Patents

Literature

412results about How to "Improve dust collection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

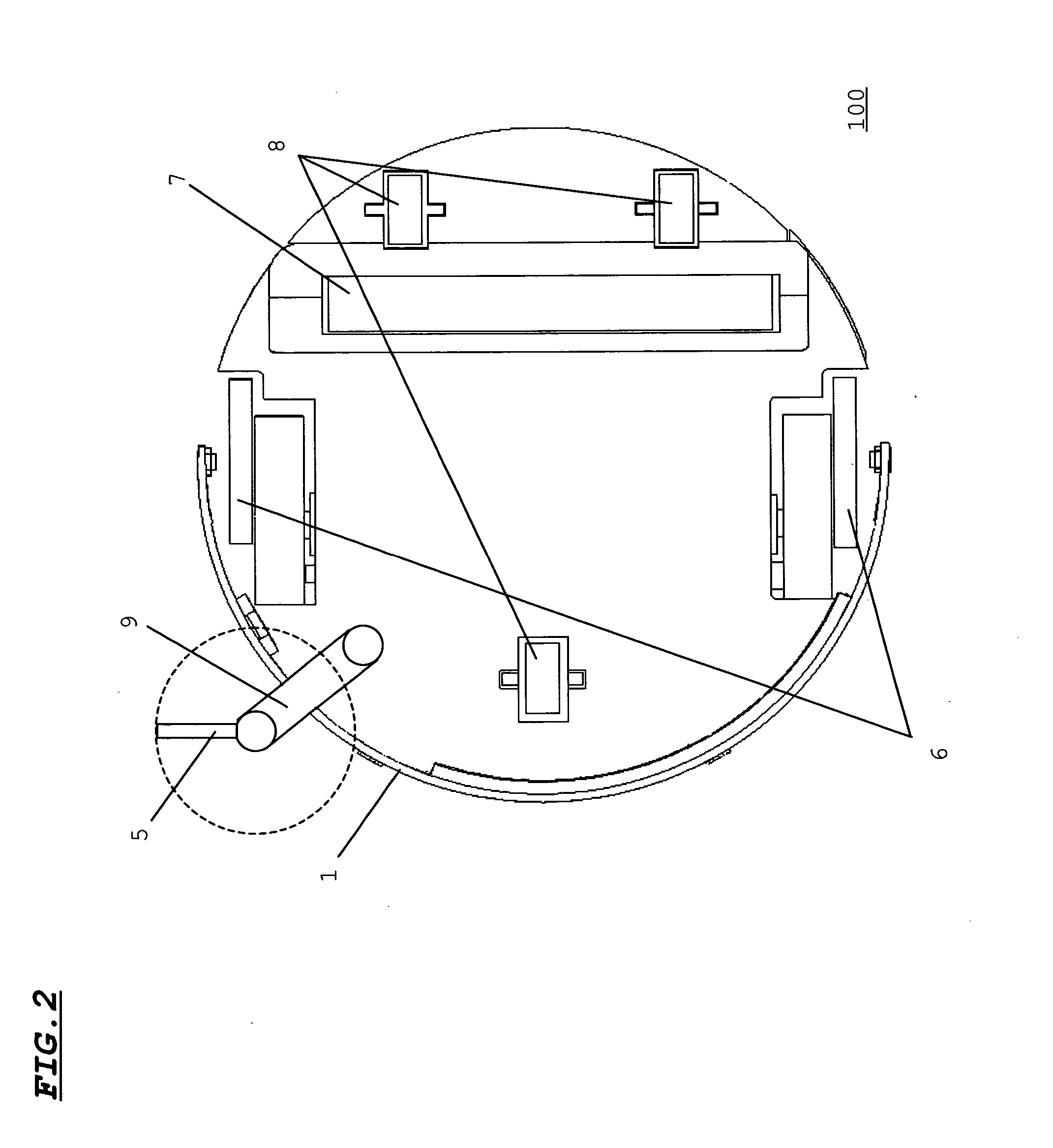

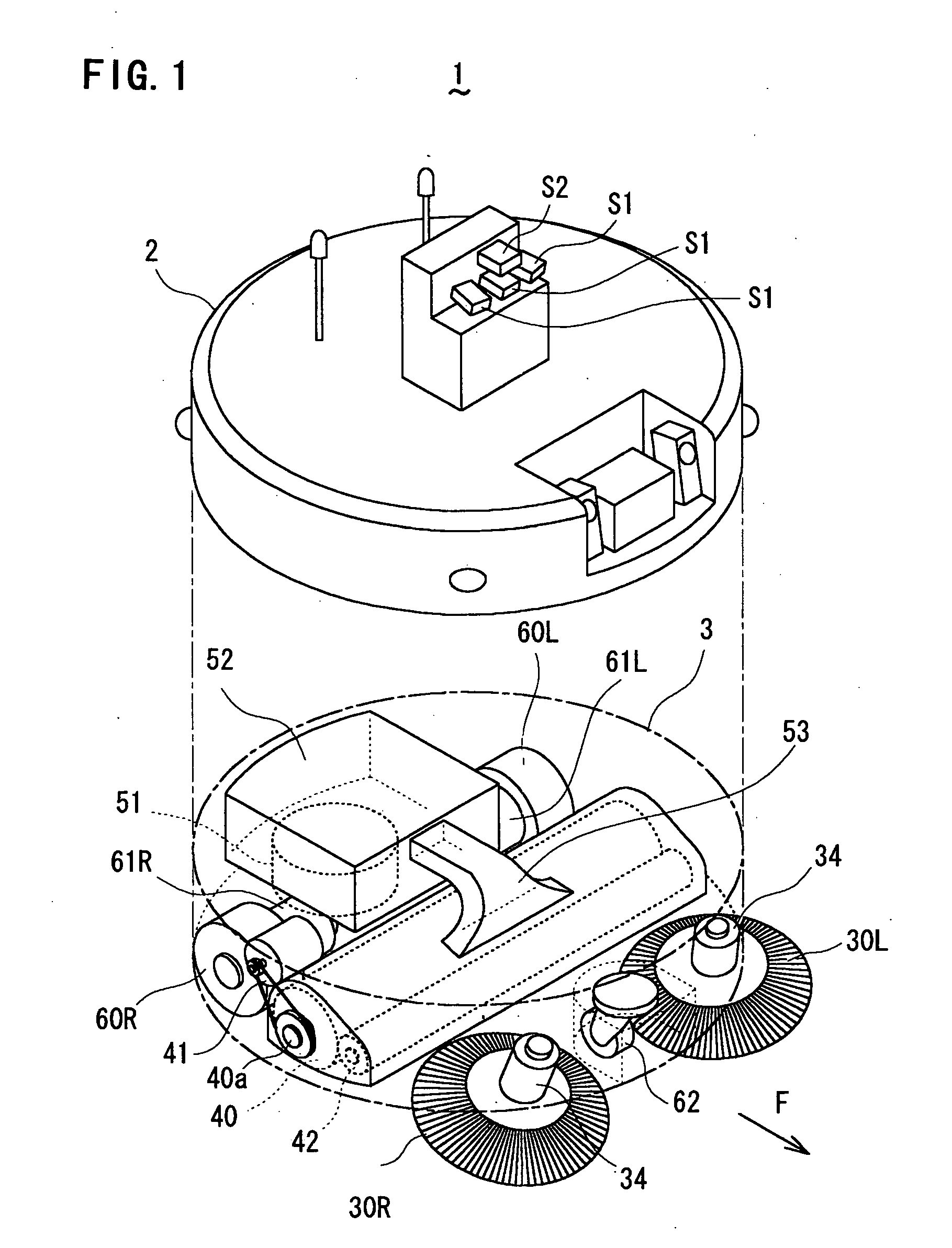

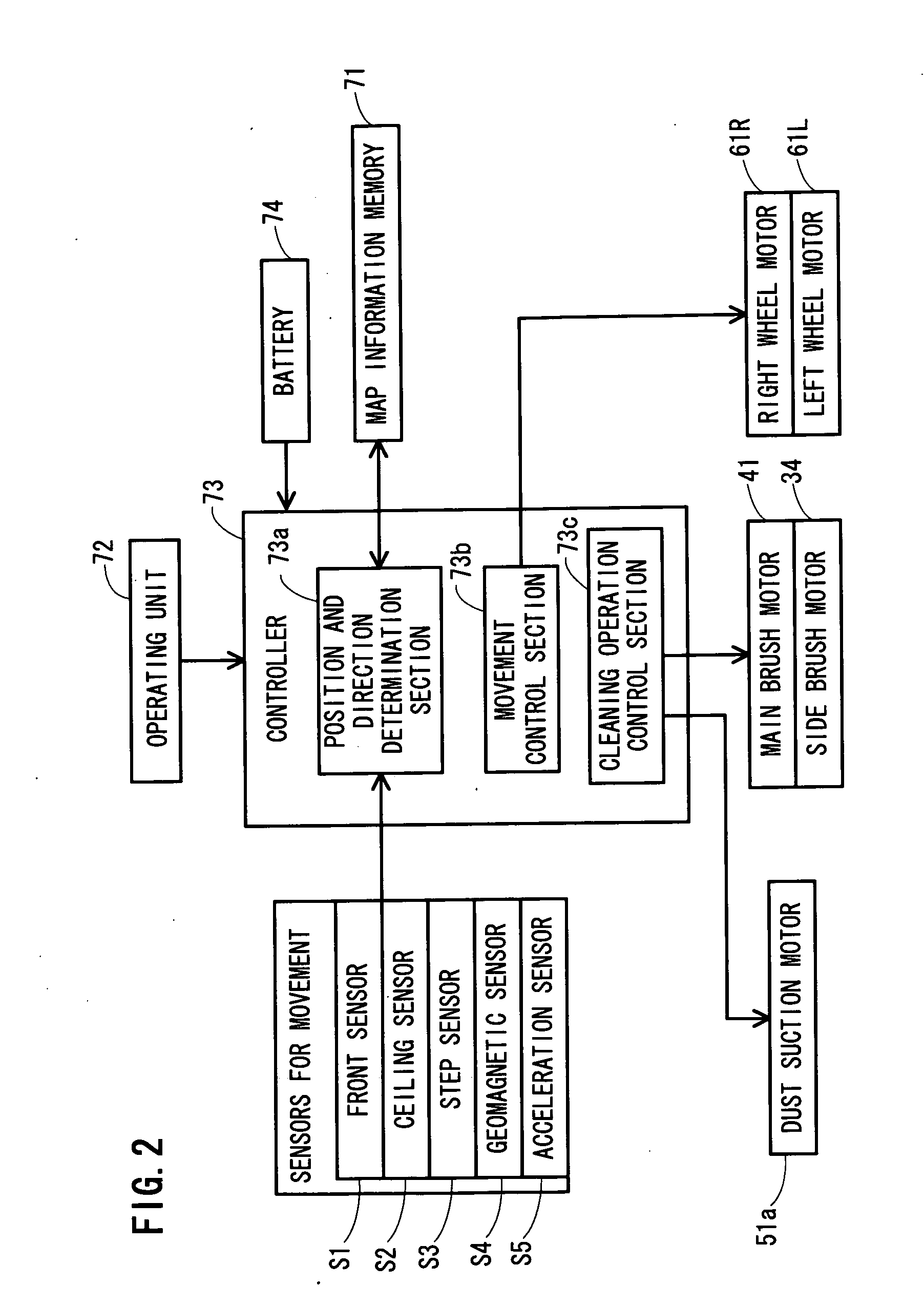

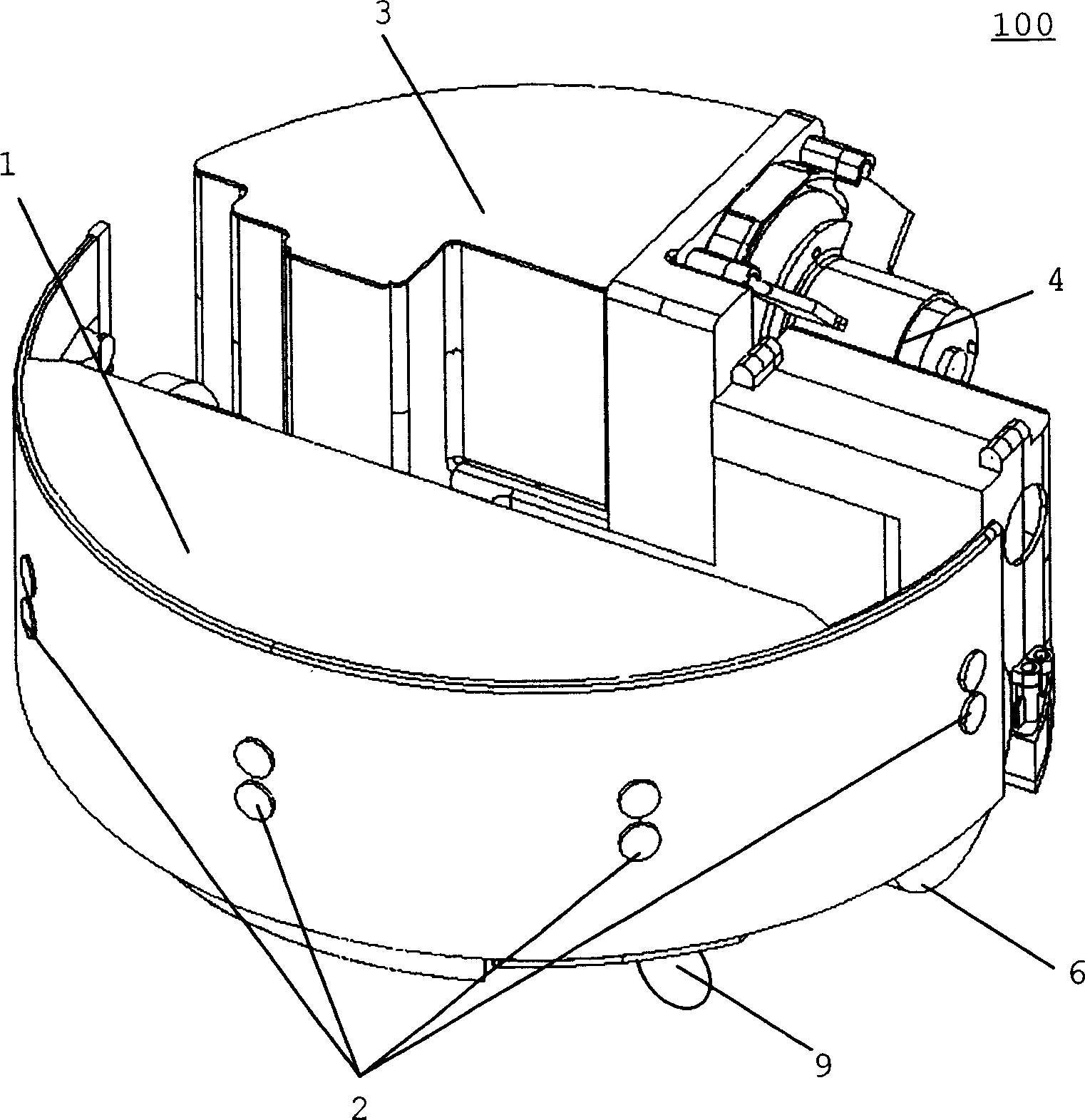

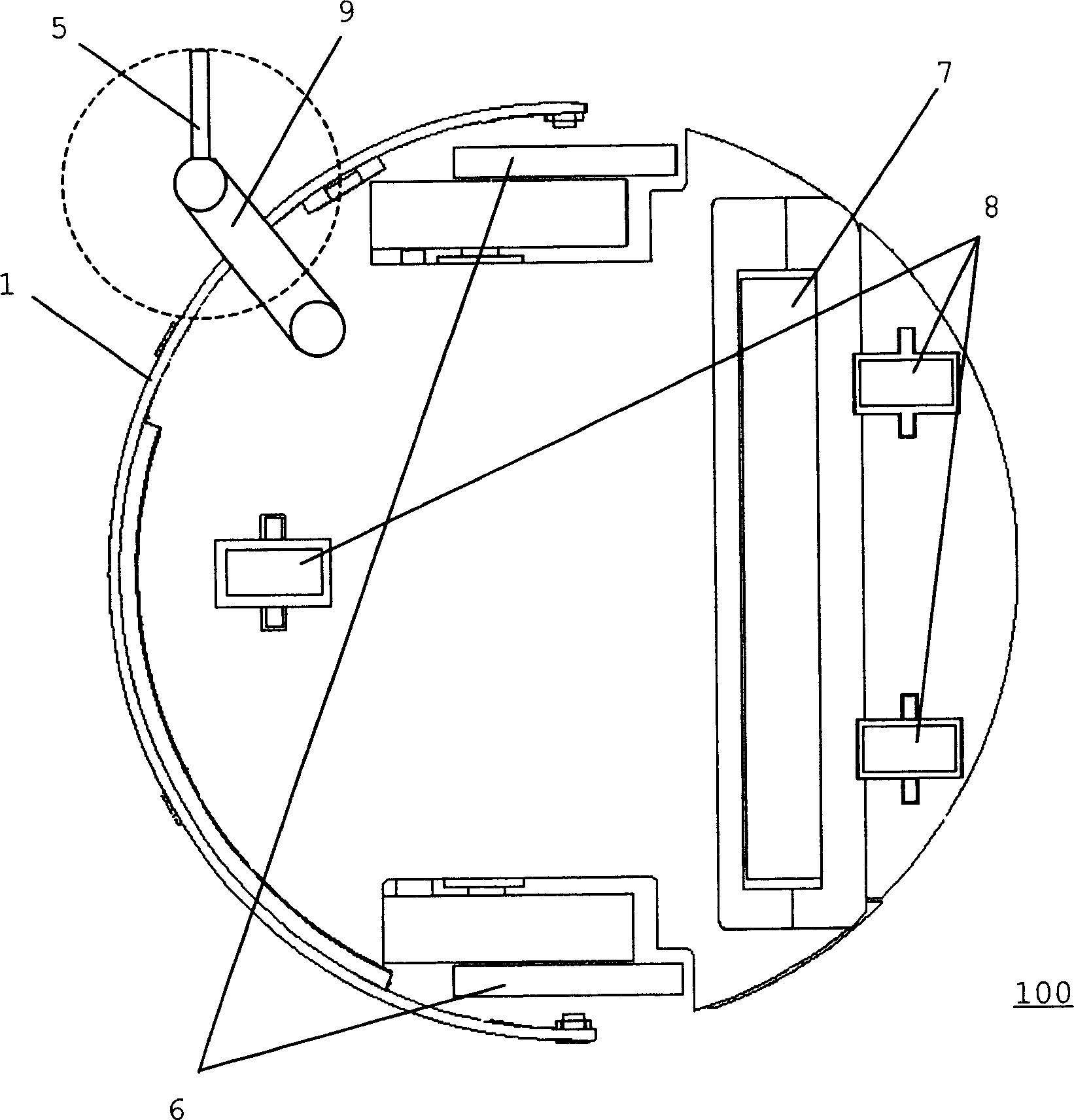

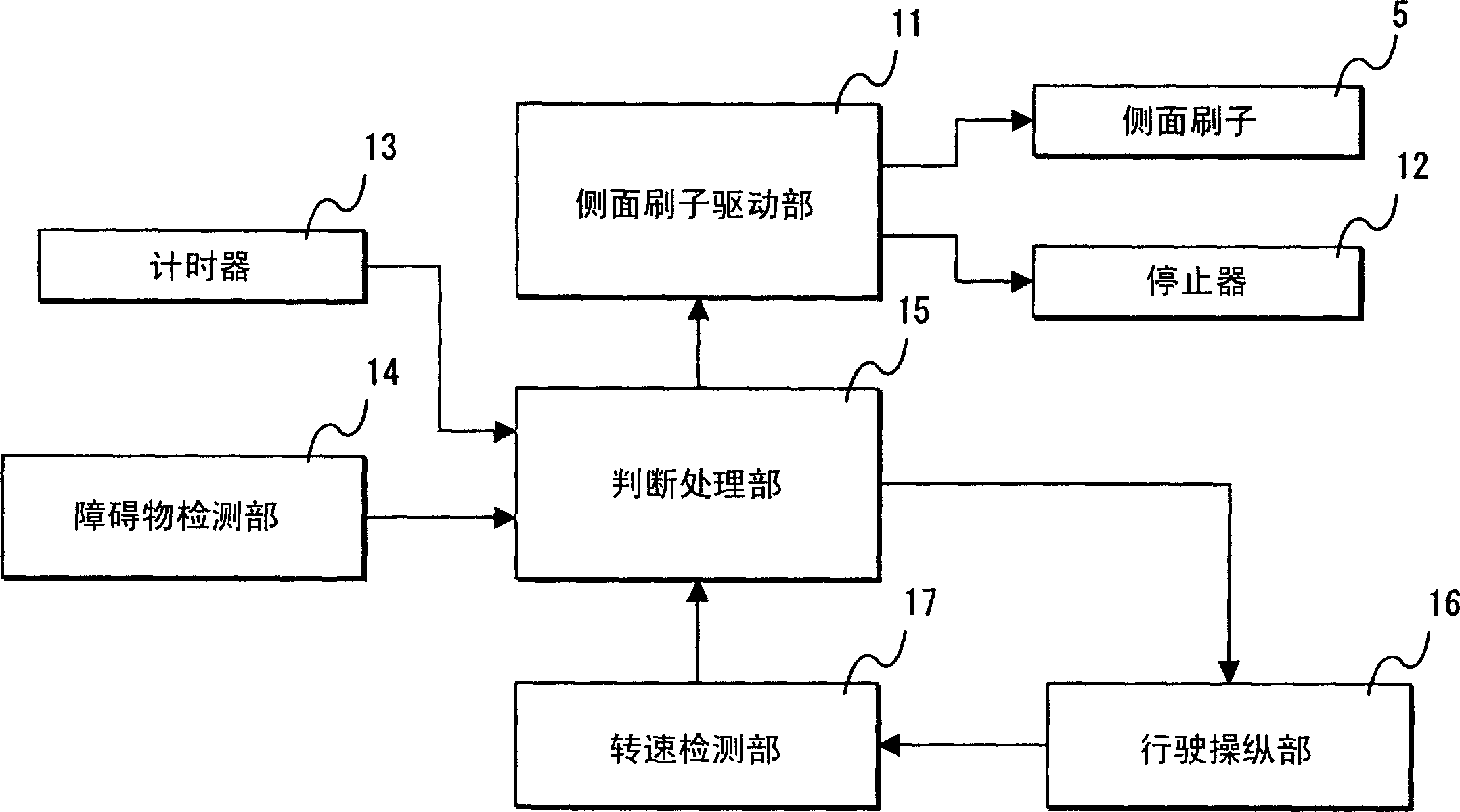

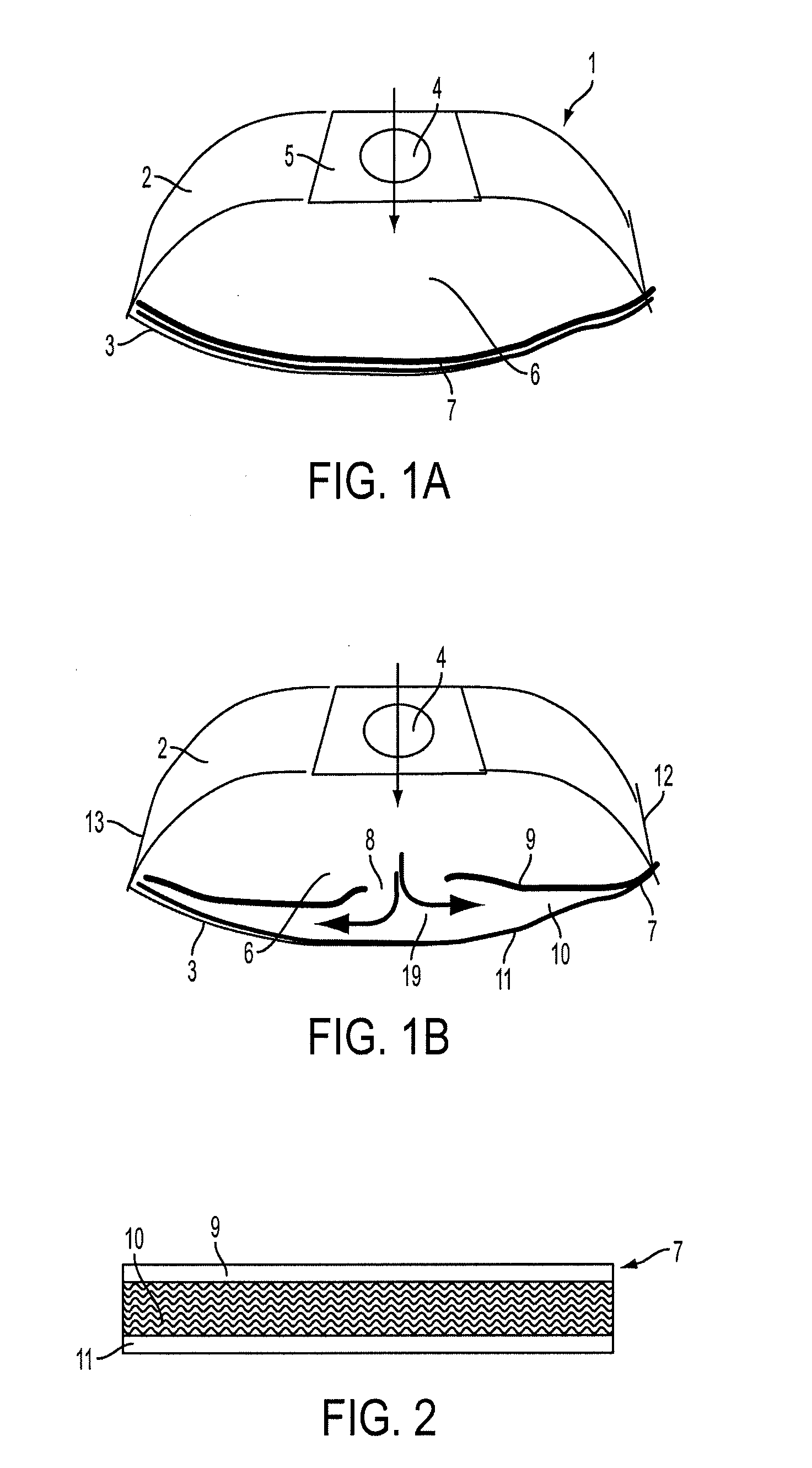

Cleaner

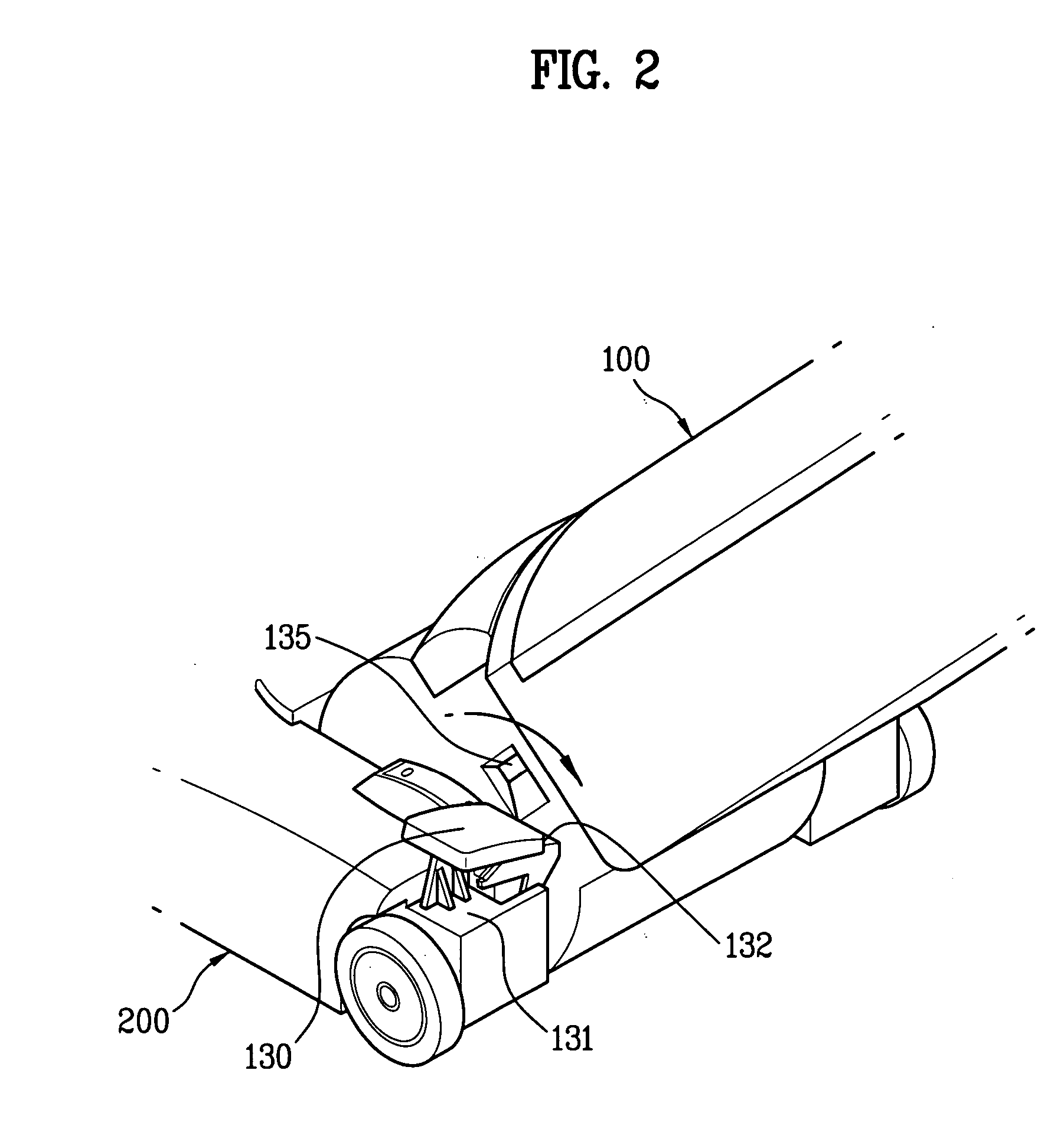

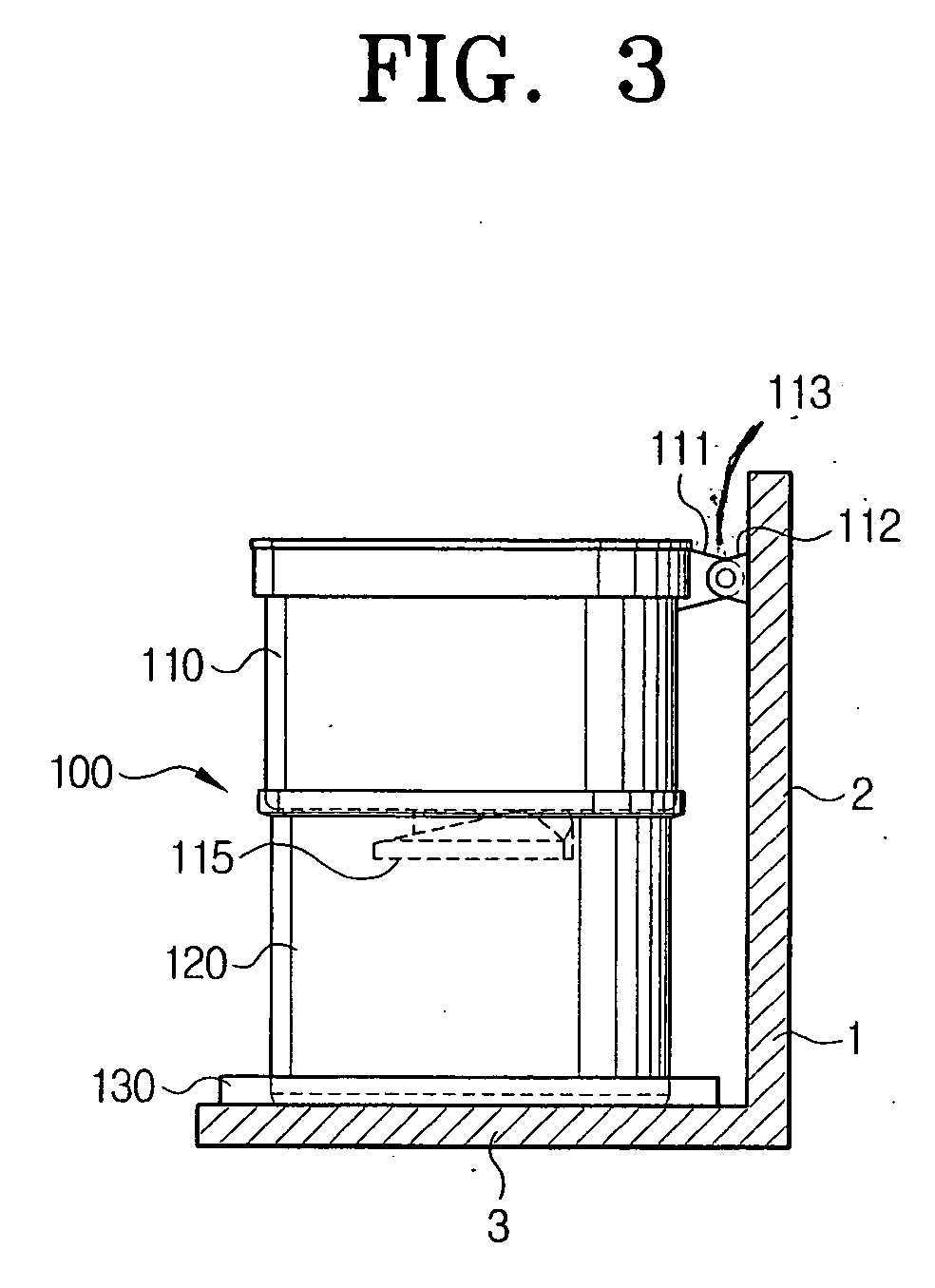

InactiveUS20060010638A1Preventing a side brush from scattering dustSuppress noiseAutomatic obstacle detectionTravelling automatic controlMechanical engineeringElectric power

Only when a wall side and the vicinity of an obstacle are cleaned, a side brush is operated and the cleaning is carried out, and when any other place than the wall side and the vicinity of the obstacle is cleaned, the side brush is maintained in a stoppage state. When a place such as the wall side or the vicinity of the obstacle in which dust is easy to accumulate is cleaned, the side brush is operated to enhance the dust collecting property. When any other place than the wall side or the vicinity of the obstacle is cleaned, the side brush is stopped to suppress power consumption and generation of a noise. A judgment processing portion detects based on a detection signal from an obstacle detecting portion that a cleaner is approaching a wall or an obstacle. In response to such detection, the judgment processing portion instructs a travel steering portion to carry out immediate rotation and change of a travel direction, or travel along a wall side. Also, the judgment processing portion instructs a side brush driving portion to drive a side brush only in the rotation and in the wall side travel, and to stop the side brush in straight advance travel.

