Patents

Literature

197 results about "Double pendulum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics and mathematics, in the area of dynamical systems, a double pendulum is a pendulum with another pendulum attached to its end, and is a simple physical system that exhibits rich dynamic behavior with a strong sensitivity to initial conditions. The motion of a double pendulum is governed by a set of coupled ordinary differential equations and is chaotic.

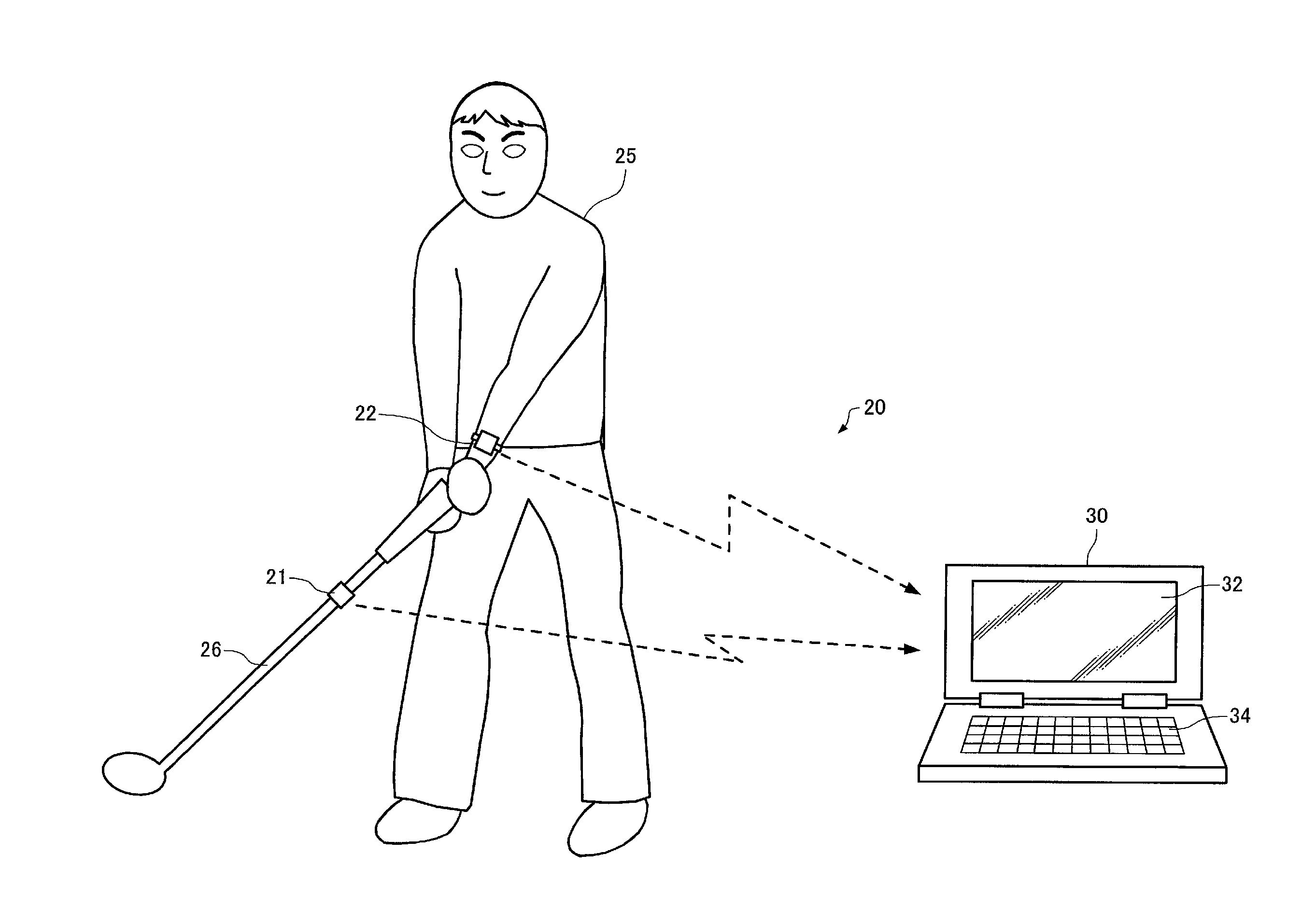

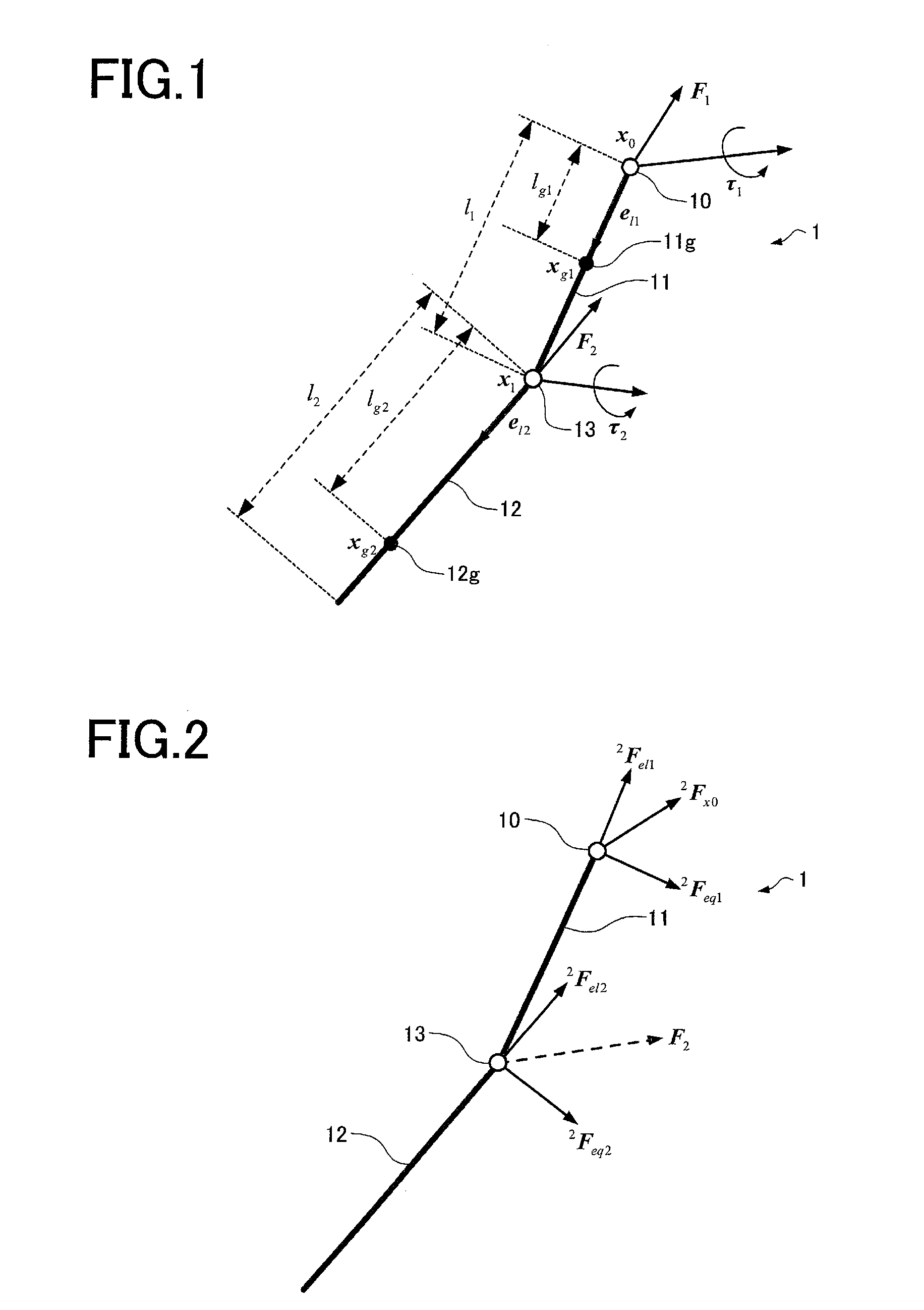

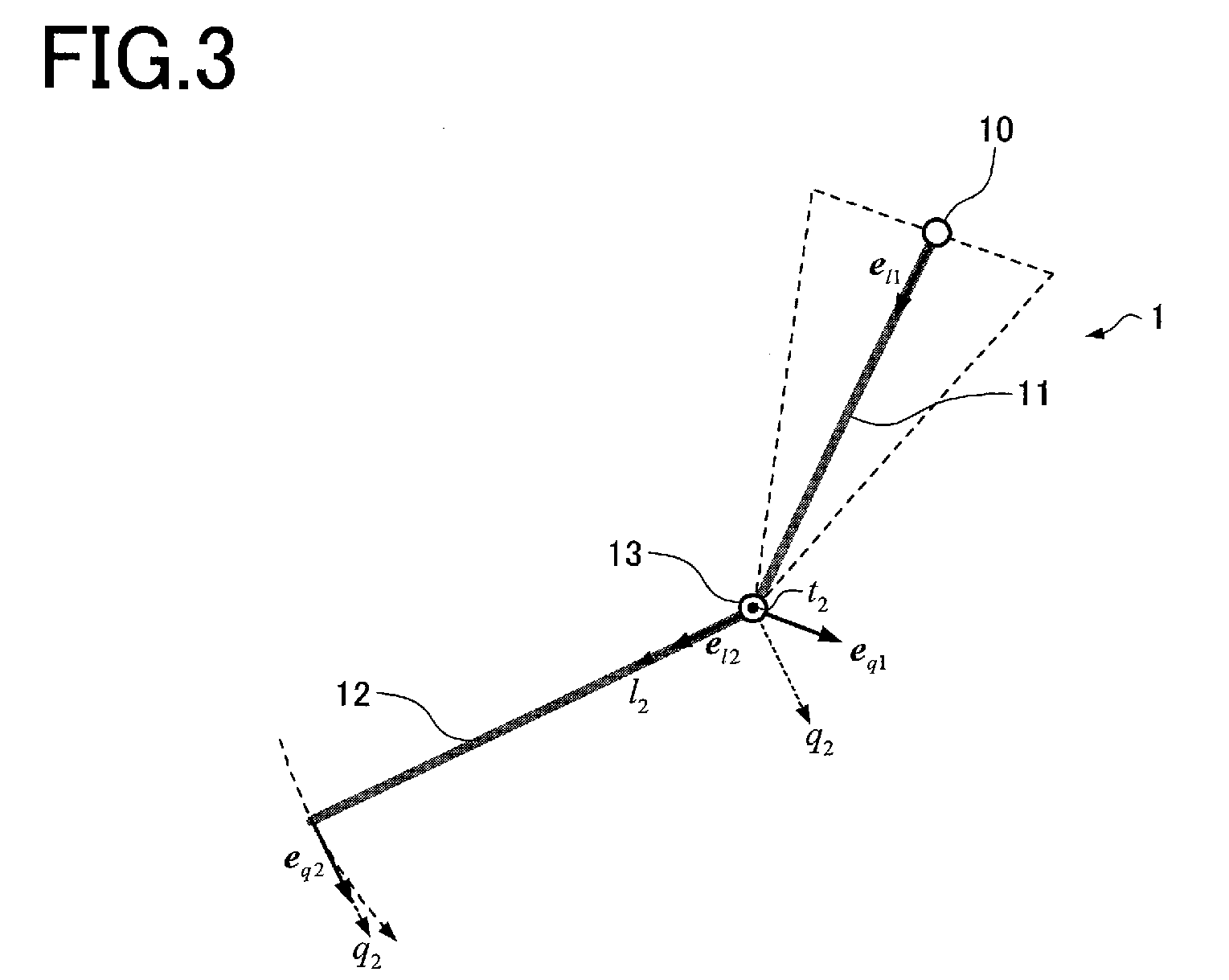

Golf swing analysis device and golf swing analysis method

A golf swing analysis device includes a joint force calculation section and a torque extraction section. The joint force calculation section generates a double pendulum model that includes a first link that corresponds to an upper part of a body of a golfer, a second link that corresponds to a golf club, and a joint that links the first link and the second link, and calculates a joint force applied to the joint along with a swing motion using an acceleration measured by an inertial sensor attached to the golf club. The torque extraction section extracts a torque that causes the second link to make a rotational motion around a first axis from the joint force.

