Patents

Literature

262 results about "Support group" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a support group, members provide each other with various types of help, usually nonprofessional and nonmaterial, for a particular shared, usually burdensome, characteristic. Members with the same issues can come together for sharing coping strategies, to feel more empowered and for a sense of community. The help may take the form of providing and evaluating relevant information, relating personal experiences, listening to and accepting others' experiences, providing sympathetic understanding and establishing social networks. A support group may also work to inform the public or engage in advocacy.

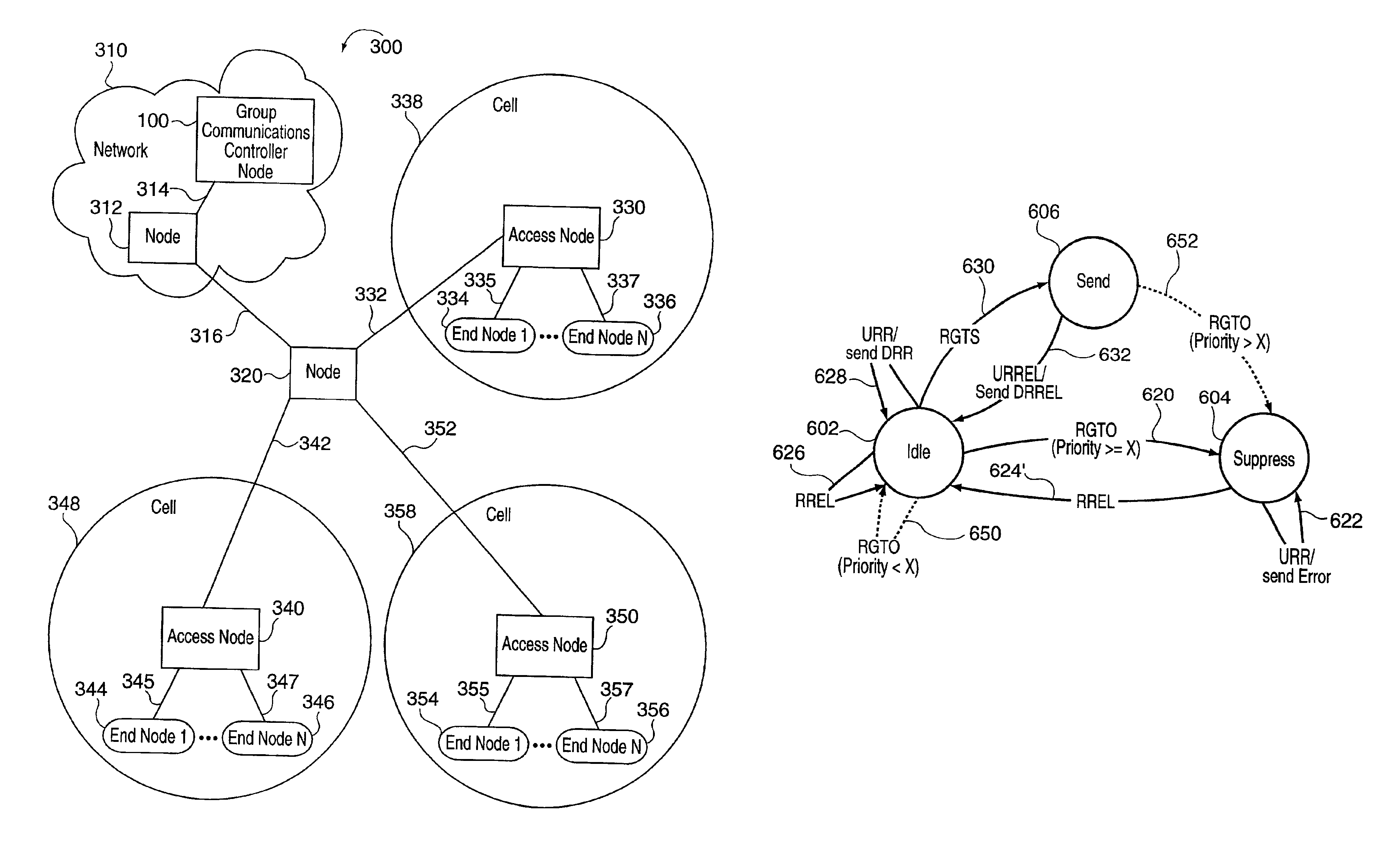

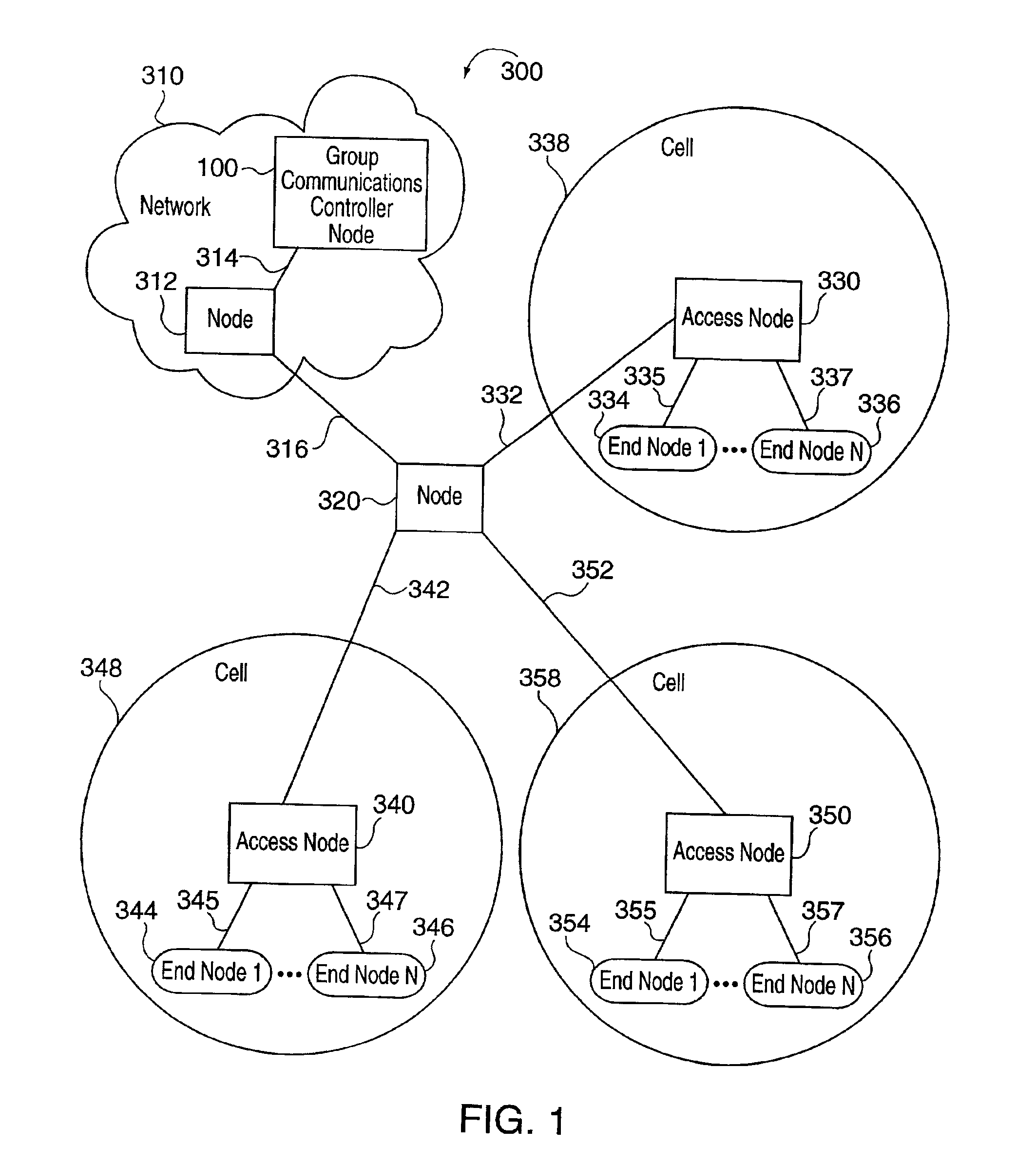

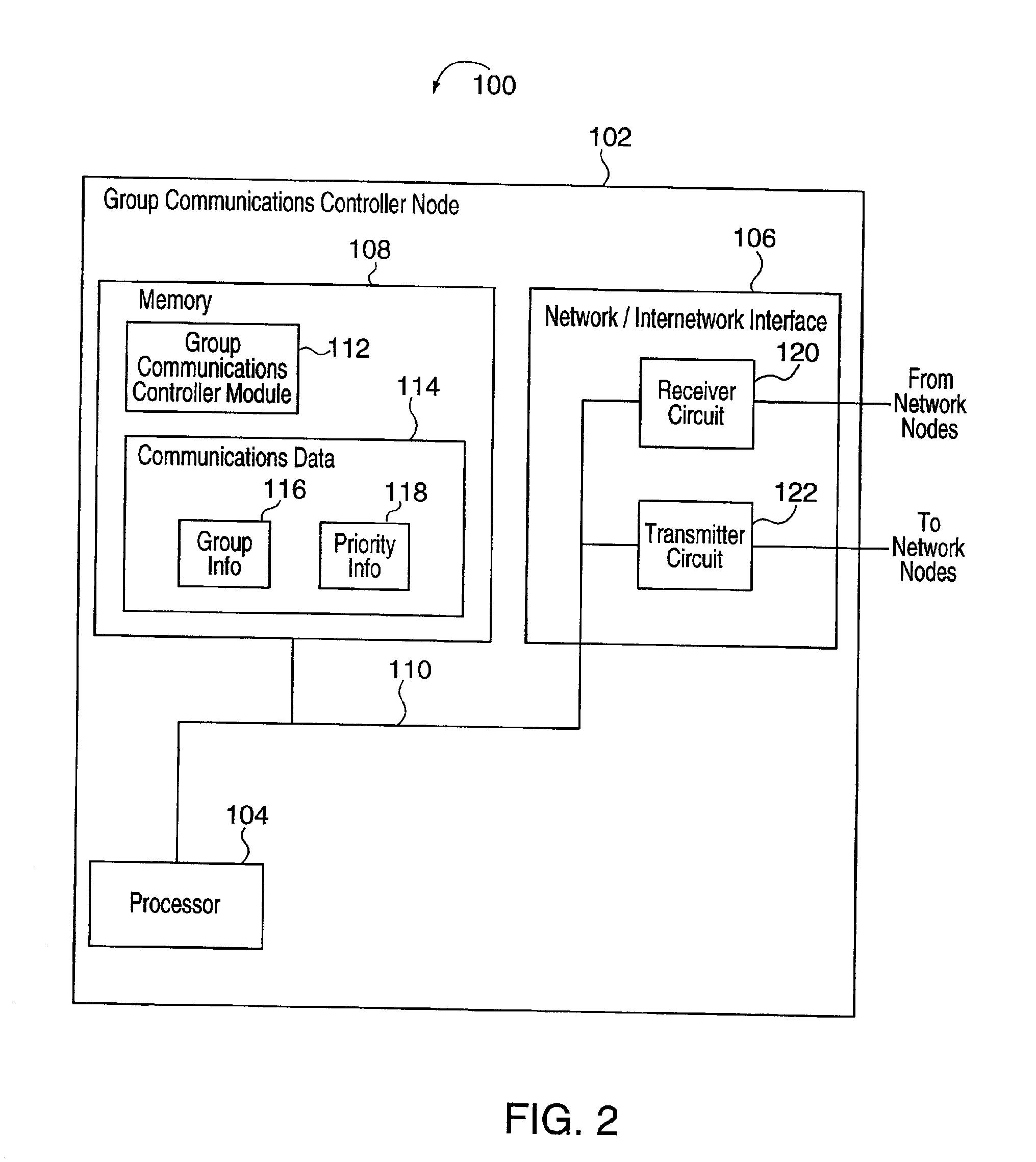

Methods and apparatus for supporting group communications

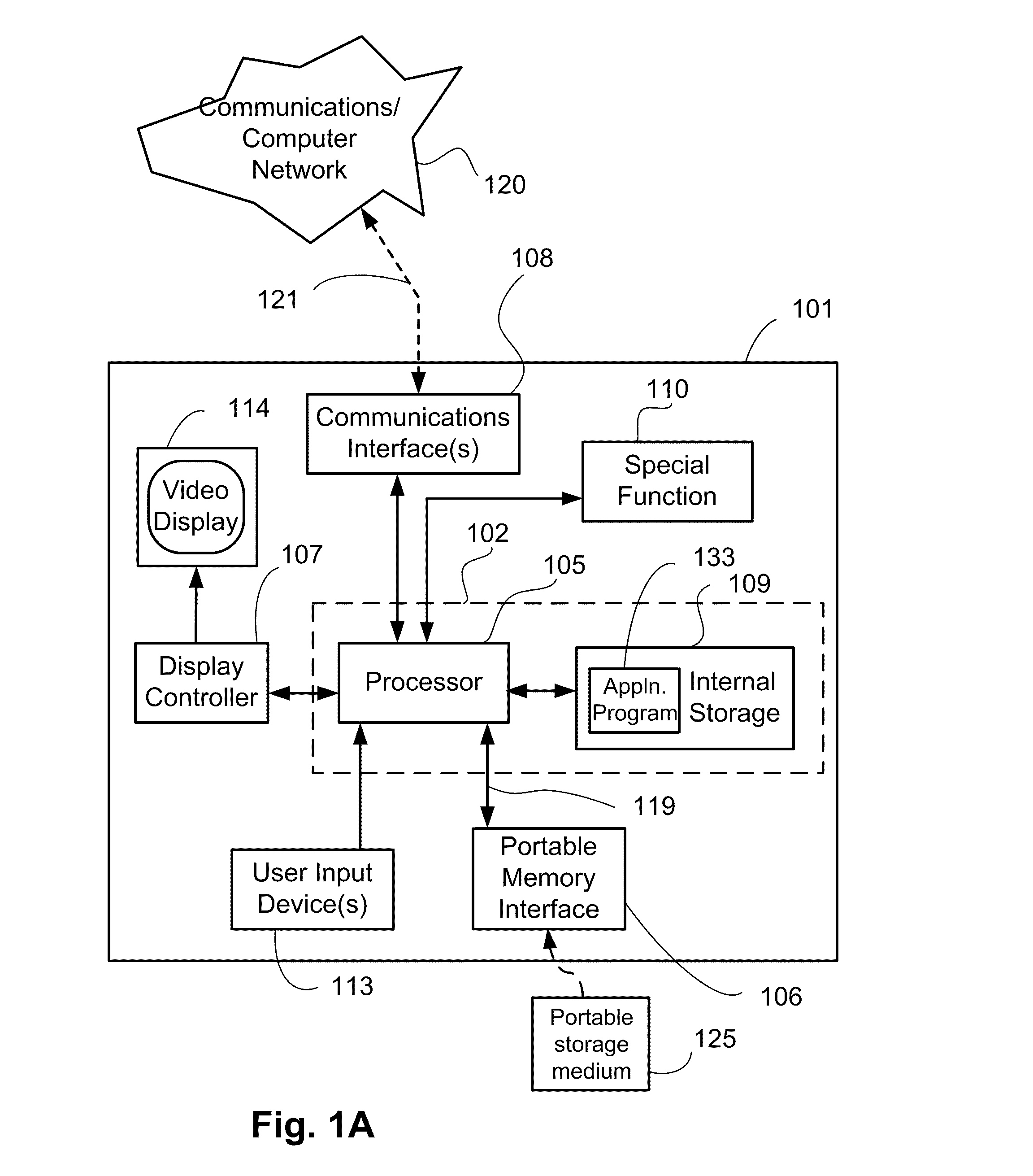

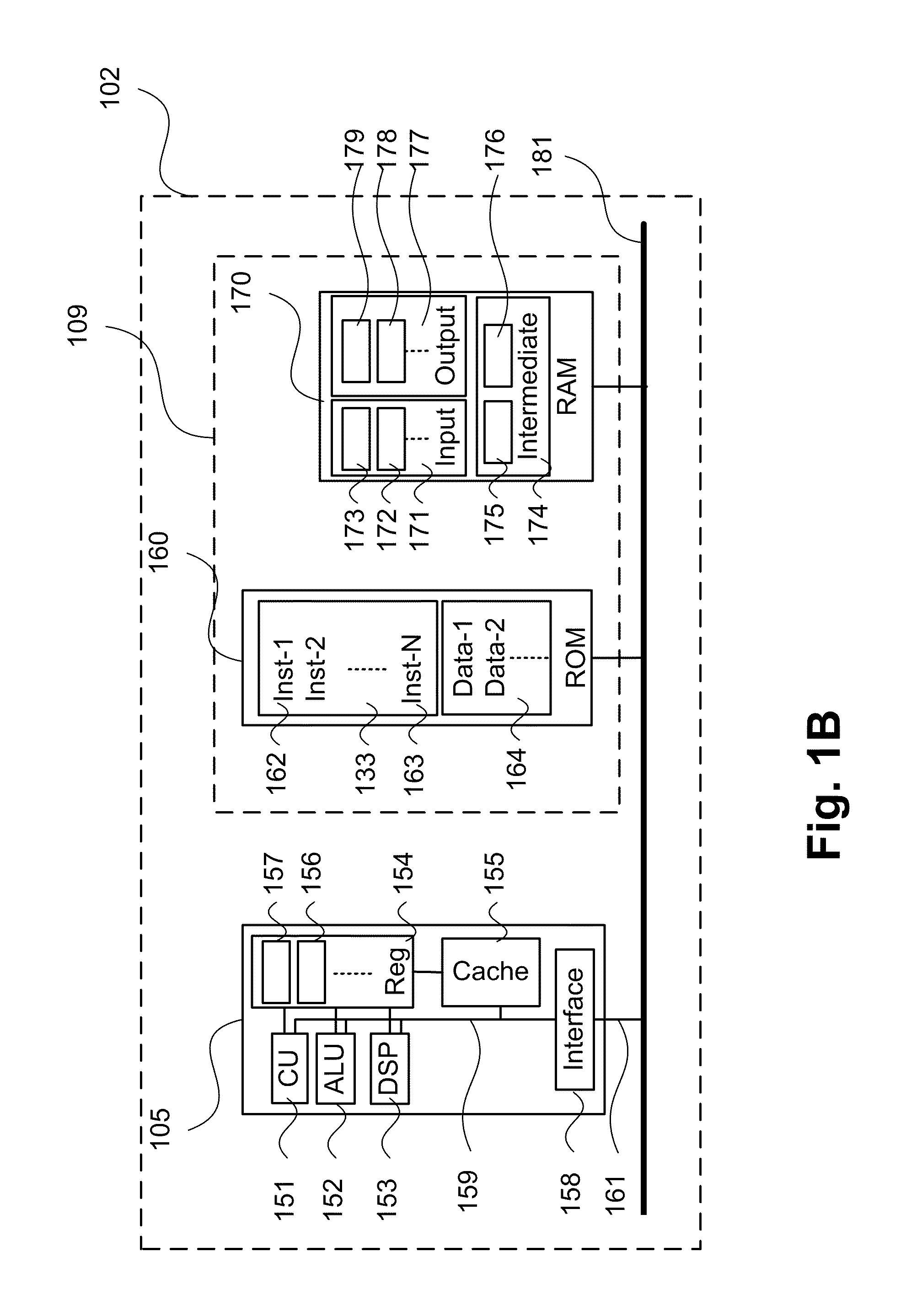

InactiveUS6922547B2Low costEasy to usePower managementNetwork traffic/resource managementSupport groupComputer network

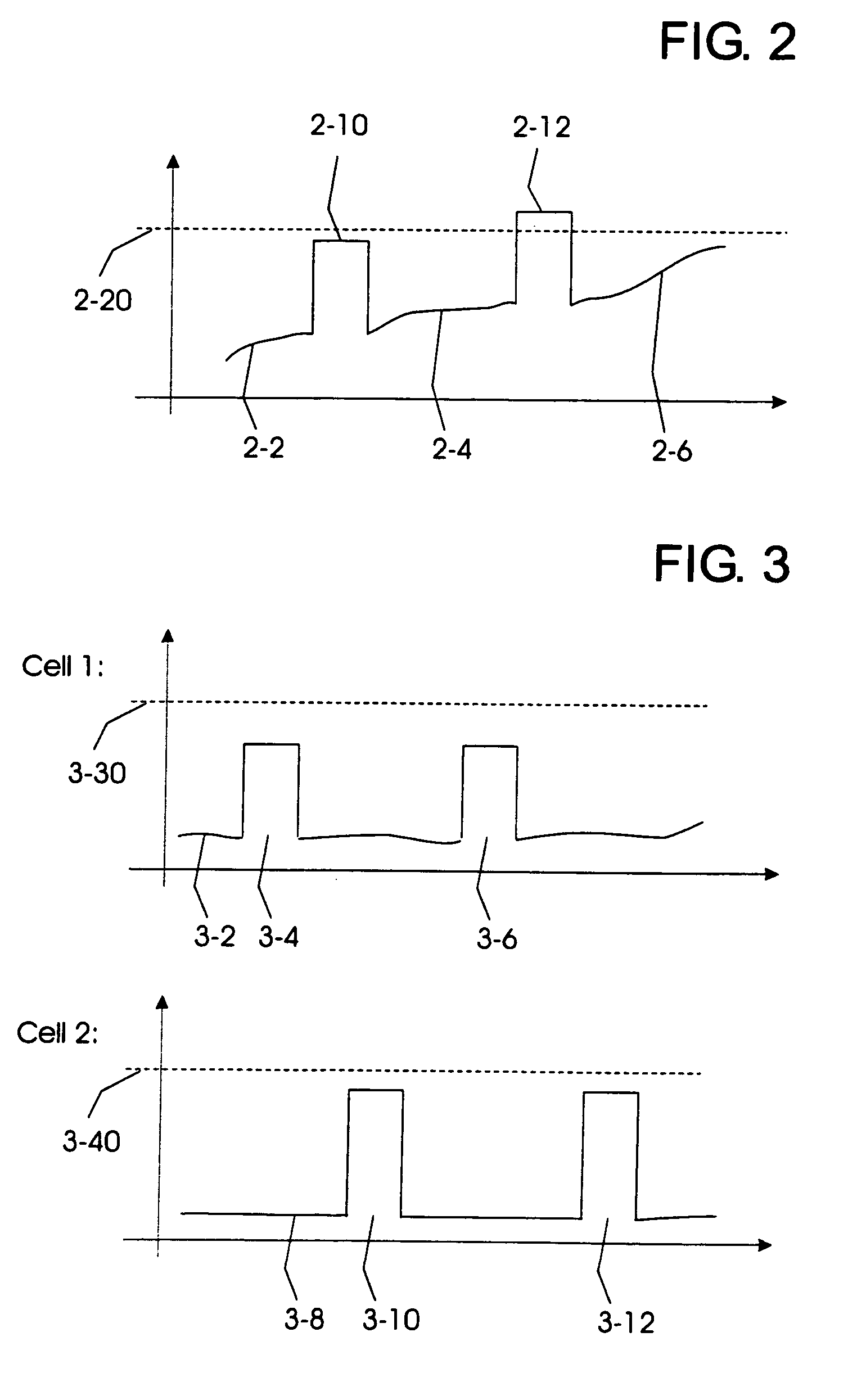

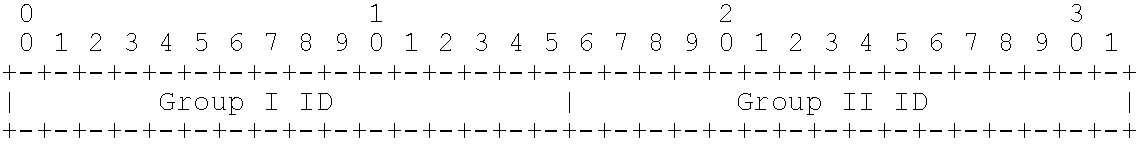

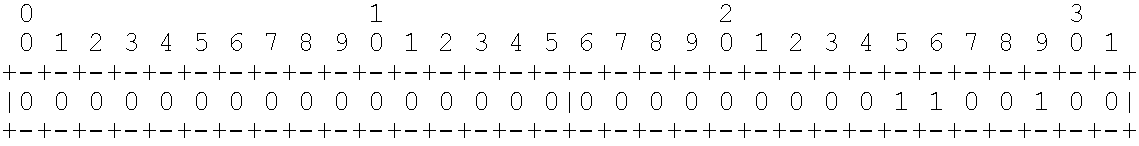

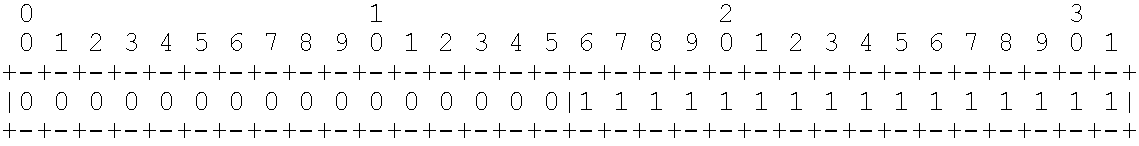

Group communications methods and apparatus are described. In particular, methods for granting a mobile device access to a communications resource, e.g., the right to transmit data, associated with a group are described. User requests for the communications resource are suppressed by the corresponding mobile device, for periods during which the communications resource has been granted to another mobile device. A mobile device may store a suppressed user request so that a resource request signal may be transmitted after the communications resource has been released by the mobile device that was previously granted the resource. In this manner requests that cannot be granted are not transmitted, increasing communications efficiency as compared to systems where requests are not suppressed at the mobile devices. A priority scheme is used in some embodiments to determine whether or not a request should be suppressed while another device has been granted the communications resource.

Owner:QUALCOMM INC

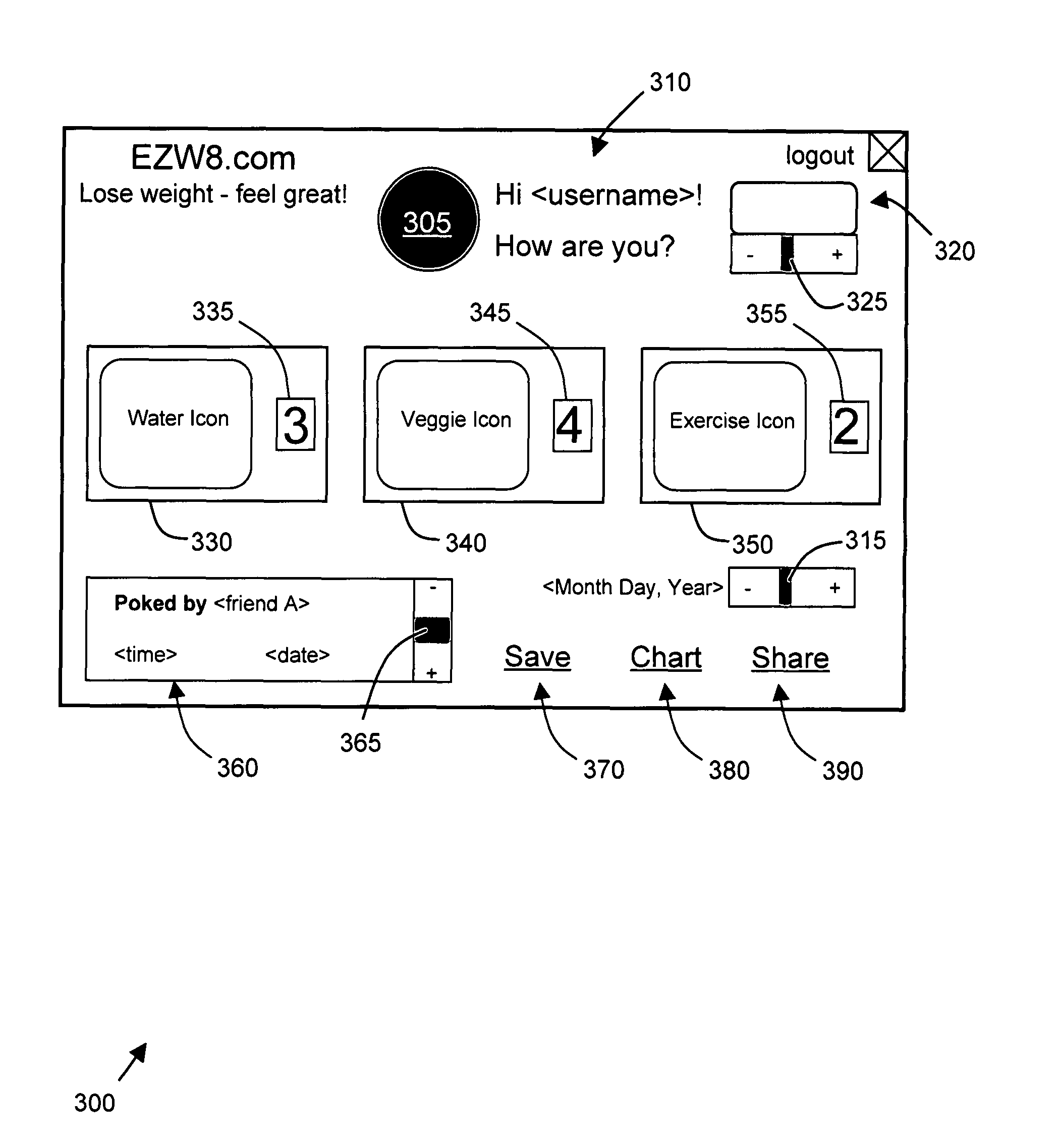

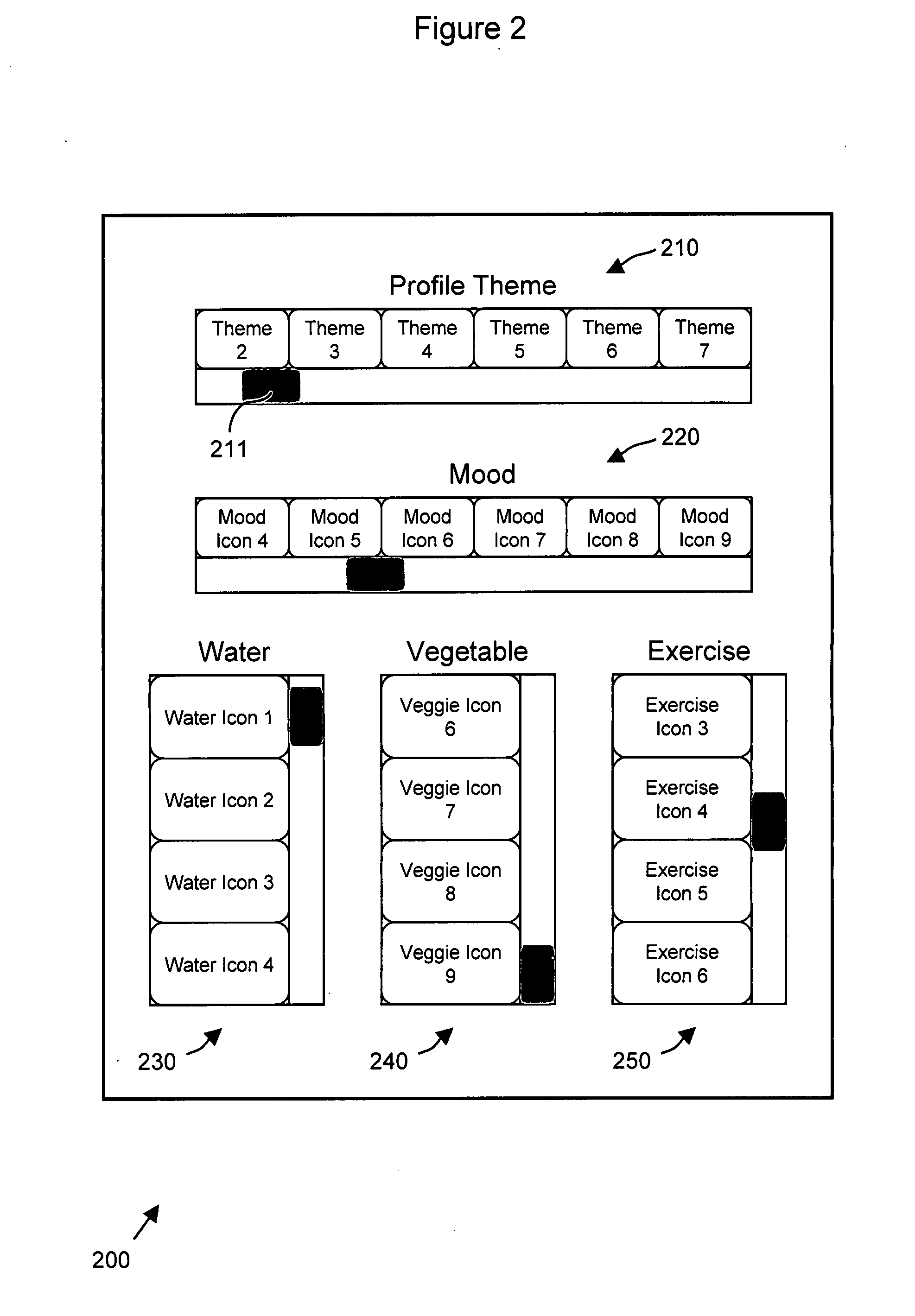

Social network for affecting personal behavior

ActiveUS7720855B2Easy to createEasy to customizeDigital data processing detailsMultiple digital computer combinationsSupport groupSocial web

Owner:INVENT LY LLC

Social network for affecting personal behavior

ActiveUS20090012988A1Easy to createEasy to customizeDigital data processing detailsMultiple digital computer combinationsSupport groupSocial web

