Washing device and washing method for marine exhaust flue gases

A technology of washing device and washing method, applied in the direction of separation method, chemical instrument and method, use of liquid separating agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

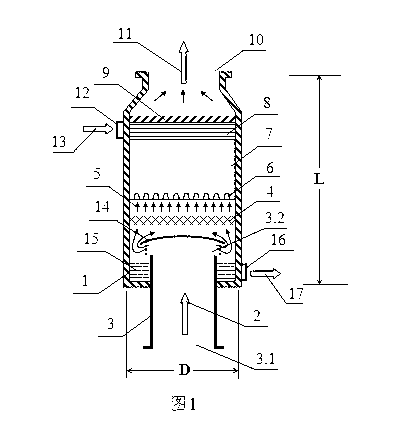

[0089] The flue gas inlet 3.2 in the housing 1 is fixed at the bottom of the housing 1 and extends to the outlet of the flue gas duct 3 inside the housing 1. There is a right to the outlet for preventing washing seawater from entering the flue gas duct 3. The liquid collecting cover 14;

[0090] The flue gas inlet 3.2 in the housing 1 is a through hole on the side wall of the housing 1, or the outlet of the flue gas duct 3 fixedly connected to the side wall of the housing 1;

[0091] The liquid collection pool 15 is composed of the lower side wall and the bottom of the housing 1 and the pipe wall of the flue gas conduit 3, and can also be fixed by a partition outside the pipe wall. A partition can prevent the pipe wall of the flue gas conduit 3 from Corroded;

[0092] The material of the high-temperature-resistant component that forms the cooling uniformity layer 4' is a high-temperature-resistant inorganic material. This example uses a ceramic material, or a metal material, ...

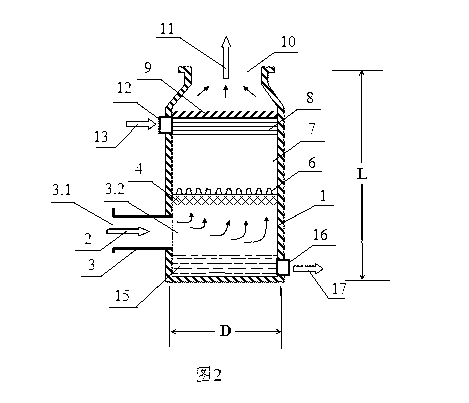

Embodiment 2

[0102] The difference from the above-mentioned embodiments is that the cooler 4 is installed on the flue gas duct 3, and can also be a water spray system connected to the housing 1 for spraying cooling water into the high-temperature flue gas 2. The water spray system For the combination nozzle.

Embodiment 3

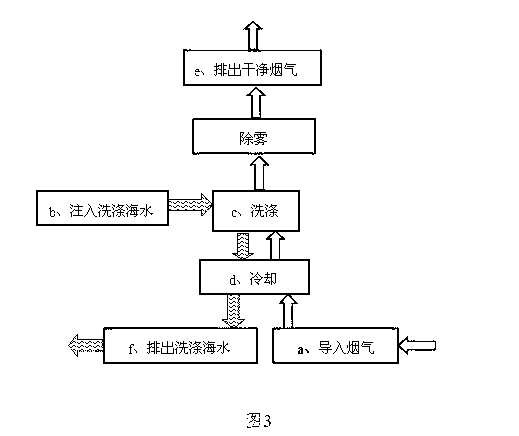

[0103] B, the embodiment of the sea-going ship smoke exhaust cleaning method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com