Patents

Literature

246 results about "Artificial knee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhering to an exercise program can make your artificial knee as strong as that of a healthy adult of the same age. Bruising. Some bruising after surgery is normal. It disappears as the wound drains.

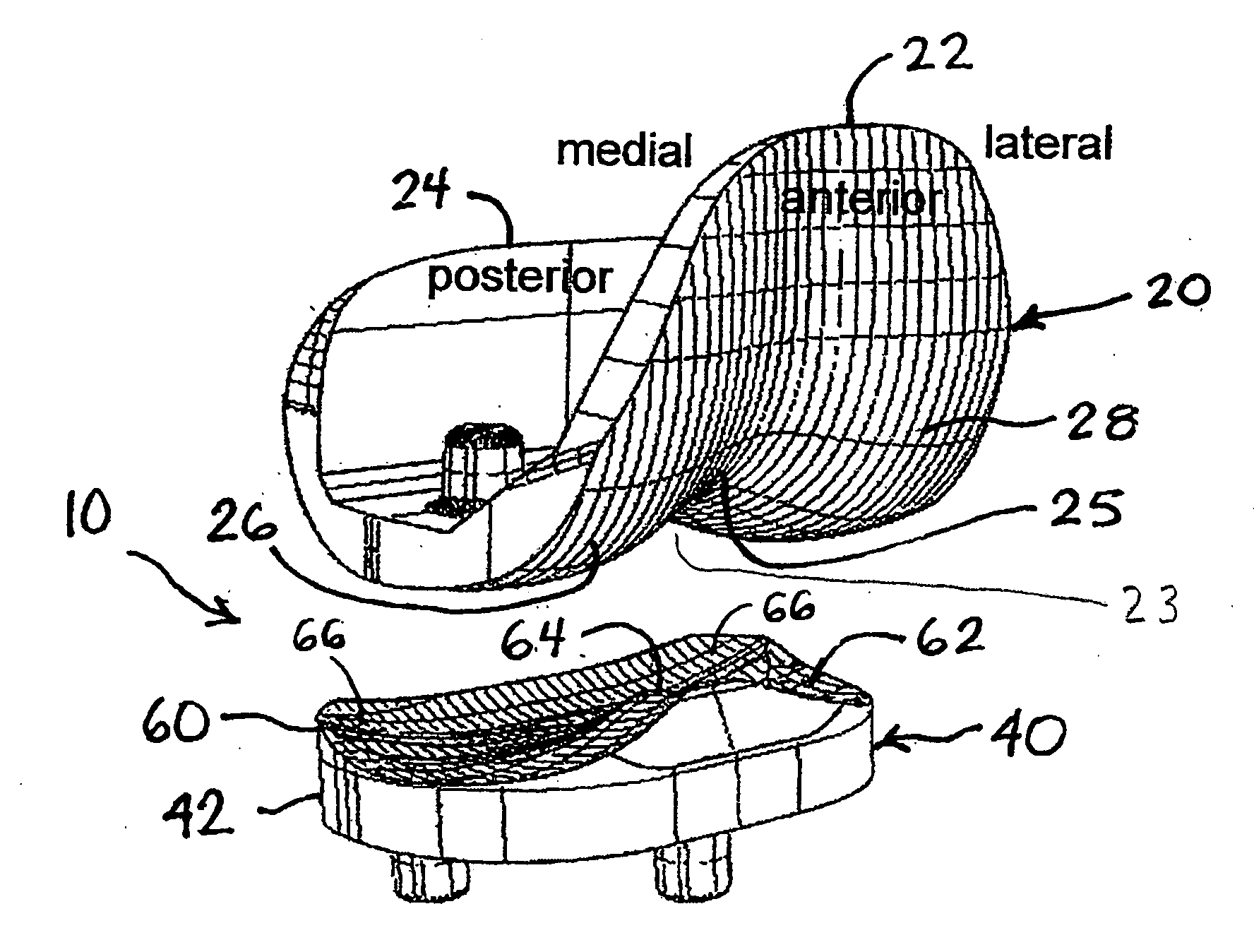

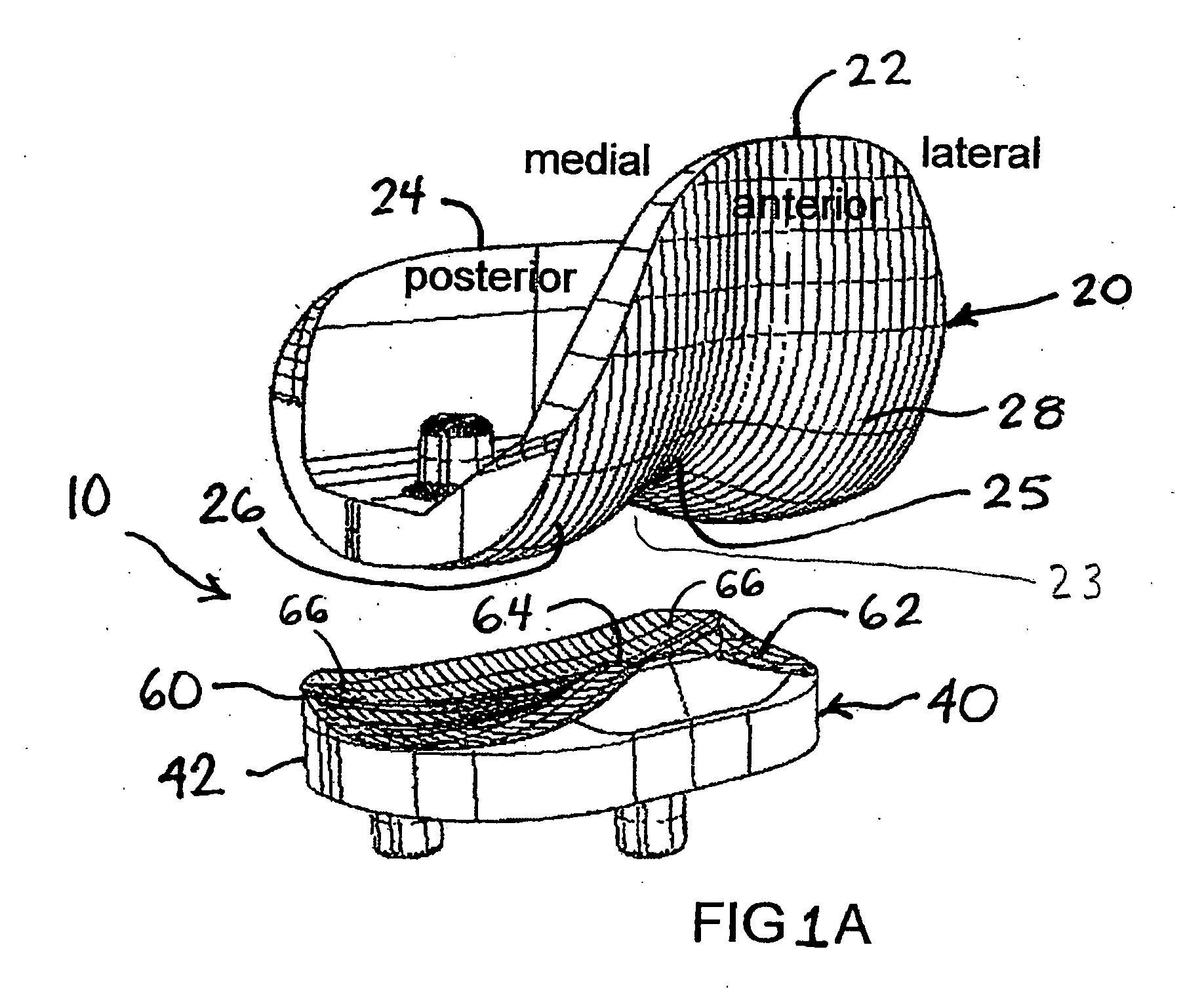

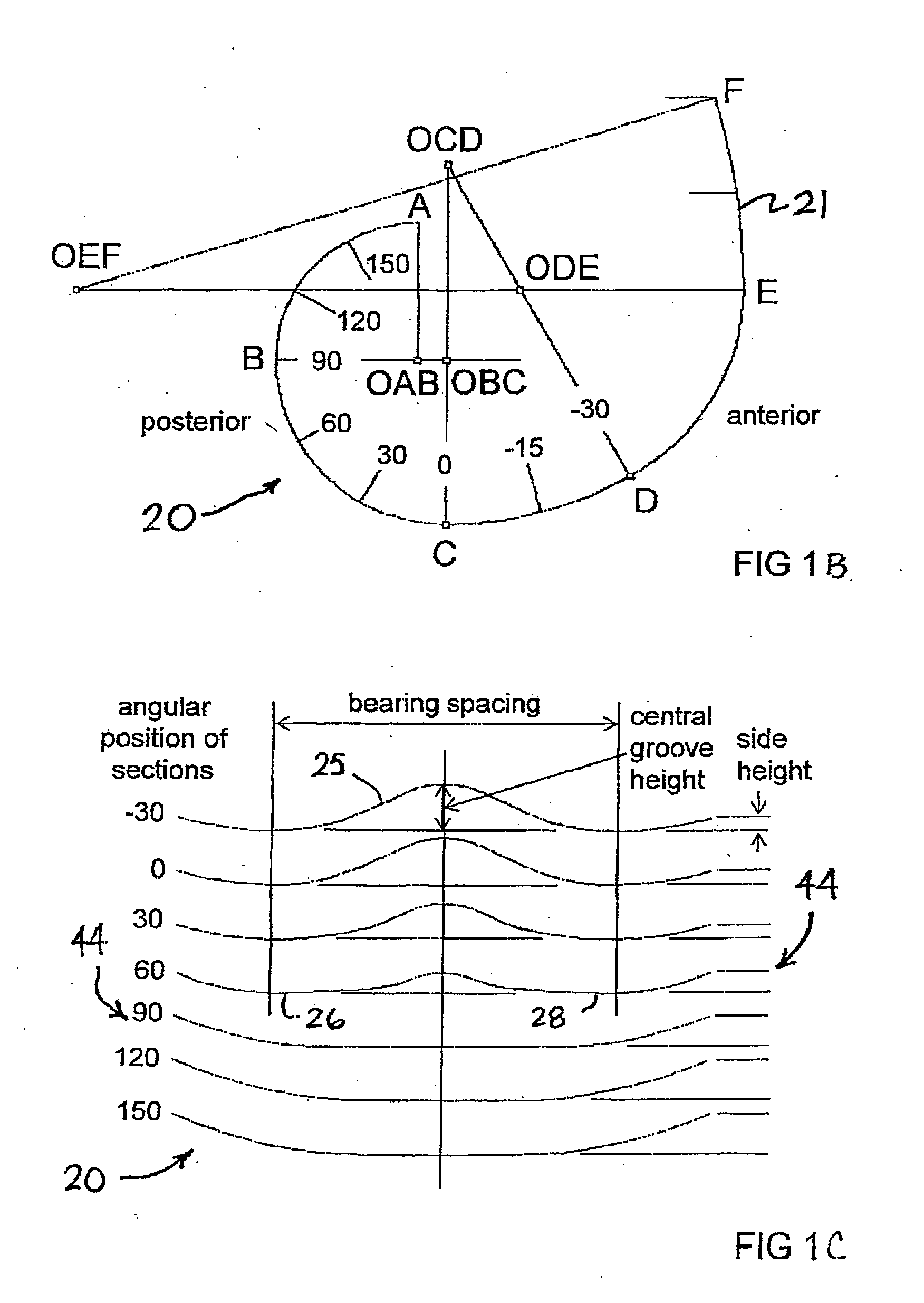

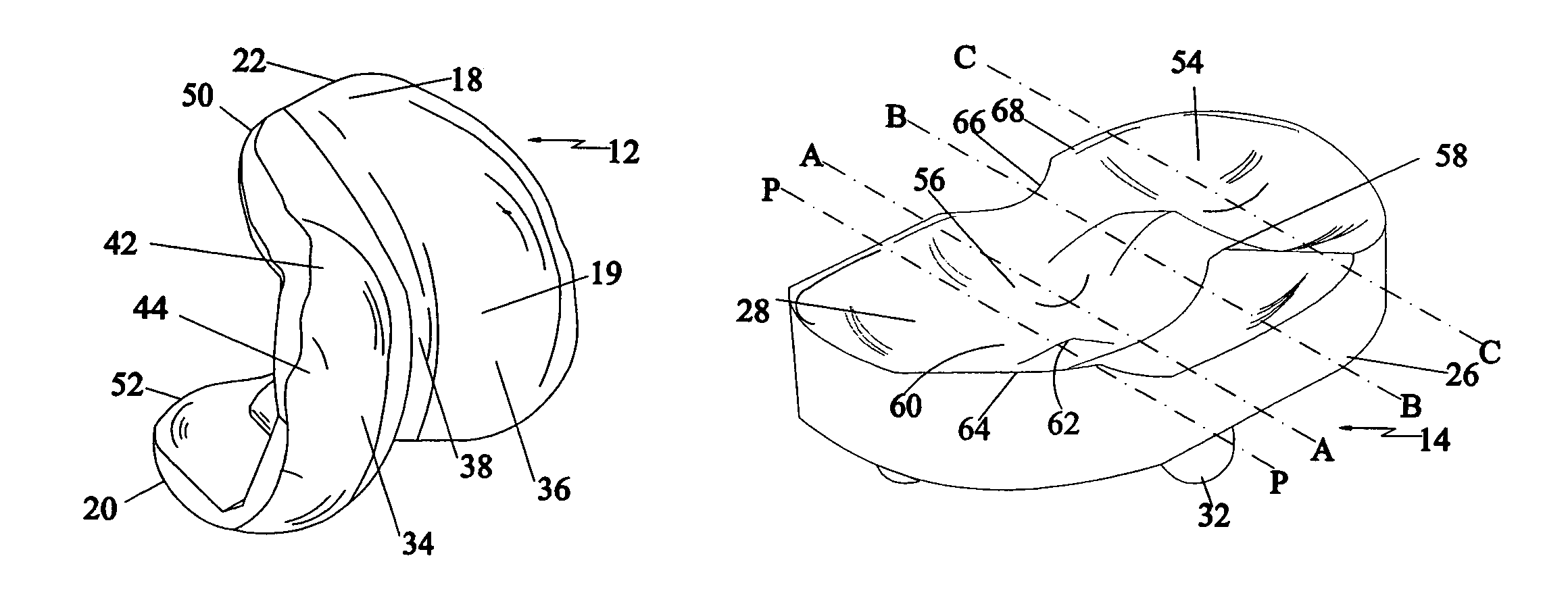

Surface guided knee replacement

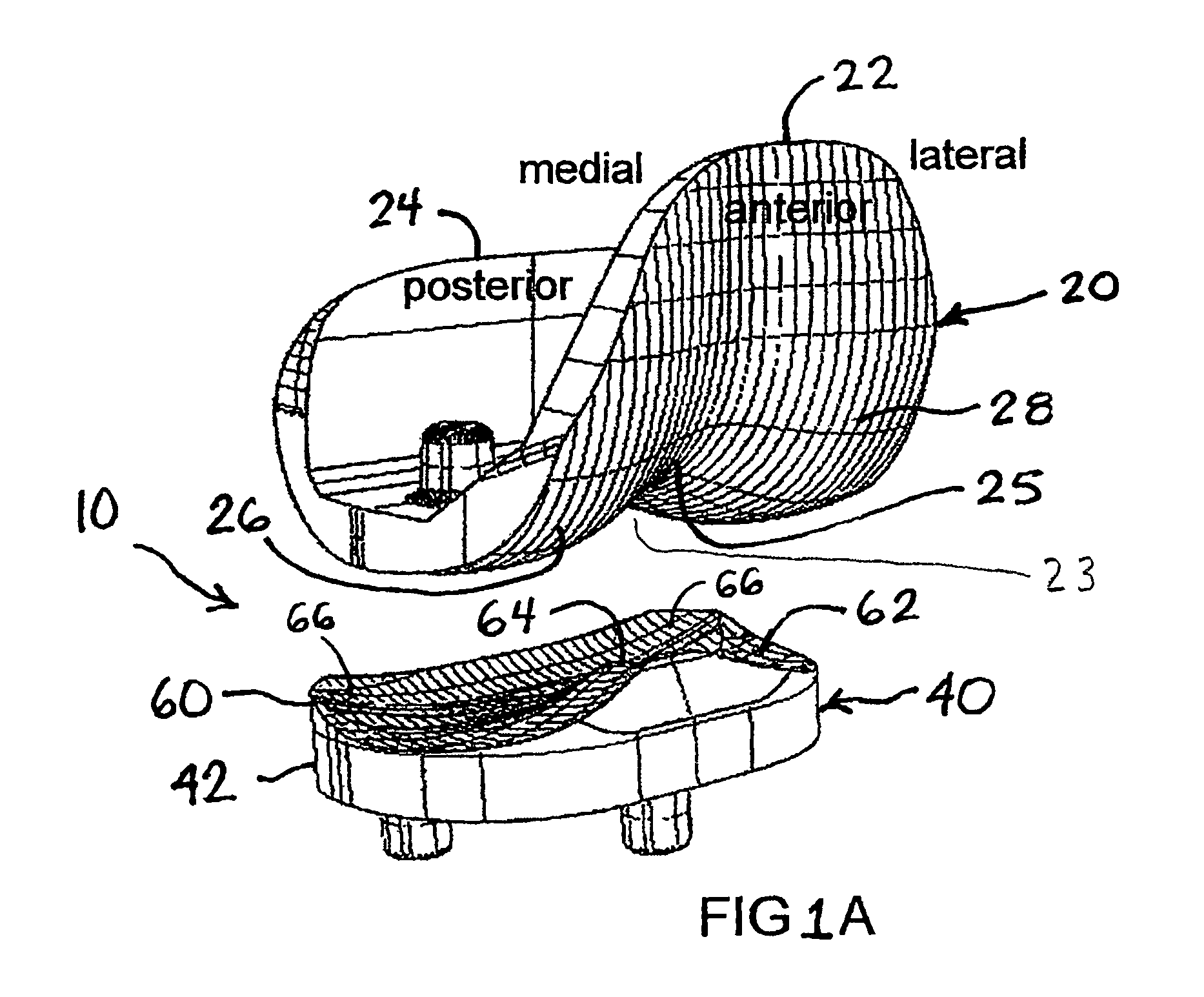

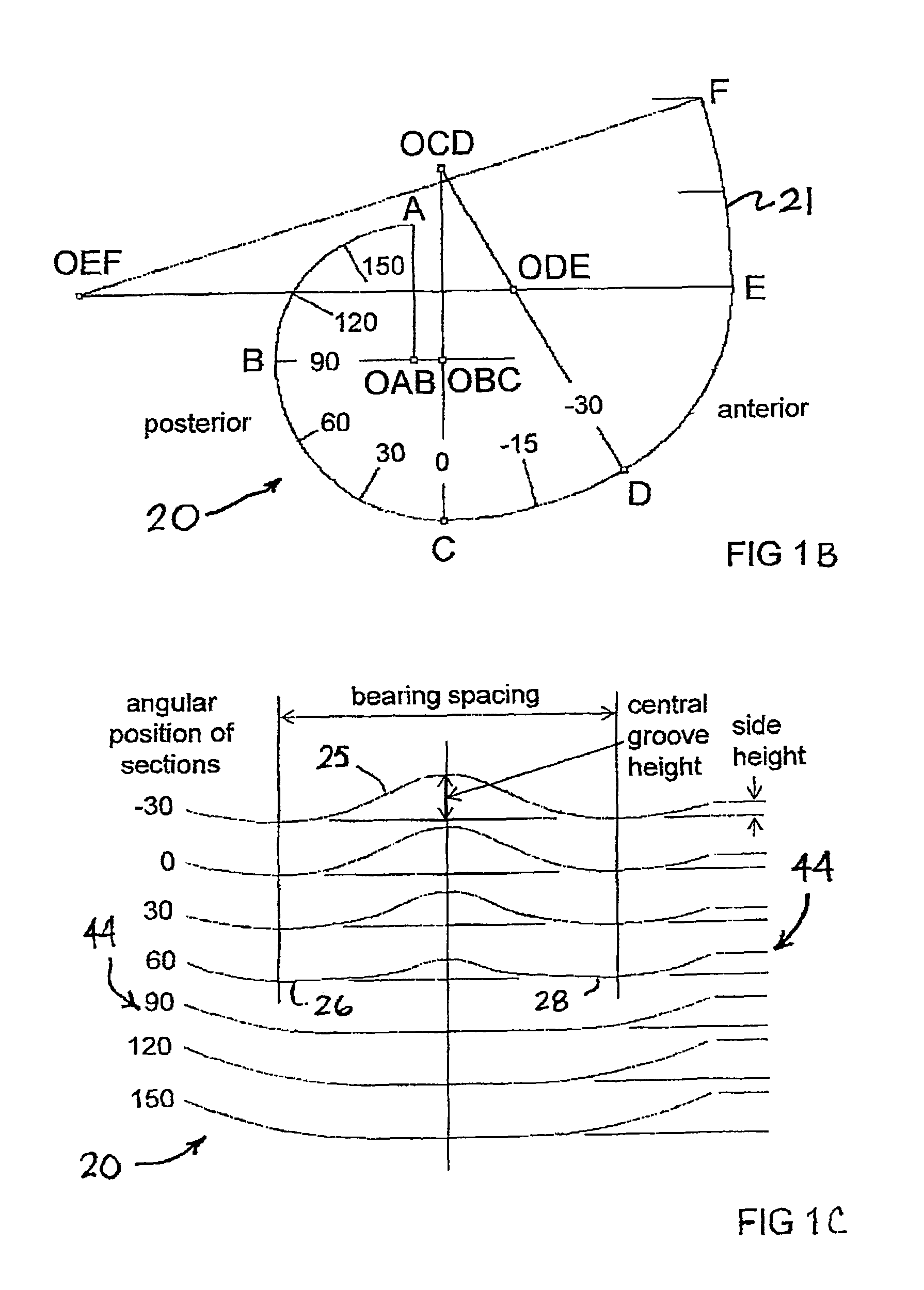

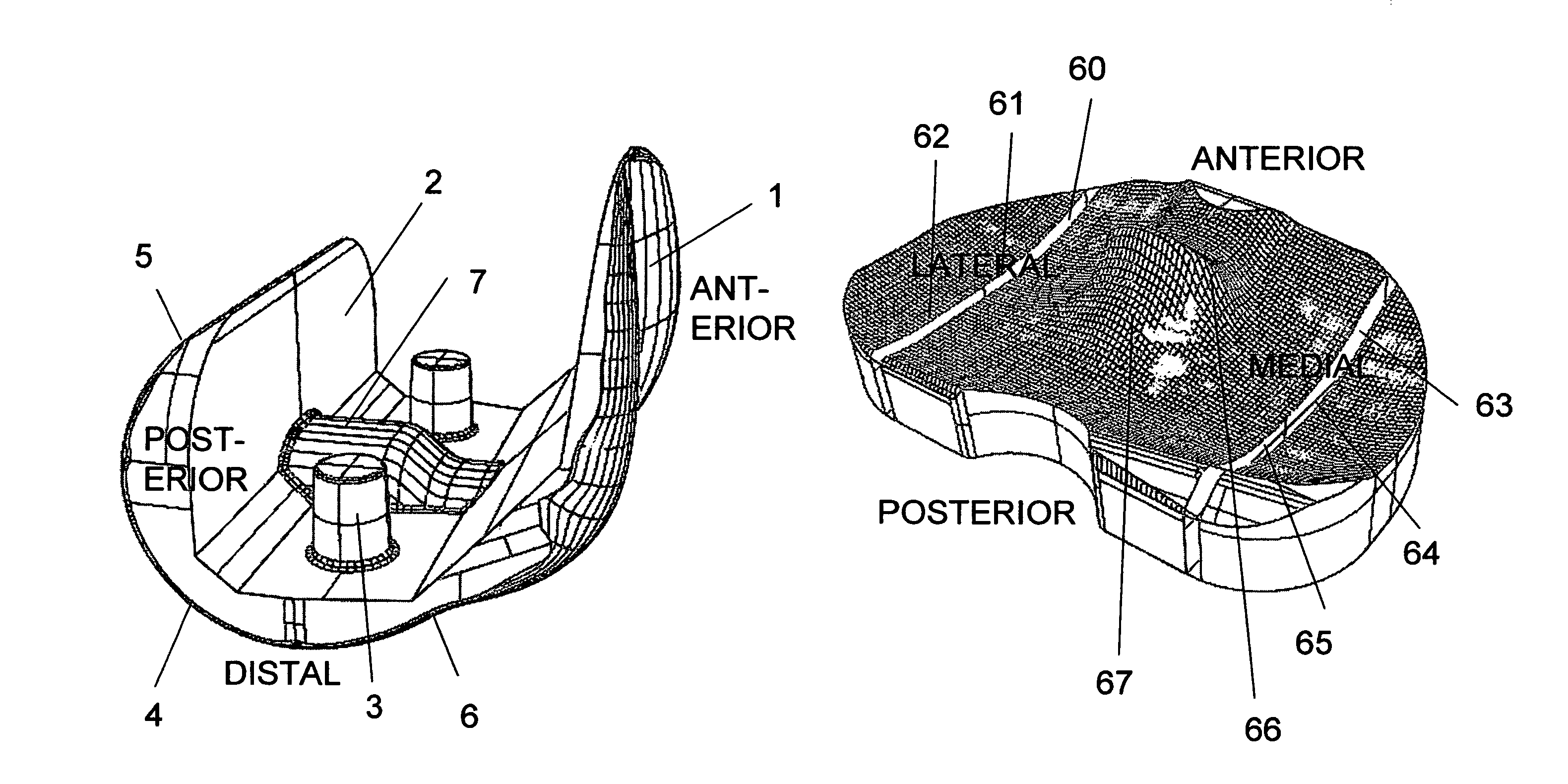

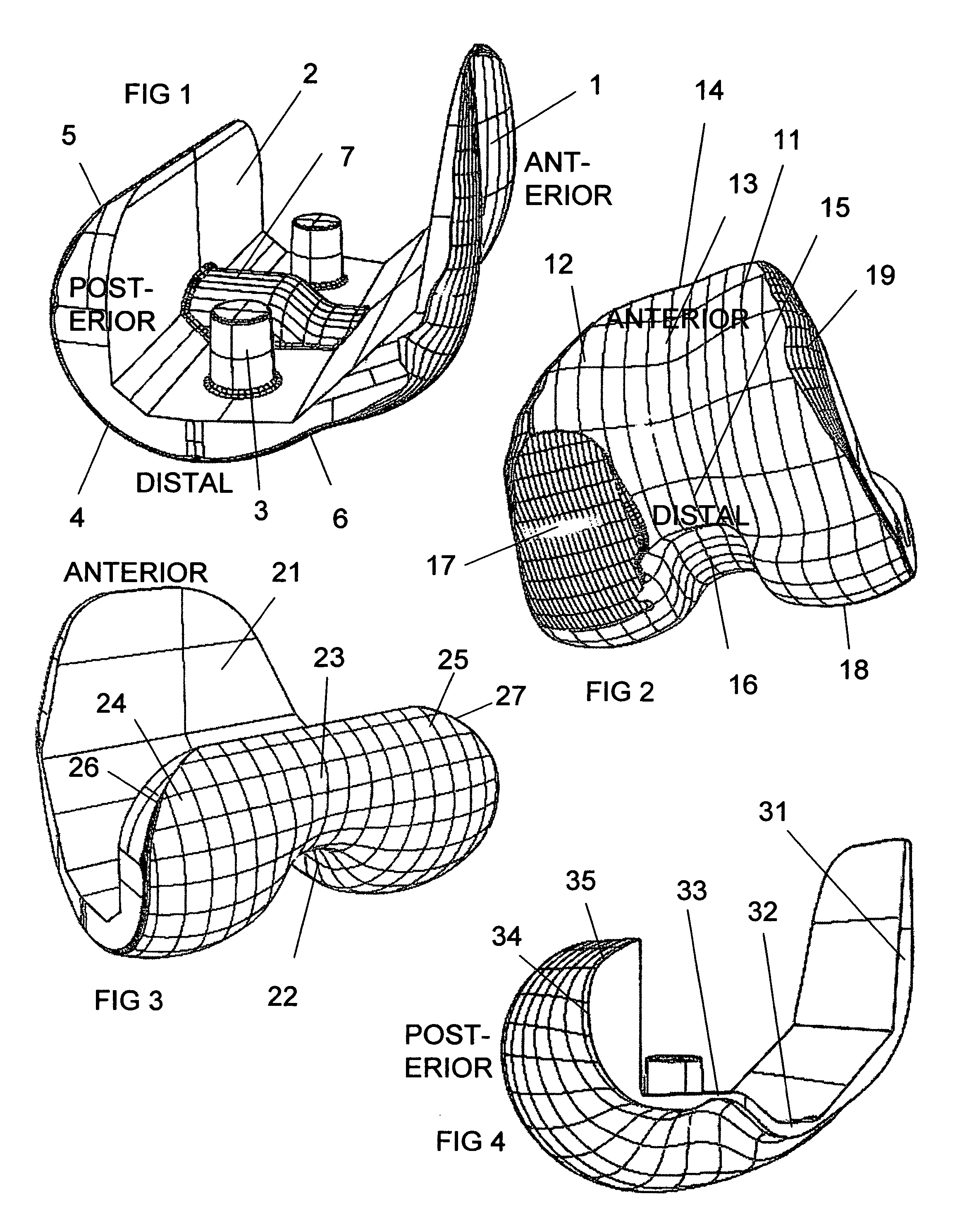

ActiveUS20070135926A1Increase contact areaIncrease flexibilityJoint implantsKnee jointsTibiaTibial surface

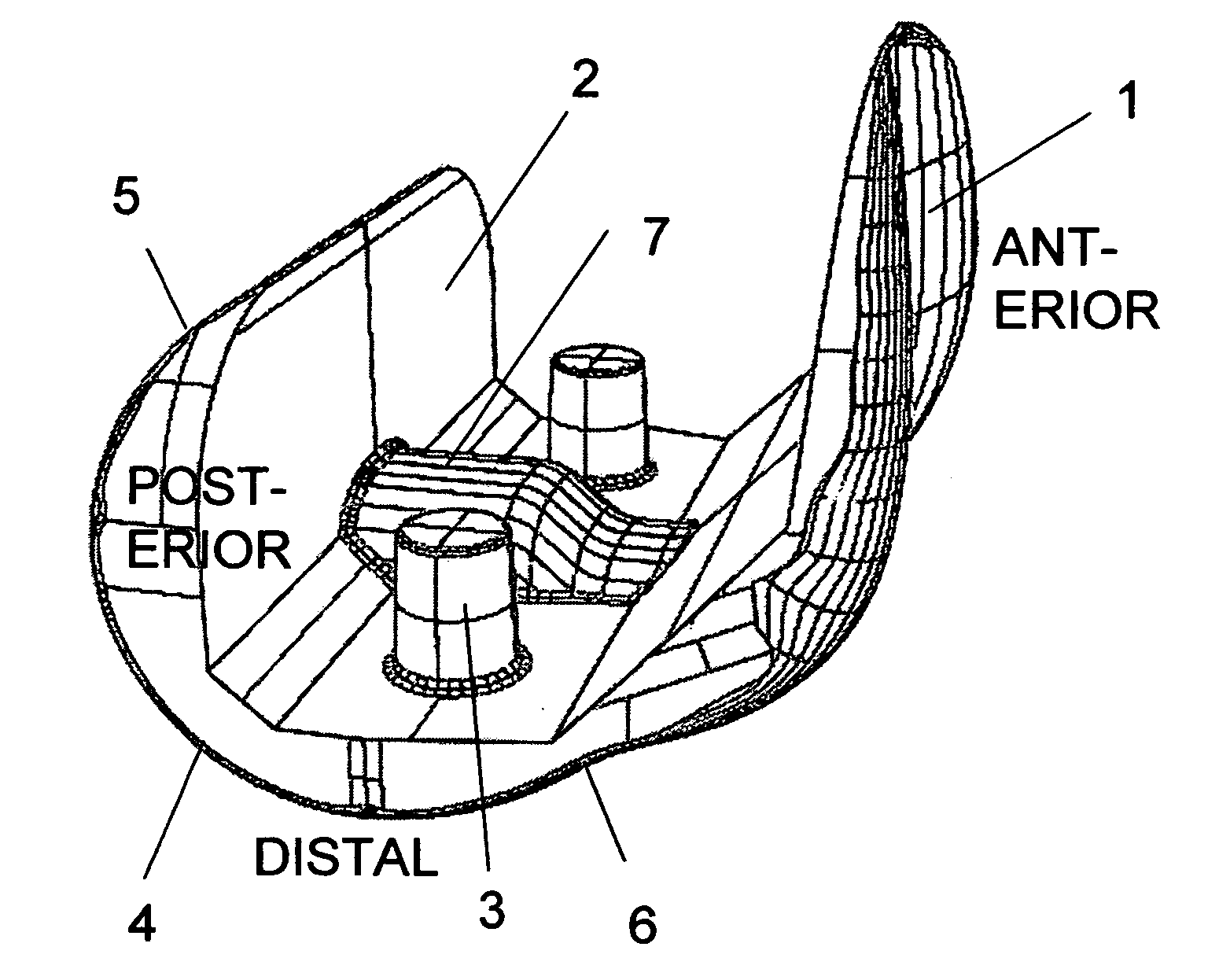

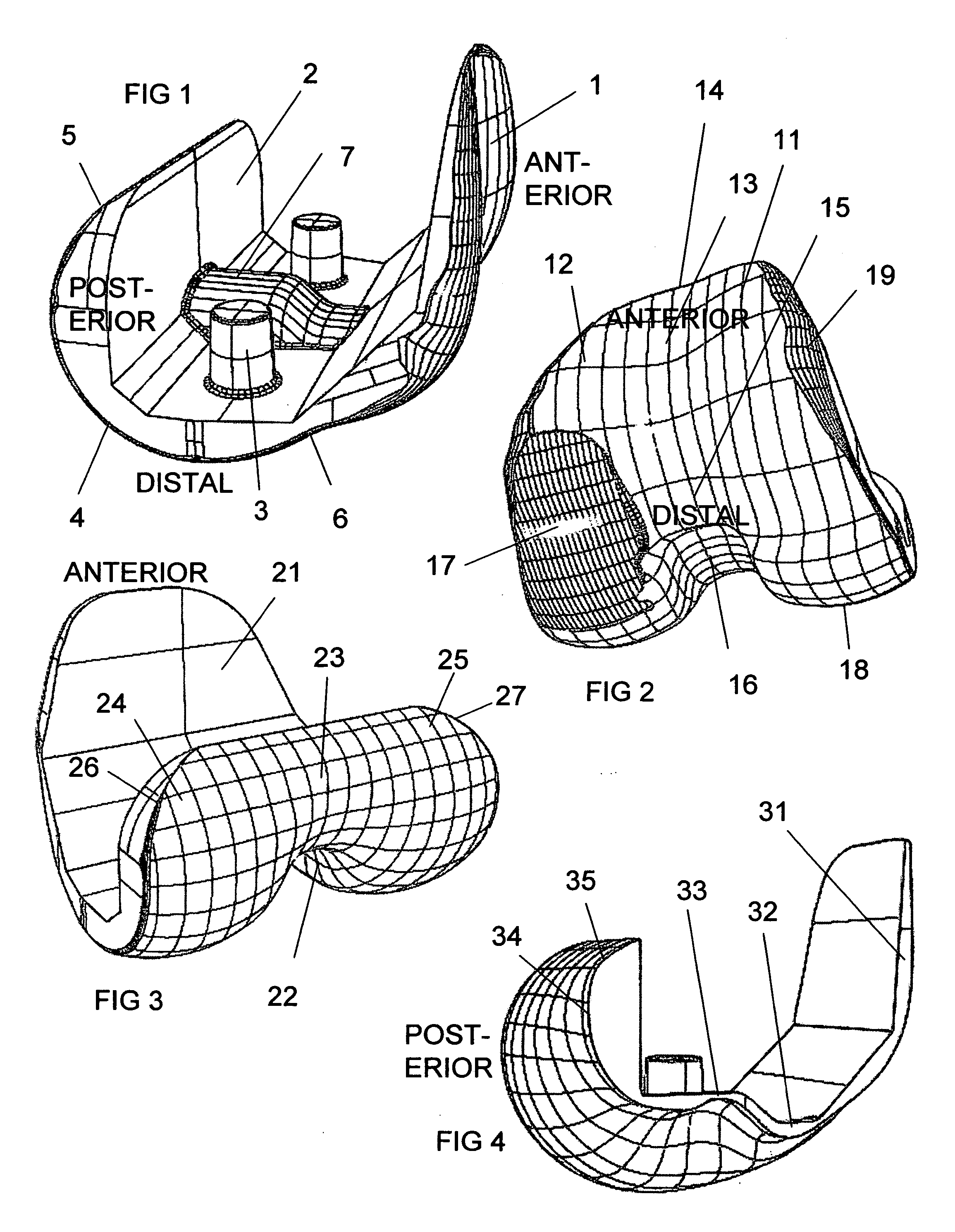

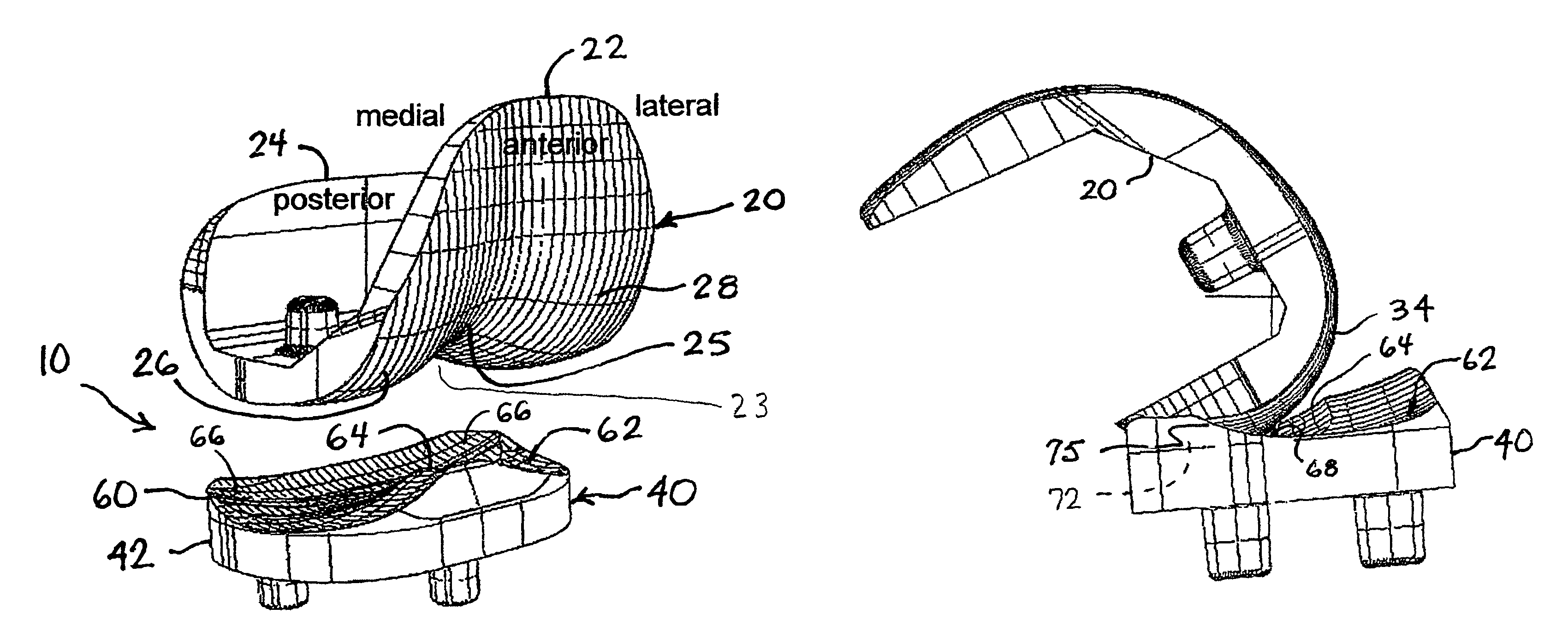

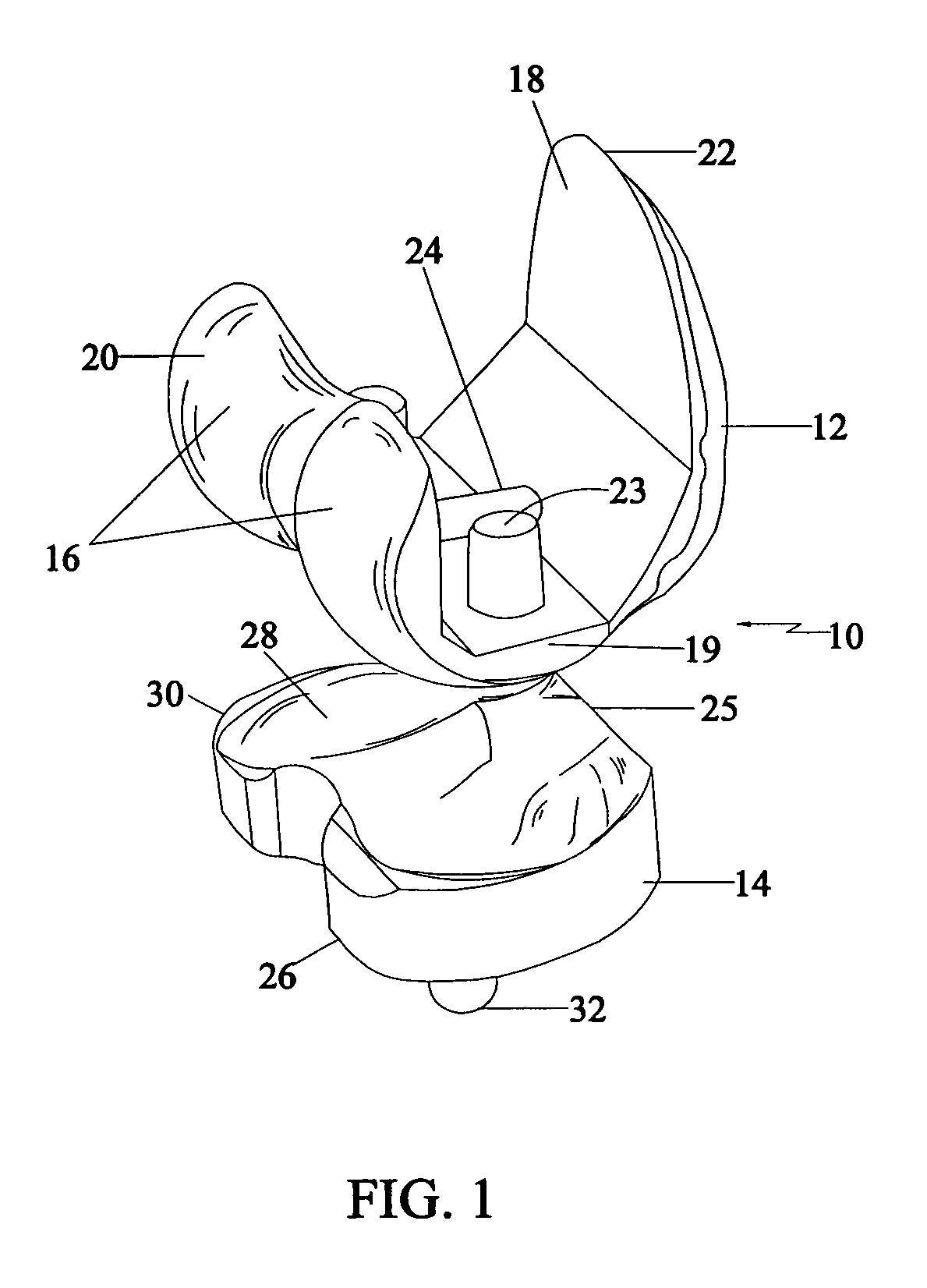

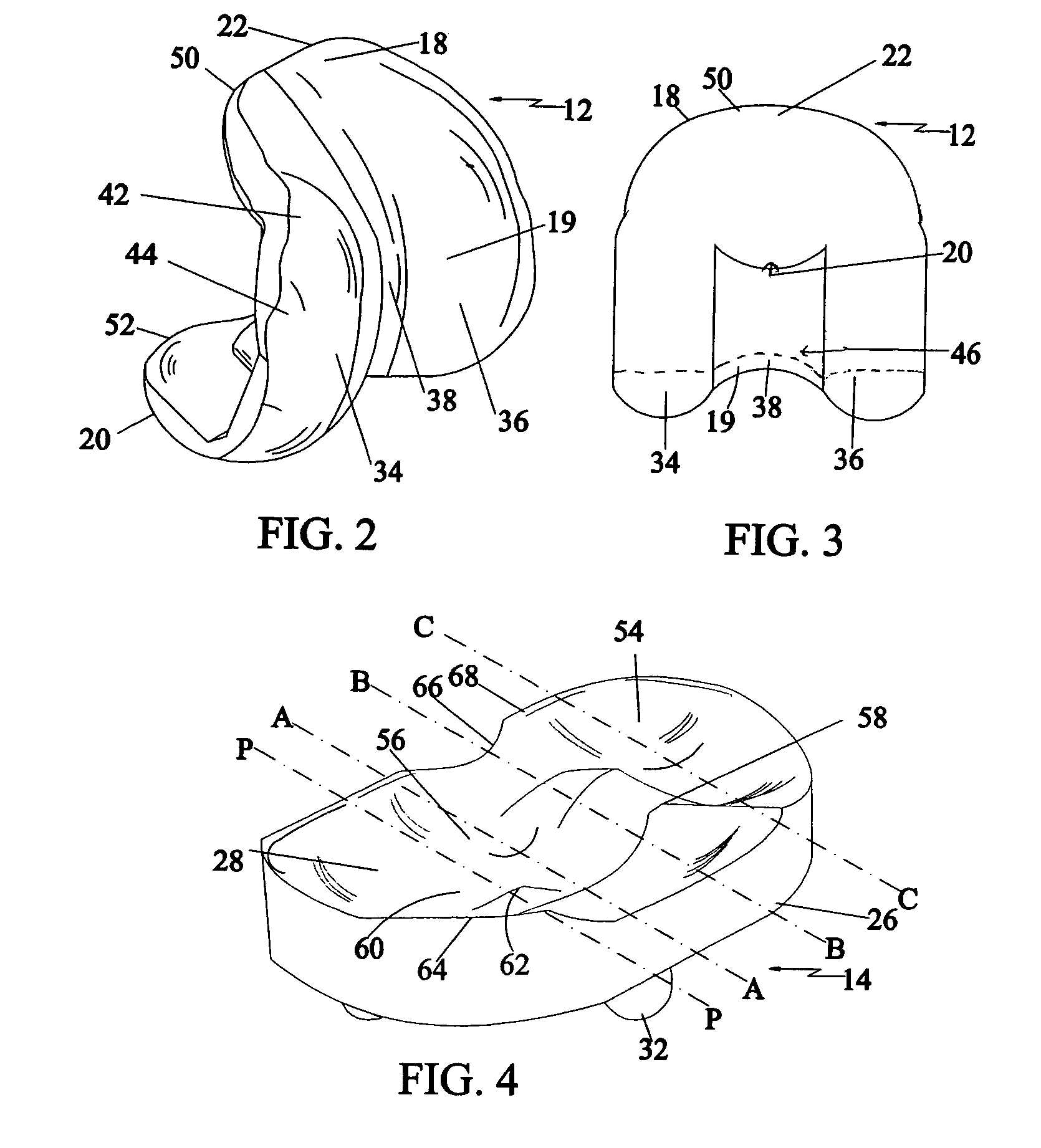

An artificial knee joint that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the required motion and stability characteristics. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, by an amount similar to that in the anatomic knee. This is accomplished primarily by the depth and width of the femoral trochlea diminishing as the femoral component is flexed from zero to maximum, together with a ramp on the center of the tibial surface. The opposite motion, roll forward of the femur from a fully flexed to a more extended position, is accomplished by varying the outward radii of the lateral and medial femoral bearing surfaces, together with a ramp on the postero-lateral and postero-medial regions of the tibial surfaces. A variation of this is to generate a tibial surface which provides for a progressive internal rotation of the tibia as flexion proceeds.