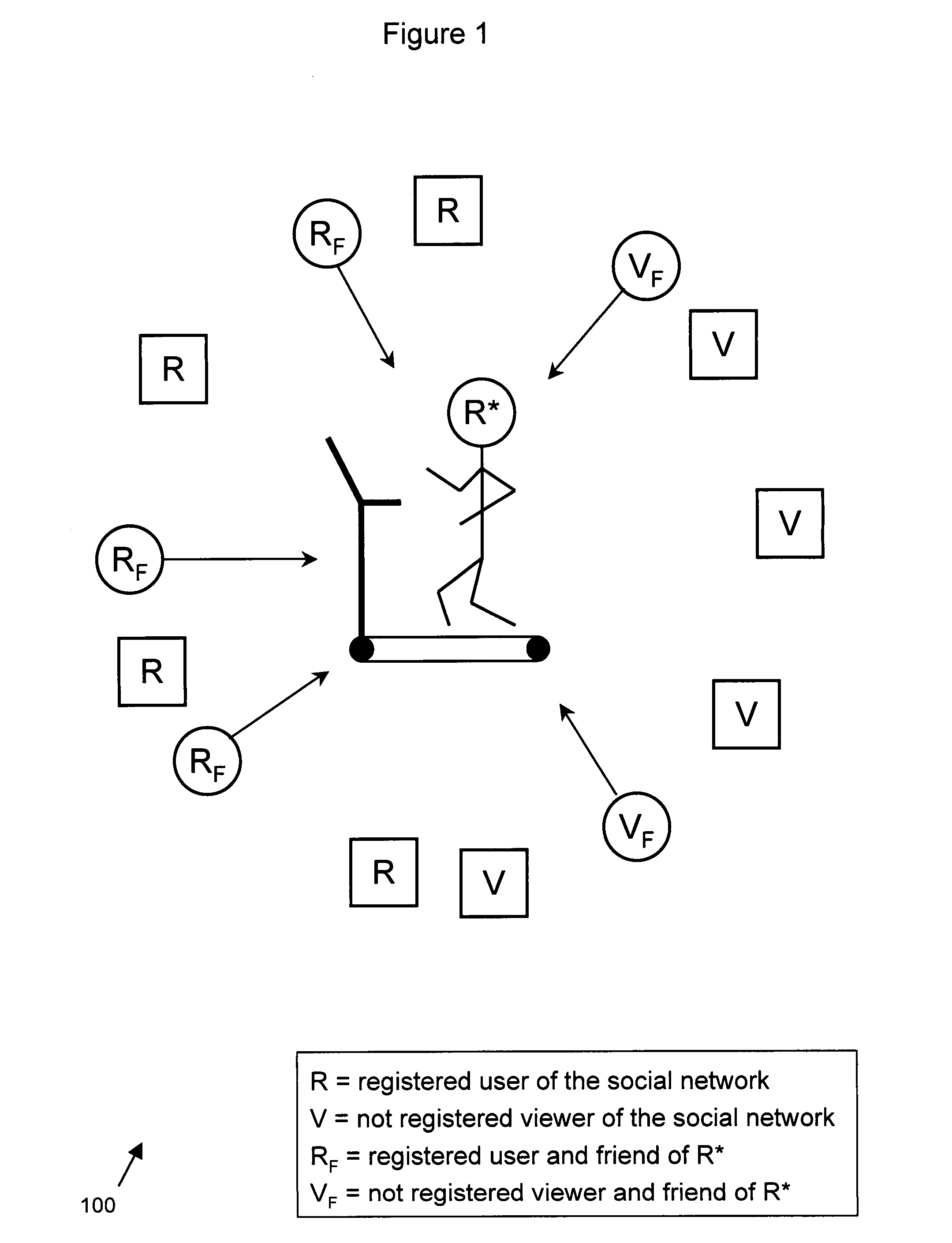

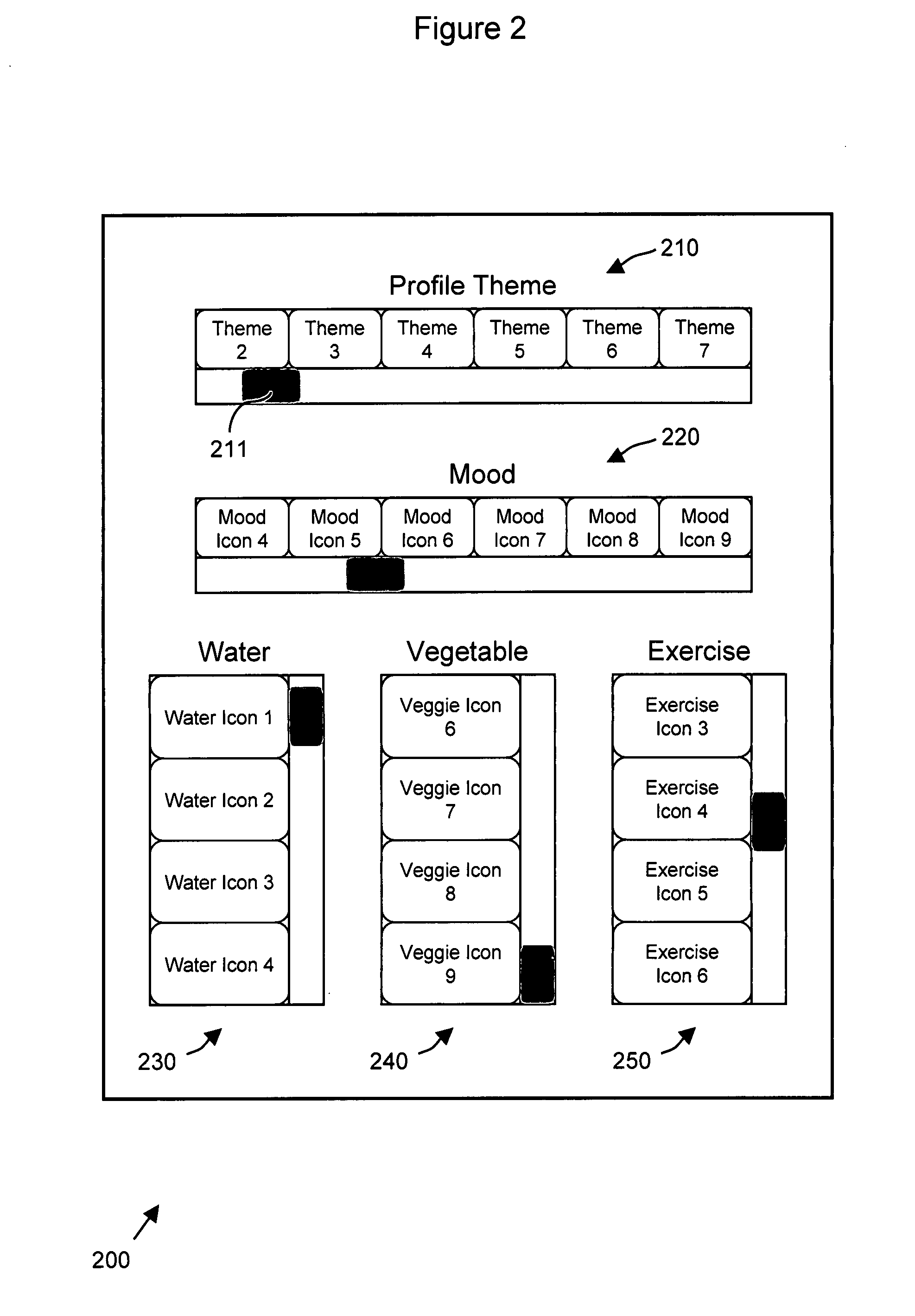

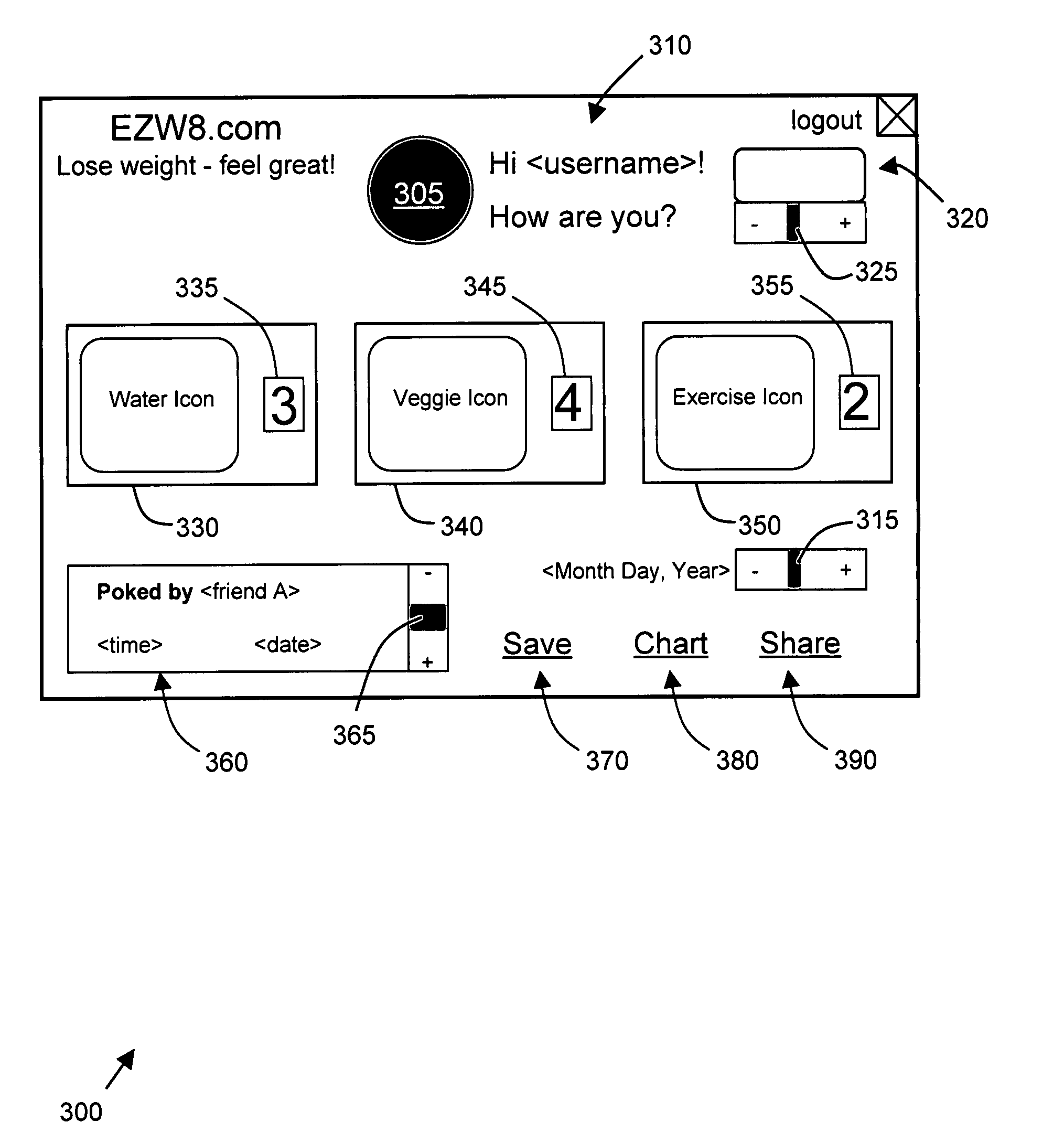

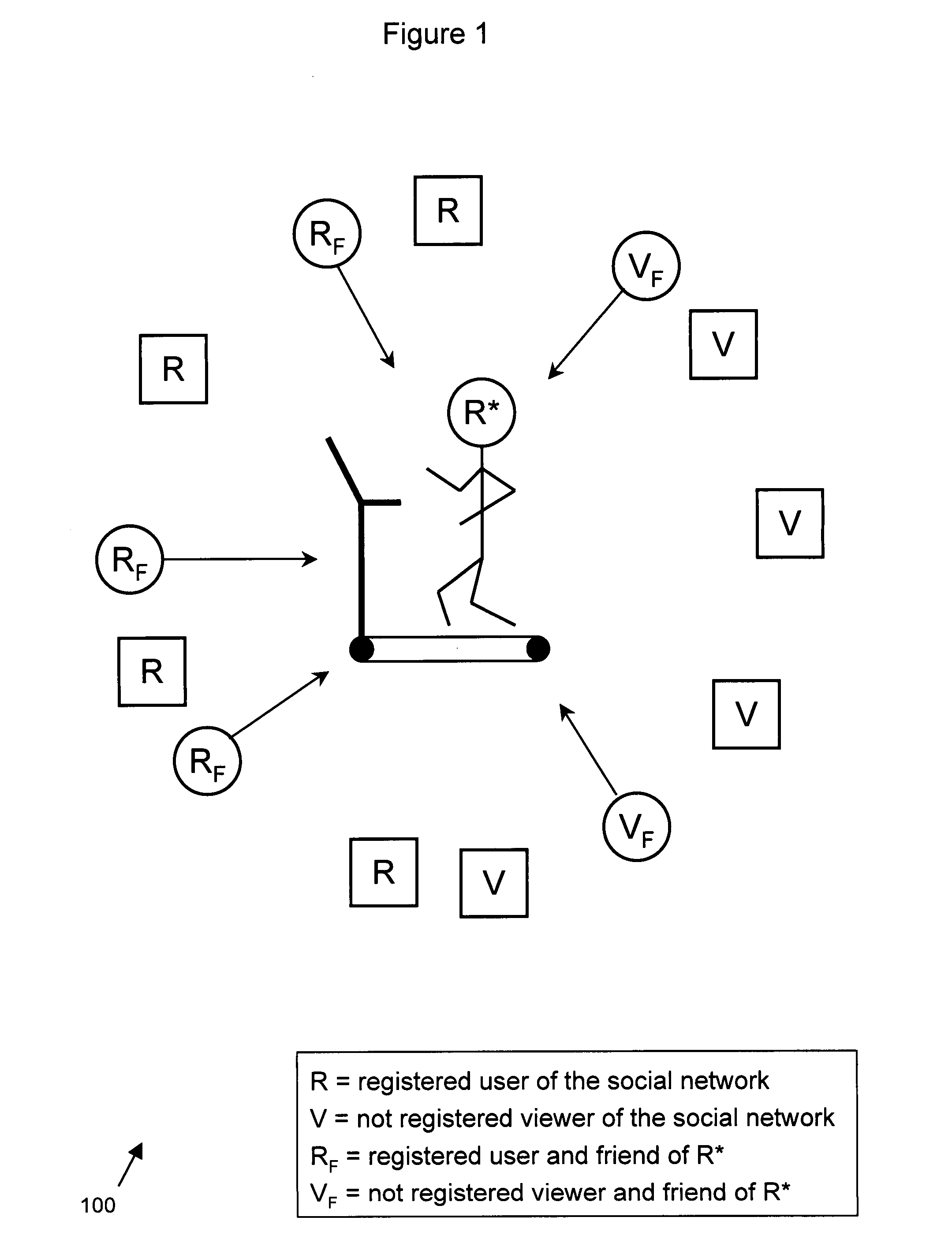

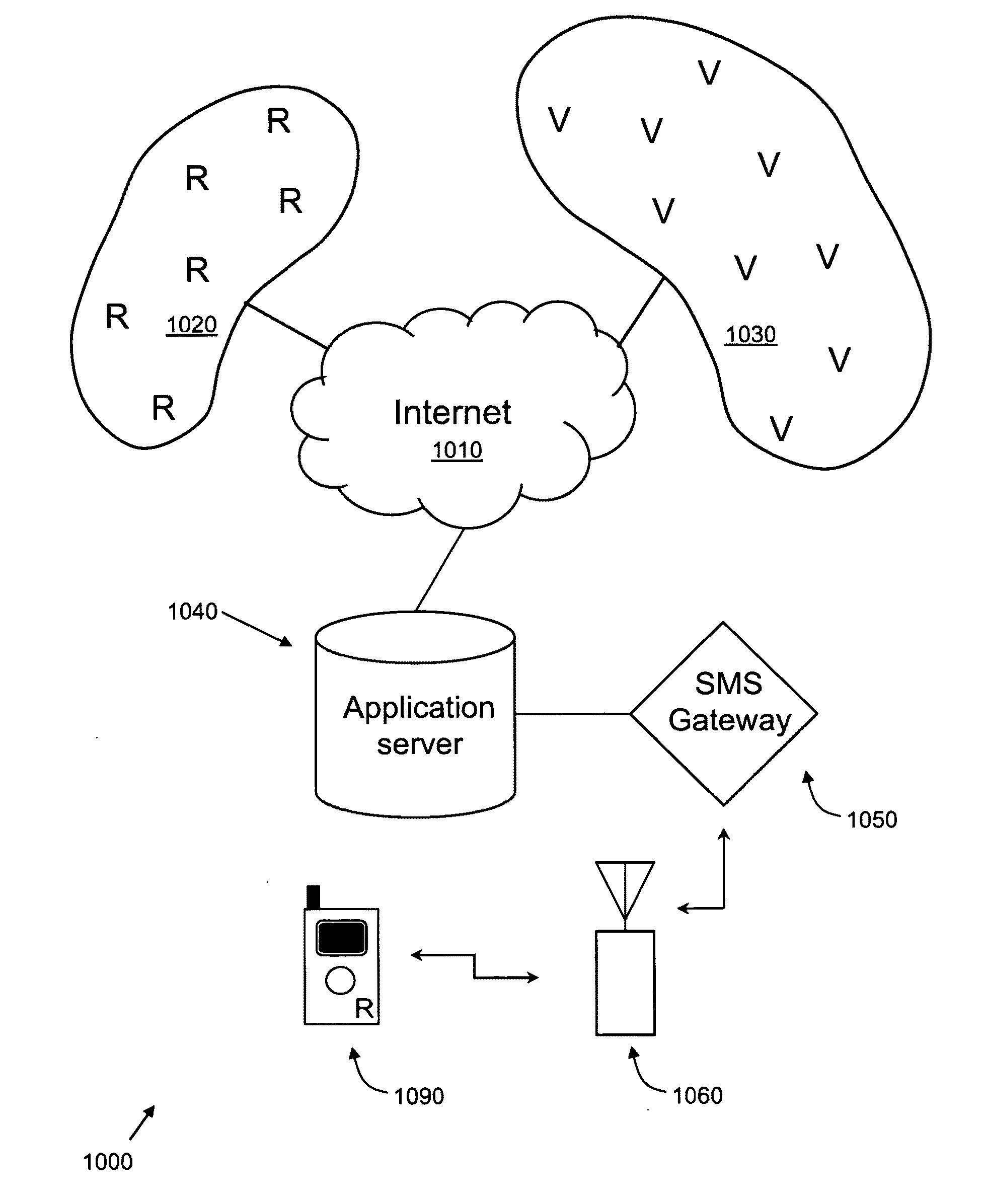

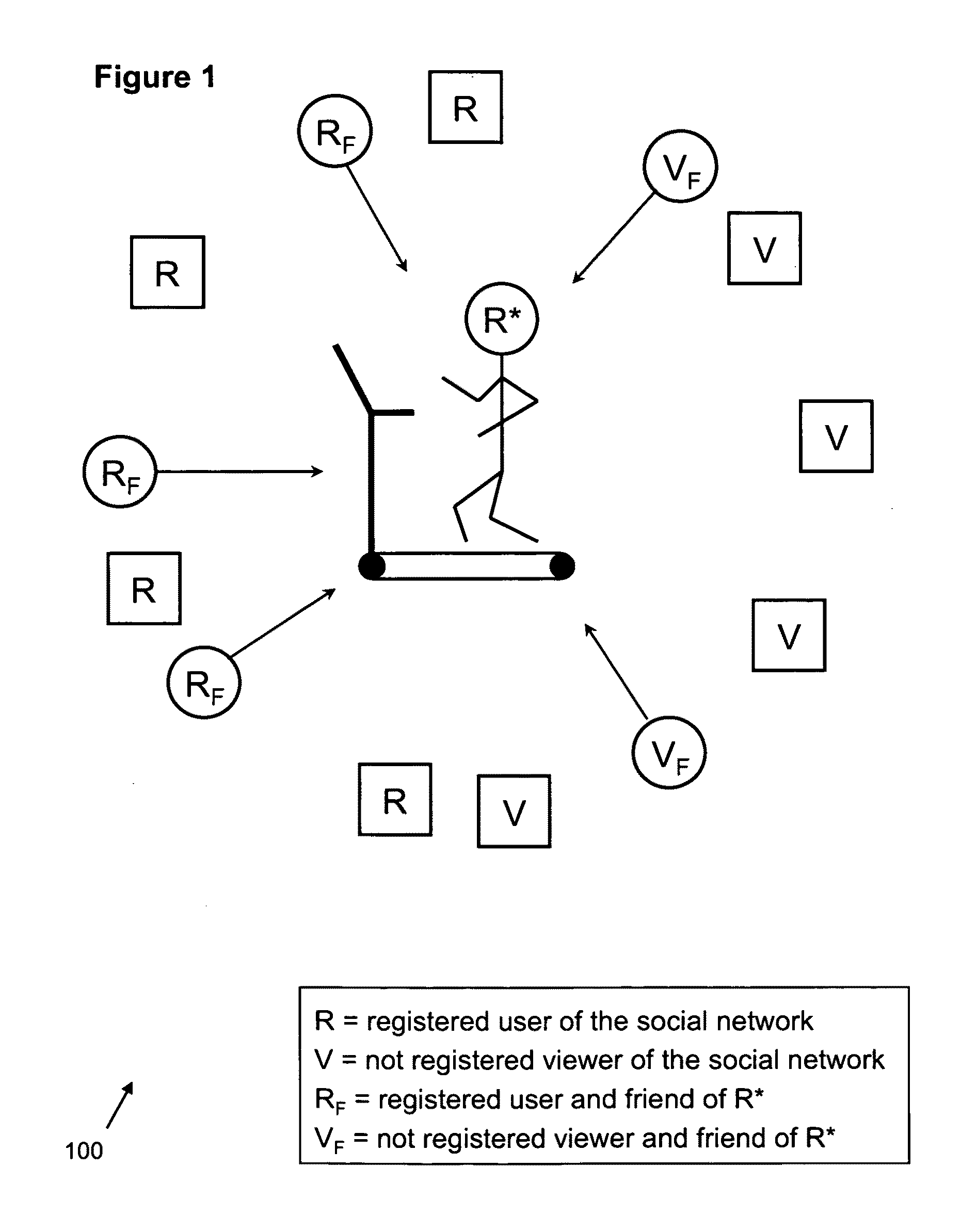

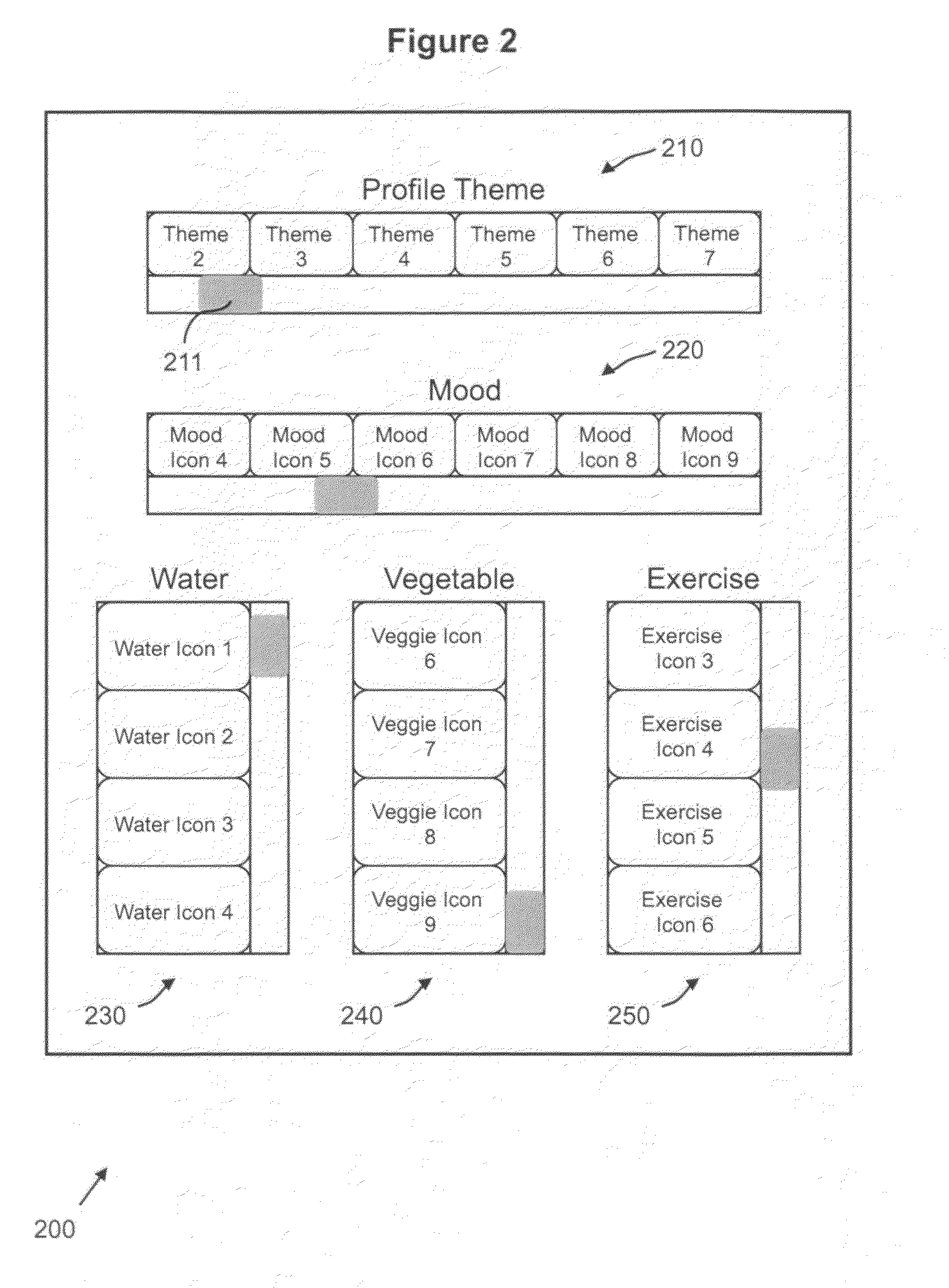

A social network for affecting personal behavior is provided. The psychological and behavioral progress of a registered user of the social network is maintained. The social network provides the registered user with friends who can track the user's progress and encourage the user by communications with the user. The friends of the user can be anybody, including people who are not registered with the social network. A dynamic mechanism for grouping different users into support groups is also provided. The grouping is based on the user's progress, satisfaction with the user's supporters, and the user's traits and preferences. User-customized profiles are used to elucidate user traits instead of standard direct forms to avoid incorrect or misleading responses to the forms. In addition, a wireless portable device in communication with the social network of friends and supporters is provided for constant access to sources of motivation.

Owner:INVENT LY LLC

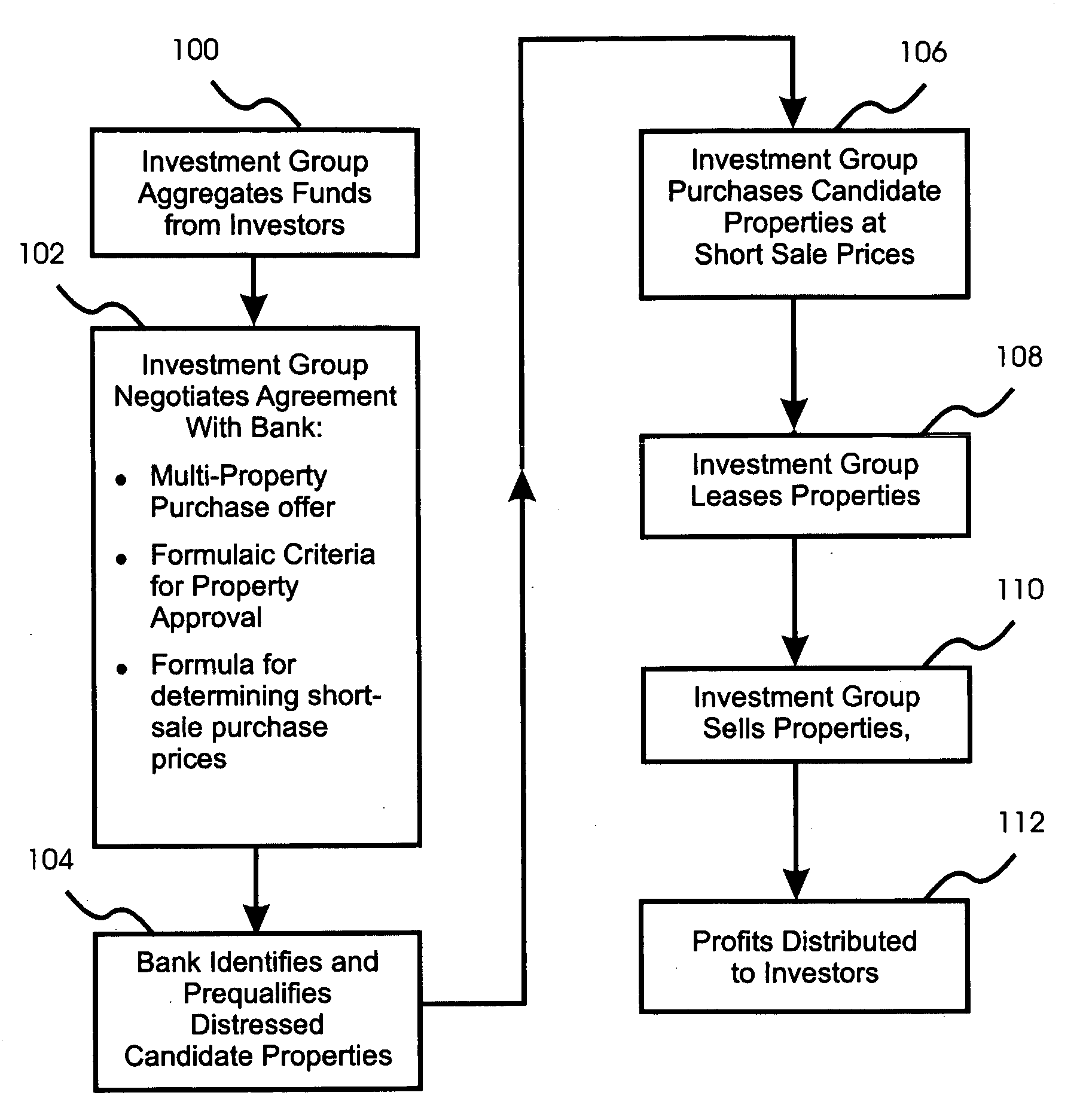

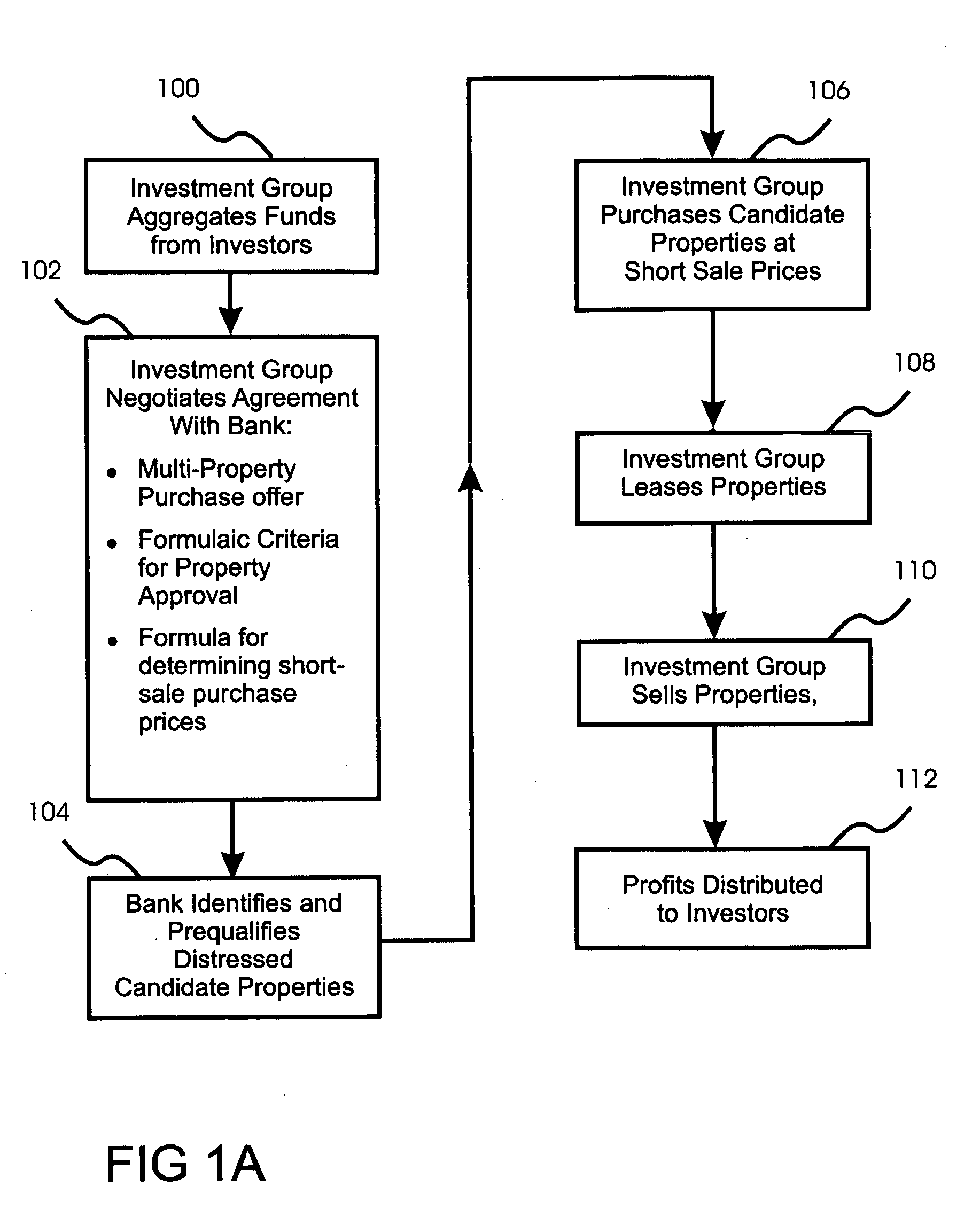

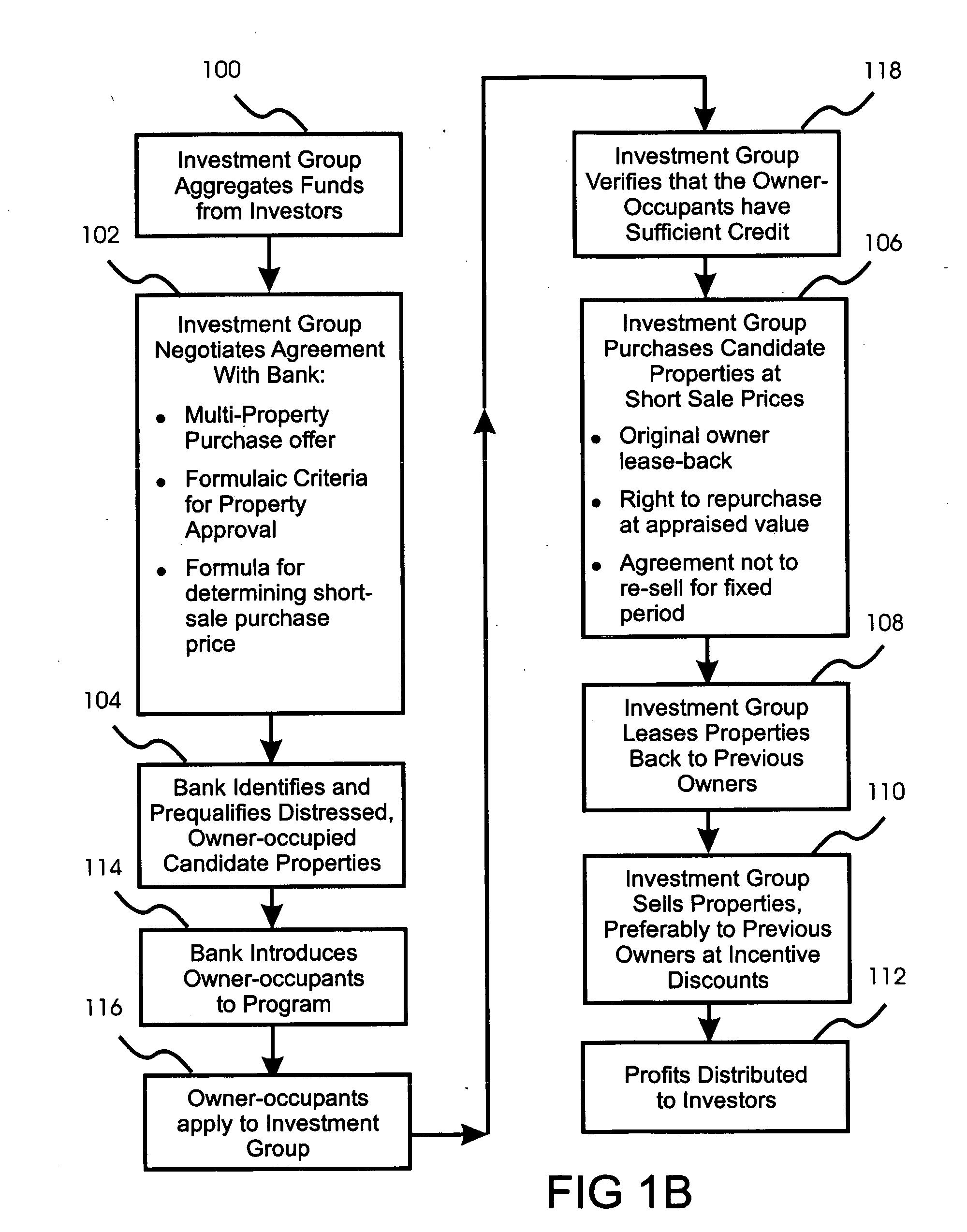

Real estate investment method for purchasing a plurality of distressed properties from a single institution at formula-derived prices

InactiveUS20100293114A1Remove the burdenRemoval can be quite burdensomeFinanceSpecial data processing applicationsSupport groupService provision

A real estate investing method is disclosed in which aggregated investment capital is used to purchase a plurality of properties from a single lending institution at short-sale prices calculated using a pre-negotiated formula. The lending institution agrees to identify and qualify properties, and accept the short-sale prices, in return for selling a plurality of distressed properties under a single agreement. Owners avoid foreclosure and consequent damage to their credit. Investors aren't burdened by property selection and / or maintenance. In preferred embodiments, owner-occupied homes are purchased, leased back to their occupants, and eventually resold to the occupants if their finances recover. Repurchase credit incentives can be offered to occupants, providing limited participation in property appreciation and motivating occupants to maintain the properties and strive to repurchase them. During leases, landlord services are provided under contract by local service providers and / or regional warranty providers. A central support group can provide centralized tenant support.

