Patents

Literature

158results about How to "Avoid secondary dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

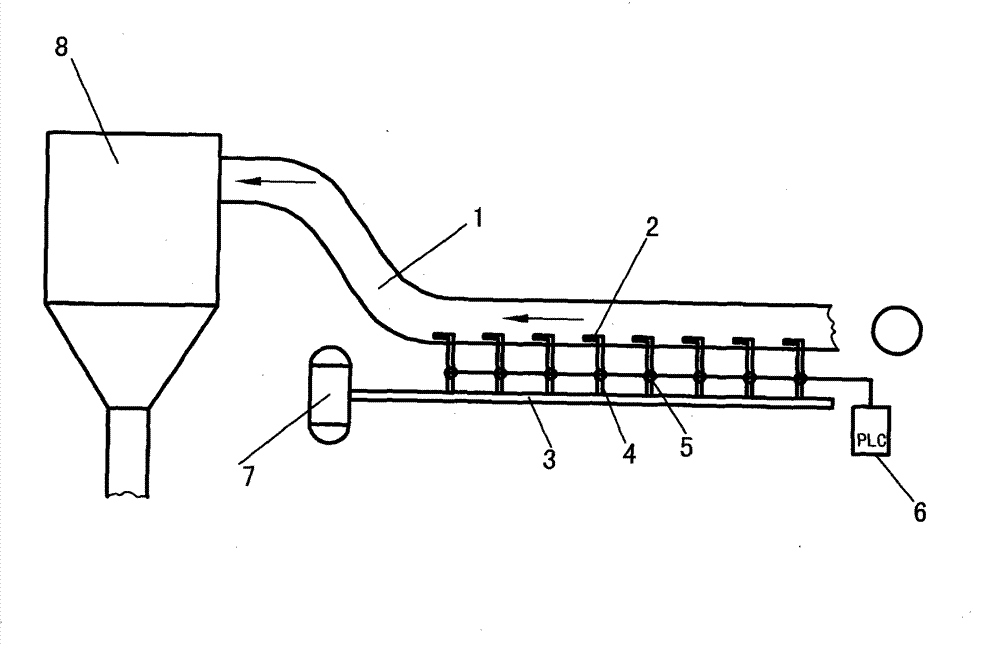

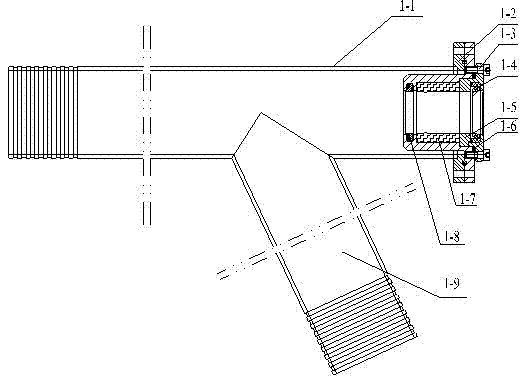

Automatic small-dip-angle dusty pipeline cleaning device

InactiveCN103042015AIncrease the ventilation areaDoes not affect normal productionHollow article cleaningDirt cleaningProgrammable logic controllerHigh pressure

An automatic small-dip-angle dusty pipeline cleaning device comprises a high-pressure main pipeline, a plurality of blowing nozzles, electromagnetic valves, branch pipes, a pneumatic supply and a PLC (programmable logic controller) control cabinet, wherein the electromagnetic valves and the branch pipes are corresponding to the blowing nozzles in number. The automatic small-dip-angle dusty pipeline cleaning device is characterized in that the blowing nozzles are mounted at one ends of the branch pipes which are mounted at the bottom of an air inlet pipeline or a dust pipeline of a dust collector according to a set distance, the electromagnetic valves are mounted in the middles of the branch pipes, the other ends of the branch pipes are communicated with the high-pressure main pipeline, the blowing direction of the blowing nozzles is consistent with the air flow direction in the air inlet pipeline or the dust pipeline of the dust collector, the electromagnetic valves are communicated with the PLC control cabinet, one end of the high-pressure main pipeline is communicated with the pneumatic supply, and the dust collector is mounted at one end of the air inlet pipeline or the dust pipeline. With normal production unaffected, the automatic small-dip-angle dusty pipeline cleaning device automatically cleans accumulated dust inside the small-dip-angle and horizontally arranged dust collecting pipelines and air ducts on line; and dust is guaranteed to be not accumulated inside the pipelines, pipeline ventilation area is increased, normal operation of a system is guaranteed, and product quality is improved while product output is increased.

Owner:DENGFENG SONGJI CEMENT

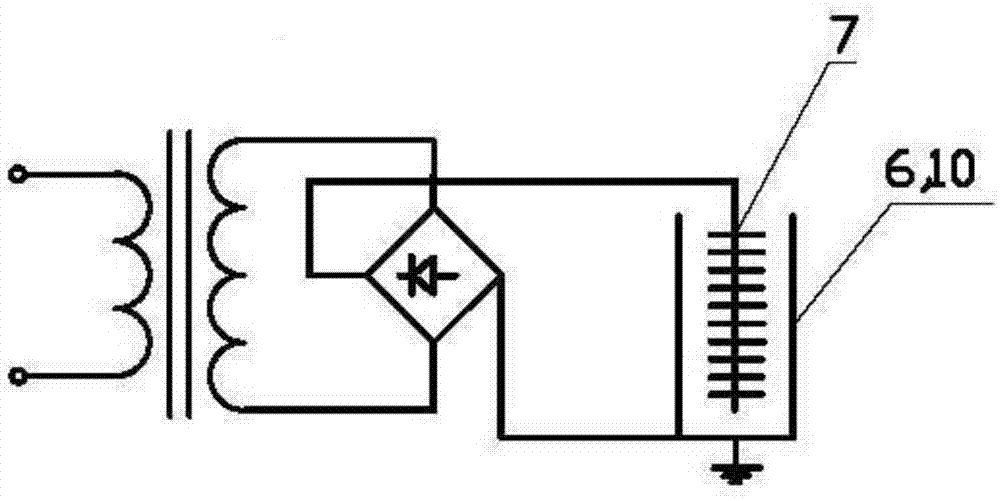

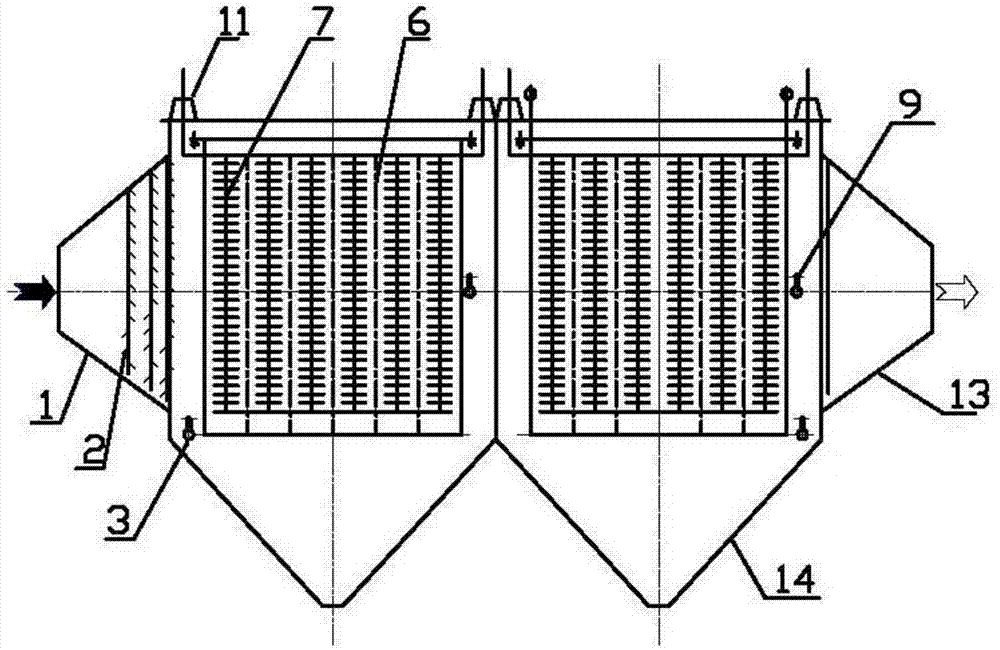

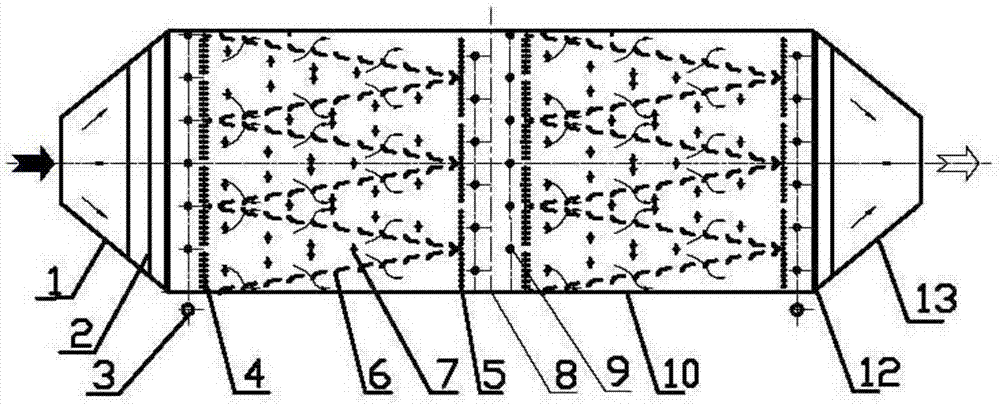

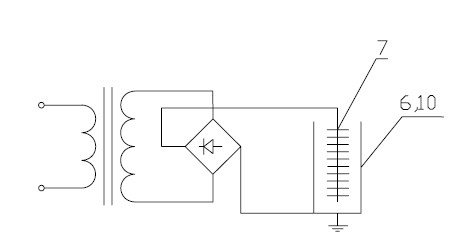

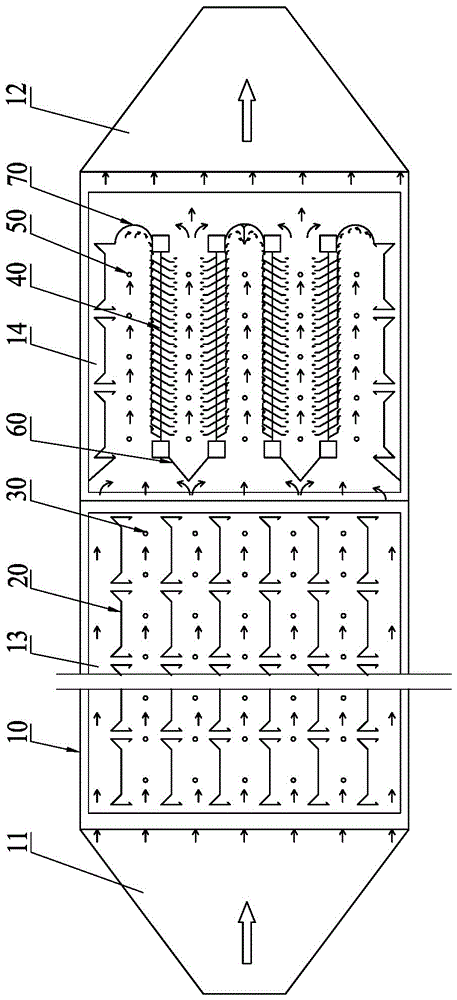

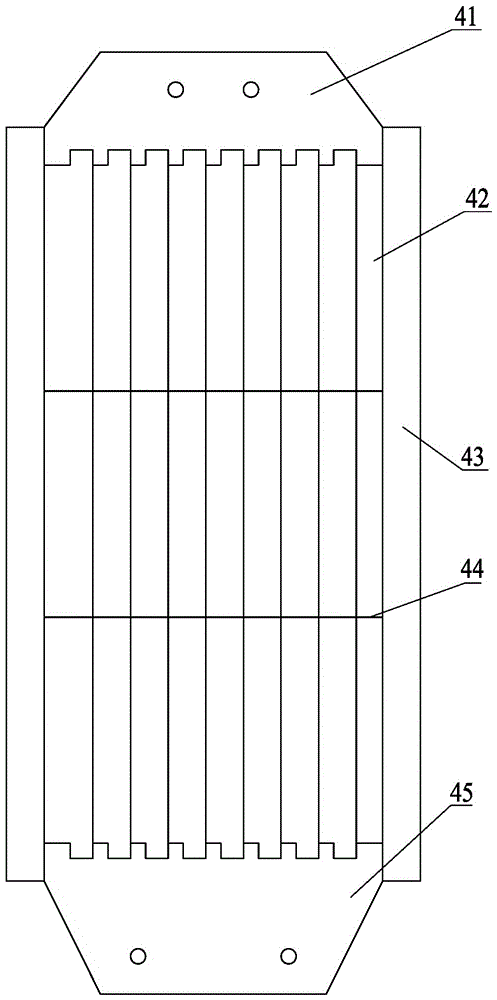

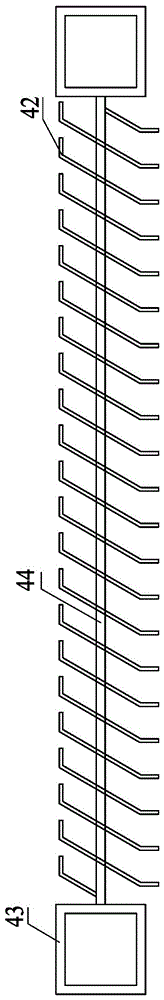

Efficient multi-field-coordination fine particulate matter removal device and method

ActiveCN103768886AAvoid back coronaAvoid secondary dustSemi-permeable membranesAuxillary pretreatmentMulti fieldWater vapor

The invention discloses an efficient multi-field-coordination fine particulate matter removal device and an efficient multi-field-coordination fine particulate matter removal method. The device comprises an outer field coagulation area, a direct current dust pre-collecting area, a pulse charge coagulation area and a direct current dust collecting area which are connected in sequence, wherein water steam and a chemical agglomeration agent are introduced from a nozzle of the outer field coagulation area respectively; the direct current dust pre-collecting area and the direct current dust collecting area are arranged in a line-plate type symmetric structure, a line electrode applies negative direct current high voltage, and a plate electrode is grounded and adopts layout of a water film electrode; the pulse charge coagulation area is arranged in the line-plate type symmetric structure, the line electrode applies positive pulse high voltage, and the plate electrode is grounded and adopts layout of the water film electrode. The device and the method aim at mineral particulate matters discharged by a fixed source; aerosol particulate matters, particularly fine particulate matters, can be subjected to efficient coagulation removal in a structural form of double coagulation areas and double dust collecting areas by using a multi-field-coordination method combined by a phase-change coagulation growth technology, a chemical agglomeration and flocculation mechanism and an electric coagulation technology, so that the phenomena of back corona, re-entrainment of dust, ash deposition and corrosion of the plate electrode are effectively avoided.

Owner:ZHEJIANG UNIV

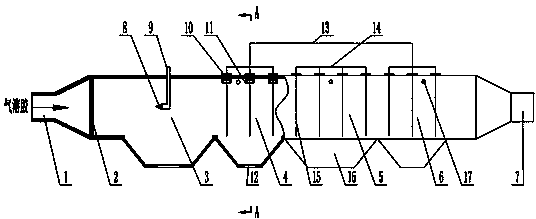

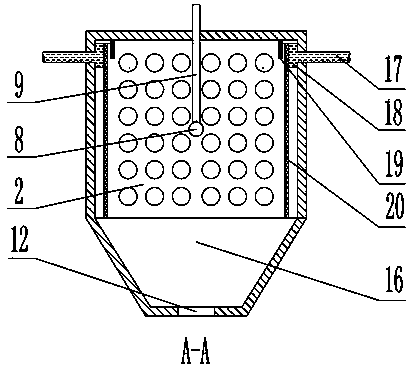

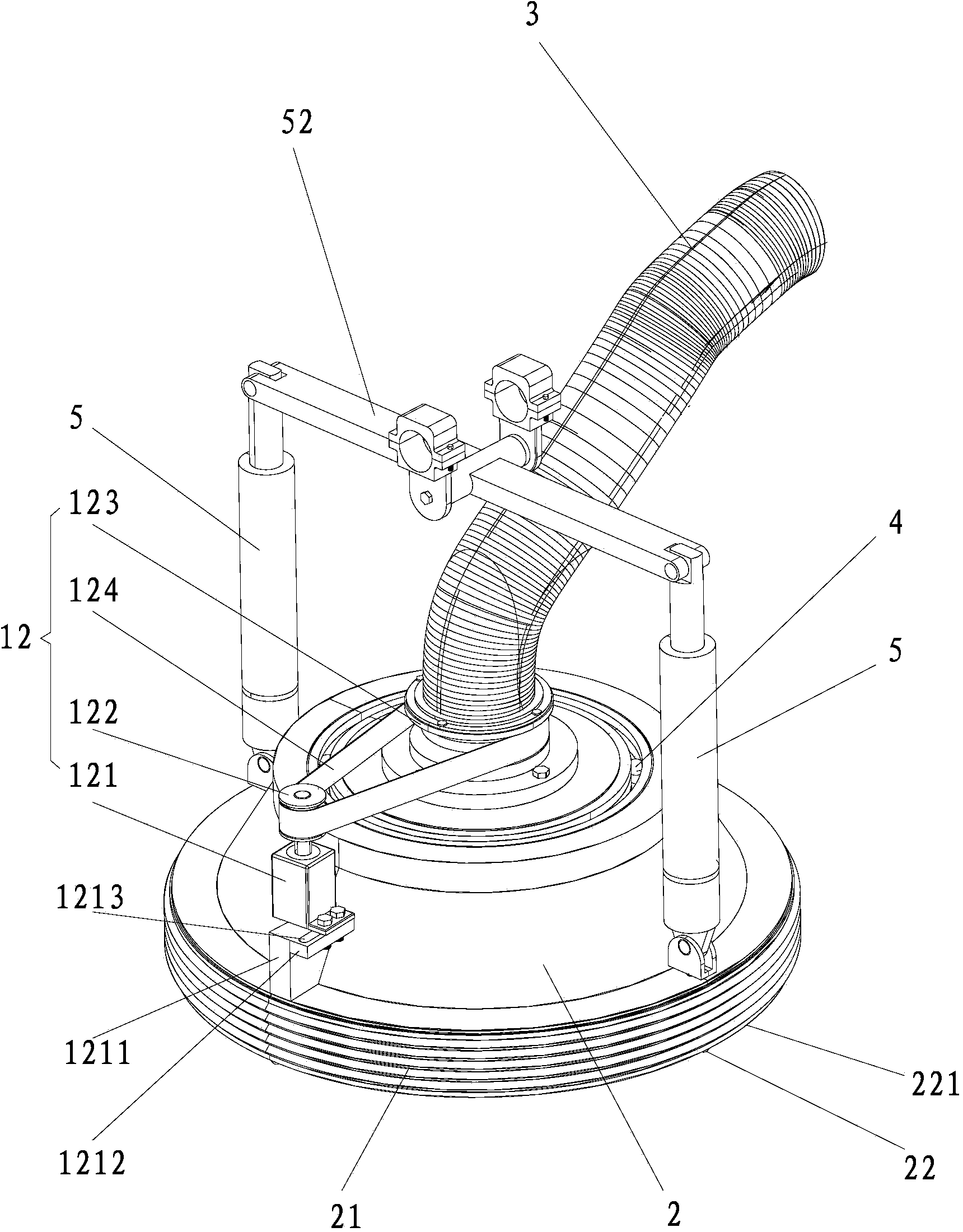

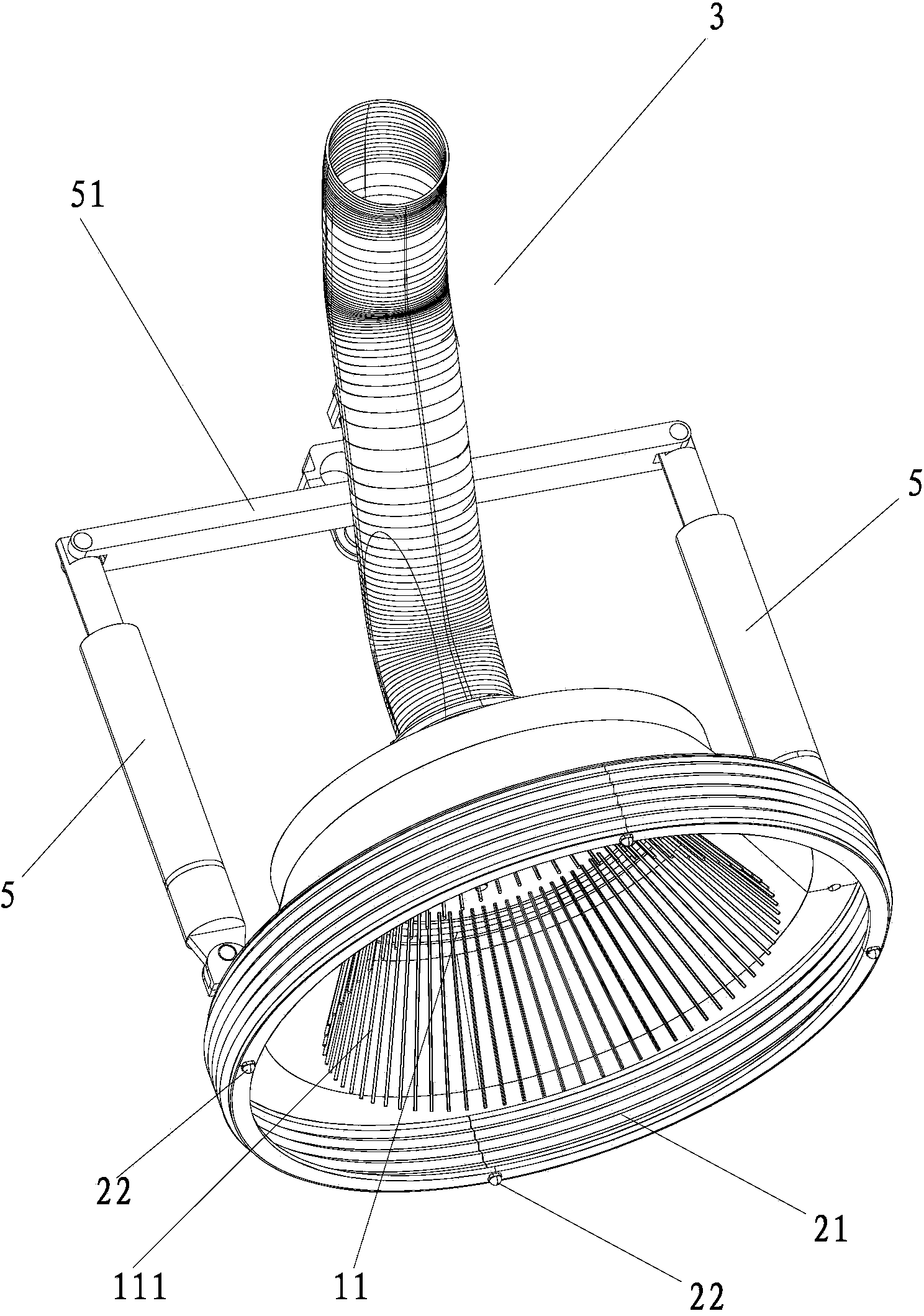

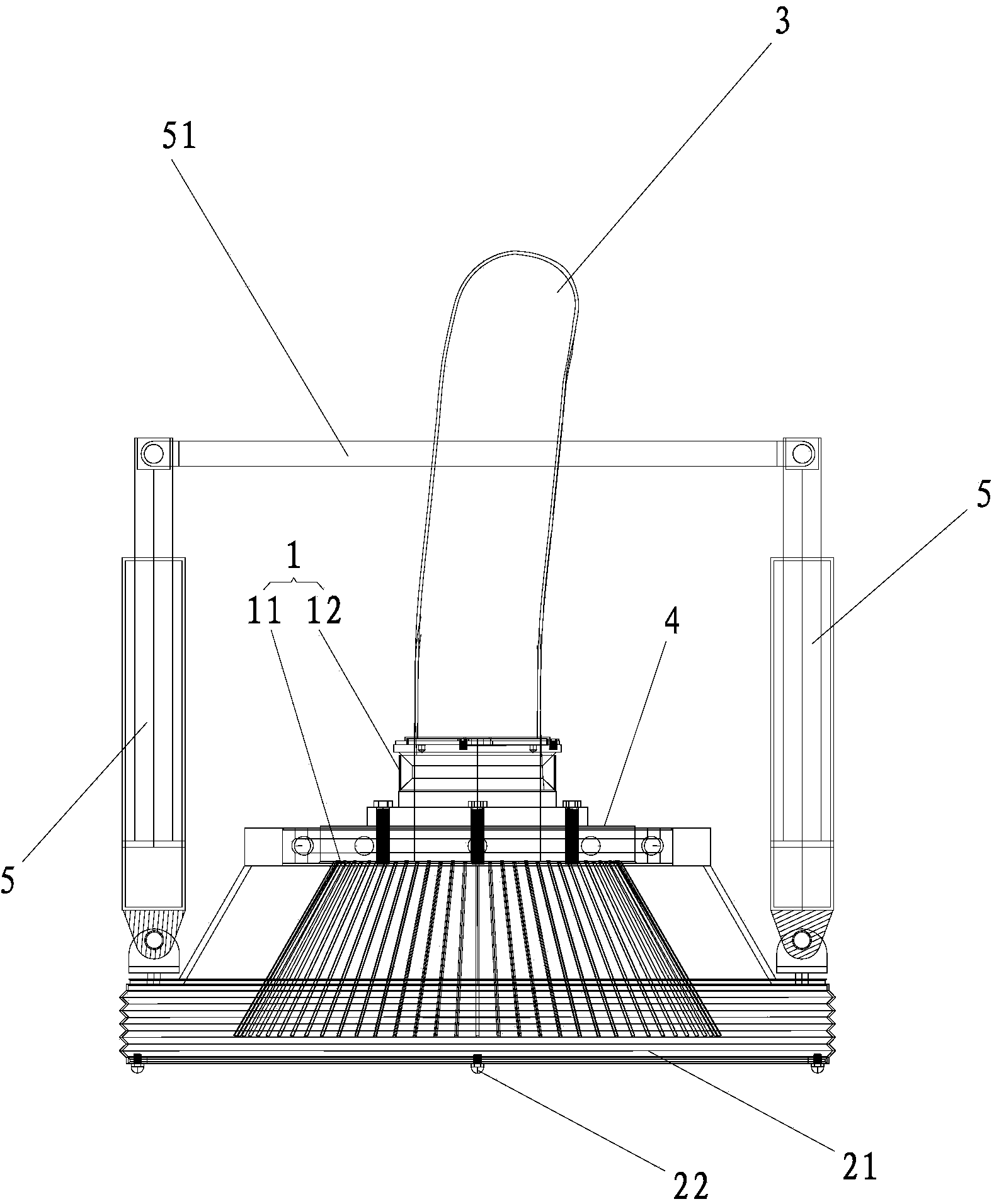

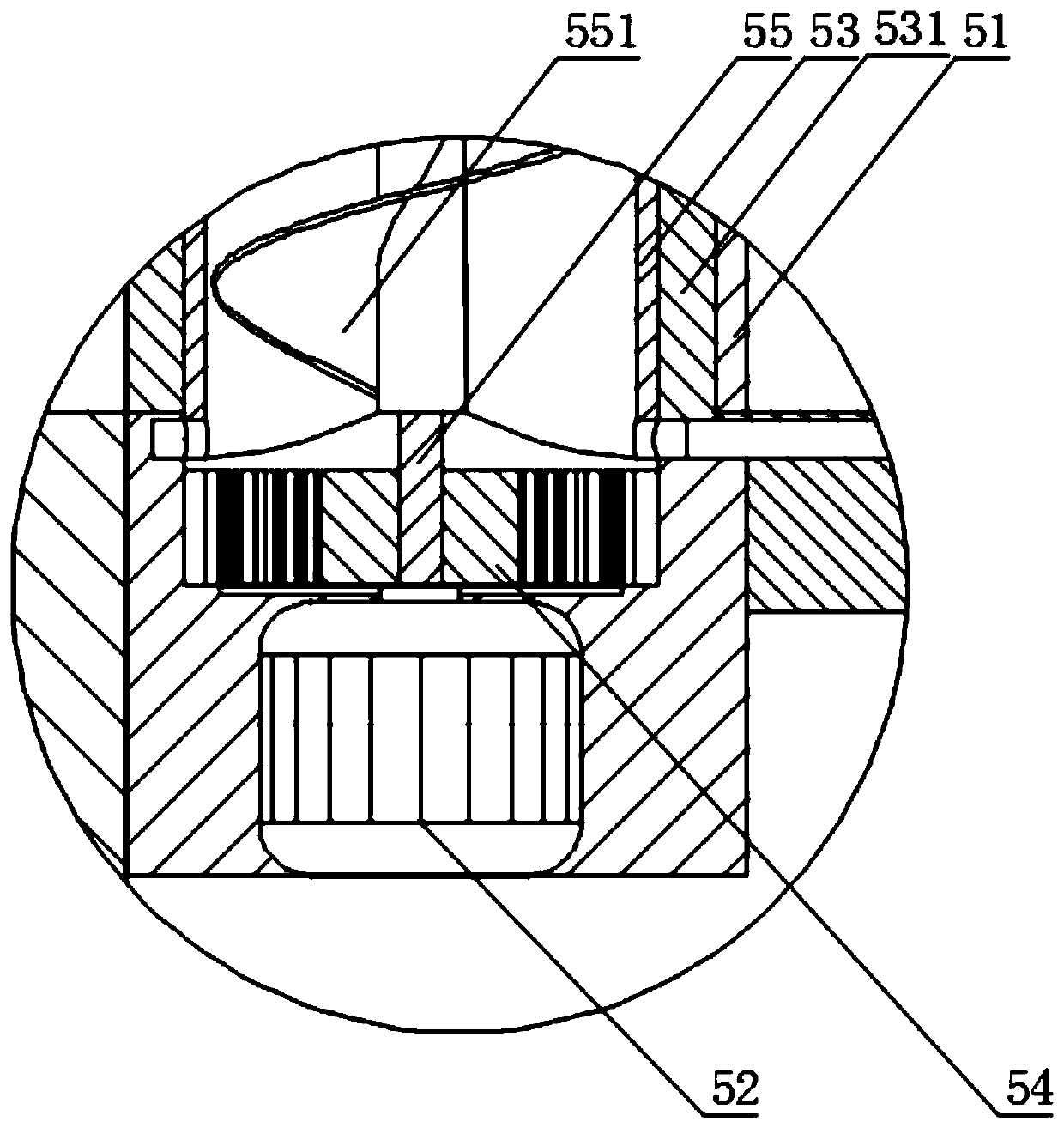

Novel sweeping and absorbing integrated cleaning mechanism

ActiveCN103510484AOvercome structureOvercome the defect of poor cleaning abilityRoad cleaningRoad surfaceEngineering