Owner:SANYO ELECTRIC CO LTD

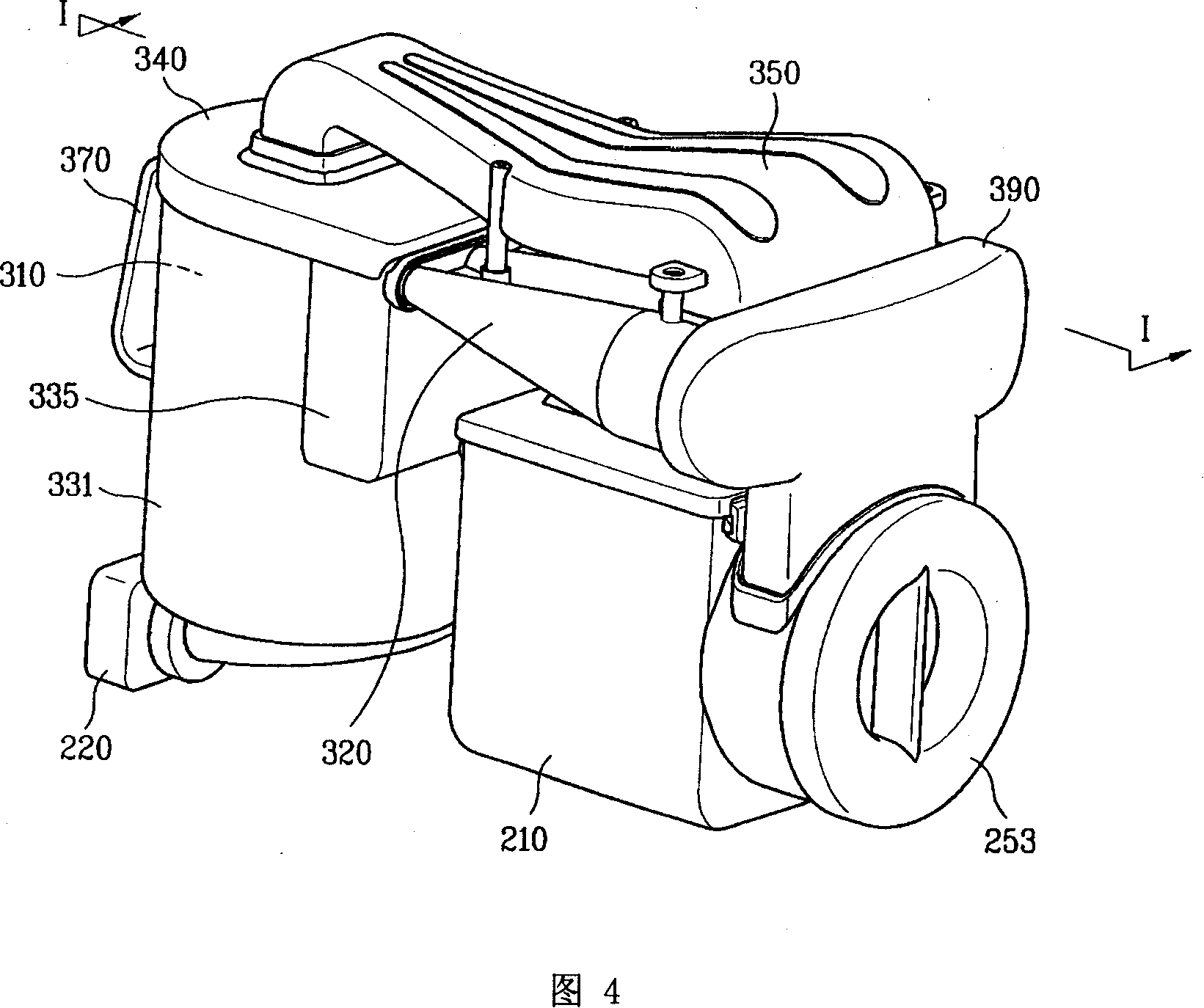

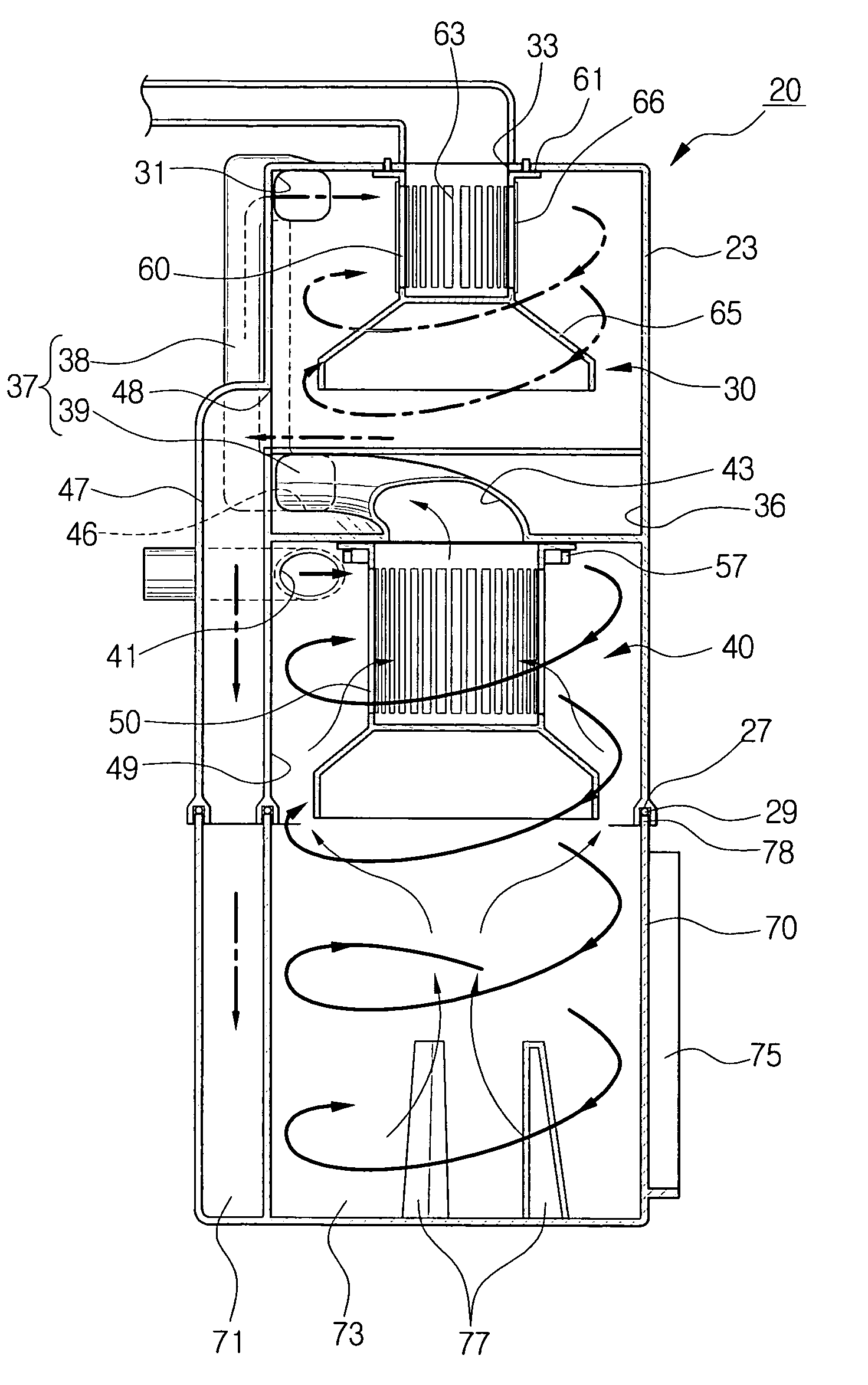

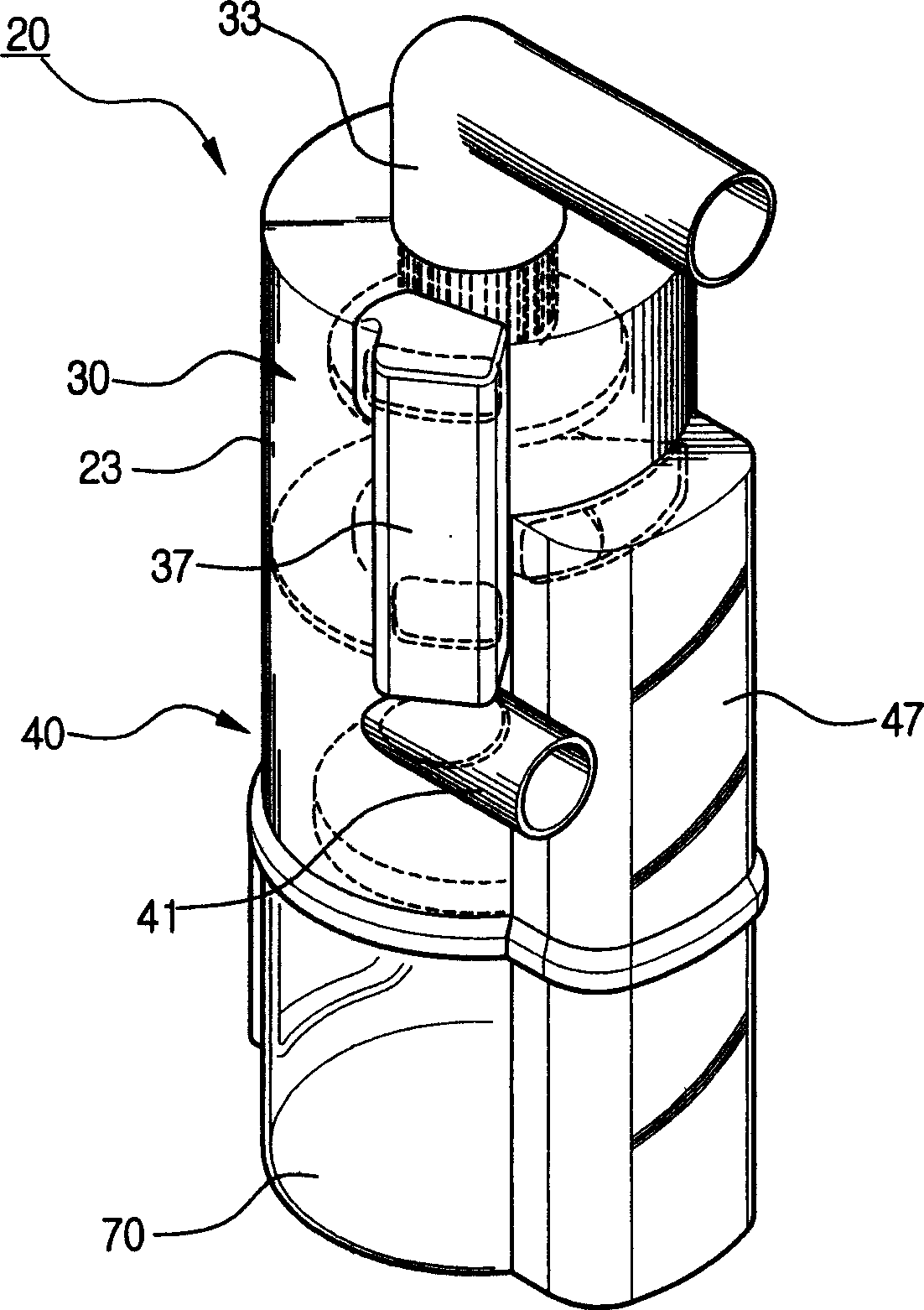

Multiple cyclonic dust collector

InactiveCN1887437AImprove dust collection effectImprove suction efficiencyReversed direction vortexInterior spaceForeign matter

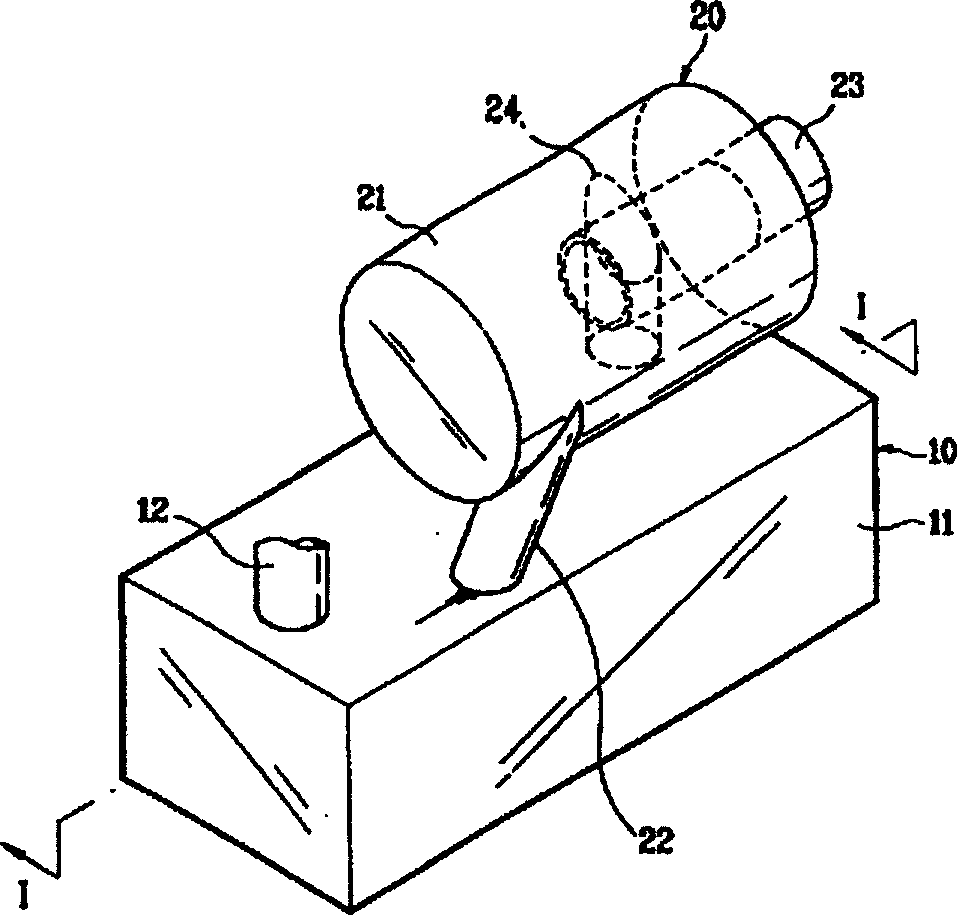

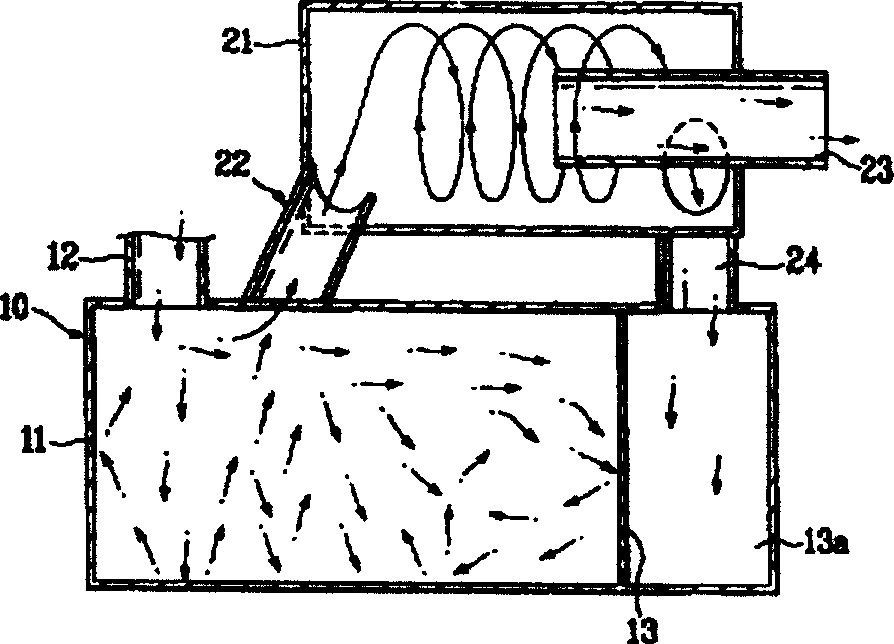

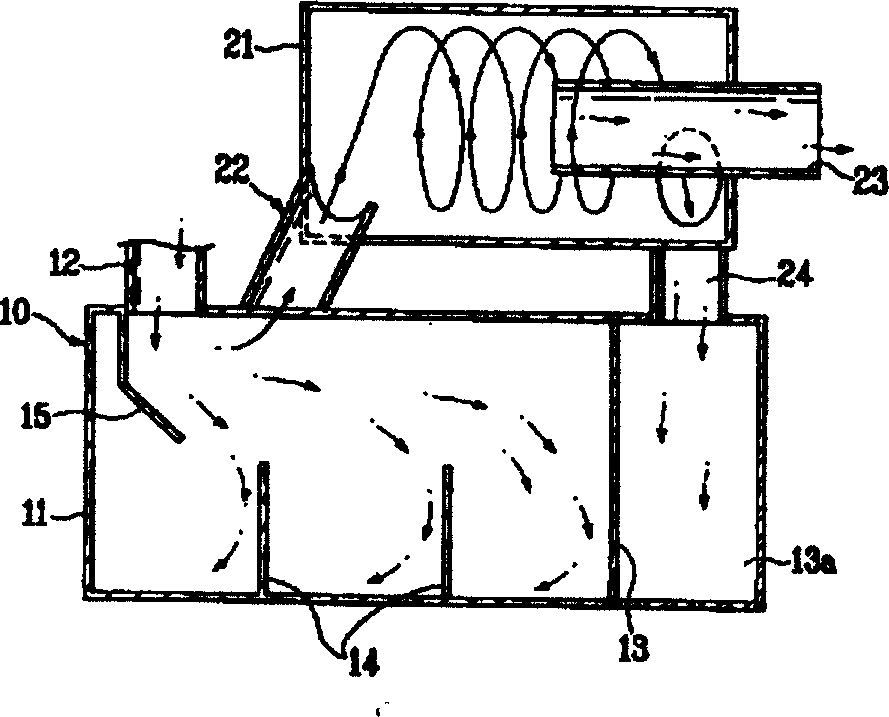

The multiple cyclonic dust collector includes one primary cyclonic dust collecting device with first air inflow unit, the first main body to separate out foreign matters from the inflow air, one dust collecting tub set in the side bottom of the first main body to collect the foreign matters the first main body separates out, one extending unit extending from the bottom of the first main body and set inside the dust collecting tub, and the first air outflow unit for air to flow out of the first main body; and one secondary cyclonic dust collecting device installed outside the primary cyclonic dust collecting device to suck air from the primary cyclonic dust collecting device for secondary dust collection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

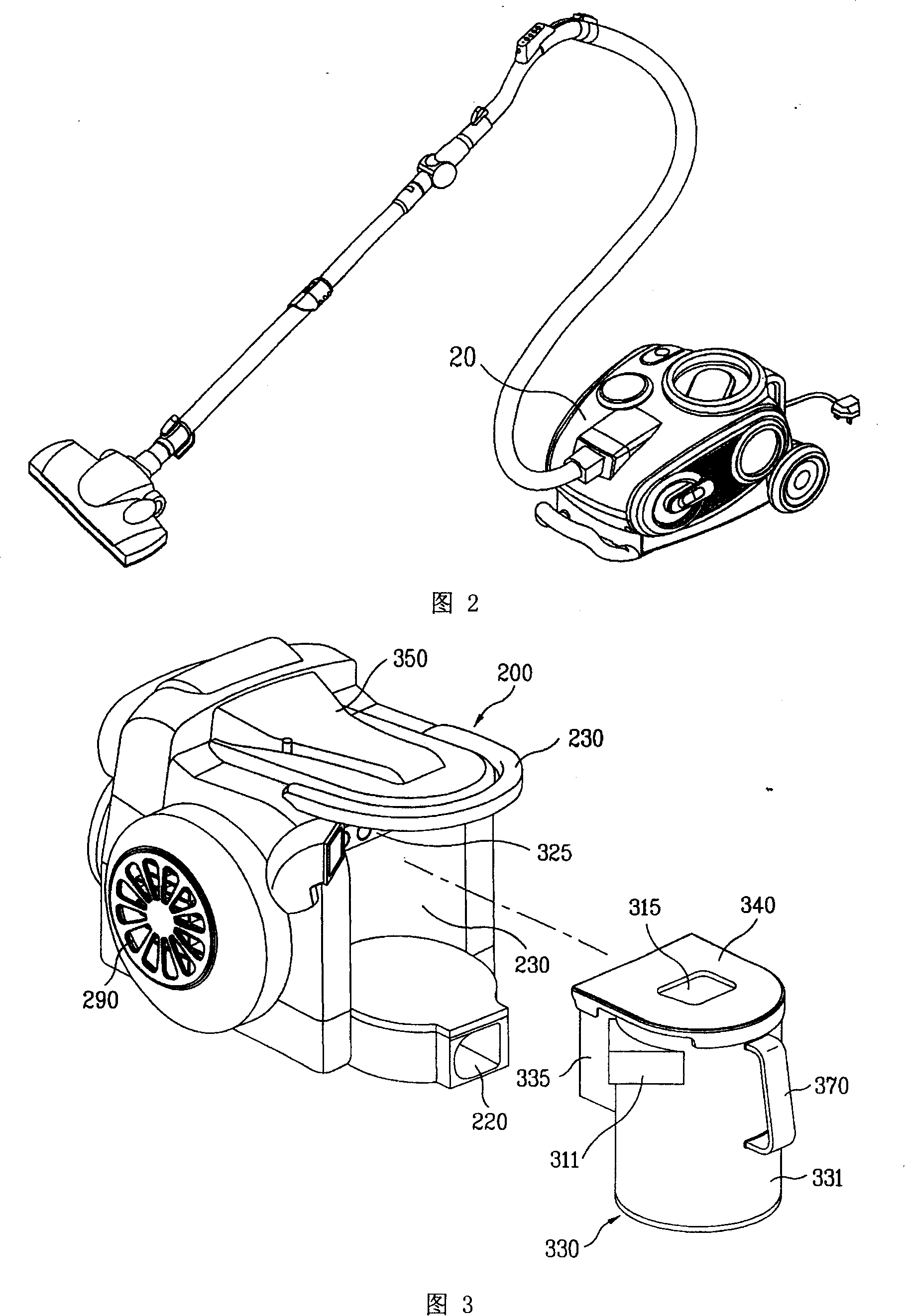

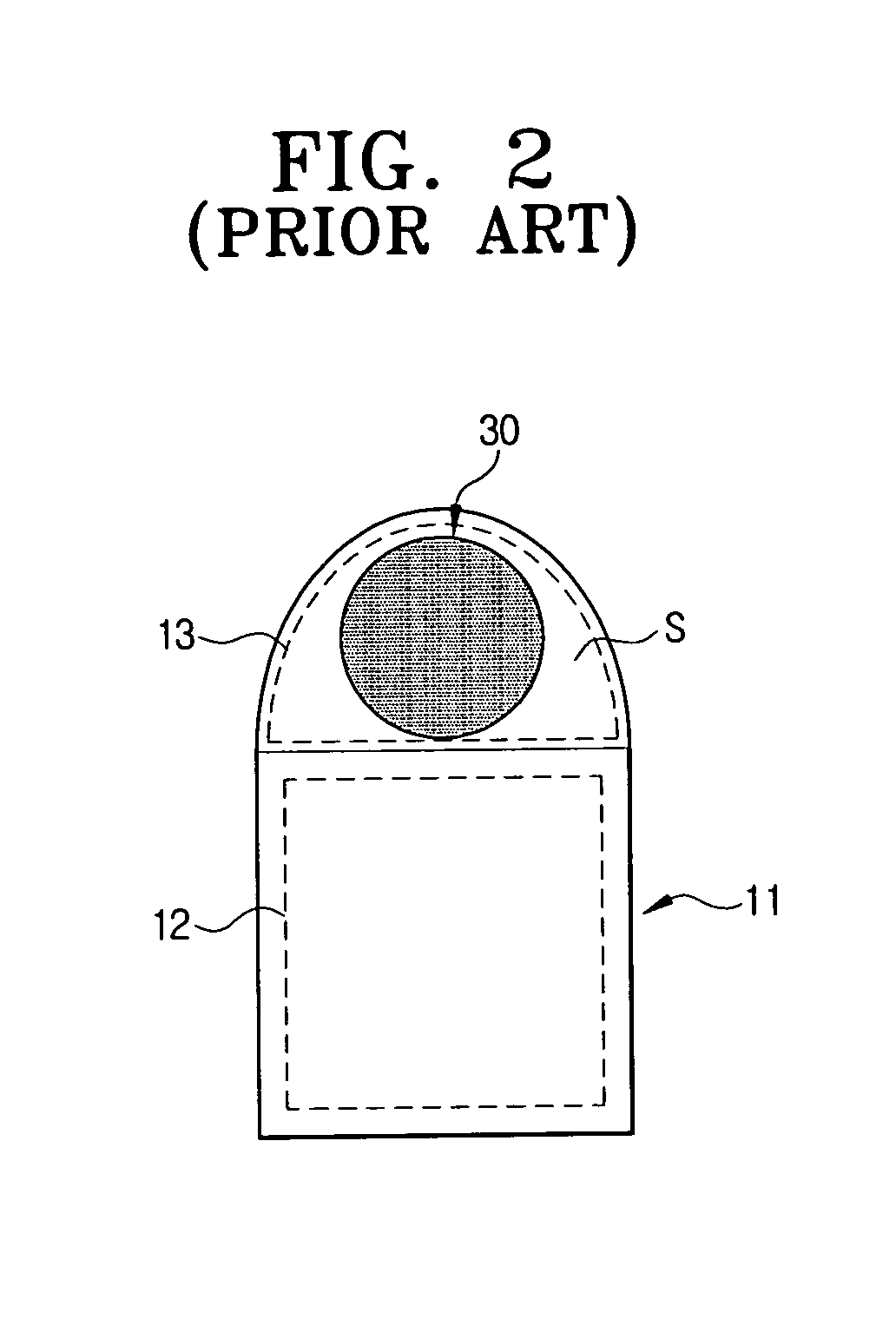

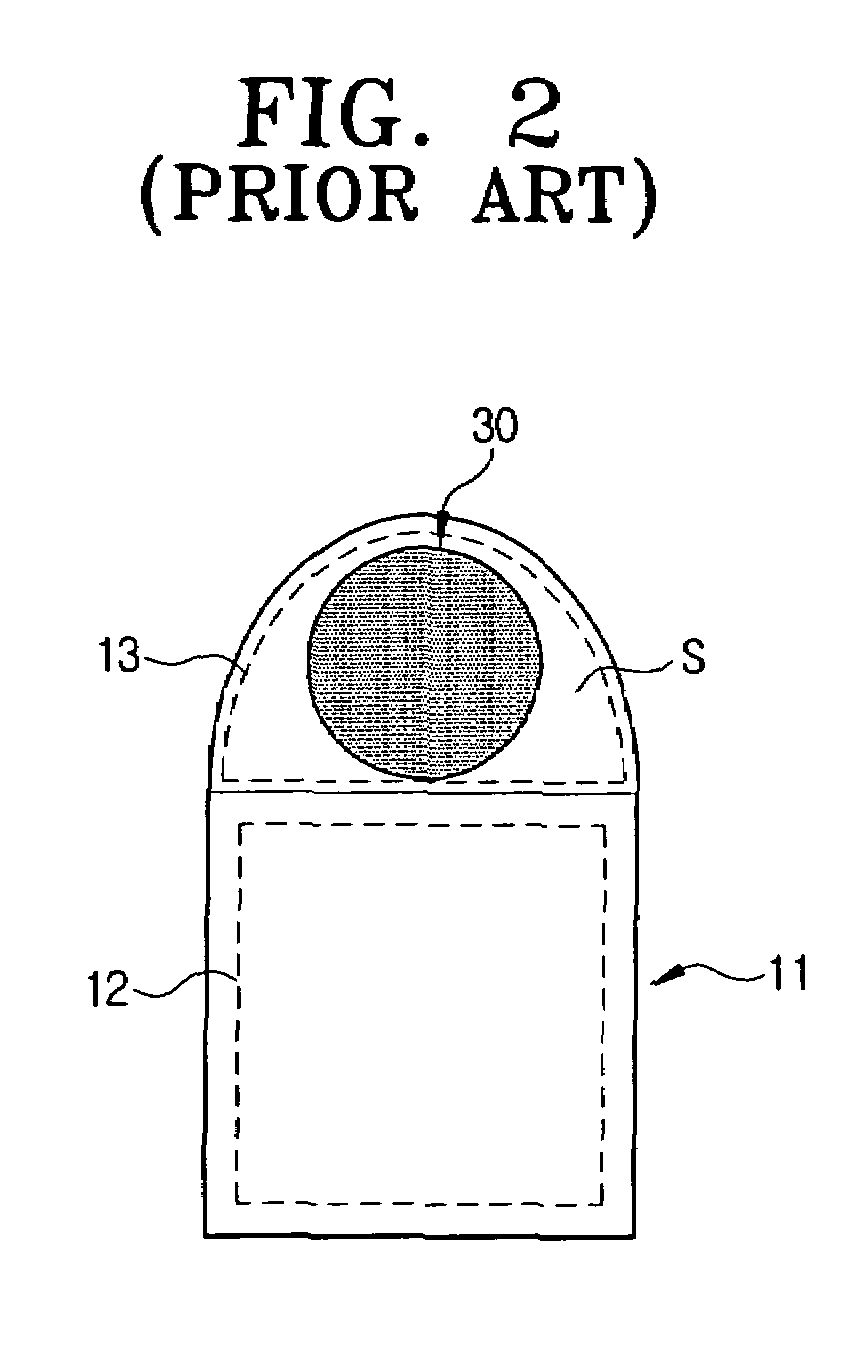

Vacuum cleaner

The invention discloses a vacuum cleaner, which comprises a driving unit generating attrition, a cyclone unit for separating dust in air, a clearer body provided with the cyclone unit, a dust entering section positioned on side face of the clearer body and a dust barrel detachably arranged on the clearer body, a dust barrel mounting section mounted on the clearer body for mounting the dust barrel and a dust discharging section positioned on inner wall of the dust mounting section. When the dust barrel is mounted to the dust barrel mounting section, the dust discharging section contacts the dust entering section to discharge the dust separated out by the cyclone unit to the dust entering section. The invention has the advantages of simple structure, small weight and convenient cleaning, which strengthens the air tightness between the dust barrel and the dust discharging section, prevents the air being sucked and damaged, thus improving the dust collecting performance of the clearer.

Owner:NANJING LG PANDA APPLIANCES

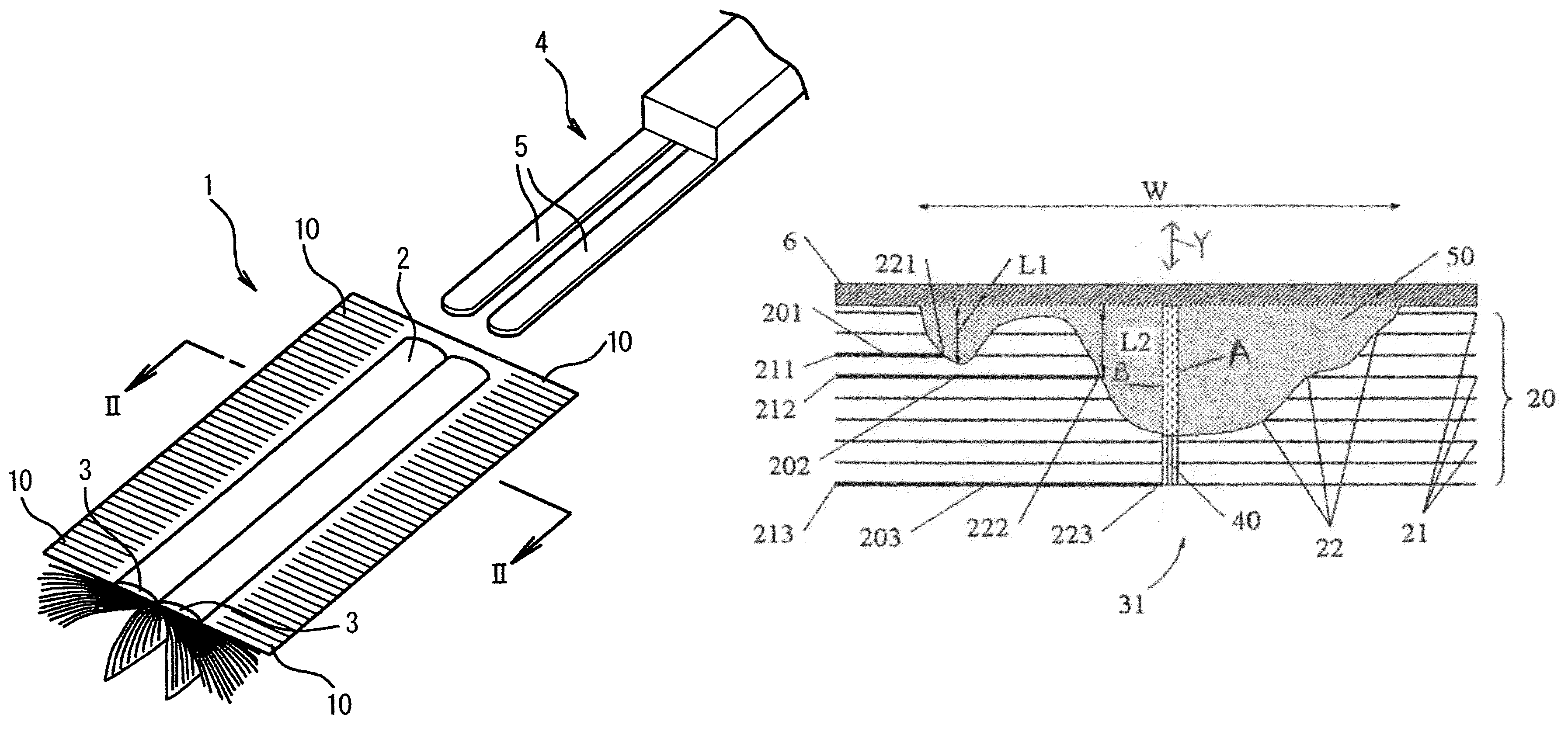

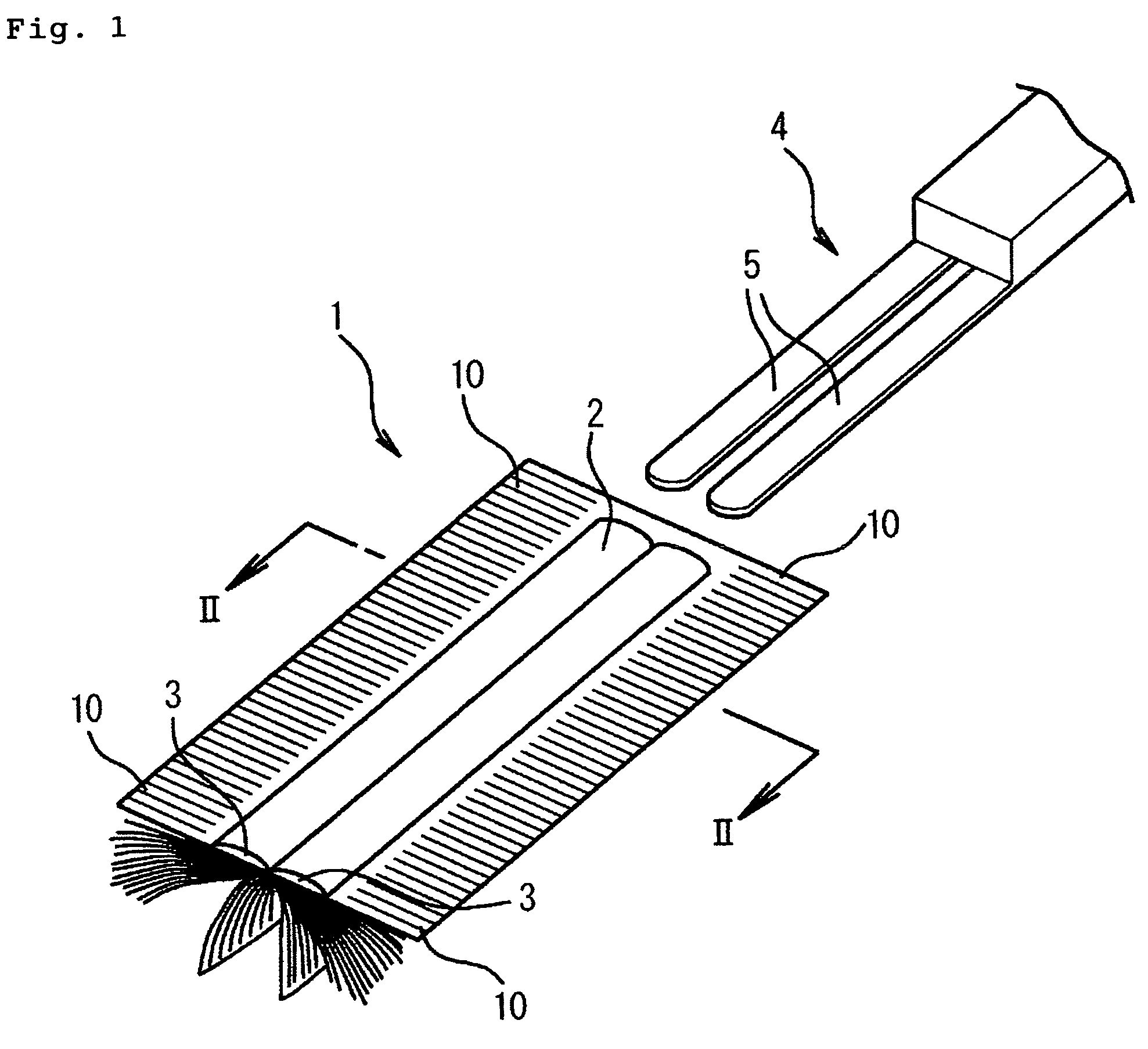

Cleaning device and process for producing the same

InactiveUS8146197B2Long operating timeLow costBoard cleaning devicesCarpet cleanersFiber bundleAdhesive

