Self-propelling cleaner

a cleaner and self-propelling technology, applied in the field of self-propelling cleaners, can solve the problems of clogging the dust filter, complex configuration of the dust full detection unit, and frequency of the sound picked by the microphon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

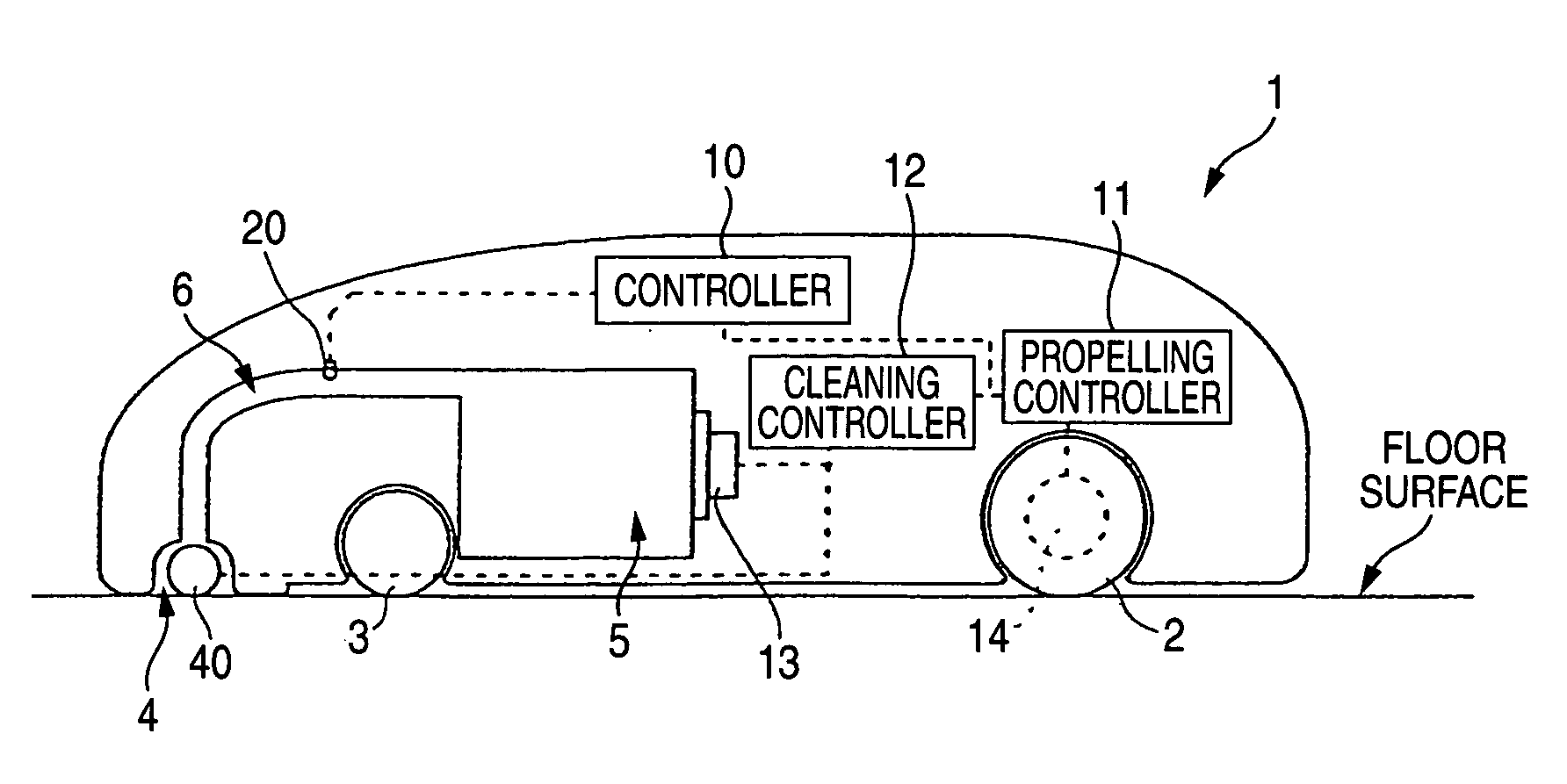

[0024]FIG. 1 is a configuration diagram showing a schematic configuration of a self-propelling cleaner according to a

[0025] The self-propelling cleaner includes propelling unit for moving a main body 1 along a preset track within a cleaning region, and cleaning unit for removing dust from a floor surface within the cleaning region and receiving the dust.

[0026] The right and left of a backward lower portion of the main body 1 are provided with drive wheels 2 and a driving motor 14 which is connected to each of the drive wheels 2 and rotates the drive wheels 2, and a forward lower portion of the main body 1 is provided with a driven wheel 3. Also, the driving motor 14 is electrically connected to a propelling controller 11 for controlling travel of the main body 1. These propelling controller 11, drive wheels 2, driving motor 14 and driven wheel 3 correspond to “propelling unit” of the invention.

