Patents

Literature

164 results about "Pentaprism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

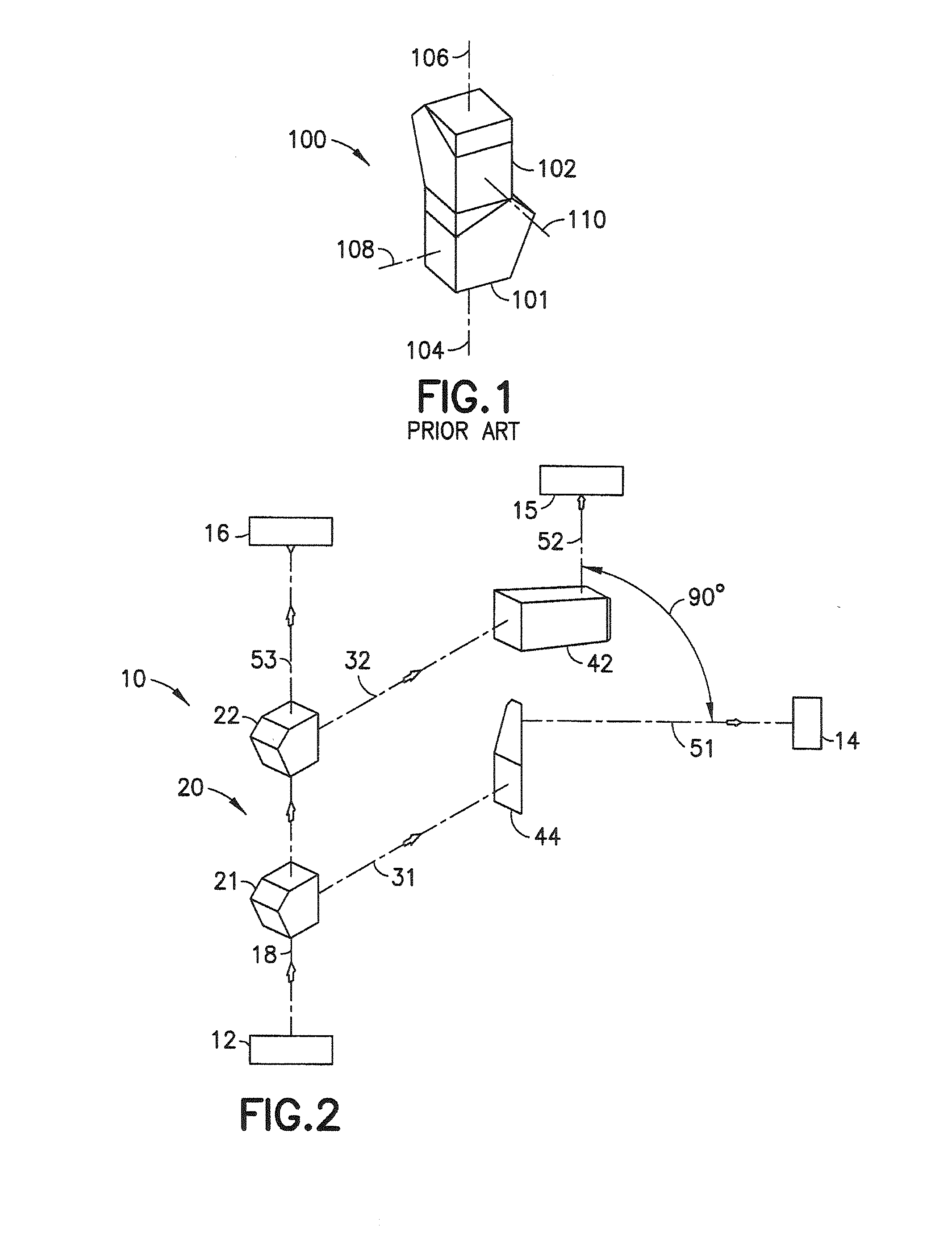

A pentaprism is a five-sided reflecting prism used to deviate a beam of light by a constant 90°, even if the entry beam is not at 90° to the prism. The beam reflects inside the prism twice, allowing the transmission of an image through a right angle without inverting it (that is, without changing the image's handedness) as an ordinary right-angle prism or mirror would.

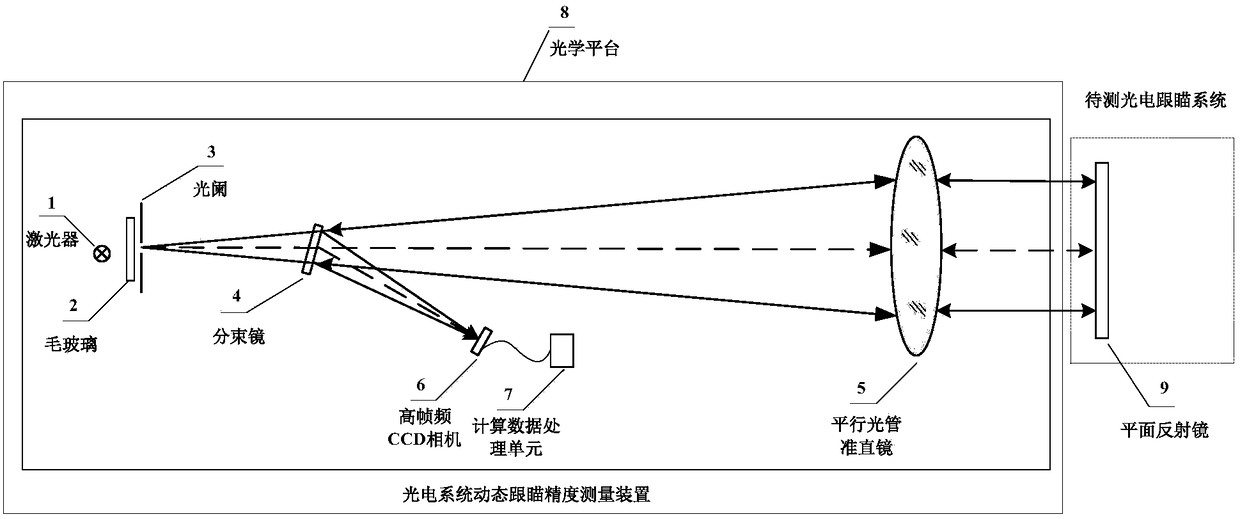

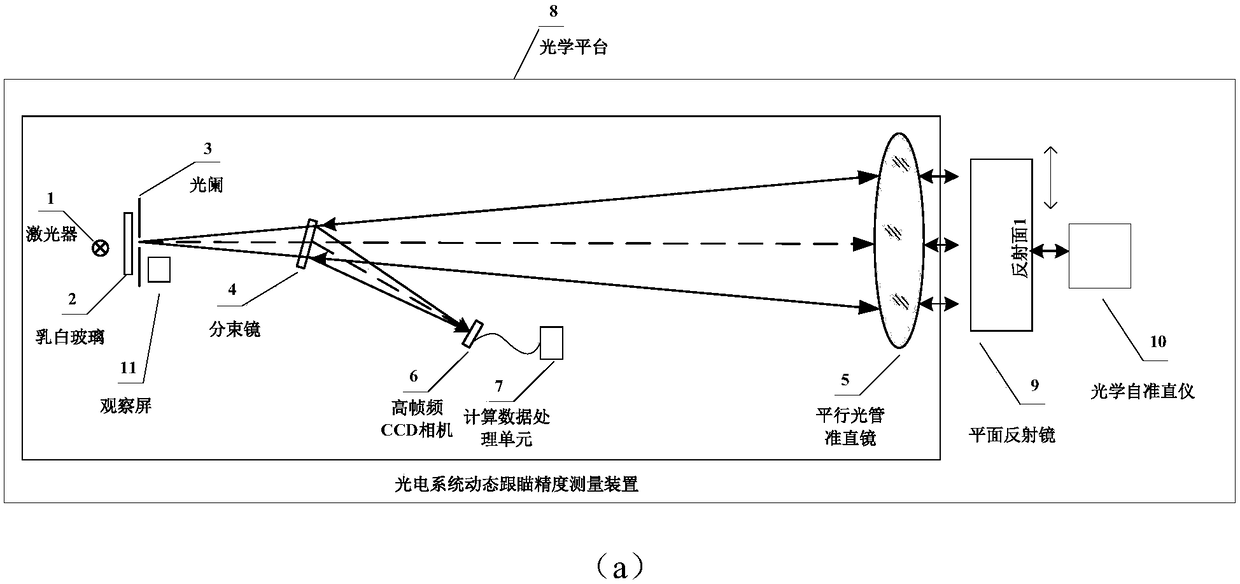

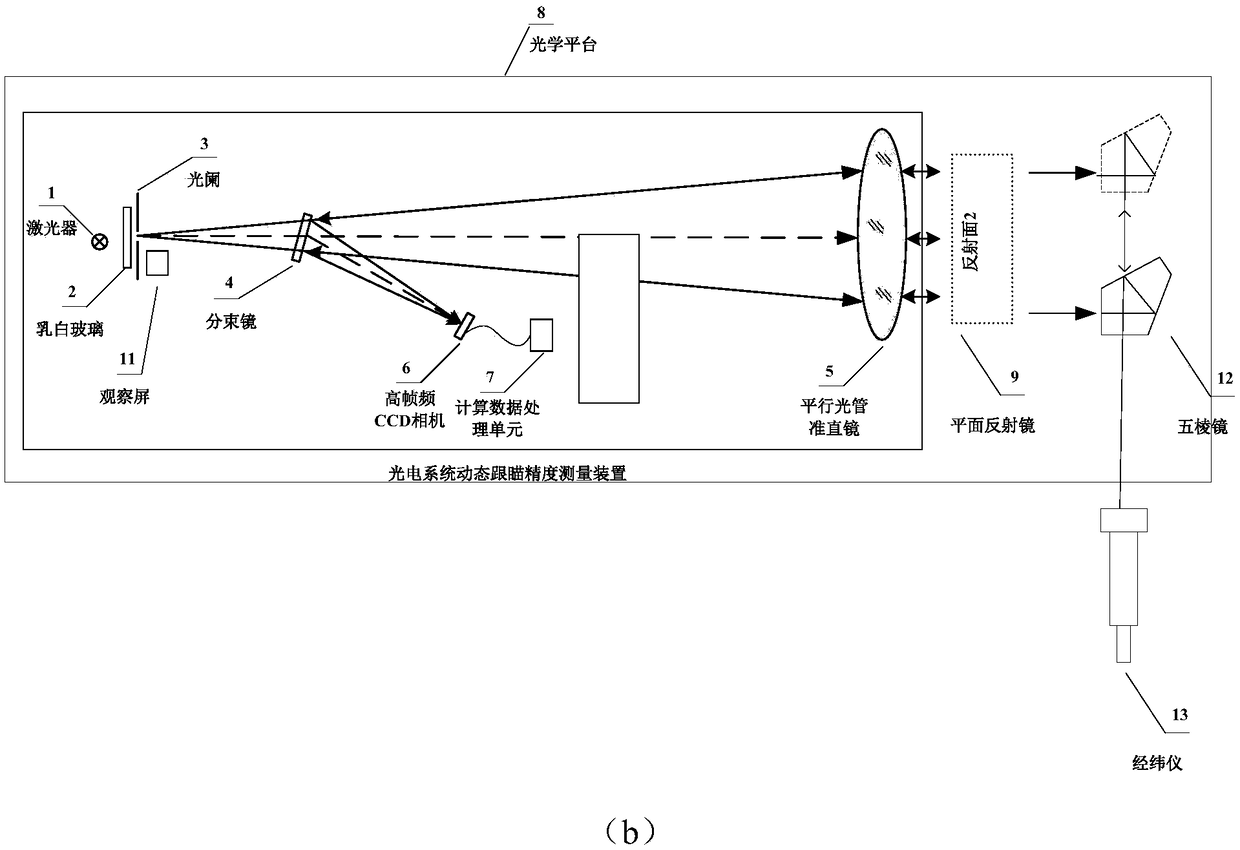

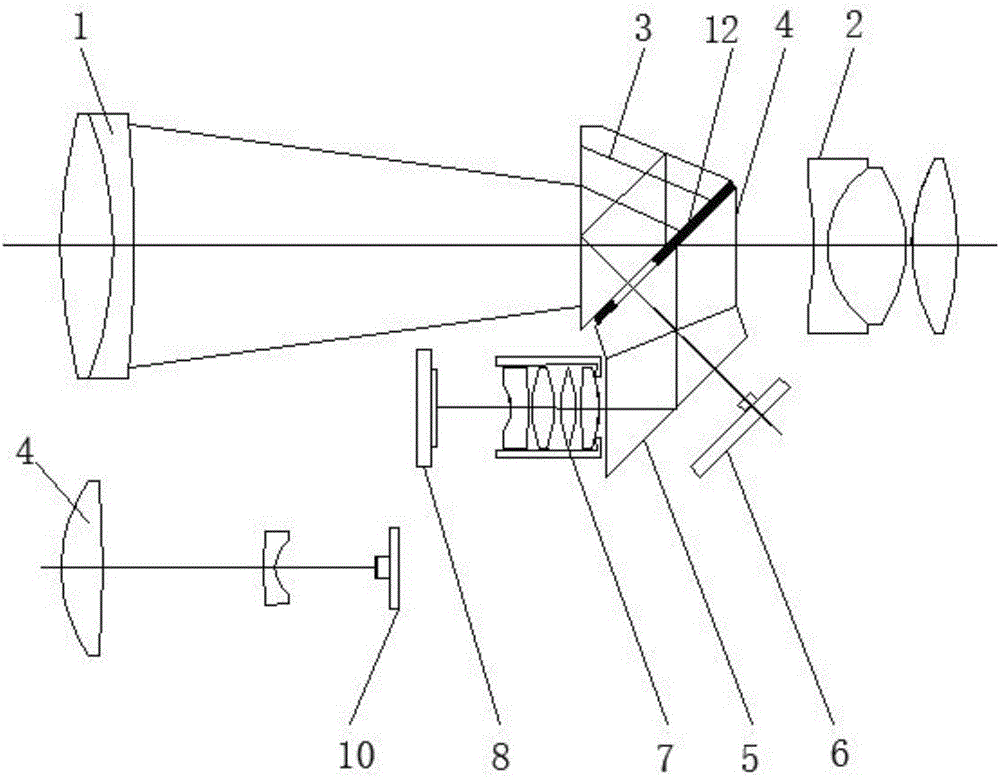

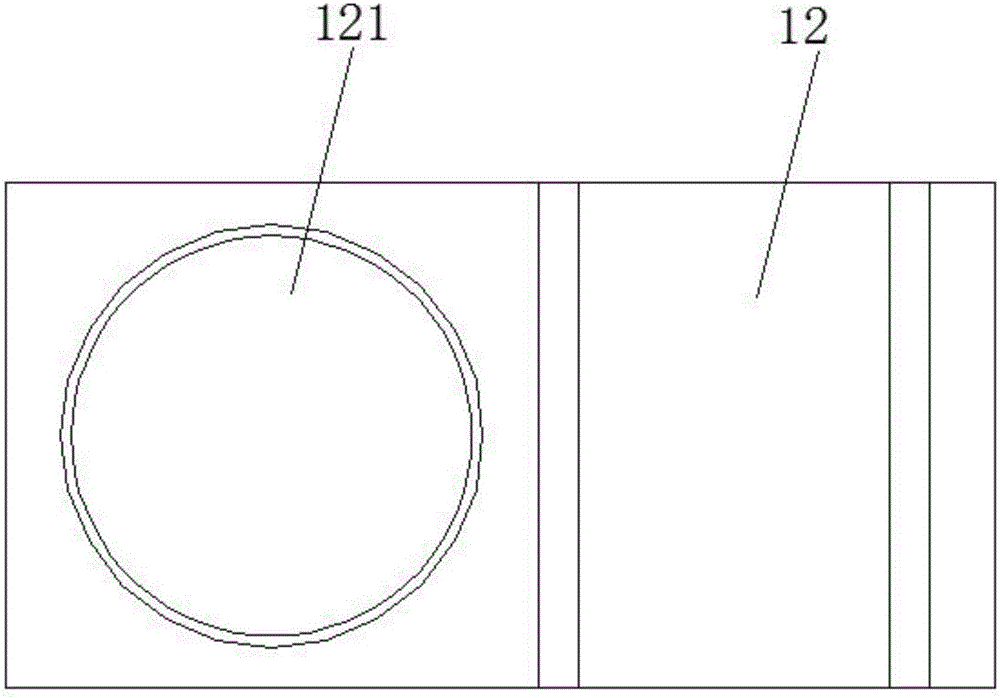

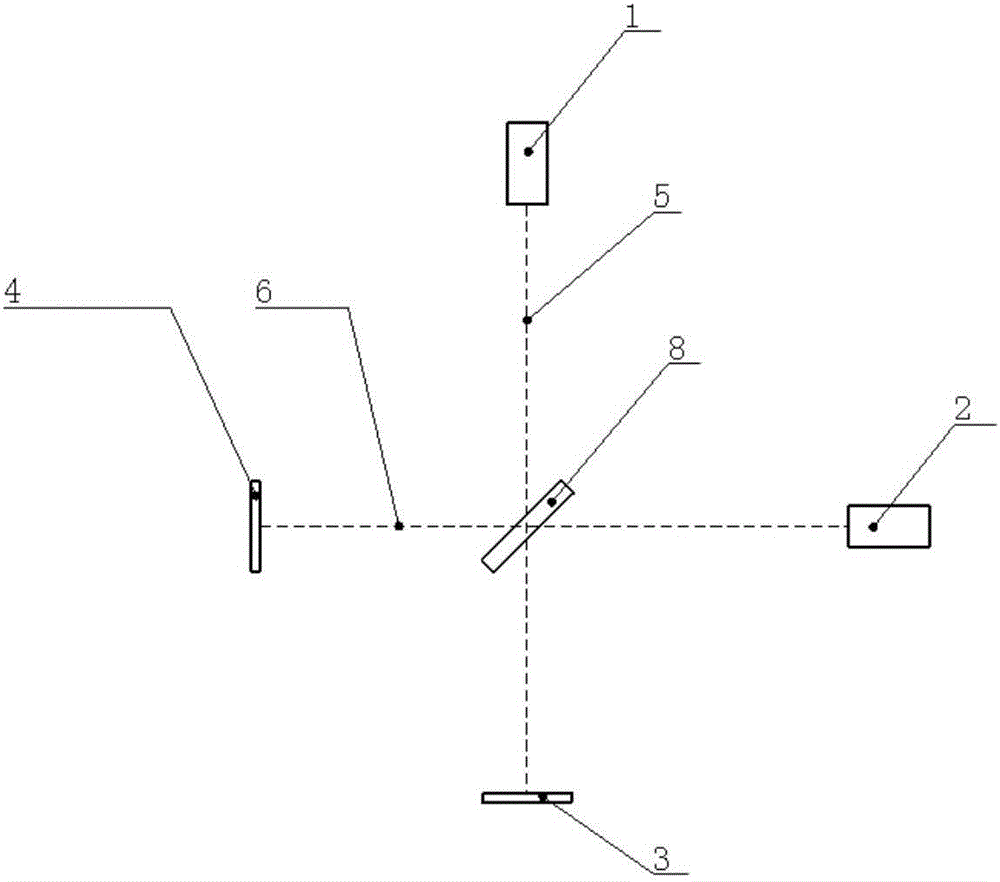

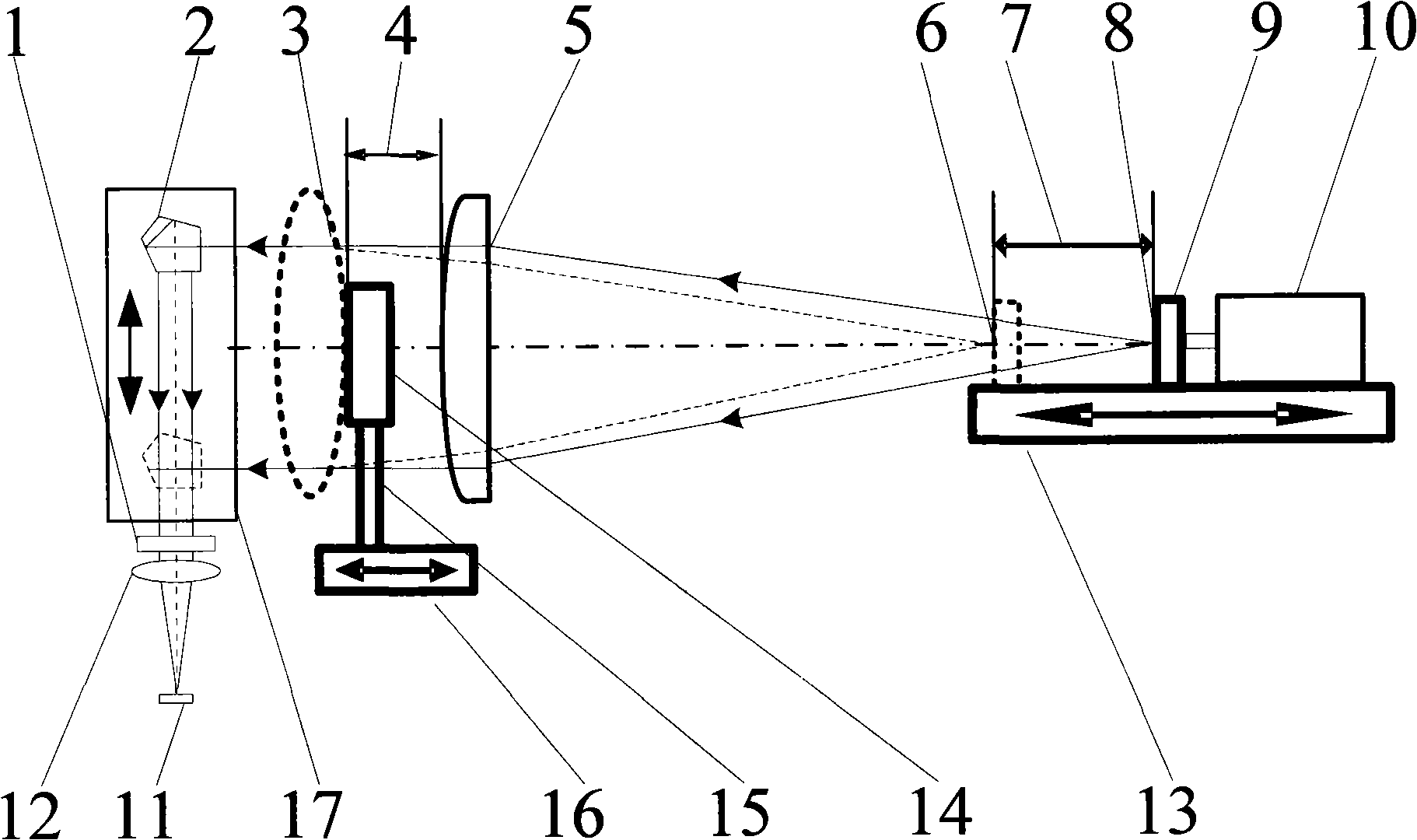

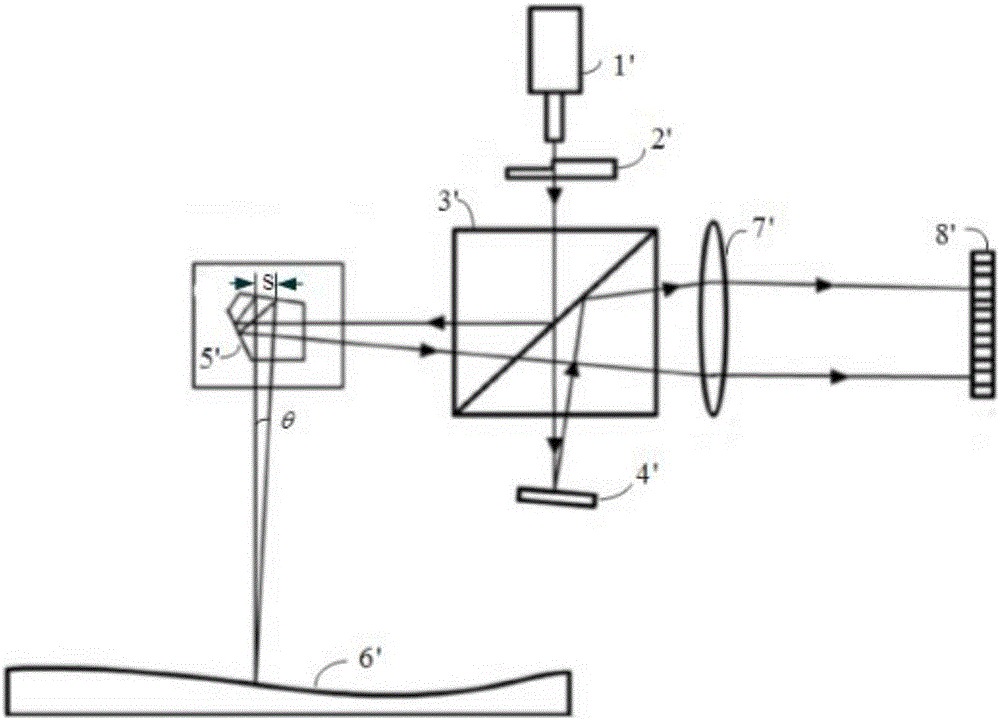

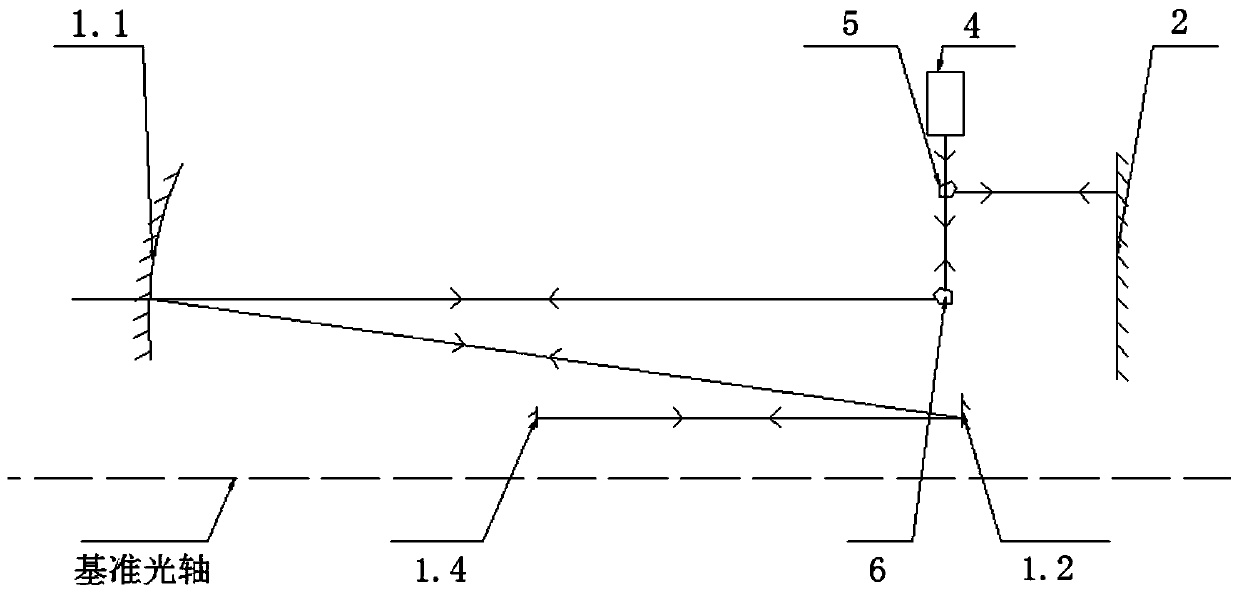

Adjusting and correcting method of light path of photoelectric system tracking-pointing precision measuring device

ActiveCN108152013ASolve adjustment problemsHigh precisionTelevision systemsOptical apparatus testingBeam splitterTheodolite

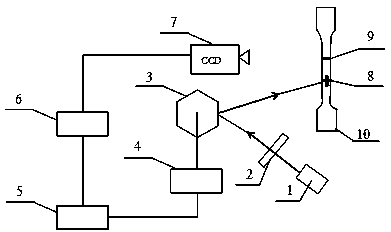

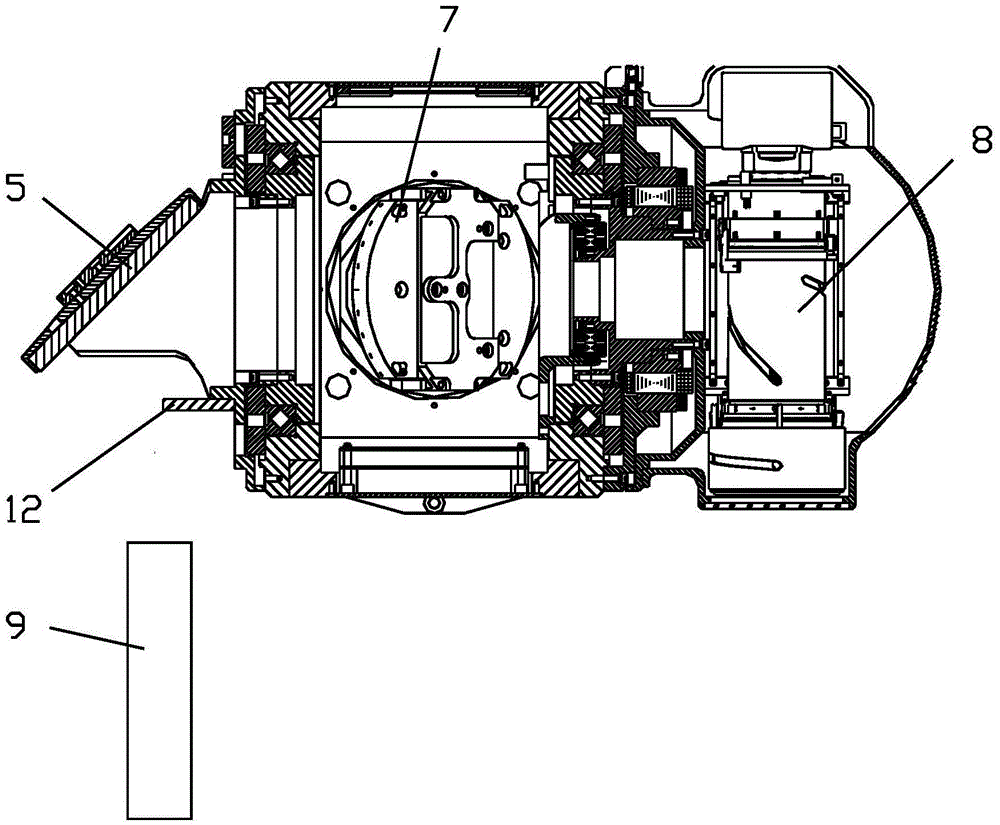

The invention provides an adjusting and correcting method of a light path of a photoelectric system tracking-pointing precision measuring device. The measuring device is mainly composed of an opticalplatform, a laser light source, ground glass, a small-hole diaphragm, a beam splitter, a parallel light pipe collimating mirror, a high-frame-frequency CCD camera and the like, wherein the laser lightsource, the ground glass, the small-hole diaphragm, the beam splitter, the parallel light pipe collimating mirror, the high-frame-frequency CCD camera and the like are installed on the optical platform. By the adoption of a plane mirror, an optical autocollimation, a pentaprism and a theodolite, the positions of the laser light source, the small hole diaphragm and the high-frame-frequency CCD camera of the photoelectric system tracking-pointing precision measuring device are adjusted and corrected, the adjusting and correcting method has the advantages of being high in precision, easy to operate, convenient and visual, the problem of adjusting and correcting the light path of the photoelectric system tracking-pointing precision measuring device is solved, and not only is technological guarantee provided for the development of a space laser communication tracking-pointing technology, but also a reference basis is provided for designing a space laser communication system tracking-pointing precision measuring device.

