Patents

Literature

2249results about "Robotic cleaning machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

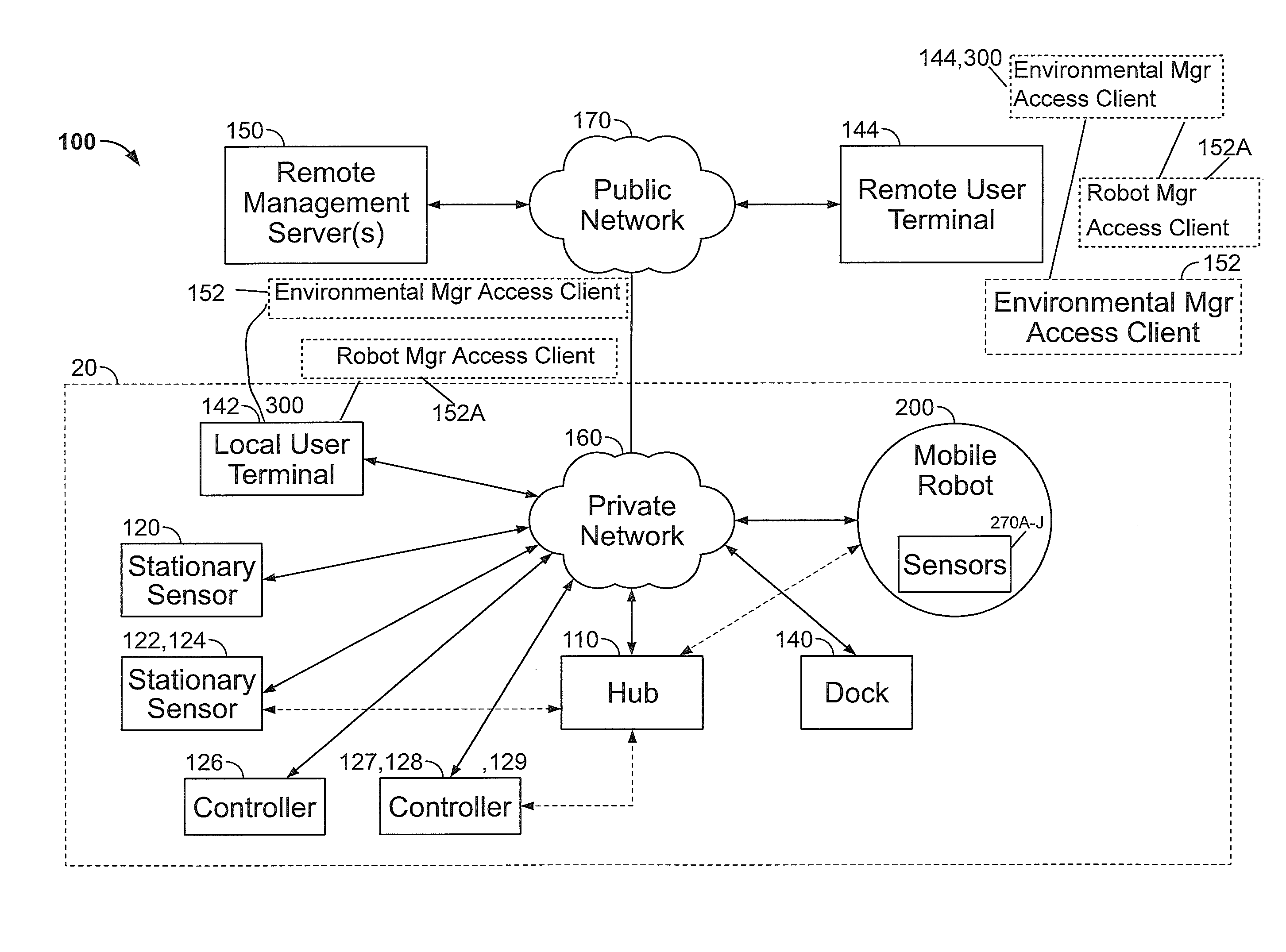

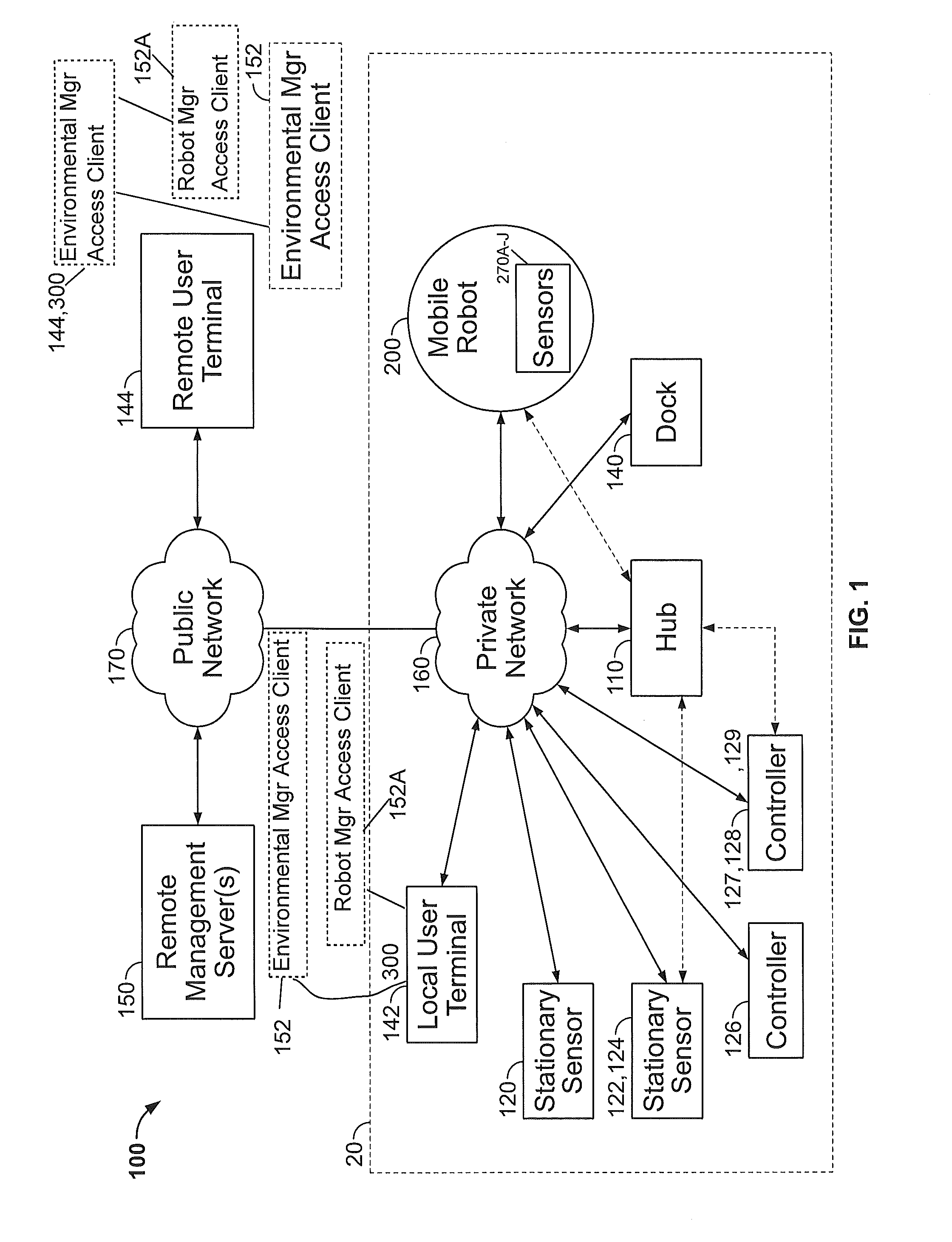

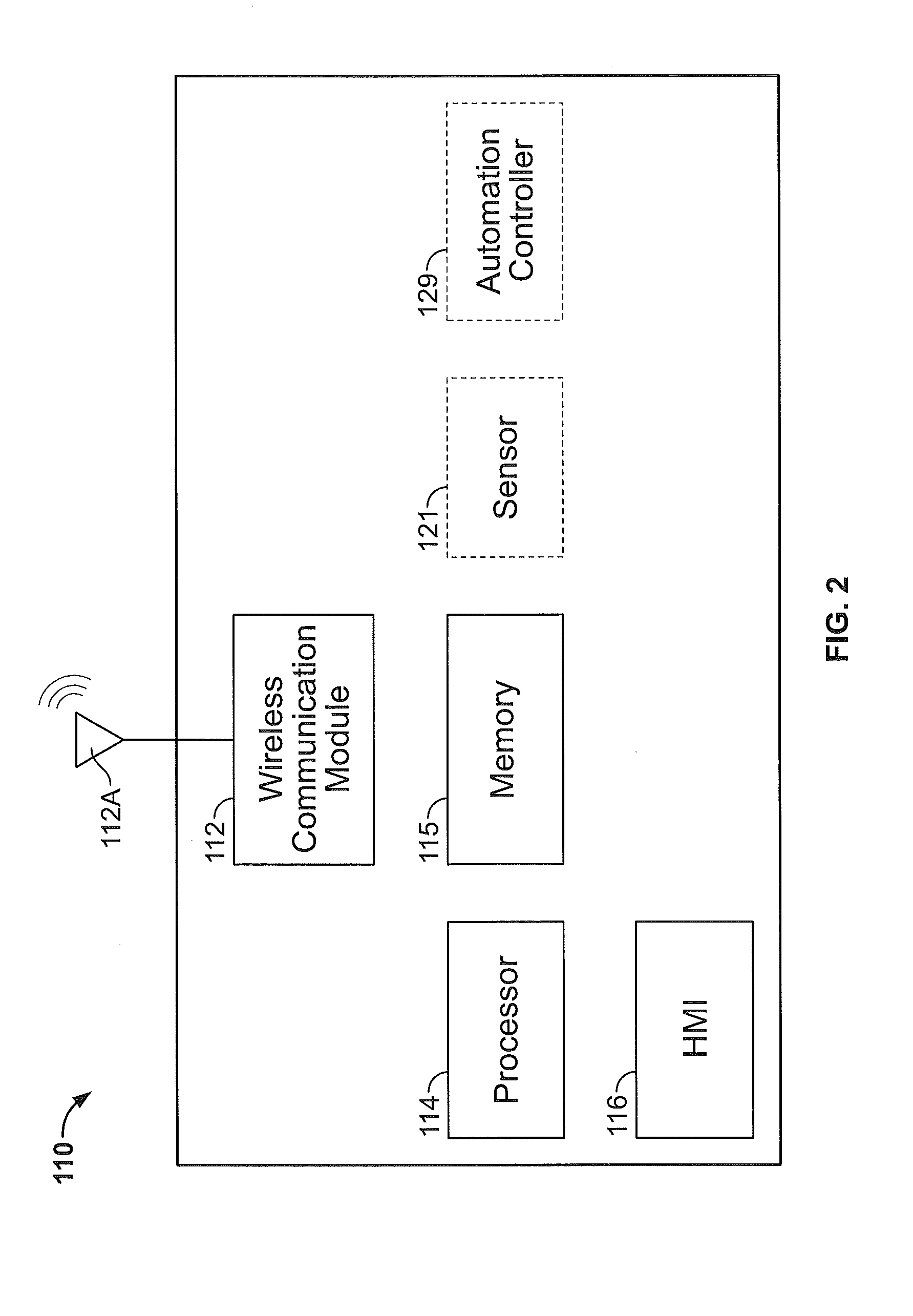

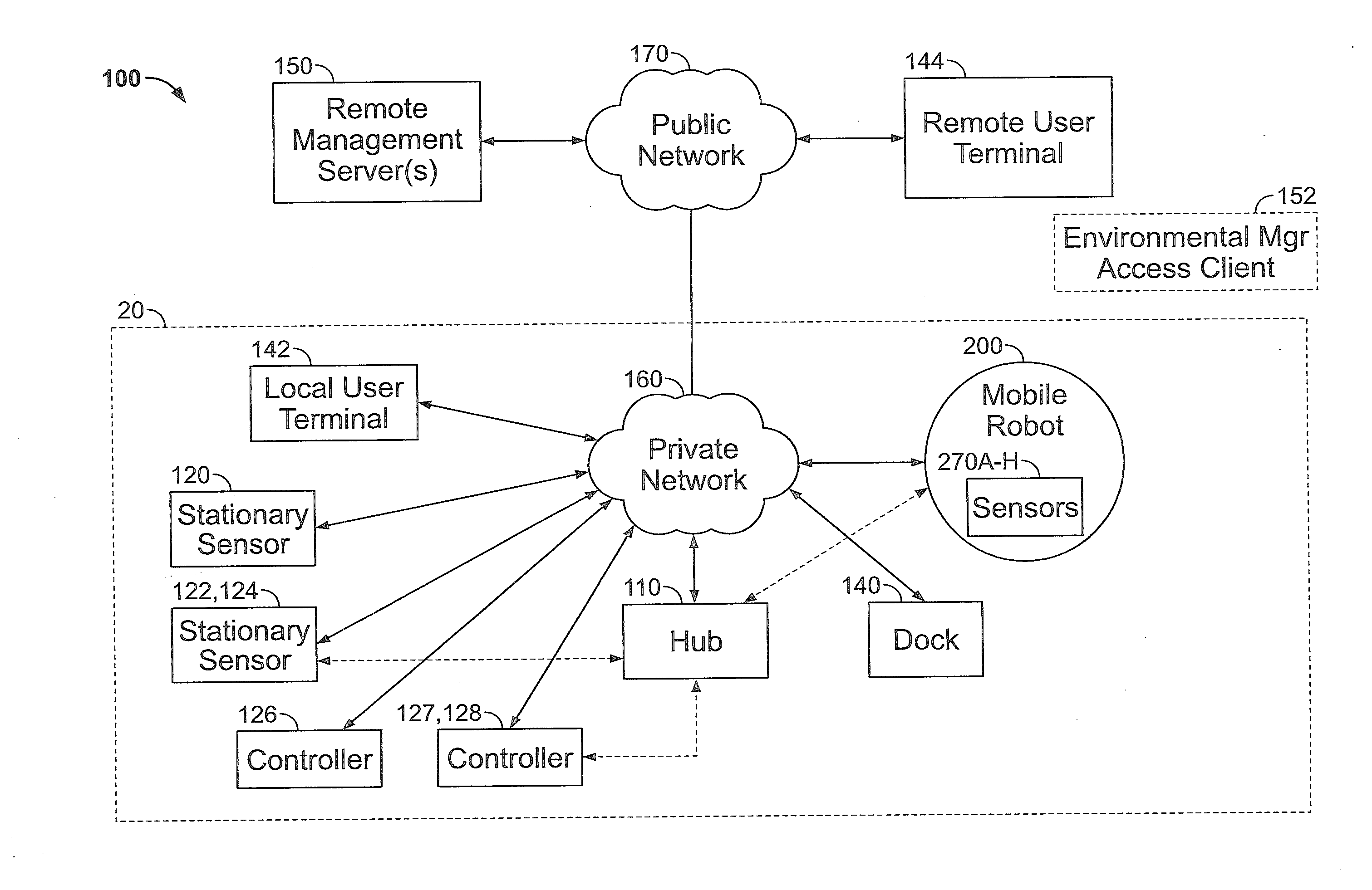

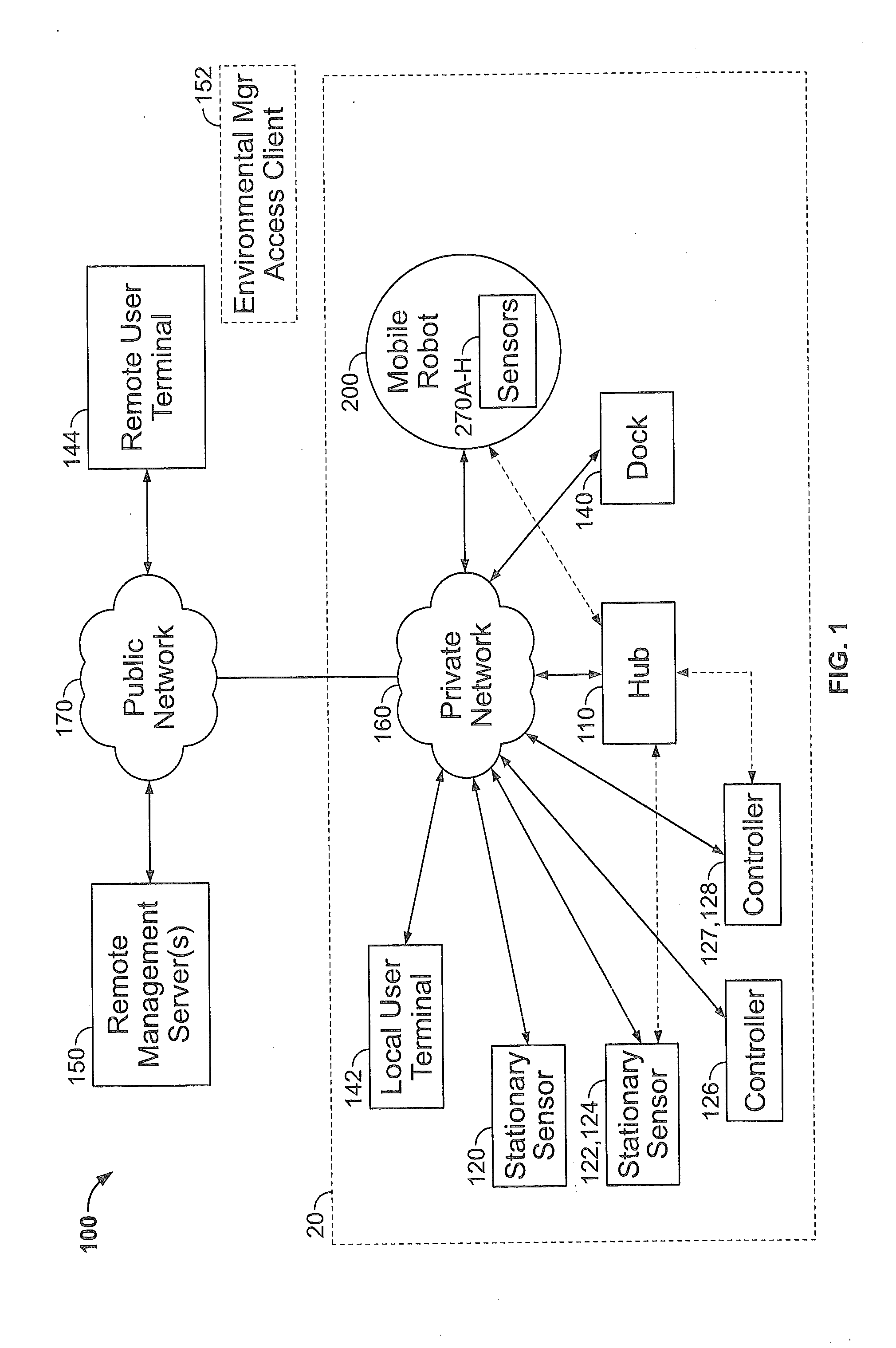

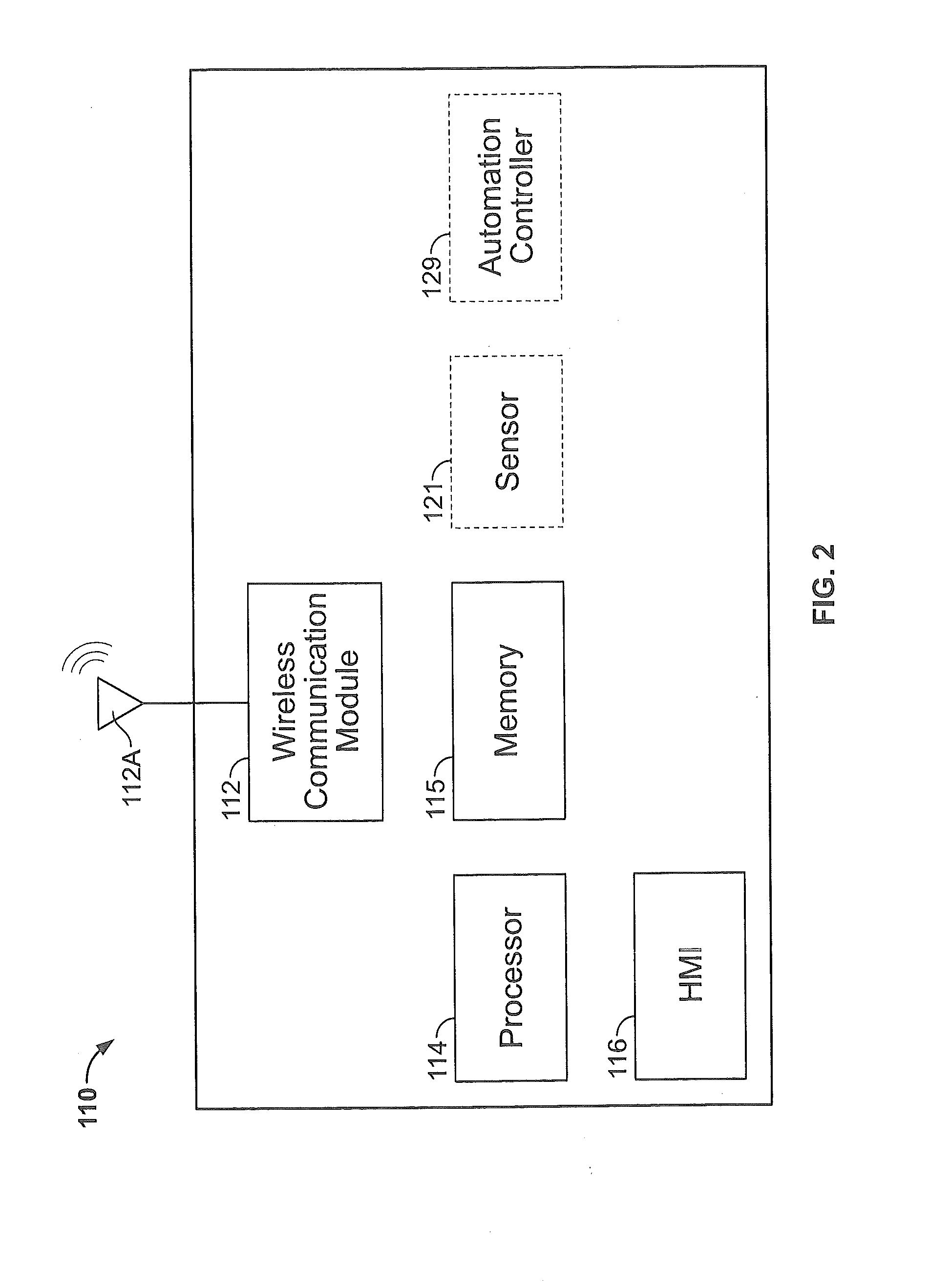

Mobile Robot Providing Environmental Mapping for Household Environmental Control

ActiveUS20140207282A1Improve reliabilityConfidenceProgramme-controlled manipulatorNear-field transmissionActuatorAction status

A mobile robot includes a processor connected to a memory and a wireless network circuit, for executing routines stored in the memory and commands generated by the routines and received via the wireless network circuit. The processor drives the mobile robot to a multiplicity of accessible two dimensional locations within a household, and commands an end effector, including at least one motorized actuator, to perform mechanical work in the household. A plurality of routines include a first routine which monitors a wireless local network and detects a presence of a network entity on the wireless local network, a second routine which receives a signal from a sensor detecting an action state of one of the network entities, the action state changeable between waiting and active, and a third routine which commands the end effector to change state of performing mechanical work based on the presence and on the action state.

