Patents

Literature

540results about How to "Reduce consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

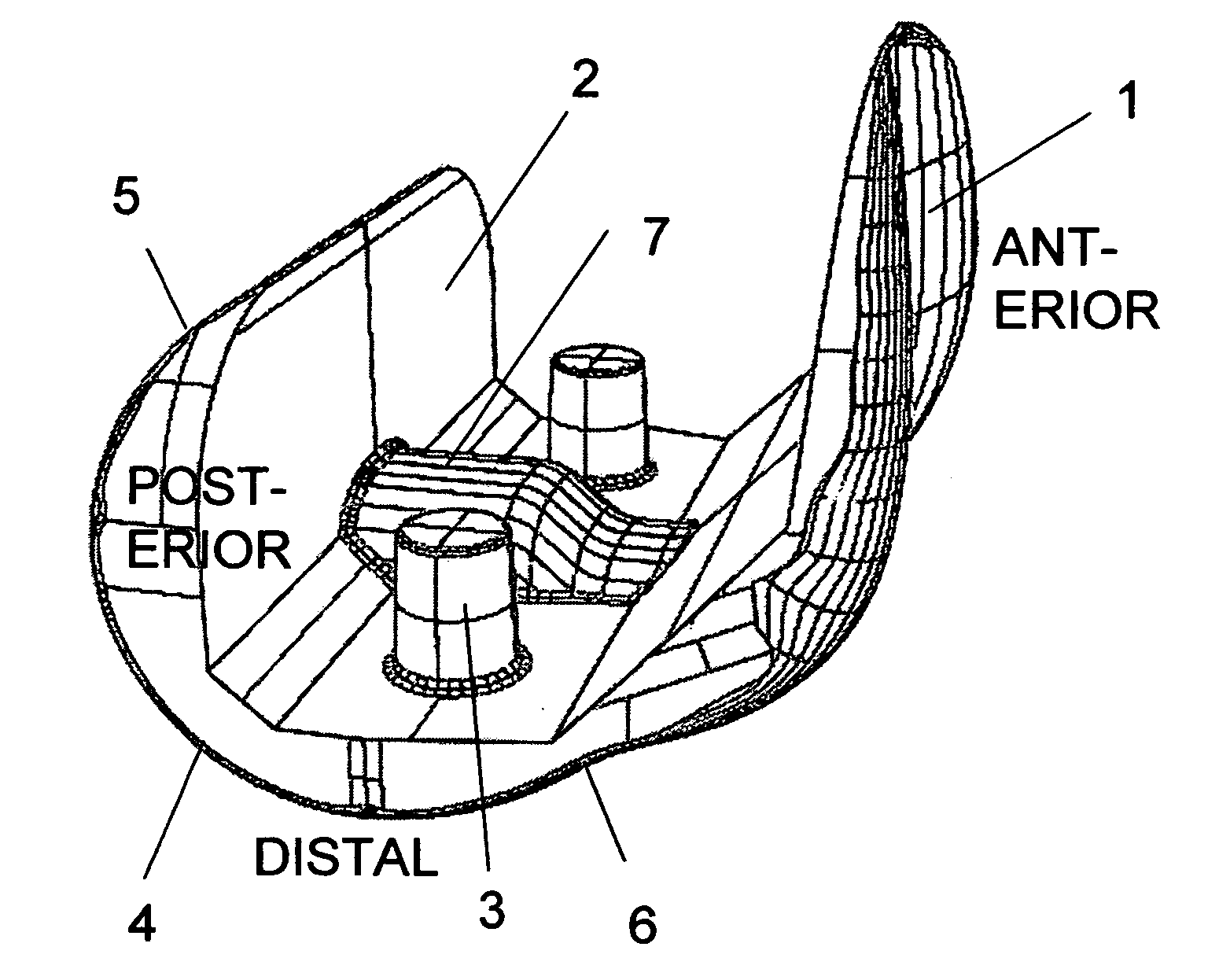

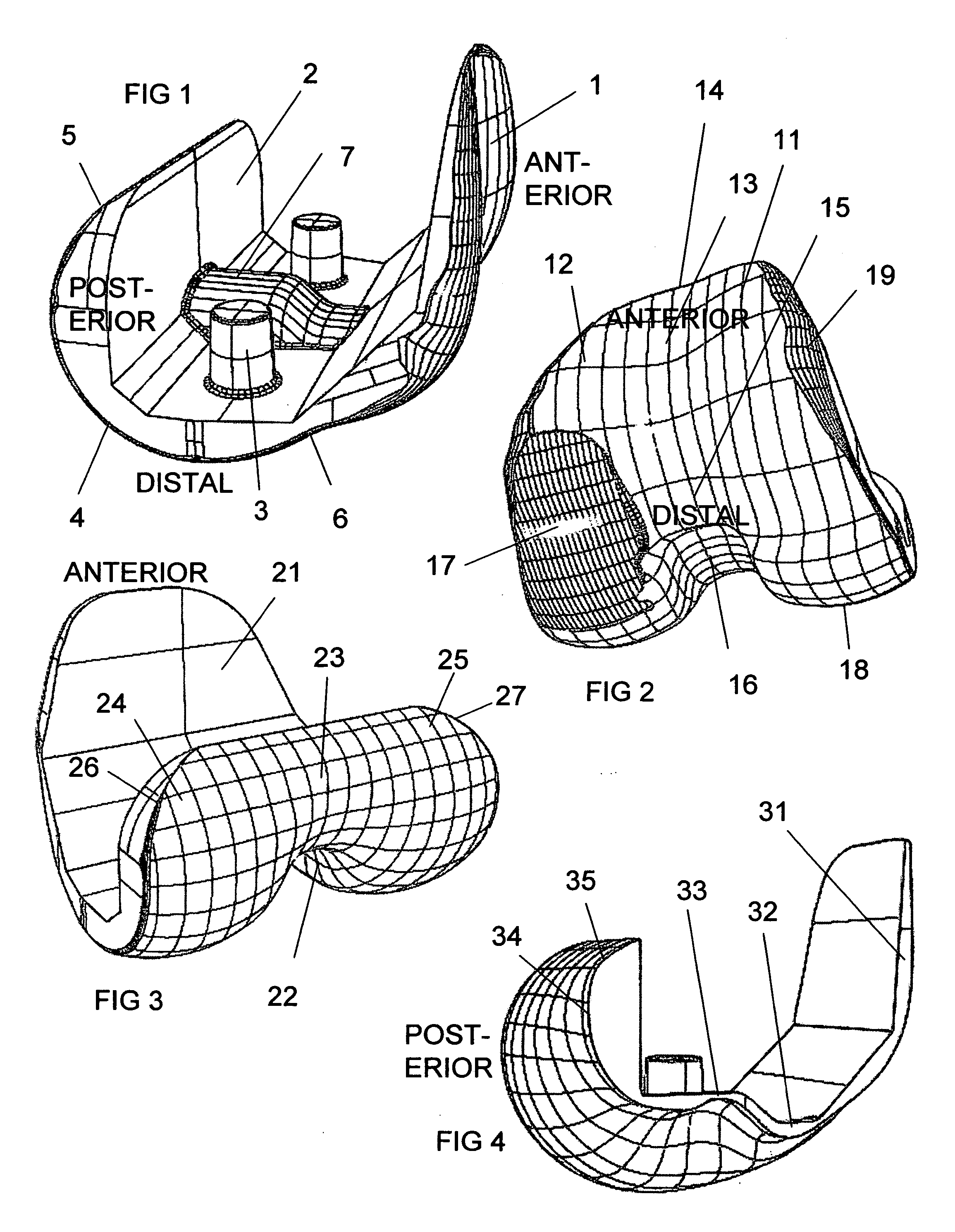

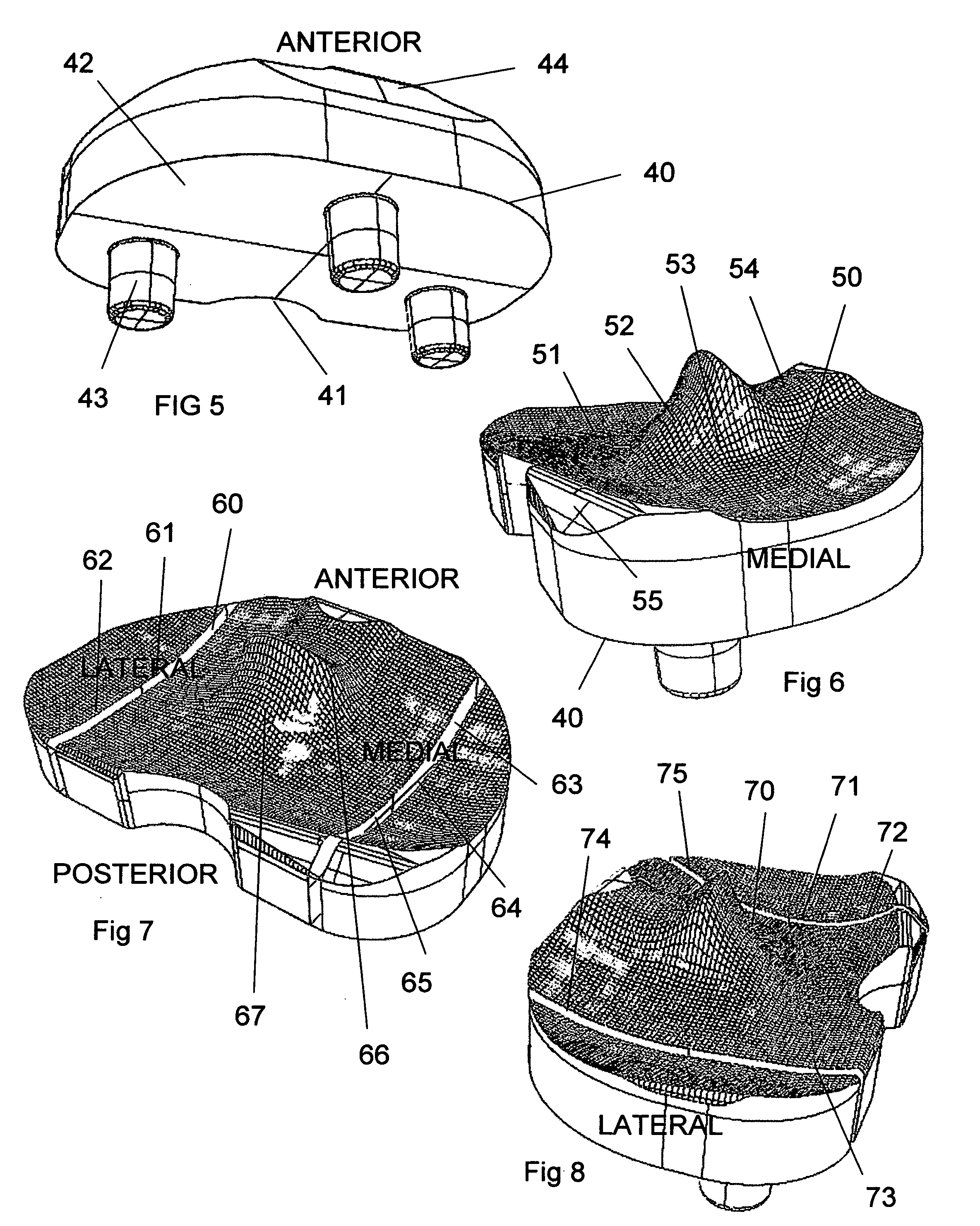

Surface guided knee replacement

InactiveUS20070135925A1Reduce consistencyAvoid large displacementJoint implantsKnee jointsGonial angleTibial surface

An artificial knee joint that includes a femoral component with a specially shaped bearing surface and a tibial component, whose surface interacts with the femoral surfaces. The interaction provides for the motion and stability characteristics of the anatomic knee. The interaction between the femoral and tibial surfaces is such that as the knee is flexed to maximum, the femoral component moves posteriorly on the tibial surface, more so on the lateral side than on the medial side. This is accomplished by the interaction of a projecting tibial post inside a cupola in the center of the femoral component, and by the saggital radius on the medial side being smaller than that on the lateral side. The prevention of anterior sliding of the femur on the tibia in early flexion is accomplished by the interaction between a distal-anterior recess on the medial side of the femur and an apposing raised pad on the tibial surface. Rotational laxity at all angles is allowed by the presence of only one recess pad and by non-conforming femoral-tibial surfaces on the lateral side.

Owner:NEW YORK UNIV

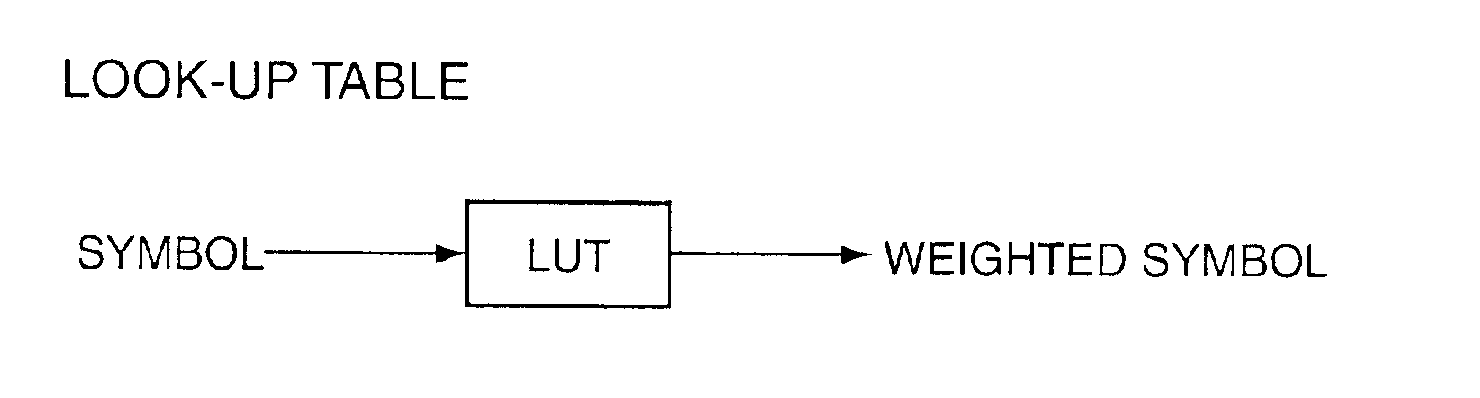

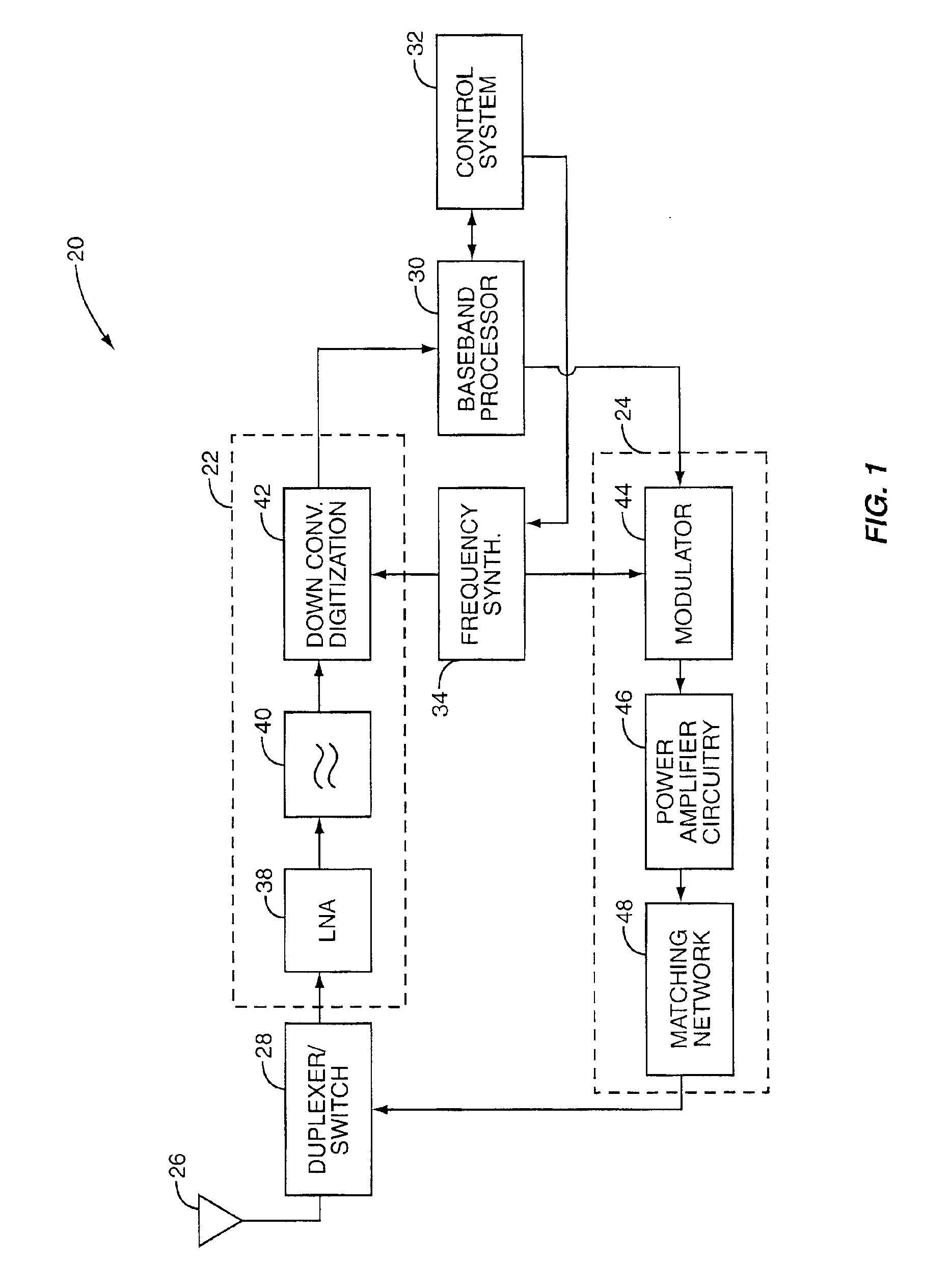

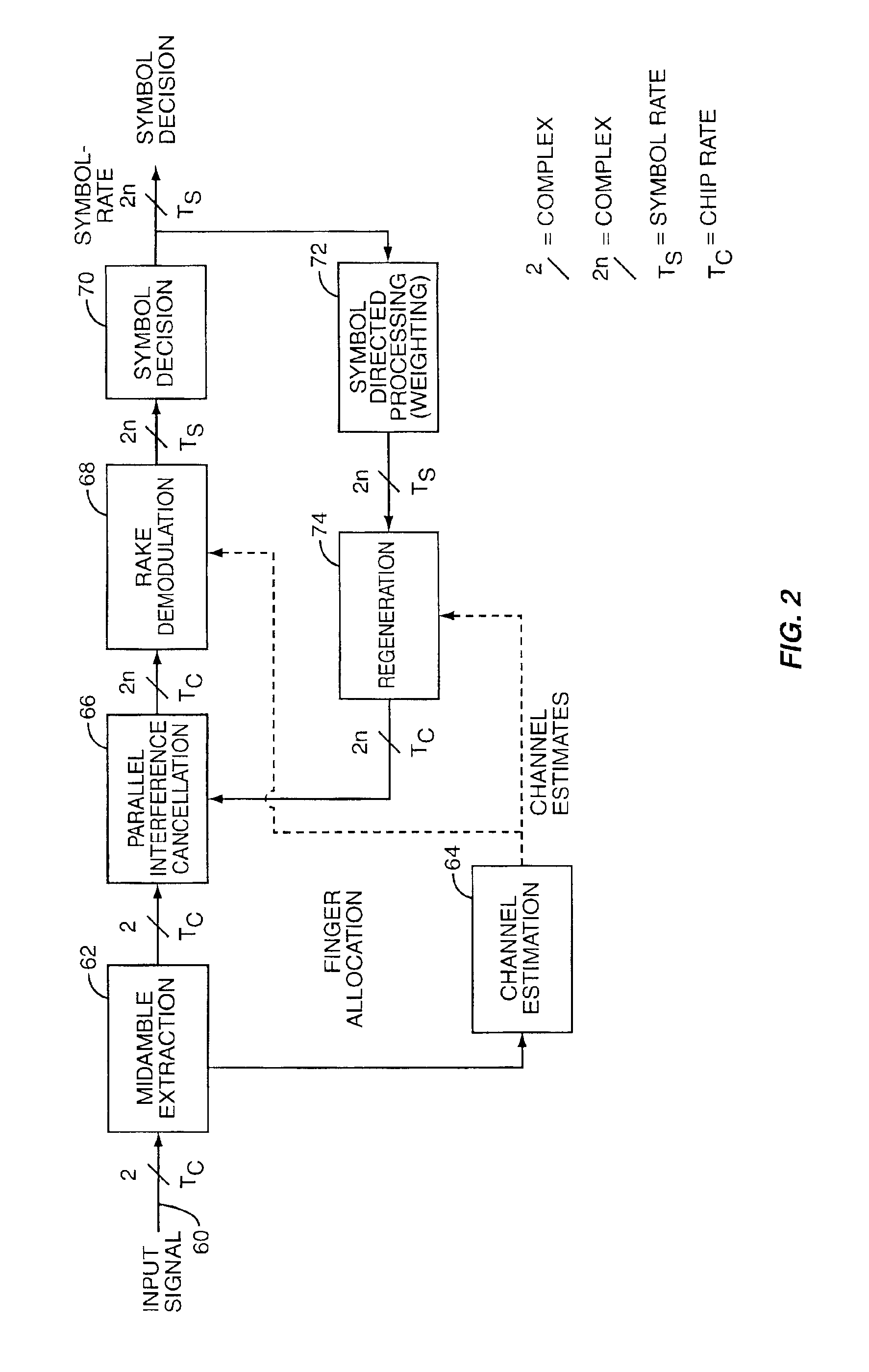

Symbol-directed weighting in parallel interference cancellation

InactiveUS6931052B2Improve consistencyImprove the level ofRadio transmissionInterference cancelationComputer science

The present invention provides for improved parallel interference cancellation. An input signal composed of multiple user signals is processed over a select time duration. The input signal is separated into individual signals corresponding to each of the multiple users and demodulated to recover symbols for each of the individual signals. The recovered symbols are processed based on the consistency of previous estimates of the given symbol to provide weighted symbol estimates. The respective weighted symbol estimates for each of the users are modulated with the appropriate coding and processed using channel estimates to create individual, regenerated signals. For each user, the regenerated signals for the other users are subtracted from the original input signal to form new individual signals. The new individual signals are each demodulated and reprocessed for multiple iterations. The output of the last iteration is used to form the final symbol decisions for each user signal.

Owner:APPLE INC

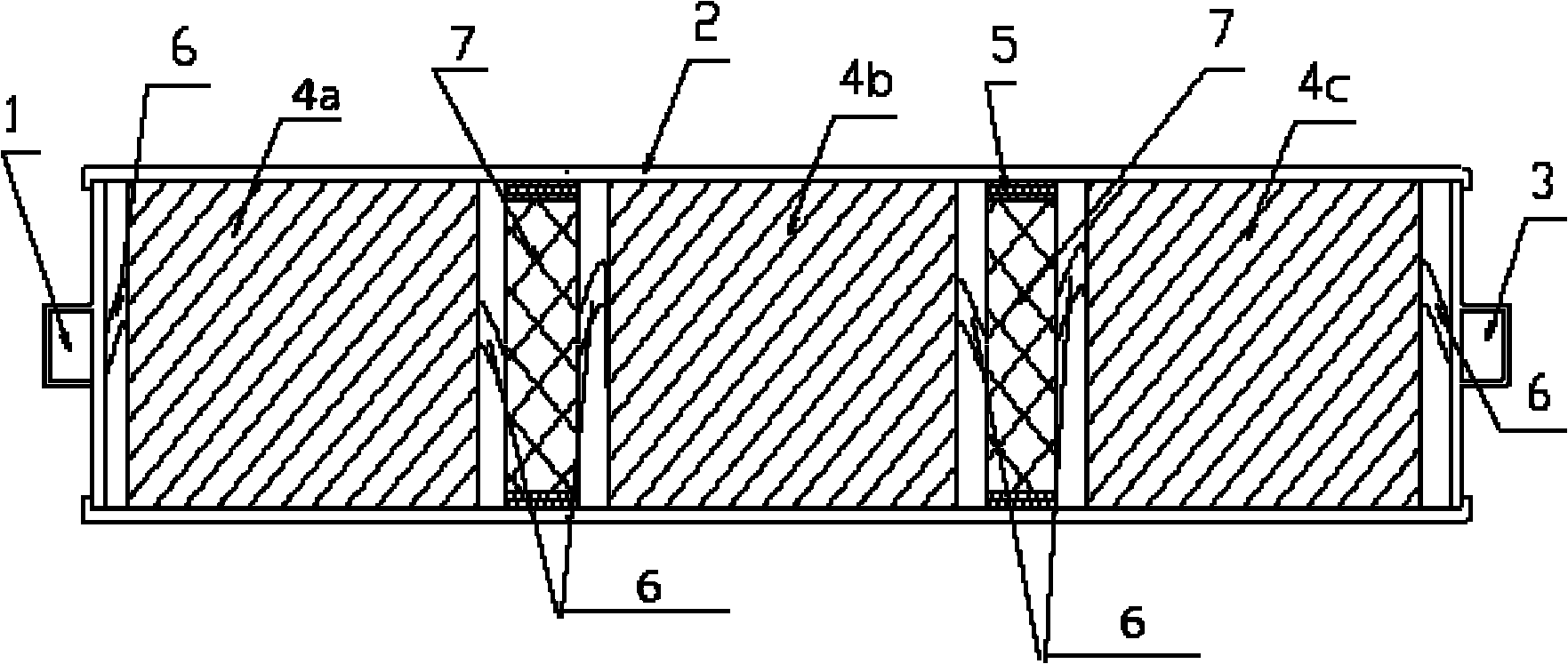

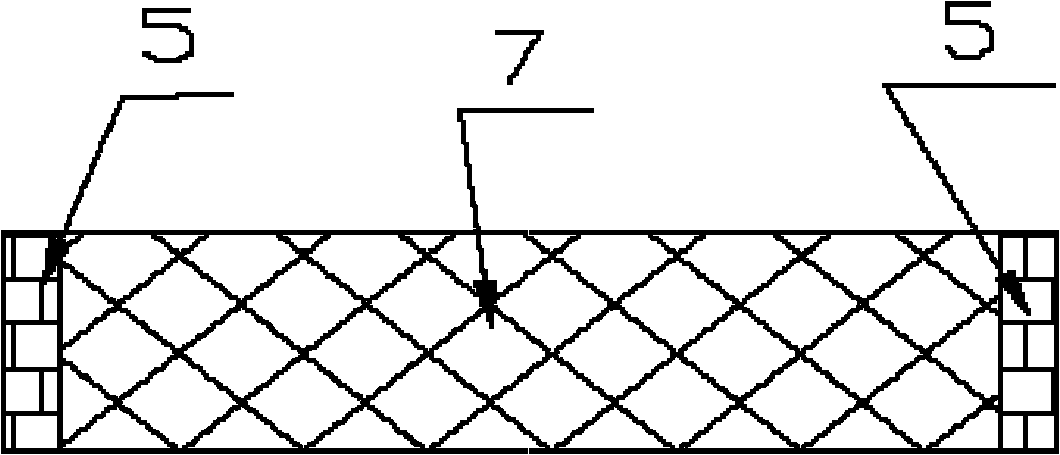

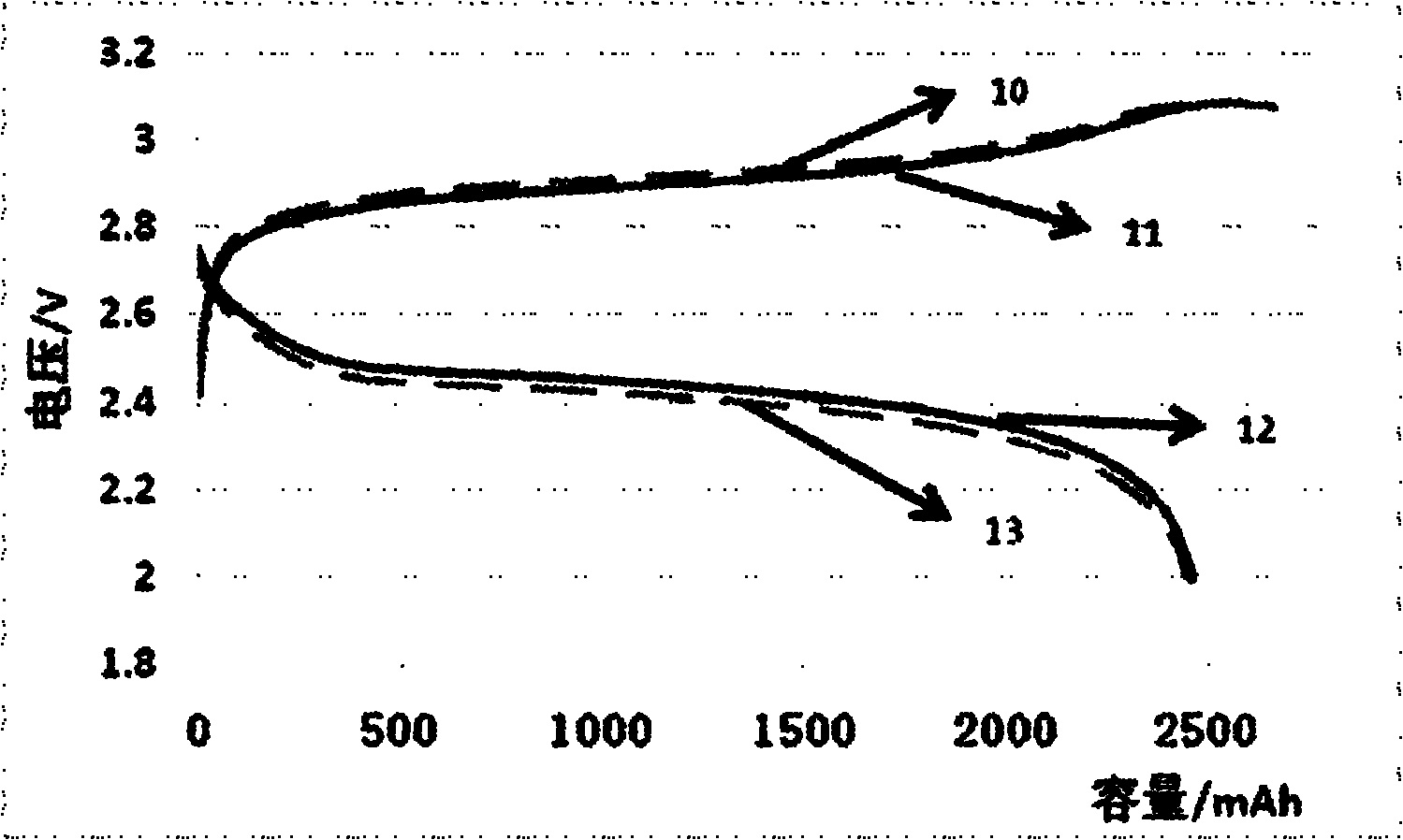

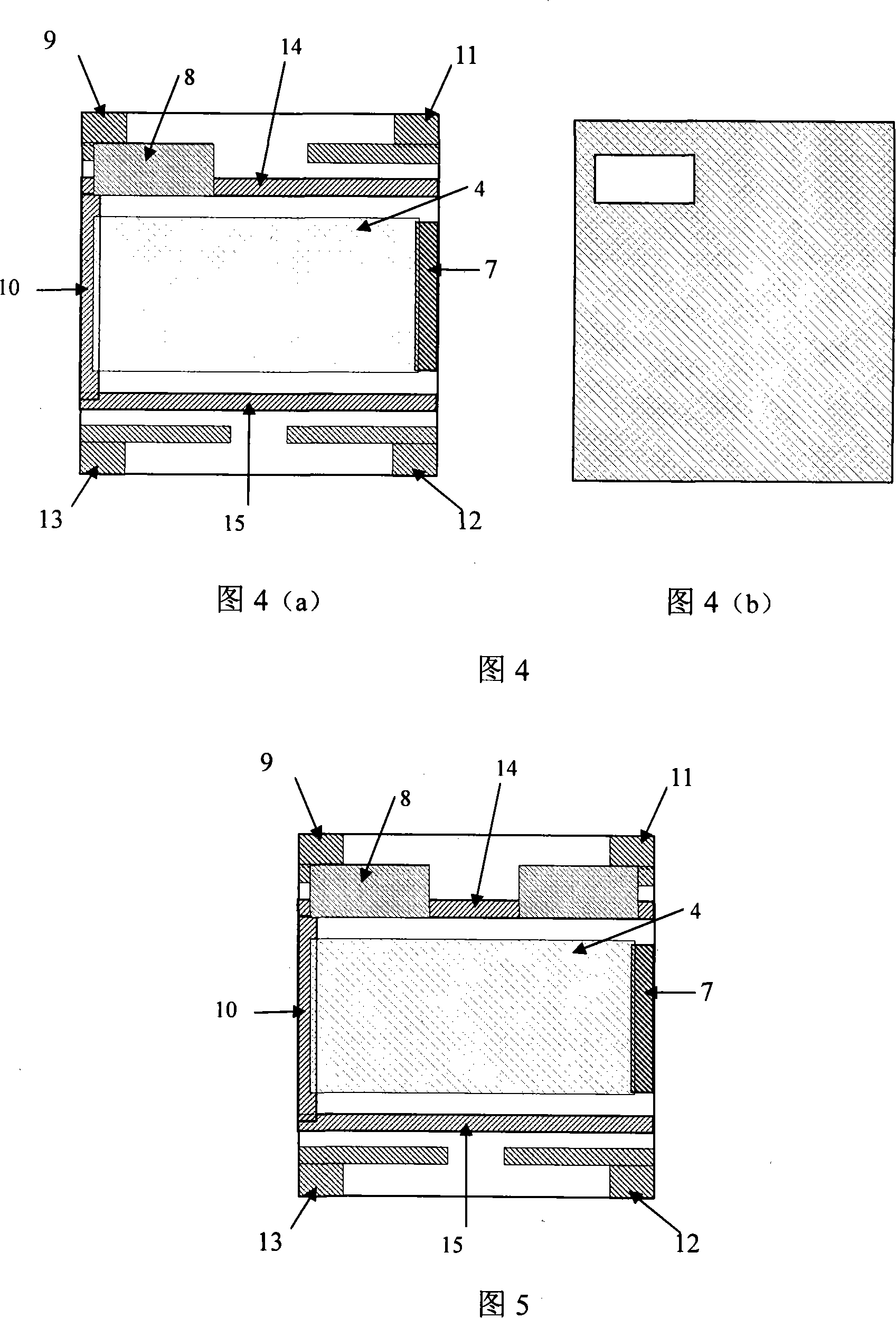

Battery pack with internal serial structure and manufacture method thereof

InactiveCN102104167AMeet voltage requirementsReduce volumeFinal product manufactureSecondary cells manufactureElectrical batteryEngineering

The invention provides a battery pack with an internal serial structure and a manufacture method thereof. The battery pack comprises N pole groups, N-1 baffles with conductivity, an electrolyte and sealing rings in a battery shell and top covers on the battery shell. The manufacture method comprises the following steps of: separating two adjacent pole groups with the baffles; connecting the anode of one pole group with a baffle; connecting the cathode of the other pole group with the other edge of the baffle; and serially connecting the adjacent pole groups. The battery pack is designed according to a needed voltage so that a plurality of unit battery cores are connected serially in the same battery shell for use as a whole to meet the voltage requirement. The battery pack provided by the invention has smaller battery size and lighter mass under the same voltage while meeting the voltage requirement on various electric appliances and has low requirement for a battery packing technology. Meanwhile, due to no connectors for conduction among cell batteries when the batteries are combined, the external short circuit of the batteries can be reduced.