Owner:NEW YORK UNIV

Artificial knee joint

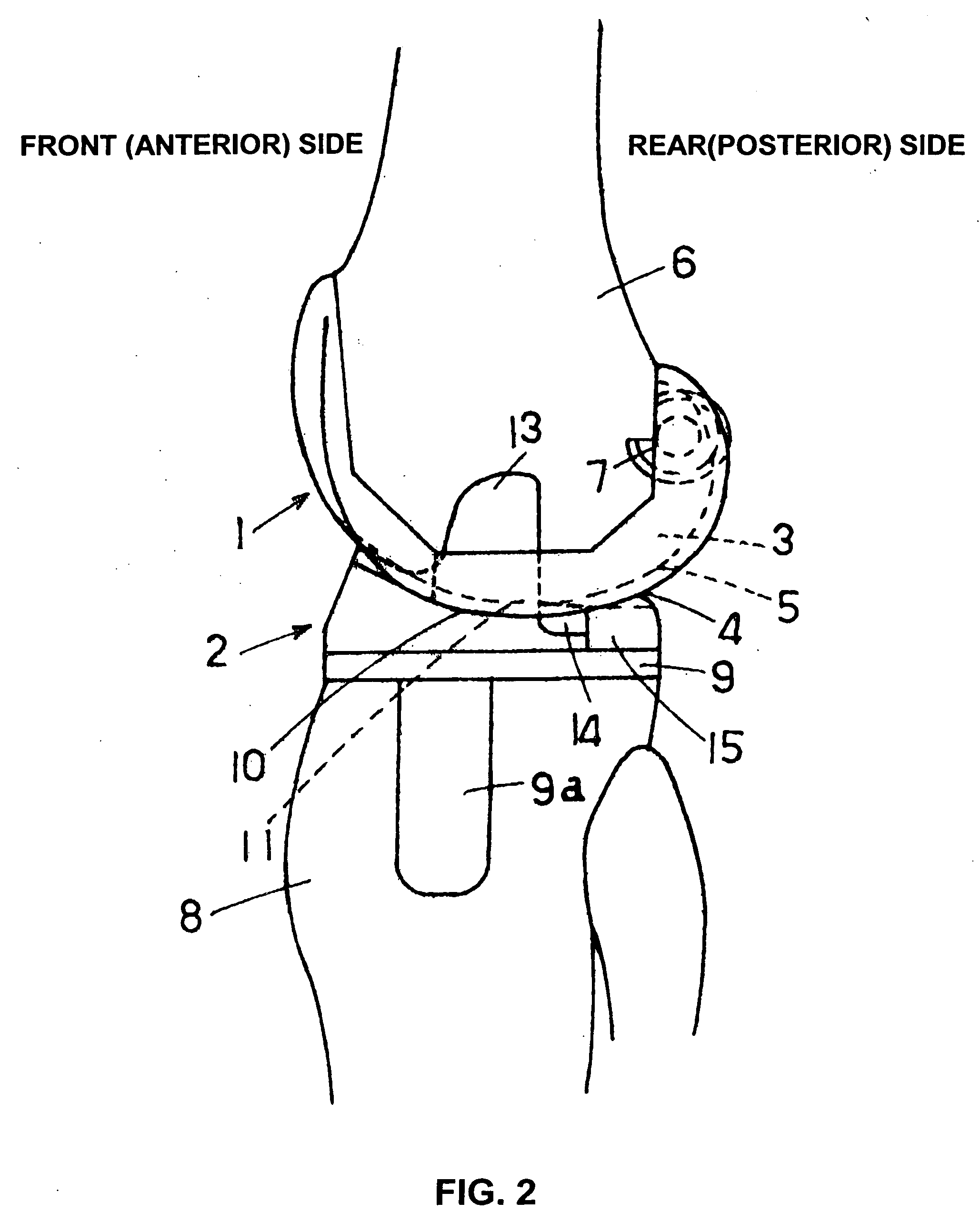

InactiveUS20050209701A1Readily induce rotationReduce wearJoint implantsArtificial legsArticular surfacesTibia

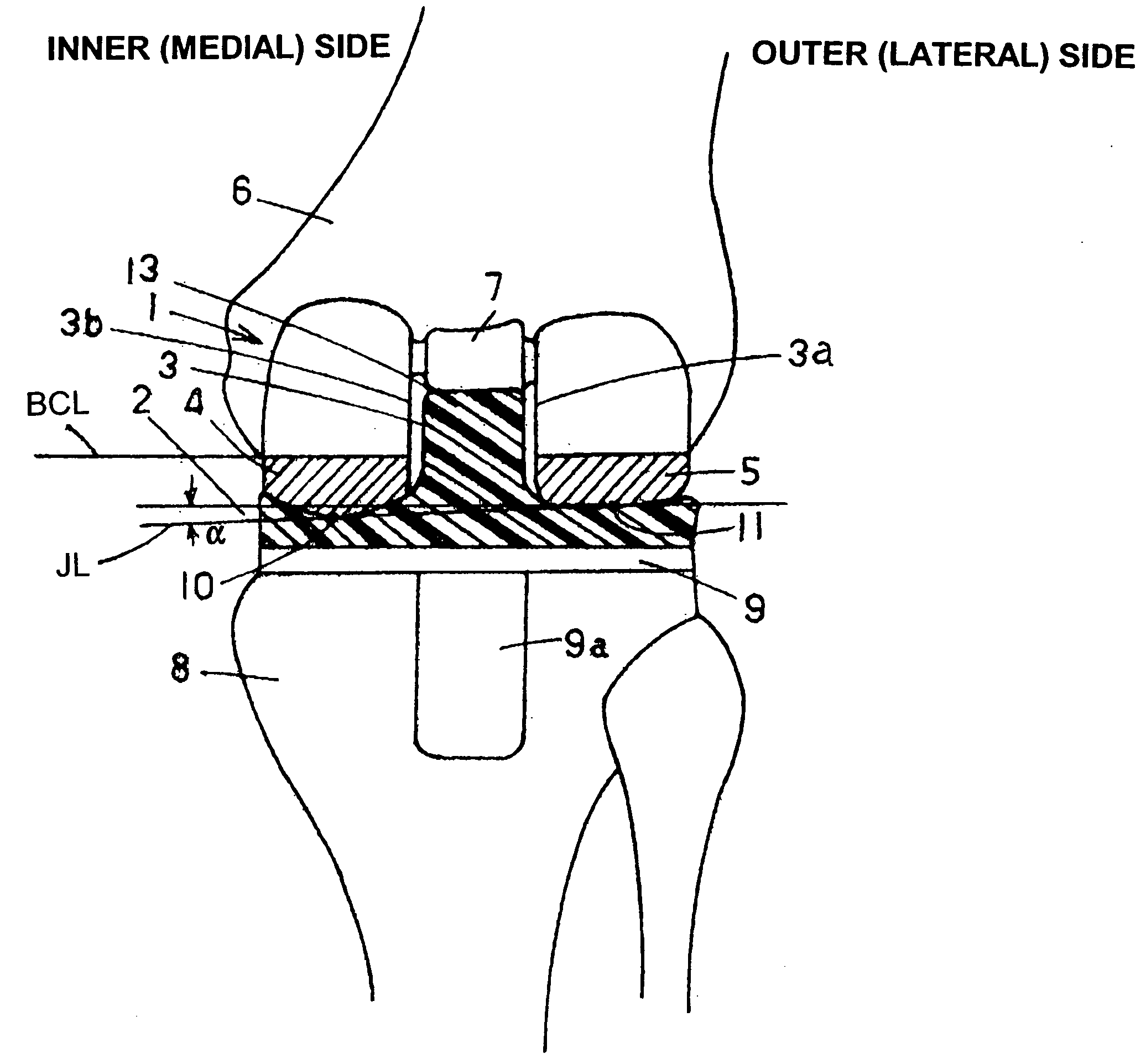

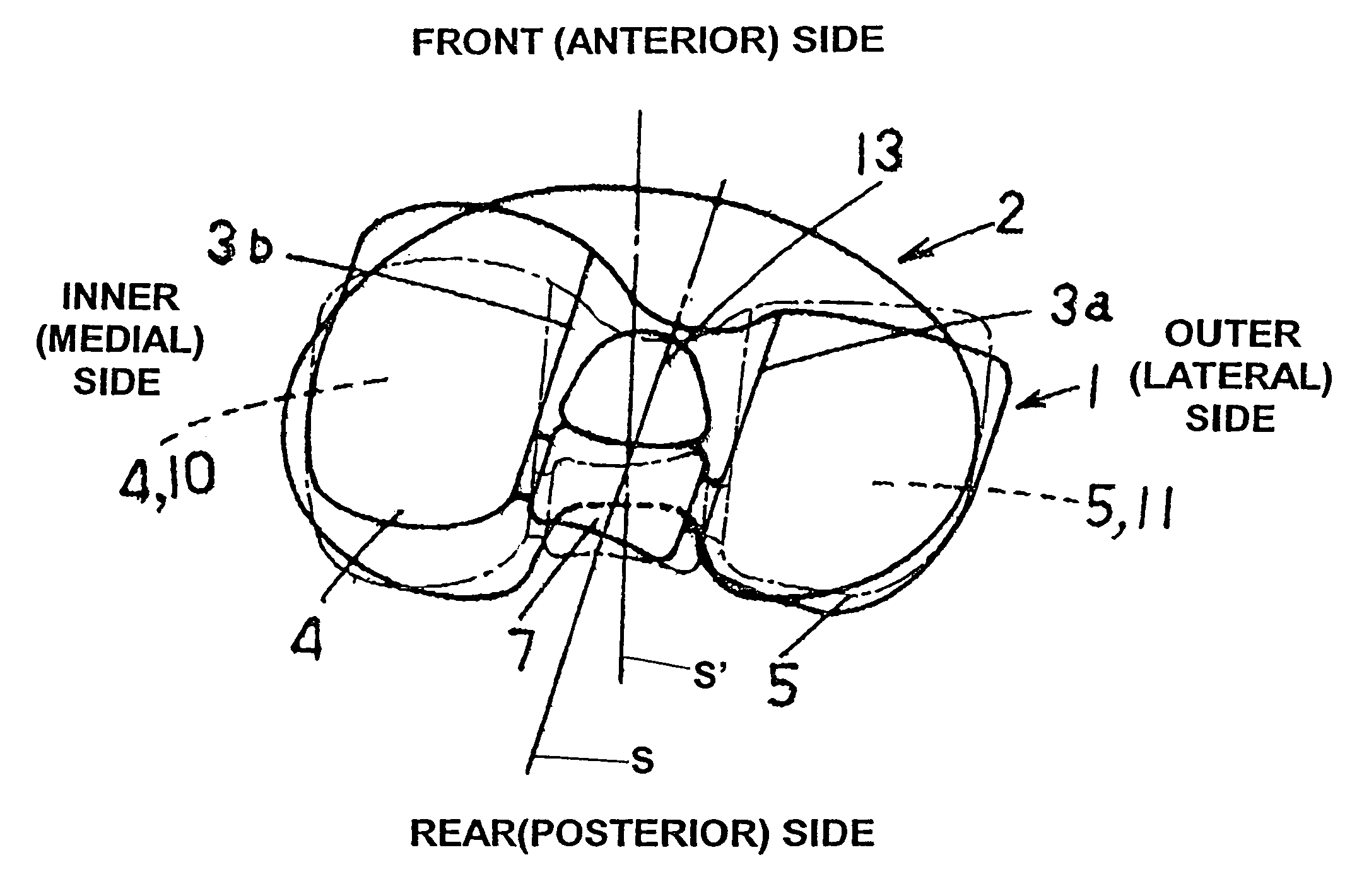

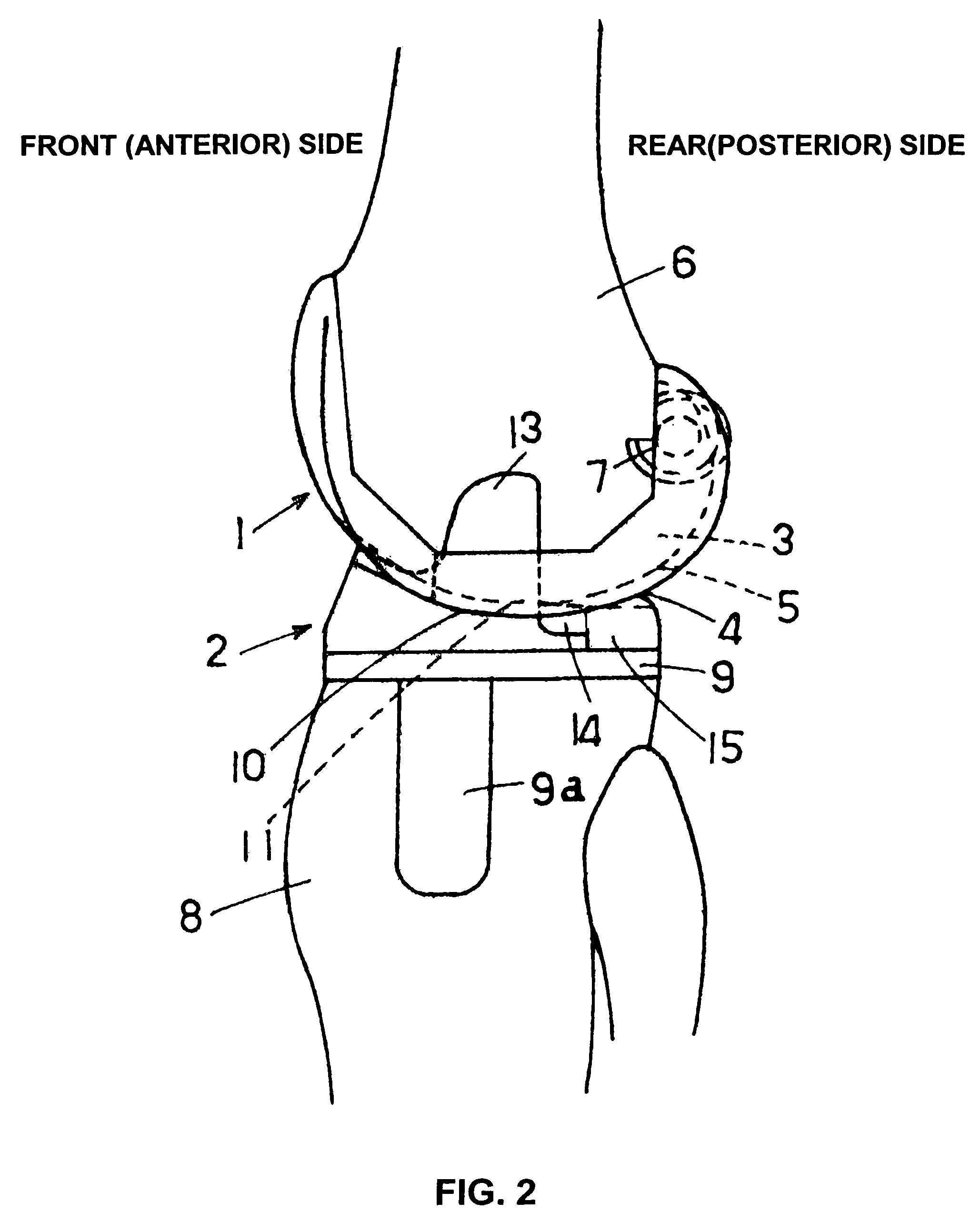

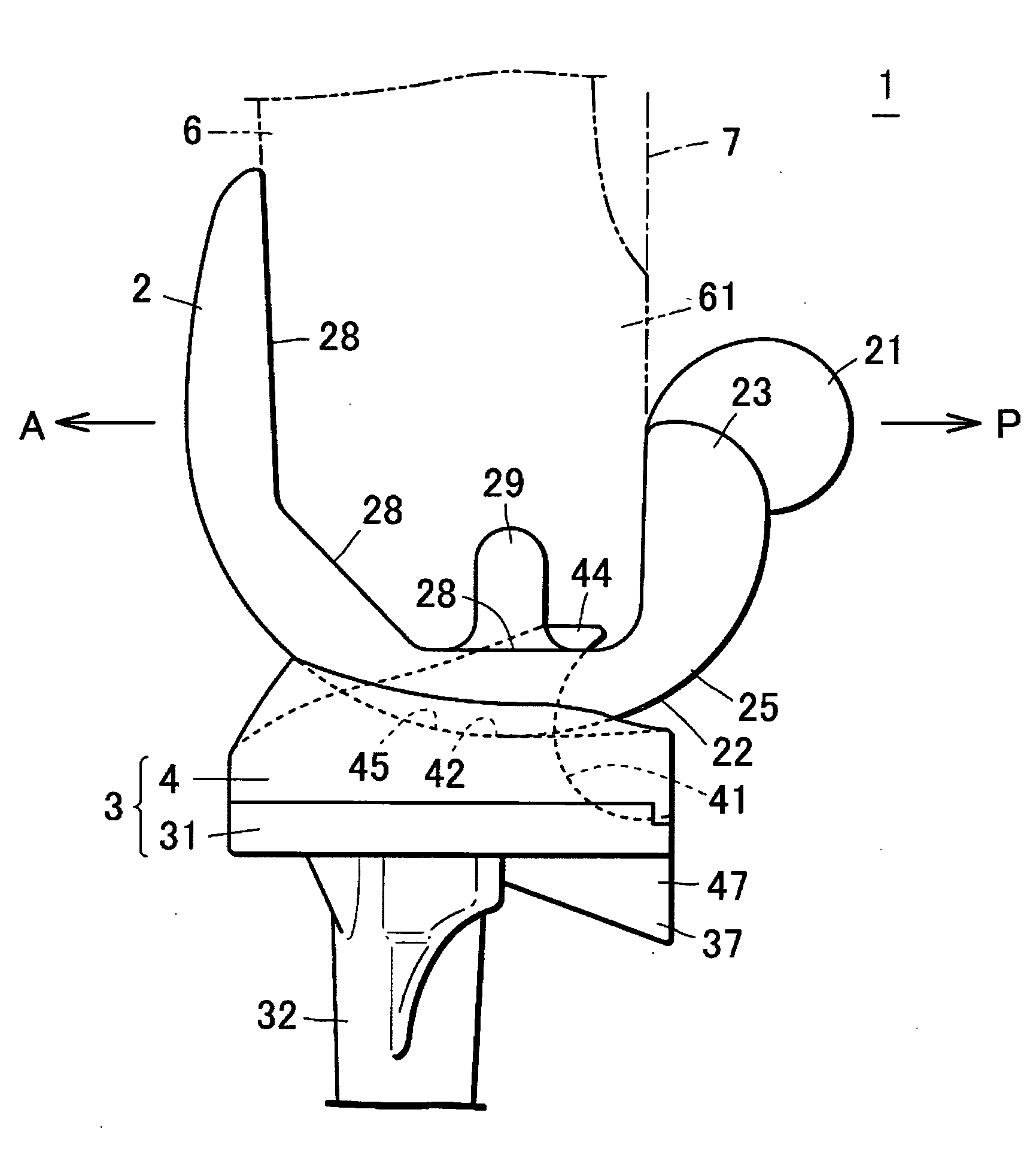

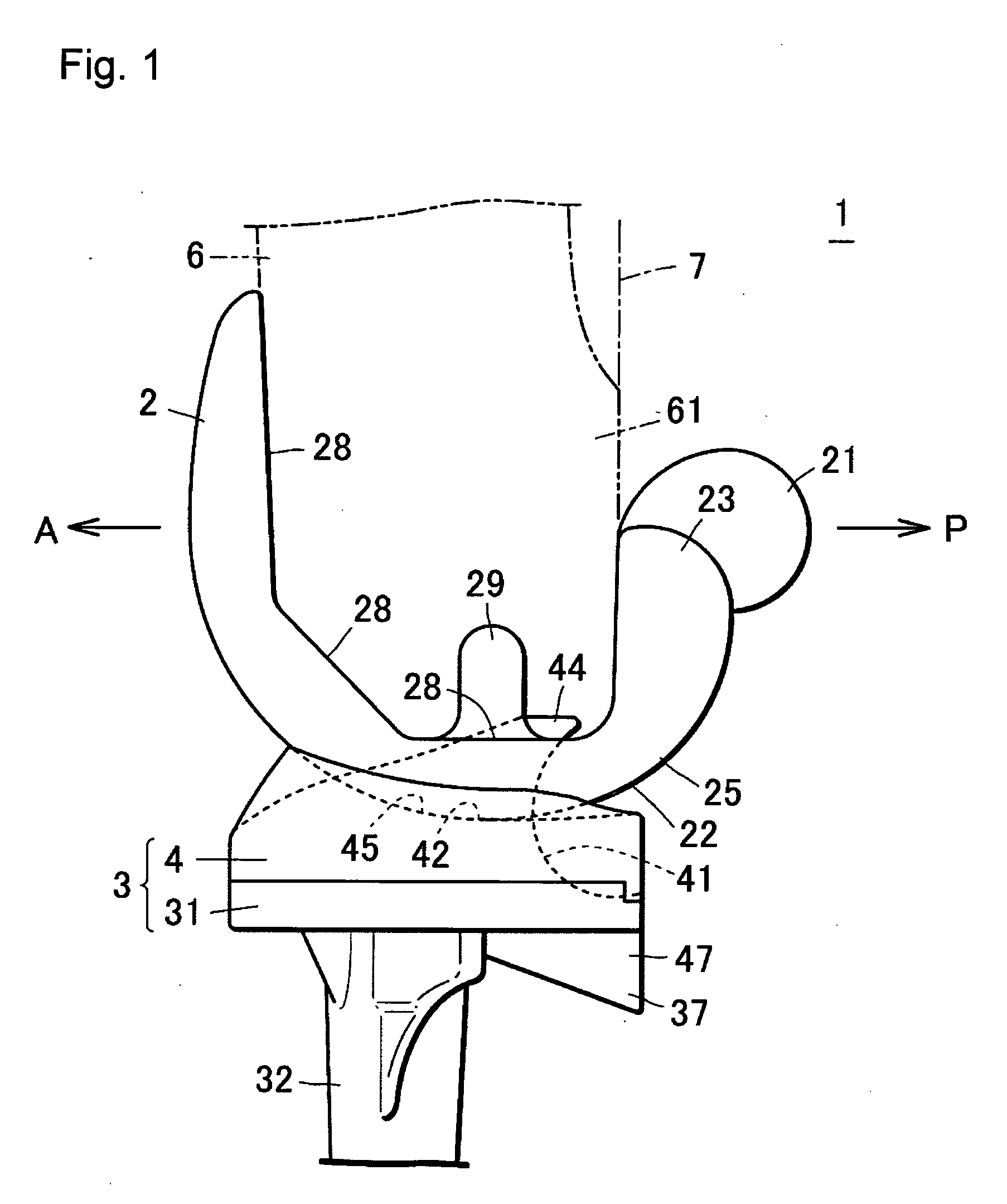

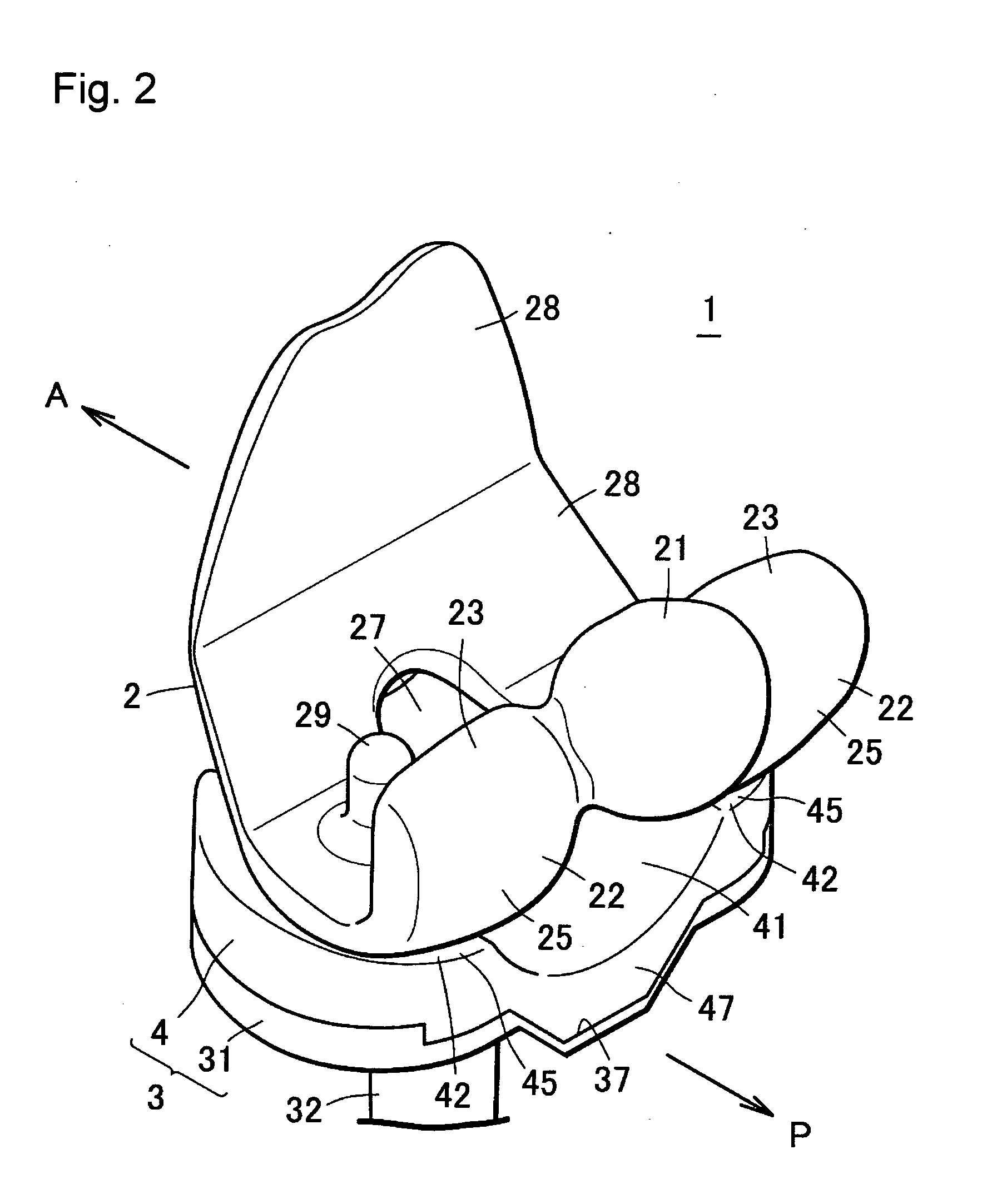

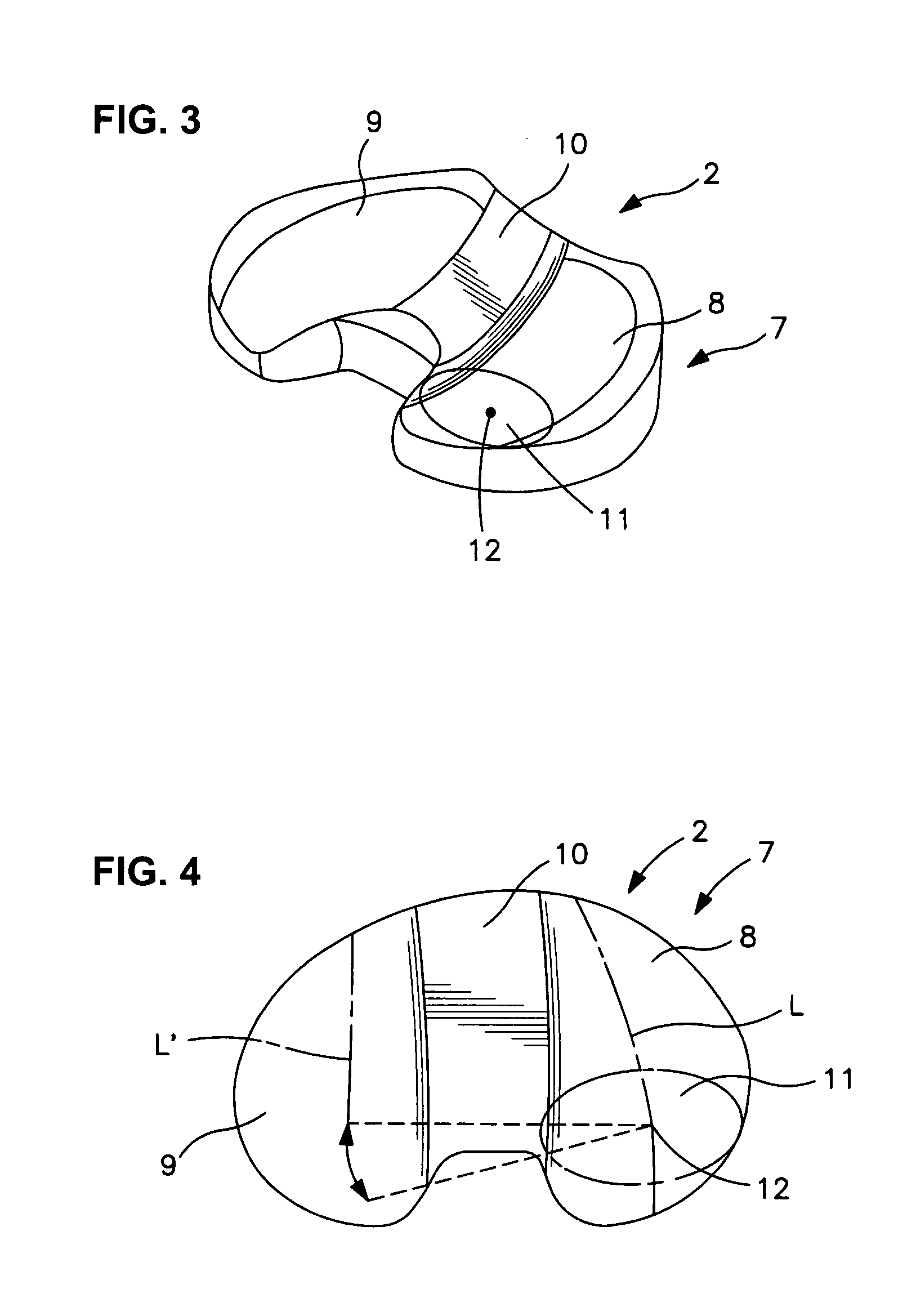

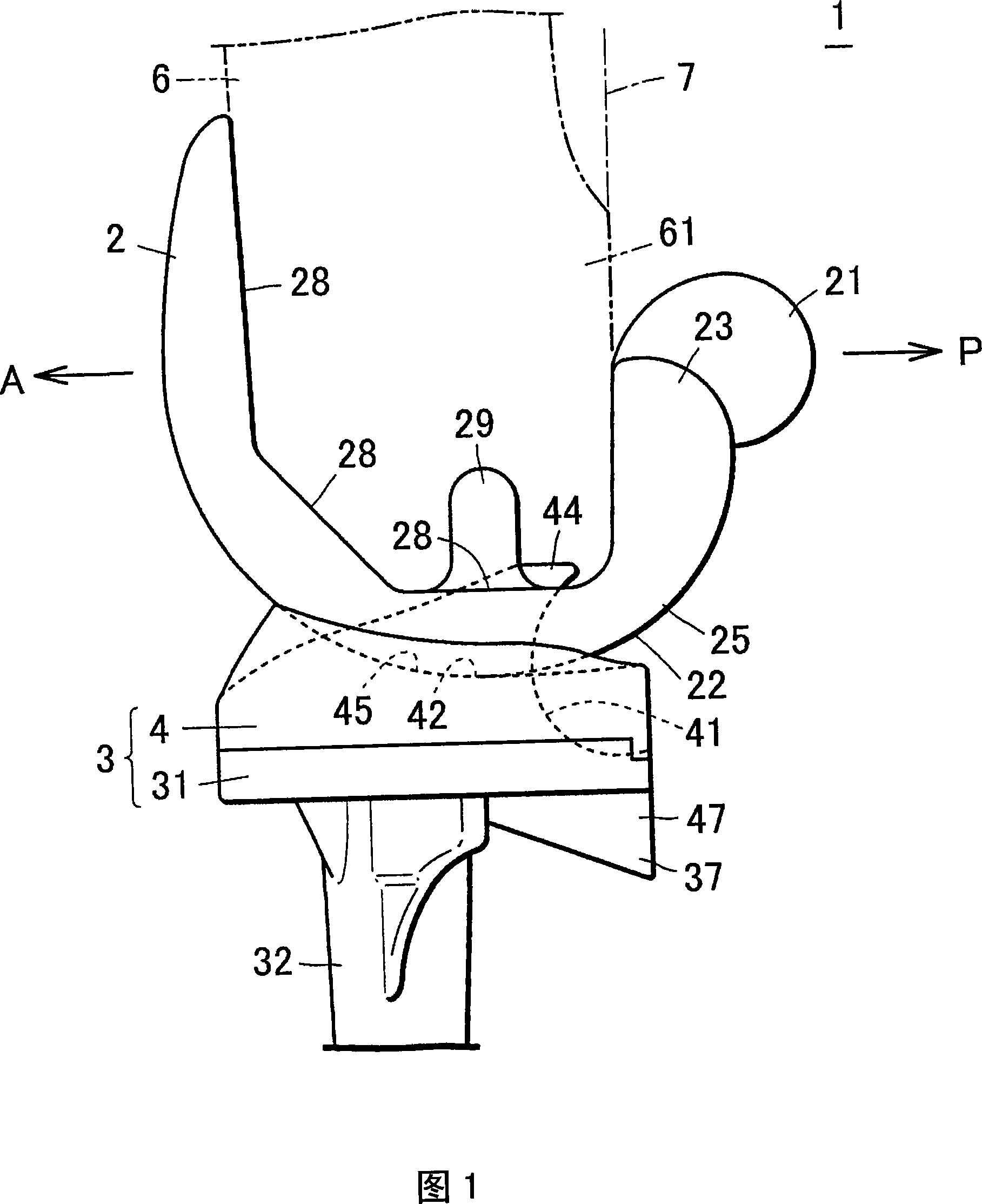

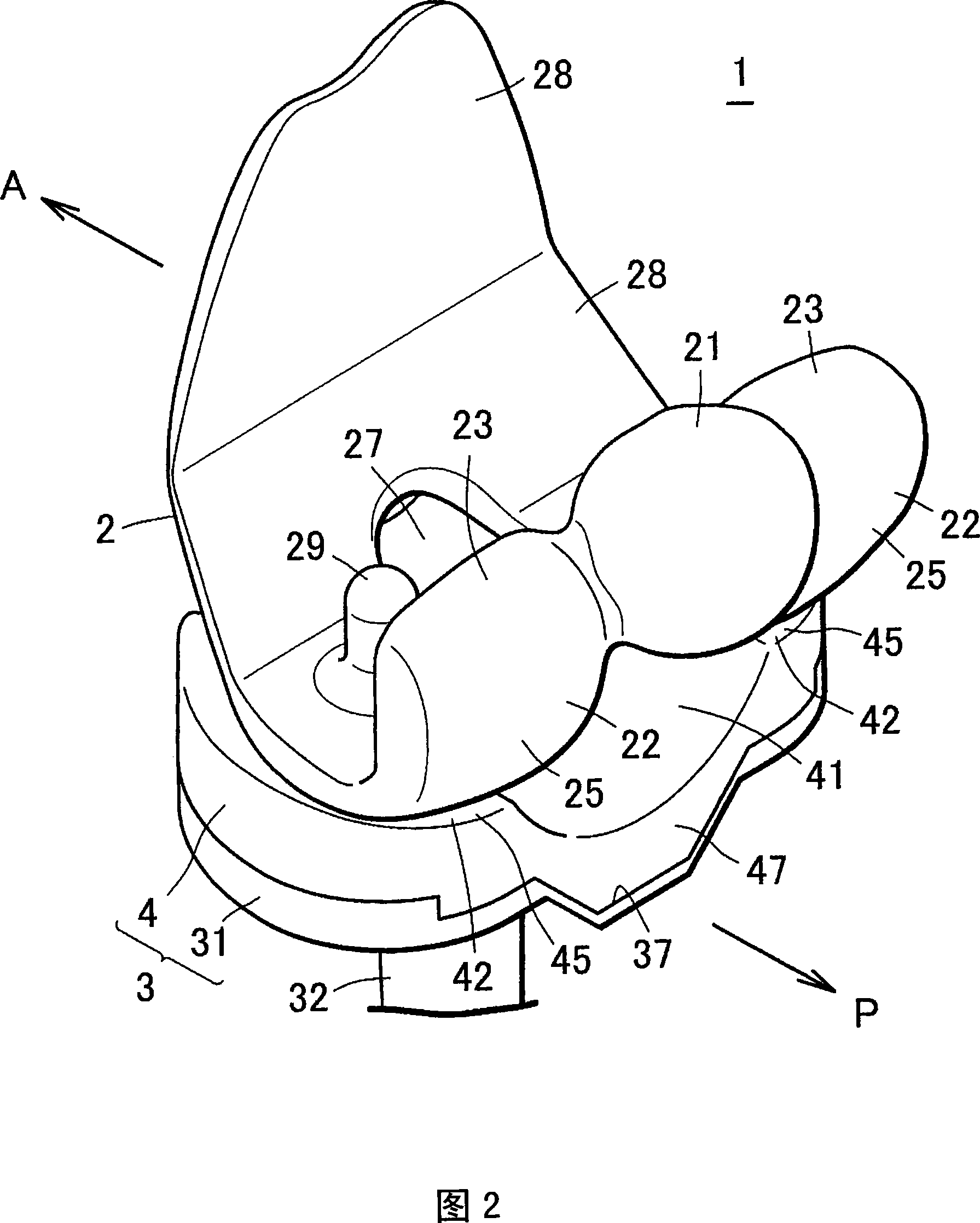

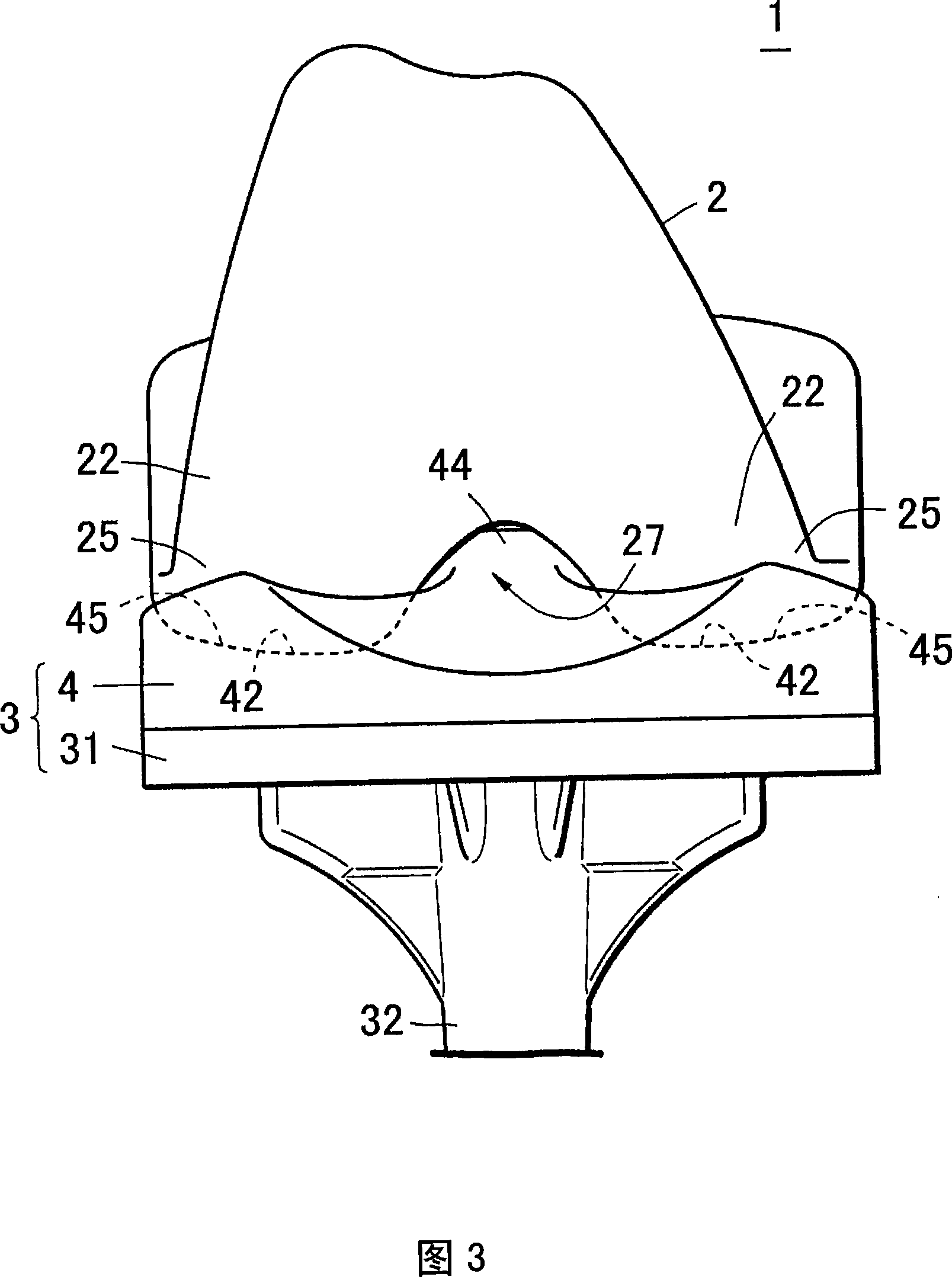

An artificial knee joint including a femoral component and a tibial component which are in relation of making relative rotation, in which the tibial component has a post that has an outwardly curving posterior surface and is disposed approximately in the longitudinal center between the articular surfaces so that the post is inside an intercondylar groove that is between the medial and lateral condyles and extends from the posterior end to the anterior end of the femoral component; and the femoral component has a cam that is disposed at the posterior portion of the intercondylar groove and comes into contact with the posterior surface of the post when the above-described rotation proceeds; and the post and the cam are shaped so that the femoral component is turned outwardly when the cam comes into contact with the post as a result of the rotation and as the rotation proceeds.

