Patents

Literature

3629results about How to "Stable clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

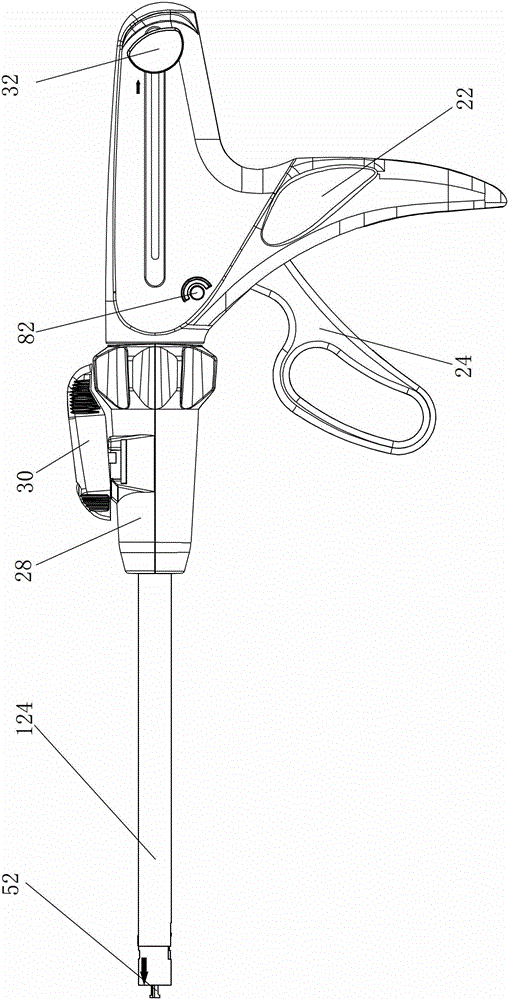

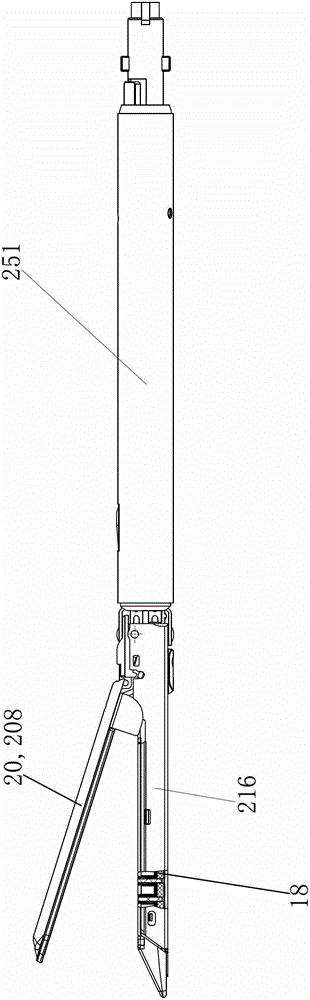

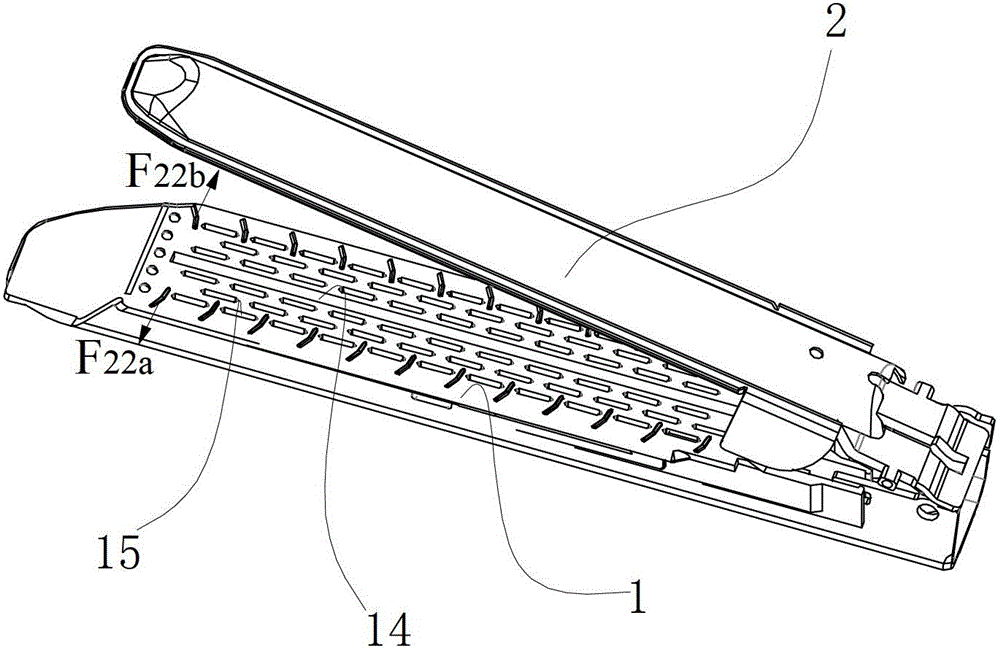

Tissue clamping part of linear cutting stapler and its staple cartridge seat

ActiveCN102973300BCause some damagesNot easy to slip offSurgical staplesEngineeringStructural engineering

The invention discloses a tissue clamping member of a linear cutting anastomat and a nail granary of the tissue clamping member. The left side and the right side of a nail discharging surface of the nail granary are respectively provided with one column of barrier bars and barrier bulges, which are parallel to a knife pushing groove, and the front end part of a nail supporting surface of a nail supporting base of the tissue clamping member is provided with one row of semi-spherical concave holes along the left-right direction. During the use, the barrier bulges apply an acting force with the direction which is opposite to the advancing direction of a cutting knife to the clamped human body tissue, the two columns of barrier bars apply leftwards and rightwards acting forces which have the direction opposite to the advancing direction of the cutting knife and face outside to the clamped human body tissue, therefore the clamped tissue is stable and firm without slipping, wherein the left column of barrier bar applies to a leftwards acting force to the human body tissue and the right column of barrier bar applies to a rightwards acting force to the human body tissue, therefore, the clamped tissue is tightened, and the cutting knife carries out cutting more smoothly when advancing forwards.

Owner:CHANGZHOU XIN NENG YUAN MEDICAL STAPLER

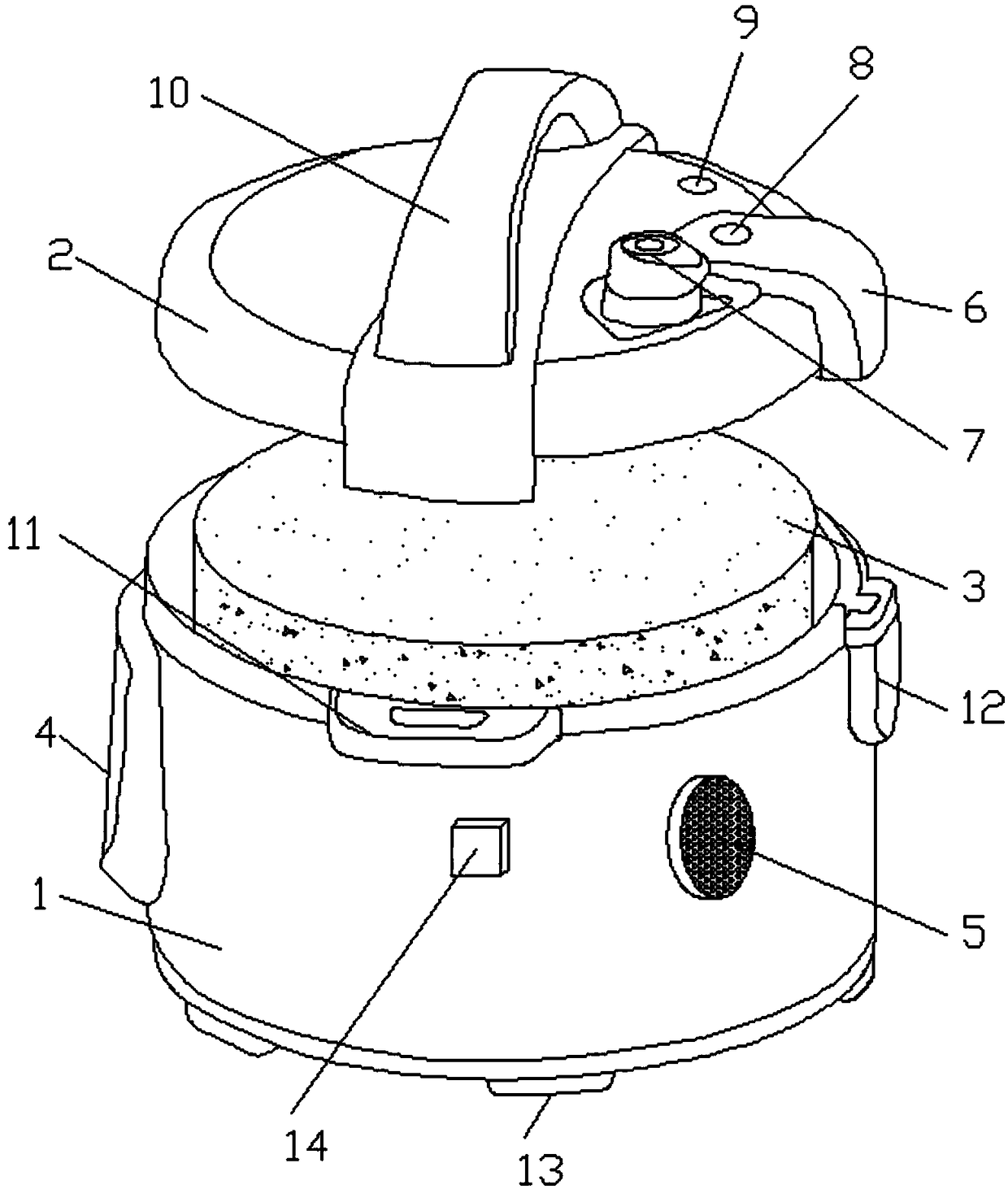

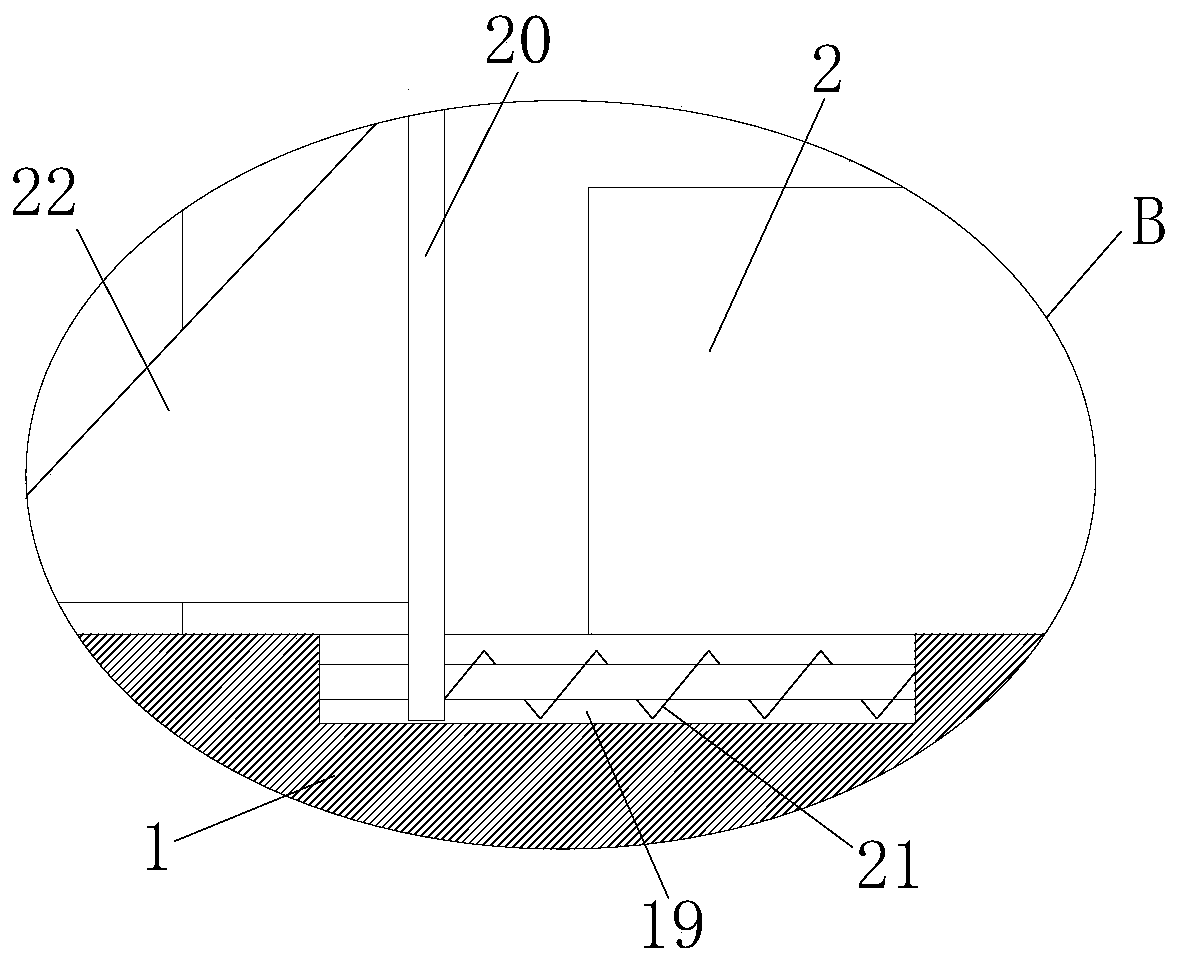

Diffuse reflection type intelligent electric pressure cooker

InactiveCN108903620AAvoid shakingEasy to useCooking-vessel materialsPressure-cookersCookerEngineering

The invention discloses a diffuse reflection type intelligent electric pressure cooker. The diffuse reflection type intelligent electric pressure cooker structurally comprises an electric pressure cooker body, a cooker cover, an inner container, a control panel and an alarming device, wherein the cooker cover is arranged at the top part of the electric pressure cooker body; a lifting device is arranged in the middle part of the cooker cover; the control panel is arranged at the left part of the electric pressure cooker body; a heating tray is arranged at the bottom part of the interior of theelectric pressure cooker body; the inner container is arranged in the electric pressure cooker body; diffuse reflection type photoelectric sensors are distributed around the bottom part of the inner side of the electric pressure cooker body; air cylinders are distributed at the top parts of the diffuse reflection type photoelectric sensors; a horizontal sensor is arranged at the top part of each air cylinder; the alarming device is arranged at the outer side of the electric pressure cooker body. The diffuse reflection type intelligent electric pressure cooker has the advantages that the size of the inner container can be sensed via diffuse reflection at high efficiency, so as to conveniently control the heating temperature, and achieve more intelligent effect; the inclining degree of the inner container can be monitored at high efficiency, and the alarming device is automatically started to produce buzz sound; the operation is intelligent, the efficiency is high, and the implementing is easy.