Owner:KHAN MOHAMMED SALAHUDDIN +1

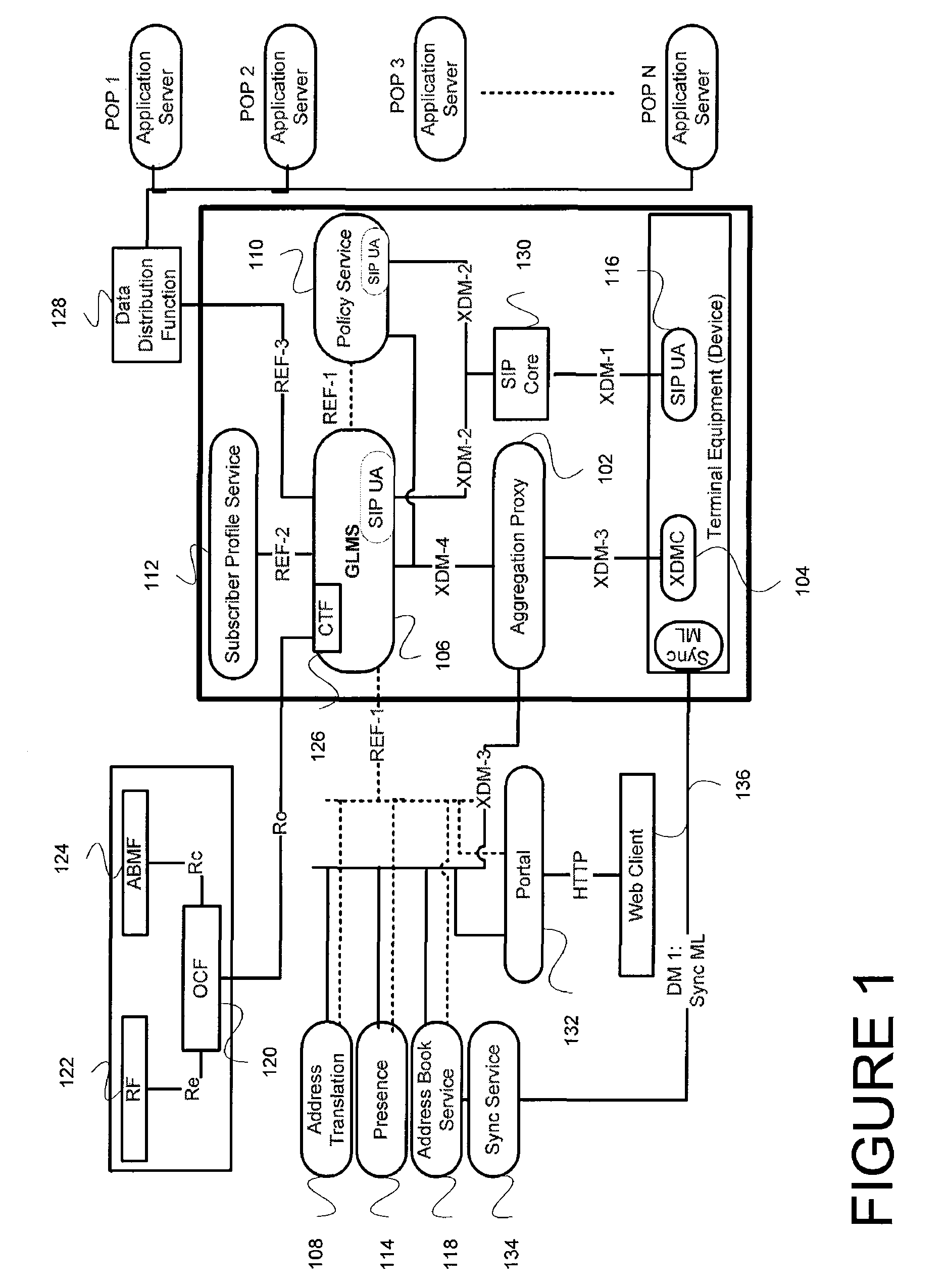

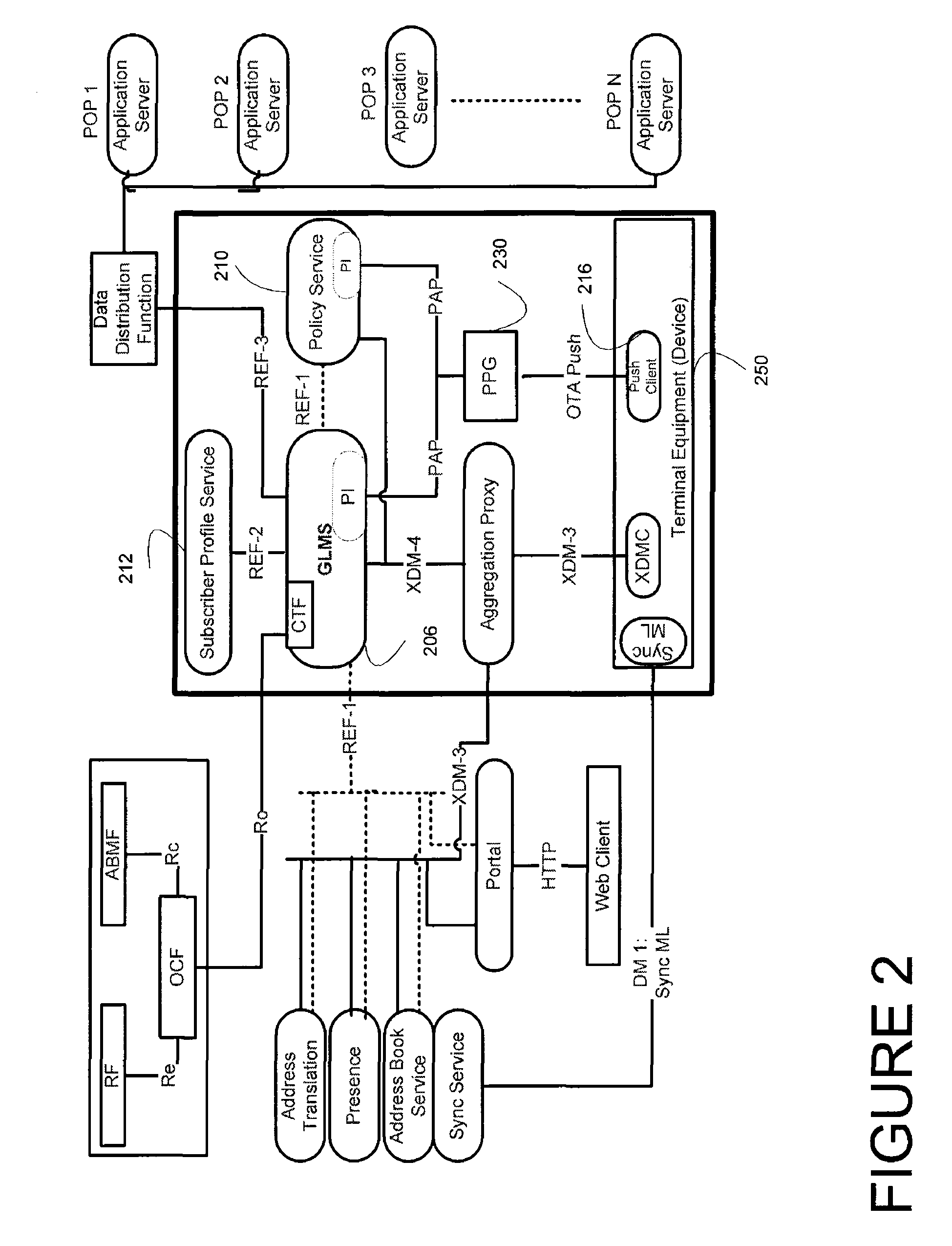

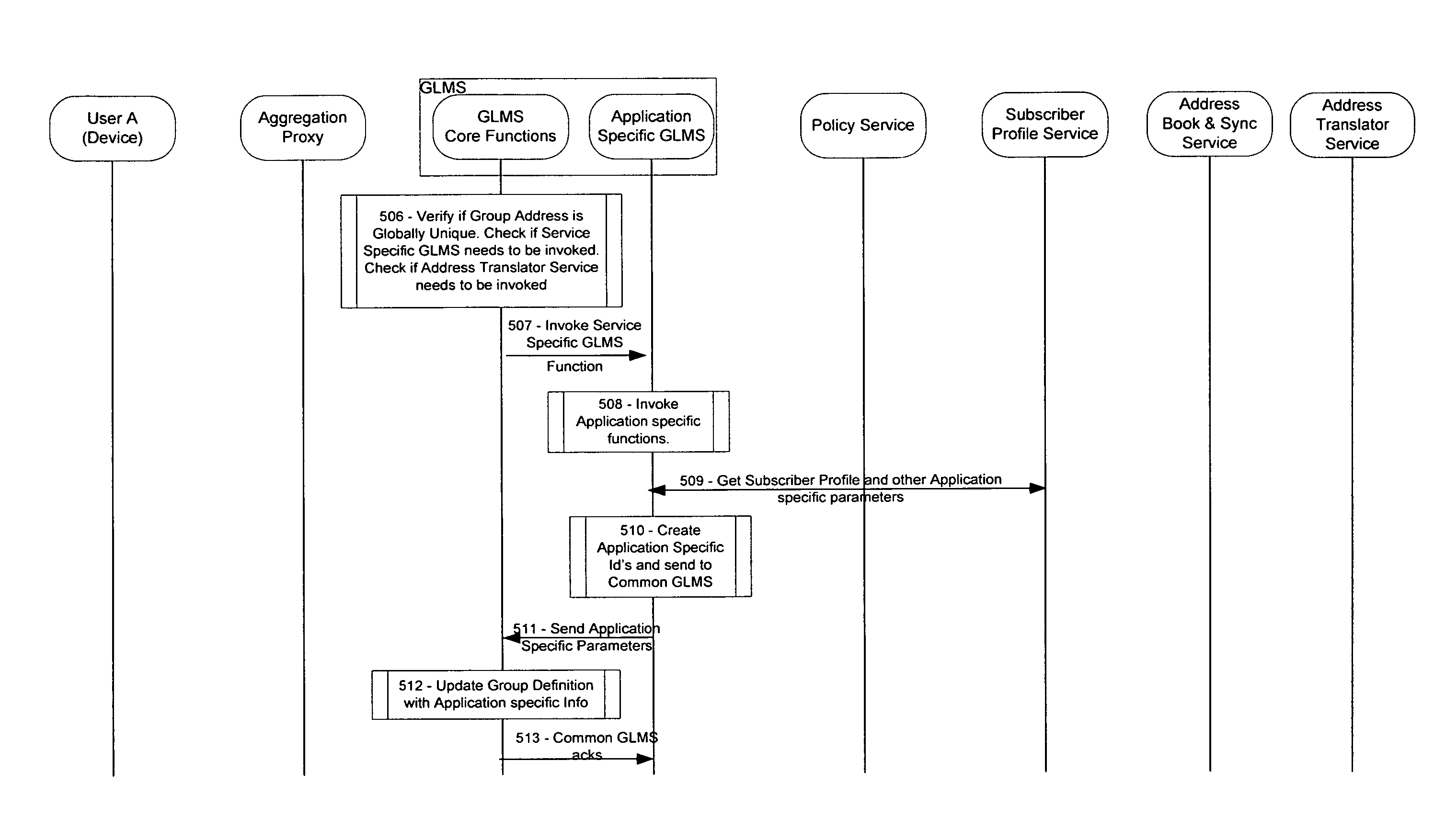

Systems and methods for talk group distribution

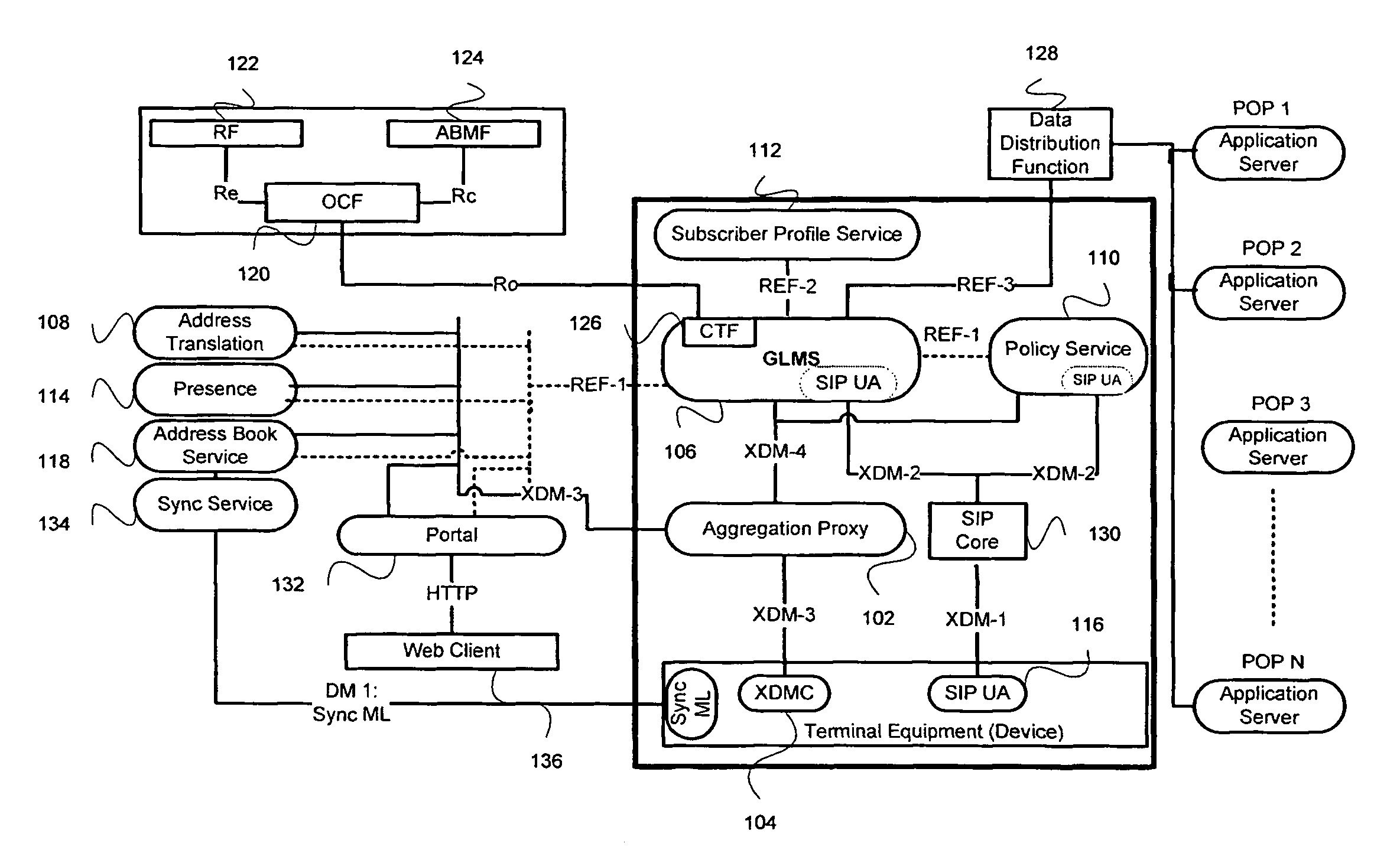

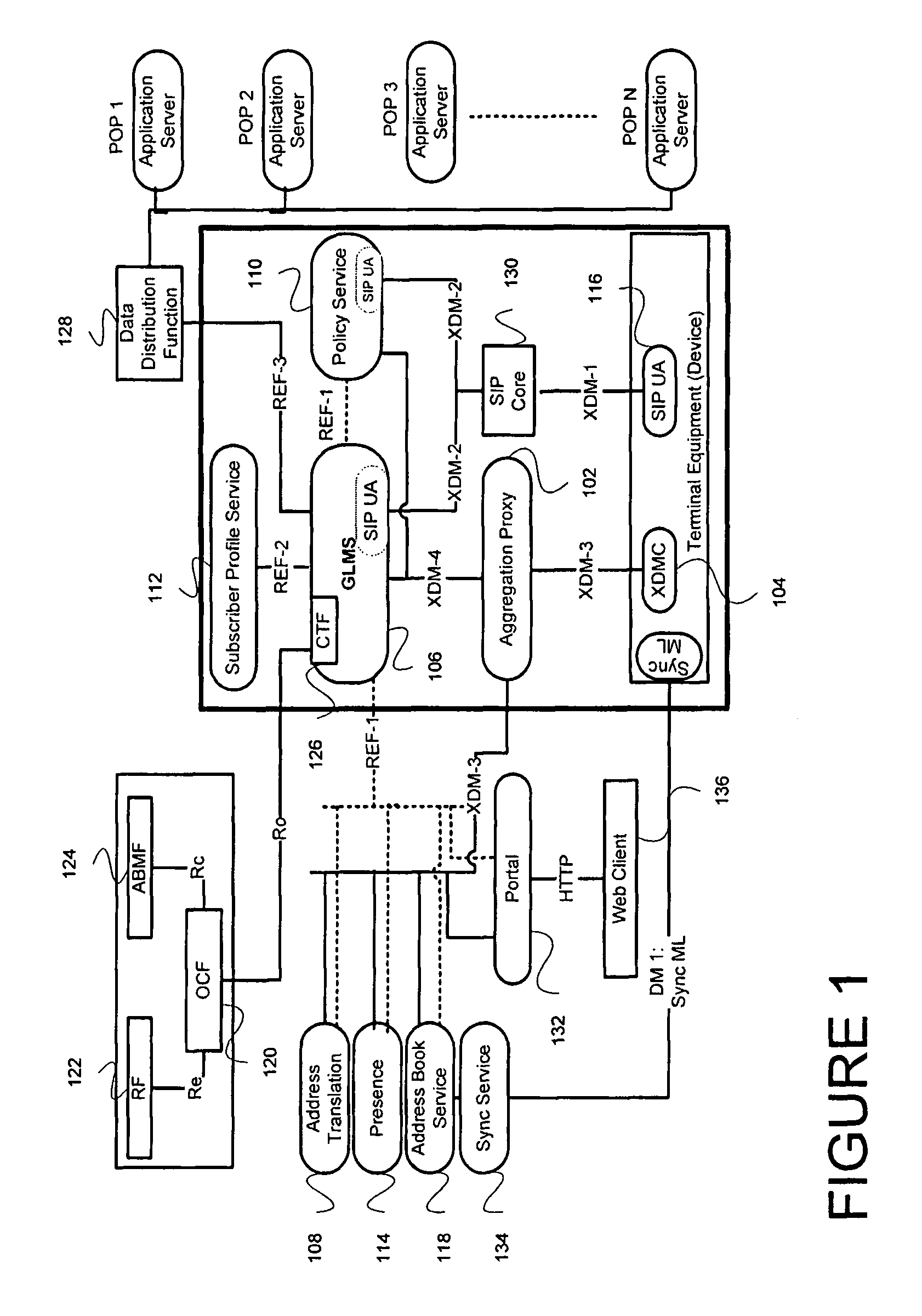

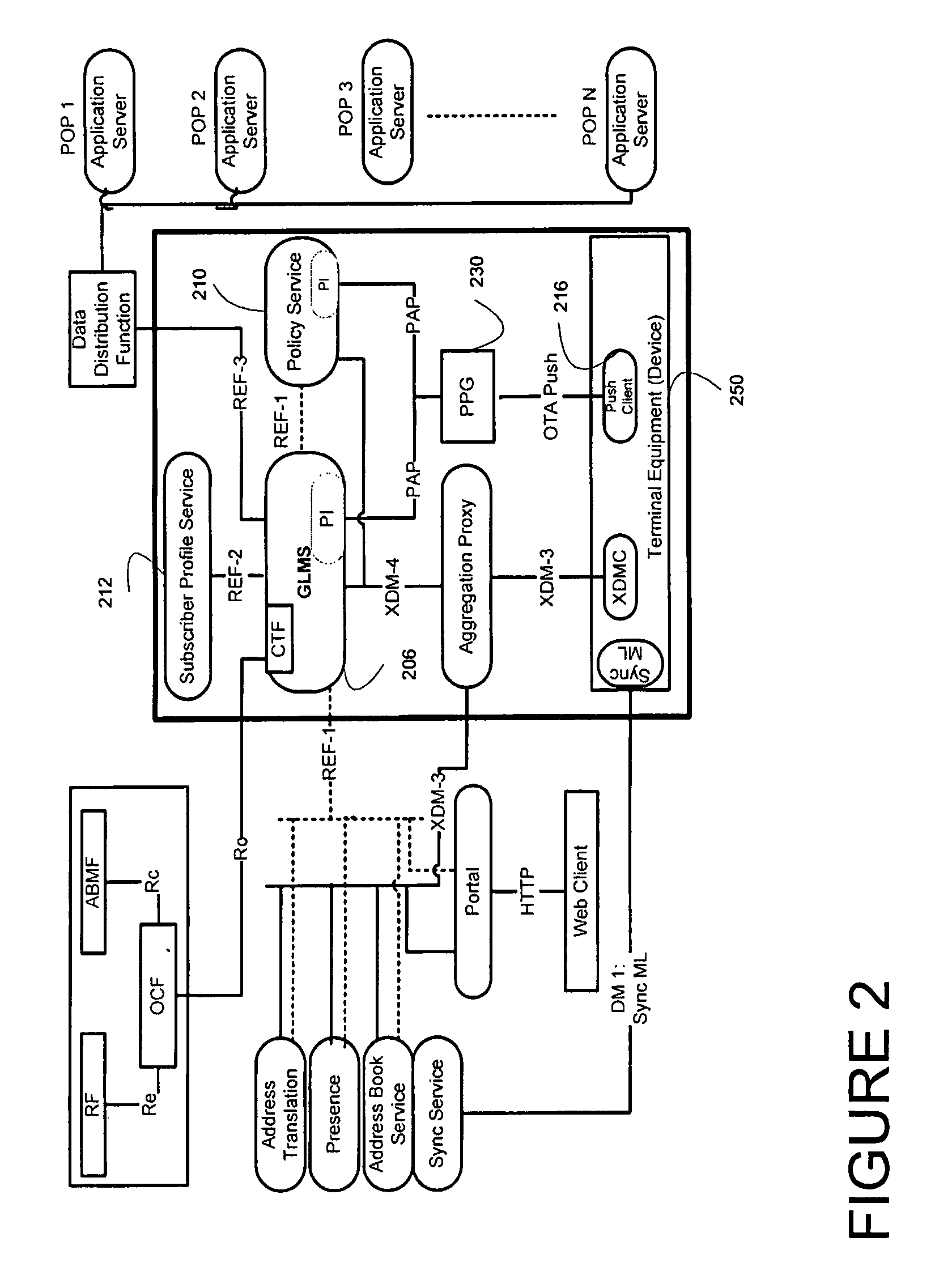

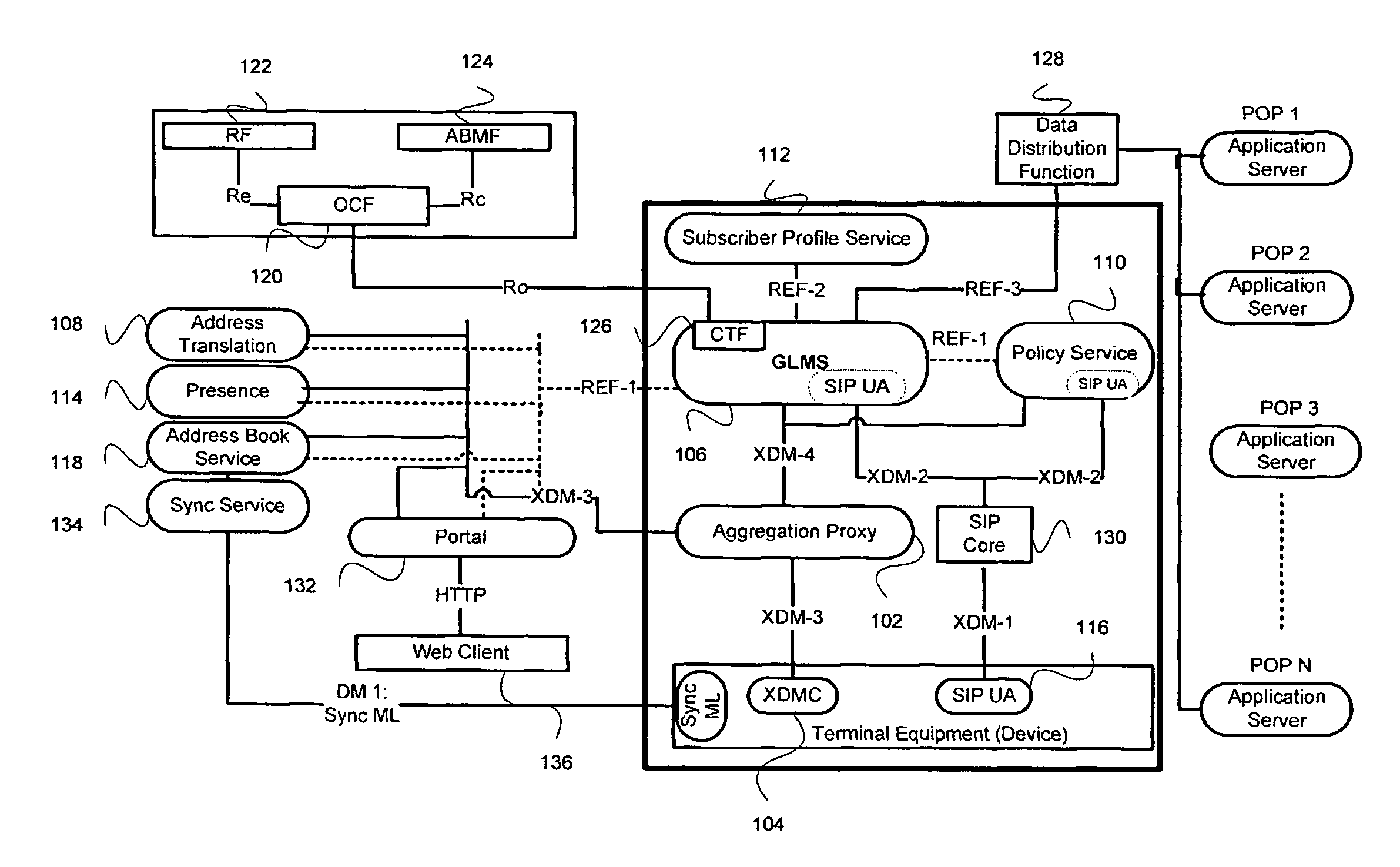

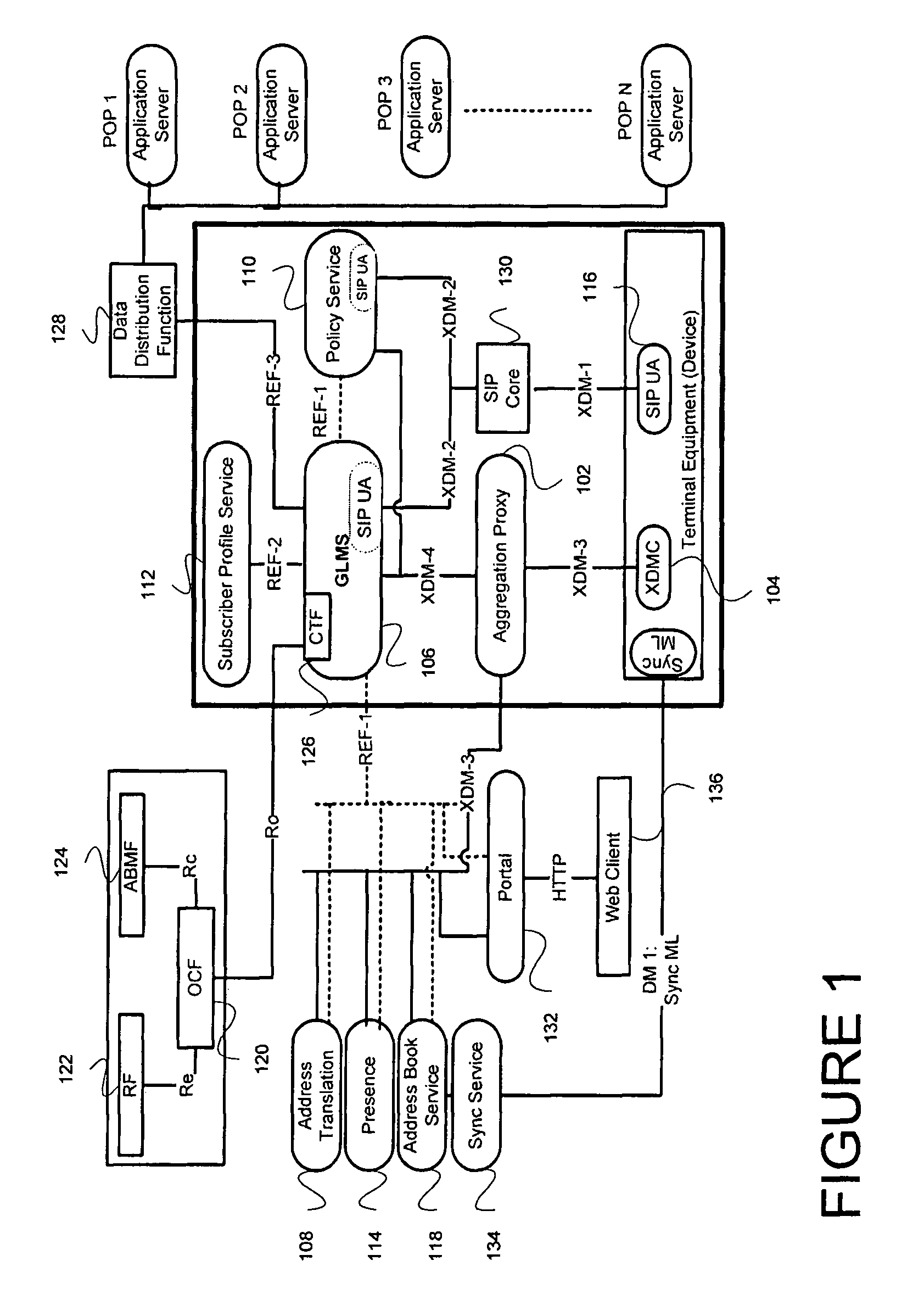

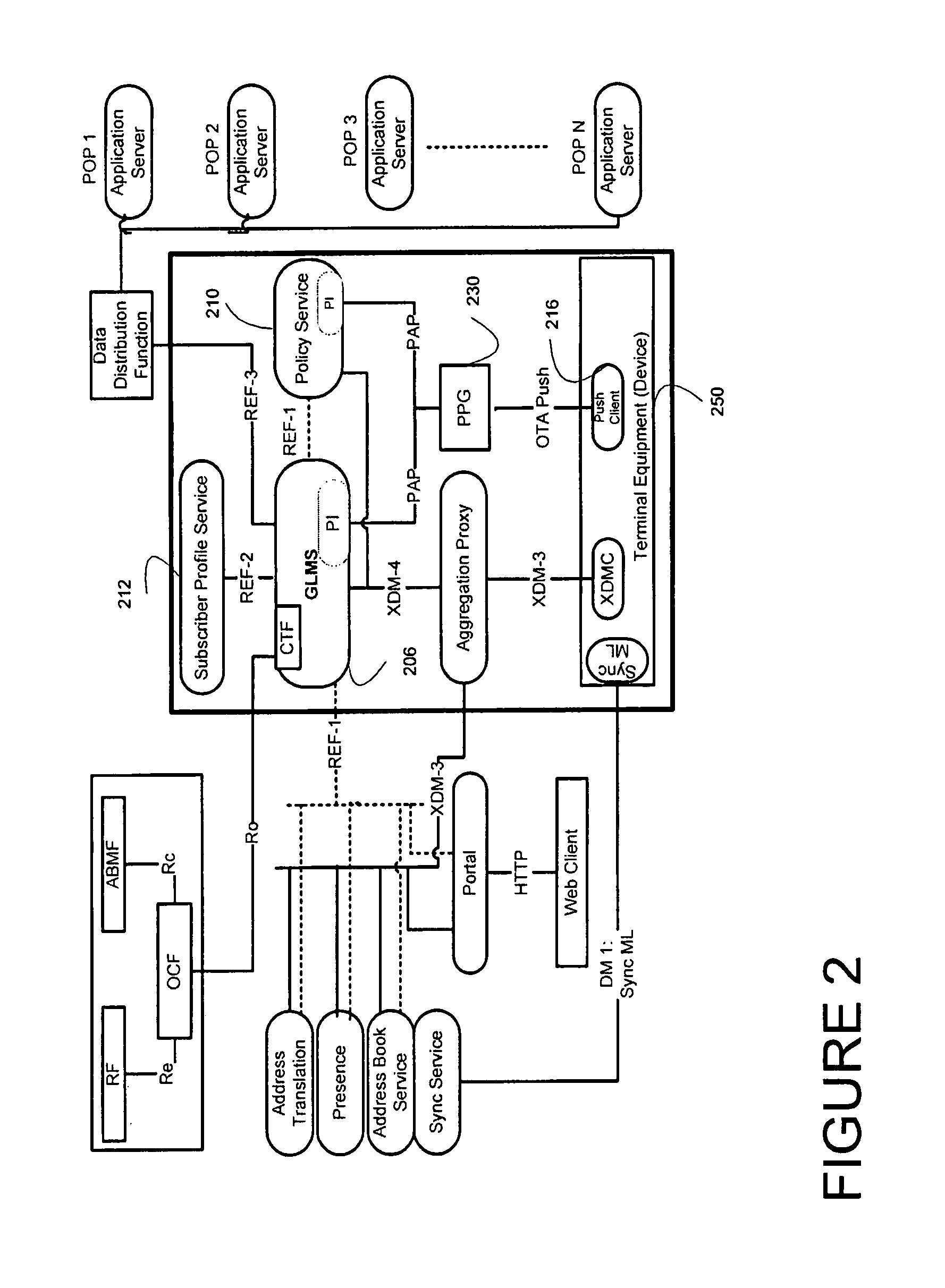

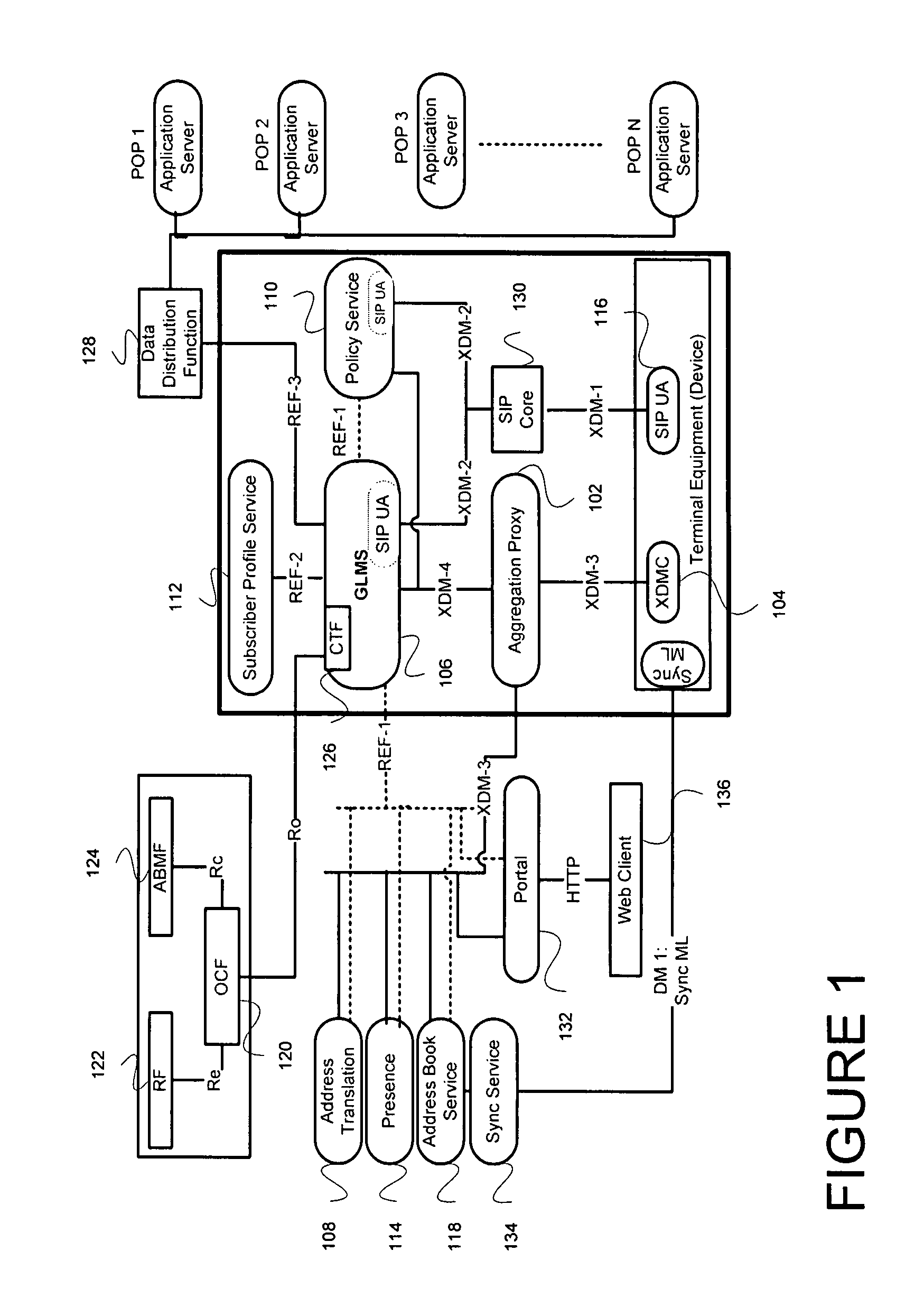

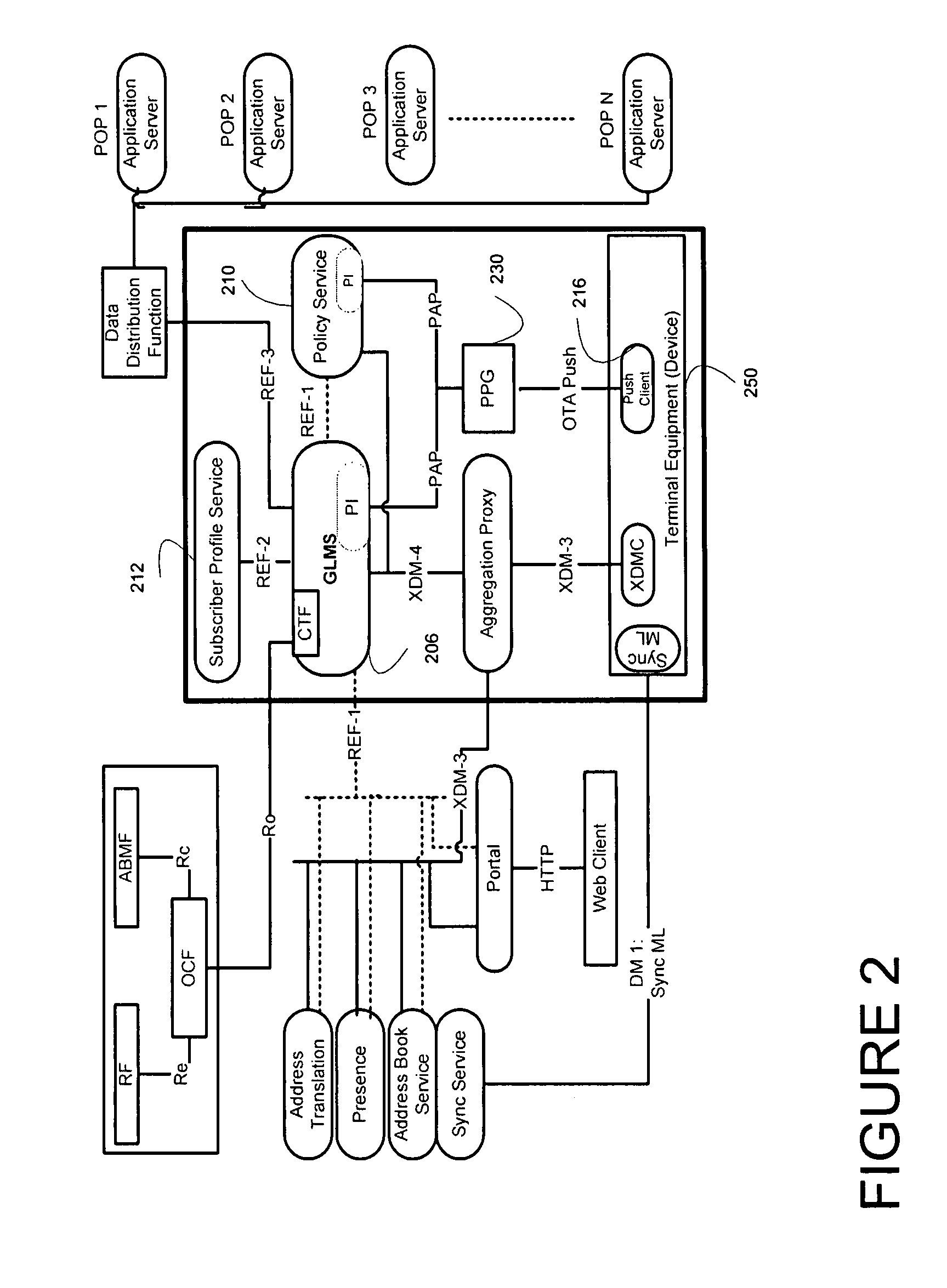

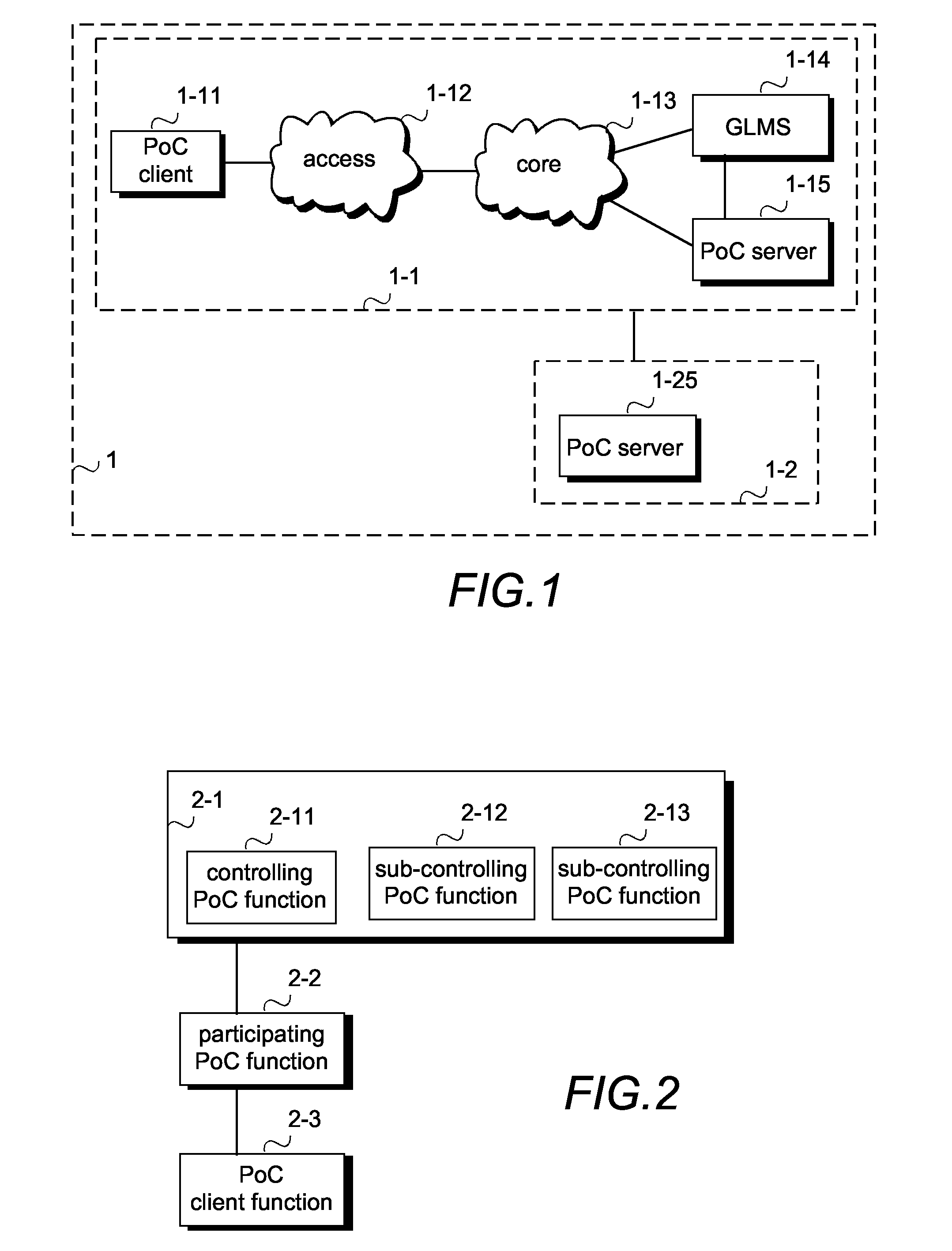

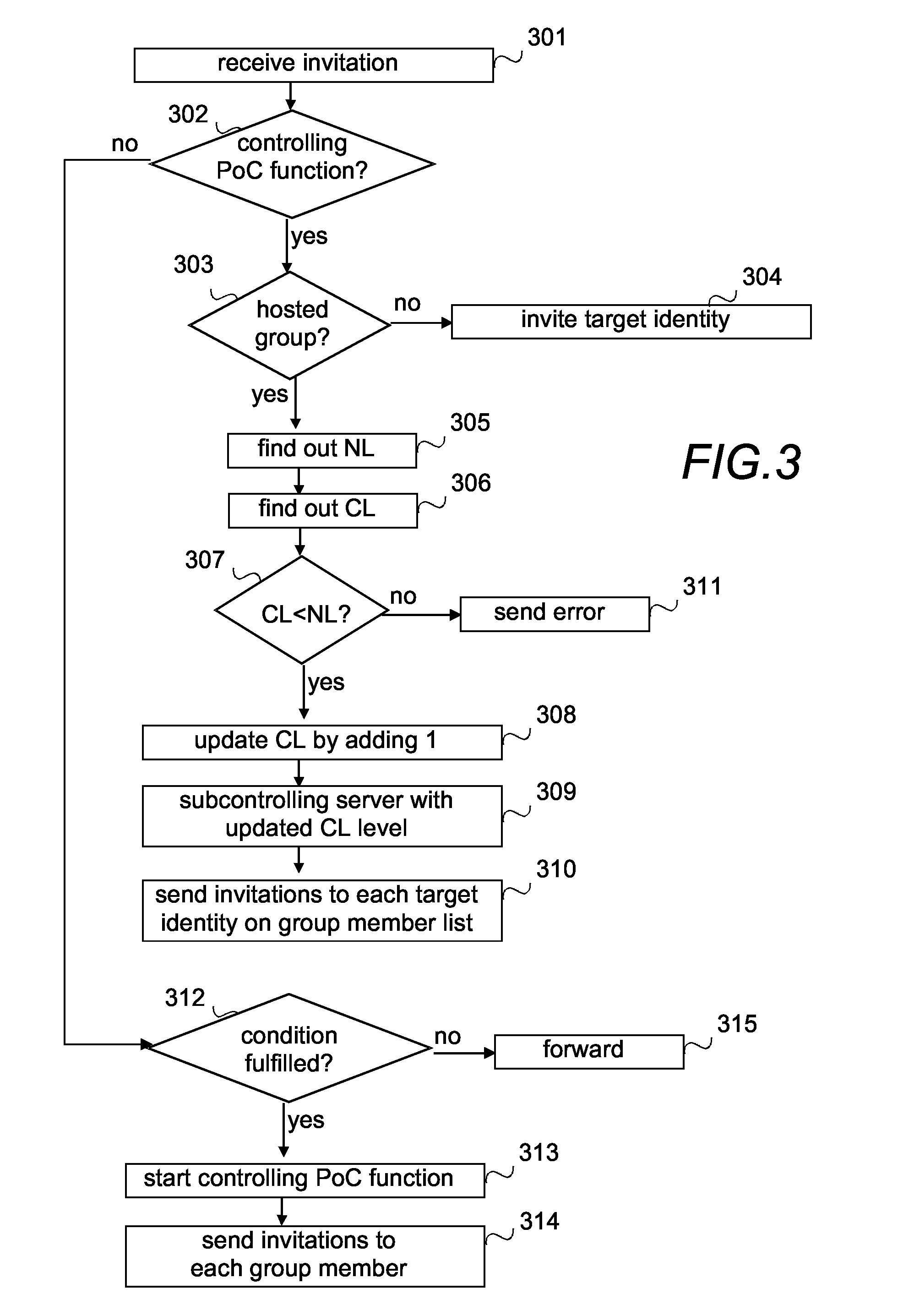

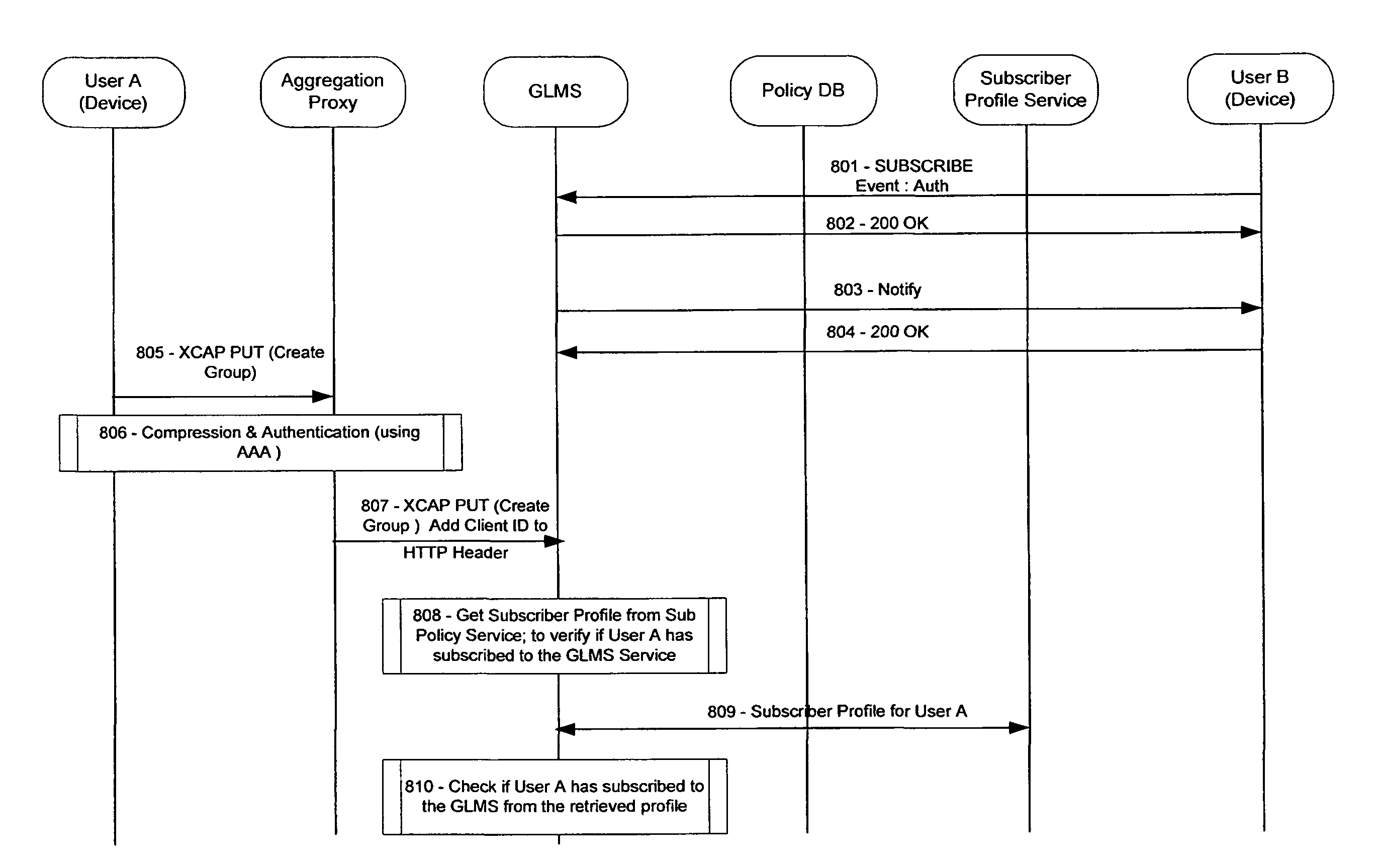

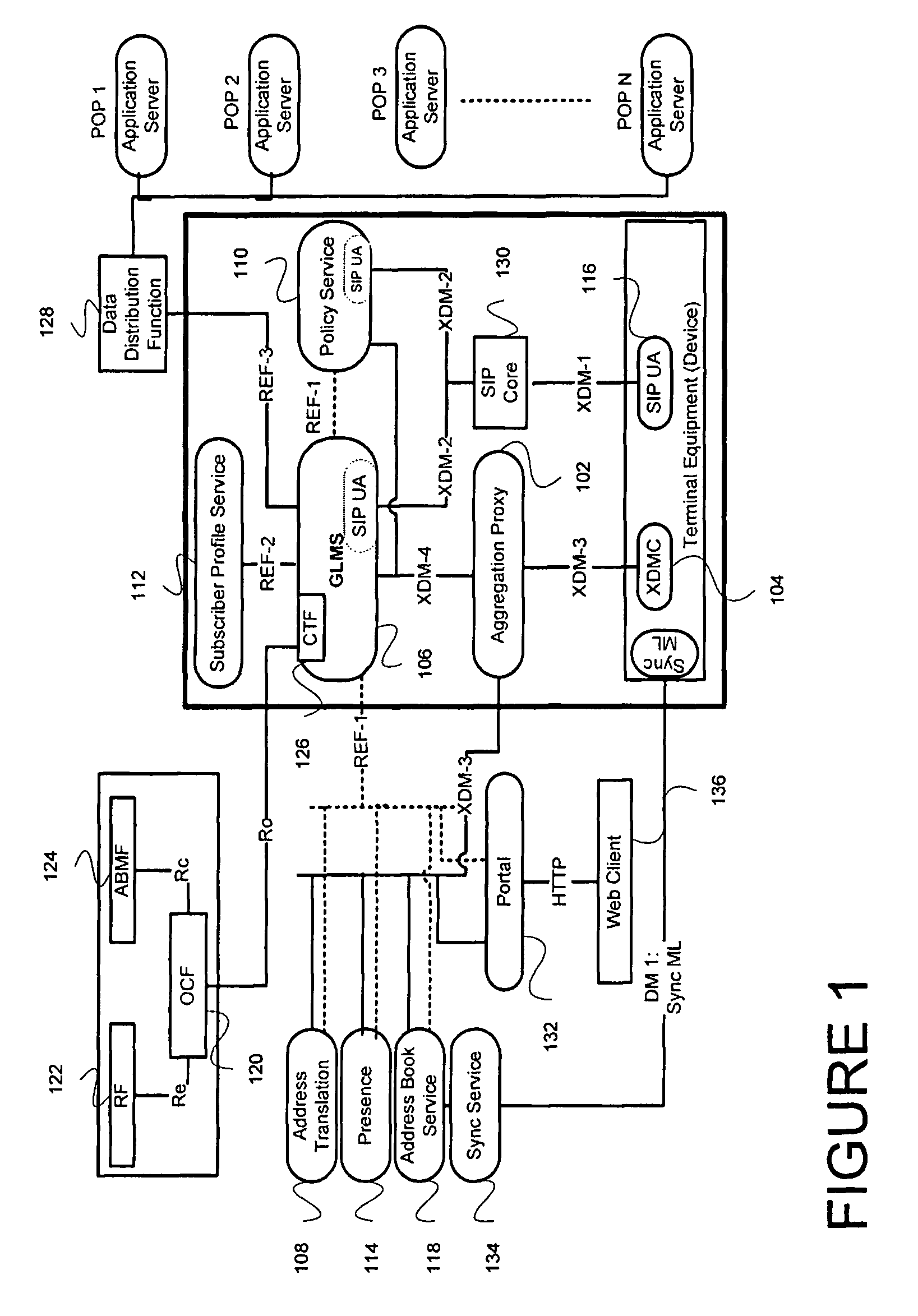

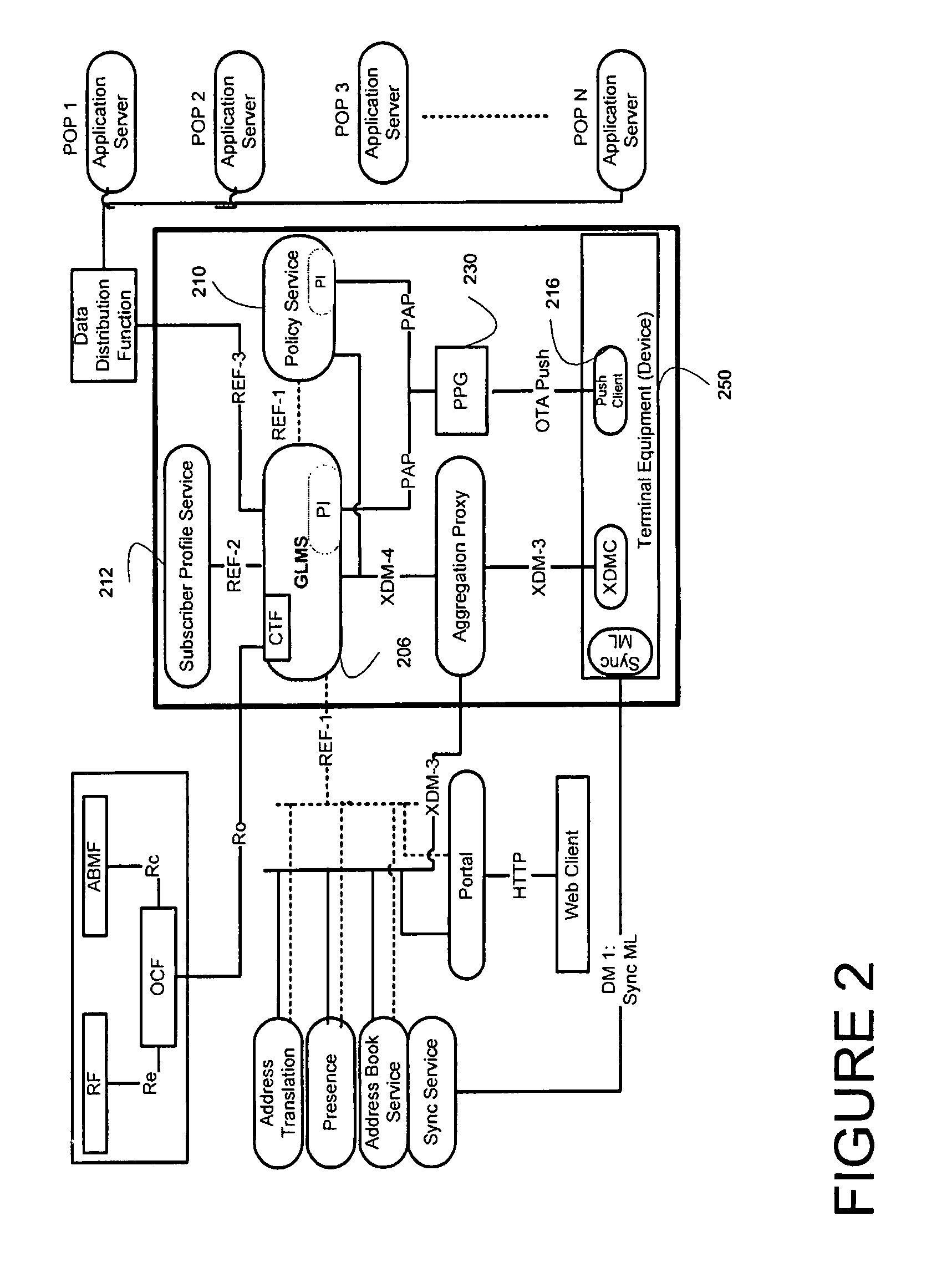

Systems and methods for supporting group communications are provided. A group list management server (GLMS) stores communications group definitions in documents, such as extensible mark-up language (XML) documents. The communications group can include communication addresses for different types of communication applications, including electronic mail, voice telephone, data, instant messaging, voice dispatch, short messaging service (SMS), and multimedia service (MMS). Various methods for managing communications groups and features provided for communications groups are provided.

Owner:NEXTEL COMMUNICATIONS

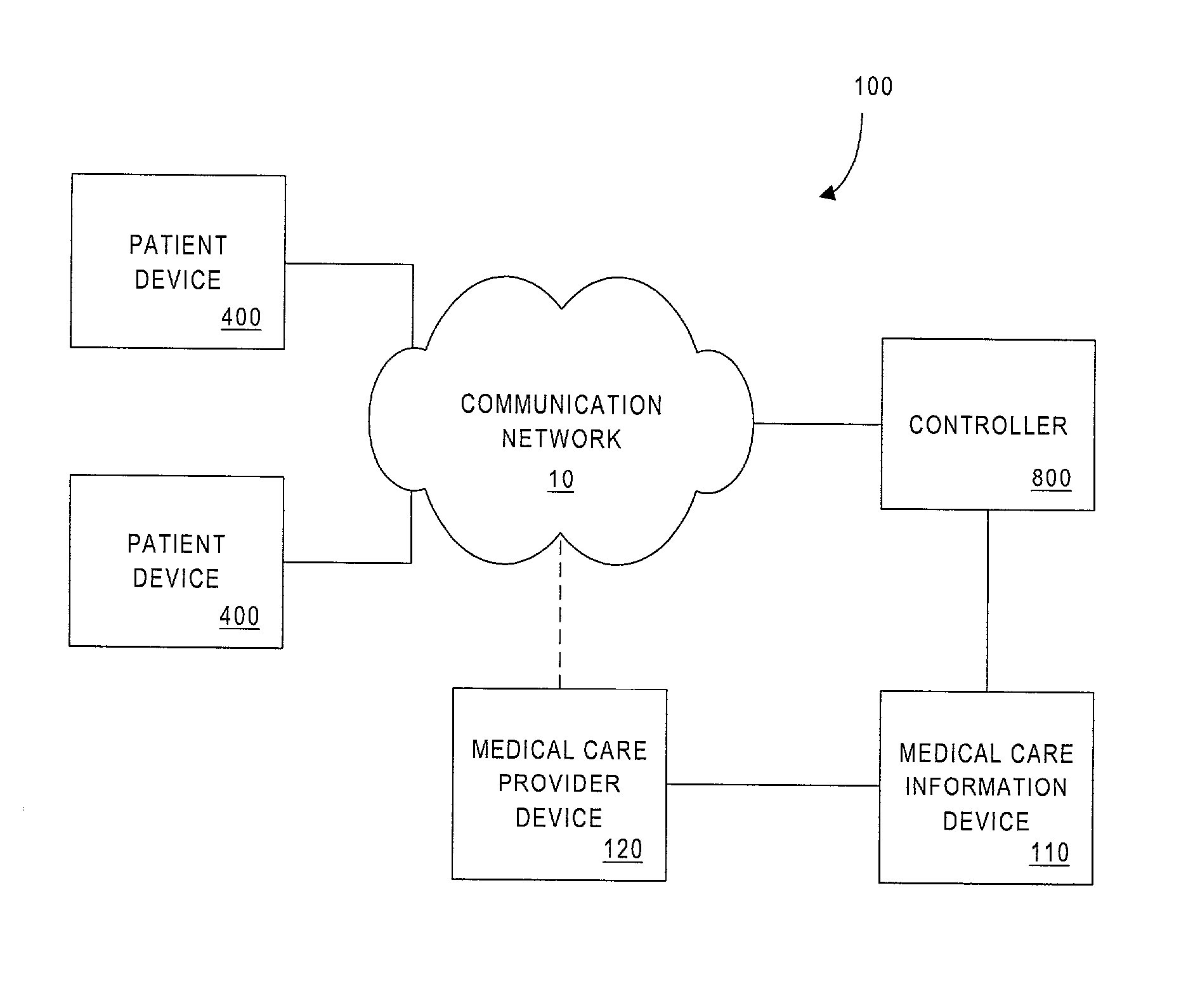

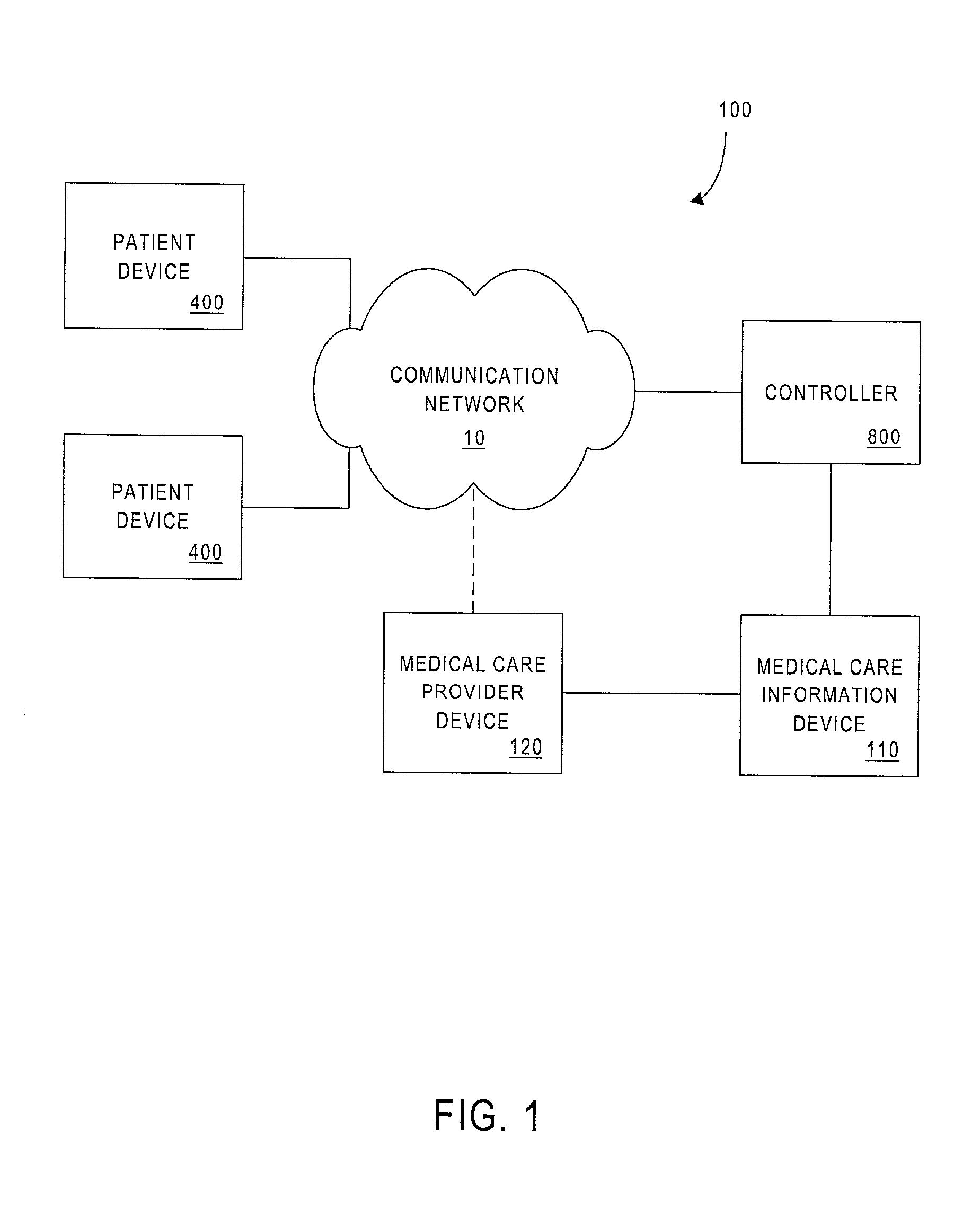

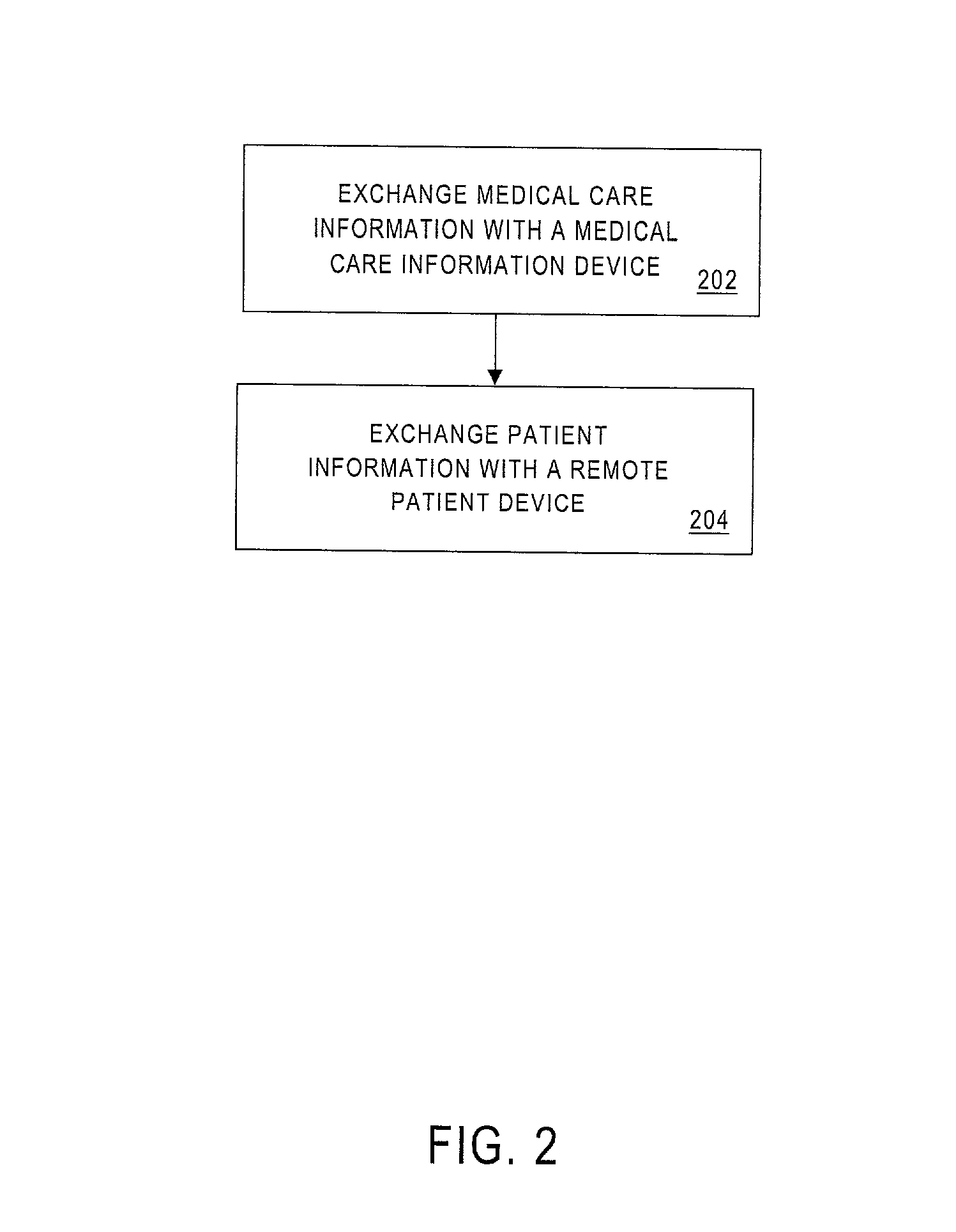

Systems and methods to facilitate an exchange of information associated with medical care provided to a patient

Systems and methods are provided to facilitate an exchange of information associated with a patient's medical care. According to one embodiment, medical care information is exchanged with a medical care information device, such as the LANTIS(R) Oncology Management System. Patient information is then exchanged with a remote patient device via a communication network, the patient information being associated with the medical care information. For example, the patient may exchange scheduling information, journal information, information associated with another patient or a support group, educational information, and / or medical instructions via a Web site.

