Patents

Literature

4729 results about "Transition layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transition Layer. a layer of water in which the vertical gradients of oceanographic parameters, including temperature, salinity, and density, increase sharply compared to the vertical gradients in the layers above and below.

Thin films

InactiveUS20050181555A1Quality improvementHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

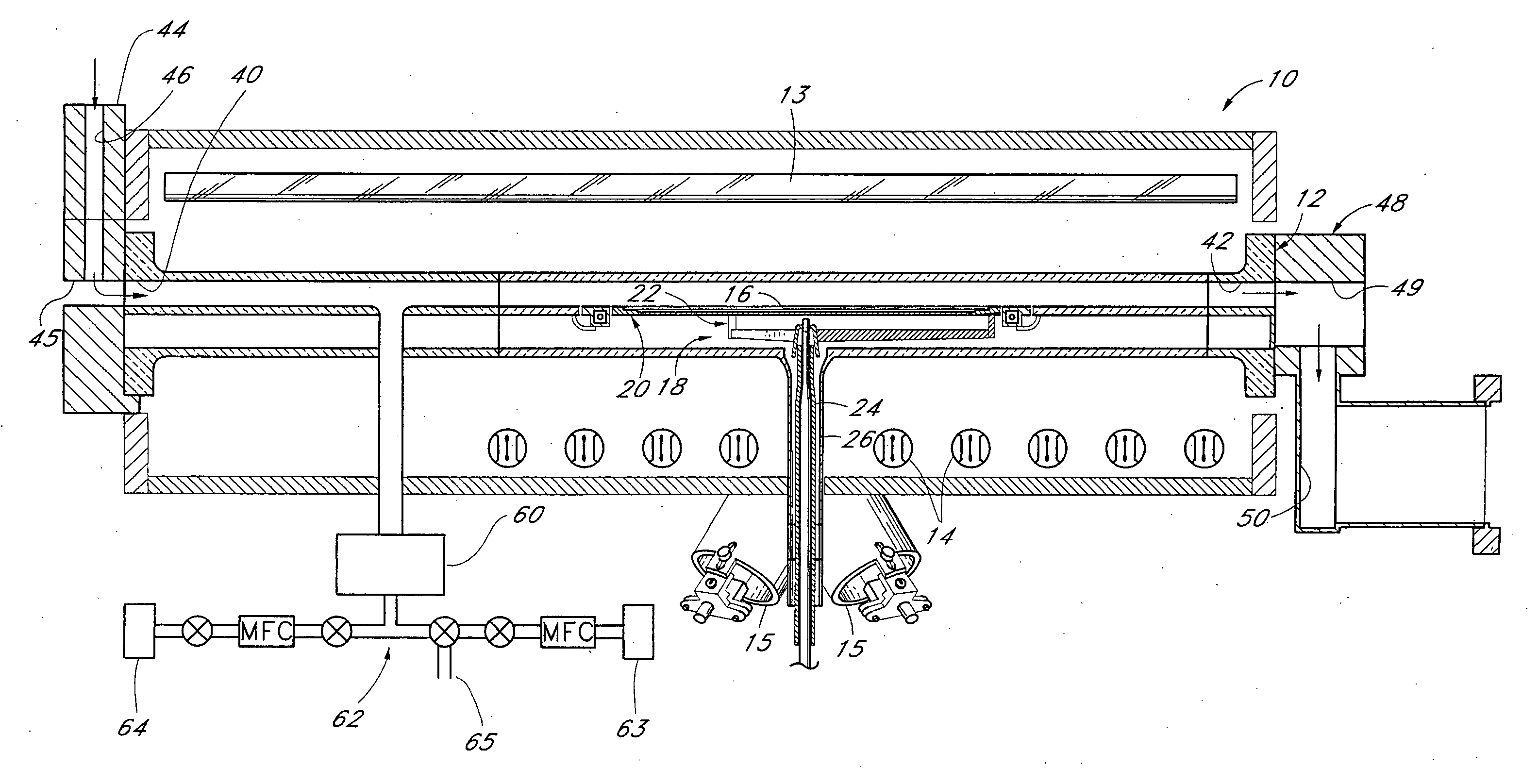

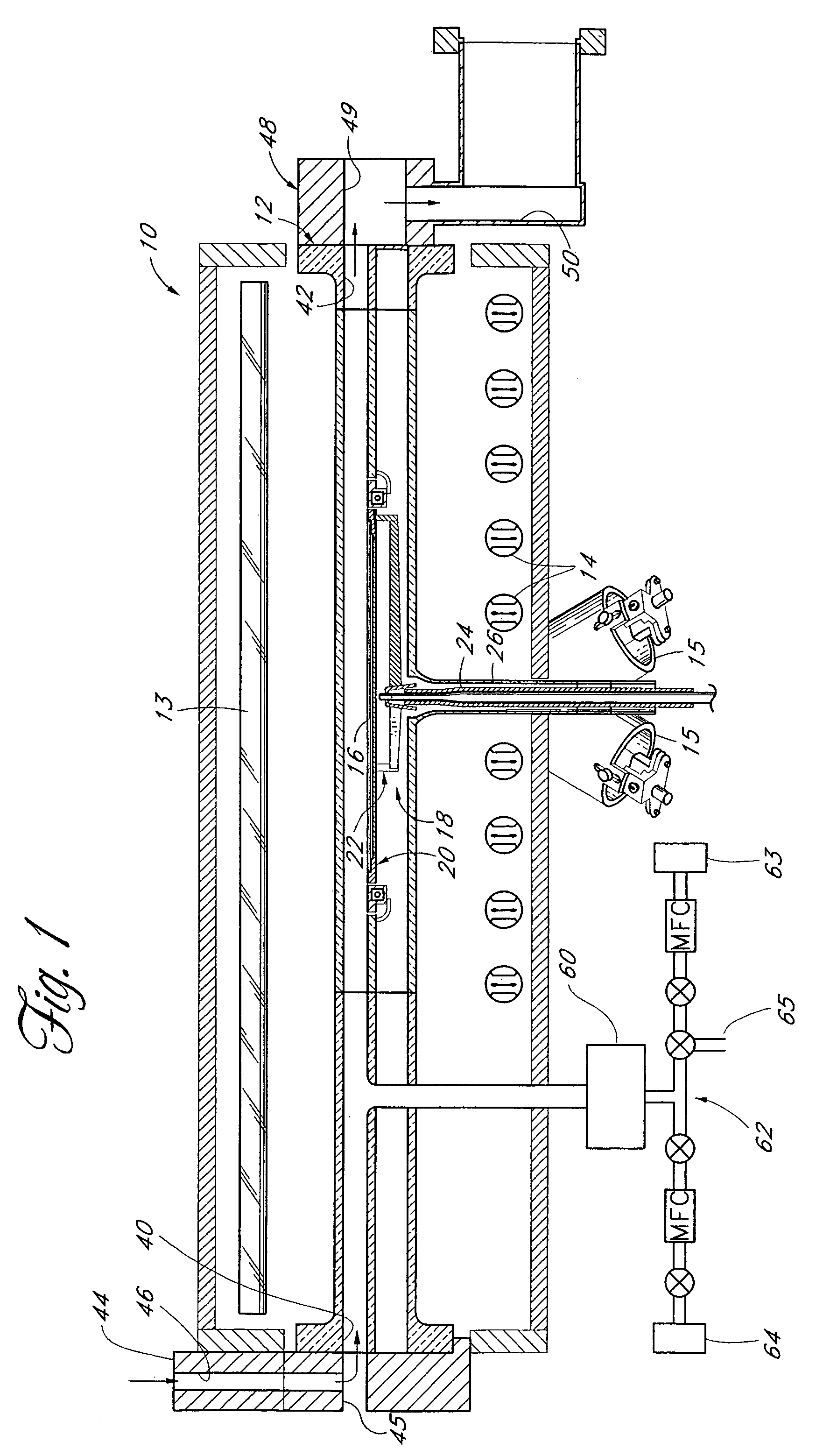

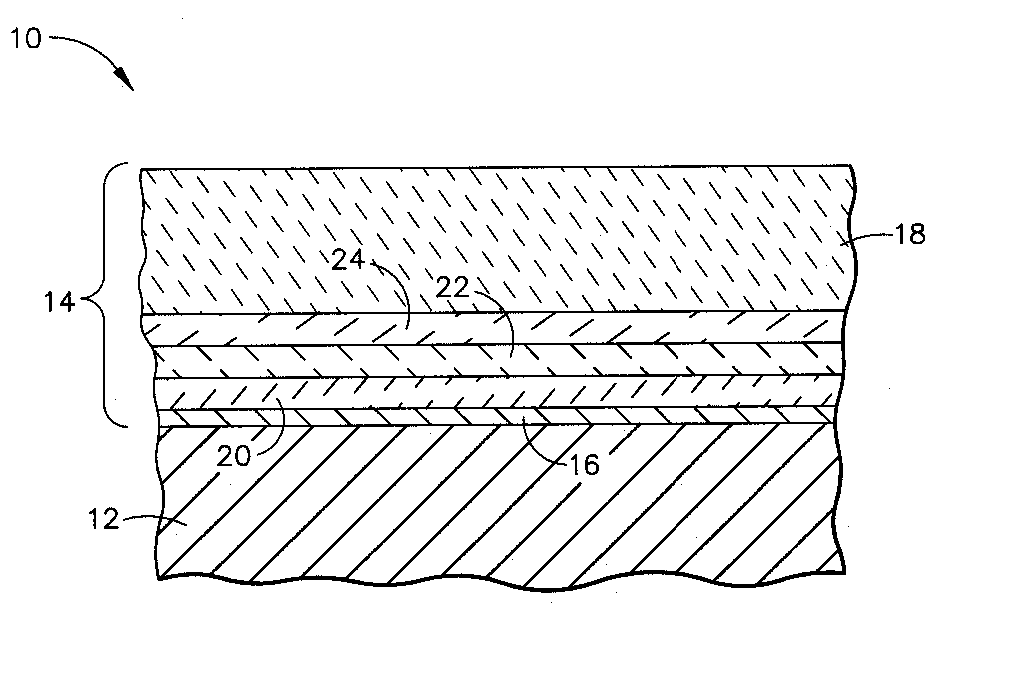

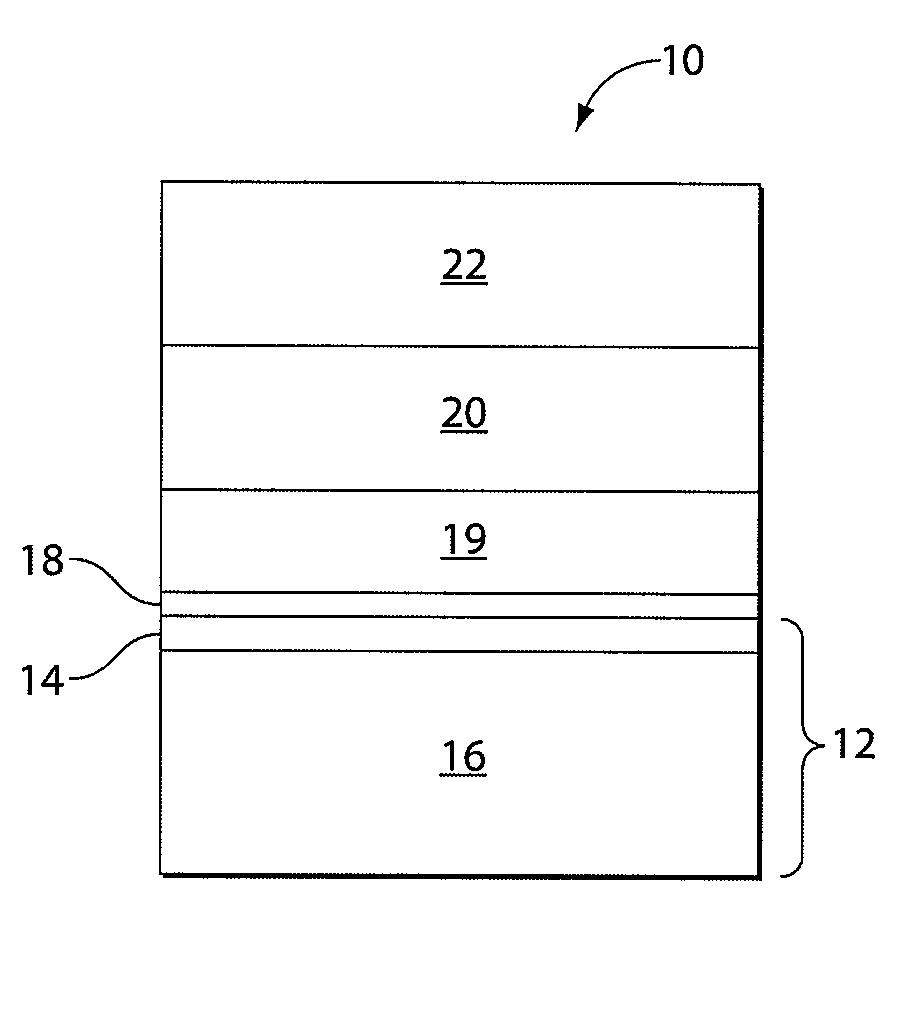

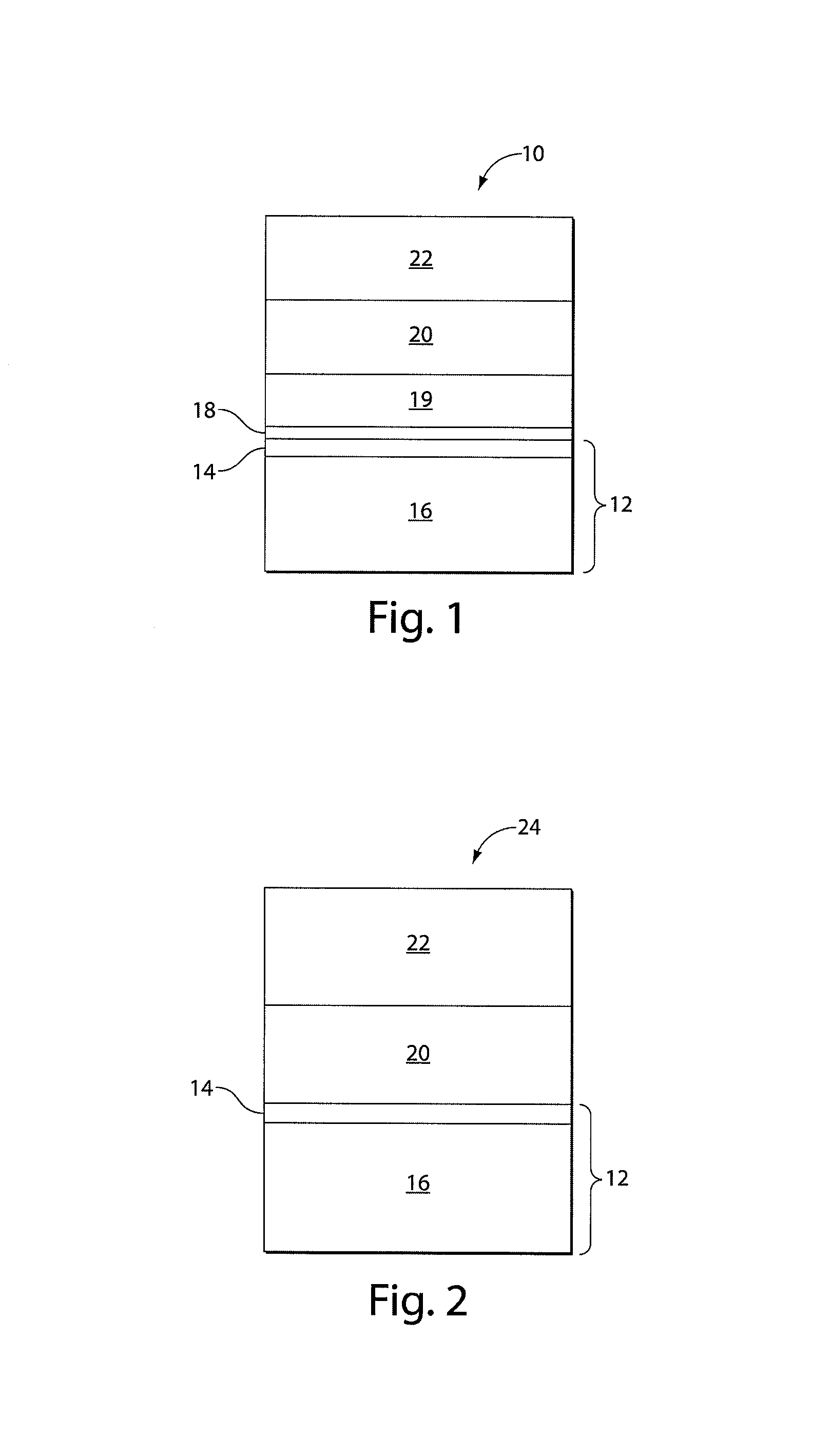

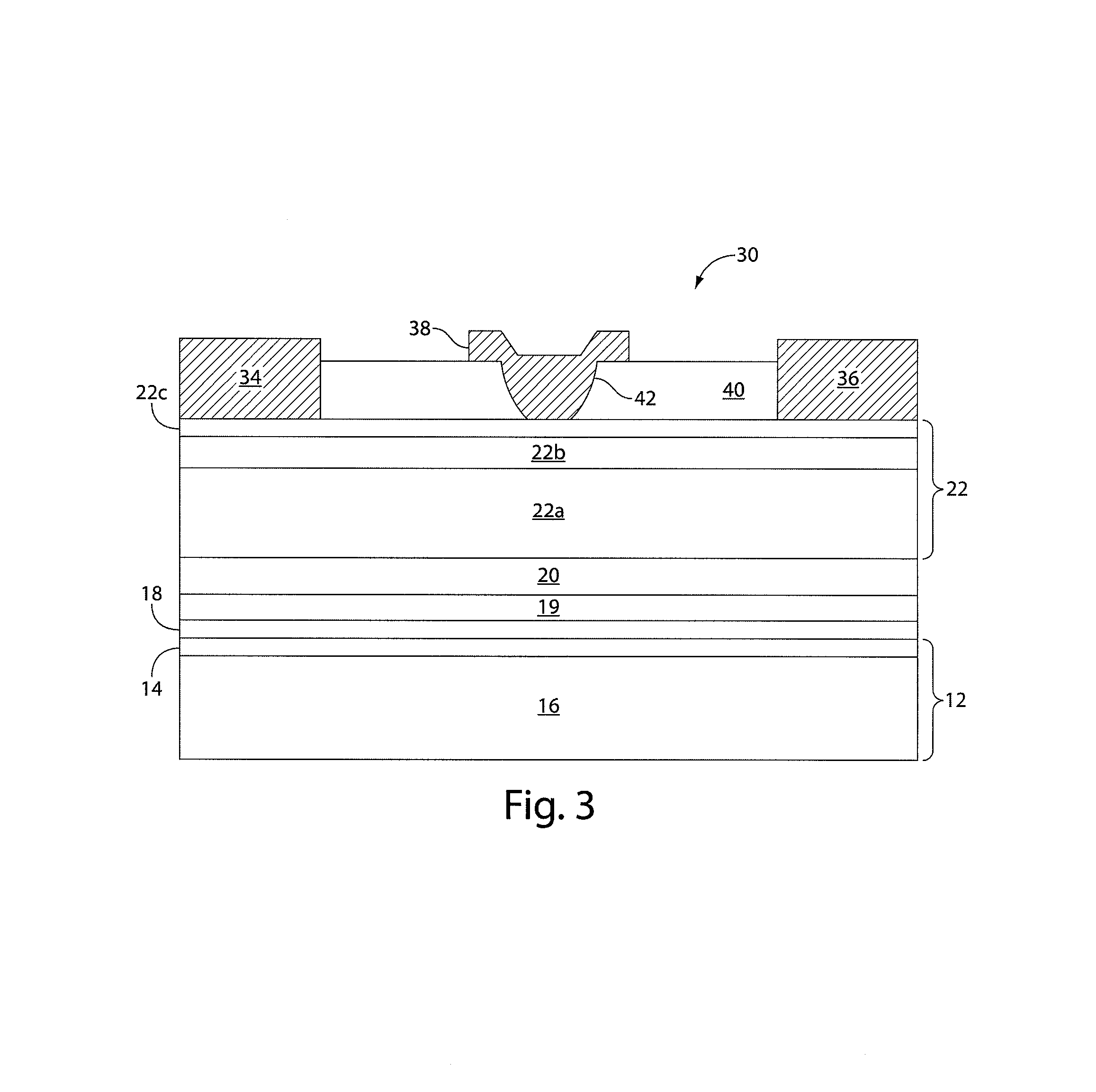

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

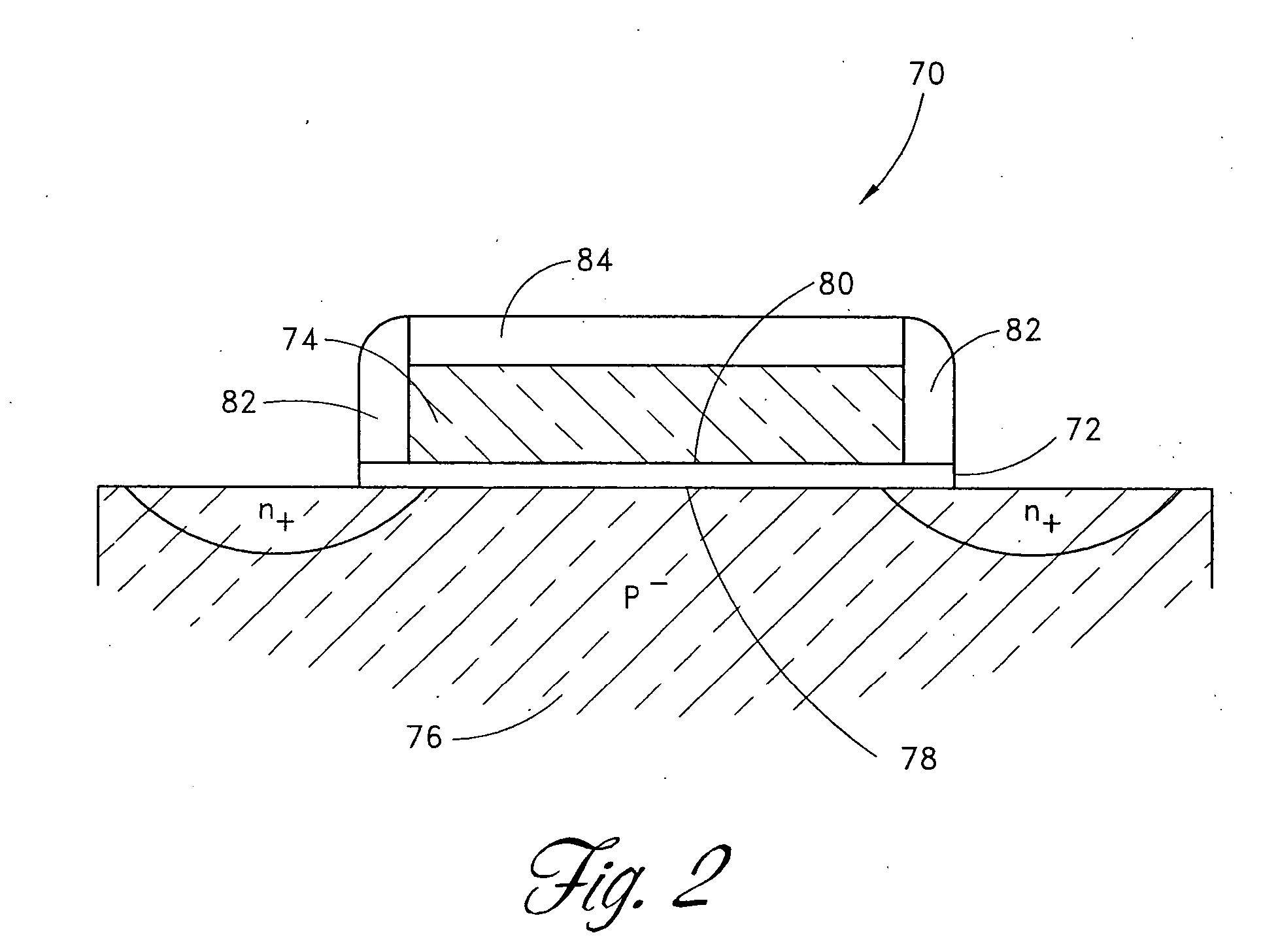

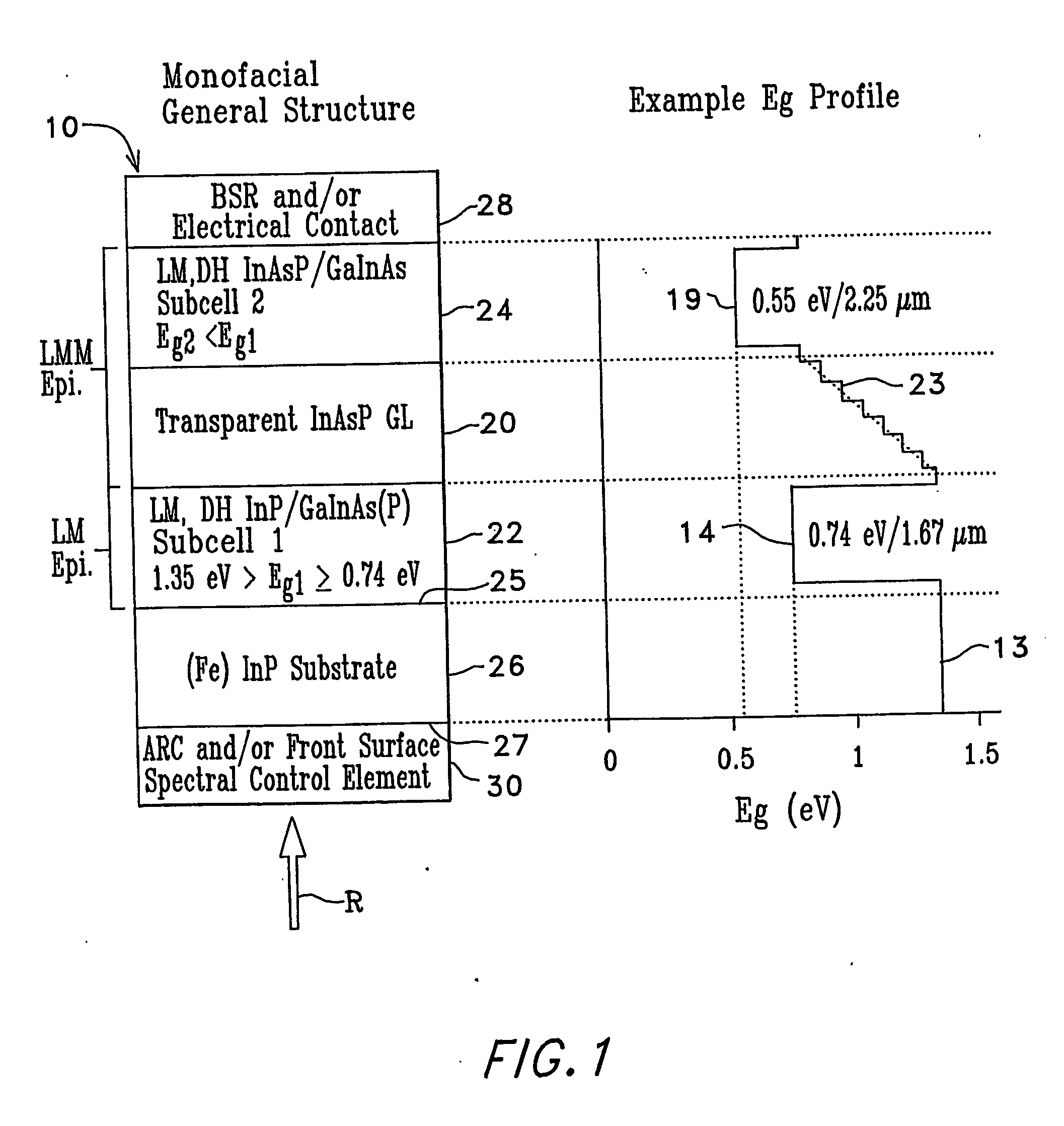

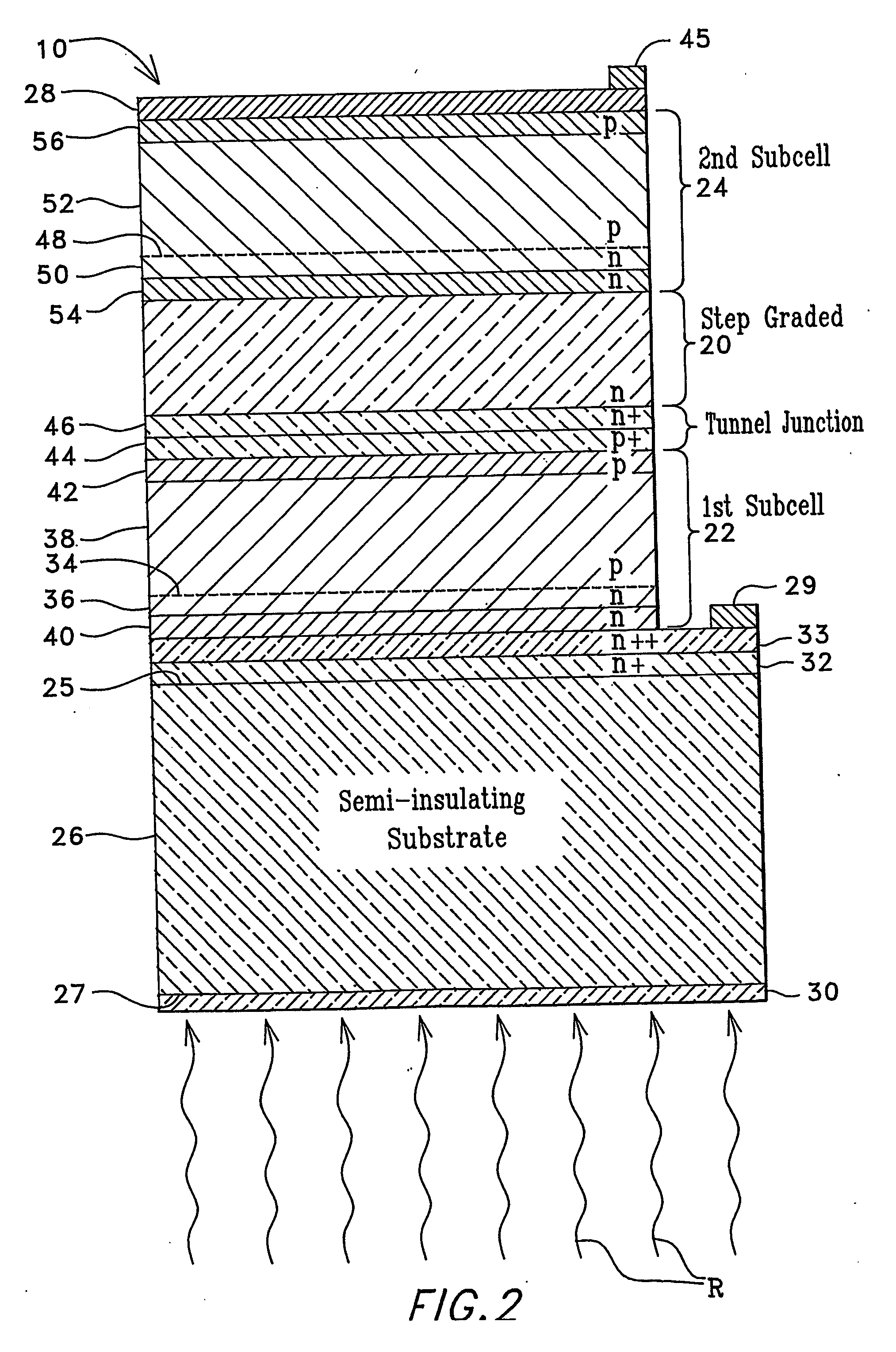

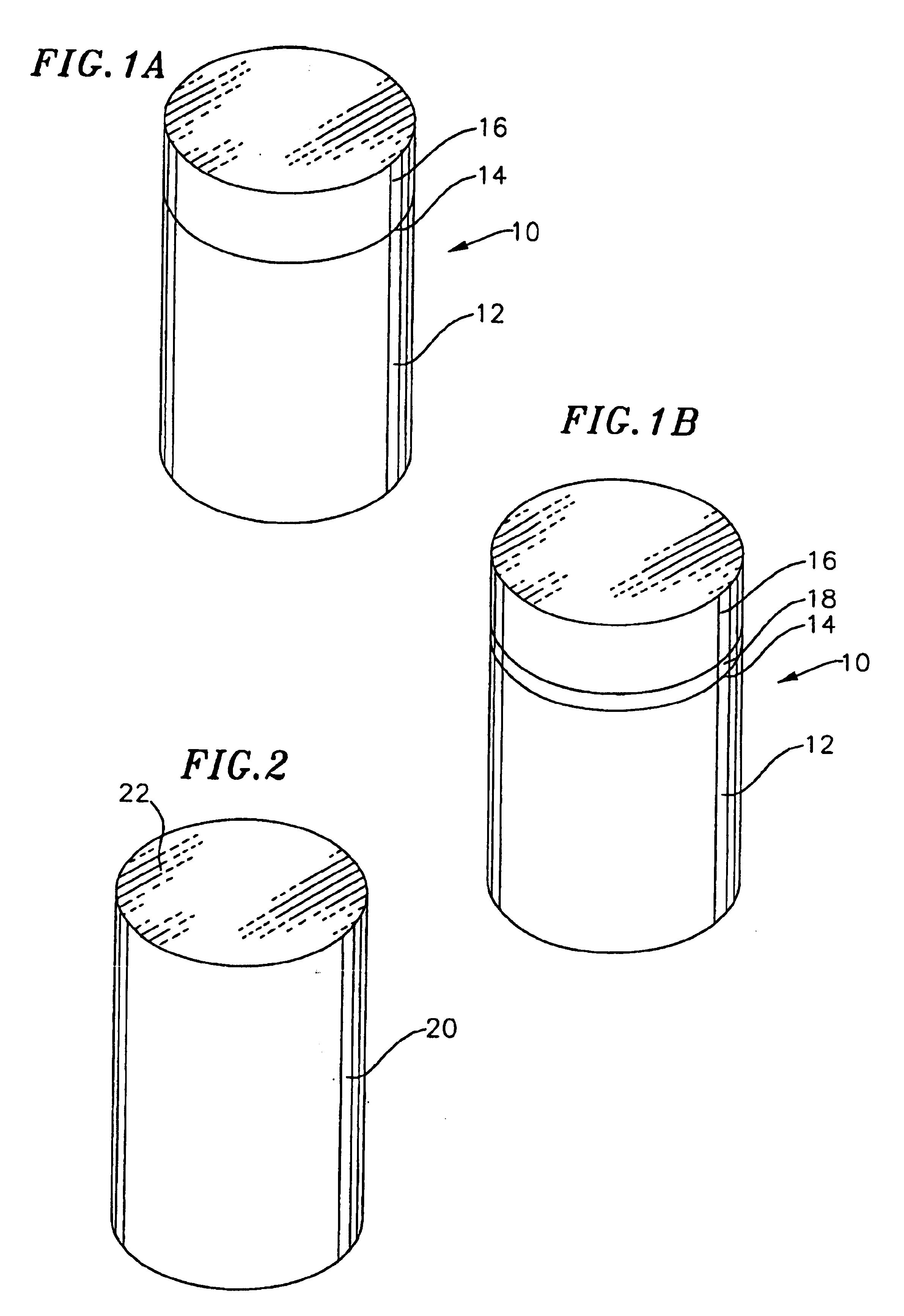

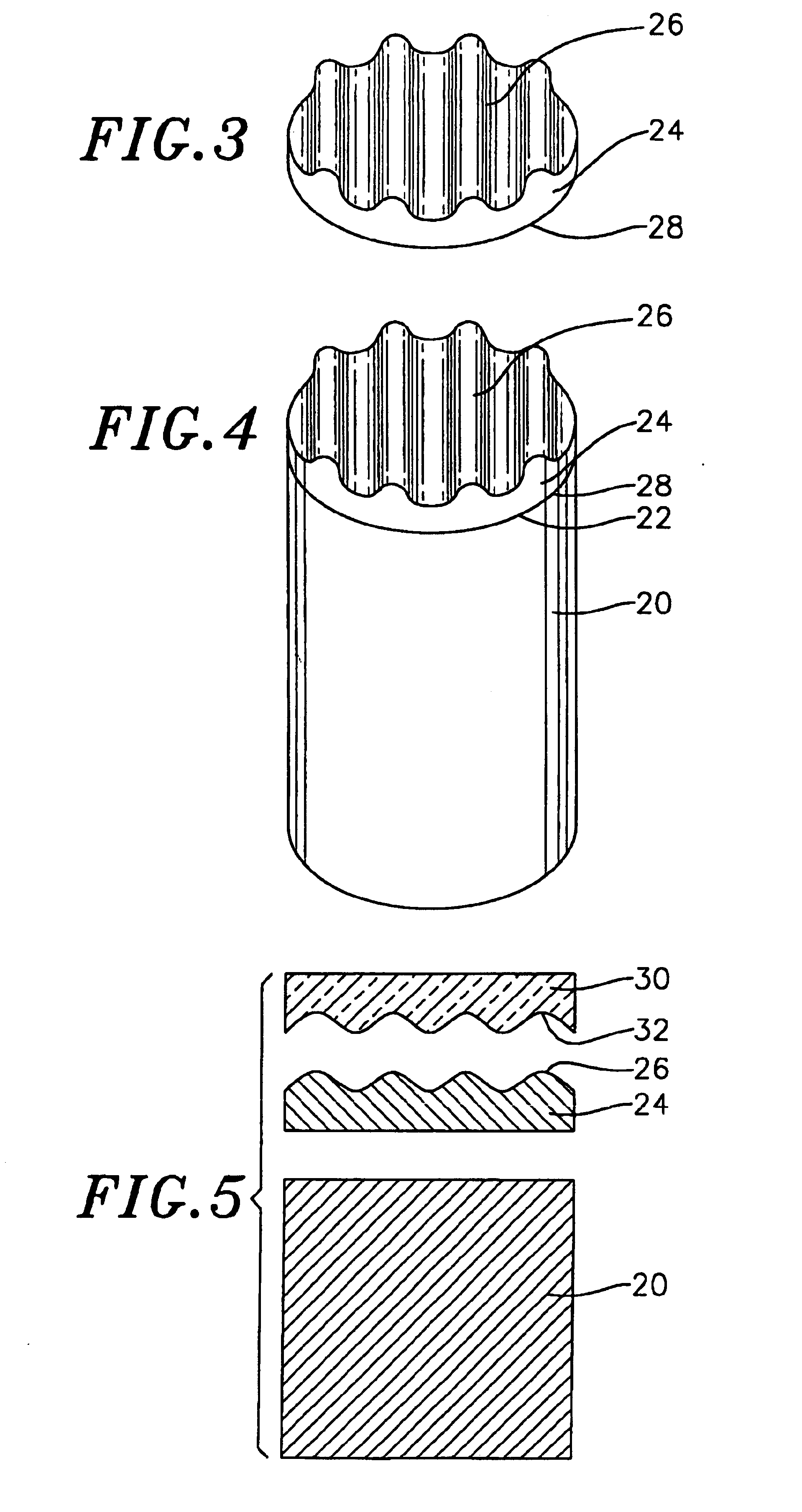

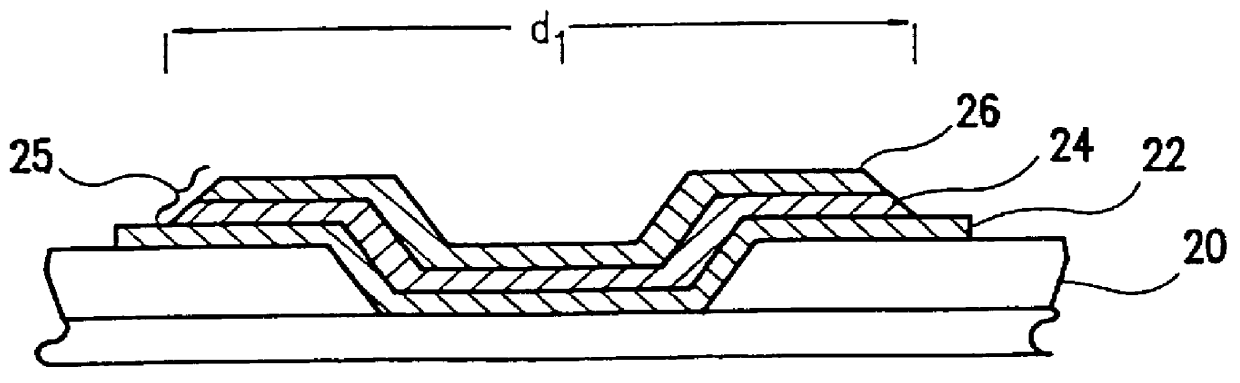

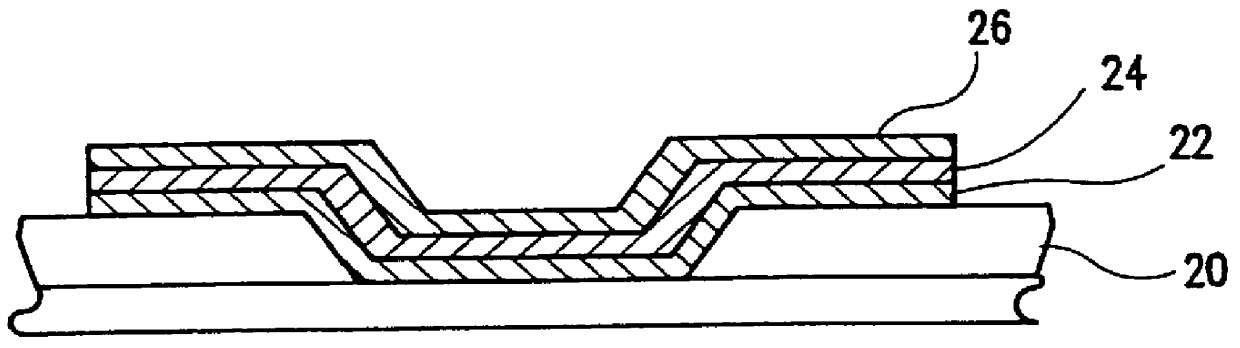