Owner:西安应用光学研究所

Laser planeness detector

InactiveCN102109331AGuaranteed measurement accuracySolve the detection speed is slowUsing optical meansLight beamHeight difference

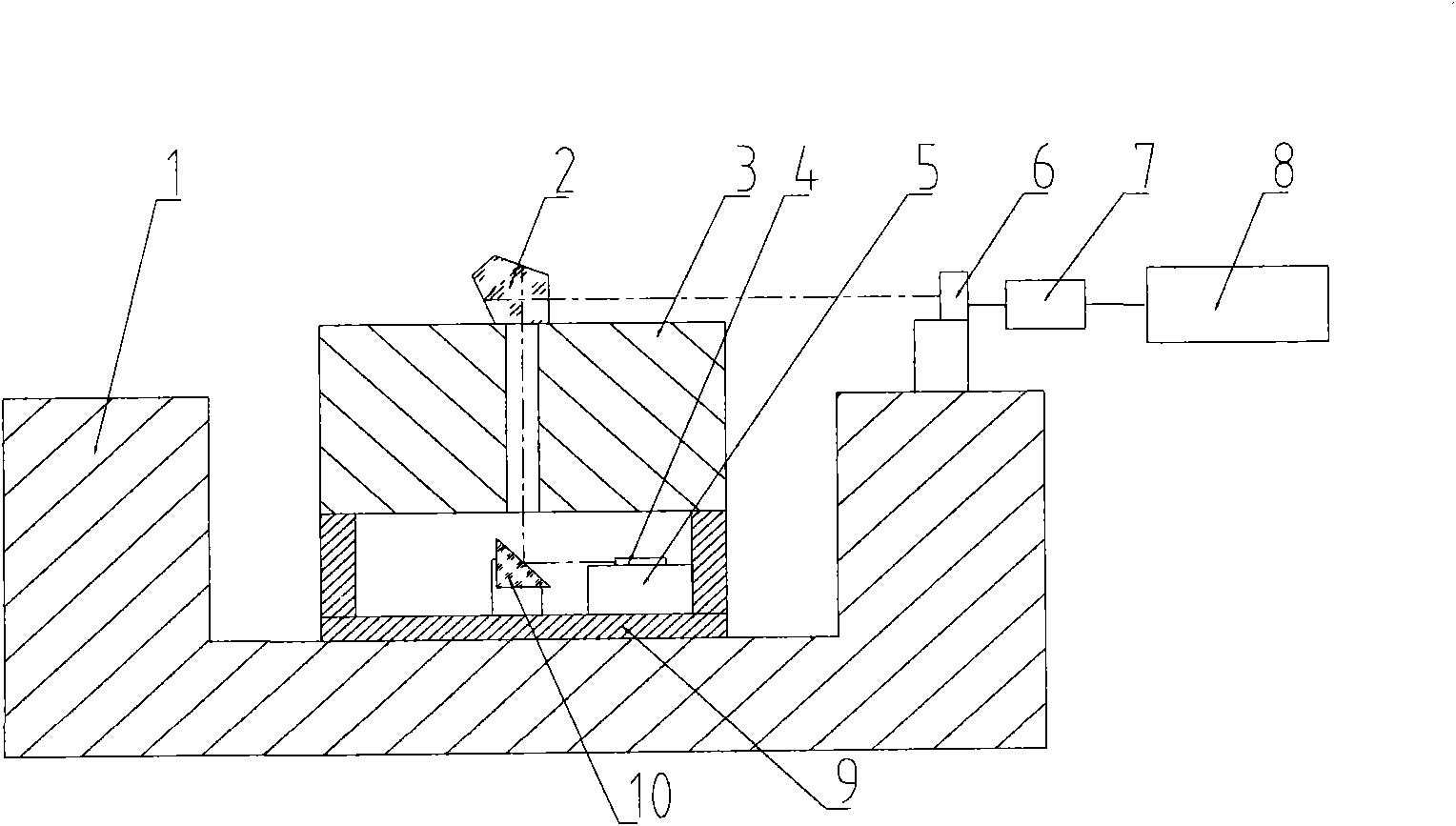

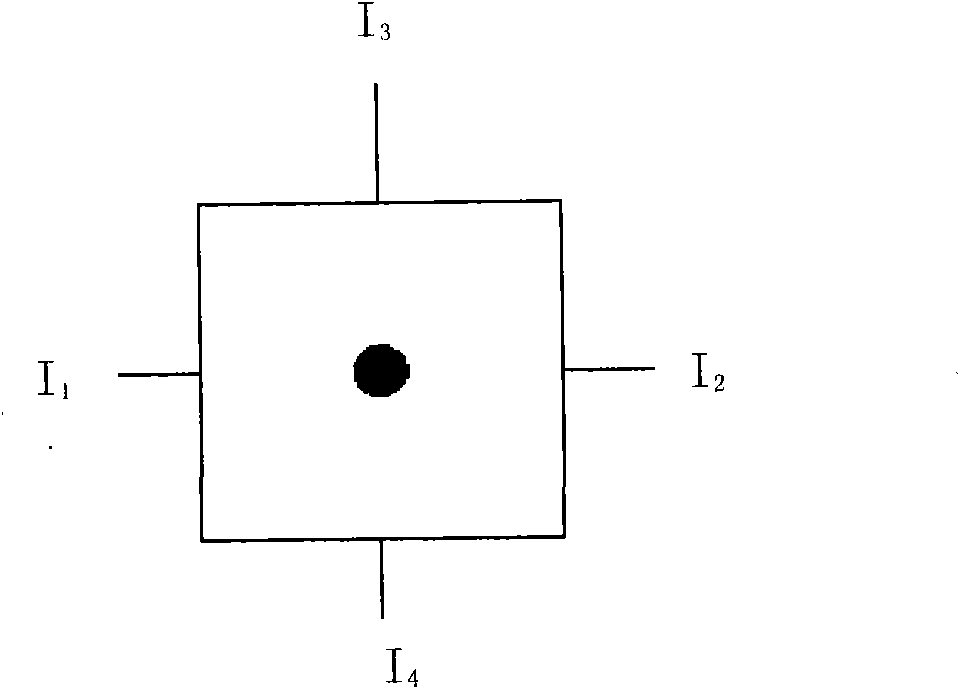

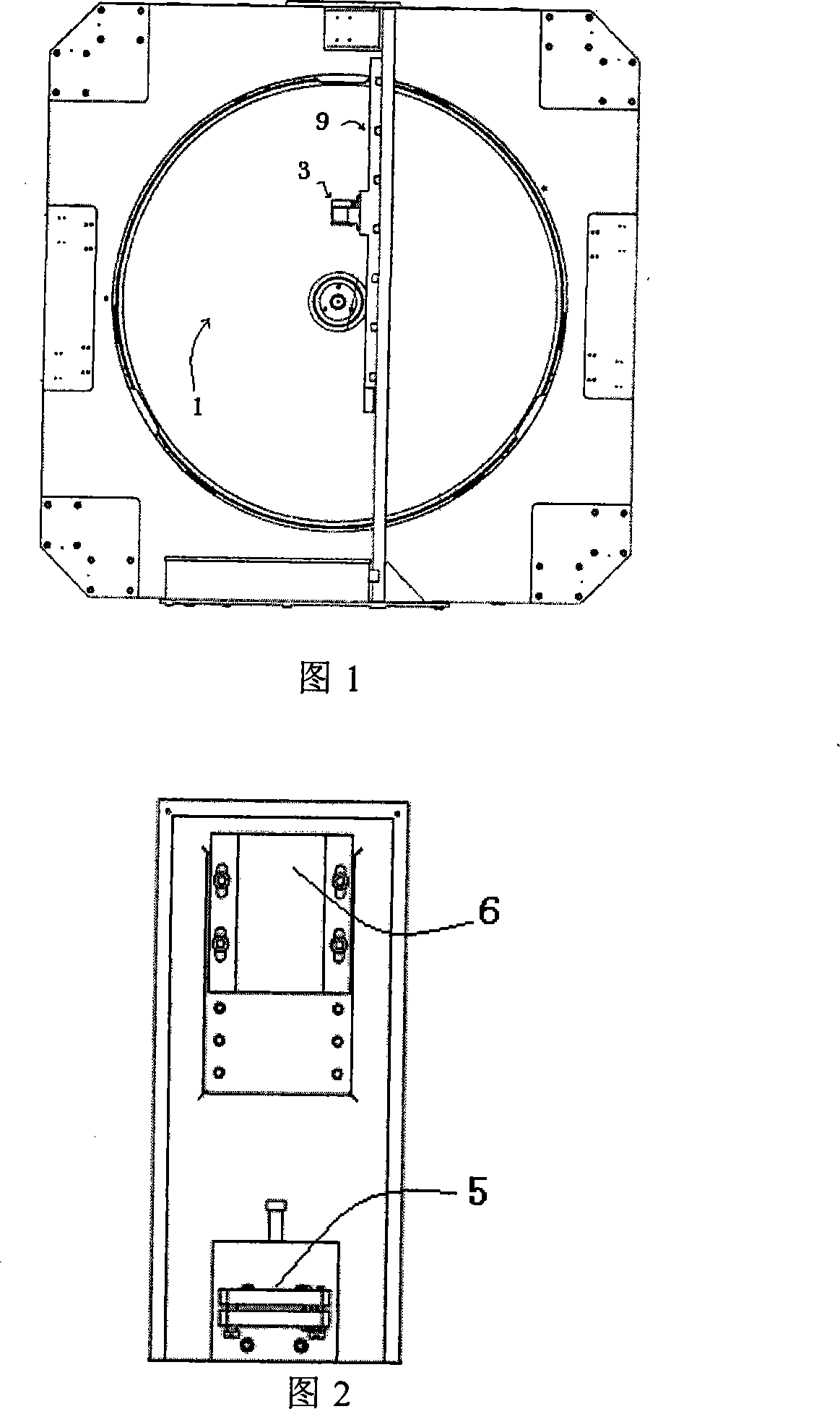

The invention relates to a laser planeness detector, consisting of a pentaprism, a rotary platform, a laser, a four-dimensional working platform, a PSD (Position Sensitive Detector) position sensor, a computer data acquisition unit, a data processing unit, a base and a planar reflecting mirror, wherein light emitted by the laser is ejected horizontally after passing through the center of the rotary platform and being reflected by the pentaprism. The pentaprism rotates along with the rotary platform, and laser which is ejected horizontally by the pentaprism also rotates along the rotary platform; and the horizontal laser beams rotate to form a reference plane. The PSD position sensor is placed on the measured plane, so that the height difference between a measured point and the reference plane formed by the laser beams can be measured, the planeness error of a detected plane can be obtained after data processing.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

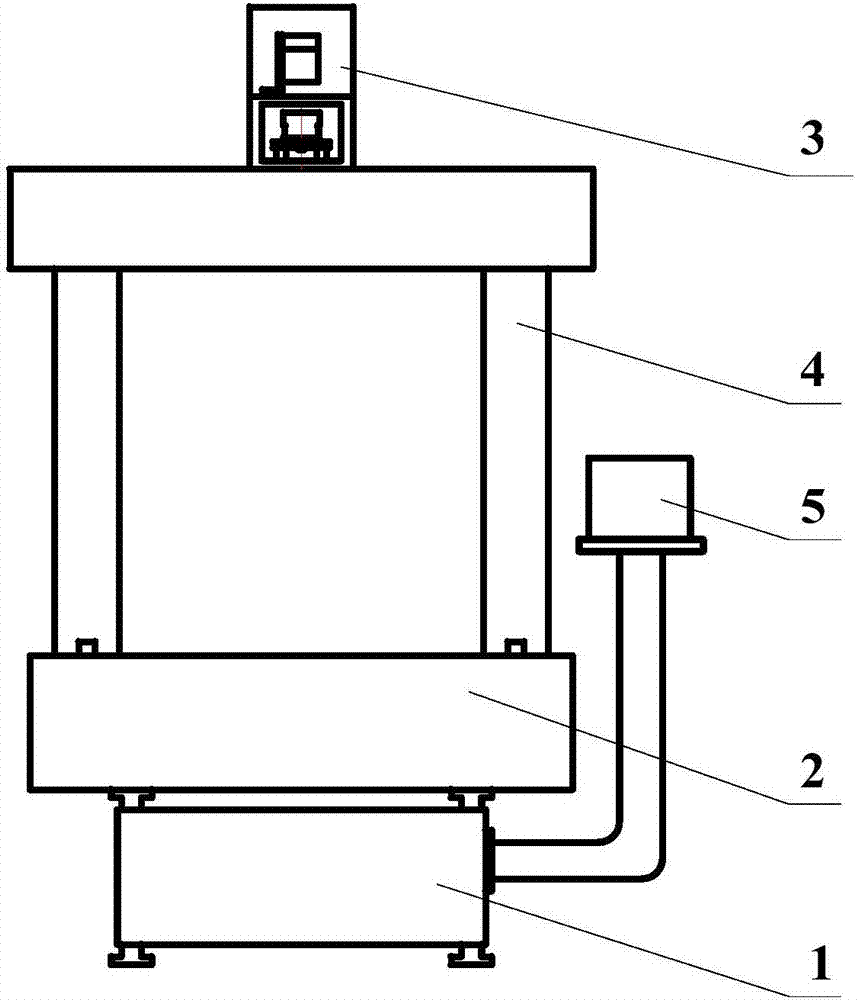

Surface shape detection apparatus and method for large-bore plane optical element

InactiveCN101476880AOvercome mechanical propertiesOvercome errorUsing optical meansMovement controlFace shape

The invention relates to a device and a method for detecting the surface shape of large-caliber plane optical elements, and belongs to a device and a method for detecting the quality of optical elements. The device and the method aim to solve the problems in the prior device and the prior method for detecting the large-caliber plane optical elements. The device comprises a stand, an image acquisition and processing system and a three-dimensional precision motion control system, wherein the three-dimensional precision motion control system comprises a vertical motion guide rail which is rotatably arranged on the stand, and a horizontal motion guide rail which can slide on the vertical motion guide rail; a rotary shaft which is fixed on the vertical motion guide rail is connected with a rotary power mechanism; and the image acquisition and processing system comprises a first scanning penta prism which is arranged on a slider of the horizontal motion guide rail, a first reference penta prism and a second scanning penta prism which are coaxially fixed with the horizontal motion guide rail, a second reference penta prism which is coaxially fixed with the vertical motion guide rail, and an optical head which is coaxially fixed with the horizontal motion guide rail. The device and the method can be applied to detection of the large-caliber plane optical elements, and are particularly suitable for online detection.

Owner:范勇

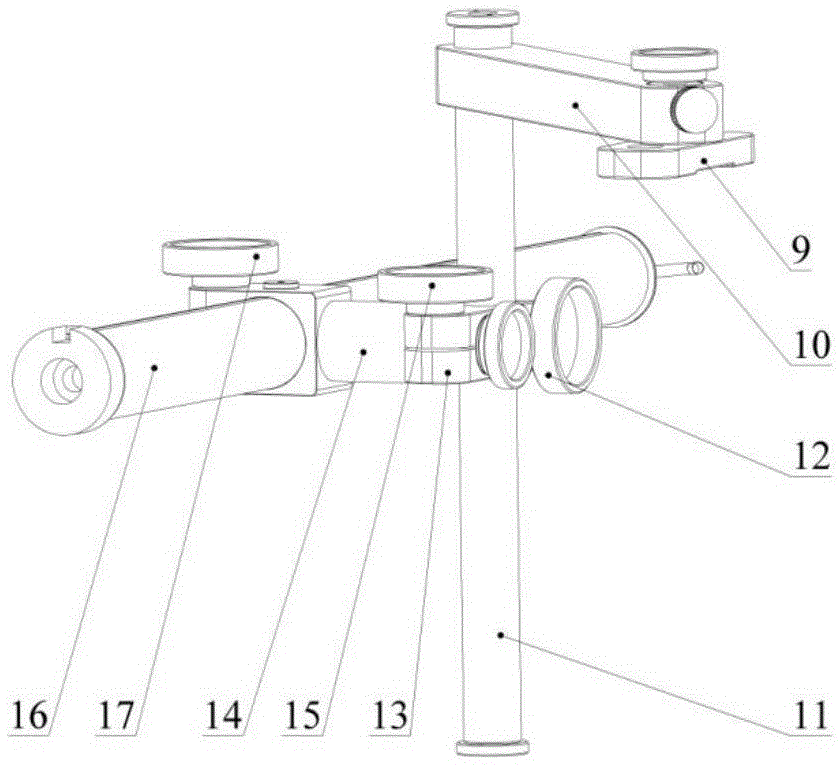

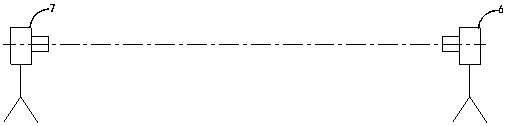

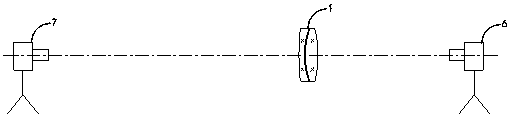

Device for detecting wide distance light beam parallelism

The invention relates to a wide distance beam parallelism detecting apparatus, comprising a photoelectric auto-collimator and a diameter-expanding collimating arm. The apparatus can detect the parallelism of the wide distance parallel beams and the detecting distance can reach 1.5m; and two parallel beams do not need to be contained into the caliber of the photoelectric auto-collimator so as to reduce the caliber of the photoelectric auto-collimator and largely reduce the manufacturing cost of the photoelectric auto-collimator. Simultaneously, the adoption of pentaprism and optical wedge largely reduces the processing precision requirement of the pentaprism and has no impact on the detecting precision of the whole apparatus and higher precision can be provided. The use of an optical splitting system in the photoelectric auto-collimator leads the detecting wave band of the apparatus to be expanded to the laser and infrared spectrum band from the white spectrum band so as to become a multi-spectrum optical system.

Owner:CHANGCHUN UNIV OF SCI & TECH

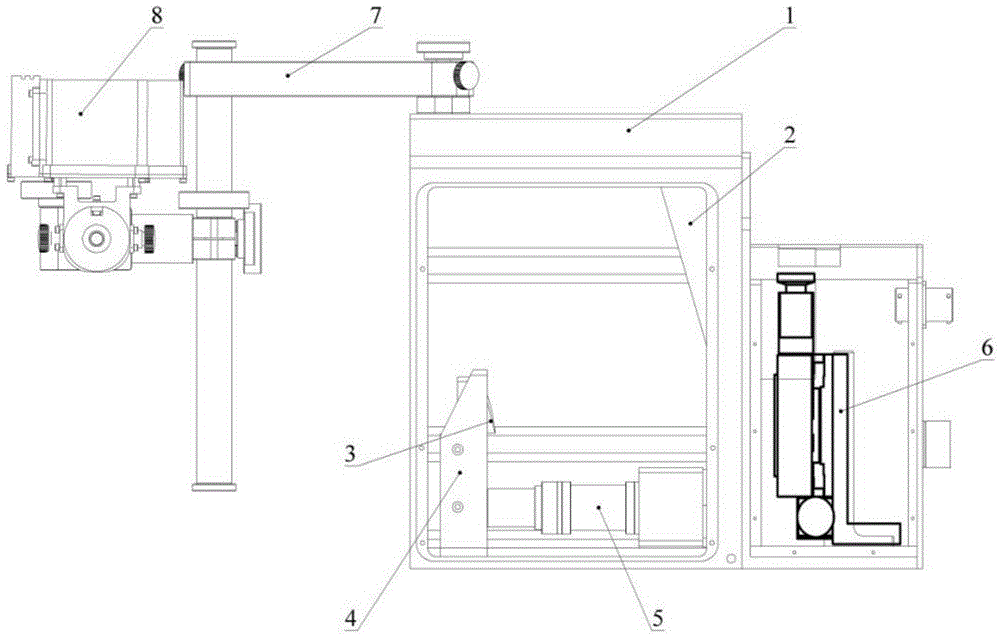

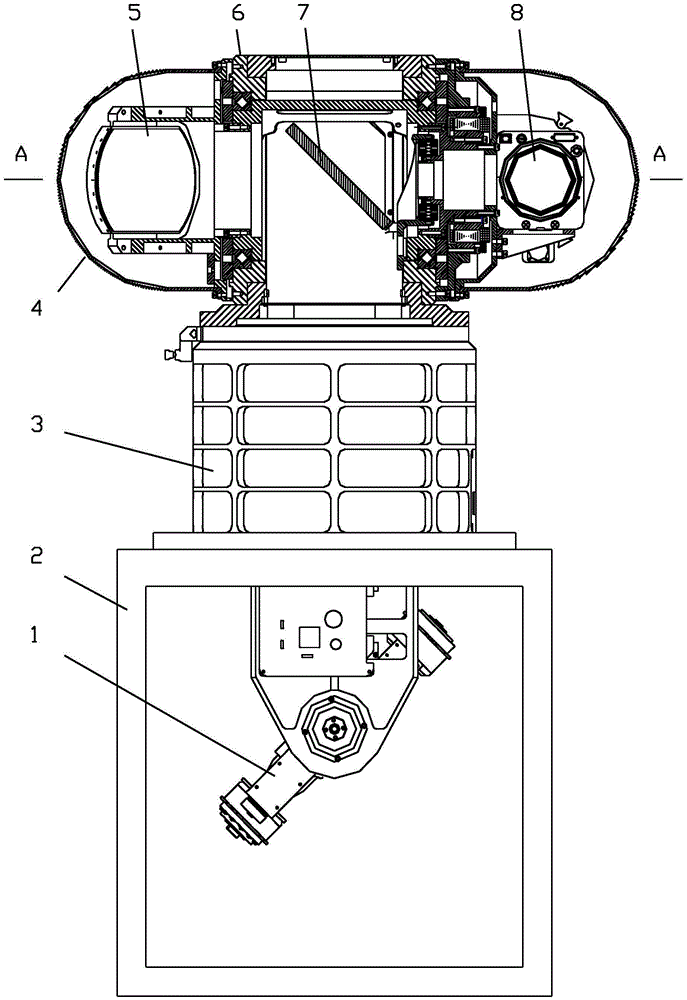

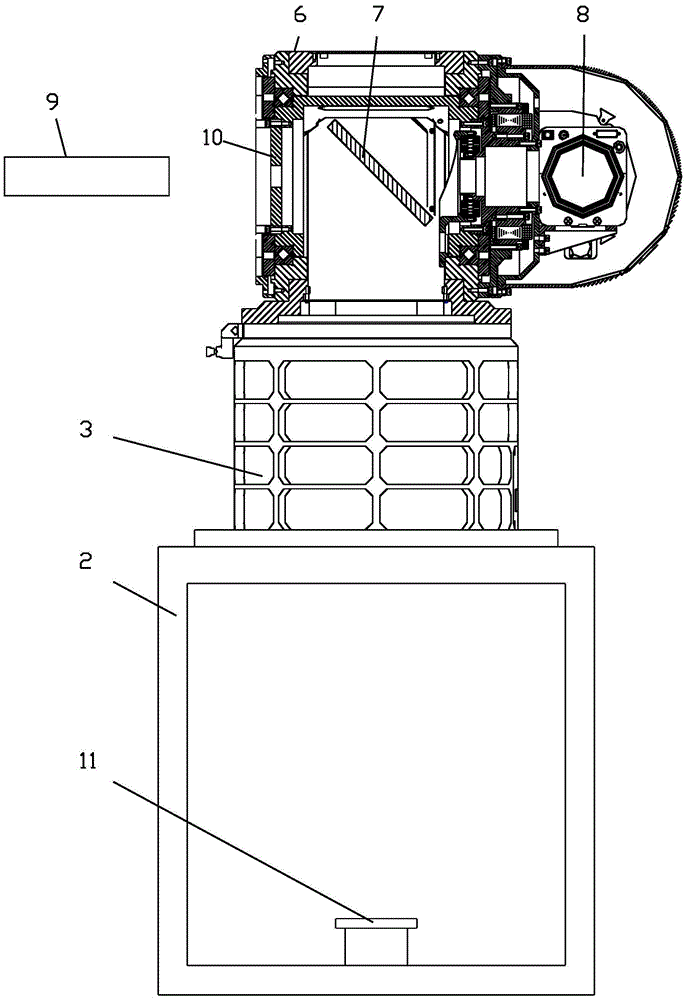

Photoelectric equipment multi-optical-axis parallelism quantitative detection device

ActiveCN105571526AWith broad spectral characteristicsRealize on-site dynamic quantitative detectionUsing optical meansTesting optical propertiesMulti bandOptical axis

The invention discloses a photoelectric equipment multi-optical-axis parallelism quantitative detection device. The device comprises an off-axis folded aspheric optical system, a CCD image sensor, a two-dimensional translation bench, a double-pentaprism expanding assembly and a control system. The off-axis folded aspheric optical system forms a collimation parallel light tube. The two-dimensional translation bench is installed behind a housing. A cross scale surface of the two-dimensional translation bench is superposed with a focal plane of the parallel light tube. A transition prism group is arranged below an aspheric secondary mirror to realize light parallel inversion. The lens of the CCD image sensor is aligned to the transition prism group. A support group is installed on the housing. Two ends of a beam expanding guide rod of the support group are respectively provided with a pentaprism, and the relative distance between the two pentaprisms is adjustable. The device is capable of realizing quantitative and precise parallelism measurement of every two laser / infrared / white light optical axes of multi-band photoelectric equipment, is advantageous by being wide in spectrum range, high in measurement precision, miniature and portable, and is applicable to optical axis parallelism testing among multi-band photoelectric equipment.

