Automatic cocoon harvesting machine used for industrialized rearing

A cocoon-picking machine and factory-like technology, applied in animal husbandry and other fields, can solve the problems of slow manual cocoon picking, large failures, small scale, etc., and achieve direct and thorough cocoon picking operations, low probability of failure, clamping powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

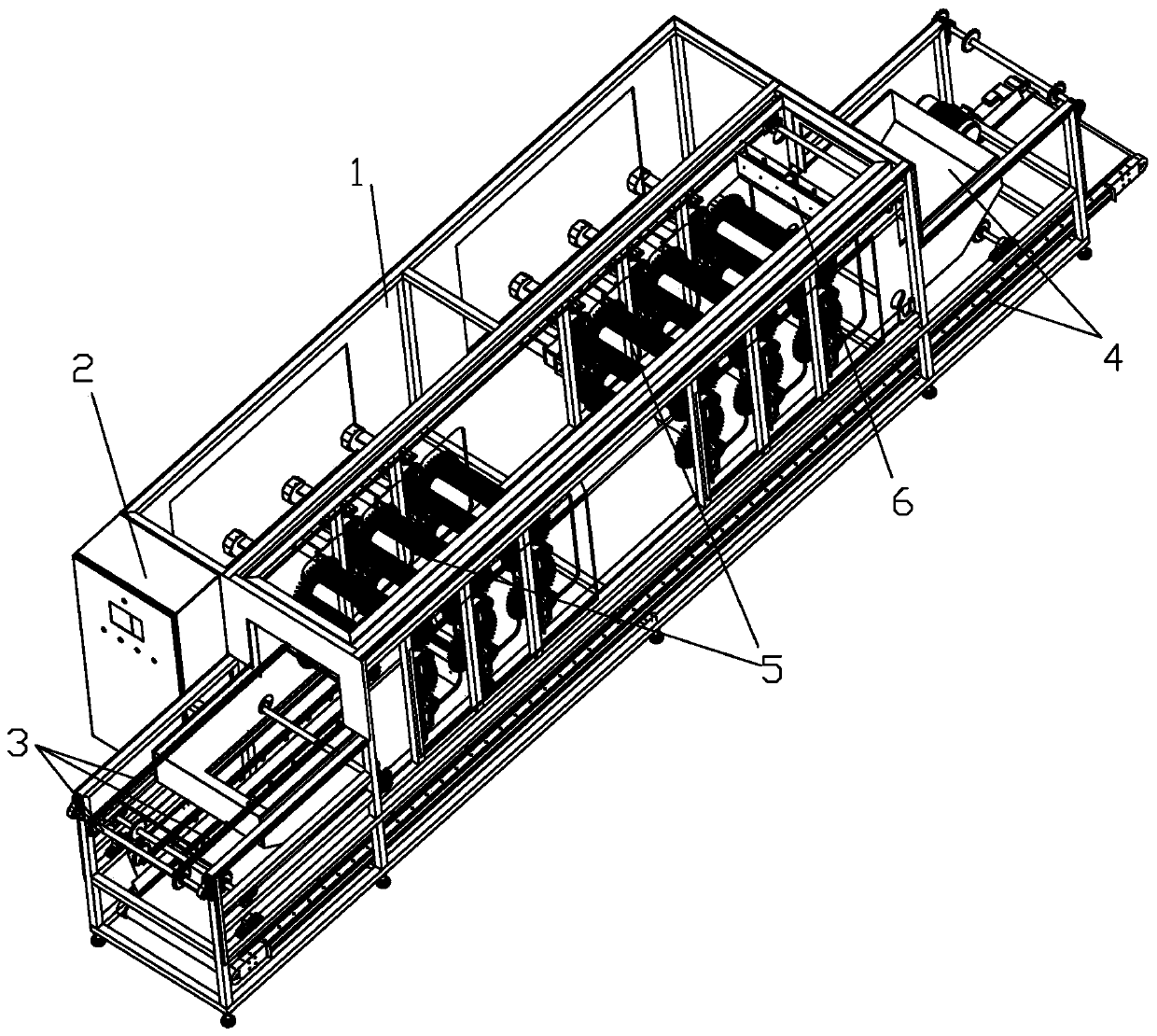

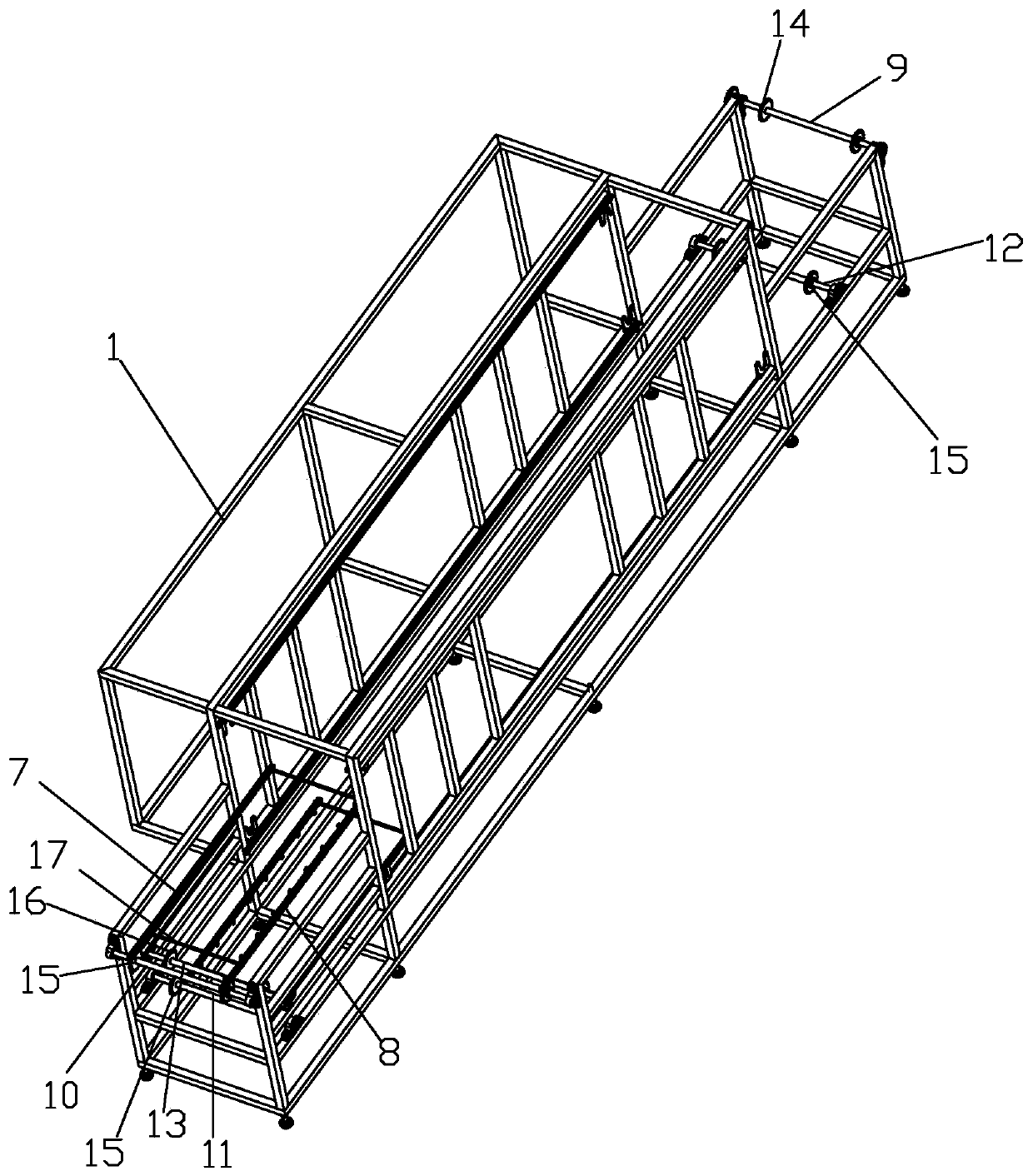

[0045] Such as Figure 1 to Figure 12 As shown, an automatic cocoon harvesting machine for industrial farming includes a frame 1 and a power distribution box 2. The frame 1 is divided into two parts, which are the cocoon picking area and the power distribution area, and the power distribution box 2 is located in the power distribution area. . The cocoon-picking mechanism is mainly composed of a double-chain propulsion mechanism 3, a brush system 5, a cocoon guiding mechanism 4 and a hair comb. The following parts are introduced in detail:

