Patents

Literature

64results about How to "Reduce particulate matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

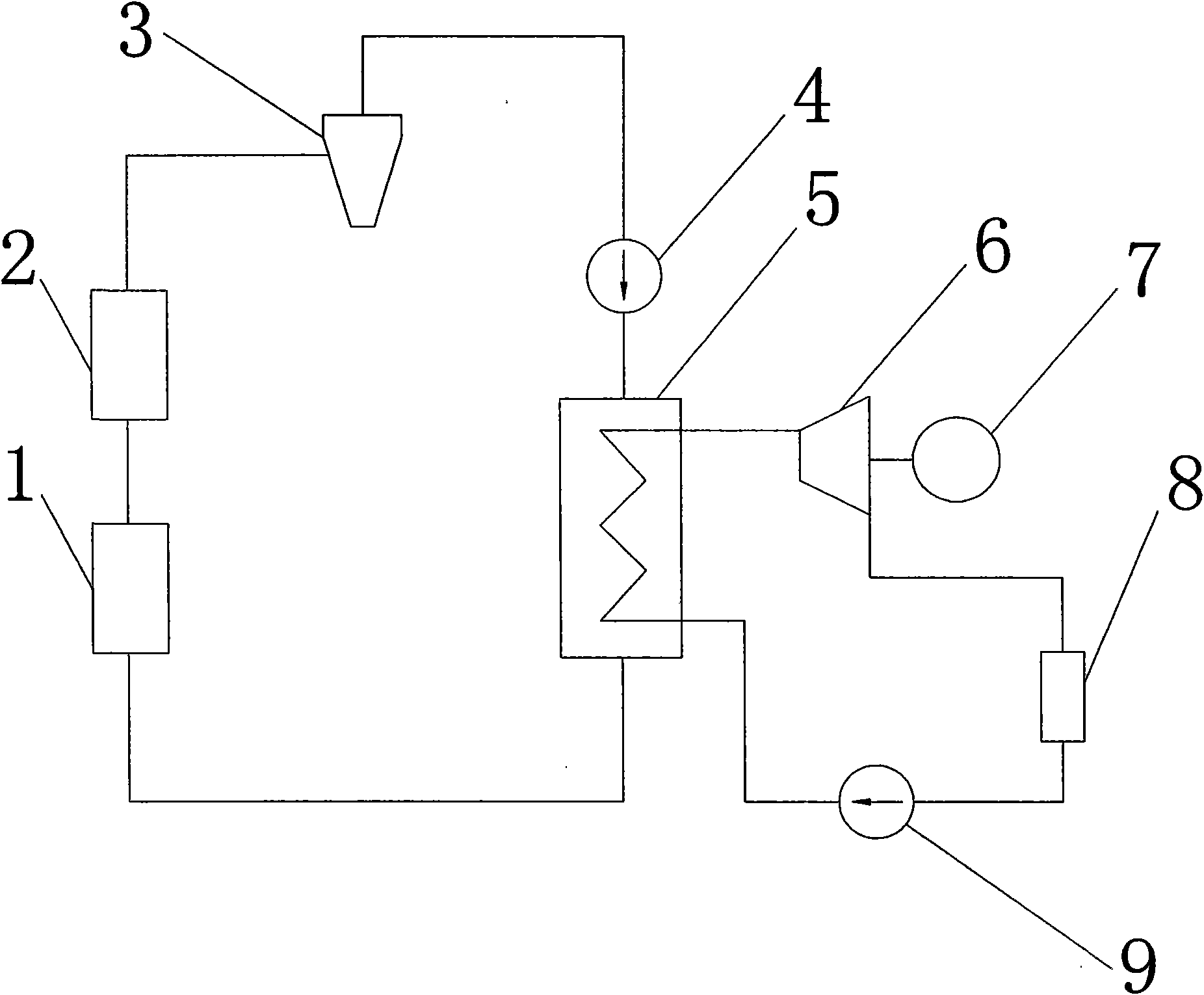

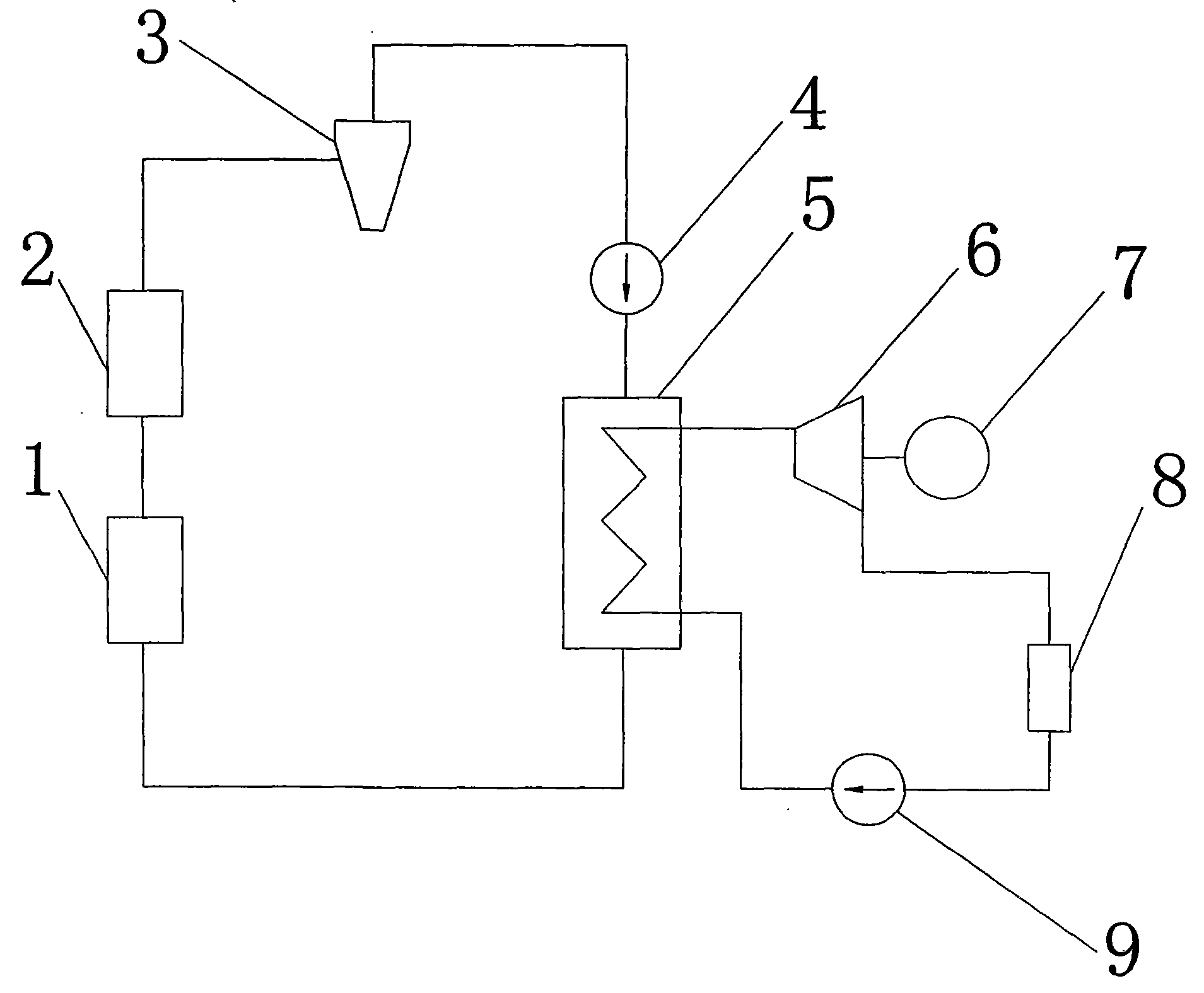

Recovery method of blast furnace slag water residual heat and method thereof

ActiveCN101550461AEnsure safetyGuaranteed lifeIncreasing energy efficiencyWaste heat treatmentRecovery methodSlag

The invention discloses a recovery method of blast furnace slag water residual heat and method thereof. The recovery system of resudual heat includes a blast furnace slag system, a sedimentation tank, a hydrocyclone separator, a water pump, a heat exchanger, a steam turbine, a refrigerant condenser, a refrigerant pump. The recovery method is that applying bicirculating low temperature hot water generation system to recovery residual heat and penerating power. The specific process is: guiding the blast furnace slag water into the heat exchanger after preprocessing of impurity precipitation and transmitting heat to low boiling refrigerant; the low boiling refrigerant absorbing heat in the heat exchanger and entering the steam turbine for expansion of doing work; the refrigerant after doing wirk changing into low-pressure superheated steam, the low-pressure superheated steam entering the concenser to releast heat and changing into liquid refrigerant of low-temperature and low-pressure, then being sent to the heat exchanger by the refrigerant pump for absorbing heat, becoming the superheated steam again to push the steam turbine to do work. The invention can recovery residual heat of the blast furnace slag water and generate power, and reduce energy consumption in steel production; and reduce temperature of blast furnace slag water which is benefit to improve quality of blast furnace water slag and reduce discharge of sulphide in slag washing process.

Owner:HANGZHOU BOILER GRP CO LTD

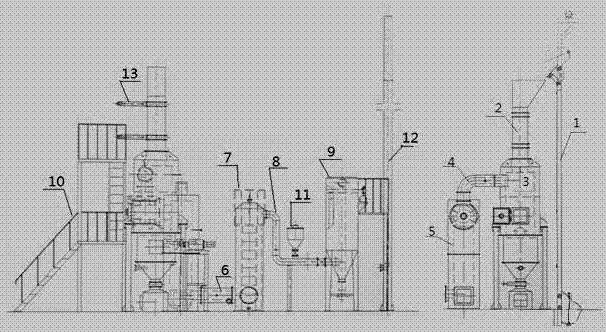

Continuous pyrolysis incineration device for full-scale electronic and electrical product waste

ActiveCN105509062AGuaranteed incineration temperatureGuaranteed incineration efficiencyEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING UNIV OF TECH

Land restoration method for abandoned sand mining field

ActiveCN104641755AThe ingredients of land restoration are scientific and reasonableQuality improvementSoil-working methodsQuality assuranceEcosystem

The invention discloses a land restoration method for an abandoned sand mining field and relates to the technical field of abandoned land recycling methods. The restoration method includes the following steps: raw materials are transported to the field, the raw materials are smashed for preparation, the smashed raw materials are mixed and stirred, the stirred raw materials are fermented, and the processed raw materials are paved and rolled so that the abandoned sand mining field is filled and leveled up. The land restoration method for the abandoned sand mining field has the advantages that the land restoration burdening is scientific and reasonable, the quality of comprehensive backfill is high, and the physical properties of the land such as the bearing capacity and the shear force and the physical and chemical indexes of soil are fully considered. Therefore, the land restoration method for the abandoned sand mining field fully ensures the stability of the land topography restoration and the good cultivation function, provides quality assurance for the restoration and reconstruction of the ecological system, facilitates inspection and management, and is high in economic benefits, ecological benefits and environmental protection benefits.

Owner:北京天地丰源环保科技有限公司 +1

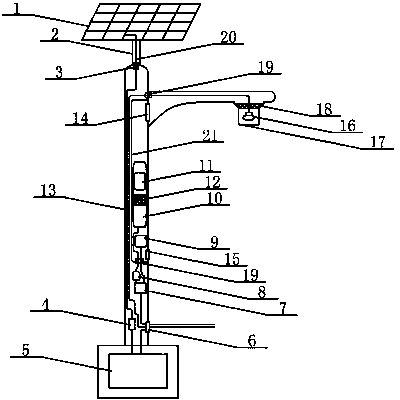

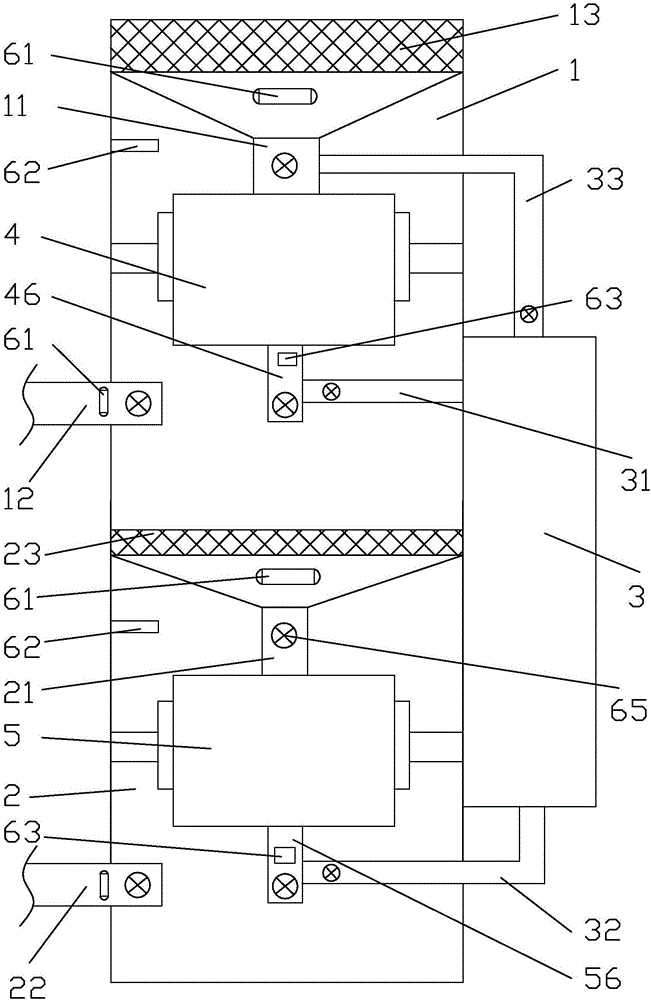

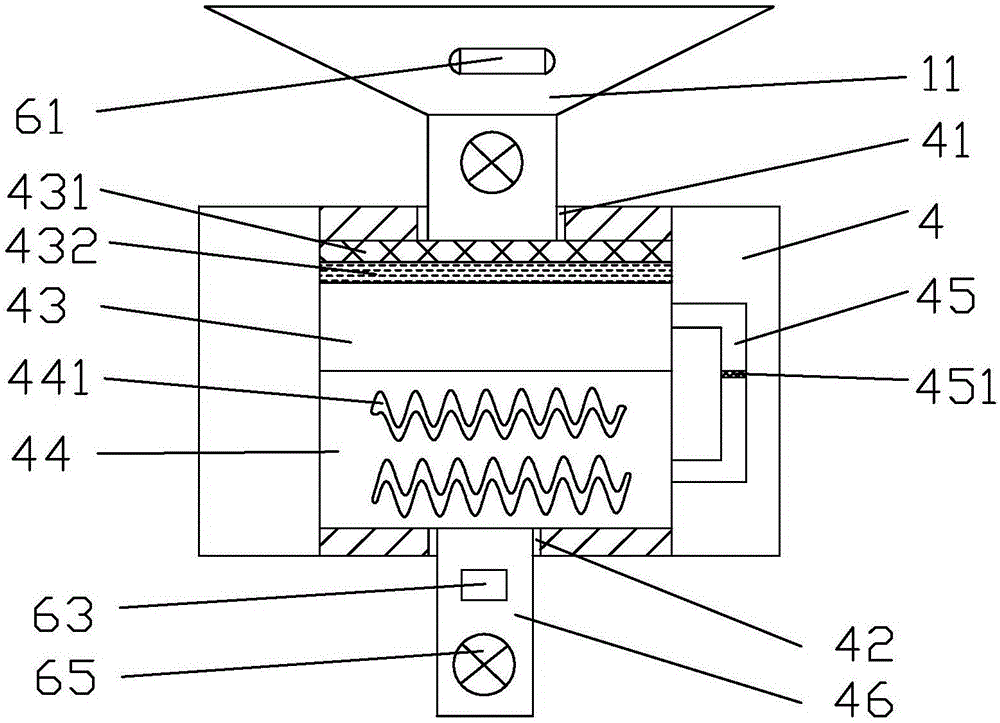

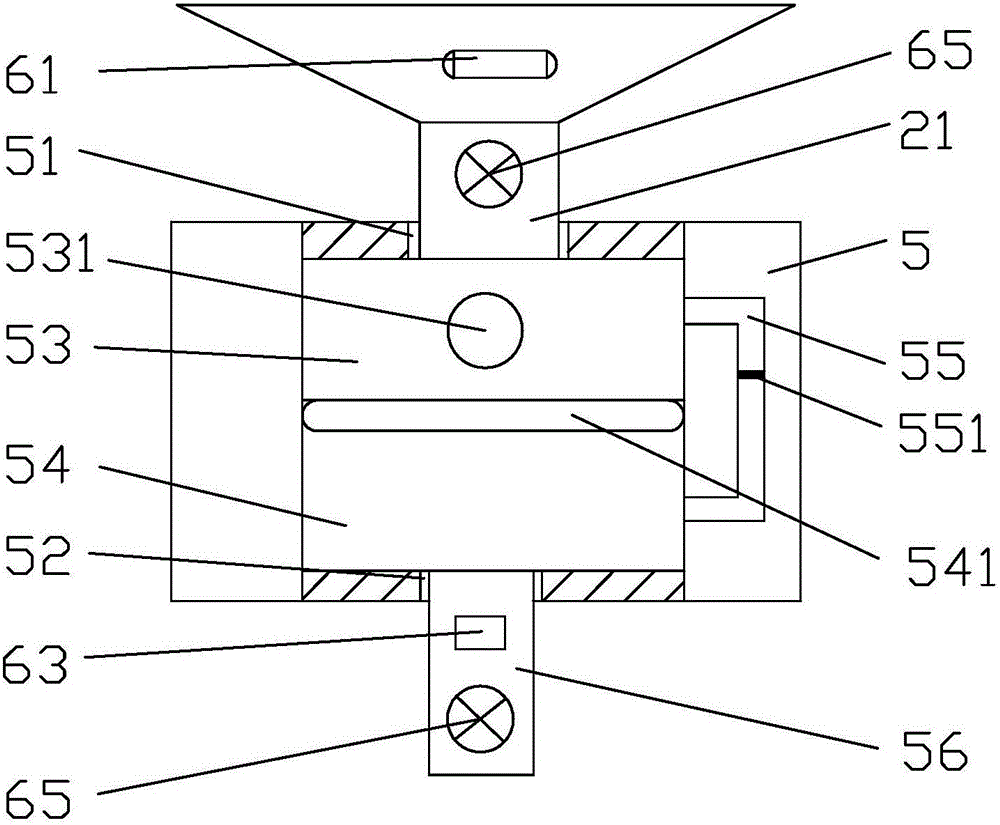

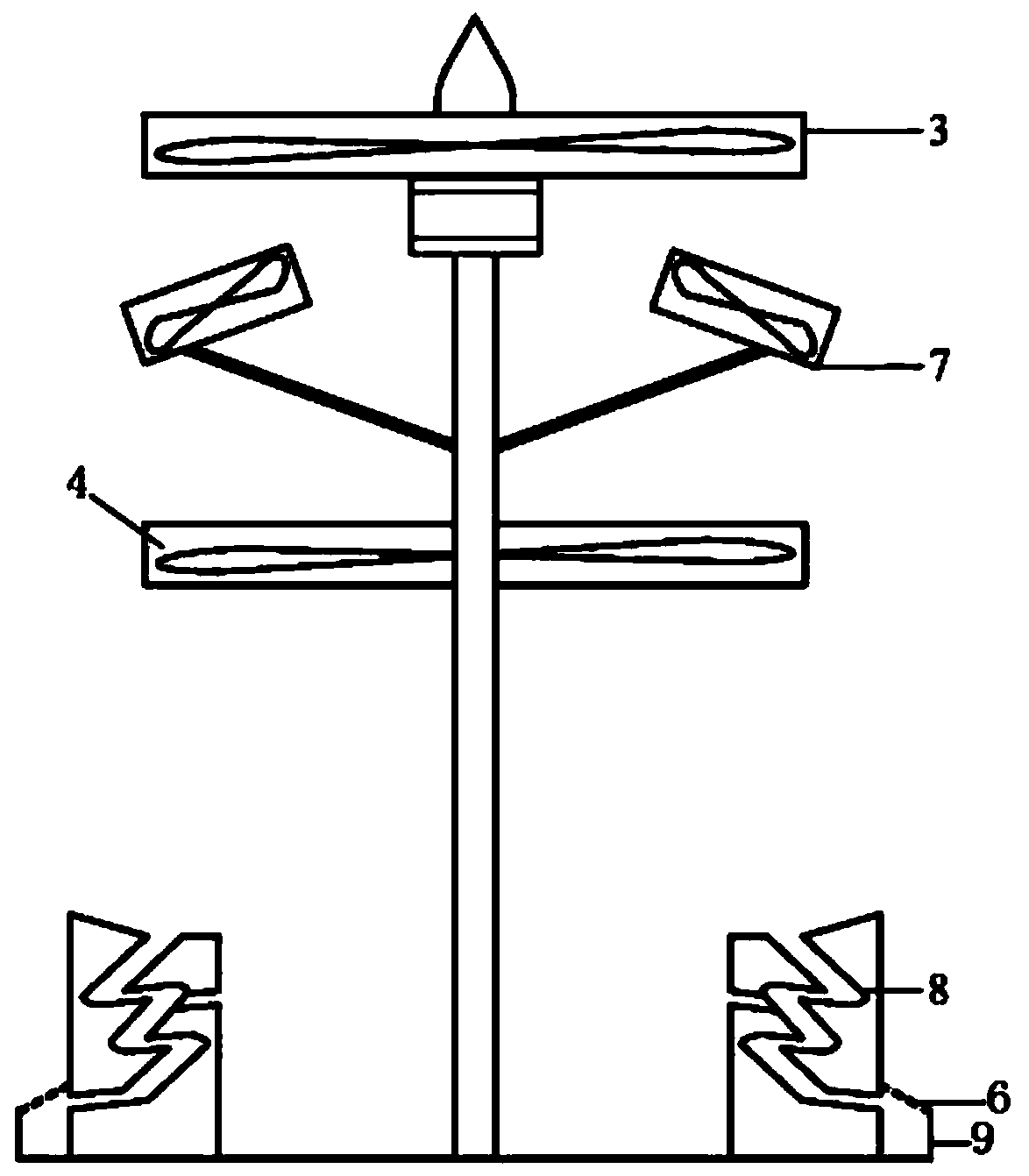

Street lamp device with photovoltaic power generation as power supply source and used for collecting fine particles in air