Owner:ARMY ENG UNIV OF PLA

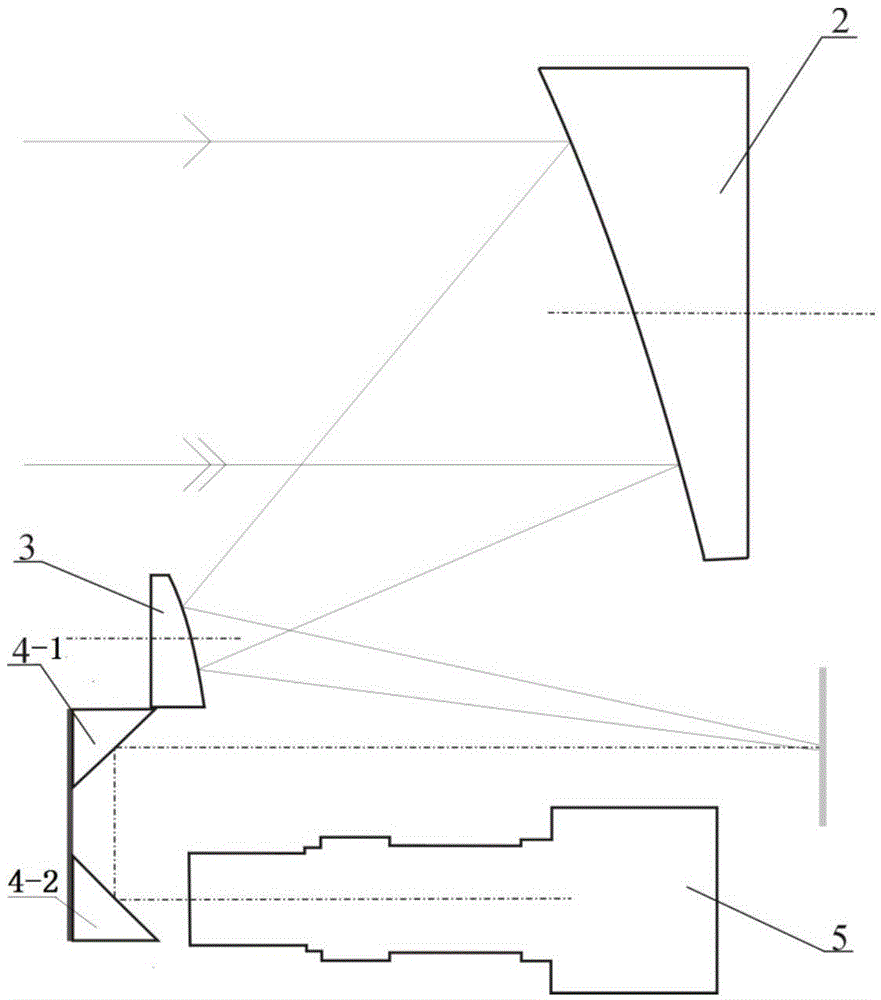

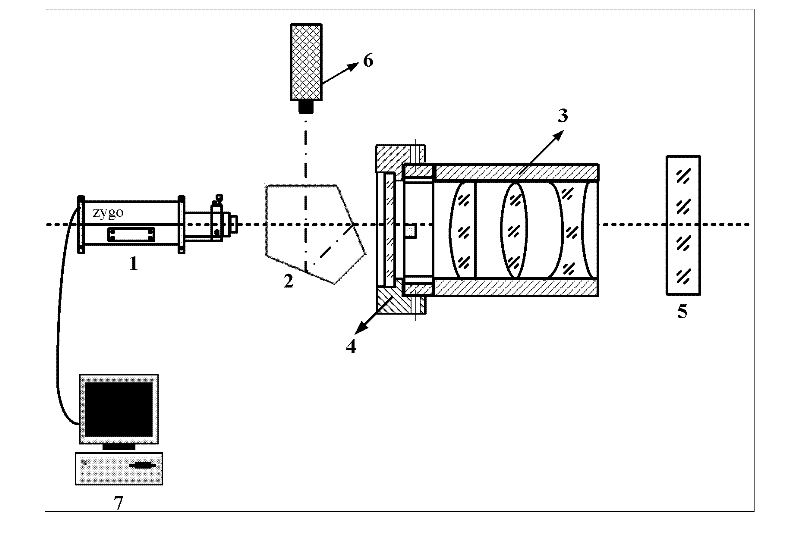

System capable of solving inclination problem of narrow field of view lens in wave aberration detection and method thereof

InactiveCN102393255AAccurate CalibrationGuaranteed verticalityOptical measurementsTheodoliteOptical axis

The invention relates to a system capable of solving an inclination problem of a narrow field of view lens in a wave aberration detection process and a method thereof. The system comprises a laser interferometer, a pentagonal prism, an autocollimation theodolite, a planar mirror and an optical axis directional tool which is in common optical axis with a narrow field of view lens to be detected. The laser interferometer, the pentagonal prism, the optical axis directional tool and the planar mirror are provided on a same optical path in order. The pentagonal prism is provided on an emitting optical path of the autocollimation theodolite. The system capable of solving the inclination problem of the narrow field of view lens in wave aberration detection and the method thereof have the characteristics of high detection precision, a short detection period and good repeatability.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

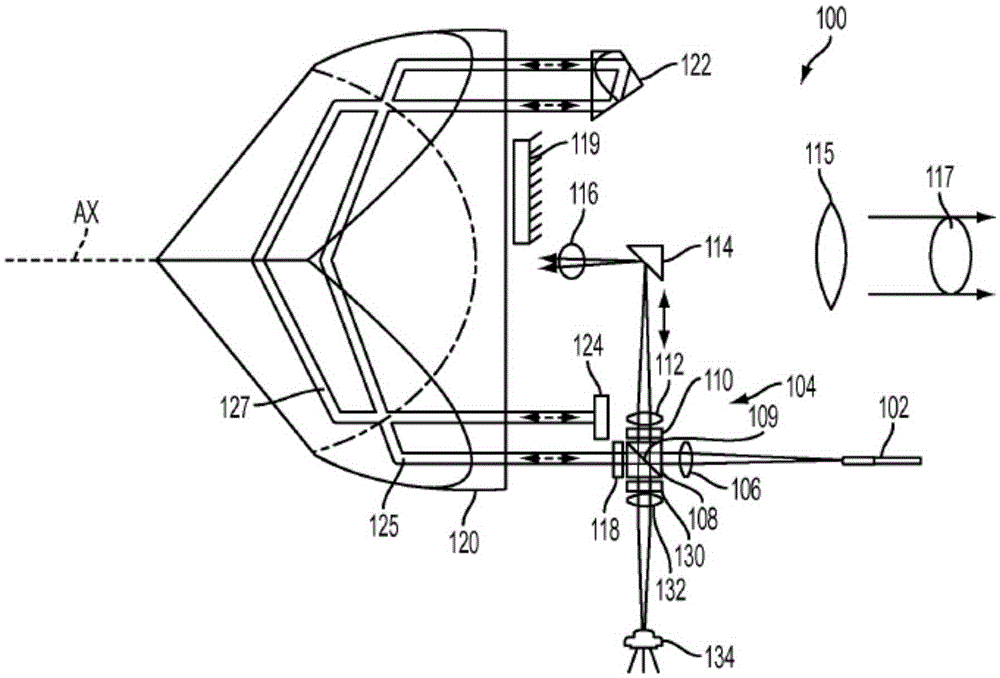

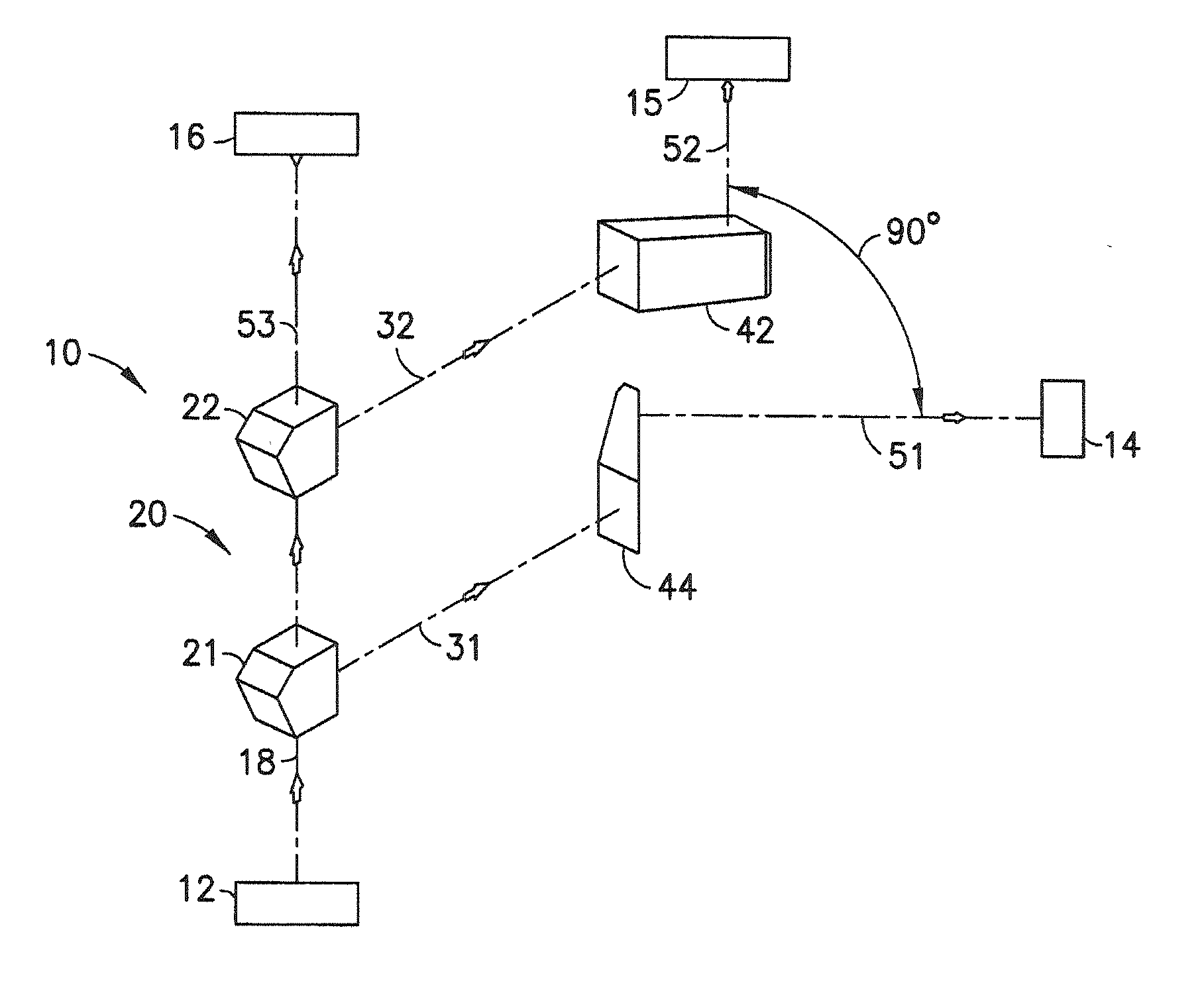

Low drift reference for laser radar

Laser radar systems include a pentaprism configured to scan a measurement beam with respect to a target surface. A focusing optical assembly includes a corner cube that is used to adjust measurement beam focus. Target distance is estimated based on heterodyne frequencies between a return beam and a local oscillator beam. The local oscillator beam is configured to propagate to and from the focusing optical assembly before mixing with the return beam. In some examples, heterodyne frequencies are calibrated with respect to target distance using a Fabry-Perot interferometer having mirrors fixed to a lithium aluminosilicate glass-ceramic tube.

Owner:NIKON METROLOGY

Device for detecting large-sized perspective glass primary and secondary mirror spacing

InactiveCN101236073AImplement pan scanSolve the problem of adjusting the distance between primary and secondary mirrorsUsing optical meansTelescopesOptical axisEngineering

An apparatus for detecting spacing between a primary mirror and a secondary mirror, which comprises an auto-collimator, a pentaprism, a guide rail, a reticle, a CCD detection system and a monitoring computer, wherein the guide rail is arranged in parallel direction of vertical diameter of the primary mirror, the pentaprism is arranged at the guide rail and can be translated along the vertical direction, parallel rays emitted from the auto-collimator is turned 90 degrees via the pentaprism and then via telescope optical system to converge at primary optical axis, the reticle is arranged at Cassegrain focus, the CCD detection system is employed for image-forming of the parallel rays convergent point and the reticle, the monitoring computer is capable of calculating the centre of mass of the images detected by CCD detection system and obtaining a group of image points position, while another group of image points position can be obtained by moving the pentaprism, radial scanning of the primary mirror can be achieved by continue moving, and a movement path of the centre of mass of image points can be obtained, thereby spacing error between the primary mirror and the secondary mirror is obtained via processing of the monitoring computer. The apparatus achieves auto-detecting of the spacing between the primary mirror and the secondary mirror of the telescope, increasing the detecting accuracy, thereby providing important guarantee for later system adjusting of large telescope.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

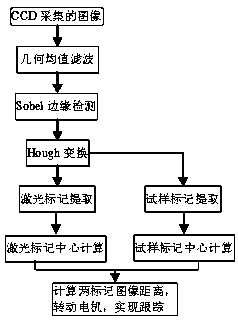

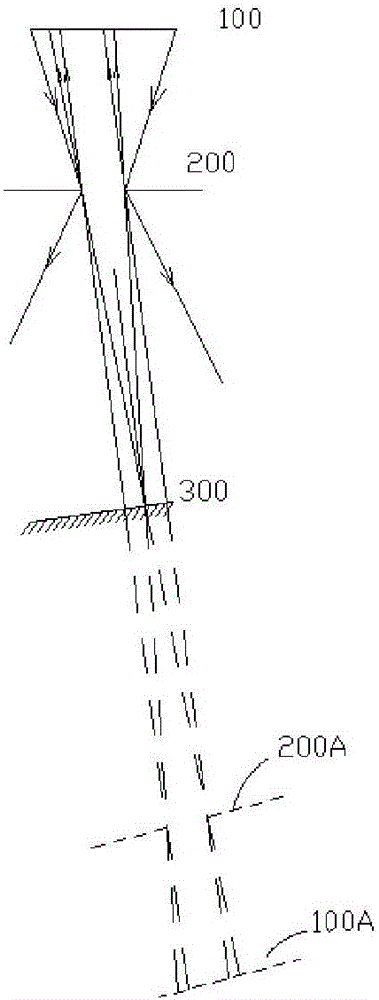

Laser mark automatic tracking extensometer control method based on uncalibrated visual servo

InactiveCN103439981AAvoid calibrationAvoid measurement errorsUsing optical meansControl using feedbackObservational errorVisual servoing

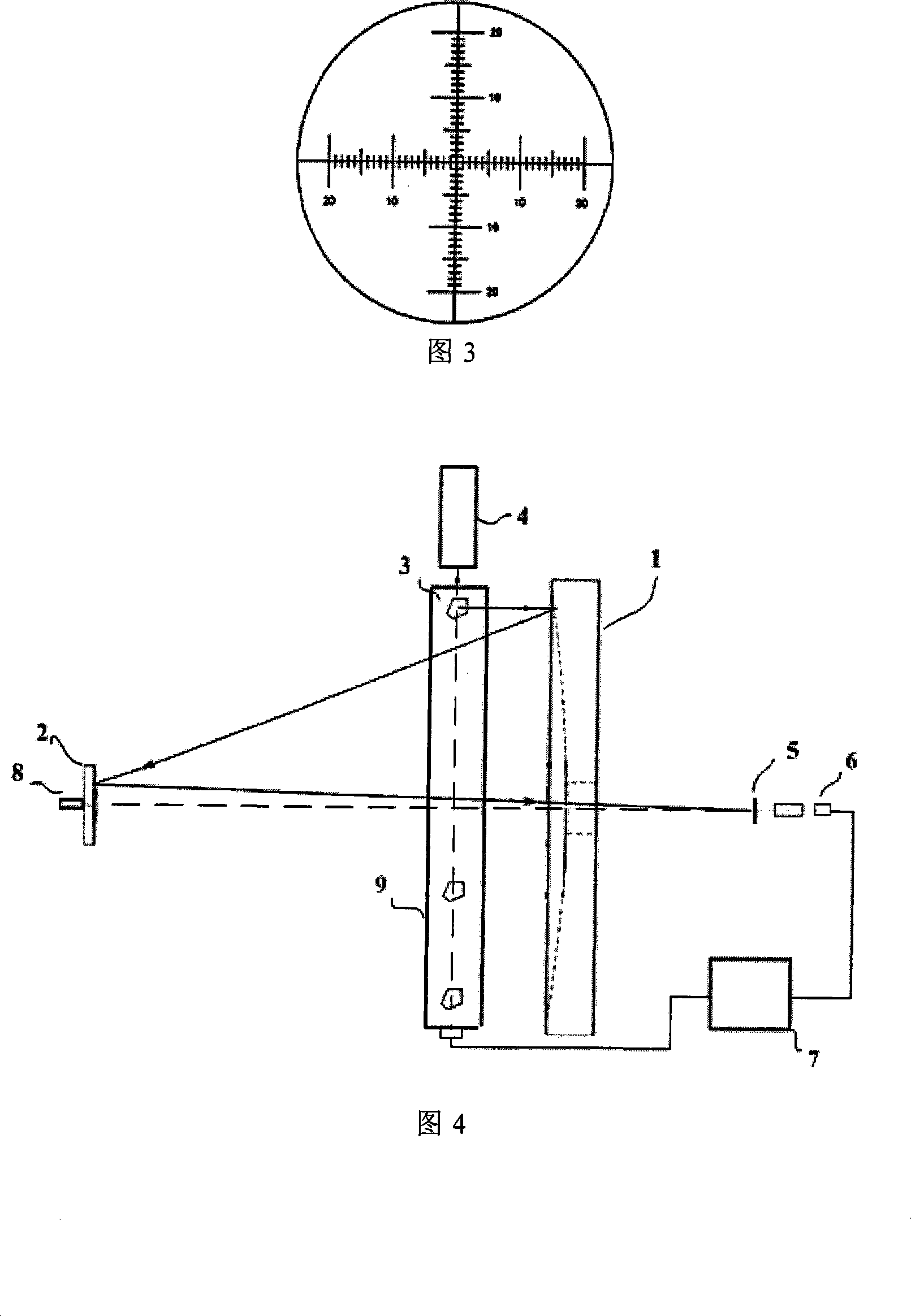

The invention discloses a laser mark automatic tracking extensometer control method based on uncalibrated visual servo. An image Jacobian matrix on-line identification method is adopted, the mapping relation between the actual distance between a laser mark and a sample mark, namely, the tracking displacement of the laser mark and image space tracking displacement is built, a controlled quantity is calculated by identifying the pixel distance difference between a Jacobian matrix and the central points of the two marks through a Karman filter, a servo motor is controlled to drive a pentaprism to rotate, the automatic tracking of the laser mark on the sample mark is achieved, and the laser mark displacement in the extending process is a sample deformation quantity. The method not only avoids the camera calibration step of an existing video extensometer and measuring errors introduced from the step, but also achieves the precise whole-process tracking of the laser mark on the sample mark, and is strong in environmental disturbance resistance capacity and high in tracking precision.

Owner:ZHEJIANG SCI-TECH UNIV

Telescope range finder

InactiveCN106444003ALarge clear apertureAchieve the purpose of sharingPrismsOptical rangefindersEyepieceOptoelectronics

The invention discloses a telescope range finder. The telescope range finder comprises a telescope object lens, a laser receiver, a display element, a laser emission module, a spectroscope set and an ocular lens set, wherein the laser receiver receives the laser emitted from the laser emission module; the spectroscope set is formed by a ridge prism, a prism separator plate, a No.1 half-pentaprism and a No.2 half-pentaprism; the shape of the No.1 half-pentaprism is similar to the shape of the No.2 half-pentaprism; the ridge prism is provided with a light input plane, a ridge plane and an output plane; the No.1 half-pentaprism is provided with a No.1 light output input plane which is also used as a reflection plane, a No.1 input output plane, and a No.1 cemented plane; and the No.2 half-pentaprism is provided with a No.2 light output input plane which is also used as a reflection plane, a No.2 input output plane, and a No.2 cemented plane. The telescope range finder enables the light paths of the telescope object lens, the laser receiver and the display element to be coaxial through the spectroscope set so as to achieve the aim of reducing the volume of the product and prism sharing.

Owner:甘晟华

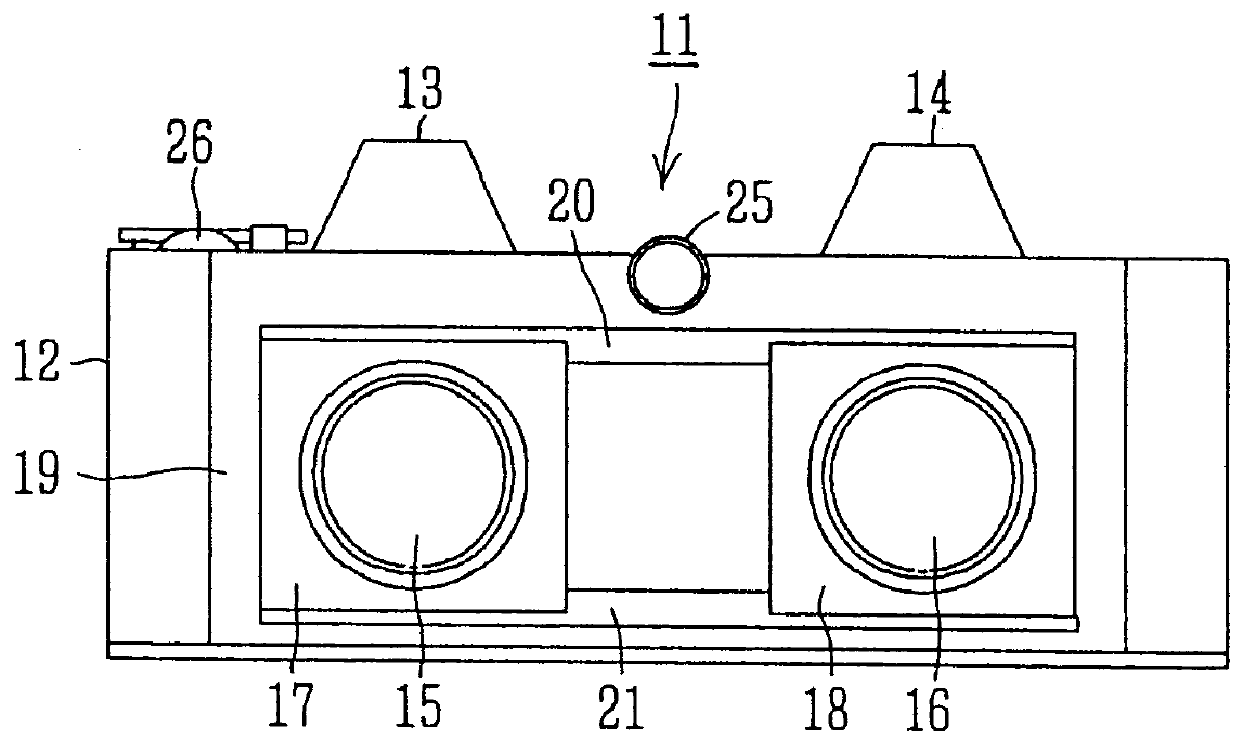

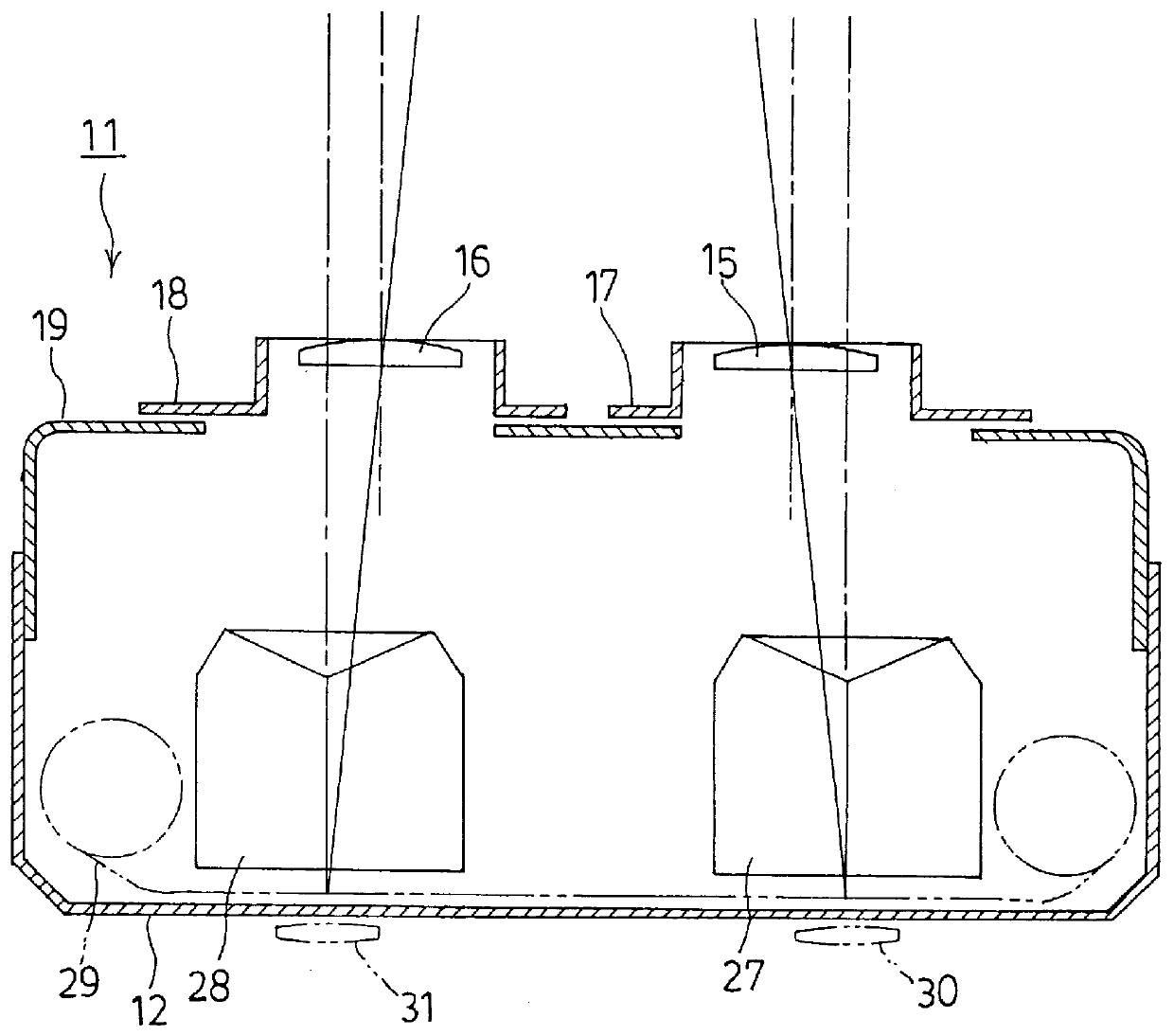

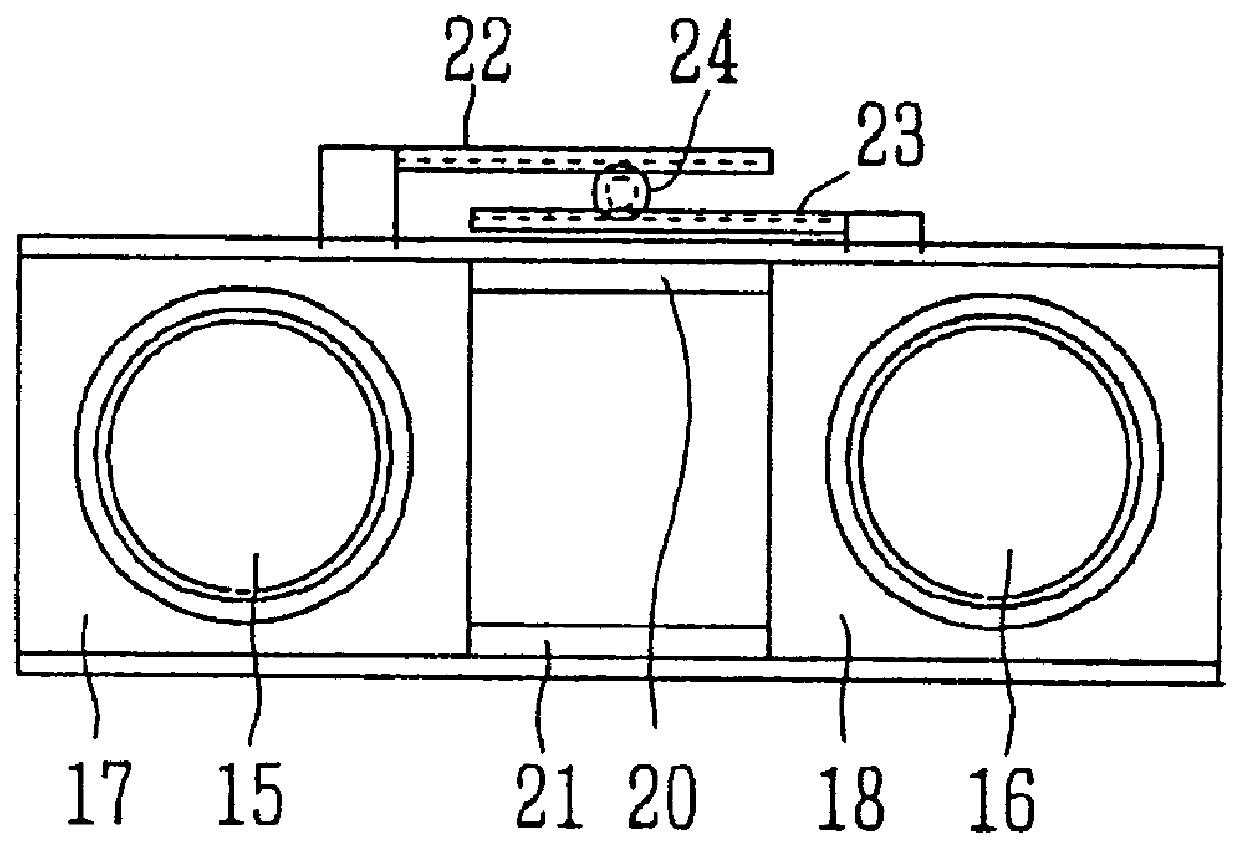

Stereoscopic camera

A stereoscopic camera for stereoscopic photography, which reduces losses in the screen when taking a picture in a close range and provides optimum stereoscopic effect without the need of adjusting the distance between the slides that are being mounted. A camera body is furnished with reflex finders constituted by a pair of right and left photographing lenses and pentaprisms. The distance between optical axes of the photographing lenses is adjusted by a horizontal shifting mechanism. Focusing plates of the right and left finders are marked with vertical lines at the centers and on the right and left sides thereof. The distance between optical axes is adjusted depending upon the distance to the subject and vertical lines of the right and left focusing plates are brought into agreement. Then, the right and left photographing areas are nearly brought into agreement on the real screen and no loss occurs on the screen.