Owner:SIEMENS MEDICAL SYST INC

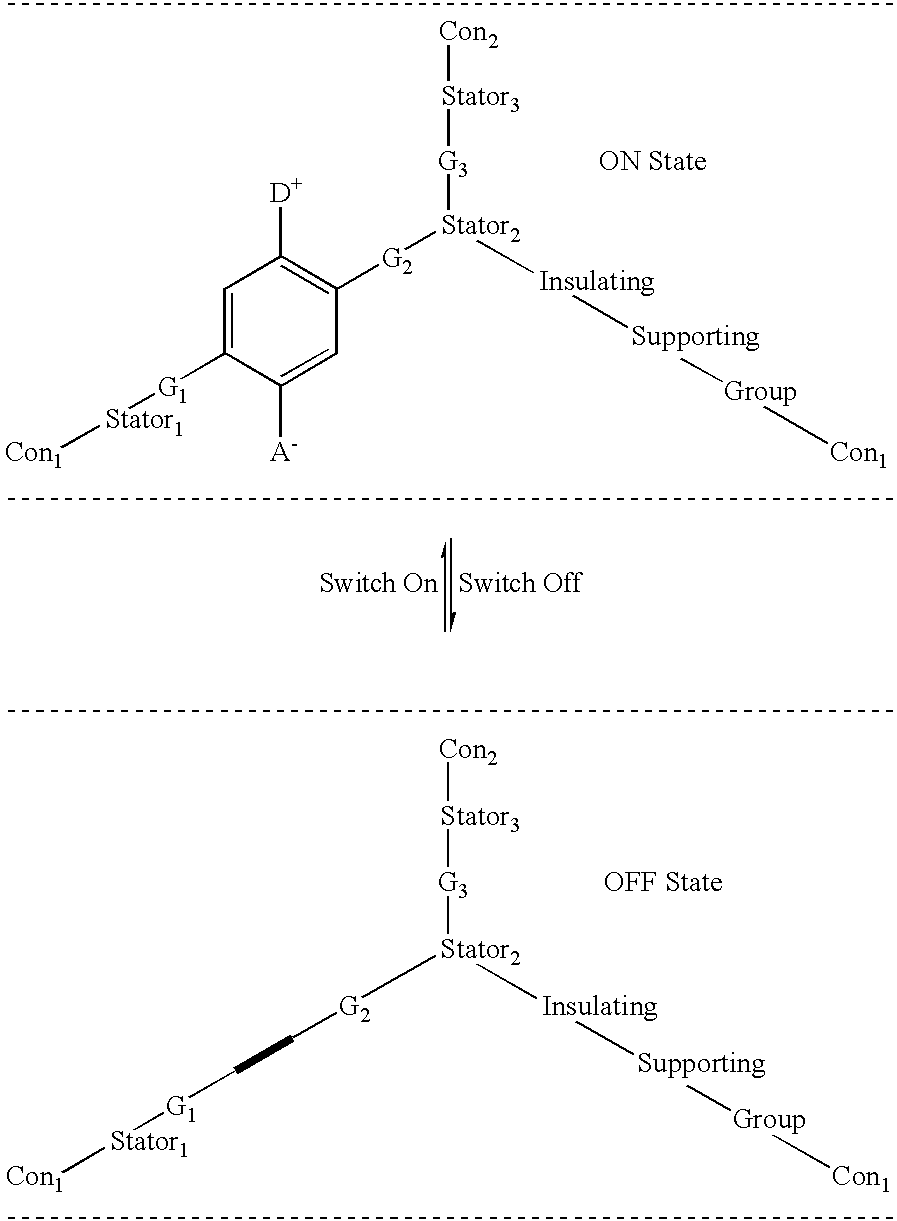

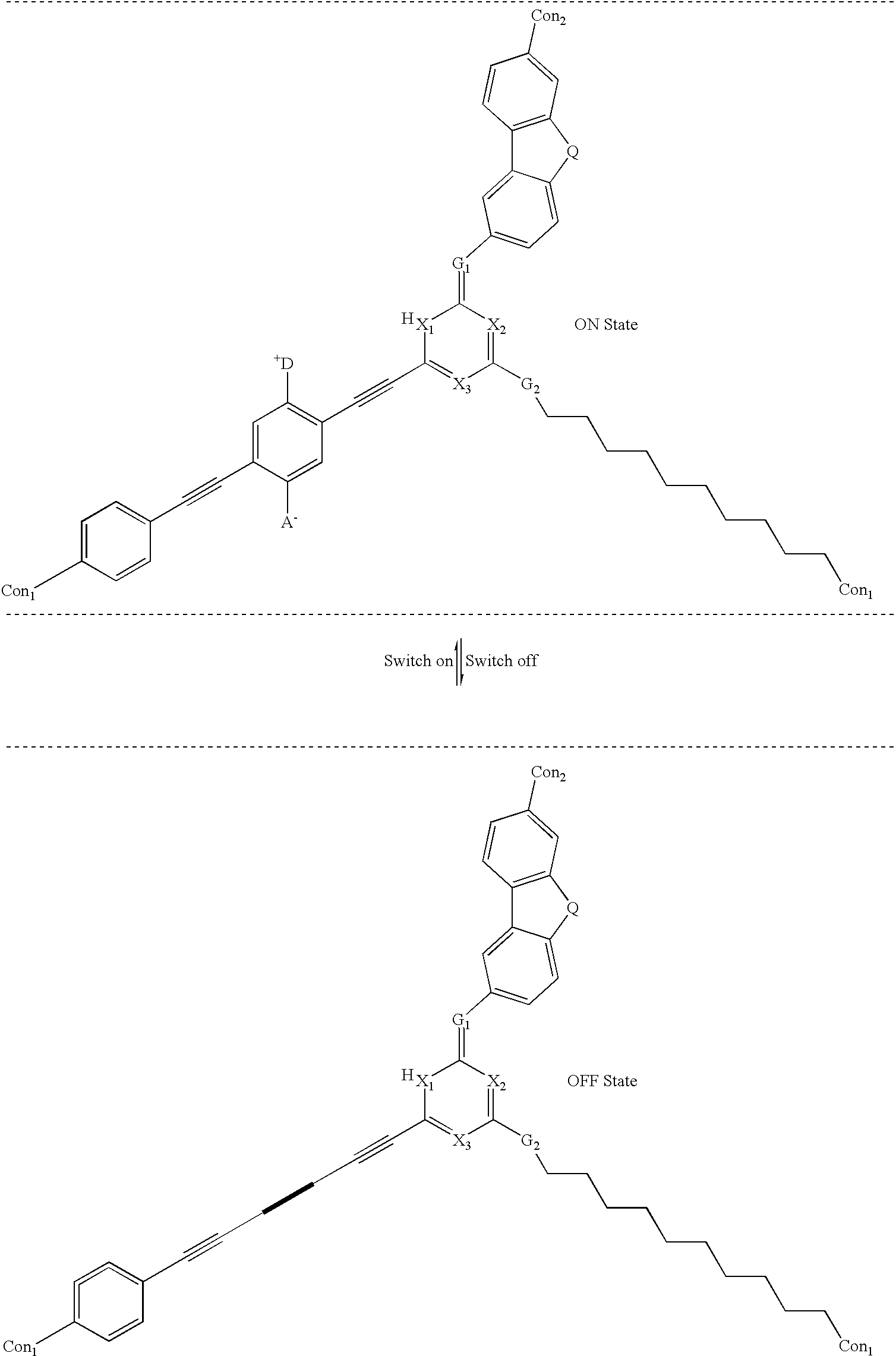

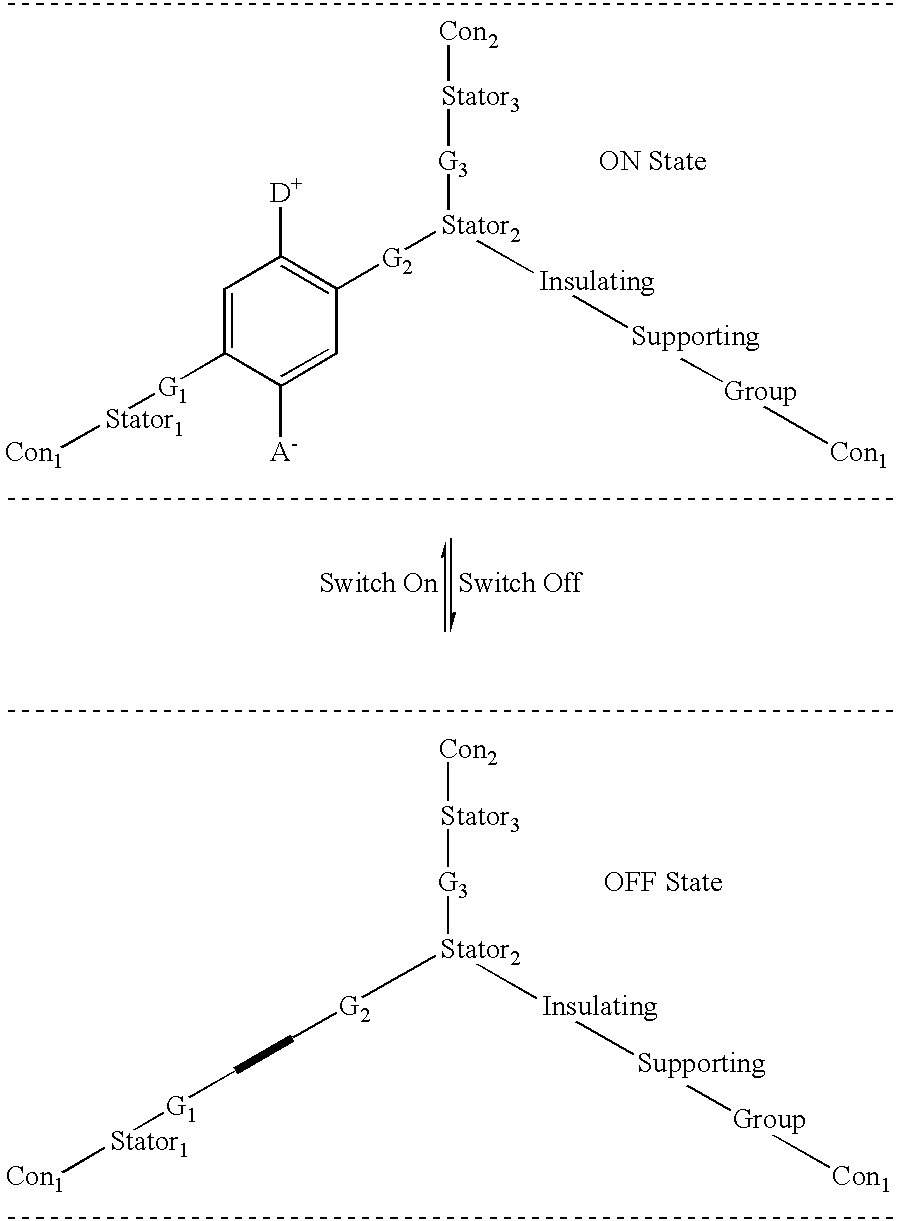

New E-field-modulated bistable molecular mechanical device

InactiveUS20020114557A1Enhance the interaction strengthFast switching timeNanoinformaticsSolid-state devicesElectric field modulationSupport group

A molecular system is provided for nanometer-scale reversible electronic and optical switches, specifically, electric field-activated molecular switches that have an electric field induced band gap change that occurs via a molecular conformation change or a tautomerization. Changing of extended conjugation via chemical bonding change to change the band gap is accomplished by providing the molecular system with one rotating portion (rotor) and two or more stationary portions (stators), between which the rotor is attached. The molecular system of the present invention has three branches (first, second, and third branches) with one end of each branch connected to a junction unit to form a "Y" configuration. The first and second branches are on one side of the junction unit and the third branch is on the opposite side of the junction unit. The first branch contains a first stator unit in its backbone, the junction unit comprises a second stator unit, and the first branch further contains a rotor unit in its backbone between the first stator unit and the second stator unit. The second branch includes an insulating supporting group in its backbone for providing a length of the second branch substantially equal to that of the first branch, wherein the rotor unit rotates between two states as a function of an externally-applied field.