Owner:YAMADA KIKUO

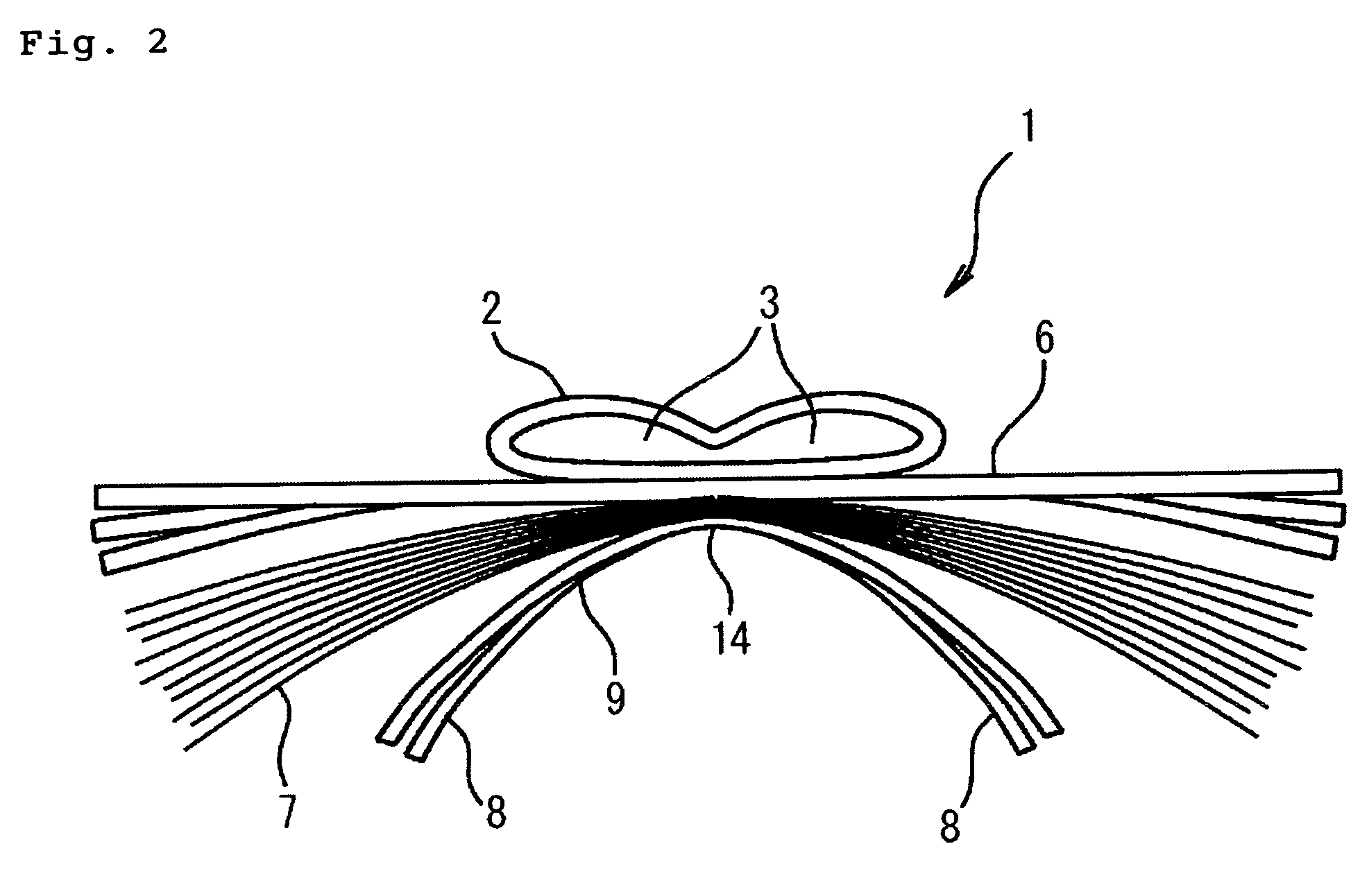

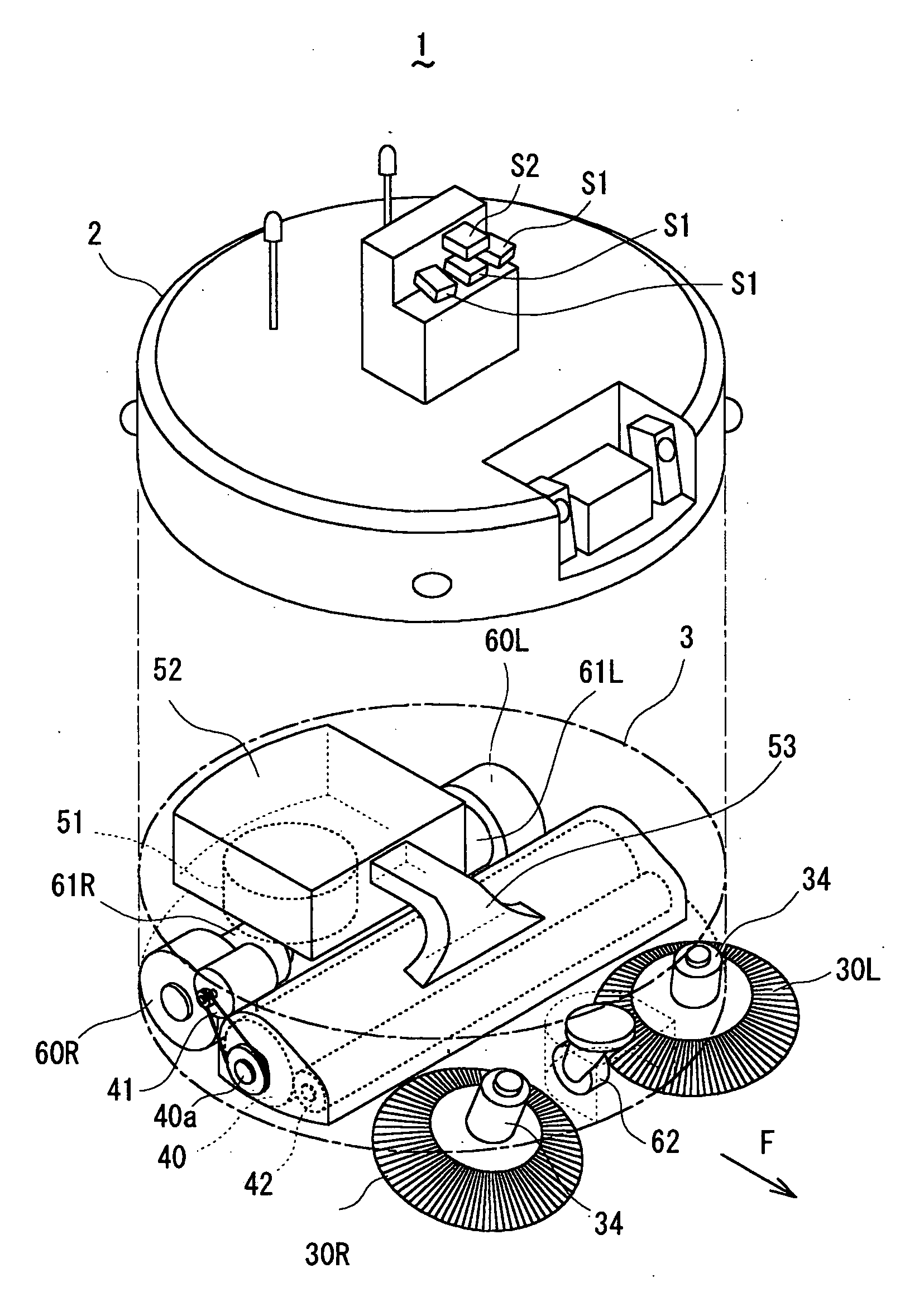

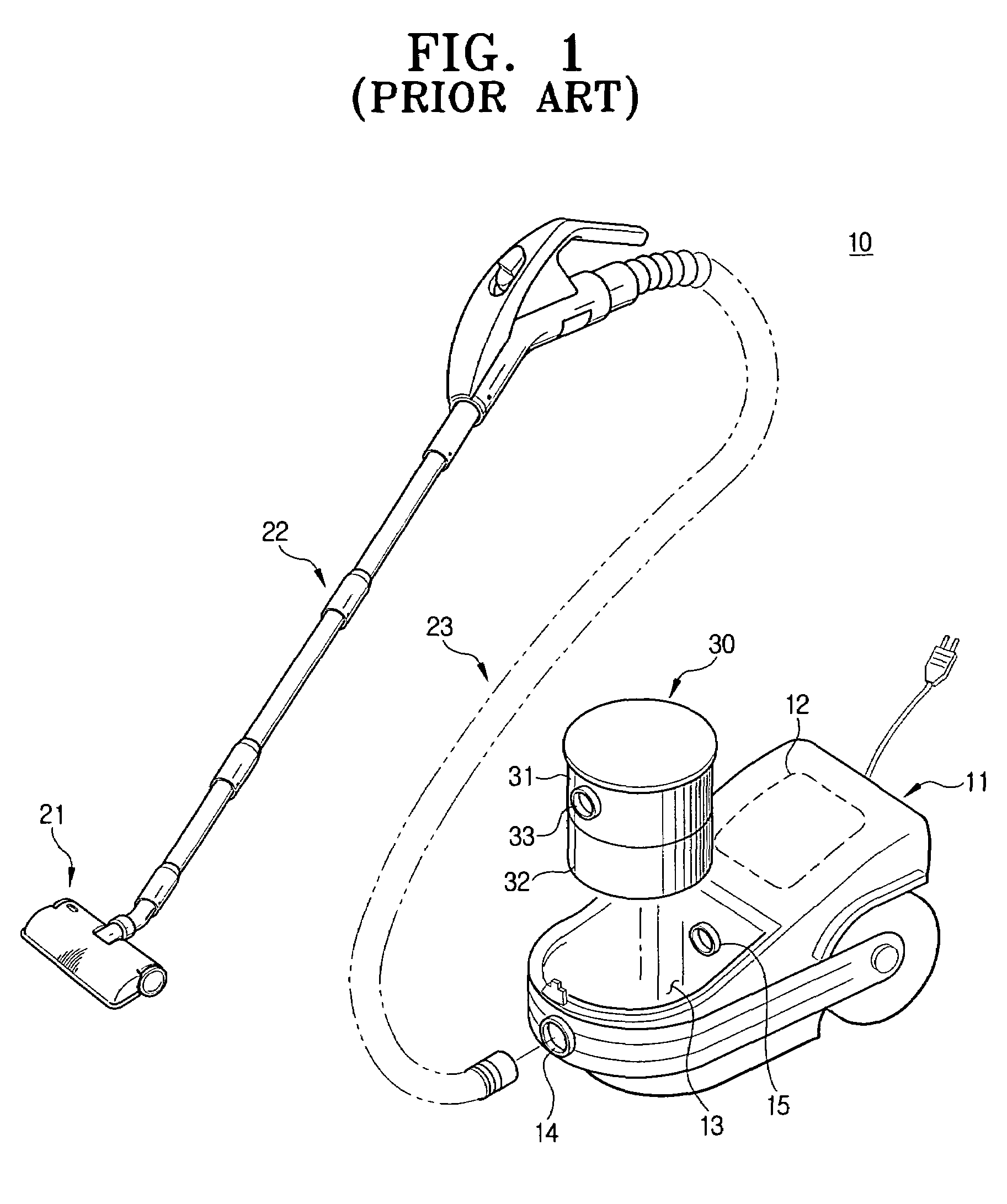

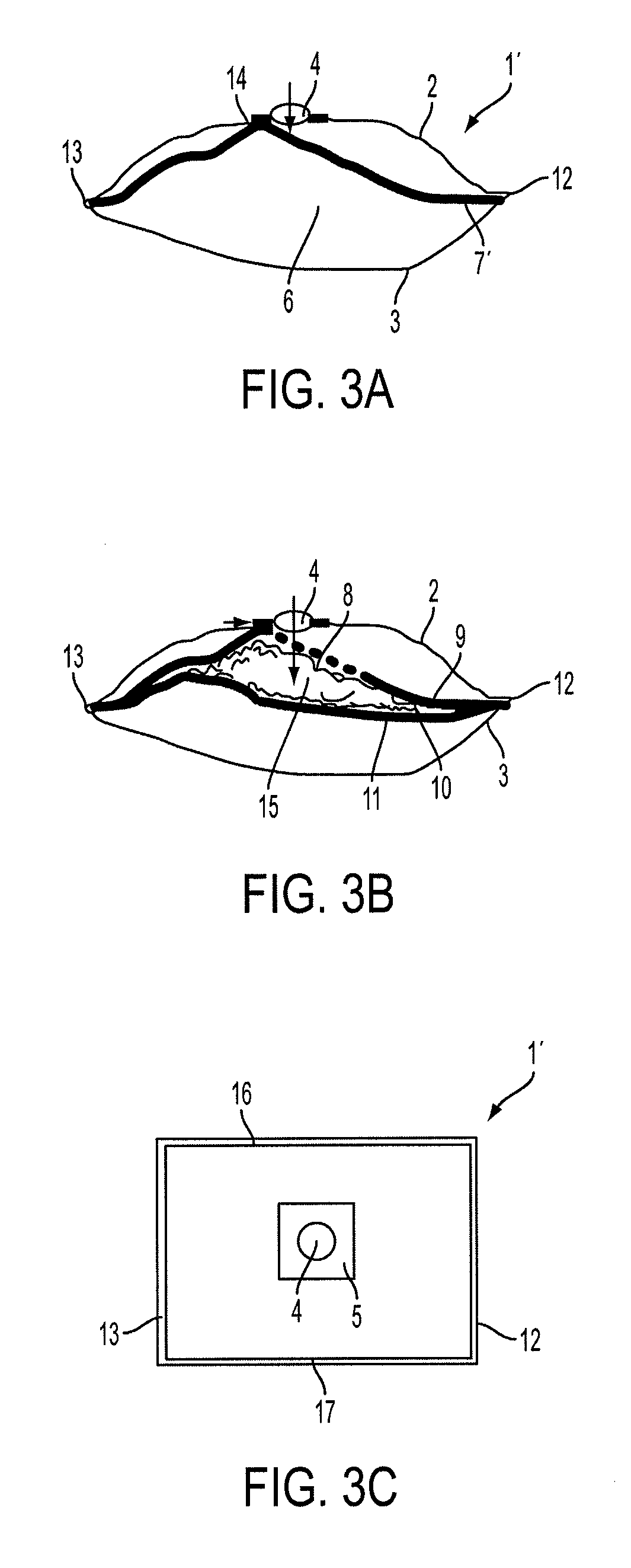

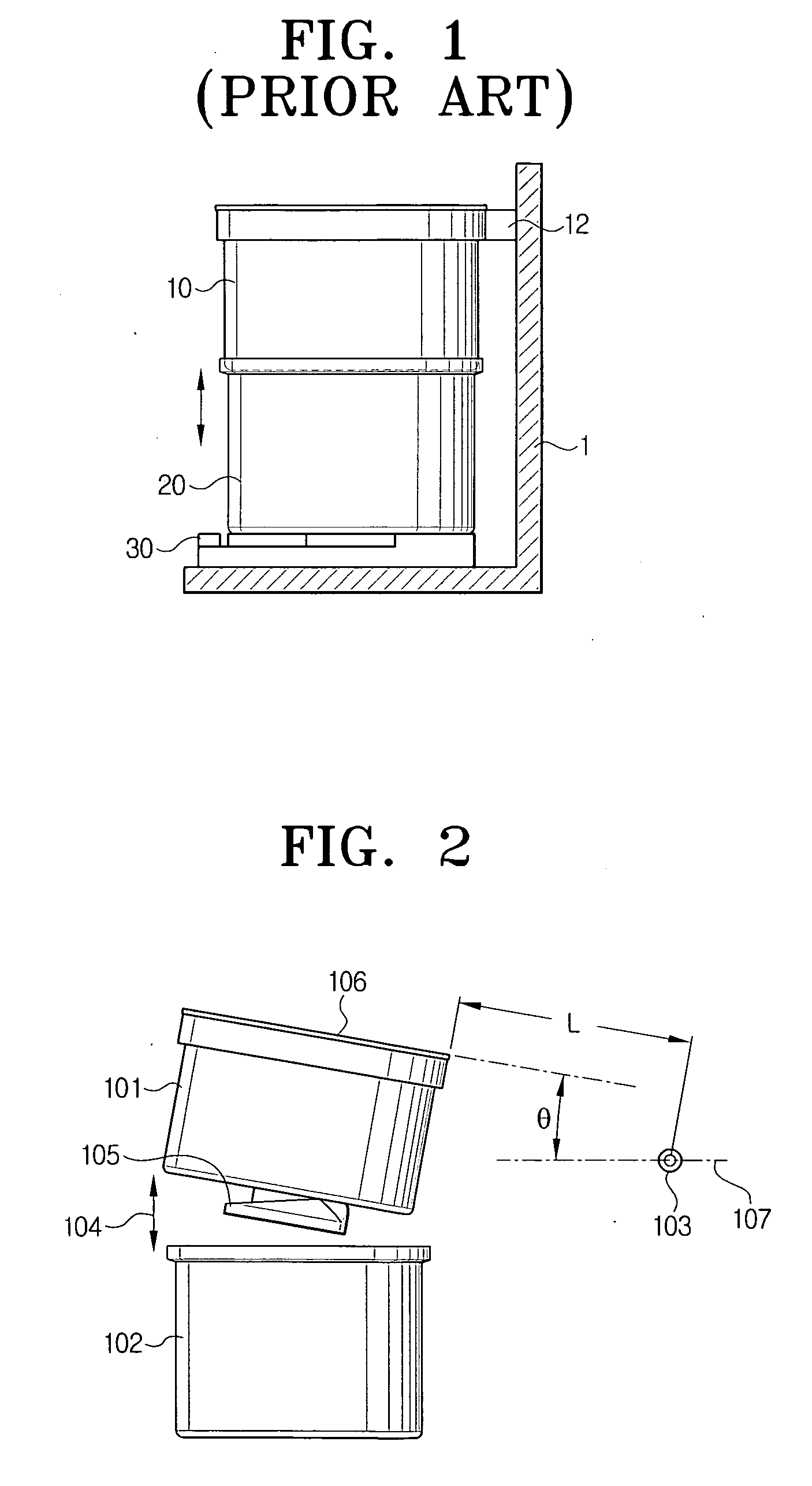

Self-propelled vacuum cleaner

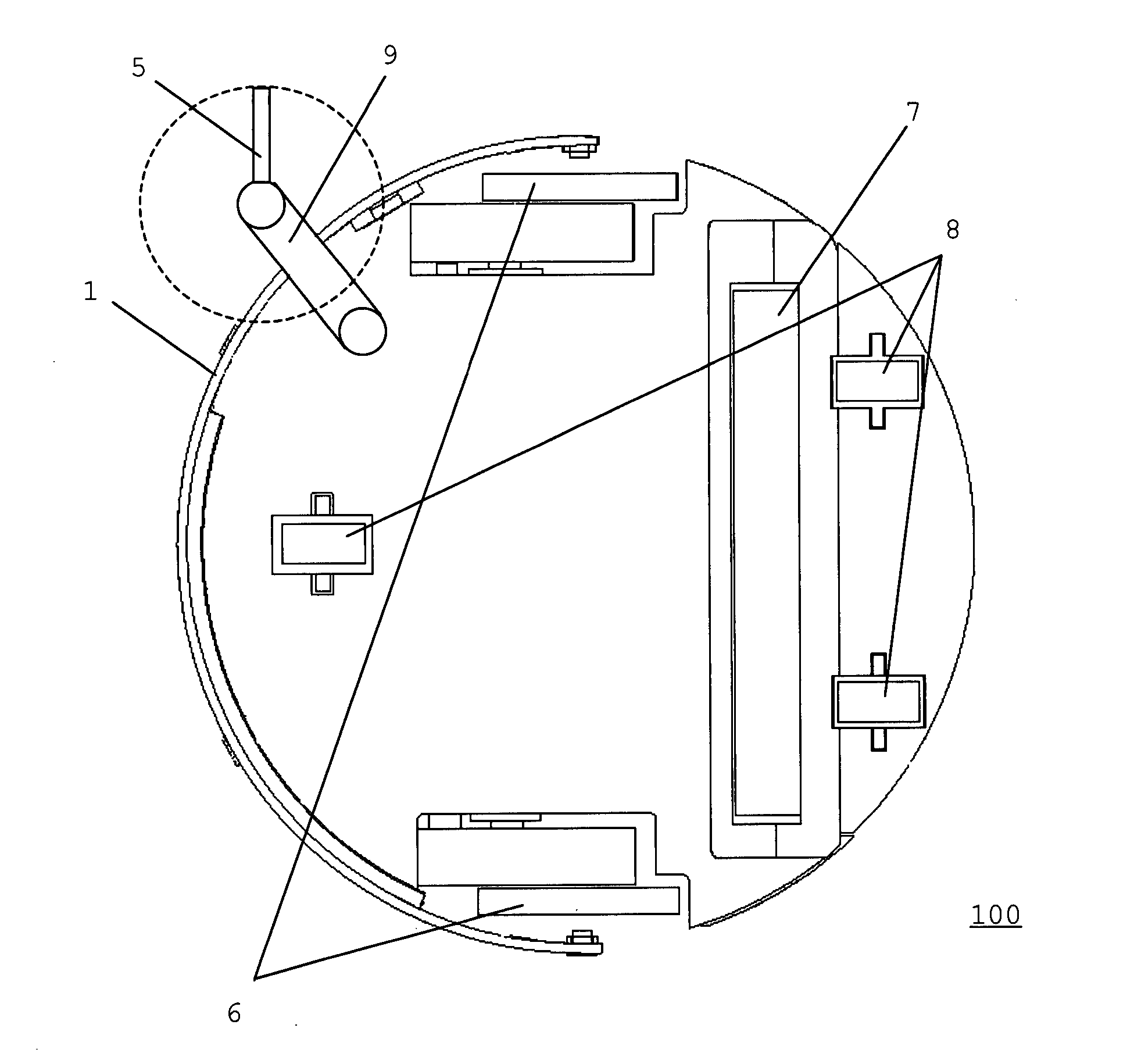

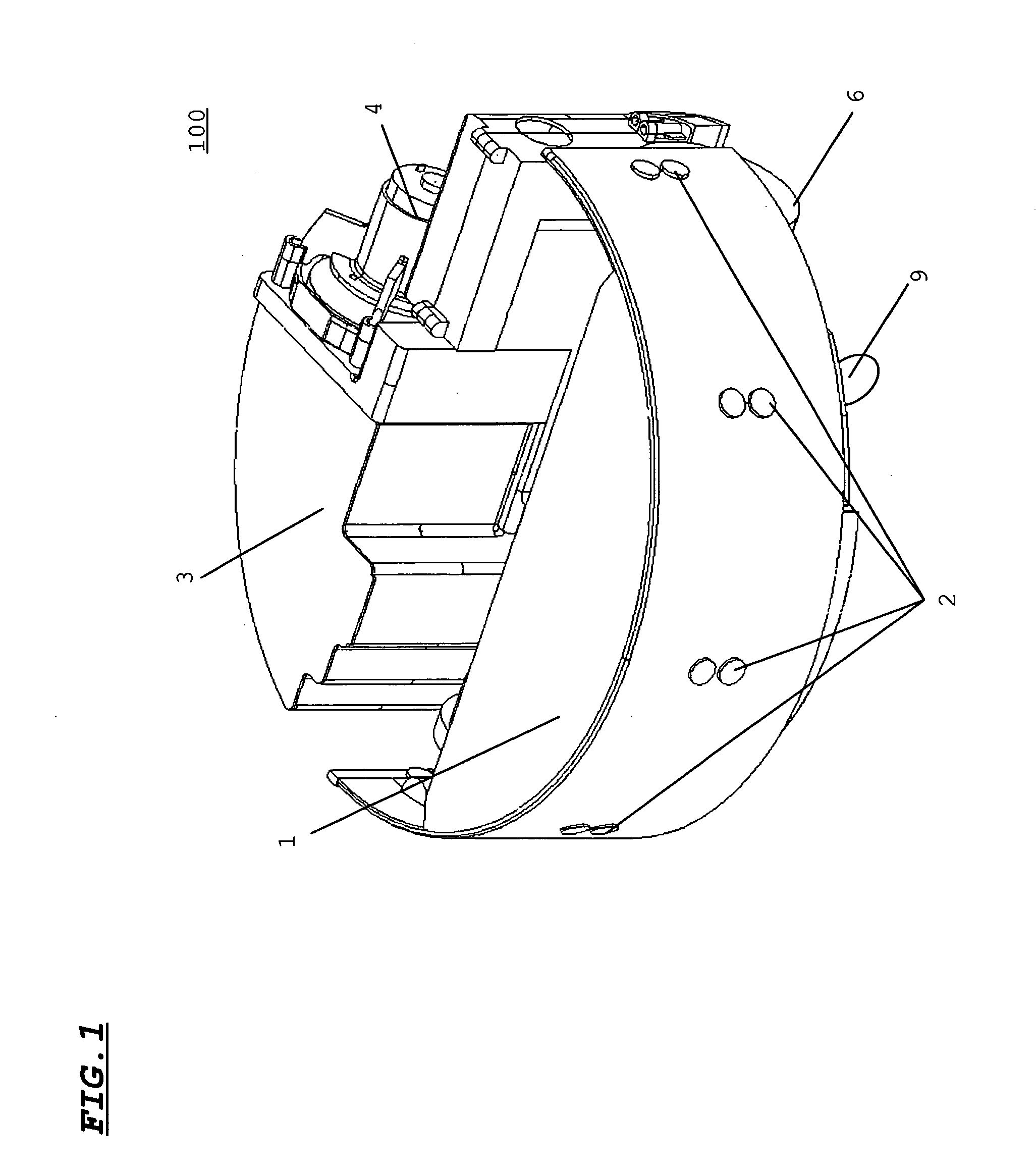

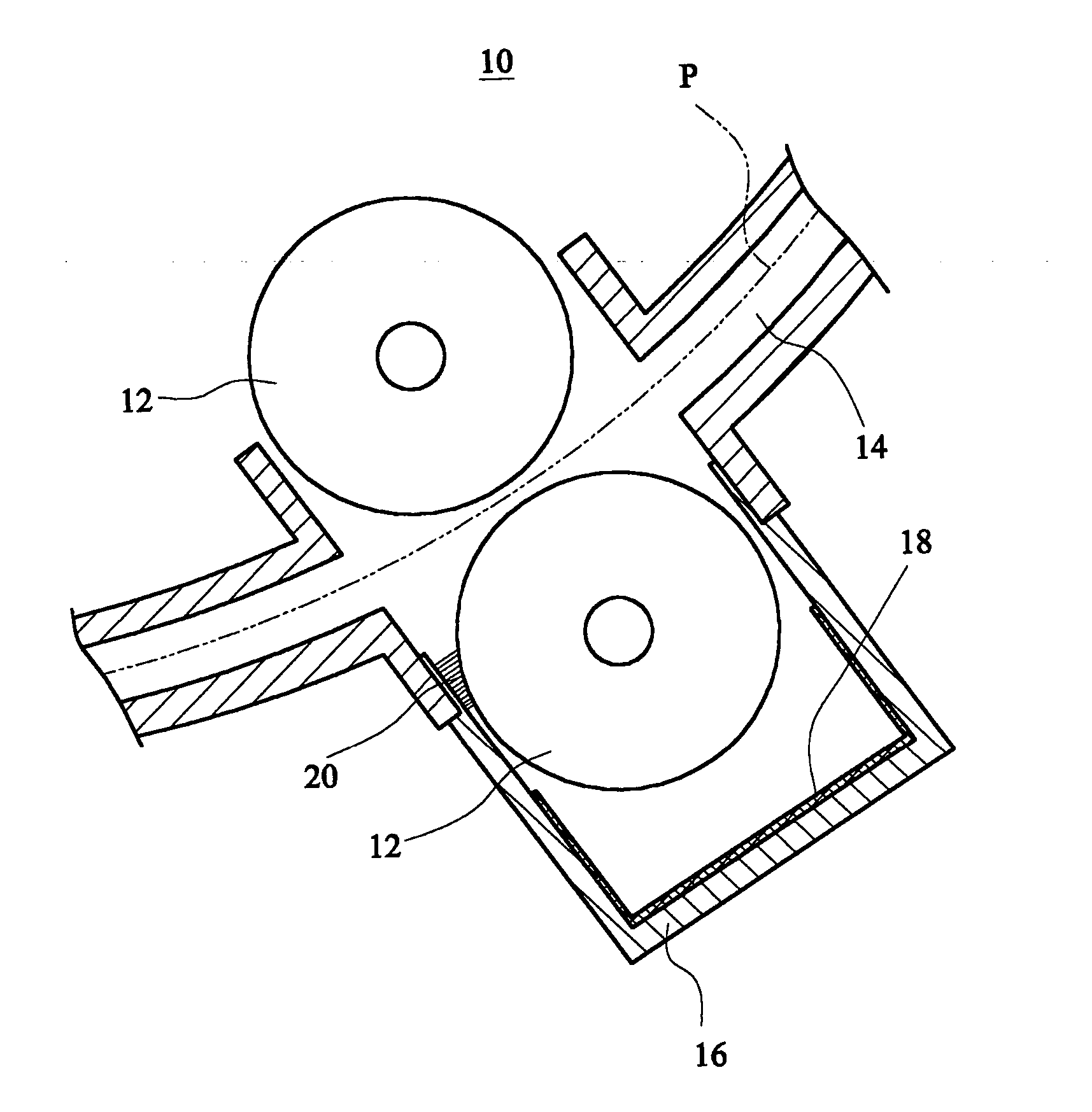

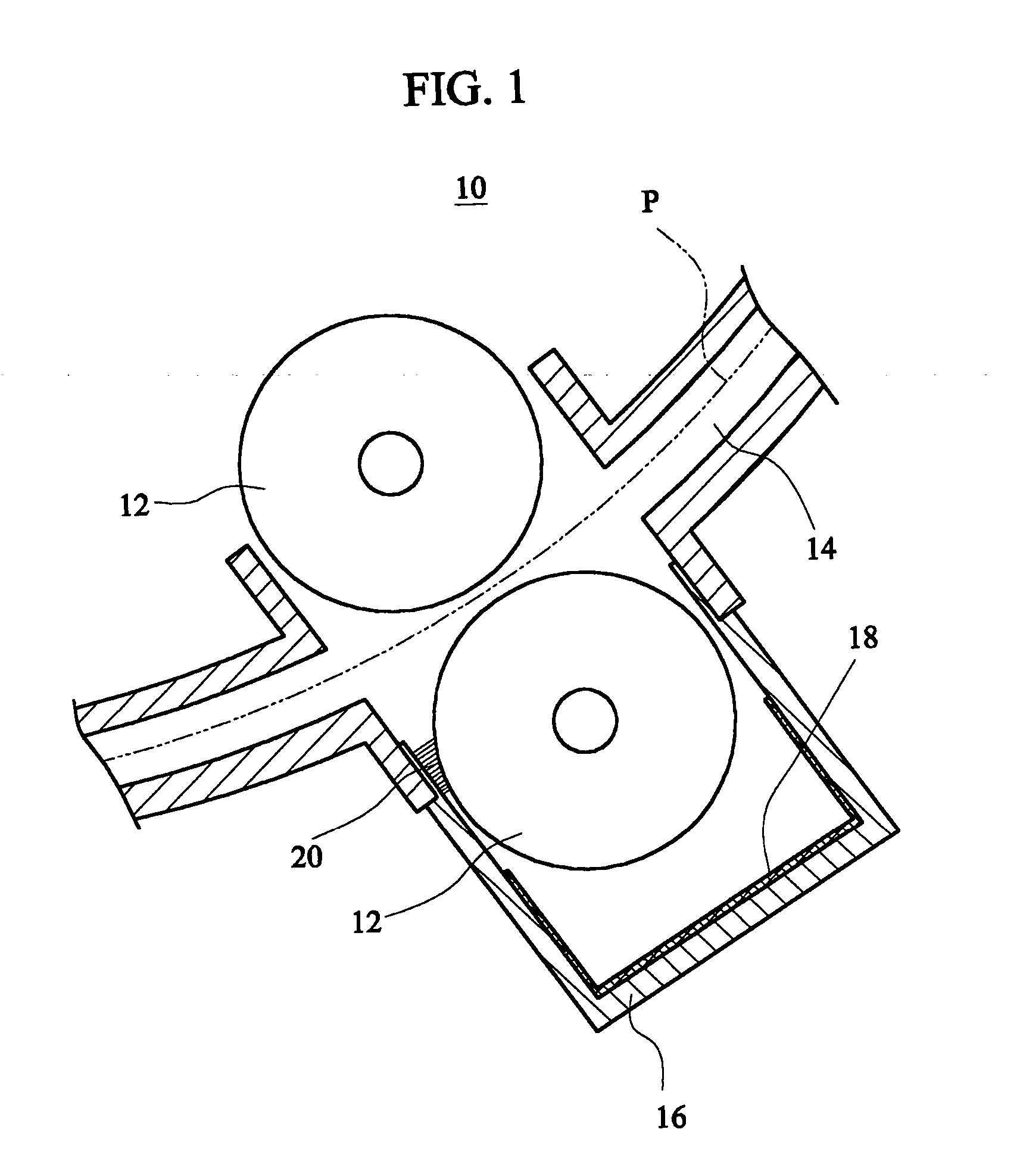

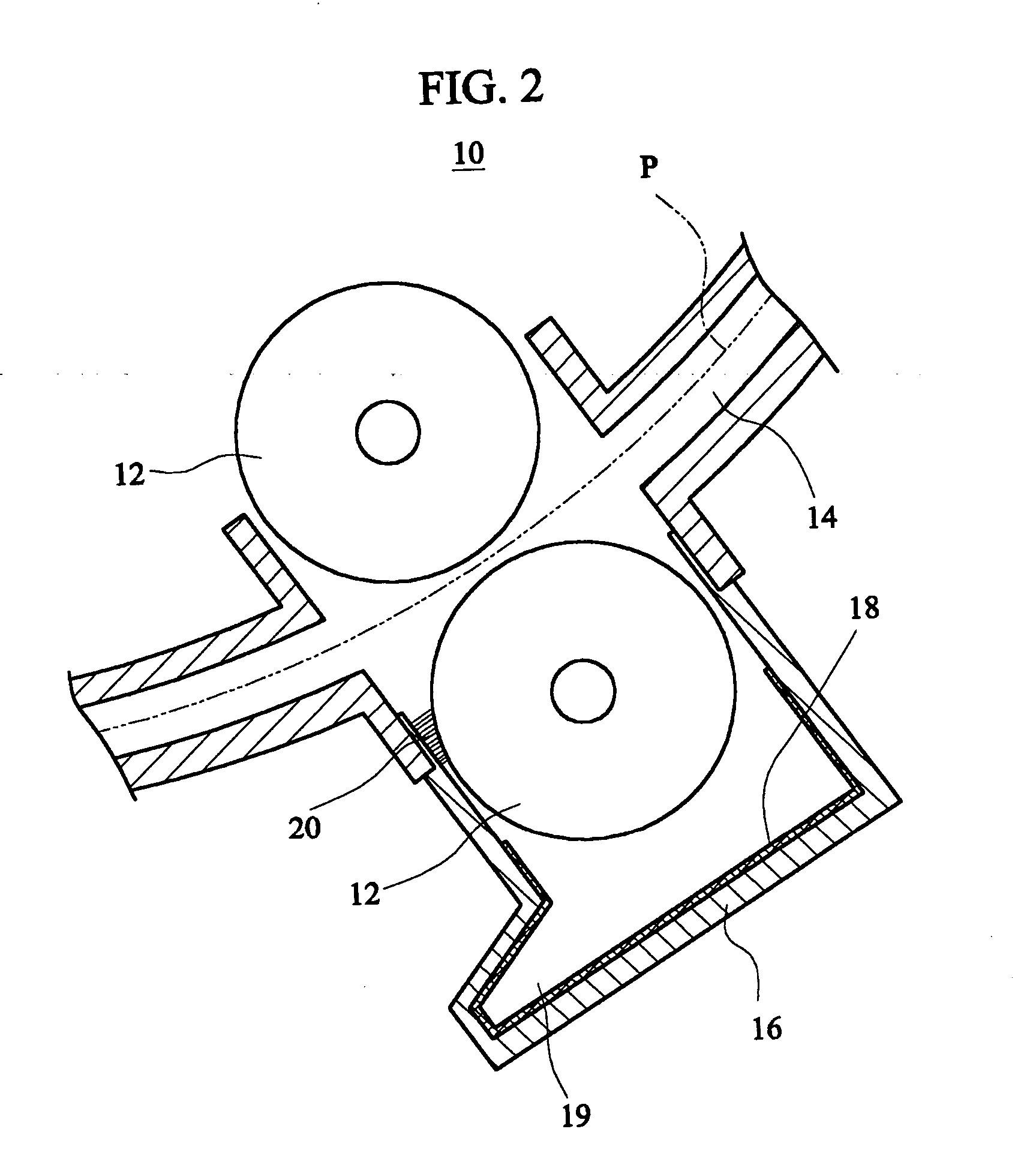

InactiveUS20050166356A1Improve dust collection effectIncrease powerCarpet cleanersFloor cleanersEngineeringClockwise

A self-propelled vacuum cleaner having right and left side brushes for directing dust on a floor surface toward the inside of the bottom of the cleaner body. The right side brush rotates in a counterclockwise direction as viewed from top on a rotary shaft, which is tilted so that the lower end is located toward the right of and the rear of the cleaner body as compared with the upper end. The left side brush rotates in a clockwise direction as viewed from top on a rotary shaft, which is tilted so that the lower end is located toward the left of and the rear of the cleaner body as compared with the upper end. The tilted rotary shafts can prevent the outer portions of the side brushes at their rear portions from contacting a floor surface, thereby preventing dust collected by the front portions of the side brushes from being scattered to the outside of the cleaner body by the rear portions of the brushes.