Owner:NAKASHIMA PROPELLER +1

Artificial knee joint

An artificial knee joint comprising: a femoral component comprising a femoral condylar portion made of a medial condylar section and a lateral condylar section which extend in an anteroposterior direction of the knee joint and have convex exterior surfaces, and a tibial component comprising a tibial condylar portion made of a medial condylar section and a lateral condylar section which extend in an anteroposterior direction of the knee joint and have concave interior surfaces so as to slidably receive the medial and lateral condylar sections of the fermoral condylar portion therein; and a space between the respective medial and lateral condylar sections of the femoral condylar portion and of the tibial condylar portion being formed so as to be gradually narrower toward the rear side of the knee joint, thus forming a "rear-in" configuration.

Owner:TSUNENORI TAKEI +2

Artificial knee joint

An artificial knee joint including a femoral component and a tibial component which are in relation of making relative rotation, in which the tibial component has a post that has an outwardly curving posterior surface and is disposed approximately in the longitudinal center between the articular surfaces so that the post is inside an intercondylar groove that is between the medial and lateral condyles and extends from the posterior end to the anterior end of the femoral component; and the femoral component has a cam that is disposed at the posterior portion of the intercondylar groove and comes into contact with the posterior surface of the post when the above-described rotation proceeds; and the post and the cam are shaped so that the femoral component is turned outwardly when the cam comes into contact with the post as a result of the rotation and as the rotation proceeds.

Owner:NAKASHIMA PROPELLER +1

Artificial knee joint

An artificial knee joint that compresses both osseous impingement and soft tissue impingement from occurring and can endure usage over a long period of time is provided.The artificial knee joint of the present invention comprises a femoral component, a tibial tray and an insert plate fixed onto the top surface of the tibial tray. The femoral component comprises a femoral articular surface and a cam that is provided on the rear end of the femoral articular surface and protrudes from the femoral articular surface, the insert plate comprises a tibial articular surface that makes contact with the femoral articular surface and a cam-receiving slide surface that makes contact with the cam. When the knee is extended, the joint takes a first sliding state in which the femoral articular surface slides against the tibial articular surface. When the knee is bent at an angle in a range from 90 to 160 degrees, the joint shifts from the first sliding state to a second sliding state in which the cam slides on the cam-receiving slide surface. When the knee is bent deeply with a bending angle of 180 degrees, the second sliding state is assumed in which a resection surface of the femoral component and the rear end of the insert plate are offset.

Owner:KYOCERA CORP +1

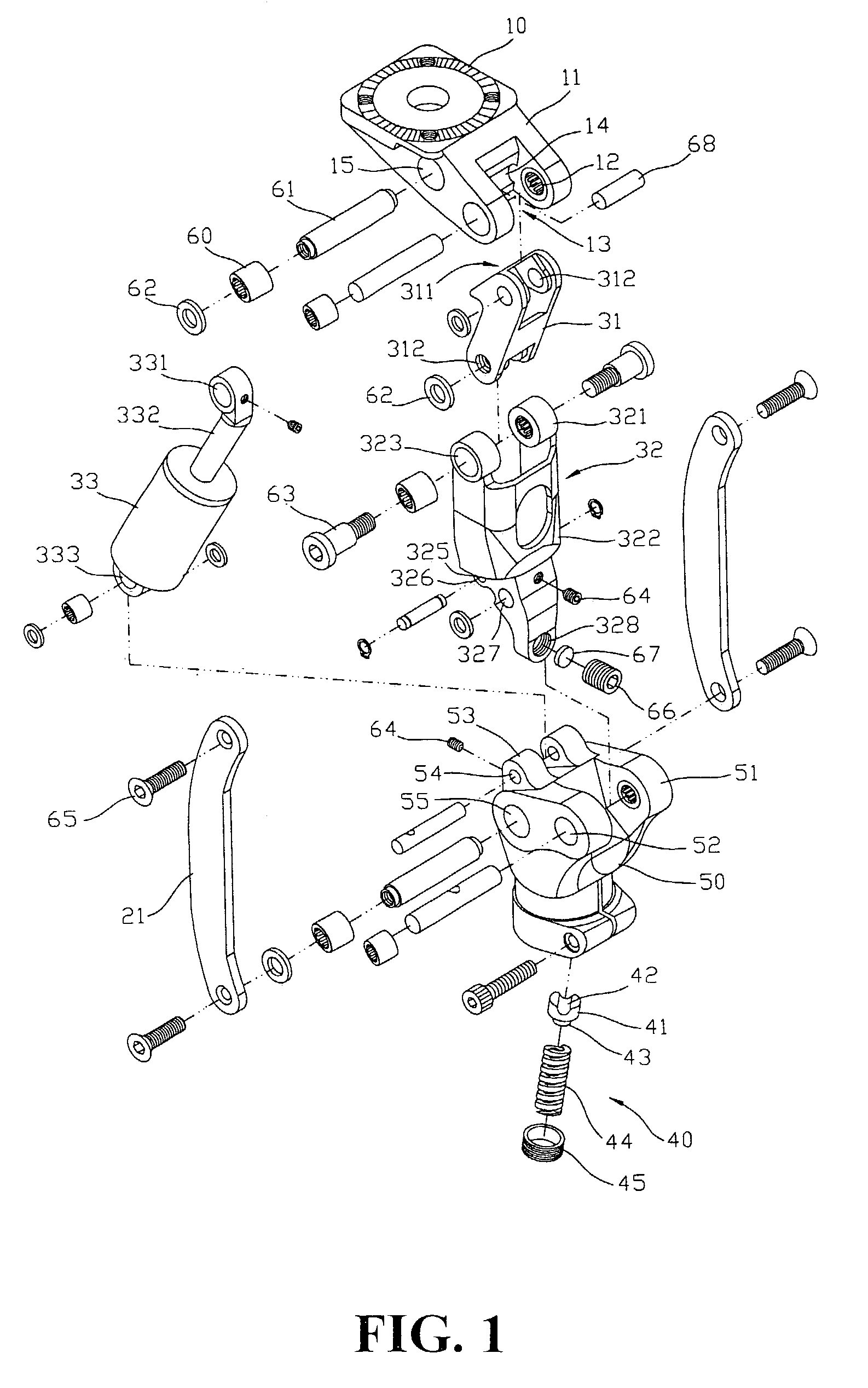

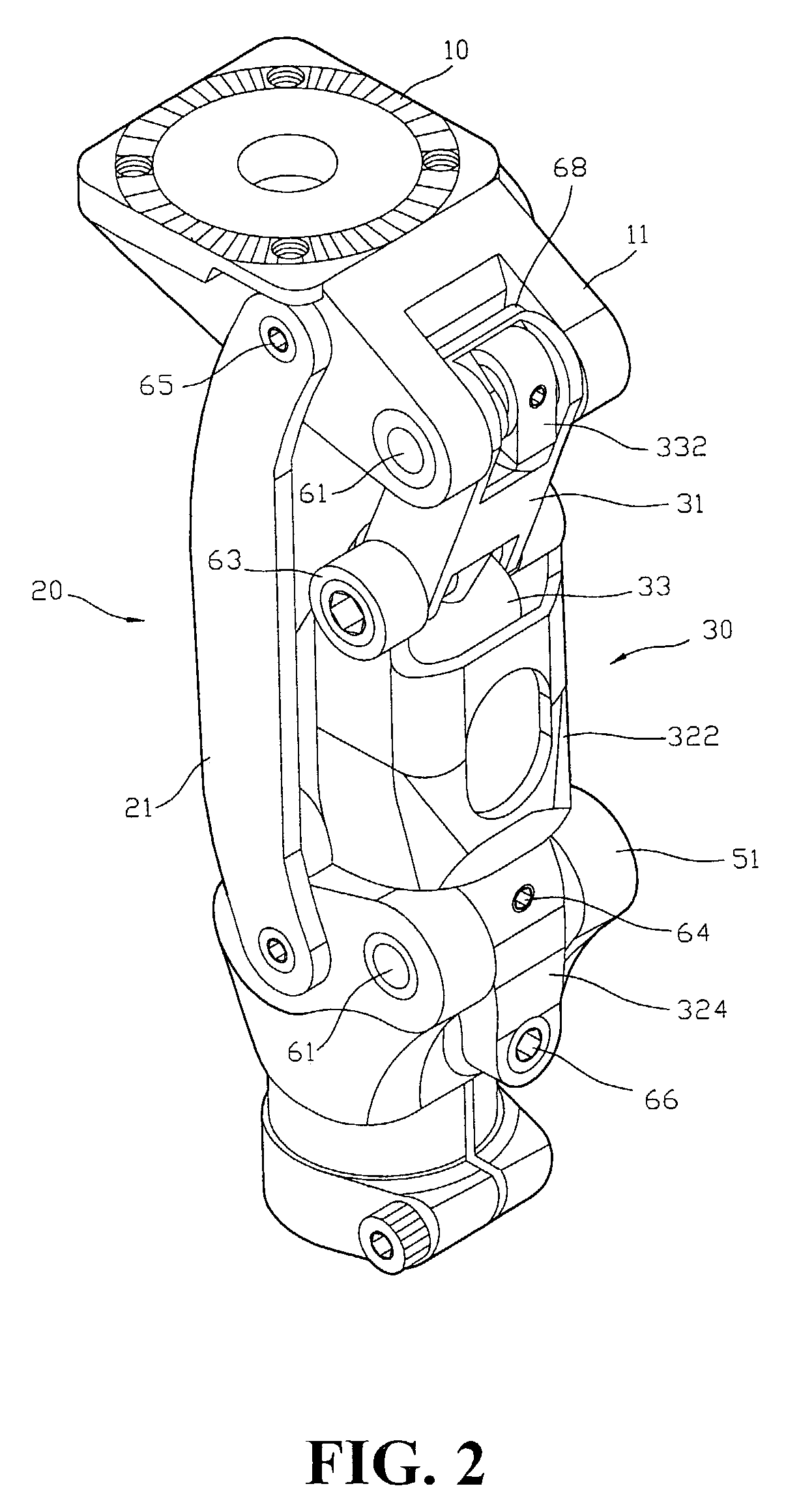

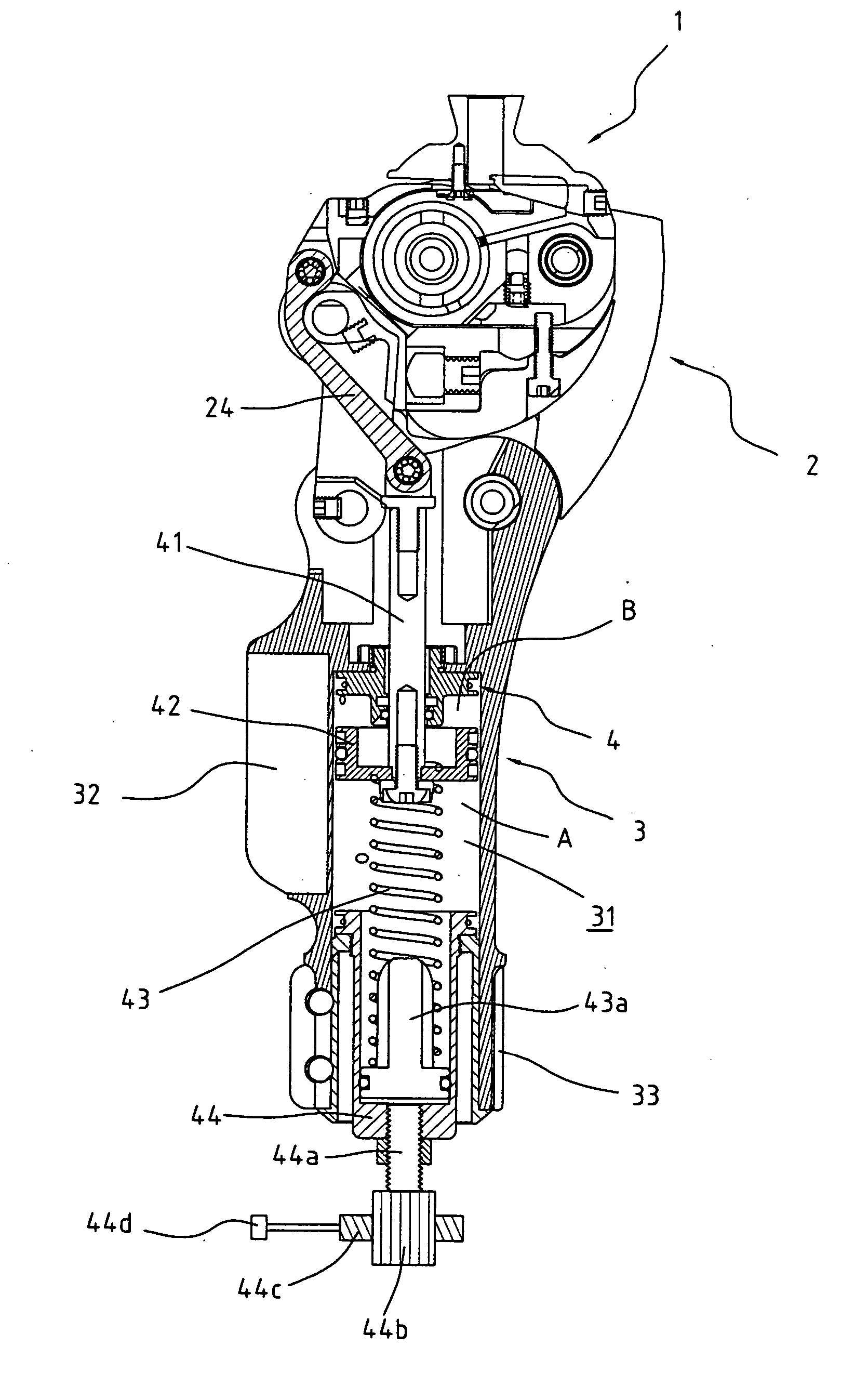

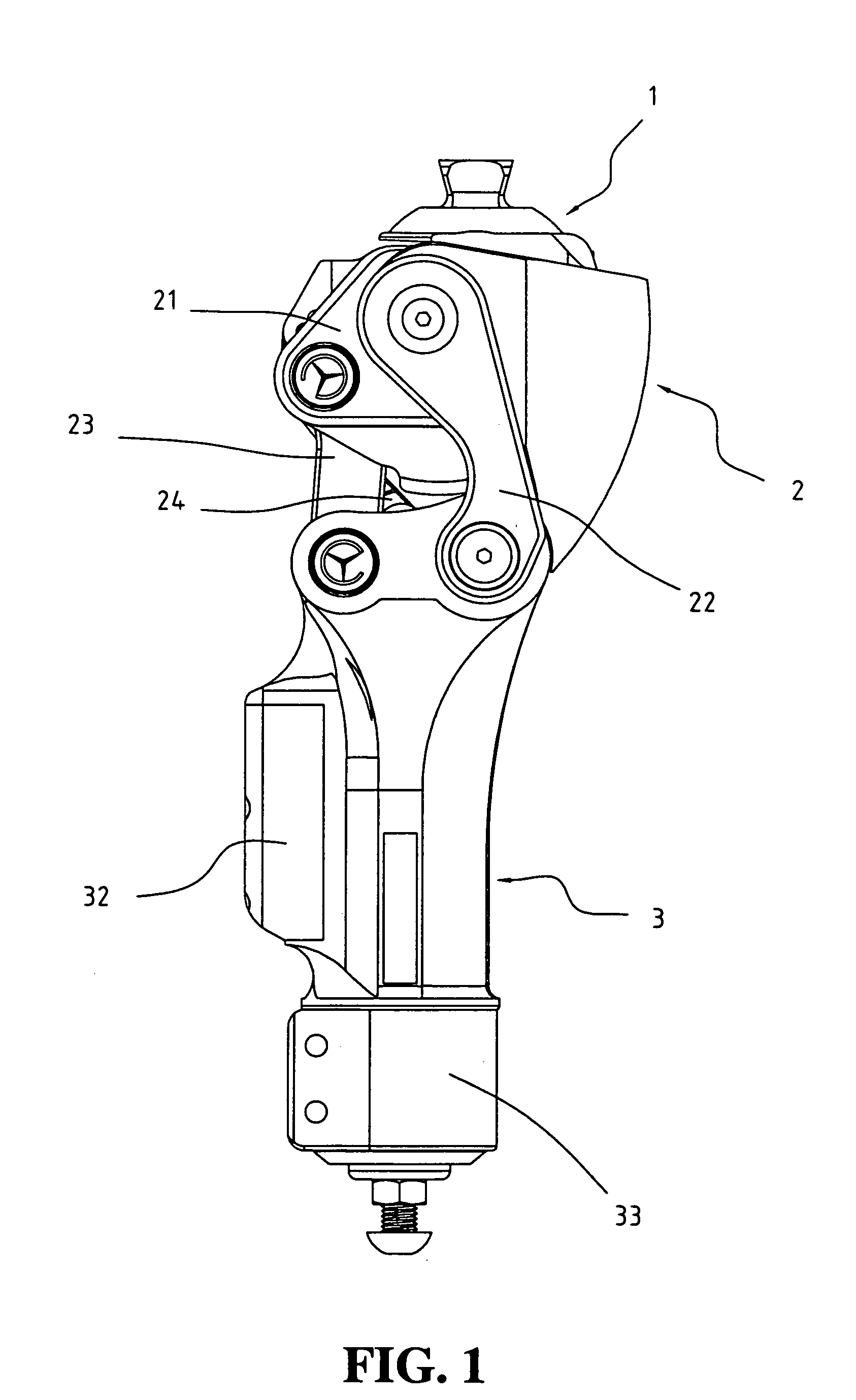

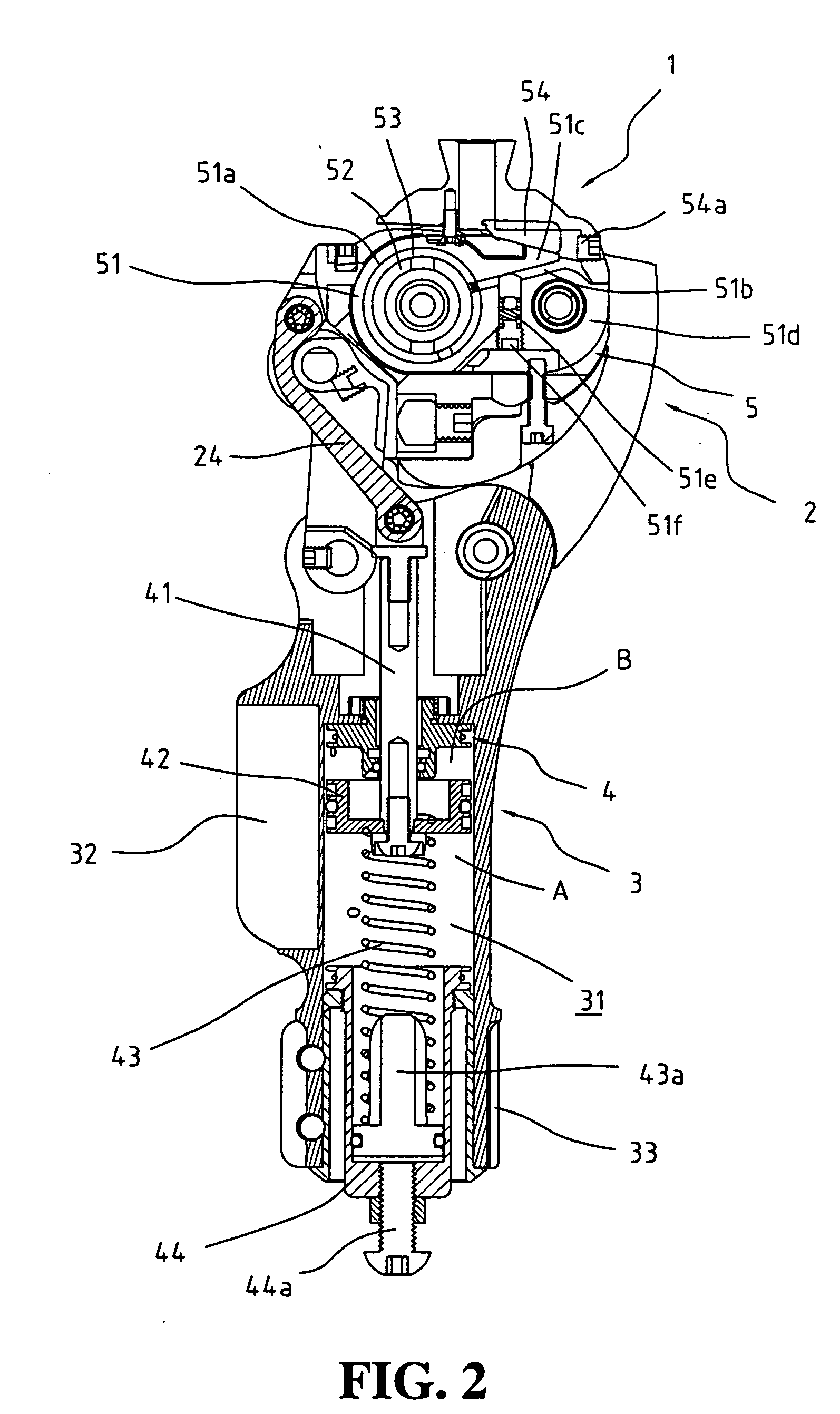

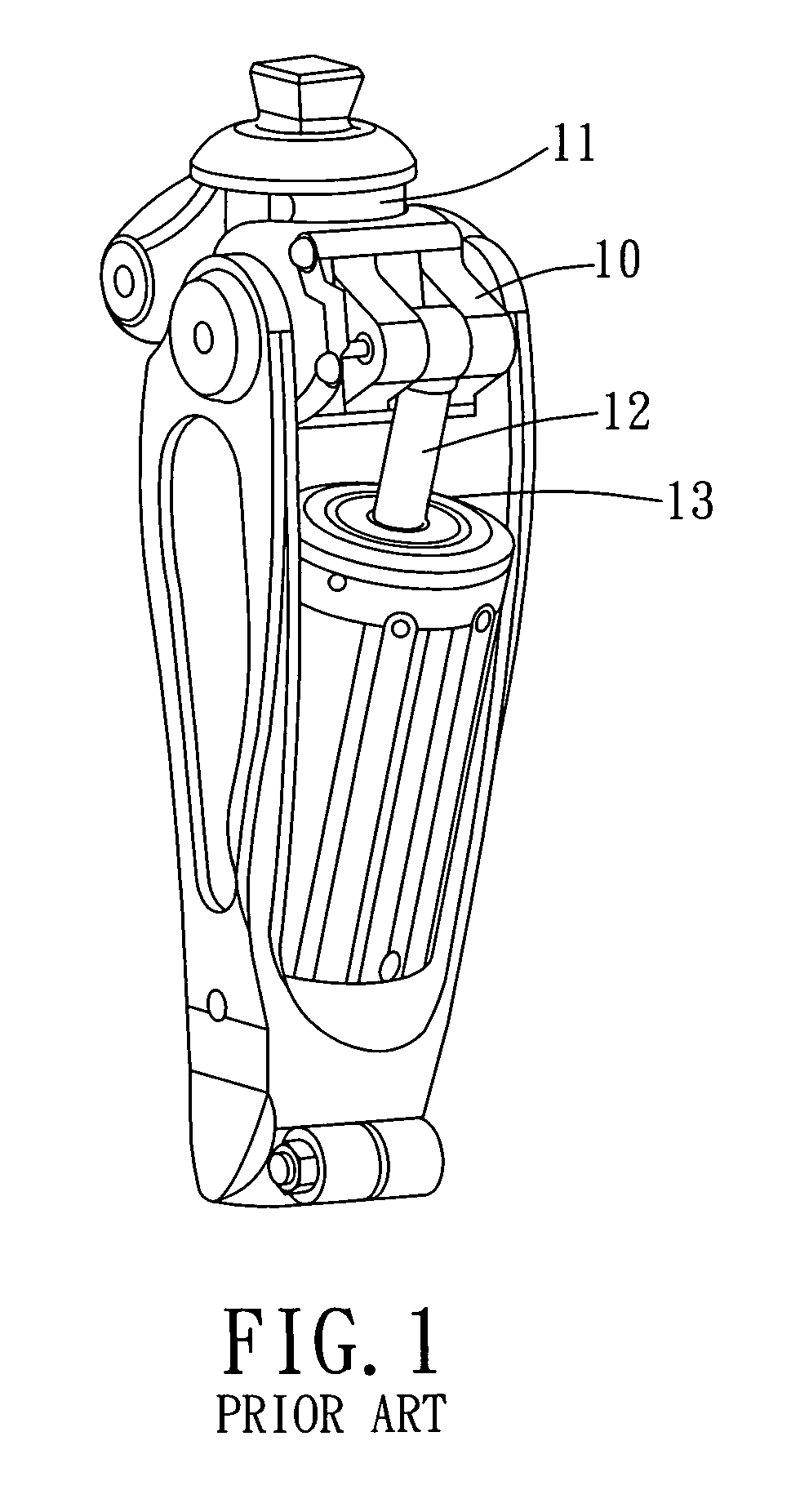

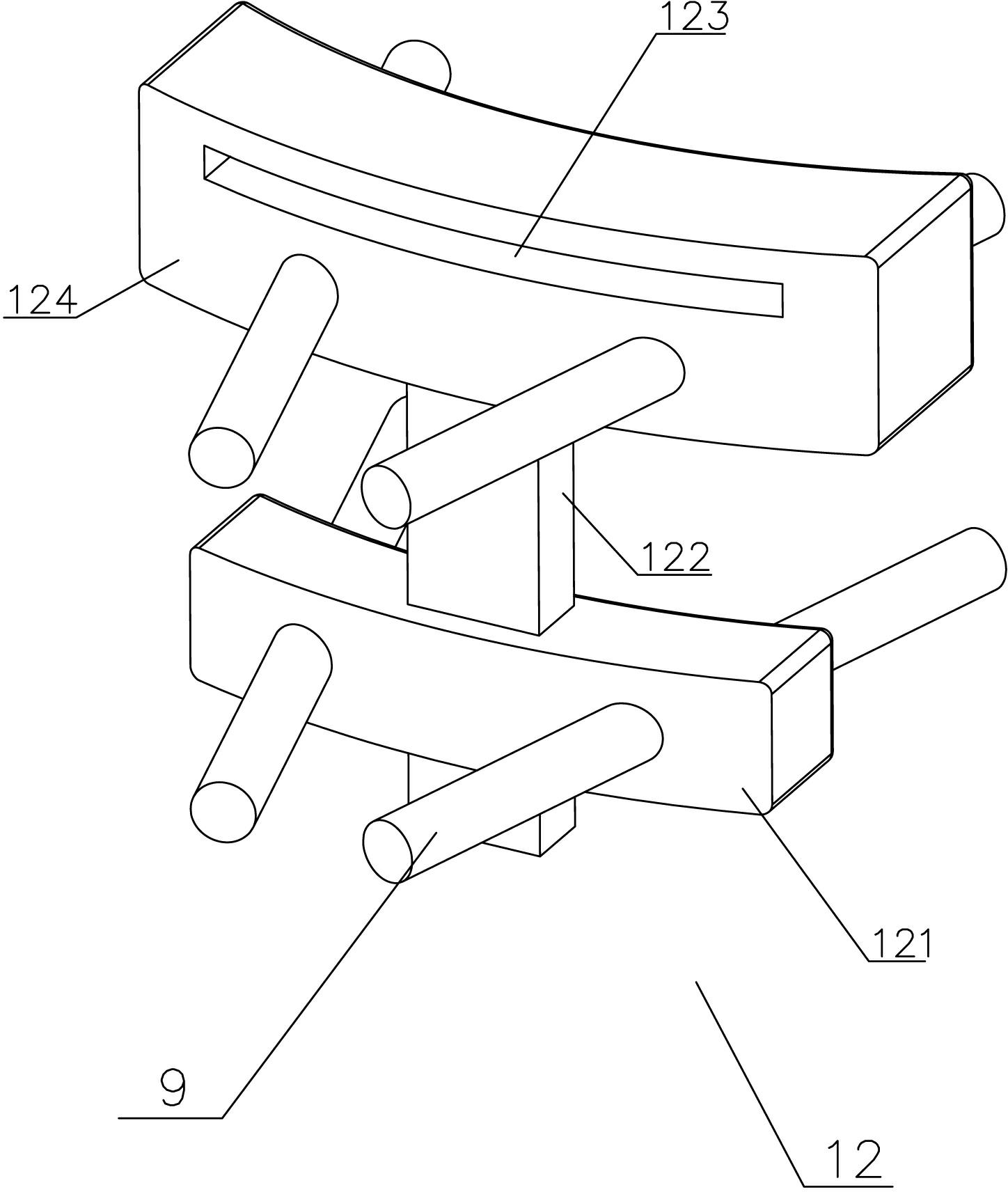

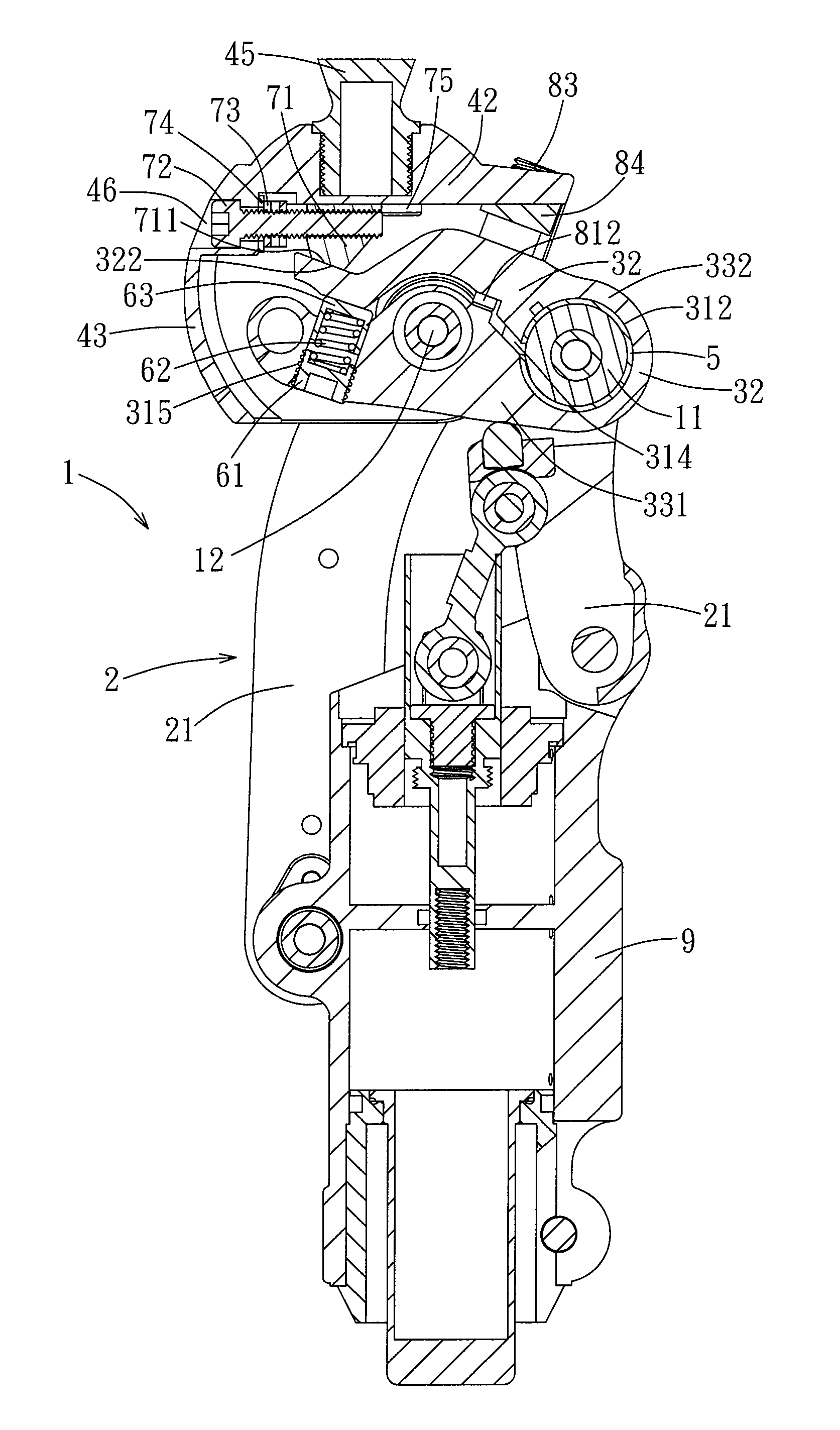

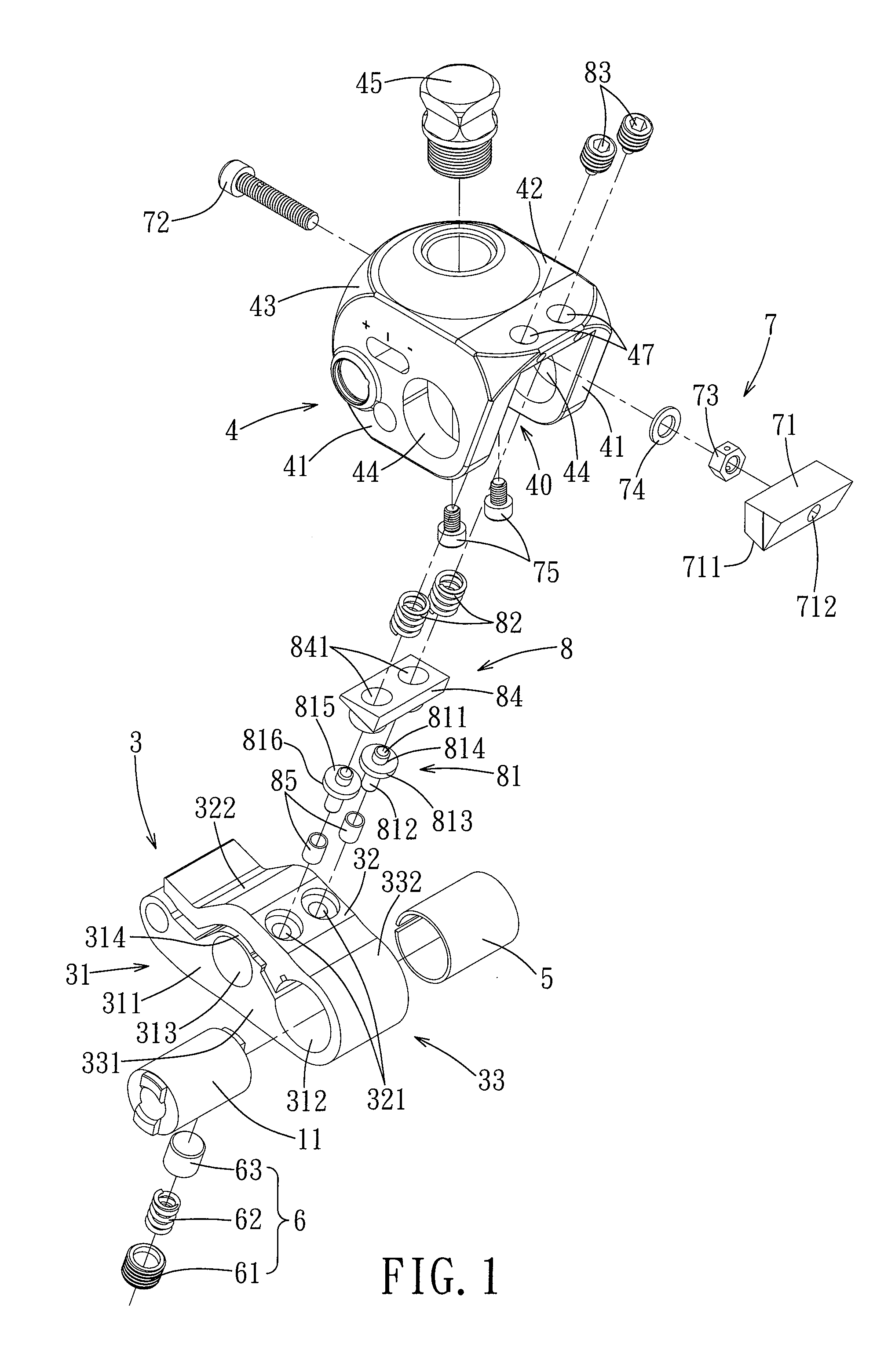

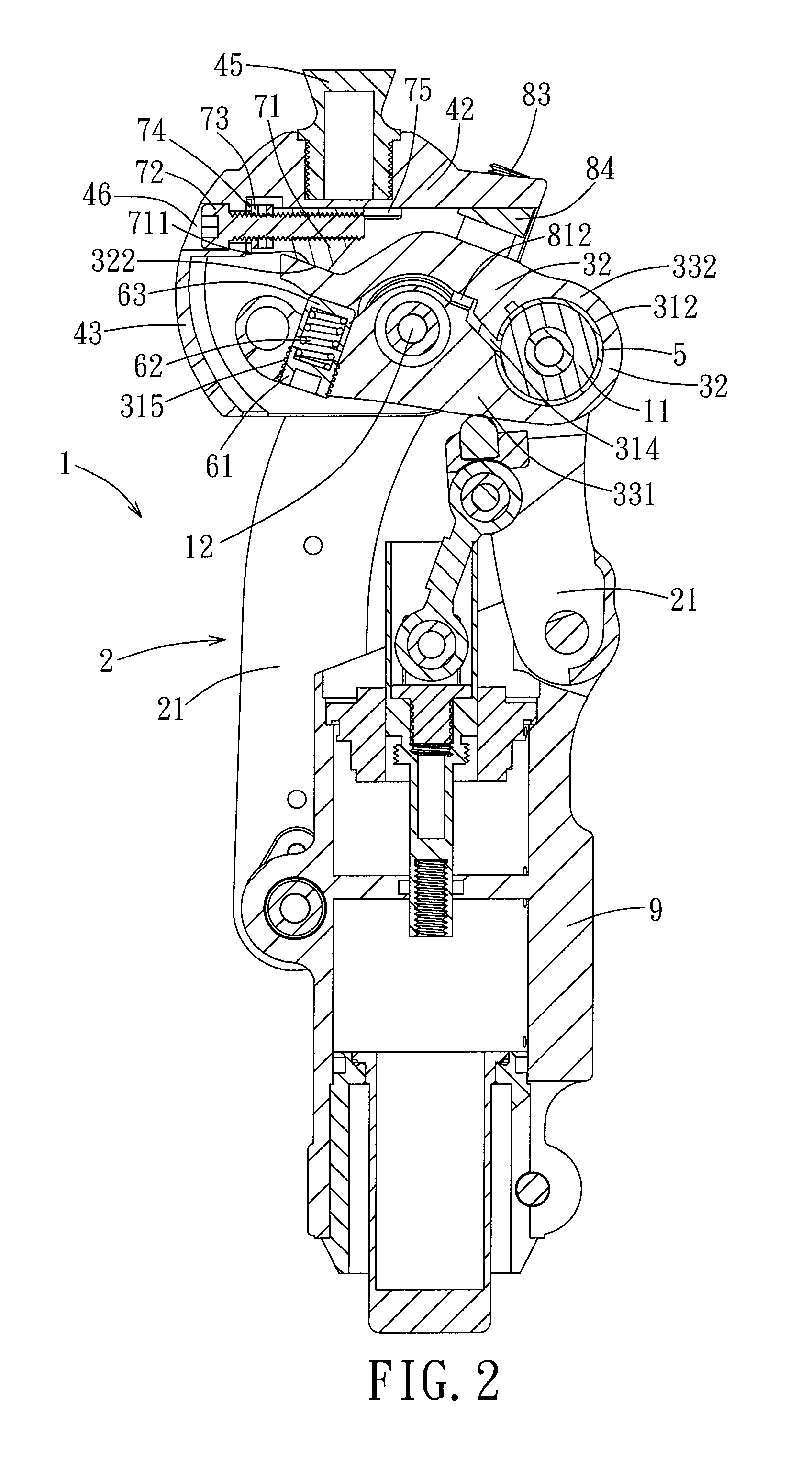

Positioning and buffering device for artificial knee joint

A positioning and buffering device of a knee joint for artificial limb is disclosed. The device comprises a knee cap head, an interlinking device including two arch plates, a buffering device including an interlinking rod, an interlinking support and a hydraulic cylinder; a spring device having a spring and a spring support; and a knee cap body module. The knee cap body is used to connect to the thigh and the lower edge of the knee cap body is for connection to the shank and the leg bottom portion. By means of the interlinking rod and the linking support, when the leg is stretched or is standing, a pressure exerted changes the angle between the interlinking rod and the interlinking support such that the knee joint is at a fixed position, the shank will not bent or knee down and the buffering device will produce a buffering and shock absorbing effect.