InactiveCN103968320AReduce particulate matterProtect environmentElectric circuit arrangementsLighting elementsVoltageSolar cell

The invention relates to a street lamp device with photovoltaic power generation as a power supply source and used for collecting fine particles in air, and belongs to the technical field of environment protection application. A solar cell generates currents under irradiation of sunshine, and the currents are input into a photovoltaic controller through a conductive line for adjustment and then input into an energy storage battery for storing. When particle collection is needed, the currents output from the energy storage battery are input into an absorption control device through a power distribution device, and the absorption control device supplies power to an air pump and a current control device. When the air pump starts to work, external air is absorbed into an electrostatic adsorption device, meanwhile, the current control device changes voltage of the input currents according to set requirements and then the currents are transmitted to the electrostatic adsorption device, air entering the electrostatic adsorption is ionized in an ionization chamber, the particles in the air are charged, the charged particles move to an absorption chamber under the action of electric field force and air flow formed in the electrostatic adsorption device and are attached to absorption poles in the absorption chamber due to discharging, and the purified air is exhausted from an air outlet of a street lamp rod along with the air flow.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Surface water recycling system for sponge city and construction method of surface water recycling system

ActiveCN106082536AWide range of actionPromote degradationTreatment involving filtrationRunoff/storm water treatmentWater storageControl system

The invention mainly discloses a surface water recycling system for a sponge city. The surface water recycling system comprises a pure water storage system, a sewage treatment system and a water flow control system, wherein the pure water storage system comprises a first water well, a second water well and a circulation well which are connected with one another; the sewage treatment system comprises a first sewage treatment device located in the first water well and a second sewage treatment device located in the second water well. The surface water recycling system can realize effective percolation, treatment and collection of surface water, improves the water quality and facilitates surface water recycling. A construction method of the surface water recycling system comprises steps of ground treatment, foundation pit treatment, building of the water wells, installation of the sewage treatment system, building of the circulation well, laying of filtering plates, laying of internal pipes, laying of water guide pipes and ground surface treatment. The construction method is reasonable in design and adopts simple and reliable construction steps, the construction steps are joined and arranged properly, accumulated water can be guided effectively to infiltrate to underground, and the effect of sufficiently recovering rainwater and surface water is realized.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