Owner:IROBOT CORP

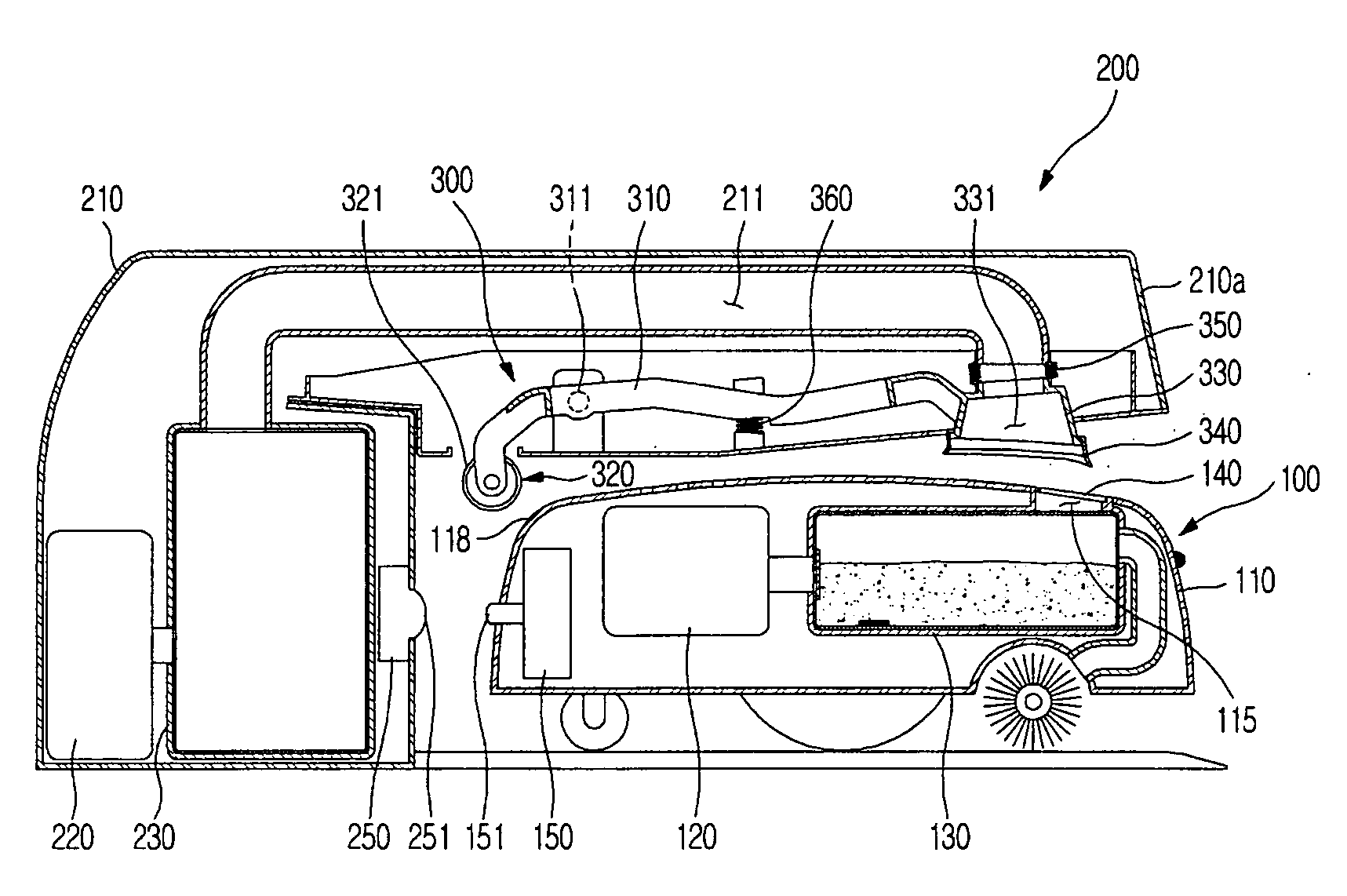

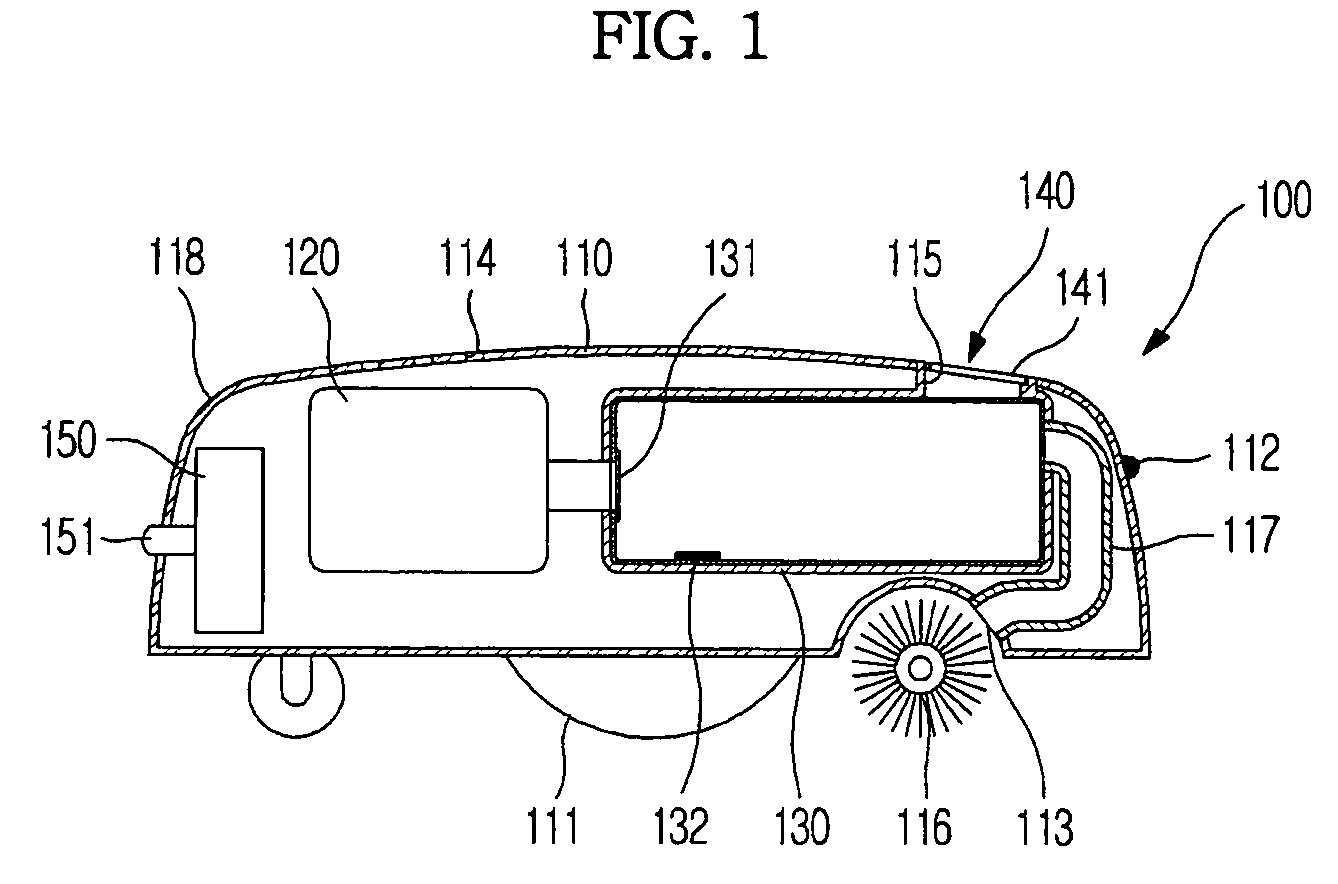

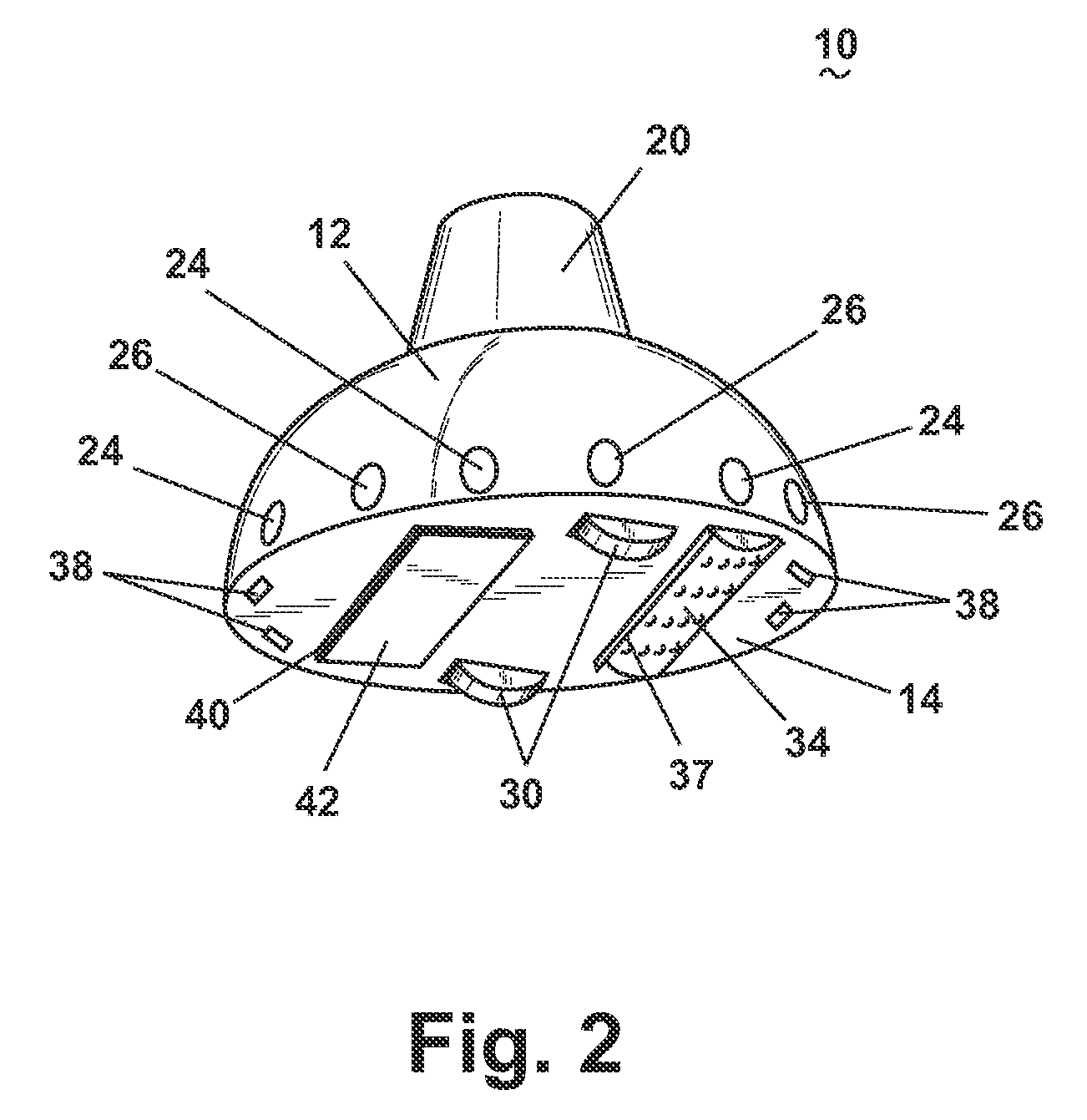

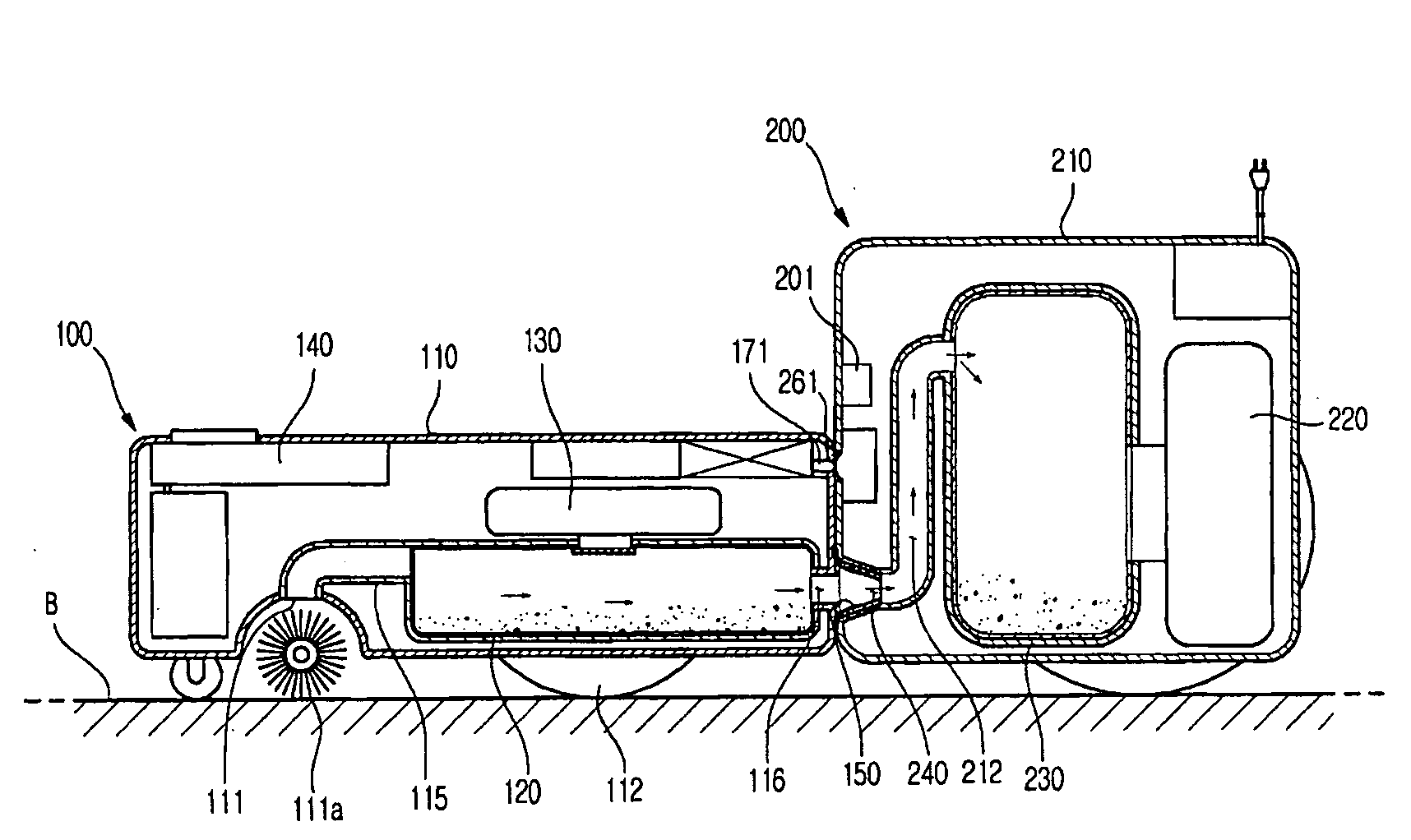

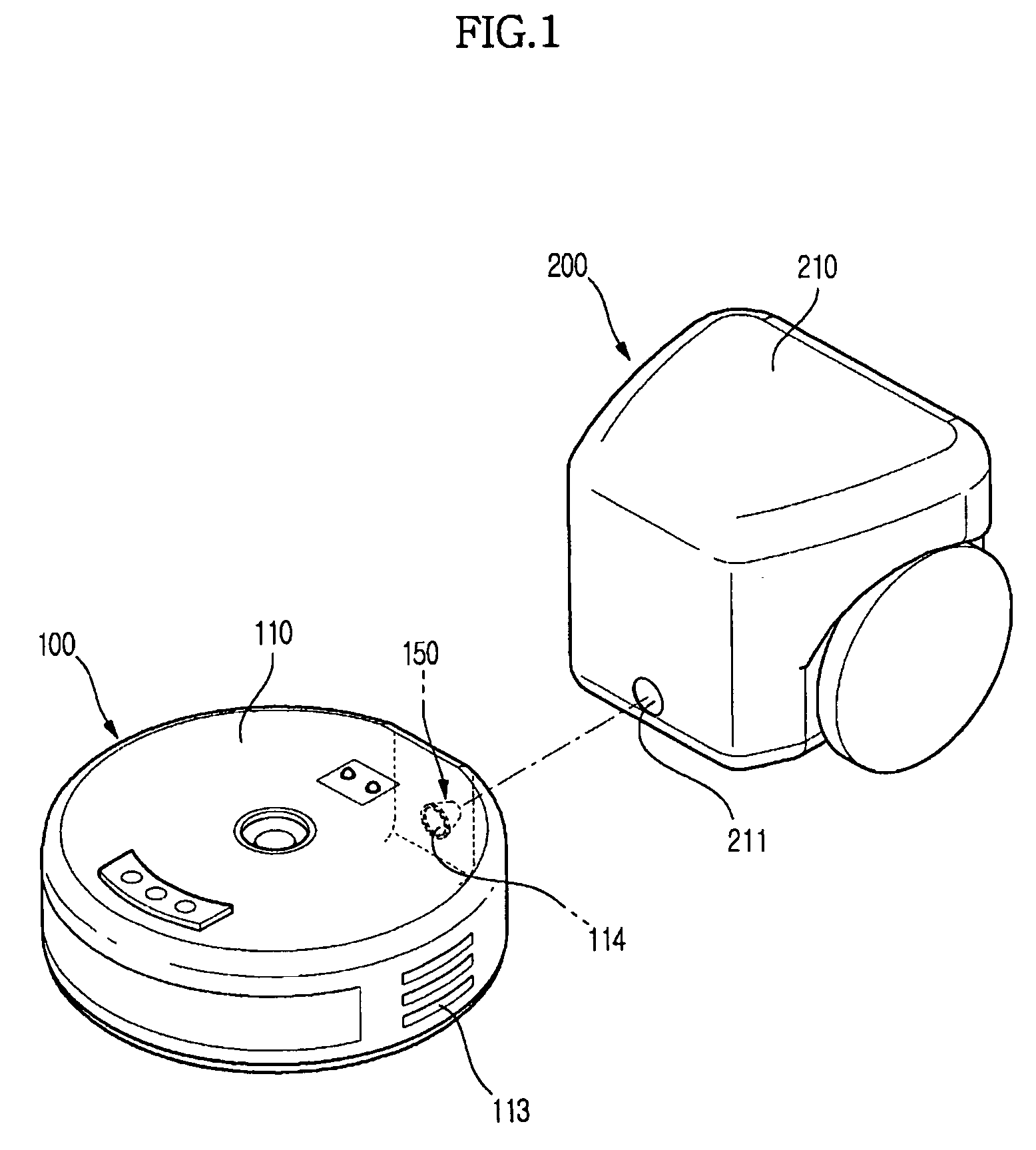

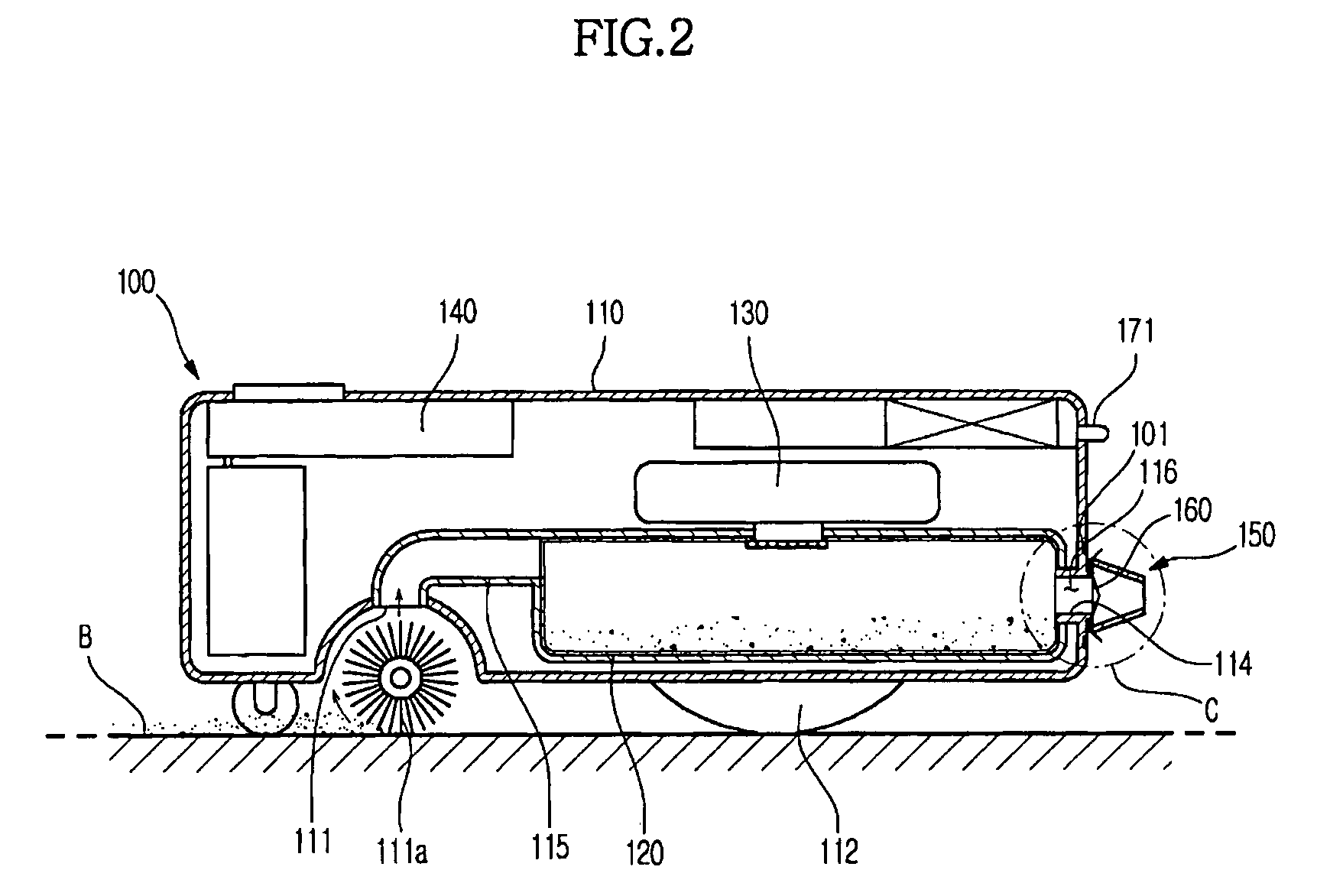

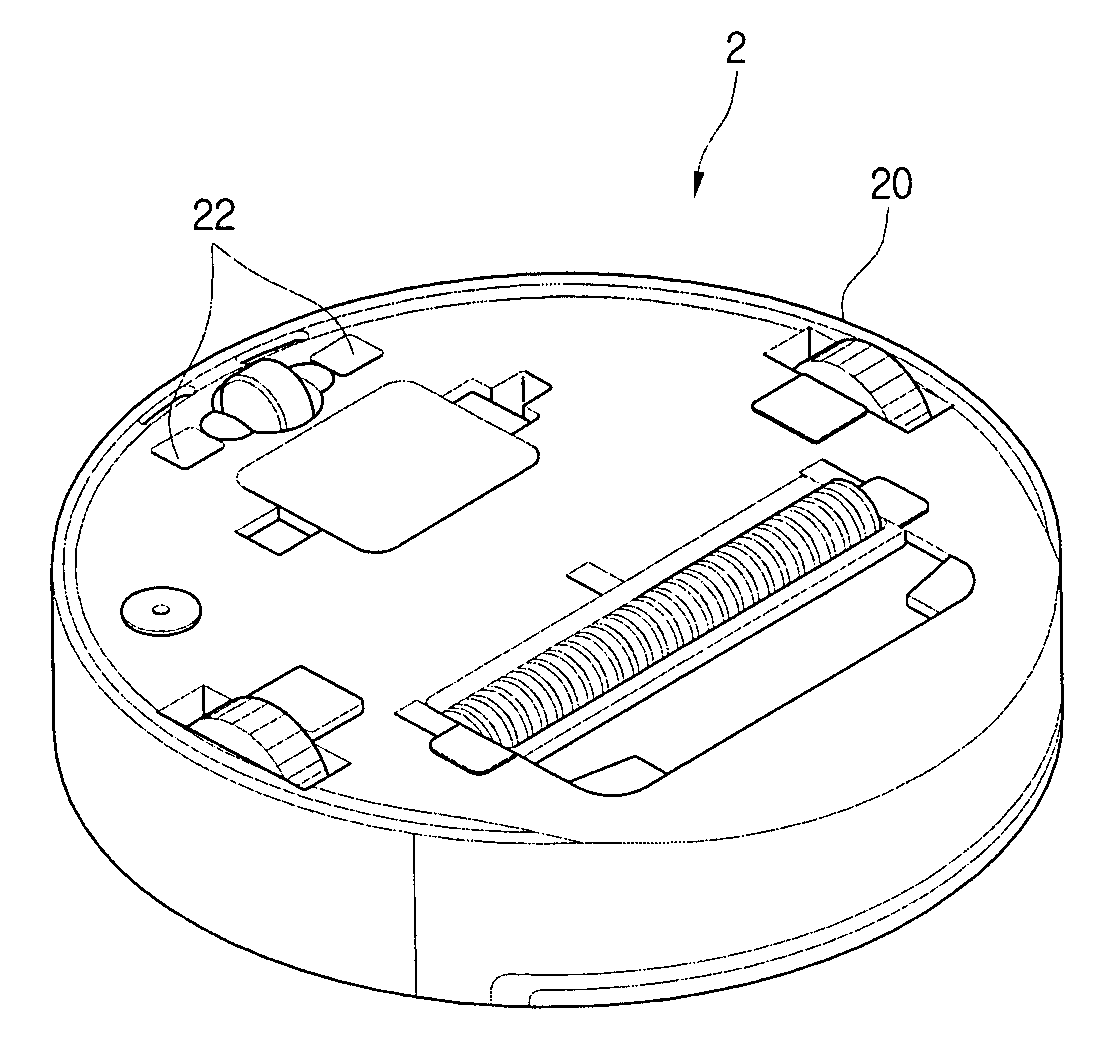

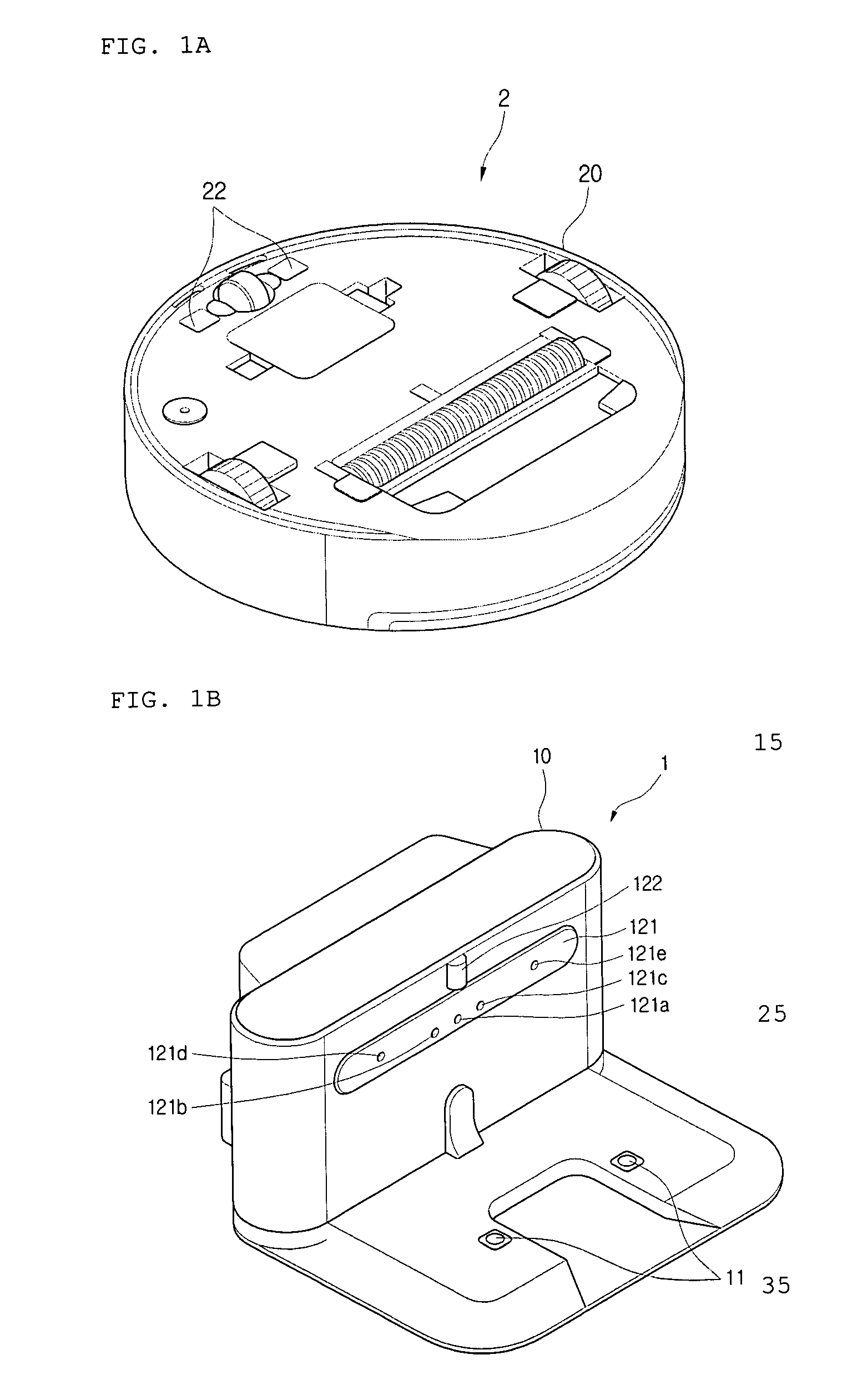

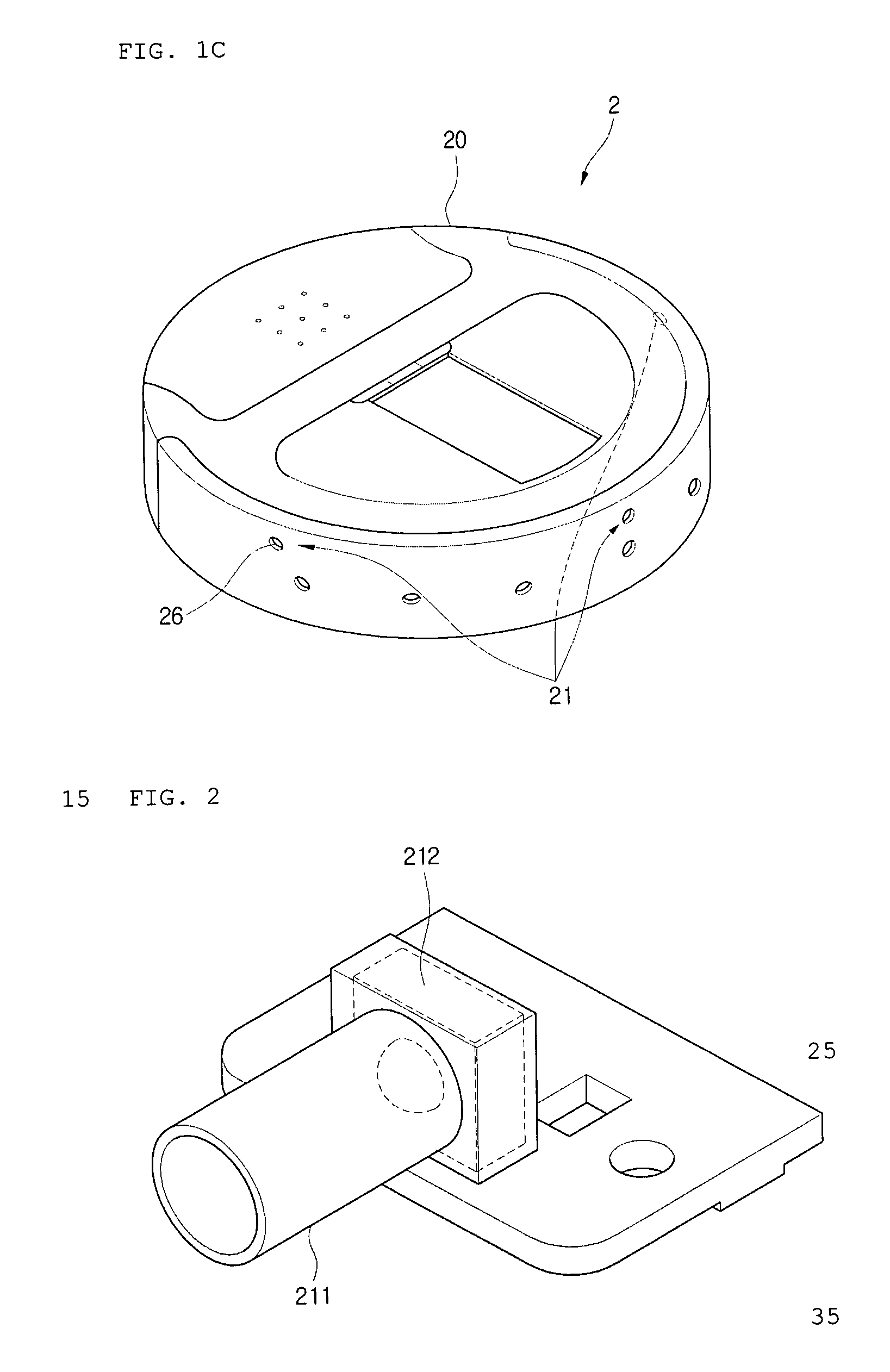

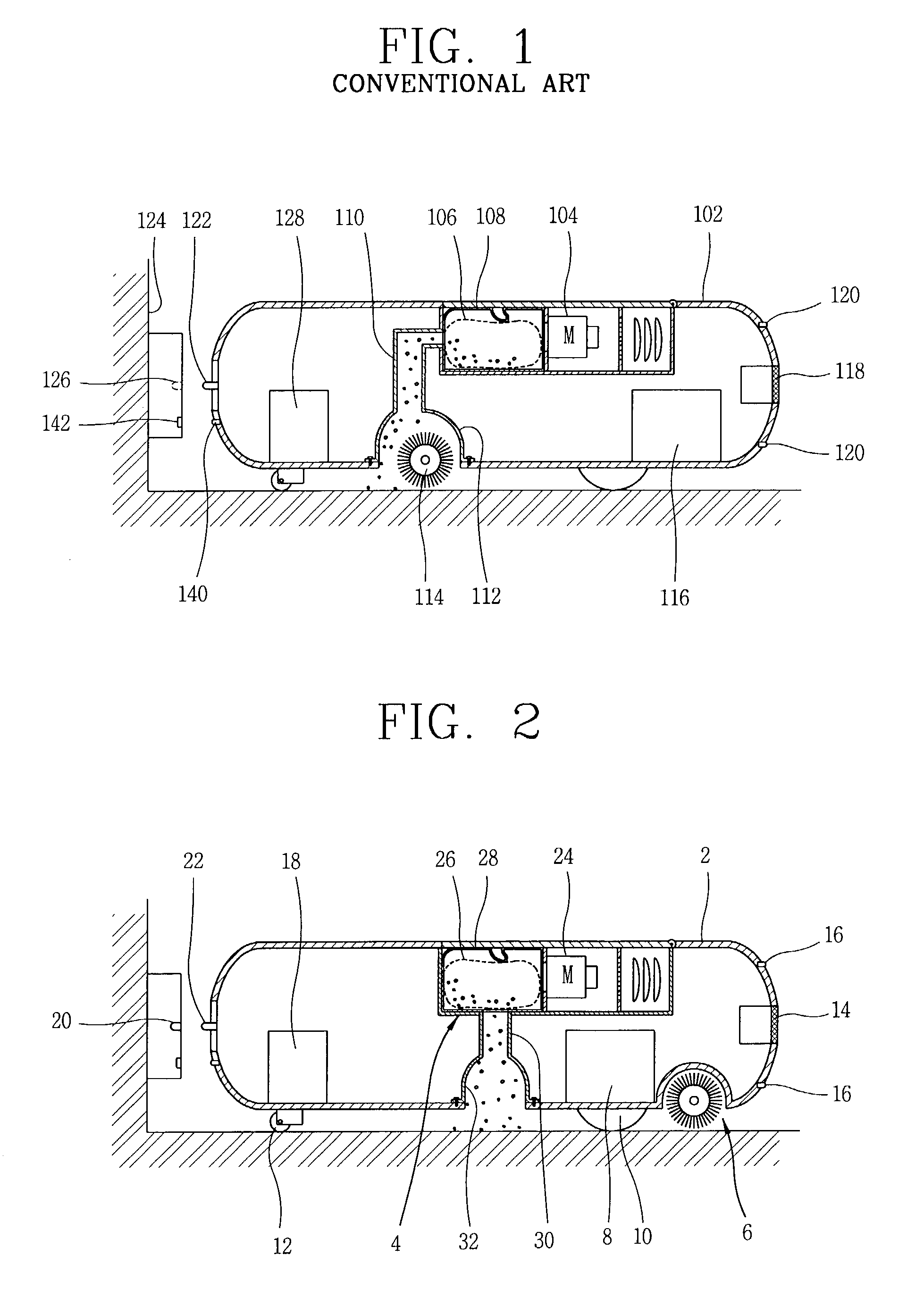

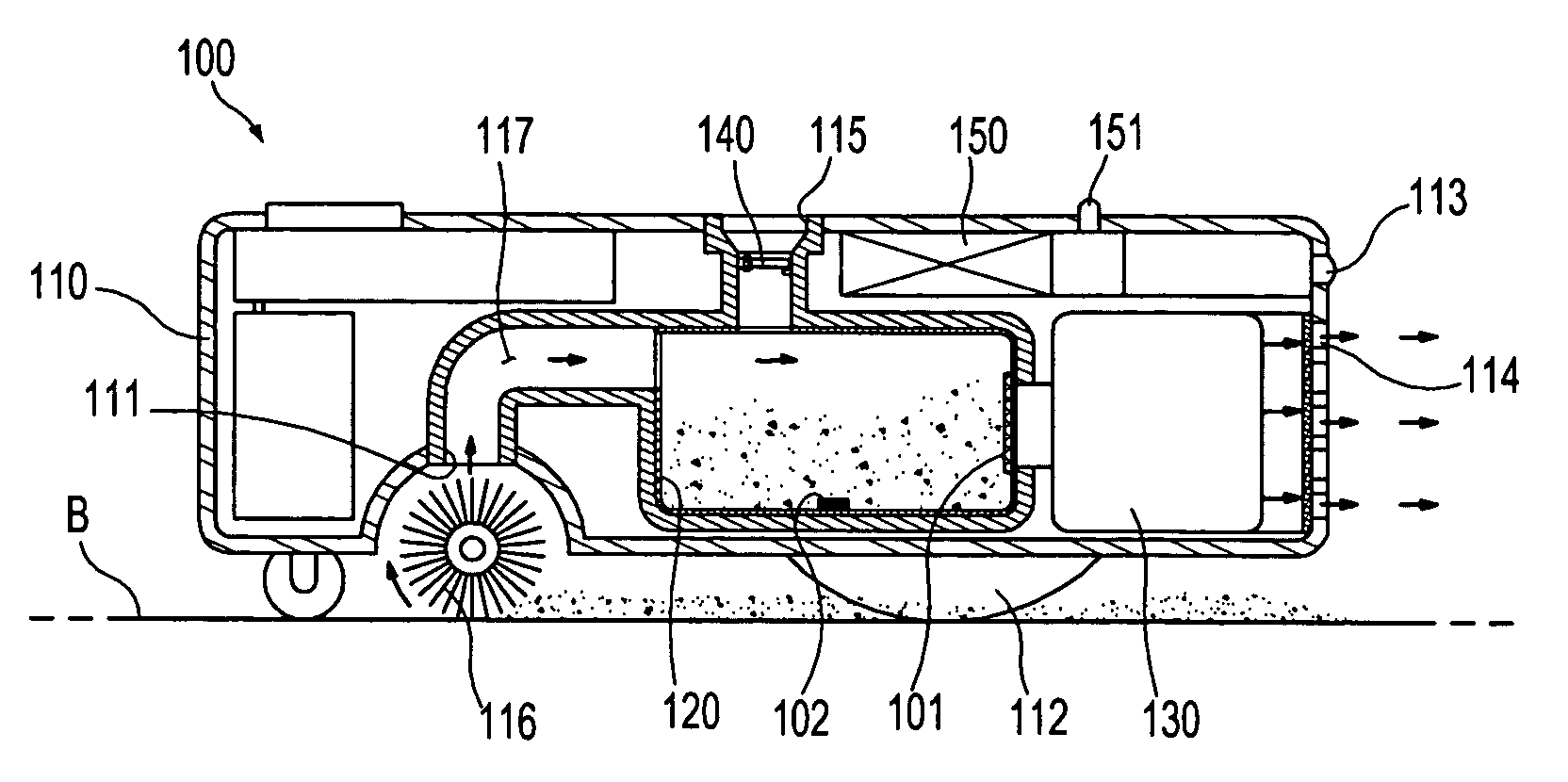

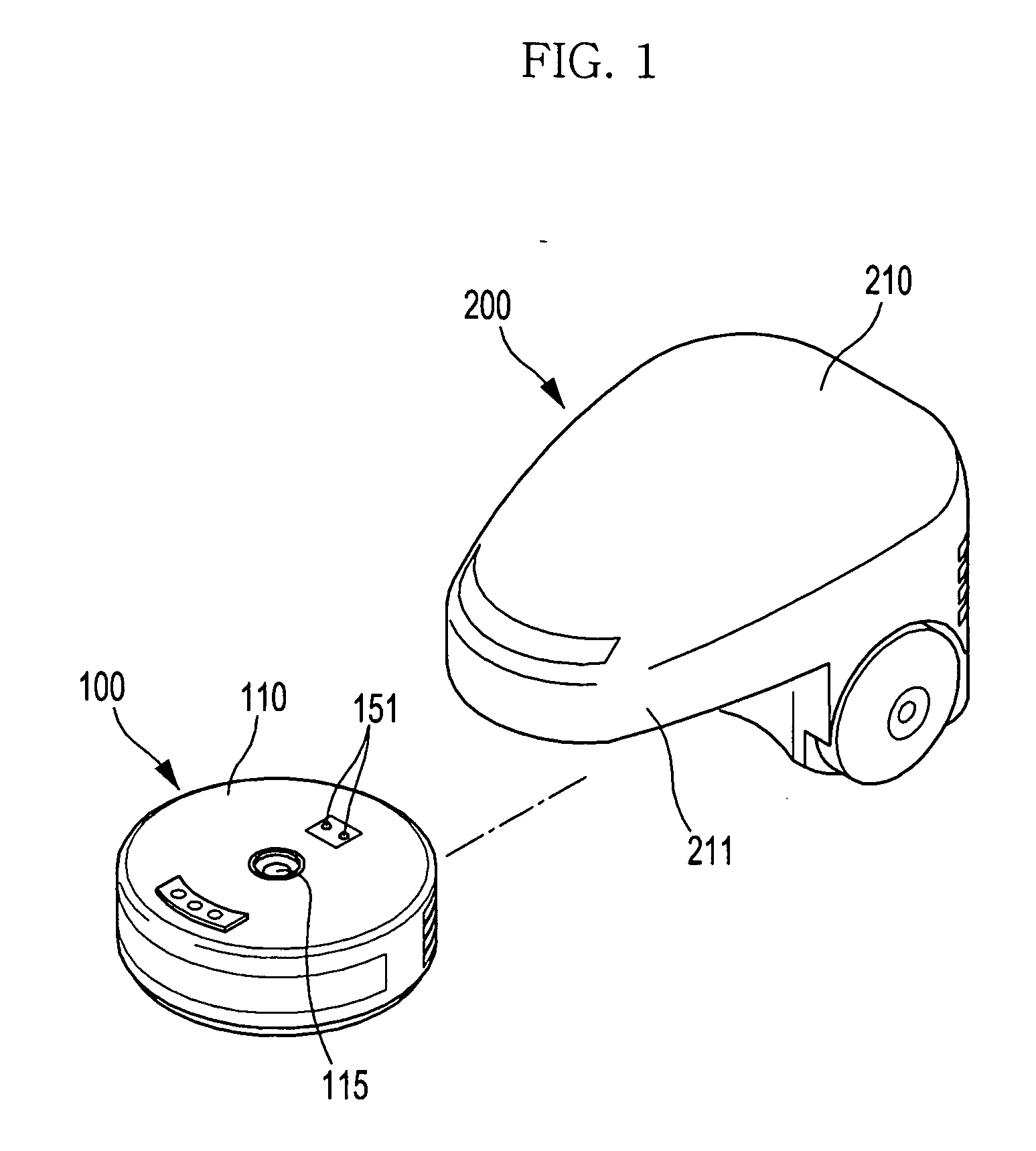

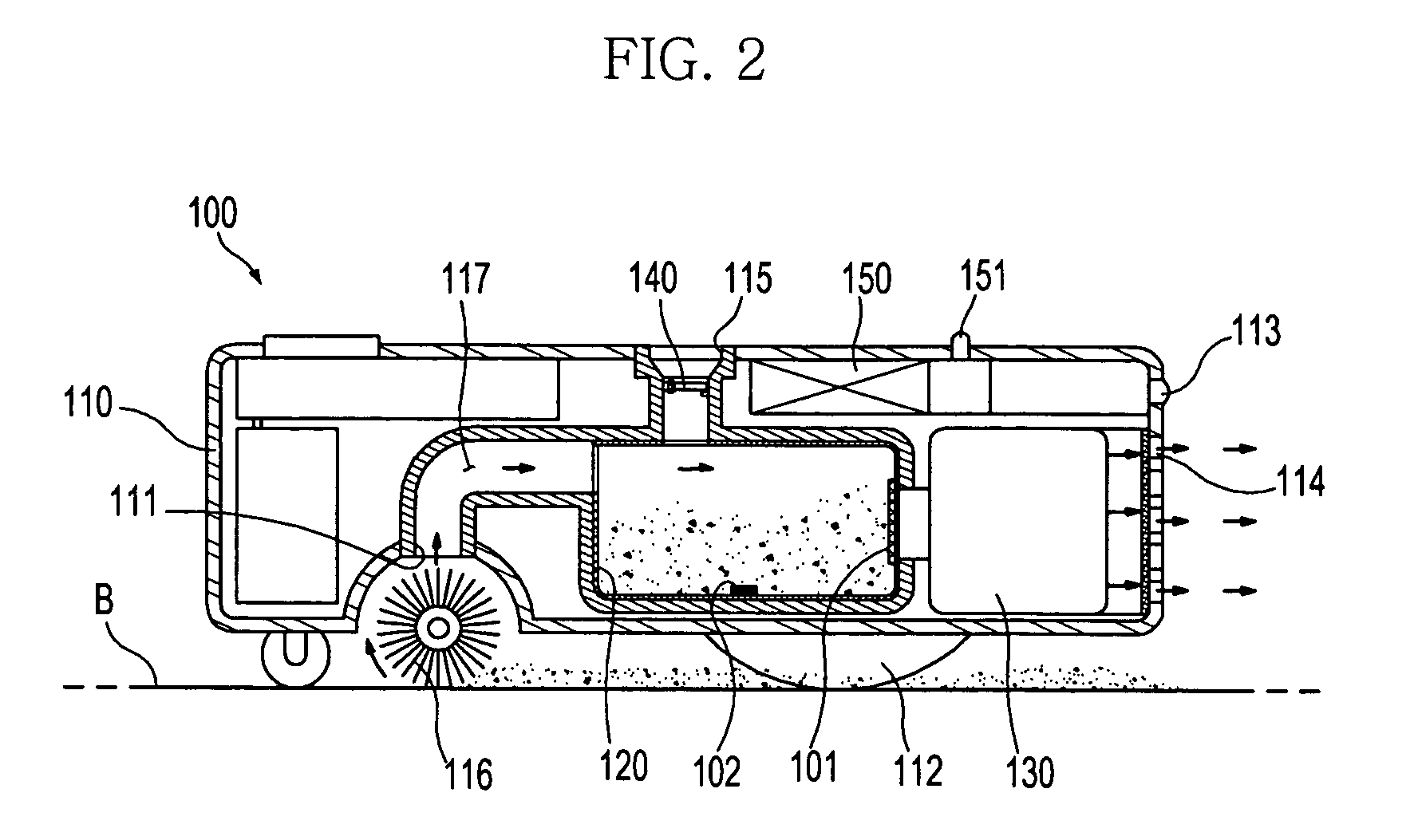

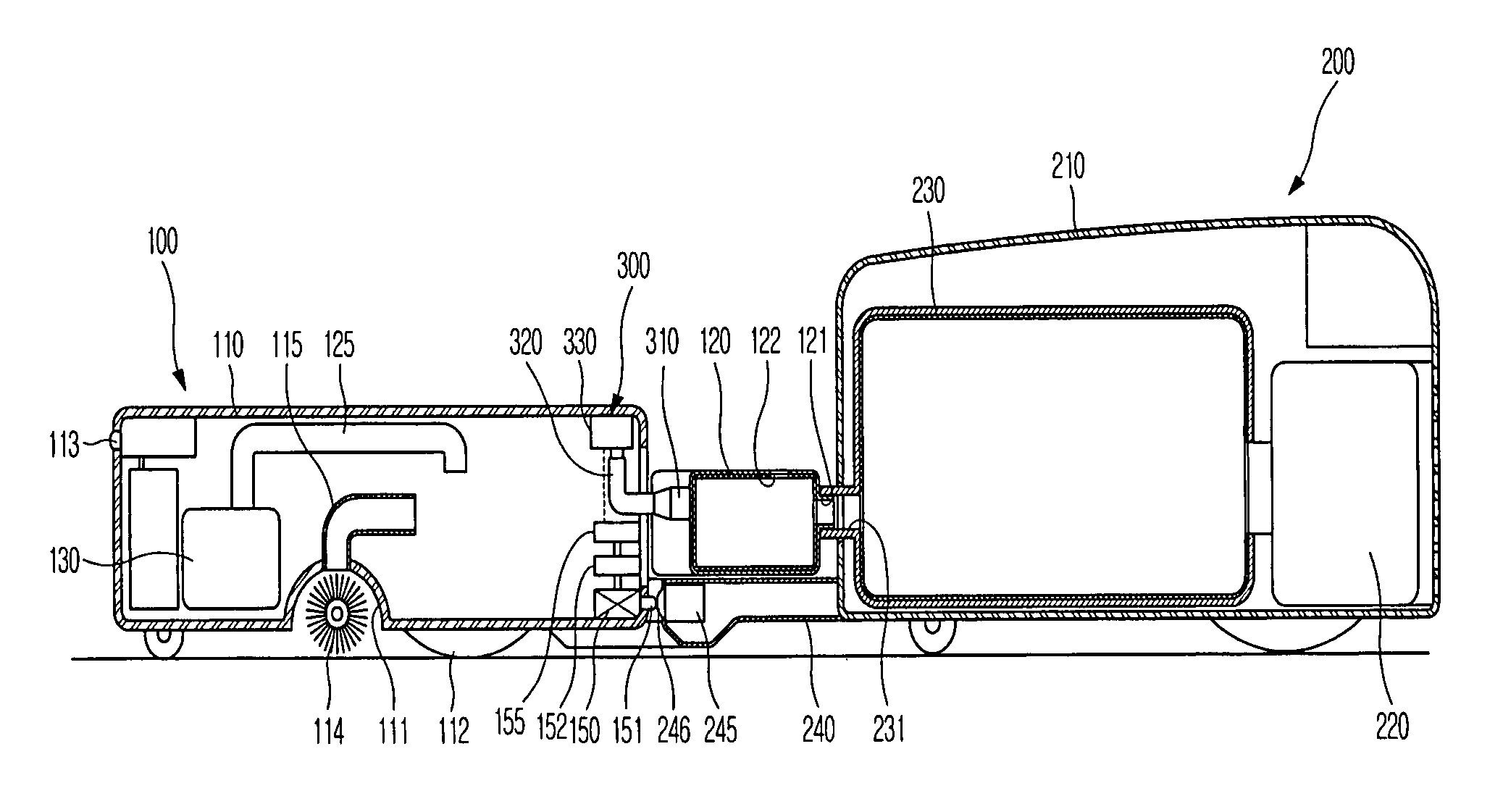

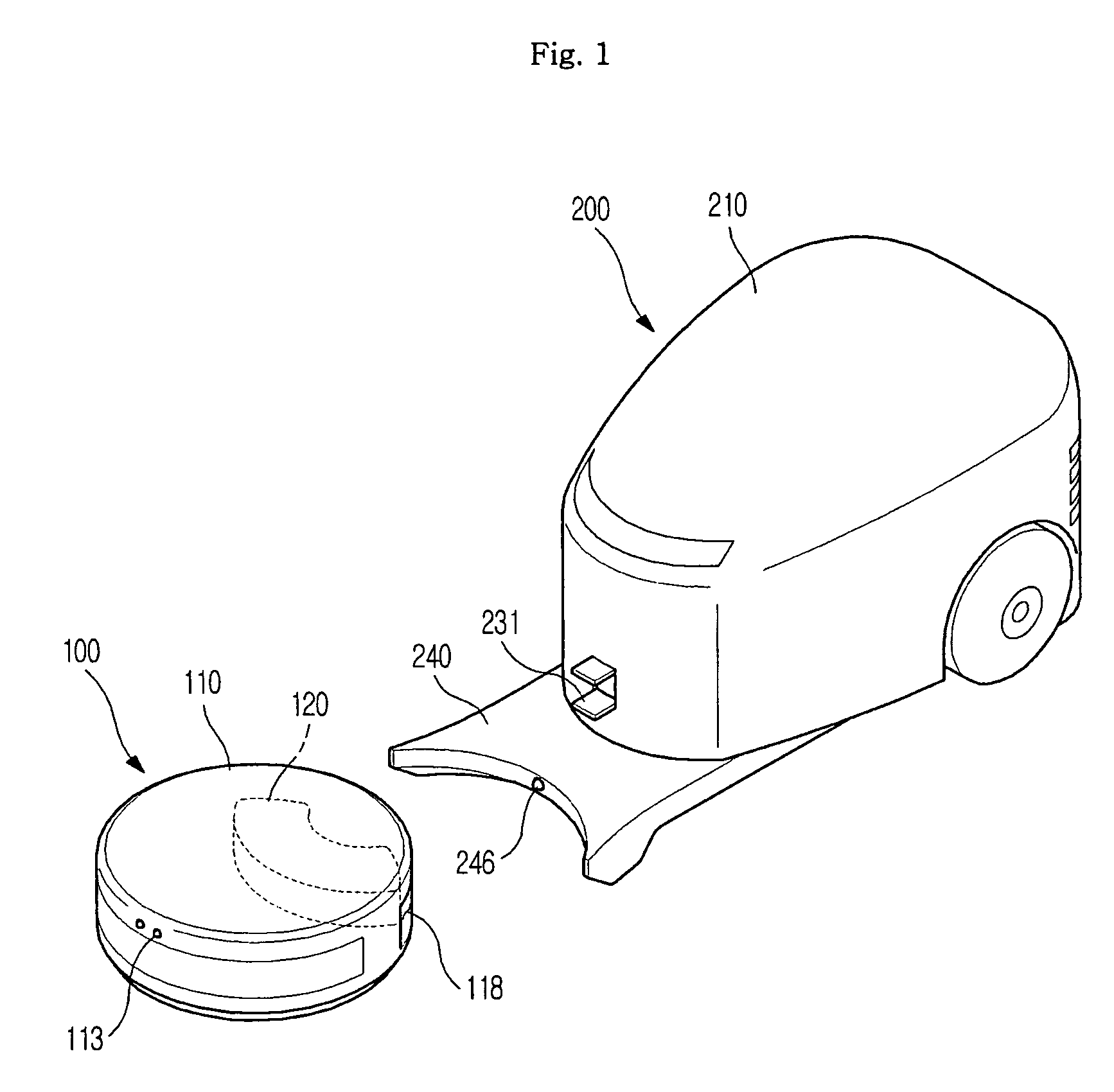

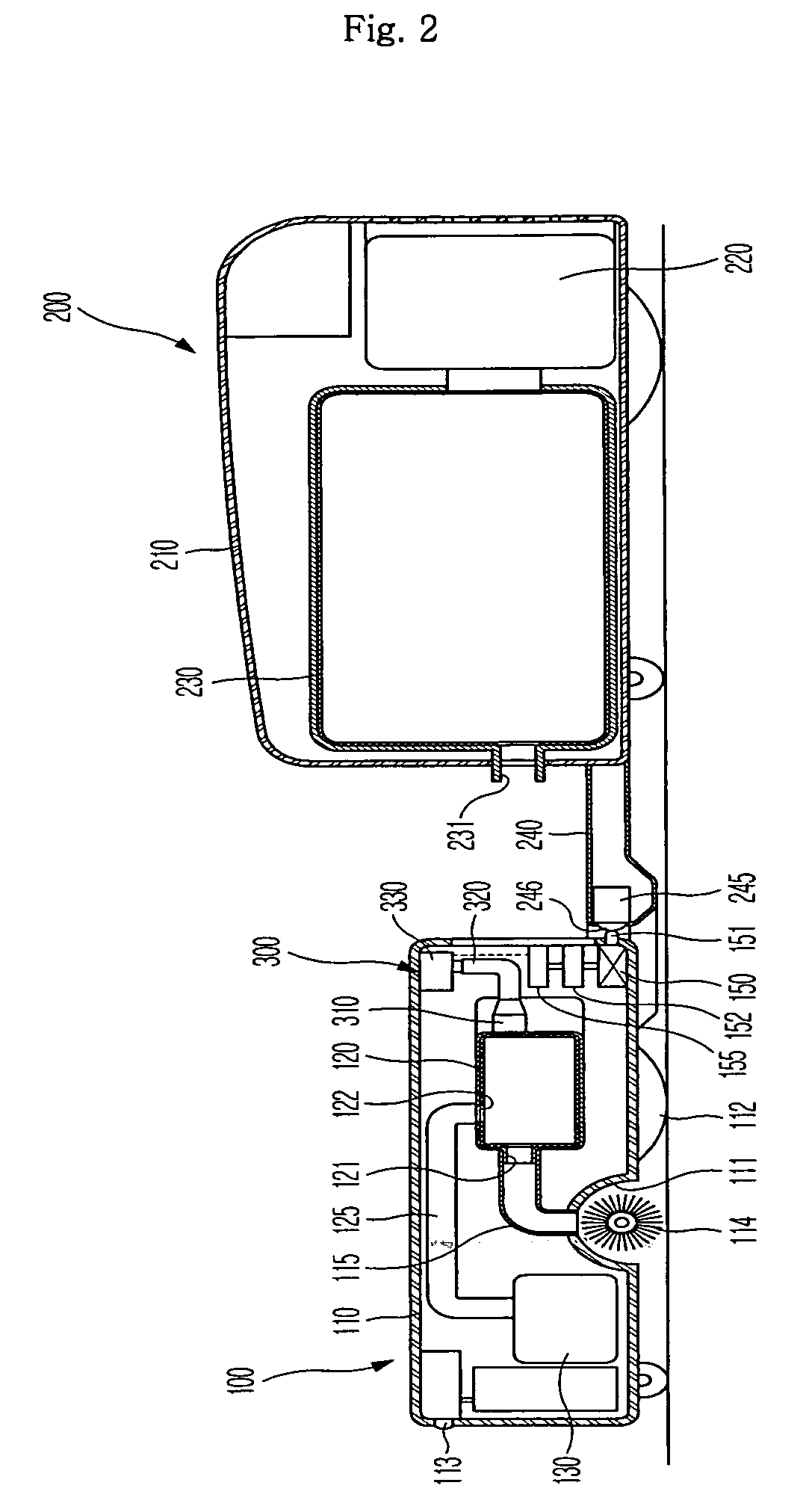

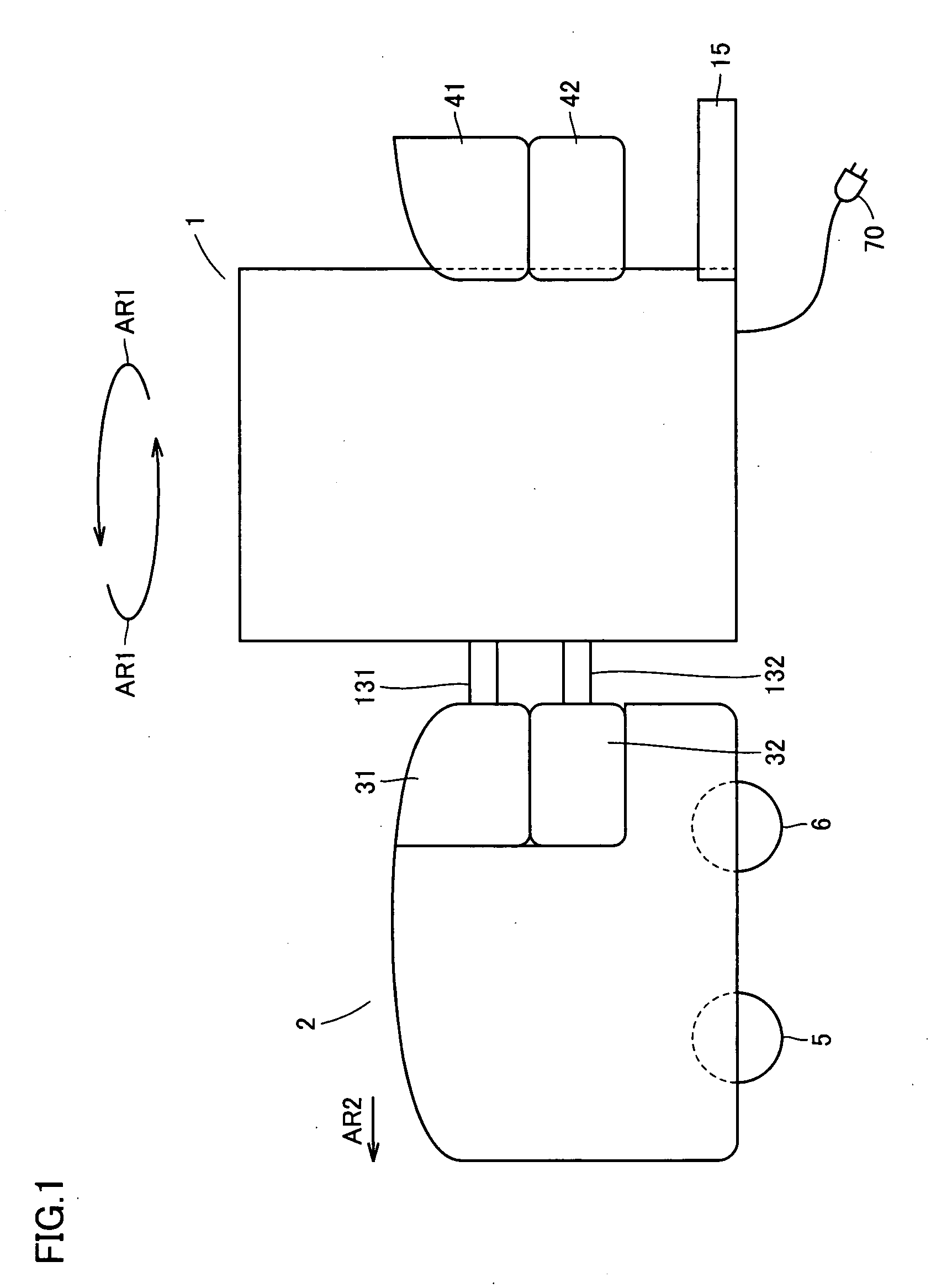

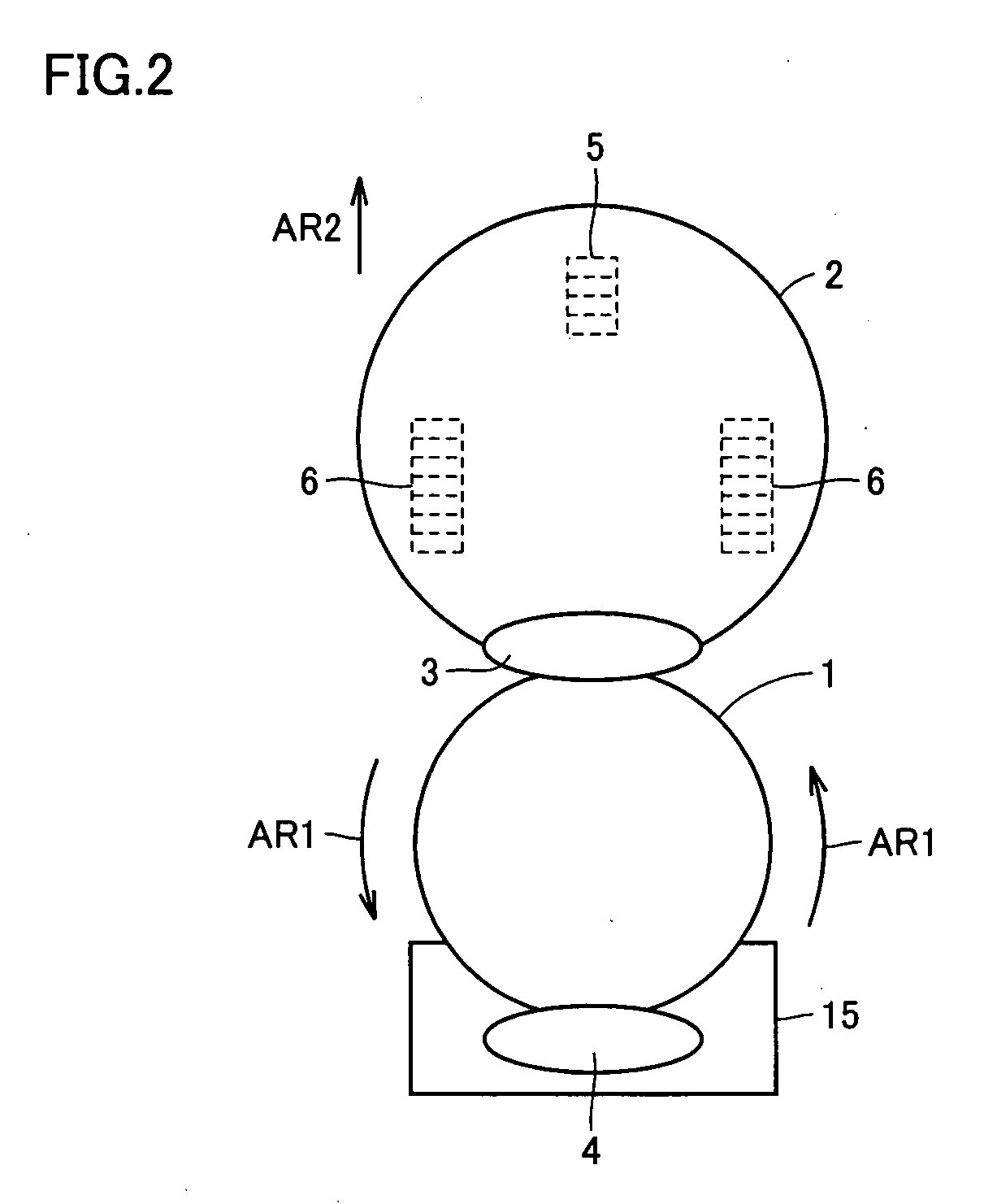

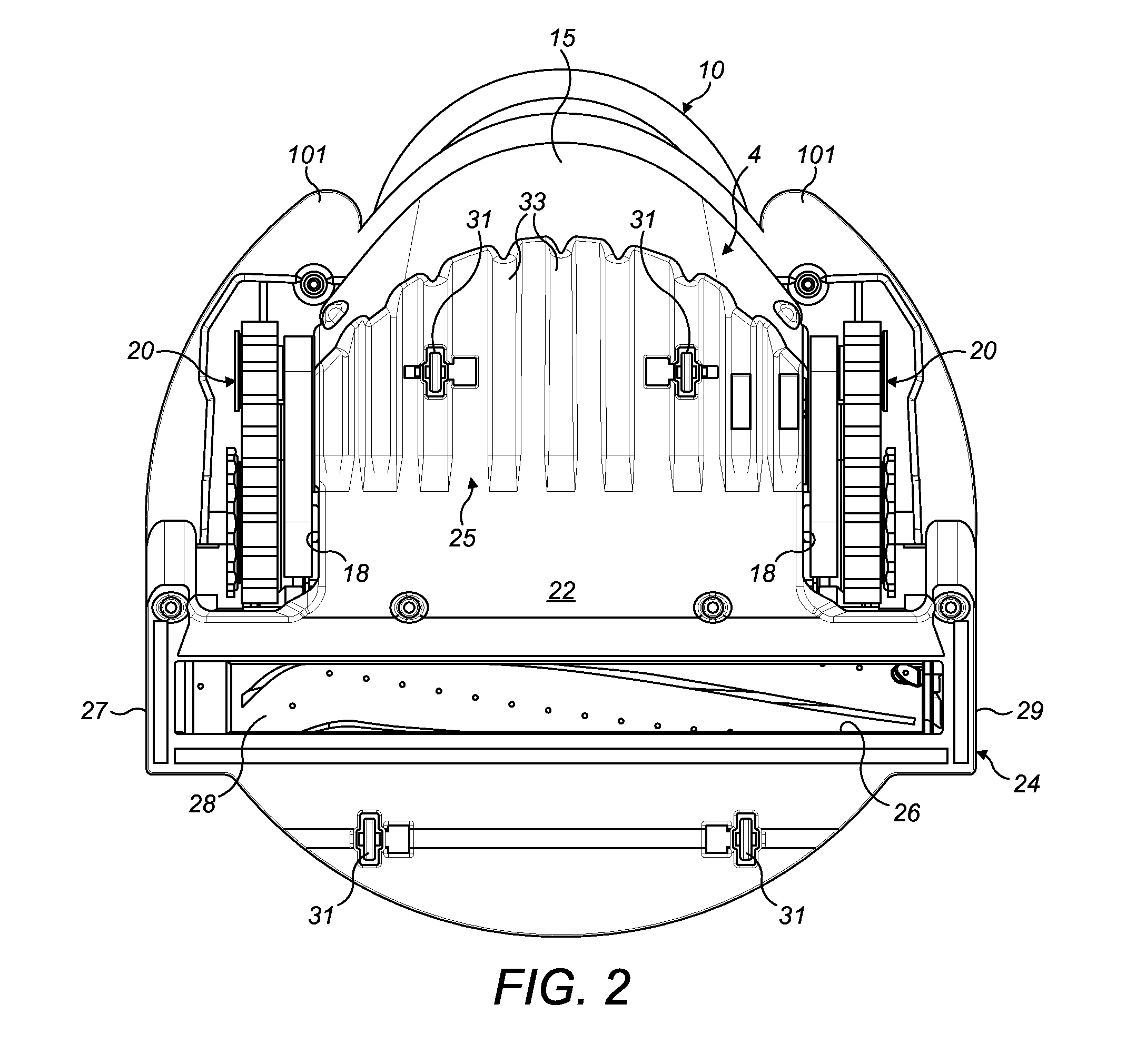

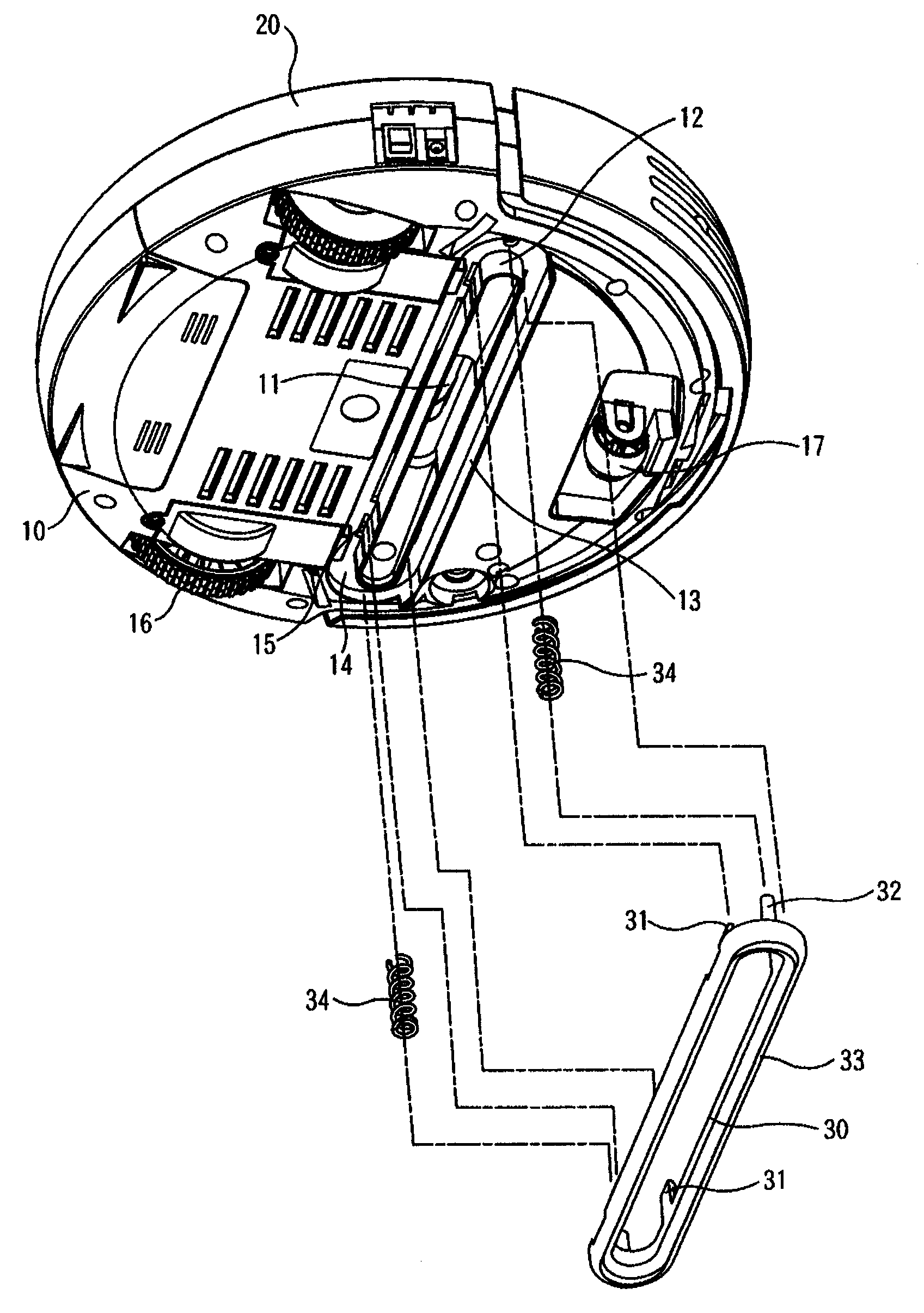

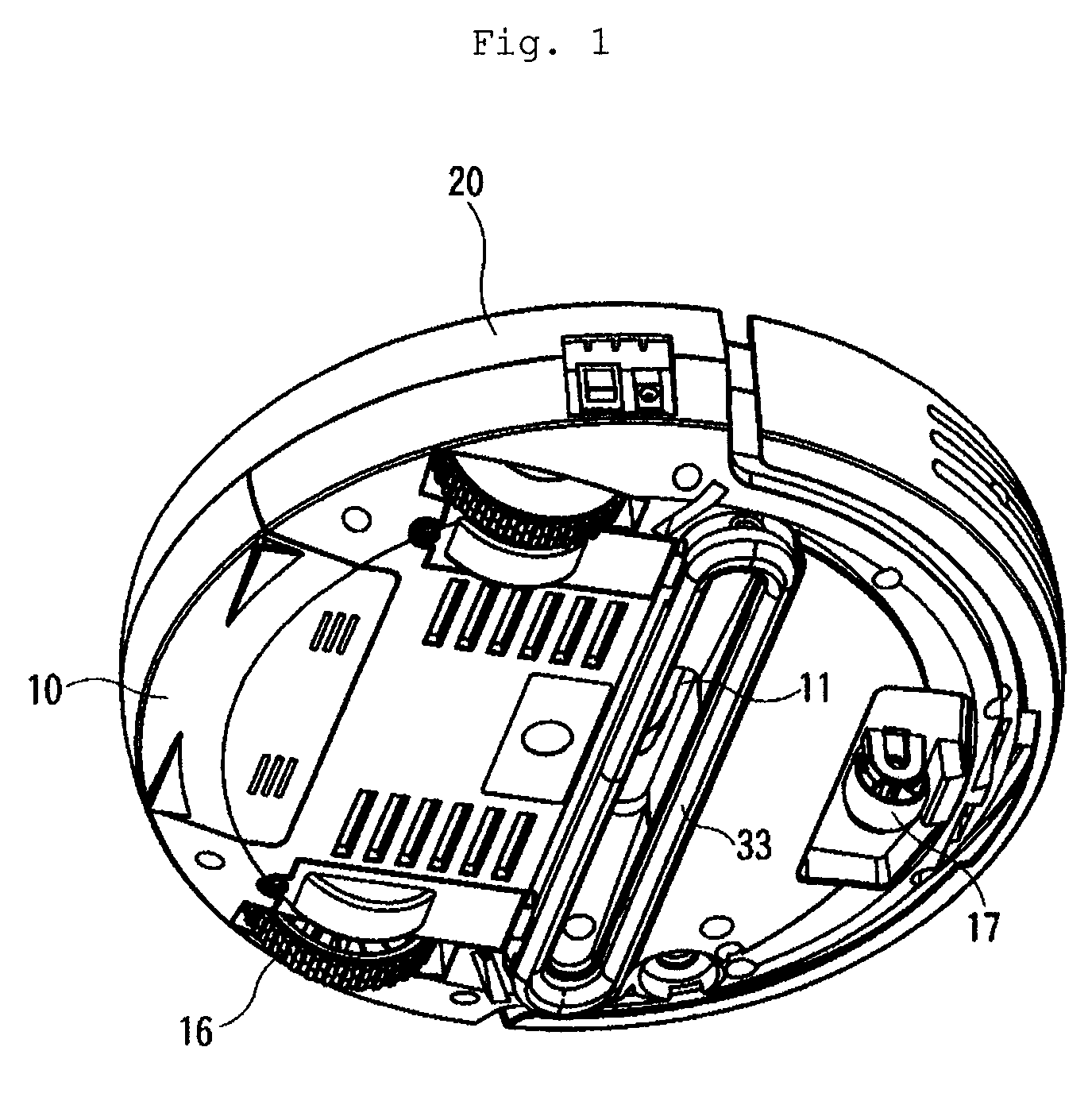

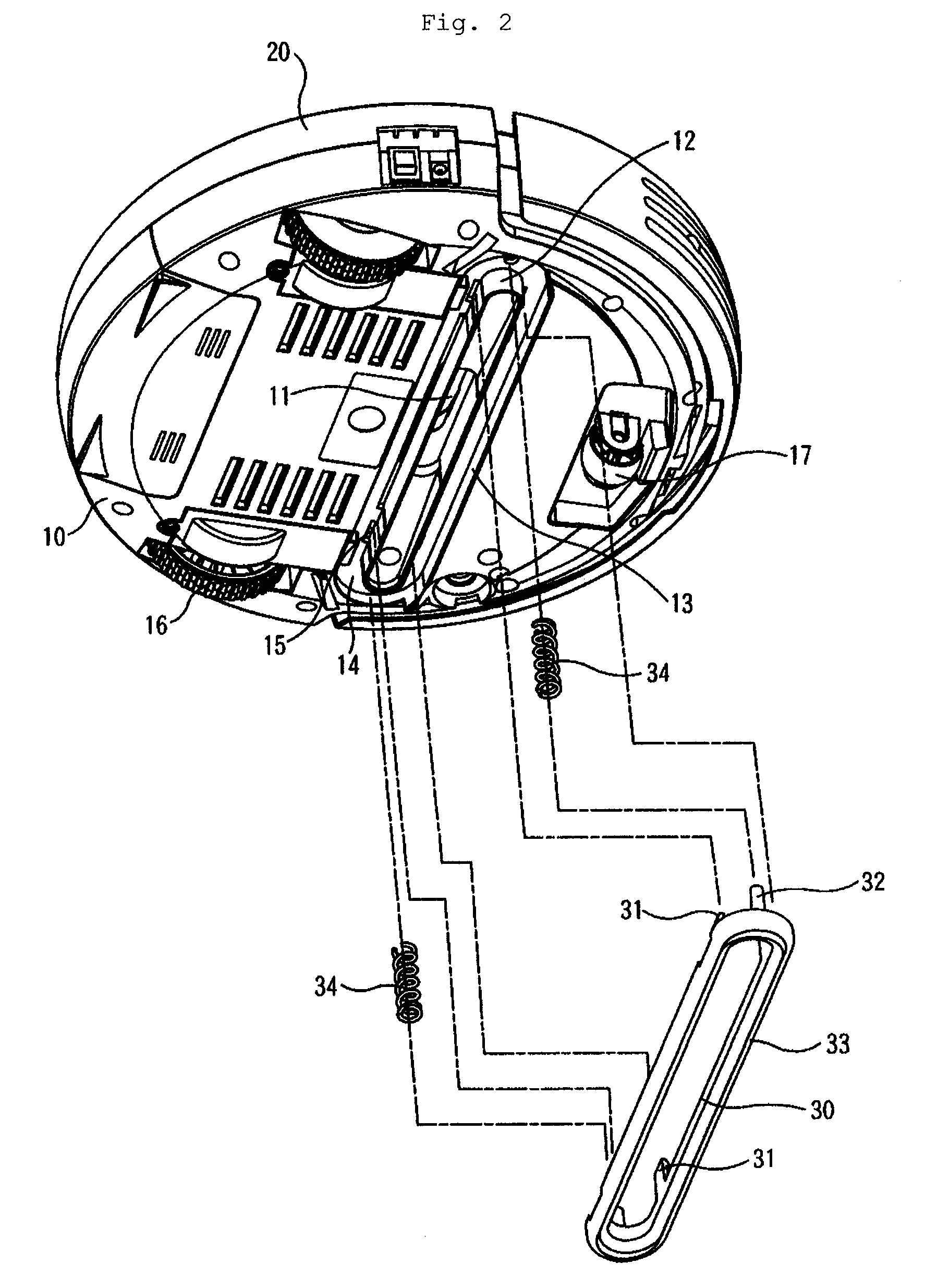

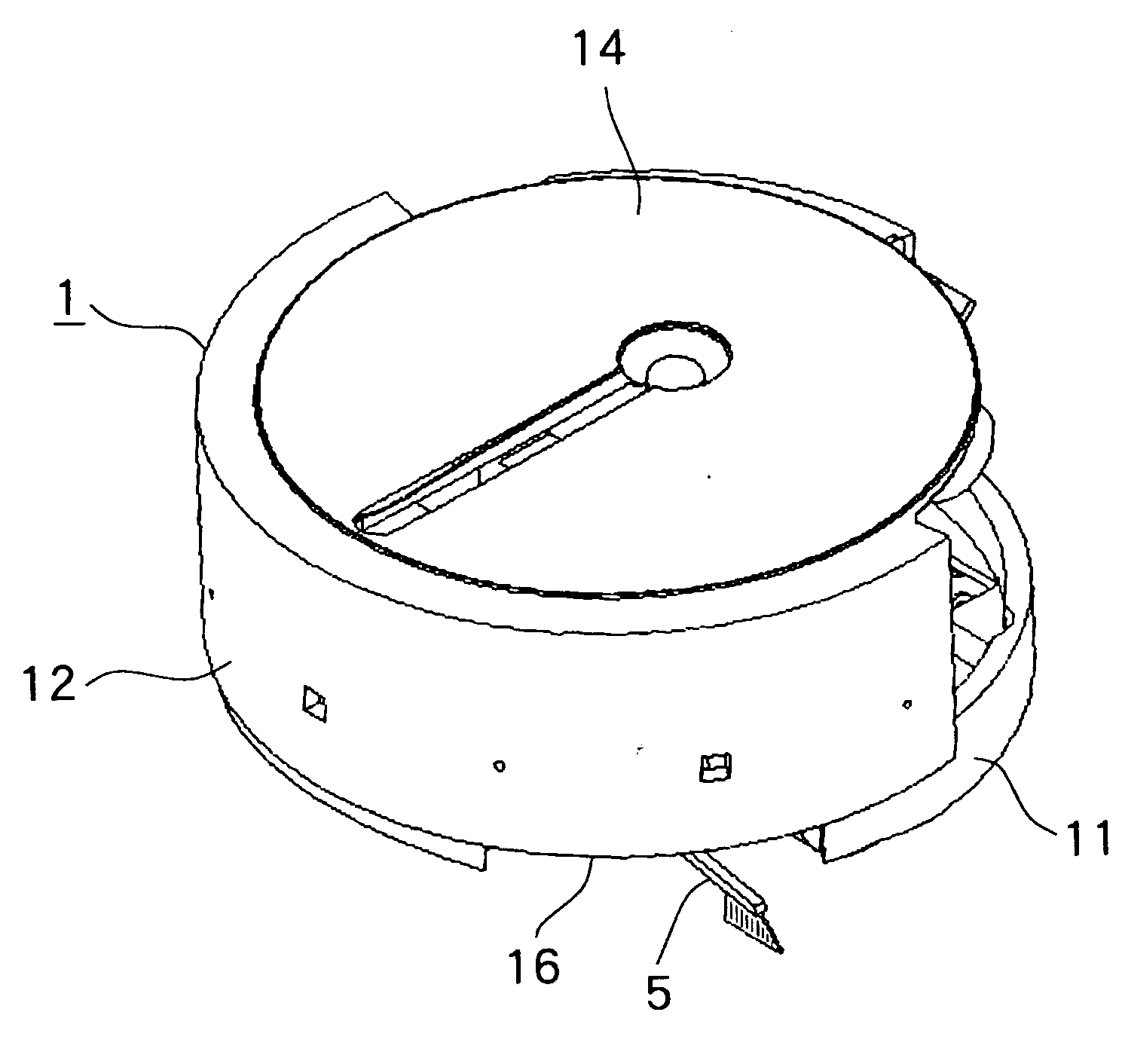

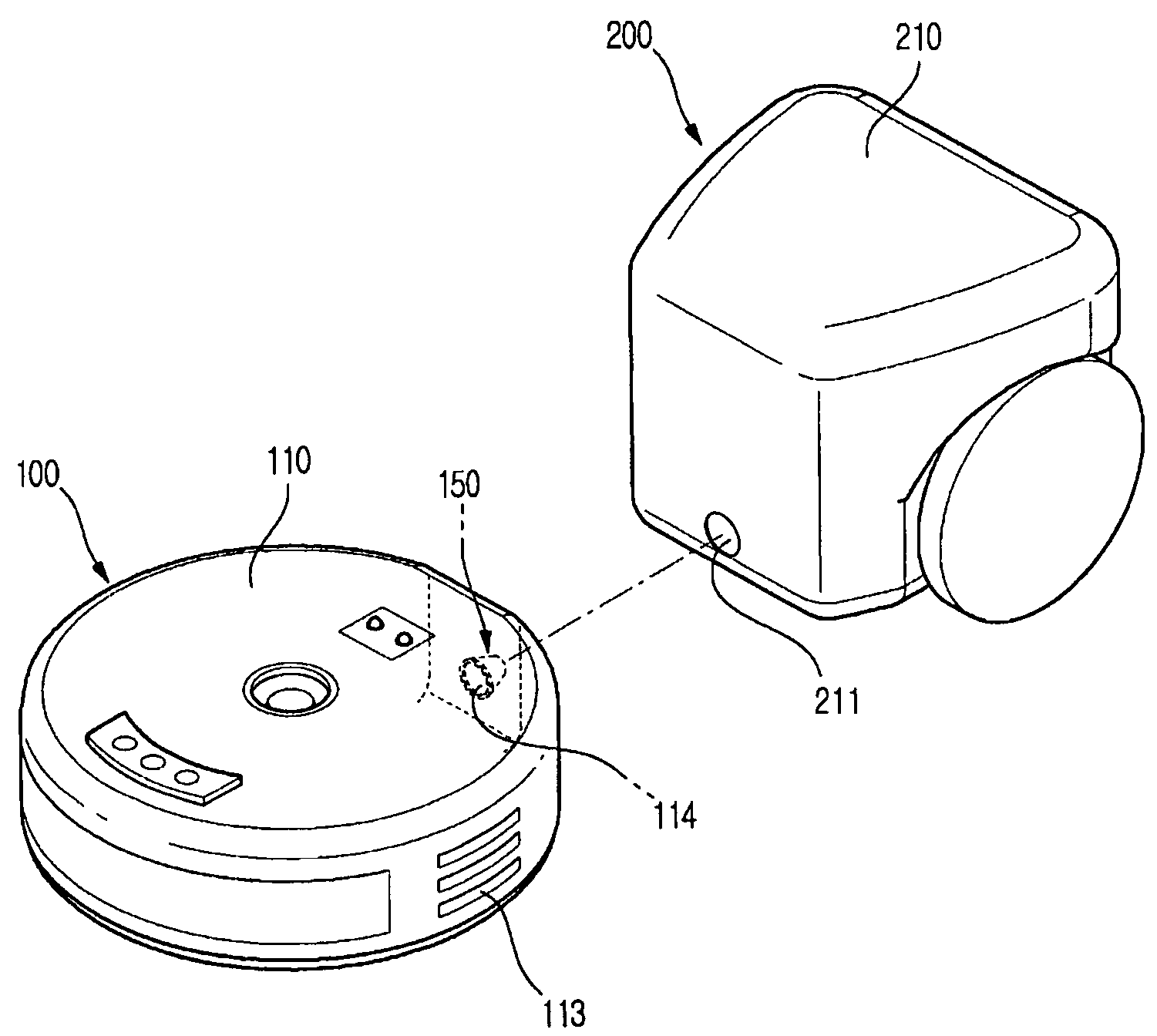

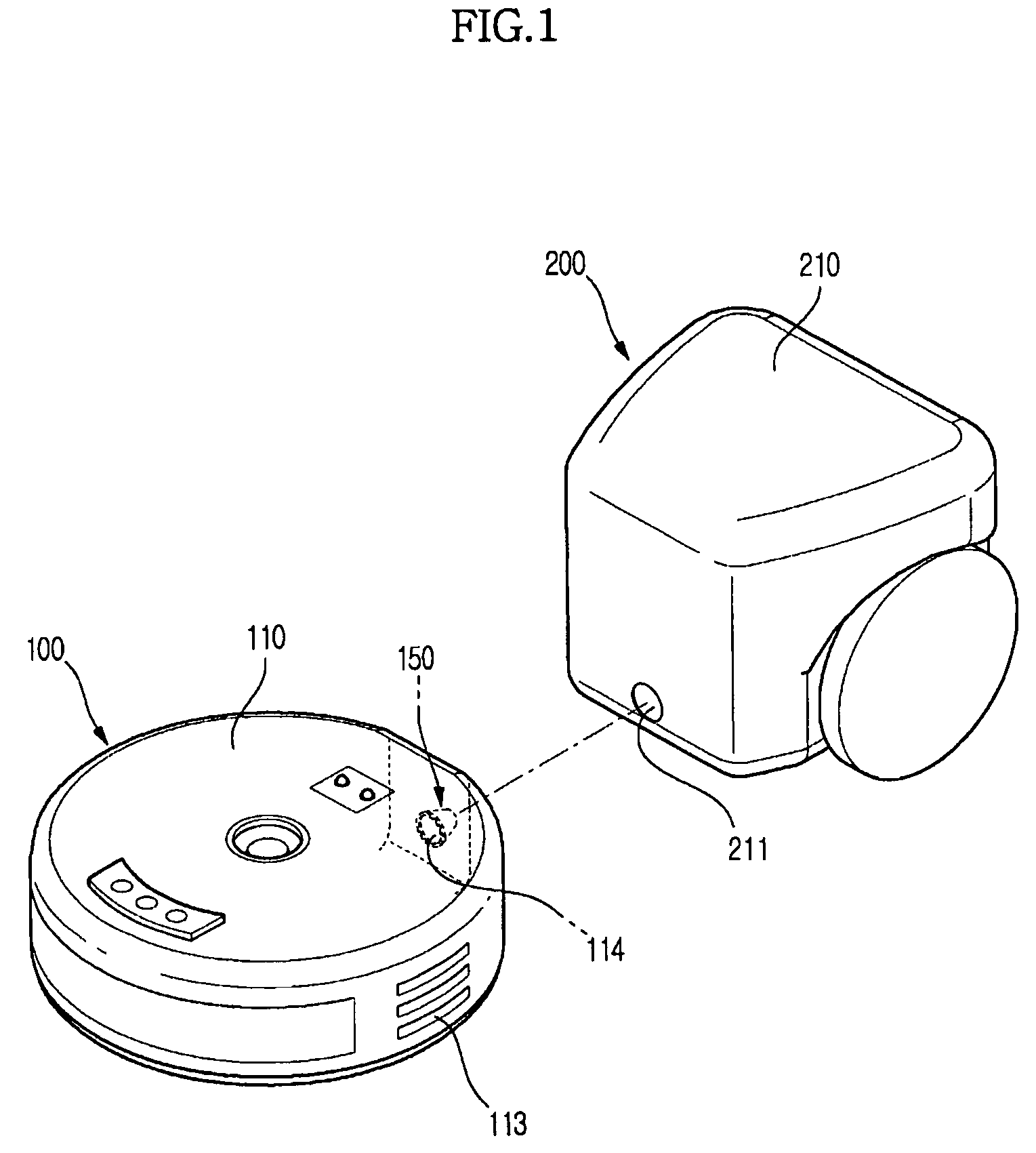

Robot cleaner system having robot cleaner and docking station

InactiveUS20090049640A1Prevent leakageImproved docking structureCleaning filter meansSuction filtersDocking stationEngineering

A robot cleaner system having an improved docking structure to allow a dust discharge port of a robot cleaner to come into close contact with a dust suction port of a docking station without an additional drive device. The robot cleaner system includes a robot cleaner having a dust discharge