Owner:CHENG CHIA PAO

Artificial knee joint

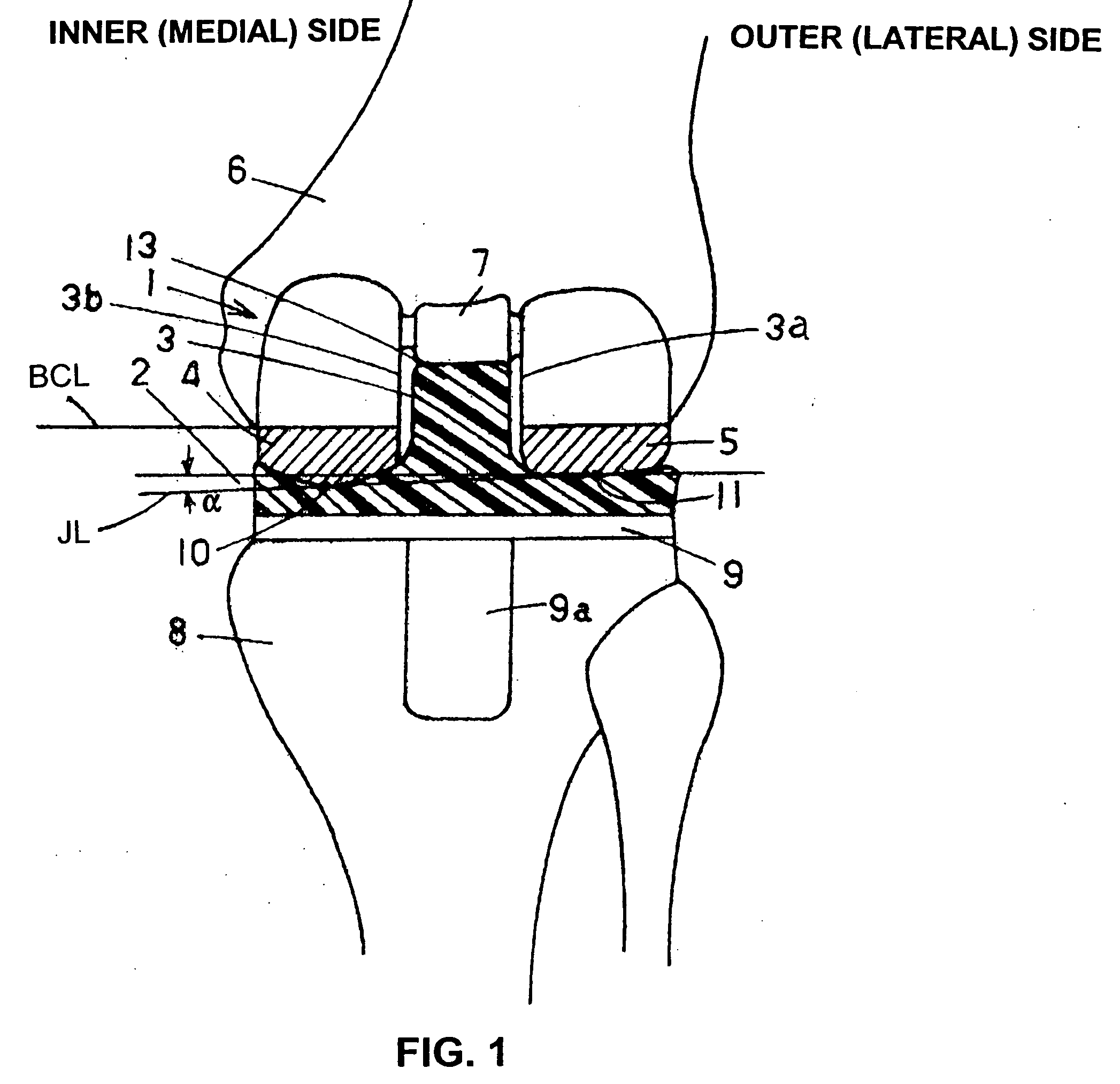

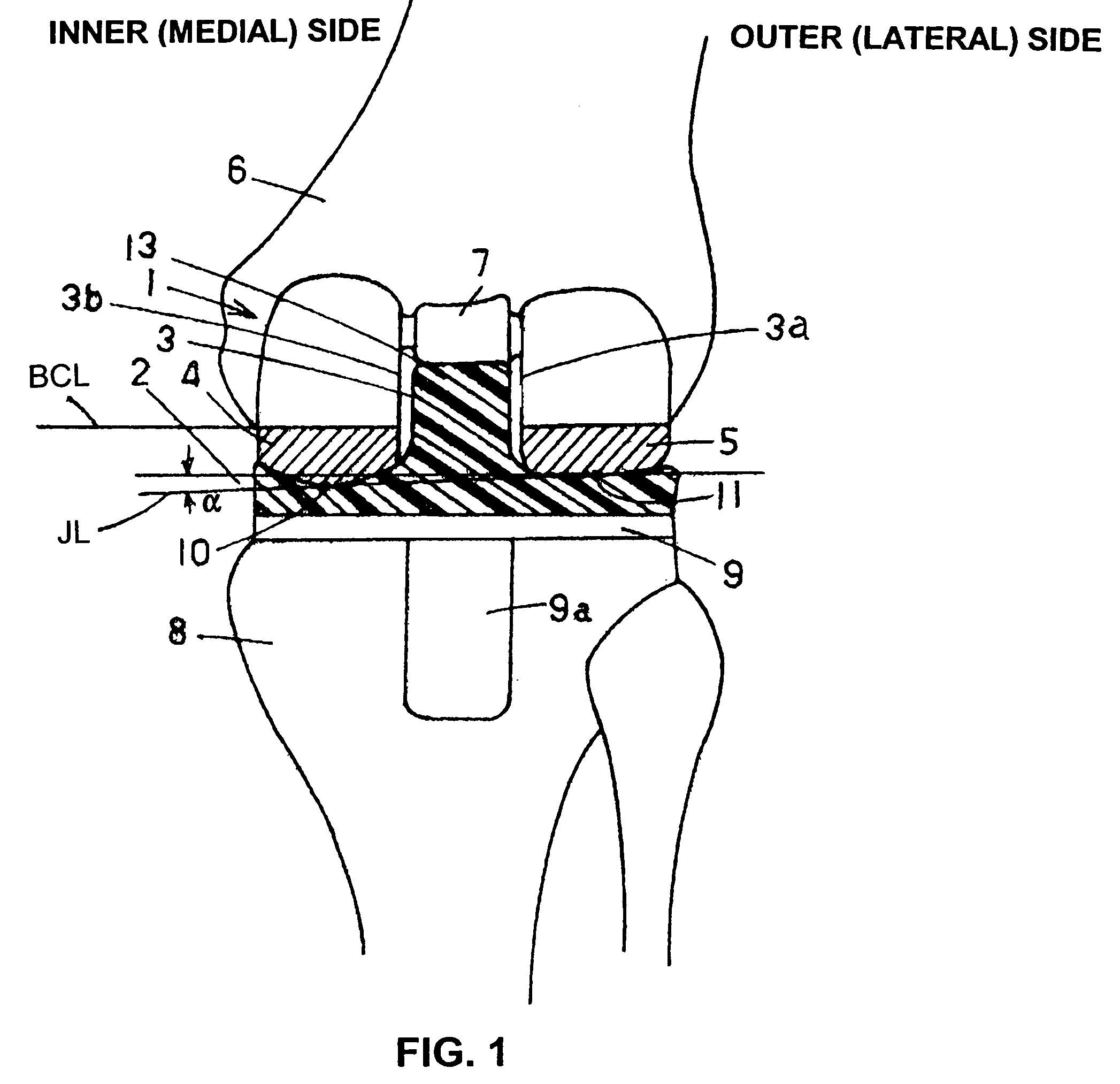

InactiveUS7264635B2Easy to getSmooth flexion-extensionJoint implantsKnee jointsArticular surfacesTibia

An artificial knee joint including a femoral component to be attached to a femur and a tibial component to be attached to a tibia, wherein in the femur component a medial condyle thereof is thicker than a lateral condyle thereof; in the tibial component, a medial articular surface thereof, which supports the medial condyle of the femur component, is thinner or deeper than a lateral articular surface thereof, which supports the lateral condyle of the femur component; and a joint line joining the lowest points of contact surfaces between the medial and lateral condyles of the femur component and the medial and lateral articular surfaces of the tibial component in a longitudinal cross section in a medial-lateral direction is inclined inward at virtually the same angle over the entire region of an angle of flexion-extension.

Owner:NAKASHIMA PROPELLER +1

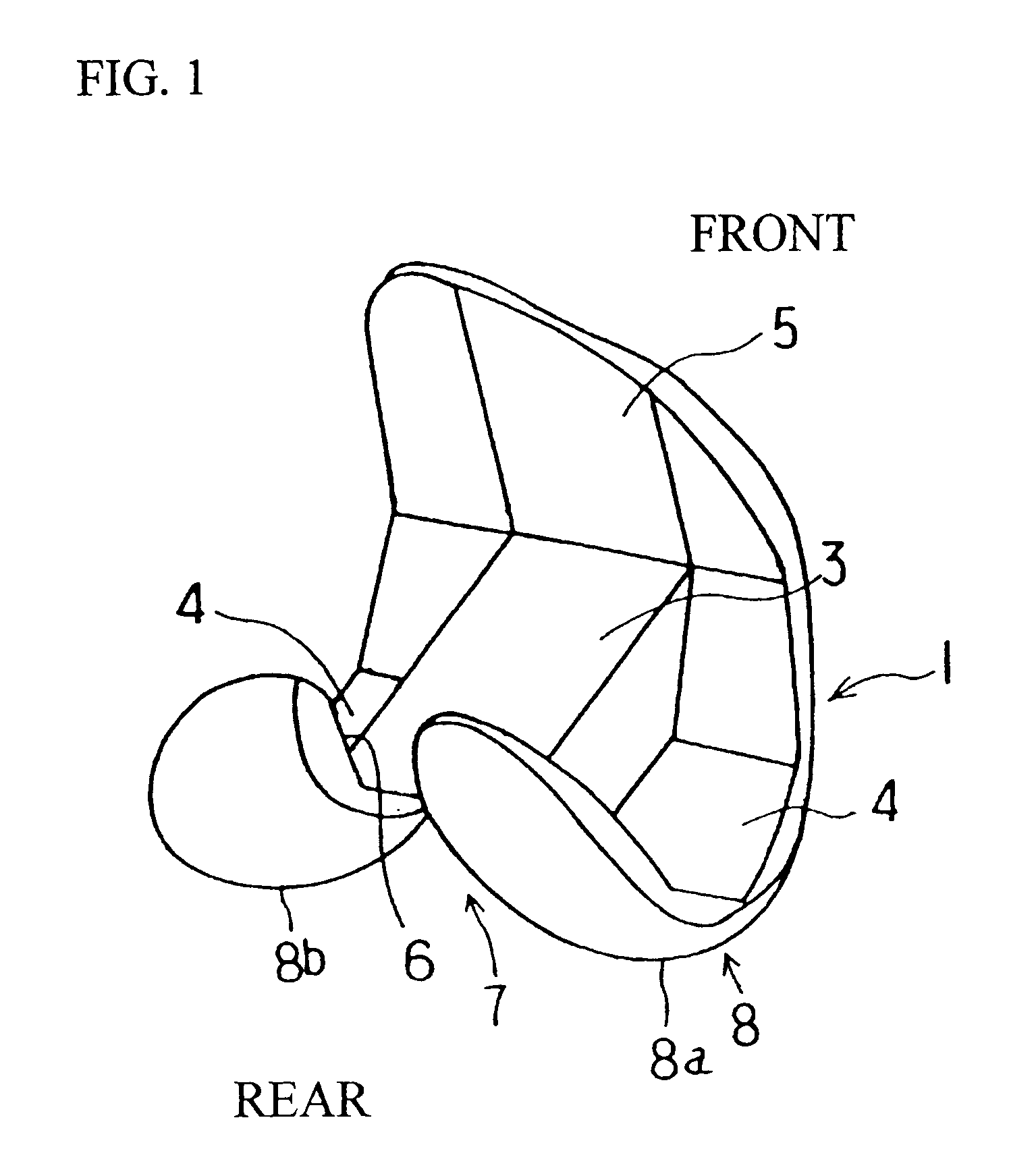

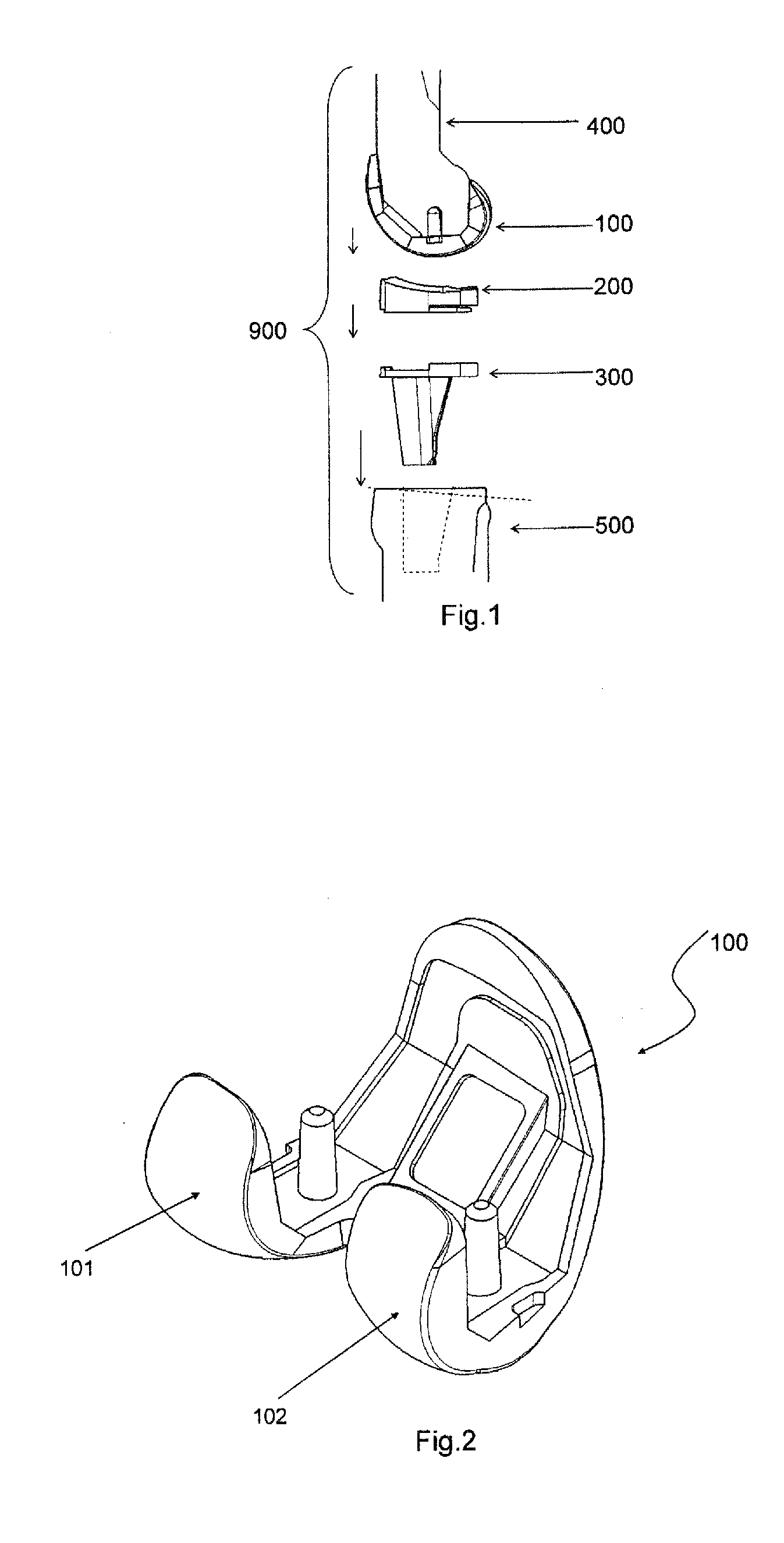

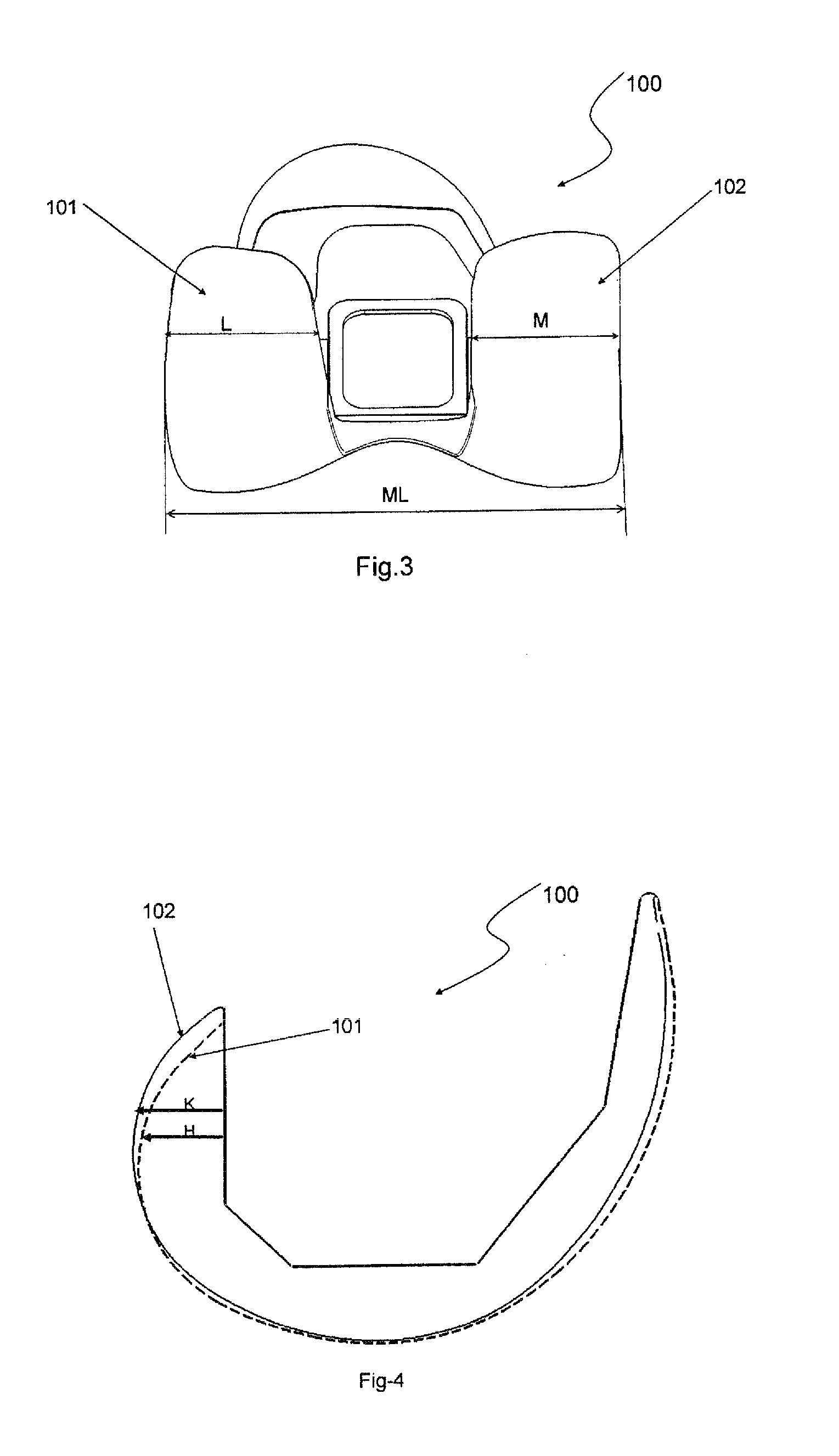

Femoral component of an artificial knee joint

InactiveUS20090265011A1Add flexiblySimplify different cutJoint implantsKnee jointsFemoral prosthesisArtificial knee

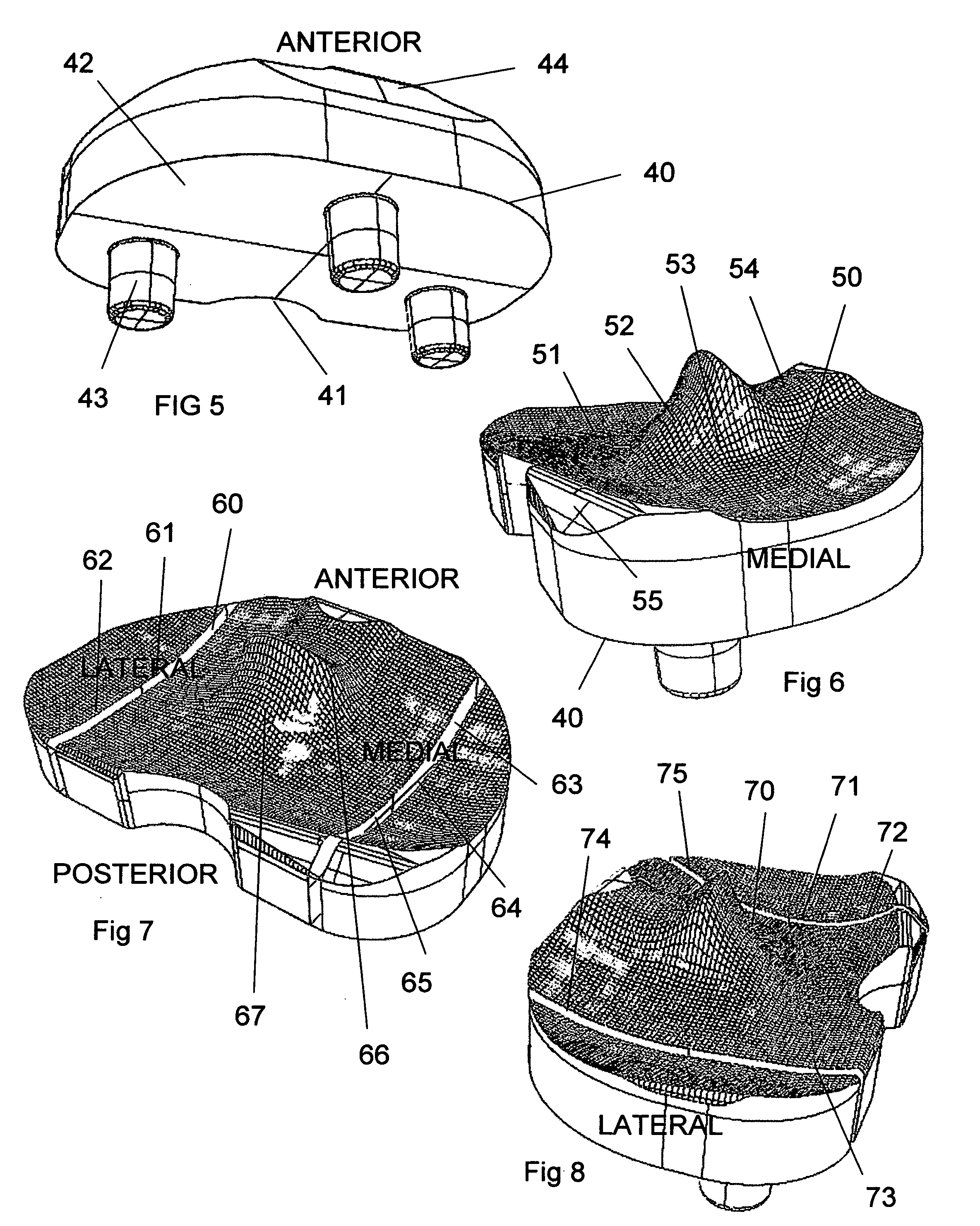

A femoral component of an artificial knee joint is configured with multiple different facets which are similar in size and shape for many different sizes, to simplify an associated method for forming a distal end of the femur to receive the femoral component. Jig embodiments are provided to form surfaces on a distal end of a femur to correspond with facets of the femoral component, with the same jig usable for femoral components of differing size. The femoral component includes medial and lateral condylar legs with a posterior facet of the femoral component exhibiting a negative angle relative to a central axis of the femur, to maximize contact and increase flexion of the artificial knee joint.

Owner:MANDELL STEVEN L

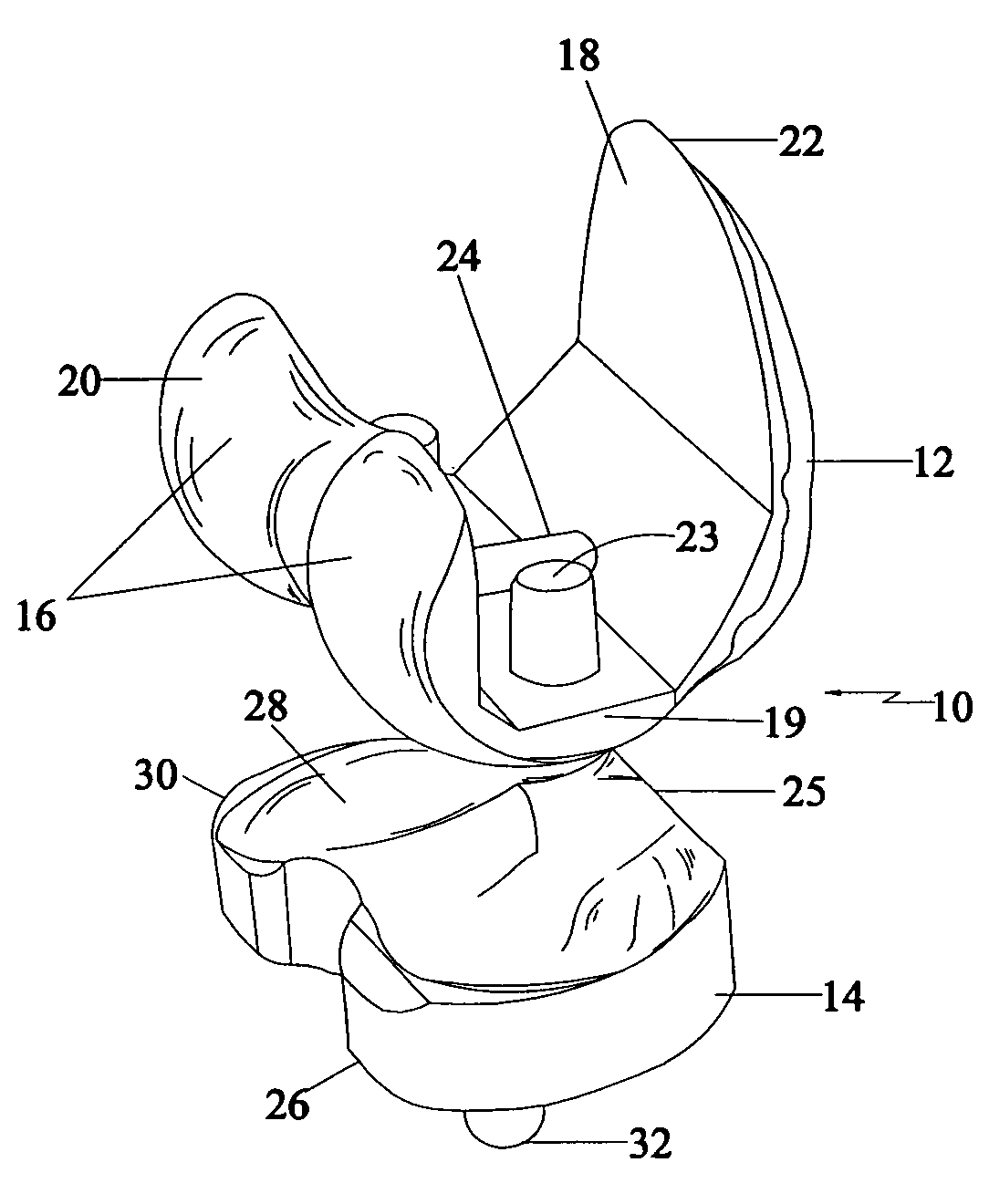

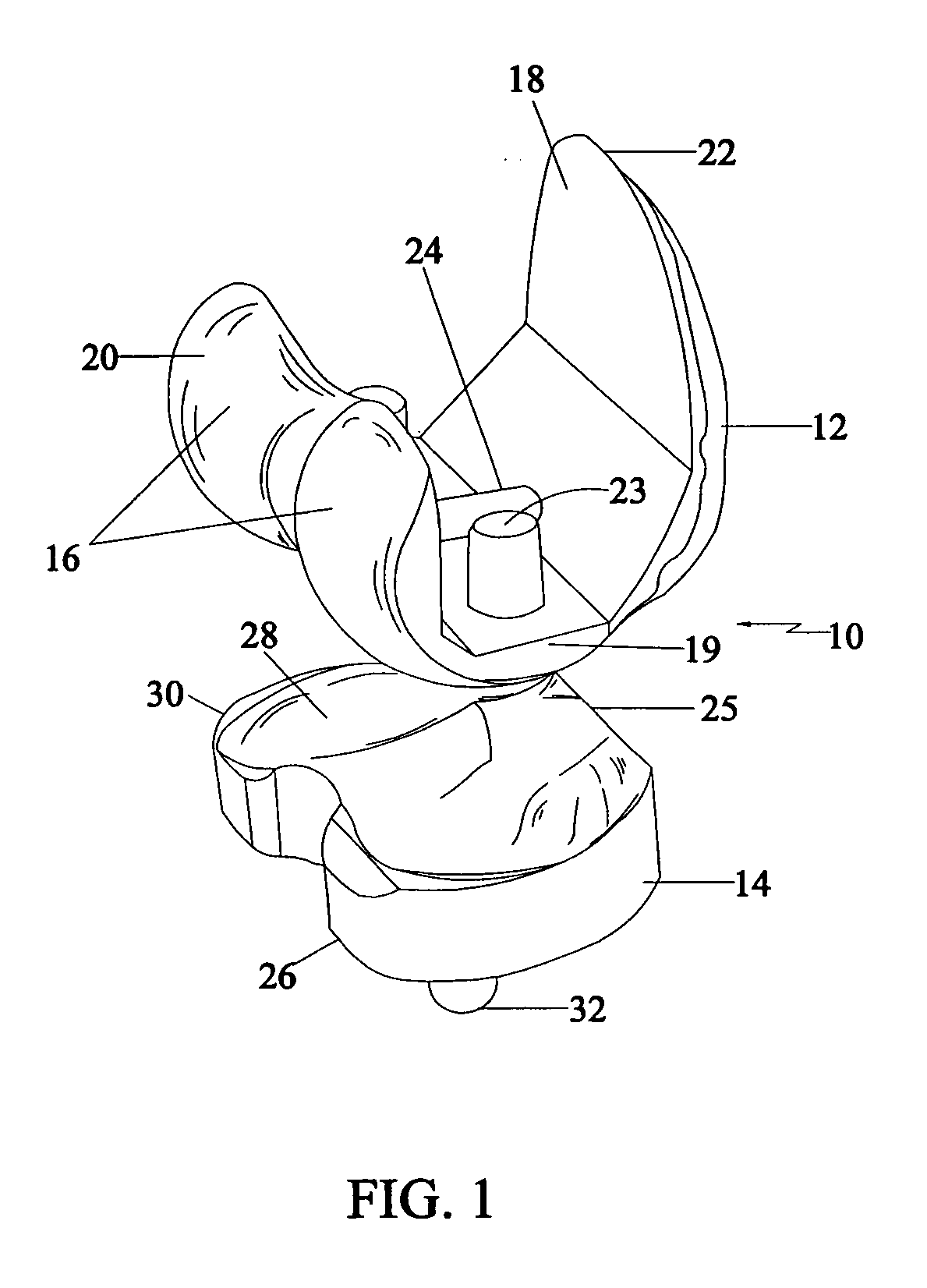

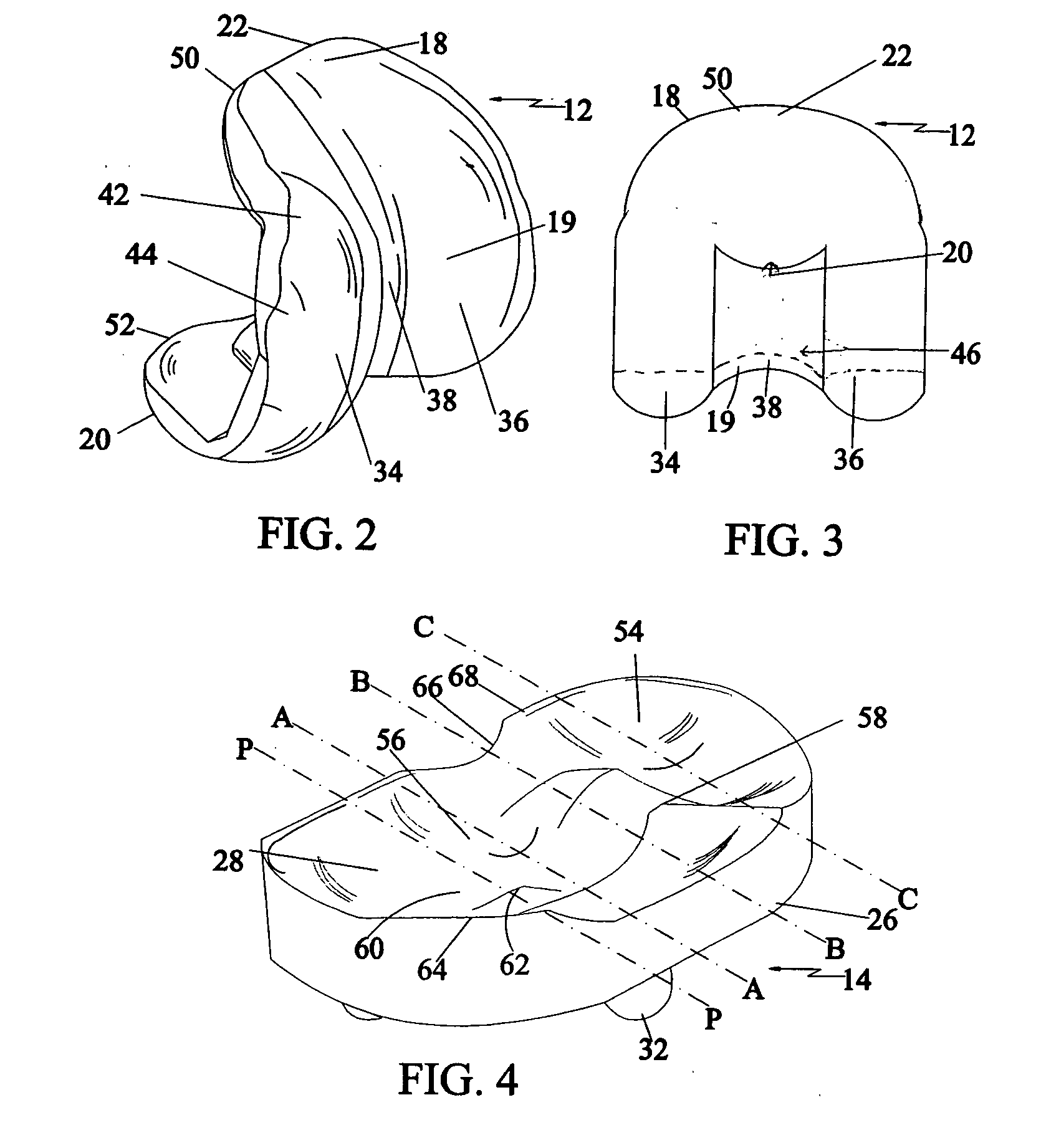

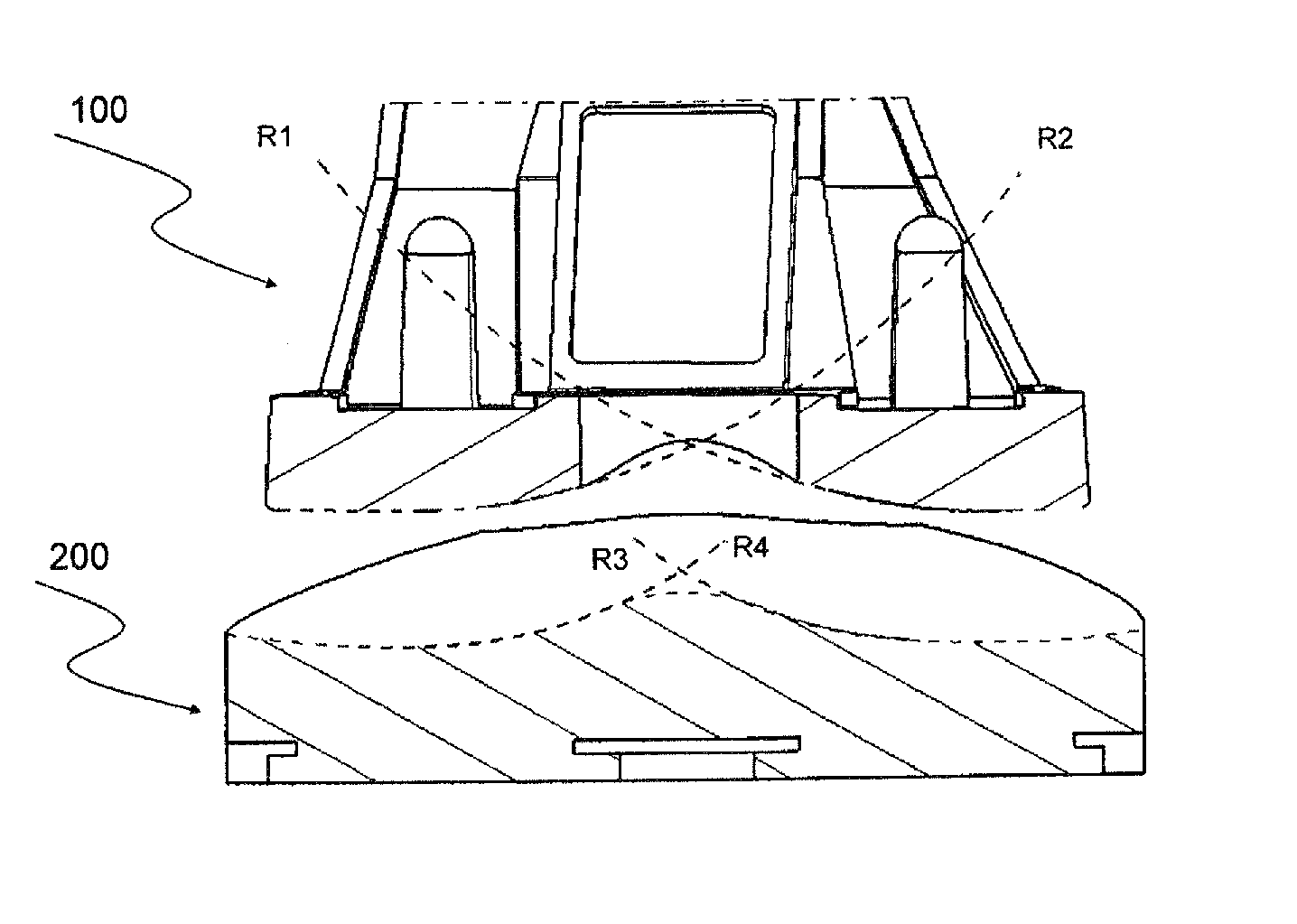

Surface guided knee replacement

InactiveUS20070135925A1Reduce consistencyAvoid large displacementJoint implantsKnee jointsGonial angleTibial surface

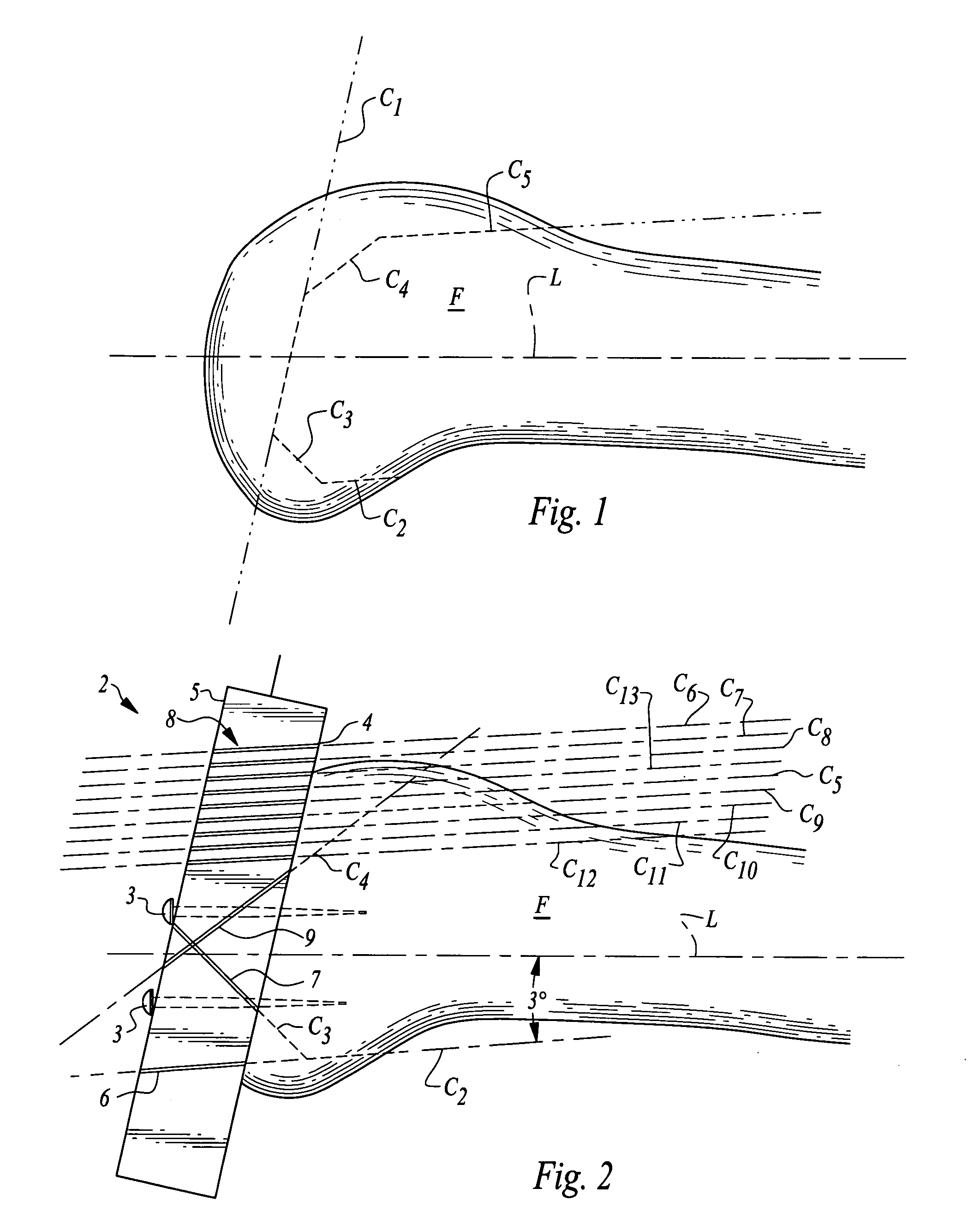

An artificial knee joint that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the motion and stability characteristics of the anatomic knee. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, more so on the lateral side than on the medial side. This is accomplished by the interaction of a projecting tibial post inside a cupola in the center of the femoral component, and by the saggital radius on the medial side being smaller than that on the lateral side. The prevention of anterior sliding of the femur on the tibia in early flexion is accomplished by the interaction between a distal-anterior recess on the medial side of the femur and an apposing raised pad on the tibial surface. Rotational laxity at all angles is allowed by the presence of only one recess pad and by non-conforming femoral-tibial surfaces on the lateral side.

