Manufacturing method of multilayer shell-core composite structural part

A composite structure and multi-layer shell technology, which is applied in the direction of chemical instruments and methods, layered products, ceramic layered products, etc., can solve the problem of inability to obtain multi-layer shell-core composite structure parts, inability to organize, precise control of performance, and mechanical bearing Good capacity and other issues, to achieve the effect of good lasting stability, strong impact load capacity, and strong mechanical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

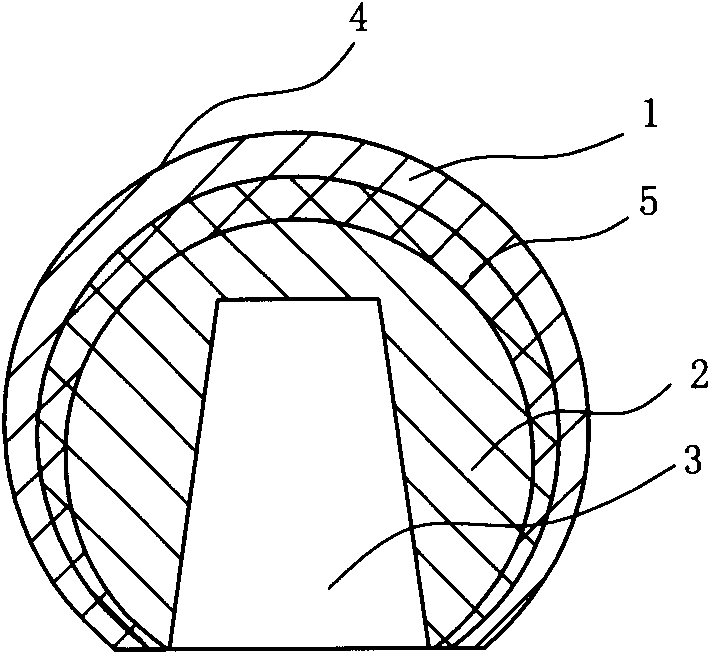

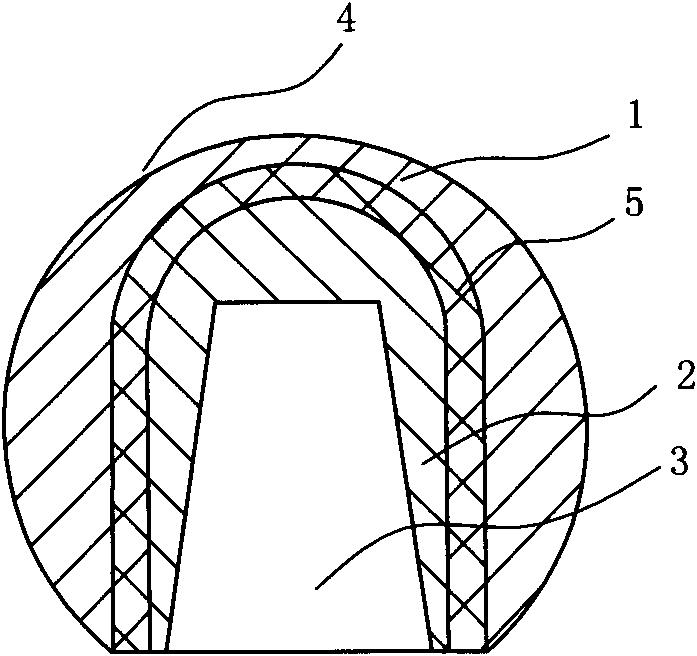

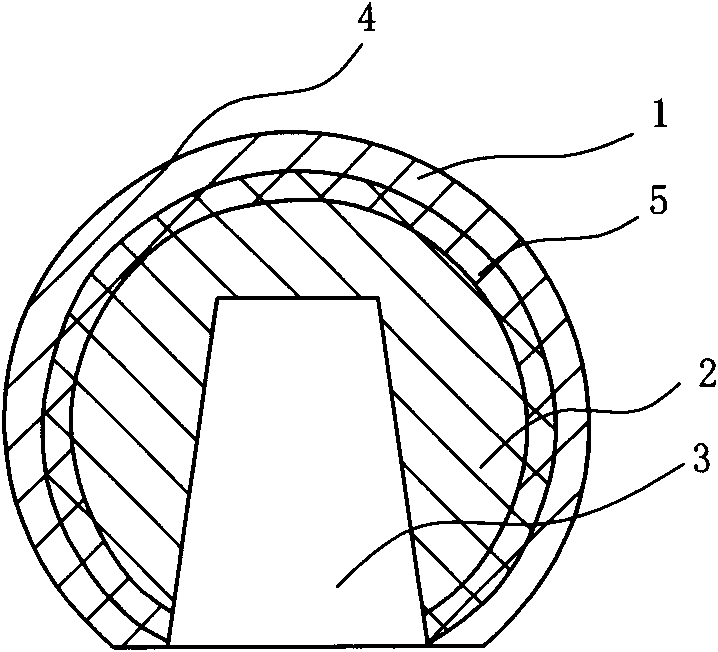

[0038] A femoral head with a multilayer shell-core composite structure, which is composed of a high-purity ultrafine alumina ceramic spherical shell layer 1, an alumina-based (niobium) cermet middle layer 5 (i.e. transition layer) and a niobium metal inner core 2. The composite structure of multilayer tissue has such Figure 1 to Figure 5 The five forms shown can be selected according to the application requirements.

[0039] see Image 6 , the specific preparation process is:

[0040] (1) Prepare high-purity ultrafine alumina powder, alumina-based (niobium) cermet composite powder and niobium metal powder injection molding feedstock respectively. The purity of the high-purity ultrafine aluminum oxide powder is greater than 99.9 wt%, and the particle size is 0.5-10 μm; the purity of the niobium metal powder is greater than 99.8 wt%, and the particle size is 0.5-10 μm. In order to reduce the sintering temperature and improve the sintering performance, 0.25wt.% MgO powder is a...

Embodiment 2

