Cyclone-electrostatic-coupled wet dust removal device

An electrostatic coupling, wet dust removal technology, applied in the field of dust removal devices, can solve the problems of increasing the area of dust removal devices and equipment costs, low efficiency of classification and dust removal, and high investment costs, and achieves a convenient cleaning method, simple structure, and low investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

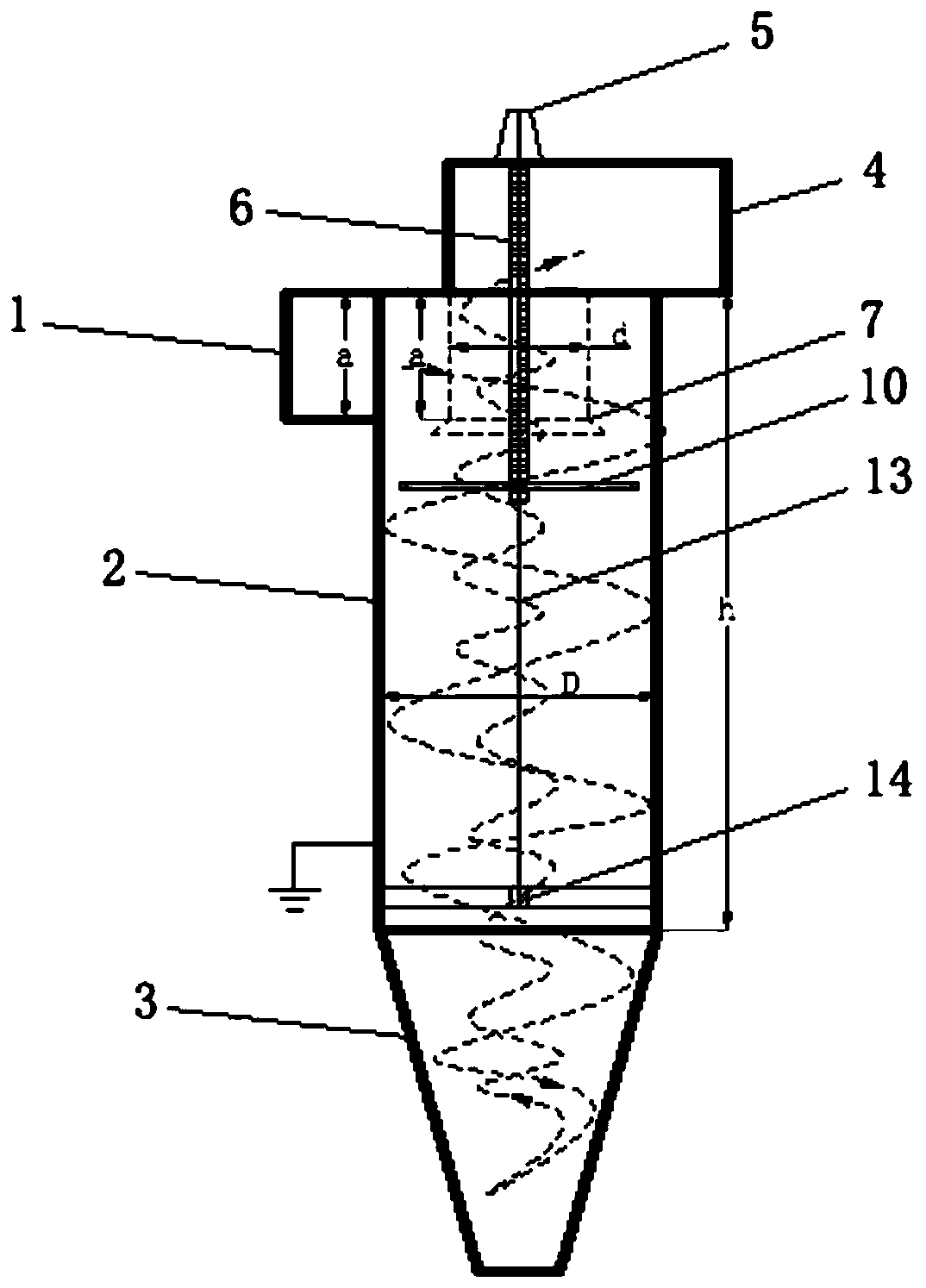

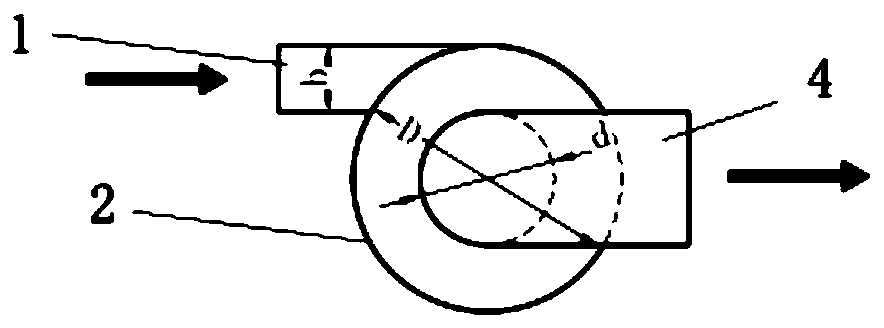

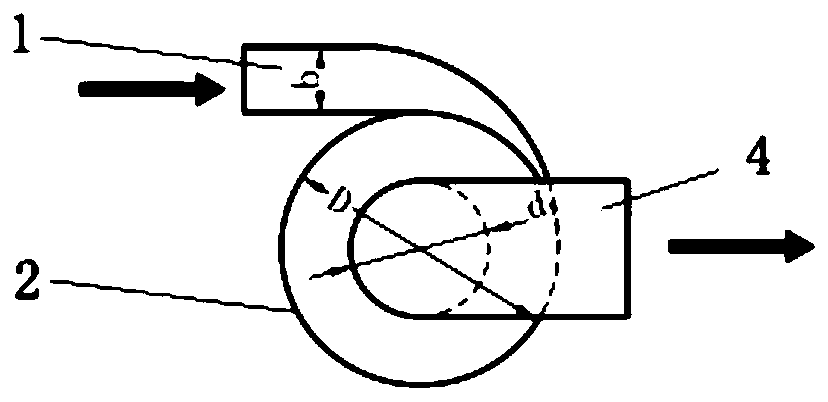

[0030] The cyclone electrostatic coupling wet dust removal device includes a gas inlet section 1, a straight section 2, a conical shrinkage section 3, and a gas outlet section 4, and its internal structure includes an insulating support section 5 at the top of the cathode line, an insulating shielding sleeve 6, and an outlet gas collector 7. Rinsing water ring pipe 10, cathode wire 13, insulation support frame 14 at the bottom of cathode wire, such as figure 1 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com