Owner:NEW YORK UNIV

Surface guided knee replacement

Owner:NEW YORK UNIV

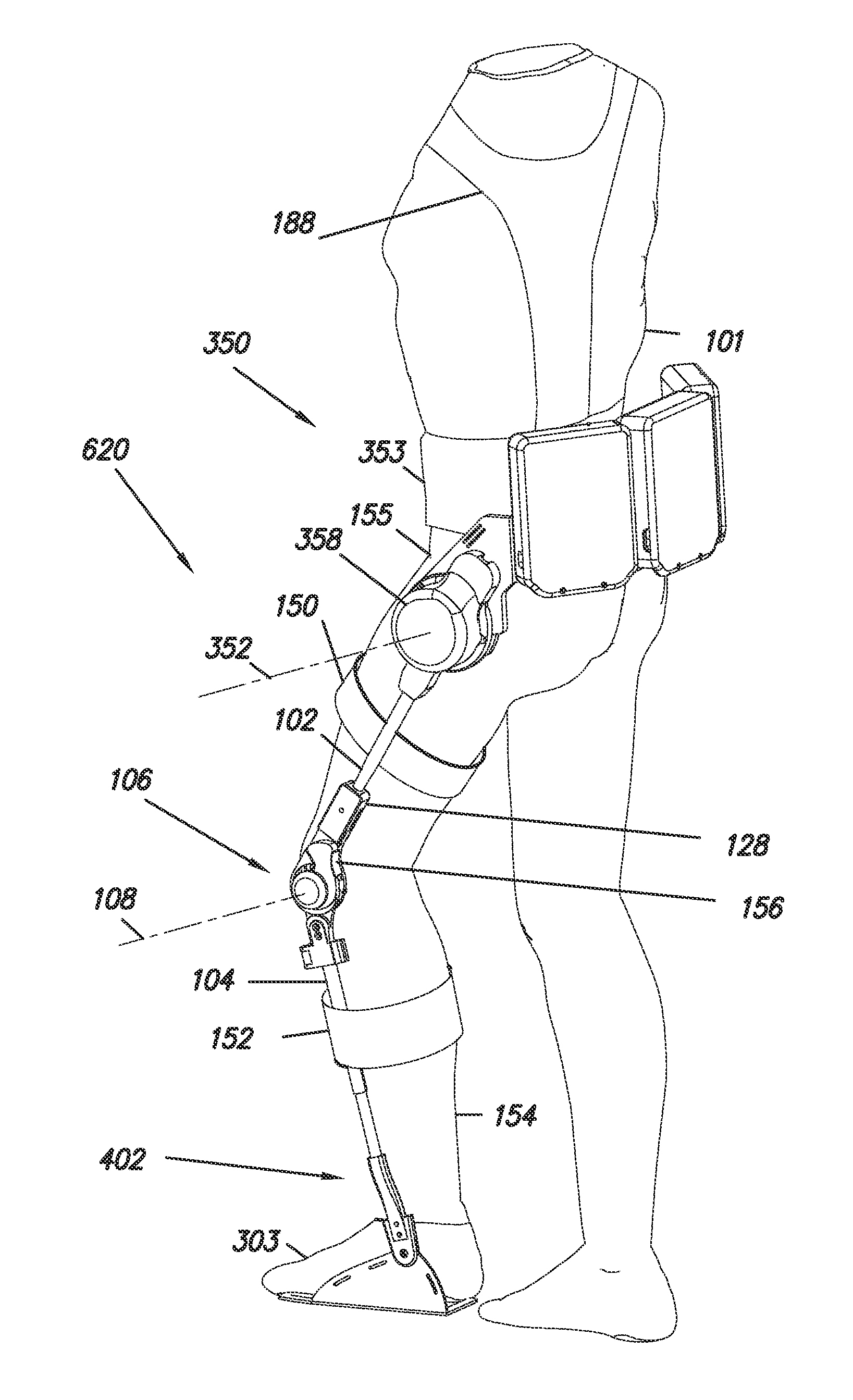

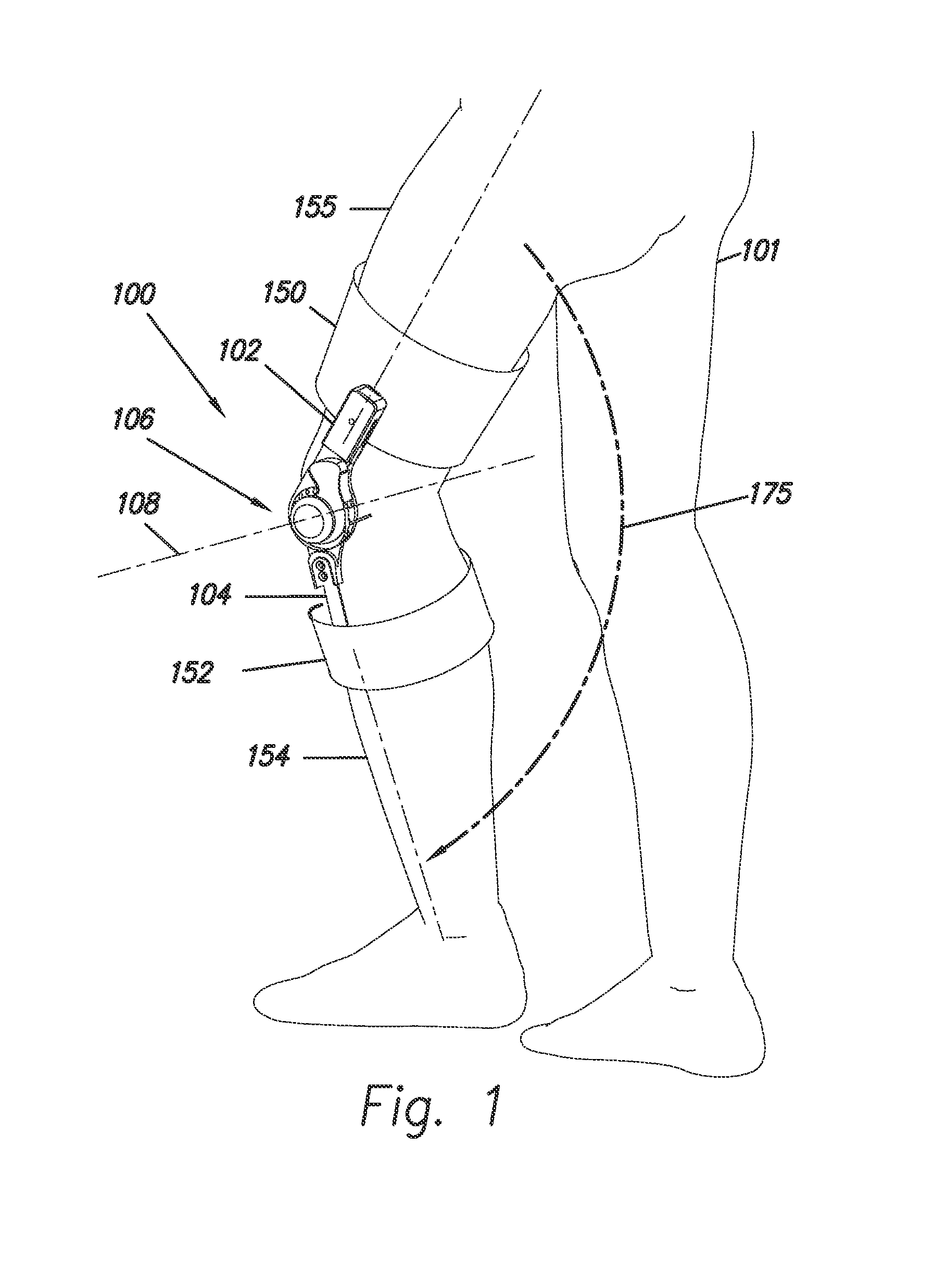

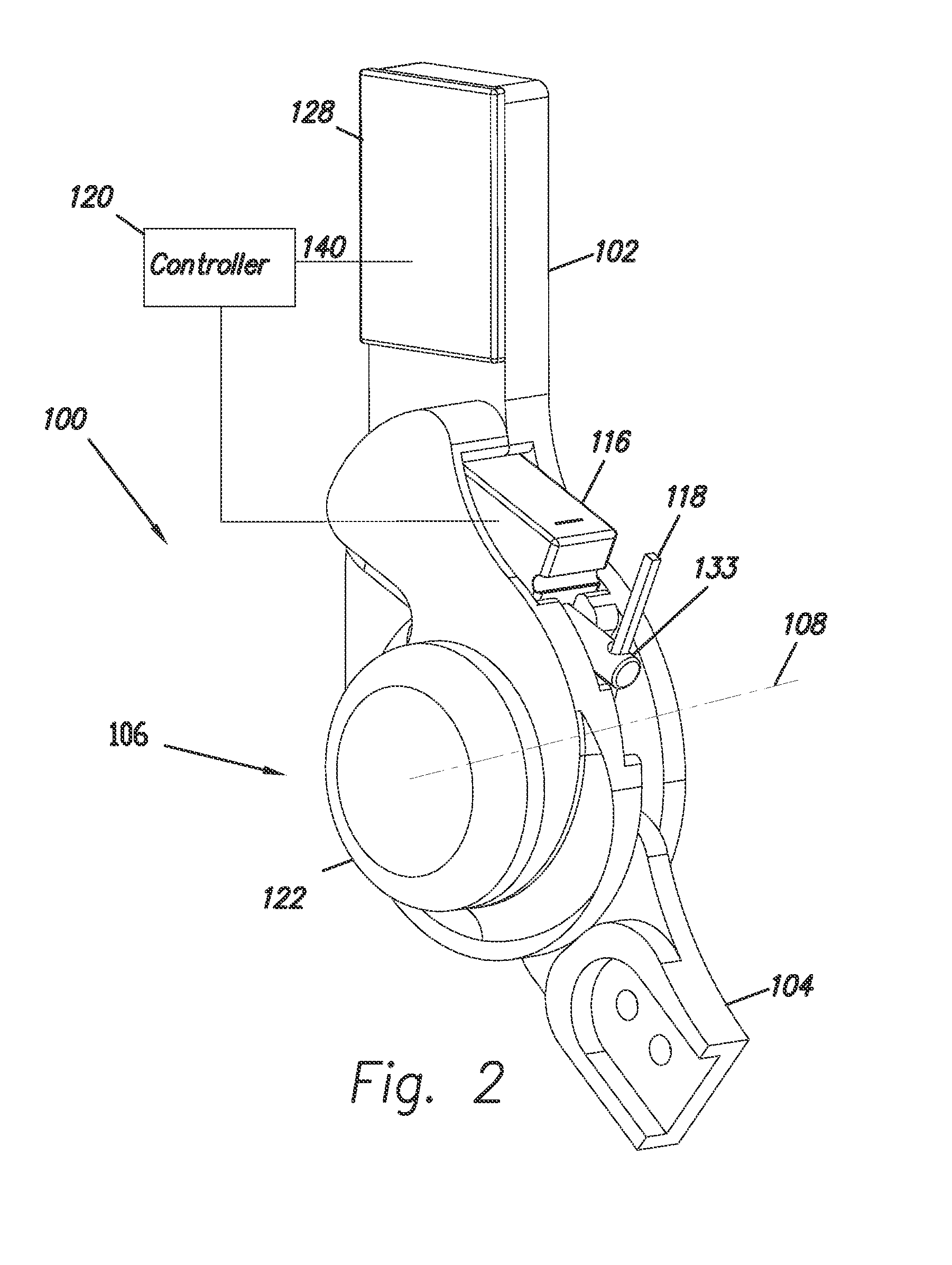

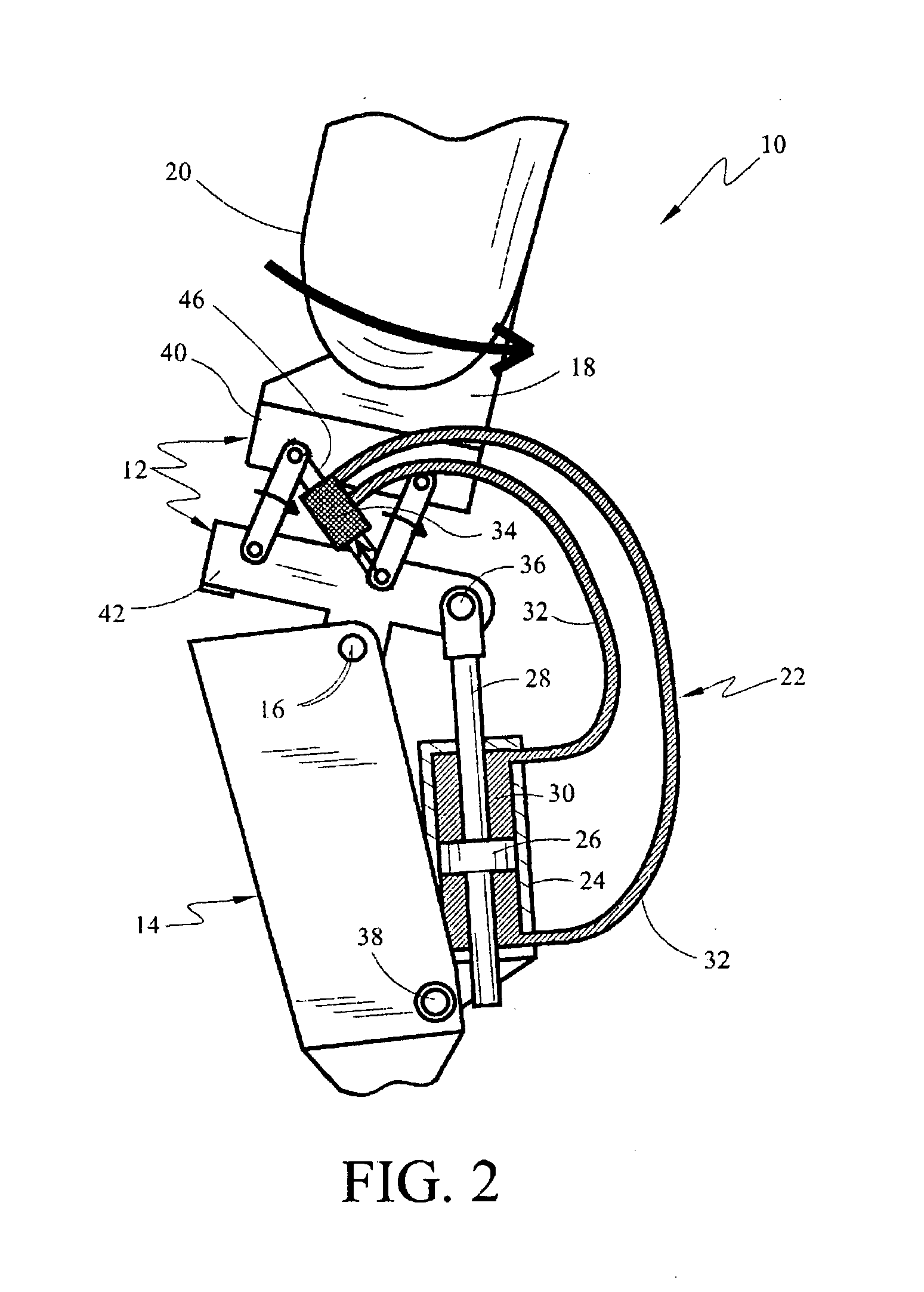

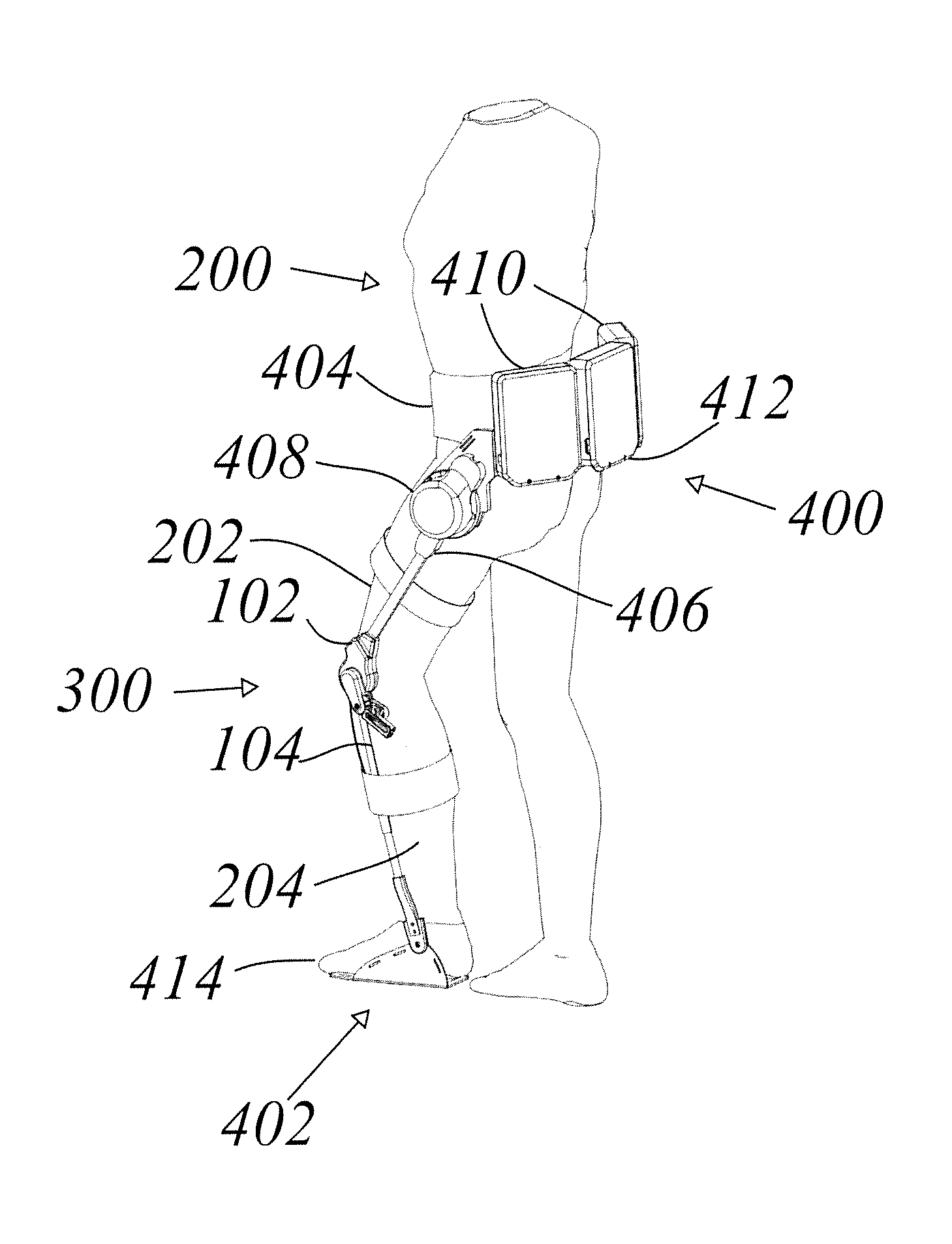

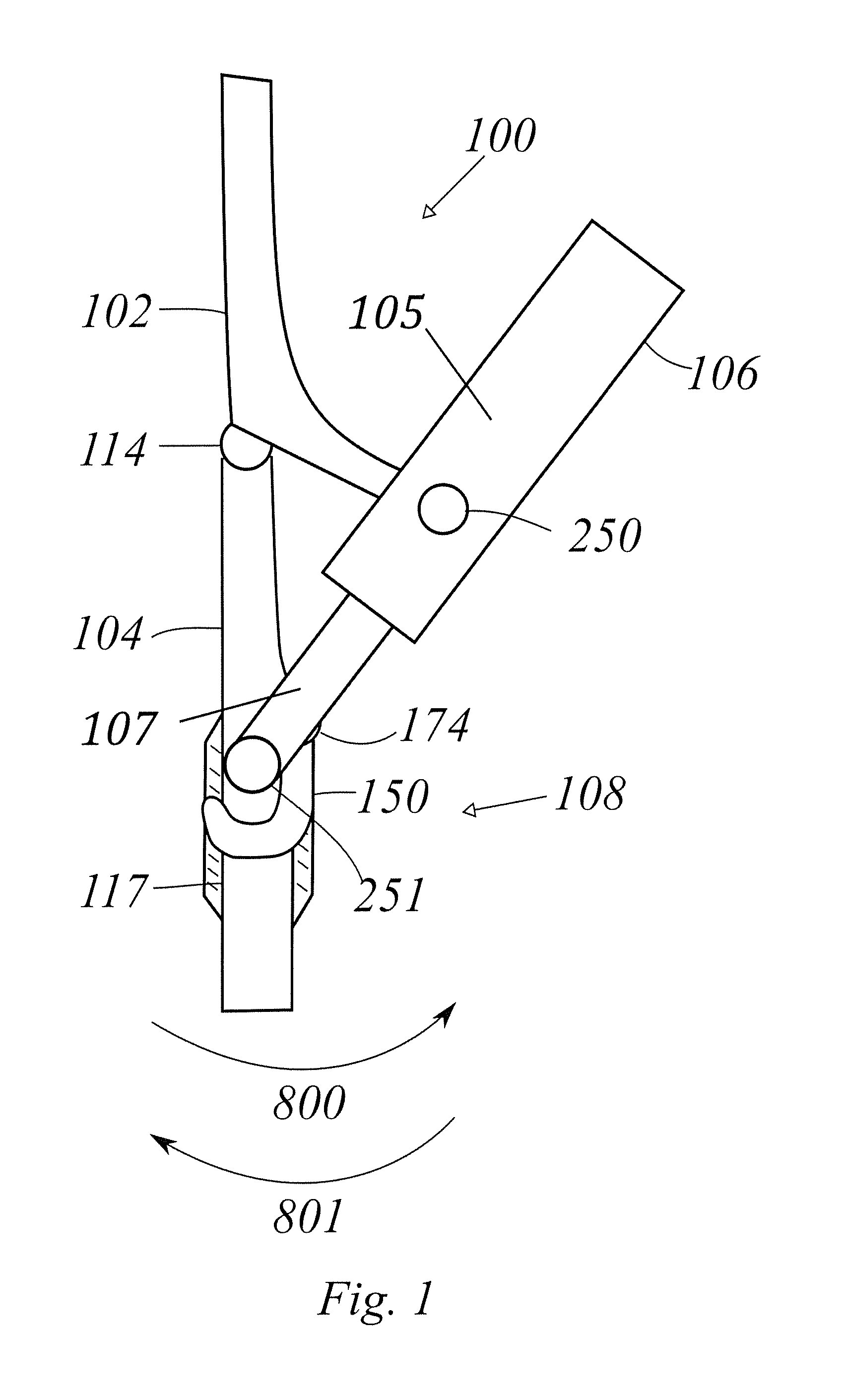

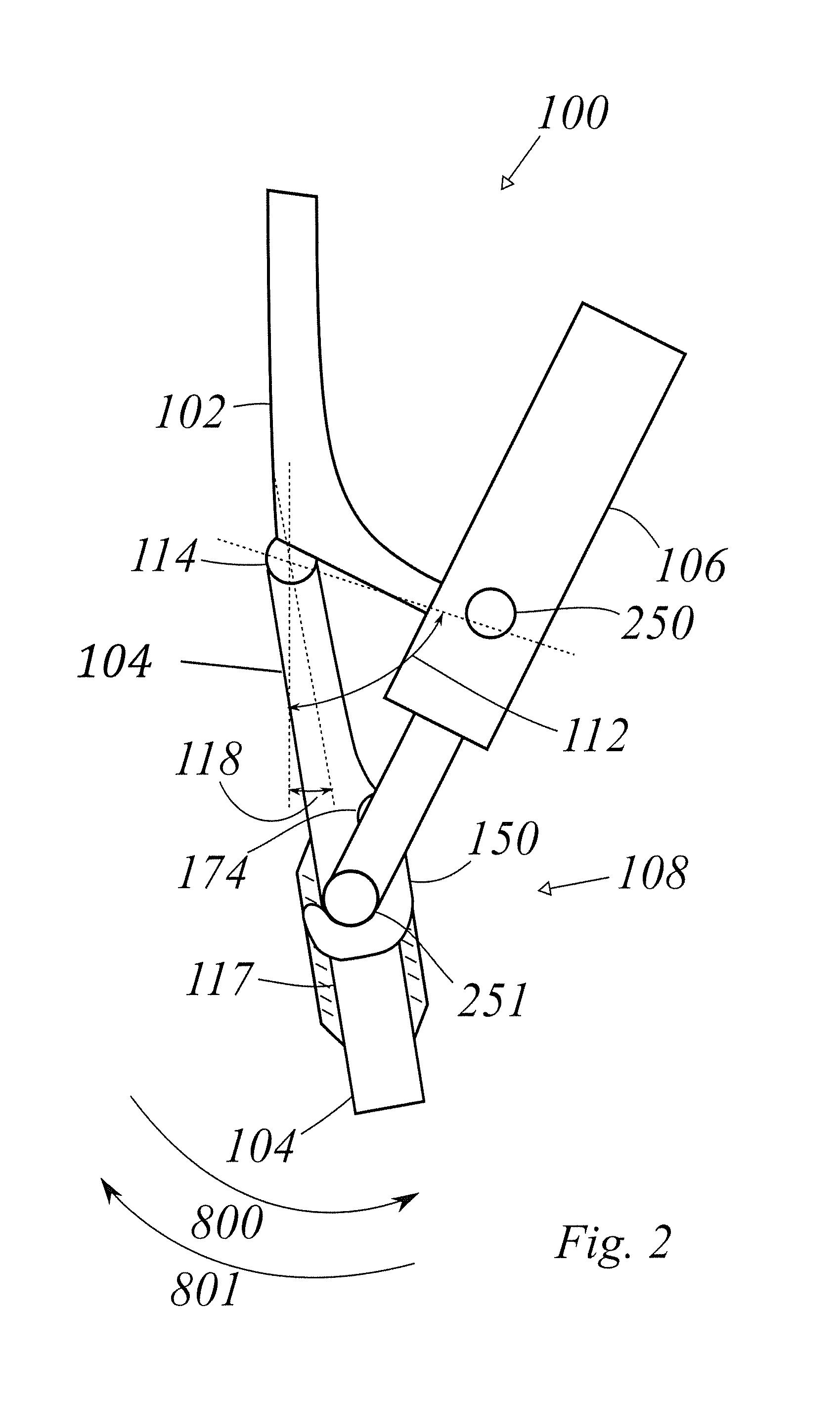

Controllable passive artificial knee

ActiveUS20150173929A1Reduce torqueProgramme-controlled manipulatorChiropractic devicesThighEngineering

An exoskeleton (100) adapted to be coupled to a lower extremity of a person includes a thigh link (102), a shank link (104) and a knee joint (106) allowing flexion and extension between the thigh and shank links (102, 104). A torque generator (156) connected to the knee joint (106) includes a wrap spring (110) having a first end (112) coupled to the thigh link (102), and a second end (118) coupled to an electric actuator (116) capable of selectively positioning the second end (118) of the wrap spring (110). A controller (120) causes the electric actuator (116) to position the wrap spring (110) to provide a selective torque between the thigh and shank links (102, 104) based on a signal (212, 214, 216) produced by a sensor (164, 166, 168).

Owner:RGT UNIV OF CALIFORNIA

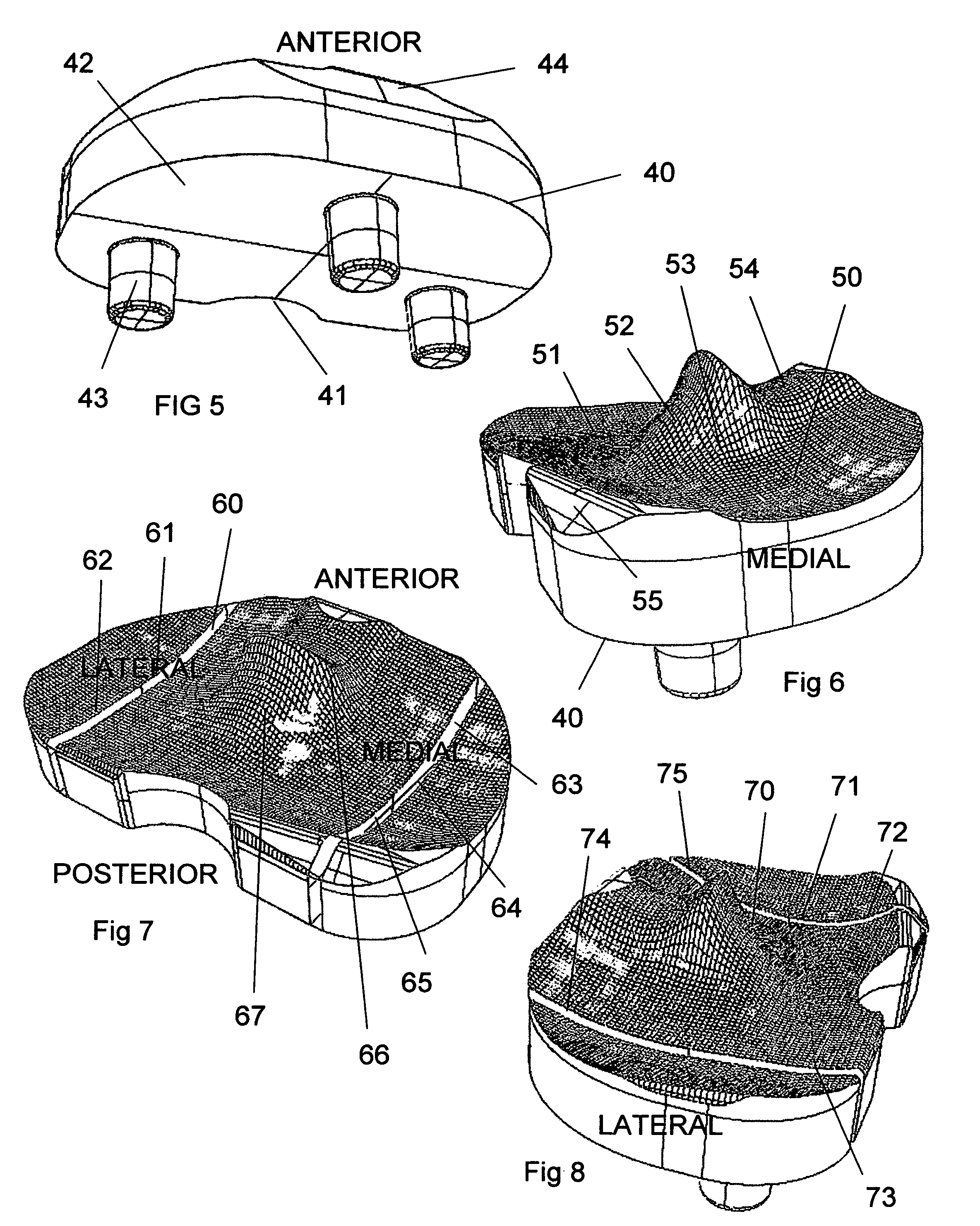

Knee joint with a ramp

InactiveUS20090204221A1Minimize wear and deformationIncrease the areaJoint implantsKnee jointsTibiaTibial surface

An artificial knee joint is described that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the required motion and stability characteristics. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, by an amount similar to that in the anatomic knee. The opposite motion, roll forward of the femur from a fully flexed to a more extended position, is accomplished by varying the outward radii of the lateral and medial femoral bearing surfaces, together with a ramp on the postero-lateral and postero-medial regions of the tibial surfaces.

Owner:NEW YORK UNIV

Artificial knee with cushion function

InactiveUS20060259153A1Provide securityArtificial legsPhysical medicine and rehabilitationPneumatic cylinder

An artificial knee has a supporting portion, a knee portion, and a leg portion. The knee portion has a saddle-like body, a front knee pivotally connected to the saddle-like body and a rear knee. The leg portion has a pneumatic cylinder received in the receiving space in the leg portion. Pivotal movement of the saddle-like body relative to the front knee is able to activate the pneumatic cylinder to provide a cushion effect to a load on top of the supporting portion.

Owner:CHANG YU MECHANICAL SYST

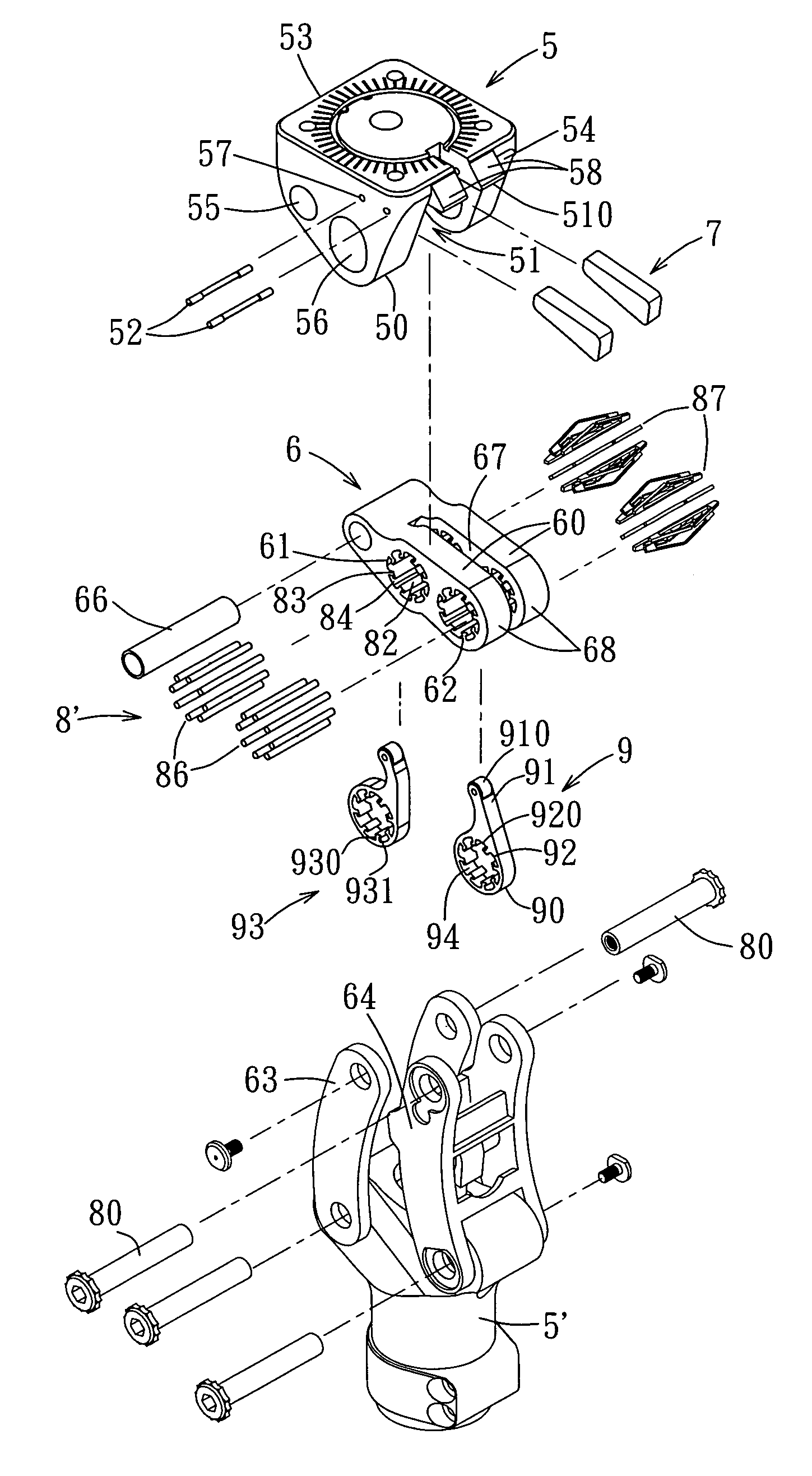

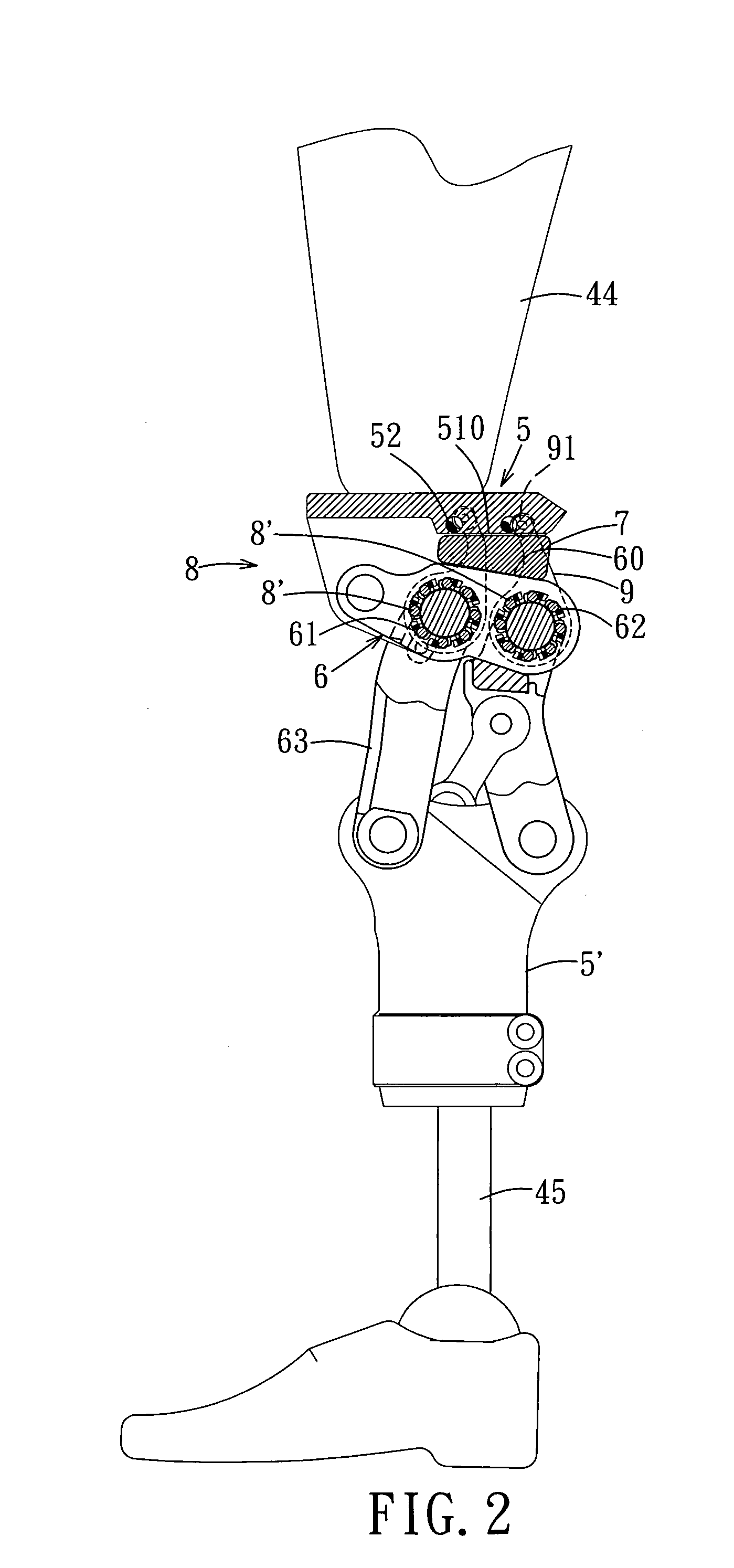

Artificial knee joint having a minimum knee angle

An artificial knee joint includes a knee seat attached to a residual thigh, a support frame attached to a prosthetic lower leg, and a driving member disposed pivotally in a mounting recess in the knee seat. A cushion device is disposed between the knee seat and the driving member. Two links have lower ends connected pivotally to the support frame. Two pivot pins extend respectively through upper ends of the links, and are journalled respectively within two mounting holes in the driving member by two bearing members, at least one of which is configured as a unidirectional bearing. When a knee angle is equal to a threshold angle, a pin-locking member is disposed in a pin-locking position so as to prevent rotation of the pivot pins within the driving member and, thus, relative rotation between the knee seat and the support frame.

