Electric dust collector

A technology of electric dust collection and dust collection electrode, which is applied in the direction of electrode structure, electrostatic separation, electrostatic effect separation, etc., can solve the problems of reduced dust collection efficiency of the device, difficulty in properly maintaining the load balance, poor dust collection ability and dust collection ability. , to achieve the effect of improving the dust collection capacity, suppressing the increase in the size of the device, and improving the dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

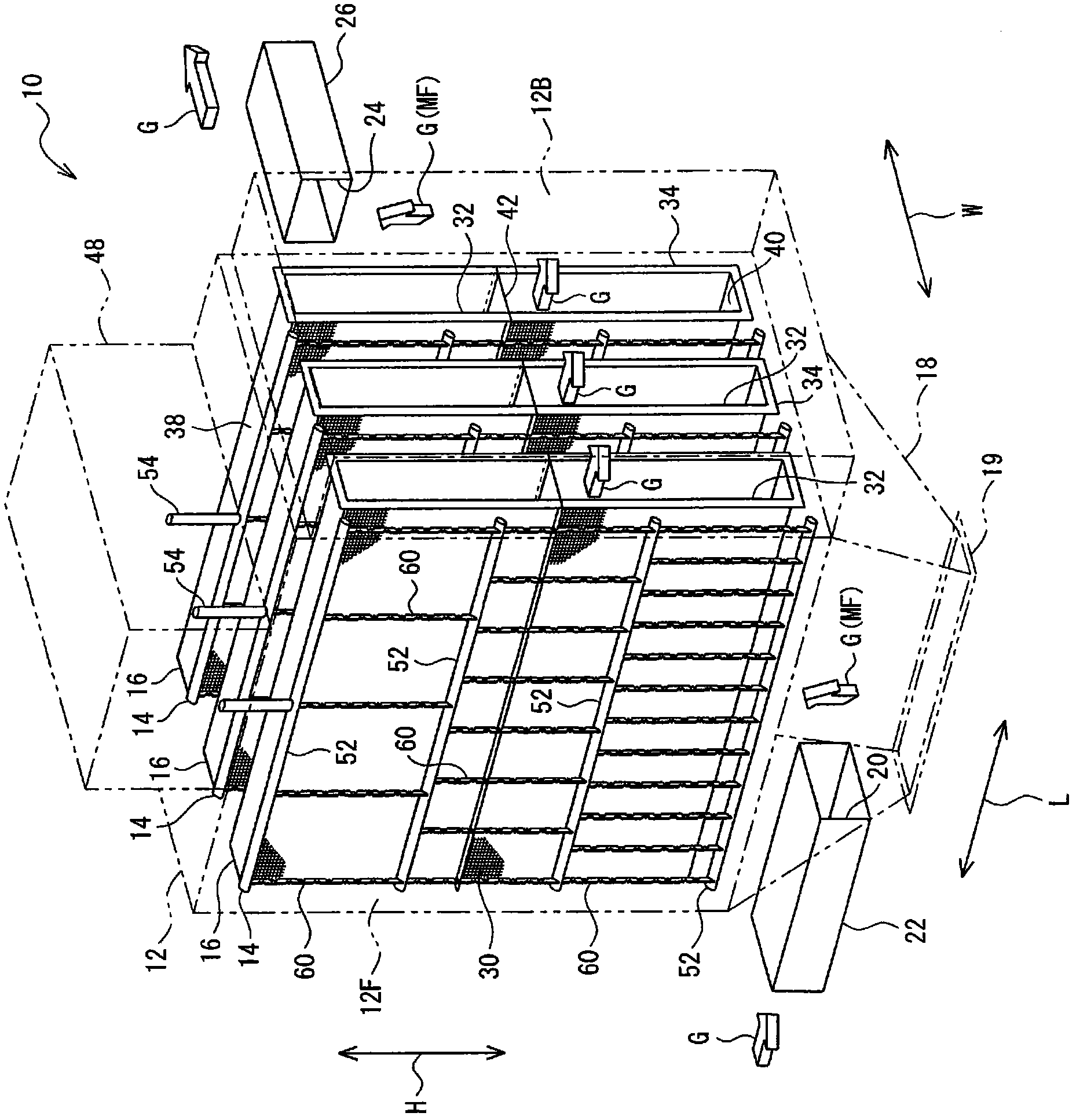

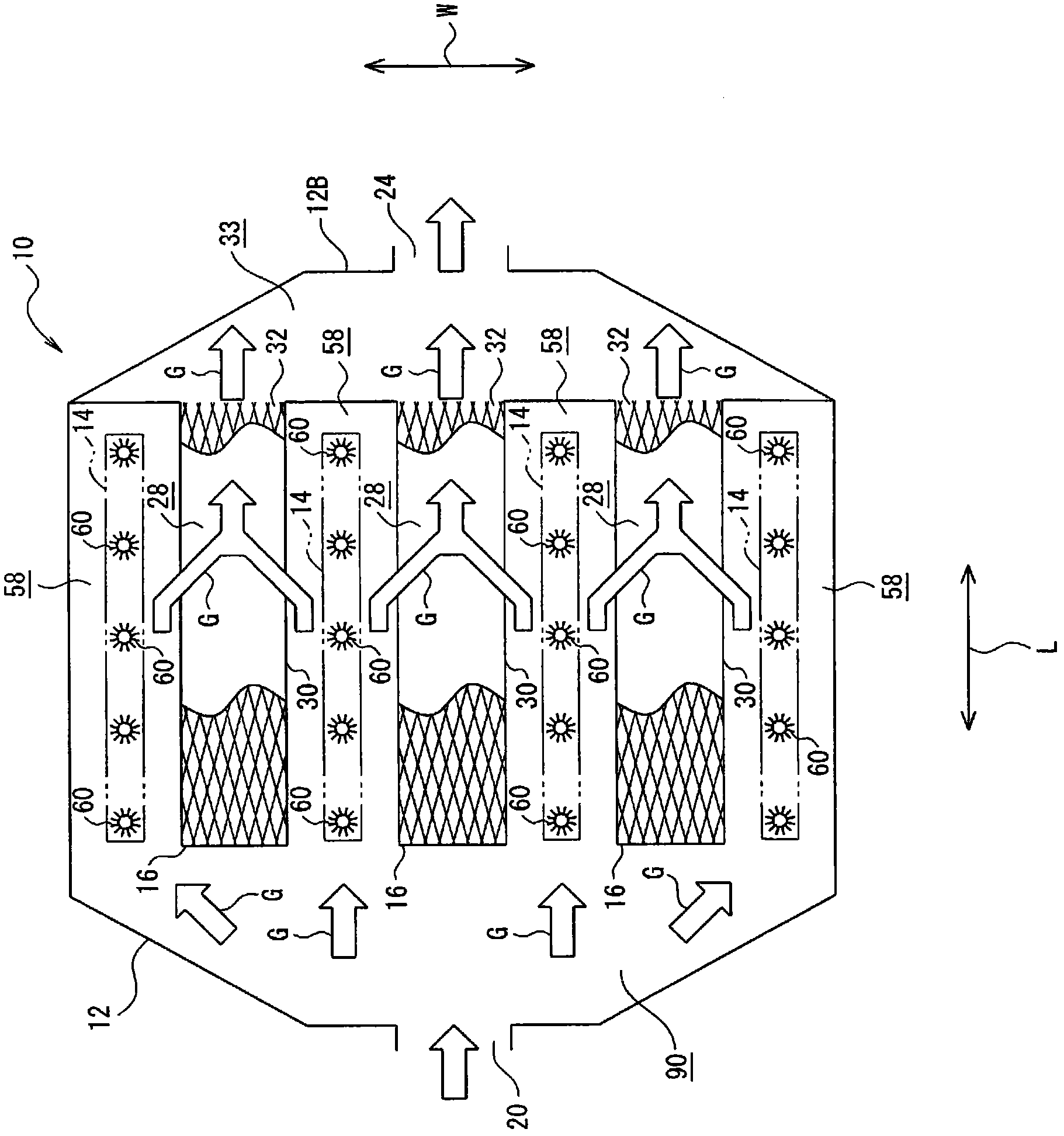

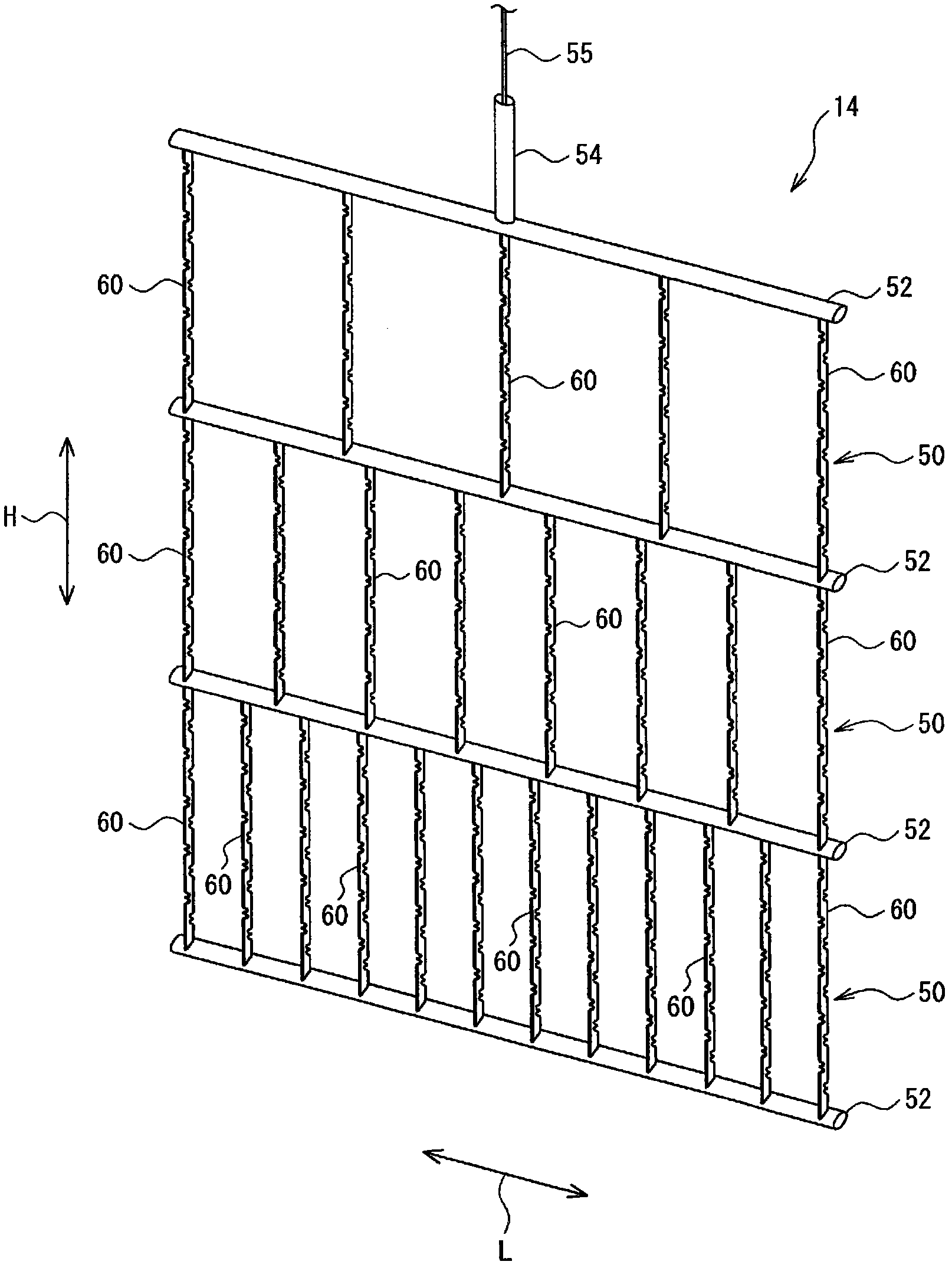

[0032] Next, an electric dust collector according to an embodiment of the present invention will be described with reference to the drawings.

[0033] exist figure 1 and figure 2 The configuration of the electric dust collector according to the embodiment of the present invention is shown in . This electric dust collector 10 includes: a hollow case 12 formed in a substantially rectangular parallelepiped shape; and a discharge electrode 14 and a dust collecting electrode 16 arranged inside the case 12 . like figure 1 As shown, a funnel-shaped hopper (hopper) 18 is provided on the bottom plate portion of the casing 12 so as to protrude downward. The bucket 18 is formed in the shape of a square tube whose cross-sectional area gradually decreases from the upper end side to the lower end side and penetrates in the height direction of the device (arrow H direction). Thereby, the dust-like objects collected inside the electric dust collector 10 can be stored in the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com