Owner:SAMSUNG ELECTRONICS CO LTD

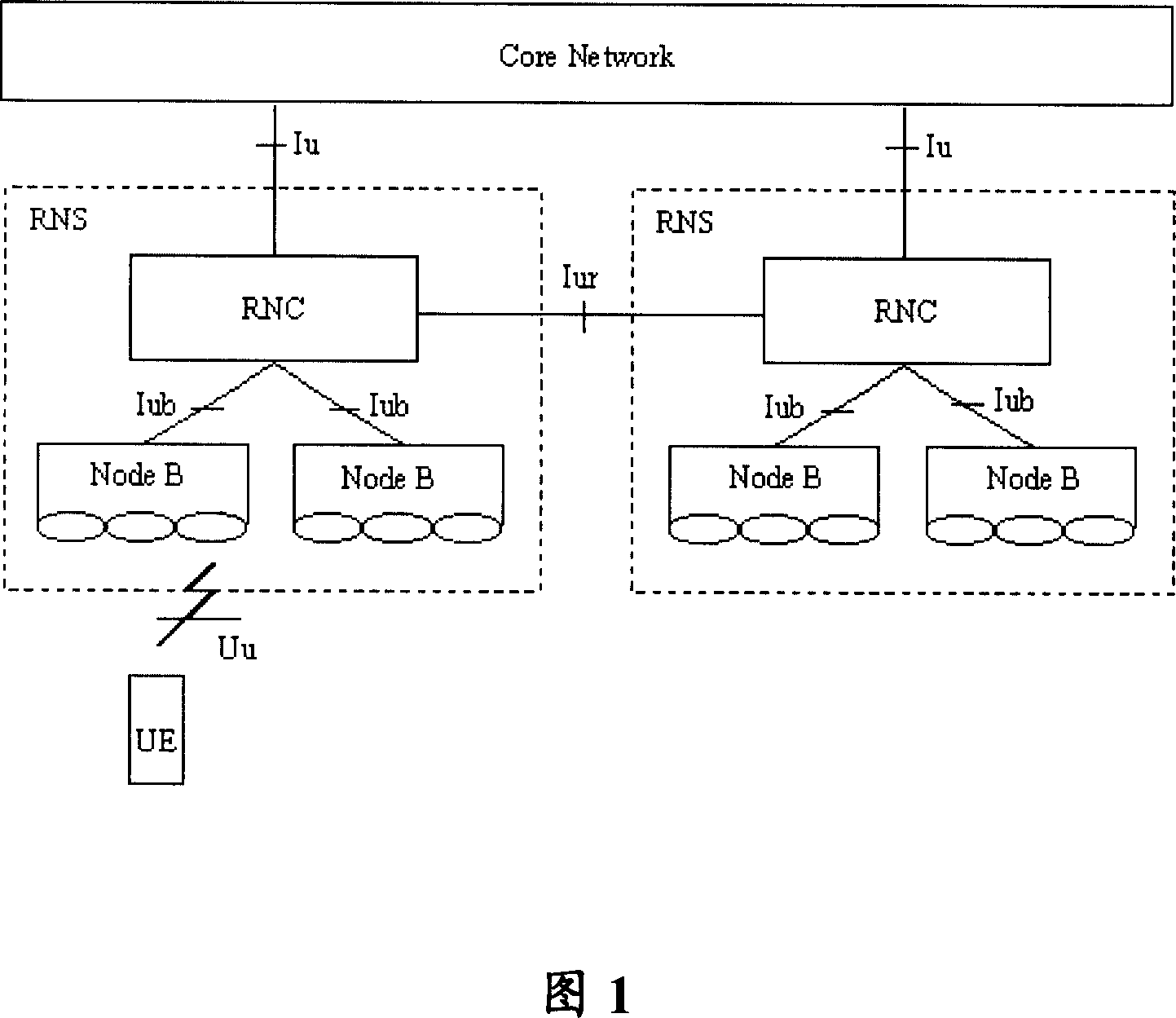

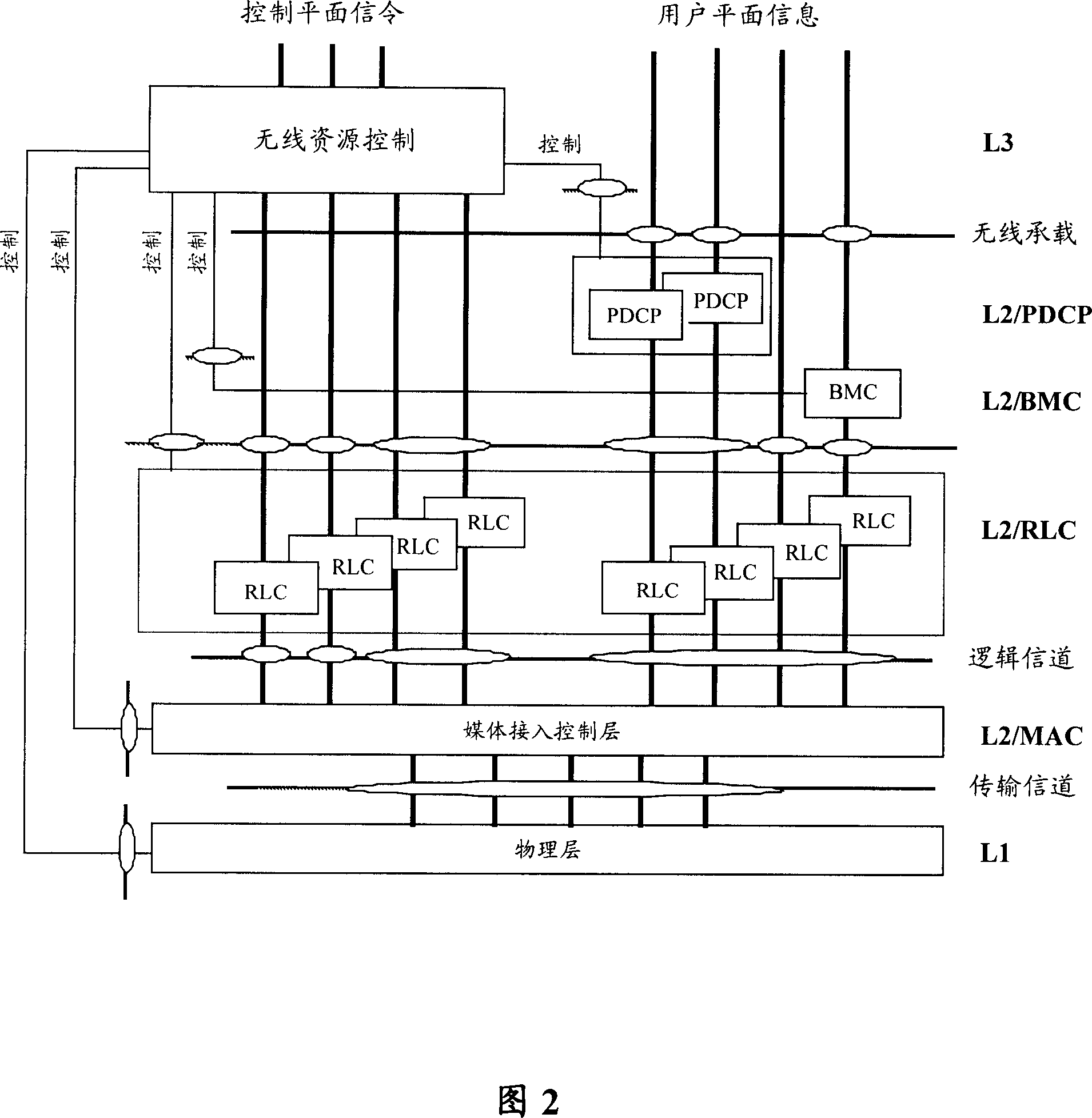

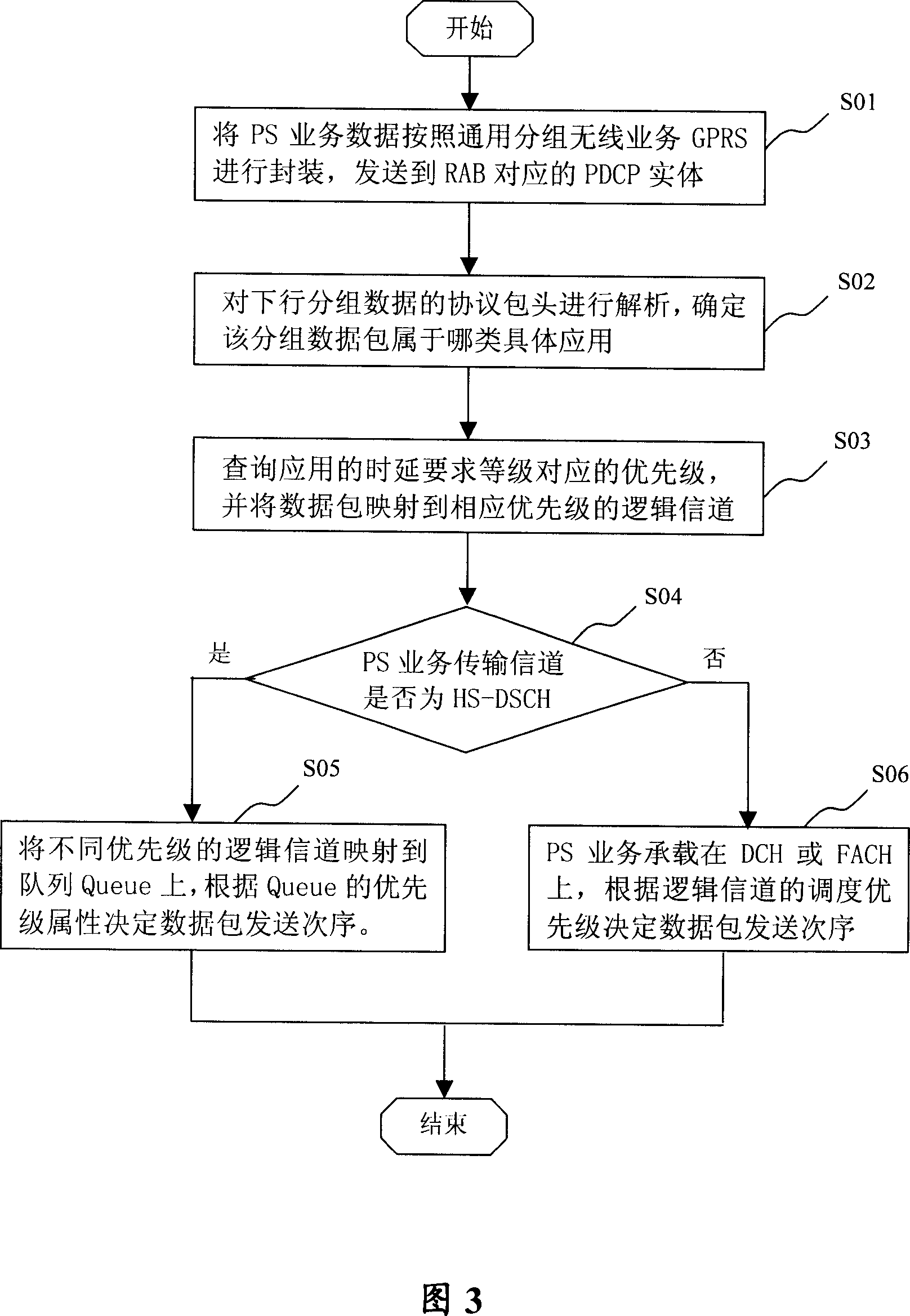

Wireless access loaded packet data service QoS management method.

InactiveCN1968198ASend quicklyMeet performance requirementsRadio/inductive link selection arrangementsData switching networksTraffic capacitySupport group

The invention relates to a QoS manage method of wireless access support group data service, wherein it comprises that: judging the service type of data supported by wireless access; based on said type, finding the sending priority of data pack; projecting the data pack with high priority to the channel with high priority, to be sent out. When the time delay demand of application service, based on the data flux of target address, classifying the priorities; projecting the data pack with low data flux to the logic channel with high priority, to confirm the application data pack with high time delay demand to be sent quickly, to meet the service quality QoS of different application services.

Owner:HUAWEI TECH CO LTD

Systems and methods of group distribution for latency sensitive applications

ActiveUS7738900B1Special service for subscribersBroadcast transmission systemsSupport groupShort Message Service

Systems and methods for supporting group communications are provided. A group list management server (GLMS) stores communications group definitions in documents, such as extensible mark-up language (XML) documents. The communications group can include communication addresses for different types of communication applications, including electronic mail, voice telephone, data, instant messaging, voice dispatch, short messaging service (SMS), and multimedia service (MMS). Various methods for managing communications groups and features provided for communications groups are provided.

Owner:NEXTEL COMMUNICATIONS

Method of compositing variable alpha fills supporting group opacity

ActiveUS20110109642A1More disadvantageCathode-ray tube indicatorsEditing/combining figures or textGraphicsSupport group

A method of compositing a plurality of graphic objects with a compositing buffer, is disclosed. The plurality of graphic objects forming a group is attenuated by group opacity and is composited from a top object to a bottom object. Based on a first mask and the group opacity, a second mask is generated. The first mask stores a remaining possible contribution for further graphic objects below and including the plurality of graphic objects. The plurality of graphic objects in a top down order is processed. In particular, for each graphic object of the plurality of graphic objects: (a) a contribution value for the graphic object using the second mask is determined, the contribution value representing a contribution of the graphic object to the compositing buffer; (b) a colour value of the graphic object is composited with the compositing buffer using the contribution value; and (c) the second mask is updated using the contribution value. The first mask is then updated using the second mask and the group opacity. The updated first mask is configured for further compositing of objects below the plurality of graphic objects.

Owner:CANON KK

Method and a network element for providing a handover in a communications system

InactiveUS20060148485A1Easy to useRadio/inductive link selection arrangementsRadio transmissionCommunications systemSupport group

The invention relates to a method for providing a group communication handover in a communications system supporting group communication. In the invention communications terminals are detected that belong to a communications group; a load of the communications group is monitored in a first resource; and if the load exceeds a preset load level in the first resource, to at least one of the communications terminals of the group the group communication handover is performed from the first resource to a second resource.

Owner:NOKIA CORP +1

Method and Provider Edge Device for Advertising and Processing Pseudo-Wire Information

The present invention discloses a method for advertising and processing pseudo-wire (PW) information, which comprises: the sending provider edge (PE) device using two or more methods to group PWs, identifying the group identifier assigned to each PW with each grouping method, and sending all group identifiers of each PW to the receiving PE device; the sending PE device sending to the receiving PE device the notification message that carries information identifying the affected PW group, and the receiving PE device identifying the PWs belonging to the affected PW group according to the received notification. The present invention also discloses the sending and receiving PE devices for advertising and processing PW information. The method and the devices of the present invention can support grouping PWs with more than one method, allowing for flexible use of PW group-based messaging and message processing.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

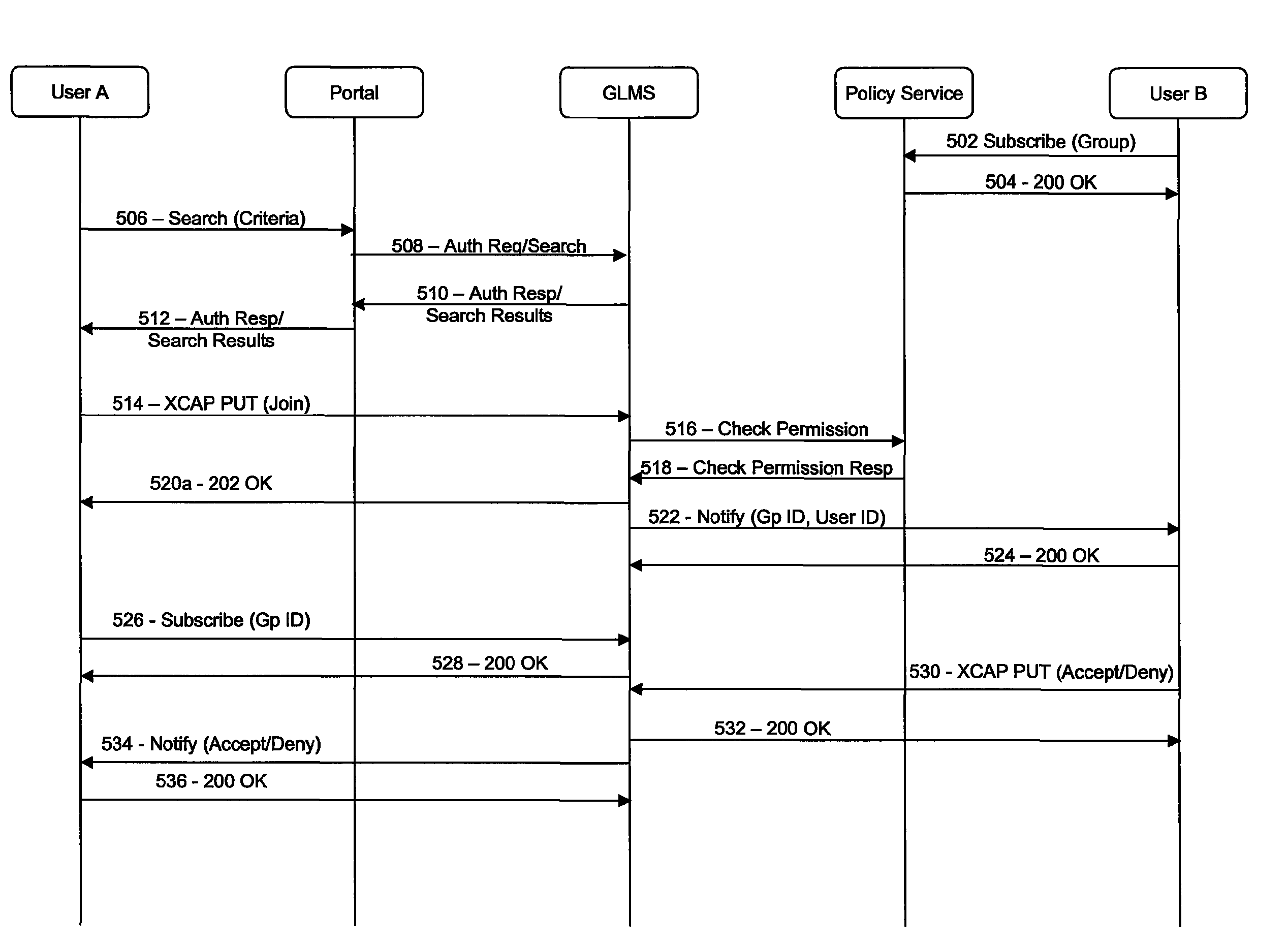

System and method for joining communication groups

ActiveUS7818020B1Special service for subscribersBroadcast transmission systemsSupport groupShort Message Service

Systems and methods for supporting group communications are provided. A group list management server (GLMS) stores communications group definitions in documents, such as extensible mark-up language (XML) documents. The communications group can include communication addresses for different types of communication applications, including electronic mail, voice telephone, data, instant messaging, voice dispatch, short messaging service (SMS), and multimedia service (MMS). Various methods for joining communications groups are provided.

Owner:NEXTEL COMMUNICATIONS

Talk group management architecture

InactiveUS7864716B1Multiplex system selection arrangementsSpecial service provision for substationSupport groupShort Message Service

Systems and methods for supporting group communications are provided. A group list management server (GLMS) stores communications group definitions in documents, such as extensible mark-up language (XML) documents. The communications group can include communication addresses for different types of communication applications, including electronic mail, voice telephone, data, instant messaging, voice dispatch, short messaging service (SMS), and multimedia service (MMS). Various methods for managing communications groups and features provided for communications groups are provided.

Owner:NEXTEL COMMUNICATIONS

Group invitation

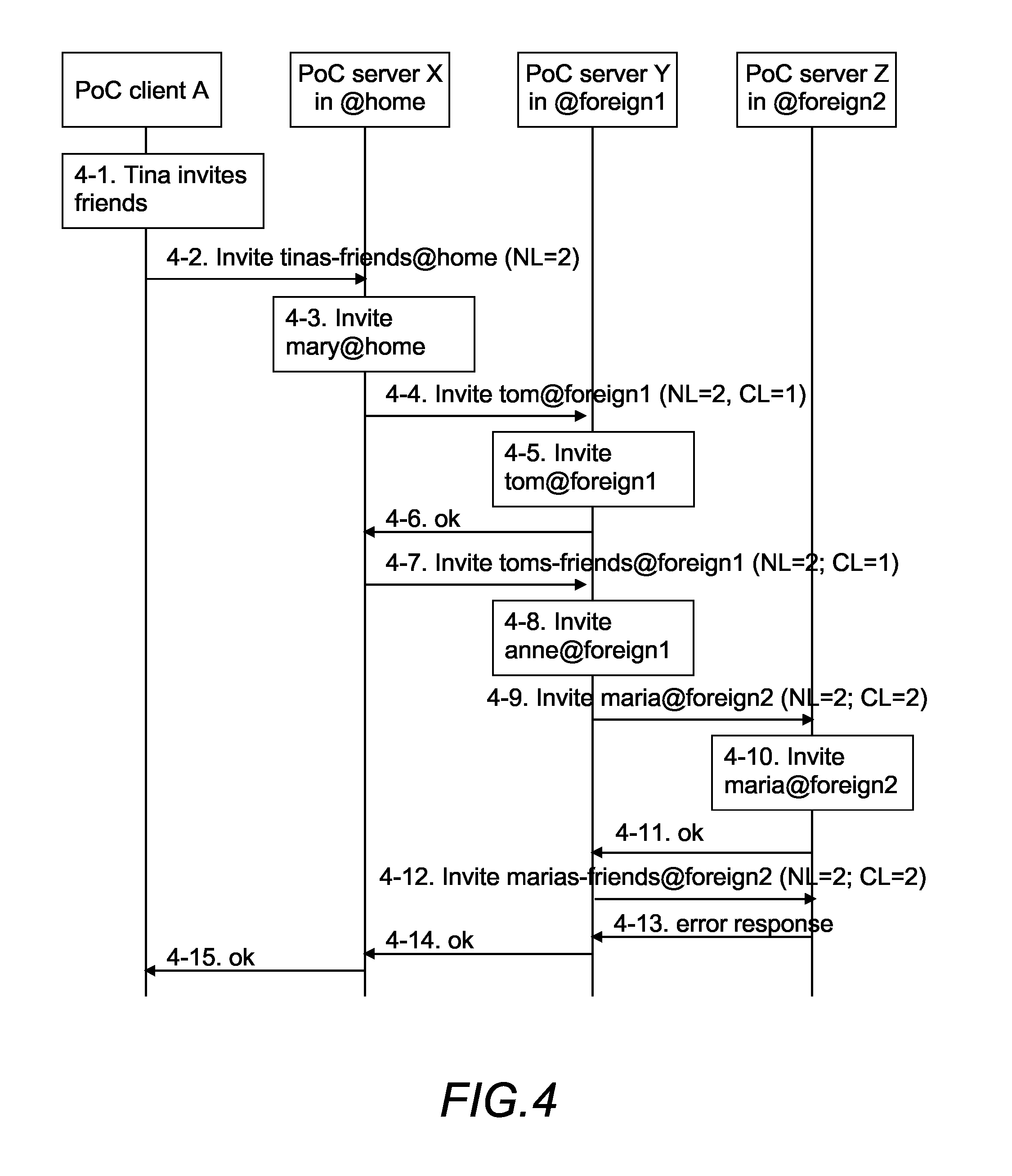

InactiveUS20070208809A1Simple interfaceConnection managementMultiple digital computer combinationsSupport groupMultimedia

Owner:NOKIA CORP

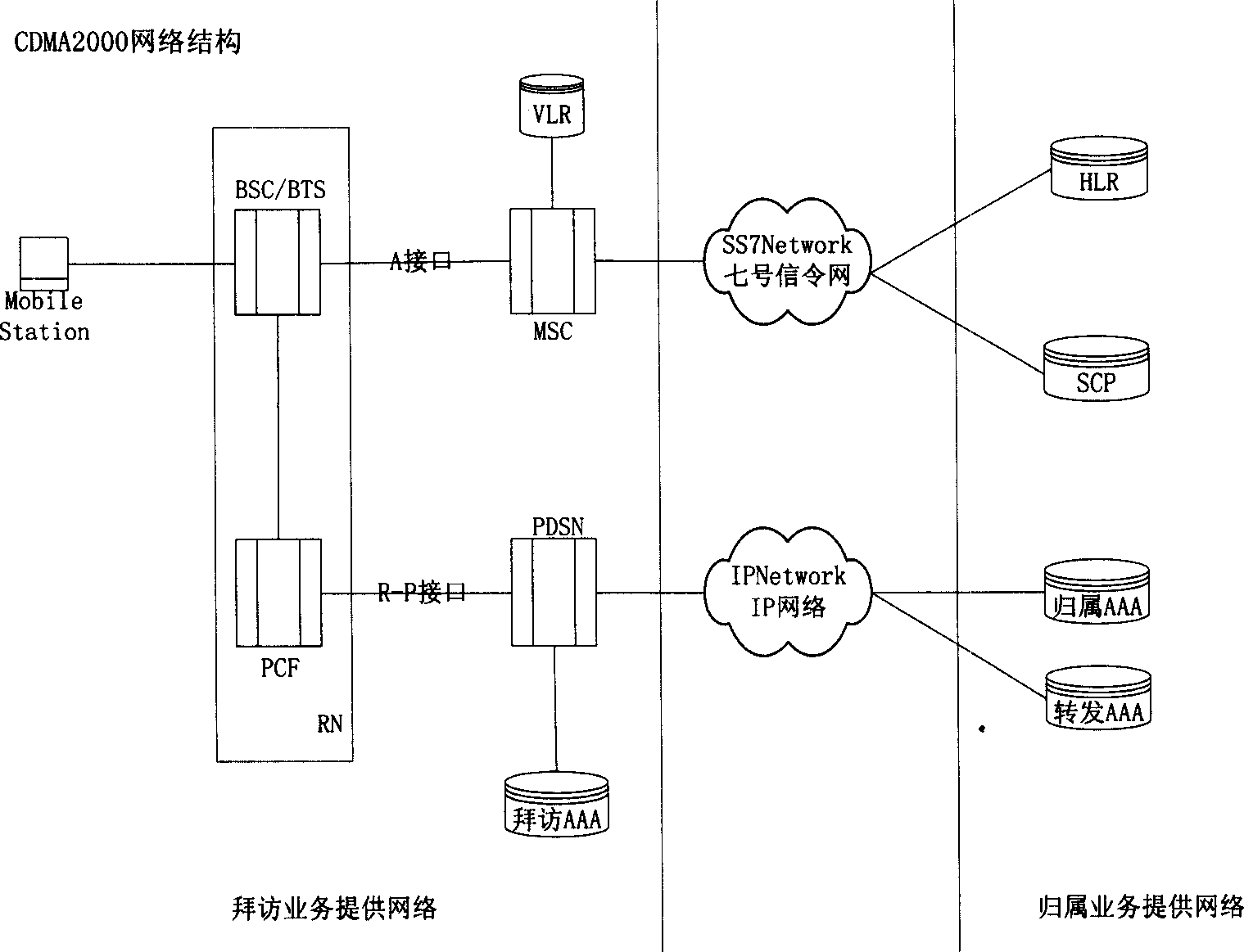

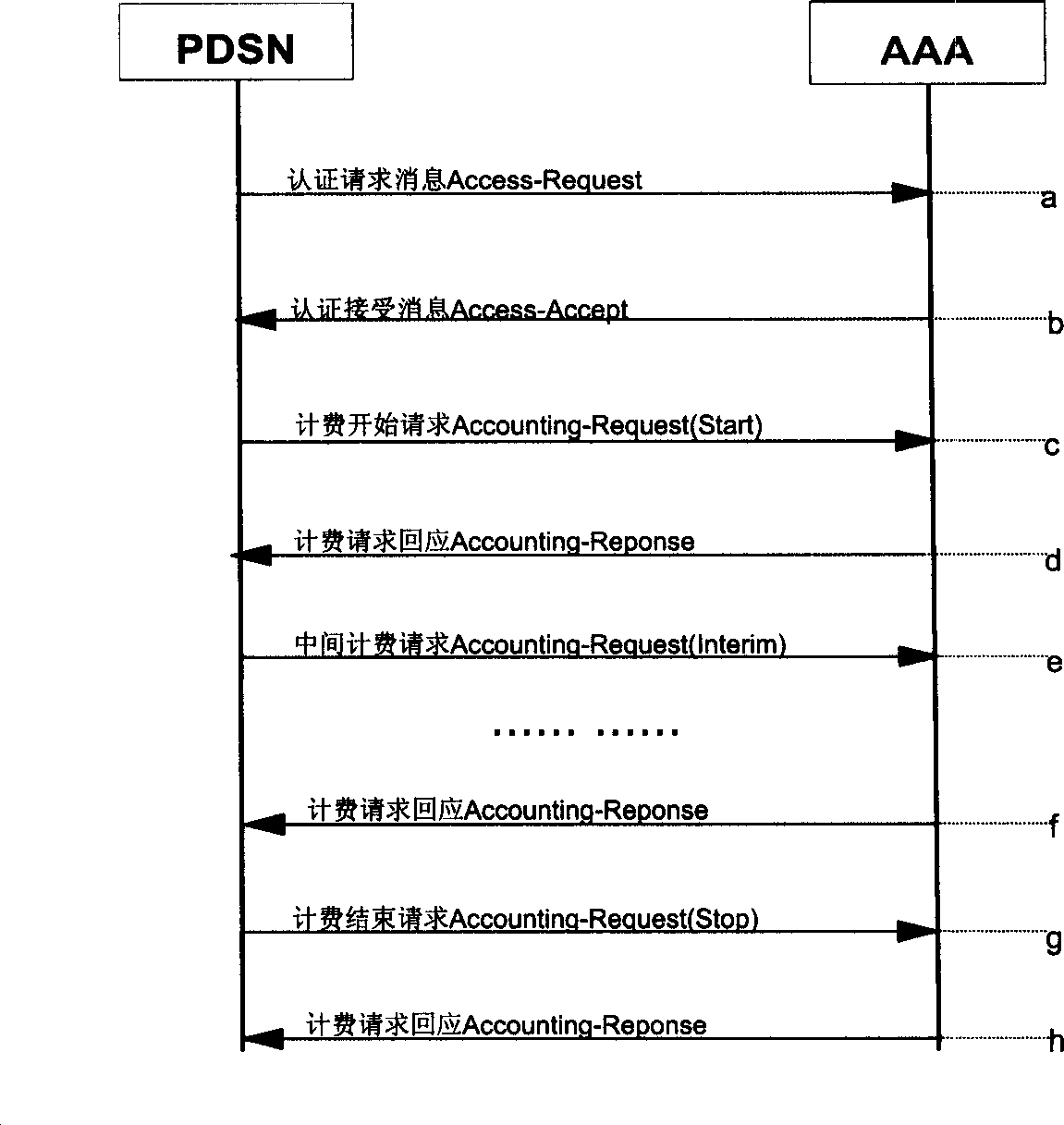

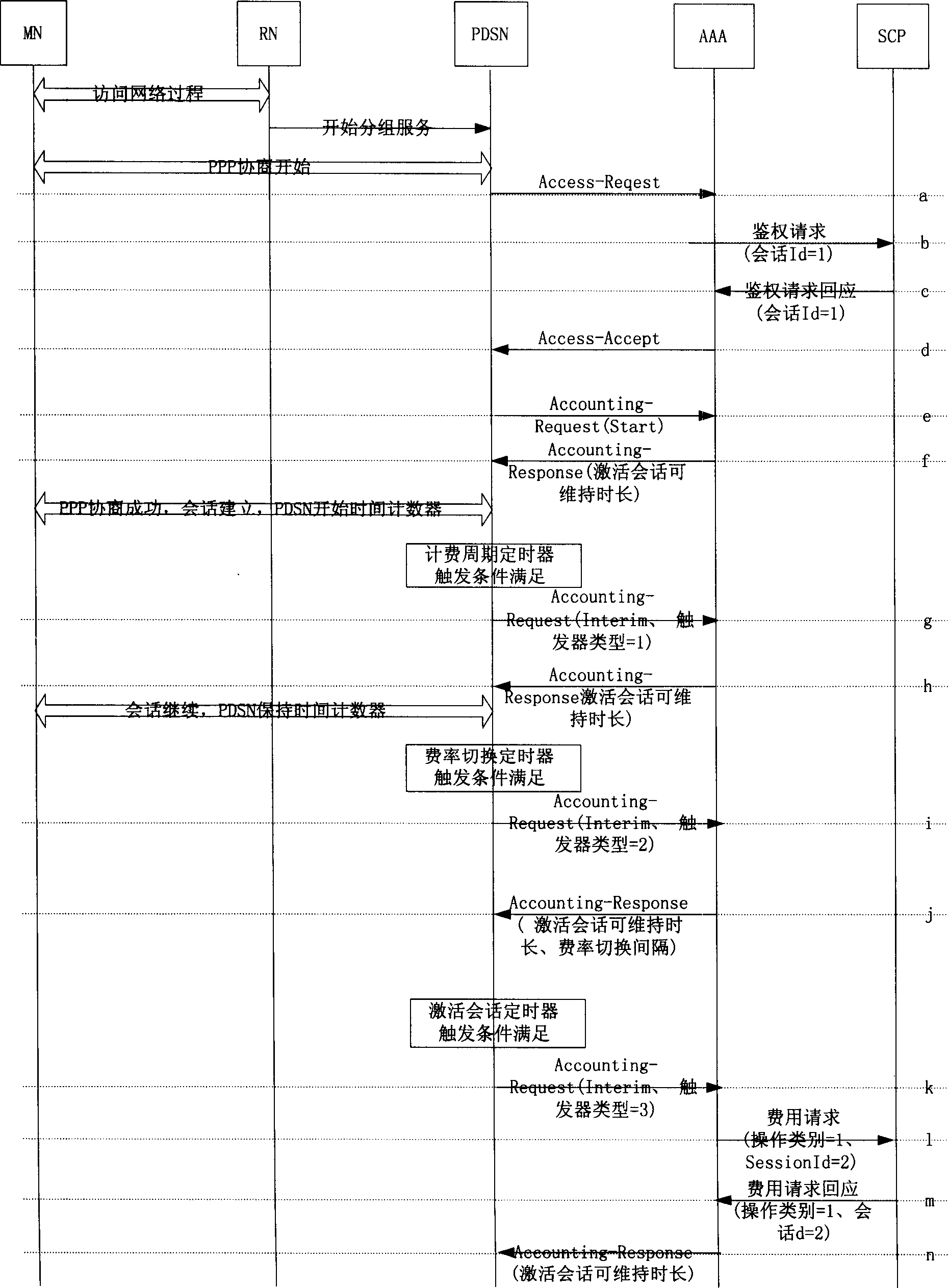

Mobile phone user authentication charging method supporting grouped data prepayment characteristic

InactiveCN1464662AAccurate prepaid functionPrecise time controlAccounting/billing servicesUser identity/authority verificationSupport groupUser authentication

The present invention discloses a mobile user authentication charging method supporting grouped data prepaying property characterized by that, the charging request responding message which AAA sending to PDSN contains dialogue activating time length sustainable information. Accordingly, the PDSN contains dialogue activating trigger and charge cycle trigger which can proceed parameter resetting based on the information that AAA has received. When the trigger condition is met, the corresponding intermediate charging request information is triggered and submitted to AAA. AAA recounts dialogue activating sustainable time length after receiving any intermediate charging request information, and sends charge request responding message to PDSN. This enables the PDSN make sectional fees application to AAA, overcoming the limitation of one-time fee, and realizing the accurate prepaying function.

Owner:HUAWEI TECH CO LTD

Social network for affecting personal behavior

InactiveUS20100235776A1Easy to createEasy to customizeMultiple digital computer combinationsOffice automationSupport groupComputer science

A social network for affecting personal behavior is provided. The psychological and behavioral progress of a registered user of the social network is maintained. The social network provides the registered user with friends who can track the user's progress and encourage the user by communications with the user. The friends of the user can be anybody, including people who are not registered with the social network. A dynamic mechanism for grouping different users into support groups is also provided. The grouping is based on the user's progress, satisfaction with the user's supporters, and the user's traits and preferences. User-customized profiles are used to elucidate user traits instead of standard direct forms to to avoid incorrect or misleading responses to the forms. In addition, a wireless portable device in communication with the social network of friends and supporters is provided for constant access to sources of motivation.

Owner:INVENT LY LLC

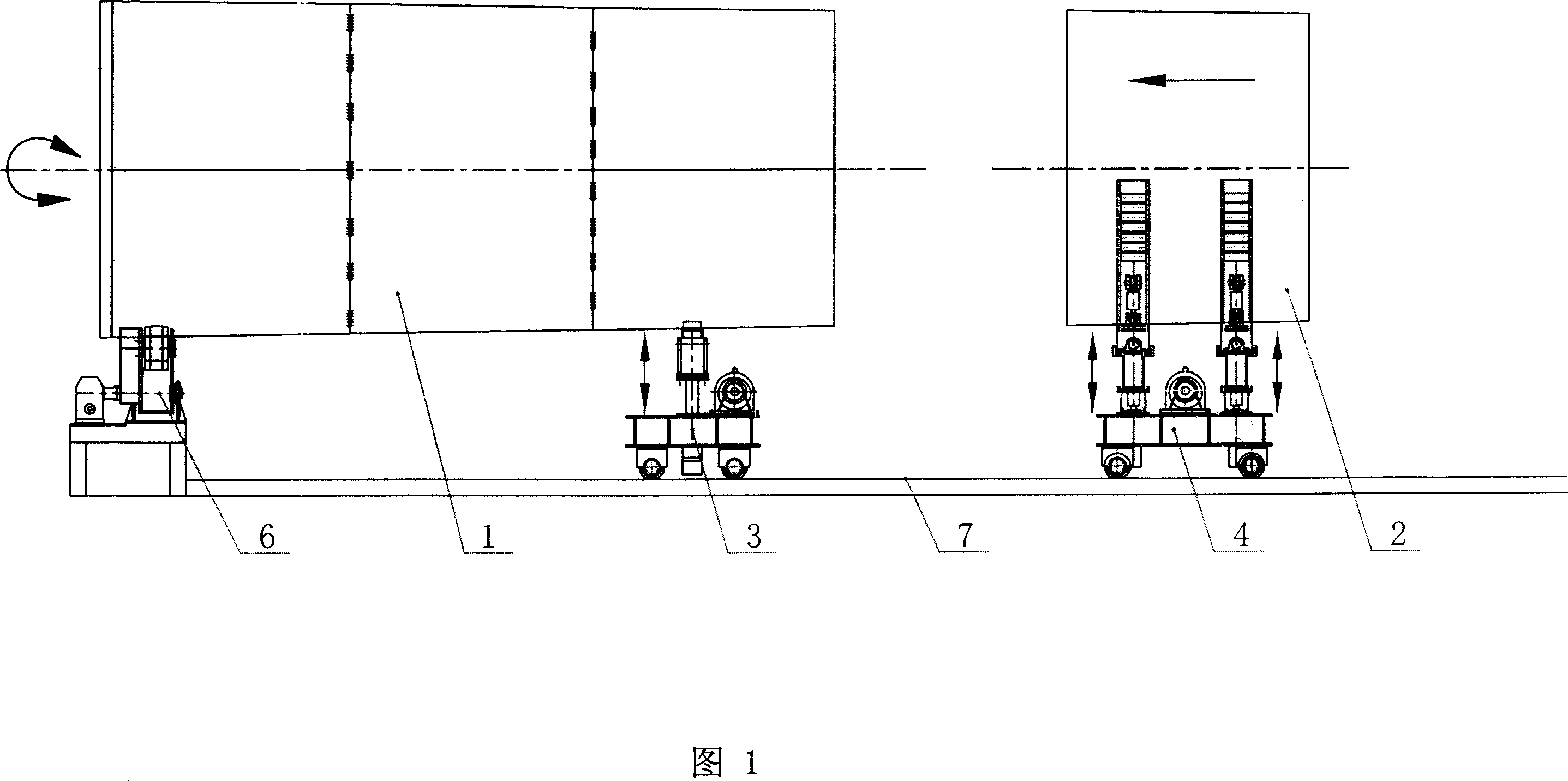

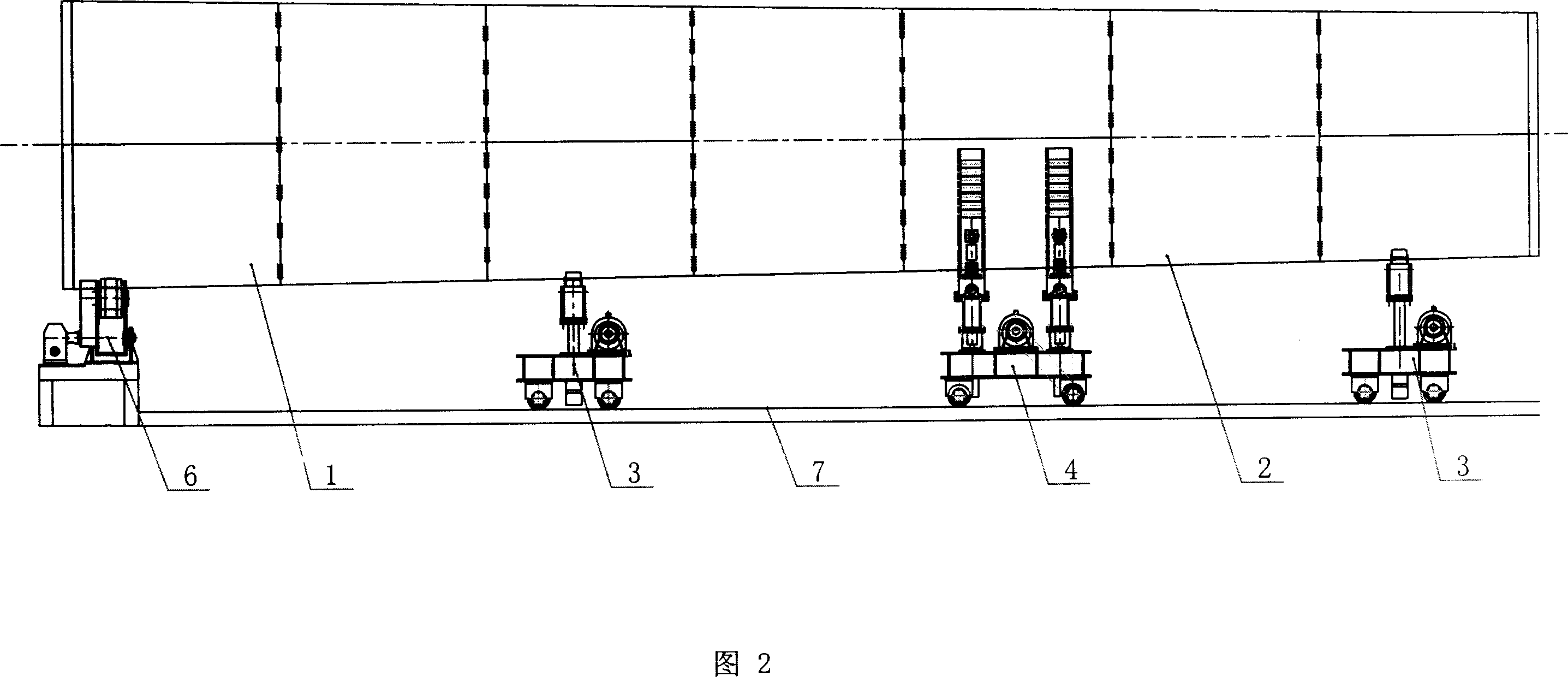

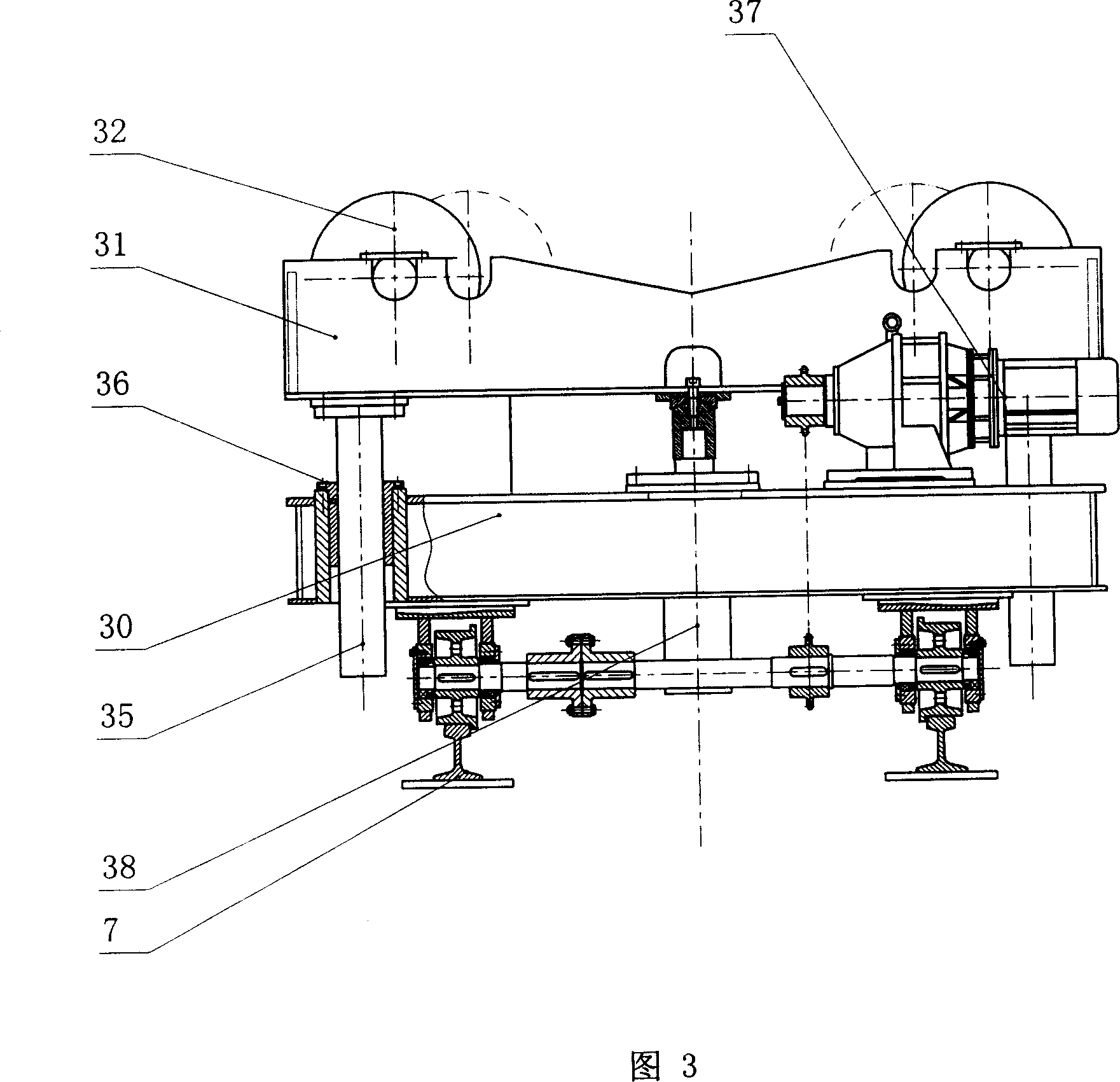

Tower or silo frame section pairing method and pairing platform

ActiveCN101016806ASo as not to damageOccupies a small working areaArtificial islandsTowersSupport groupGroup method

A group method for a tower or a tubular holder set provides a method that a plurality of tower portions are positioned on a rotary roller holder and a lifting supporting group car on a track, and the axis of the tower portions is positioned on a horizontal direction or a better butting direction via adjusting the rotary roller holder and the supporting group car, another tower portion needed to weld with the tower portion is hold by a moving-tubular swing-arm group car, or with the lifting supporting group car, or with the rotary roller holder together, and then the tower portion is moved to another along the track with adjusting the space between them and the arm lifting or the arm moving of the moving-tubular swing-arm car to match the tower portion and the tower axis together and group weld seams. The invention has advantages of not only small working space and low intensity of labor, but also safety, highly effective, keeping work pieces non-broken, and good quality of grouping.