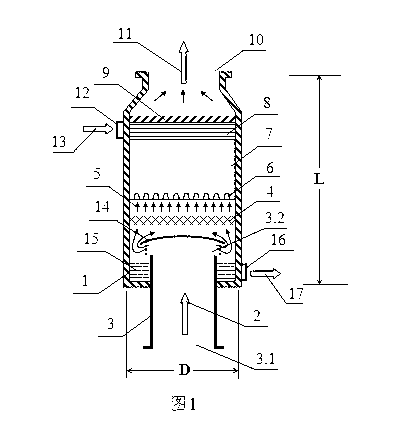

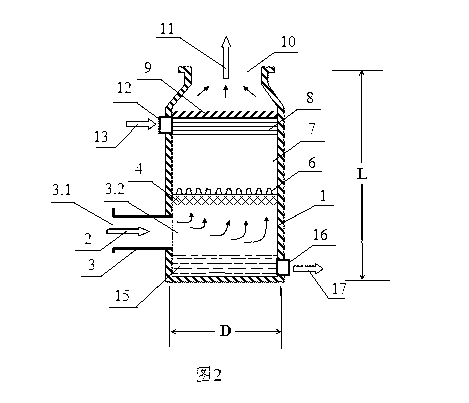

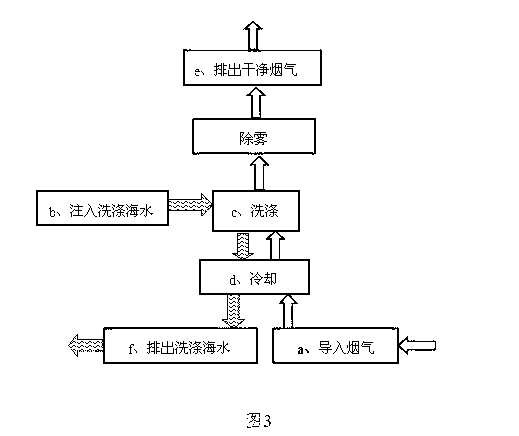

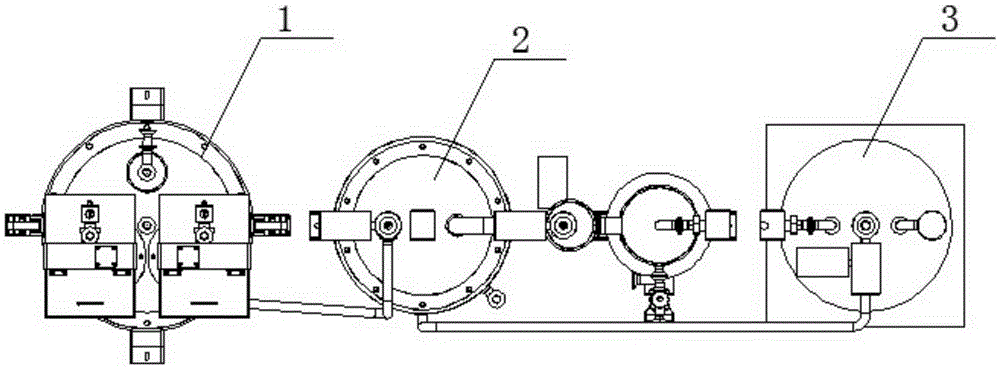

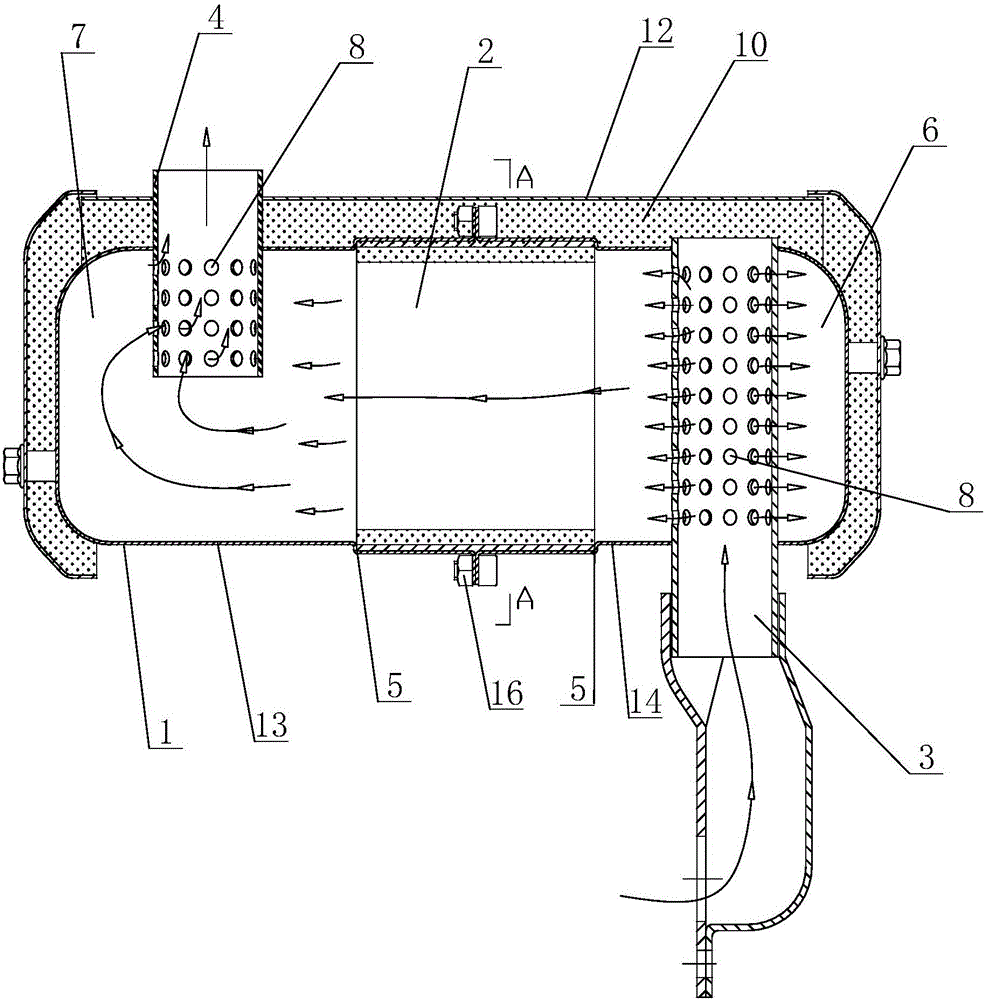

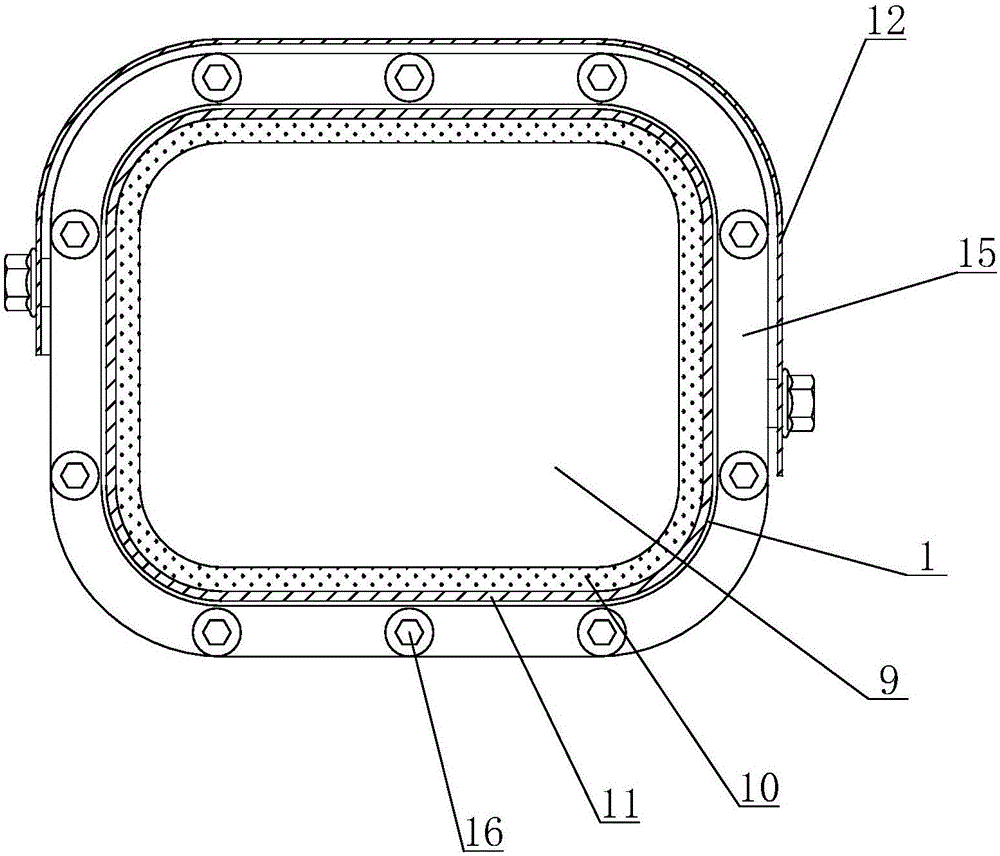

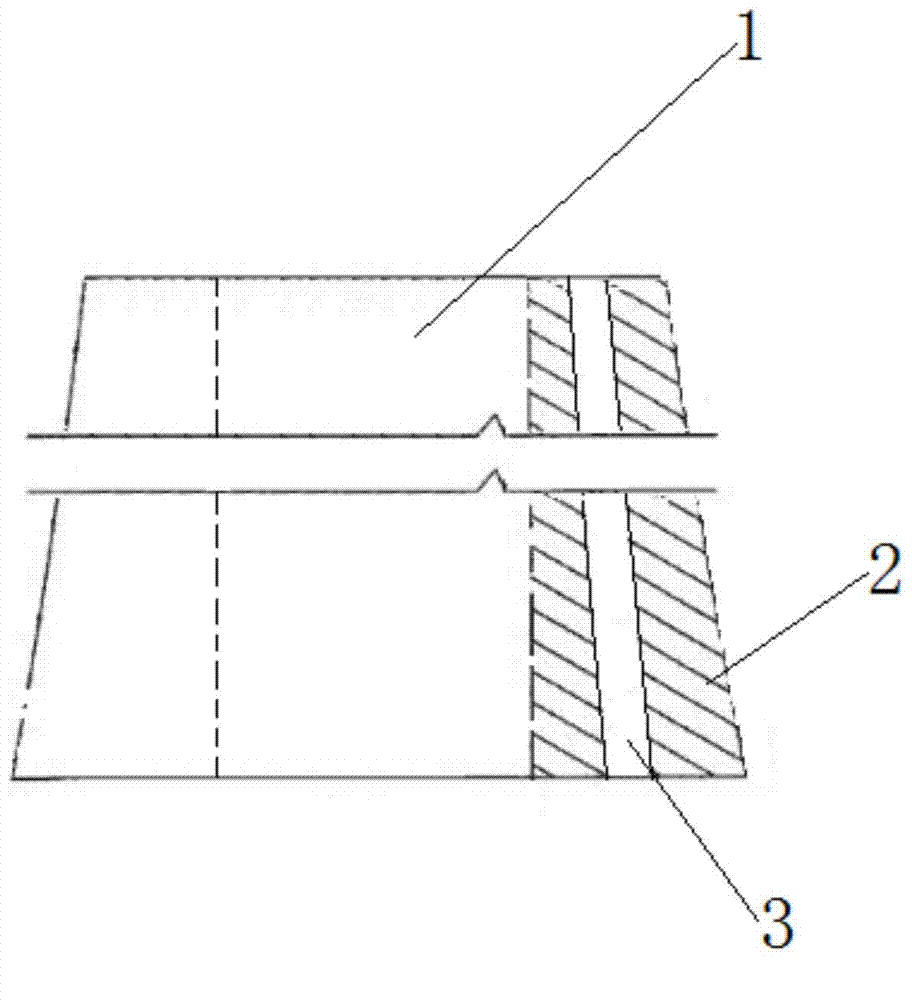

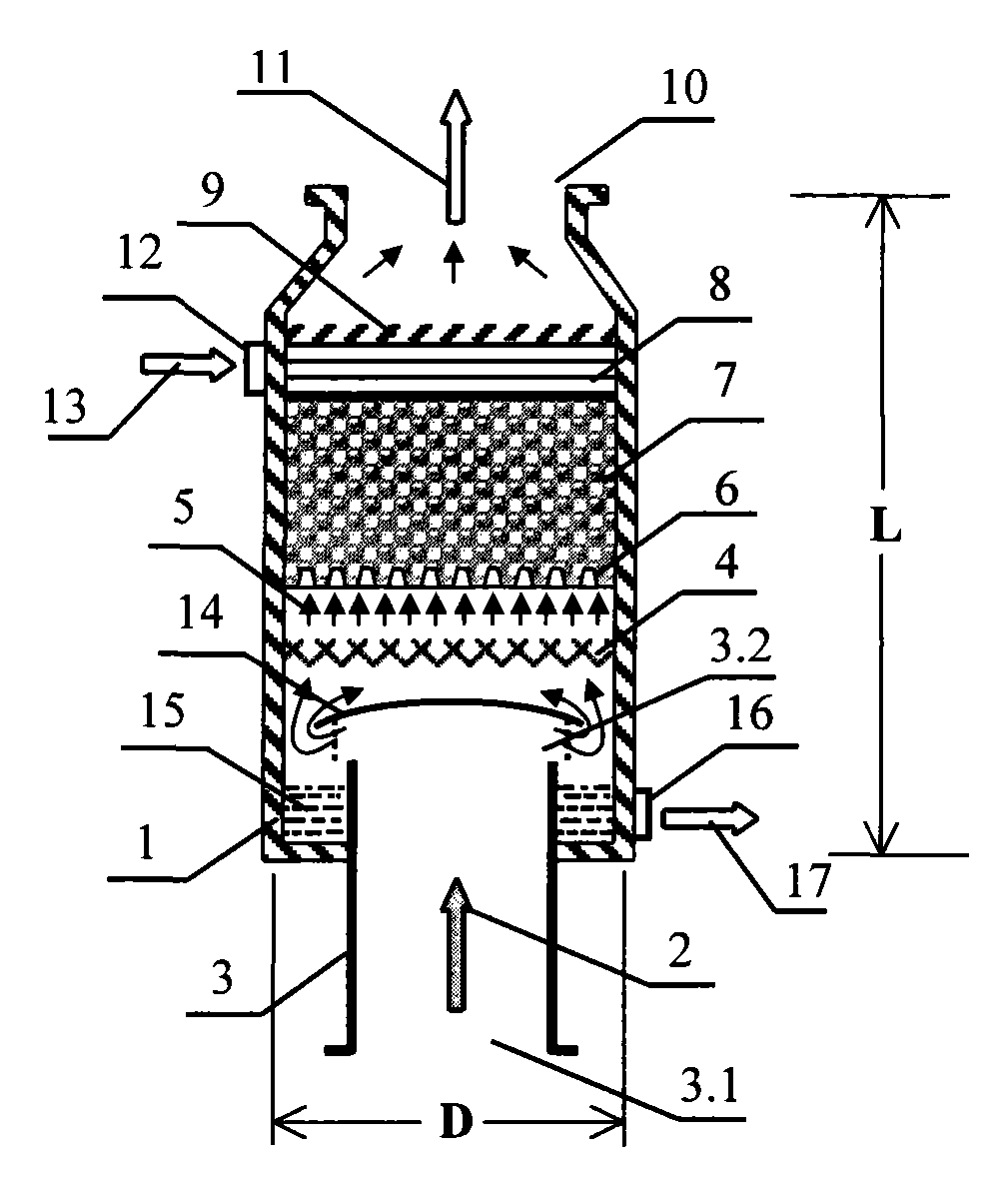

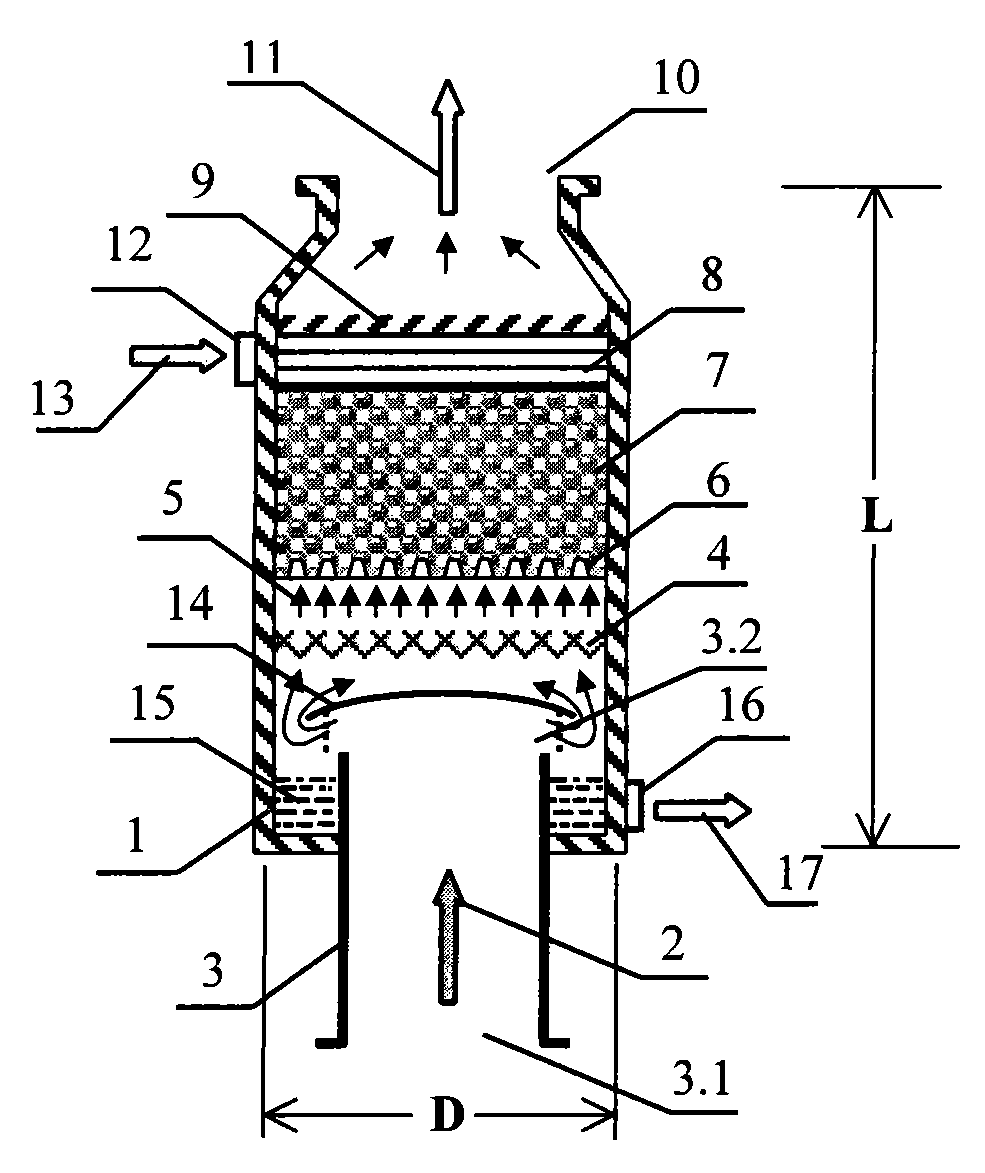

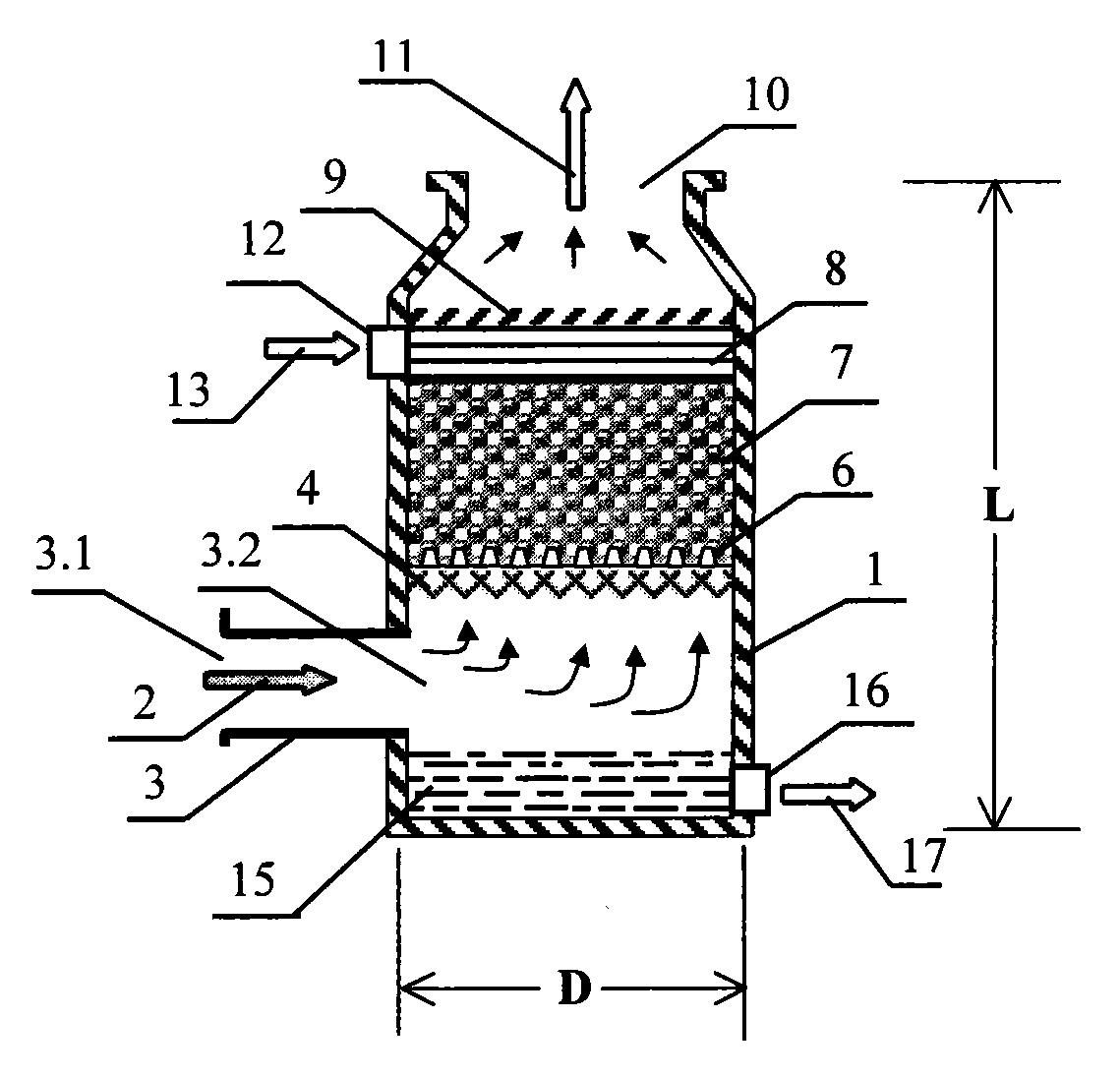

Washing device and washing method for marine exhaust flue gases

ActiveCN102112207BEfficient washingLow running costGas treatmentUsing liquid separation agentFlue gasEnvironmental engineering

This invention relates to a ship flue gas scrubbing apparatus and scrubbing method. The apparatus includes a housing (1), an upper scrubbing layer (7) at the upper side inside the housing (I), and a liquid collecting pool (15) in the lower side inside the housing (1), a flue gas leading-in port (3.2) between the scrubbing layer (7) and the liquid collecting pool (15), a scrubbing seawater inlet (12) above the scrubbing layer (7), and a cooler (4) located at a flue gas passage between the flue gas inlet (3.1) outside the housing and the scrubbing layer (7). The method includes leading flue gas, cooling, injecting scrubbing seawater, scrubbing and other steps.

Owner:CLEAN ENERGY PROJECT TECH INC

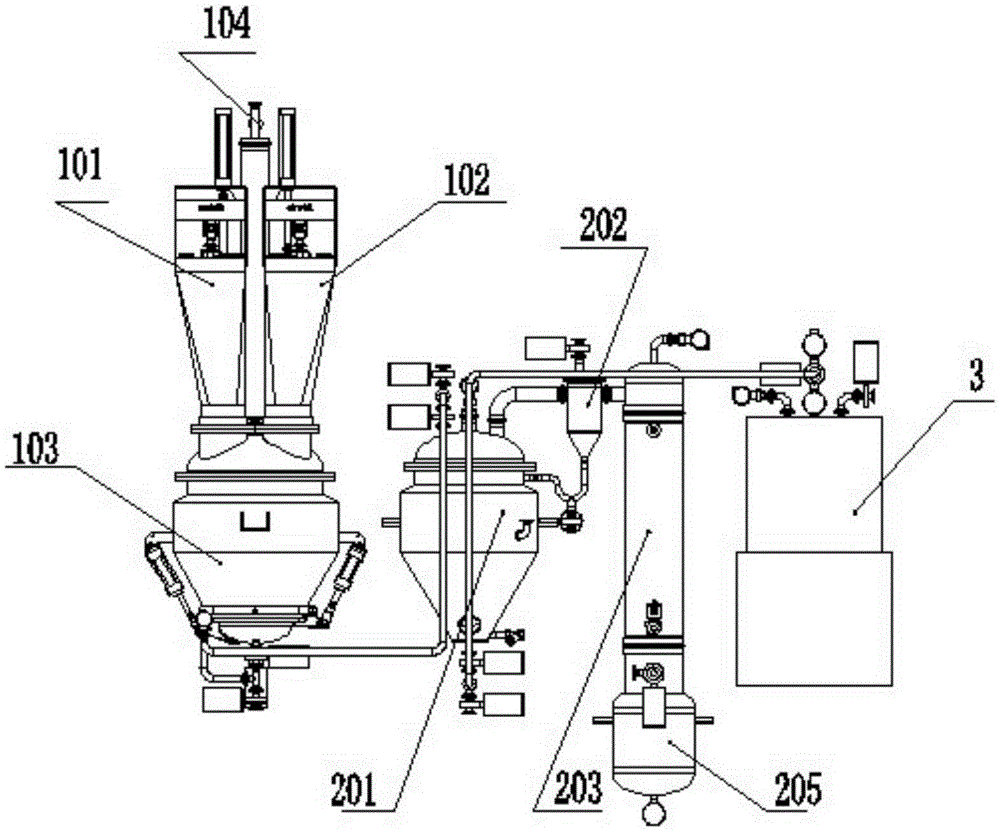

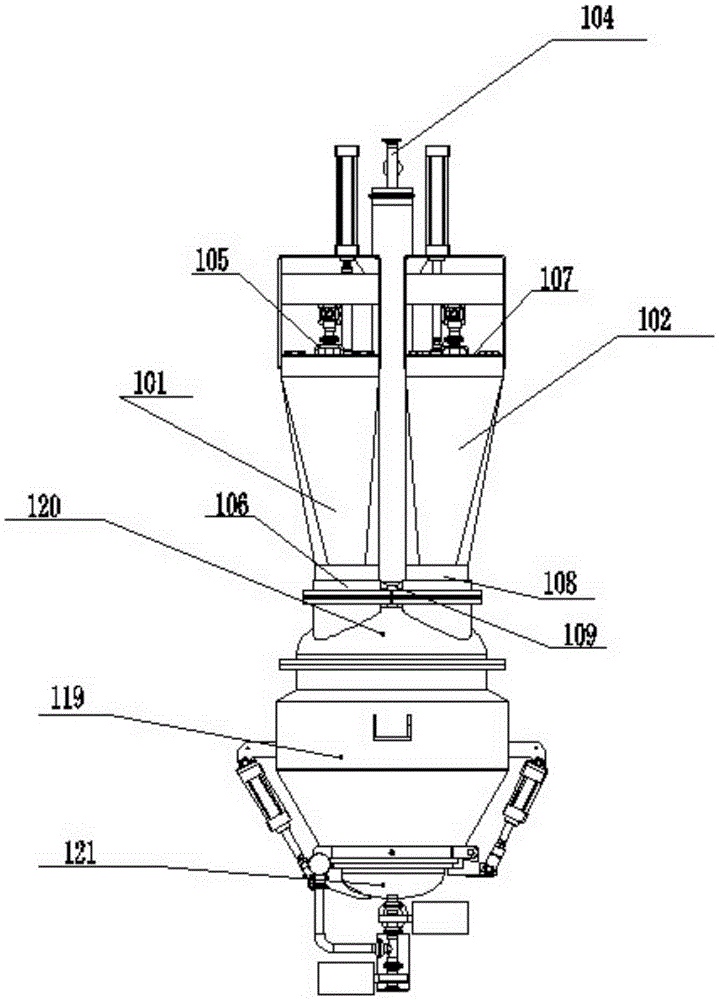

Full-automatic traditional Chinese medicine decoction preparation device

InactiveCN105342856AMeet the requirements of frying first and then servingReduce particulate matterPharmaceutical product form changeDomestic articlesMedicinal herbsMedicine

The invention relates to a full-automatic traditional Chinese medicine decoction preparation device which comprises more than one set of a medicine feeding and decocting device, a concentrating and condensing device, a packaging mechanism and a control system, wherein the medicine feeding and decocting device comprises a main medicine soaking tank, a subsequently-added medicine feeding tank, an extracting tank and a first condenser; and the main medicine soaking tank and the subsequently-added medicine feeding tank are arranged in parallel and are fixed above the extracting tank. The full-automatic traditional Chinese medicine decoction preparation device is provided with the main medicine soaking tank, the subsequently-added medicine feeding tank and the extracting tank, wherein the main medicine soaking tank is used for soaking the firstly-decocted medicines, the subsequently-added medicine feeding tank is used for containing the subsequently-added medicines or soaking the subsequently-added medicines, and the extracting tank is used for decocting, so that batched and staged feeding can be realized by combining the tanks, and the requirements of firstly decocting and then adding are met.

Owner:南京迦南众心和医药科技有限公司

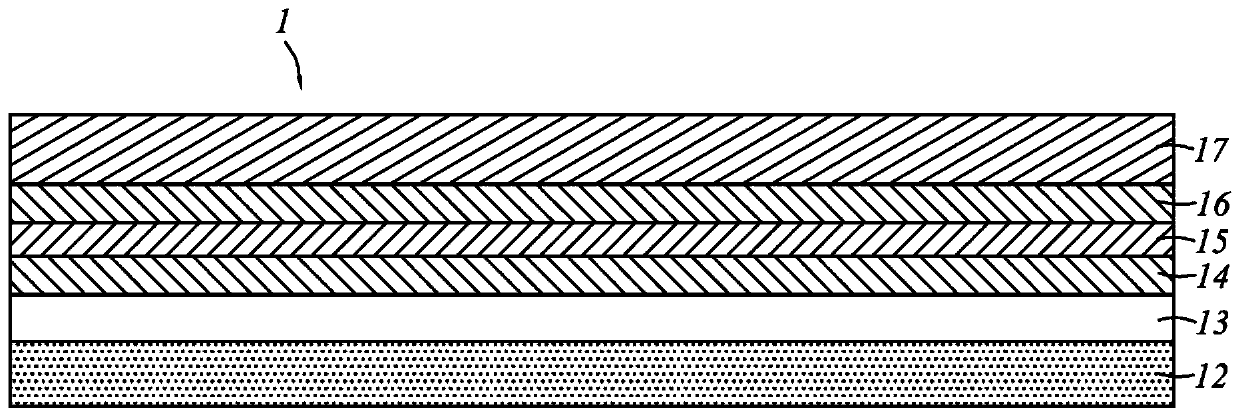

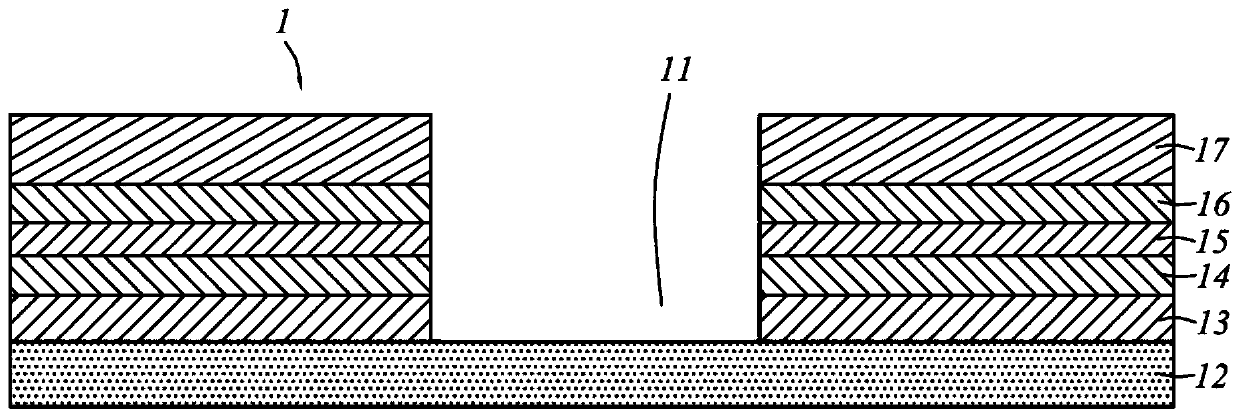

Display panel and manufacture method thereof

ActiveCN109904118AImprove reliabilityAvoid failureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhotoresist

The invention provides a display panel and a manufacture method thereof. The manufacture method of the display panel comprises steps of: providing an array substrate; reserving at least one pre-grooved area for forming an installation groove on the array substrate; forming a photoresist layer in the pre-grooved area; providing a mask plate with a designed pattern so as to block the array substrate, exposing and developing the pre-grooved area through the mask plate, so as to form at least one pre-etched area in the pre-grooved area; and grooving the pre-grooved area so as to form the installation groove. The display panel meets the requirement of etching on the array substrate so as to make a large-area installation groove, reduces particles in later grooving process and keeps the functional layer effective.

