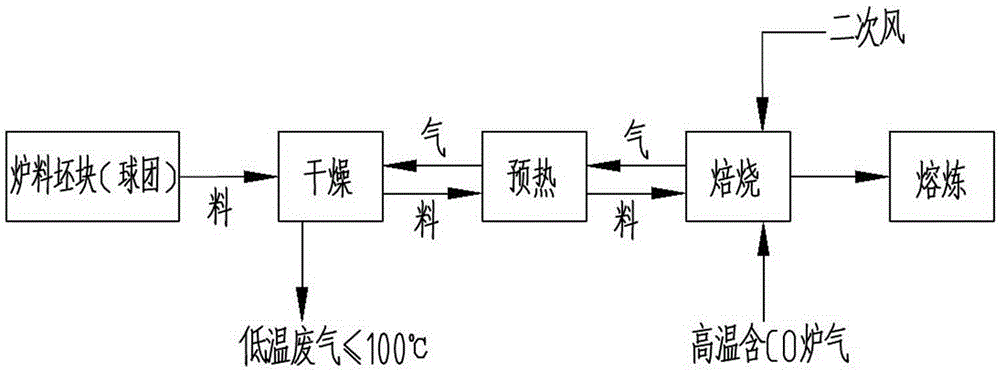

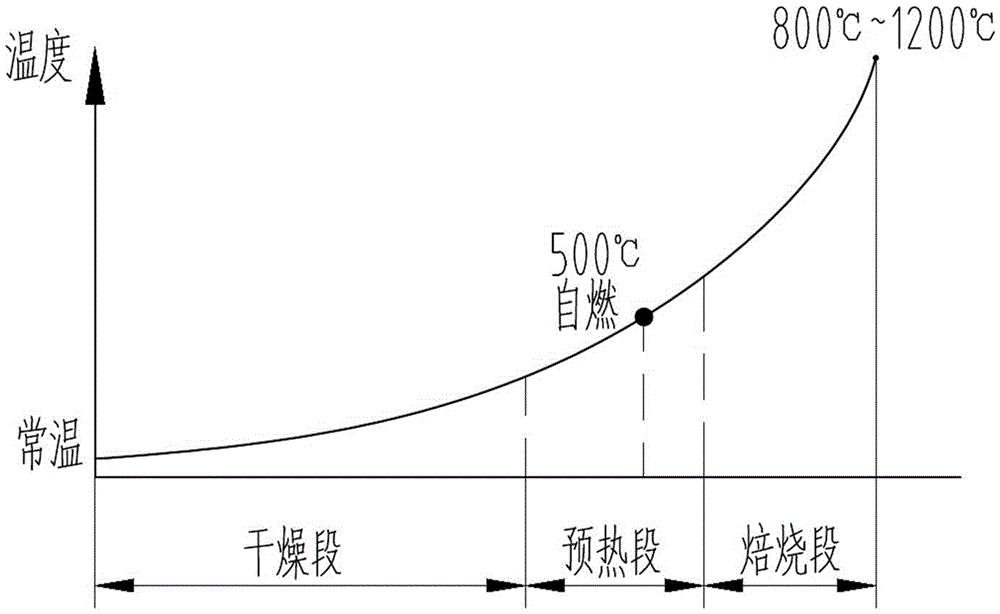

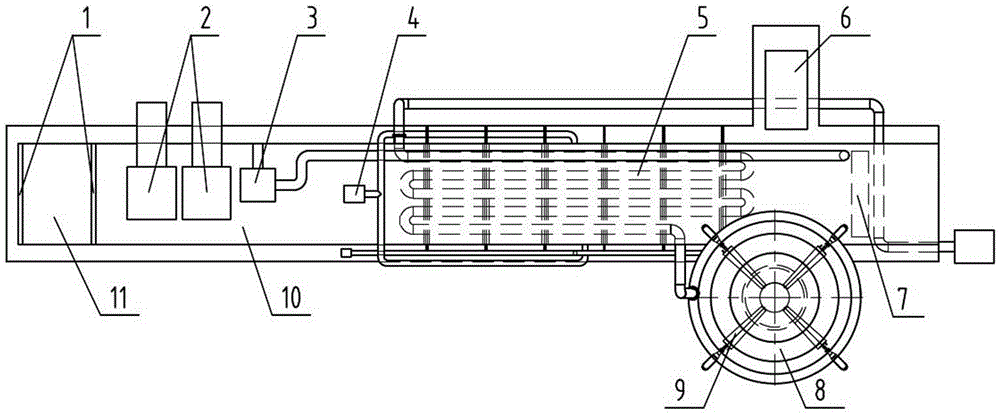

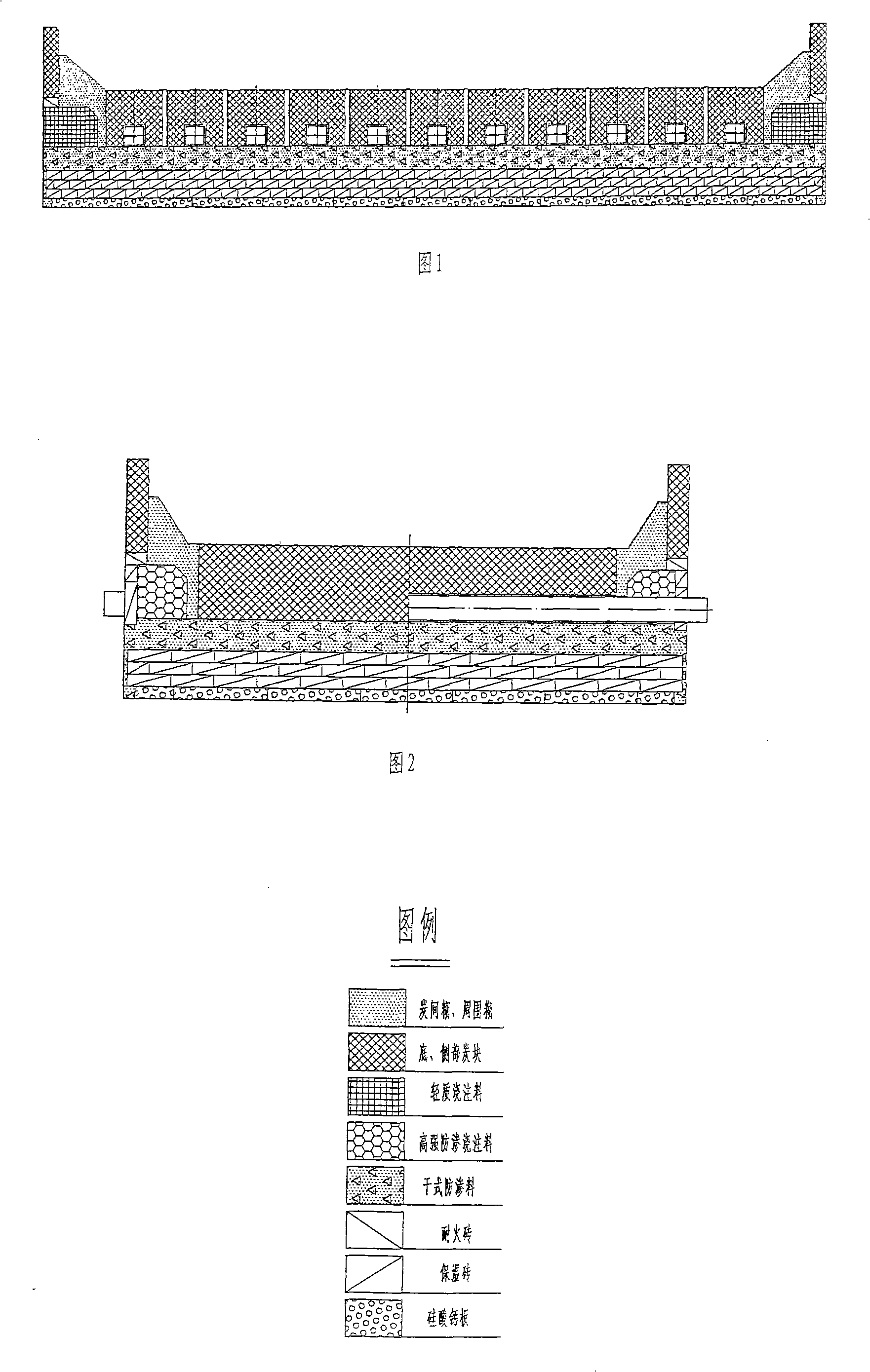

Spontaneous combustion reduction method iron-smelting method and smelting device

InactiveCN105349725AReduce heat loadIncrease smelting strengthFluidised-bed furnacesTunnel kilnSpontaneous combustion