Owner:黄文才

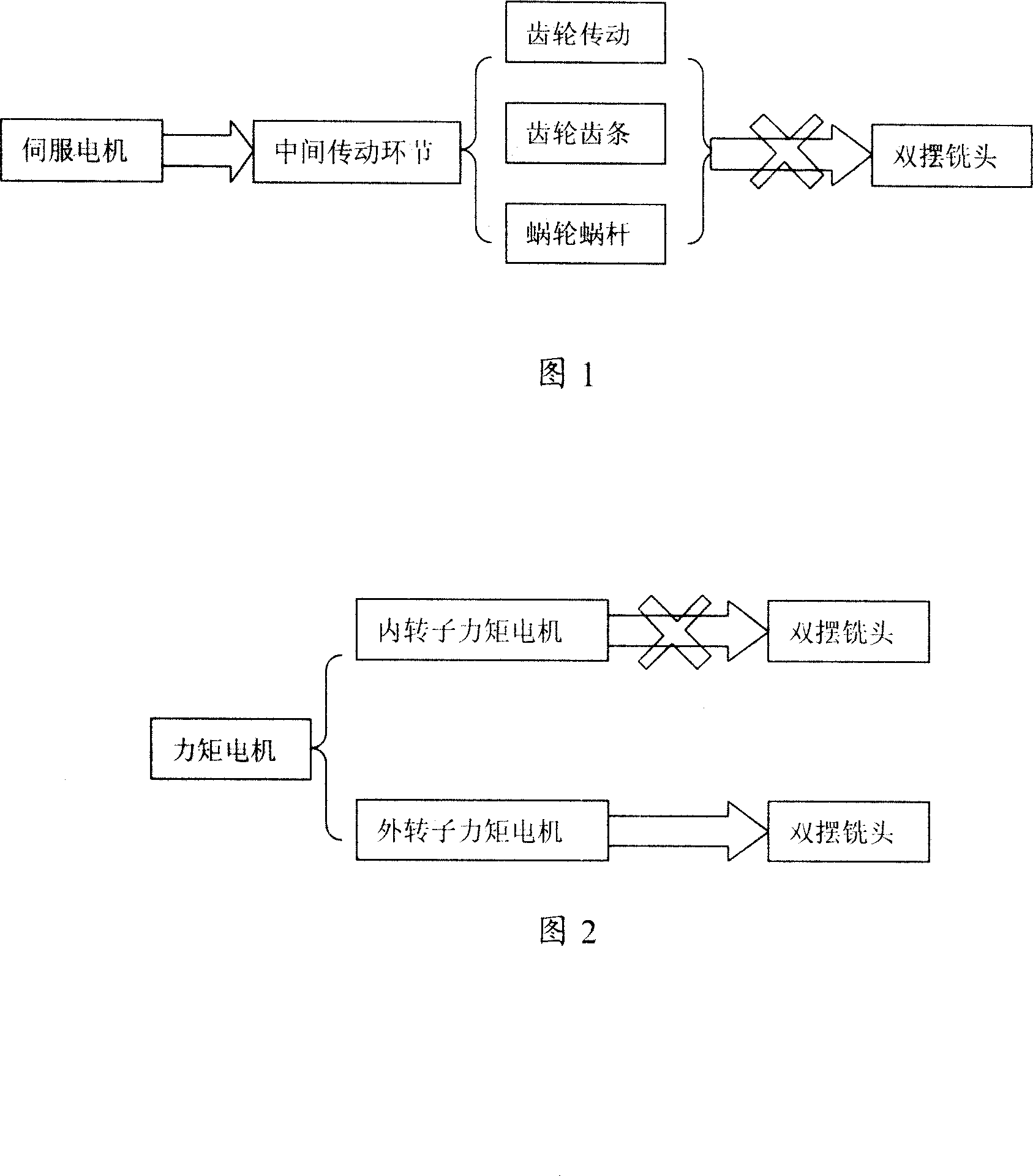

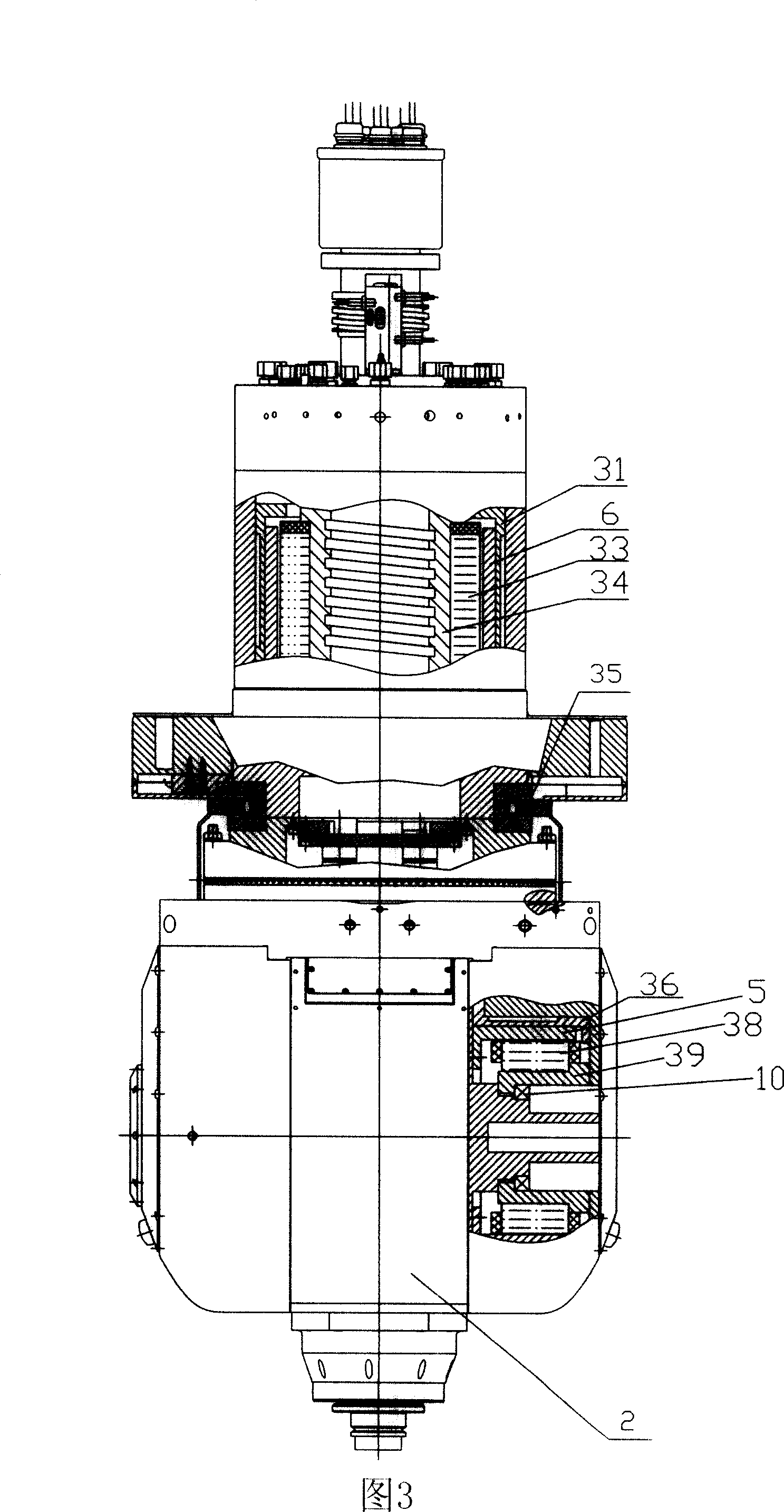

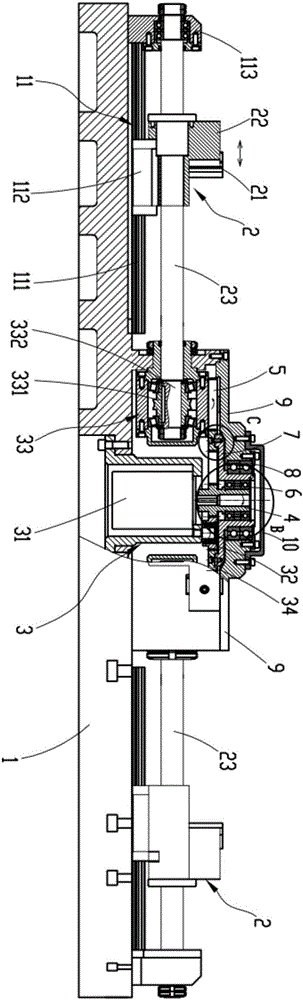

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

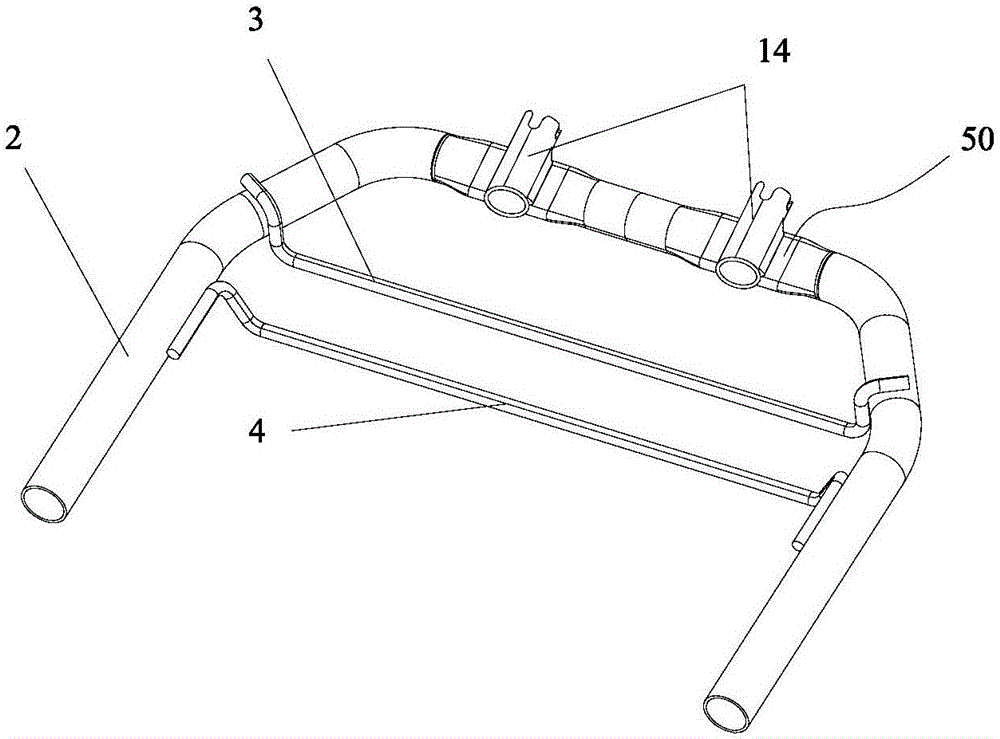

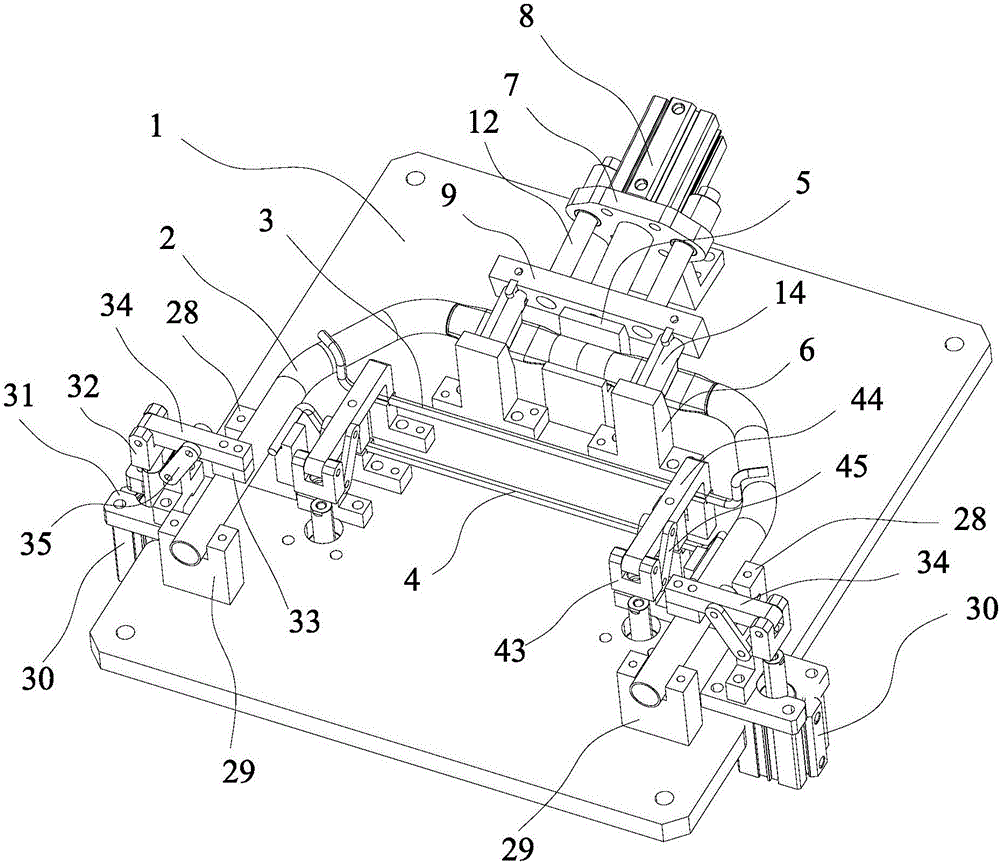

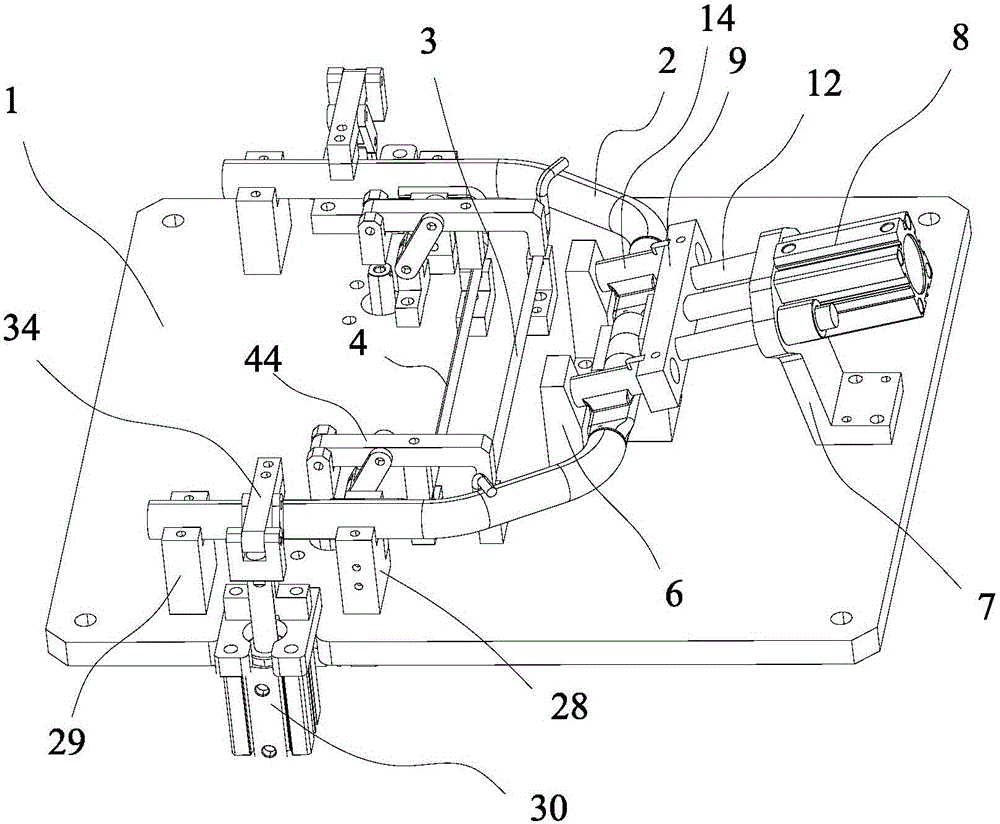

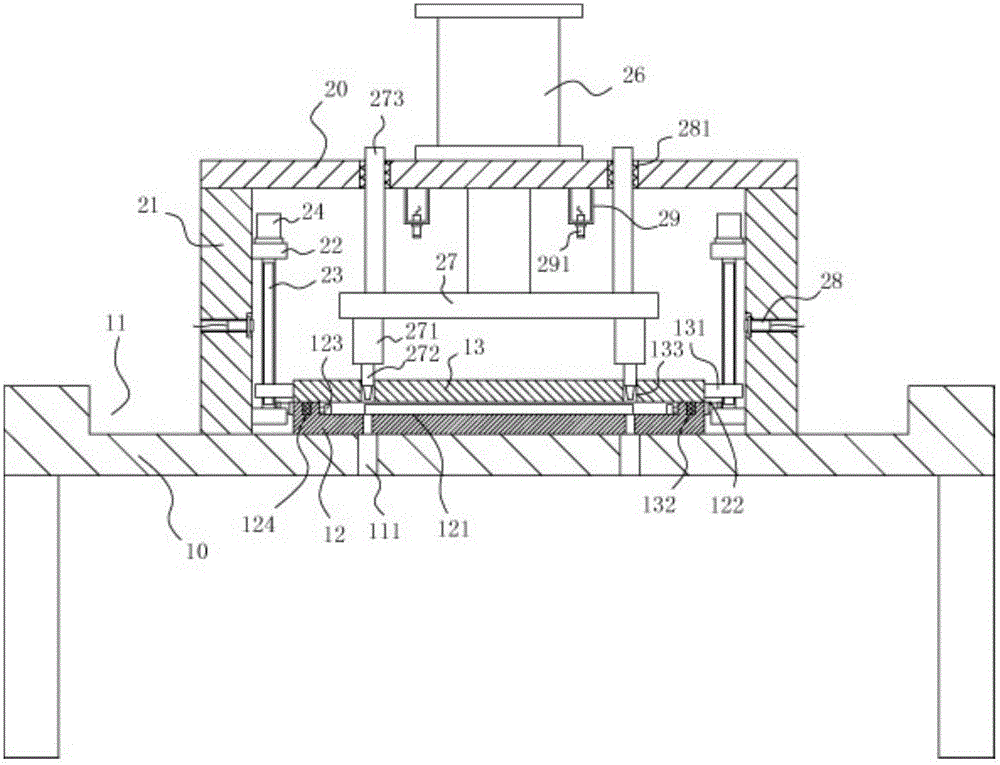

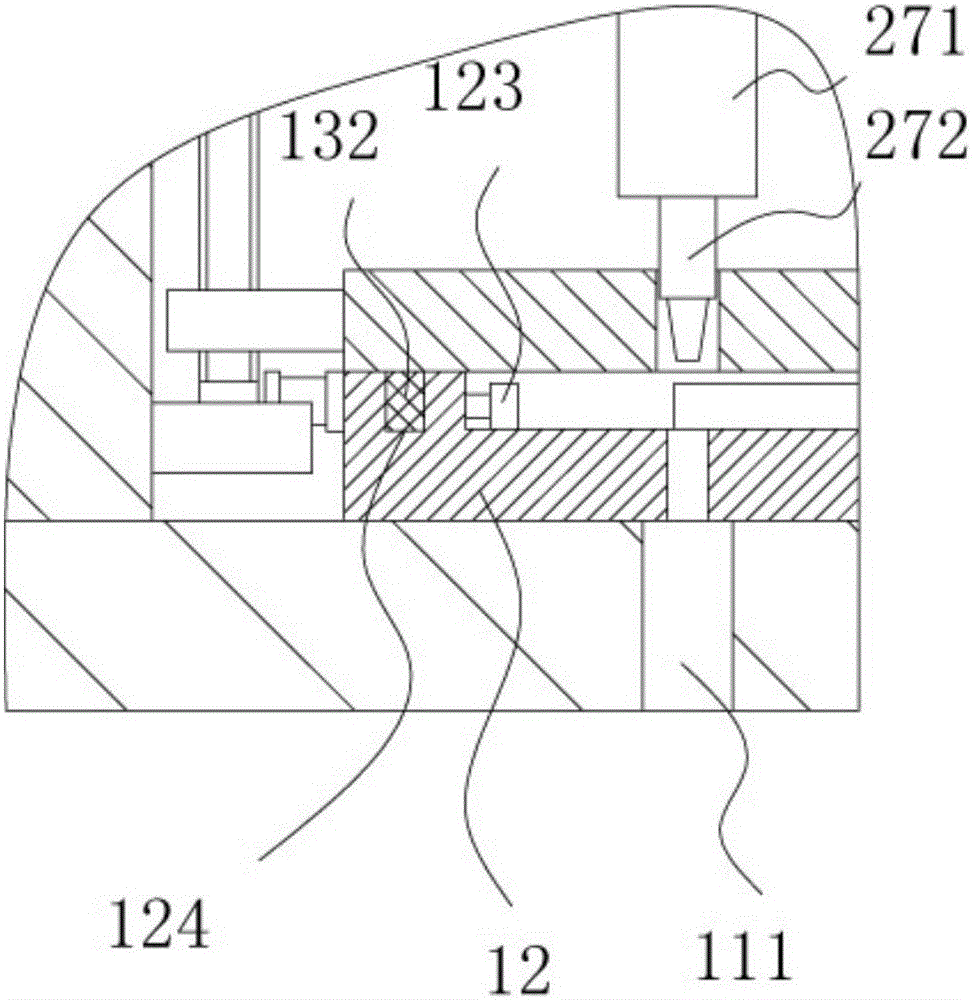

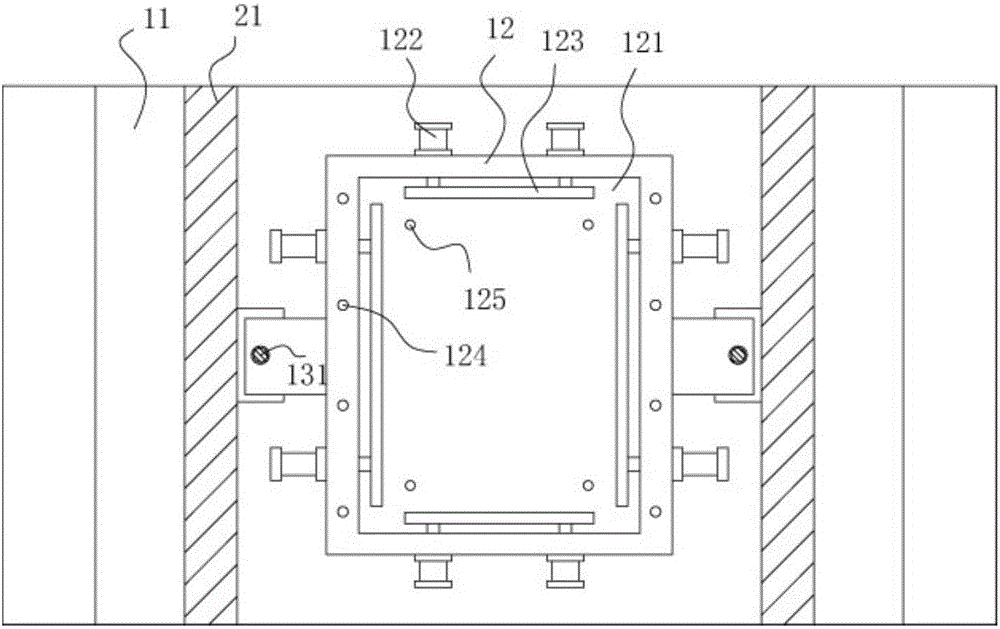

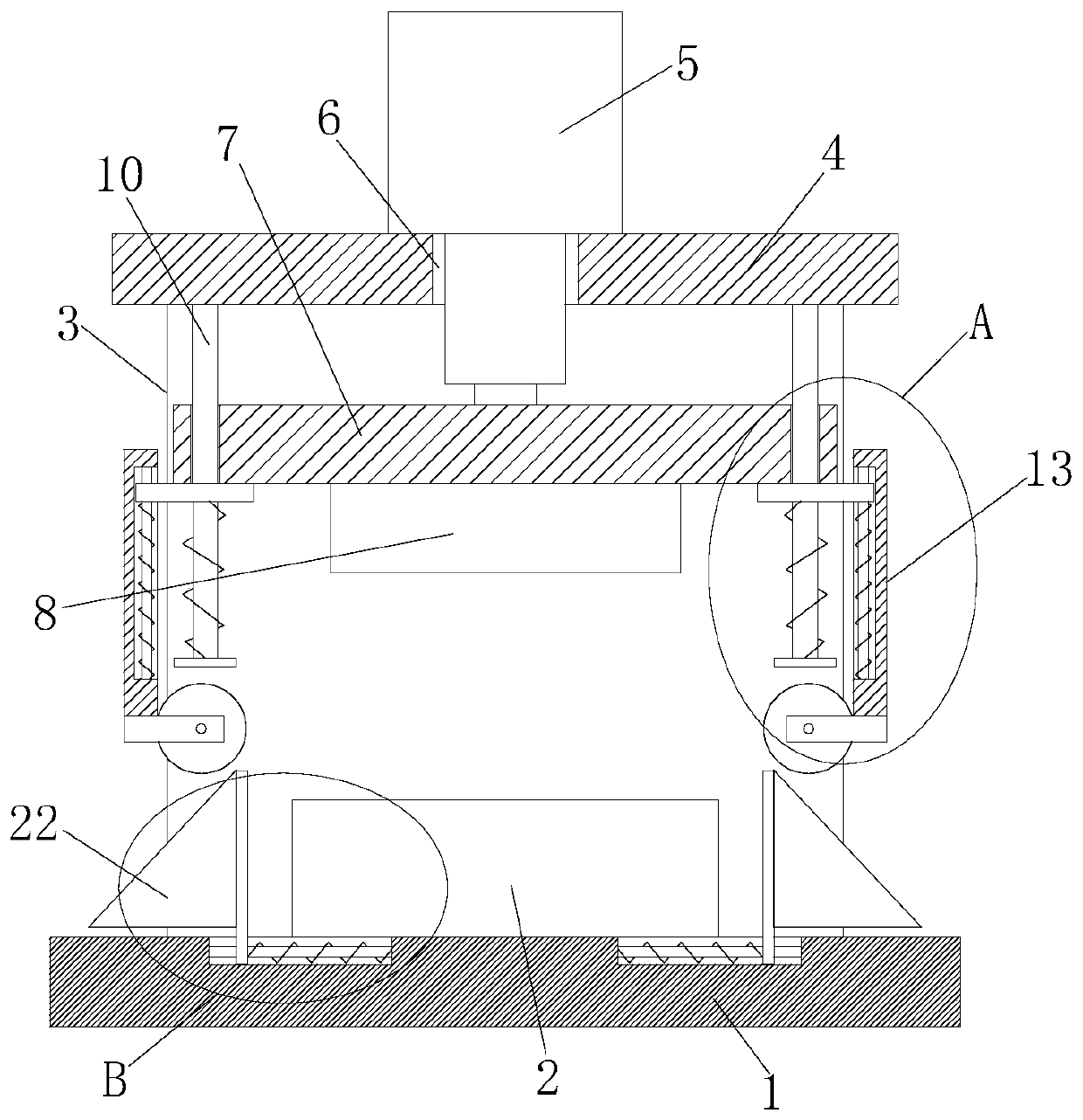

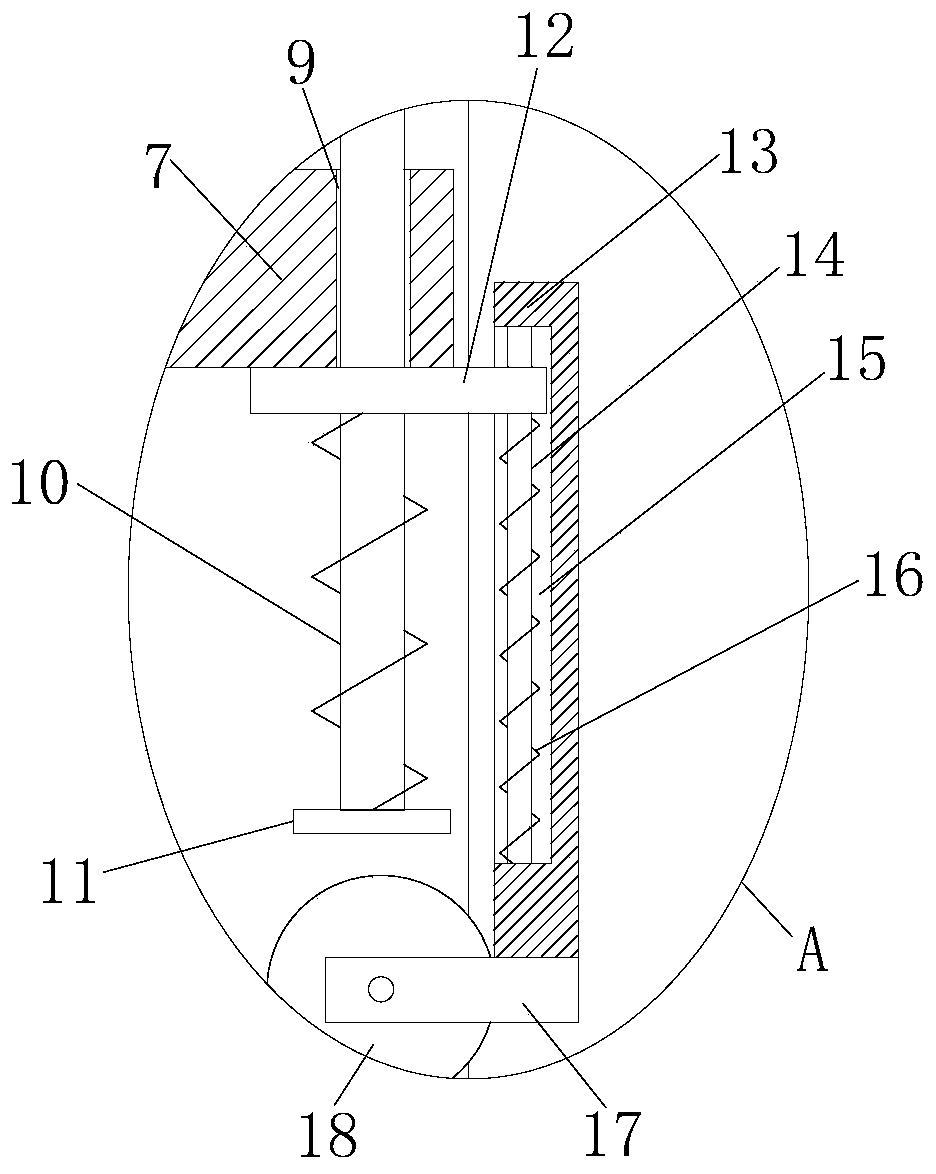

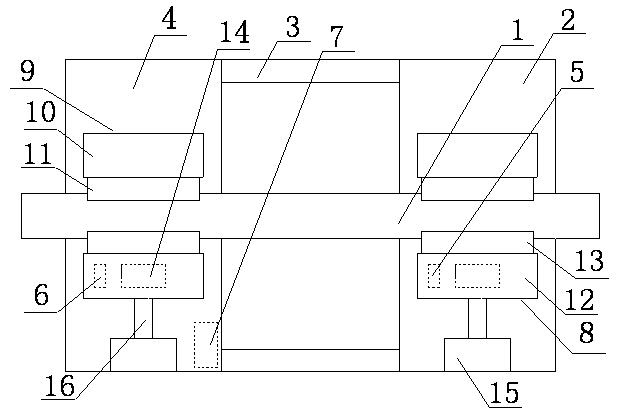

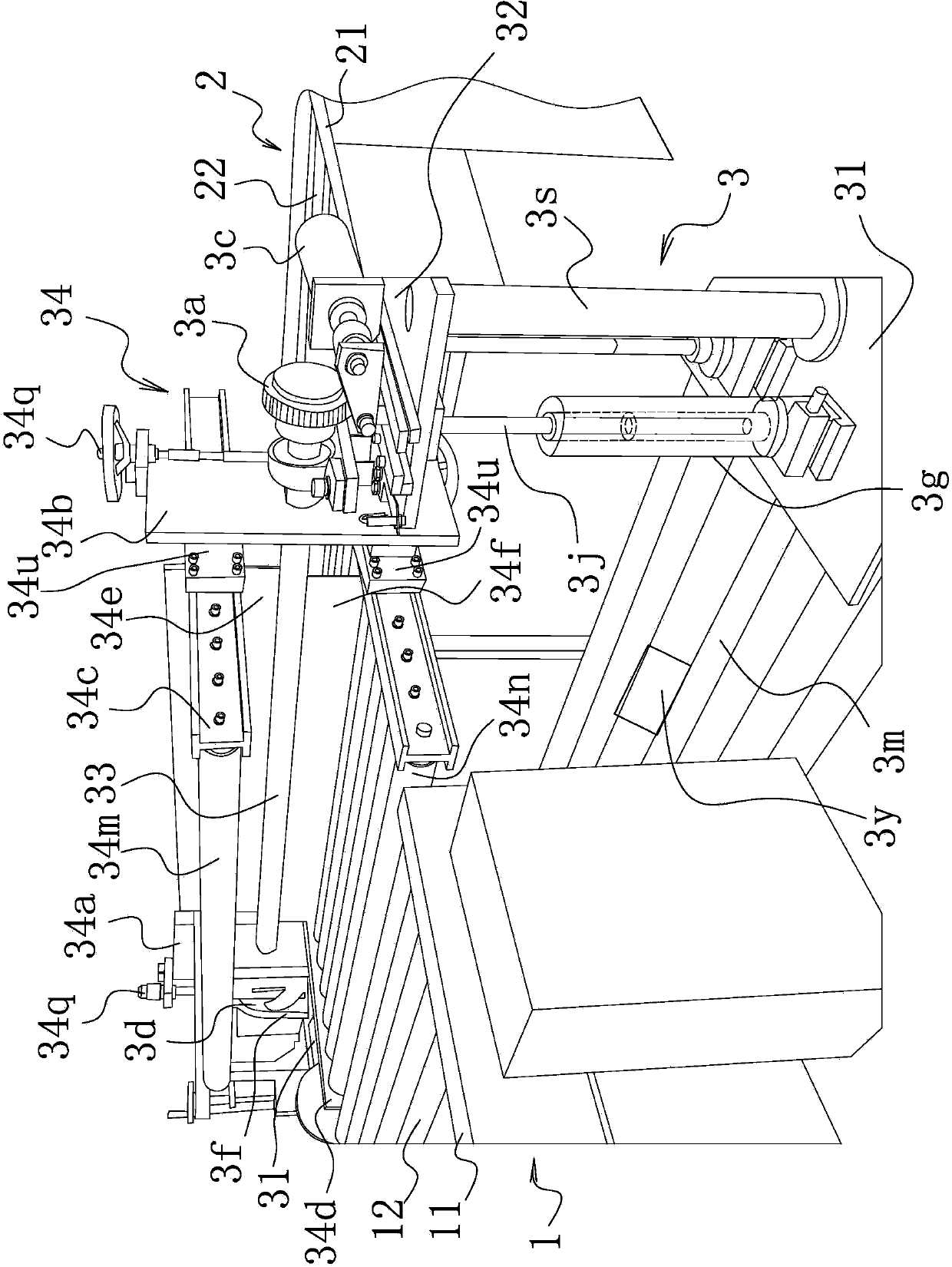

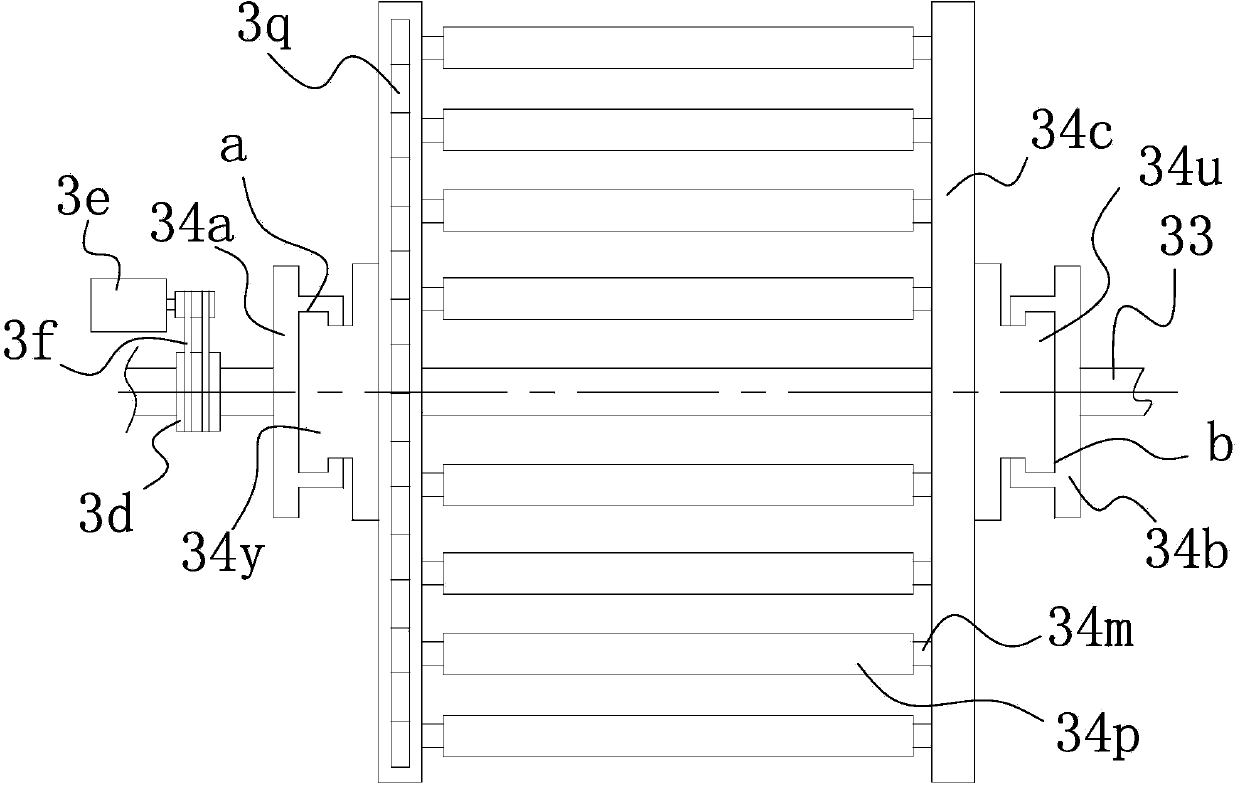

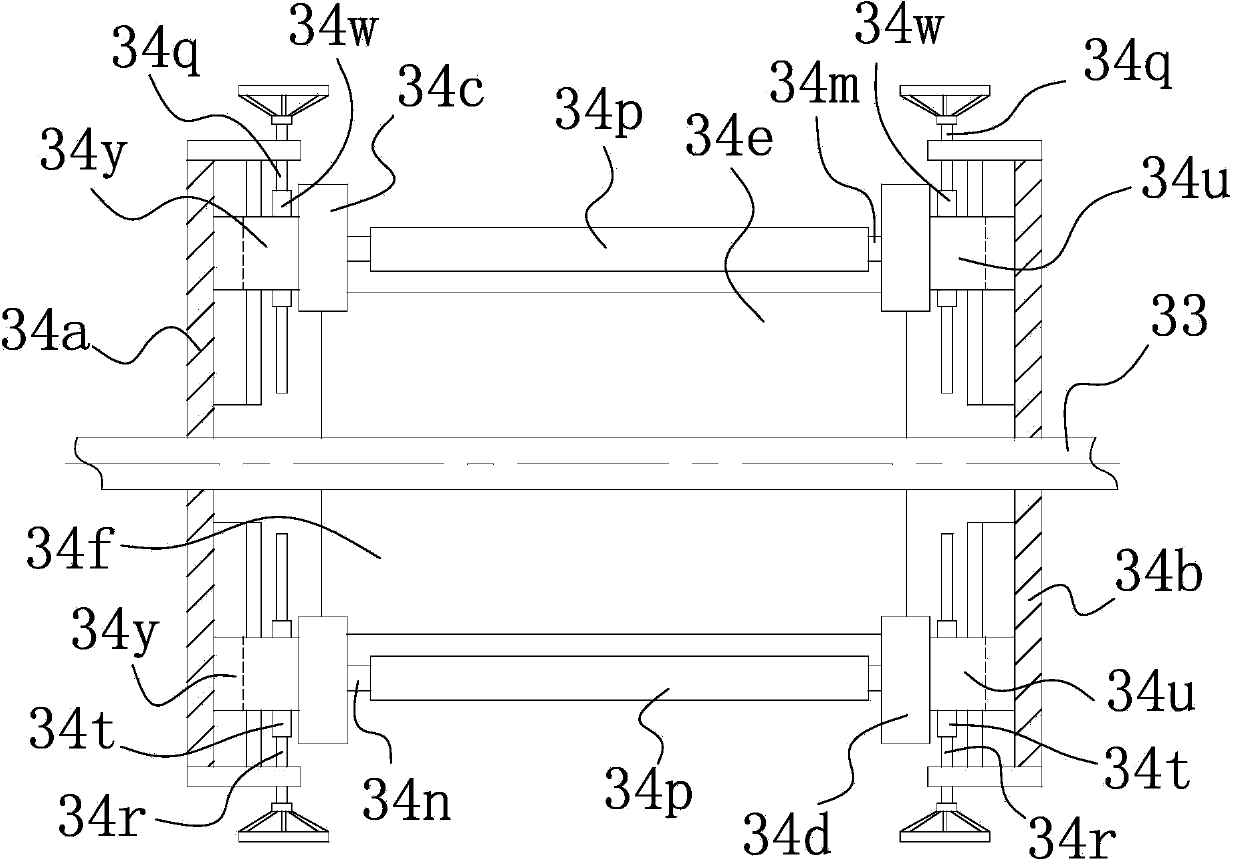

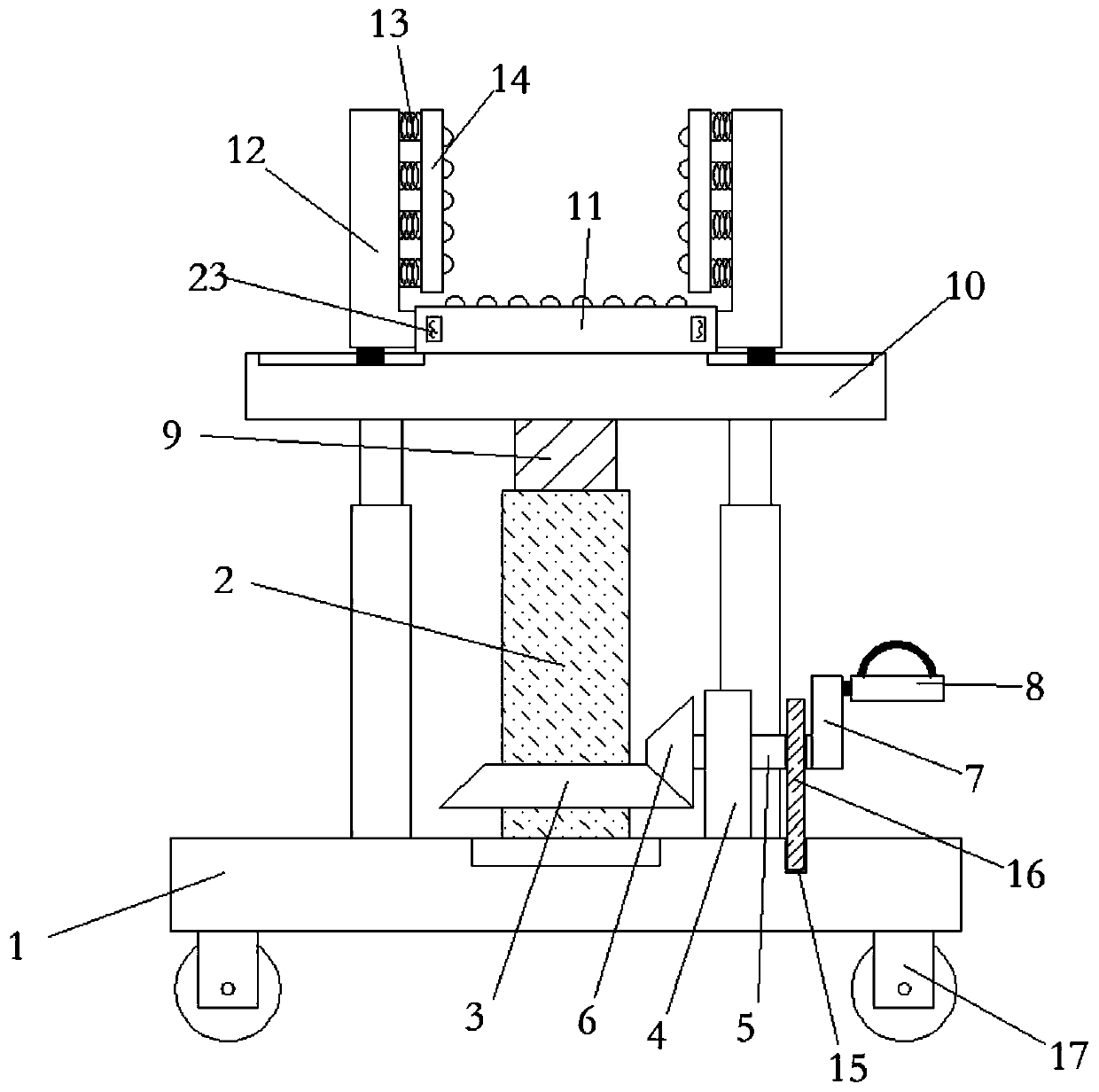

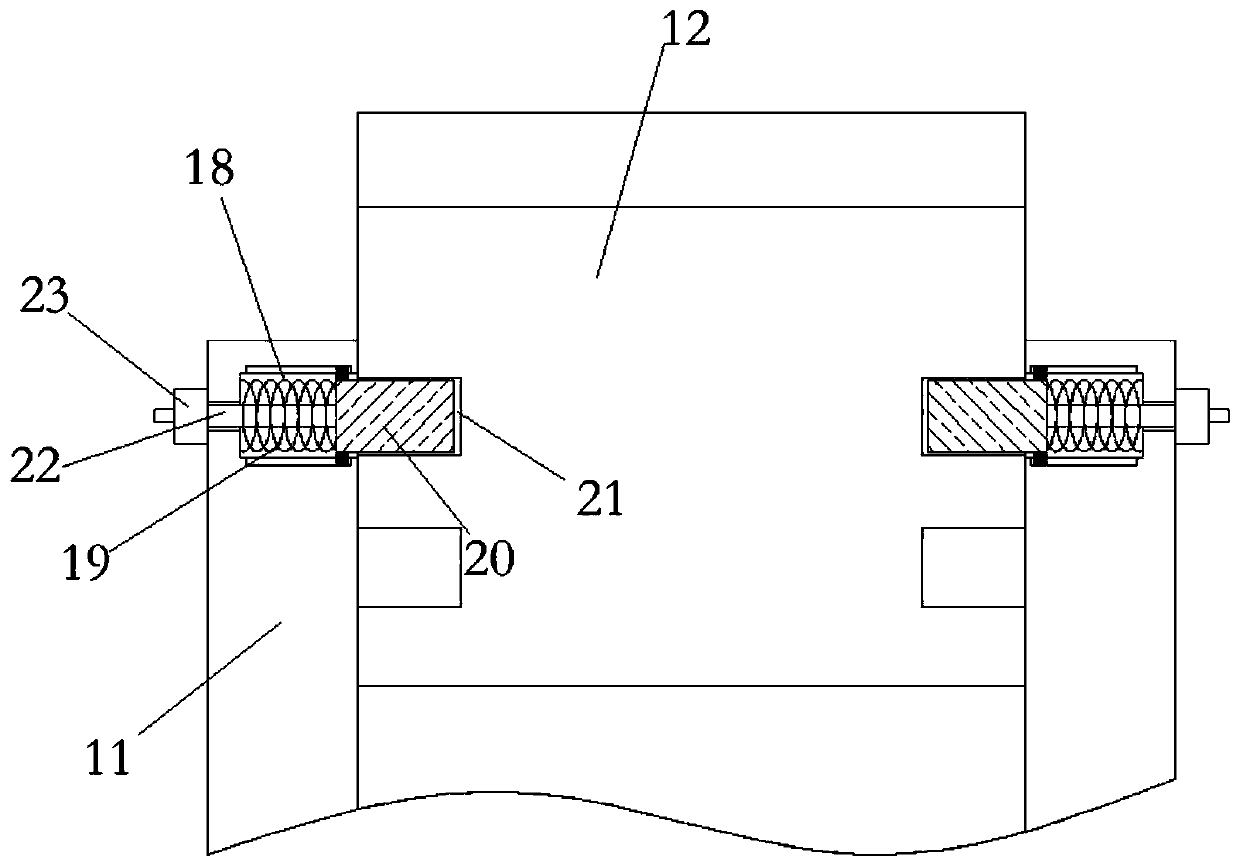

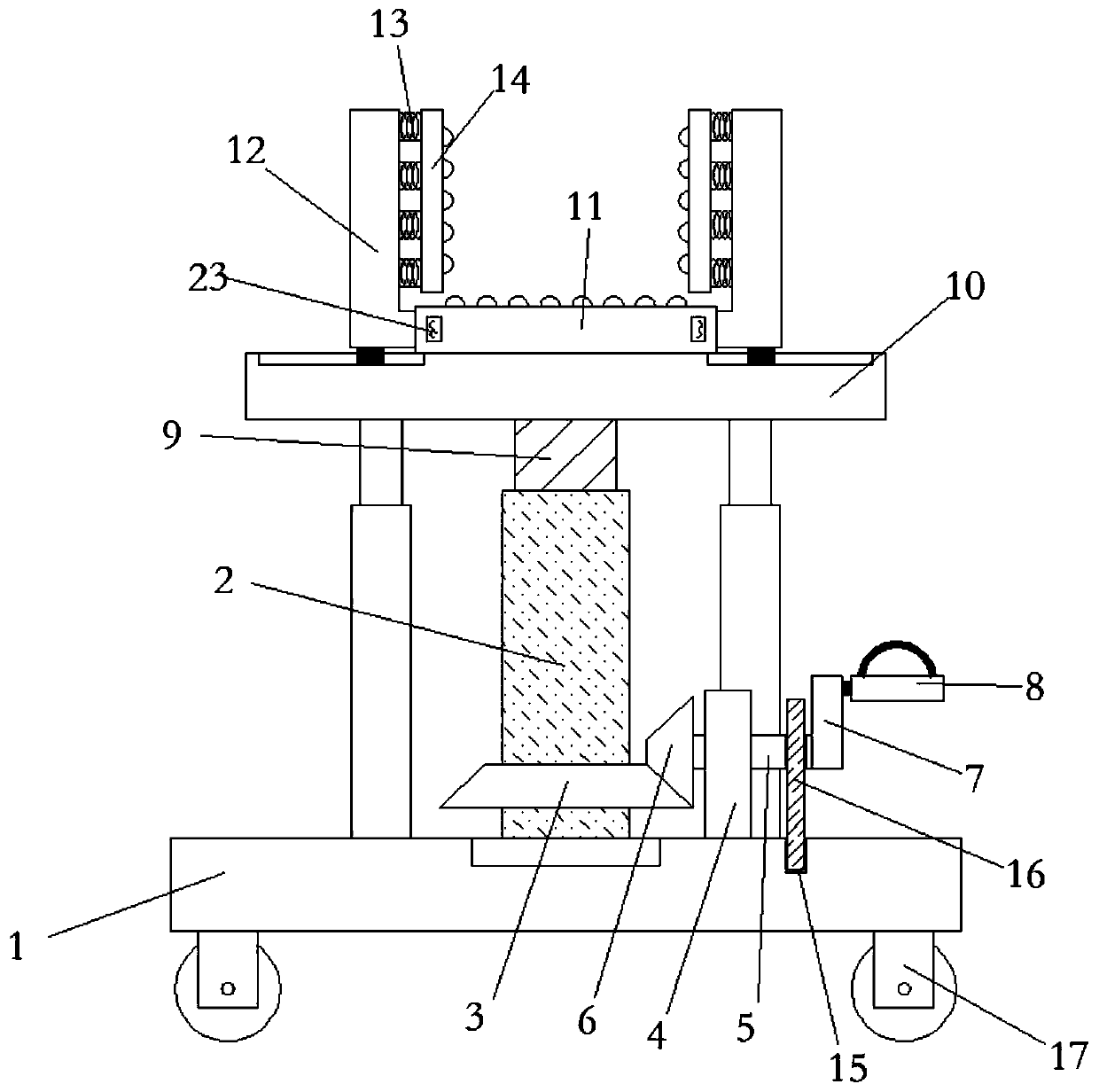

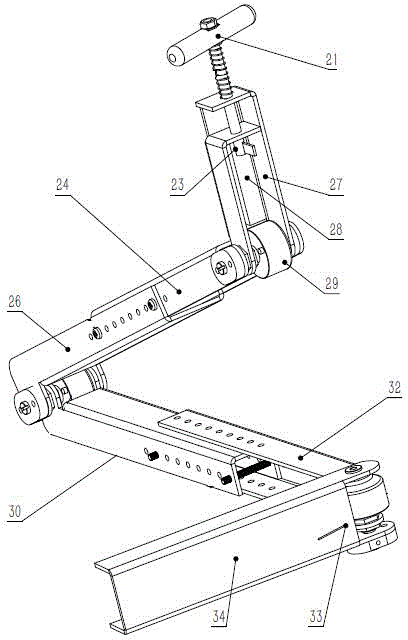

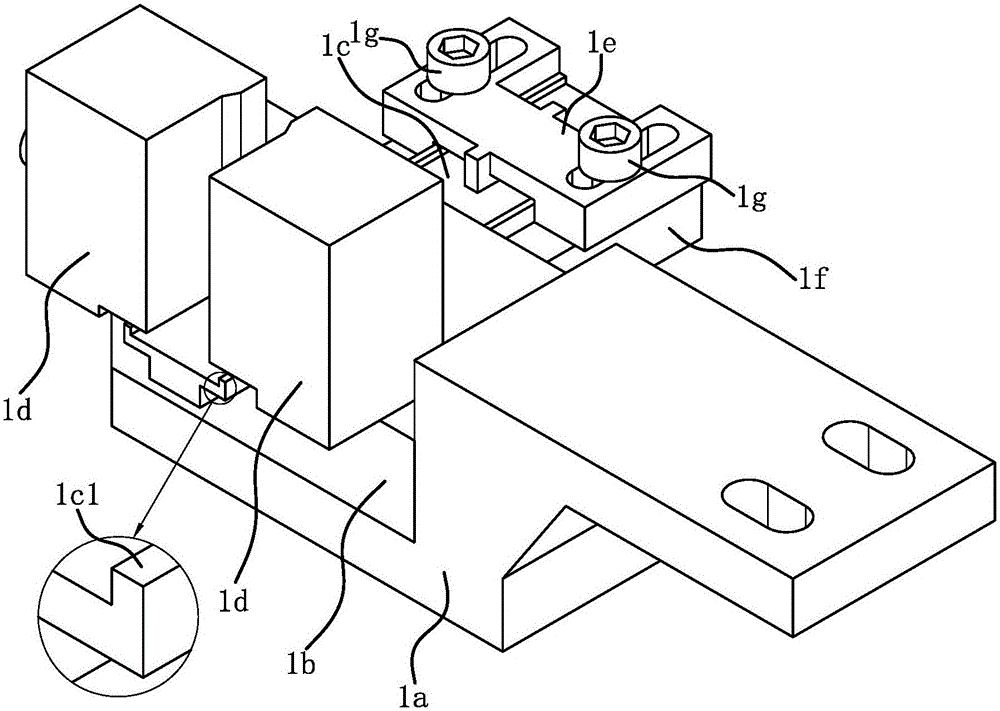

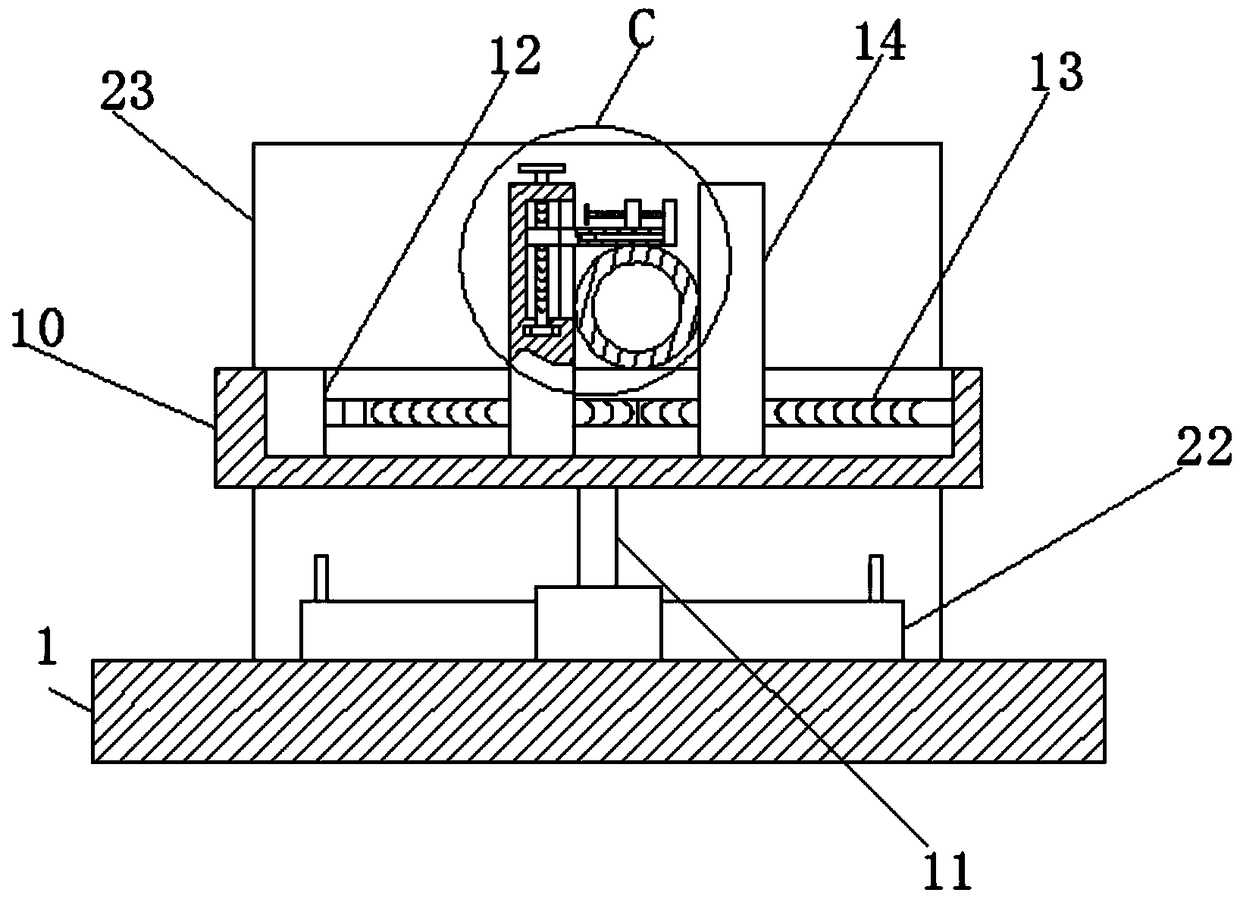

Welding tool for production of automobile seat framework

ActiveCN106112371AEnsure consistencyGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

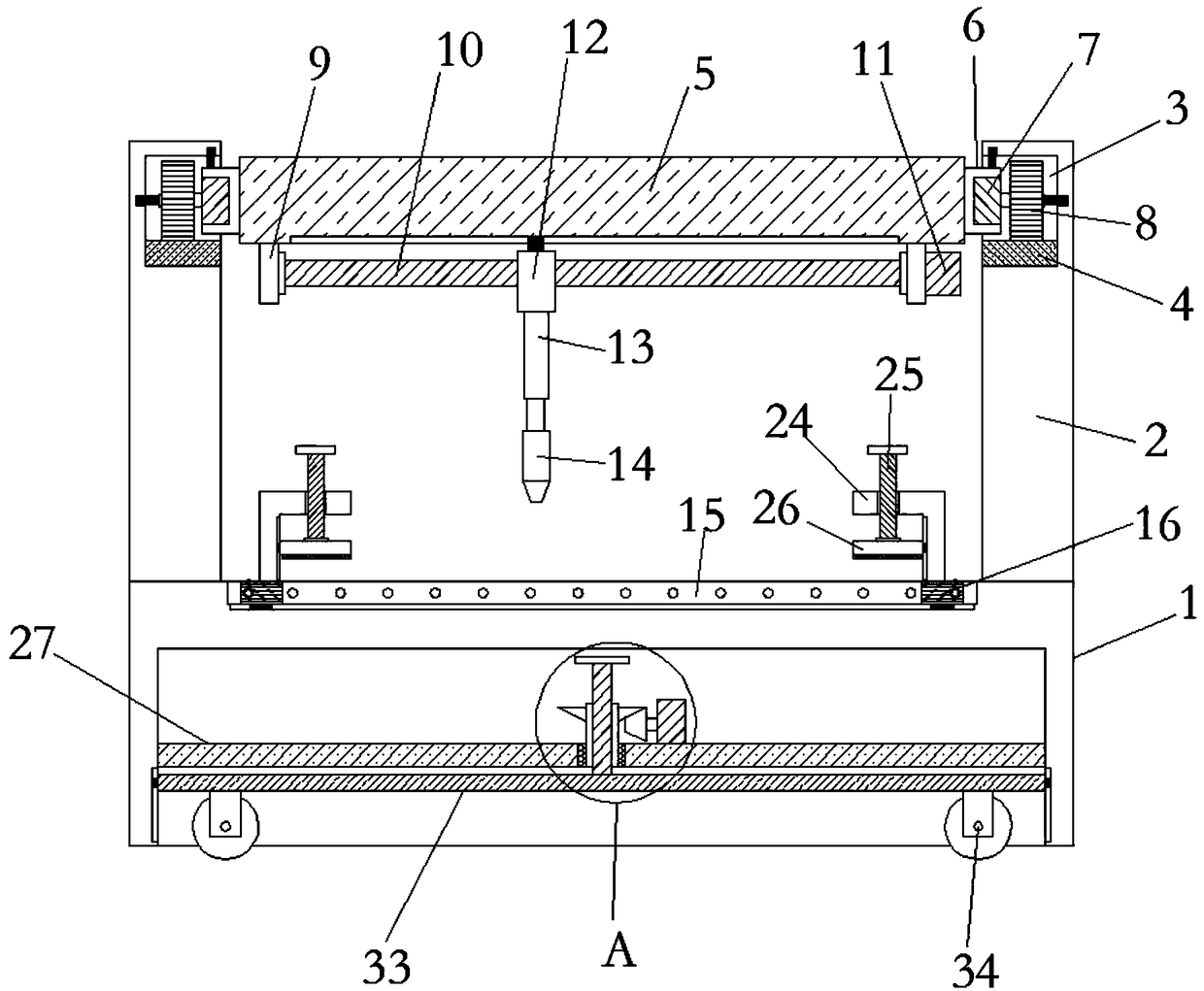

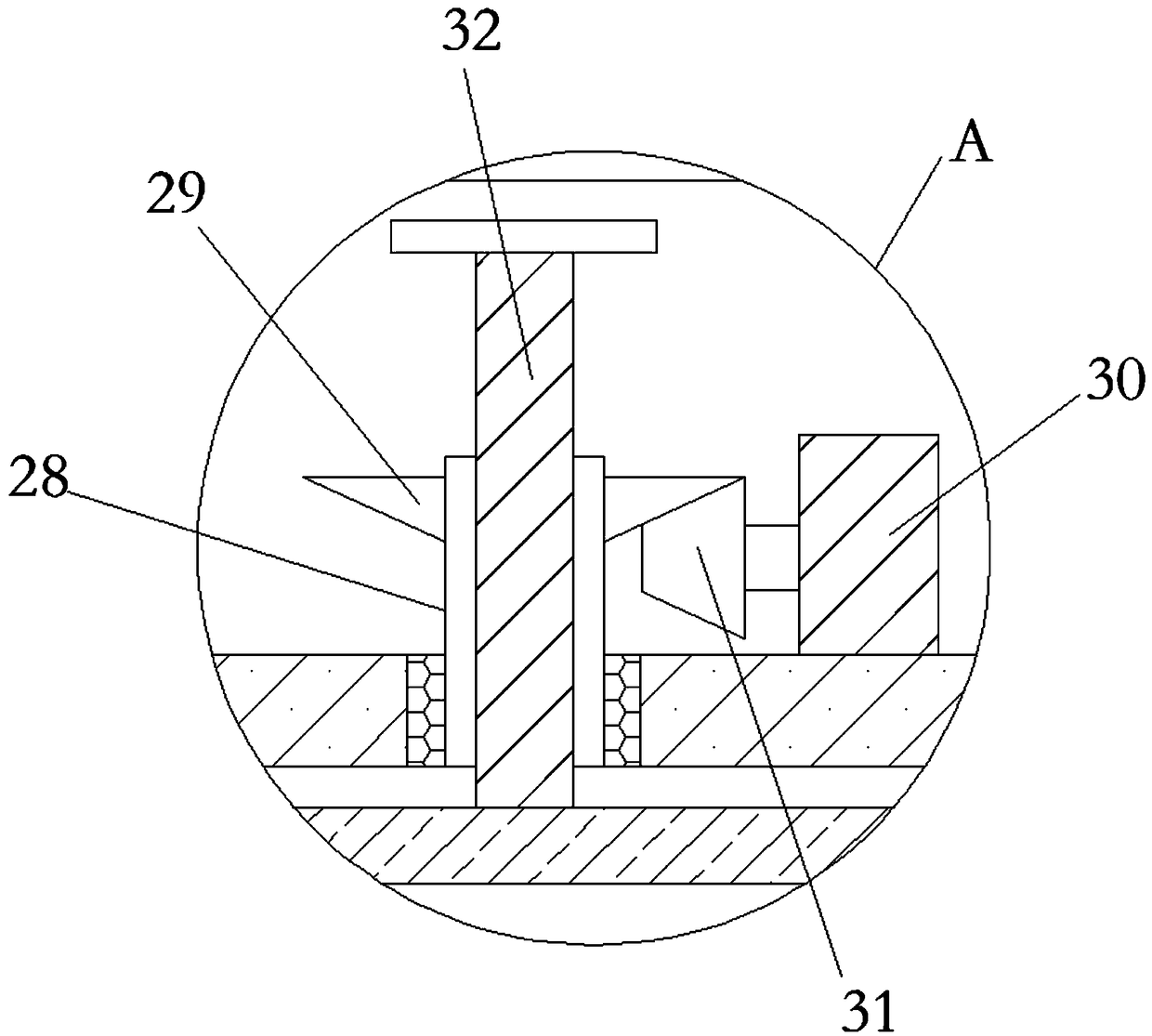

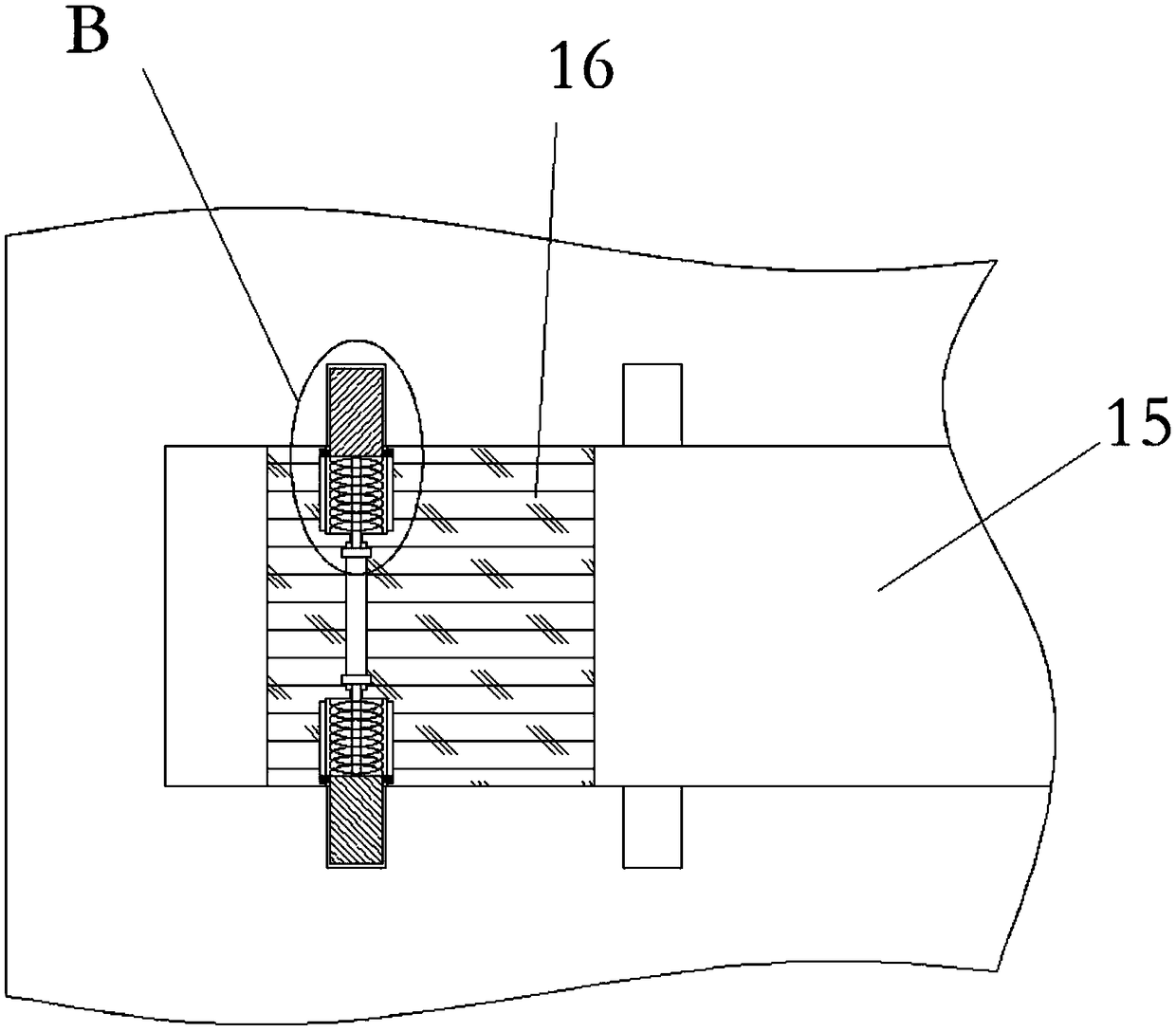

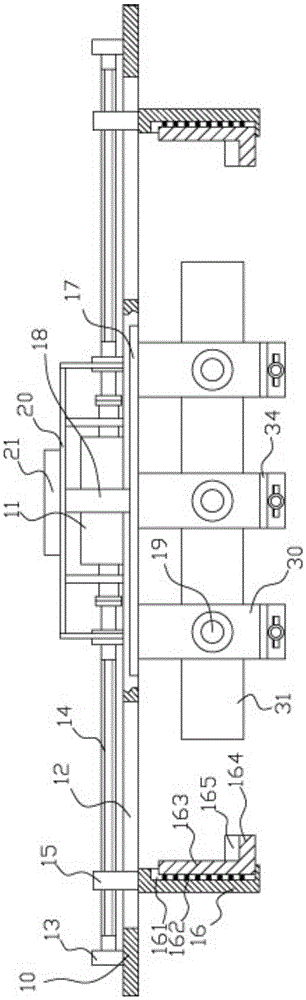

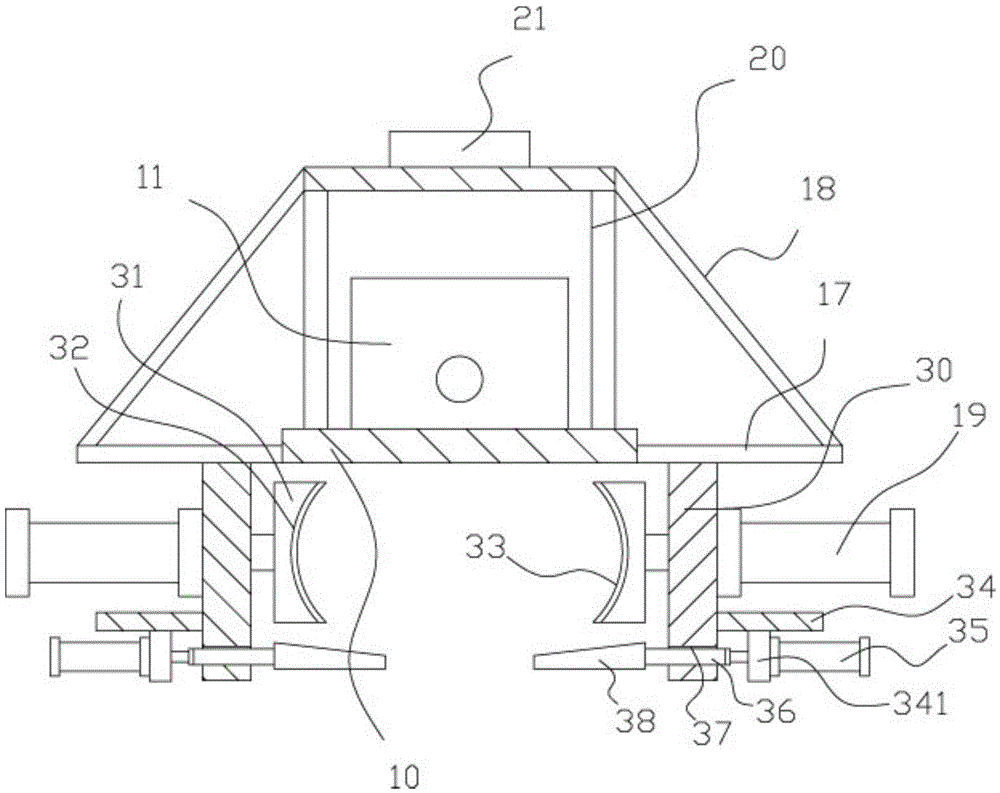

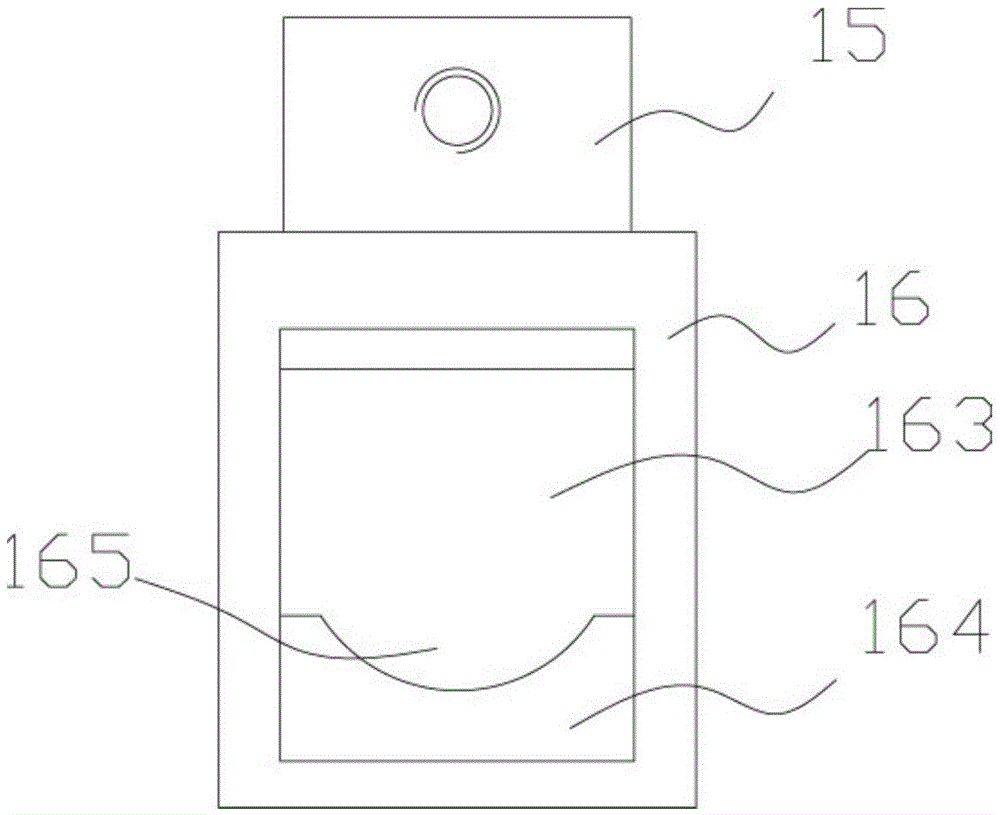

The invention discloses a welding tool for production of an automobile seat framework. The welding tool for production of the automobile seat framework comprises a base (1), a feed clamping device, two side section clamping devices and a supporting bar clamping device, wherein the feed clamping device is provided with a sleeve (14) in advance and pushes the sleeve to the position above a slope (50) of the bottom section of a U-shaped bent pipe (2) in the automobile seat framework, the two side section clamping devices are used for fixedly clamping two side sections of the U-shaped bent pipe (2), and the supporting bar clamping device is used for fixedly clamping a first supporting bar (3) and a second supporting bar (4) so that the two ends of the first supporting bar (3) and the two ends of the second supporting bar (4) can be in fixed lap joint to the two side sections of the U-shaped bent pipe (2) correspondingly. By the adoption of the structure, the U-shaped bent pipe, the first supporting bar and the second supporting bar can be fixedly clamped, and therefore the welding tool for production of the automobile seat framework can guarantee fixed clamping of the U-shaped bent pipe and the welding precision and the product consistency of the first supporting bar and the second supporting bar during automatic welding.