Owner:INABA MINORU

Levelling and horizontal error testing device

ActiveCN107462227AReduce alignment timeFast Optical Alignment SpeedActive open surveying meansArtificial horizonsEngineeringElectric control

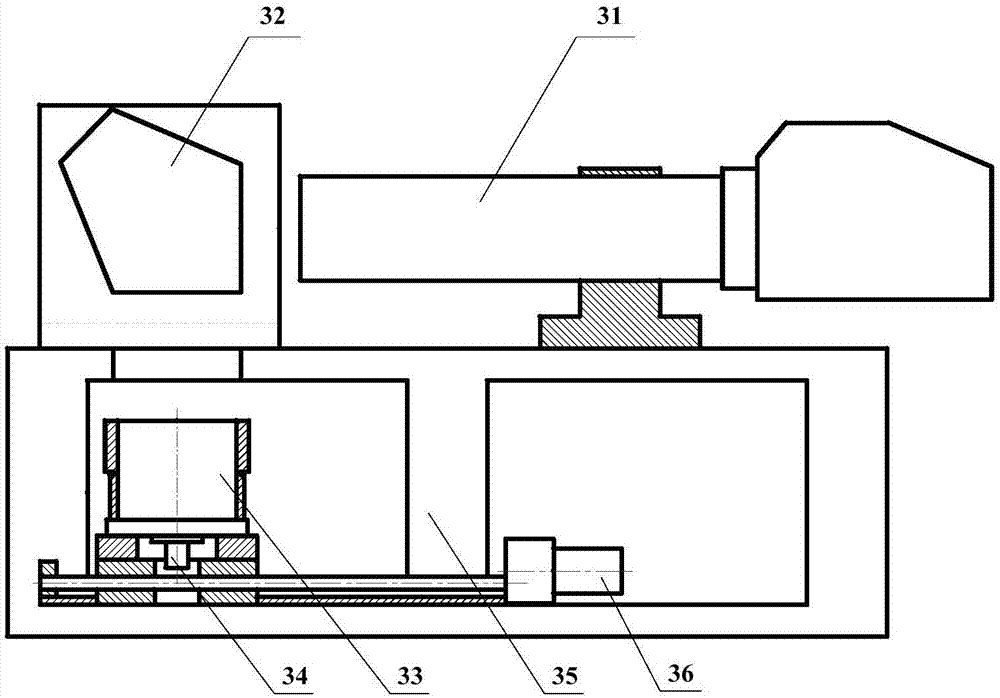

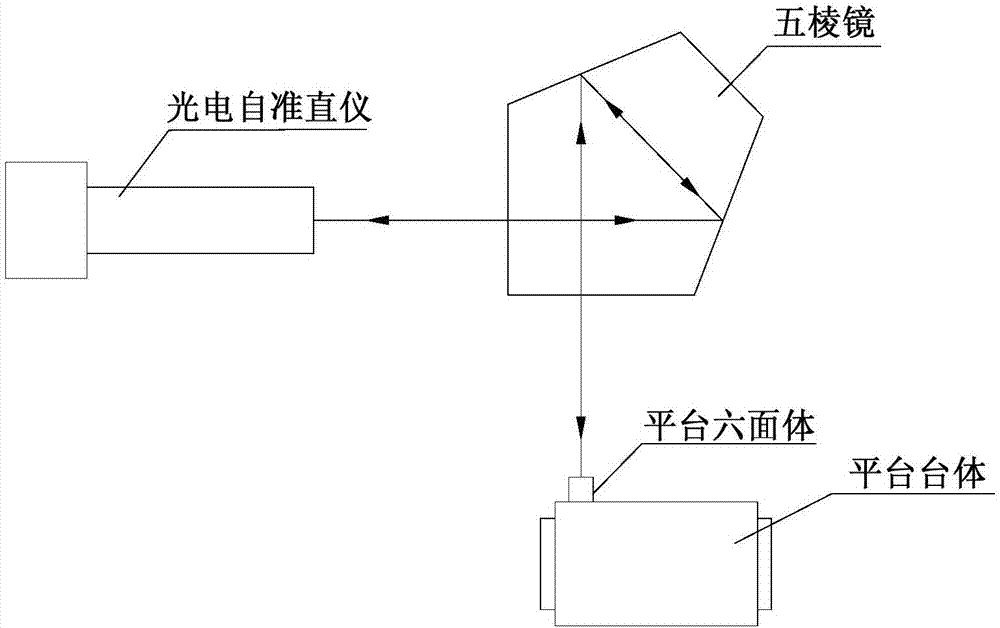

The invention provides a levelling and horizontal error testing device which comprises a base, a granite surface plate, a levelling and aiming device, a transmission system and an electric control box. The levelling and aiming device comprises a photoelectric auto-collimator, a pentaprism, a silicone oil tray, a single-axial laser alignment device and a support, wherein the photoelectric auto-collimator is used for optical aiming of platform leveling errors, the pentaprism is used for bending and turning the measuring optical axis of the photoelectric auto-collimator at 90 degrees and then aims to a platform standard hexahedron, the silicone oil tray is used for zero correction of the photoelectric auto-collimator, the single-axial laser alignment device is used for accurate alignment of the optical axis of the auto-collimator, and the support is used for installing the photoelectric auto-collimator, the pentaprism, the silicone oil tray and the single-axial laser alignment device. The levelling and horizontal error testing device can achieve automatic alignment of the optical axis, meanwhile achieves automatic measurement of leveling errors and is high in testing efficiency and good in test data consistency.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

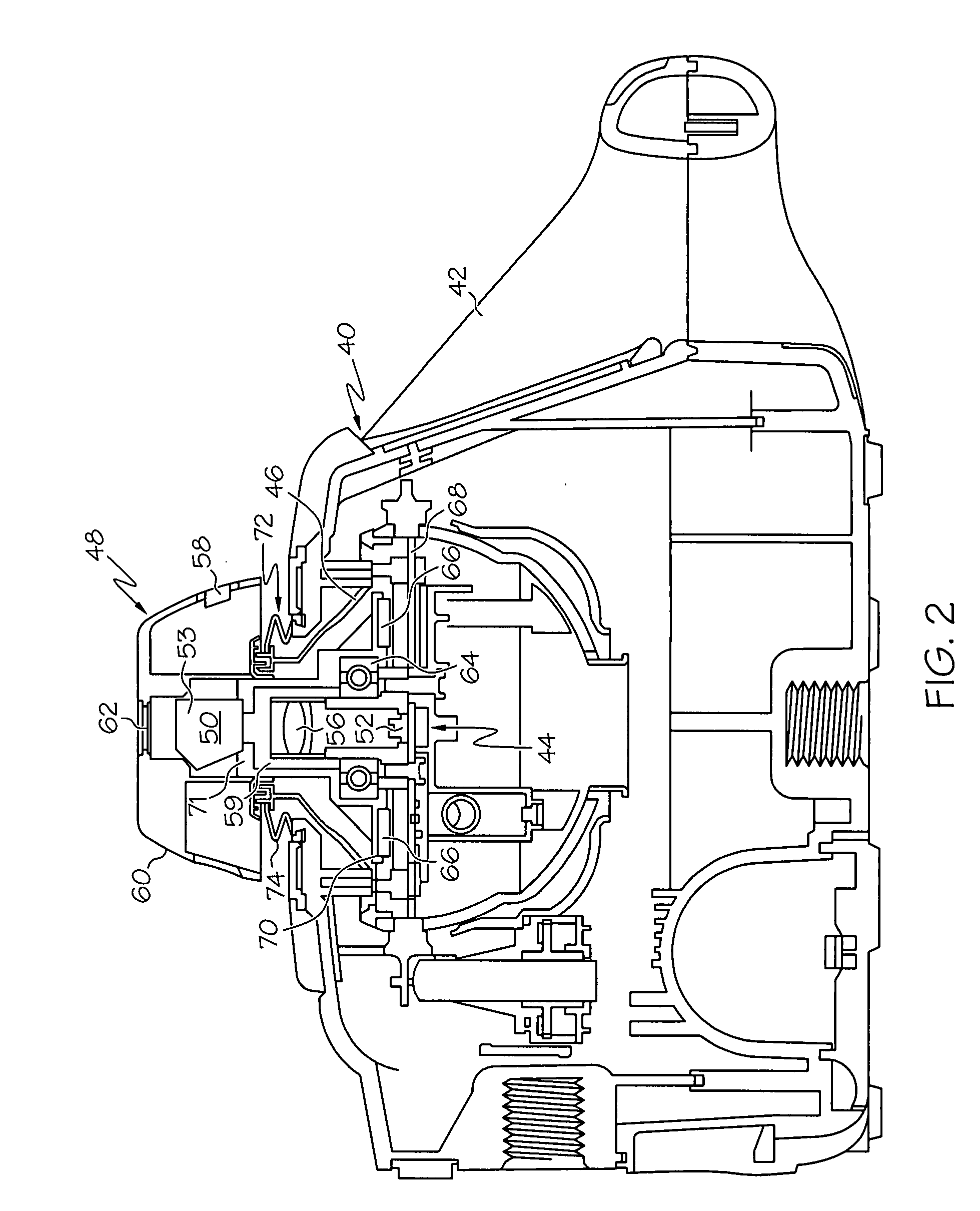

Rotating laser transmitter

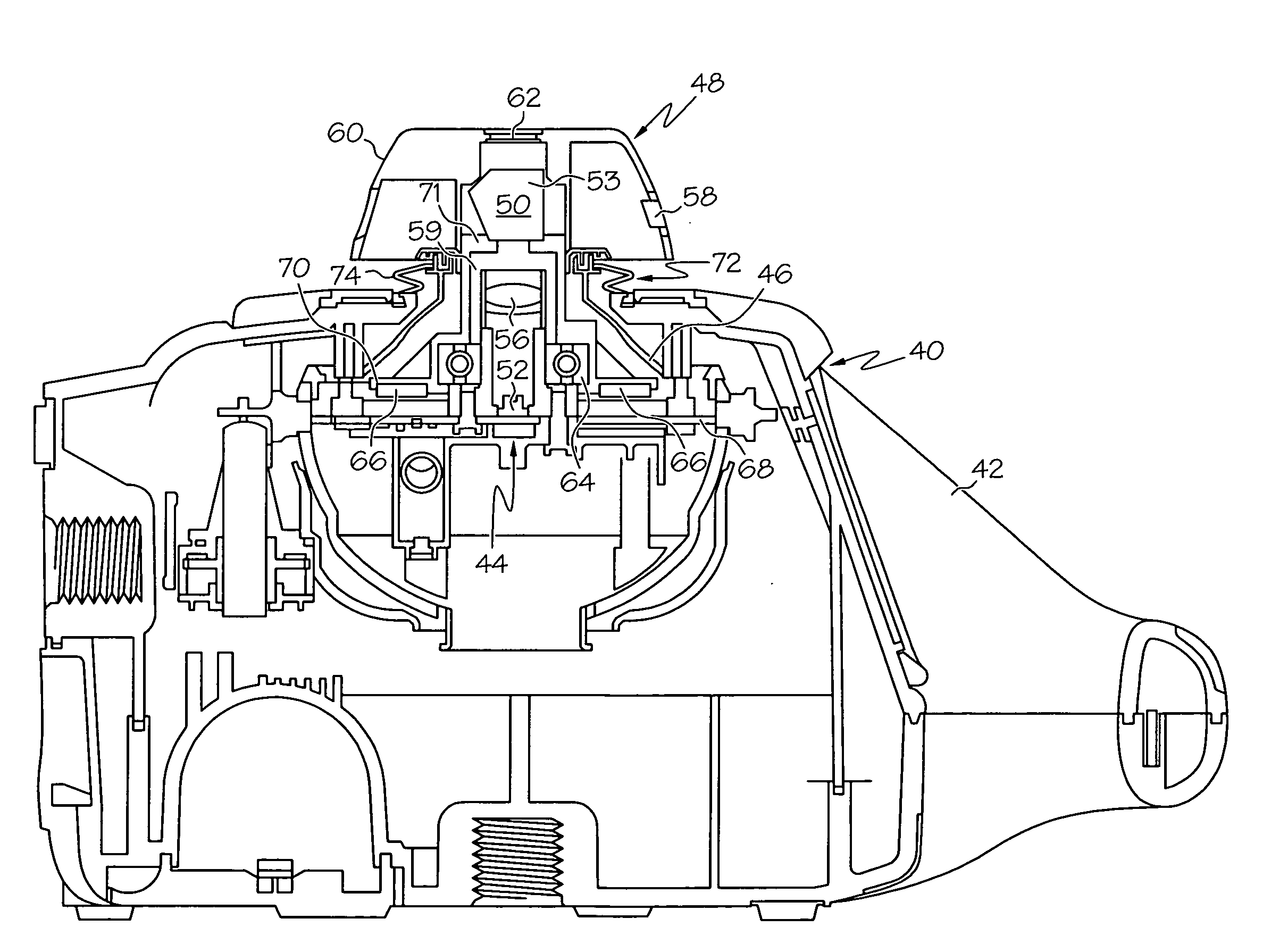

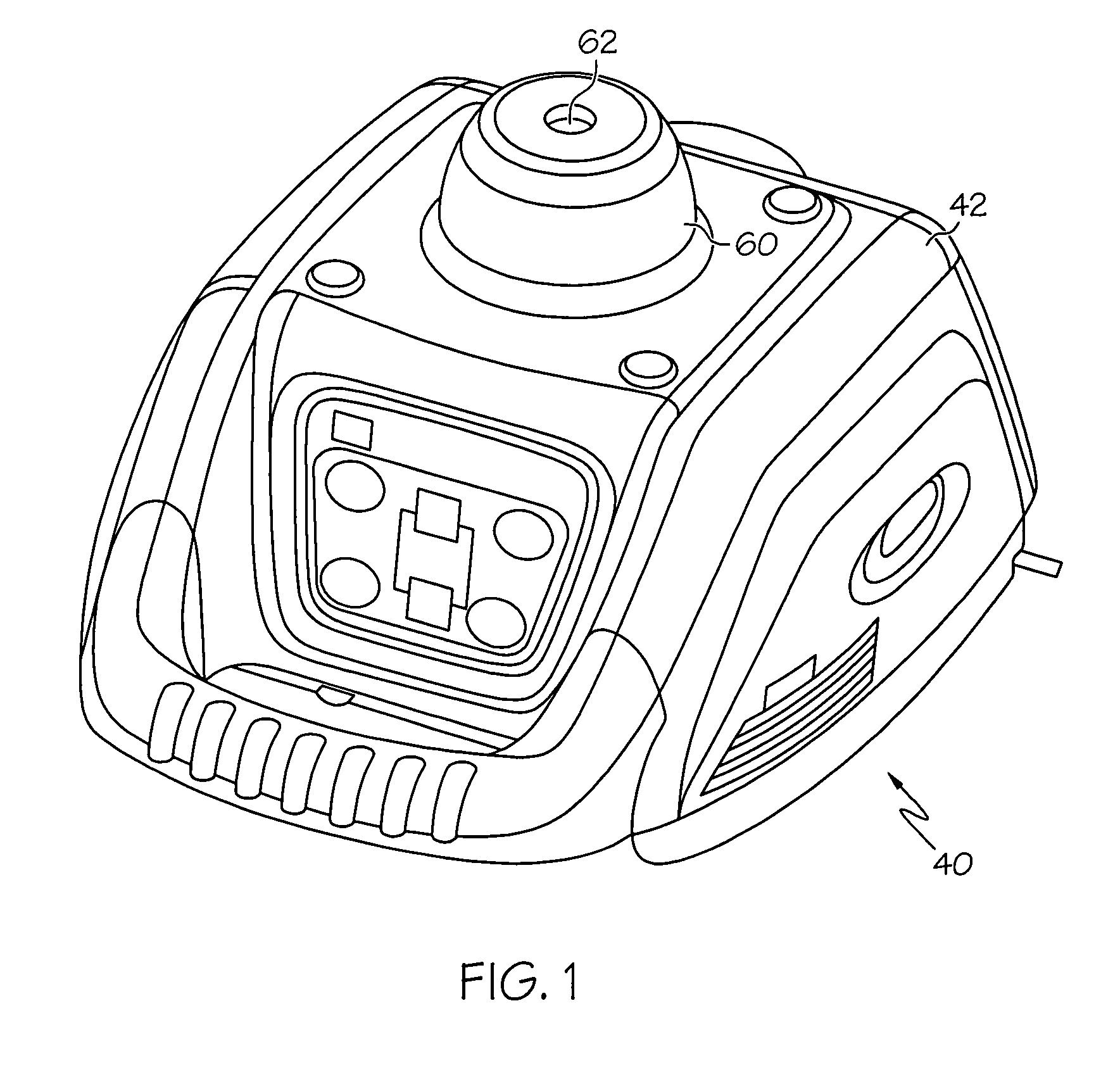

ActiveUS20090067461A1Eliminate playEasy constructionLaser detailsHeight/levelling measurementLaser transmitterLight beam

The transmitter has a generally flat, circuit board stator, a rotor including a plurality of magnets mounted in a ring around a central opening, and a bearing, supporting the rotor for rotation about an axis that extends through the central opening, A pentaprism assembly including an optics holder is mounted on the rotor for rotation therewith. The pentaprism assembly receives a beam of laser light through the central opening and redirects at least a portion of the laser light outward in a direction normal to the rotation axis. A laser source, mounted on the stator, provides a beam of laser light through the central opening to the pentaprism assembly. The beam of laser light is aligned with the rotation axis. The laser source includes a collimating lens positioned within the rotor. A shield plate of magnetic material beneath the stator exerts a force on the rotor in conjunction with the magnets, taking play out of the bearing. The transmitter uses Hall effect sensors on the stator to control switching current to coils on the stator. The transmitter also uses the outputs of the Hall effect sensors and a timer output to control dithering of the laser beam.

Owner:SPECTRA PRECISION (USA) LLC

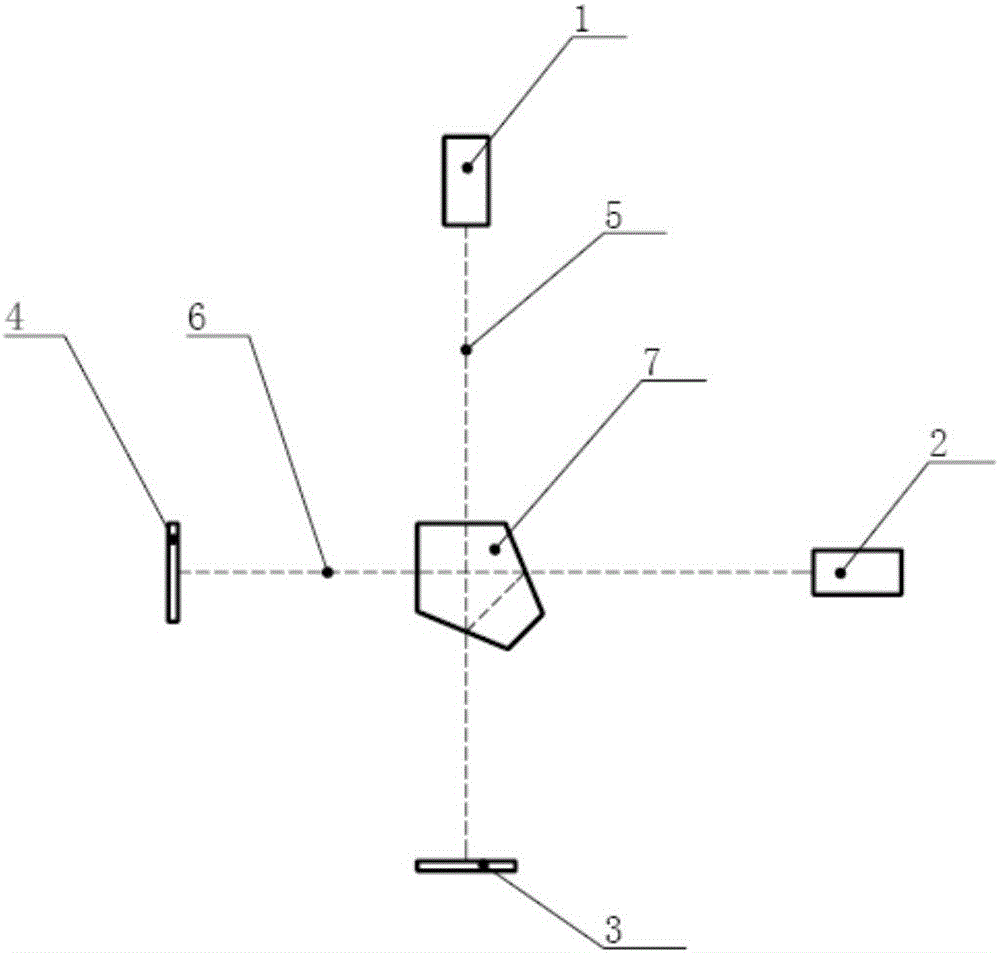

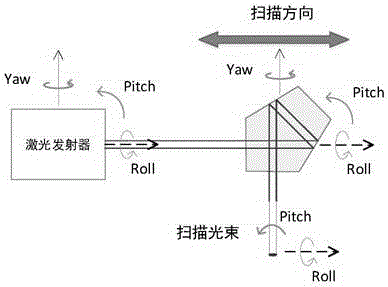

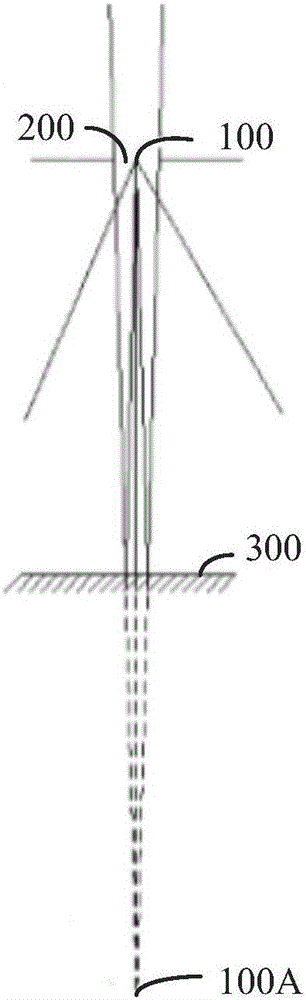

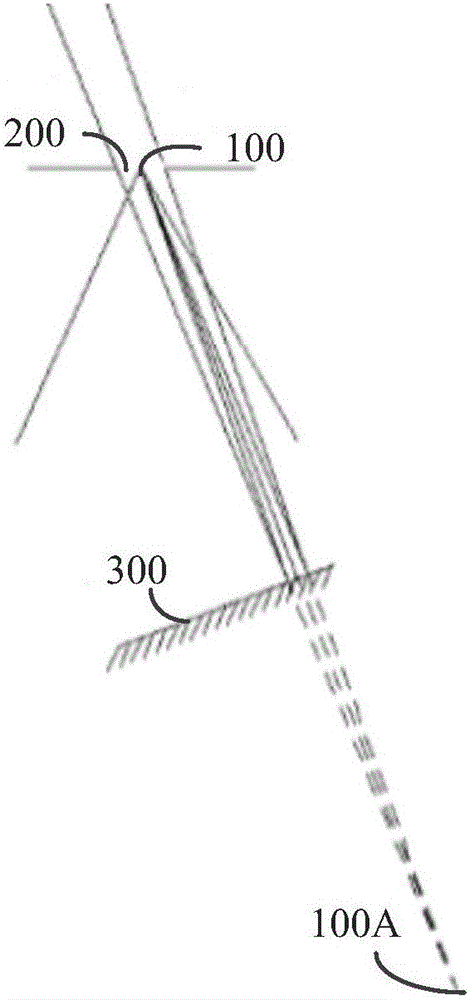

Orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing

ActiveCN106735961AEasy to implementHigh measurement accuracyLaser beam welding apparatusLaser processingClassical mechanics

The invention provides an orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing. The calibrating method comprises the steps that a pentaprism is arranged at the intersection of the rotation axes of two pendulum shafts, and after the rotation axis of one of the pendulum shafts is reflexed by 90 degrees through the pentaprism, the actual included angle between the rotation axes of the two orthogonal pendulum shafts can be calibrated through an autocollimator arranged on the rotation axis of the other pendulum shaft. According to the orthogonal double-pendulum shaft calibrating and debugging method as well as reflector assembling and adjusting method for laser processing, special optical equipment do not need to be adopted when the actual included angle between the laser processing orthogonal double-pendulum shafts is calibrated, and the calibrating method is simple.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