port, a docking station having a dust suction port to suction dust collected in the robot cleaner, and a docking device to perform a seesaw movement as it comes into contact with the robot cleaner when the robot cleaner docks with the docking station, so as to allow the dust suction port to come into close contact with the dust discharge port. The docking device further includes a link member installed in the docking station in a pivotally rotatable manner. The link member has one end provided with a contact portion to come into contact with the robot cleaner, and the other end provided with a docking portion defining the dust suction port therein.

Owner:SAMSUNG ELECTRONICS CO LTD

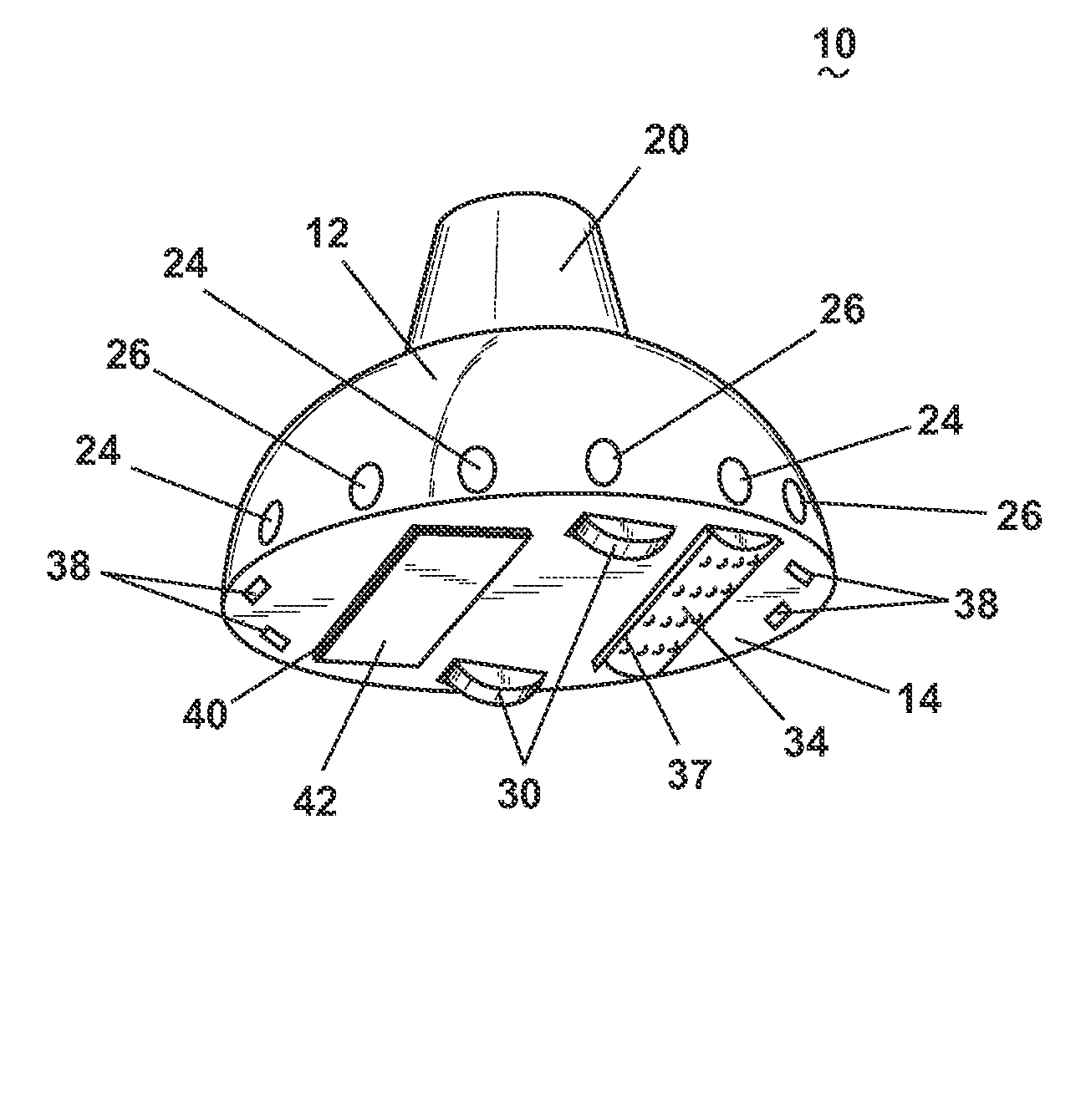

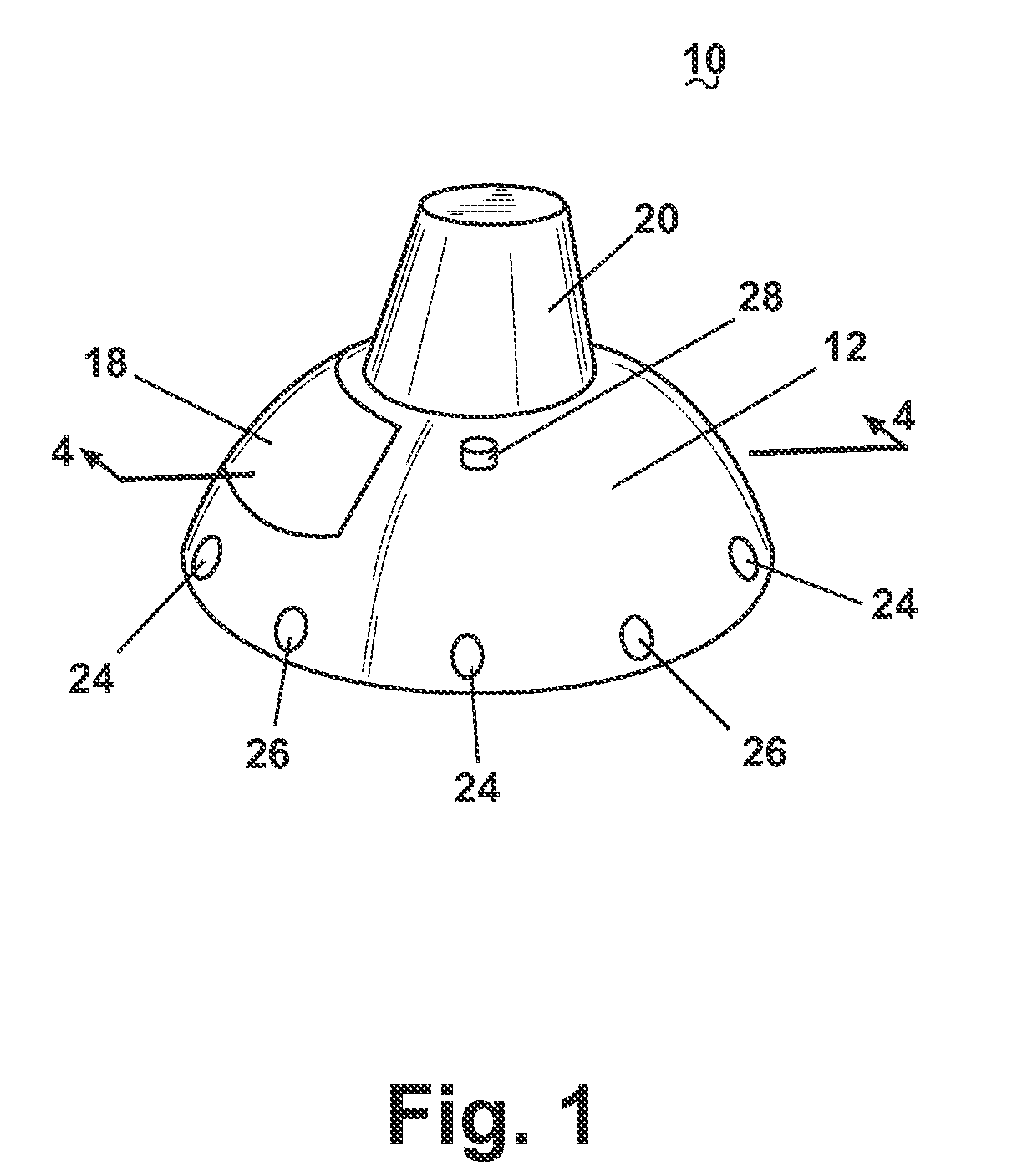

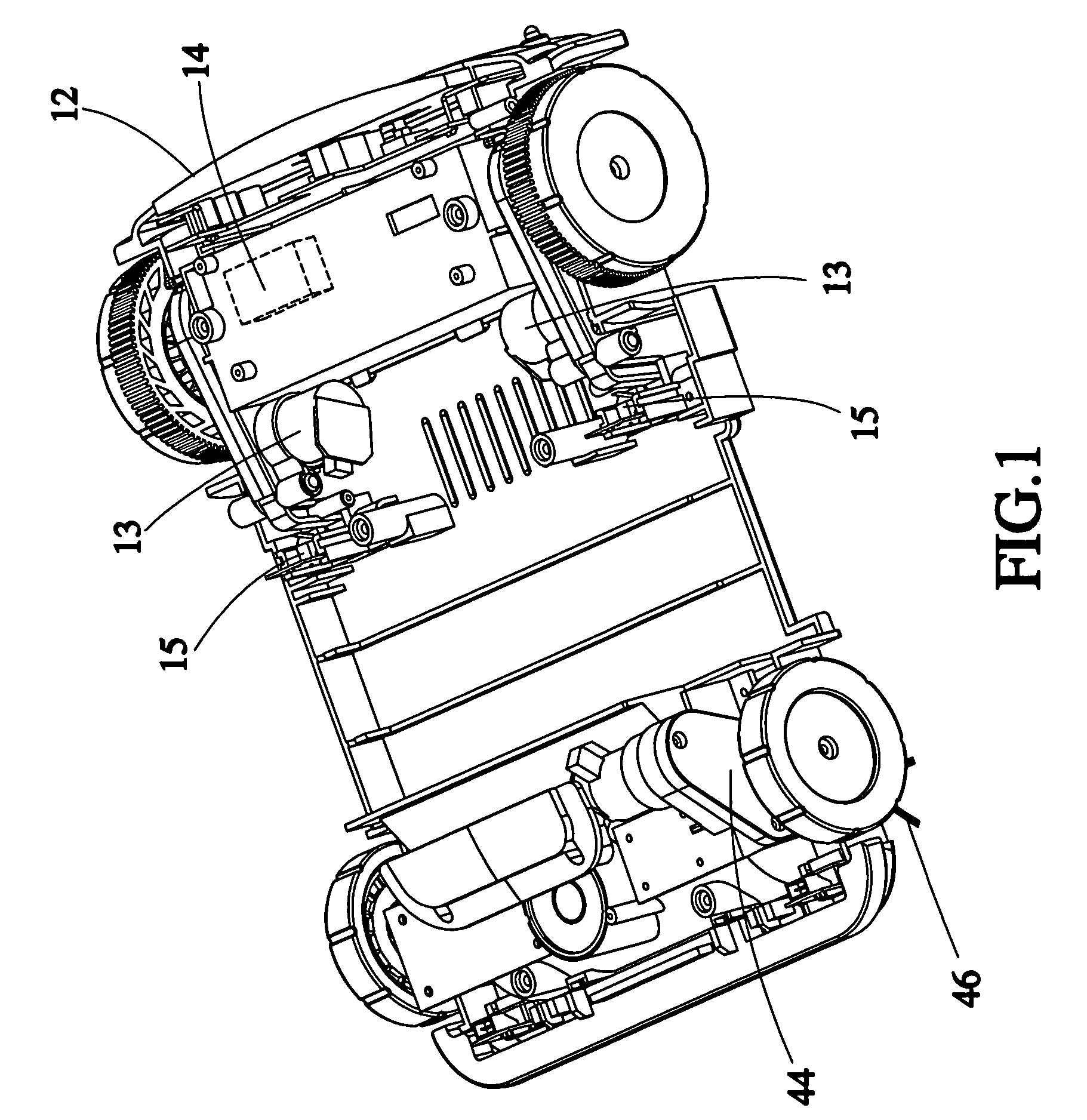

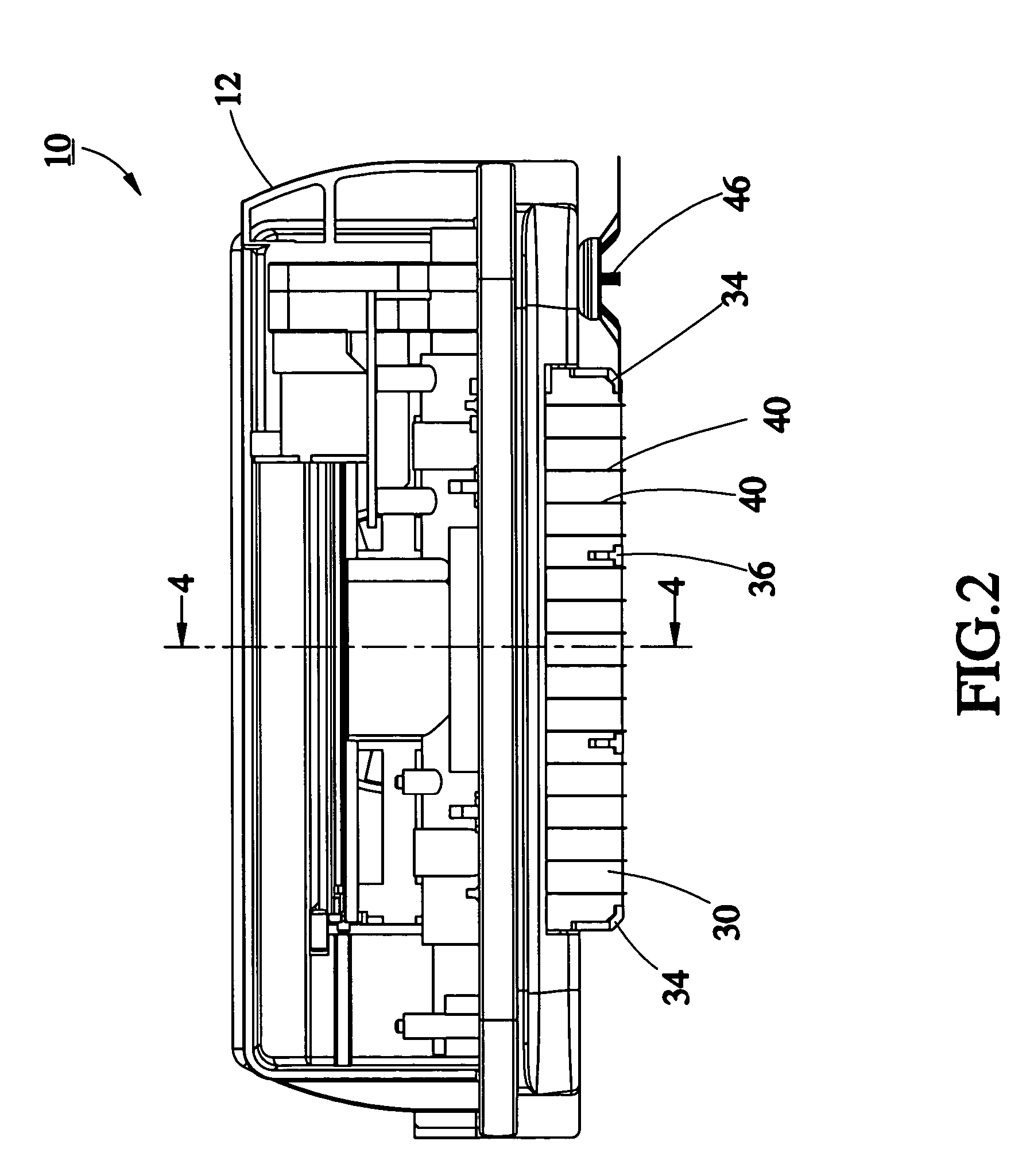

Robotic extraction cleaner with dusting pad

An vacuum cleaning robot has a drive system adapted to autonomously move a base housing along a horizontal surface and is controlled by a computer processing unit. A dusting assembly is mounted to the base housing and is adapted to selectively rest on a surface to be cleaned. A suction source draws dirt and debris through a suction nozzle and deposits the same in the recovery tank. A power source is connected to the drive system and to the computer processing unit. The computer processing unit is adapted to direct horizontal movement of the base housing within boundaries of the surface to be cleaned based upon input data defining said boundaries.