The invention belongs to a non-blast-furnace smelting technology which achieves new energy development, replaces coke with coal and is low in cost and energy consumption, environment-friendly and short in technological procedure, and relates to a spontaneous combustion reduction method iron-smelting method and a smelting device. The method comprises the steps of furnace charge preparing, drying, preheating and roasting and smelting. According to the method, no sintering material or coke is adopted, and no coal gas is generated. The smelting device comprises a tunnel kiln and a smelt separation furnace. Waste heat generated by the smelt separation furnace is all used for drying and preheating of furnace charge blocks. Negative pressure operation and weak reduction smelting atmosphere completely opposite to those in a traditional iron-smelting method are adopted, the heat value of fuel is given into full play to the greatest extent, and energy is utilized most effectively.

Owner:HENGNAN YANGGANG METALLURGICAL TECH CO LTD

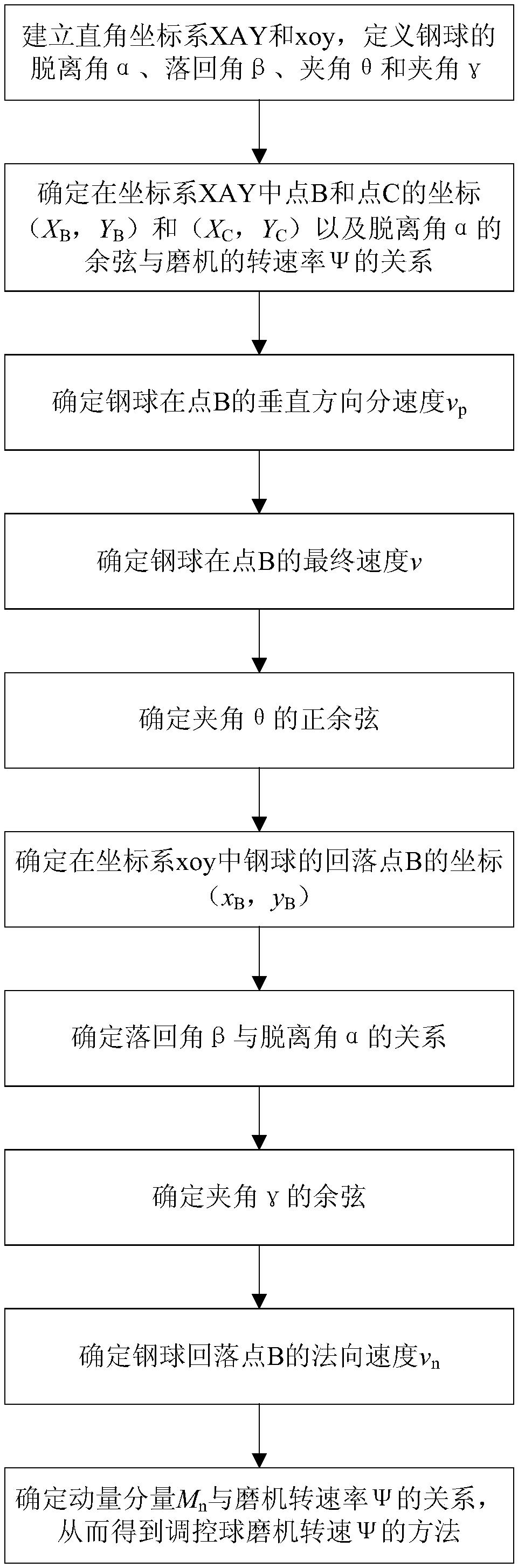

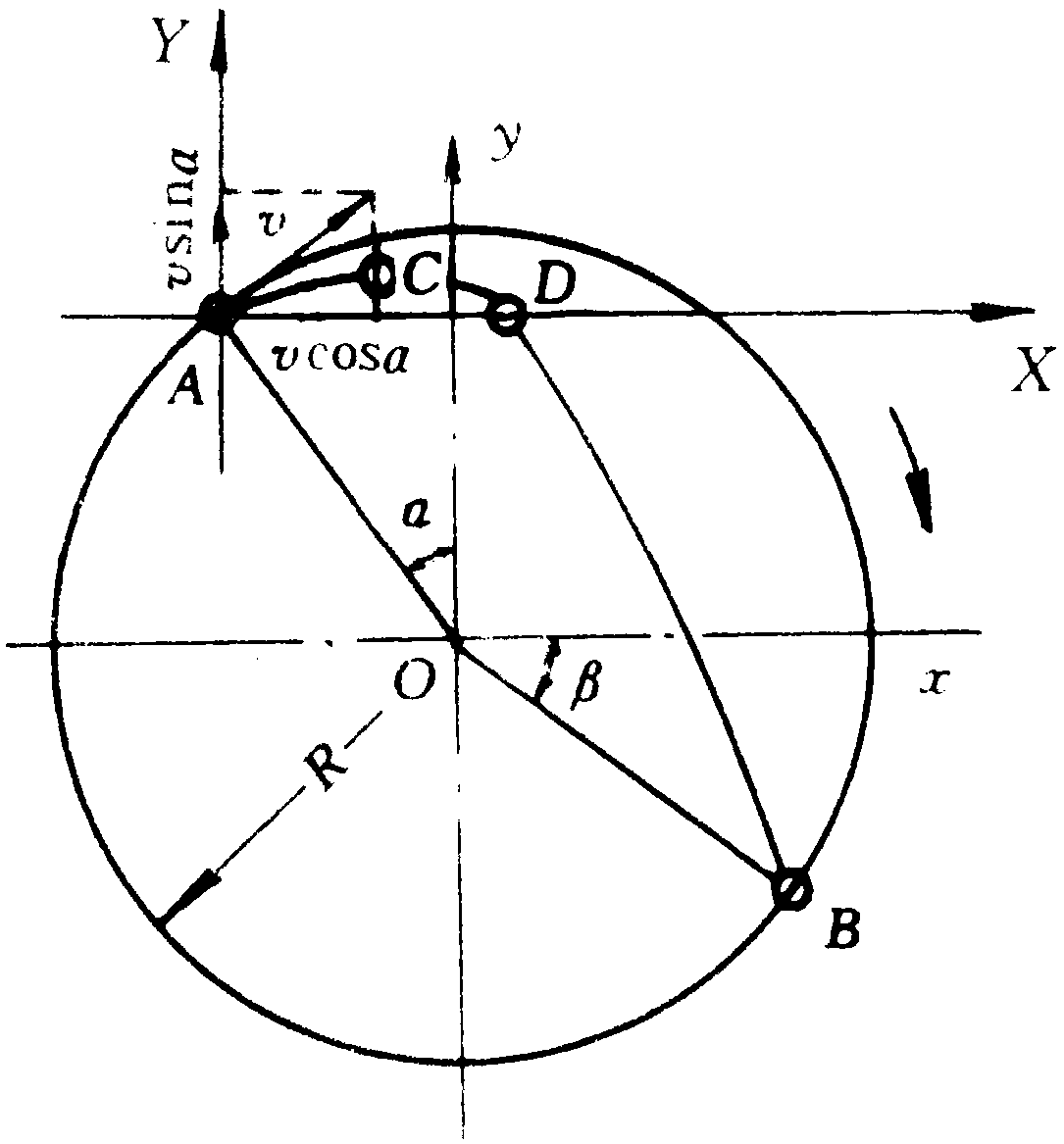

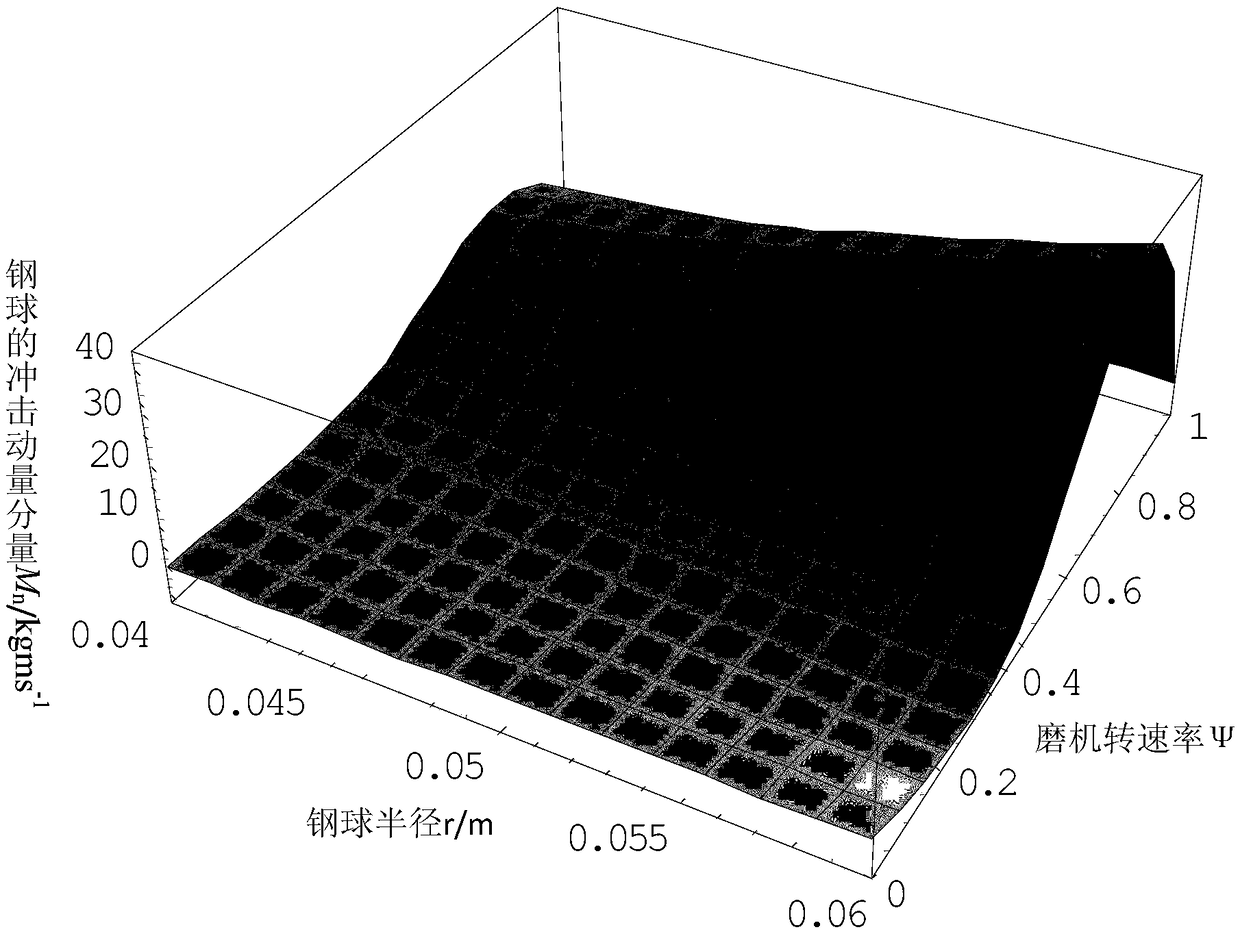

Rotating speed control method of ball mill based on grinding effect of steel balls in ball mill

ActiveCN109201221ATimely adjustment of speedGood technical and economic indicatorsGrain treatmentsFrequency conversionSteel ball