Owner:YUNGU GUAN TECH CO LTD

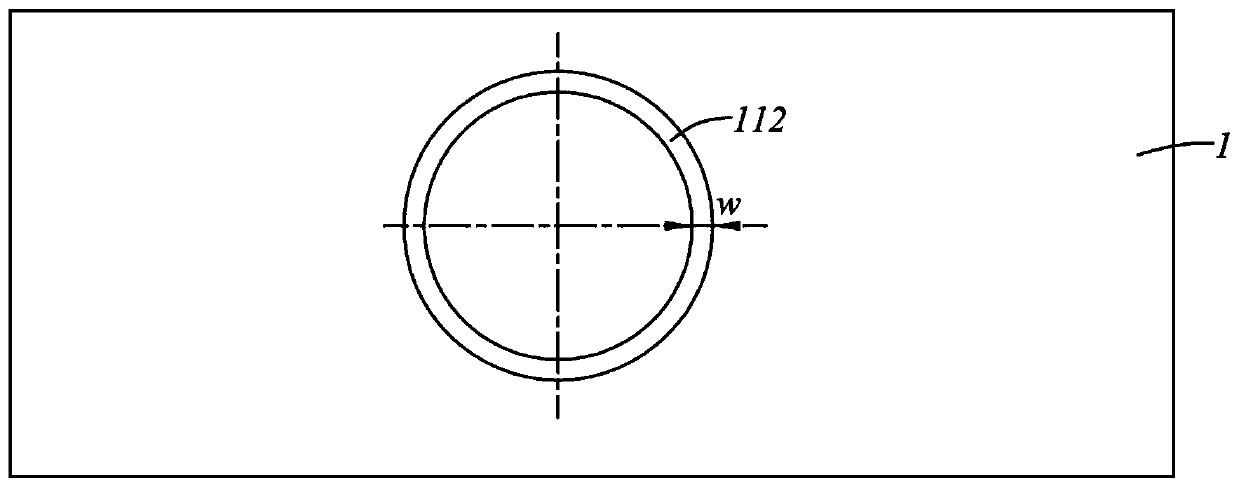

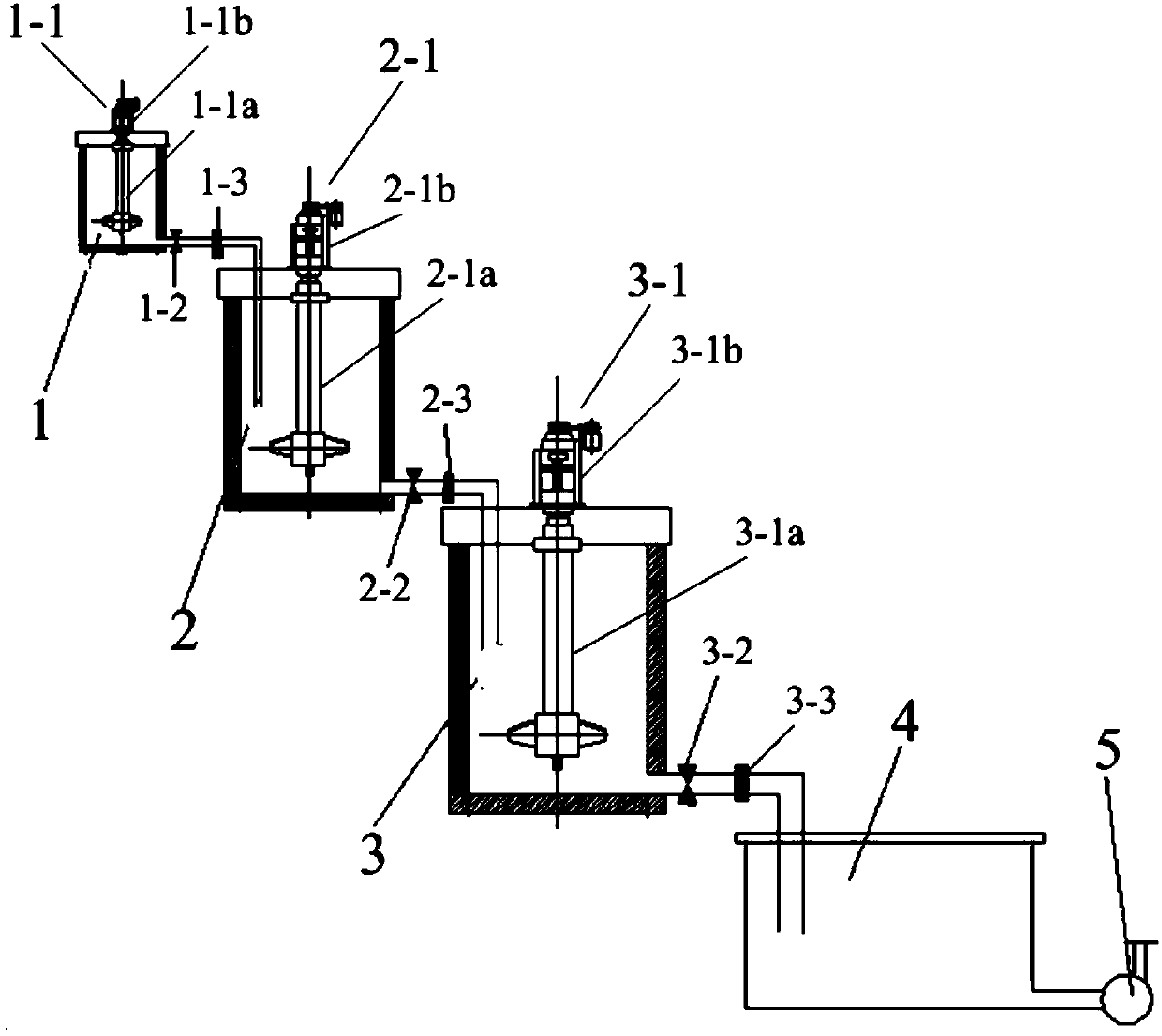

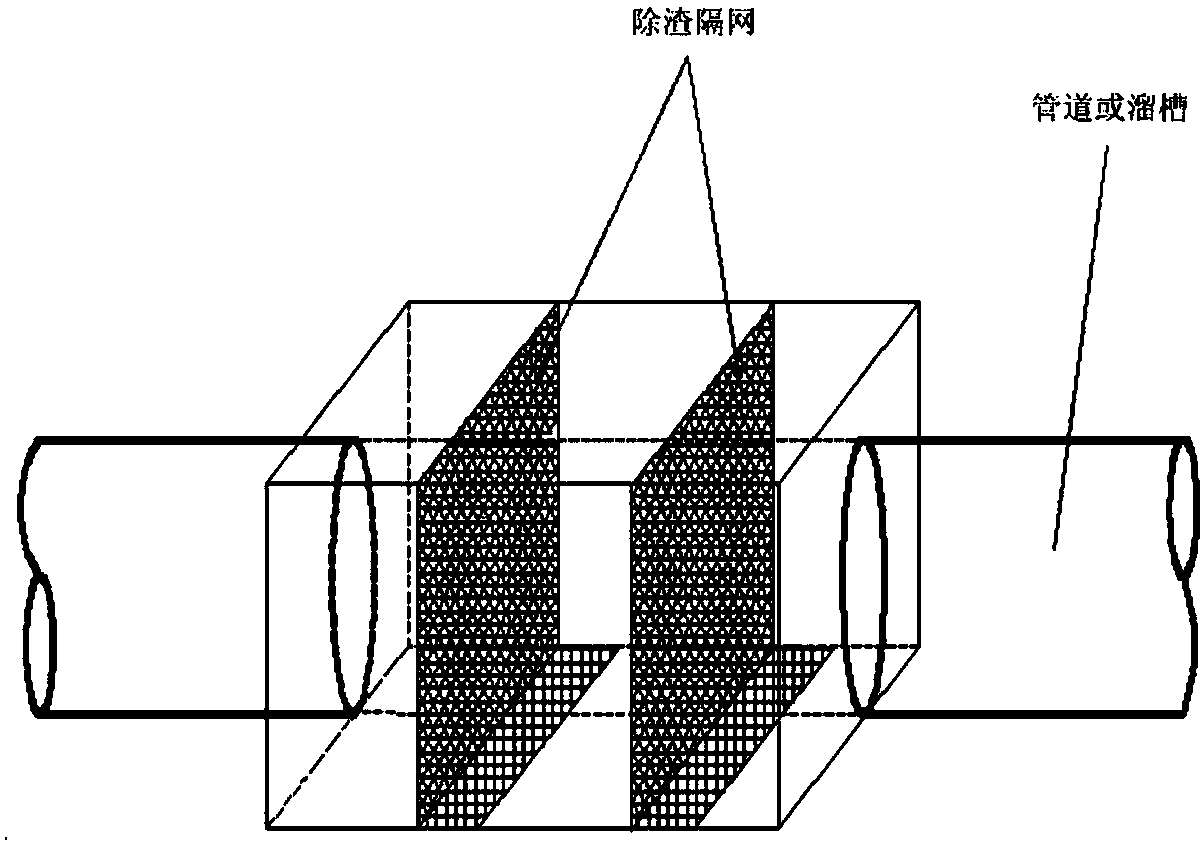

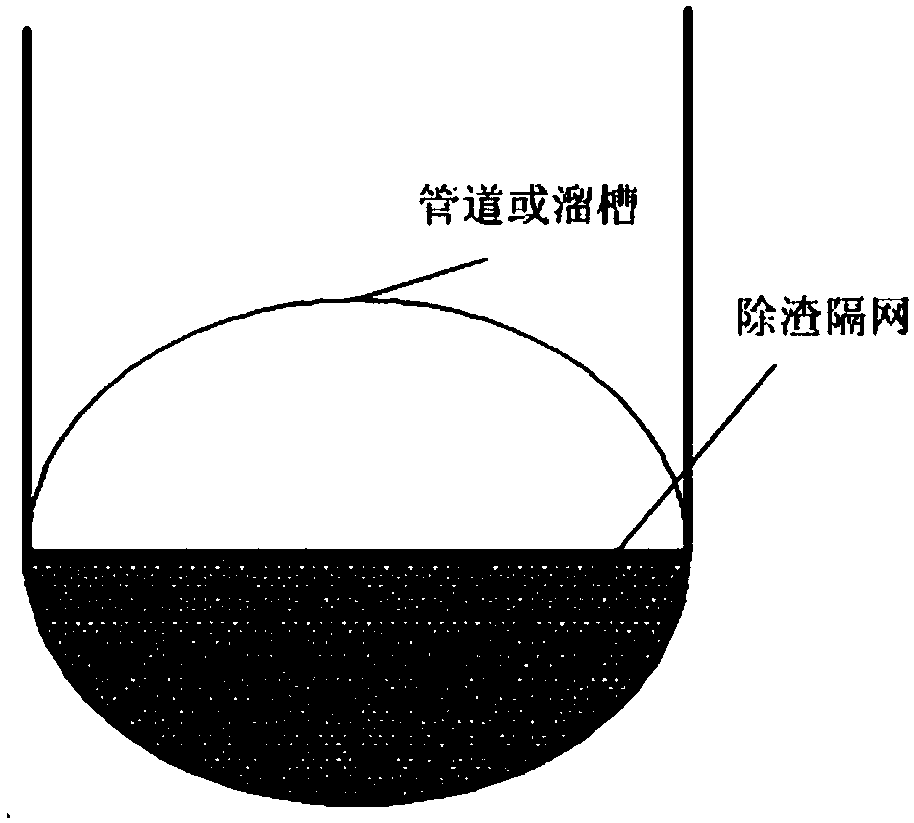

Preparation device of floating agent

ActiveCN107551942AReduce particulate matterFull flowRotary stirring mixersMixture aftertreatmentDrug reservoirParticulates

The invention provides a preparation device of a floating agent. The preparation device comprises a first stirring groove, a second stirring groove, a third stirring groove and an agent collecting pool in sequential series connection, wherein the first stirring groove, the second stirring groove, the third stirring groove and the agent collecting groove are in sequential step arrangement, so thatthe floating agent can sequentially and automatically flow to the second stirring groove, the third stirring groove and the agent collecting pool from the first stirring groove through the self gravity. The provided assembly device comprises three stirring grooves; water can be respectively added into each stirring groove for dilution stirring; the stirring effect of the pasty agent is improved, so that the floating agent is more uniform; particles are fewer; in addition, the three stirring grooves and the agent collecting pools are in step arrangement, so that the agent automatically flows tothe subsequent medication device, the agent of each stirring groove can sufficiently flow out; the agent utilization rate is improved; the simple and convenient agent transmission mode is also provided.

Owner:PANGANG GRP MINING

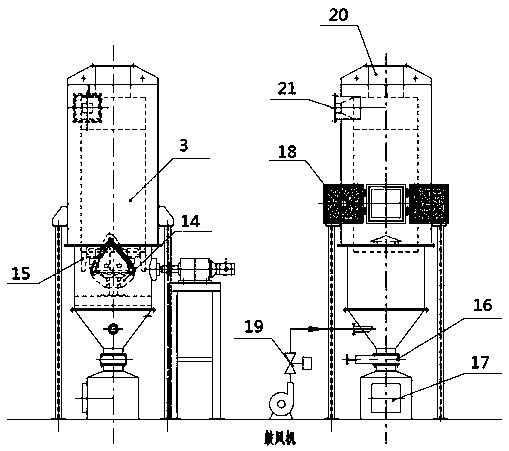

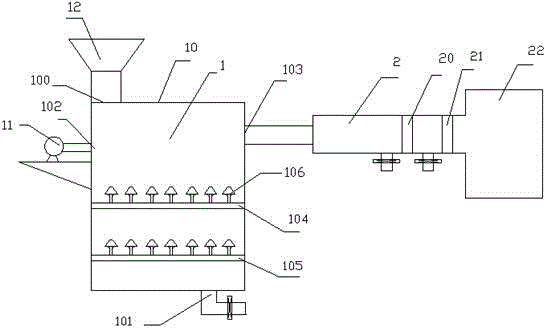

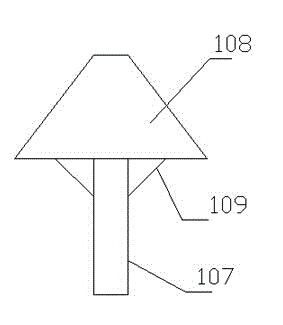

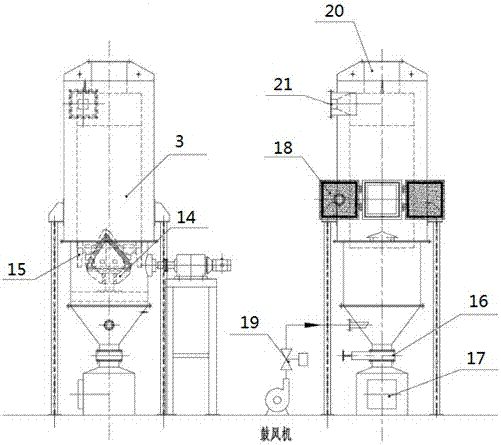

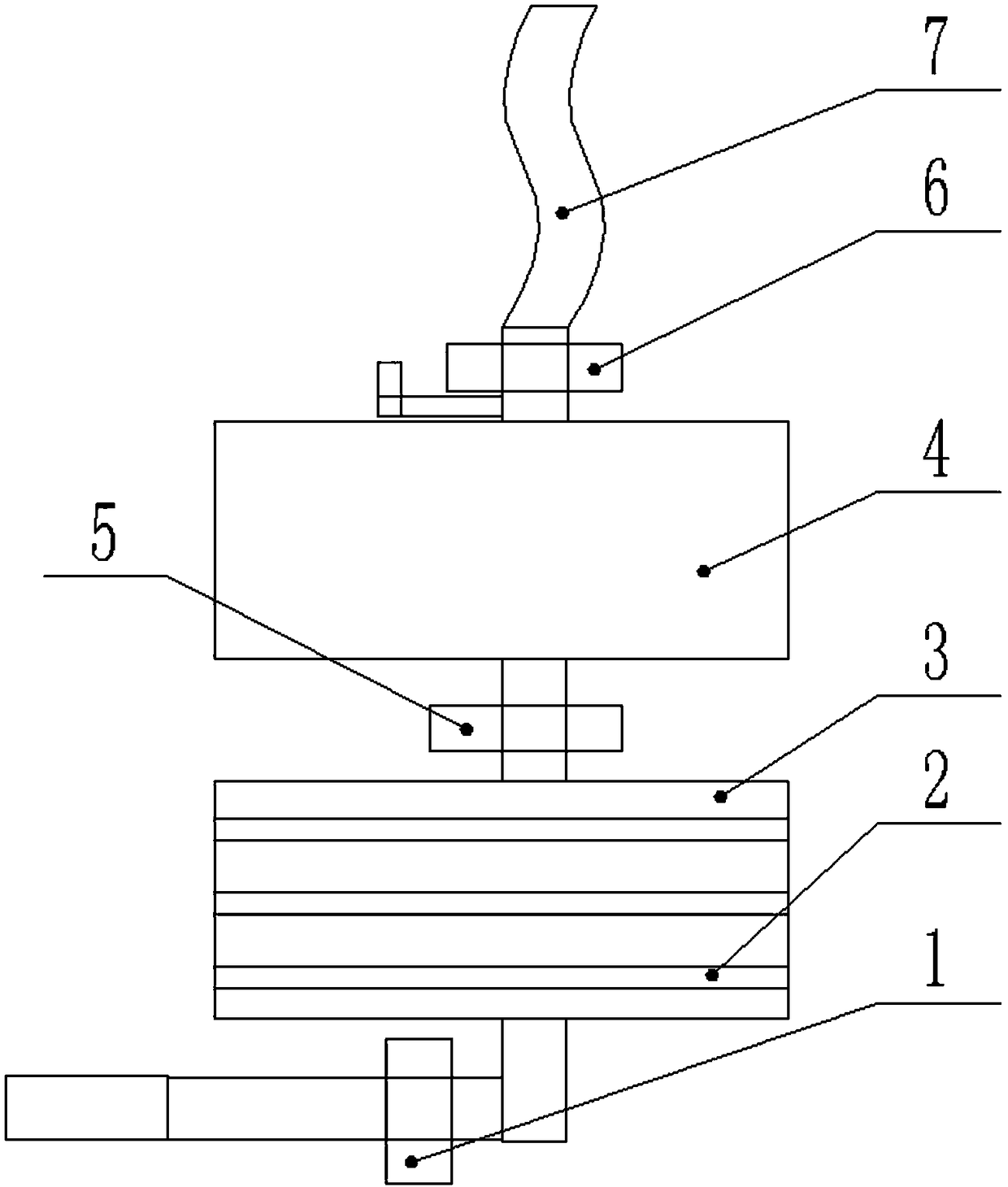

Material drying system

InactiveCN102564070AUniform coolingReduce generationDrying solid materials with heatHearth type furnacesCycloneParticulates

The invention discloses a material drying system, comprising a drying tower, a fluidized bed and a cyclone separating tower; wherein a wind inlet is arranged at the upper end of the drying tower and is connected with a fan through a pipeline; a wind exhaust is arranged at the side of the drying tower and is connected with the cyclone separating tower through a wind exhaust pipeline; a discharge hole is arranged at the lower end of the drying tower and is connected with the fluidized bed through the pipeline; at least two wind inlets are arranged at the lower end of the fluidized bed; the wind outlet arranged at the upper end of the fluidized bed is connected with the wind exhaust pipeline of the drying tower through the wind outlet pipeline and then is connected with the cyclone separating tower; the top end of the cyclone separating tower is configured into an air outlet; the diameter of the cyclone separating tower is 3270mm; one cyclone separating tower is added to the material drying system, the diameter of the cyclone separating tower is increased to 3270mm from initial 400mm, the spiral length is increased, therefore, the unit volume is increased, the separating effect is improved, and the amount of the grain materials in the exhausted wind is decreased. In this way, the environment pollution is decreased to minimal.