Low bandgap, monolithic, multi-bandgap, optoelectronic devices

InactiveUS20060162768A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotovoltaic detectorsPhotodetector

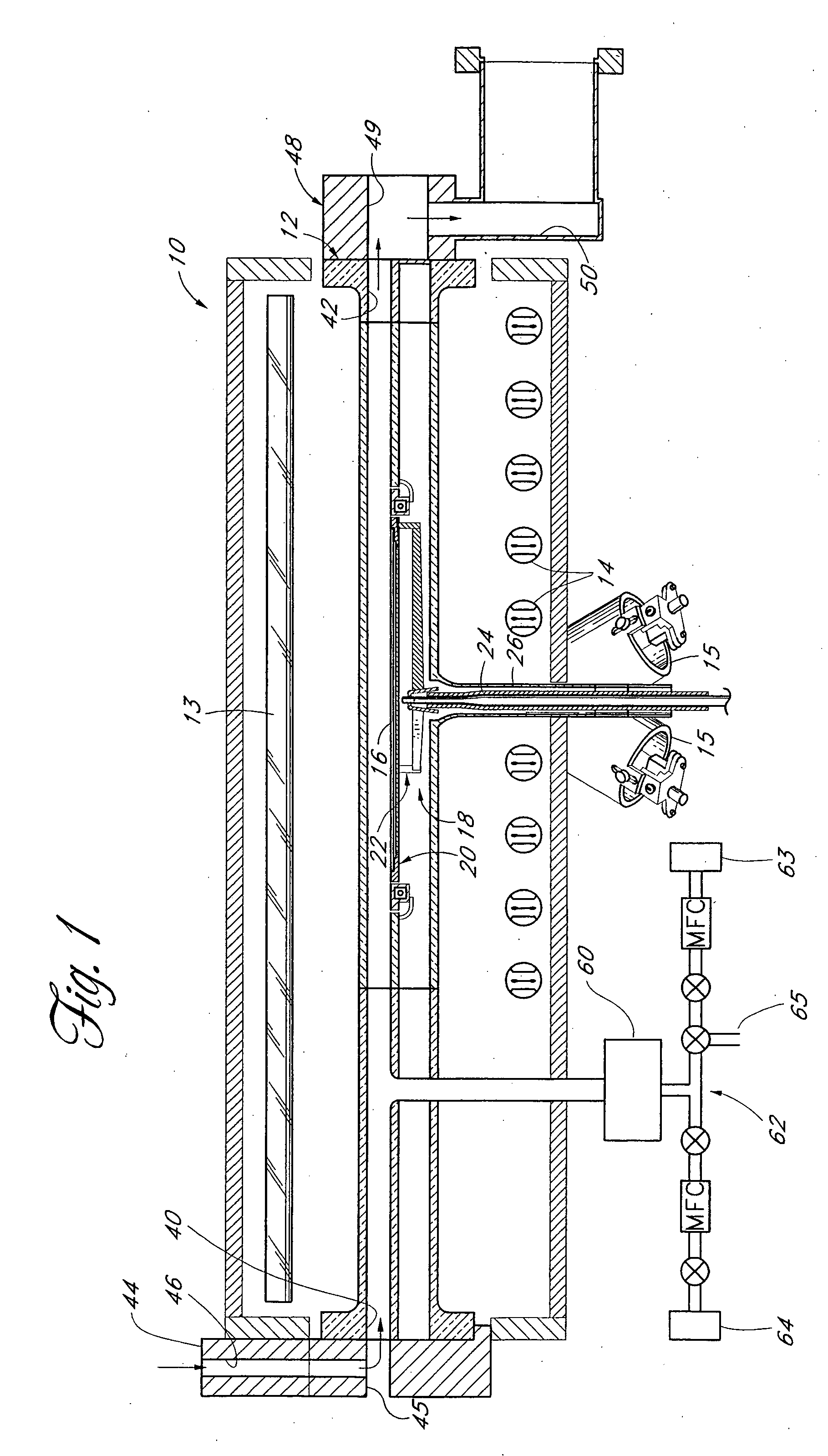

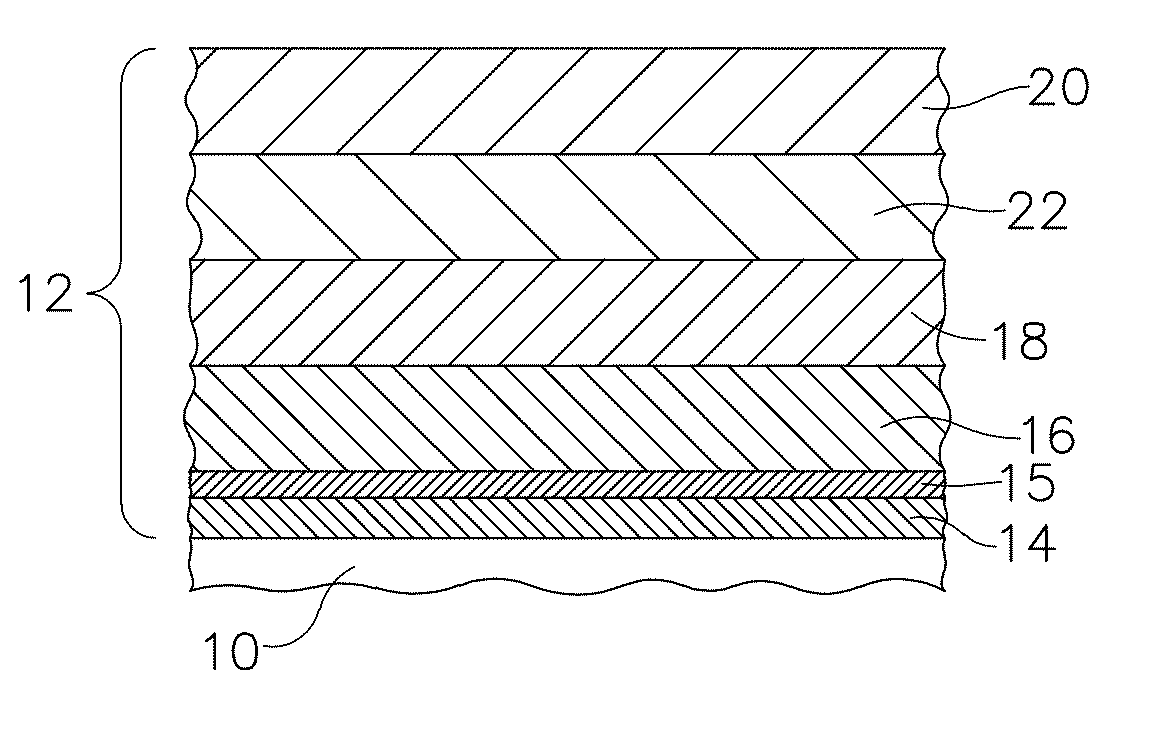

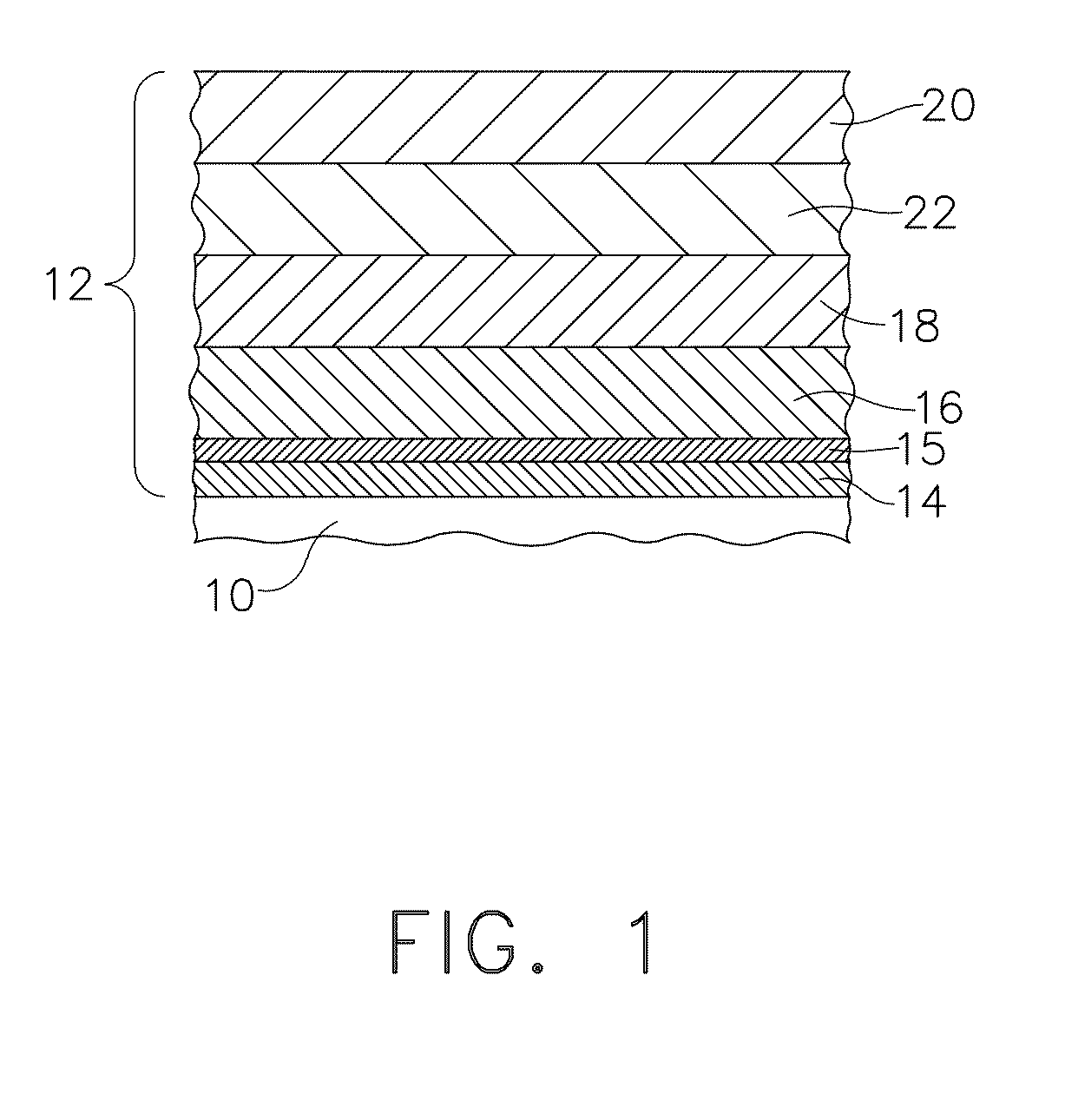

Low-bandgap, monolithic, multi-bandgap, optoelectronic devices (10), including PV converters, photodetectors, and LED's, have lattice-matched (LM), double-heterostructure (DH), low-bandgap GaInAs(P) subcells (22, 24) including those that are lattice-mismatched (LMM) to InP, grown on an InP substrate (26) by use of at least one graded lattice constant transition layer (20) of InAsP positioned somewhere between the InP substrate (26) and the LMM subcell(s) (22, 24). These devices are monofacial (10) or bifacial (80) and include monolithic, integrated, modules (MIMs) (190) with a plurality of voltage-matched subcell circuits (262, 264, 266, 270, 272) as well as other variations and embodiments.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