The invention provides a novel sweeping and absorbing integrated cleaning mechanism. The novel sweeping and absorbing integrated cleaning mechanism comprises a rotating cleaning brush carried by a sweeper. A shell making contact with the ground in a soft mode covers the rotating cleaning brush. A pumping pipeline is communicated with the upper portion of the shell. Due to the adoption of the technical scheme, the novel sweeping and absorbing integrated cleaning mechanism breaks through the structural form of traditional sweepers and integrates a rubbish brushing and sweeping mechanism and a rubbish pumping mechanism; the cleaning brush is rotated to brush and sweep rubbish in the shell in a rotating mode, is prevented from being absorbed on the ground and is in a free floating state. Negative pressure is formed in the shell through the pumping pipeline, the rubbish is pumped to a rubbish can of the sweeper through the pumping pipeline and is stored, and the cleaning brush is rotated to be matched with the shell and the pumping pipeline to form an Archimedes spiral type rubbish absorbing structure. The novel sweeping and absorbing integrated cleaning mechanism is strong in rubbish pumping and intake capacity and overcomes the defects that the traditional sweepers are single in structure and poor in cleaning ability. Compared with the prior art, the novel sweeping and absorbing integrated cleaning mechanism is thorough in road surface rubbish cleaning, efficient, novel and reasonable in structure and strong in practicability.

Owner:HUAQIAO UNIVERSITY

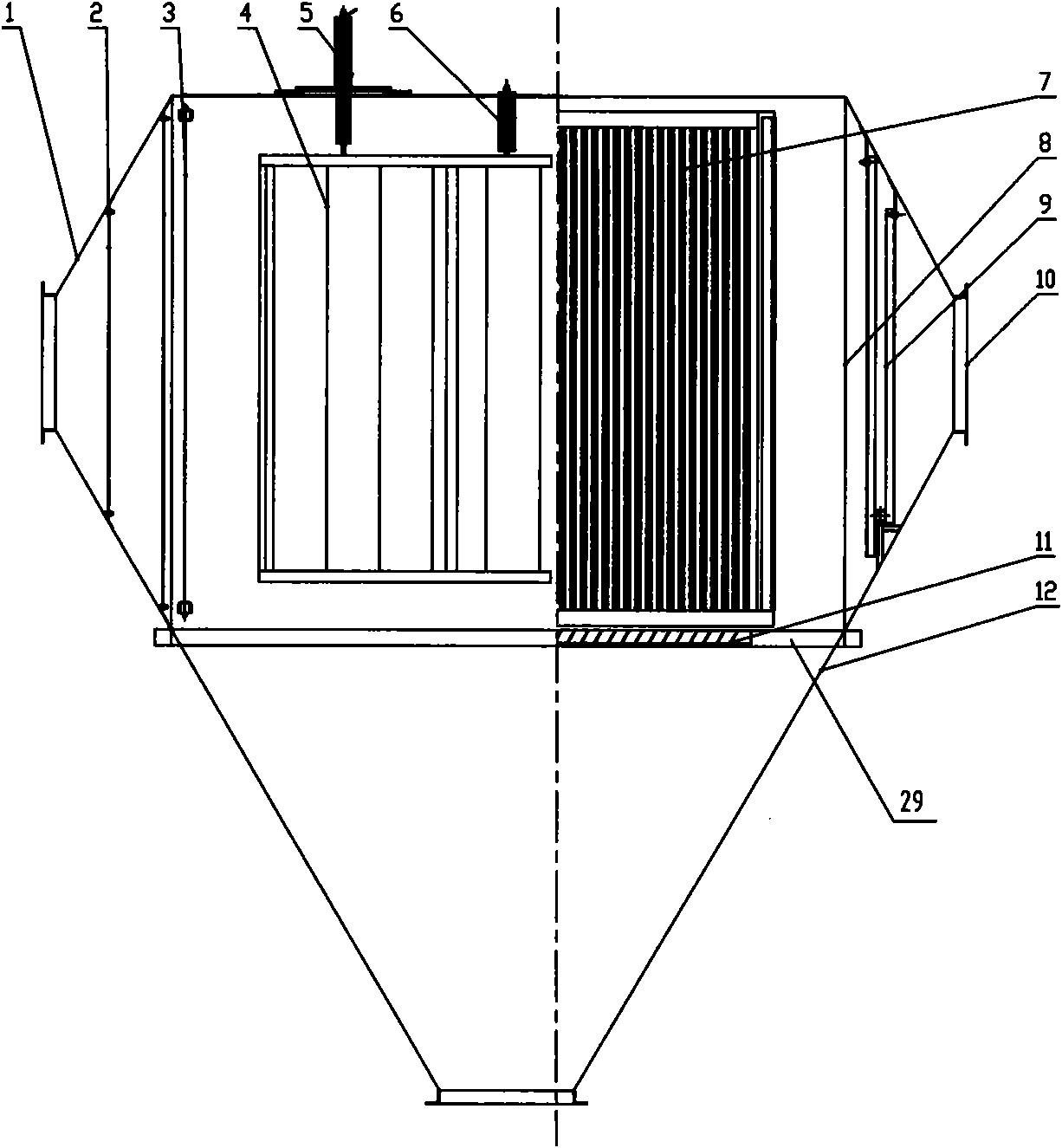

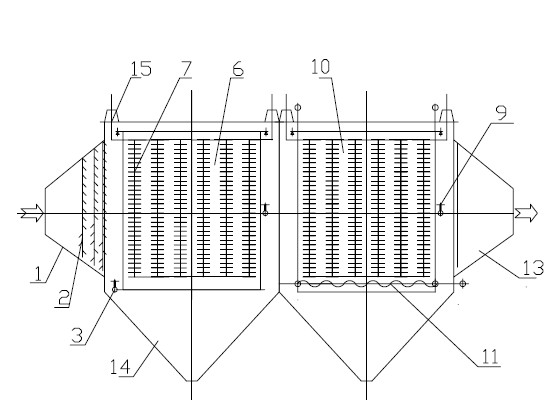

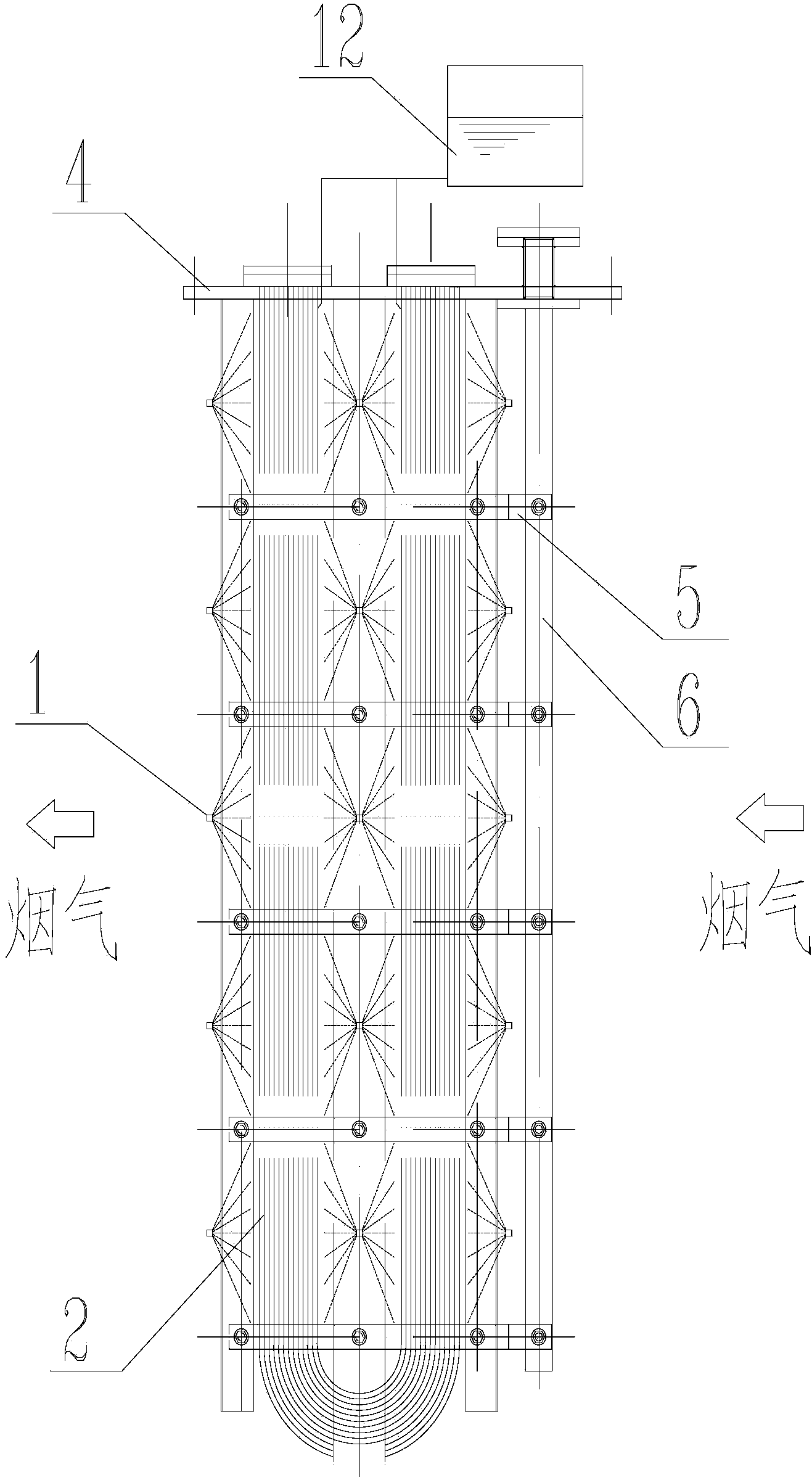

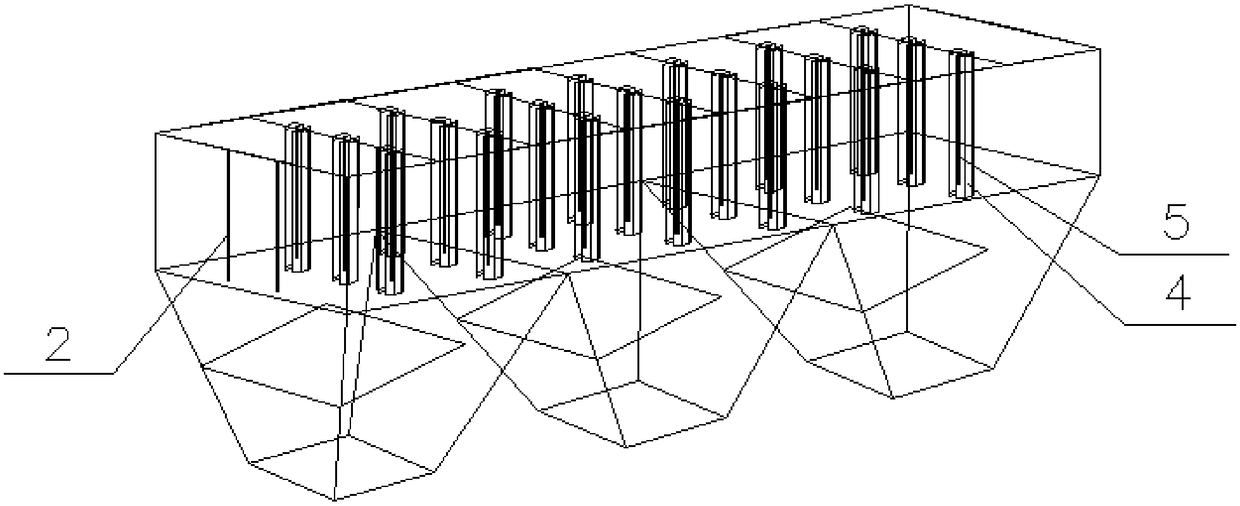

Differential electric precipitator

InactiveCN101804383AReduce spacingReduce flow rateExternal electric electrostatic seperatorElectrode constructionsElectrical resistance and conductanceEngineering

The invention discloses a differential electric precipitator, which comprises a shell, an ash bucket, an inlet seal head, an outlet seal head, a cathode system and an anode system. The ash bucket is connected with the shell through a bottom beam and is arranged below the shell, the inlet seal head and the outlet seal head are respectively arranged on the two sides of the shell, the cathode system and the anode system are arranged in the shell, and an auxiliary discharge system is arranged on the rear end of the inlet seal head, the anode system comprises a plurality of through type anodes for fume to transversely penetrate through, each two through type anodes form a wedge shape from the inlet seal head side to the outlet seal head side, and the contacts of the through type anodes on the inlet seal head side are connected via a V-shaped deflector; and the cathode system consists of a plurality of small cathode frameworks, and each small framework is independently hanged in an insulating way and is arranged in a triangular space between the anode system and the auxiliary anode discharge system. The invention reduces the average distance between dust and the anode plate, avoids the anti-corona scene caused by the dust with high specific resistance, improves the ash cleaning effect, and prevents the secondary dust.

Owner:江苏力洁达环保设备工程有限公司

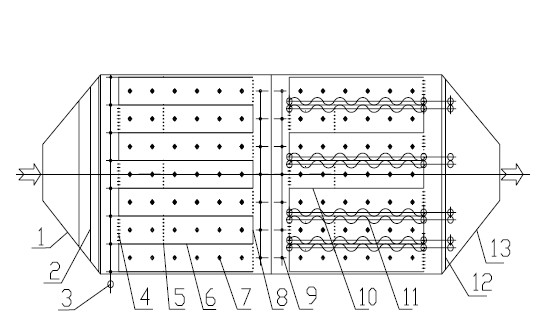

Coulomb electric precipitator

InactiveCN103878064ABreak through the problem of floating againAvoid secondary dustExternal electric electrostatic seperatorElectrode constructionsThermodynamicsCorona discharge

The invention relates to equipment for performing dust removal by utilizing static electricity. An inlet distribution plate is arranged in an inlet seal head; an anode plate is arranged in an electric field and is matched with a corona discharge electrode; the anode plate is arranged in a V shape; inlet ventilating boards are alternately arranged at the inlet end; the corona discharge electrode is electrically insulated from a shell on the top of the electric field by using a high voltage insulator; the corona discharge electrode is vibrated by adopting a middle or top cathode; the anode plate is vibrated by adopting a bottom anode; an ash bucket is arranged on the lower part of the electric field and is used for collecting the shaking dust; an outlet seal head and an outlet distribution plate are arranged at the outlet of the electric field; outlet ventilating boards are alternately arranged at the outlet end of the electric field. The equipment has the beneficial effects that secondary dust raising caused in the process of removing dust on the electric precipitation plate is overcome, and the problem that the collected dust escapes again is solved, so that the charged dust particles are not influenced by wind force. Moreover, the wind power is assisted to be forced to push to a dust collection plate, the bottleneck that the national emission standard cannot be reached due to high specific resistance trapping difficulty is broken through, and the overall construction cost is greatly saved.

Owner:金烈水

Coulomb electric precipitator

InactiveCN101954312ABreak through the problem of floating againLess investmentElectrode constructionsElectrodes cleaningCorona dischargeEngineering

The invention discloses a coulomb electric precipitator which comprises a dedusting tank body, wherein the two ends of the dedusting tank body are provided with an air inlet tank and an air outlet tank; one side, which is adjacent to the air inlet tank, of the dedusting tank body is provided with a front electric field which comprises fixed polar plates and corona discharge electrodes; the fixed polar plates and the corona discharge electrodes are arranged alternately; the fixed polar plate is provided with fixed polar plate air vents through which smoke passes; an electric field channel is formed between adjacent fixed polar plates; a rear electric field comprises movable polar plates and the corona discharge electrodes, and the movable polar plates and the corona discharge electrodes are arranged alternately; the movable polar plates are connected with an elevator mechanism for driving the movable polar plates to move up and down; rotary brushes are arranged below the movable polar plates, and the corona discharge electrodes are provided with negative electrode rappers; ash buckets are arranged below the rotary brushes; and the movable polar plates are provided with movable polar plate air vents through which the smoke passes, and an electric field channel is formed between adjacent movable polar plates. The Coulomb electric precipitator can effectively prevent secondary dust flying in the dedusting process, maintains stable and high dedusting efficiency and lowers the cost.

Owner:金烈水

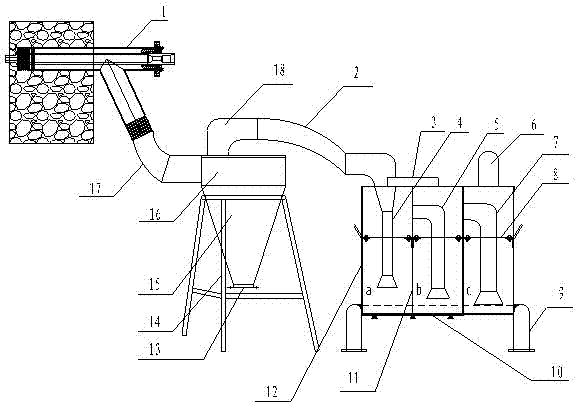

Ultra-fine magnetized foam drilling dust collector

InactiveCN102269009AImprove the effect of dust suppressionImprove dust suppression efficiencyDust removalFire preventionMicro devicesMagnetization

The invention discloses an ultra-micro magnetized foam drilling dust remover, which is applicable to the underground dust removal of a coal mine. The dust remover is mainly composed of a drilling stopper, a first-stage dust settling device and an ultra-micro magnetized foam dust capturing device. The drilling stopper is connected with the first-stage dust settling device. The first-stage dust settling device is connected with the ultra-micro magnetized foam dust capturing device. By means of the first-stage dust settling device connected onto the drilling stopper, large-particle coal dust generated in the drilling process of coal and rock mass is led out through a conical cylinder; the coal dust and gas enter the ultra-micro magnetized foam dust capturing device and are gradually subjected to dust settling in three compartments of the dust collecting device; compared with the prior art, the dust remover has the advantages of simple structure, safety for operation and convenience for use; and by adopting the graded dust settling theory in a dry-process and wet-process combined way, the dust removing process and the drilling process are carried out synchronously, and the efficiency for settling whole dust, in particular respiratory dust, is high.