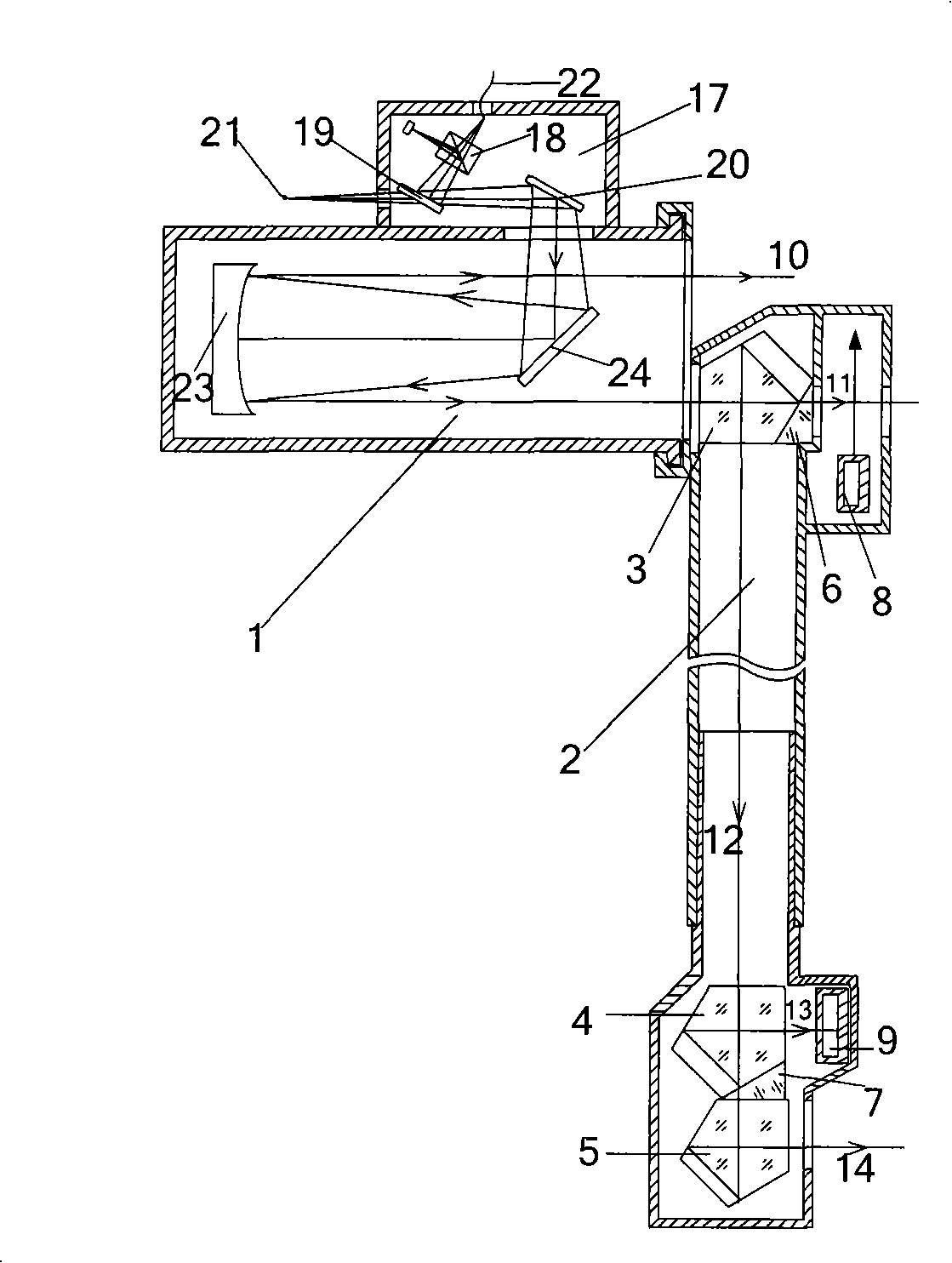

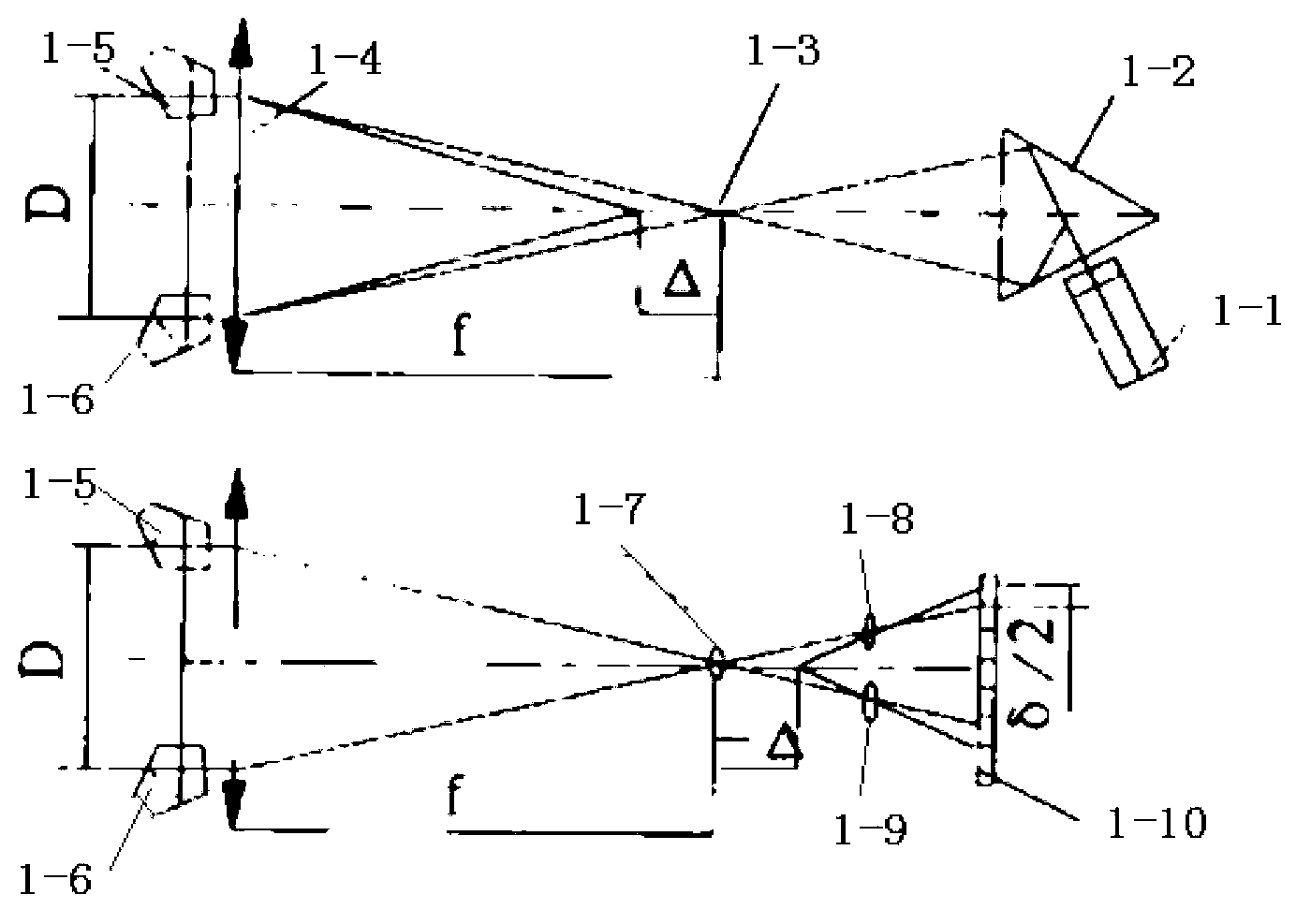

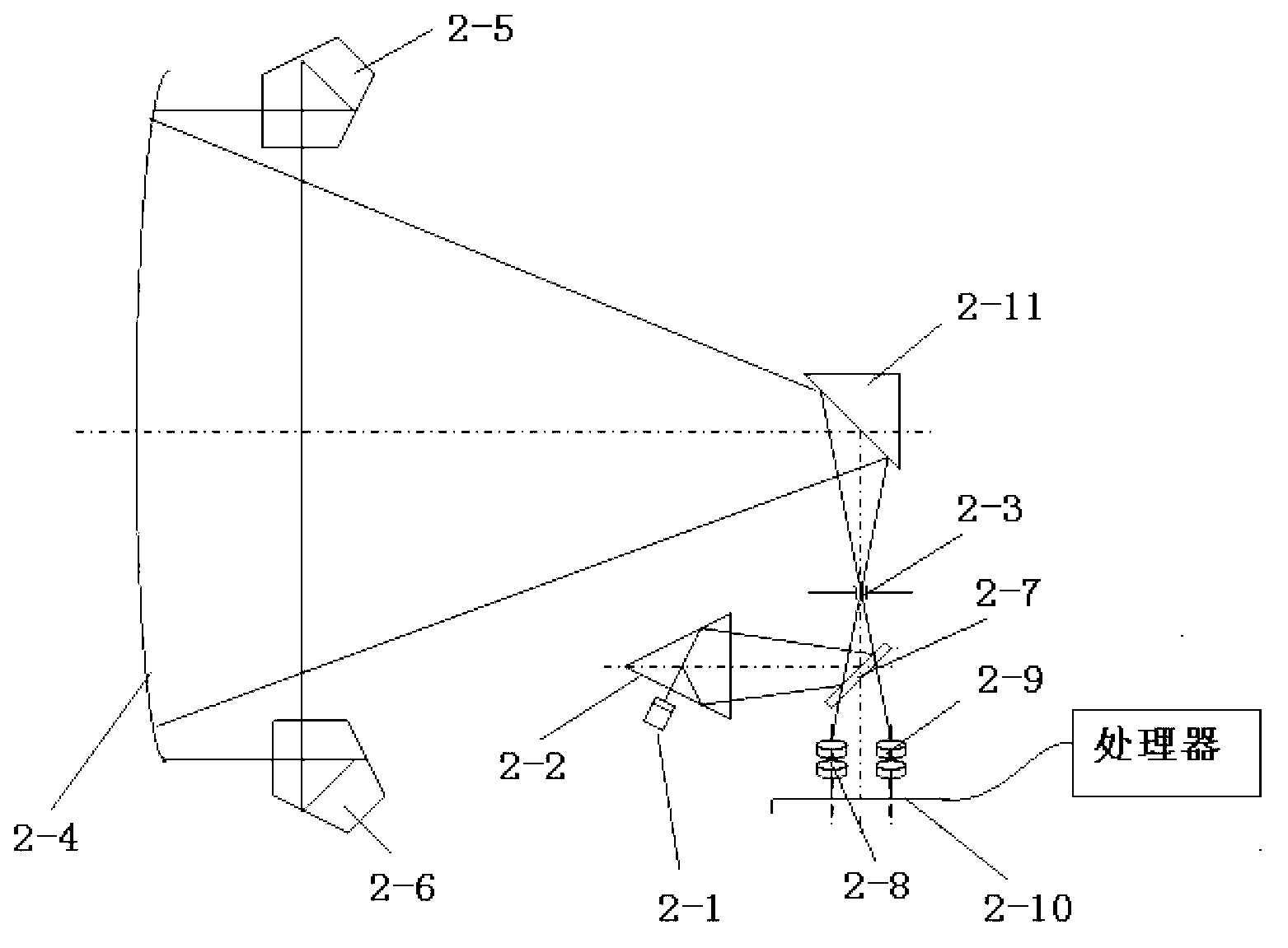

Large-caliber long-focus collimator focal point real-time monitoring system

InactiveCN102840964AReduce the impactDoes not affect relative positionOptical apparatus testingOptical elementsBunchesPentaprism

The invention relates to a large-caliber long-focus collimator focal point real-time monitoring system. A laser device of the system emits laser beams, and the laser beams are divided into two bunches of lasers through a laser beam splitter. The two bunches of lasers pass through a slit after being reflected by a semi-reflecting and semi-transparent lens, and then are reflected to a main lens of the collimator through a reflecting lens. The two bunches lasers reflected by the main lens are reflected four times in turnover mode by two pentaprisms, and then are reflected back through the main lens. The two bunches lasers pass through the slit again after being reflected by the reflecting lens, and pass through two sets of dialyte lenses behind the semi-reflecting and semi-transparent lens and are converged on a charge coupled device (CCD). A processor calculates the distance between two faculaes according to image data received by the CCD, and then size and direction of defocusing amount can be obtained. An emitting light path and a receiving light path are in the same plane, and relative positions of elements are easy to guarantee when the large-caliber long-focus collimator focal point real-time monitoring system is mounted so as to reduce mounting and adjusting difficulty of the whole system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

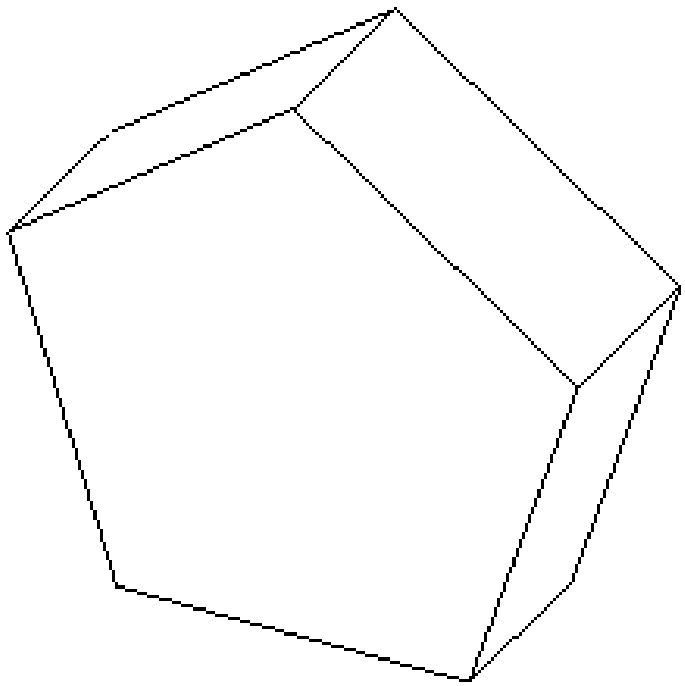

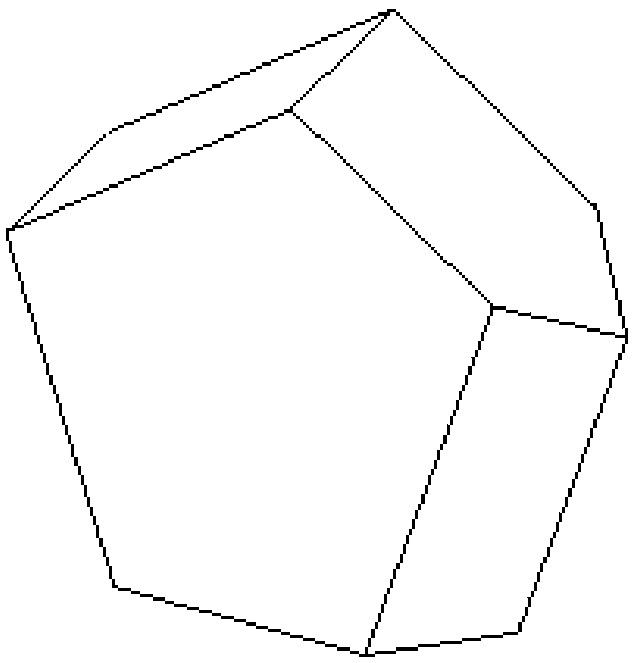

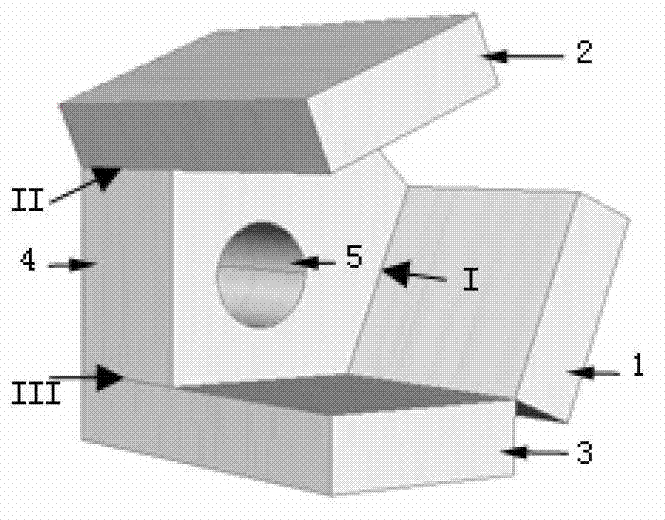

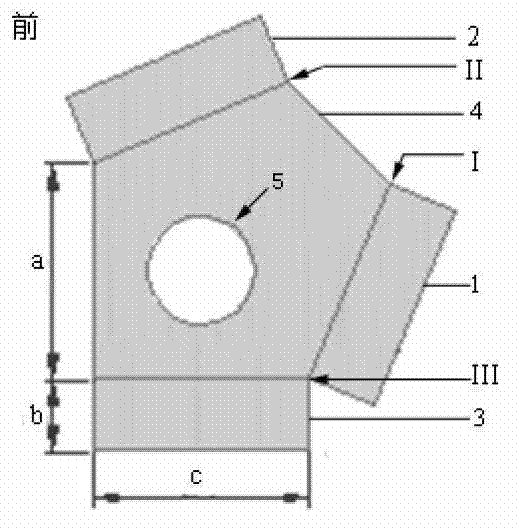

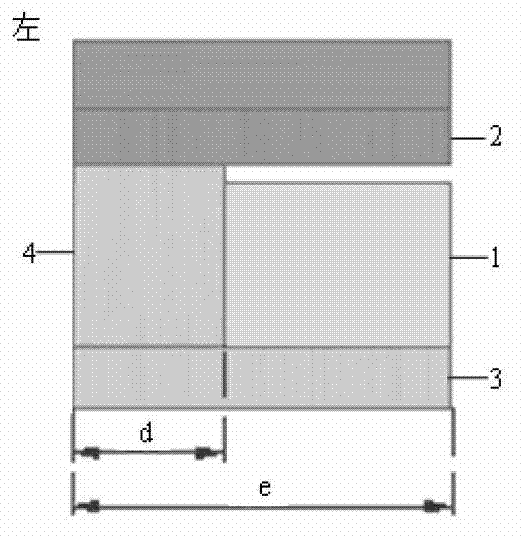

Pentaprism production process

The invention discloses a pentaprism production process which solves the problem that a pentaprism does not meet requirements as an existing machining process is complicated and softening temperature is improperly controlled. The pentaprism production process includes the steps: (1) cutting raw materials into small glass blanks by a cutting machine; (2) grinding corners of the glass blanks; (3) coating boron nitride powder on the surfaces of the glass blanks; (4) feeding the coated glass blanks into a softening furnace for softening; (5) profiling the softened glass blanks in a profiling mould to form an initial product; (6) annealing the initial product. The annealing temperature is 10-20 DEG C lower than a glass softening point. The cutting machine is used for cutting the raw materials, the same sizes and weights of the glass blanks are effectively ensured, so that division and rolling procedures are decreased, manpower cost is greatly saved, and machining time is shortened.

Owner:成都恒达光学有限公司

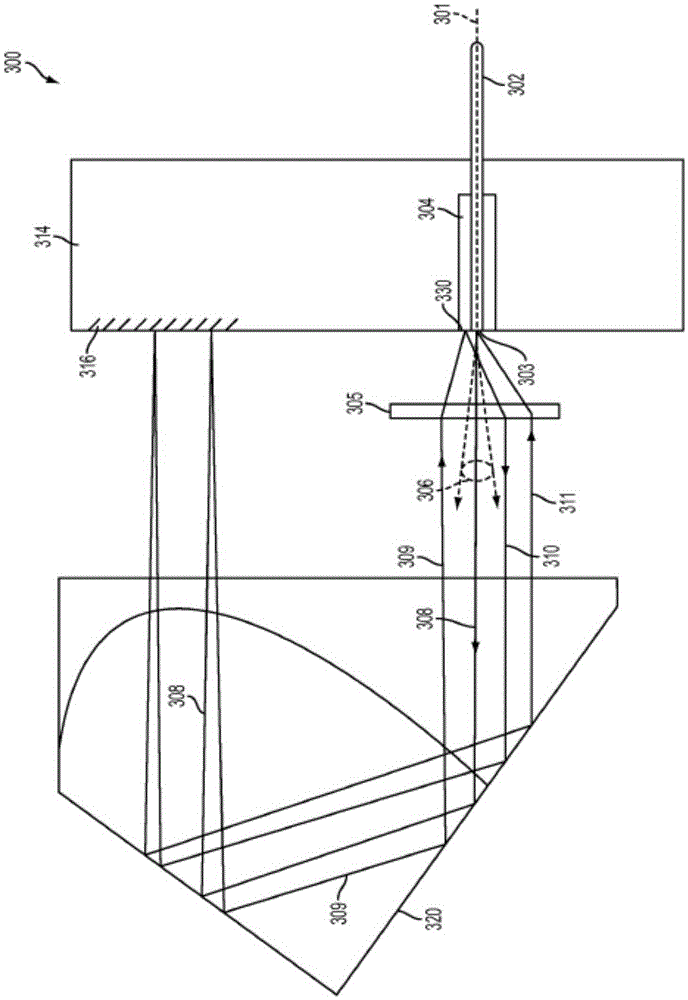

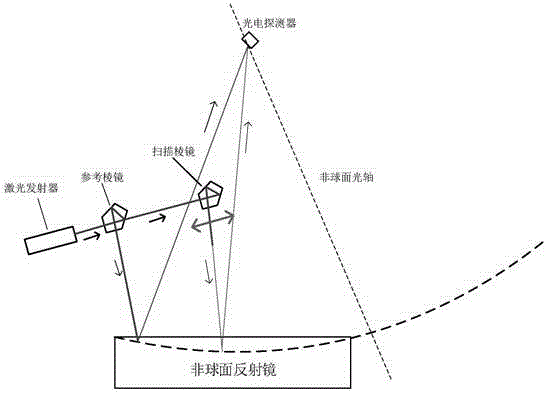

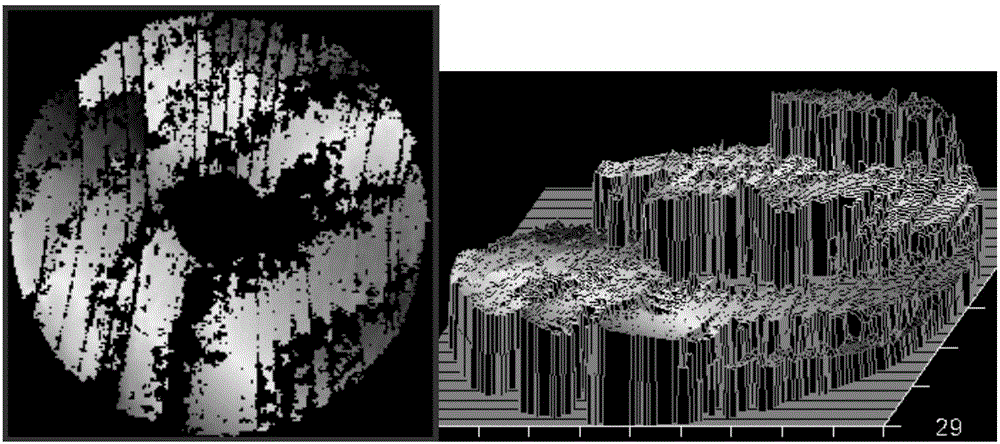

Pentaprism scanning detection method for aspheric reflector

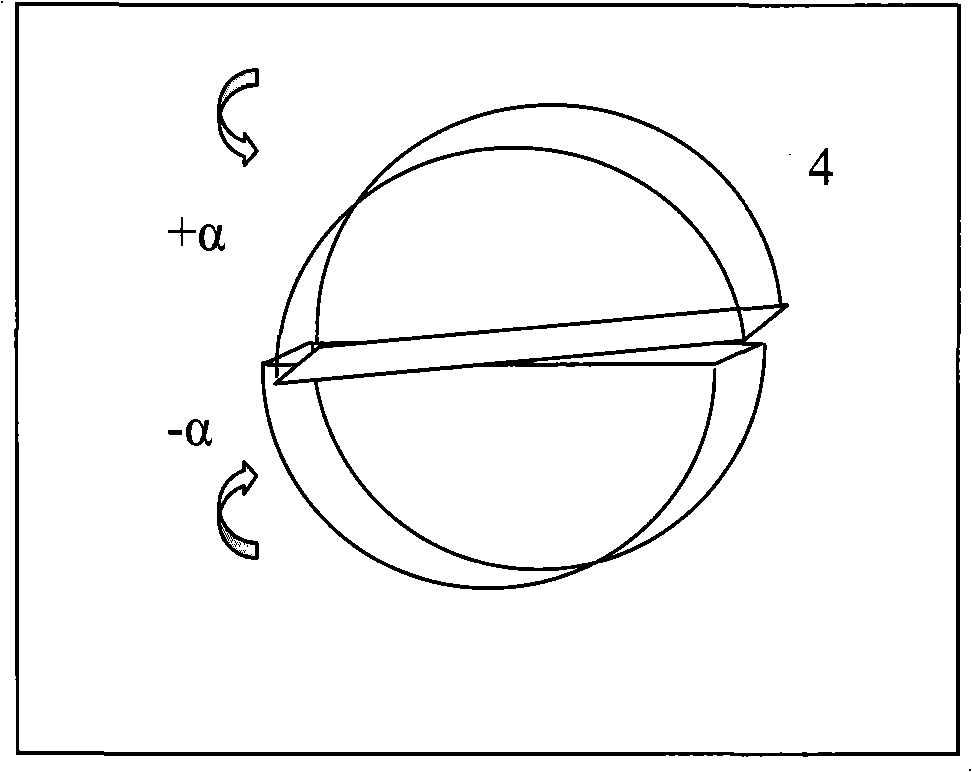

InactiveCN106225715AMeet the detection rangeMeet precision requirementsUsing optical meansFace shapePhysics

The present invention discloses a pentaprism scanning detection method for an aspheric reflector. The method comprises: 1) arranging a device required for detection; 2) performing scanning detection of a single bus; 3) performing scanning detection of the next bus of the rotation angle a of the aspheric reflector after the scanning of the single bus is completed; and 4) performing detection data processing and fitting. All the angle differences are transited to the slope values of the corresponding positions of the reflective surface of the aspheric reflector, the slope values are fitted with the Zernike gradient polynomial, and the low-order surface-shaped error parameters of the aspheric reflector are obtained. The high-precision low-order surface-shaped error parameters of the aspheric reflector can be obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