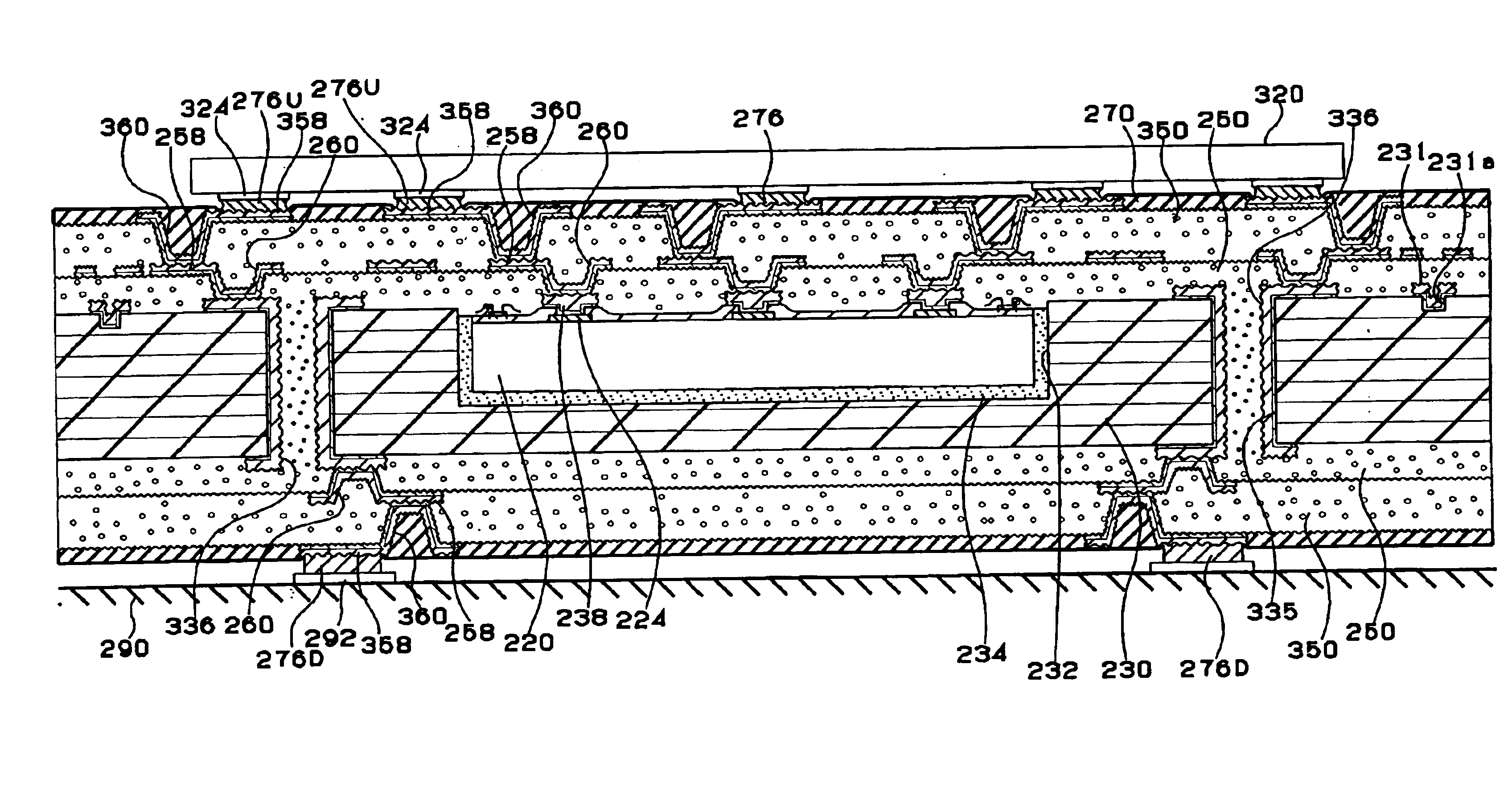

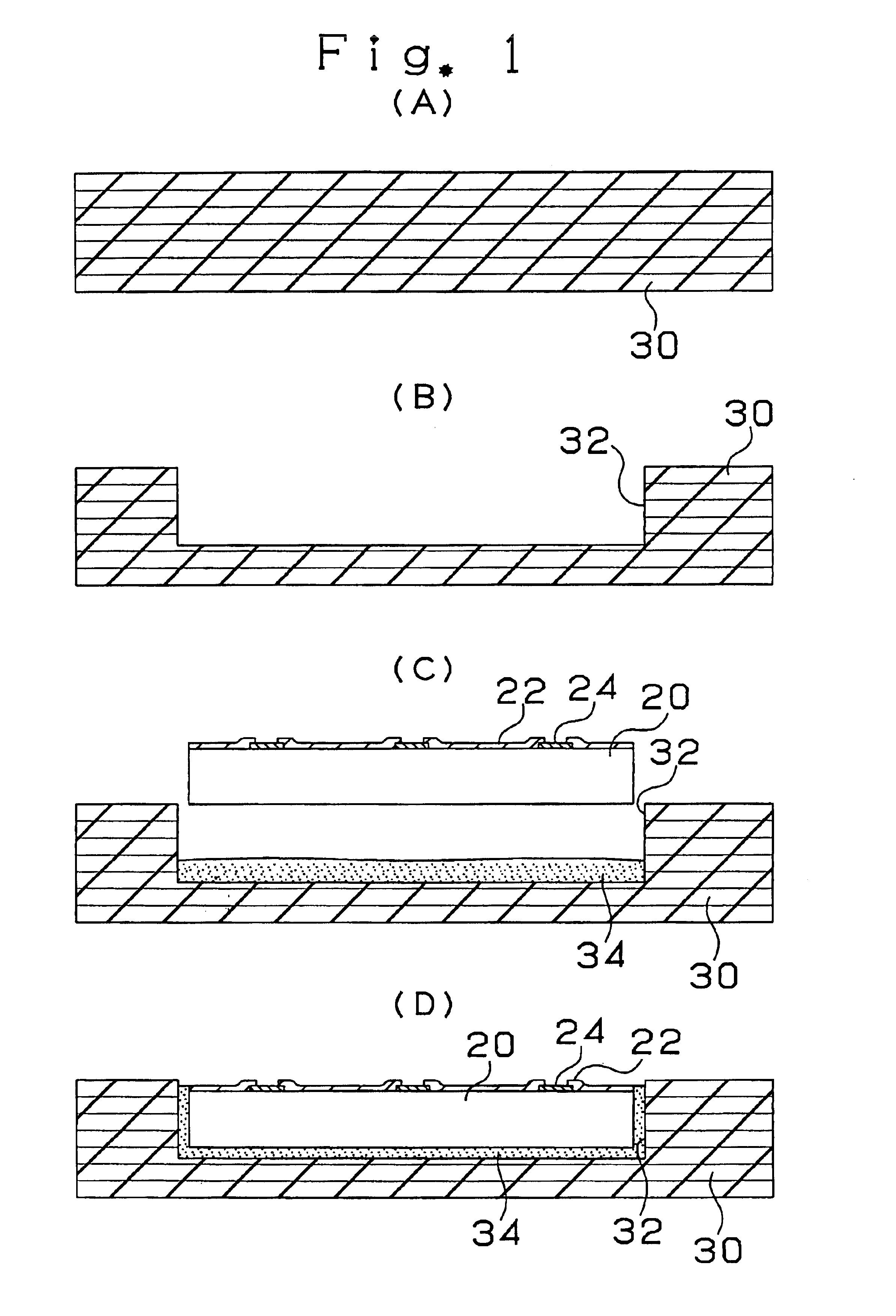

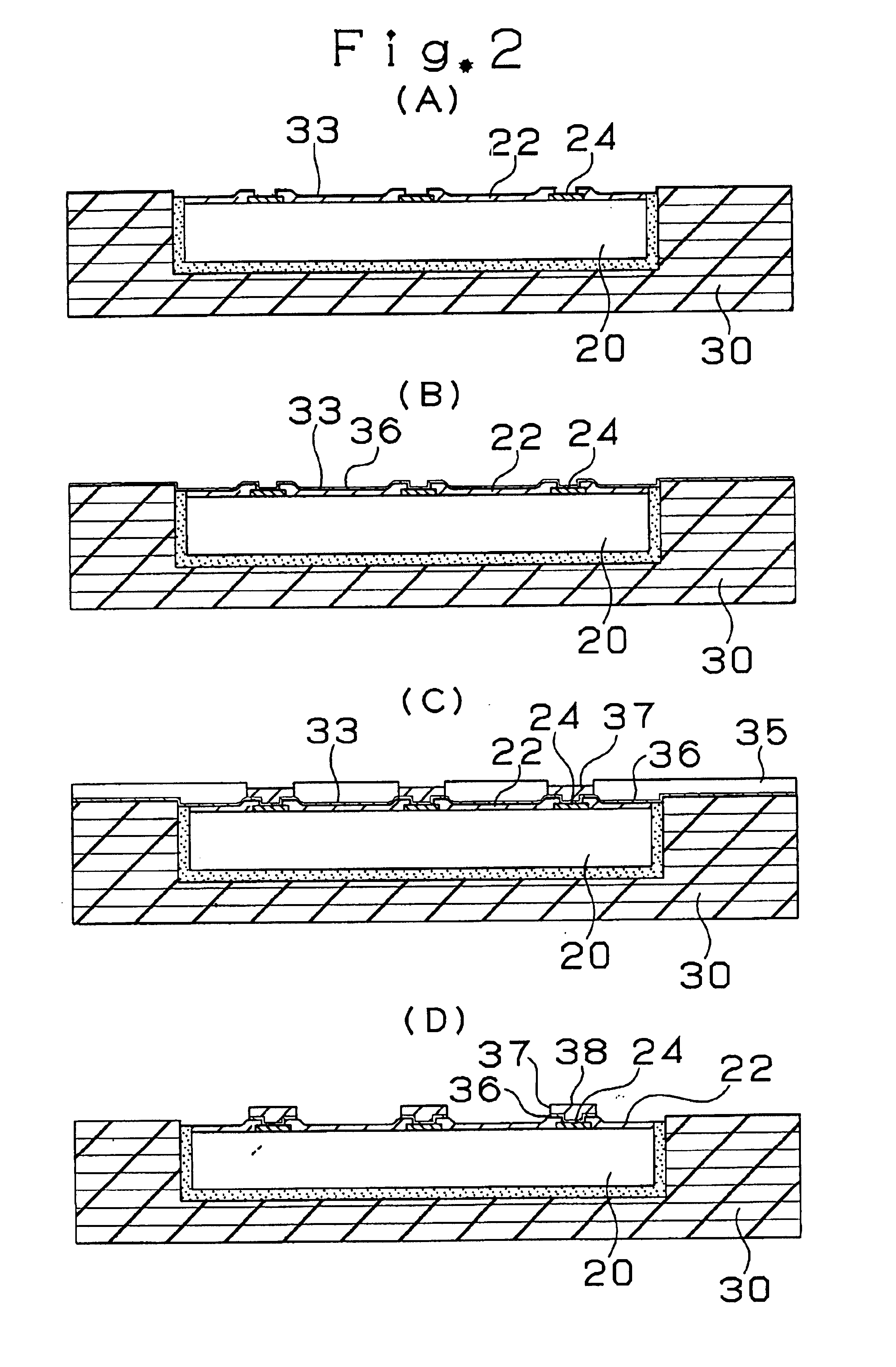

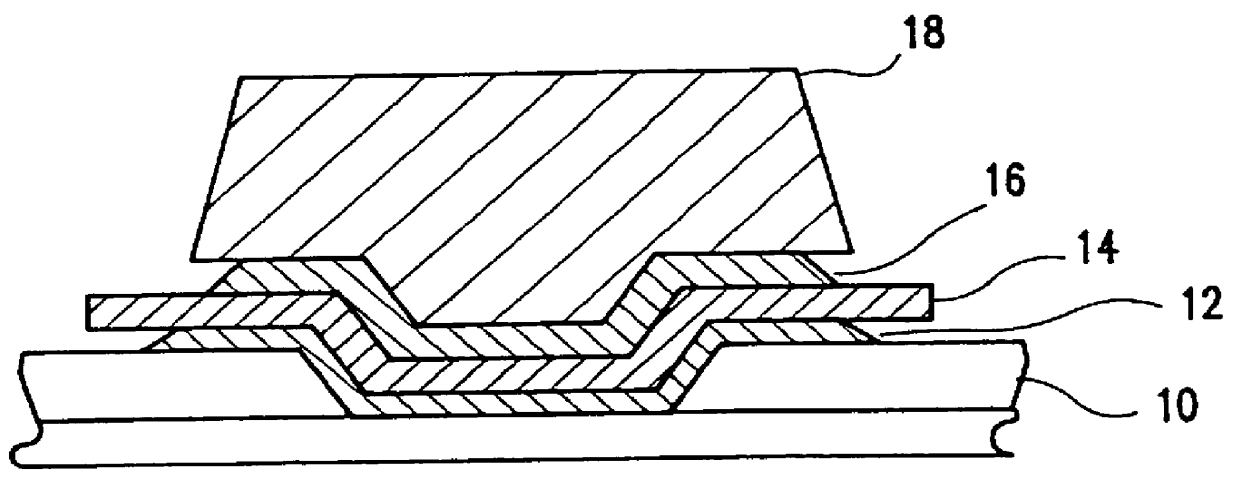

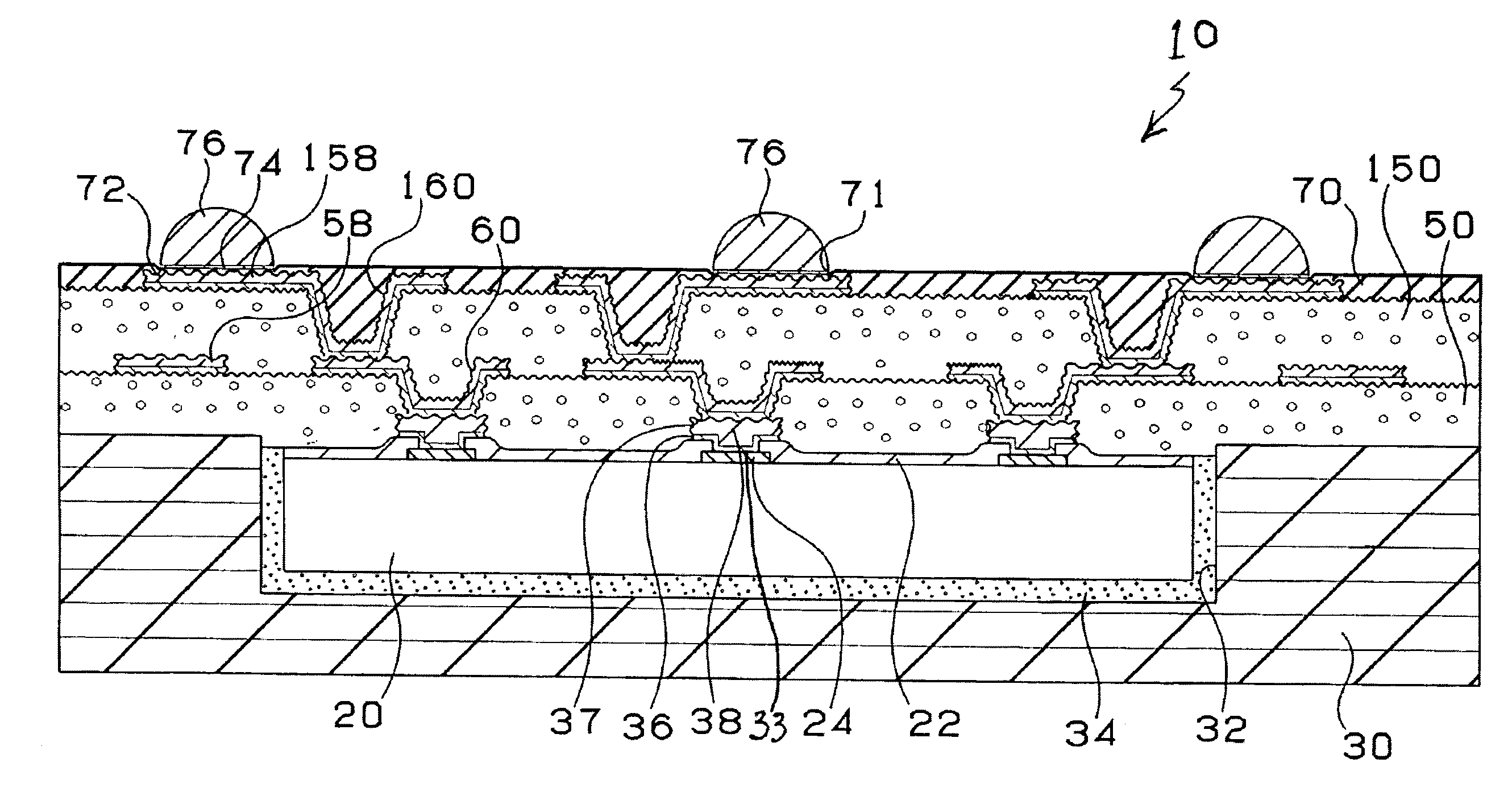

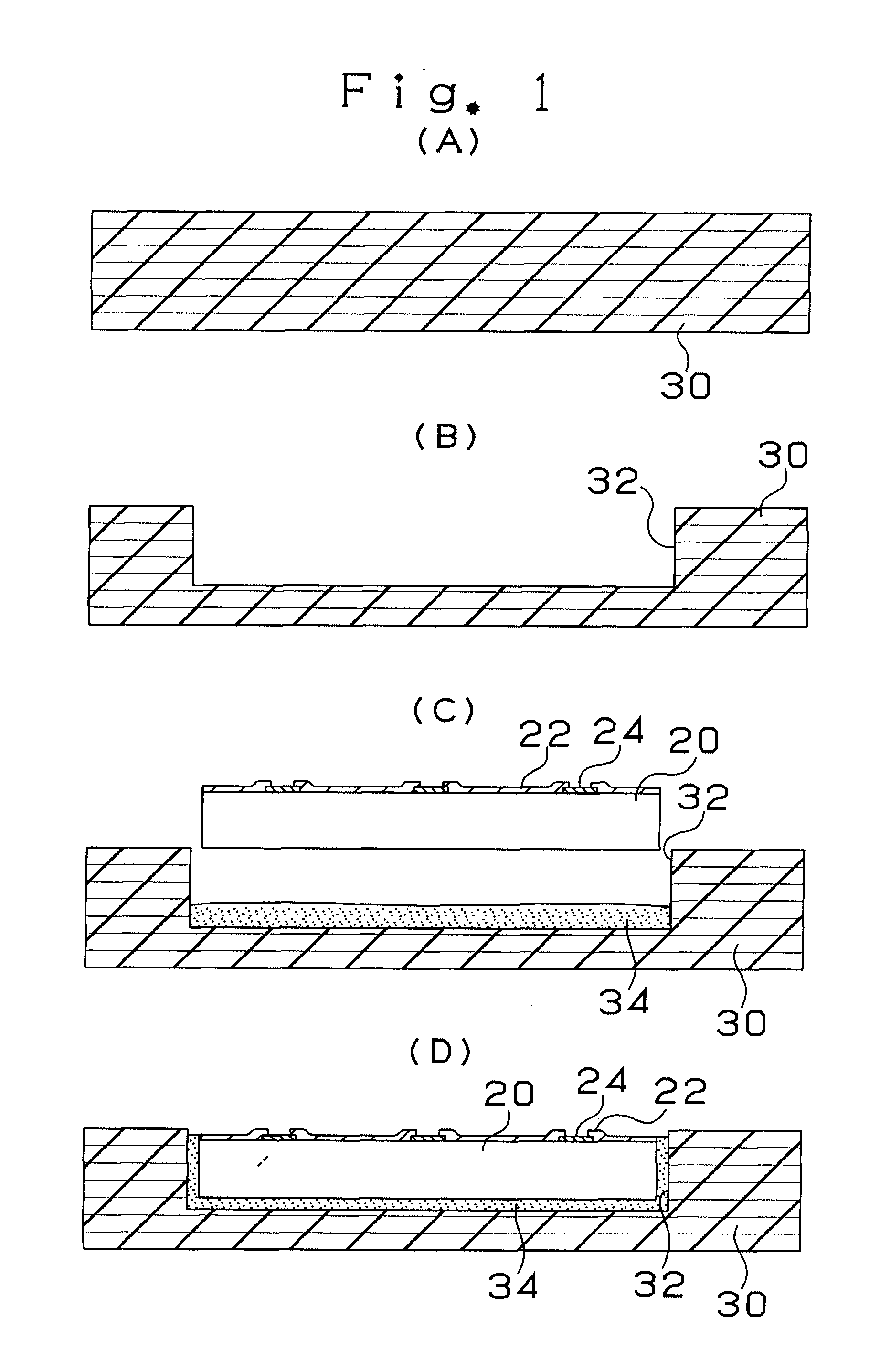

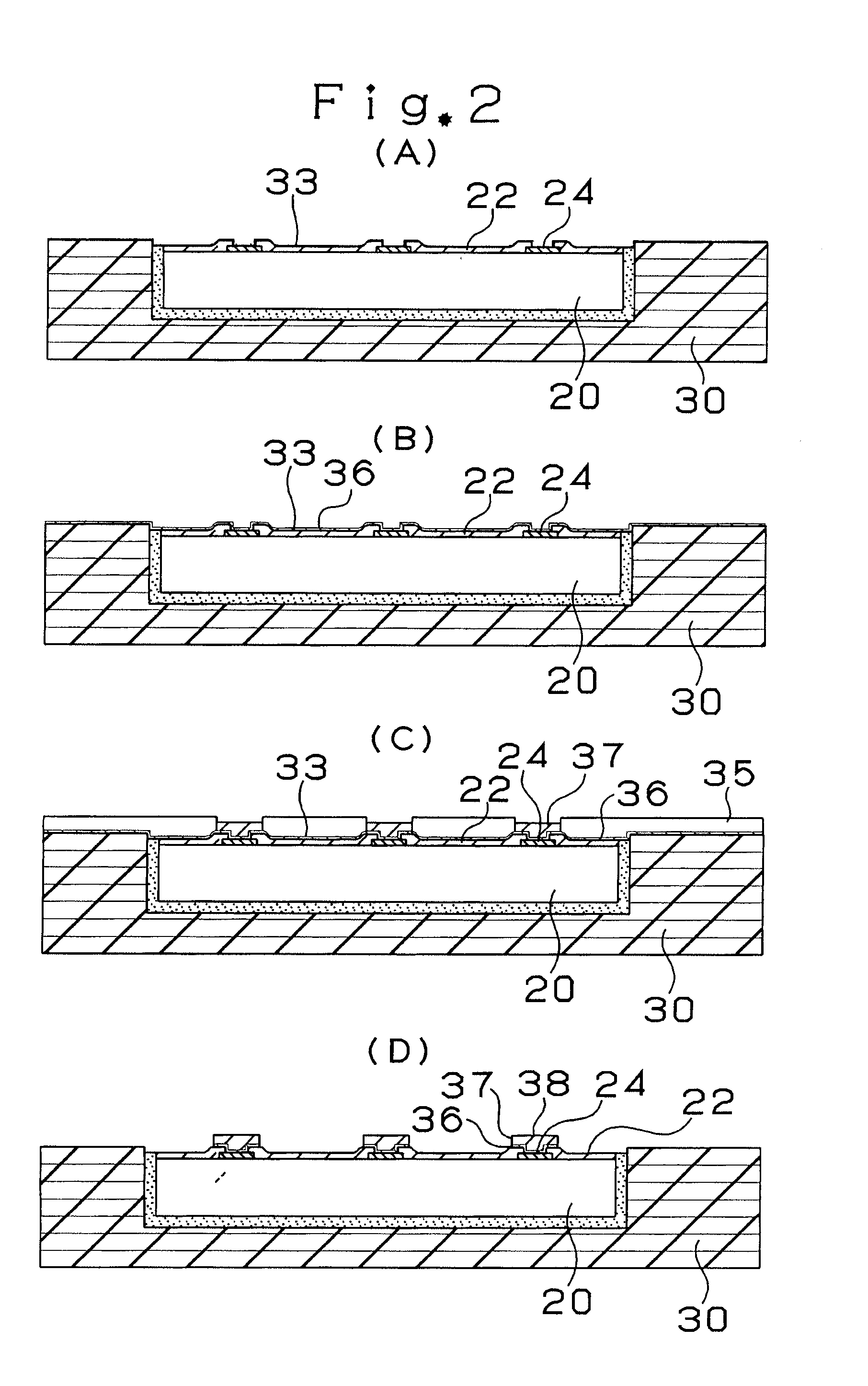

Multilayer printed wiring board and method for producing multilayer printed wiring board

InactiveUS6909054B2Low yieldWithout usingSemiconductor/solid-state device detailsPrinted electric component incorporationCopperPrinted circuit board

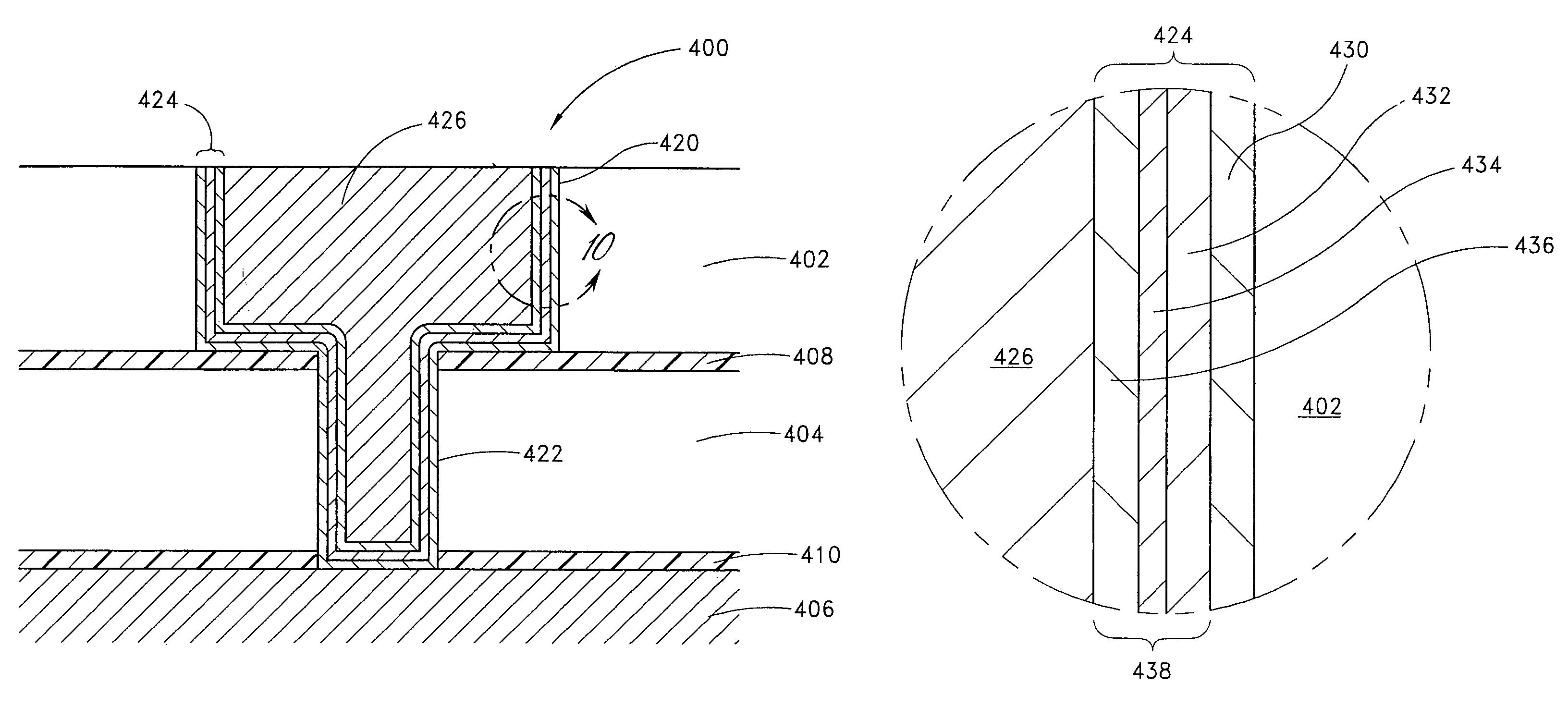

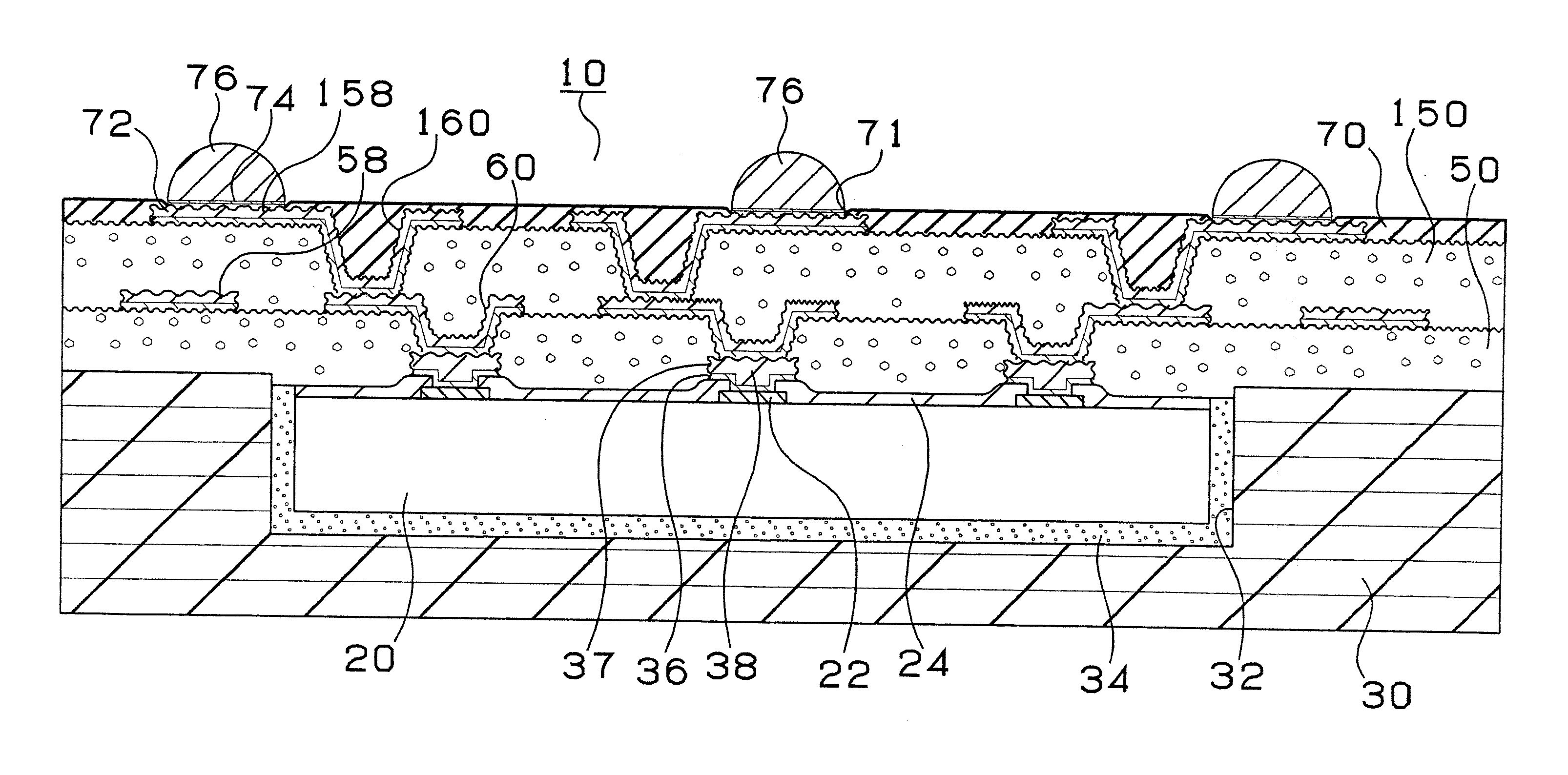

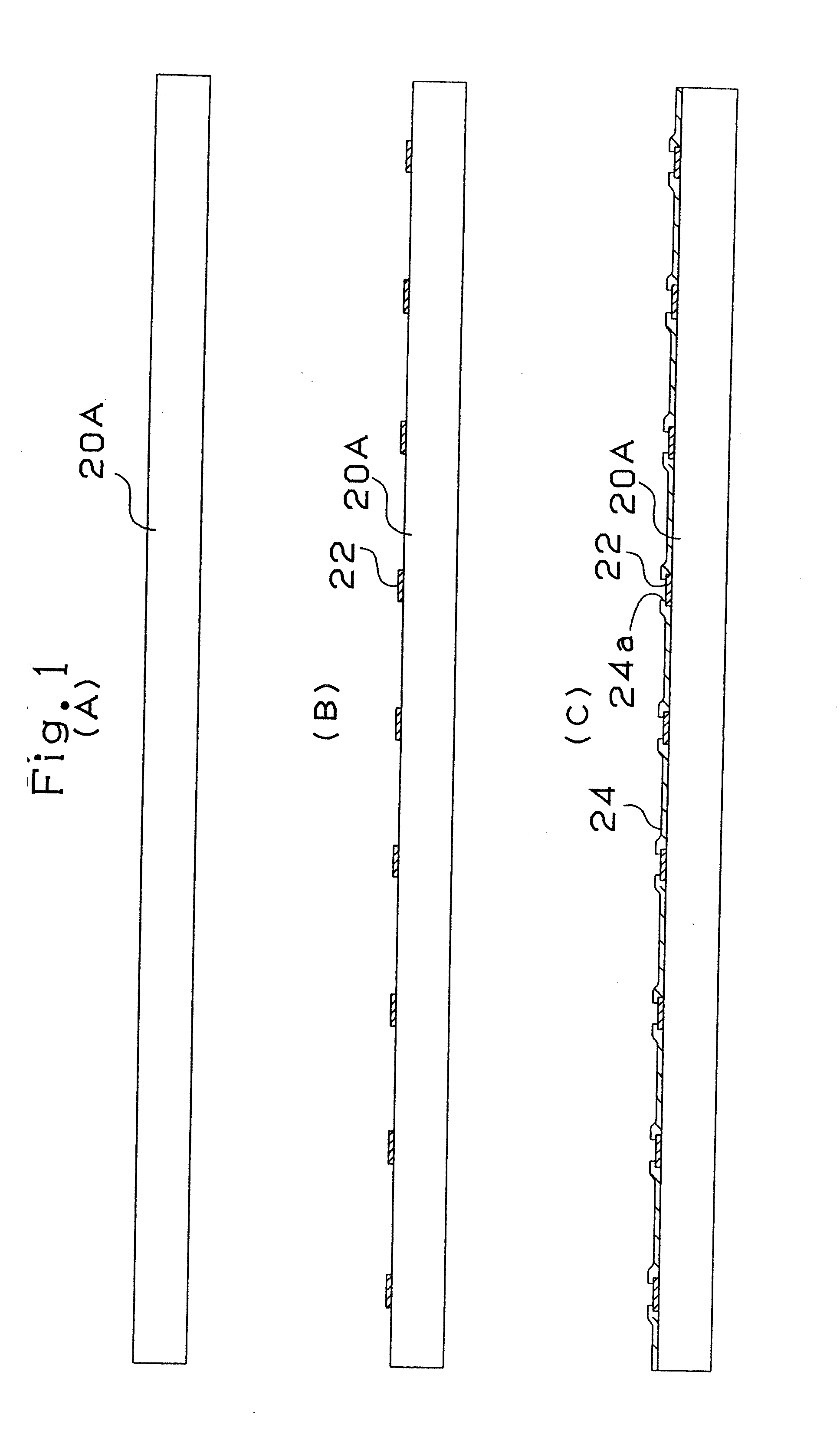

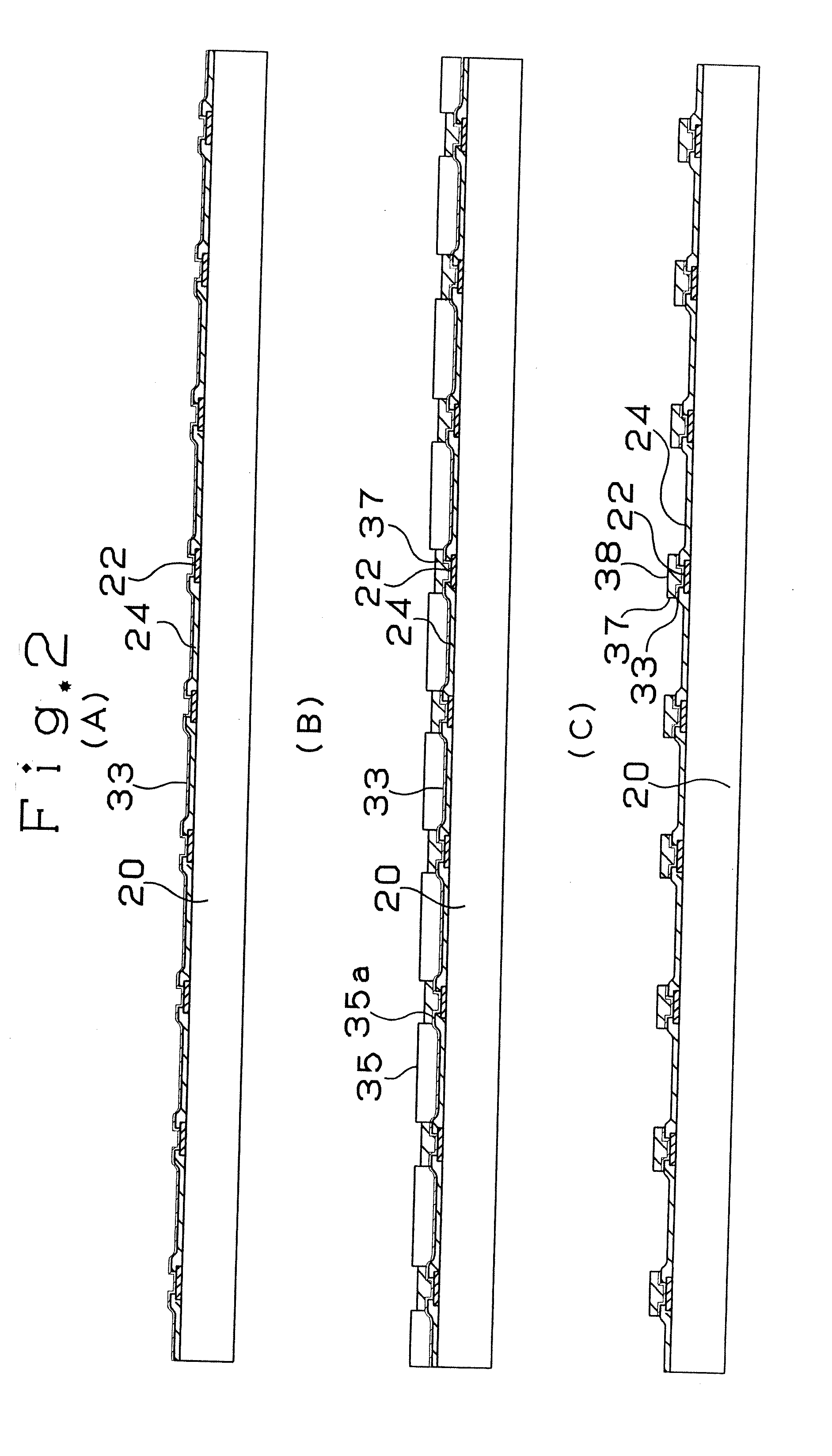

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electrically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