Owner:BISSELL INC

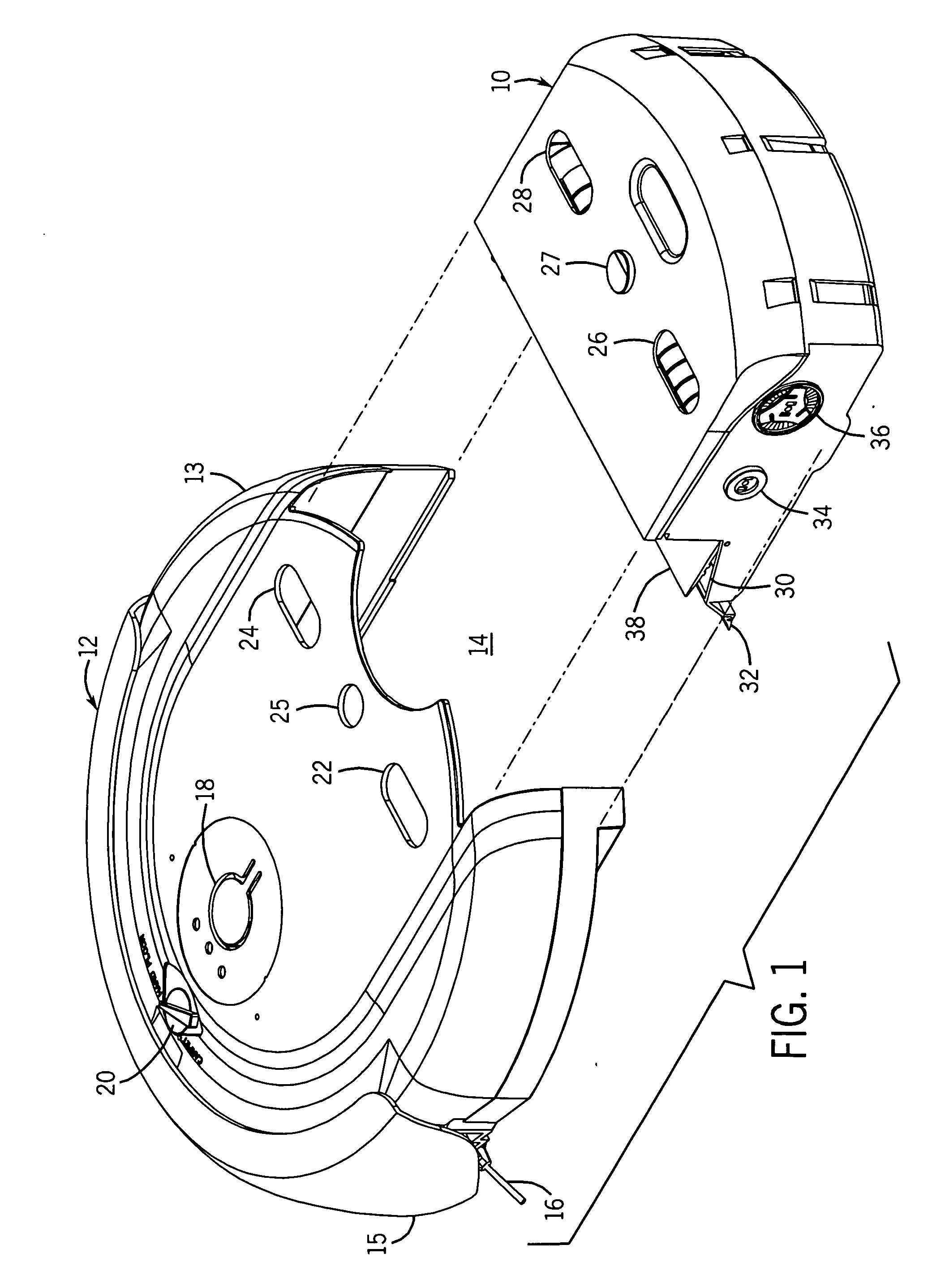

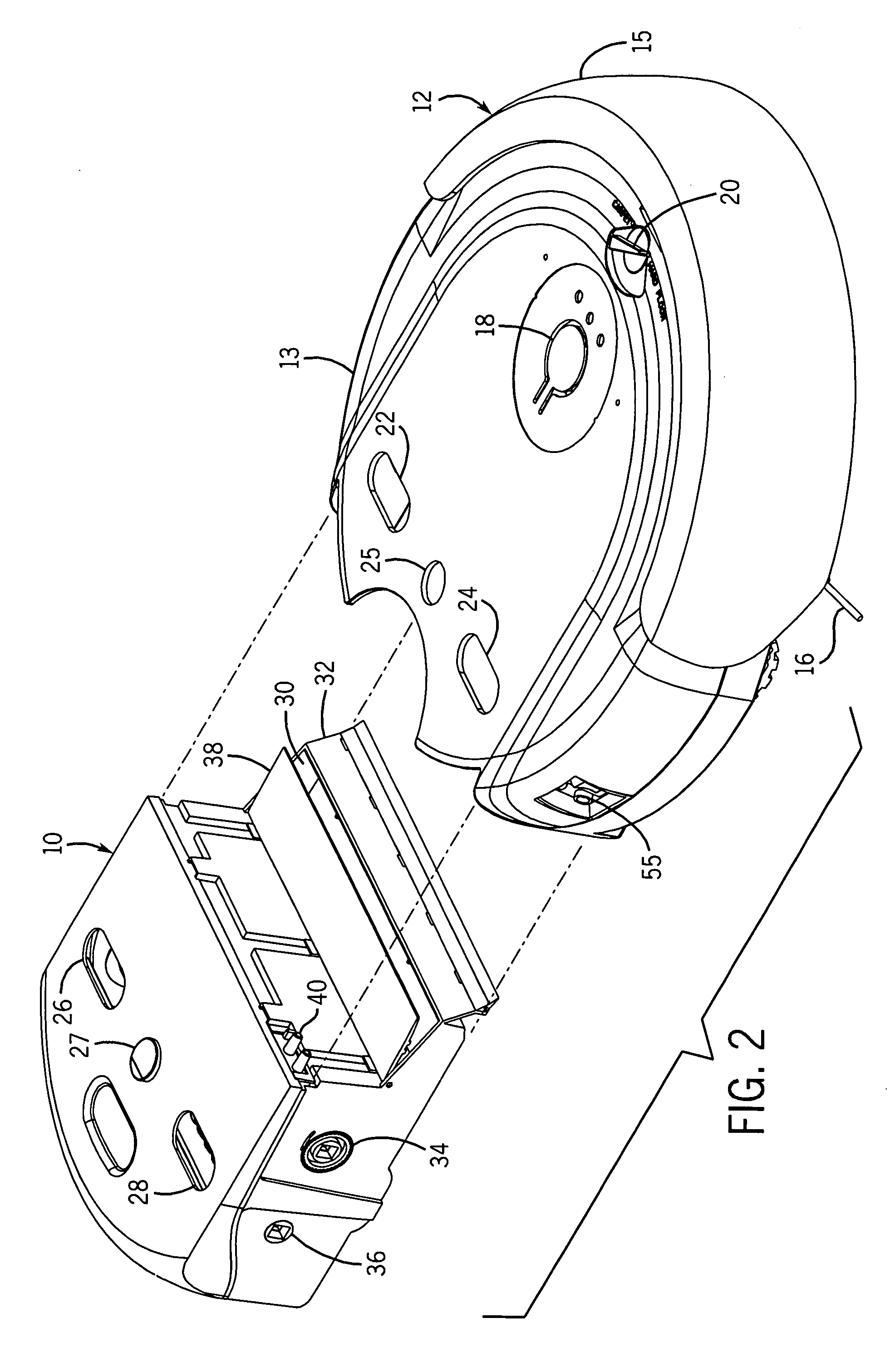

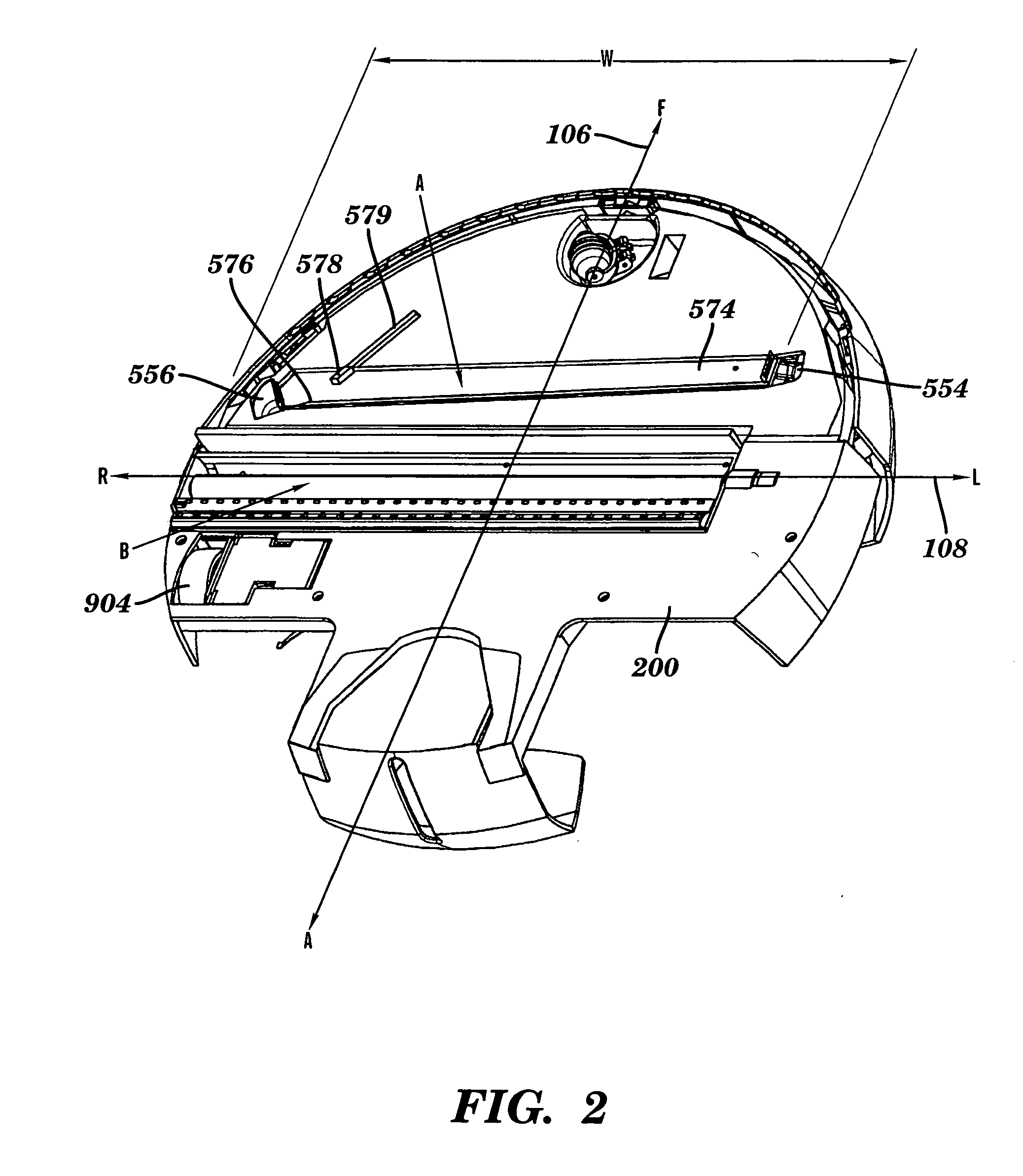

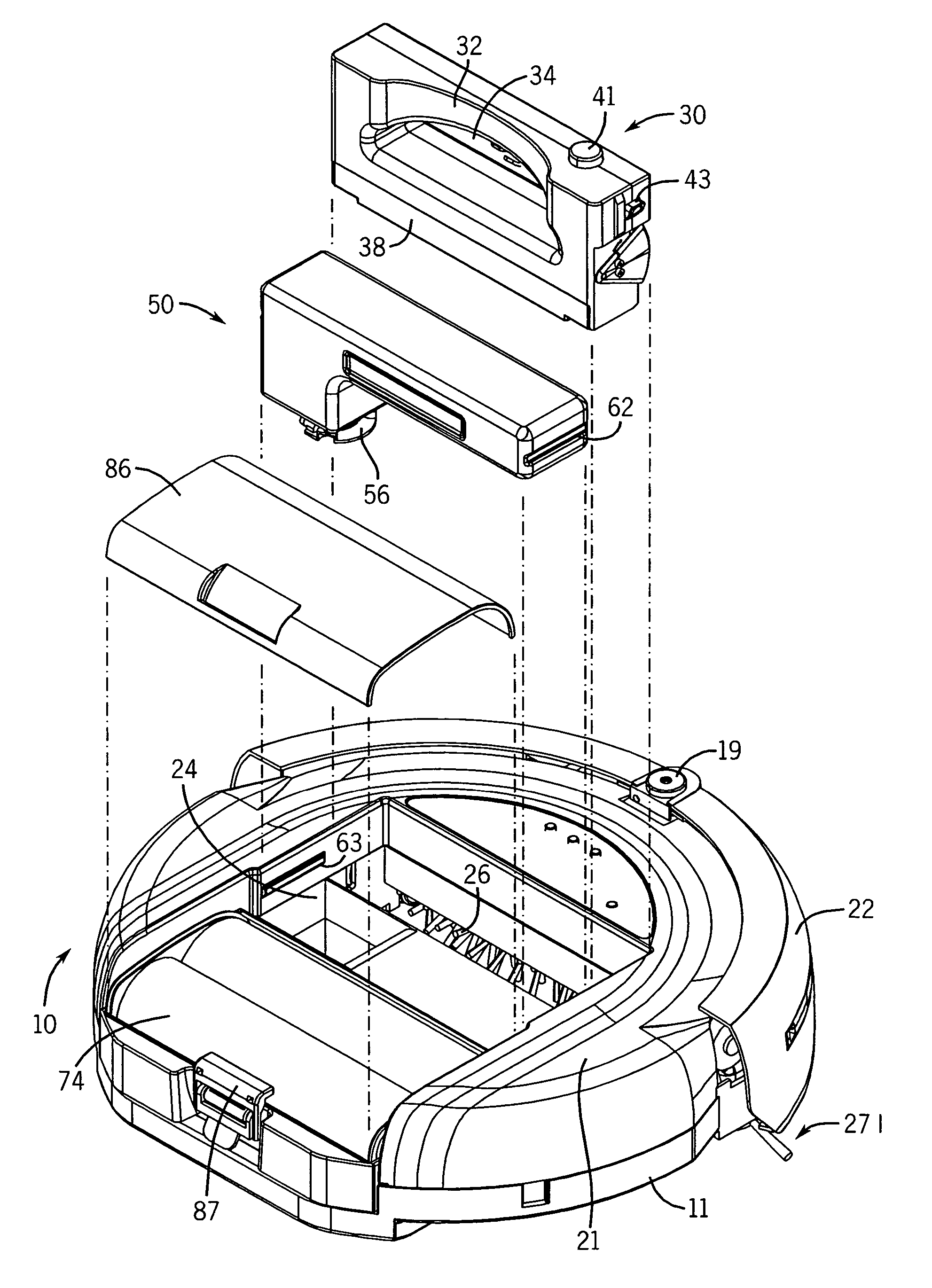

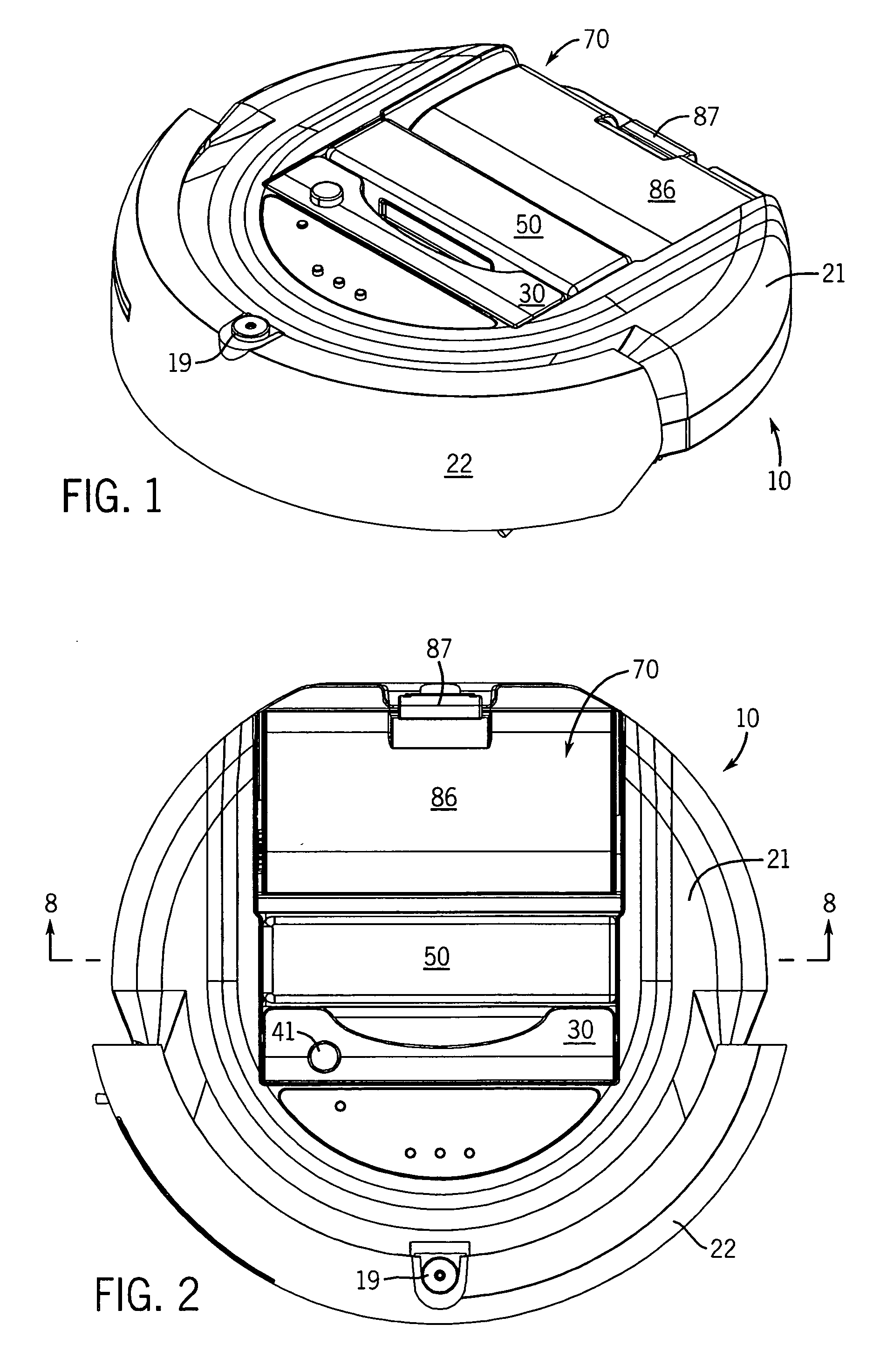

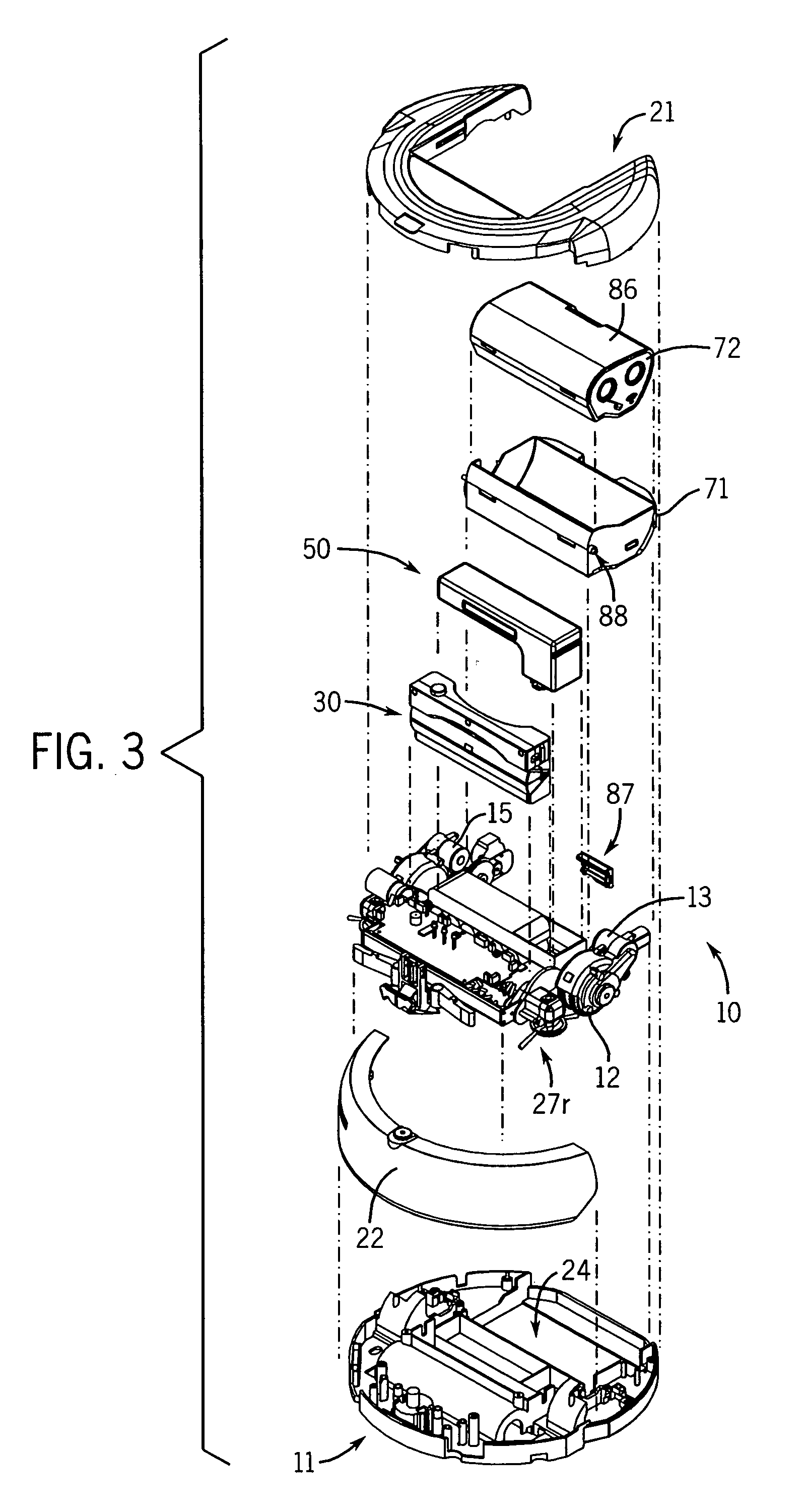

Surface treating device with top load cartridge-based cleaning systsem

ActiveUS20060288519A1Easy loadingFluid delivery is preventedLiquid processingCarpet cleanersBiomedical engineeringDelivery system

A robotic surface treating device that can perform carpet sweeping, hard-surface dry sweeping / wiping, and hard-surface sweeping / mopping is disclosed. The robotic surface treating device includes a sweeper brush, a dust bin for collecting debris from the brush, a reel-to-reel sheet of cleaning material, and a fluid delivery system for delivering fluid from a fluid reservoir onto the sheet of cleaning material and / or onto the surface to be treated. The dust bin, reel-to-reel sheet of cleaning material, and the fluid reservoir are separately installed from the top of the device, and may be separately removed for replacement.

Owner:SC JOHNSON & SON INC

Robot cleaner system having robot cleaner and docking station

InactiveUS20070226949A1Improved docking structurePrevent suction lossCleaning filter meansSuction filtersDocking stationSuction force

A robot cleaner system having an improved docking structure between a robot cleaner and a docking station, which is capable of an easy docking operation of the robot cleaner and preventing loss of a suction force generated in the docking station. The robot cleaner includes a docking portion to be inserted into a dust suction hole of the docking station upon a docking operation. The docking portion may be a protrusion, which protrudes out of a robot body to be inserted into a dust suction path defined in the docking station, the protrusion communicates a dust discharge hole of the robot cleaner with the dust suction path of the docking station. The robot cleaner system includes a coupling device to keep the robot cleaner and the docking station in their docked state. The coupling device is configured to have a variety of shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

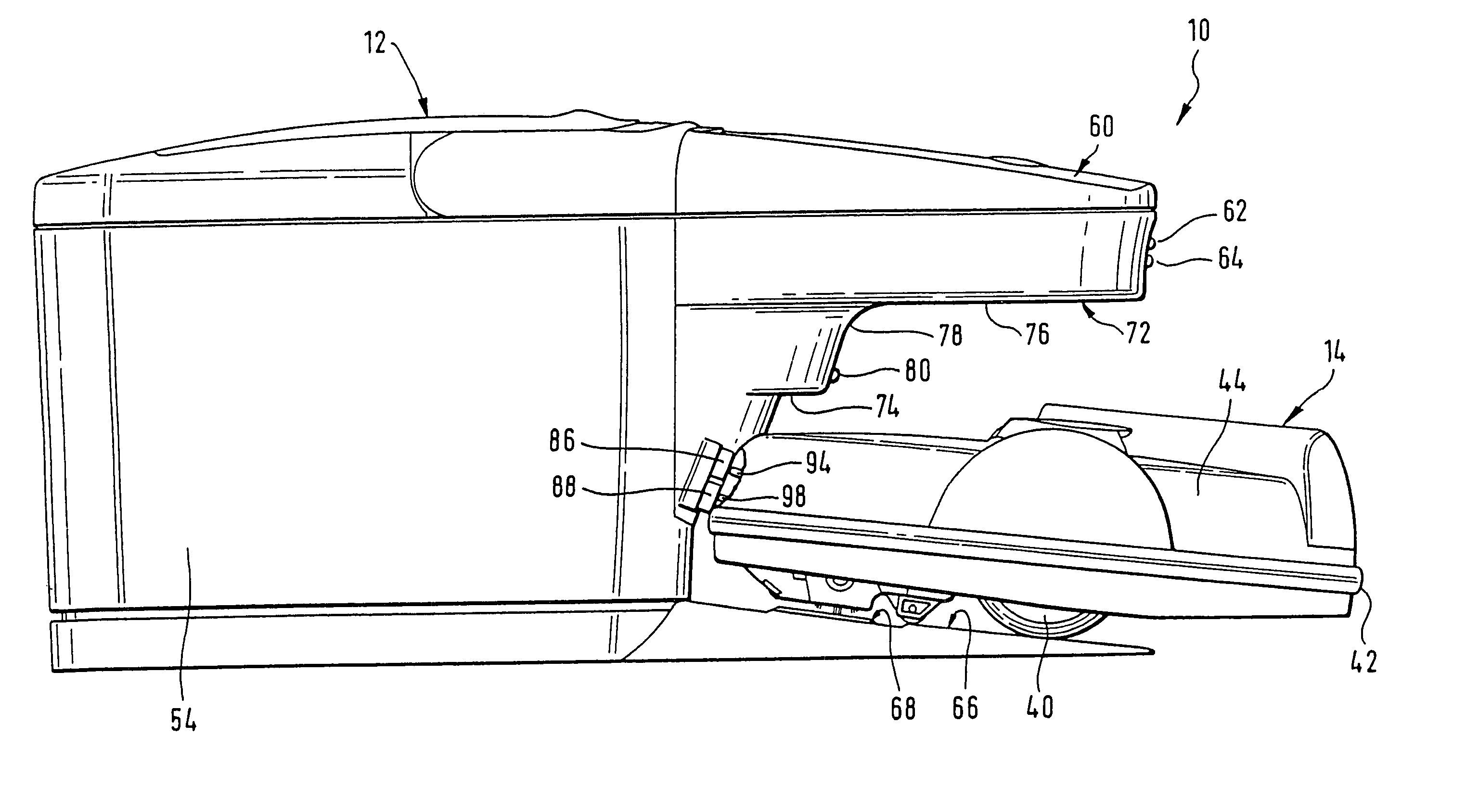

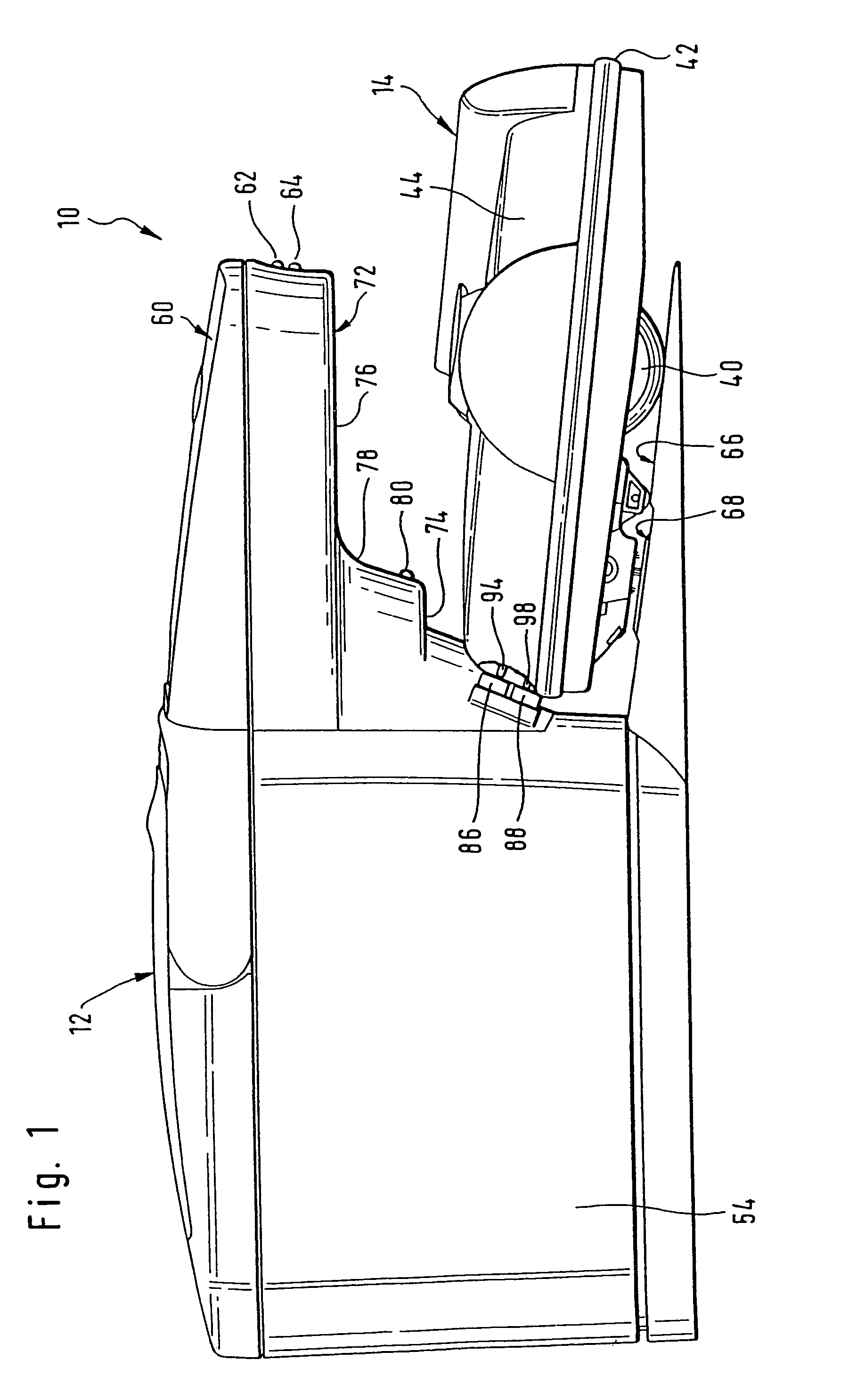

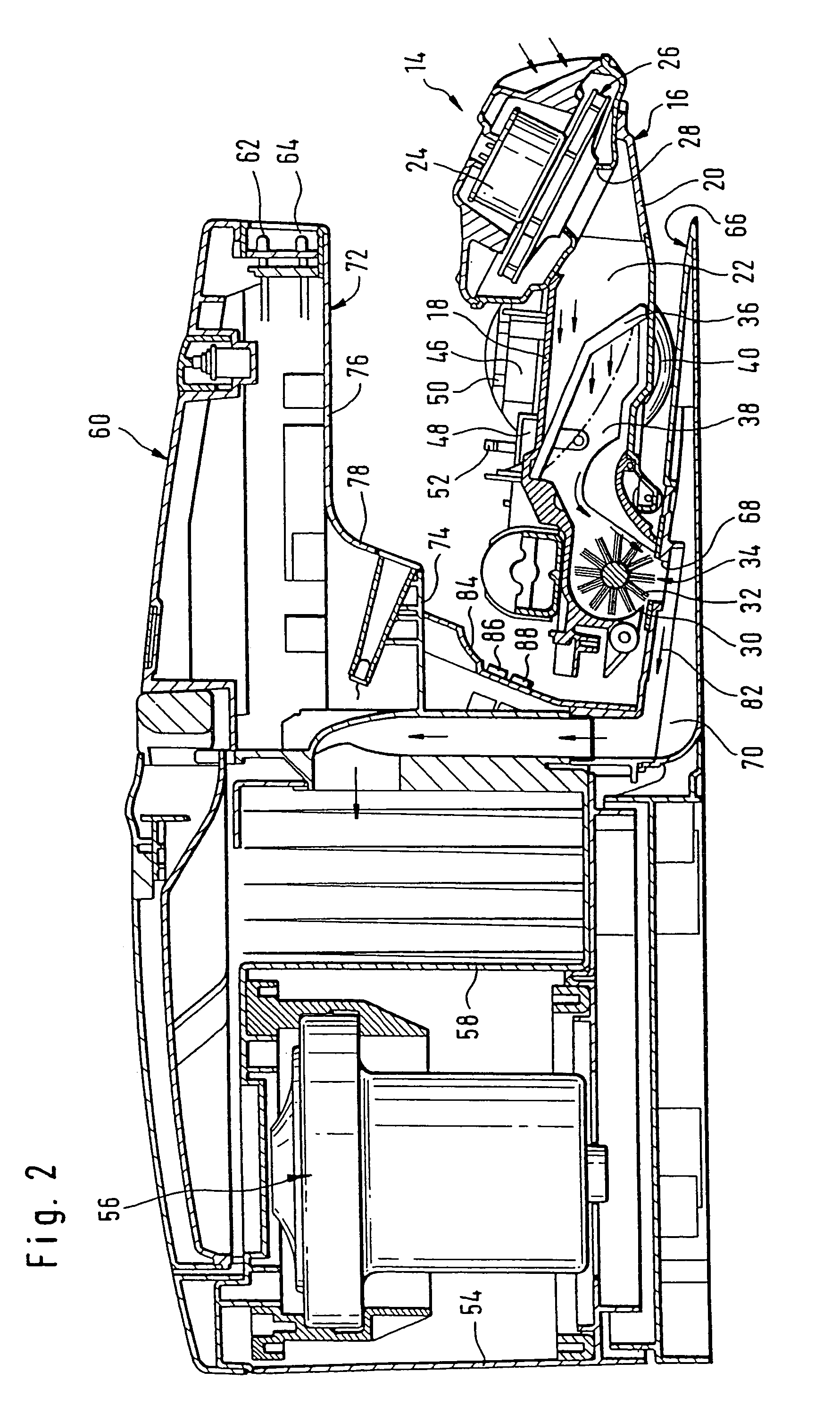

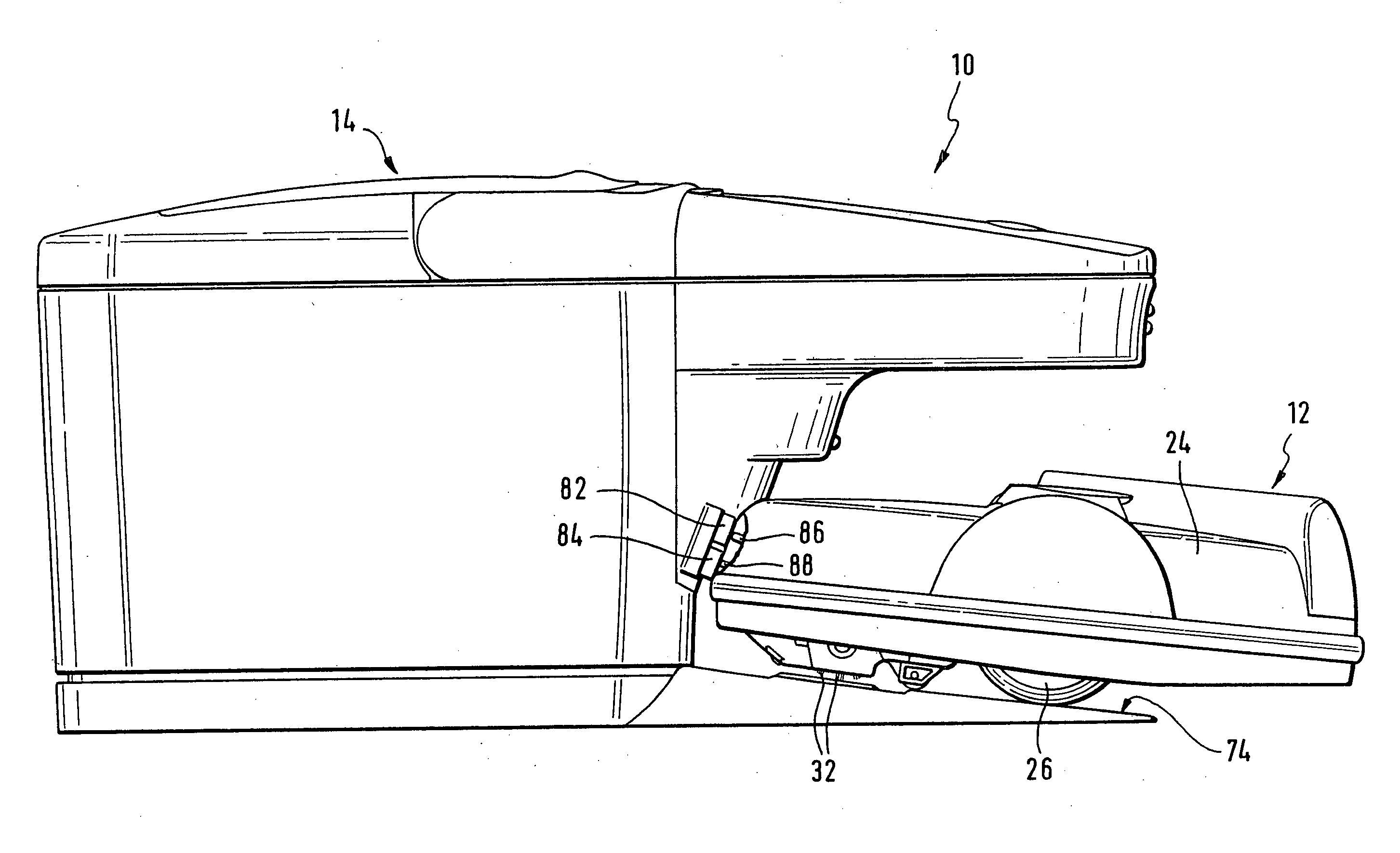

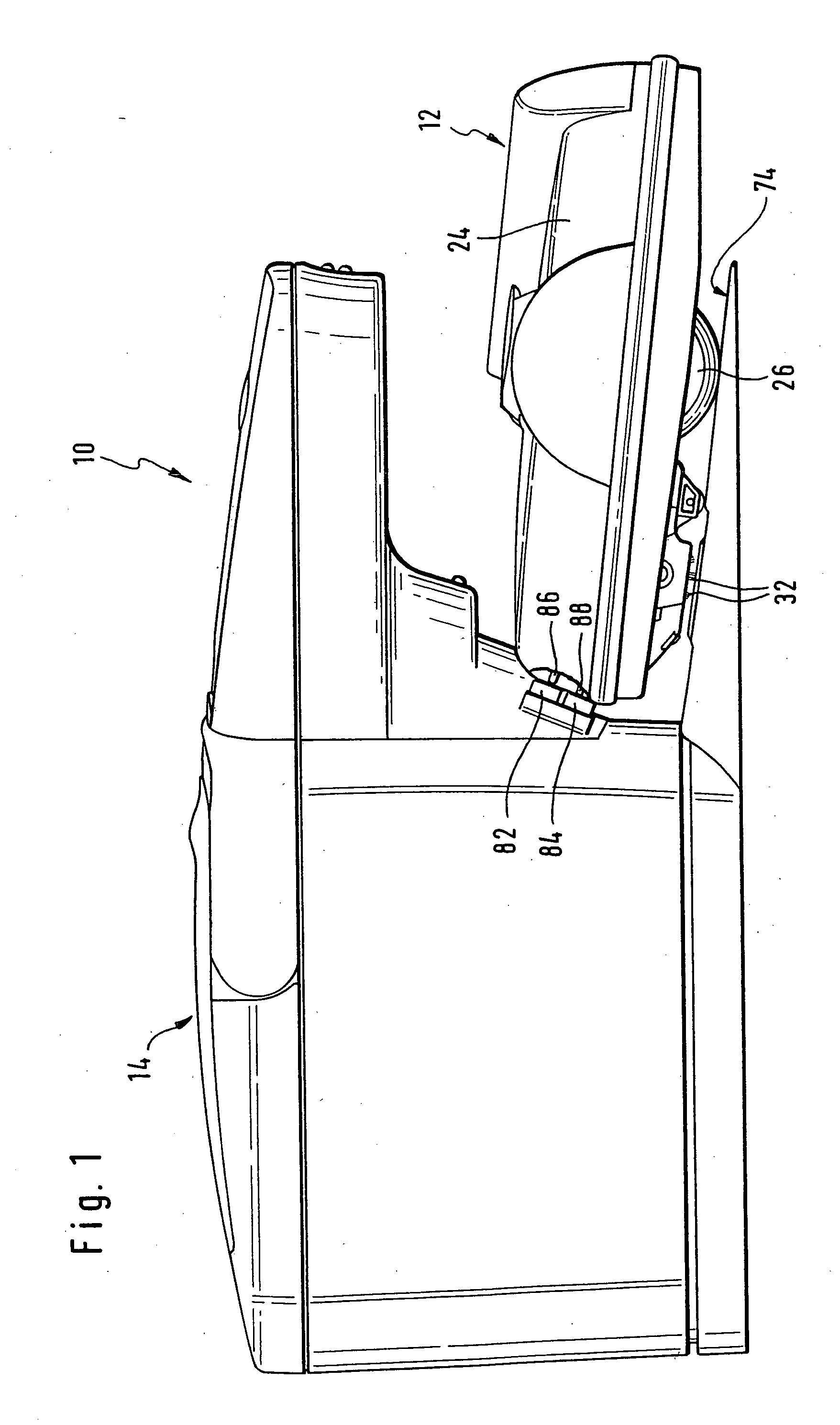

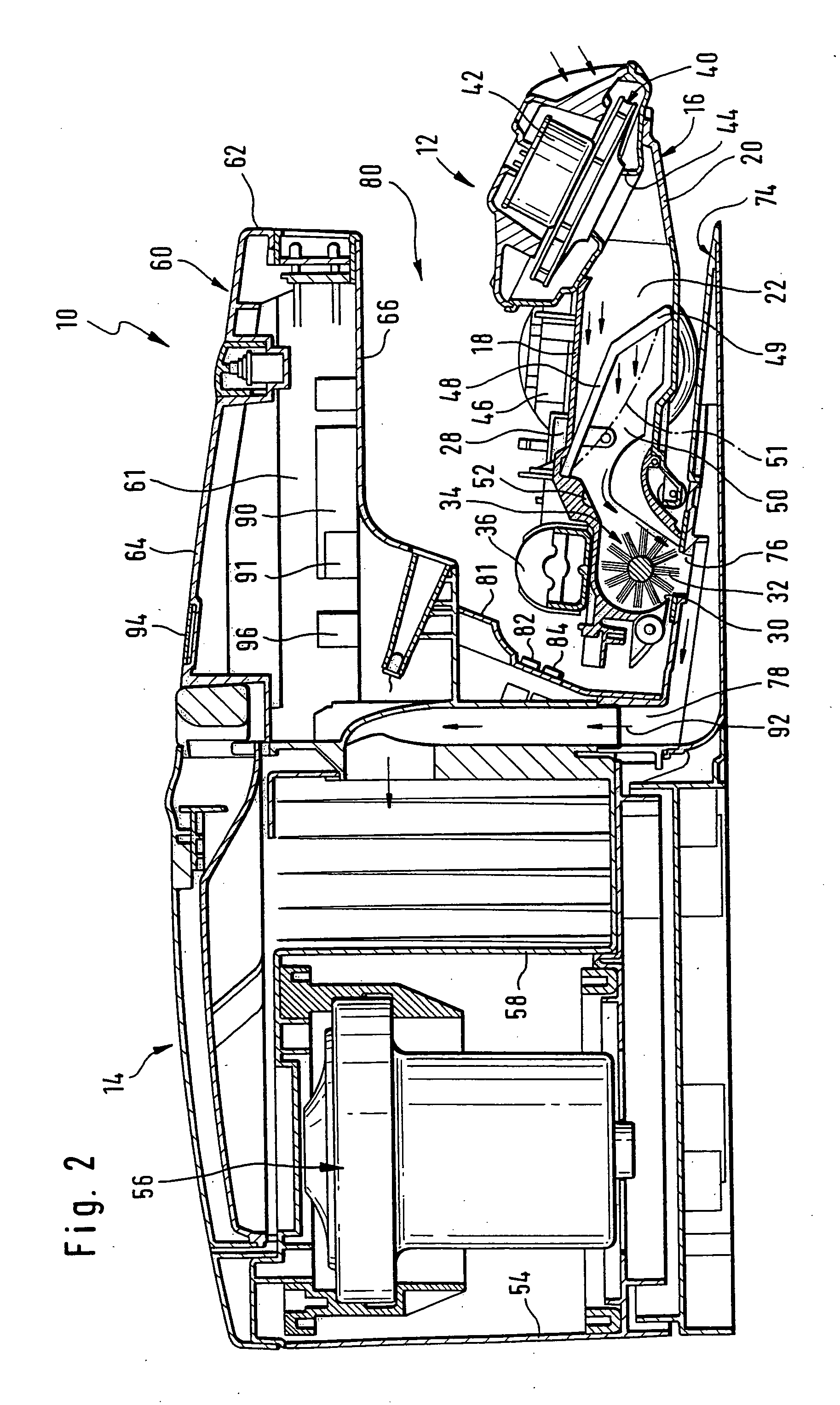

Floor treatment system with self-propelled and self-steering floor treatment unit

InactiveUS7055210B2Efficient transferEnhanced couplingSuction filtersCoupling contact membersElectricityCoupling

Owner:ALFRED KARCHER GMBH & CO KG

Method for operating a floor cleaning system, and floor cleaning system for use of the method

InactiveUS20050150519A1Reduce noiseReduce cleaningSuction filtersLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a method for operating a floor cleaning system having a central suction station with which there is associated a self-propelled and self-steering suction appliance, dirt being picked up from a floor surface that is to be cleaned by means of the suction appliance and being transferred into a dirt collection vessel of the suction appliance, and the suction station having a suction unit, and the dirt collection vessel being sucked out by means of the suction unit. To refine the method in such a manner that the levels of noise produced by the floor cleaning system can be reduced, it is proposed, according to the invention, that the suction unit is optionally operated with a maximum suction power or a reduced suction power. The invention also proposes a floor cleaning system for carrying out the method.

