Self-propelled vacuum cleaner

a self-propelled, vacuum cleaner technology, applied in carpet cleaners, carpet sweepers, electric equipment installation, etc., can solve the problems of cleaners that cannot prevent the rear portions of the side brushes from contacting with the floor, and the outer end portions of the side brushes cannot prevent dust scattering at the rear portions of the side brushes. achieve the effect of improving dust collection power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

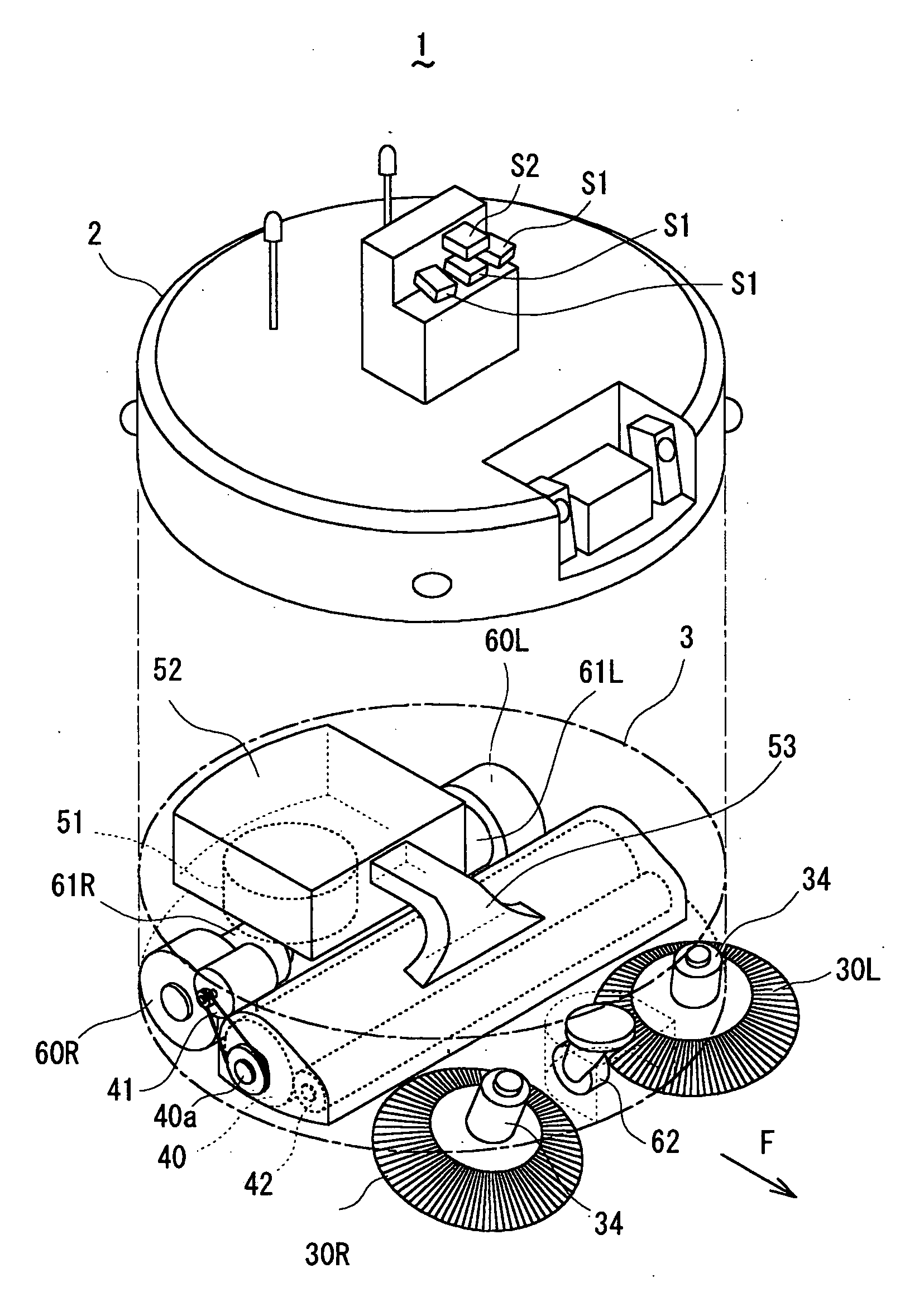