The invention provides a rotating speed control method of a ball mill based on the grinding effect of steel balls in the ball mill, and relates to the field of energy conservation and consumption reduction of efficient development and utilization of solid mineral resources. The rotating speed control method comprises the steps that coordinate systems XAY and xoy are established, and a detachment angle alpha, a fall-back angle beta and included angles theta and gamma of the steel balls are defined; the coordinates of a point B and a point C in the coordinate system XAY and the relationship between the angle alpha and the rotating speed of the mill are determined; the velocity component in the vertical direction of the steel balls at the point B is determined; the final speed of the steel balls at the point B are determined; the sine and cosine of the angle theta are determined; the coordinates of the point B of the steel balls in the coordinate system xoy are determined; the relationship between the angle beta and the angle alpha is determined; the cosine of the angle gamma is determined; the normal velocity of the steel balls falling back to the point B is determined; and a methodfor adjusting and controlling the rotating speed psi of the ball mill is determined. The rotating speed control method realizes the timely adjustment of the rotating speed of the ball mill by means ofa frequency conversion speed regulation technology, so that the working state of the ball mill is adapted to the specific properties of a processing object at any time, and the technical and economicindexes of the ore grinding process are always in the best state.

Owner:中冶沈勘工程技术有限公司

A Classified Suspension Roasting Device for Complicated Refractory Iron Ore

A complex refractory iron ore classification suspension roasting device, including a suspension preheating oxidizer, a two-stage cyclone classifier, a two-stage suspension reducer, a cyclone separator and a fan; the suspension preheating oxidizer is connected to the first-stage cyclone classifier ; The first-level cyclone classifier is connected with the second-level cyclone classifier, the second-level cyclone classifier is connected with the cyclone separator, and the cyclone separator is connected with the fan; the discharge ports of the first-level cyclone classifier and the second-level cyclone classifier are respectively inserted into a In the first-level suspension reducer and the second-level suspension reducer. The device of the present invention can classify coarse and fine materials for magnetization and roasting, so that the reduction conditions of different levels of materials can be controlled, and it can significantly reduce energy consumption and obtain better technical and economic indicators.