Owner:无锡超科食品有限公司

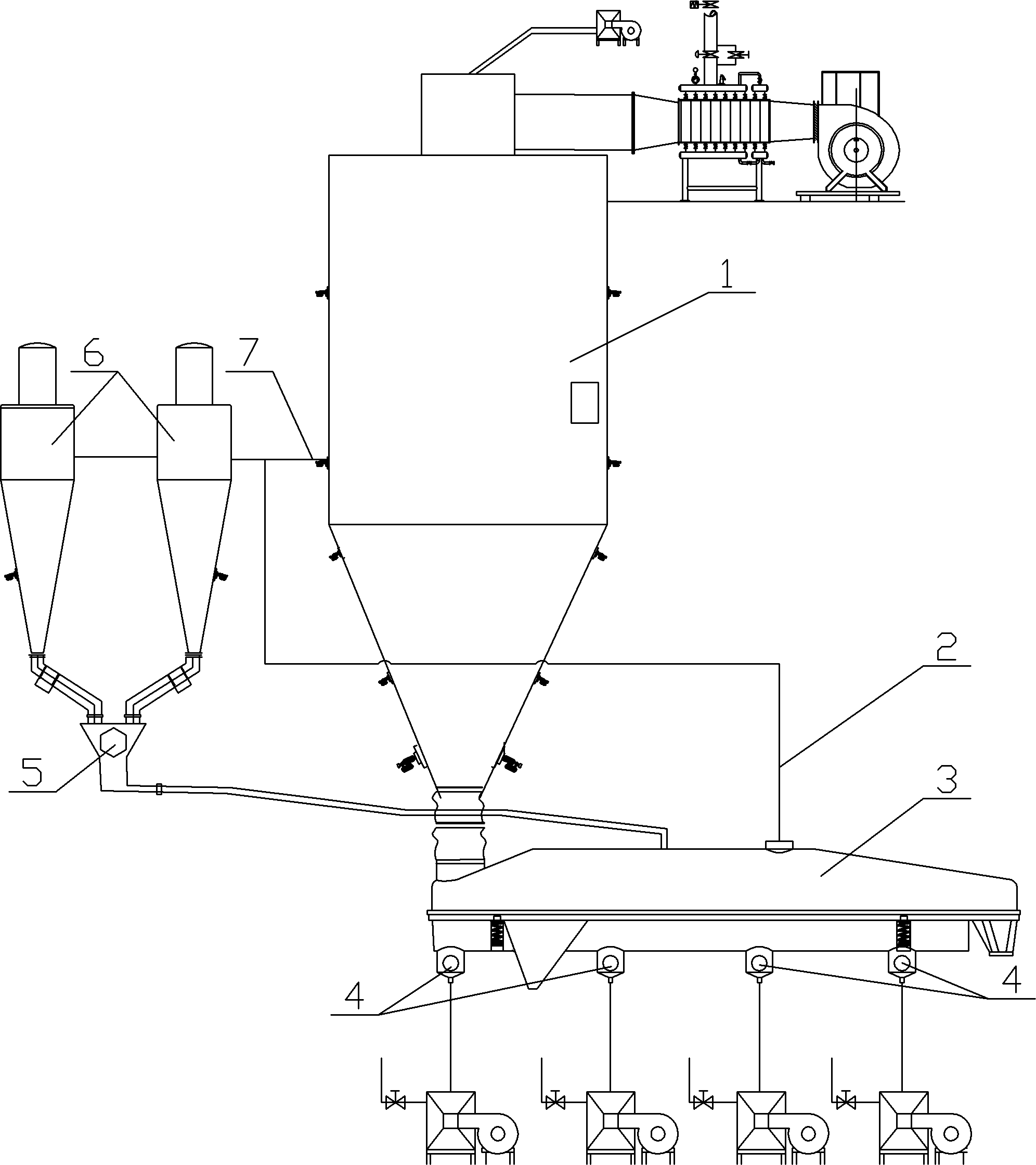

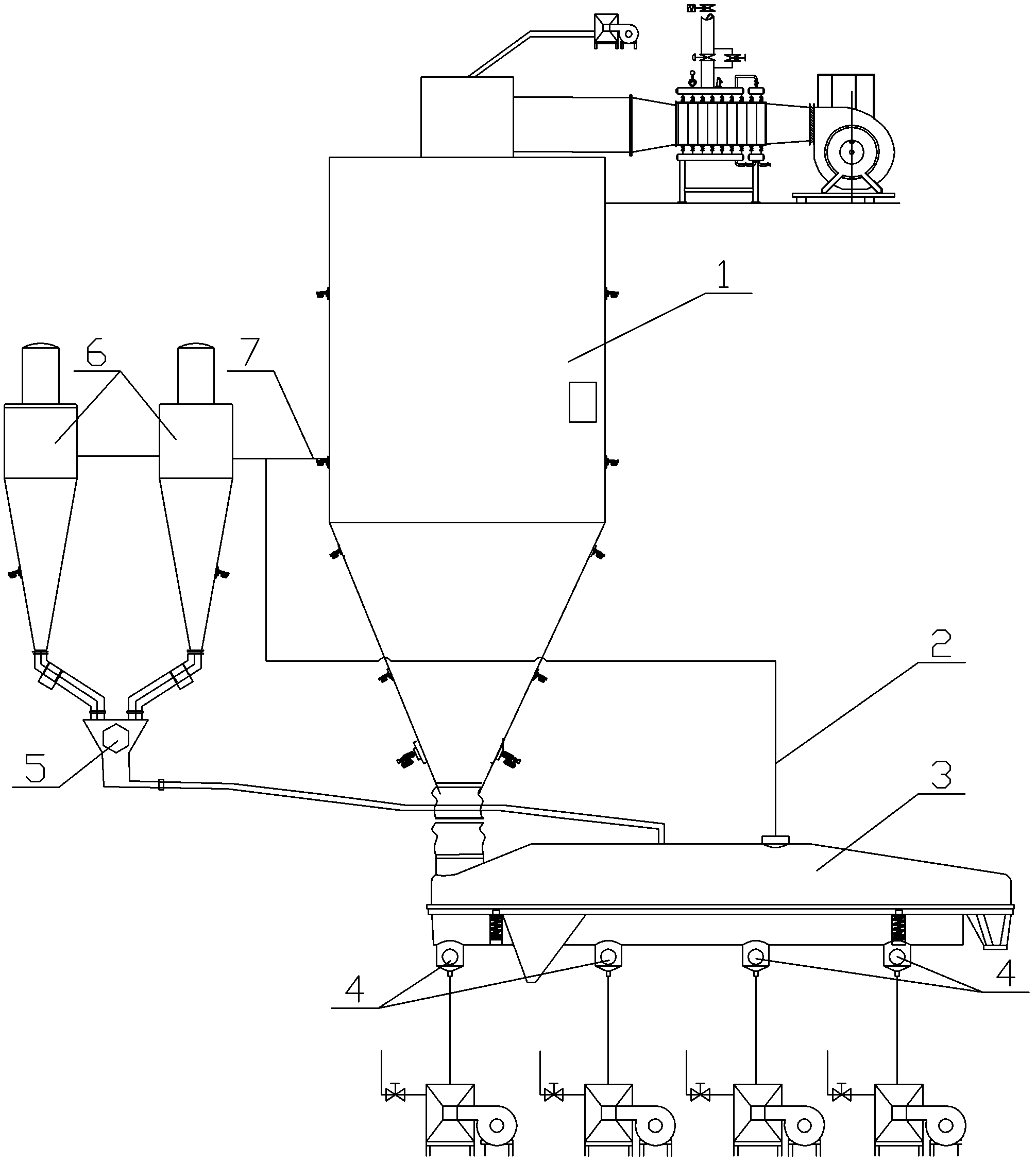

Air separation machine for powder coating production

ActiveCN104689990AHigh yieldReduce particulate matterSievingGas current separationEngineeringAir separation

The invention discloses an air separation machine for powder coating production. The air separation machine comprises an air separation box and an air separation tank, wherein the air separation tank is connected to the air separation box; the air separation box comprises a box body and an air blower; a feeding hole is formed in a top end of the box body; a discharging hole is formed in the bottom of the box body; an air blowing hole and an air suction hole are formed in an upper part of the box body; an upper sieve and a lower sieve are mounted in the box body; the air blower is mounted on the box body; the air blower is connected to the air blowing hole of the box body through a pipeline; the air separation tank is connected to the air suction hole of the box body through a pipeline; an air suction fan is mounted in the pipeline between the air suction hole and the air separation tank; a left sieve and a right sieve are mounted in the air separation tank; the tail of the air separation tank is connected with a collector. The air separation machine is used for performing air separation on a produced powder coating and removing tiny particles and impurities in the powder coating to obtain a clean powder coating; air bubbles cannot appear when the air separation machine is used.

Owner:枣庄高新区立正建筑工程有限公司

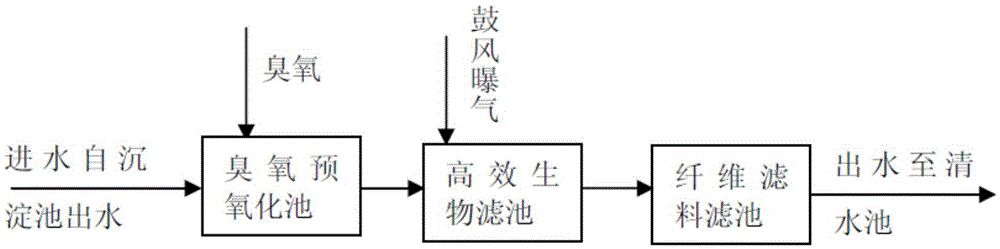

Advanced water treatment method for micro-polluted water source

InactiveCN105585216AReduce chromaImprove biodegradabilityTreatment using aerobic processesTreatment involving filtrationSuspended particlesFiber

The invention discloses an advanced water treatment method for a micro-polluted water source. Effluent from a sedimentation tank enters an ozone pre-oxidation tank, macromolecular organic matters in water are decomposed into micromolecular organic matters under strong oxidation of ozone, effluent from the ozone pre-oxidation tank is lifted to an efficient biofilter, the filtration rate of the efficient biofilter is 6-10 m / h, and filtering media comprise briquette broken carbon and ceramsite filter materials; effluent from the efficient biofilter flows to a fiber filtering media filtration tank under gravity, suspended particles are intercepted by fiber filtering media and finally enters a sludge system along with backwashing water and a precipitation process, and effluent from the fiber filtering media filtration tank enters a clear water tank, is disinfected by chlorine and pumped into an urban water supply network through a booster pump. The purified effluent enters the clear water tank and is disinfected by chlorine, so that the treated effluent meets the Standards for drinking water quality (GB5749-2006), the problems of blockage of a filtration tank, low organic matter removal rate and high operation cost of an ozone-biological activated carbon advanced treatment technology are solved, and the advanced water treatment method is suitable for advanced treatment of the micro-polluted water source, especially a micro-polluted water source in southern hot and humid areas.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

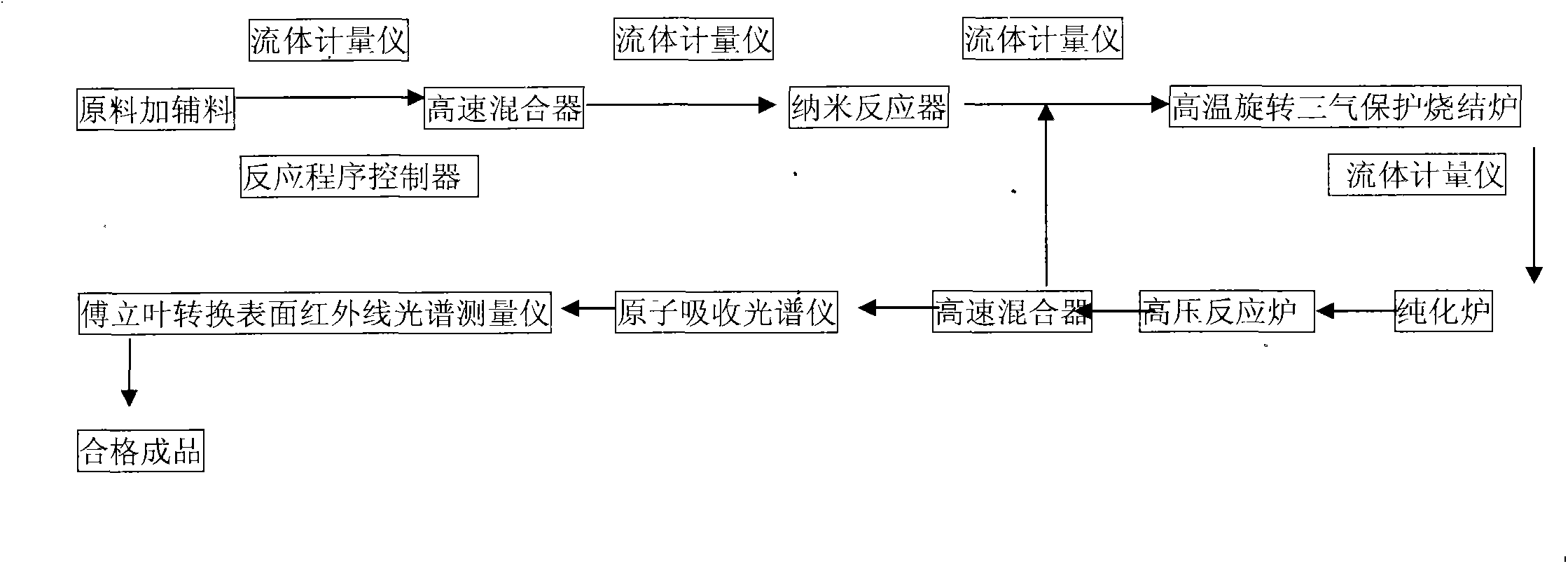

Nanoscale metal ceramization lubricant additive and preparation method therefor

InactiveCN103396862ARetain plasticityBoth super hard and super wear-resistantAdditivesChemical structurePhosphate

The invention provides a nanoscale ceramic metallization lubricant additive and a preparation method therefor, and aims to provide a nanoscale ceramic metal lubricant extreme pressure-antiwear additive which can improve the friction pair antiwear property and has self-lubricating functions. The invention is realized through the following technical scheme: quantification of raw materials is carried out according to the formula of the lubricant additive; nano ceramic powder is added into the raw materials; the above mixture is placed in a reactor wherein a coupling reaction is carried out under the atmosphere of hydrogen, nitrogen and helium; a coupling agent is added and the mixture is subjected to a coupling reaction to form ceramic primer gel with chemical covalent bonds, and one end of the coupling agent is a silicon-oxygen connection structure-Si[OEt]3 and the other end of the coupling agent is a chemical structure with molybdenum phosphate and boron nitride primer functional groups; the gel is added into a reactor through a metering pump, and is subjected to pressurization and carbon dioxide supercutical fluid solvent exchange, and the liquefied gel is converted into gasified gel; the gasified gel is then placed in a reactor atmosphere protection sintering furnace and sintered; the sintered ceramic coupling objects are placed in a stirring mixer and mixed with a surfactant additive, a dispersant, and a basic oil solvent to obtain finished products.

