Patents

Literature

85results about How to "Improve the sweeping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

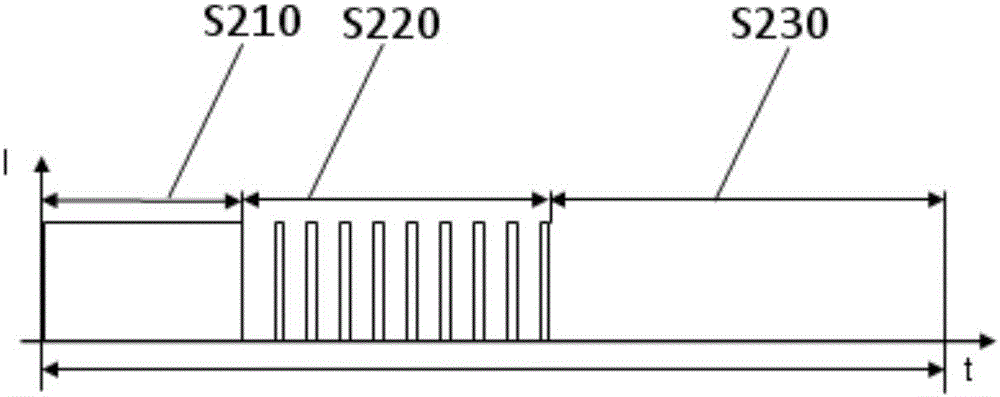

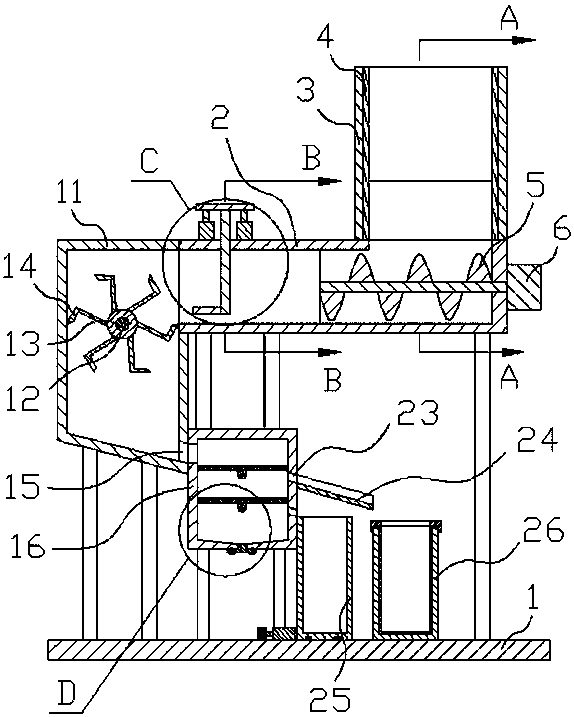

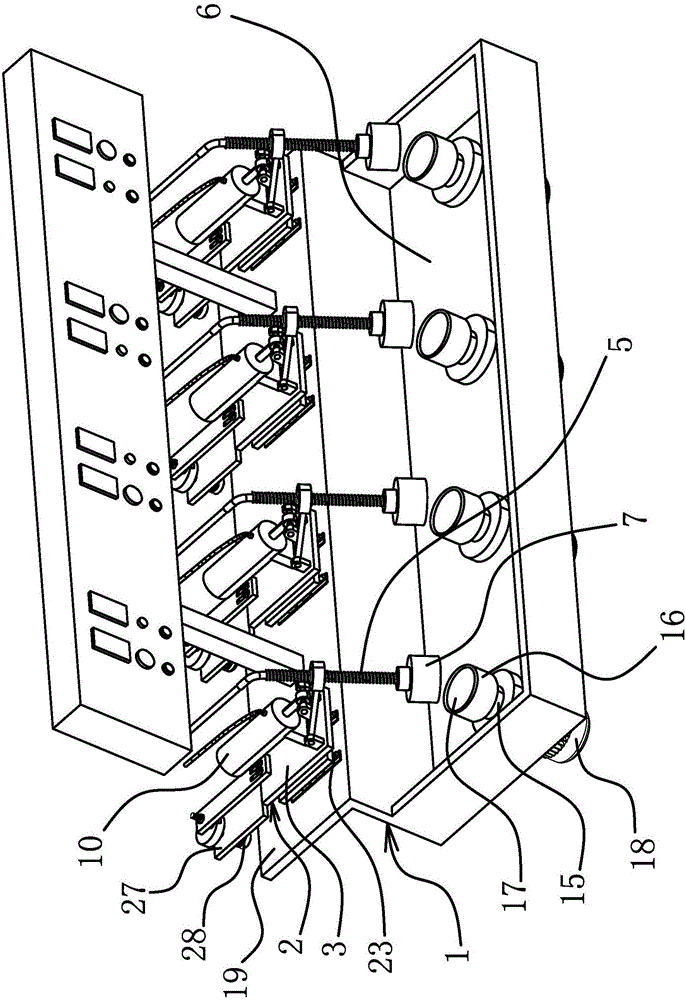

Suction nozzle work control system and method and controller of sweeping vehicle and sweeping vehicle

ActiveCN103293984AFlexible control of working statusEfficient cleaningRoad cleaningProgramme control in sequence/logic controllersControl signalControl system

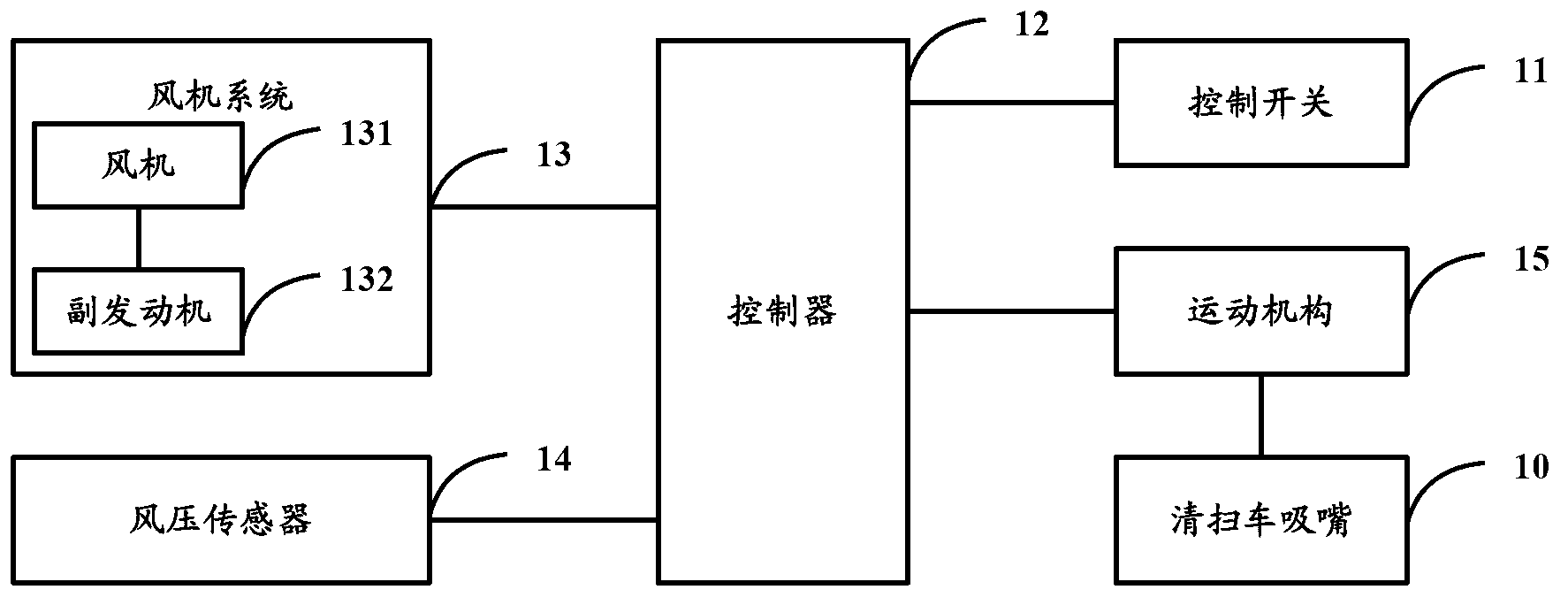

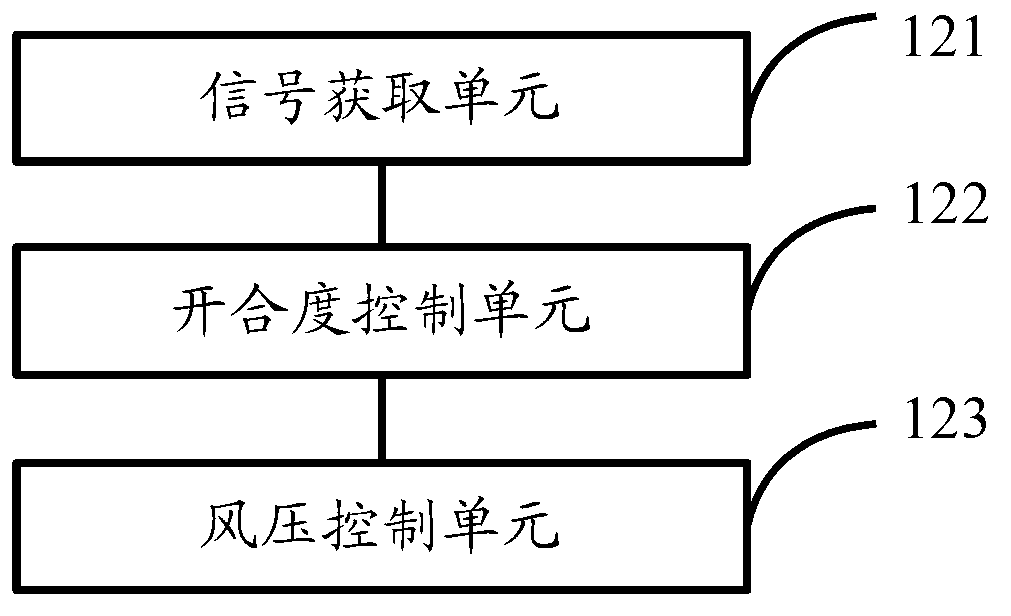

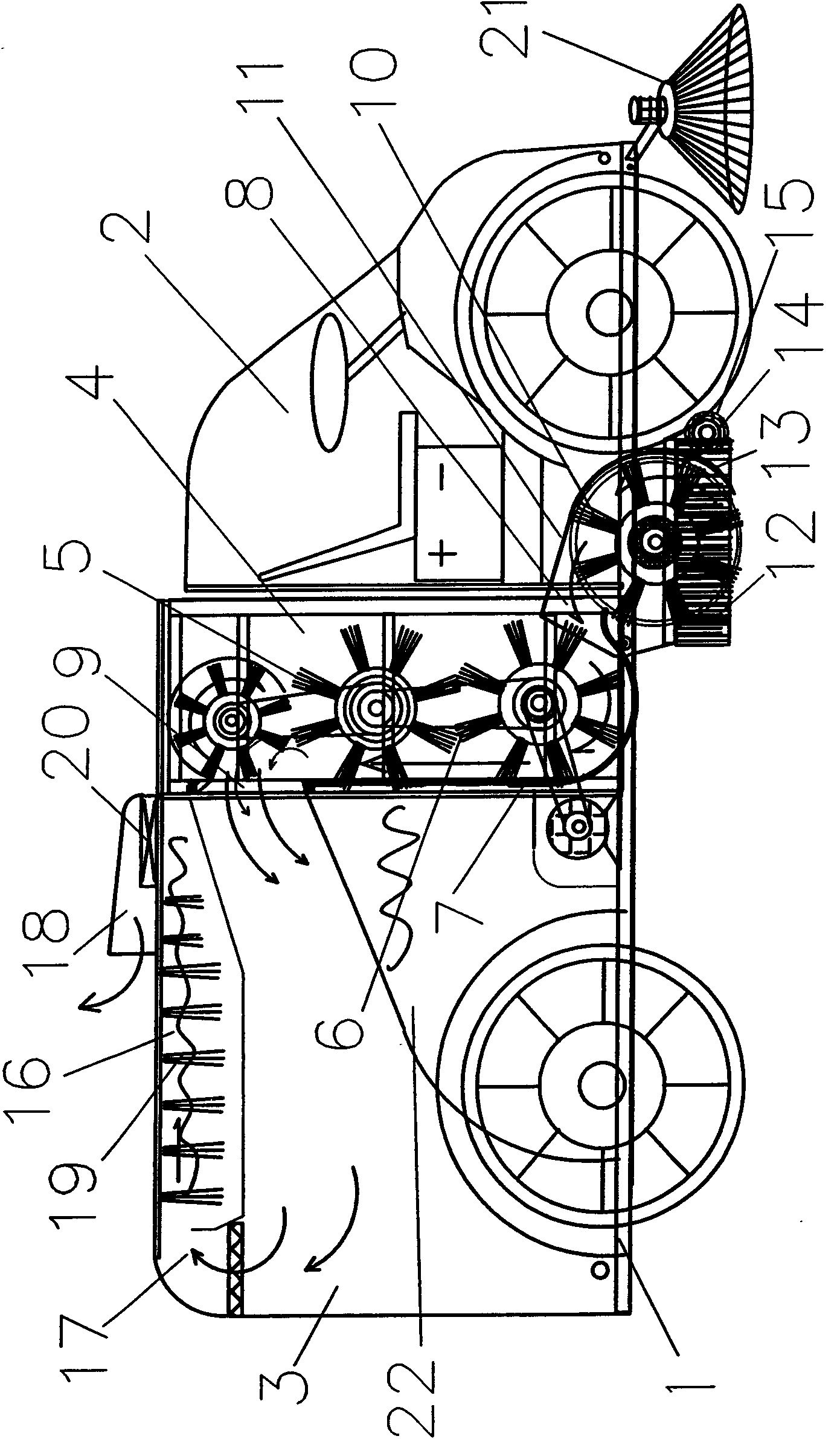

The invention discloses a suction nozzle work control system and method and a controller of a sweeping vehicle and the sweeping vehicle. The suction nozzle work control system comprises a control switch, a controller and a movement mechanism connected with a suction nozzle, wherein the control switch sends a control signal of controlling opening degree of the suction nozzle to the controller. The controller controls the movement mechanism according to the control signal. The movement mechanism is used for controlling the opening degree of the suction nozzle. The suction nozzle can be adjusted and controlled according to different road conditions and can be in different working modes, and accordingly good sweeping effect can be achieved under various road conditions.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

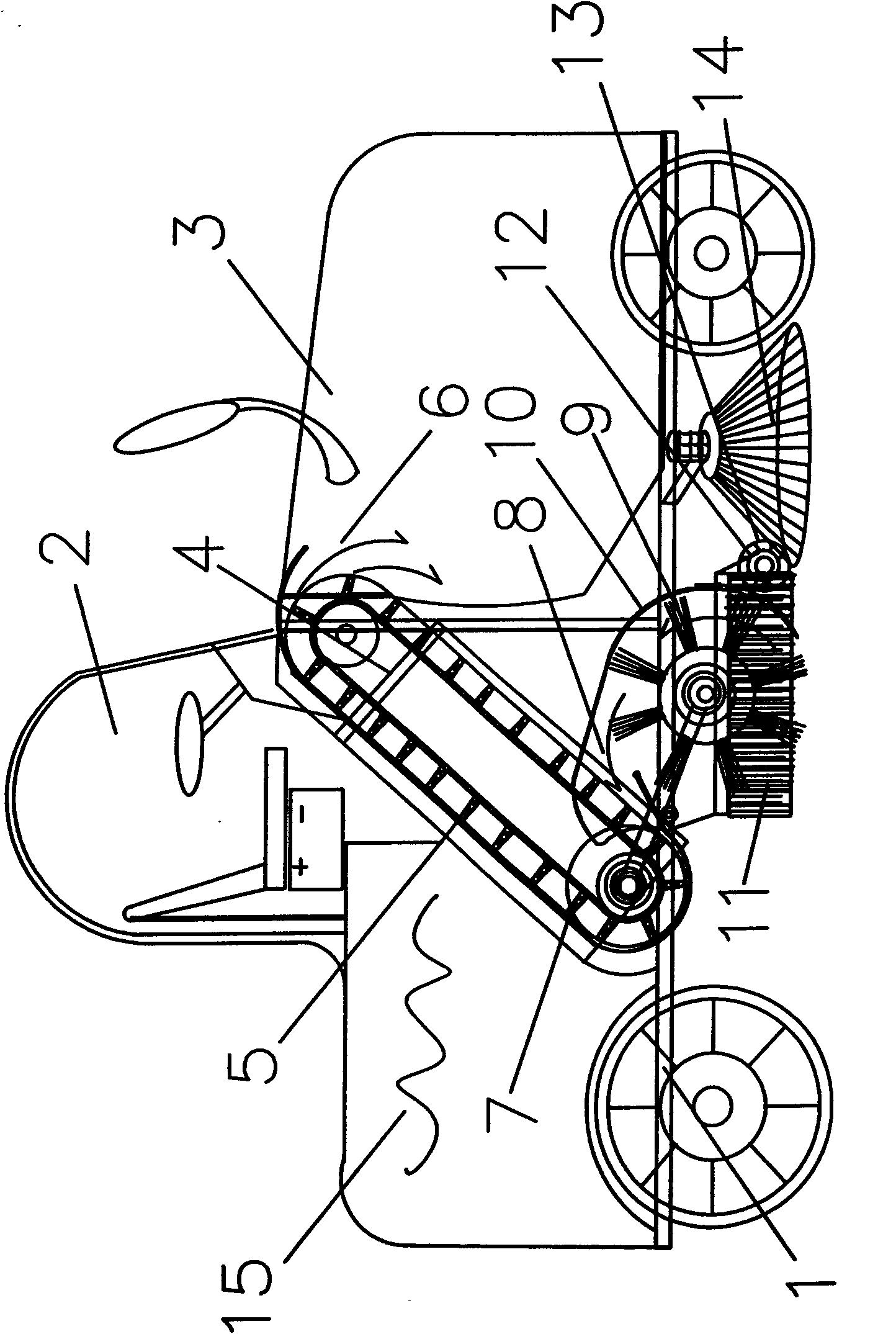

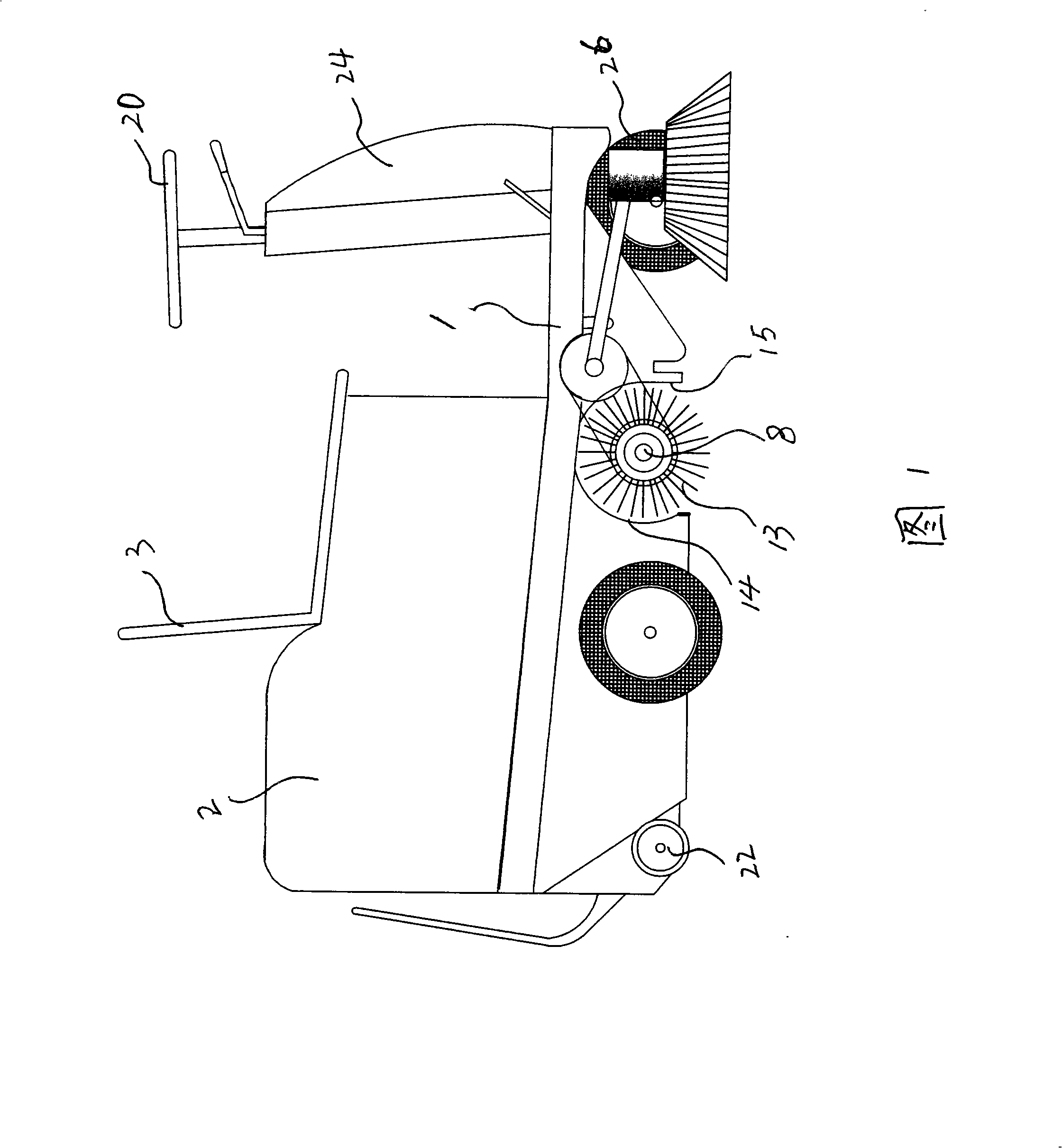

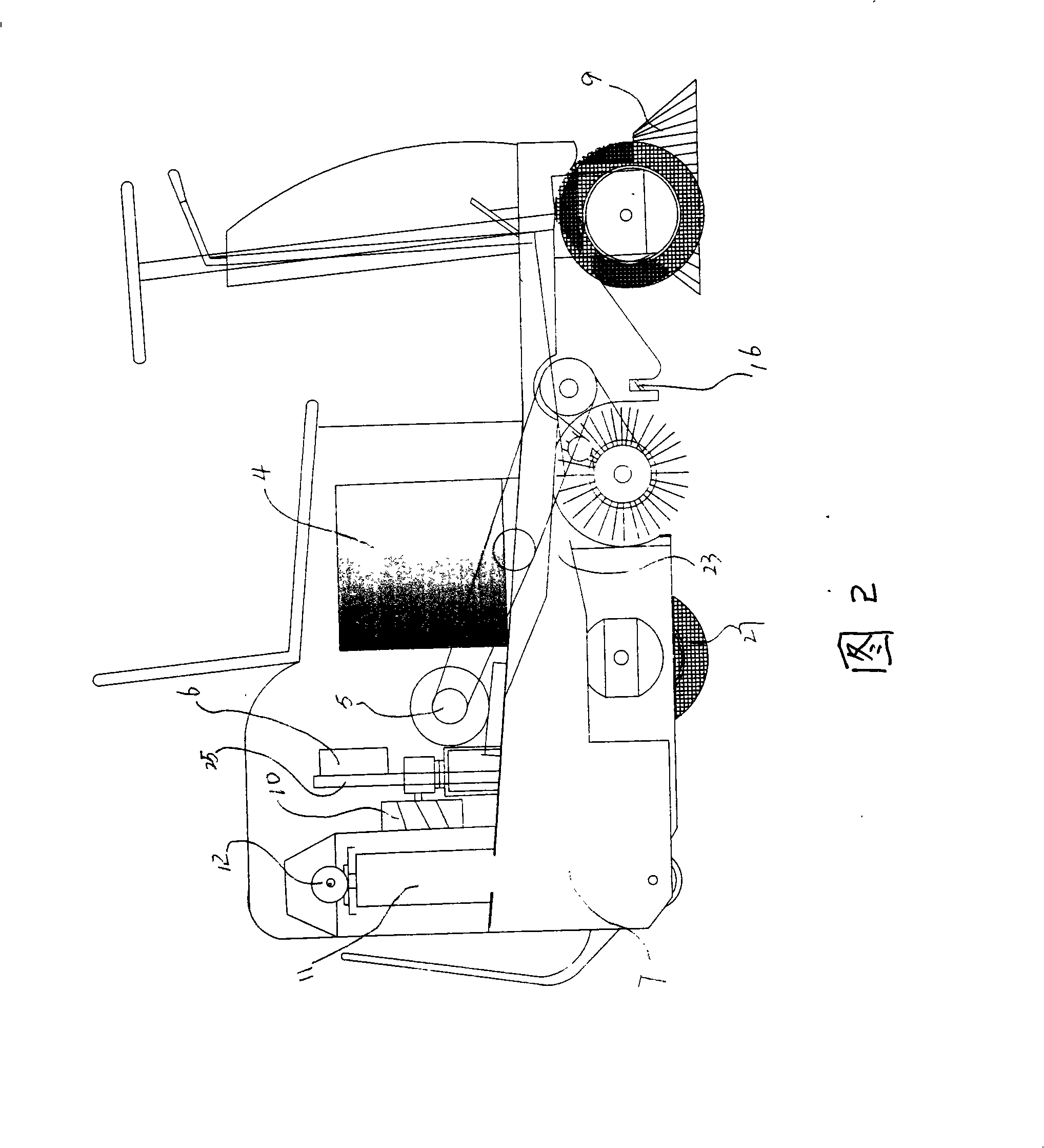

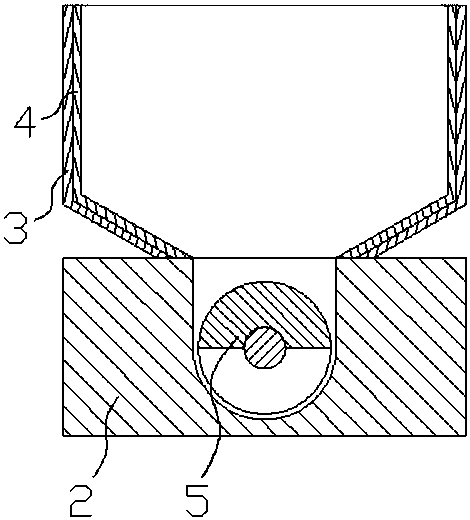

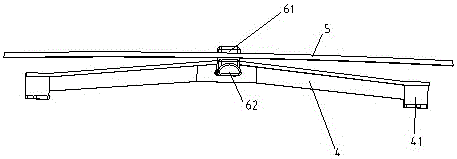

A transfer type sweeper

A transfer-type cleaning vehicle, which includes a car body, is characterized in that: several forward-rotating transfer rubbish rolling brushes are installed horizontally between the tipping garbage bin and the driver's cab; An arc-shaped guide garbage cover is formed at the lower end, and a garbage inlet is installed to facilitate the entry of the garbage to be swept; at an appropriate position above the guide garbage cover, a garbage outlet and a tipping bucket are installed backward At the proper position in front of the garbage entrance, install a reverse rotating sweeping roller brush that can move up and down freely following the height of the road; The small roller brush is equipped with a one-way rotating small tire on both sides of the small roller brush to cooperate with each other, so as to achieve the effective sweeping distance of the roller brush, and to assist the small roller brush to rotate in the same direction. The counter-rotating sweeping roller brush (5) works together to sweep the floor.