Owner:CHINA UNIV OF MINING & TECH

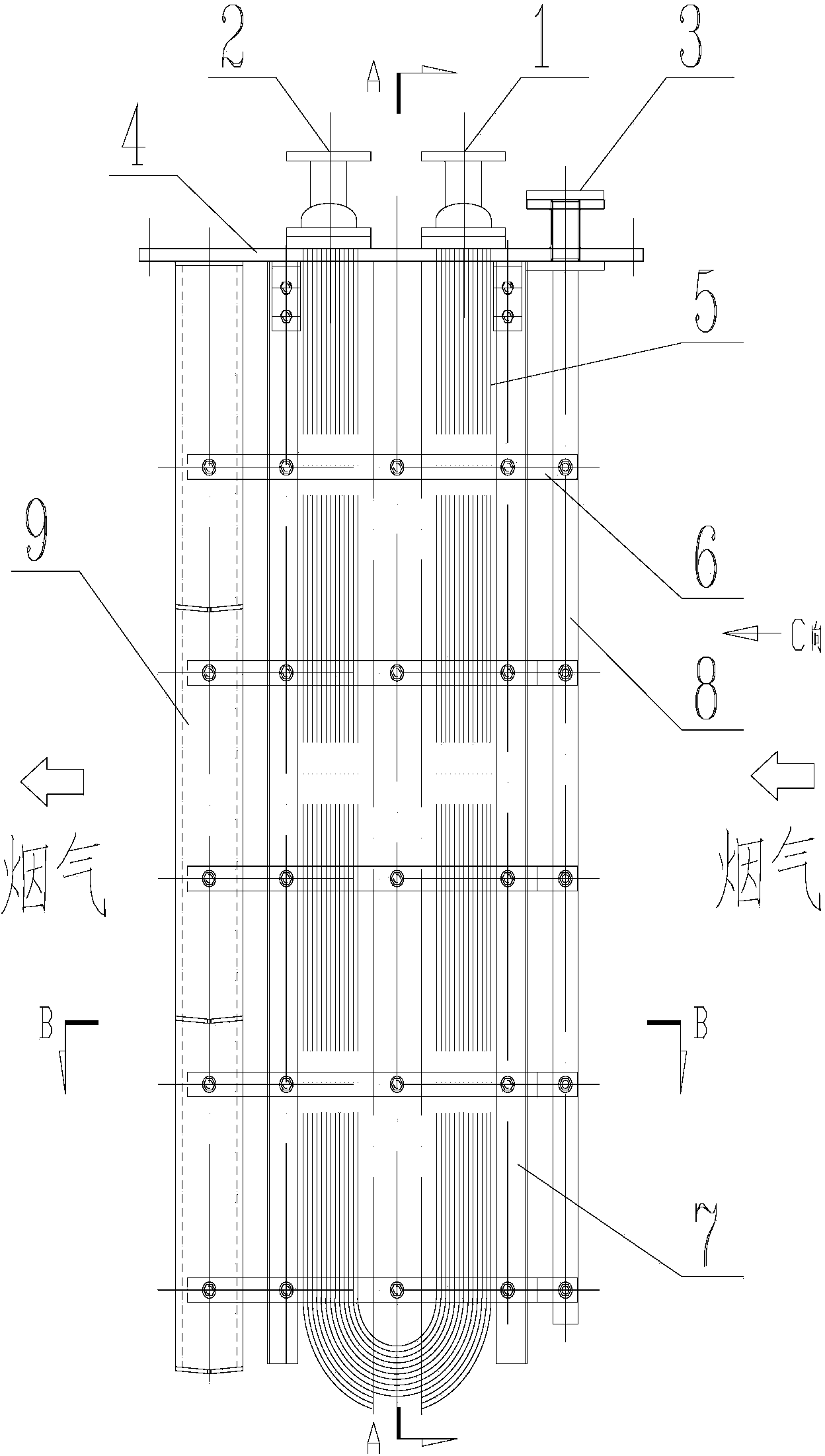

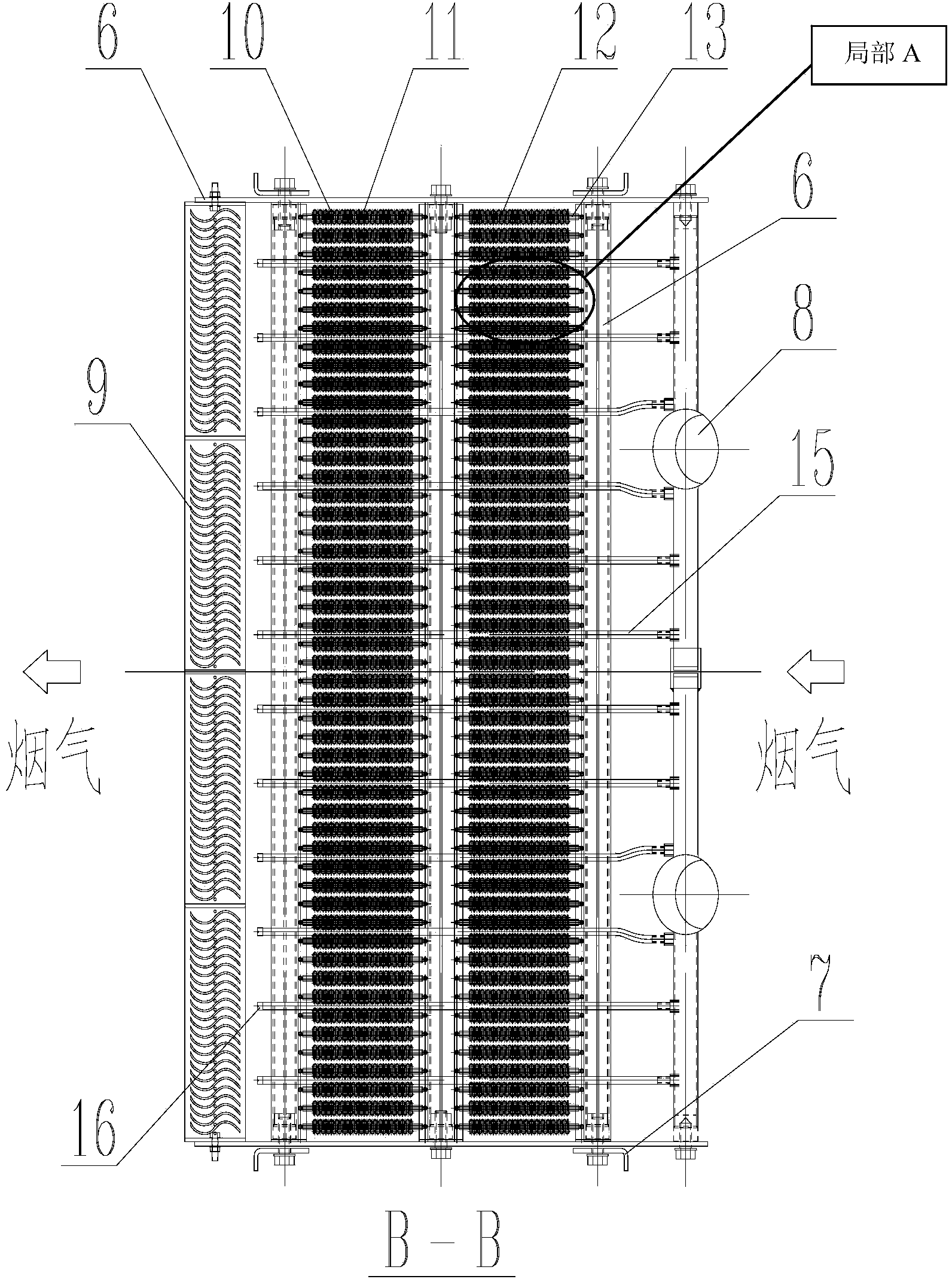

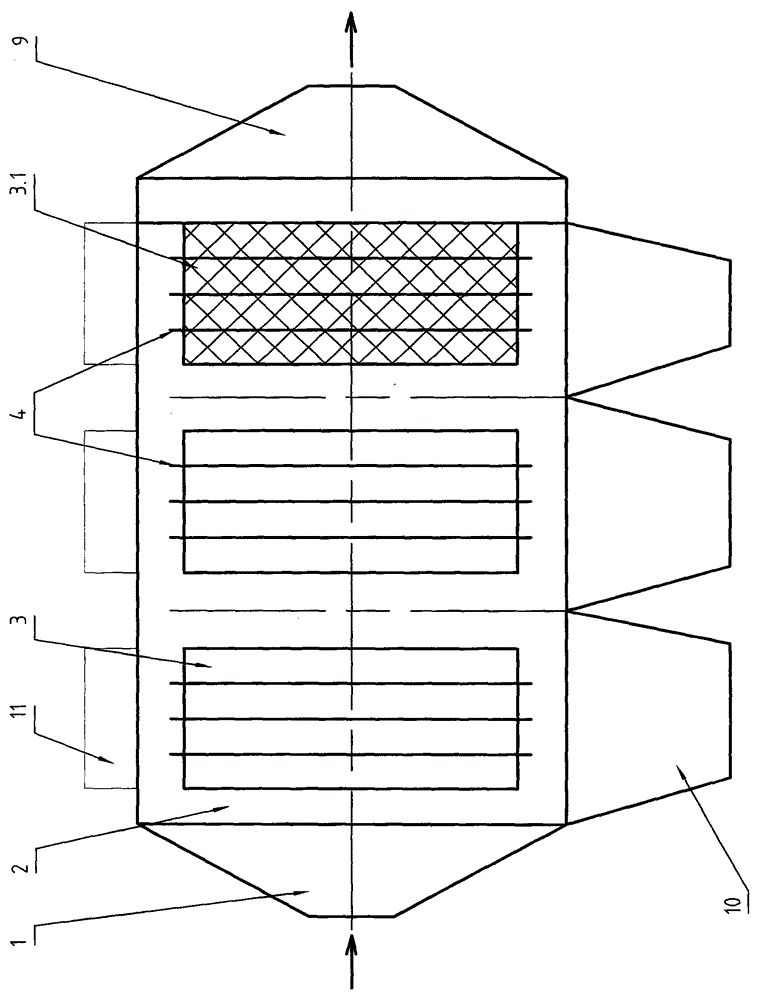

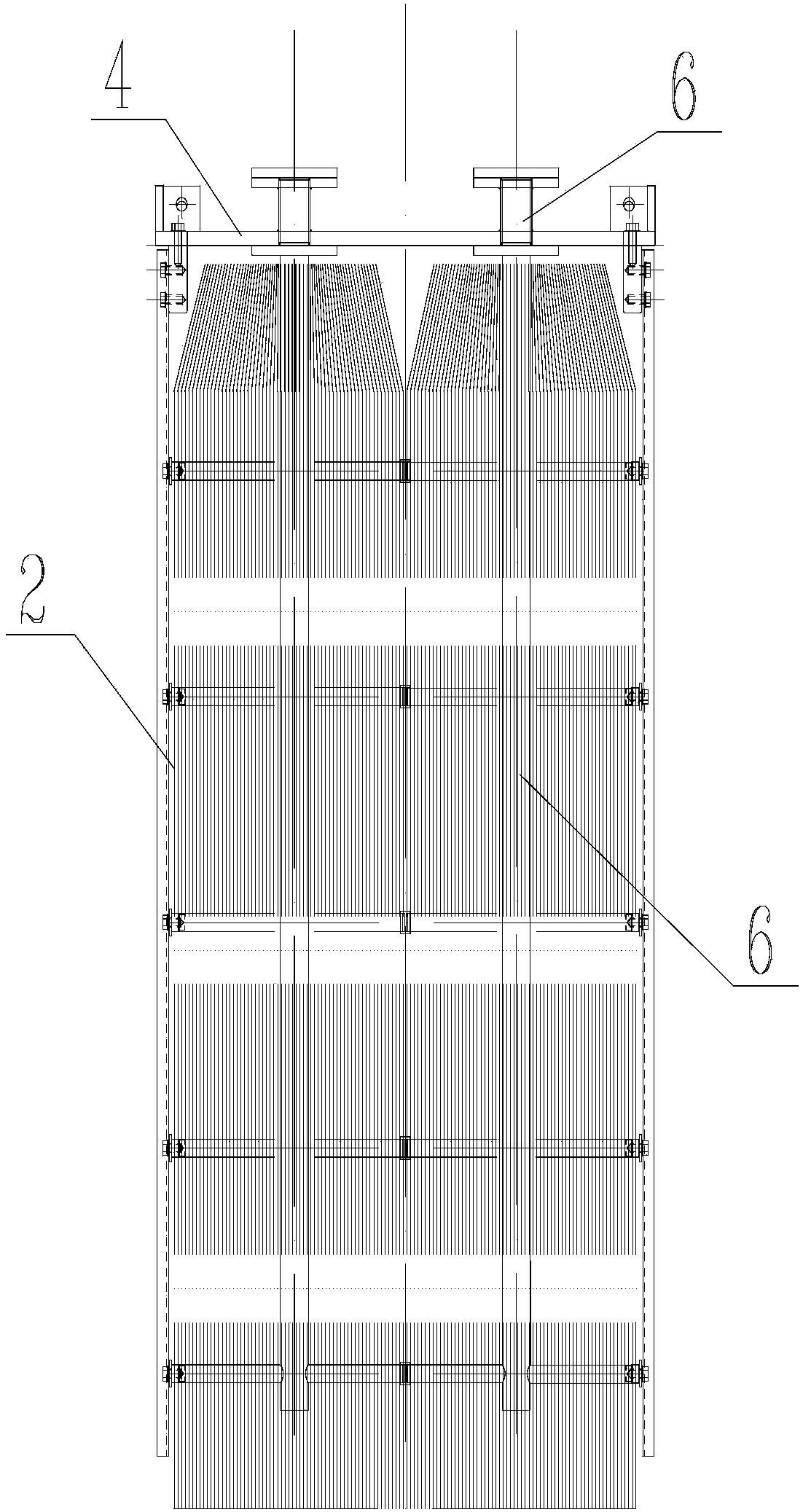

Waste heat recovery condensation water-saving device

InactiveCN103861420AAchieve clean emissionsImprove capture abilityCombination devicesVapor condensationWater savingFlue gas

The invention belongs to the technical field of waste gas purification, and particularly relates to a waste heat recovery condensation water-saving device used for flue gas which is treated by a wet desulfurization device. According to the waste heat recovery condensation water-saving device provided by the invention, the technical principles of a tubular heat exchanger, a tubular dust collector and a water collection drop catcher are combined together, so that waste heat recovery, condensation water recovery and deep dust removal for the wet saturated flue gas treated by the wet desulfurization device can be realized, the problems of dedusting and demisting the flue gas treated by the wet desulfurization device can be solved, and a great deal of water in the flue gas and part of latent heat of vaporization can be recycled. The waste heat recovery condensation water-saving device is generally applied to the energy source environmental protection industry, has the working position at the downstream part of the flue gas wet desulfurization device (FGD) of a thermal power plant, and can be used for catching fine particle dust and gypsum in the flue gas, so that the clean emission of the flue gas of the thermal power plant can be realized, and the dust removing efficiency and the long-term operation stability of equipment are guaranteed.

Owner:北京新世翼节能环保科技股份有限公司

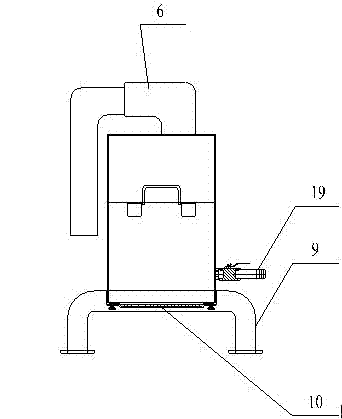

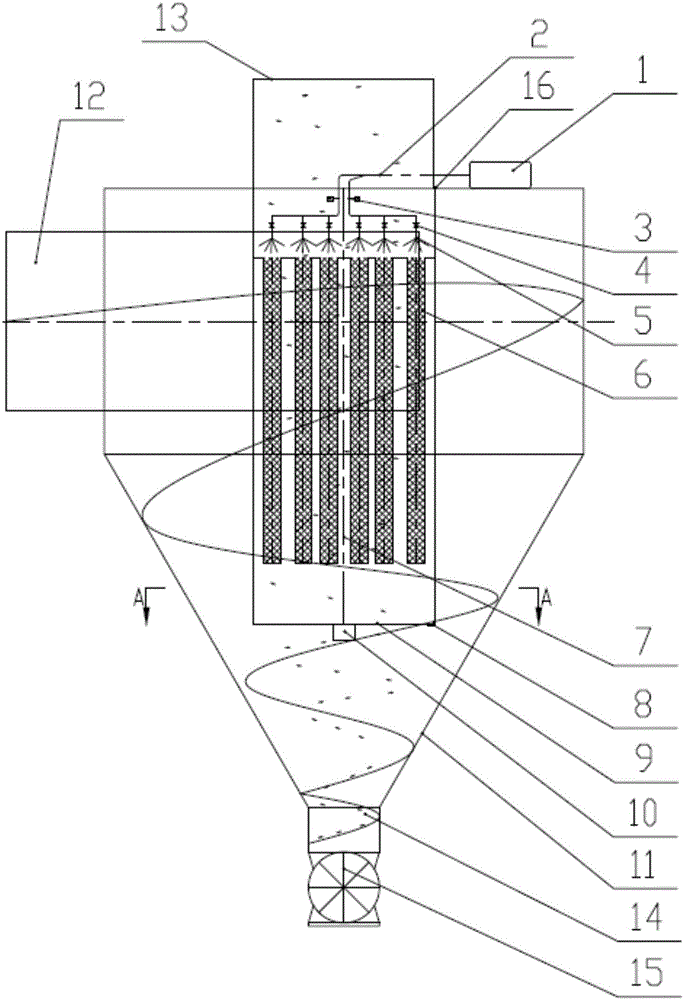

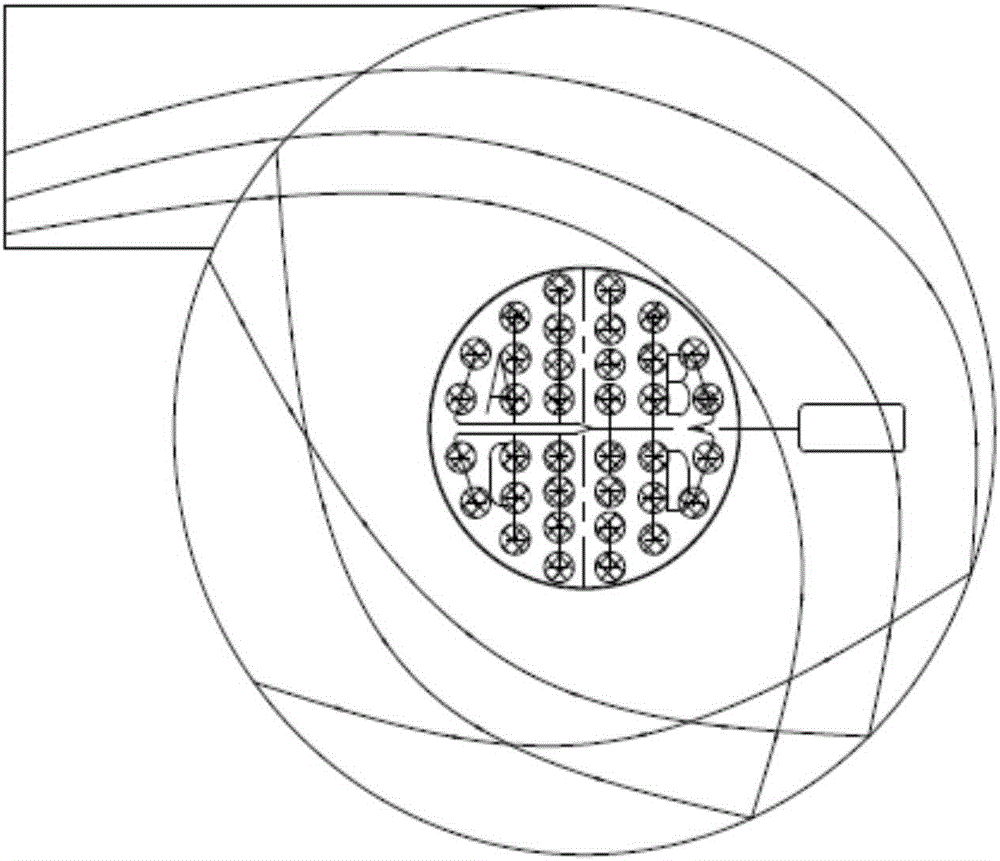

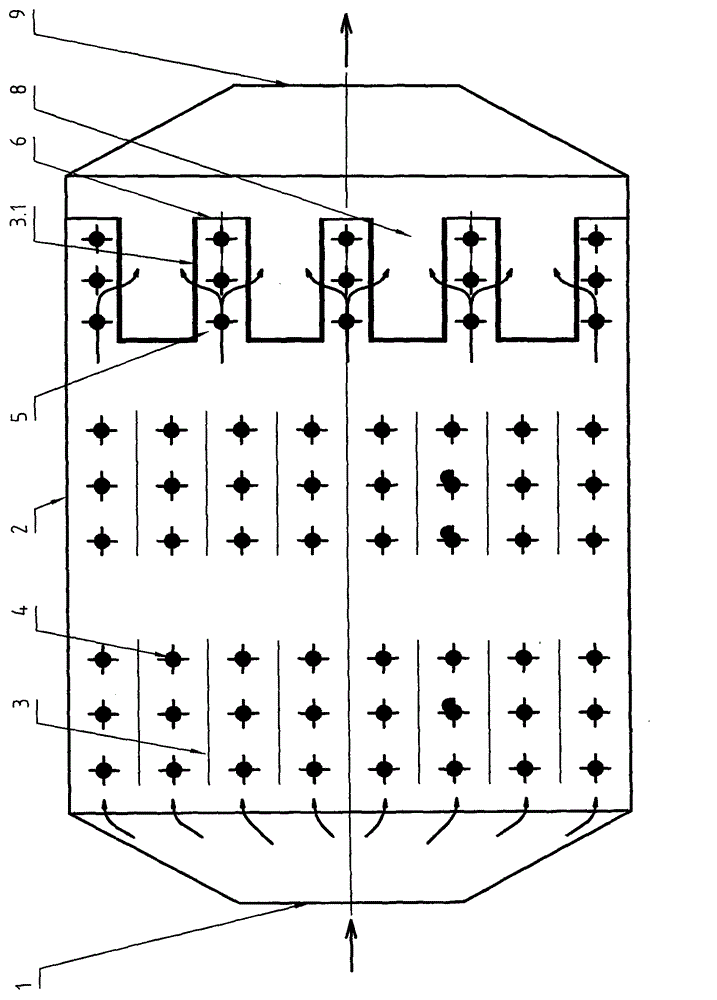

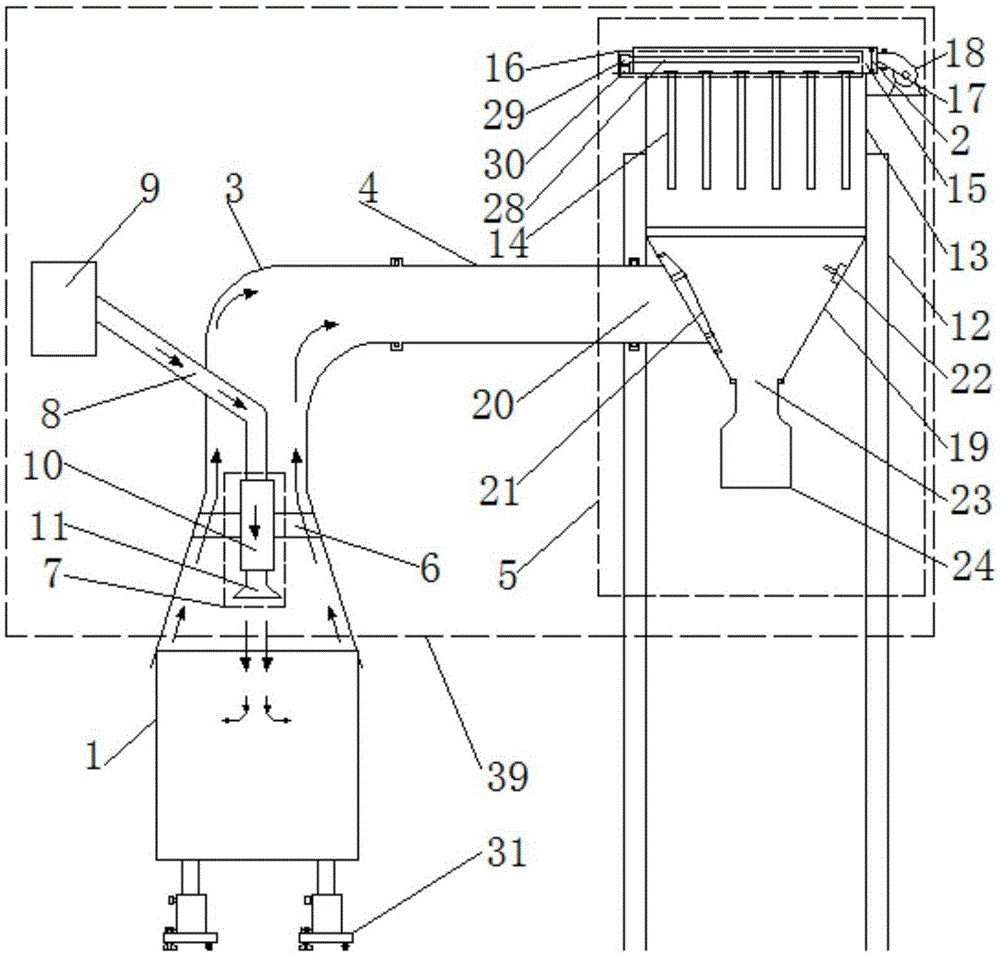

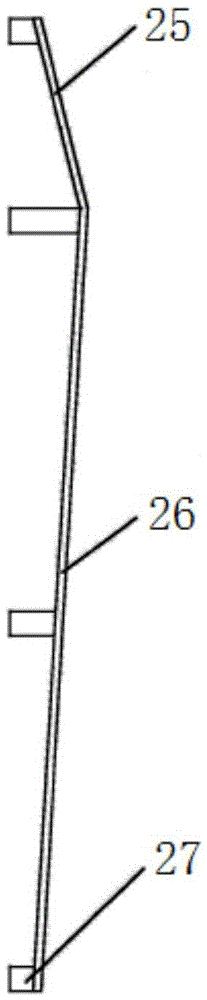

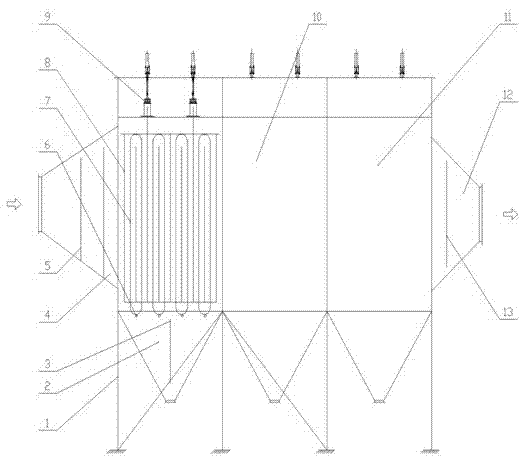

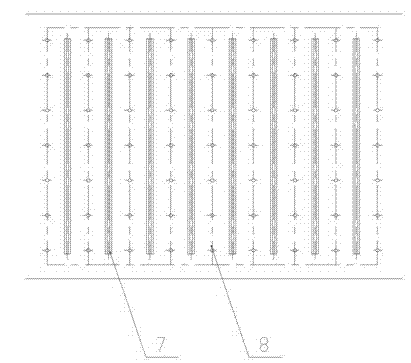

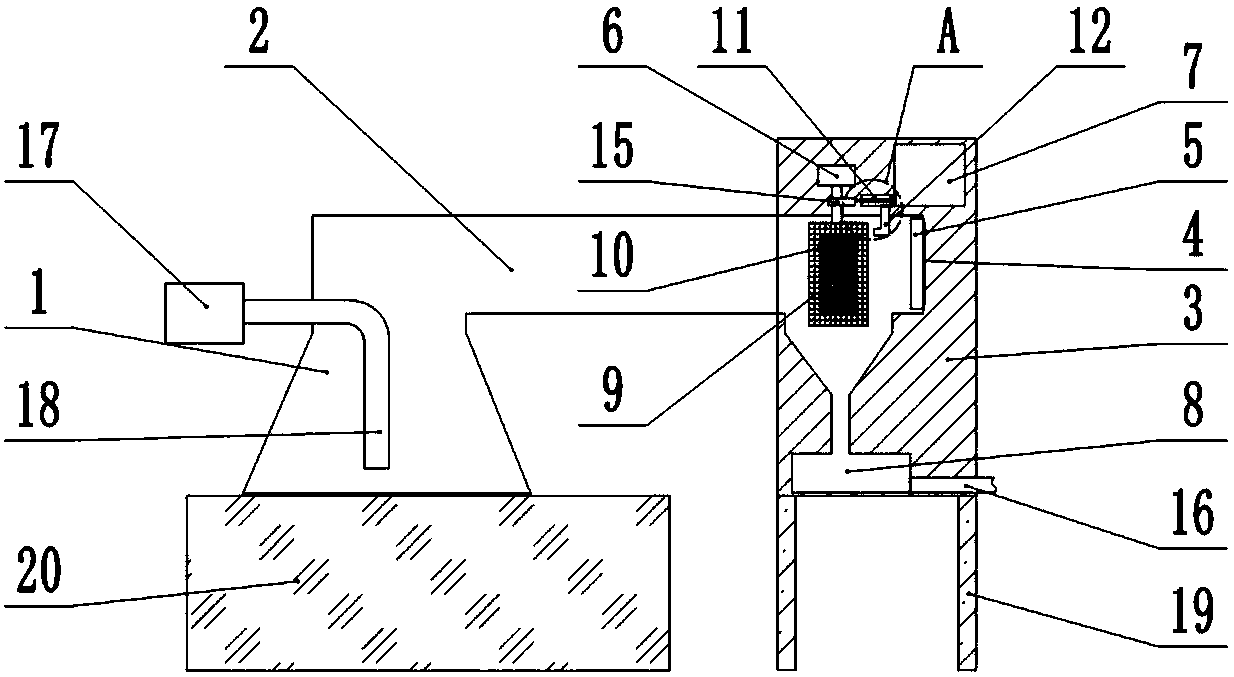

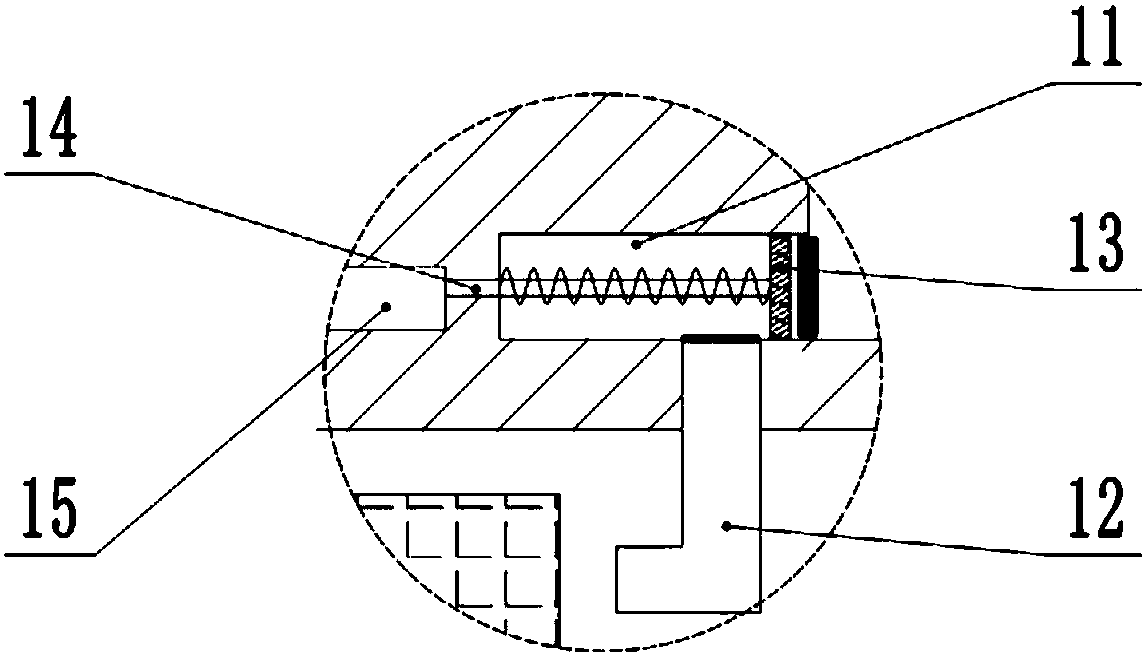

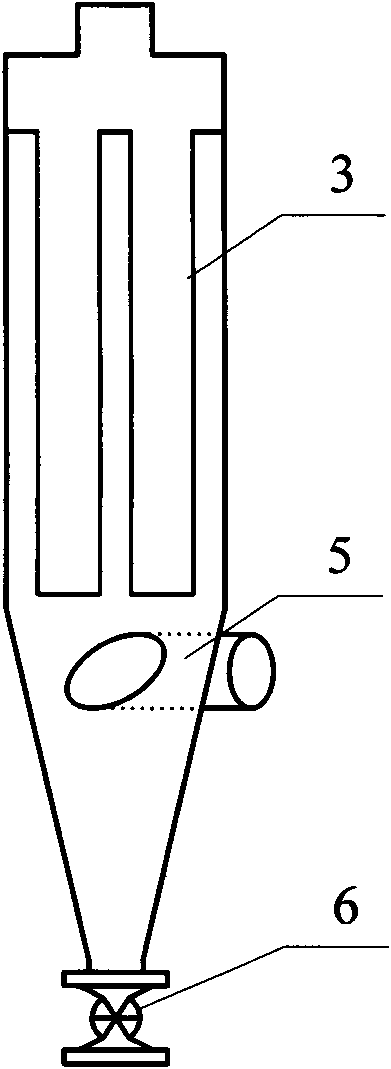

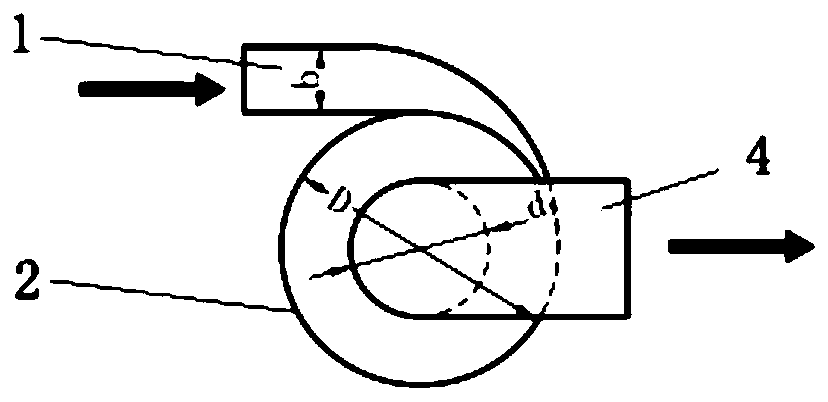

Cyclone bag type dust collector for rotary chamber pulse jet system

InactiveCN106110785ASolve the disadvantages of inconvenient cleaningAvoid secondary dustCombination devicesDispersed particle filtrationSolenoid valveEngineering