Owner:CHEN SEN JUNG

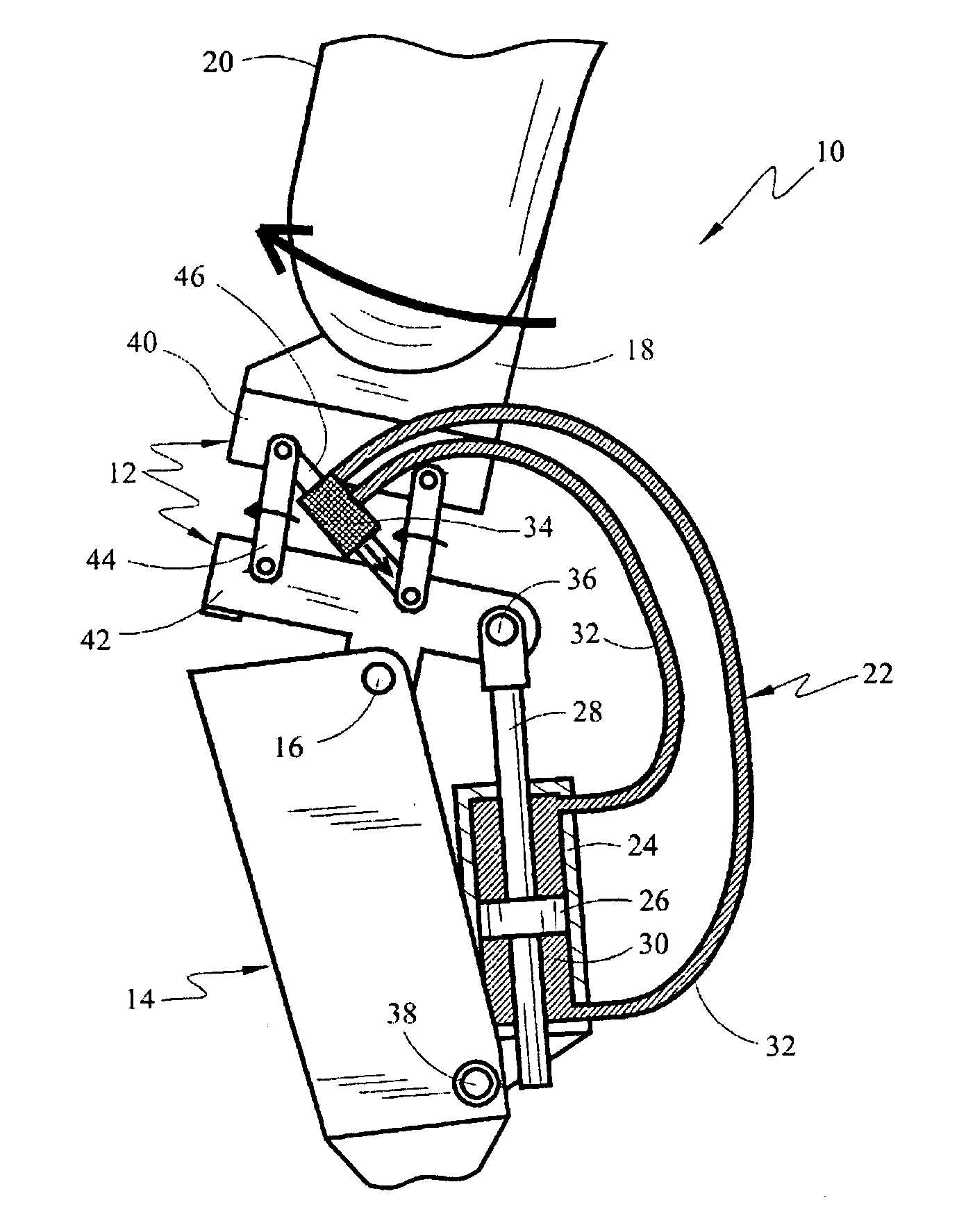

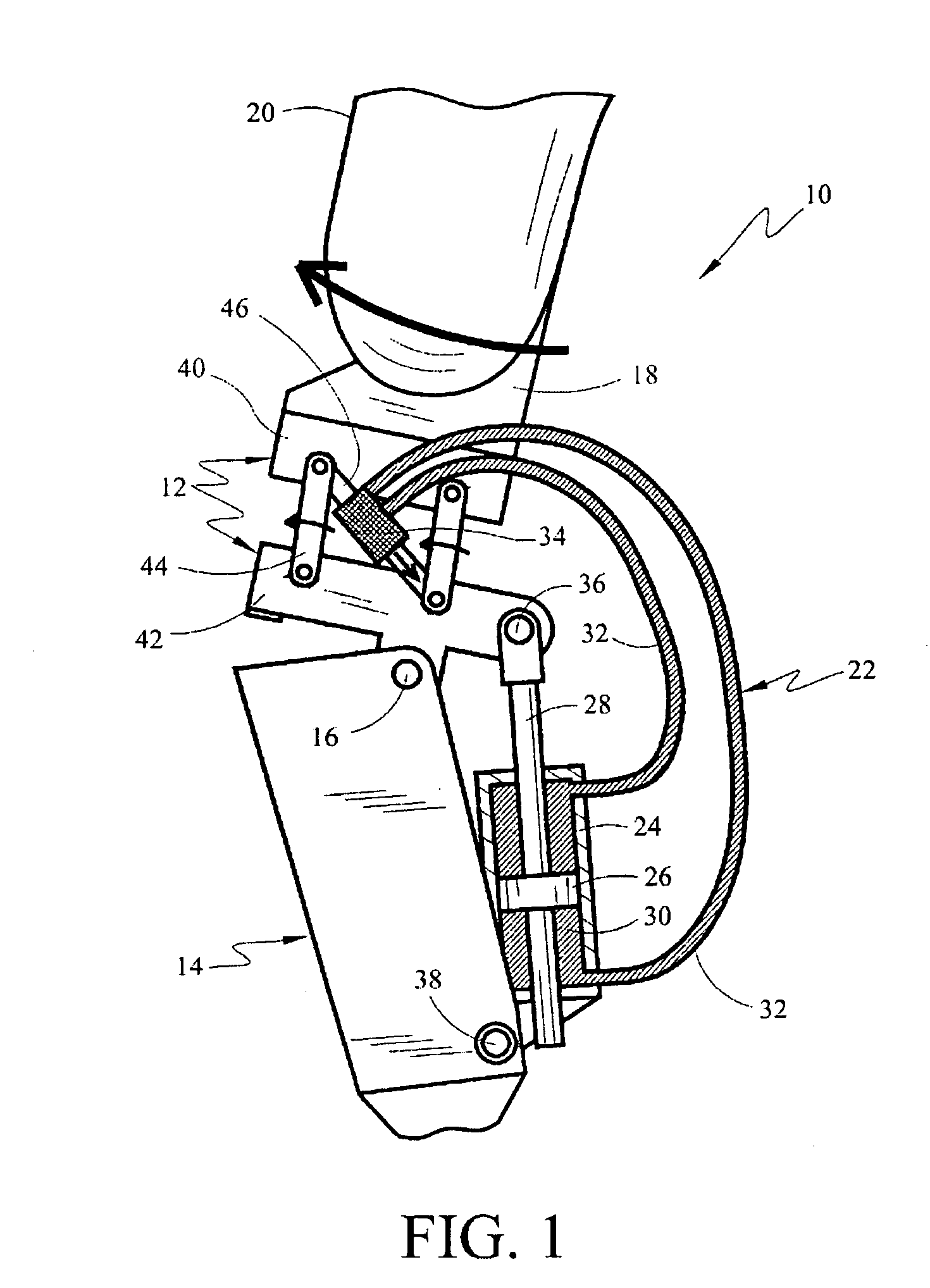

Above-knee prosthesis with variable resistance knee joint

InactiveUS20050015156A1Decrease resistance of flexion and extensionImprove the immunityArtificial legsFree rotationVALVE PORT

An above-knee prosthesis that allows the user to control the resistance of knee flexion or extension, and to voluntary lock and release the knee joint, at any and all bending angles, comprising a thigh frame assembly that receives a thigh stump; a leg frame assembly with foot attached; a hinge interconnecting the thigh frame and leg frame assemblies to form an artificial knee joint; a closed hydraulic system further interconnecting the thigh frame and leg frame assemblies to provide resistance to the bending of said artificial knee joint, a means to vary the resistance provided by said closed hydraulic system, and a means to translate the AP movement of said thigh stump into the degree of resistance provided by said closed hydraulic system. In its preferred embodiments, the AP movement of the thigh stump is communicated by means of a linkage, sliding or screw assembly, to a flow rate control valve. The flow rate control valve varies the amount of the resistance provided by the closed hydraulic system controlling, thereby, the amount of resistance within the artificial knee. Pressing the thigh stump backwards within the thigh frame assembly increases the resistance within the hydraulic system and slows knee bending until the knee locks. Pressing the thigh stump forward decreases the hydraulic resistive force and allows the artificial knee joint to yield to outside forces, such as gravity and / or stump thrust, until the prosthesis rotates freely about the knee hinge. The above-knee prosthetic prevents the knee joint from giving way, promotes a balanced stance, and facilitates a near normal reciprocating gate while ascending and descending stairs and slopes.

Owner:HIKICHI YUICHI

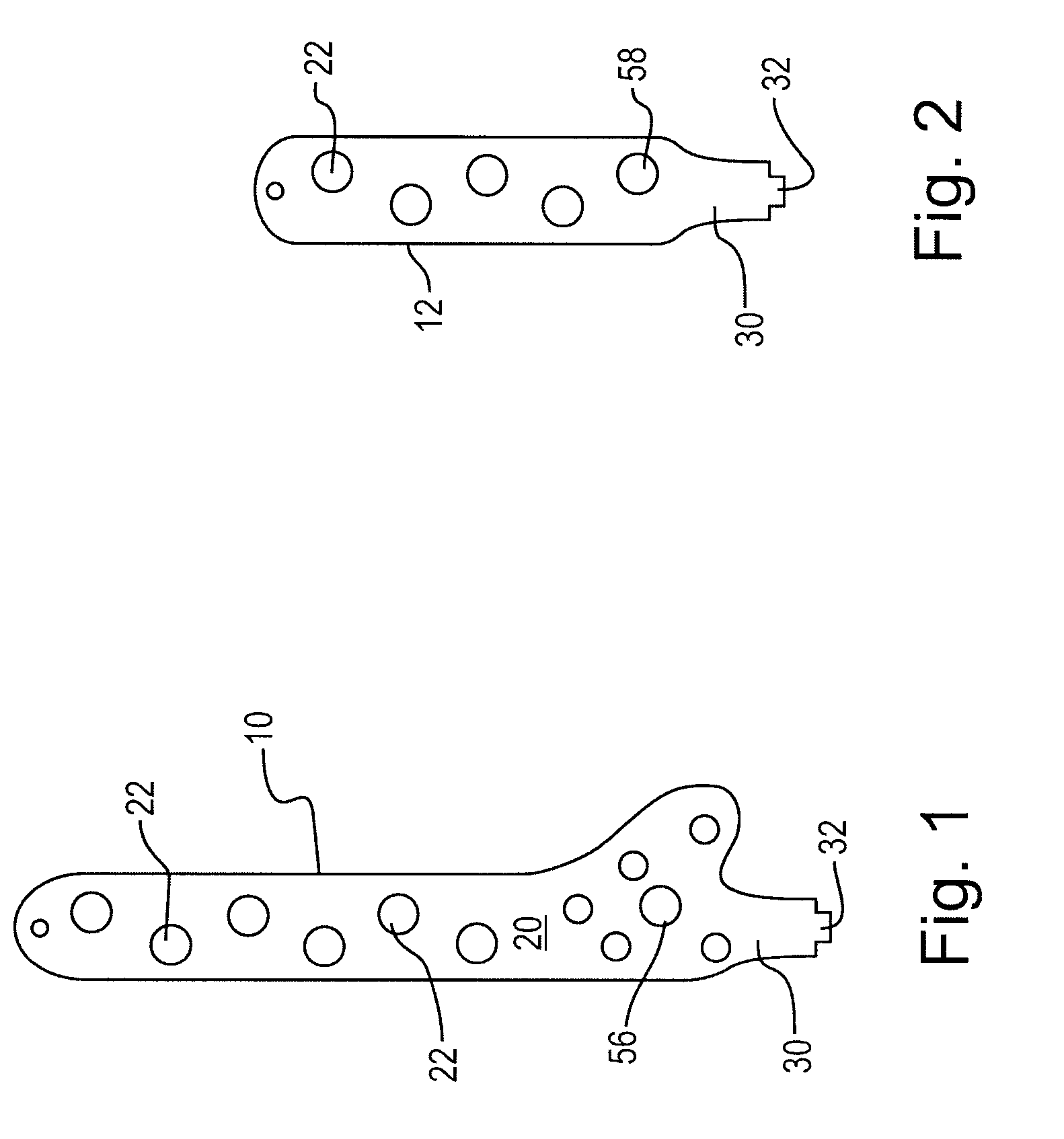

Method and apparatus for treating periprosthetic fractures of the distal femur

InactiveUS20100318086A1High strengthMinimize disruptionInternal osteosythesisJoint implantsCouplingMedial side

A medical device is provided for attachment to a patient's femur to treat a fracture in the distal region of the femur, in a patient with an artificial knee joint. The apparatus includes first and second elongate plates for attaching to the femur at the location of the fracture. The plates include coupling means to rigidly coupling the plates to the femoral component of the artificial knee joint. The apparatus further includes a transverse link for connecting the first and second plates together in a spaced apart relationship to form a rigid linkage between said plates. The invention further includes a system for treating a fracture of the femur, especially in patients with weak bones, by attaching such plates in an opposed spaced apart relationship on the lateral and medial sides of the femur, and fastening the lower ends of the plates to the femoral component of the knee. The transverse link is engaged to form a monolithic, rigid structure for bracing the femur.