Owner:FUNAI ELECTRIC CO LTD

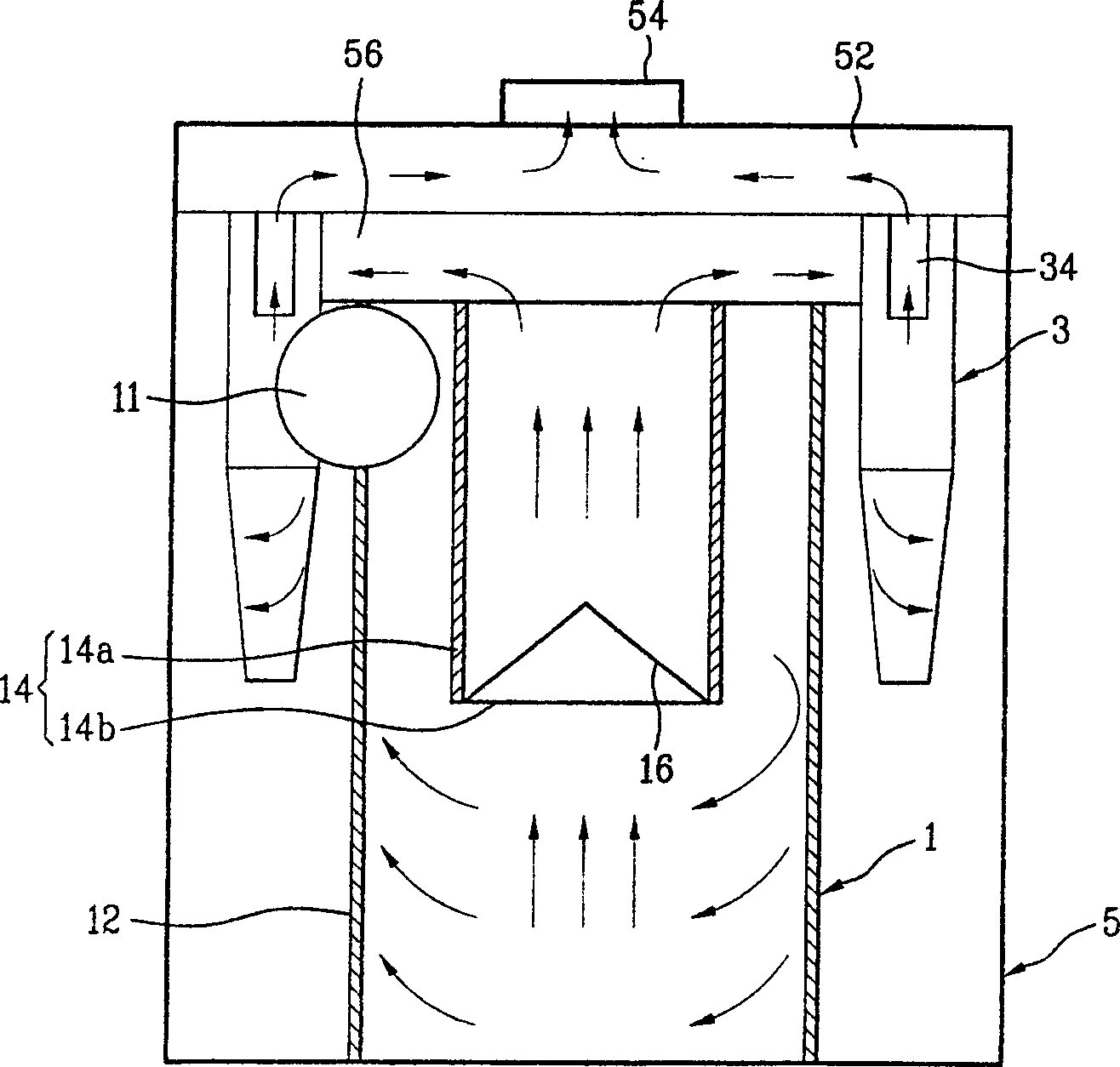

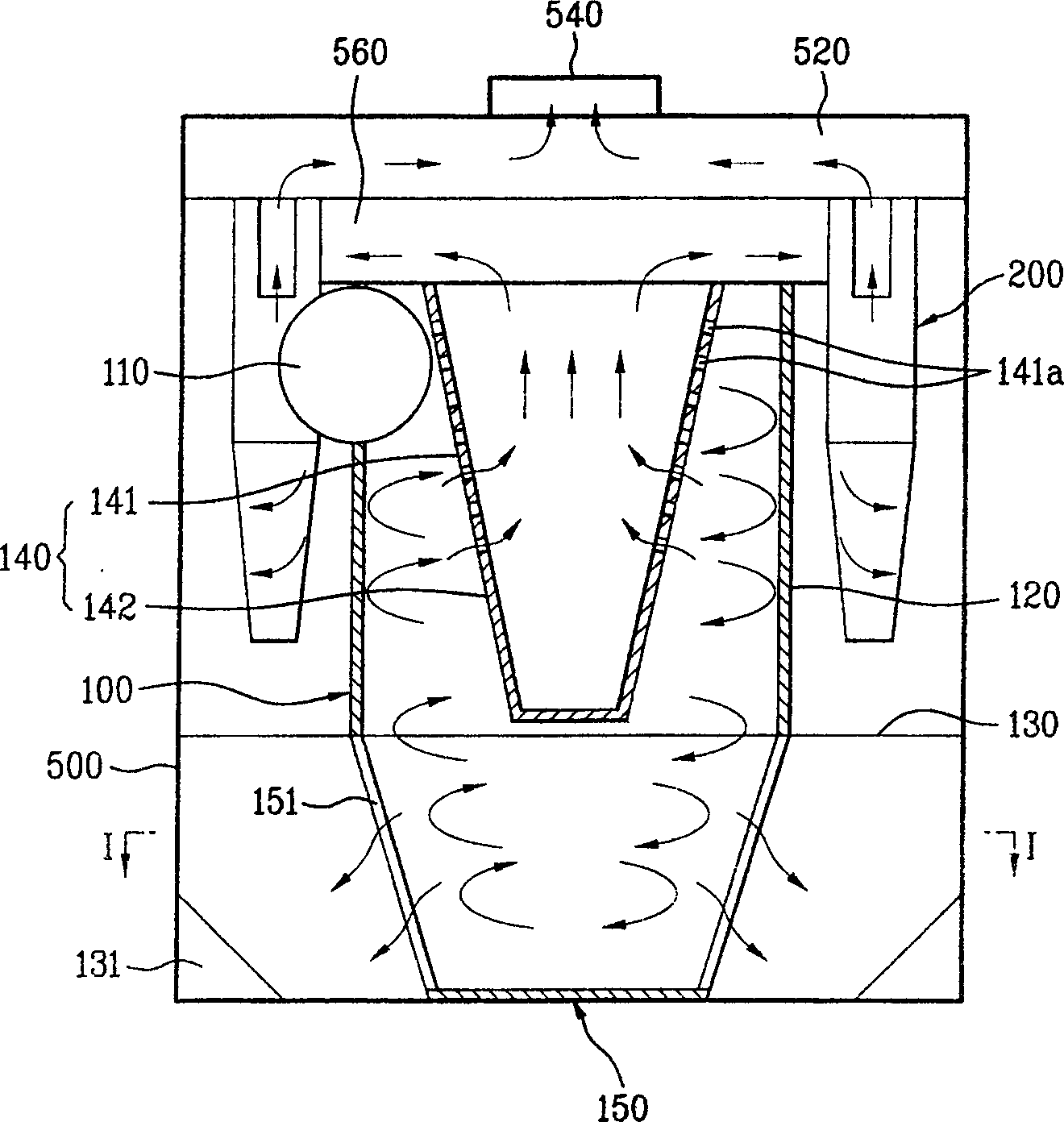

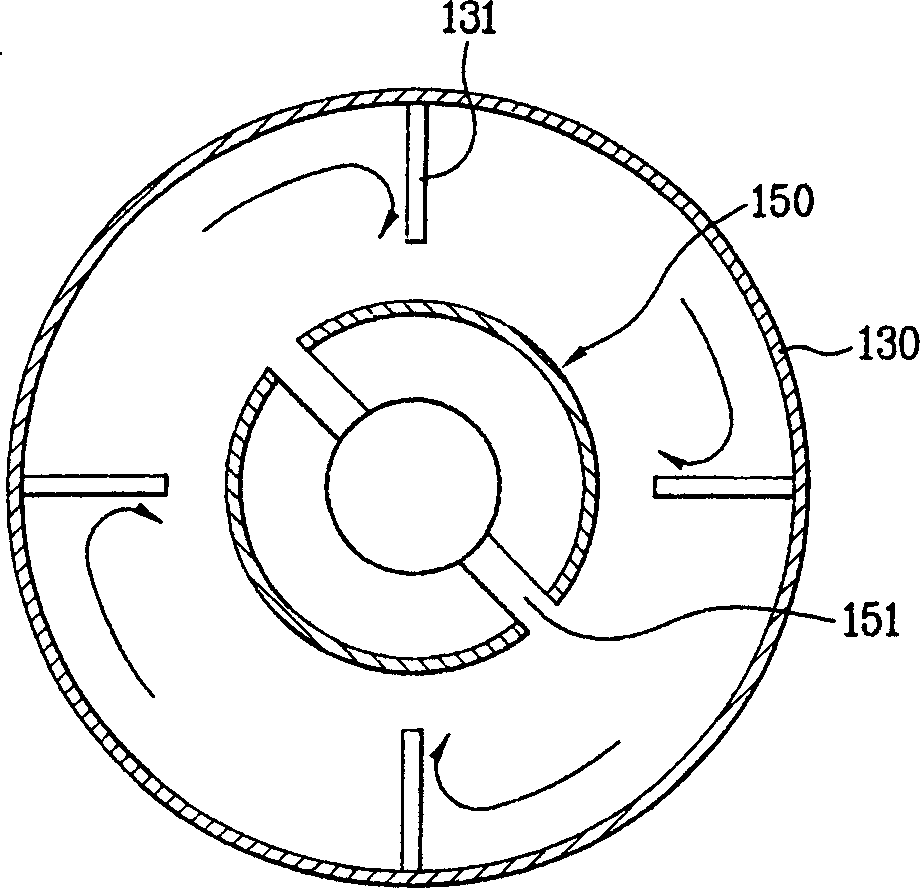

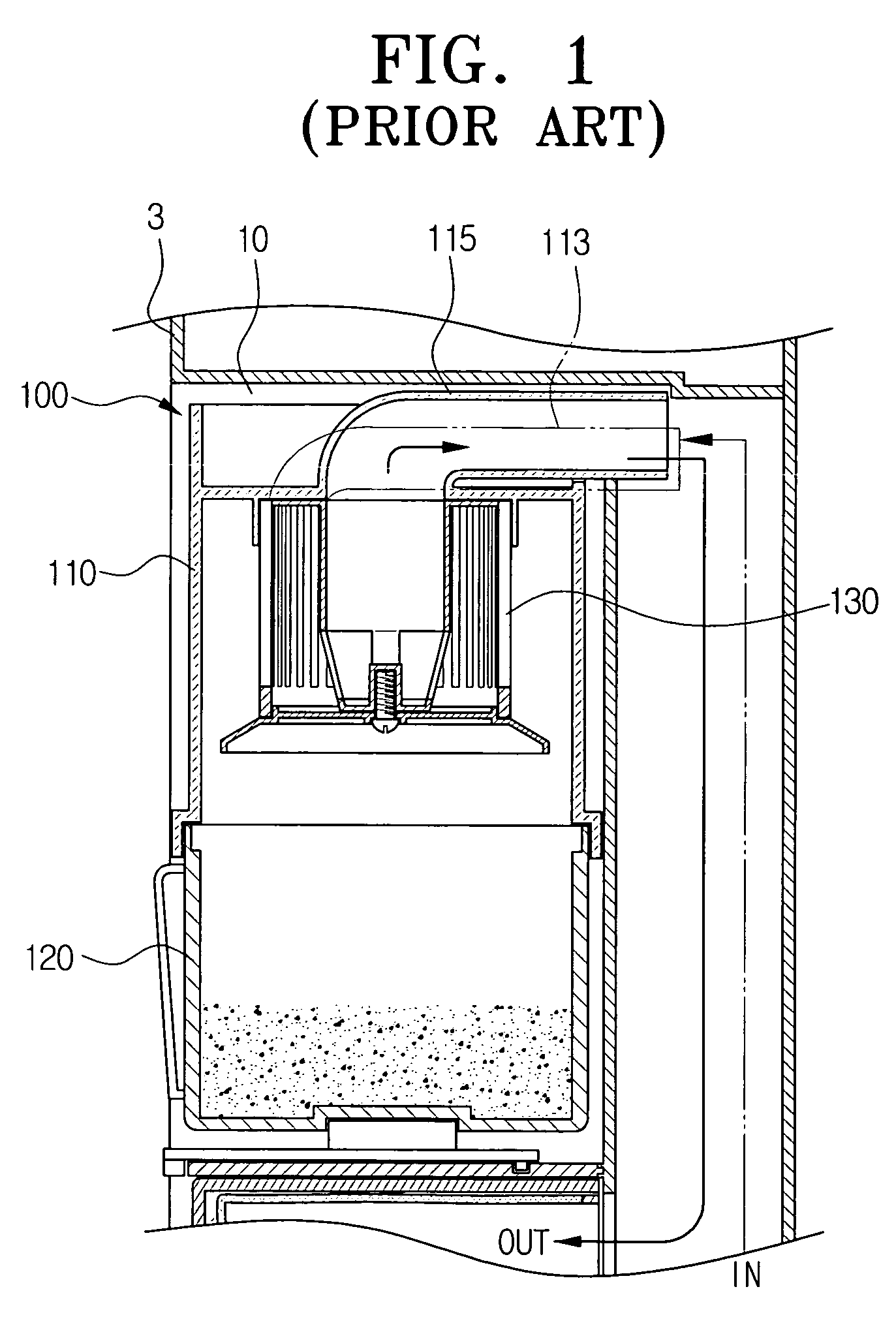

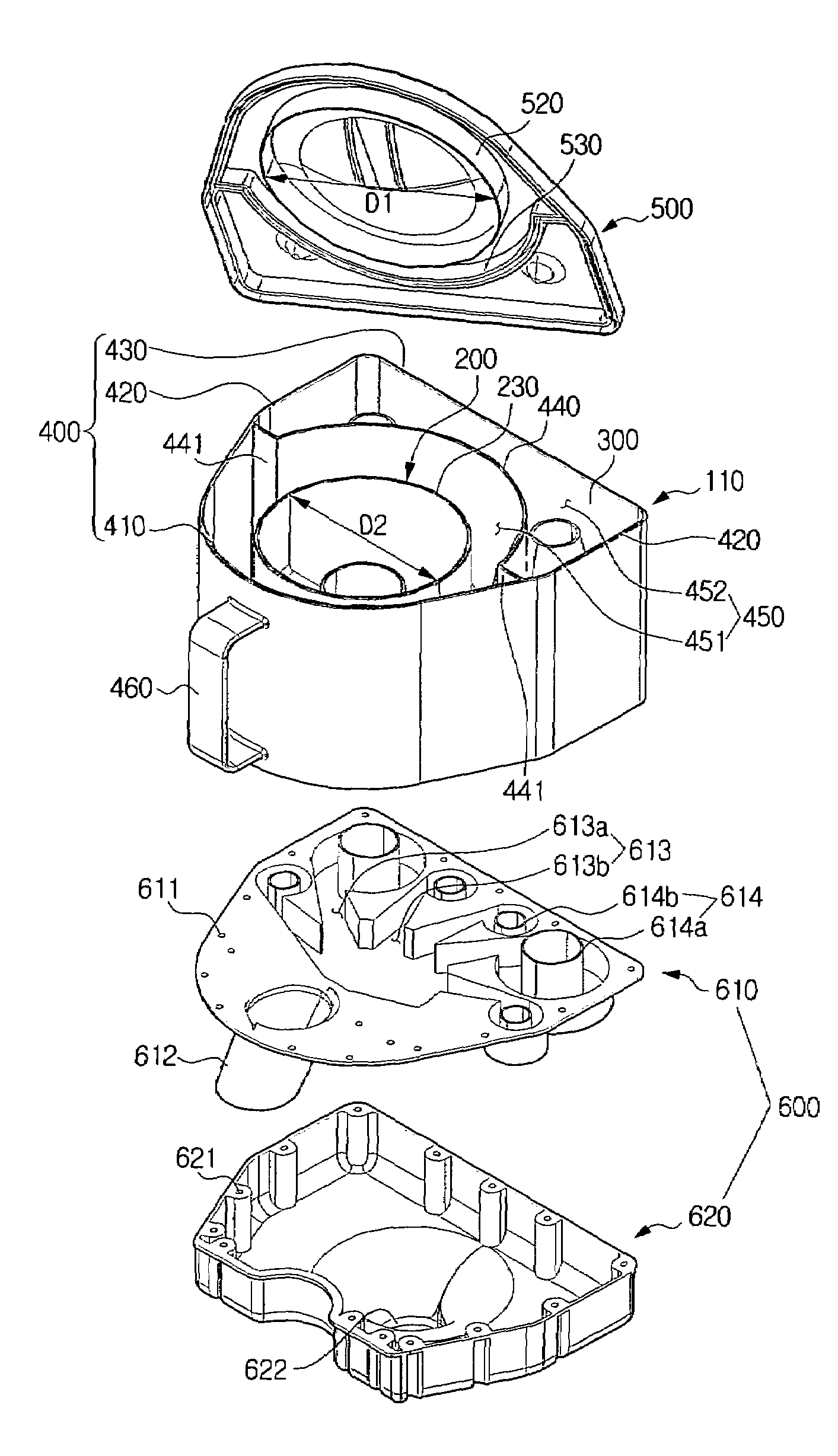

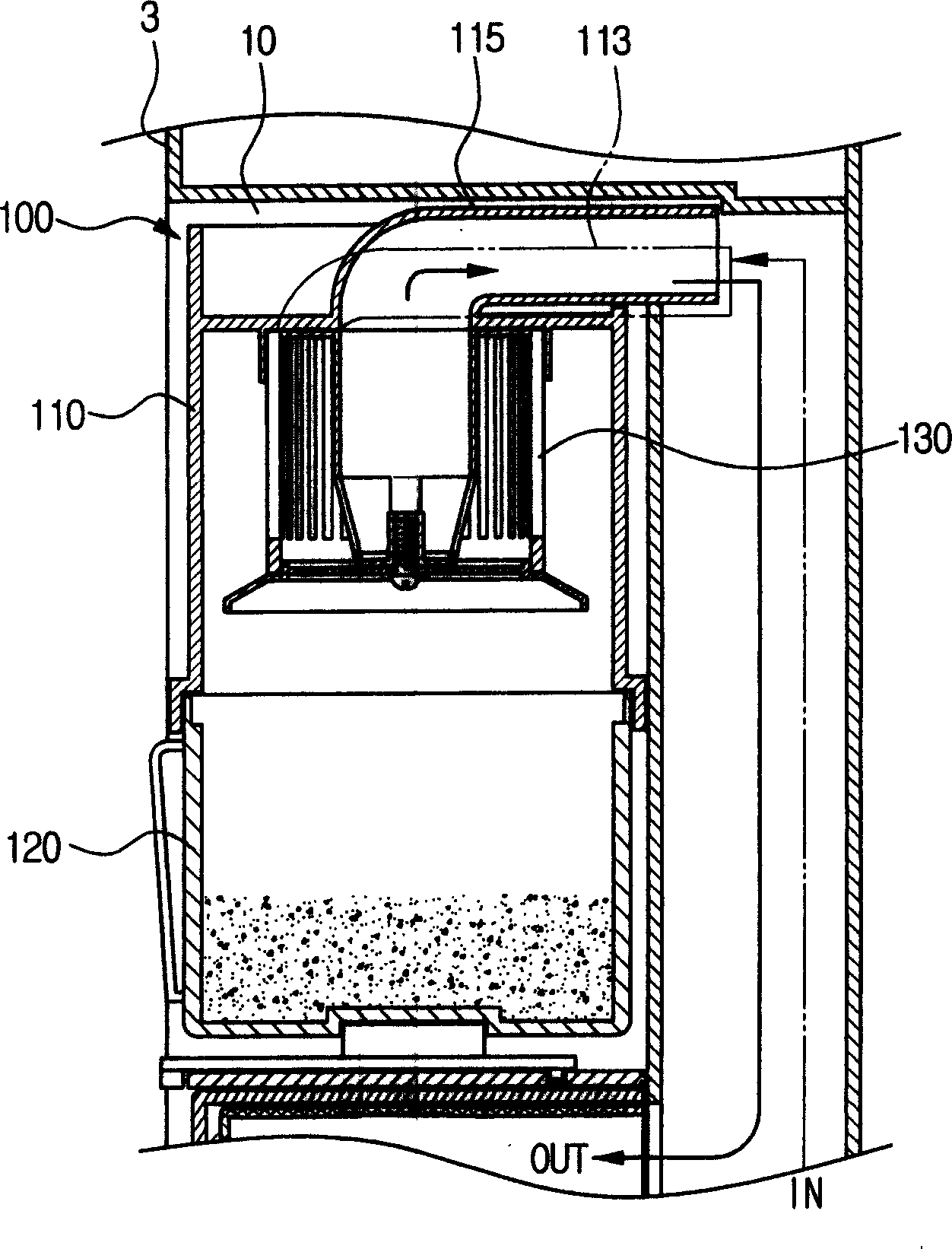

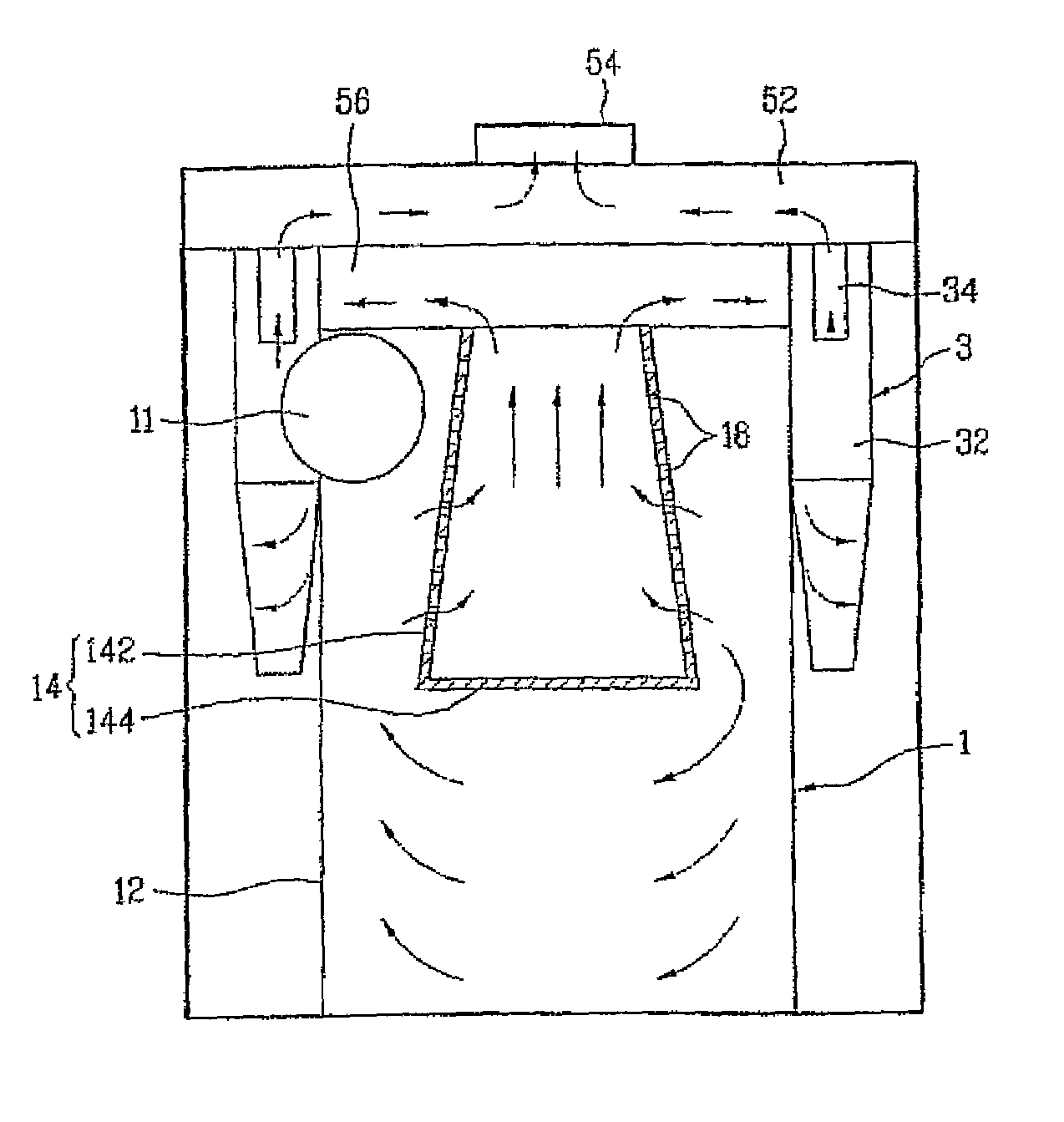

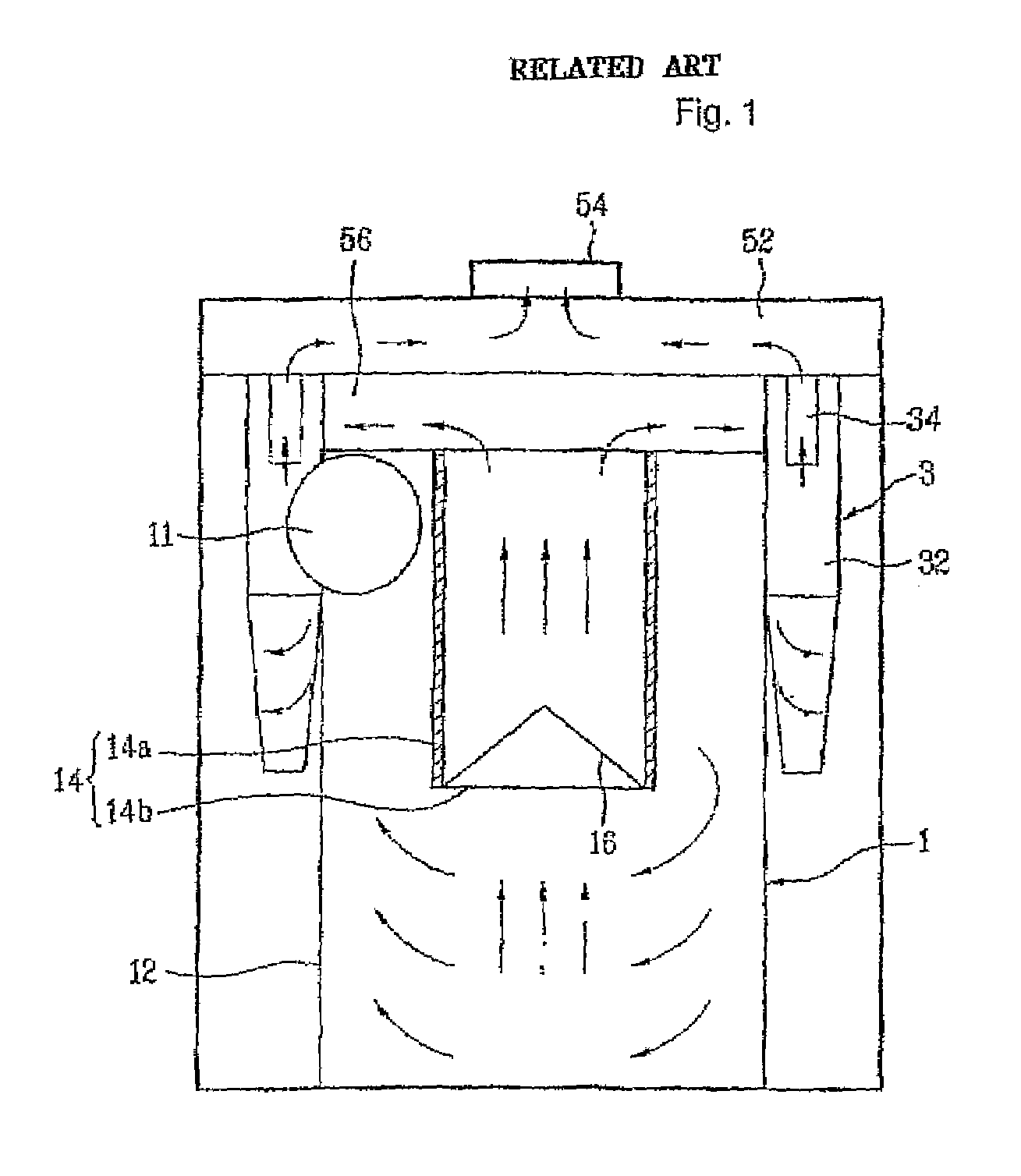

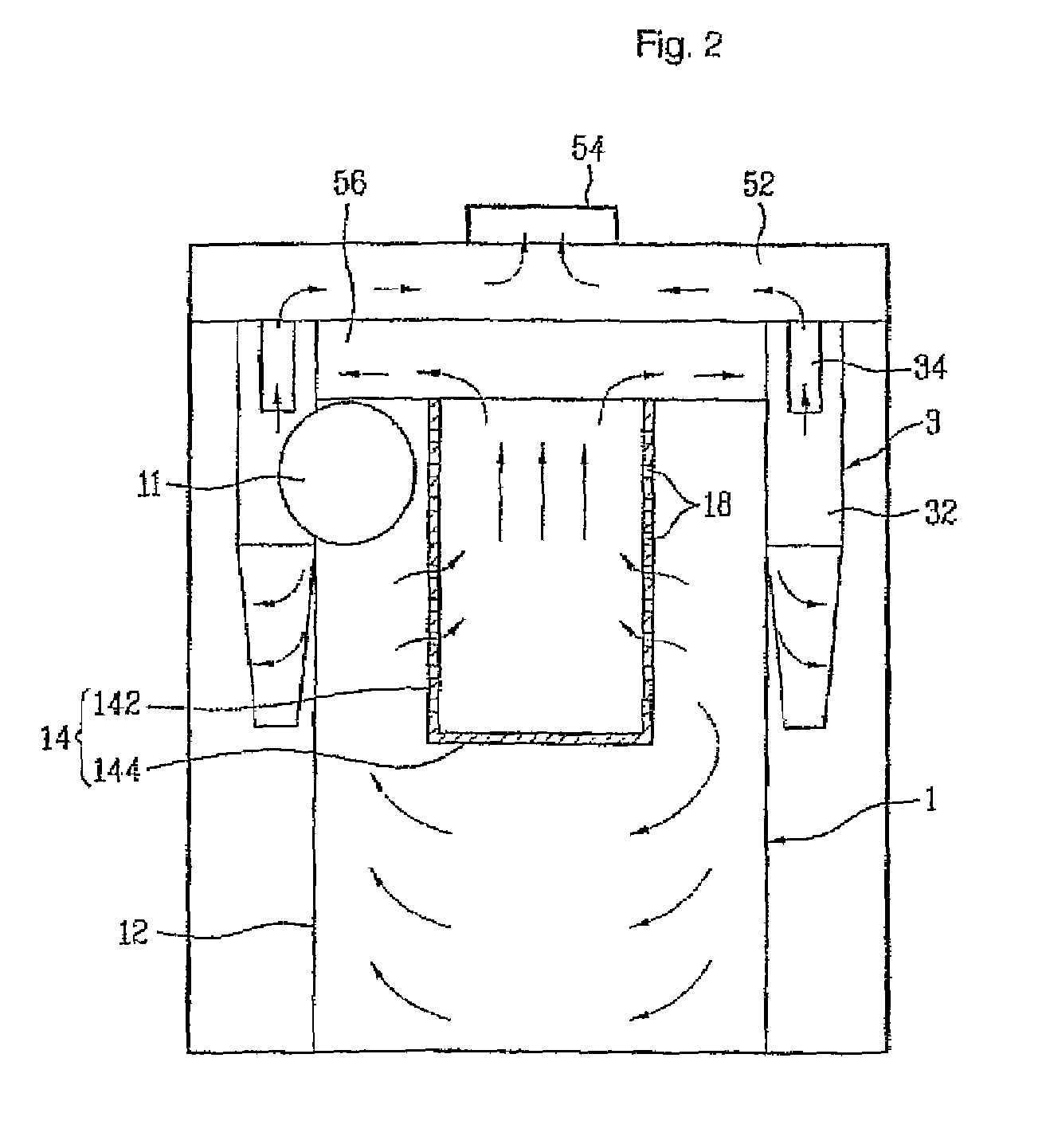

Cyclone type dust collecting apparatus of vacuum cleaner

InactiveUS7014671B2Improve dust collection effectReduce noiseCombination devicesSuction filtersForeign matterCyclone

A cyclone type dust collecting apparatus of a vacuum cleaner. The apparatus includes a lower cyclone body for centrifuging and collecting large-sized foreign substances contained in inhaled outside air. At least one upper cyclone body is disposed at an upper portion of the lower cyclone body for centrifuging and collecting small-sized foreign substances contained in air discharged from the lower cyclone body. Inhaled foreign substances are sequentially centrifuged in order of size thereof, by the lower and upper cyclone bodies.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

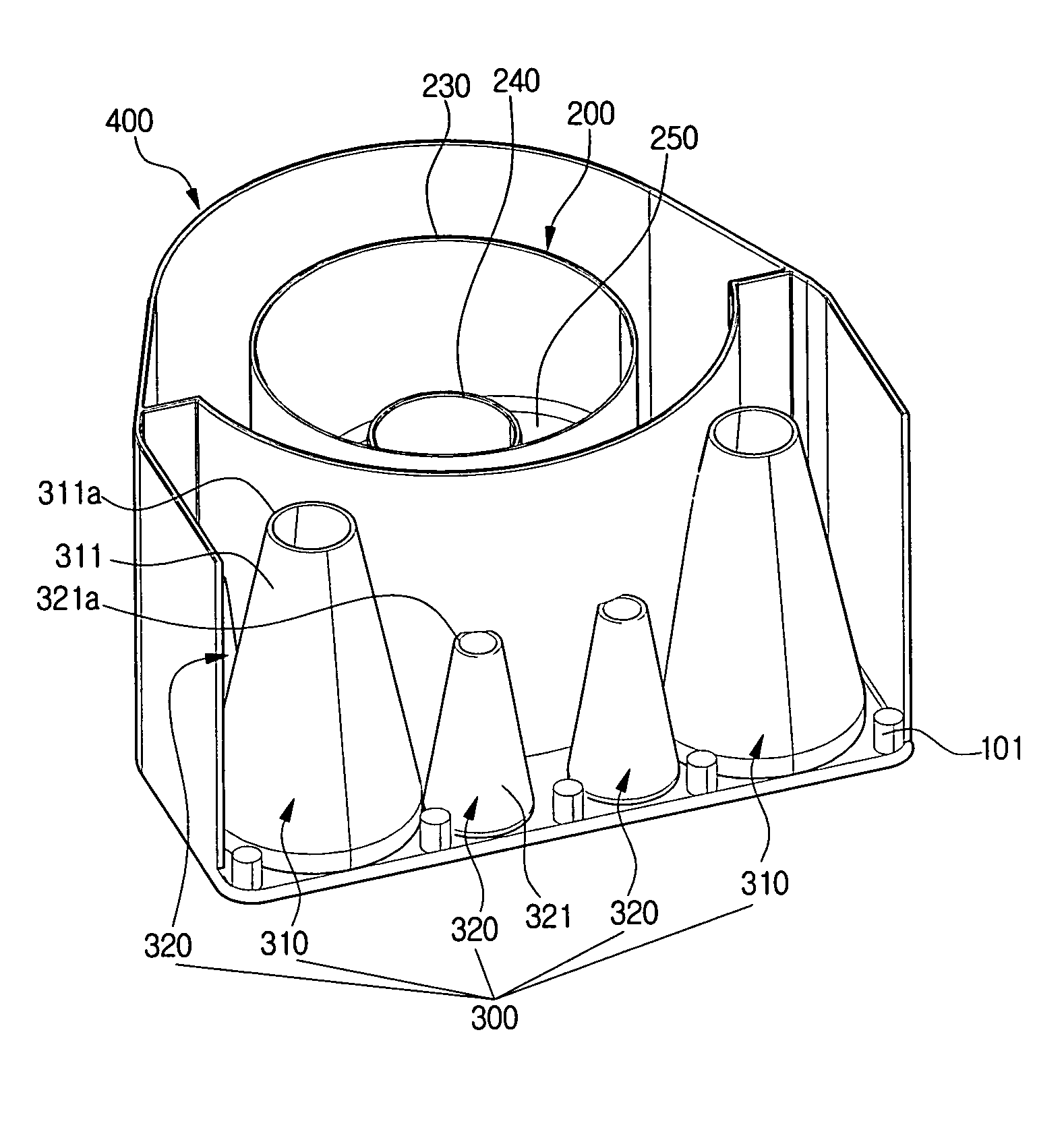

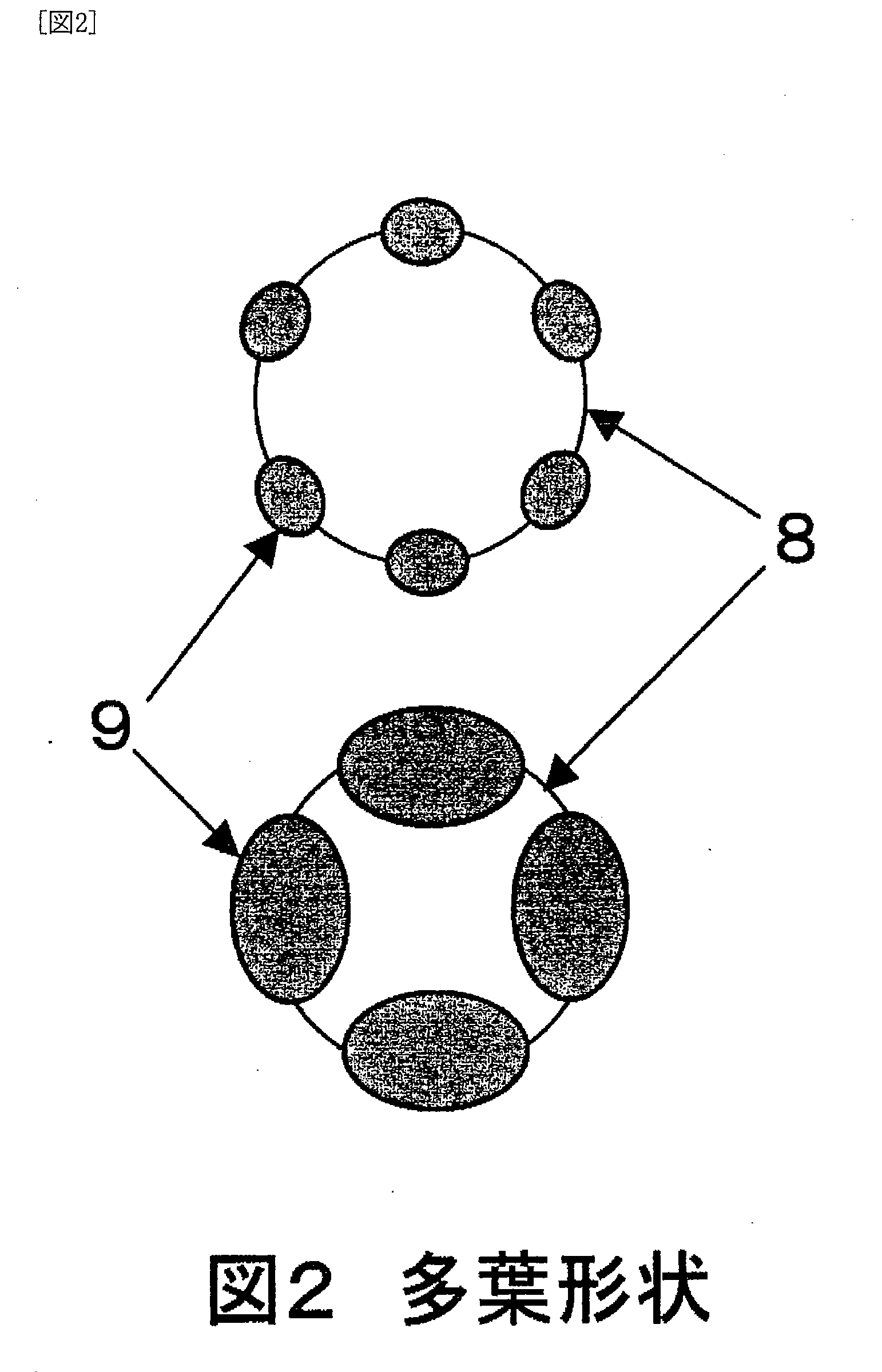

Multi-cyclone dust separating apparatus

InactiveUS20070095030A1Improve dust collection effectSmall sizeCleaning filter meansCombination devicesCycloneAir separation

A multi-cyclone dust separating apparatus has a main cyclone comprising one or more cyclones, a sub cyclone comprising one or more cyclones, and being arranged around a part of the main cyclone in parallel relation, and a dust collecting casing provided to enclose the main and the sub cyclones, and collects dust as the dust is separated from the air in the main and the sub cyclones. At least a part of the dust collecting casing enclosing the main cyclone is formed in a half-circular shape.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Multi-cyclone dust separating apparatus

InactiveUS7628833B2Improve dust collection effectSmall sizeCleaning filter meansCombination devicesCycloneWaste management

A multi-cyclone dust separating apparatus has a main cyclone comprising one or more cyclones, a sub cyclone comprising one or more cyclones, and being arranged around a part of the main cyclone in parallel relation, and a dust collecting casing provided to enclose the main and the sub cyclones, and collects dust as the dust is separated from the air in the main and the sub cyclones. At least a part of the dust collecting casing enclosing the main cyclone is formed in a half-circular shape.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