Owner:宁波明望汽车饰件有限公司

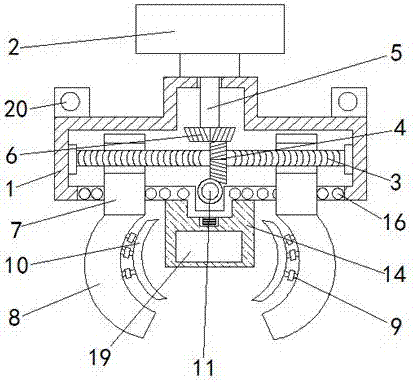

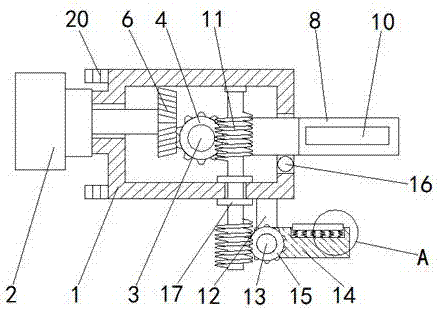

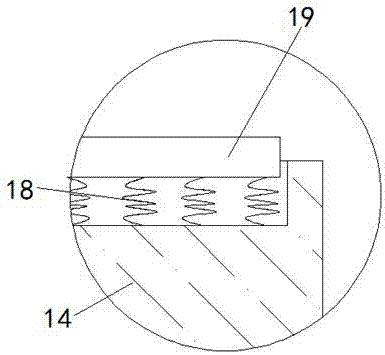

Clamping device for robot arm

InactiveCN107186741AStable clampingGuaranteed stabilityGripping headsThreaded rodIndustrial engineering

The invention discloses a clamping device for a robot arm. The clamping device for the robot arm comprises a rack body and a servo motor, wherein the servo motor is fixedly connected with the outer wall of one side of the rack body; a cavity is formed in the rack body, a threaded rod is rotationally connected to the interior of the cavity and fixedly sleeved with a first gear; the output end of the servo motor is fixedly connected with a rotating rod; the end, away from the servo motor, of the rotating rod penetrates through the outer wall of the rack body and extends into the cavity; the extending end of the rotating rod is fixedly sleeved with a second gear which is engaged with the first gear; the threaded rod is in threaded connection with two supporting blocks in a sleeved mode; and the inner wall of one side of the cavity is provided with sliding openings corresponding to the supporting blocks. Through arrangement of arc plates and a bearing plate, the clamping device is simple in structure and convenient to operate, and can stably clamp an object and prevent the object from falling off.

Owner:陕西舜洋电子科技有限公司

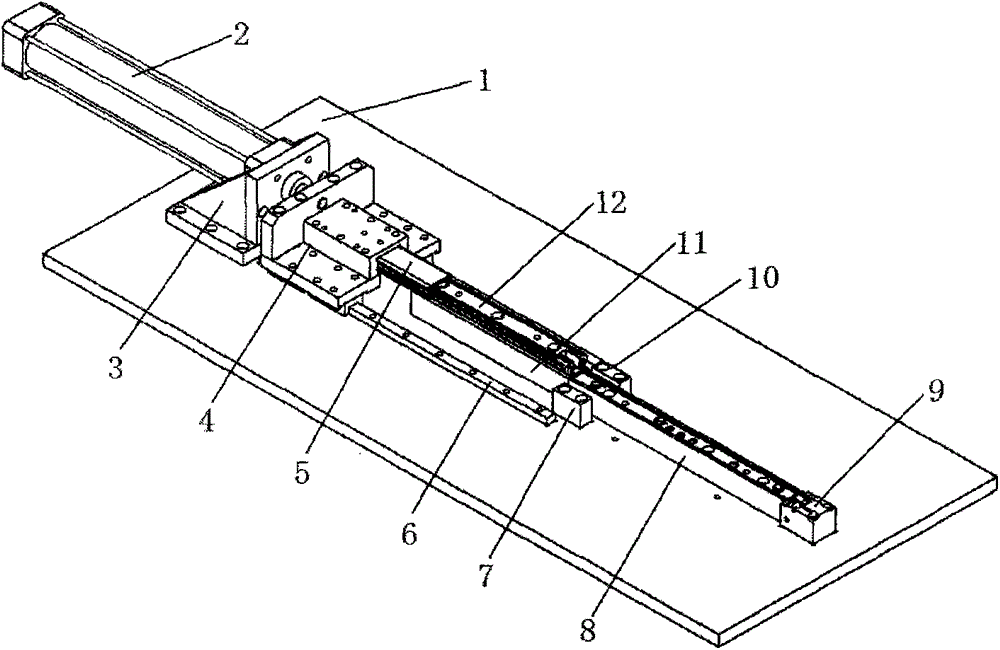

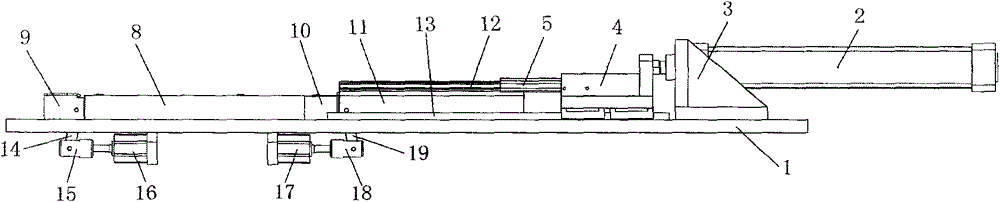

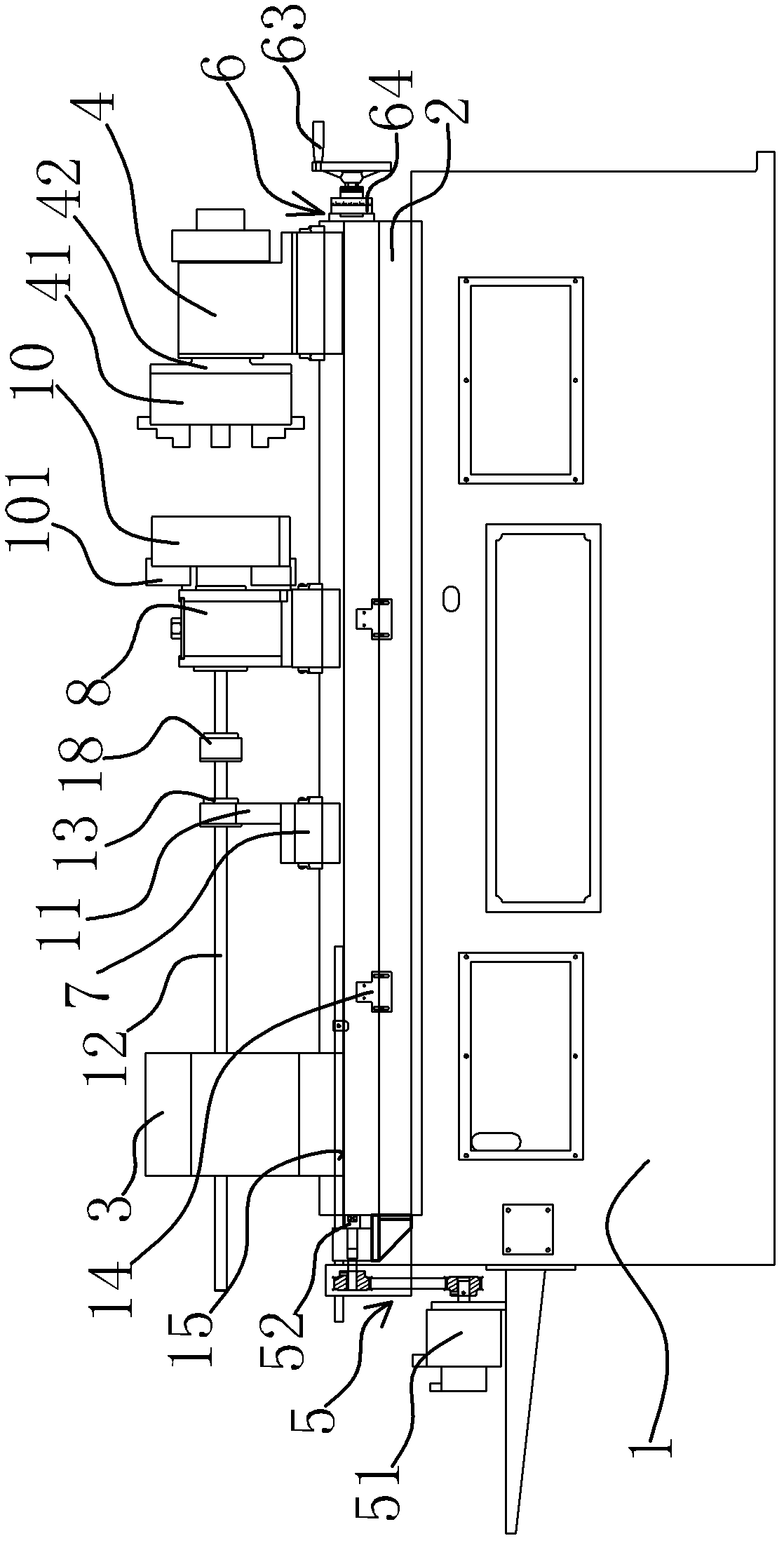

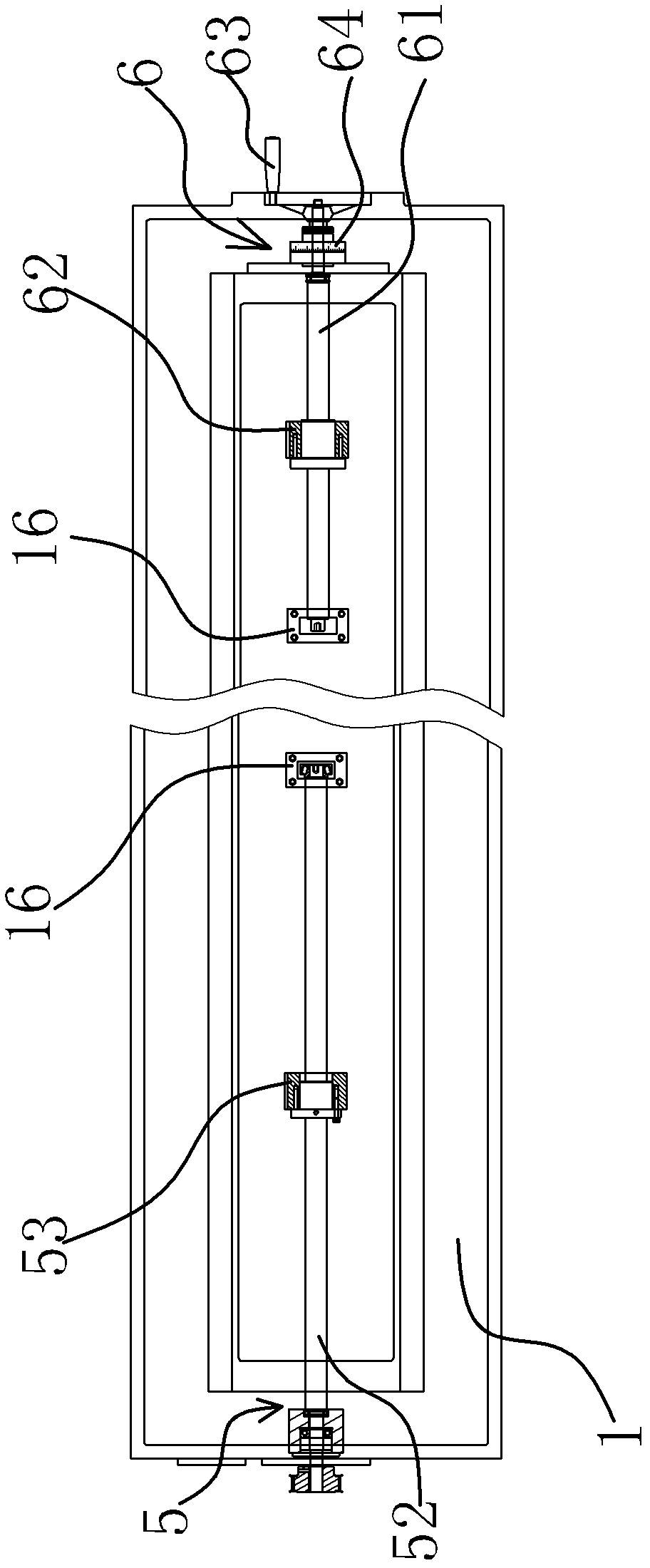

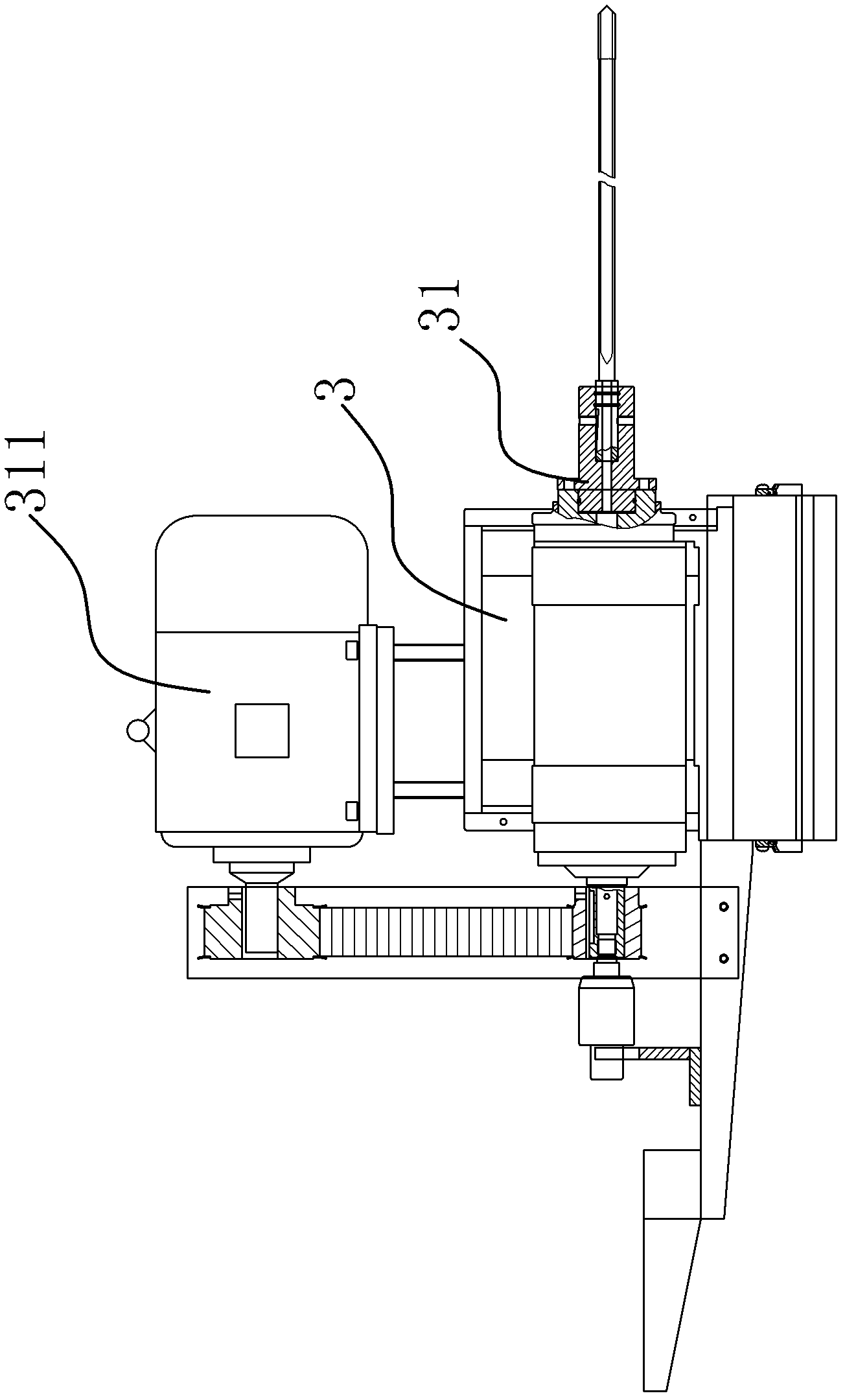

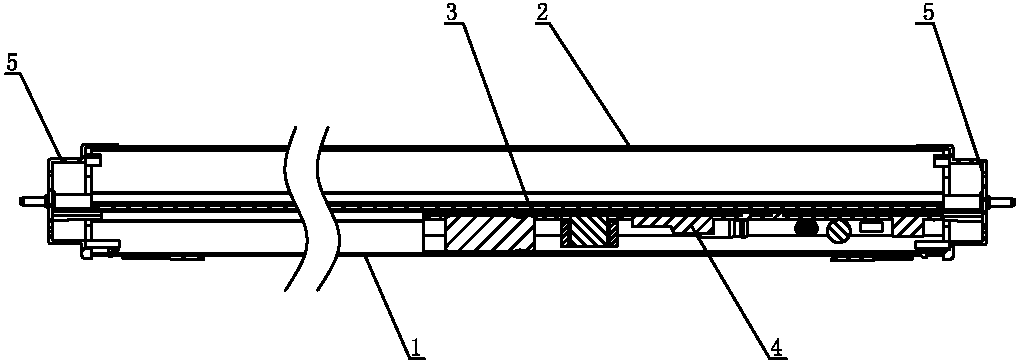

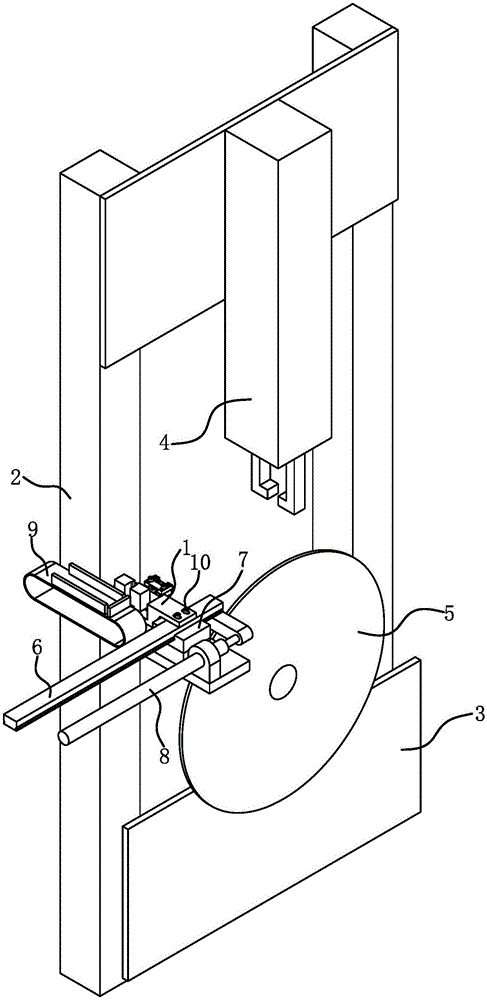

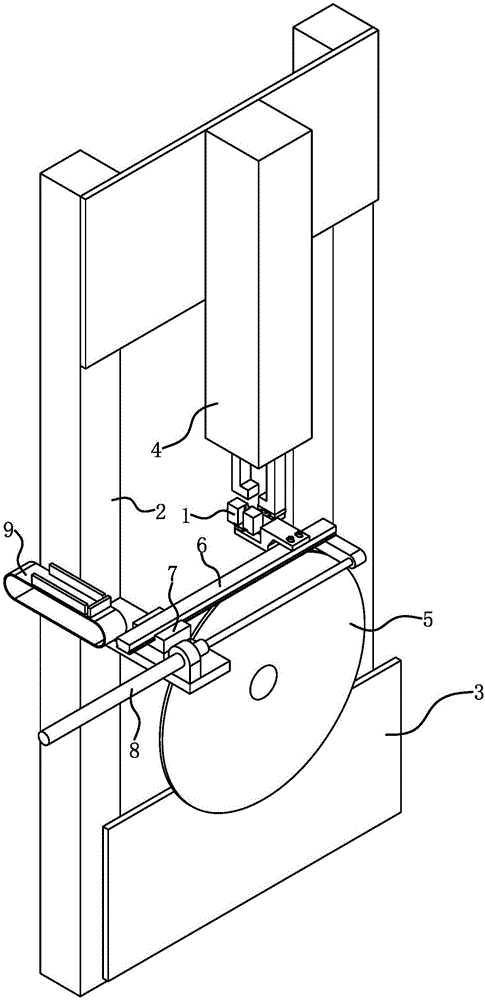

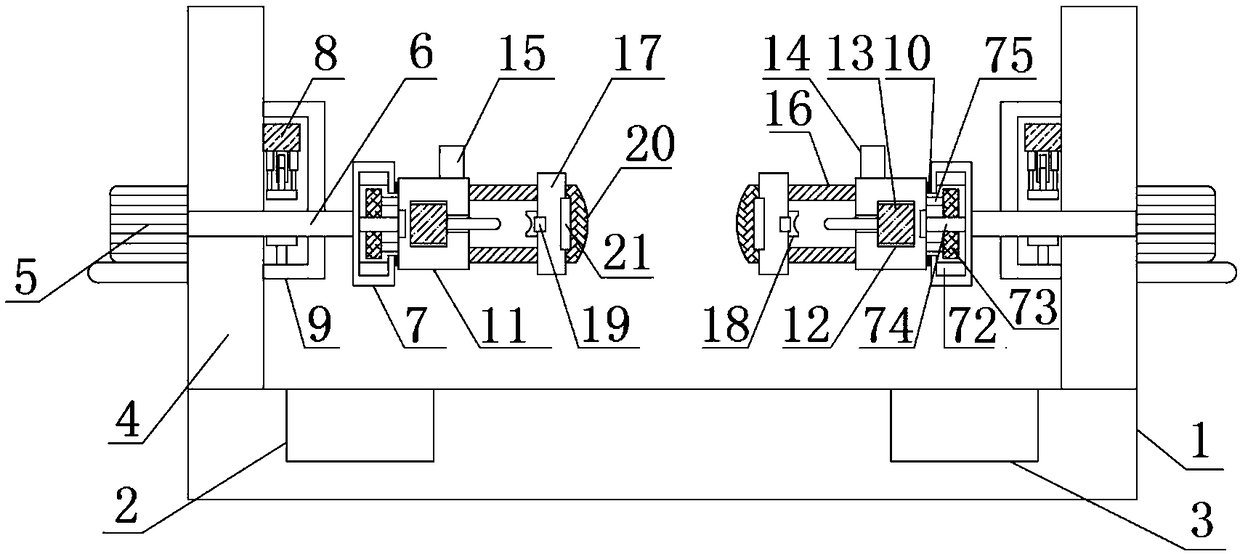

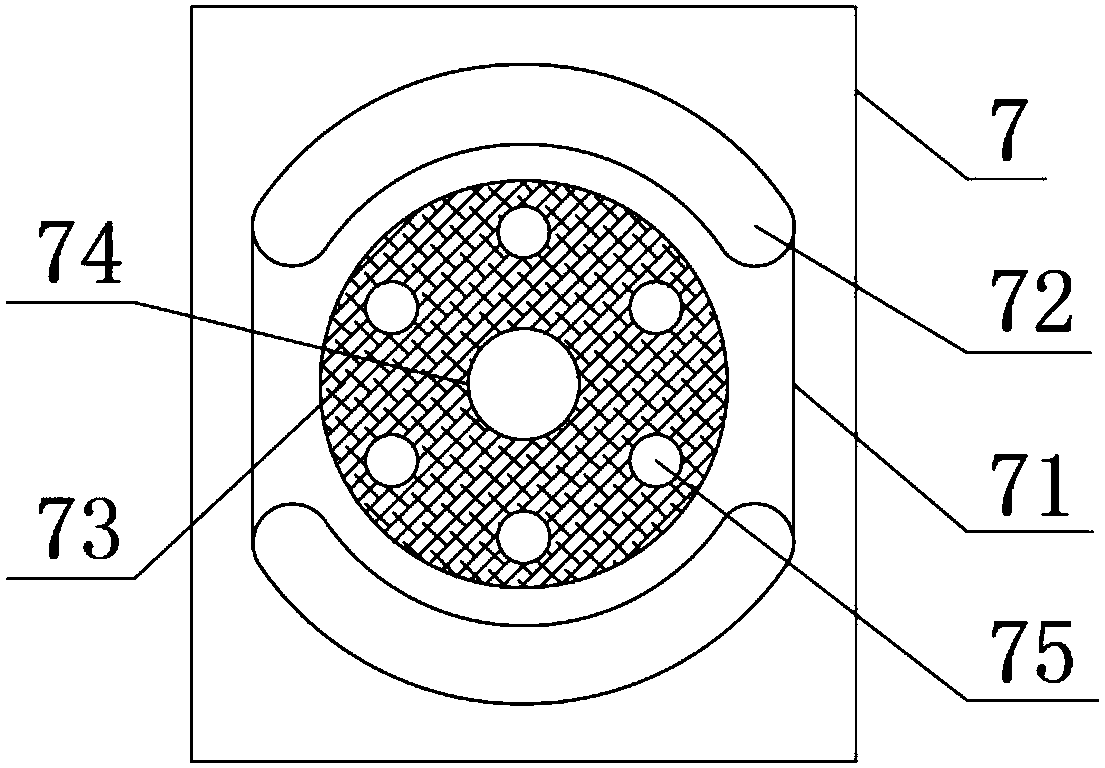

Automobile seat sliding track assembling machine and assembling method for same

ActiveCN103551834AImprove assembly efficiencyEfficient assembly workMetal working apparatusCar seatEngineering

The invention discloses an automobile seat sliding track assembling machine and an assembling method for same. The automobile seat sliding track assembling machine comprises a base, an assembling cylinder, a cylinder rack, an outer ejector block, an inner ejector block, a right guide track, a right limiting block, an inner sliding track rack, an end stopping block, a left limiting block, a supporting block, a side sliding track rack, a left guide track, a front clamping jaw, a front connecting rod, a front clamping cylinder, a rear clamping cylinder, a rear connecting rod and a rear clamping jaw. The automobile seat sliding track assembling machine is suitable for assembling automobile seat slide tracks. By the automobile seat sliding track assembling machine, assembly operation can be finished instead of manual work, and slide track components are clamped and assembled by the different cylinders. The automobile seat sliding track assembling machine has the advantages of large output force, high assembling speed, high efficiency, high quality and the like; the labor intensity of workers is effectively reduced; and the quality uniformity of products of assembly parts is ensured. In addition, the automobile seat sliding track assembling machine is compact in structure, high in reliability, stable in operation and low in cost.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