Owner:SHANGHAI MILESTONE TECH CO LTD

A comprehensive recovery and beneficiation method of low-grade uranium-containing polymetallic ore

ActiveCN108787159BGuaranteed recyclingReduced uranium contentSolid separationNiobiumMining engineering

The invention provides a comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore. The comprehensive recovery and beneficiation method comprises the followingsteps that (1) overflow products obtained by grinding the uranium-containing polymetallic ore are subjected to direct flow magnetic separation roughing operation and reverse flow magnetic separation concentration operation in sequence, and iron concentrate and first tailings are obtained; (2) the tailings are subjected to condensation and flotation to obtain first concentrate and second tailings,the first concentrate is subjected to concentration to obtain lead silver concentrate, and the second tailings are subjected to scavenging to obtain third tailings; and (3) the third tailings are subjected to flotation roughing and condensation, and then uranium, niobium and rare earth mixed concentrate is obtained. The beneficiation index is good, the purpose of fully recovering all useful components in coarse-grain coarse concentrate subjected to tailing discarding through gravity concentration under the coarse grinding condition is achieved, an efficient beneficiation separation and enrichment technology is provided for large-scale development and utilization of the low-grade complex polymetallic hard rock uranium ore in China, and the subsequent cost of extracting uranium, niobium andrare earth in the uranium ore through hydrometallurgy is greatly lowered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

