Patents

Literature

2560results about "Variable inductances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

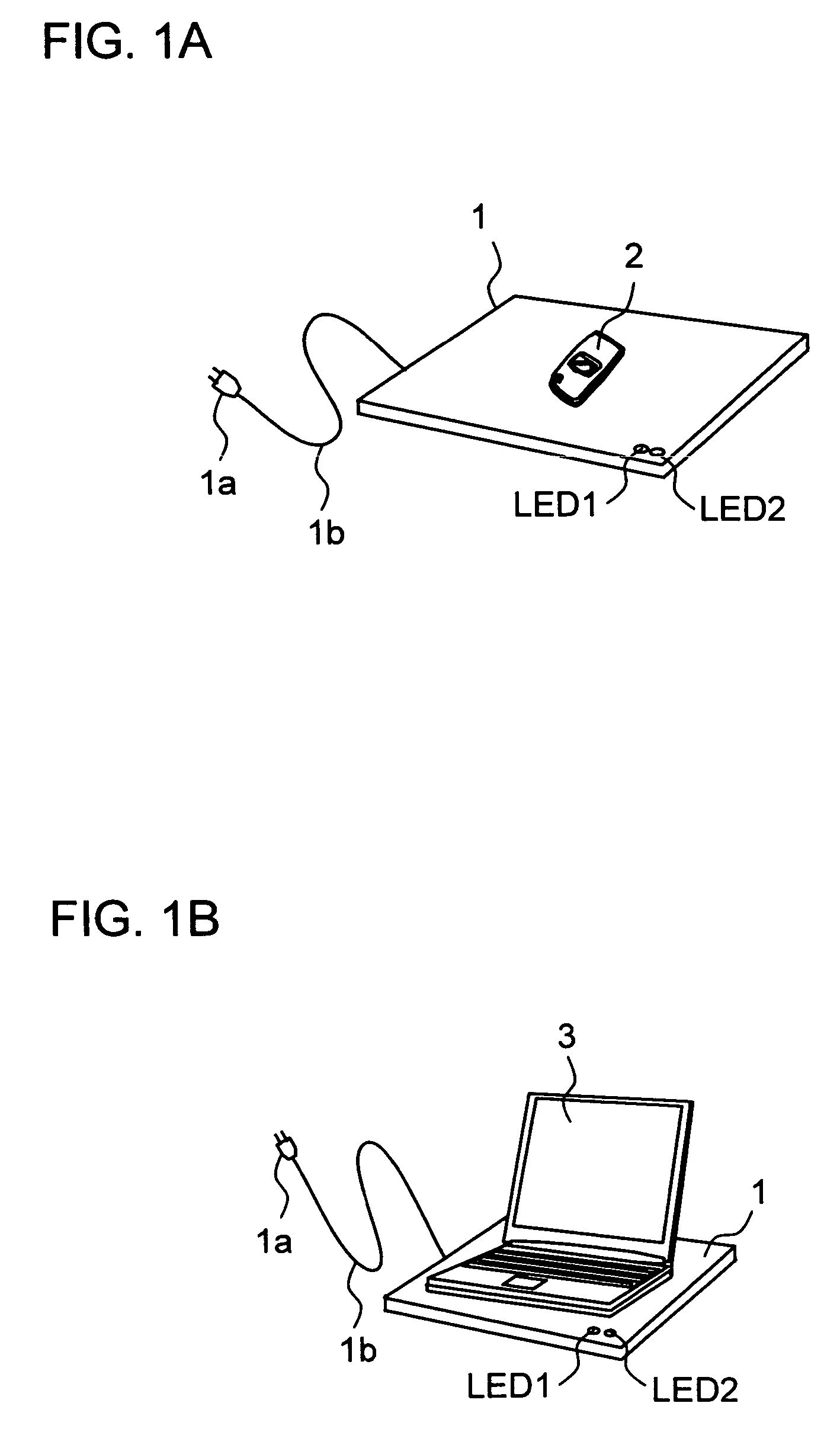

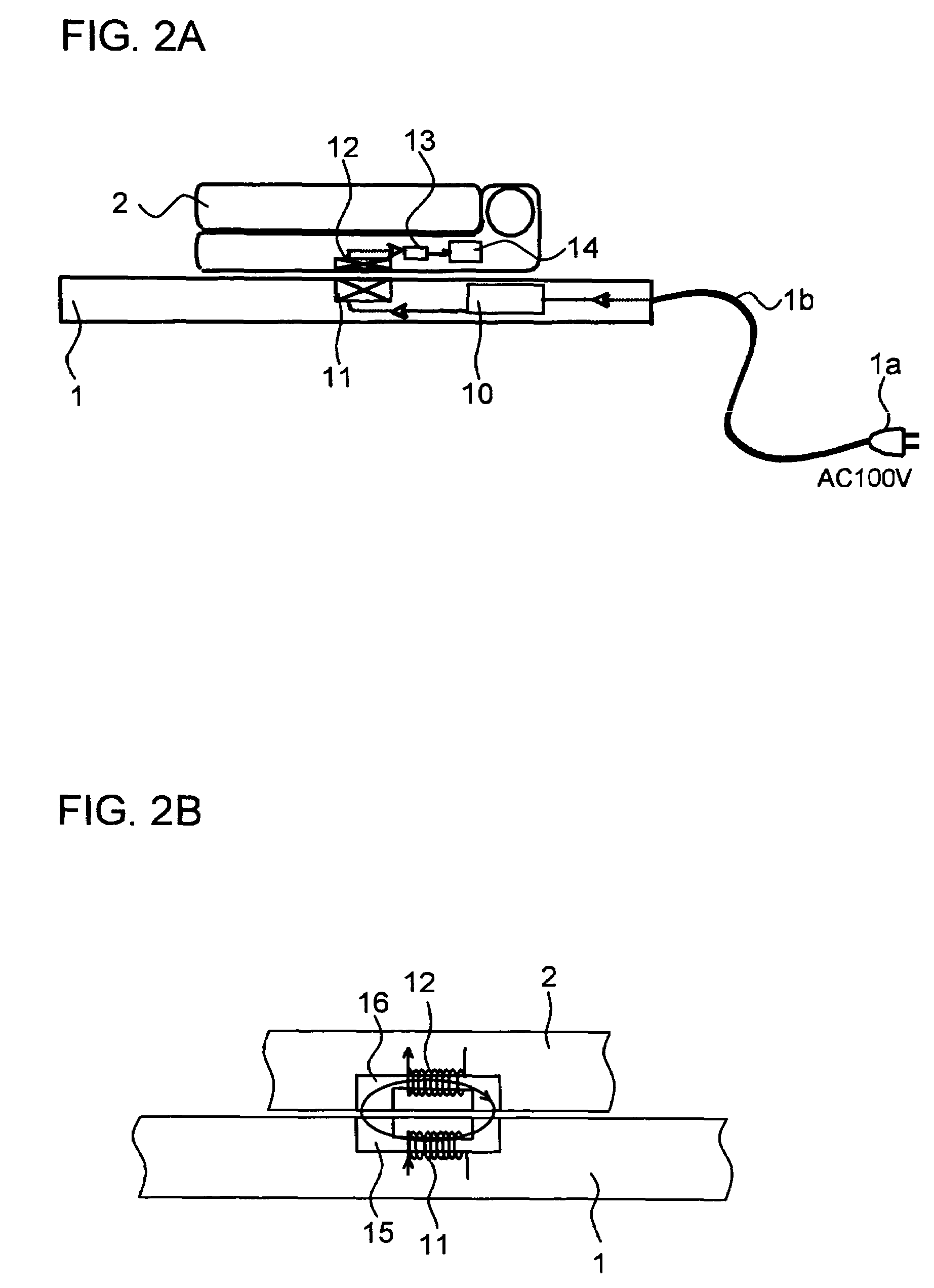

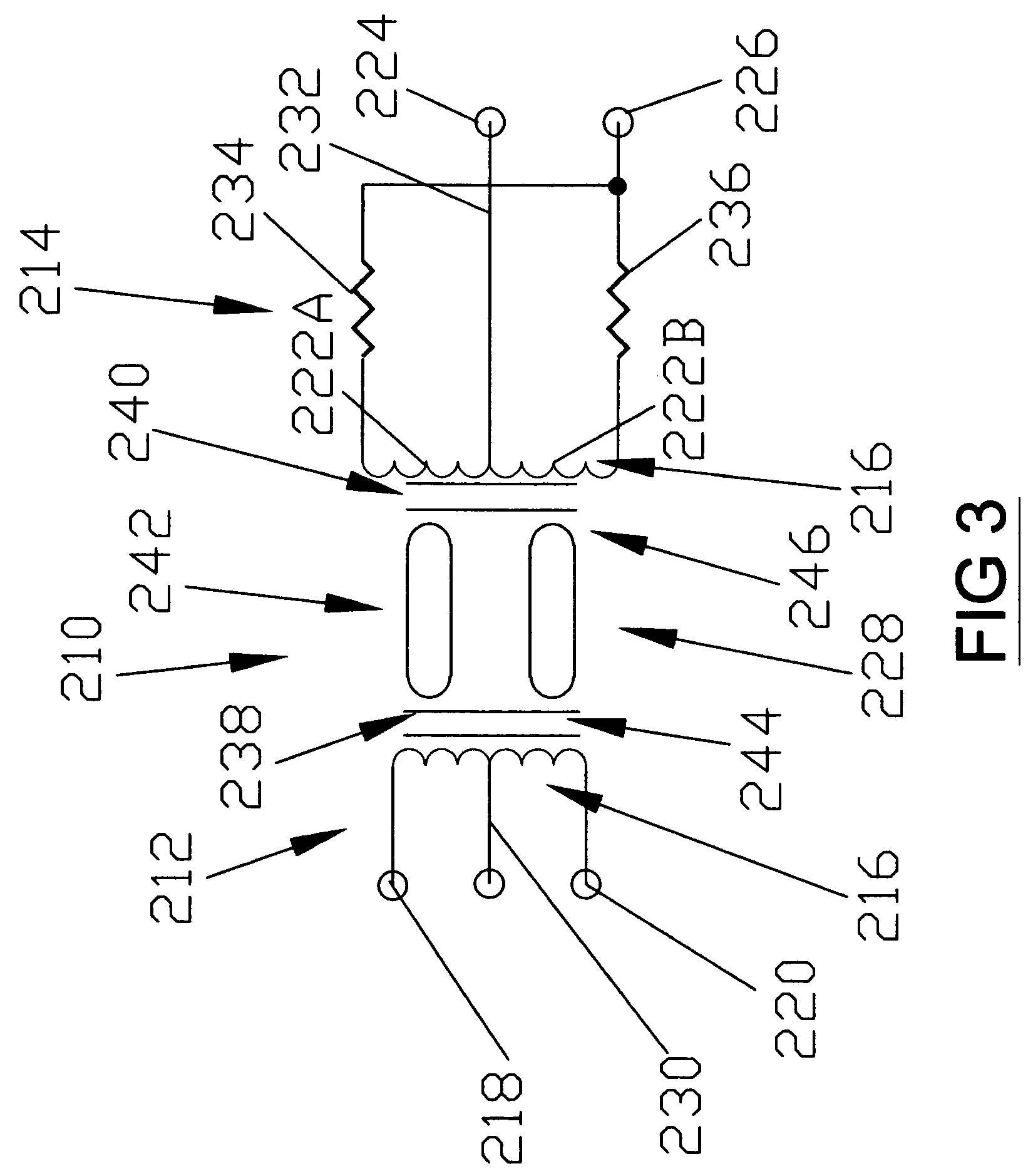

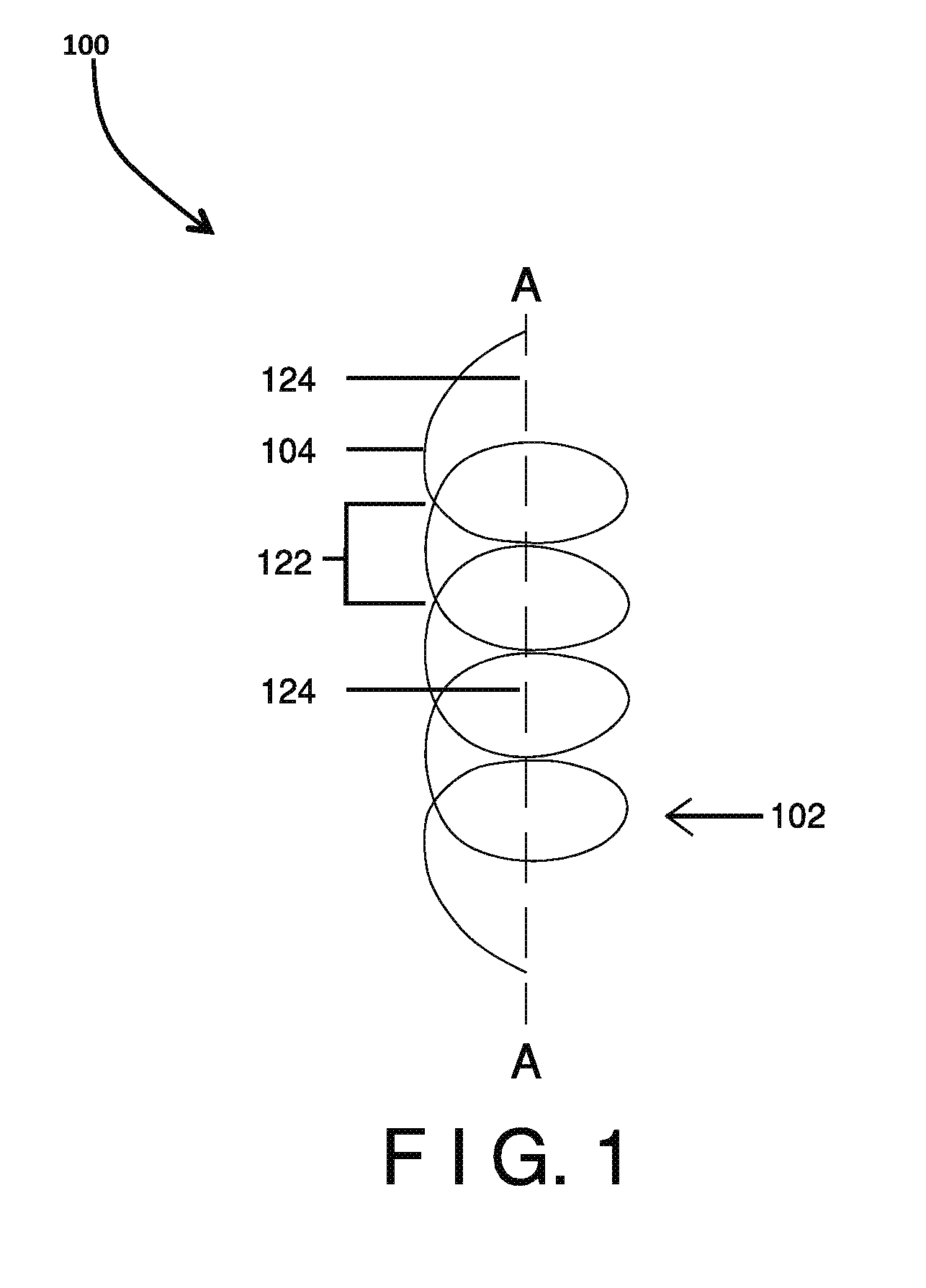

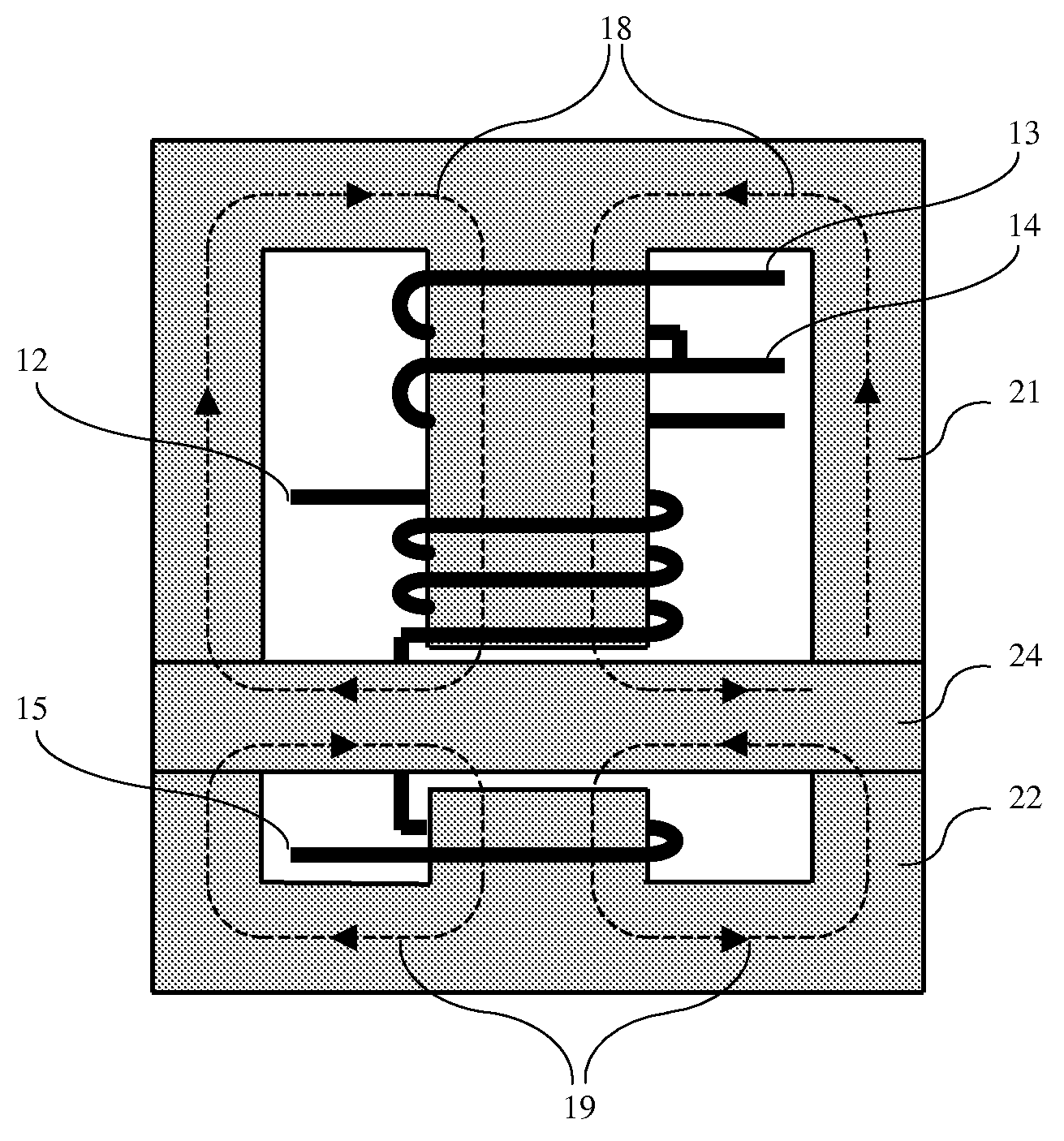

Power supply system

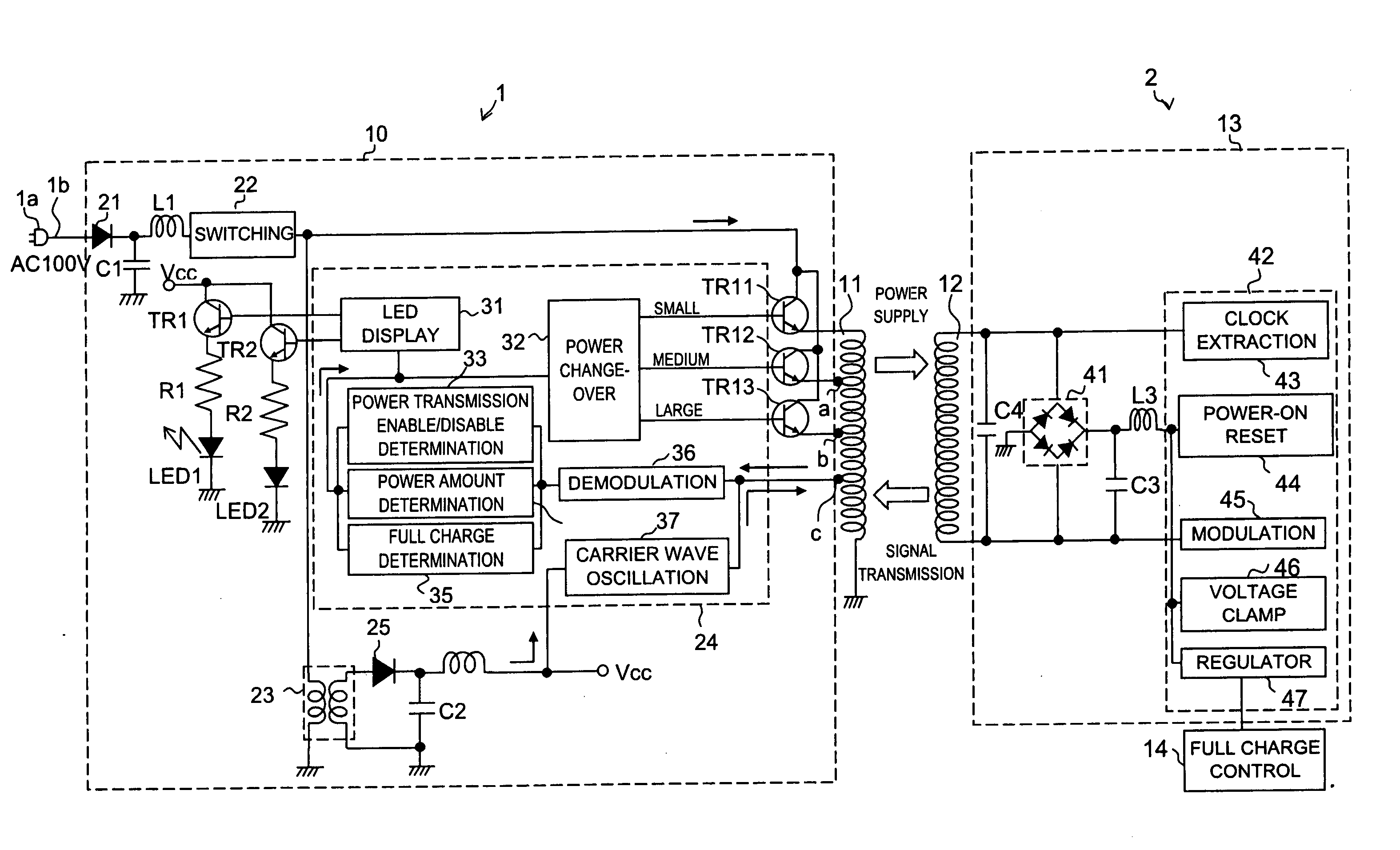

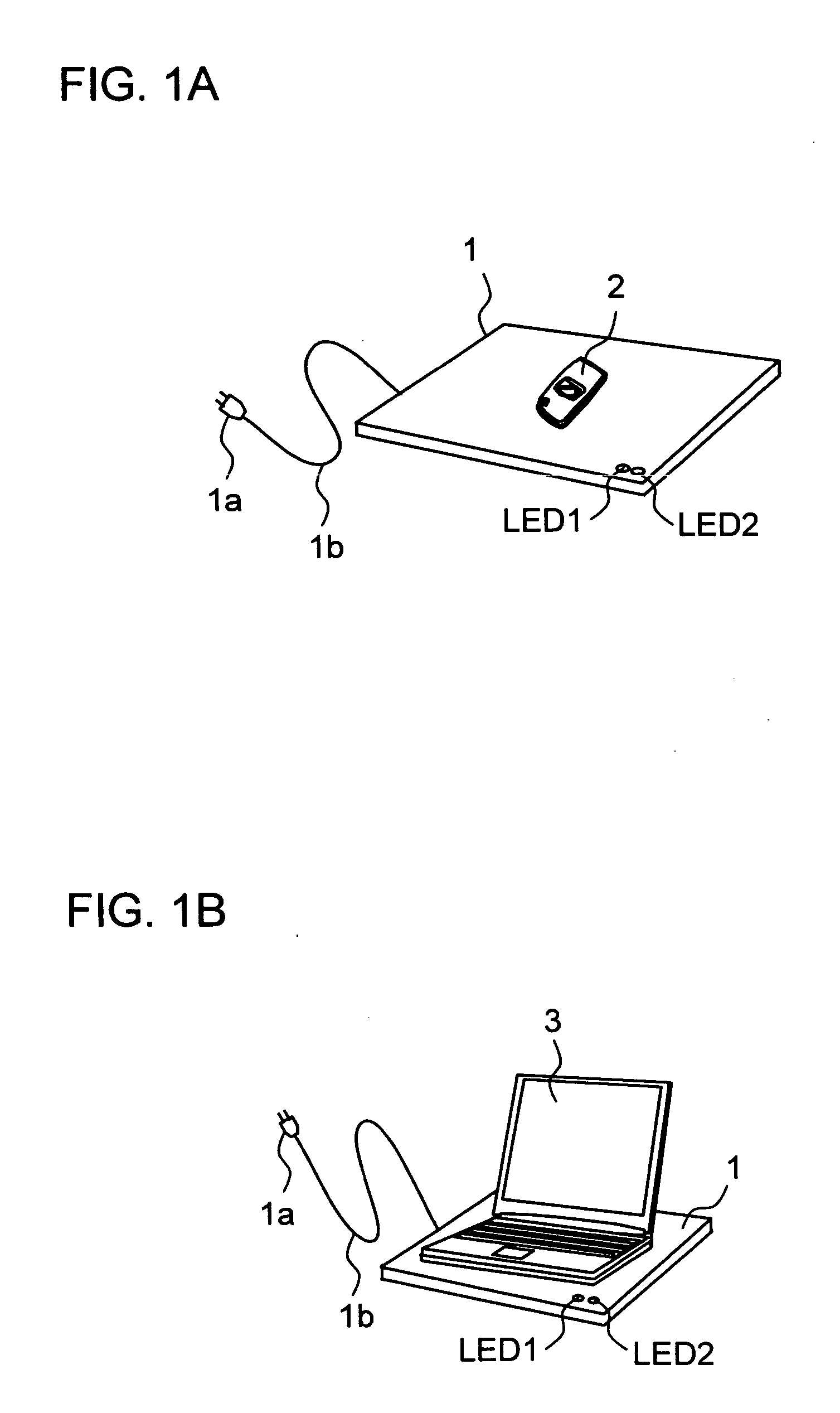

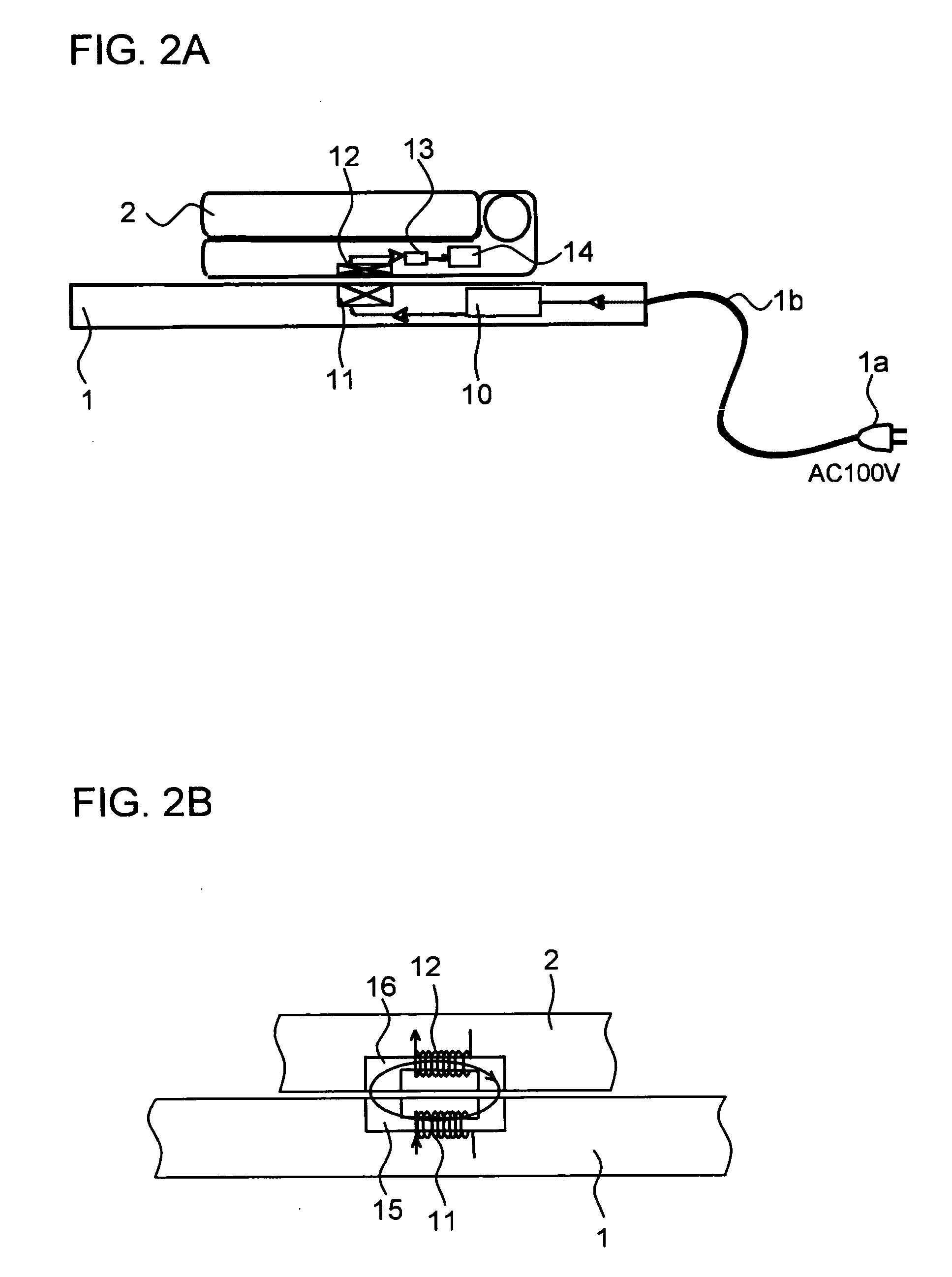

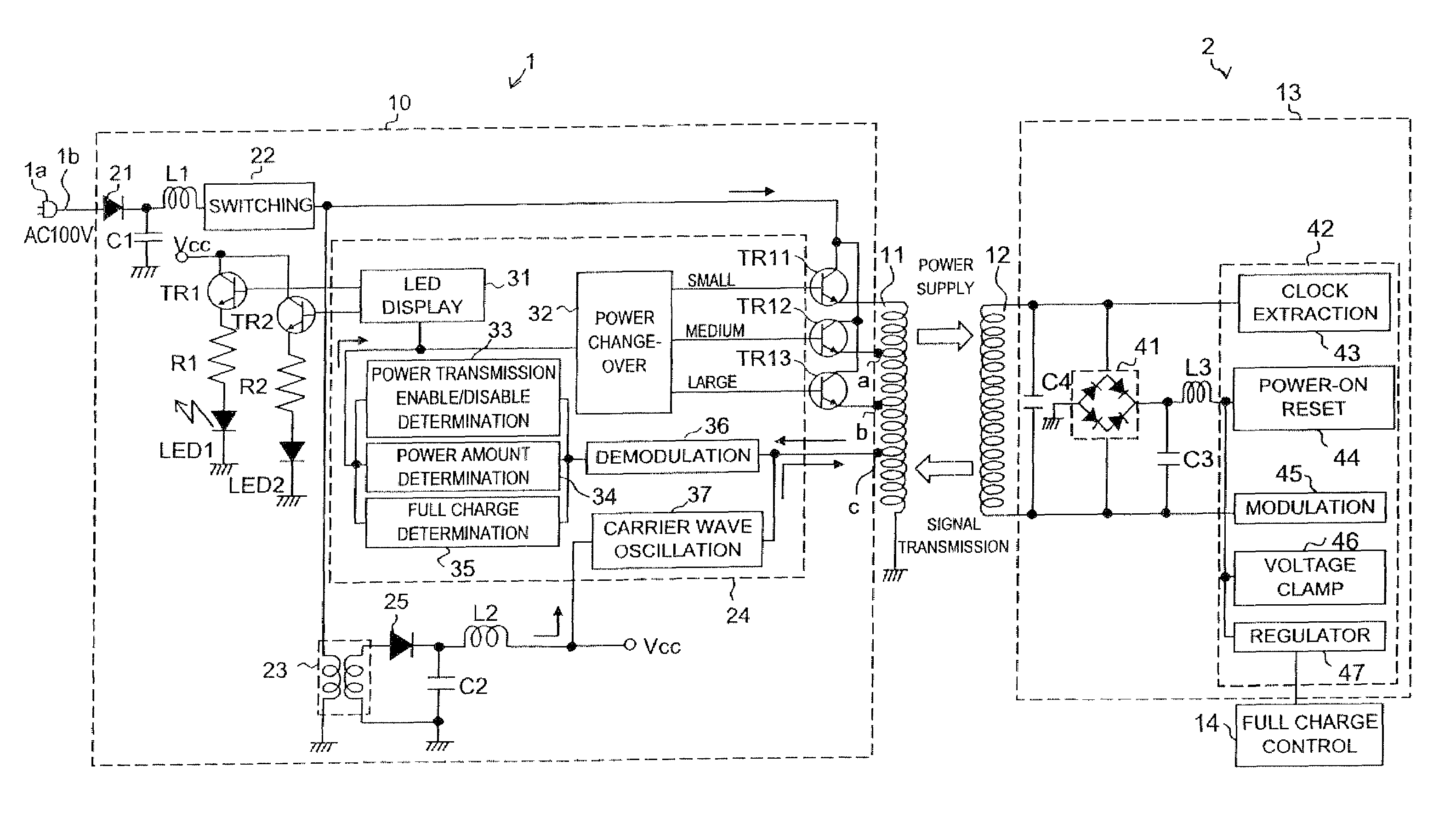

InactiveUS20050068019A1Save spaceDc network circuit arrangementsCircuit monitoring/indicationElectric forceElectricity

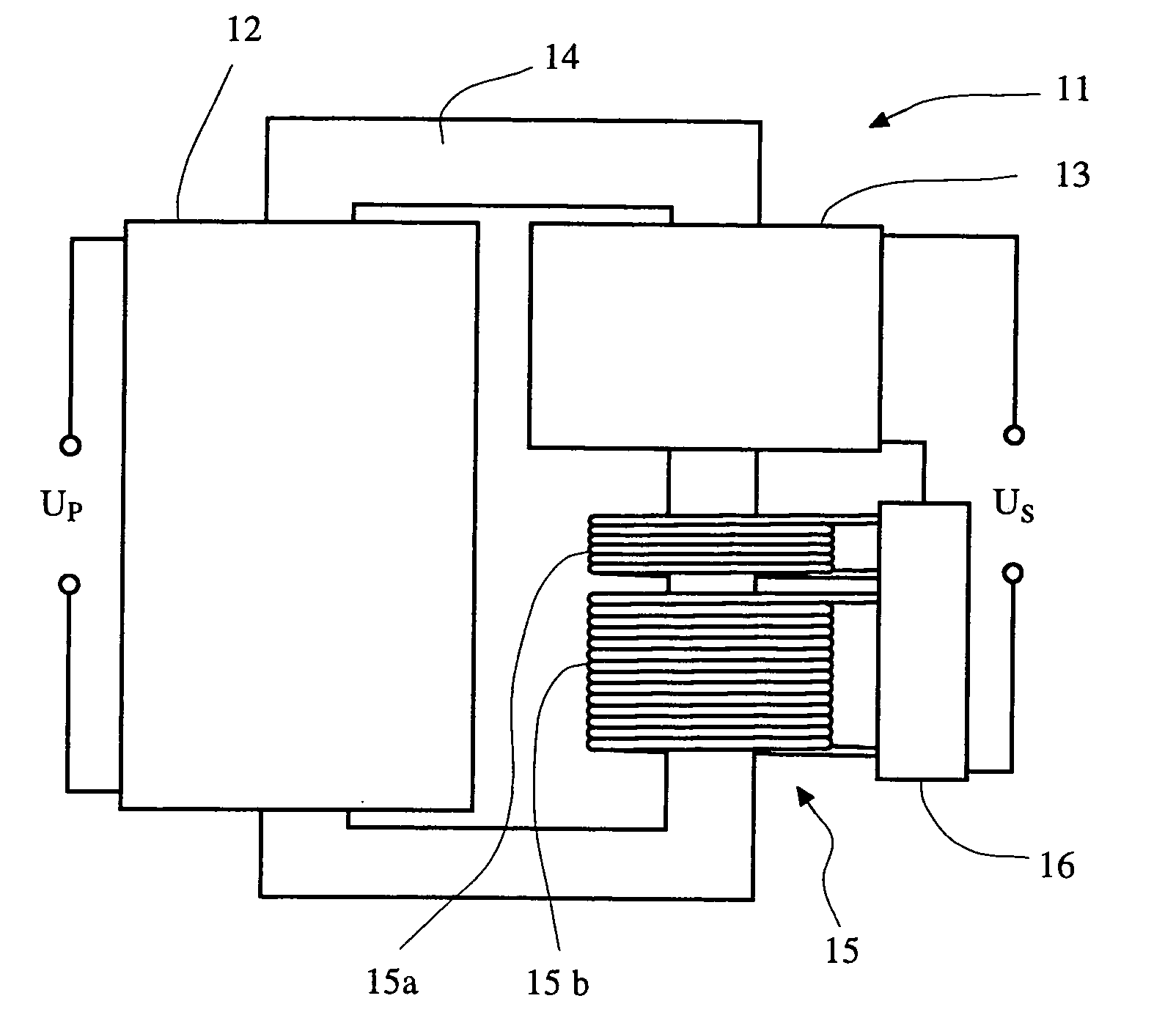

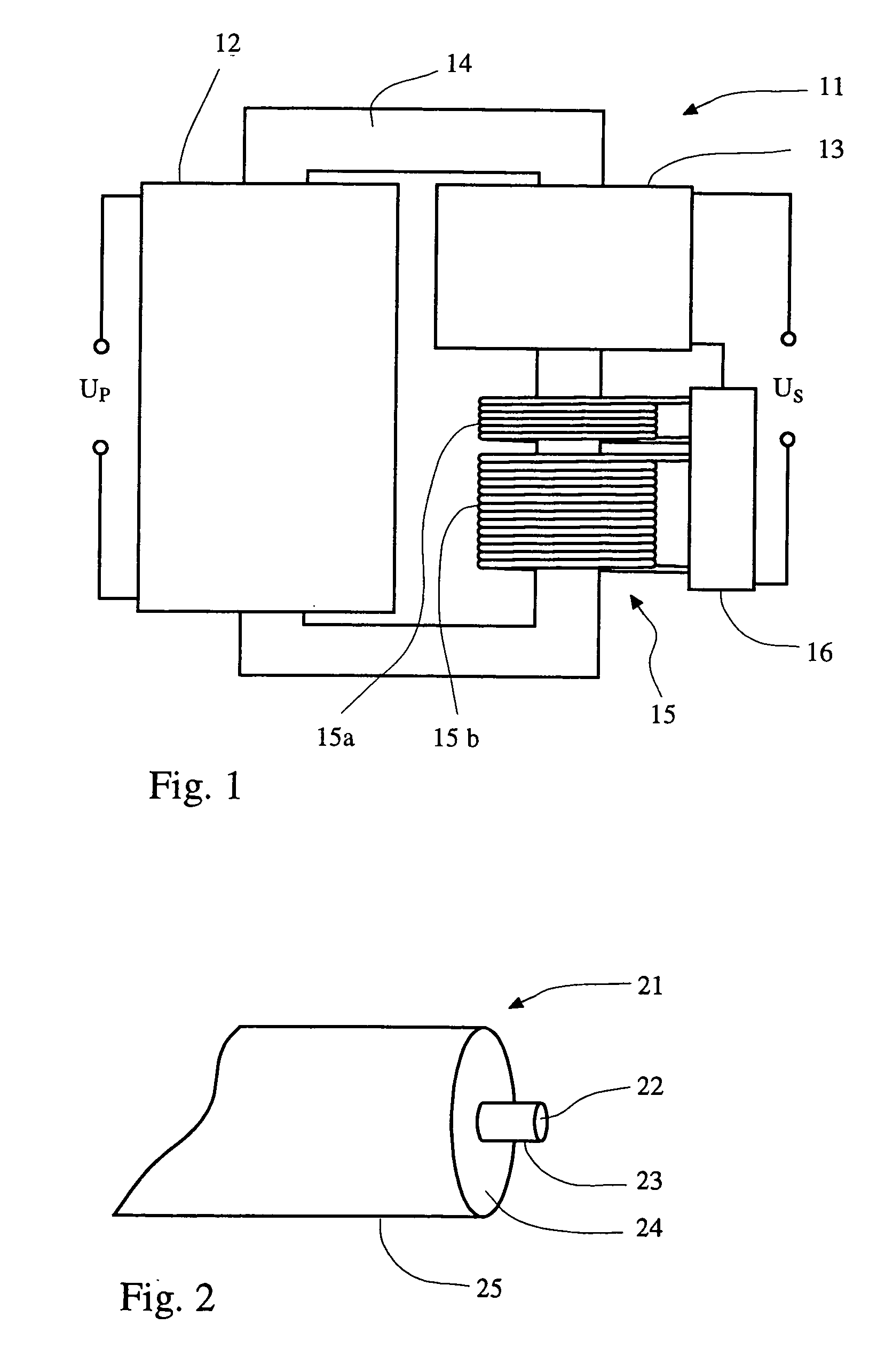

A power supply system according to the present invention comprises: a primary side coil; a power transmission apparatus having a primary side circuit for feeding a pulse voltage resulted from switching a DC voltage which is obtained by rectifying and smoothing a commercial power supply to the primary side coil; a secondary side coil magnetically coupled to the primary side coil; and power reception equipment having a secondary side circuit for rectifying and smoothing voltage induced across the secondary side coil, wherein there is provided a