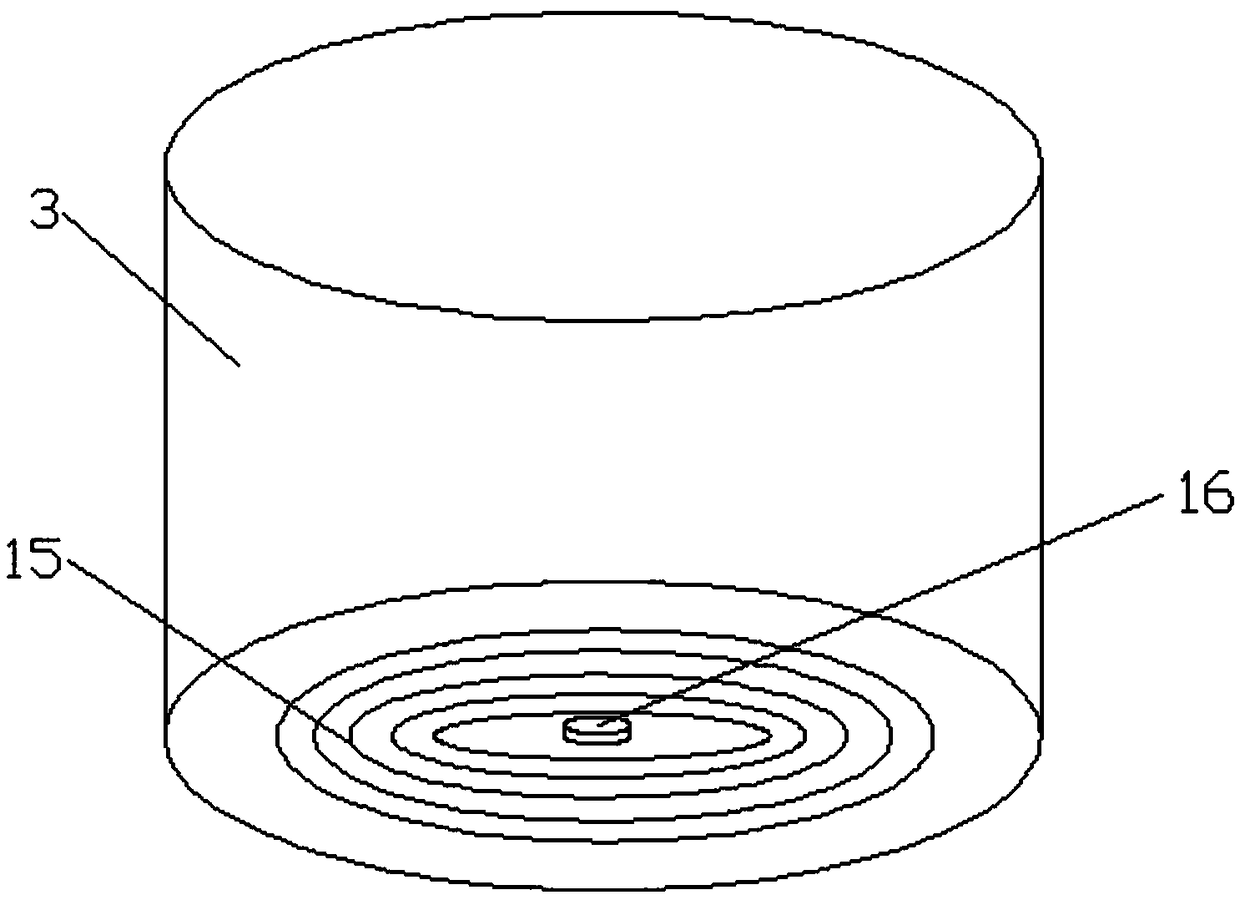

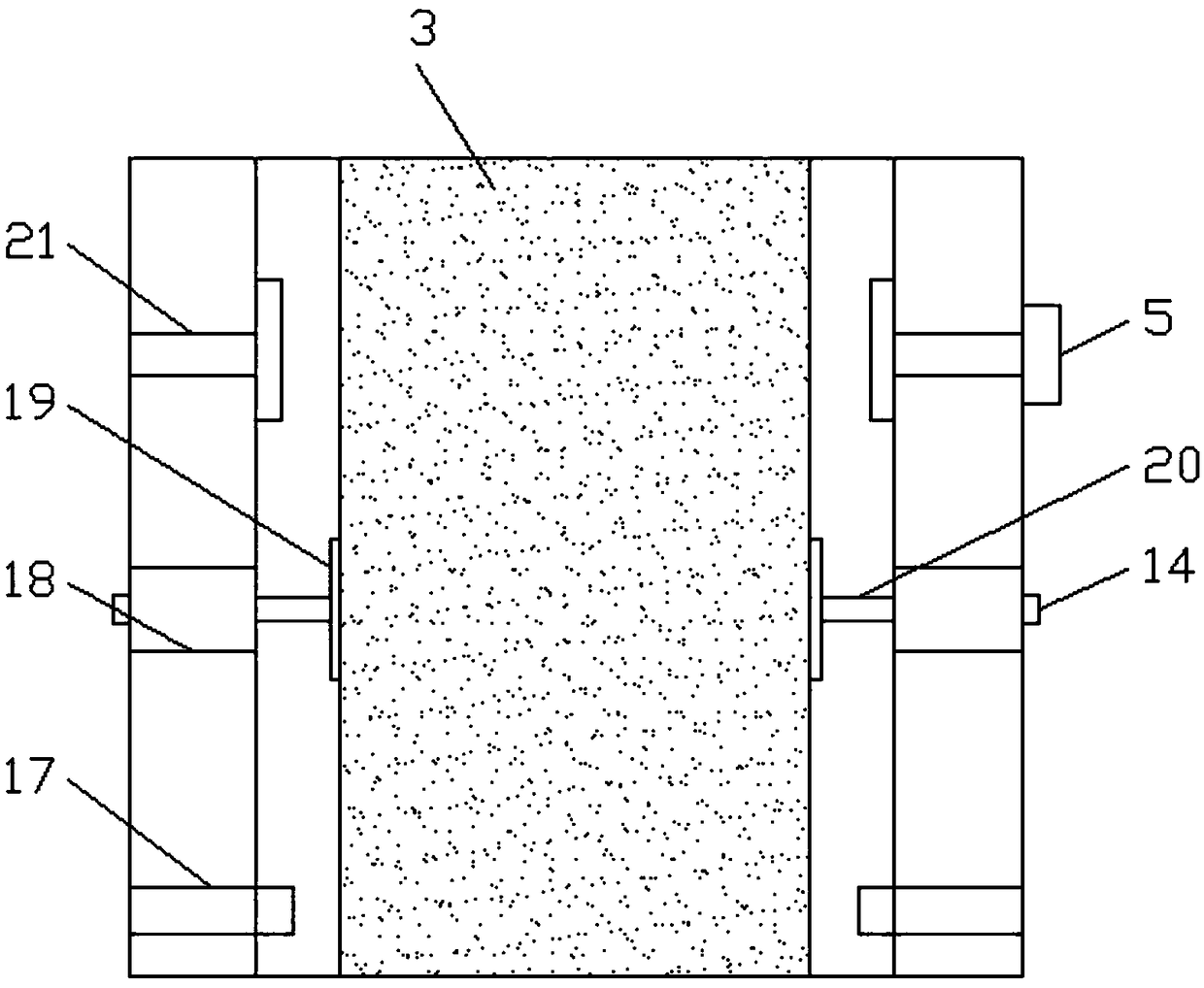

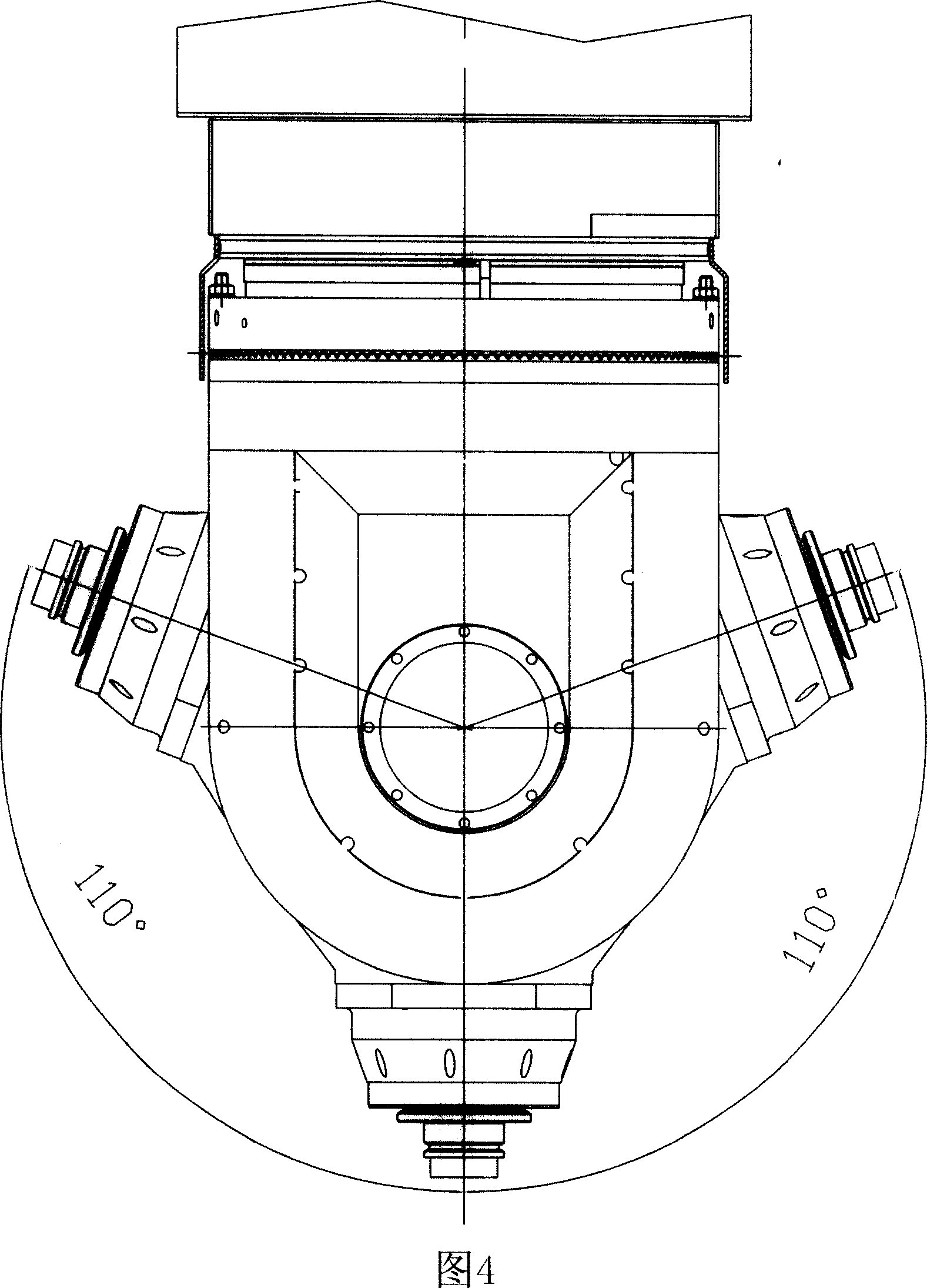

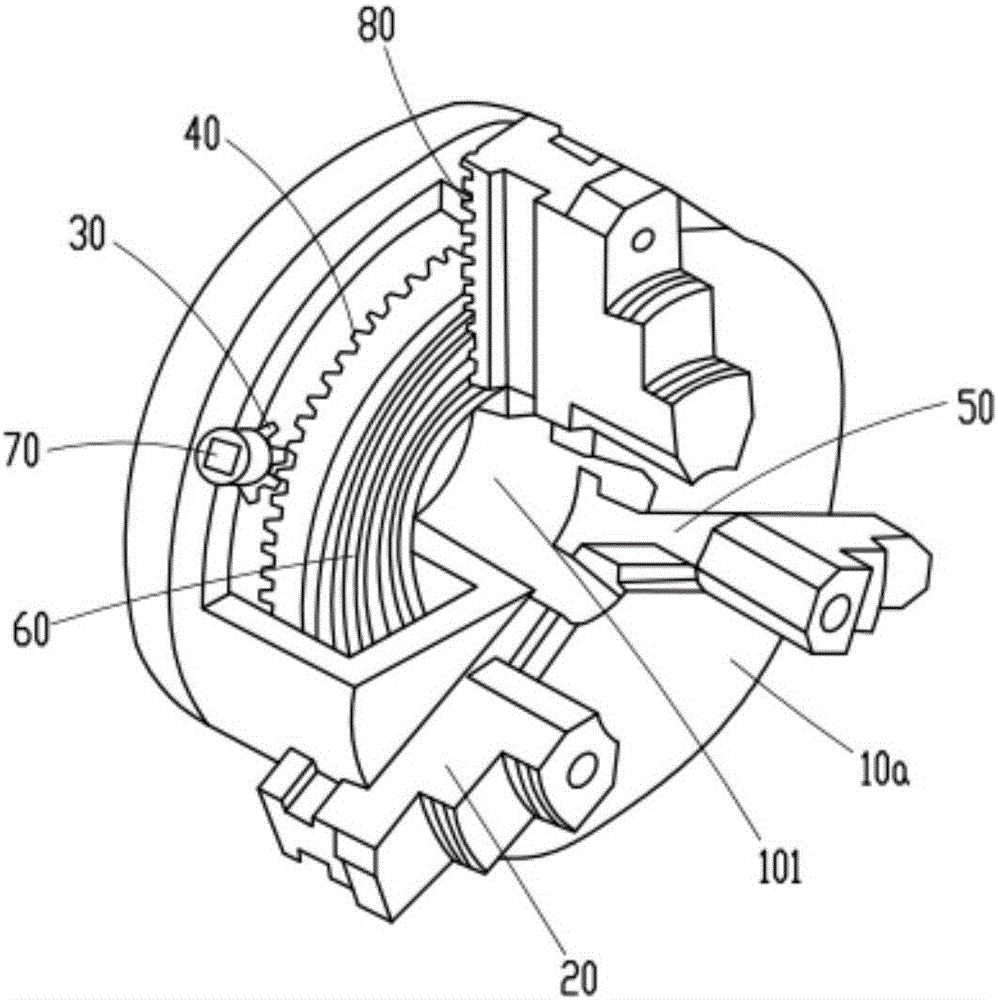

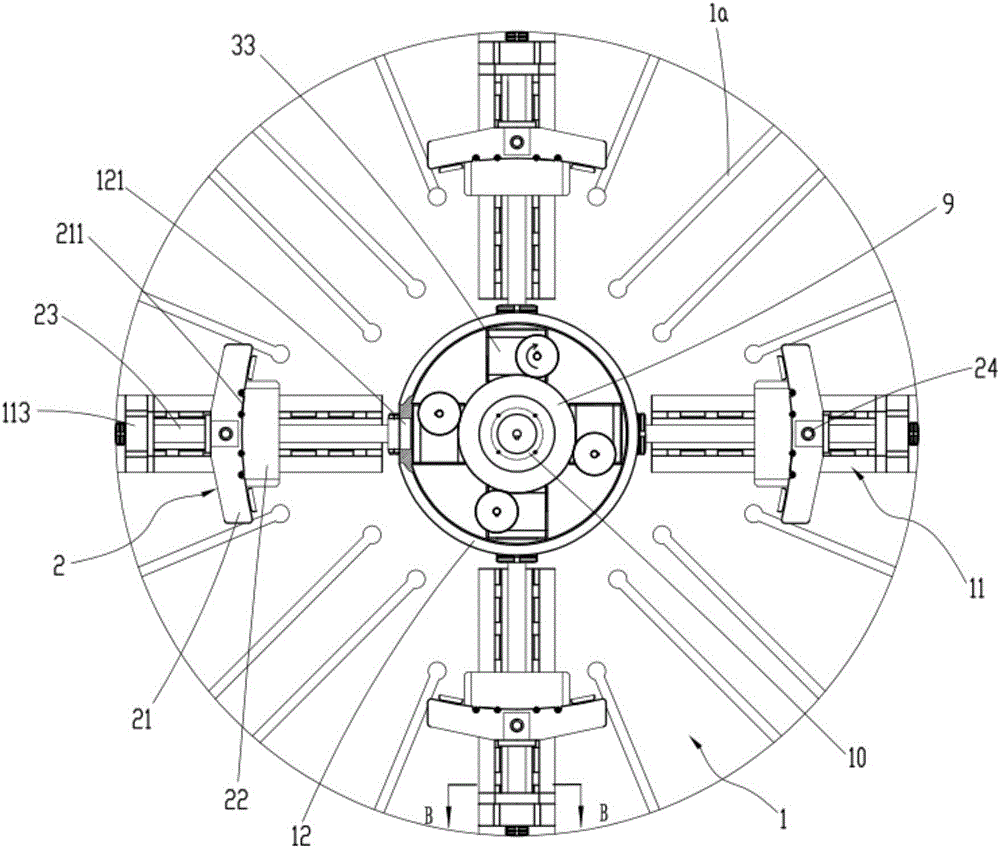

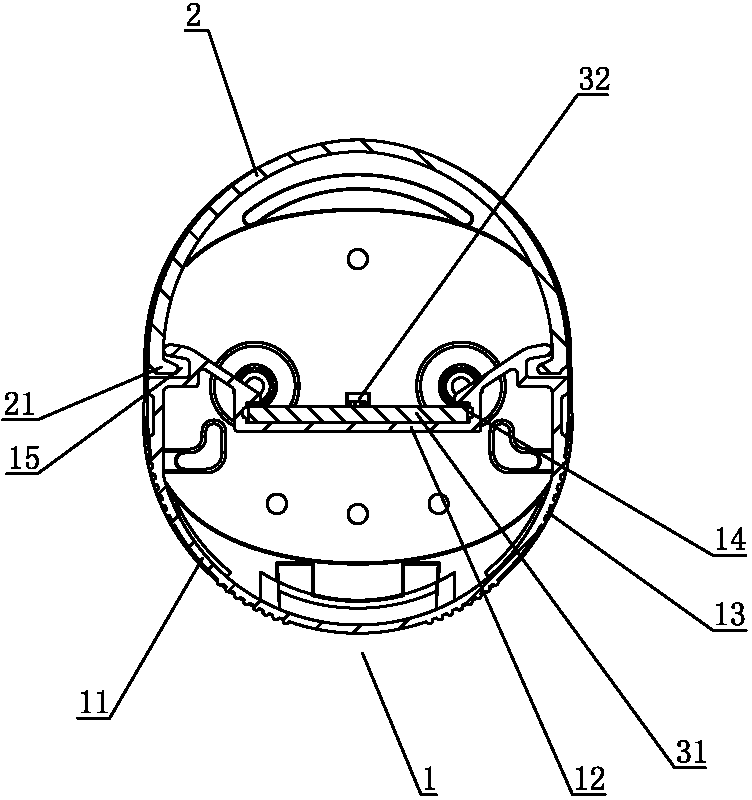

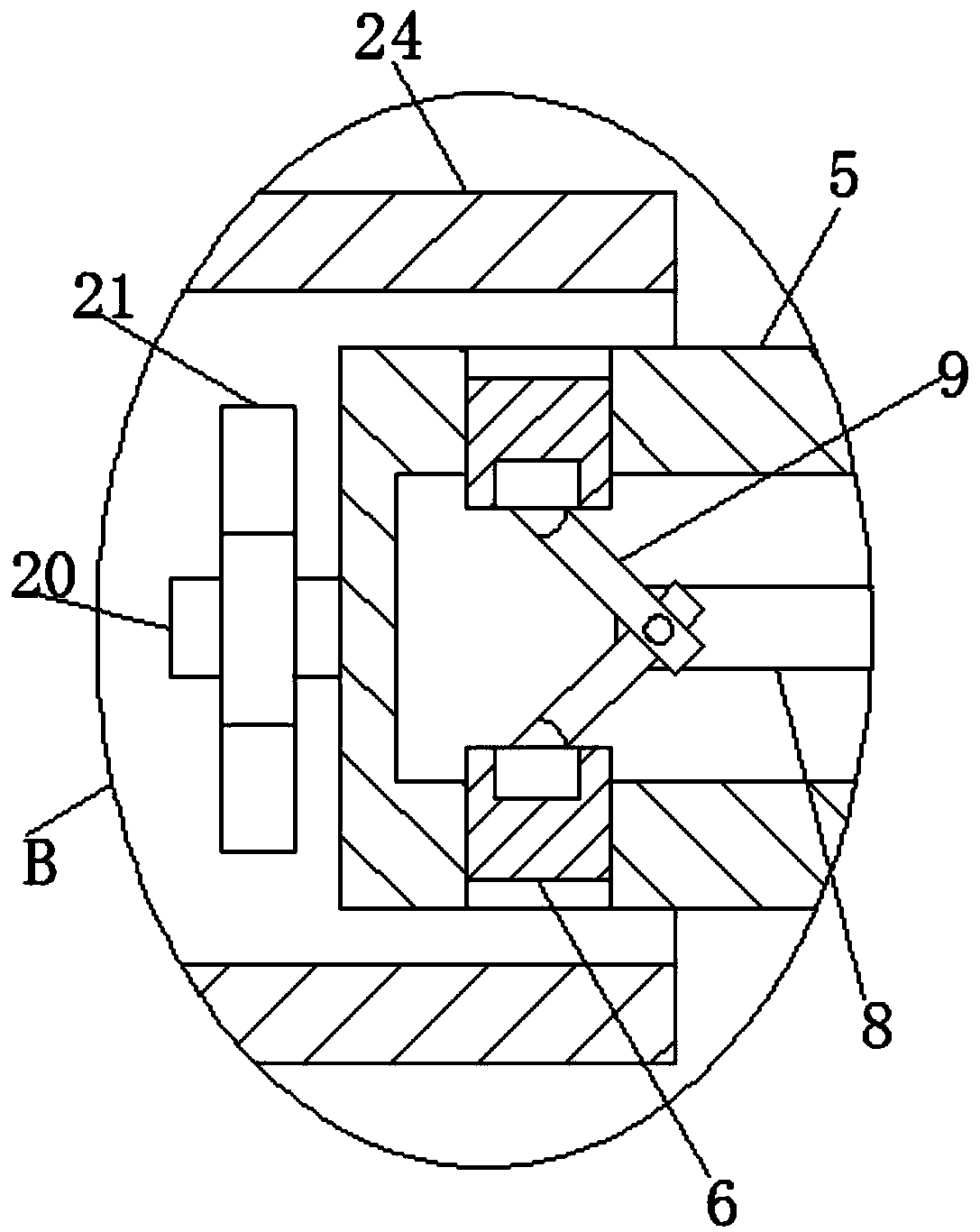

Precise self-centering chuck suitable for super-large workpieces

The invention relates to a precise self-centering chuck suitable for super-large workpieces. The precise self-centering chuck suitable for the super-large workpieces comprises a chuck body and a plurality of jack catch mechanisms arranged on the chuck body in a sliding mode. A jack catch driving mechanism is further arranged on the chuck body and comprises a numerical control moment motor, a plurality of transition gears, a plurality of double-enveloping speed reducers and a first gear. The inner circular surface and the outer circular surface of the first gear are provided with inner teeth and outer teeth correspondingly. The numerical control moment motor is provided with motor teeth. The multiple transition gears are all engaged with the motor teeth and the inner teeth of the first gear. The outer teeth of the first gear are engaged with second gears of the multiple double-enveloping speed reducers. The double-enveloping speed reducers drive the jack catch mechanisms to reciprocate to clamp or release the annular workpieces to be machined. The numerical control moment motor is used for sequentially driving the multiple transition gears and the double-enveloping speed reducers to rotate in a matched mode, so that the multiple jack catch mechanisms move inwards or outwards synchronously. The super-large annular workpieces are subjected to automatic centering clamping or releasing, and the clamping positioning accuracy is high.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

Steel plate punching clamping mechanism

ActiveCN105798107AStable clampingEasy to holdMetal-working feeding devicesPositioning devicesPunchingArchitectural engineering

The invention discloses a steel plate punching clamping mechanism. The steel plate punching clamping mechanism comprises a rack, a main groove is formed in the middle portion of the top face of the rack, a bottom containing block is fixed to the middle portion of the main groove, a containing groove is formed in the middle portion of the bottom containing block, and the four outer side walls of the bottom containing block are each provided with a pushing oil cylinder fixedly; a push rod of each pushing oil cylinder extends into the containing groove and is fixed to a corresponding clamping plate, and the clamping plates are parallel to the corresponding inner side walls of the containing groove; a main connecting support is fixed to the bottom face of the main groove, connecting plates are fixed to the upper portions and the lower portions of the inner side walls of two vertical supporting plates of the main connecting support, and the two ends of a transmission screw are hinged to the two connecting plates; one connecting plate is provided with a driving motor fixedly, an output shaft of the driving motor is a spline shaft, and the spline shaft is inserted into a corresponding spline hole formed in the end of the transmission screw in a sleeved manner; and an upper pressing plate is located above the bottom containing block, and adjusting fixing blocks are fixed to the two side walls of the upper pressing plate. The steel plate punching clamping mechanism is firm and convenient to clamp, accurate in punching and good in effect.

Owner:宁夏远高绿色科技建筑有限公司

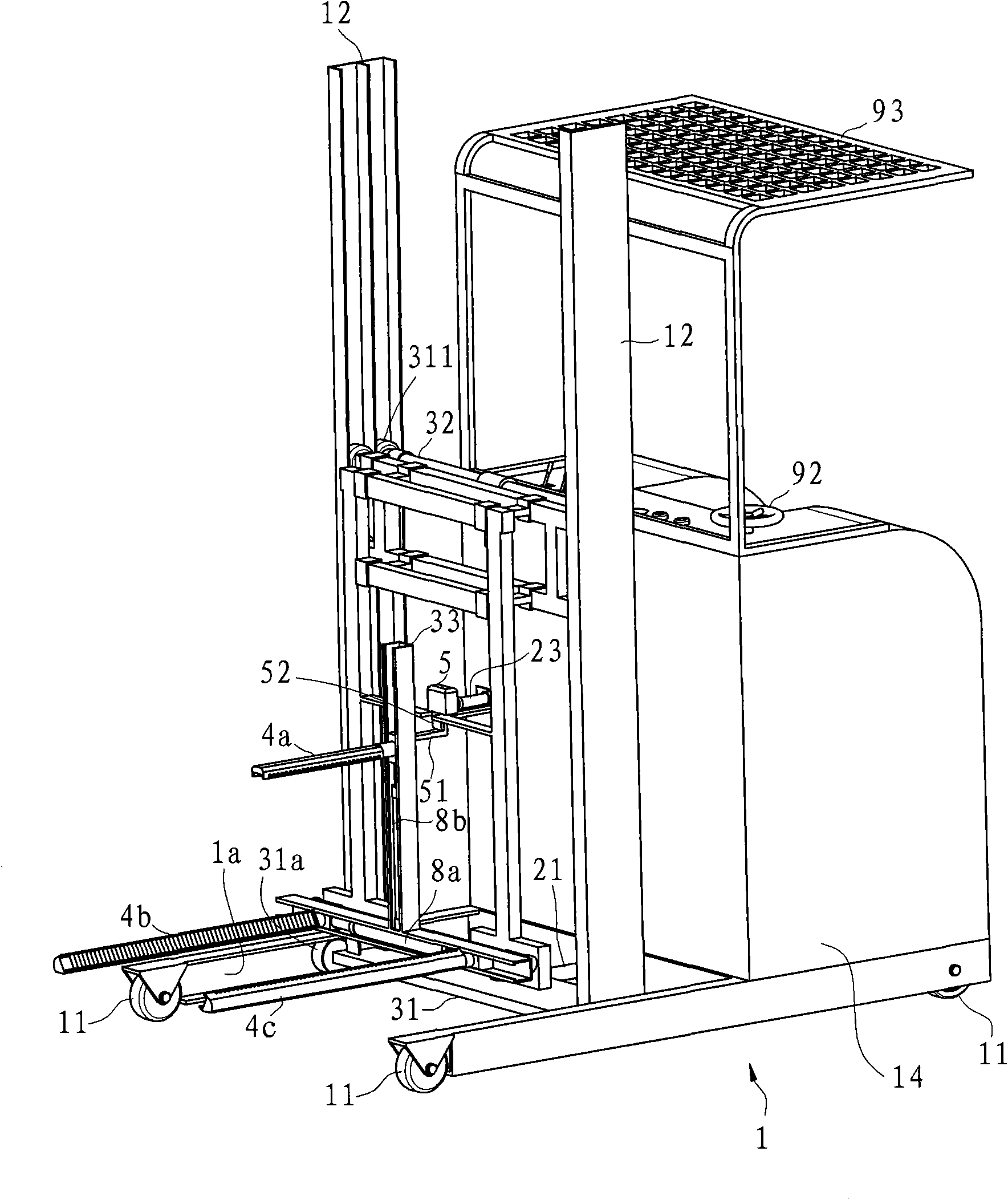

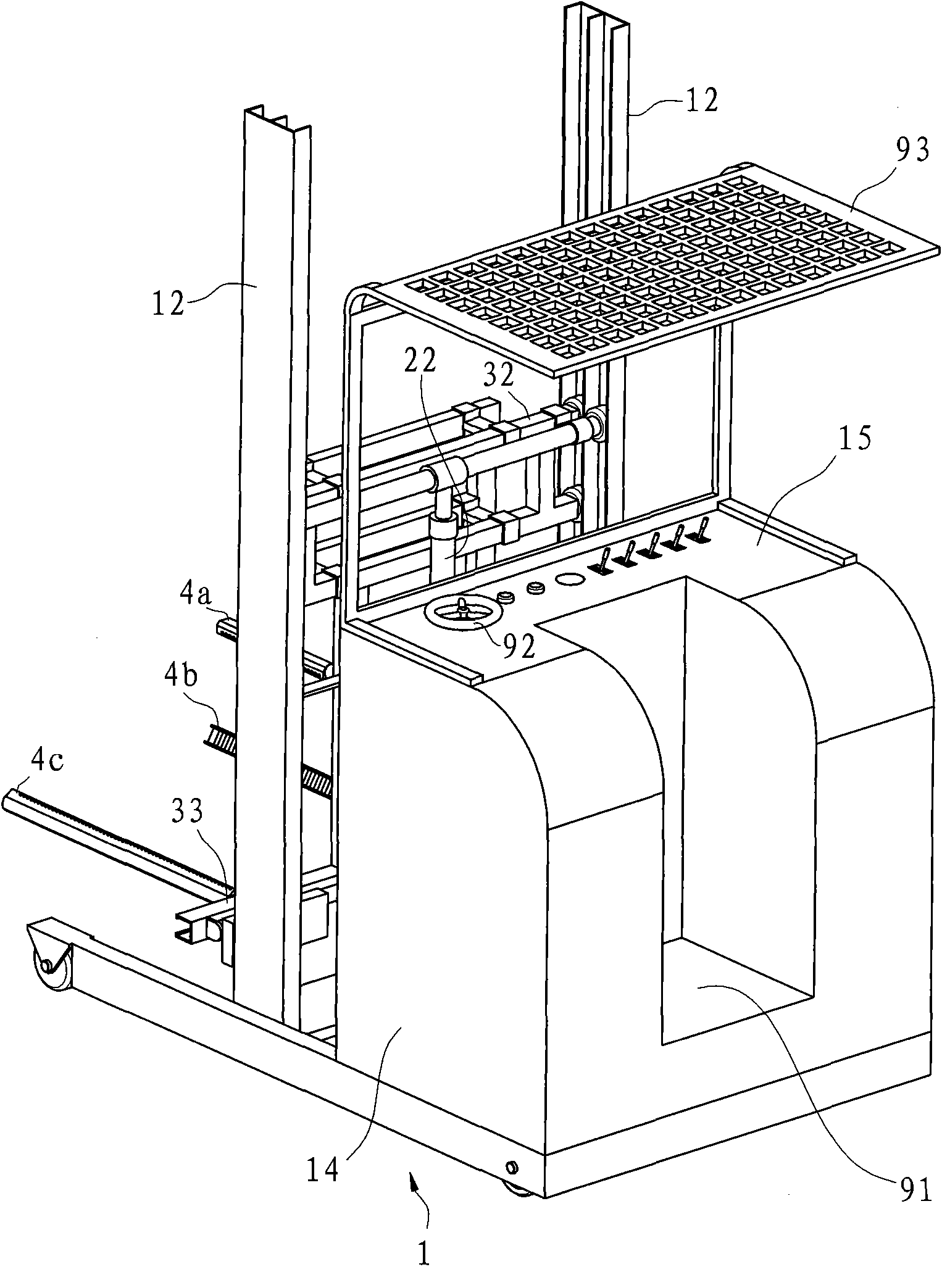

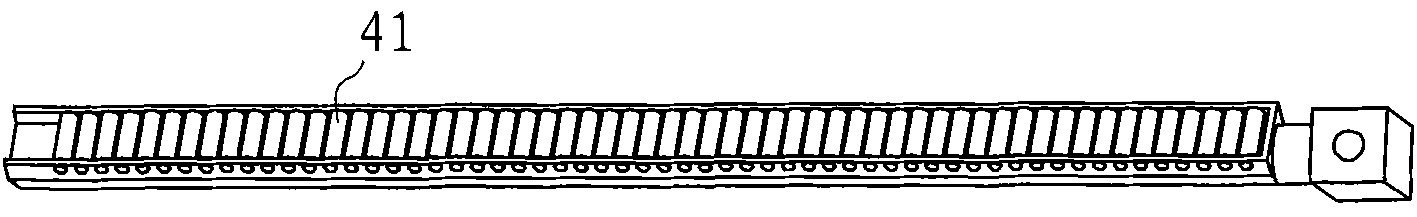

Turning and lifting van

The invention relates to a turning and lifting van which comprises a chassis, a controller, a cab, a clamping mechanism and a driving mechanism capable driving the clamping mechanism to move transversely and vertically, wherein the bottom of the chassis is provided with wheels for moving back and forth; the clamping mechanism comprises a connecting frame, a guide slot bracket, clamping rods and a driving source; the connecting frame is connected with the driving mechanism, and the guide slot bracket is arranged on the connecting frame; three clamping rods are movably arranged on the guide slot bracket; and the controller is provided with a first control output end connected with the lifting mechanism and a second control output end connected with the driving source. Compared with the prior art, the invention has the advantages that the three adjustable clamping rods are used for achieving the purpose that gaps among the clamping rods can be adjusted; the van can be used for carrying rolled objects with different diameters without clamper equipment of various specifications, thereby the cost is greatly reduced; in addition, by utilizing an electromagnetic valve, the turning of carried objects can be realized by combining a first hook and a second hook.

Owner:NINGBO SOKEN CHEM

Welding robot

InactiveCN108907546AHeight adjustableEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesBall bearingArchitectural engineering

The invention relates to the field of robot technology, and discloses a welding robot. The welding robot comprises a base. The upper end of the base is fixedly connected with two vertical plates in abilateral symmetry mode. The opposite sides, close to the upper ends, of the two vertical plates are symmetrically provided with grooves. The inner walls of the bottoms of the grooves are fixedly provided with longitudinally-arranged racks. A support rod is arranged between the two vertical plates. The two ends, corresponding to the two vertical plates, of the support rod are fixedly connected with connecting blocks. First motors are fixedly embedded in one ends of the connecting blocks. Output shafts of the first motors are fixedly connected with gears meshing with the racks. The lower end ofthe support rod is fixedly connected with two clamping plates in a bilateral symmetry mode. The opposite sides of the two clamping plates are rotationally connected with a screw through ball bearings. The rod wall of the screw is in threaded connection with a moving block. The lower end of the moving block is vertically and fixedly connected with an electric push rod. The output end of the lowerend of the electric push rod is fixedly connected with a welding gun. The welding robot is capable of performing welding work in all aspects and can be moved conveniently.