The invention discloses a cyclone bag type dust collector for a rotary chamber pulse jet system. The cyclone bag type dust collector comprises an air tank, a compressed air tube, a solenoid valve, a pulse valve, an air lock, a pressure difference transmitter and the like, wherein the air tank is connected to the solenoid valve, the pulse valve and an air nozzle through the compressed air tube so as to form a system for supplying compressed air to the air nozzle by an air source; a filter bag is nested in an inner barrel of the cyclone bag type dust collector; the filter bag is divided into multiple areas by chamber separators, so that chamber ash removal is conveniently performed; a rotating door rotates around an intermediate shaft, and the other end of the rotating door overlaps on a door shield so as to form a closed space with the chamber separators and the door shield; a stepping motor is inlaid on the lower side of the intermediate shaft; and the pressure difference transmitter is used for detecting pressure difference inside and outside the filter bag. According to the dust collector disclosed by the invention, the problem that ash is inconvenient to remove because the filter bag is nested inside the cyclone dust collector is solved in an integrated manner, closed ash removal in a pressure difference increase area is completed, in-turn ash removal in different filter bag areas is completed, a compressed air system is started by the solenoid valve so as to supply sufficient air, barrier-free continuous blowing is guaranteed, and the cyclone bag type dust collector is applied to the technical field of environmental-friendly dust collection.

Owner:NORTHERN HEAVY IND GRP CO LTD

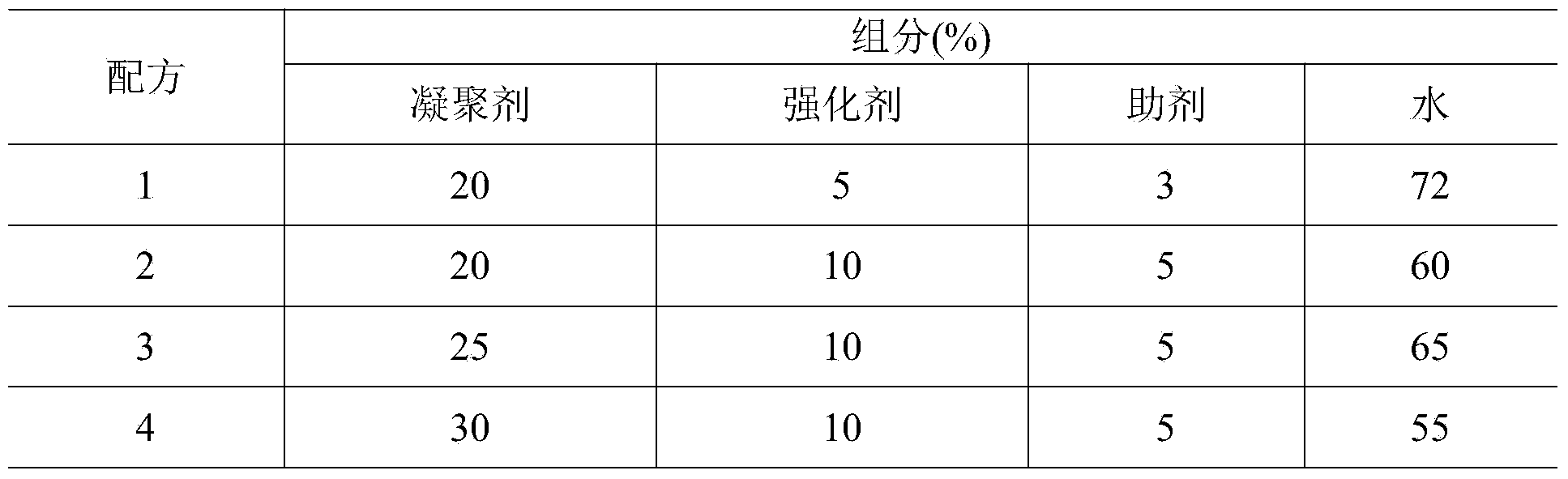

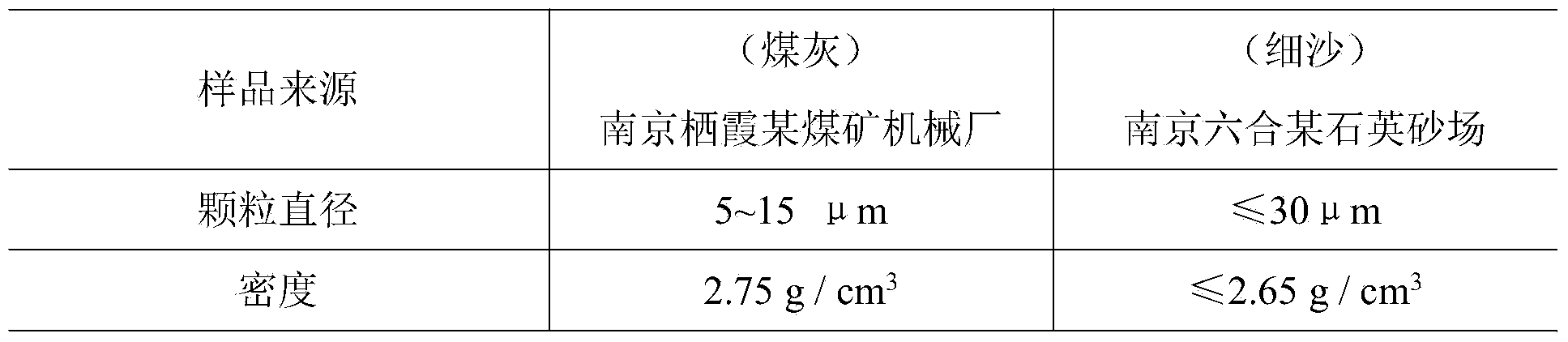

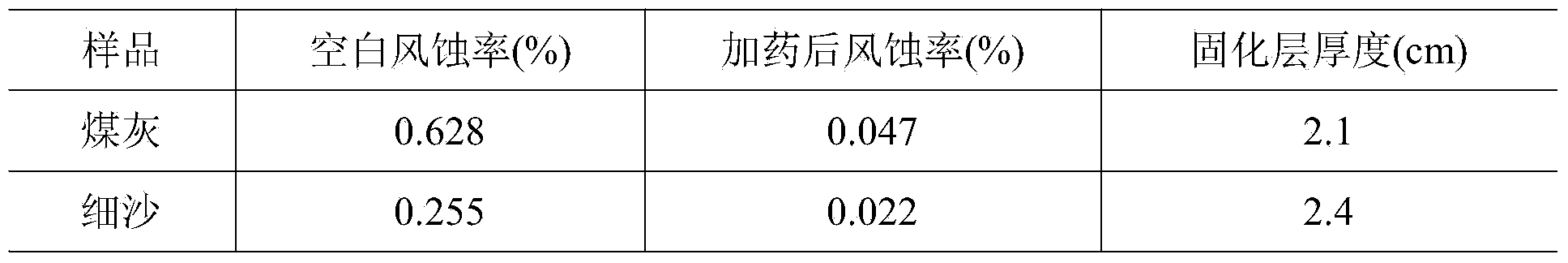

Composite adhesive type dust flying inhibitor and preparation method thereof

InactiveCN104073223AReduce lift rateReduce surface tensionOther chemical processesLignin material coatingsSlagCoal

The invention discloses a composite adhesive type dust flying inhibitor and a preparation method thereof. The composite adhesive type dust flying inhibitor is used for sand fields and soil fields on construction sites as well as coal fields, ash fields and raw material, mineral powder and ash slag yards of enterprises and is prepared from the following components in parts by weight: 20-30 parts of coagulant, 5-10 parts of enhancer, 3-5 parts of promoter and 55-72 parts of water. Practice shows that after the composite adhesive type dust flying inhibitor is sprayed in the coal and mineral powder yards, a layer of cured film can be formed on the surface of the ash field, and the film is uniform in thickness, high in viscosity, good in stability, has certain environmental adaptability and can be used for effectively reducing pollution to the surrounding environment and dust flying loss in the storage and transportation processes of coal, mineral powders and the like. As the cured type dust flying inhibitor and components thereof do not have toxic or side effects or corrosion effect, are low in cost, are economical and easily available, the cured type dust flying inhibitor is an effective, economical environmental-friendly cured type dust flying inhibitor.

Owner:NANJING UNIV OF SCI & TECH

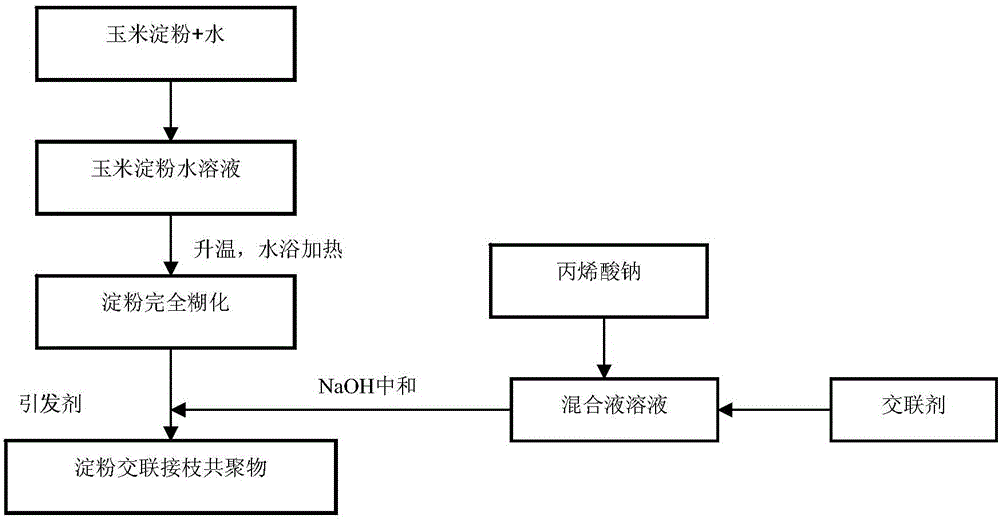

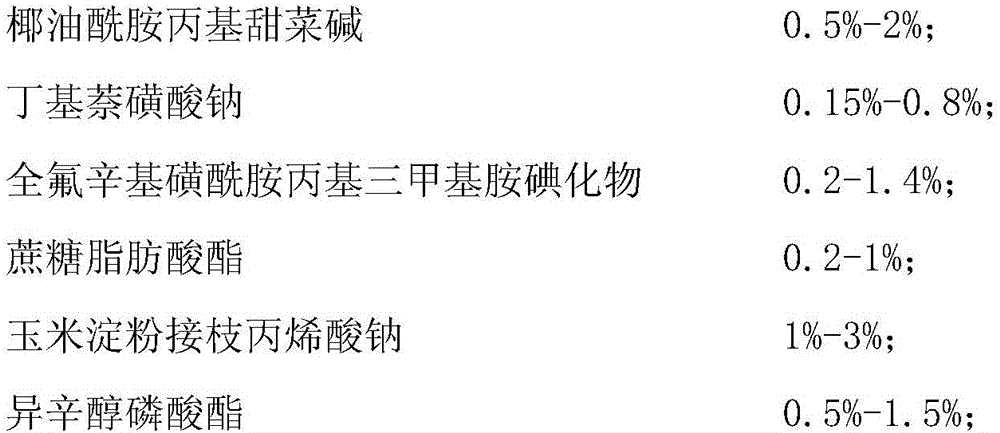

Permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control

ActiveCN105778867AReduce surface tensionIncrease surface tensionOther chemical processesDust removalSucrosePhosphate

The invention discloses a permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control. The permeability-increasing and coagulation-accelerating wetting agent comprises 0.5%-2% of cocamidopropyl betaine, 0.15%-0.8% of butylnaphthalenesulfonic acid sodium salt, 0.2%-1% of trimethyl-1-propanaminium iodide, 0.2%-1% of sucrose fatty acid ester, 1%-3% of corn starch grafting sodium acrylate, 0.5%-1.5% of isooctanol phosphate, 0.06%-0.35% of sodium alcohol ether sulphate, 0.5%-1.3% of sodium diethylhexyl sulfosuccinate, 0.2%-1.2% of polyacrylamide, 0.1%-0.8% of chitin derivative-carboxymethyl chitosan, 0.1%-0.2% of polyaspartic acid, 0.3%-0.6% of calcium chloride and the balance water. The ermeability-increasing and coagulation-accelerating wetting agent for wet-type dust control has the advantages that wetting ability of water for coal is enhanced and water molecules can wrap coal dust particles quickly, so that coagulation and falling of the coal dust particles are facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

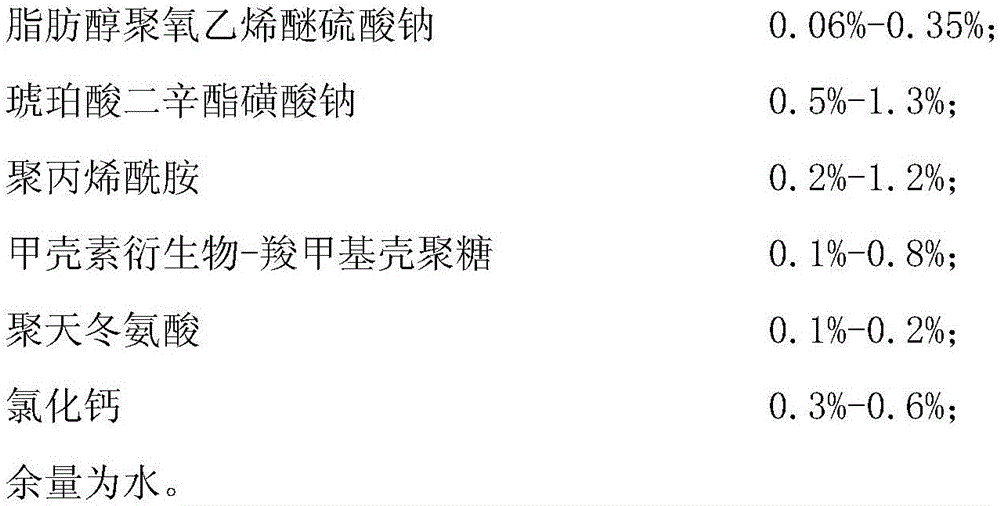

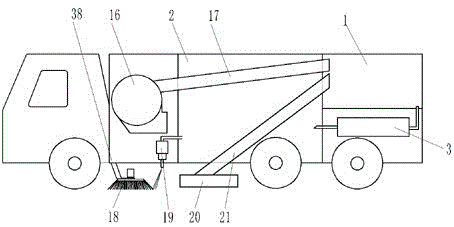

Washing and sweeping vehicle with double-circulation filter system

ActiveCN105464031AIncrease flow rateImprove filtration efficiencyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFilter systemWater resources

The invention discloses a washing and sweeping vehicle with a double-circulation filter system. The washing and sweeping vehicle comprises a vehicle chassis, a draught fan, a suction air duct, a suction pipe, a suction plate, a brush plate and a water spraying device. According to the double-circulation filter system, a sewage box is connected with a first-stage water pump through a pipeline, the first-stage water pump is connected with a second-stage water pump through a pipeline, the second-stage water pump is connected with one or more filters. The filter is connected with the sewage box through a pipeline. A pressure regulation valve is arranged on the connection pipeline between the filter and the sewage box. The connection pipeline between the first-stage water pump and the second-stage water pump is connected with the connection pipeline between the filter and the pressure regulation valve through a pipeline. The clear water outlet of the filter is connected with a clear water box through a pipeline. The filter is a ceramic membrane filter which comprises a ceramic membrane pipe arranged in a sealed shell. The two ends of the sealed shell are used as a sewage inlet and a sewage outlet respectively to be connected with pipelines. A clear water outlet is formed in the sealed shell. By means of the washing and sweeping vehicle, the effective working time of environmental sanitation devices can be greatly prolonged, the sewage discharge amount can be decreased, and the utilization rate of water resources is increased.

Owner:YANTAI HAIDE SPECIAL VEHICLE

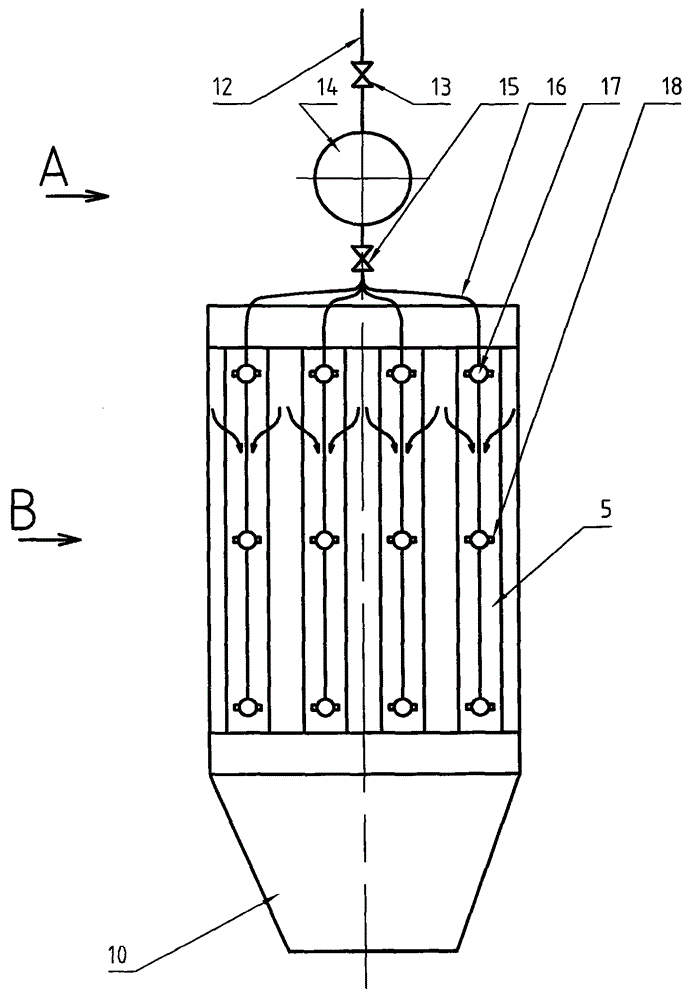

Dust collection electrode back-flushing filtering electrostatic precipitator

ActiveCN104785372ASolve secondary dustImprove dust removal efficiencyElectrode constructionsElectrodes cleaningElectrostatic precipitatorElectricity

The invention belongs to the field of environmental protection, and provides a dust collection electrode back-flushing filtering electrostatic precipitator. The electrostatic precipitator comprises a housing, dust buckets, an air inlet, an air outlet, negative electrodes, positive electrodes, a power supply system, and the like. In a dust-contained air flowing direction, at least a part of dust collection electrodes at the rear part of the dust collection electrodes are meshy dust collection electrodes; the meshy dust collection electrodes are arranged in parallel and are connected to separators to form meshy dust collection electrode air-intake spaces and meshy dust collection electrode air-exhaust spaces; and the negative electrodes are arranged in the meshy dust collection electrode air-intake spaces among the meshy dust collection electrodes. An injection box is arranged outside the housing, and is provided with a plurality of injection branch pipes and injection valves; each meshy dust collection electrode air-exhaust space is internally provided with one injection pipe; and each injection pipe having a branch pipe extending upwards out of the housing and connecting the injection branch pipes of the injection box. According to the invention, electric precipitation is effectively combined with filtering precipitation, so that the dust removing efficiency is greatly improved; the problem of dust cleaning of meshy dust collection electrodes is effectively solved; and the dust collection electrode back-flushing filtering electrostatic precipitator is suitable for reconstruction and renovation of a project.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

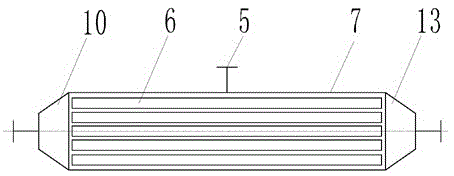

Water-spray-type tubular dust collector

InactiveCN103861402AAchieve clean emissionsGuaranteed dust removal efficiencyUsing liquid separation agentFlue gasLiquid water

The invention belongs to the technical field of waste gas purification, and particularly relates to a water-spray-type tubular dust collector. According to the water-spray-type tubular dust collector provided by the invention, the technical principles of an impingement dust collector and a water-film-type dust collector are combined together, the dust of the saturated wet flue gas can be removed, and the problems of dedusting and demisting the flue gas treated by a wet desulfurization device can be solved. The water-spray-type tubular dust collector is generally applied to the electric power environmental protection industry, and has the working position at the downstream part of the flue gas wet desulfurization device (FGD) of a thermal power plant; a water film is formed on the surface of a dust collection tube bundle in a water pouring way or a water spray way, so that impurities such as fine particle dust, gypsum, liquid water and the like in the flue gas can be caught; therefore, the clean emission of the flue gas of the thermal power plant can be realized, and the dust removing efficiency and the long-term work stability of equipment are guaranteed.