power adjusting section for adjusting a level of power to be transmitted according to power required by the power reception equipment. The power adjusting section has, in the primary side circuit, a carrier wave oscillation circuit for supplying a carrier wave to the primary side coil, a demodulation circuit for demodulating a modulated signal transmitted from the secondary circuit and received by the primary side coil, and a power change-over section for selecting a level of power to be transmitted according to an information signal from the power reception equipment and demodulated by the demodulation circuit. The power adjusting section has, in the secondary side circuit, a modulation circuit for modulating the carrier wave fed from the carrier wave oscillation circuit and received by the secondary side coil with the information signal from the power reception equipment and transmitting the modulated signal.

Owner:SHARP KK

Power supply system

InactiveUS7233137B2Save spaceCircuit monitoring/indicationVolume/mass flow measurementElectric power transmissionCarrier signal

A power supply system is provided, having: a primary side coil; a power transmission apparatus having a primary side circuit for feeding a pulse voltage resulted from switching a DC voltage which is obtained by rectifying and smoothing a commercial power supply to the primary side coil; a secondary side coil magnetically coupled to the primary side coil; and power reception equipment having a secondary side circuit for rectifying and smoothing voltage induced across the secondary side coil, wherein there is provided a power adjusting section for adjusting a level of power to be transmitted according to power required by the power reception equipment. The power adjusting section has, in the primary side circuit, a carrier wave oscillation circuit for supplying a carrier wave to the primary side coil, a demodulation circuit for demodulating a modulated signal transmitted from the secondary circuit and received by the primary side coil, and a power change-over section for selecting a level of power to be transmitted according to an information signal from the power reception equipment and demodulated by the demodulation circuit. The power adjusting section has, in the secondary side circuit, a modulation circuit for modulating the carrier wave fed from the carrier wave oscillation circuit and received by the secondary side coil with the information signal from the power reception equipment and transmitting the modulated signal.

