Film encapsulation method

A thin film encapsulation and thin film technology, which is applied in thin material processing, transportation and packaging, gaseous chemical plating, etc., can solve the problems of many operation steps, damage to the organic layer of the device, and long processing cycle, so as to simplify the operation steps and shorten the processing The cycle and the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

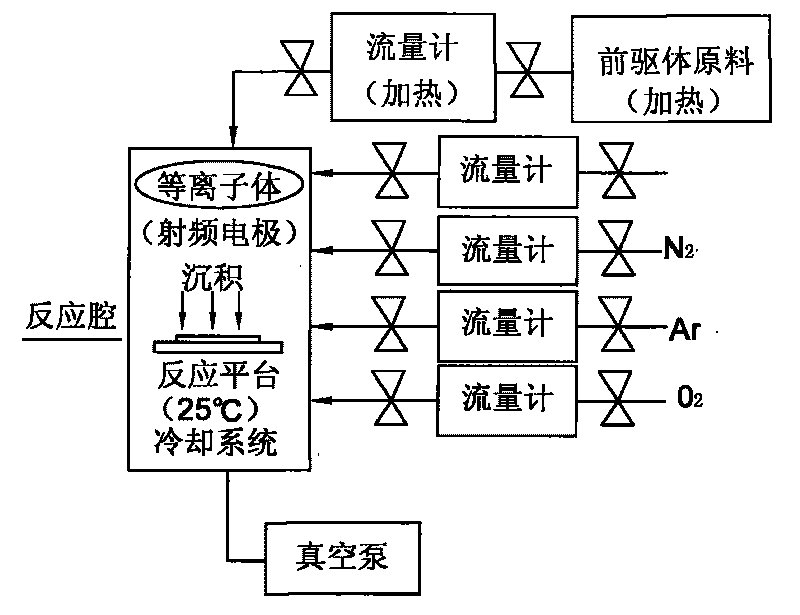

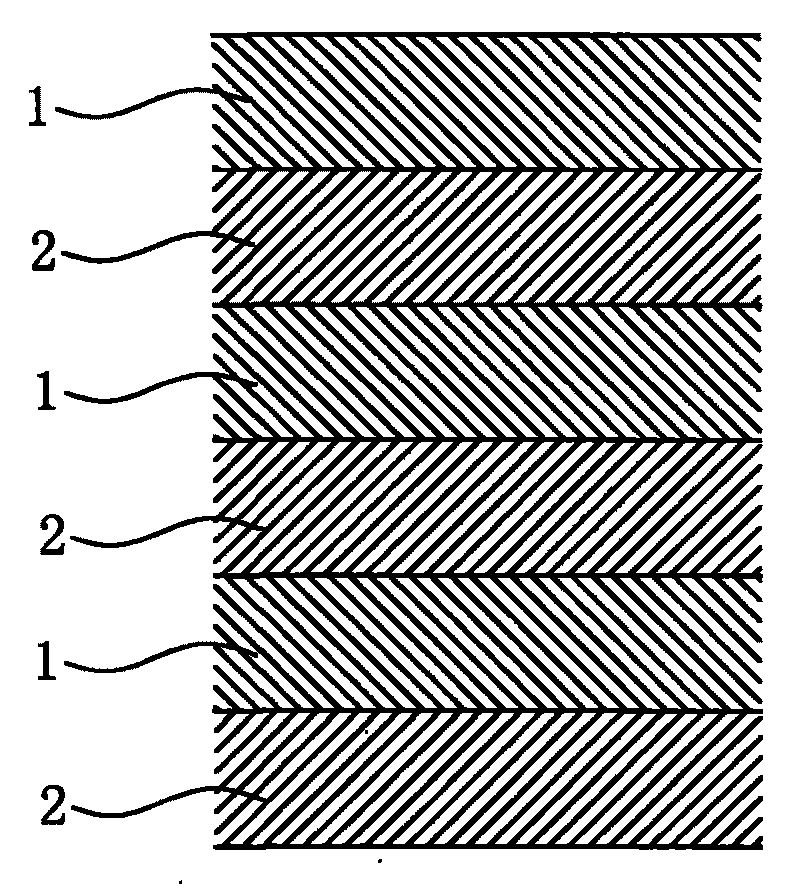

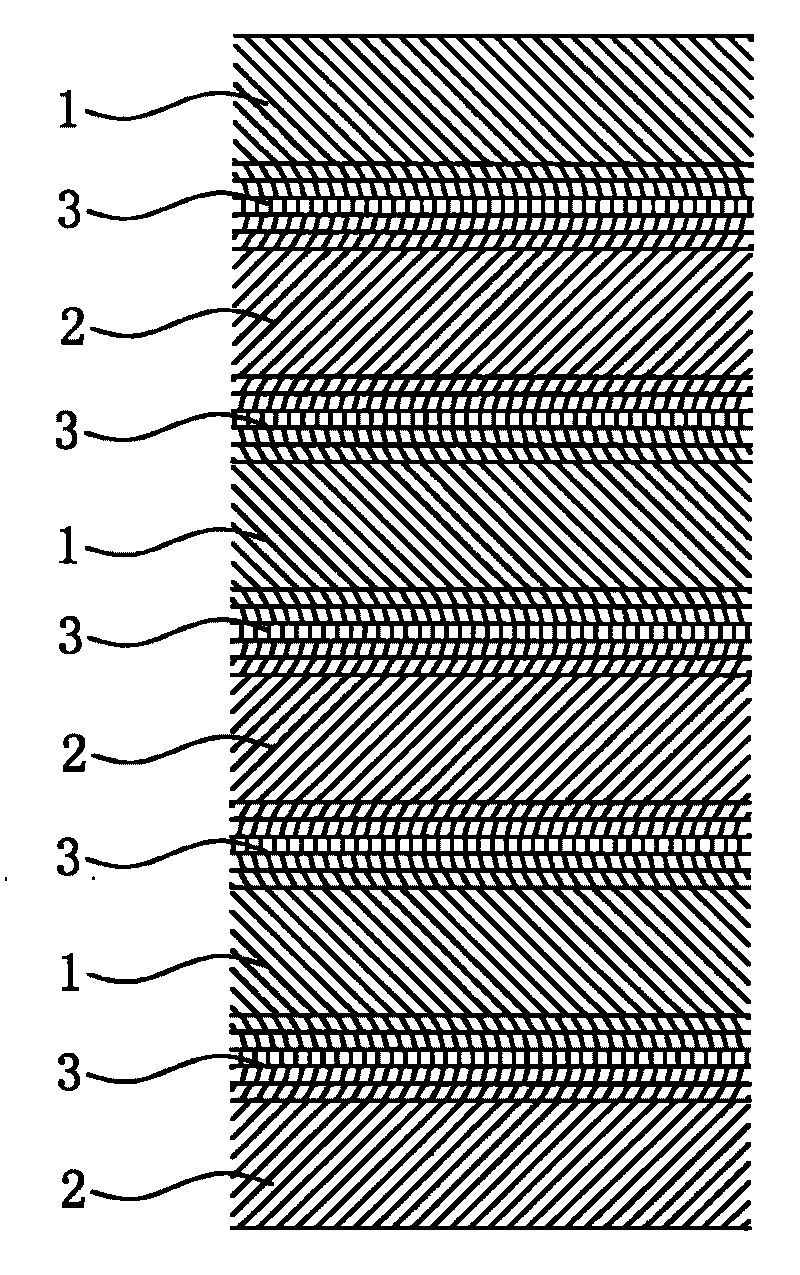

[0038] After the preparation of the OLED device is completed, a CuPc protective film of about 100nm is vacuum-deposited on the aluminum metal electrode of the device so that the device will not be damaged during the packaging process, and then the OLED device is transferred to the PECVD (PECVD) for packaging under an inert atmosphere. Such as figure 1 ) cavity, the cavity is about 200 mm in diameter and 200 mm in height, and the device is placed on the substrate tray facing up, and the area and area of the package are controlled by a mask. Vacuum the cavity to 1.5Pa, pass through hexamethyldisiloxane (HMDSO), adjust the radio frequency intensity to 60mA under the plasma (microwave electron cyclotron resonance (ERC), frequency 40KHz), and realize it under the condition of Ar carrier gas For the growth of the organic silicon polymer film, the growth time is one minute, and the pressure in the chamber is 6Pa during the growth. Then turn off the plasma source, stop feeding argo...

Embodiment 2