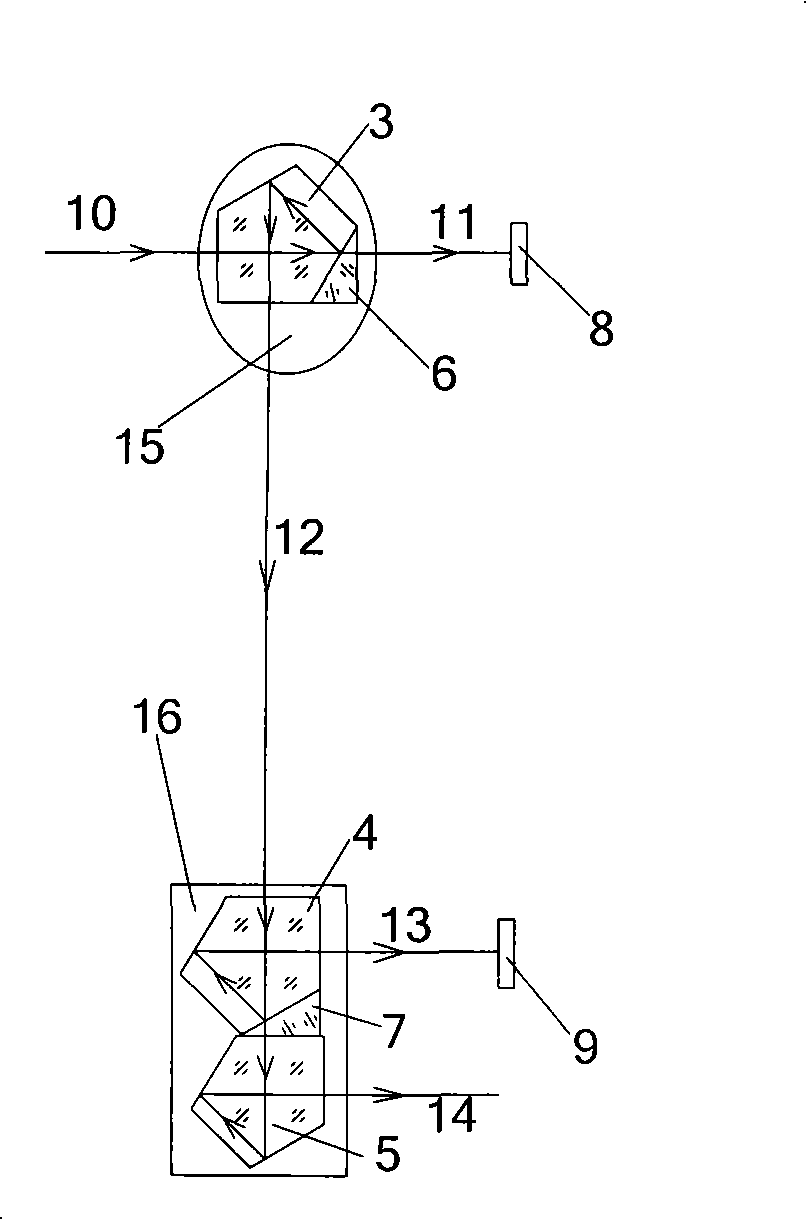

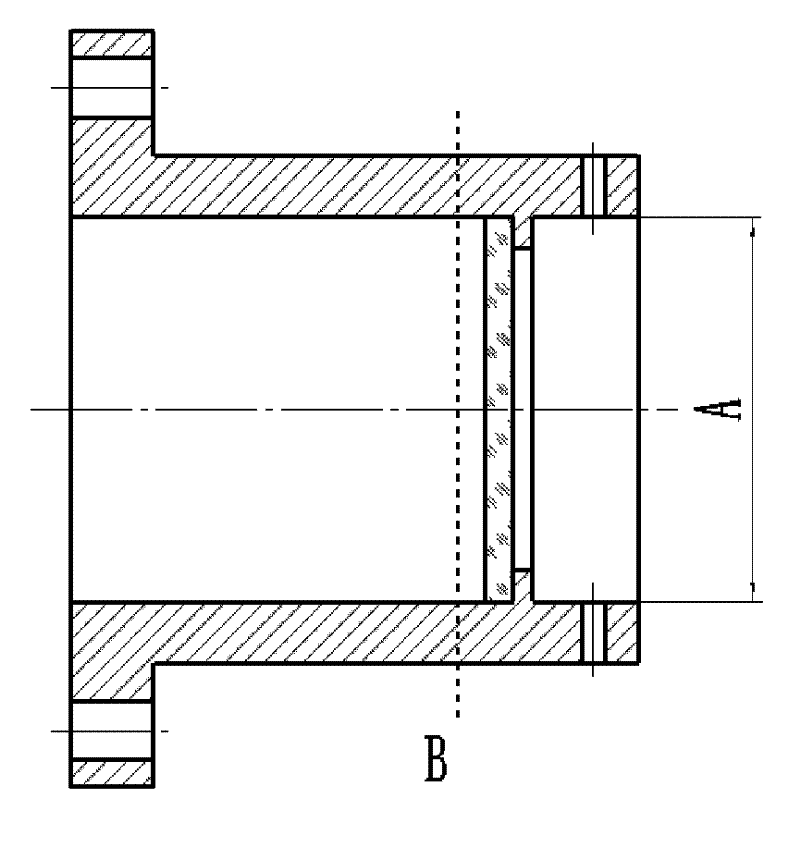

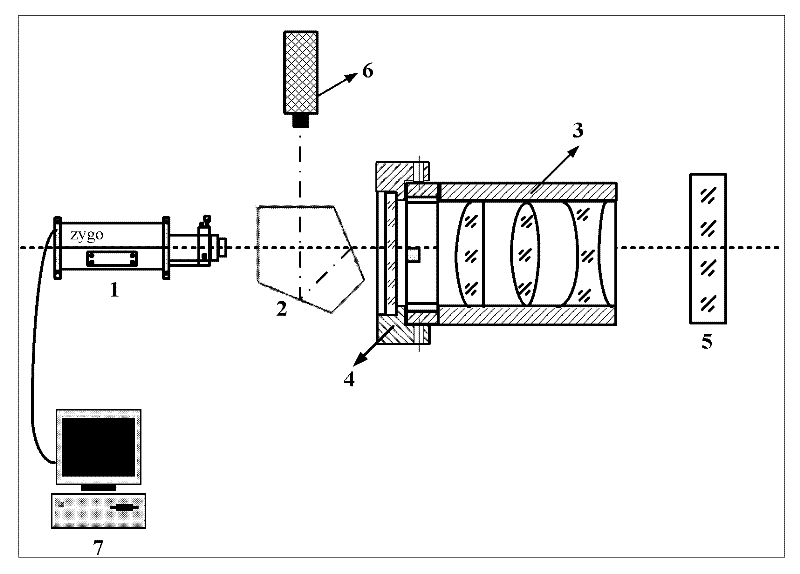

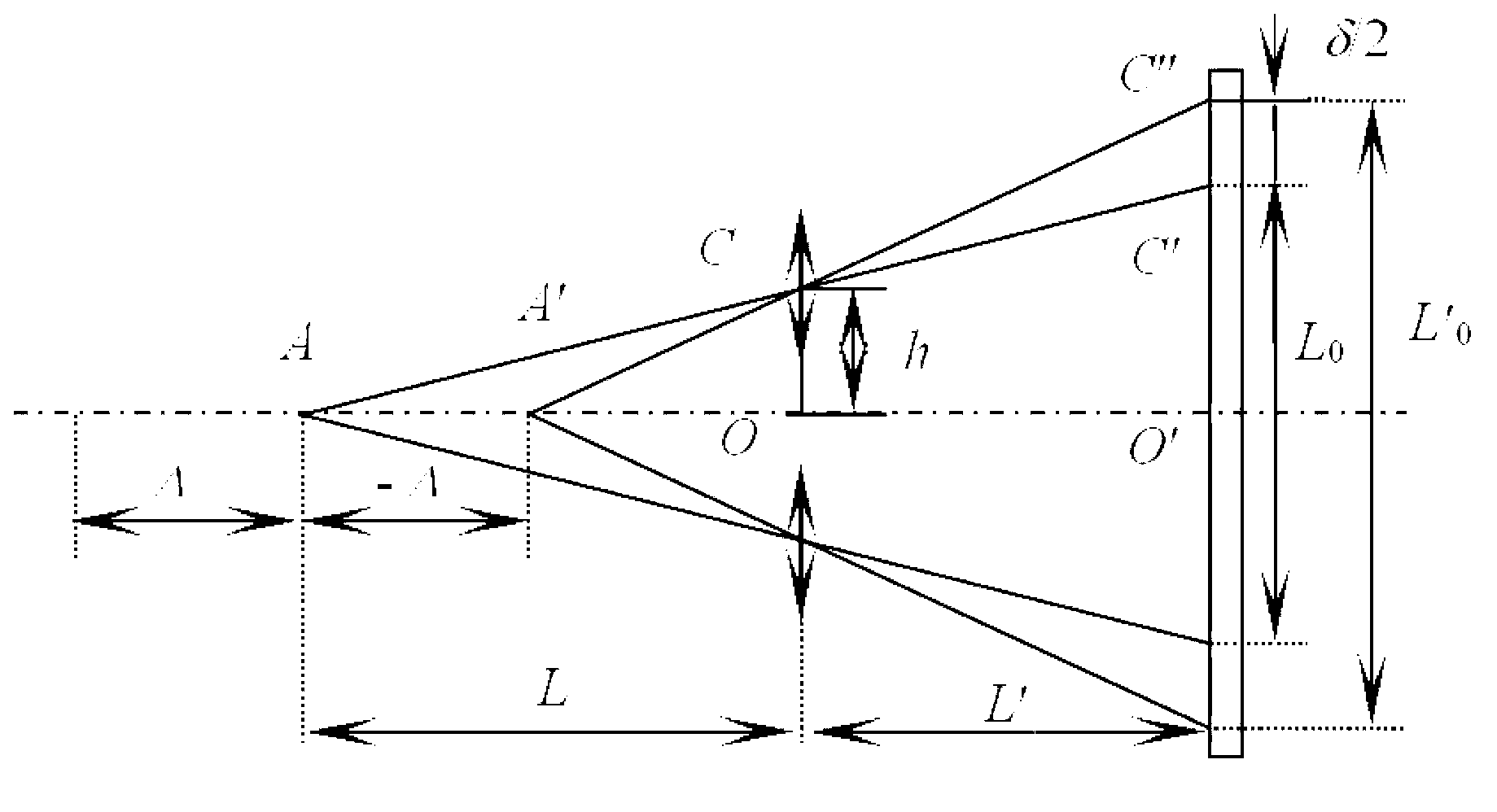

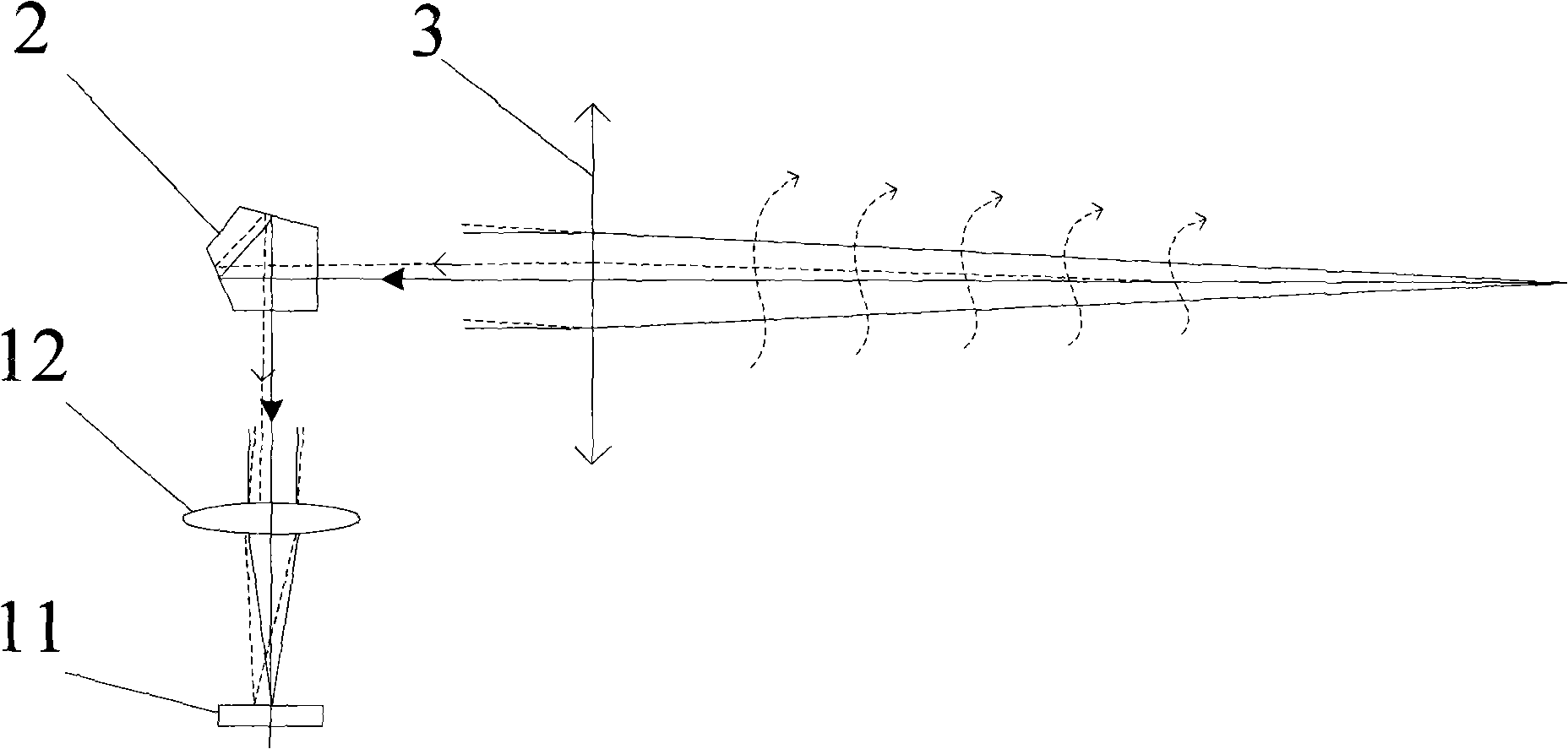

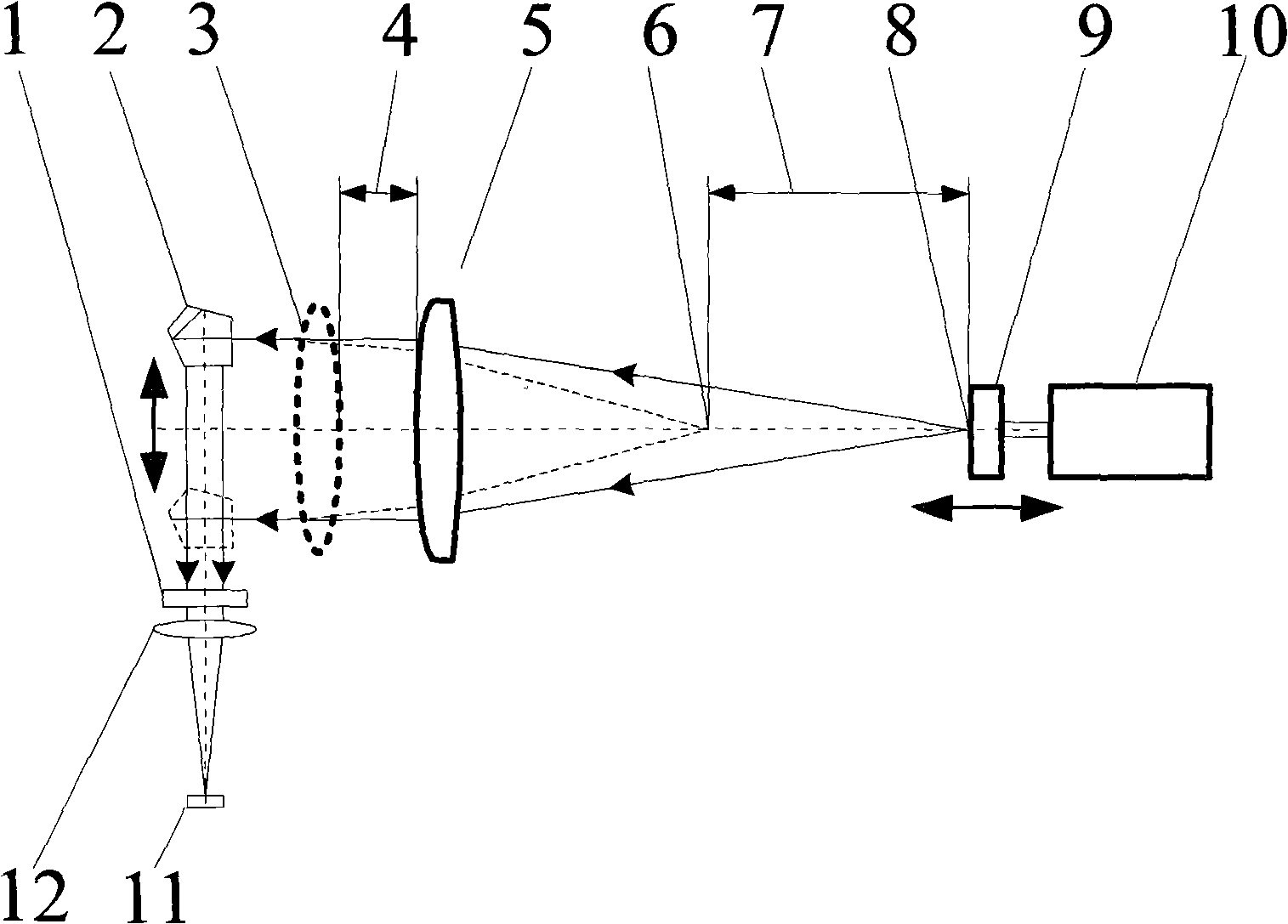

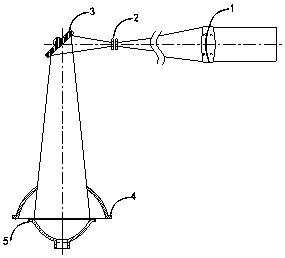

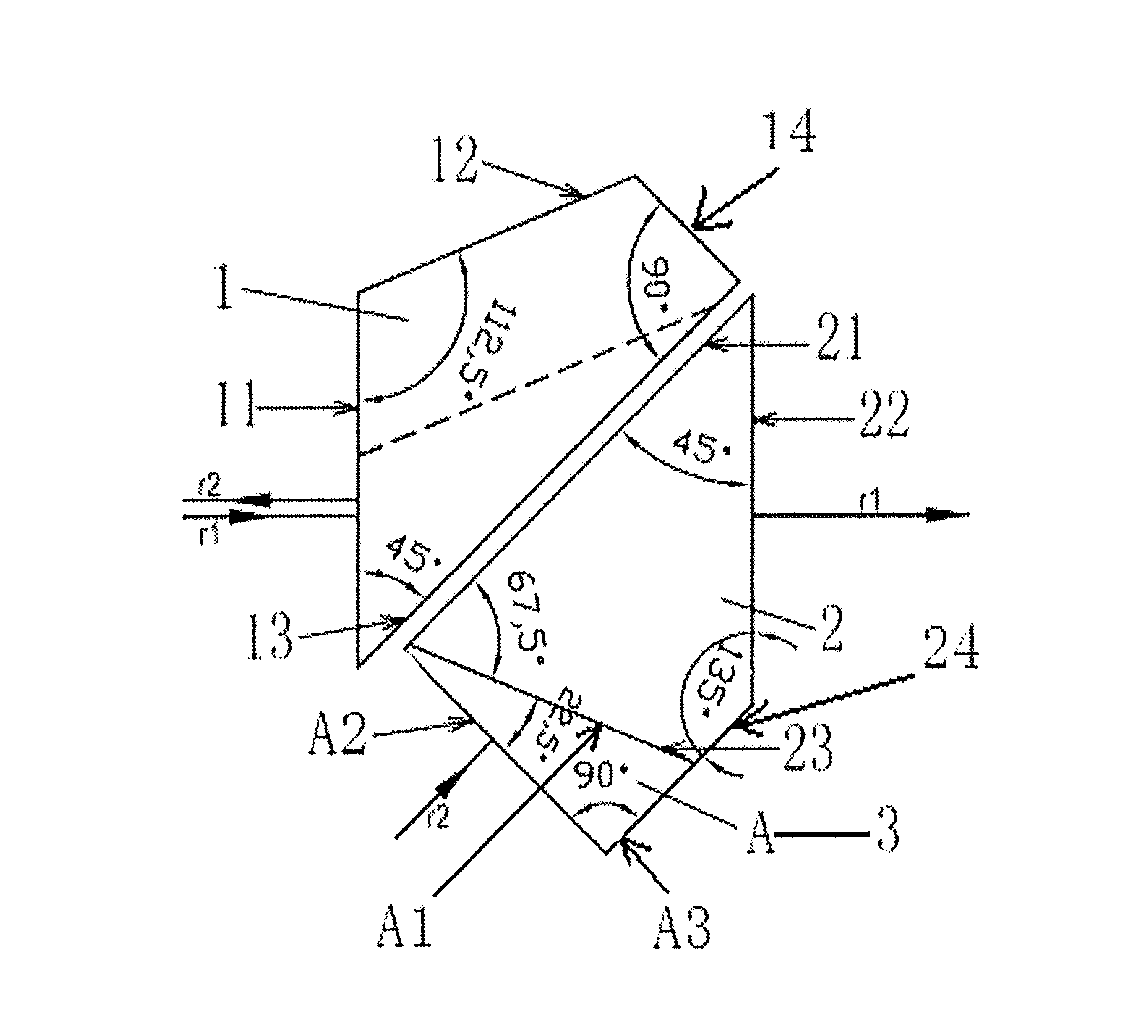

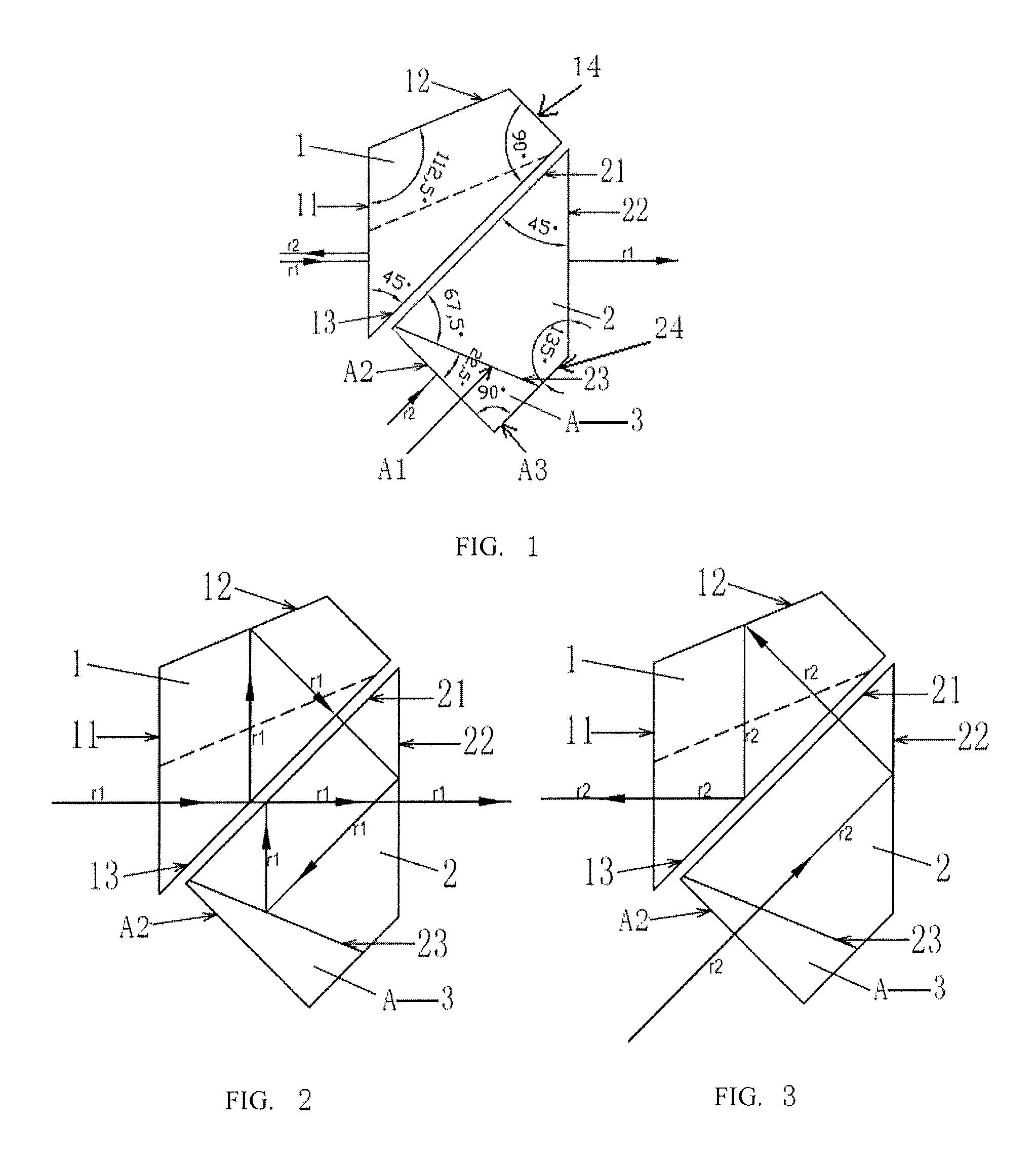

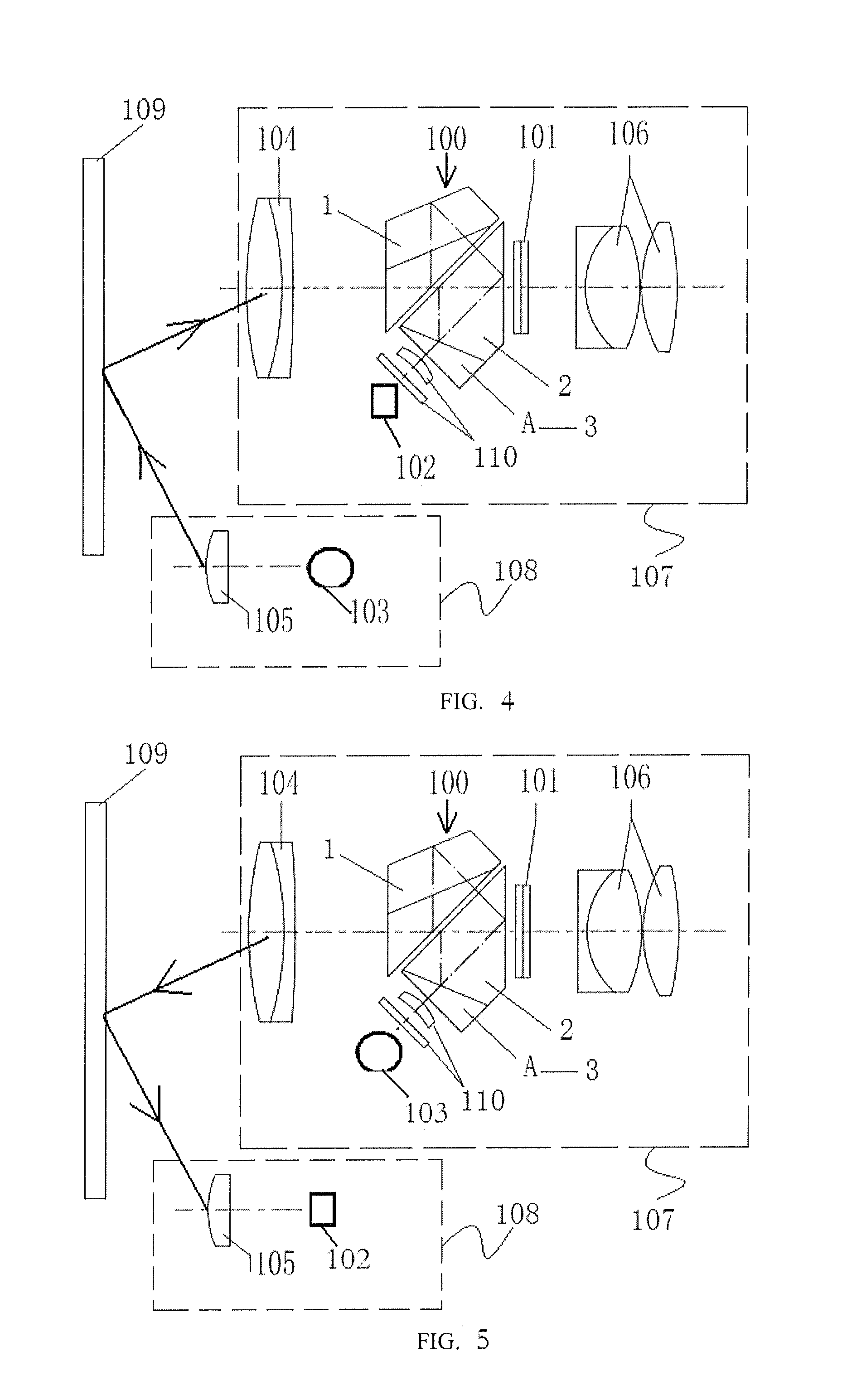

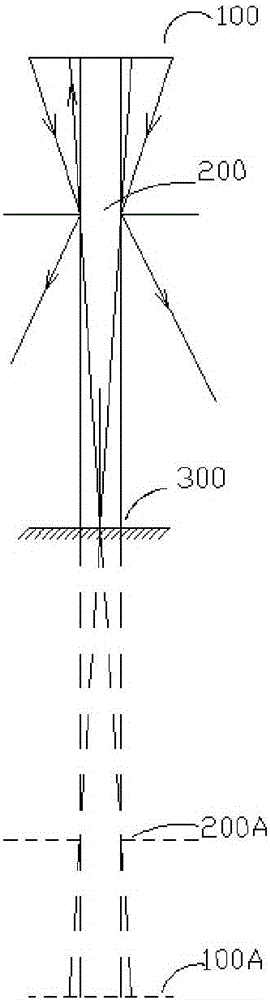

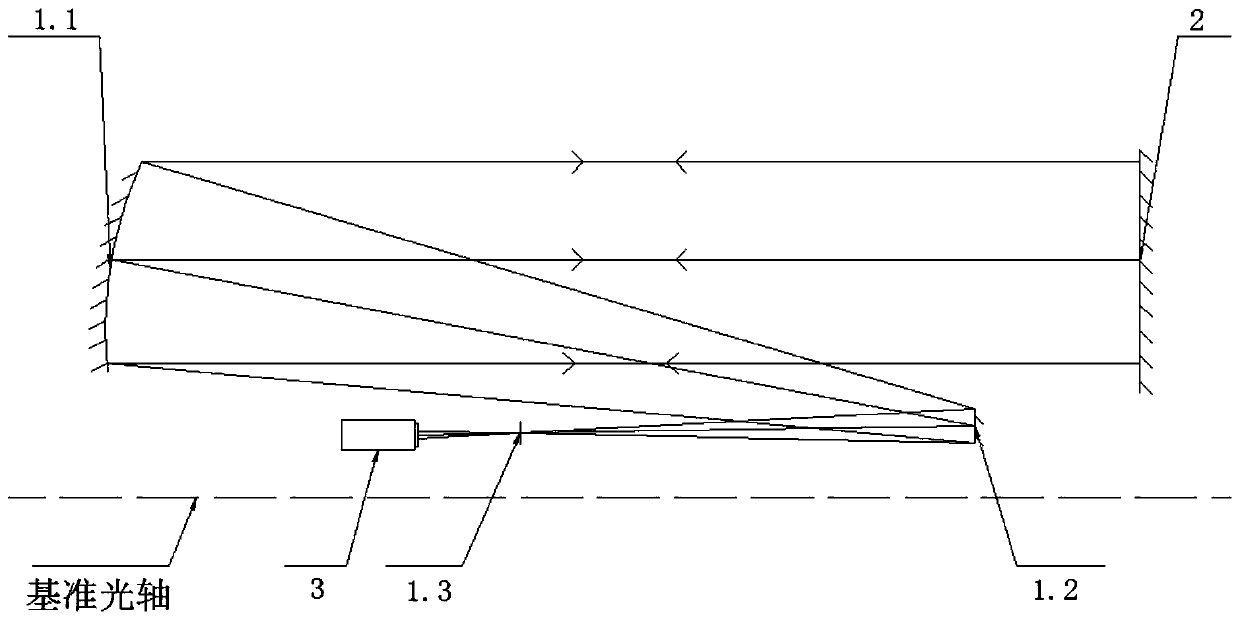

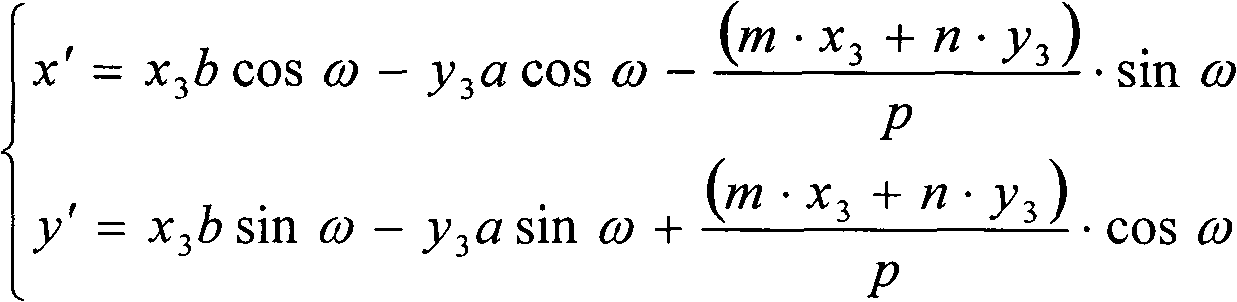

Pentaprism combination ultralong focal-length measurement method and apparatus

InactiveCN101493376AImprove anti-interference abilityHigh sensitivityTesting optical propertiesHigh resistanceOptical axis