Owner:SEIKO EPSON CORP +1

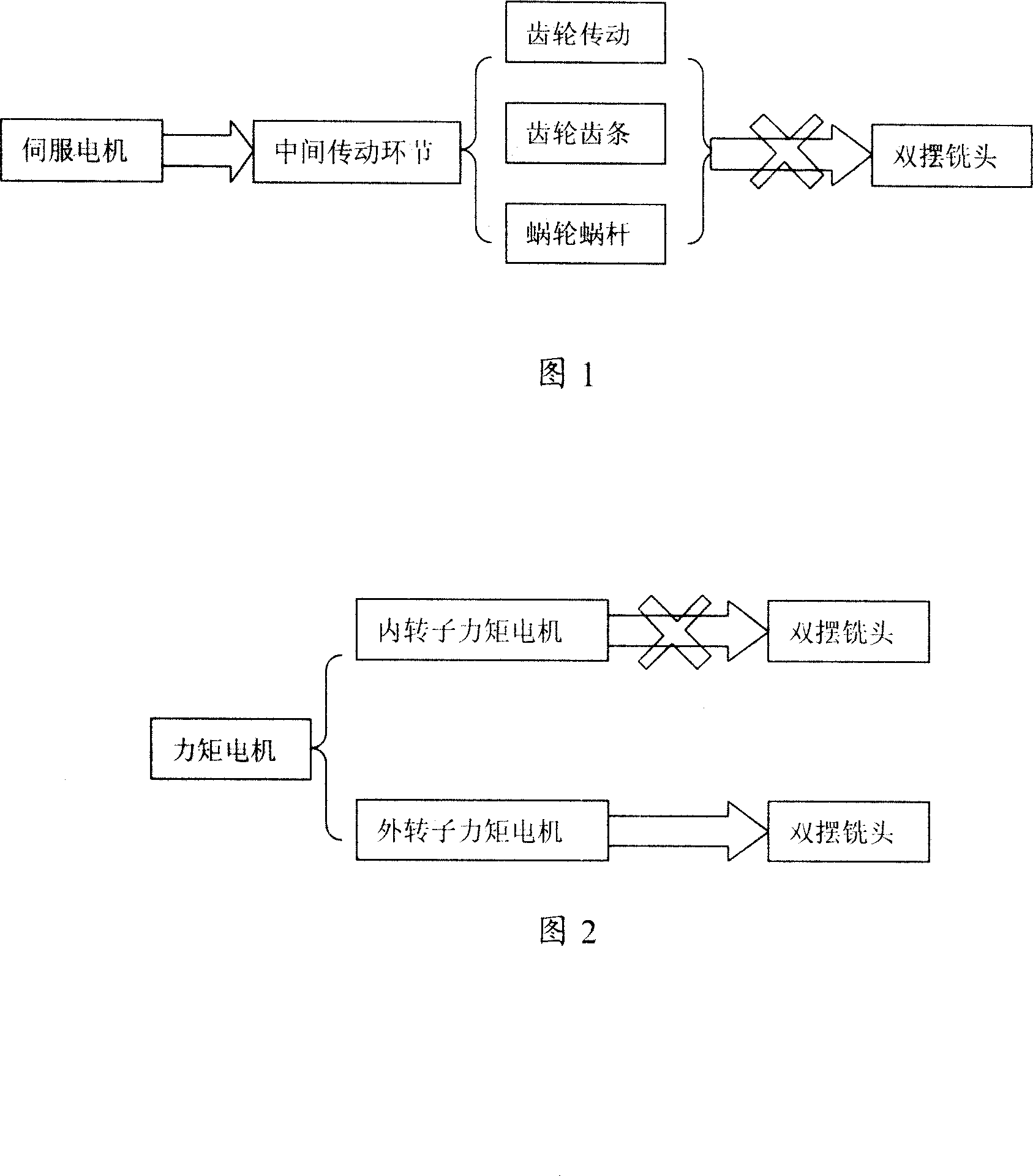

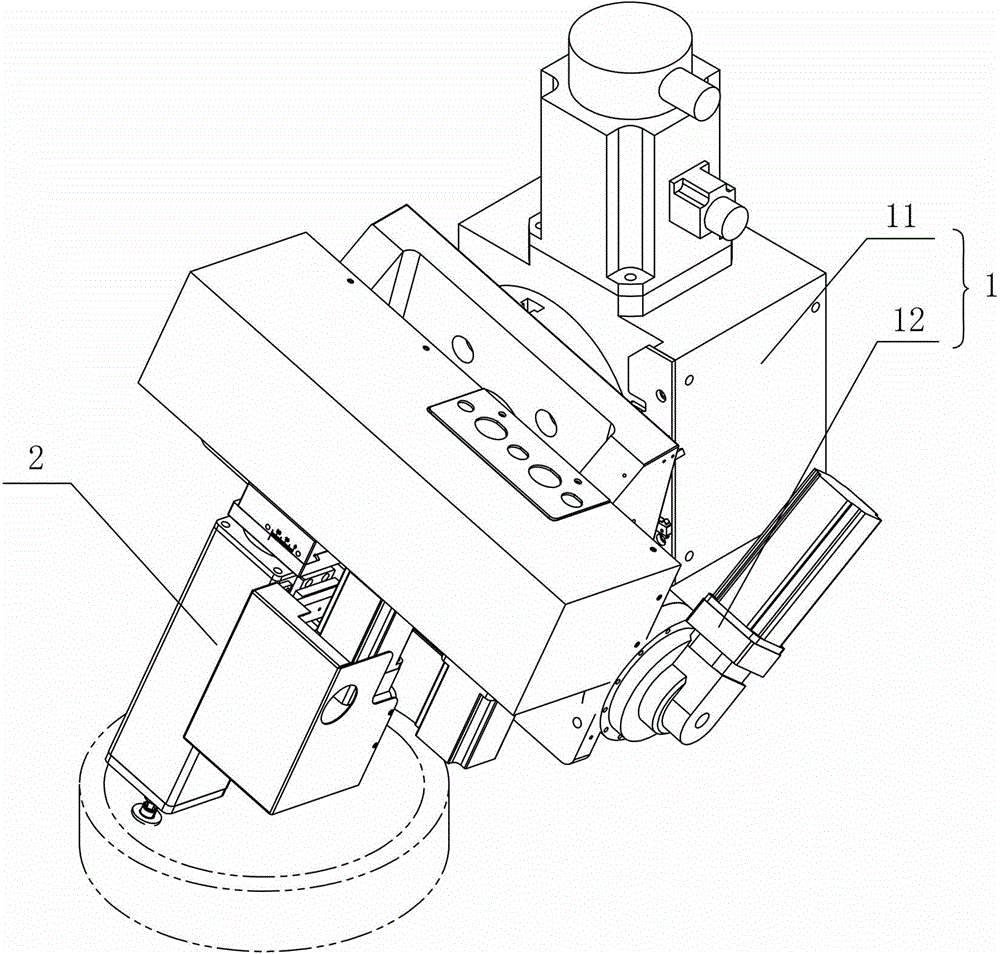

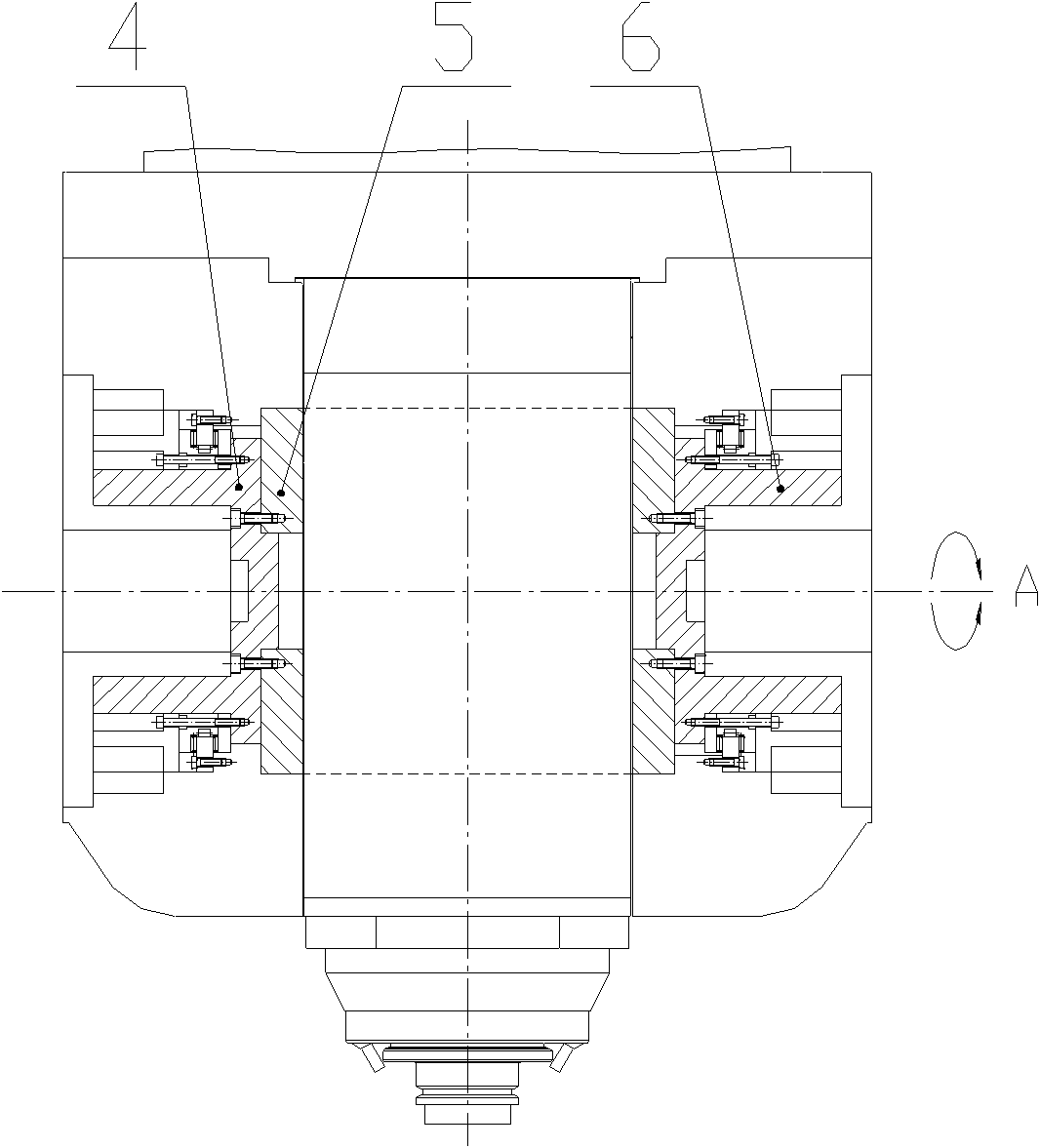

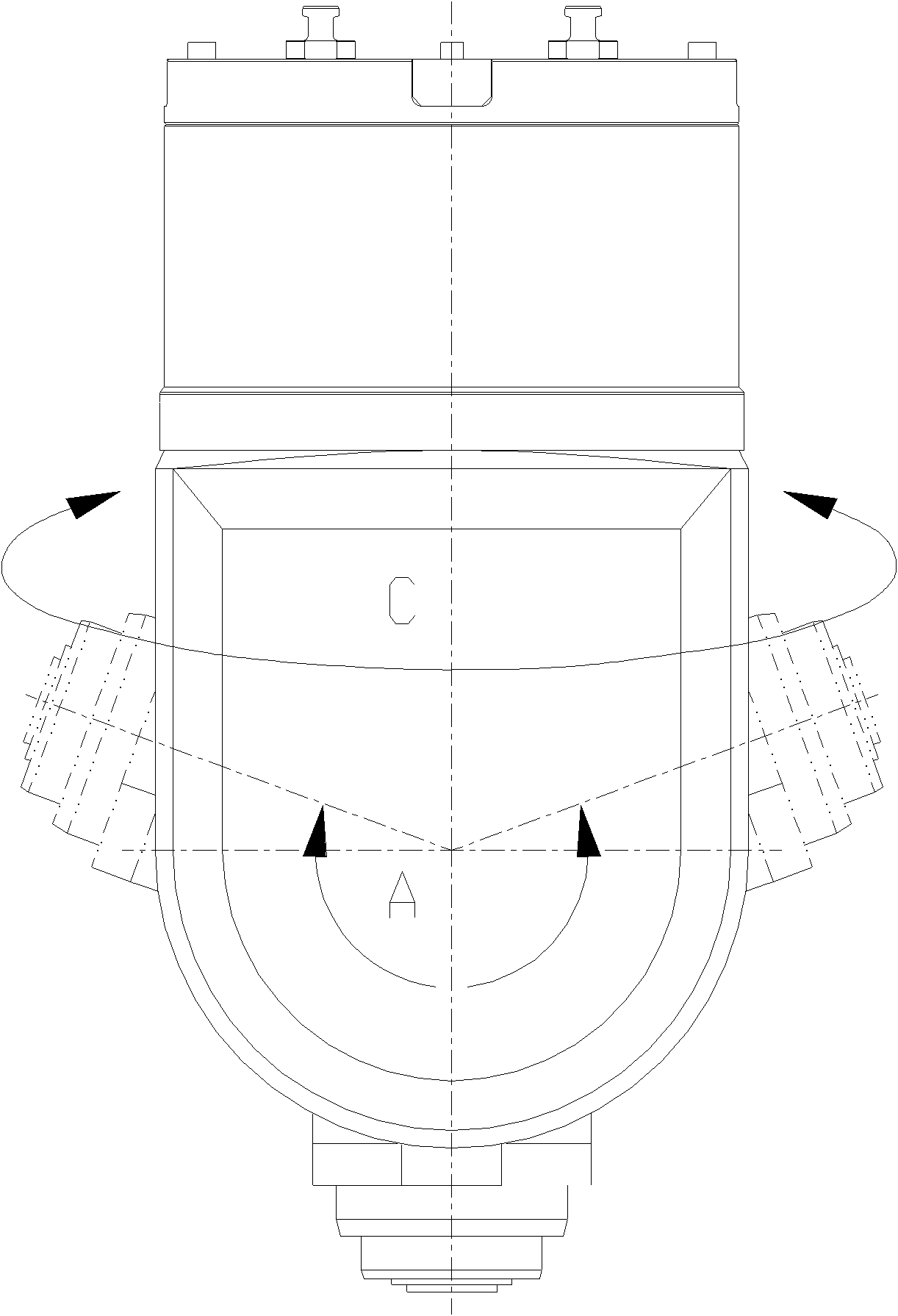

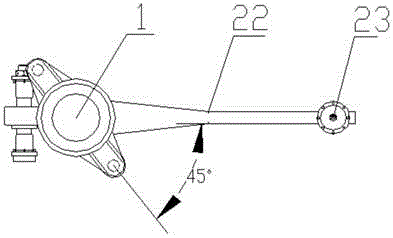

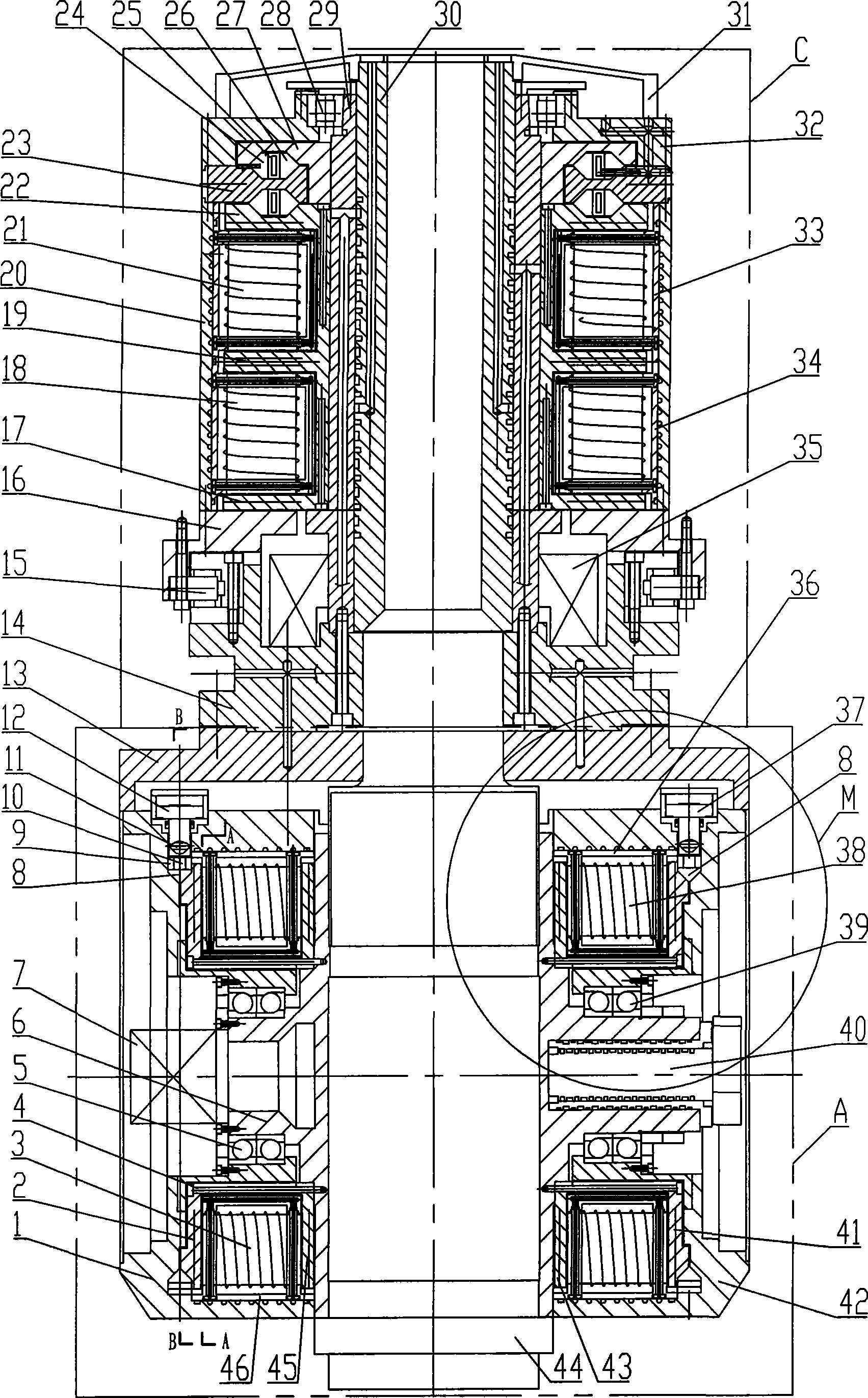

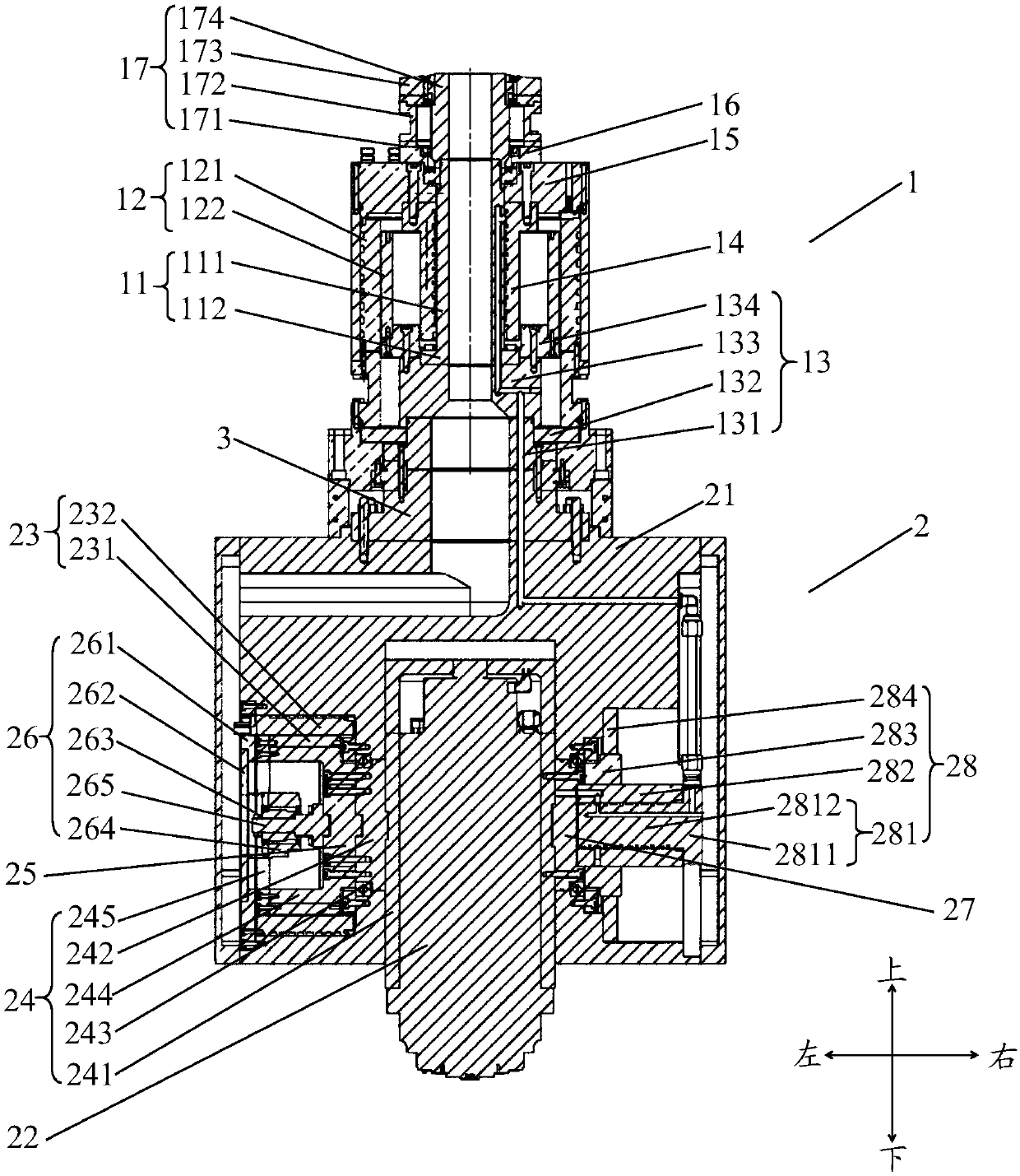

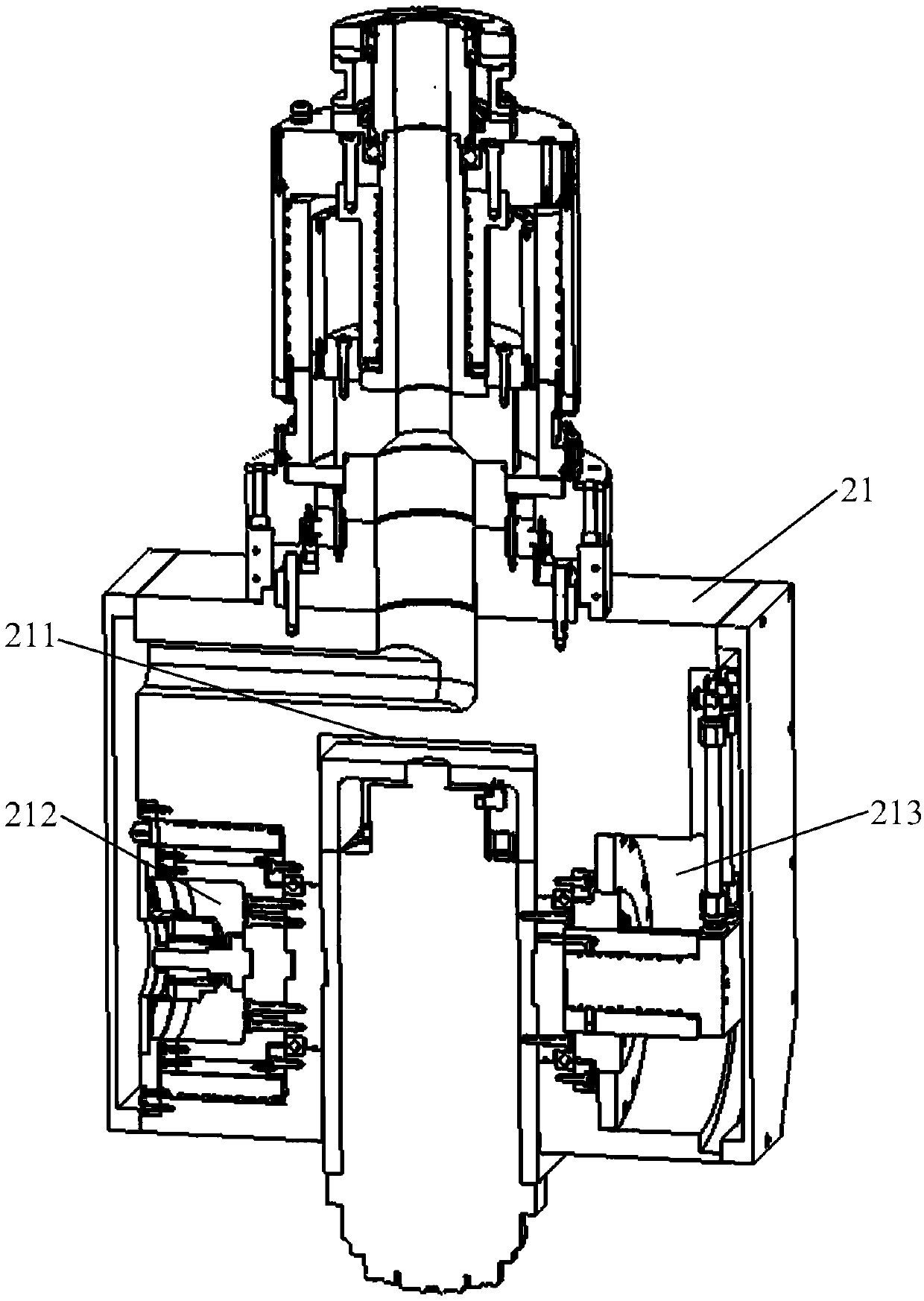

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

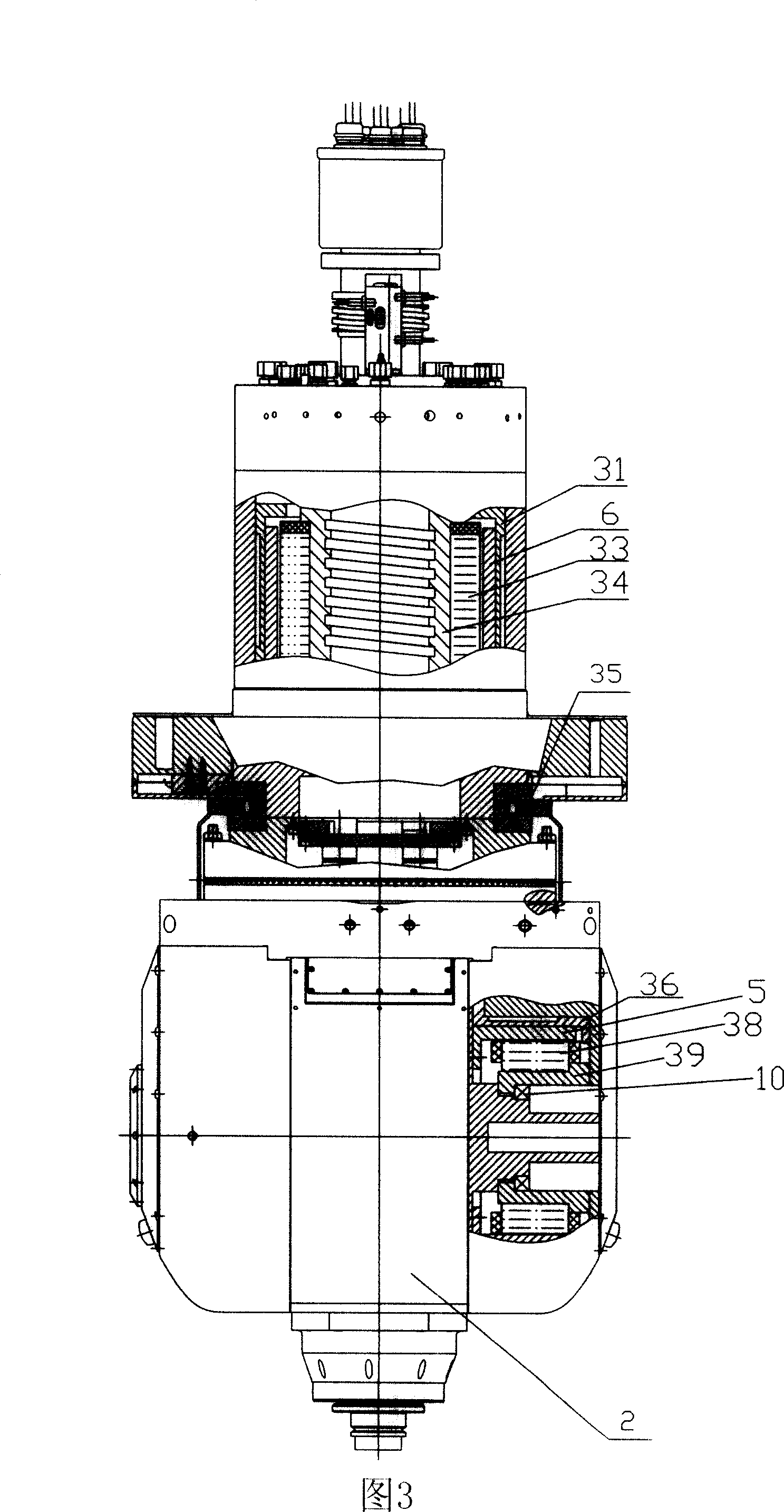

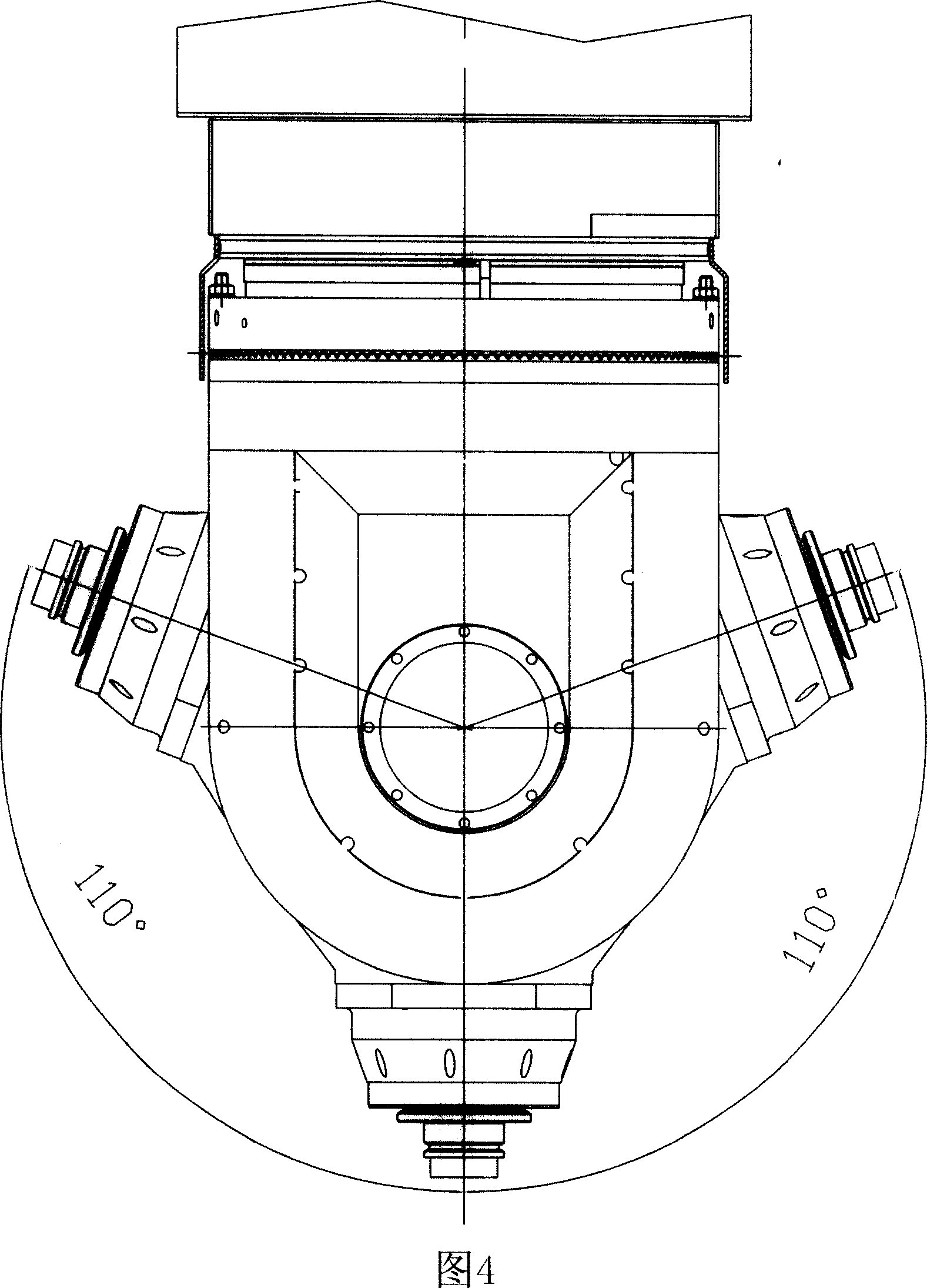

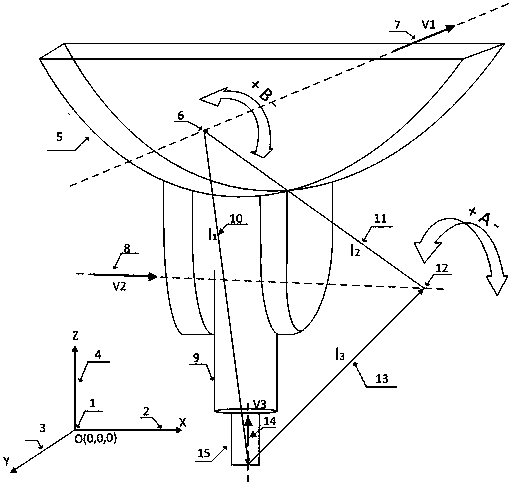

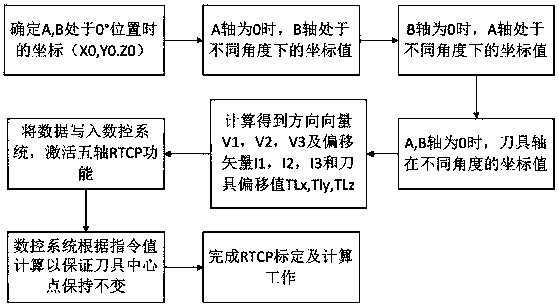

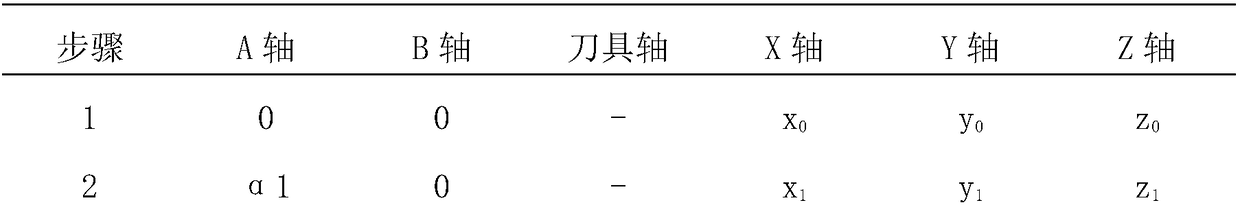

RTCP calibration and compensation method for five-axis NC machine tool of double-pendulum-head structure

ActiveCN108334030AHigh precisionReduce the error valueProgramme controlComputer controlEngineeringMachine tool

The invention discloses an RTCP calibration and compensation method for a five-axis NC machine tool of a double-pendulum-head structure. The method comprises the steps of recording the calibrated coordinate values of each rotating shaft at different angle positions, and calculating to obtain the offset vector of each rotating shaft and the vector data of each rotating shaft in the axis direction;writing the data into corresponding machine tool parameters of a numerical control system; and activating the five-axis linkage function of the numerical control system. In this way, the problems thatthe characteristic data of the five-axis machine tool cannot be directly acquired and the precision of a traditional method is low can be effectively solved. The accuracy of calibrated data is guaranteed, and the rapidity and the accuracy of the five-axis RTCP calibration are improved. As a result, the adjustment time is shortened, and the introduction of human errors is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

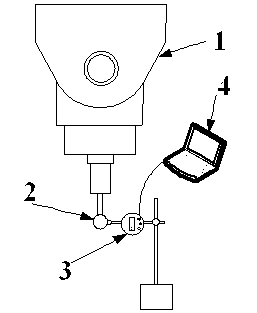

Method for detecting linkage accuracy of C-shaft of multi-shaft linkage double-pendulum numerical control milling machine

ActiveCN103273379AAcquisition is fast and efficientFast and effective analysisMeasurement/indication equipmentsNumerical controlMeasuring instrument

The invention discloses a method for detecting the linkage accuracy of a C-shaft of a multi-shaft linkage double-pendulum numerical control milling machine. The method comprises the following steps that a standard linkage ball is installed on a machine tool spindle, and the working length L and the linkage ball diameter D of the standard linkage ball are set in a machine tool system; a digital display dial indicator used for data collection and data output is arranged on a machine tool bed frame, and after a measuring head of the digital display dial indicator makes contact with the standard linkage ball, the measuring head is pressed inward by a certain distance d, and the current position of the digital display dial indicator is reset to zero; a machine tool RTCP motion mode is switched on, and the C-shaft is made to rotate around the center of the standard linkage ball; the digital display dial indicator is used for collecting displacement deviation delta 1 generated between the standard linkage ball and the measuring head in the rotation process, and the value of the displacement deviation delta 1 at a certain rotation angle is the linkage accuracy of the C-shaft at the angle. The method for detecting the linkage accuracy of the C-shaft of the multi-shaft linkage double-pendulum numerical control milling machine is more rapid and effective in data collection and data analysis, and can serve as a basis for accuracy compensation of a C-shaft of a follow-up machine tool; a large number of trial cuts does not need to be conducted, a three-coordinate measuring instrument does not need to be arranged for special inspection, and therefore cost is low and efficiency is high.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

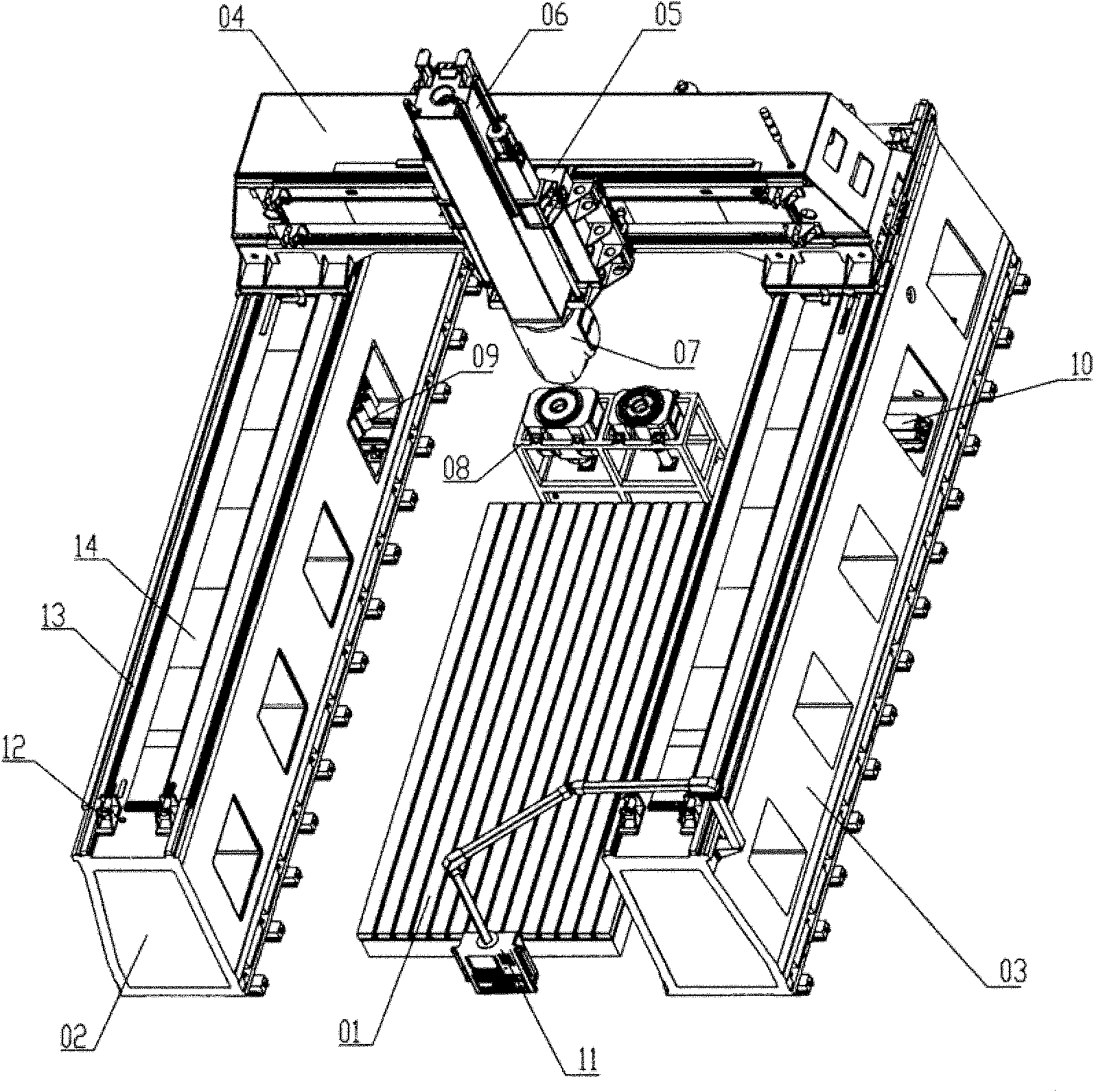

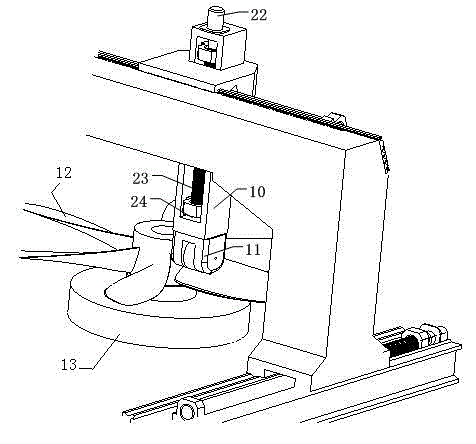

Direct-drive high-speed five-axis gantry machining center with replaceable milling head

ActiveCN102049705AImprove machining accuracyQuick responseFeeding apparatusLarge fixed membersAviationSlide plate

The invention relates to the field of five-axis gantry machining center tools, in particular to a direct-drive high-speed five-axis gantry machining center with a replaceable milling head, which solves the problems in the prior art, such as low precision and the like. Two linear guide rails are arranged on a left bridge and a right bridge respectively; a slide plate is in slide fit with a guide rail on a crossbeam through a slide block; a ram is in transmission fit with the slide plate through double lead screws, a double-pendulum head with A and C shafts is mounted at the bottom of the ram, and a head magazine is arranged on one side of a worktable; two ends of the crossbeam are mounted on the left bridge and the right bridge through slide seats; linear motors are adopted on the X direction and Y direction of the five-axis machining center for direct driving, the crossbeam moves horizontally along the left bridge and the right bridge in the X direction, and the slide plate moves horizontally along the crossbeam in the Y direction, double motors in the Z direction of the five-axis machining center drive the ram through gravity centers, and the ram moves vertically on the slide plate in the Z direction. The machining center has stable running and performance, and is suitable for precision finishing of dies in the industries of aviation, spaceflight, automobiles, and the like.