Owner:北京新世翼节能环保科技股份有限公司

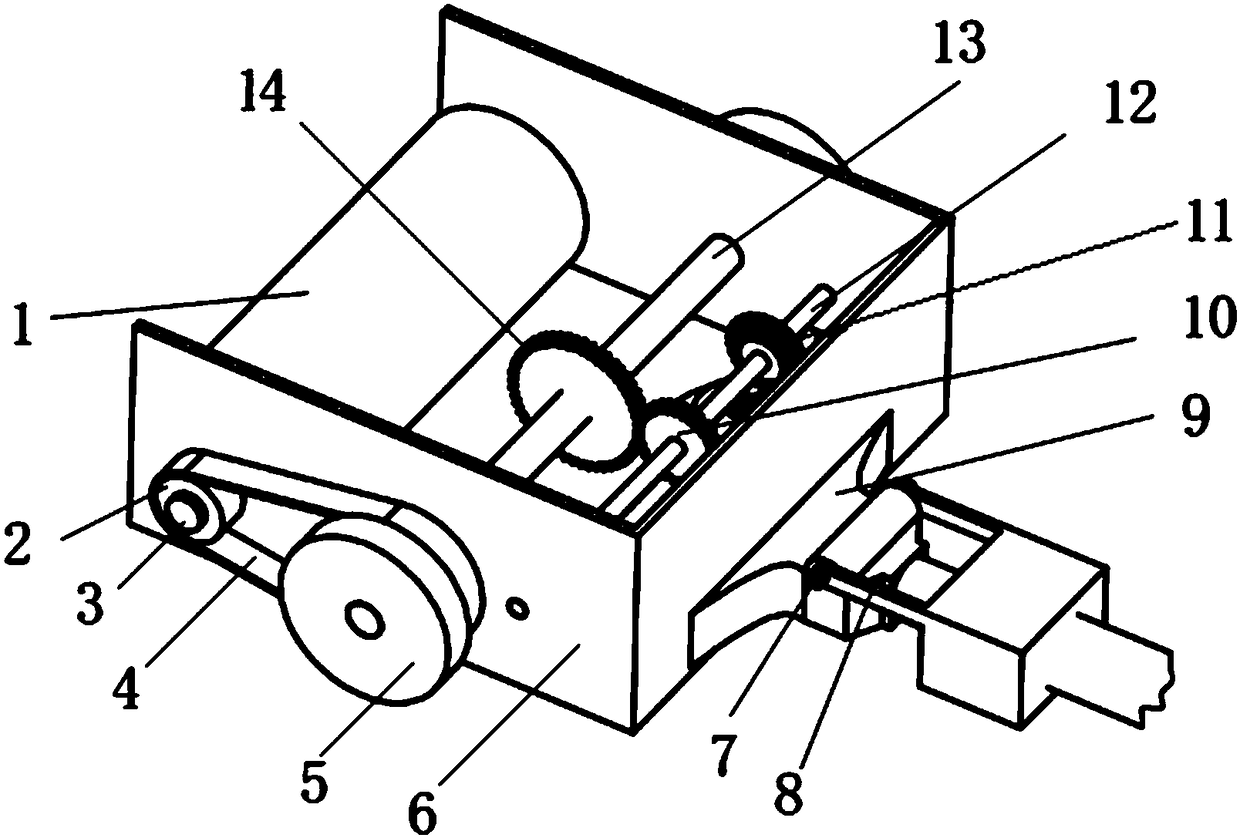

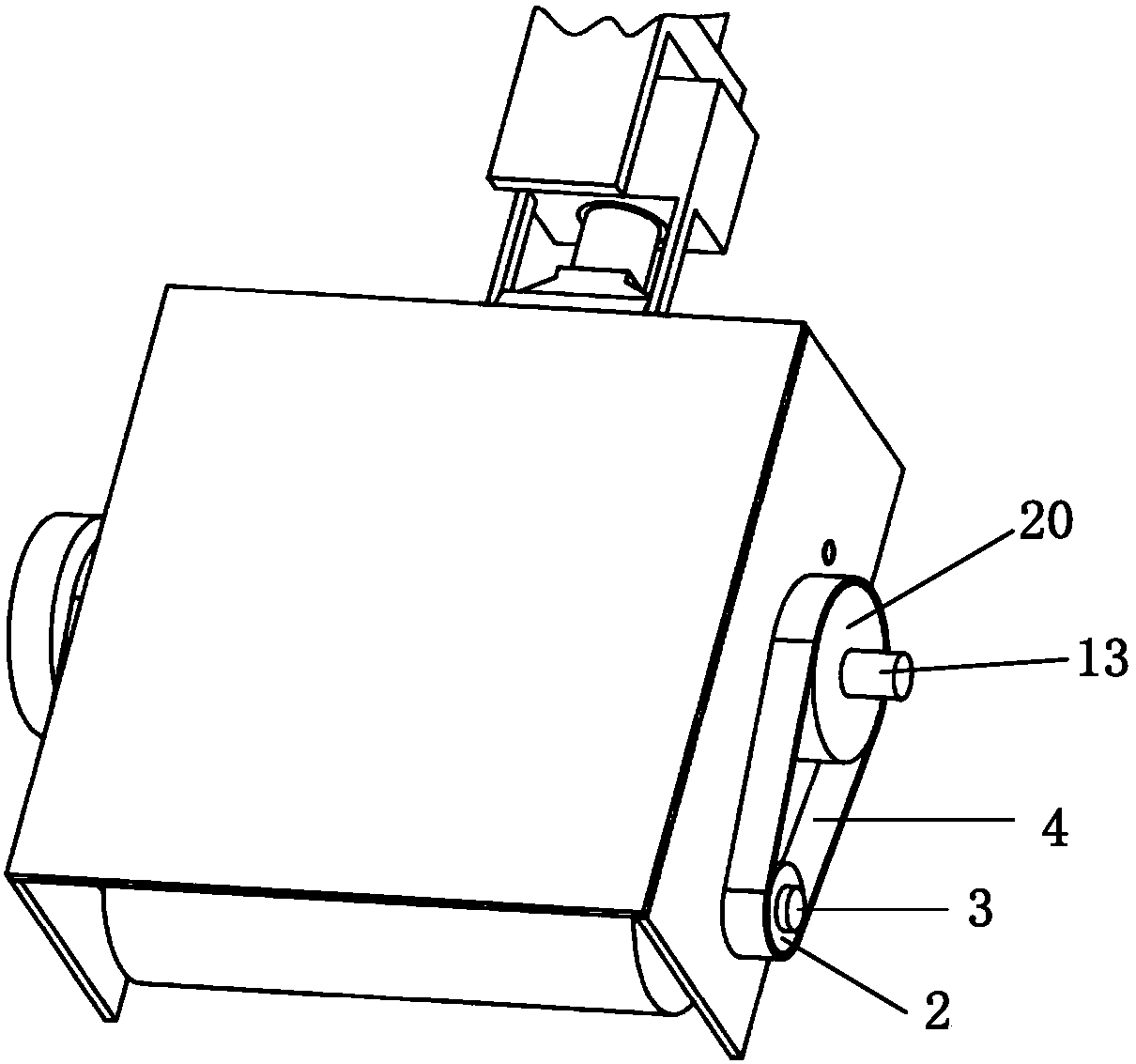

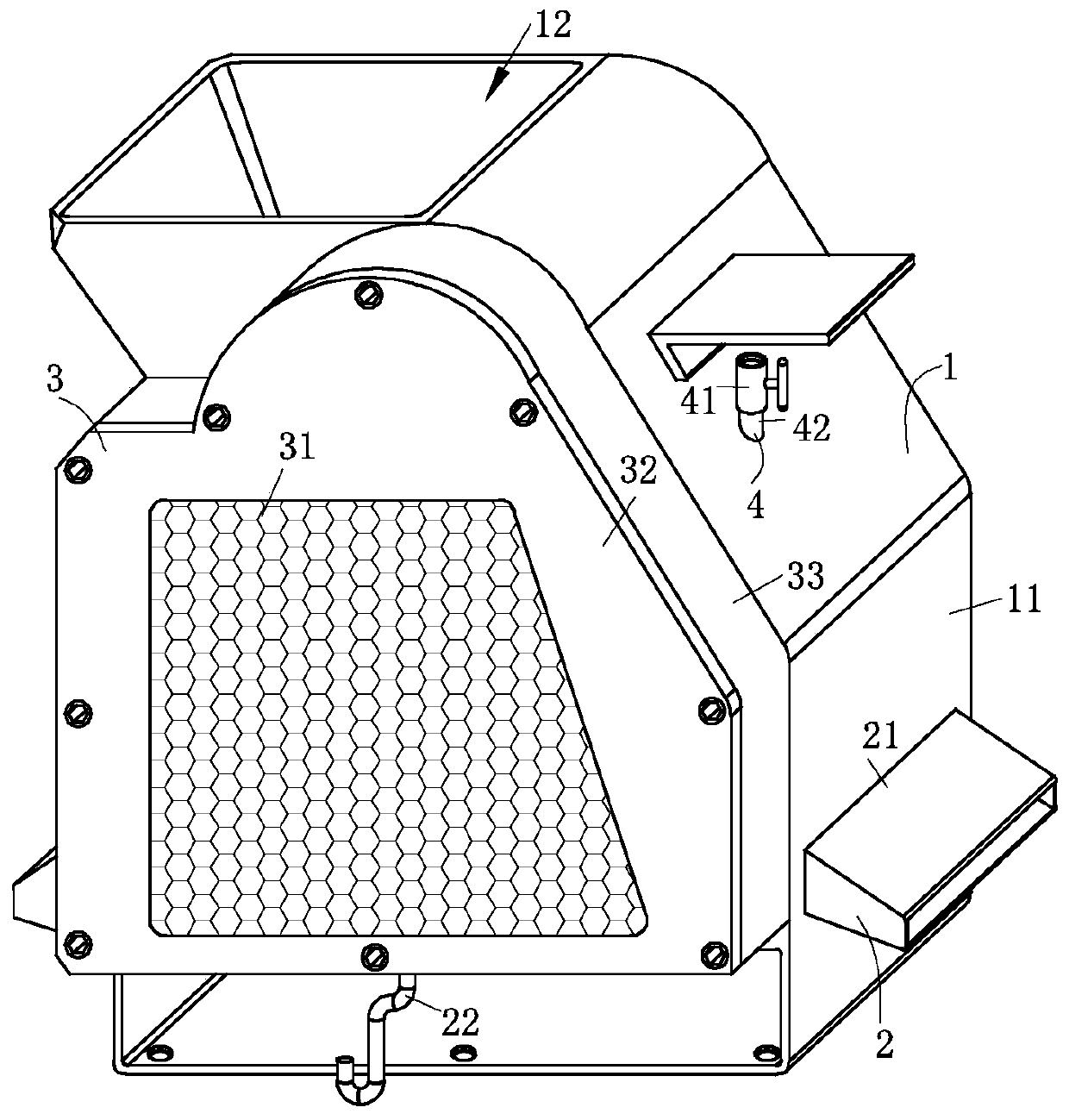

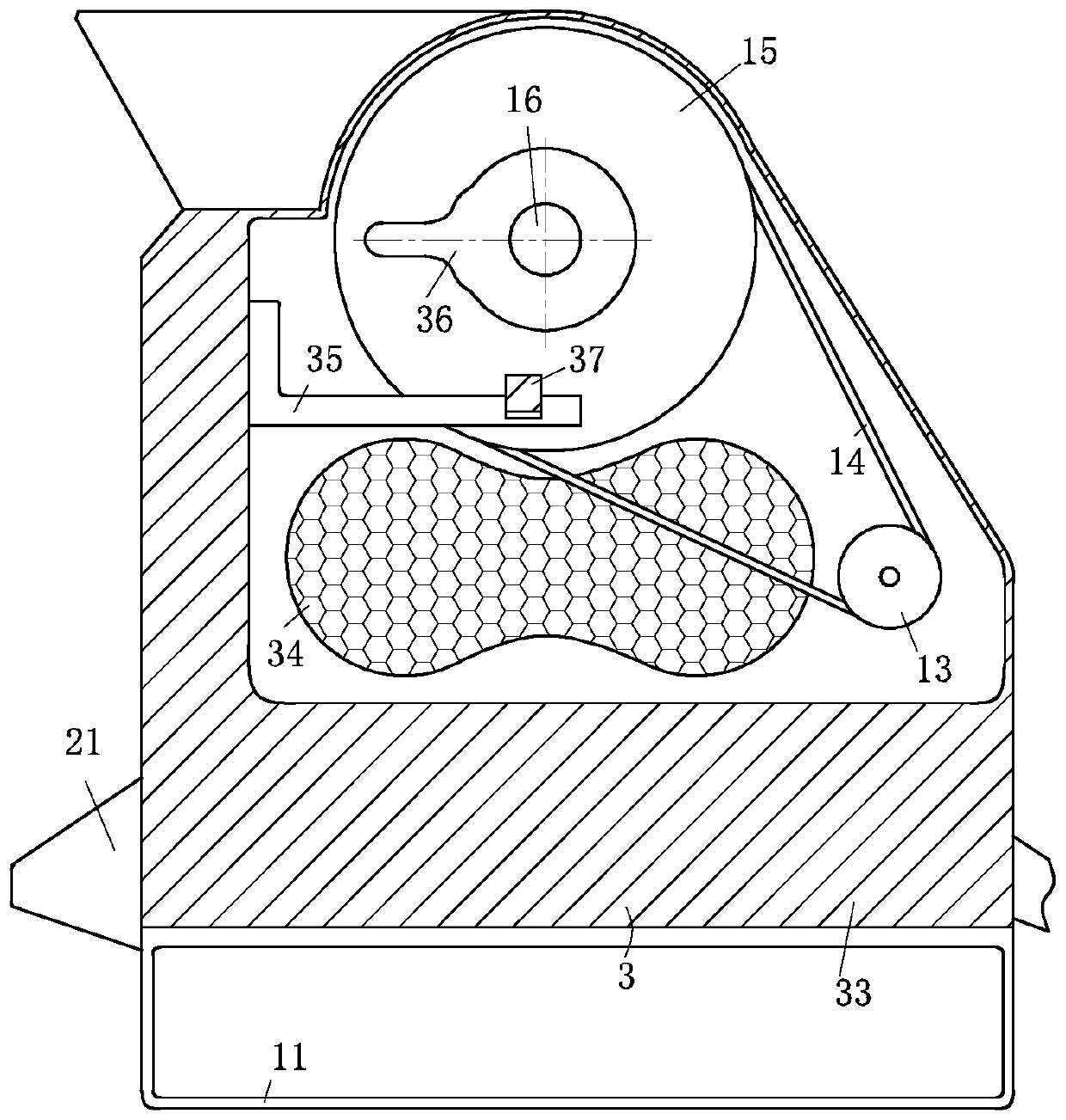

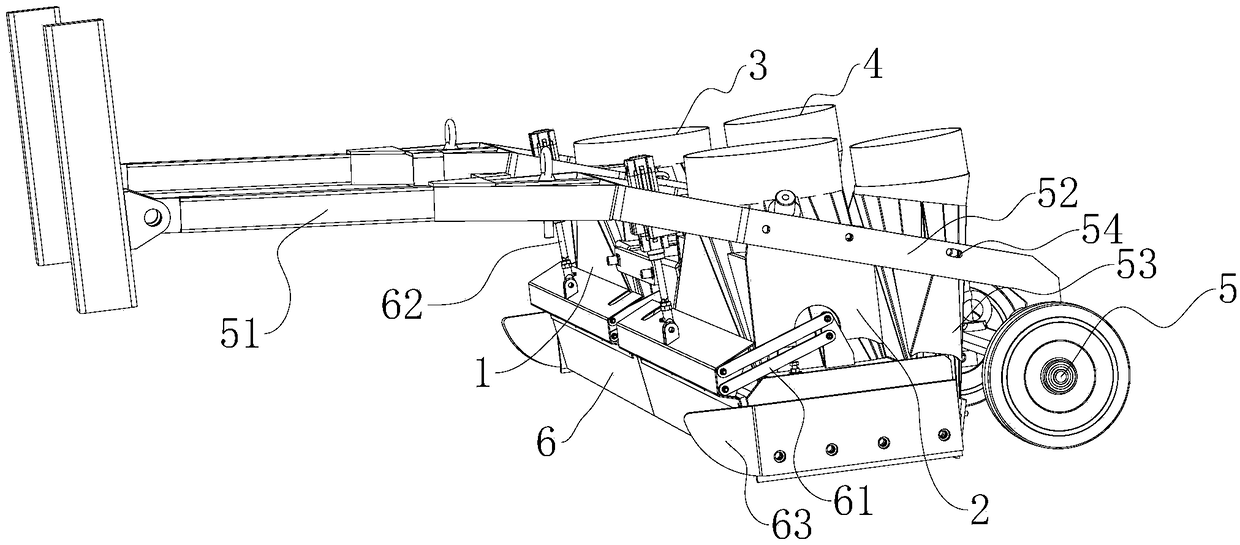

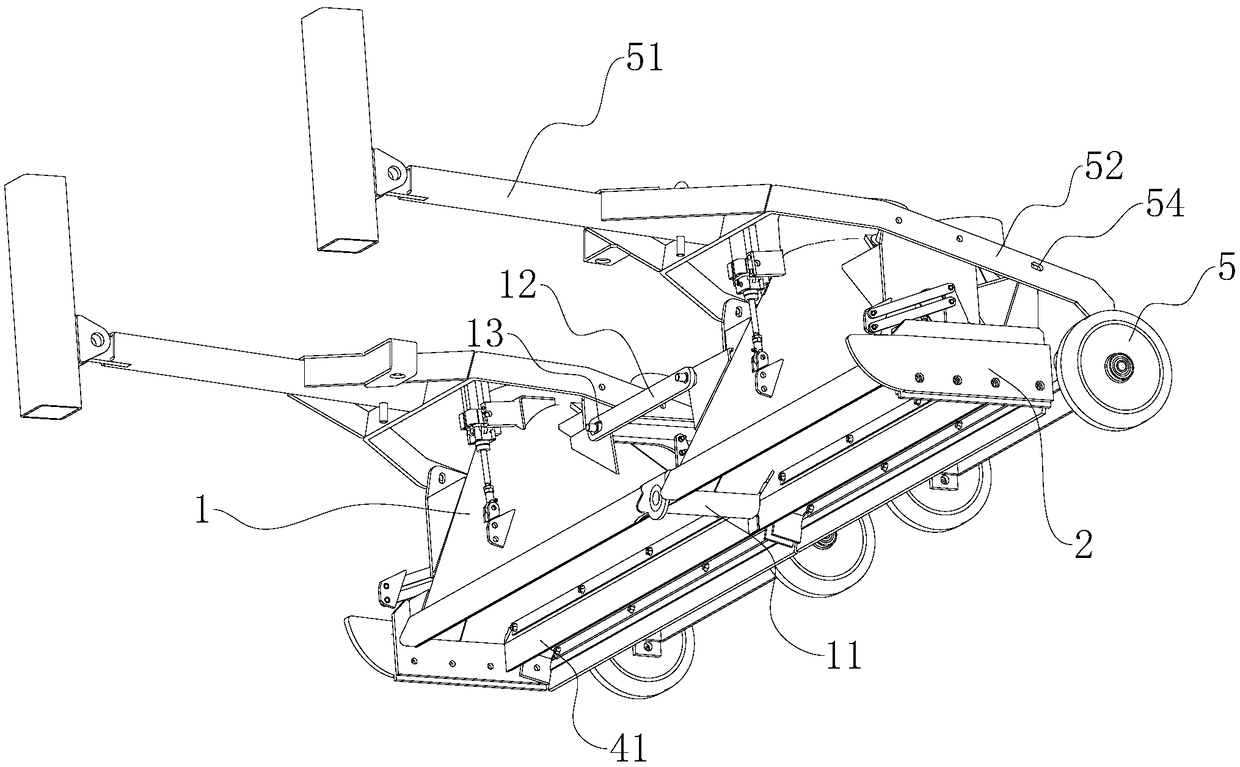

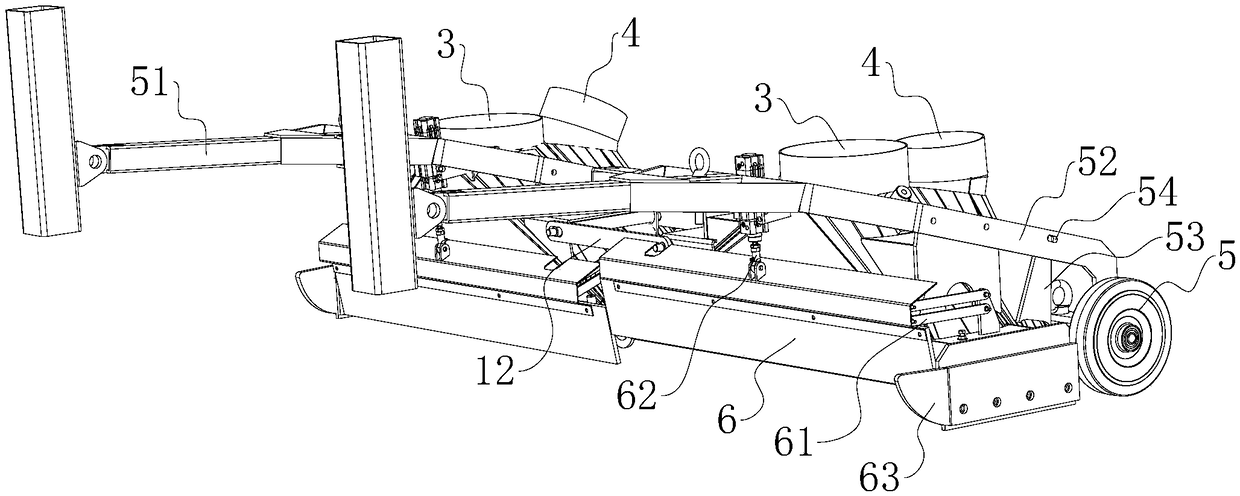

Solar panel cleaning trolley with mechanical sweeping and electrostatic dust removing functions

PendingCN108607864AReduce weightReduce installationElectrostatic separationDirt cleaningEngineeringPinion

A solar panel cleaning trolley with mechanical sweeping and electrostatic dust removing functions is characterized in that four wheels are mounted on a box body; a cleaning and dust removing mechanismmounted in an outer box body is that a power wheel and a big belt pulley are coaxial; the big belt pulley is in transmission connection with a small belt pulley through a synchronous belt; a rollingbrush is mounted on a shaft of the small belt pulley; a gearwheel on a shaft of the big belt pulley drives a pinion in an engaging manner; two driving bevel gears are mounted on a shaft of the pinion,and each driving bevel gear drives a driven bevel gear in an engaging manner, and a disc brush is mounted on a shaft of each driven bevel gear. An electrostatic dust removing mechanism is that a cathode plate, a first filtering net, a second filtering net and an anode plate are sequentially mounted in the box body from bottom to top; the lower end of a hose communicates with the box body, and theupper end of the hose communicates with the outer box body through a flat sucker. The cleaning trolley has the advantages of being convenient to move, capable of mechanically sweeping and electrostatically removing dust, high in cleaning effect, free from secondary flying dust, low in energy consumption, and long in service life.

Owner:SOUTHWEST JIAOTONG UNIV

Loom convenient to move and provided with dust collecting system

InactiveCN105483878AUniform loadAvoid secondary dustCombination devicesAuxillary apparatusNozzleDust collector

The invention discloses a loom convenient to move and provided with a dust collecting system. The loom comprises a loom body, wherein a support mechanism is arranged at the bottom of the loom body and comprises a support rod, a casing pipe, a fastening bolt, a cross bar, a universal wheel, a support leg and an adjusting disk; the dust collecting system is arranged at the top of the loom body and comprises a first dust suction pipe, a second dust suction pipe and a dust collector; a shock absorbing frame is arranged in the first dust suction pipe, and an air cannon is fixed on the shock absorbing frame; the air cannon consists of a buffer cavity and an air nozzle; the dust collector comprises a support and a box, a filter bag, an air purifying chamber and a jetting device are arranged in the box, an air suction device is arranged at one end of the air purifying chamber, an ash hopper is arranged at the lower end of the box, the side of the ash hopper is connected with the second dust suction pipe, an air equalizing plate and an atomization nozzle are arranged on the inner side wall of the ash hopper, and a dust collecting box is arranged at the lower end of the ash hopper; the air equalizing plate comprises an upper perforated plate and a lower perforated plate. The loom has the characteristics of higher dust removal efficiency, capability of removing dust completely and convenience in movement.

Owner:HUZHOU NANXUN SHICONG SHENGYAN SILK

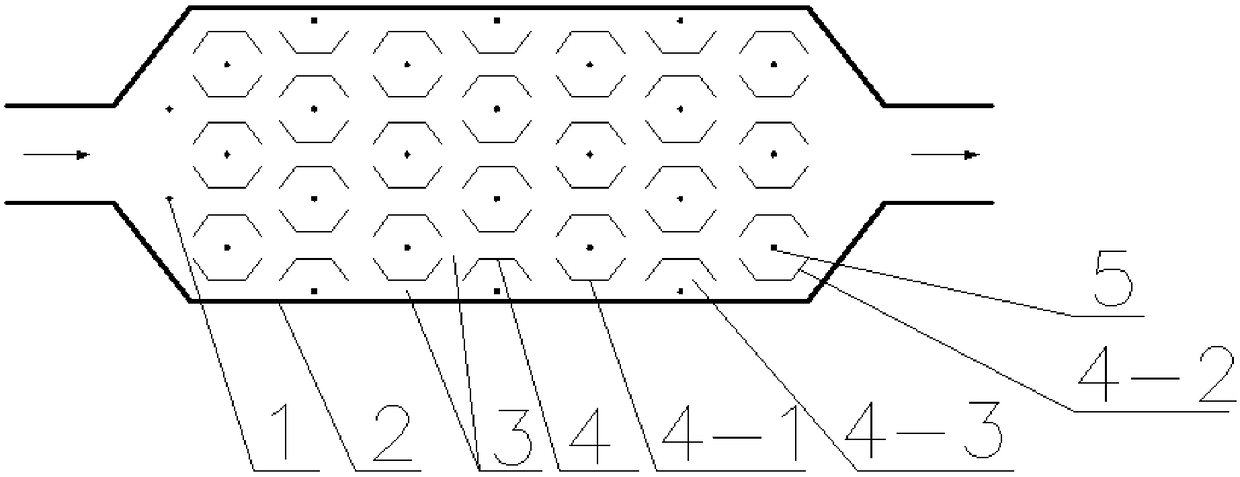

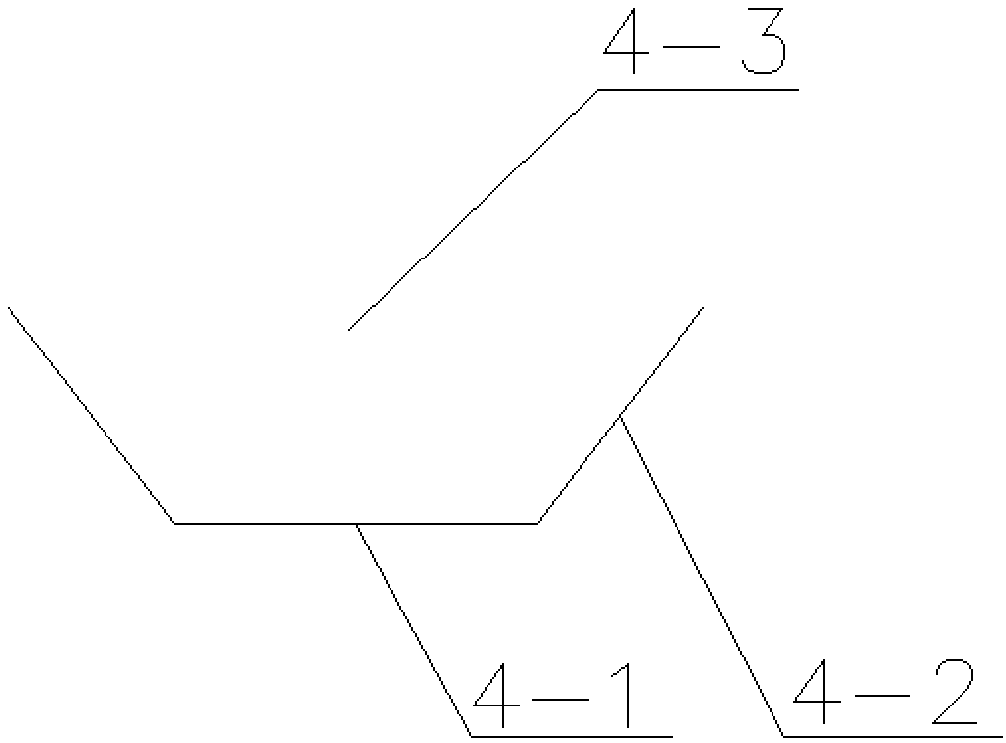

Industrial waste gas fine particulate matter removing device

ActiveCN108405184AExtended stayIncreased chance of collisionExternal electric electrostatic seperatorElectrode constructionsHoneycombExhaust fumes

The invention relates to the technical field of energy conservation and environment protection, in particular to an industrial waste gas fine particulate matter removing device. The industrial waste gas fine particulate matter removing device is a half honeycomb type dust collecting pole plate electric deduster, and comprises a shell, a first corona electrode and multiple half honeycomb dust collecting units. The industrial waste gas fine particulate matter removing device provided by the invention has a unique structure, so that a waste gas produces double vortexes in a passageway, the particle collision probability is effectively improved, the standing time of a waste gas flow carrying fine particulate matters is prolonged, and the removal efficiency of the fine particulate matters is improved compared with a conventional device.

