Cyclone dust-collector for vacuum cleaning

A vacuum cleaner and cyclone technology, applied in the direction of vacuum cleaners, suction filters, applications, etc., can solve the problems of generating static electricity, reducing product quality, increasing the number of collisions between pollutant particles and walls in the inertial dust collection shell, etc., to reduce frictional static electricity, improve Reliability, effect of improving dust collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] First of all, it is explained that the problems of the traditional cyclone dust collection technology have been described before, so they are omitted here. Only parts with the same structure as conventional technology use the same symbols.

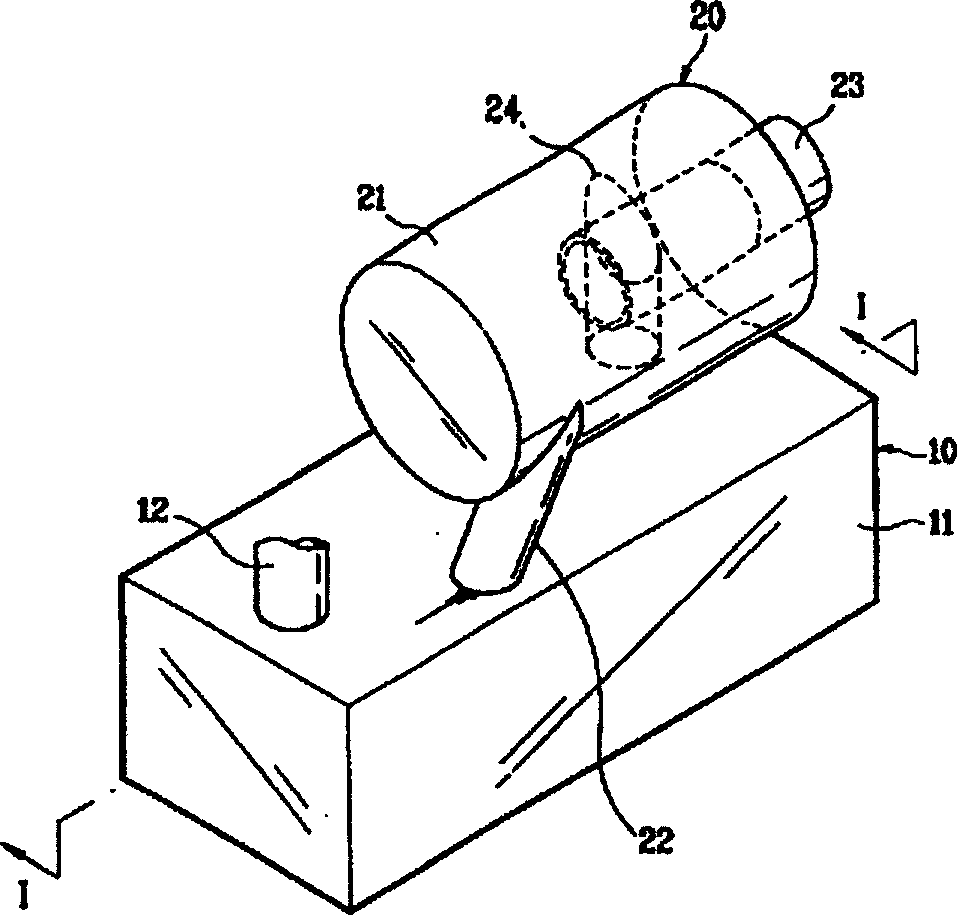

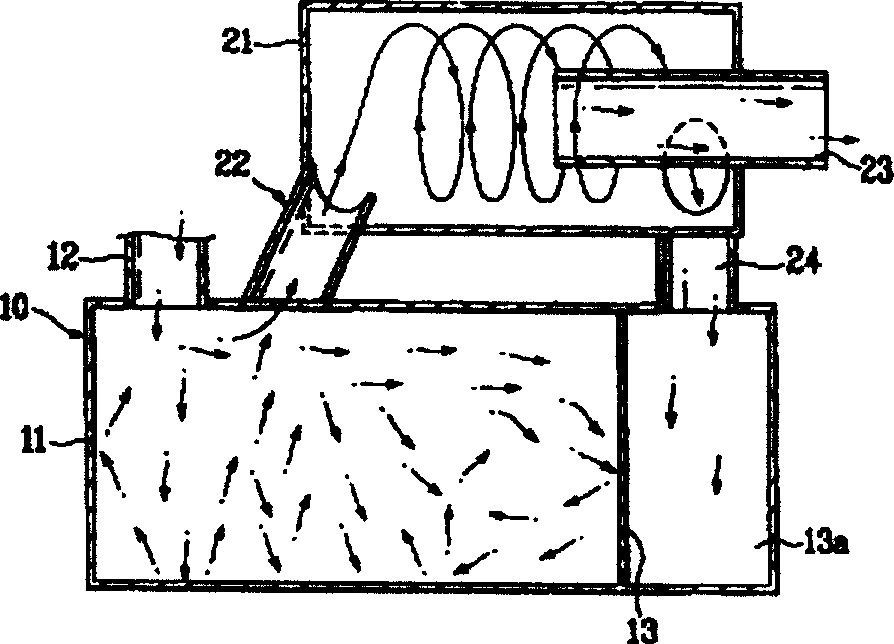