Owner:韩炳德

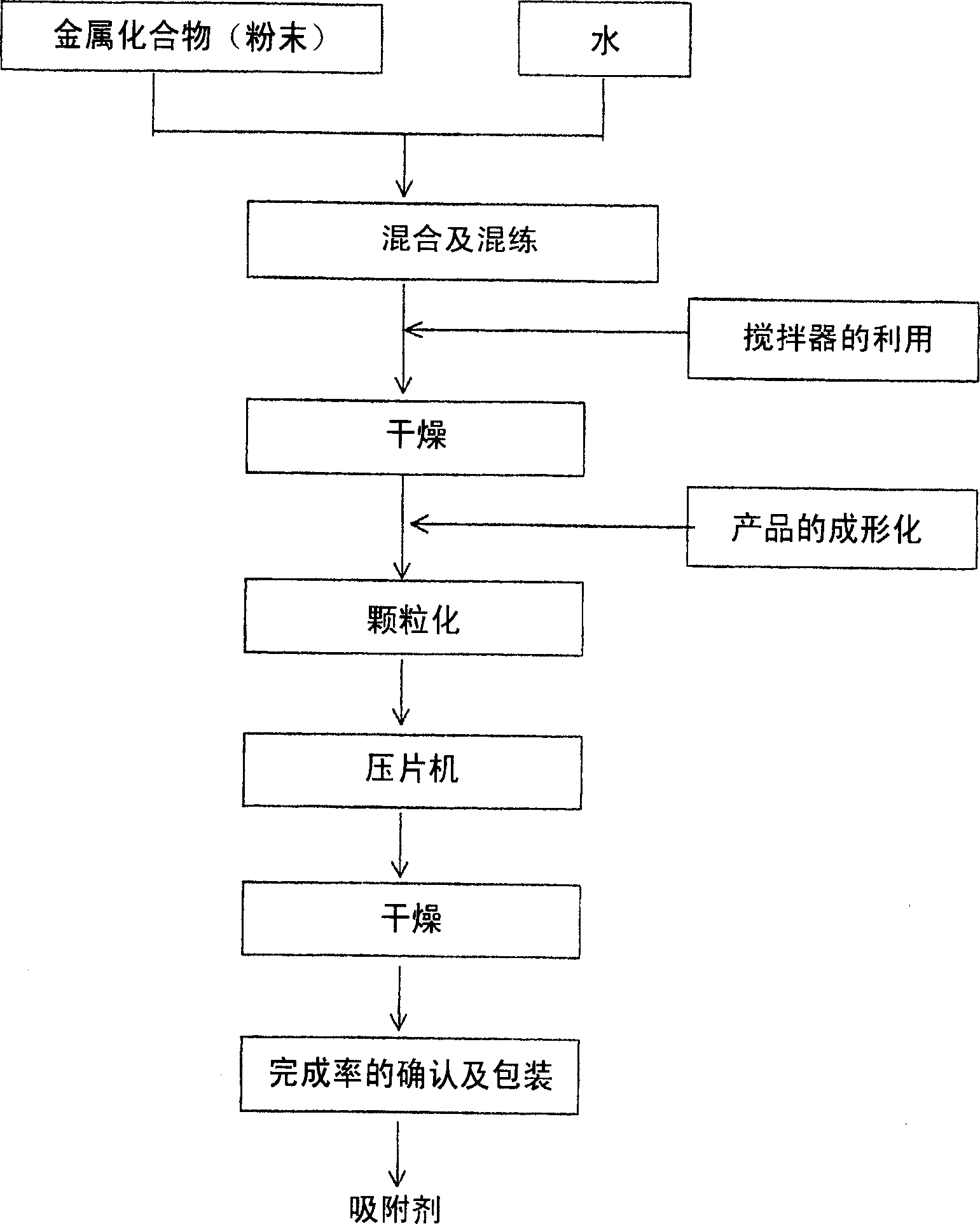

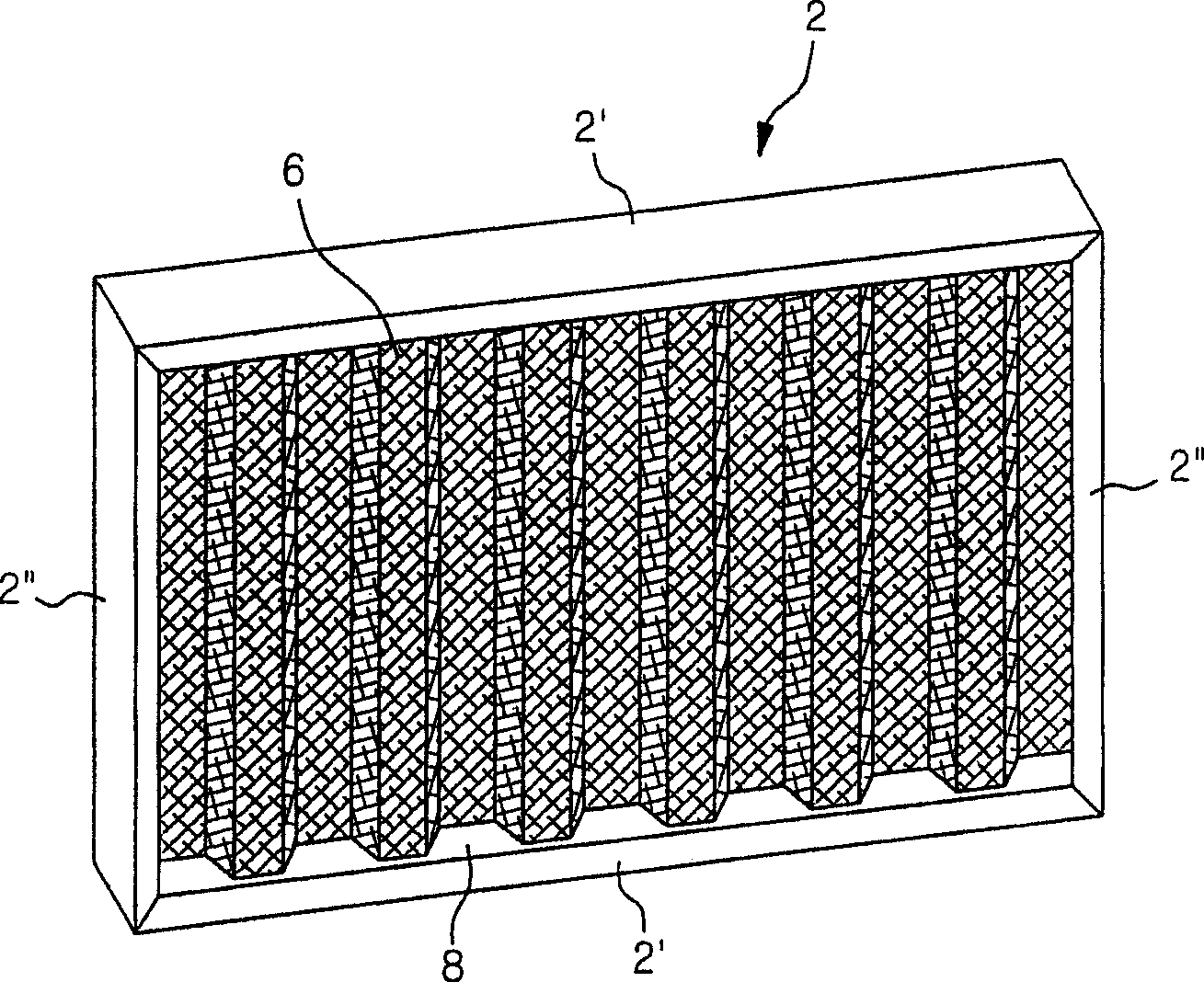

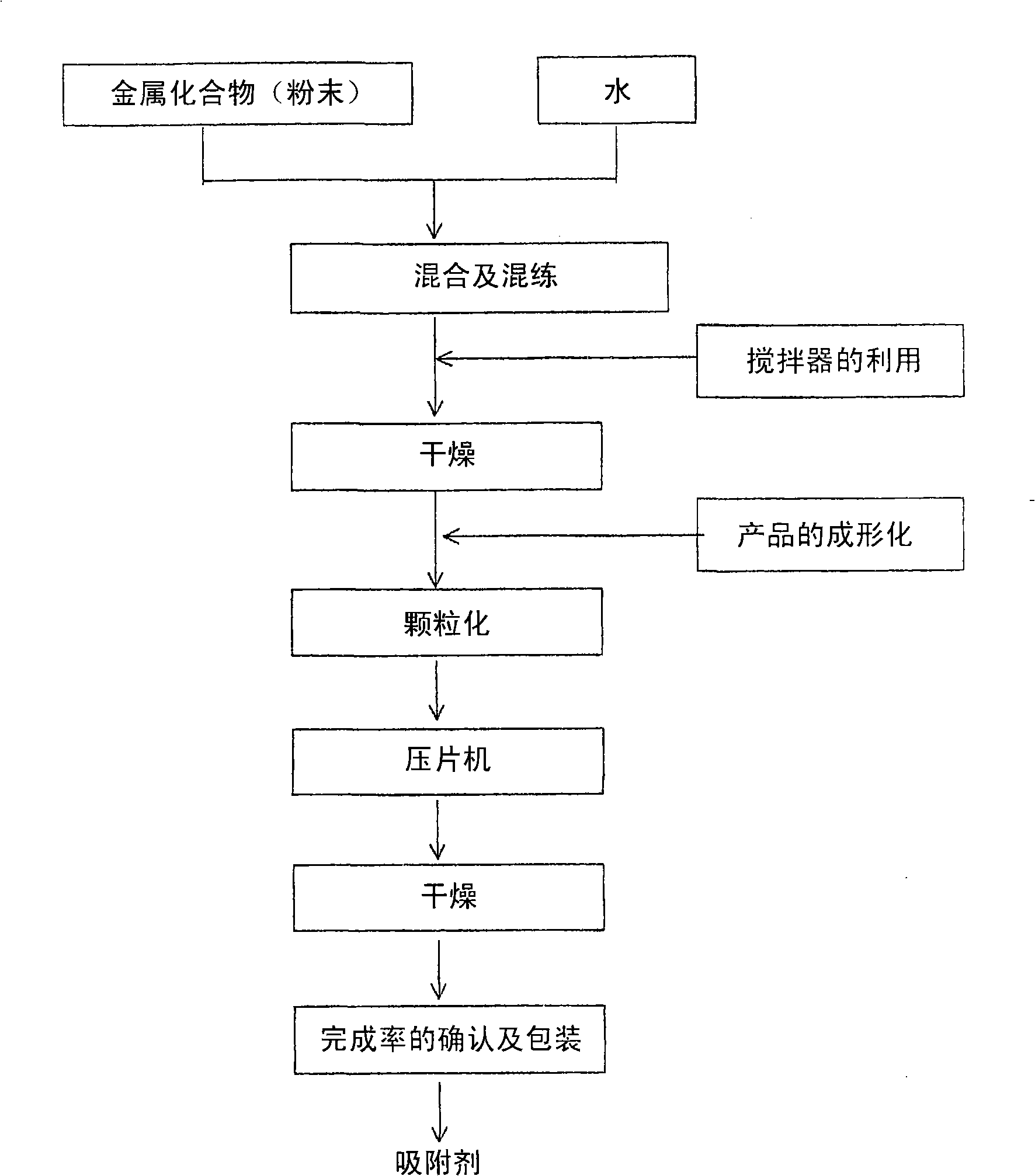

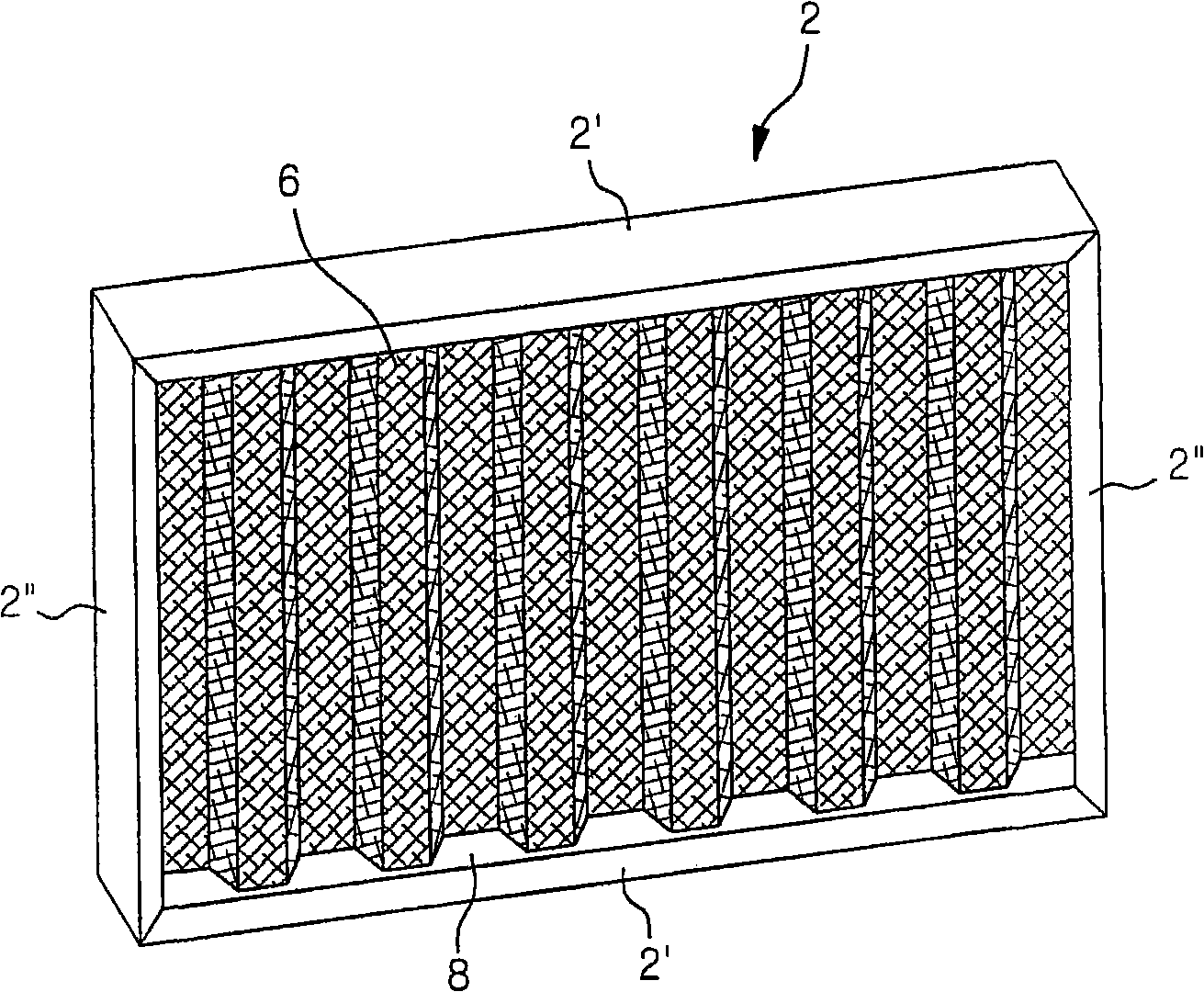

Chemical filter employing metal compound and manufacturing method thereof

InactiveCN1840233AExtend your lifeImprove removal efficiencyOther chemical processesMetal working apparatusCompound (substance)Product gas

The present invention provides a chemical filter using a metal compound to increase efficiency of removing poisonous gas and life of the chemical filter without leaking out the gas adsorbed by strong chemical bonding force of the metal compound and the poisonous gas by manufacturing an adsorbent for the chemical filter using metal oxide, metal hydroxide, metallic salt, or a mixture of those and to provide a method for manufacturing the chemical filter. The adsorbent of this chemical filter includes 10-99 wt.% of metal oxides, metal hydroxide, a metal salt or a mixture of those and 1-90 wt.% of an organic or inorganic bonding agent or a mixture of those.

Owner:KOCAT

Haze protection cap

The invention discloses a haze protection cap. The haze protection cap comprises a cap body, a cylindrical mask, a transparent viewing window and a waterproof pocket, wherein the cap body comprises a cap crown and a cap brim; the periphery of the cap brim is connected with the cylindrical mask by utilizing a zipper; the transparent viewing window is positioned at the position, close to the cap brim, at the top of the cylindrical mask; the waterproof pocket is arranged at the lower part of the transparent viewing window; soaked water absorption sponge is arranged in the waterproof pocket. The haze protection cap is simple and practical in structure, good in protection effect and capable of completely protecting parts such as the eyes, the ears, the respiratory tract, the skin and the hair of a wearer.

Owner:XUZHOU NORMAL UNIVERSITY

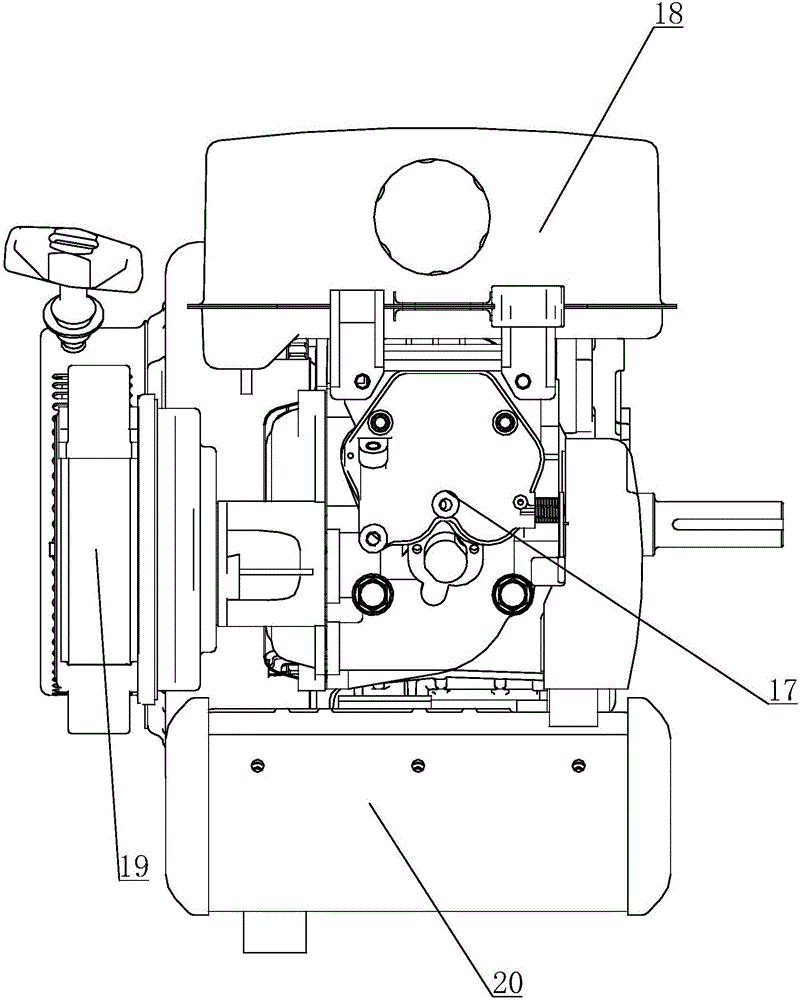

Engine exhaust device being convenient to maintain and engine

InactiveCN106321207AImprove liquidityReduce exhaust noiseExhaust apparatusSilencing apparatusEngineeringExhaust pipe

The invention discloses an engine exhaust device being convenient to maintain and an engine. The engine exhaust device comprises a shell, wherein the shell comprises a first shell body and a second shell body; a thrust step is arranged on the inner wall of the open end of each of the first and second shell bodies; a purification catalyst converter is arranged between the two thrust steps; a working cavity is divided by the purification catalyst converter into a first working cavity body and a second working cavity body; an exhaust pipe is arranged in the first working cavity body; a gas outlet pipe is arranged in the second working cavity body; the gas circulation area of the first working cavity body is larger than that of the exhaust pipe; the gas circulation area in the purification catalyst converter is smaller than that of the first working cavity body and that of the second working cavity body; and the gas circulation area of the second working cavity body is larger than that of the gas outlet pipe. The above engine exhaust device not only is simple and compact in structure and convenient to maintain, but also has the advantage that the compactness of the original engine structure can be guaranteed. Meanwhile, the engine exhaust device has the functions of purifying exhaust and effectively reducing the noise of the engine.

Owner:WUXI KIPOR POWER CO LTD

Methyl diesel

InactiveCN102732330ASimple preparation processSuitable for large-scale industrial productionLiquid carbonaceous fuelsFuel efficiencyEngineering

The invention aims to provide a methyl diesel. The methyl diesel comprises methanol, oleic acid, cyclohexylamine, ethanolamine and inevitable impurities. The preparation technique is simple, only needs to manually or mechanically stir the diesel and admixtures, and thus, is suitable for large-scale industrial production; and the invention has the advantages of sufficient raw materials, low cost, low pollution and environment protection, greatly enhances the fuel efficiency, and is economical and efficient.

Owner:王国平

Method for preparing biological fertilizer by utilizing traditional Chinese medicine residue waste containing fat, saponins and proteins

InactiveCN110615704APlay a therapeutic rolePlay a preventive roleCalcareous fertilisersBio-organic fraction processingResource utilizationHydrolysis

The invention relates to the technical field of resource utilization of traditional Chinese medicine residues, in particular to a method for preparing a biological fertilizer by utilizing traditionalChinese medicine residue waste containing fat, saponins and proteins; the method comprises the steps of rinsing, centrifugal dewatering, constant-temperature low-pressure hydrolysis, enzymolysis, fermentation and the like. The method solves the problems of long period, incomplete fermentation and secondary pollution of the fertilizer prepared from the traditional Chinese medicine residues at present, the biological fertilizer prepared by the method plays a role in both pesticide and fertilizer, and the traditional Chinese medicine residues of plants are truly absorbed and utilized completely.

Owner:广州日日红水环境处理有限公司

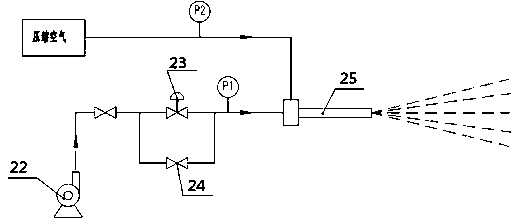

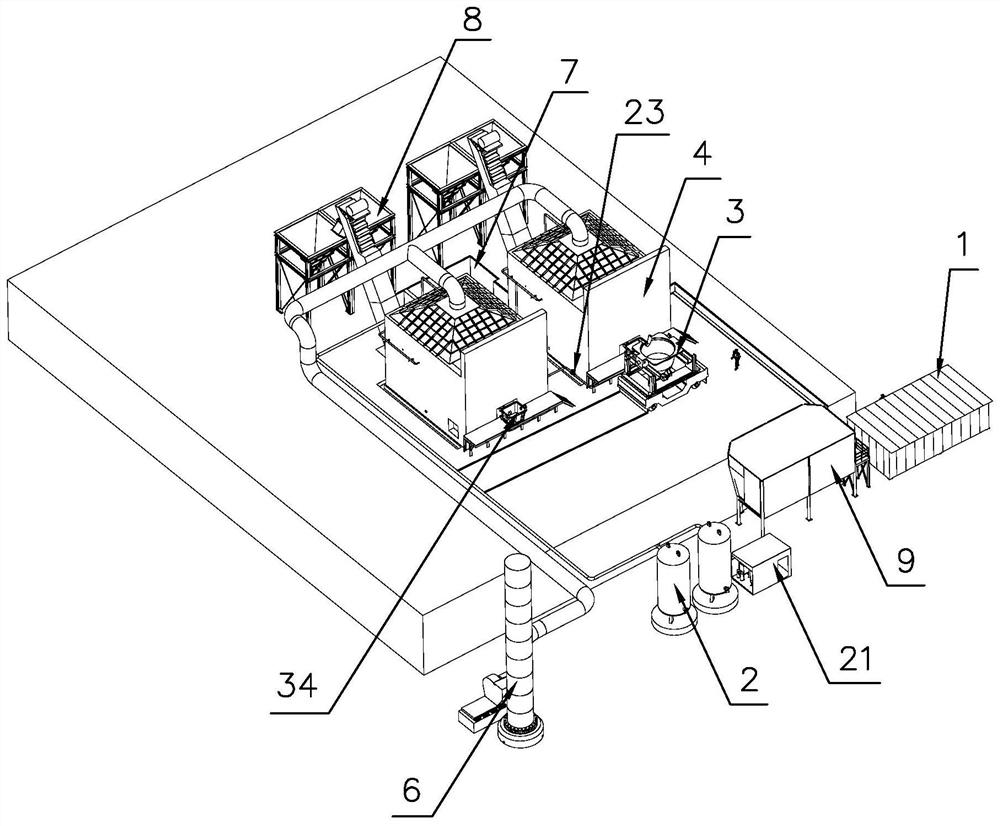

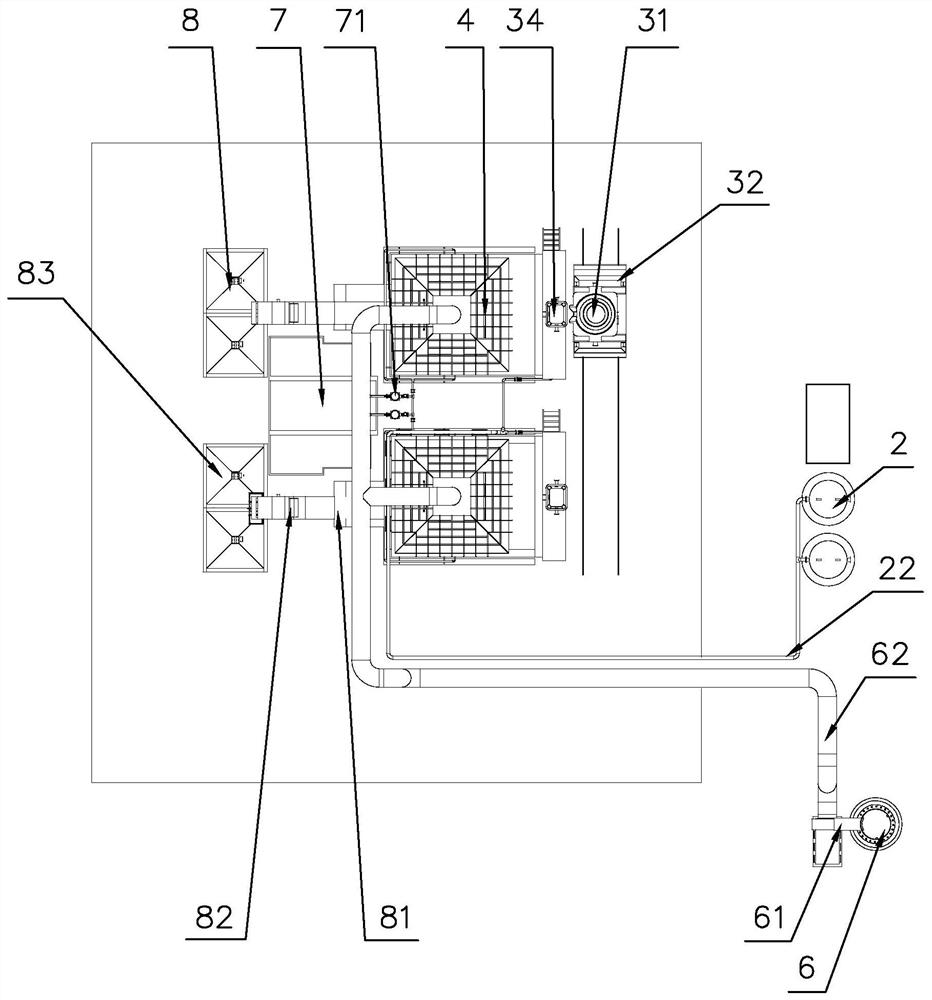

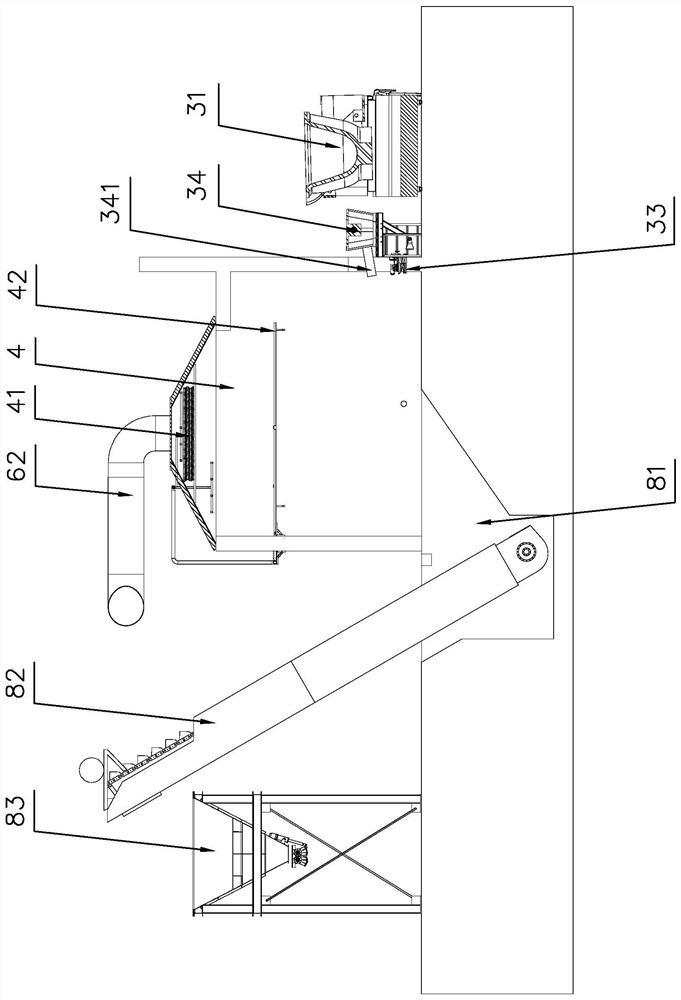

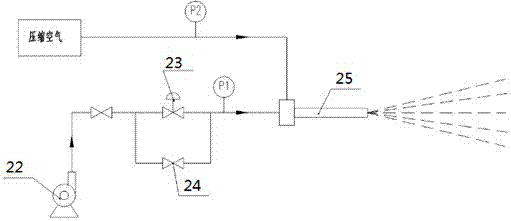

Liquid steel slag wind quenching granulation production line and production technology thereof

PendingCN111979366ARapid Granulation CoolingFine grainRecycling and recovery technologiesProcess efficiency improvementSlagExhaust pipe

The invention discloses a liquid steel slag wind quenching granulation production line and a production technology thereof. The liquid steel slag wind quenching granulation production line comprises apower control room, a compressed air source, an air pipeline, a steel slag granulation mechanism, a steel slag processing chamber, an exhaust air purification tower, an exhaust duct, a cooling circulation pool, a slag material recycling mechanism, a slag extracting pool and an observation chamber; a liquid steel slag wind quenching granulation production technology comprises gas introduction, steel slag pouring, granulator regulation, wind quenching granulation, smoke dust processing and granulated particle cooling and collection; and according to the production line and the production technology provided by the invention, the compressed air source is enabled to directly act on a supersonic gas ejector in the granulator through an air pipeline, thus, an air flow is enabled to perform centralized wind quenching for the liquid steel slag, a processing technology is optimized, regulation of the granulator is added before wind quenching granulation, so an optimal work position is found torealize a relatively ideal liquid steel slag granulation effect, a spraying water pipe performs certain washing for smoke dust, then, the smoke enters into the exhaust air purification tower, and thus, further filtering and purification is realized.