Owner:通用技术集团沈阳机床有限责任公司

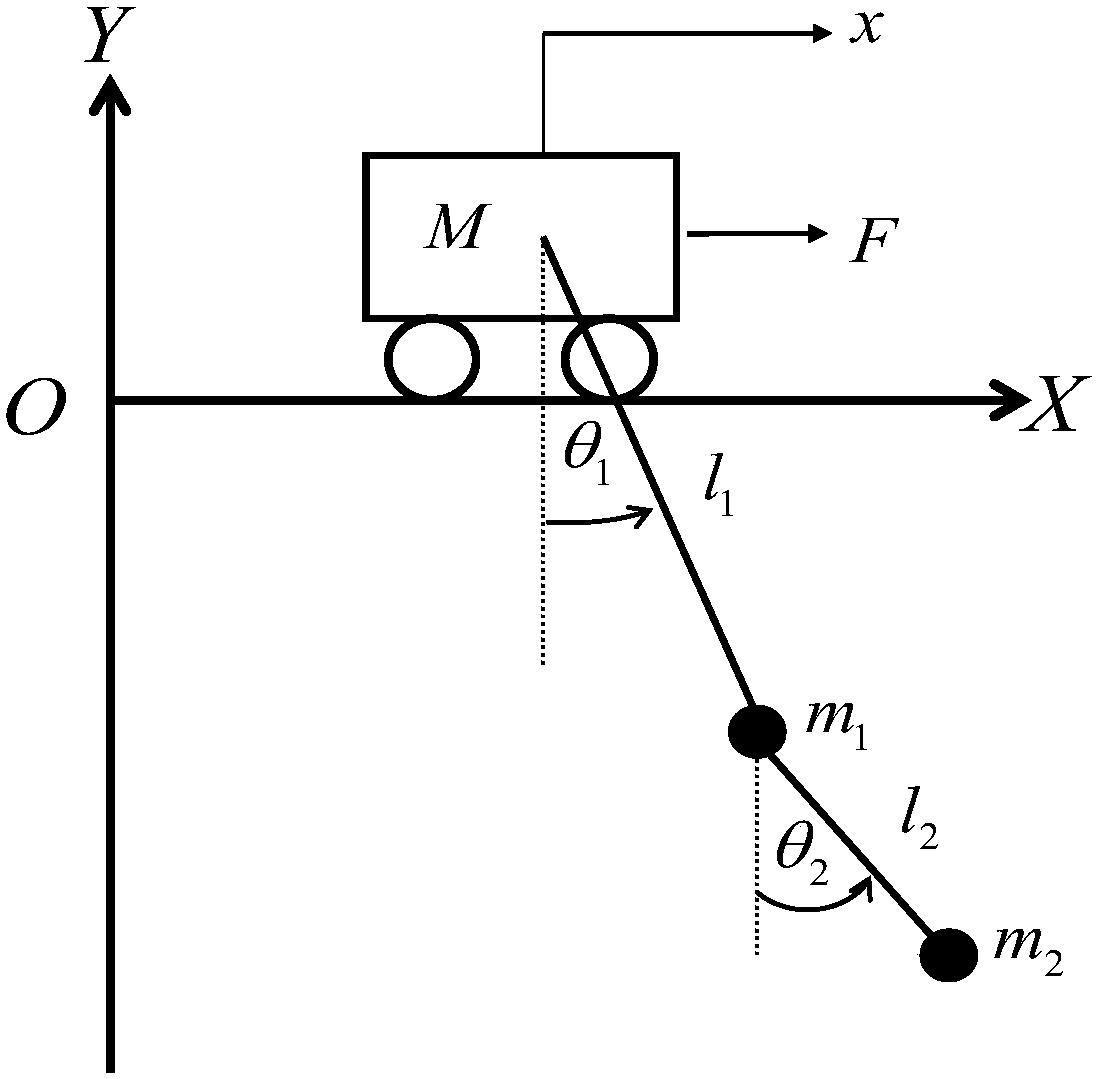

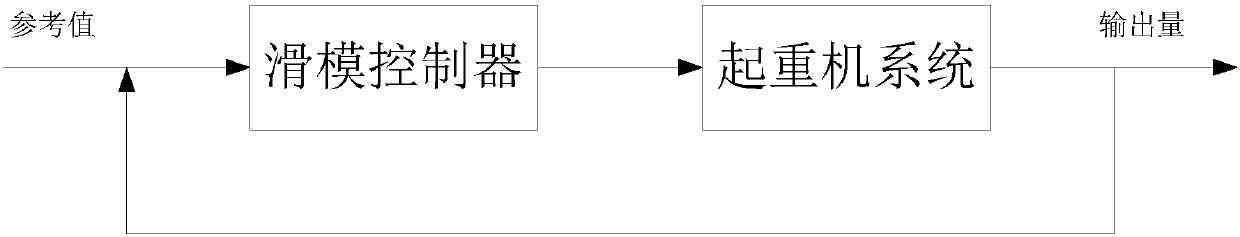

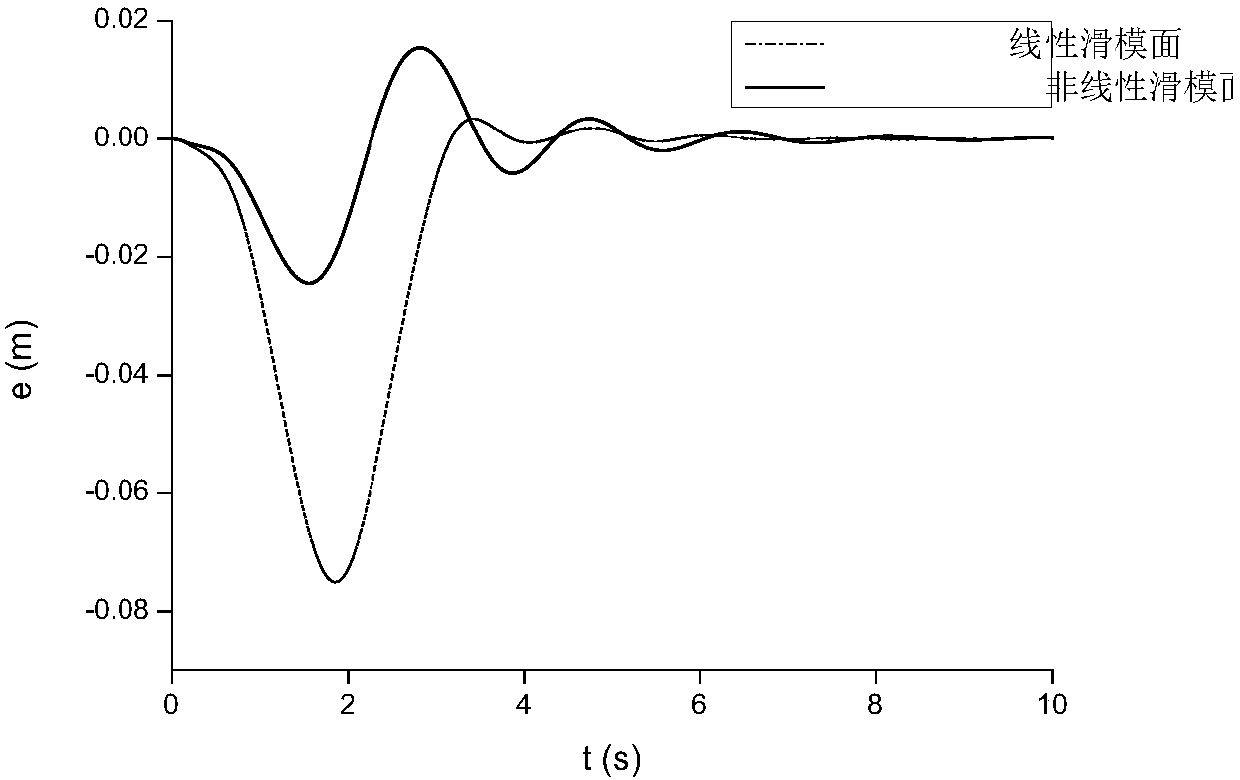

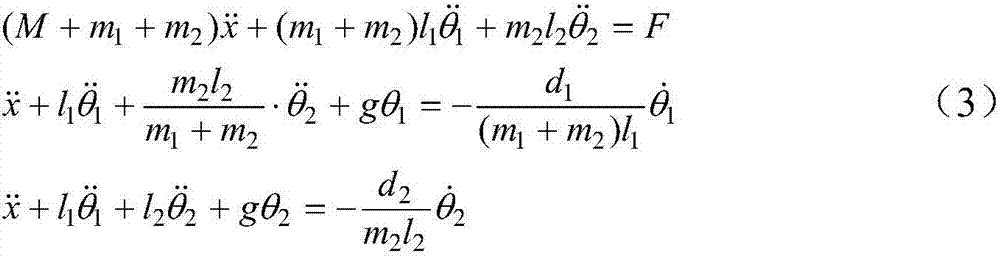

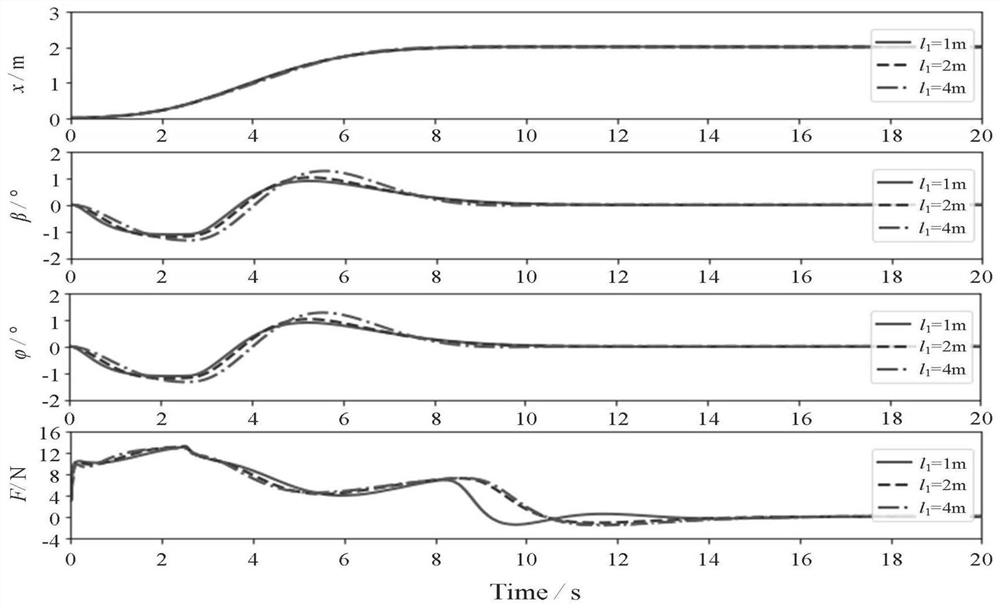

Sliding mode control method for double-pendulum bridge crane nonlinear sliding mode surface

ActiveCN107678277ASmall overshootProven StabilityTrolley cranesLoad-engaging elementsClosed loopDamping ratio

The invention discloses a sliding mode control method for a double-pendulum bridge crane nonlinear sliding mode surface, so as to eliminate double-pendulum effects of load swing of the crane system and realize high-precision trolley tracking control and load swing suppression which are important for the crane system. According to the novel sliding mode control method with the nonlinear sliding mode surface disclosed in the invention, different from the traditional linear sliding mode surface, the nonlinear sliding mode surface can change the damping ratio of a closed loop system to a final high value from an initial low value, the low value can provide a quick response, the high value can eliminate overshoot, and the trolley can track a given trajectory more accurately. The Lyapunov technology verifies the stability of the whole system.

Owner:南京黎创智能装备有限公司

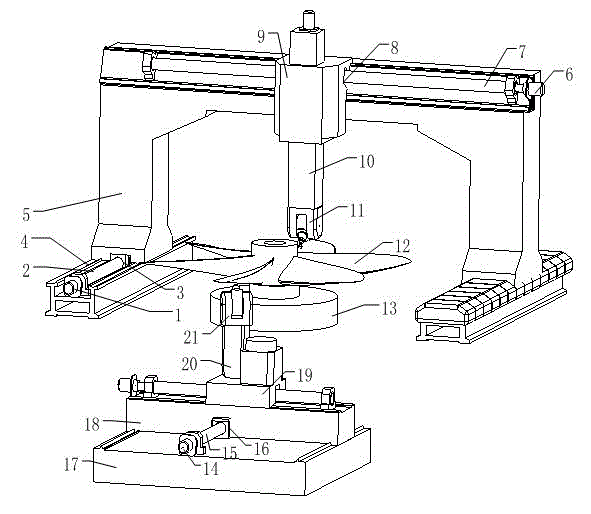

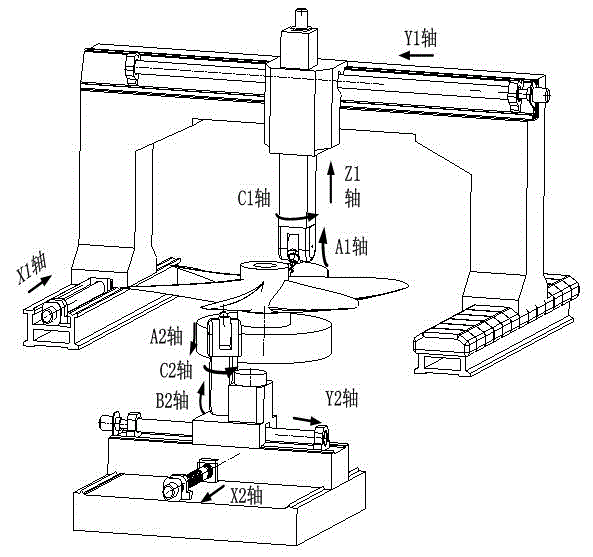

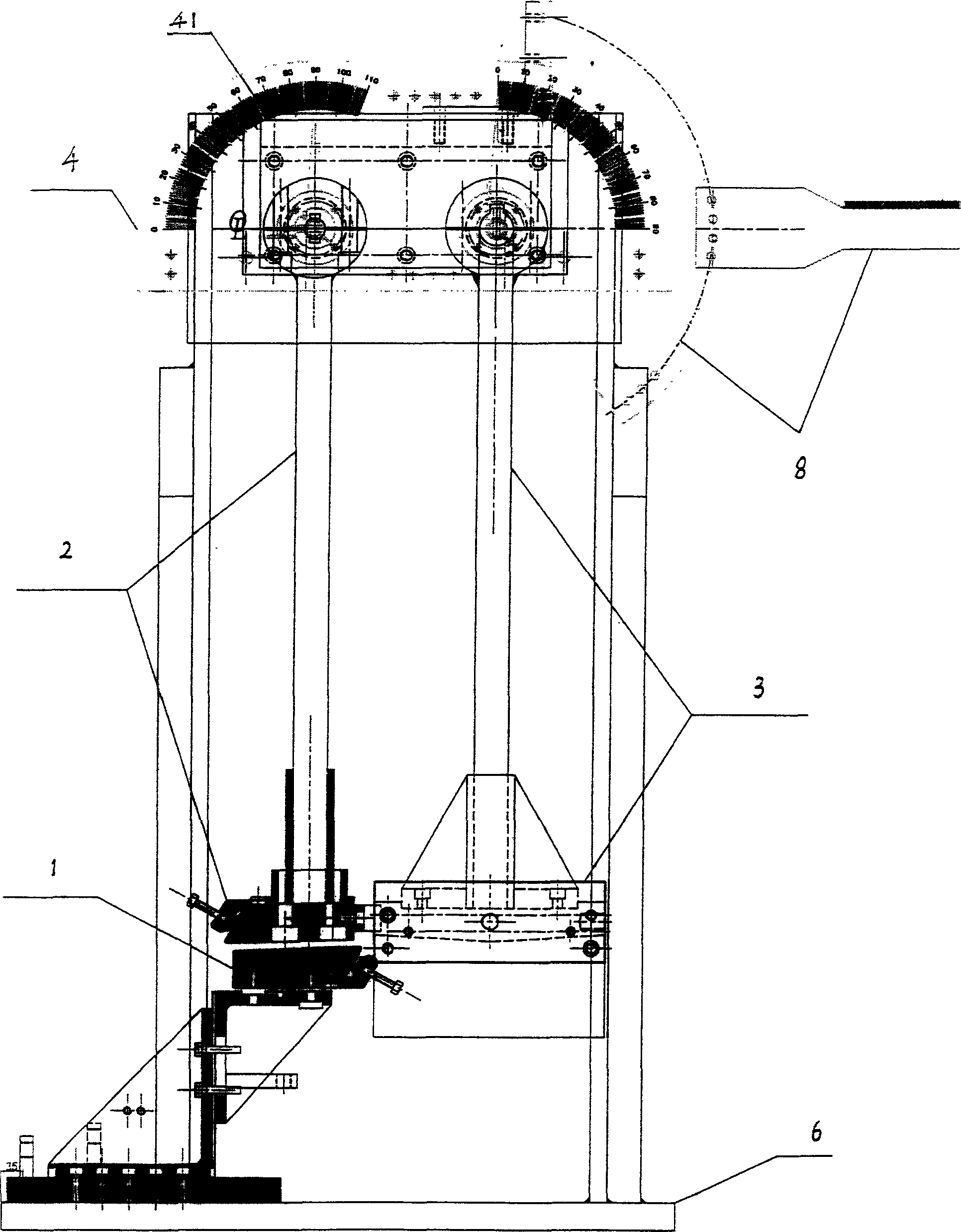

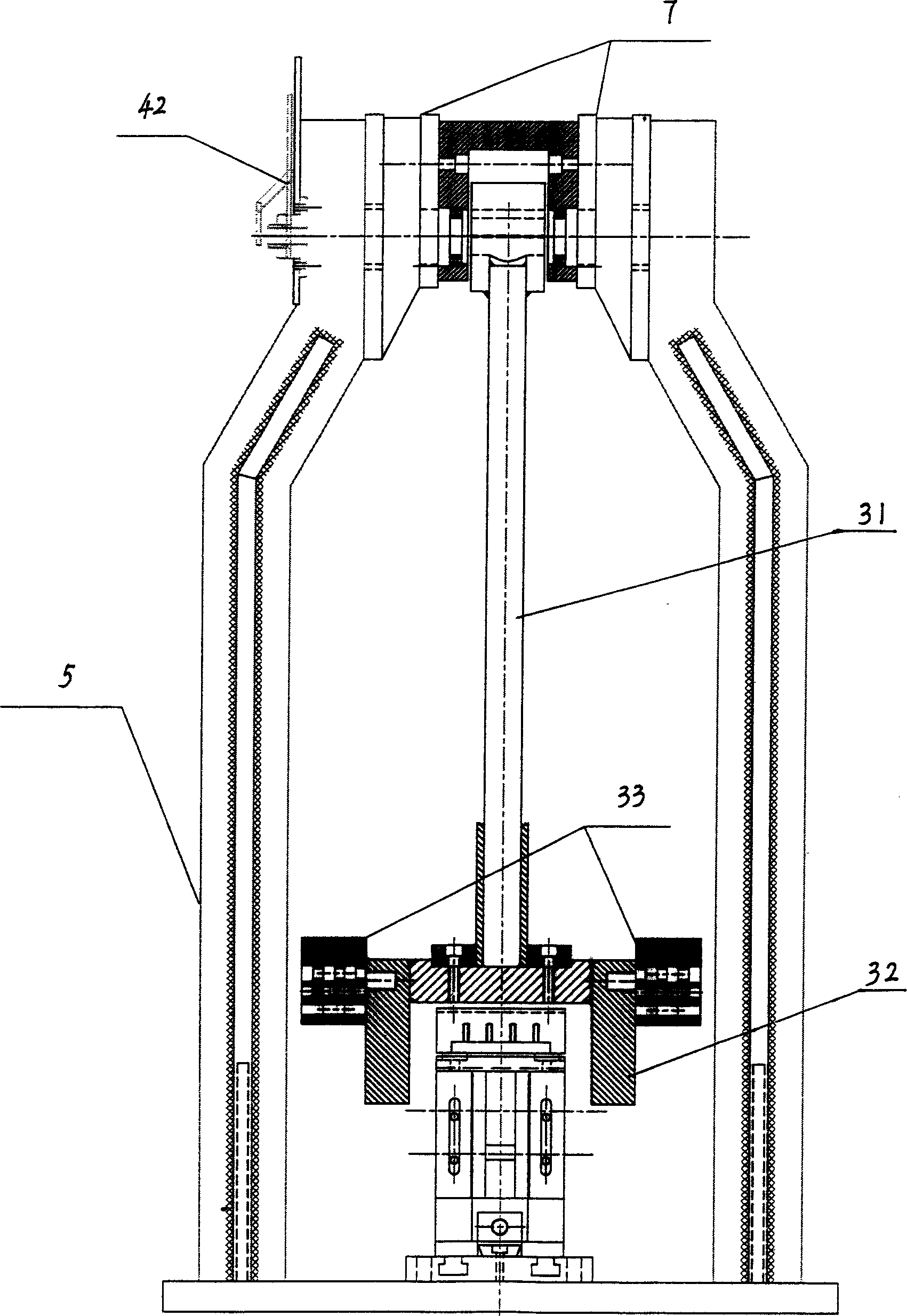

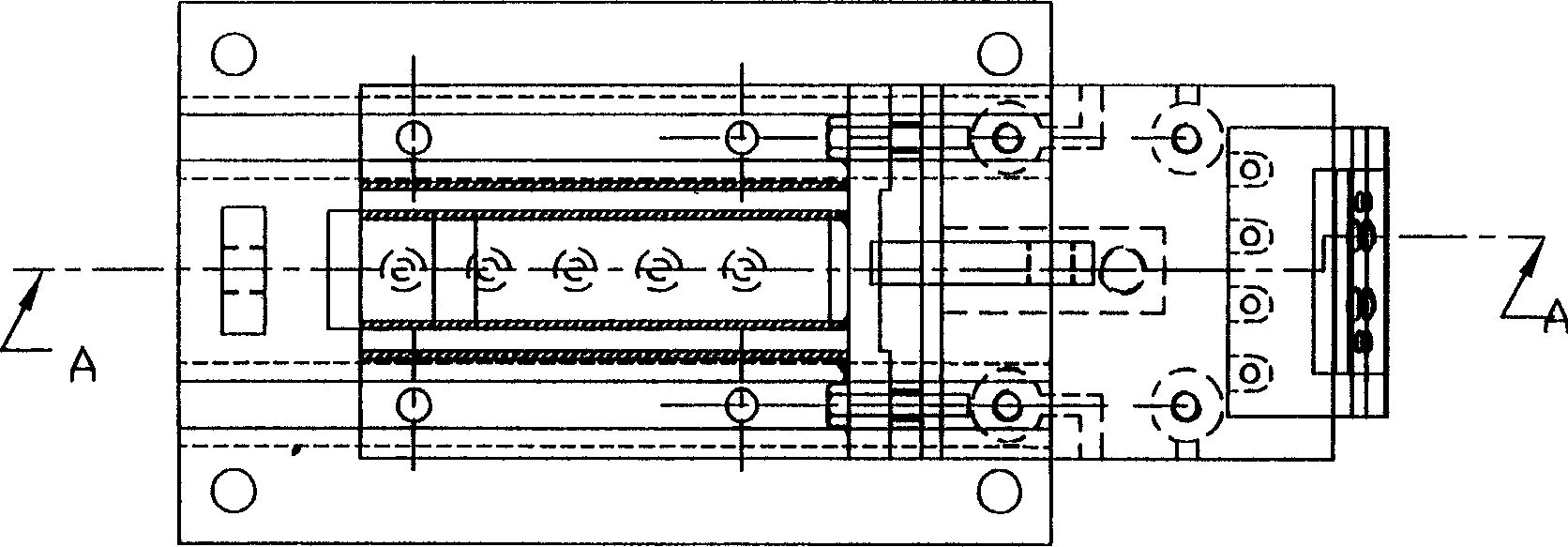

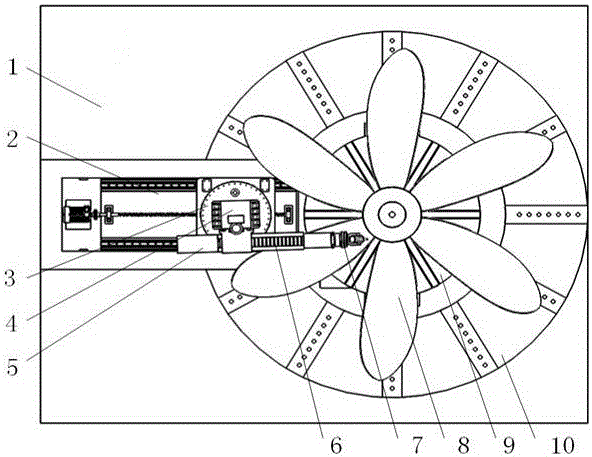

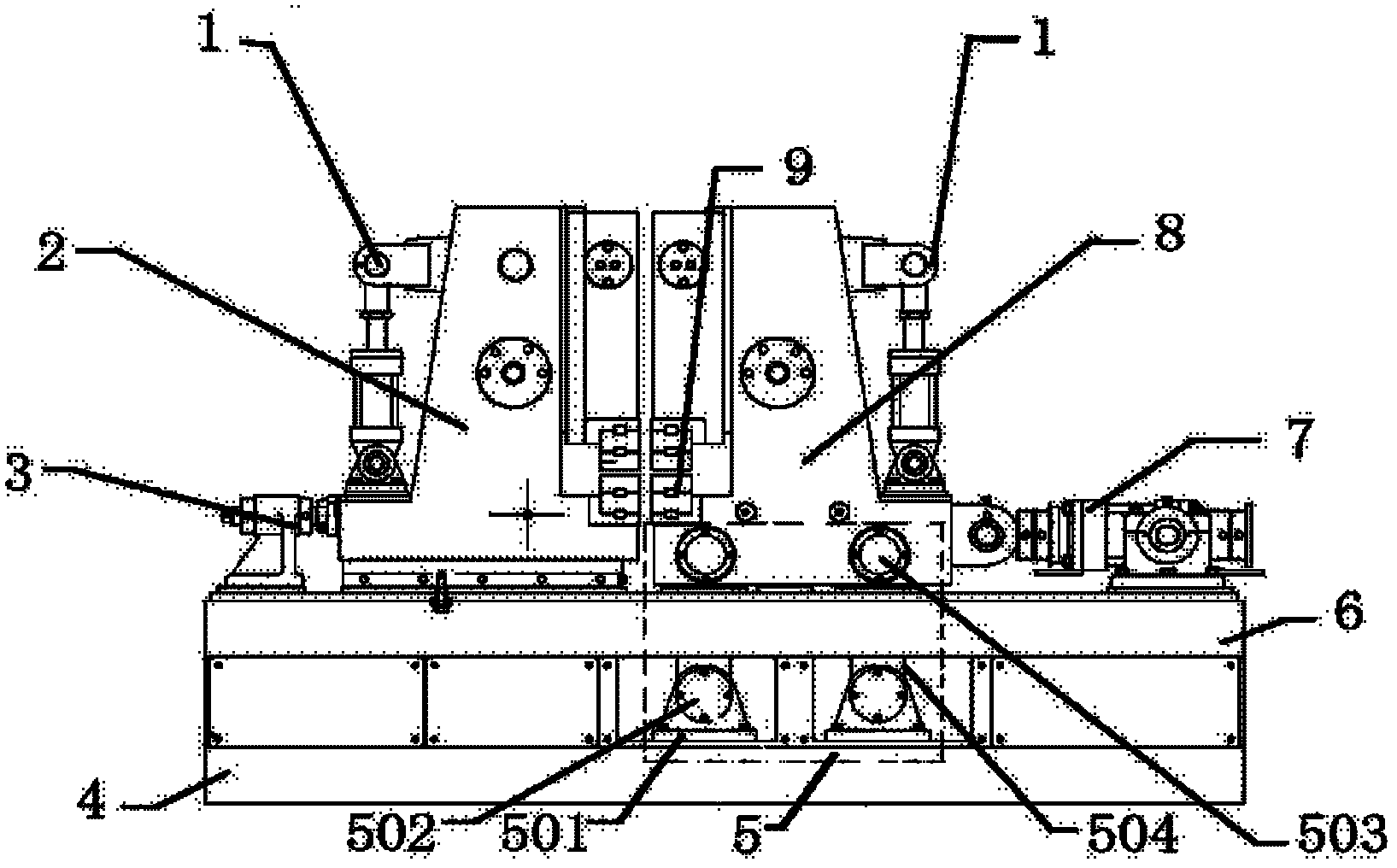

Numerical control processing machine tool and processing method special for double-power unit propeller

ActiveCN102744448AShorten the production cycleReduce labor intensityFeeding apparatusMilling equipment detailsImpellerNumerical control

The invention discloses a numerical control processing machine tool and processing method special for a double-power unit propeller of a large ship. The machine tool comprises an upper and a lower power unit system; the upper power unit system comprises an upper base, a mobile column, a lead screw nut mechanism, a motor, a guiding rail and an A / C direct-drive double pendulum power unit; the lower power unit system comprises a lower base, a lead screw nut mechanism, a motor, a guiding rail, a B2 axle assembly and a second A / C direct-drive double pendulum power milling unit. The processing method comprises the following steps that the upper surface of the propeller is cut and processed firstly, and then the lower surface is cut and processed, the operation is repeated until all impellers are processed; alternatively, the upper surface of the propeller can be cut and processed until the upper surfaces of all impellers are processed, and then the lower surface is cut and processed until the lower surfaces of all impellers are processed; the processing of the whole propeller curved surfaces such as impeller pressure surface, impeller suction surface, and propeller hub and the like is completed in one time of assembly, so that the troubles of turning over and reassembling of the large propeller can be saved, thus processing efficiency is improved and repositioning error is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