Owner:SHARP KK

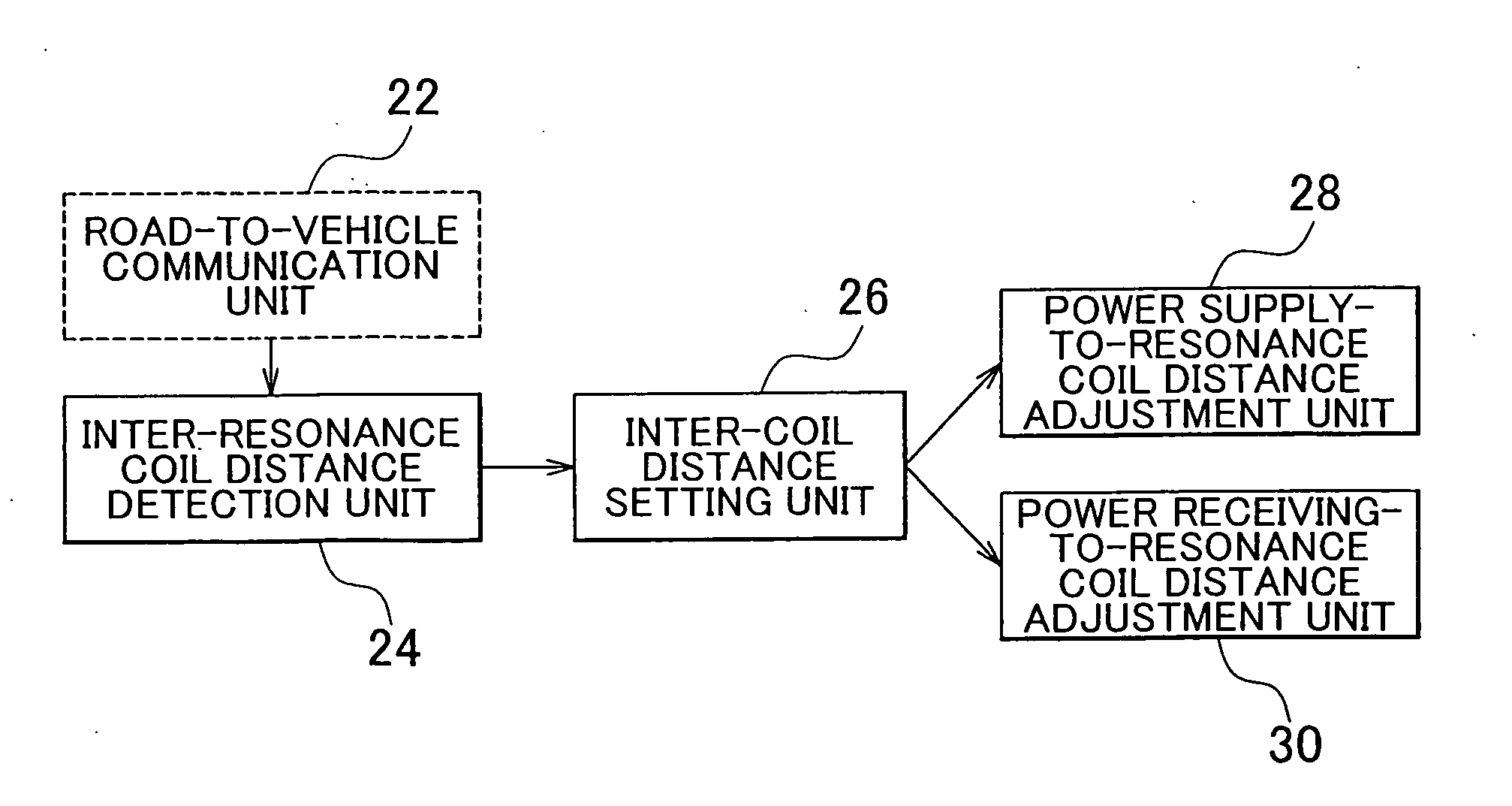

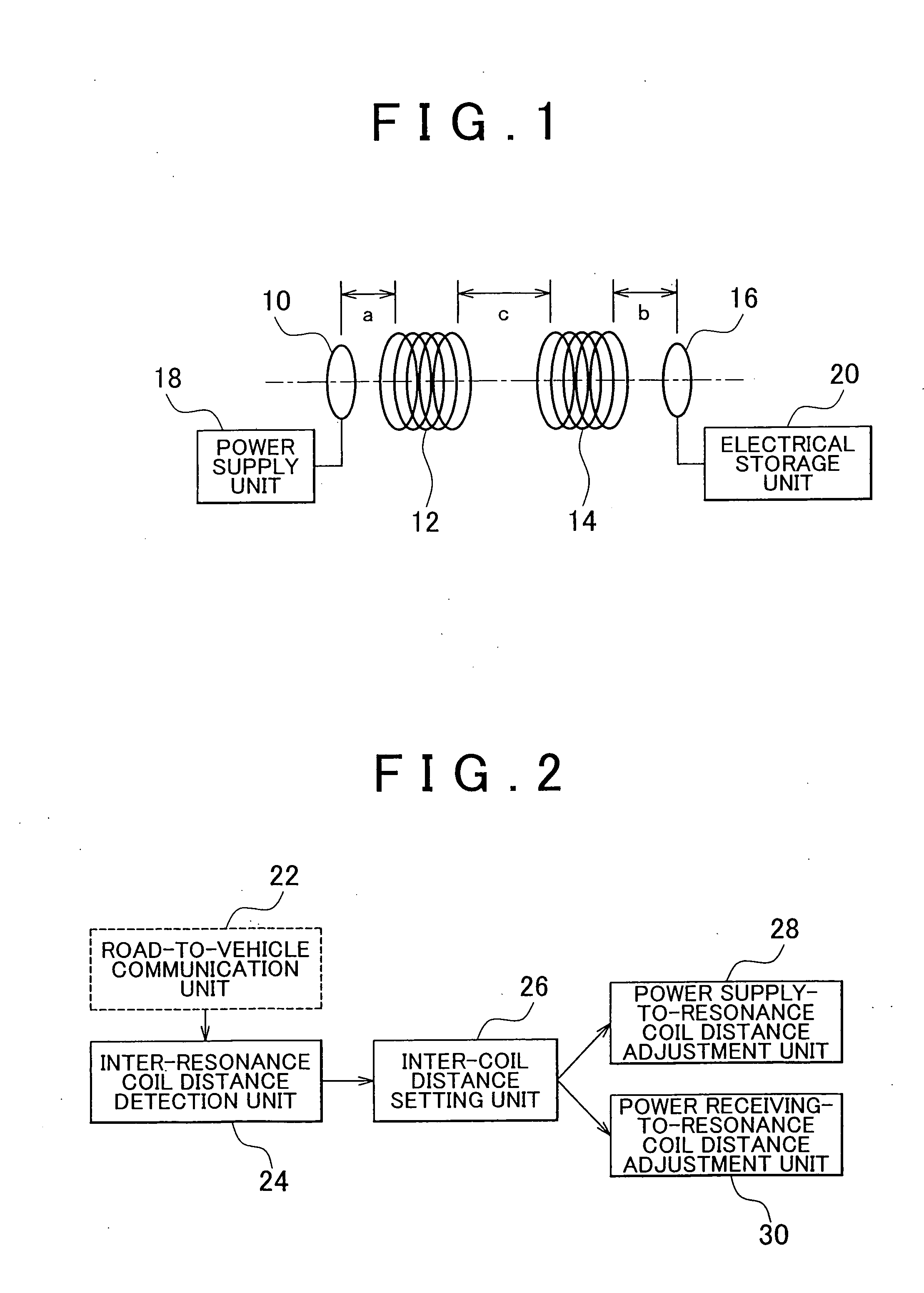

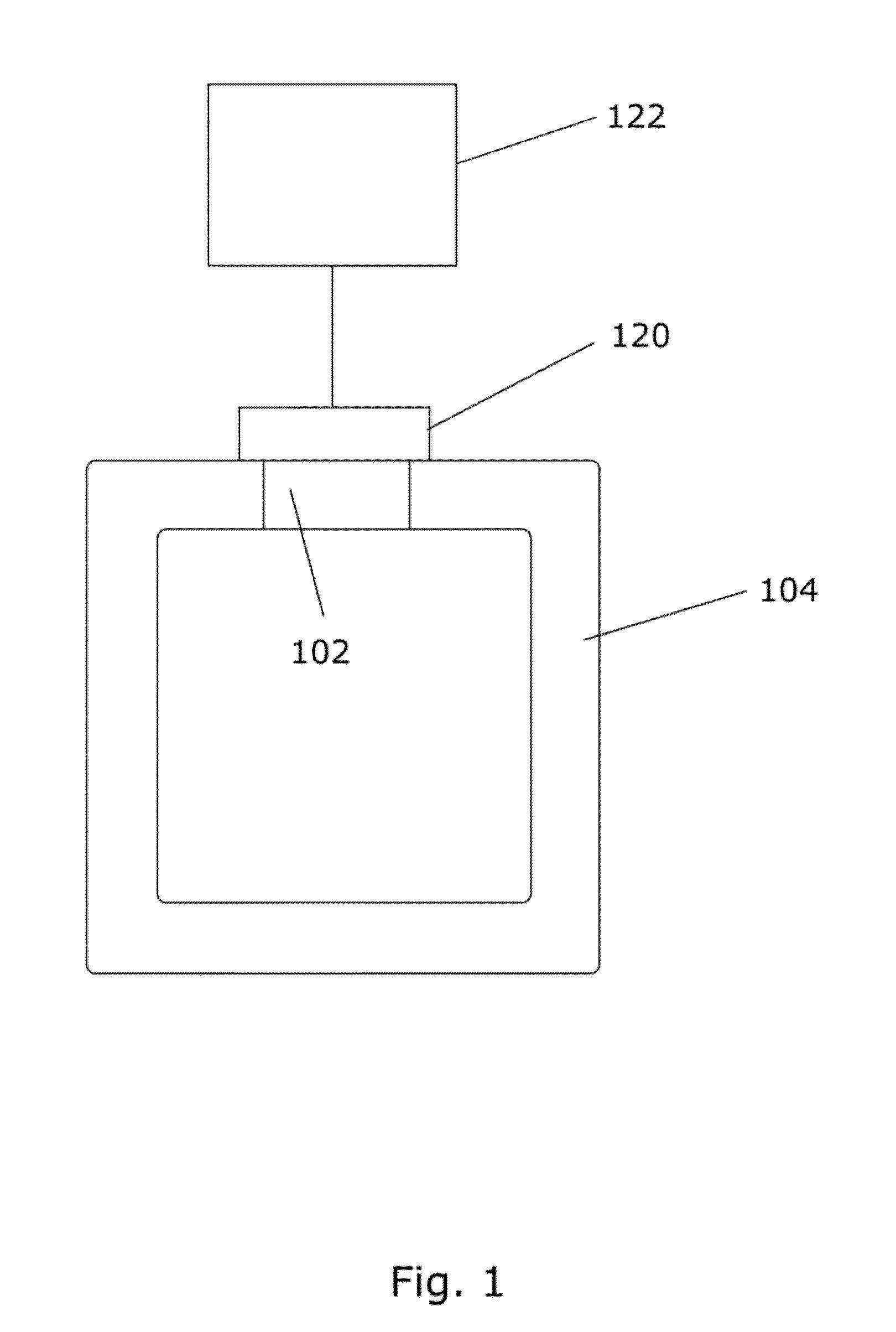

Power supply system and method of controlling power supply system

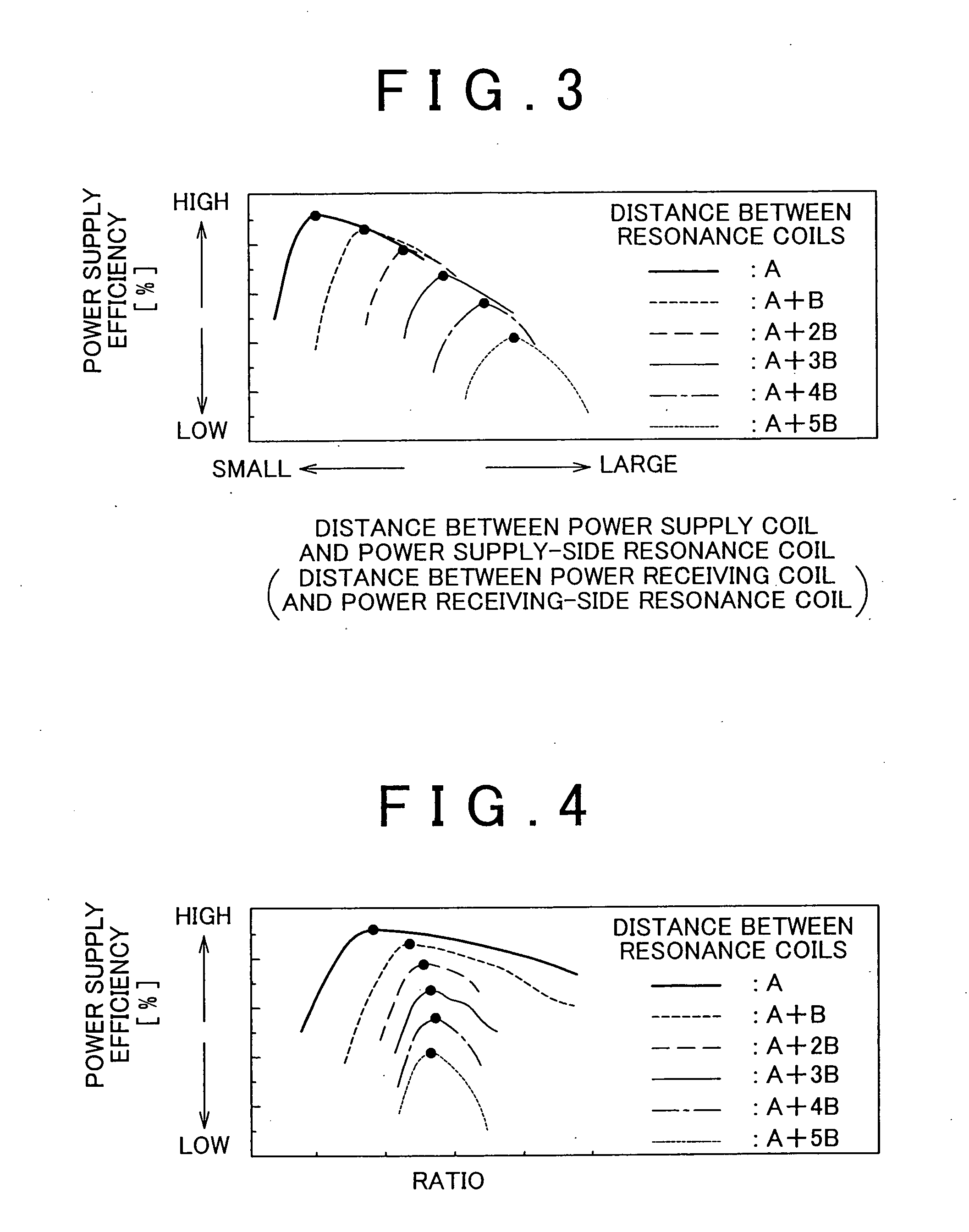

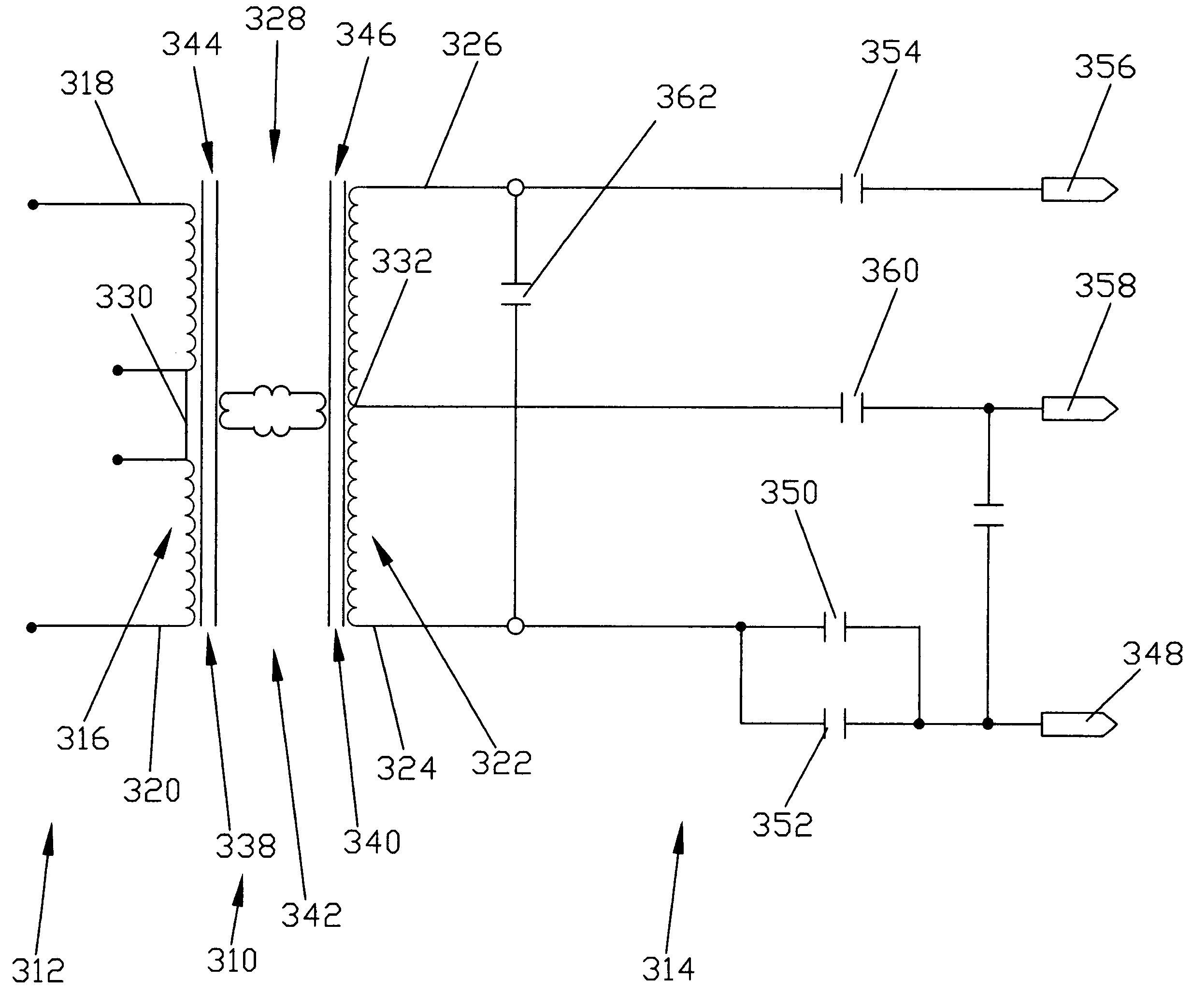

ActiveUS20100123452A1Maximize total power supply efficiencyMaintain and improve power supply efficiencyCircuit monitoring/indicationCharging stationsElectricityControl power

A power supply system that includes: a power supply coil and a power supply-side resonance coil that are provided at a facility; a power receiving coil and a power receiving-side resonance coil that are provided for a mobile unit; a power supply-side detection unit that detects a position of the power supply-side resonance coil; a power receiving-side detection unit that detects a position of the power receiving-side resonance coil; and an adjustment unit that adjusts a relative position of the power supply coil with respect to the power supply-side resonance coil and a relative position of the power receiving coil with respect to the power receiving-side resonance coil on the basis of the position of the power supply-side resonance coil and the position of the power receiving-side resonance coil.