Owner:ALFRED KARCHER GMBH & CO KG

Surface treating device with cartridge-based cleaning system

A cartridge is disclosed comprising a reel-to-reel roll of cleaning material, for use in a hand-held or robotic cleaning device. The cartridge provides either an electrostatic dust cloth or wet mop, and includes a fluid reservoir for maintaining the wet mop cloth during use. A dust bin is also provided on the cartridge, and includes a hinged lid for providing selective access to the dust inside of the bin. A motor, optical sensor, and fluid pump inside of a cleaning apparatus control the operation of the reel-to-reel cloth, and control fluid delivery to the wet cloth.

Owner:SC JOHNSON & SON INC

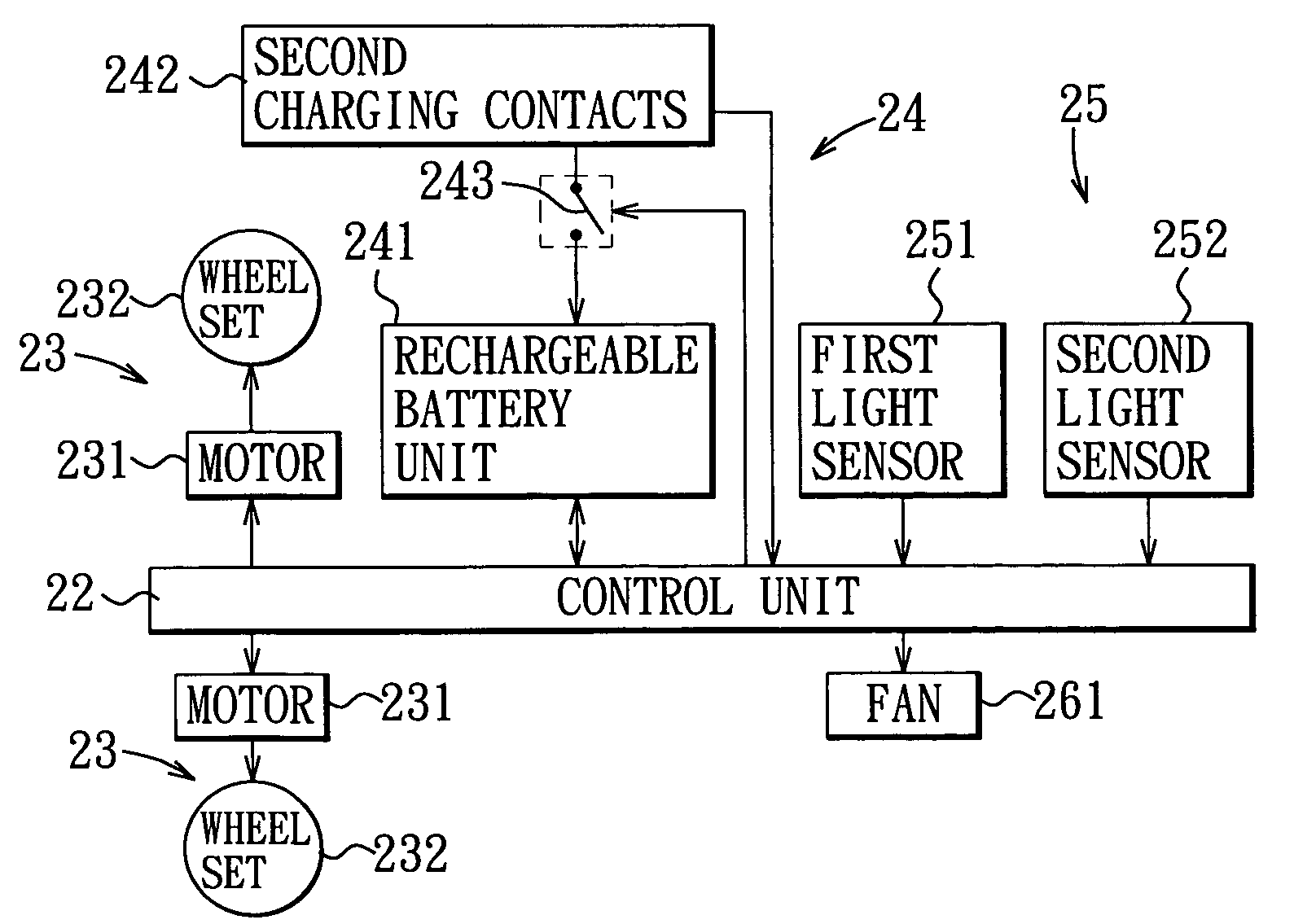

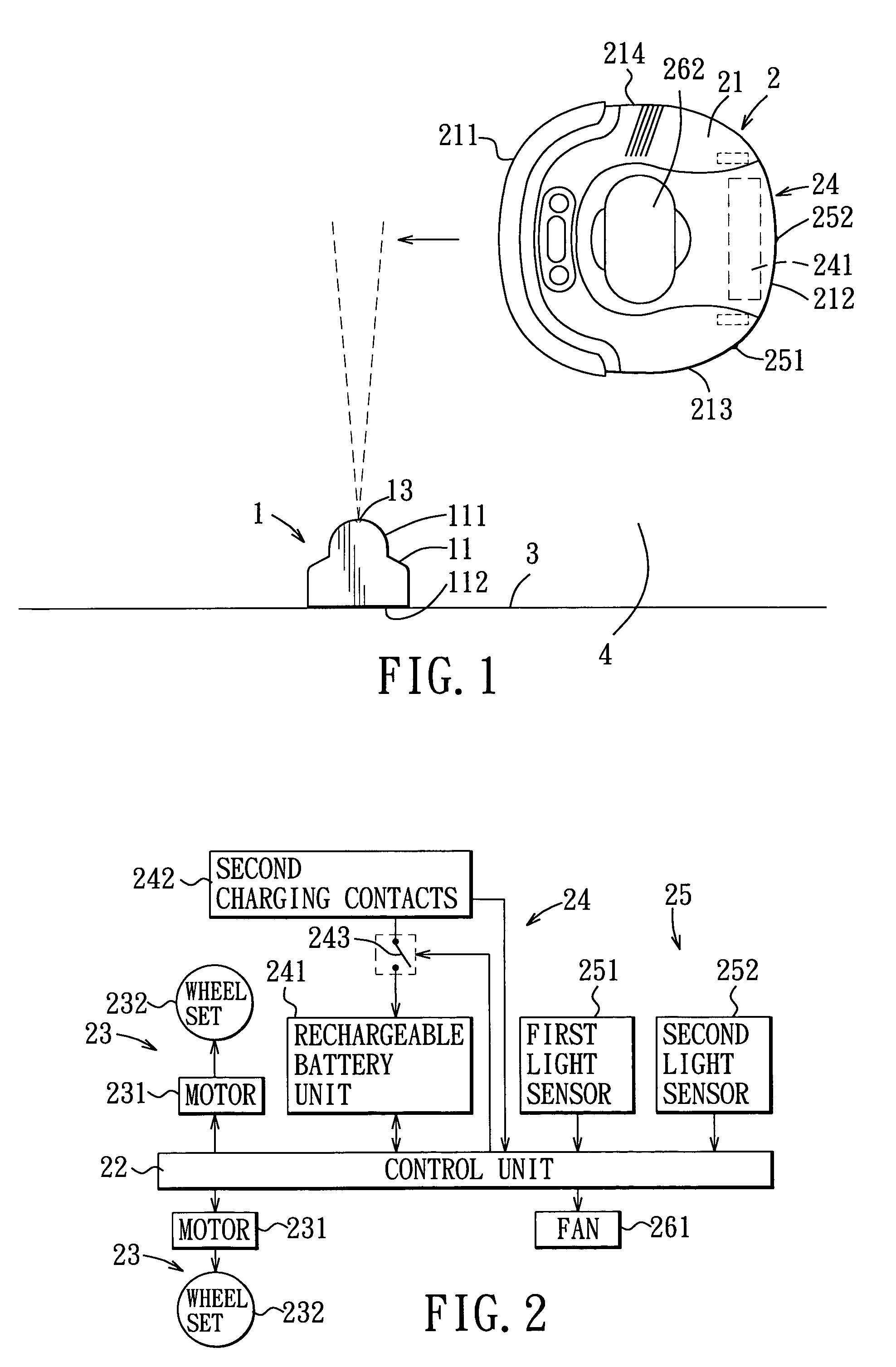

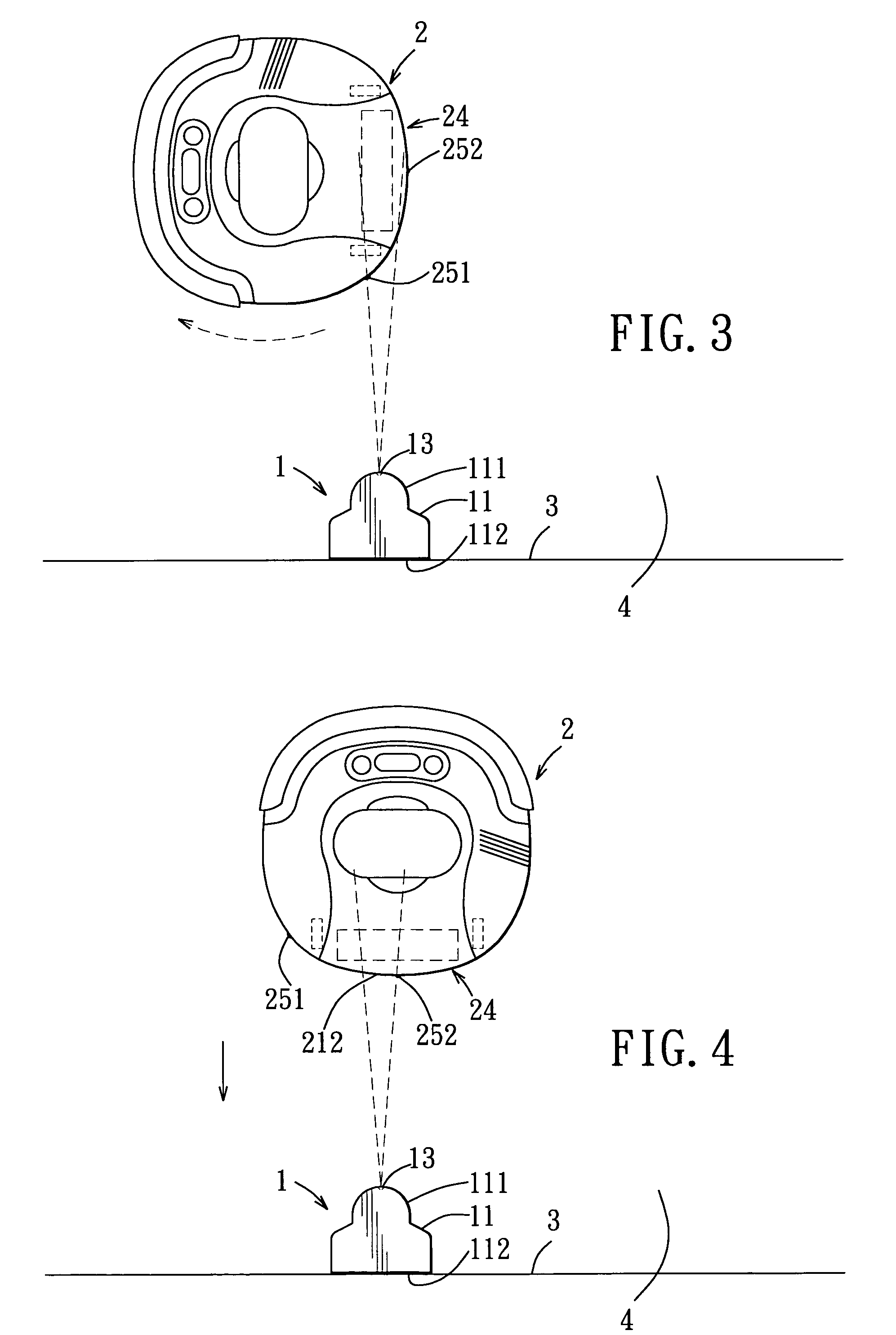

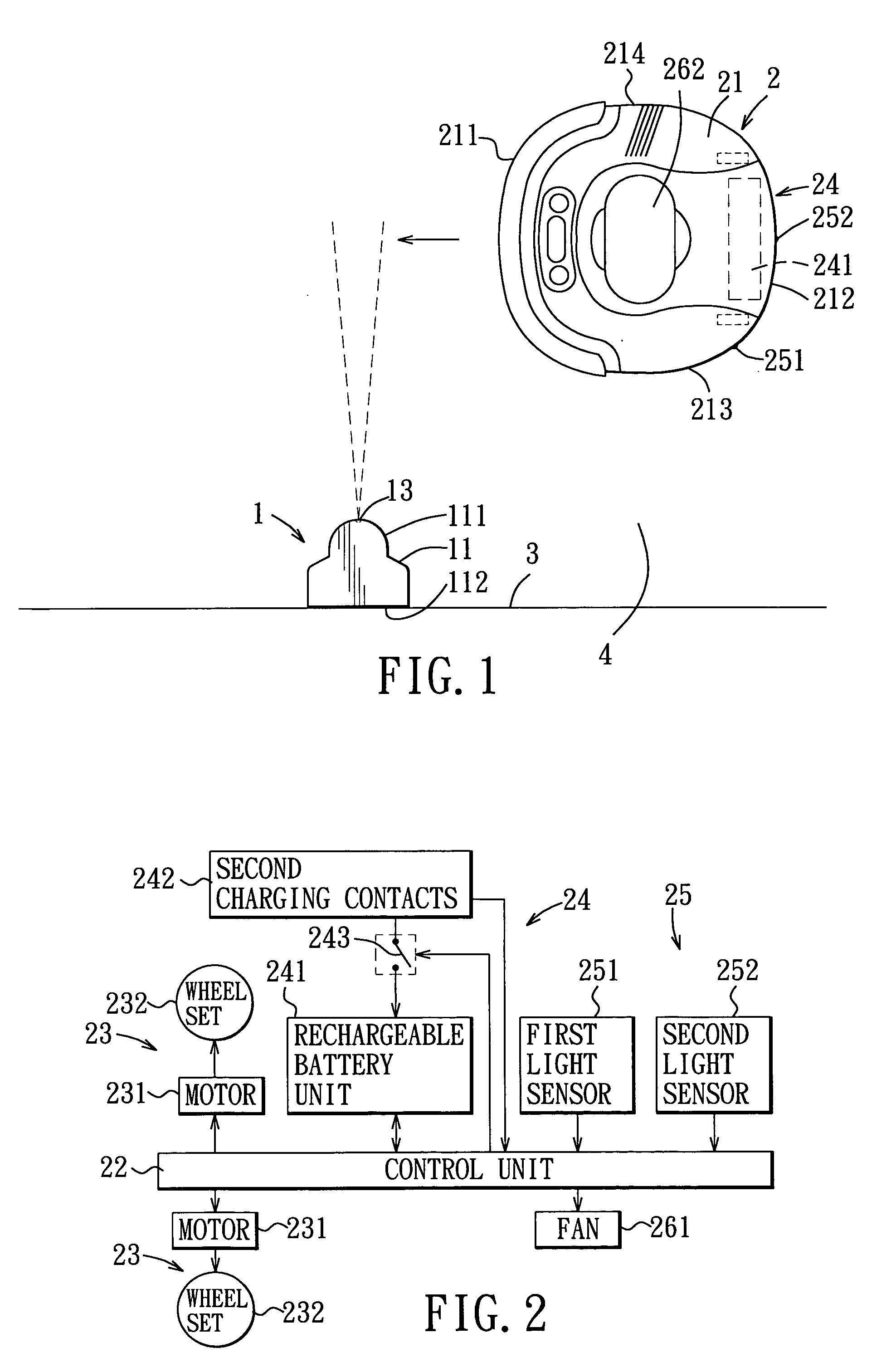

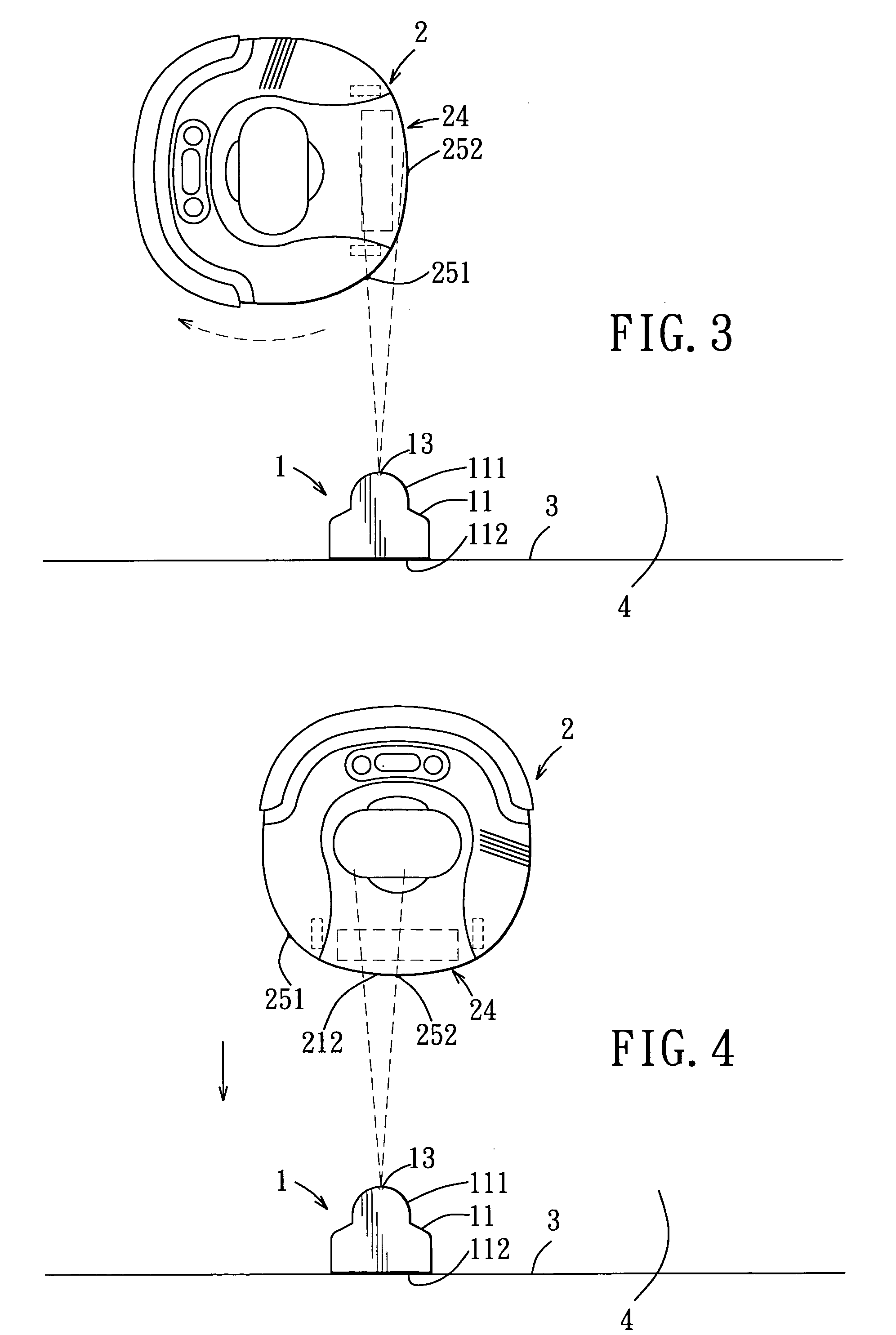

Mobile robotic system and battery charging method therefor

ActiveUS7352153B2Overcomes drawbackProgramme-controlled manipulatorBatteries circuit arrangementsRobotic systemsElectrical battery

A mobile robotic system includes a charging device and a mobile robot. The charging device is provided with a light emitter and a set of first charging contacts for supplying a charging signal. The mobile robot has a first side provided with a first light sensor, a second side provided with a second light sensor and a set of second charging contacts corresponding to the first charging contacts, a rechargeable battery unit, and a control unit. When charging of the battery unit is intended, the control unit enables movement of the mobile robot until the first light sensor detects light emitted by the light emitter, subsequently enables rotation of the mobile robot until the second light sensor detects the light from the light emitter, and then enables movement of the mobile robot toward the charging device until the first and second charging contacts come into contact.

Owner:HUNAN GRAND PRO ROBOT TECH

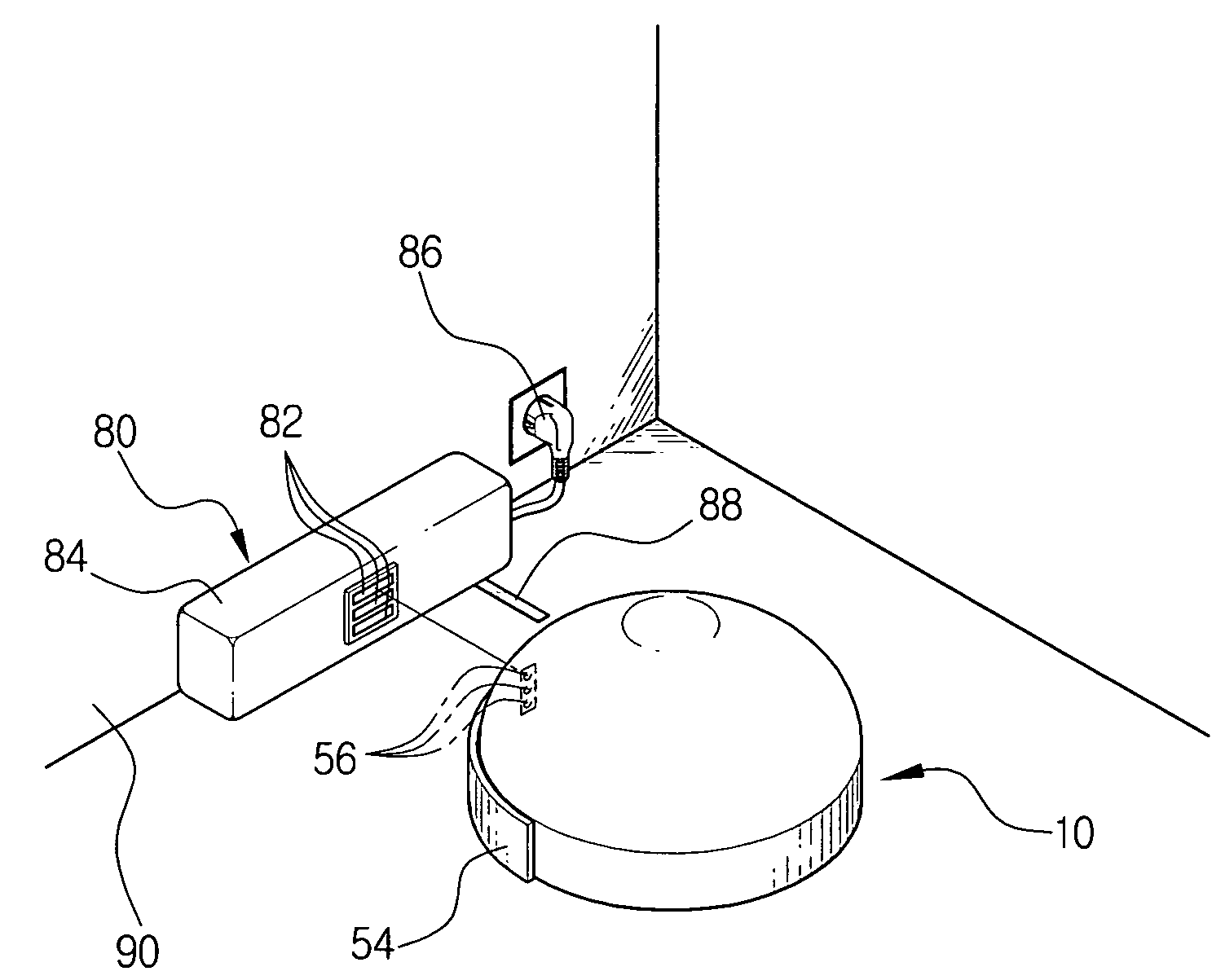

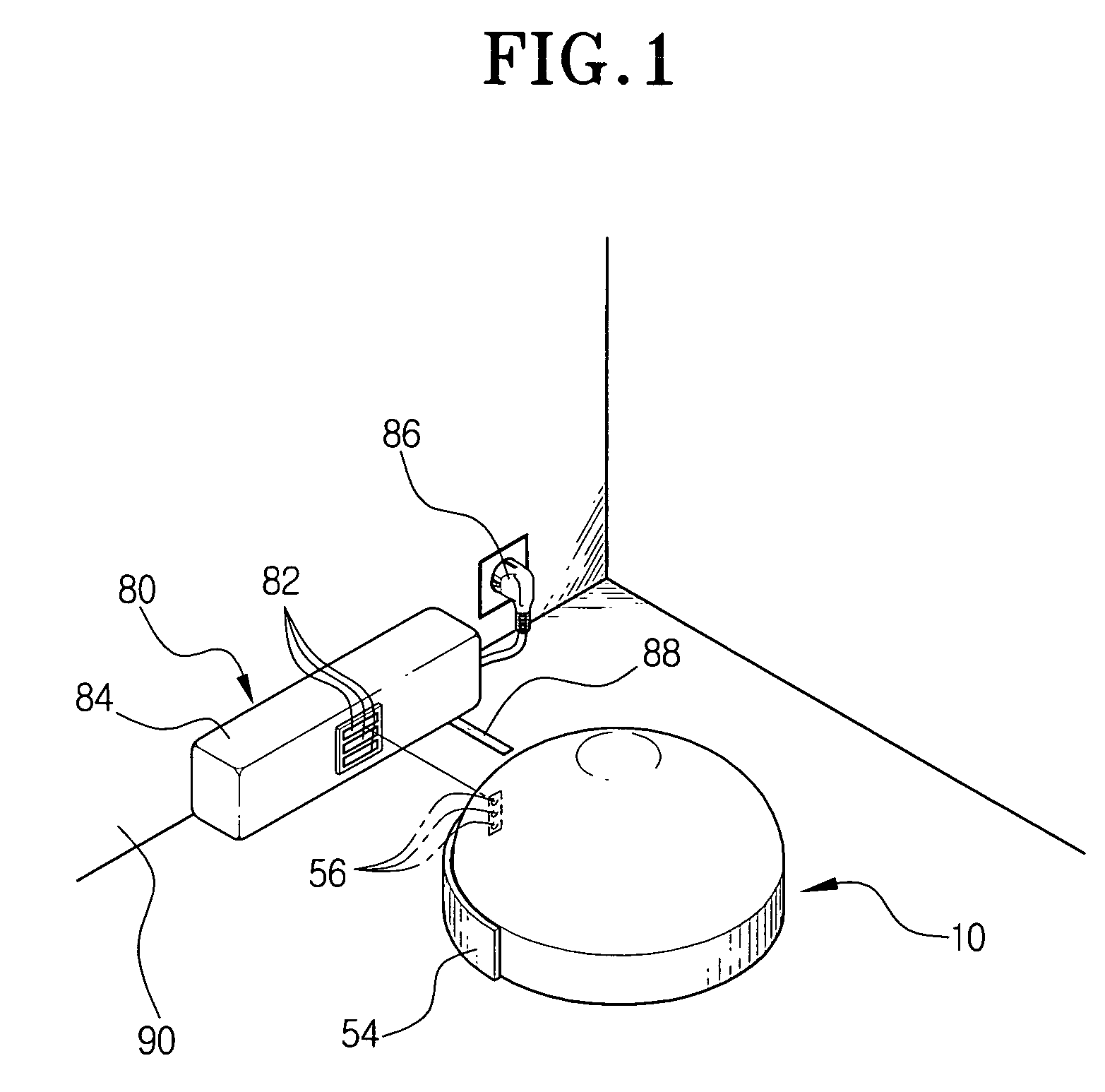

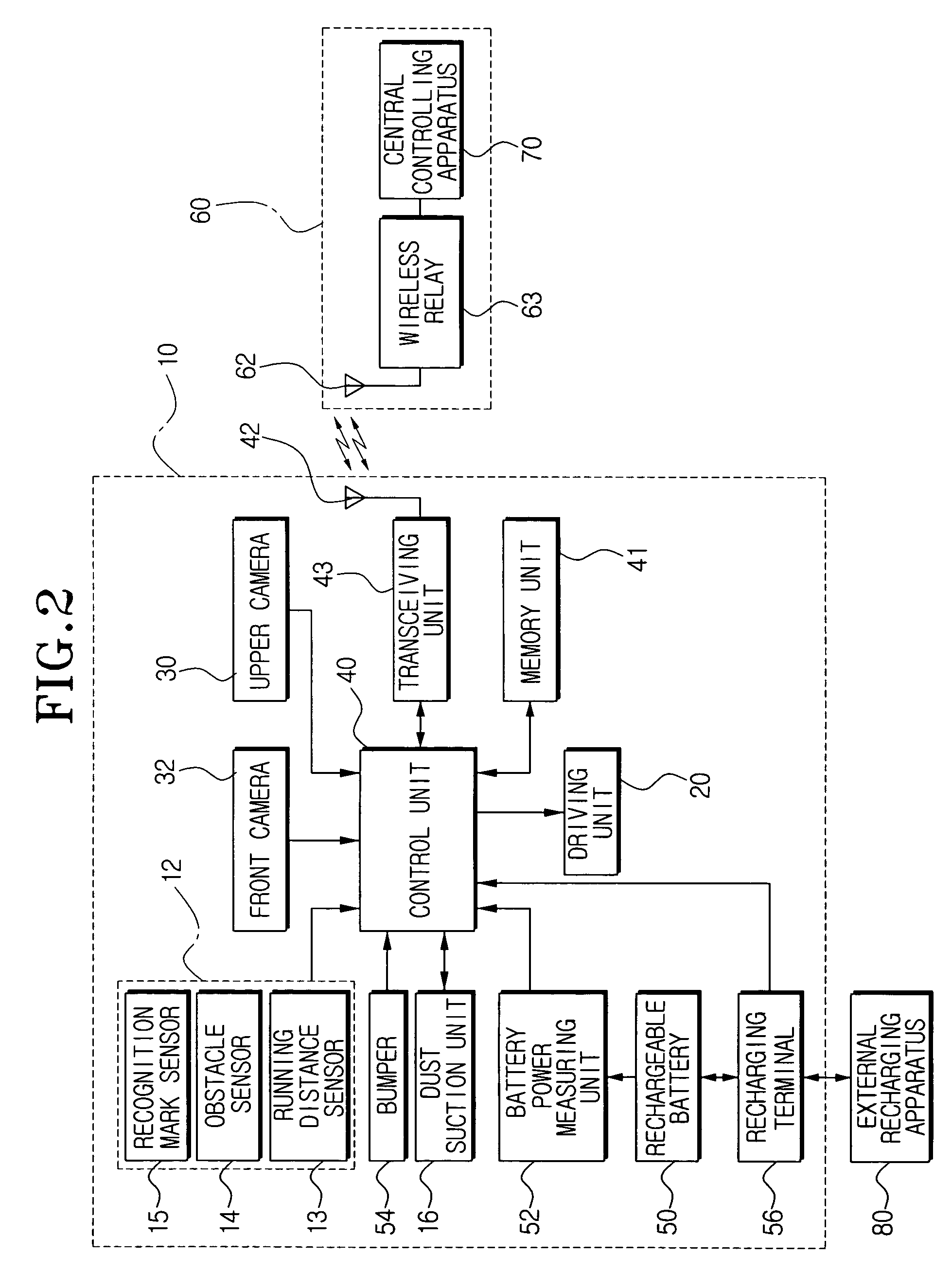

Robot cleaner system having external recharging apparatus and method for docking robot cleaner with external recharging apparatus

InactiveUS7031805B2Find exactlyPrecise dockingMachine detailsVehicular energy storageProximity sensorElectrical battery

A robot cleaner system for detecting an external recharging apparatus which is positioned in a non-detectable area by an upper camera thereof, and a docking method for docking the robot cleaner system with the external recharging apparatus. The robot cleaner system includes an external recharging apparatus with a power terminal connected to a utility power supply, a recharging apparatus recognition mark formed on the external recharging apparatus, and a robot cleaner, having a recognition mark sensor that detects the recharging apparatus recognition mark, and a rechargeable battery. The robot cleaner automatically docks to the power terminal to recharge the rechargeable battery. The recharging apparatus recognition mark is made of retroreflective material or a metal tape, and the recognition mark sensor may be a photosensor or a proximity sensor.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Automatic charging apparatus of autonomous mobile robot and automatic charging method using the same

InactiveUS20080174268A1Improve convenienceBatteries circuit arrangementsSuction cleanersMicrocomputerElectricity

Disclosed are an automatic charging apparatus of an autonomous mobile robot and an automatic charging method using the same in that a moving robot can automatically detect infrared signals emitted from a charging station and can automatically induce charging station so as to automatically charge a battery of the robot, whereby improving convenience thereof. The automatic charging apparatus of the autonomous mobile robot, comprises a charging station having connecting terminals for charging the battery and an infrared signal generator for emitting infrared signals on a position information thereof; and a moving robot having an infrared receiving apparatus for receiving the infrared signals from the infrared signal generator in a cast that a remnant capacity of the battery is insufficient or a charging order is inputted, a microcomputer for controlling a traveling of the moving robot by using a detected position information of the charging station through the infrared signals received from the infrared receiving apparatus, and charging terminals for charging the battery with electricity through the contact with the connecting terminal.

Owner:YUJIN ROBOT

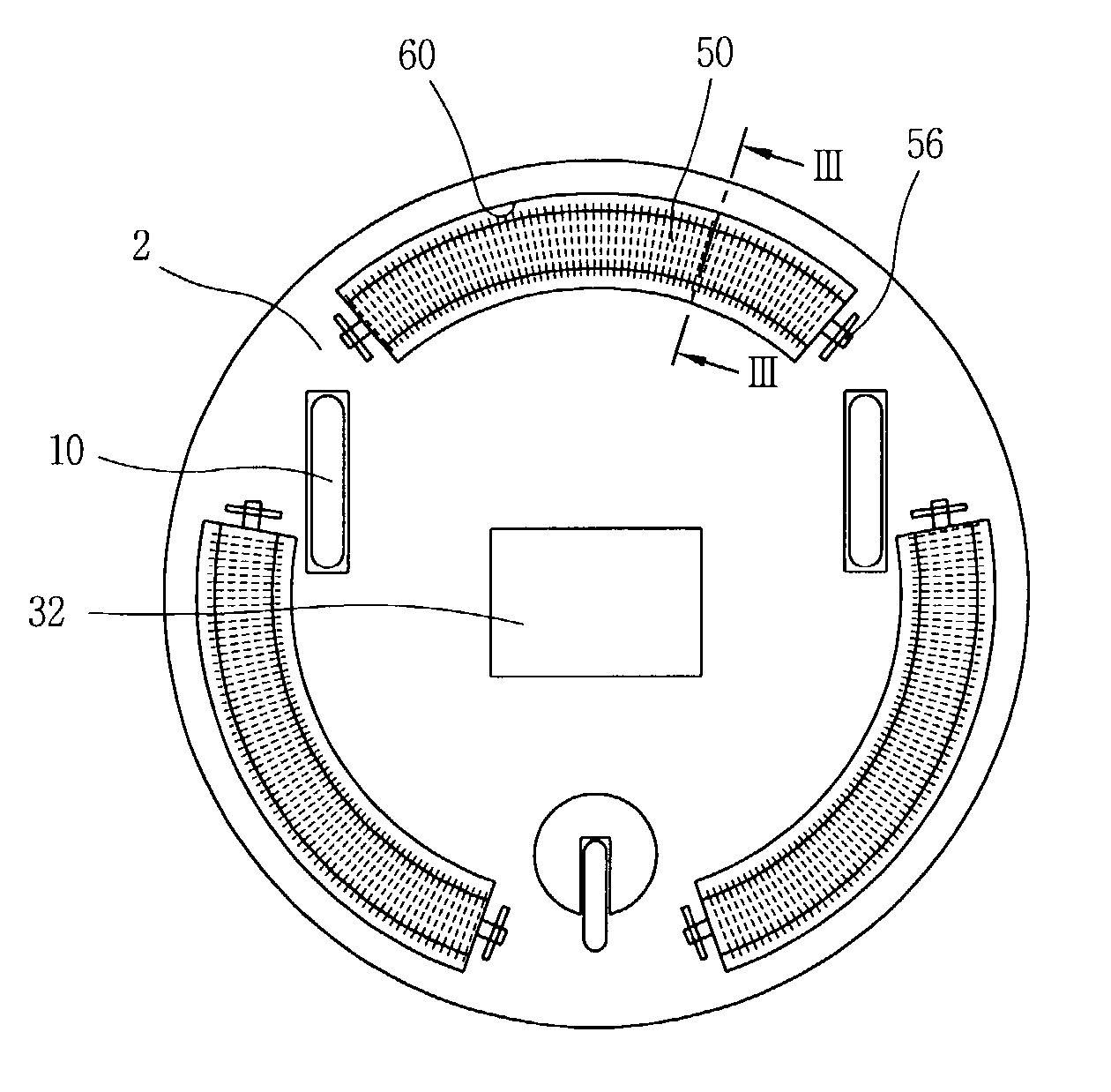

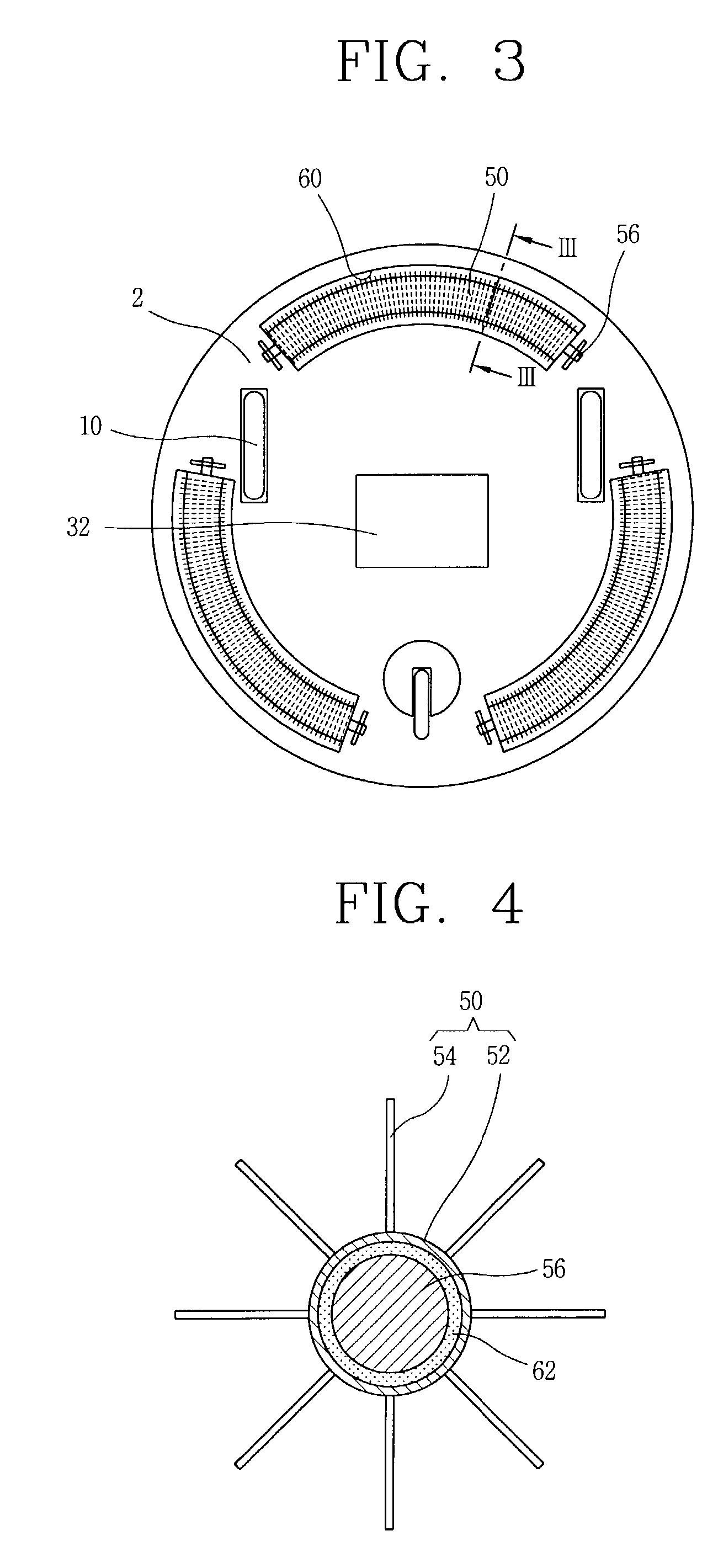

Brush assembly of cleaner

InactiveUS6971140B2Easy to cleanSmall sizeMechanical cleaningPressure cleaningEngineeringMechanical engineering

In a brush assembly of a cleaner including plural brushes arranged at the bottom surface of a cleaner body radially at regular intervals; plural supporting shafts for rotatively supporting the brushes; and a driving unit connected to the brushes in order to rotate the brushes, by arranging the plural brushes radially, dust and filth can be collected in a wider region, and accordingly a cleaning performance can be improved. In addition, by forming the brushes as a curved shape, it is possible to compact a size of the cleaner.