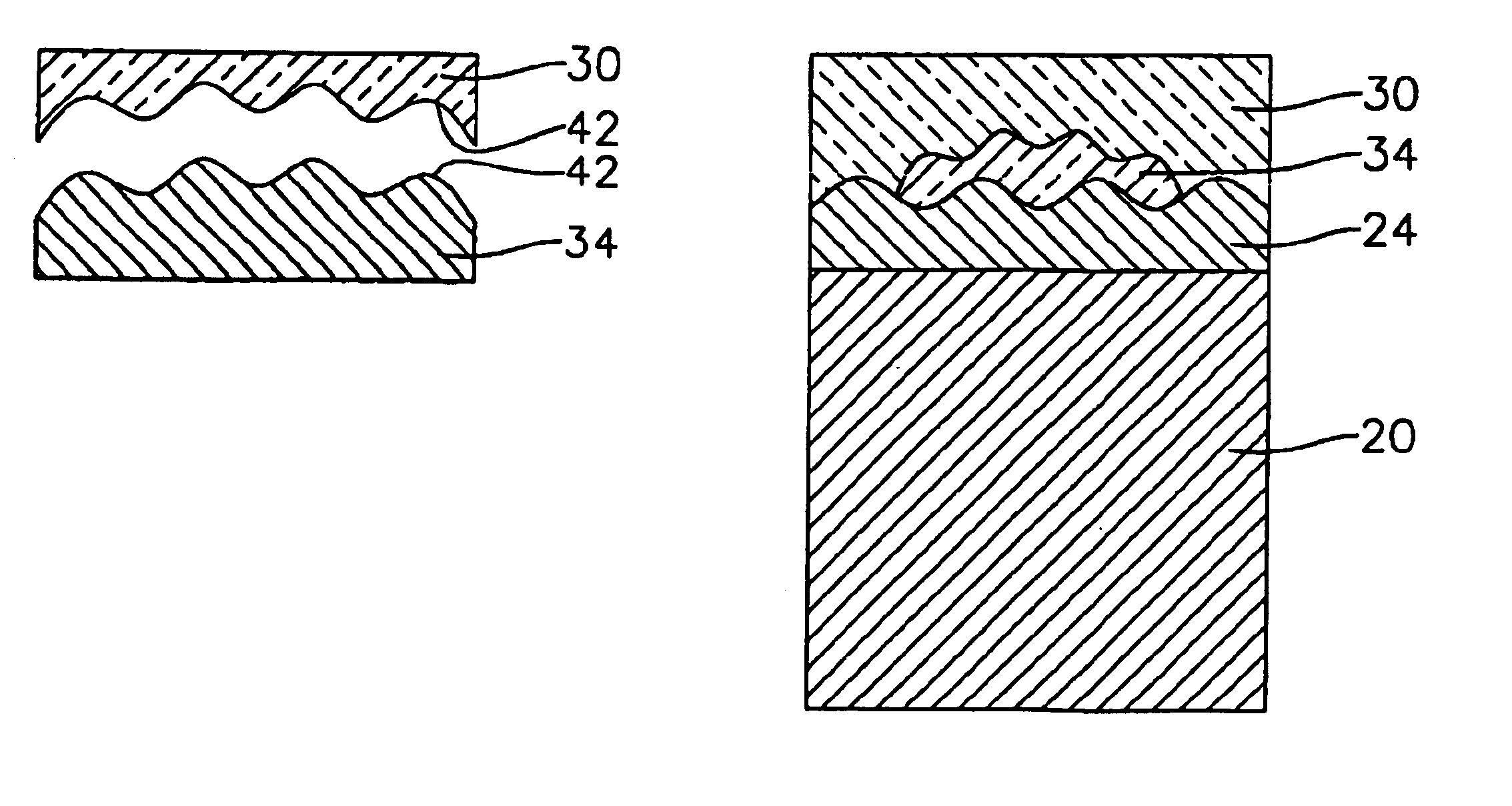

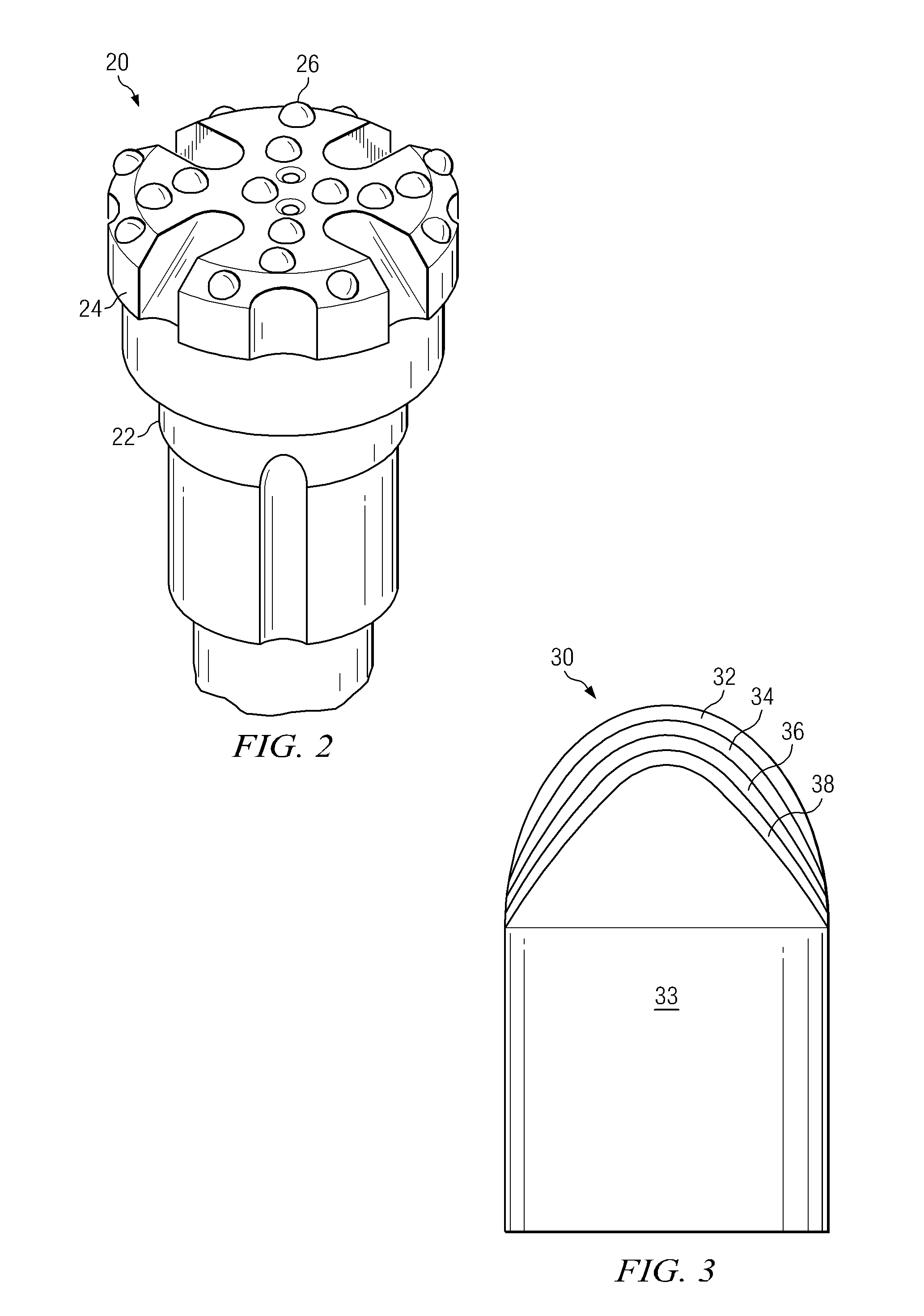

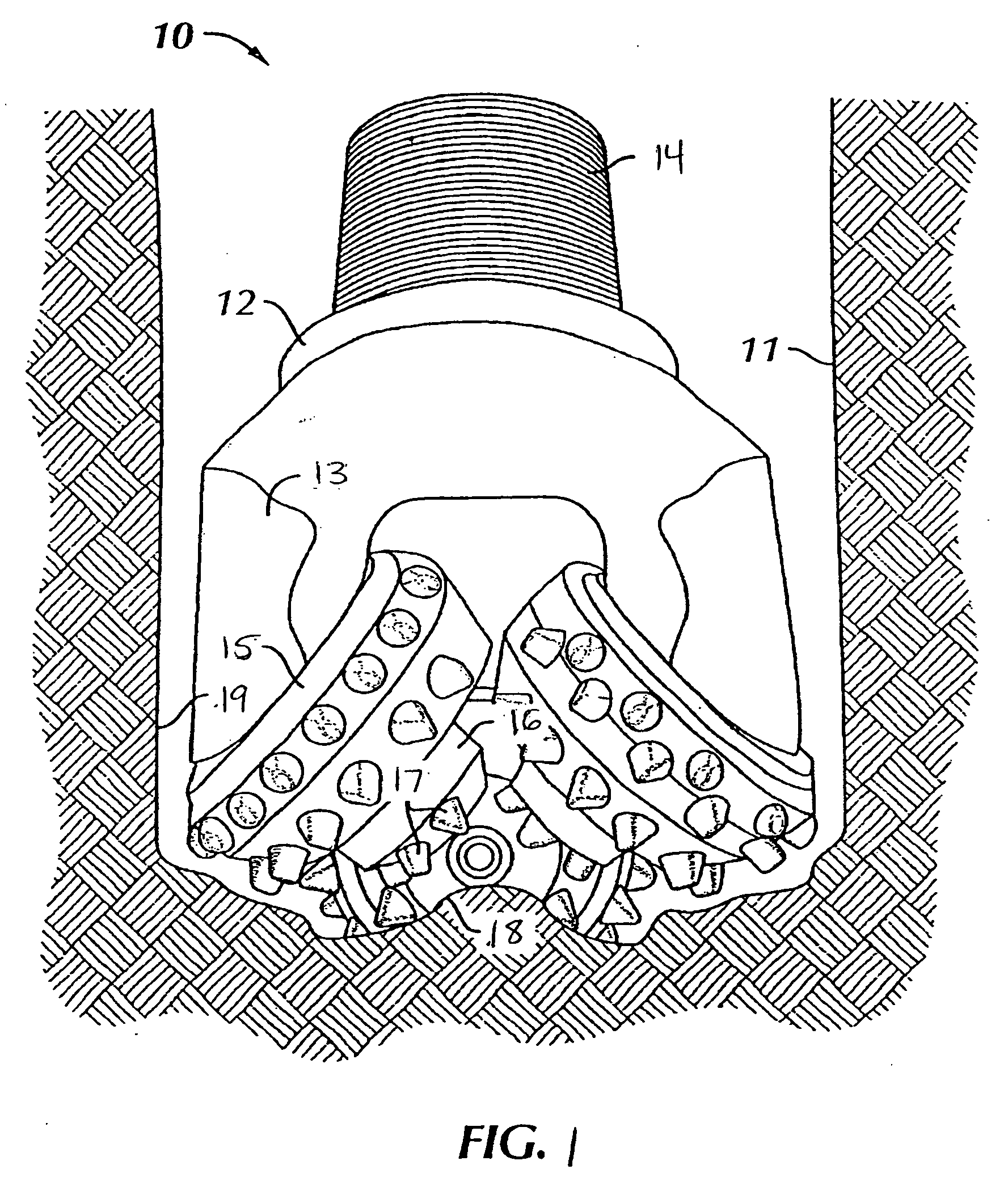

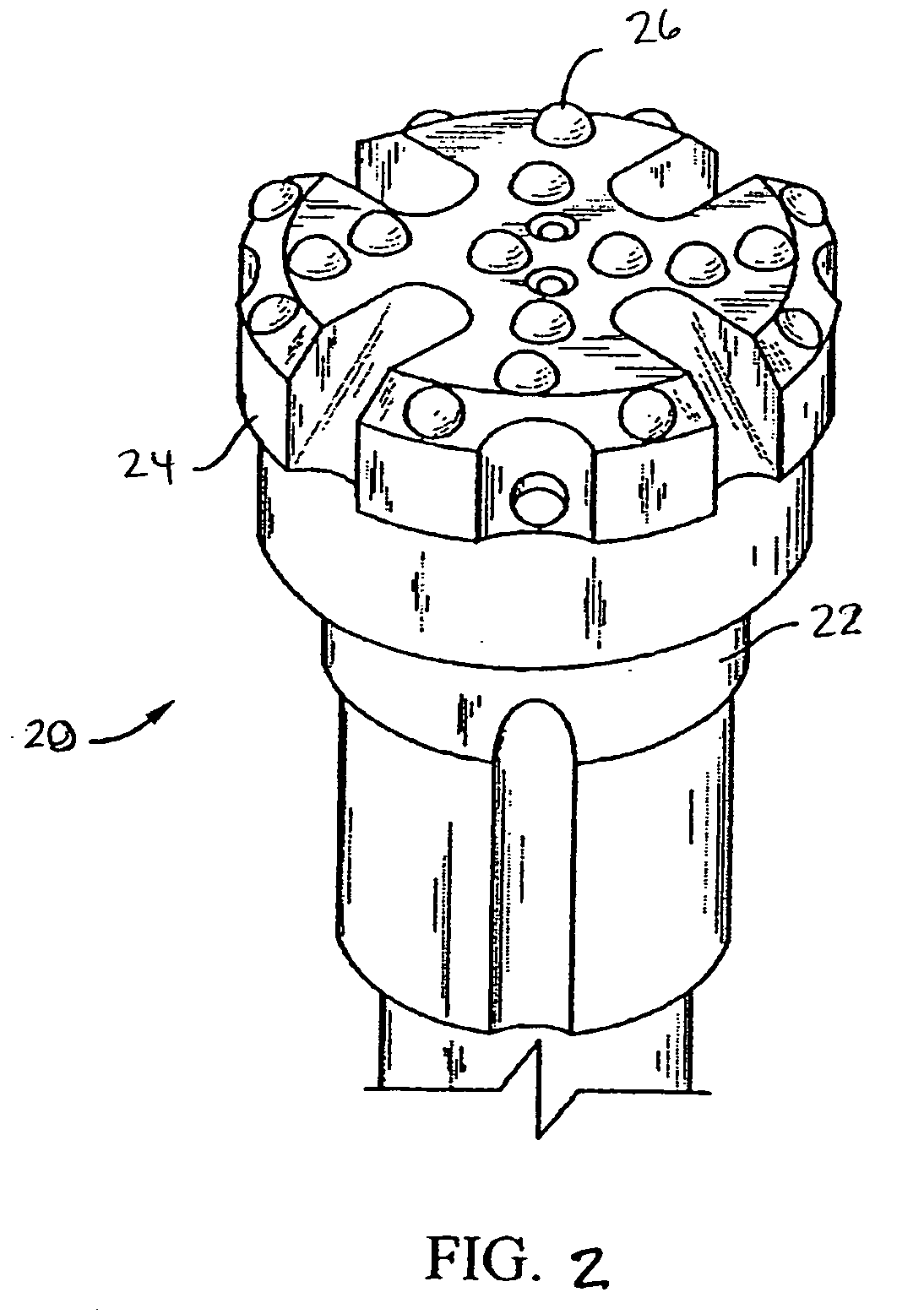

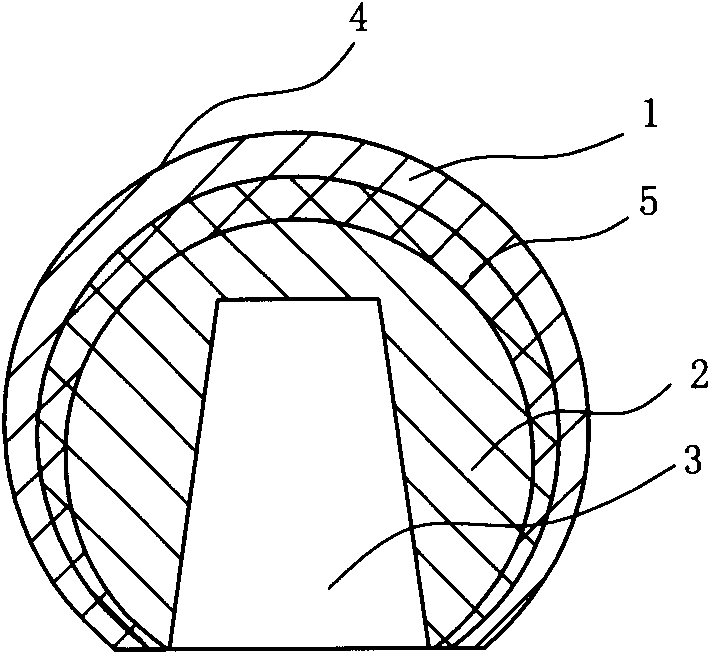

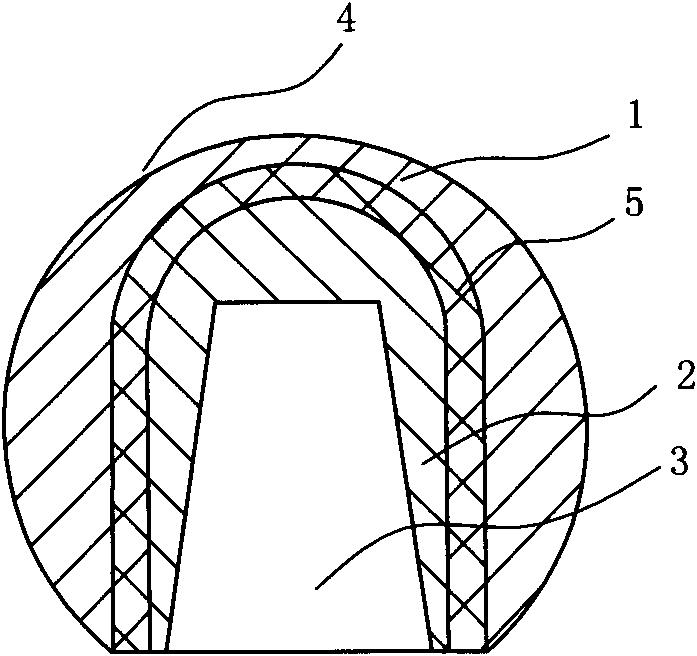

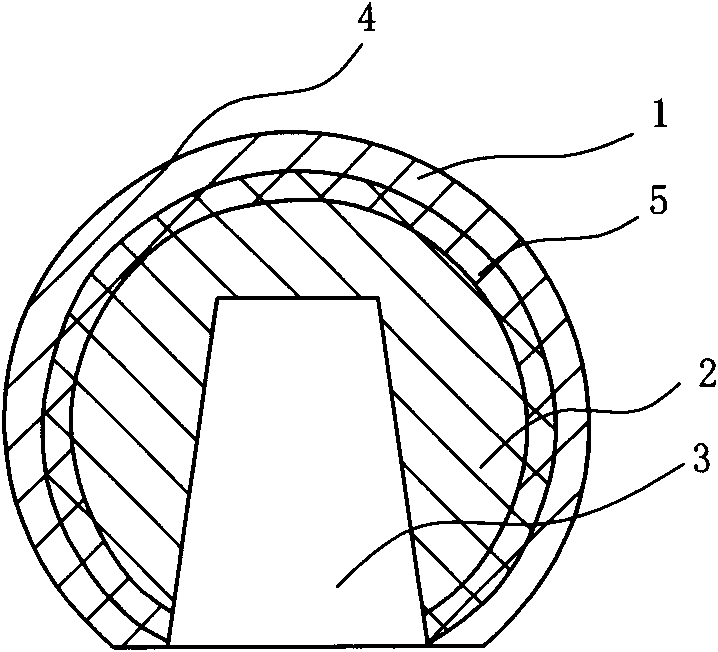

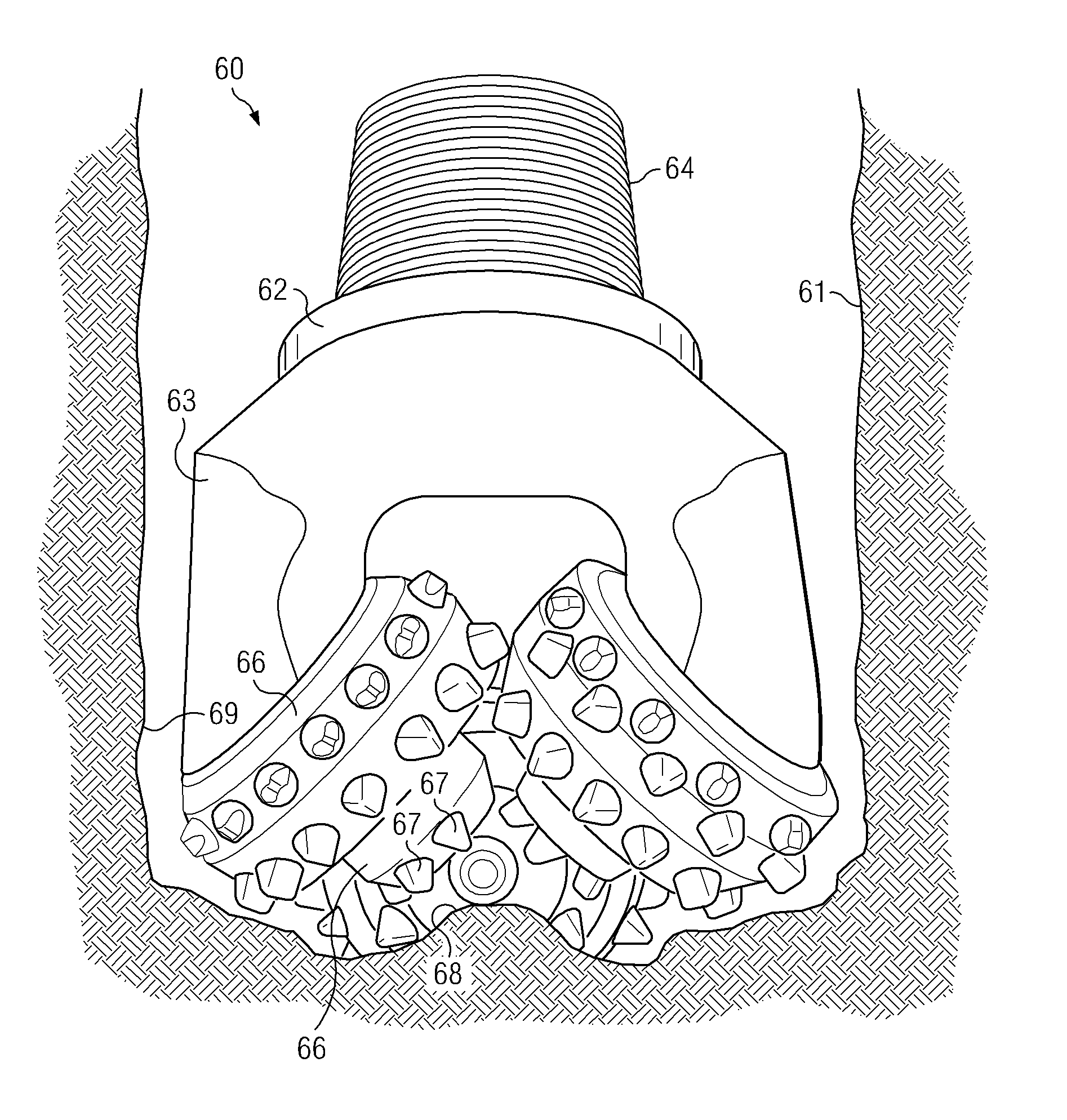

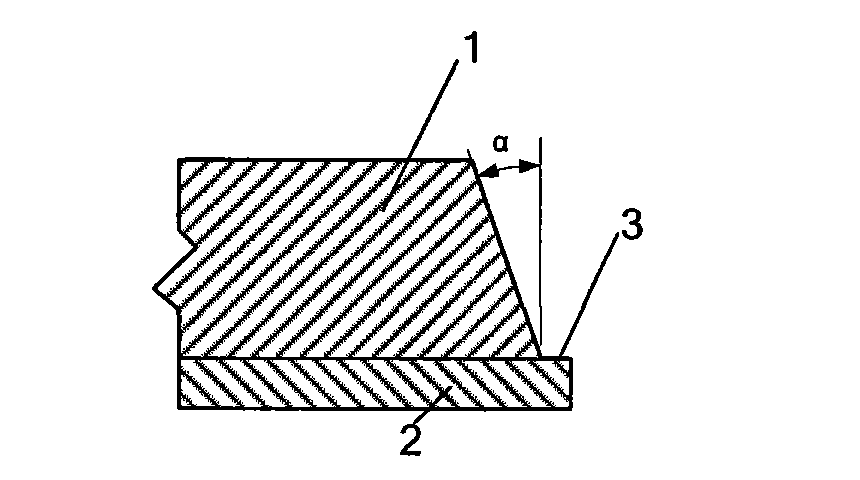

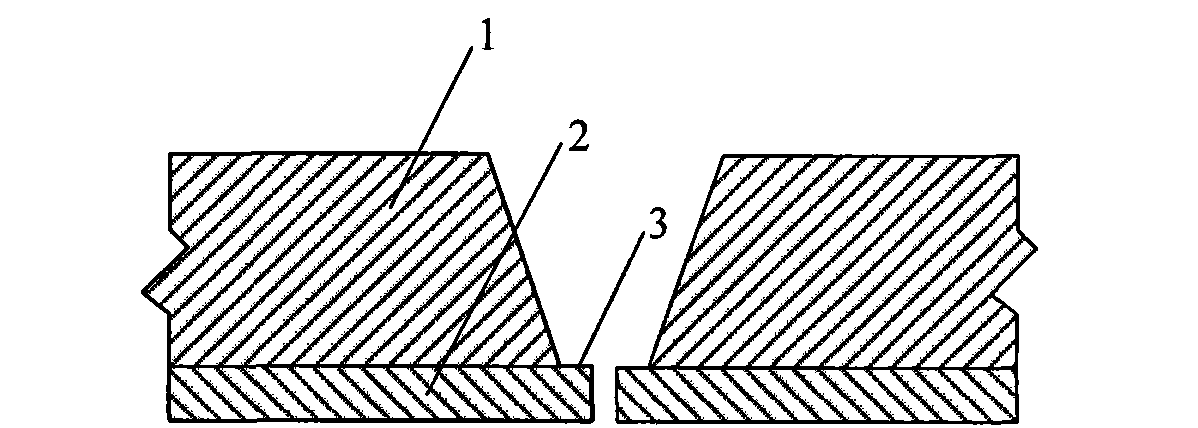

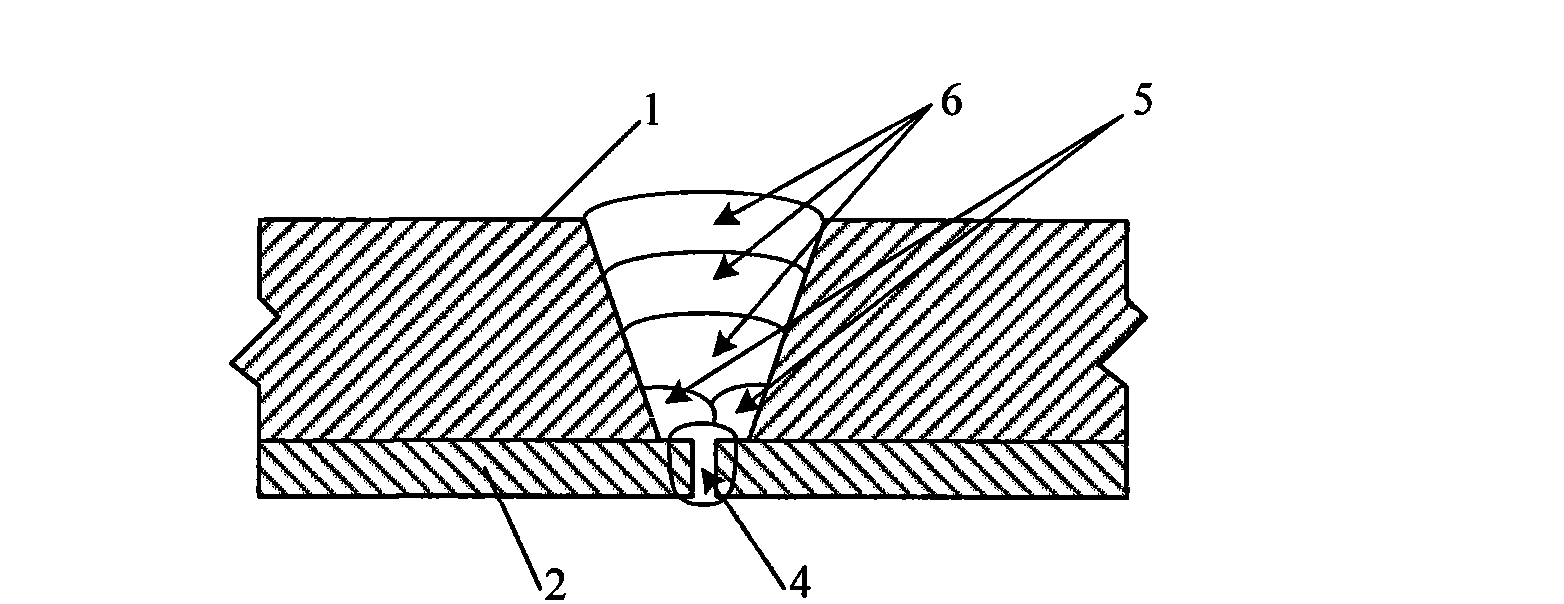

Cutting element having a substrate, a transition layer and an ultra hard material layer

A non-uniform interface is formed between a polycrystalline ultra hard material layer and a cemented tungsten carbide substrate, or a polycrystalline ultra hard material layer and a transition layer, or a transition layer and a substrate of a cutting element. A first sheet made from an intermediate material is formed and embossed on one face forming a non-uniform pattern raised in relief on the face. The embossed sheet is placed on a face of a presintered substrate. An ultra hard material sheet is formed and embossed, forming a non-uniform face complementary to the non-uniform face on the sheet of intermediate material. The ultra hard material sheet is placed over the intermediate material sheet so that the complementary faces are adjacent to each other. The assembly of substrate and sheets is sintered in a HPHT process. The sintering process causes the first sheet to become integral with the substrate and results in a substrate having a non-uniform cutting face onto which is bonded a polycrystalline ultra hard material layer. Embossed transition material sheets may be employed between the ultra hard material sheet and the first sheet to form transition layers with uniform or non-uniform interfaces.

Owner:SMITH INT INC

Ball limiting metalization process for interconnection

InactiveUS6111321APrinted circuit assemblingInsulating substrate metal adhesion improvementResistSemiconductor chip

A two-step masking process is disclosed for forming a ball limiting metallurgy (BLM) pad structure for a solder joint interconnection used between a support substrate and a semiconductor chip. A solder non-wettable layer and a solder wettable layer are deposited on the surface of a support substrate or semiconductor chip which are to be connected. A phased transition layer is deposited between the wettable and non-wettable layers. A thin photo-resist mask defines an area of the solder wettable and phased layers which are etched to form a raised, wettable frustum cone portion. A second mask is deposited on the surface of the support substrate or semiconductor chip, and has an opening concentrically positioned about the frustum cone. Solder is deposited in the opening and covers the frustum cone and the area about its periphery. When solidified, the solder, acting as a mask, is used to sub-etch the underlying solder non-wettable layer thereby defining the BLM pad. When reflowed, the solder beads away from the surface of the solder non-wettable layer to form a ball which securely adheres about the frustum cone.