Owner:HUNAN CORUN NEW ENERGY CO LTD

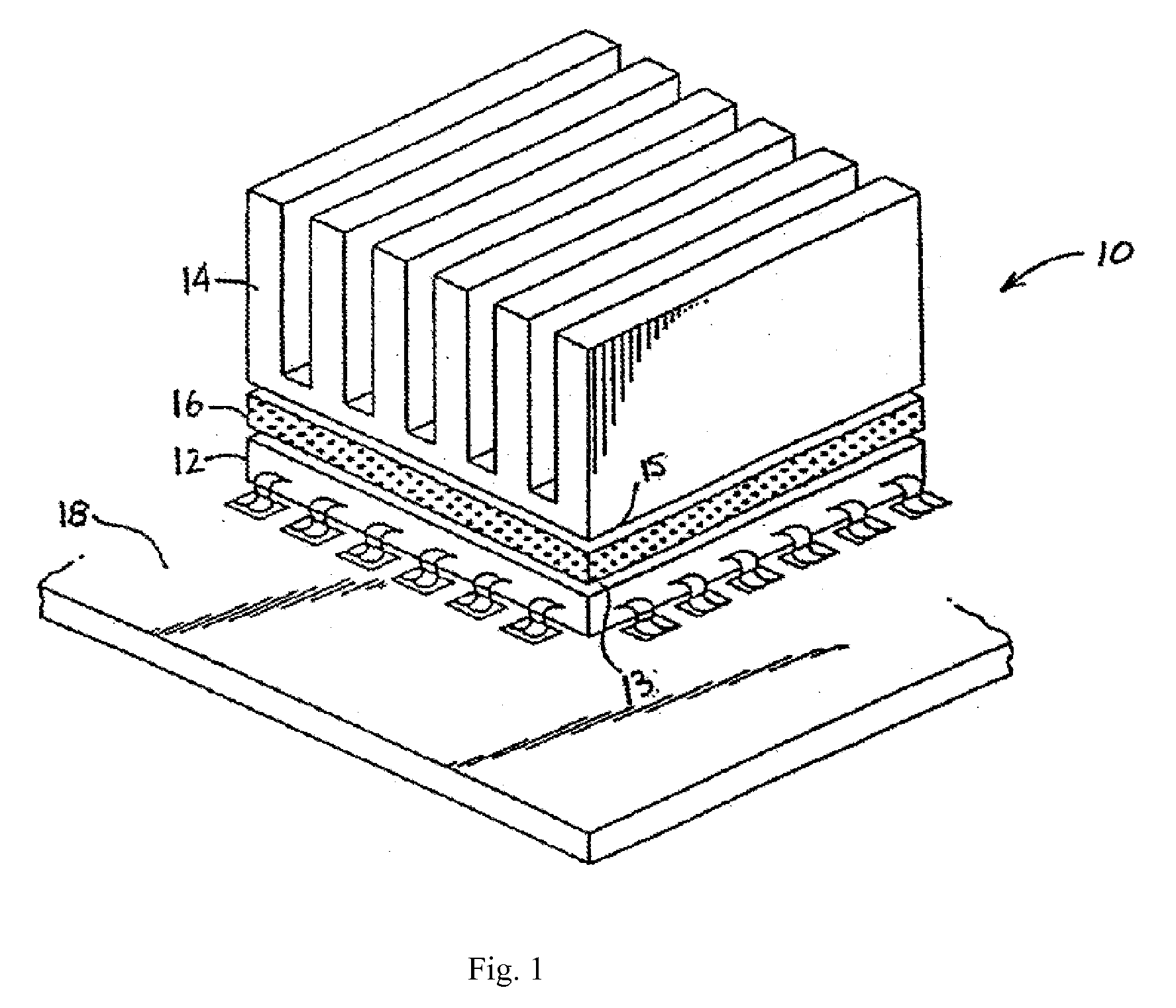

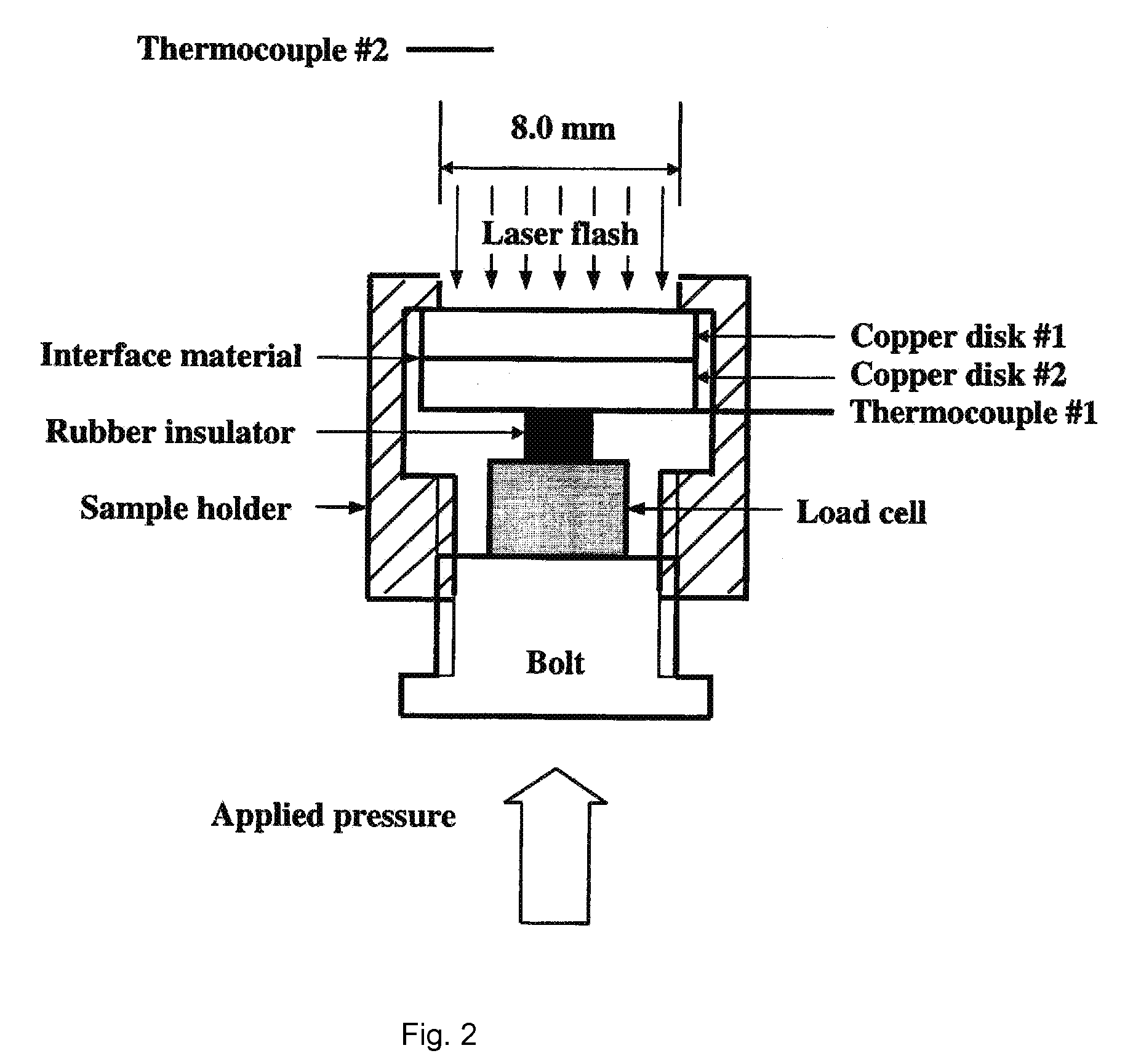

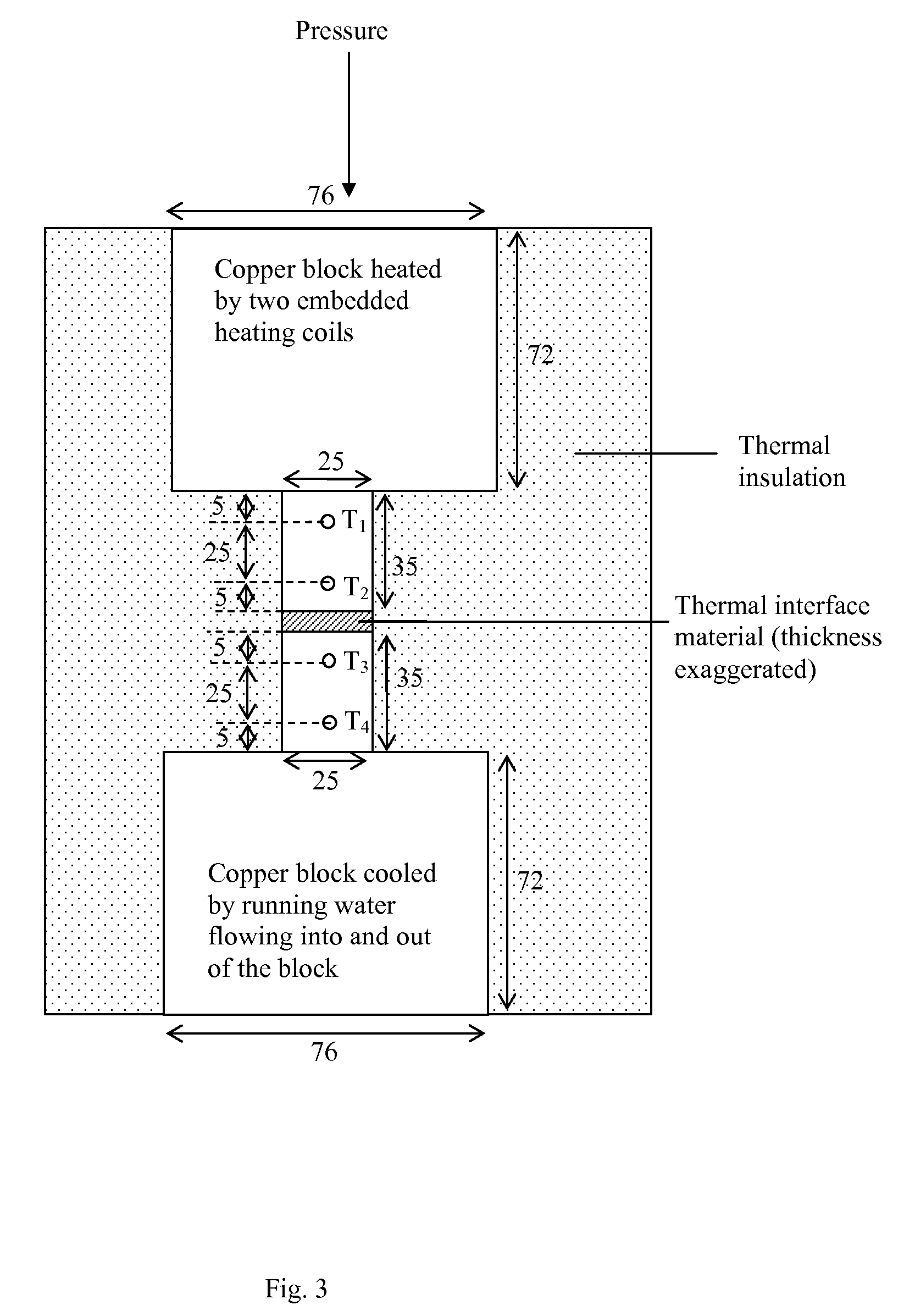

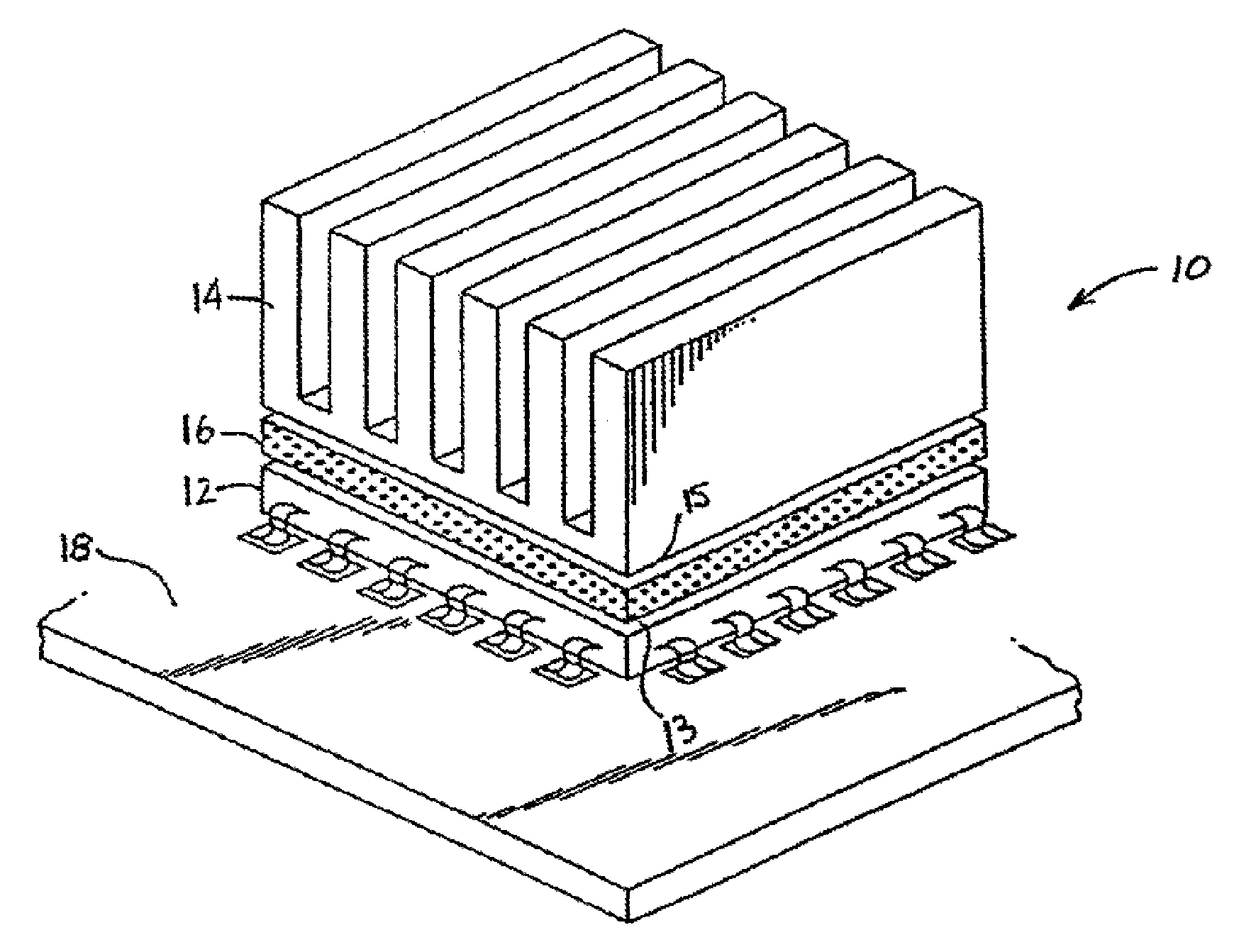

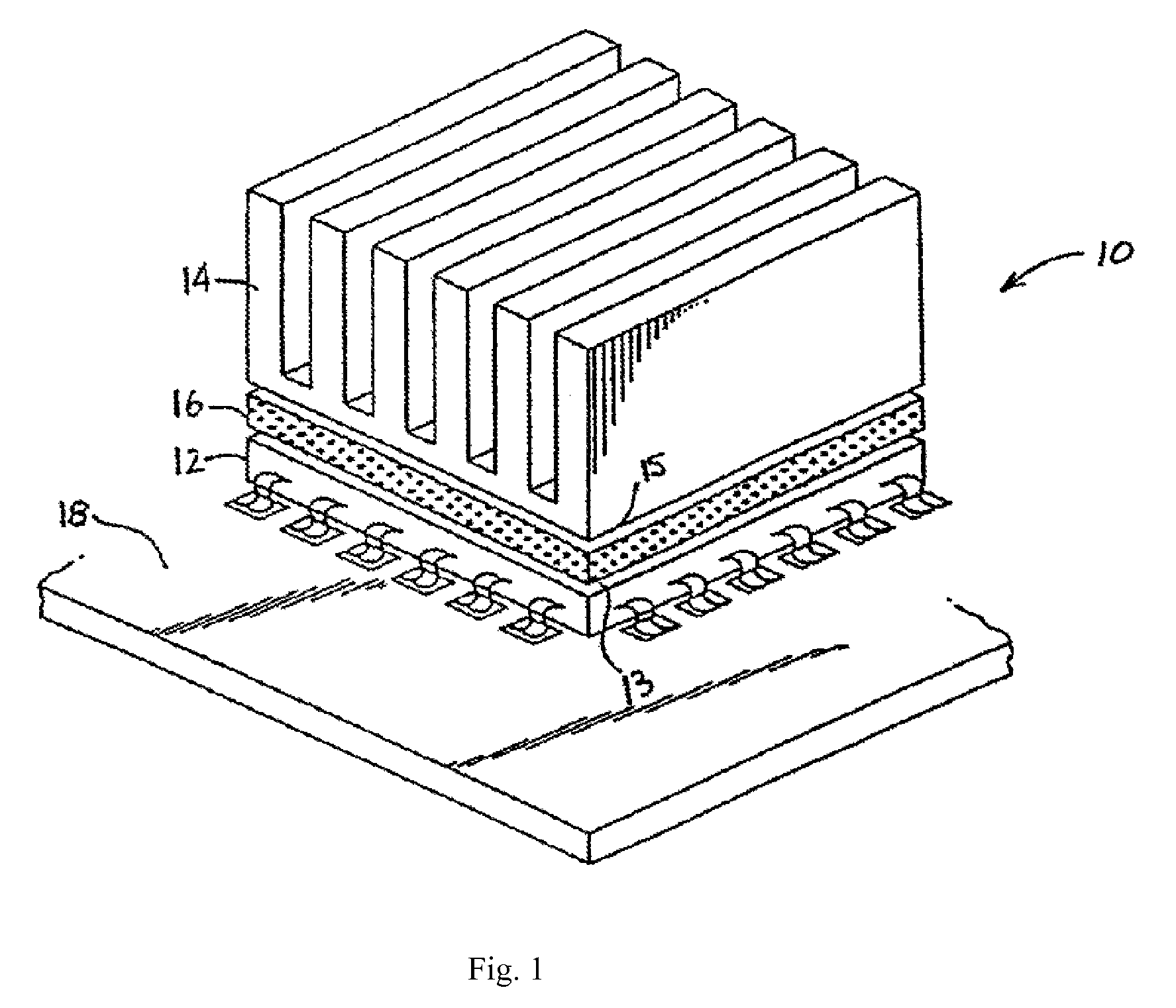

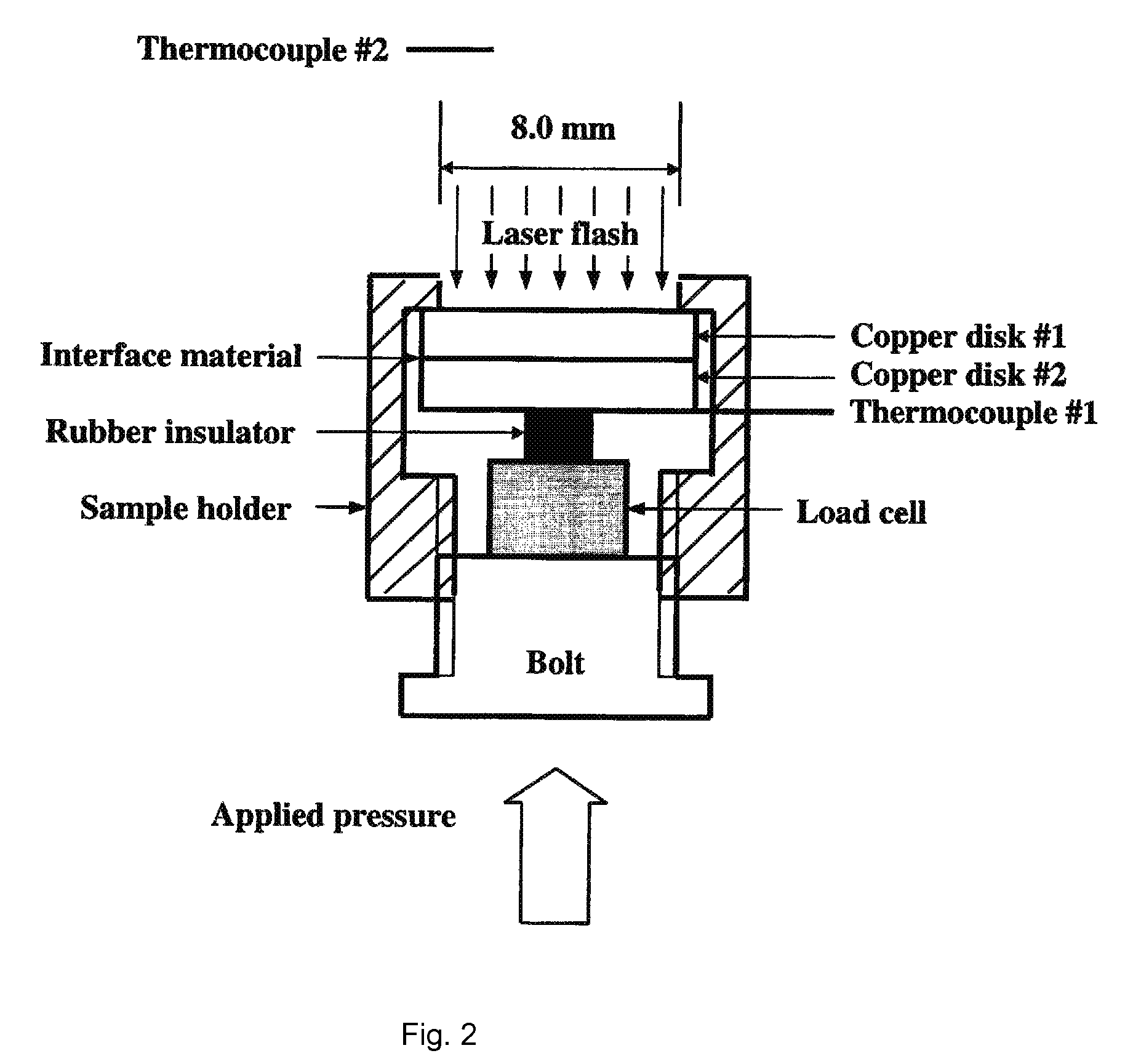

Conformable interface materials for improving thermal contacts

InactiveUS20060246276A1Improve effectivenessImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteThermal contact

A conformable paste comprising porous agglomerates of carbon black dispersed in a paste-forming vehicle is disclosed. The paste is useful as an interface material for improving the thermal contact between two proximate solid surfaces, such as the surfaces of a heat source and a heat sink. Upon compression between the two solid surfaces, the paste forms a material that enhances the thermal contact between said surfaces. This invention also discloses a conformable interface material which, upon compression between two proximate solid surfaces, forms a material that enhances the thermal contact between said surfaces. This interface material comprises (i) a sheet and (ii) a conformable, spreadable and thermally conductive paste on each of the two opposite sides of the sheet, said paste comprising porous agglomerates of carbon black dispersed in a paste-forming vehicle. In addition, a method of providing a thermal contact between two solid surfaces is disclosed. This method comprises disposing between and in contact with said surfaces a material comprising: a conformable, spreadable and thermally conductive paste comprising porous agglomerates of carbon black dispersed in a paste-forming vehicle, and applying a pressure to cause said material to conform to the topography of said surfaces.

Owner:CHUNG DEBORAH D L

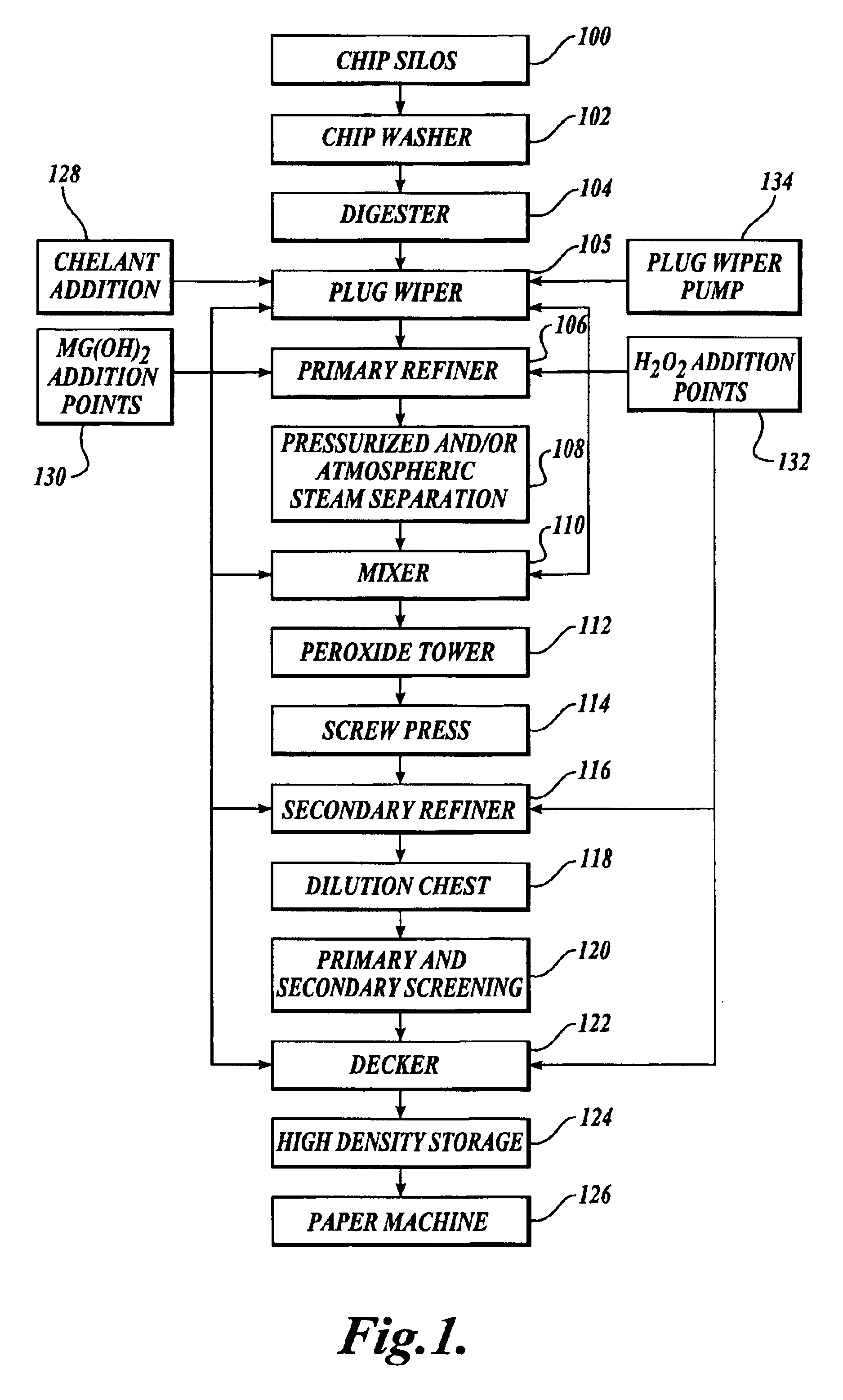

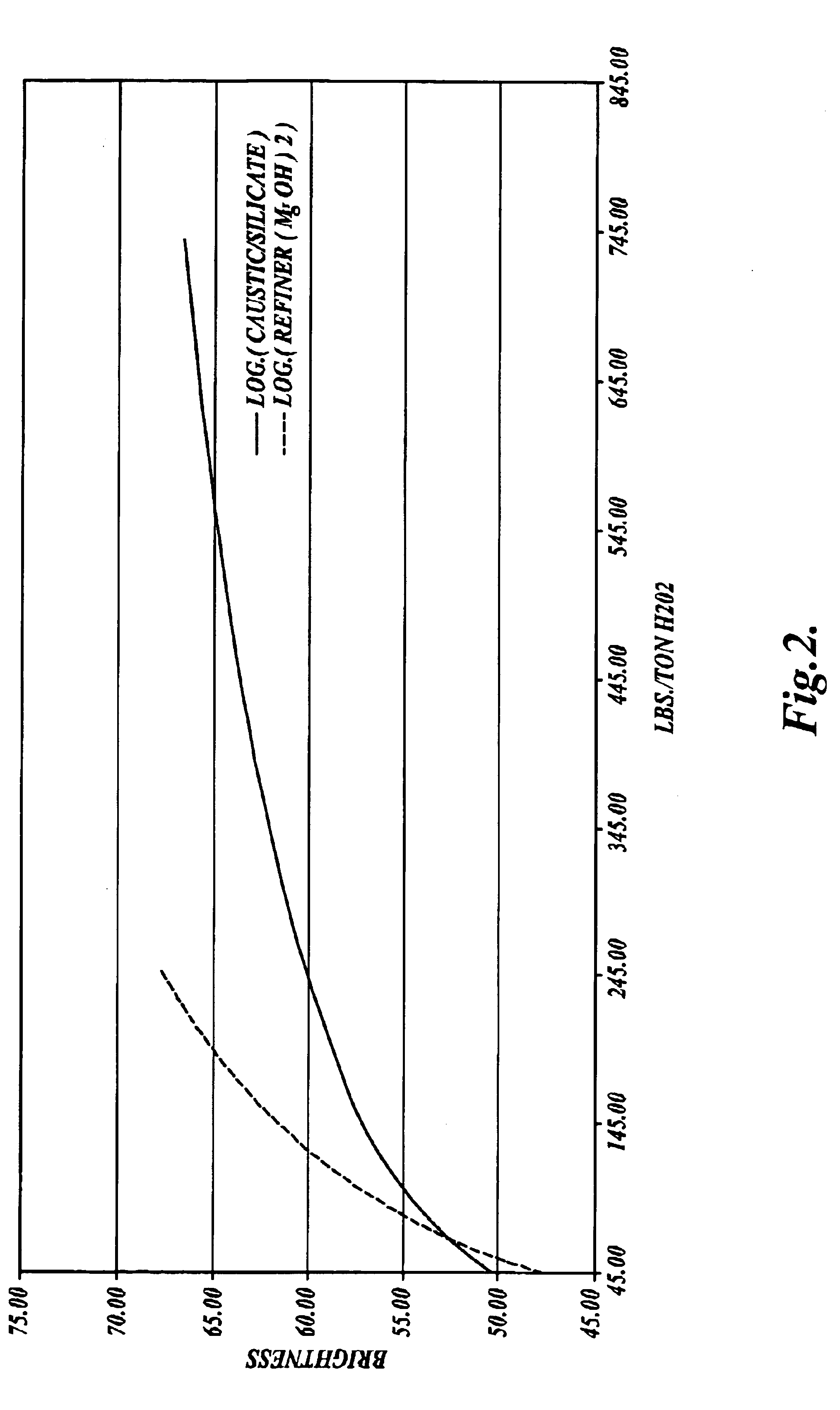

Refiner bleaching with magnesium oxide and hydrogen peroxide

InactiveUS6881299B2Eliminate useHigh retention rateFats/resins/pitch/waxes removal in pulpPulp de-wateringParticulatesMagnesium ion

Methods of bleaching mechanical pulp under alkaline conditions with hydrogen peroxide. The methods include introducing a source of magnesium ions and hydroxyl ions to a refiner. The wood particulates are refined into a pulp in the presence of the magnesium ions and hydroxyl ions, and optionally perhydroxyl ions to simultaneously refine and bleach the pulp in a refiner.

Owner:NORTH PACIFIC PAPER

Food packaging articles

ActiveUS20200063367A1High air permeabilityHigh thicknessFlexible coversWrappersSynthetic fiberFood packaging

Containers and lids made from cellulose fibers and cellulose ester fibers are provided that have enhanced air permeability, stiffness, R-heat insulation values, or thickness at equivalent grammage basis weights are provided, or alternatively, maintaining one or more of these properties while lowering the basis weight of the containers or lids. The container and lids with this synthetic fiber can be biodegradable when made with cellulose ester fibers having a degree of substitution of not more than 2.5. Examples of such containers are food packaging such as hot or cold delivery boxes.

Owner:EASTMAN CHEM CO

Conformable interface materials for improving thermal contacts

InactiveUS7535715B2Improve effectivenessImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteThermal contact

Owner:CHUNG DEBORAH D L

Composite material and shaped article with thermal conductivity and specific gravity on demand

InactiveUS20040094863A1DelayImprove fluencyCeramic shaping apparatusCeramicwareSuperplasticizerMachinability

Described is a composite material and therefrom produced cured, preferably shaped, articles having a thermal conductivity and specific gravity on demand by selecting an appropriate inorganic aggregate and a cementiteous binder composition, said binder composition comprising a binder and ultrafine particles. With the addition of a polymer based superplasticizer self compacting properties at any desired specific gravity can be achieved. No mechanical compaction or vibration is needed for the production of shaped articles. The mixture can be polymer- and / or fiber reinforced. Workability time and hardening can be adapted to job site needs by addition of set retarders and / or accelerators and / or by heating.

Owner:SIKA SCHWEIZ AG

Cellulose and cellulose ester film

ActiveUS20200063353A1Reduce consistencyLow variabilityNon-fibrous pulp additionSpecial paperCellulose ester membranePolymer science

A film is made from a wet laid product containing cellulose fibers and cellulose ester fibers and a plasticizer. The film can be made by heat pressing the wet laid sheet to form a film having a continuous phase of cellulose ester resin and a discontinuous phase of cellulose fibers.