Owner:张珉

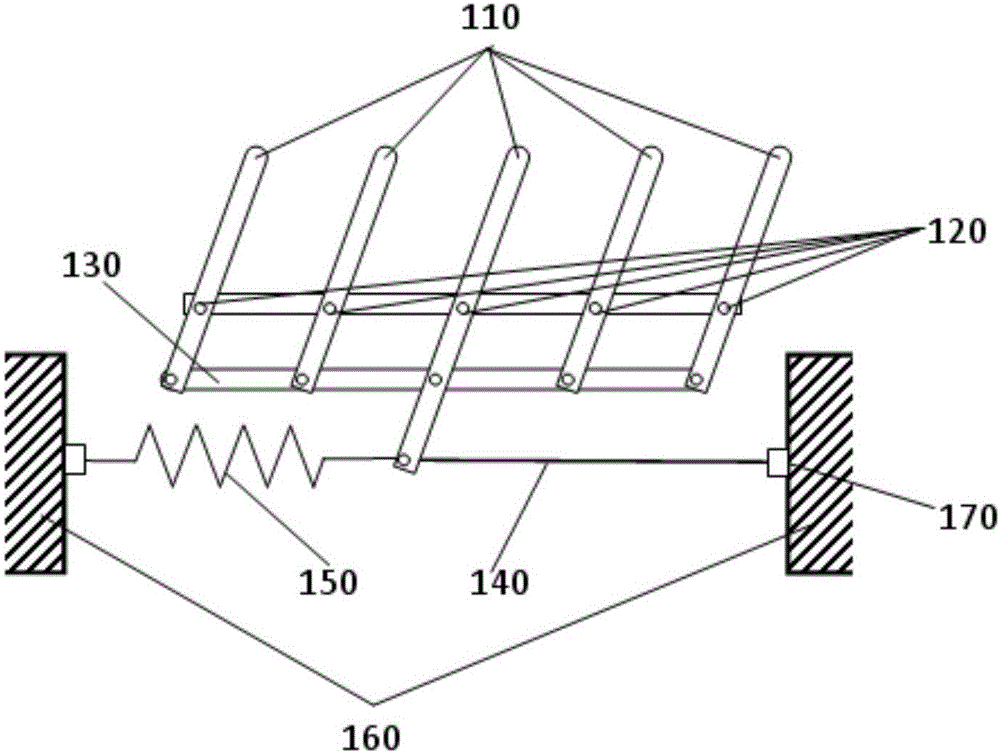

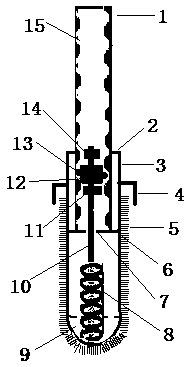

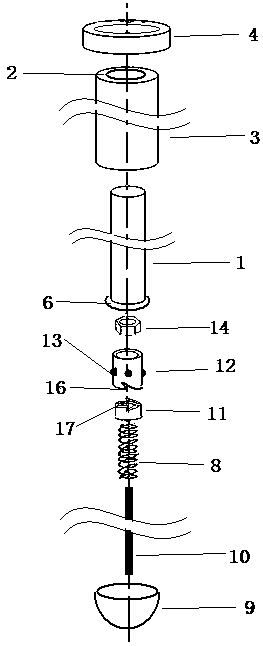

Vehicle-mounted air condition air sweeping device driven by electric control shape memory alloy

InactiveCN105946515AReduce volumeNo electromagnetic interferenceAir-treating devicesVehicle heating/cooling devicesMicrocontrollerMicrocomputer

The invention discloses a vehicle-mounted air condition air sweeping device driven by an electric control shape memory alloy. The vehicle-mounted air condition air sweeping device is composed of a drive part, a control part, a transmission part and an execution mechanism. The drive part adopts the shape memory alloy as a drive element, the shape memory alloy shrinks when electrified to be heated and is lengthened when cooled, and output of displacement and force of a driver is achieved. The control part is composed of a sensor, a single-chip microcomputer and a manual control key, the current on a shape memory alloy wire is controlled, and therefore the temperature of the shape memory alloy wire is controlled. The transmission part is mainly composed of a clutch device or a reset device. The execution mechanism is vehicle-mounted air conditioner air sweeping blades. The vehicle-mounted air condition air sweeping device has the beneficial effects of being small in size, simple in structure, convenient to install, easy to achieve, free of electromagnetic interference, good in periodical control effect and the like.

Owner:JILIN UNIV

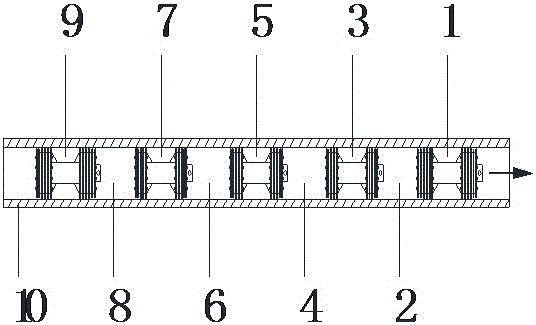

Water-sweeping, drying and inerting integrated process for natural gas transportation pipeline

InactiveCN105107801AImprove sealingExtended walking distanceDrying solid materials without heatHollow article cleaningWater basedDesiccant

The invention relates to a water-sweeping, drying and inerting integrated process for a natural gas transportation pipeline. The water-sweeping, drying and inerting integrated process for the natural gas transportation pipeline comprises the following steps: putting a pipeline cleaner train into the natural gas transportation pipeline by virtue of a pipeline head-end ball launching barrel, wherein the pipeline cleaner train consists of a pipeline cleaner I, a freshwater section plug, a pipeline cleaner II, a water-based gel section plug, a pipeline cleaner III, a chemical drying agent section plug, a pipeline cleaner IV, a dry gas section plug and a pipeline cleaner V; injecting compressed and dried nitrogen gas into the natural gas transportation pipeline from a gas inlet pipeline to push the pipeline cleaner train to travel forwards in the natural gas transportation pipeline, and exhausting pressure test water from a pipeline tail-end ball receiving barrel and a water exhausting pipeline; and after the pipeline cleaner train reaches the pipeline tail end, sequentially taking out the pipeline cleaners from the pipeline tail-end ball receiving barrel, and exhausting freshwater, water-based gel, a chemical drying agent and dry gas from a water drainage pipeline. After passing balls once, the water-sweeping, drying and inerting integrated process can reach conditions of introducing natural gas and putting the introduced natural gas into production.

Owner:HENAN ZHONGTUO PIPELINE ENG

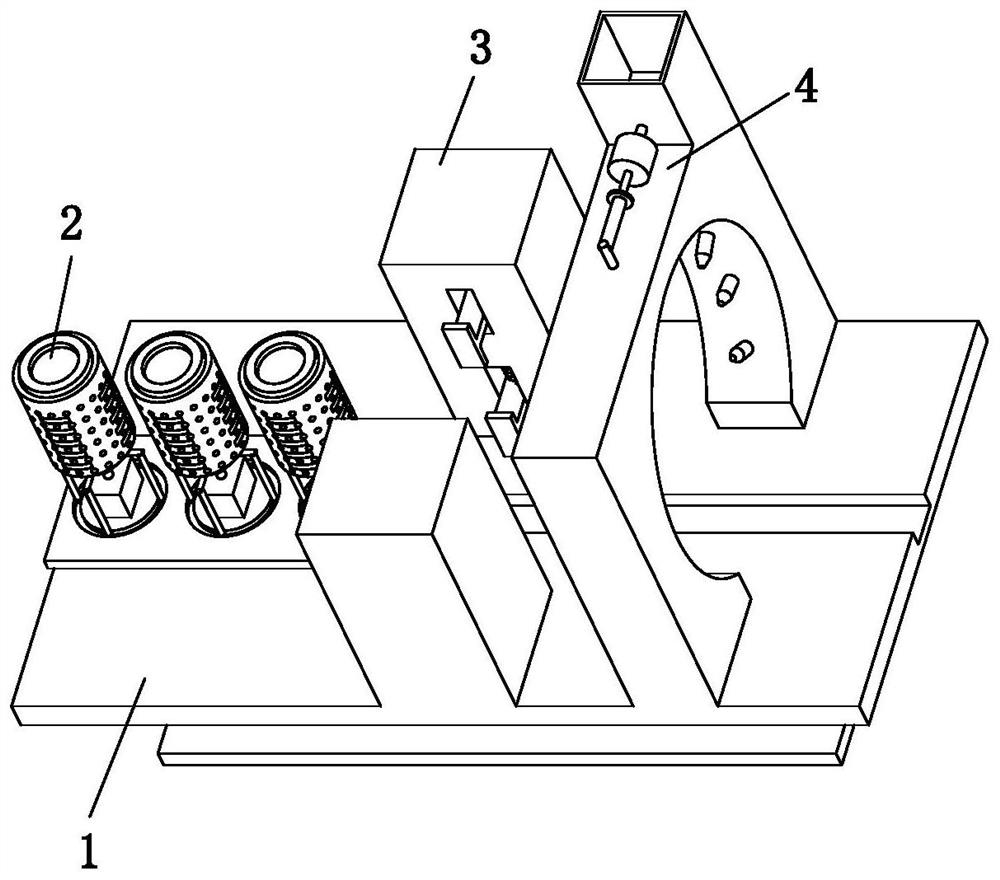

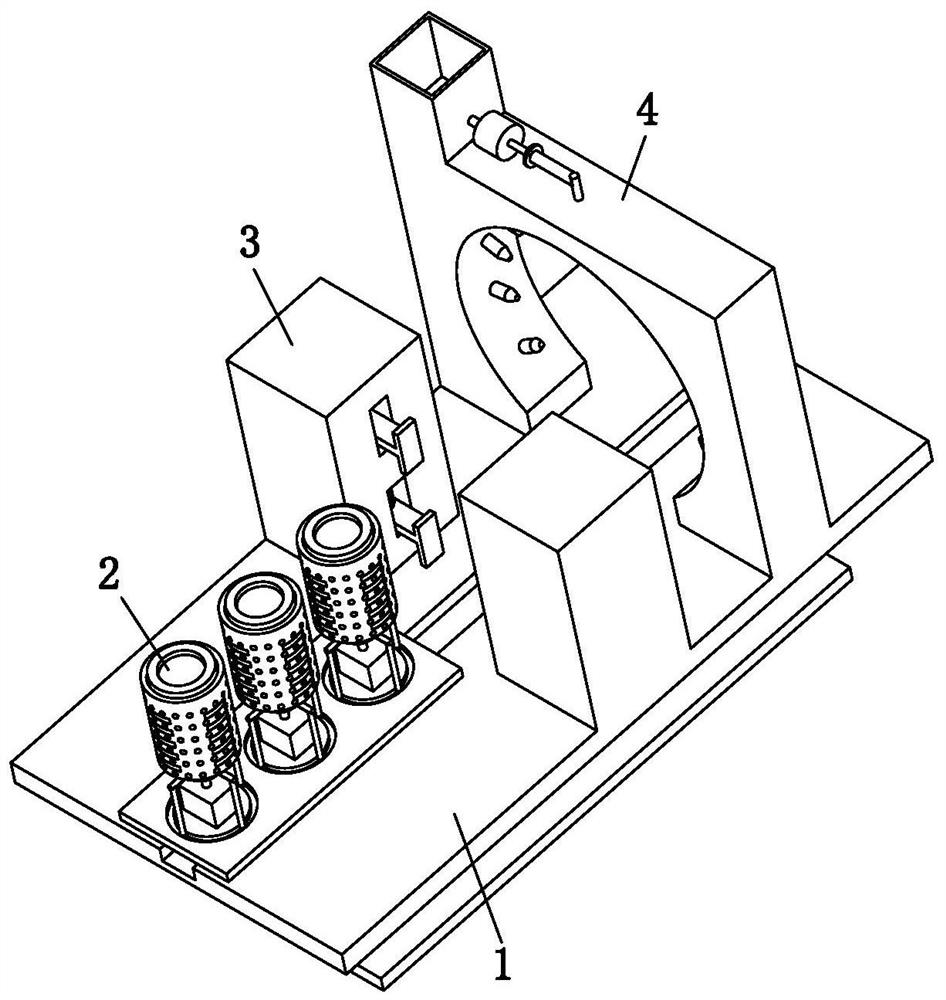

Plastic woven bag recycling pretreatment system and method

InactiveCN113071023AImprove cleaning efficiencyEasy to cleanPlastic recyclingCleaning using toolsProcess engineeringMechanical engineering

The invention relates to a plastic woven bag recycling pretreatment system and method. The plastic woven bag recycling pretreatment system comprises a supporting device, a bagging device, a sweeping device and a cleaning device. The plastic woven bag recycling pretreatment system provided by the invention can solve the problems that in the existing plastic woven bag recycling and reusing process, a, a used plastic woven bag is manually shaken, so that attachments on the surface of the plastic woven bag are shaken off, more manpower is needed in the mode, time and labor are wasted in the shaking process, attachments and dust which are shaken off can be scattered in the air in a mist form, so that certain harm is caused to the human body; and b, manual shaking cannot ensure that the attachments on the inner side wall of the plastic woven bag are completely shaken off, so that the shaking effect is poor, and a certain influence is caused on the re-use of the plastic woven bag.

Owner:王振

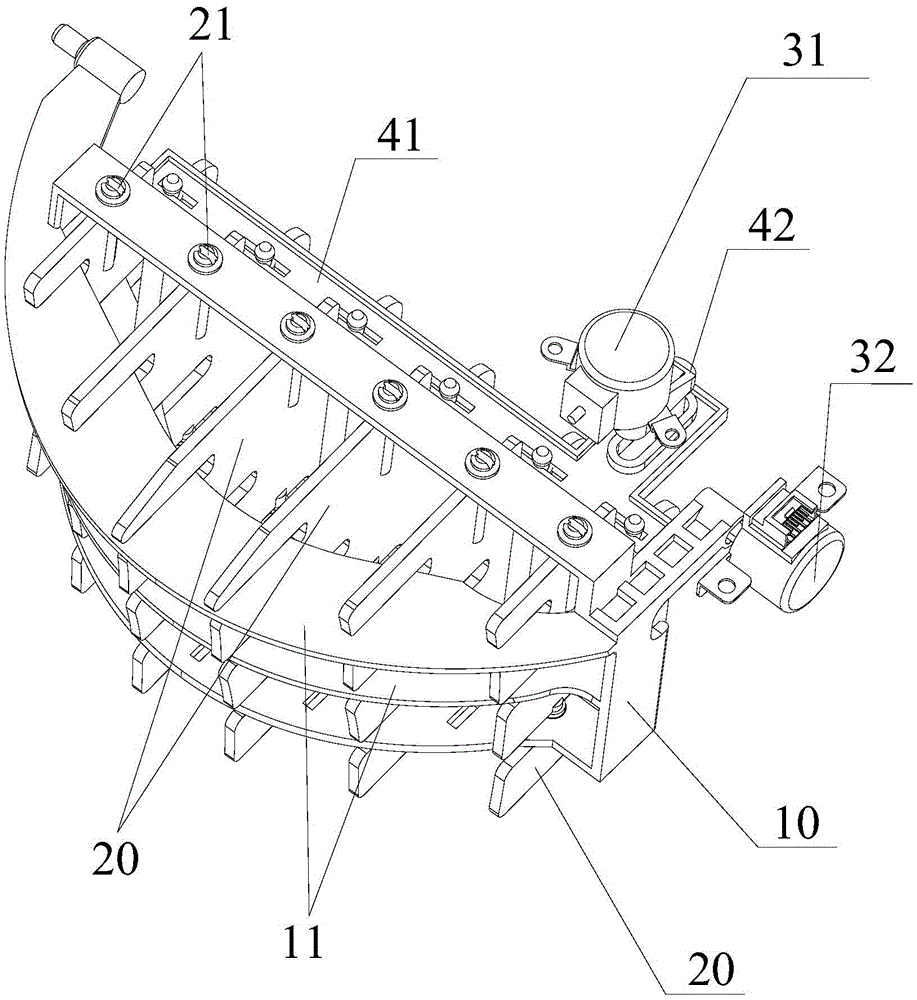

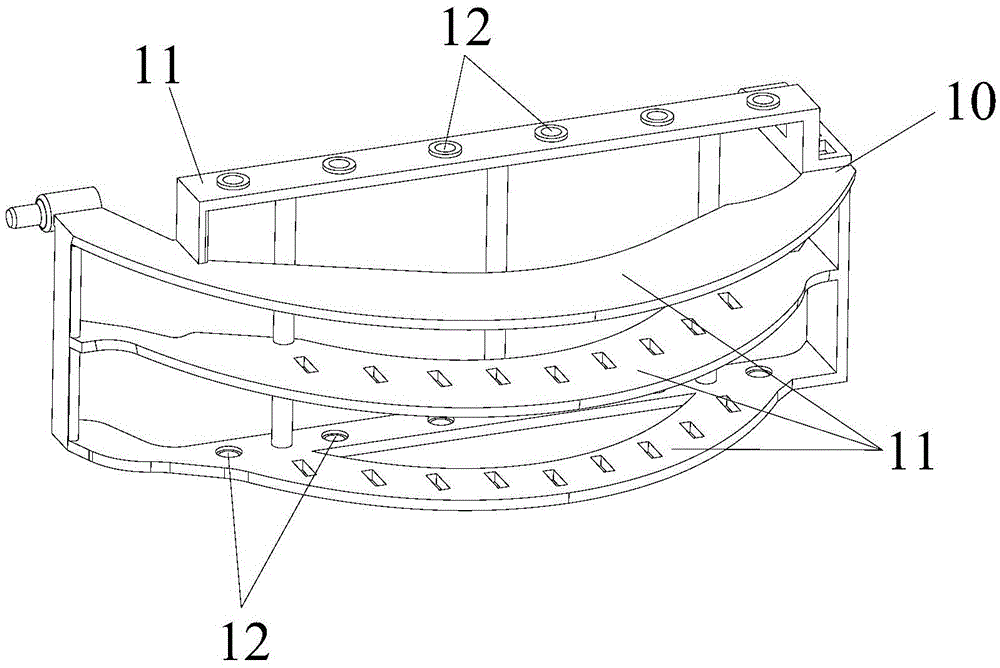

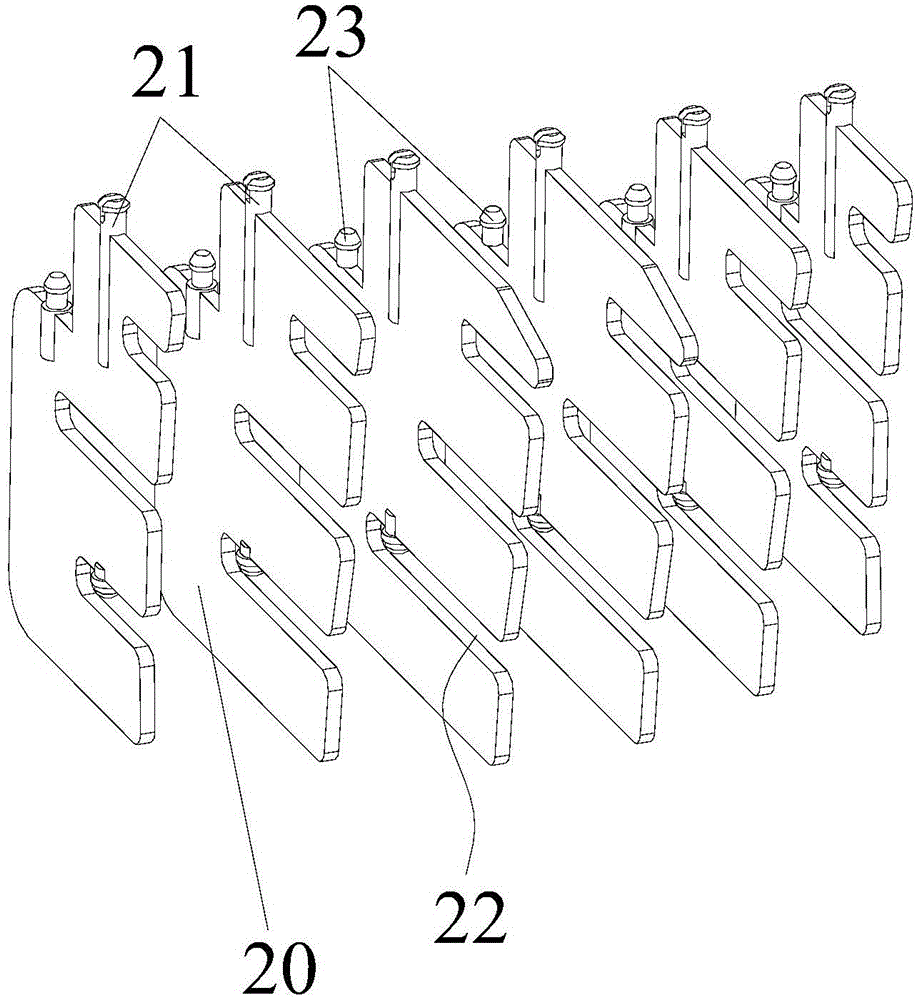

Air sweeping support and air conditioner

ActiveCN105823189AImprove the sweeping effectLighting and heating apparatusAir-flow control membersAir volumeEngineering

The embodiment of the invention discloses an air sweeping support and an air conditioner. The air sweeping support is arranged at the head of an indoor unit and comprises a rotary drum, a first drive assembly and a transmission assembly arranged at the top of the rotary drum. An air outlet is formed in the side face of the rotary drum. The first drive assembly can drive the rotary drum to rotate forwards or reversely through the transmission assembly. When leftward air supply is needed, the first drive assembly drives the rotary drum to rotate leftwards through the transmission assembly, so that the air outlet is leftward, air is blocked by the edges of the two sides of the rotary drum and prevented from being supplied rightwards, the air volume in the air outlet are all supplied leftwards, and the rightward air sweeping loss is avoided; and when rightward air supply is needed, the first drive assembly drives the rotary drum to rotate rightwards through the transmission assembly, so that the air outlet is rightward, the air is blocked by the edges of the two sides of the rotary drum and prevented from being supplied leftwards, air volume in the air outlet is all supplied rightwards, and the leftward air sweeping loss is avoided. Therefore, by the adoption of the air sweeping support, the air sweeping effect can be improved while the air is supplied in a concentrated manner.

Owner:GREE ELECTRIC APPLIANCES INC

Manual purging adjusting device and air conditioner comprising same

InactiveCN104422095ASimple adjustment structureEasy to adjust manuallyLighting and heating apparatusVehicle heating/cooling devicesPulp and paper industry

Owner:GREE ELECTRIC APPLIANCES INC

Automatic floor-sweeping robot based on infrared sensing

ActiveCN109998425AIncrease sweeping rangeImprove the sweeping effectFloor sweeping machinesPhysical well beingEngineering

The invention relates to the technical field of floor-sweeping robots, and discloses an automatic floor-sweeping robot based on infrared sensing. The automatic floor-sweeping robot comprises a floor-sweeping robot main body, a deep groove is formed in the floor-sweeping robot main body, a suction fan is fixedly connected to the inner wall of the deep groove, an electric push rod is fixedly connected to the top wall of the deep groove, a fixing block is fixedly connected to the output end of the electric push rod, a first cavity is formed in the fixing block, a dust collecting head is fixedly connected to the side wall of the fixing block, a guide pipe is fixedly connected to the top end of the dust collecting head, one end, far away from the dust collecting head, of the guide pipe penetrates through the side wall of the fixing block to communicate with the first cavity, a through hole is formed in the cavity wall of the first cavity, and a collecting box is movably connected to the hole wall of the through hole. The automatic floor-sweeping robot based on infrared sensing has the advantages that the floor-sweeping range is wide, the floor-sweeping effect of the floor-sweeping robotis improved, meanwhile, disinfection treatment can be carried out in the family environment through spraying of a disinfectant, so that the phenomenon that family members are infected with bacteria is avoided, and thus the body health of the family members is guaranteed.

Owner:嘉兴倍创网络科技有限公司

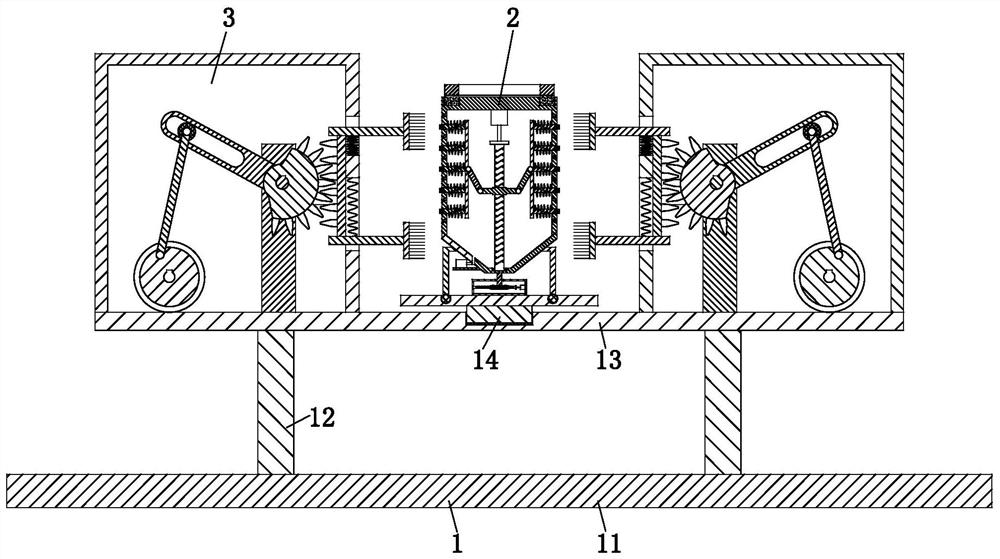

Novel mechanical type grape vine taking-out machine

PendingCN107466499AReduce labor costsReduce manufacturing costSoil-working equipmentsUniversal jointReduction drive

The invention discloses a novel mechanical type grape vine taking-out machine, and belongs to the technical field of agricultural equipment. The machine comprises a rack, a left universal joint and a right universal joint, a left secondary speed reducer, a main speed reducer and a right secondary speed reducer are installed on the rack from left to right in sequence, the left secondary speed reducer, the right secondary speed reducer and the rack are connected in an articulated mode through articulated mechanisms, the main speed reducer is fixedly connected with the rack, a suspension frame is installed on the rack, and the suspension frame is connected with a machine body of a tractor. Accordingly, by arranging the left secondary speed reducer, the right secondary speed reducer, the left universal joint, the right universal joint, the articulated mechanisms and an angle adjustment device, the left secondary speed reducer, the right secondary speed reducer and the rack are connected in an articulated mode, in the working process, the work breadth and angle can be adjusted according to the actual situation of a cold-proof soil layer, the soil sweeping effect is good, the relative height between a depth wheel and the rack is adjusted through a height adjusting shaft, and then the soil sweeping depth of a soil sweeping mechanism is adjusted.