Owner:山东盛阳工程机械有限公司

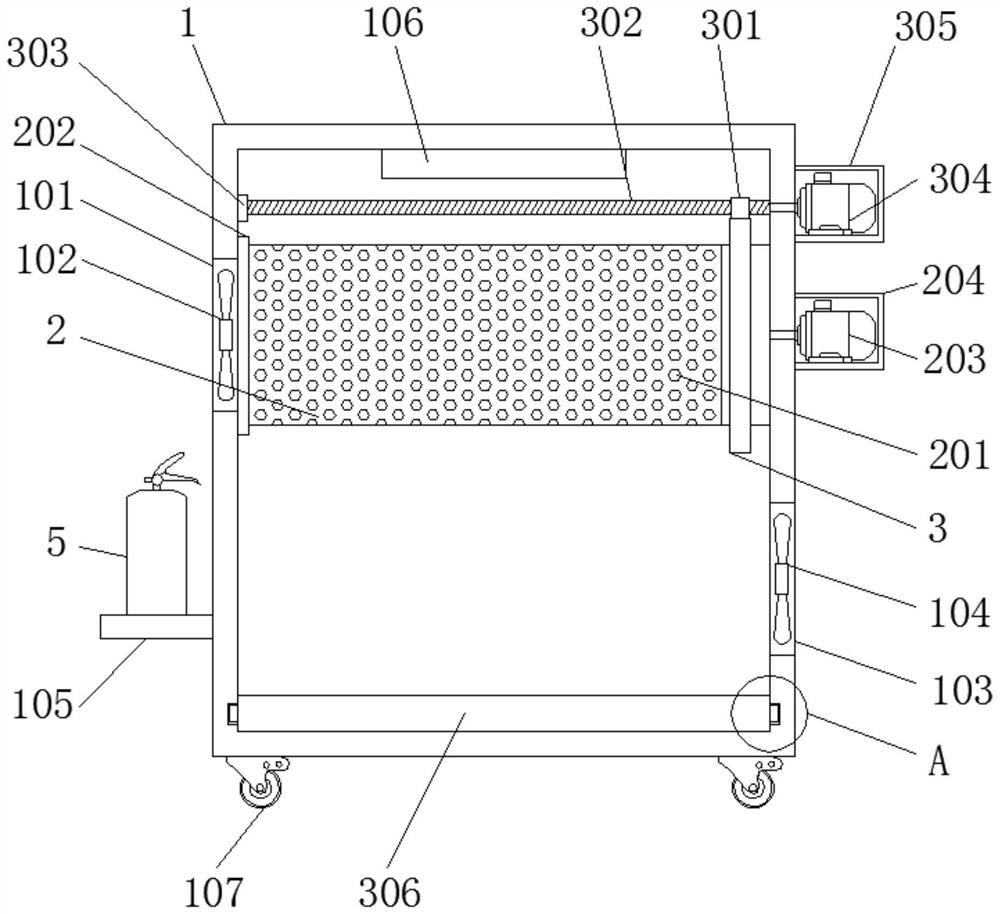

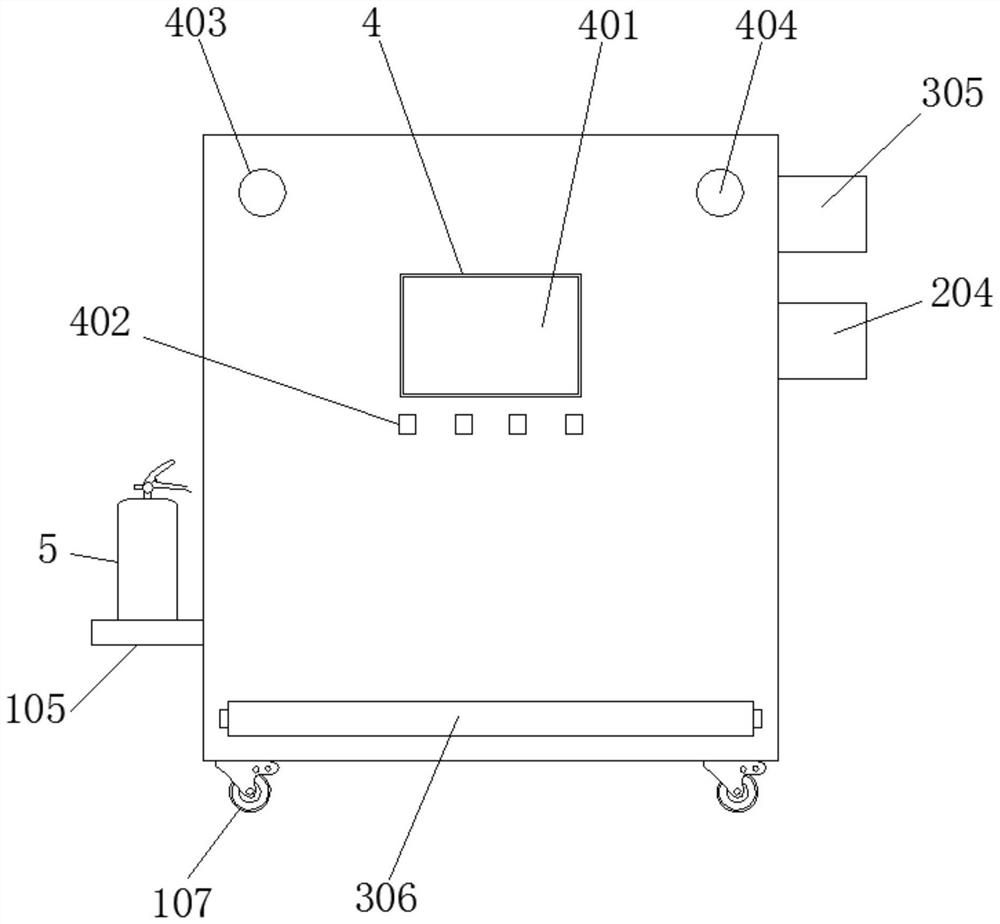

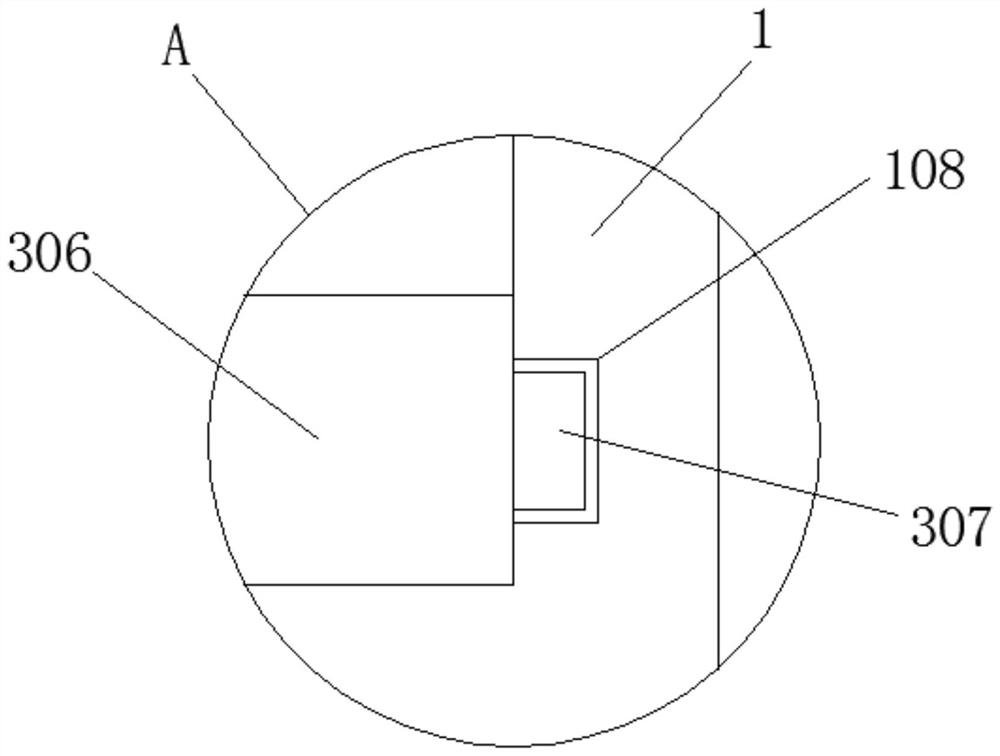

Self-starting air filter with dust monitoring function

InactiveCN112815455AWith dust monitoring functionRealize automatic start and stopMechanical apparatusDispersed particle filtrationAir filterSmoke Emission

The invention discloses a self-starting air filter with a dust monitoring function. The self-starting air filter with the dust monitoring function comprises an outer shell, a filter cartridge, a dust cleaning structure and a control assembly; an air inlet is formed in the upper portion of the left wall of the outer shell; an air outlet is formed in the lower portion of the right wall of the outer shell; the filter cartridge is installed on the upper portion of the interior of the outer shell; the dust removal structure is arranged inside the outer shell; a driving block is installed at the top of the dust removal structure; a lead screw penetrates through the driving block; the control assembly is arranged on the front side of the outer shell; a dust sensor is installed on the upper left portion of the front end of the outer shell; and a smoke sensor is installed on the upper right portion of the front end of the outer shell. The self-starting air filter with the dust monitoring function is provided with the dust sensor, the smoke sensor and a PLC, the dust sensor and the smoke sensor detect the concentration of smoke and dust in air respectively and transmit data to the PLC, the PLC determines whether to start the air filter or not according to the data, and automatic starting and stopping of the air filter are achieved.

Owner:岚山环保科技(上海)有限公司

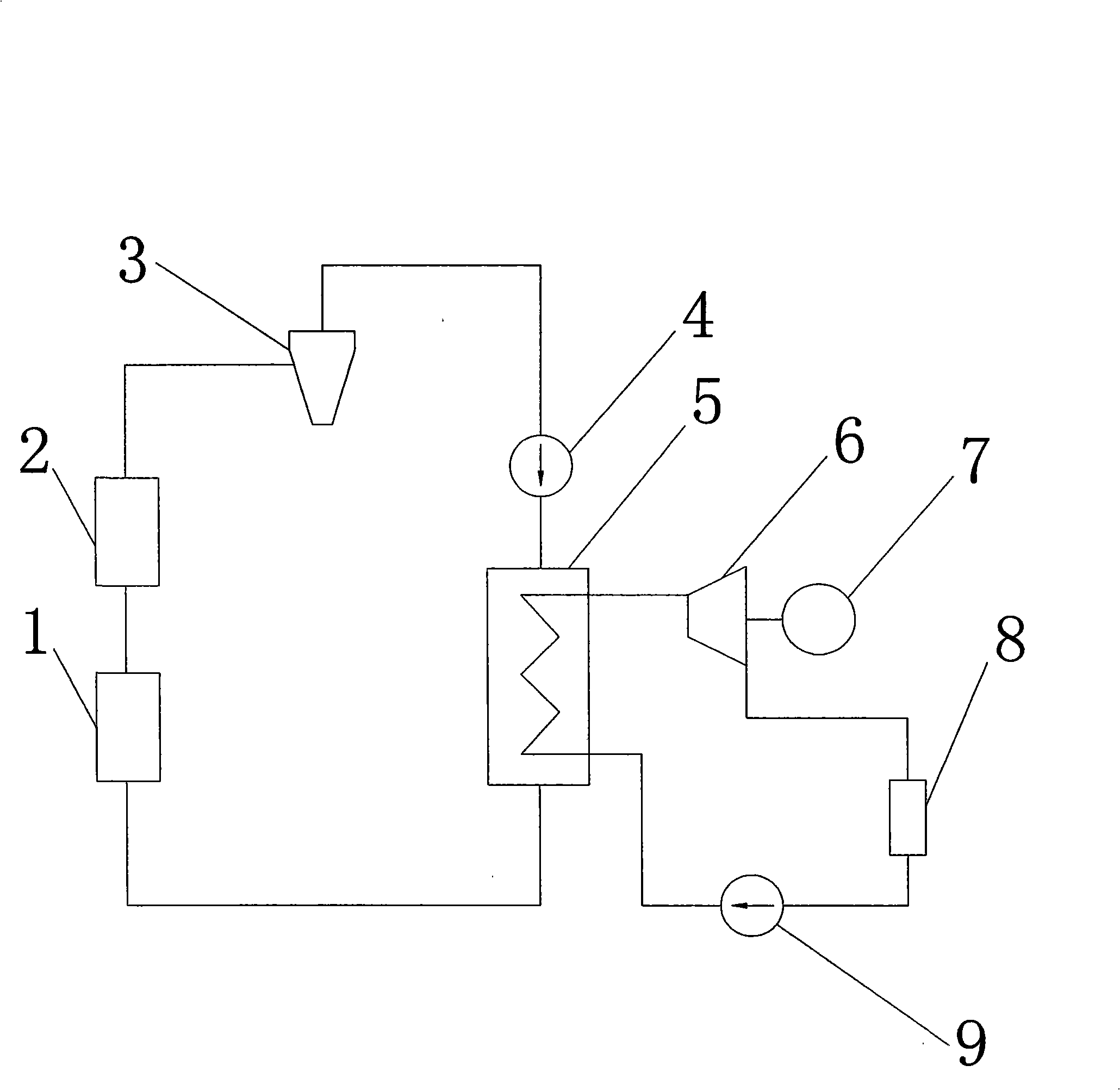

Recovery method of blast furnace slag water residual heat and system thereof

ActiveCN101550461BEnsure safetyGuaranteed lifeIncreasing energy efficiencyWaste heat treatmentRecovery methodSlag

The invention discloses a recovery method of blast furnace slag water residual heat and method thereof. The recovery system of resudual heat includes a blast furnace slag system, a sedimentation tank,a hydrocyclone separator, a water pump, a heat exchanger, a steam turbine, a refrigerant condenser, a refrigerant pump. The recovery method is that applying bicirculating low temperature hot water generation system to recovery residual heat and penerating power. The specific process is: guiding the blast furnace slag water into the heat exchanger after preprocessing of impurity precipitation andtransmitting heat to low boiling refrigerant; the low boiling refrigerant absorbing heat in the heat exchanger and entering the steam turbine for expansion of doing work; the refrigerant after doing wirk changing into low-pressure superheated steam, the low-pressure superheated steam entering the concenser to releast heat and changing into liquid refrigerant of low-temperature and low-pressure, then being sent to the heat exchanger by the refrigerant pump for absorbing heat, becoming the superheated steam again to push the steam turbine to do work. The invention can recovery residual heat of the blast furnace slag water and generate power, and reduce energy consumption in steel production; and reduce temperature of blast furnace slag water which is benefit to improve quality of blast furnace water slag and reduce discharge of sulphide in slag washing process.

Owner:HANGZHOU BOILER GRP CO LTD

Chemical filters using metallic compounds and preparation method thereof

InactiveCN101306299AExtend your lifeImprove removal efficiencyDispersed particle filtrationMetal working apparatusSorbentCompound (substance)

The invention provides a chemical filter using a metal compound and a manufacturing method thereof, efficiency of removing poisonous gas and life of the chemical filter can be increased without leaking out the gas adsorbed by strong chemical bonding force of the metal compound and the poisonous gas by manufacturing an adsorbent for the chemical filter using metal oxide, metal hydroxide, metallic salt, or a mixture of those. The invention provides an adsorbent for the chemical filte, characterized by including 10-99 wt.% of metal oxides, metal hydroxide, a metal salt or a mixture of those and 1-90 wt.% of an organic or inorganic bonding agent or a mixture of those.

Owner:KOCAT

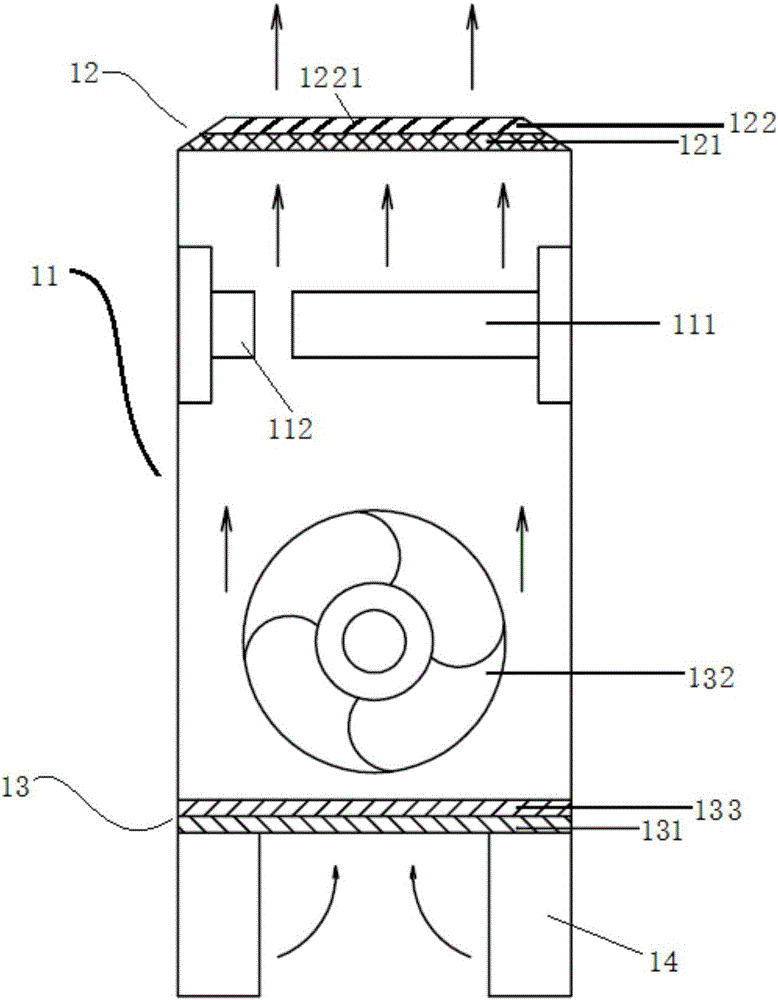

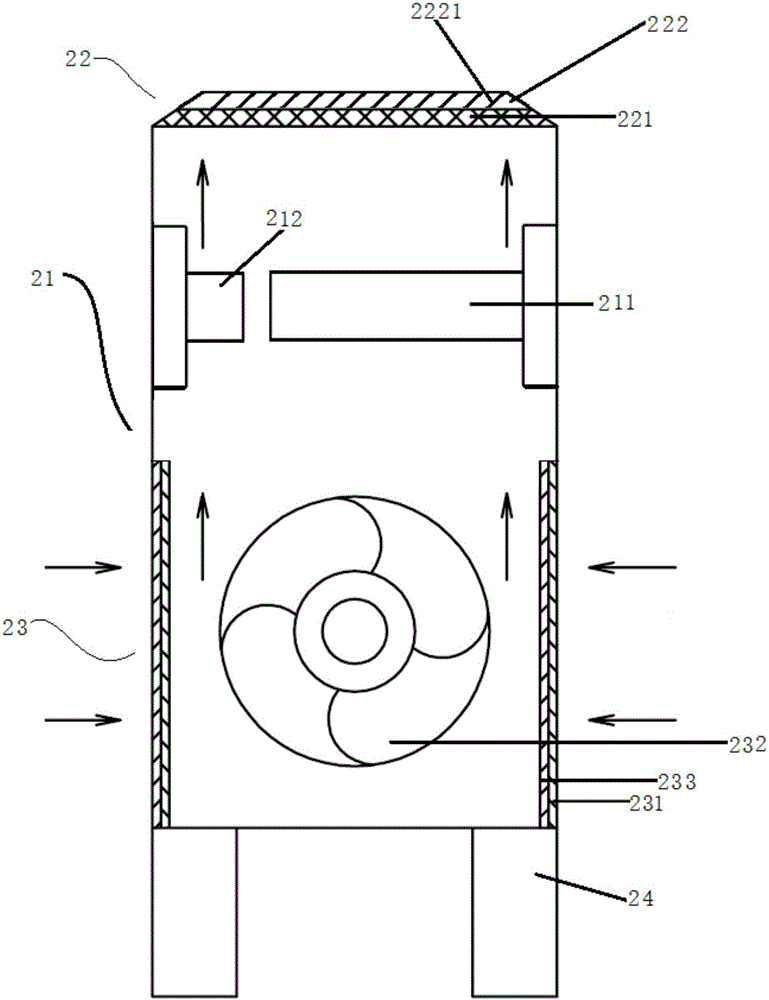

Air purification device

InactiveCN106823633AImprove air qualityReduce particulate matterGas treatmentMembrane filtersSitting PositionsAerospace engineering

The embodiment of the present invention relates to air purification treatment technology, in particular to an air purification device, comprising; The wind structure is set on the top of the box to output the purified air; the air intake structure is set on the bottom of the box, including the air inlet and the fan, to absorb the air and transmit the absorbed air to the Inside the box; the supporting structure is arranged below the box to carry the box so that the box is higher than the ground surface by a predetermined distance; wherein, the height of the box combined with the supporting frame is 85.6 cm. Set the height of the cabinet combined with the support frame to 85.6cm, and the air flow area is concentrated between 92.5cm and 124.8cm. This height design is more ergonomic, especially suitable for office workers who maintain a sitting posture for a long time in the office. high.