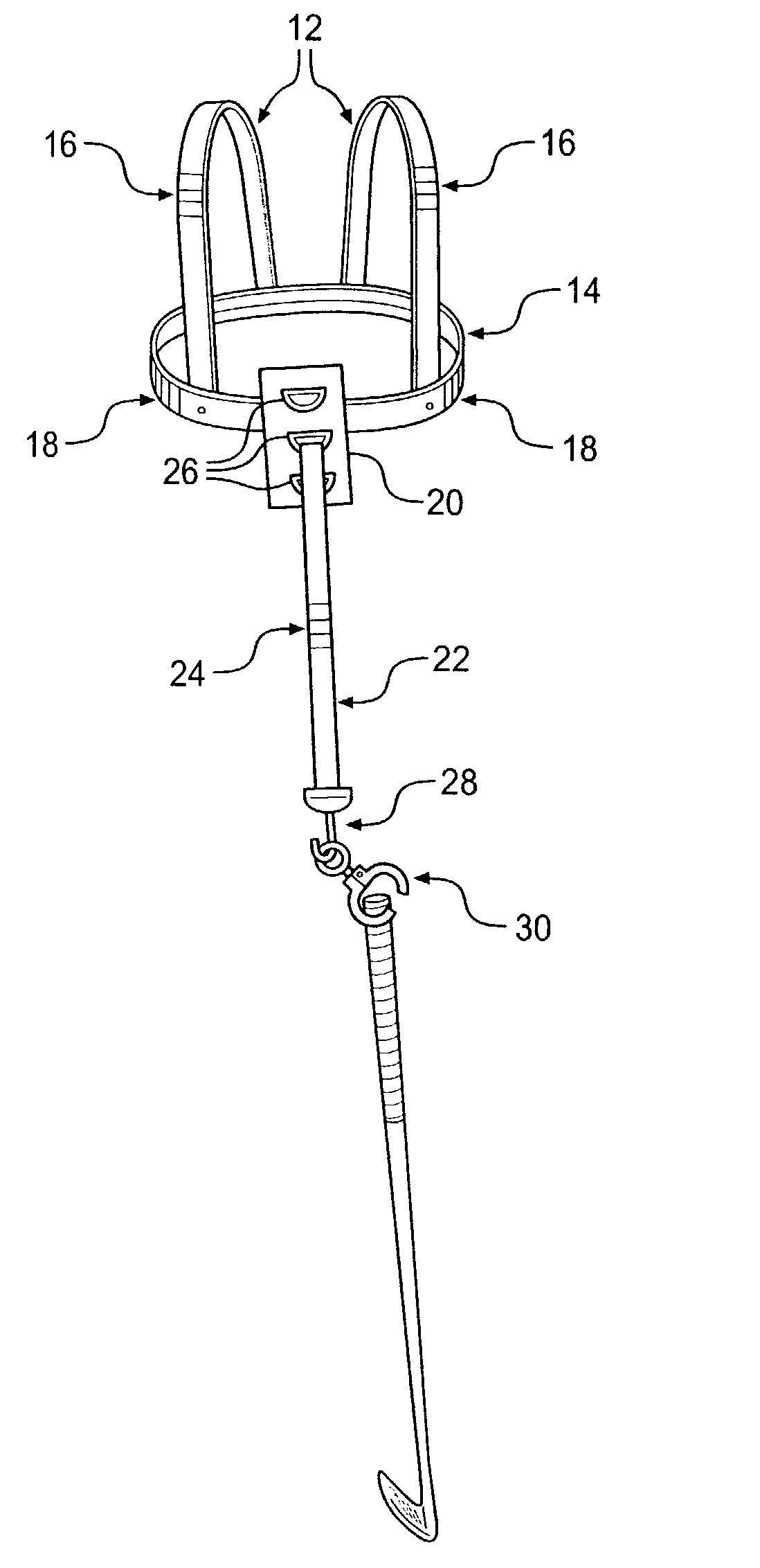

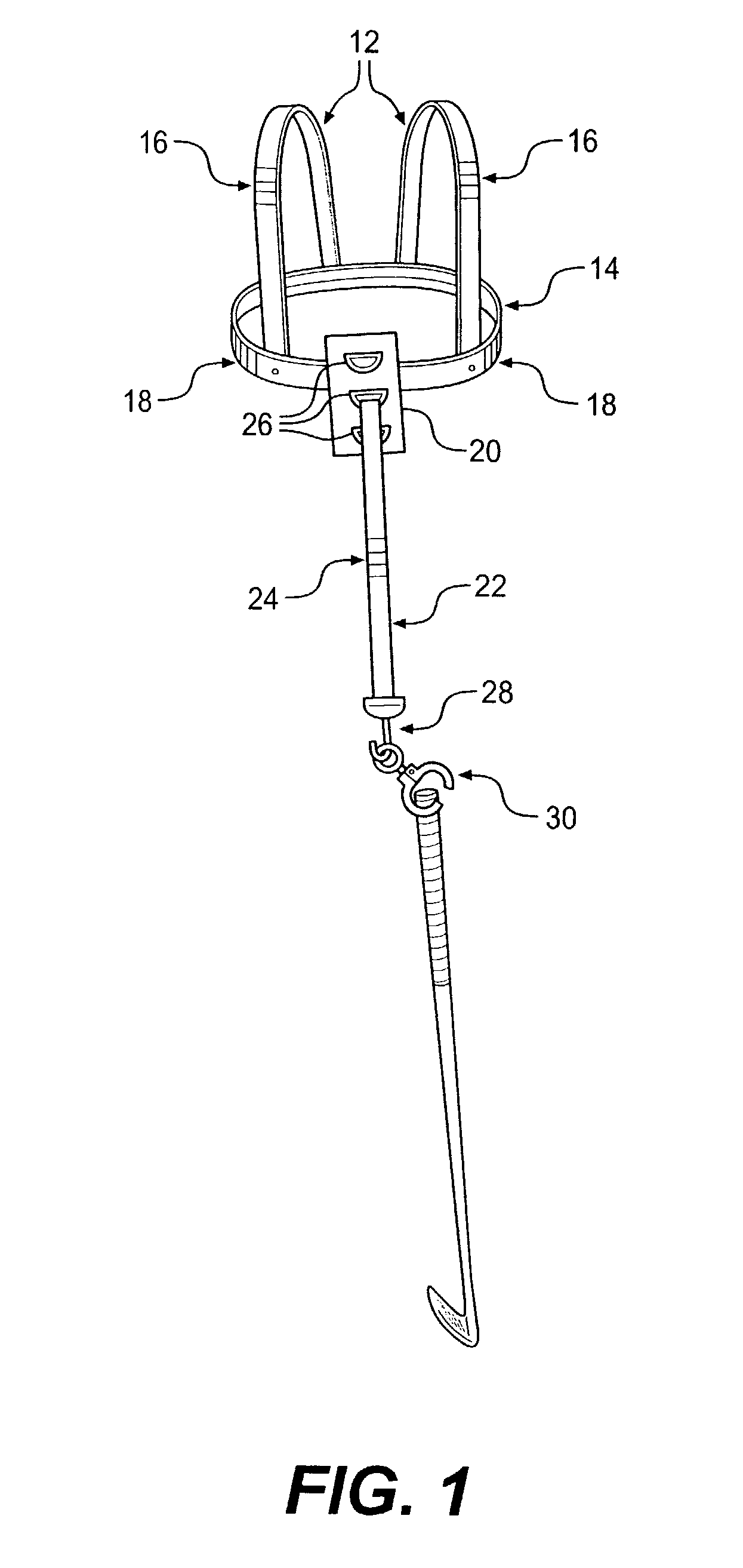

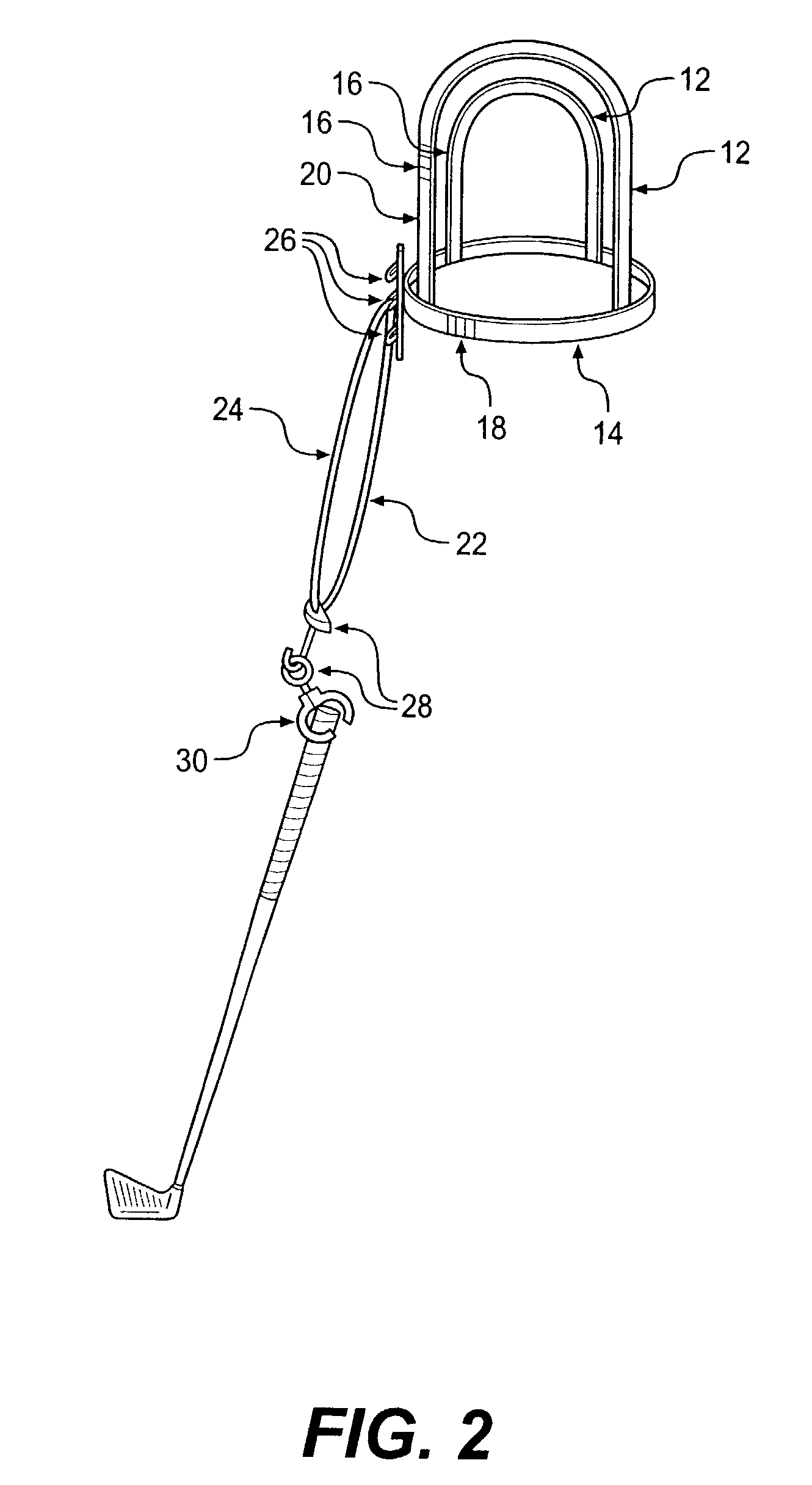

Golf swing training apparatus

A method and device for golf swing training is disclosed wherein a double pendulum model swing is replicated by defining a point on a golfer's chest about which a golfer's swing rotates and extending therefrom a inelastic flexible strap for attachment to the grip of a golf club. The inelastic flexible strap encourages the golfer to fully extend his arms throughout the golf swing to maintain a proper swing radius without inhibiting the movement of the golfer's wrists; therefore, allowing the golfer to experience the ideal golf swing.

Owner:KATEMA

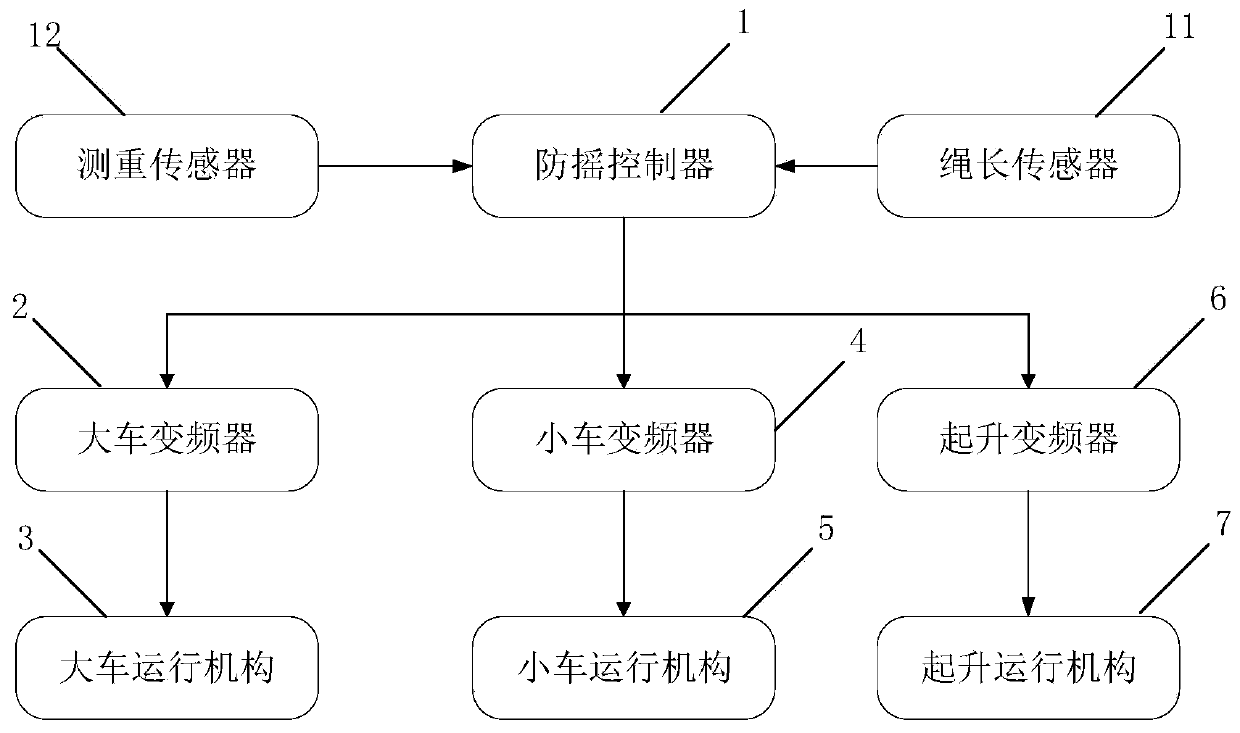

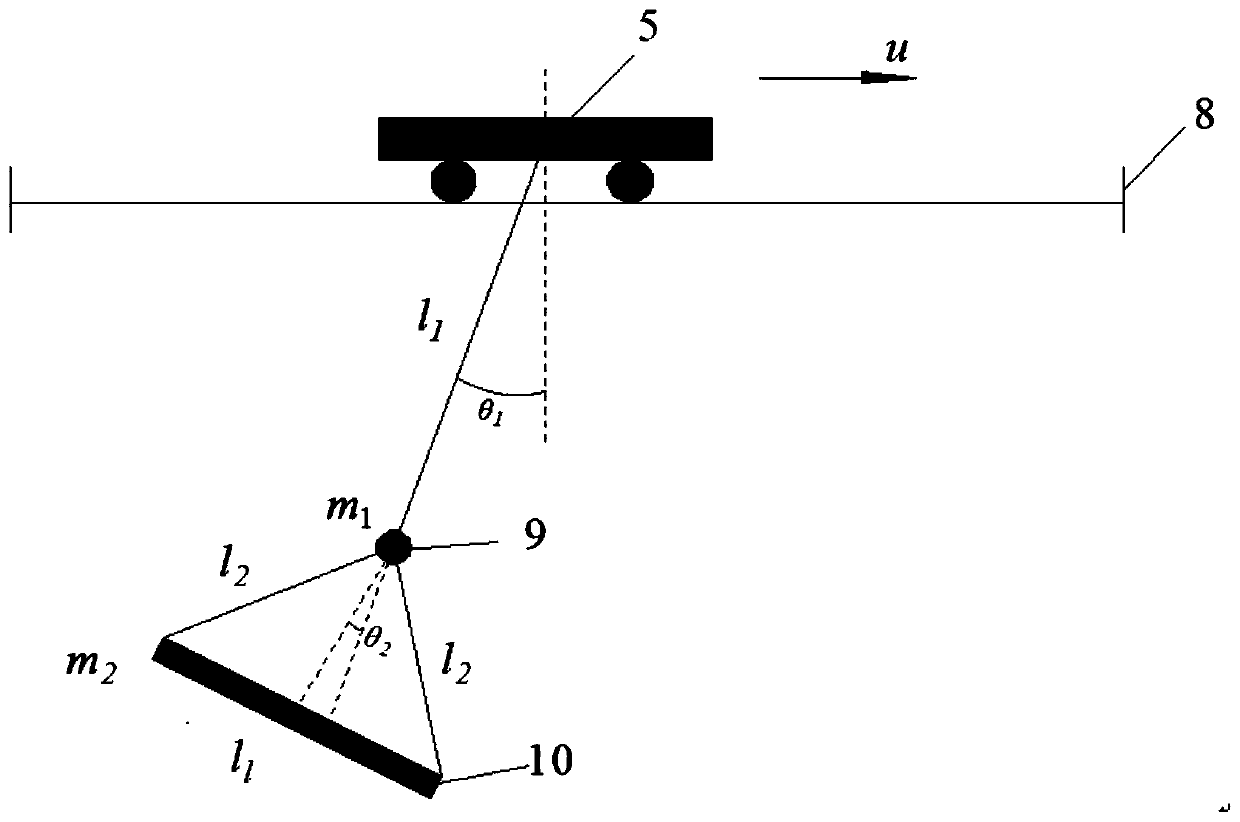

Optimized anti-shake control method for double-pendulum system of bridge crane

ActiveCN110436347AImprove work efficiencyImprove running stabilityLoad-engaging elementsDual modeEngineering

The invention provides an optimized anti-shake control method for a double-pendulum system of a bridge crane. The method comprises the steps that the running speeds of a cart and a trolley are calculated according to the load weight and the rope length measured in real time; based on the dynamic differential equation of the crane, an analytical solution of a single-pendulum model of the bridge crane is obtained; using a quadratic objective function of an analytic solution under the action of three pulses, an optimal input shaper with a zero initial state is calculated; and then, according to acascade method for solving a dual-mode input shaper, the optimal input shaper for the double-pendulum system of the bridge crane is designed, and the swing of the load is eliminated by driving a cartrunning mechanism and a trolley running mechanism through a cart frequency converter and a trolley frequency converter respectively, so that the optimal anti-shake control of the double-pendulum of the crane is realized. The optimized anti-shake of long load horizontal lifting is realized, and the working efficiency and operation safety of the bridge crane are improved, so that the running speedsand running tracks of the cart and the trolley are more reasonable, and the engineering application is facilitated.

Owner:WUHAN UNIV OF TECH

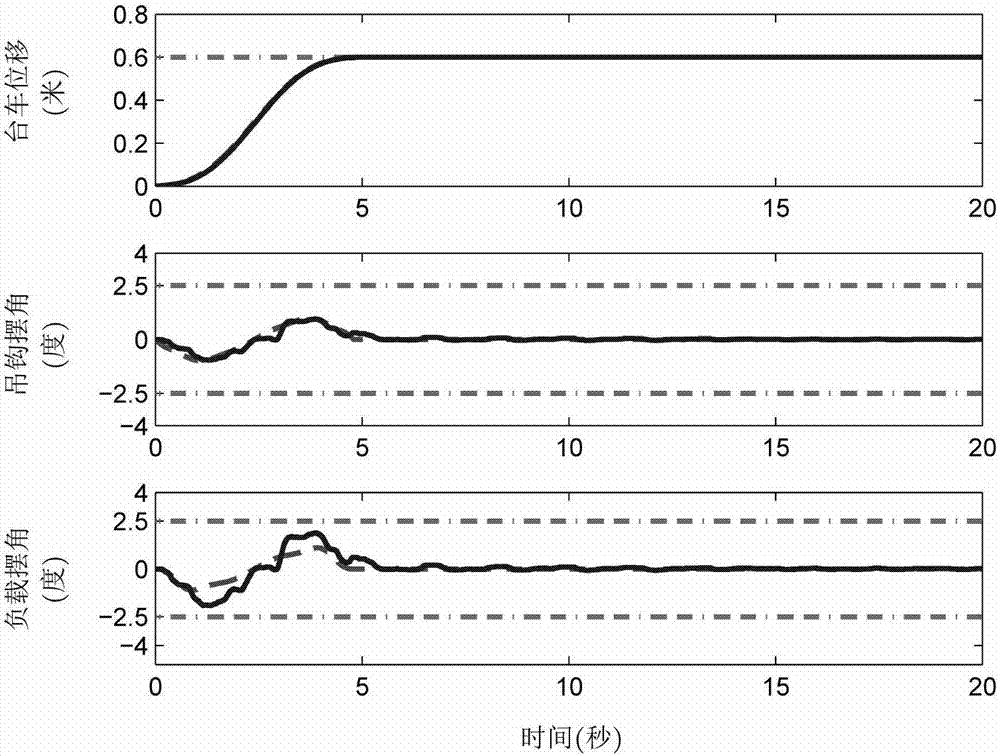

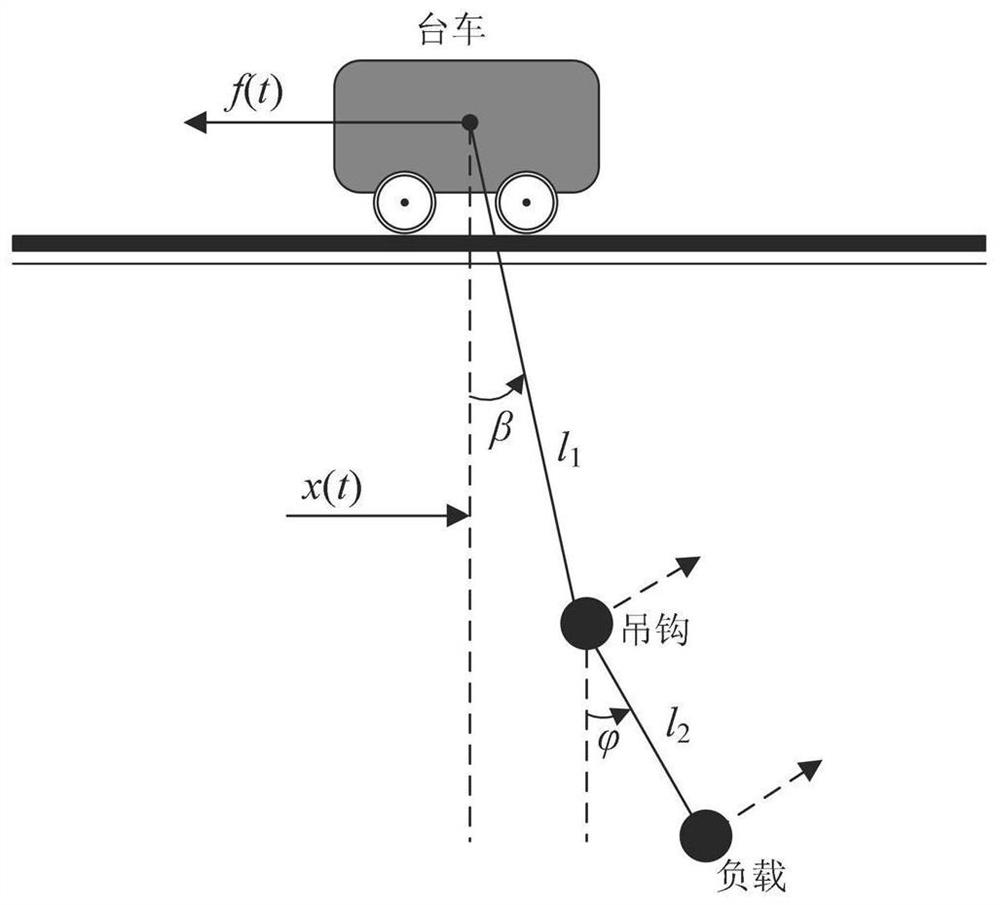

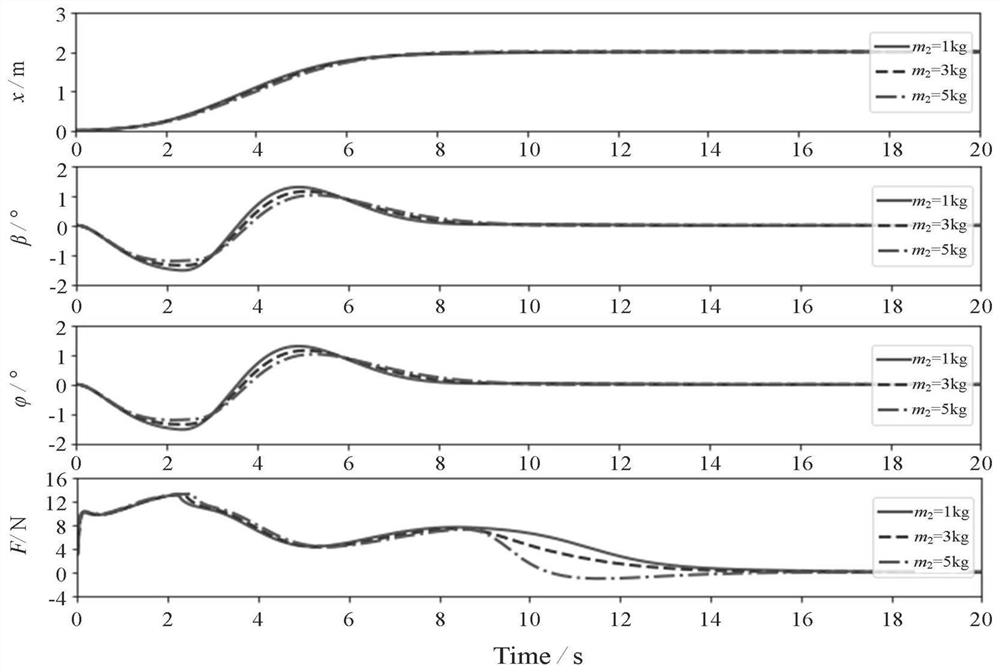

Double-pendulum crane global time optimal trajectory planning method based on pseudo-spectral method

ActiveCN105174061AImprove work efficiencyEasy to solveLoad-engaging elementsAutomatic controlEngineering

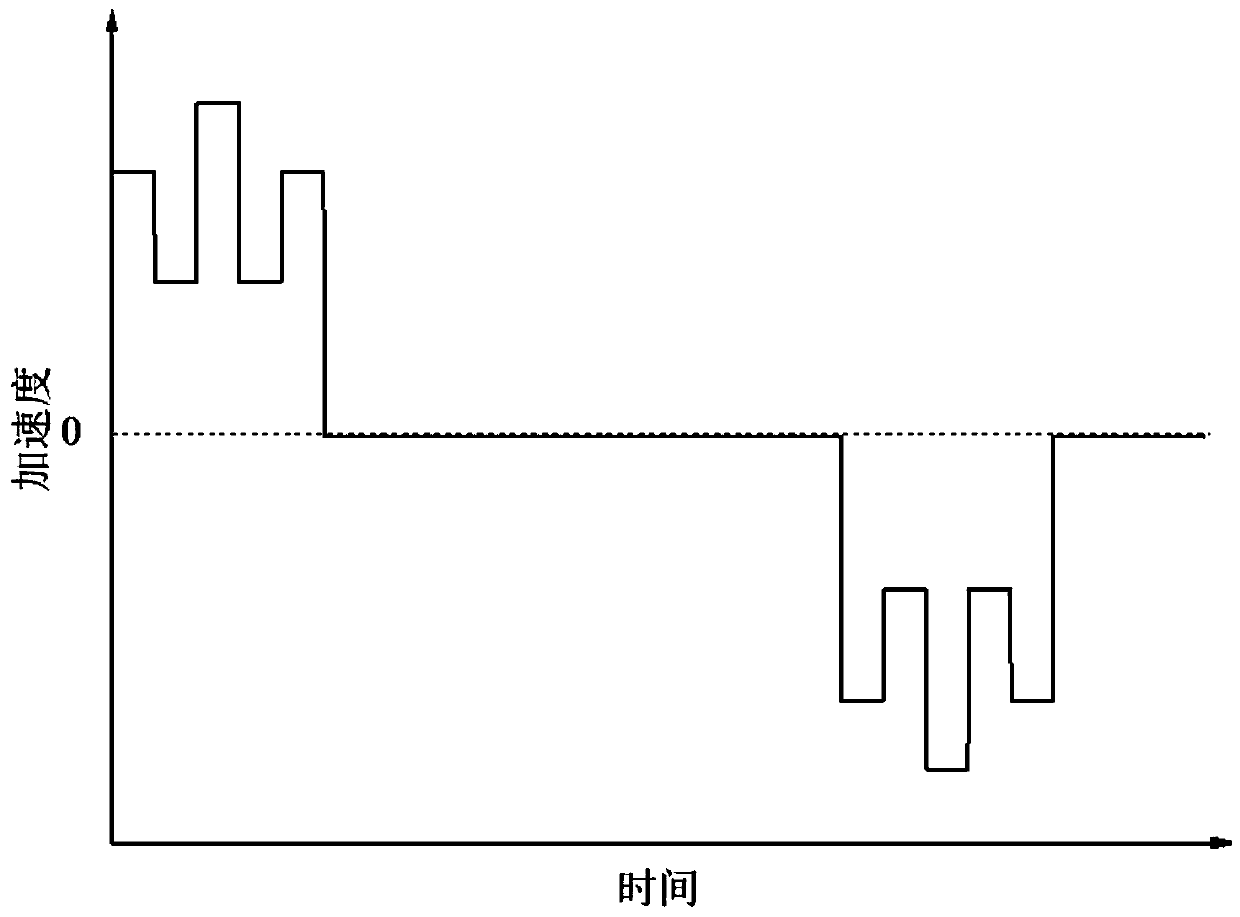

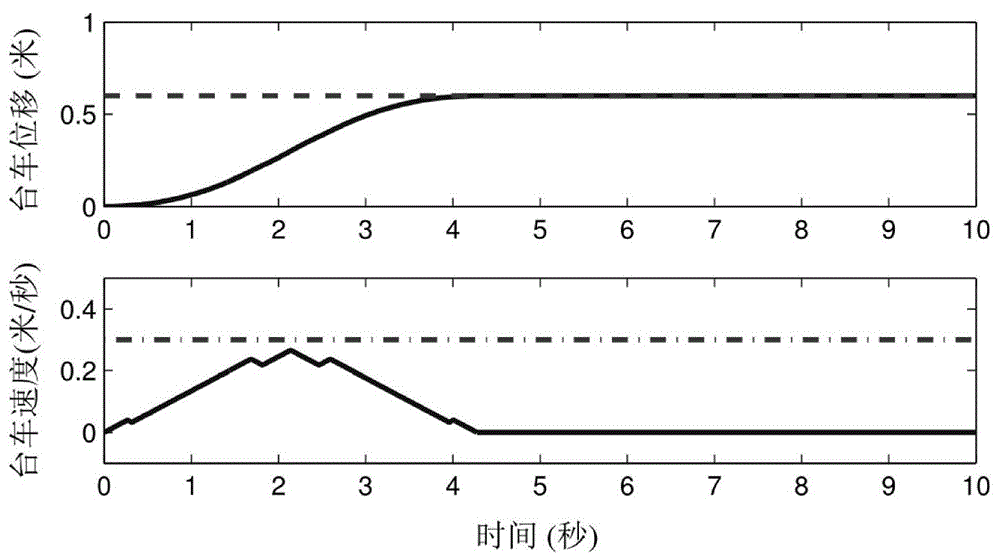

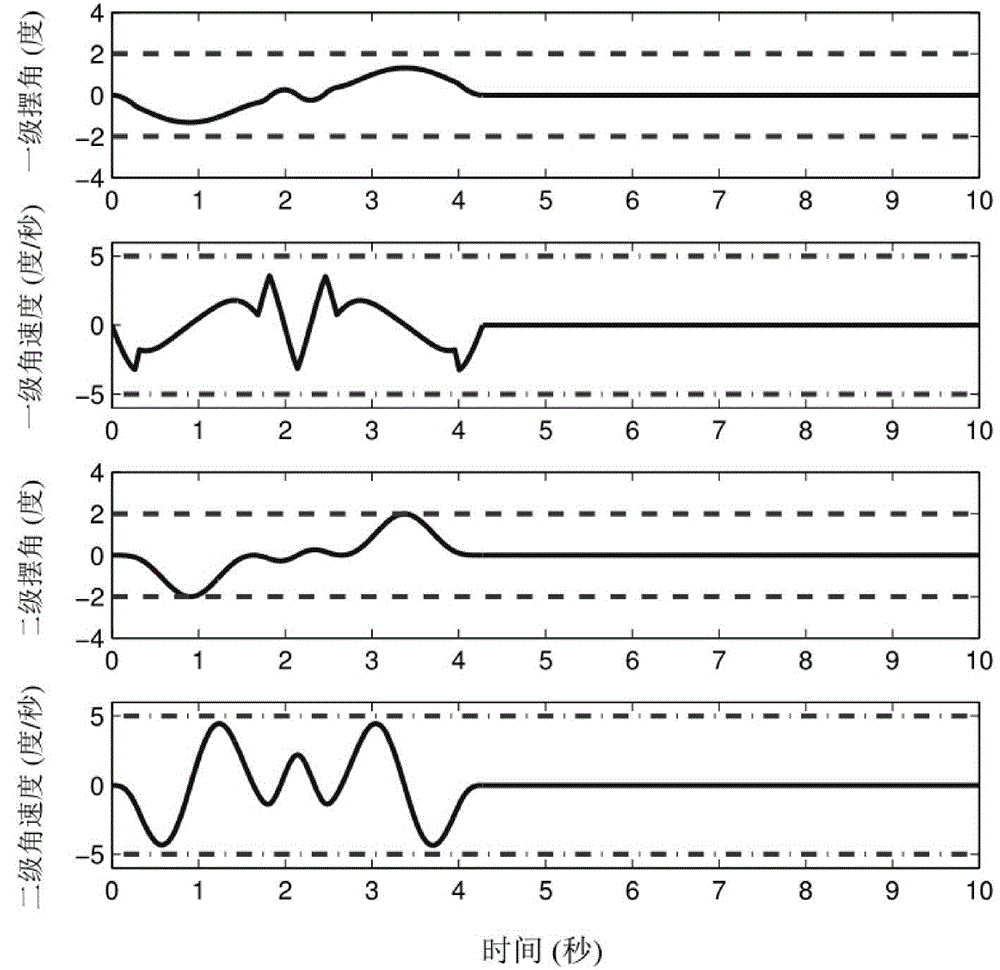

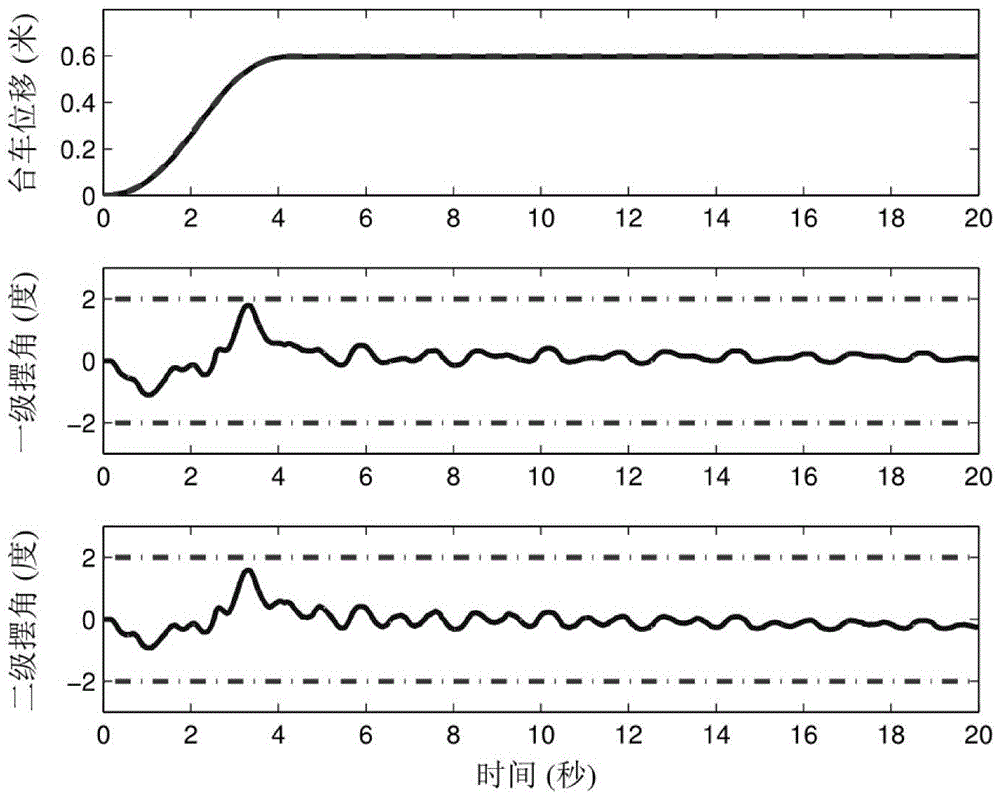

Disclosed is a double-pendulum crane global time optimal trajectory planning method based on a pseudo-spectral method. The purpose of automatic control over a nonlinear double-pendulum bridge crane system is achieved. The method has the good functions of trolley positioning and two-stage load pendulum elimination. The method comprises the steps that firstly, a system kinematic model is transformed so as to facilitate following analysis; then, corresponding optimization problems are constructed by considering various constraints including two-stage pendulum angles and trolley speed and acceleration upper limit values; and then, the Gaussian pseudo-spectral method is used for transforming the optimization problems with the constraints into nonlinear programming problems easy to solve to be solved to obtain a trolley trajectory with the optimal time. The thought of the pseudo-spectral method is utilized for handling and transforming the complex time optimal problem, the solving difficulty is lowered; and meanwhile, the result with the optimal global time can be obtained through the method, and the working efficiency of a crane system can be greatly improved. Simulation and experiment results show that the good control effect can be obtained and the good actual application value is achieved.

