Photoelectric equipment multi-optical-axis parallelism quantitative detection device

A technology for quantitative detection and optoelectronic equipment, which is applied to measurement devices, the use of optical devices, and the testing of optical performance. , to meet the effect of accurate detection of wide-spacing optical axis parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

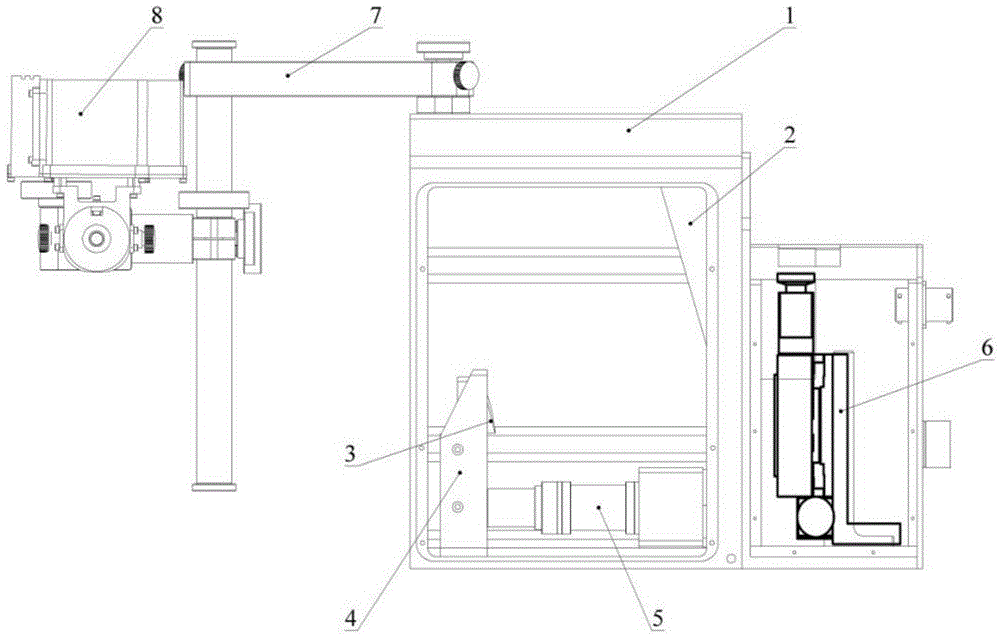

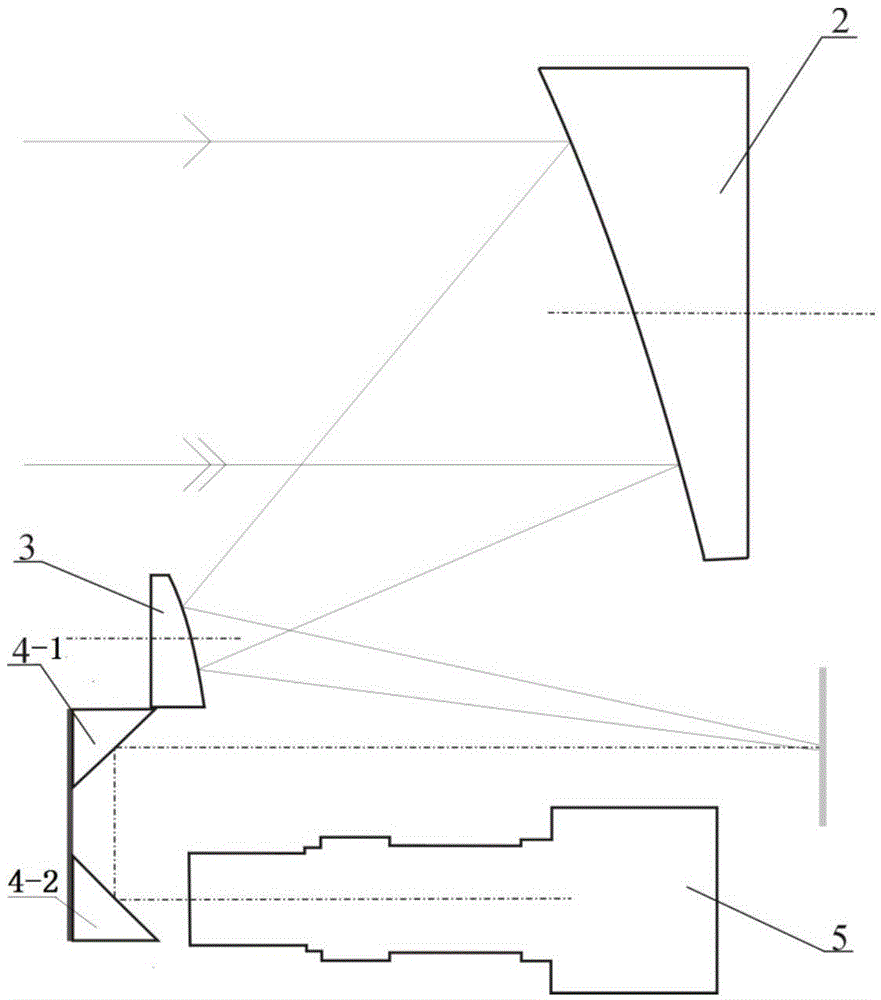

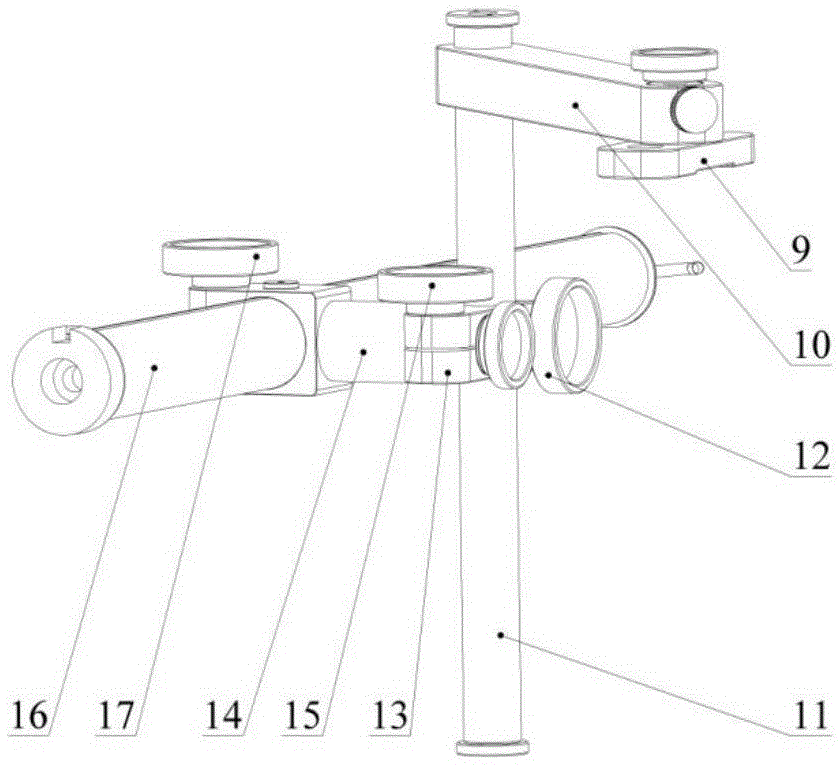

[0021]A photoelectric device multi-optical axis parallelism quantitative detection equipment, including off-axis folding aspheric optical system, CCD image sensor 5, two-dimensional translation stage 6, pentaprism assembly 8, bracket group 7 and control system, the off-axis The folded double-mirror optical system includes a housing 1, an aspheric primary mirror 2, an aspheric secondary mirror 3, and a turning prism group 4. The aspheric primary mirror 2 and the aspheric secondary mirror 3 in the housing 1 form a collimated light pipe. Both the aspheric primary mirror 1 and the aspheric secondary mirror 2 adopt hyperboloid reflectors to form an off-axis Cassegrain type collimator, the curvature of the aspheric primary mirror 2 is -400.17mm, and the off-axis amount is 102.5, The curvature of the aspheric secondary mirror 3 is -129.77 mm, and the off-axis distance is 24 mm. The distance between the aspheric primary mirror 2 and the aspheric secondary mirror 3 is 153 mm. The cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com