[0027] Also, the main body 1 is provided with a nozzle 4 which is provided in a forward ...

second embodiment

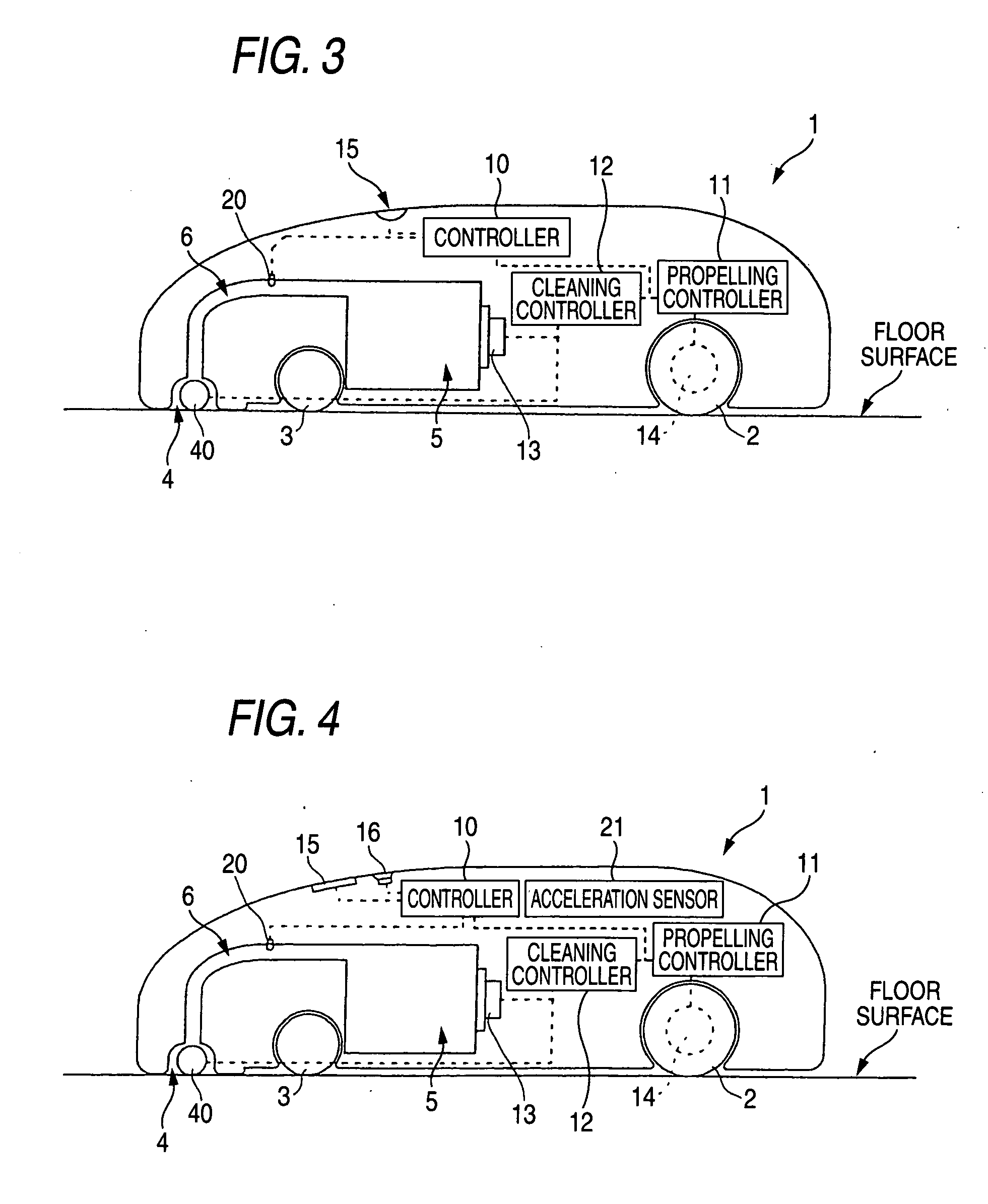

[0043] Next, a self-propelling cleaner will be described with reference to FIG. 3.

[0044]FIG. 3 is a block diagram showing a schematic configuration of a self-propelling cleaner according to the second embodiment.

[0045] The self-propelling cleaner shown in FIG. 3 includes a display part 15 in the upper side of a main body 1, and other configurations are equal to those of the self-propelling cleaner shown in FIG. 1.

[0046] The display part 15 includes, for example, plural LED lamps, and notifies the outside of an operation state etc. of the main body 1 by changing luminous colors and luminous patterns. Luminous control of the display part 15 is performed by a controller 10, and the controller 10 outputs each control command to a propelling controller 11 and a cleaning controller 12 and also outputs a luminous control command according to the control command to the display part 15.

[0047] In such a self-propelling cleaner, as described above, when sound volume picked by a microphone ...

third embodiment

[0050] In the self-propelling cleaner an acceleration sensor 21 corresponding to “speed detection unit” of the invention is fixed and installed in the main body 1, and the acceleration sensor 21 always observes acceleration of the main body 1 and outputs the acceleration to the controller 10. Thus, the controller 10 can always calculate a speed, a moving distance and a direction of the main body 1 by always observing the acceleration of the main body 1 by the acceleration sensor 21.

[0051] Initial amplitude according to sound volume of the inside of the dust transporting pipe 6 in the case of sucking dust in a state in which dust is not deposited inside the dust chamber 5 at all and the amount of change in amplitude indicating what amount amplitude changes with respect to the initial amplitude in the case of sucking dust in a state in which the nozzle 4 or the dust transporting pipe 6 is clogged with dust are previously stored in the controller 10. Then, the controller 10 computes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com