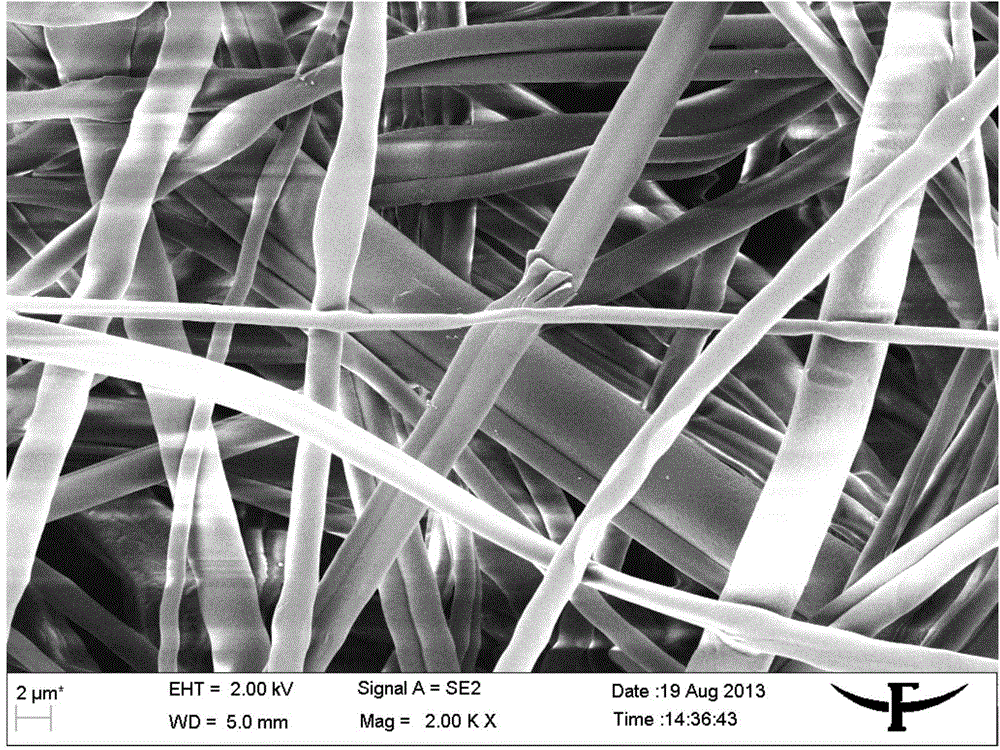

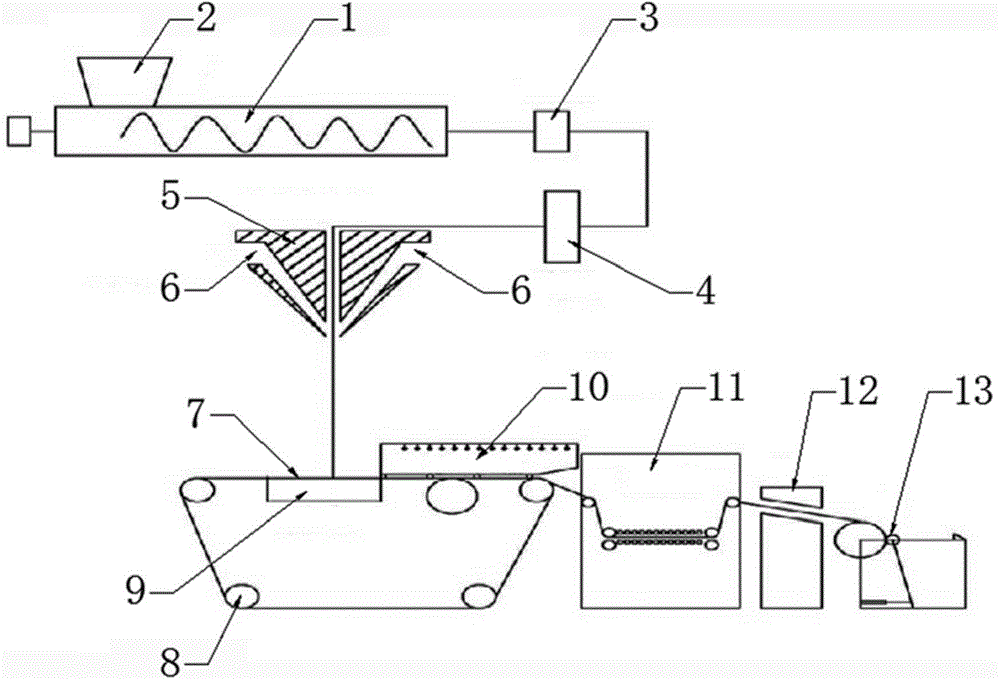

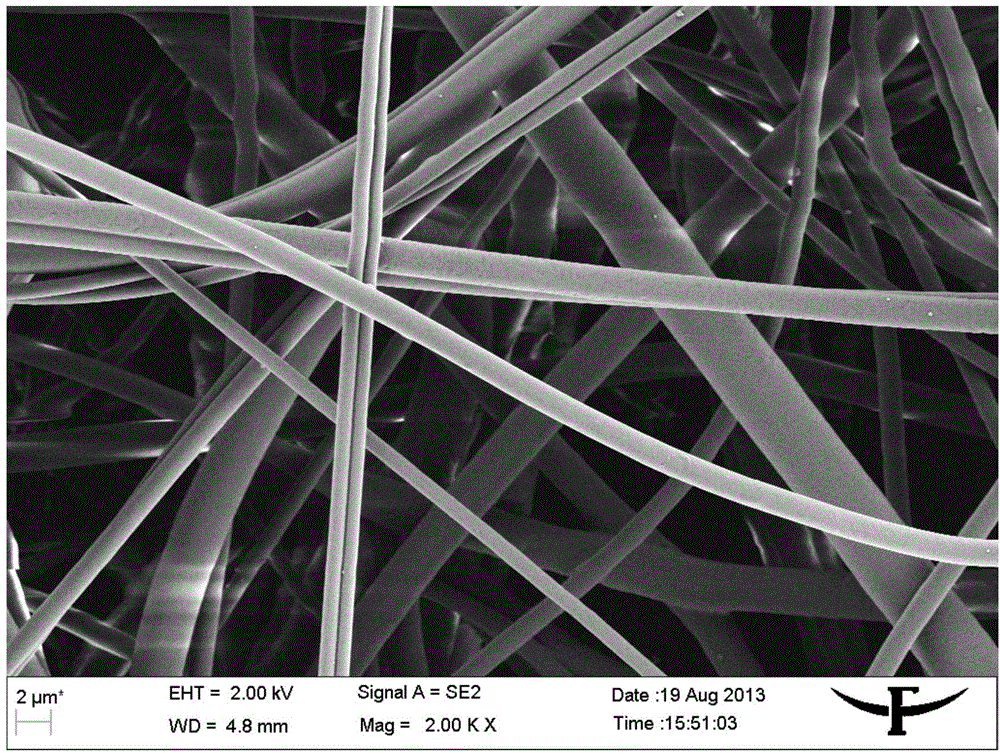

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

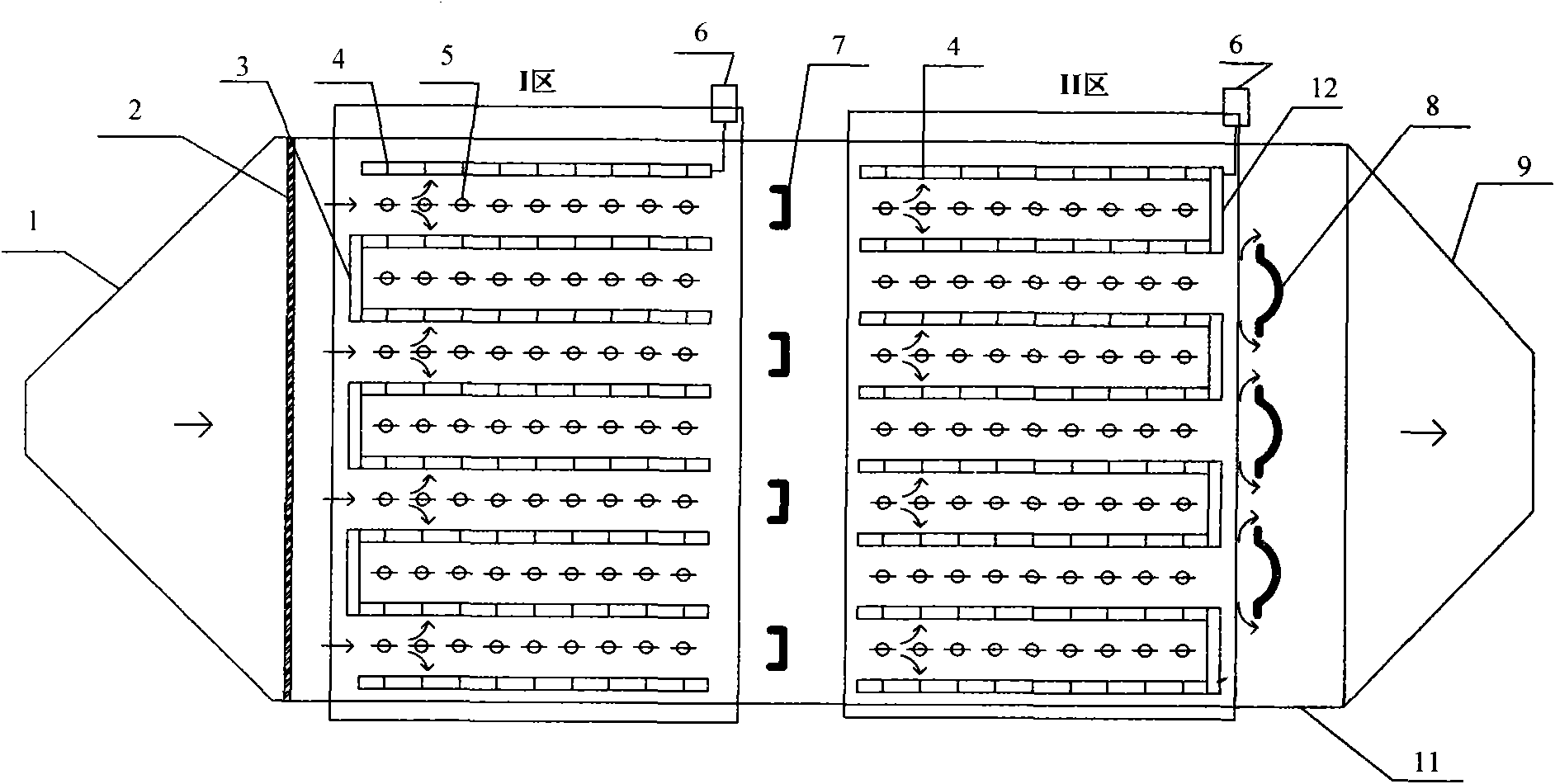

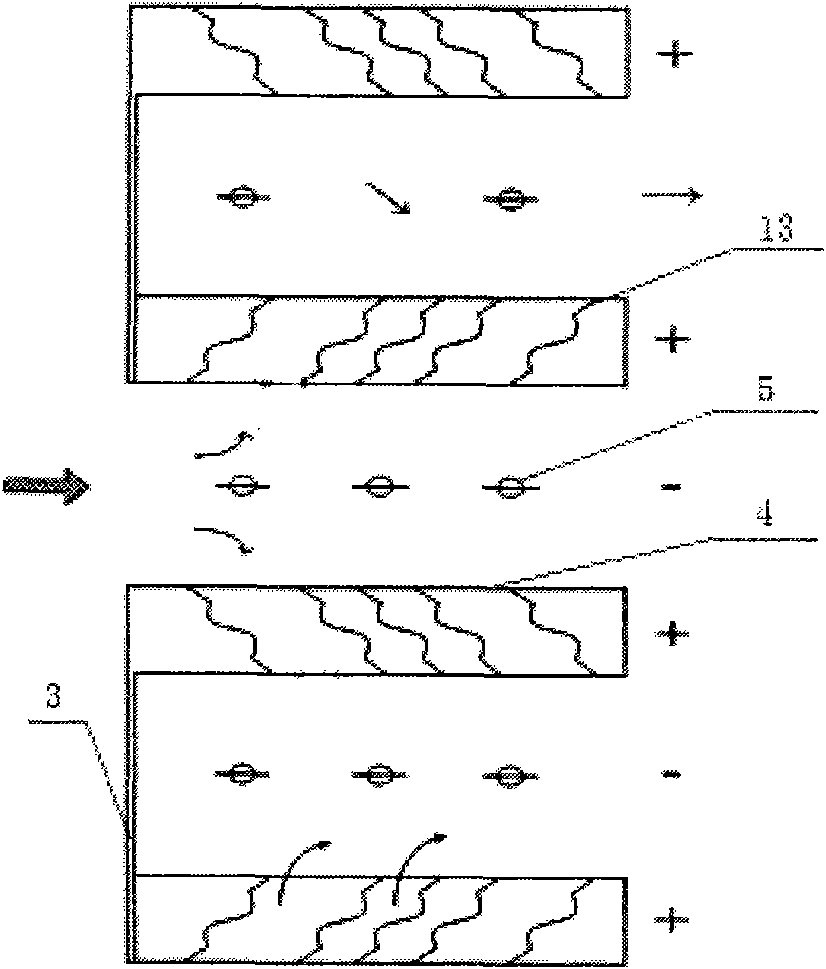

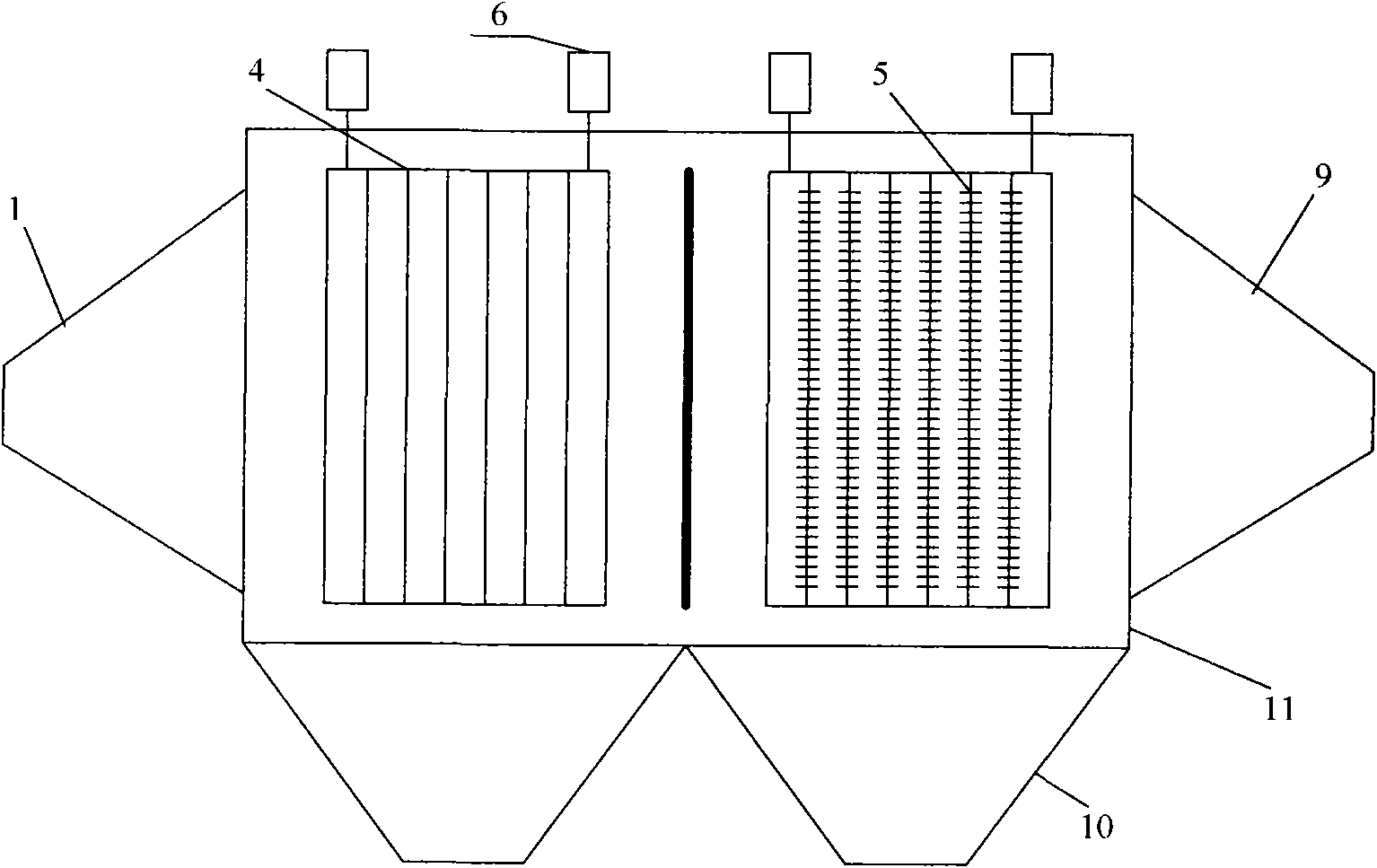

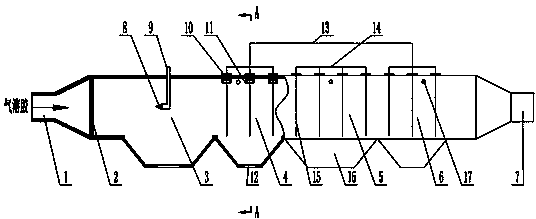

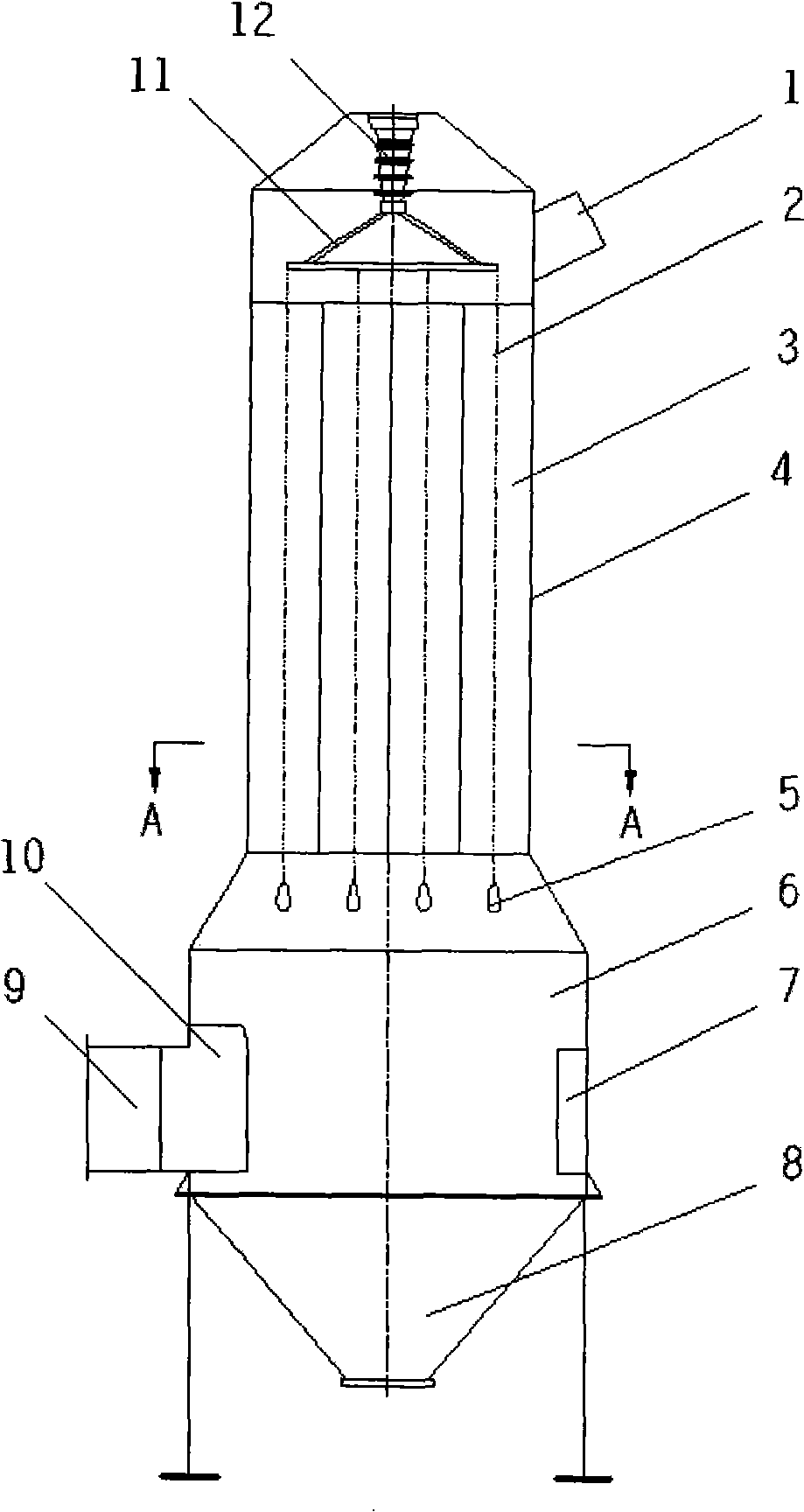

Mixed-flow electric dust collector

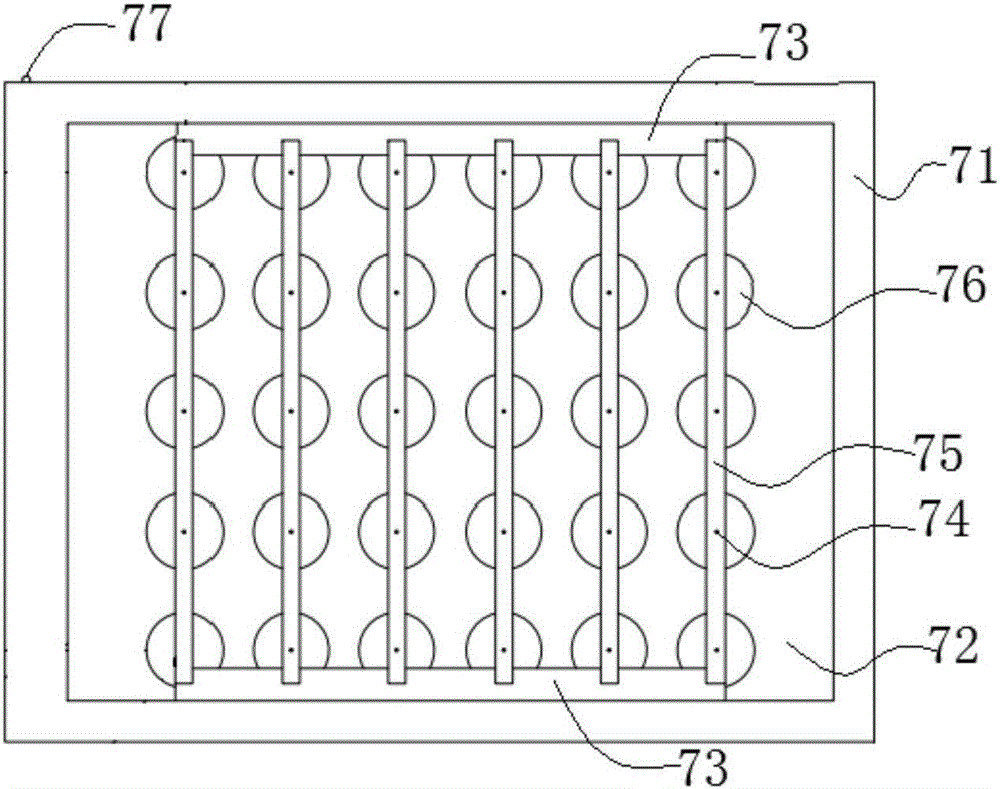

ActiveCN101862705AAvoid affecting the dust collection effectReduce volumeExternal electric electrostatic seperatorElectrode constructionsMixed flowEqualization

The invention relates to a mixed-flow electric dust collector, wherein an air flow distribution plate is arranged at the joint of a dust removing chamber and a smoke inlet; a first vertical electric field and a second vertical electric field, through which an air flow flows, are arranged in the dust removing chamber; parallel dust collecting electrodes are distributed in the electric fields at equal interval; main air flow channels are formed among the dust collecting electrodes; a corona electrode is arranged between adjacent dust collecting electrodes; some of the air flow channels are provided with an incoming air flow baffle at an air flow inlet, and the other air flow channels are provided with an outgoing air flow baffle at an air flow outlet; a plurality of dust collecting electrode plates are arranged on the dust collecting electrodes and fixed in the dust collecting electrode in a separated manner; and the main air flow channels are provided with a plurality of air equalization plates having through holes on the surface at the outlet of the first electric field and baffles at the outlet of the second electric field. With simple structure and few electric fields, the invention solves the problem that the conventional dust collector has poor dust removal effect, large size, complicated structure and high cost.

Owner:浙江海宁经编产业园区开发有限公司

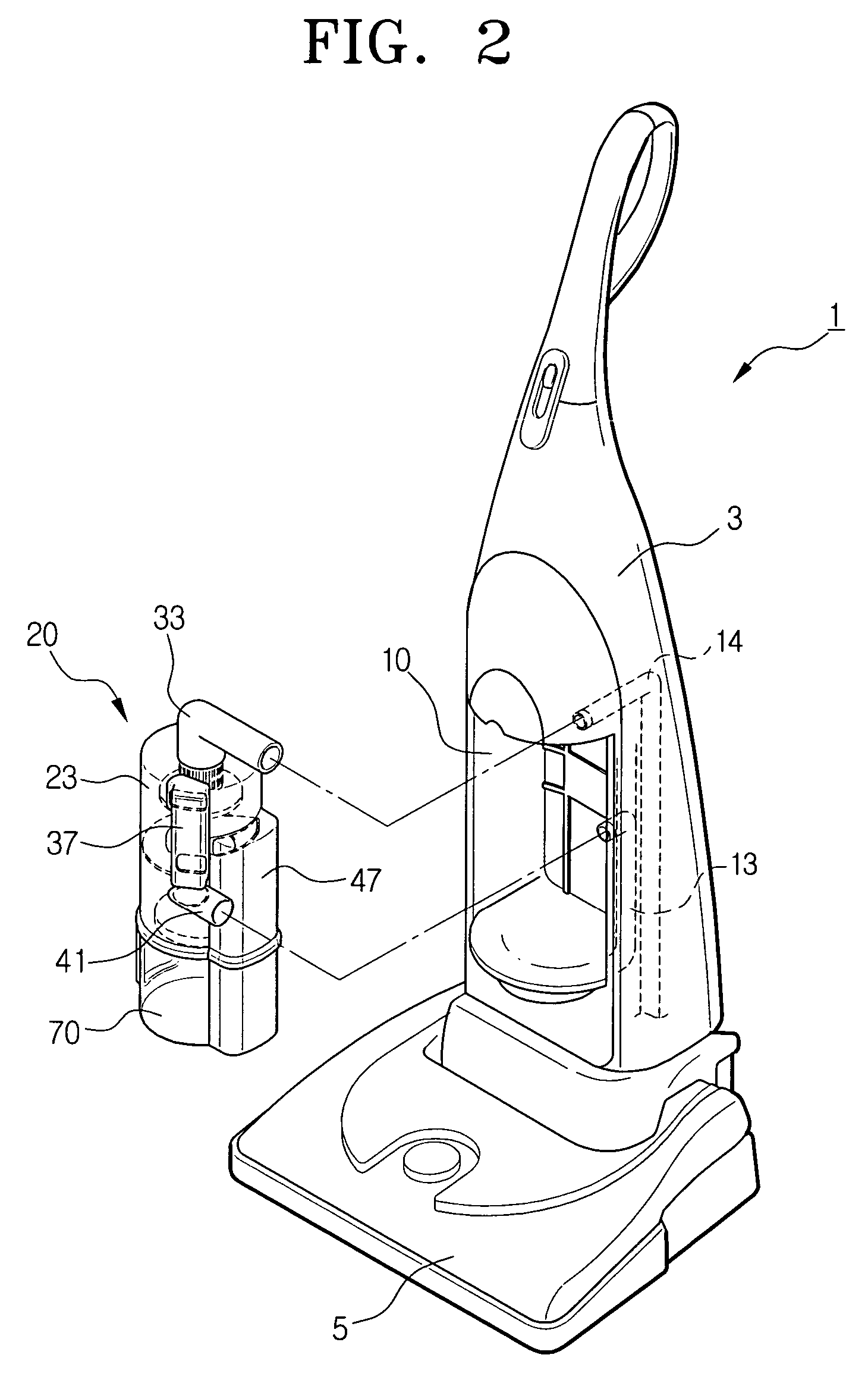

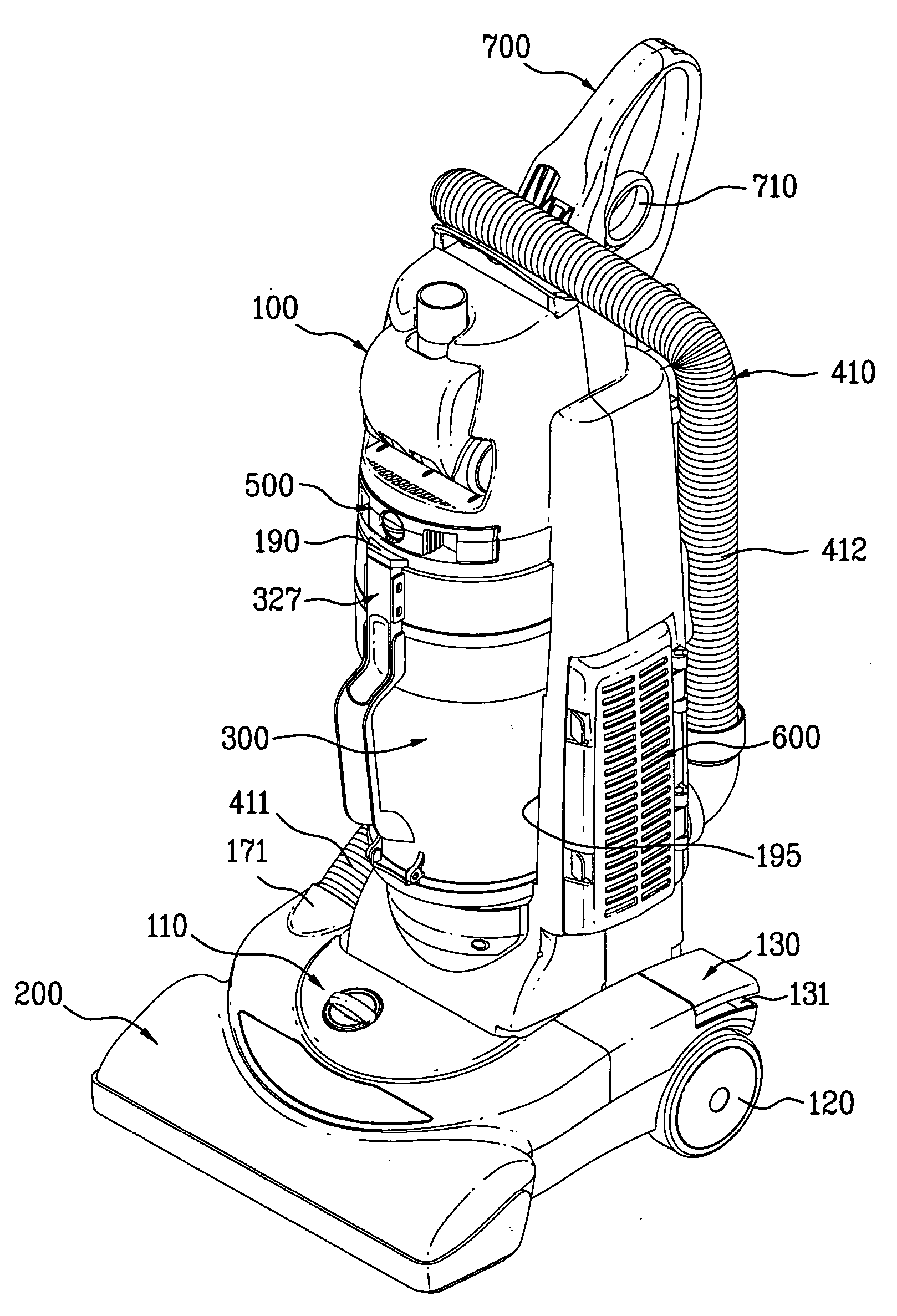

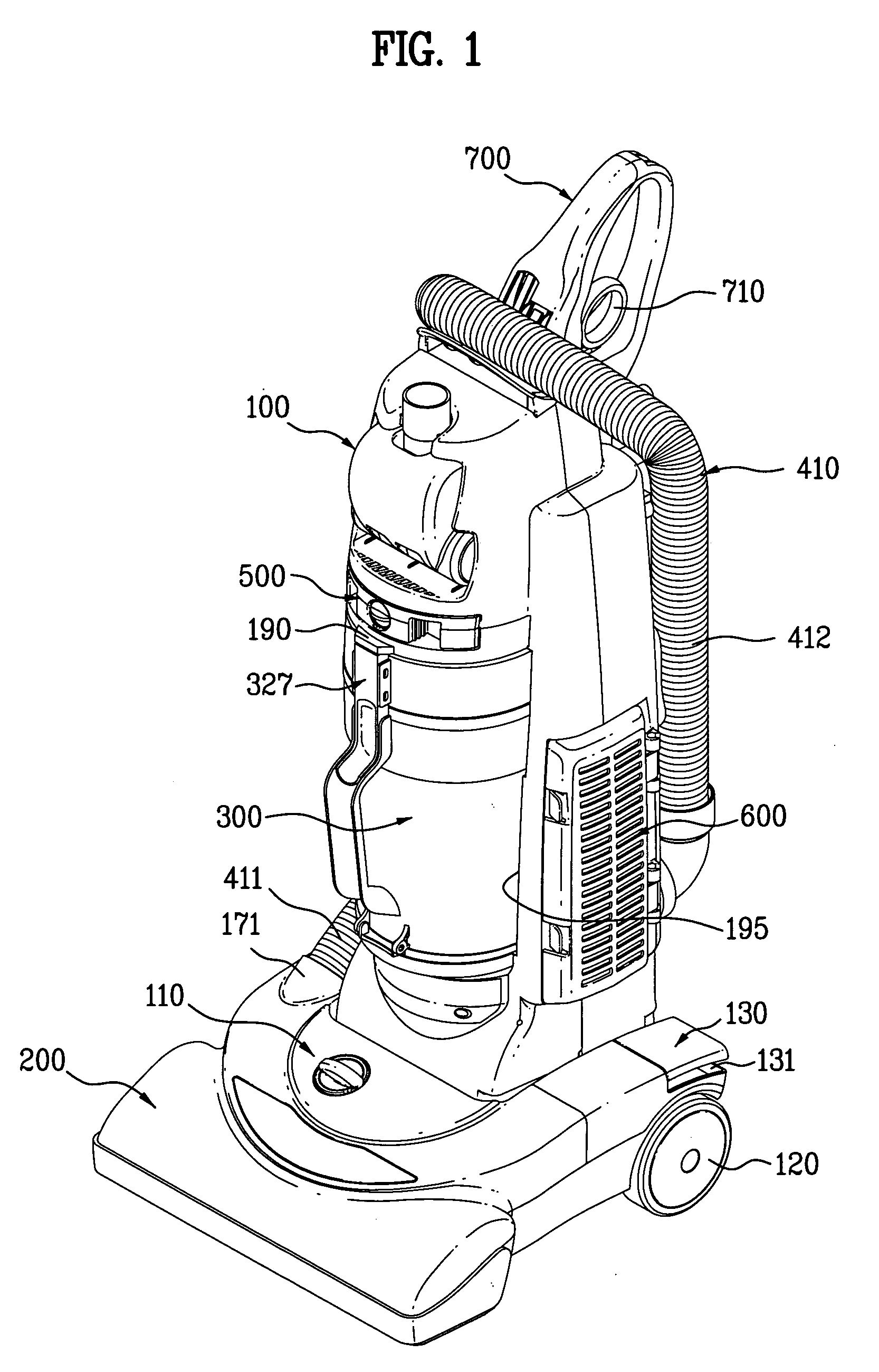

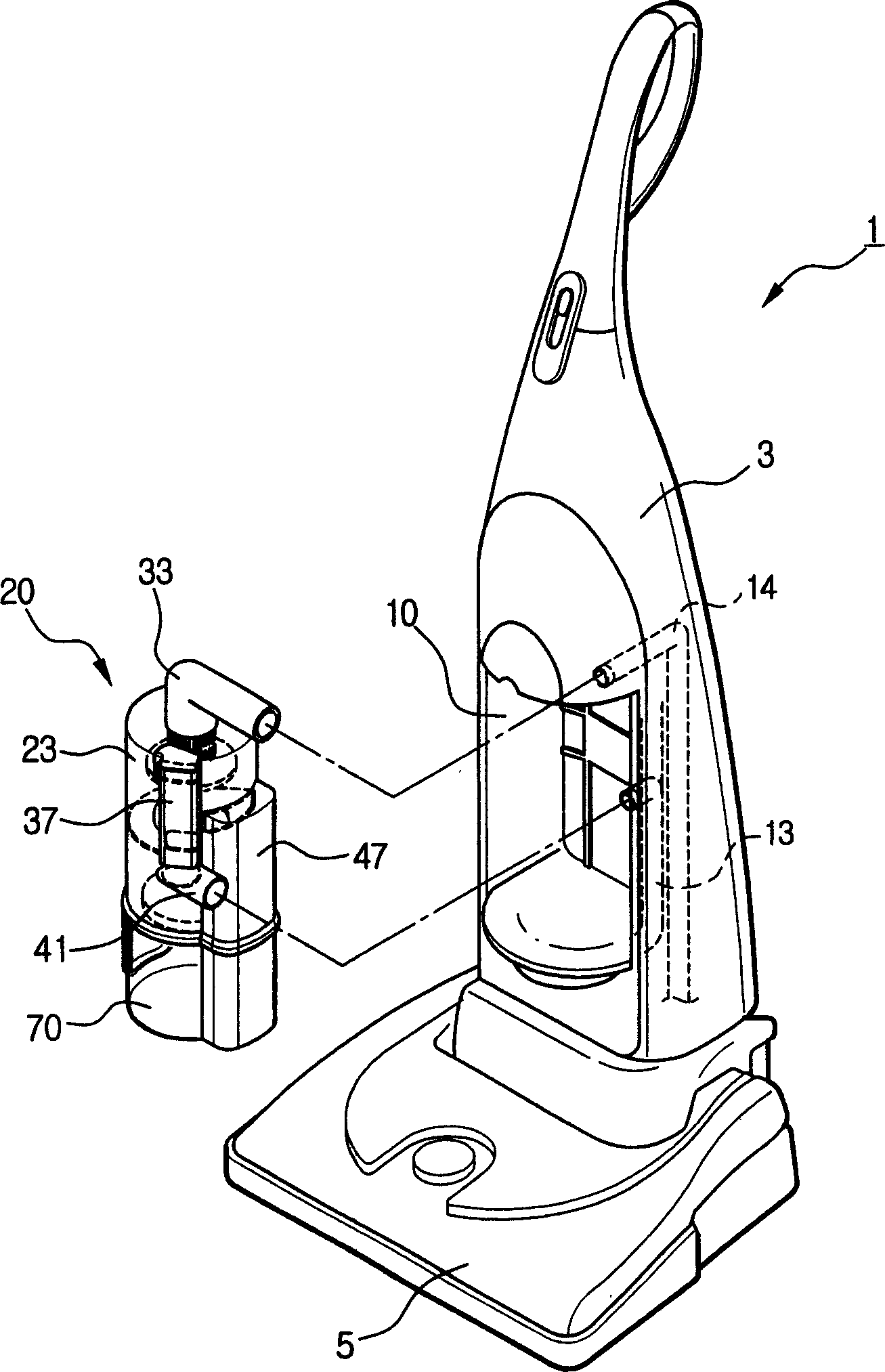

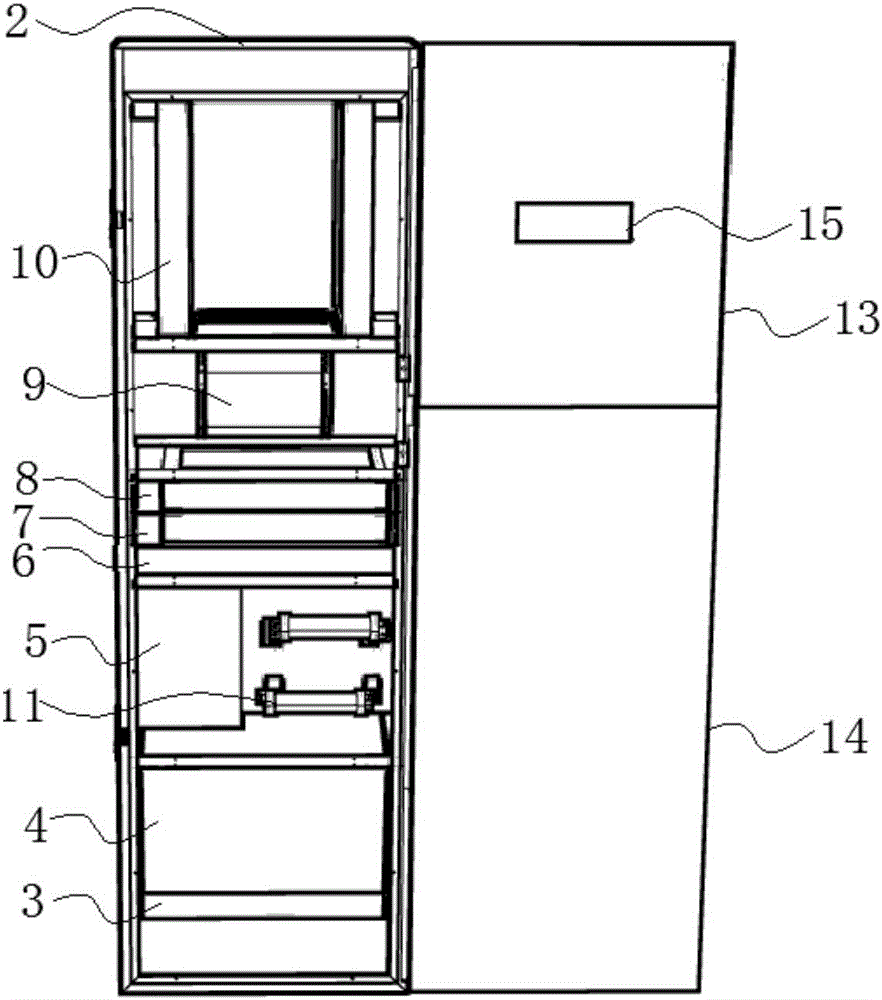

Upright vacuum cleaner

InactiveUS20070079474A1Simple coupling structureConvenient to useCleaning filter meansSuction filtersPhysicsEngineering

A vacuum cleaner is disclosed. The vacuum cleaner comprises a cleaner body, a cyclonic chamber comprising a primary cyclone and at least one secondary cyclone disposed around the primary cyclone, a flow passage guide for guiding the airflow discharged from the primary cyclone to a secondary airflow inlet of the secondary cyclone, a first conduit for fludically connecting a nozzle section defining a suction opening to a primary airflow inlet of the primary cyclone, a suction source having an suction source inlet and an suction source outlet, and a second conduit for fludically connecting a secondary airflow outlet to the suction source inlet of the suction source. Accordingly, it is possible to achieve a low flow resistance by virtue of the flow passage guide and an enhanced dust collecting performance by virtue of a sealing effect of the sealing member.