[0040] The Alq3 OLED device prepared on the ITO glass substrate that adopts the method described in embodiment one to package, carries out test and characterization, and carries out the comparison of device life-span, efficiency with traditional glass cover epoxy resin encapsulation, the result finds: this method encapsulation device and Devices without any encapsulation are equivalent in efficiency, indicating that the encapsulation has no damage to the device. If the CuPc layer is not deposited before OLED encapsulation, there will be a small amount of damage; in the life test, the life of the glass encapsulation device is 3000 hours, and the encapsulation device of the present invention More than 3000 hours, it shows that the barrier ability of the present invention to water and oxygen is basically equal to that of epoxy resin encapsulation with glass cover.

Embodiment 3

[0042] After the preparation of the OLED device is completed, a CuPc protective film of about 100nm is vacuum-deposited on the aluminum metal electrode of the device to prevent the device from being damaged during the packaging process, and then the OLED device is transferred to the PECVD chamber for packaging in an inert atmosphere In the body, and use a mask to control the area and area of the package. At the same time, a thin steel sheet with a thickness of 1 micron is placed next to the device, so that the same packaging film grows on the steel sheet while the device is packaged. Vacuum the cavity to 1.5Pa, pass through hexamethyldisiloxane (HMDSO), adjust the radio frequency intensity to 60mA under plasma (microwave electron cyclotron resonance (ERC), frequency 40KHz), and adjust the radio frequency intensity to 60mA in NH 3 The growth of the silicon nitride film is realized under the condition of the carrier gas, the growth time is one minute, and the pressure in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com