Owner:NANKAI UNIV

Impacting tester with double pendulum and testing method thereof

InactiveCN1680798AEasy to detectSimple test methodMaterial strength using single impulsive forceTest sampleEngineering

An impact tester with double pendulum consists of driven pendulum formed by the first link lever and bob, driving pendulum formed by the second link lever and bob as well as sample base. Its test method includes lifting the driving pendulum up to preset angle, fixing it temporarily, fixing test sample in 'Z' shape on base and driven bob through packing device, resetting two pointers on scale, releasing the driving pendulum to shock driven pendulum for breaking test sample, recording frontlash angle of driving pendulum and calculating out consumed impact work.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

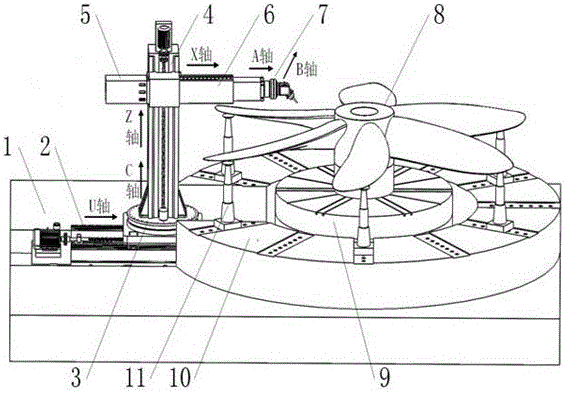

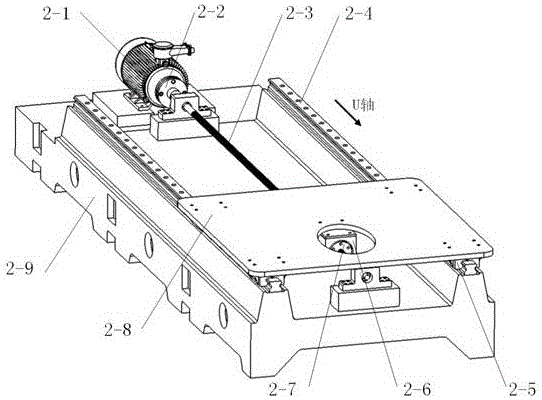

Horizontal propeller five-axis linkage numerical control machining tool and machining method

InactiveCN107520630AMaximum stroke reductionSave layout spaceFeeding apparatusLarge fixed membersNumerical controlPropeller

The invention discloses a horizontal propeller five-axis linkage numerical control machining tool and a machining method. A vertical propeller is coaxially connected to a part right above a rotary working table. A U-axis transmission mechanism, a C-axis rotation mechanism and a vertical Z-axis transmission mechanism are arranged beside the propeller. The lower end of the Z-axis transmission mechanism is coaxially connected with the C-axis rotation mechanism capable of driving the Z-axis transmission mechanism to rotate. The U-axis transmission mechanism, which is horizontally arranged in the diameter direction of the propeller, is connected to the bottom of the C-axis rotation mechanism. The U-axis transmission mechanism can drive the C-axis rotation mechanism and the Z-axis transmission mechanism to move to and fro along a center shaft of the U-axis transmission mechanism. The upper section of the Z-axis transmission mechanism is connected with a horizontal X-axis transmission mechanism and a balancing mechanism. The inner end of the X-axis transmission mechanism is coaxially connected with an A / B direct-drive swinging force head. The space layout of the tool is greatly reduced on the whole, the front and back surfaces of the propeller are machined after one-time clamping of parts, and the machining efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Double-pendulum crane energy consumption optimal trajectory planning method

ActiveCN106976804AHigh energy consumptionSuppresses and eliminates residual swingLoad-engaging elementsAutomatic controlProcess engineering

The invention discloses a double-pendulum crane energy consumption optimal trajectory planning method, and belongs to the technical field of automatic control of under-actuated mechanical systems. The method comprises the following steps: an energy consumption optimal trajectory planning method aiming at a double-pendulum crane system is designed by fully considering double-pendulum characteristics of a crane system and the energy consumption demands in actual production for realizing the control targets of positioning and pendulum elimination of a double-pendulum crane. Firstly, in order to conveniently analyze and calculate, system kinetic equations are converted. Then, corresponding optimization problems are configured according to each state quantity constraint, an initial state and a target state of the system. Finally, the optimization problems are converted to a form of convex optimization problems, and are solved by a convex optimization tool. The method can guarantee the double-pendulum crane system to reach the target state from the initial state, reaches the lowest energy consumption in the operation process, constrains all system states in a given range, and meanwhile, effectively inhibits and eliminates residual pendulum of the system.

Owner:NANKAI UNIV

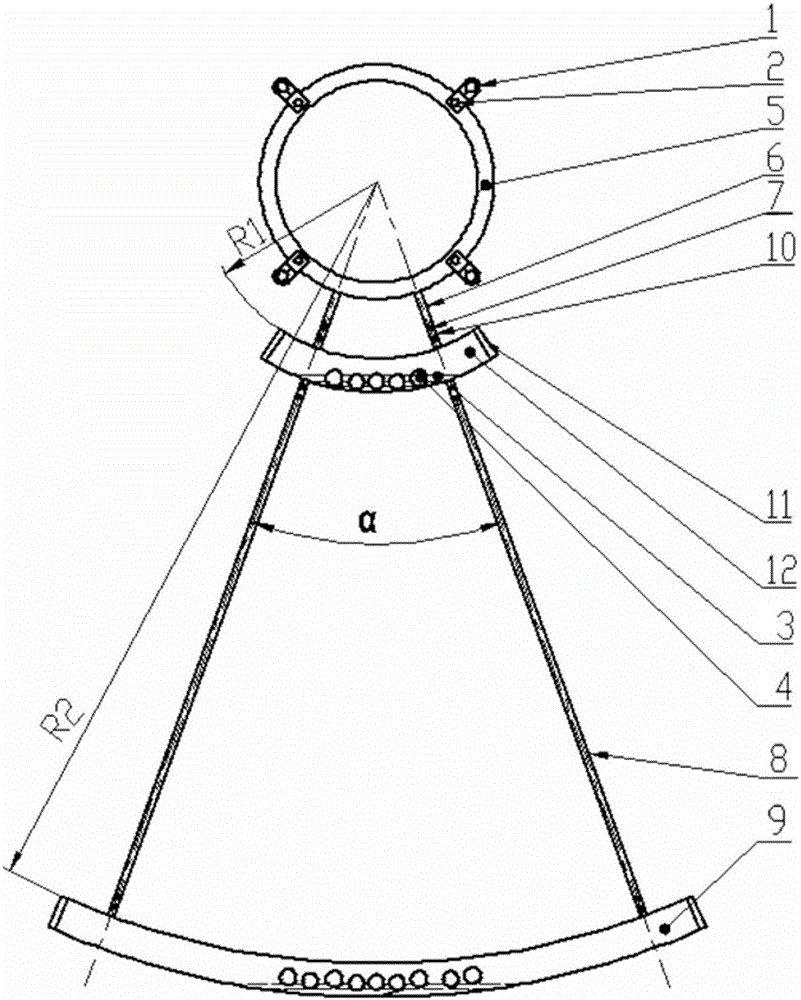

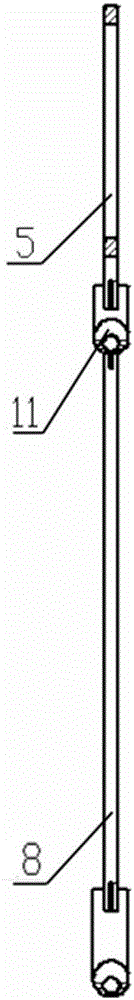

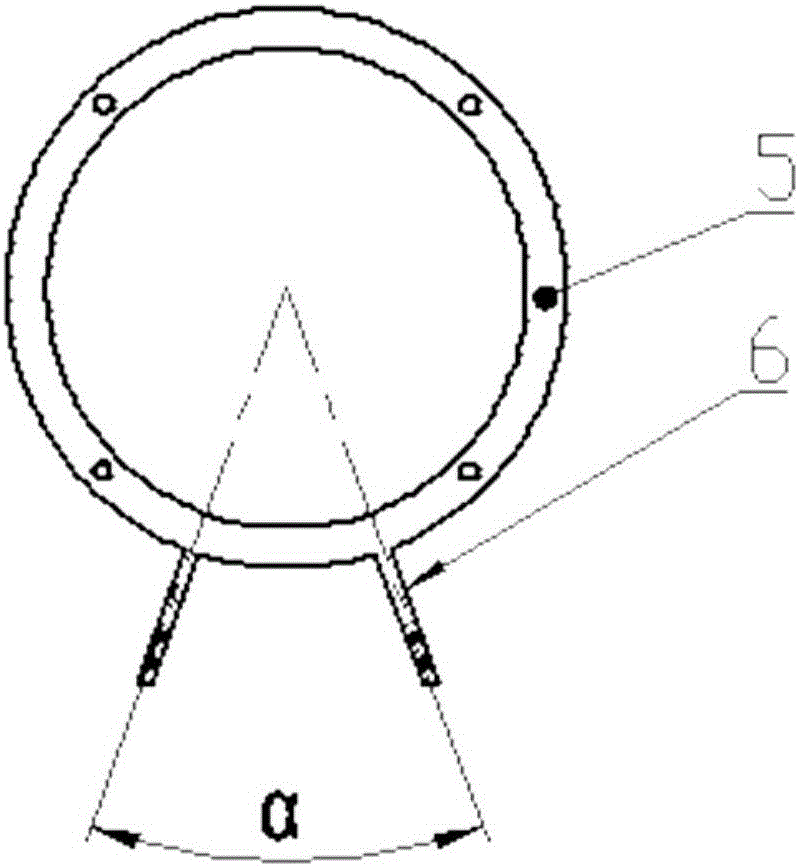

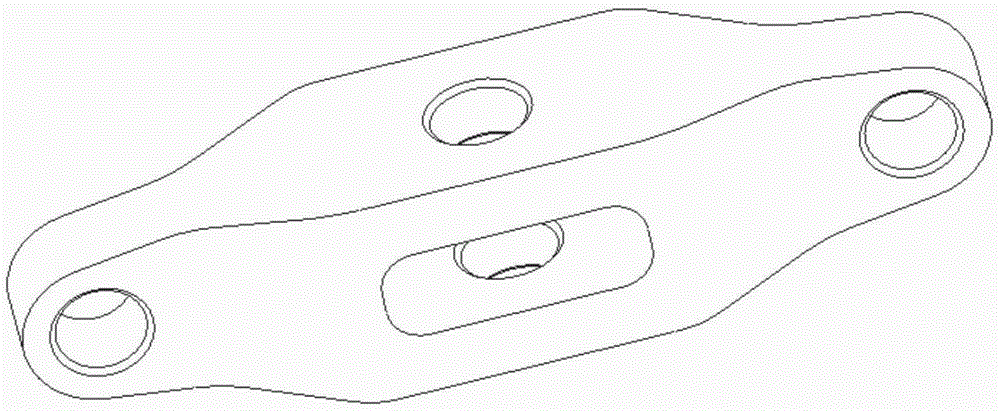

Double-pendulum anti-galloping device of overhead transmission lines and application method of double-pendulum anti-galloping device

ActiveCN106300198AReduce vibration in any directionReduce rolling frictionDevices for damping mechanical oscillationsVertical vibrationResonance

The invention relates to a double-pendulum anti-galloping device of overhead transmission lines and an application method of the double-pendulum anti-galloping device. The double-pendulum anti-galloping device comprises wire clamps, small bolts, an annular isolation ring, short connecting rods, a resonance-pendulum absorber and a parametric-resonance-pendulum absorber, wherein one ends of the wire clamps are fixedly connected to transmission wires, the other ends of the wire clamps are fixedly connected to the annular isolation ring in an even distribution manner through the small bolts, and the number of the wire clamps is matched with the number of the transmission wires; a plurality of through holes are evenly formed in the annular isolation ring, the two short connecting rods are arranged at the bottom of the annular isolation ring, the included angle of the two short connecting rods is alpha, the symmetry axis of the short connecting rods passes the circle center of the annular isolation ring, and the bottom ends of the short connecting rods are connected with the resonance-pendulum absorber which swings in a reciprocating manner around the center of a bundle conductor to absorb the vibration energy of the transmission wires so as to reduce the vibration of the transmission wires. The double-pendulum anti-galloping device has the advantages that the resonance-pendulum absorber and the parametric-resonance-pendulum absorber are combined to form the integral double-pendulum anti-galloping device, and horizontal vibration, vertical vibration and inclined vibration can be reduced at the same time.

Owner:NORTHEASTERN UNIV

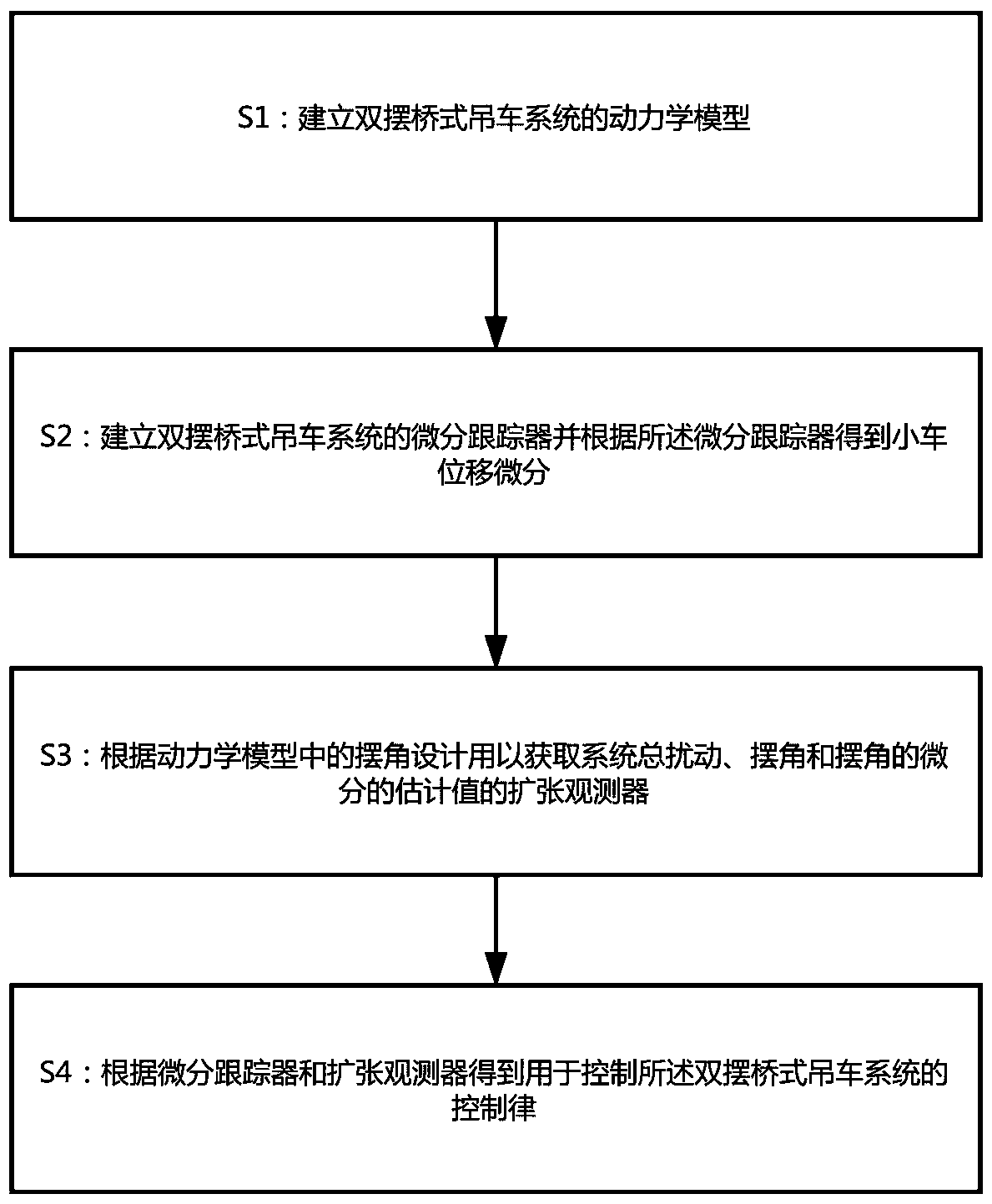

Underactuated bridge crane double-pendulum anti-swing control method based on active disturbance rejection technology

ActiveCN108545610AEnsure controlImprove reliabilityLoad-engaging elementsState observerDynamic models

The invention provides an underactuated bridge crane double-pendulum anti-swing control method based on the active disturbance rejection technology and belongs to the technical field of bridge crane anti-swing control. The underactuated bridge crane double-pendulum anti-swing control method comprises the following steps: S1, establishing a dynamics model; S2, establishing a differential tracker and obtaining the displacement differential of a trolley; S3, designing an extended state observer; and S4, obtaining a control law. With adoption of the method, the contradiction between the swing angle and the displacement is coordinated, the control performance of the double-pendulum bridge crane can still be ensured when the system model is not precise, has external disturbance and is nonlinear,the swing angle is reduced as soon as possible and the transportation task is finished, and the system reliability and efficiency are improved.

Owner:WUHAN UNIV OF SCI & TECH

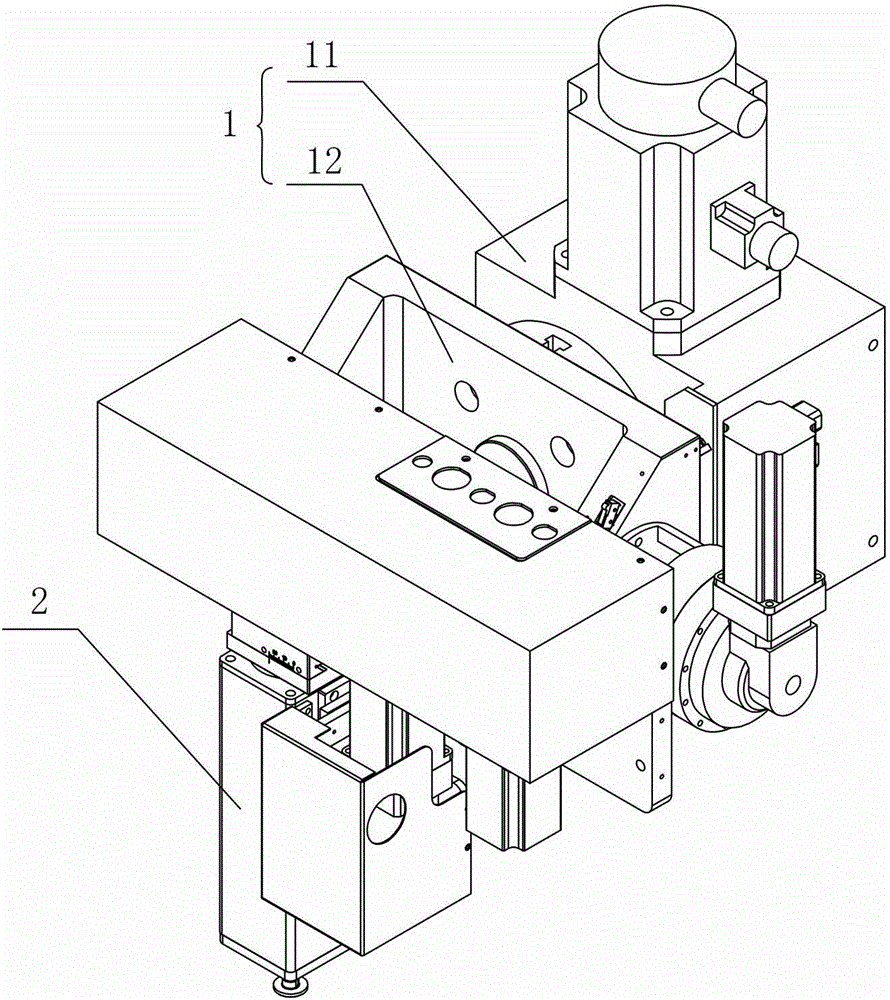

Polishing device with two swing shafts for high-gradient aspheric optical parts

InactiveCN103056744AImprove efficiencyGood precisionOptical surface grinding machinesEngineeringDouble pendulum

The invention discloses a polishing device with two swing shafts for high-gradient aspheric optical parts. The polishing device comprises a two-swing-shaft mechanism and a two-rotor polishing mechanism. The two-swing-shaft mechanism comprises a deflection component and a pitching component which is arranged at a deflection output end of the deflection component. The two-rotor polishing mechanism is arranged at a pitching output end of the pitching component. By means of the polishing device with two swing shafts for high-gradient aspheric optical parts, the Gaussian removal function which is constant in pressure and stable in removal performance can be provided at any time, and the efficiency is high and the accuracy is easy to achieve for processing of high-gradient aspheric optical parts.

Owner:NAT UNIV OF DEFENSE TECH

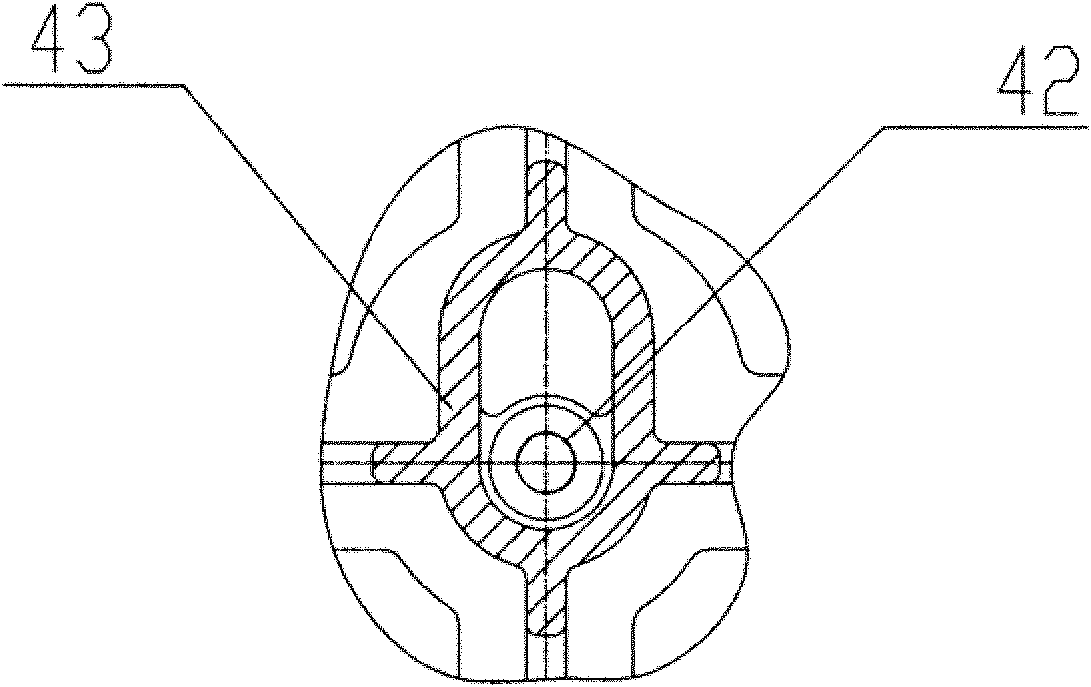

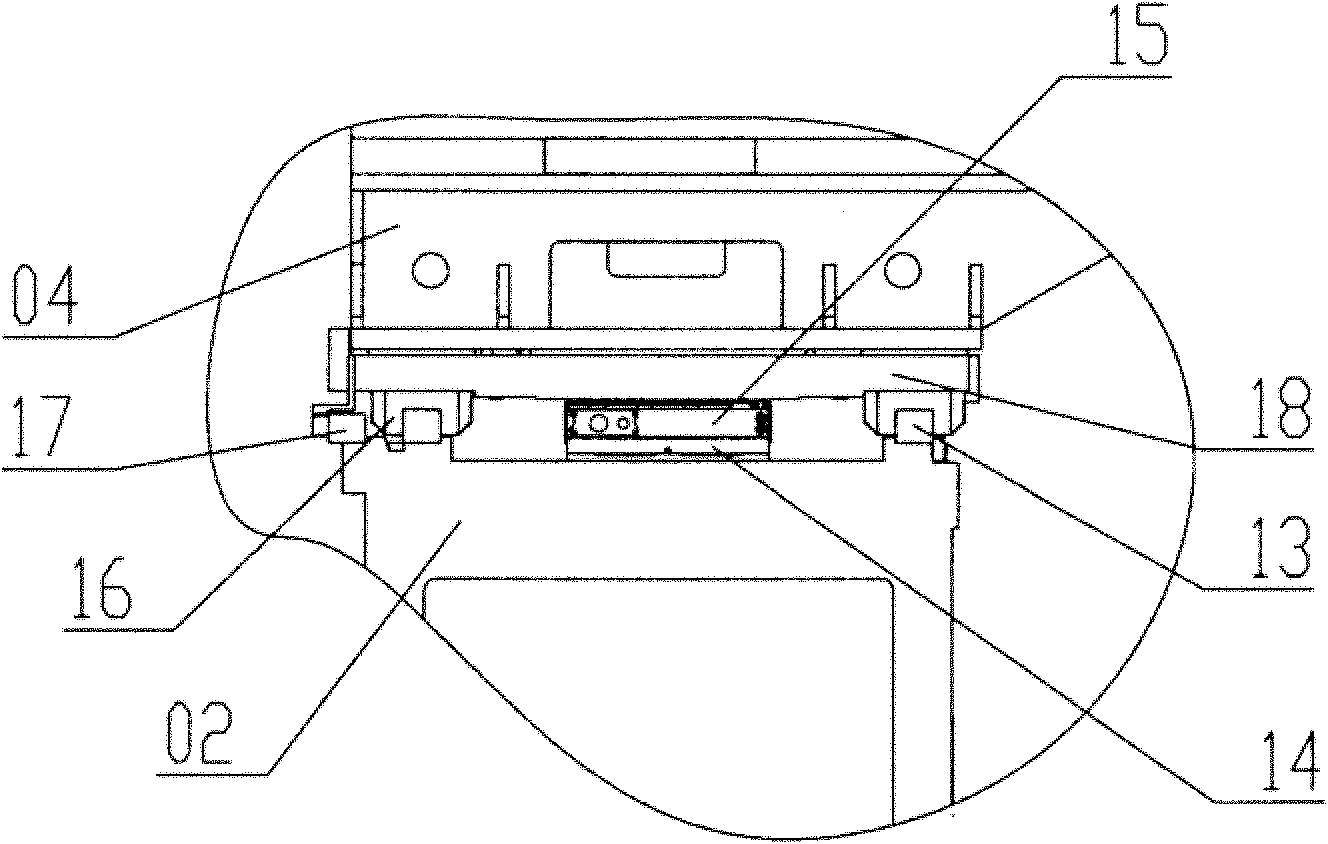

Accessory type double pendulum angle milling head driven by alternating-current permanent-magnet synchronous inner rotor torque motor

InactiveCN102091947AIncrease stiffnessLow costMachine tool componentsLarge fixed membersTorque motorEngineering

The invention discloses an accessory type double pendulum angle milling head driven by an alternating-current permanent-magnet synchronous inner rotor torque motor, and mainly solves the problems of low integral rigidity and complicated structure of the conventional double pendulum angle milling head. The accessory type double pendulum angle milling head is characterized in that: a forked frame (22) and a main shaft (24) respectively have an integral structure; the upper part of the forked frame (22) is provided with a motor seat (10); the top of the motor seat (10) is fixed with a connecting plate (8); and the upper part of the connecting plate (8) is fixed with a blind rivet (7) used for connecting a host, and the side face is provided with a positioning key (19). The double pendulum angle milling head has the characteristics of simple structure and high rigidity, and can be used as a host accessory.