Owner:江苏常诺能源环保科技有限公司

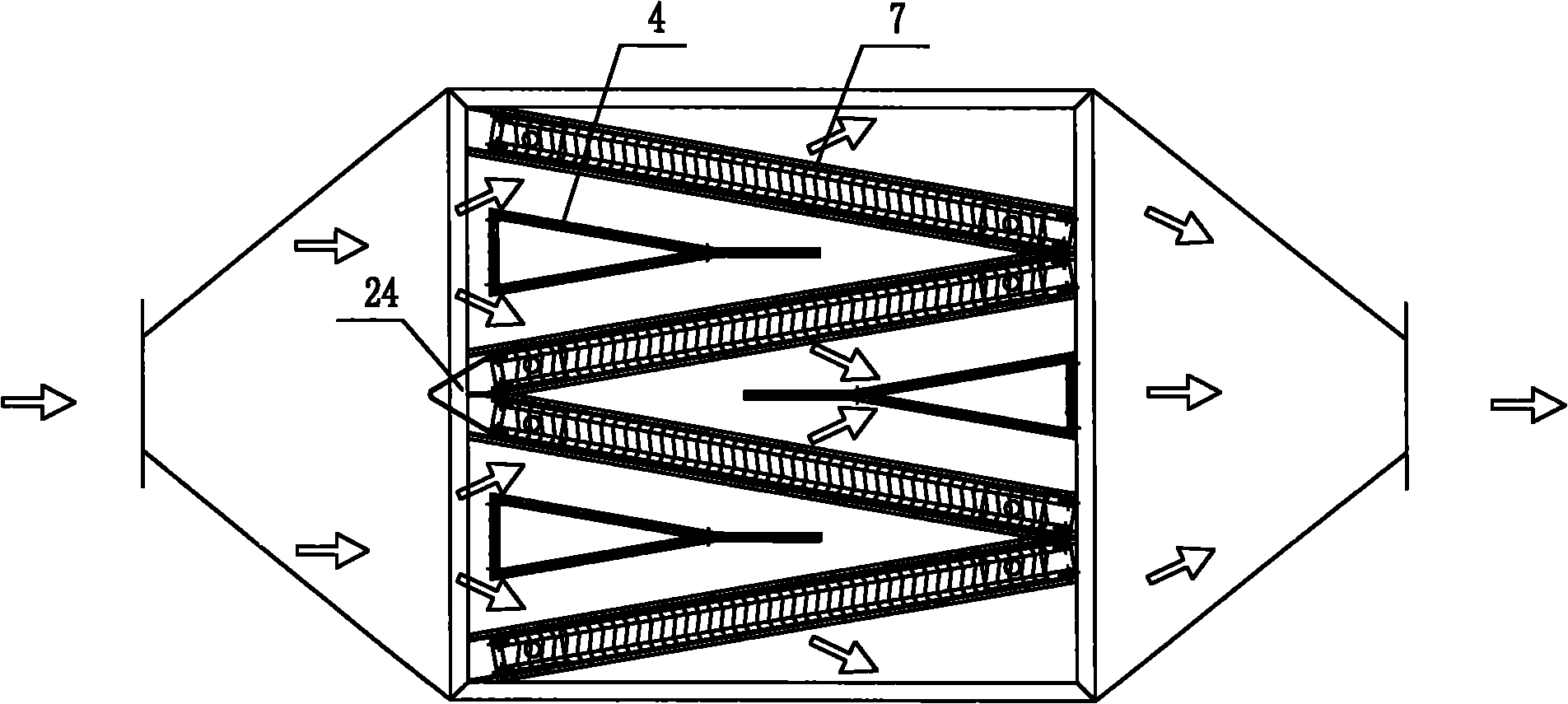

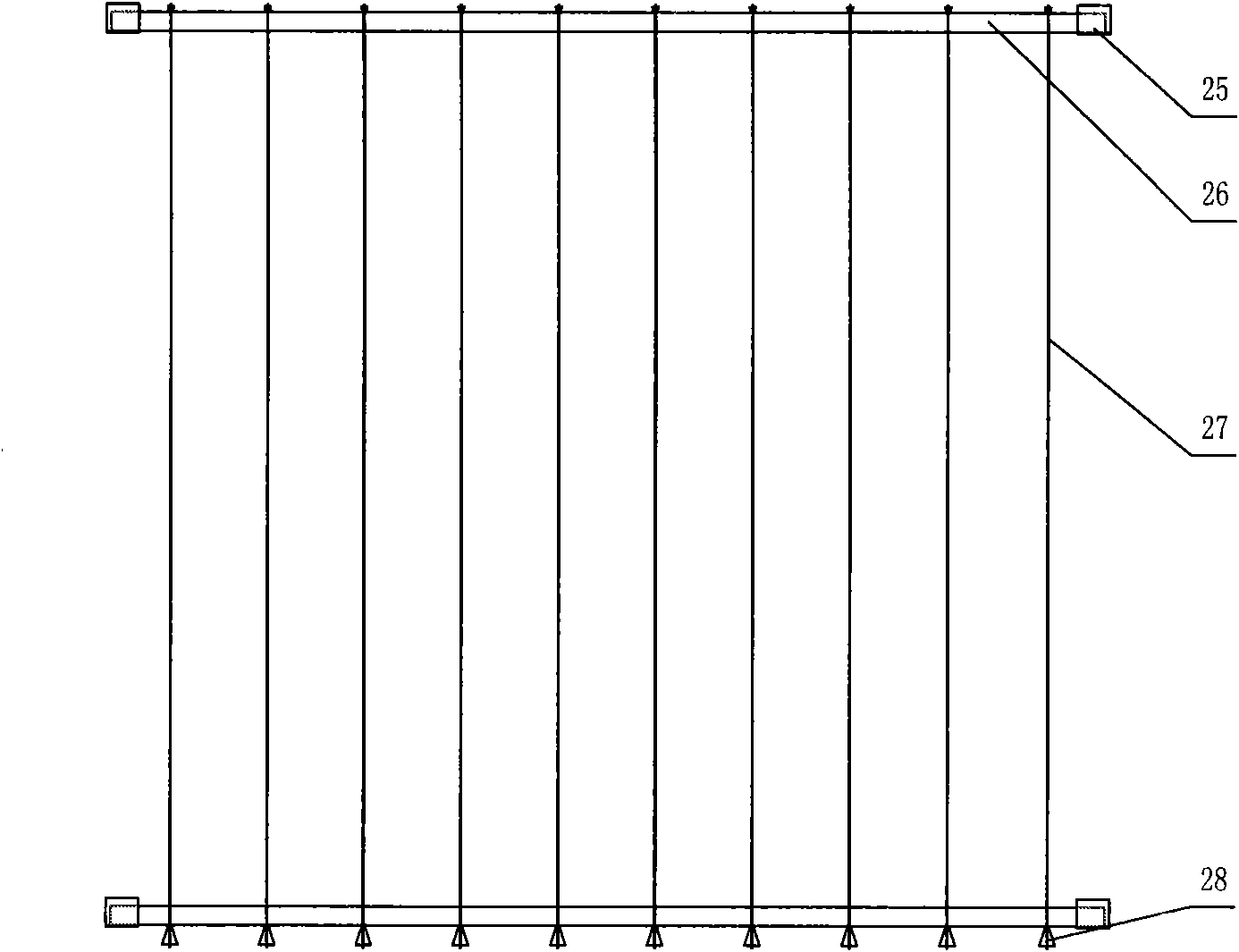

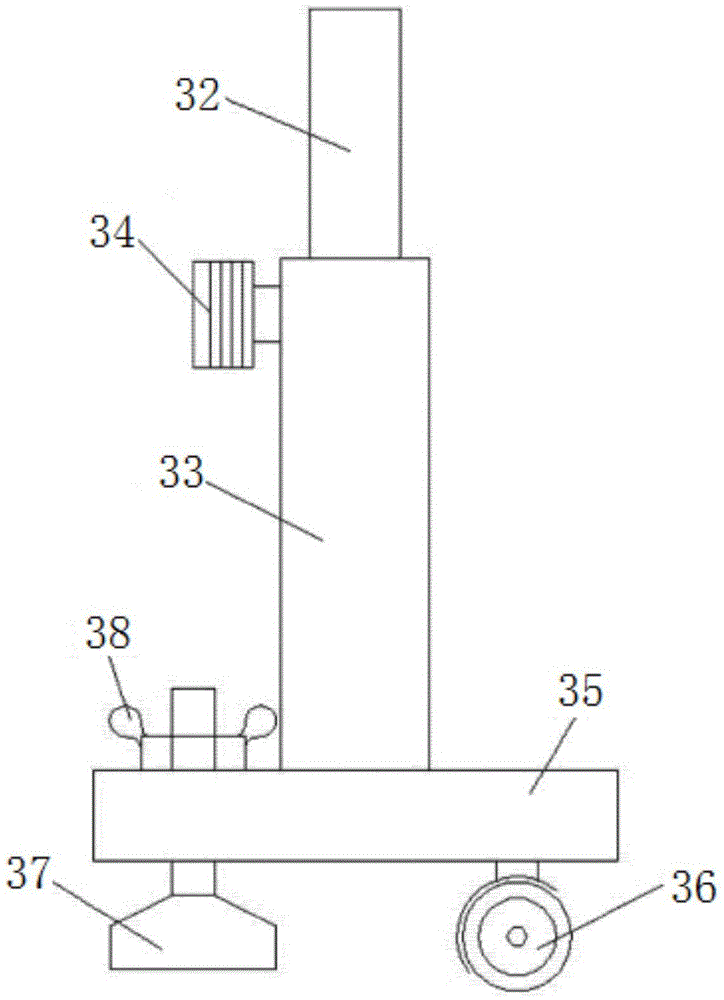

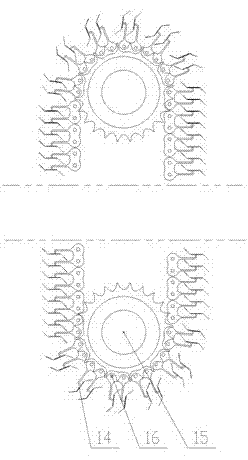

Differential movable type transverse electrode electrostatic precipitator

InactiveCN102728467AGood vibration effectPrevent secondary flyingExternal electric electrostatic seperatorElectrode constructionsPhysicsElectric field

The invention relates to a differential movable type transverse electrode electrostatic precipitator which comprises a housing. Two ends of the housing are provided with an inlet seal head and an outlet seal head, the lower part of the housing is provided with an ash bucket, and an anode system and a corresponding cathode system are provided in the housing; the anode system is composed of a plurality of vertically arranged annular anode rows at equal intervals, each anode row annularly moves under the driving of a transmission device, the bottom of each anode row is provided with an anode plate striking gear used for rapping and ash removal, and the cathode system and the anode system form a plurality of evenly-spaced, parallel and alternatively arranged sets of movable type differential electric field perpendicular to the direction of air flow. According to the invention, through cooperation between the movable annular anode rows and the anode plate striking gears at the bottom of the anode rows, the problem of secondary stirring of dust generated by rapping and ash removal of the anode of an electrostatic precipitator is overcome; gaps among anode plates are decreased, migration distance of charged dust is reduced, and an effective dust collecting area of a single electric field is increased.

Owner:江保祥

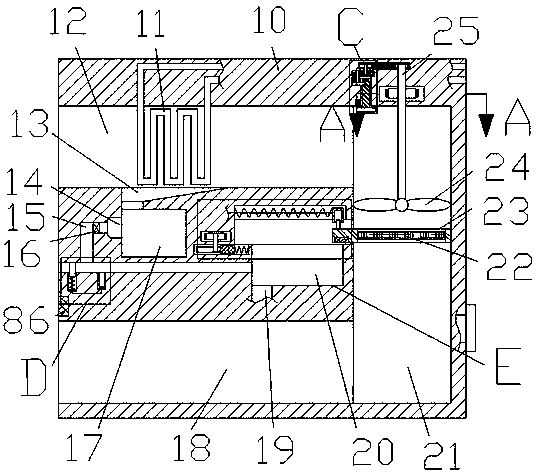

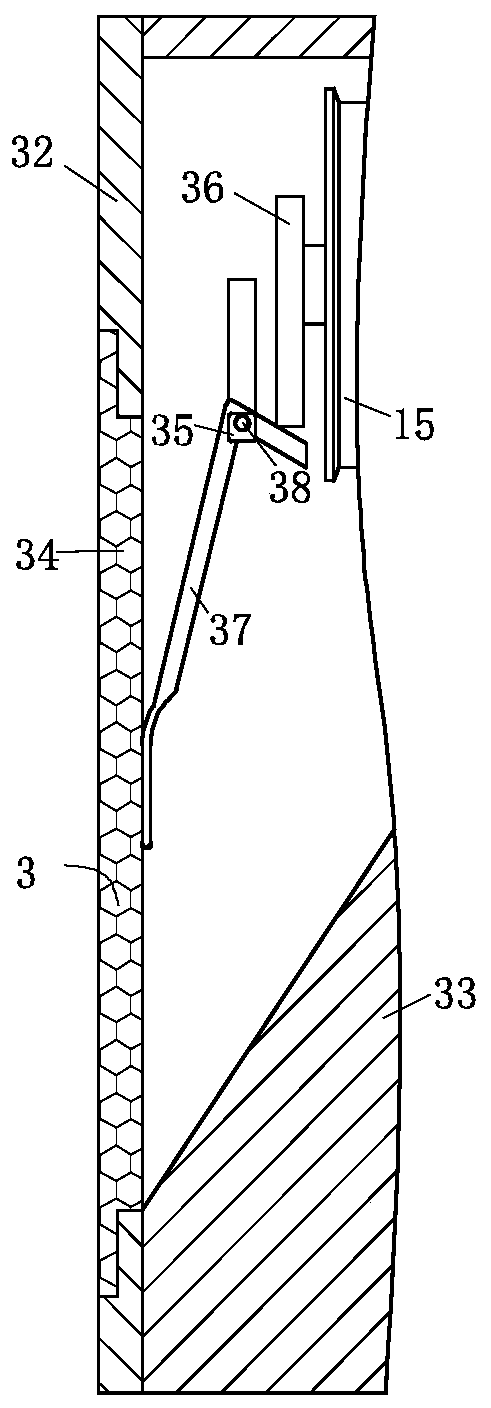

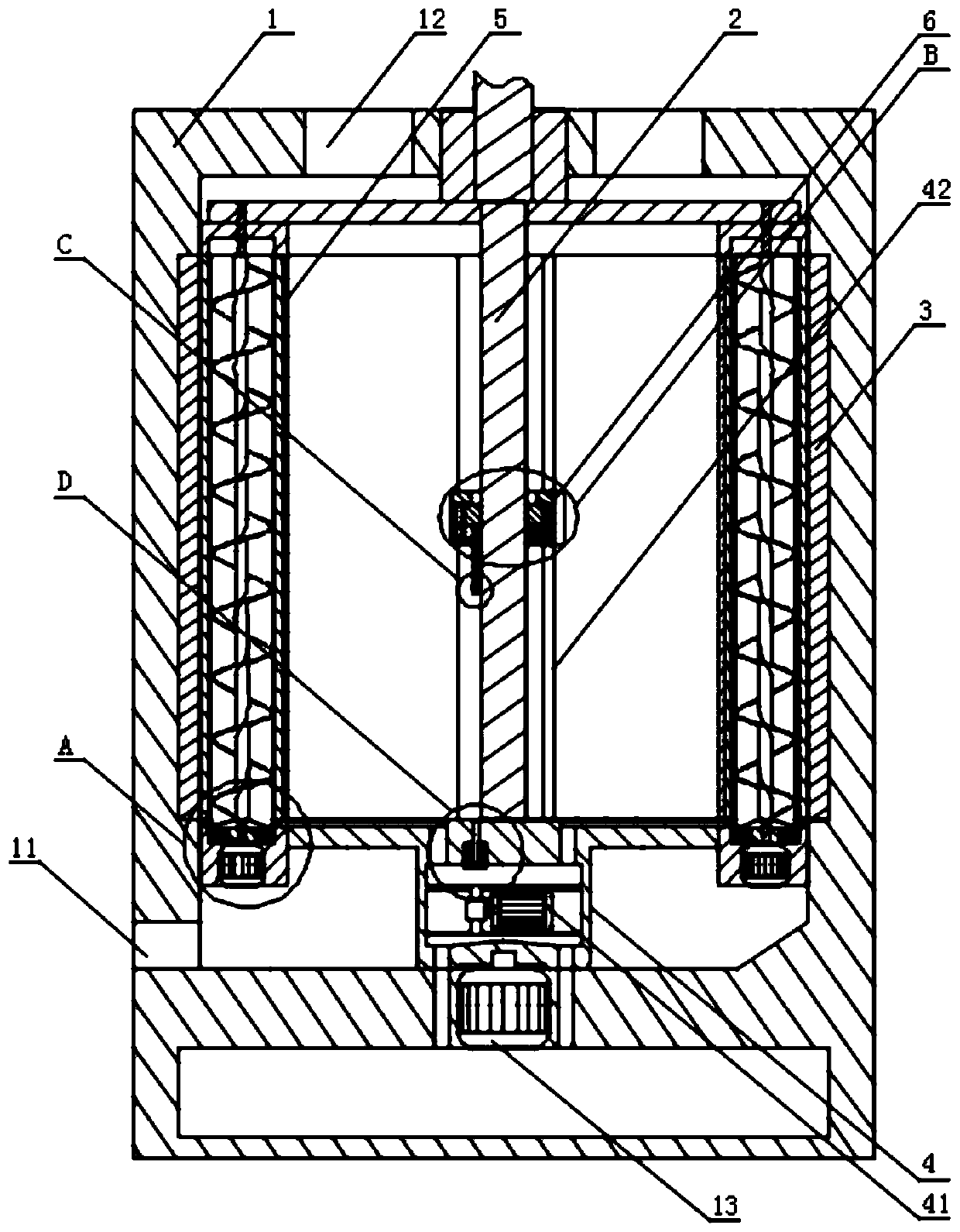

Anti-drying air conditioner capable of achieving filter screen automatic cleaning

ActiveCN111237905AIndoor humidity is normalAvoid secondary dustMechanical apparatusCondensate preventionVertical vibrationEnvironmental engineering

The invention provides an anti-drying air conditioner capable of achieving filter screen automatic cleaning. The device comprises a main body box. An air inlet cavity with a leftward opening is formedin the main body box. A filter cavity extending upwards is formed in the right side of the air inlet cavity in a communicating manner. An exhaust port provided with a leftward opening and located onthe upper side of the air inlet cavity is arranged on the left side of the filter cavity in a communicating manner. A shaking cavity located between the exhaust port and the air inlet cavity is further formed in the left side of the filter cavity in a communicating manner. An adsorption cavity is formed in the lower side of the shaking cavity in a communicating manner. It is ensured that the indoor humidity is normal by atomizing condensed water again and using a humidity sensor; the wind speed is sensed through a sensing plate so that whether dust is accumulated on a filter screen or not canbe judged; and after the dust is accumulated on the filter screen, removal of the accumulated dust is completed through vertical vibration of a filter screen fixing plate after the filter screen fixing plate is moved leftwards, the accumulated dust which is shaken off is adsorbed through condensed water spray at the same time, the condensed water is secondarily utilized while secondary flying dustis prevented, and resources are saved.

Owner:山东东行制冷股份有限公司

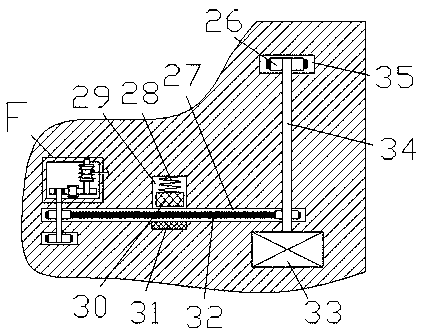

Stone crusher for railway construction system provided with dust reducing mechanism

The invention relates to the field of stone crushers in railway construction systems, in particular to a stone crusher for a railway construction system provided with a dust reducing mechanism. The stone crusher comprises a transmission structure, a screening structure, a dust preventing structure, a dust removing structure and a sealing structure; the dust removing structure is arranged in the transmission structure; when sandy stones are crushed, water currents are adopted for wet dust removal again, so that dust in the crushing process is quickly settled; meanwhile, primary-crushed small sand particles are conveniently stored in the dust removing structure, so that the influence on the railway pavement by nonuniform crushing of the sandy stones in secondary crushing of small sand particles is prevented; through arrangement of the dust removing structure, a sandy stone blockage preventing effect is achieved, so that the discharge effect of crushed sandy stones is better; and the screening structure for screening the sandy stones is arranged in the transmission structure, so that the sandy stones are conveniently screened during crushing, the space utilization efficiency and the sandy stone crushing efficiency and quality are greatly improved, and meanwhile, the secondary dust rise is prevented.

Owner:长沙凯泽工程设计有限公司

Multi-pole distribution combination type current inversion efficient electric precipitator

InactiveCN105772220AIncrease effective contact frequencyOvercoming Secondary DustExternal electric electrostatic seperatorVapor flow controlPhysicsElectric field

The invention discloses a multi-pole distribution combination type current inversion efficient electric precipitator which comprises a shell, common electric field positive plates, common electric field negative poles, grating and blind positive plates, end electric field negative poles, front deflection baffles and rear deflection baffles. A smoke inlet is formed in the front end of the shell. A smoke outlet is formed in the rear end of the shell. The front deflection baffles are mounted at the front ends of the corresponding grating and blind positive plates. A first channel is formed behind each front deflection baffle. The front end of each first channel is sealed. The rear end of each first channel communicates with the smoke outlet. The rear deflection baffles are mounted at the rear ends of the grating and blind positive plates. A second channel is formed in front of each rear deflection baffle. The front ends of the second channels communicate with a front containing cavity. The rear ends of the second channels are sealed. According to the multi-pole distribution combination type current inversion efficient electric precipitator, by changing the air flow flowing direction and the flowing speed for multiple times, increasing the dust impact frequency and the like, the problems of back corona and reentrainment of dust are prevented effectively, superfine dust is collected more efficiently, and the dust collection efficiency is improved.

Owner:FUJIAN XINLONG ENVIRONMENTAL PROTECTION CO LTD

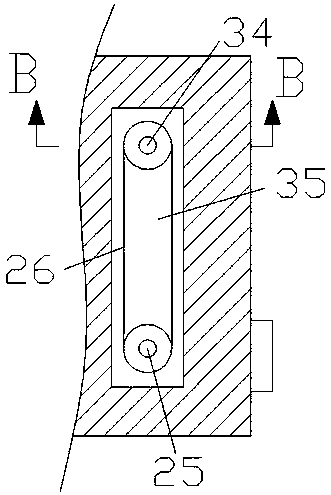

Spinning dust collection device

InactiveCN108442024AGood dust removal effectAvoid secondary dustCombination devicesUsing liquid separation agentEngineeringCam

The invention discloses a spinning dust collection device. The spinning dust collection device comprises a first dust collection pipe, a second dust collection pipe and a dust collection box, whereina motor and a water tank are fixed in the dust collection box, an adsorption cylinder is connected on an output shaft of the motor, a sponge block is fixedly connected in the adsorption cylinder, a wastewater pool is arranged at the lower portion of the adsorption cylinder and is communicated with the second dust collection pipe, a water absorption pipe is communicated on the side wall, close to the motor, of the water tank, a water spraying pipe is communicated to one end, close to the water tank, of the water absorption pipe, the communication portion between the water tank and the water absorption pipe and the communication portion between the water absorption pipe and the water spraying pipe are each provided with a one-way valve, a piston is slidingly connected in the water absorptionpipe, a piston rod is connected on the piston, the part, located in the water absorption pipe, of the piston rod is sleeved with a tension spring, a cam is connected on the output shaft of the motor,the piston rod abuts against the cam, and a first negative-pressure draught fan is fixed at the end of the second dust collection pipe. By means of the spinning dust collection device in the technical scheme, the problems that the dust collecting device needs to be manually cleaned, and the dust collecting and cleaning effect is poor are solved.

Owner:NINGBO WENZE TEXTILE CO LTD

Dust removal device for thermal power plant

InactiveCN110237934AAvoid secondary dustExtended service lifeElectrodes cleaningEngineeringDust particles

The invention discloses a dust removal device for a thermal power plant. The device is provided with an electrode plate dust removal portion and a corona pole dust removal portion, wherein the electrode plate dust removal portion is connected with a dust removal device base, the dust removal base is made to rotate by a motor, the electrode plate dust removal portion rotates around the central axis of the base to periodically and continuously clean dust adsorbed on an inner wall of a dust collecting electrode plate, and the corona pole dust removal portion is set on periphery of a corona pole and is driven to move up and down on an outer wall of the corona pole to remove dust particles adsorbed on a surface of the corona pole. Not only secondary dust is avoided, but also the electrode plate dust removal portion and the corona pole dust removal portion do not exert impact and vibration on the dust collecting electrode plate and the corona pole, service life of the dust collecting electrode plate and the corona pole is prolonged, a specific resistance detecting module is provided, the dust removal speed and duration of power supply interruption are controlled by detecting specific resistance of the dust particles, and thereby dust removal efficiency is improved.