Owner:EASTMAN CHEM CO

Ultrasonic welding of wet laid nonwoven compositions

ActiveUS20200299900A1Reduce consistencyLow variabilitySpecial paperPaper/cardboardPolymer scienceUltrasonic welding

The present invention relates to ultrasonic welding of compositions, and wet laid articles made from the compositions, containing cellulose fibers and cellulose ester fibers, as well as wet laid processes using the compositions. More specifically, the present invention relates to a wet laid nonwoven comprising cellulose and cellulose ester fibers. The wet laid nonwoven is bonded to itself and / or to other substrates, and this bonding is accomplished at least in part by ultrasonic welding.

Owner:EASTMAN CHEM CO

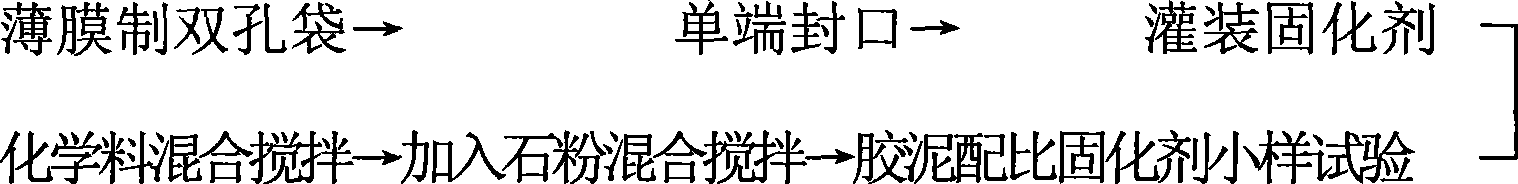

Resin mastic cement for anchorage agent and anchorage agent thereof

InactiveCN101508540AReduce consistencyHigh compressive strengthAnchoring boltsDimethylaniline N-oxideCompressive strength

The invention relates to an anchoring agent, which is resin mortar for an anchoring agent and the anchoring agent, and is used for anchoring large-diameter anchor cables used in the construction of the support of coal mine roadways and the protection of underground engineering. The resin mortar comprises the following compositions in portion by mass: 800 to 1,200 portions of MG unsaturated polyester resin, 4,000 to 6,000 portions of limestone powder, 3 to 10 portions of dimethylaniline, and 6 to 12 portions of white carbon black, wherein the particle size of the limestone powder is between 80 and 120 meshes. The resin mortar and a curing agent form a bi-component anchoring agent. The anchoring agent can effectively reduce the consistency of the resin mortar, and improve the compressive strength after the solidification of the anchoring agent, thereby realizing the effects during the use such as high adhesive force, low stirring resistance and the like; and the anchoring agent meets the requirement of using large-diameter and high-strength anchor cables in the support of the coal mine roadways, reduces anchoring length, construction time and construction personnel, and improves the production efficiency.

