Flexible tool for assembling row-line chuck type wall board

A flexible tooling and suction cup technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of lack of versatility, reduce the number of tooling, poor reconfiguration, etc., achieve strong flexibility and versatility, ensure safety, and high The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

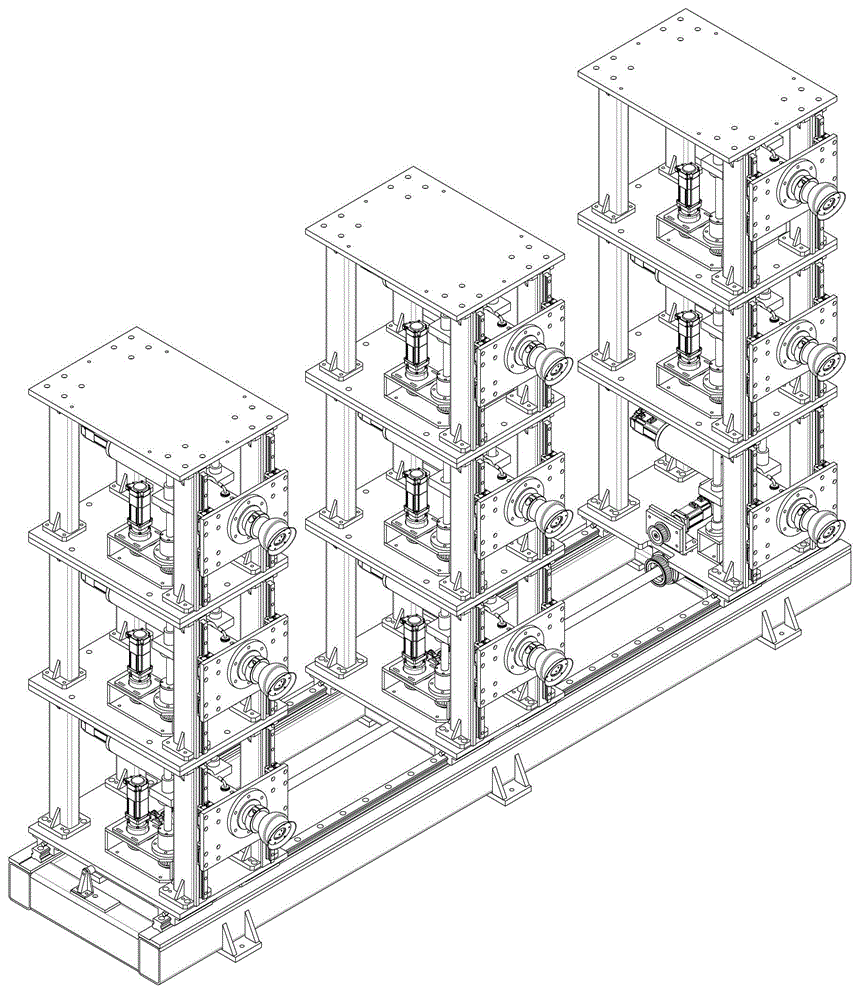

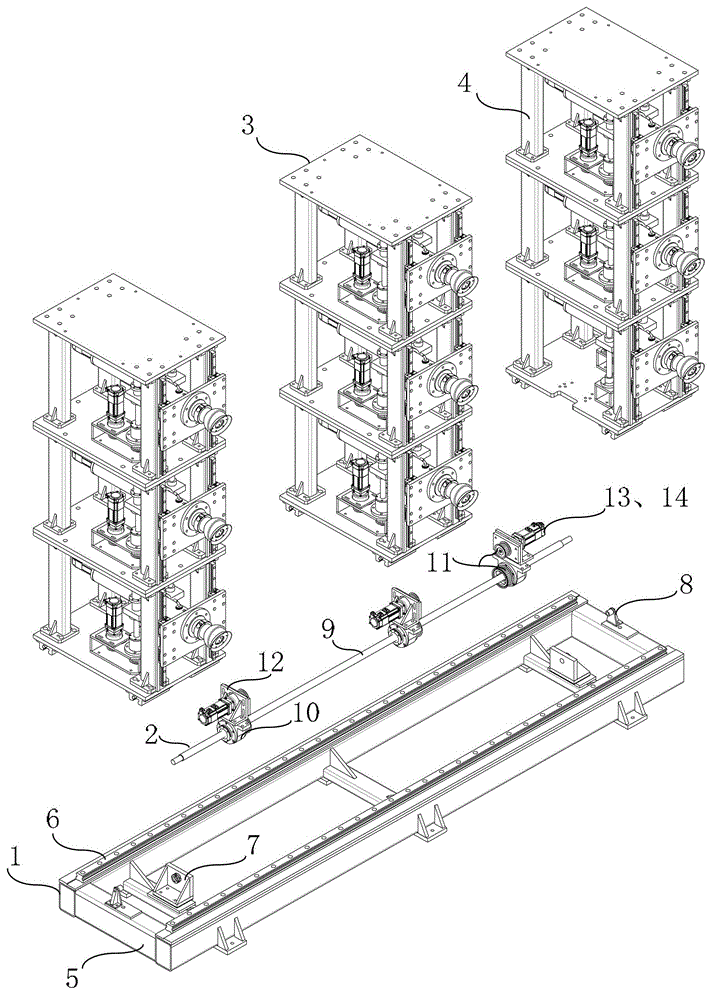

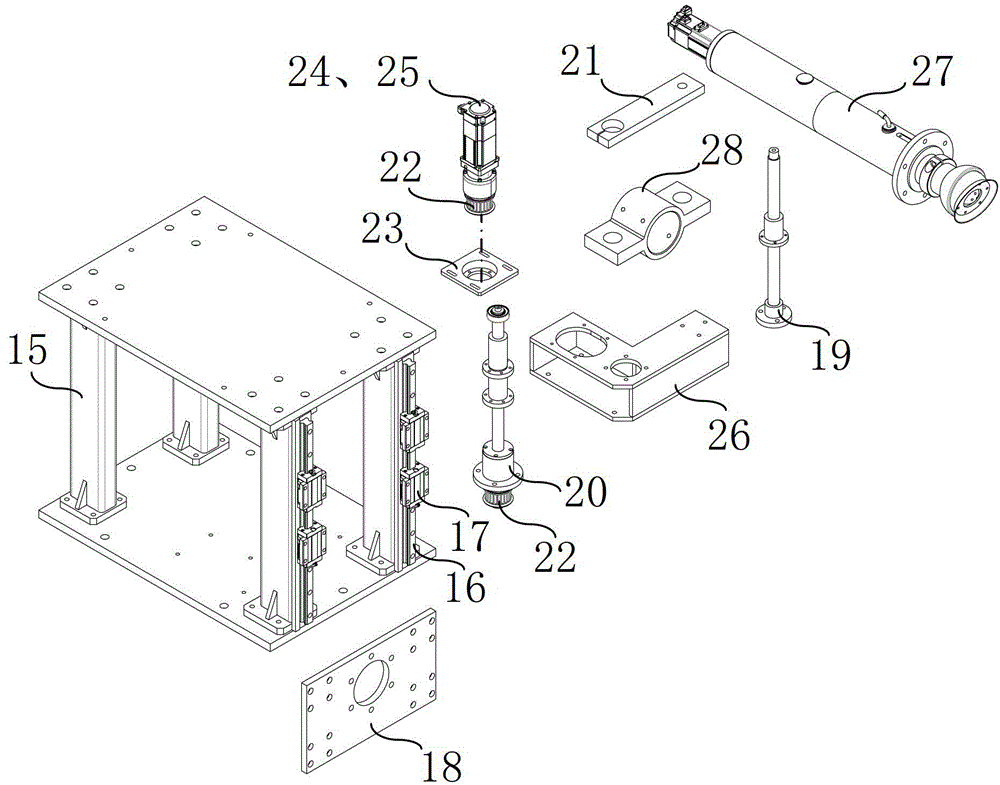

[0034] The present invention is a flexible tool for assembling row and column suction cup type wall panels, such as figure 1 , 2 As shown, it mainly includes guide rail base 1, X-direction drive unit 2 and column shape adjustment assembly 3 units. The rail base 1 is fixedly connected to the ground, the column shape-adjusting assembly unit 3 is installed on the two X-direction linear guide rails 6 of the guide rail base 1, and can move along the X-direction linear guide rails 6, and the X-direction drive unit 2 is located in the column shape-adjusting assembly unit Between the bottom of 3 and the guide rail base 1, it is fixedly connected with the guide rail base 1, and is connected with the bottom of the column shape-adjusting assembly unit 3.

[0035] The guide rail base 1 is composed of a base 5, an X-direction linear guide rail 6, an X-direction ball screw fixing seat 7 and an X-direction movement limiting seat 8. X-direction linear guide rail 6, X-direction ball screw fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com