[0048] A multi-layer shell-core composite structure femoral head, which is made of high-purity ultra-fine alumina ceramic spherical shell layer 1, ZrO 2 (3Y 2 o 3 )-80wt.%Al 2 o 3 Toughened ceramic interlayer 5 and ZrO 2 (3Y 2 o 3 )-20wt.%Al 2 o 3 Toughened ceramic core 2 consists of three parts.

[0049] see Image 6 , the specific preparation process is:

[0050] (1) Prepare high-purity ultra-fine alumina powder, ZrO 2 (3Y 2 o 3 )-80wt.%Al 2 o 3 Composite powder and ZrO 2 (3Y 2 o 3 )-20wt.%Al 2 o 3 Composite powder injection molding feed. The purity of high-purity ultra-fine alumina powder is greater than 99.9wt%, and the particle size is 0.5-10 μm; ZrO 2 The purity of the powder is greater than 99.8 wt%, and the particle size is 0.5-10 μm. In order to reduce the sintering temperature and improve the sintering performance, 0.25wt.% MgO powder is added to the high-purity ultrafine alumina powder as a sintering aid. Prepared modified alumina powder, ZrO ...

Embodiment 3

[0058] A femoral condyle prosthesis (one of artificial knee joint components) with a multi-layer shell-core composite structure, consisting of Ti6Al4V core layer 1, Ti6Al4V-20vol.%Al 2 o 3 Transition layer 2, Ti6Al4V-60vol.%Al 2 o 3 Transition layer 3 and high-purity ultra-fine Al 2 o 3 The ceramic shell layer 4 is composed.

[0059] see Image 6 , the specific preparation process is:

[0060] (1) Separately prepare high-purity ultra-fine Al 2 o 3 Powder, Ti6Al4V-60vol.%Al 2 o 3 Composite powder, Ti6Al4V-20vol.%Al 2 o 3 Composite powder and Ti6Al4V powder injection molding feedstock. High-purity ultra-fine Al 2 o 3 The purity of the powder is greater than 99.9wt%, and the particle size is 0.5-5μm; the purity of the Ti6Al4V powder is greater than 99.5wt%, and the particle size is 10-35μm. In order to reduce the sintering temperature and improve the sintering performance in high-purity ultra-fine Al 2 o 3 Add 0.1wt.% MgO powder to the powder as a sintering aid. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com