Owner:LG ELECTRONICS INC

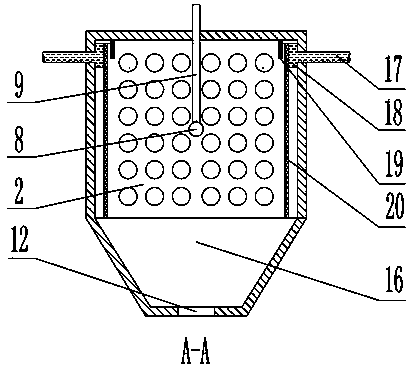

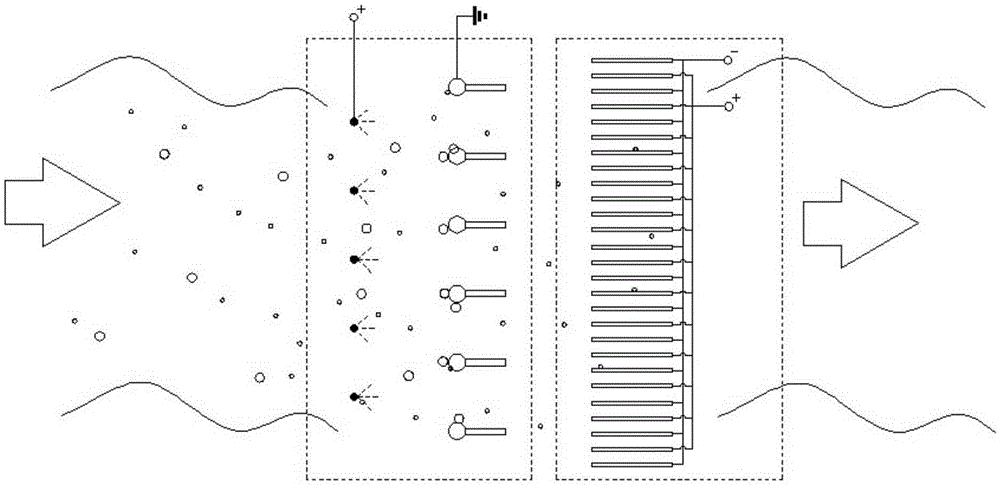

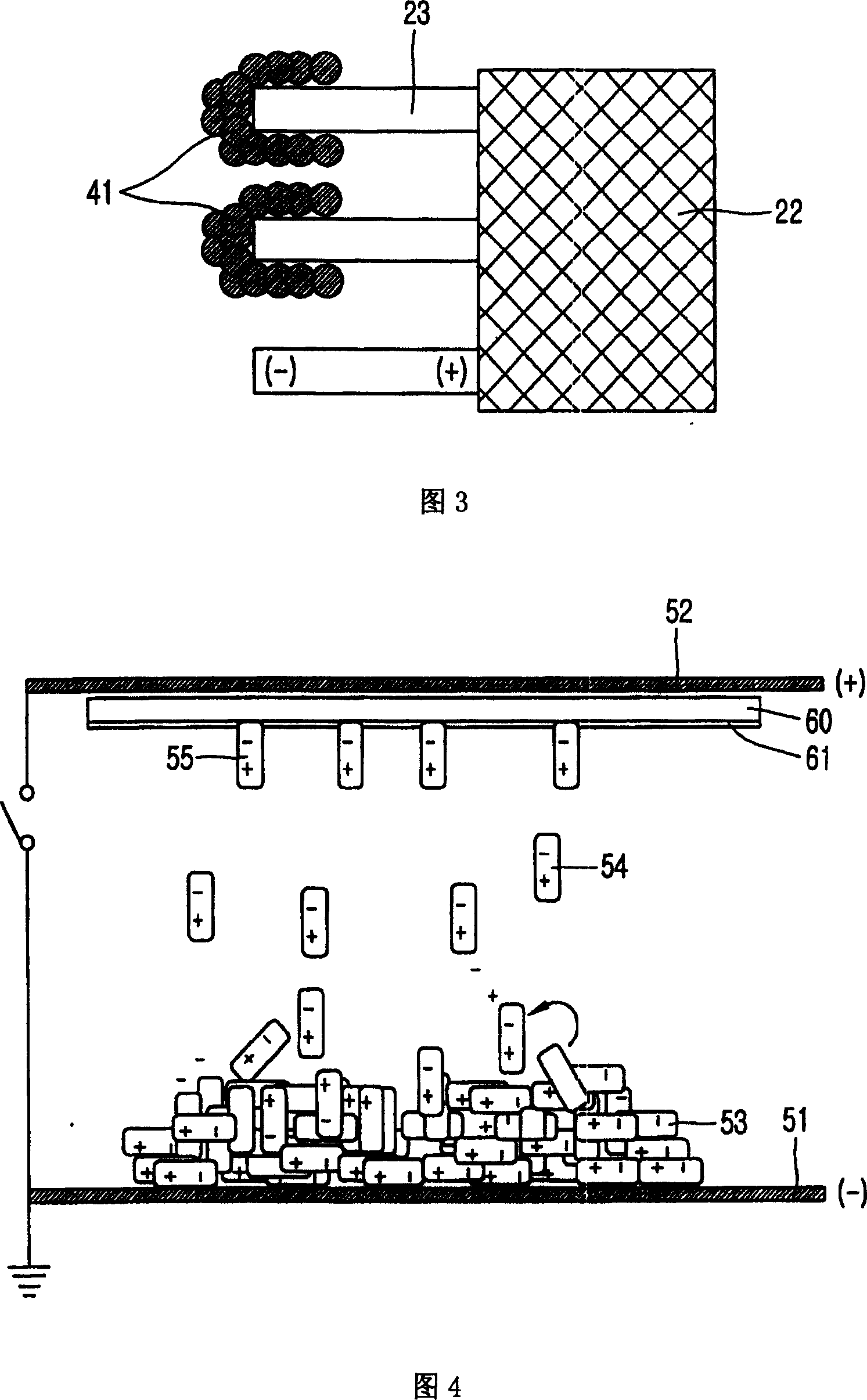

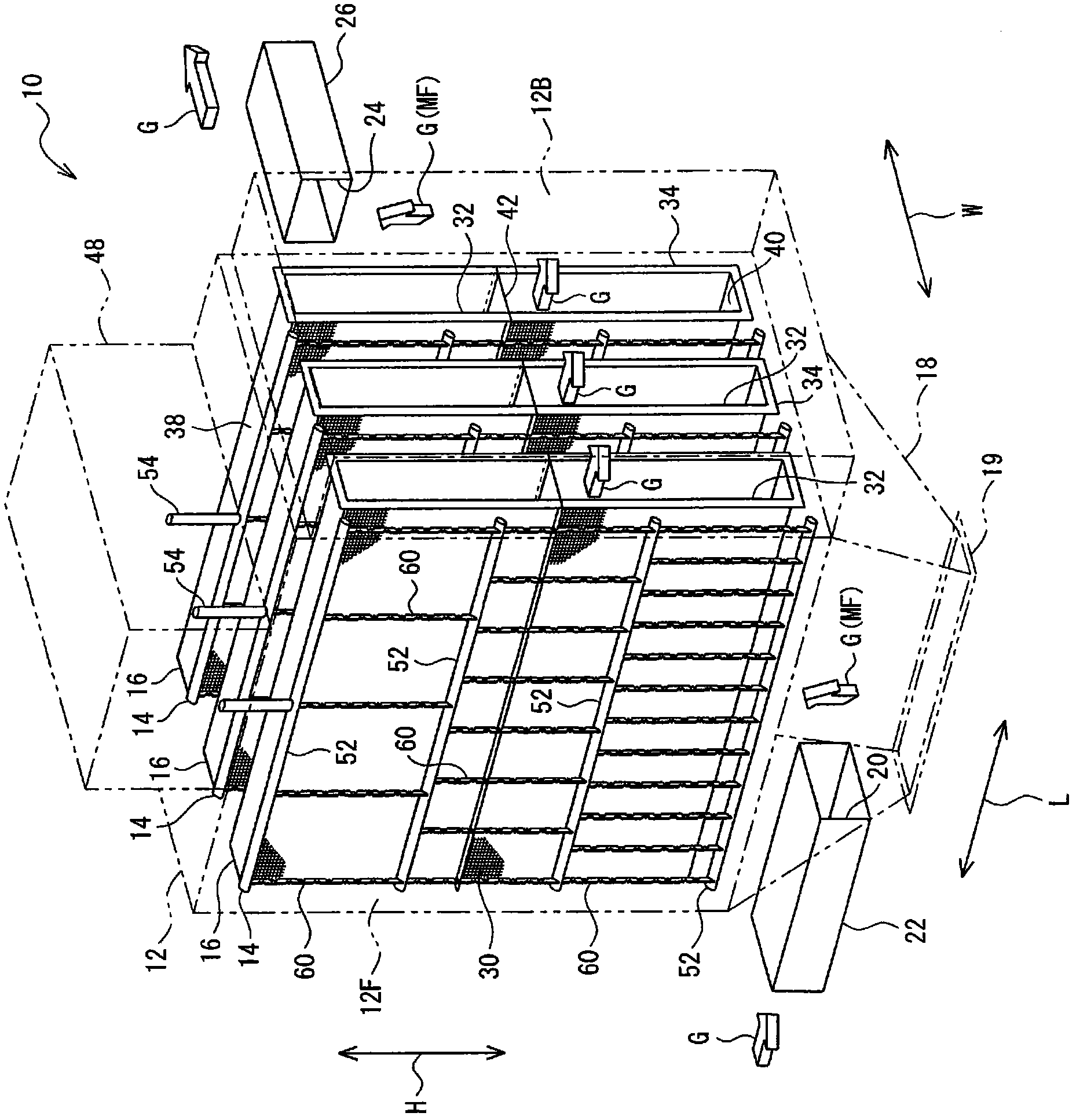

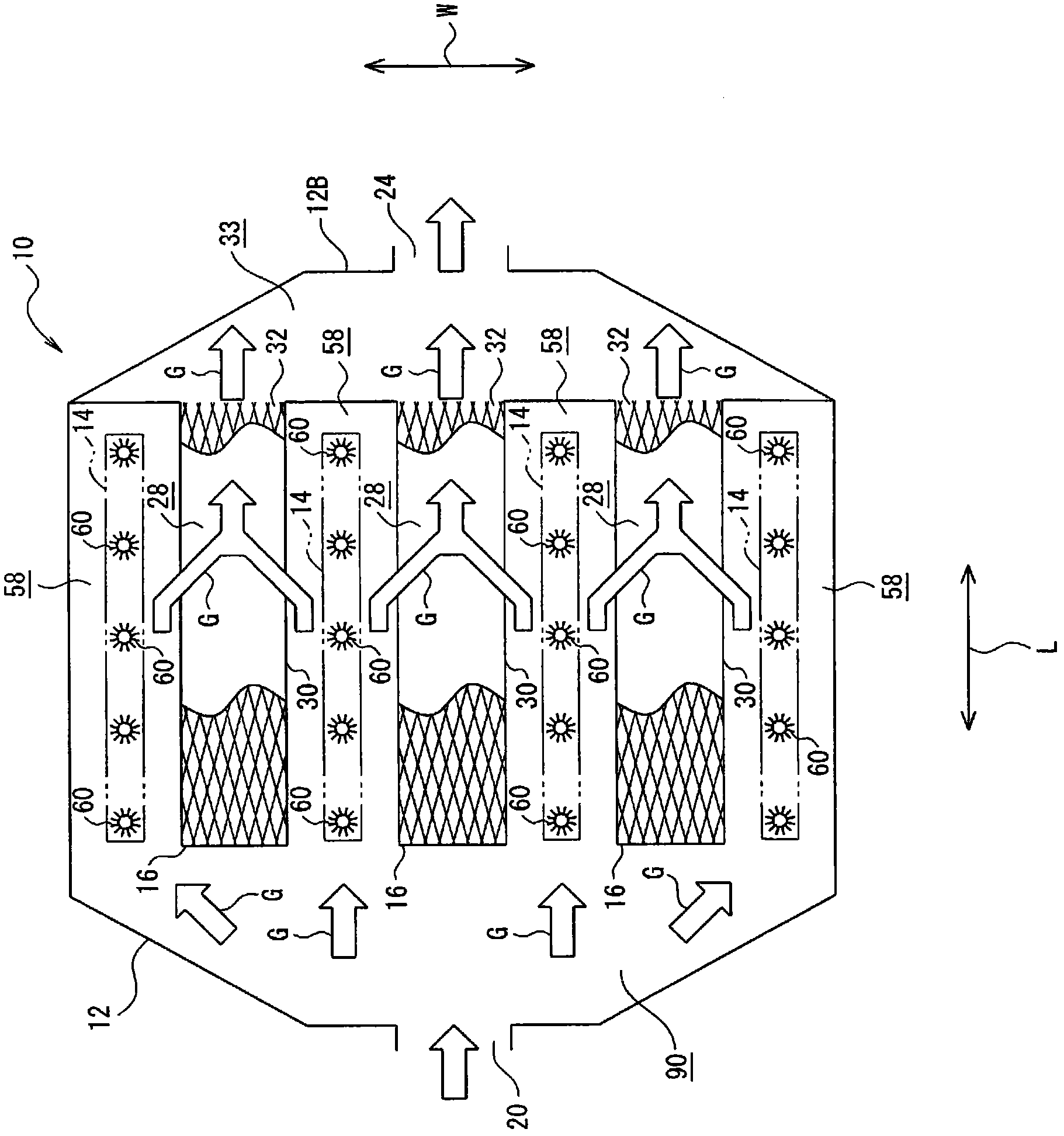

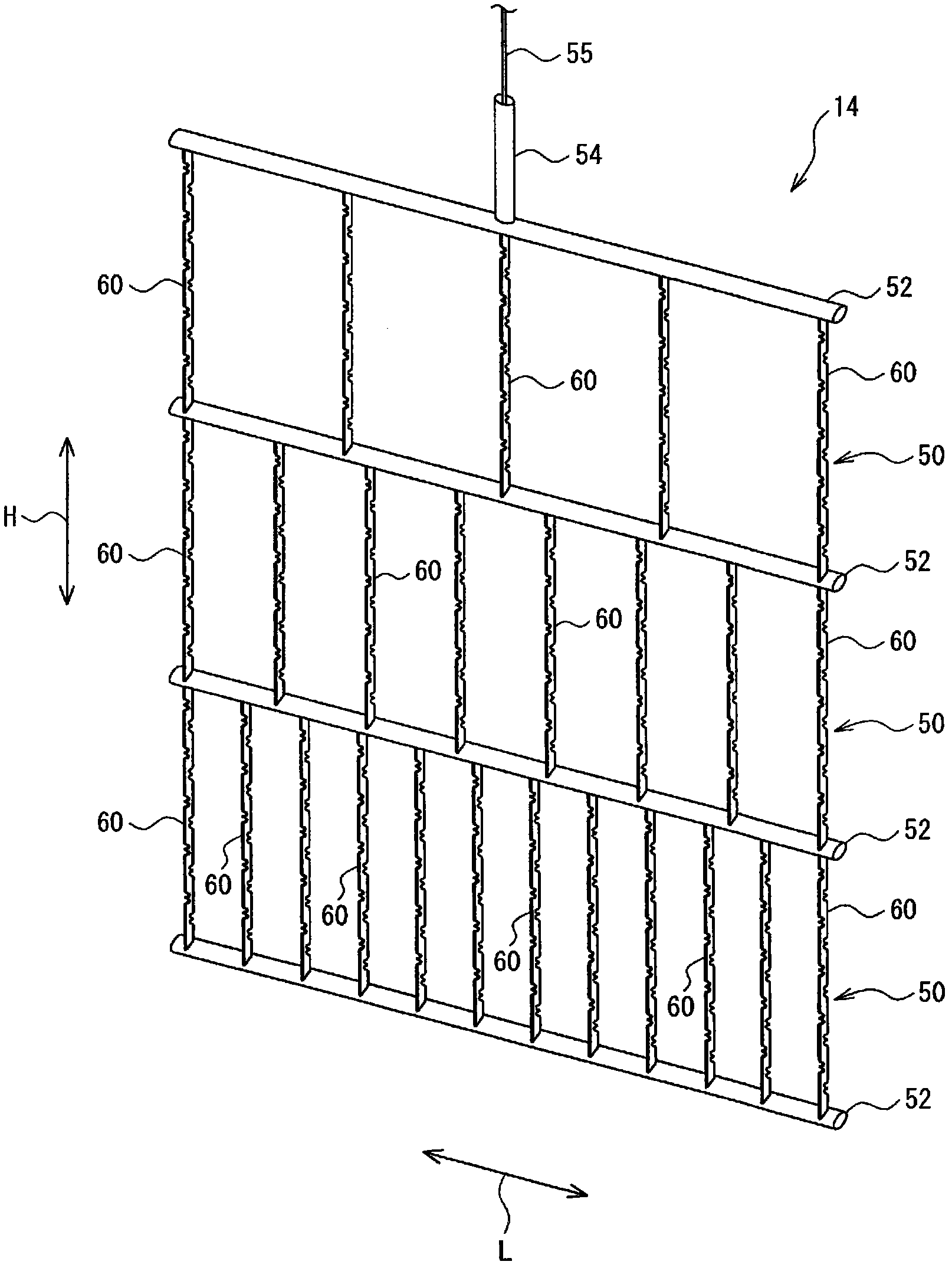

Efficient multi-field-coordination fine particulate matter removal device and method

ActiveCN103768886AAvoid back coronaAvoid secondary dustSemi-permeable membranesAuxillary pretreatmentMulti fieldWater vapor

The invention discloses an efficient multi-field-coordination fine particulate matter removal device and an efficient multi-field-coordination fine particulate matter removal method. The device comprises an outer field coagulation area, a direct current dust pre-collecting area, a pulse charge coagulation area and a direct current dust collecting area which are connected in sequence, wherein water steam and a chemical agglomeration agent are introduced from a nozzle of the outer field coagulation area respectively; the direct current dust pre-collecting area and the direct current dust collecting area are arranged in a line-plate type symmetric structure, a line electrode applies negative direct current high voltage, and a plate electrode is grounded and adopts layout of a water film electrode; the pulse charge coagulation area is arranged in the line-plate type symmetric structure, the line electrode applies positive pulse high voltage, and the plate electrode is grounded and adopts layout of the water film electrode. The device and the method aim at mineral particulate matters discharged by a fixed source; aerosol particulate matters, particularly fine particulate matters, can be subjected to efficient coagulation removal in a structural form of double coagulation areas and double dust collecting areas by using a multi-field-coordination method combined by a phase-change coagulation growth technology, a chemical agglomeration and flocculation mechanism and an electric coagulation technology, so that the phenomena of back corona, re-entrainment of dust, ash deposition and corrosion of the plate electrode are effectively avoided.

Owner:ZHEJIANG UNIV

Static electric cloth bag compact mixed type dust remover and its running method

InactiveCN101121152AGuaranteed efficiencyGuaranteed removalCombination devicesElectrode constructionsFlue gasEngineering

An electrostatic bag closely hybrid dust remover and the operation method are mainly used for the flue gas disposal in a power plant etc. A grounding collecting plate is placed between a high voltage discharge electrode and the bag inside a dust removing room. An electrostatic dust removing area is formed by two sides of the high voltage discharge electrode and the grounding collecting plate; a filtering and dust removing area is formed by two sides of the bag and the grounding collecting plate. When the bag filters, the grounding collecting plate is closed, and the flue gas enters into the dust removing room and goes through the electrostatic dust removing area to arrive at the end of the grounding collecting plate and then enters into the filtering and dust removing area. When the bag reversely blows and cleans ash, the grounding collecting plate opens, the gas and dust for reverse blowing and ash cleaning pass through the grounding collecting plate directly and reach the electrostatic dust removing area, and the dust for reverse blowing and ash cleaning is collected by static electricity. Compared with the prior invention, the dust removal is separated into two steps: when the bag filters, an electrostatic dust remover is completely used to greatly reduce a dust-containing concentration of the flue gas which enters into the bag; when the bag reversely blows and cleans ash, the electrostatic dust remover is used to effectively remove the dust for ash cleaning.

Owner:TSINGHUA UNIV +1

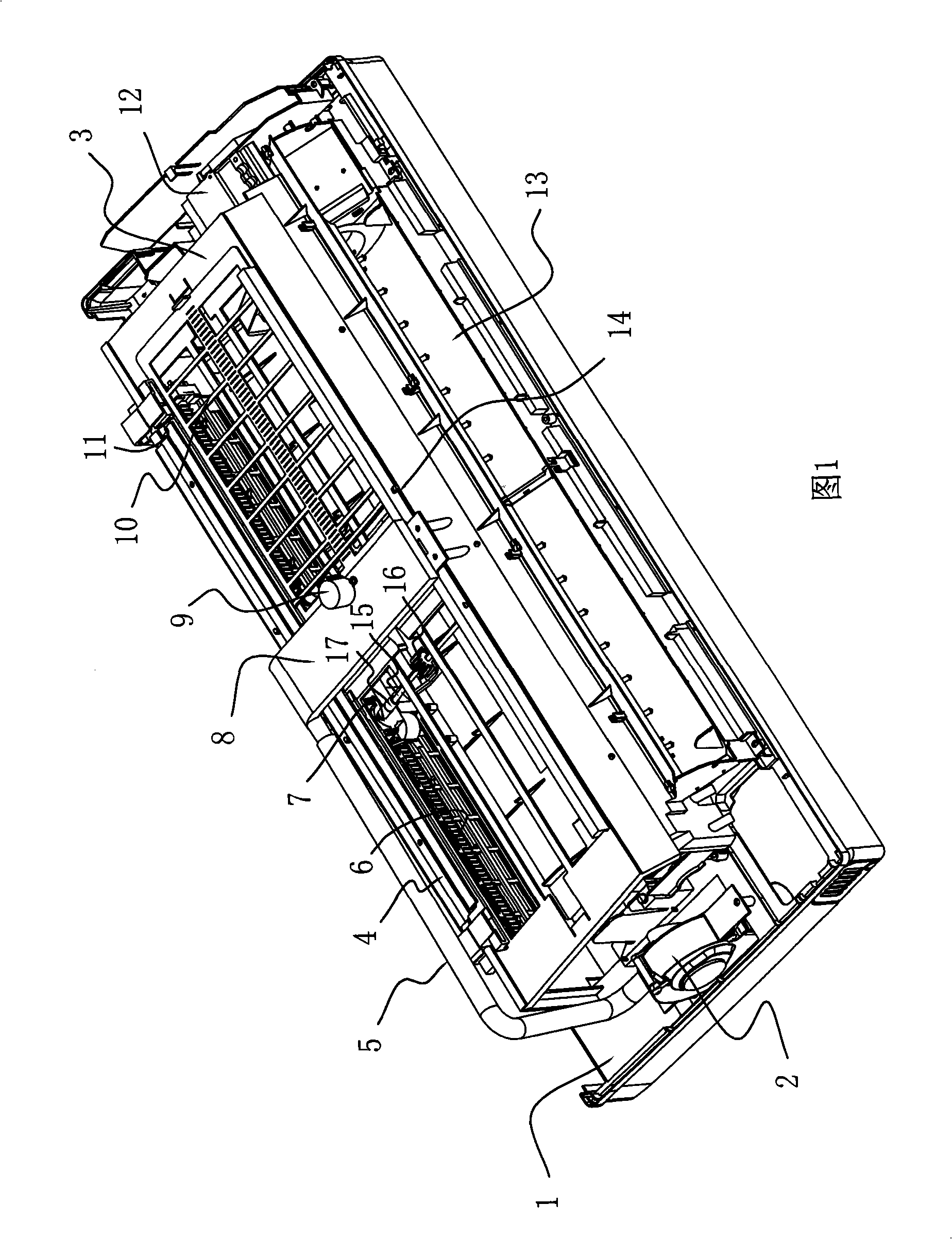

Split hanging machine air conditioner with filtering net automatic cleaning device

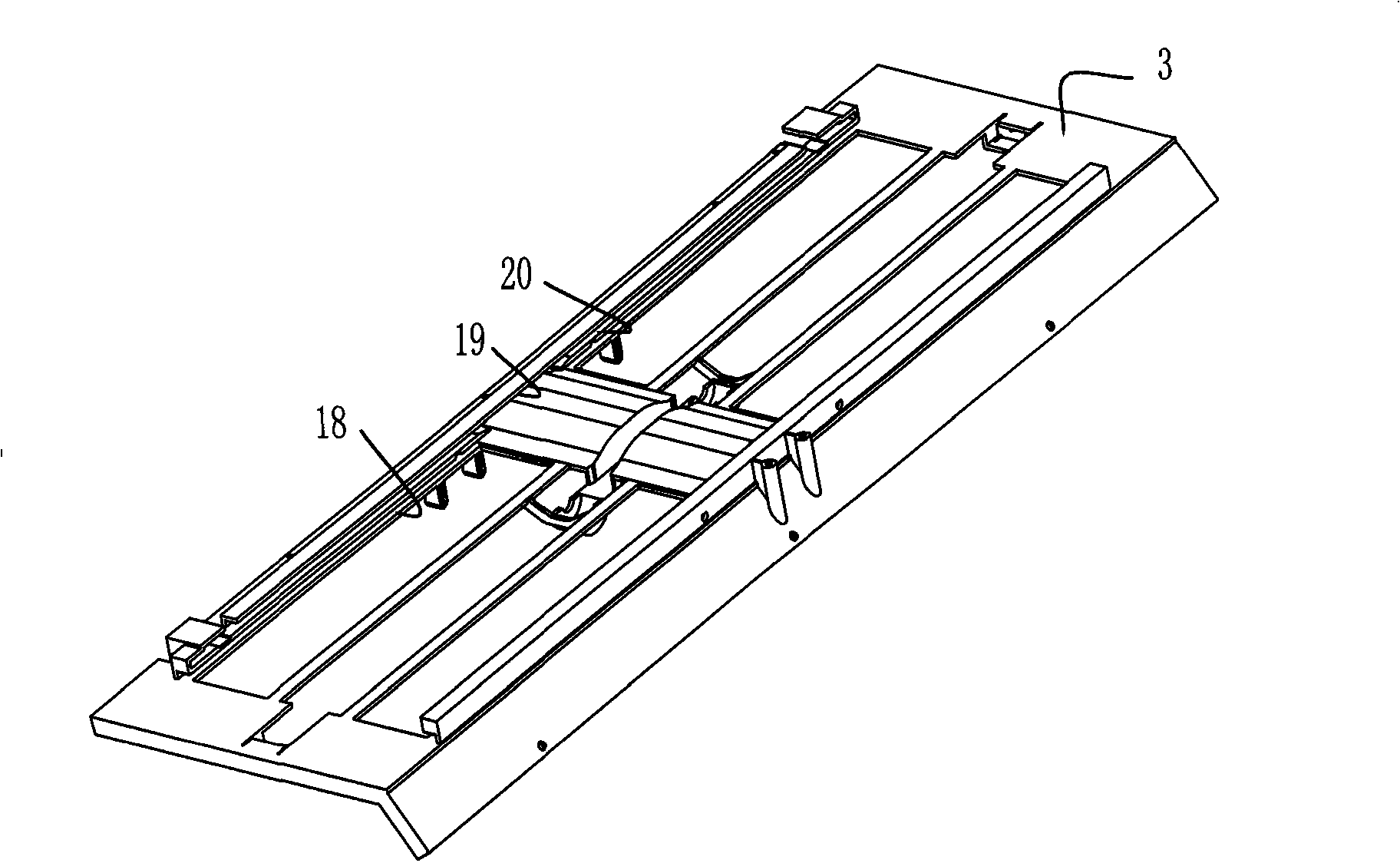

ActiveCN101338924AIncrease travel distanceIncrease sweep lengthLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention discloses an split type on-hook air conditioner with an automatic cleaning device of a filter screen, including the filter screen and a fixing framework. The filter screens are respectively arranged at the left and the right sides in the air inlet of the air conditioner and are embedded in guide slots arranged on the two sides of the fixing framework. The guide slots of the left and the right filter screens are respectively provided with a lower guide slot and an upper guide slot which are connected by a transition guide slot. Each filter screen can move left and right along the lower guide slot, the transition guide slot and the upper guide slot thereof. The automatic cleaning device includes a filter screen driving device which drives the filter screen to move left and right and a suction component. The suction component includes a suction box and a suction fan. The suction box is arranged above the transition guide slot and spans the fixing framework. The suction box is connected with the suction fan by a suction pipe. Compared with the prior technology, the split type on-hook air conditioner of the invention has simple structure, which can remove dust automatically and clean the dust of the filter screen thoroughly.