Owner:秦皇岛市晟杰葡萄酒产业研究发展中心 +2

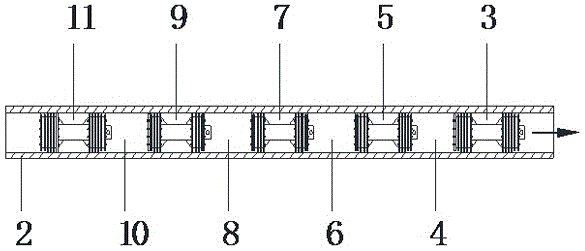

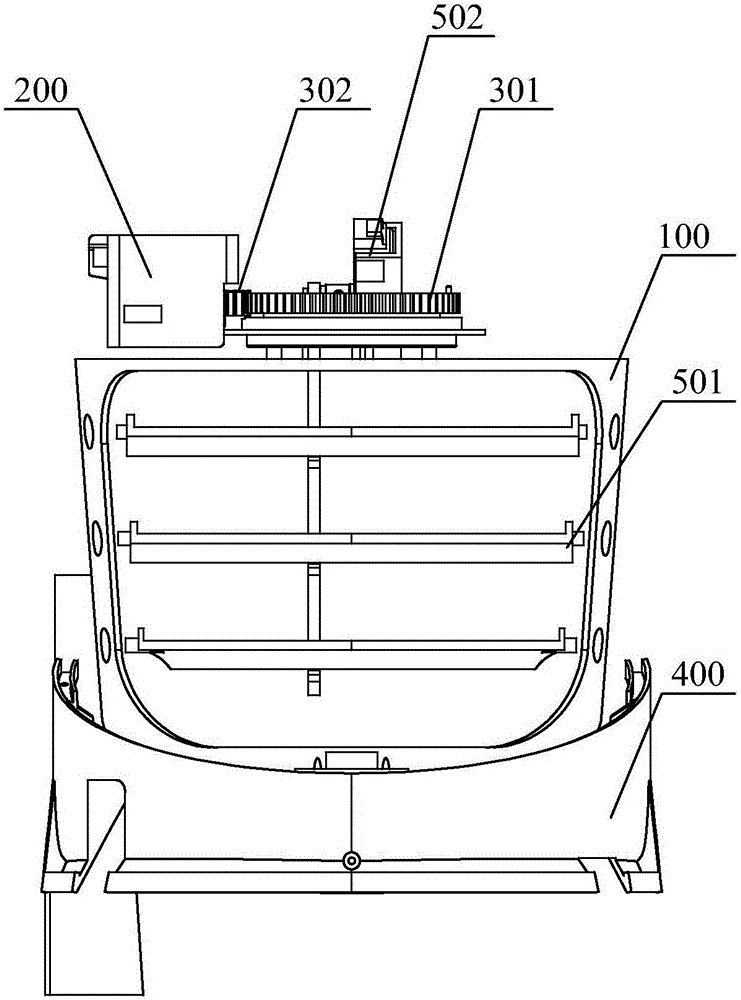

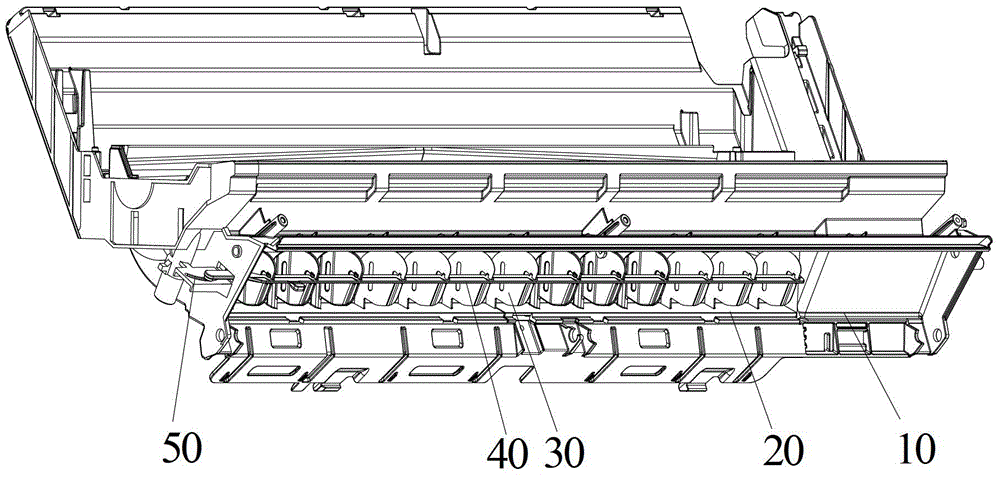

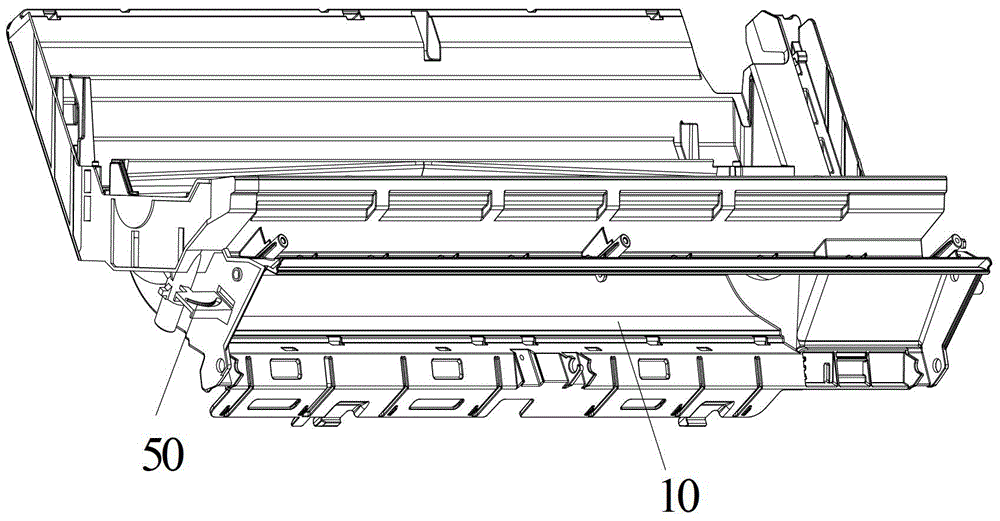

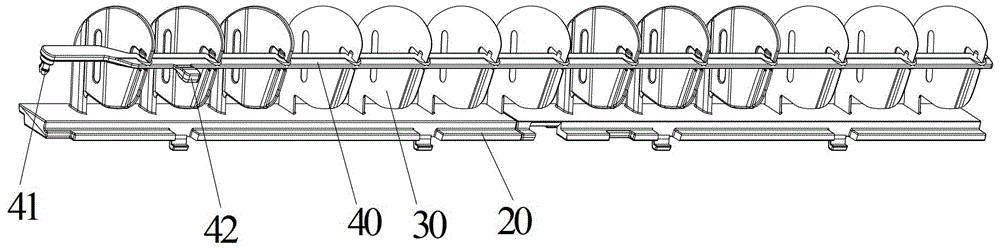

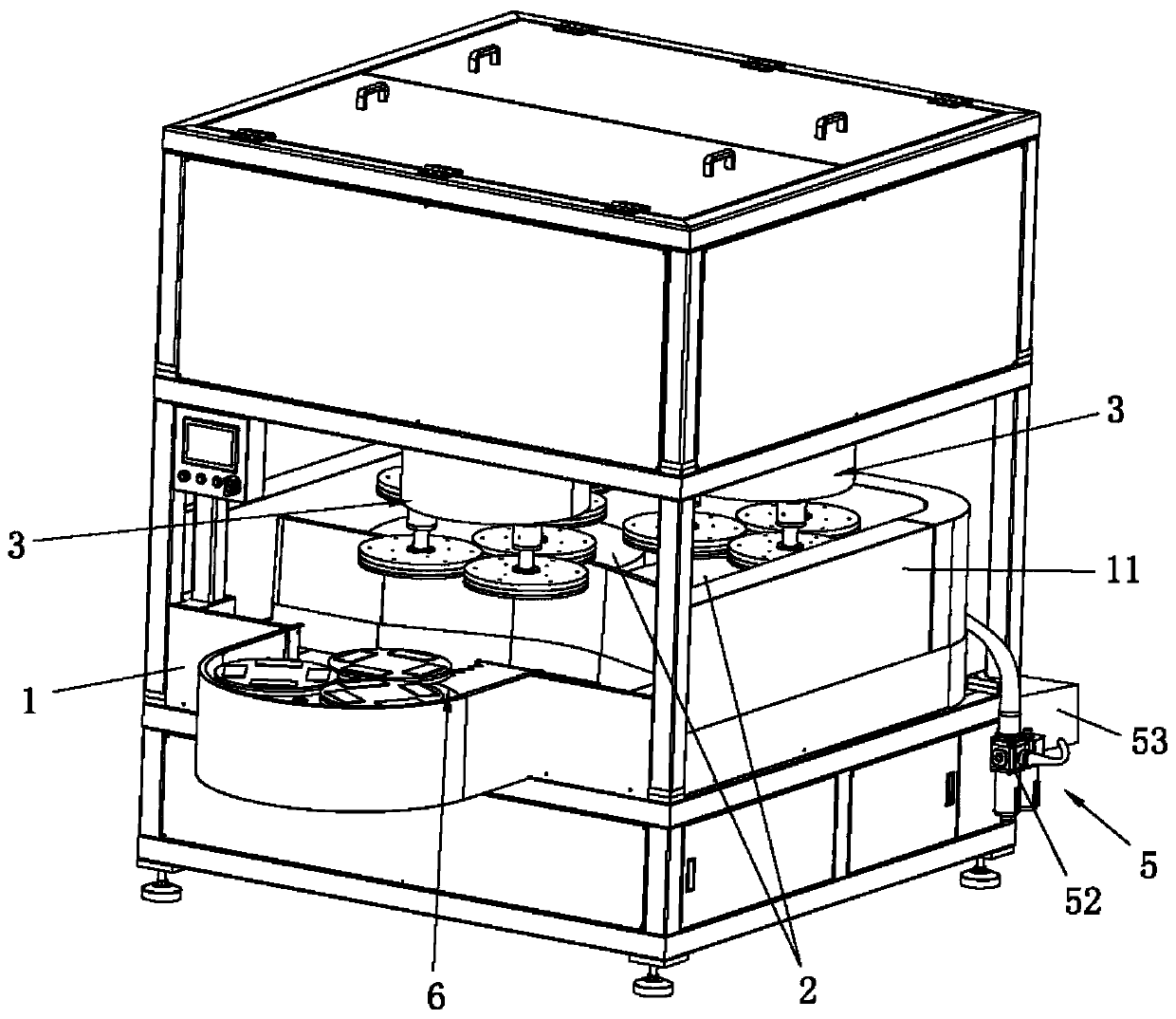

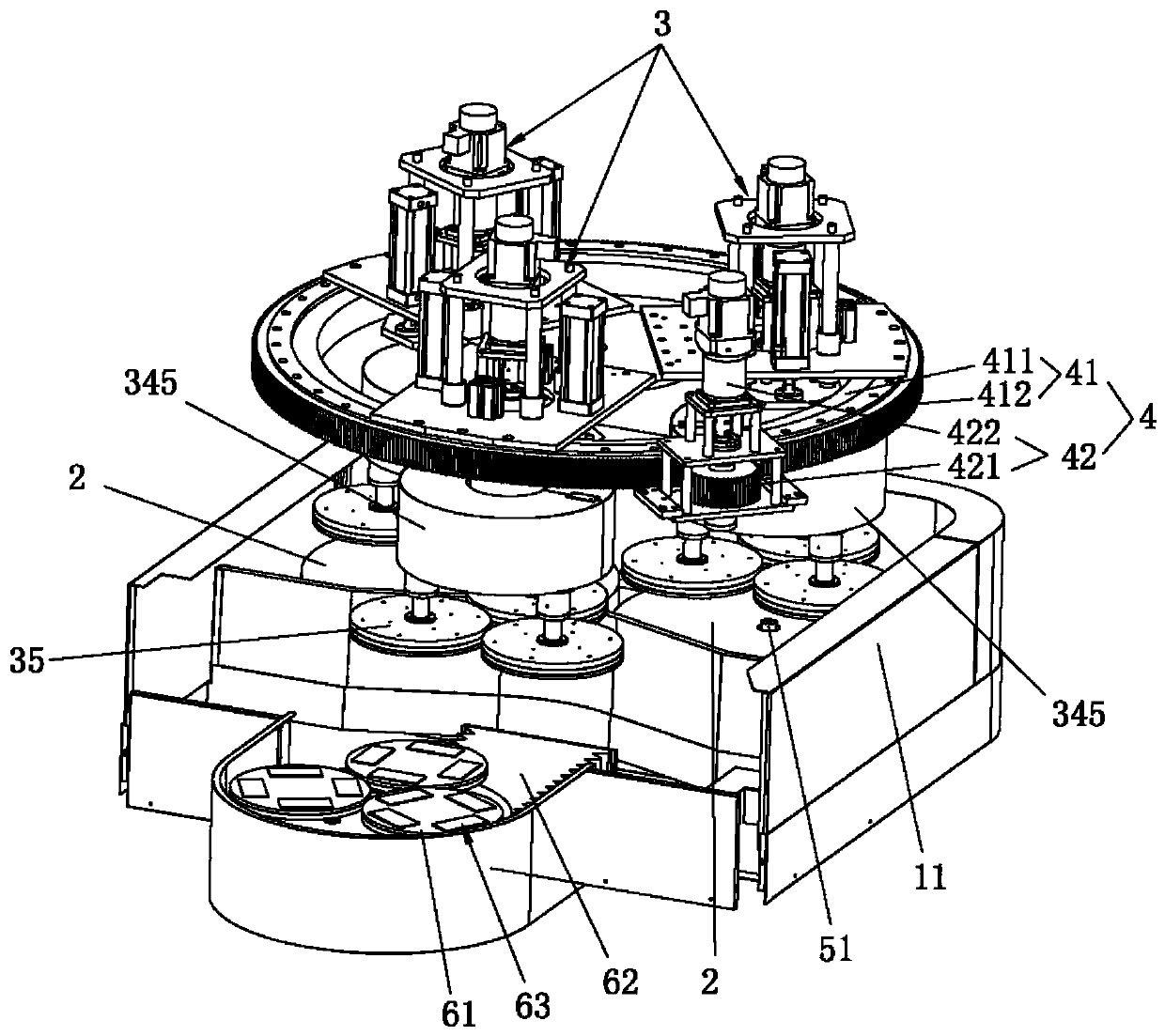

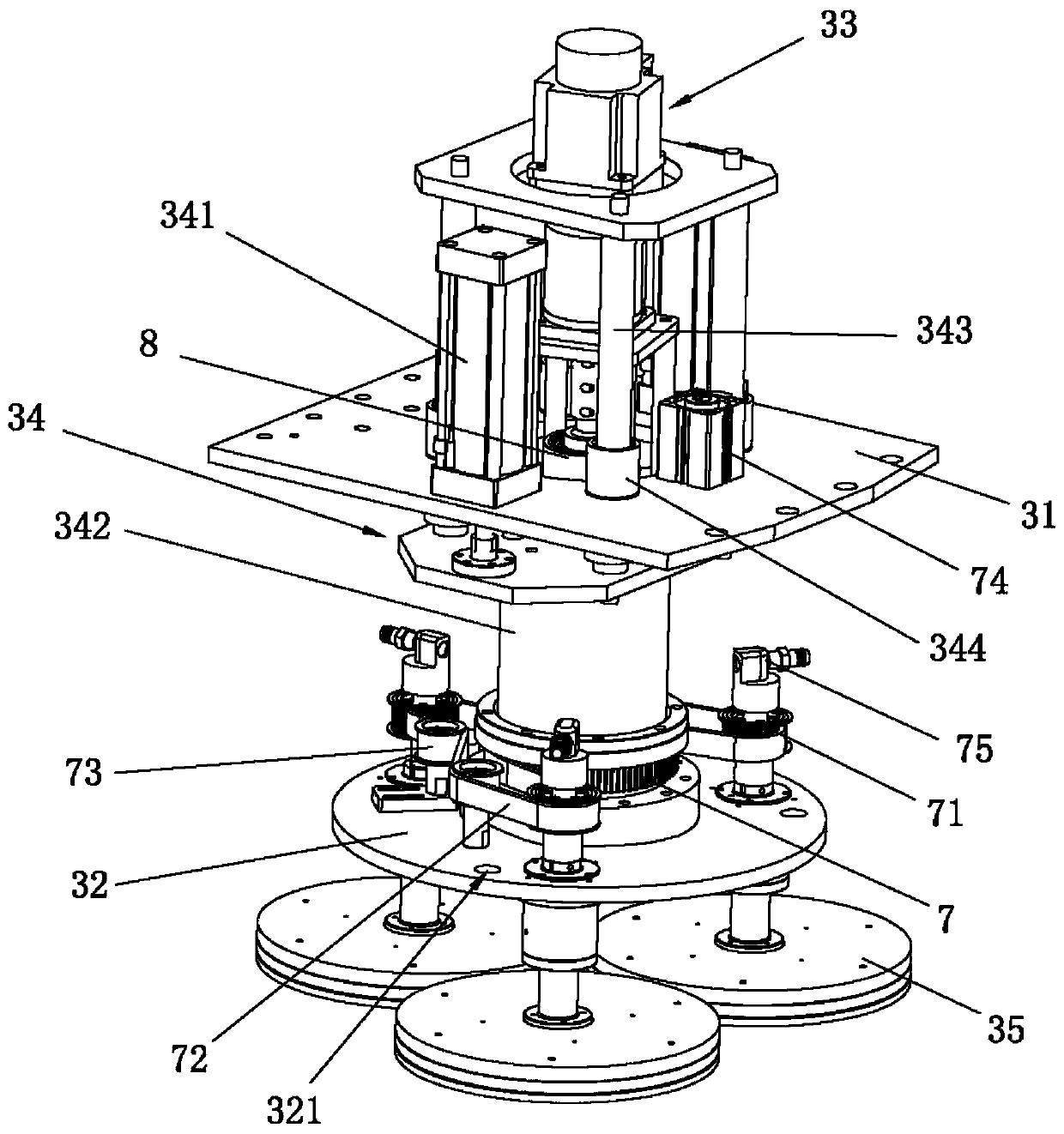

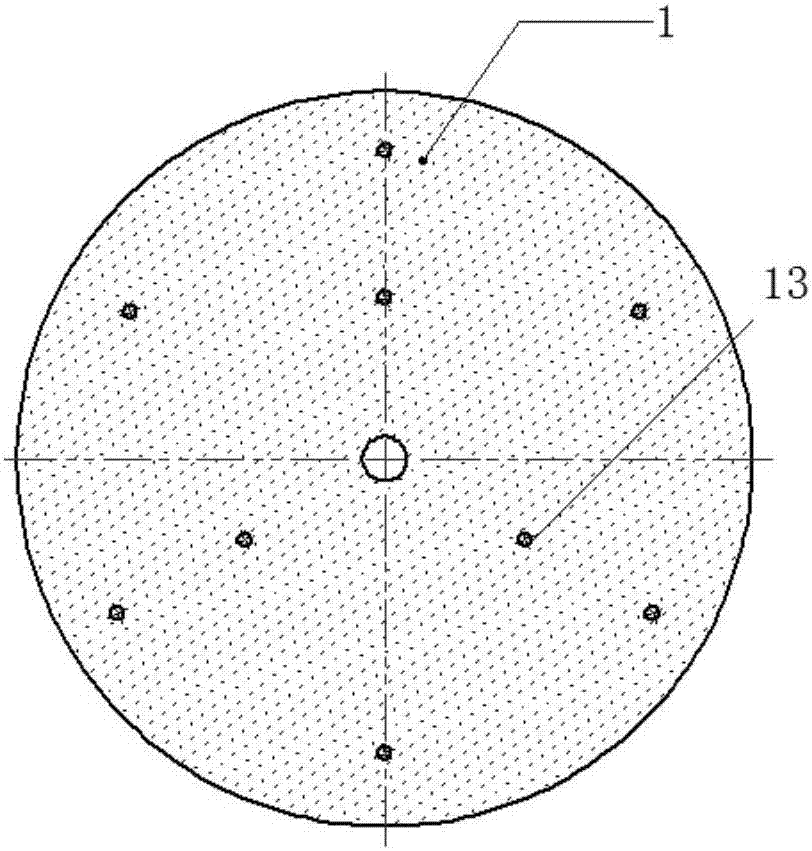

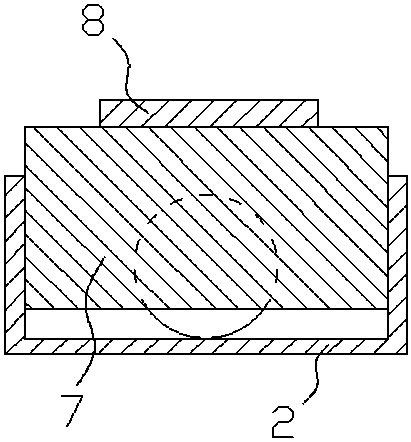

Sweeping machine

PendingCN109894963AStable structureShorten sweep timePolishing machinesGrinding machinesEngineeringRotating disc

The invention relates to the technical field of sweeping equipment, in particular to a sweeping machine. The sweeping machine comprises a sweeping machine table, at least two lower grinding discs, a plurality of upper grinding disc devices and a conversion driving mechanism, wherein the upper grinding discs are matched with the lower grinding discs and used for sweeping materials, the conversion driving mechanism is used for driving the positions of the multiple upper grinding disc devices to be switched, and a liquid supply device used for supplying sweeping liquid is arranged in the middle of the lower grinding discs; and each upper grinding disc device comprises a grinding disc seat, a rotating disc, a rotating driving mechanism, a lifting driving mechanism and a plurality of upper grinding discs, the rotating disc is rotationally arranged on the grinding disc seat, the rotating driving mechanism is used for driving the rotating disc to rotate, the lifting driving mechanism is usedfor driving the rotating disc to be close to or far away from the lower grinding disc, the upper grinding discs are rotationally arranged on the rotating disc, and the upper grinding discs are provided with a plurality of material sucking cavities used for containing the materials. According to the sweeping machine, the time for material-sweeping is shortened, the material-sweeping efficiency is improved, the production cost is reduced, the diffusion of the sweeping liquid is stable and uniform, the rotating disc and the upper grinding disc in a combined mode, the sweeping effect is good, andthe precision of material sweeping is improved.

Owner:东莞市力优机械设备有限公司

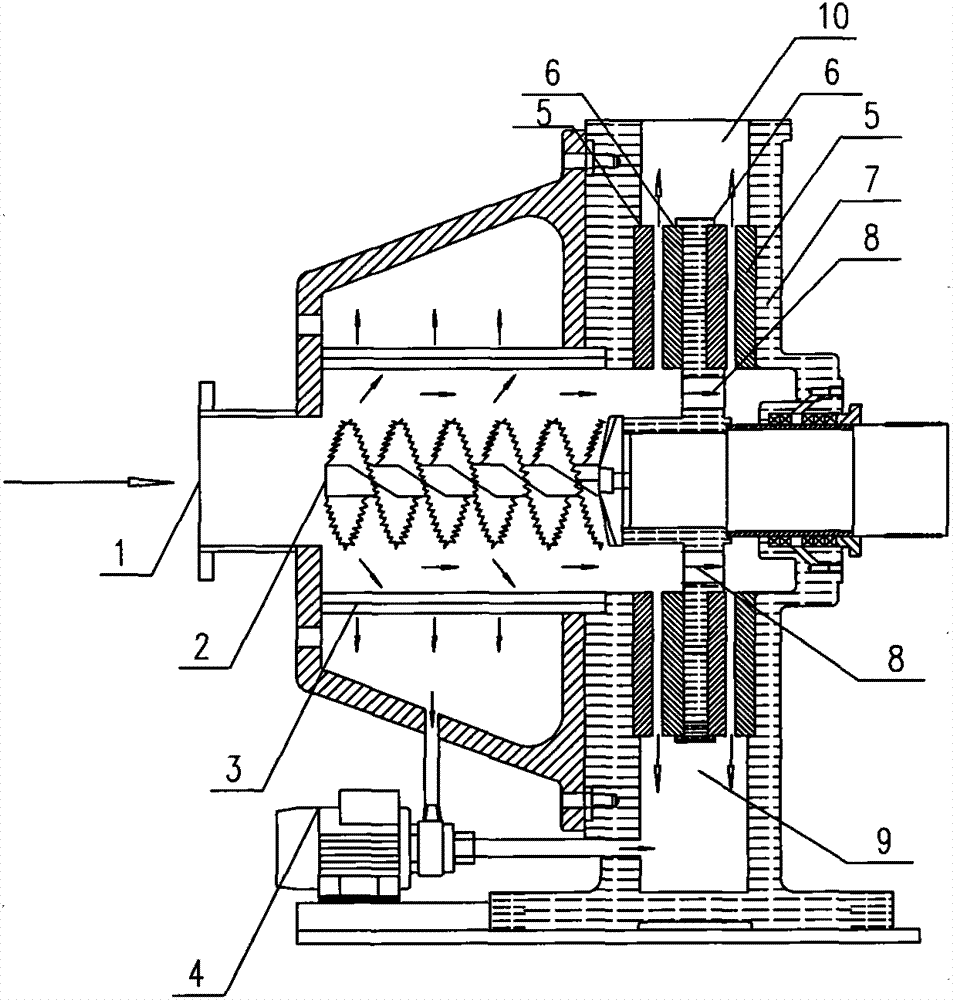

High-concentration pulping machine

InactiveCN102787522AIncrease concentrationHigh tensile strengthPulp beating/refining methodsHigh concentrationImpeller

The invention relates to a high-concentration pulping machine, which comprises a machine case, a dehydration screen cylinder, a conveying impeller, a grinding case and a grinding disc, wherein the conveying impeller is positioned in the dehydration screen cylinder, the dehydration screen cylinder is positioned in the machine case, the machine case is provided with a pulp inlet, the dehydration screen cylinder is communicated with the outer part of the machine case through the pulp inlet, the machine case is provided with a grinding case communication opening, the grinding case is communicated with the machine case through the grinding case communication opening and is provided with the grinding disc, and the grinding disc is coaxially connected with the conveying impeller. The high-concentration pulping machine provided by the invention has the advantages that the pulping concentration is improved, the labor consumption can be saved for 50 percent, a low-concentration pump can be used for pumping pulp, the pulp blockage is avoided, in addition, the cost is reduced, the product quality is greatly improved, and the economic and social benefits are obvious.

Owner:谢摞富

Electric drive type sweeper

The invention discloses a sweeper comprising a chassis, a break gear, a hood, a chair, an accumulator battery, a dust-collector, a DC motor, a controller, a dust collecting chamber, a sweeper driving device, a roller brush box body, two front brushes and a steering gear, wherein, the hood is movably linked with the upper part of the chassis; the chair is arranged on the hood; the accumulator battery, the dust-collector, the DC motor and the controller are arranged in the hood; the dust collecting chamber, the sweeper driving device, the roller brush box body and the two front brushes driven by a front brush motor are arranged at the lower part of the chassis; and the steering gear is fixed at the front end of the chassis. The sweeper can sweep up the ground through the roller brush box body and the two front brushes, and the swept dust is sucked into the dust collecting chamber through the dust-collector; in addition, the sweeper adopts the electromotive operation, no noise is produced, and no waste gas is discharged, thereby being an advanced sweeper.

Owner:艾和金

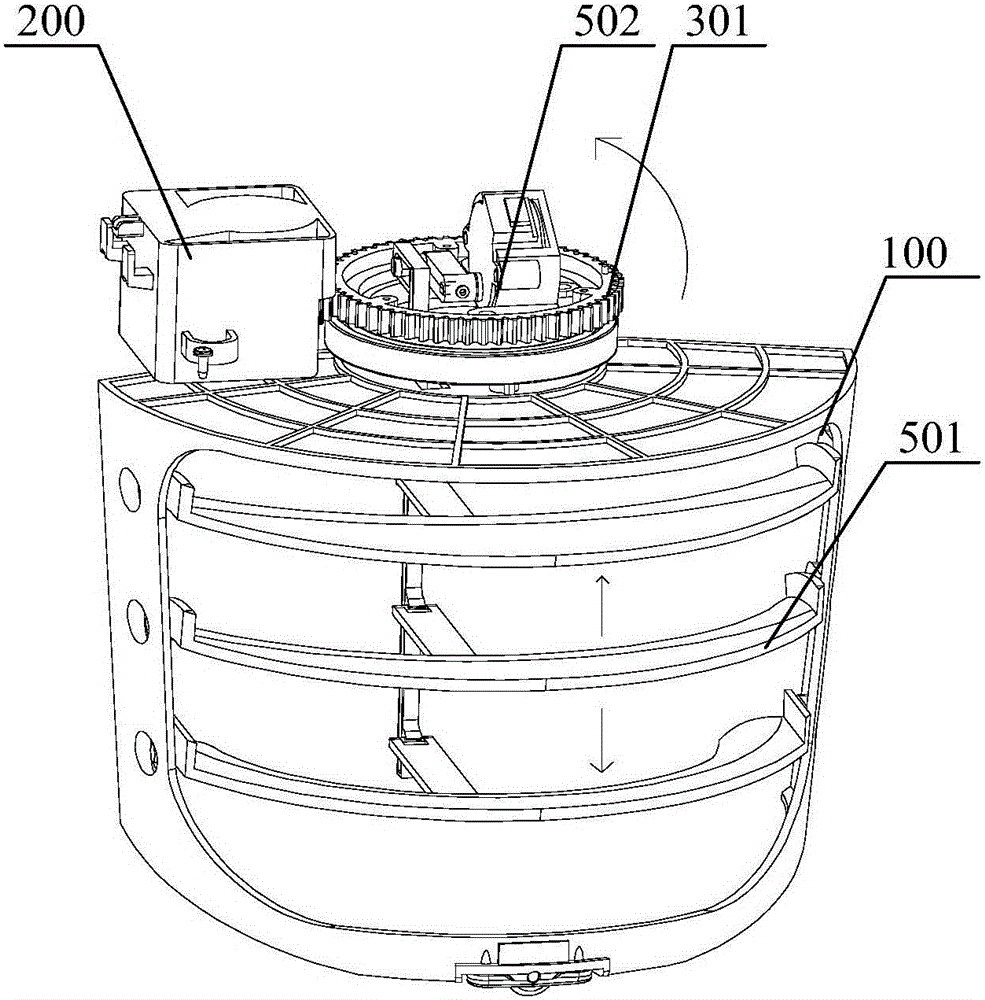

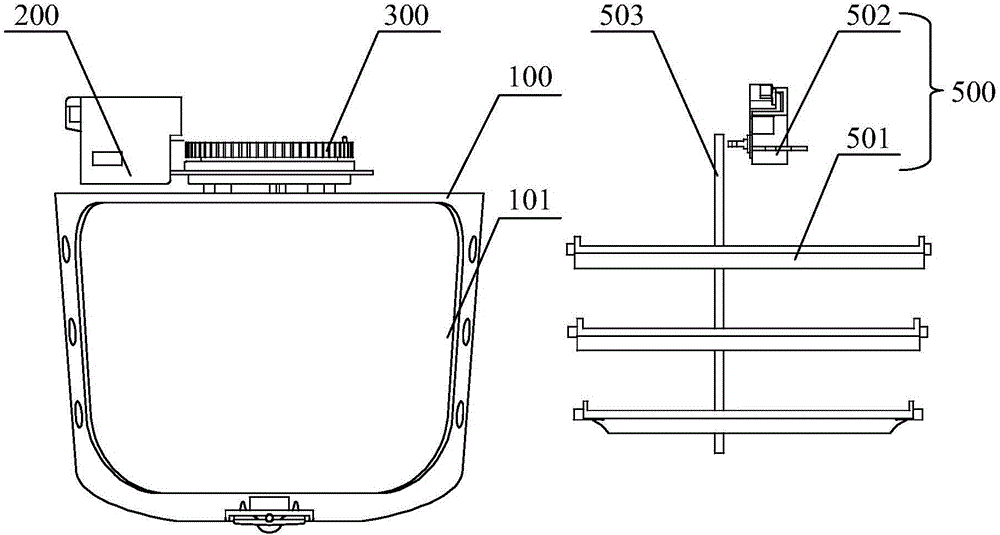

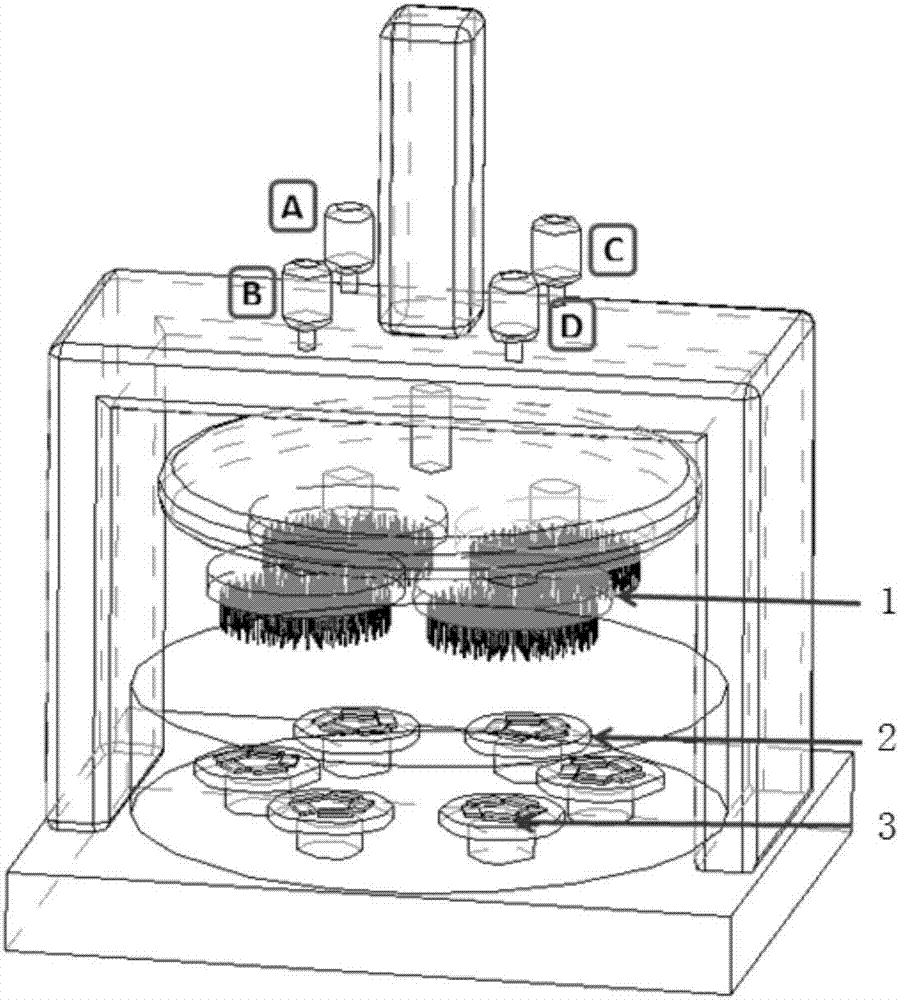

Glass product sweeping device and method

PendingCN107336099ASolve efficiency problemsSolve the yield problemGrinding drivesFlexible-parts wheelsBristleGlass cover

The invention provides a glass product sweeping device and method. The glass product sweeping device comprises at least one upper sweeping disc and a plurality of lower bearing discs arranged below the upper sweeping discs. A plurality of product containing discs are installed on each lower bearing disc. The upper sweeping discs are driven to rotate through an upper driving motor. The multiple lower bearing discs are driven to independently rotate through different lower driving motors correspondingly. To-be-swept products are placed on the product containing discs. The upper sweeping discs are provided with brushing hairs. Relative movement occurs between the upper sweeping discs and the multiple independently rotating lower bearing discs in the rotating process of the upper sweeping discs, so that sweeping machining is conducted on the products placed on the product containing discs. The brushing hairs are made of bristles and sisal. The bristles and the sisal are uniformly and mixedly distributed on the upper sweeping discs. The length of the brushing hairs is 15-35mm, preferably 20-25mm. According to the glass product sweeping device, a glass cover plate can be swept to be smooth, cutter mark in fingerprint recognition holes in the glass cover plate can be eliminated, uniform high-quality sweeping is achieved, and foaming can be inhibited.