Owner:QINGDAO WUXIAO GRP

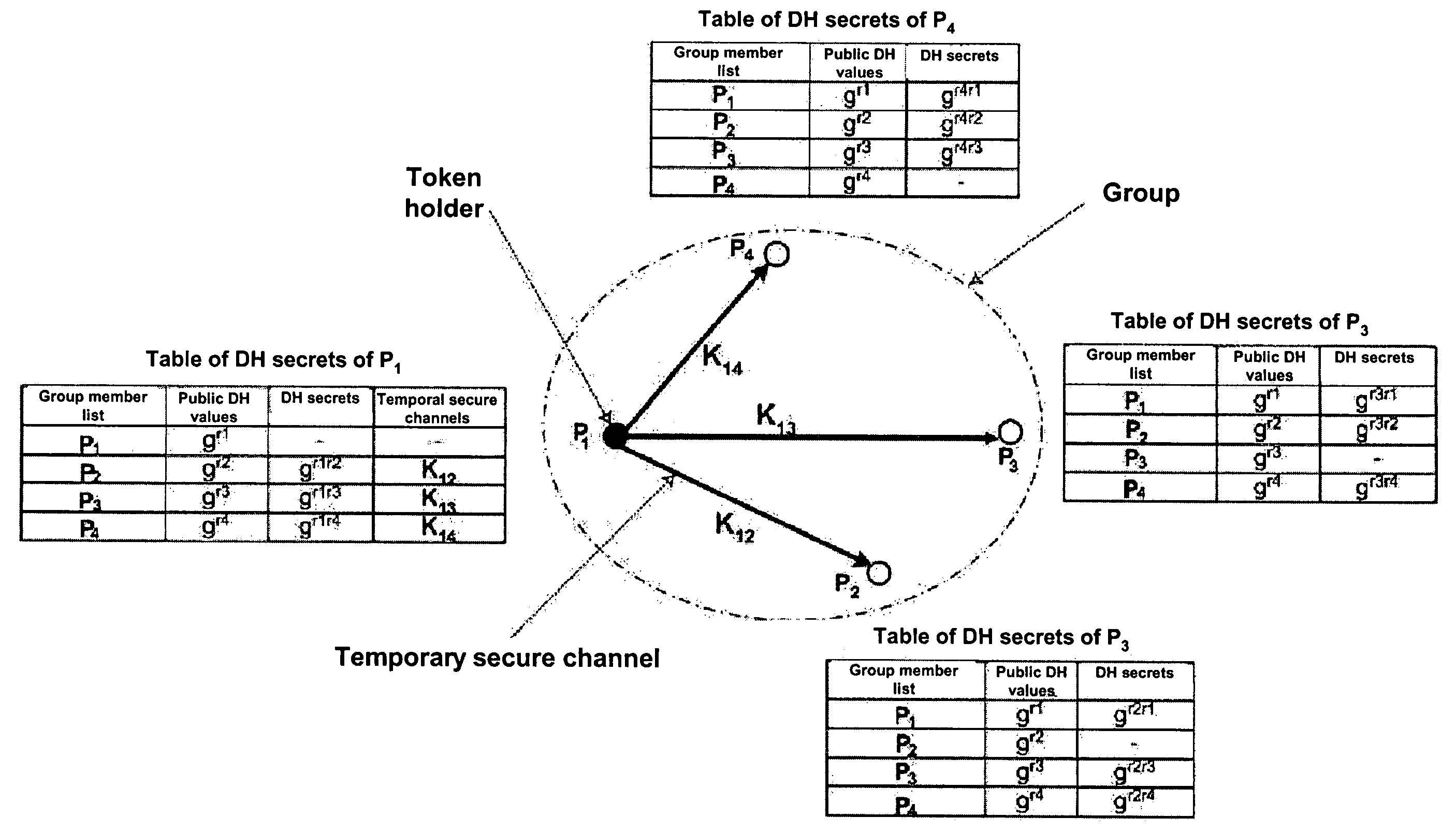

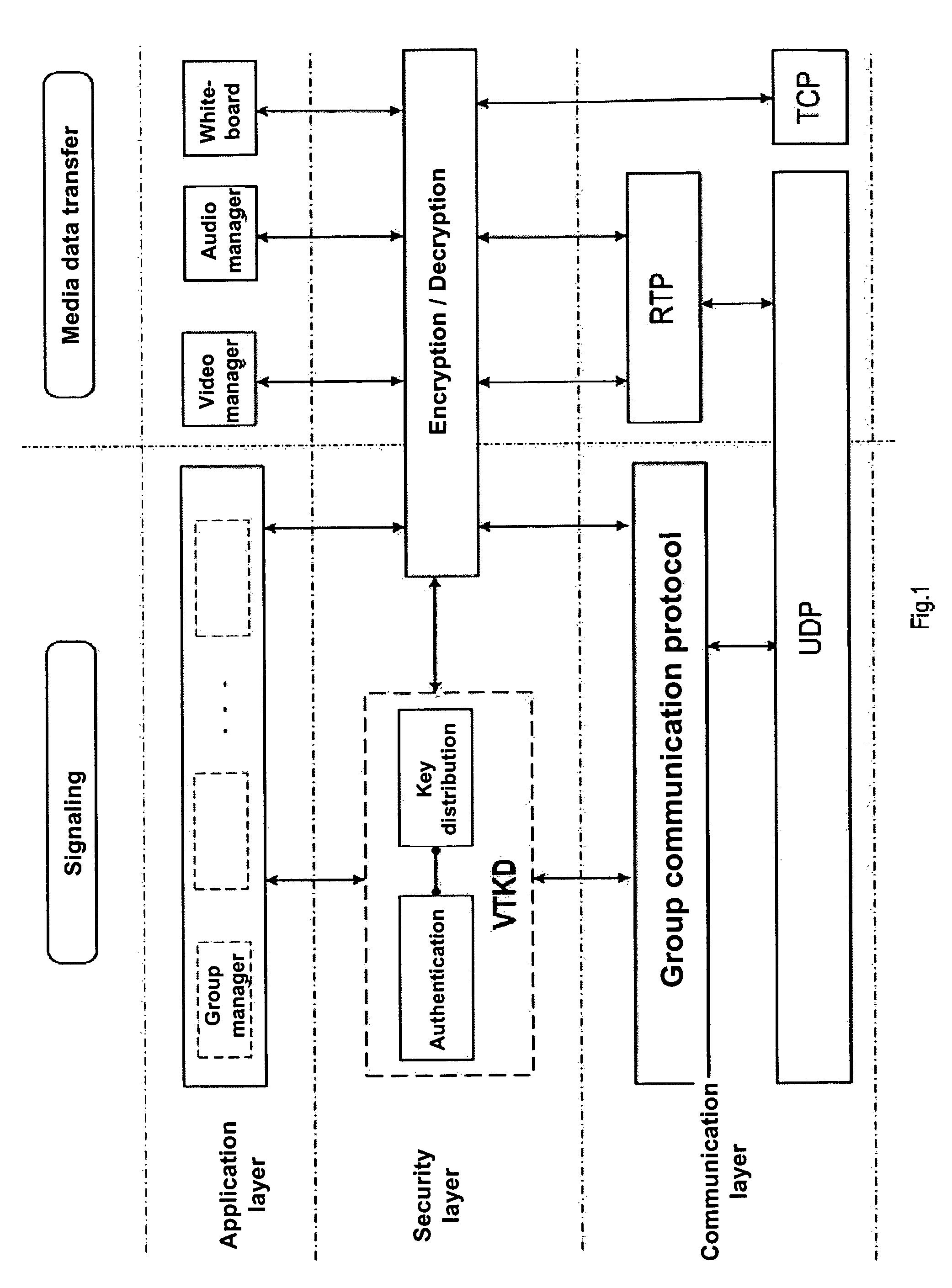

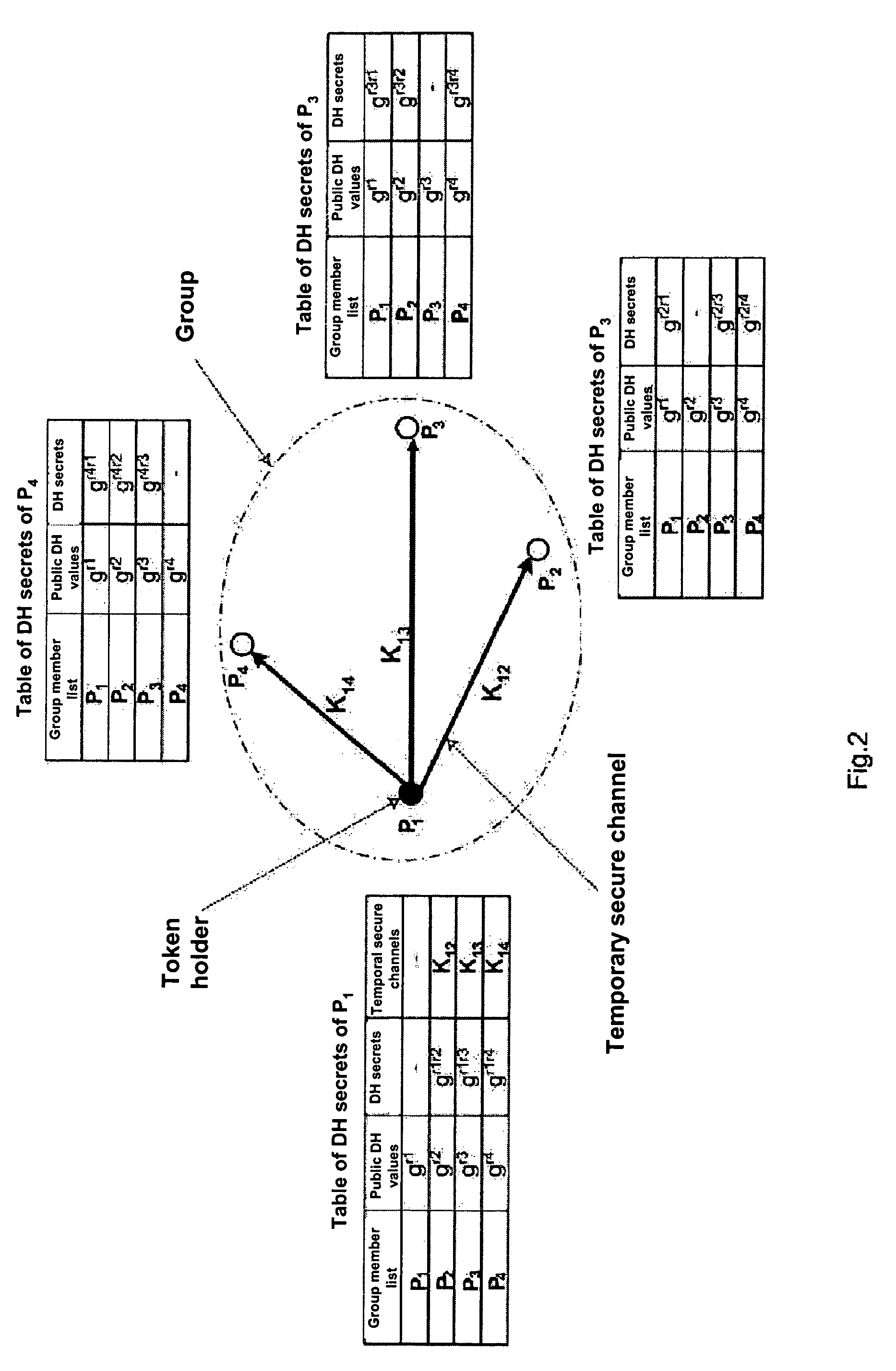

Method for changing a group key in a group of network elements in a network system

InactiveUS7957320B2Efficient and reliable generation and distributionHigh safety standardsUser identity/authority verificationData switching by path configurationKey exchangeVirtual synchrony

The invention relates to a method for changing a group key GK for a secure data exchange in a group of network elements P1 . . . Pn (n=2, 3, . . . ) in a network system having a closed peer-to-peer configuration and a virtual synchronism supporting group communication protocol in a communication layer of a system architecture of the network system, wherein in the case of a change in a composition of the group of network elements P1 . . . Pn, caused by the join of a new network element Pn+1 into the group of network elements P1 . . . Pn or by the leave of a network element Pv (1≦v≦n) from the group of network elements P1 . . . Pn, a group key renewal, in which a network element Pi* (1≦i≦n) selected from the group of network elements P1 . . . Pn generates a new group key GKneu, is carried out and the new group key GKneu is transferred from the selected network element Pi to all the remaining network elements Pk (1≦k≦n, k≠i) of the group of network elements P1 . . . Pn in the changed composition, which the selected network element Pi* achieves by carrying out a key exchange with all the remaining network elements Pk in accordance with the Diffie-Hellman principle in order to transfer the new group key GKneu.

Owner:BRANDENBURGISCHE TECHN UNIV COTTBUS SENFTENBERG

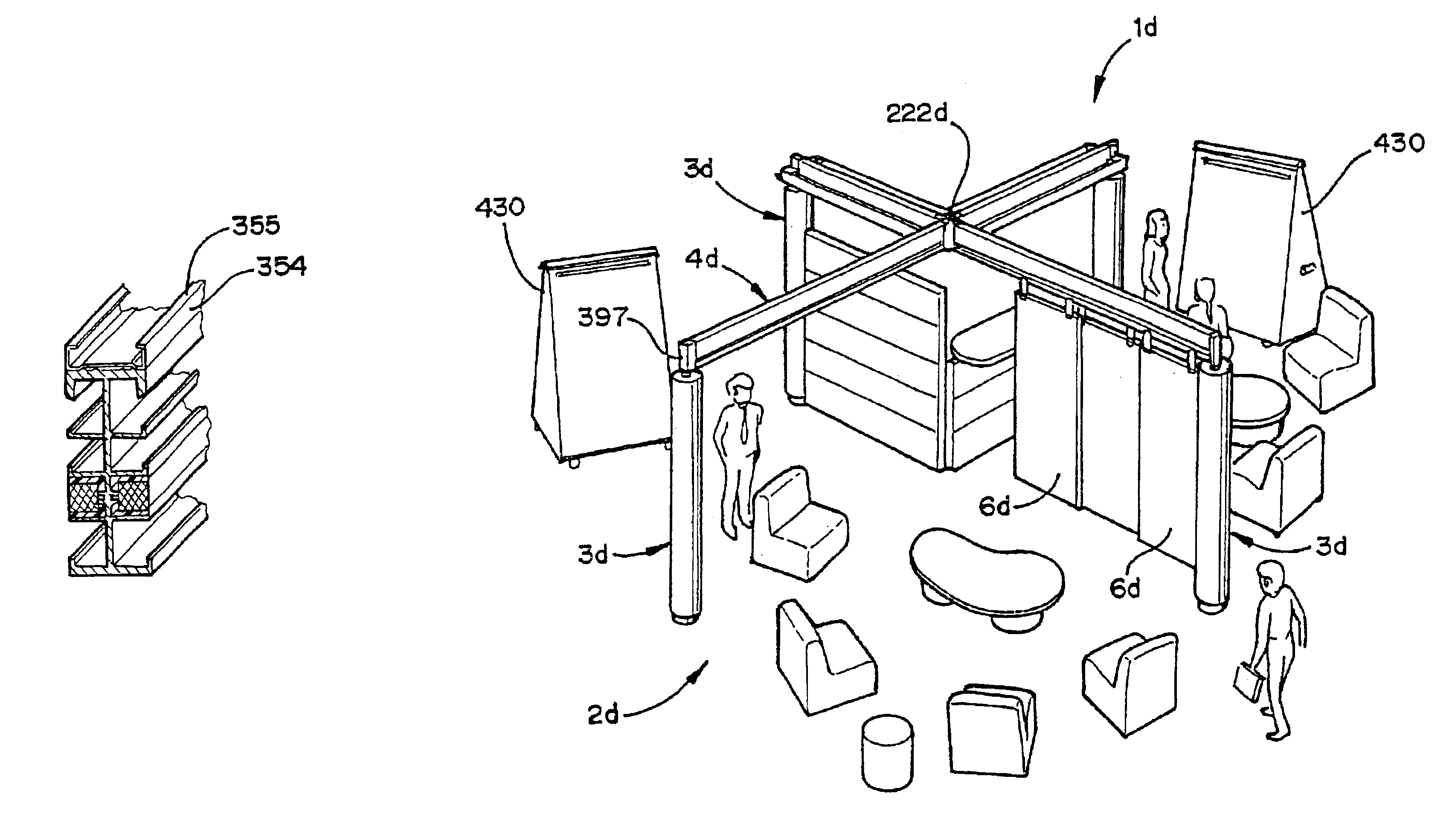

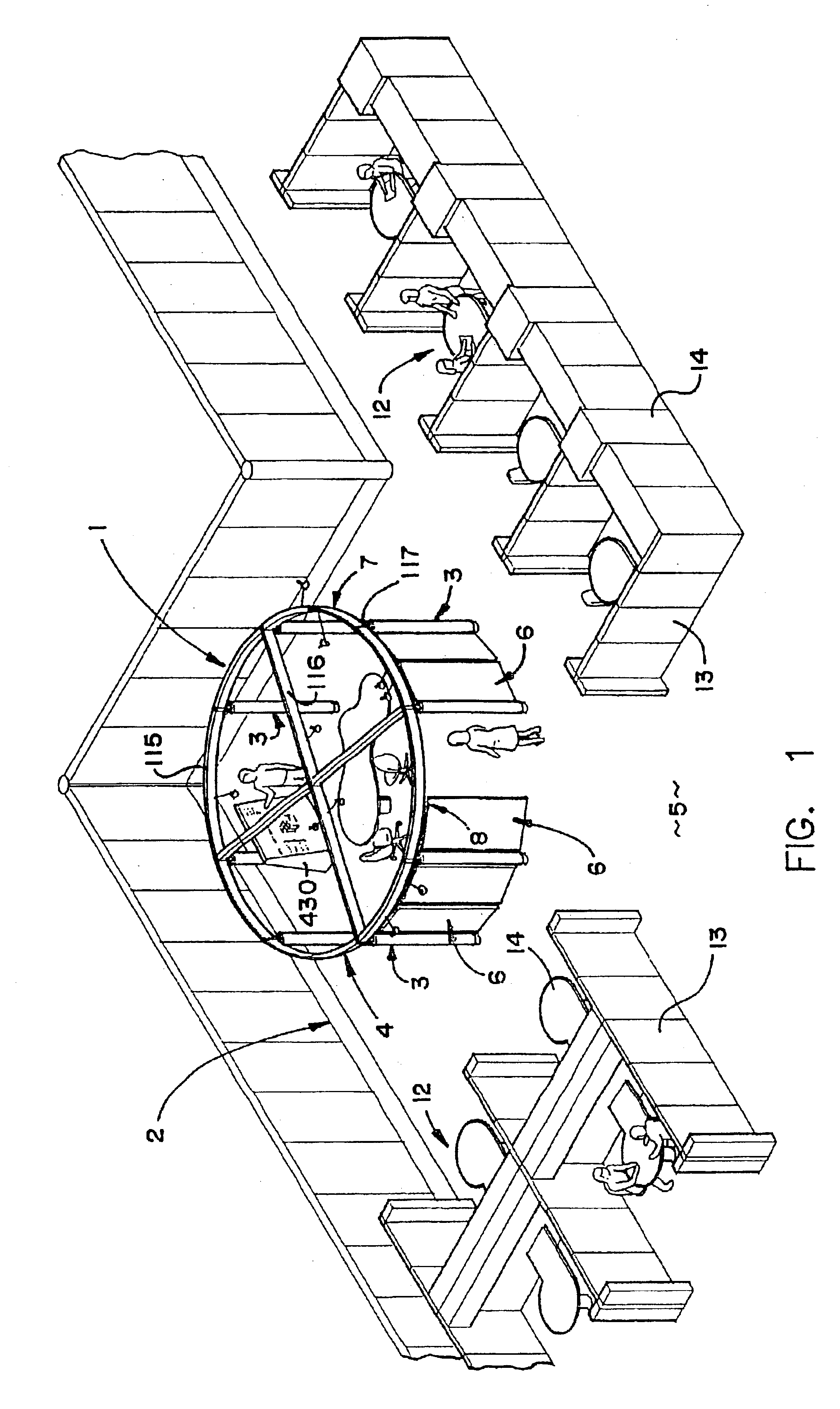

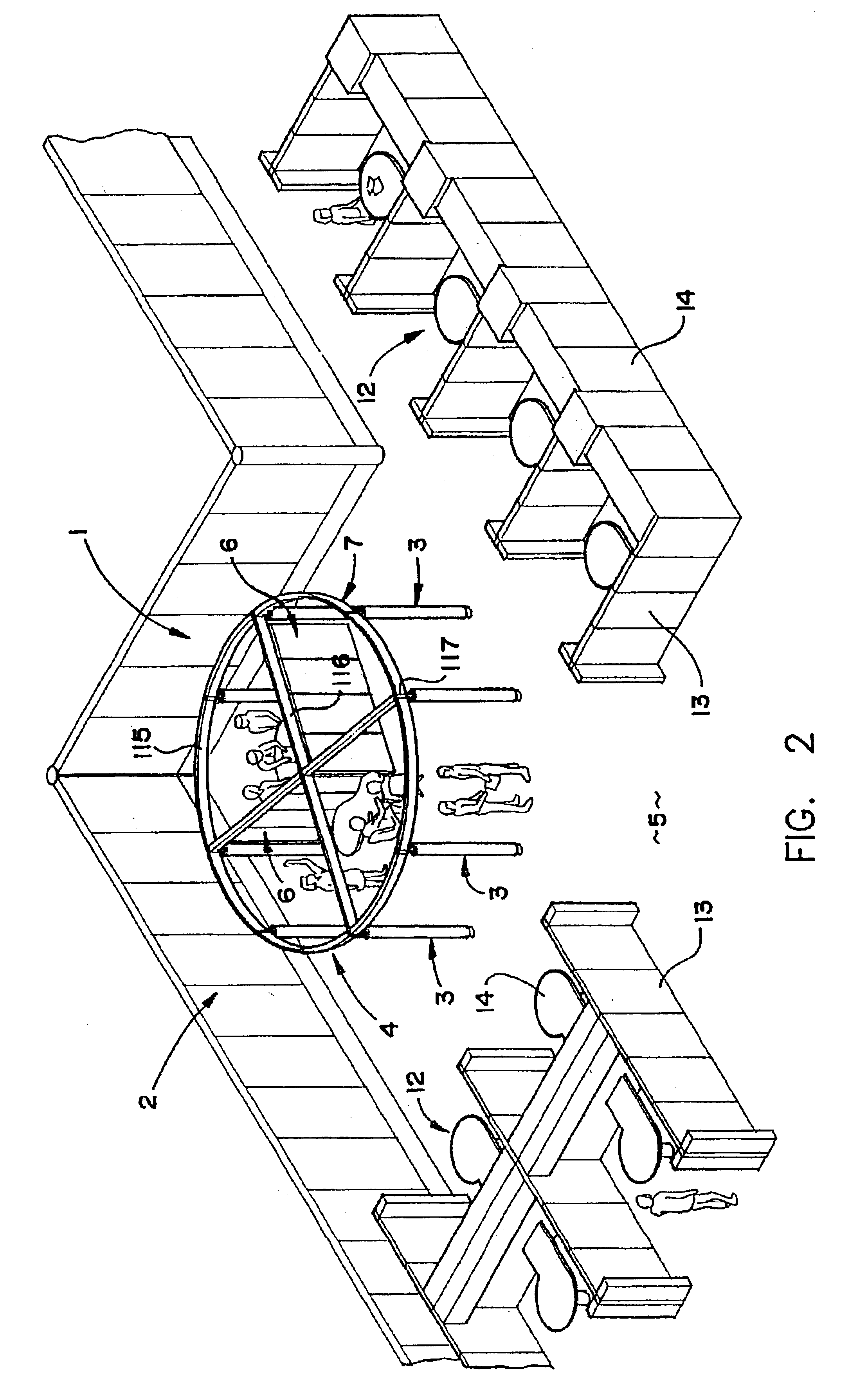

Furniture system

InactiveUS6922949B2Effectively and efficiently supportEasy to assemble and disassembleScreensRevolving doorsSupport groupOpen plan

A furniture system is particularly adapted to support group activities in open plans, and the like. A plurality of columns support an overhead framework on the floor of a building in a freestanding fashion at a predetermined elevation, generally above average user height. A plurality of individual panels are provided, wherein each panel is constructed to permit easy, manual, bodily translation of the same by an adult user. A hanger arrangement is associated with the overhead framework, and cooperates with connectors on the panels to detachably suspend the panels at various locations along the overhead framework. The panels are manually reconfigurable between many different arrangements to efficiently and effectively support different group activities. Preferably, the panels are capable of providing a partitioning function to visually divide at least a portion of the workspace, and / or a display function to facilitate group communications.

Owner:STEELCASE INC

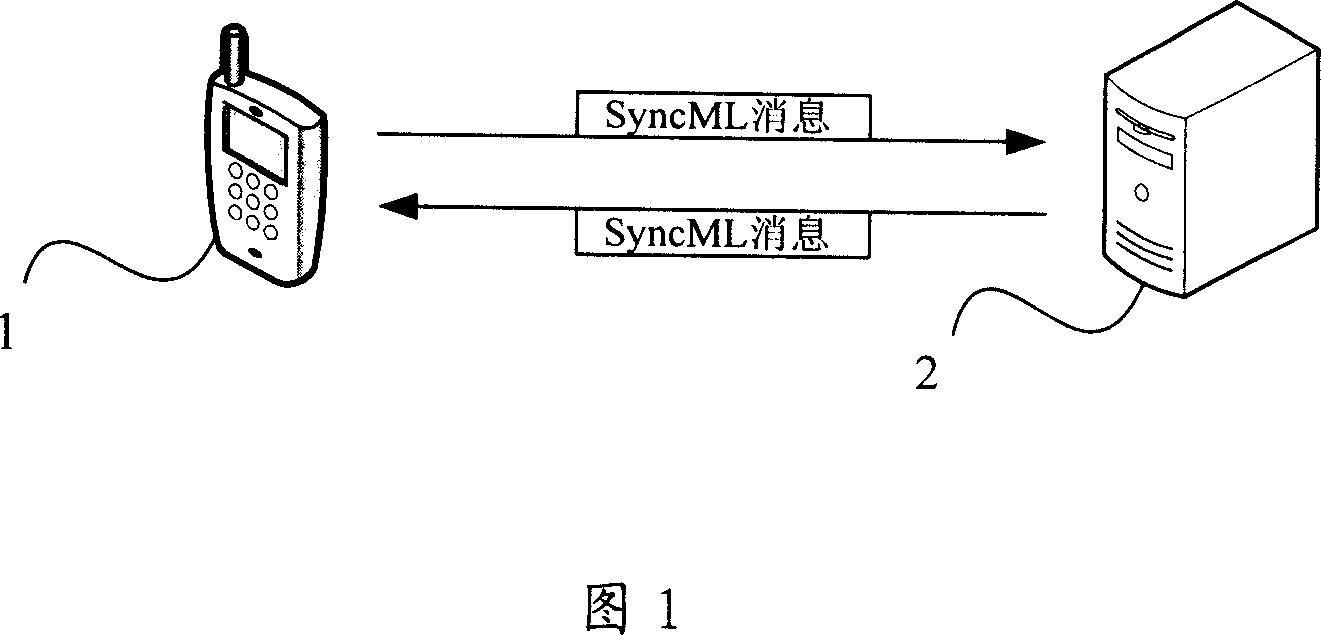

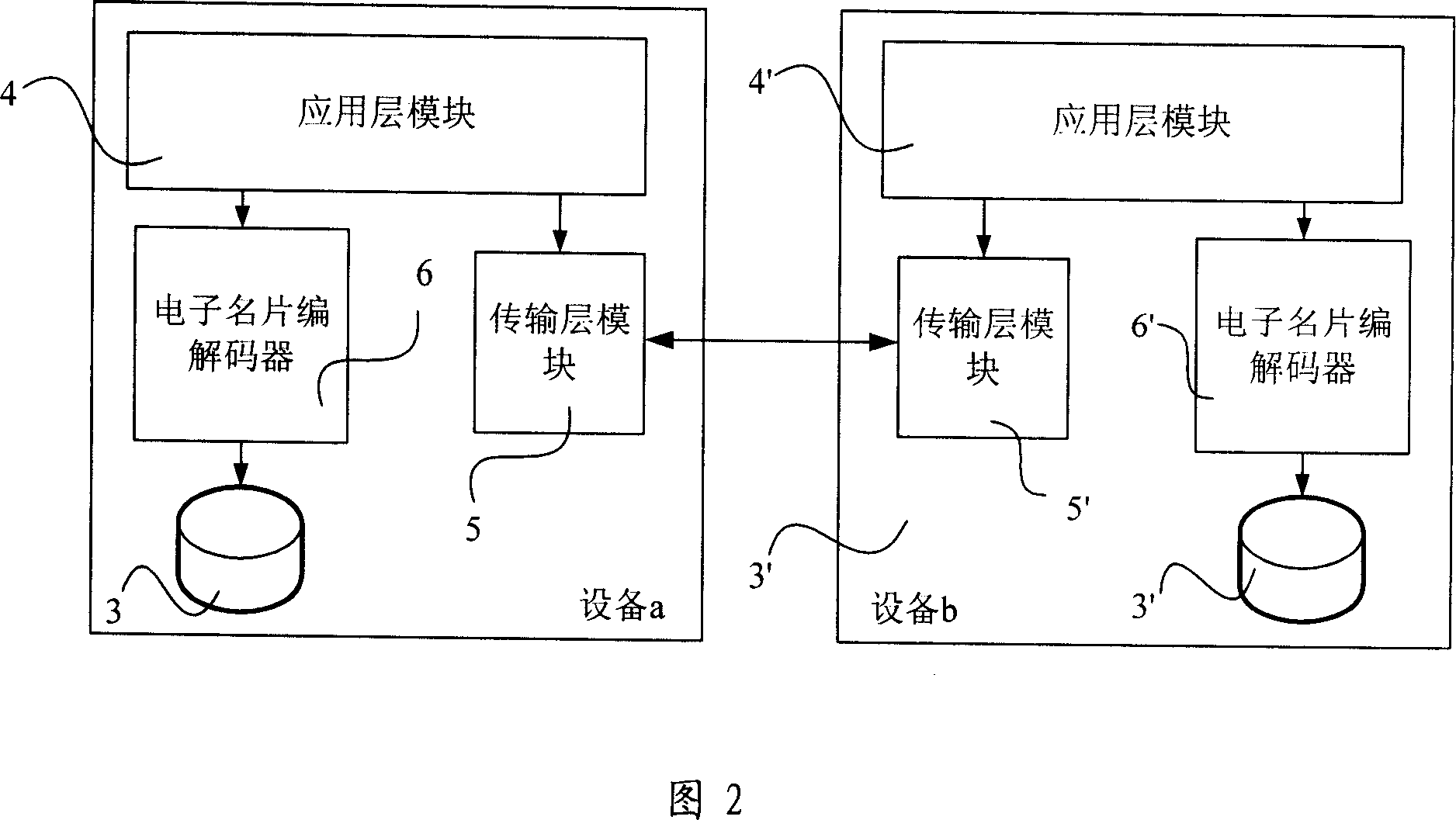

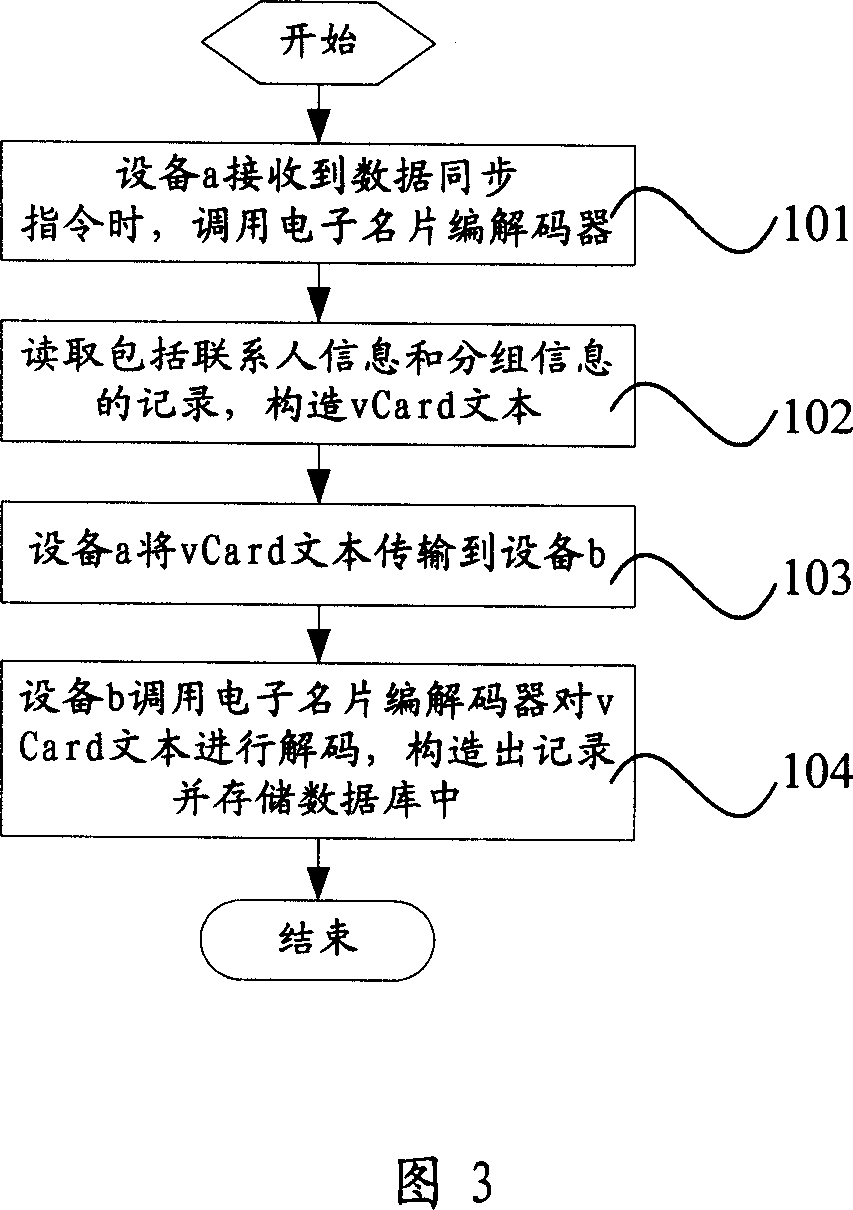

Method for data synchronization between devices

ActiveCN1968076AEasy to classify and manageSpecial data processing applicationsSynchronising arrangementData synchronizationSupport group

The invention relates to a method for making data synchronous between devices, wherein when the first device receives the data synchronous command, distributing the electric card coder / decoder in first device; the coder / decoder reads the recode in database which comprises communicator information and group information, to build the electric card context with group information; the first device transmits the electric card context to the second device; the second device distributes itself coder / decoder to decode the electric card context, to get out the communicator information and group information, and build up the record with said communicator information and group information, to be stored in itself database. The invention utilizes the expand mechanism of electric card, adds group information, while devices communicate electric card, it can keep group information, to support group management on communicator information.