Owner:GUANGDONG CHIGO AIR CONDITIONING

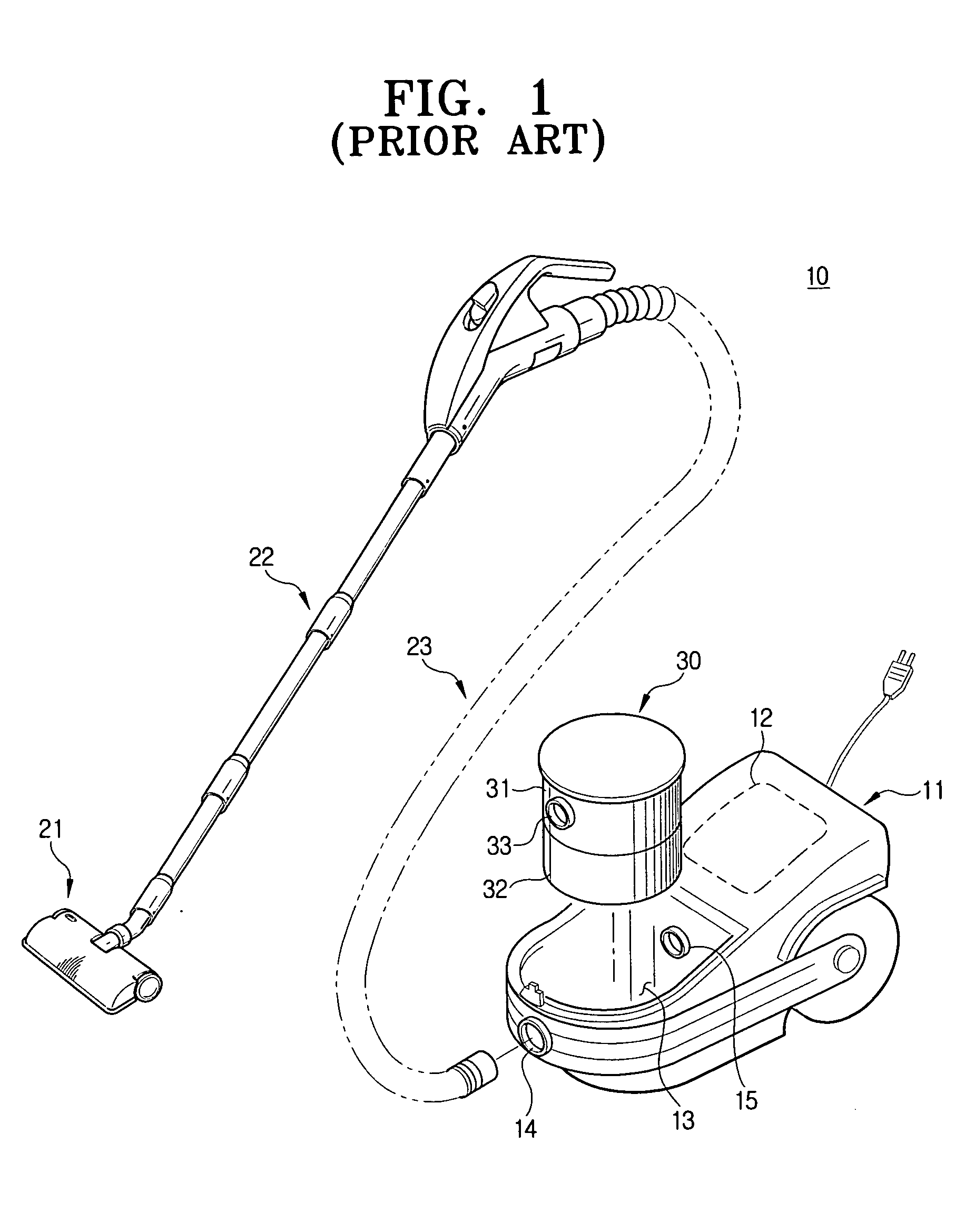

Cyclone dust-collector for vacuum cleaning

InactiveCN1212095CReduced leakage to the second dust collectorImprove dust collection effectSuction filtersDispersed particle separationEngineeringCentrifugal force

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

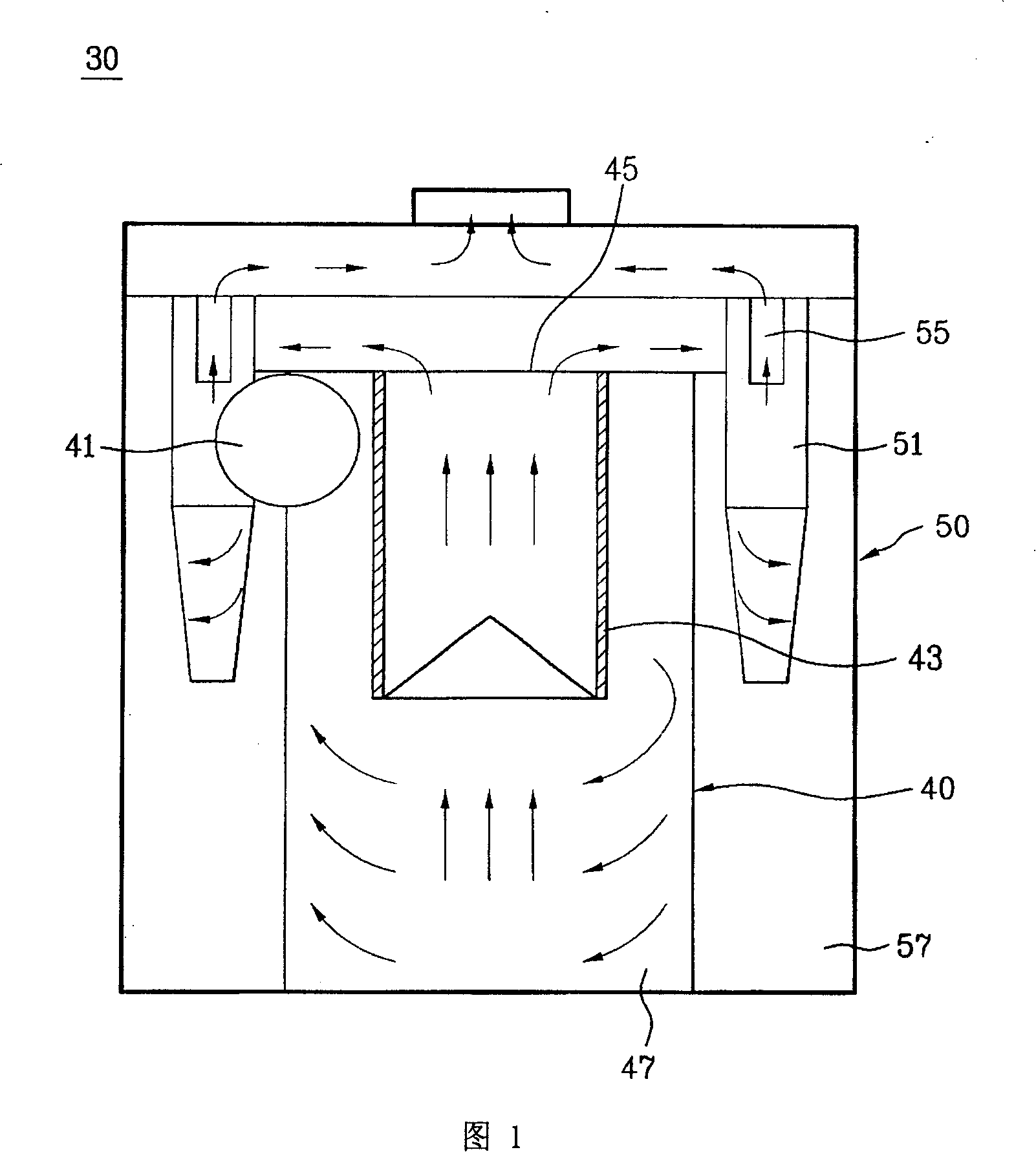

Cyclone type dust collecting apparatus of vacuum cleaner

InactiveCN1572220AImprove cleaning efficiencyImprove dust collection effectSuction filtersReversed direction vortexCycloneEngineering

The device has a lower body (40) to centrifuge and collect large size foreign substances contained in air sucked from outside. An upper body (30) is arranged in an upper part of the body (40) and has an inlet hole (31). The body (30) centrifuges and collects small size foreign substances contained in the air blown back from the body (40), in the order of sizes of the substances.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

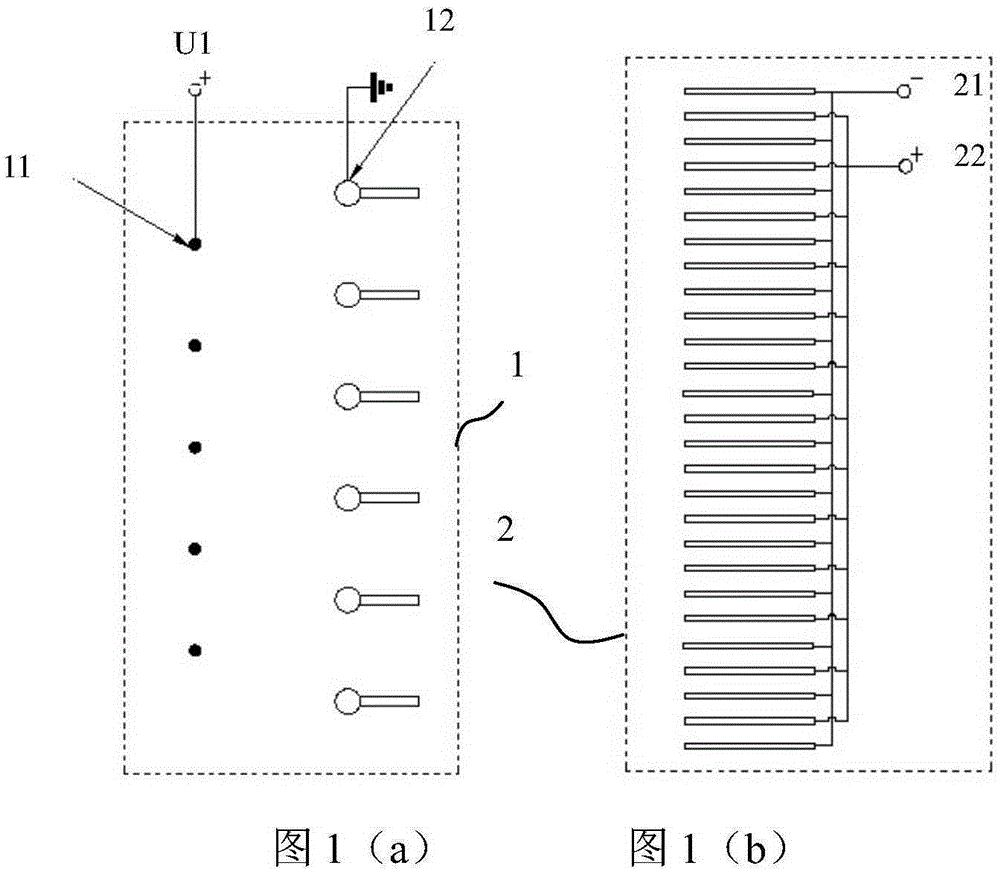

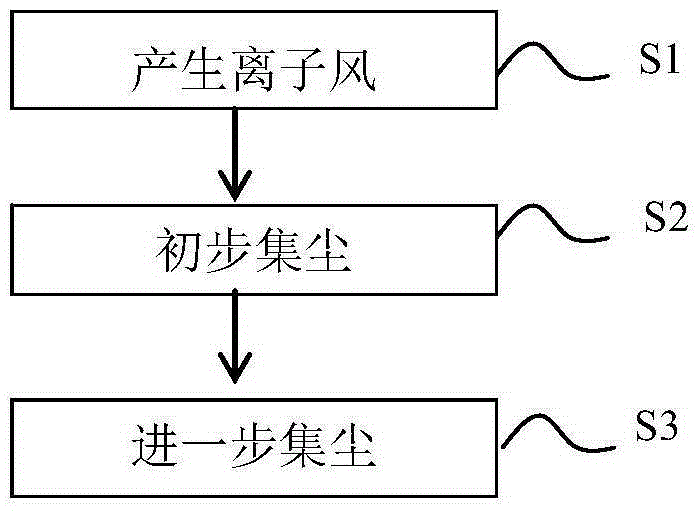

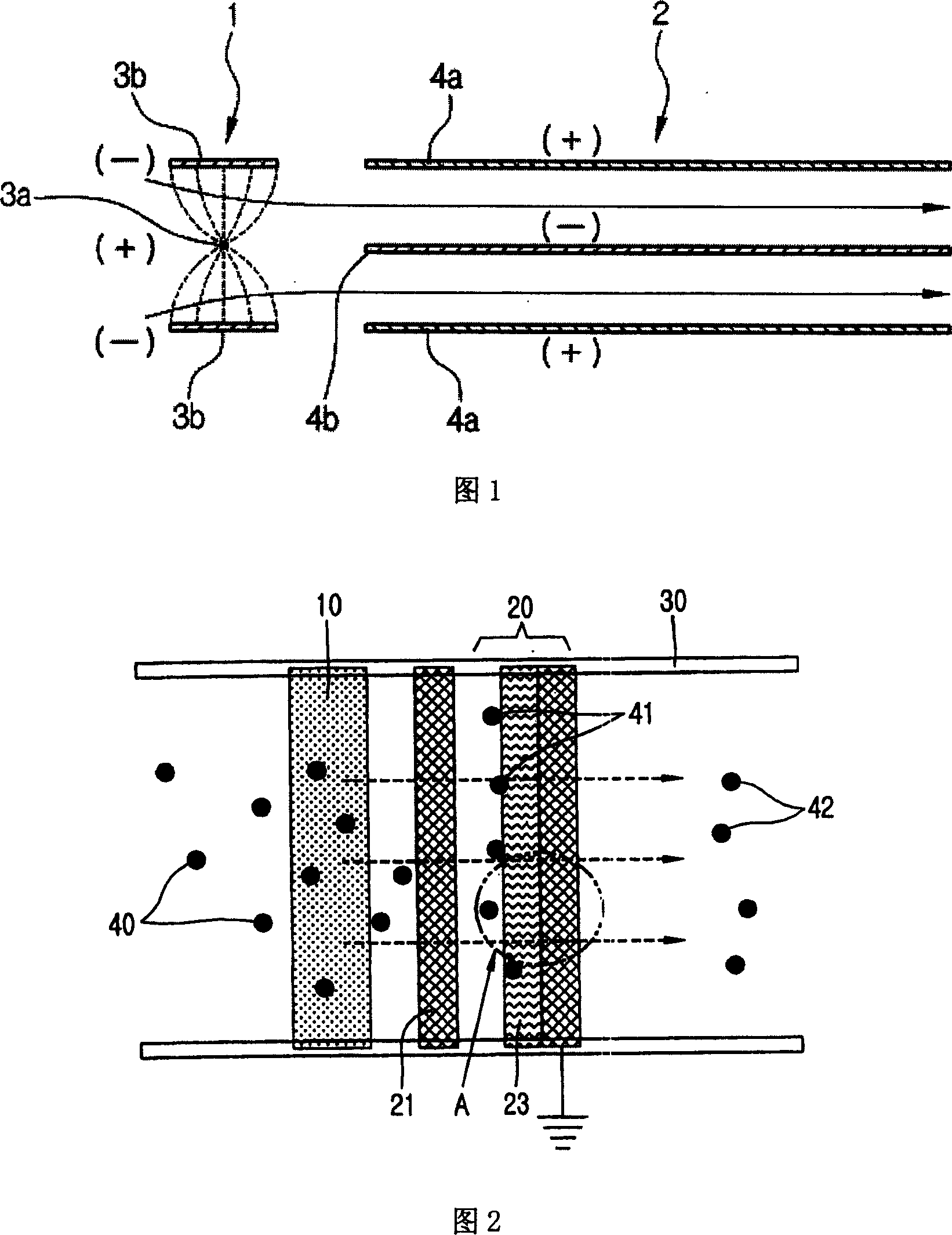

Electrode structure, dust collecting method and air purifier

InactiveCN105268554AImprove dust collection effectThe beneficial effect is clearExternal electric electrostatic seperatorElectrode constructionsParticulatesEngineering

The invention provides an electrode structure, a dust collecting method and an air purifier with the electrode structure. The electrode structure has the remarkably-improved dust collecting effect for formed ionic wind. The electrode structure for the ionic wind comprises a first electrode and a second electrode. According to the first electrode, air flowing through the first electrode is subjected to ionization so as to generate ions, and particles in air carry charges; and an electric field is applied, so that the ionic wind is formed in the electric field through the charged particles, and the charged particles are preliminarily collected. The second electrode is arranged behind the first electrode in the direction of the ionic wind and used for further collecting the charged particles.

Owner:GREE ELECTRIC APPLIANCES INC

Nonwoven fabric for filters

ActiveUS20100146921A1Improve stabilityHigh strengthCombination devicesDispersed particle filtrationPolytetramethylene terephthalateMetallurgy

This invention relates to a nonwoven fabric for filters, in which a melt blown nonwoven fabric formed of polybutylene terephthalate or polypropylene terephthalate fibers with an average fiber diameter of 1 to 8 μm and a spunbonded nonwoven fabric formed of polyester-based fibers with an average fiber diameter of 10 to 30 μcm are laminated for integration.

Owner:TORAY IND INC

Cleaner

InactiveCN1720852AImprove dust collection effectReduce power consumptionAutomatic obstacle detectionTravelling automatic controlMechanical engineeringPower consumption

Only when a wall side and the vicinity of an obstacle are cleaned, a side brush is operated and the cleaning is carried out, and when any other place than the wall side and the vicinity of the obstacle is cleaned, the side brush is maintained in a stoppage state. When a place such as the wall side or the vicinity of the obstacle in which dust is easy to accumulate is cleaned, the side brush is operated to enhance the dust collecting property. When any other place than the wall side or the vicinity of the obstacle is cleaned, the side brush is stopped to suppress power consumption and generation of a noise. A judgment processing portion detects based on a detection signal from an obstacle detecting portion that a cleaner is approaching a wall or an obstacle. In response to such detection, the judgment processing portion instructs a travel steering portion to carry out immediate rotation and change of a travel direction, or travel along a wall side. Also, the judgment processing portion instructs a side brush driving portion to drive a side brush only in the rotation and in the wall side travel, and to stop the side brush in straight advance travel.

Owner:SANYO ELECTRIC CO LTD

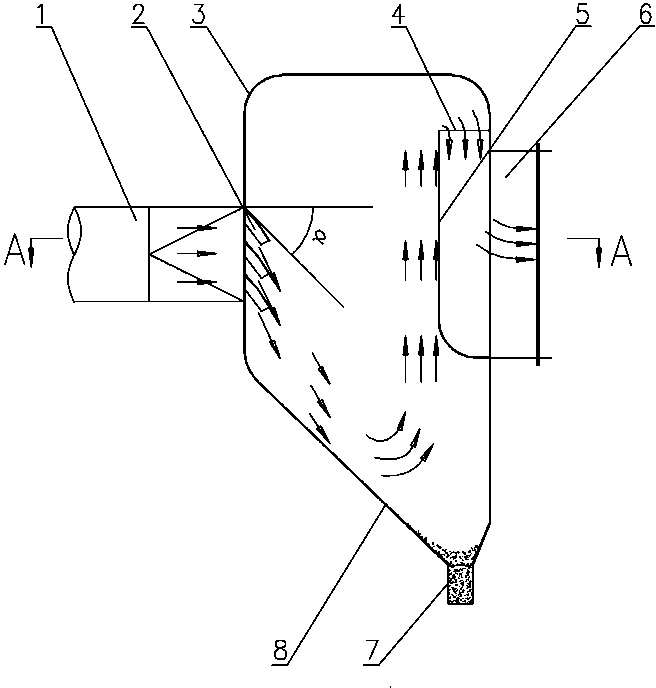

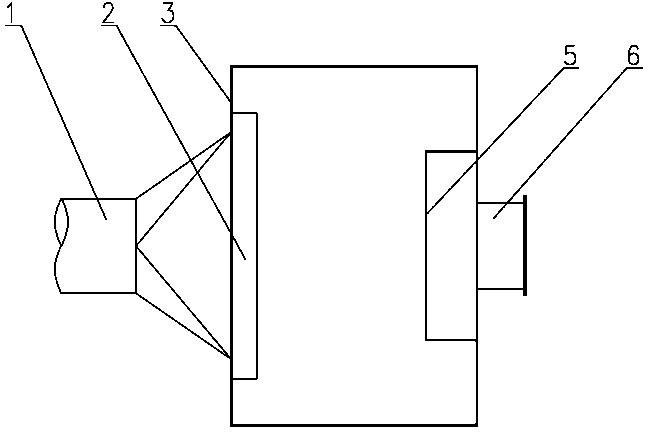

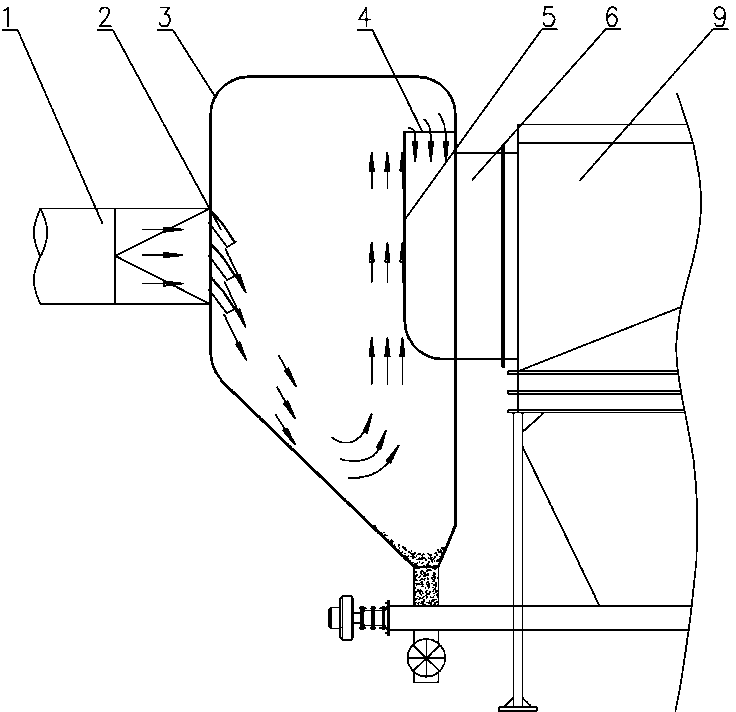

Inertia gravity dust collector

The invention relates to environmental protection equipment, and discloses an inertia gravity dust collector applied to industrial production. The inertia gravity dust collector is provided with a shell and is characterized in that the middle of one side of the shell is provided with a smoke inlet pipe, the bottom of the shell is provided with a dust outlet pipe, a smoke discharging pipe is arranged on the top or the side wall of the shell, and a plurality of guide plates with a downward guiding direction are arranged on the shell and at the opening of the smoke inlet pipe. The inertia gravity dust collector provided by the invention has the advantages of simple structure, small resistance, low manufacturing cost and remarkable dust collection effect, is mainly used for preprocessing of a bag collector and other dust collectors, and can be used for improving the treatment efficiency and effects of the bag collector and the other tail end dust collectors.

Owner:HUBEI JINLU ENERGY SAVING LTD CO

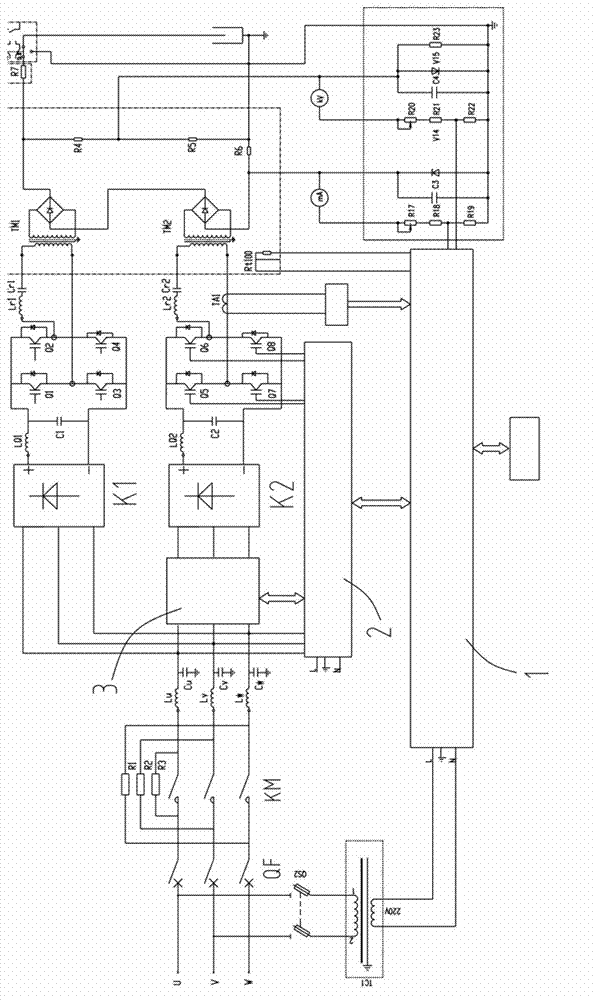

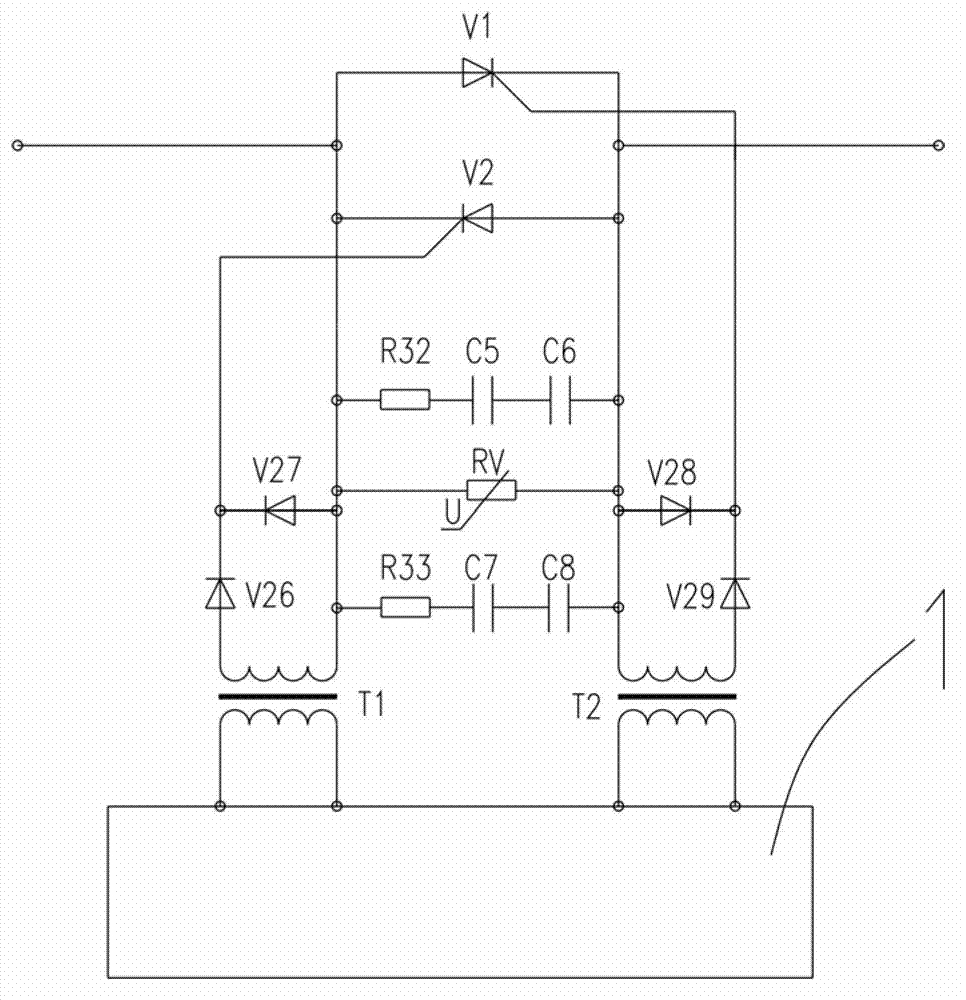

Electrostatic-precipitation pulse power supply control system

ActiveCN103028494AWith dynamic response characteristicsFast switching speedElectric supply techniquesPower control systemTransformer

The invention discloses an electrostatic-precipitation pulse power supply control system, which comprises a major loop, a controller and a trigger driving sampling loop, wherein the major loop comprises a first loop which provides a continuous fundamental wave voltage for a dust remover, and a second loop which provides a discontinuous pulse voltage for the dust remover; the controller controls the fundamental wave voltage to be lower than full breakdown voltage of spark discharge inside the electric field of the dust remover; and the controller controls the pulse voltage to be 3-5 times of the fundamental wave voltage. The voltage output by the system is large; when the dust remover performs spark discharge, the turn-off time is not required; the field energy is quickly recovered; the back corona site can be overcome; the dust collection effect is obvious, in particular to small dust in the electrostatic precipitator; the working frequency is high; the power factor is large; a three-phase power supply is used for supplying power; the three-phase power grid is balanced, so that the harmonic pollution to the power grid is low, the volume and the weight of a transformer are reduced, and the consumable is saved.

Owner:浙江连成环保科技有限公司

Sheet feeder capable of removing dust

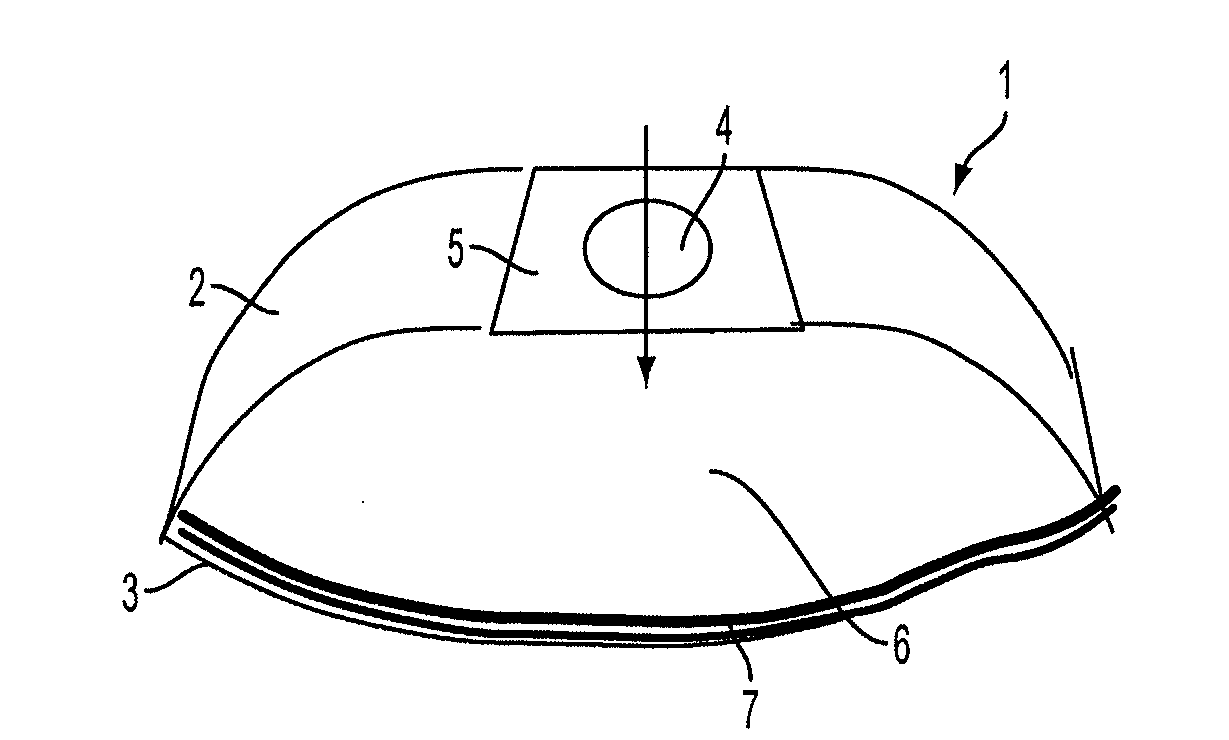

InactiveUS20060029446A1Improve dust collection effectLow costElectrographic process apparatusPaper dustEngineering

A sheet feeder capable of removing dust includes a sheet-feeding roller, a dust collecting box and a brush. The sheet-feeding roller transports a sheet along a sheet passageway. The dust collecting box is disposed at a side of the sheet-feeding roller. The dust collecting box has an adhesive layer for collecting and retaining paper flakes and dust coming from the sheet-feeding roller so as to prevent the paper flakes and the dust from being blown back to the sheet passageway. The brush in contact with the sheet-feeding roller brushes the paper flakes and the dust away from the sheet-feeding roller and into the dust collecting box.

Owner:AVISION

Filter bag

InactiveUS20090301043A1Effective protectionImprove dust collection effectCleaning filter meansCombination devicesIntermediate spaceFilter material

A filter bag includes a first filter material layer including an inflow opening, a second filter material layer having edges along which the second filter layer is joined to the first filter material layer to form an inside space; and a flat, multi-layer filter insert arranged in the inside space and having sections connected, respectively, to the first and second material layers. The filter insert has at least two outer layers defining an intermediate area there between. The intermediate area includes a center layer or an intermediate space for dust collection.

Owner:WOLF PVG GMBH & CO KG

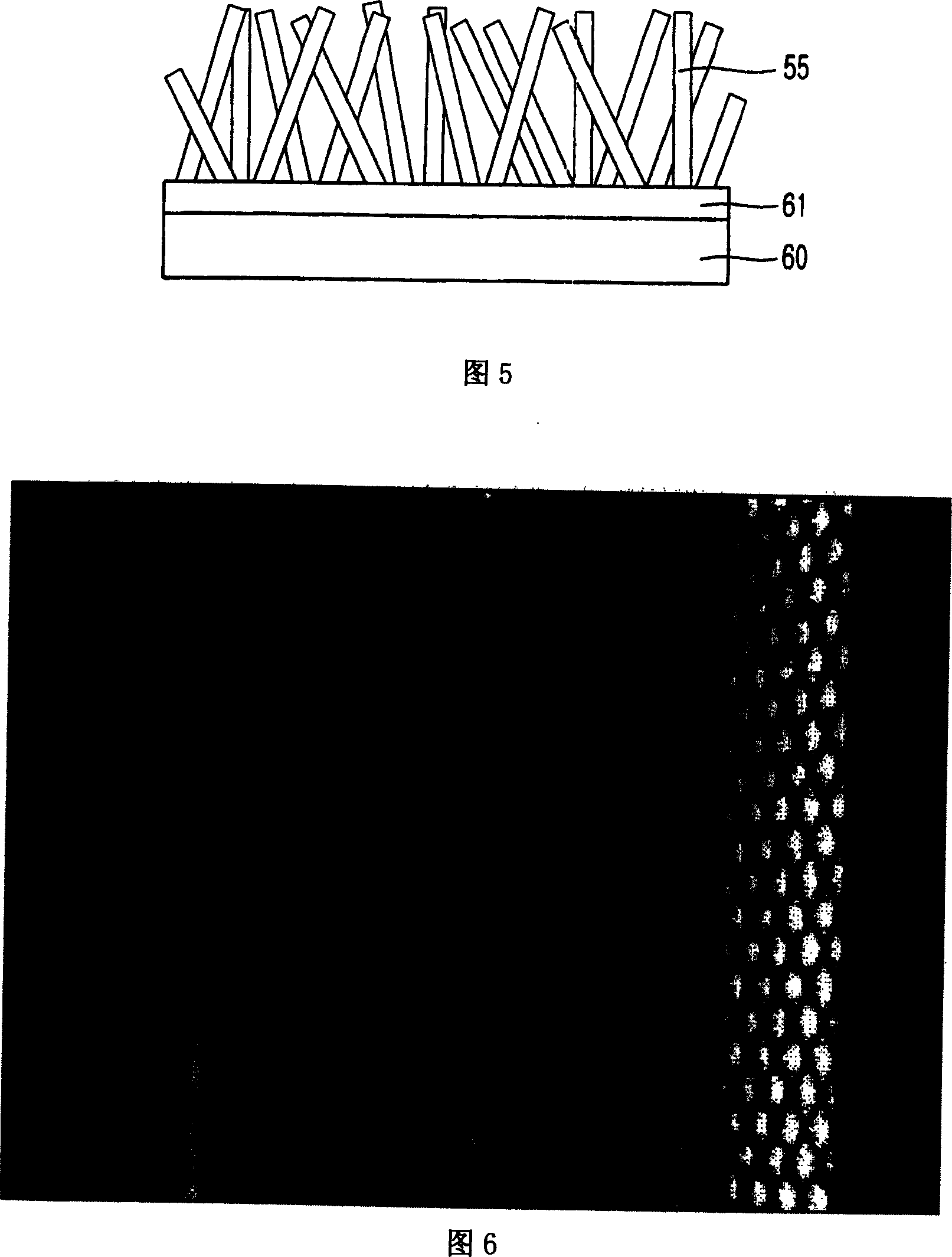

Air purifier with electrostatically flocked fiber

InactiveCN1986070AImprove dust collection effectImprove dust collection functionExternal electric electrostatic seperatorElectrode constructionsFiberForeign matter

The air purifier with electrostatically flocked fiber includes an ionizing part for high voltage discharging and a dust collecting part to collect the foreign matter ionized in the ionizing part and has electrostatically flocked fiber set in the ionizing part or the dust collecting part. The electrostatically flocked fiber filters out the foreign matter by means of physical contact, and the ionized foreign matter is further filtered out through electrostatic force filtering to raise the air purifying performance. The air purifying mode may be applied widely in common air purifier and various kinds of air conditioners.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