Owner:DONGGUAN HUAQING OPTICAL TECH

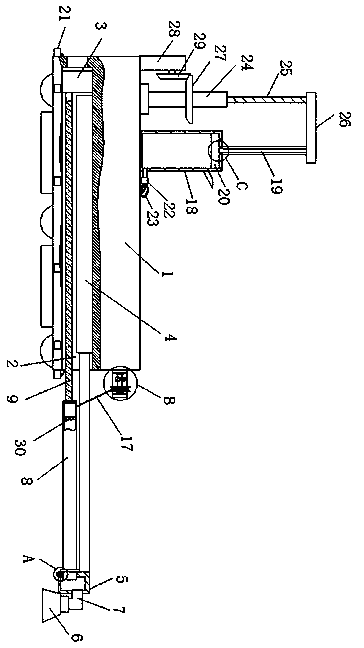

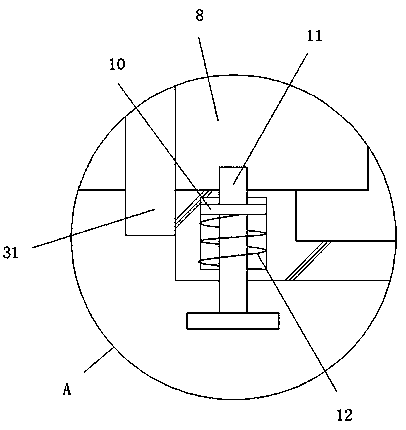

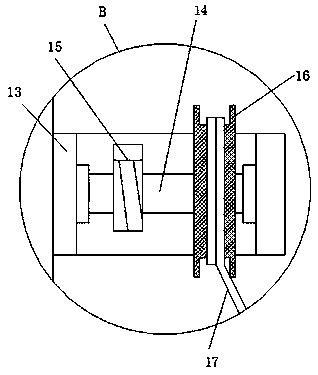

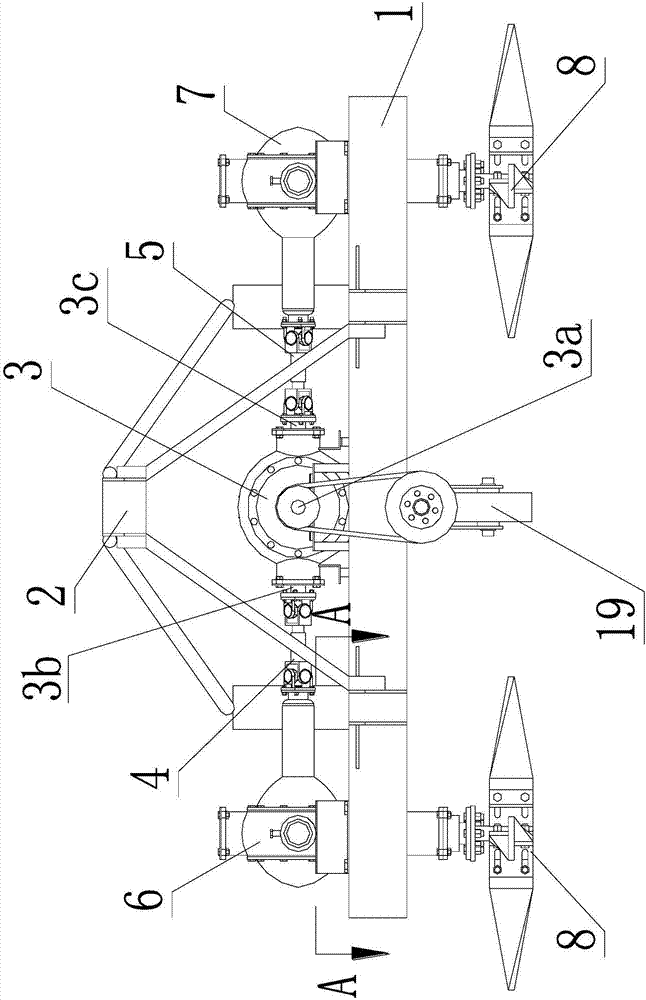

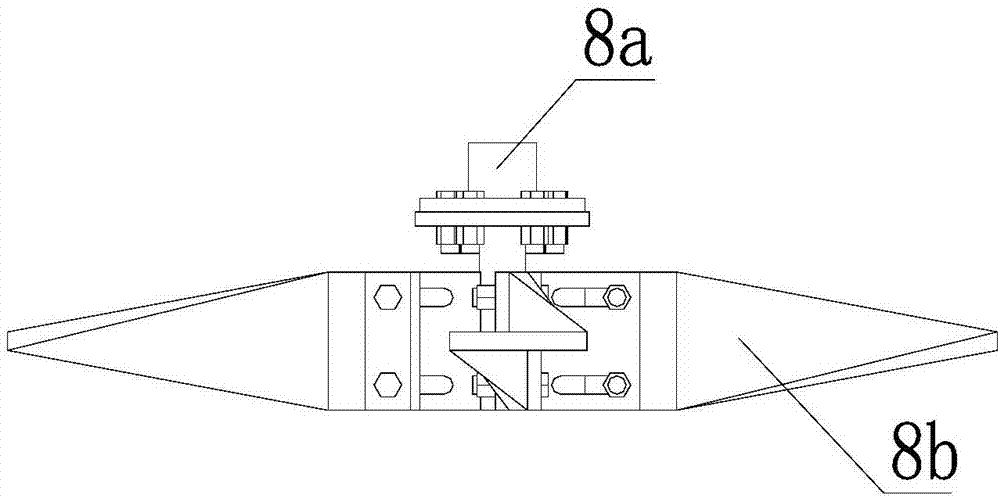

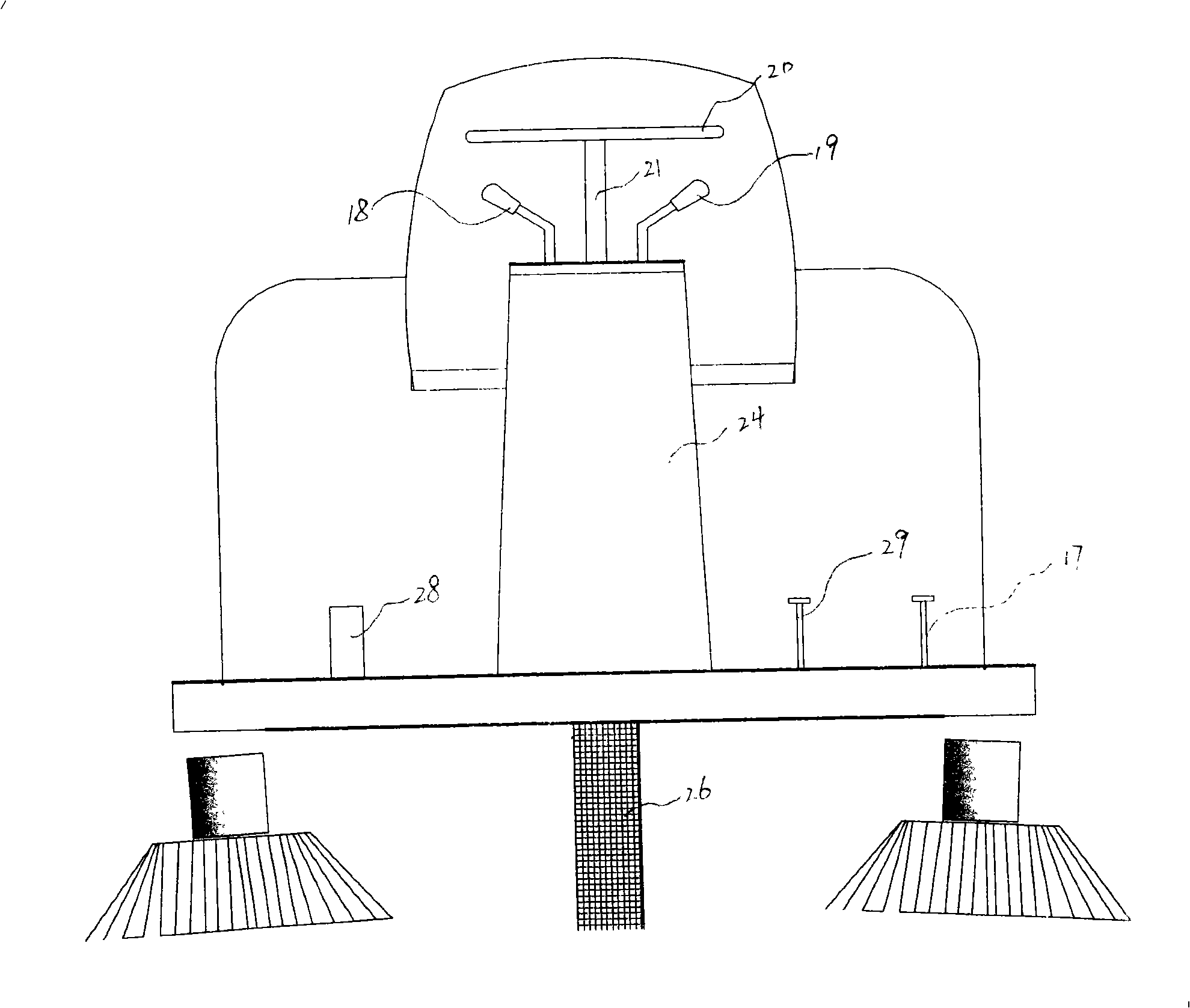

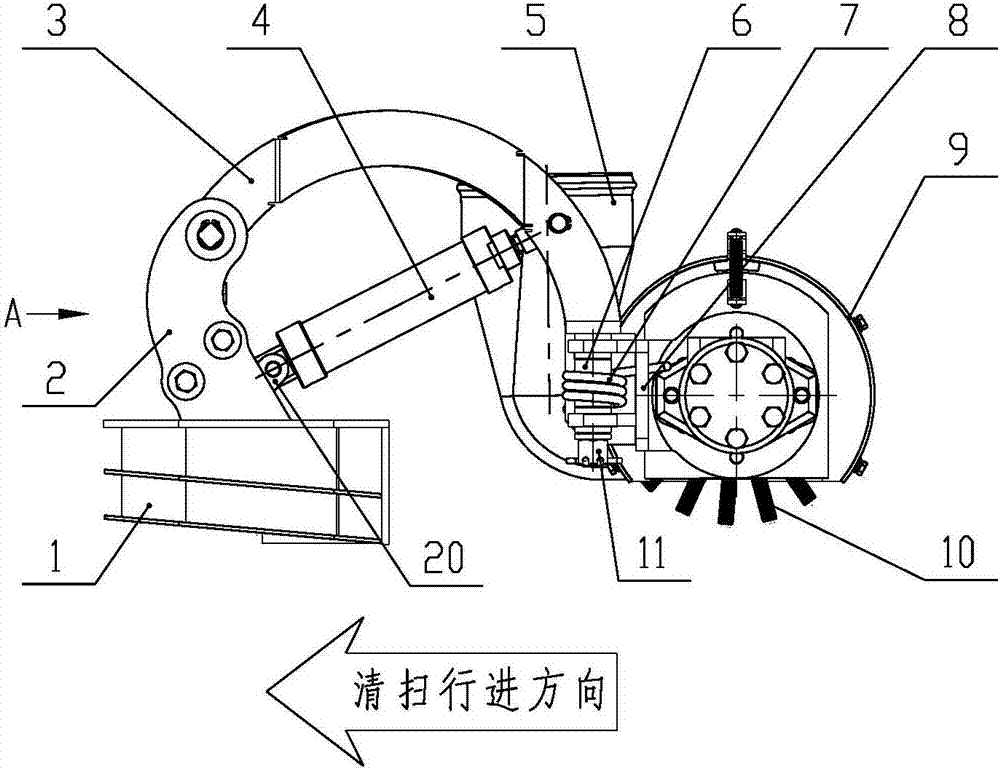

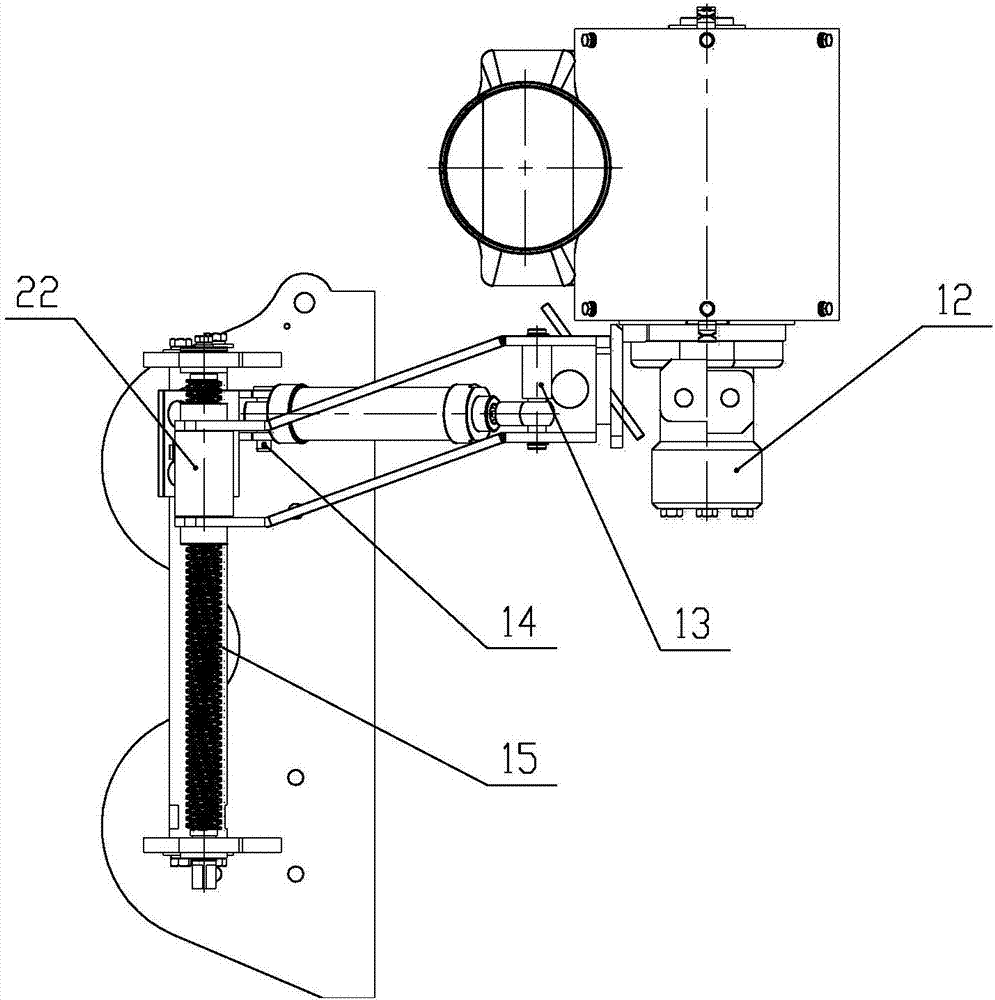

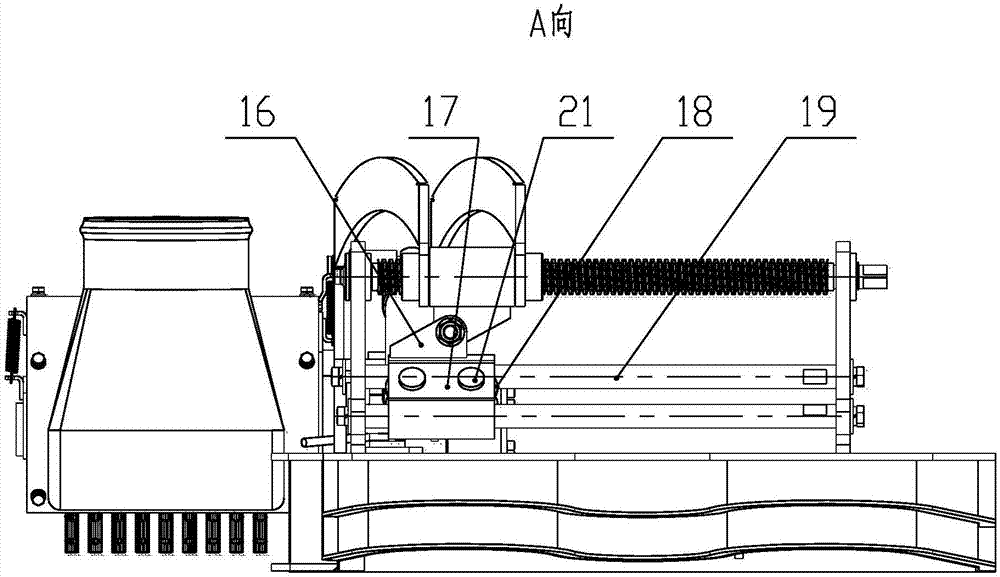

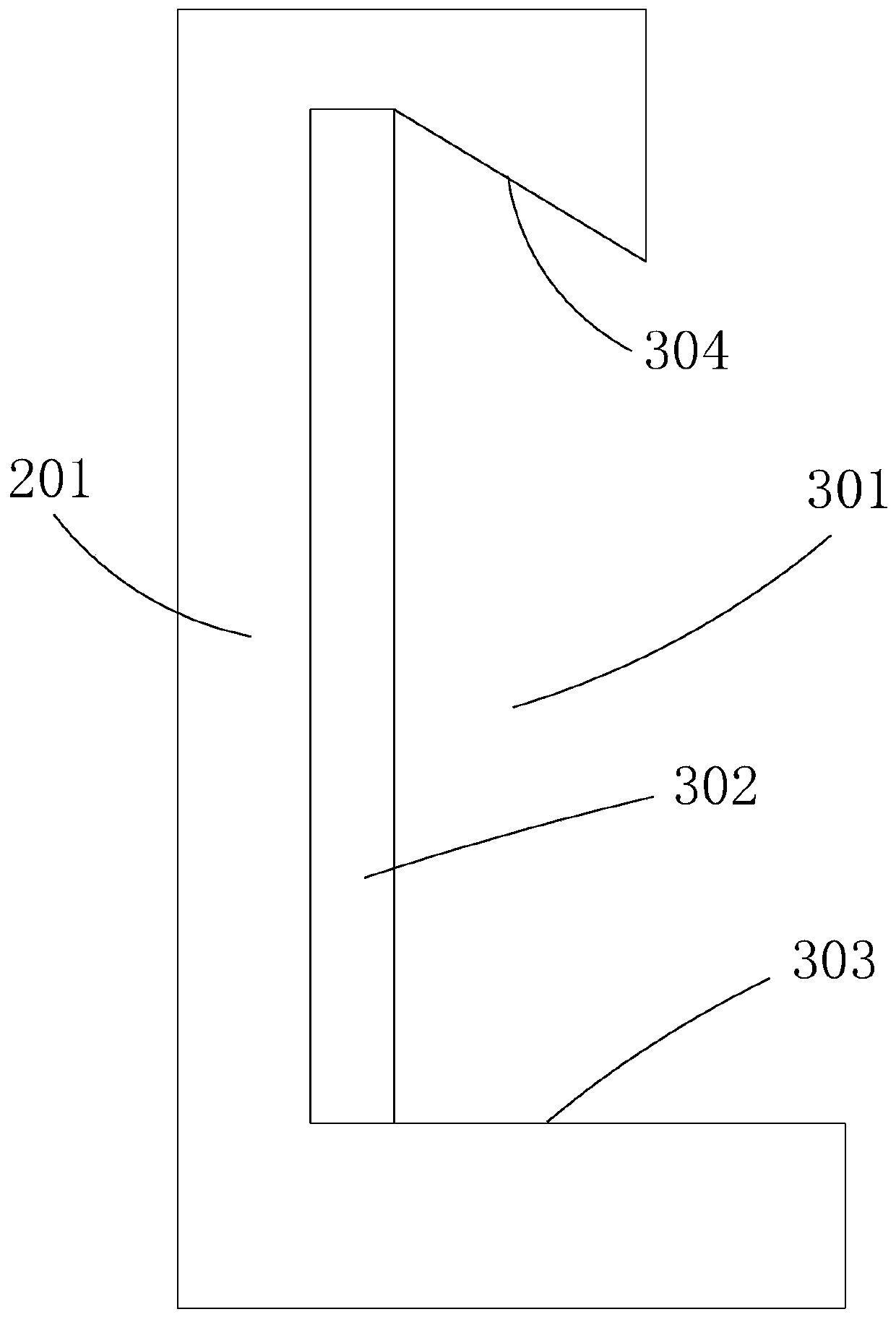

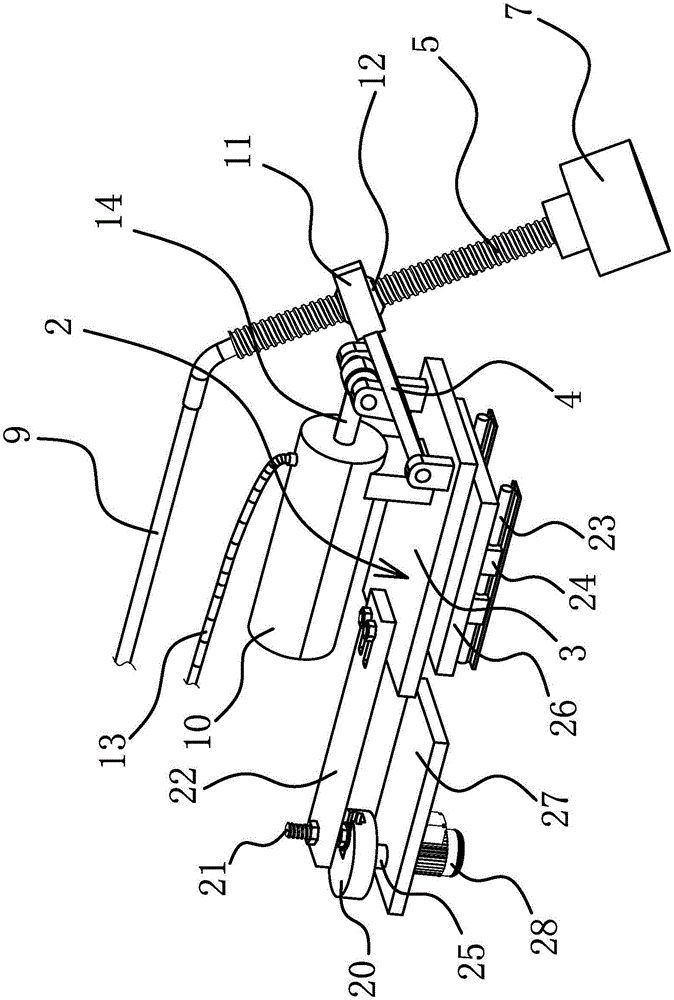

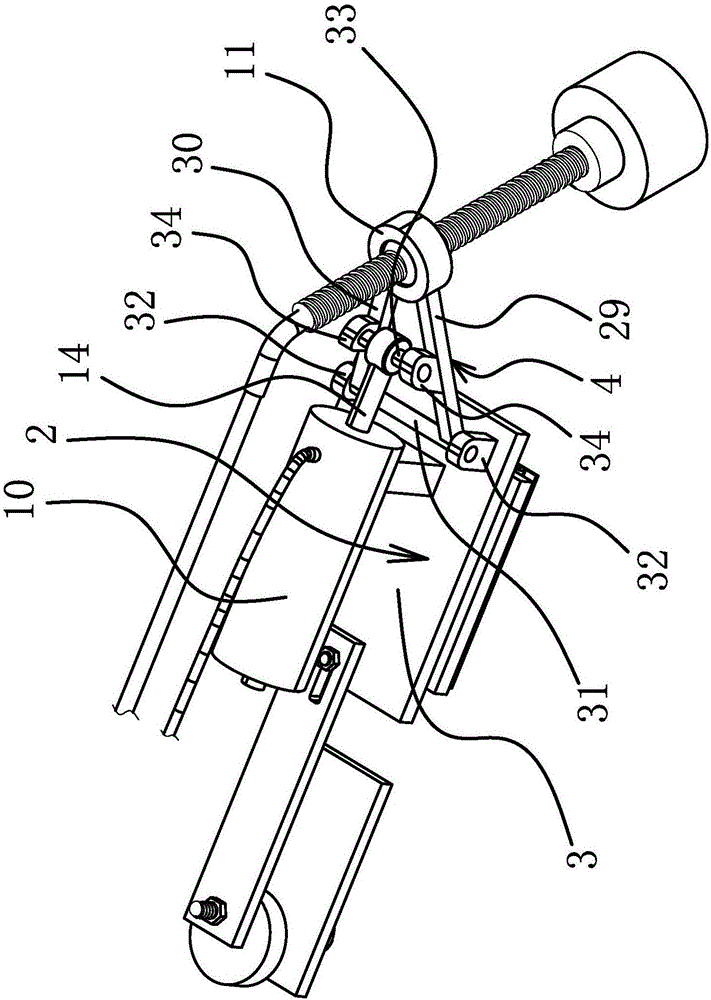

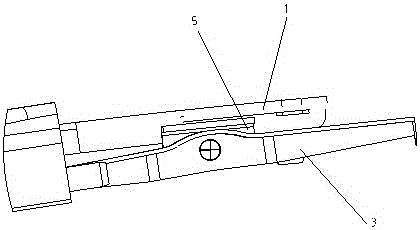

Horizontal suction sweeping support device for curbstones

The invention discloses a horizontal suction sweeping support device for curbstones. The device comprises a vertical plate base assembly, a movable bending plate assembly, a cylinder support seat assembly, a cylinder, a rolling brush connecting bending plate assembly and a rolling brush assembly, wherein the vertical plate base assembly is formed by welding a vertical plate base and two vertical plates; two horizontal guide rods of the cylinder support seat assembly are arranged between the two vertical plates of the vertical plate base assembly in parallel, a middle guide wheel is in rolling assembly connection with the two horizontal guide rods, and a cylinder support seat is fixedly connected with a long circular sleeve; a movable bending plate of the movable bending plate assembly is fixed between the two vertical plates by a screw rod, one end of the movable bending plate is connected with the screw rod by a guide screw nut, and the other end of the movable bending plate is connected with the rolling brush connecting bending plate assembly; the two ends of the cylinder are respectively connected with the movable bending plate and the cylinder support seat by a shaft; the rolling brush connecting bending plate assembly is rotatably connected with the end of the movable bending plate assembly, and the rolling brush connecting bending plate assembly is fixedly connected with the rolling brush assembly. Therefore, a horizontal suction sweeping assembly can better adapt to the working conditions of different surface slopes and different upper planes of the curbstones.