Owner:MCMASTER UNIV

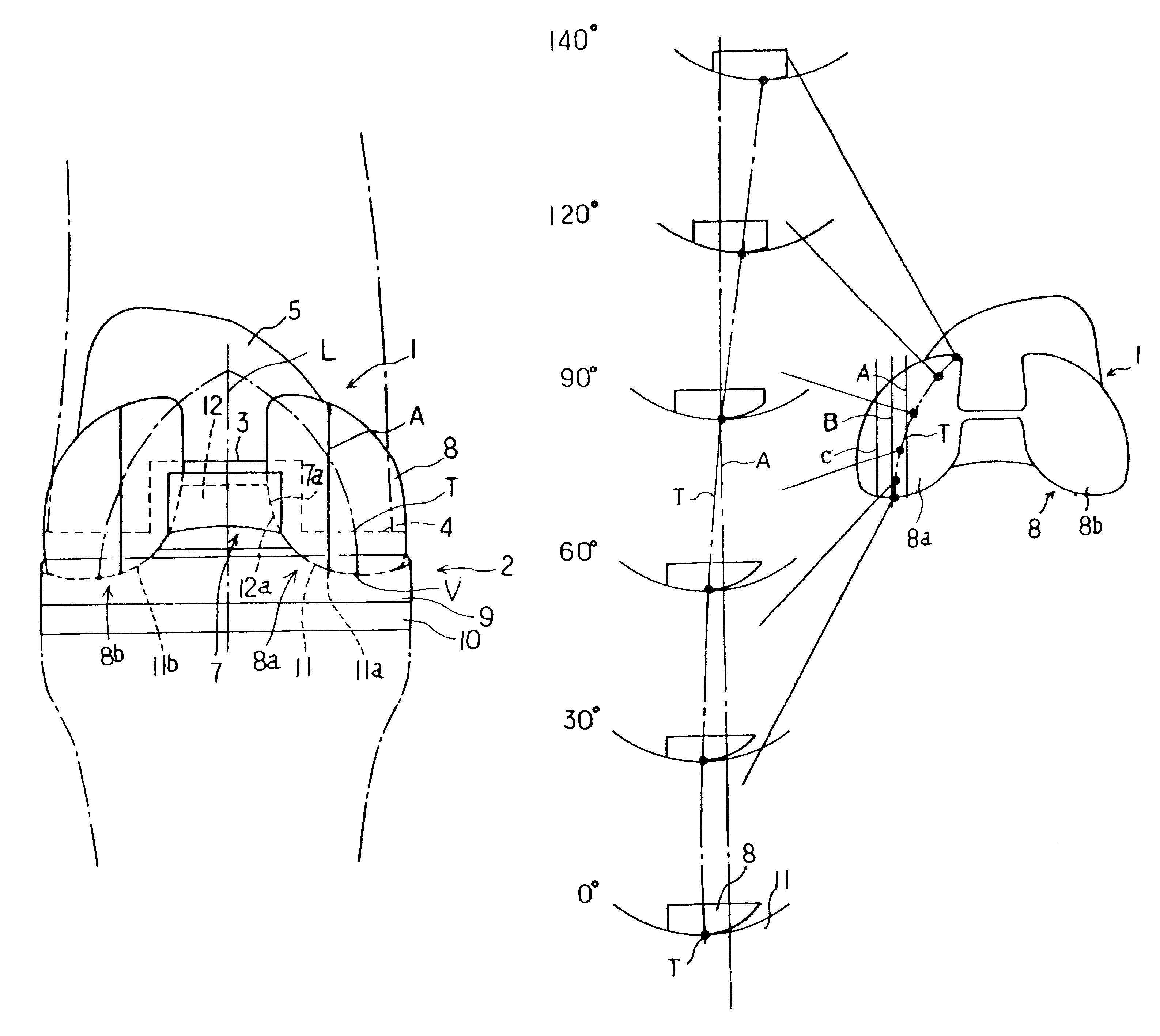

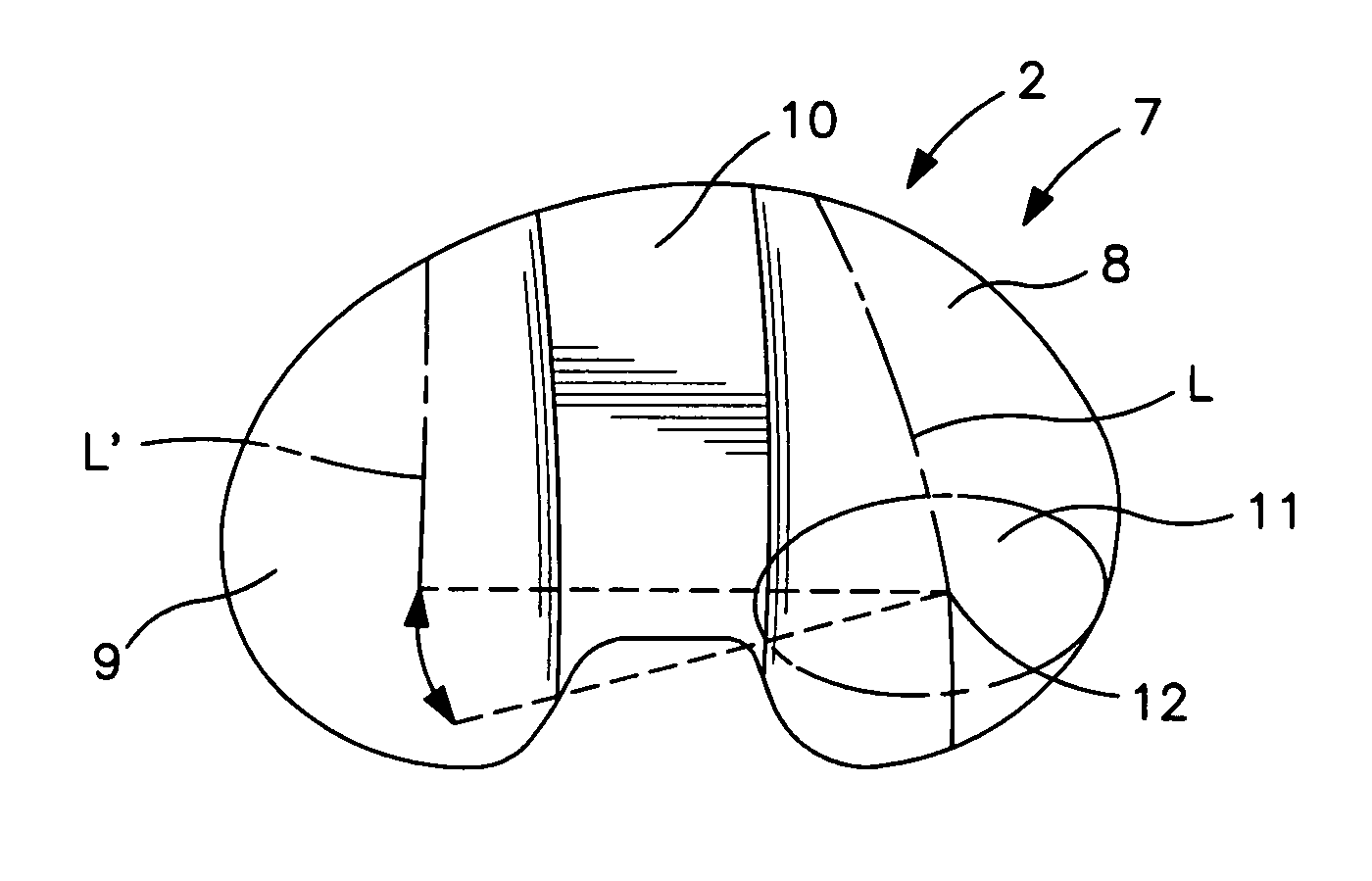

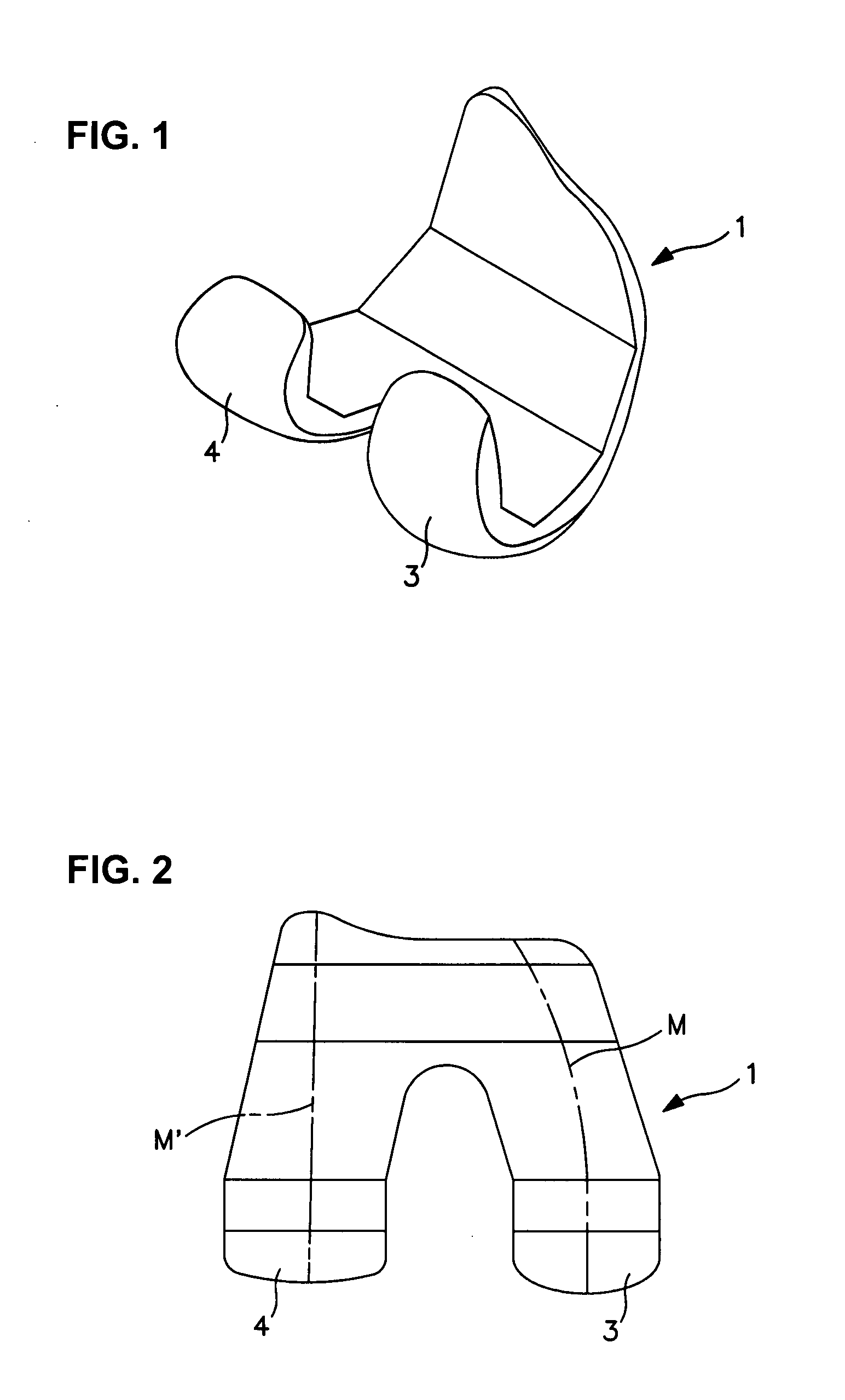

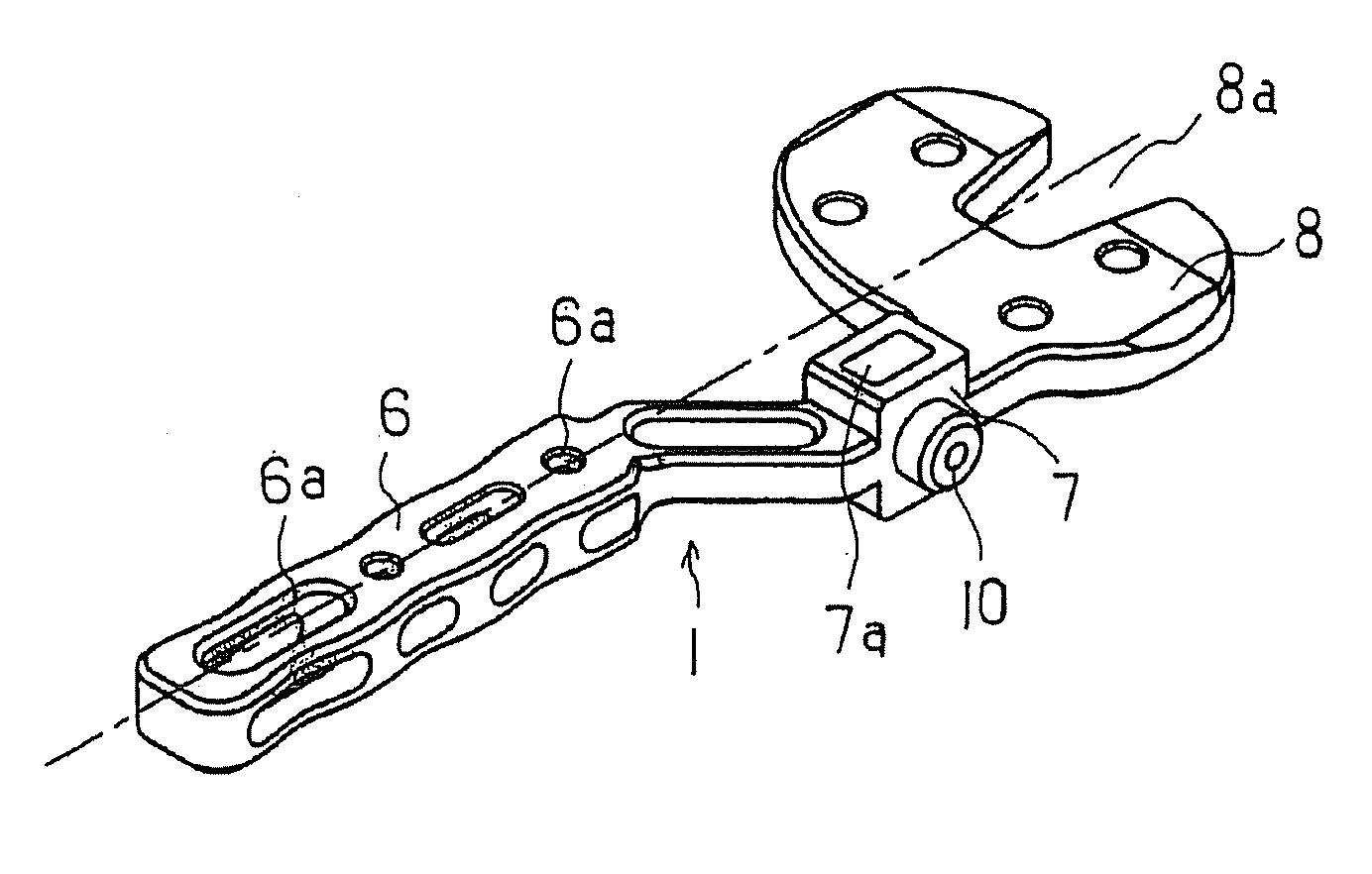

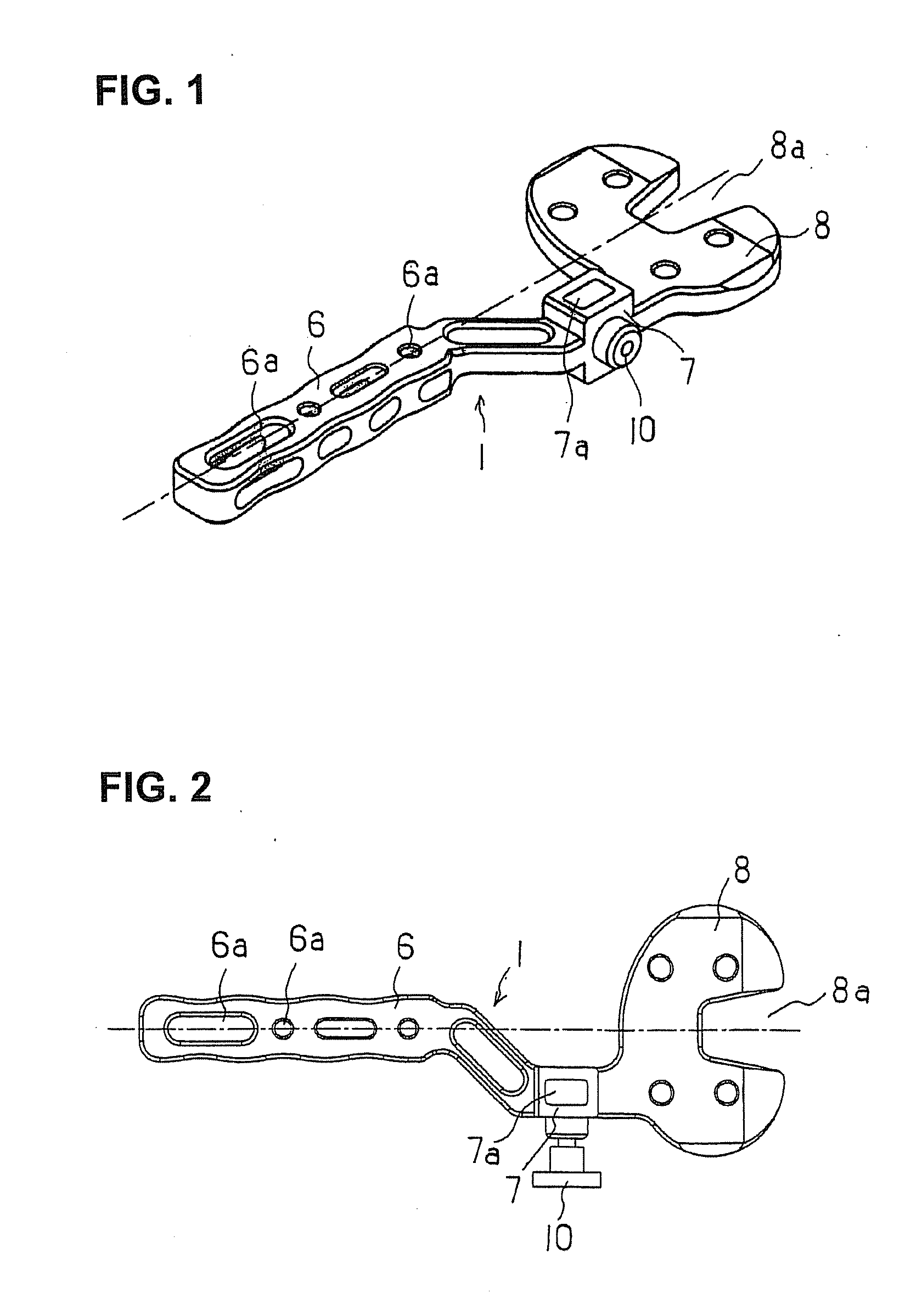

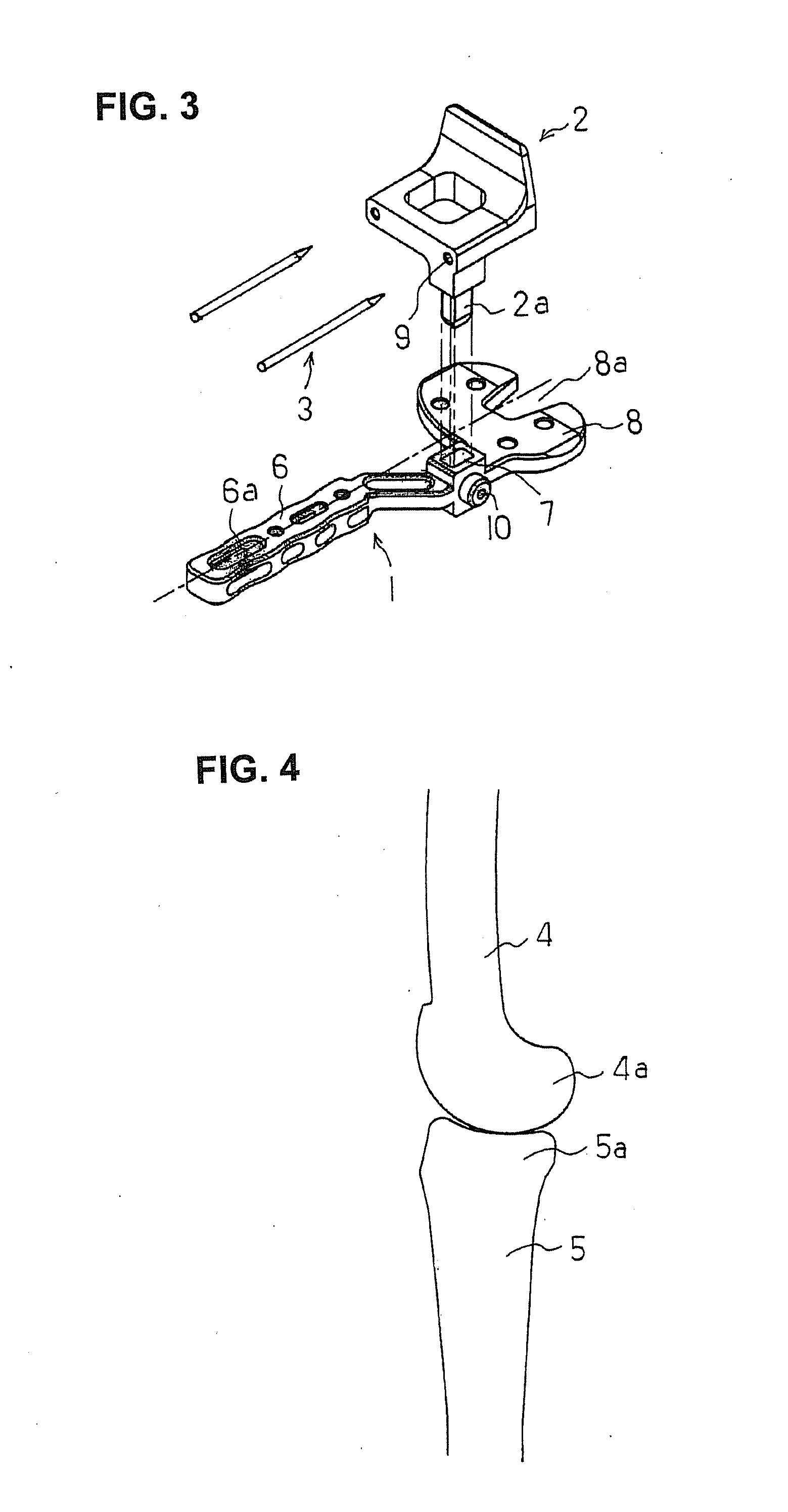

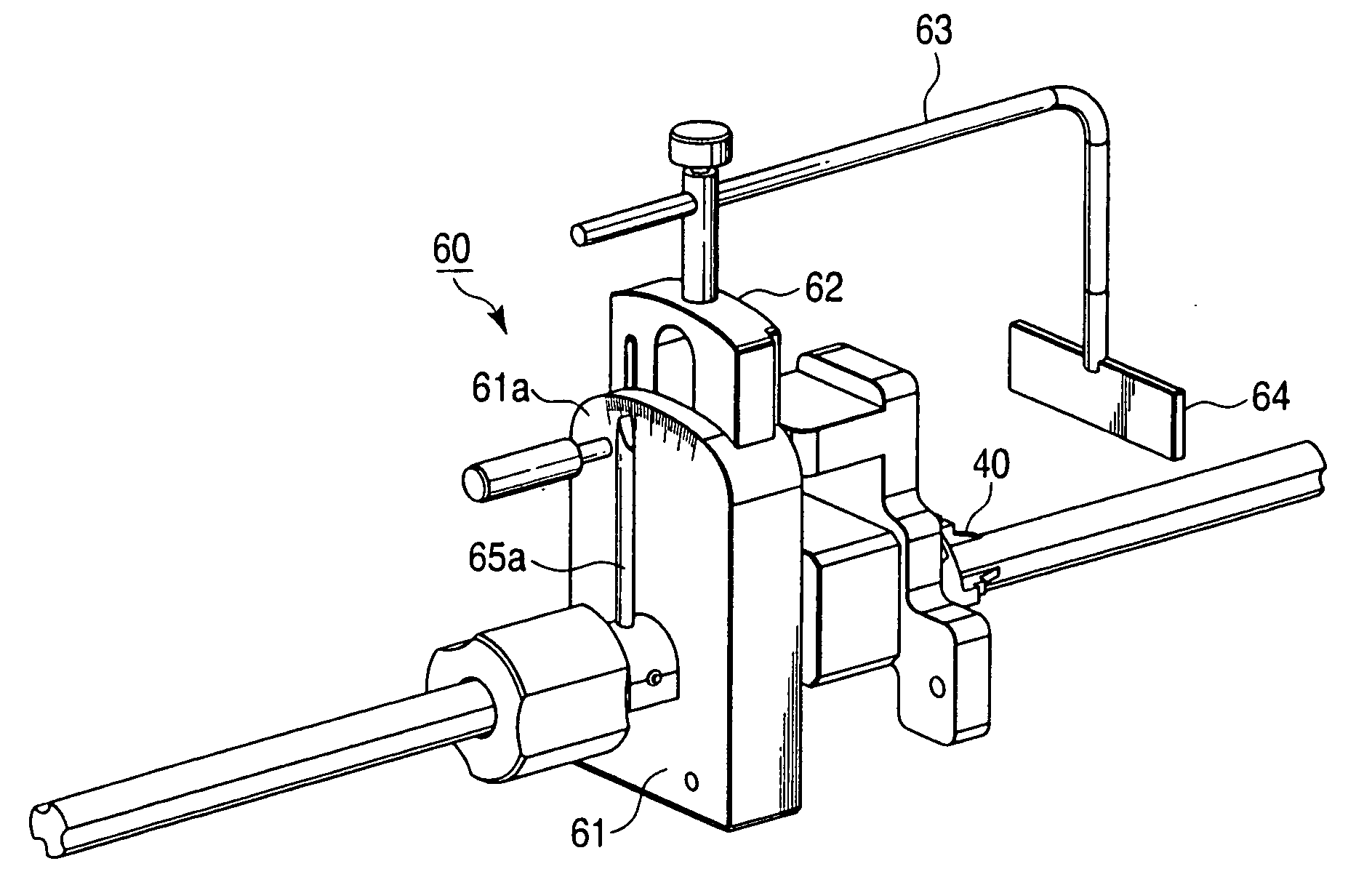

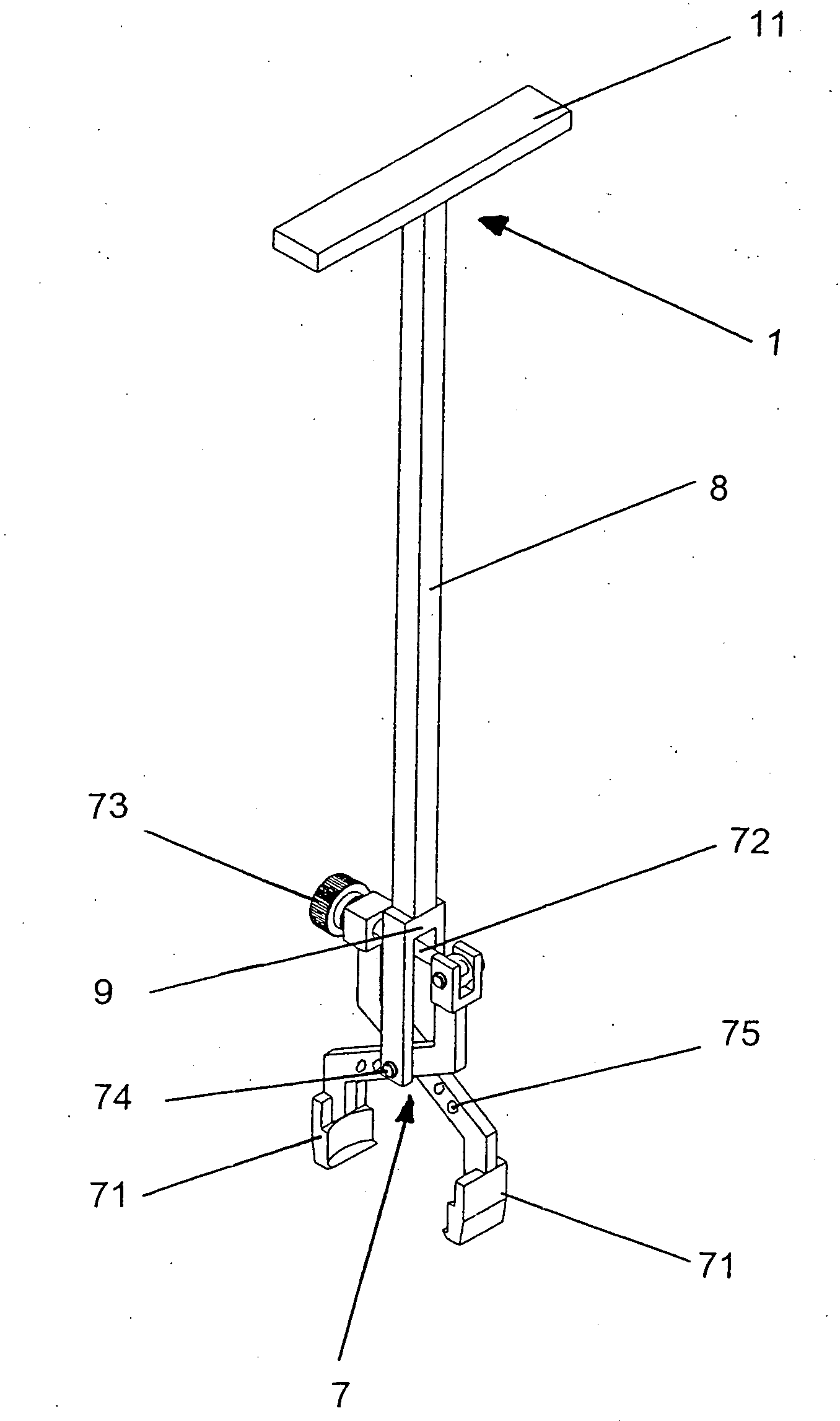

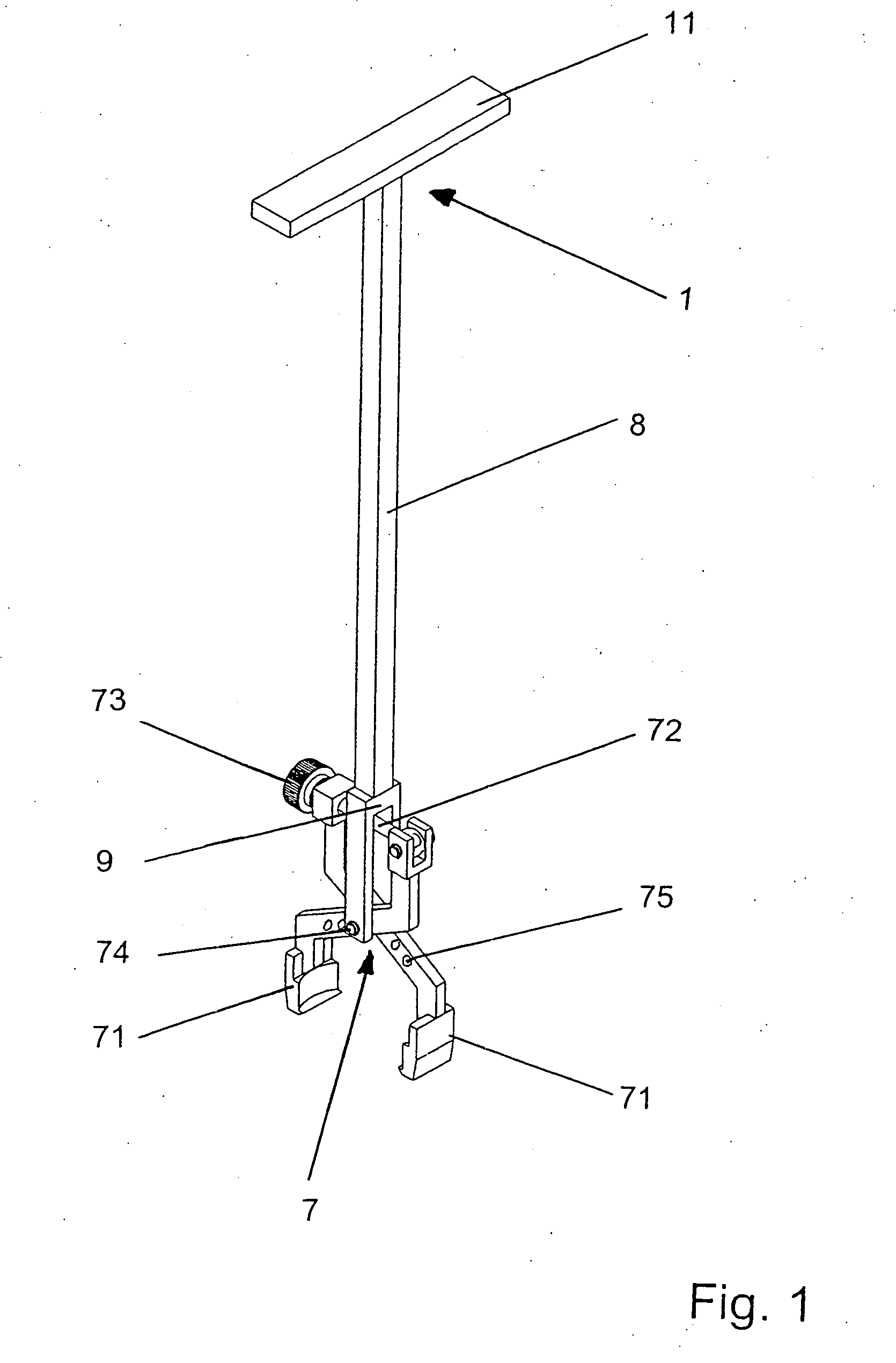

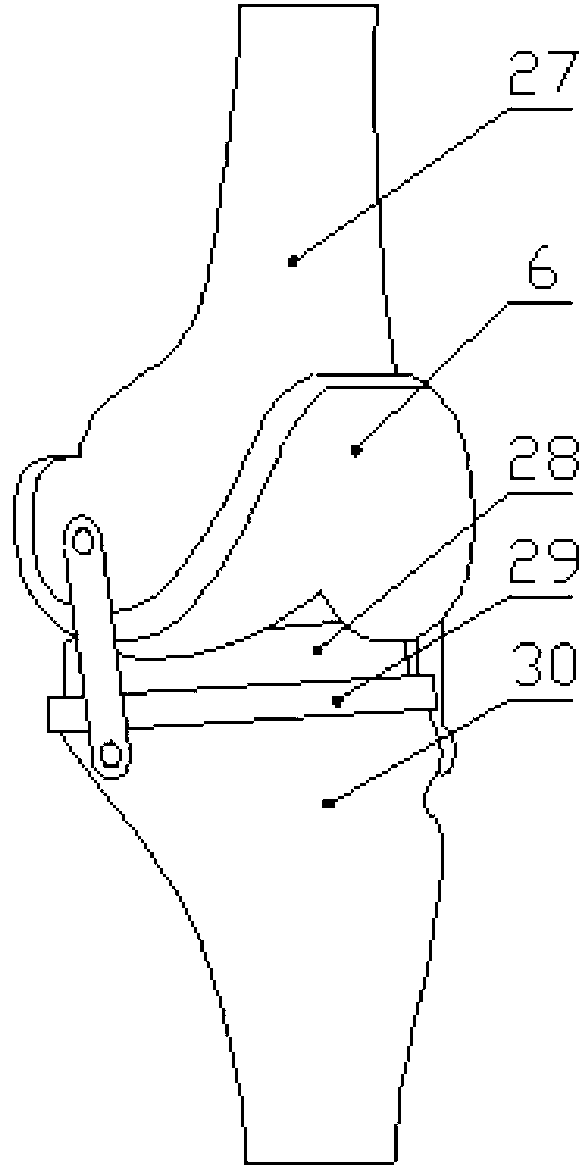

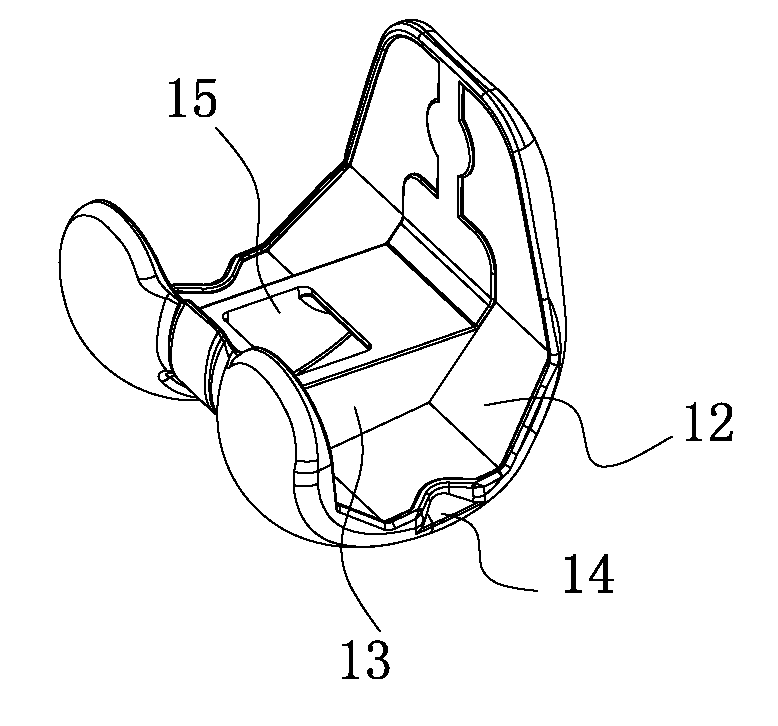

Bone Resection Jig Used in Artificial Knee Joint Replacement Surgery

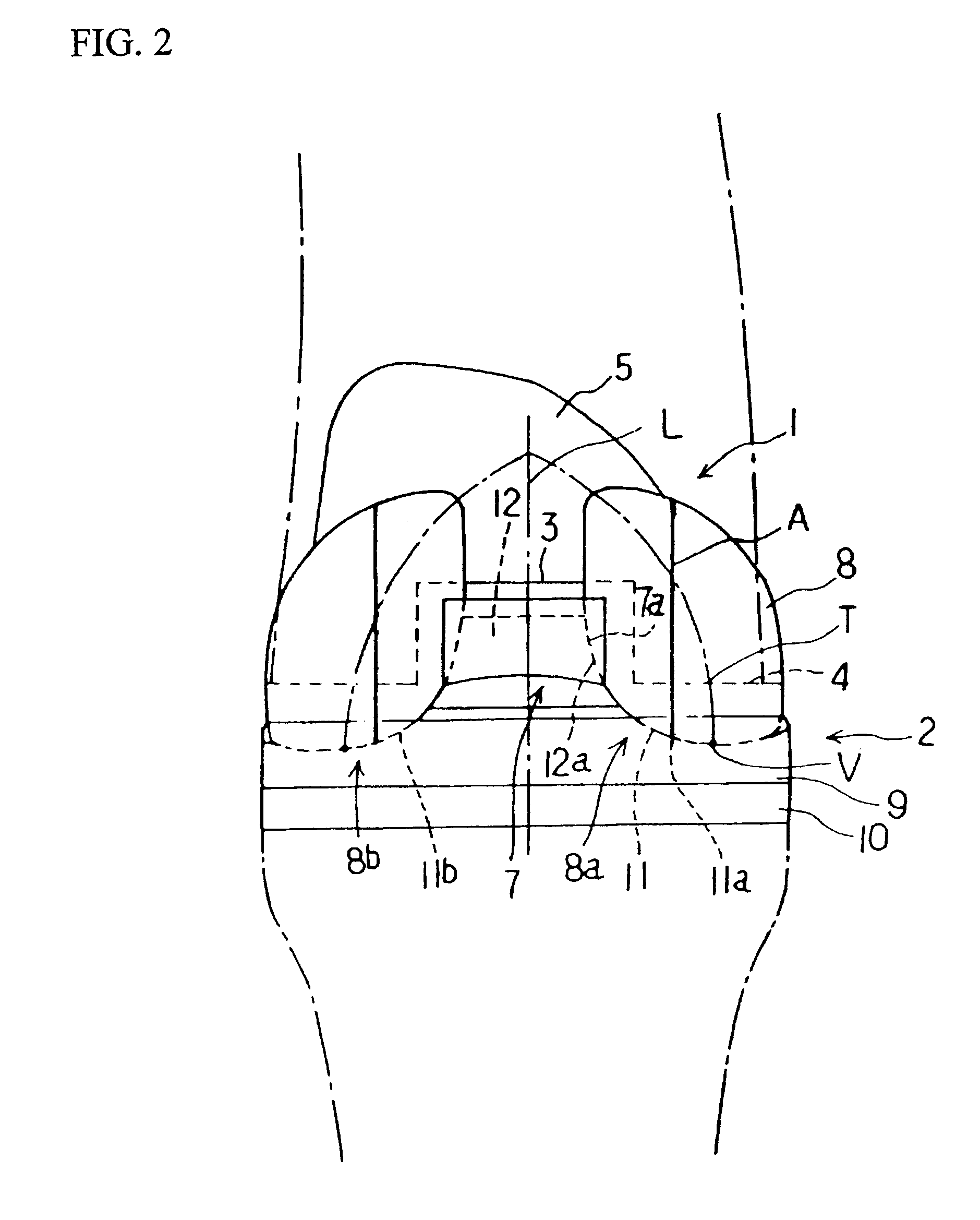

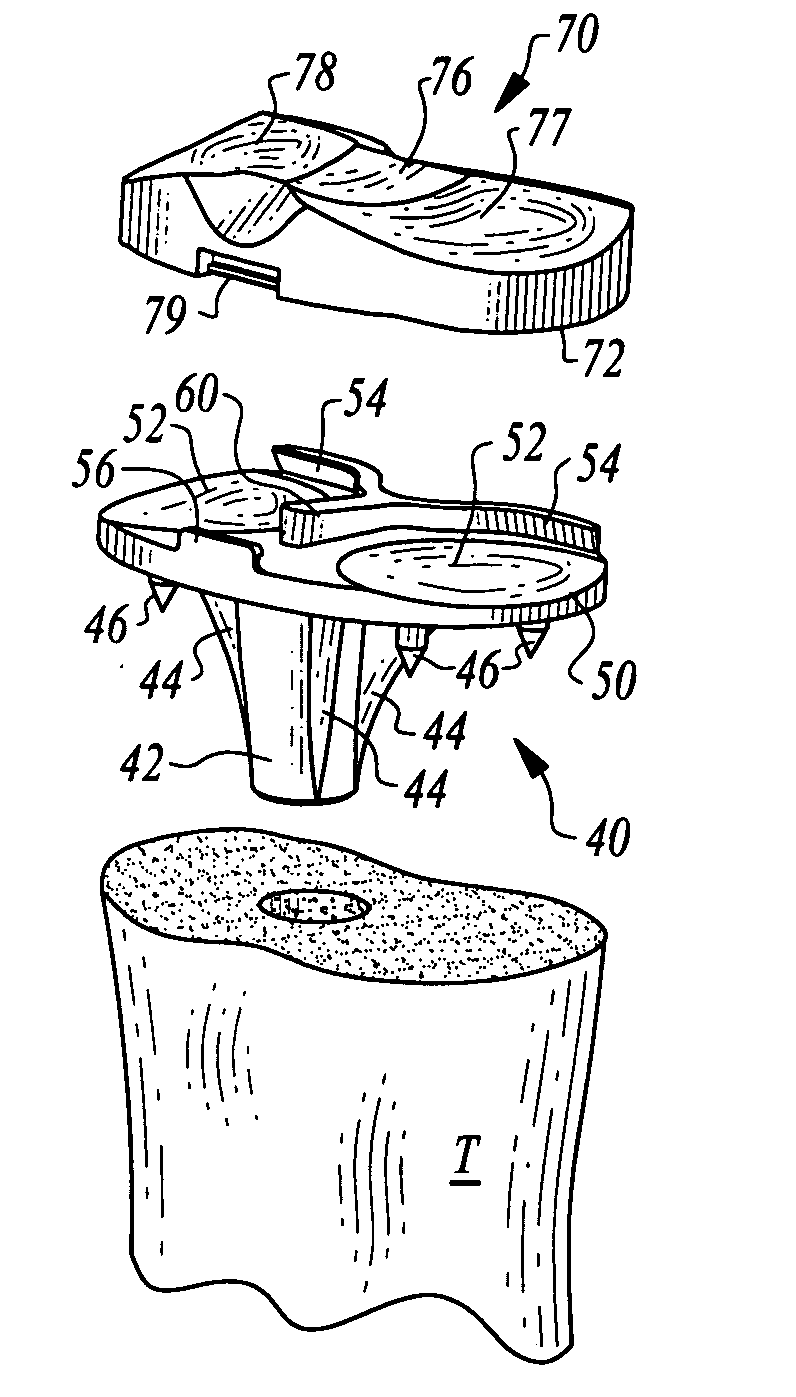

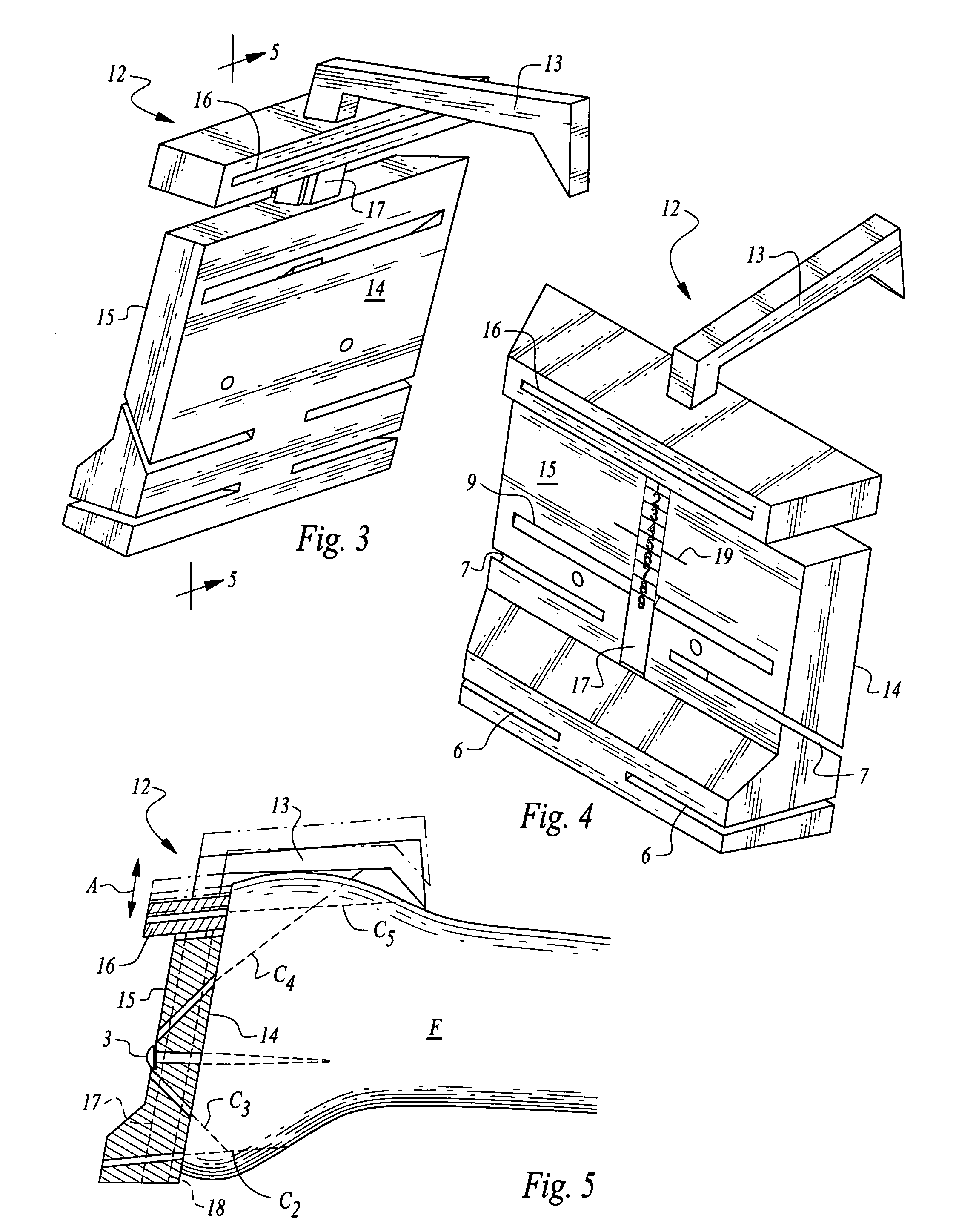

A bone resection jig that can make ligament tension equal at extension and flexion positions without any actual measurements when resecting femur and tibia during artificial knee joint replacement surgery. The bone resection jig used in artificial knee joint replacement surgery includes a spacer block (1) comprised of a grip (6), a hollow box (7) that is provided on an other end side of the grip and has a vertical hole (7a) therein, and a reference spacer part (8) that extends out from the hollow box (7) and is adapted be inserted into the resection region between femur and tibia; a reference pin guide (2) which, when the femur and tibia are in the flexion position, is inserted into the vertical hole (7a) of the hollow box, extends on the reference spacer part (8) to the other end side of the grip so as to come into contact with a resection plane (FH) of the tip of the distal end of the femur, and is formed with guide holes (9) for guiding reference pins (3) to be installed from a front side into the resection plane (FH) of the tip of the distal end of the femur; and an aiming member (12) which is, after the spacer block (1) has been removed from a space between the femur and tibia leaving the reference pins (3), brought onto the reference pins (3) by being guided thereby, the aiming member being provided with an indicator (14) that indicates a resection plane (FR) at a back of the distal end of the femur when the aiming member (12) comes into contact with the resection plane (FH) of the tip of the distal end of the femur.

Owner:NAKASHIMA MEDICAL +1

Artificial knee joint

InactiveUS20110082558A1Maximum flexionEasy to bendJoint implantsKnee jointsFemoral componentSurface geometry

An artificial knee joint comprise a femoral component and tibial component. The posterior side of the femoral component comprises medial and lateral condyles, wherein the width and offset of the posteromedial condyle is greater than the width and offset of the posterolateral condyle. At the posterior the tibial bearing component comprises medial and lateral articulating surface geometries, wherein the posterior slope of the lateral articulating geometry is greater than the posterior slope of the medial articulating geometry. The medial articulating surface geometry of the tibial bearing component supports the medial condyle of the femoral component and the lateral articulating surface geometry of the tibial bearing component supports the lateral condyle of the femoral component. The greater slope of the lateral articulating geometry allows the femoral component condyle to roll down to the posterior during knee flexion. This invention of an artificial knee joint for a prosthetic knee implant system facilitates deep knee flexes beyond 130 degrees.

Owner:OTISBIOTECH

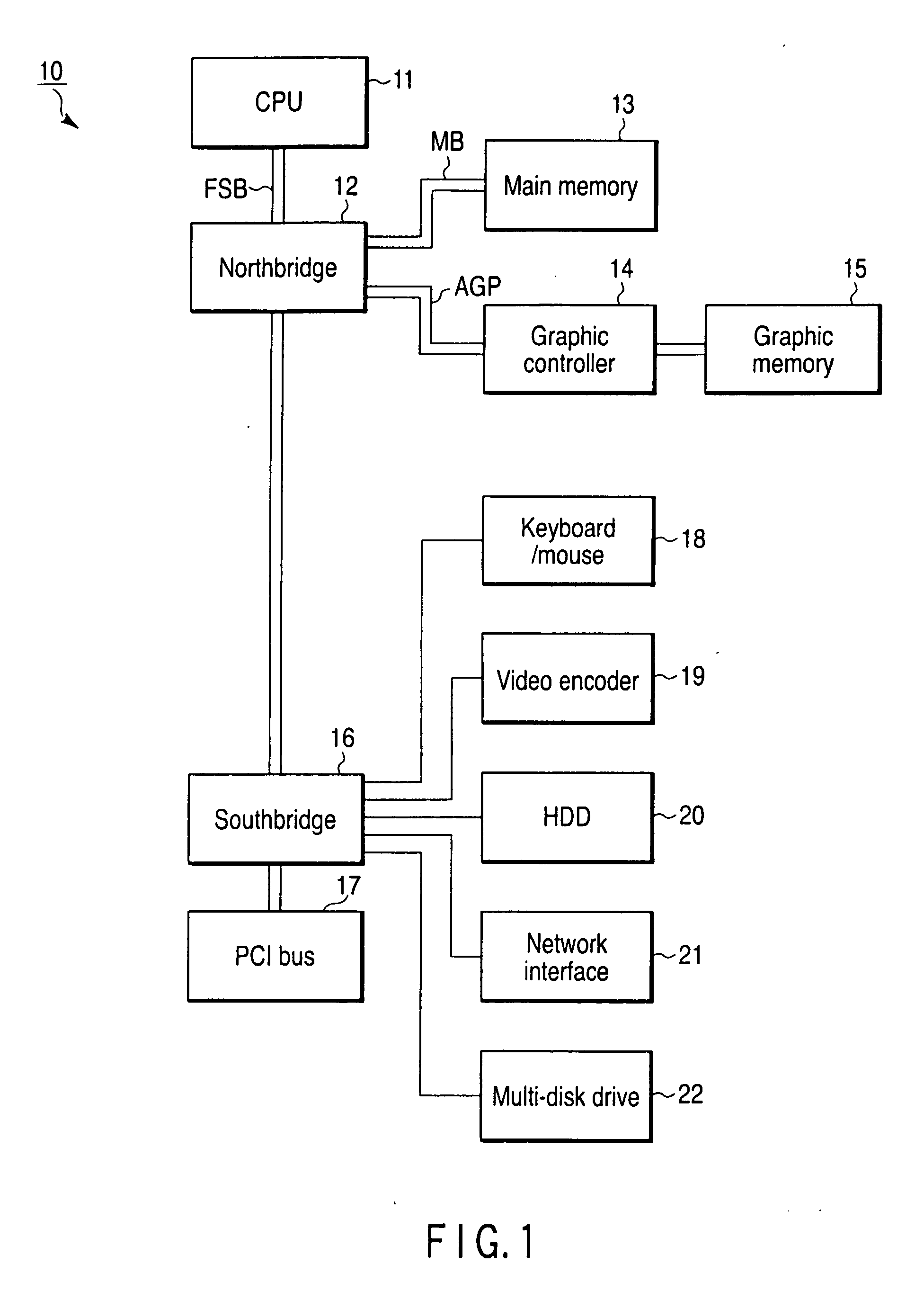

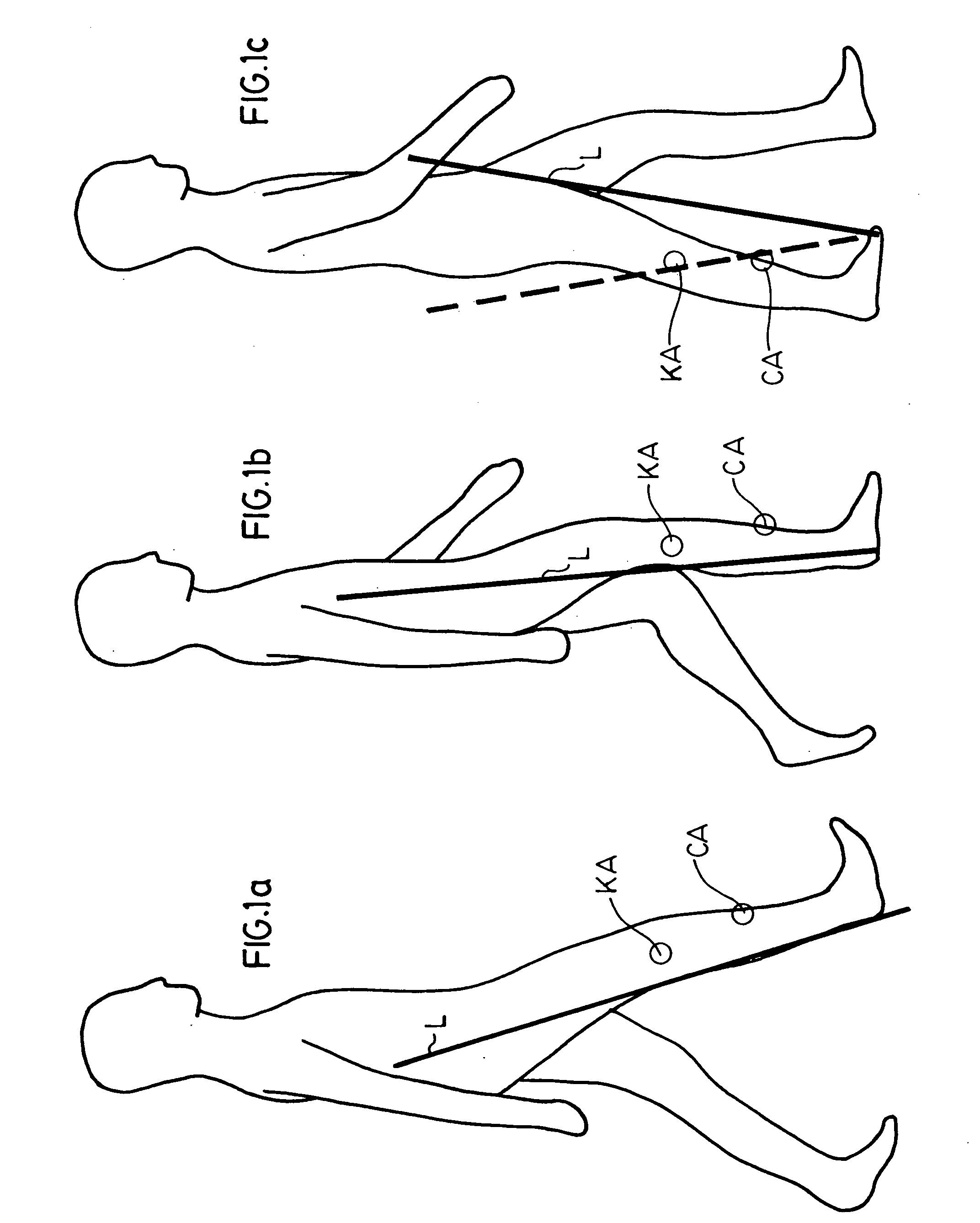

Apparatus for preoperative planning of artificial knee joint replacement operation and jig for supporting operation

InactiveUS20110009868A1Precise positioningAccurate angleImage enhancementReconstruction from projectionTibiaTomographic image

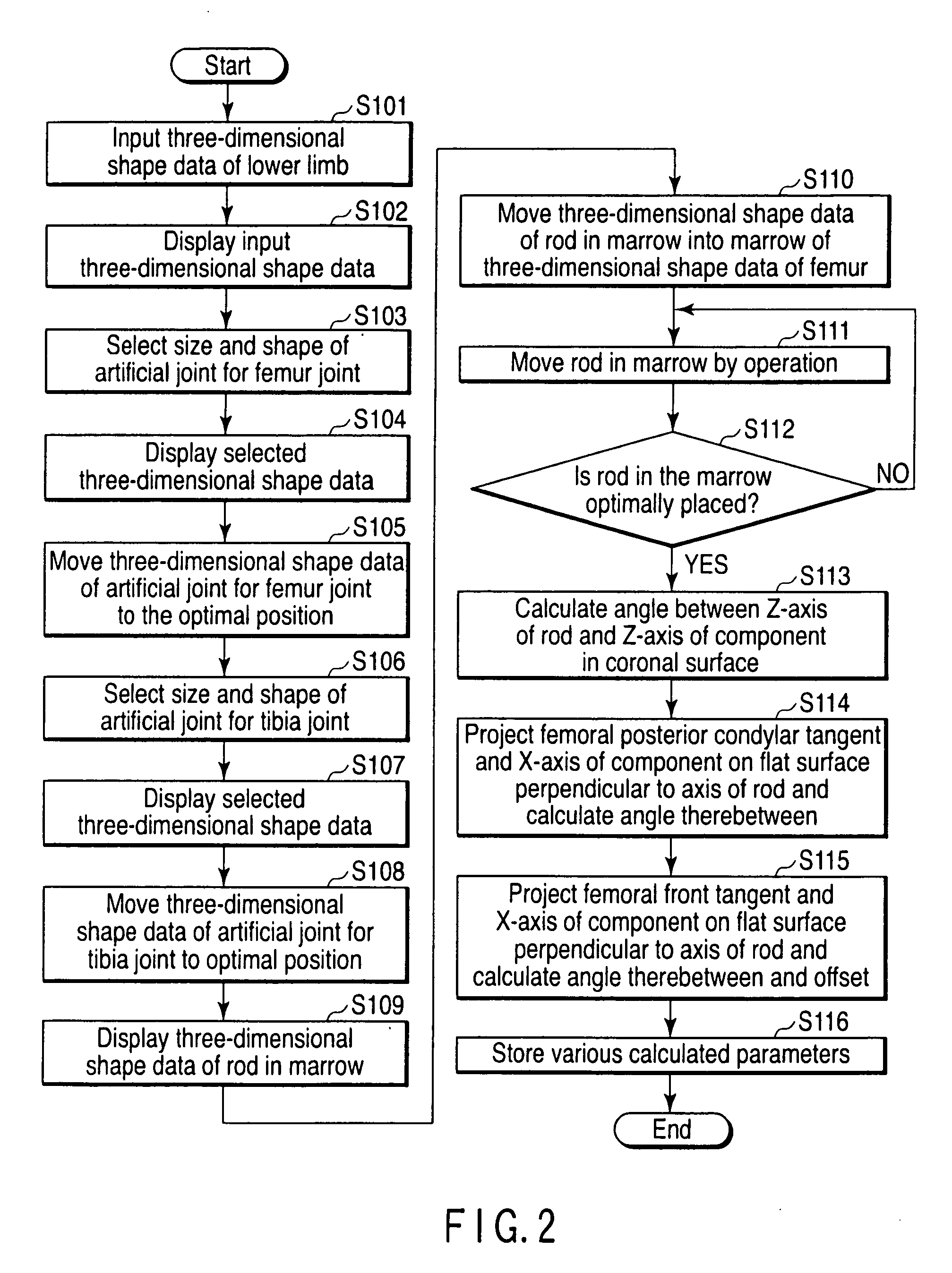

Steps S101 and S102 of displaying images which input two-dimensional tomographic images of the lower limb including the knee joint and displays three-dimensional images of the femur and the tibia including the knee joint from the image input, steps S103 to S105 and S106 to S108 of determining artificial joint which determine the artificial joint to be replaced from the three-dimensional images of each knee joint of the femur and tibia, and steps S113 and S114 of parameter determination which determine various parameters used in an artificial knee joint replacement operation using an alignment rod in the marrow to be inserted into the femur based on the artificial joint and reference points of the knee joint determined in steps S103 to S105 of determining femur side artificial joint are performed by a computer.

Owner:LEXI CO LTD

Artificial knee joint

InactiveCN101222886ANatural movementWalking smoothlyJoint implantsKnee jointsTibiaArticular surfaces

An object of the present invention is to provide an artificial knee joint that can avoid both bony contact and soft tissue contact and is durable for long-term use. The artificial knee joint of the present invention includes a femur, a tibial tray, and an insertion plate fixed to the tibial tray. The femur portion includes: a femoral articular surface, and a cam portion protruding from the femoral articular surface provided at the rear end of the femoral articular surface, and the insertion plate includes: a tibial articular surface that abuts on the femoral articular surface, and A cam sliding movement surface that abuts on the cam portion. When the knee is extended, it is the first sliding state where the articular surface of the femur slides on the articular surface of the tibia, within the bending angle of 90° to 160°, from the first sliding state to the sliding movement of the cam part on the cam sliding surface The second sliding movement state shifts. When the knee is bent at a bending angle of 180°, the osteotomy surface of the femur and the rear end of the insertion plate are offset through the second sliding movement state.

Owner:SAGA UNIVERSITY +1

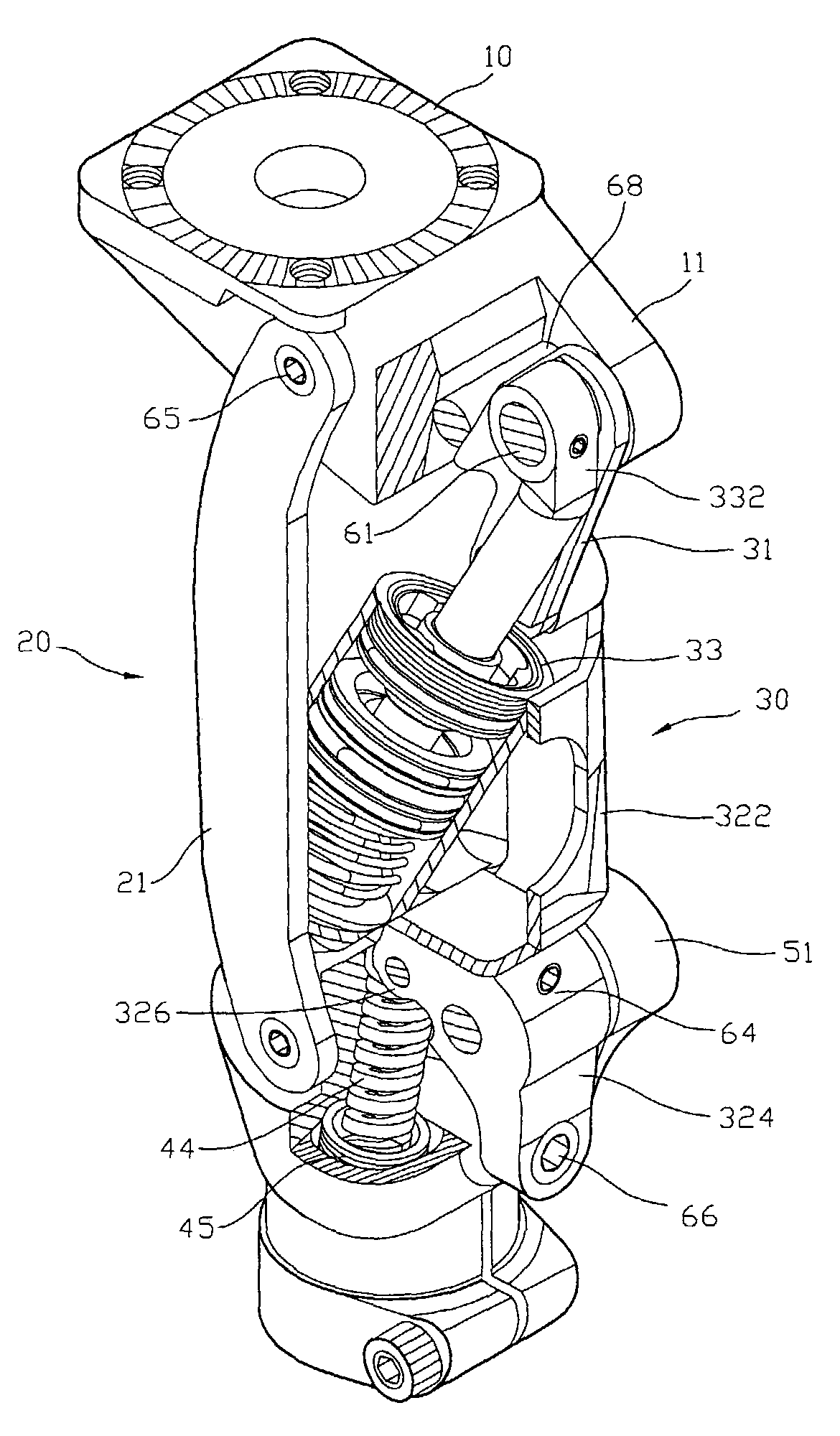

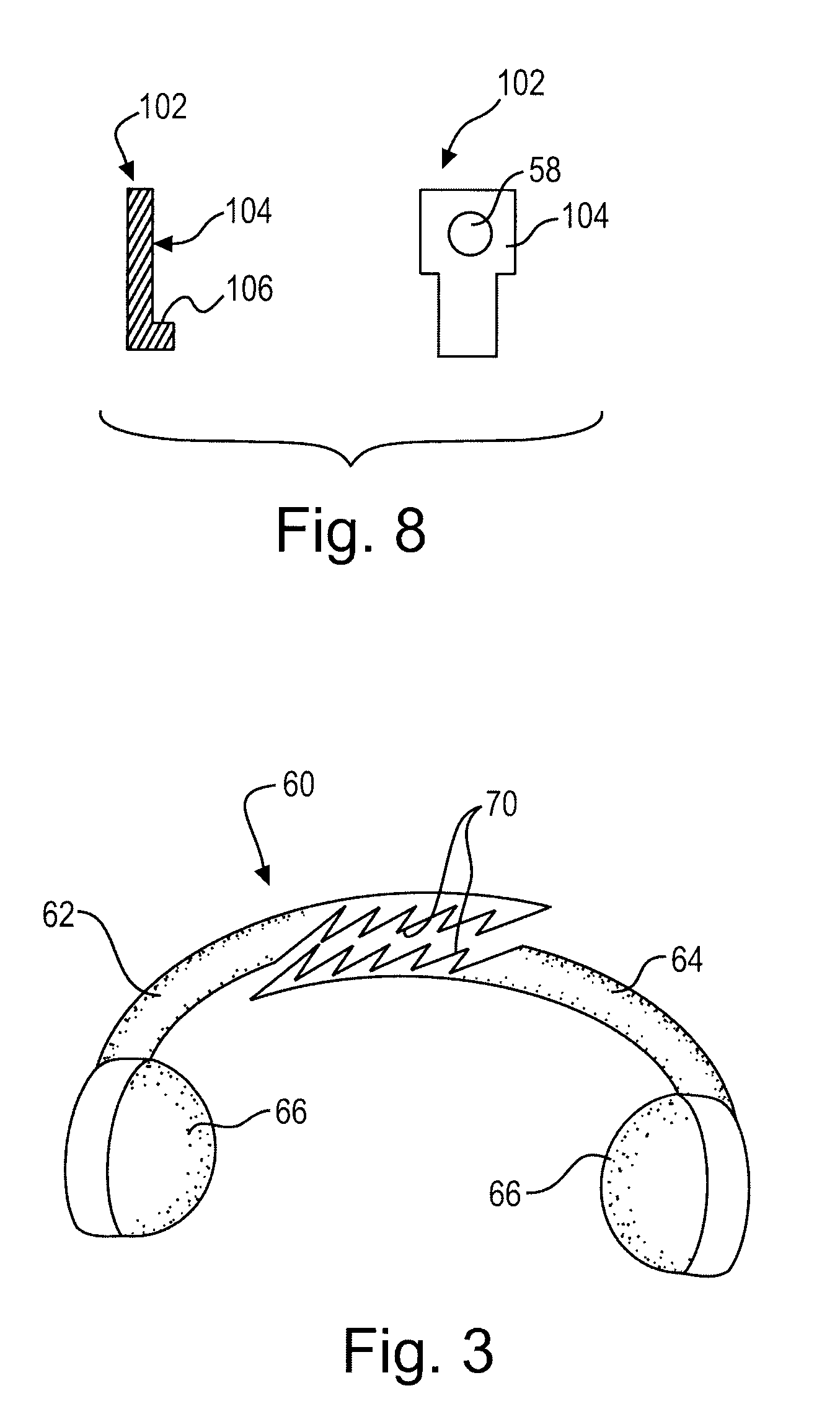

Passive power-conservative artificial knee

ActiveUS20160374887A1Flexible enoughEncourages flexionChiropractic devicesWalking aidsEngineeringArtificial knee

A passive artificial knee comprises first and second links rotatably coupled at a knee joint, a passive compressive force generator rotatably coupled to the second link, and a release mechanism coupled to the first link. When a relative angle of the first and second links is less than a toggle angle, the release mechanism locks in a first operational mode, and the force generator compresses, resisting the flexing of the second link relative to the first link. When the relative angle is larger than the toggle angle, the force generator decompresses and encourages the flexion of said second link relative to said first link. When the force generator is substantially extended and said compressive force is substantially small, the release mechanism moves into a second operational mode, wherein the force generator neither resists nor encourages the extension and flexion of said second link from said first link.

Owner:RGT UNIV OF CALIFORNIA

Knee joint with a ramp

InactiveUS8292965B2Minimize wear and deformationIncrease the areaJoint implantsKnee jointsTibiaTibial surface

An artificial knee joint is described that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the required motion and stability characteristics. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, by an amount similar to that in the anatomic knee. The opposite motion, roll forward of the femur from a fully flexed to a more extended position, is accomplished by varying the outward radii of the lateral and medial femoral bearing surfaces, together with a ramp on the postero-lateral and postero-medial regions of the tibial surfaces.