Owner:ZHEJIANG SHUREN UNIV

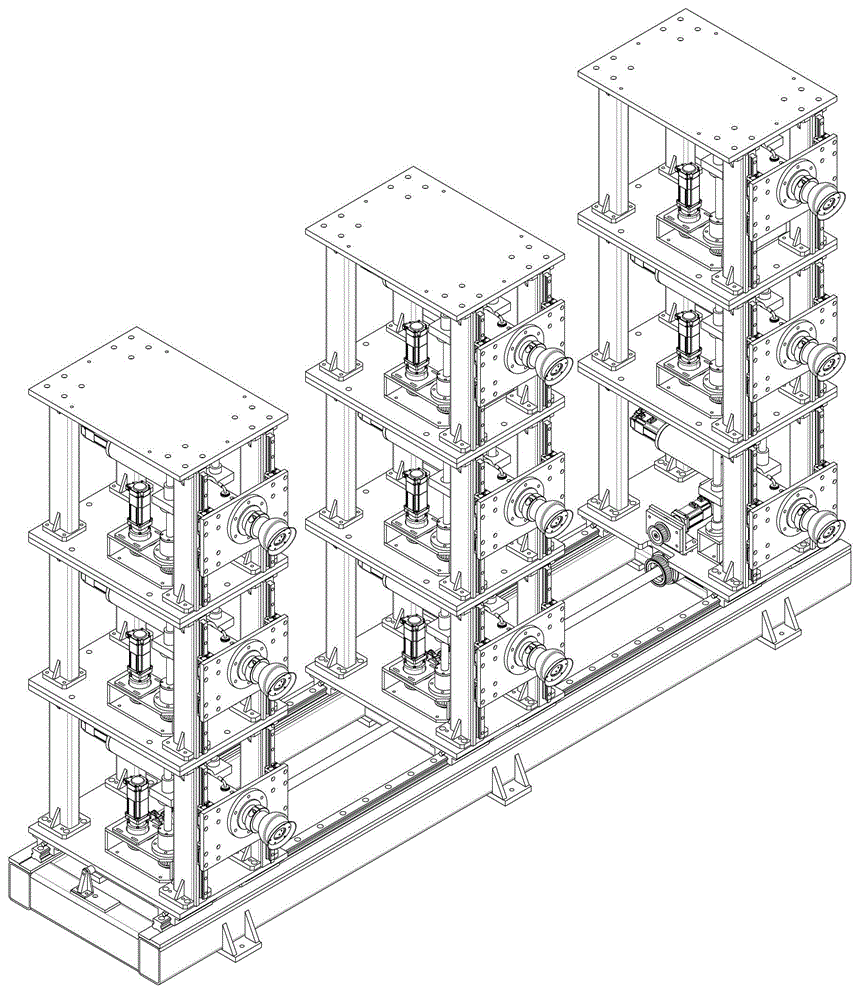

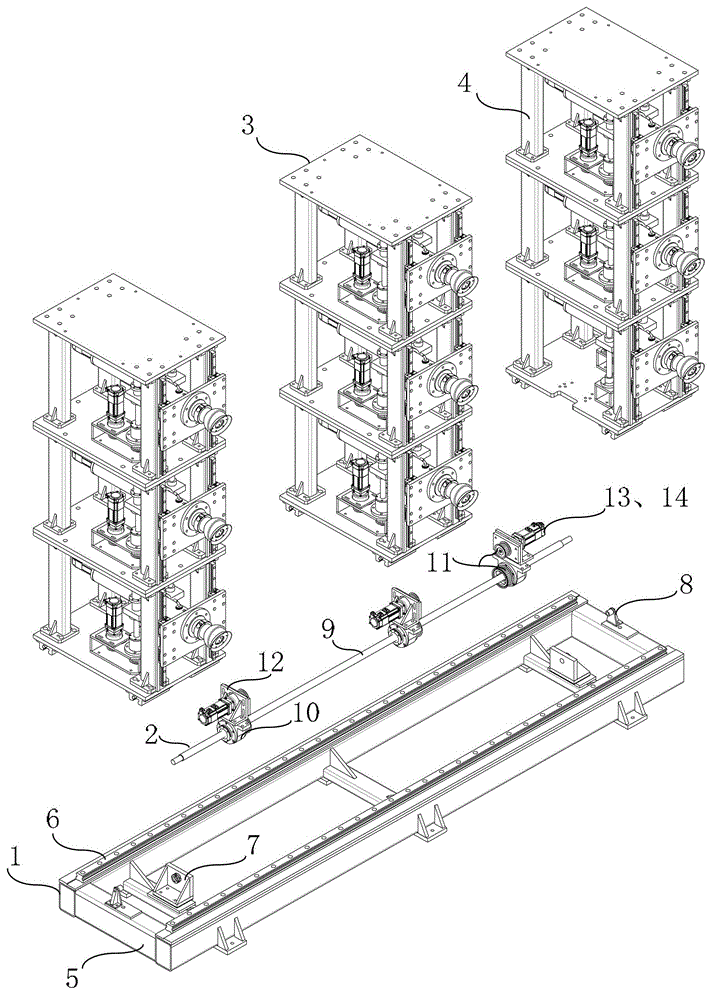

Flexible tool for assembling row-line chuck type wall board

A flexible tool for assembling a row-line chuck type wall board comprises a guide rail base, an X-direction driving unit and an upright post shape-adjusting assembly unit, wherein the guide rail base is fixedly connected to the ground; the upright post shape-adjusting assembly unit is arranged on two X-direction linear guide rails of the guide rail base and can move along the X-direction linear guide rails; and the X-direction driving unit is positioned between the bottom of the upright post shape-adjusting assembly unit and the guide rail base, is fixedly connected with the guide rail base and is connected with the bottom of the upright post shape-adjusting assembly unit. According to the flexible tool disclosed by the invention, aircraft panel assemblies are adsorbed, clamped and digitally positioned by a dot matrix vacuum chuck and stability and reliability in clamping and positioning and high positioning precision are obtained; and the digitalized positioning and drilling and riveting assembly of different wall board assemblies can be realized by reconfiguration through the dot matrix chuck of the tool. The flexible tool has higher practical value and broad application prospect in the fields of mechanical engineering / aircraft assembly.

Owner:BEIHANG UNIV

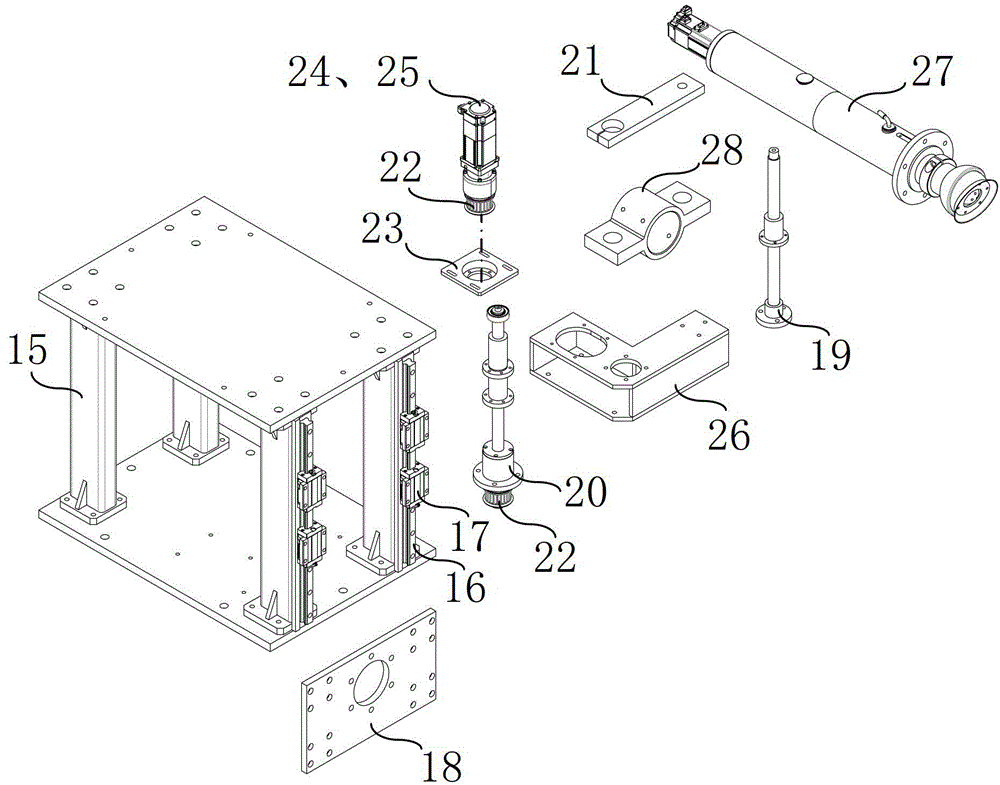

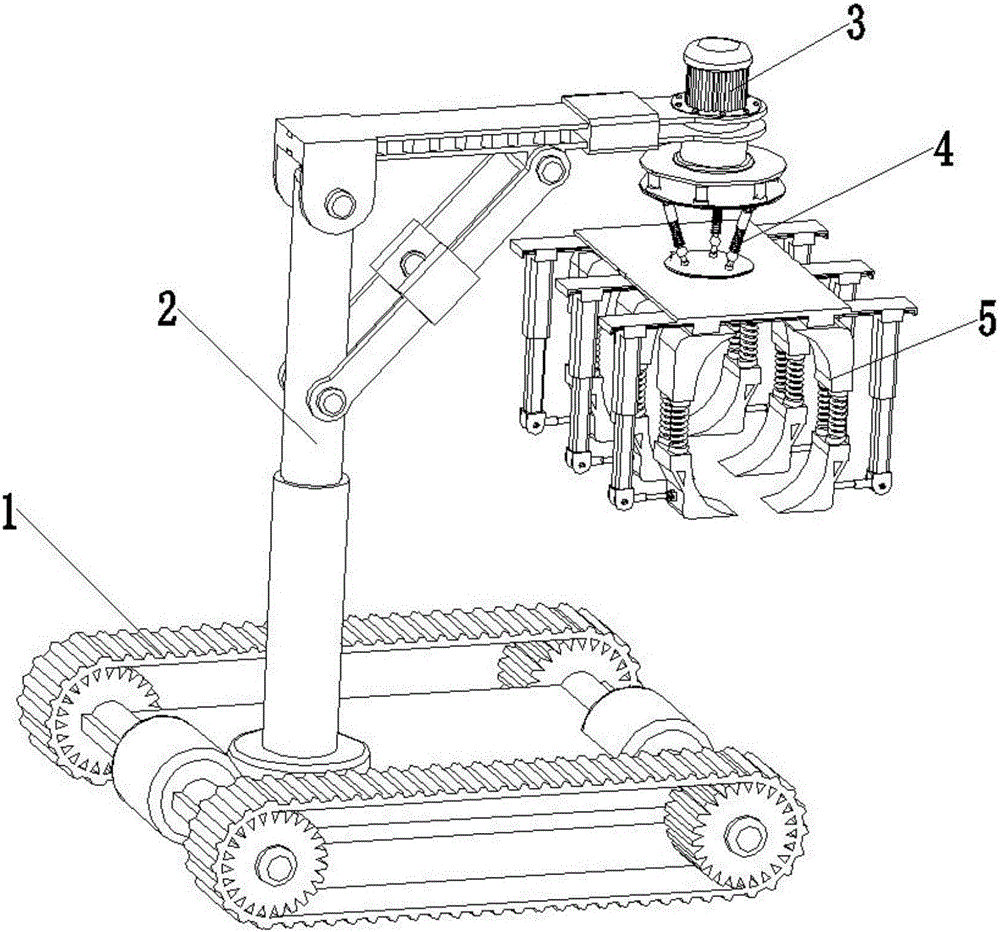

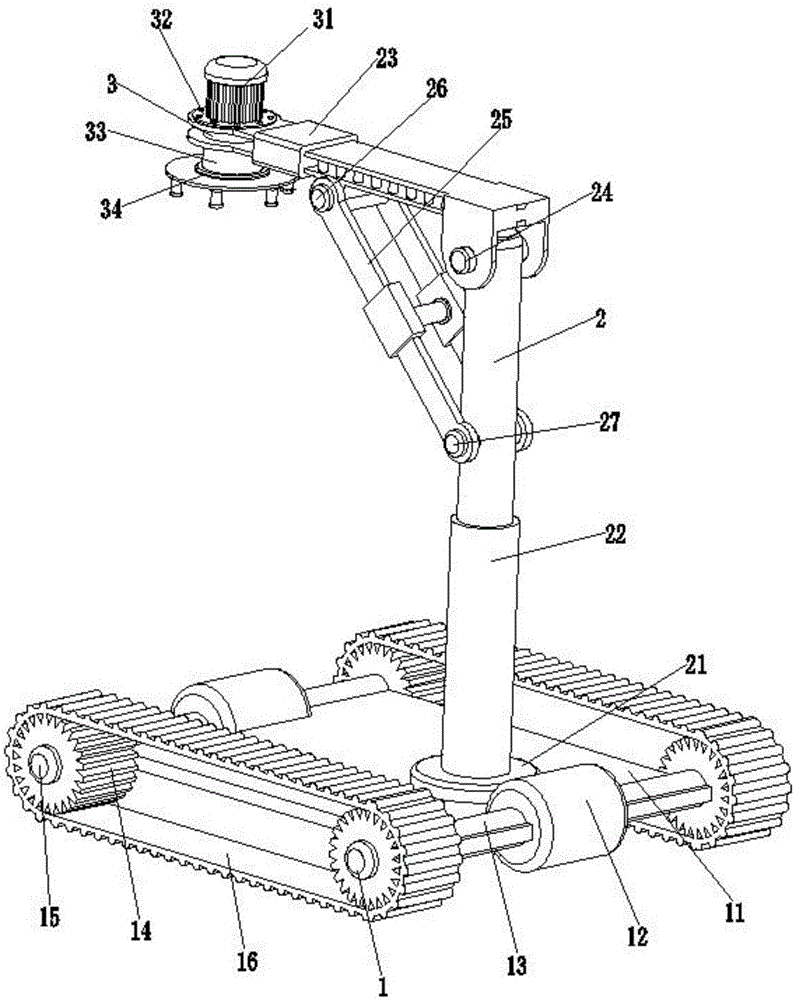

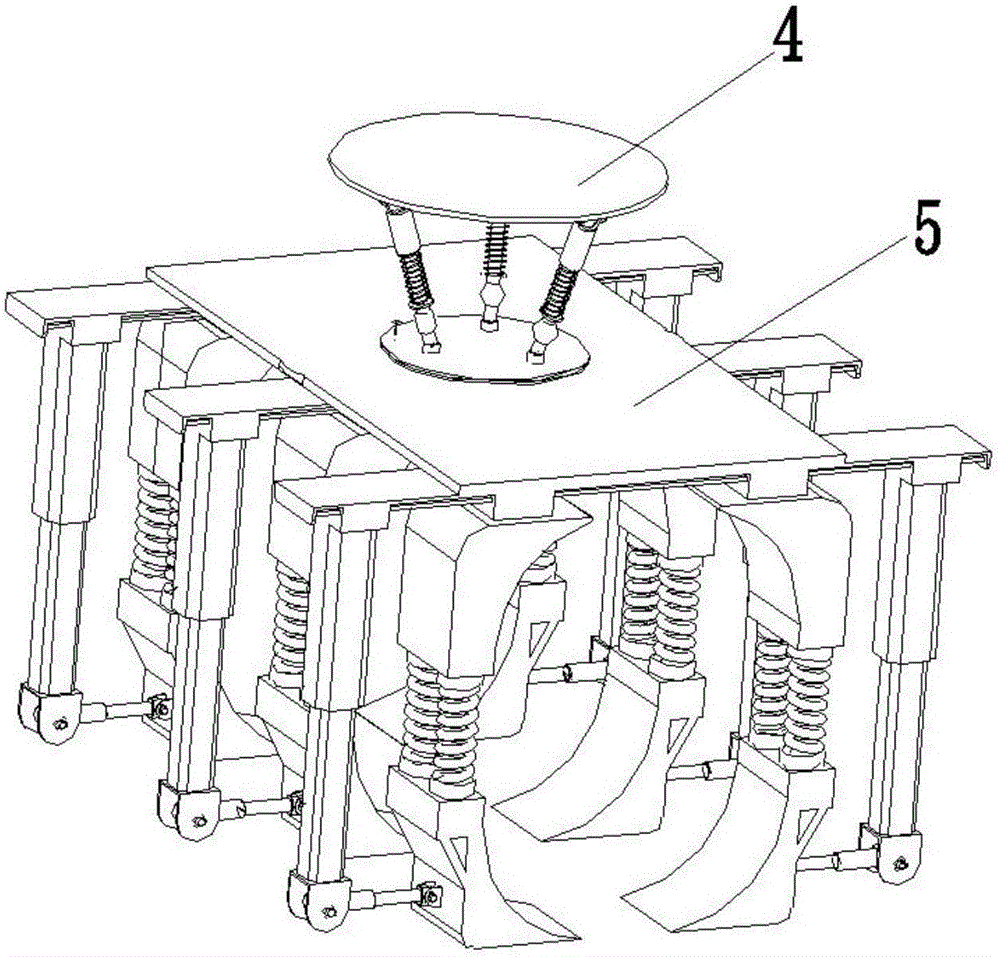

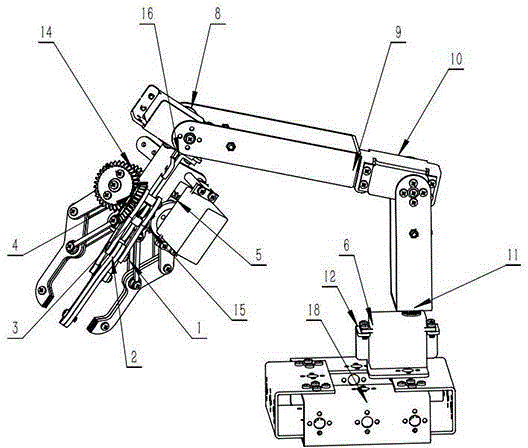

Hydraulic engineering pipe fitting stacking industrial robot

InactiveCN105904432AHigh degree of automationImprove work efficiencyProgramme-controlled manipulatorGripping headsThree degrees of freedomPipe fitting

The invention relates to a hydraulic engineering pipe fitting stacking industrial robot. The hydraulic engineering pipe fitting stacking industrial robot comprises a traveling device, an adjustable support, a rotary device, a three-degree-of-freedom parallel mechanism and a clamping device; the adjustable bracket is located on the rear upper side of the traveling device; the rotary device is located in the front end position of the adjustable support, and is fixedly connected with the adjustable support; the three-degree-of-freedom parallel mechanism is located between the rotary device and the clamping device; the upper end of the three-degree-of-freedom parallel mechanism is connected with the rotary device; and the lower end of the three-degree-of-freedom parallel mechanism is connected with the clamping device. The hydraulic engineering pipe fitting stacking industrial robot can realize a series of operation including grabbing, carrying and stacking of water conservancy and hydropower pipelines, is high in automation degree and stable and flexible in motion, solves such problems as high manual carrying operation cost, low efficiency and high dangerousness, the horizontal interval and vertical interval of the clamping device are adjustable, thereby facilitating grabbing of the water conservancy and hydropower pipelines with different diameter sizes, grabbing and stacking are convenient and rapid, clamping is stable and firm in the carrying process, slipping is not easy to occur, and the safety is good.

Owner:陈薇

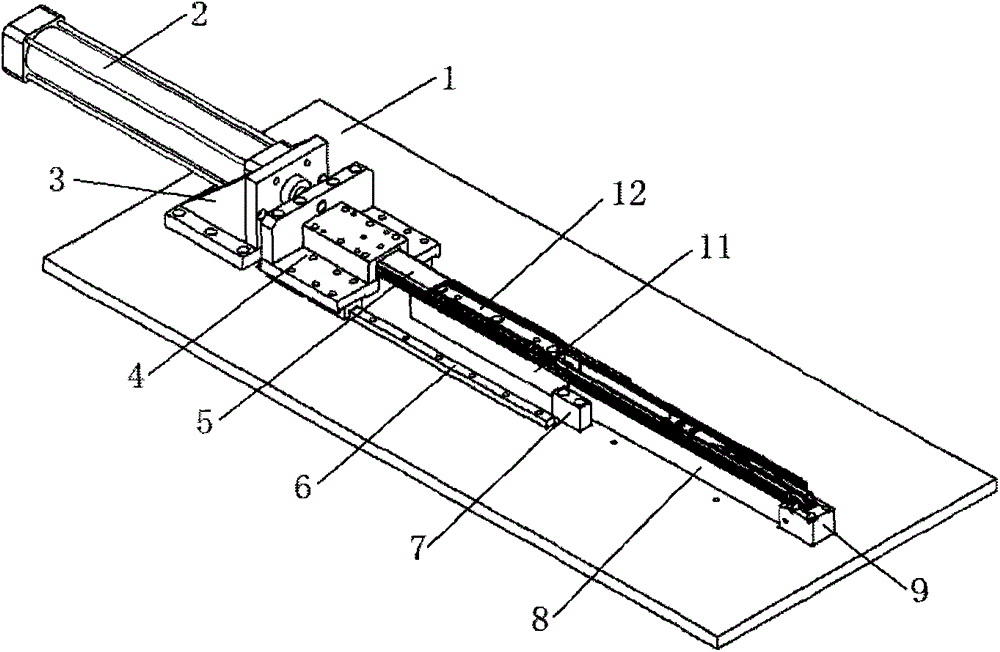

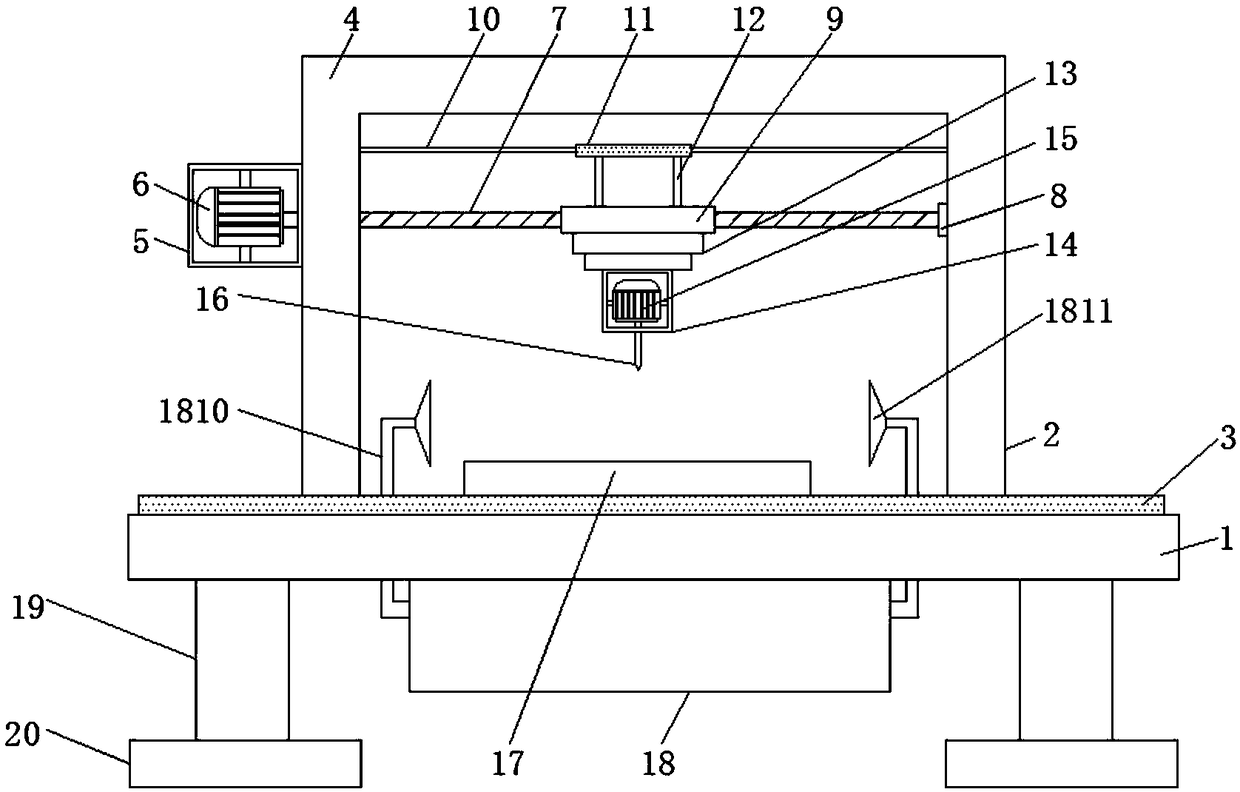

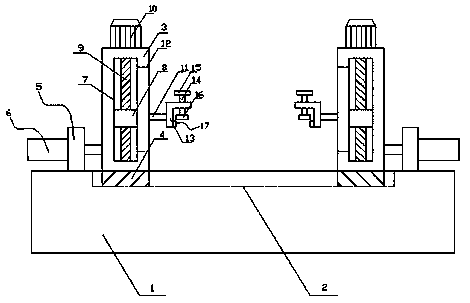

Deep hole drilling machine

ActiveCN102198529AReasonable designCompact structureBoring/drilling componentsBoring/drilling machinesEngineeringTailstock

The invention provides a deep hole drilling machine which belongs to the technical field of machining equipment. The drilling machine solves the problems that the traditional deep hole drilling machine has poor guidance, poor stability, no high machining precision, no high efficiency and a not enough compact structure. The deep hole drilling machine comprises a lathe bed, a power head and a tailstock, wherein the lathe bed is provided with a horizontally arranged slide rail ; the tailstock and the power head are arranged on the slide rail; the power head is provided with a horizontally arranged feed main shaft and a driving motor I for driving the feed main shaft to rotate; one end of the feed main shaft can be connected with a cutting tool; a driving mechanism I is arranged between the power head and the lathe bed and can drive the power head to slide along the slide rail; the tailstock is provided with a jig; and a driving mechanism II is arranged between the tailstock and the lathe bed and can drive the tailstock to slide along the slide rail. The lathe bed of the deep hole drilling machine is provided with the driving mechanism I for driving the power head to slide along the slide rail and the driving mechanism II for driving the tailstock to slide along the slide rail, so that the design is reasonable and the structure is compact; moreover, the lathe bed is provided withthe guide rail and a guide holder, thereby the machining precision of deep holes is improved.

Owner:ZHEJIANG XILING

Drilling machine for hardware manufacturing

PendingCN108422014AEasy to adjustEasy to usePositioning apparatusBoring/drilling componentsMotor driveElectric machinery

The invention provides a drilling machine for hardware manufacturing and relates to the technical field of hardware manufacturing equipment. The drilling machine for hardware manufacturing comprises abaseplate, a polishing device is fixedly arranged at the top of the baseplate and comprises a mounting plate, and a rack is fixedly arranged at the top of the mounting plate; a first machine box is fixedly arranged at the left side of the rack, and a first motor is fixedly arranged in the machine box through a motor mounting block. According to the drilling machine for hardware manufacturing, through cooperation of the rack, the first motor, a rotation rod, a first bearing, a sliding ring, a guide rod, a guide ring, a fixing rod, a hydraulic retractable rod and a polishing motor, the slidingring is in threaded connection with the rotation rod, and therefore when the first motor drives the rotation rod to rotate, the sliding ring can drive the polishing motor at the bottom of the slidingring to move left and right; meanwhile, the polishing motor can be moved up and down through the hydraulic retractable rod so that drilling operation on hardware can be conducted, and the drilling machine is convenient to adjust and use during use and helps to improve the efficiency of machining and manufacturing the hardware.

Owner:SUQIAN RONGJIN INFORMATION TECH

Clamping tooling with high stability

The invention discloses a clamping tooling with the high stability. Slide grooves are formed in the inner and outer sides of the upper end surface of a base correspondingly. Mounting bases are arranged on the left and right sides of the upper end surface of the base in a sliding mode correspondingly. Piston rods of air cylinders penetrate through fixing blocks and are fixedly connected with the mounting bases on the same sides correspondingly. Longitudinal rectangular grooves are formed in the mounting bases correspondingly. Lead screws are rotationally mounted in the rectangular grooves correspondingly through bearings, penetrate through slide blocks and are in threaded connection with threaded holes of the slide blocks correspondingly. Output shafts of motors are fixedly connected with the upper ends of the lead screws correspondingly. The end surfaces, facing the center side of the base, of the slide blocks are horizontally and fixedly connected with connecting rods correspondingly.Strip-shaped holes allowing the connecting rods to penetrate through are formed in the end surfaces, facing the center side of the base, of the mounting bases correspondingly. The other ends of the connecting rods are fixedly connected with L-shaped plates correspondingly. The upper portion of a horizontal portion of each L-shaped plate is in threaded connection with a screw vertically. The upperend of each screw is fixedly connected with a handle. The lower end of each screw is fixedly connected with a pressing block. A clamping plate is fixedly connected to the end surface, facing the center side of the base, of a vertical portion of each L-shaped plate. The clamping tooling has the advantages of being novel in structure and stable in clamping.