Owner:晋城宏圣科威矿用材料有限公司

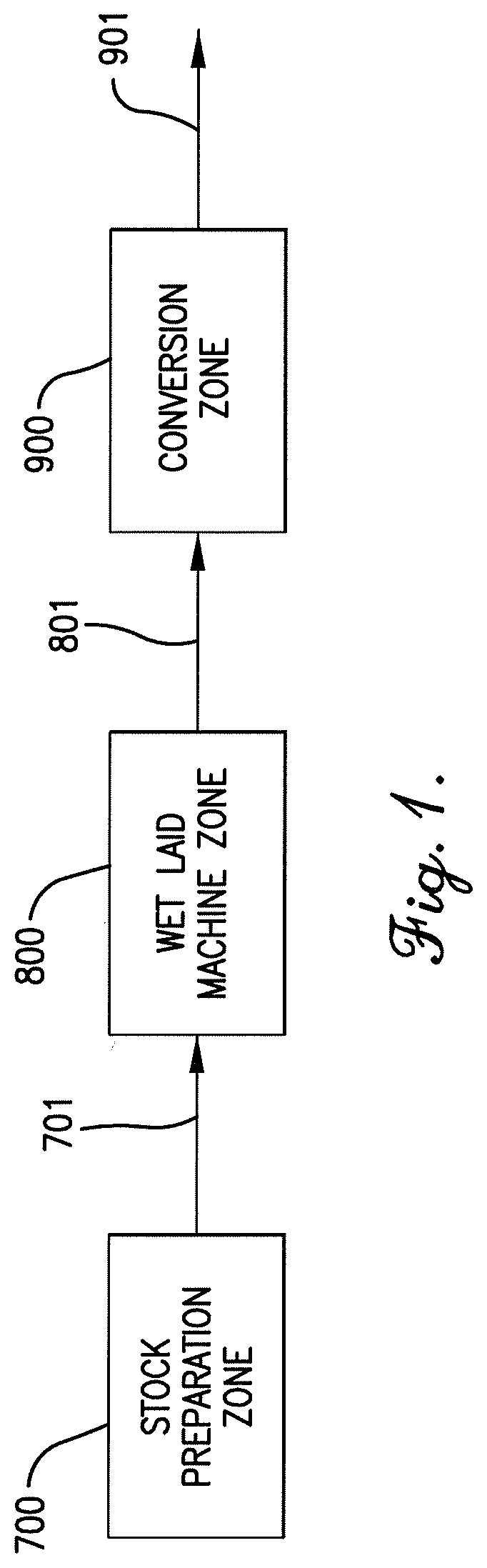

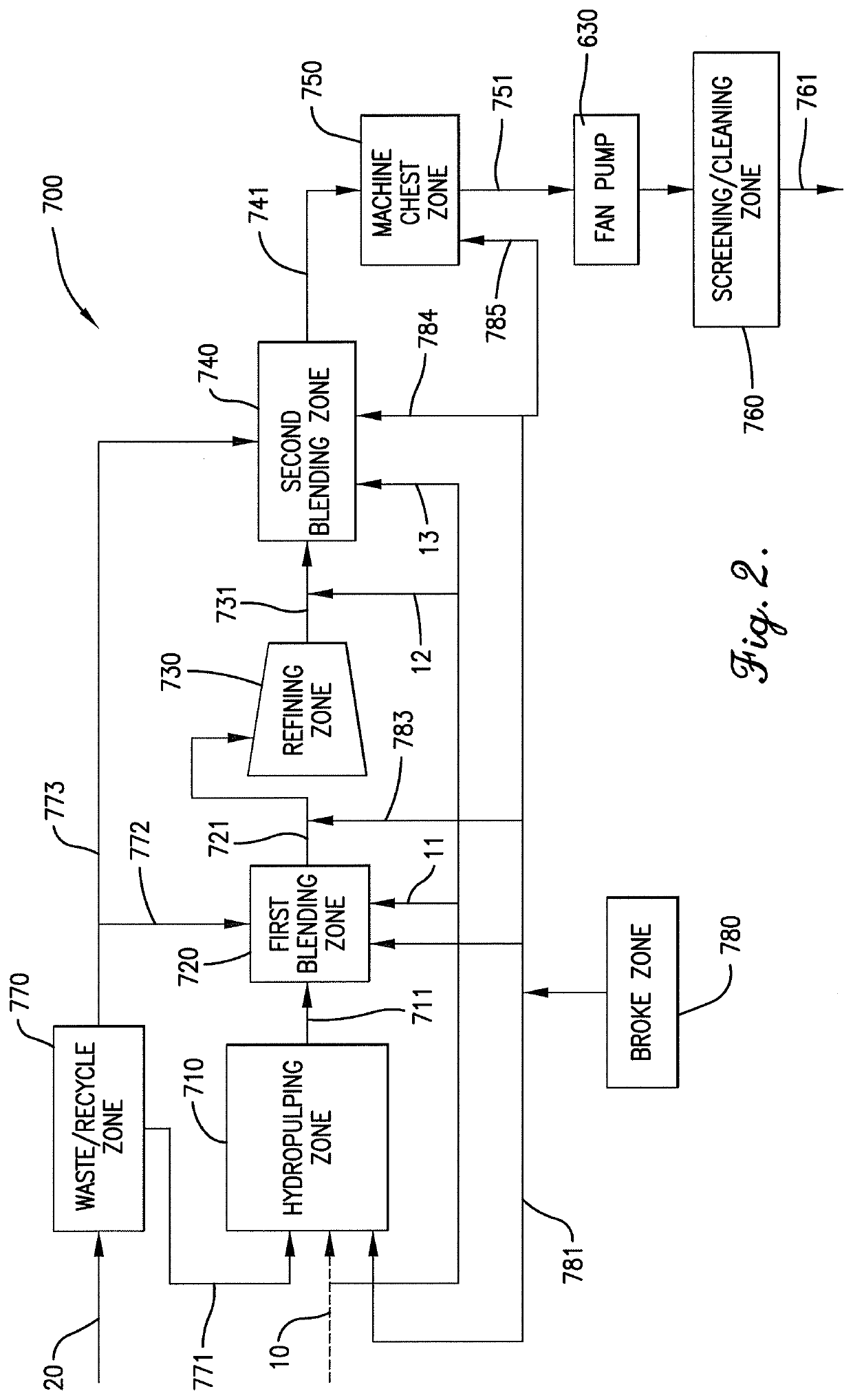

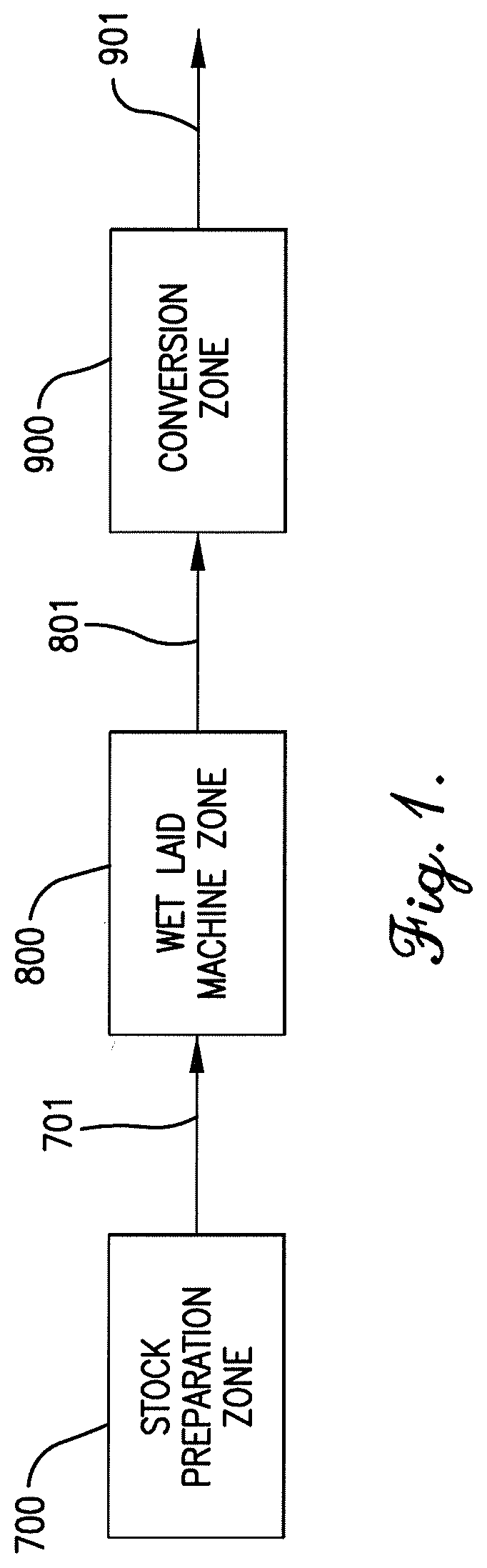

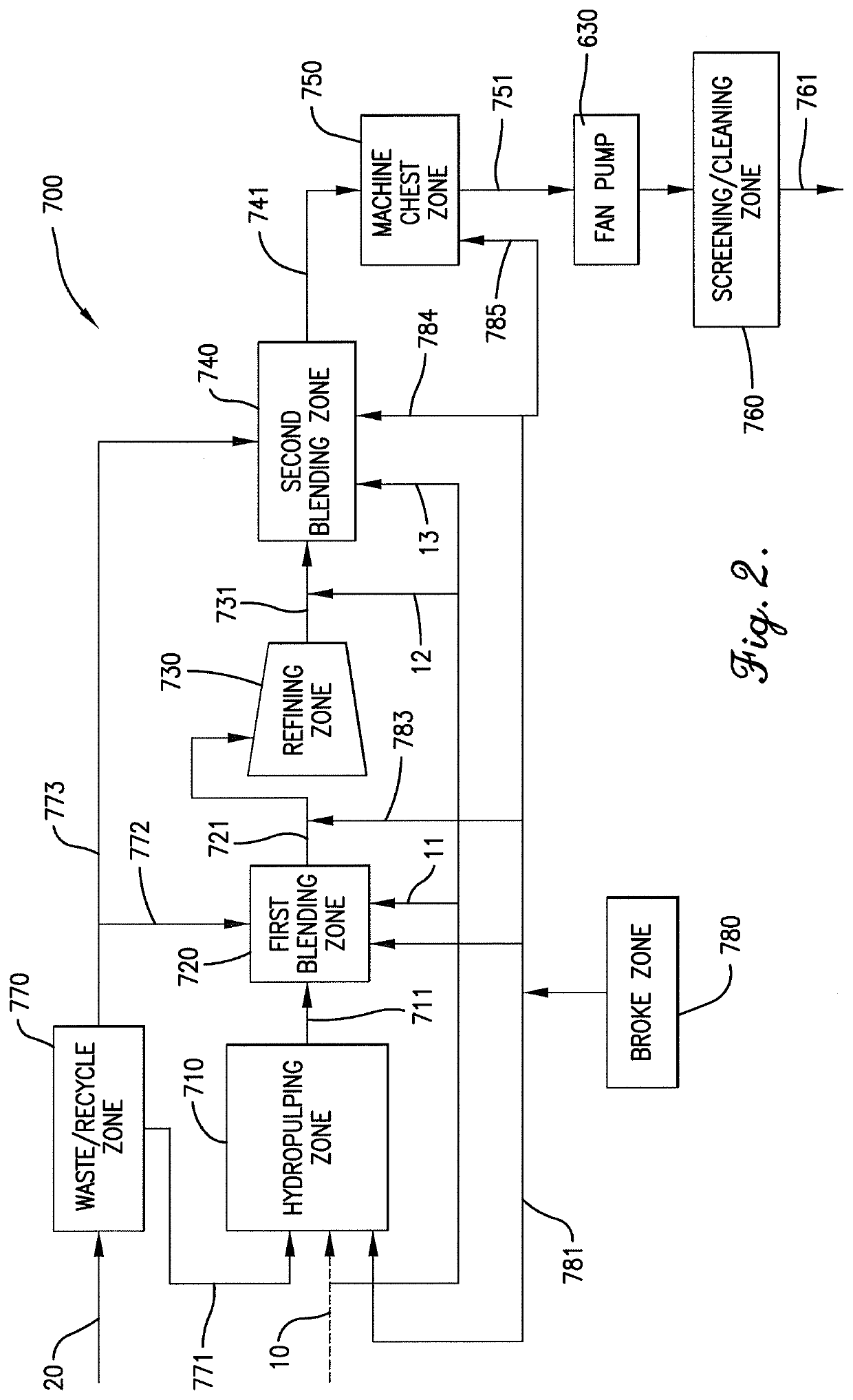

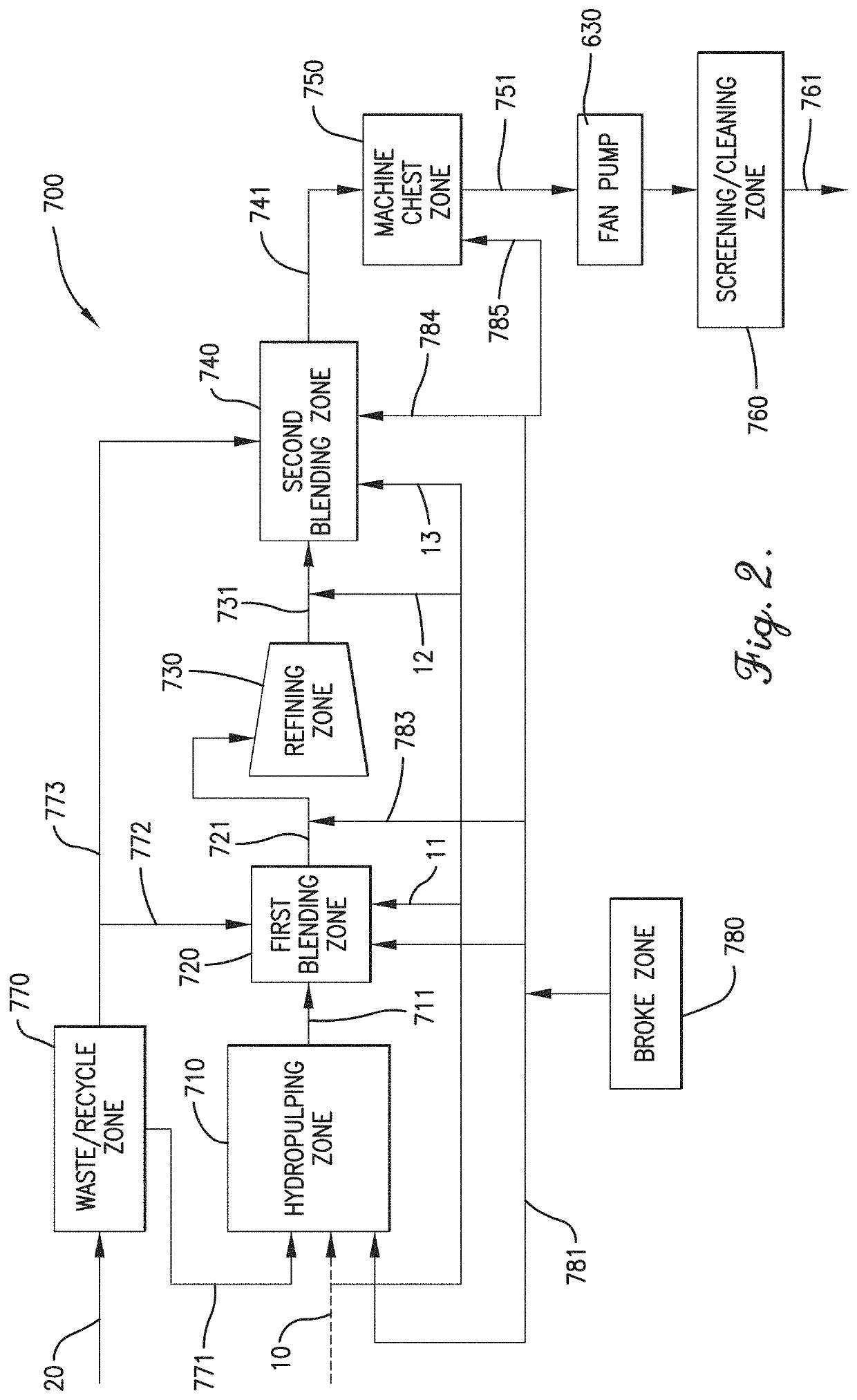

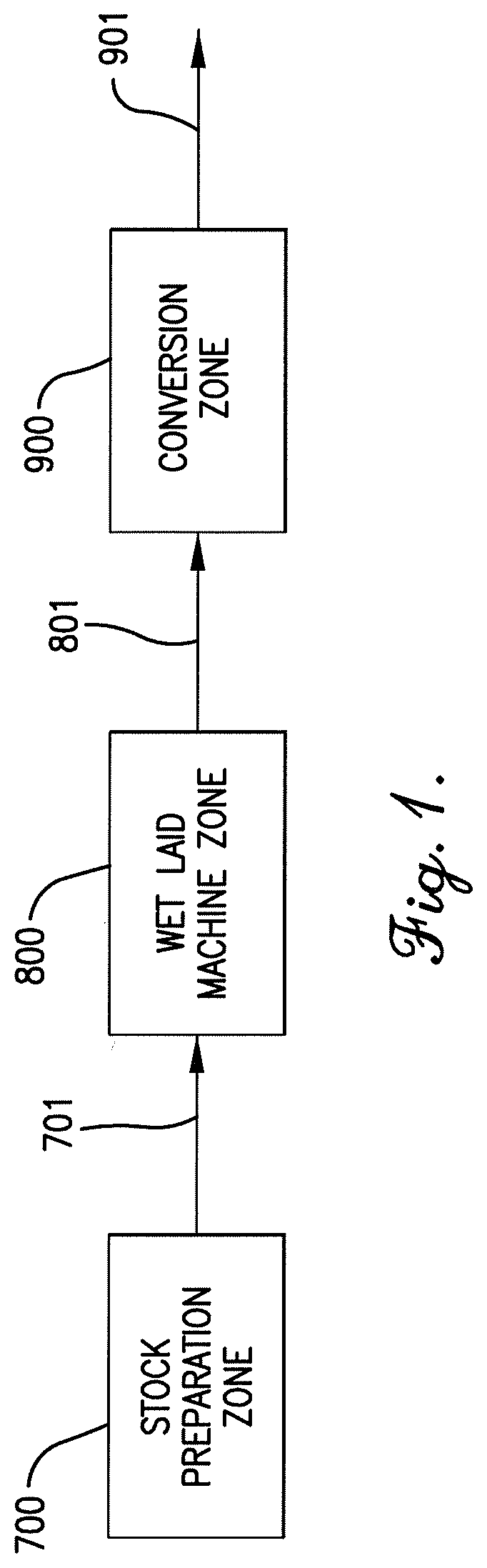

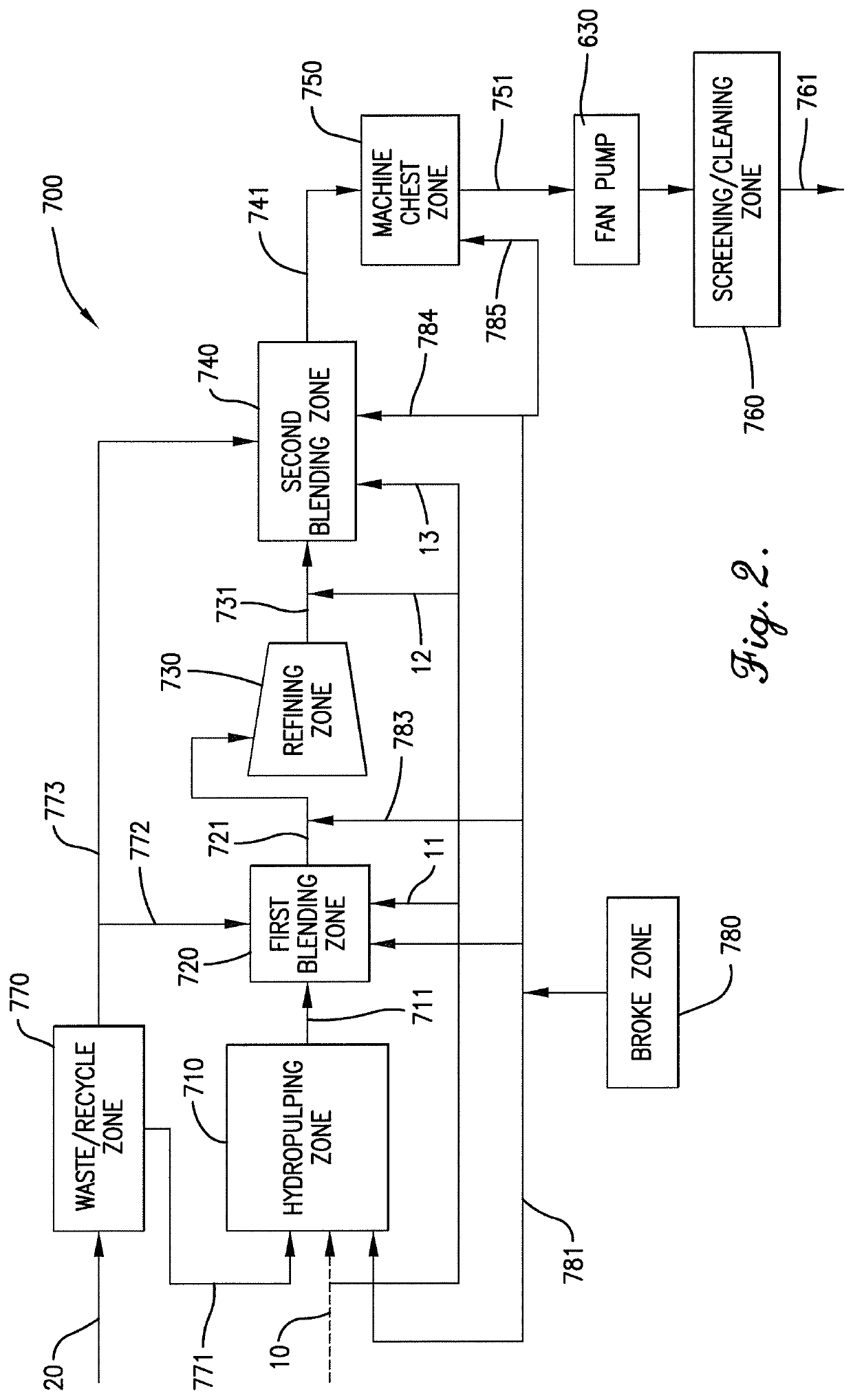

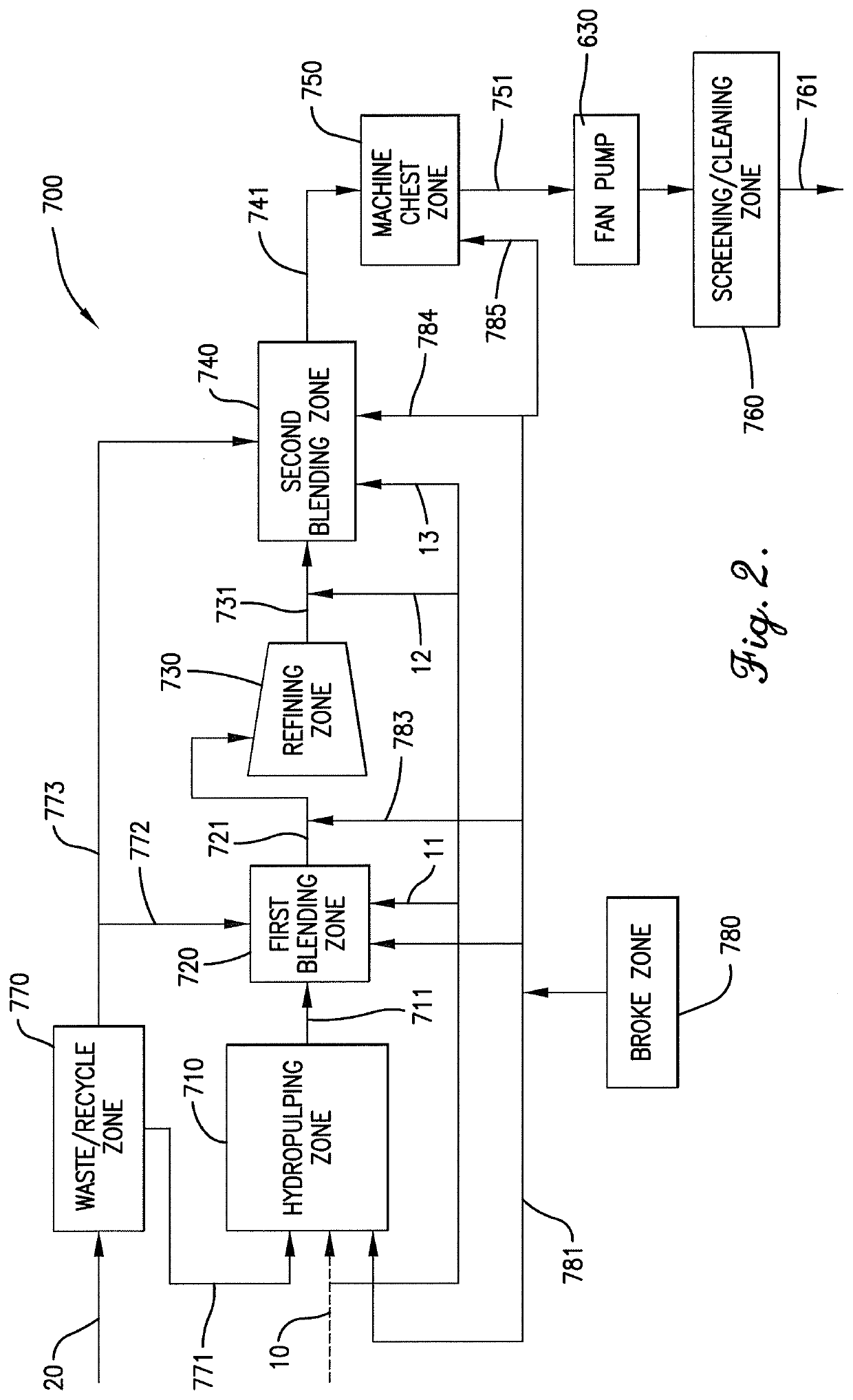

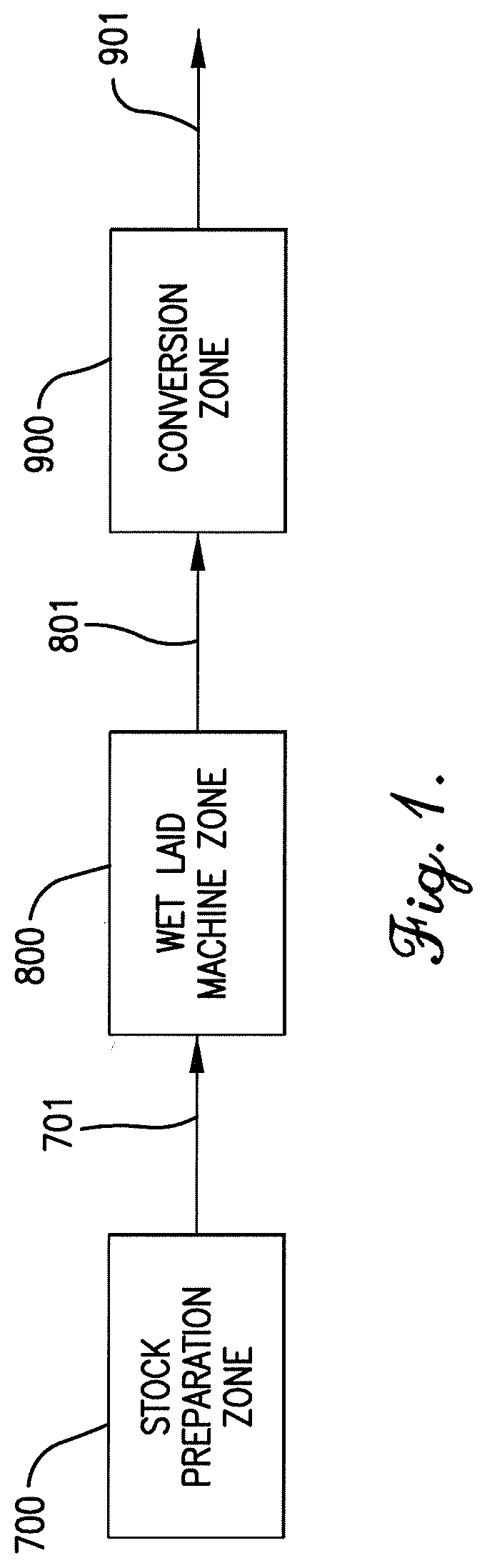

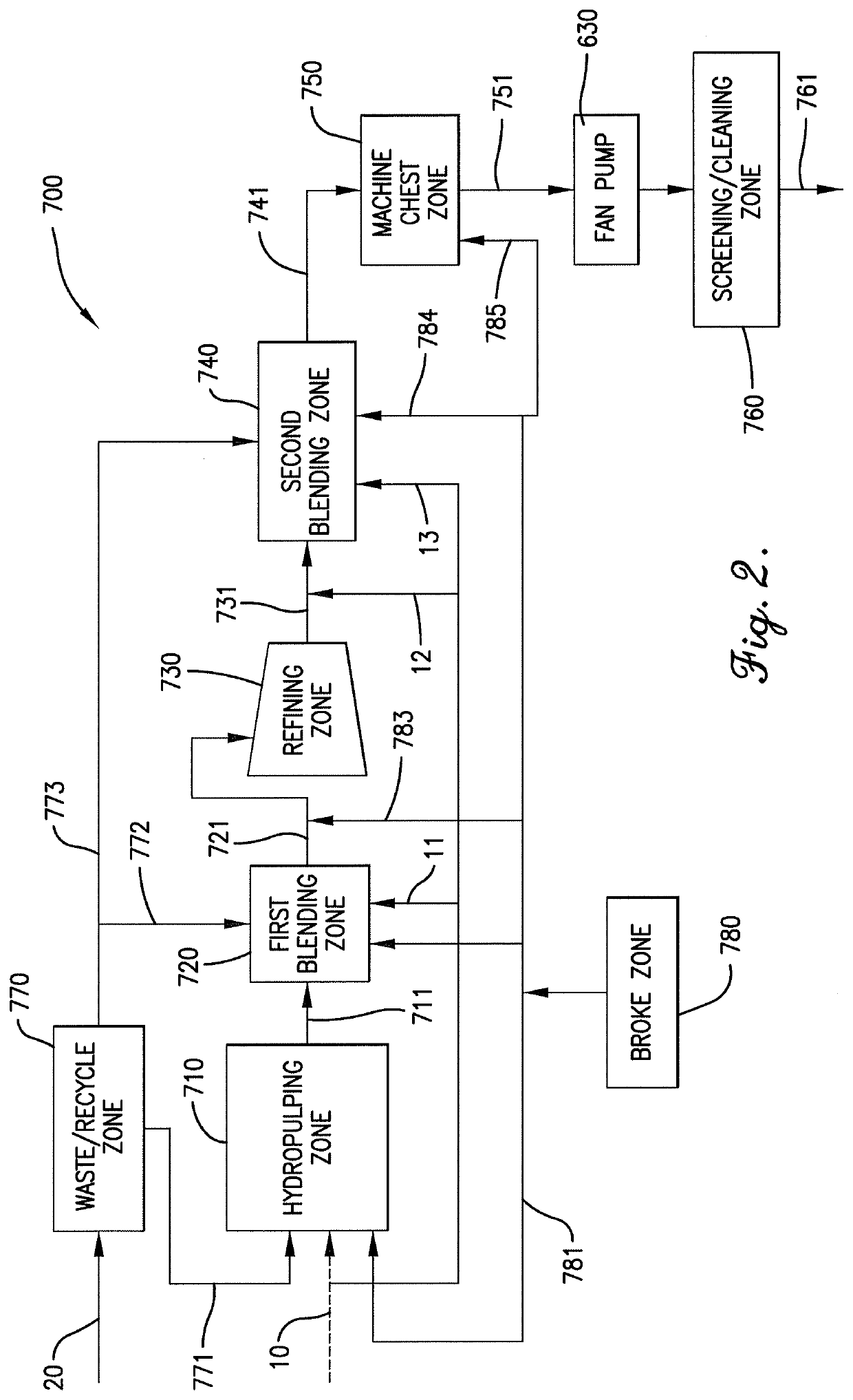

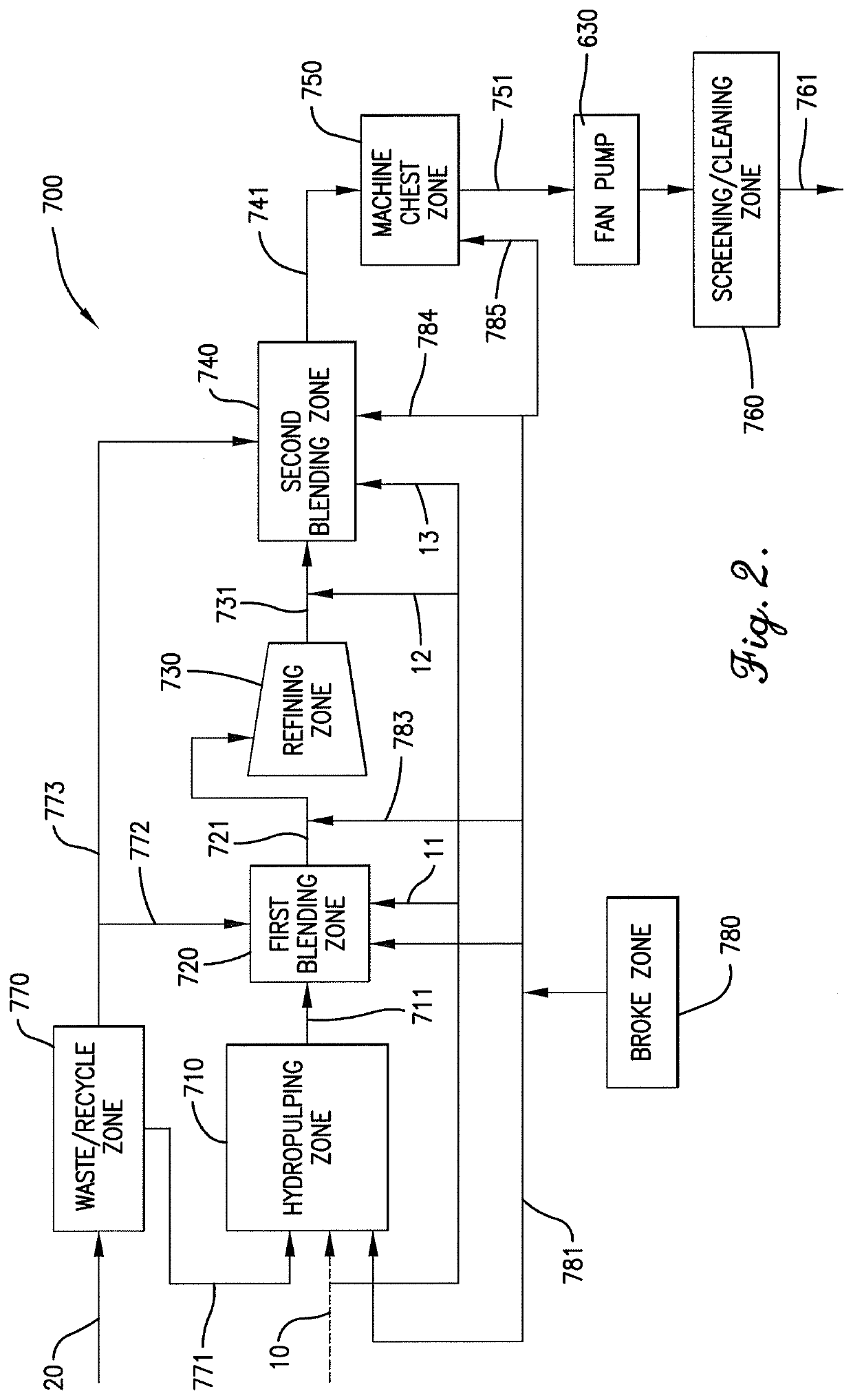

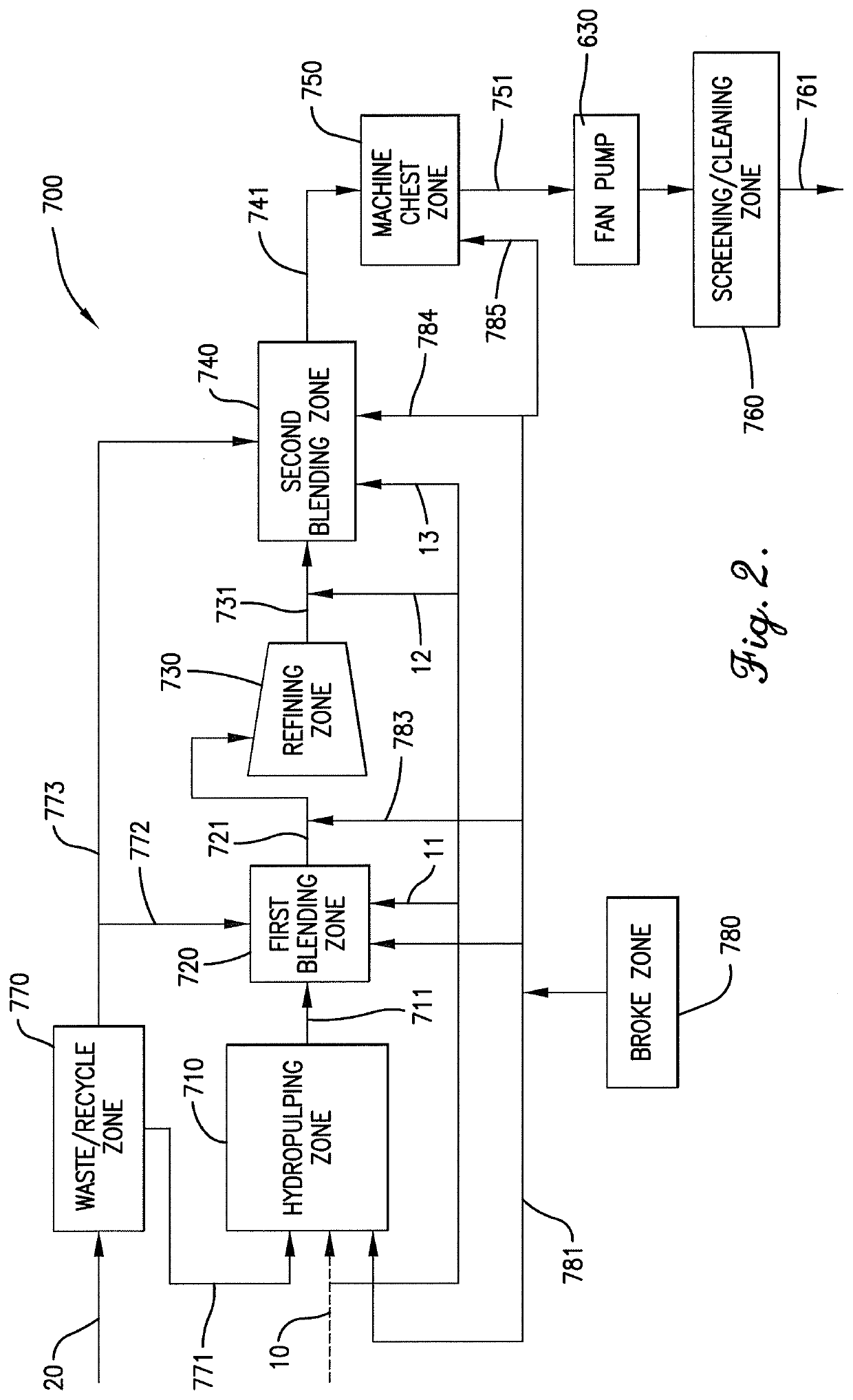

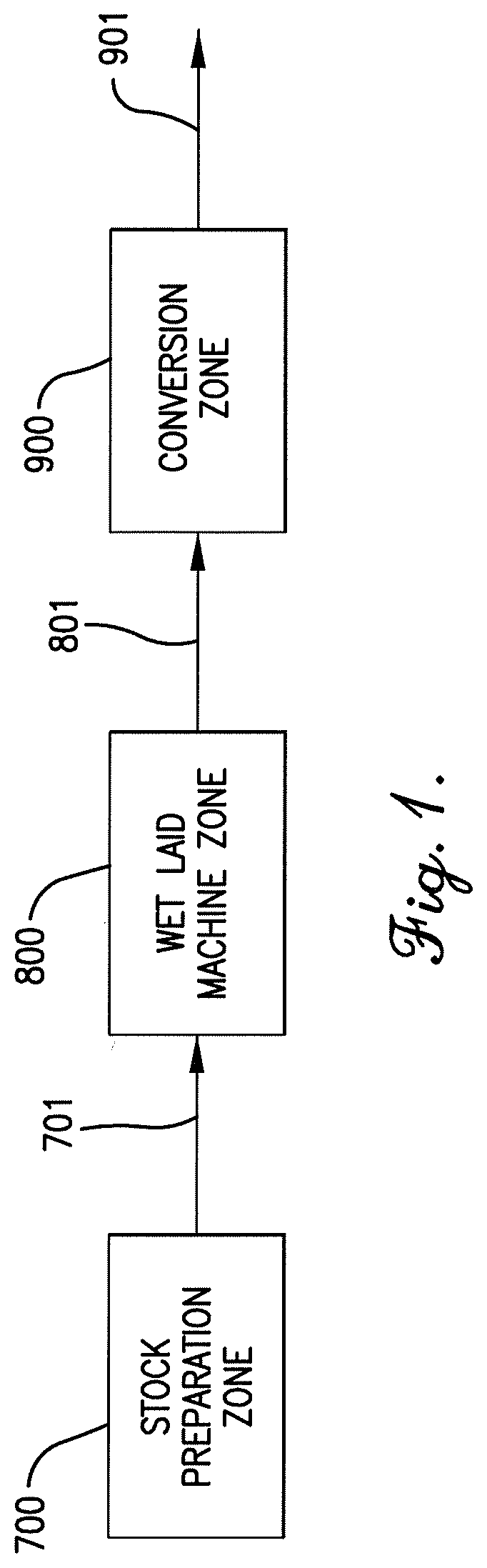

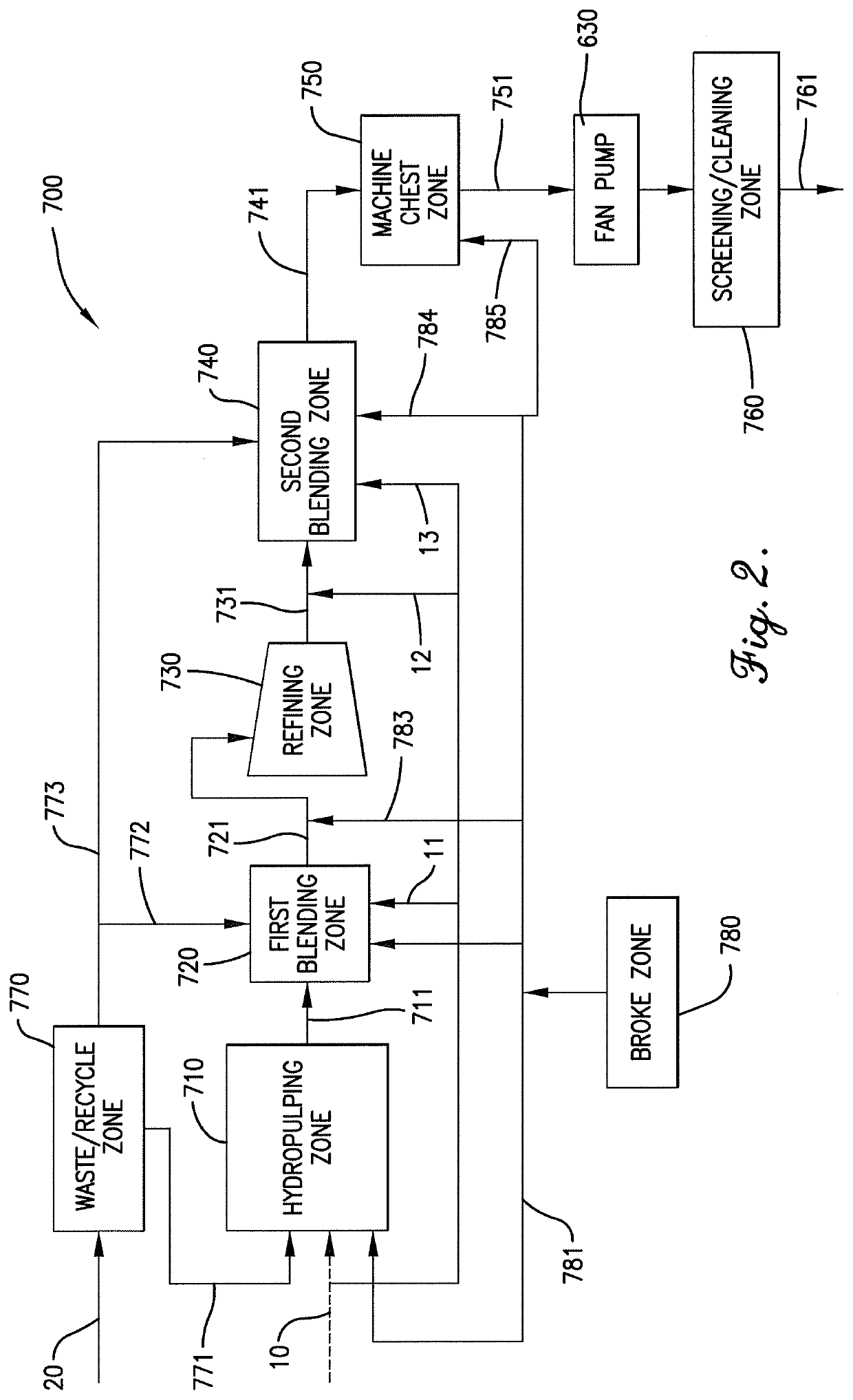

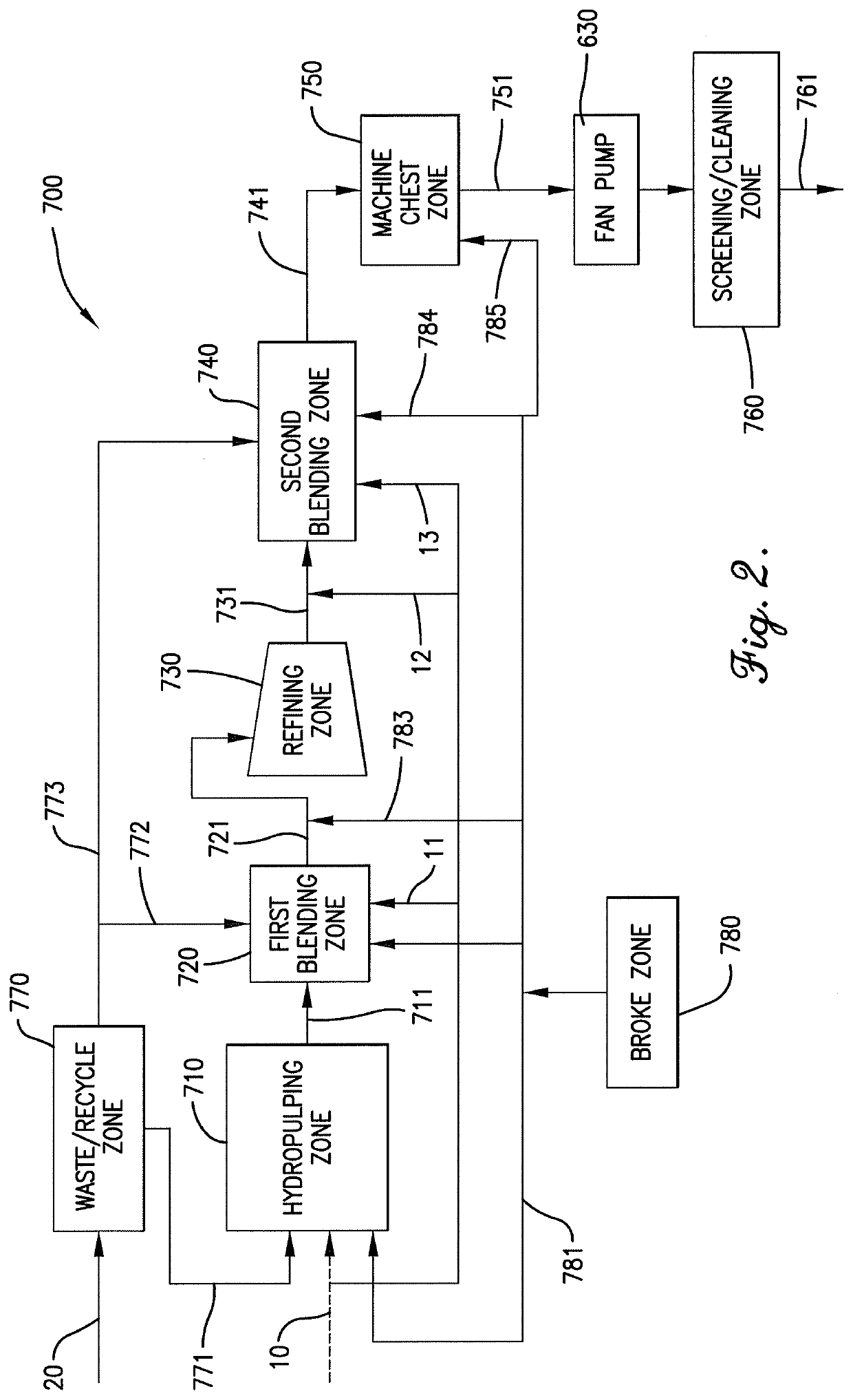

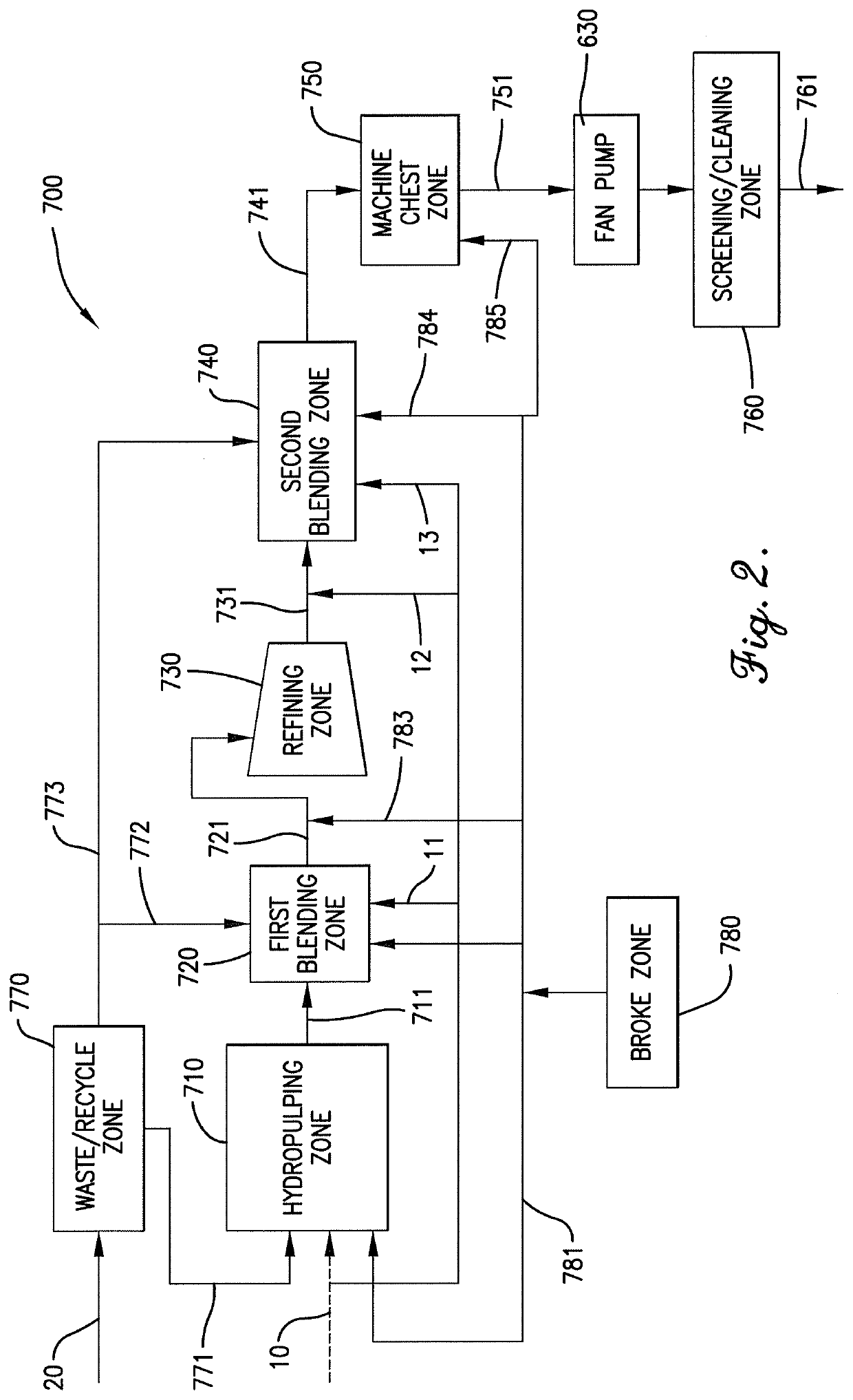

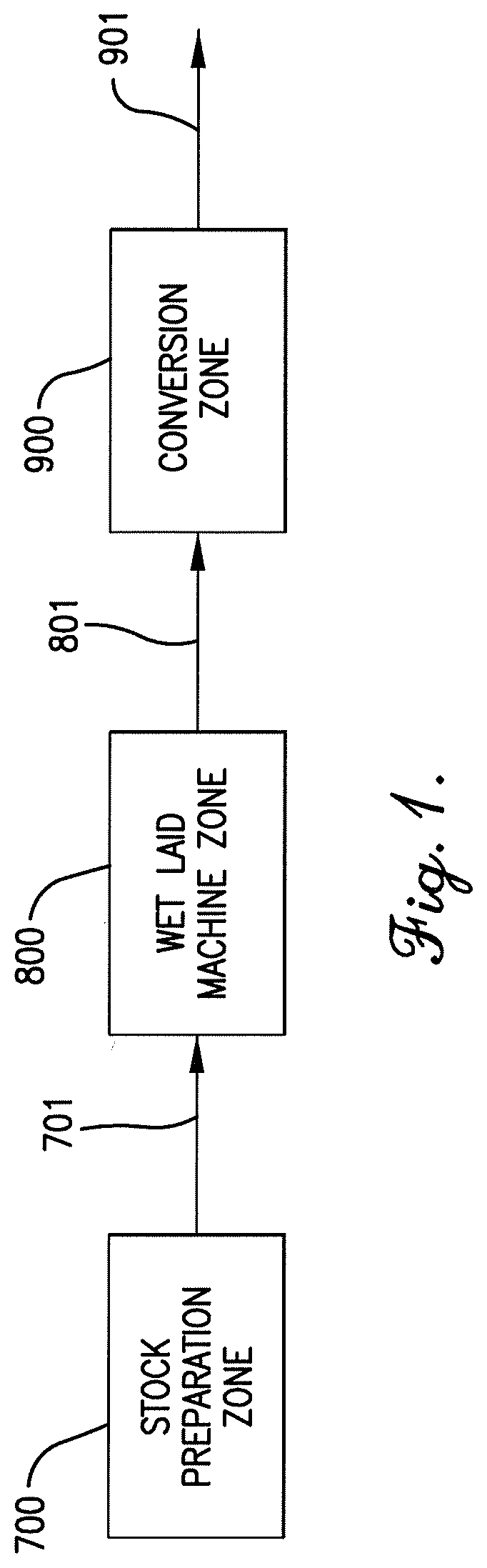

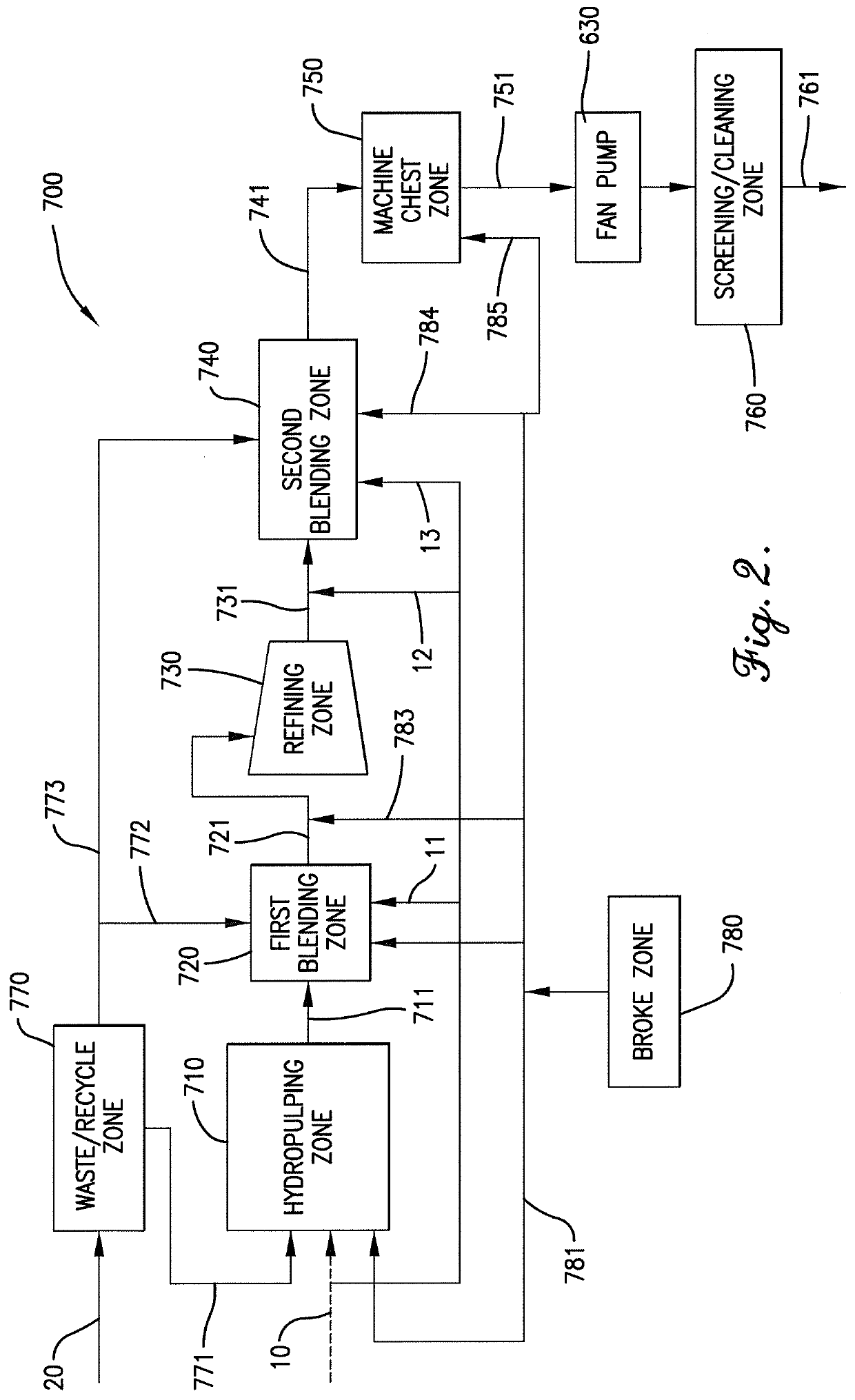

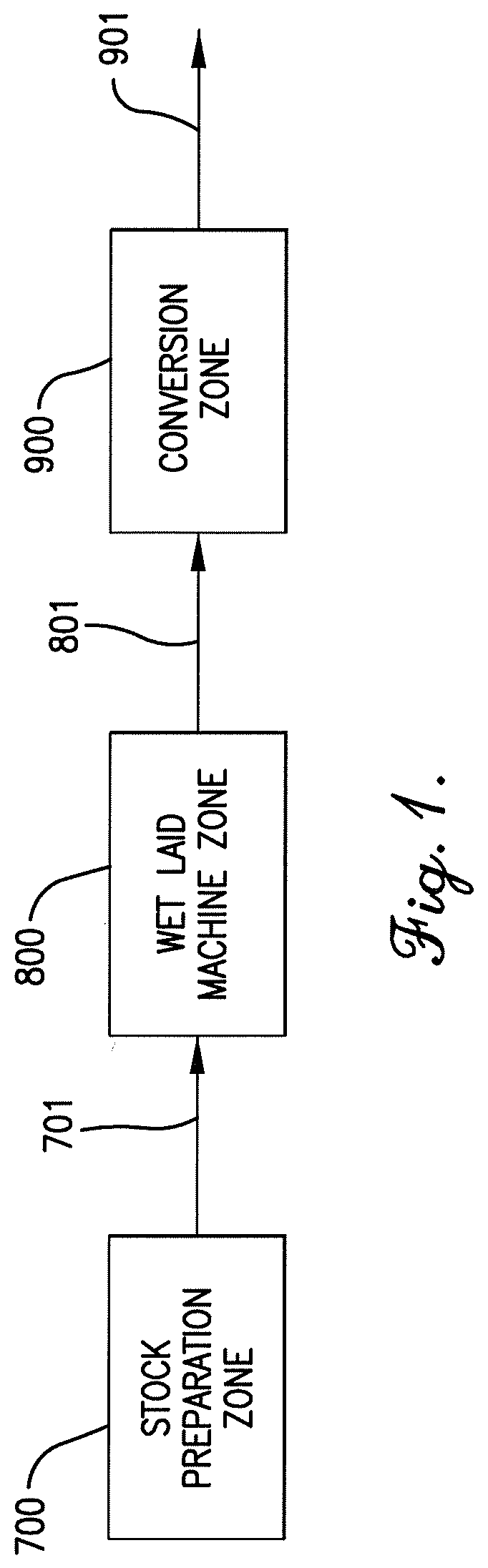

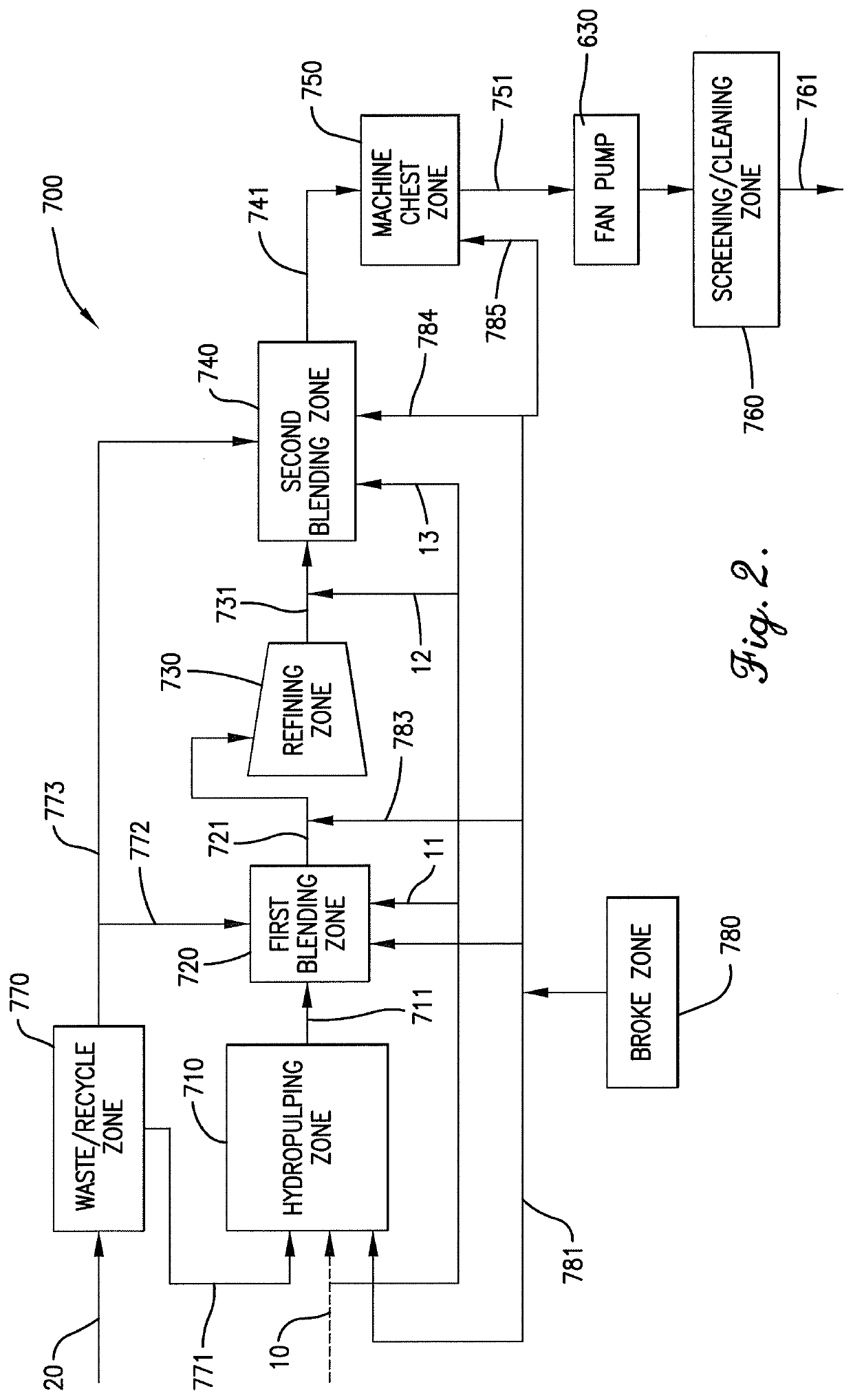

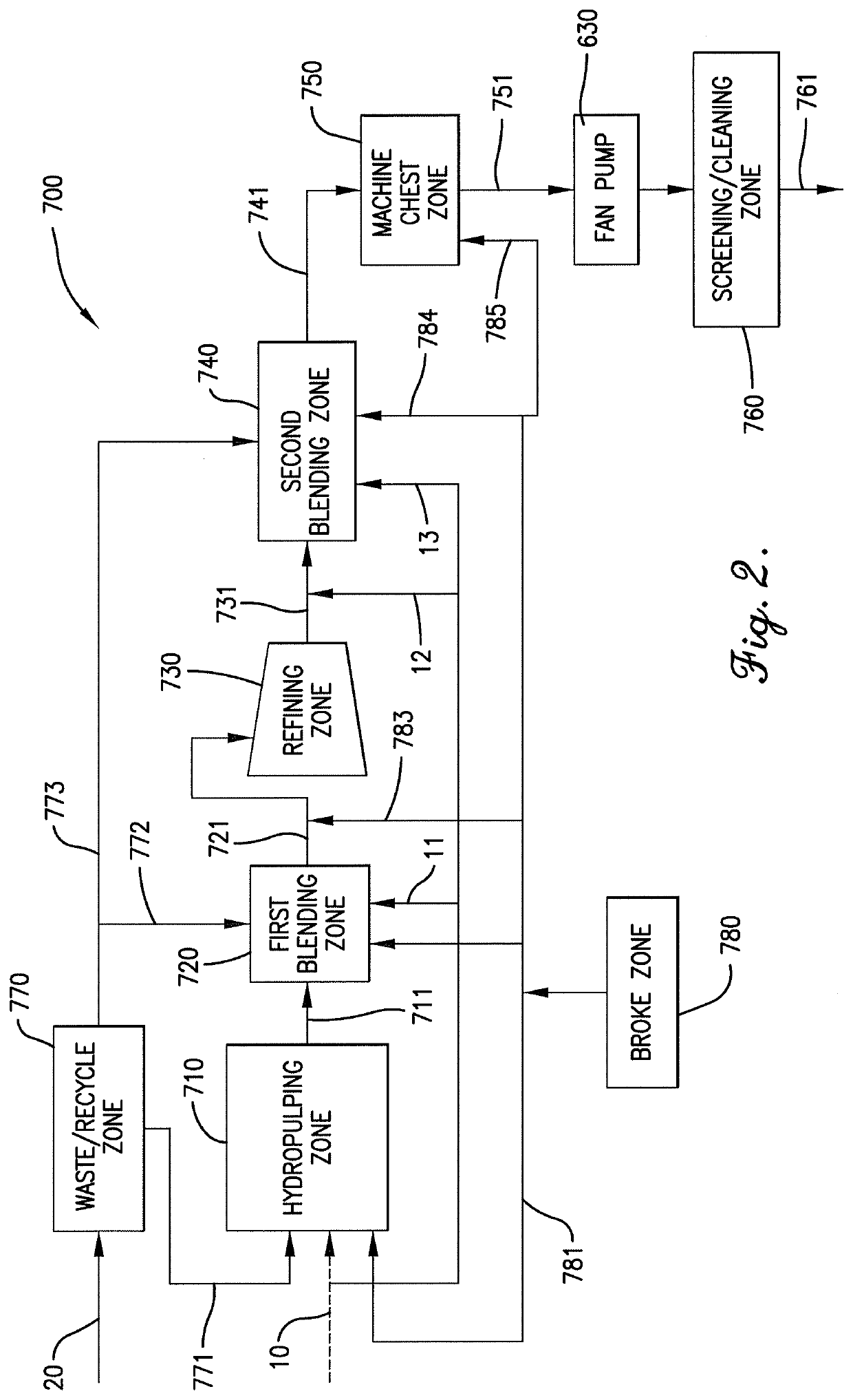

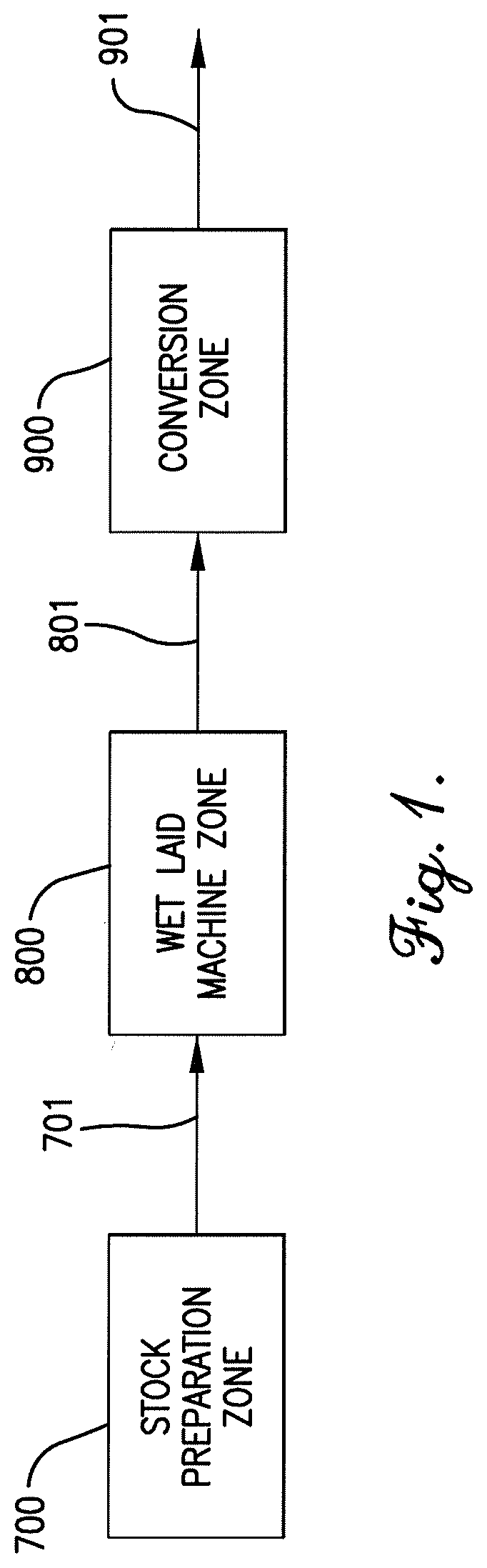

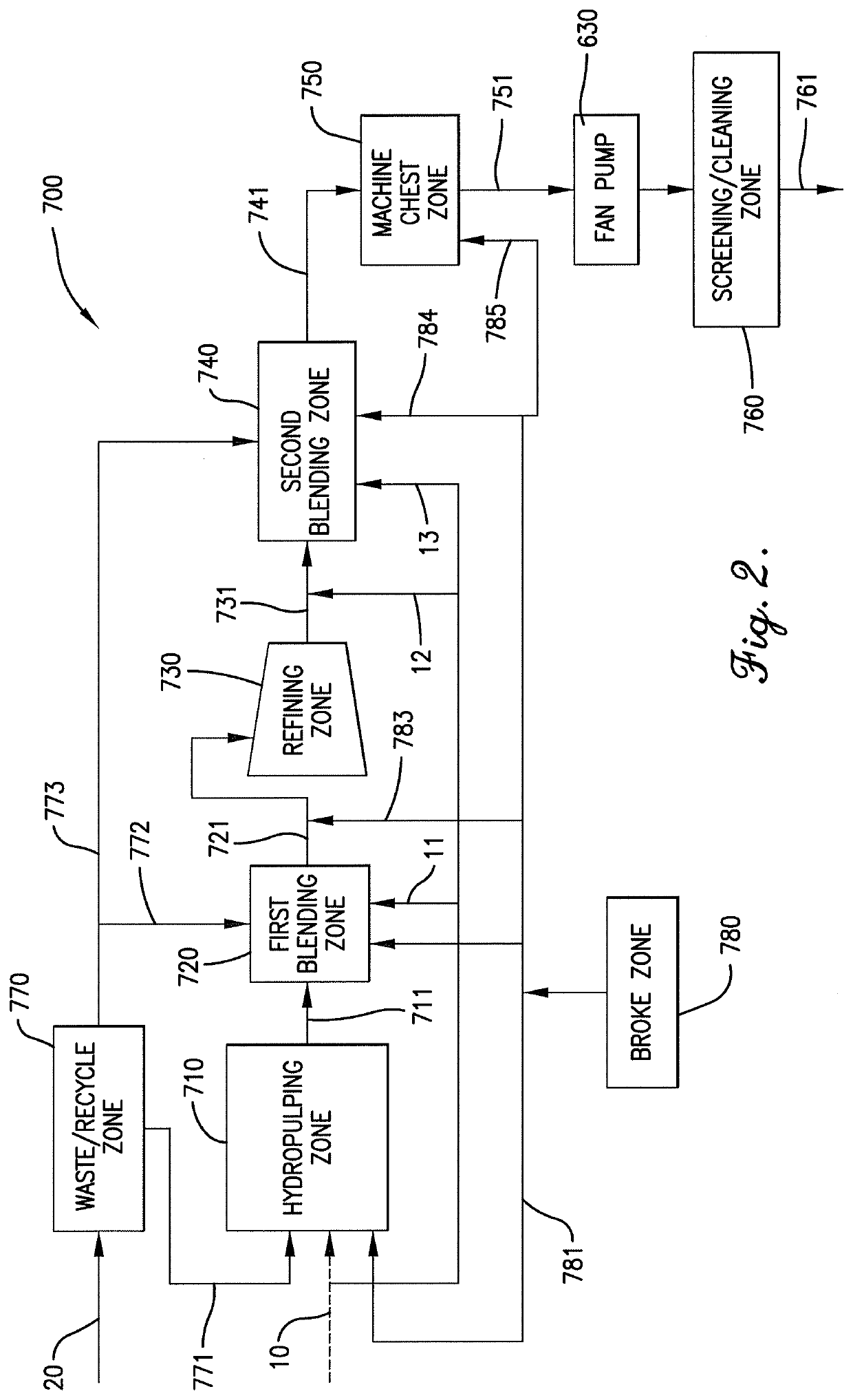

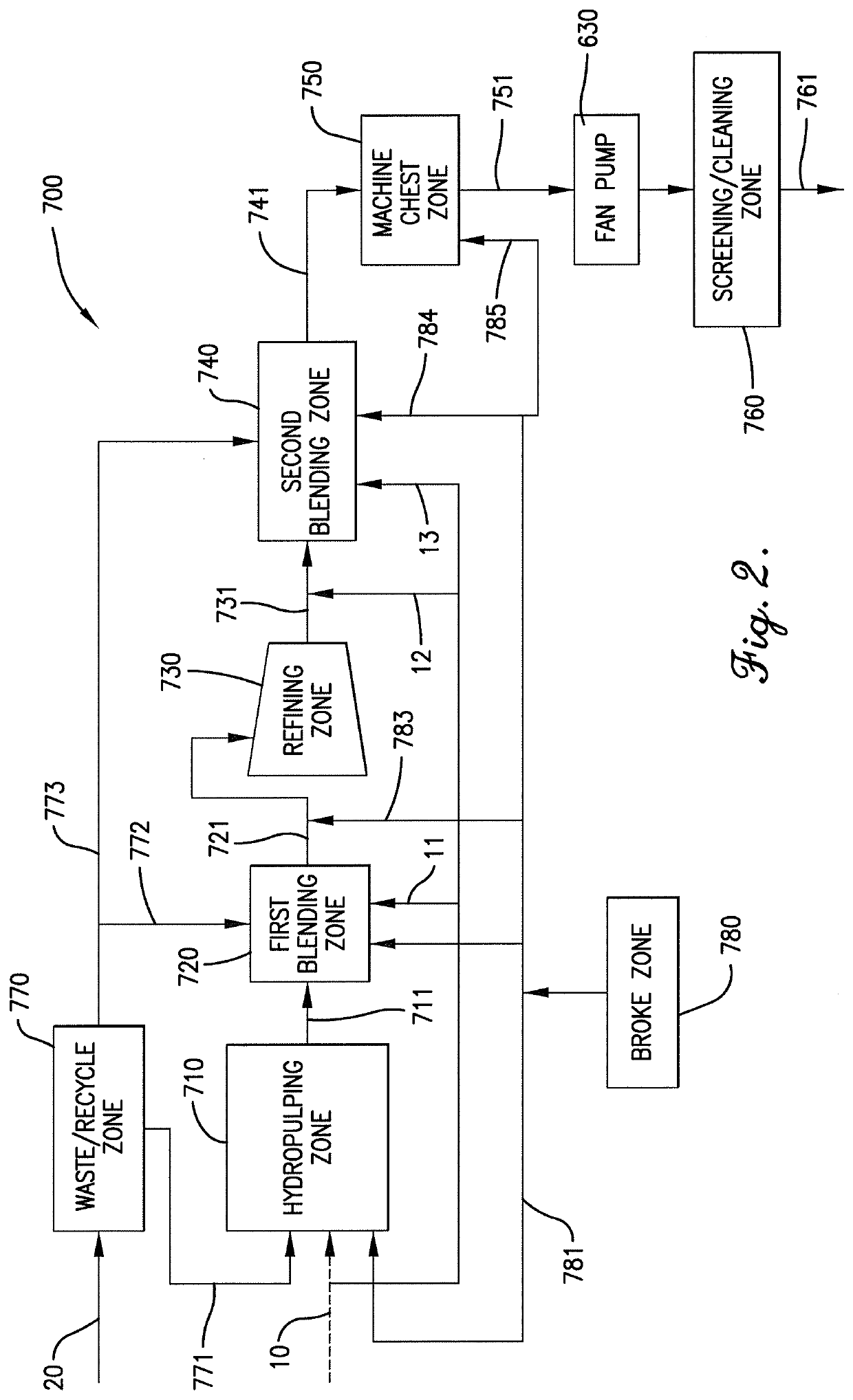

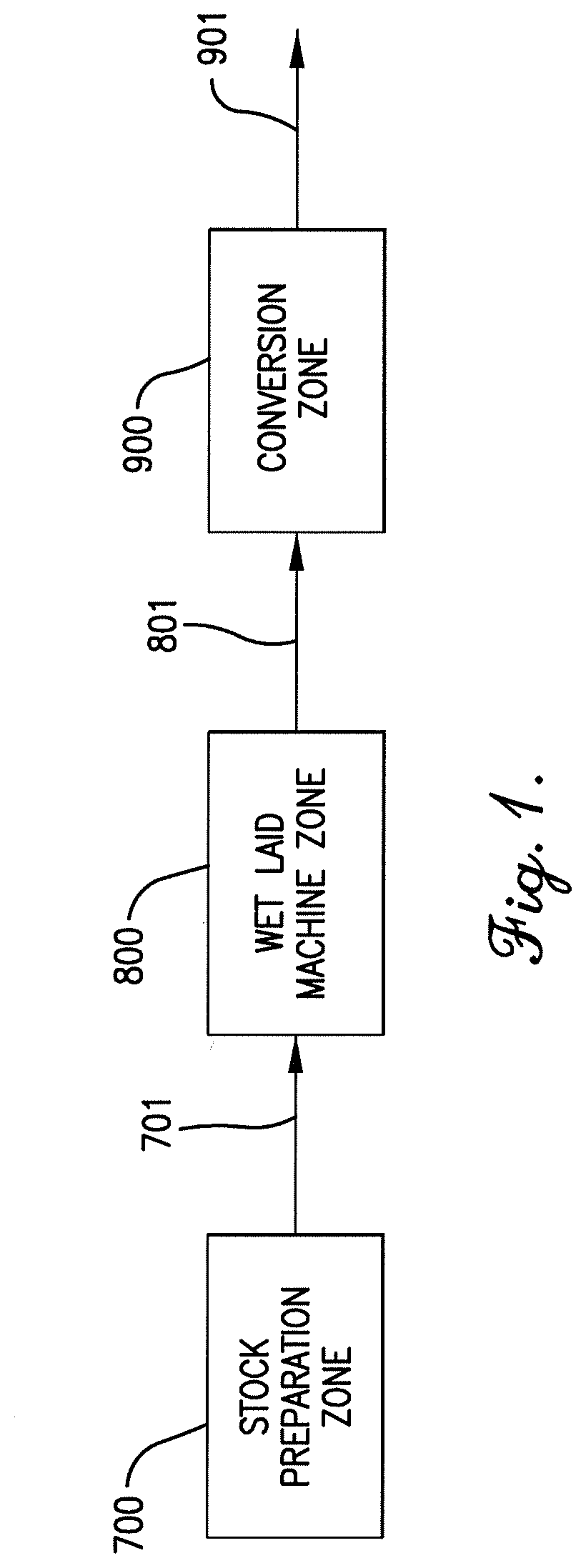

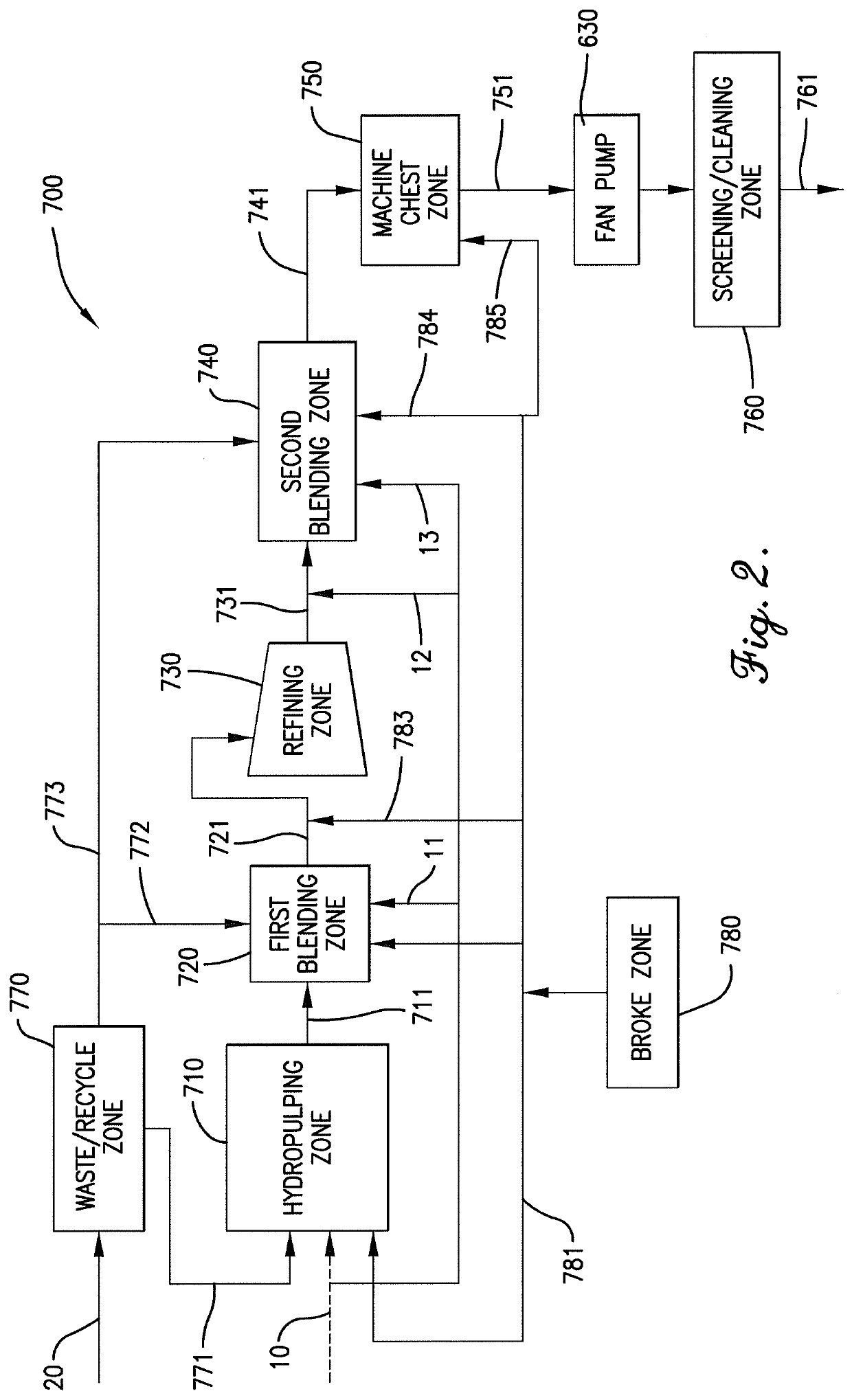

Composition of matter in a post-refiner blend zone

ActiveUS20200063358A1Reduce consistencyLow variabilityWater-repelling agents additionReinforcing agents additionPolymer scienceCellulose fiber

