Engine exhaust device being convenient to maintain and engine

A technology for exhaust devices and engines, which is applied in the direction of exhaust devices, engine components, machines/engines, etc., to achieve the effects of improving maintainability, reducing noise, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

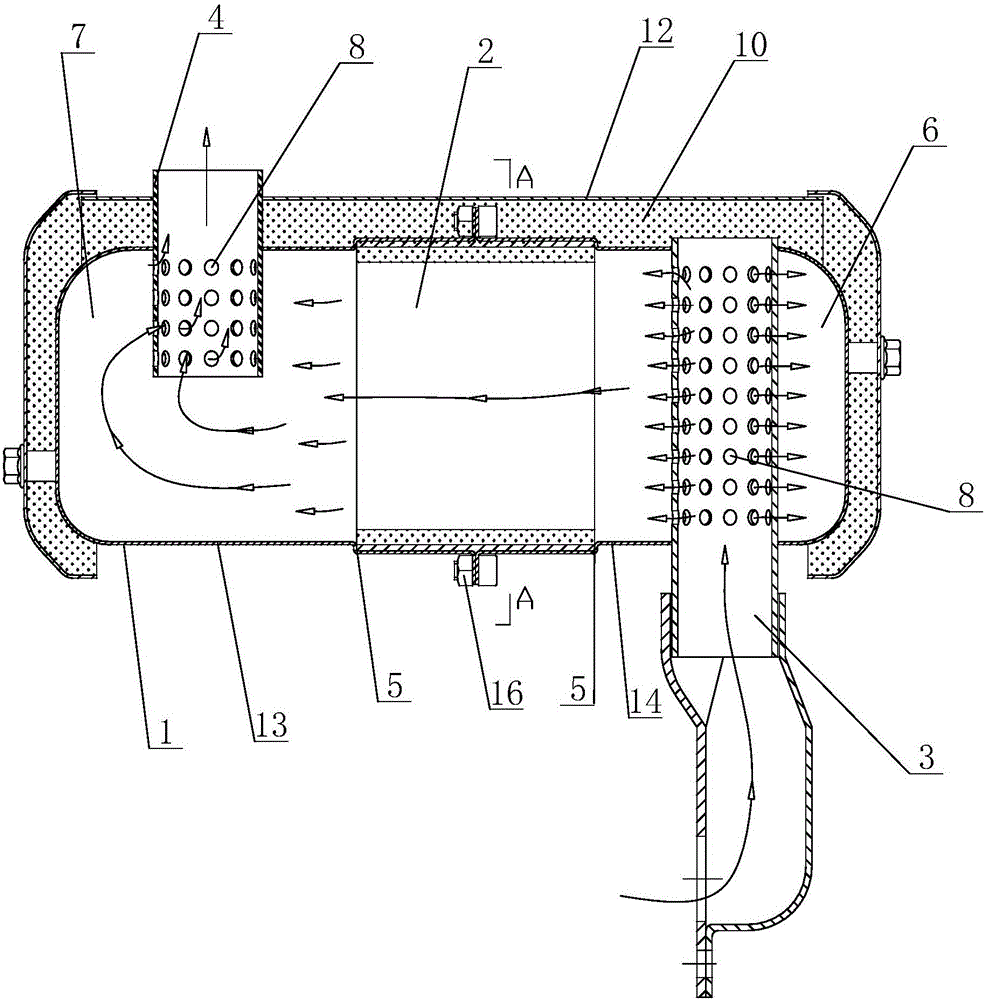

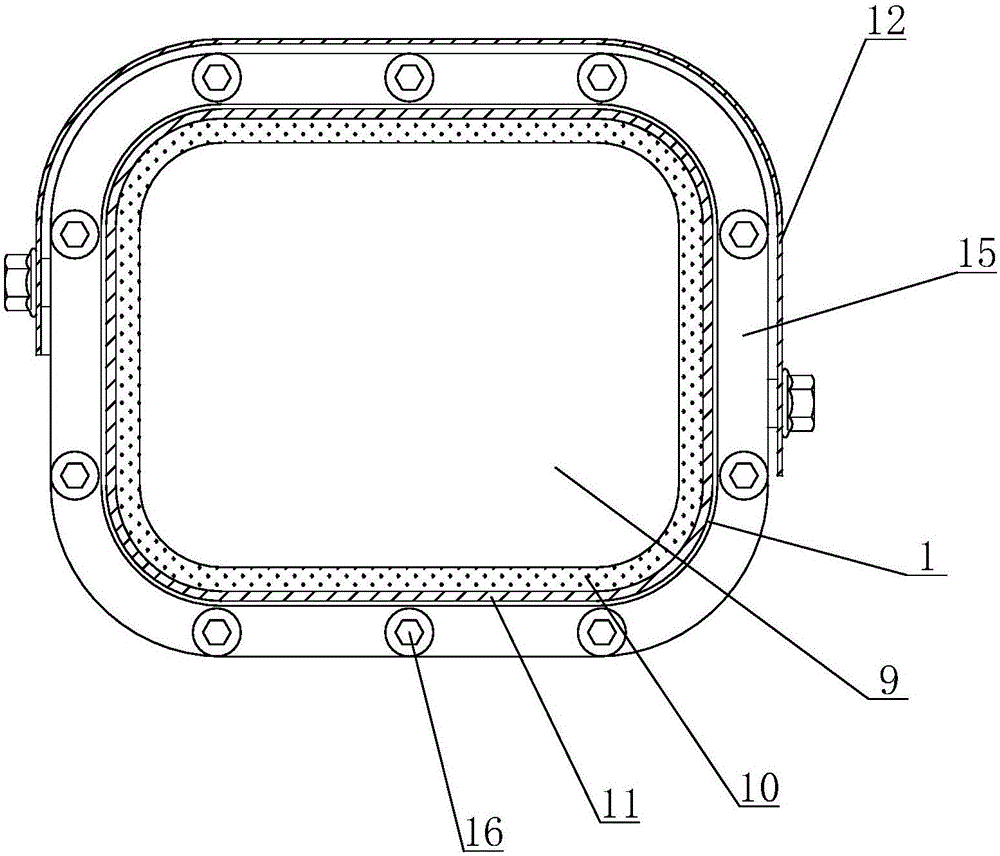

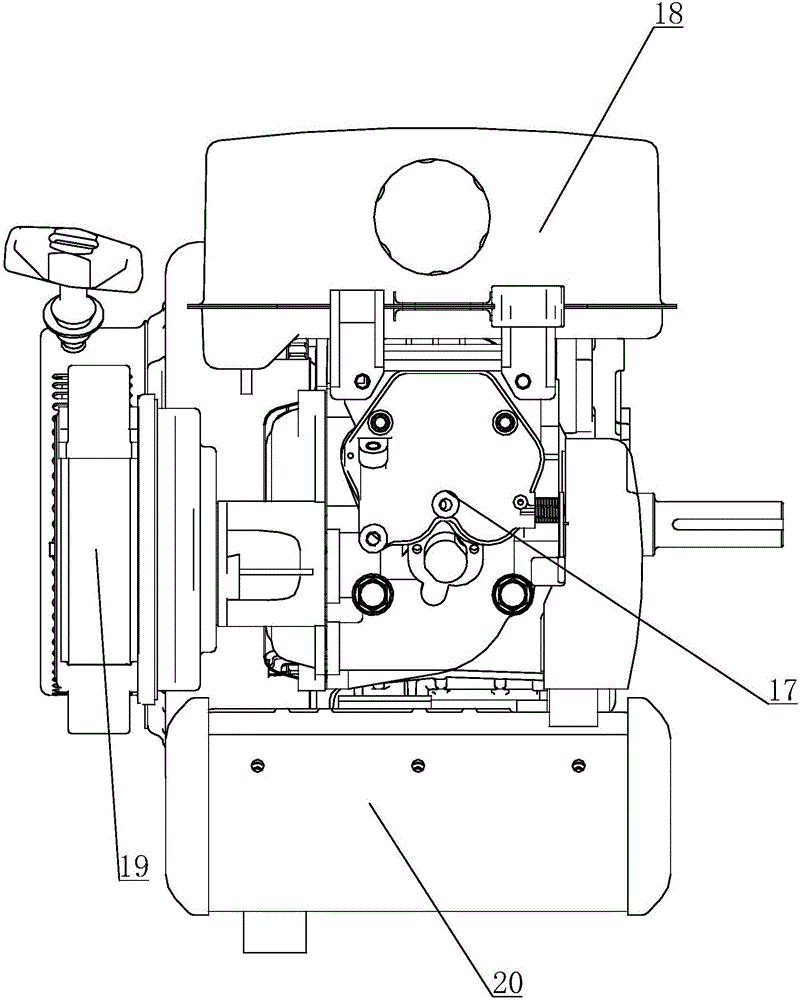

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0020] see Figure 1 to Figure 3 As shown, in this embodiment, a kind of engine exhaust device that is easy to maintain comprises casing 1, purifying catalytic converter 2, exhaust pipe 3 and air outlet pipe 4, and described casing 1 is working cavity, and described casing Two thrust steps 5 are arranged at intervals on the inner wall of 1, and the distance between the two thrust steps 5 is set in accordance with the purifying catalytic converter 2, and the purifying catalytic converter 2 is positioned on the housing through the two thrust steps 5 within 1. The purifying catalytic converter 2 divides the working chamber into a first working chamber 6 and a second working chamber 7 and serves as an intermediate working chamber itself, and the exhaust pipe 3 is inserted into the first working chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com