Owner:安徽龙锐模塑有限公司

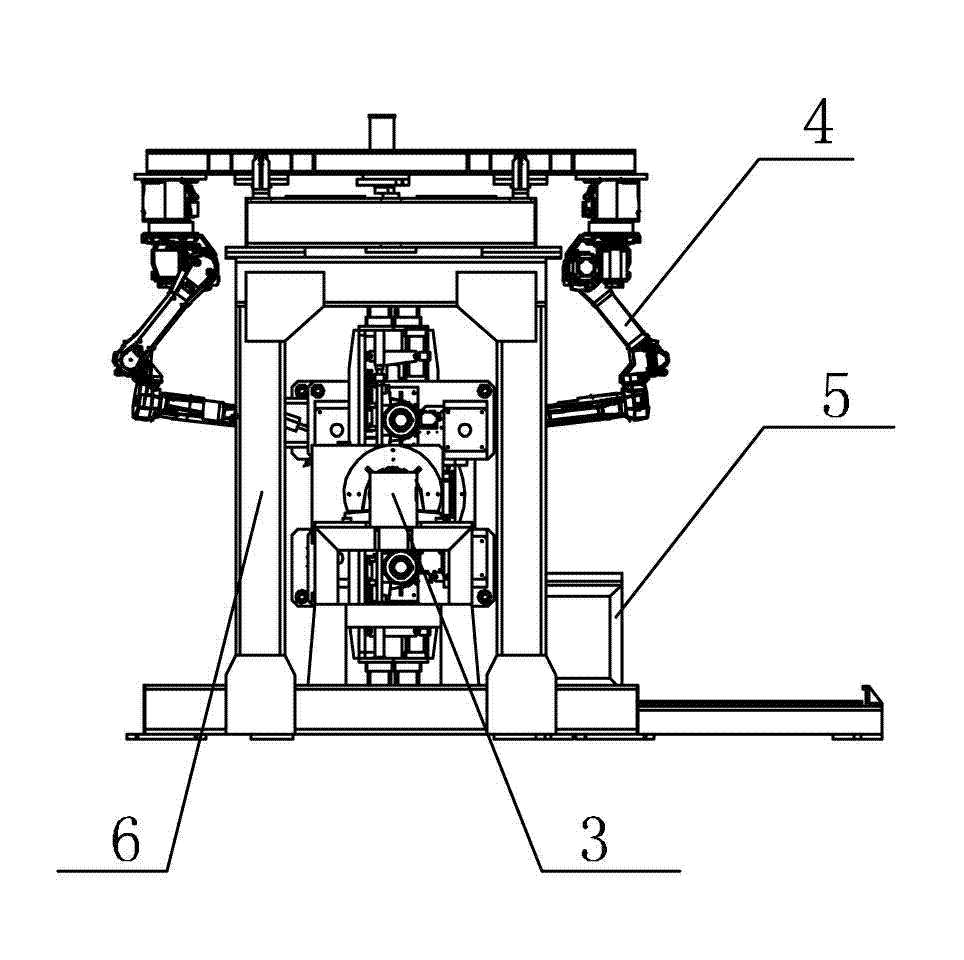

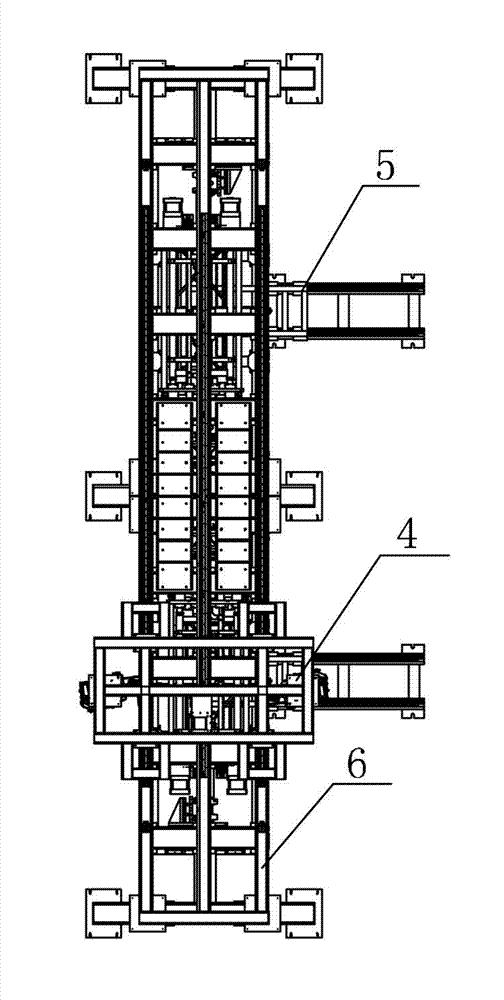

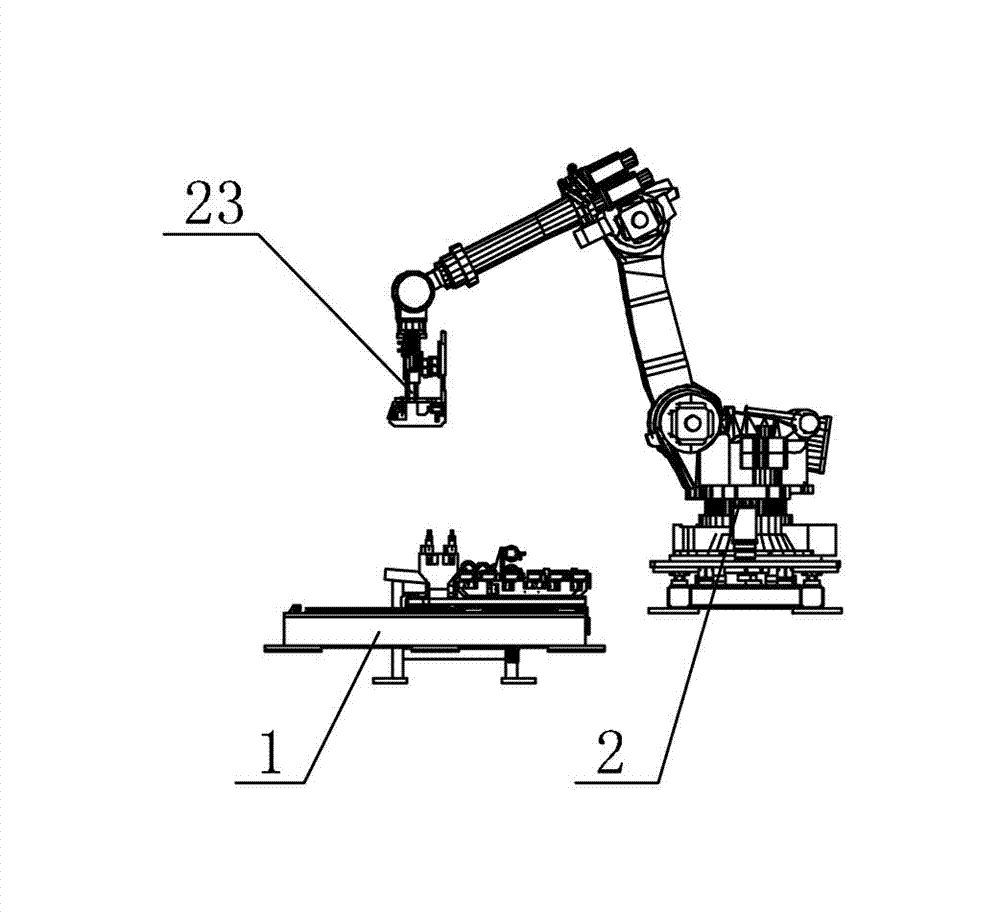

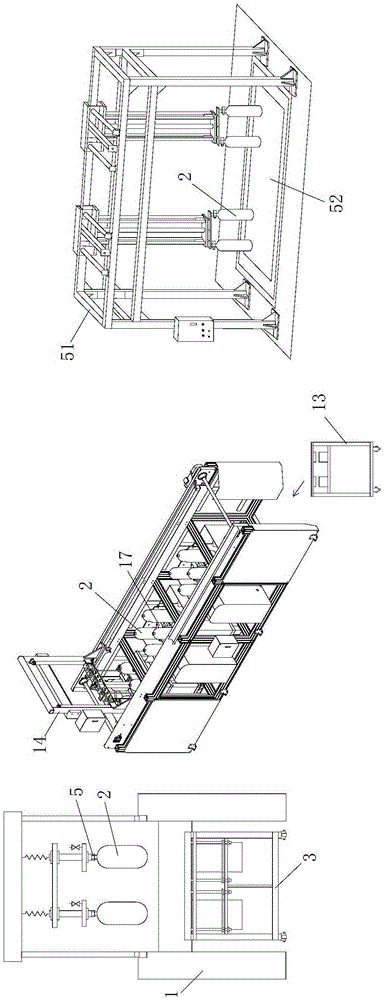

Integrated equipment of automatic robot welding system of standard knots

ActiveCN102896445AGuaranteed synchronicityImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesManipulatorRobot welding

The invention discloses integrated equipment of an automatic robot welding system of standard knots. The integrated equipment comprises a feeding sliding table tooling, a transporting manipulator, a standard knot deflection tooling, a welding manipulator and a discharging mechanism, wherein a three-dimensional coordinate detection device of the standard knot tooling is arranged on the standard knot deflection tooling; an electromagnetic clamp is arranged on the transporting manipulator; a welding gun guide track is arranged on the arm of the transporting manipulator; a welding gun sliding mechanism is connected with two sides of the welding gun guide track; a welding gun is fixed on the welding gun sliding mechanism; the rotary disc of the standard knot deflection tooling is integrally connected with a standard knot positioning bracket; the rotary disc is driven by a speed change motor; the welding manipulator is hung on a truss; and the standard knot deflection tooling is arranged below the truss. Compared with the traditional manual welding method, the consistency in welding quality, the welding efficiency and the safety reliability can all meet the requirements on the quality and the number in manufacturing modern high-tech products.

Owner:重庆立诚重工科技集团有限公司

Stamping machining equipment

ActiveCN110238276AAchieve separationAvoid stickingShaping toolsPress ramHydraulic cylinderEngineering

The invention belongs to the technical field of machining, particularly relates to stamping machining equipment, and aims to solve the problems that the stamping quality is affected by unstable clamping and easy offset of an existing stamping plate, the stamping plate easily adheres to a pressing block after the stamping is completed, and time and labor are wasted to separate the stamping plate. According to the scheme, the stamping machining equipment comprises a machining table, wherein the stamping plate is arranged at the top of the machining table, the top of the machining table is fixedly provided with two fixing plates, the tops of the two fixing plates are fixedly provided with a same top plate, a hydraulic cylinder is fixedly arranged at the top of the top plate, a through hole is formed in the top plate, a piston rod of the hydraulic cylinder penetrates through the through hole to extend below the top plate and is fixedly provided with a lifting plate, and a pressing block is fixedly arranged at the bottom of the lifting plate. The stamping machining equipment is simple in structure, the stamping plate can be clamped, the problem of offset of the stamping plate is avoided, the stamping quality of the stamping plate is improved, and meanwhile, the stamping plate and the pressing block can be conveniently separated, and the problem that the pressing block adheres to the stamping plate is solved.

Owner:苏州茂速拓机械科技有限公司

Automatic pipe sawing fixture

InactiveCN103659382AClamp firmlyPrevent fallingMetal working apparatusPositioning apparatusEngineeringUltimate tensile strength

The invention discloses an automatic pipe sawing fixture. The automatic pipe sawing fixture comprises a fixture body. The fixture body comprises a pipe sawing worktable provided with a feed inlet. One clamping device is arranged on the upper surface of the pipe sawing worktable. Sliding guide rails are arranged on the two sides, facing the feed inlet, of the bottom of the pipe sawing worktable respectively. A feeding worktable is slidably connected to the sliding guide rails, and another clamping device is arranged on the upper surface of the feeding worktable. A first control chip and a second control chip which are connected with the corresponding clamping devices respectively are arranged in the pipe sawing worktable and the feeding worktable respectively. A third control chip controlling the feeding worktable to move on the sliding guide rails is further arranged in the feeding worktable. The clamping devices can be controlled by the first control chip, the second control chip and the third control chip to be automatically loosened or to automatically clamp a pipe after the pipe is cut one time, and the feeding worktable can be controlled to automatically conveying materials and return back. Labor intensity is reduced, working efficiency is improved, the phenomenon that the pipe falls because the fixture is loosened is avoided, product quality is guaranteed, cost is reduced, safety accidents caused by falling of the pipe are avoided, and safety is improved.

Owner:WUHU POWER TECH

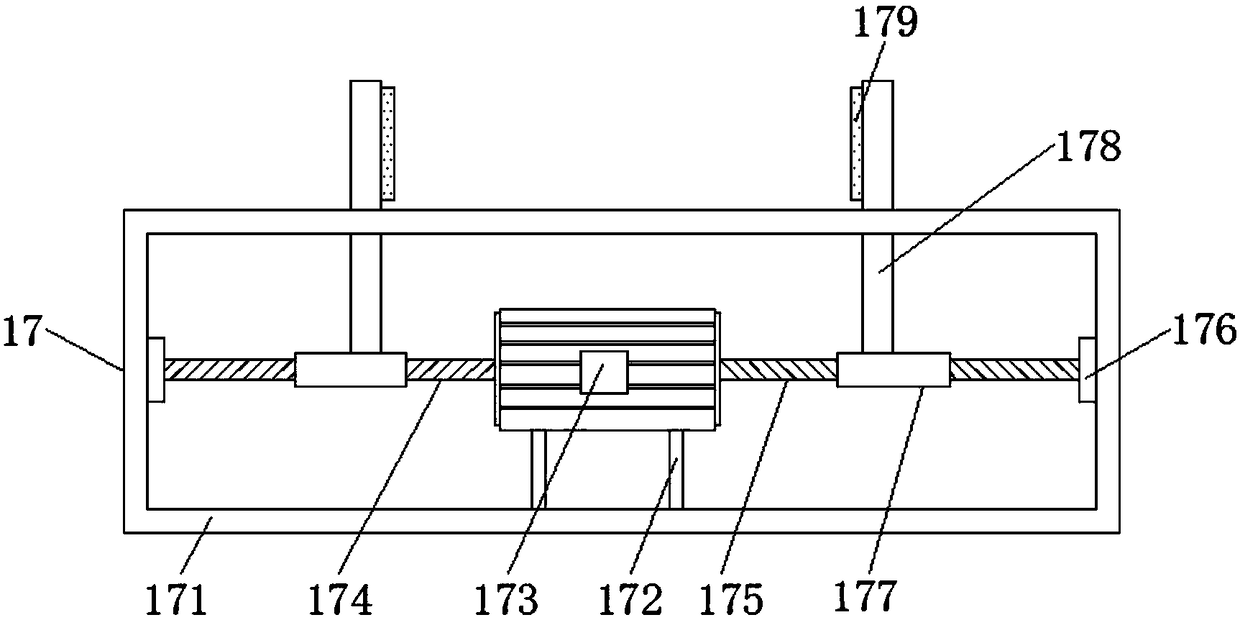

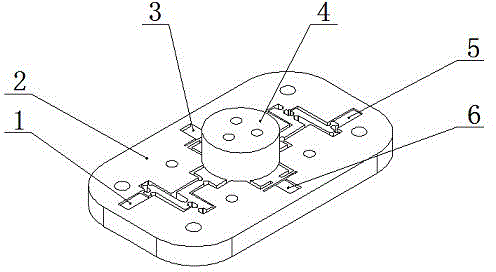

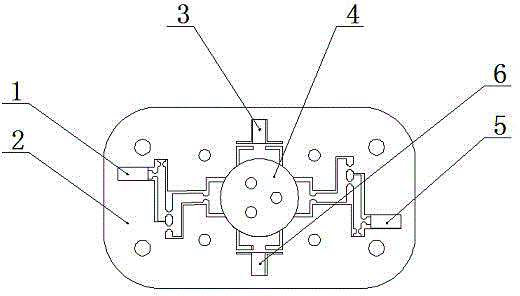

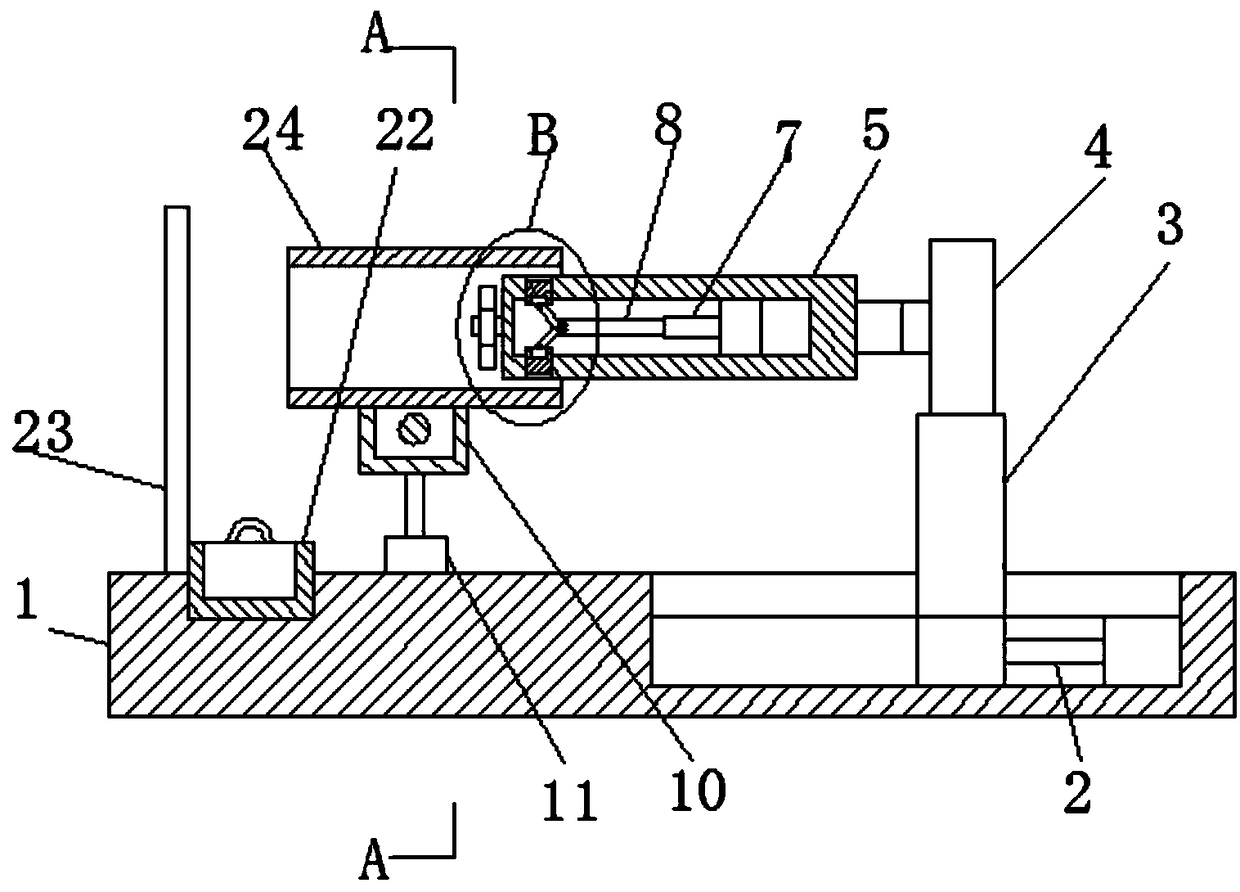

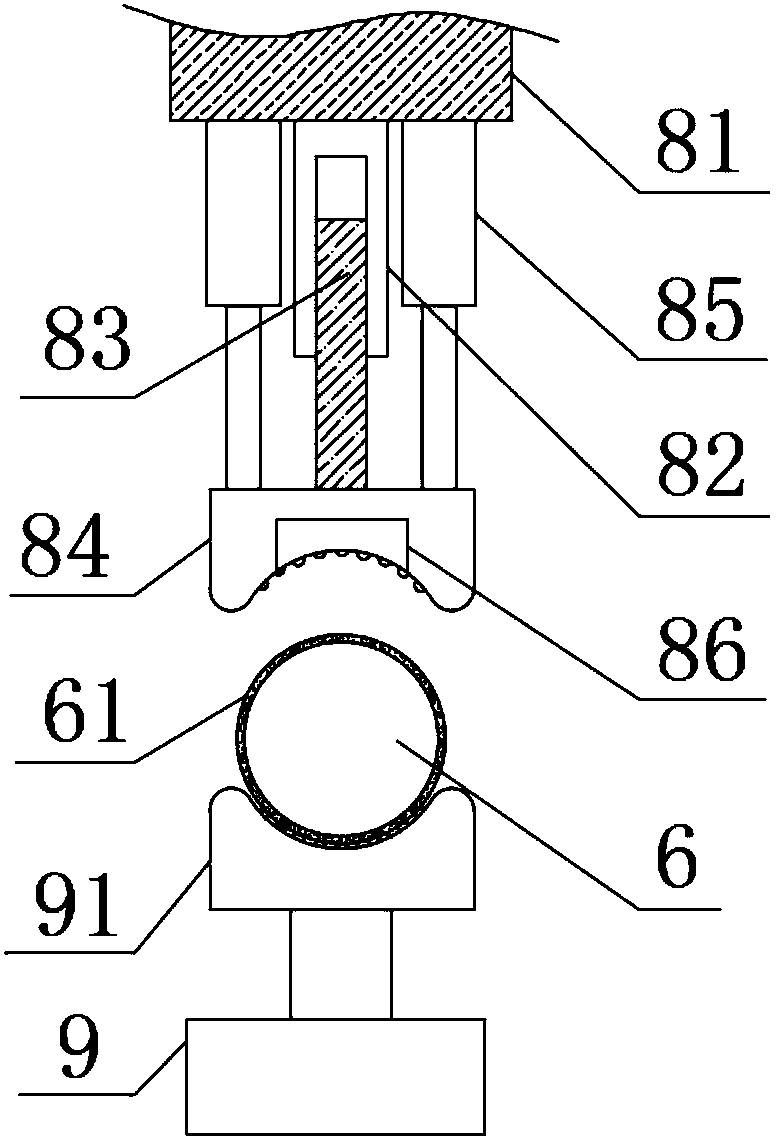

Micro-nano simulation rotating drive device

InactiveCN102723893ANovel structureSimple structurePiezoelectric/electrostriction/magnetostriction machinesMicro nanoElectricity

The invention relates to a micro-nano simulation rotating drive device, which belongs to the precise and super-precise machining field. The micro-nano simulation rotating drive device mainly consists of a stator and a rotor, wherein a drive piezoelectric stack is encapsulated inside the stator; and the rotor is a variable-type interface shaft. A high-precision piezoelectric drive device is used for driving a lever amplification flexible hinge structure to perform associated clamping, and the stepper super-precision rotation movement for the rotor to rotate along a fixed shaft is realized by controlling the clamping sequence of a piezoelectric clamping mechanism in the stator. The micro-nano simulation rotating drive device can be used for the high-precision drive and machining field, and has advantages of less investment, low cost, fast effect, high benefit and the like. The micro-nano simulation rotating drive device is a piezoelectric single-degree-of-freedom precision rotating drive device which can improve the system micro precision and reduce the structural size and can make super-precision stepper rotation movement along a determined direction.

Owner:JILIN UNIV

Reinforced clamping mechanism for conveying round steel

The invention discloses a reinforced clamping mechanism for conveying round steel. The reinforced clamping mechanism comprises a conveying plate; a double-extension-shaft drive motor is fixed to the top face of the middle portion of the conveying plate; long through grooves are formed in the two sides of the conveying plate; supporting plates are fixed to the positions, on the left side and the right side of the long through grooves, of the top face of the conveying plate; the two ends of a transmission screw rod are hinged to the two corresponding supporting plates; moving blocks are connected into the transmission screw rod in a screwing mode, and are inserted into the corresponding long through grooves; clamping blocks are arranged on the lower portions of the moving blocks and located below the conveying plate; the opposite walls of the two clamping blocks are provided with placing grooves; a plurality of buffer springs are fixed to the walls of the placing grooves; the buffer springs are fixed to main clamping end plates which are inserted into the placing grooves; the lower portions of the opposite walls of the two main clamping end plates are provided with bottom convex blocks; and arc-shaped placing grooves are formed in the top faces of the bottom convex blocks. The reinforced clamping mechanism can clamp the round steel firmly, facilitate conveying, prevent the round steel from falling off and has high safety.

Owner:陈玲婷

Conveying mechanism with turnover function

InactiveCN104192549AMeet the requirements of manufacturingGuaranteed temperatureConveyor partsManipulator

Owner:福建鑫天宏电子科技有限公司

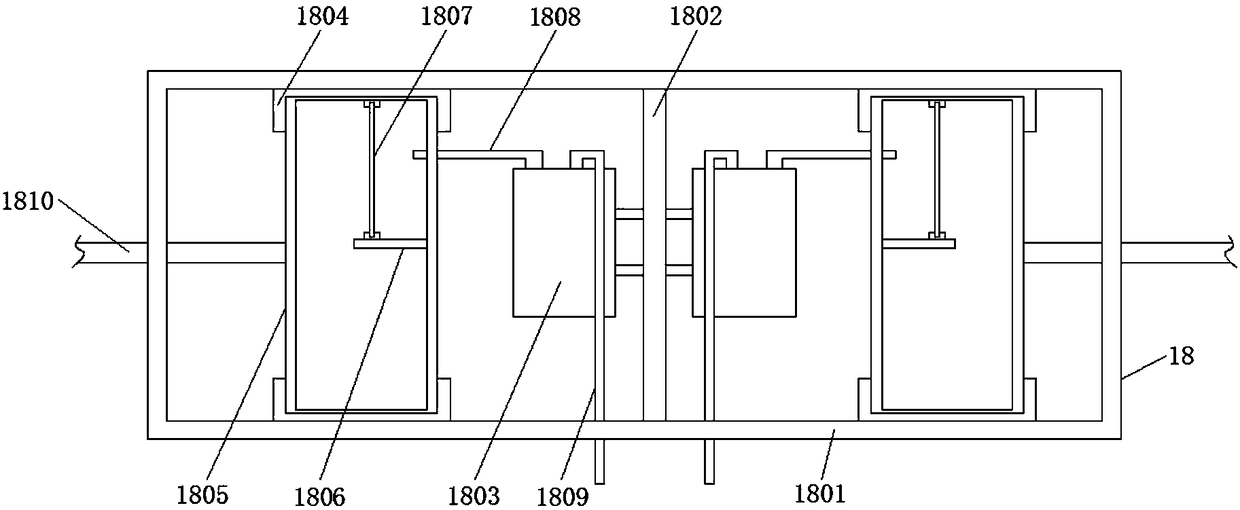

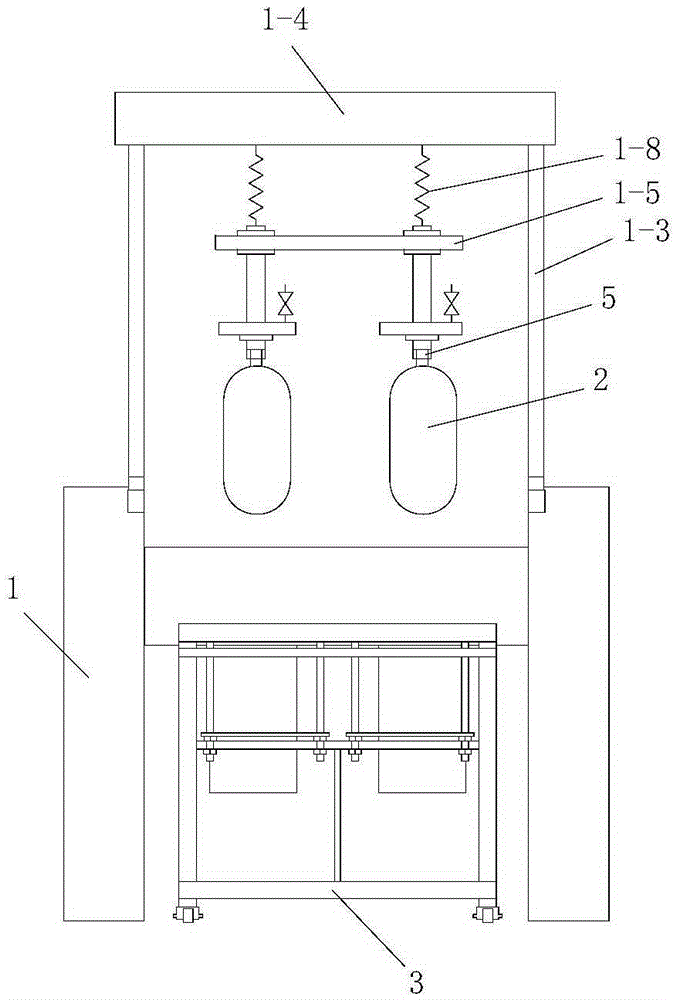

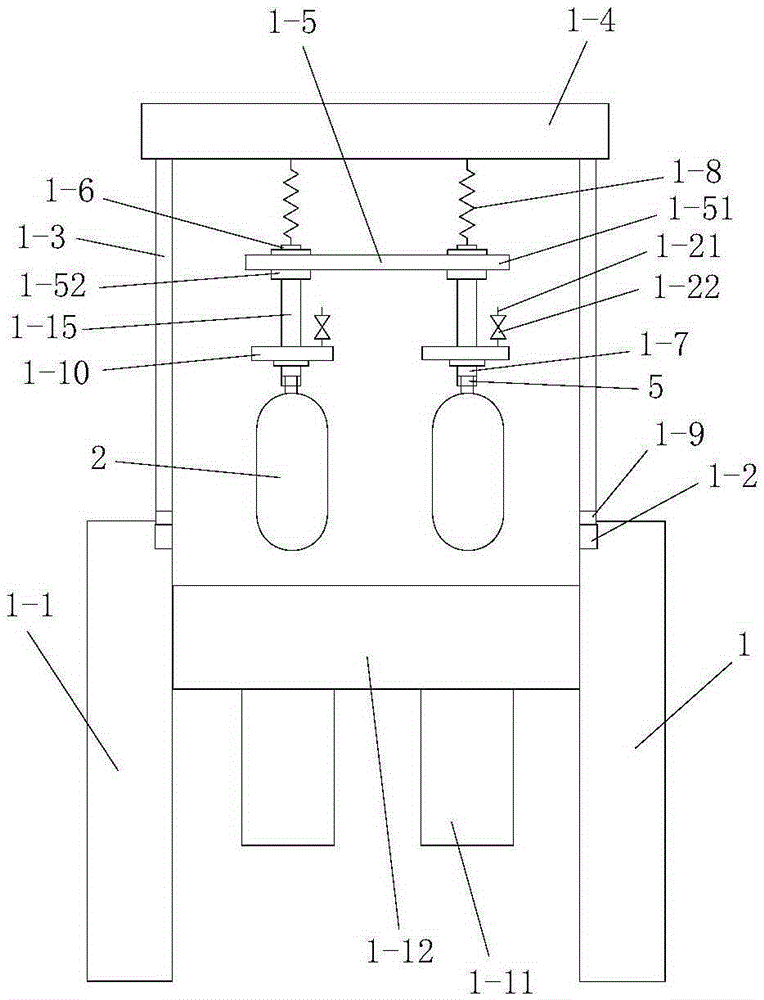

Carbon fiber gas cylinder detection line and carbon fiber gas cylinder detection method

InactiveCN105424489ASimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesFiberCarbon fibers

The invention discloses a carbon fiber gas cylinder detection line and a carbon fiber gas cylinder detection method. The detection line includes, in a front-to-back arrangement manner, a water pressure test apparatus, a water pressure auxiliary test apparatus and an air tightness test apparatus. The water pressure test apparatus includes a test rack, a test operation bench, a pressurizing apparatus, a test case installed on the test rack, and test trolleys for stably placing a plurality of to-be-tested gas cylinders. The water pressure auxiliary test apparatus includes a gas cylinder fixture, a transporting trolley, and a gas cylinder water-pouring-away and drying device. The air tightness test apparatus includes an air tightness detection apparatus and a second air supply apparatus for supplying air to the to-be-tested gas cylinders. The air tightness test apparatus is in a cabinet structure or a ground trough structure. The detection method includes the steps of 1) water pressure test; 2) water pouring-away and drying treatment; and 3) air tightness test. The detection line is reasonable in design and simple in operations, is good in use effects, and can easily and quickly complete water pressure test and air tightness test for a plurality of carbon fiber gas cylinders.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

Adaptive supporting device for installation of building pipe

The invention relates to the technical field of pipe installation, and discloses an adaptive supporting device for the installation of a building pipe. The adaptive supporting device comprises a base,a thread cylinder is rotatably connected with the center of the upper end of the base through a ball bearing, a driven oblique gear is fixedly connected with the outer wall of the lower end of the thread cylinder in a sleeving mode, a bearing seat is further fixedly connected with the upper end of the base, and a rotating rod is rotatably connected within the bearing seat through a ball bearing;and a driving oblique gear meshed with the driven oblique gear is fixedly connected with one end of the rotating rod, a deflecting rod is fixedly connected with the other end of the rotating rod, a pedal plate is rotatably connected with the side wall of the end, away from the rotating rod, of the defelcting rod, a lifting screw rod is connected with the inner thread of the thread cylinder, and alifting plate is fixedly connected with the upper end of the lifting screw rod. The adaptive supporting device can be suitable for the supporting of the pipes of different sizes, the adjustment of theheight of the device can be quickly and conveniently achieved without the electricity, and the use is facilitated.