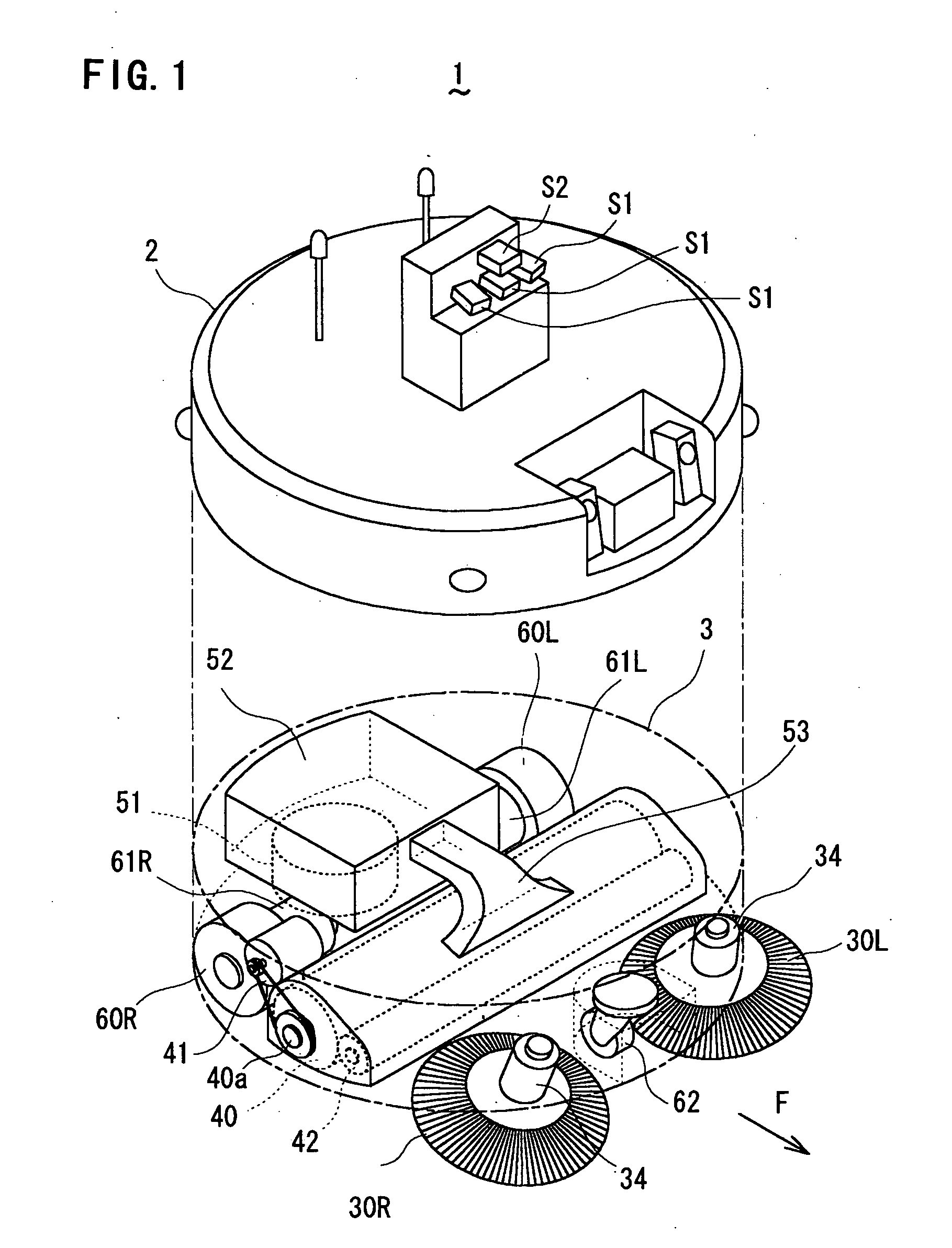

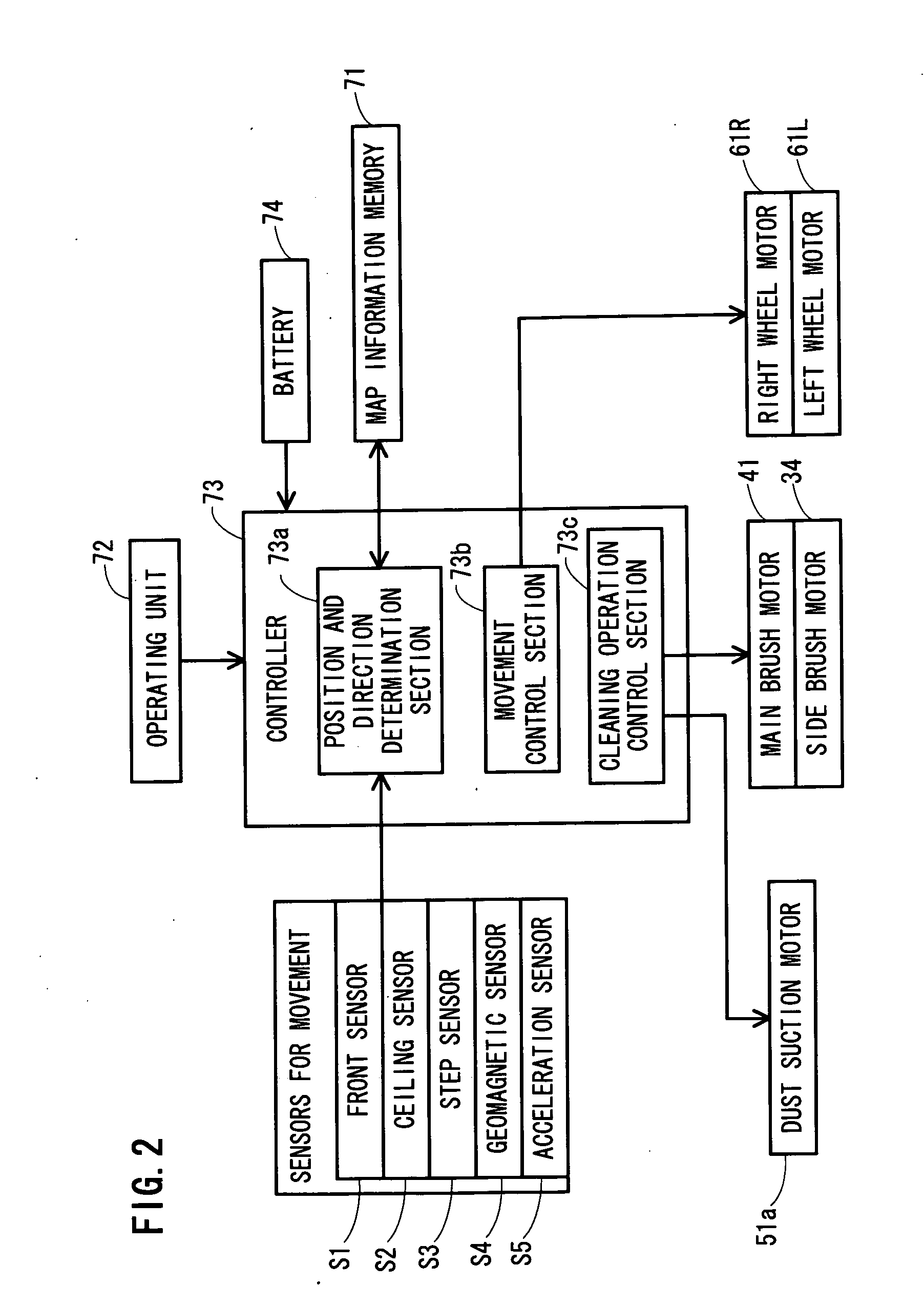

[0021] Referring now to the accompanying drawings, a self-propelled vacuum cleaner embodying the present invention will be described. FIG. 1 shows a cleaner body 1 of the self-propelled vacuum cleaner according to this embodiment, which is a device that autonomously moves on a floor surface to clean the floor surface. The cleaner body 1 comprises: a behavior control unit 2 that determines an area to be cleaned based on output signals of a plurality of sensors S1, S2, etc. and controls a cleaning operation of the cleaner body 1; and a dust collection unit 3 that moves around a floor surface based on control signals from the behavior control unit 2 to remove dust from the floor. In FIG. 1, the cleaner body 1 comprising the behavior control unit 2 and the dust collection unit 3 is separated into the behavior control unit 2 and the dust collection unit 3 for purposes of illustration.

[0022] The dust collection unit 3 comprises a pair of side brushes 30R and 30L provided at right and lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com