Owner:王海维

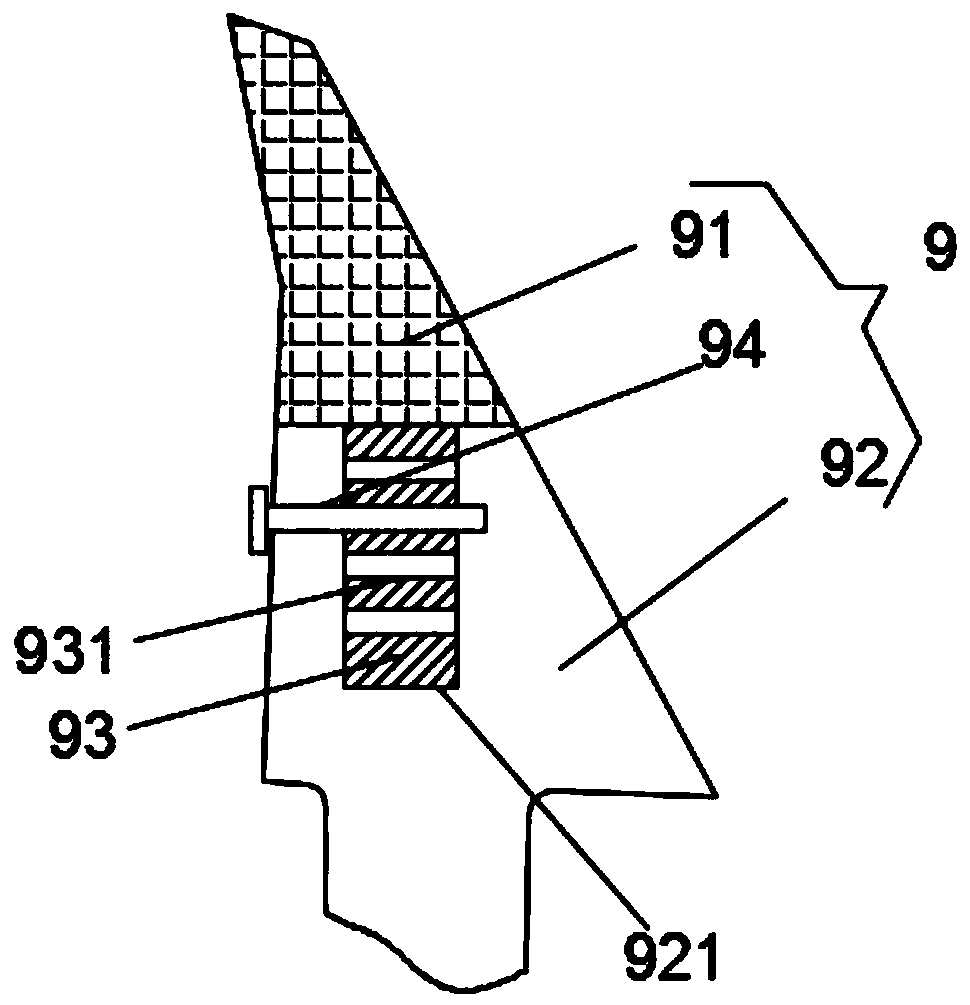

Shelling mechanism for camellia oleifera fruits

InactiveCN108552540AAvoid damageImprove shelling efficiencySievingScreeningCamellia oleiferaMechanical engineering

The invention relates to a shelling mechanism for camellia oleifera fruits. The shelling mechanism for camellia oleifera fruits comprises a machine frame; a shelling conveyor groove and a shelling barrel, which are in mutual cooperation, are arranged on the machine frame; an shelling conveyor auger is arranged in the shelling conveyor groove, and is connected with an auger motor; a shelling rotating shaft, which rotates forwards and backwards, is arranged in the shelling barrel, and is connected with a shelling rotating motor; a shelling rotating sleeve sleeves on the shelling rotating shaft;shelling material-receiving grooves, which are in cooperation with the shelling conveyor groove, uniformly sleeve on the shelling rotating sleeve; a lower part of the shelling rotating sleeve is a slope; and a shelling material outlet is formed at the lowest point of the slope. The purpose of the invention is to provide a shelling mechanism for camellia oleifera fruits in which the rotatable shelling material-receiving grooves and the shelling conveyor groove are adopted in cooperation so as to realize shelling of cracked camellia oleifera fruits by performing downward dropping and collision,and thus, the shelling mechanism for camellia oleifera fruits has improved shelling efficiency compared with manual shelling; moreover, damages on camellia oleifera seeds are also avoided so as to improve shelling effects.

Owner:DONGGUAN UNIV OF TECH

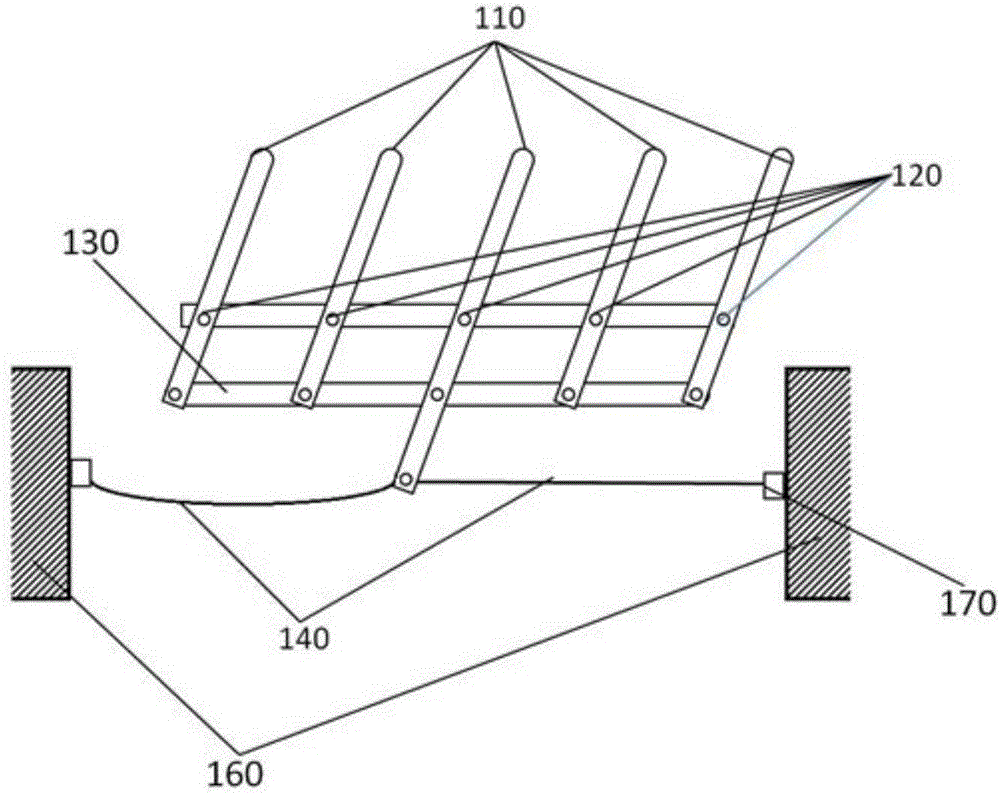

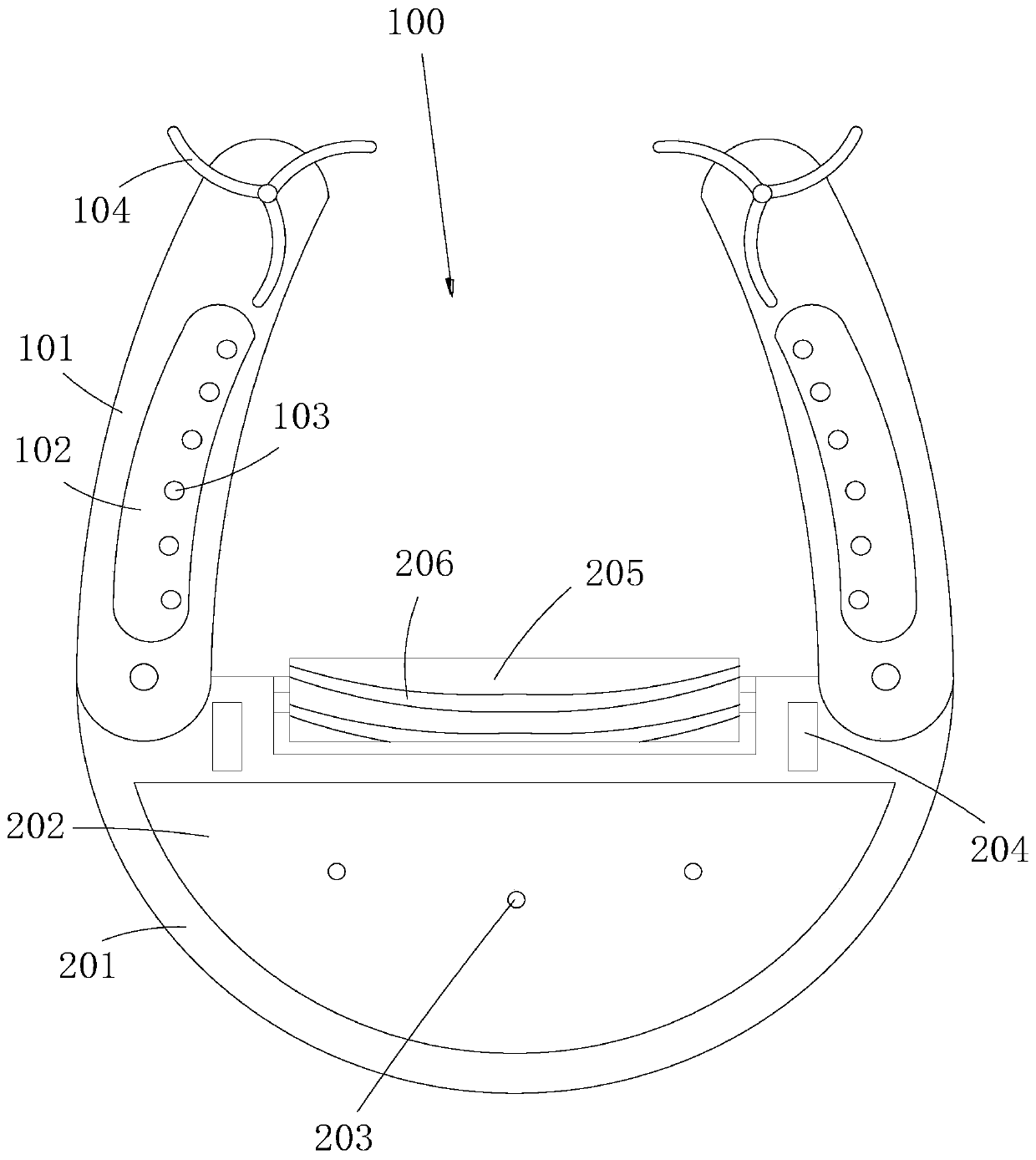

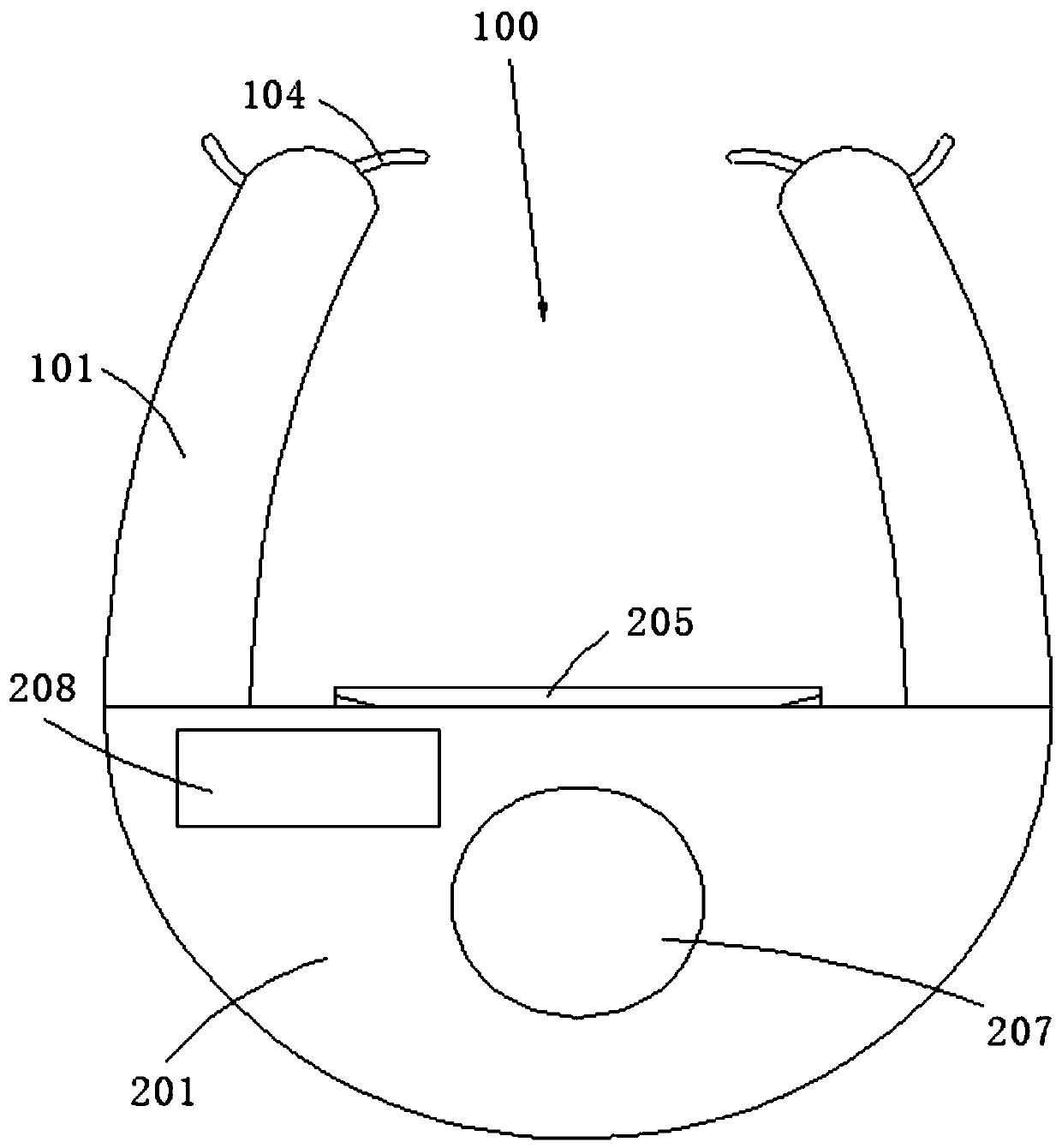

Swing arm type floor-sweeping robot

ActiveCN110403530AImprove the sweeping effectCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention relates to a swing arm type floor-sweeping robot, and belongs to the technical field of floor-sweeping robots. The swing arm type floor-sweeping robot comprises a machine body, two swingarms realizing swing towards the opposite directions or the deviating directions are connected to the front end part of the machine body, and a surrounding area is formed between the two swing arms and the front end part of the machine body in a surrounding manner; a plurality of rotating bristles are arranged on the peripheries of rotating wheels of the swing warms; a bottom accommodating cavityis arranged in the machine body, an accommodating opening is formed in the front end part of the machine body, the accommodating opening is provided with a rolling shaft, and rolling bristles are arranged on the periphery of the rolling shaft; side accommodating cavities are arranged in the middles of the swing arms, and dust collecting holes are arranged in the side walls of the inner ends of the swing arms; when the machine body walks, the rotating bristles sweep garbage in the surrounding area, the dust collecting holes suck the garbage into the side accommodating cavities, and the rollingbristles suck the garbage into the bottom accommodating cavity through the accommodating opening; and the swing arms enter the narrow space for sucking away the garbage, the two swing arms can surround an obstacle, so that sweeping and dust collecting can be carried out on the periphery of the obstacle, the floor sweeping effect is good, and the operation is more convenient.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

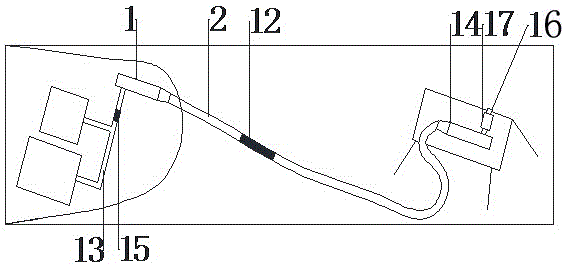

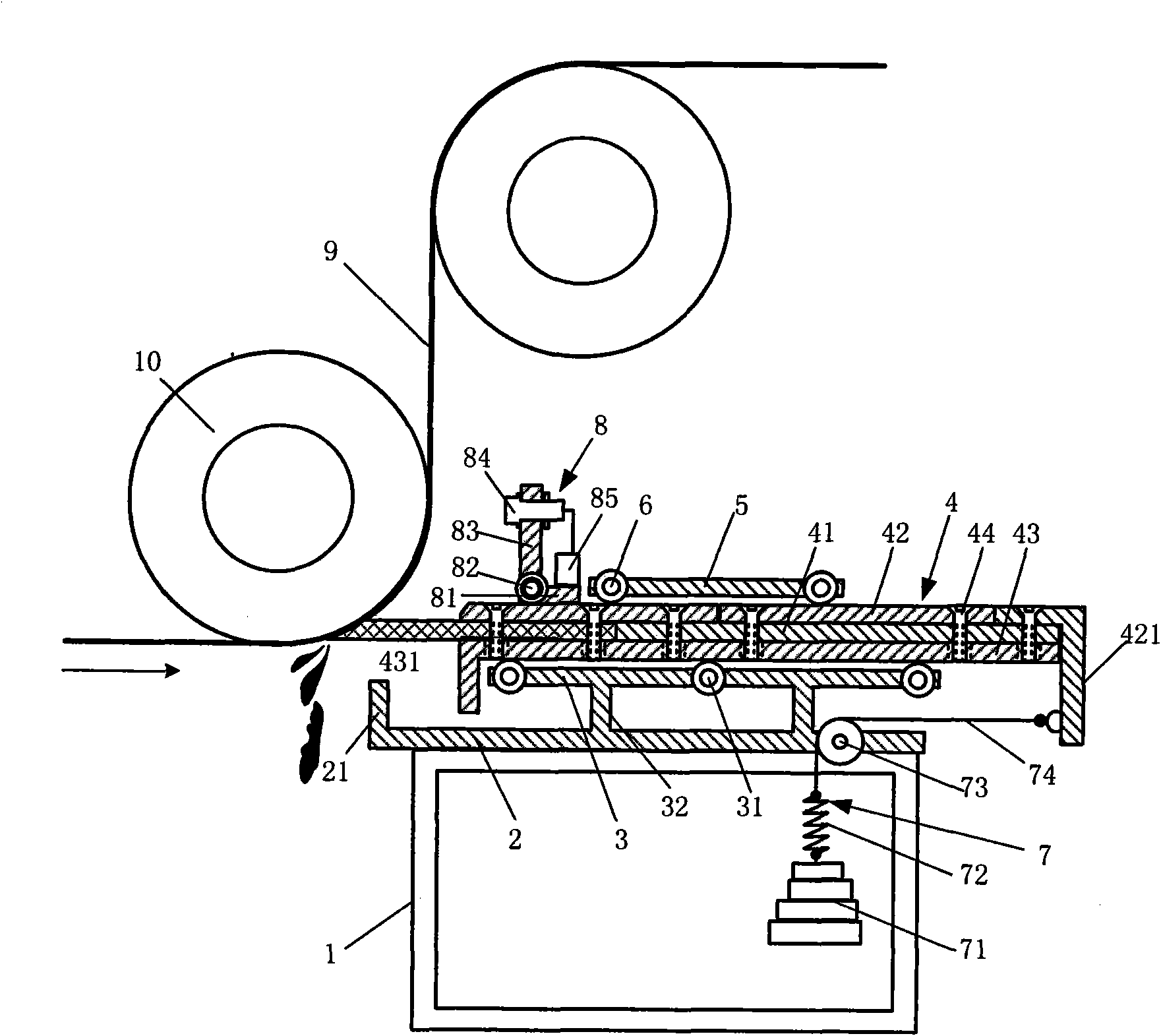

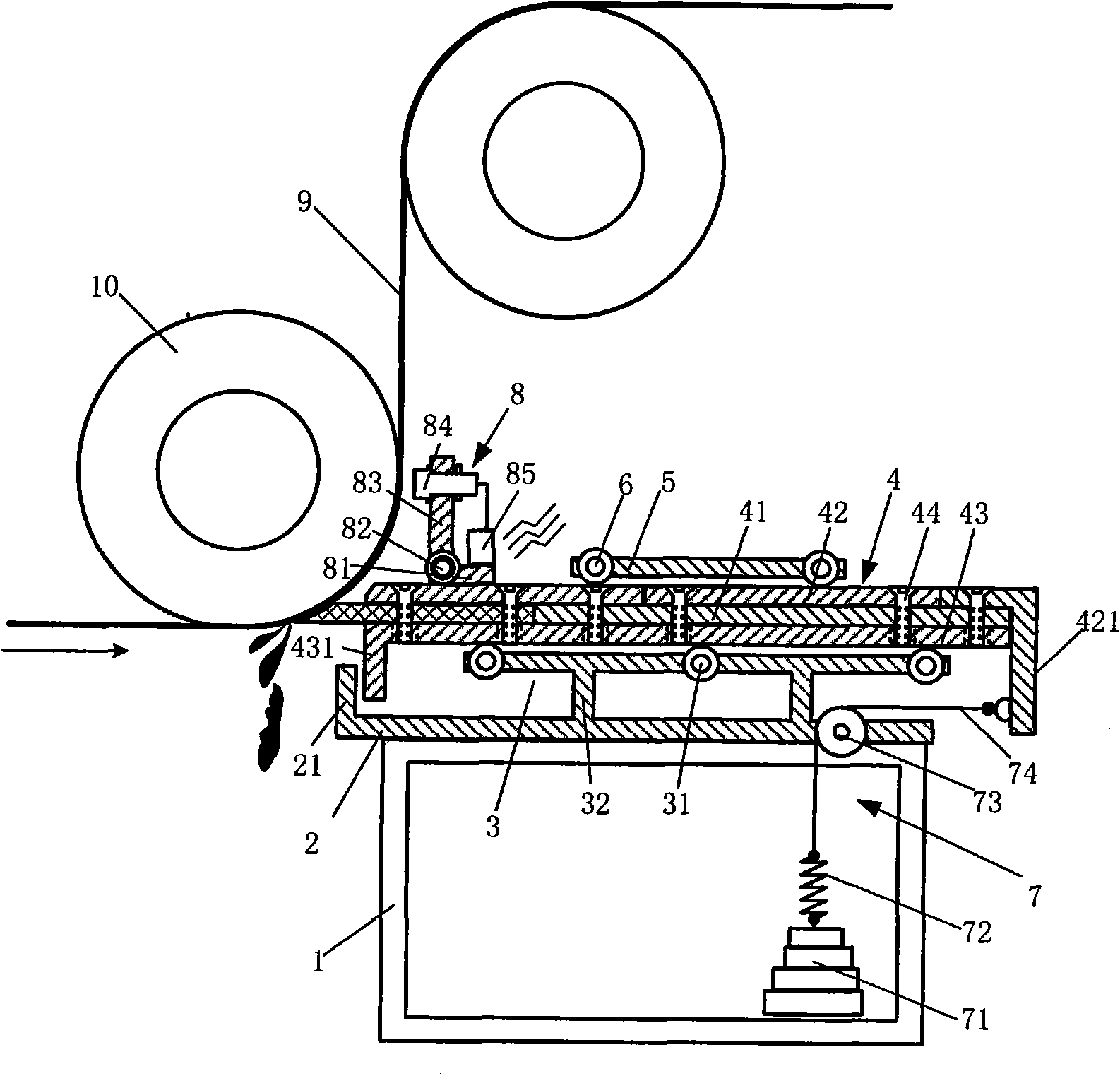

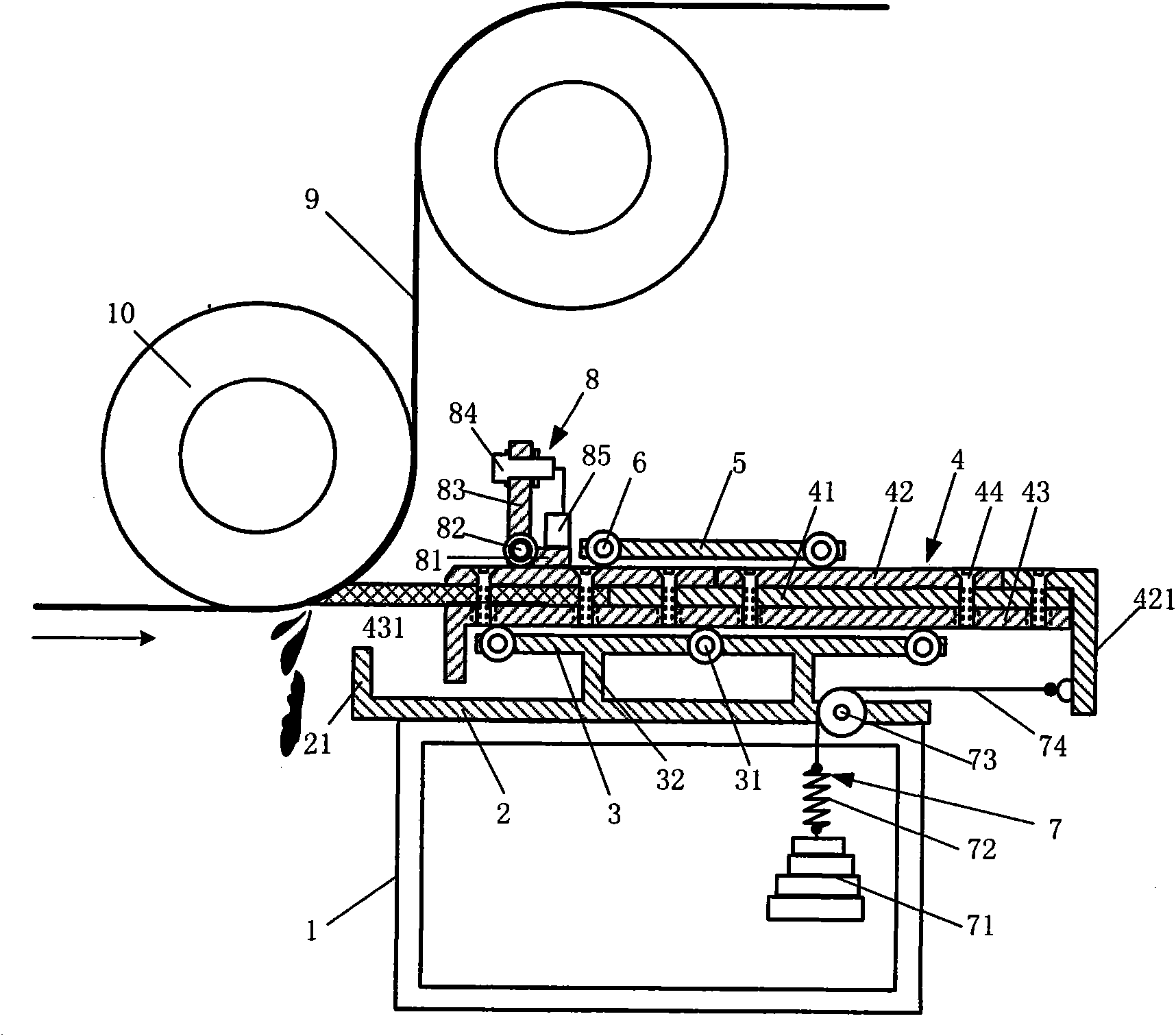

Self-propelled compensating return stroke sweeper for conveying belt

The invention discloses a self-propelled compensating return stroke sweeper for a conveying belt, and the self-propelled compensating return stroke sweeper for the conveying belt comprises a base, a bottom plate, a lower carrier roller seat, a sweeper framework, an upper carrier roller seat, a self-propelled compensating return stroke mechanism and an alarming mechanism, wherein the bottom plate is arranged on the base; one end of the bottom plate is bent upwards to form a limiting stop dog; the lower carrier roller seat is fixed on the bottom plate; the sweeper framework comprises a sweepingrubber eraser, an upper splint, a lower splint and a bolt; the lower splint is bent downwards to form a synchronous shifting stop dog; the upper carrier seat is positioned on the upper splint of the sweeper framework; the self-propelled compensating return stroke mechanism comprises a counterweight, a buffering spring, a hanging steel wire and a fixed pulley; the fixed pulley is fixed on the base; the buffering spring is connected with the counterweight; the other end of the buffering spring is connected with the hanging steel wire; the other end of the hanging steel wire is wound on the fixed pulley and is connected with the fixing part of the upper splint; the alarming mechanism comprises the bottom plate, a fixing bracket connected with the pivot shaft of the bottom plate, a proximity switch fixed on the fixing bracket, and an alarm connected with the proximity switch. The self-propelled compensating return stroke sweeper for the conveying belt has a self-propelled compensation function for the sweeping rubber eraser, the sweeping rubber eraser can be flexibly adjusted when the conveying belt has an uneven surface, and equal pressure is guaranteed to be applied to the surface of the running conveying belt.