Owner:DATANG YUNCHENG POWER GENERATION CO LTD

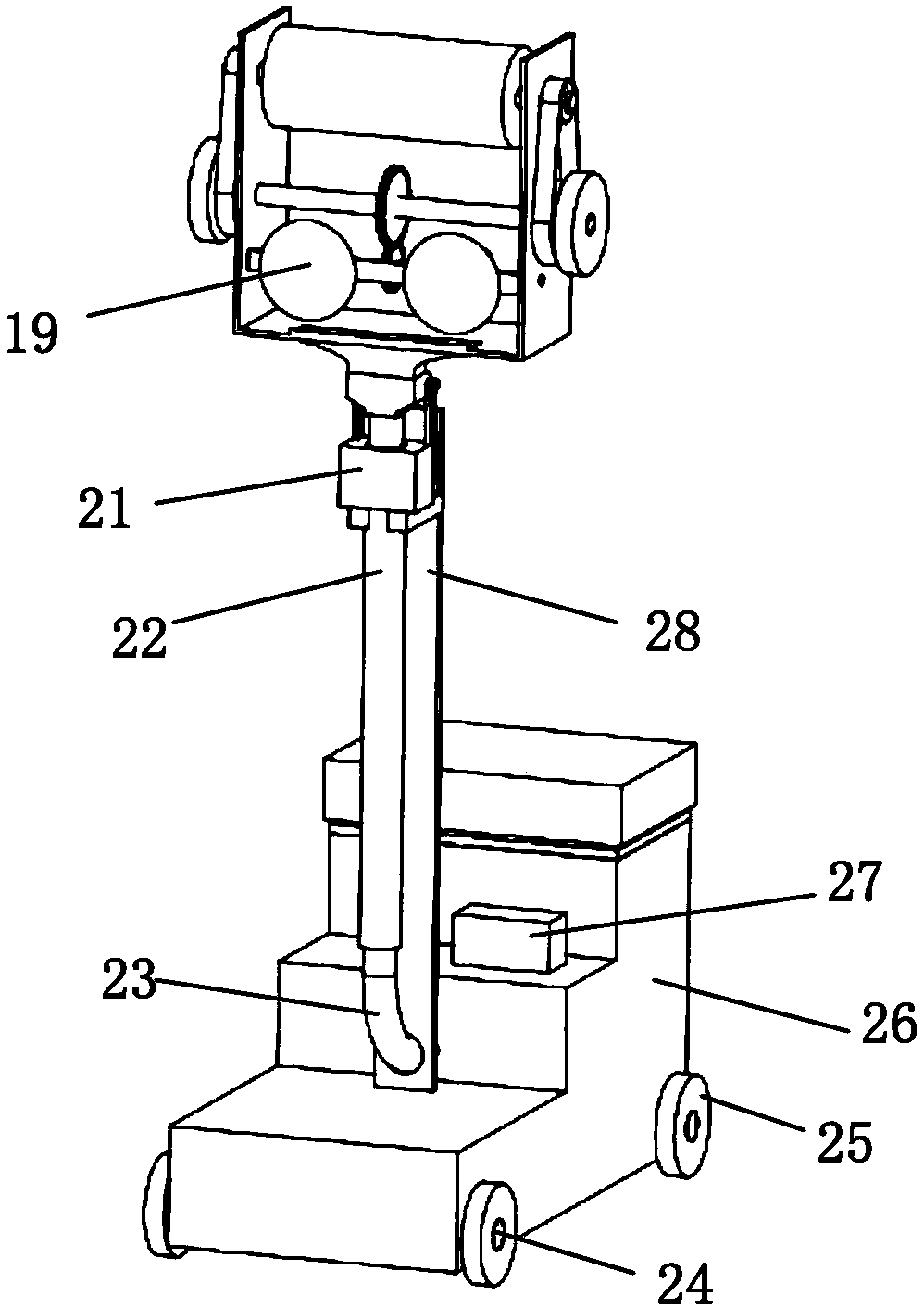

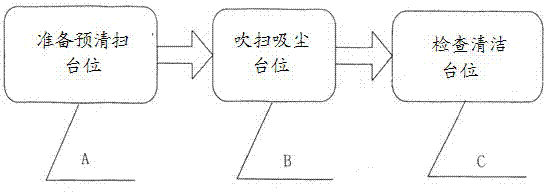

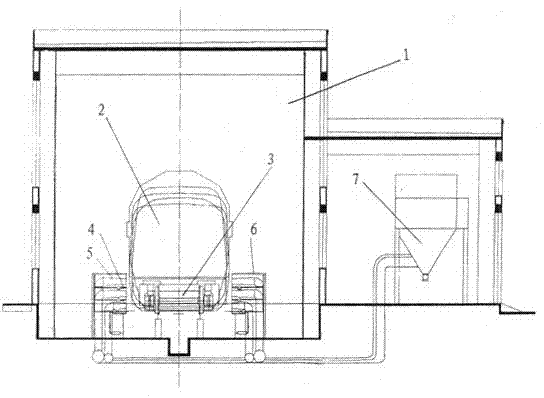

Method for cleaning bottom equipment of bullet trains

ActiveCN102343890ADoes not affect other jobsGuarantee checkCleaning apparatus for vehicle exteriorsHigh pressureWaste management

Owner:CHINA RAILWAY DESIGN GRP CO LTD

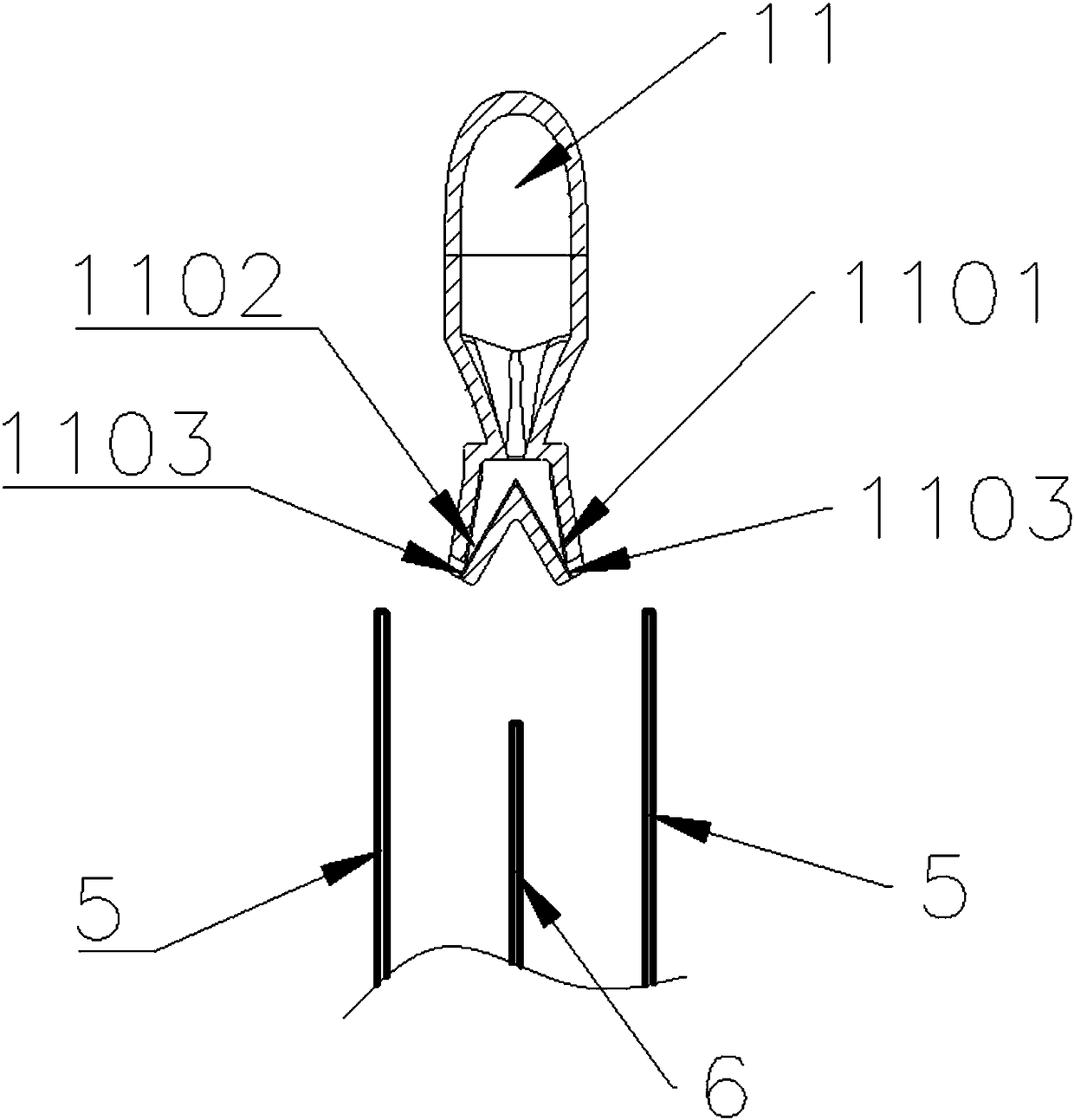

Road sweeper suction nozzle

PendingCN109356070AEquivalent diameter increaseGuaranteed height from the groundRoad cleaningRoad sweeperInhalation

The invention discloses a road sweeper suction nozzle. The road sweeper suction nozzle comprises left suction nozzles, right suction nozzles, suction tubes, air blow pipes, walking wheels and baffles,wherein the air blow pipes are arranged in right rears of the suction tubes, the left suction nozzles are hinged with the right suction nozzles, the upper portions of the left suction nozzles and right suction nozzles are connected with movable connecting rods, the rear portions of the left suction nozzles and right suction nozzles are provided with the walking wheels and fixed brackets, the front portions of the left suction nozzles and right suction nozzles are provided with the baffles respectively, the two sides of the baffles are hinged with suction nozzle seats through two parallel connecting rods respectively, and the middles of the baffles are connected with baffle air cylinders. The road sweeper suction nozzle has the advantages that the air blow pipes are arranged to supplementair for the suction tubes, residual garbage is blown to the suction tubes, thereby greatly increasing the cleanness suction rate and effectively avoiding secondary dust raising; the arranged hinged left and right suction nozzles replace a single width suction nozzle so that the suction nozzles can automatically level on the uneven road surface, and the front ends of the suction nozzles are provided with the liftable baffles so as to improve the equivalent diameter of inhalation and the cleanness suction rate.

Owner:福建环海环保装备股份有限公司

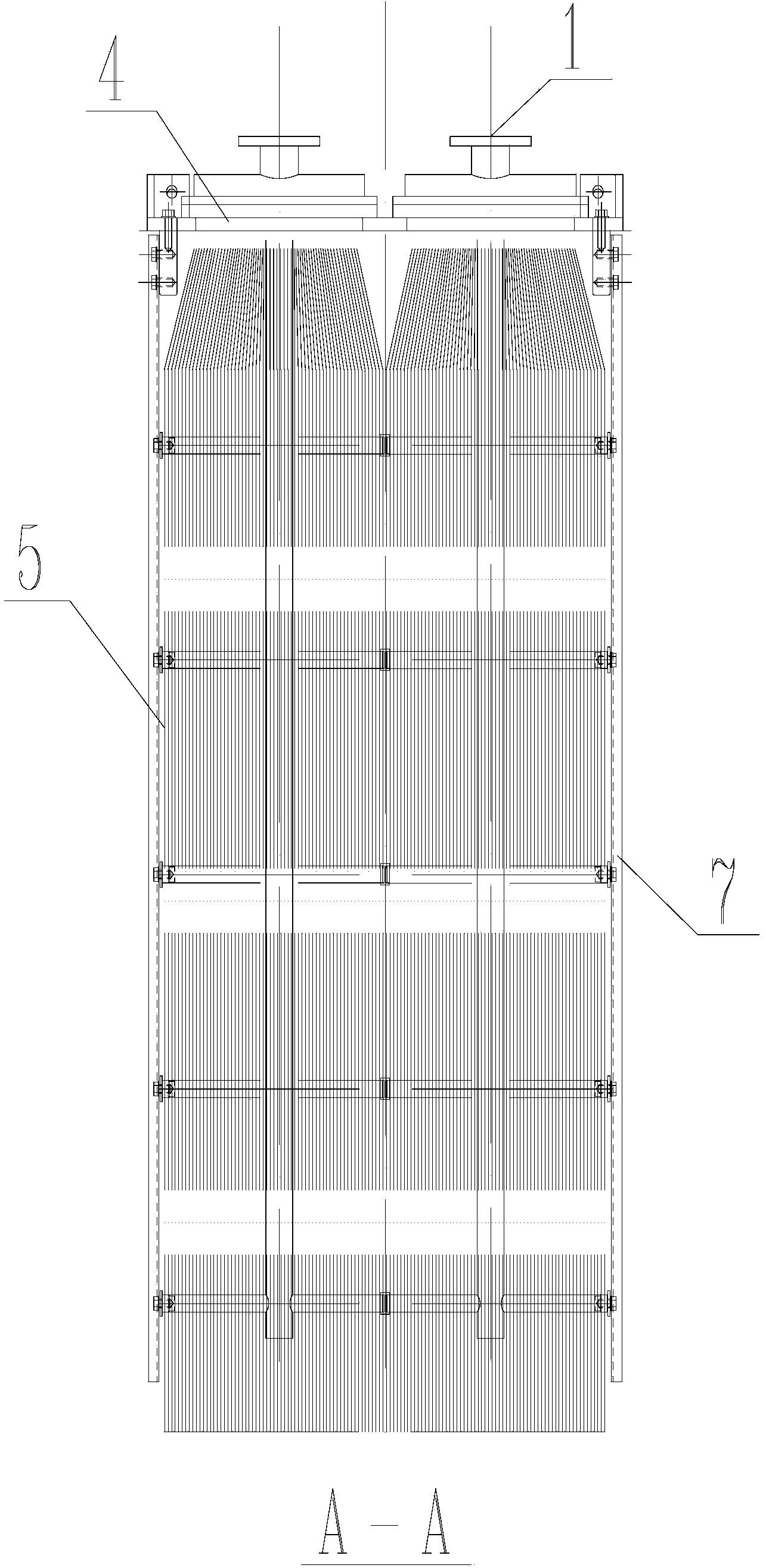

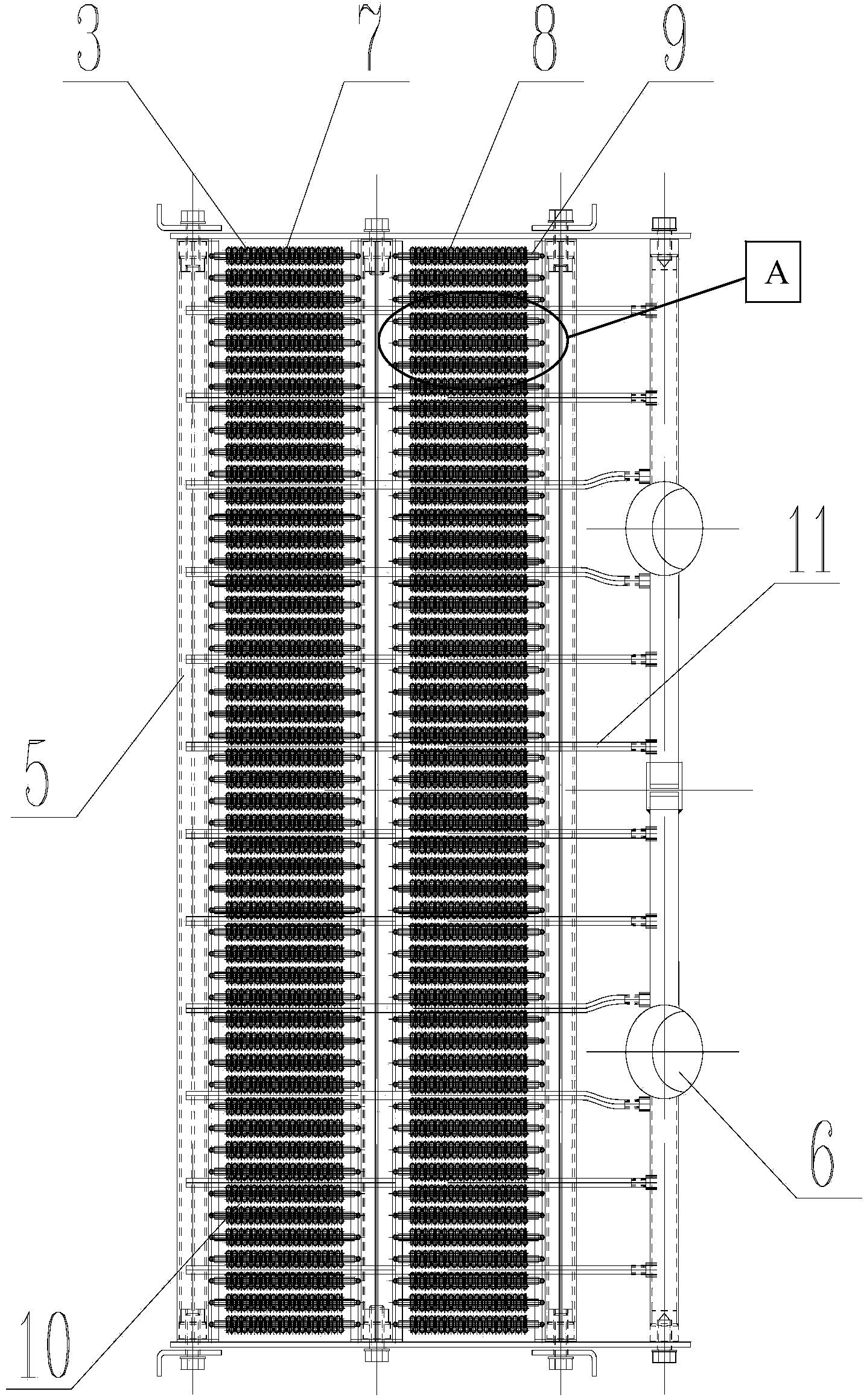

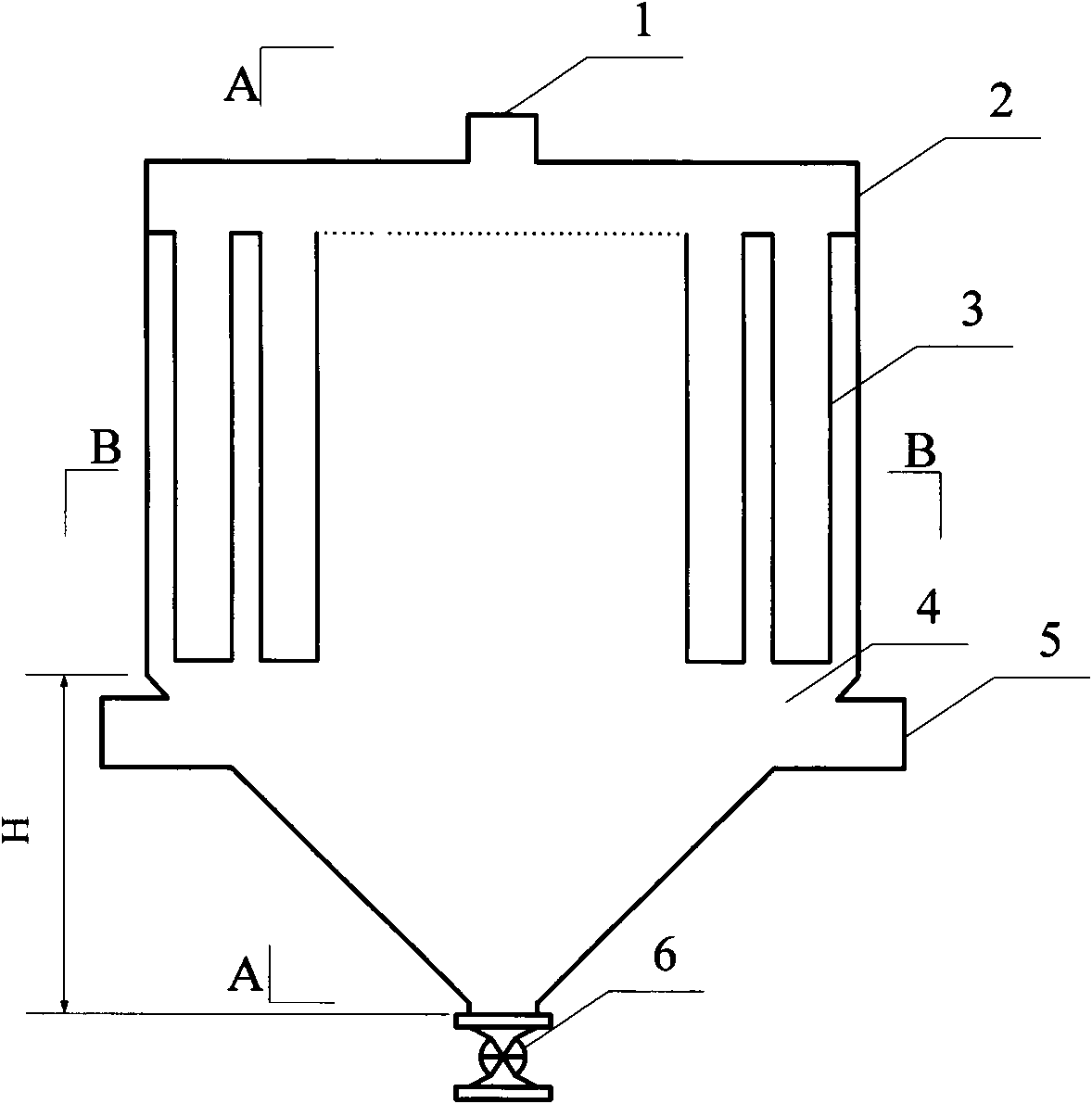

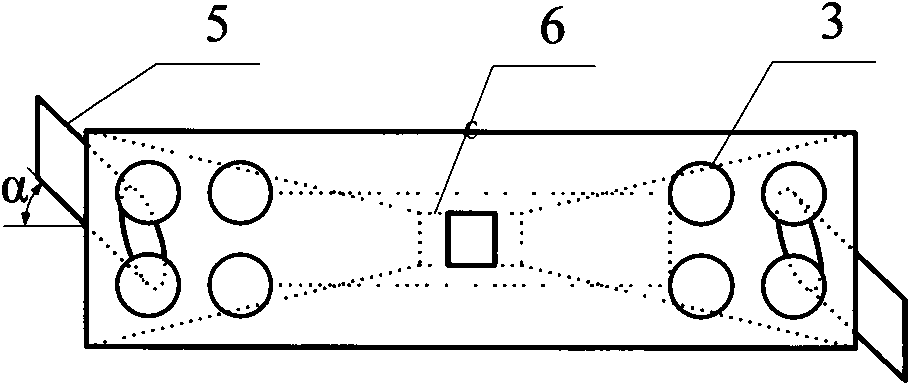

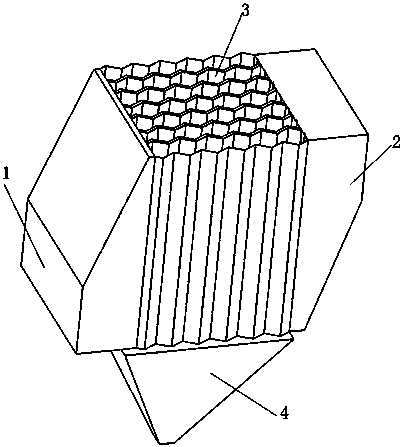

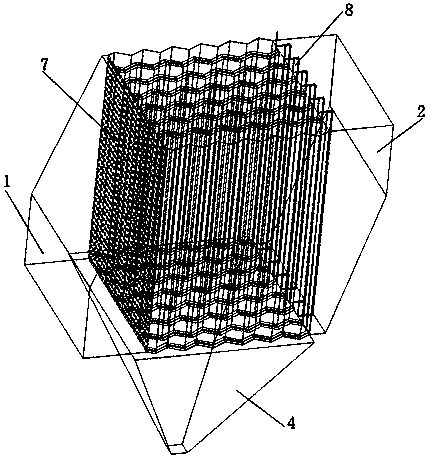

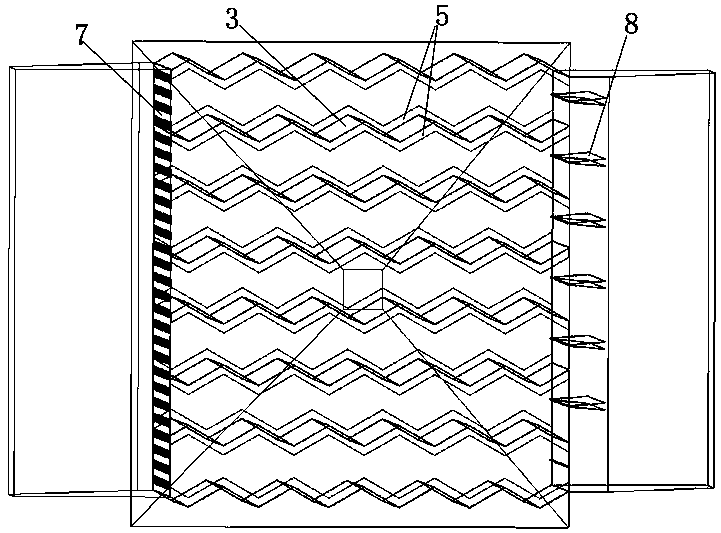

Bag type dust collector with bags in arithmetic arrangement

InactiveCN102160952AImprove efficiencyExtend effective lifeCombination devicesDispersed particle filtrationEngineeringAngle alpha

The invention relates to a bag type dust collector with bags in arithmetic arrangement, and the bag type dust collector comprises a tank body, bags, air flow inlets, an air outlet and a dust discharge valve. The bag type dust collector is characterized in that the tank body consists of an upper tank body and a lower tank body, the lower tank body is of a bucket shape, axes of two air flow inlets are parallel to each other and horizontally arranged at two sides of the lower tank body; a plane included angle alpha is formed between the axes of the air flow inlets and the wall face of the upper tank body, and the included angle alpha is more than or equal to 30 degrees and less than 90 degrees; and at least two rows of bags are distributed in the upper tank body, the bags in each row are in arithmetic arrangement toward the center in sequence, and the bags in adjacent rows are in line alignment front and back, and the row distance and line distance of bag walls are between 60 and 100mm.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