After cellulose fibers and cellulose ester fibers are co-refined, they are fed to a blend tank continuously feeds a wet laid process. The composition in the blend tank includes co-refined cellulose fibers and cellulose ester fibers and one or more additives, and the cellulose ester fibers have a denier per filament (DPF) of less than 3, a cut length of less than 6 mm, crimped, or non-round with a DPF of less than 3.

Owner:EASTMAN CHEM CO

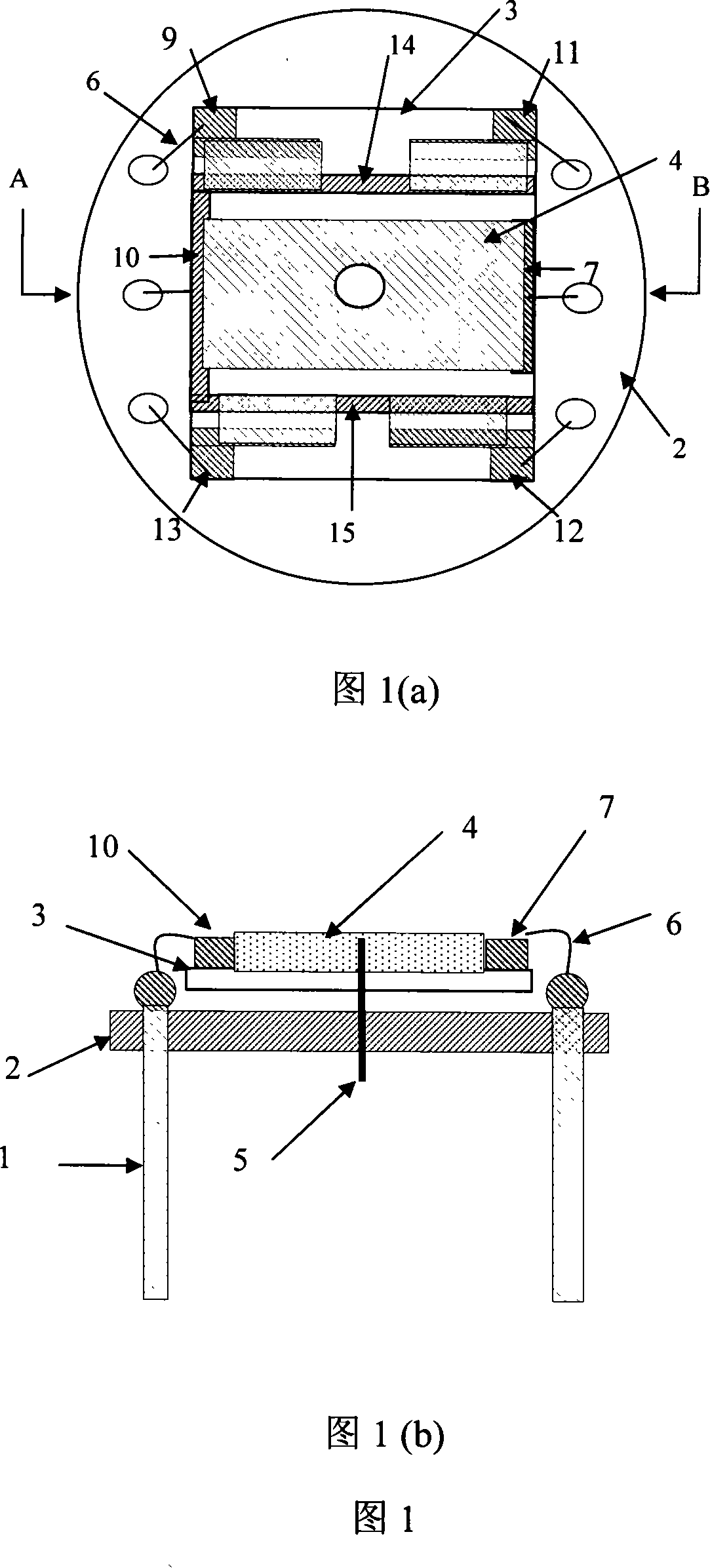

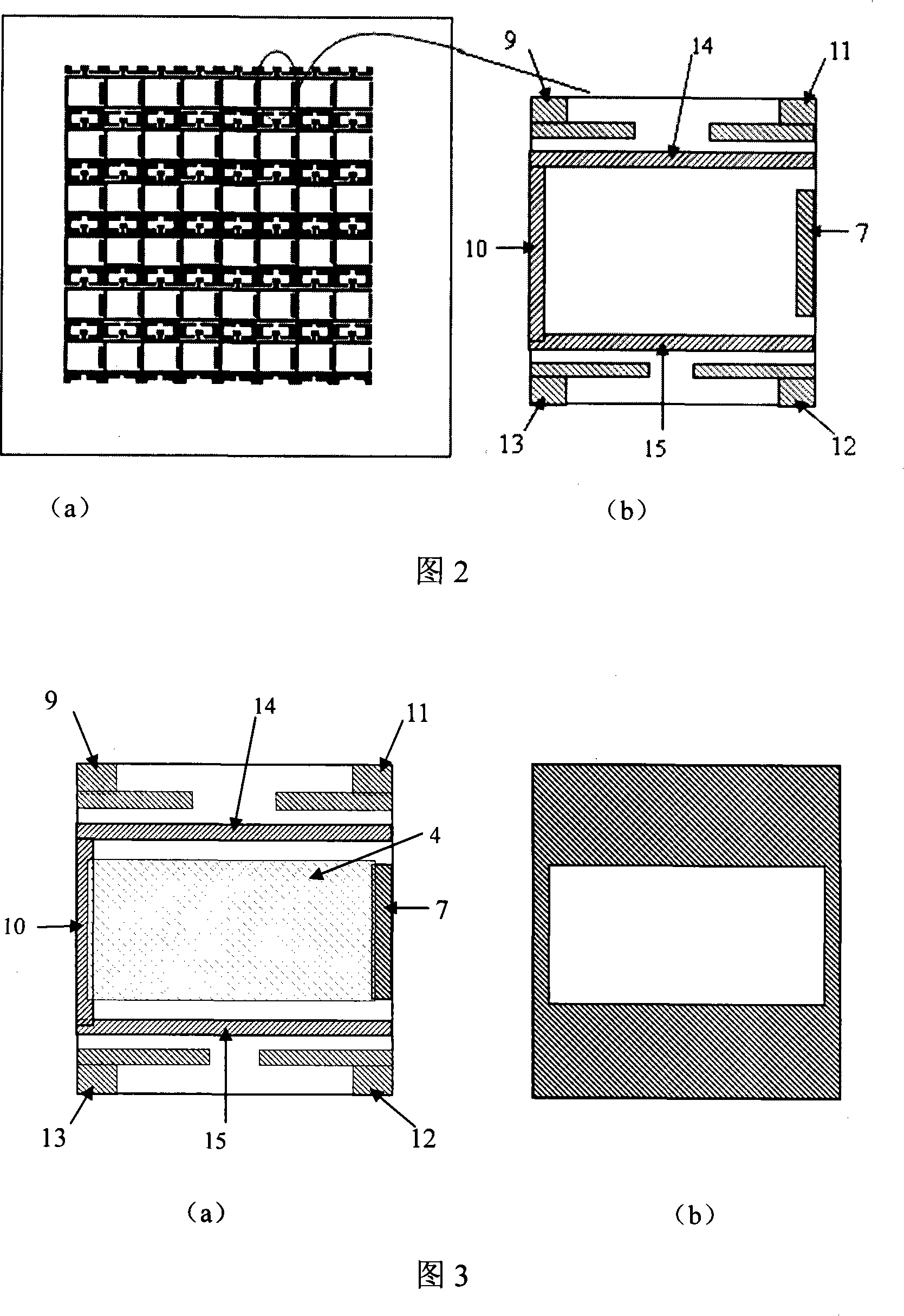

Gas sensitization array sensor and its manufacture method

InactiveCN101149354AOvercome deficienciesReduce power consumptionMaterial resistanceHeat conductingConductive materials

The invention discloses a kind of array sensor for gas and the preparing method. The sensor uses the aurum, platinum or argentum as electrode; the RuO2, MoSi2, W or Pt is as heating membrane material; the random one or several kinds of the ZnO, SnO2 or Fe2O, or ZnO, SnO2 or Fe2O3 and Pt0.1wt%-3wt%, Pd0.1wt%-3wt%, Ni1wt%-30wt%, TiO21wt%-30wt%, WO31wt%-40wt%, Co2O3 1wt%-15wt%, V2O51wt%-30wt%, Al2O31wt%-20wt%, MnO21wt%-30wt% is as the sensing layer material. It gets the gas sensing array on the alumina, aluminium nitride or silicon base sheet with anti high temperature, electric insulating and heat conducting by the screen printing technology. The gas sensing array