Owner:LG ELECTRONICS INC

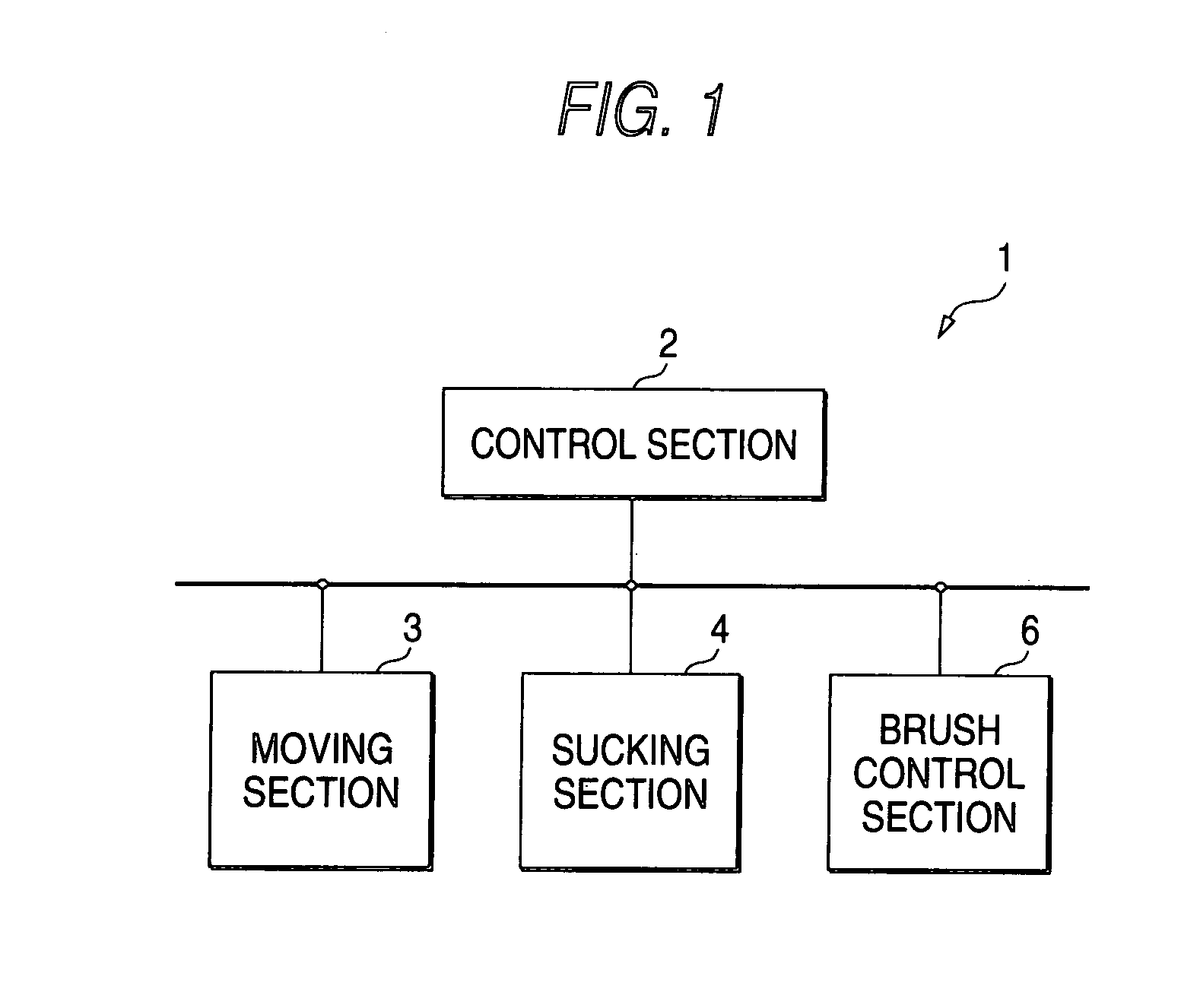

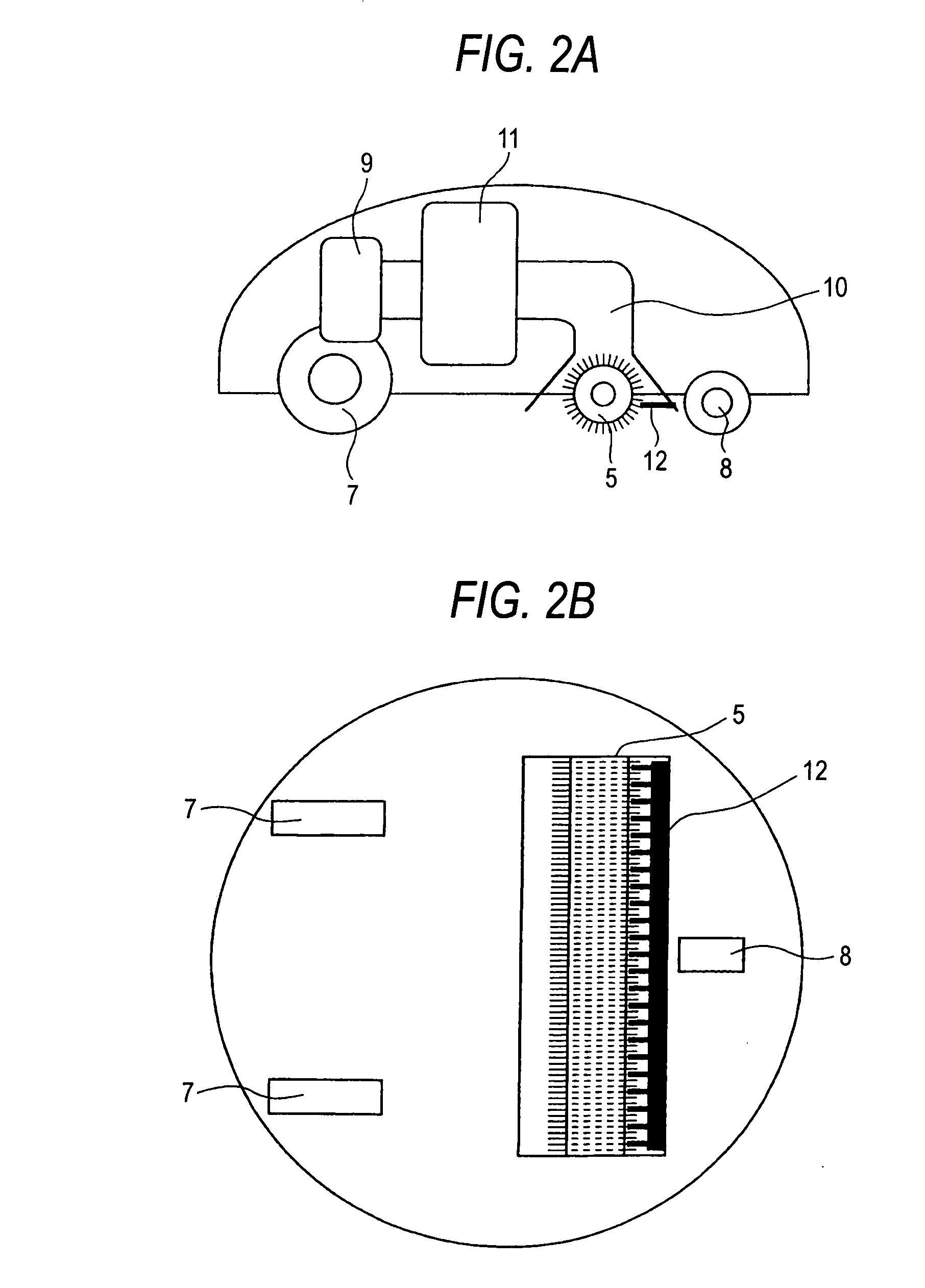

Self-propelling cleaner

A self-propelling cleaner 1 performs dust removal processing in which a comb is brought close to a rotary brush with prescribed timing and dust is removed from the rotary brush. In the dust removal processing, the comb is slid in such a direction as to come closer to the brush, even dust that is stuck to the base portions of bristles of the rotary brush can be removed. A self-propelling cleaner is provided that is free of an event that it performs cleaning in a state that a large amount of dust is stuck to the rotary brush.

Owner:FUNAI ELECTRIC CO LTD

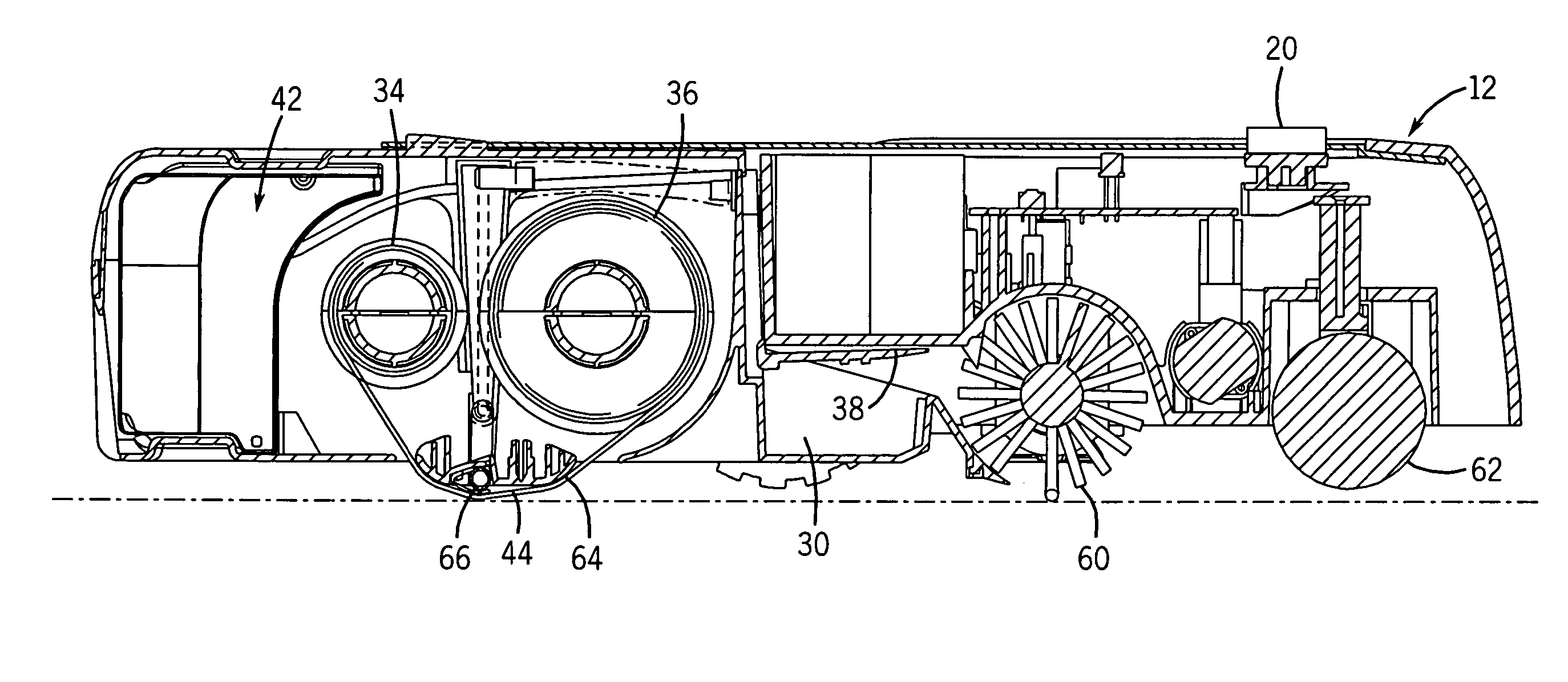

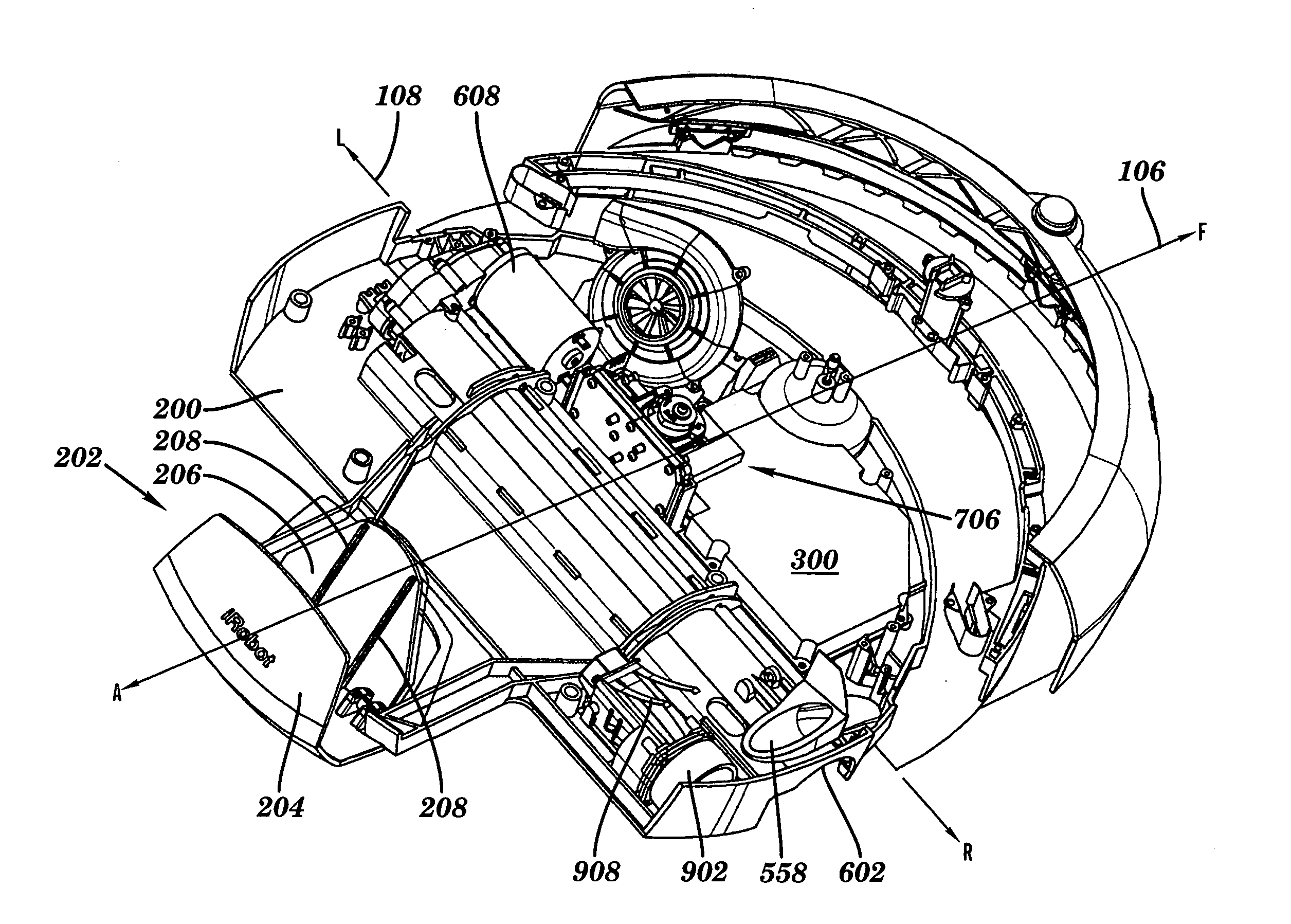

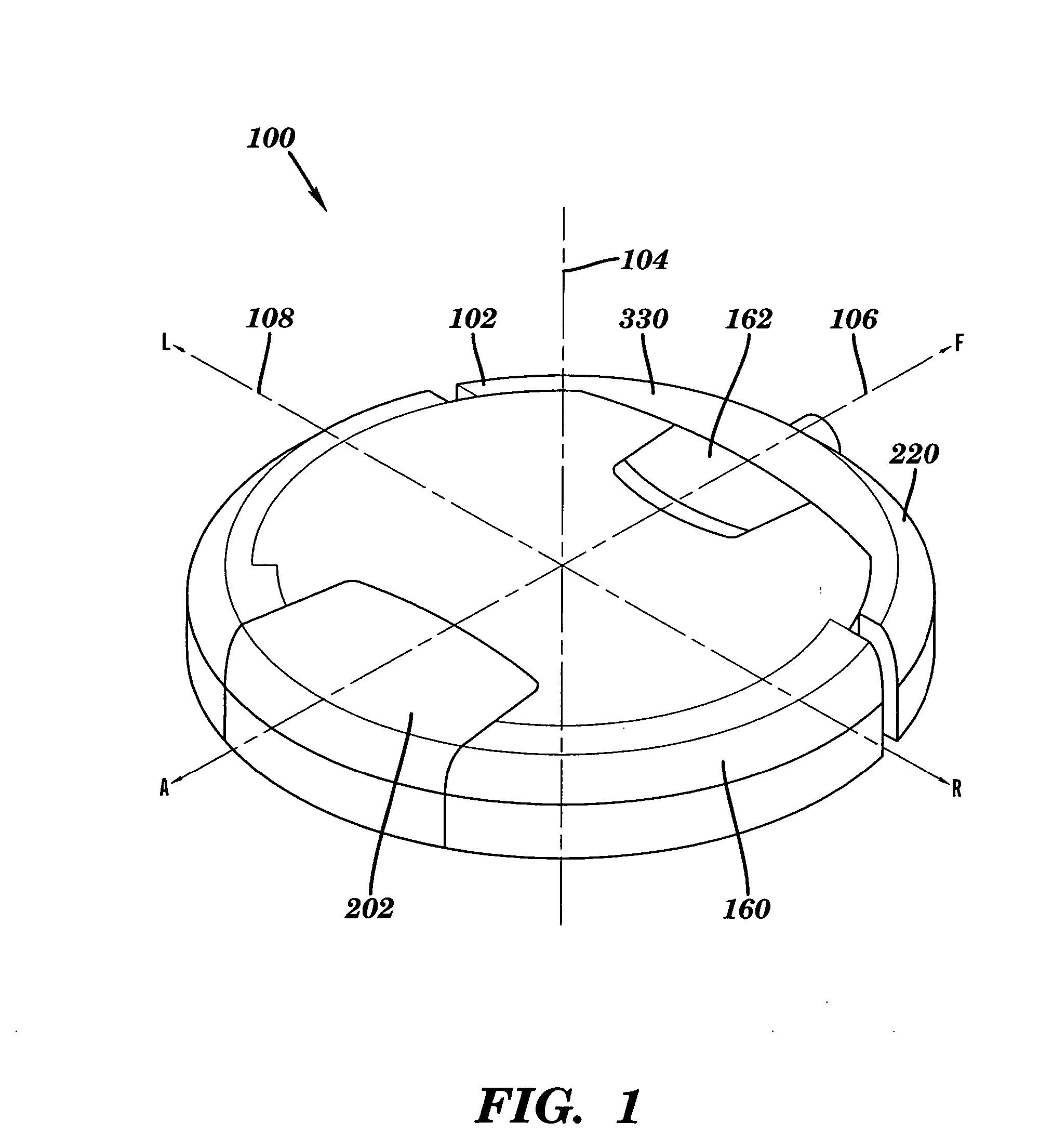

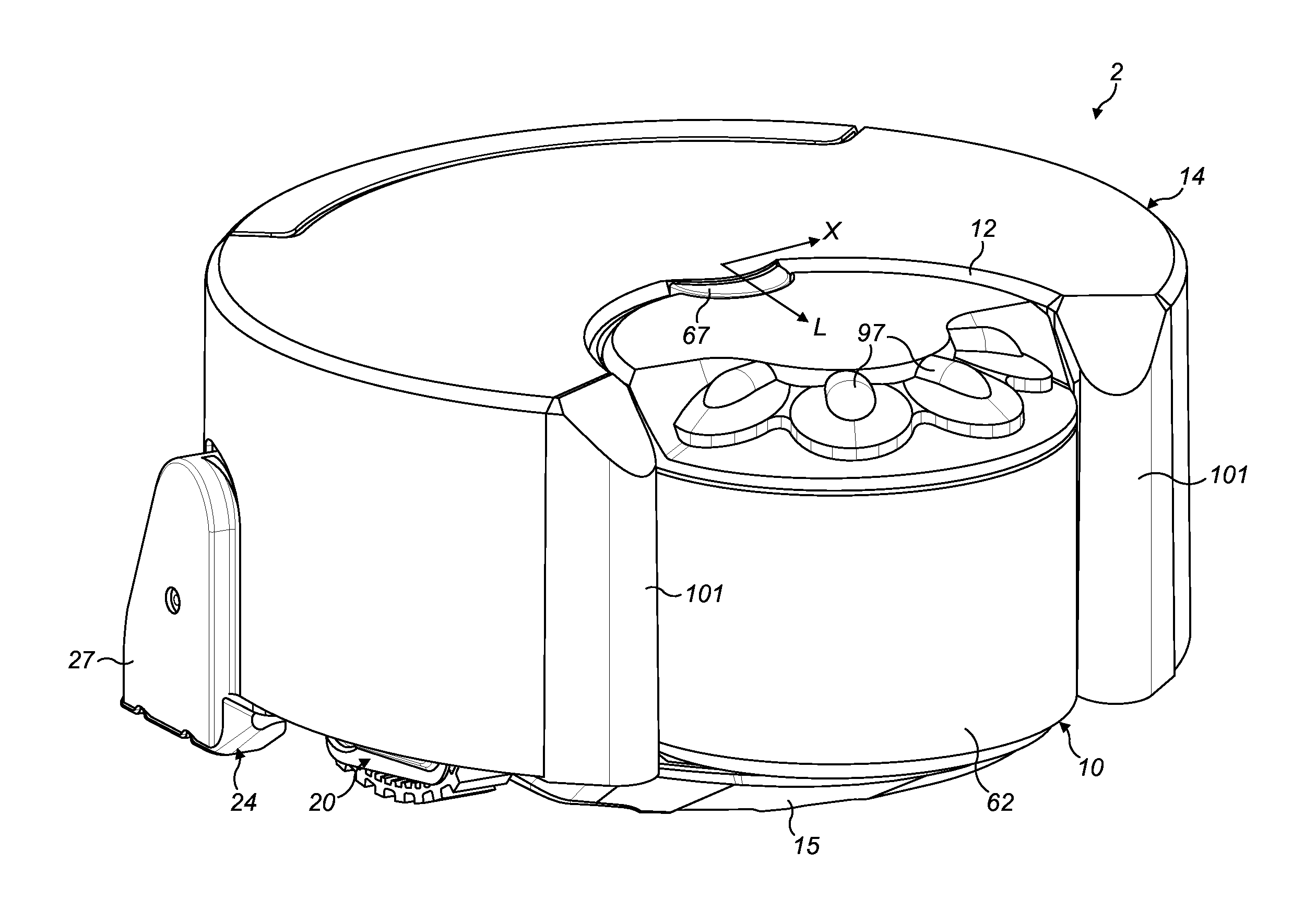

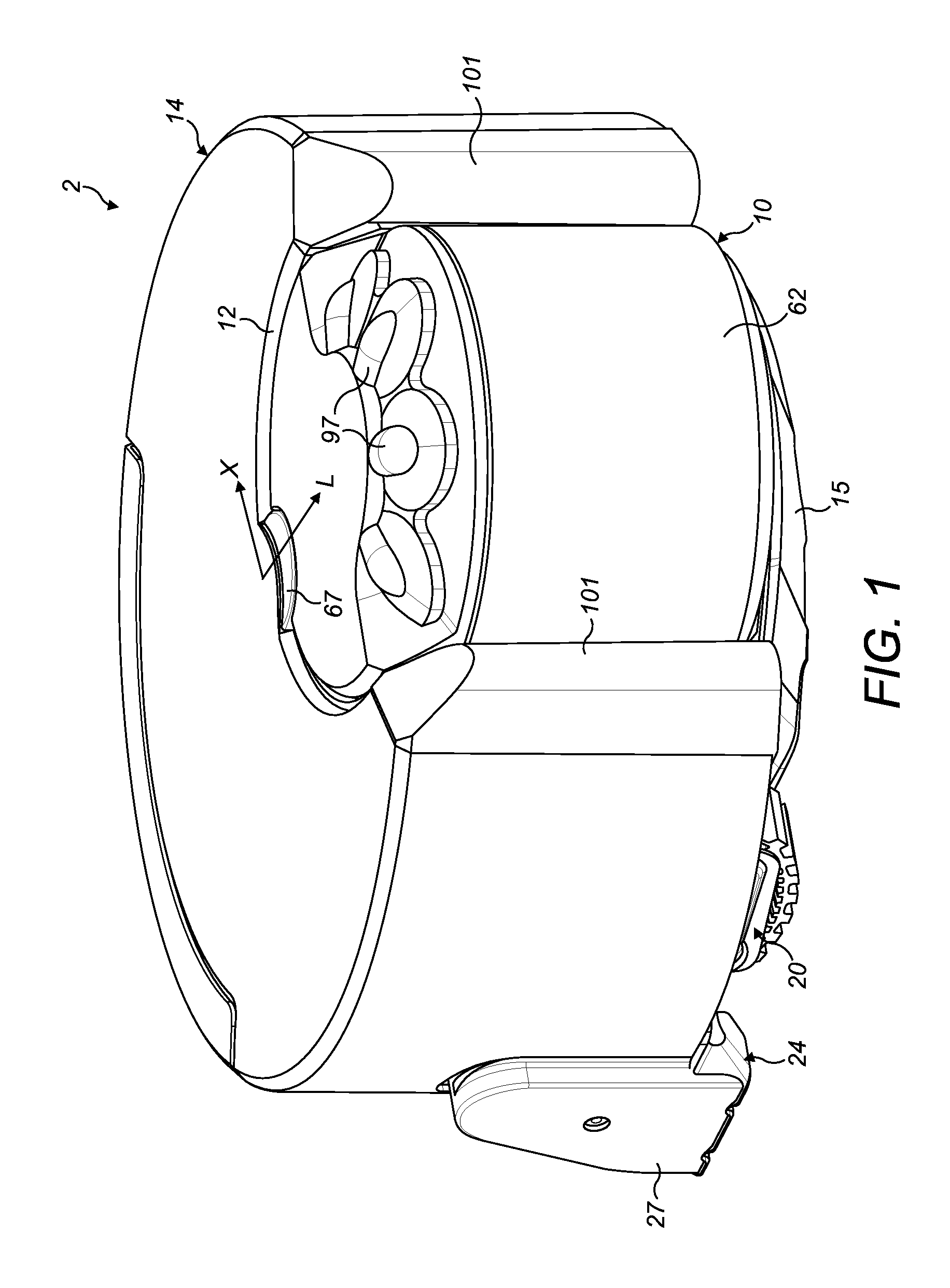

Autonomous surface cleaning robot for dry cleaning

InactiveUS20060190146A1Low costWet cleaningProgramme-controlled manipulatorActuated automaticallyParticulatesControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

Cleaner system

InactiveUS20070157415A1Improved connecting position and structureImprove dust removal effectEngine sealsSuction cleanersDocking stationEngineering

A cleaner system having an improved connecting position and structure between a robot cleaner and a docking station for achieving an improvement in dust removal performance of the docking station. The docking station performs manual cleaning. The robot cleaner has a dust outlet at a top wall of the robot body to discharge the dust collected in the first dust collector into the docking station, and the docking station has a connection port at a position thereof corresponding to the dust outlet to receive the dust discharged from the dust outlet. The robot cleaner or docking station includes a connector to connect the dust outlet to the connection port. The docking station includes a suction part, suction pipe, and suction hole for manual operation. A channel switching member is mounted in the docking station to selectively apply power required to suck dust to the connection port or suction hole.

Owner:SAMSUNG ELECTRONICS CO LTD

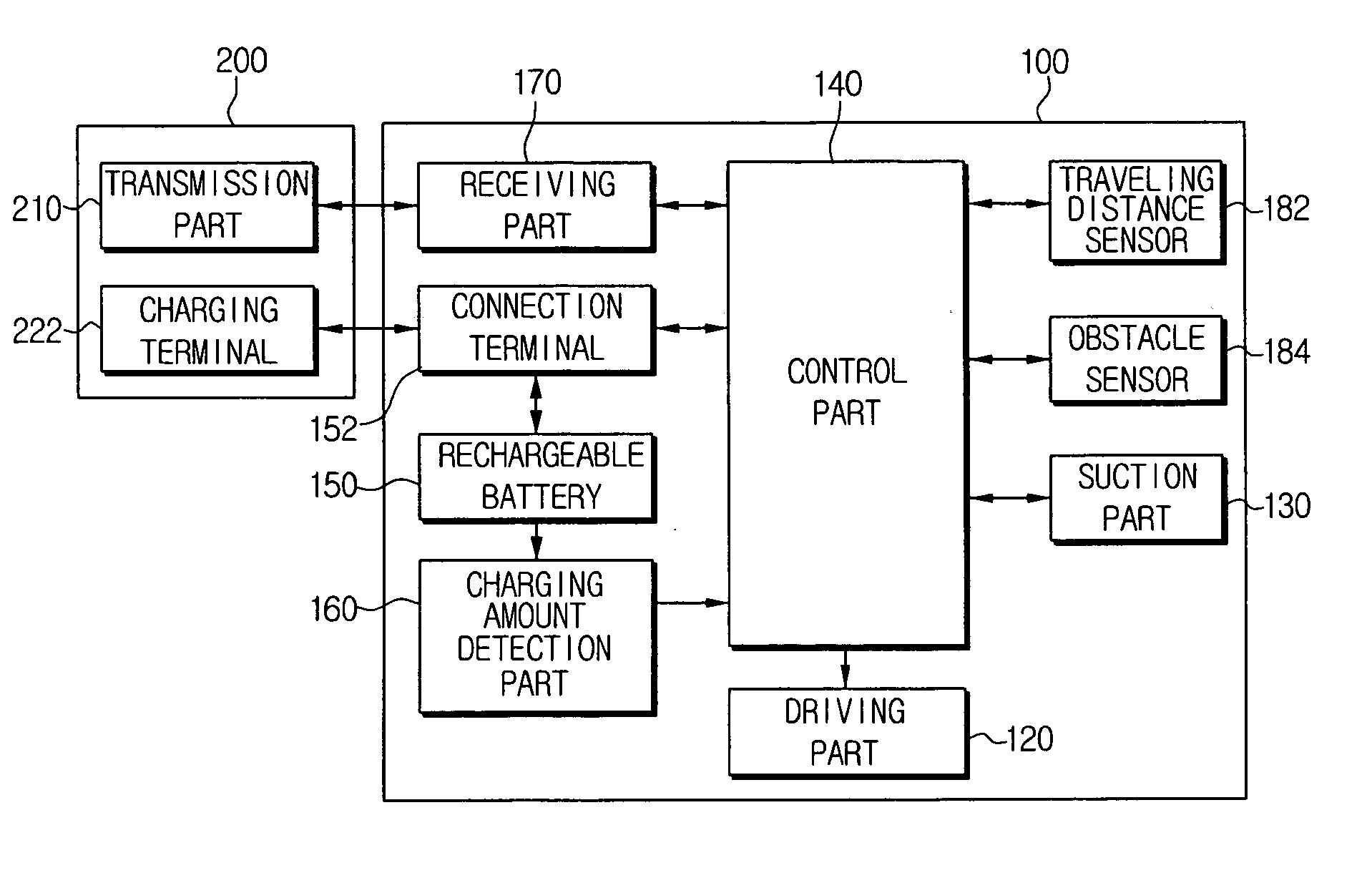

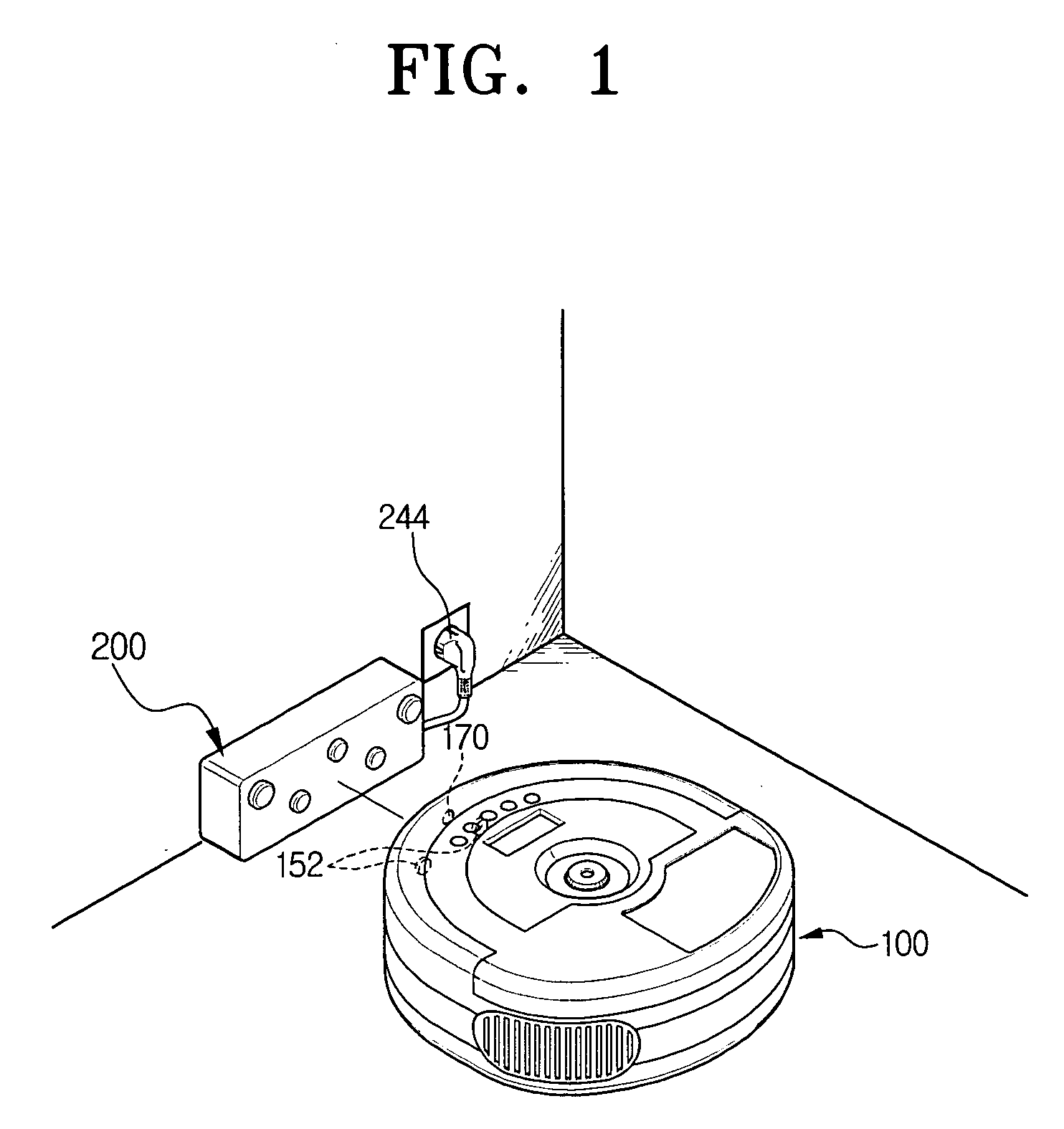

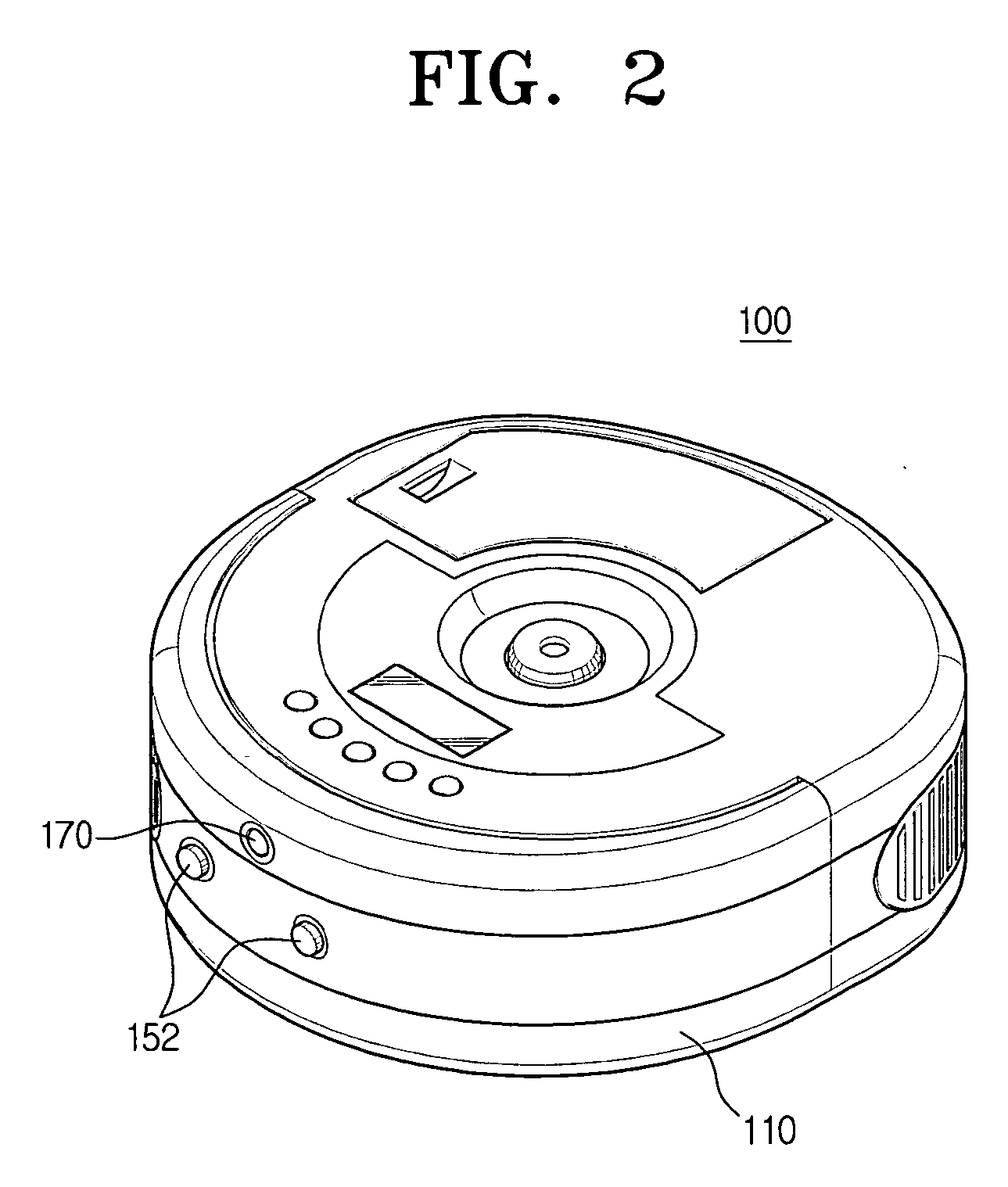

Robot cleaner system and a method for returning to external recharging apparatus

InactiveUS20060087273A1Improve abilitiesIncrease manufacturing costCarpet cleanersFloor cleanersElectrical batteryRechargeable cell

A robot cleaner system and a method for the robot cleaner to return to an external recharging apparatus. The robot cleaner system has an external recharging apparatus including a charging stand having a charging terminal, and a plurality of transmission parts for sending signals having different codes and strengths; a robot cleaner including a rechargeable battery, a connection terminal for connection with the charging terminal to supply power to the rechargeable battery, a receiving part for receiving signals from the plurality of transmission parts, and a control part for controlling a movement of the robot cleaner using the signals received by the receiving part, so that the connection terminal is connected to the charging terminal.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

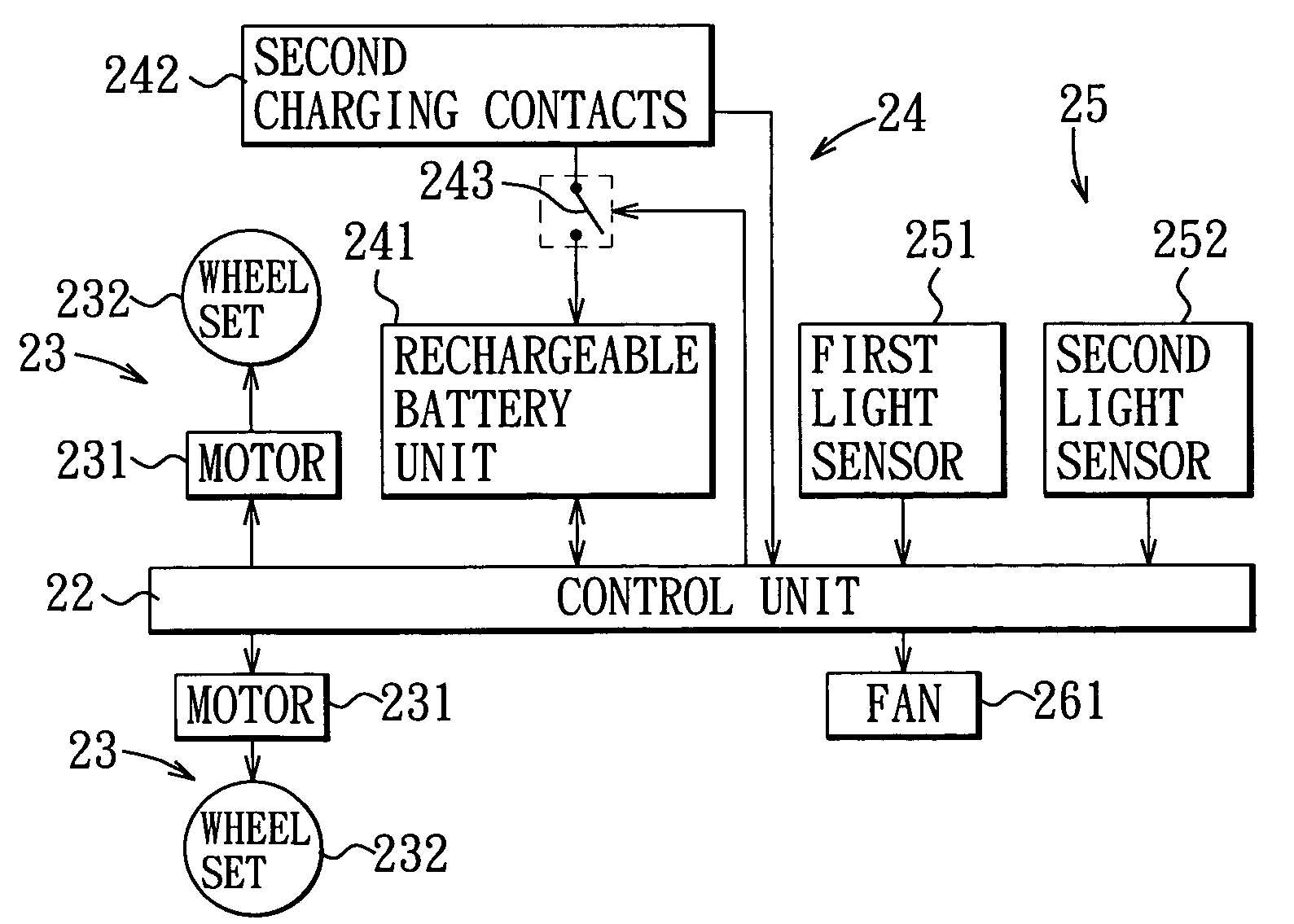

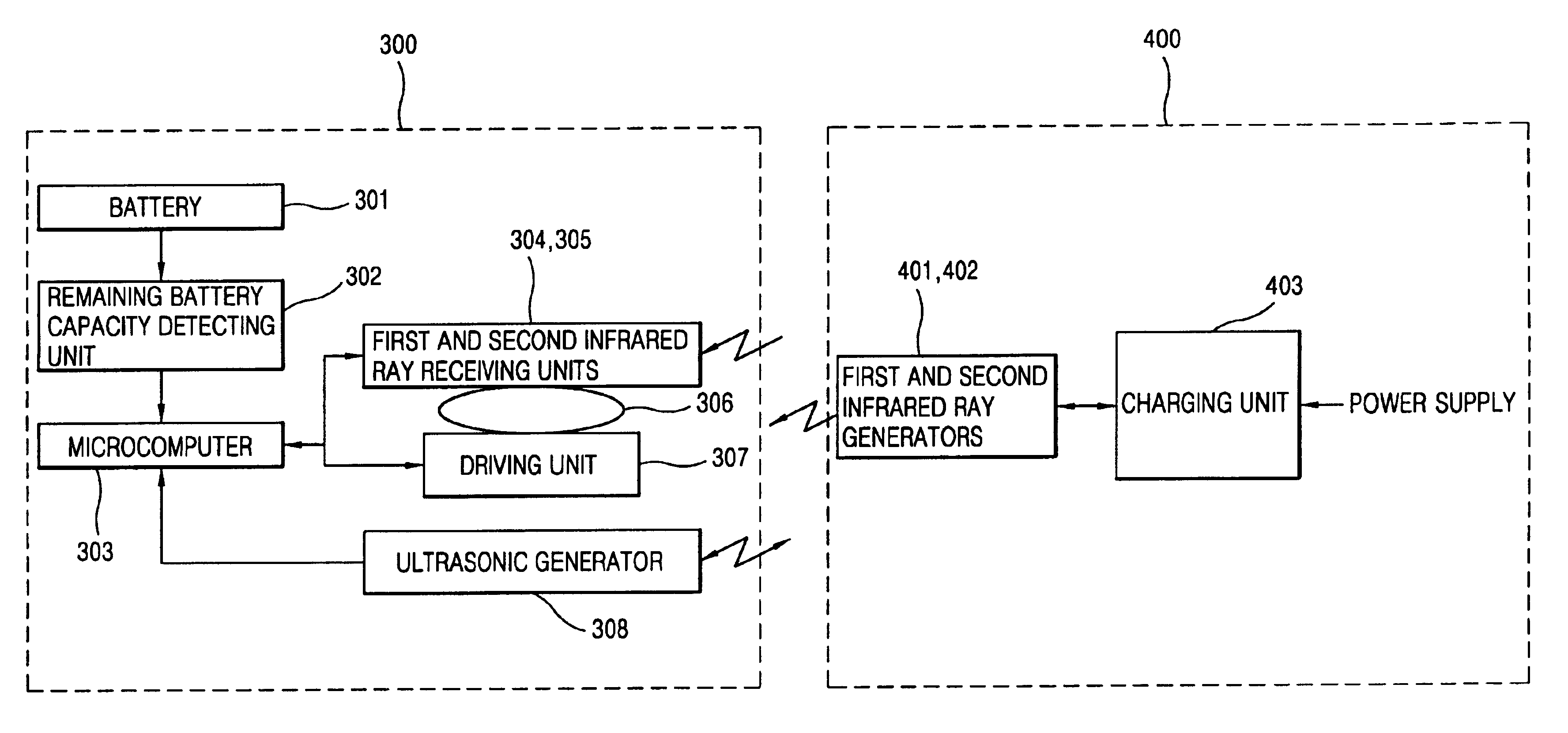

Mobile robotic system and battery charging method therefor

ActiveUS20050231156A1Overcomes drawbackBatteries circuit arrangementsCleaning equipmentRobotic systemsElectrical battery

A mobile robotic system includes a charging device and a mobile robot. The charging device is provided with a light emitter and a set of first charging contacts for supplying a charging signal. The mobile robot has a first side provided with a first light sensor, a second side provided with a second light sensor and a set of second charging contacts corresponding to the first charging contacts, a rechargeable battery unit, and a control unit. When charging of the battery unit is intended, the control unit enables movement of the mobile robot until the first light sensor detects light emitted by the light emitter, subsequently enables rotation of the mobile robot until the second light sensor detects the light from the light emitter, and then enables movement of the mobile robot toward the charging device until the first and second charging contacts come into contact.