Owner:HUAWEI TECH CO LTD

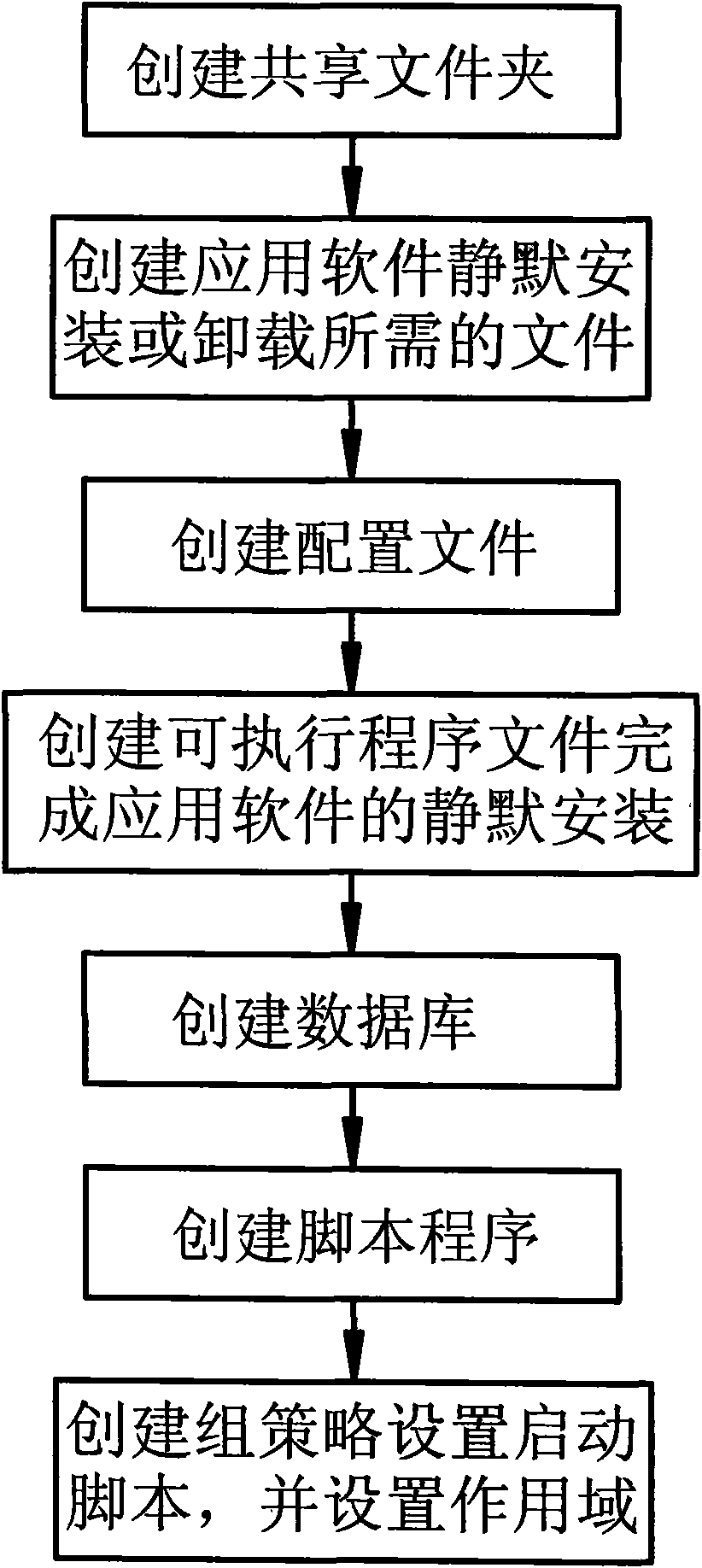

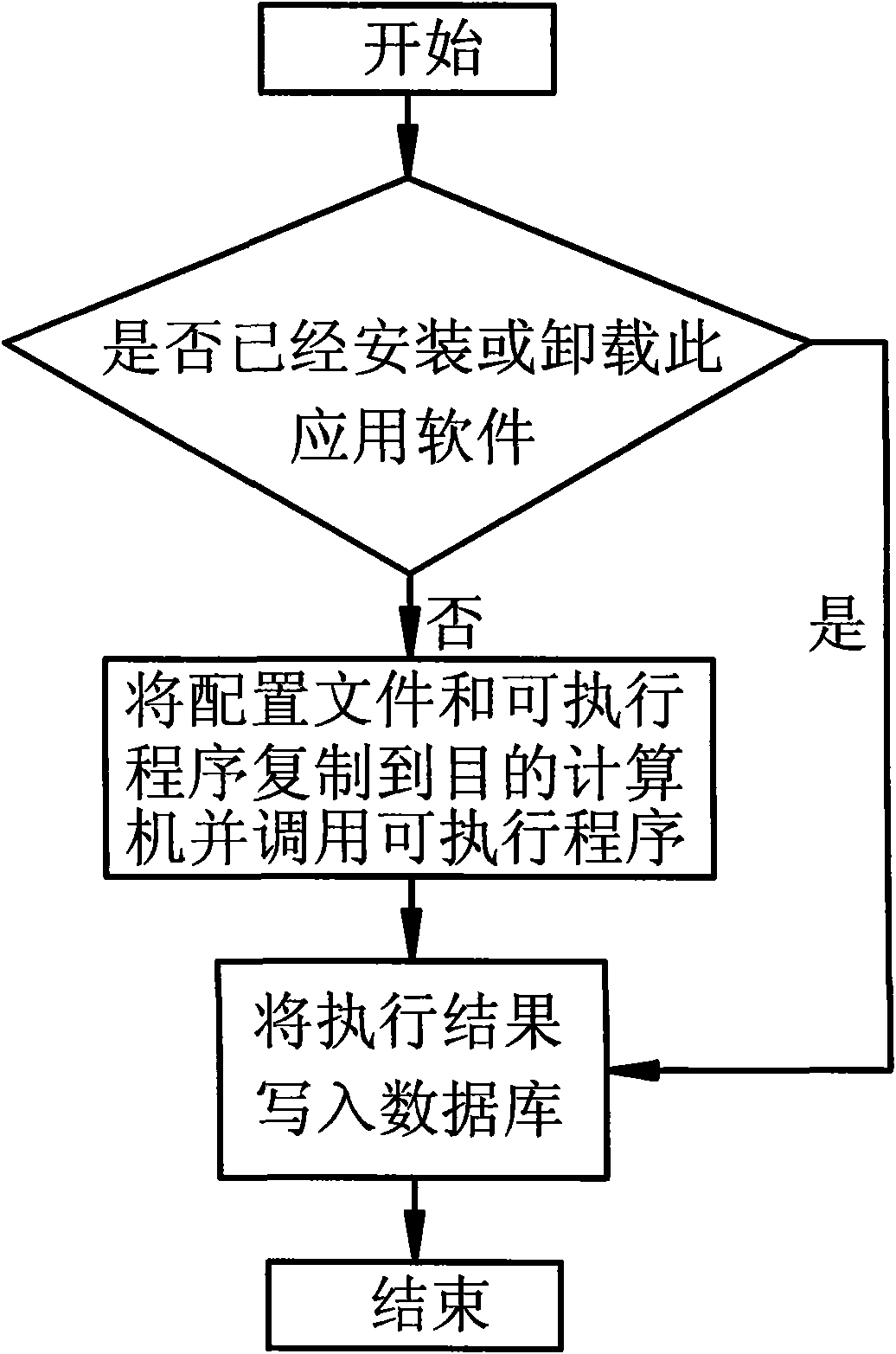

Method for automatically installing or uninstalling application software of computers and a device thereof

InactiveCN101515238AFlexible and automatic installationFlexible offloadingProgram loading/initiatingSupport groupApplication software

The invention discloses a method for automatically installing or uninstalling application software of computers and a device thereof; the device comprises a booting script supporting group policy based on Windows Server 2003 active directory; the method comprises the followings steps: executing appointed script programs through the group policy during booting of the computer, creating a shared folder on a server; creating program files required by silent installation or uninstallation and storing the program files in the shared folder, creating a configuration file for storing the shared path of the files obtained in the previous step, creating the path stored according to the configuration file, creating a database for storing the results of installing or uninstalling application software of the target computer, creating booting script programs, and creating new group policy to set the scripts as booting scripts and establish link between the booting scripts and an organization unit. The invention has the positive effects of achieving the flexible automatic installation or uninstallation of application software, facilitating use, simplifying the operations, returning the installation results and reducing the human intervention.

Owner:LUXI CHEM GRP

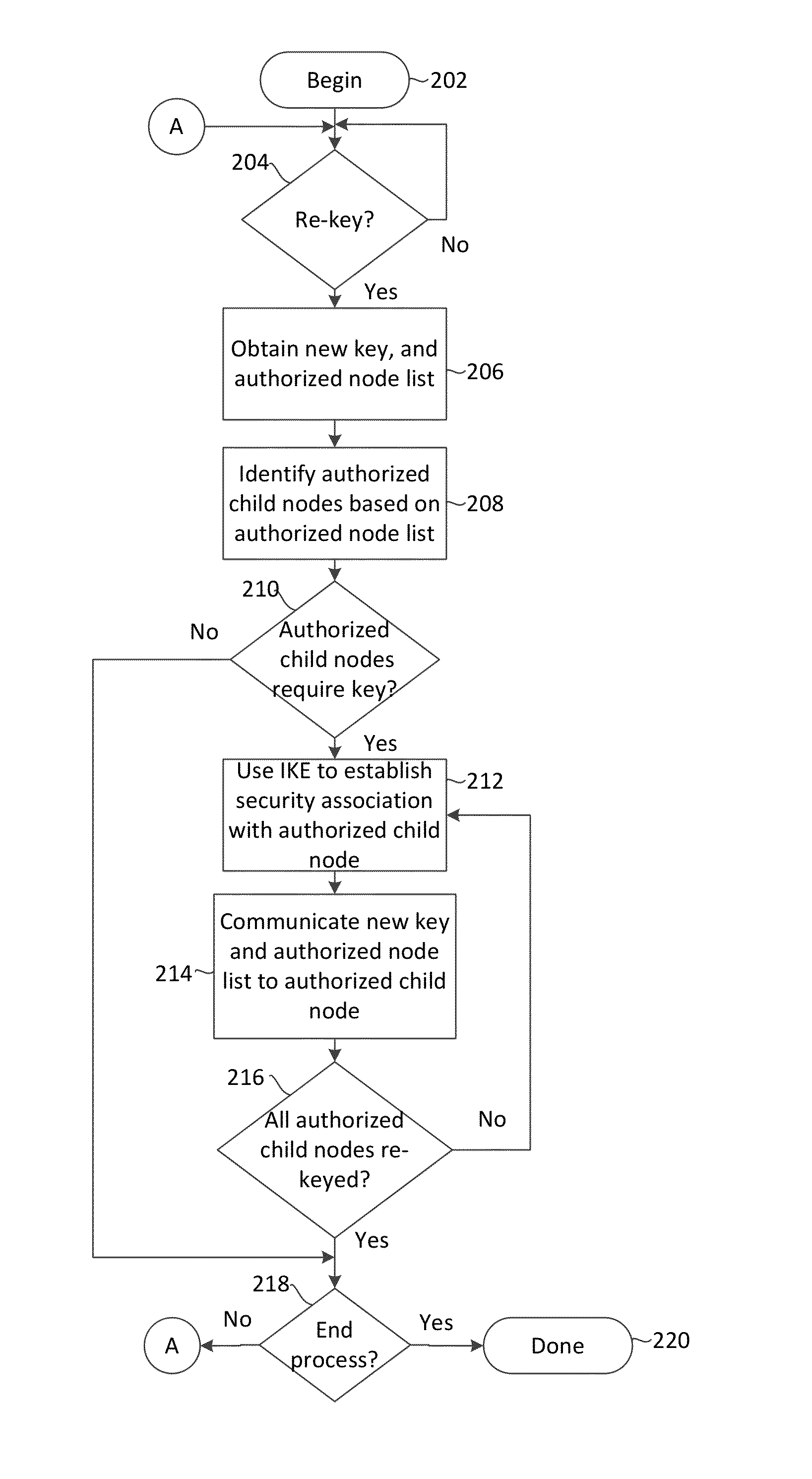

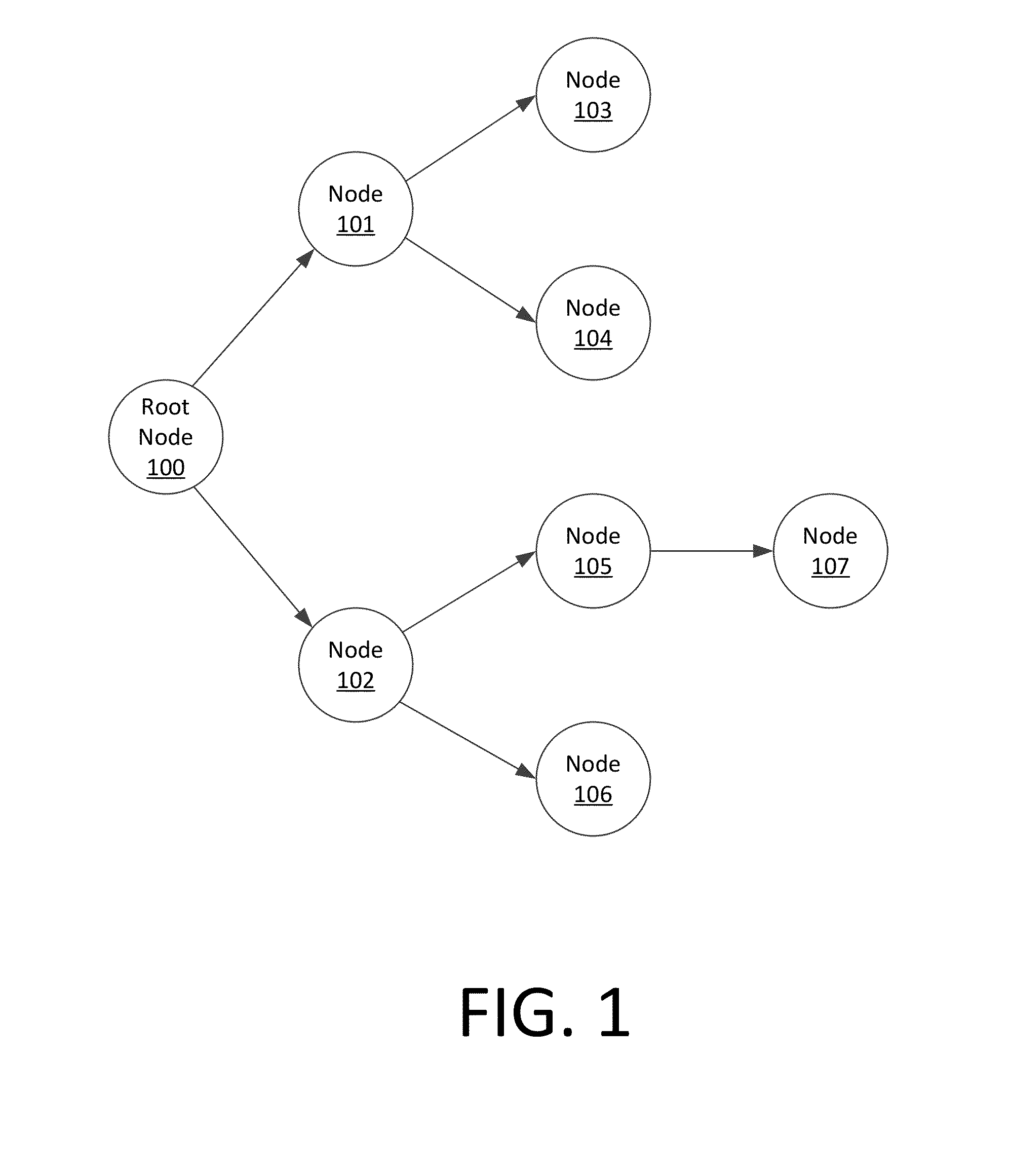

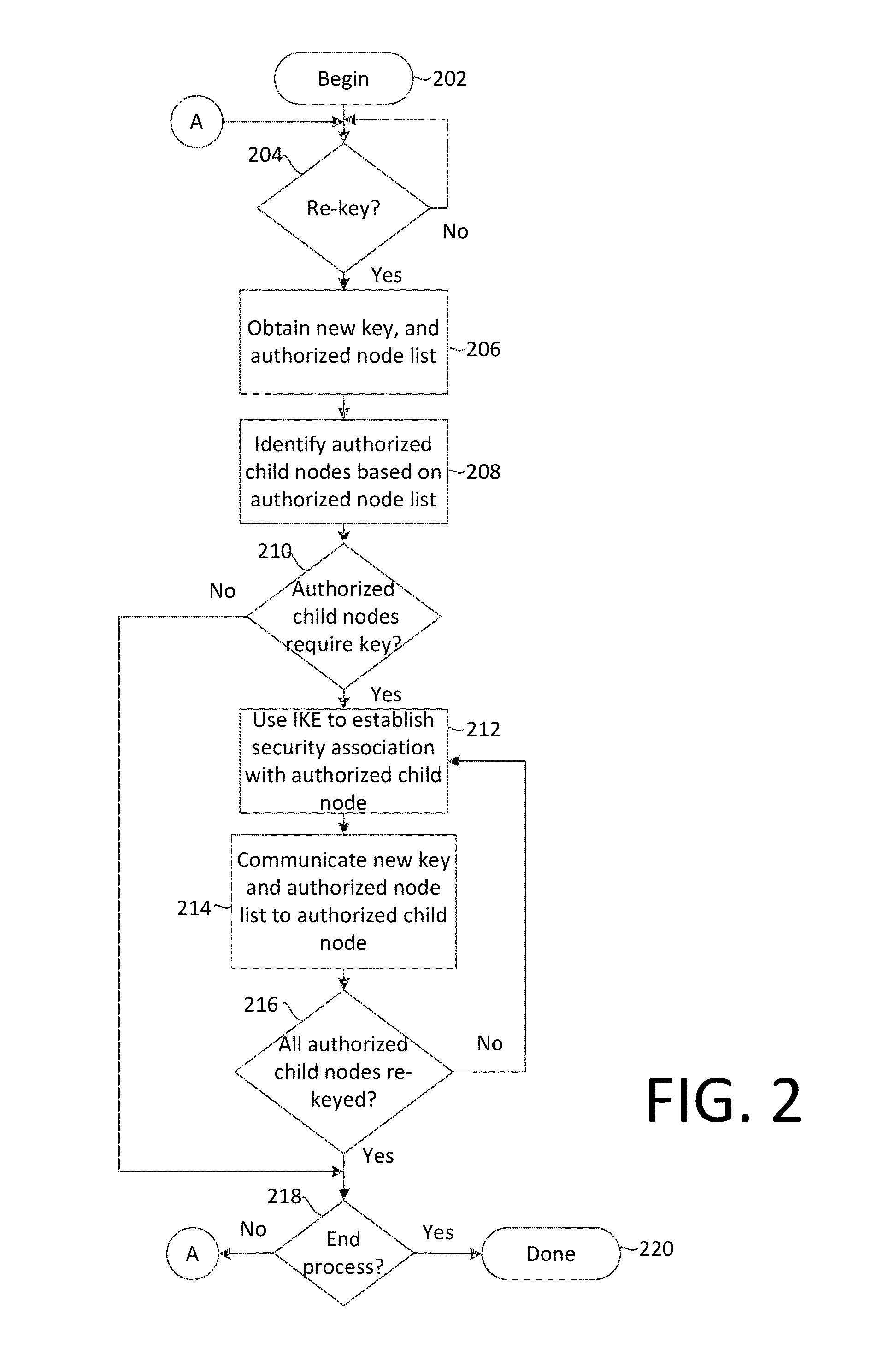

Electronic key management using pki to support group key establishment in the tactical environment

ActiveUS20140226821A1Key distribution for secure communicationPublic key infrastructure trust modelsComputer hardwareSupport group

Method for distributing a group session cryptographic key includes initiating at least one pairwise key distribution session including a root node (100) and at least one communication node (101-107). The method further includes performing at a communication node which has received the group session cryptographic key a propagated pairwise key distribution session with at least one of the communication nodes which has not previously received said group session cryptographic key. The propagated pairwise key distribution sessions are performed at each of the communication nodes which subsequently receives the group session cryptographic key until the group session cryptographic key has been securely provided to all authorized communication nodes.

Owner:HARRIS GLOBAL COMMUNICATIONS INC

Systems and methods for opt-in and opt-out talk group management

Systems and methods for supporting group communications are provided. A group list management server (GLMS) stores communications group definitions in documents, such as extensible mark-up language (XML) documents. The communications group can include communication addresses for different types of communication applications, including electronic mail, voice telephone, data, instant messaging, voice dispatch, short messaging service (SMS), and multimedia service (MMS). Various methods for managing communications groups and features provided for communications groups are provided.

Owner:NEXTEL COMMUNICATIONS

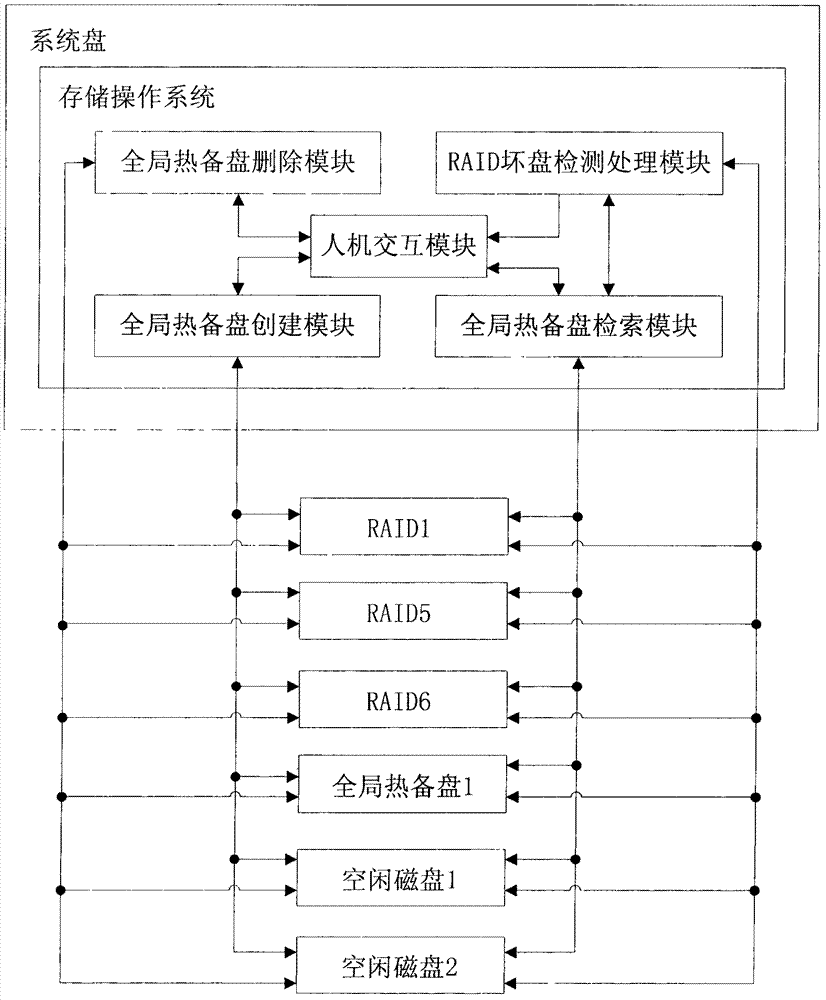

Disk array system supporting grouping-free overall situation hot standby disks based on flexible redundant array of independent disks (RAID)

The invention relates to a disk array system supporting grouping-free overall situation hot standby disks based on flexible redundant array of independent disks (RAID). The disk array system comprises one or more RAID, one or more free disks, 0 or more than one overall situation hot standby disks, a system disk and a memory operating system. The RAID are established by using '-C' or '-create' parameters of mdadm software in a Linus operating system and are managed by mdadm. The system disk is connected with each of RAID, the overall situation hot standby disks and the free disks. Contents memorized by the system disk include but not limited to the memory operating system and application programs managing the RAID. The memory operating system is memorized in the system disk, is the Linus operating system with an expanded kernel and comprises a man-machine interaction module, an overall situation hot standby disk establishing module, an overall situation hot standby disk retrieval module, an overall situation hot standby disk deleting module and an RAID damaged disk detecting and processing module. The overall situation hot standby disks are not limited by RAID groups, do not need configuration files and facilitate data transfer.

Owner:TOYOU FEIJI ELECTRONICS

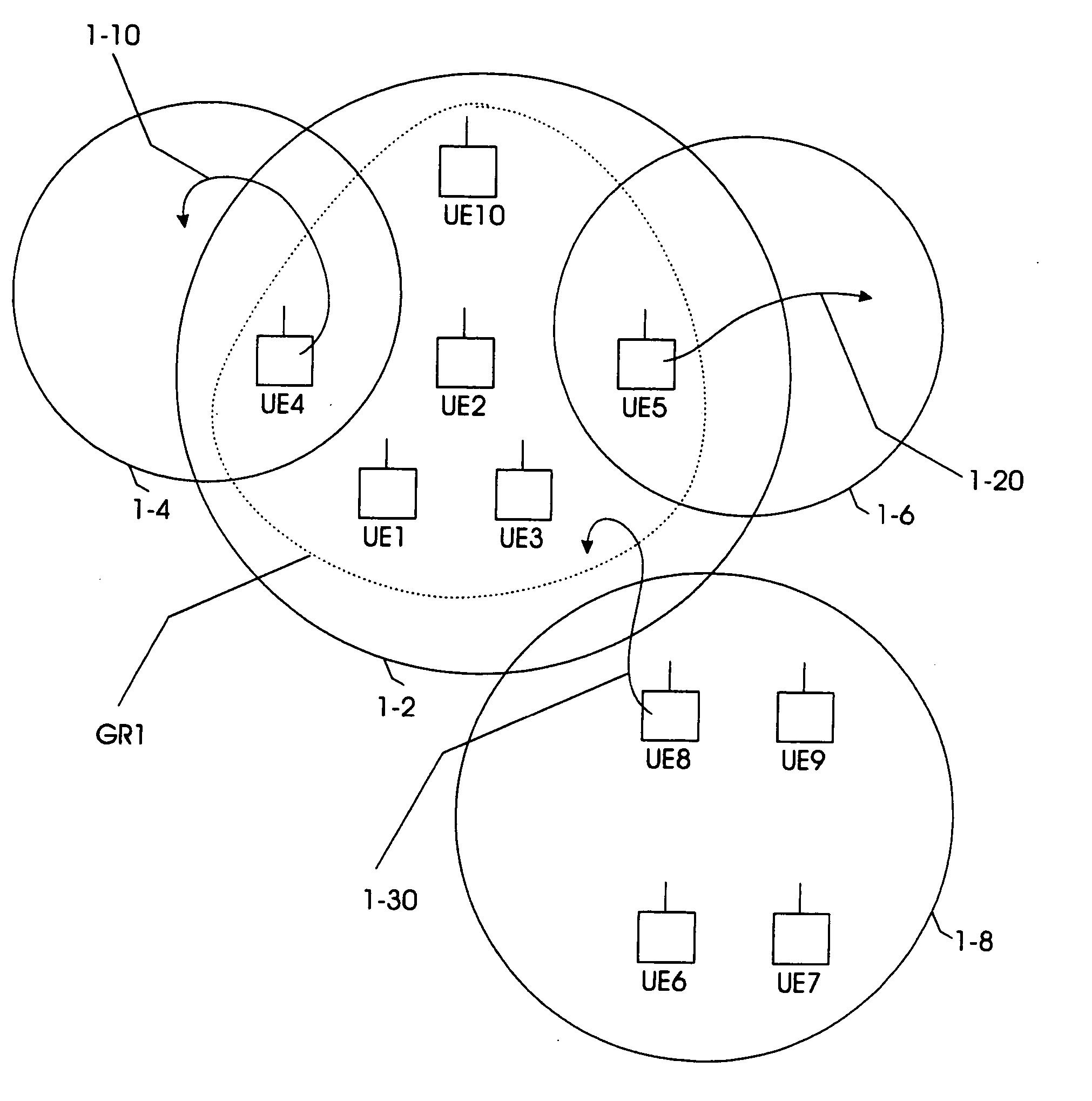

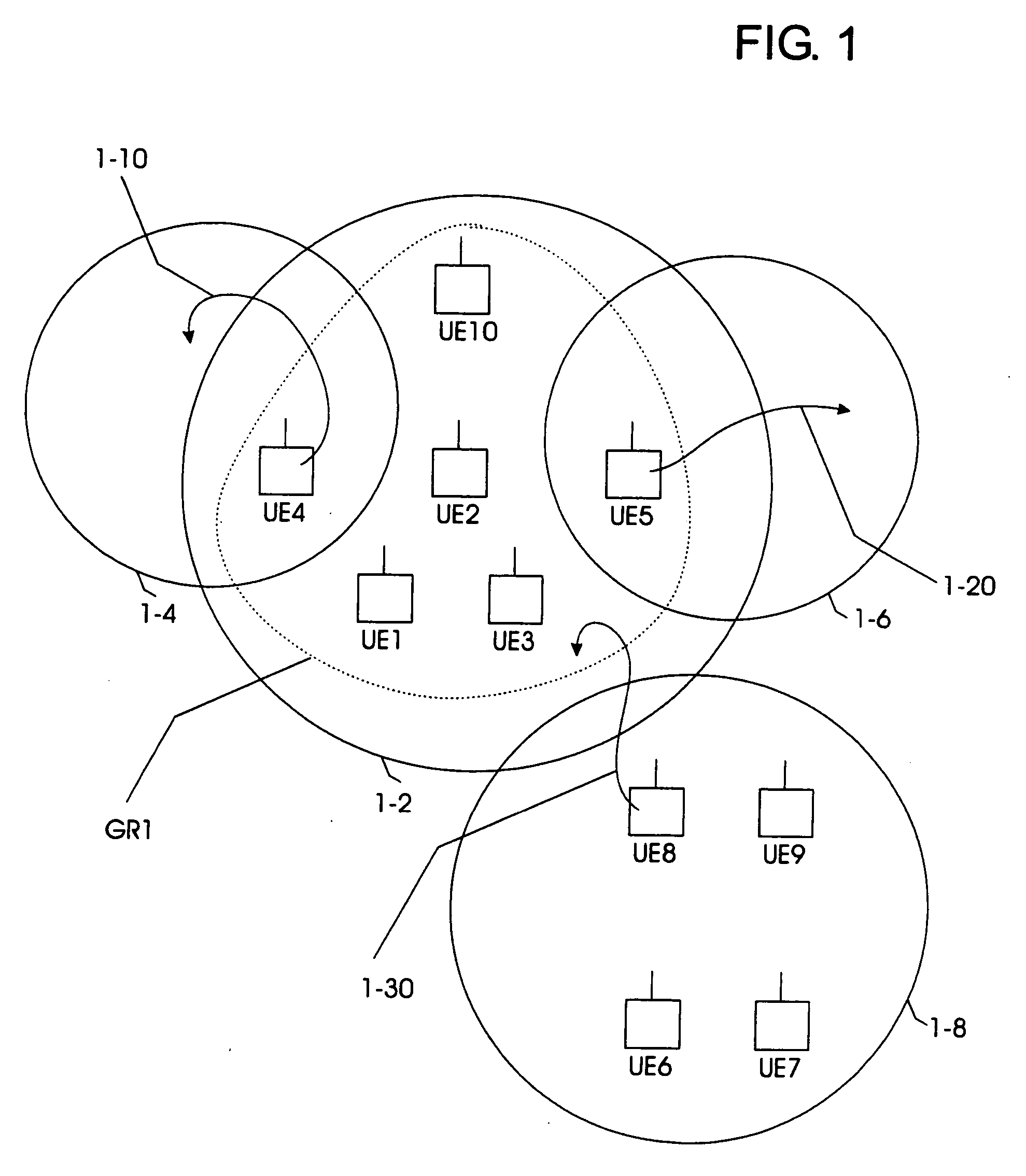

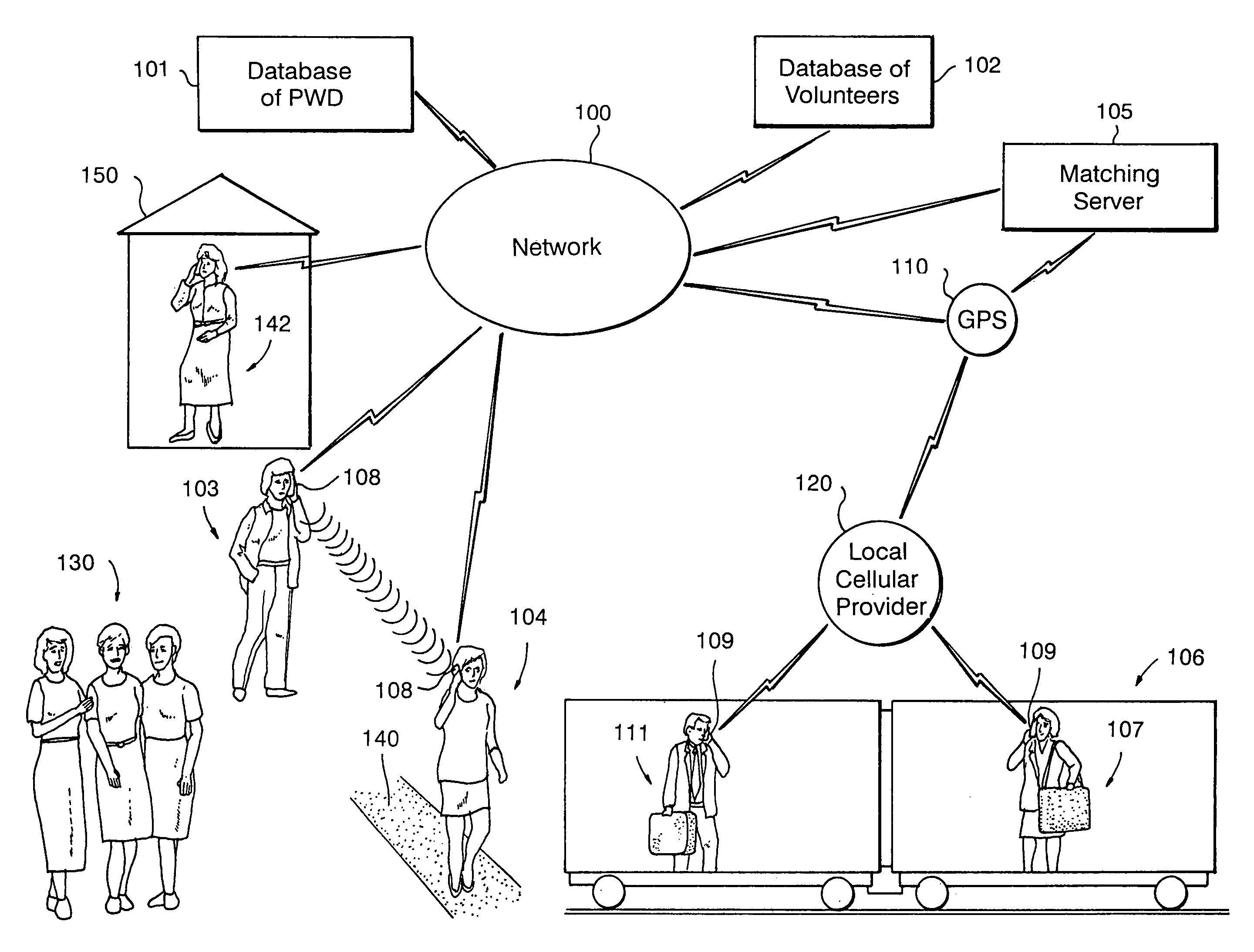

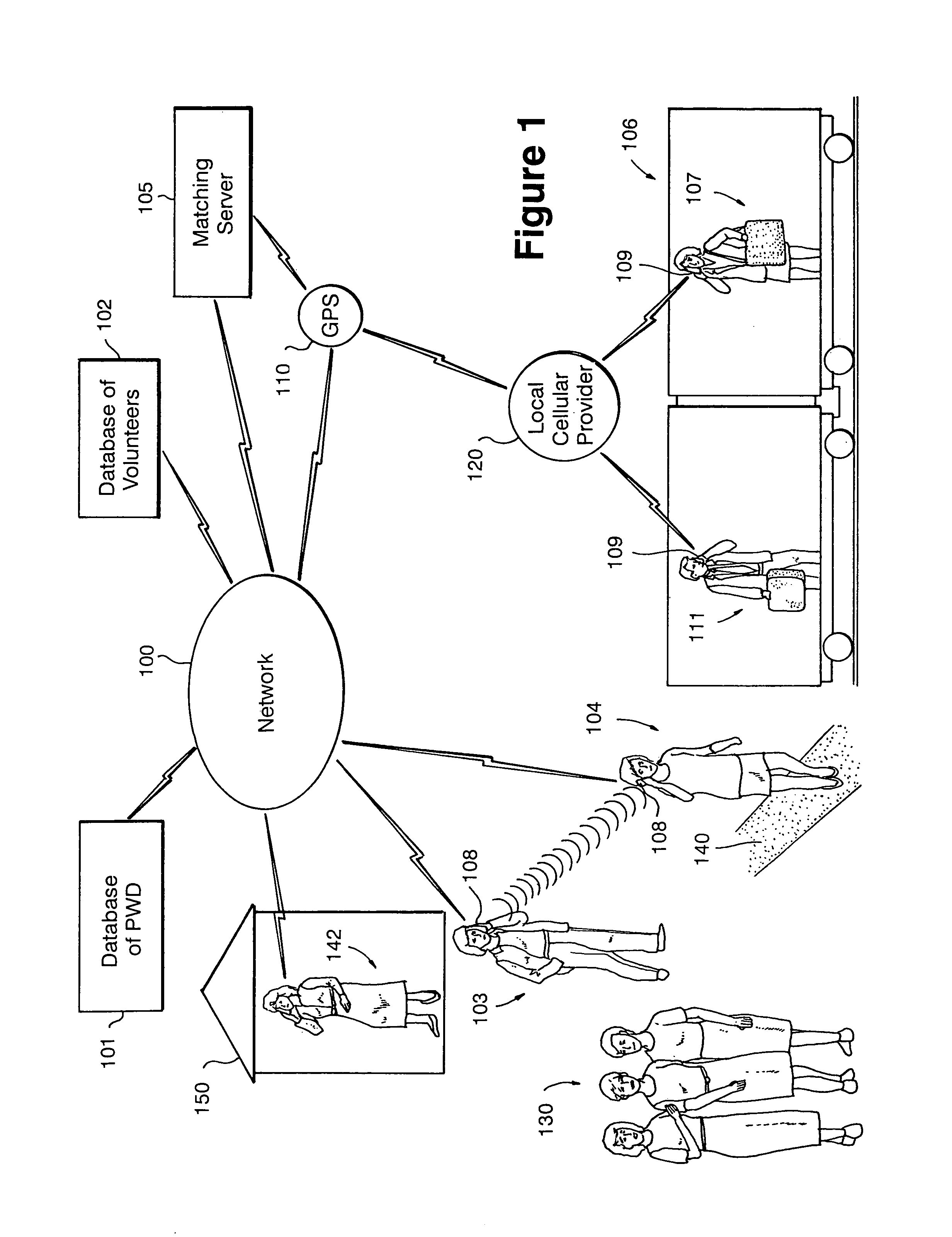

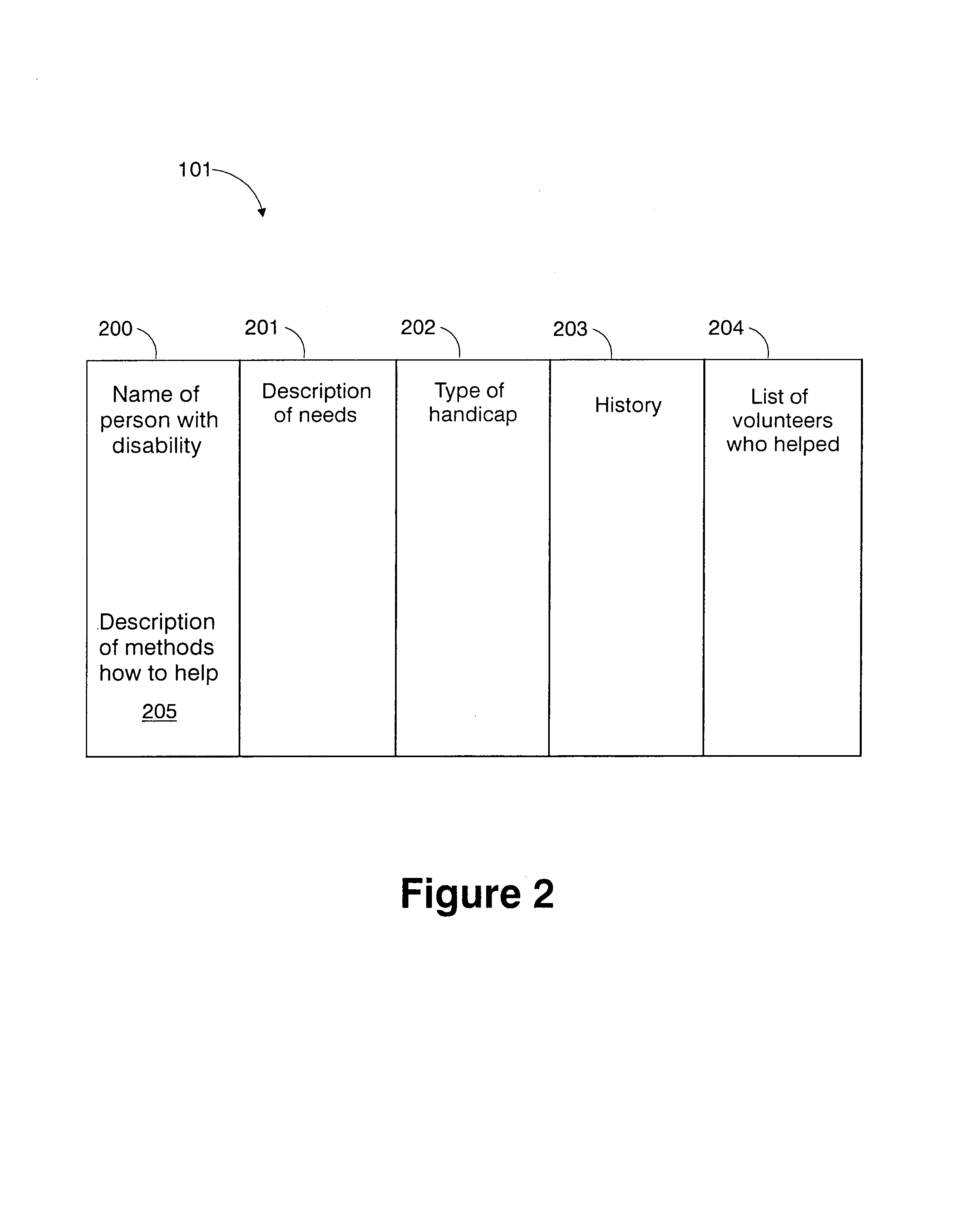

Network of portable, wireless communication devices

InactiveUS7181407B1Efficient and expedient assistanceData processing applicationsTelecommunicationsSupport group

A volunteer network support group for people with disabilities. People who would like to assist people with disabilities may join a service and receive a wearable device or a palmtop that can communicate wirelessly through a network. People that join the volunteer network describe the type of disability they are willing / certified to assist with, available time and other relevant information. People with disabilities also join the volunteer service network and are provided with a wearable wireless device (i.e. Palm top). Disabled persons also specify their particular disability as well as services that they may require. An example of how these volunteers may be of use is: When a volunteer is gong to work in the morning on the train, the service can connect them through the network to a blind person, and the volunteer may assist the blind person by reading a newspaper through the wireless device (like a cellular telephone).