is fixed on the basal seat by the axis to form the gas sensing array sensor by ultrasonic hot press welding electrode leg wire. The sensor has the low production cost, low power cost, good mechanism stability. Each unit has the good gas sensing character and the process is proper for the big batch production.

Owner:HUAZHONG UNIV OF SCI & TECH

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Compostable wet-laid articles comprising cellulose and cellulose esters

InactiveUS20200063365A1Reduce consistencyLow variabilityFlexible coversWrappersPolymer scienceCellulose fiber

Wet laid products including packaging is obtained from co-refined cellulose fibers and synthetic fibers are made biodegradable, and can also be compostable and soil biodegradable. The synthetic fibers include staple cellulose ester fibers. Desirably, such staple cellulose ester fibers have a denier per filament of 3 or less, a cut length of 6 mm or less, are crimped, or are non-round and crimped, and have a degree of substitution of 2.5 or less.

Owner:EASTMAN CHEM CO

Paper bag

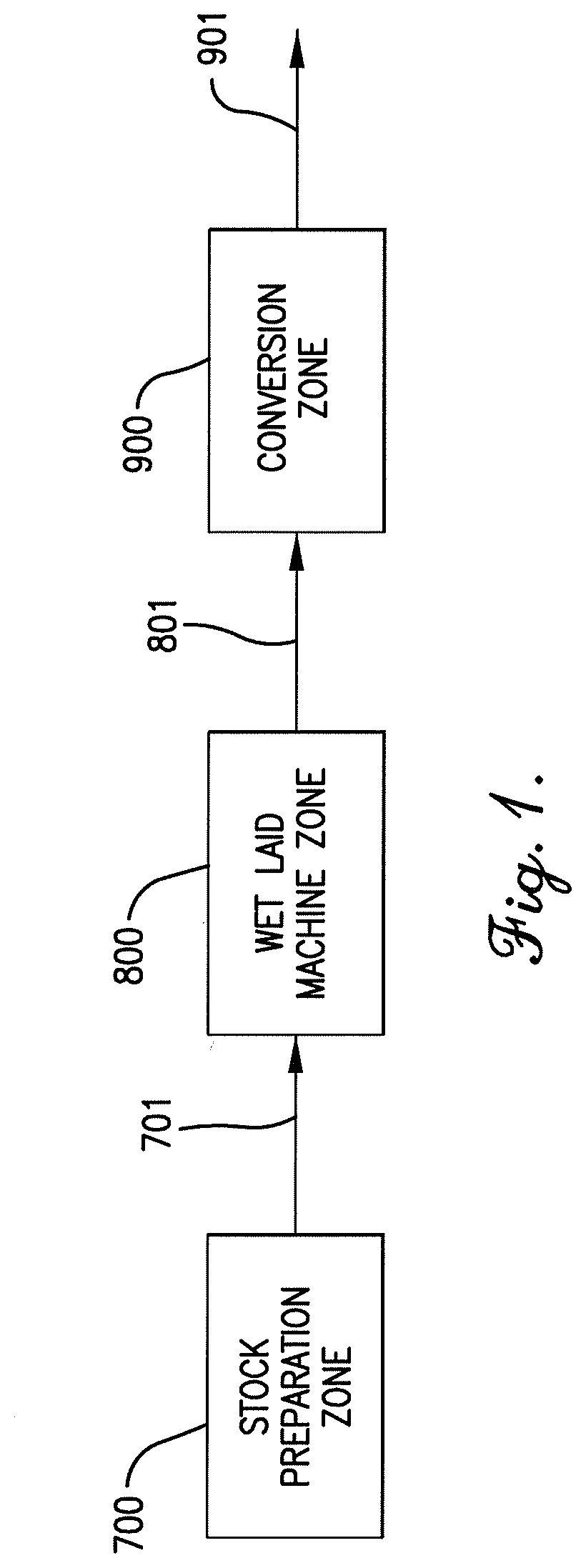

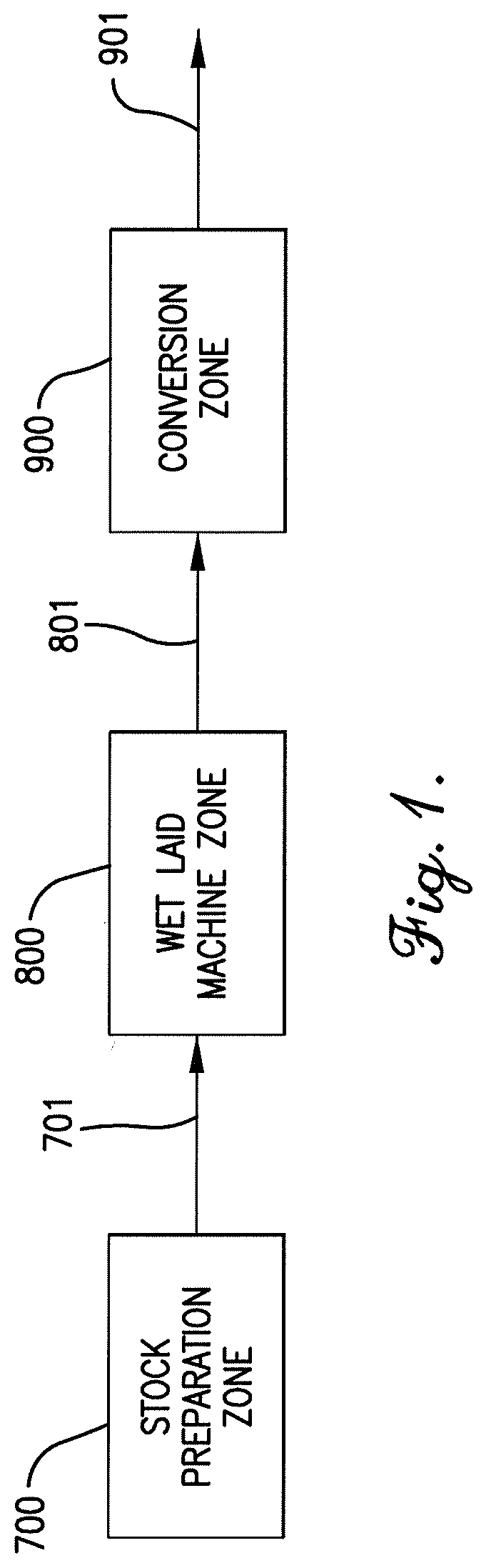

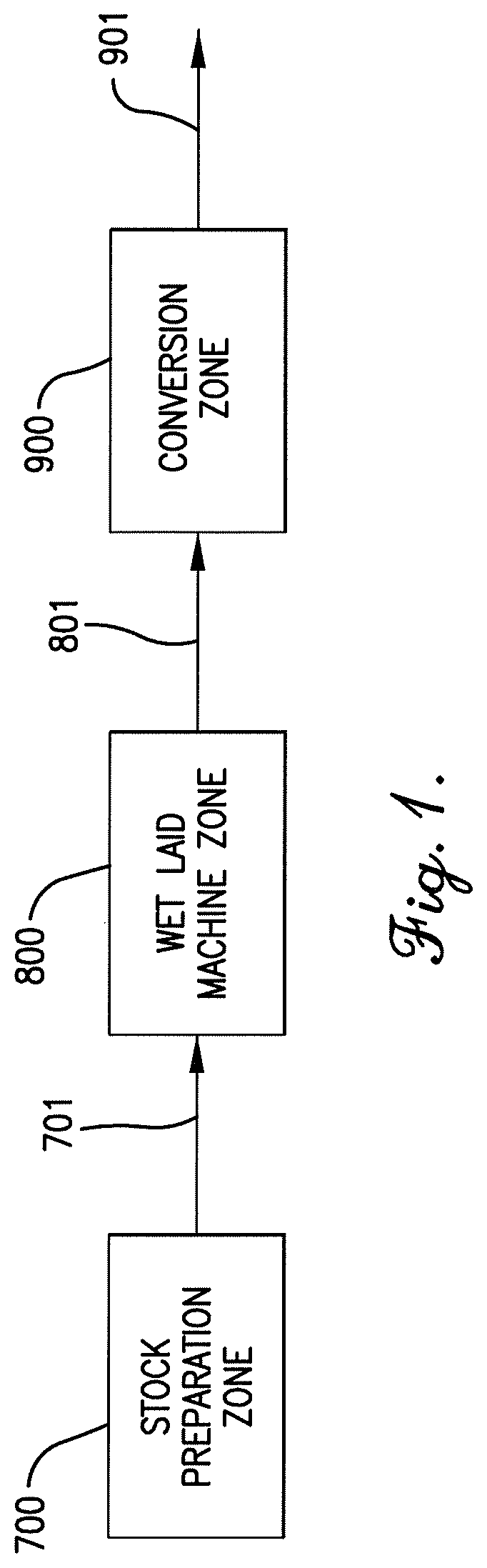

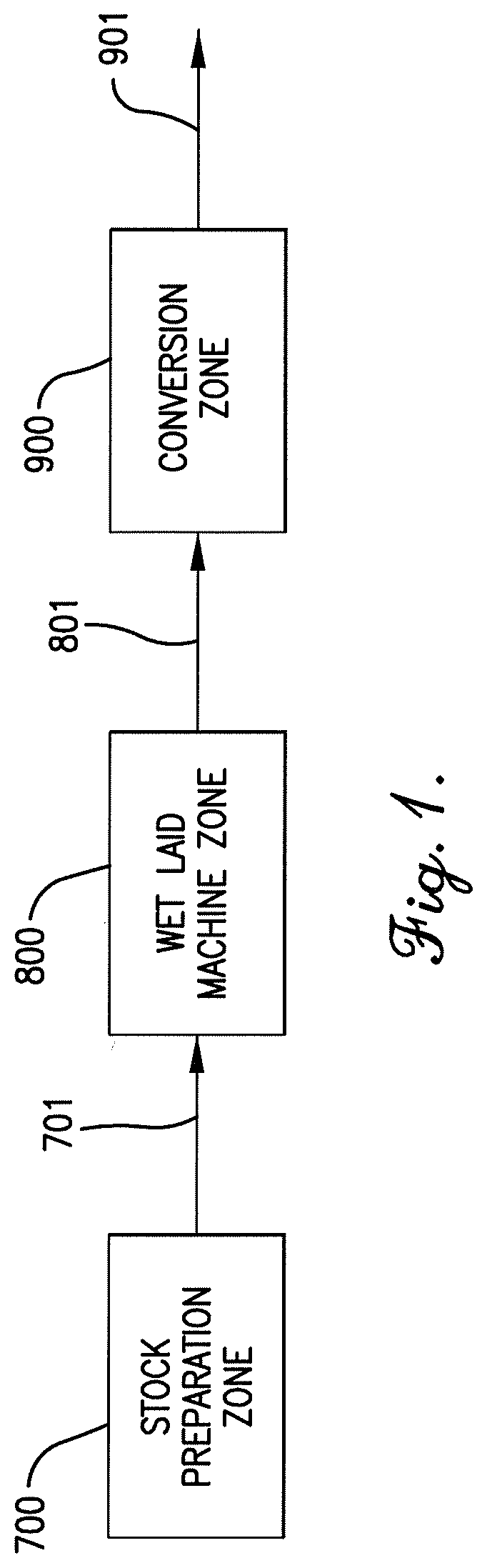

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. This invention also relates to a biodegradable bag.