Owner:TOYOTA JIDOSHA KK

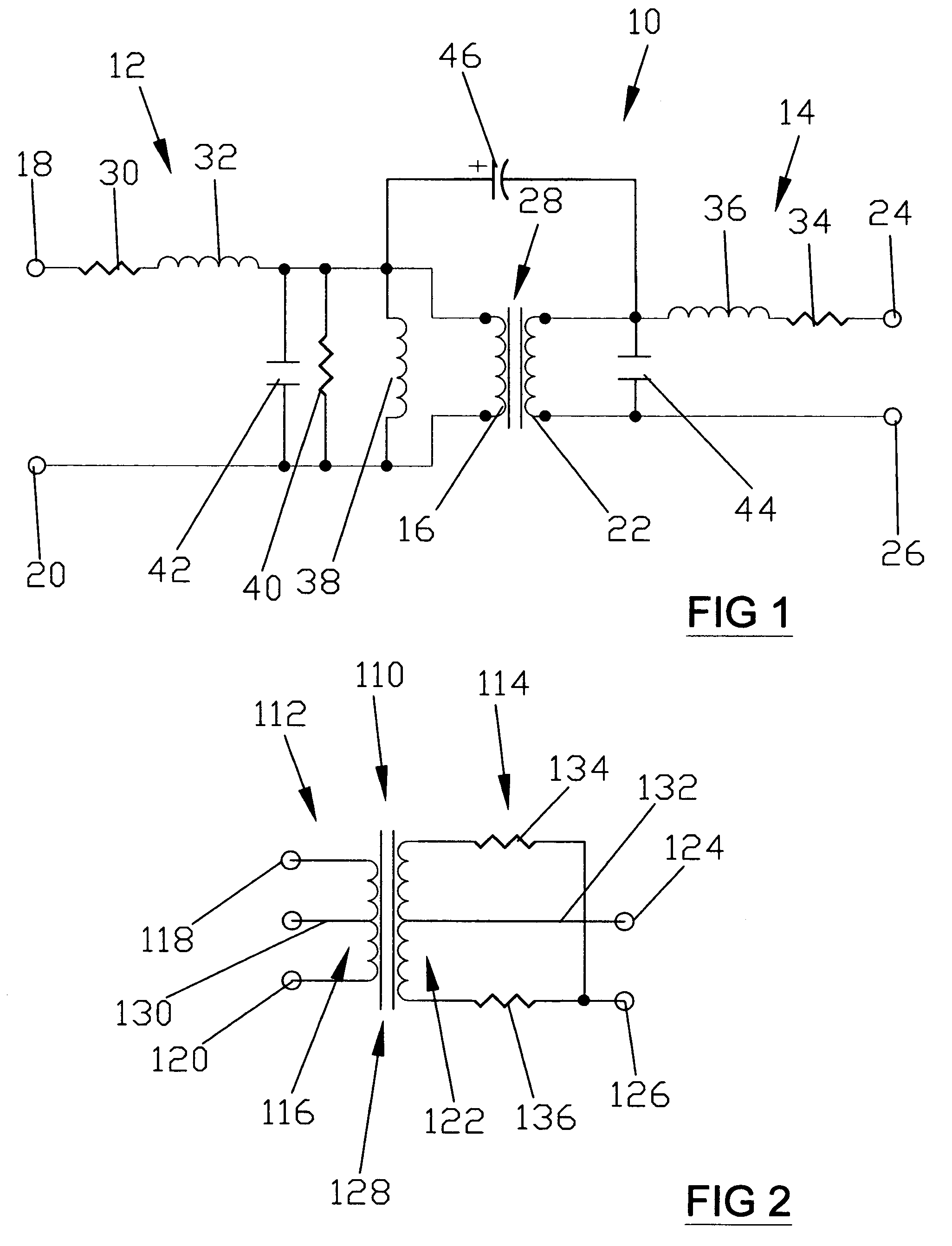

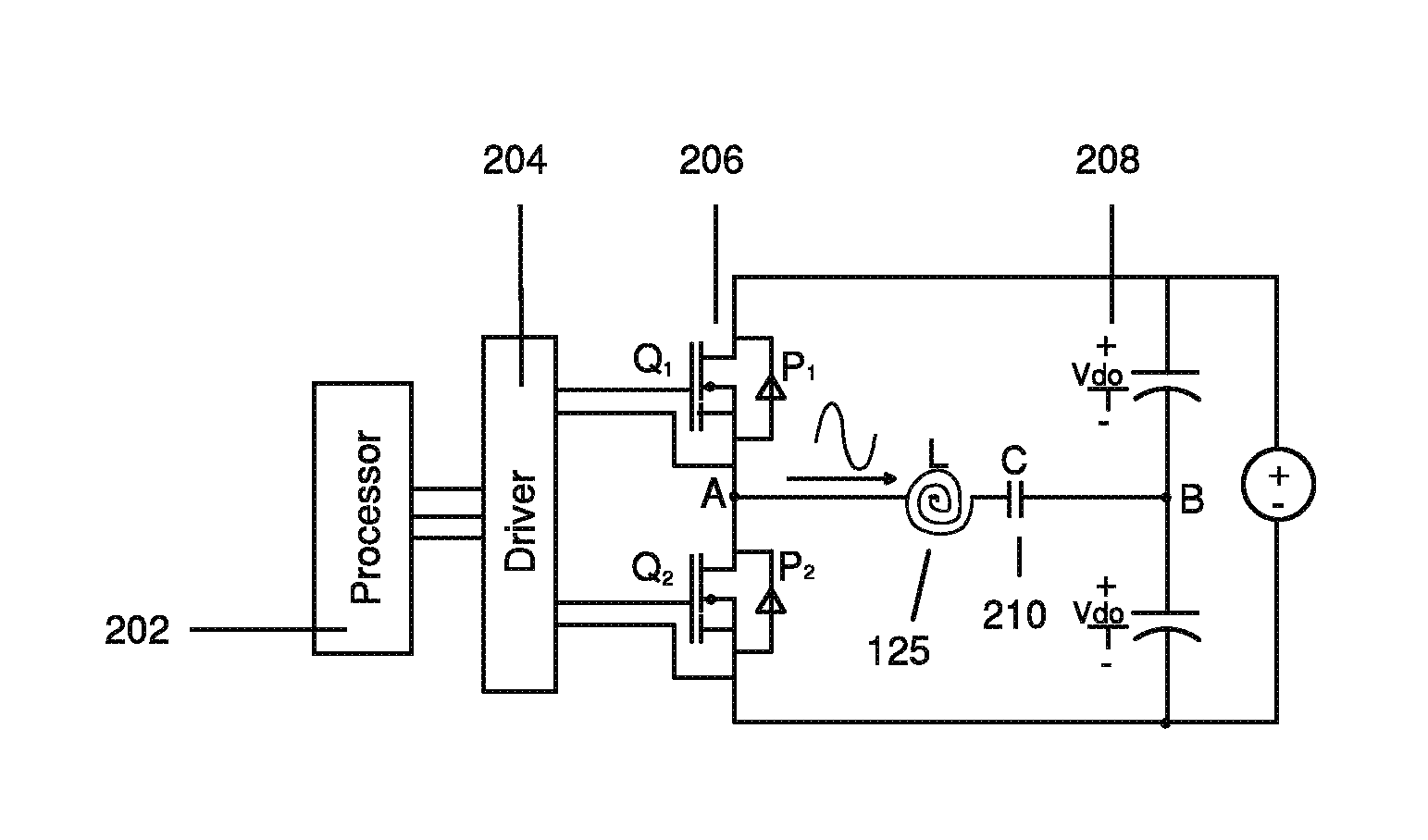

Planar transformer power supply

ActiveUS7502234B2Reduce negative impactMinimizing stray capacitanceDc-dc conversionConversion without intermediate conversion to dcCapacitanceLow load

A planar transformer power supply for an electrosurgical device to minimize stray capacitance comprising a step down / step-up isolation transformer and circuitry to limit the effects of a short circuit in the output of the planar transformer power supply on the input to the planar transformer power supply to enhance power capacity at a low load impedance as low as from about 5 ohms to about 10 ohms and to operate at resonance at the output of the planar transformer power supply.