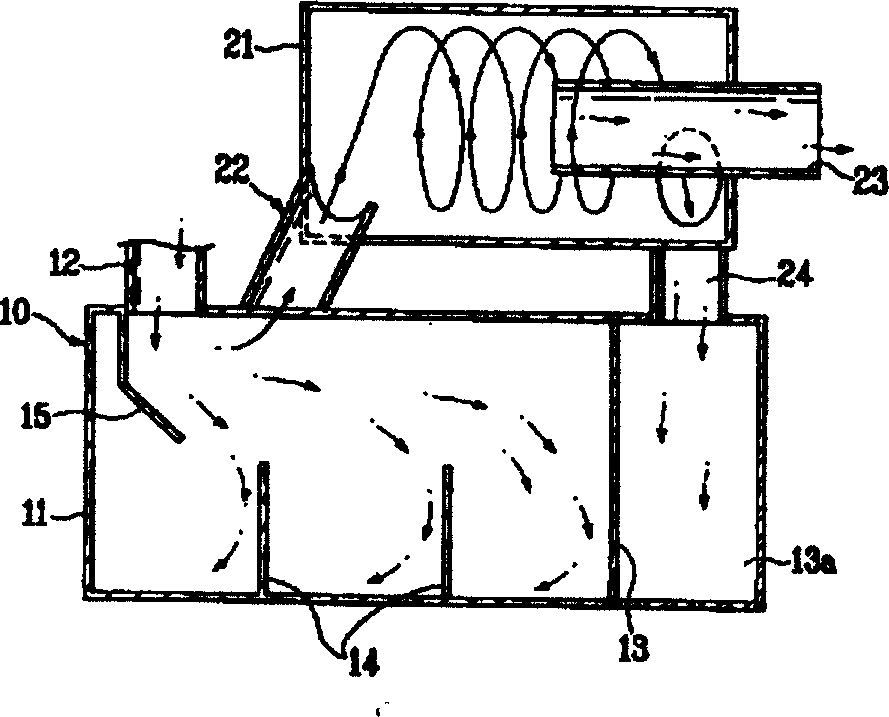

[0030] Cyclone vacuum cleaner of the present invention such as image 3 As shown, it includes a first dust collector (10) that utilizes inertial force to complete the first dust collection, a second dust collector (20) that utilizes centrifugal force to complete the second dust collection, and in order to allow the dust to flow into the first dust collector The pollutant particles reduce the flow in the first dust collector, and the components (14) for preventing turbulent flow are installed inside the first dust collector.

[0031] Anti-turbulence components (14) such as image 3 As shown, at least one is installed in the inertial dust collection housing (11) of the first dust collector. The turbulence preventing member (14) in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com