The invention belongs to the technical field of optical precision measurement and relates to a measuring method of an ultralong focal length of a penta prism combination, and a measuring device thereof. The method integrates a penta prism focus fixing method and an ultralong focal length measuring technology of a composite lens and helps realize low-cost and high-precision ultralong focal length measurement of large-caliber lenses. The method helps transform a focus fixing process in an optical axis direction into a variance measurement process of an imaging position in a vertical optical axis direction by using the penta prism to refract an optical path, and is further combined with the ultralong focal length measuring technology of the composite lens to compress length of the optical path and improve measurement resolution. The measuring device comprises a light source, the penta prism, a reference lens, an alignment target, a CCD detector and a collimator mirror, has the advantages of simple optical path structure, less aberration introduced by an optical component, less systematic error, high measurement sensitivity, high resistance to ambient interference, and can be applied to detection of the ultralong focal length lens and high-precision focal length measurement during assembling an optical system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Installing and adjusting method for collimation type solar simulator optical system

ActiveCN108506893AImprove simulation accuracyGuaranteed optical axis consistencyLighting device detailsTheodoliteLight energy

The invention discloses an installing and adjusting method for a collimation type solar simulator optical system. A reference optical axis is established through a theodolite I and a theodolite II, and a pentaprism, a guide rail, a tool reflector and a laser device are matched to conduct installing and adjusting capable of guaranteeing optical axis consistency on a collimator objective, an opticalintegrator, a steering plane reflector, a spherical reflector and an ellipsoid collecting lens, and the light energy utilization rate and irradiation uniformity of a collimation type solar simulatorcan be effectively improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

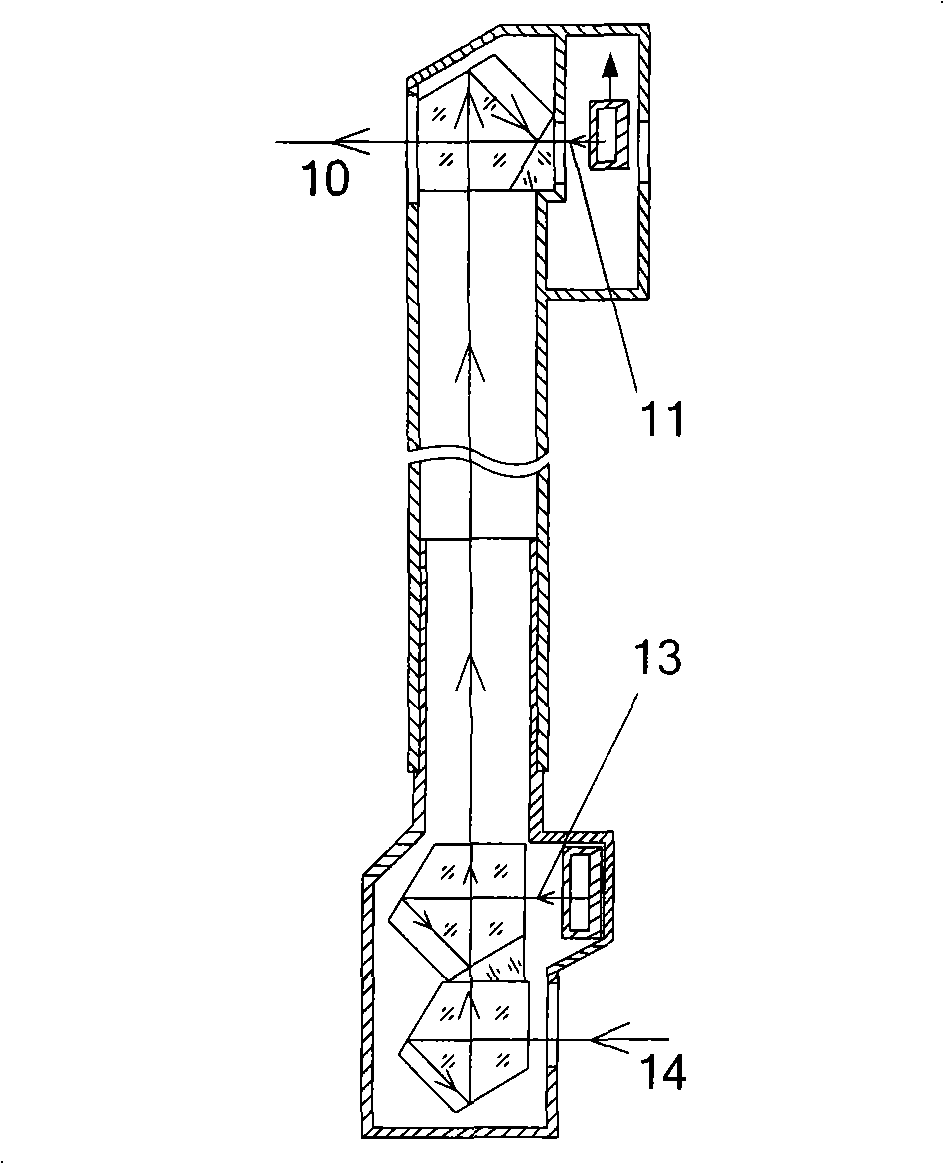

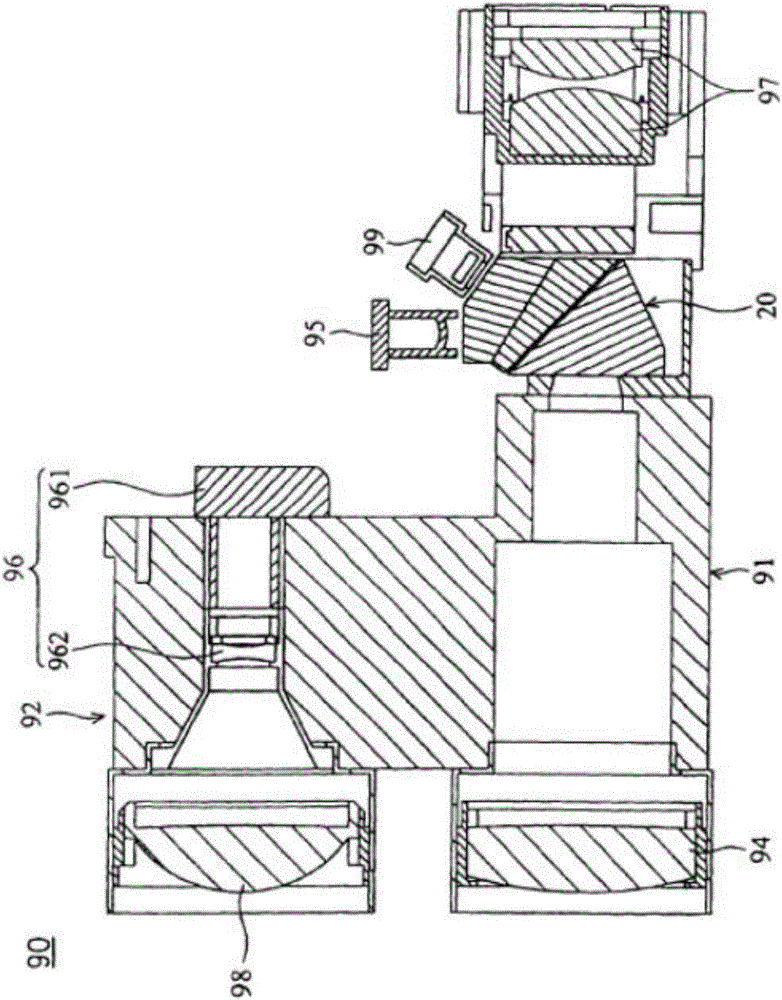

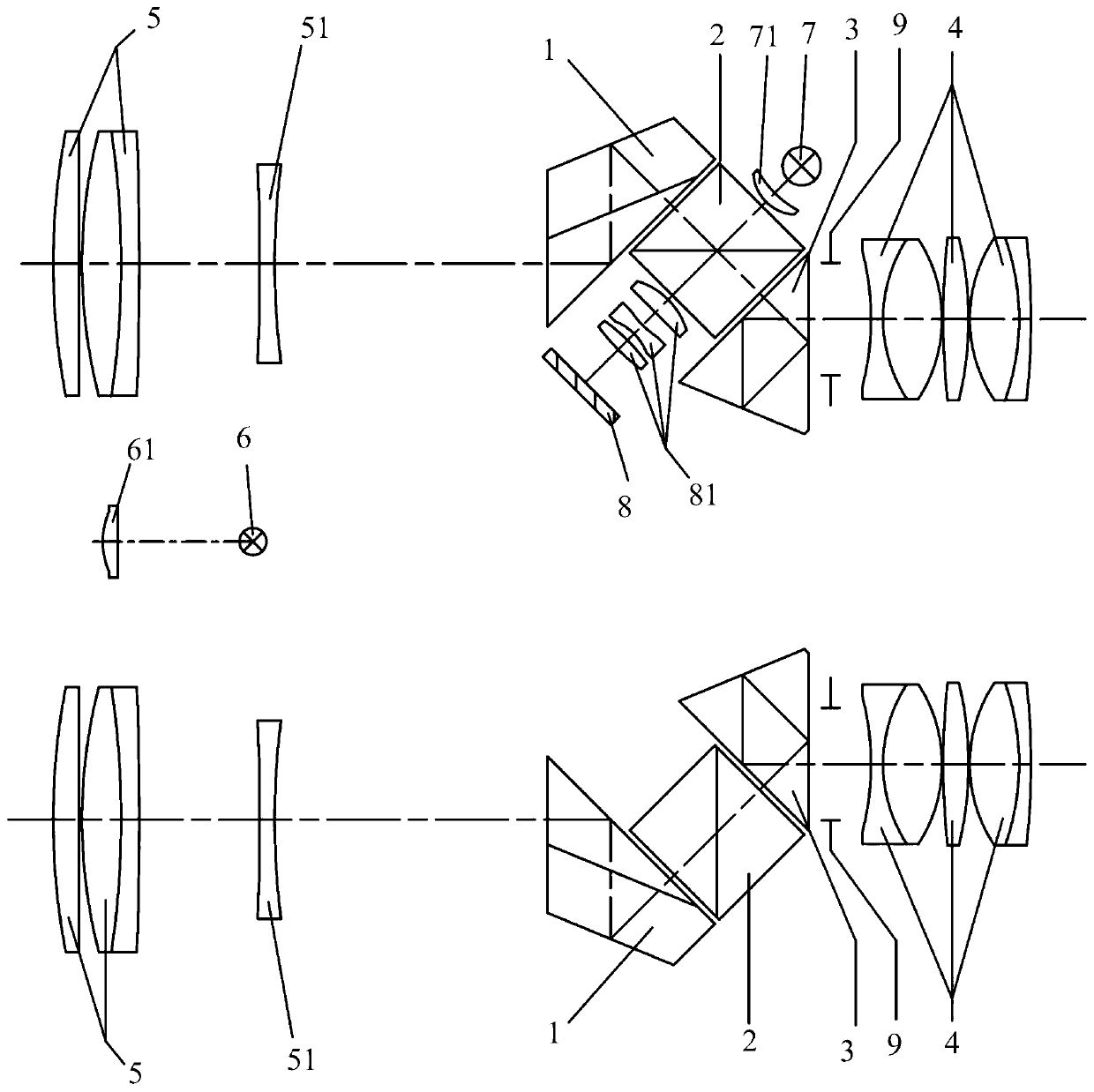

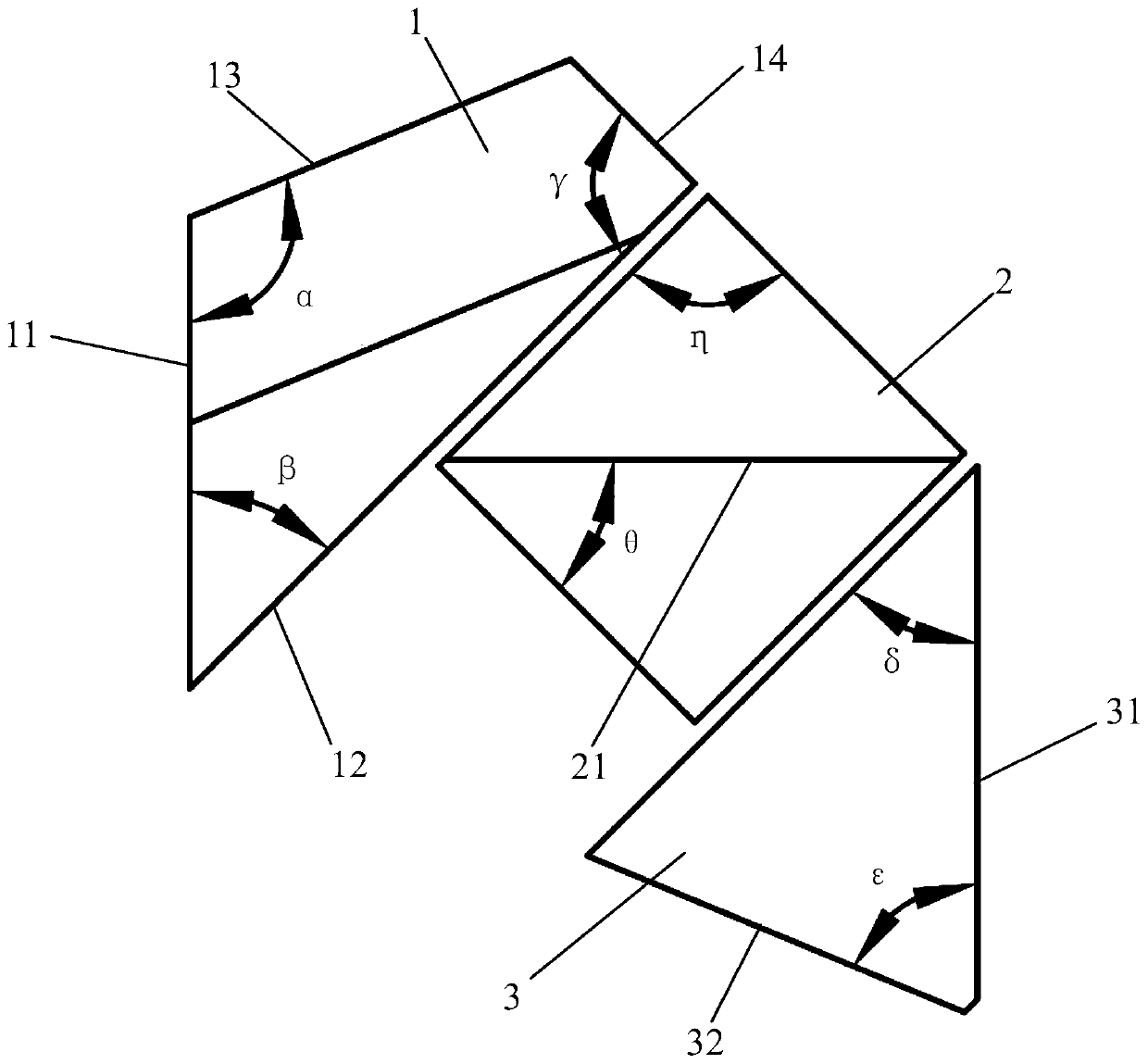

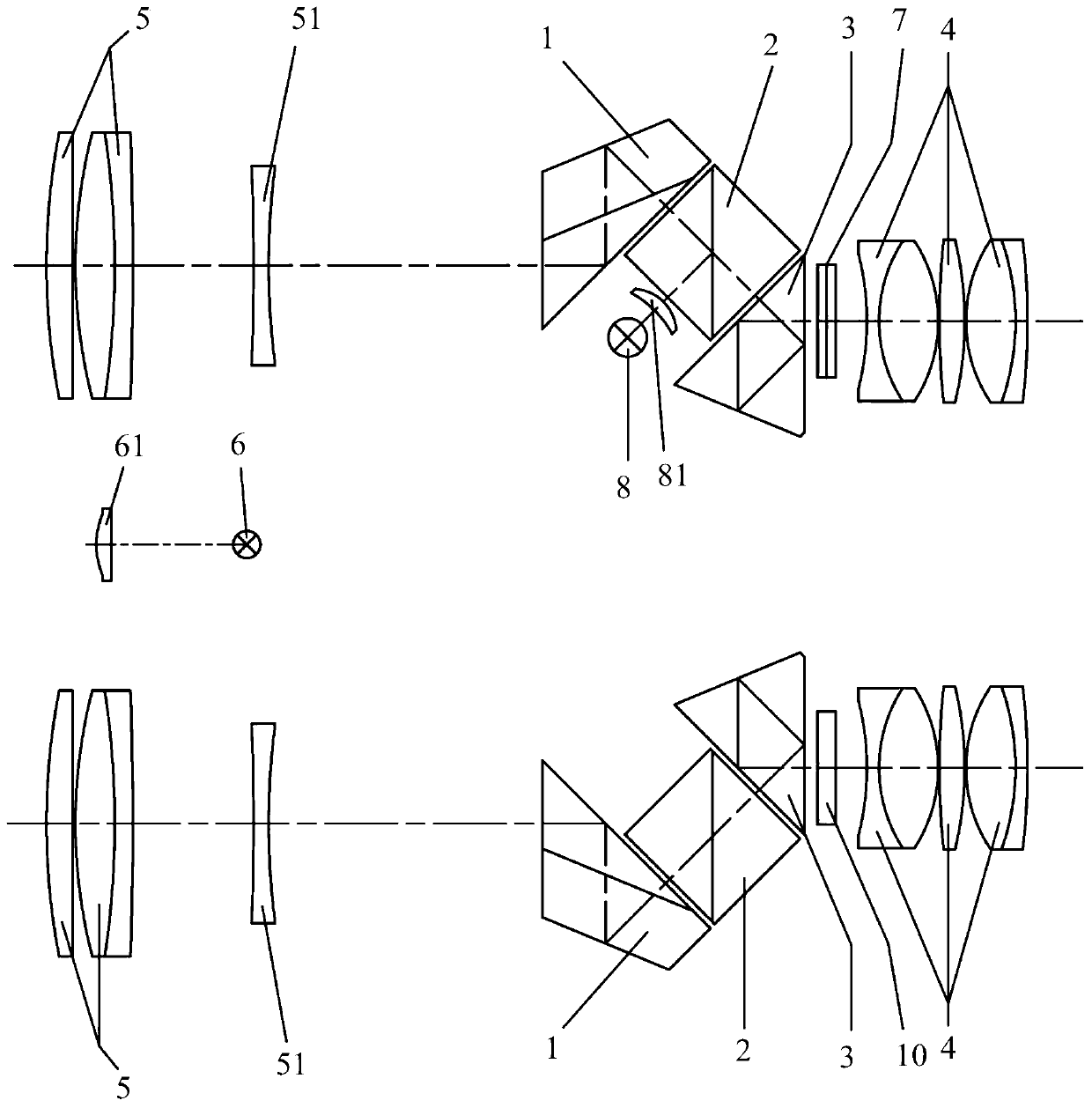

Erect image system and binocular laser ranging telescope

ActiveCN110058419AReduce volumeReduce the impactTelescopesElectromagnetic wave reradiationLaser rangingBeam splitter

The invention discloses an erect image system and a binocular laser ranging telescope, wherein the erect image comprises a roof half pentaprism, a beam splitter prism and an isosceles prism; the beamsplitter prism is located between the roof half pentaprism and the isosceles prism, the beam splitter prism is formed by two rectangular prisms through agglutination, and an agglutination face of thetwo rectangular prisms is provided with a beam splitting film. The erect image system and the binocular laser ranging telescope provided by the invention are simple in structure and small in size, moreover, are convenient to use, can realize binocularly observing and aiming at a measured object, and while observing the object, can display distance to the measured object in real time in the field of view.

Owner:LANHAI PHOTOELECTRICITY TECH CO LTD

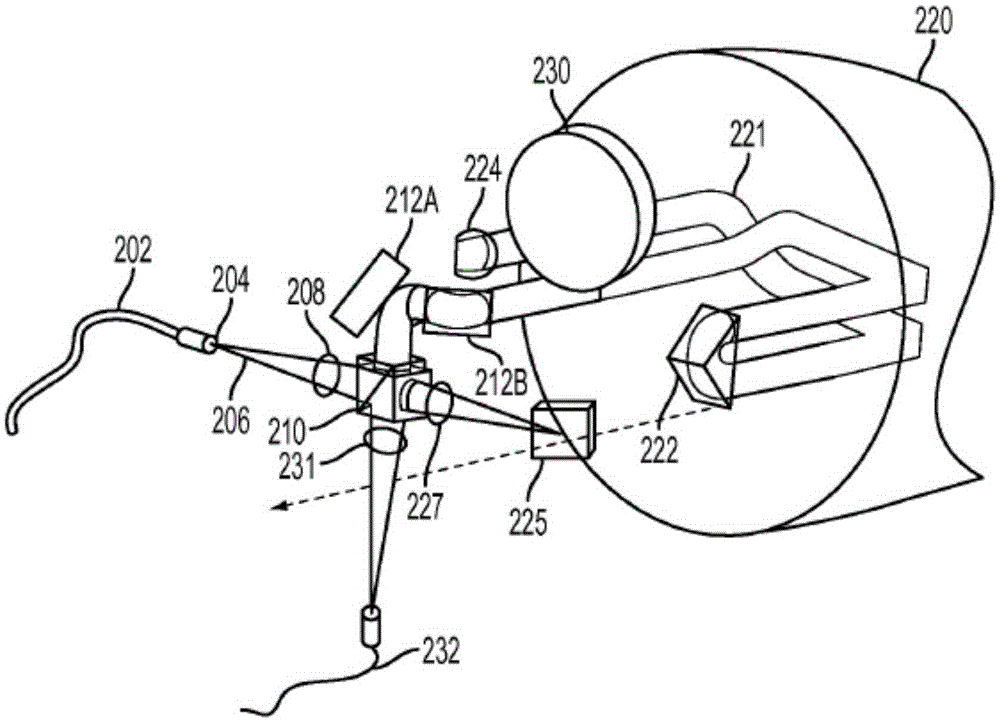

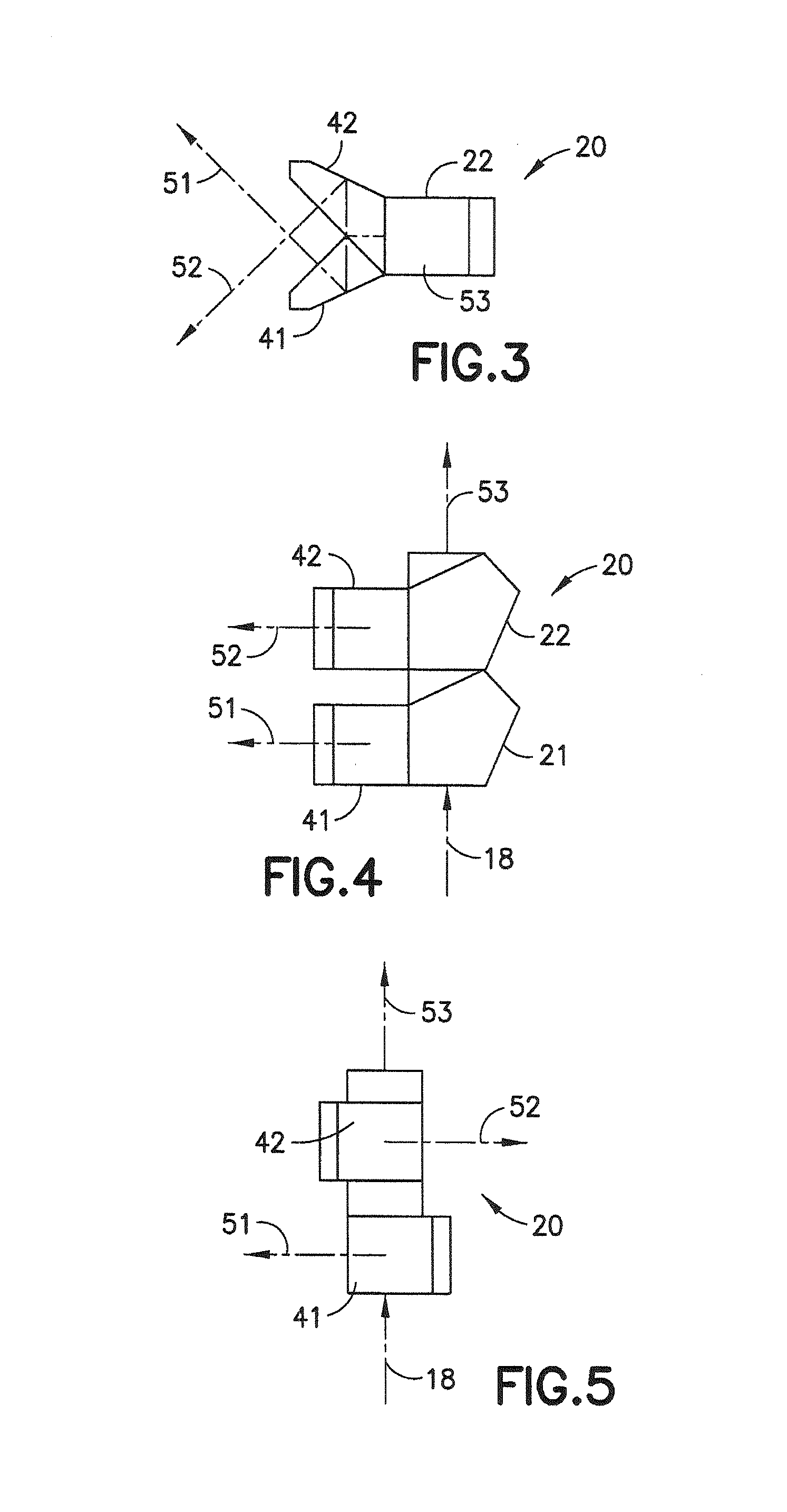

Optical assembly and laser alignment apparatus

InactiveUS20140111813A1Accurately determine positions and alignments relativeUsing optical meansOptical elementsLaser transmitterLight beam

An optical assembly is provided for use with a laser alignment system that has a laser emitter and at least one photosensitive target. The optical assembly includes a right angle prism disposed for receiving an input beam produced by the laser emitter and first and second 90° pentaprisms disposed receiving the output from the right angle prism. The first and second 90° pentaprisms are oriented to produce first and second reflected beams that are parallel to one another. The optical assembly further includes first and second beam diverters disposed and oriented to receive the reflected beams from the first and second 90° pentaprisms and to produce first and second output beams that are mutually perpendicular. The first and second 90° pentaprisms may be see-through pentaprisms to produce a third output beam that is colinear or parallel with the input beam and perpendicular to the first and second output beams.

Owner:HAMAR LASER INSTR

Reflector adjusting method of laser rotary table

InactiveCN105549217AImprove launch pointing accuracyHigh adjustment accuracyMountingsLight pipeOptoelectronics

The invention relates to a reflector adjusting method of a laser rotary table. The method comprises the following steps that 1) a third reflector is adjusted by fixing a first tool reflector at the left end surface of the laser rotary table and adjusting the third reflector so that a reflection image coincides with a cross wire of a parallel light pipe; 2) a second reflector is adjusted by mounting the second reflector at the left end surface of the laser rotary table, pasting a third tool reflector to the front end surface of a second reflector fixing rack so that a reflection image of the third tool reflector coincides with the cross wire of the parallel light pipe; 3) a first reflector is adjusted by arranging the first reflector on a horizontal platform and placing a second tool reflector under a central hole of the first reflector that a reflection image coincides with the cross wire of the parallel light pipe; and 4) the first reflector is mounted by placing the parallel light pipe in front of the first reflector and using left and right pentaprisms, so that light is reflected into a sighting piece of a TV set and the sighting piece is adjusted to coincide with the cross wire of the parallel light pipe.