Owner:上海市全保环境科技有限公司

Full-scale electronic and electrical waste continuous pyrolysis incineration device

ActiveCN105509062BInhibitionTo achieve the purpose of volume reductionEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING TECH UNIV

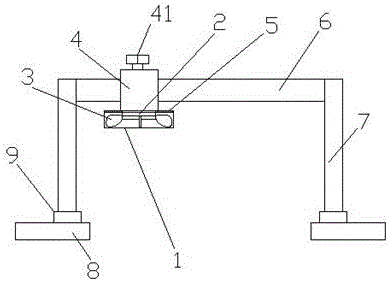

Laterally-adjusted circuit board cooling device

InactiveCN106102417AImprove protectionFlexible adjustmentCooling/ventilation/heating modificationsEngineeringLateral displacement

The invention discloses a laterally-adjusted circuit board cooling device, which comprises a mobile mounting rack and a motor, wherein the motor is arranged on the mobile mounting rack; the bottom of the motor is provided with an output shaft pointing downwardly; the outer circle of the output shaft is provided with a plurality of fan blades, a filter screen located above the fan blades is arranged on the mobile mounting rack; the top of the mobile mounting rack is provided with a guide sleeve; a lateral rod is arranged in the guide sleeve in a penetrating mode; two ends of the lateral rod are provided with supporting rods pointing downwardly; and the bottom part of each supporting rod is provided with a fixing seat respectively. Through the above mode, according to the laterally-adjusted circuit board cooling device, the lateral rod crosses above the circuit board, sliding of the guide sleeve on the lateral rod is used for adjusting the lateral displacement of the fan blades, requirements of an element with large heat amount generation can be met, the adjustment is flexible, particles in the air flow are reduced due to the filter screen, and the element can be well protected.

Owner:FOREWIN FPC SUZHOU

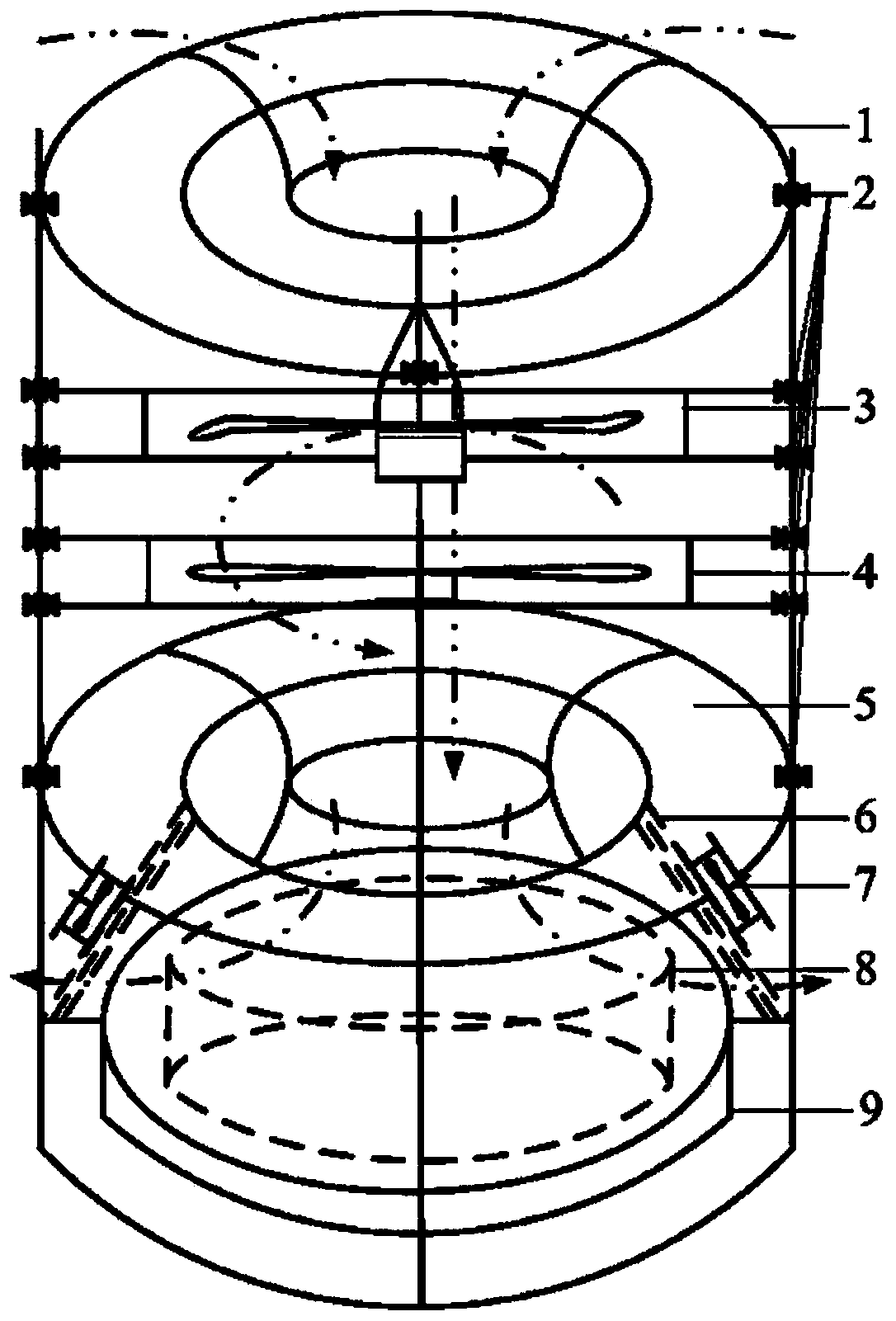

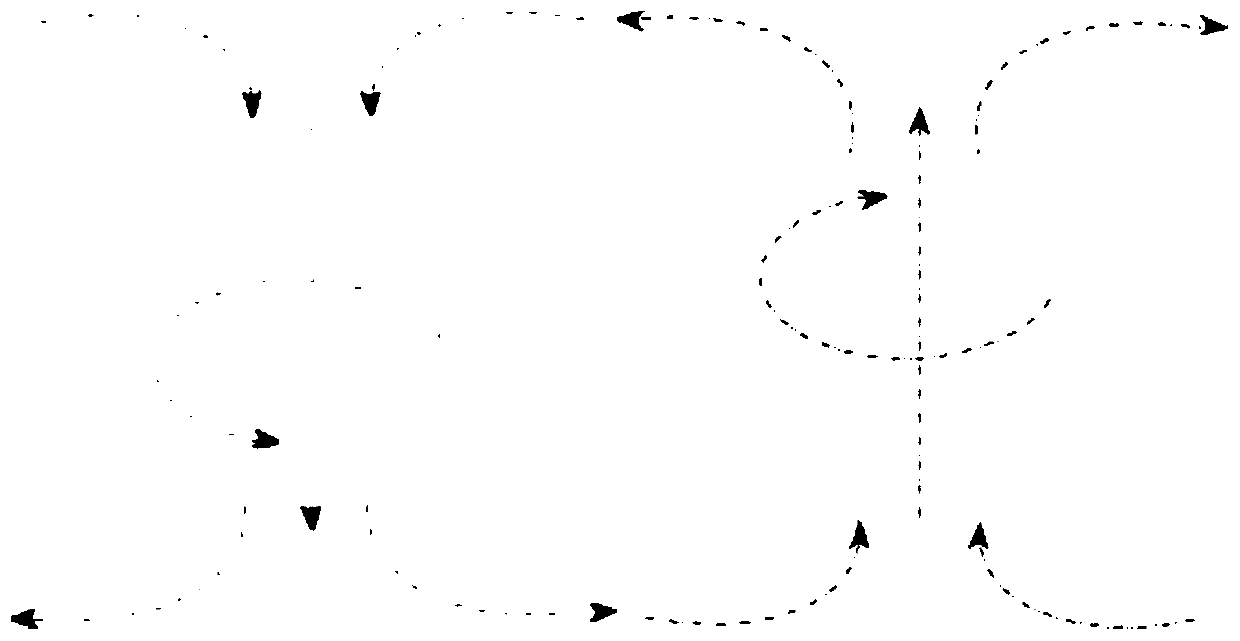

Air purification method and purification device thereof

ActiveCN107335307BLow running costPurify thoroughlyCombination devicesMachines/enginesCycloneElectricity

The invention discloses an air purification method and a purification device thereof. The purification device includes a negative pressure generating device that generates negative pressure in the purification passage; the cyclone conversion device that converts the atmosphere introduced into the purification passage due to the negative pressure into an artificial cyclone and passes the artificial cyclone into the purification passage through the purification passage. A wind turbine that converts part of the wind energy into electricity before and / or after the unit. Through the air purification method and its purification device, the external atmosphere is converted into an artificial cyclone and enters the purification unit to remove smog particles in the atmosphere to purify the atmosphere. The negative pressure generating device generates negative pressure in the purification channel, which can continuously introduce the external atmosphere into the purification channel. , The excess wind energy of the artificial cyclone is converted into electrical energy, and this cycle can purify the air pollution in the open system and also generate electricity, producing green renewable energy and reducing the operating cost of the purification device.

Owner:GUANGZHOU SAVETECH LTD CO +2

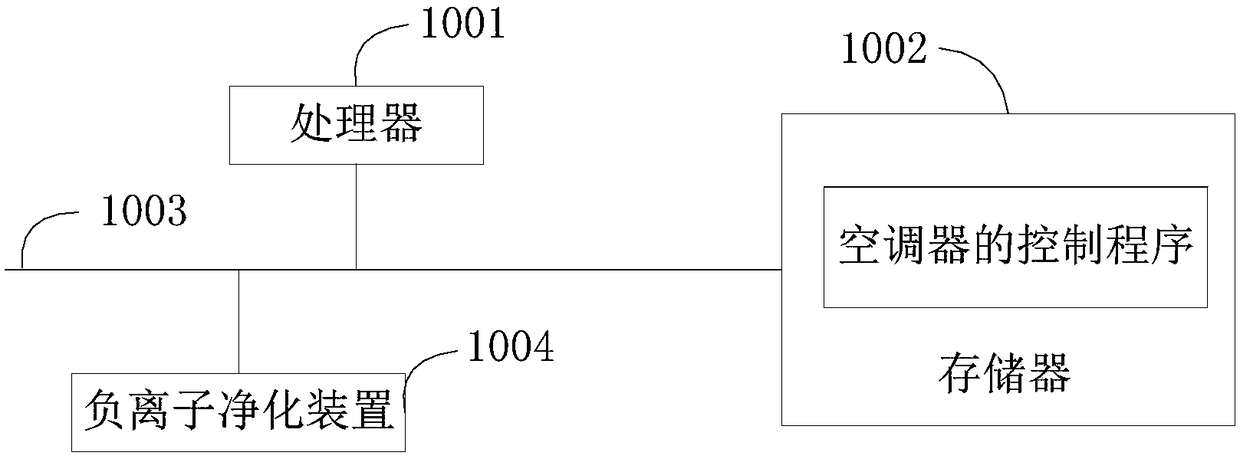

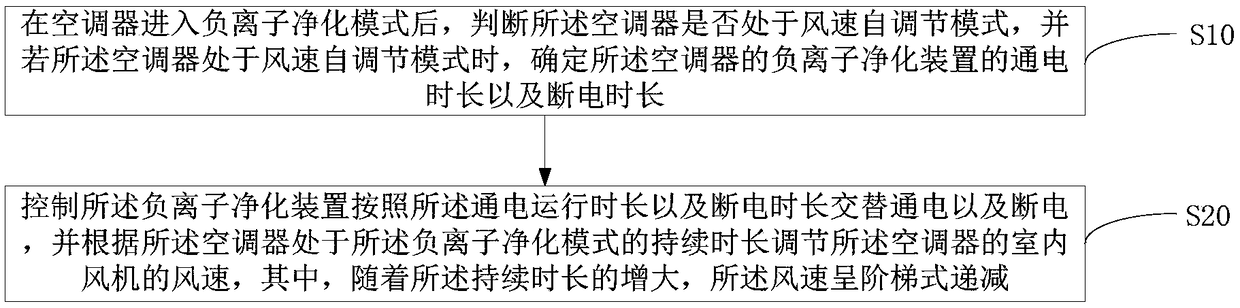

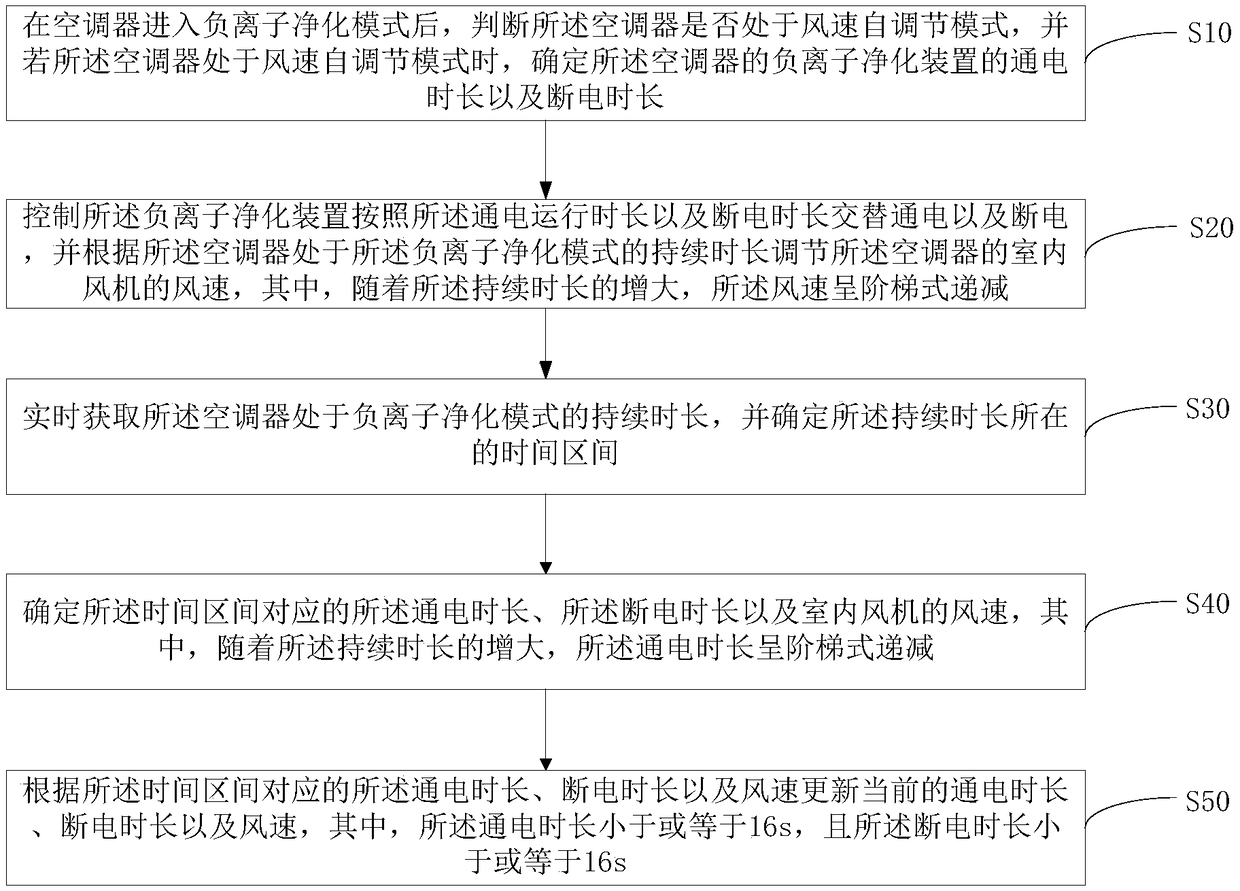

Air conditioner, control method thereof and computer readable storage medium

ActiveCN109140671AReduce particulate matterImprove dust collection effectMechanical apparatusSpace heating and ventilation safety systemsWind speedControl theory

The invention discloses a control method of an air conditioner. The control method of the air conditioner comprises the steps ofjudging whetherthe air conditioner is located in an air speed self-adjusting mode or not after the air conditioner enters a negative ion purifying mode; determining the electrification time length and the power failure time length of the negative ion purifying device of the air conditioner if the air conditioner is located in the air speed self-adjusting mode; controlling the negative ion purifying device to alternativelybe electrifiedand lose power according to the electrification time length and the power failure time length; and adjusting the air speed of an indoor fan of the air conditioner according to the lasting time length of the air conditioner located inthe negative ion purifying mode.Along with increment of the lasting time length, the air speed is gradually reduced in a step form. The invention further discloses the air conditioner and a computerreadable storage medium. The blackening condition of a wall for mounting the air conditioner is prevented.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Fire extinguishing system for automobile exhaust gas recovery

PendingCN108825333ASolve the use problemSolve the problem of car fire protectioExhaust apparatusSilencing apparatusExhaust pipeExhaust gas

The invention discloses a fire extinguishing system for automobile exhaust gas recovery, belongs to the technical field of automobile equipment, and aims at solving the problems of exhaust gas utilization and automobile fire extinguishing. The fire extinguishing system for automobile exhaust gas recovery comprises a gas diversion pipe, a first containing case, a storage cabinet and a fire extinguishing hose, wherein the gas diversion pipe is connected with an outlet of an automobile exhaust pipe, the first containing case is arranged on the gas diversion pipe, the storage cabinet is connectedwith the first containing case through a gas guide pipe, and the fire extinguishing hose is arranged on the storage cabinet. According to the fire extinguishing system for automobile exhaust gas recovery, the problems of exhaust gas utilization and automobile fire extinguishing are solved.

Owner:安徽华兴车辆有限公司

Energy-saving chimney of thermal power plant

InactiveCN104748136AEfficient exchangeReduce particulate matterCombustion technology mitigationChimneysParticulatesEngineering

The invention discloses an energy-saving chimney of a thermal power plant. The energy-saving chimney is tubular and composed of a chimney wall, a flue is formed on the inner side of the chimney wall, an interlayer is arranged between the outer side and the inner side of the chimney wall and is filled with water, and smoke heat exchanges heat with water in the inner layer via the chimney wall. Heat contained in the smoke can be effectively exchanged, energy utilization efficiency is improved, particles in the smoke after heat exchange can be reduced and resultantly air pollution is alleviated.

Owner:常熟市第二热电有限公司

Sea boat smoke evacuation washing device and its washing method

InactiveCN101288823BEfficient washingLow running costDispersed particle separationFlue gasProcess engineering

Owner:武汉晶源环境工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com