Owner:HUNAN GRAND PRO ROBOT TECH

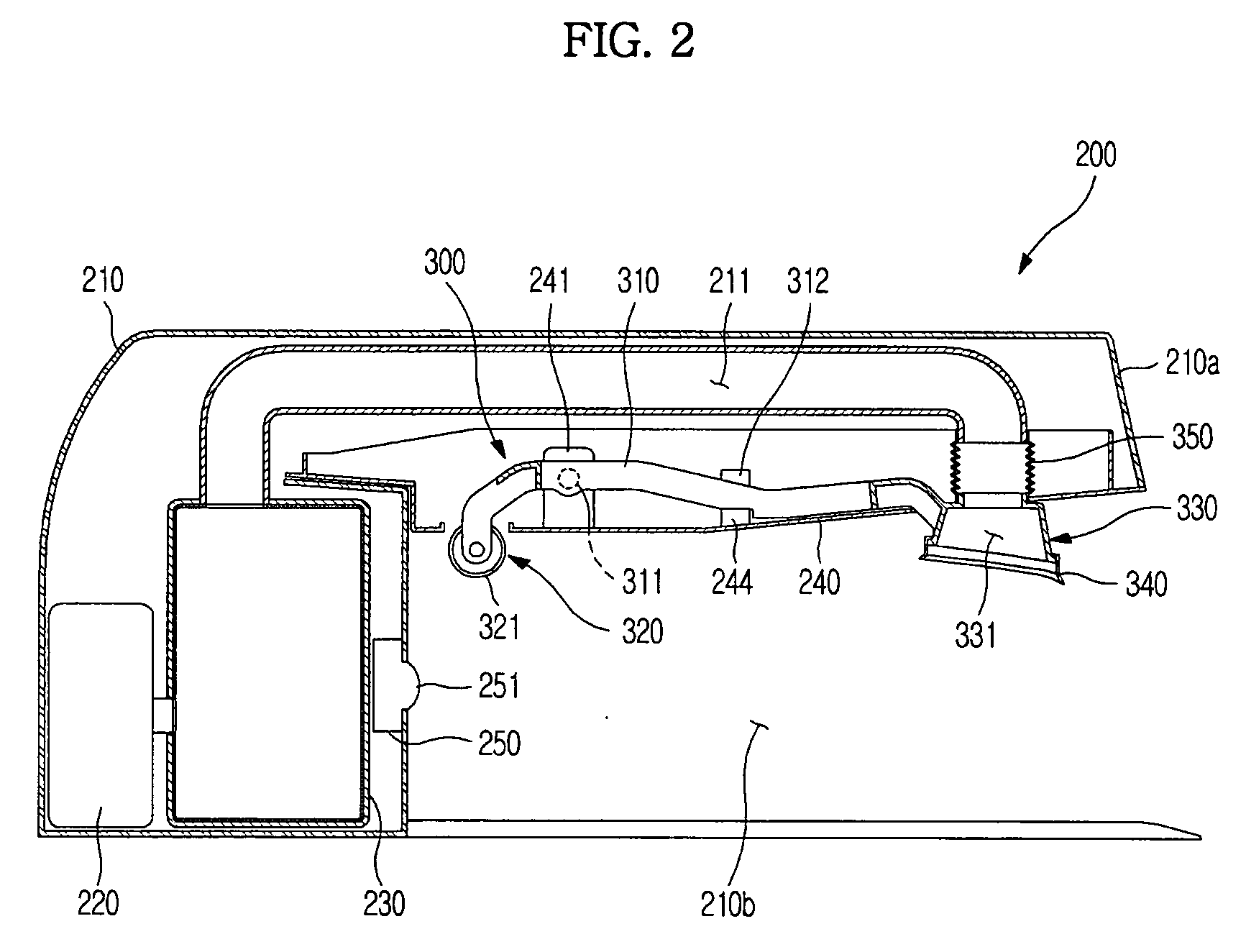

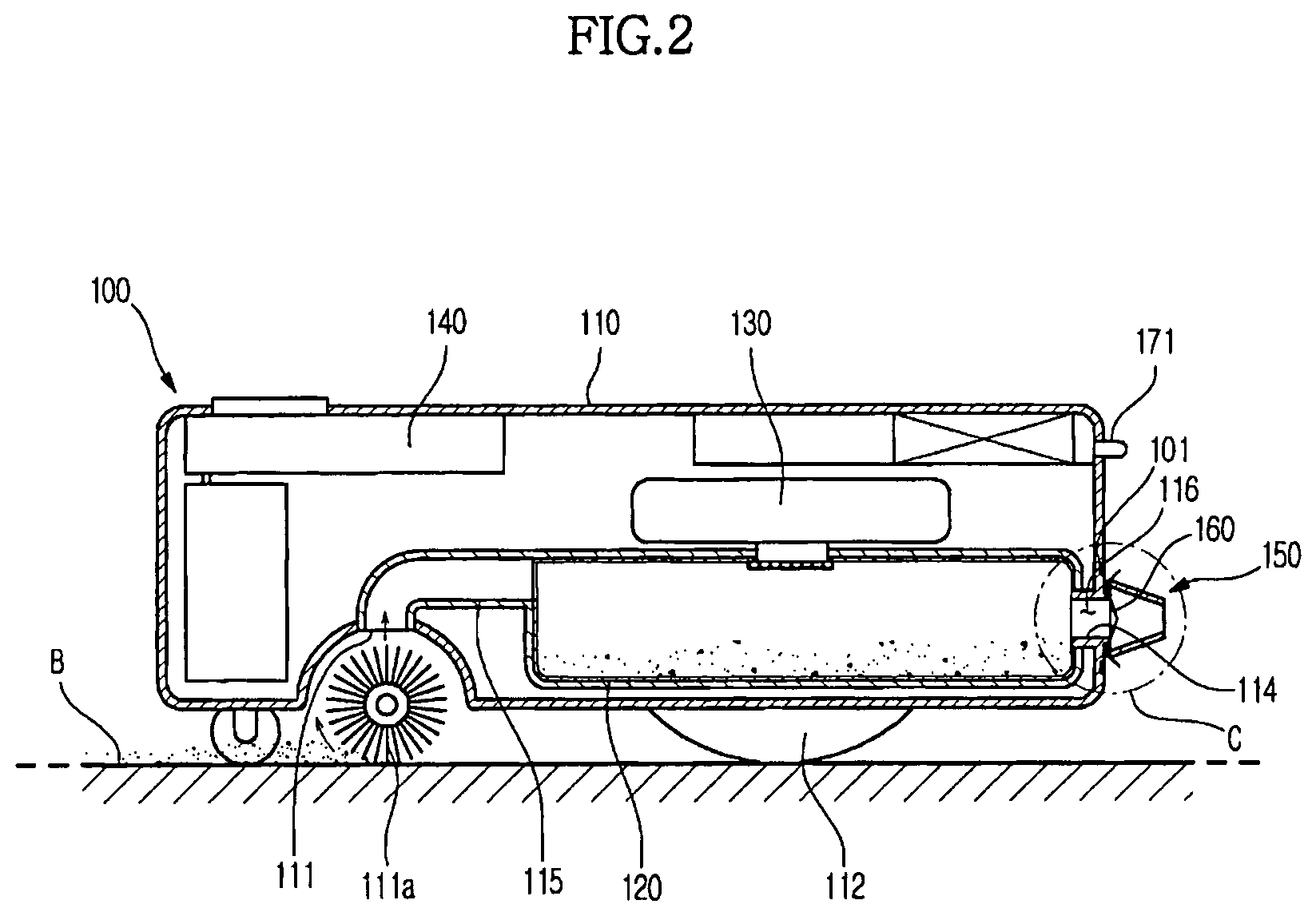

Robot cleaning system and dust removing method of the same

InactiveUS7849555B2Shorten the lengthSmall sizeCleaning filter meansMechanical cleaningDocking stationControl theory

A robot cleaning system and a dust removing method of the same that are capable of moving a first dust collector mounted in a robot cleaner to a docking station to remove dust collected in the first dust collector. The robot cleaning system includes a robot cleaner having an opening, though which a first dust collector to collect suctioned dust is carried in and out of the robot cleaner, a docking station, to which the robot cleaner is docked to remove the dust collected in the first dust collector, and a collector moving unit to move the first dust collector to the docking station.

Owner:SAMSUNG ELECTRONICS CO LTD

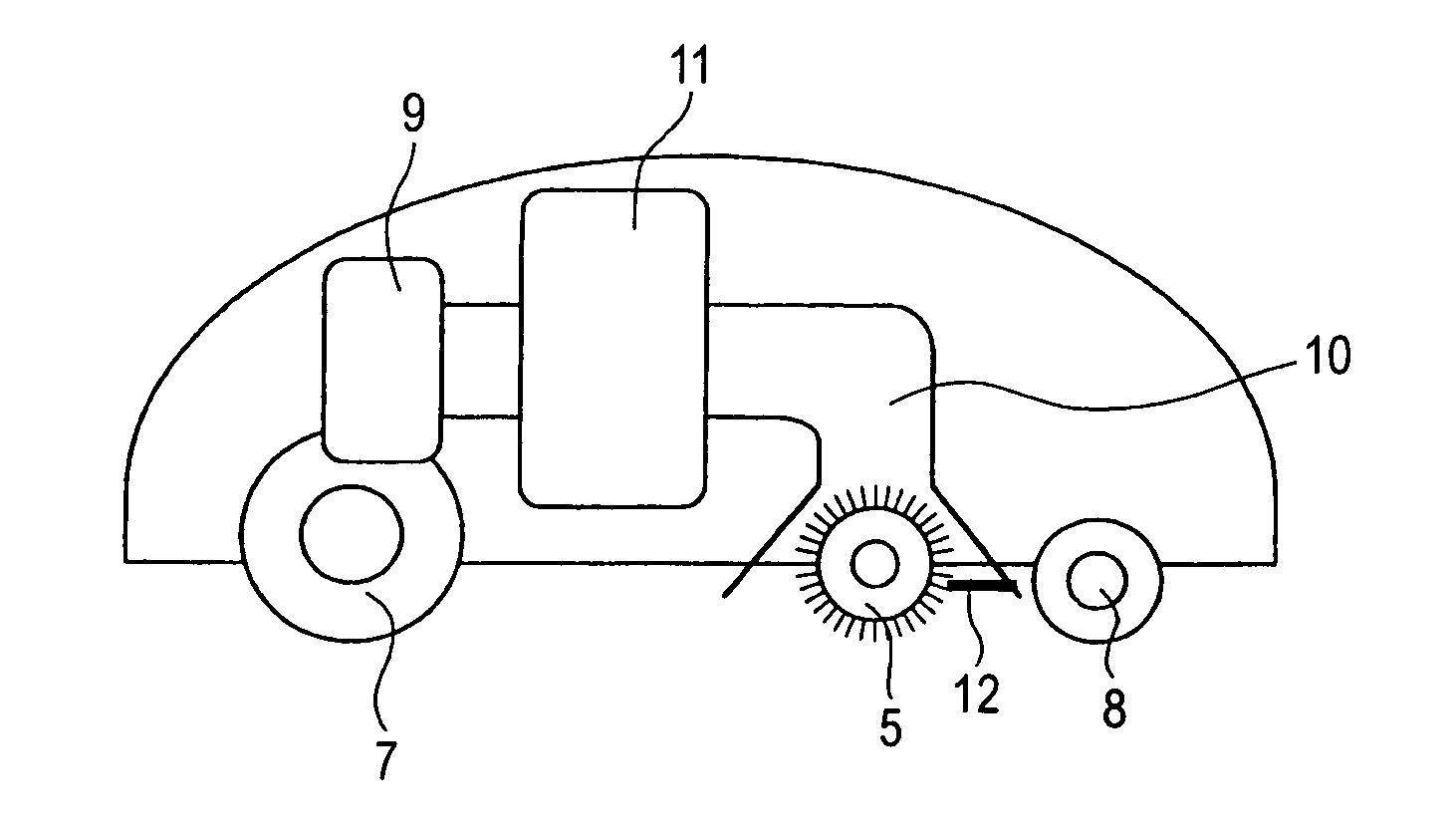

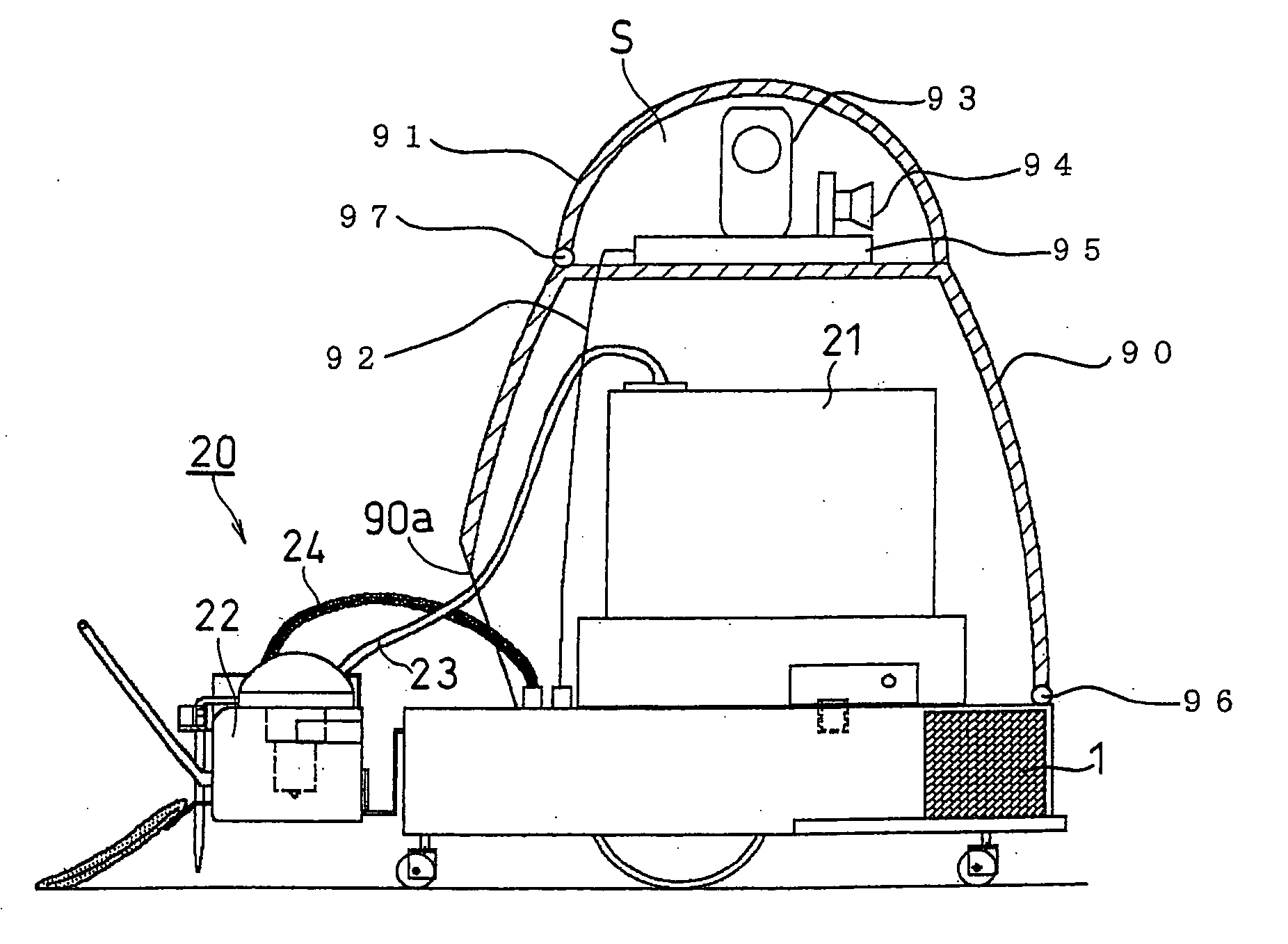

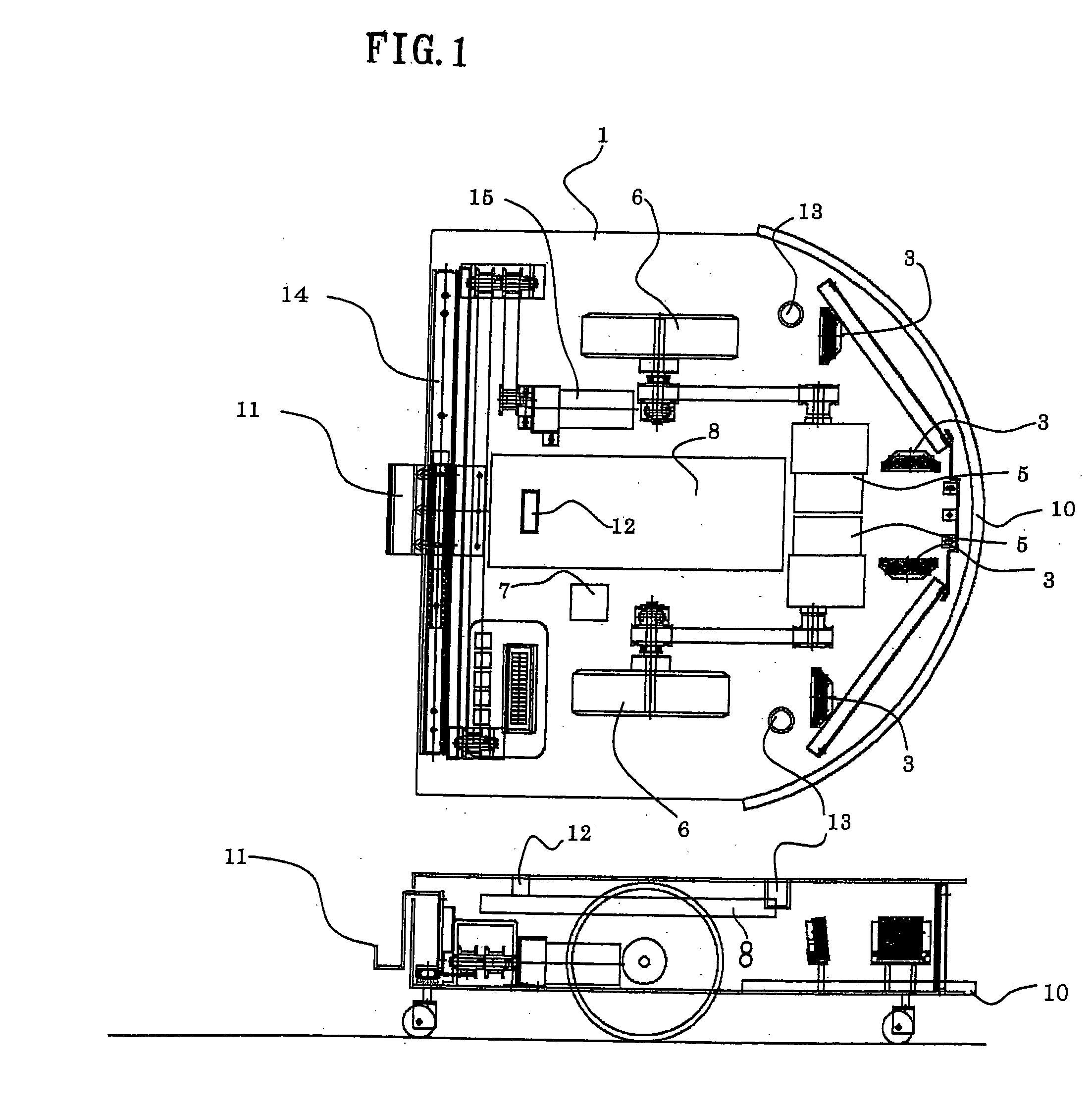

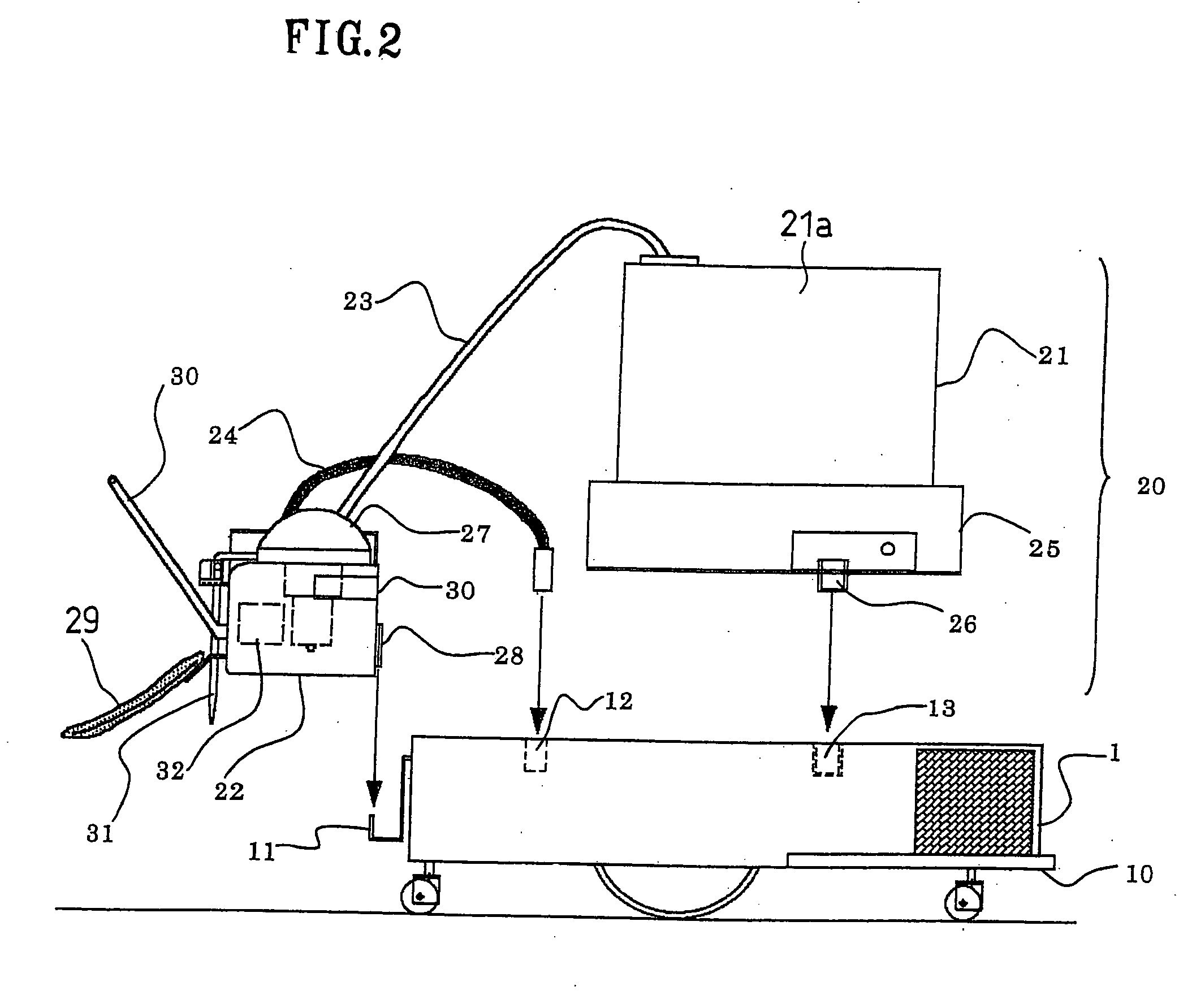

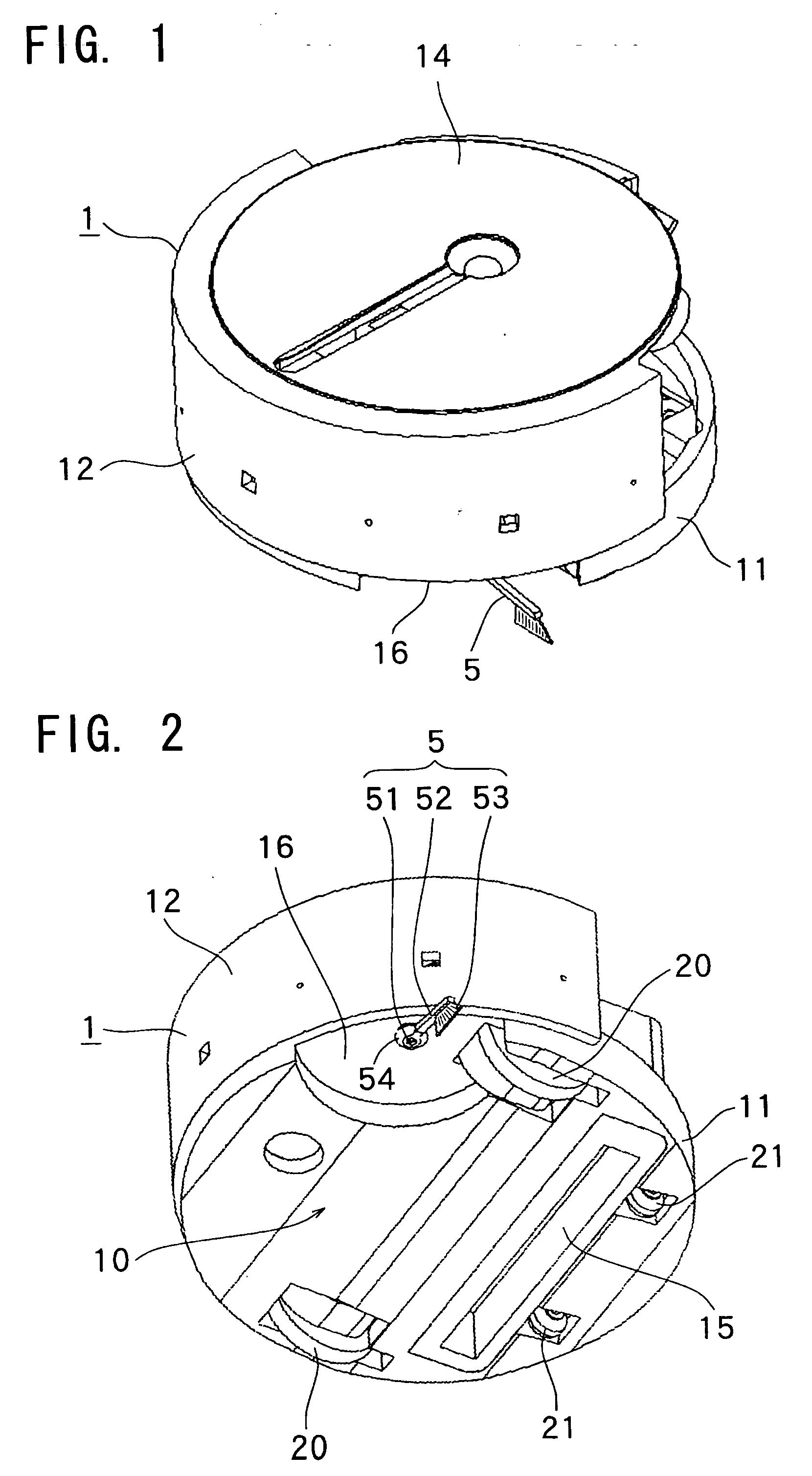

Self-propelled working robot

A self-propelled working robot according to the present invention comprises a traveling assembly (1) having a wheel (6) and first and second working assemblies (20, 50) that are detachable from the traveling assembly 81). One of the first and second working assemblies (20, 50) is selectively mounted on the traveling assembly (1). Each working assembly has a type identification means (33) that enables identification of a type of the working assembly. The traveling assembly (1) has a driving motor (5) that drives the wheel (6), a wheel controlling means (41) that controls rotation of the driving motor (5), a discriminating means (38) that discriminates which of the working assemblies is mounted and a work signal output means (39) that outputs a work signal for actuating the working assembly (20, 50) in response to a result of a discrimination.

Owner:FIGLA

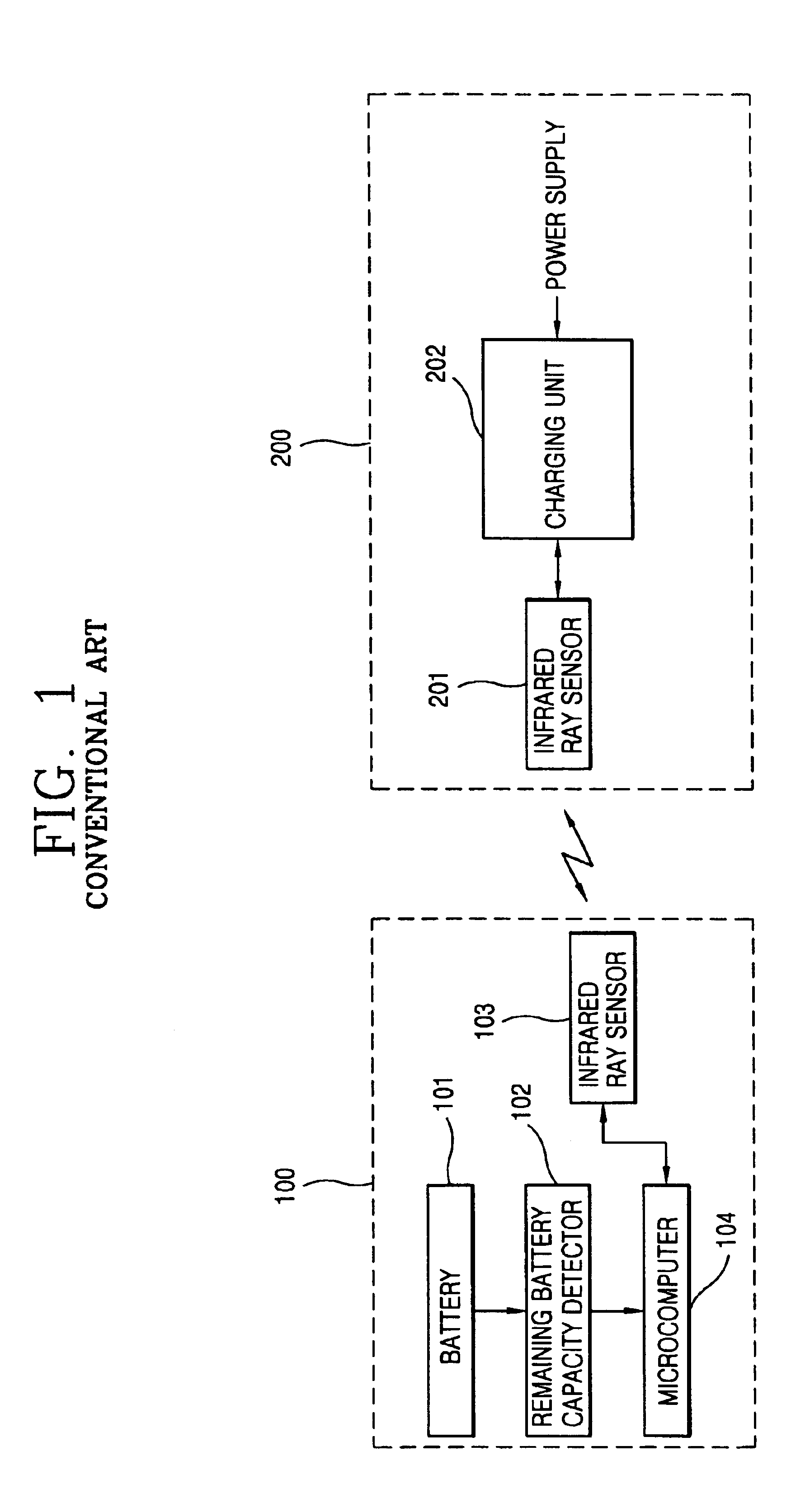

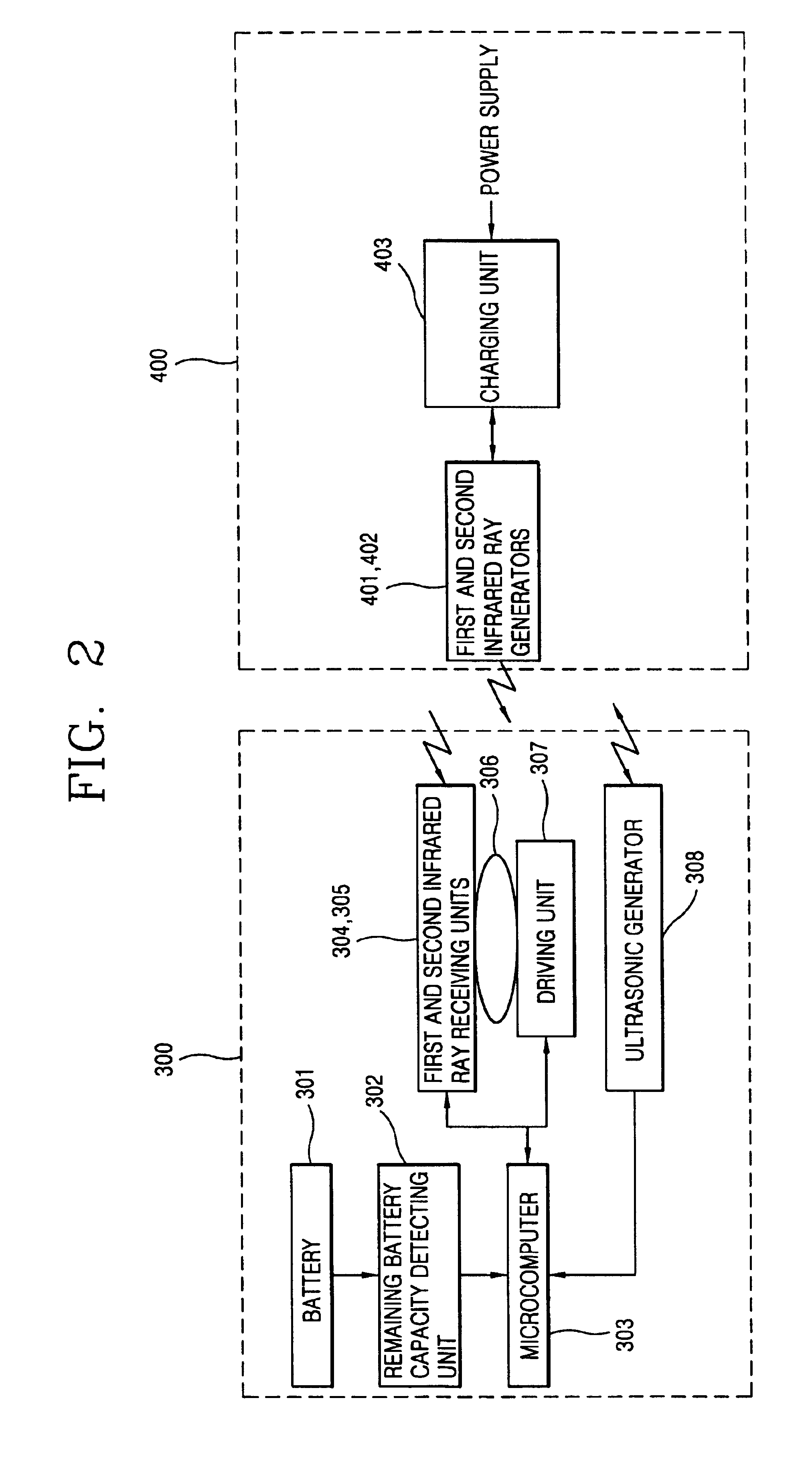

Automatic charging system and method of robot cleaner

ActiveUS6859010B2Accurately and quickly moveAccurately and quickly connectBatteries circuit arrangementsCleaning equipmentInfraredMicrocomputer

An automatic charging system of a robot cleaner includes: a rotating plate installed at a robot cleaner; an infrared ray receiving unit mounted at the rotating plate and receiving an infrared signal generated from a power supply unit while being rotated; a microcomputer for moving the robot cleaner to the power supply unit on the basis of the received infrared signal; and an ultrasonic generator for generating a stop signal when the robot cleaner nears to the power supply unit. A robot cleaner can be accurately and quickly moved to a power supply unit for a rapid charging operation, and a cost for implementing the robot cleaner can be reduced.

Owner:LG ELECTRONICS INC

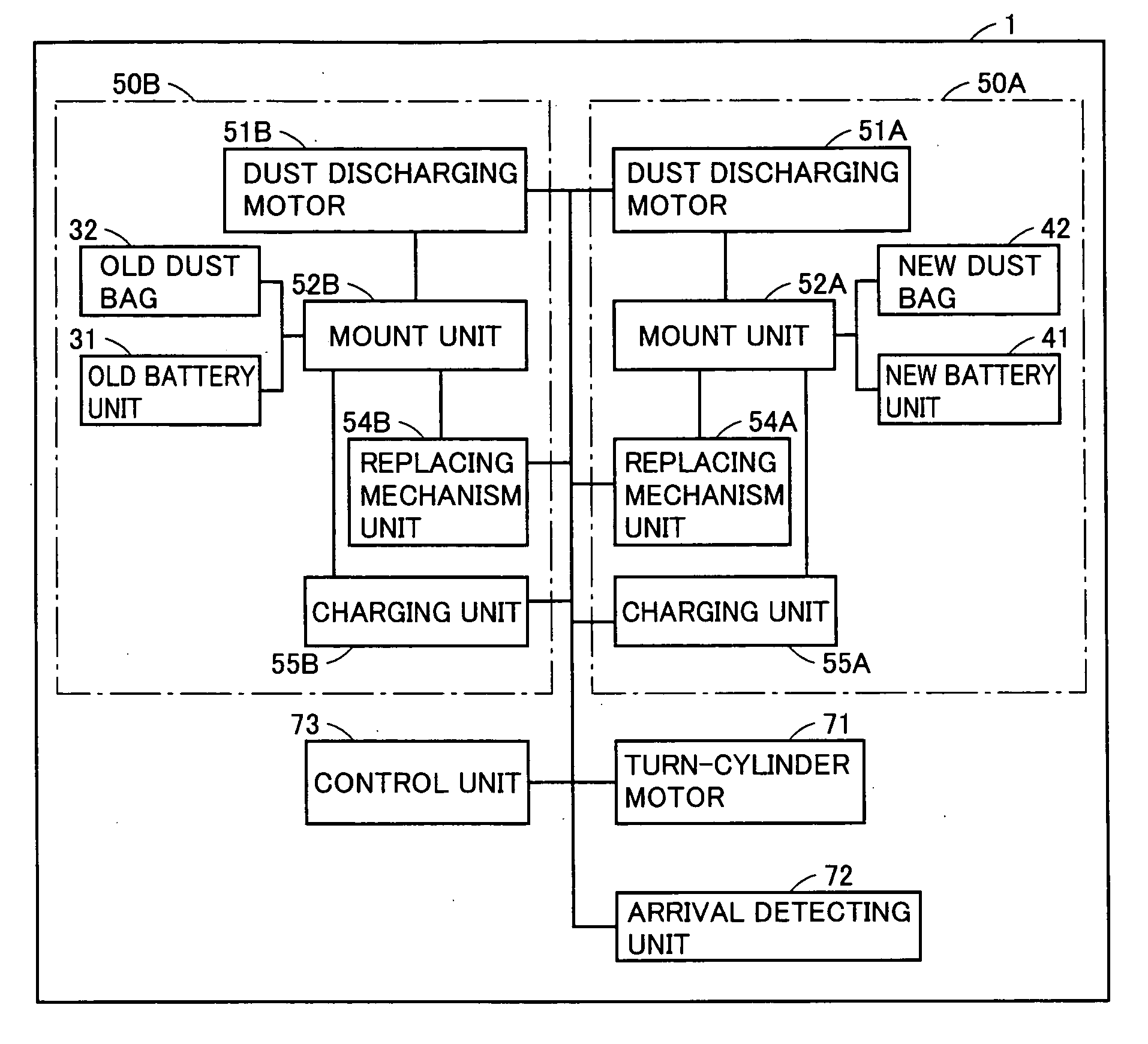

Station for self-propelled robot

InactiveUS20050212478A1High availability factorIncreased availability factorBatteries circuit arrangementsSuction filtersMarine engineeringControl unit

A control unit of a station concentrically rotates a plurality of unit replacing units by a motor on a first horizontal plane parallel to a floor bearing the station when arrival of the self-propelled cleaner is detected. The control unit activates, as a unit for removing an old battery unit from the self-propelled cleaner, the unit replacing unit included among the plurality of unit replacing units and opposed to the self-propelled cleaner located on the station. After the old battery unit is removed from the self-propelled cleaner, the control unit activates the motor. By the rotation of this motor, another unit replacing unit opposed to the self-propelled cleaner is activated as a unit for attaching a new battery unit to the self-propelled cleaner instead of the unit replacing unit previously activated as the removing unit.