Owner:HEBEI HANGUANG HEAVY IND

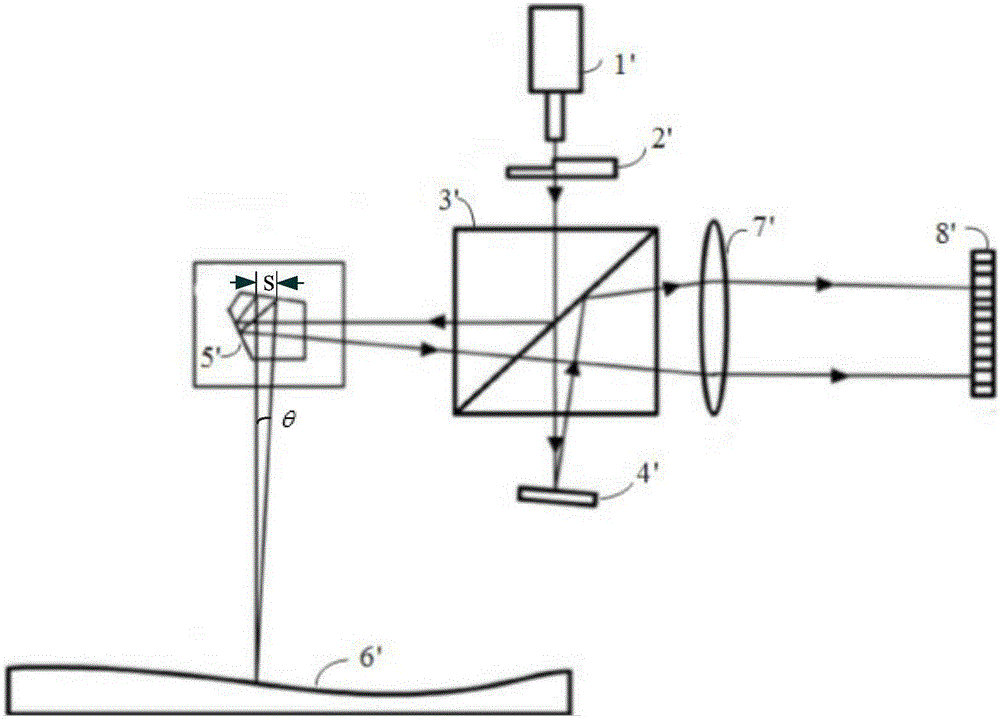

Mach-Zehnder shear wave surface measuring system and measuring method thereof

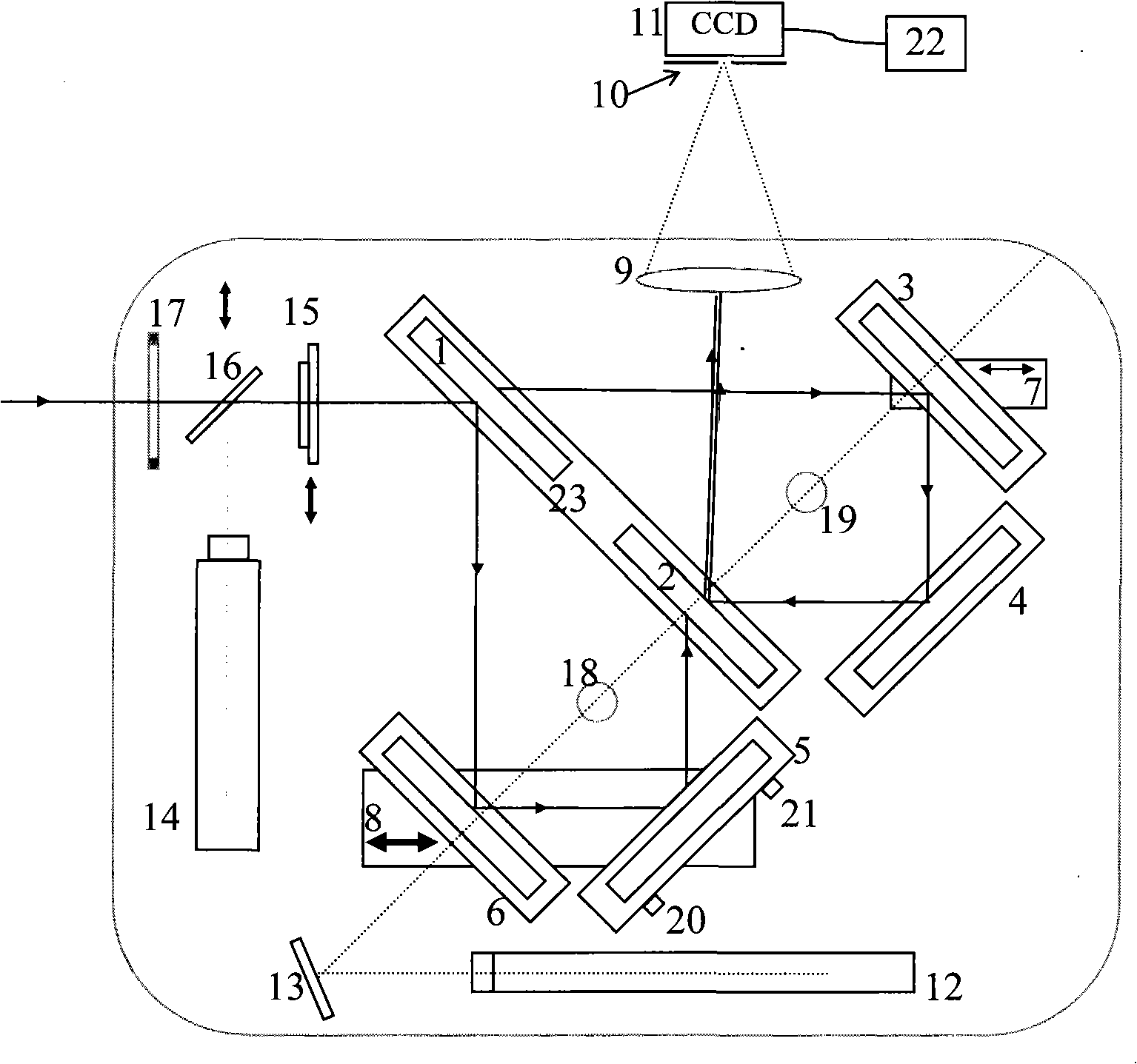

InactiveCN101315302AGuaranteed to work independentlyEasy to process and inspectOptical measurementsPiezo electricImaging lens

The invention relates to a Mach-Zundel type shearing waveform measuring system and a shearing waveform measuring method thereof. The system comprises an interference system consisting of an incident panel, an emission panel, a fixed seat, a first reflecting panel, a second reflecting panel, a third reflecting panel, a fourth reflecting panel, a first guide rail, a second guide rail, an imaging lens, an aperture and a CCD imaging instrument. An adjusting device for ensuring accuracy comprises an auto-collimation collimator tube, a first reflecting mirror, a laser collimating light source, a reference transmitting and reflecting mirror, a second reflecting mirror, a lens screen, a first pentaprism, and a second pentaprism. A control processing system comprises a piezo-electric controller and a computer processing system. The system and the method are suitable for measuring waveform with large aperture and under a diffraction limit, and particularly suitable for being used on a light source waveform with short coherent length. The system and the method can conduct dephasing processing, and are provided with an entire system for real-time adjustment and calibration.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Beam splitting system for laser ranging

A beam splitting system for laser ranging includes a roof half-pentaprism, an isosceles prism and a compensating prism. Due to different compensating prisms, there are four light splitting combinations in total. Light of a certain wavelength is incident from one side of the roof half-pentaprism, and is reflected therein for several times and finally emergent into the isosceles prism where it is reflected for several times and finally emergent in a direction consistent with an incident light axis. Light of another wavelength is incident from one side of the compensating prism, and finally emergent from one side of the roof half-pentaprism or one side of the isosceles prism. Different light splitting ways may be caused due to different positions of both prisms and data LCDs. A number of different optical ranging systems will be provided if a laser rangefinder employs different light splitting combinations.

Owner:LANHAI PHOTOELECTRICITY TECH CO LTD

Detection system for long-range optical surface profile

The invention provides a detection system for a long-range optical surface profile. The detection system comprises a mobile optical head and an f-theta angle detection system. The mobile optical head consists of a tail fiber, a beam splitter, and a concave mirror, wherein the beam splitter and the concave mirror form an equivalent pentaprism. The mobile optical head is configured to emit an input light beam through the tail fiber, so that the light beam passes through the beam splitter and then enters a surface of a to-be-detected optical device; the light beam is reflected to the beam splitter by the surface of the to-be-detected optical device; the part of reflected light beam is reflected to the concave mirror by the beam splitter; and then the light beam is reflected to the f-theta angle detection system by the concave mirror along a direction perpendicular to a normal of a corresponding measuring point of the surface of the to-be-detected optical device, so that a measuring light spot is formed in the f-theta angle detection system. According to the invention, the number of reflection and transmitting optical devices causing errors can be reduced; a system error caused by horizontal movement of a measuring light beam during measurement of different angles can be reduced; and the measuring precision is improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Long trace profile

ActiveCN105737758AReduce the numberReduce lateral movementUsing optical meansBeam splitterPlane mirror

A long trace profile provided by the present invention is used to carry out the profile detection on the surface of a to-be-tested optical device, and comprises a scanning optical head and a f-theta angle detection system. The scanning optical head comprises a surface light source, a beam splitter, a single-hole screen and a plane mirror. The surface light source is placed horizontally, the beam splitter is arranged below the surface light source aslant, the single-hole screen is attached to the bottom surface of the beam splitter tightly, and the plane mirror is arranged below the single-hole screen aslant and forms a dual-reflection surface of a similar pentaprism structure with the beam splitter. According to the present invention, a system error introduced by the lateral movement of a measurement light beam when different angles are measured is reduced, thereby improving the measurement precision.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

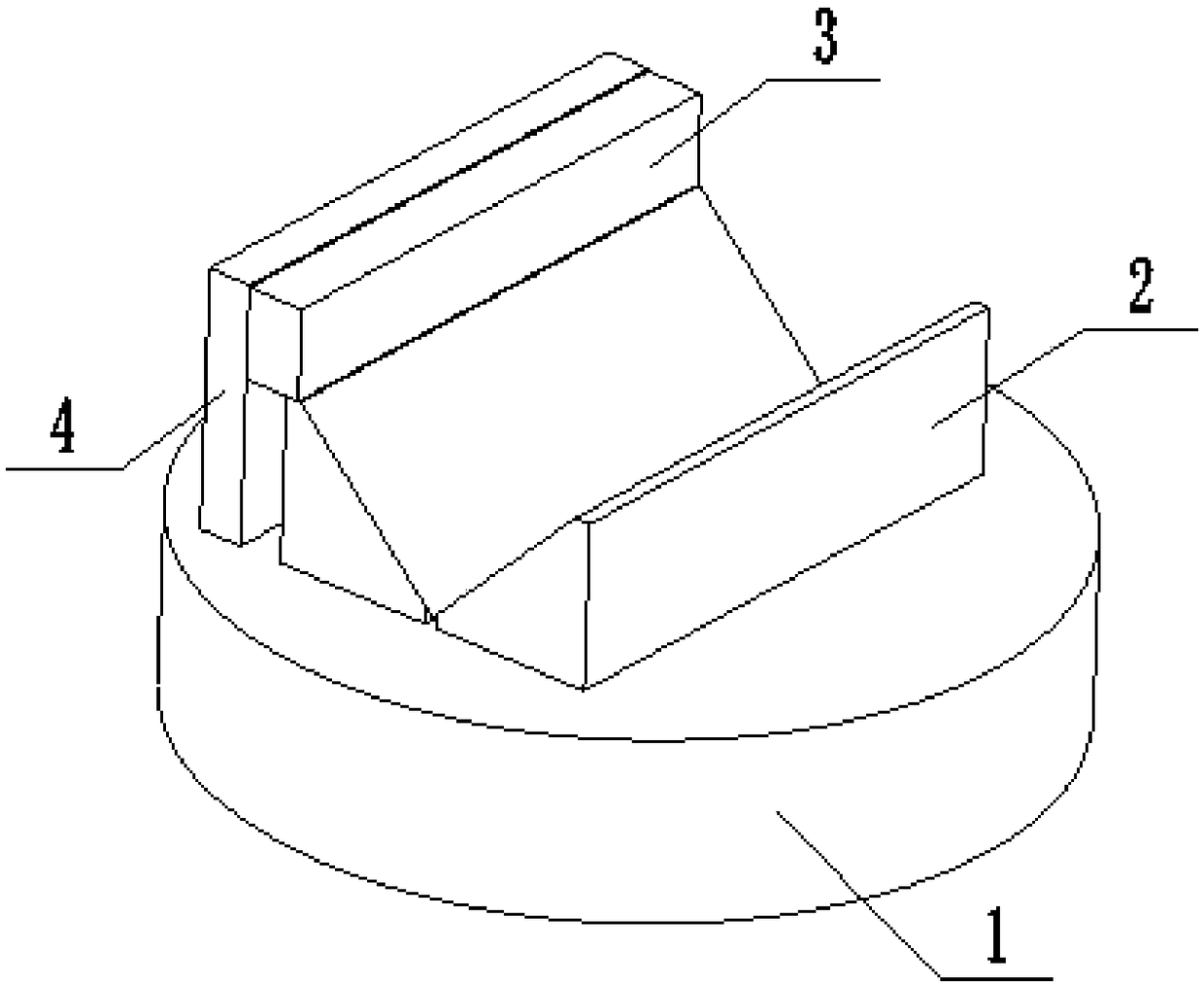

Location fixture for prism roof ridge as well as location and manufacturing methods thereof

ActiveCN108274340APrecise positioningIncrease productivityOptical surface grinding machinesMachiningRidge

The invention discloses a location fixture for a prism roof ridge as well as location and manufacturing methods thereof, and belongs to the technical field of optical prisms. The location fixture comprises a base plate, location triangular prisms and a roof ridge surface location block, wherein two location triangular prisms are arranged, oppositely arranged on the base plate, and form a V-shapedlocation groove; and the roof ridge surface location block is arranged above the location triangular prisms, and provided with a roof ridge location surface, and the roof ridge location surface is vertical to the end surfaces of the location triangular prisms and vertical to the upper surface of the base plate. The machining method for the prism roof ridge comprises the following steps: preparinga pentaprism blank at first, then locating a pentaprism through the location fixture, and then grinding two roof ridge surfaces separately to form the roof ridge. The location fixture disclosed by theinvention is especially designed for location during the pentaprism grinding for the roof ridge surfaces, capable of enabling the angle accuracy between the roof ridge formed by the two roof ridge surfaces and the rectangular side surface opposite to the roof ridge to be not easily reach a range of less than 30 seconds, and simple and rapid in location.

Owner:马鞍山市江南光学有限公司

Atomic beam two-dimension cooling optical prism frame

InactiveCN103116212AEasy to detectGuaranteed accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusAtomic beamVacuum chamber

The invention provides an atomic beam two-dimension cooling optical prism frame which comprises a pentaprism, a first reflector, a second reflector and a third reflector, wherein the first reflector, the second reflector and the third reflector are respectively bound on the pentaprism, a reflecting face extends out of a prism on the same side, a bonding face is the pentaprism, and two faces which are reflected by a medium light line and any face of two faces of light transmission are used. The atomic beam two-dimension cooling optical prism frame has the advantages of being capable of achieving two-dimension cooling alignment of an atomic beam, providing a high, accurate and straight atomic source, ensuring compatibility and high integration of an existing experimental device, not transforming a vacuum chamber, saving cost, having expansibility, and providing an achieving means for two-dimension atomic photoetching.

Owner:TONGJI UNIV

Large-aperture off-axis reflection type vacuum collimator optical axis calibration method and device

ActiveCN111006855AAccuracy BreakthroughSimplify workloadTesting optical propertiesGoniometerOptical axis

The invention relates to the technical field of collimator optical axis calibration, in particular to a large-aperture off-axis reflection type vacuum collimator optical axis calibration method and adevice, and solves the problems of low calibration precision and large machining workload. The method comprises the steps of using a collimator off-axis primary mirror as a reference mirror, and usinga large-diameter plane mirror and an interferometer for collimator debugging; removing the interferometer, a pentaprism I and a pentaprism II are arranged between the collimator off-axis main mirrorand the large-aperture plane mirror; and arranging a digital display auto-collimation goniometer corresponding to the pentaprism I and the pentaprism II, arranging a target plate of the collimator onthe focal plane of the collimator, and debugging the target plate based on the digital display auto-collimation goniometer, the pentaprism I and the pentaprism II until the debugging of the target plate is completed, thereby completing the calibration. According to the method, the collimator off-axis primary mirror is used as the reference mirror, the calibration precision makes a precision breakthrough compared with the prior art, the early-stage processing work is not needed, only the user site installation and adjustment are needed, and the operation is simple and rapid when the user site installation and adjustment are carried out.

Owner:CHANGGUANG SATELLITE TECH CO LTD

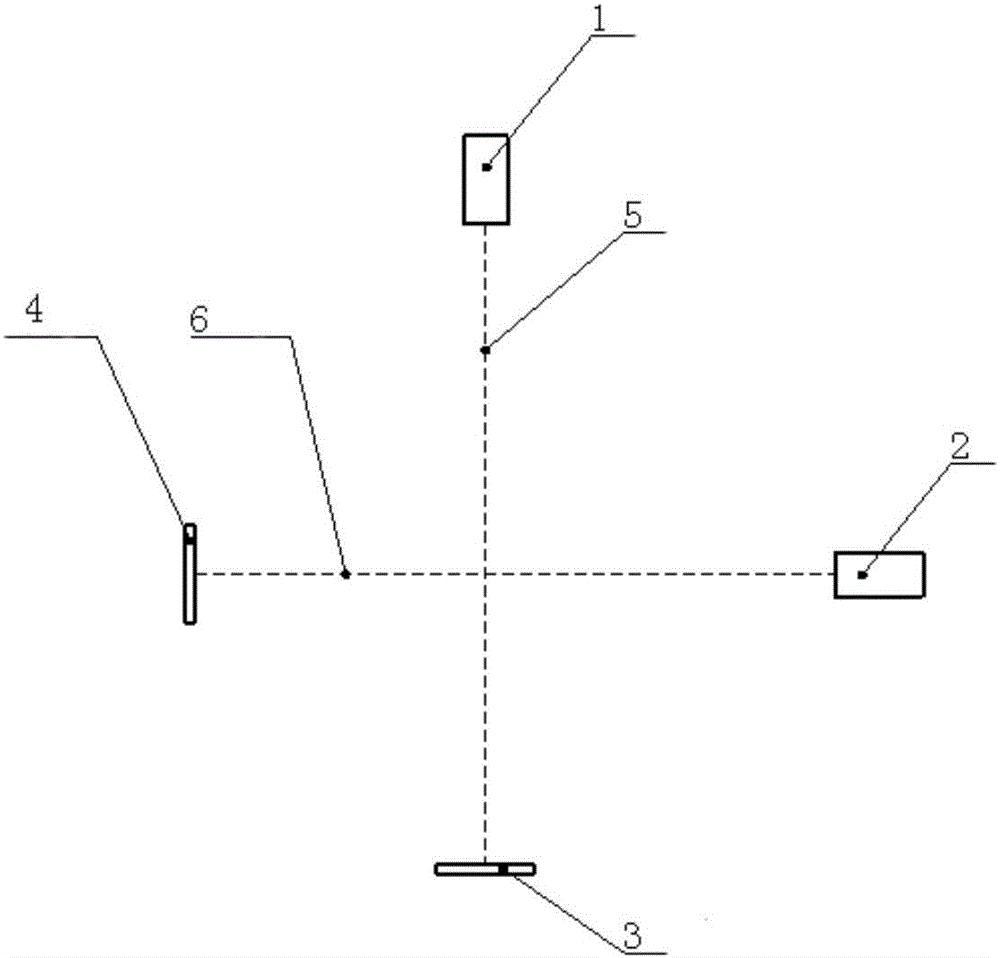

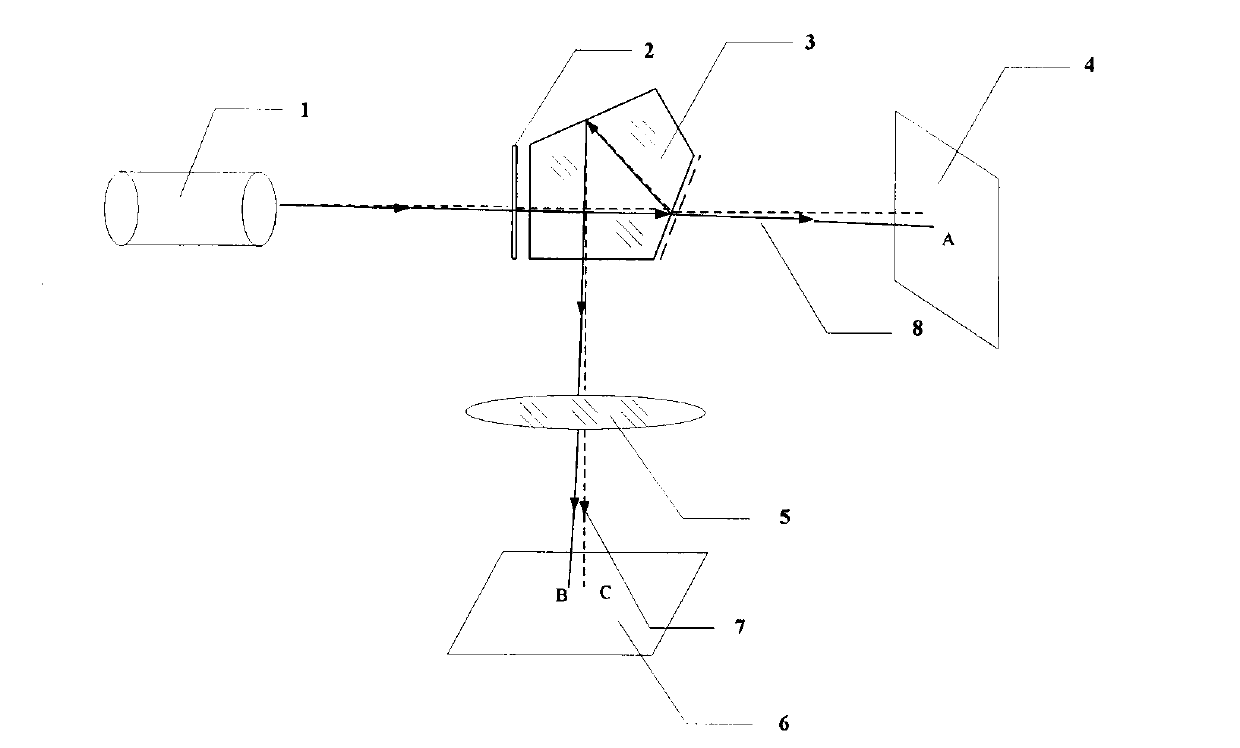

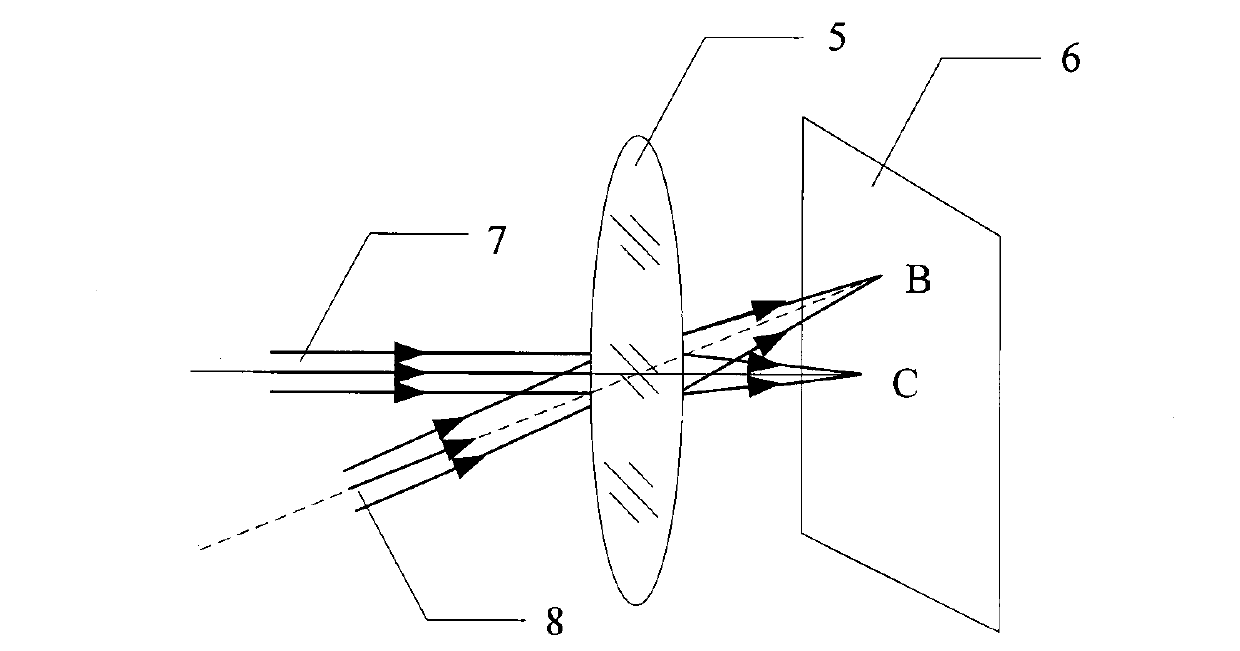

Laser space corner correction method based on double phase-sensitive detectors (PSDs)

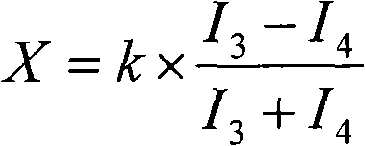

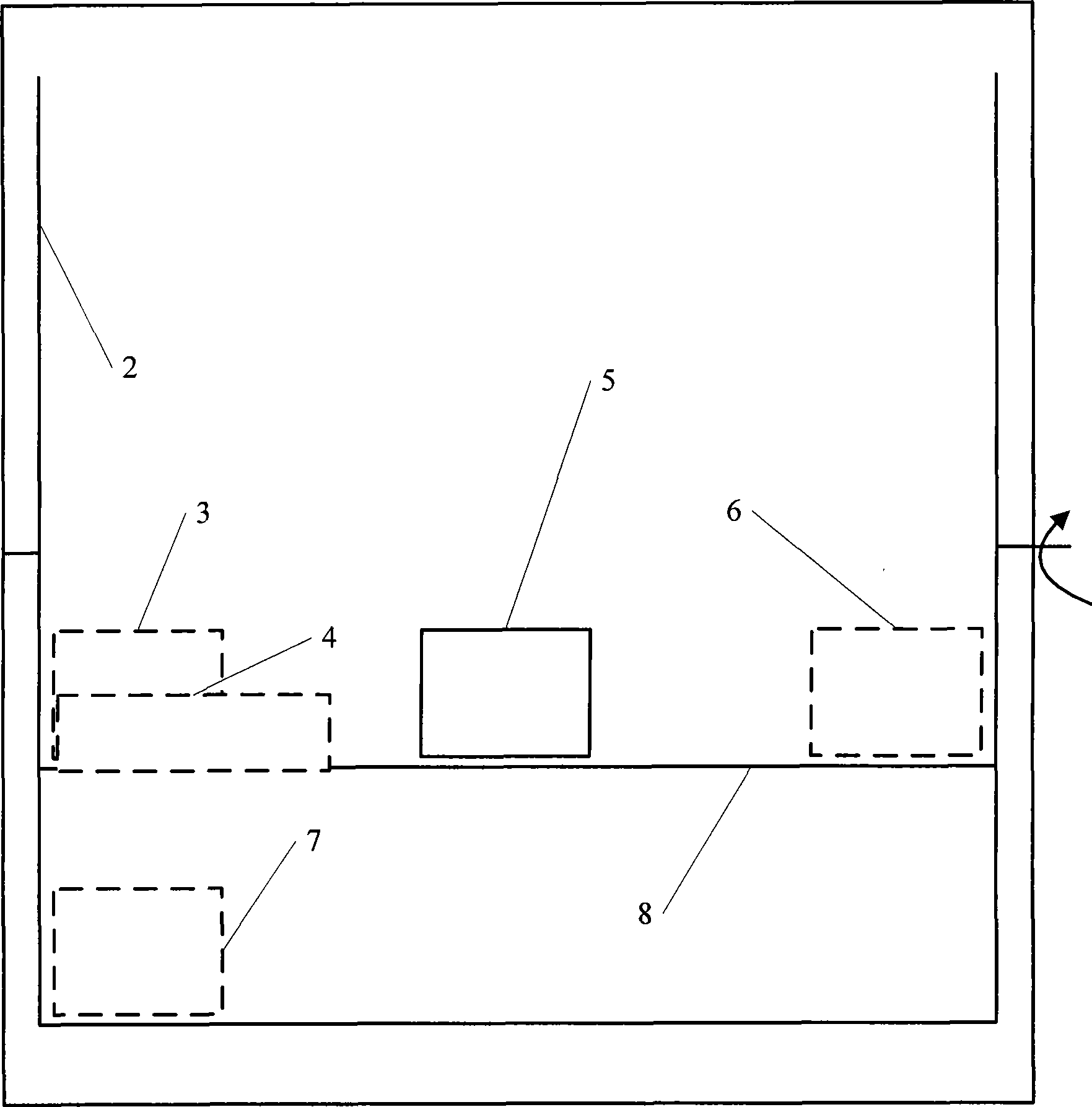

InactiveCN103134468ACorrection of vertical incidence position errorImprove environmental adaptabilityAngle measurementLaser technologyLight spot

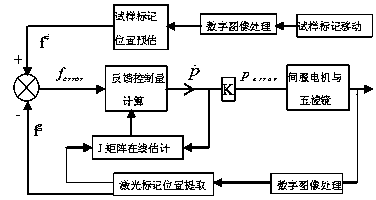

The invention provides a laser space corner correction method based on double phase-sensitive detectors (PSDs), and belongs to the fields of measuring technologies and laser technology application. In the process of measurement, due to the fact that a space corner exists on a plane where a laser beam and a laser receiver are arranged, the space corner needs to be corrected to obtain a laser vertical incidence point coordinate. The laser space corner correction method based on the double PSDs mainly comprises a laser 1, a filtering piece 2, a pentaprism 3, a two-dimension PSD position transducer 4, a lens 5 and a two-dimension PSD position transducer 6. In the process of actual use, the space corner can be corrected by calculating position coordinates of light spots which is irradiated on the two-dimension PSD position transducer 4 and the two-dimension PSD position transducer 6, and then a coordinate of a point which is obtained by laser vertical incidence on the laser receiver.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com