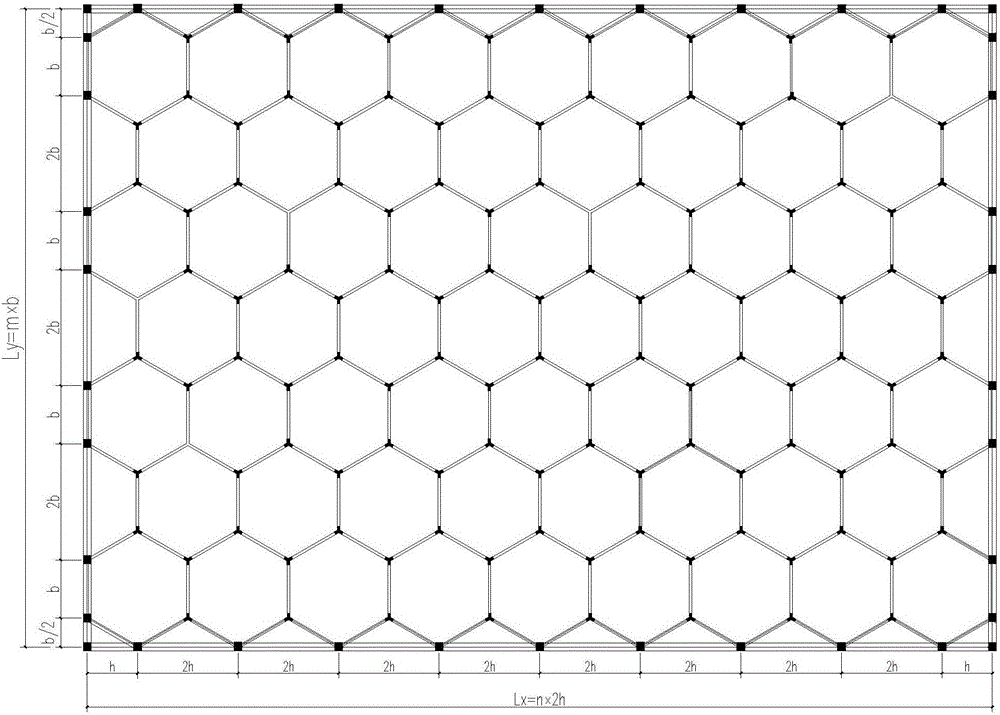

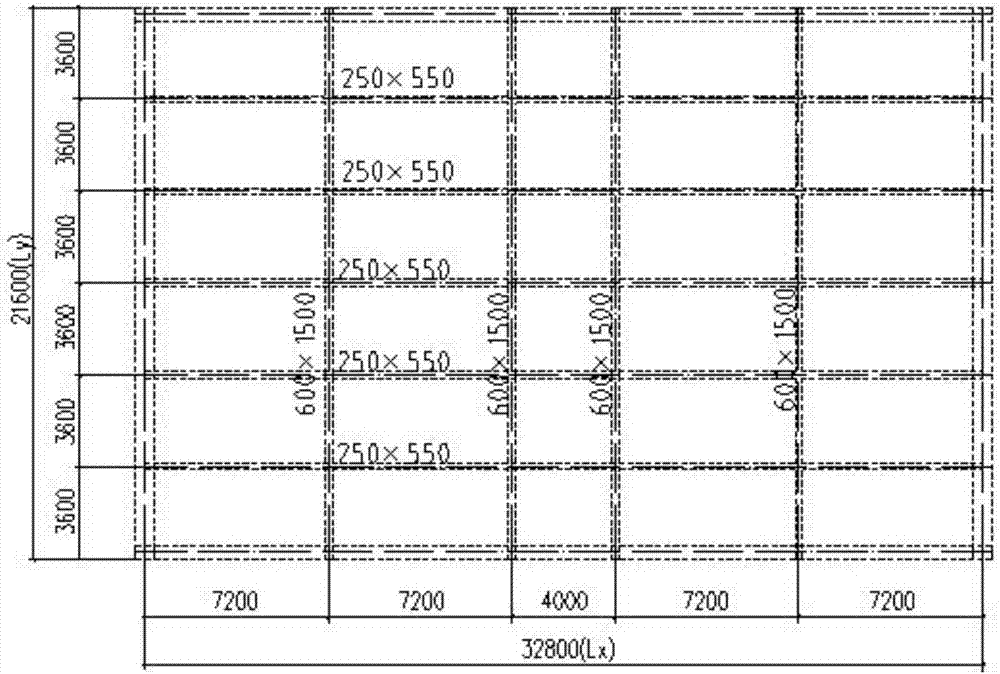

Irregular II type large-span concrete vierendeel sandwich plate floor and making method thereof

PendingCN107514082AGood technical and economic indicatorsFloorsReinforced concreteArchitectural engineering

The invention discloses an irregular II type large-span concrete vierendeel sandwich plate floor. The ratio of the long side and the short side of the reinforced concrete is that Lx / Ly is large than 1.5, a one-way stress plate is formed, the ratio of the long side Lx and support spacing does not have common divisor, the position where the support spacing is large is located in the center of the long side, and a grid structure comprises a square grid a, a right angled isosceles triangle grid b, a parallelogram grid c, an irregular quadrilateral grid d and a non-right angled isosceles triangle grid e. The invention further provides a making method of the irregular II type large-span concrete vierendeel sandwich plate floor. Accordingly, energy conservation and emission reduction are promoted, and the good technical-economic index is achieved.

Owner:GUIZHOU UNIV

Sublever caving mining model in large subsection without sill pillar

InactiveCN1760669AGood technical and economic indicatorsImprove accuracyMaterial analysisMathematical modelEngineering

Comparing with prior method for determining structure parameters based on transitional theory, the invention builds mathematic model to calculate parameters accurately so as to overcome disadvantages of determining parameters based on operating experience and engineering analogy. Thus, production efficiency and technical economical index of mine is raised. The technical scheme is as following: after height of subsection is selected in mining model in large subsection without sill pillar, drawing off height Hf is determined. C is determined based on relational expression Cú¢0.000819Hf2-0.025Hf+2.578. Then, entrance span L is determined based on Hú¢(3 / 2)í‡Cí‡L. Advantages are: simple technical scheme, high accuracy for parameters, better technical economical index. The invention is suitable to exploitation for underground mine.

Owner:宝钢集团上海梅山有限公司

Energy-saving aluminum electrolysis bath

The invention relates to an energy-saving aluminum electrolytic cell, which comprises a Hall-Heroult electrolytic cell and is characterized in that: the surface of a cathode carbon block of the electrolytic cell is provided with a dovetail groove, namely the dovetail groove which is perpendicular to the vertical direction of the carbon block. The energy-saving aluminum cell can reduce groove voltage, and the current efficiency is stable and even improved; moreover, the investment cost of the aluminum cell can be reduced. The energy-saving electrolytic cell belongs to an origination at home and abroad, obtains obvious technical and economic targets and brings significant economic benefit for enterprises. The application of the energy-saving electrolytic cell can have an important impact on the aluminum industry at home and abroad and contribute to energy conservation in the world aluminum industry. The energy-saving electrolytic cell is suitable for all aluminum cells.