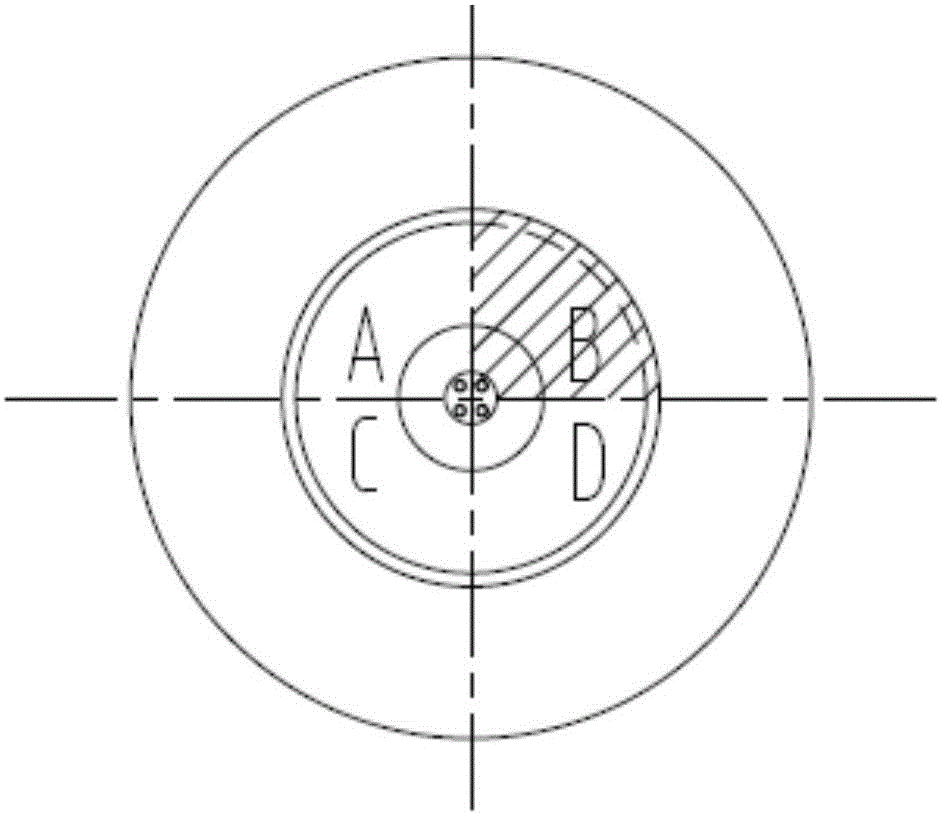

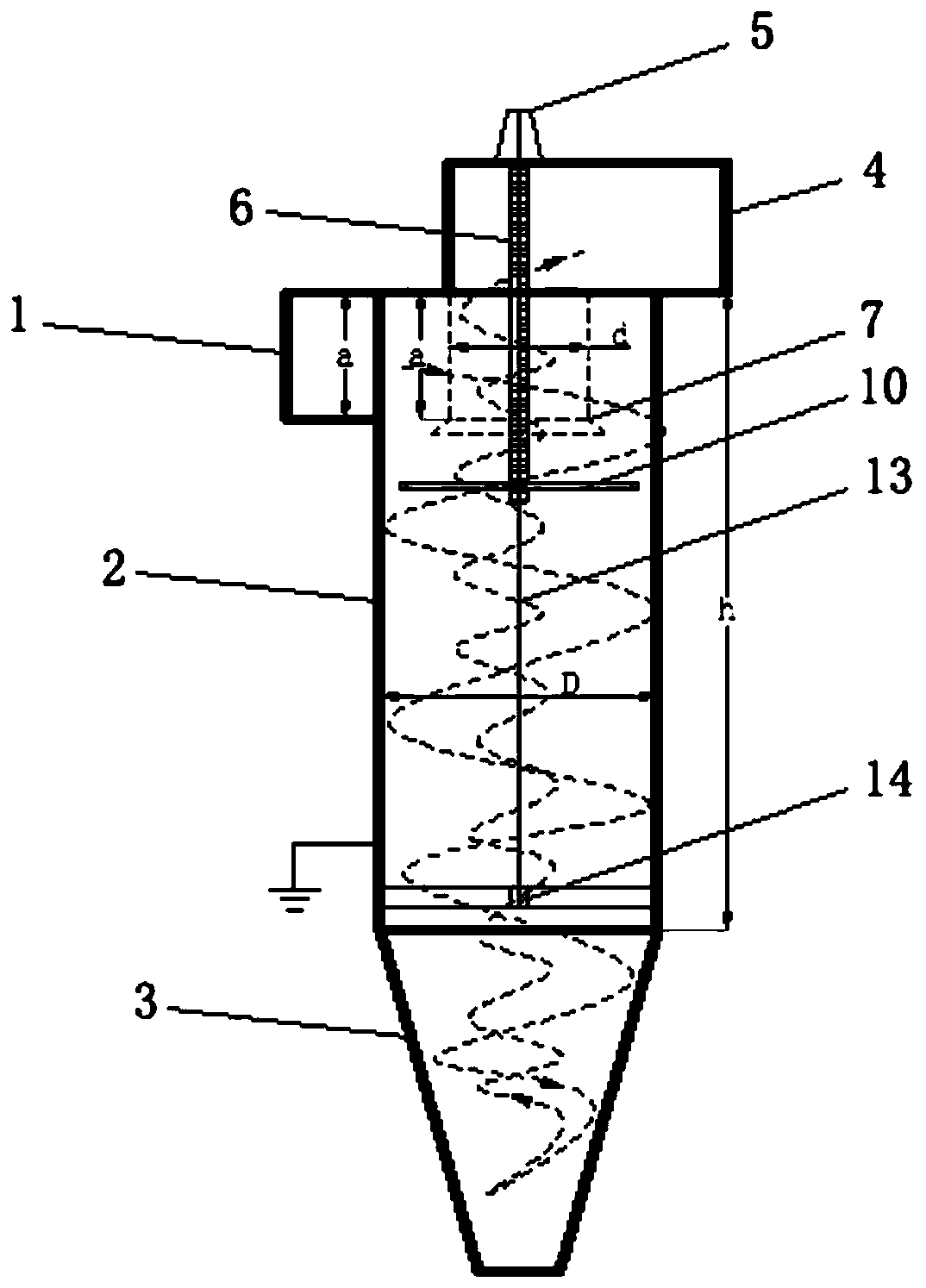

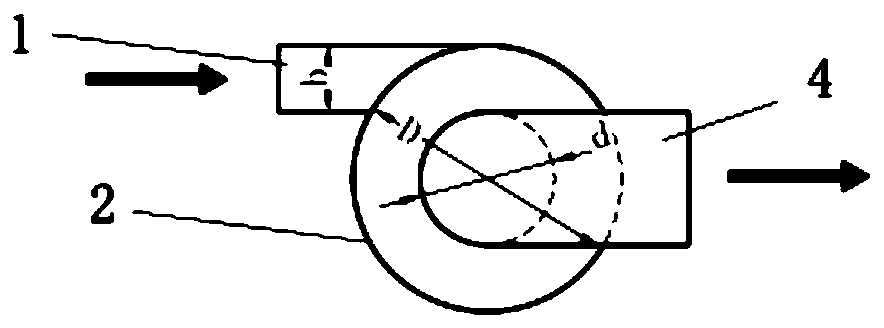

Cyclone-electrostatic-coupled wet dust removal device

PendingCN111318370AEasy cleaningImprove performanceCombination devicesElectrodes cleaningParticulatesDust control

The invention relates to a cyclone-electrostatic-coupled wet dust removal device, which comprises a gas inlet section, a straight cylinder section, a conical contraction section, a gas outlet section,a cathode wire top insulation supporting section, an insulation shielding sleeve, an outlet gas collecting cylinder, a washing water ring pipe, a cathode wire and a cathode wire bottom end insulationsupporting frame. The top face of the gas inlet section is flush with the top face of the straight cylinder section. The side face of the gas inlet section is circumferentially tangent to the side face of the straight cylinder section. The bottom of the straight cylinder section communicates with the conical contraction section. The beneficial effects of the device are that: according to the device, through combination of the gas inlet section, the straight cylinder section, the conical contraction section, the gas outlet section and the cathode wire, meanwhile, by utilizing centrifugal forcegenerated by gas rotational flow and electrostatic force generated by an electrostatic field, the centrifugal force and the electrostatic force are coupled to act on the particles in the gas, and removal force larger than that of a single cyclone dust collector and an electrostatic dust collector can be generated, so that the particles with the particle size smaller than 10 microns can be removed, and high dust removal efficiency is achieved for the particles with the particle size smaller than 2.5 microns.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

High-efficiency purification electrostatic dust collector

PendingCN108568347AReduce secondary dustSimple structureElectrode constructionsElectrodes cleaningHigh humidityBaghouse

The invention relates to a high-efficiency purification electrostatic dust collector, aiming at solving the problem that the dust removal efficiency is reduced, caused by reverse corona and secondarydust rising. The high-efficiency purification electrostatic dust collector comprises a gas inlet, a gas outlet, a dust collection plate, a discharging wire and an ash bucket, wherein the dust collection plate is provided with an ash cleaning device; ash cleaning boxes with a special design are adopted and are used for squeezing dust swept by an ash cleaning brush at the top of the box body, so that the secondary dust rising is avoided; two ash cleaning boxes form one group, and form a loop through a rope; when one ash cleaning box is ascended, the other ash cleaning box is descended to clean ash. The ash cleaning brush is designed to keep vertical with the dust collection plate in an ash cleaning process; when the ash cleaning brush is ascended to be reset, a brush head is folded, so thatthe service life is prolonged. According to the dust collector provided by the invention, the disadvantages of a conventional electrostatic dust collector that the specific resistance is high, ultrafine dust and high-viscosity dust are difficult to collect and clean, the secondary dust rising is easy to cause and the like are overcome, and the defects of a bag dust collector that the equipment resistance is great, the operation cost is high, the working amount of daily maintenance is great, high-temperature and high-humidity flue gas is difficult to treat and the like are also made up; the high-efficiency purification electrostatic dust collector is simple in structure, high in ash cleaning efficiency, low in cost and easy to maintain.

Owner:CITIC HEAVY INDUSTRIES CO LTD

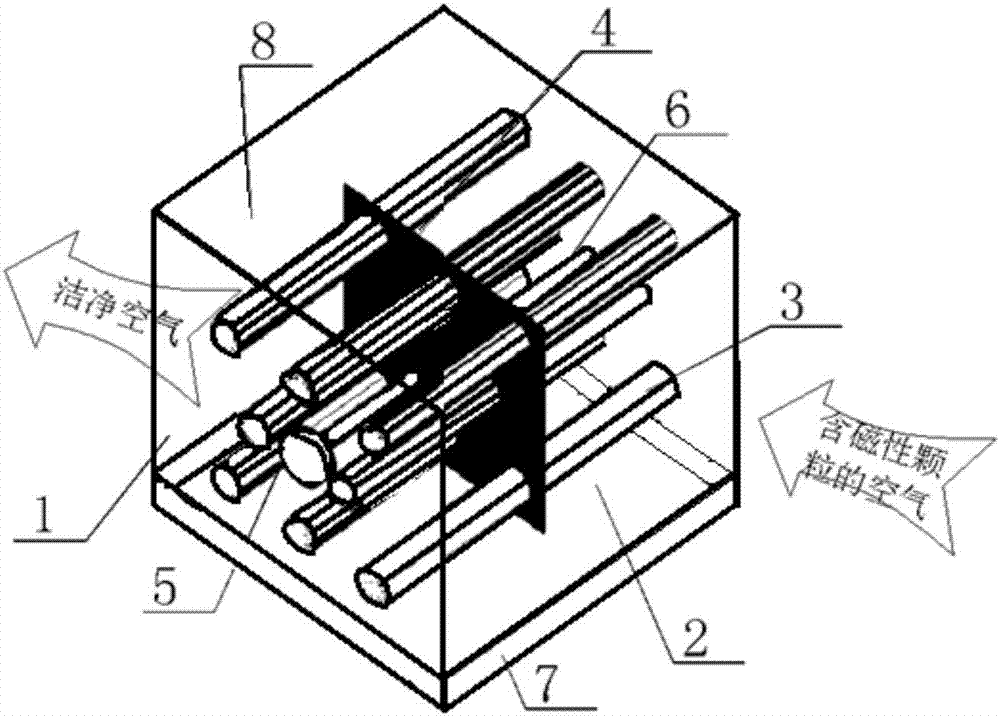

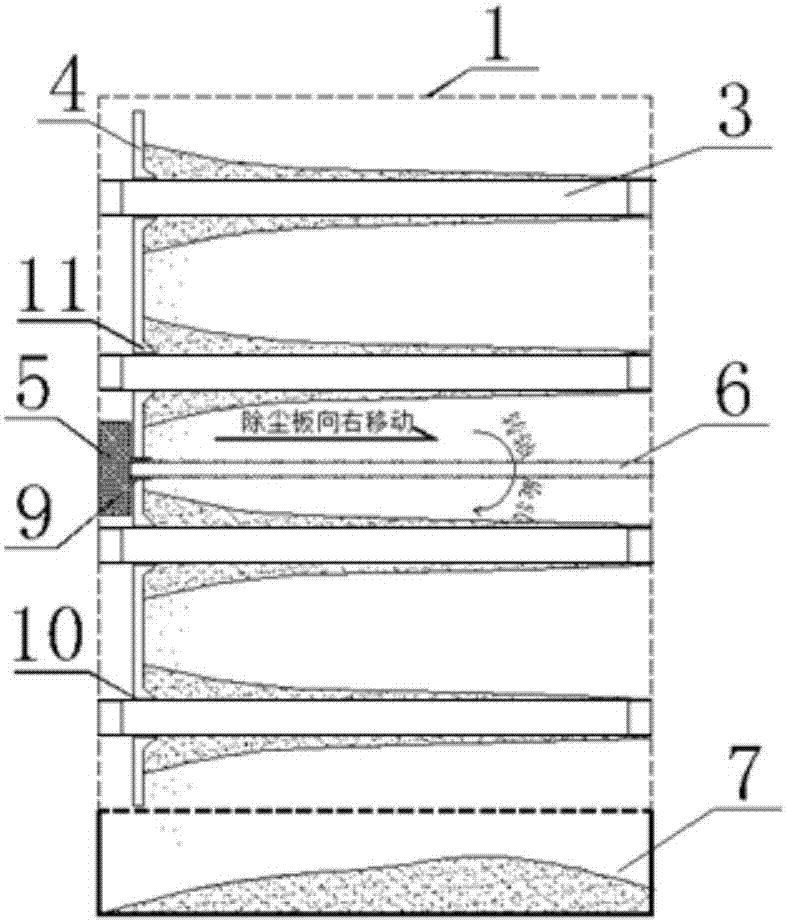

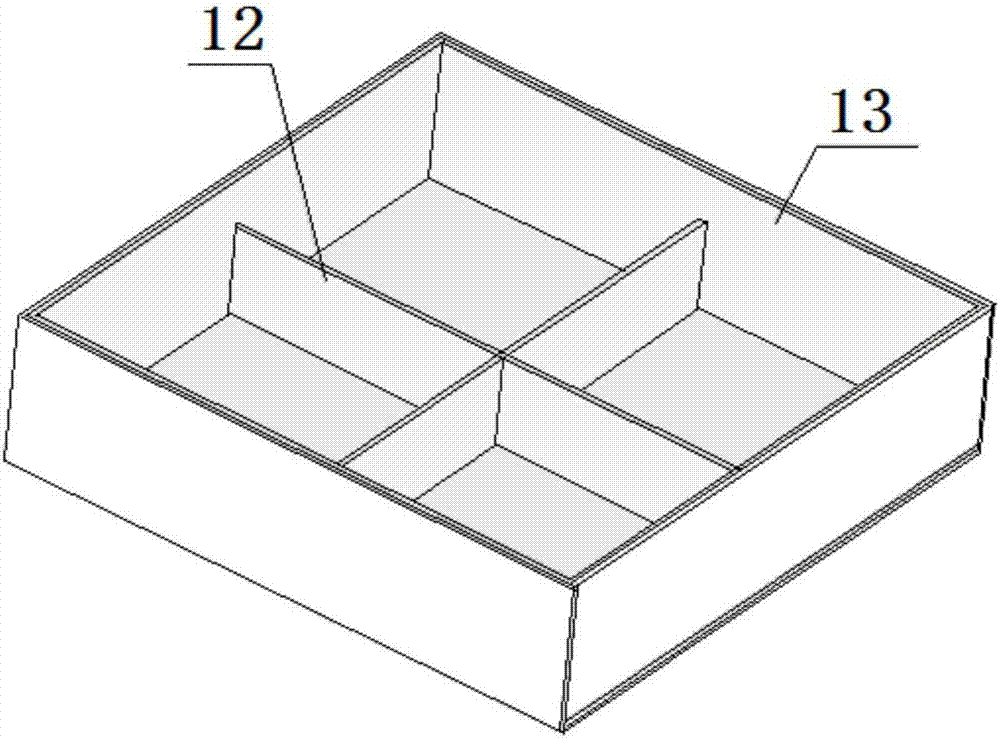

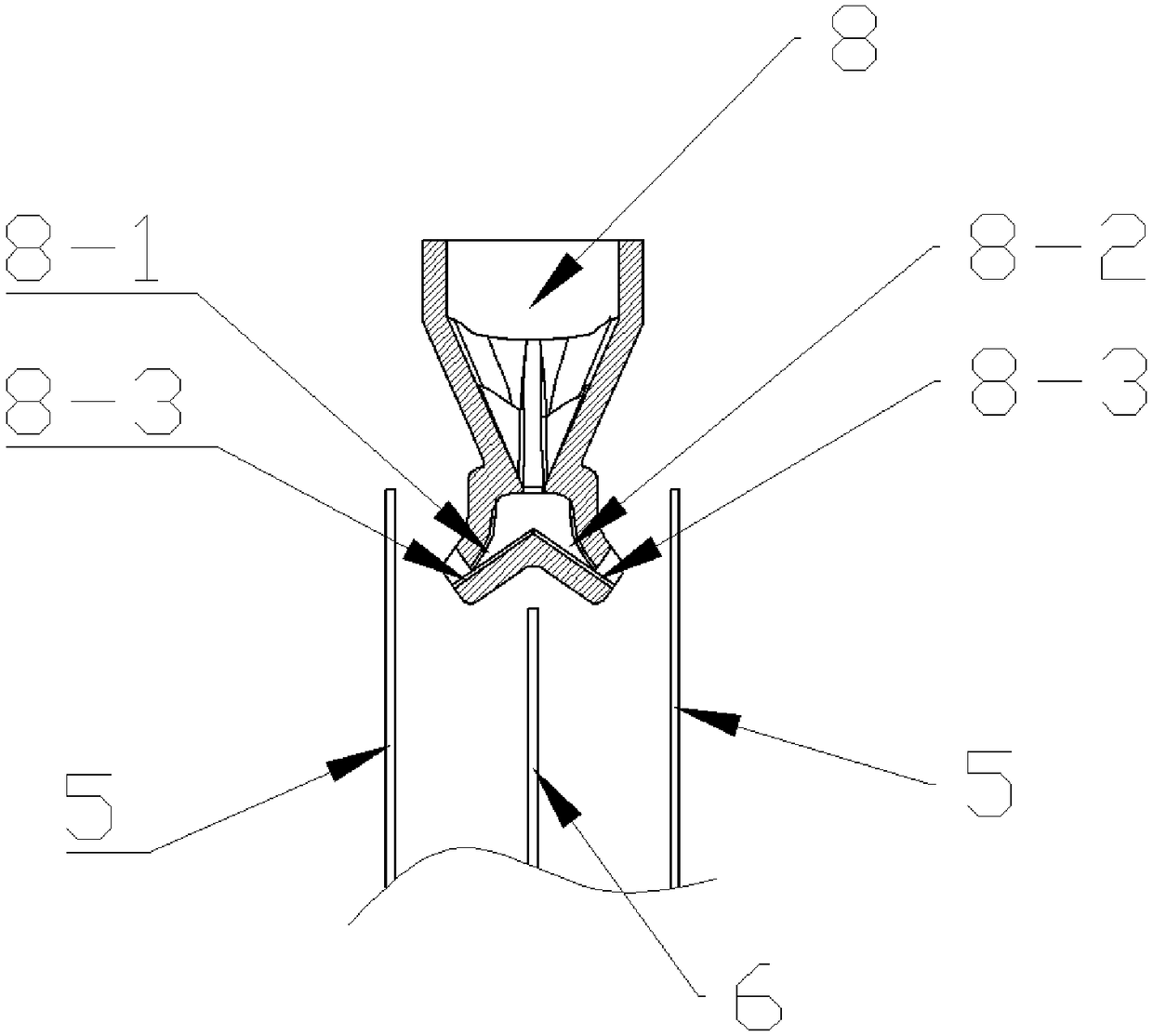

Self-cleaning type magnetic particle separating device

PendingCN107497596AExtended cleaning cycleLow maintenanceCleaning using toolsMagnetic separationMotor driveMagnetic poles

The invention relates to a self-cleaning type magnetic particle separating device. The self-cleaning type magnetic particle separating device comprises a shell, an air inlet, magnetic bodies, a dust extraction plate, a motor, a rotating shaft, a dust raise preventing dust collecting box and an air outlet, the air inlet is formed in one end of the shell, the air outlet is formed in the other end of the shell, the dust raise preventing dust collecting box is arranged at the bottom of the shell, all magnetic bodies are transversely arranged in an air runner in an arrayed manner, and the dust extraction plate is arranged on multiple magnetic poles in a sliding and penetrating manner. According to the self-cleaning type magnetic particle separating device, in the dust extraction manner, air containing magnetic particles enters the self-cleaning type magnetic particle separating device through the air inlet to be attracted to the magnetic bodies, and clean air flows out from the air outlet; under the self-cleaning mode, the motor drives the dust extraction plate to move along the magnetic bodies, the particles are separated from the magnetic bodies, the separated particles sink into the dust raise preventing dust collecting box under the action of gravity, a surface magnetic plate and a middle magnetic plate are arranged inside the dust raise preventing dust collecting box, and therefore the sinking magnetic particles can be effectively attracted, and reentrainment of dust is avoided. The self-cleaning type magnetic particle separating device has the beneficial effects of being long in cleaning period, low in maintaining cost, free of reentrainment of dust and the like.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

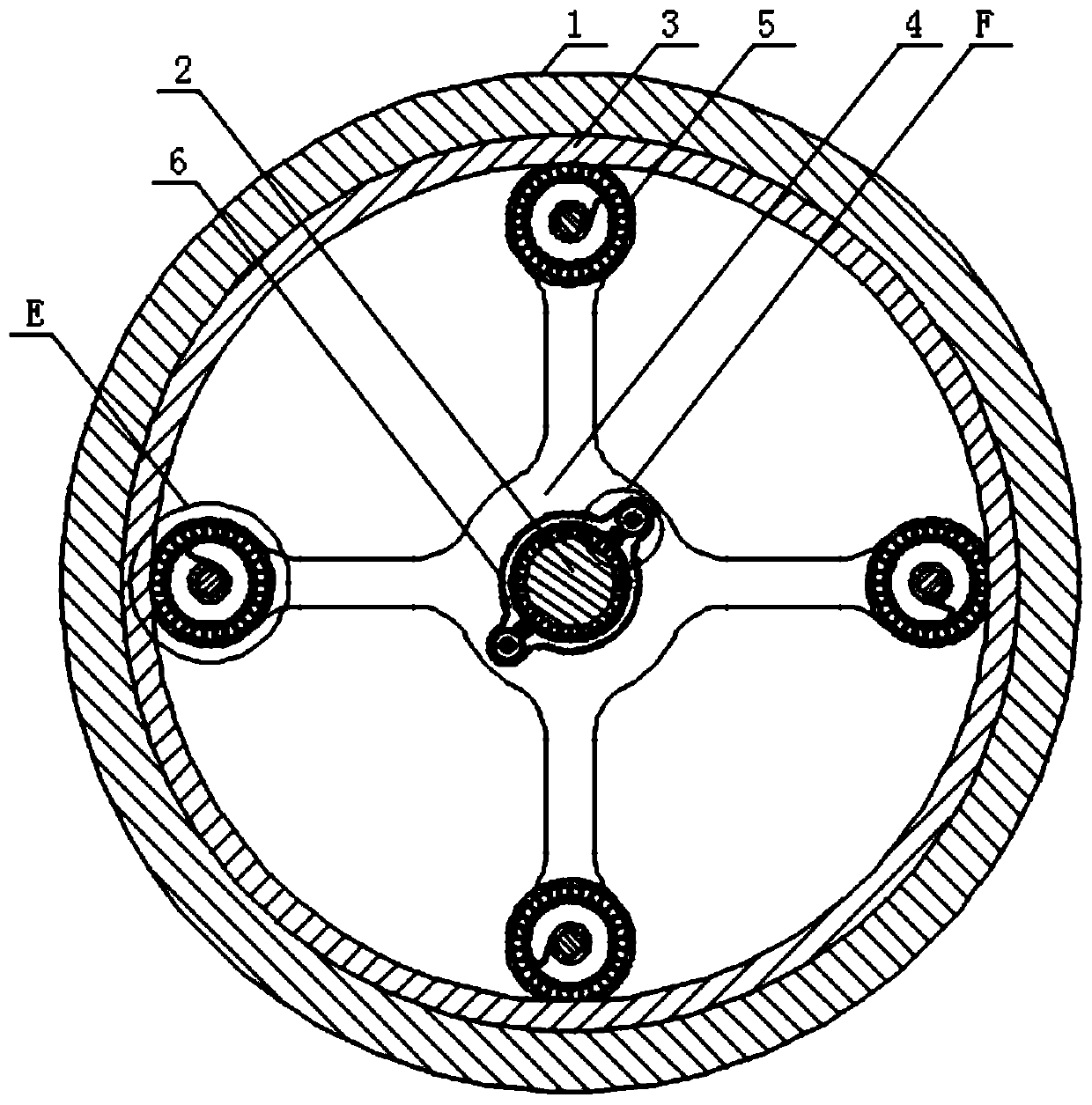

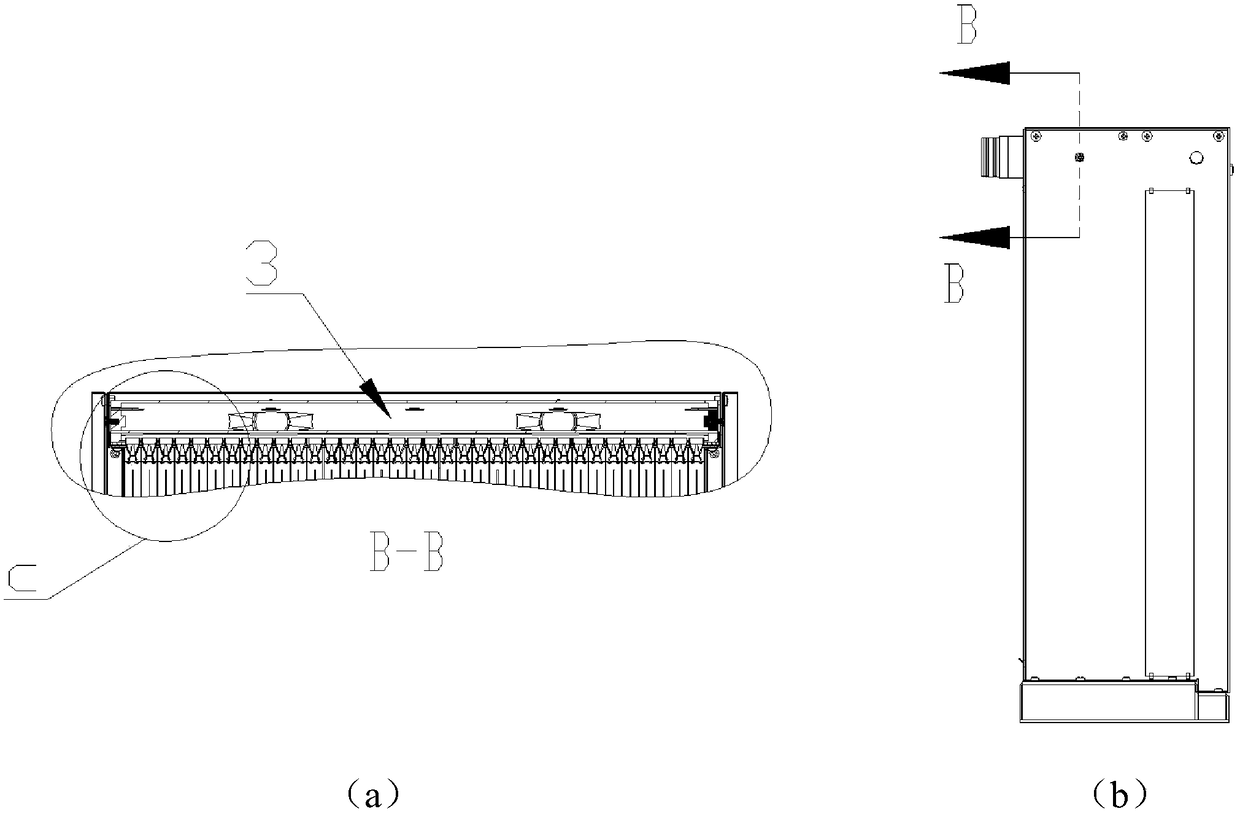

Array type nozzle plane cleaning device and self-cleaning maintenance-free electrostatic purification system

The application discloses an array type nozzle plane cleaning device. The array type nozzle plane cleaning device can continuously keep a plurality of to-be-cleaned surfaces to be clean at the same time, simultaneously performs spray cleaning on all planes, does not require manual cleaning and manual maintenance, is provided with fixed nozzles, is higher in reliability and lower in failure rate, and is an effective scheme for high efficiency simultaneous cleaning of the multiple planes. The array type nozzle plane cleaning device comprises the fixedly arranged cleaning nozzles; each cleaning nozzle is provided with at least one liquid outlet; each plane to be cleaned is at least provided with a liquid outlet. The application also discloses a self-cleaning maintenance-free electrostatic purification system adopting the array type nozzle plane cleaning device, and an embedded module of the self-cleaning maintenance-free electrostatic purification system.

Owner:SUZHOU ZEKA ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com