Owner:合肥梅薇涛电子科技有限公司

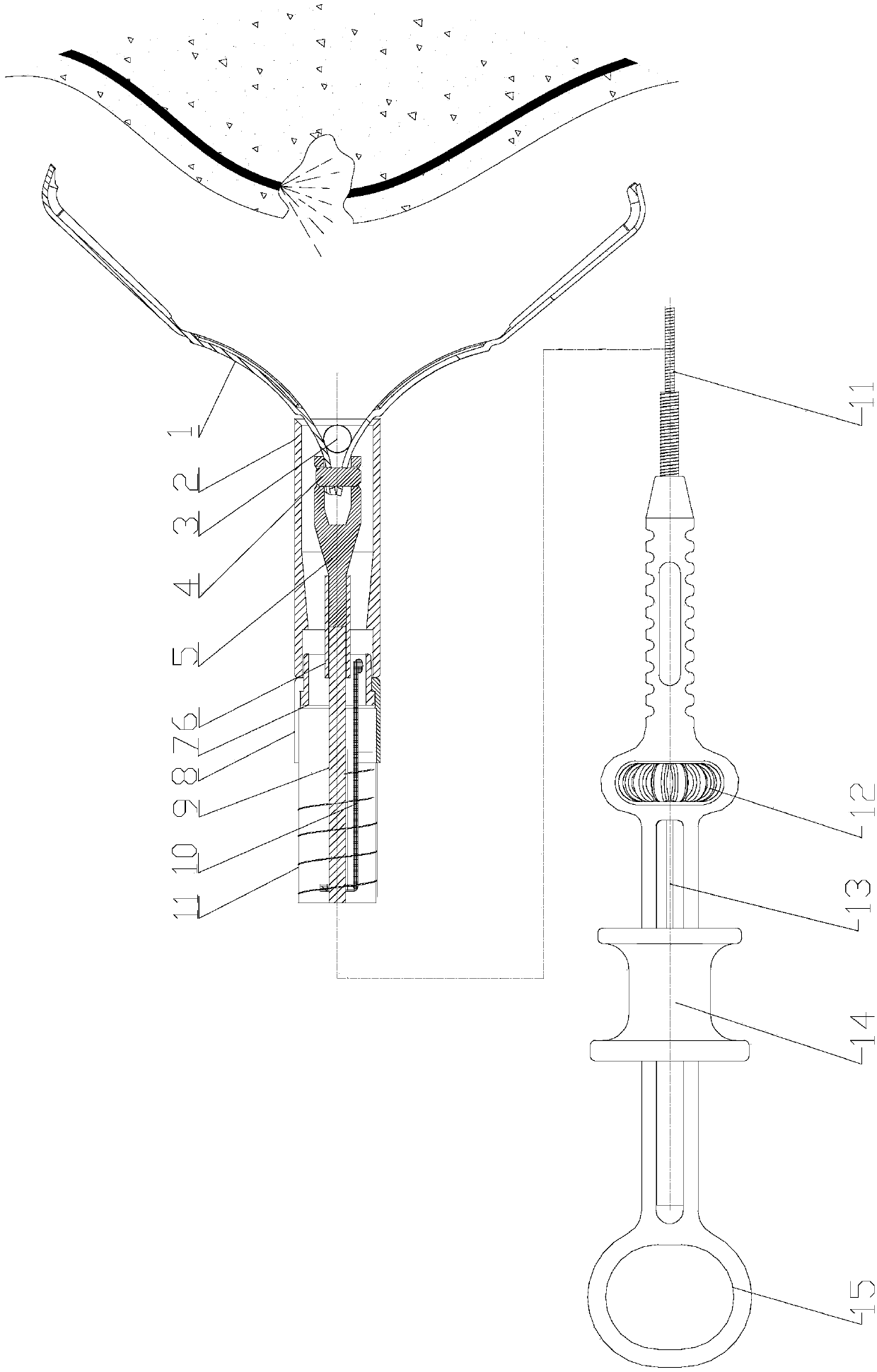

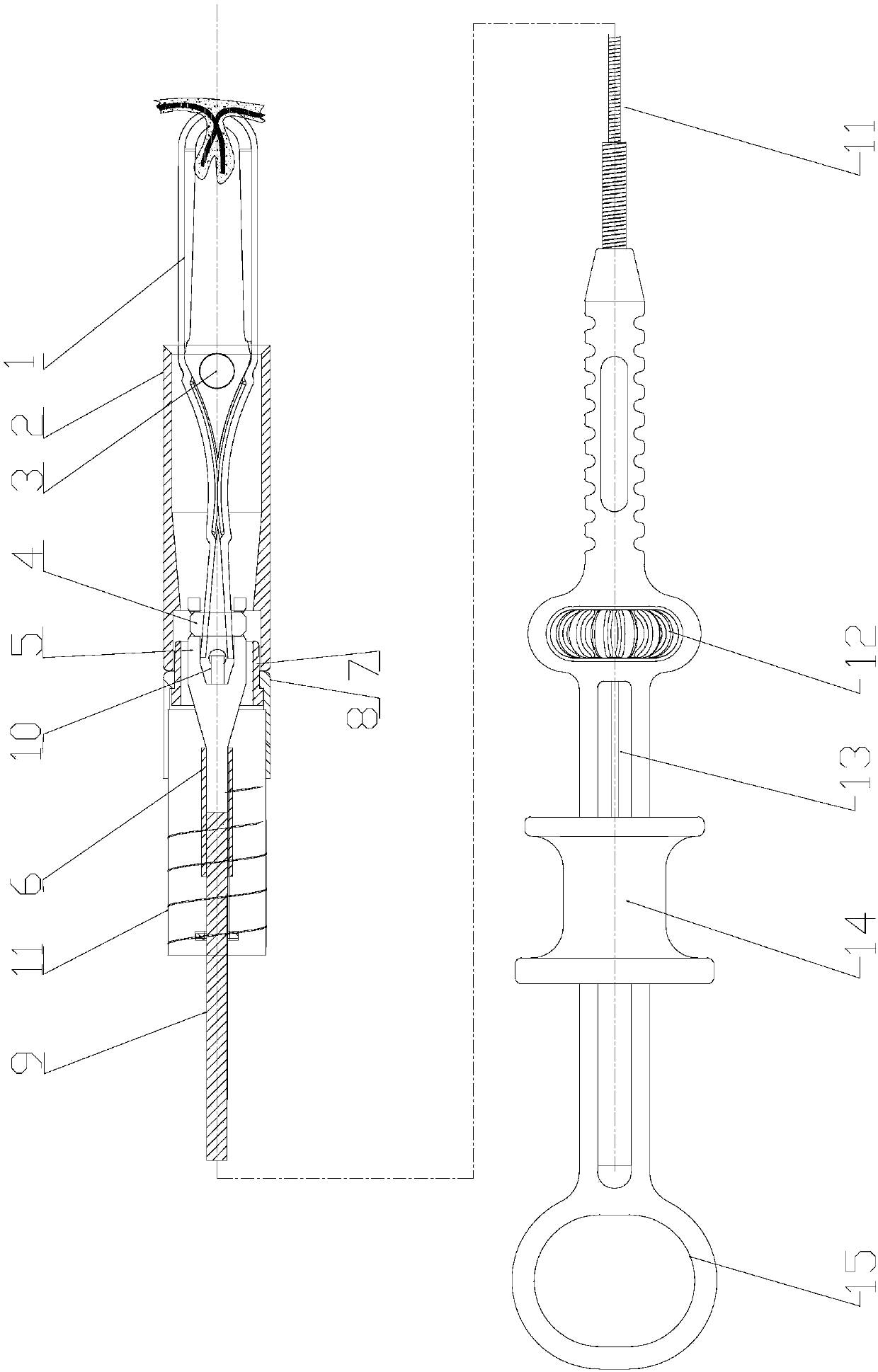

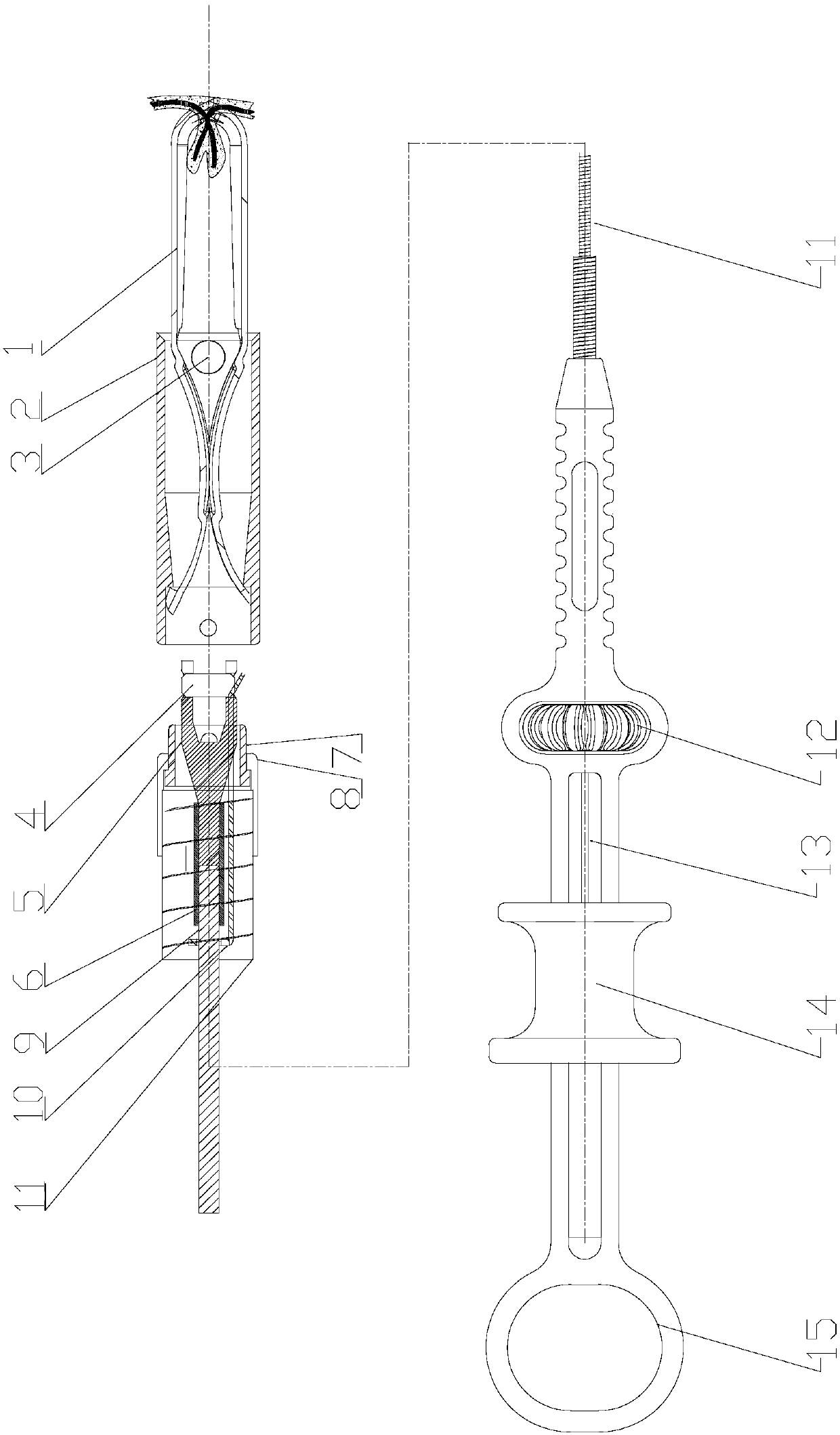

Improved hemostasis clamp for being used under endoscope and clamp part thereof

ActiveCN108013914AAvoid damageIncrease clamping strengthWound clampsAgainst vector-borne diseasesEngineeringEndoscope

The invention relates to an improved hemostasis clamp for being used under an endoscope and a clamp part thereof. The clamp part comprises clamping pieces, a clamp tube, a stop pin, a connecting pin,a clamping piece fixing base and a connecting tube; the clamping piece fixing base is arranged inside the clamp tube and can move back and forth, an open deformation hole is formed in the tail of eachclamping piece, the connecting pin runs through the deformation holes in the two clamping pieces and then is fixedly connected with the front end of the clamping piece fixing base, and one side of each deformation hole in the tail of the clamping piece is provided with a protrusion turned outwards; an annular stop step is arranged at the tail of the inner wall of the clamp tube, when the two clamping pieces are clamped, the protrusions at the tails of the clamping pieces are clamped to the stop step, and the stop pin is fixed to the front portion of the clamp tube and therefore the clamping piece fixing base is limited from sliding out of the clamp tube. By adopting the technical scheme, the purposes that part breakage happens from beginning to end, and no fragment residue exists; the tails of the clamping pieces are connected with a release part, the maximum space utilization is obtained, after clamping is released, and the total length is the smallest.

Owner:ANREI MEDICAL HZ

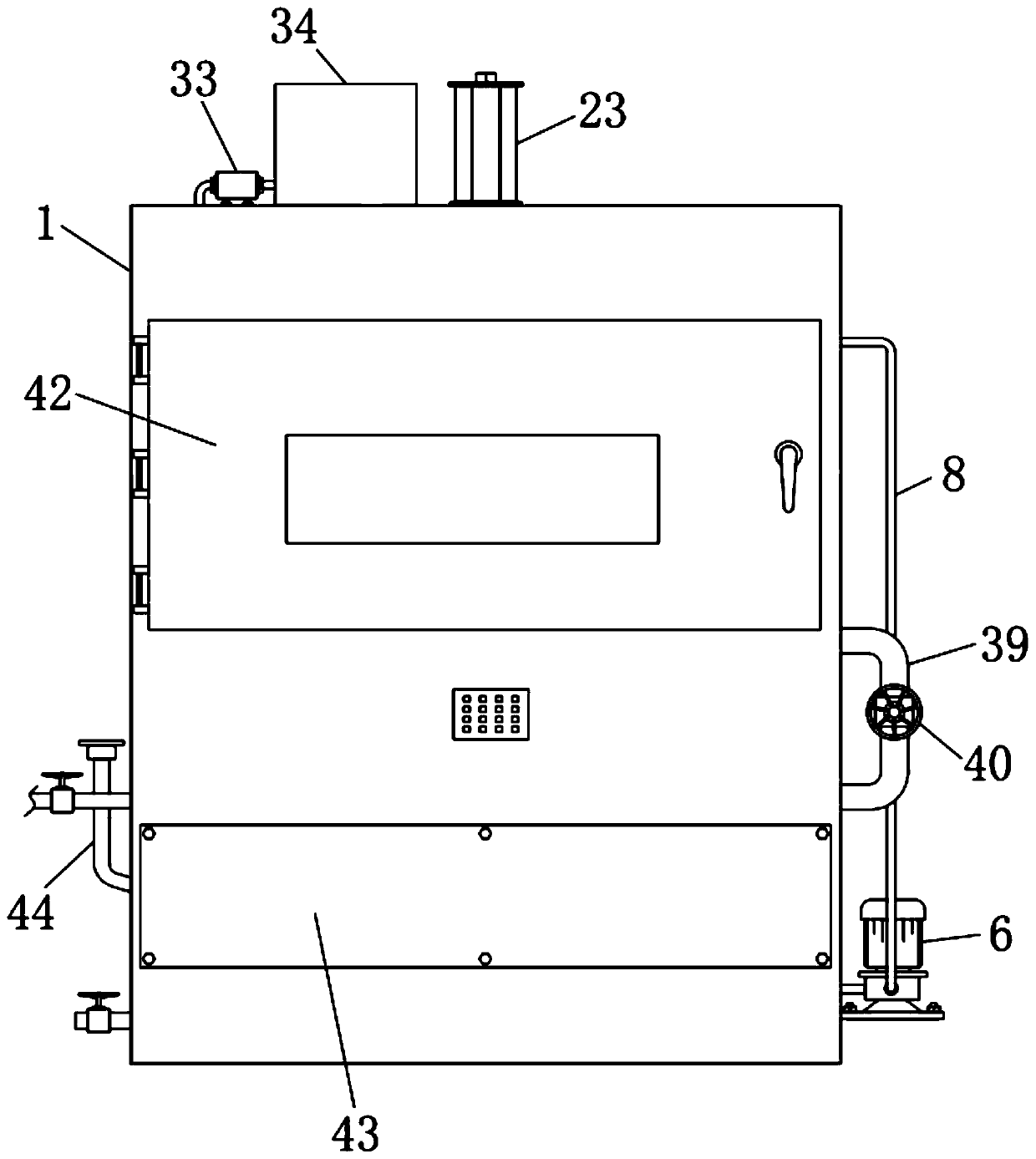

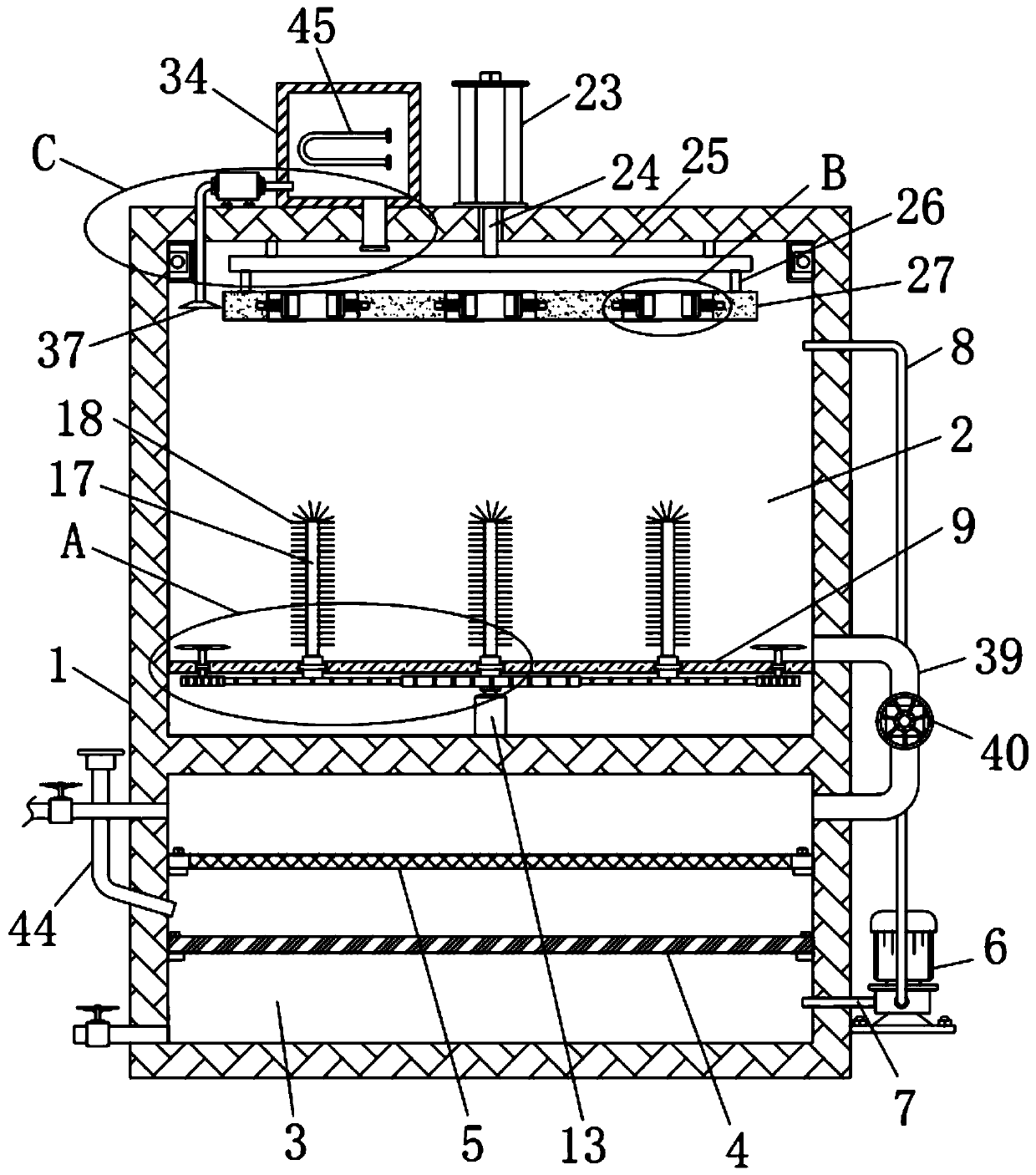

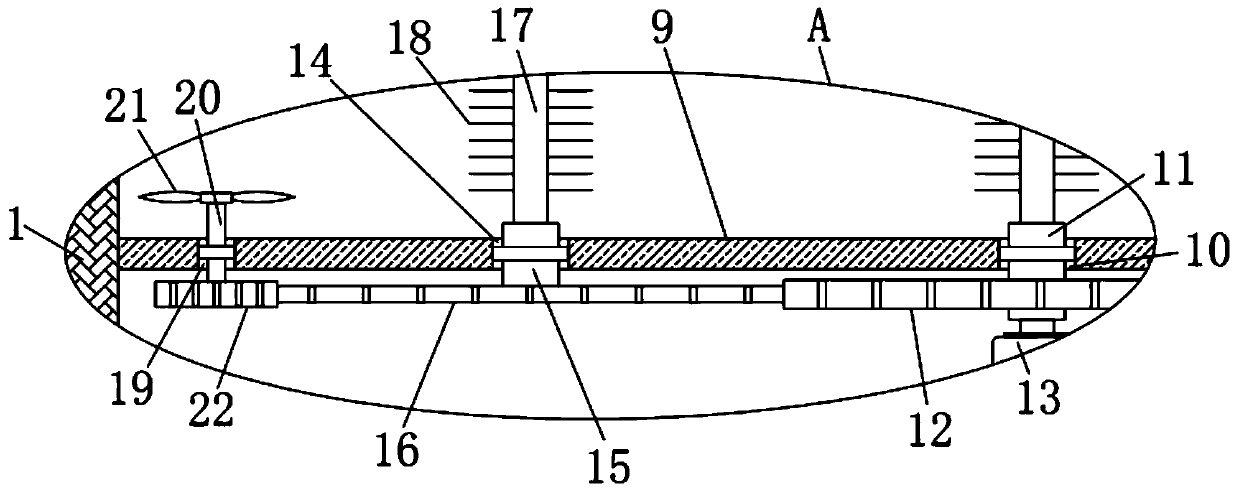

Biological test tube cleaning, disinfecting and drying equipment

InactiveCN111515201AStable clampingIncrease frictionHollow article cleaningTreatment involving filtrationActivated carbonWater resources

The invention discloses biological test tube cleaning, disinfecting and drying equipment. The biological test tube cleaning, disinfecting and drying equipment comprises a box. The box is provided witha cleaning cavity and a water cavity. An activated carbon plate and a filter plate are fixedly mounted in the water cavity. The activated carbon plate is located under the filter plate. A water pumpis fixedly mounted on one side of the box. The suction end of the water pump is fixedly connected with a water suction pipe. The end, far away from the water pump, of the water suction pipe extends into the water cavity and is located below the activated carbon plate. The discharge end of the water pump is fixedly connected with a drain pipe. The end, far away from the water pump, of the drain pipe extends into the cleaning cavity. A partition plate is fixedly mounted in the cleaning cavity. The biological test tube cleaning, disinfecting and drying equipment is reasonable in design, good in practicality, capable of realizing integration operation of cleaning, drying and disinfecting of test tubes without manual cleaning and capable of saving time and labor, improves the working efficiency, has the good cleaning, drying and disinfecting effects on the test tubes and can filter and purify waste water obtained after cleaning for recycling and save water resources.

Owner:顾海燕

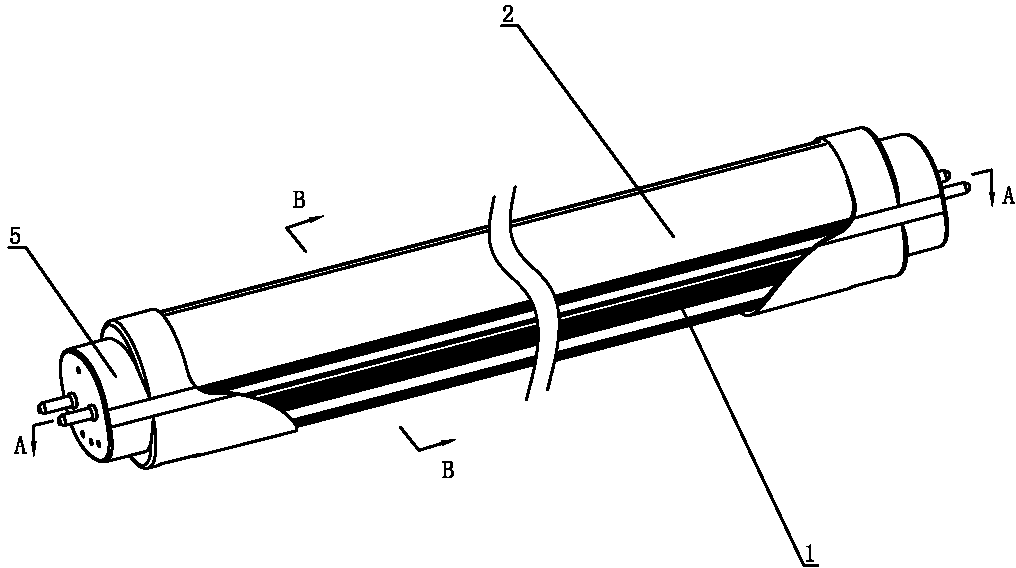

Automatic assembling method of light emitting diode (LED) lamp tube

ActiveCN103231243AImprove assembly efficiencyNo manual labor requiredAssembly machinesEngineeringLight head

The invention discloses an automatic assembling method of a light emitting diode (LED) lamp tube. The automatic assembling method includes that a mechanical arm is controlled to take a casing onto a special clamp located on an automatic conveyor; (2) the special tool clamping the casing is conveyed to a first station; (3) the mechanical arm is controlled to take and insert an LED light source into a first clamp slot; (4) the casing is conveyed to the next station; (5) the mechanical arm is controlled to take a lampshade and insert a clamp strip of the lampshade into a second clamp slot; (6) the casing is conveyed to the next station; (7) a lead wire is welded between the LED light source and an electrode; (8) the casing is conveyed to the next station; (9) the mechanical arm is controlled to take a lamp head, the lamp head is arranged at two ends of the casing, the casing and two ends of the lampshade are clamped into the clamp slots, and a buckle is clamped onto a bayonet at the moment to complete installation of the LED lamp tube; and (10) the LED lamp tube is detached from the special clamp. The automatic assembling method improves assembling efficiency of the LED lamp tube and reduces cost.

Owner:GUANGZHOU LEDIA LIGHTING CO LTD

Controllable three-finger manipulator and control method thereof

InactiveCN104972478AStable clampingLarge operating spaceProgramme-controlled manipulatorGripping headsGear wheelEngineering

The invention relates to a controllable three-finger manipulator. The controllable three-finger manipulator comprises a mechanical part and a control frame, wherein the mechanical part comprises a hand part, a wrist and an arm; the hand part consists of fingers and a force transfer mechanism; each finger consists of two pieces of mechanical fingers; the force transfer mechanism consists of six support rods, six gear pieces and four bevel gears; the arm comprises a small arm connecting frame and a large arm connecting frame; steering engines are respectively mounted on swing pairs in the connected place between the hand part and the small arm connecting frame, the connected place between the small arm connecting frame and the large arm connecting frame and the connected place between the large arm connecting frame and a base; the control frame is mounted on an arm of an operator, and comprises potentiometers; and the potentiometers can obtain rotating angles of the arm and the fingers of the operator. The invention further relates to a control method of the controllable three-finger manipulator. The controllable three-finger manipulator and the control method thereof have the beneficial effects of improving the finger sensitivity and the grabbing and releasing speed, realizing the human-computer synchronization motion and becoming more humanized.

Owner:SOUTHEAST UNIV

Diamond cutting tool welding machine

ActiveCN106181012AOmit the measurement and sorting processImprove general performanceWelding/cutting auxillary devicesOther manufacturing equipments/toolsDiamond cuttingTool bit

The invention provides a diamond cutting tool welding machine and belongs to the technical field of work. The diamond cutting tool welding machine solves the problem that the manufacturing cost of an existing diamond cutting tool welding machine is high. The diamond cutting tool welding machine comprises a rack, a tool bit clamping device and a diamond tool bit positioning seat. The tool bit clamping device is located above a cutting tool base body positioning tool. The tool bit clamping device is provided with a connecting seat fixedly connected with the rack. The diamond tool bit positioning seat is located on one side of the tool bit clamping device. The rack is provided with a mechanical moving device capable of moving the diamond tool bit positioning seat to the position under the tool bit clamping device. The invention provides a diamond cutting tool welding machine of another arrangement structure. According to the diamond cutting tool welding machine, due to the fact that the mechanical structure and the control program are simplified, the precision of movement parts can be reduced, and especially the precision of the movement parts in the tool bit clamping device is reduced; and therefore the machining precision can be ensured, and the manufacturing cost can also be obviously reduced.

Owner:项大清

Automobile component grinding device

InactiveCN109129064AStable clampingEasy to polishRevolution surface grinding machinesGrinding/polishing safety devicesCouplingEngineering

The invention relates to the technical field of automobile component machining, and discloses an automobile component grinding device. The automobile component grinding device comprises a base. A T-shaped first sliding groove is formed in the top of the base. A first electric push rod is fixedly connected to the inner side wall of the first sliding groove. A first sliding block matched with the first sliding groove is in sliding connection into the first sliding groove. The push rod tail end of the first electric push rod is fixedly connected with the side wall of the first sliding block. Thetop end of the first sliding block extends to the outer portion of the first sliding groove and is fixedly connected with a drive motor. An output shaft of the drive motor is fixedly connected with afirst connecting rod through a coupler. The side wall, away from the drive motor, of the first connecting rod is fixedly connected with a rotation rod. A cavity is formed in the rotation rod. Two symmetrically-arranged installing holes are formed in the outer side wall of the rotation rod. The automobile component grinding device can conveniently grind the inner walls of pipe fittings different ininner diameter and conveniently collect scraps generated in the grinding process.

Owner:嘉兴万顺精密机械有限公司

Intelligent clamping device for car part production

ActiveCN108297003AIncrease clamping forceStable clampingWork holdersWork benchesHydraulic cylinderHigh intensity

The invention discloses an intelligent clamping device for car part production. The intelligent clamping device for car part production comprises a base, a controller is arranged on the one side in the base, a power supply module is arranged on the other side in the base, supporting seats are arranged on the two sides of the top end of the base, and hydraulic cylinders are fixedly arranged on theouter sides of the supporting seats. The hydraulic cylinders are connected with one sides of installation boxes through connecting rods, limiting devices are arranged on the inner side walls of the supporting seats, protective covers are arranged on the outer sides of the limiting devices, and the other sides of the installation boxes are connected with one ends of connecting blocks through a sealrotary table. Empty slots are arranged in inner cavities of the connecting blocks, electric push rods are arranged in the empty slots, and the other ends of the connecting blocks are connected with clamping blocks through high strength springs. The two connecting blocks are separately provided with an infrared transmitter and an infrared sensor, the infrared transmitter and the infrared sensor are matched with the controller, so that the intelligent clamping device automatically clamps the car part and the intelligent clamping device can work intelligently, and a lot of manpower is saved.

Owner:湖州龙溢机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com