Owner:EASTMAN CHEM CO

Elongated tubular articles from wet-laid webs

ActiveUS20200063349A1Reduce consistencyLow variabilitySpecial paperWater-repelling agents additionPolymer scienceCellulose fiber

Embodiments of the present invention relate to elongated tubular members that include at least one layer comprising a cellulose ester. In some cases, the cellulose ester may be in the form of staple fibers. The layer may be formed via a wet-laid fiber web that may also include cellulose fibers. The elongated tubular members may be suitable for use with food and / or beverage items as, for example, drinking straws or other similar items.

Owner:EASTMAN CHEM CO

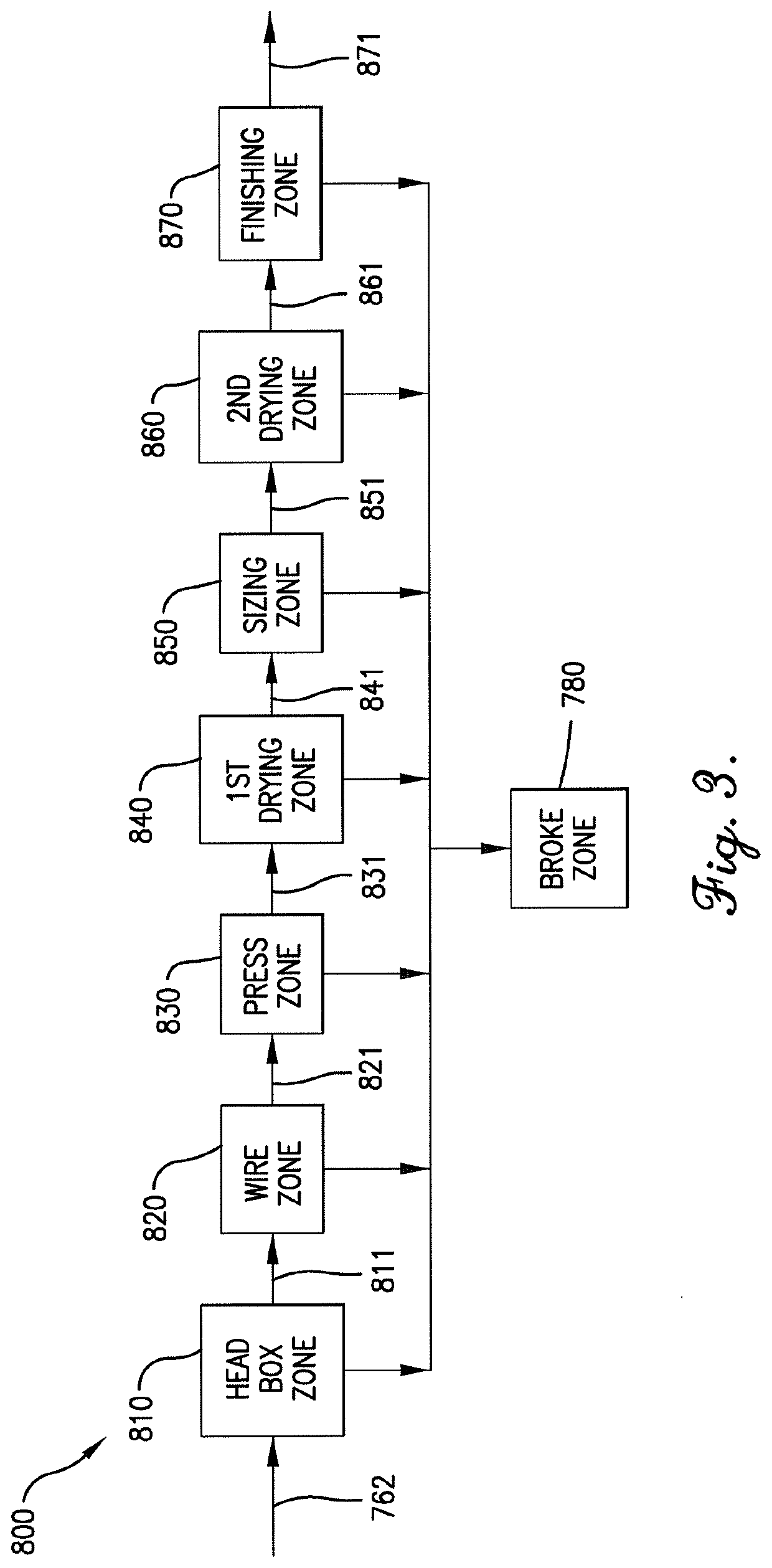

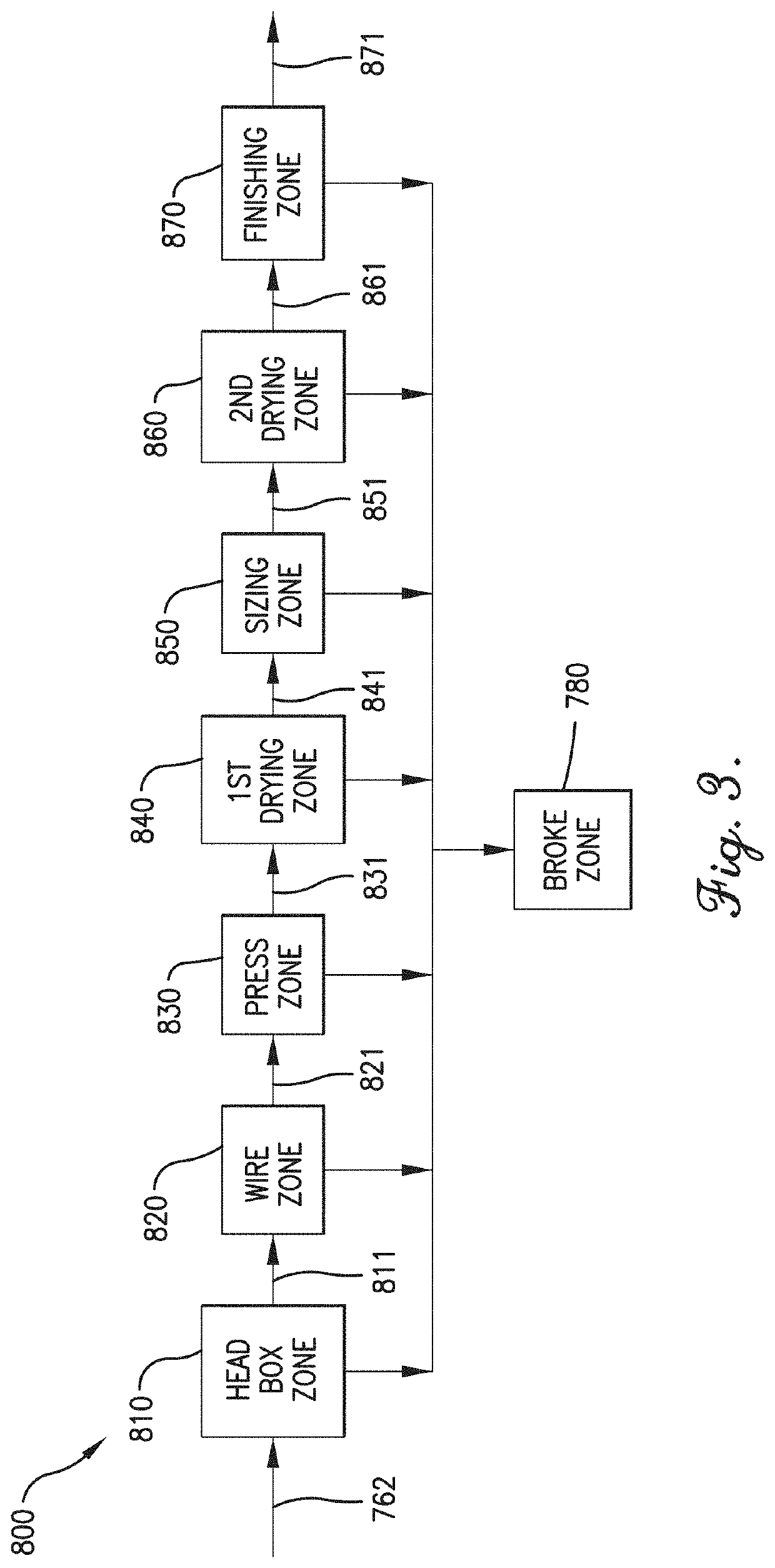

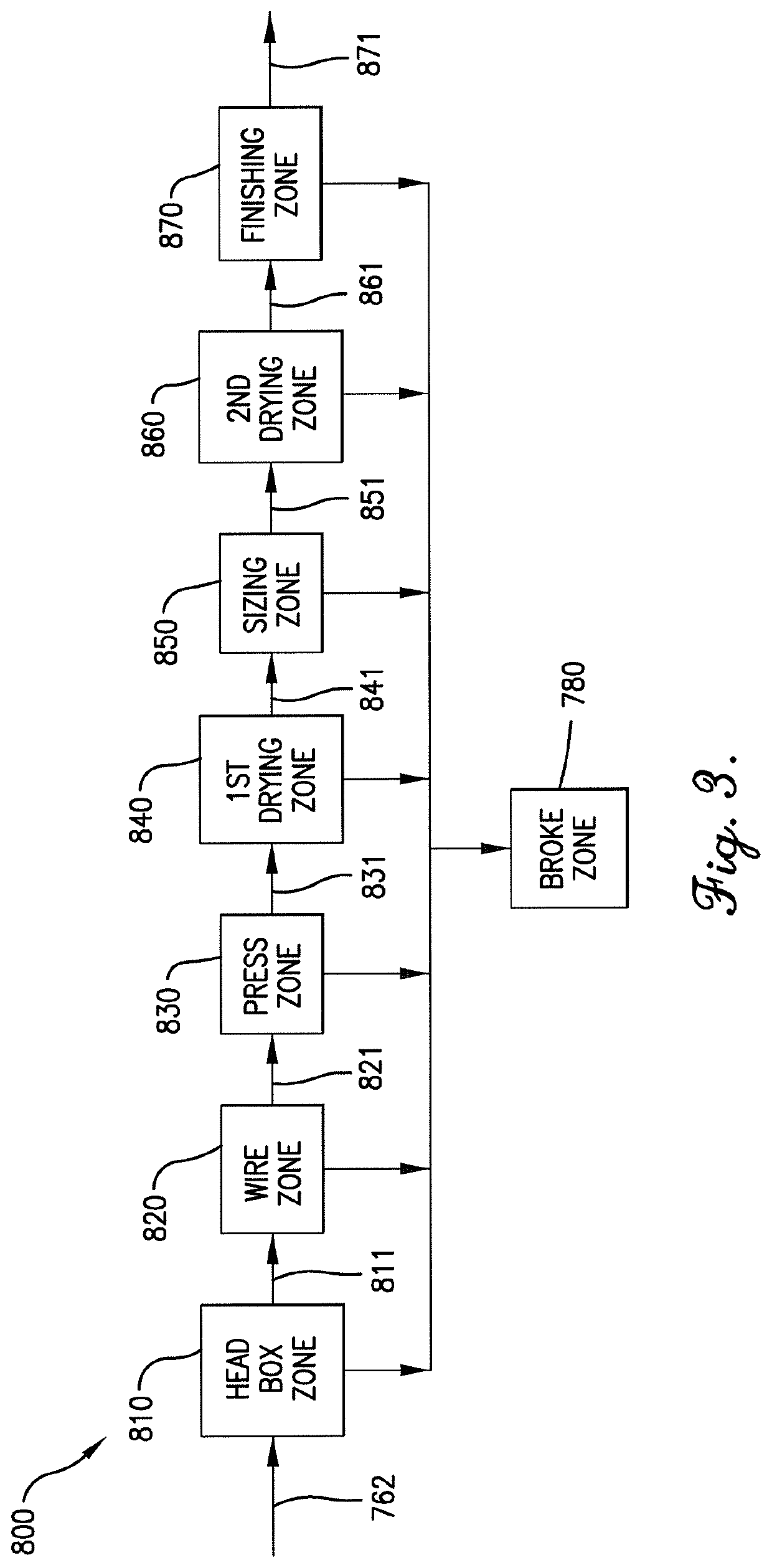

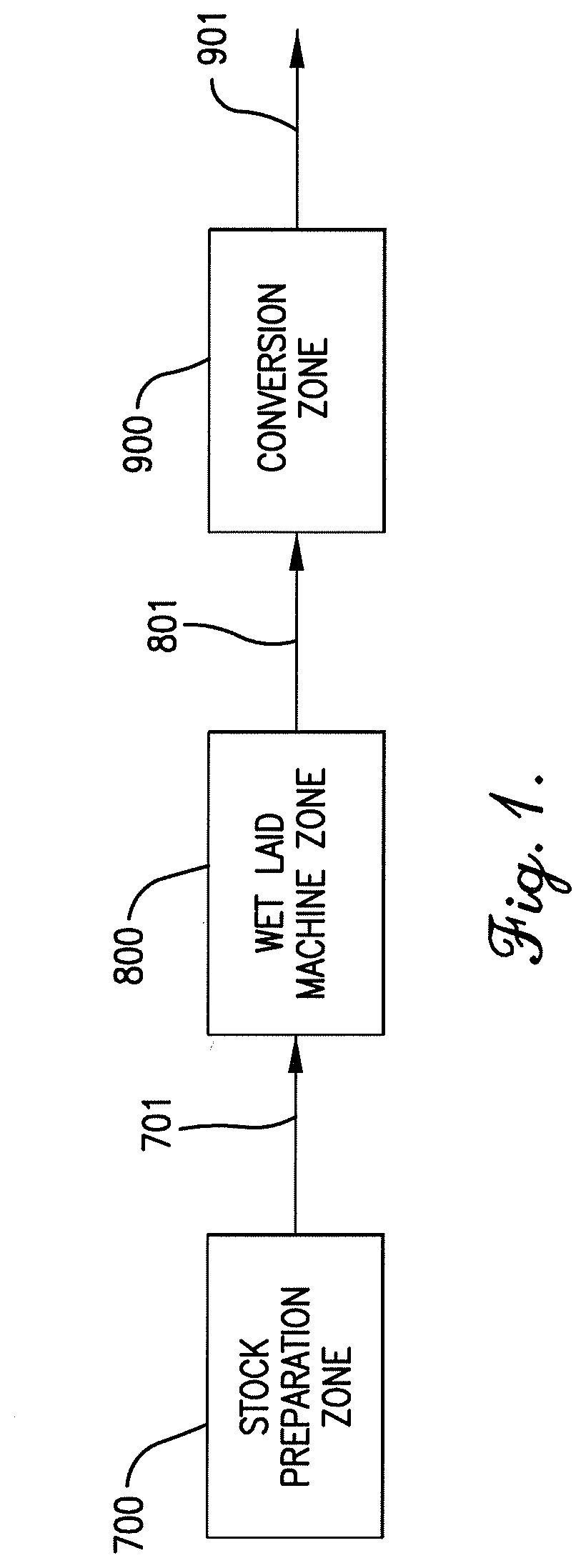

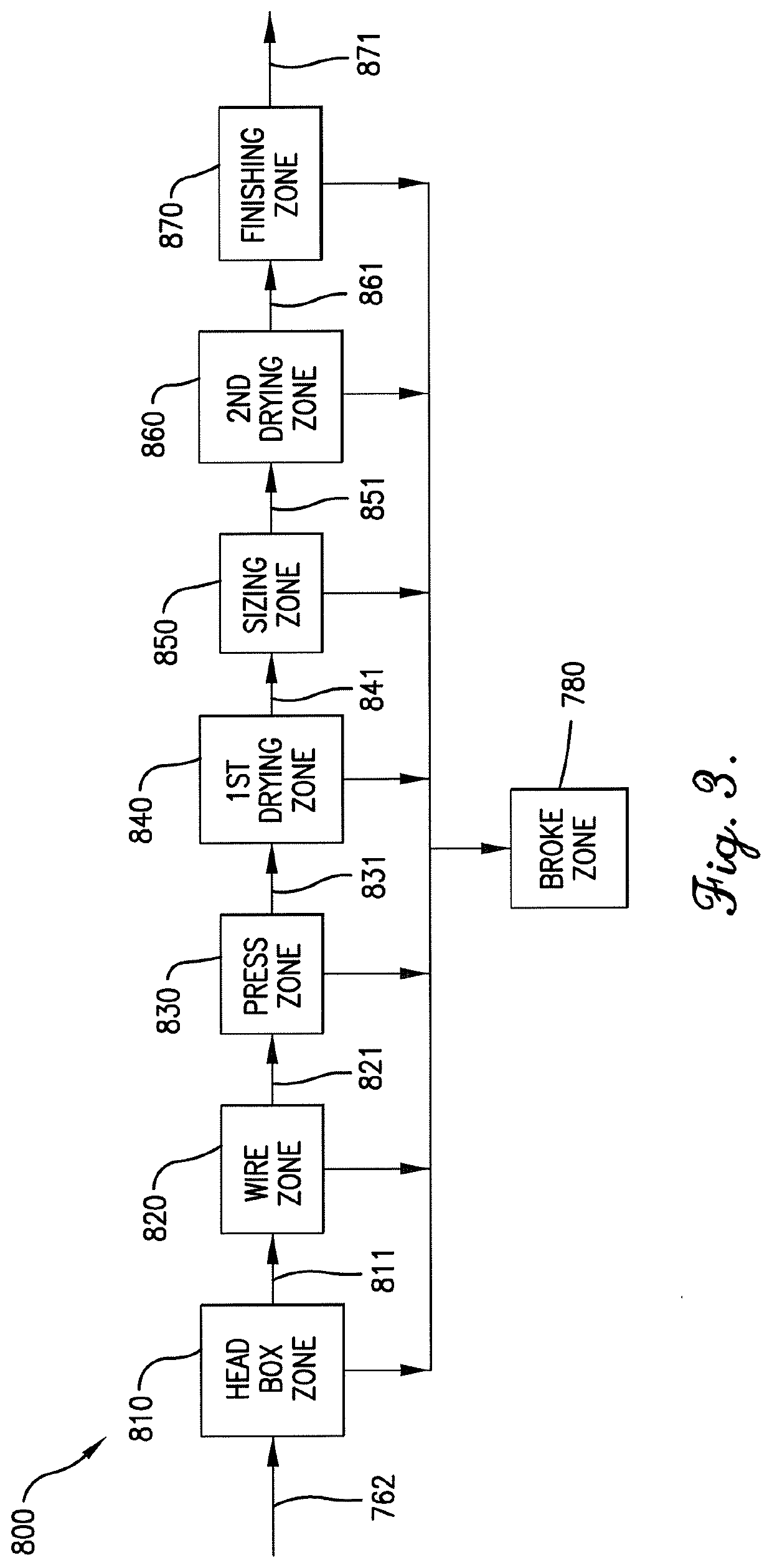

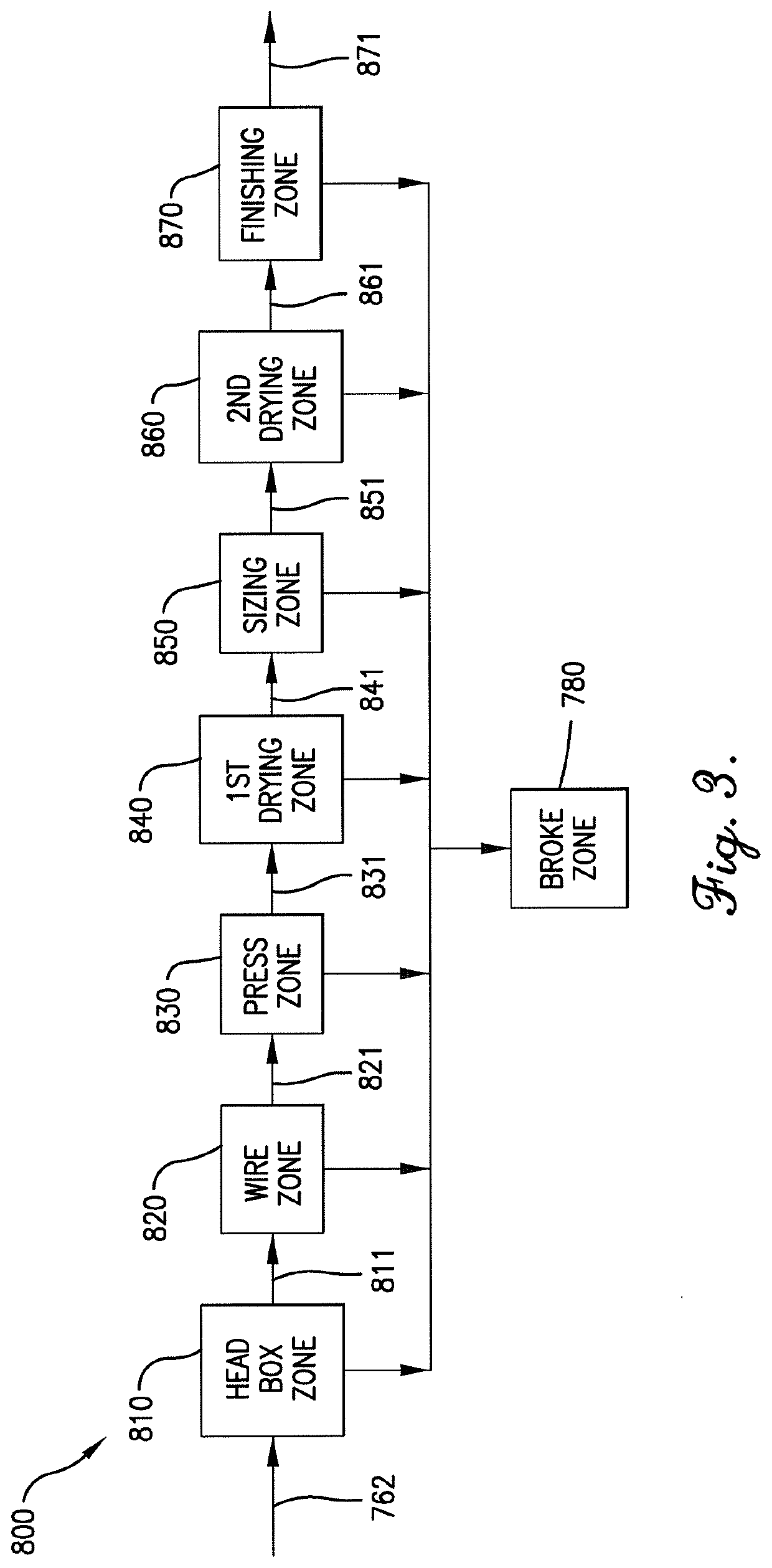

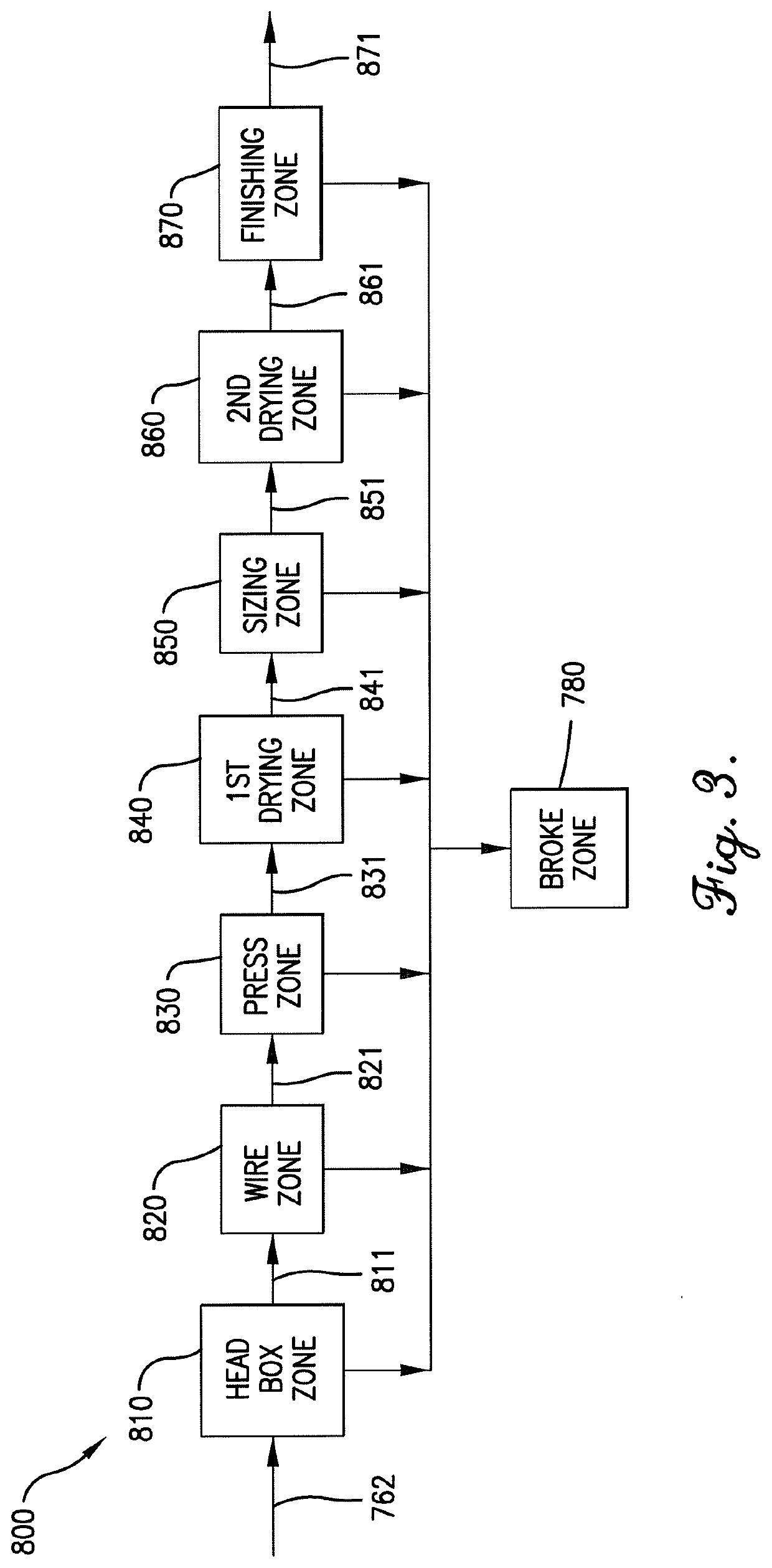

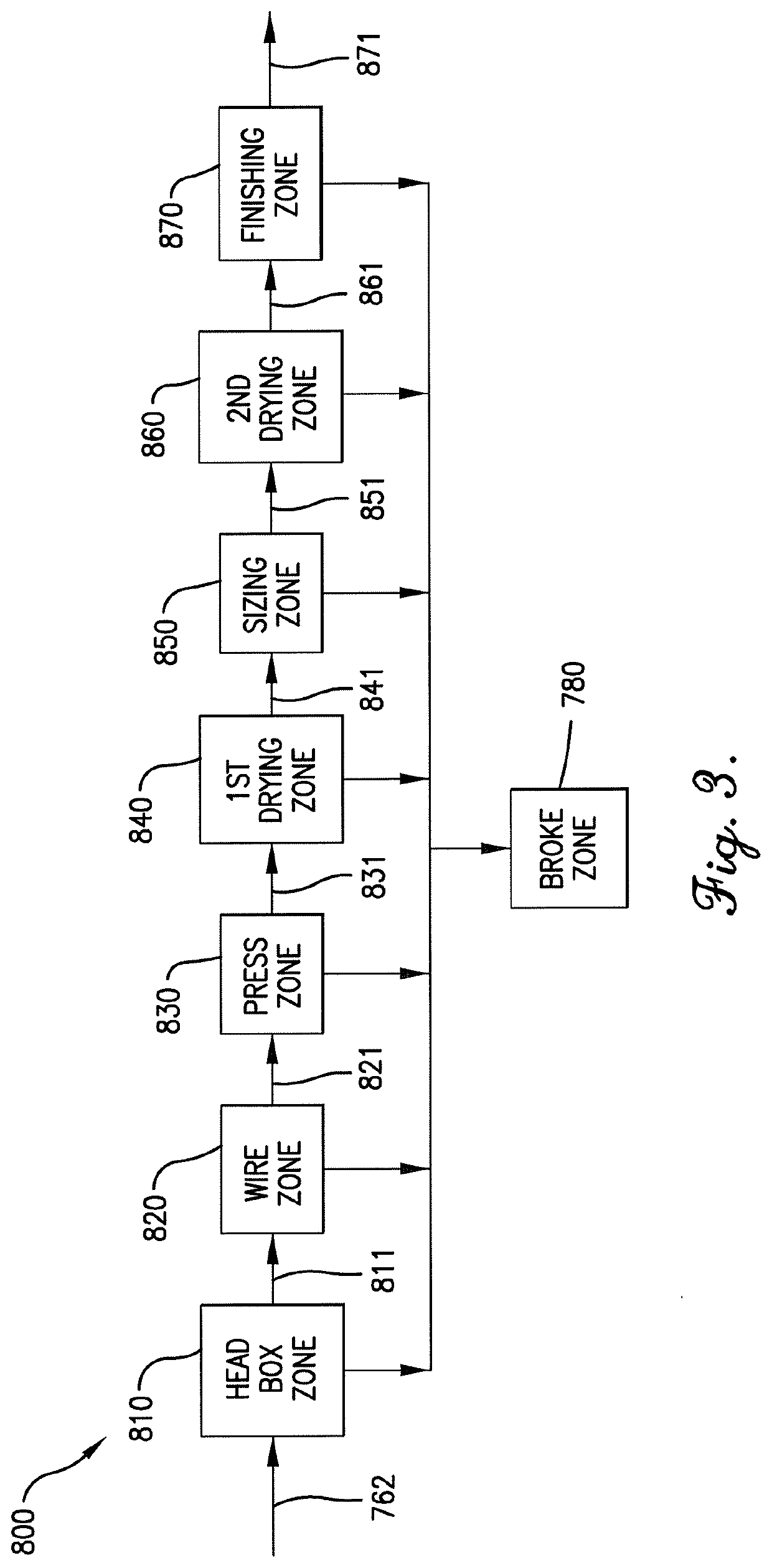

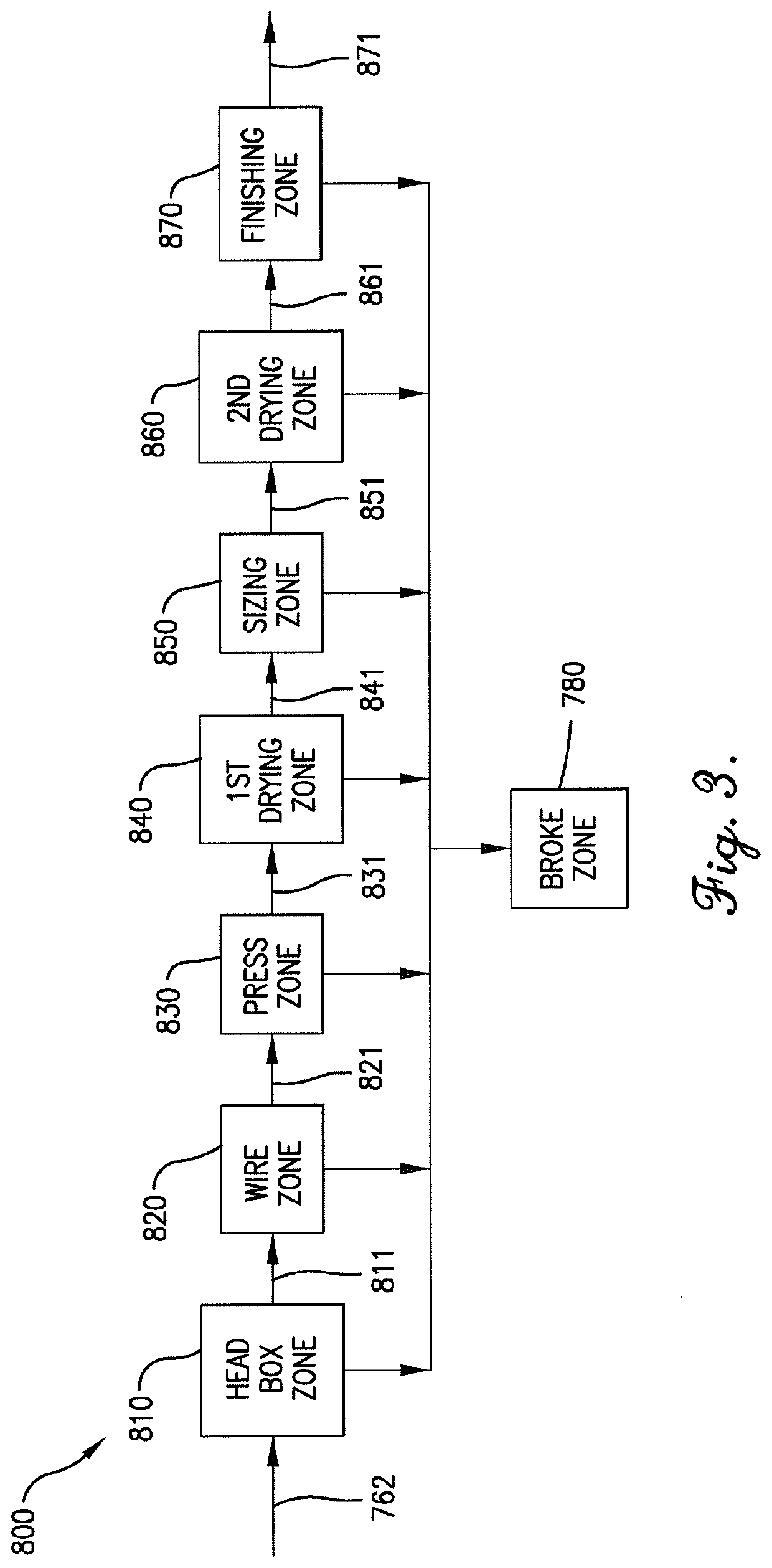

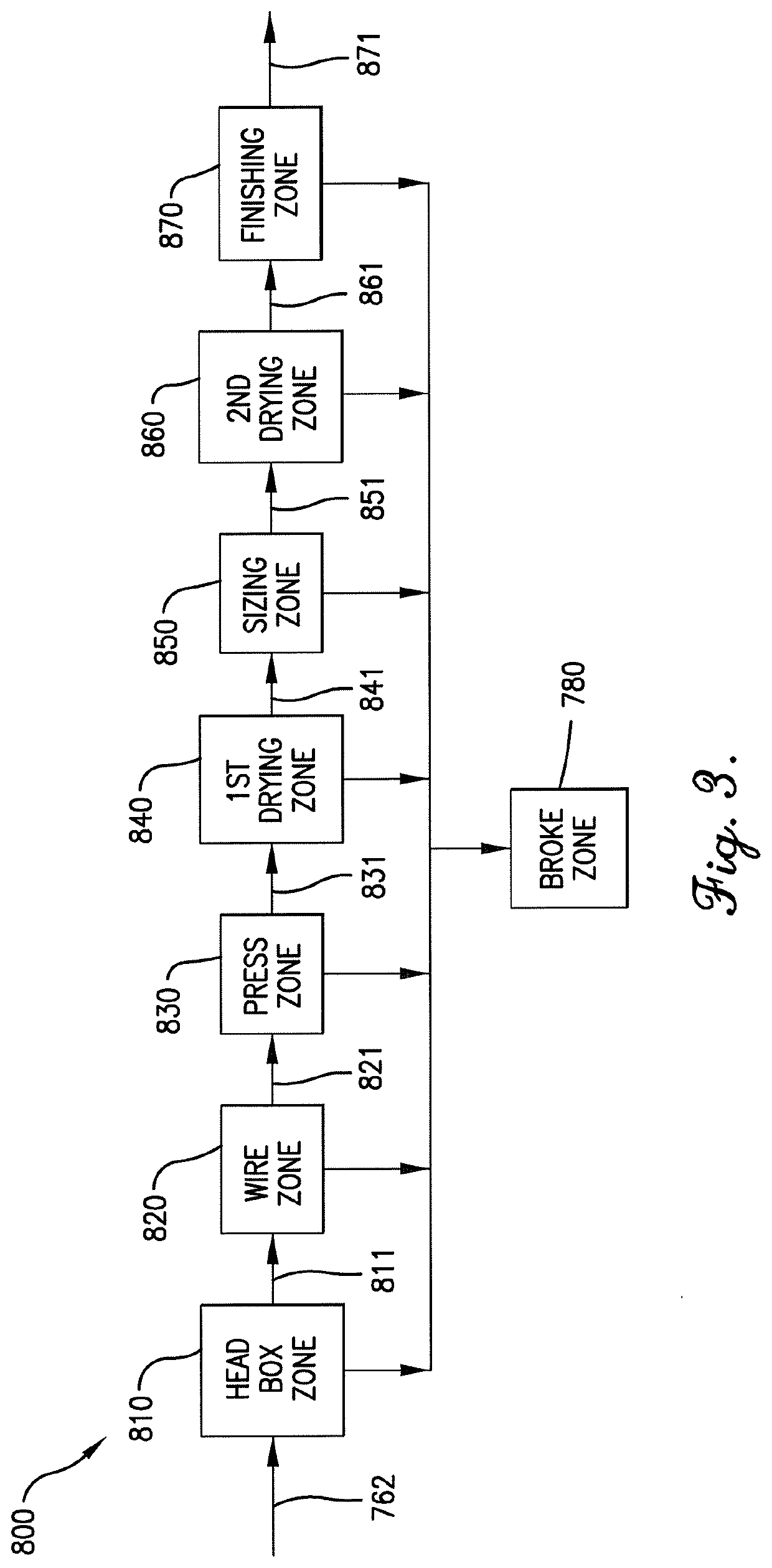

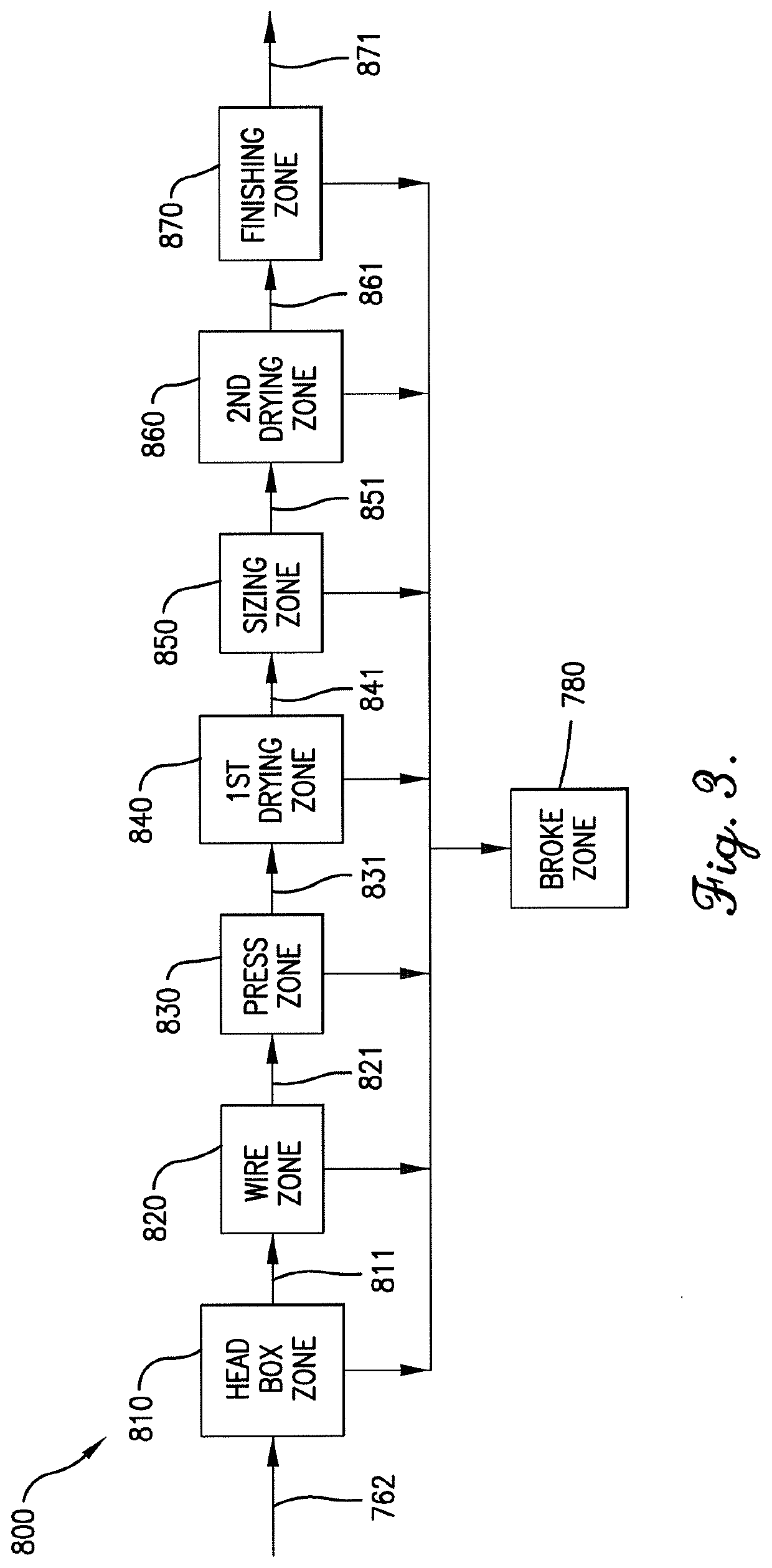

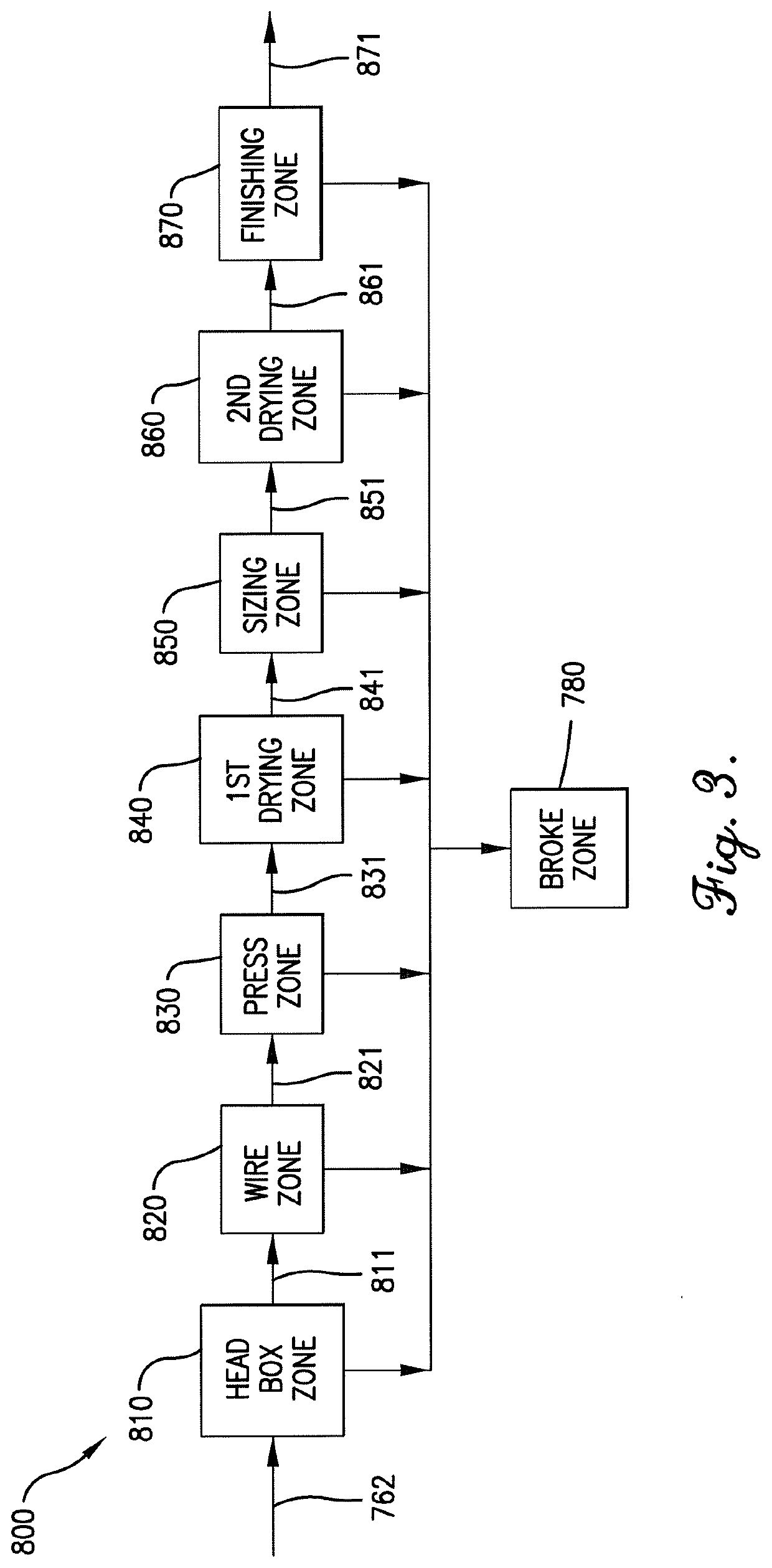

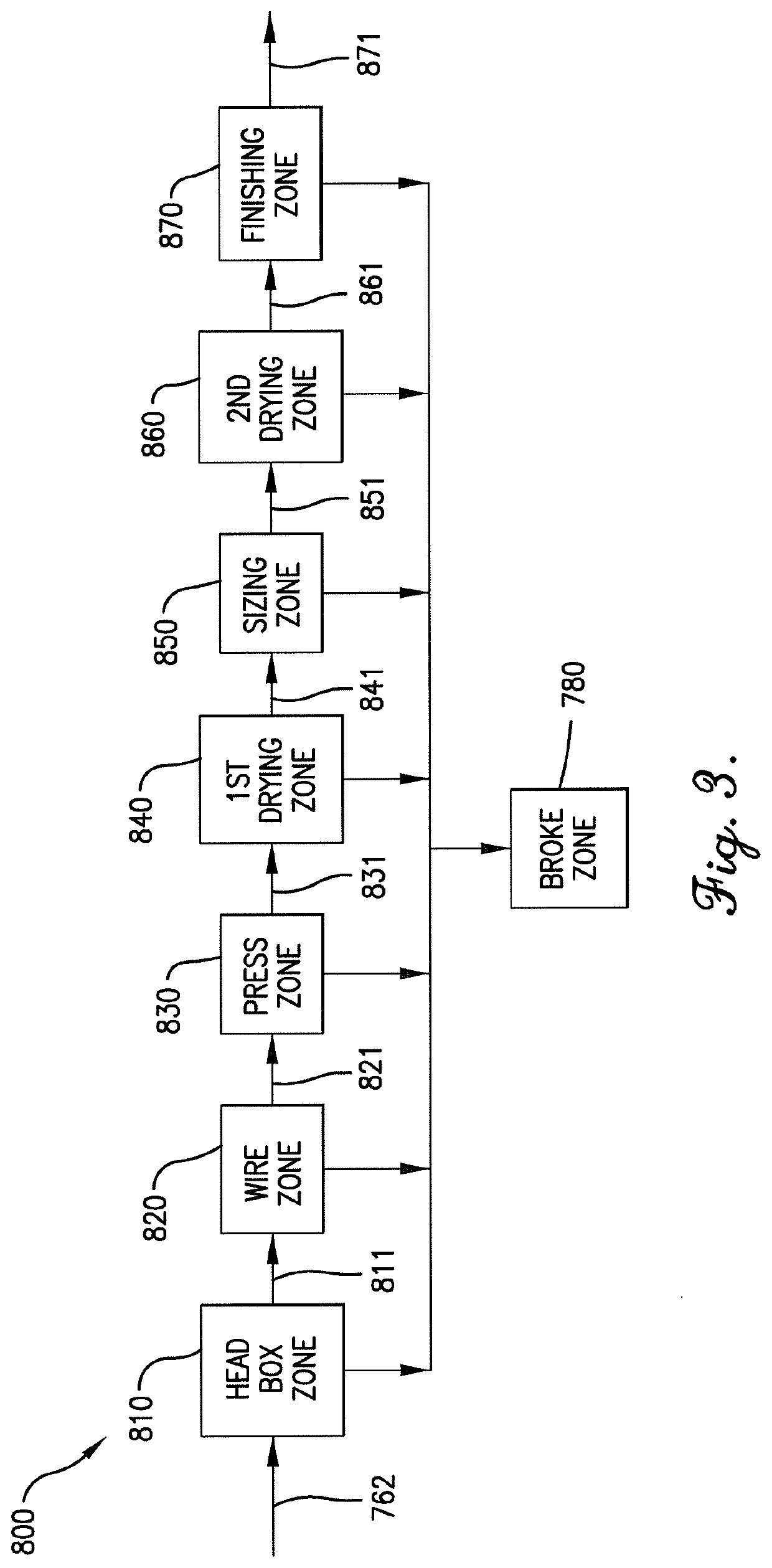

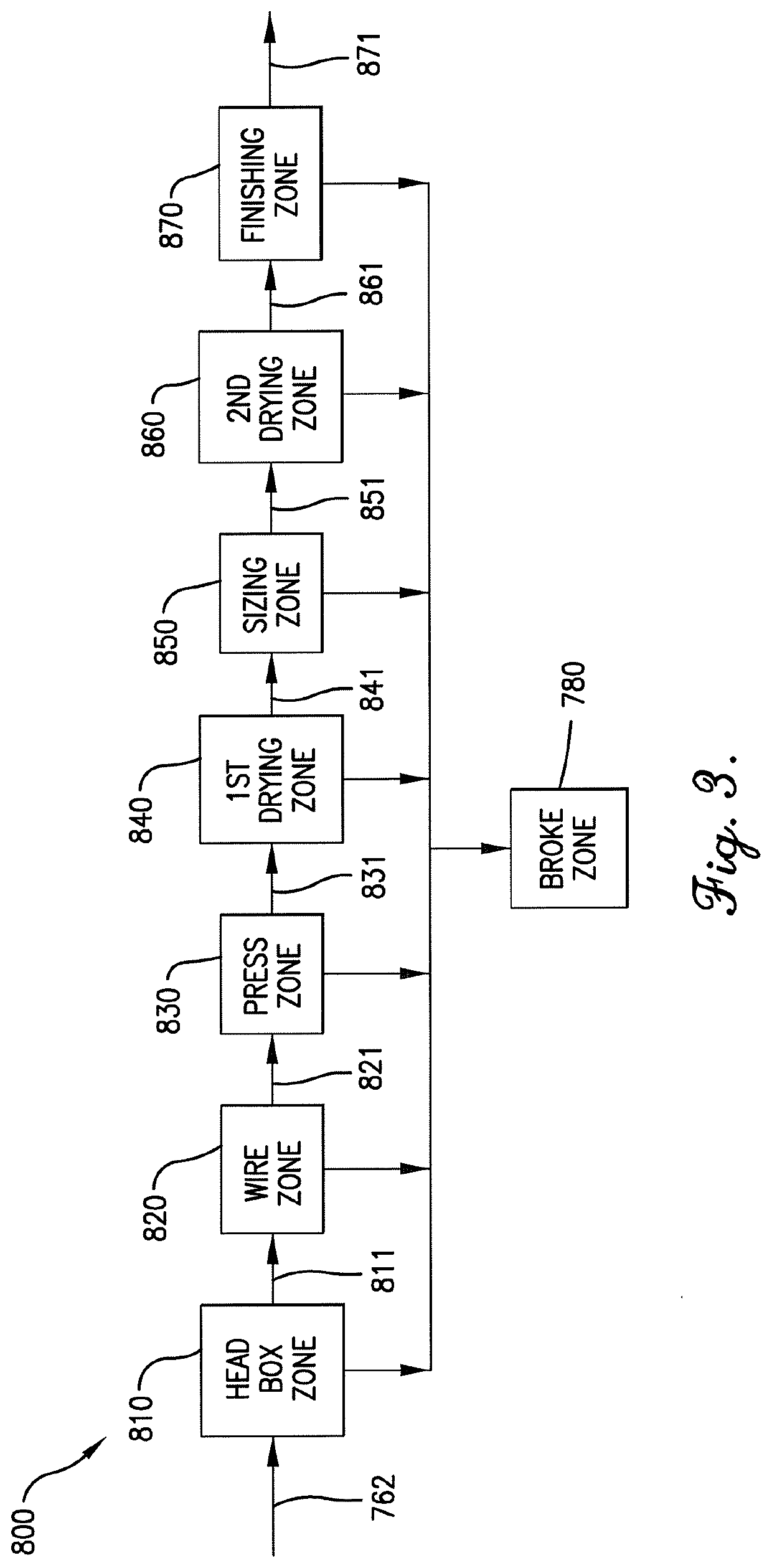

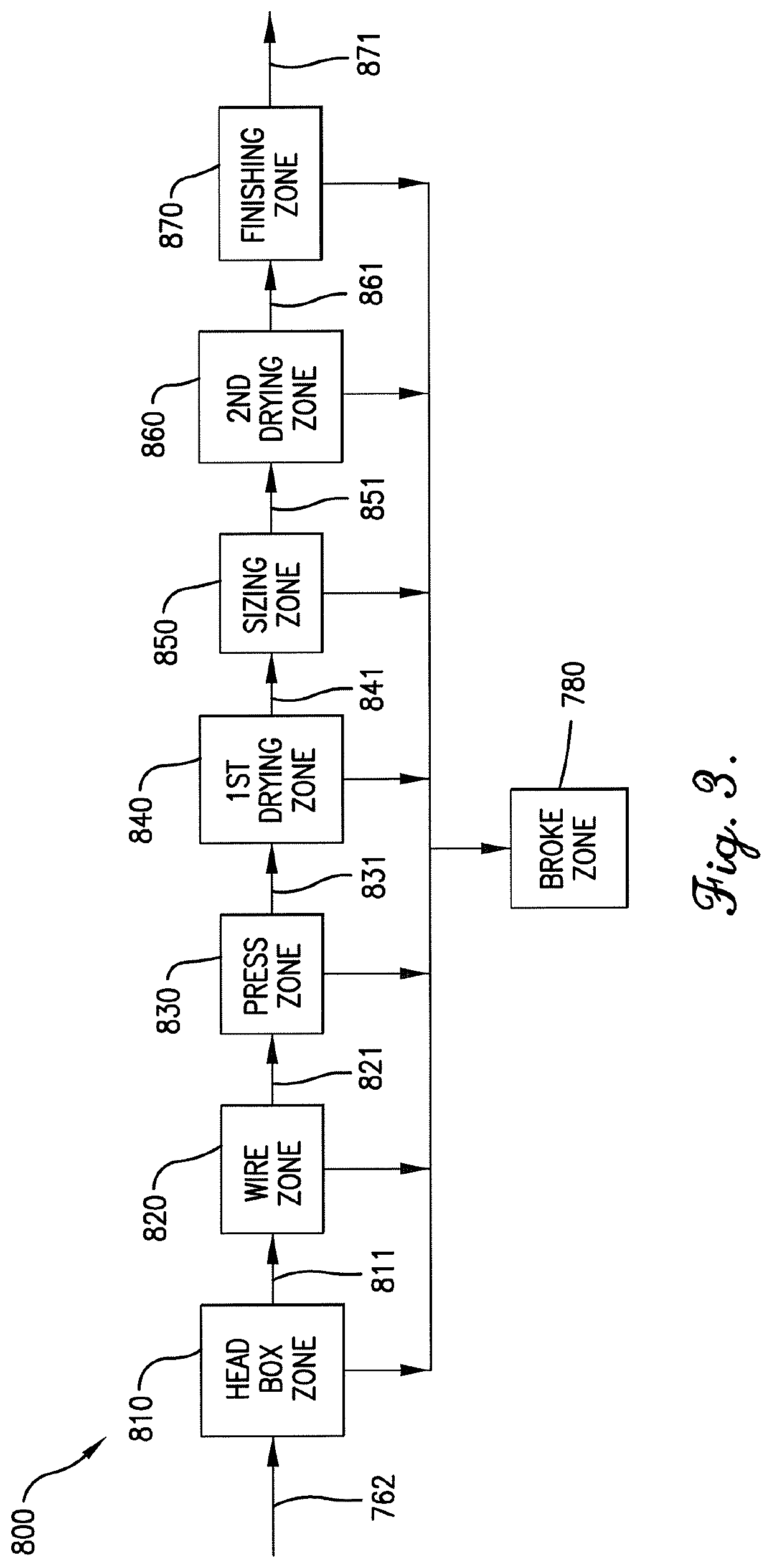

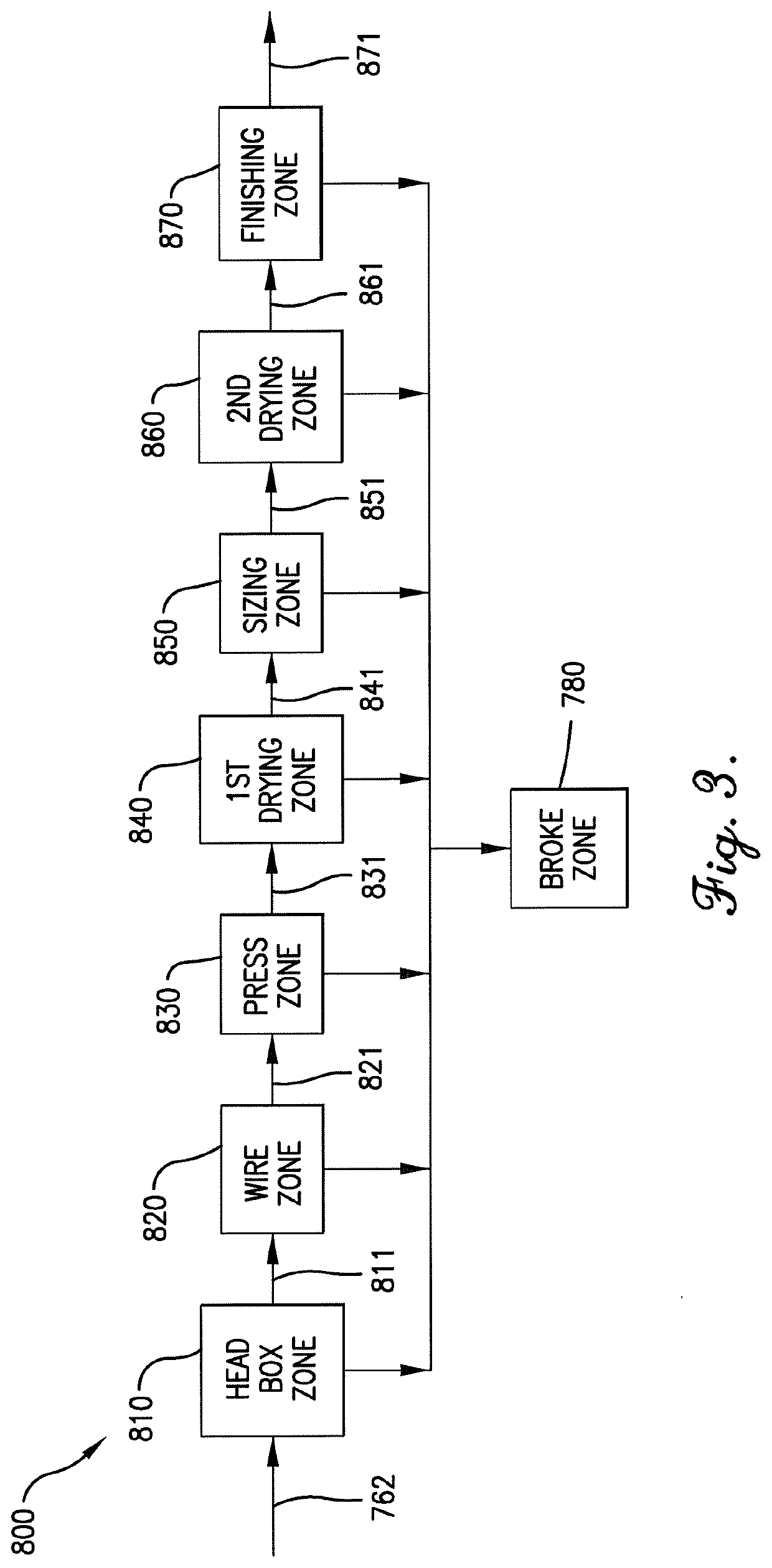

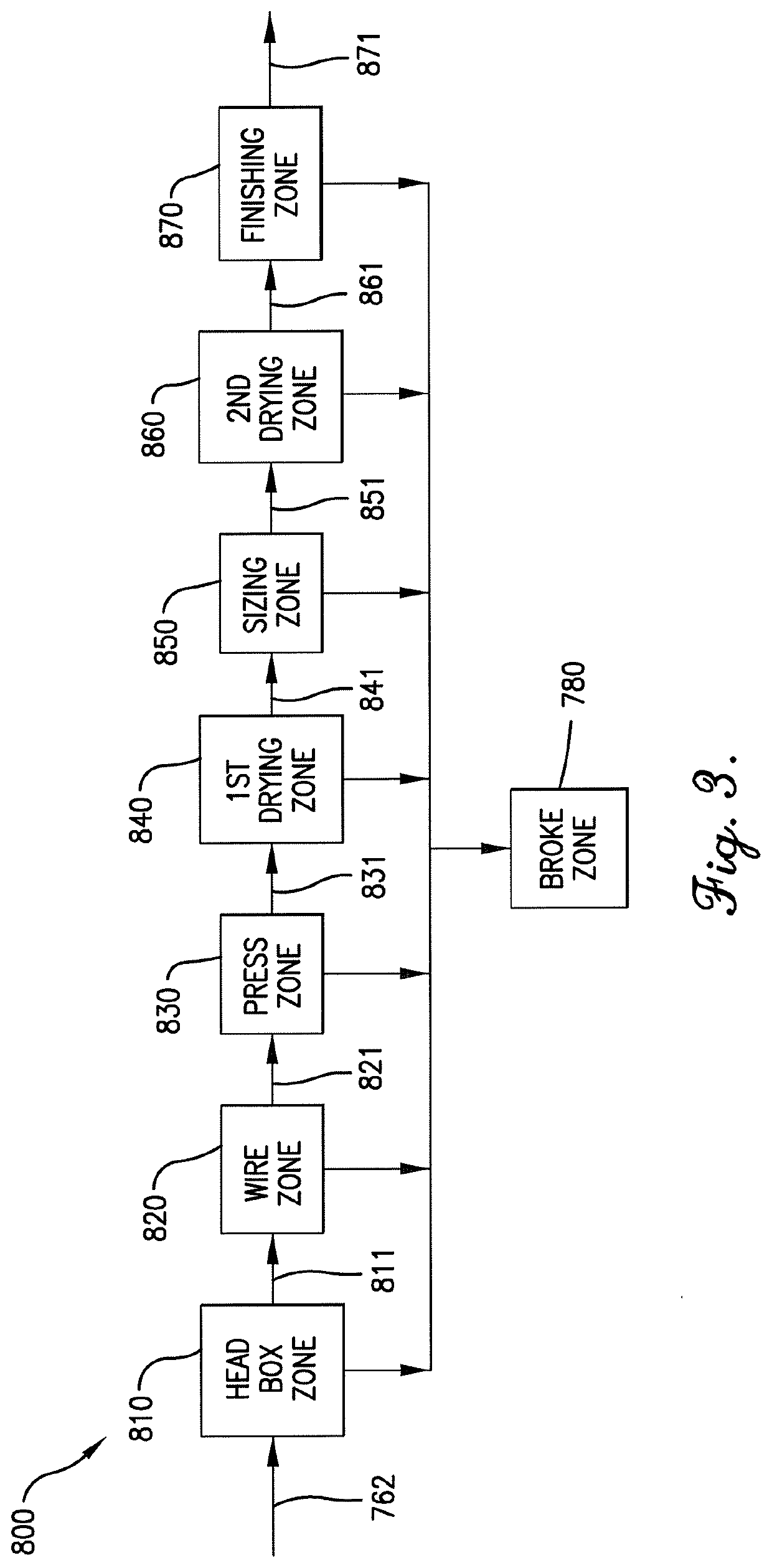

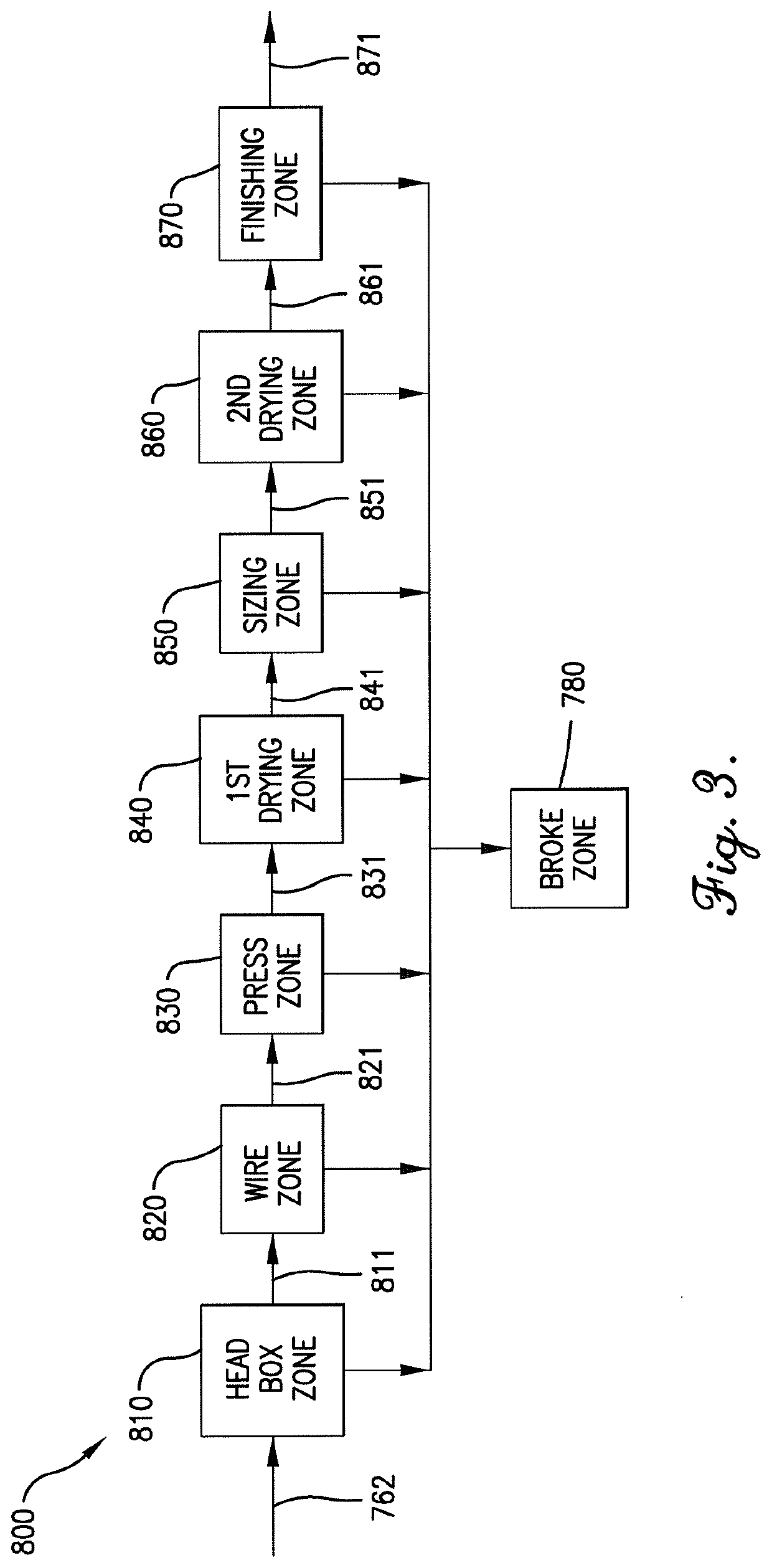

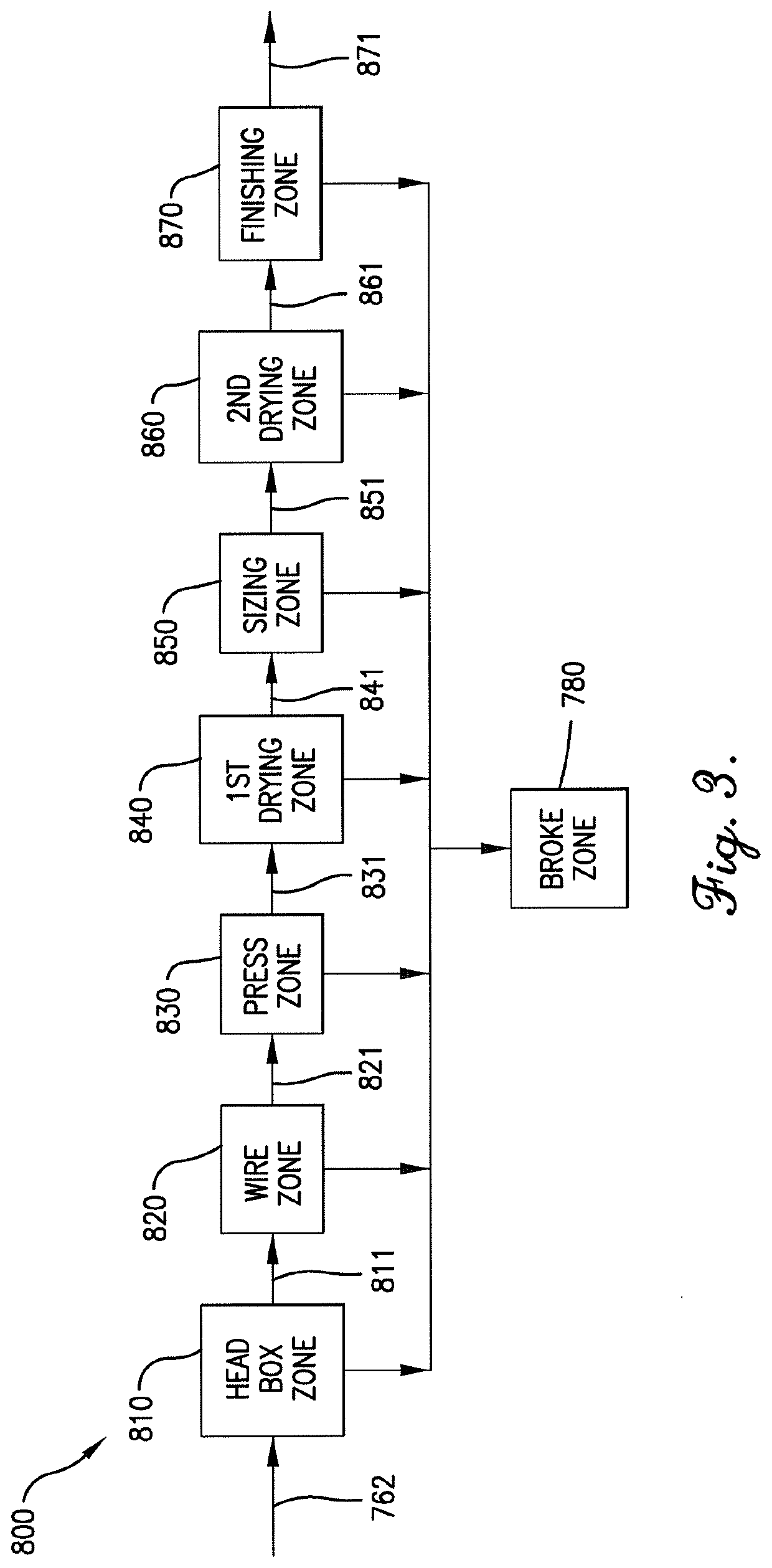

Composition of matter feed to a head box

ActiveUS20200063359A1Reduce consistencyLow variabilityWater-repelling agents additionWashing/displacing pulp-treating liquorsProcess engineeringCellulose fiber

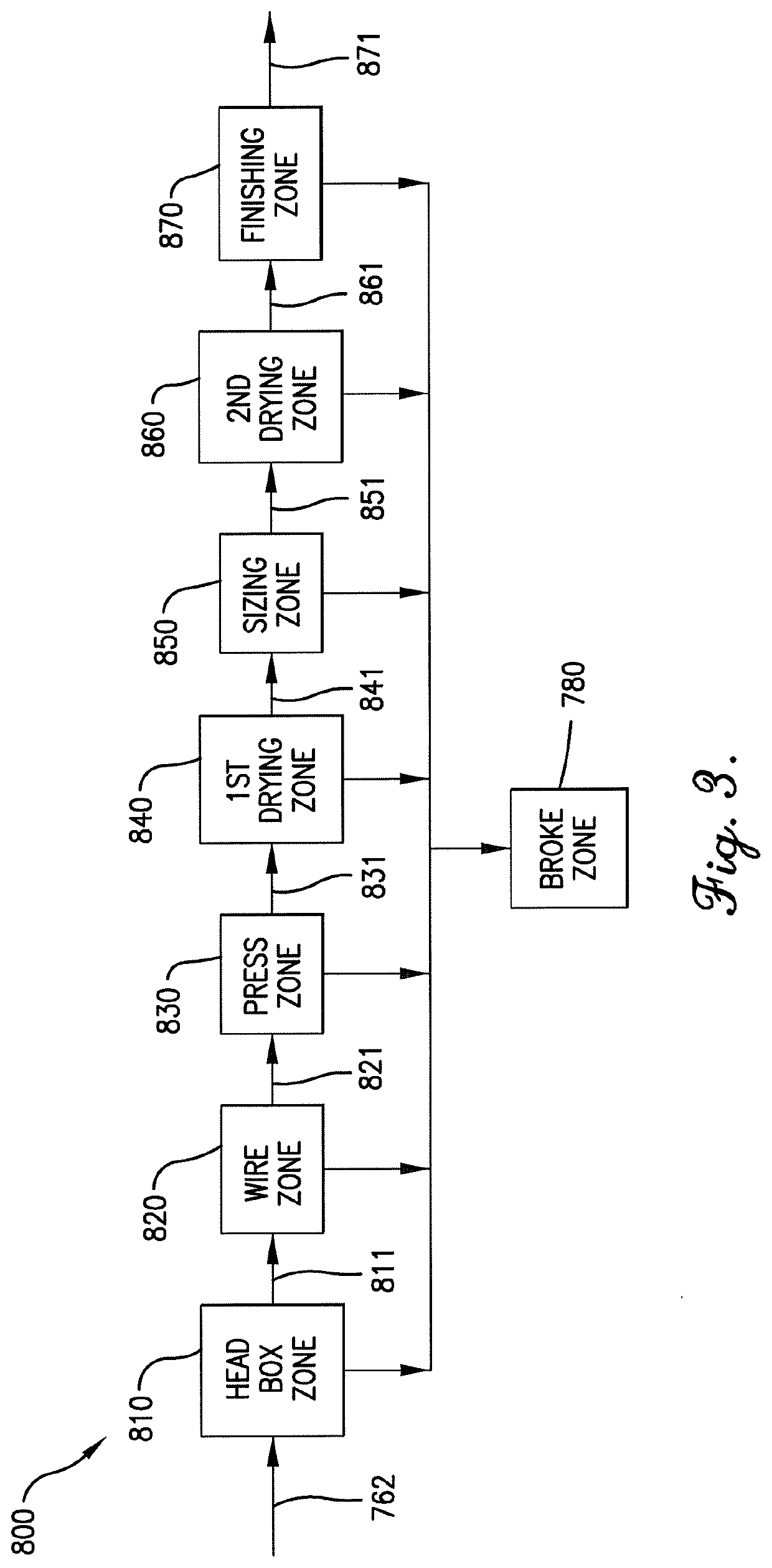

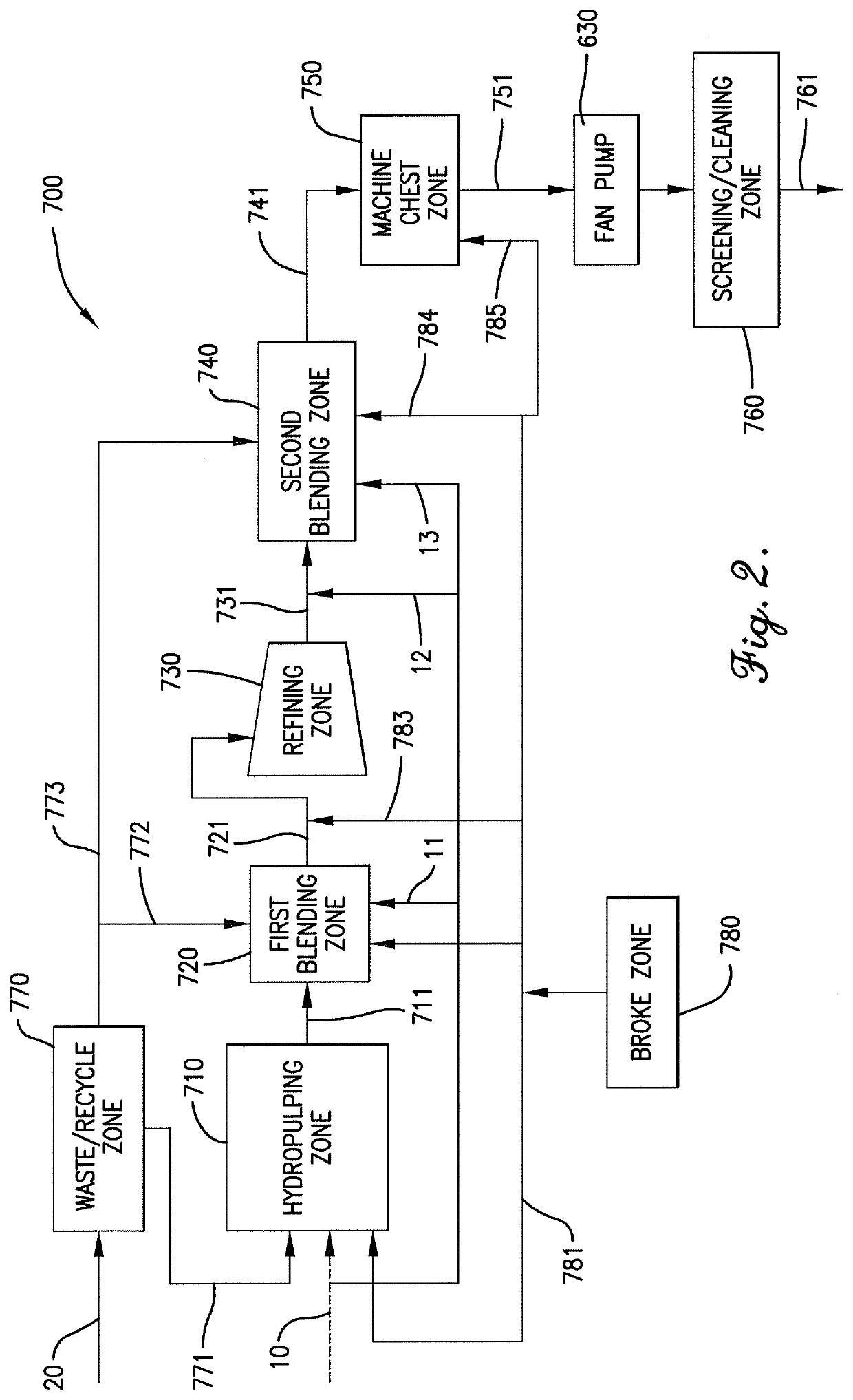

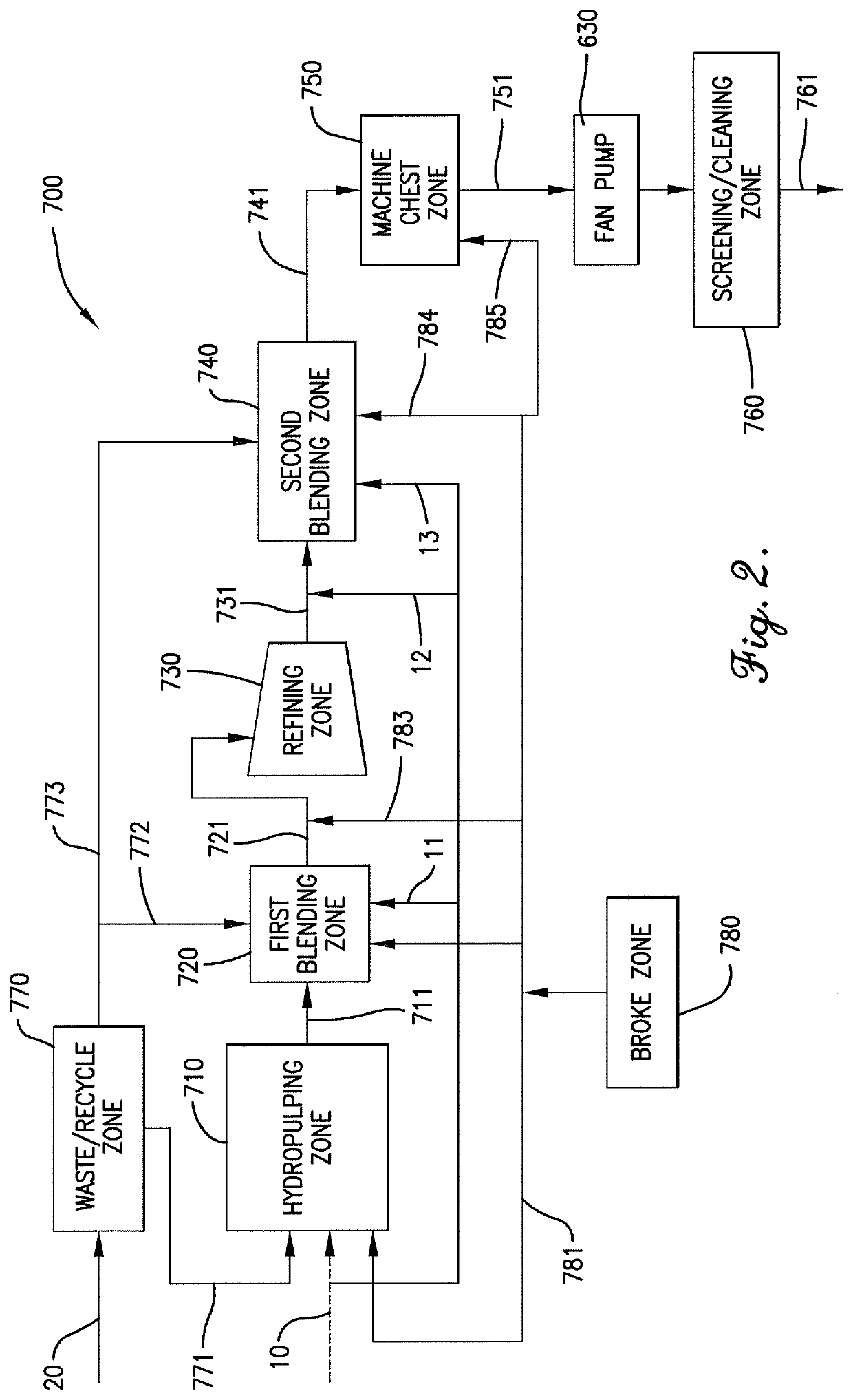

A wet laid process includes a method for making paper in which a composition containing co-refined cellulose fibers and cellulose ester fibers made into a thick stock composition in a machine chest, the thick stock is fed to a cleaning / screening zone through a device that regulates the flow rate of thick stock, the consistency of the thick stock fed to the screening / cleaning zone is reduced to form a thin stock composition; the thin stock composition is subjected to a process for cleaning the thin stock and feeding the cleaned thin stock through screens to form a cleaned and screened thin stock composition, and the cleaned and screened thin stock composition is fed to a headbox.

Owner:EASTMAN CHEM CO

Paper press process with high hydrolic pressure

ActiveUS20200063352A1Reduce consistencyLow variabilityPress sectionSynthetic cellulose fibresPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. Specifically, a wet laid process comprising a process that allows the quantity of water removed from a web passed through press rolls is increased relative to a web made from a 100% cellulose comparative composition or any composition without cellulose ester staple fibers co-refined with cellulose at the same press loading

Owner:EASTMAN CHEM CO

Lightweight cardboard and paper articles

InactiveUS20200063361A1Reduction in Gurley stiffnessLow densityFlexible coversWrappersPaperboardProcess engineering

Wet laid products such as cardboard, paperboard, and packaging and container board can be light-weighted or made thicker, while retaining Gurley stiffness. The wet laid products contain co-refined CE staple fibers that have:i. a denier per filament (DPF) of less than 3, orii. a cut length of less than 6 mm, oriii. crimping, oriv. a combination of any two or more of (i)-(iv).

Owner:EASTMAN CHEM CO

Molded articles from a fiber slurry

ActiveUS20200063373A1Reduce consistencyLow variabilityFibreboardLayered productsPolymer scienceCutlery

Contoured articles formed in a mold from a fiber slurry are provided. The articles comprise a blend of cellulose fibers and cellulose ester, such as cellulose ester staple fibers. The articles are suitable in a wide array of end uses, including as cups, lids, boxes or pouches, storage containers, trays, plates, food trays, cutlery, coffee cups, coffee cup lid, packaging, bowls, clam shells, bottle caps, straws, covers, and packaging inserts.

Owner:EASTMAN CHEM CO

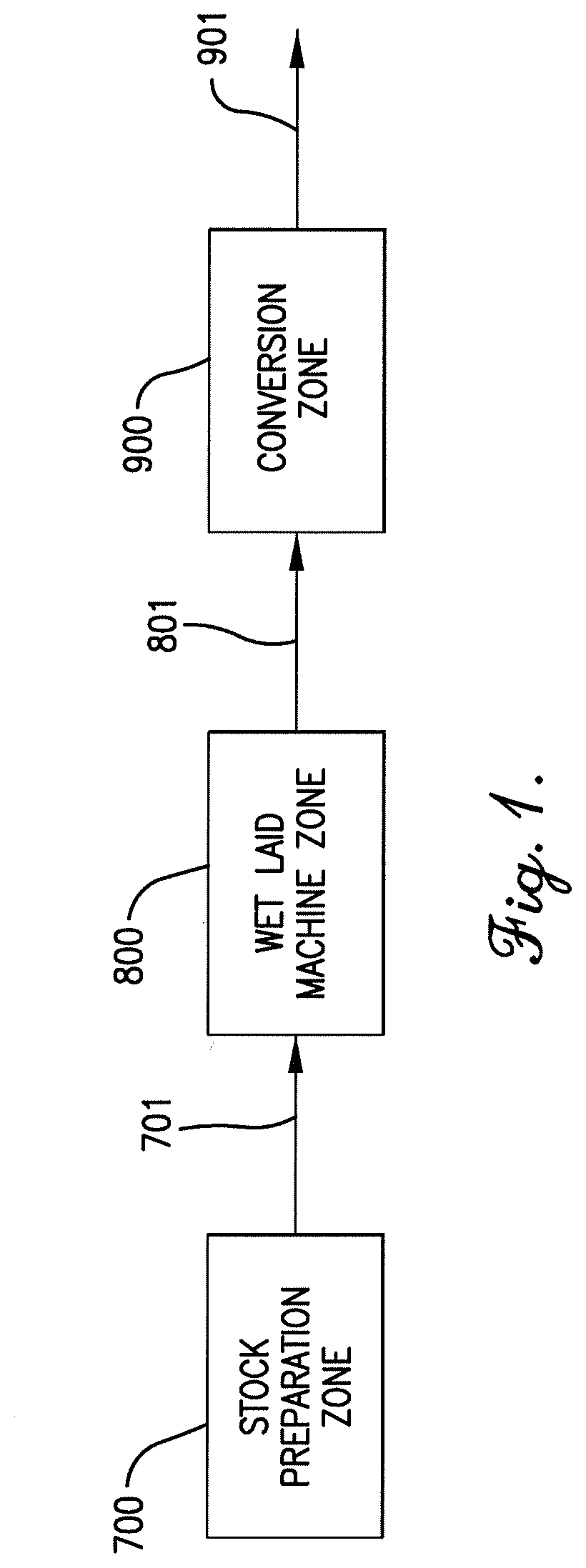

Process to produce a paper article comprising cellulose fibers and a staple fiber

ActiveUS20200063346A1Reduce consistencyLow variabilityReinforcing agents additionPaper/cardboardPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits.

Owner:EASTMAN CHEM CO

Paper composition cellulose and cellulose ester for improved texturing

ActiveUS20200063368A1Reduce consistencyLow variabilityPaper/cardboardTissue/absorbent paperPaper sheetPolymer chemistry