Owner:IBM CORP

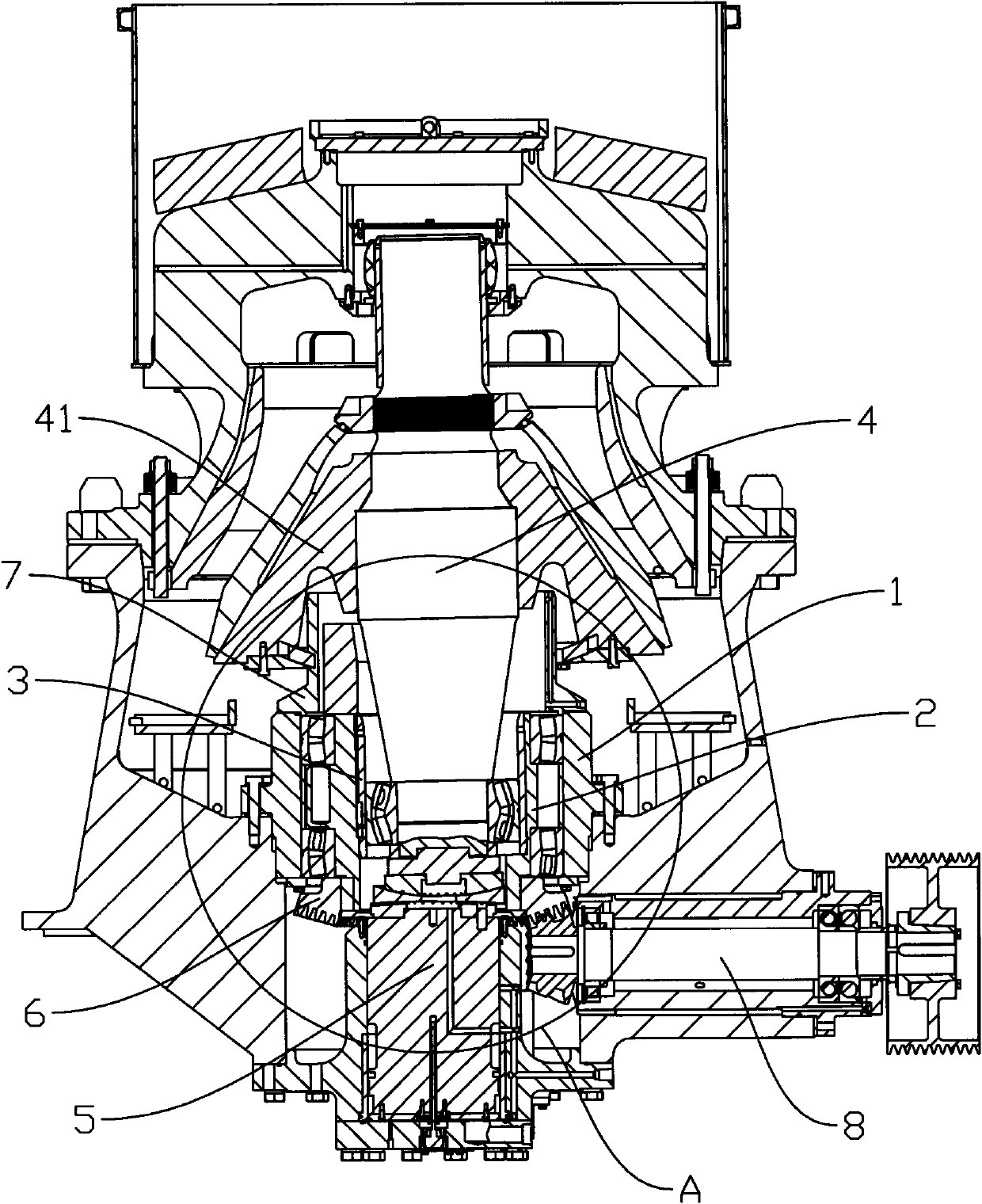

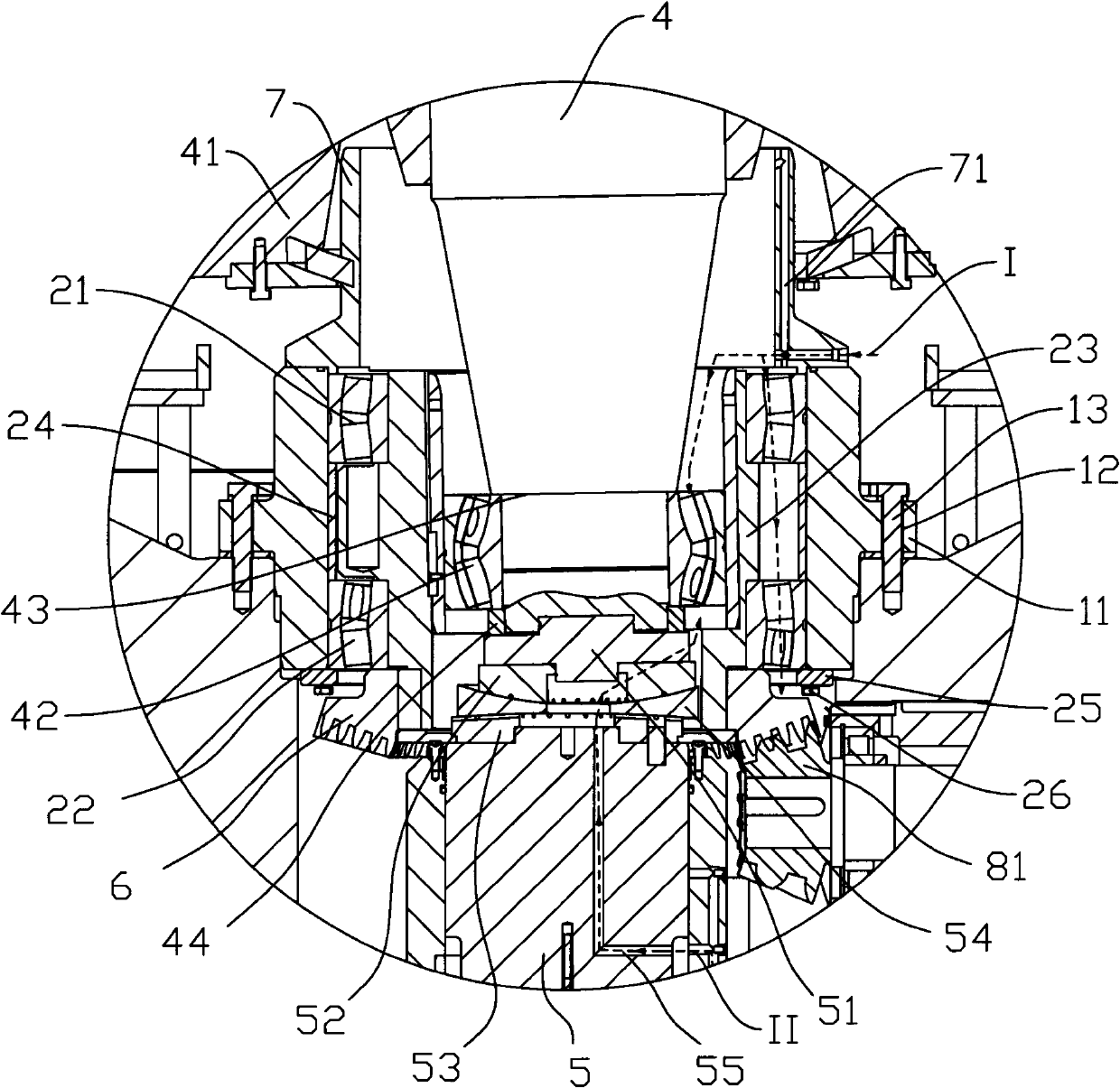

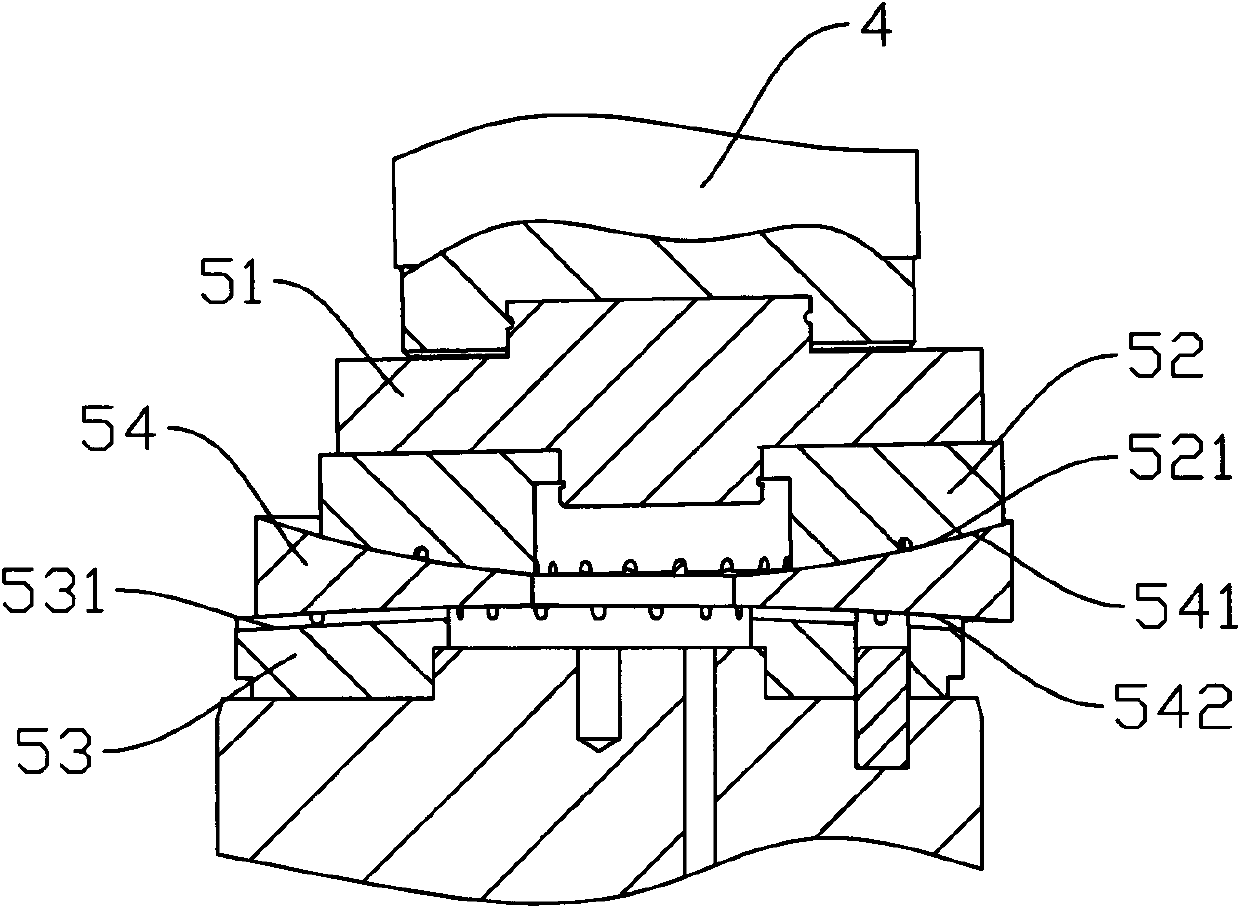

Eccentric sleeve mechanism for cone crusher

ActiveCN101947476AFully lubricatedReduce coefficient of frictionGrain treatmentsSupport groupAgricultural engineering

The invention discloses an eccentric sleeve mechanism for a cone crusher. The eccentric sleeve mechanism comprises a central sleeve arranged on a frame, wherein an eccentric sleeve is arranged inside the central sleeve; a bearing assembly is arranged between the eccentric sleeve and the central sleeve; an eccentric bushing is arranged inside the eccentric sleeve; a moving cone spindle of the cone crusher passes through the eccentric bushing to be pressed on a supporting seat; a bearing III is arranged between the eccentric bushing and the moving cone spindle; a gear which is in engaged transmission with a bevel gear on a transmission spindle of the cone crusher is arranged at the lower end of the eccentric bushing; and a spherical supporting group is arranged between the lower end of the moving cone spindle and the supporting seat. Due to the adoption of a three-rolling bearing structure, the eccentric sleeve mechanism for the cone crusher has the advantages of reducing the friction coefficient between the eccentric sleeve and the central sleeve and between the eccentric sleeve and the moving cone spindle, improving the rotating speed of the eccentric sleeve, improving the crushing efficiency and yield of the cone crusher, prolonging the service life of the machine, reducing the using cost of equipment, and guaranteeing sufficient lubrication of the rolling bearings by adopting a mode of simultaneously lubricating up and down by a lubricating channel I and a lubricating channel II.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

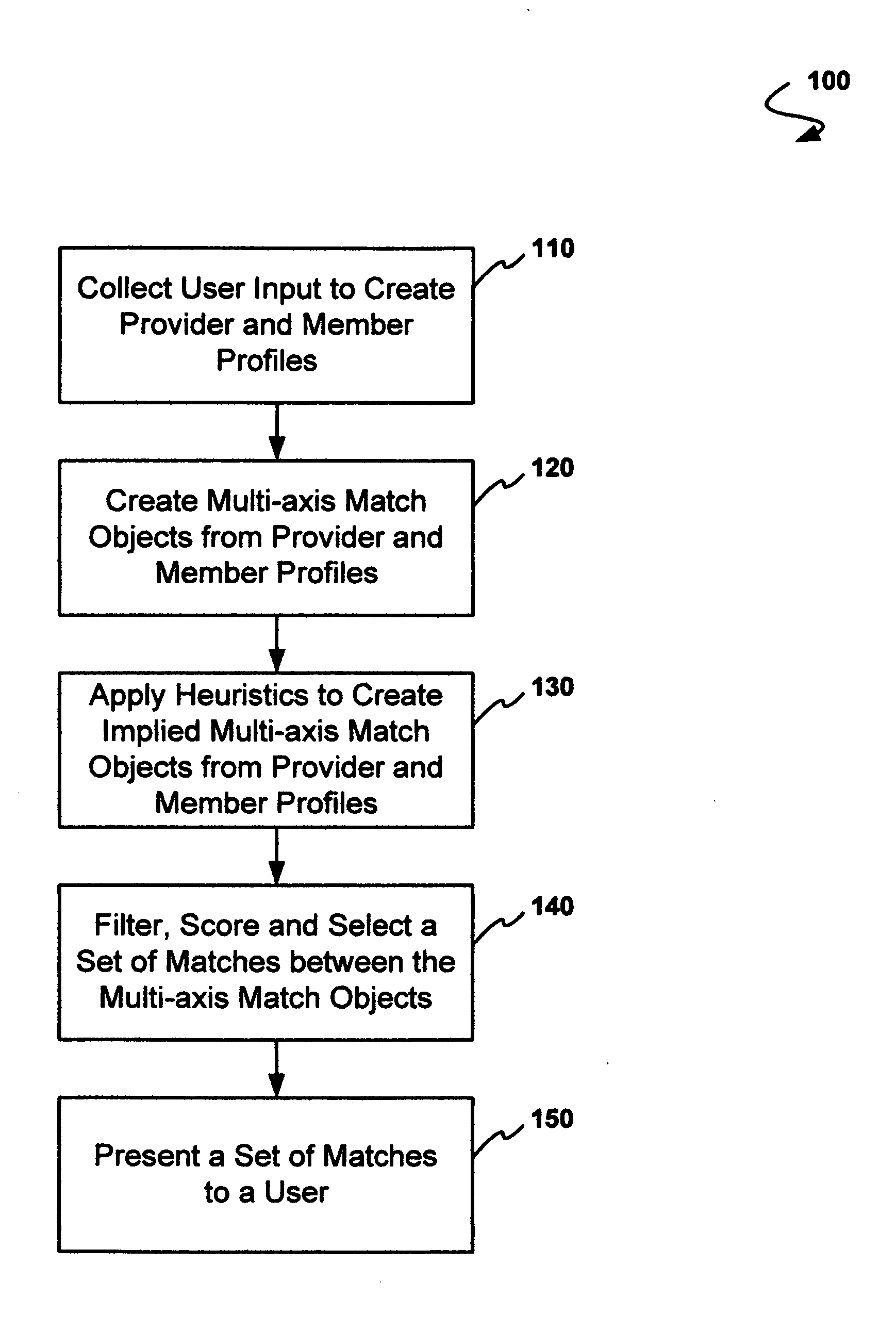

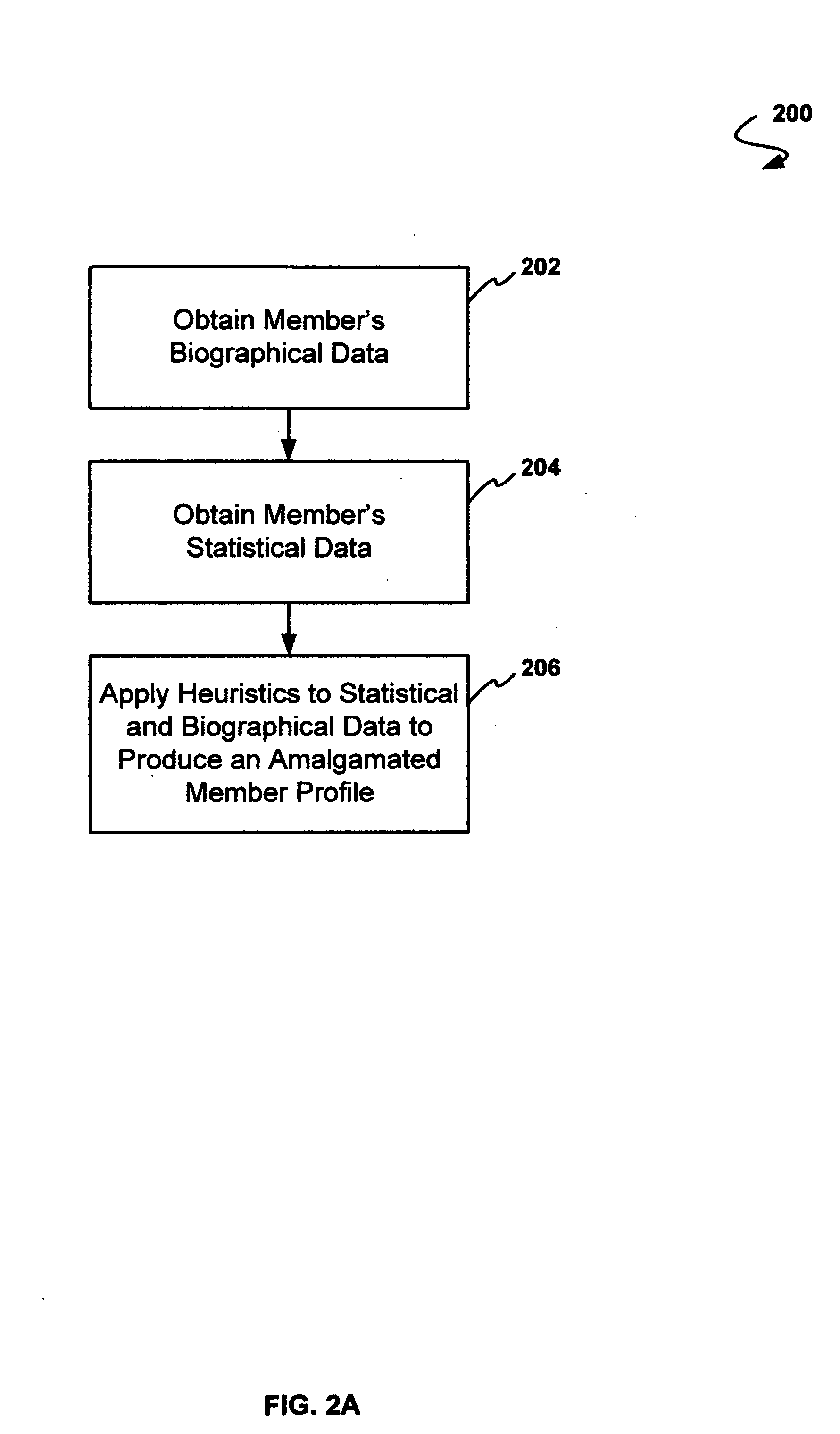

Method and system for universal life path decision support

A method for life path decision support. Methods or computer programs are used for collecting a person's true or prophetic biographical and goal-related data. Such data is used in the creation of a mathematical representation of a profile. Similar profiles are created by various goods or service providers. Methods or computer programs are used for creating mathematical, multi-axis objects that match a person's articulated or implied life path needs or goals to one or more goods or service providers. Polynomial matchmaking as well as heuristic matchmaking is employed. Matches are filtered, ranked and presented, typically using a computer screen. Support groups or industry-specific groups or other groups may be formed automatically based on the profiles or matches. Neither the patentee nor the USPTO intends for details set forth in this abstract to constitute limitations to claims not explicitly reciting those details.

Owner:UNIVERSAL PASSAGE

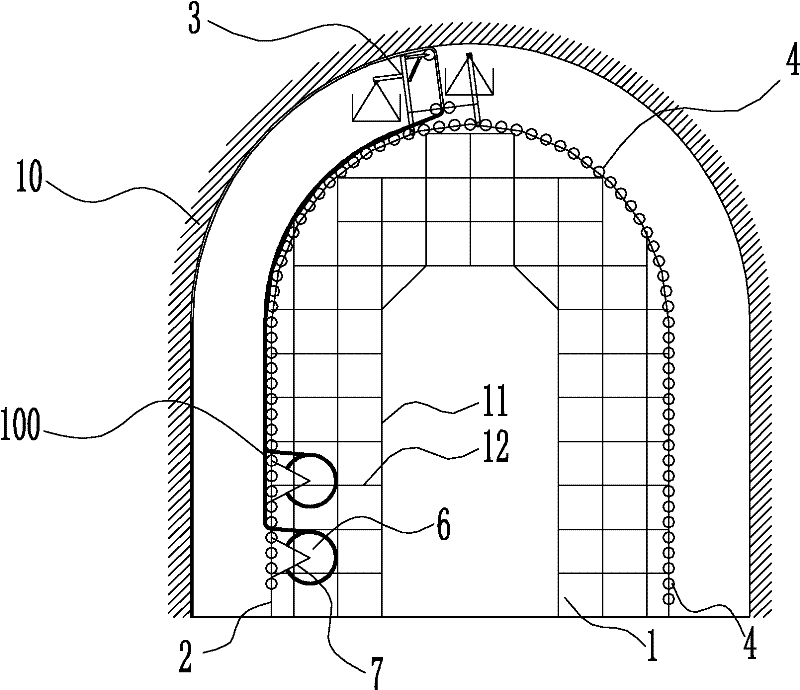

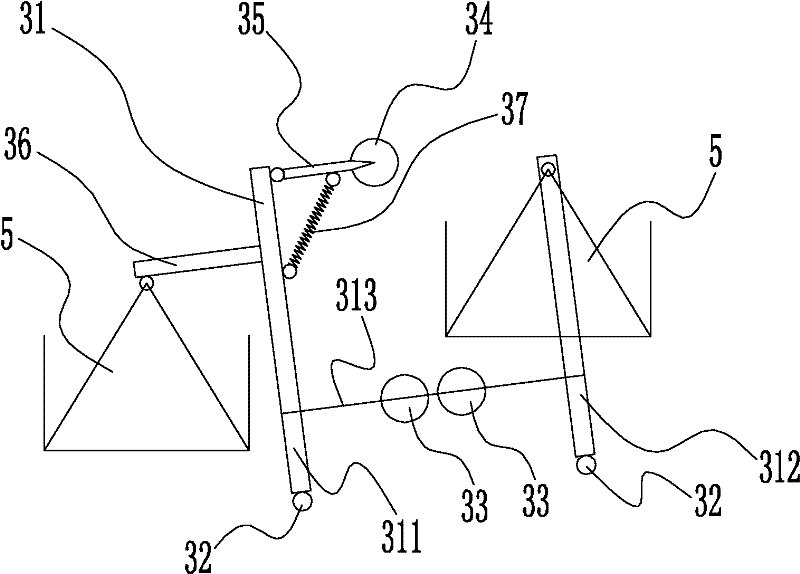

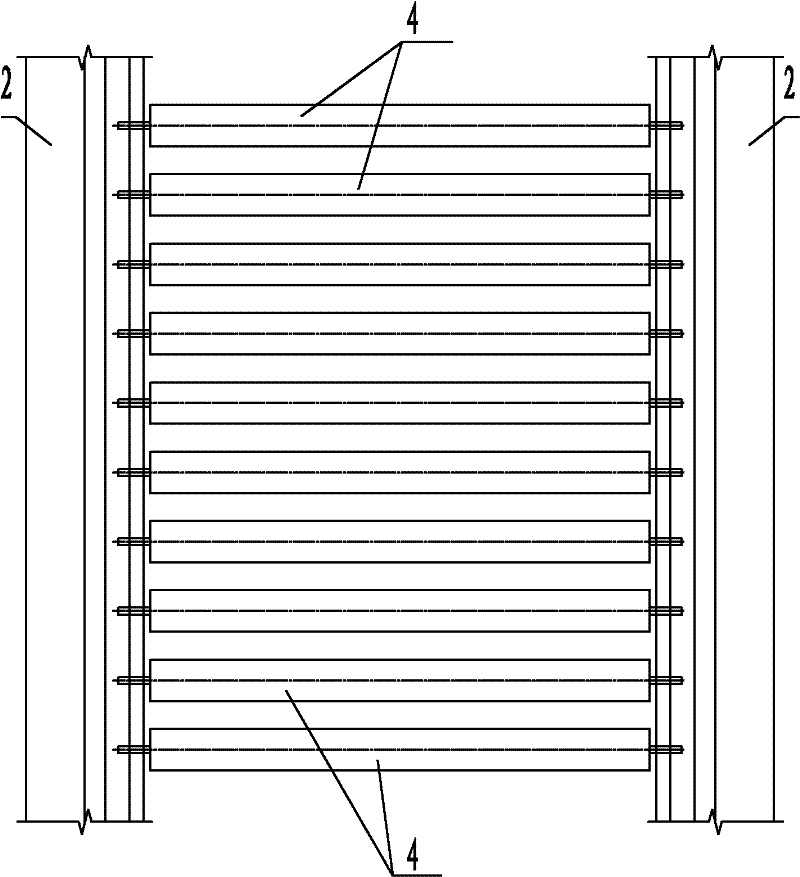

Auxiliary device and method used for laying tunnel waterproofing plates

ActiveCN102226402ARealize the laying operationWell laidUnderground chambersTunnel liningSupport groupEngineering

The invention discloses an auxiliary device and method used for laying tunnel waterproofing plates, and the auxiliary device comprises an arch-shaped support, a guide rail, a plurality of guide rolls and a traveling trolley, wherein, the guide rail is arranged along the outer outline of the arch-shaped support; the guide rolls are arranged at the inner side of the guide rail horizontally and parallelly; the guide rolls are supported by the arch-shaped support; the traveling trolley comprises a traveling wheel, a clamp component, a guide component and a trolley support, wherein, the trolley support comprises a first support group and a second support group; the upper part of the first support group is provided with the guide component which is a steering roll; the other end of a support rod of the steering roll is connected with the first support group; and the clamp component is arranged on a connection rod, and comprises two clamp rolls rotationally connected on the connection rod; and a clearance is formed between the two clamp rolls. The auxiliary device and method provided by the invention have the advantages of being beneficial to laying, lowering the construction difficulty and labor intensity, improving the working efficiency and ensuring the laying quality.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

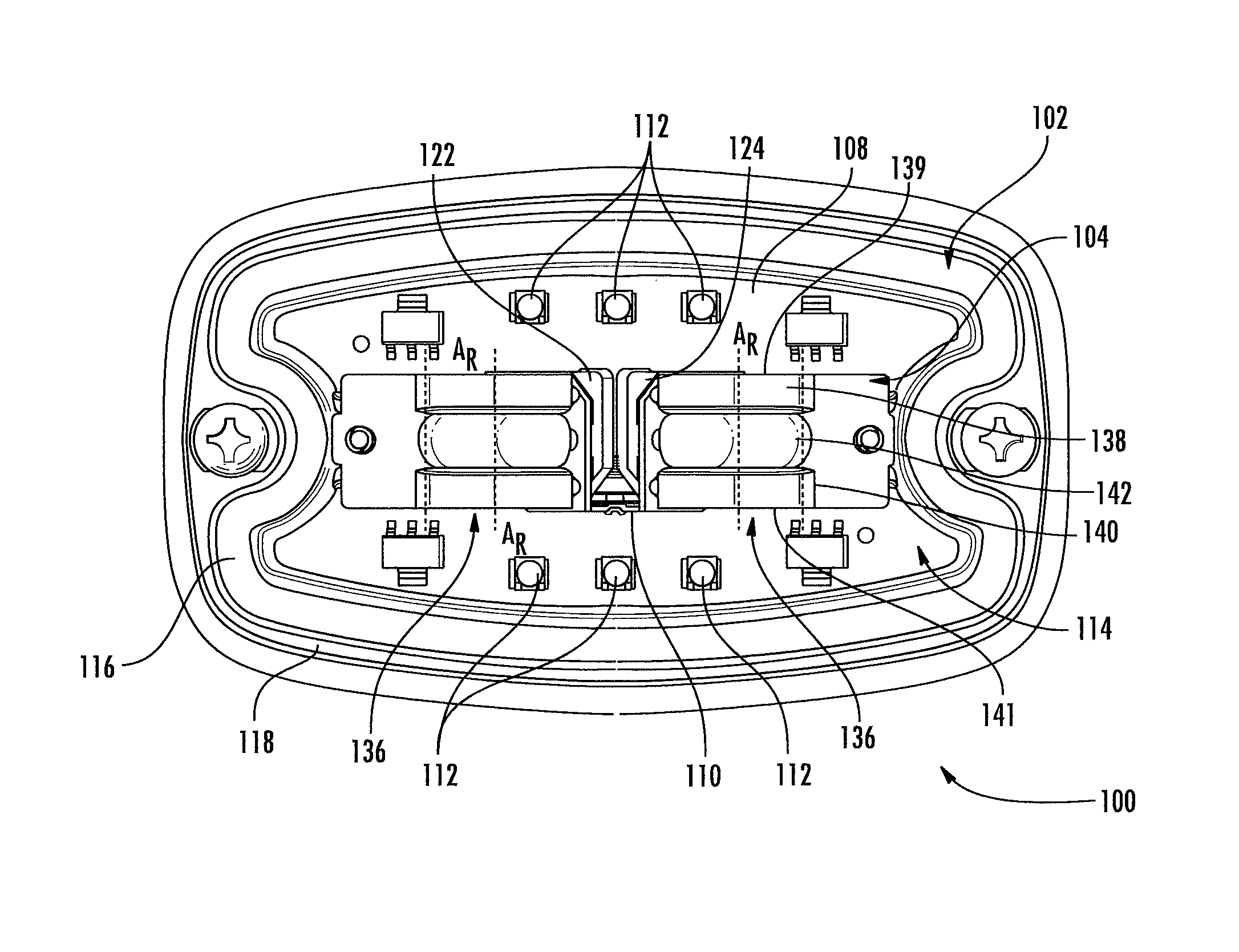

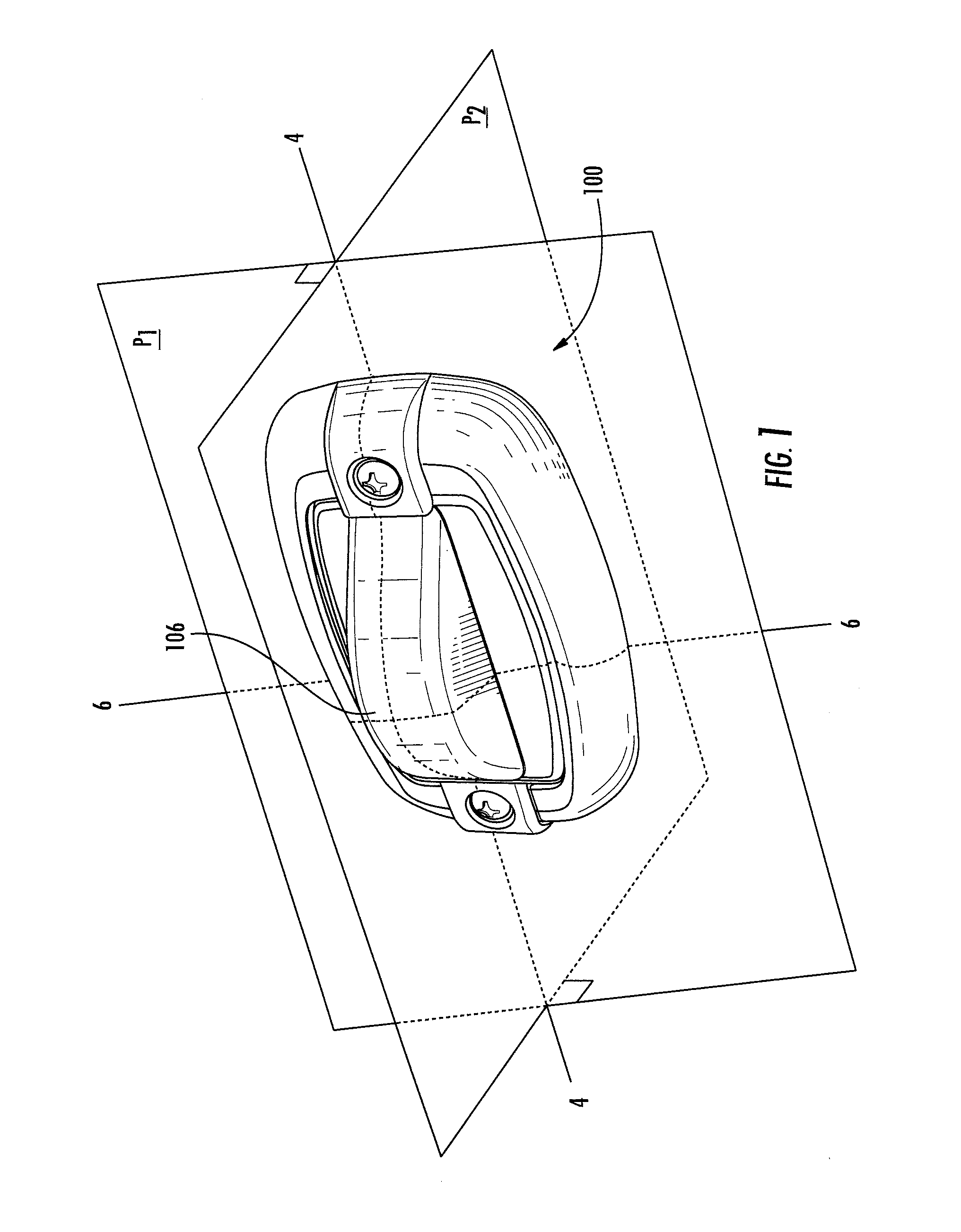

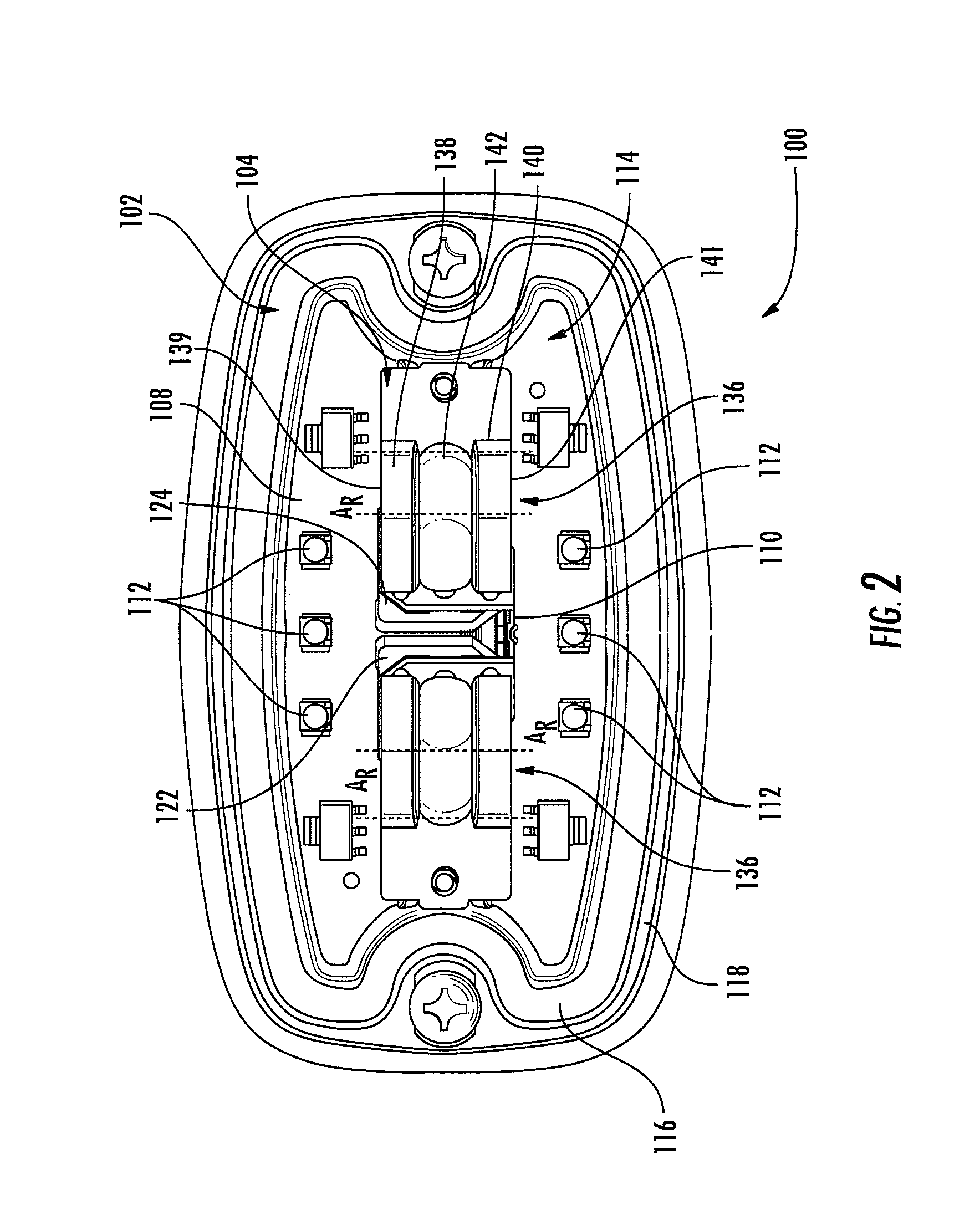

Compact Multi-Function LED Lighthead

ActiveUS20140268855A1Reduce confusionEliminate needOptical signallingVehicle lighting systemsVisibilitySupport group

A multifunction lighthead for mounting to a vehicle includes several groups of LEDs arranged to provide distinct light emission patterns. Each group of LEDs and associated optics are selected and positioned to produce light emission patterns needed to meet lighting standards applicable to the vehicle. Such standards may require wide angle light emission, which is enhanced by supporting groups of LEDs that project away from the vehicle body, enhancing visibility of the lighthead from directions close to a plane defined by the body panel. The projecting support for the LEDs and optics for a wide angle light emission pattern may be employed to support LEDs arranged for ground illumination. Other groups of LEDs in the same lighthead may be arranged with optics to provide area illumination in support of arrest, search, triage or other emergency functions.

Owner:WHELEN ENGINEERING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com