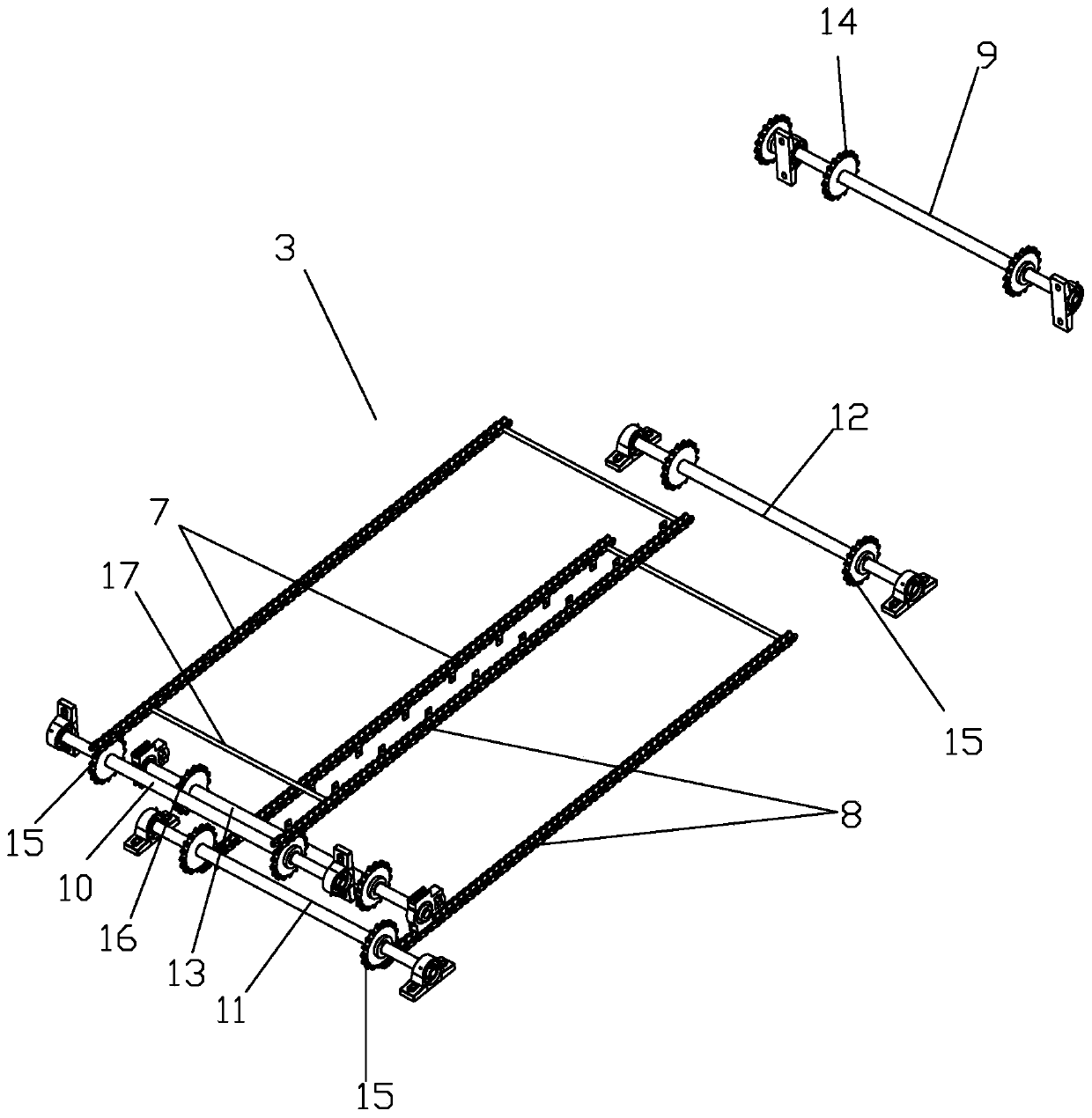

[0046] 1. Double chain propulsion mechanism 3:

[0047] The double-chain propelling mechanism 3 is installed in the frame 1 and extends from the front end of the frame 1 to the rear end of the frame 1 . The double-chain propulsion mechanism 3 includes a left chain 7, a right chain 8, a driving shaft 9 and a driven shaft, and the left chain 7 and the right chain 8 are driven by the driving shaft 9 and the driven shaft. The transmission mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com