Owner:FUNAI ELECTRIC CO LTD

Autonomous vacuum cleaner

InactiveUS20130305484A1Reduce lossesSave spaceCleaning filter meansSuction filtersVacuum cleanerWaste management

An autonomous vacuum cleaner comprising a main body comprising a dirty air inlet, a clean air outlet, an airflow path extending between the dirty air inlet and the clean air outlet, a separating apparatus arranged in the airflow path between the dirty air inlet and the clean air outlet, and an airflow generator for generating an airflow along the airflow path from the dirty air inlet to the clean air outlet. The airflow generator has a discharge portion which discharges airflow into a chamber formed in the main body, the chamber including an opening that is closable by a removable panel, wherein a power source is receivable within the chamber formed in the main body and is removable from the chamber through the opening.

Owner:DYSON TECH LTD

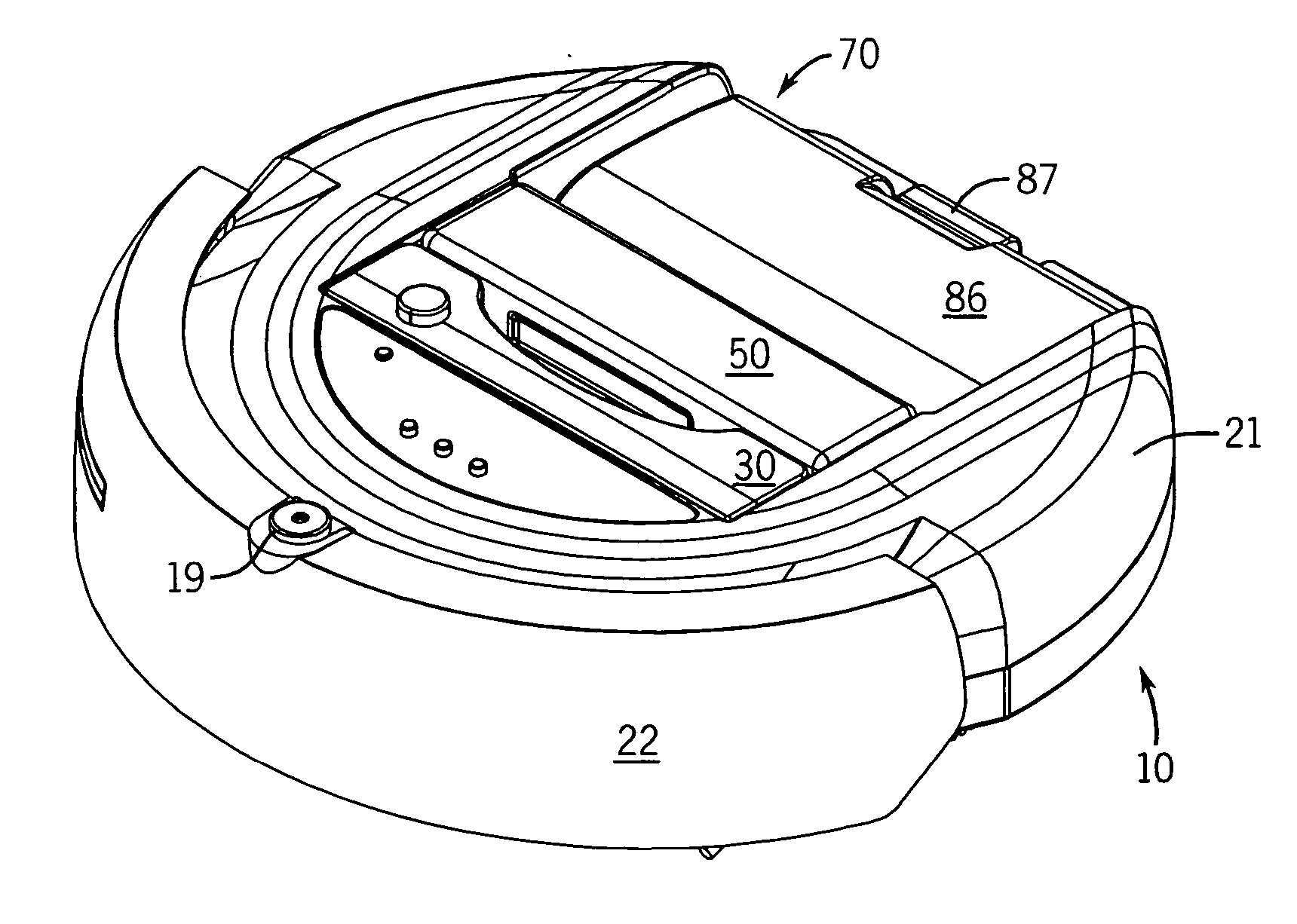

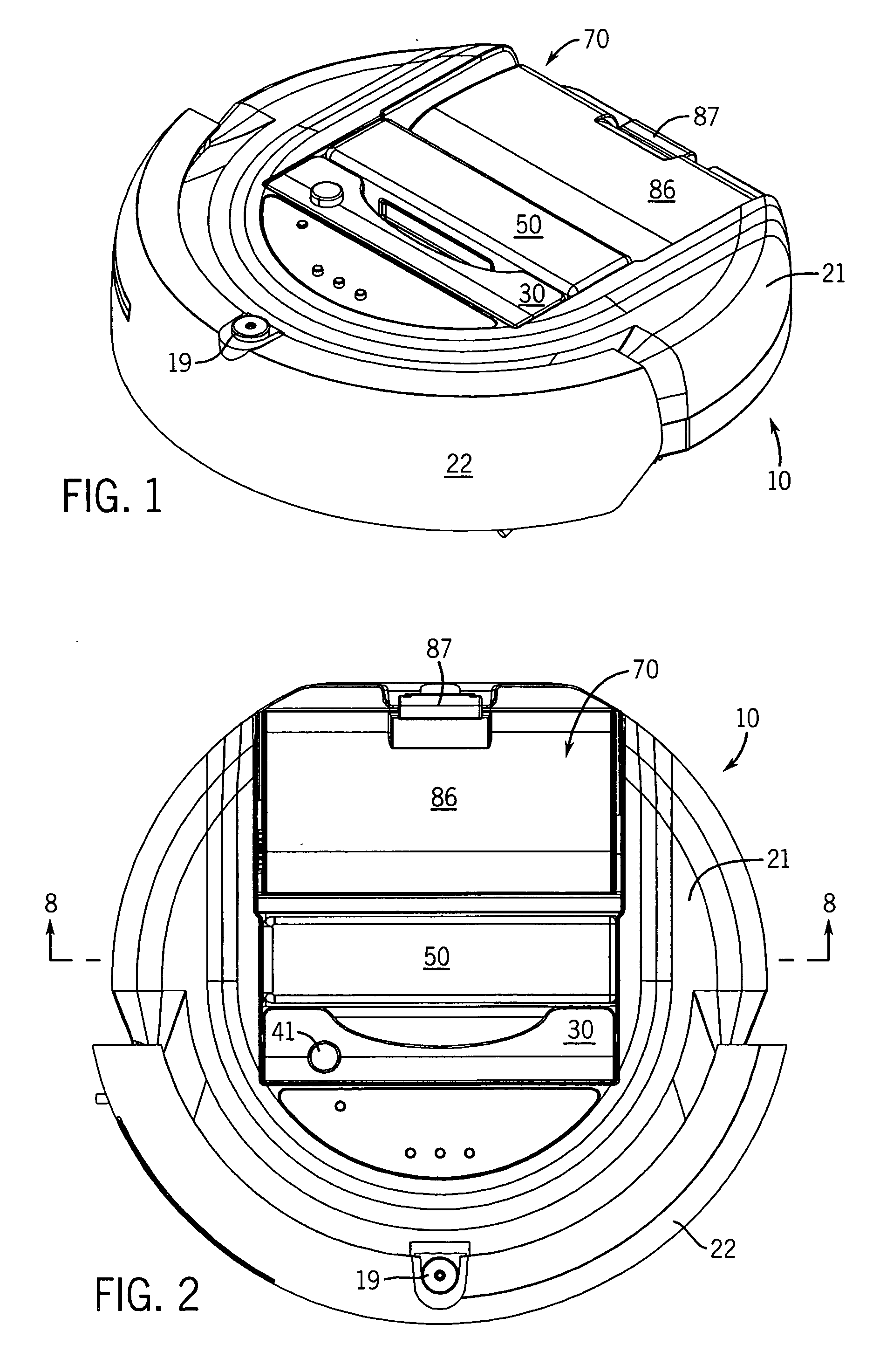

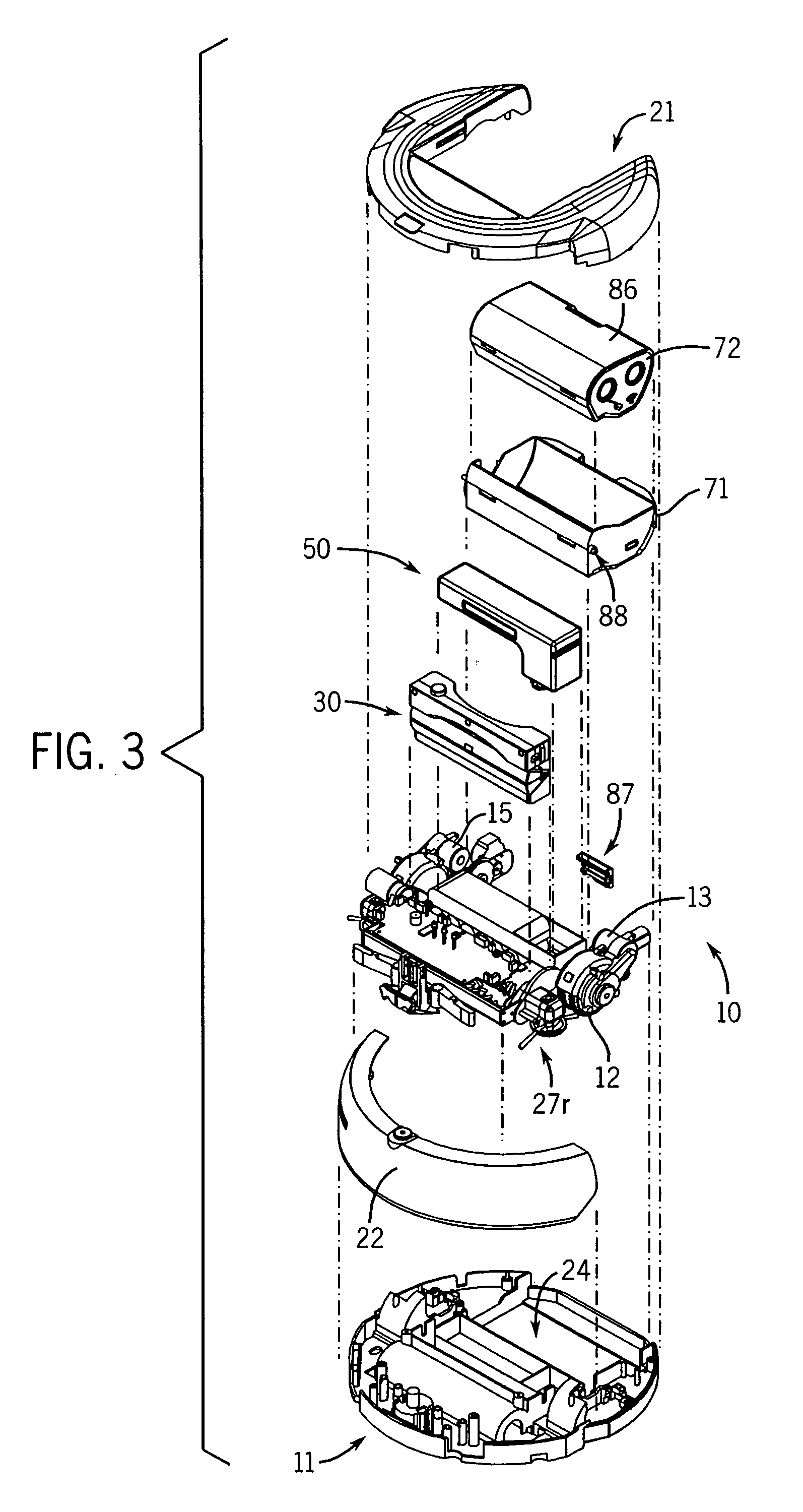

Surface treating device with top load cartridge-based cleaning system

ActiveUS7578020B2Easy loadingBlock deliveryLiquid processingCarpet cleanersBiomedical engineeringDelivery system

A robotic surface treating device that can perform carpet sweeping, hard-surface dry sweeping / wiping, and hard-surface sweeping / mopping is disclosed. The robotic surface treating device includes a sweeper brush, a dust bin for collecting debris from the brush, a reel-to-reel sheet of cleaning material, and a fluid delivery system for delivering fluid from a fluid reservoir onto the sheet of cleaning material and / or onto the surface to be treated. The dust bin, reel-to-reel sheet of cleaning material, and the fluid reservoir are separately installed from the top of the device, and may be separately removed for replacement.

Owner:SC JOHNSON & SON INC

Robot cleaner

InactiveUS7650666B2Improve usabilityEasy to assembleSuction nozzlesCleaning equipmentSpring forceRobot

A robot cleaner is mainly comprised of a base case whose upper portion is equipped with a driving part for running and a suction part for removing dust or dirt; and a top case covering on top of said base case, wherein said base case is formed at lower portion thereof with an inside vertical wall protruding so as to surround dust suction aperture, and with an outside vertical wall external to said inside vertical wall so that a hollow part may be formed in-between surrounding said inside vertical wall; and an auxiliary suction wall is installed between said inside vertical wall and outside vertical wall in such a manner that said auxiliary suction wall is movable by force of spring external to said inside vertical wall between a No. 1 position locating toward floor (F) and a No. 2 position locating withdrawn from said No. 1 position opposite to floor (F), said auxiliary suction wall being positioned toward floor (F) when no external forces are applied. According to this configuration, it is easy and convenient to install the auxiliary suction wall around dust suction inlet for enhancing easiness in dust suction.

Owner:KYUNGMIN MECHATRONICS

Self-traveling cleaner

InactiveUS20060021168A1Avoid entanglementFacilitated releaseMechanical cleaningPressure cleaningEngineeringMechanical engineering

In a self-traveling cleaner of the present invention, a cleaning mechanism includes a brush mechanism rotatable along a floor surface and a driving mechanism for rotatingly driving the brush mechanism. The brush mechanism includes a rotation axis extending perpendicular to the floor surface, one arm projecting laterally from a lower end of the rotation axis, and a brush planted on the arm. The rotation axis is provided within a reverse side of the main body, and the arm has a rotation angle range in which the arm projects outwardly from an outer periphery of the main body and a rotation angle range in which the arm is contained within the outer periphery of the main body.

Owner:SANYO ELECTRIC CO LTD

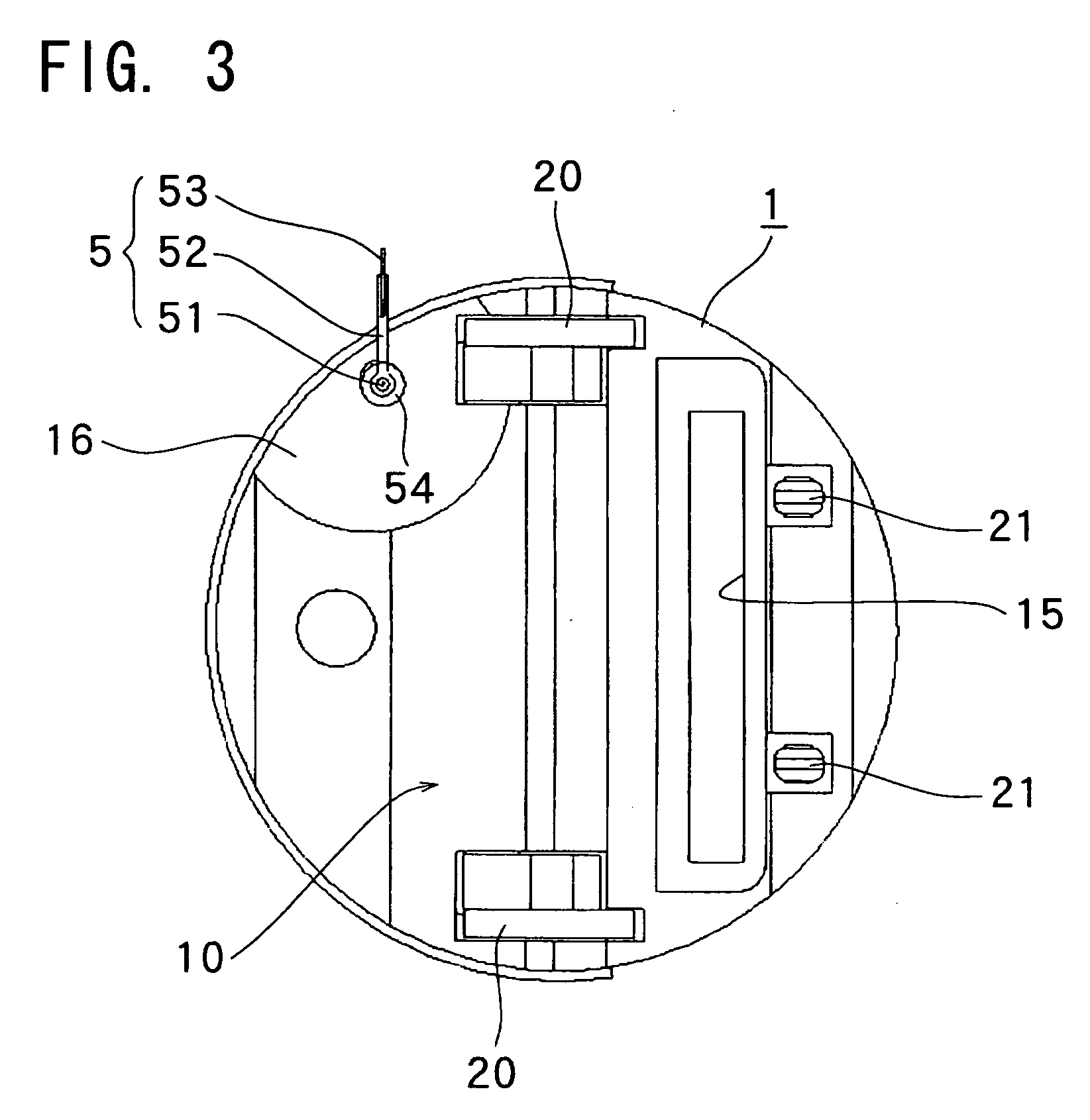

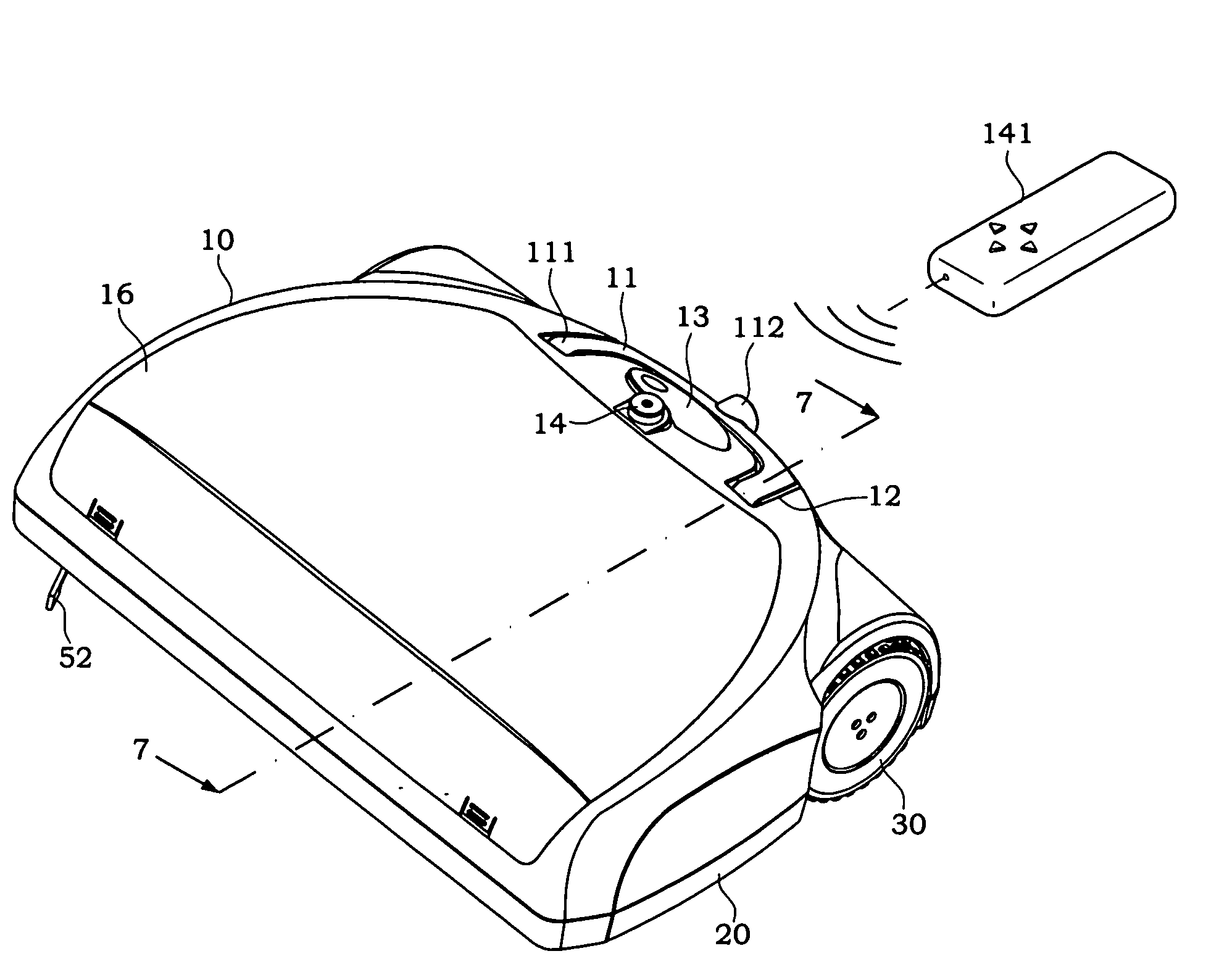

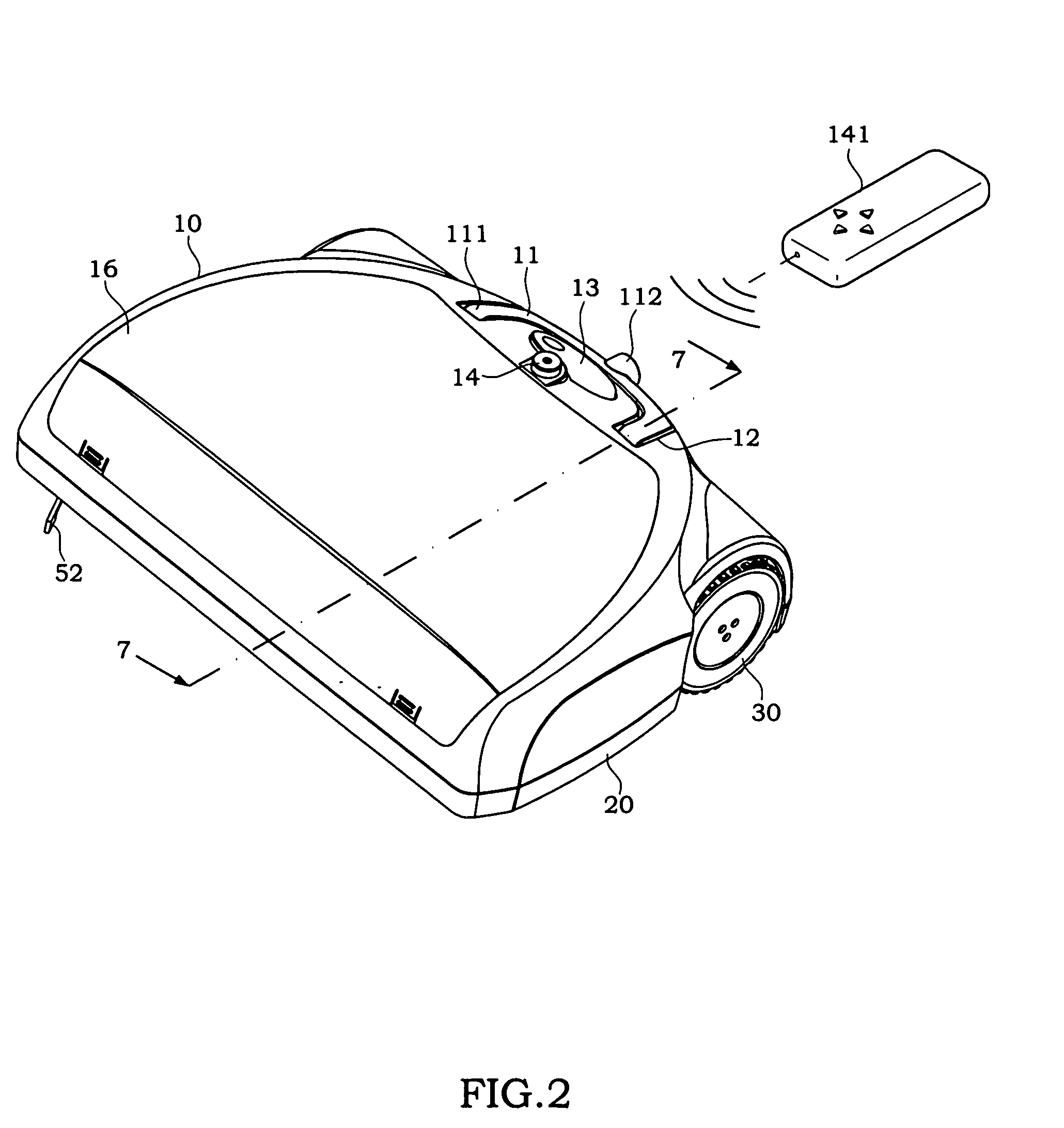

Remote control sweeper

InactiveUS20070006404A1Direction is limitedSmall sizeMechanical cleaningPressure cleaningWireless transmissionControl signal

A remote control sweeper includes a wireless remote control receiver installed at the sweeper; a remote control for transmitting a direction control signal to the remote control receiver via a wireless transmission to control the moving direction of the sweeper, such that the sweeper can be moved to automatically clean up the dirt and collect the dust on a floor.

Owner:GUTEN ELECTRONICS IND

Robot cleaner system having robot cleaner and docking station

InactiveUS7861366B2Improved docking structurePrevent suction lossCleaning filter meansSuction filtersDocking stationSuction force

A robot cleaner system having an improved docking structure between a robot cleaner and a docking station, which is capable of an easy docking operation of the robot cleaner and preventing loss of a suction force generated in the docking station. The robot cleaner includes a docking portion to be inserted into a dust suction hole of the docking station upon a docking operation. The docking portion may be a protrusion, which protrudes out of a robot body to be inserted into a dust suction path defined in the docking station, the protrusion communicates a dust discharge hole of the robot cleaner with the dust suction path of the docking station. The robot cleaner system includes a coupling device to keep the robot cleaner and the docking station in their docked state. The coupling device is configured to have a variety of shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

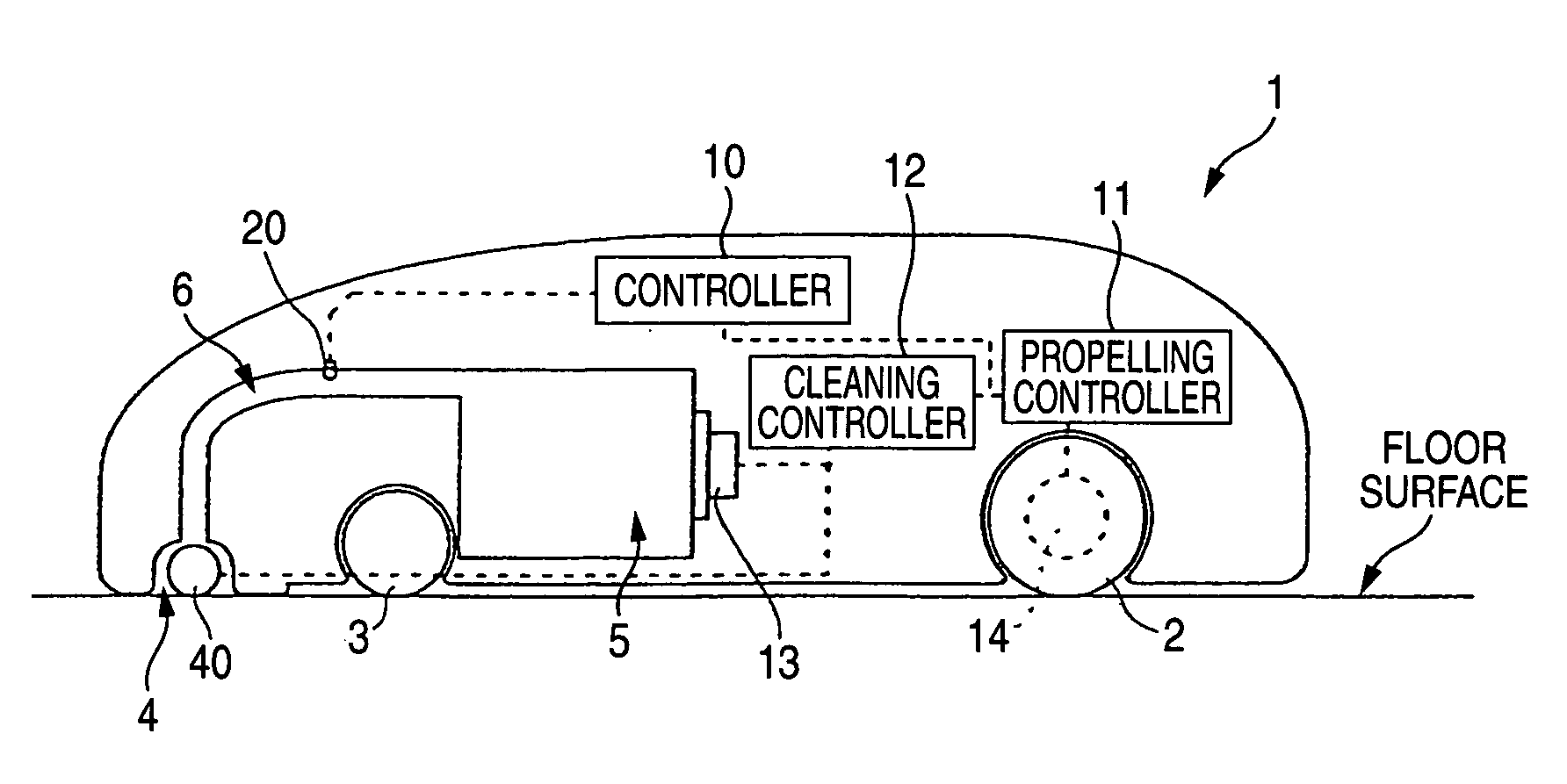

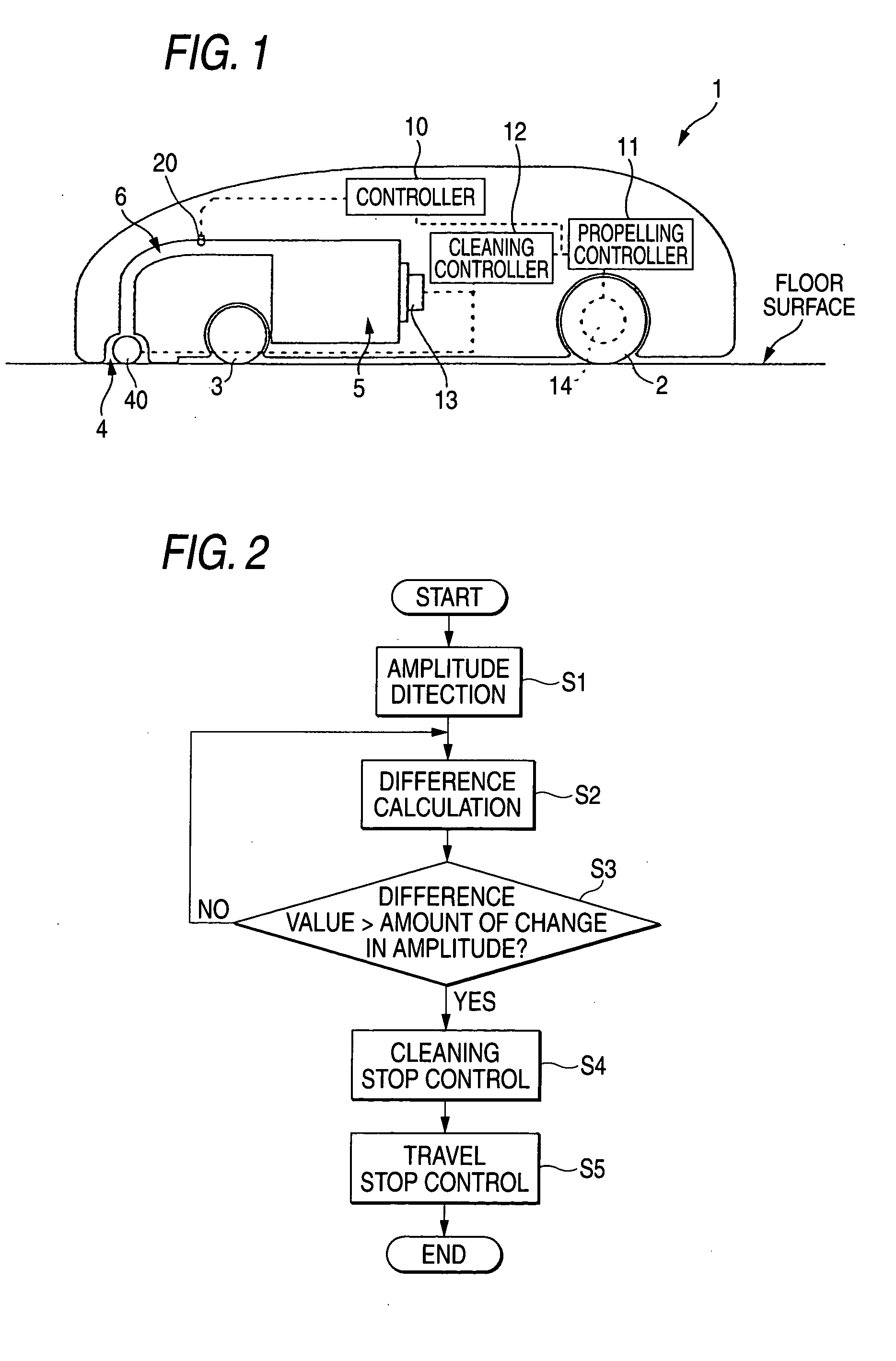

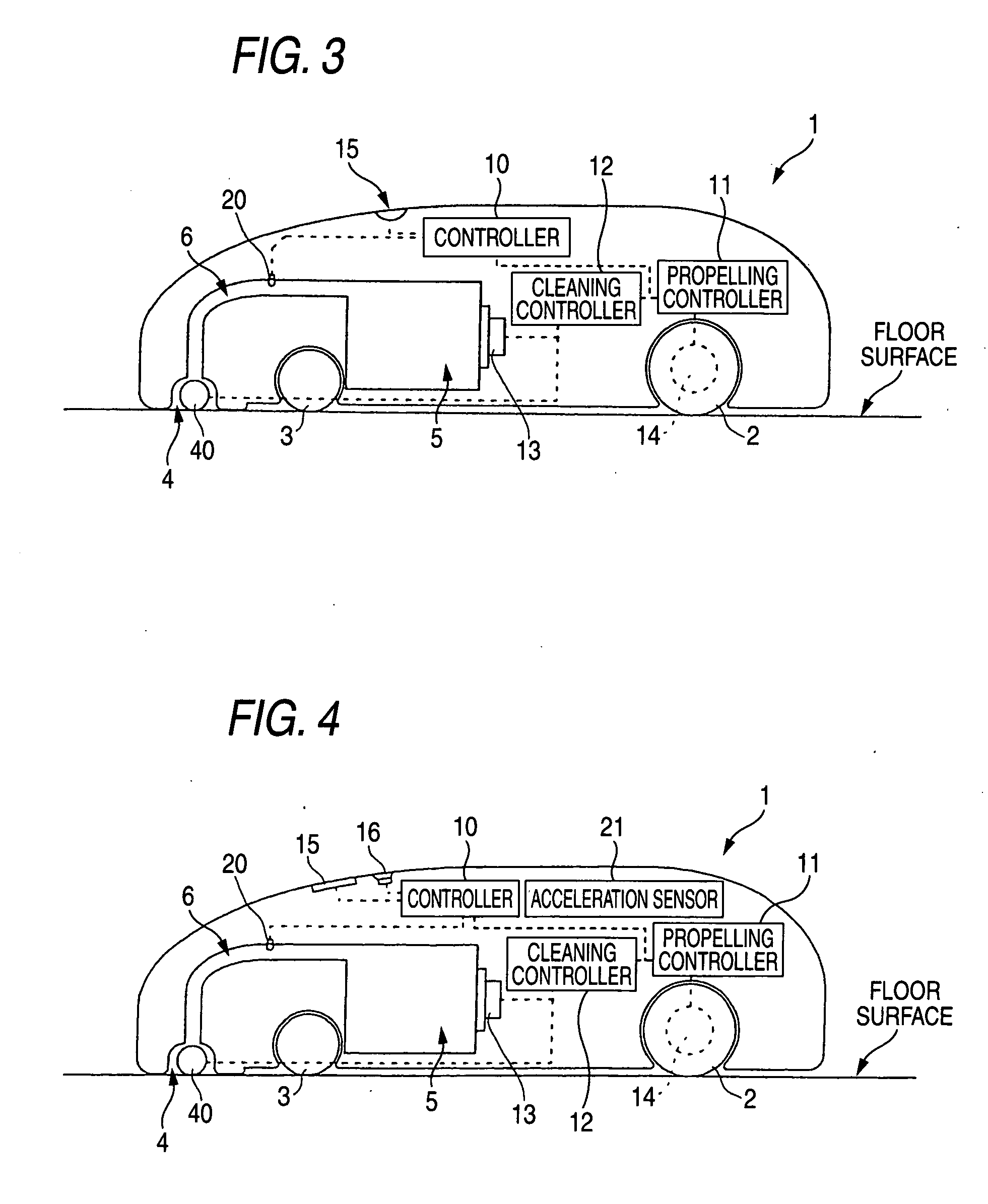

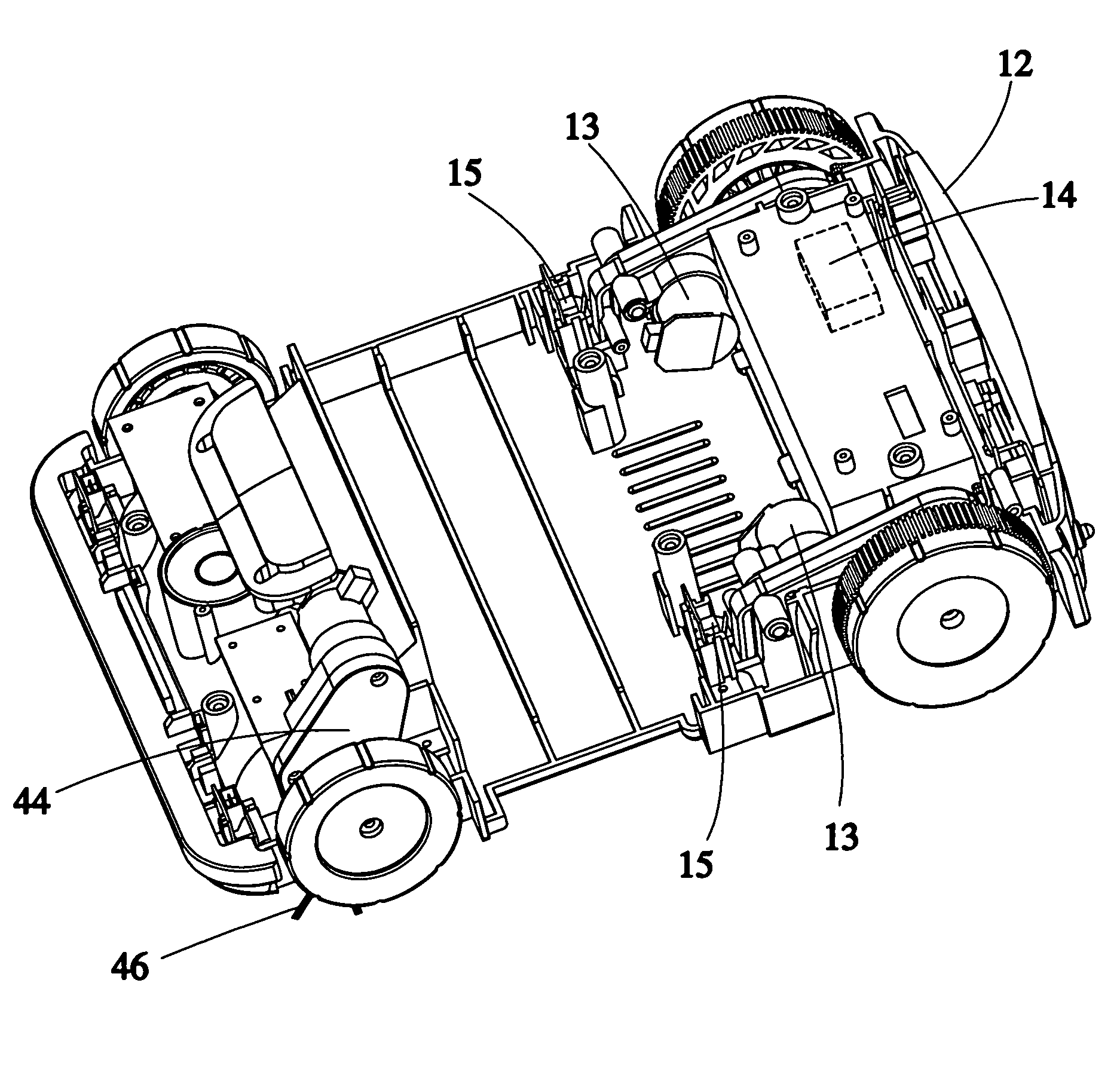

Self-propelling cleaner

In a dust transporting pipe 6, a microphone 20 is installed in a predetermined position. An output signal of the microphone 20, that is, a voltage signal of amplitude according to sound volume of the inside of the dust transporting pipe 6 picked is inputted to a controller 10. Initial amplitude according to sound volume of the inside of the dust transporting pipe 6 in the case of sucking dust in a state in which there is no dust inside a dust chamber 5 at all and the amount of change in amplitude indicating what amount amplitude changes from the initial amplitude in the case that the dust chamber 5 becomes full of dust are previously stored in the controller 10.

Owner:FUNAI ELECTRIC CO LTD

Dust-collectable mobile robotic vacuum cleaner

A dust-collectable mobile robotic vacuum cleaner includes a base frame, a driving device mounted to the base frame, a control device mounted to the base frame and electrically connected with the driving device, a collision-detectable unit mounted to the base frame electrically connected with the control device, and a dust-collecting device mounted to the base frame. The dust-collecting device has dust-collecting box, a dust guider, a round brush, and a dust entrance formed at one side of the dust-collecting box. The dust guider is located at a lower edge of the dust entrance, having two opposite sides pivotably mounted to the dust-collecting box and lying against the ground at a predetermined angle respectively, for upward and downward pivoting movement. The round brush is rotatably located at a front end of the dust guider for sweeping dust particles.

Owner:E SUPPLY INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com