Owner:NEW YORK UNIV

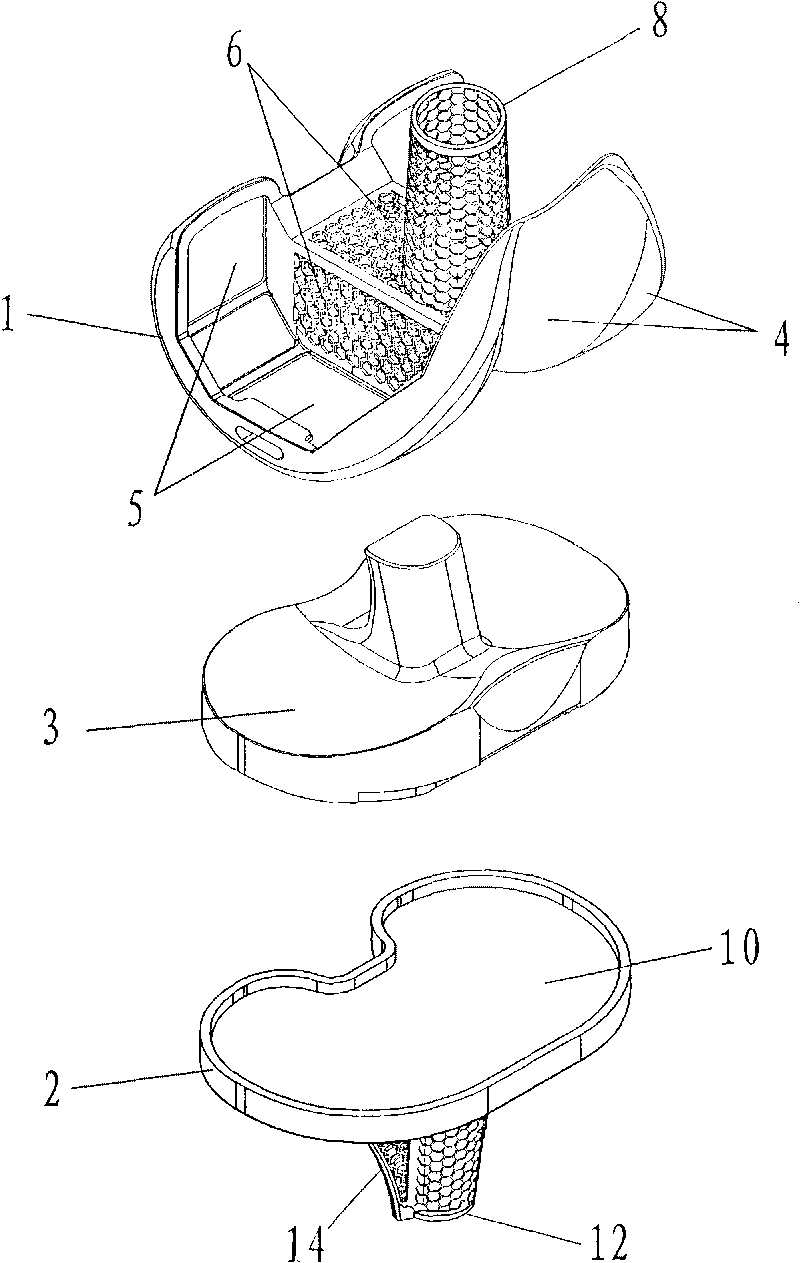

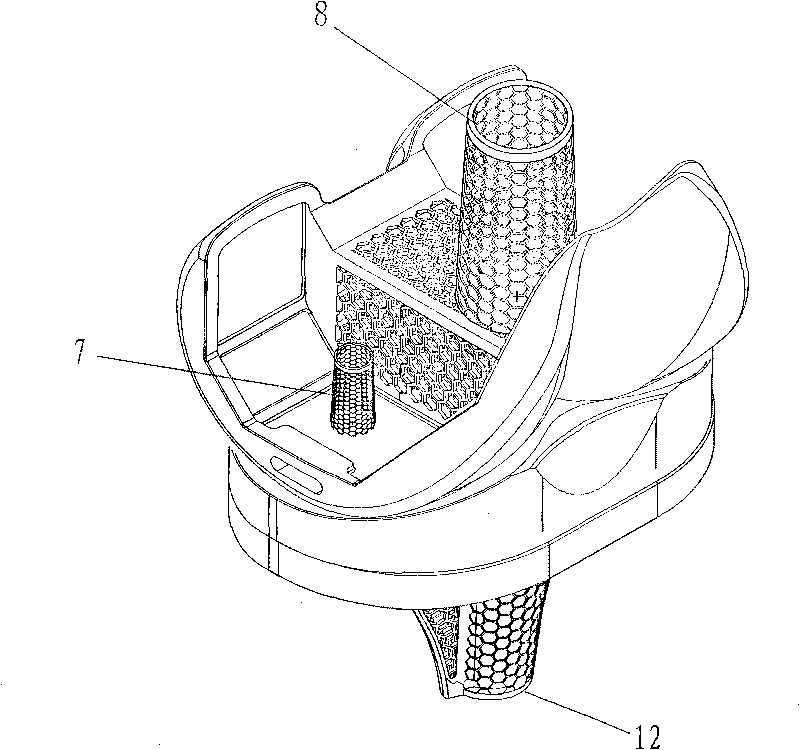

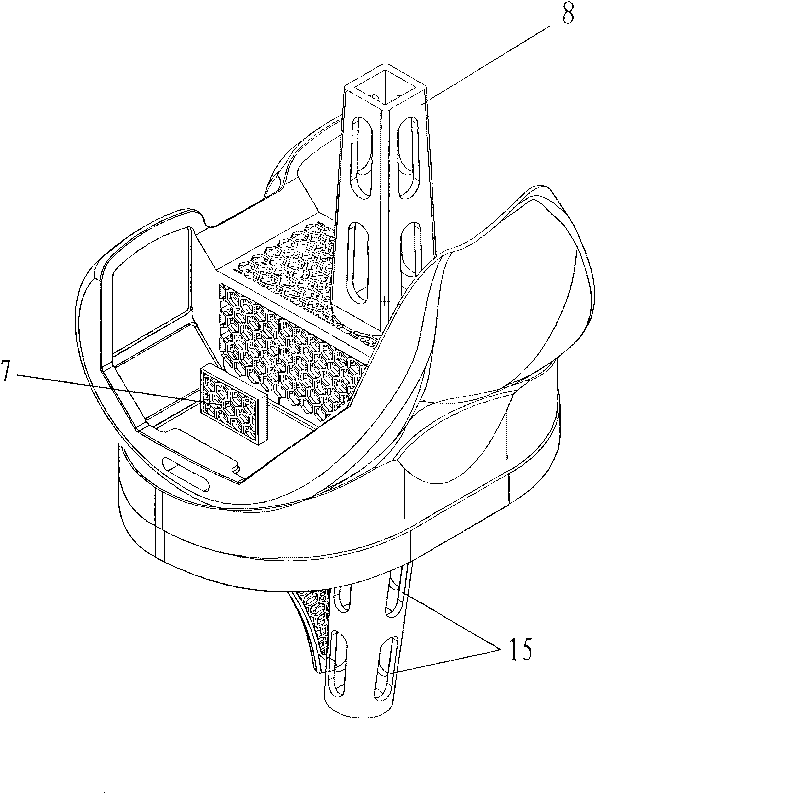

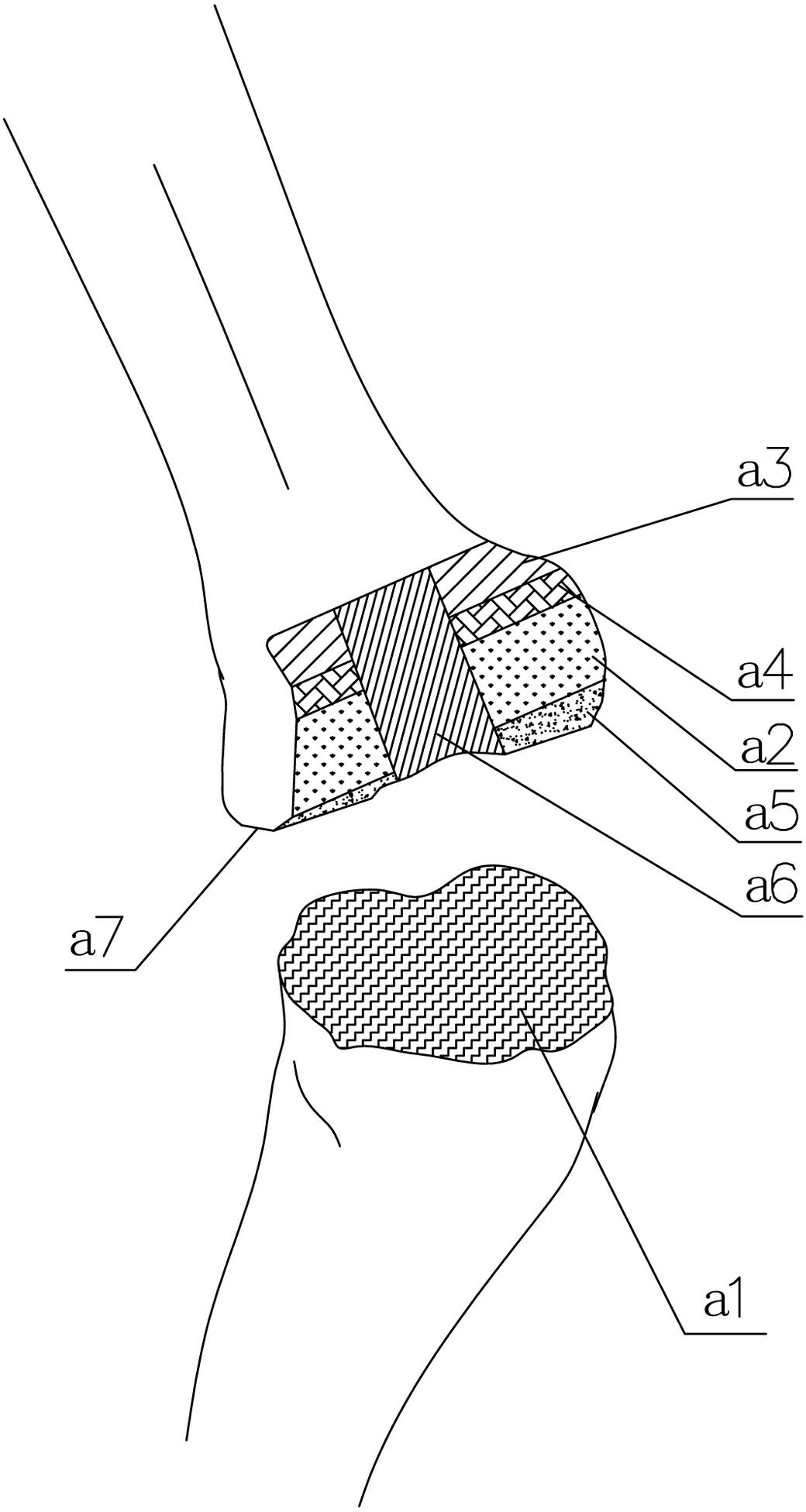

Artificial knee joint bone fusion prosthesis

InactiveCN101708138AGuaranteed connectivityPrevent looseningJoint implantsCoatingsTarsal JointBone particle

The invention relates to an artificial knee joint bone fusion prosthesis. The artificial knee joint bone fusion prosthesis comprises a femur condyle prosthesis, a tibia platform prosthesis and a joint pad, wherein the femur condyle prosthesis comprises a joint surface, a condyle combination surface, a intercondylar combination surface, a positioning body, a femur intramedullary stem and a femur intramedullary extending stem; the tibia platform prosthesis comprises a platform body, a tibia combination surface, a wing plate or a positioning body, a tibia intramedullary stem and a tibia intramedullary extending stem; the femur intramedullary stem, the femur intramedullary extending stem, the tibia intramedullary stem and the tibia intramedullary extending stem are hollow, the surfaces of the intramedullary stems and the extending stems have porous or mesh structure so as to ensure that the hollow parts in the stem body can be communicated with the external part; when in use, autograft or allograft crushed bone particles are filled in the hollow parts of the intramedullary stems and the intramedullary extending stems, and after the external bone tissue fuses and grows together with the crushed bone particles filled in the intramedullary stems, the overall elastic modulus can be very close to that of the human bone, thus reaching the aim of effectively preventing the loose between the artificial knee joint bone fusion prosthesis and the sclerotin for long time.

Owner:BEIJING AKEC MEDICAL

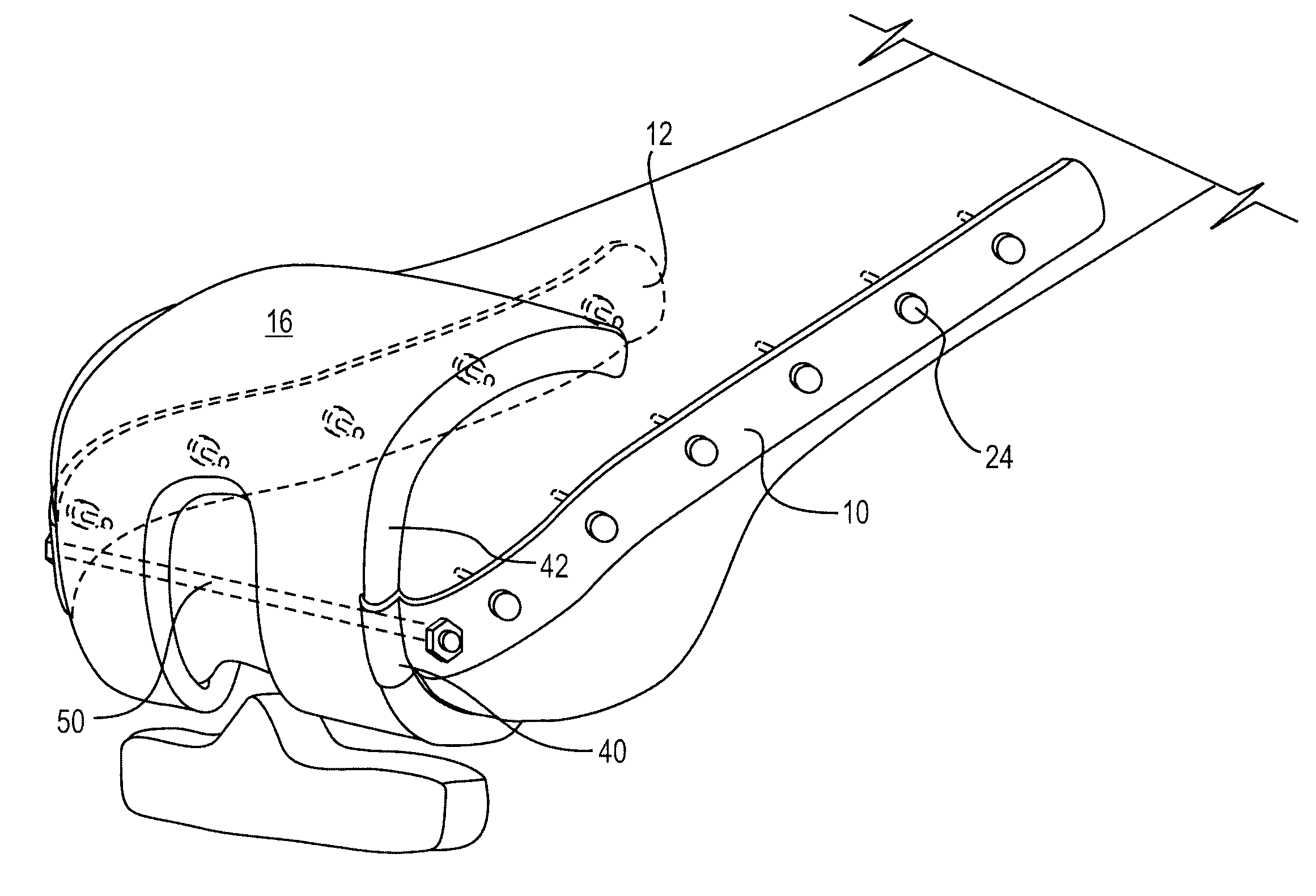

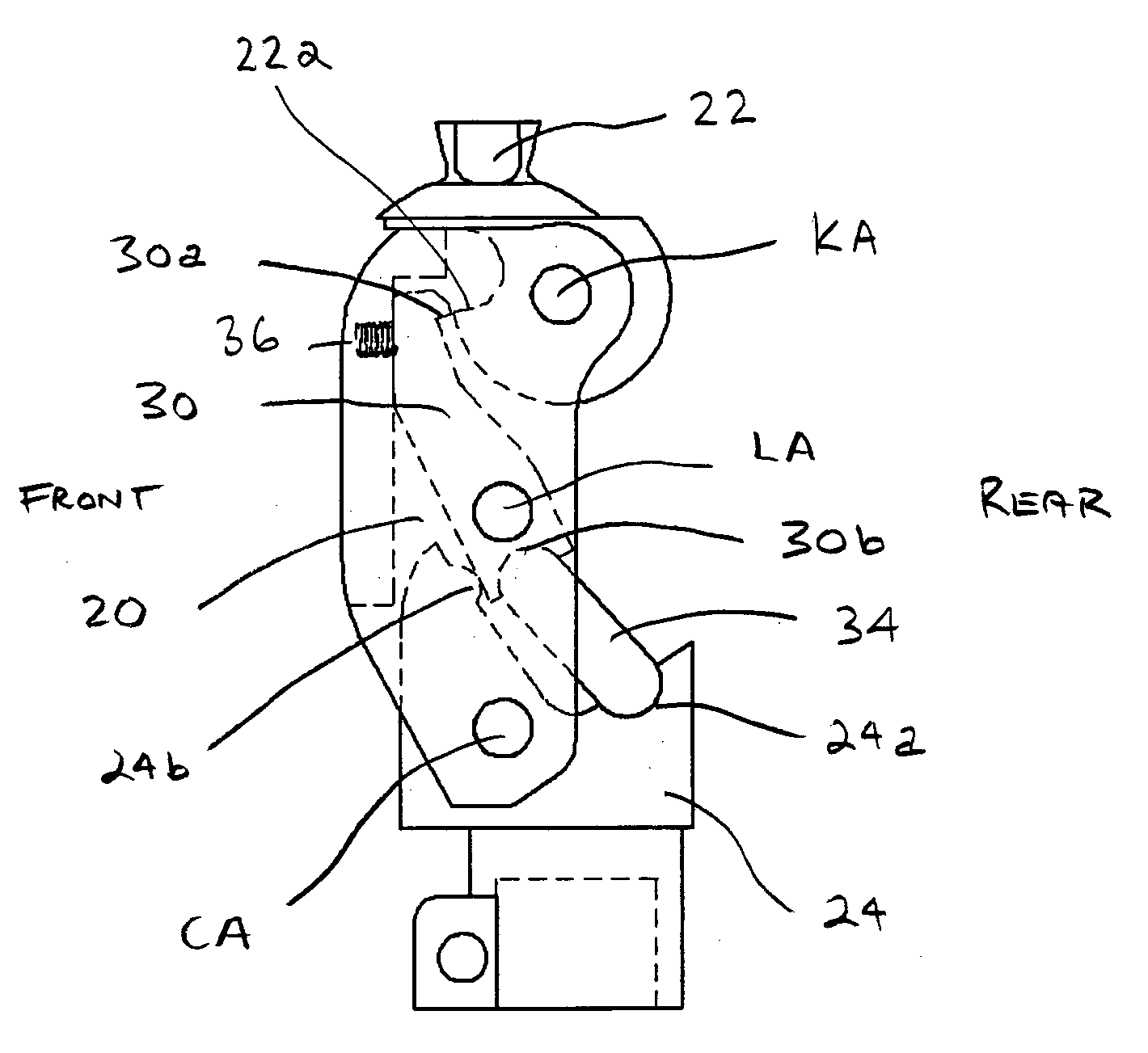

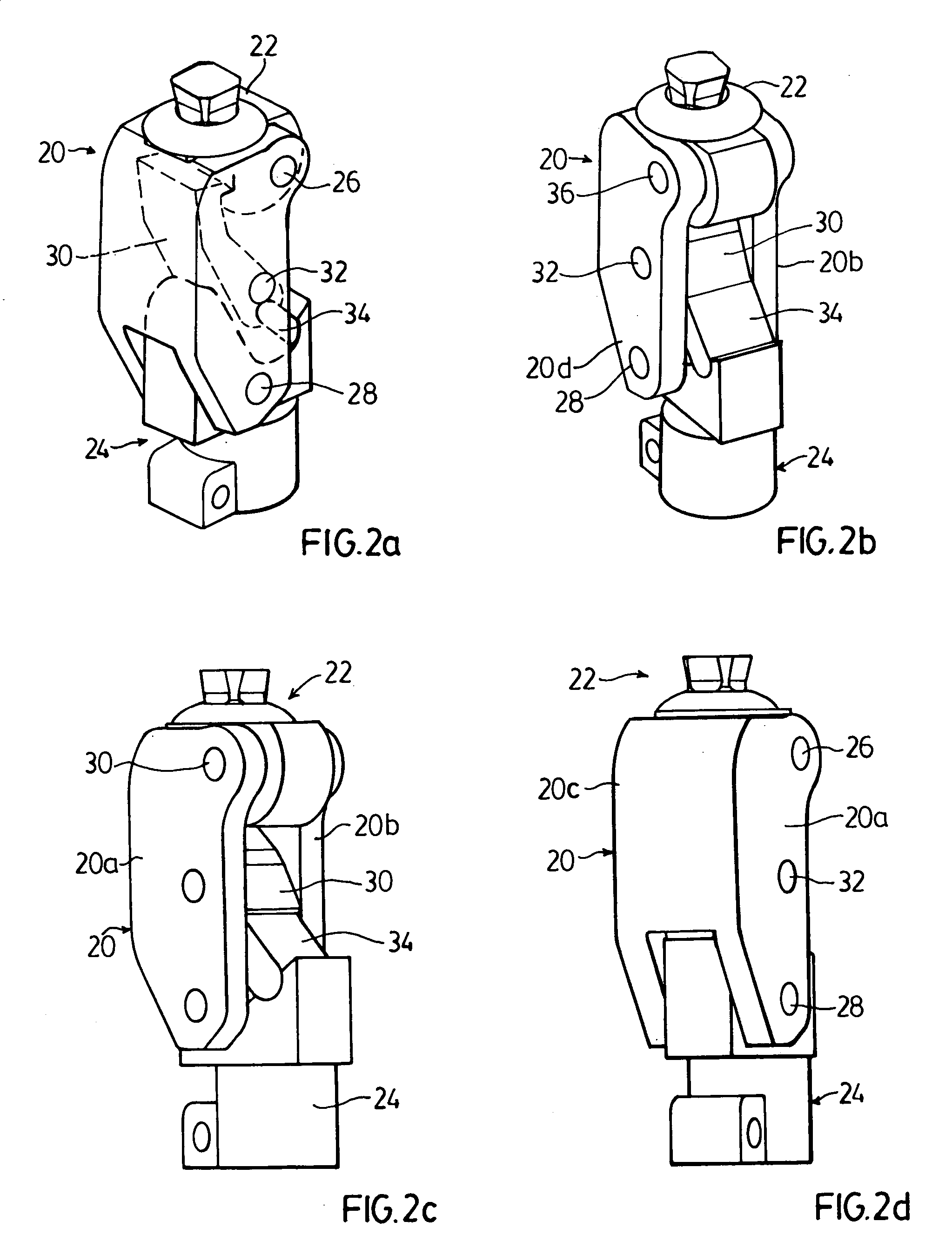

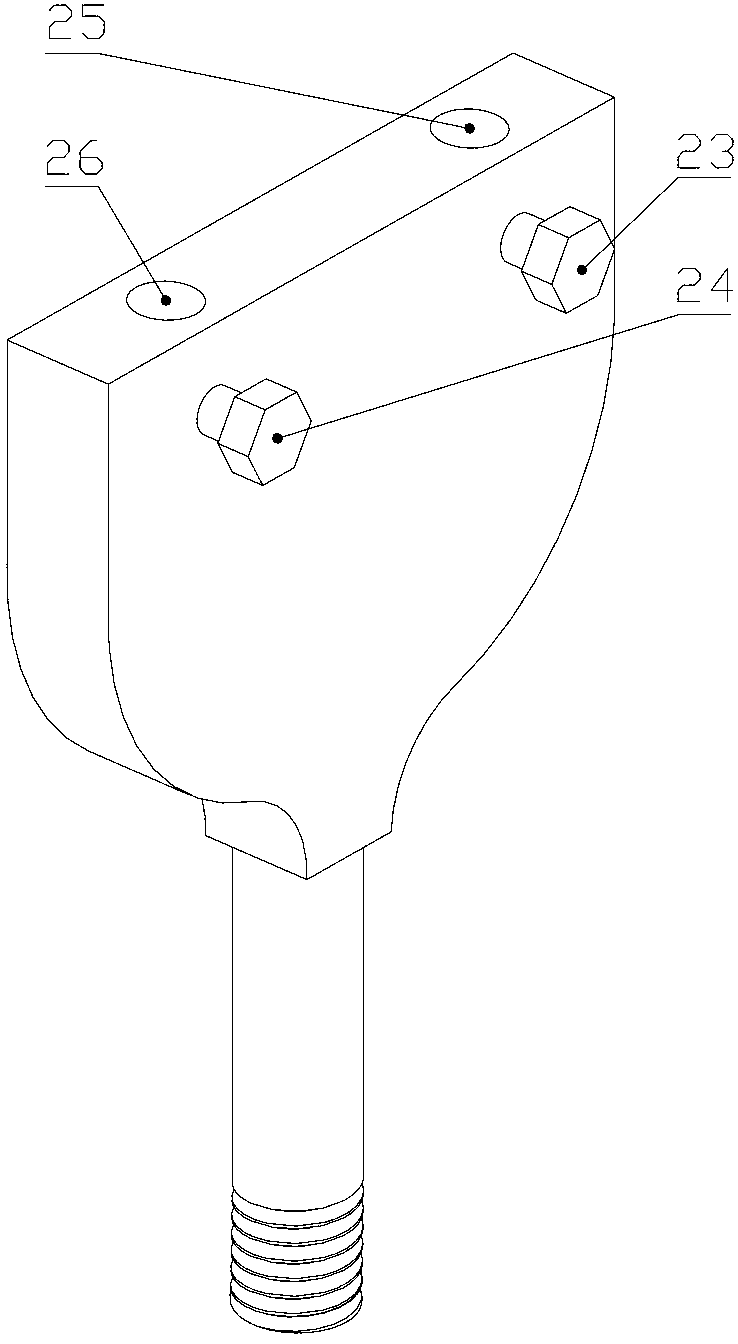

Universal extractor for total endoprostheses of (tep) of the knee joint

InactiveUS20090240254A1Coupling stabilityStable self-centering fixationKnee jointsOsteosynthesis devicesProsthesisShovel

The invention relates to a universal extractor for total endoprostheses (TEP) of the knee joint. The object of the invention, namely to make available a universal extractor for artificial knee joints that avoids the disadvantages of the prior art, is achieved by the fact that the universal extractor comprises the following parts:a T-piece with an extraction plate and with a securing arm, the securing arm being fork-shaped and slotted at its distal end and supporting the extraction plate at its proximal end;a scissor mechanism with clamping jaws located at its free distal ends, said securing arm holding the scissor mechanism by means of a securing pin about which the scissor mechanism can move;andan eyebolt which is mounted on the proximal end of the scissor mechanism and has a knurled nut, the eyebolt being adjustable and connecting the ends of the scissor mechanism to each other, so as to permit fixing or release of the clamping jaws which have a shovel-shaped, U- to V-shaped geometry.

Owner:ARNHOLD CHRISTIAN

Artificial knee joint

ActiveUS20050149203A1Easy to optimizePrevent movementArtificial legsSacroiliac jointArtificial limbs

A prosthetic knee joint including stance-phase control means comprising lock or latch for holding the knee in a straight condition, and means determining the status of the latch, said status determining means defining a control axis located so that the lock or latch is activated when a load imposed on the joint passes through a line posterior to said axis, and is de-activated when the load passes through a line anterior to said axis.

Owner:BLOORVIEW MACMILLAN CENT

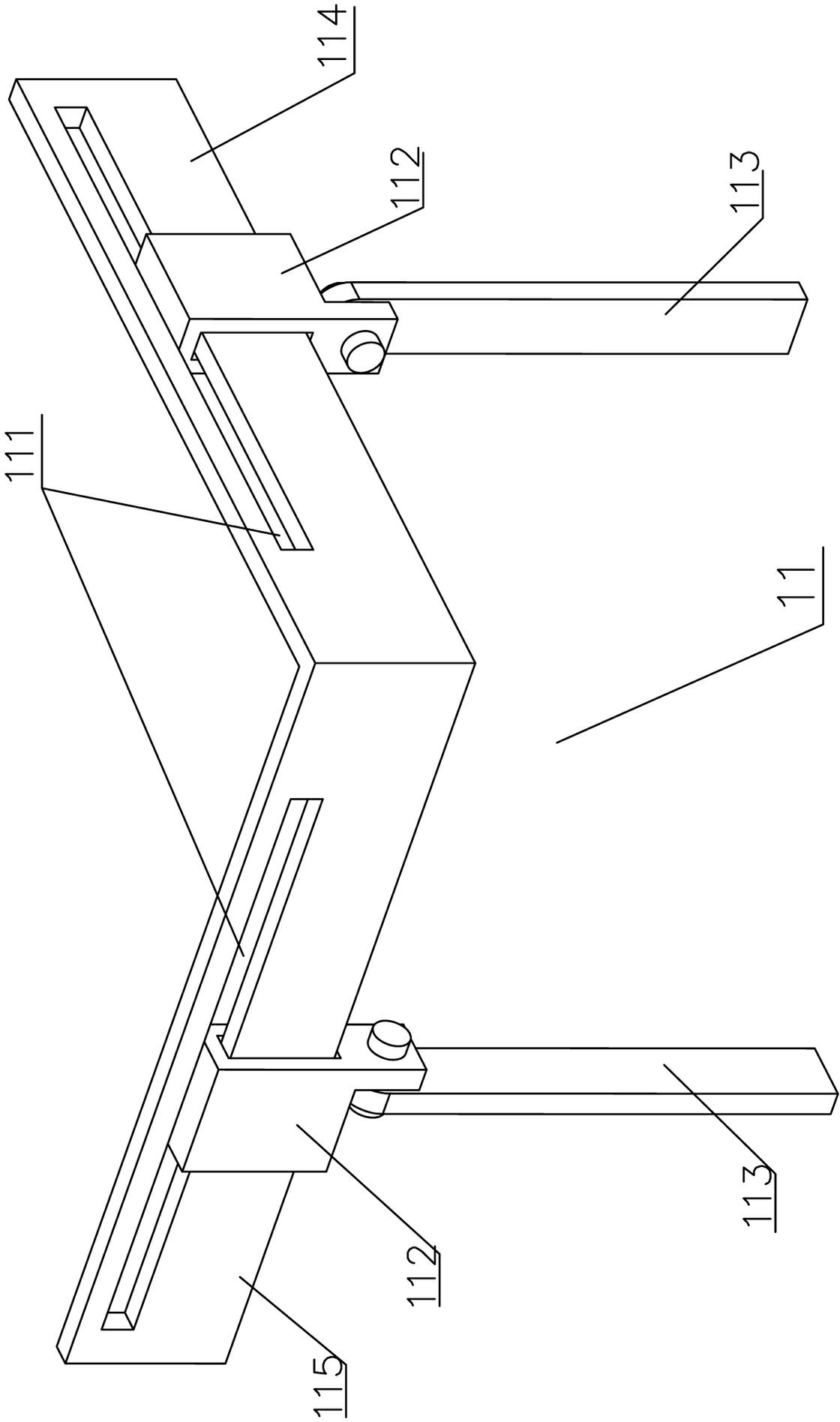

Positioning and bone-cutting system used for minimally invasive artificial knee joint replacement

InactiveCN102113910AReduced volume of osteotomy instrumentsImprove performanceDiagnosticsSurgical sawsOrthodonticsPositioning system

The invention discloses a positioning and bone-cutting system used for minimally invasive artificial knee joint replacement, which comprises a positioning sub-system and bone-cutting sub-system, wherein the positioning sub-system comprises a plurality of reference modules and a positioning barrier module coupled with the reference modules; the bone-cutting sub-system comprises a plurality of bone-cutting drills, a plurality of bone-cutting saws, a patella trimming drill used for trimming a patella and a bone cut section trimming drill used for trimming a bone cut section; and the bone-cutting drills and the bone-cutting saws are limited by the positioning barrier module during the operation. In the positioning and bone-cutting system used for the minimally invasive artificial knee joint replacement, the positioning sub-system and the bone-cutting sub-system cooperate to accurately control the bone-cutting precision and the bone-cutting depth, reduce the wound area and protect the soft tissues. The positioning and bone-cutting system used for the minimally invasive artificial knee joint replacement has a simple structure, is easy to use, achieves the effect of rapidly and accurately positioning and cutting the bone, and can be widely applied to minimally invasive artificial knee joint replacement.

Owner:徐栋梁 +1

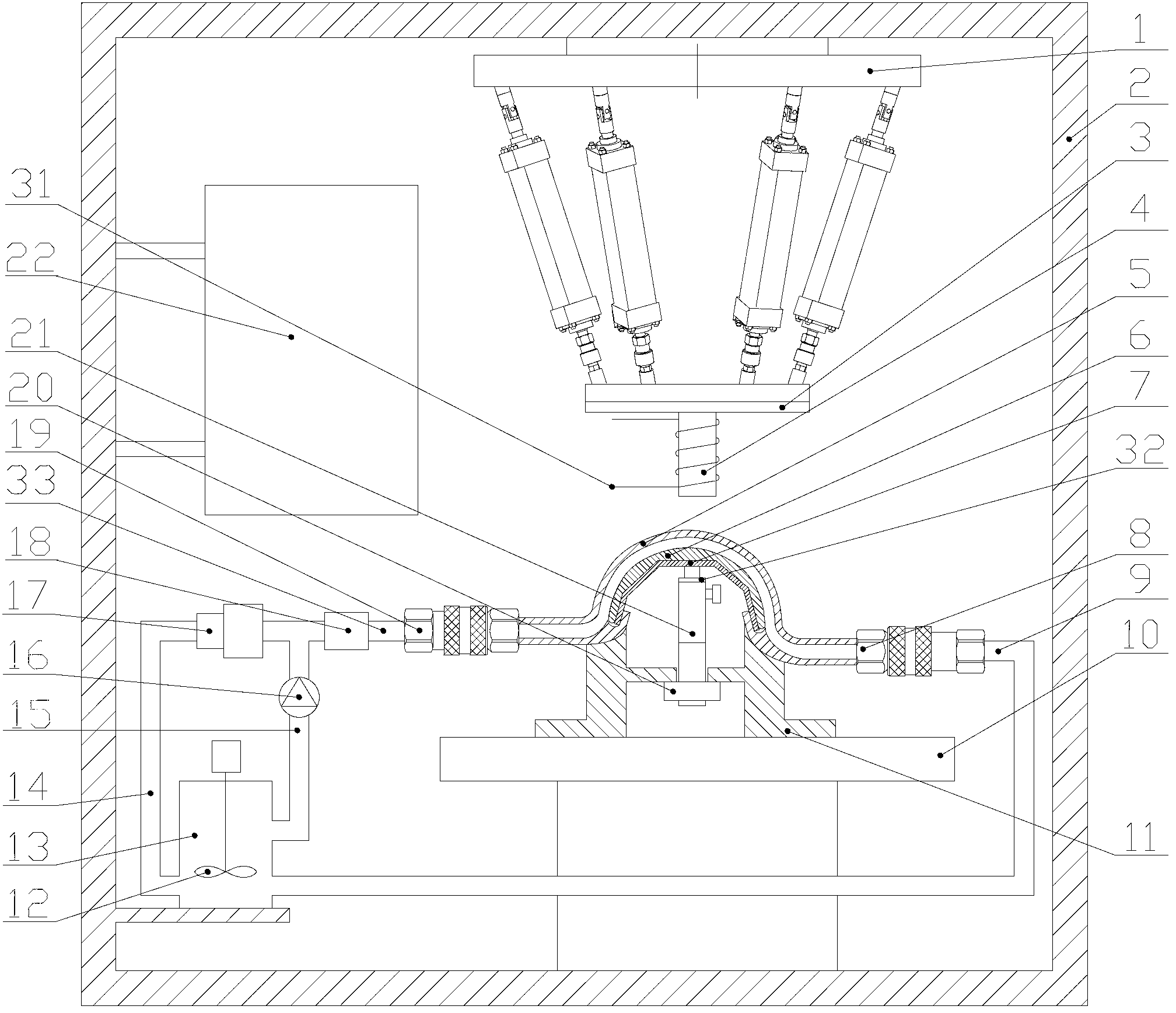

Titanium alloy artificial knee joint magnetorheological polishing device

The invention relates to a titanium alloy artificial knee joint magnetorheological polishing device. The device has the characteristics that the device is high in magnetic current liquid utilization ratio, and uniform and consistent in polishing quality, and can polish a complicated curved surface, so that the device can meet the existing clinic requirement completely. A workbench is arranged at the lower part of a rack; a corresponding six-freedom-degree parallel machine tool is arranged above the workbench; a closed circulating magnetic current liquid loop is connected with a magnetic current liquid channel; the magnetic current liquid channel is placed on a support of the workbench; mounting holes of a titanium alloy prosthesis are formed below the magnetic current liquid channel; a sealing washer is mounted between the magnetic current liquid channel and the titanium alloy prosthesis; the titanium alloy prosthesis is fixed in a pressure rod; the six-freedom-degree parallel machine tool is connected with an electromagnet; the magnitude of the magnetic field intensity of a magnetic current liquid is controlled by adjusting a gap between the end face of the electromagnet and the surface of the magnetic current liquid channel, so that the magnitude of a cutting force of abrasive particles in the magnetic current liquid on the surface of a titanium alloy is controlled; and the six-freedom-degree parallel machine tool, the electromagnet and the magnetic current liquid loop are connected with a control device.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Surface guided knee replacement

An artificial knee joint that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the motion and stability characteristics of the anatomic knee. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, more so on the lateral side than on the medial side. This is accomplished by the interaction of a projecting tibial post inside a cupola in the center of the femoral component, and by the saggital radius on the medial side being smaller than that on the lateral side. The prevention of anterior sliding of the femur on the tibia in early flexion is accomplished by the interaction between a distal-anterior recess on the medial side of the femur and an apposing raised pad on the tibial surface. Rotational laxity at all angles is allowed by the presence of only one recess pad and by non-conforming femoral-tibial surfaces on the lateral side.

Owner:NEW YORK UNIV

Artificial knee joint

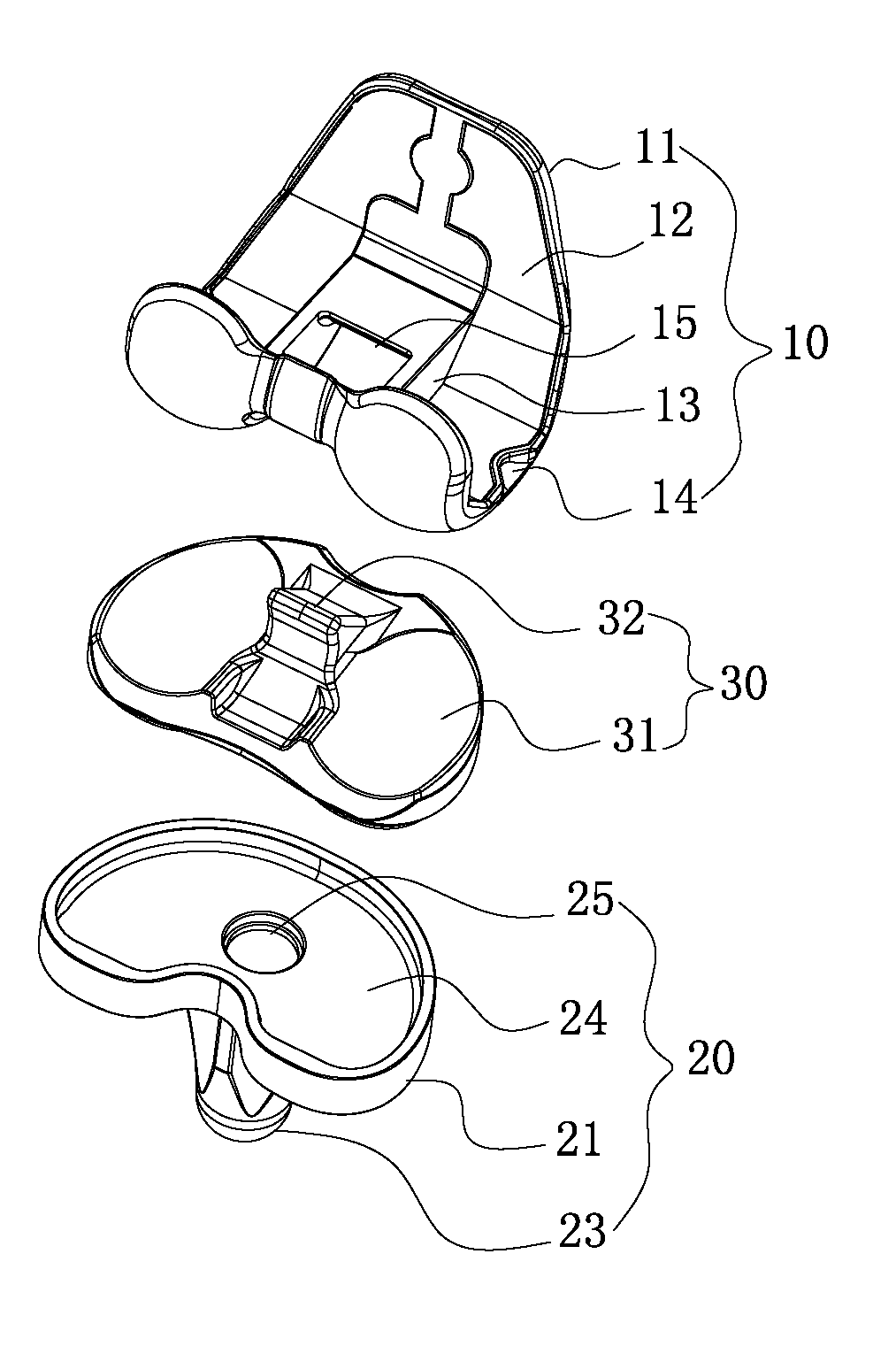

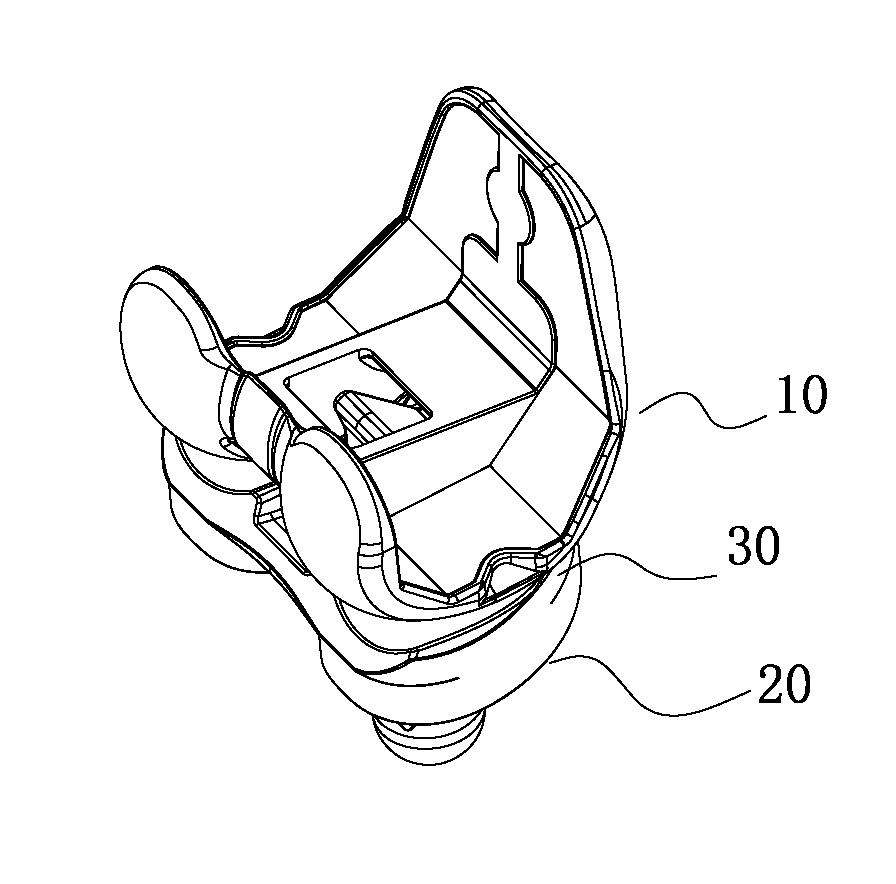

InactiveUS20110270415A1Sensitivity adjustableSuitable weightNon-surgical orthopedic devicesArtificial legsJoint componentThigh

An artificial knee joint includes a lower joint member, an axle, a kneecap member, and a press member. The lower joint member is formed with a horizontally extending axle-receiving hole, and a clearance extending from and in spatial communication with the axle-receiving hole. The axle is received in the axle-receiving hole. The kneecap member is pivoted to the lower joint member, and is adapted to be connected to a prosthetic thigh. The press member is mounted to the kneecap member for pressing the lower joint member when the kneecap member pivots in a direction relative to the lower joint member. Therefore, the clearance and the axle-receiving hole are constricted to result in tightened connection between the lower joint member and the axle and resistance to relative rotation between the lower joint member and the axle.

Owner:CHEN CHIEN WEN +1

Artificial knee joint

InactiveCN102793594AIn line with the characteristics of daily behavior sportsReduce stressJoint implantsKnee jointsTibiaFEMORAL CONDYLE

The invention relates to an artificial knee joint. The artificial knee joint comprises a femoral condyle prosthesis, a tibial platform prosthesis and a joint gasket, wherein the femoral condyle prosthesis is movably placed on the tibial joint surface of the joint gasket through the femoral joint surface after being assembled; a projection in the middle of the joint gasket extends into a square hole in the middle of the femoral condyle prosthesis to limit the motion range of the knee joint and prevent the dislocation of the joint; a protrusion part of the joint gasket is movably mounted on a profiled groove of the femoral condyle prosthesis; and a gibbosity part of the joint gasket is movably mounted on a middle circular groove of the tibial platform prosthesis. Due to the adoption of the structure, the technical problem of mismatching of anatomic forms of the conventional artificial knee joint product and the oriental knee joint due to different anatomic forms of the oriental knee joint and the occidental knee joint is solved. The artificial knee joint is suitable for the orientals or the oriental patients requiring total knee arthroplasty.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com