Tower or silo frame section pairing method and pairing platform

A technology of grouping and tower section, applied in the field of tower section grouping method and grouping platform, can solve the problem of low labor intensity, achieve the effect of low labor intensity, good quality of grouping, and small occupation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

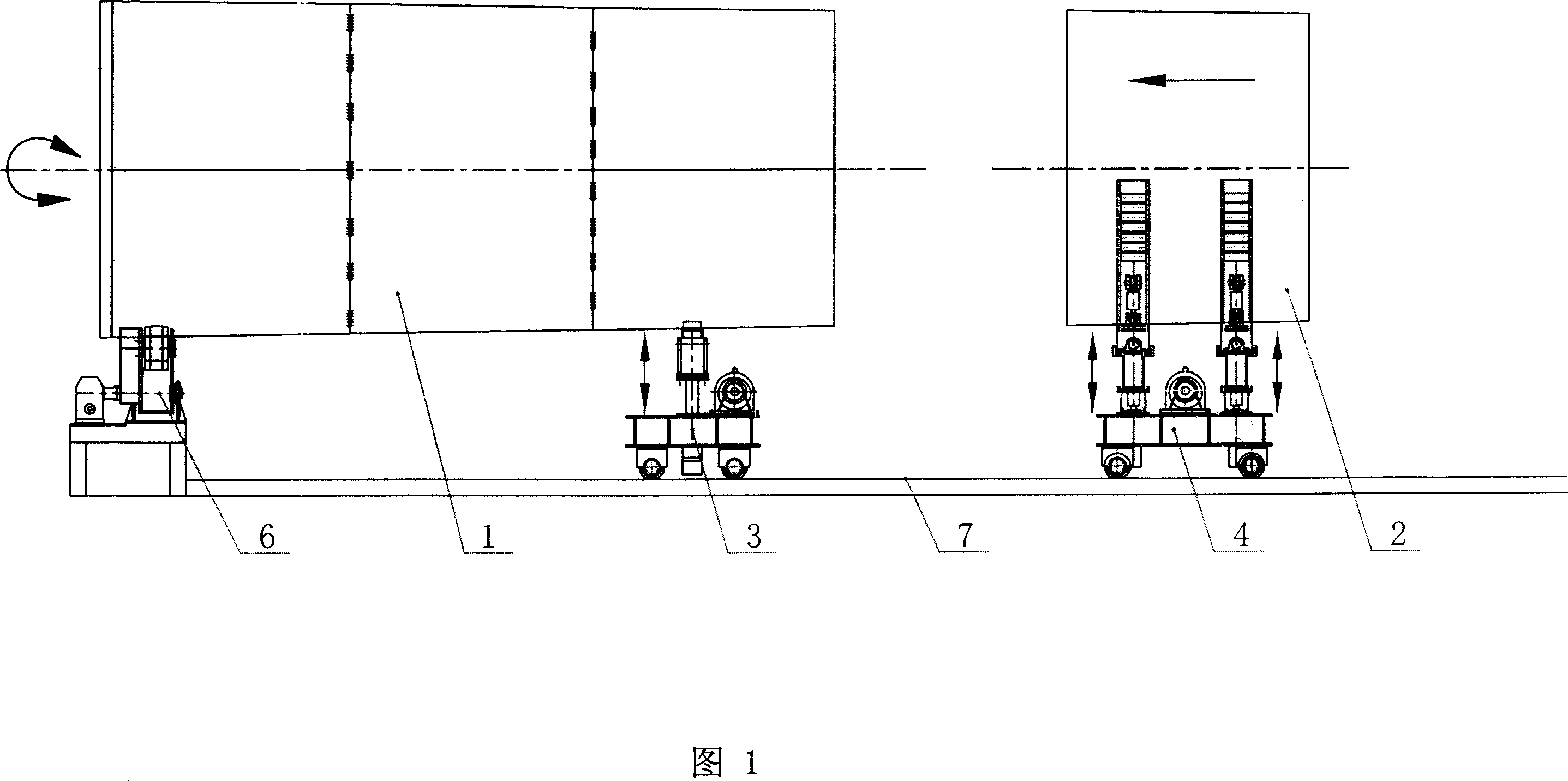

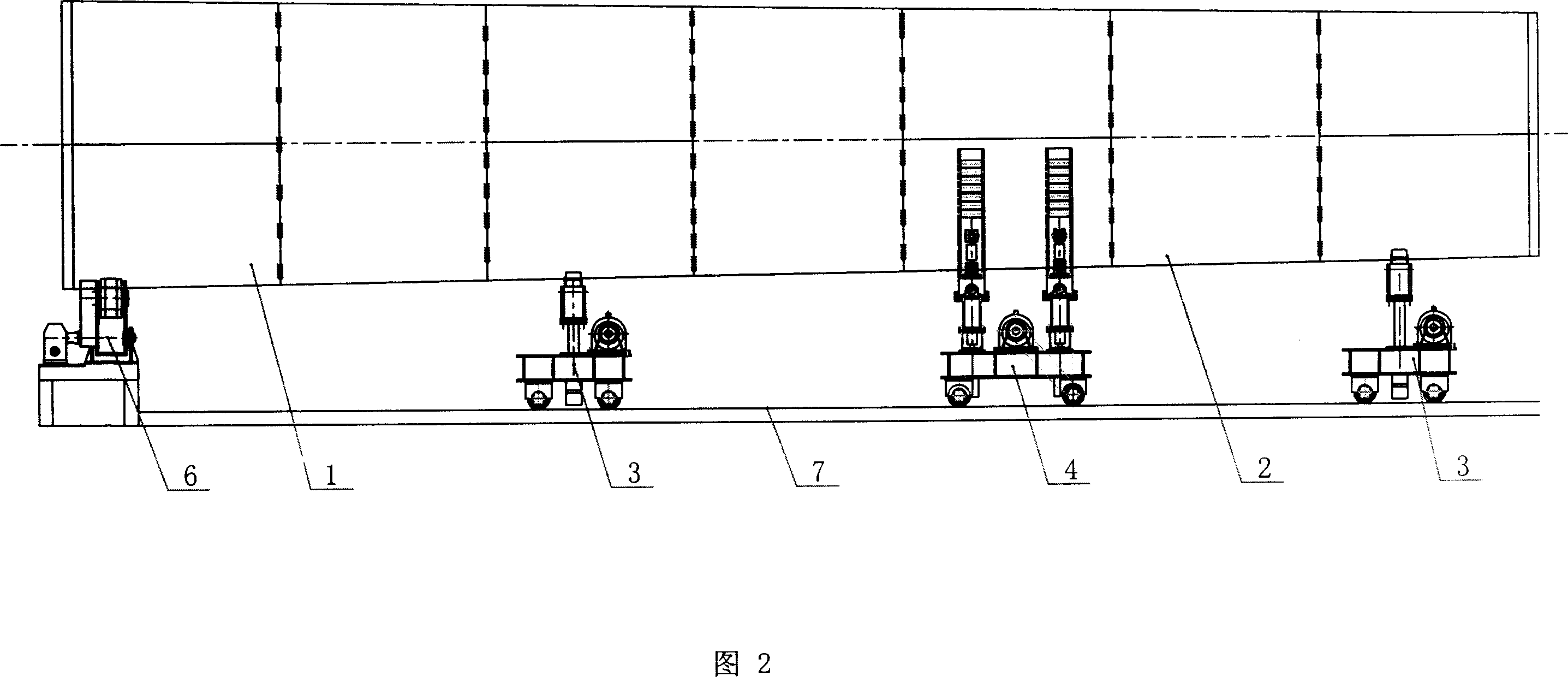

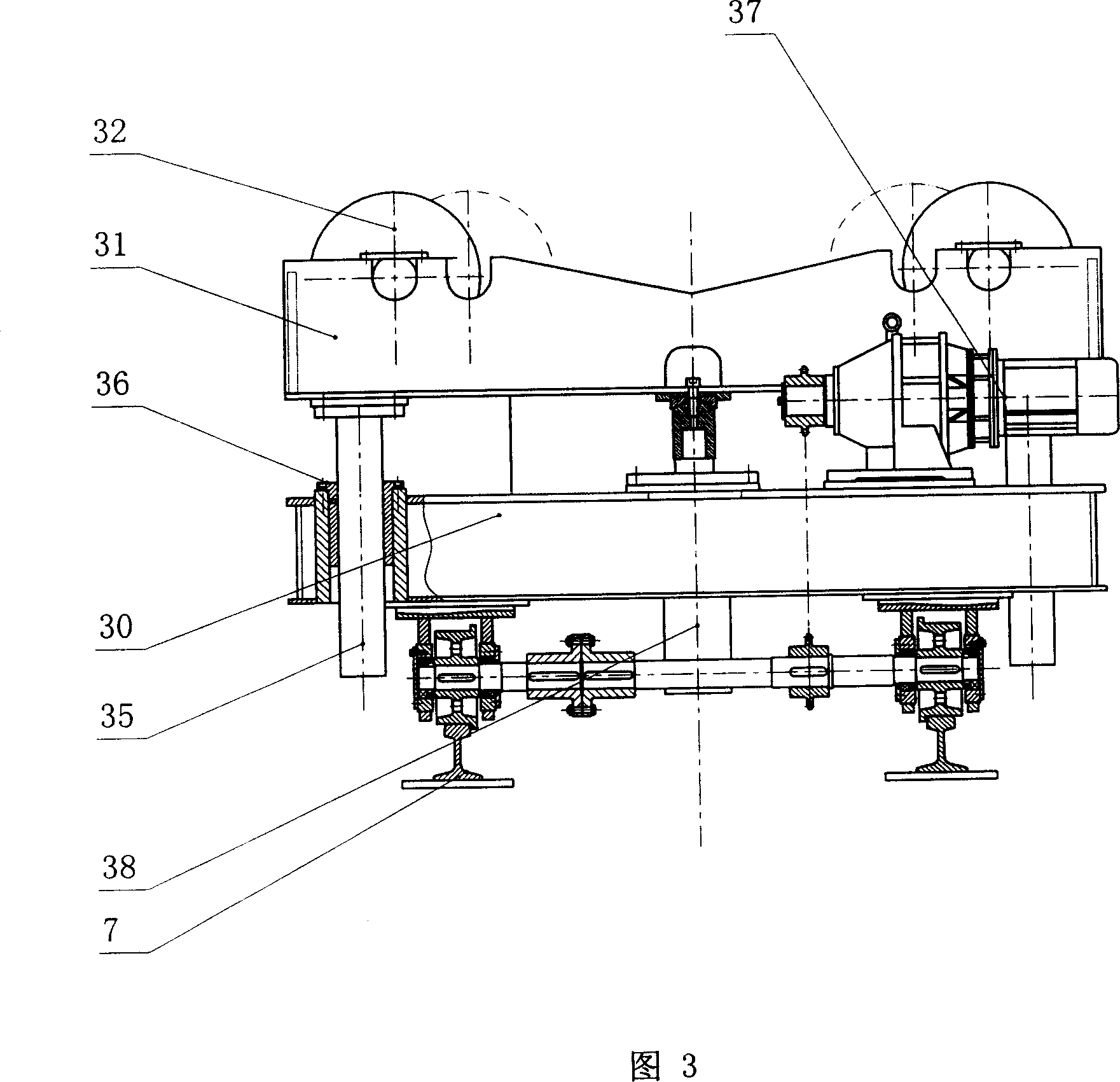

[0027] A schematic diagram of the assembly process using the method of the present invention shown in Figure 1, the track 7 fixed on the ground is laid along the axial direction of the tower section 1 and the single-section tower section 2 with flanges at the left end, and the drum roller frame 6 is placed on On the left side of the track 7, the wheels of the barrel-moving swing arm car 4 and the group pair support dolly 3 cooperate with the track 7. The tower section 1 is placed on the drum roller frame 6 and the paired supporting trolley 3, and is supported by the rollers of the drum roller frame 6 and the supporting wheels 32 of the supporting trolley 3, and the tower section 2 is supported by the pendulum of the paired cylinder shifting swing arm trolley 4. Arm 42 holds the support. By adjusting the roller frame 6 of the drum, the longitudinal welds of the tower section 1 and the tower section 2 are staggered by 180 degrees, and the height of the support roller 32 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com