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to composition, process, wet laid product, or articles exhibiting any one of many desired benefits. The invention also relates to a composition comprising cellulose fiber and a staple fiber exhibiting improved texturing.

Owner:EASTMAN CHEM CO

Paper product articles

ActiveUS20200063351A1High air permeabilityHigh permeabilityPaper/cardboardMembrane filtersCellulose acetatePolymer science

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. The Present invention also relates to a wet laid product having higher air permeability the same or lower pore size relative to a 100% cellulose comparative composition

Owner:EASTMAN CHEM CO

Soft wipe comprising cellulose acetate

ActiveUS20200063348A1Low densityIncreasing the thicknessTissue/absorbent paperNon-woven fabricsPolymer scienceCellulose acetate

A soft wipe article is provided comprising a wet-laid sheet which comprises cellulosic fibers and cellulose ester staple fibers, wherein the cellulose ester staple fibers are present in an amount sufficient to provide the wet laid-sheet with a lower density and higher thickness at a given basis weight compared to a 100% Cellulose Comparative composition, when processed under similar conditions. The cellulose ester staple fibers can also provide the wet laid-sheet with a higher softness, while maintaining or increasing tear strength, compared to a 100% Cellulose Comparative composition, when processed under similar conditions.

Owner:EASTMAN CHEM CO

Air filtration articles

ActiveUS20200063354A1Improve breathabilityReduce consistencyPaper/cardboardMembrane filtersAir filtrationPolymer science

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. The present invention also relates to a filter media for air filtration comprising cellulose fiber and a staple fiber; wherein said staple filter comprises cellulose ester; wherein said air permeability is higher for a given mean pore size as compared to a filtration that comprises 100% cellulose.

Owner:EASTMAN CHEM CO

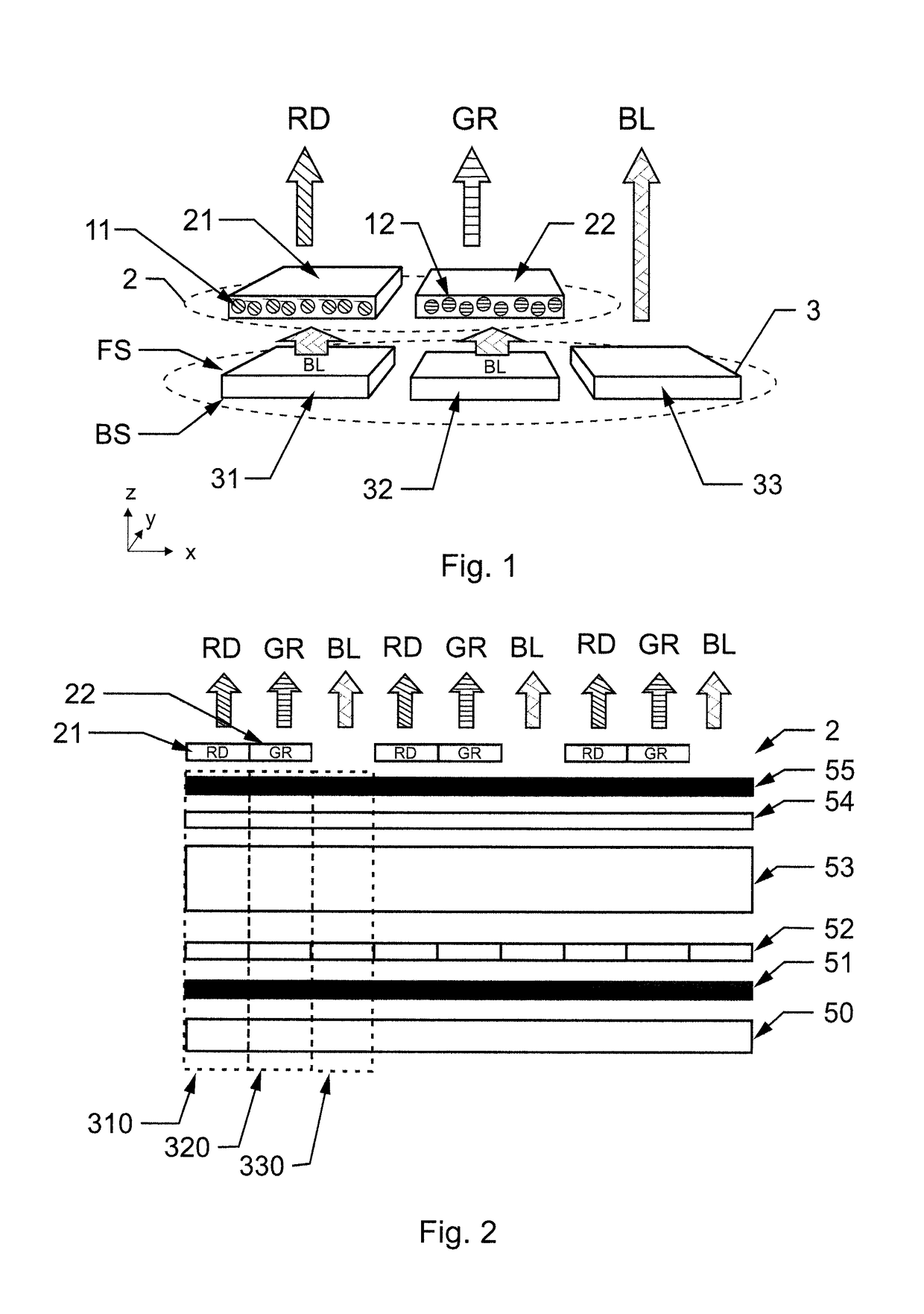

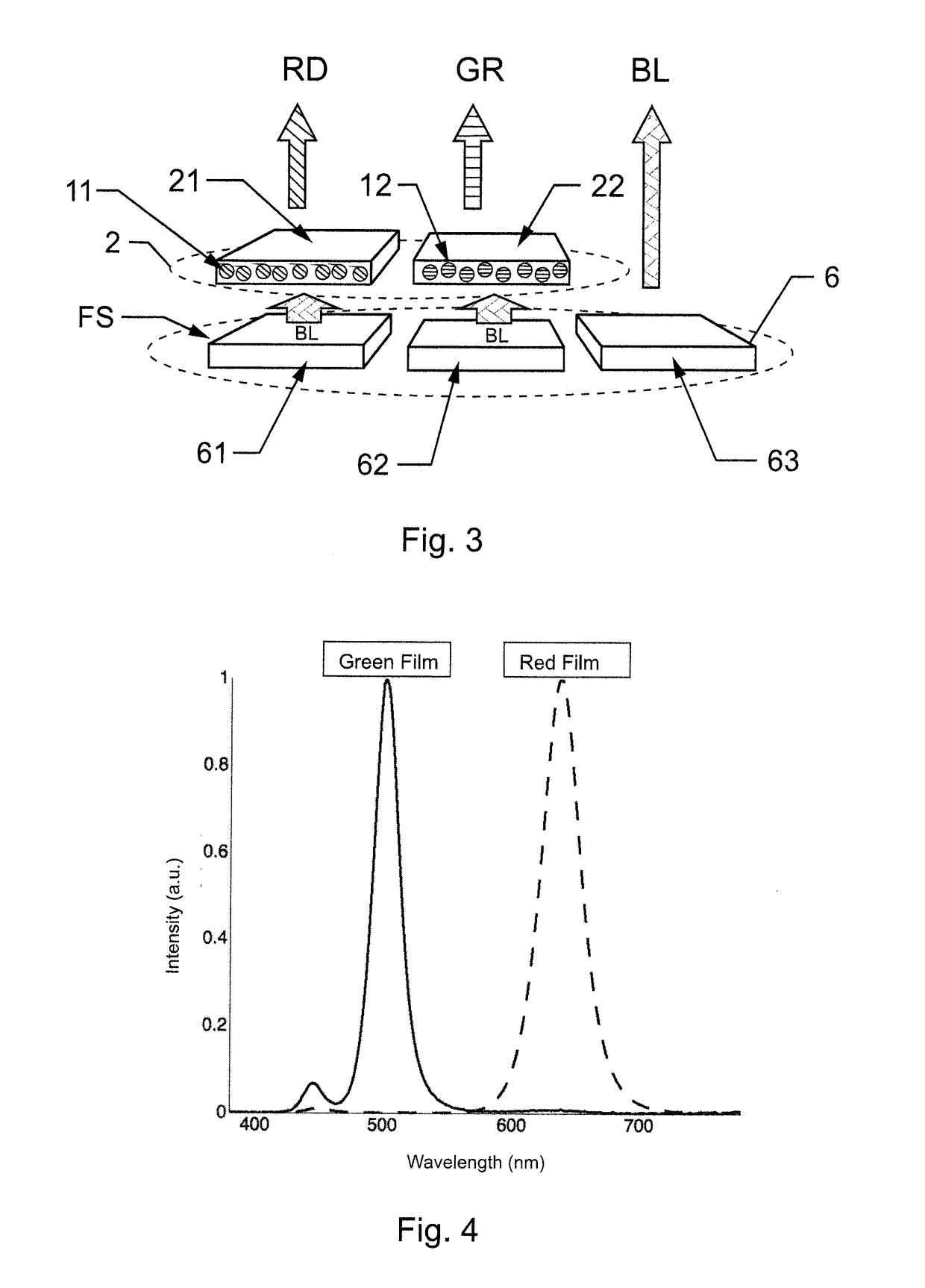

Display device

ActiveUS20190018287A1High absorption rateLess materialSolid-state devicesLuminescent compositionsCyanide compoundDisplay device

A display device includes a light emitter comprising a set of light emitter portions, wherein at least one light emitter portion of the set is configured to emit light with an excitation wavelength, and a color conversion layer including a set of conversion layer portions. At least one conversion layer portion of the set comprises a film comprising a solid polymer composition that includes luminescent crystals of perovskite structure, which are selected from compounds of formula (I): M1aM2bXc (I), wherein M1 represents Cs, M2 represents Pb, and X independently represents anions selected from the group consisting of Cl, Br, I, cyanide, and thiocyanate. The luminescent crystals are of size between 3 nm and 3000 nm, and emit light of a wavelength in response to excitation by the light emitted by at least one corresponding light emitter portion of the set, wherein the excitation wavelength is shorter than the wavelength.

Owner:AVANTAMA AG

Highly absorbent articles

ActiveUS20200063372A1Excellent characteristicsImprove propertiesReinforcing agents additionPaper/cardboardBursting strengthPolymer science

Absorbent wet laid products are made containing cellulose fibers and cellulose ester staple fibers that are co-refined to obtain products and articles that have improved water absorbency and tensile strength or burst strength or both. The absorbent wet laid products can now be made with a synthetic fiber in the wet laid operation since cellulose ester can be subjected to a refining operation.

Owner:EASTMAN CHEM CO

Beverage filtration article

ActiveUS20200063350A1Reduce consistencyLow variabilityPaper/cardboardBeverage vesselsPolymer scienceBeverage filtration

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits. The present invention relates a filtration article comprising a wet-laid composition comprising cellulose fibers and staple fibers.

Owner:EASTMAN CHEM CO

Composition of matter in stock preparation zone of wet laid process

ActiveUS20200063356A1Reduce consistencyLow variabilityPaper/cardboardNon-woven fabricsBursting strengthCardboard

A composition obtained by combining virgin cellulose fibers, cellulose ester (CE) staple fibers having a denier per filament (DPF) of less than 3, and water, and water. The CE staple fibers can also have a short cut length of less than 6 mm and can be crimped. The compositions, when co-refined, are useful to make wet laid products such as paper, cardboard, and filters that have improved water drainage, air permeability, tensile strength, bulk, burst strength, or stiffness, or a combination of these properties.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com