Owner:BOVIE MEDICAL CORP

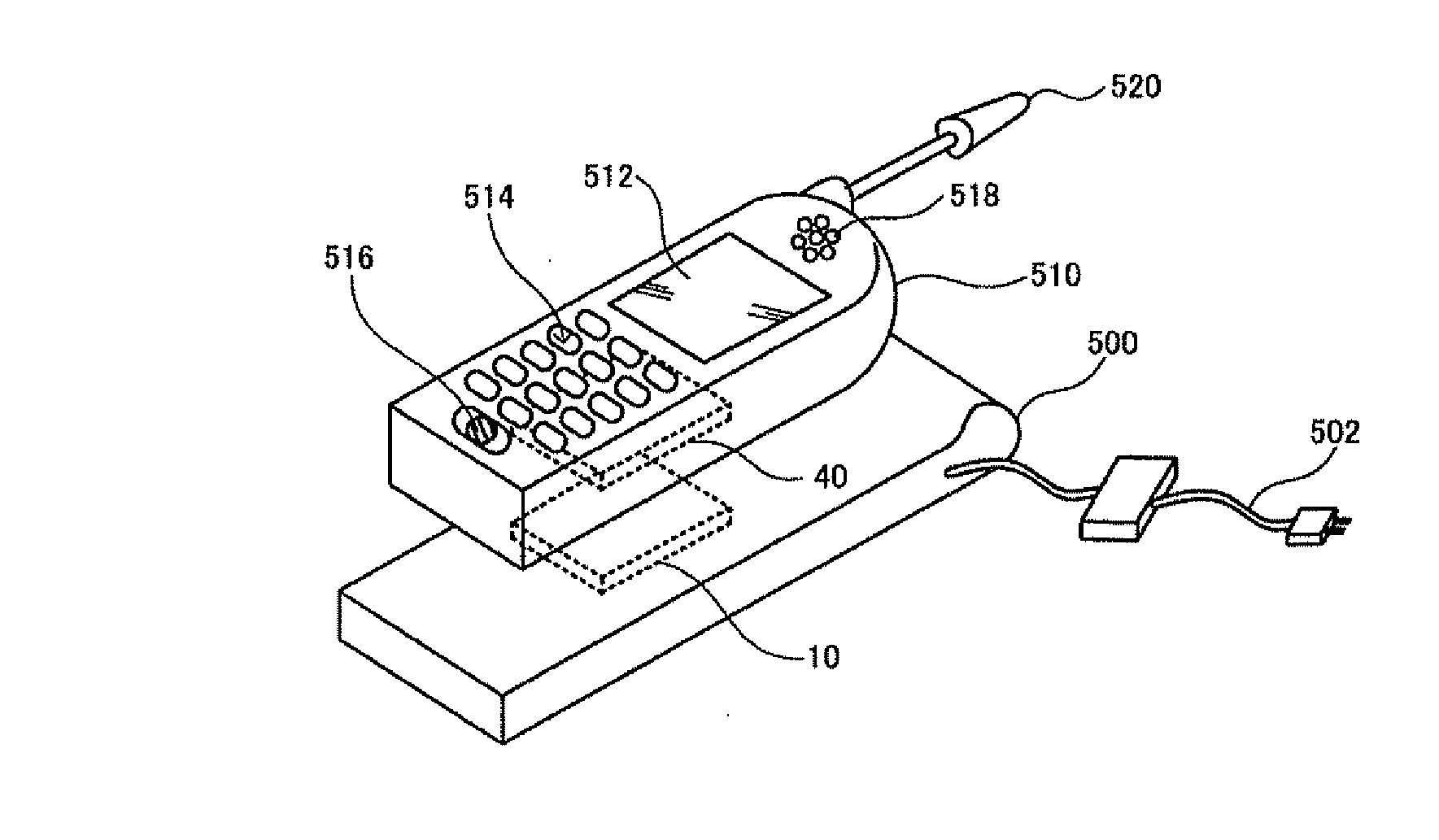

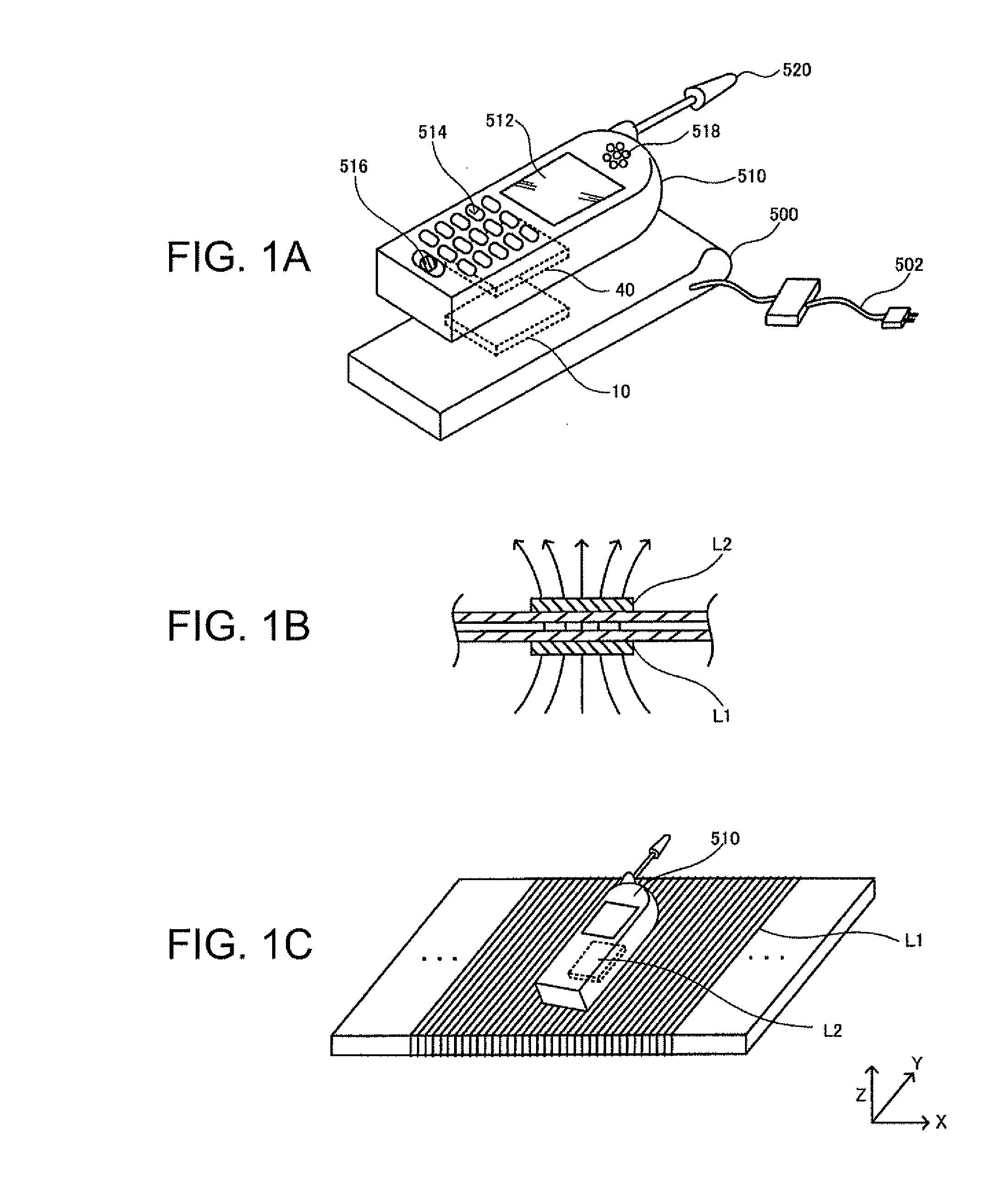

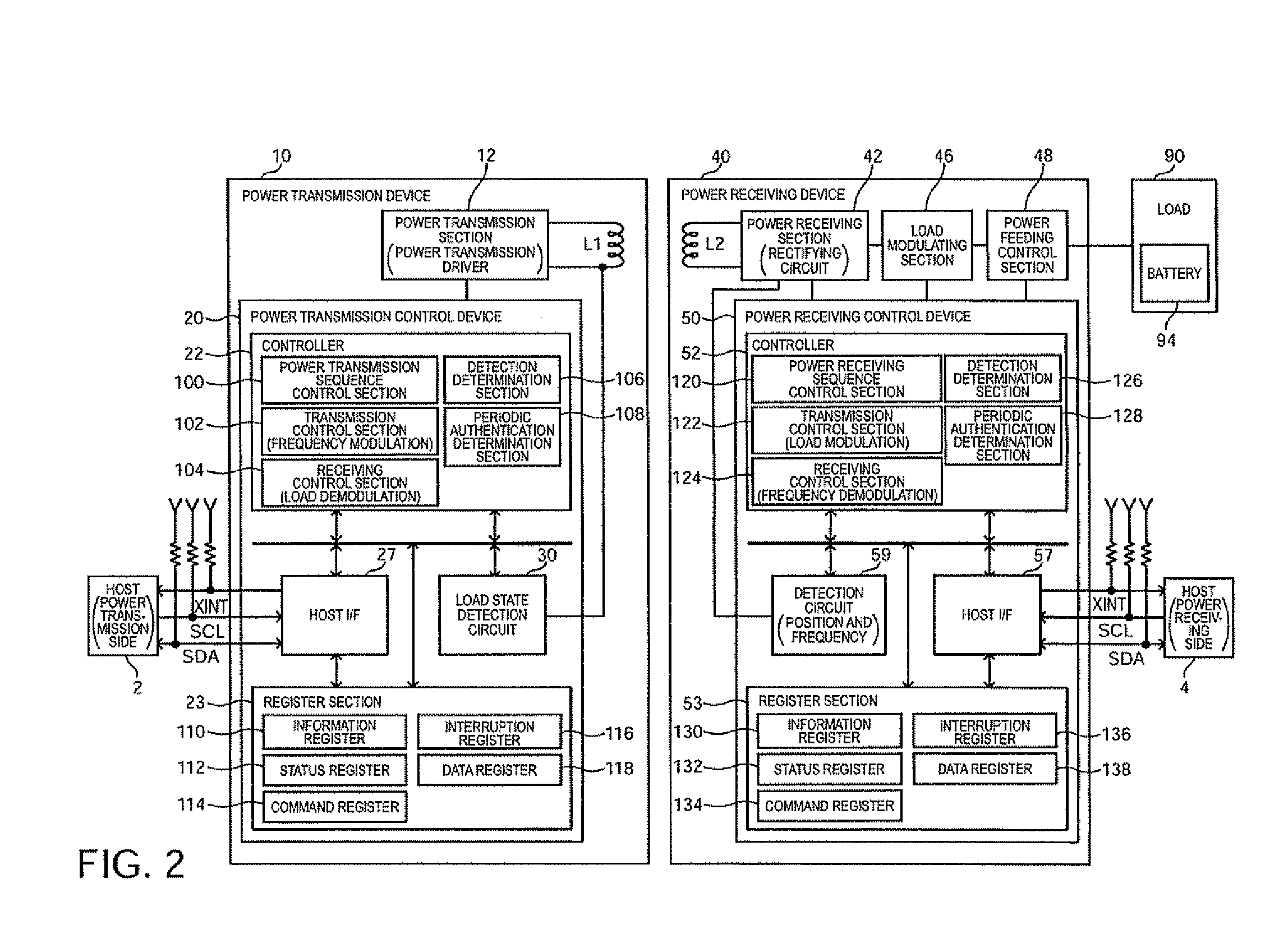

Power transmission control device, power transmission device, power receiving control device, power receiving device, and electronic apparatus

ActiveUS20100013319A1Efficient use ofReduce electricity loadVariable inductances/transformersSubstation equipmentElectricityElectric power transmission

There is provided a power transmission control device included in a power transmission device in a contactless power transmission system that transmits power from the power transmission device to a power receiving device by electromagnetically coupling a primary coil to a secondary coil to supply the power to a load of the power receiving device. The power transmission control device includes a controller controlling the power transmission control device, a host interface communicating with a power transmission-side host, and a register section accessible from the power transmission-side host via the host interface. The controller shifts into a communication mode that executes communication between the power transmission-side host and a power receiving-side host, when the power transmission-side host writes, via the host interface, a communication request command that requests the communication between the hosts in the register section. Then, the controller transmits the communication request command to the power receiving device.