Owner:云南涌鑫金属加工有限公司

Lithium slag recycled concrete, preparation method thereof and building component

The invention is applicable to the technical field of building materials, and provides lithium slag recycled concrete, a preparation method thereof and a building component, and the lithium slag recycled concrete comprises the following components: recycled coarse aggregate, fine aggregate, cement, lithium slag, an air entraining agent, a foaming agent, a water reducing agent and water. Accordingto the lithium slag recycled concrete provided by the invention, lithium slag and recycled coarse aggregate resources are utilized on site, the preparation method is simple, the pollution to the environment can be reduced, and the lithium slag contains more compounds such as amorphous silicon dioxide and aluminum oxide, has higher volcanic ash activity, and has very excellent technical and economic indexes; besides, the recycled coarse aggregate utilizes waste concrete, has the advantages of using local materials, turning waste into useful and the like, and reasonably utilizes resources and effectively protects the environment under the condition that material components meet the requirements.

Owner:EAST CHINA UNIV OF TECH +1

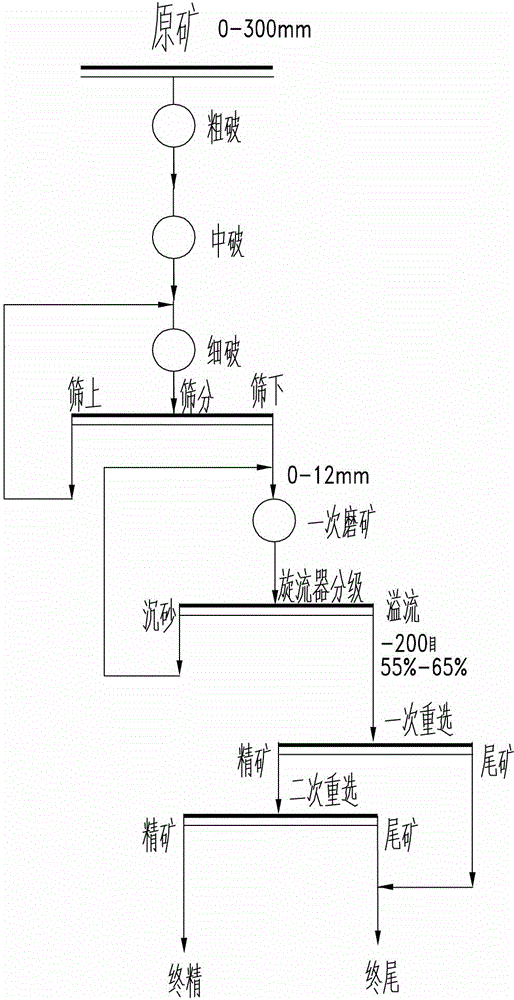

Anshan-type hematite silicon-control benefication method

InactiveCN104148160ASimple processGood technical and economic indicatorsWet separationOre concentrateGrinding

The invention relates to an Anshan-type hematite silicon-control benefication method. The Anshan-type hematite silicon-control benefication method is characterized by comprising three crushing times, screening, ball-milling classification and two reselection times, and includes particular steps of crushing, to be more specific, performing rough crushing, intermediate crushing, fine crushing and screening operation on Anshan-type hematite on working faces so that more than 90% of products have the particle sizes of 0-12mm; feeding the crushed and screened products into ball-mill and involute cyclone assemblies to be subjected to closed-circuit grinding, and classifying the crushed and screened products according to the thicknesses of the crushed and screened products; feeding flow which flows from thickness classification cyclones into roughing spiral chutes and concentration spiral chutes, and secondarily reselecting the flow to obtain ultimate concentrates with 65%-65.5% of iron and 5%-5.5% of SiO<2>. The Anshan-type hematite silicon-control benefication method has the advantages that technical processes are simple, technical and economic indexes are good, the grade of the iron concentrates is reduced from the original 67% and is 65.5%, but the contents of iron in tailings at the grade is reduced from the original 9.5% and is 9%, the recovery rate of the iron is increased by 1 percent, the yield is increased by 1.5 percents, the contents of the SiO<2> are effectively controlled and are 5%-5.5%, and excellent economic benefits can be acquired in follow-up sintering and smelting procedures.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com