Owner:通用技术齐齐哈尔二机床有限责任公司

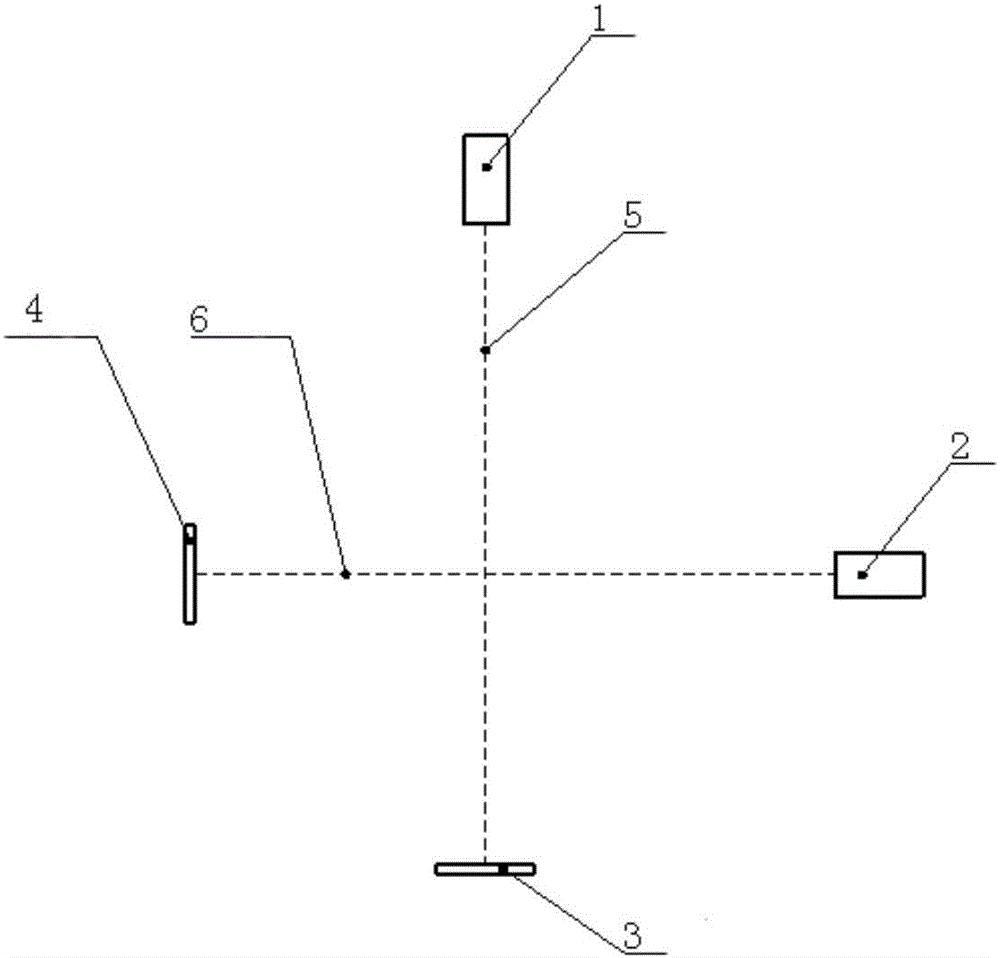

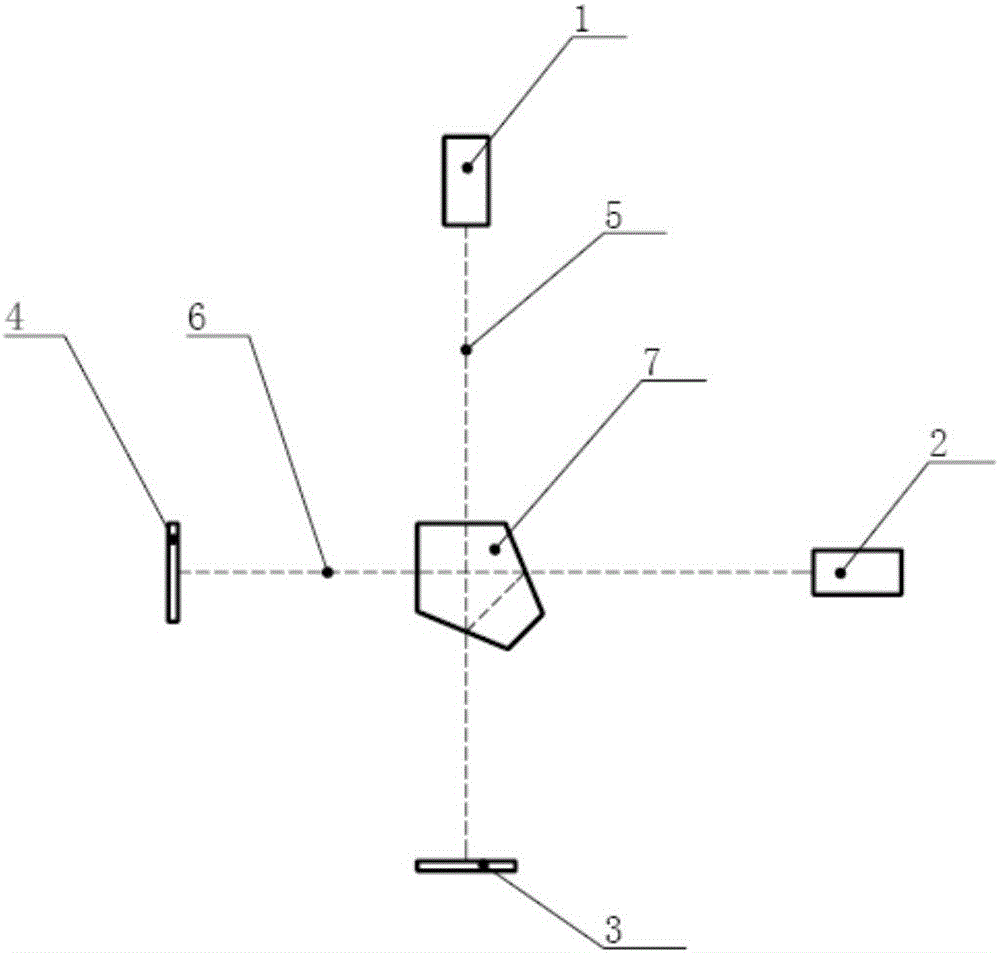

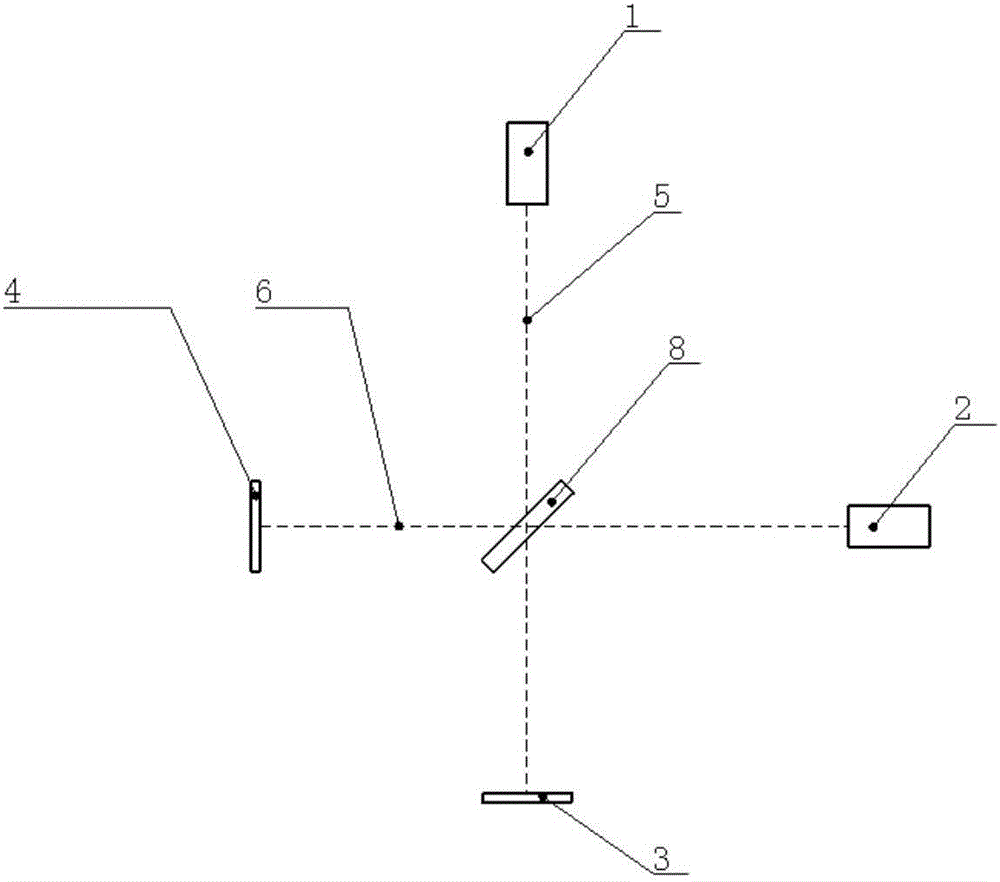

Orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing

ActiveCN106735961AEasy to implementHigh measurement accuracyLaser beam welding apparatusLaser processingClassical mechanics

The invention provides an orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing. The calibrating method comprises the steps that a pentaprism is arranged at the intersection of the rotation axes of two pendulum shafts, and after the rotation axis of one of the pendulum shafts is reflexed by 90 degrees through the pentaprism, the actual included angle between the rotation axes of the two orthogonal pendulum shafts can be calibrated through an autocollimator arranged on the rotation axis of the other pendulum shaft. According to the orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing, special optical equipment do not need to be adopted when the actual included angle between the laser processing orthogonal double-pendulum shafts is calibrated, and the calibrating method is simple.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

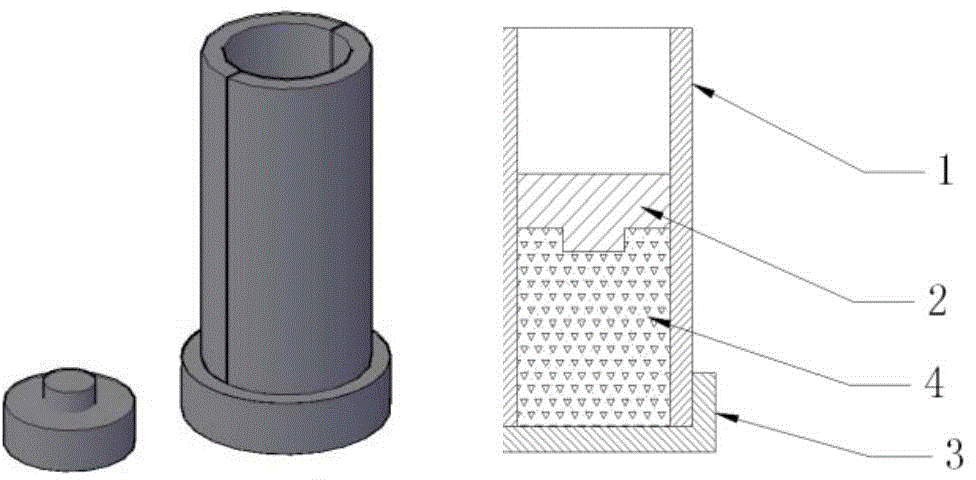

Device and method for testing power capability of composite explosives

InactiveCN104359607AHigh inert componentsAccurate measurementMaterial exposibilityMeasurement of explosion forceDetonatorTest power

The invention discloses a device and method for testing the power capability of composite explosives. The device for testing the power capability of the composite explosives is composed of winches, supports, support supporting rods, bearing bases, rotary shafts, swing arms, pendulum bobs, pendulum bob protruding teeth, a one-way limiter and angulometers. Before a test, explosive samples to be tested are prepared through special pressing molds, the samples to be tested are placed in inner cavities of the pendulum bobs and detonated through detonators, after detonation, the two pendulum bobs swing circumferentially around the rotary shafts under the limitation of the swing arms, the pendulum bobs are controlled by the one-way limiter and the pendulum bob protruding teeth to swing to the highest point and then stay still, the angulometers are used for measuring the swing angles of the pendulum bobs, and the power capability of the composite explosives after detonation is calculated and measured through the swing angles of the two pendulum bobs. According to the device and method, the improvement is made on the basis of a traditional ballistic trajectory mortar method, the conversion efficiency for converting chemical energy into mechanical energy of detonation can be improved through the two-pendulum-bob structure, and therefore the test result and the quantitative expression of the power capability of the composite explosives are more accurate.

Owner:XIAN MODERN CHEM RES INST

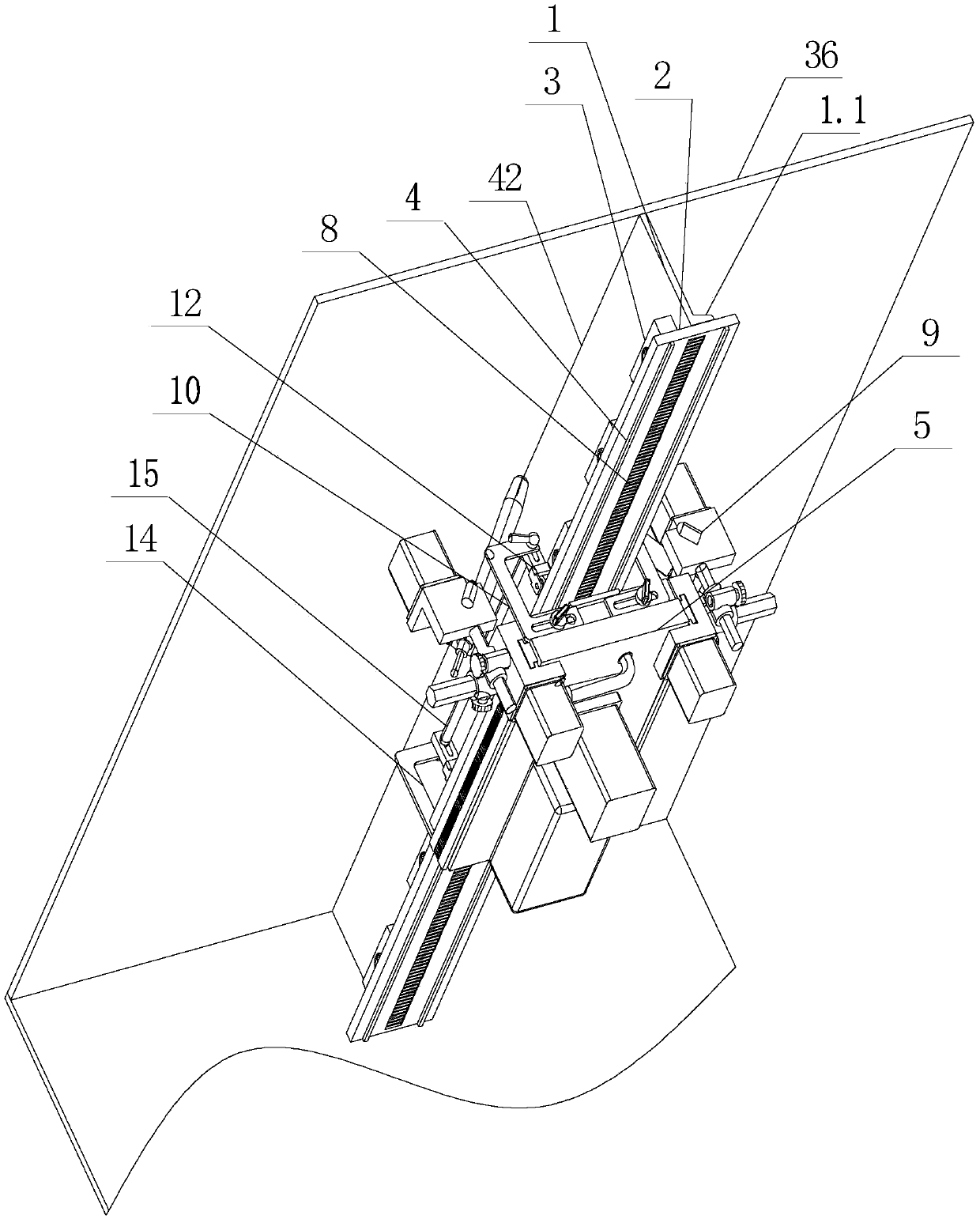

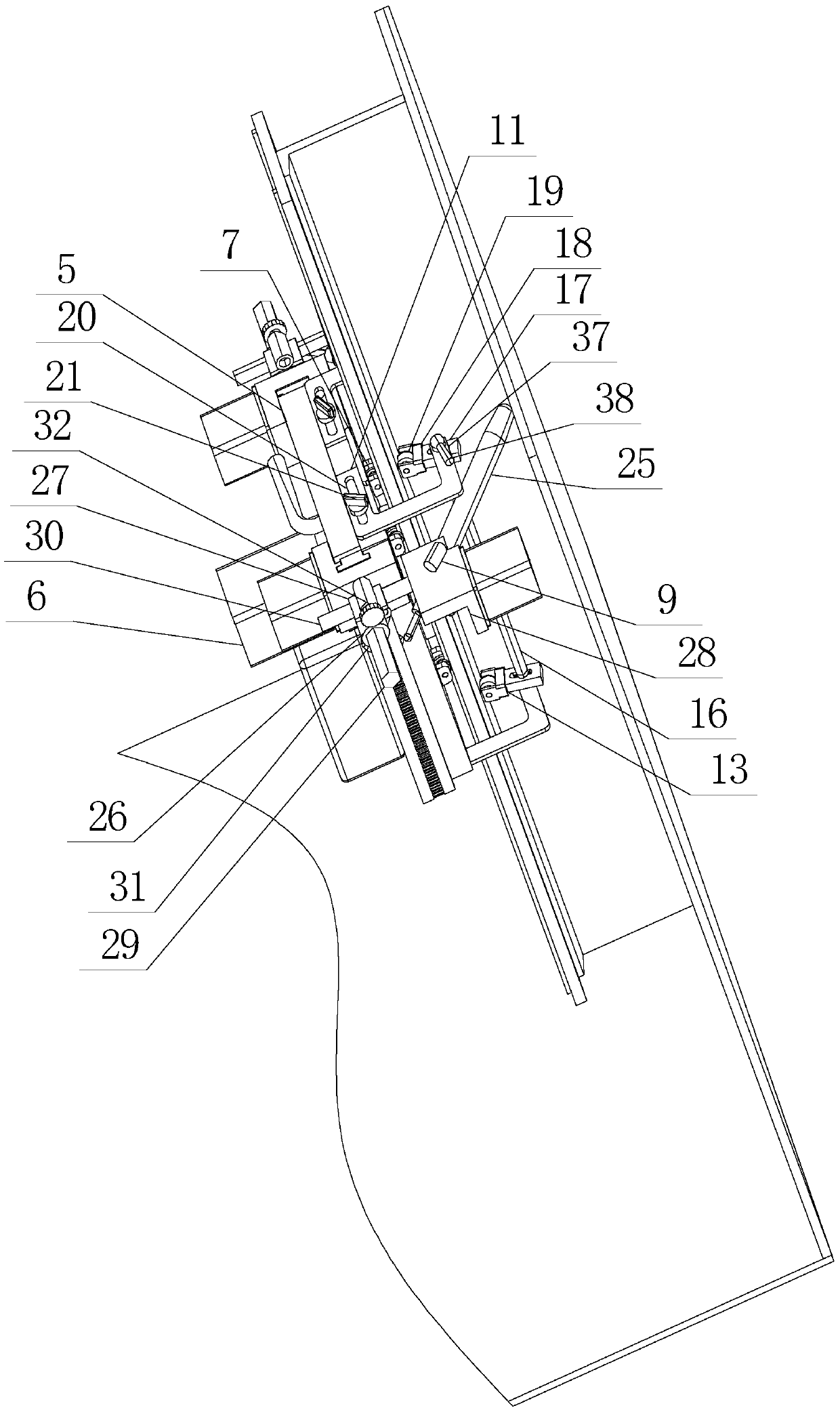

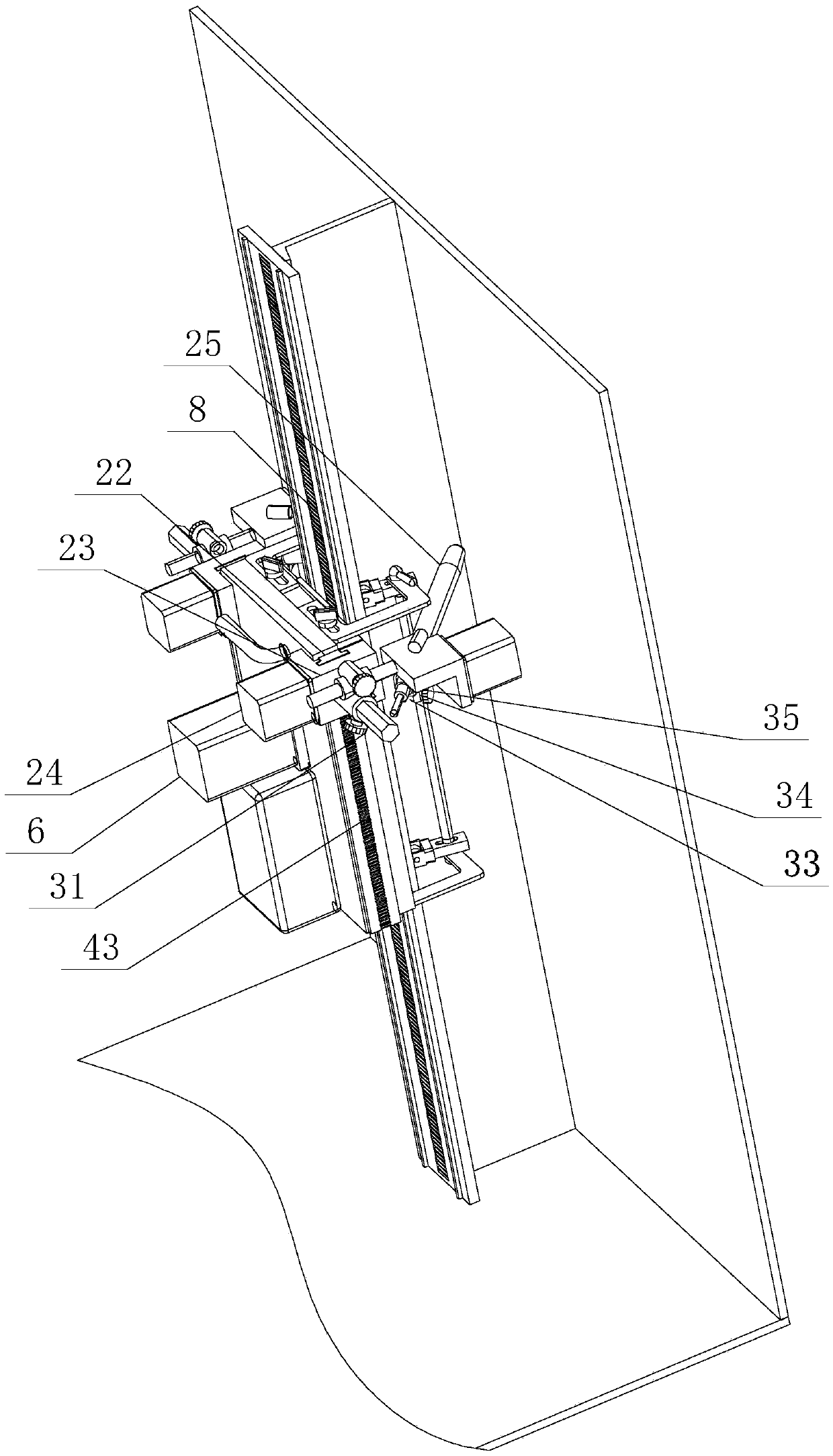

Double-sided double-pendulum blind-zone-free welding tractor and welding method thereof

InactiveCN105499861AEasy to fixSolve the deformationWelding/cutting auxillary devicesAuxillary welding devicesBlind zoneWeld seam

The invention discloses a double-sided double-pendulum blind-zone-free welding tractor. The double-sided double-pendulum blind-zone-free welding tractor comprises a rail climbing device, a welding device, a monitoring device used for monitoring and regulating welding parameters in real time and a linear rail arranged on flat-bulb steel (1), wherein the welding device and the monitoring device are mounted on the rail climbing device. The invention discloses a method for welding T-shaped vertical angle welding seams. The double-sided double-pendulum blind-zone-free welding tractor and the welding method thereof are high in welding efficiency and high in quality of welding seams.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

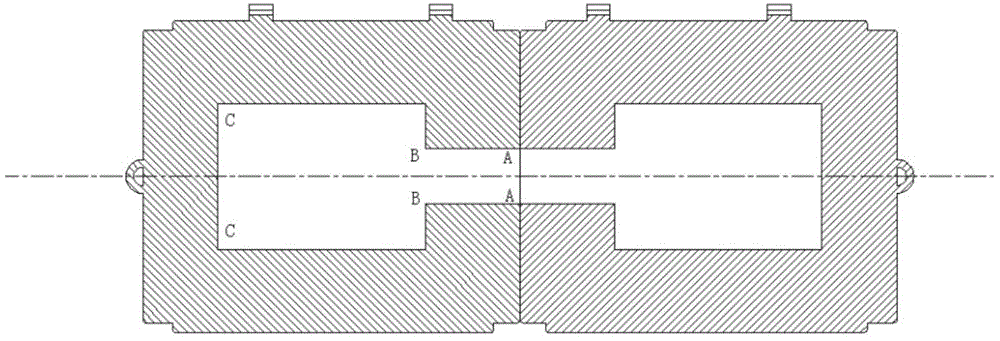

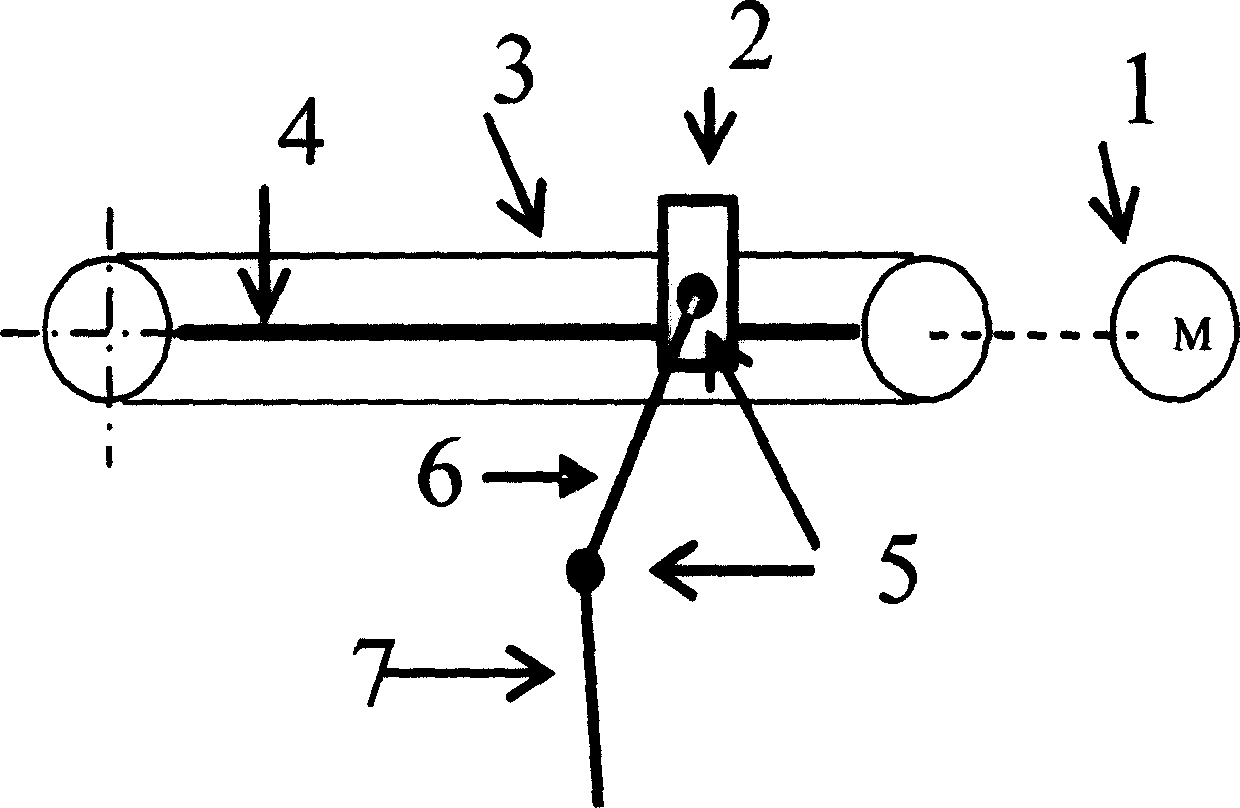

Simulation test device for thrust force of large-thrust-force double-pendulum engine

The invention relates to a simulation test device for a thrust force of a large-thrust-force double-pendulum engine, and particularly to a test device which can truly simulate the thrust force of the double-pendulum engine in flight of a rocket, wherein the large thrust force is not less than 70T. The simulation test device comprises the components of two force bearing ears, an engine frame, a base, a swinging cross shaft, a gimbal mount, two wire ropes, a connecting block, a first pin, a first joint bolt, an adjusting pull rod, a second joint bolt, a second pin, a third pin, a lever and a loading hydraulic cylinder. Two ends of each wire rope is threaded. According to the simulation test device, connection between the engine body and the loading connecting block is realized through the wire ropes which are provided with threads; and deformation of the wire rope is used for resisting an effect caused by threaded connection at two ends of each wire rope in the bidirectional swinging process of the engine. According to the simulation test device, a lever mechanism is used for realizing thrust force loading, and loading of a 70T thrust force is realized by means of a relatively small hydraulic force. A simple and reliable structure is realized.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Double-pendulum crane sliding mode control method based on load swing state observation

ActiveCN112327623ASolving Measurement ChallengesRealize positioning and anti-swing feedback controlLoad-engaging elementsAdaptive controlState observerClassical mechanics

The invention discloses a double-pendulum crane sliding mode control method based on load swing state observation. The method is characterized by comprising the following steps of: deducing a couplingrelationship between lifting hook swing and load swing according to a kinetic model of a double-pendulum type crane, and then utilizing limited model information and the coupling relationship betweenthe load swing and the lifting hook swing to design a linear extended state observer (LESO) to observe the load swing, thus achieving high precision observation on the load swing under the conditionthat the distance between a lifting hook and the gravity center of the load is unknown. The effect of replacing a load swing sensor is achieved, the measurement problem of the load swing is solved, and the load swing observation value is fed back to a sliding mode controller, a double-pendulum crane anti-swing positioning controller is obtained, and positioning anti-swing feedback control of the double-pendulum crane is achieved under the condition that load swing is not directly measured.