Owner:BAOSHAN IRON & STEEL CO LTD

Air-sweeping structure and air conditioner

InactiveCN105526696ANo mutual interferenceImprove the sweeping effectAir-flow control membersAirflowEngineering

The invention discloses an air-sweeping structure and an air conditioner. The air-sweeping structure comprises a rotatable air-sweeping frame and a plurality of air-sweeping vanes, wherein the air-sweeping frame is provided with a flowing-through region for guiding an air current; the air-sweeping vanes are rotatably connected with the air-sweeping frame and are arranged at the flowing-through region; and the air-sweeping direction of the air-sweeping vanes is different from the air-sweeping frame. The air-sweeping structure and the air conditioner, provided by the invention, effectively solve the problem that an air-sweeping structure in the prior art has a small air-sweeping region and a poor air-sweeping effect.

Owner:GREE ELECTRIC APPLIANCES INC

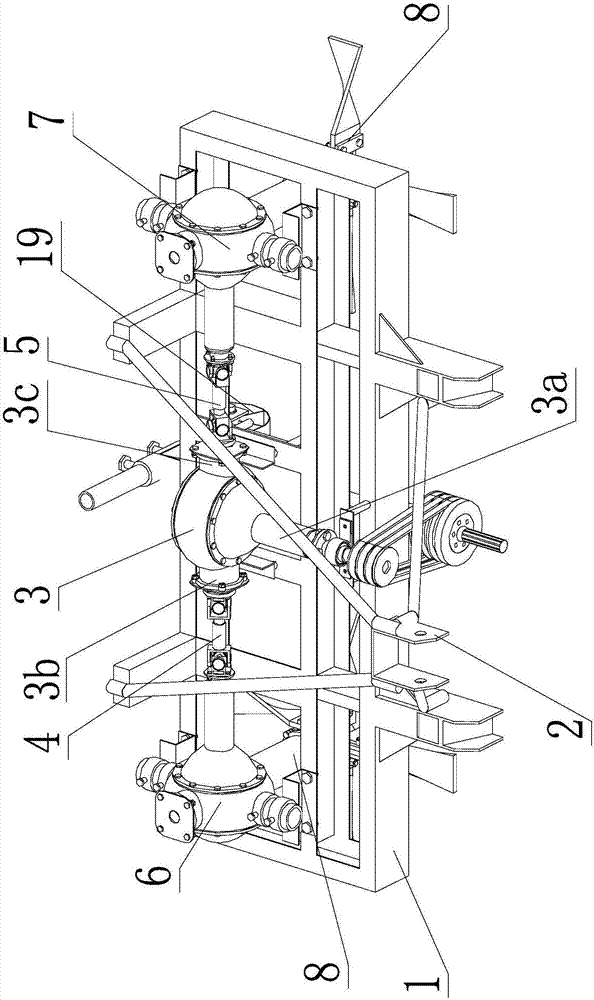

Water sweeping and drying pipe cleaner train of natural gas pipeline

InactiveCN105080916AImprove sealingExtended walking distanceHollow article cleaningWater basedFresh water

The invention relates to natural gas conveying pipeline construction equipment, in particular to a water sweeping and drying pipe cleaner train of a natural gas pipeline, and is suitable for various natural gas conveying pipelines. The water sweeping and drying pipe cleaner train of the natural gas pipeline is suitable for sweeping the natural gas pipeline, comprises multiple pipe cleaners, and further comprises a fresh water section plug, a water base gel section plug, a chemical drying agent section plug and a drying gas section plug, wherein the fresh water section plug, the water base gel section plug, the chemical drying agent section plug and the drying gas section plug are alternately arranged with the pipe cleaners in sequence. The pipe cleaner train, provided by the invention, is suitable for the water sweeping and the drying of long-distance and large-caliber natural gas conveying pipelines at the deepwater seabed.

Owner:HENAN ZHONGTUO PIPELINE ENG

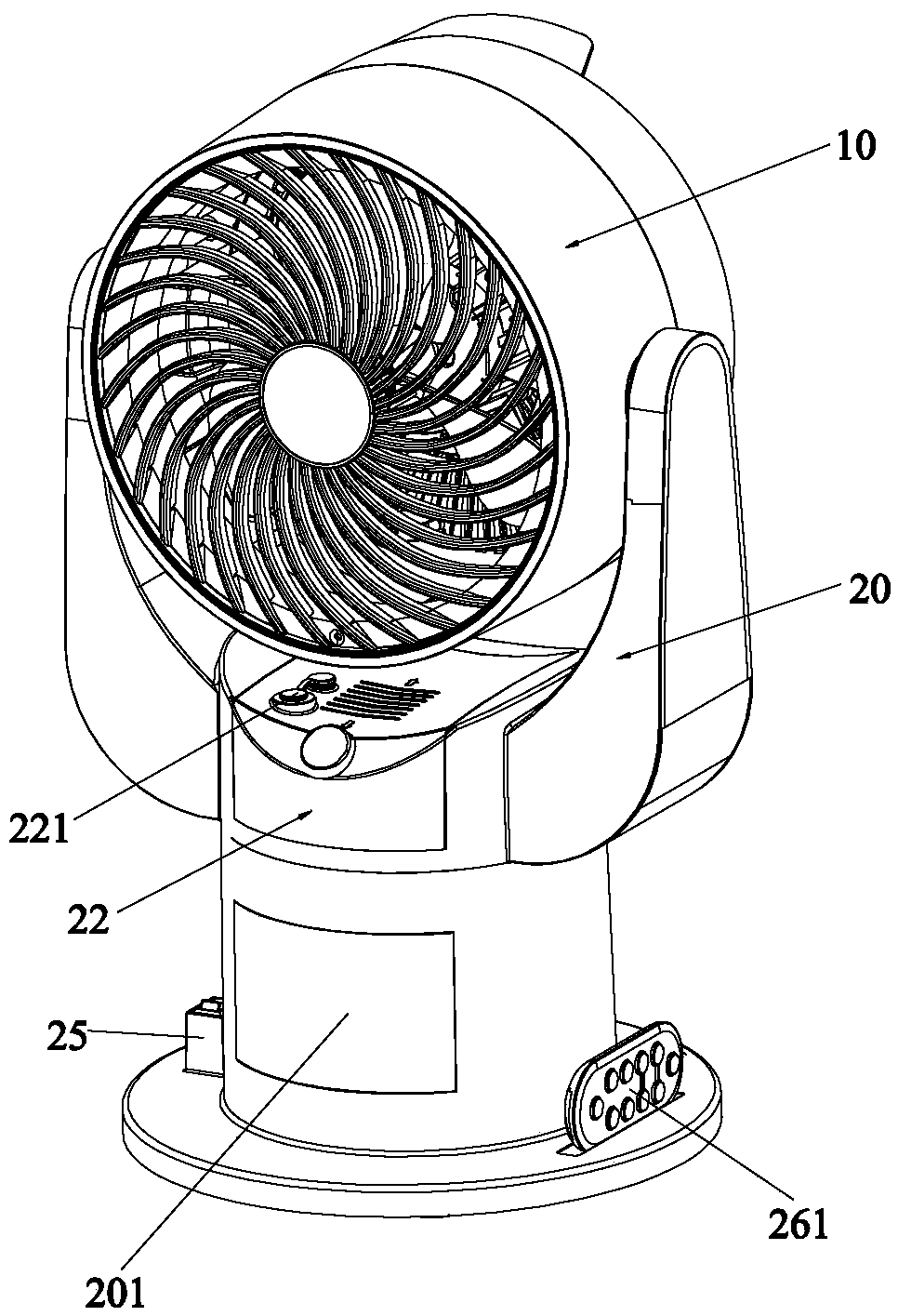

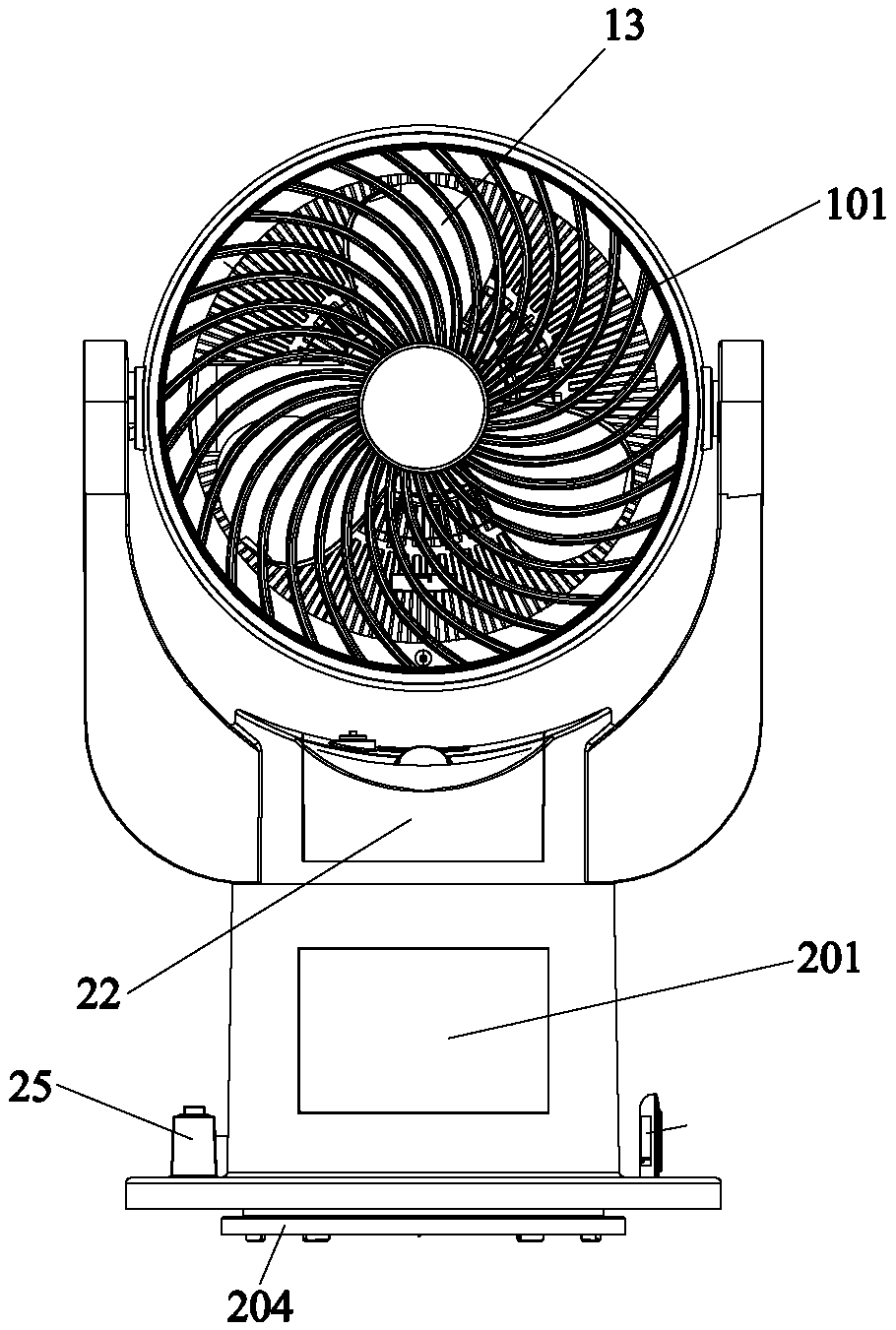

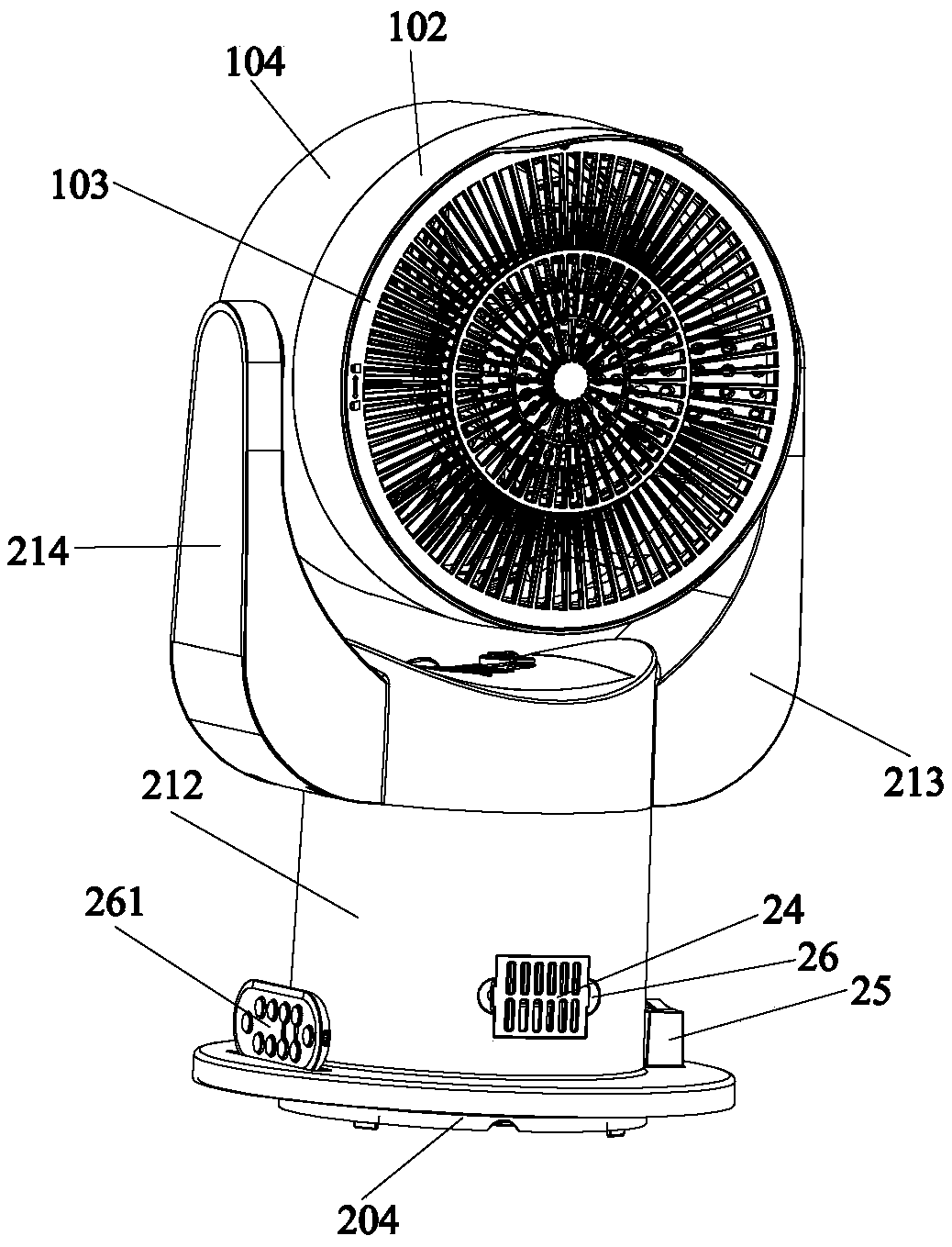

Circulating fan with humidifying and heating functions

PendingCN108844117AImprove comfortIncrease temperatureMechanical apparatusLighting and heating apparatusEngineeringHeating effect

The invention relates to a circulating fan with humidifying and heating functions. The circulating fan comprises a base assembly, a fan assembly, a main control circuit board, a driving circuit boardand a power supply board; the base assembly comprises a base, a chassis assembly, a first swinging unit and a second swinging unit, the base is provided with a water tank, the water tank is provided with a mist outlet and an atomizing sheet, and the atomizing sheet is arranged corresponding to the mist outlet; the fan assembly is internally provided with a main motor, an electric heating wire andfan blades; and rotating shafts are arranged on the left side and the right side of the outer wall of the fan assembly respectively, the main control circuit board is connected with the rotating shafton the left side of the outer wall of the fan assembly through a first swinging unit, and a main control circuit is connected with the chassis assembly through a second swing unit. The circulating fan has the humidifying and heating functions, the indoor air can improve the temperature and the humidity at the same time, the comfort degree of a human body is improved, the problem that because a short circuit of the circuit occurs after the circulating fan is poured, a fire is caused solved, the air sweeping effect, the humidifying effect and the heating effect are improved.

Owner:东莞市格尚电器有限公司

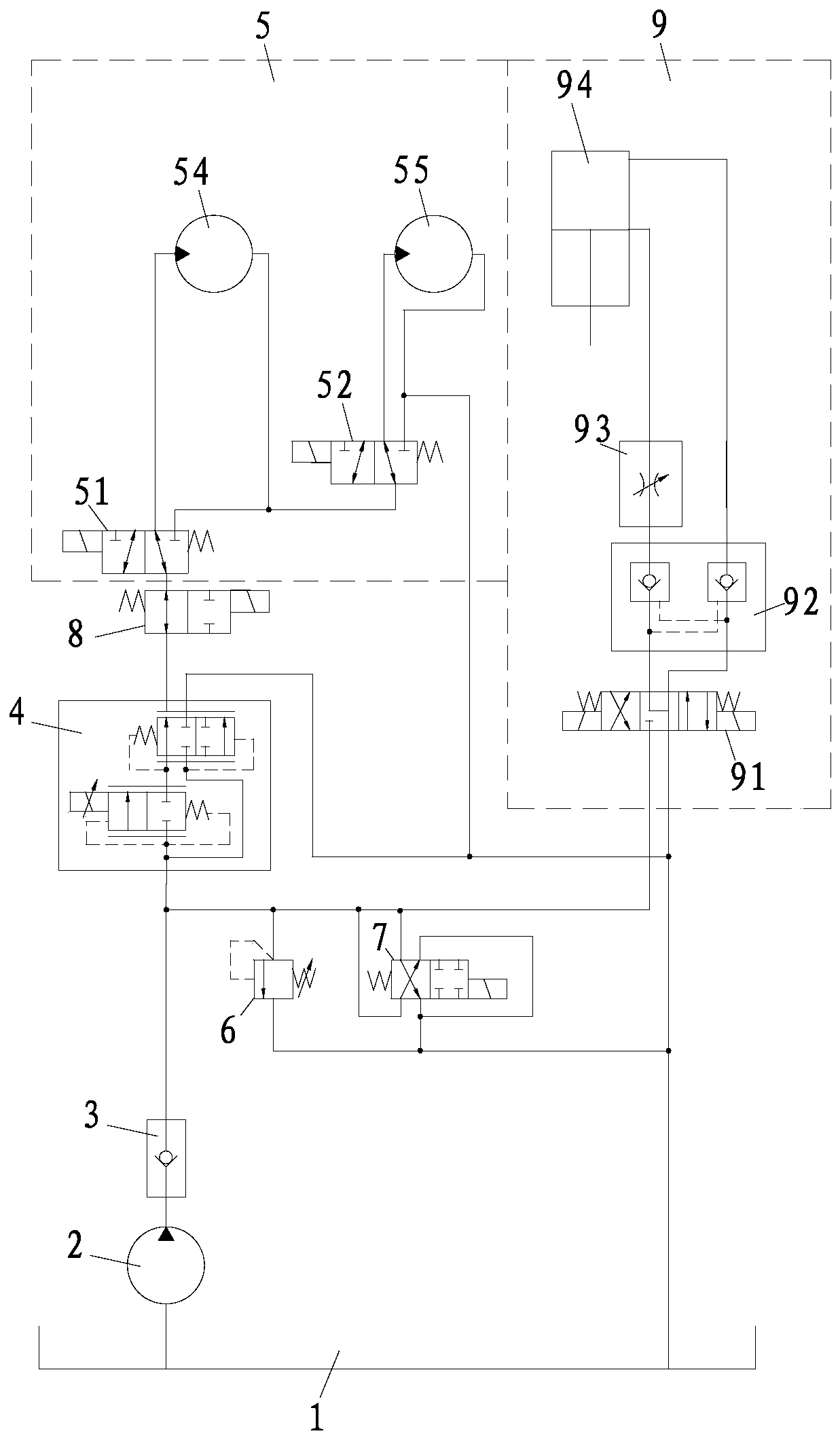

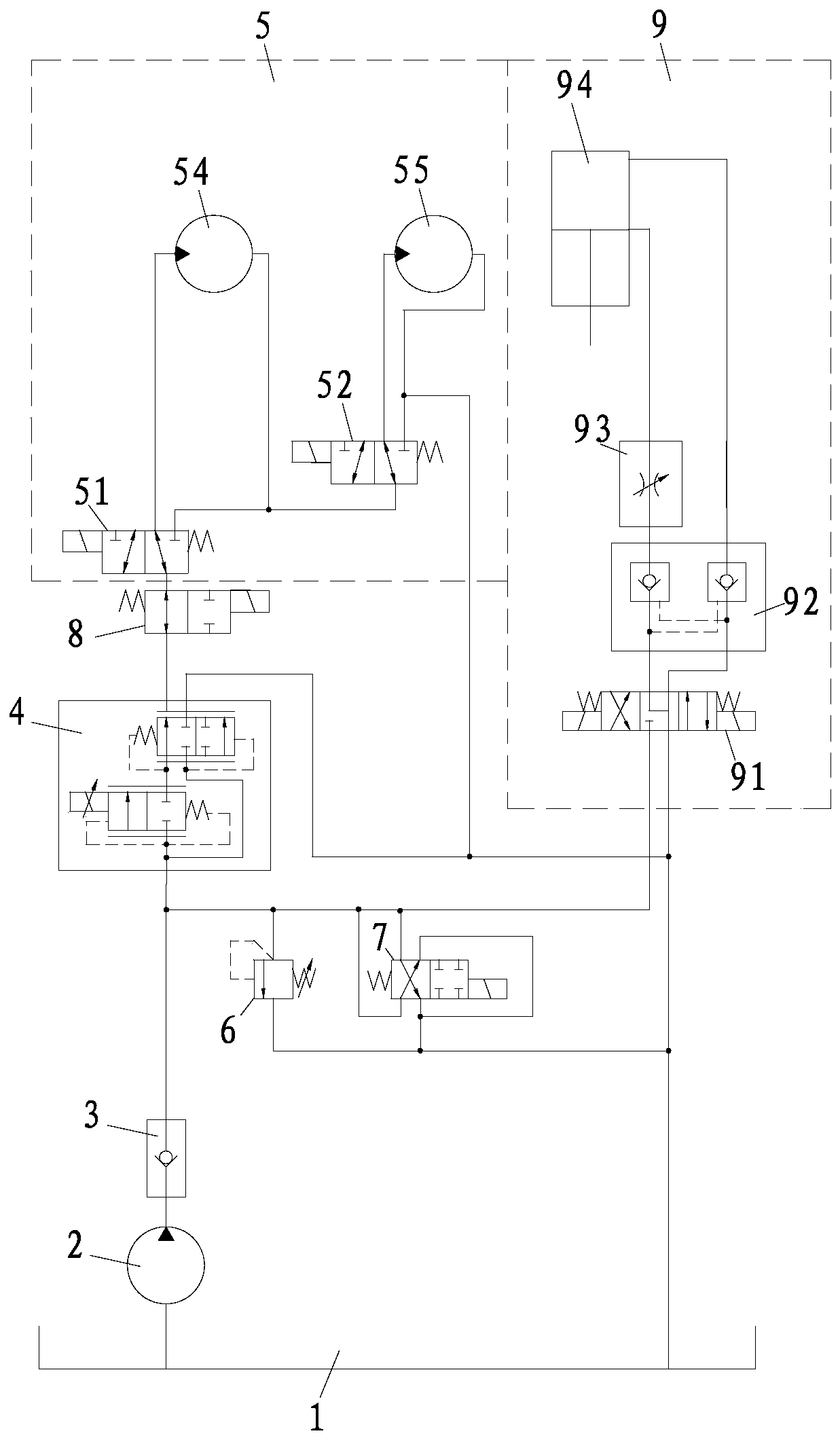

Stepless speed regulating energy-saving hydraulic system for cleaning sweeper truck

The invention discloses a stepless speed regulating energy-saving hydraulic system for a cleaning sweeper truck. A proportional flow control valve is disposed on a pipeline before a hydraulic motor unit. The proportional flow control valve is provided with an oil inlet, a flow control oil outlet, and a bypass oil leaking opening. The invention is advantageous in that through controlling the proportional flow output at the flow control oil outlet on the proportional flow control valve, the rotating speed of the hydraulic motor unit can be controlled, so that the stepless speed regulating control can be realized; in use, a user can adjust the optimized sweeping speed based on the road pollution degree of different road segments, and the best sweeping effect can be achieved; the excessive oilcan be returned from the bypass oil leaking opening of the proportional flow control valve to a hydraulic oil tank, so that energy saving of the system can be realized; energy consumption loss is little, heating is small, and substantive features and notable progress are provided; a hydraulic cylinder unit is connected between an outlet end of a one-way valve and an oil-returning mouth of the hydraulic oil tank, which is convenient to drive the sweeping discs of the cleaning sweeper truck to rotate.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

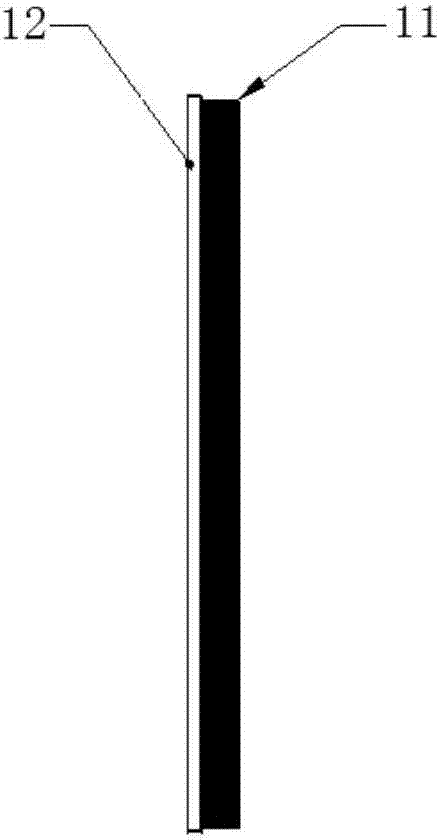

Polishing device for producing mobile phone cover

ActiveCN109048588AGood sweeping effectImprove work efficiencyGrinding drivesGrinding feed controlMobile phoneMachining

The invention provides a polishing device for producing a mobile phone cover. The polishing device comprises a base, a fixing mechanism, a convex face polishing mechanism and a concave face polishingmechanism. The top surface of a fixing plate is rotatably provided with a first gear and a plurality of first grinding disks, the multiple first grinding disks are distributed on the same side of thefirst gear and are sequentially engaged with the first gear, and the top surfaces of the first grinding disks are provided with convex face polishing jigs; the bottom face of the fixing plate is rotatably provided with a second gear and a plurality of second grinding disks, the multiple second grinding disks are distributed on the same side of the second gear and are engaged with the second gear sequentially, and the top surfaces of the second grinding disks are provided with concave face polishing jigs; and the convex face polishing mechanism is located above the fixing mechanism, and the concave face polishing mechanism is located below the fixing mechanism. According to the polishing device, the fixing mechanism is arranged for fixing a workpiece to be machined; and the convex face polishing mechanism and the concave face polishing mechanism are arranged for polishing machining of a convex face and a concave face of the workpiece correspondingly. The polishing device can perform polishing machining on the convex face and the concave face of the workpiece, and the work efficiency is high.