Owner:IBM CORP

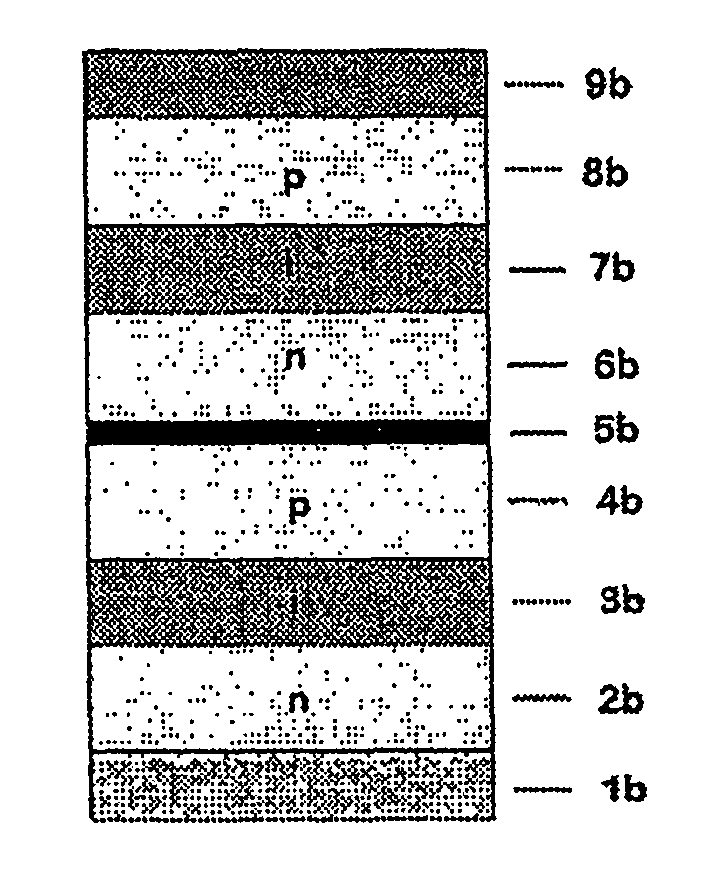

Photoactive component with organic layers

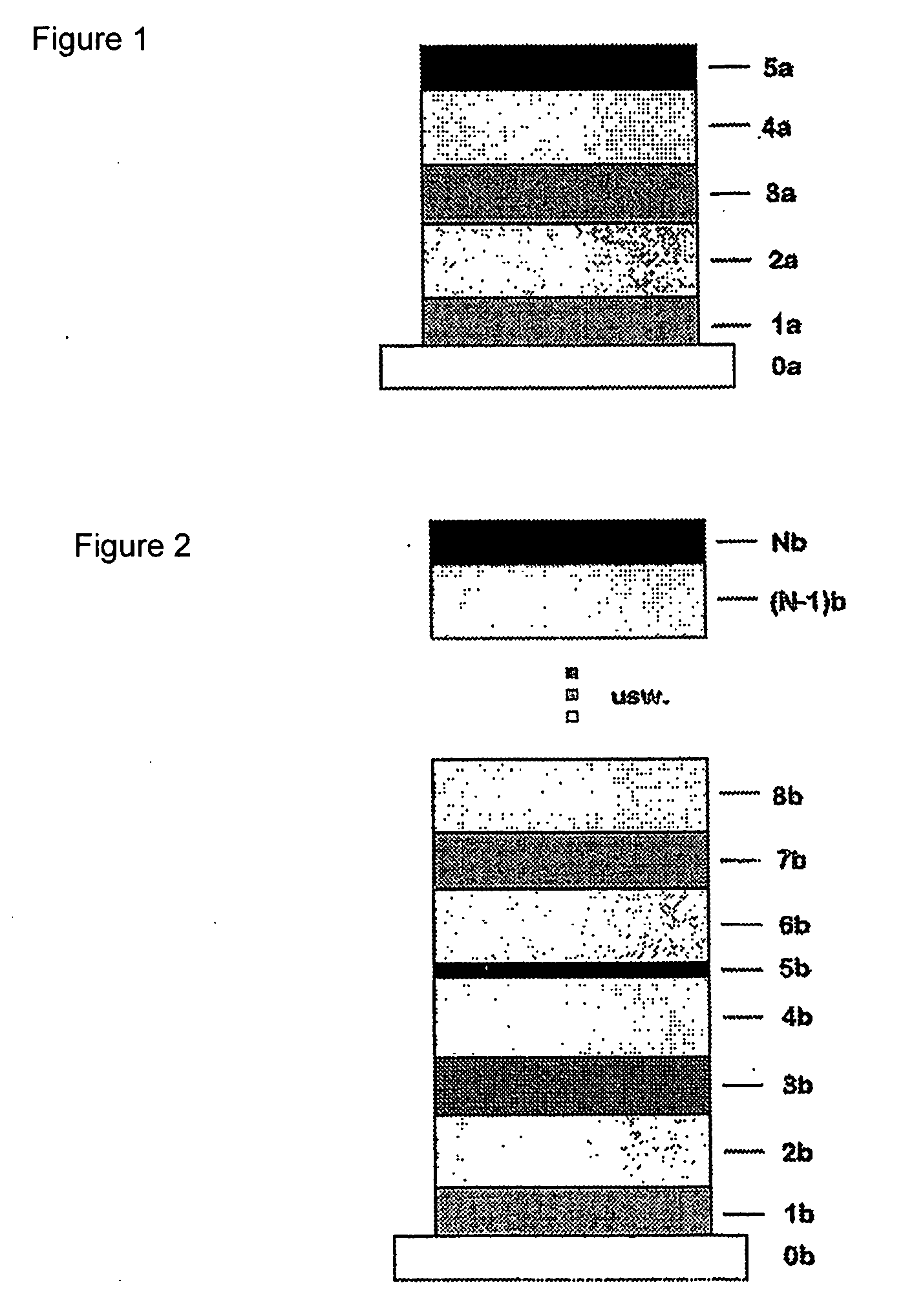

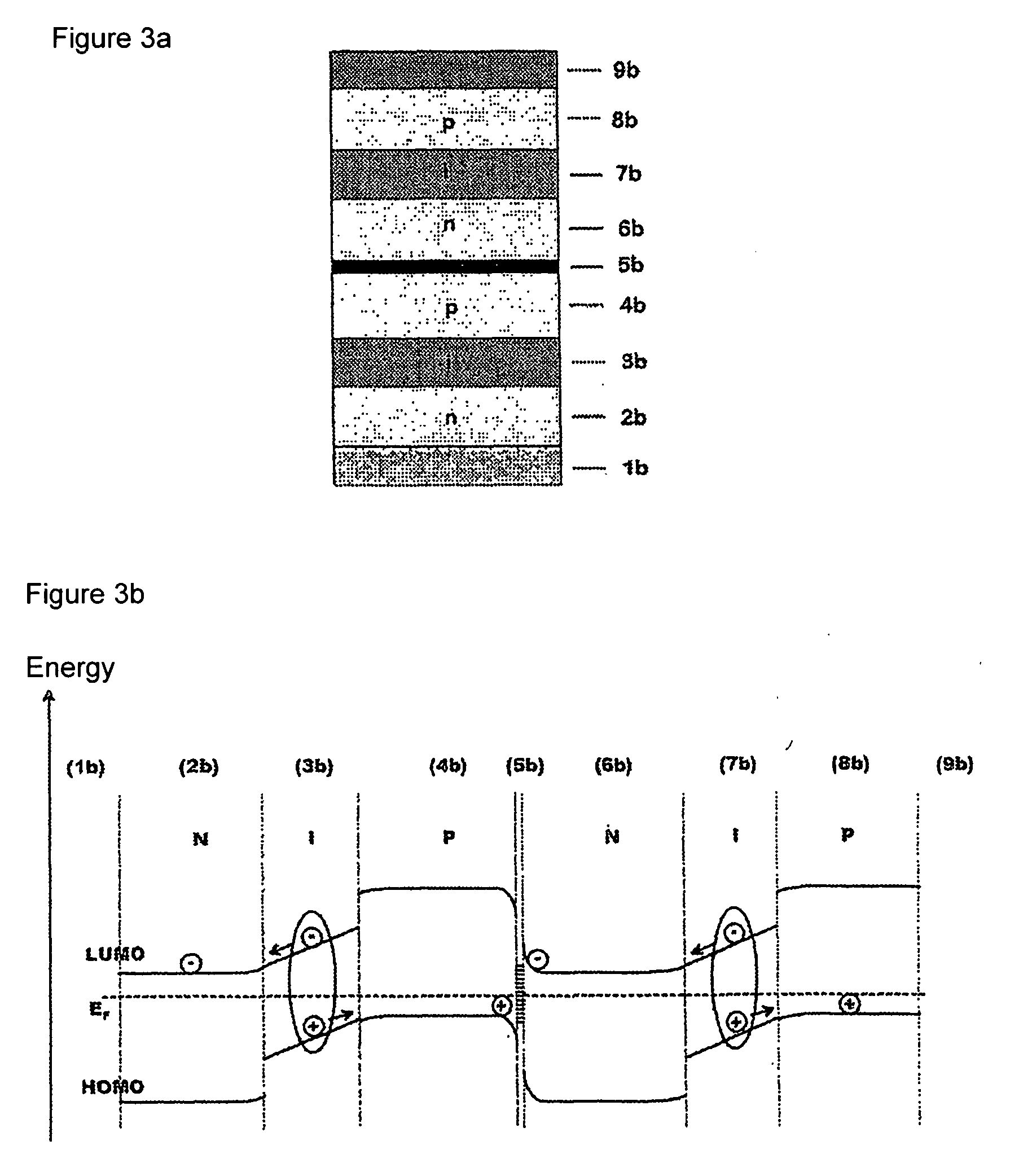

ActiveUS20070090371A1Reduce recombination lossHigh yieldNanoinformaticsSolid-state devicesQuantum yieldTransport layer

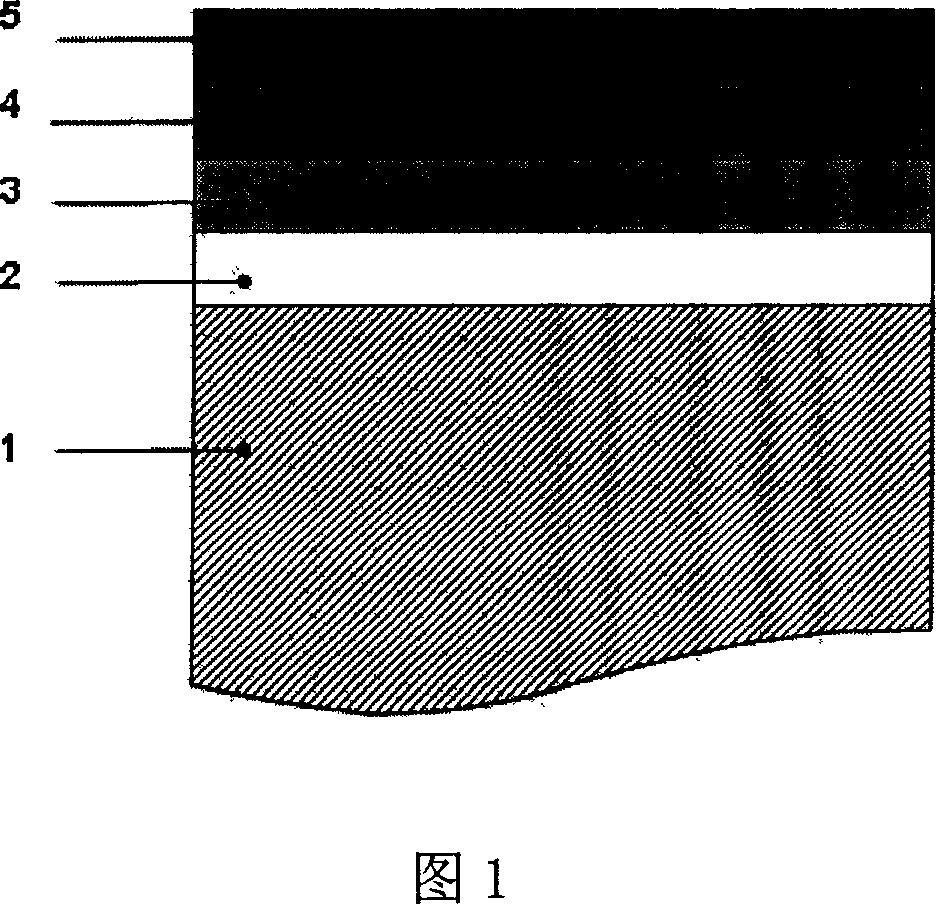

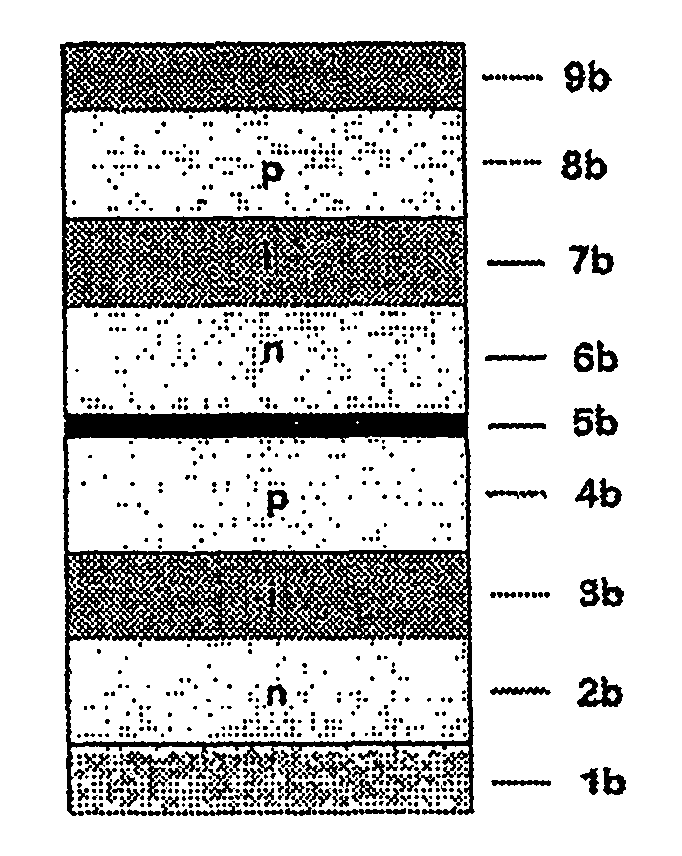

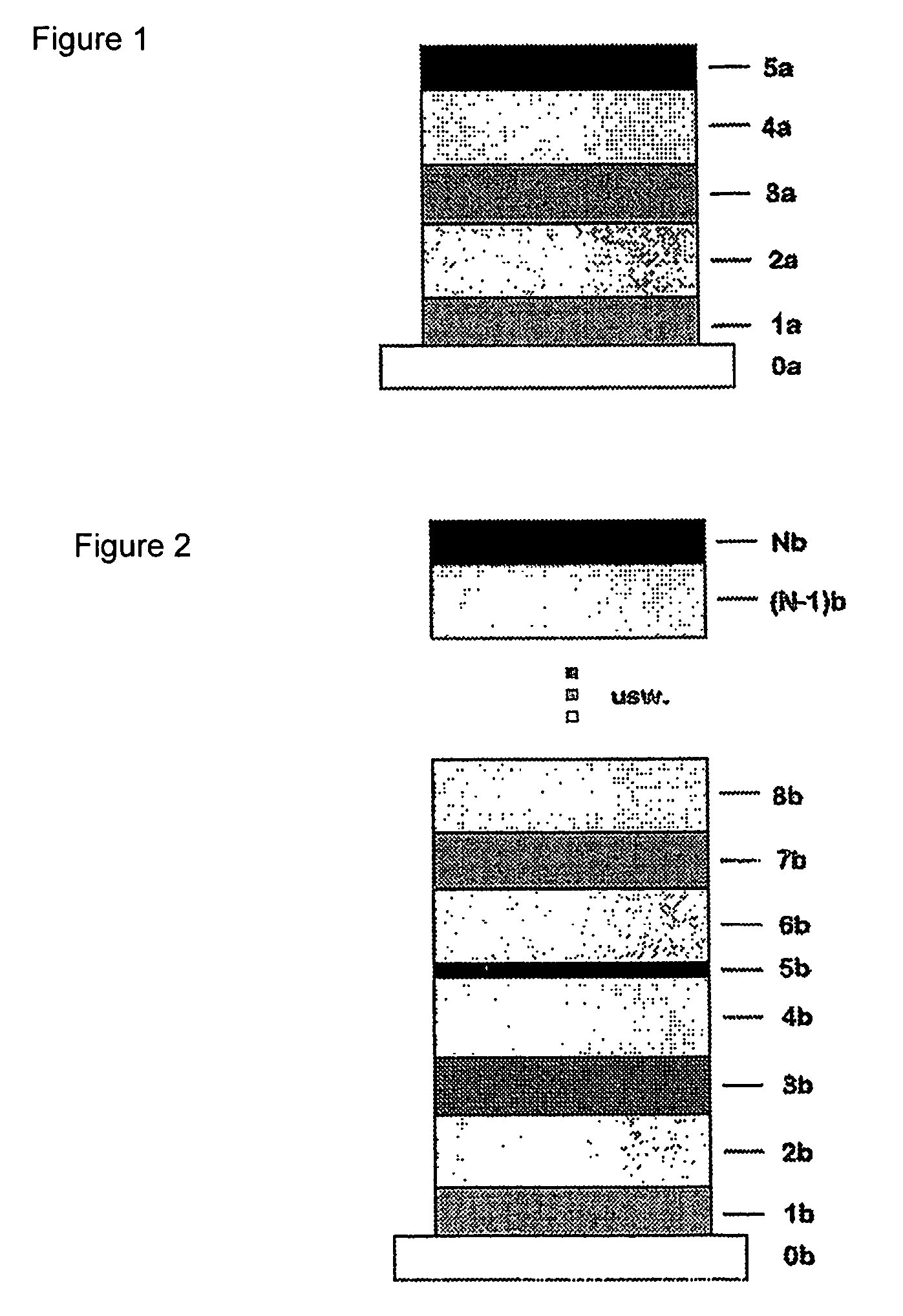

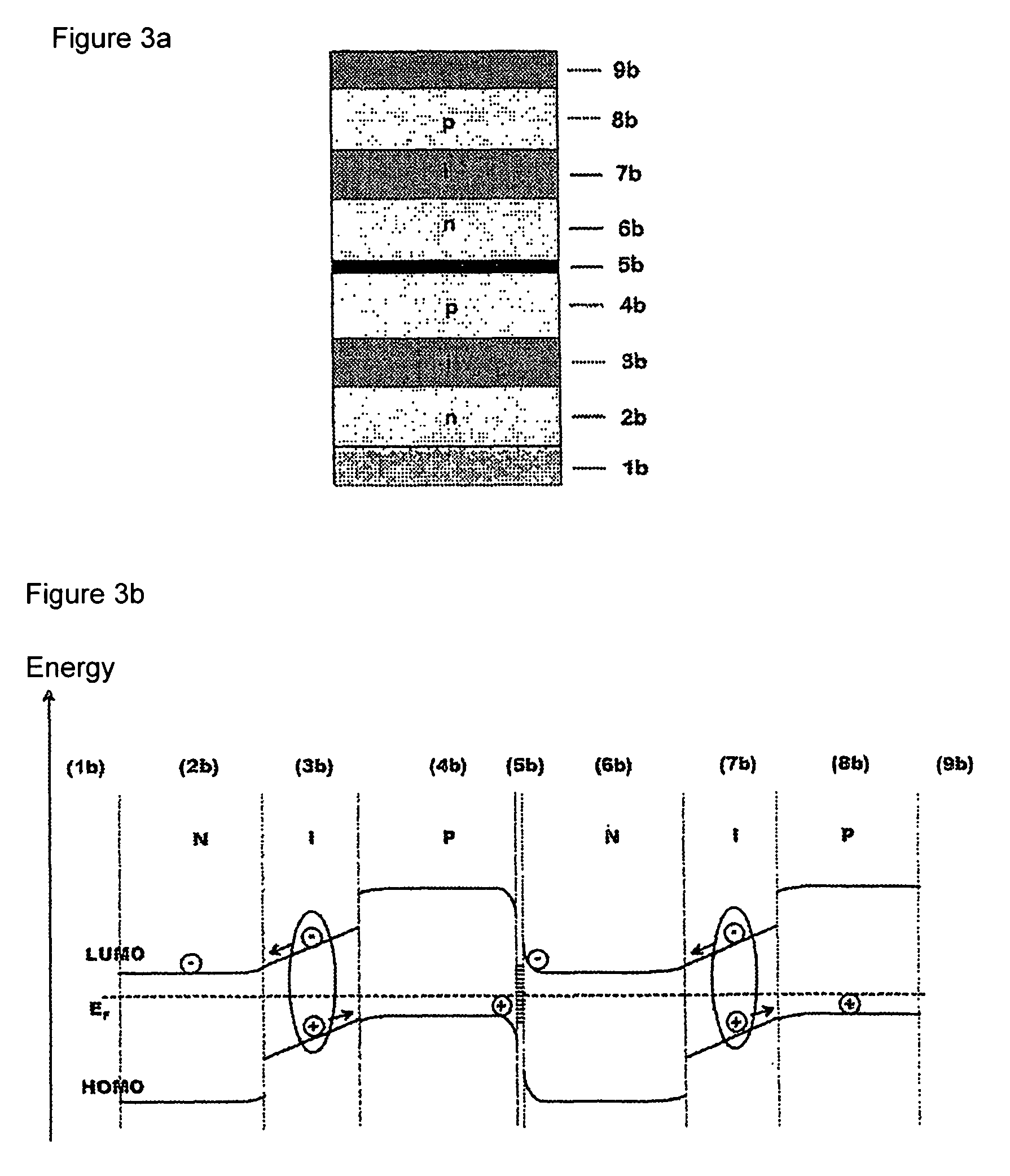

The invention relates to a photoactive component, especially a solar cell, comprising organic layers and formed by at least one stacked pi, ni, and / or pin diode. The diodes are characterised in that they comprise at least one p-doped or n-doped transport layer having a larger optical band gap than that of the photoactive layer. The individual diodes are characterised by a high internal quantum yield, but can be optically thin (peak absorption <80%). A high external quantum yield is obtained by either enlarging the optical path of the incident light in the diodes using light traps, or by stacking a plurality of the diodes. The transition between two diodes being facilitated by transition layers for the purposes of improved recombination and generation. Both forms of embodiment have a number of specific advantages using the doped transport layers with a large band gap.

Owner:HELIATEK GMBH

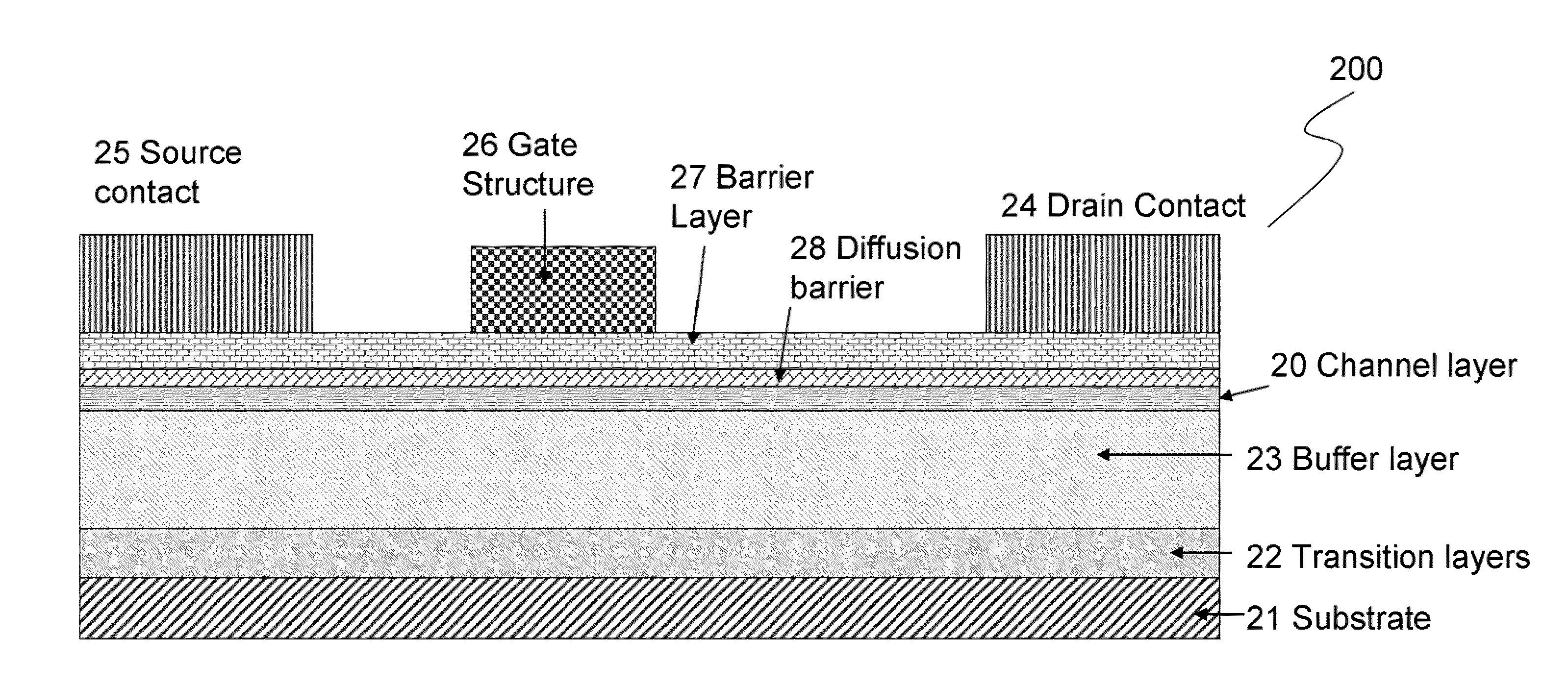

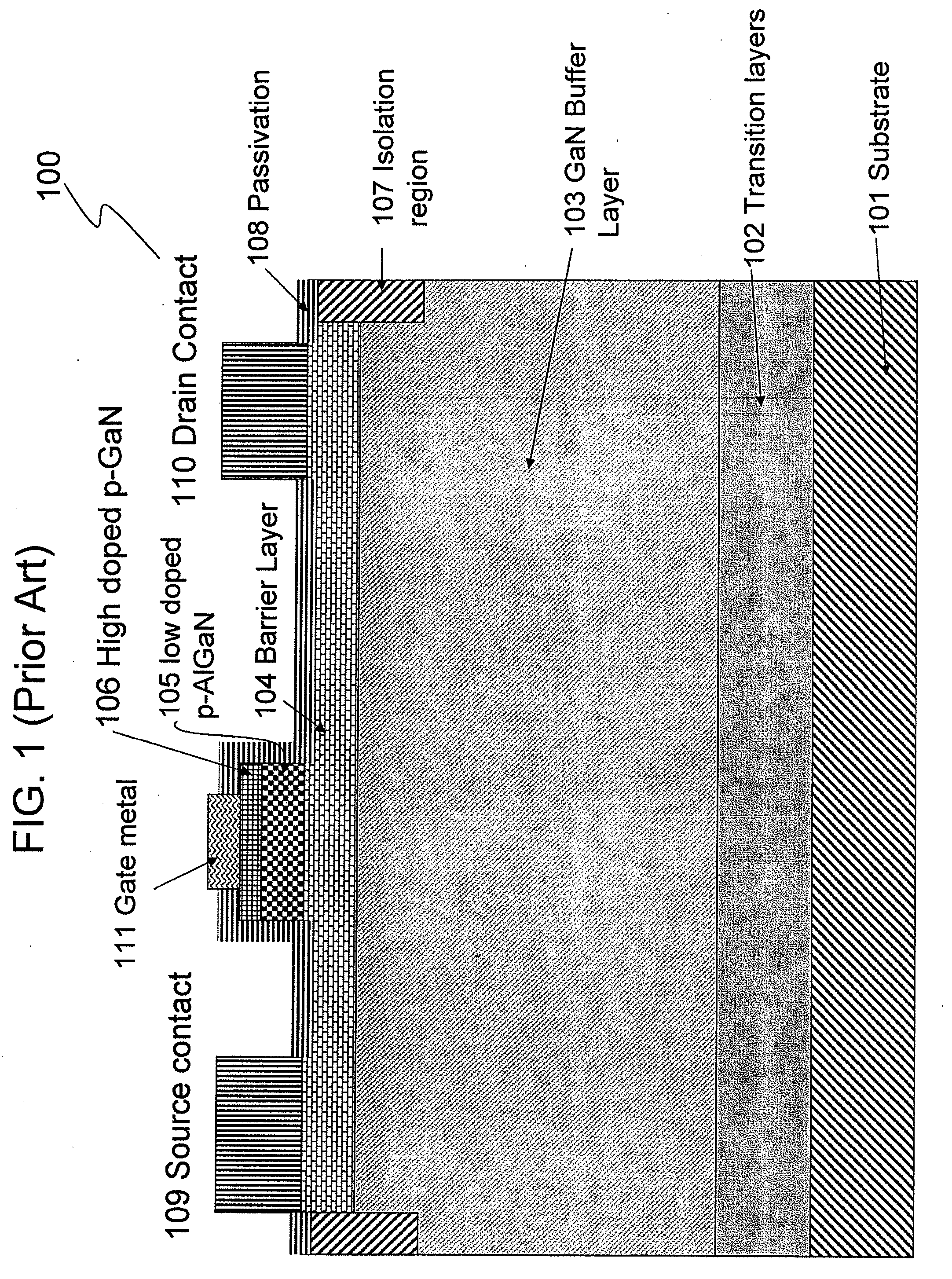

Back diffusion suppression structures

ActiveUS20100258841A1Avoid disadvantagesSemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion barrierBack diffusion

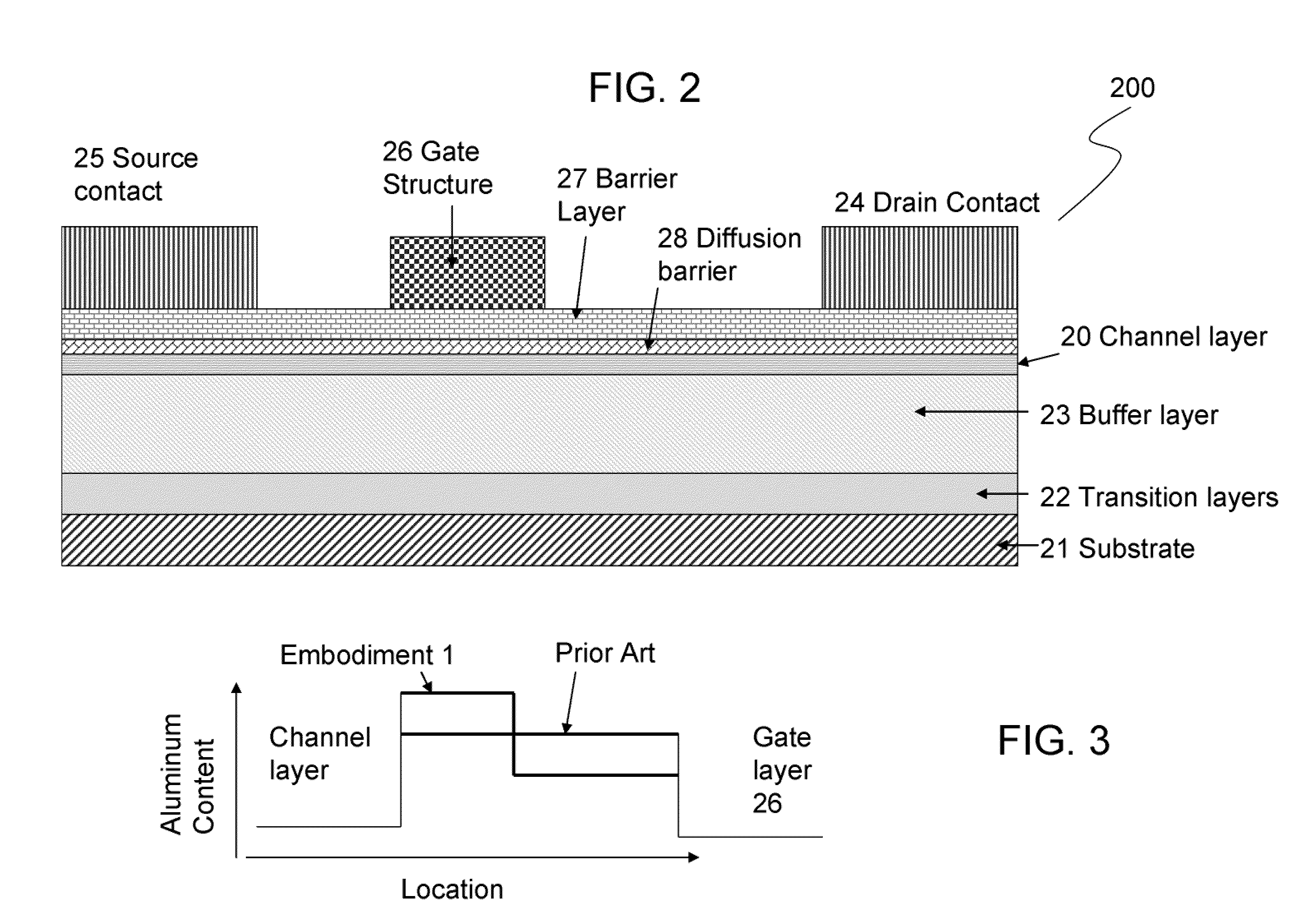

An enhancement-mode GaN transistor, the transistor having a substrate, transition layers, a buffer layer comprised of a III Nitride material, a barrier layer comprised of a III Nitride material, drain and source contacts, a gate containing acceptor type dopant elements, and a diffusion barrier comprised of a III Nitride material between the gate and the buffer layer.