Owner:138 EAST LCD ADVANCEMENTS LTD

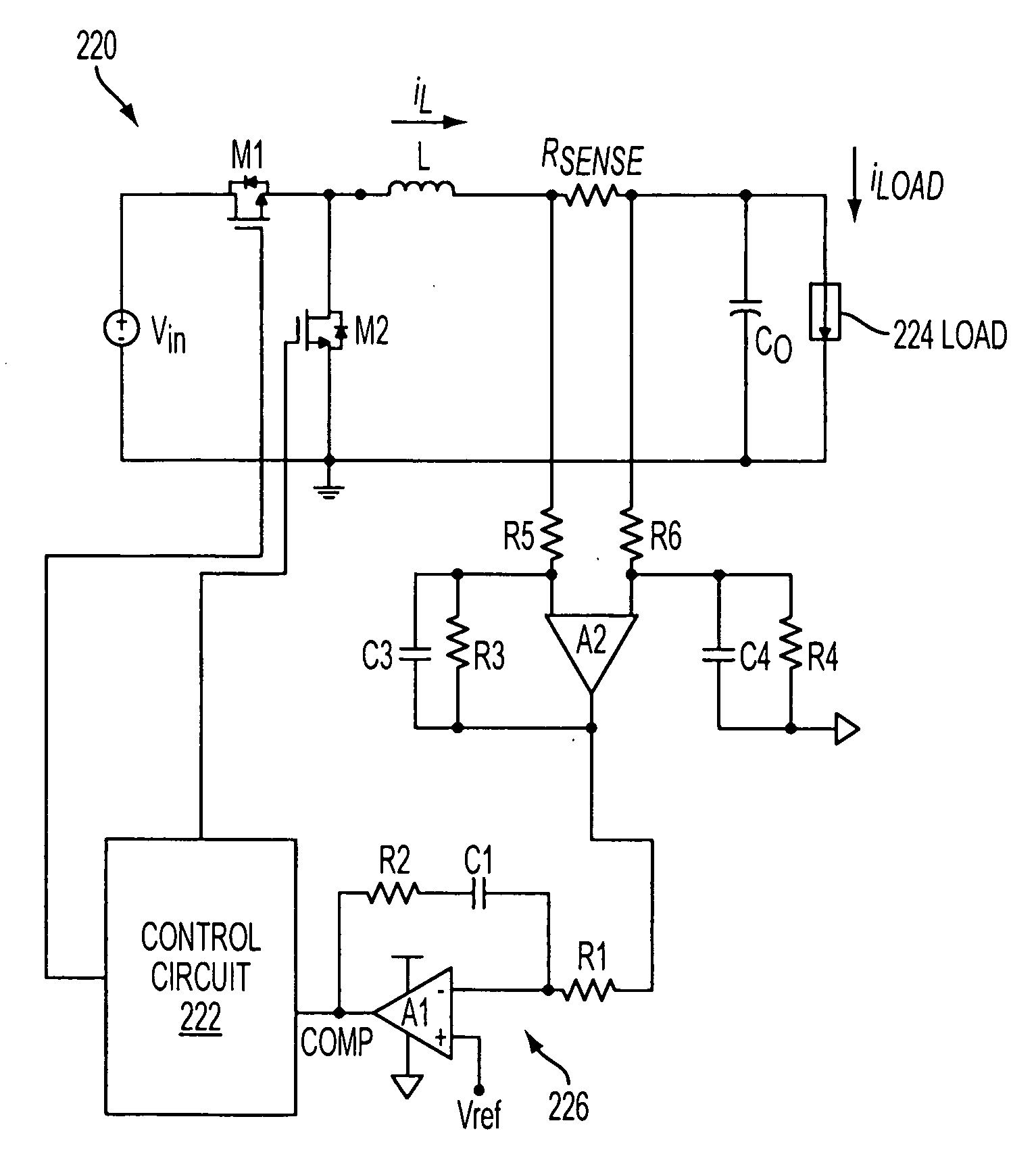

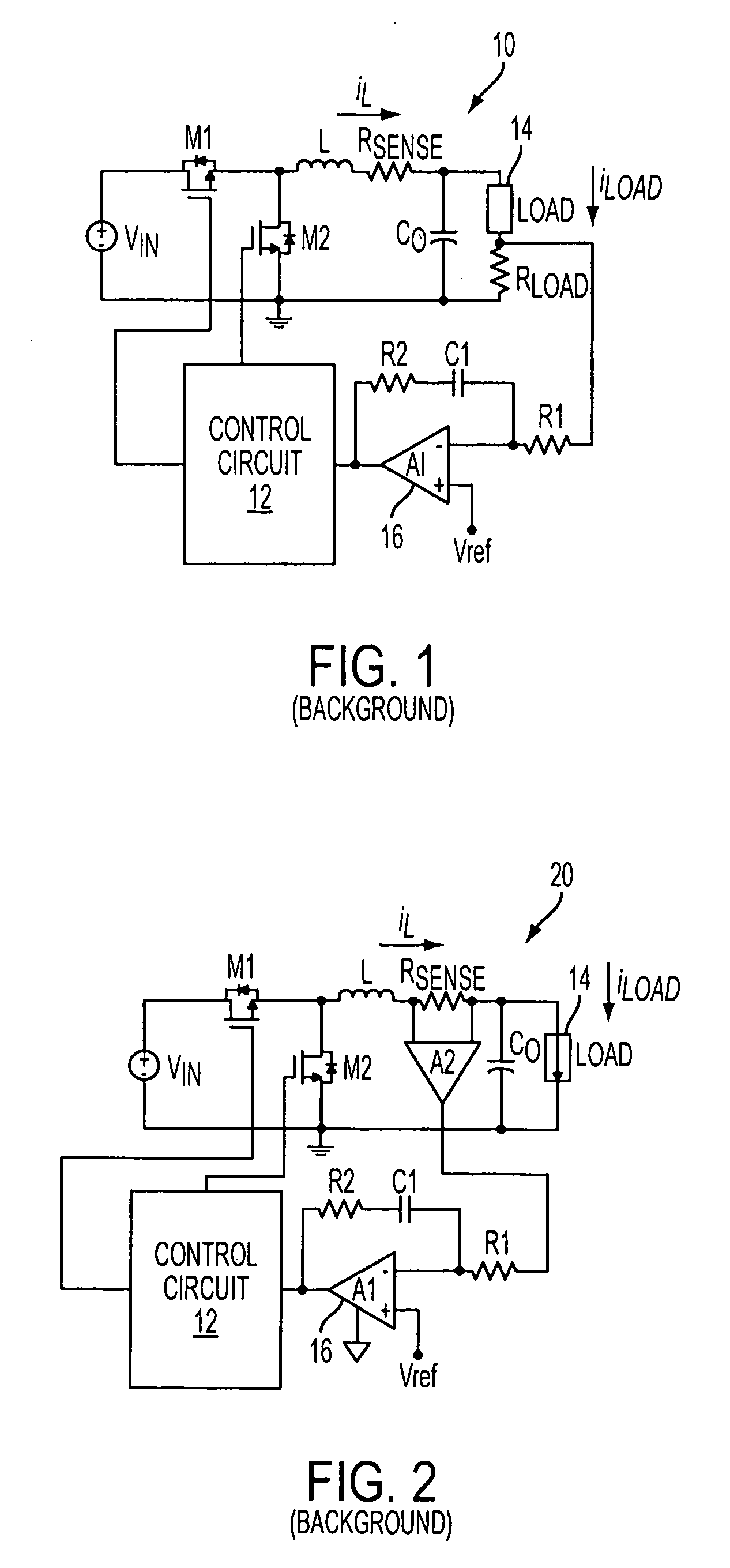

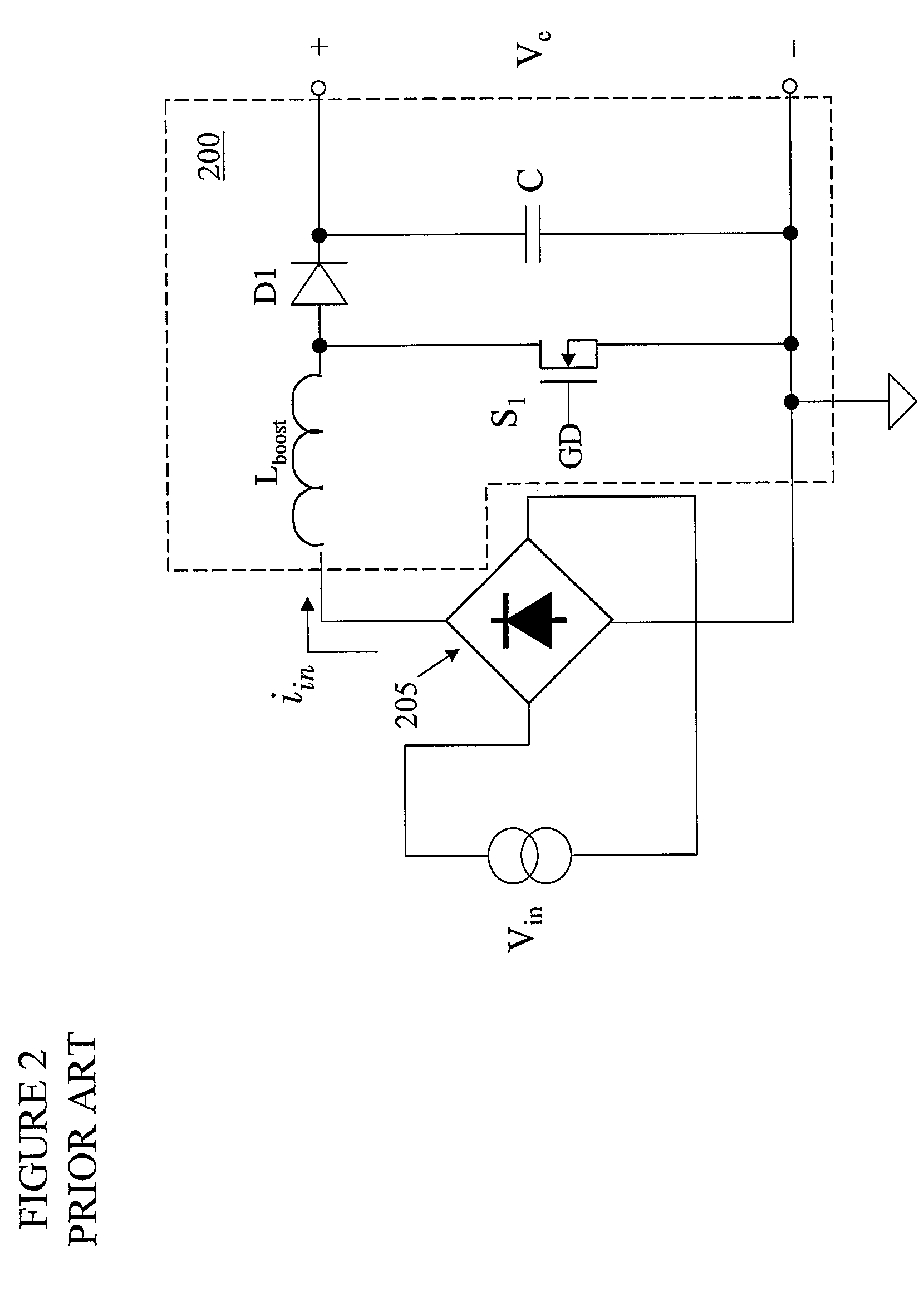

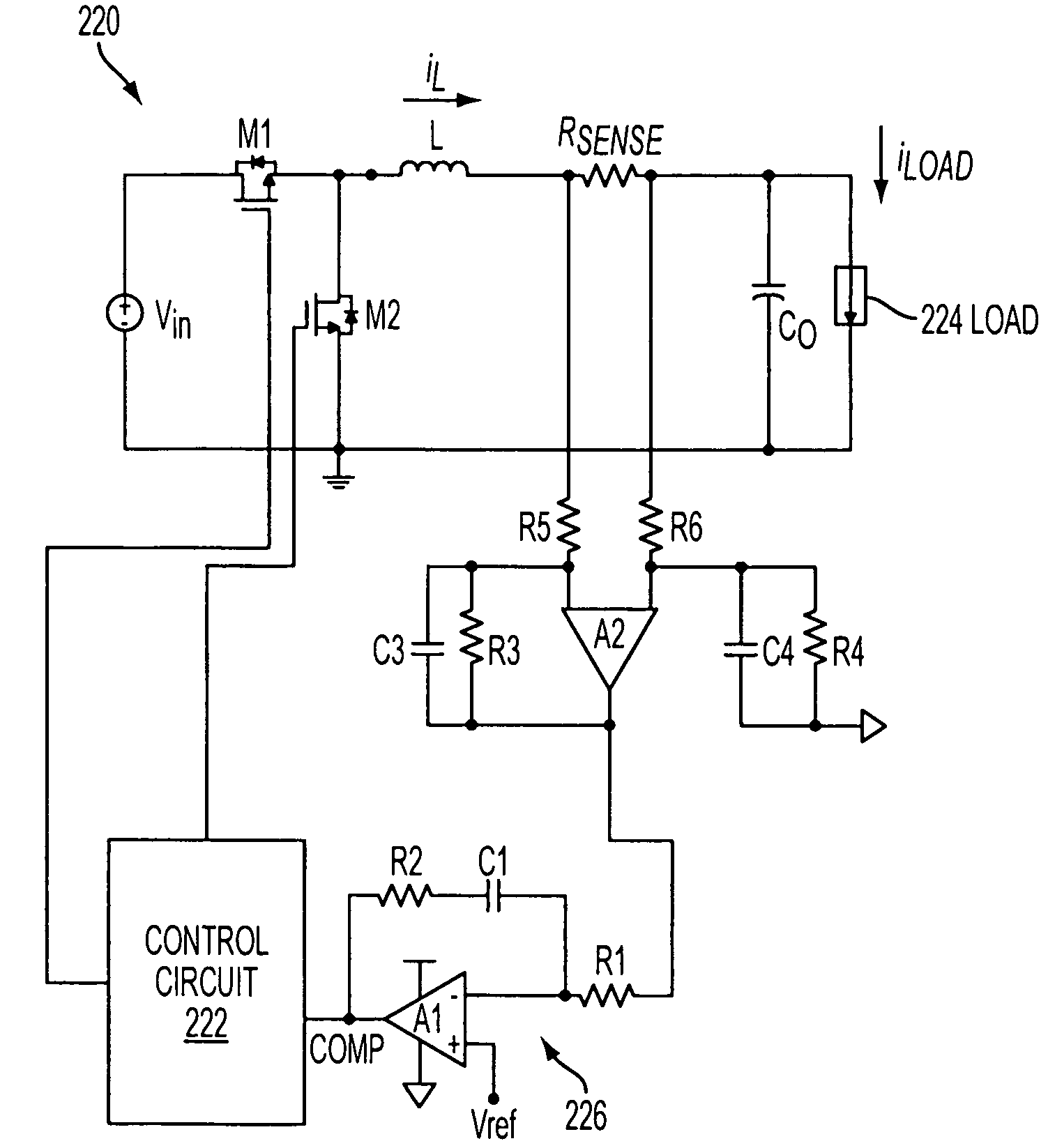

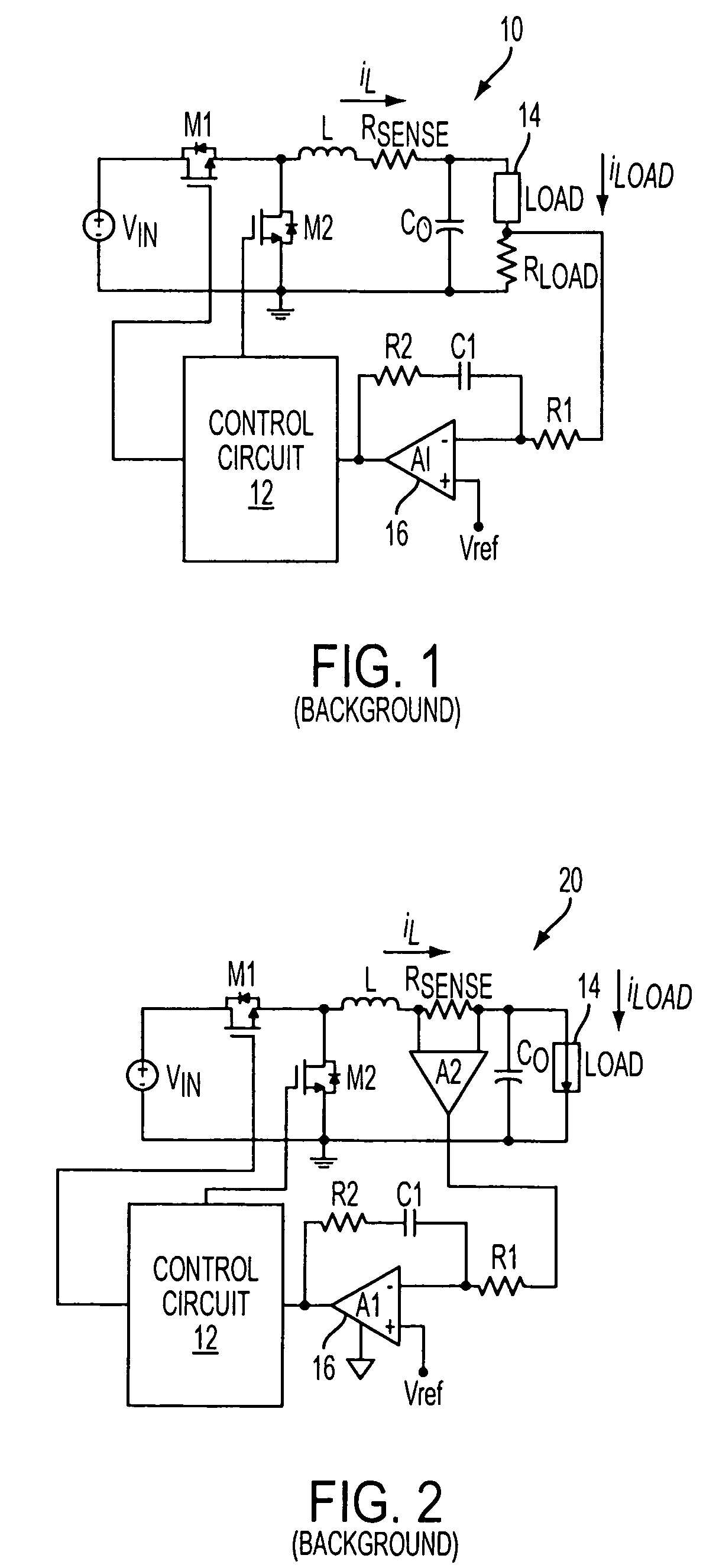

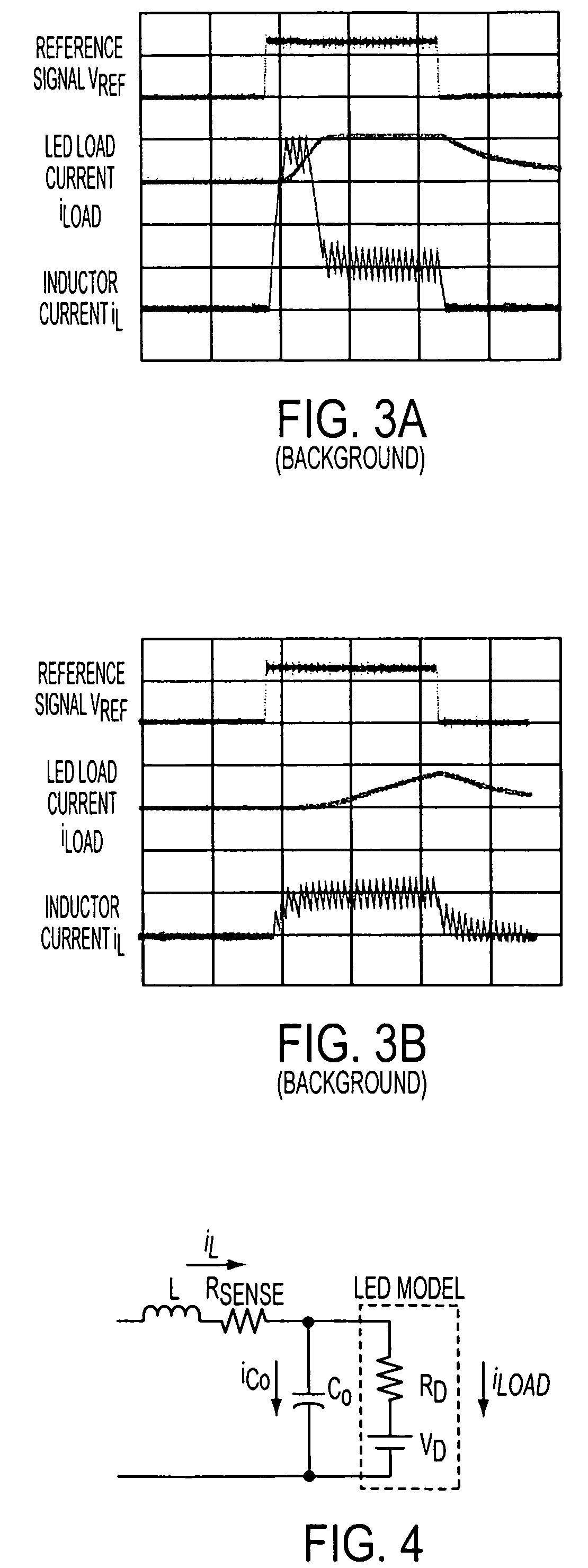

Current source with indirect load current signal extraction

A switching circuit for supplying current to a load has a switching element, an inductive element coupled to the switching element, and a load current extraction circuit responsive to current in the inductive element for producing a load current signal as a simulated current approximating current in the load.