Owner:安徽金龙浩光电科技有限公司

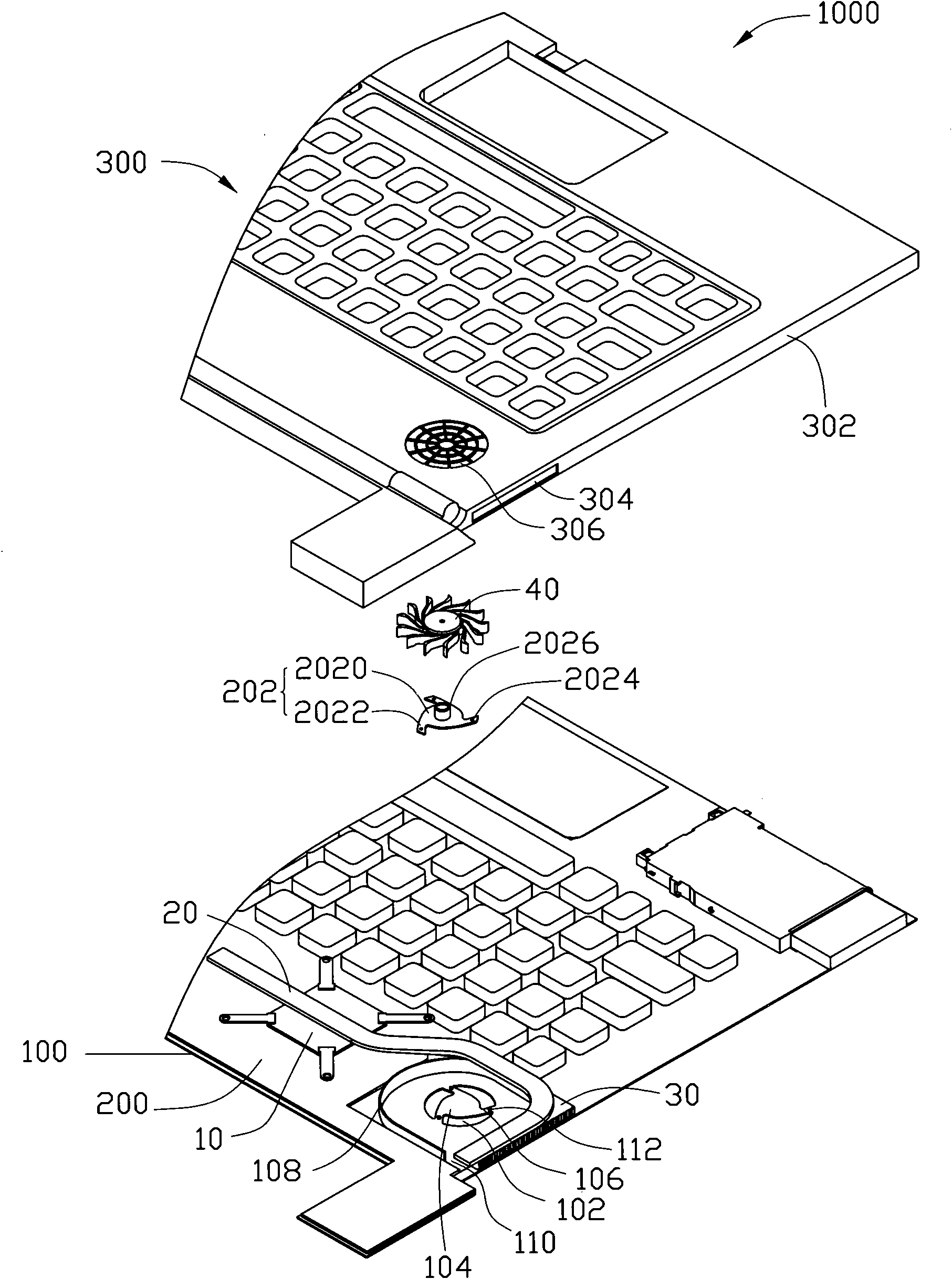

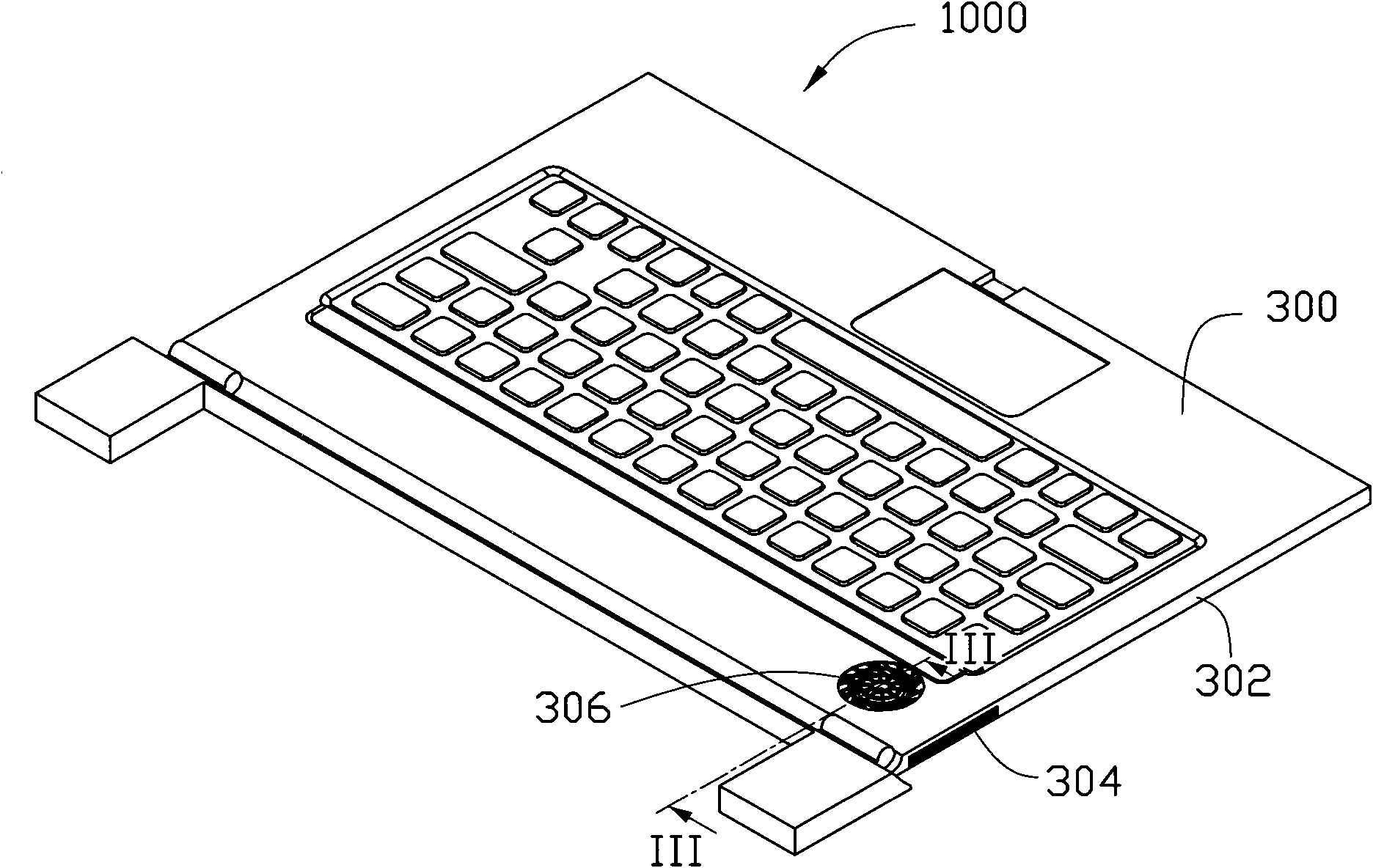

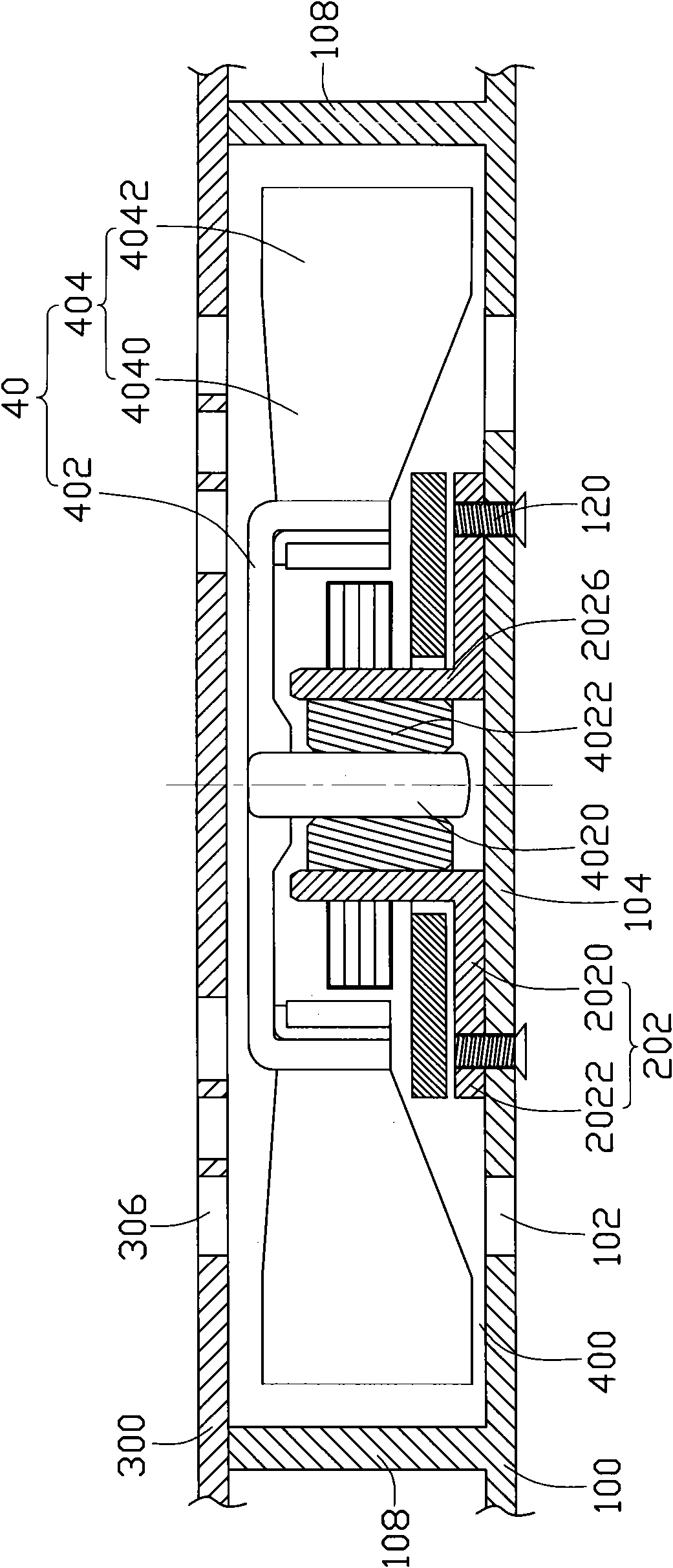

Radiator fan and electronic device adopting same

InactiveCN101600321AImprove the sweeping effectIncrease the setting spacePump componentsDigital data processing detailsImpellerPulp and paper industry

The invention relates to an electronic device comprising a bottom plate and a cover plate corresponding to the bottom plate, the bottom plate is mutually combined with the cover plate to form an accommodating space, and a fan is arranged in the accommodating space; the fan comprises an impeller and a bracket, wherein the frame is arranged on the bottom plate, the impeller is rotatably arranged on the bracket and comprises a hub and a plurality of blades annularly arranged on the hub, and the tail end of each blade directly corresponds to the bottom plate. The electronic device at least can increase the arrangement space of the tail end of the blade in a height direction and increase the sweeping capability of the fan, thereby improving the radiating performance.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