Owner:CENT SOUTH UNIV

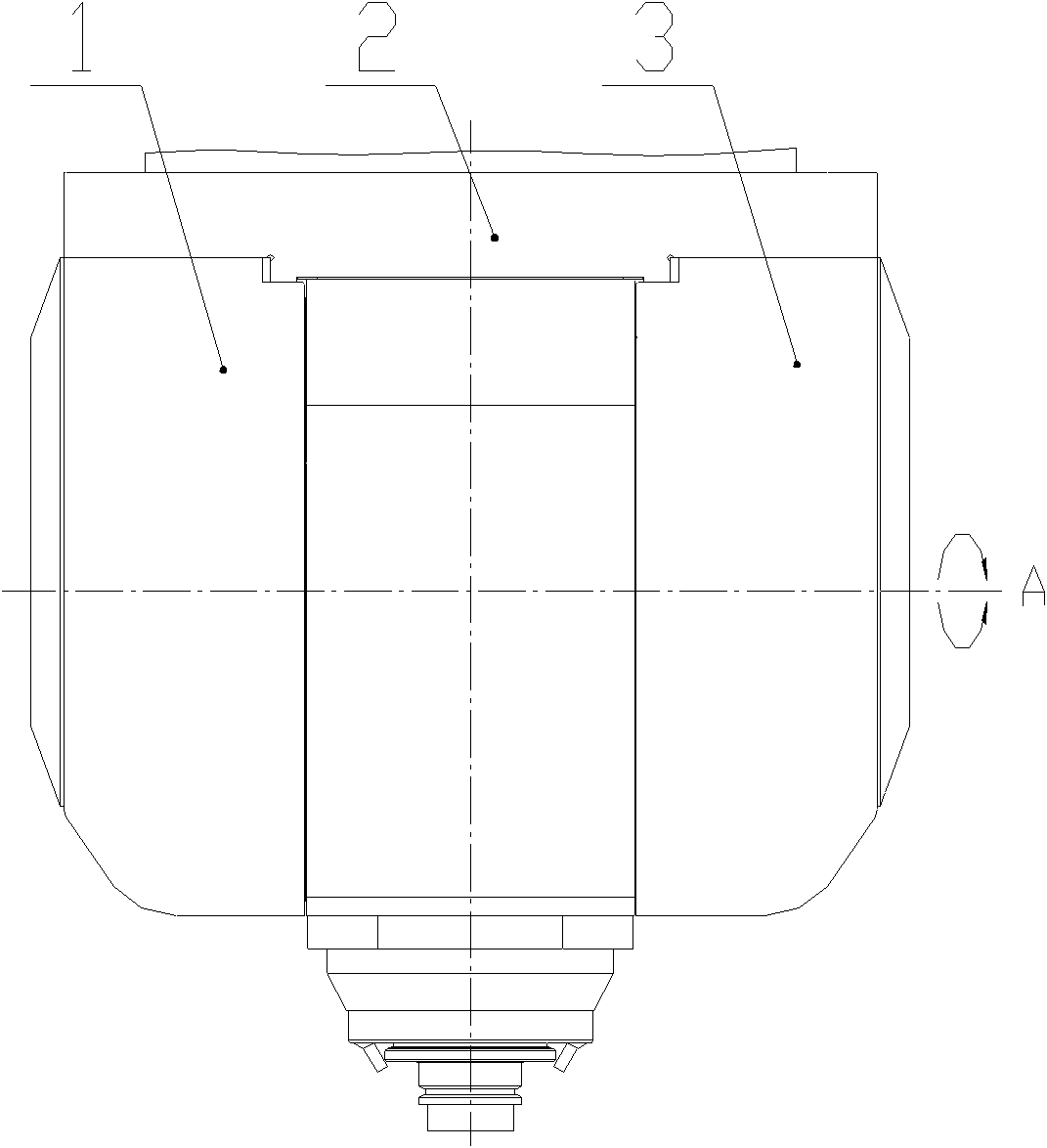

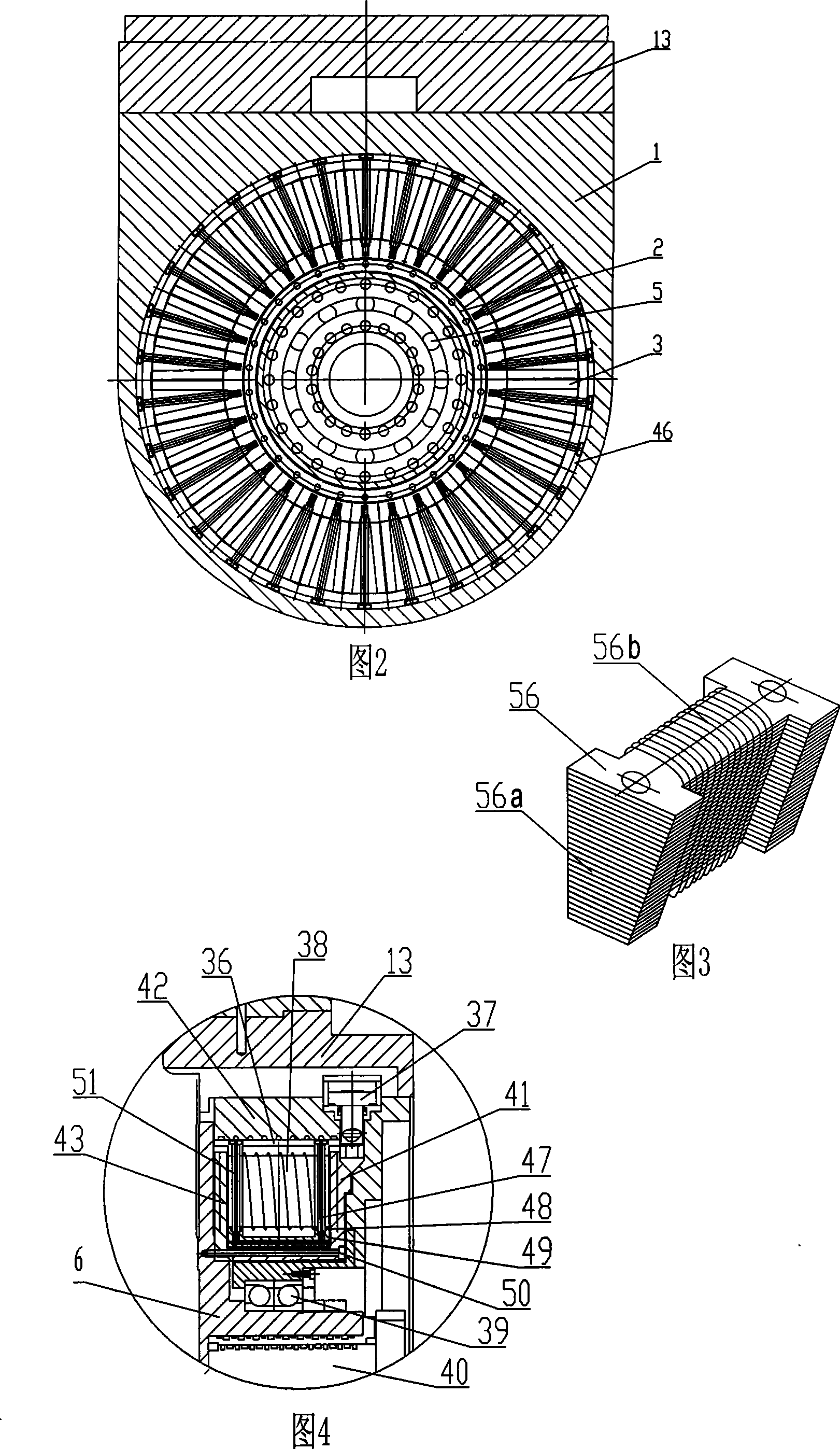

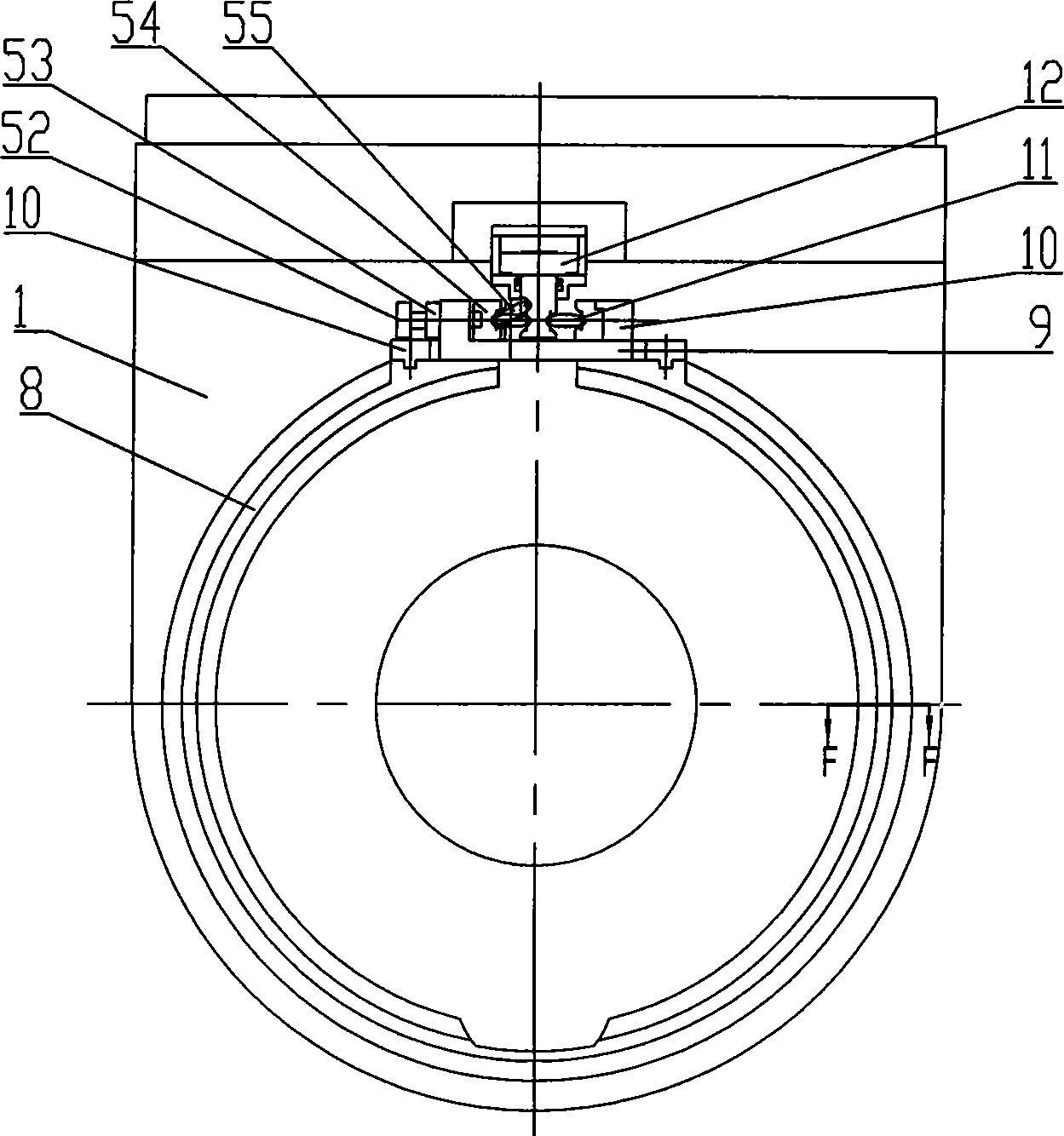

AC permanent magnet disc type torque motor drived large-torque double-pendulum milling head

InactiveCN101428395ALarge core areaIncrease the areaMagnetic circuit rotating partsMachine tool componentsTorque motorMoment of inertia

The invention relates to a large torque double-pendulum milling head driven by an AC permanent magnet disc type torque motor, which belongs to the combination mechanism for achieving the five-axis linkage processing on the machining center. The double-pendulum milling head mainly comprises a C axis part and an A axis part. The double-pendulum milling head is characterized in that the C axis part adopts the technical scheme that a rotary sleeve is rotated through driving of a double-linkage disc type torque motor, the rotary sleeve drives the A axis part to rotate together through a connecting disc and a connecting cover, and the C axis part also adopts a clamping bag type clamping mechanism; the A axis part adopts the technical scheme that a main shaft bracket with a main shaft to rotate together through driving of two disc-type torque motors mounted on the main shaft bracket, and the A axis part also adopts a rhombic block type clamping mechanism. The large torque double-pendulum milling head has the advantages that the iron core area of the disc-type torque motor is large, and the output power is great, the utilization rate of the magnetic field is high, and the efficiency of the motor is high; the double-pendulum milling head is provided with a cooling channel, and the radiating condition is good; the axial size is small, the rotary inertia of the rotor is small, the reaction rate is high, and the dynamic performance is good; and the operation of the clamping mechanism adopted is reliable and safe.

Owner:DALIAN UNIV OF TECH

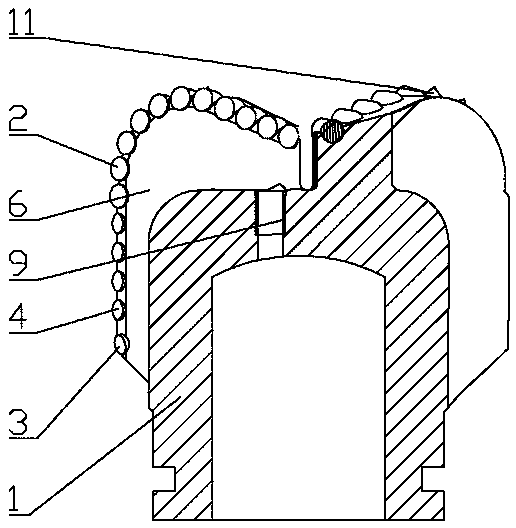

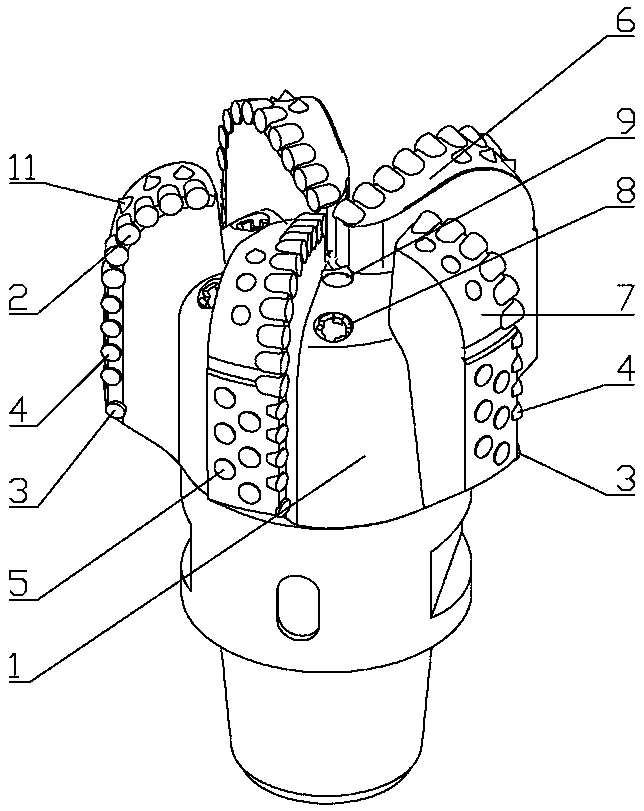

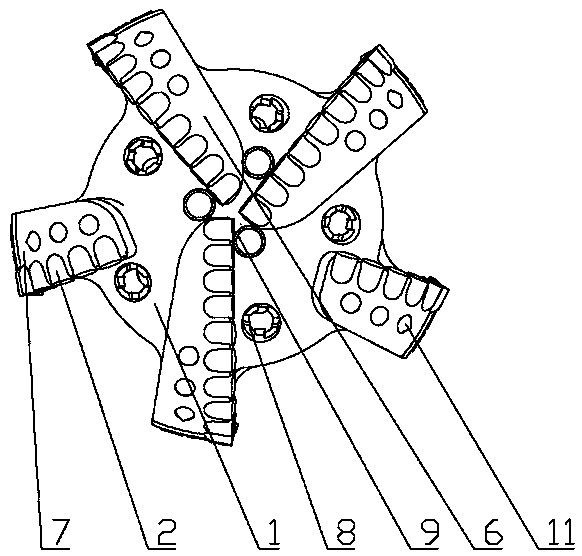

PDC drill bit suitable for double-pendulum speed-increasing drilling tool

PendingCN108952582AImprove rock breaking efficiencyReduce wearDrill bitsConstructionsDouble pendulumDrill bit

The invention relates to the technical field of PDC drill bits, in particular to a PDC drill bit suitable for a double-pendulum speed-increasing drilling tool. The PDC drill bit comprises a drill bitbody, cutting blades, main cutting teeth, reversed hole teeth, edge teeth, gauge teeth and rock breaking tine teeth; the cutting blades are circumferentially distributed at intervals around the drillbit body, the gauge teeth are distributed on the outer side faces of gauge parts of the cutting blades, the rock breaking tine teeth are distributed on the outer side faces of the noses of the cuttingblades, and the tooth tops of the rock breaking tine teeth are higher than those of the main cutting teeth. The PDC drill bit suitable for the double-pendulum speed-increasing drilling tool has the advantages that the rock breaking tine teeth are arranged to pre-break a stratum during drilling and release formation stress, thereby improving the rock breaking efficiency of the main cutting teeth and protecting the main cutting teeth to reduce abrasion; the PDC drill bit is suitable for the double-pendulum speed-increasing drilling tool, so that the combination of the PDC drill bit and the double-pendulum speed-increasing drilling tool can improve the entire drilling speed, stability is kept in a vertical well section, the wellbore quality is good, the drill bit is not stuck easily, the inhibition effect of the drilling tool on drill bit eddy can be also improved, and the purpose of assisting in speed increasing is achieved.

Owner:XINJIANG BEIKEN ENERGY ENG

Converter dry method dust-removing explosion-venting control method

ActiveCN104962680AReduce the number of explosion ventsAvoid damageManufacturing convertersAutomatic controlEngineering

The present invention discloses a converter dry method dust-removing explosion-venting control method, and belongs to the technical field of converter dry method dust-removing. In the prior art, the explosion-venting measures have problems of manual control, interference by human factors, low automation degree, and no comprehension. In order to solve the problems in the prior art, the present invention provides a converter dry method dust-removing explosion-venting control method, which comprises an explosion-venting automatic control method and an auxiliary operation method, wherein the explosion-venting automatic control method comprises that the explosion-venting automatic control system arranged in the converter automatic control system performs the explosion-venting control measure during the converter opening blowing process and the explosion-venting control measure during the converter blowing smelting process through fan rotation speed control, converter flue cover lifting control, inert gas blowing-in setting, oxygen gun flow rate program setting, feeding frequency and feeding quantity control, electrostatic dust remover double pendulum valve setting, and electrostatic dust remover oxygen content monitoring. The method of the present invention is used for the explosion-venting control in the converter dry method dust-removing process.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

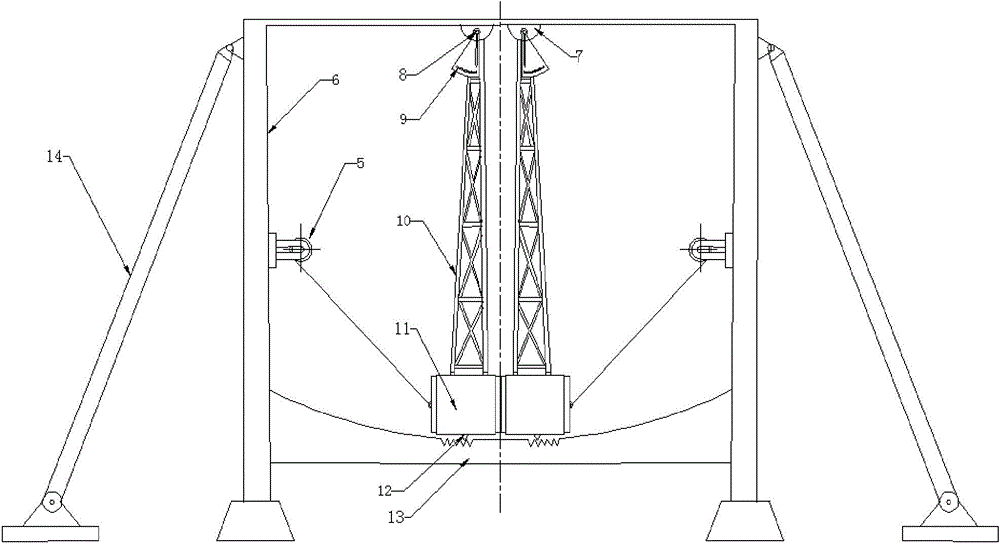

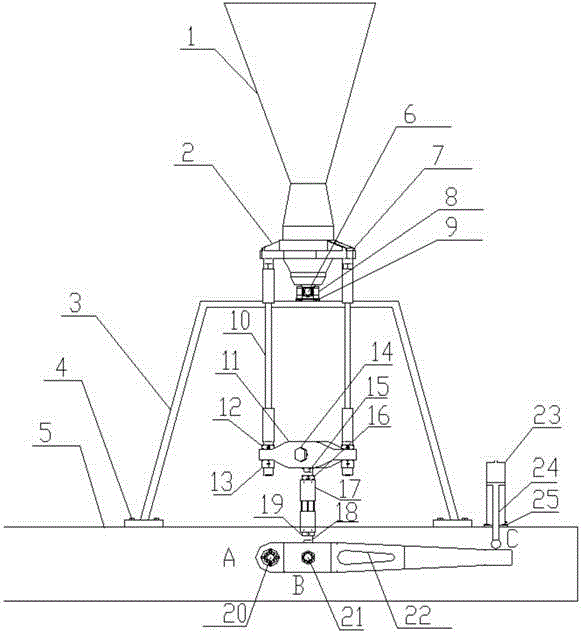

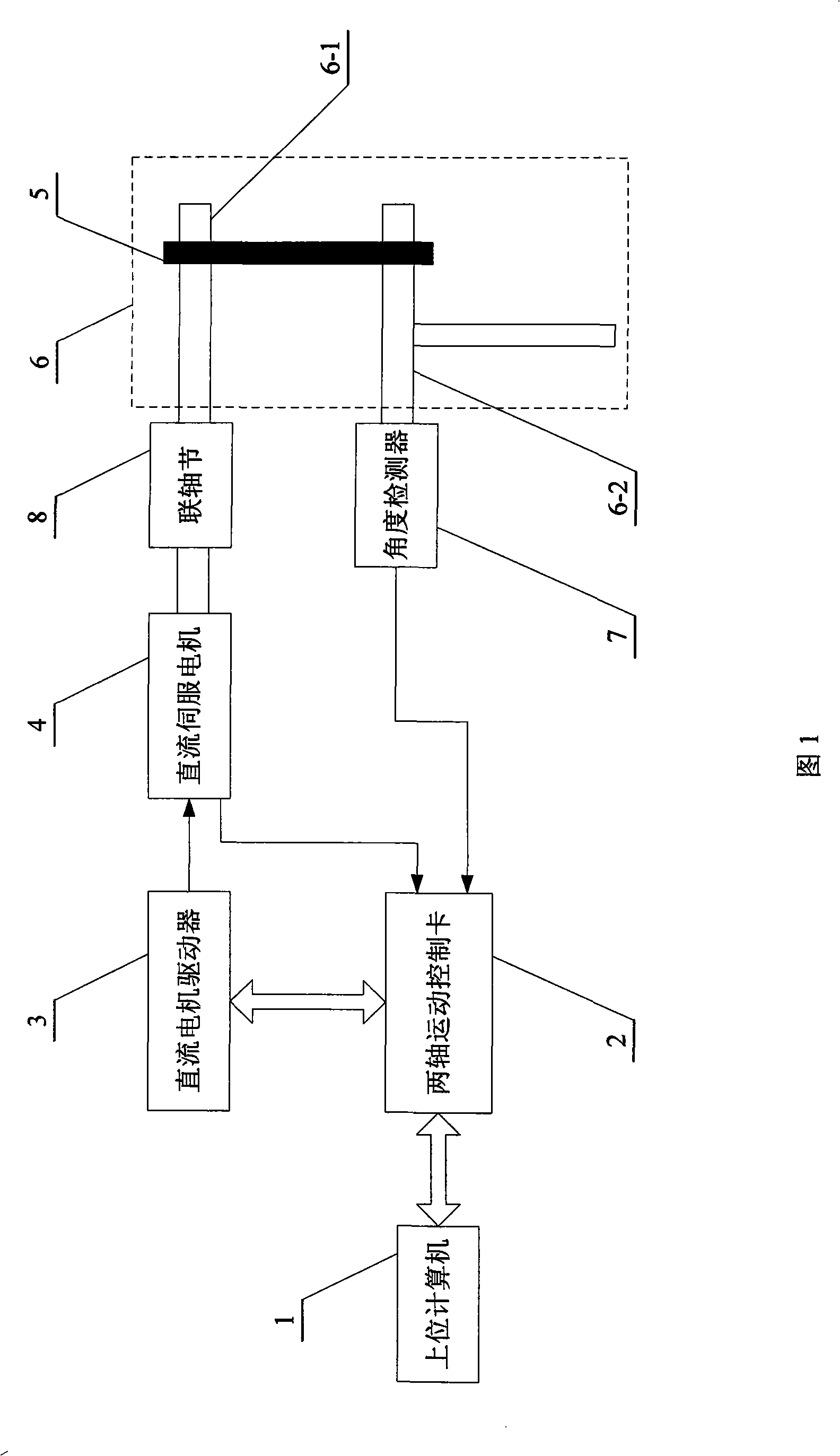

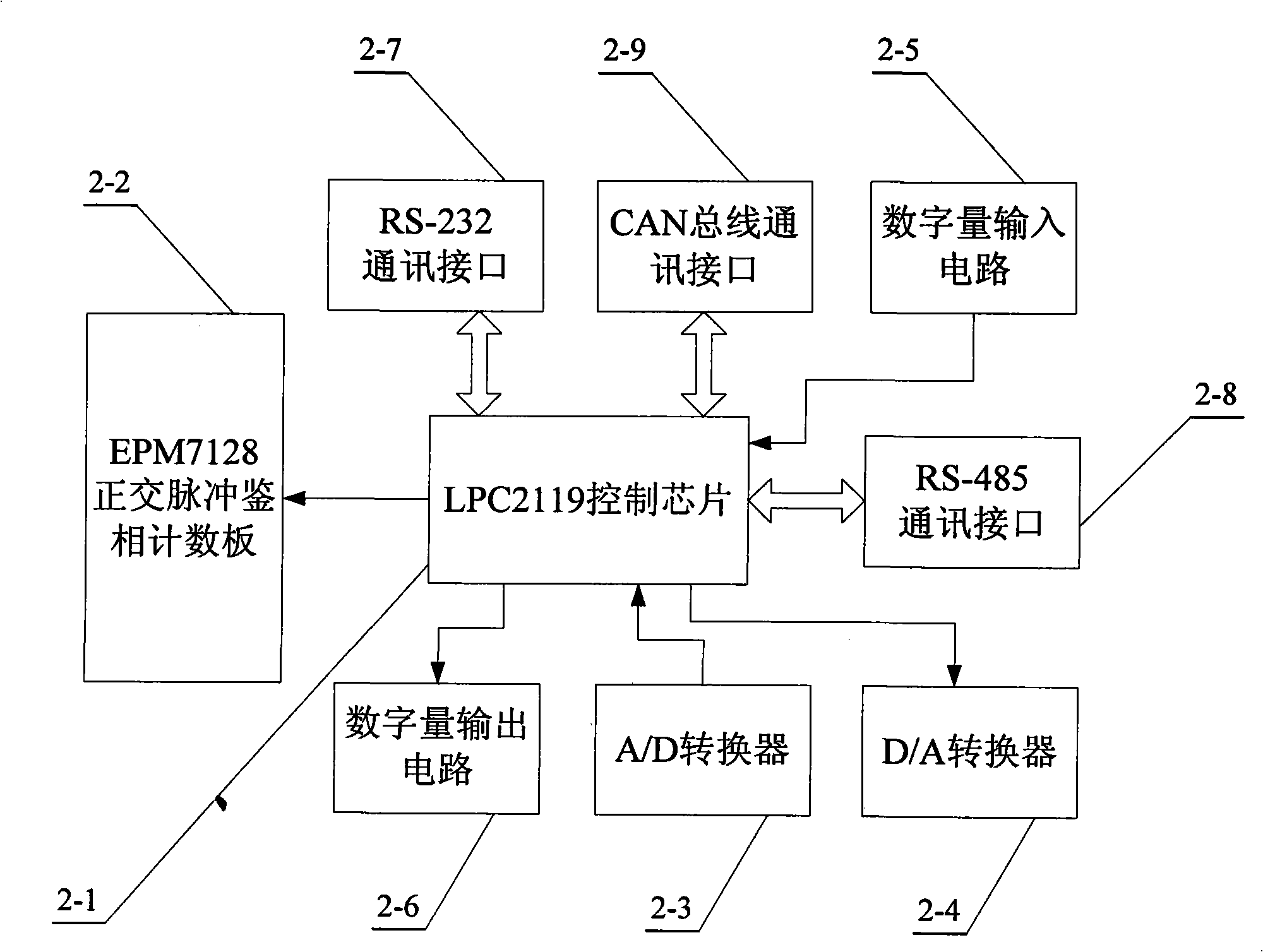

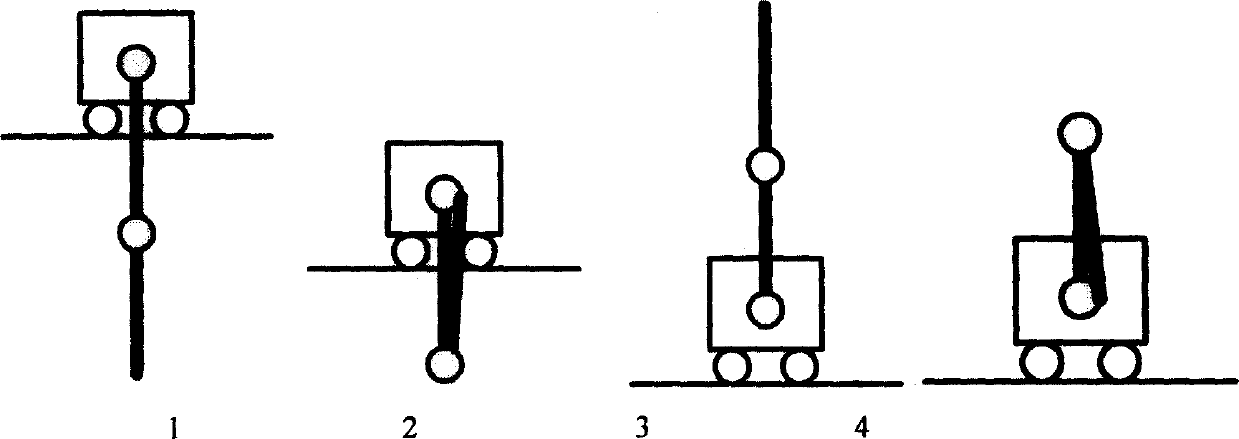

Control experimental device for under-actuated suspension swing motion

InactiveCN101261784AImprove performanceHigh precisionEducational modelsLinear control theoryCoupling

An under-actuated pendulum control experimental apparatus relates to an under-actuated control experimental apparatus applying to academic researches for control theory and control engineering discipline and electron and transmission discipline, is used for solving the problems that experimental apparatus, which is used for the academic researches of non-linear control theory in higher education institutions and scientific institutions, still stays at numerical simulation level, appropriate material system is absent and the theory is disconnected with the practice. The upper I / O terminal and drive I / O terminal on a two-shaft motion control card are respectively connected with the I / O terminal of an upper computer and the I / O terminal of a DC motor driver. The control output terminal of the DC motor driver is connected with the control input terminal of a DC servo motor. The signal output terminals of the DC servo motor and an angle detector is connected with the signal input terminal of the two-shaft motion control card. The output shaft of the DC servo motor is connected with the input shaft of an under-actuated pendulum system by a shaft coupling. The input drive torque of the input shaft of the under-actuated pendulum system is delivered to a double-pendulum output shaft through a synchronous drive system.