Owner:EFFICIENT POWER CONVERSION CORP

Thin films

InactiveUS7419903B2Desirable interface propertyQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

Multilayer printed circuit board and multilayer printed circuit board manufacturing method

InactiveUS20070227765A1Low yieldWithout usingPrinted electric component incorporationSemiconductor/solid-state device detailsCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electronically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

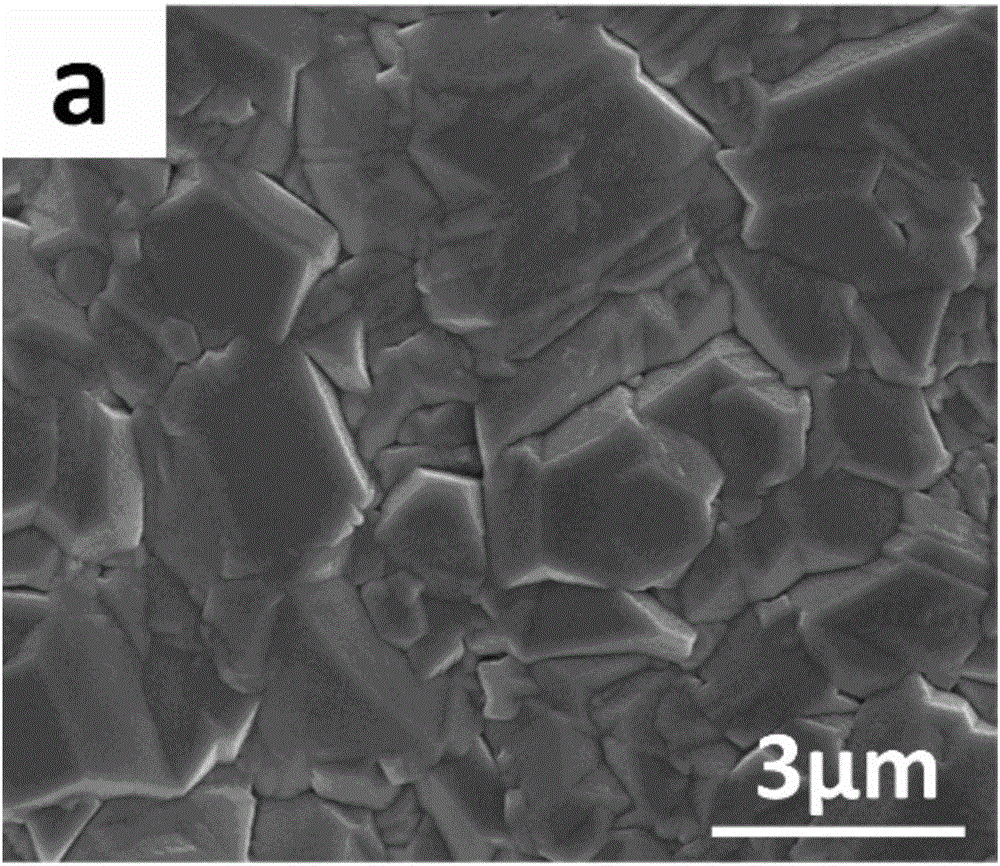

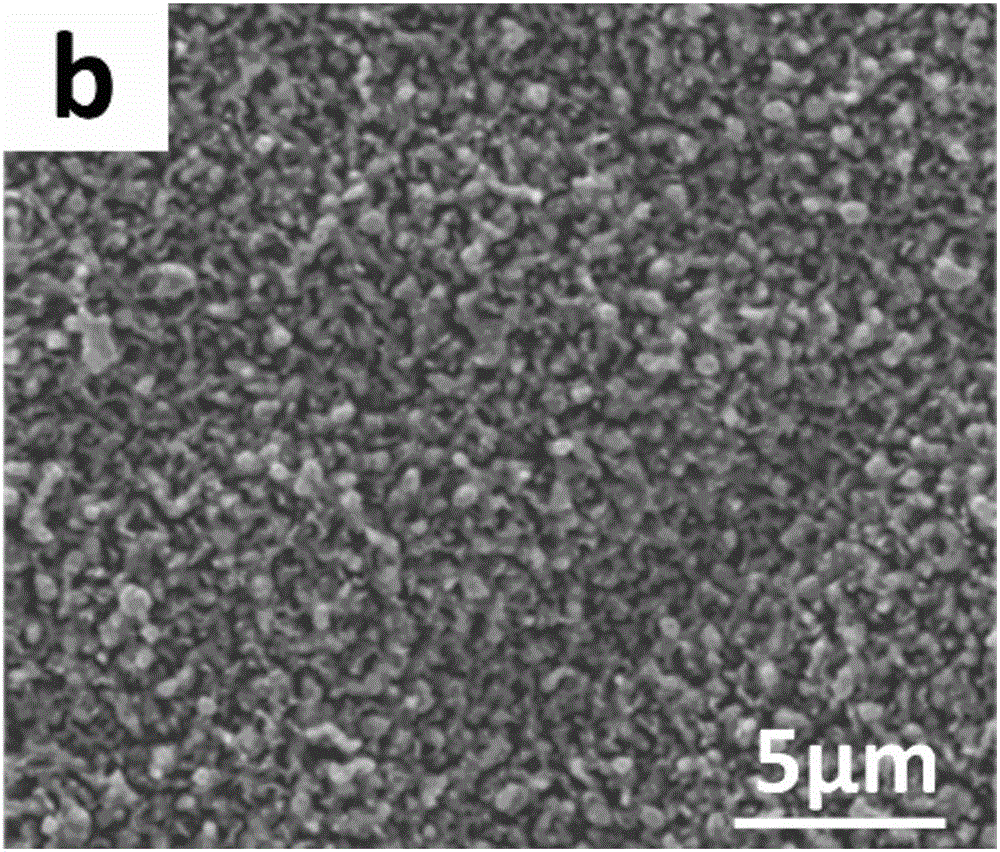

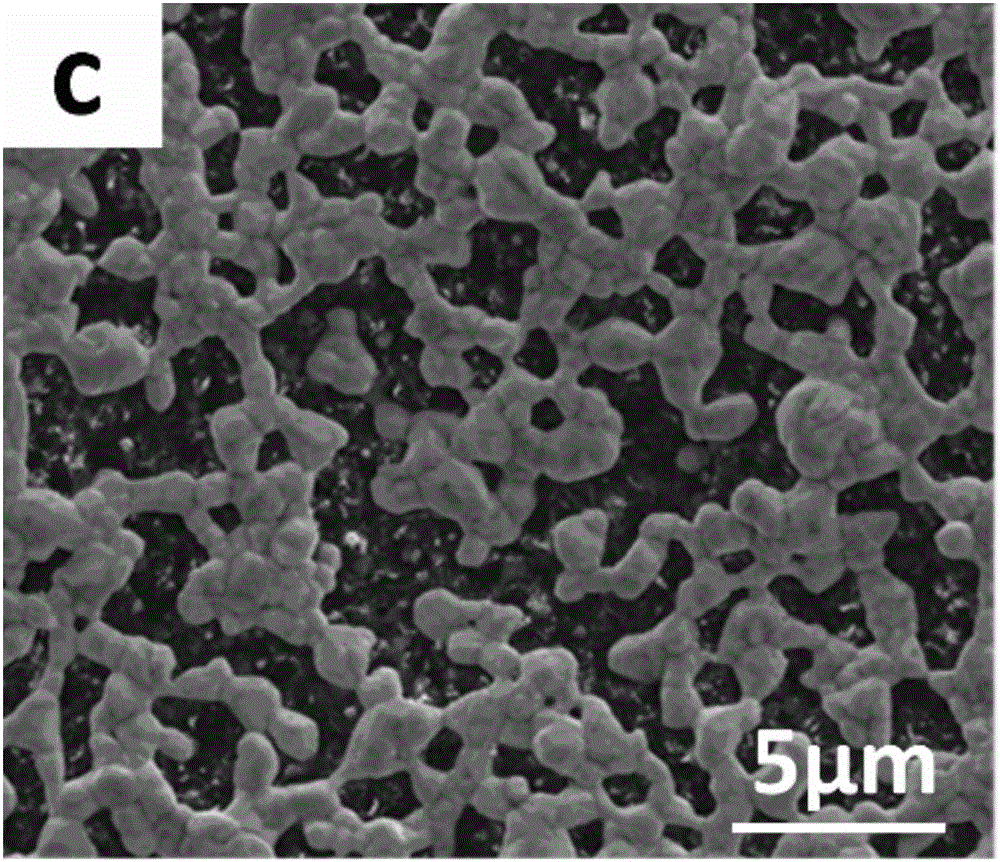

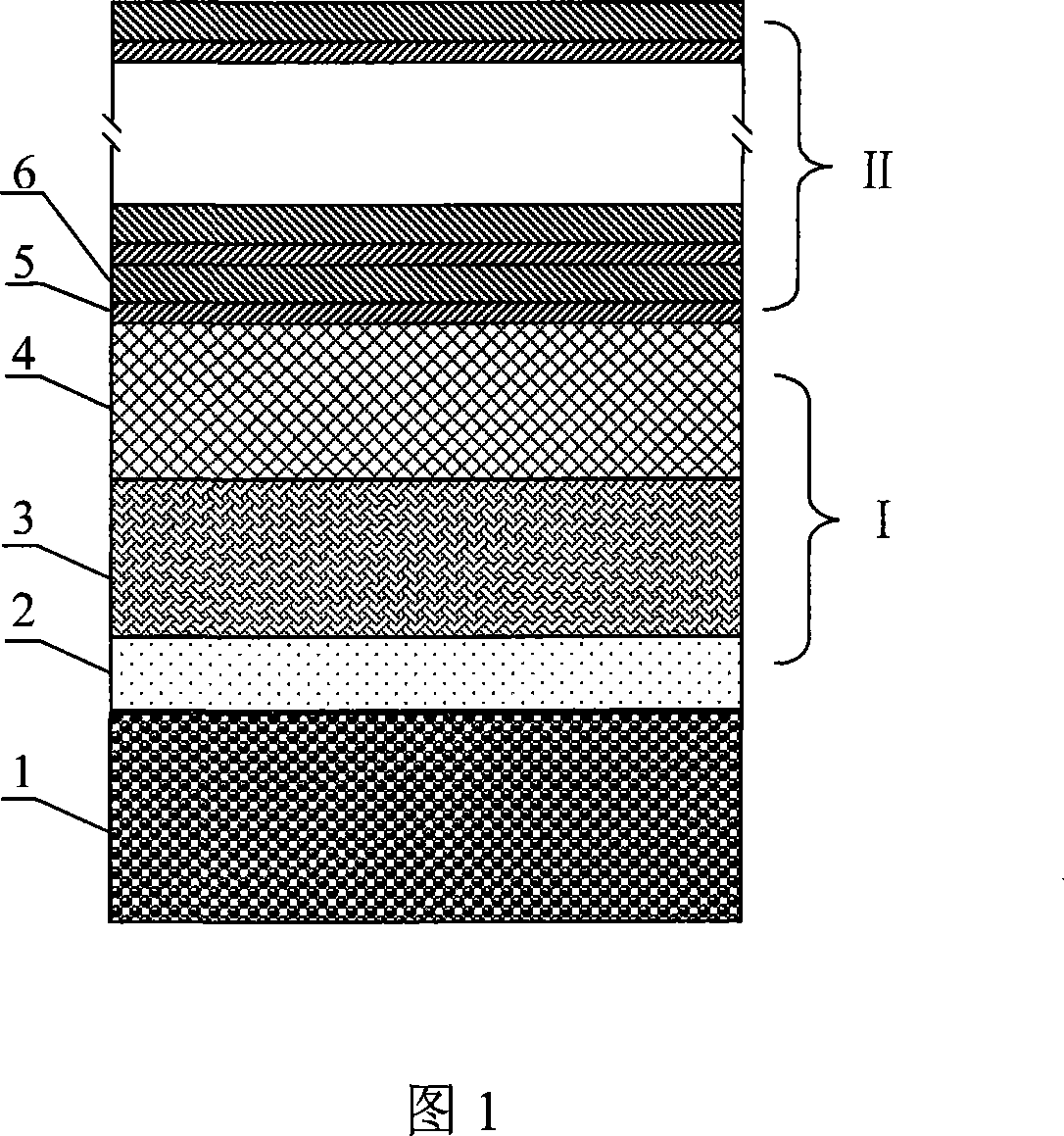

High-specific-surface-area boron-doped diamond electrode and preparation method and application thereof

ActiveCN106435518AHigh activityLarge electrochemical reaction interfaceWater contaminantsWater/sewage treatmentElectrochemical biosensorDiamond electrodes

The invention discloses a high-specific-surface-area boron-doped diamond (BDD) electrode which comprises an electrode substrate. A boron-doped diamond layer is arranged on the surface of the electrode substrate. Or, a transition layer is arranged on the surface of the substrate, and then a boron-doped diamond layer is arranged on the surface of the transition layer. Metal particles are distributed in the diamond layer, and tiny holes and / or pointed cones are distributed on the surface of the diamond layer. Compared with a traditional plate electrode, the boron-doped diamond electrode contains a large number of tiny holes and pointed cones and has the extremely high specific surface area, and the large current intensity is provided through the low current intensity; and meanwhile, due to the different electrode configurations of the substrate and modification of surface graphene and / or carbon nano tubs (CNT), the mass transfer process can be greatly improved, the current efficiency and the electrochemical property are greatly improved, and the BDD electrode with high electrocatalytic activity and high using efficiency is prepared. The electrode can be widely applied in the fields of electrochemical wastewater purification treatment, electrochemical biosensors, strong oxidant electrochemical synthesis, electrochemical detection and the like.

Owner:NANJING DAIMONTE TECH CO LTD

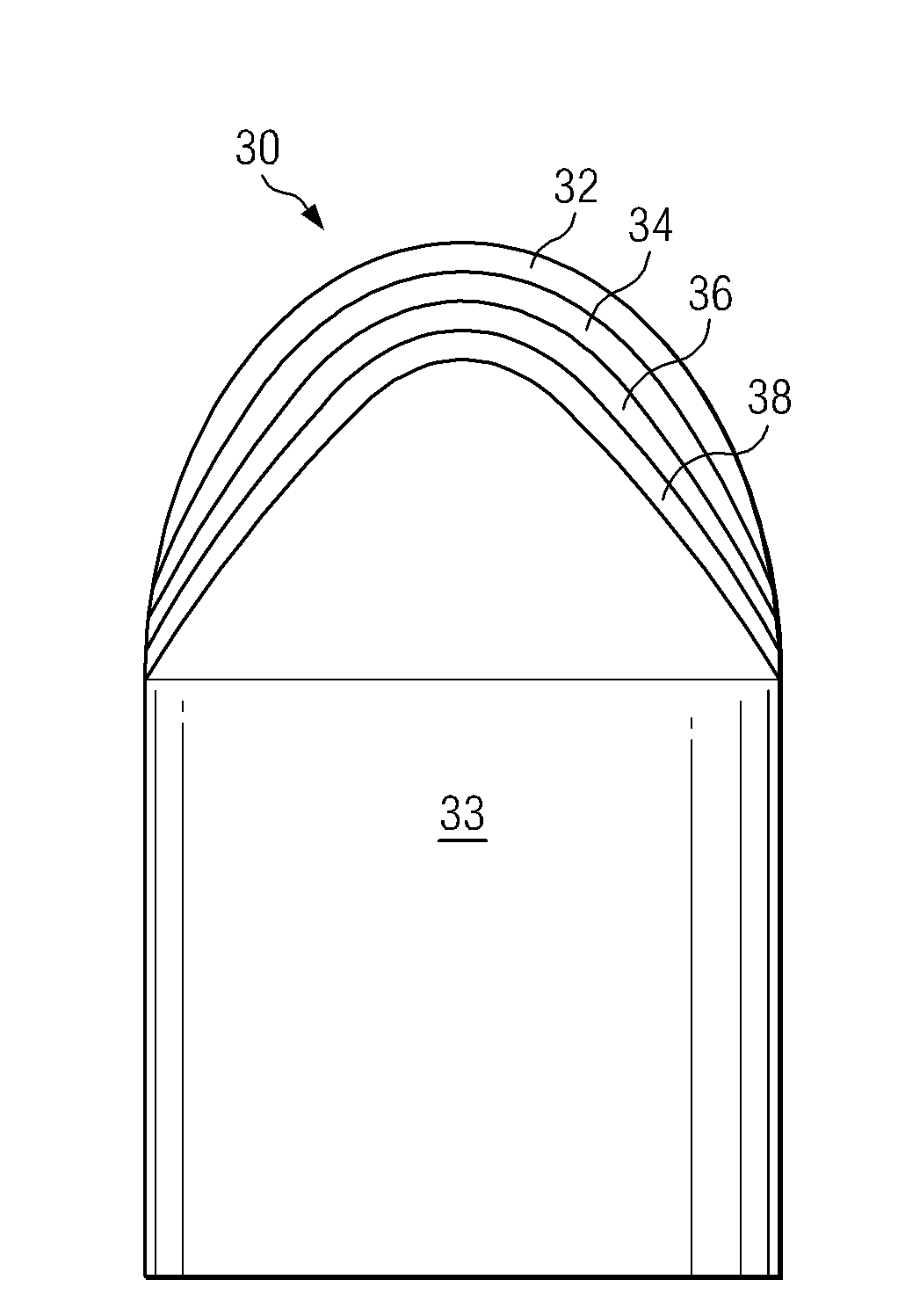

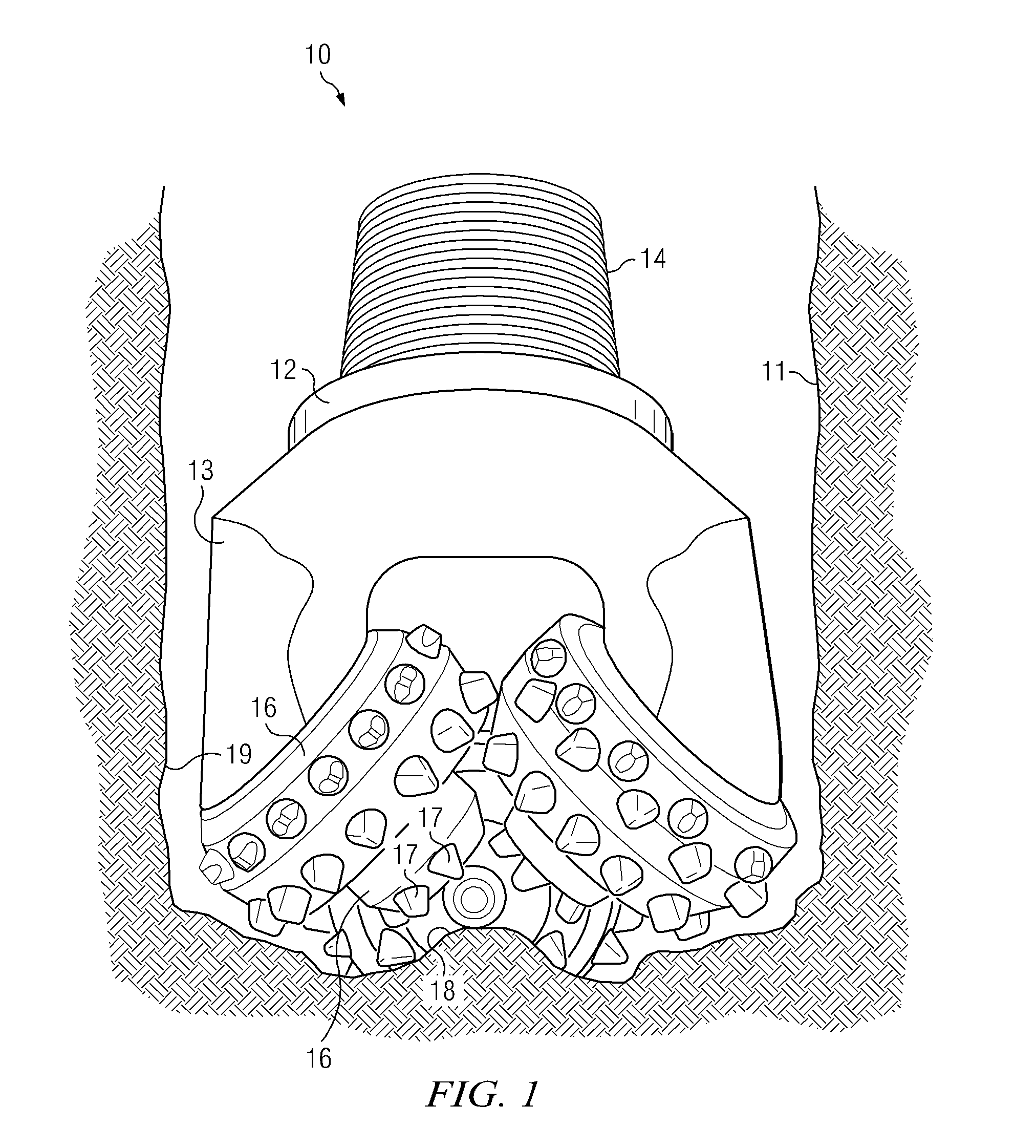

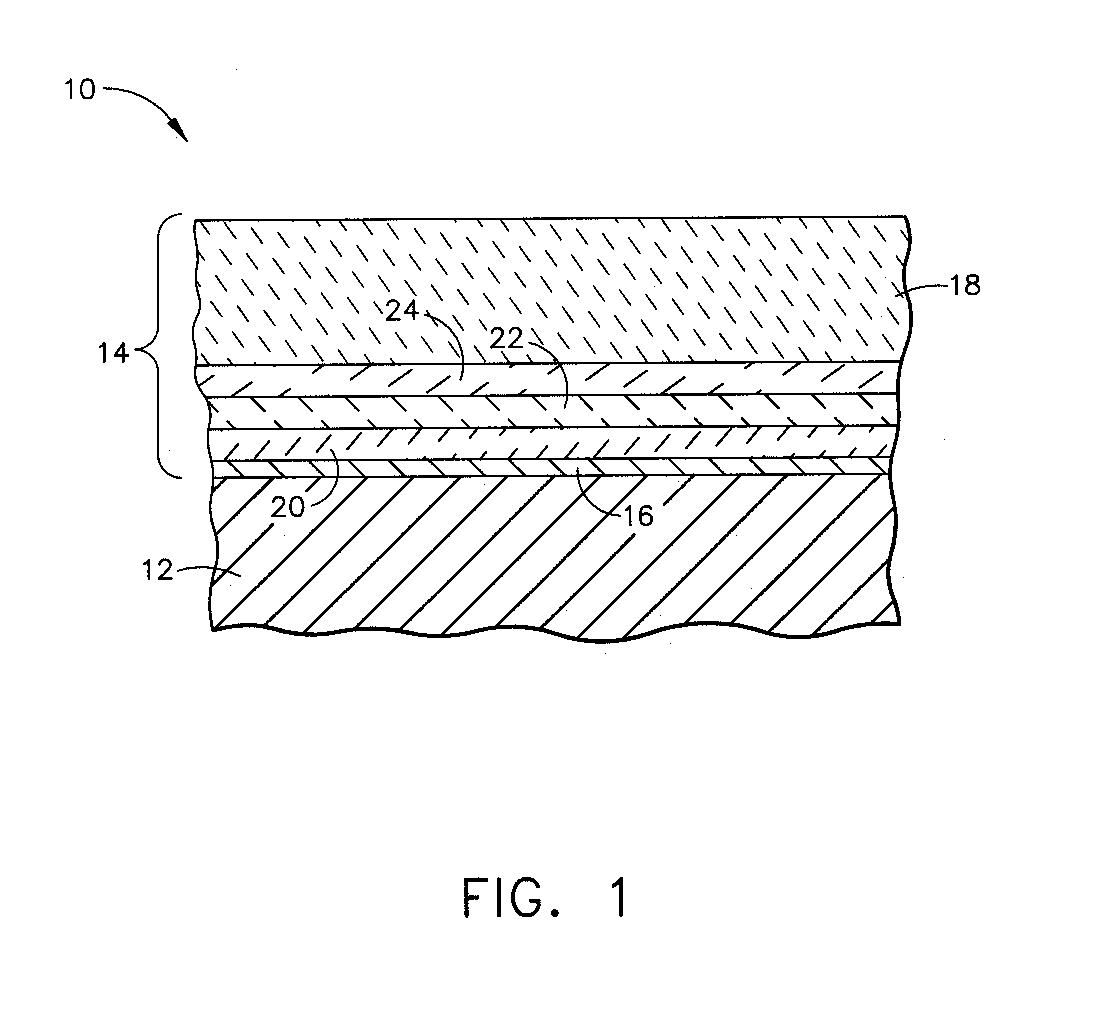

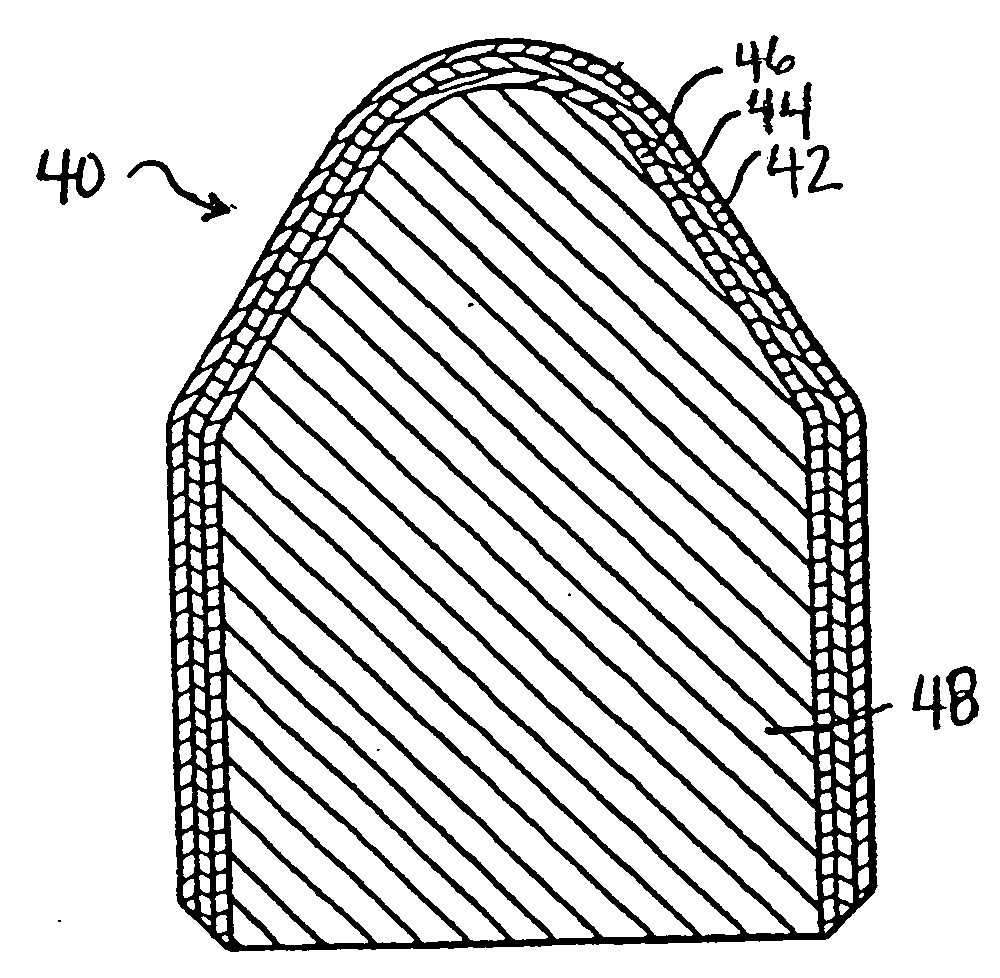

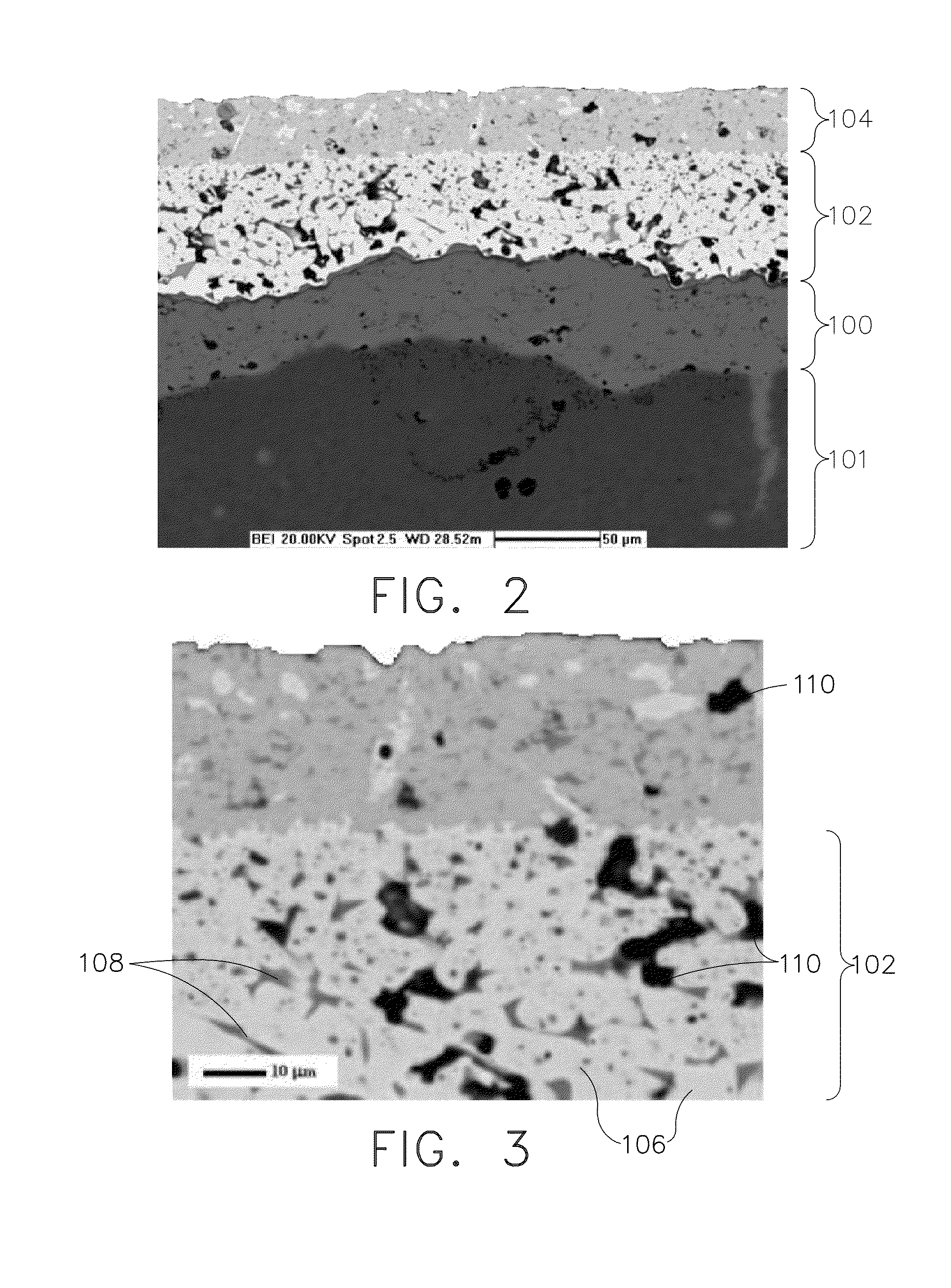

Highly wear resistant diamond insert with improved transition structure

An insert for a drill bit may include a metallic carbide body; an outer layer of polycrystalline diamond material on the outermost end of the insert, the polycrystalline diamond material comprising a plurality of interconnected first diamond grains and a first binder material in interstitial regions between the interconnected first diamond grains; and at least one transition layer between the metallic carbide body and the outer layer, the at least one transition layer comprising a composite of second diamond grains, first metal carbide particles, and a second binder material, wherein the second diamond grains have a larger grain size than the first diamond grains.