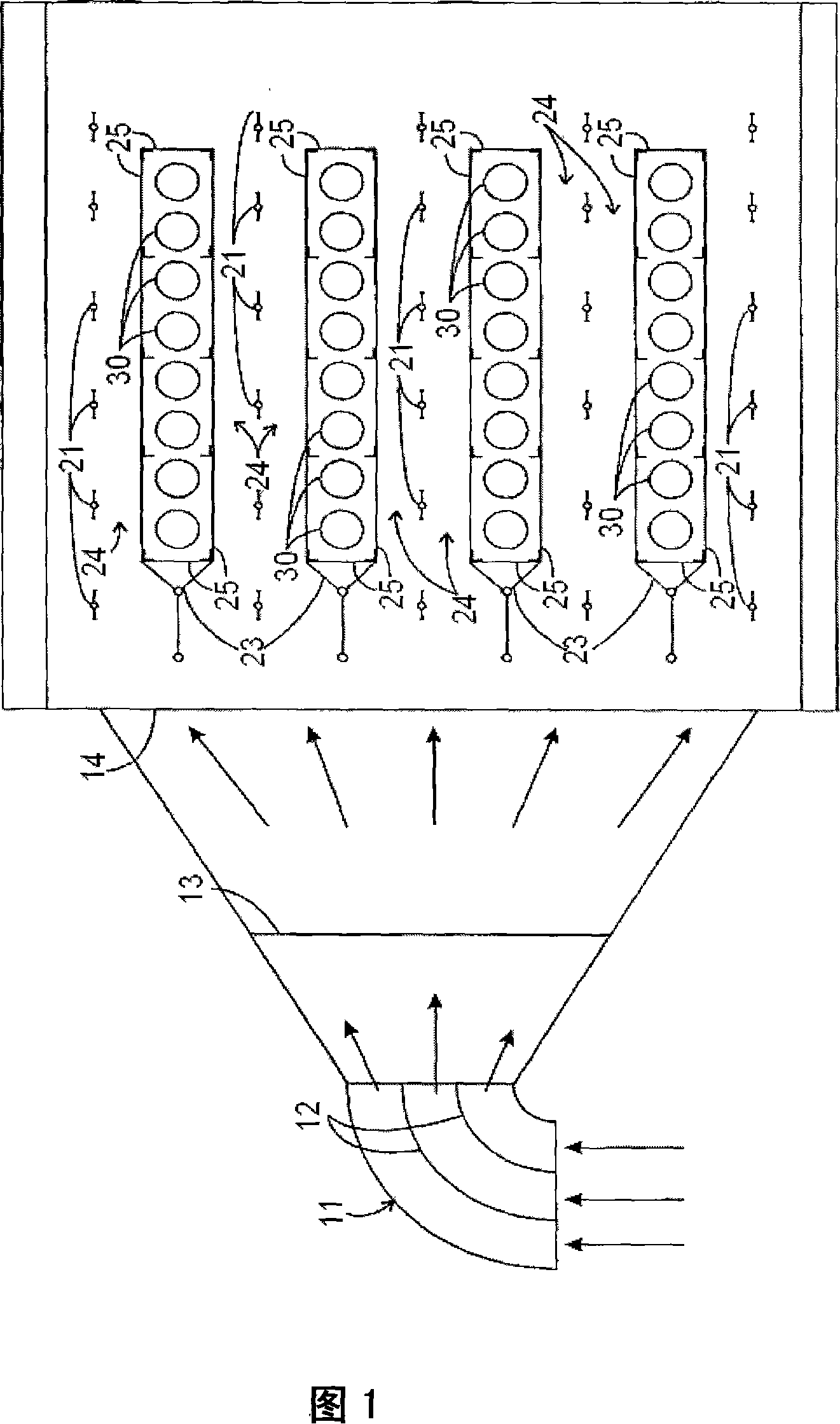

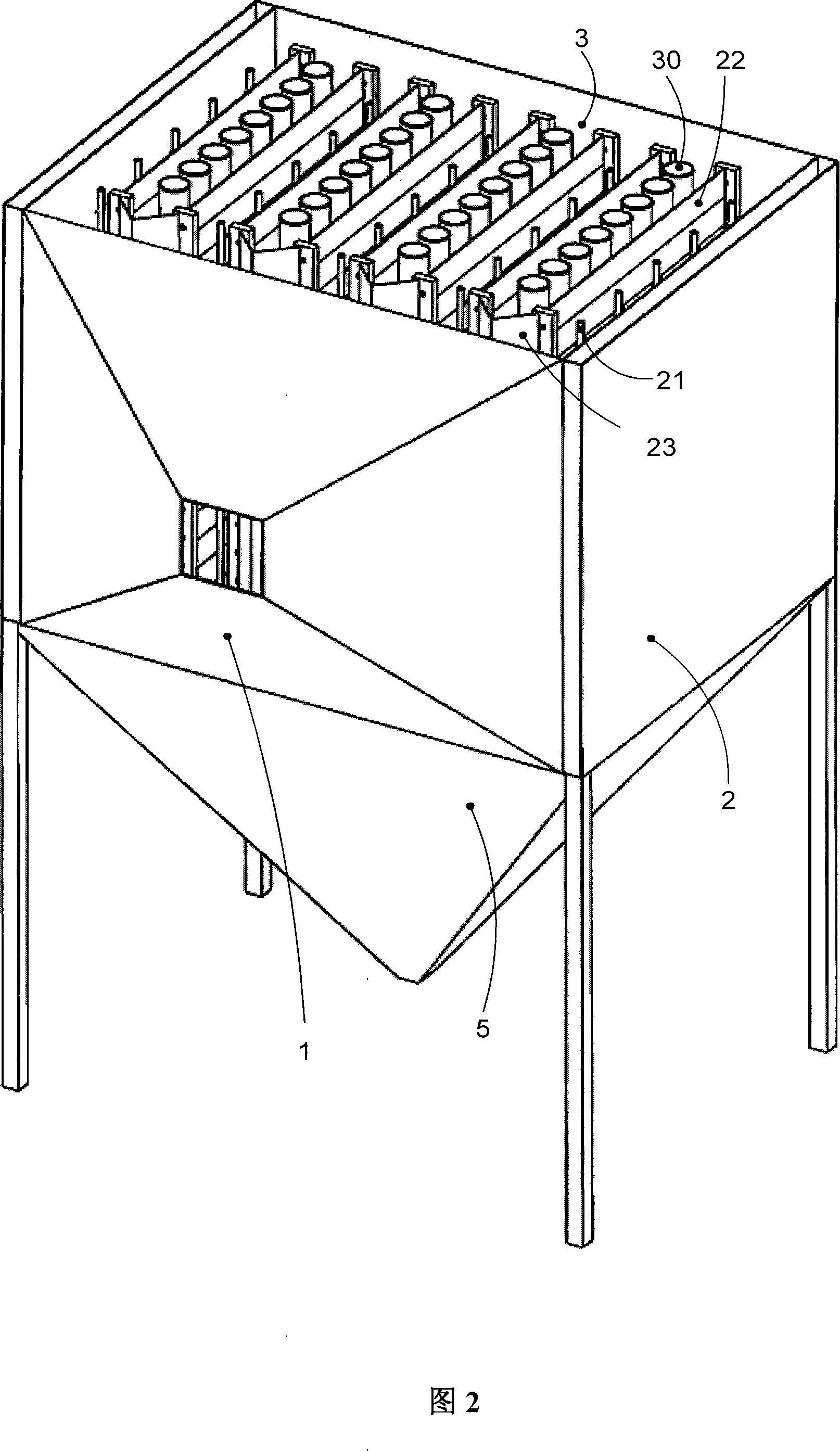

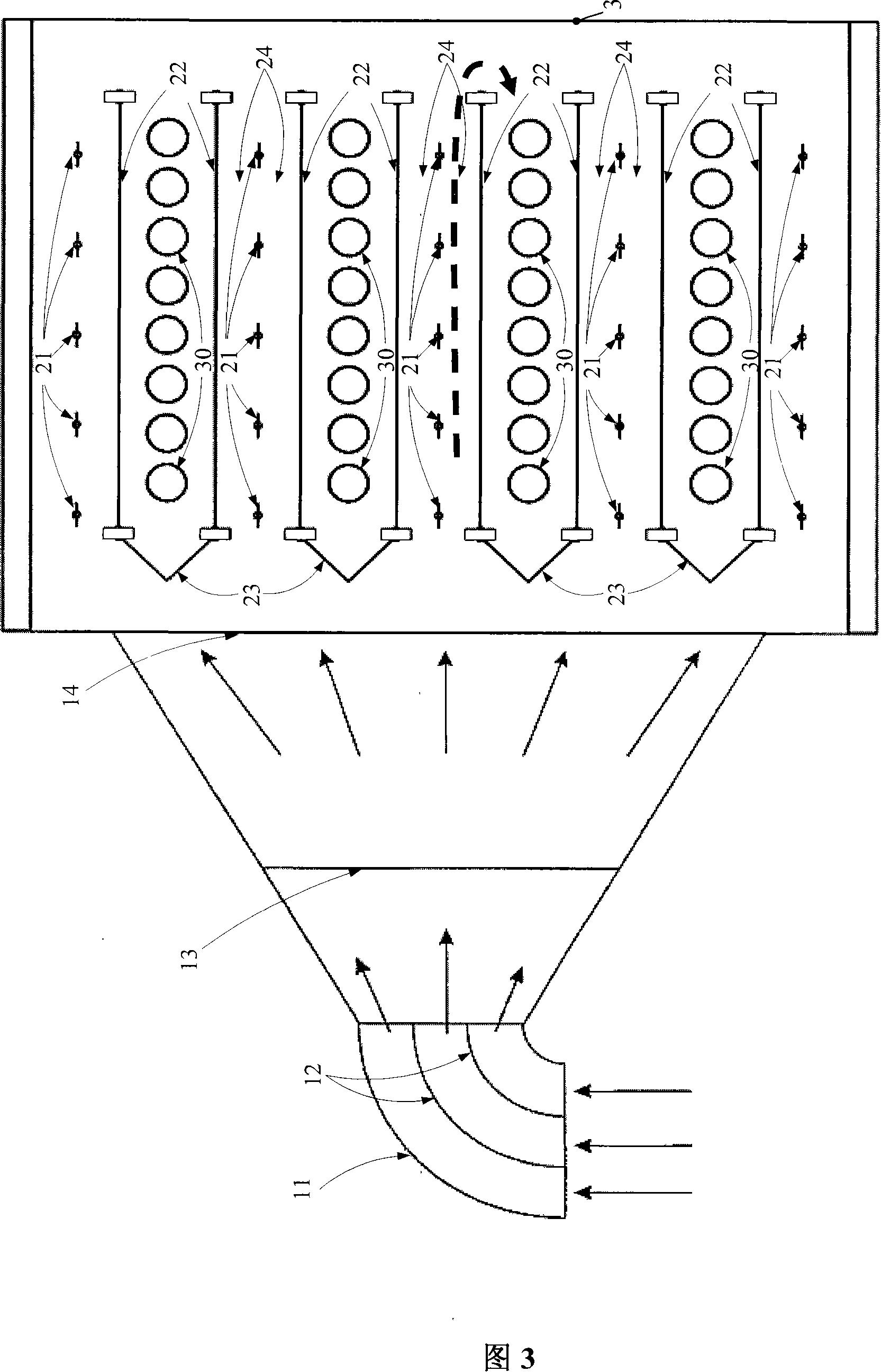

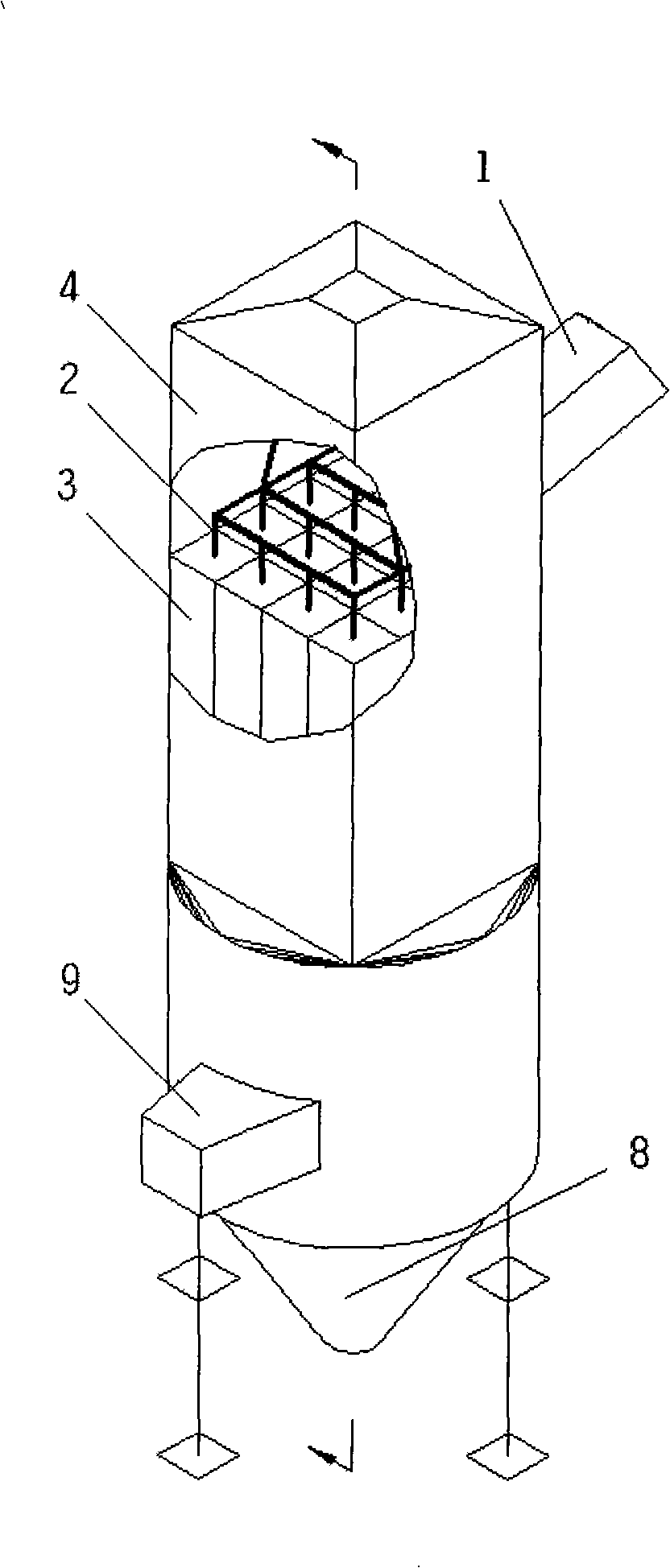

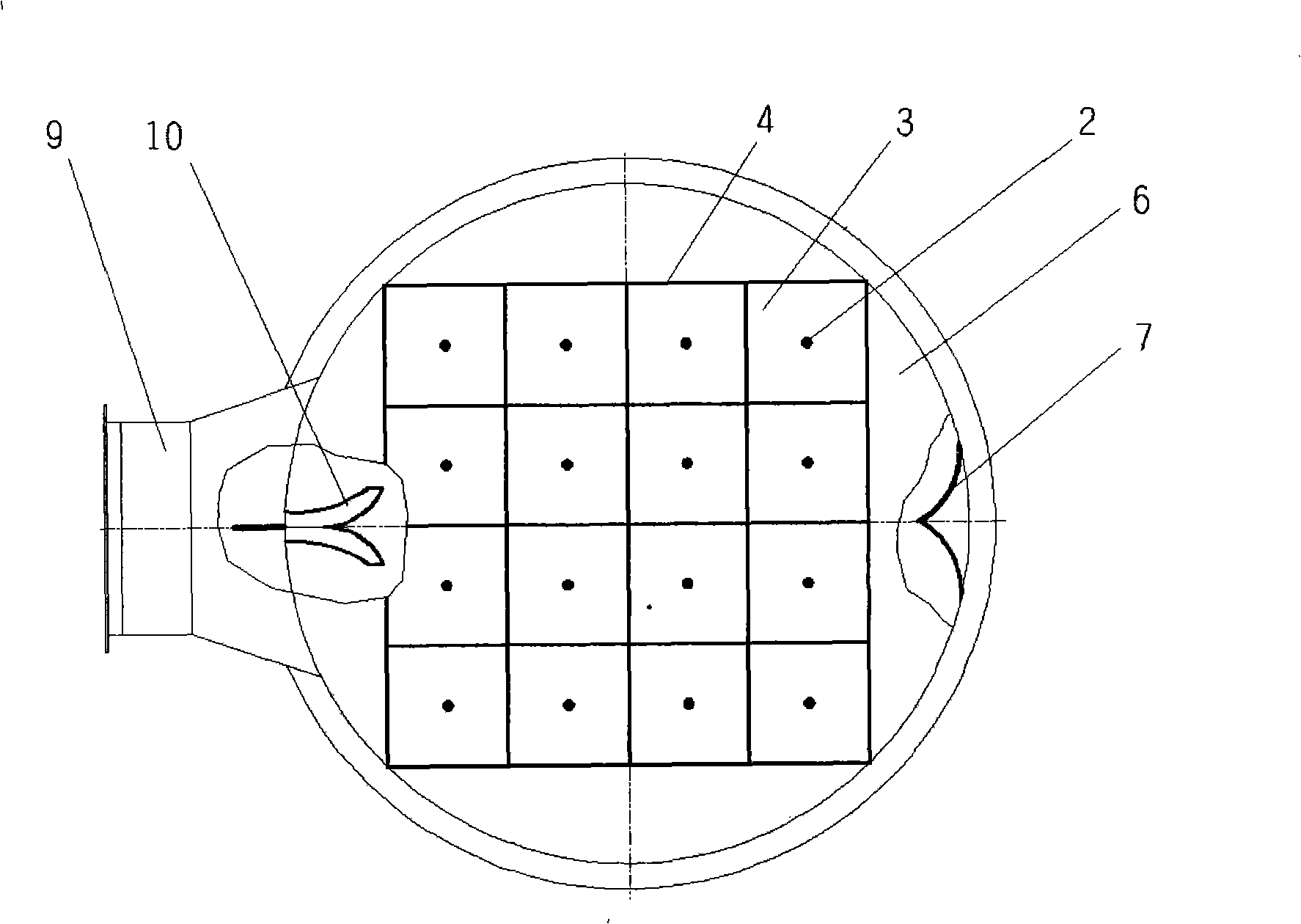

High-voltage electrostatic dust separator for industrial furnace

InactiveCN101524668AEvenly distributedWith drainage acceleration effectVapor flow controlVertical tubeEngineering

The invention provides a high-voltage electrostatic dust separator for industrial furnace. The dust separator is equipped with an air inlet and an air outlet. The dust-separation electric field is formed by multiple vertical tubes, of which inner walls are used as duct-collecting pole plates, a corona wire arranged in the centre of the vertical tube, a high-voltage insulating ceramic bottle and a corona wire group suspension bracket arranged above the vertical tubes. The lower portion of the vertical tube is connected with an air-distributing barrel, one end of the air inlet is connected with a smoke dust discharge tube of the industrial furnace and the other end is connected with the air-distributing barrel. The lower portion of the air-distributing barrel is connected with a dust hopper of the dust separator, and a whirling guide plate extending into the air-distributing barrel is arranged at the air inlet connected with the air-distributing barrel. The other side of the air-distributing barrel corresponding to the extension line of the whirling guide plate is equipped with an air-distributing plate. The air-distributing barrel of the dust separator in the invention makes the dust-containing air be distributed more uniformly before entering a dust-separation unit. The two-dimensional herringbone air-distributing plate in the air-distributing barrel guides and accelerates the air such that the air flow move in the middle of the air-distributing barrel, which is in favour of uniform distribution of air flow in the air-distributing barrel. The invention has obvious dust collection effect, and the dust-separation rate can be more than 99%. The dust separator can capture sub-micrometre-sized particles of 0.1mm at high temperature, and is conveniently operated and managed, and simply maintained.

Owner:HEBEI UNIVERSITY

Cyclone collector

ActiveUS7731771B2Improve efficiencyGreat suctionCleaning filter meansSuction filtersCycloneEngineering

Owner:LG ELECTRONICS INC

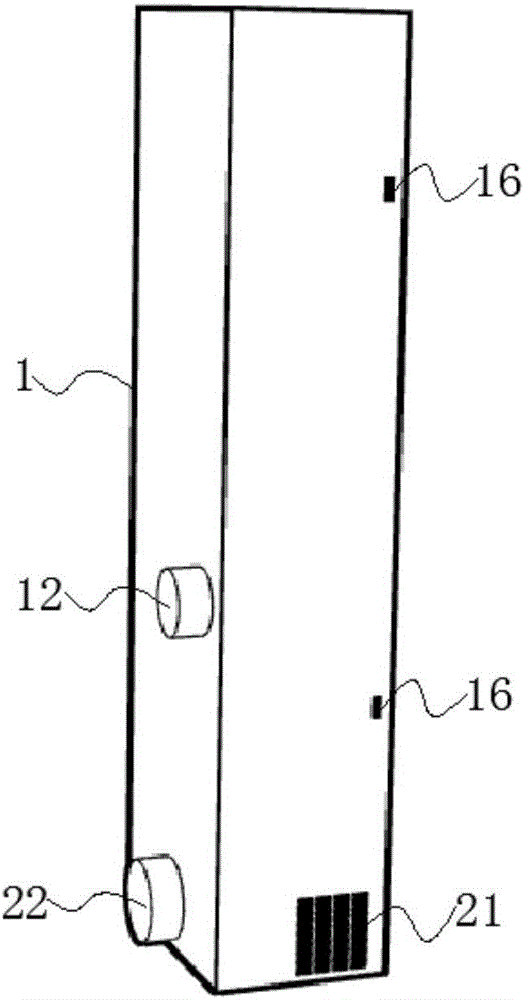

Fresh air purification all-in-one machine

InactiveCN106247601AAchieve cycleAvoid hypoxiaMechanical apparatusSpace heating and ventilation safety systemsElectricityAir cycle

The invention discloses a fresh air purification all-in-one machine, which comprises a casing, an indoor air return inlet, an outdoor fresh air inlet, a fresh air supply opening, an indoor air return exhaust opening and a power supply control device, wherein the power supply control device is arranged in the casing; a primary filter, a heat exchange core body, an exhaust machine, a secondary filter, an ion cloud dust removal module, an air supply machine and a tertiary filter are sequentially arranged in the casing; the exhaust machine, the ion cloud dust removal module and the air supplying machine are respectively and electrically connected with the power supply control device. The outdoor air and the indoor air are simultaneously introduced into a purifier; the air circulation is realized; the indoor air quality is improved; in addition, the ventilation and the air purification function are integrated; the plug-and-use effect is achieved; the problems of installation and repair difficulty and house structure damage by pipelines installing are solved; the ion cloud generating device can ionize outdoor air to generate negative ions; dust is adsorbed onto a dust collecting plate after being charged. The fresh air purification all-in-one machine has the advantages that the negative ion generating quantity is great; the conveyance distance is long; the dust removal and sterilization effects are good; in addition, no ozone is generated in the work process; the environment is protected; health is realized.

Owner:KUNSHAN SILAIMU ENERGY SAVING TECH CO LTD

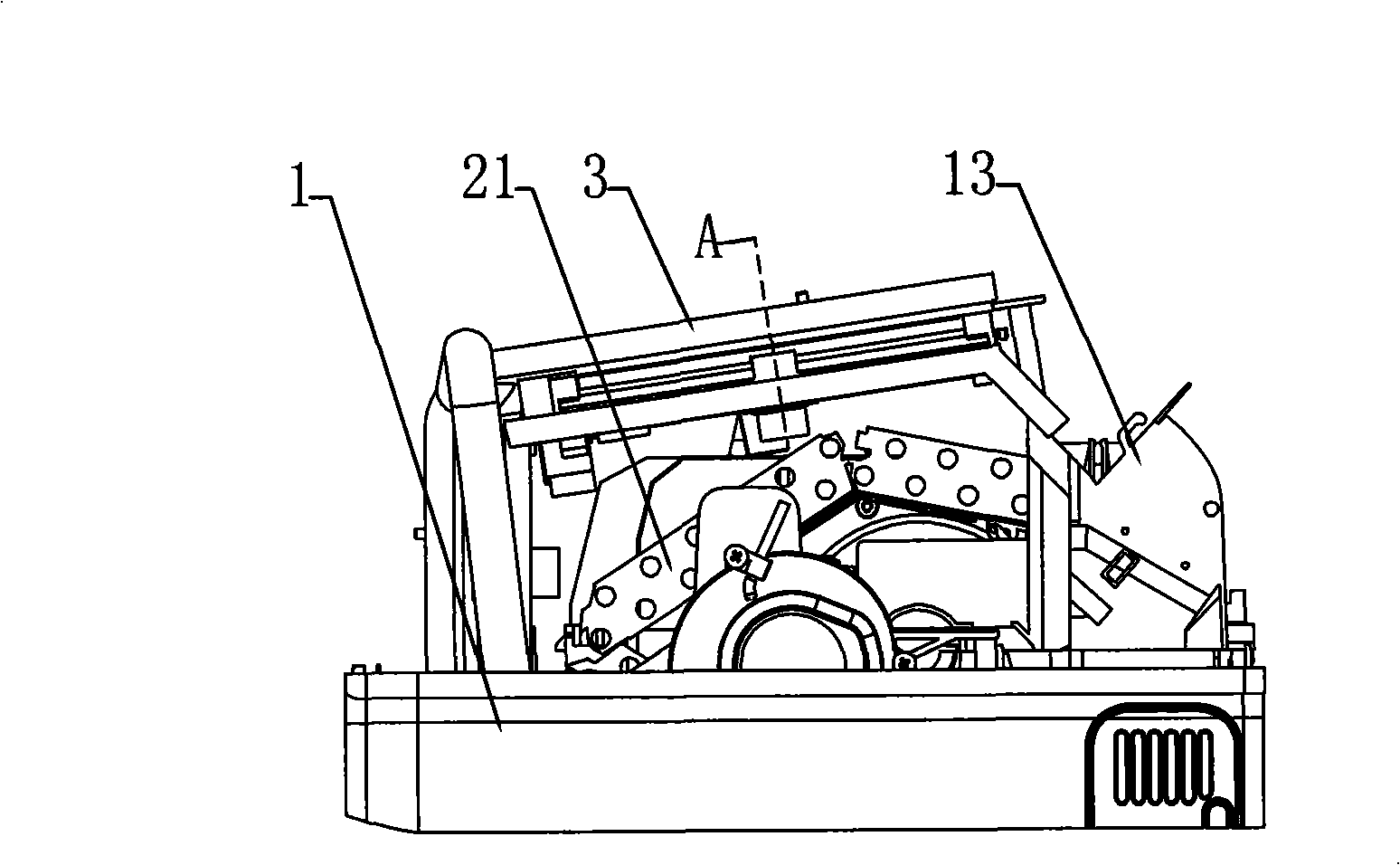

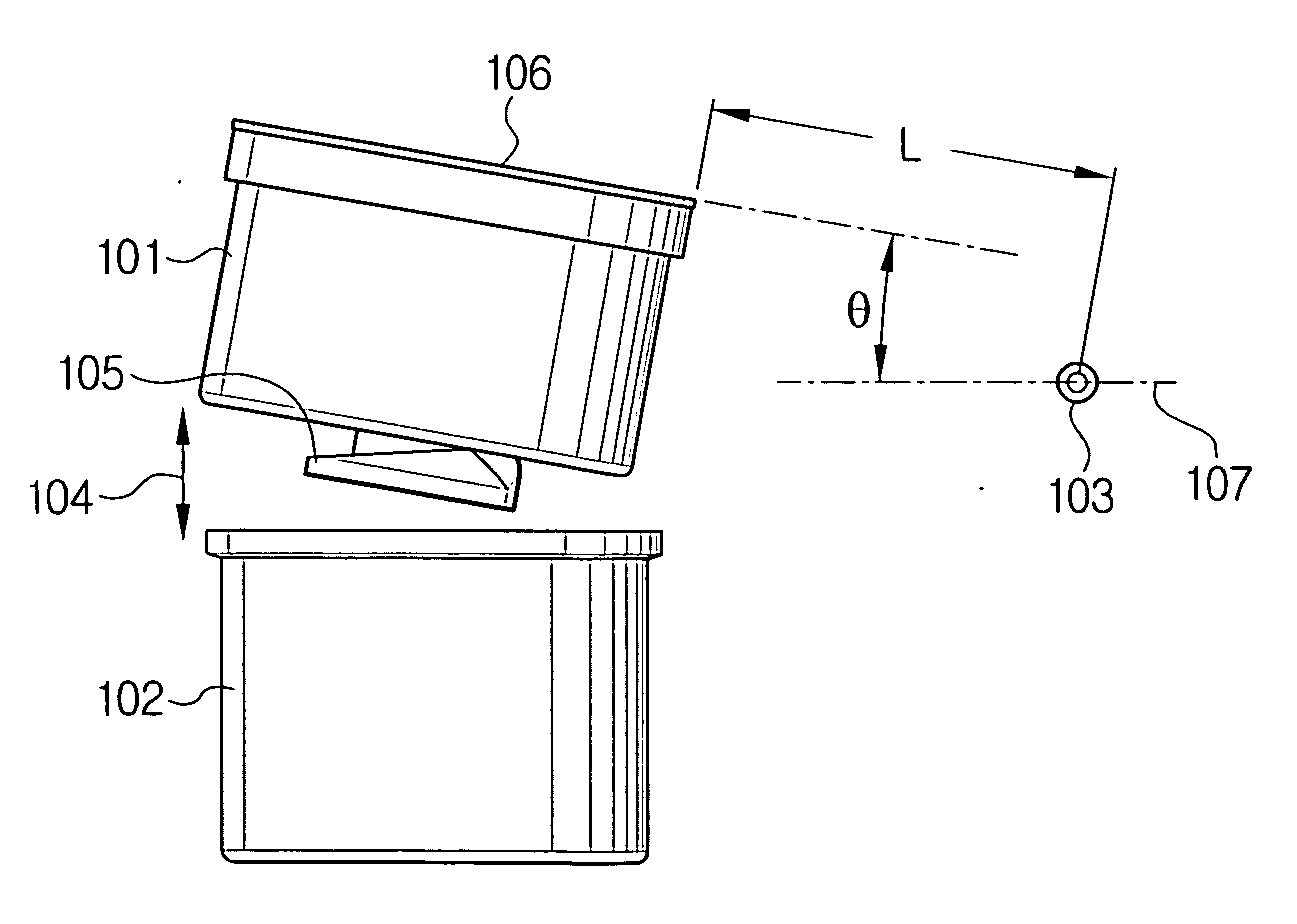

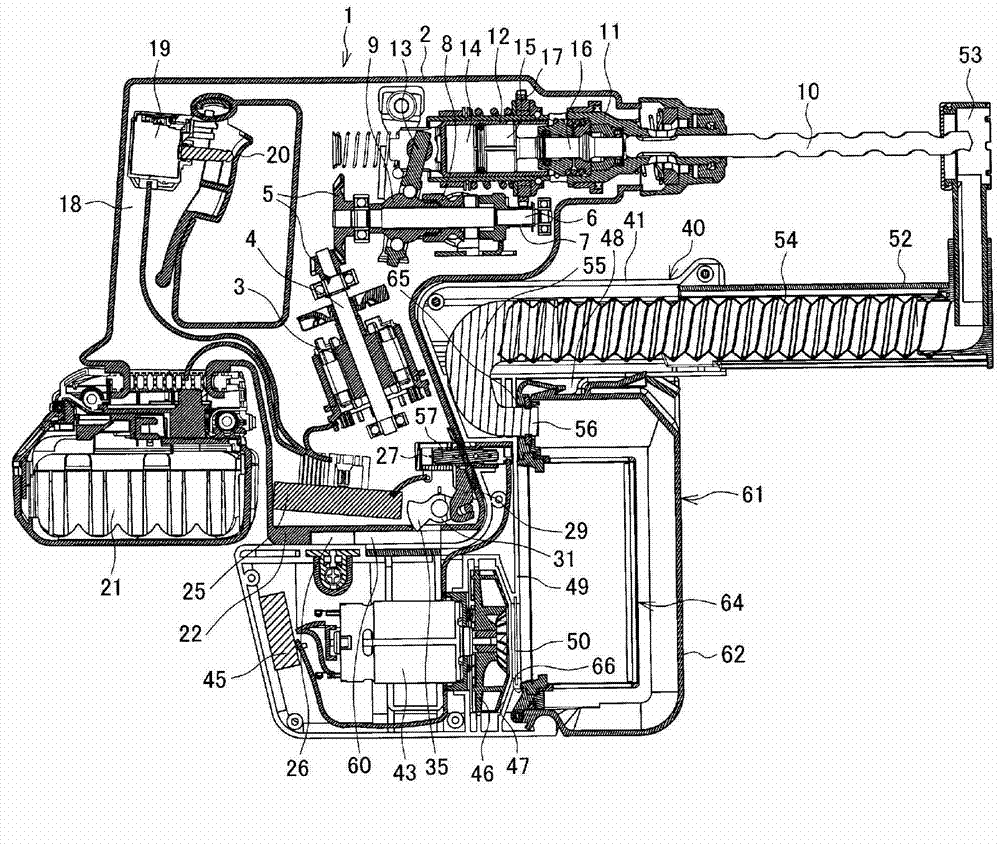

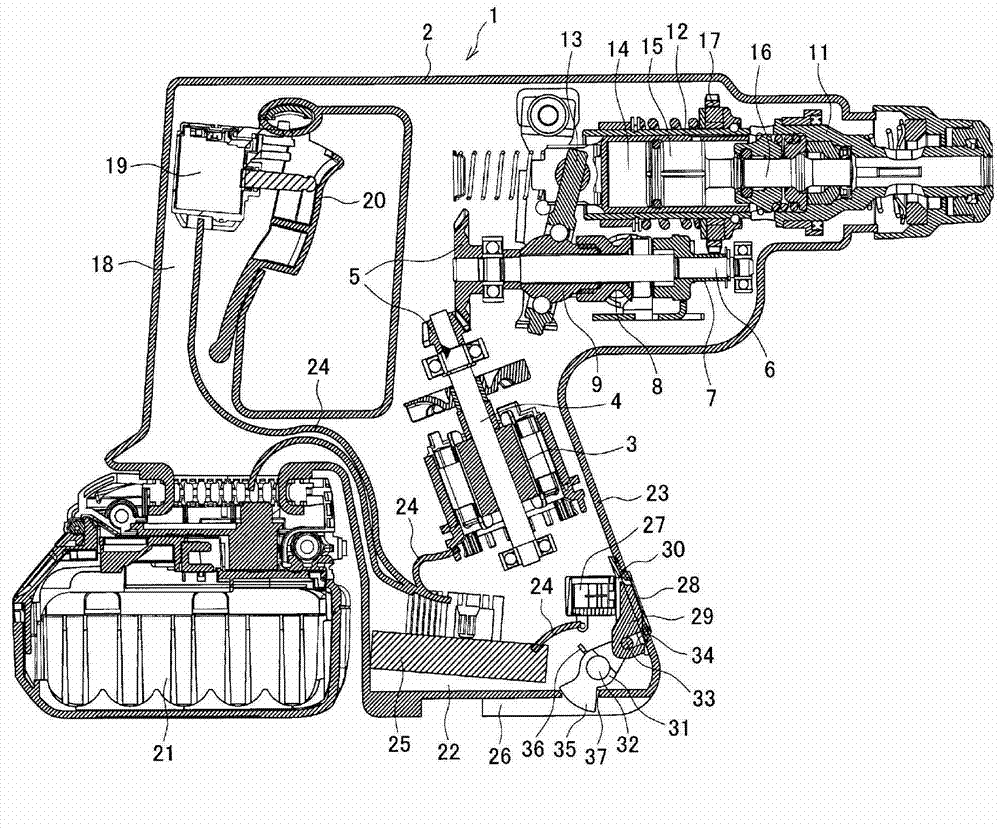

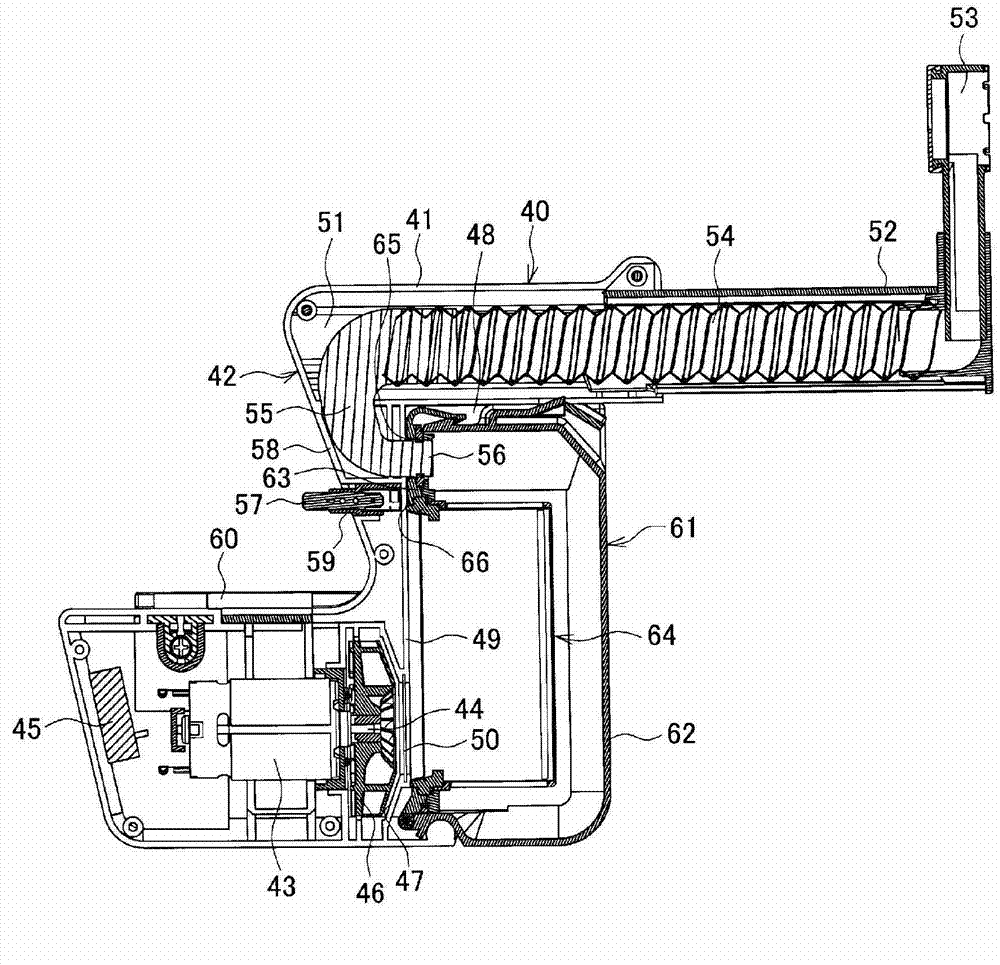

Cyclone-type vacuum cleaner

InactiveUS20060101611A1Improve dust collection effectDust receptacle can be heightenedCleaning filter meansSuction filtersCycloneMechanical engineering

A cyclone vacuum cleaner provides an improved capacity dust receptacle by structuring the cyclone body of the vacuum cleaner to be pivotally mounted to the vacuum cleaner body. The cyclone body is disconnected from the dust receptacle by rotating or “turning up” the cyclone body by rotating it about the pivotal mount. A dust receptacle removably mounted in the cleaner body and a cyclone body hinged on an upper part of the cleaner body are selectively separated and connected with respect to the dust receptacle.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

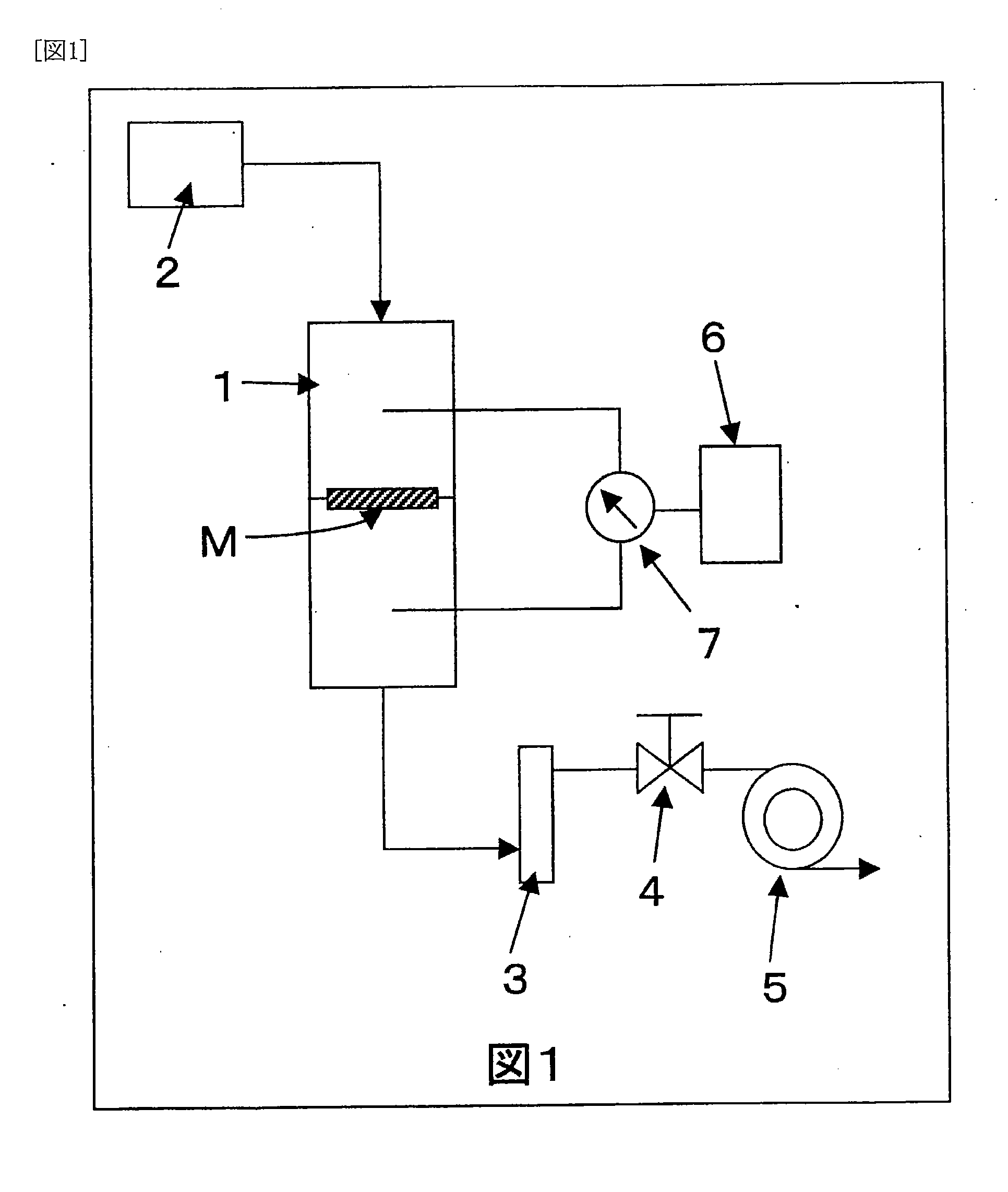

Electric dust collector

ActiveCN102056670BImprove dust collection effectSmall sizeExternal electric electrostatic seperatorElectrode constructionsThermodynamicsEngineering

Owner:FURUKAWA IND MACHINERY SYST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com