Battery pack with internal serial structure and manufacture method thereof

An internal series, battery pack technology, used in secondary battery manufacturing, battery pack components, structural parts, etc., can solve problems such as affecting overall performance, increasing combined resistance, reverse installation of positive and negative electrodes, and reducing external short circuits of batteries , Simplify the production process and ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

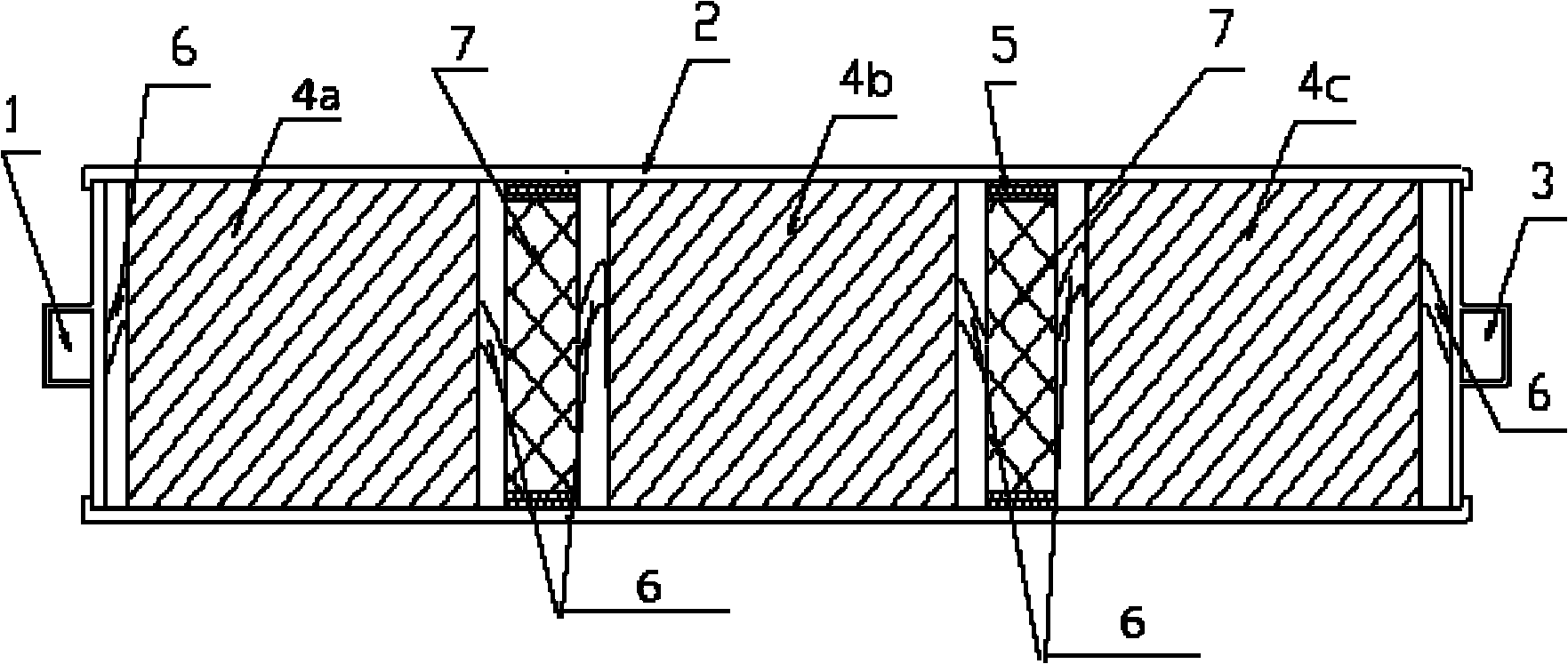

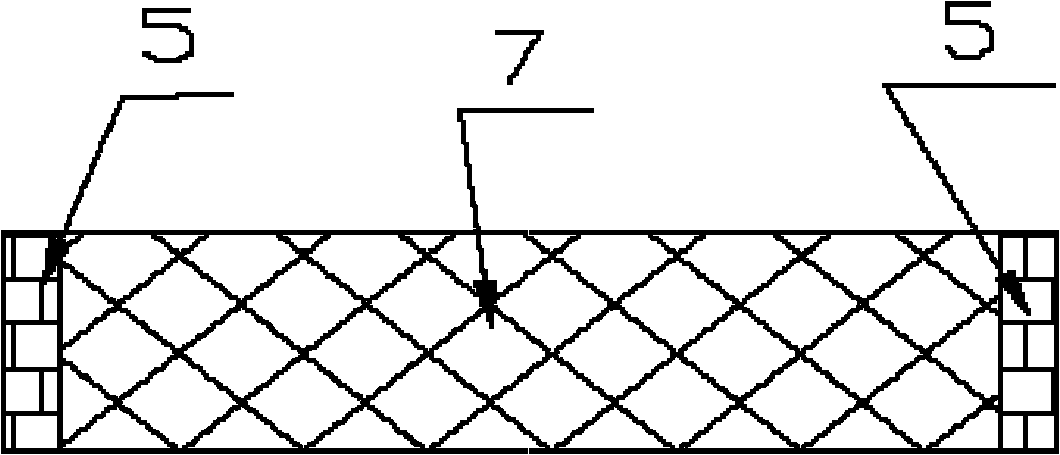

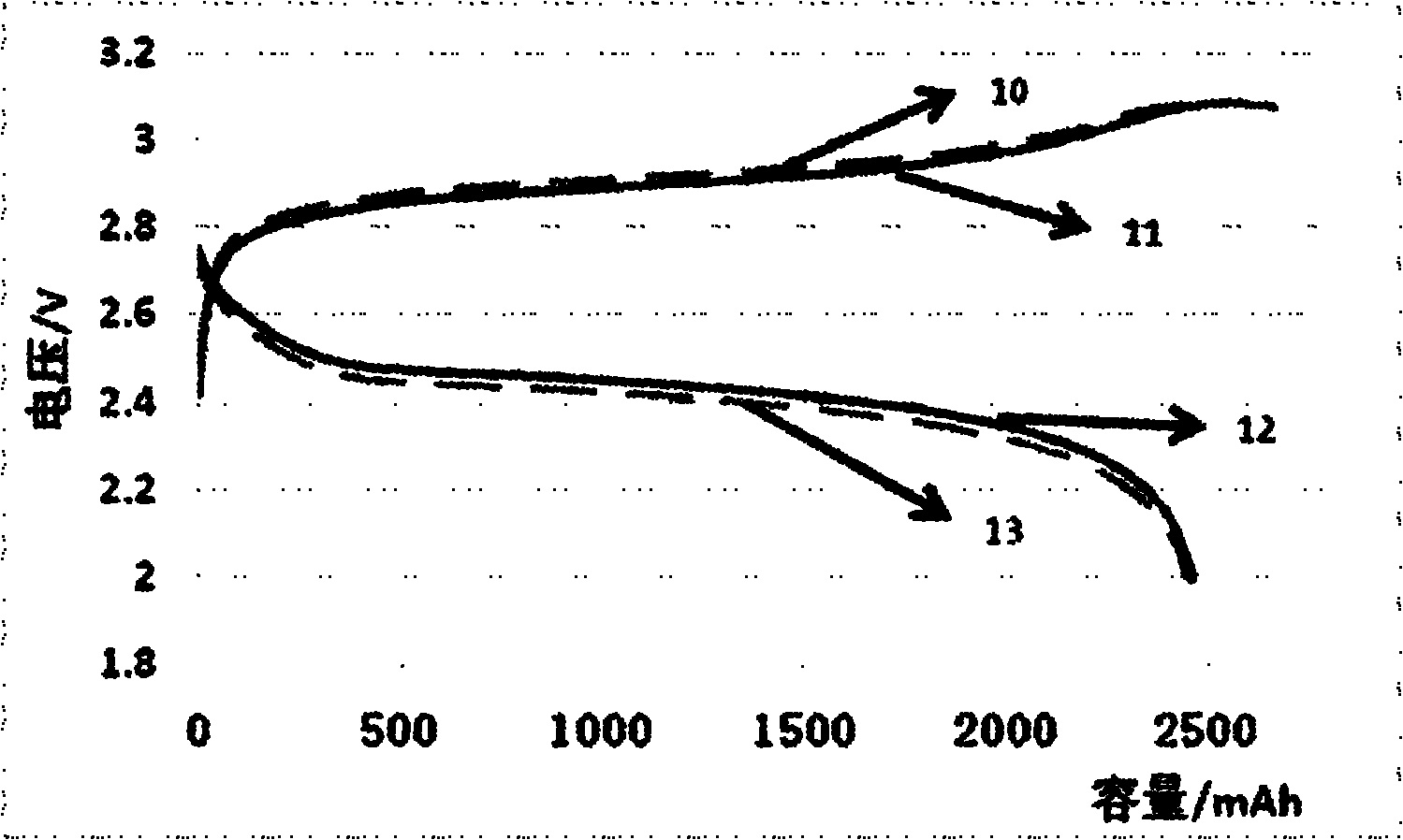

[0020] A 3.6V cylindrical AA NiMH battery pack, figure 1 is a schematic cross-sectional view of its structure. Inside the plastic shell 2 are three pole groups 4a, 4b and 4c with a capacity of 2500mAh and a voltage of 1.2V. There is a metal partition 7 to separate it, and a sealing ring 5 is placed on the partition, see the placement method figure 2 , is to cover the sealing ring 5 on the separator; the positive terminal 3 of the battery top cover and the negative terminal 1 of the casing are used to connect the battery to the outside; the negative terminal of the pole group 4a is connected to the negative terminal of the battery top cover through the ear 6 1 connection, the positive terminal of the pole group 4a is connected to the separator 7 through the tab 6; while the negative terminal of the pole group 4b is connected to the separator 7 through the tab 6, and the positive terminal is connected to the other separator 7 through the pole connected to the ear 6; the negat...

Embodiment 2

[0026] The battery pack manufacturing method of the above-mentioned embodiment 1 is as follows:

[0027] Prepare 3 pole groups (the pole group is no different from conventional high-capacity AA batteries), 1 plastic battery case, 2 sets of metal separators and sealing rings with grooves, 2 top covers (one for each positive and negative pole) ), 6 tabs, one end of the battery cell top cover is used as the negative terminal of the battery pack, and the end of the battery top cover is used as the positive terminal of the battery pack. After the positive and negative terminals of each pole group are welded to one tab respectively, put the first pole group into the shell according to the positive and negative pole marking directions on the shell, and the negative pole tab of the pole set and Connect the negative end of the battery top cover, inject electrolyte, install the metal separator with a sealing ring, and then connect the positive electrode lug of the electrode group with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com