Owner:SMITH INT INC

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Thermal/environmental barrier coating system for silicon-containing materials

ActiveUS20060280963A1Prolong lifeImprove protectionFireproof paintsBlade accessoriesAluminateCoating system

A coating system for Si-containing materials, particularly those for articles exposed to high temperatures. The coating system exhibits improved resistance to corrosion from sea salt and CMAS as a result of using aluminate compounds to protect silicate-containing layers of the coating system. The coating system includes an environmental barrier coating, a thermal barrier coating overlying the environmental barrier coating and formed of a thermal-insulating material, and a transition layer between the environmental barrier coating and thermal barrier coating, wherein the transition layer contains at least one aluminate compound and / or alumina.

Owner:GENERAL ELECTRIC CO

Stress-relieved diamond inserts

A drill bit including at least one stress-relieved cutting element, wherein the at least one cutting element is mounted on the drill bit, wherein the stress-relieved cutting element includes a substrate, at least one transition layer disposed upon the substrate and a polycrystalline diamond layer having a thickness of at least 0.008 inches disposed upon the at least one transition layer.

Owner:SMITH INT INC

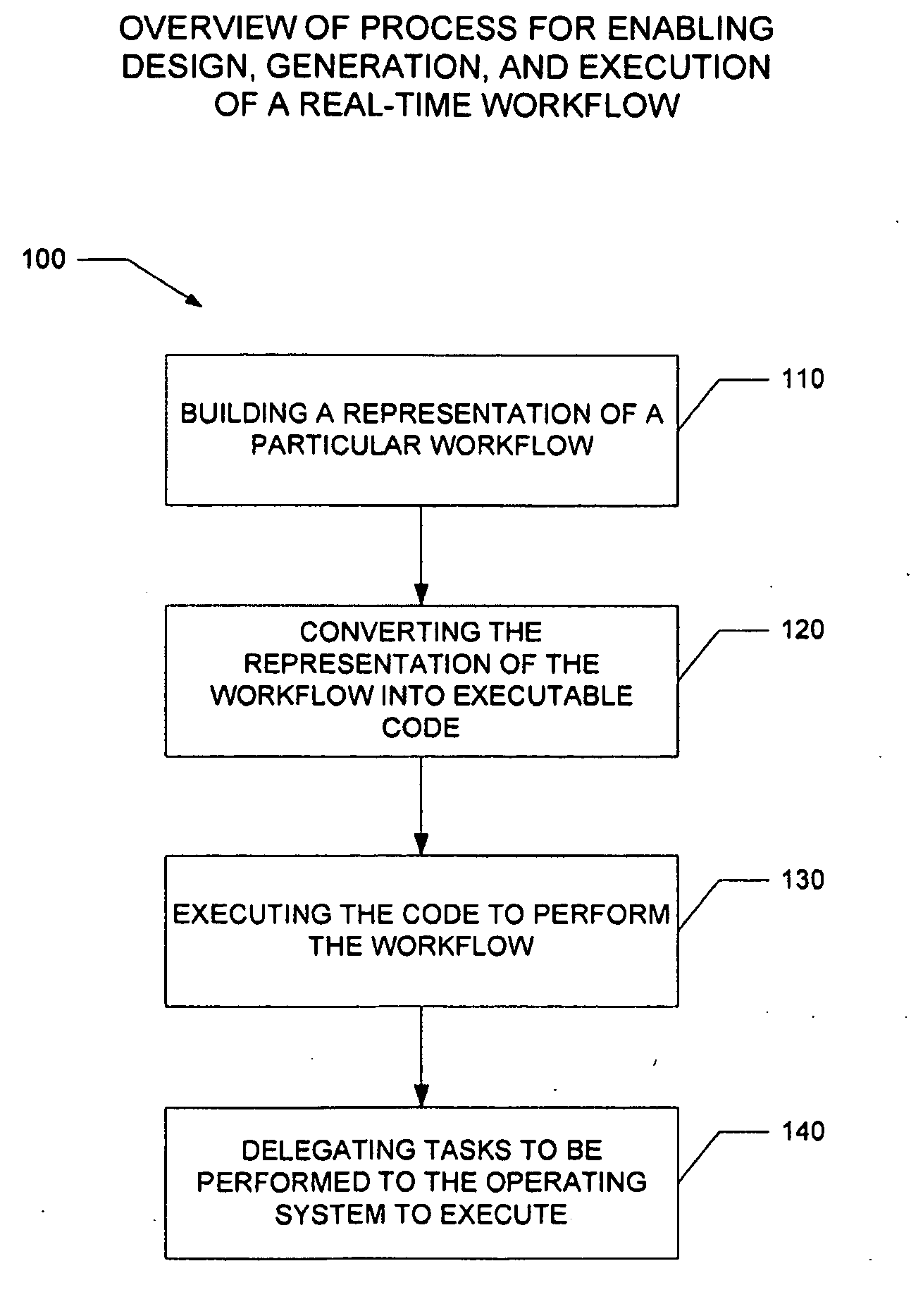

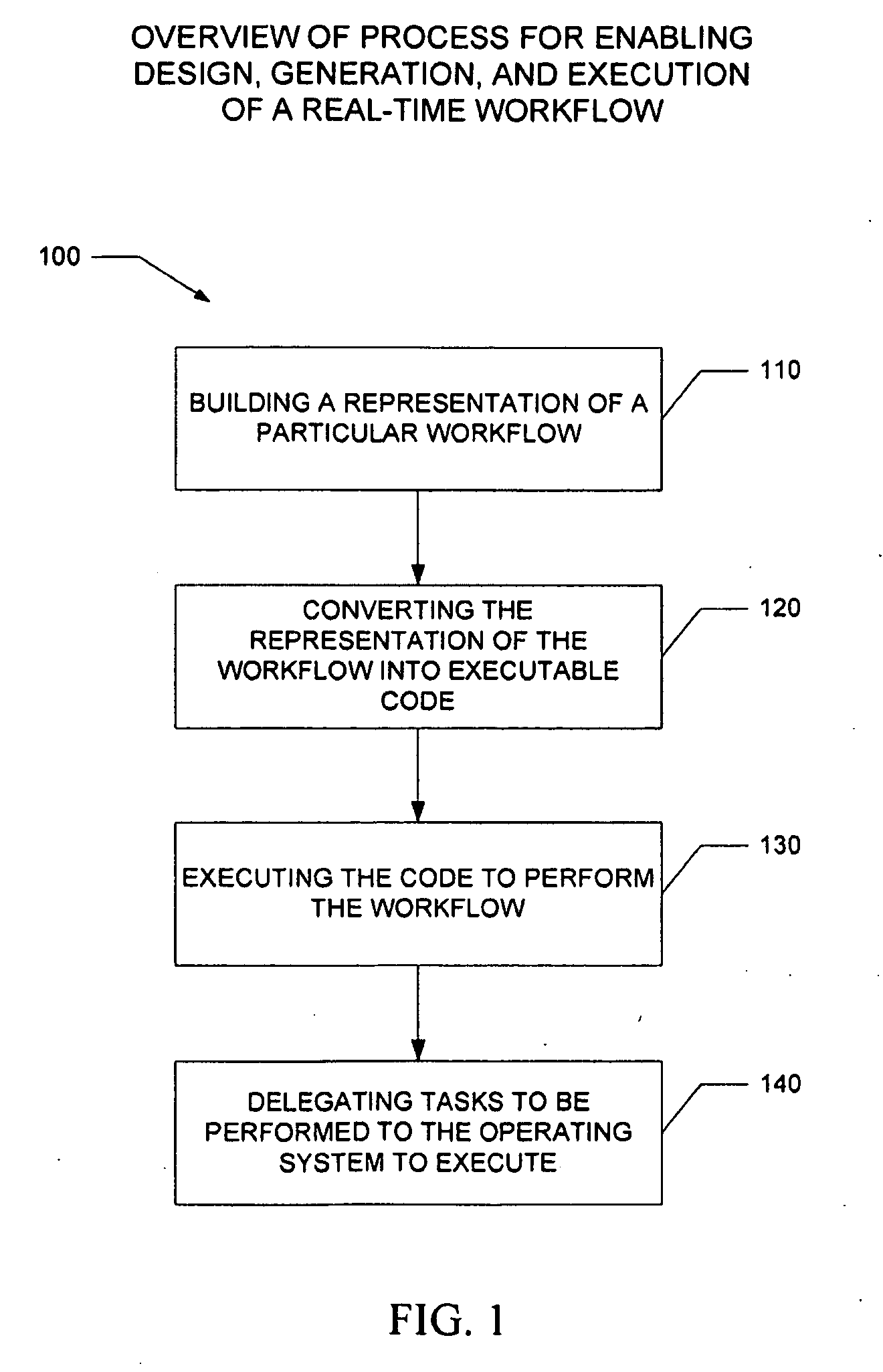

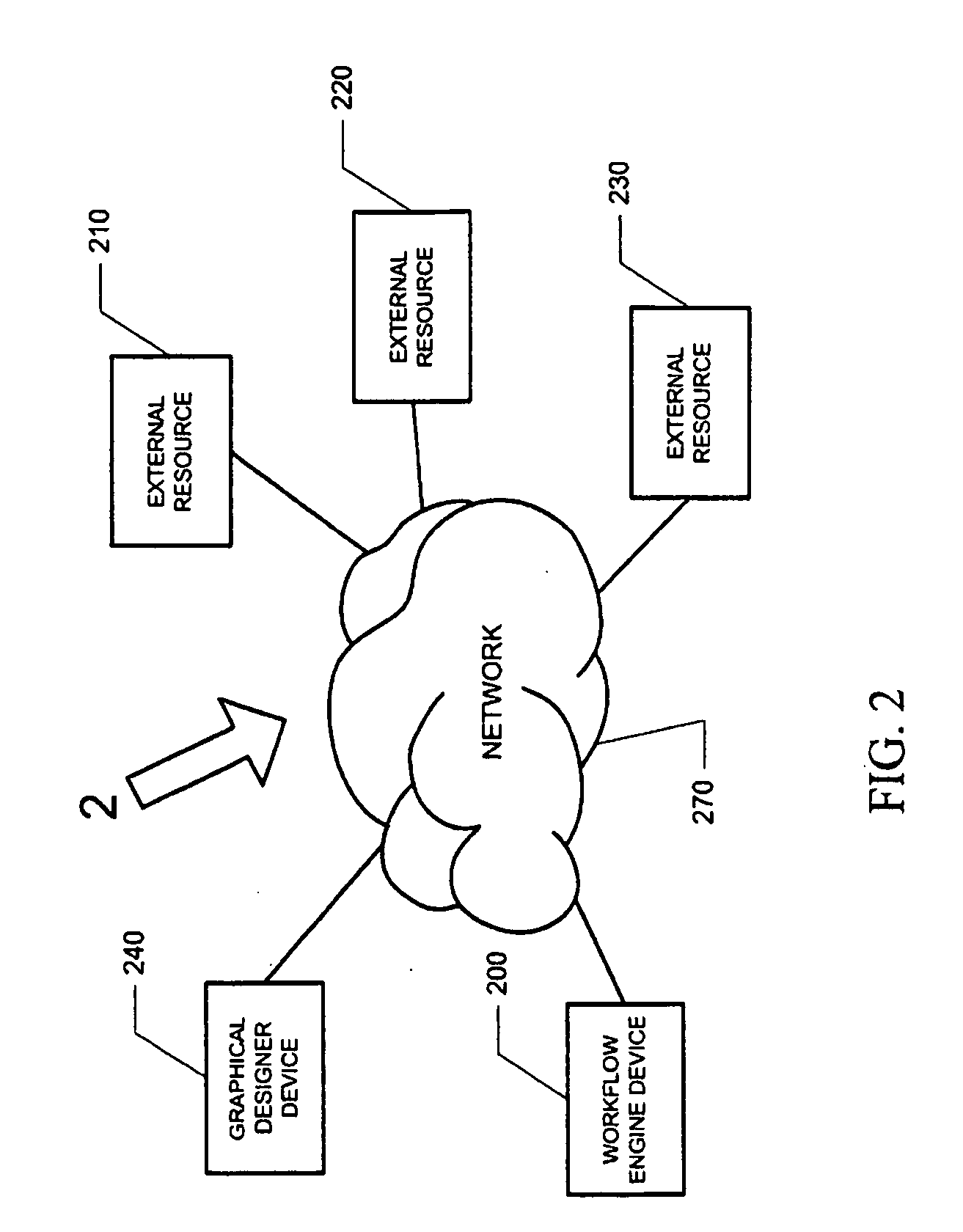

Systems and methods for generating source code for workflow platform

ActiveUS20100281462A1Multiple digital computer combinationsVisual/graphical programmingAbstraction layerGraphics

Various embodiments of the present invention provide systems and methods for enabling design, generation, and execution of real-time workflows. Such embodiments provide a graphical designer including a plurality of shapes representing the various objects of a workflow that are used to model the workflow. In addition, various embodiments of the graphical designer provide shapes to model aspects of the workflow not found in previous graphical designers. Various embodiments also provide a code generator that converts the representation of the workflow into executable code for multiple target languages. Various embodiments also provide a workflow engine based on a Petri net model responsible for executing the workflow and for delegating tasks to be performed for the workflow to an operating system. In various embodiments, the workflow engine further includes a platform abstraction layer that provides a transition layer from the Petri net language to the operating system language.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

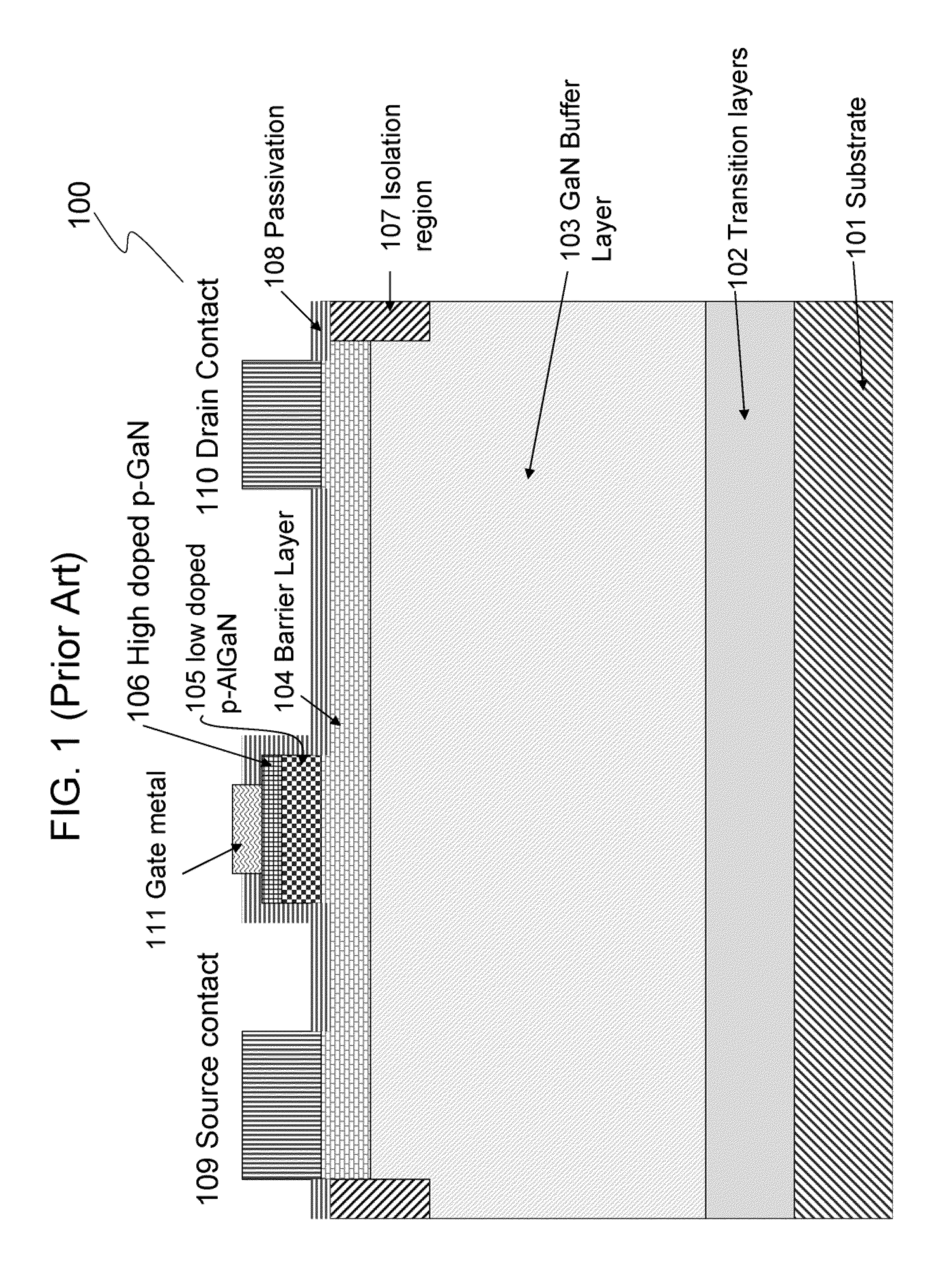

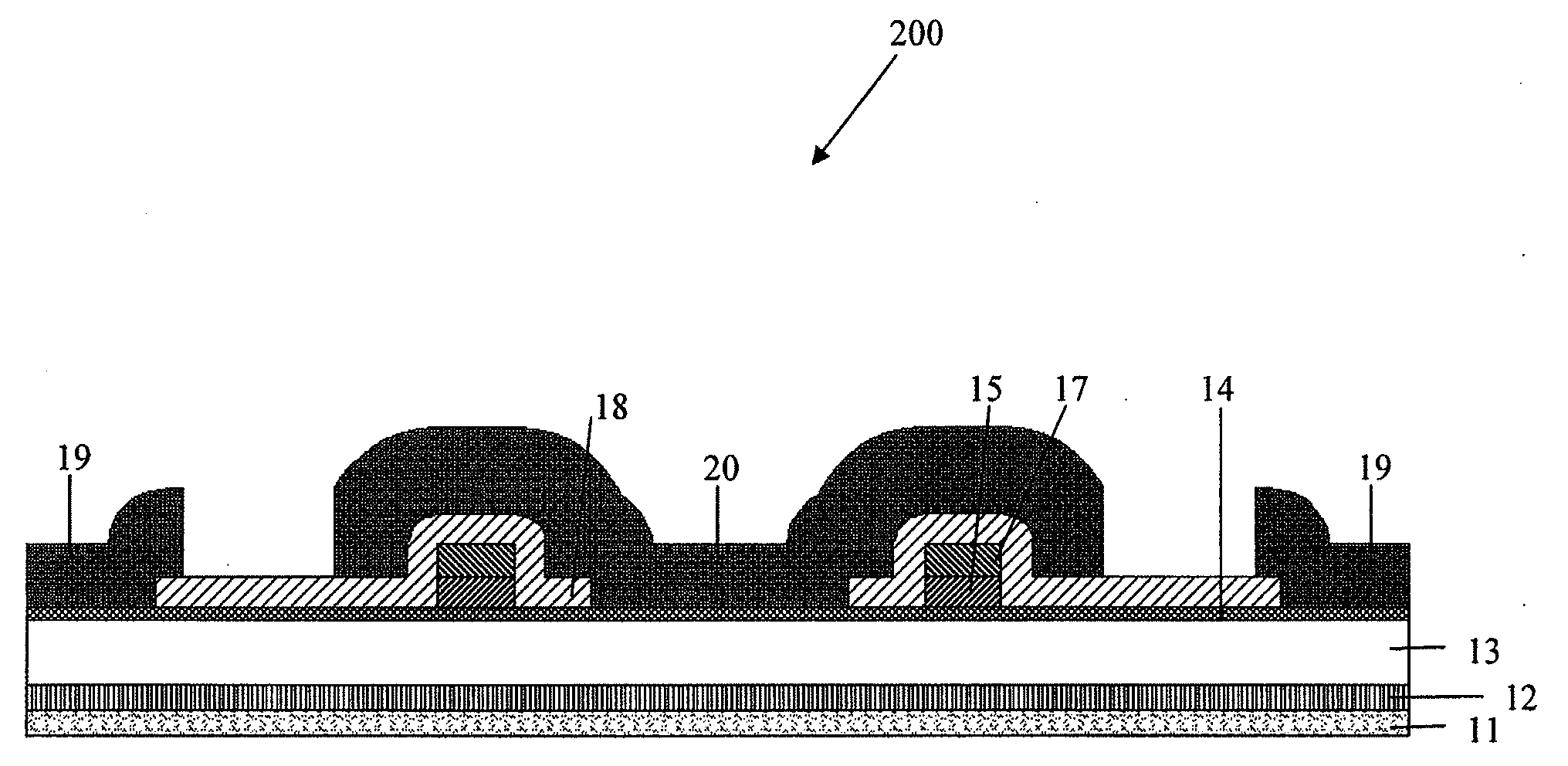

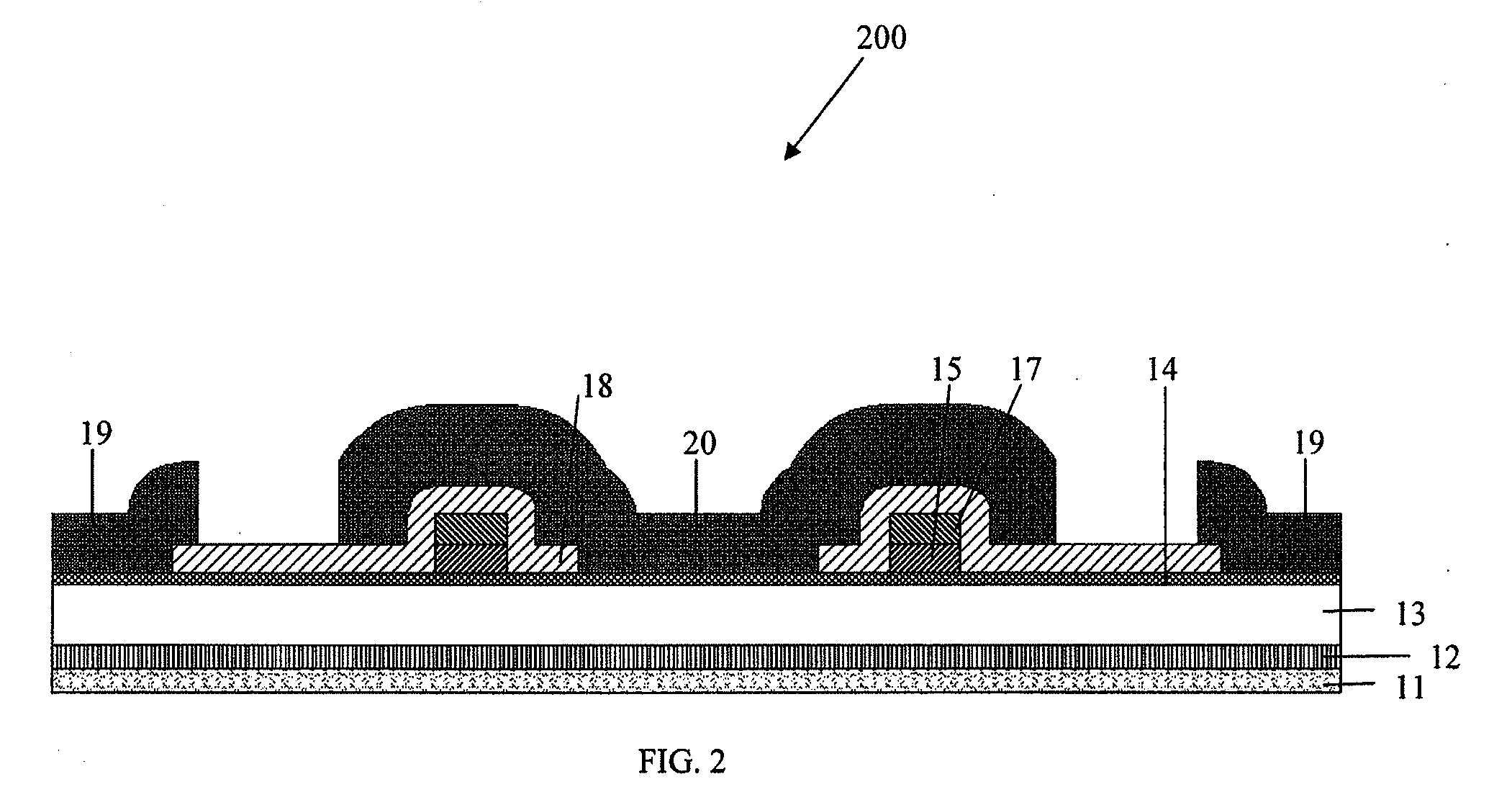

ENHANCEMENT MODE GaN HEMT DEVICE AND METHOD FOR FABRICATING THE SAME

ActiveUS20100258843A1Simple structureAvoid disadvantagesSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideTransition layer

An enhancement-mode GaN transistor and a method of forming it. The enhancement-mode GaN transistor includes a substrate, transition layers, a buffer layer comprised of a III Nitride material, a barrier layer comprised of a III Nitride material, drain and source contacts, a gate III-V compound containing acceptor type dopant elements, and a gate metal, where the gate III-V compound and the gate metal are formed with a single photo mask process to be self-aligned and the bottom of the gate metal and the top of the gate compound have the same dimension. The enhancement mode GaN transistor may also have a field plate made of Ohmic metal, where a drain Ohmic metal, a source Ohmic metal, and the field plate are formed by a single photo mask process.

Owner:EFFICIENT POWER CONVERSION CORP

Diamond transition layer construction with improved thickness ratio

An insert for a drill bit may include a metallic carbide body; an outer layer of polycrystalline diamond material on the outermost end of the insert, the polycrystalline diamond material comprising a plurality of interconnected first diamond grains and a first binder material in interstitial regions between the interconnected first diamond grains; and at least two transition layers between the metallic carbide body and the outer layer, the at least two transition layers comprising: an outermost transition layer comprising a composite of second diamond grains, first metal carbide or carbonitride particles, and a second binder material; and an innermost transition layer comprising a composite of third diamond grains, second metal carbide or carbonitride particles, and a third binder material wherein a thickness of the outer layer is lesser than that of each of the at least two transition layers.