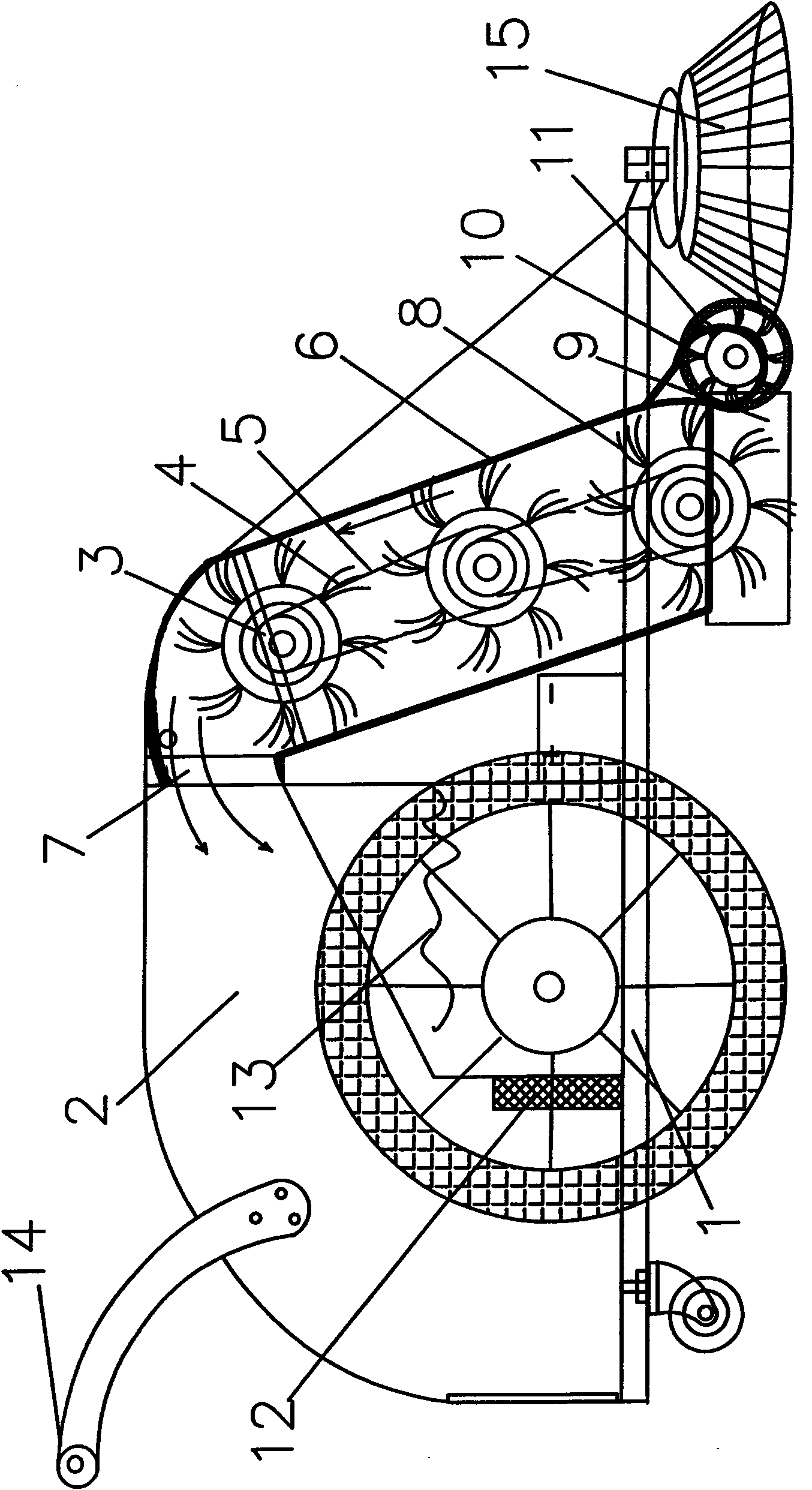

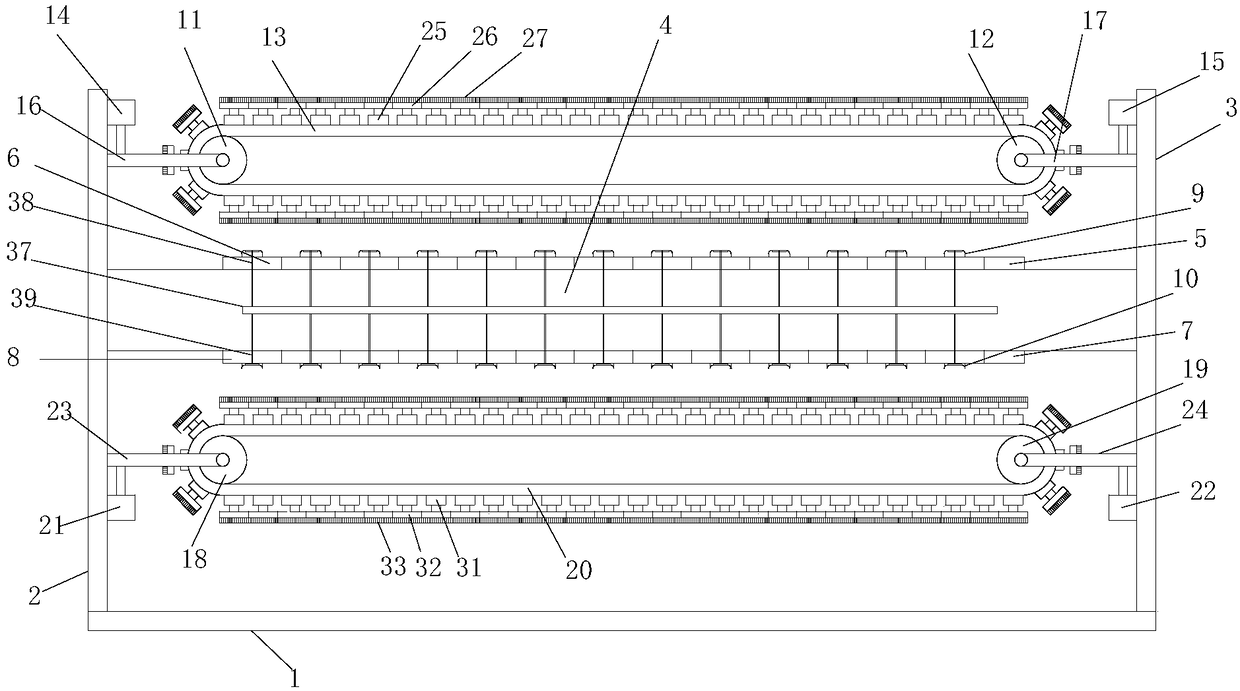

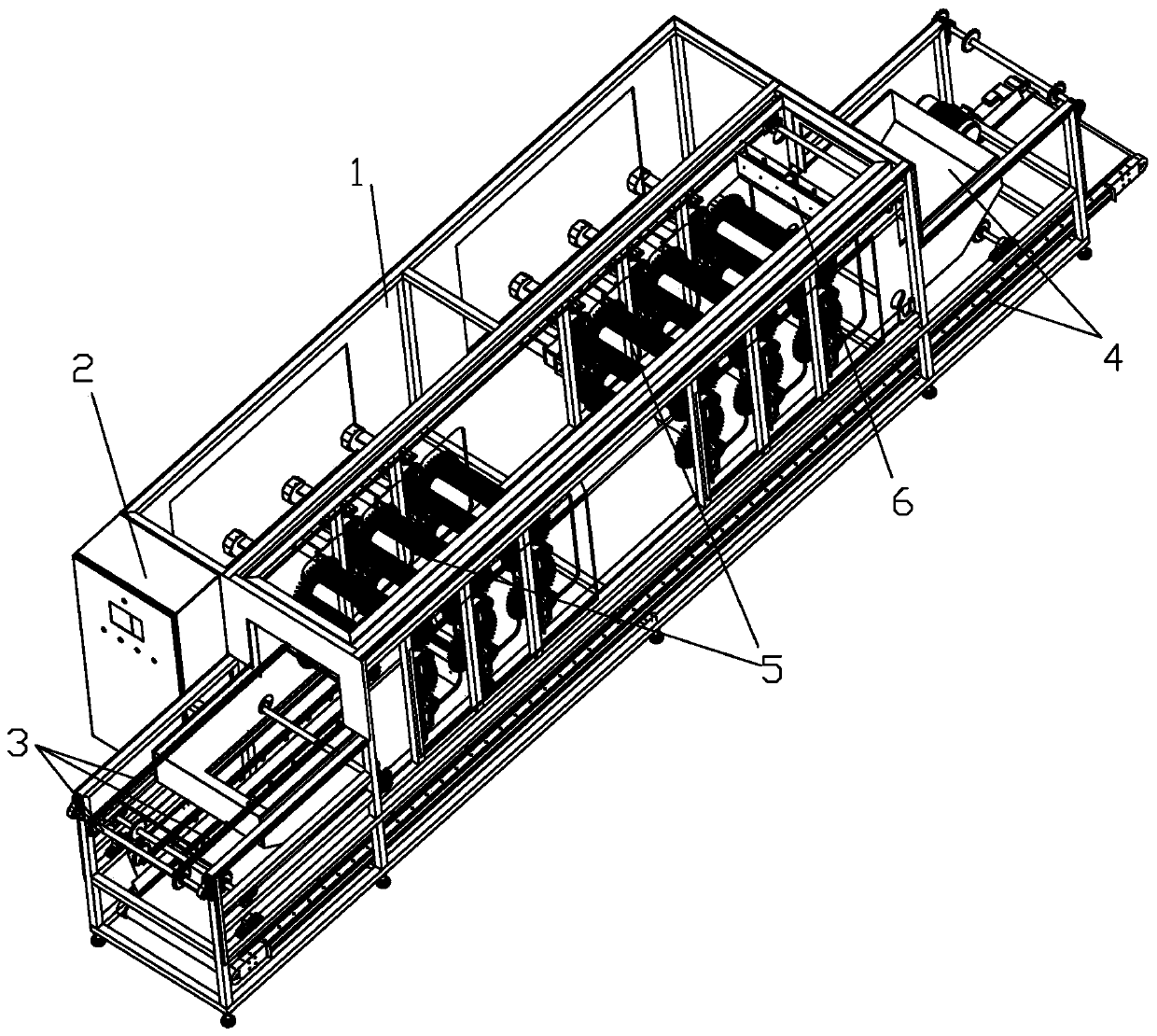

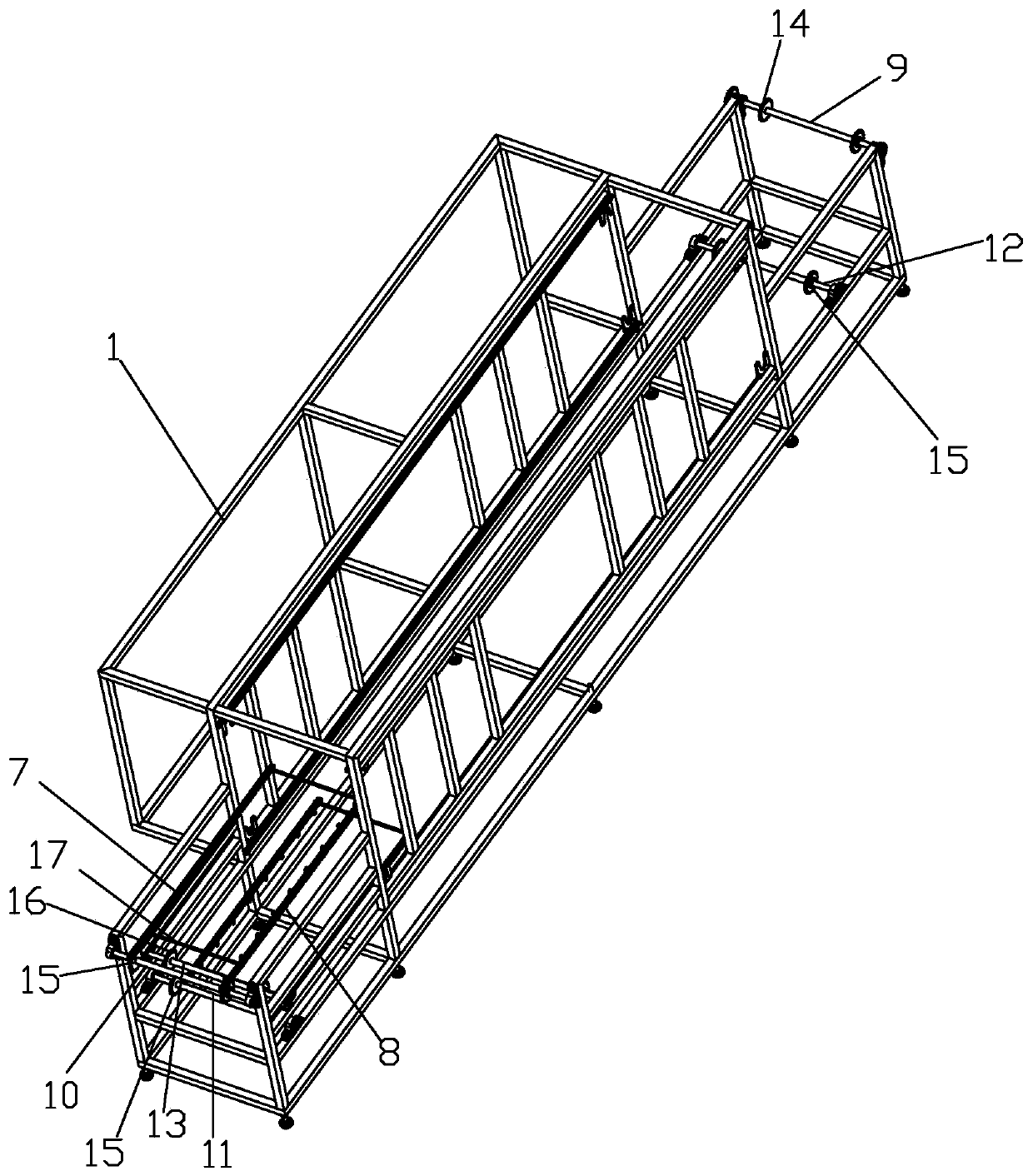

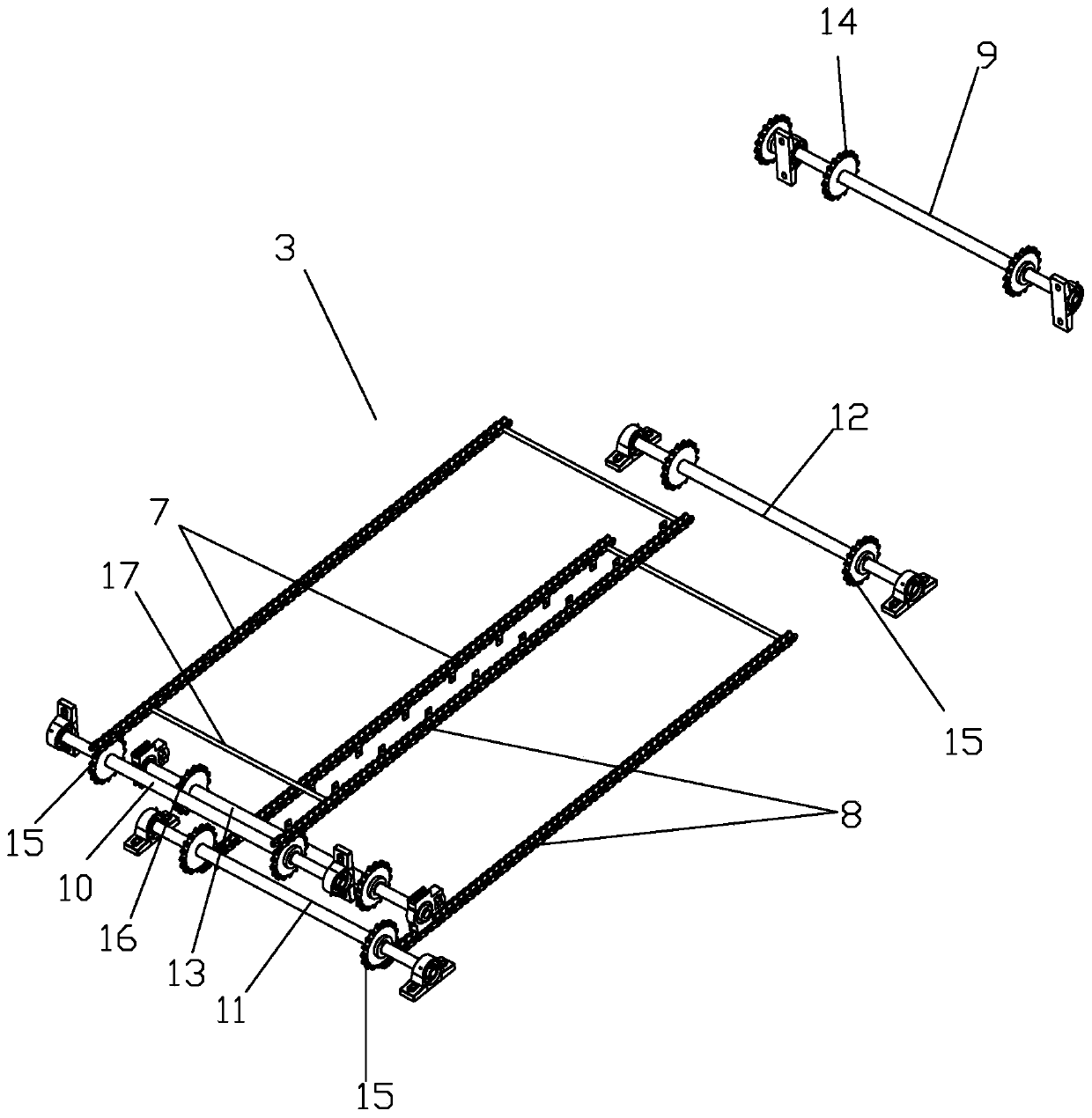

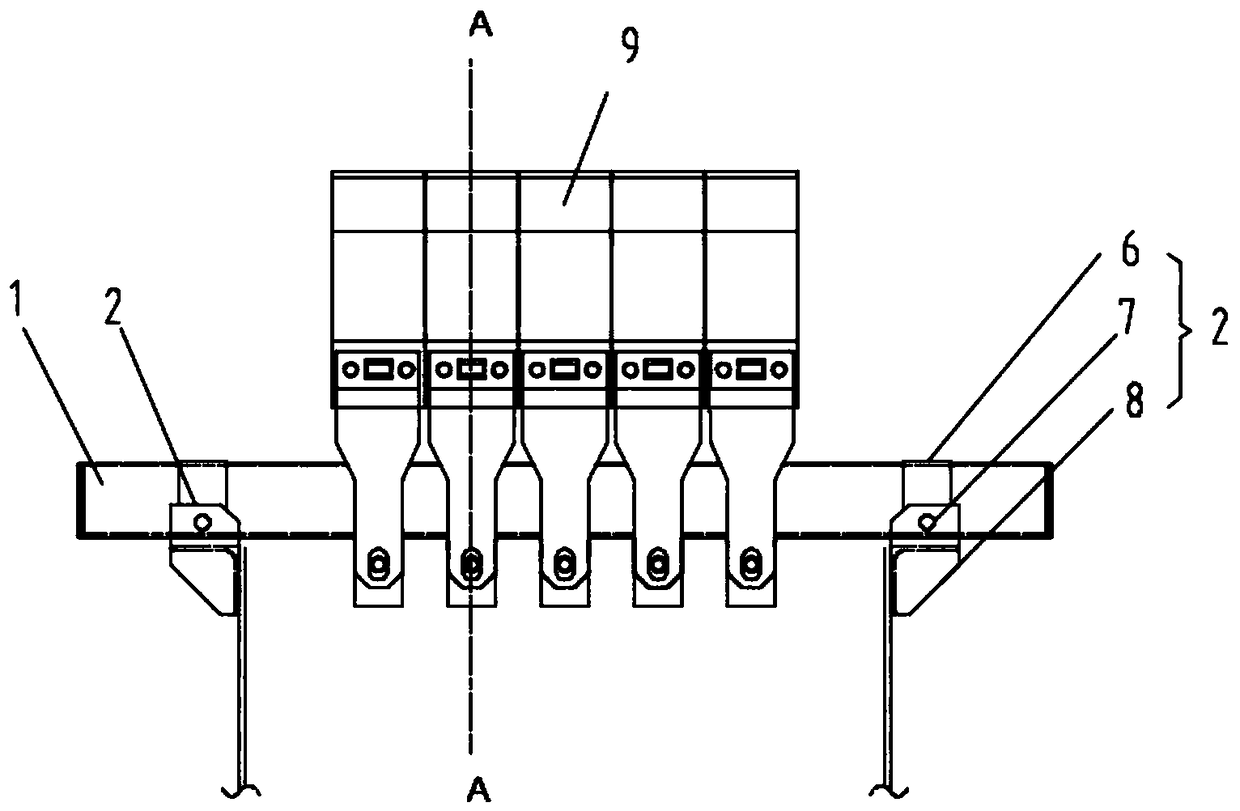

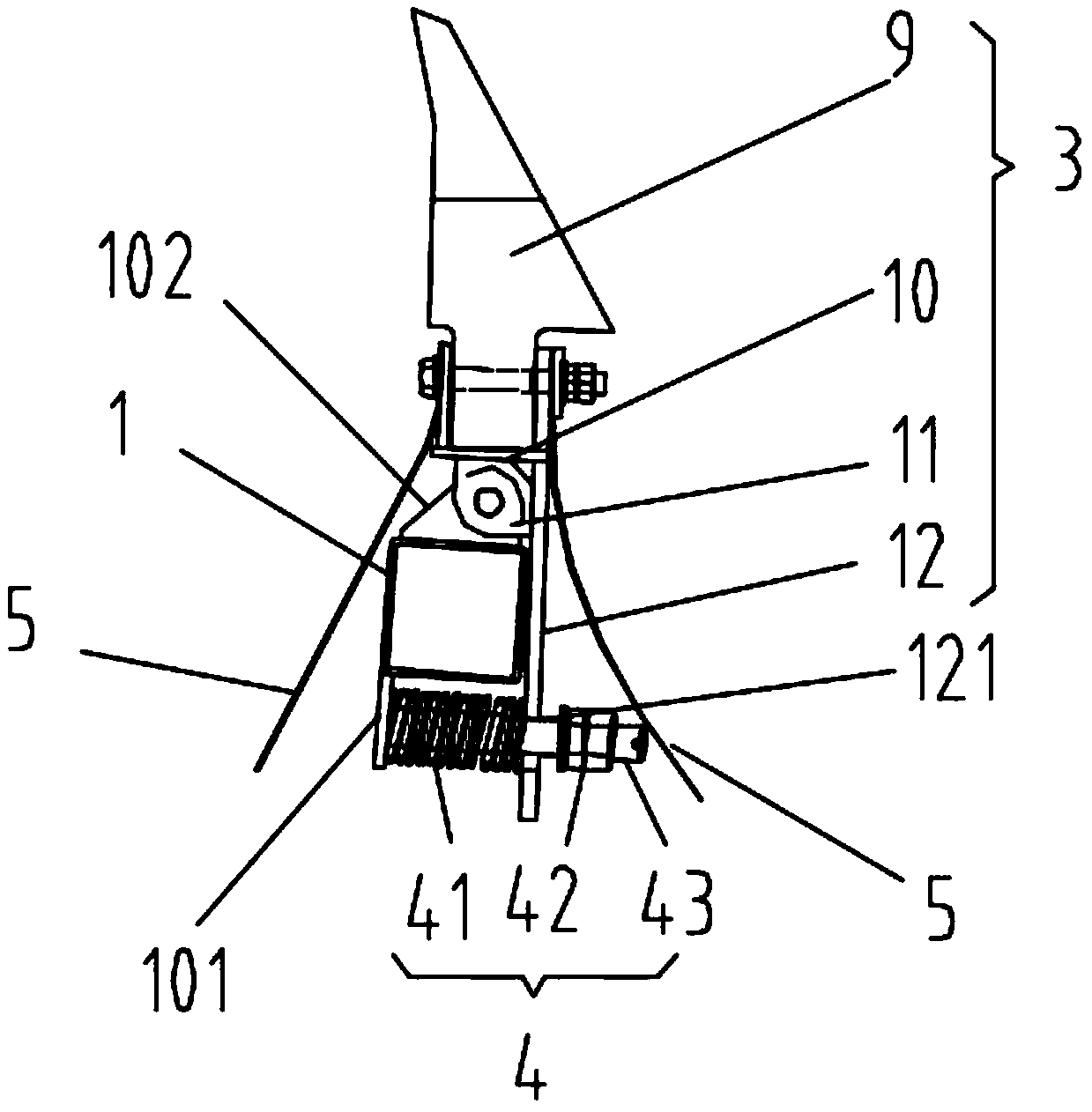

Automatic cocoon harvesting machine used for industrialized rearing

The invention discloses an automatic cocoon harvesting machine used for industrialized rearing. The automatic cocoon harvesting machine comprises a frame and a distribution box; the frame is providedwith a double-chain propulsion mechanism and hairbrush systems; the double-chain propulsion mechanism extends to the rear end of the frame from the front end of the frame; the hairbrush systems are installed in the frame; and the double-chain propulsion mechanism cooperates with the hairbrush systems. According to the automatic cocoon harvesting machine, in allusion to defects of existing automatic cocoon harvesting equipment, silkworm cocoons on cocoon cages are collected by adopting hairbrushes, so that not only can silkworm cocoons on surfaces of the cocoon cages be scraped off, but also the hairbrushes are soft in texture, and can go deep into sunk parts of the cocoon cages to bring out and scrape off silkworm cocoons at the sunk parts to achieve the goal of thoroughly harvesting the cocoons, and no cocoons remain on the cocoon cages; and meanwhile, the double-chain propulsion mechanism is equipped to convey the cocoon cages, so that continuous cocoon harvesting of batched cocoon cages is realized, and the cocoon harvesting efficiency is greatly increased.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

High-cleanness automatic compensation type sweeper

The invention discloses a high-cleanness automatic compensation type sweeper which comprises a crossbeam. Fixing seats are fixedly mounted at left and right ends of the crossbeam respectively, a scraper mechanism is mounted on the upper surface of the crossbeam, a spring compensation regulation mechanism is fixedly mounted on the lower surface of the crossbeam, and the lower end of the scraper mechanism is connected with the spring compensation regulation mechanism. The high-cleanness automatic compensation type sweeper has advantages that reasonable design, simple structure, convenience in mounting, low cost and high practicality are achieved, and surface adhesion, deviation, abrasion and the like of a conveying belt can be effectively solved; in an operating process of a belt conveyor, automatic sweeping of the conveying belt can be realized, and the spring compensation mechanism of the sweeper enables a scraper to constantly well contact with the surface of the conveying belt to achieve great sweeping effects; the sweeper is widely applicable to various types of belt conveyors and can be extensively popularized due to simple structure, remarkable sweeping effects and the like.

Owner:河北圣业机械制造有限公司

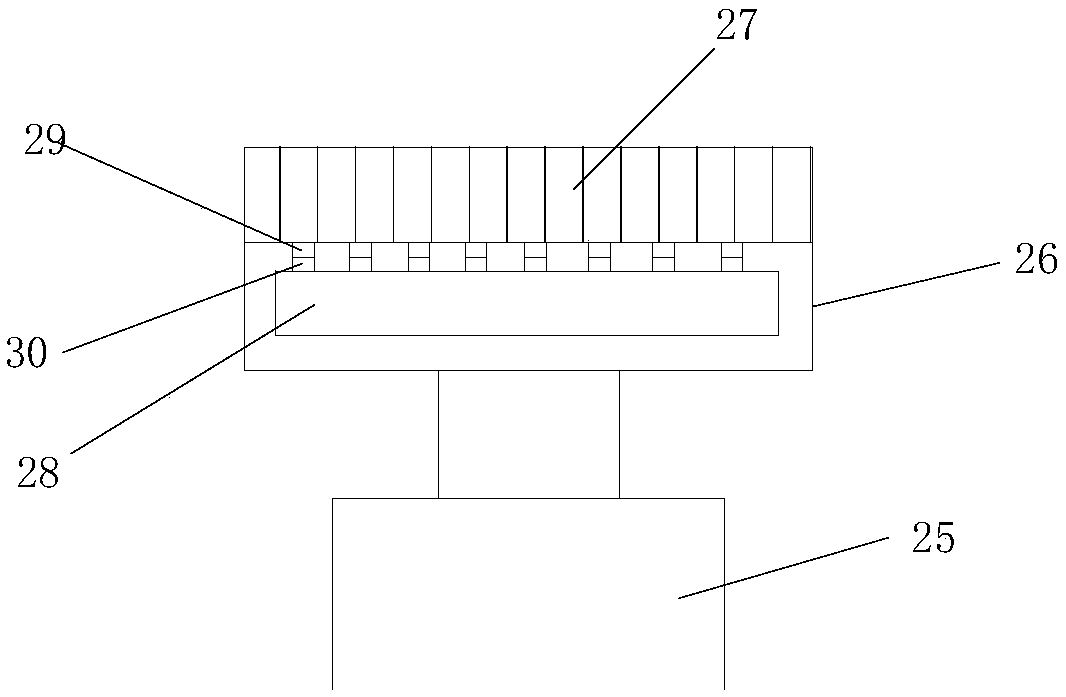

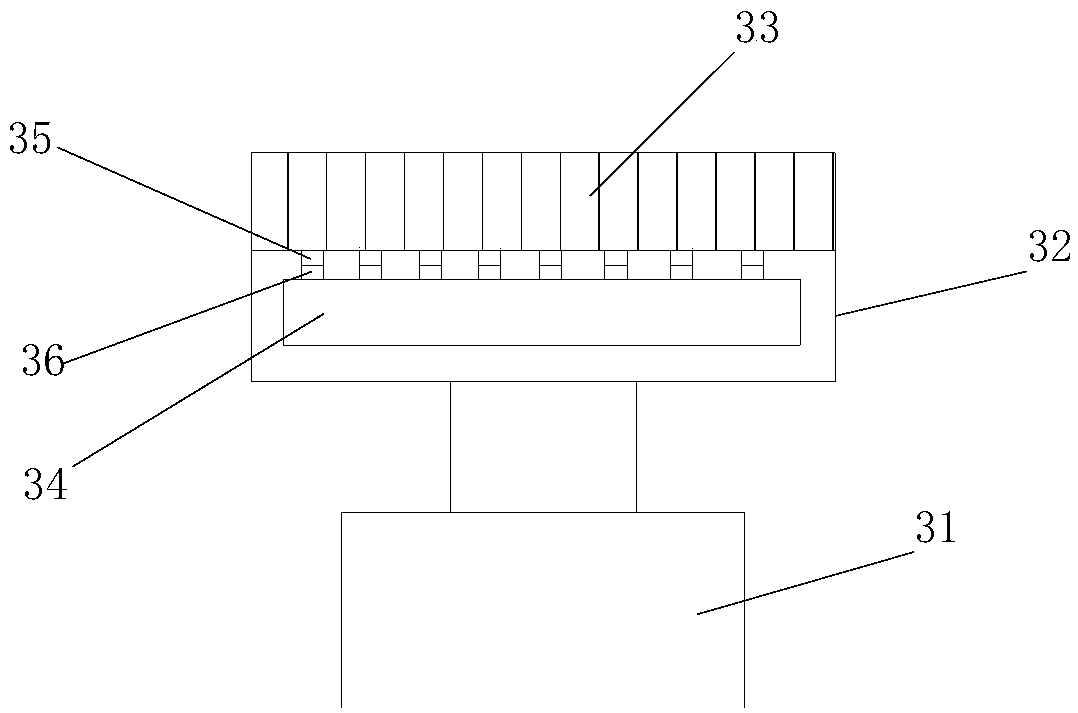

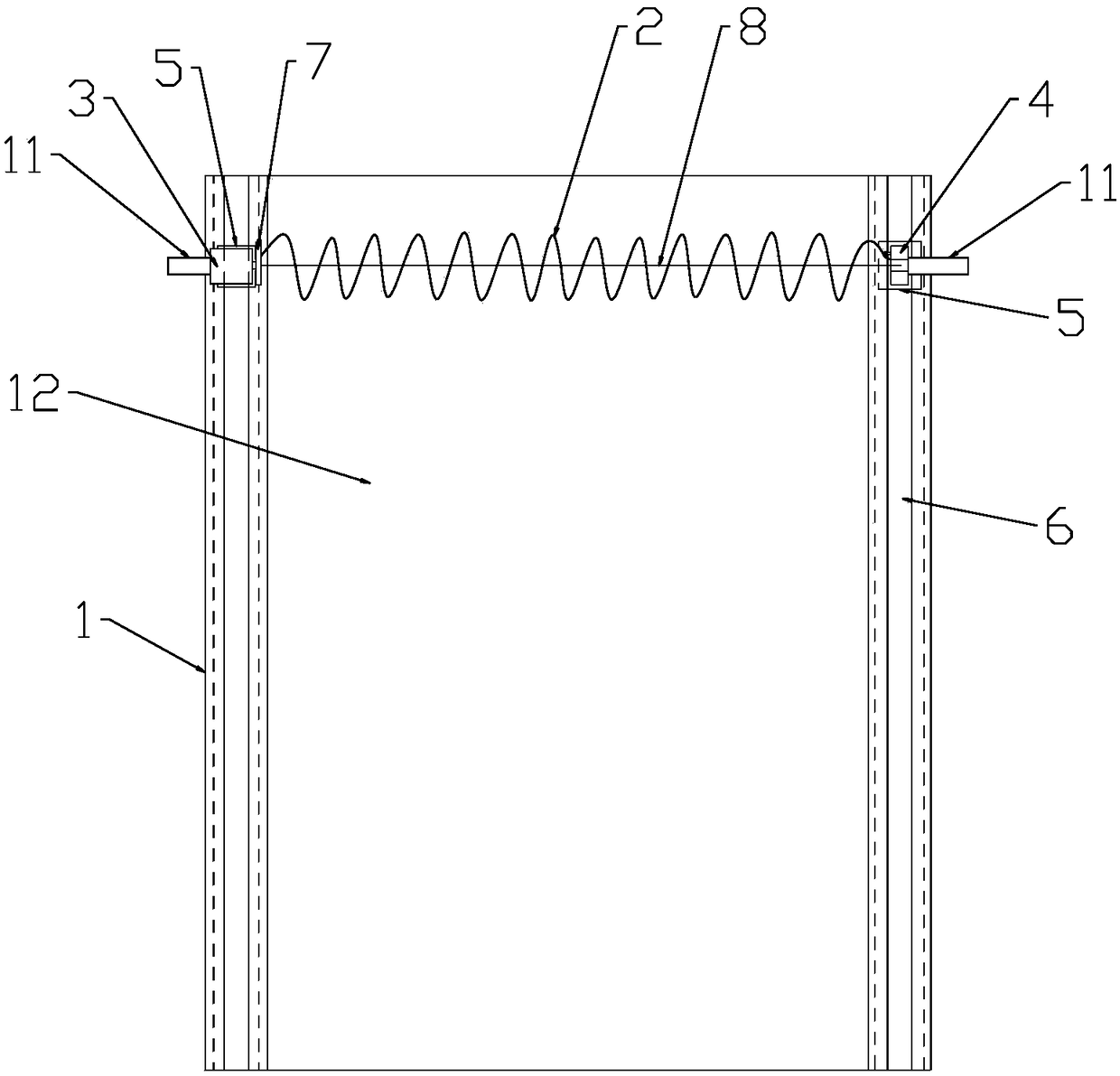

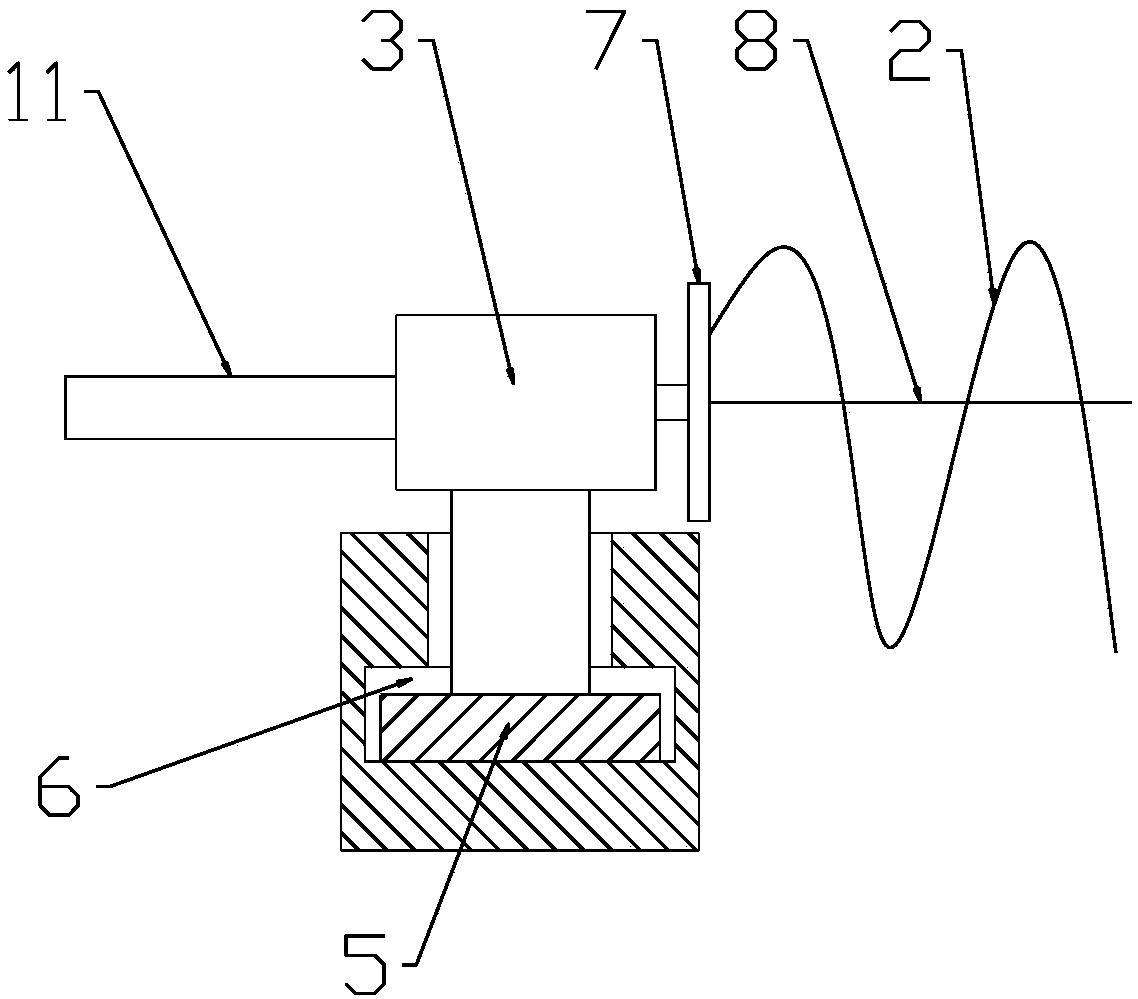

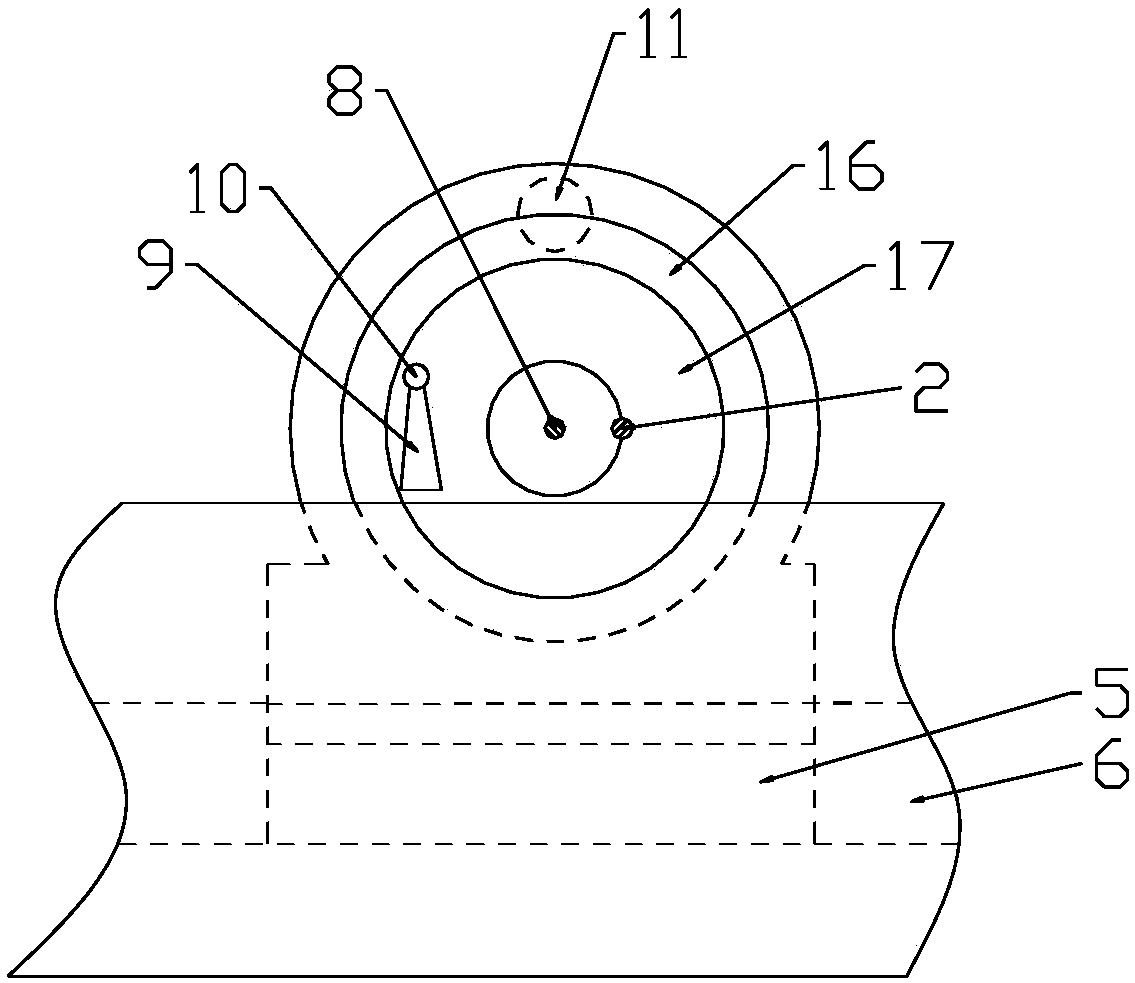

Brooming device for upper surface of prefabricated laminated slab

ActiveCN108789792ASweep evenlyImprove continuityCeramic shaping apparatusEngineeringMechanical engineering

The invention belongs to the technical field of concrete prefabricated laminated slab production equipment, and particularly relates to a brooming device for the upper surface of prefabricated laminated slab. The brooming device comprises two travelling rails and a brooming assembly, wherein the brooming assembly comprises a tension spring positioned between the travelling rails; travelling devices capable of travelling along the travelling rails are separately arranged on the travelling rails; and drive devices for driving the tension spring to rotate are mounted on the travelling devices; and the two ends of the tension spring are separately connected with the corresponding drive devices. According to the technical scheme adopted by the invention, the brooming device for the upper surface of the prefabricated laminated slab has the characteristics of being simple in structure and convenient to operate, and can be suitable for brooming requirements of prefabricated laminated slab of different dimensions.

Owner:重庆建工高新建材有限公司 +2

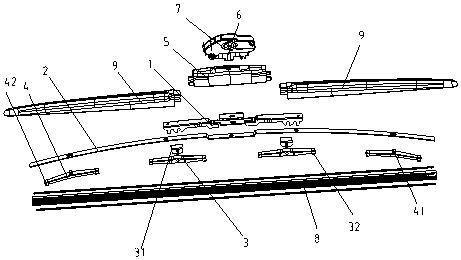

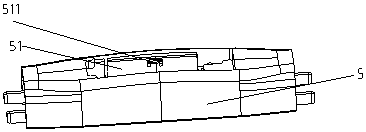

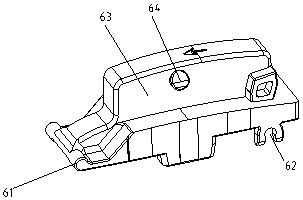

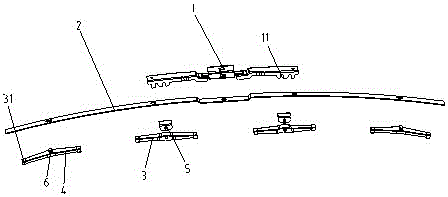

Wiper

ActiveCN106314374BImprove the sweeping effectFirmly connectedVehicle cleaningForeign matterAuxiliary memory

The invention discloses a wiper which comprises a main supporting framework, an elastic adjusting part, at least one auxiliary framework, at least one secondary framework and a connecting seat. The elastic adjusting part has a certain radian and is fixedly connected onto the main supporting framework, the auxiliary frameworks are movably connected onto the main supporting framework and have a certain swinging degree of freedom on the main supporting framework, the secondary frameworks are movably connected onto the elastic adjusting part and have a certain swinging degree of freedom on the elastic adjusting part, the connecting seat is mounted in the middle of the main supporting framework, and a connecting groove is formed in the connecting seat. The wiper is simple to assemble, force can be uniformly applied to a wiper component, so that the wiper component can be effectively fitted with glass, foreign matter removing effects are improved, the wiper can be connected with various wiper arms, the wiper is convenient to use, and production cost and assembly can be reduced.

Owner:东莞市威冠汽车配件制造有限公司

Polishing machine for anti-glare disc glass

ActiveCN106392877AImprove scanning accuracyImprove the sweeping effectEdge grinding machinesGrinding carriagesPulp and paper industryPiston rod

The invention provides a polishing machine for anti-glare disc glass and belongs to the technical field of machinery. The polishing machine for the anti-glare disc glass solves the technical problem that an existing glass polishing machine is low in polishing precision and the like. The polishing machine for the anti-glare disc glass comprises a machine frame, first installation plates, supports and first strip-shaped rods. A liquid containing tank is arranged on the lower side of the machine frame. The first installation plates are fixed to the machine frame. Suction cups are fixed to the lower ends of the first strip-shaped rods. A vent hole is formed in each suction cup. First ventilating pipes are fixed to the upper ends of the first strip-shaped rods. Air cylinders are fixed to the first installation plates. Annular sleeves are fixed to the outer ends of the supports. Round balls are rotationally connected into the annular sleeves. Second ventilating pipes are arranged on the air cylinders. A piston rod of each air cylinder is hinged to the middle portion of the corresponding support. Rotating rods are arranged on the bottom walls of the liquid containing tanks. Polishing heads are fixed to the upper ends of the rotating rods. First motors are fixed to the lower portions of the liquid containing grooves. The polishing machine for the anti-glare disc glass can improve the precision of polishing conducted by the polishing heads on the anti-glare disc glass and achieves a good polishing effect.

Owner:ZHEJIANG XINGXING TECH CO LTD

Novel test tube brush

InactiveCN108606467AAchieve cleanupReduce contact areaBrush bodiesHollow article cleaningDrive shaftEngineering

The invention discloses a novel test tube brush which comprises a rotary brush, an operating rod and a driving assembly. The rotary brush comprises a sleeve, brushes are uniformly distributed on the outer side wall and the outer bottom surface of the sleeve, and a test tube cap is arranged at the upper end of the sleeve; a spiral groove is formed in the inner wall of the operating rod; the drivingassembly comprises a driving shaft, a rotary wheel, a fastening component and a non-slip component. The novel test tube brush has the advantages that only the operating rod needs to be easily pusheddown and pulled up, accordingly, the rotary brush can rotate at the high speed, test tubes can be cleared, good clearing effects can be realized, labor and the time can be saved, and the novel test tube brush is speedy and is high in efficiency.

Owner:魏长同

Windshield wiper skeleton structure

The invention discloses a windshield wiper skeleton structure. The windshield wiper skeleton structure comprises a main body support skeleton, an elastic regulating part, at least one auxiliary skeleton and at least one secondary skeleton; the elastic regulating part has a certain radian and is fixedly connected to the main body support skeleton; the auxiliary skeletons are movably connected to the main body support skeleton and have certain swinging freedom degrees on the main body support skeleton; the secondary skeletons are movably connected to the elastic regulating part and have certain swinging freedom degrees on the elastic regulating part, and the secondary skeletons and the auxiliary skeletons are used for being jointly connected with a windshield wiper rubber strip assembly of a windshield wiper. According to the windshield wiper skeleton structure, assembly is easy, force can be uniformly applied to the wiper strip, therefore, the wiper strip can be well attached to glass, and the foreign matter removing effect is improved.

Owner:东莞市威冠汽车配件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com