Owner:HARBIN INST OF TECH

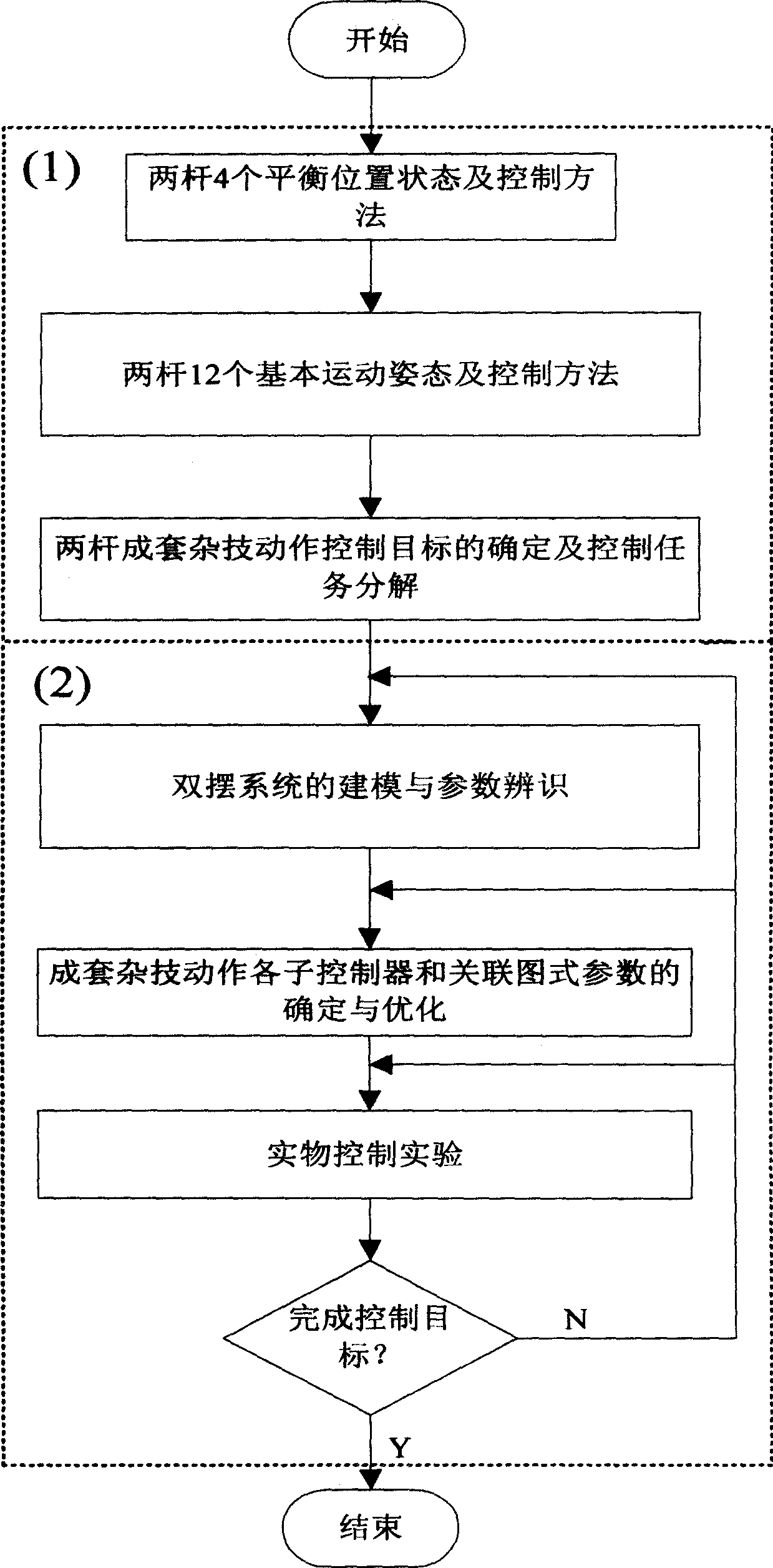

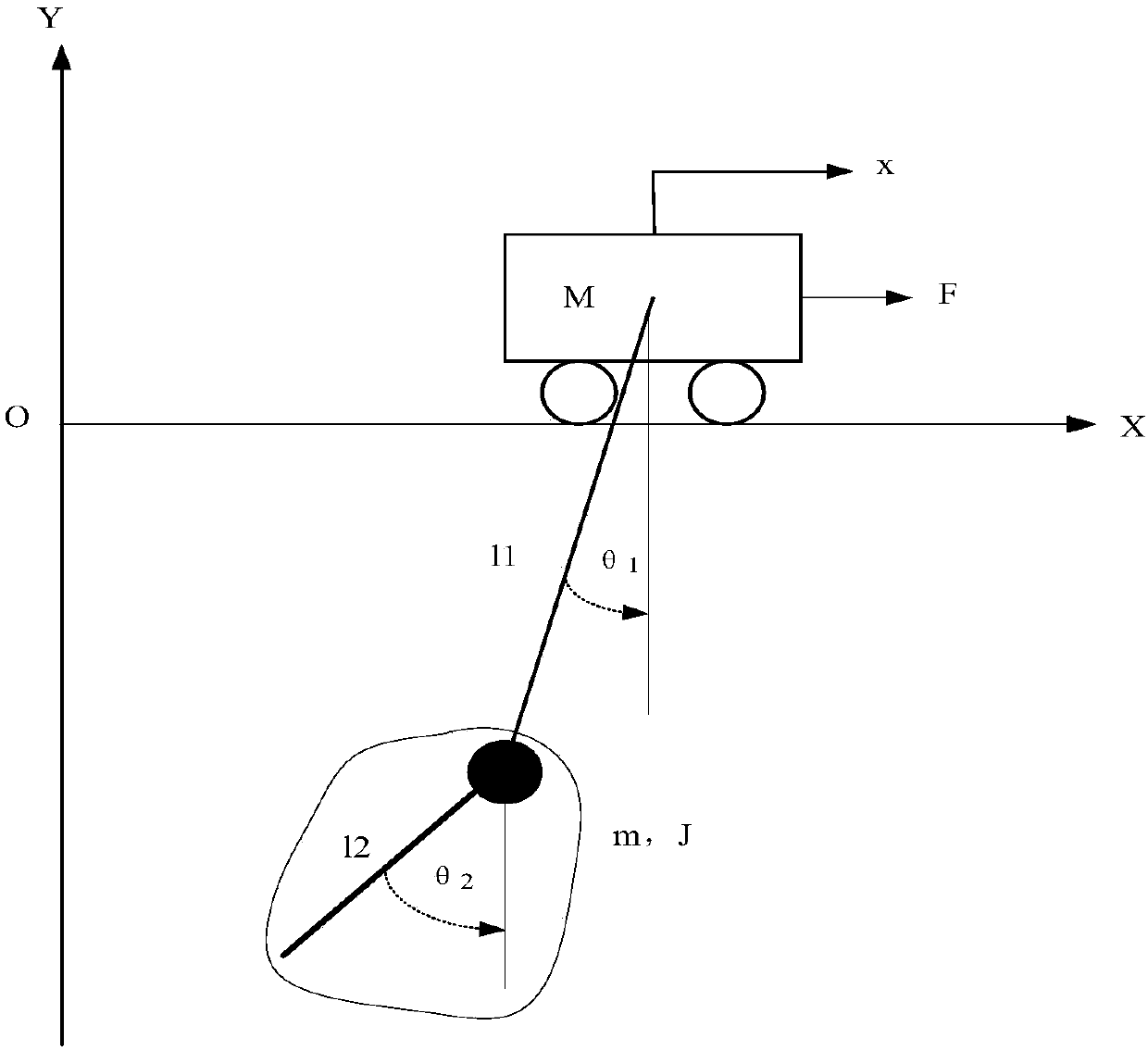

Control method for acrobatic motion of pendulums of under-actuated double pendulum system

InactiveCN1885217AEasy to controlFacilitates nonlinear large-range motion controlElectric programme controlAdaptive controlComputer control systemControl signal

The invention relates to a method for controlling the swing stem acrobatic operation of passive driving dual-swing system, wherein the invention uses passive driving dual-swing system, based on the operation character of acrobatic actor, simulates the motion intelligence of human body; uses the motion inertia of swing rod to stepped control the acrobatic motion formed by balance position and motion altitude of dual swing rods; the total controller is formed by connected sub controllers relative to each step control target; the total controller is programmed into program control code with real-time operation, to be input into relative computer control system, and the output control signal via servo motor driver is amplified, to control the motion of servo motor, to drive the small car to drive two swing rods, to complete variable acrobatic motions.

Owner:CHONGQING UNIV

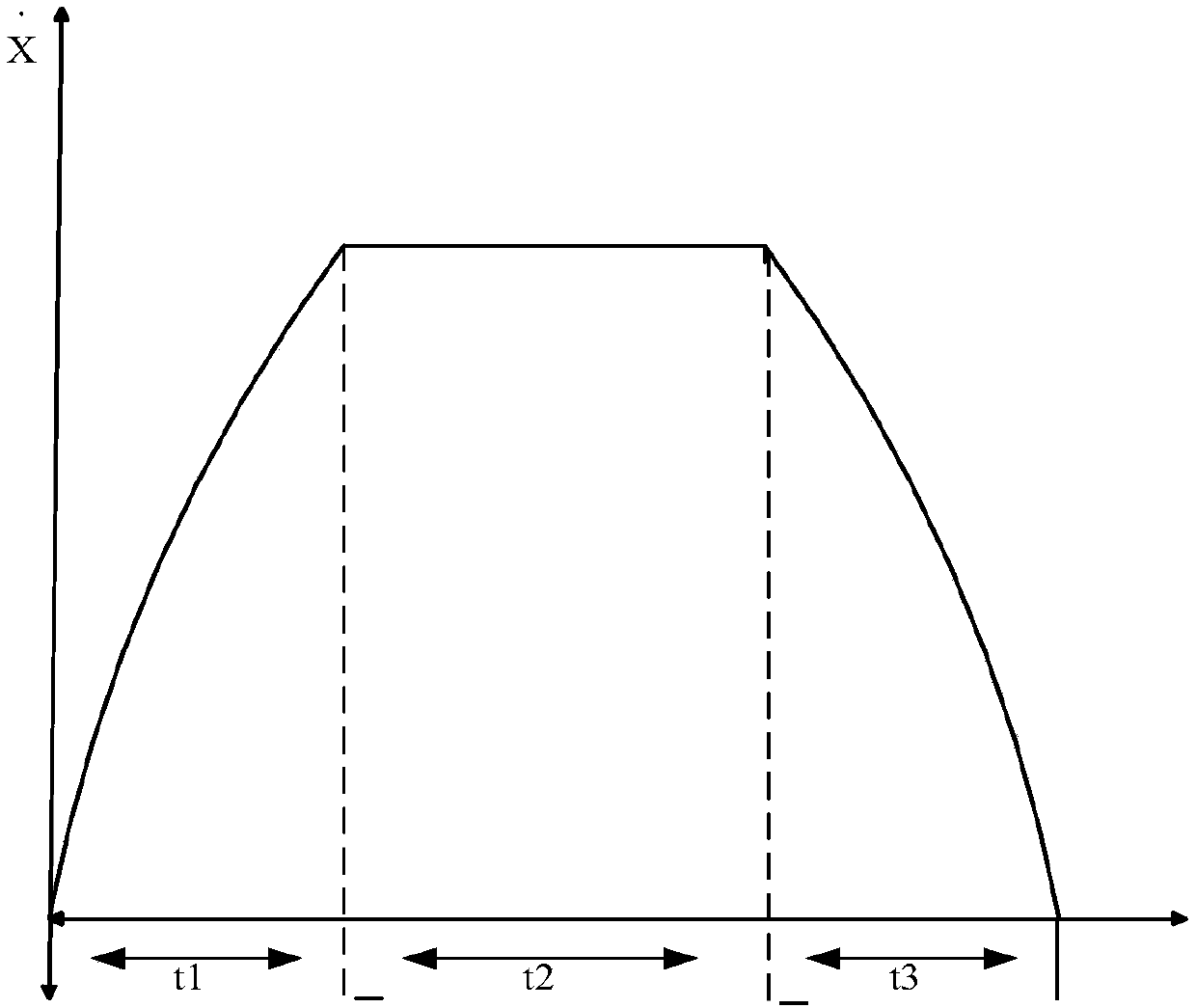

Speed trajectory planning anti-swing method of double-pendulum bridge crane

ActiveCN107826978AImprove transportation efficiencyGuaranteed operational safetyLoad-engaging elementsEngineeringTrajectory planning

The invention discloses a speed trajectory planning anti-swing method of a double-pendulum bridge crane; when a crane load is in an irregular shape (distributive mass), a crane model needs to be seenas a double-pendulum crane; and the double-pendulum crane model is nearer actual life. The main thought of the method is to build a double-pendulum crane linear model for combining with a set speed trajectory planning equation; time-optimal acceleration and deceleration time parameters are obtained by using boundary conditions; then, the car tracking speed trajectory operation is controlled to achieve swing elimination of the double-pendulum bridge crane under the condition of no sensor feedback; when the load is operated in an appointed position, and when swing of the load is zero, the time is optimal. The method considers inhibition of first-grade and second-grade swing angles at the same time, but the control method is simple and easy to realize, can greatly improve the working efficiency of the crane, can effectively prevent accidents caused by swing of goods, and achieves wide application value on future transportation industry.

Owner:南京黎创智能装备有限公司

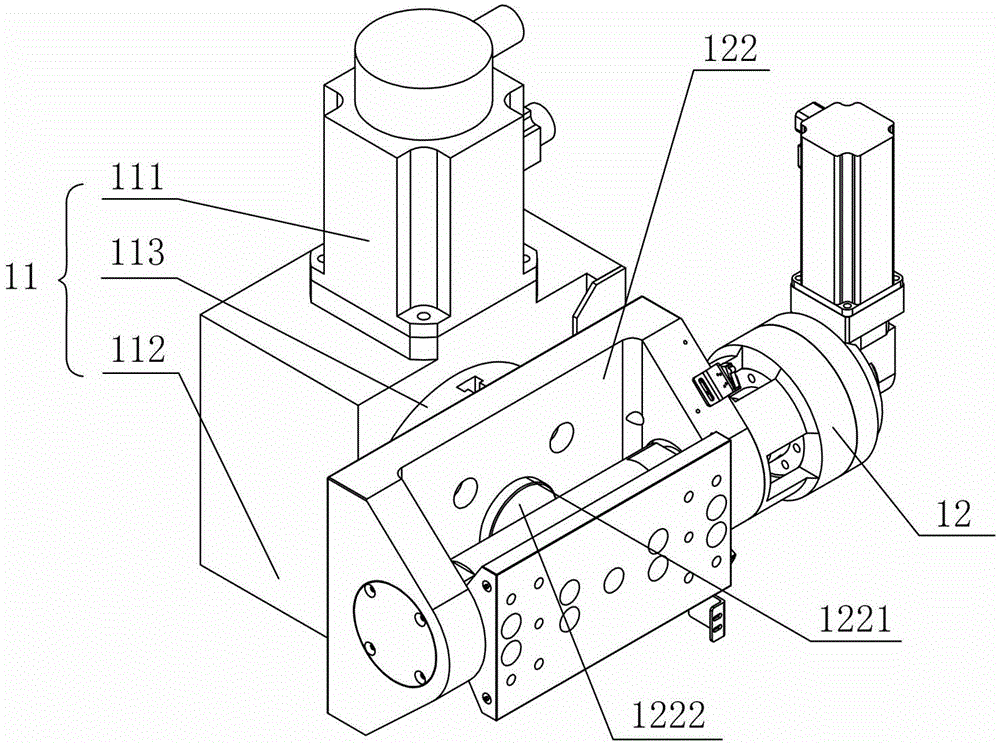

A/C axis double pendulum milling head driven by inner rotor torque motor

PendingCN109513976AReduce the transmission linkSimple transmissionMilling equipment detailsDriving apparatusTorque motorDouble pendulum

The invention discloses an A / C axis double pendulum milling head driven by a inner rotor torque motor. The A / C axis double pendulum milling head comprises an upper unit, a lower unit, and an AC connecting plate, wherein the upper unit comprises a C axis, first inner rotor torque motors and first transmission connecting pieces, and the lower unit comprises a box body, an A axis located in the box body, a second inner rotor torque motor and a second transmission connecting piece. The AC connecting plate is arranged between the upper unit and the lower unit, the first transmission connecting pieces are fixedly connected with the upper end of the AC connecting plate, and the lower end of the AC connecting plate is fixedly connected with the box body. The central line of the C axis is arrangedin up-down direction, the first inner rotor torque motors drives the C axis and the AC connecting plate to rotate through the first transmission connecting pieces, the second inner rotor torque motordrives the A axis to swing through the second transmission connecting piece, and the swing plane of the A axis is parallel to the center line of the C axis. According to the A / C axis double pendulum milling head, the A axis and the C axis are driven by the inner rotor torque motor, the transmission links are few, the transmission mode and the layout are simple, the transmission is stable, the precision is high, the heat dissipation is good, and the torque is large.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

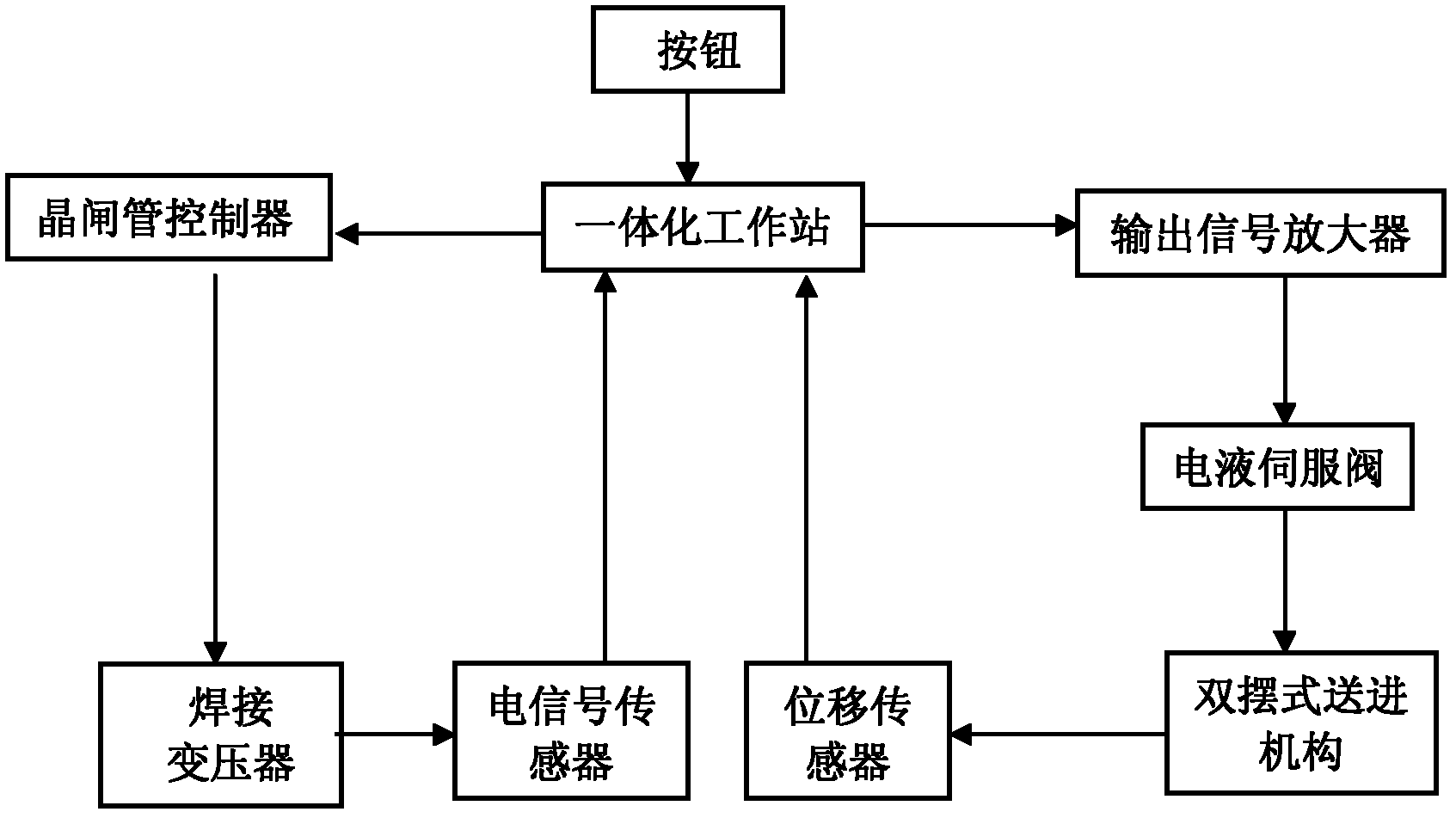

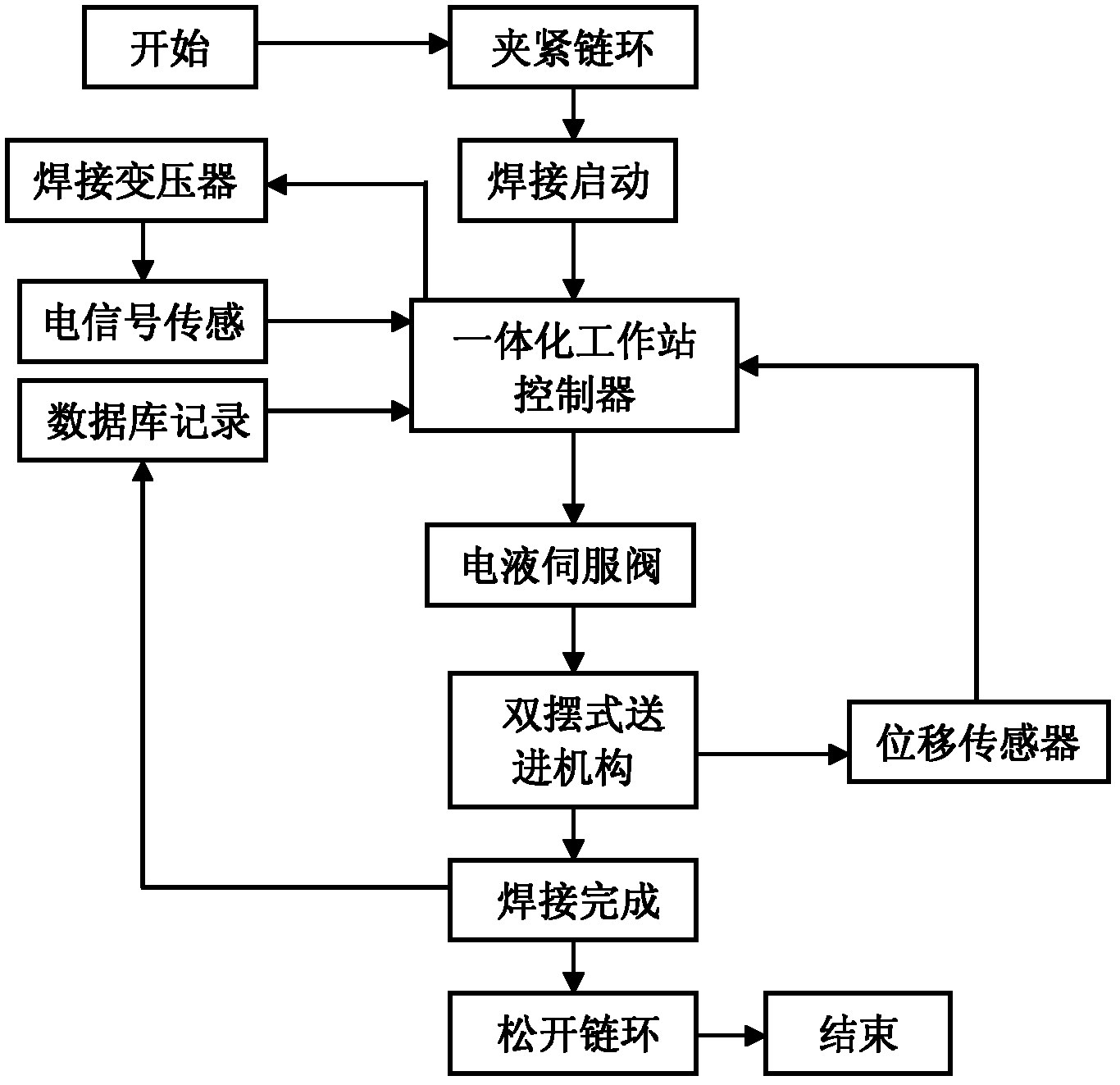

Flash butt welding machine

ActiveCN102328149AQuick responseWelding/soldering/cutting articlesMetal working apparatusButt weldingControl system

The invention discloses a flash butt welding machine, which can be used for effectively improving the welding quality and efficiency of a chain. The flash butt welding machine comprises a base, a frame, a feed-in driving device, a welding control system, a fixed workbench and a movable workbench, wherein a guide rail is arranged on the stand, and clamping mechanisms are arranged on the fixed workbench and the movable workbench. The flash butt welding machine is characterized in that: a double-pendulum type feeding-in mechanism is arranged at the bottom of the movable workbench and comprises an upper pendulum shaft and a lower pendulum shaft, wherein the upper pendulum shaft is fixed at the bottom of the movable workbench, the lower pendulum shaft is fixed on the base through a pendulum shaft seat, and the upper pendulum shaft and the lower pendulum shaft are connected through a pendulum arm. According to the flash butt welding machine, the resistance of the movable workbench in the feeding process is greatly reduced, so that the movable workbench is fed more portably, flexibly and rapidly, therefore the requirement of rapid response of the welding process is met, and the welding quality and efficiency are improved.

Owner:ZHANGJIAKOU NORTH WELDING MACHINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com