Owner:SMITH INT INC

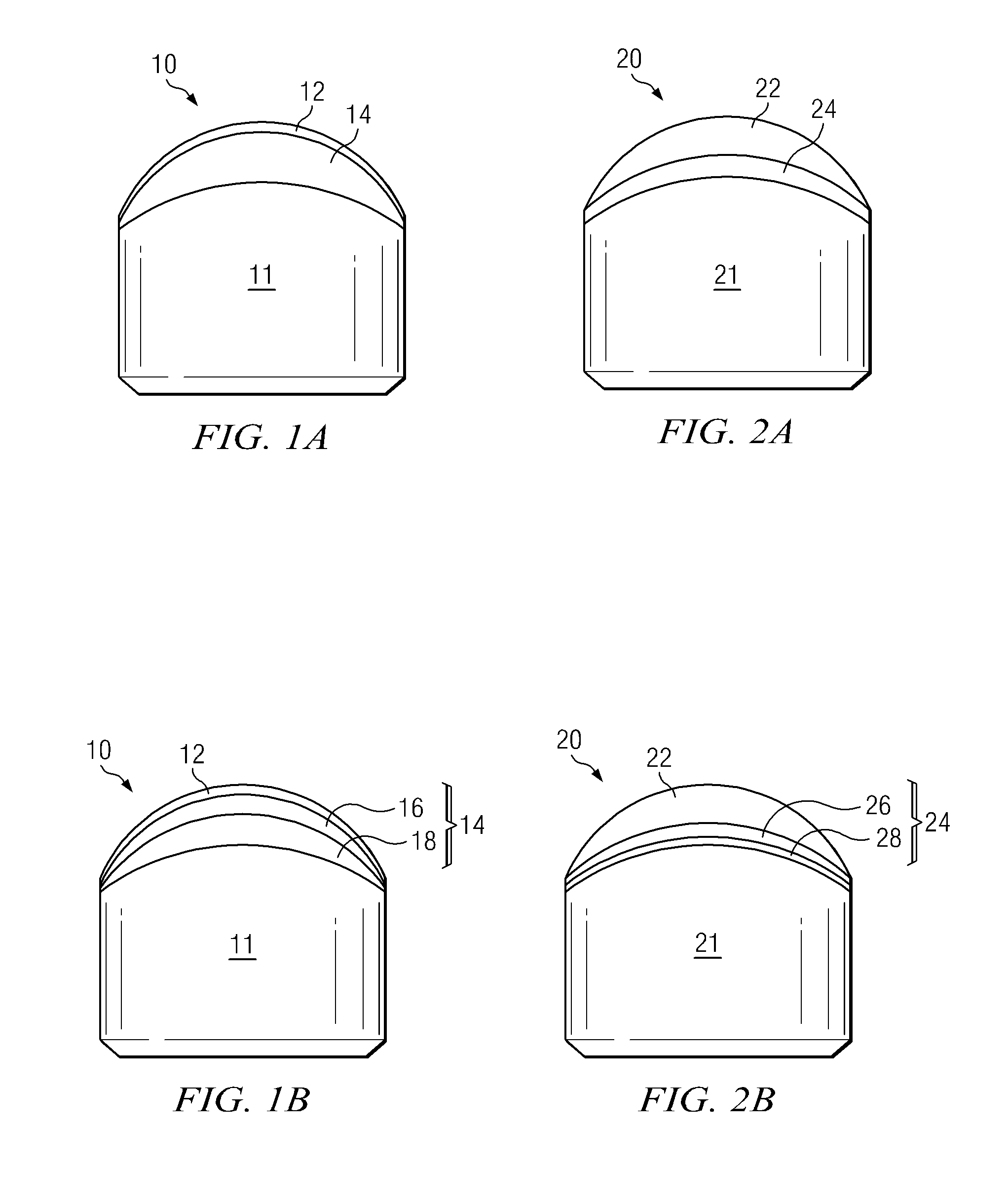

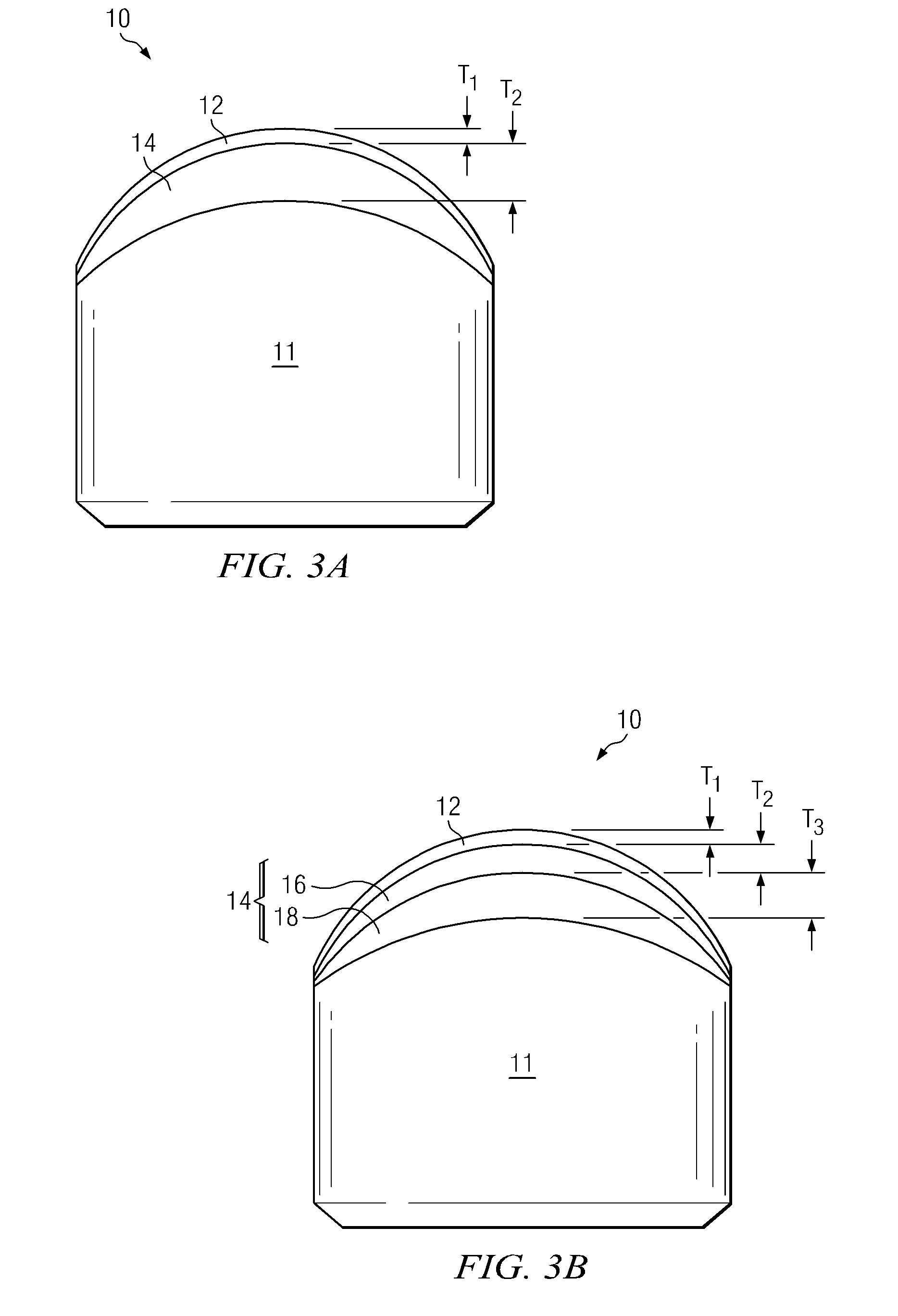

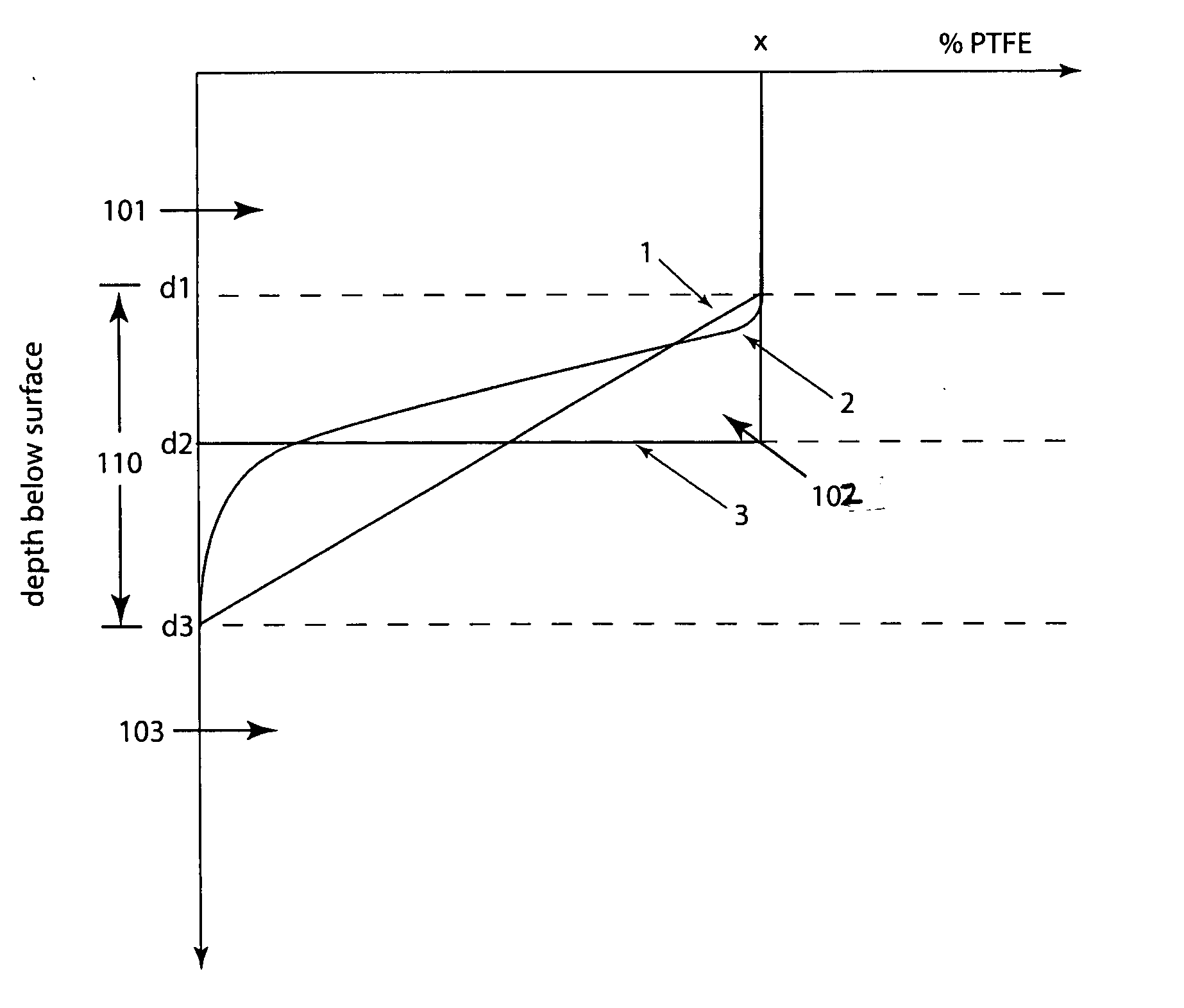

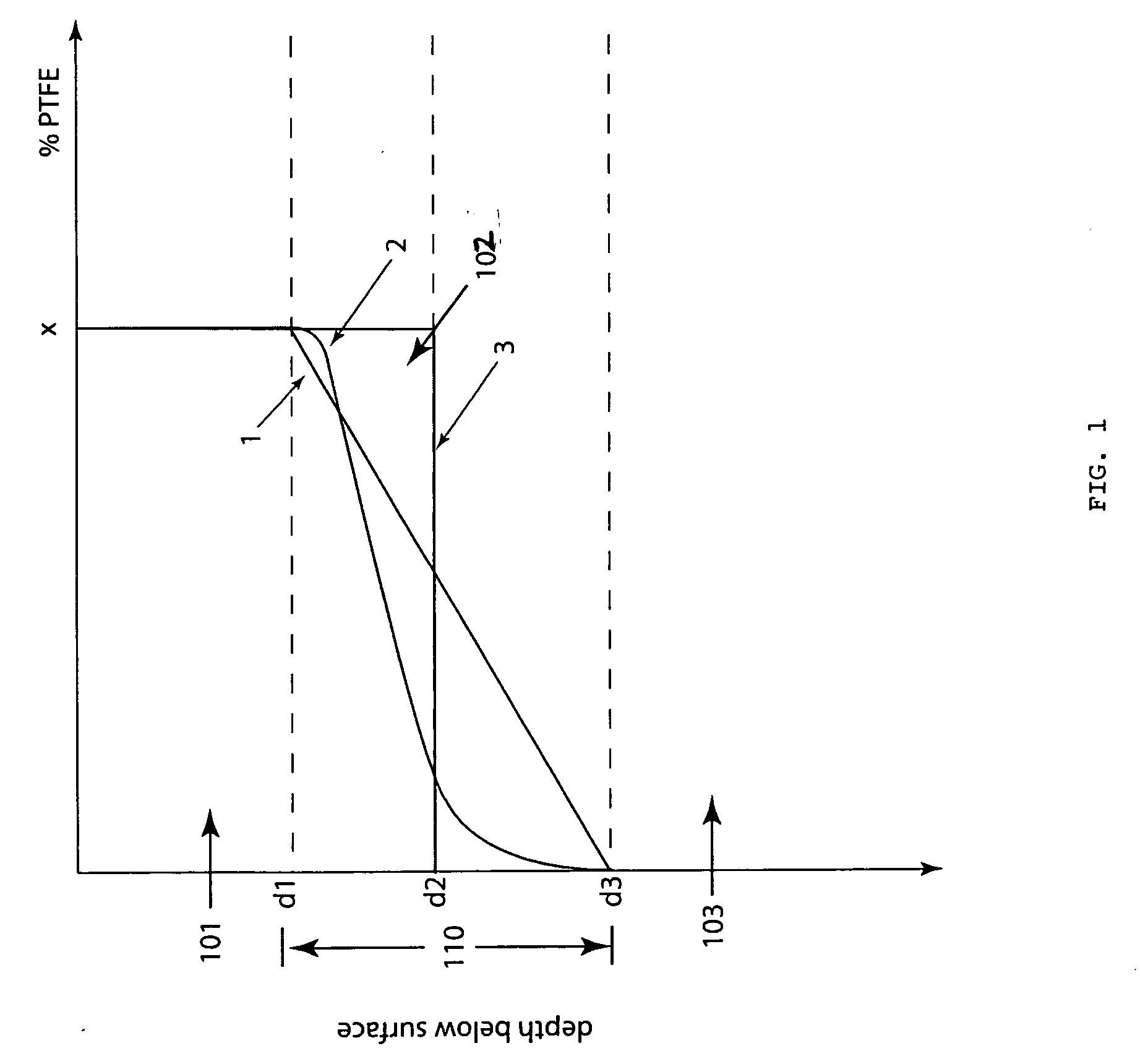

Multi-layer low friction and low wear polymer/polymer composites having compositionally graded interfaces

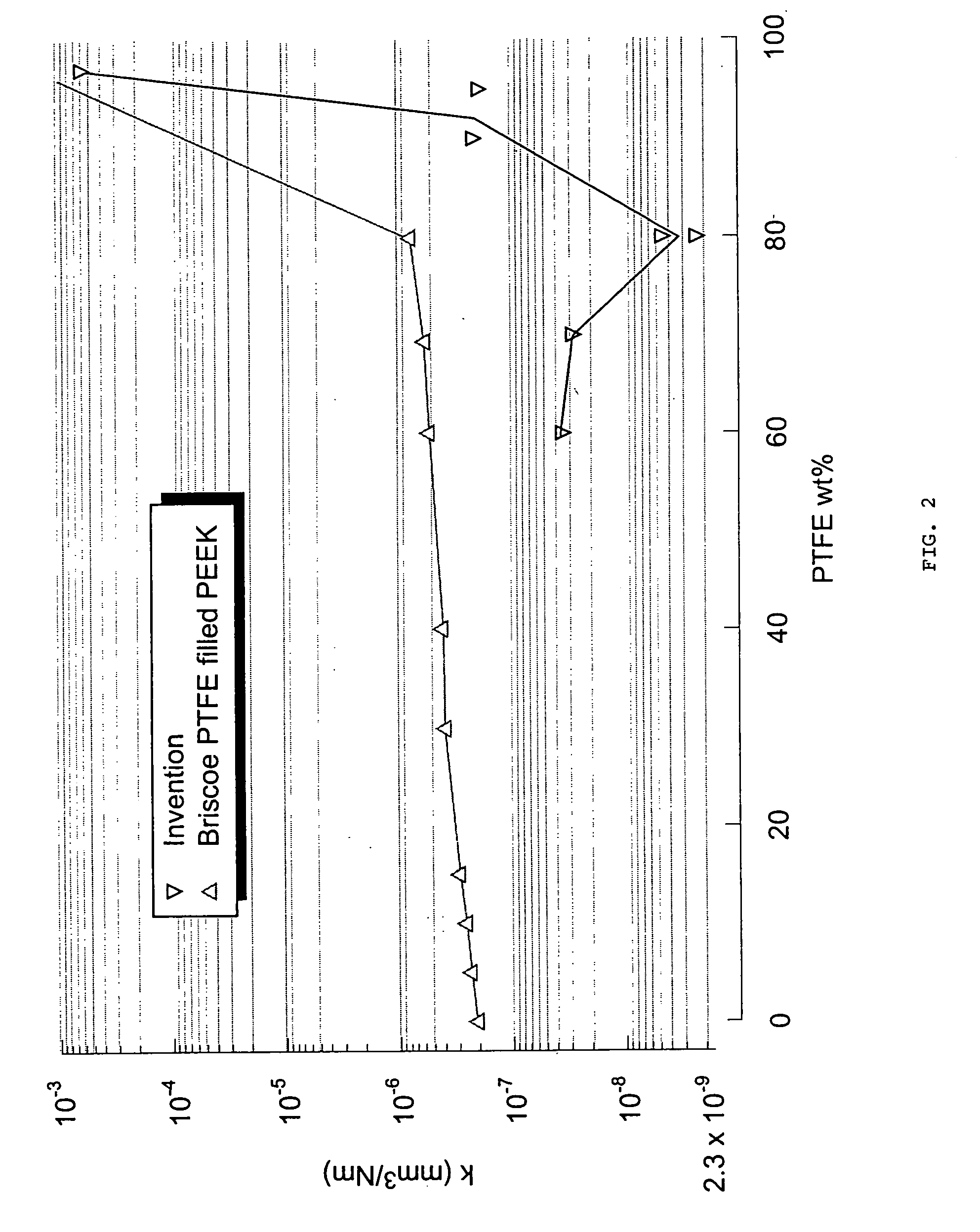

InactiveUS20060029795A1Reduce wearReduce frictionLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePolyether ether ketone

A high strength multi-layer polymeric article having a low wear surface includes a base polymer layer, and a polymer composite capping layer disposed on the base polymer layer. The capping layer includes a first polymer including a transfer film forming polymer, and a second polymer different from the first polymer for strengthening this polymer composite mixed with the first polymer. The first polymer provides at least 10 weight % of the composite capping layer. A transition layer composite including the first and second polymer is interposed between the capping layer and the base polymer layer, at least a portion of the transition layer providing a non-constant first or second polymer concentration. A wear rate of the article is <10−7 mm3 / Nm. The first polymer can be PTFE and the second polymer can be a polyaryletherketone (PEEK).

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Built up welding technique of restoring roller for shape bar

InactiveCN101003104AReduce manufacturing costArc welding apparatusFurnace typesEngineeringMechanical engineering

A build-up welding technology for repairing the rolling roller of section includes such steps as pre-turning, defect inspection, pre-heating, welding transition layer with flux-cored wire SN-YD1031 and flux SSF, welding working layer with flux-cored wire SN-YD285 and flux HJ107, heat treating, turning, and inspection.

Owner:攀枝花钢城集团有限公司协力分公司

Semiconductor element, method of manufacturing semiconductor element, multi-layer printed circuit board, and method of manufacturing multi-layer printed circuit board

InactiveUS20070209831A1Improve adhesionAvoid crackingPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringCopper

A transition layer 38 is provided on a die pad 22 of an IC chip 20 and integrated into a multilayer printed circuit board 10. Due to this, it is possible to electrically connect the IC chip 20 to the multilayer printed circuit board 10 without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on an aluminum pad 24, it is possible to prevent a resin residue on the pad 24 and to improve connection characteristics between the die pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

Method for preparing multi-metal element doped diamond film

InactiveCN101787512AImprove performanceVacuum evaporation coatingSputtering coatingCathodic arc depositionIon bombardment

The invention discloses a method for preparing a multi-metal element doped diamond film, which is characterized by comprising the following steps: removing a pollution layer on matrix surface by using the ultrasonic cleaning technology, carrying out ion beam bombardment cleaning on the matrix surface by using inert gas ion beam produced by an ion source, carrying out metal ion bombardment cleaning on the matrix surface by using metal ions produced by a cathodic arc source under a condition of high workpiece negative bias, preparing a gradient transition layer by using a cathodic arc deposition or ion beam assisted magnetron sputtering (IBAMS), and synthesizing a multi-metal element doped DLC film on the transition layer by using ion beam deposition and mosaic composite target magnetron sputtering, wherein the ion beam deposition is realized by introducing carbon gas in the ion source; and the mosaic composite target doped multiple metal are used, and the main body material of the mosaic composite target can be any one of Ti, Cr, W, Zr, Nb and Ta, and the mosaic block material is one or more of other metals except the above main body materials.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Metallic carbide/adamantine (MeC/DLC) nanometer multi-layer film material and method for preparing the same

ActiveCN101081557AImprove micro-roughnessImprove the interface binding forceLayered productsVacuum evaporation coatingCarbideHardness

The present invention is nanometer multilayer metal carbide / diamond-like film material and its preparation process. The nanometer multilayer film material includes one base material layer, one transition layer and one nanometer multilayer film layer arranged successively. The transition layer consists of one metal layer, one metal nitride layer and one metal carbonitride layer; and the nanometer multilayer film layer consists of metal carbide layers and diamond-like film layers arranged alternately. The preparation process includes: bombarding with Ti, Cr, and Zr or W targets successively to clean the base material; depositing one metal layer, one metal nitride layer and one metal carbonitride layer successively; and depositing metal carbide layers and diamond-like film layers alternately. The nanometer multilayer film material has high micro hardness, low friction coefficient and high adhesion, and may be applied in improving the surface performance of metal parts.

Owner:GUANGDONG INST OF NEW MATERIALS

Welding method of girth weld of inner cladding thin-walled stainless steel composite tube

InactiveCN101633074AResolving ingredient matchesSolve the corrosion resistanceWelding/cutting auxillary devicesAuxillary welding devicesChemical industryWeld seam

The invention relates to a welding method of a girth weld of an inner cladding thin-walled stainless steel composite tube. The welding method comprises the following steps: girth welds of the inner cladding stainless steel composite tube are respectively and gradually welded by three welding seams, an inner cladding layer welding seam and a transition layer welding seam are welded by argon tungsten-arc welding, the stainless steel inner cladding layer welding seam adopts welding wires with the same quality thereof, the transition layer welding seam adopts ER309 welding wires, and the base layer is welded by shielded metal arc welding or CO2 gas shielded welding and adopts a welding material matched with the strength of the base layer; and the inner cladding layer, the transition layer and the first layer of the base layer are welded under back argon gas protection. The welding method guarantees corrosion resistance of a joint of the inner cladding layer and mechanical property of a welding joint of the base layer; and the method plays an important role in promoting wide application of the inner cladding stainless steel composite tube in businesses such as oil-gas delivery, chemical industry, oil refining and the like, improving corrosion resistance of an inner wall of a pipe, and solving the problems of high cost and the like caused by adopting a full wall-thickness stainless steel pipe.

Owner:XI AN JIAOTONG UNIV

Self-lubricating composite soft coating cutter and manufacture method thereof

ActiveCN1927579ARealize self-lubricating functionSelf-lubricating function preventsLayered productsVacuum evaporation coatingManufacturing technologyMiddle frequency

The invention relates to a self-lubricant composite soft coat blade, and relative production. Wherein, said blade uses the MoS2 / Zr / Ti composite coat blade made from middle-frequency magnetic-control multi-arc plating method; the surface of blade is MoS2 layer, between which can base there are Ti, MoS2 / Zr / Ti, and MoS2 / Zr transition layer; when using said blade to cut, the surface of blade can form continuous lubricant layer, to realize self-lubricant function; since the solid lubricant has low shearing strength, the solid lubricant layer will be transferred to the surface of work piece, to form transfer film and the friction in the cutting process will generate inside the solid lubricant layer, to reduce friction, reduce shearing force and reduce shearing temperature.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

Gradient compound material and preparation method

InactiveCN101077644AReduce manufacturing costLarge compositional variabilityCeramic layered productsMetal layered productsAlloyCeramic

The gradient composite material consists of a base, transition layers and a working layer combined through metallurgical combination, and has composition and performance in controlled gradient change from the base to the working layer. The transition layers include several layers, and the working layer may be one or several layers. Each of the transition layers has thickness of 0.1-50 mm, preferably 0.5-5 mm, and the working layer has thickness of 0.1-1000 mm, preferably 2-30 mm. When the working layer is of ceramic or high alloy, the transition layer adjacent to the working layer has high content of ceramic or alloy. The composite material has reasonable comprehensive performance and the working layer has excellent performance.

Owner:NANJING SHENGRUN TECH

Photoactive component with organic layers

ActiveUS7675057B2Reduce recombination lossHigh yieldNanoinformaticsSolid-state devicesQuantum yieldTransport layer

Owner:HELIATEK GMBH

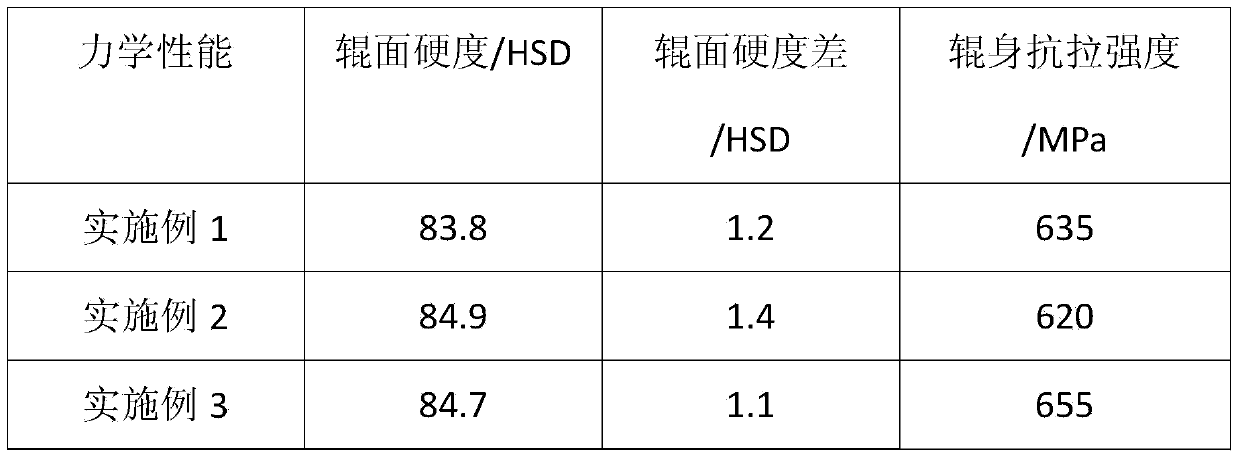

Resource-saving type high-boron high-speed steel composite roll and manufacturing method thereof

ActiveCN103624084AStrong metallurgical bondLow costRollsMetal rolling arrangementsSocial benefitsResource saving

The invention discloses a resource-saving type high-boron high-speed steel composite roll and a manufacturing method of the resource-saving type high-boron high-speed steel composite roll, and belongs to the technical field of rolls. The composite roll is composed of outer-layer high-boron high-speed steel, middle transition-layer graphitic steel and roll core hot rolling medium-carbon round steel, the outer-layer high-boron high-speed steel and the middle transition-layer graphitic steel are formed in a centrifugal combination mode, and the transition-layer graphitic steel and the roll core hot rolling medium-carbon round steel are formed in a hot charging combination mode. The composite roll is high in roll face rigidity and good in rigidity uniformity, and it is guaranteed that the composite roll is excellent in abrasive resistance. A roll core is formed by machining the hot rolling medium-carbon round steel and is good in obdurability, the roll breakage accident cannot happen in the roll using process, and good economic benefits and social benefits are achieved through popularization and application.

Owner:枣庄瑞兴机械制造有限公司

Water based environmental barrier coatings for high temperature ceramic components

Environmental barrier coatings for high temperature ceramic components including: a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material selected from a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least water, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

Gallium nitride material structures including substrates and methods associated with the same

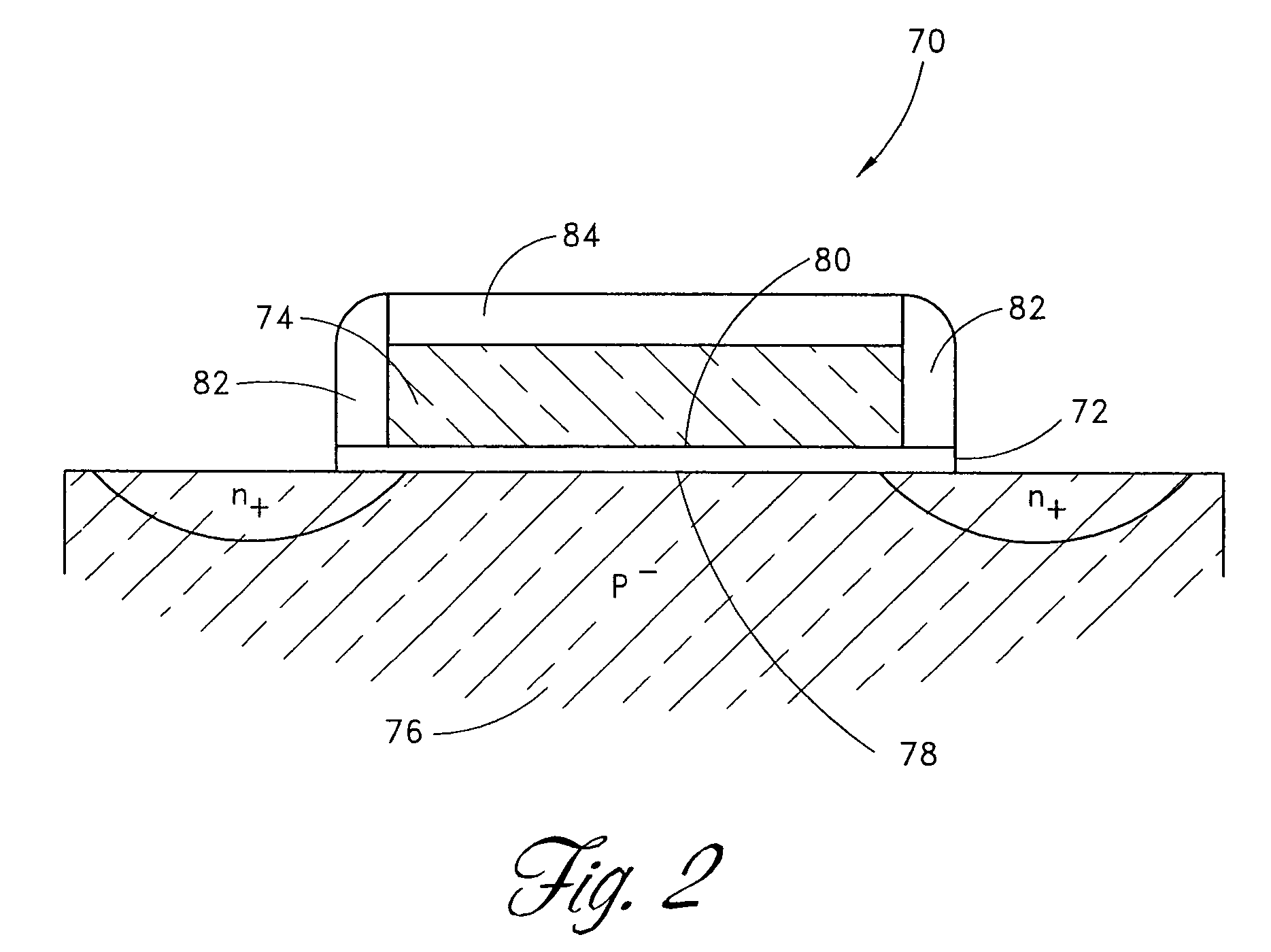

ActiveUS7365374B2Semiconductor/solid-state device manufacturingSemiconductor devicesStress conditionsSemiconductor structure

Gallium nitride material-based semiconductor structures are provided. In some embodiments, the structures include a composite substrate over which a gallium nitride material region is formed. The gallium nitride material structures may include additional features, such as strain-absorbing layers and / or transition layers, which also promote favorable stress conditions. The reduction in stresses may reduce defect formation and cracking in the gallium nitride material region, as well as reducing warpage of the overall structure. The gallium nitride material-based semiconductor structures may be used in a variety of applications such as transistors (e.g. FETs) Schottky diodes, light emitting diodes, laser diodes, SAW devices, and sensors, amongst others devices.

Owner:MACOM TECH SOLUTIONS HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com