Chemical filter employing metal compound and manufacturing method thereof

A chemical filter and metal compound technology, applied in chemical instruments and methods, other chemical processes, metal processing, etc., can solve the problems of increased pressure loss, short filter life, metal oxide powder separation, etc., to prevent secondary Sub-polluting substances, improved removal efficiency, and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

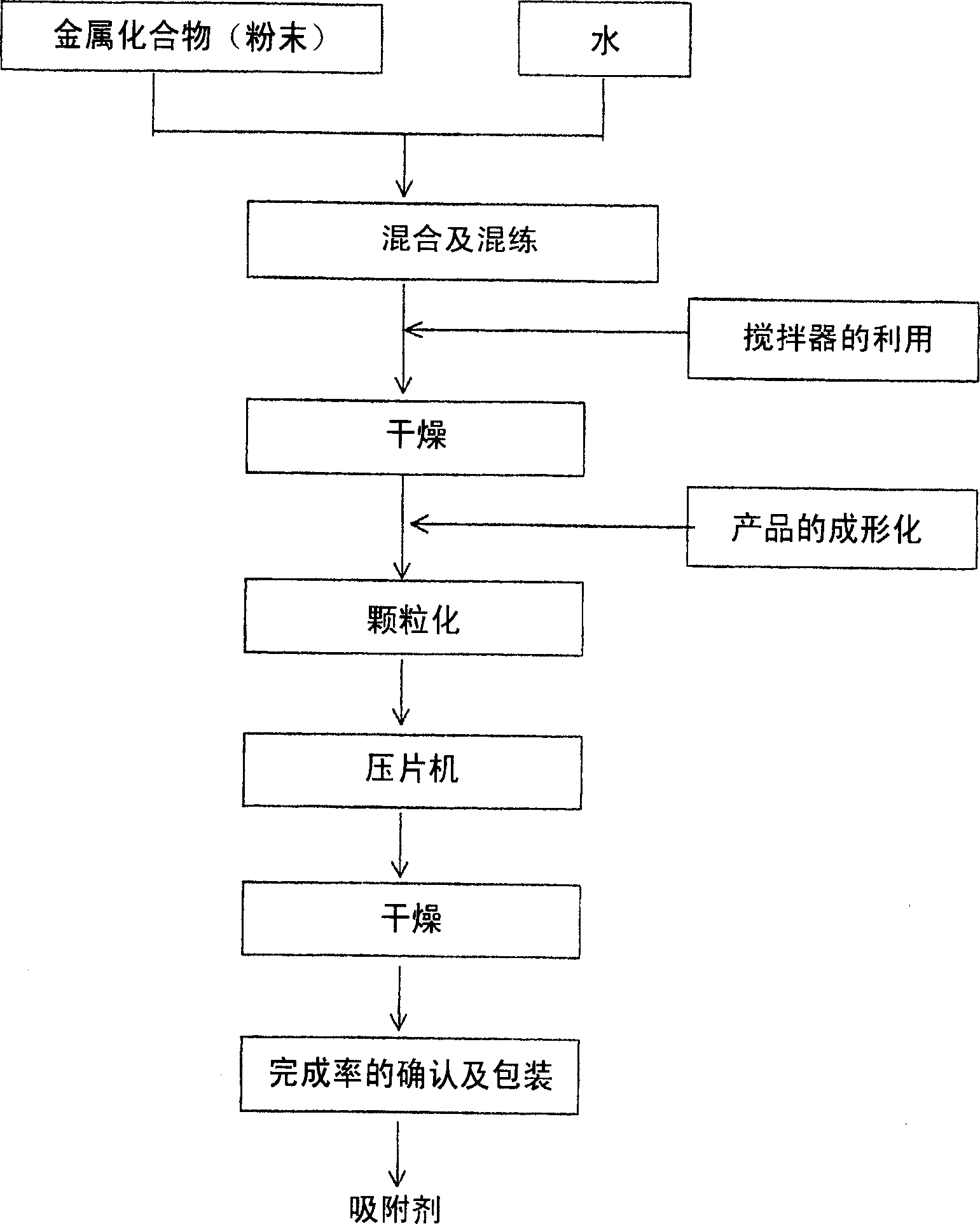

[0068] Sorbent Manufacture

[0069] Use a stirrer at room temperature to mix iron compounds (FeO(OH), Fe 2 o 3 ) [manufactured by KOCAT, Korea] 180g, strontium compound (Sr(OH) 2 ) [Made in Nai Nai Shoji, Korea] 100g, calcium compound (Ca(OH) 2 ) 80g, copper compound (CuSO 4 ) [Evergreen Chemical Manufacturing, Korea] 180g, manganese compound (MnO 2 ) [Naigai Shoji, Korea] 180g and zeolite [Naigai Shoji, Korea] 180g of harmful gas active substances and methyl cellulose [Samsung Fine Chemicals, Korea] 40g, alumina sol [Naigai Shoji, Korea] 50 g and 10 g of organic and inorganic binders of graphite [manufactured by Nai Nai Shoji, Korea] were mixed with 40 g of ultrapure distilled water.

[0070] Then, the above-mentioned mixture was dried at a temperature of 100° C. for about 1 hour and 30 minutes in a drying oven [manufactured by Dazhou Science and Technology Co., Ltd., Korea], and then naturally aged for about 4 hours.

[0071] Next, after the above-mentioned natural agi...

Embodiment 2

[0075] In addition to using iron compounds (FeO(OH), Fe 2 o 3 ) [manufactured by KOCAT, Korea], strontium compound (Sr(OH) 2 ) [manufactured by Nai Nai Shoji, Korea], methyl cellulose [manufactured by Samsung Fine Chemicals, Korea] in a weight ratio of 45:45:1 to replace harmful gas active substances and organic and inorganic binders, The same operation as in Example 1 was carried out.

Embodiment 3

[0077] In addition to using copper compounds (CuSO 4 )[manufactured by Evergreen Chemical, Korea], iron compounds (FeO(OH), Fe 2 o 3 ) [manufactured by KOCAT, Korea], methyl cellulose [manufactured by Samsung Fine Chemicals, Korea] in a weight ratio of 70:20:10 to replace harmful gas active substances and organic and inorganic binders, and Example 1 was operated in the same manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com