Owner:ANALOG DEVICES INT UNLTD

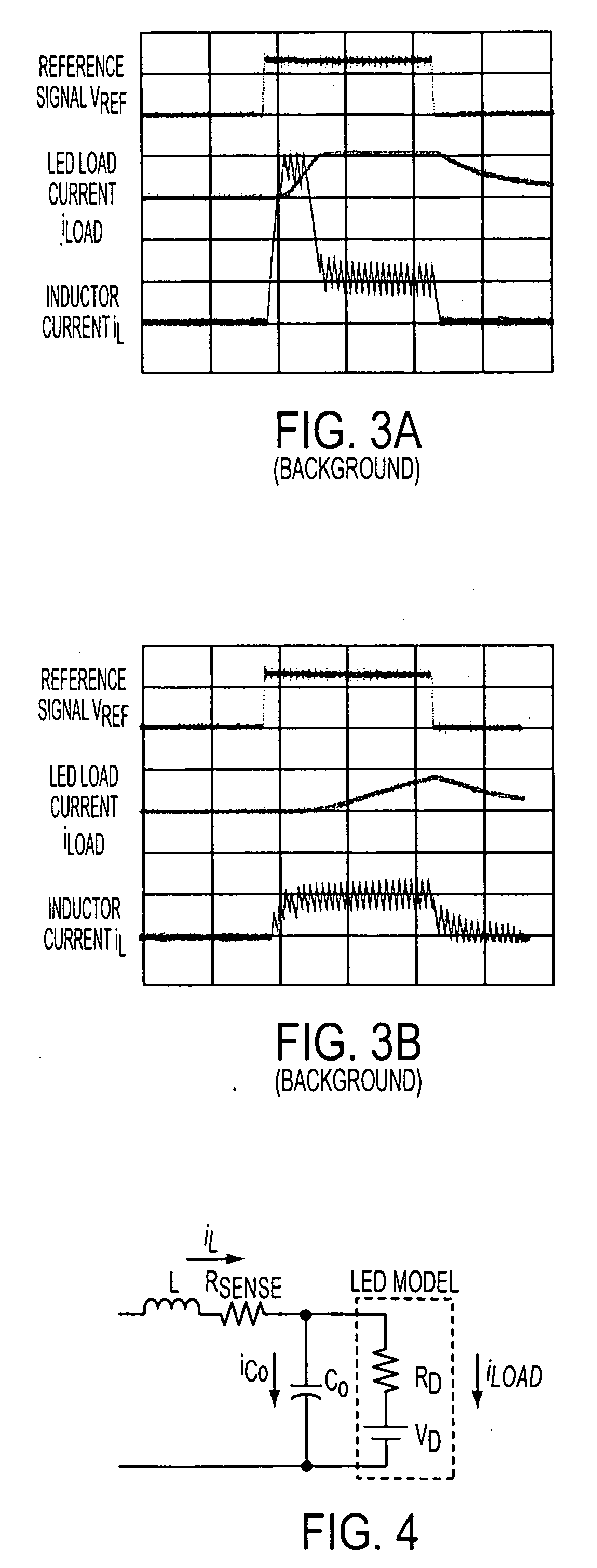

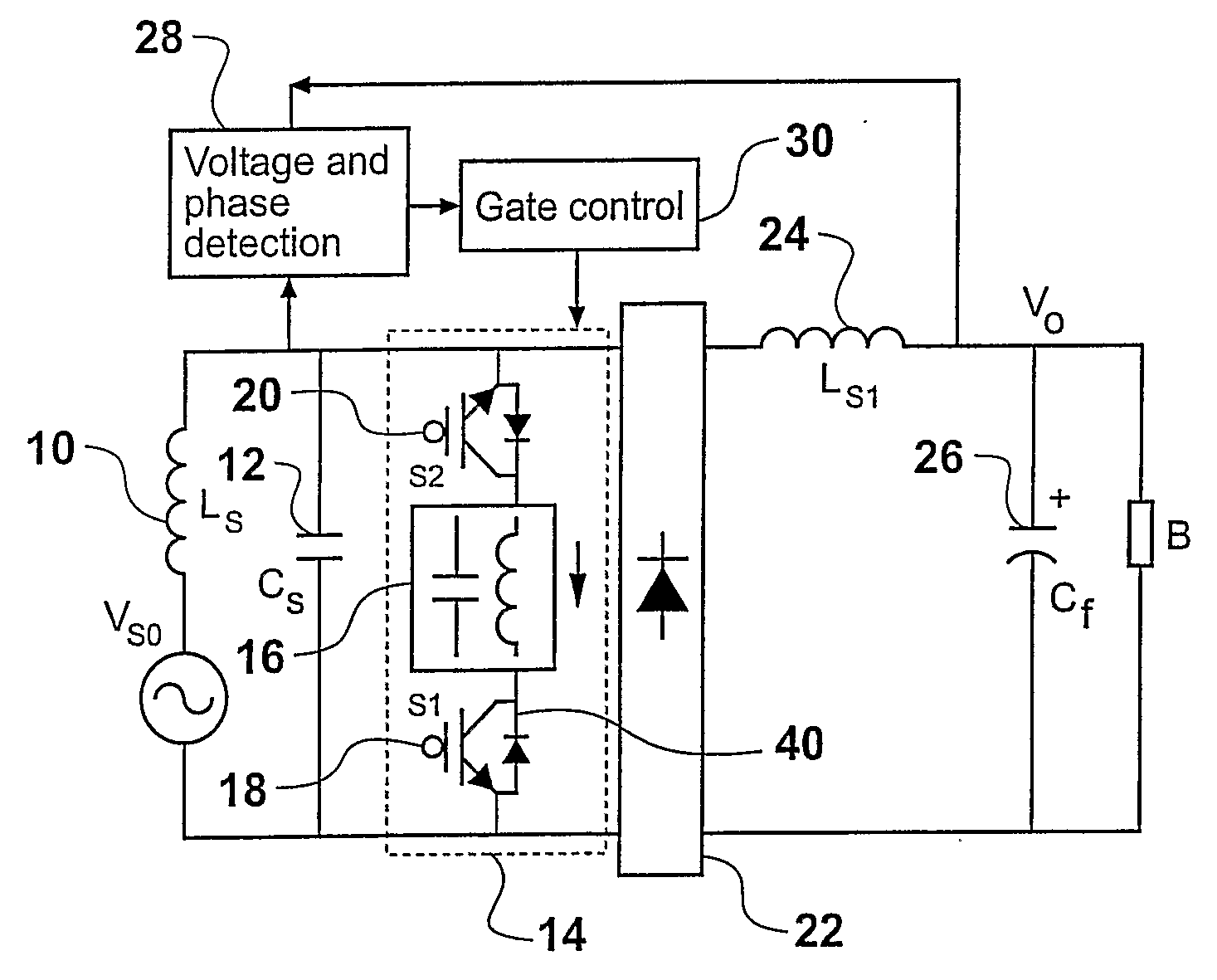

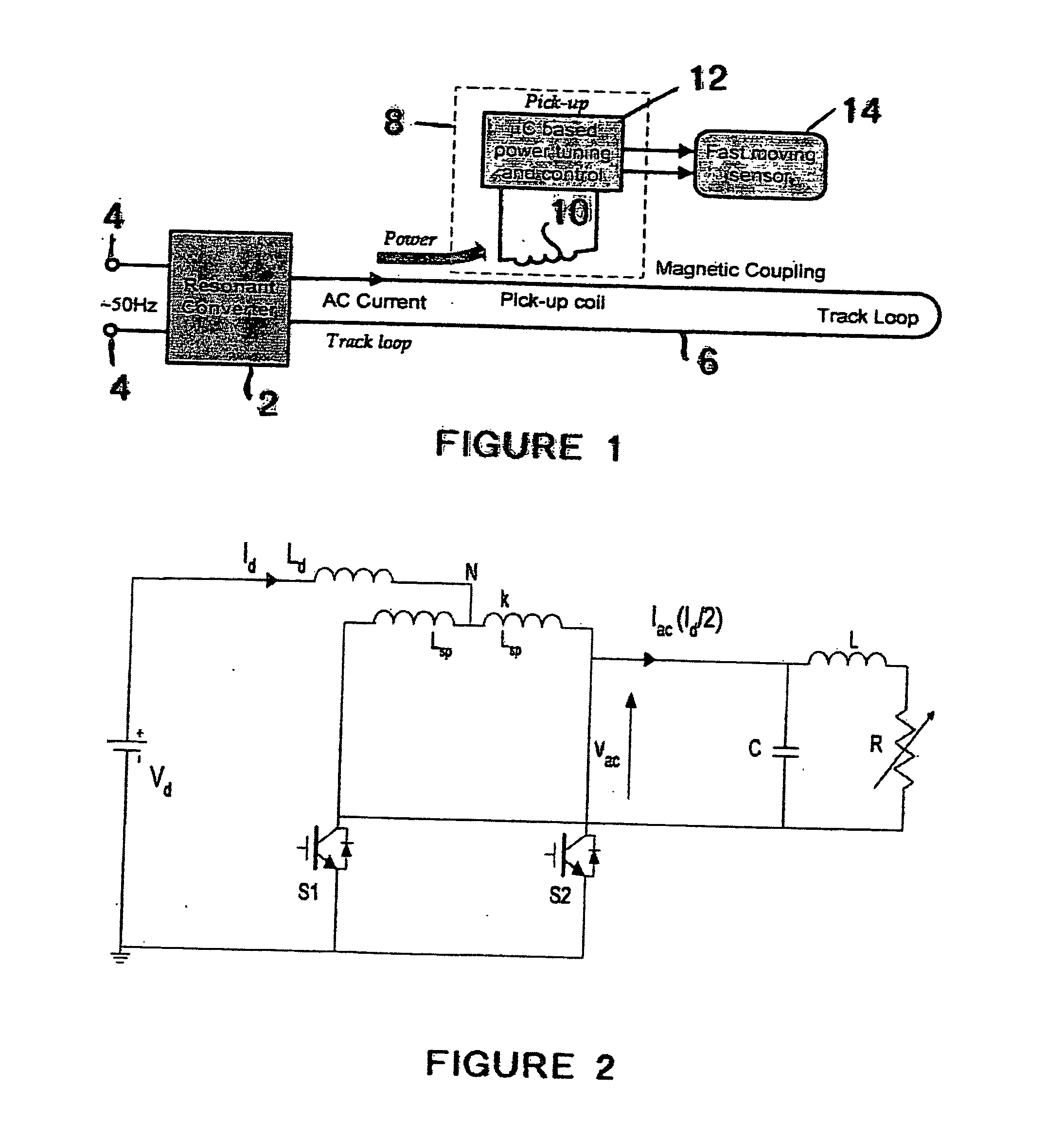

Inductively Powered Mobile Sensor System

ActiveUS20070296393A1Batteries circuit arrangementsElectromagnetic wave systemPower sensorEngineering

The present invention provides an inductively powered sensor system having a primary conductive path capable of being energized to provide an electromagnetic field in a defined space. An inductive power pick-up is associated with a sensor and is capable of receiving power from the field to supply the sensor. The system includes a first sensing unit to sense the power available to the pick-up and a control unit to increase or decrease the power available to the sensor dependant on the sensed power available. A method of inductively powering a sensor, an inductively powered sensor and an animal enclosure including one or more primary conductive path of an inductive power supply are also disclosed.

Owner:AUCKLAND UNISERVICES LTD

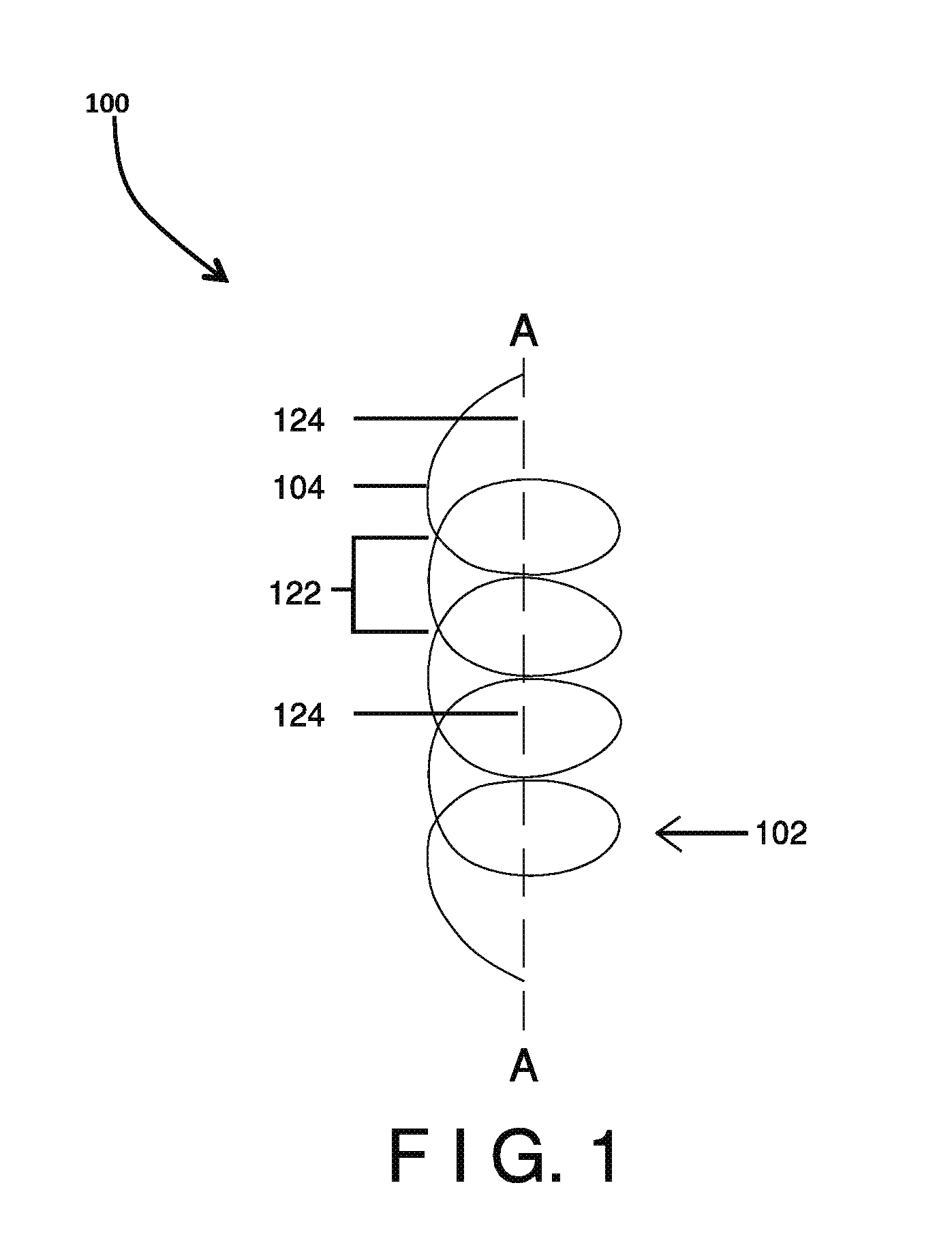

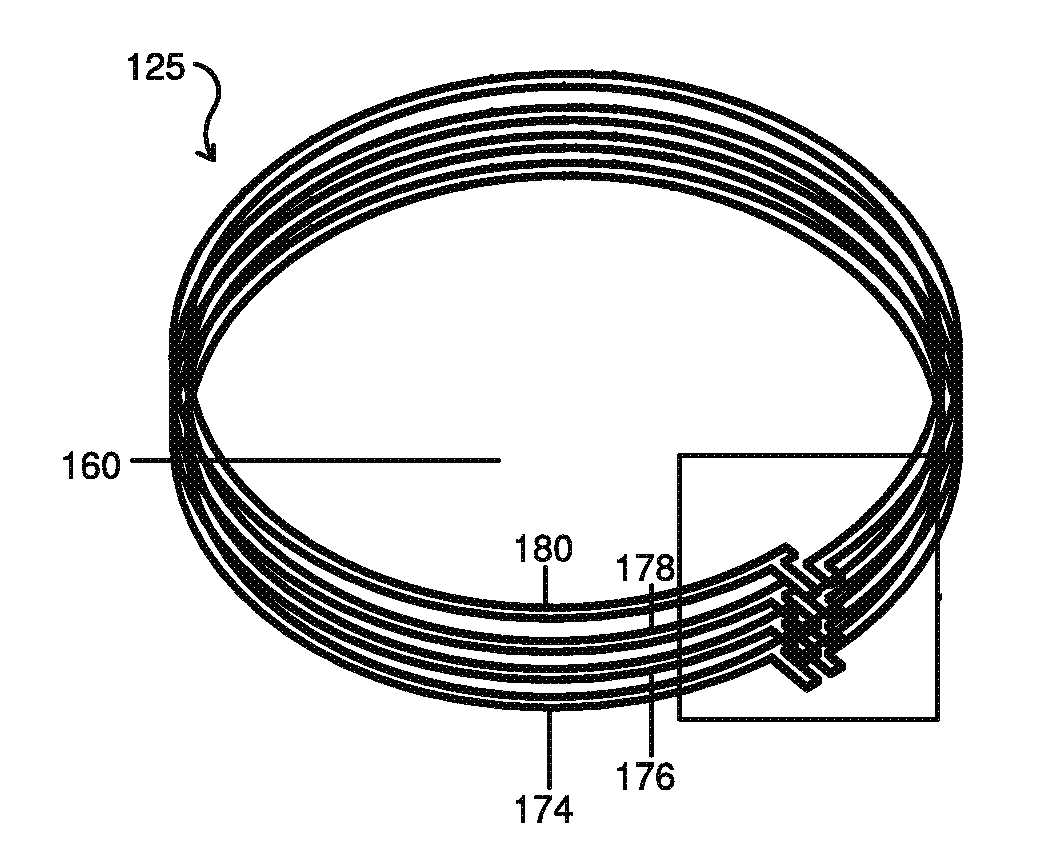

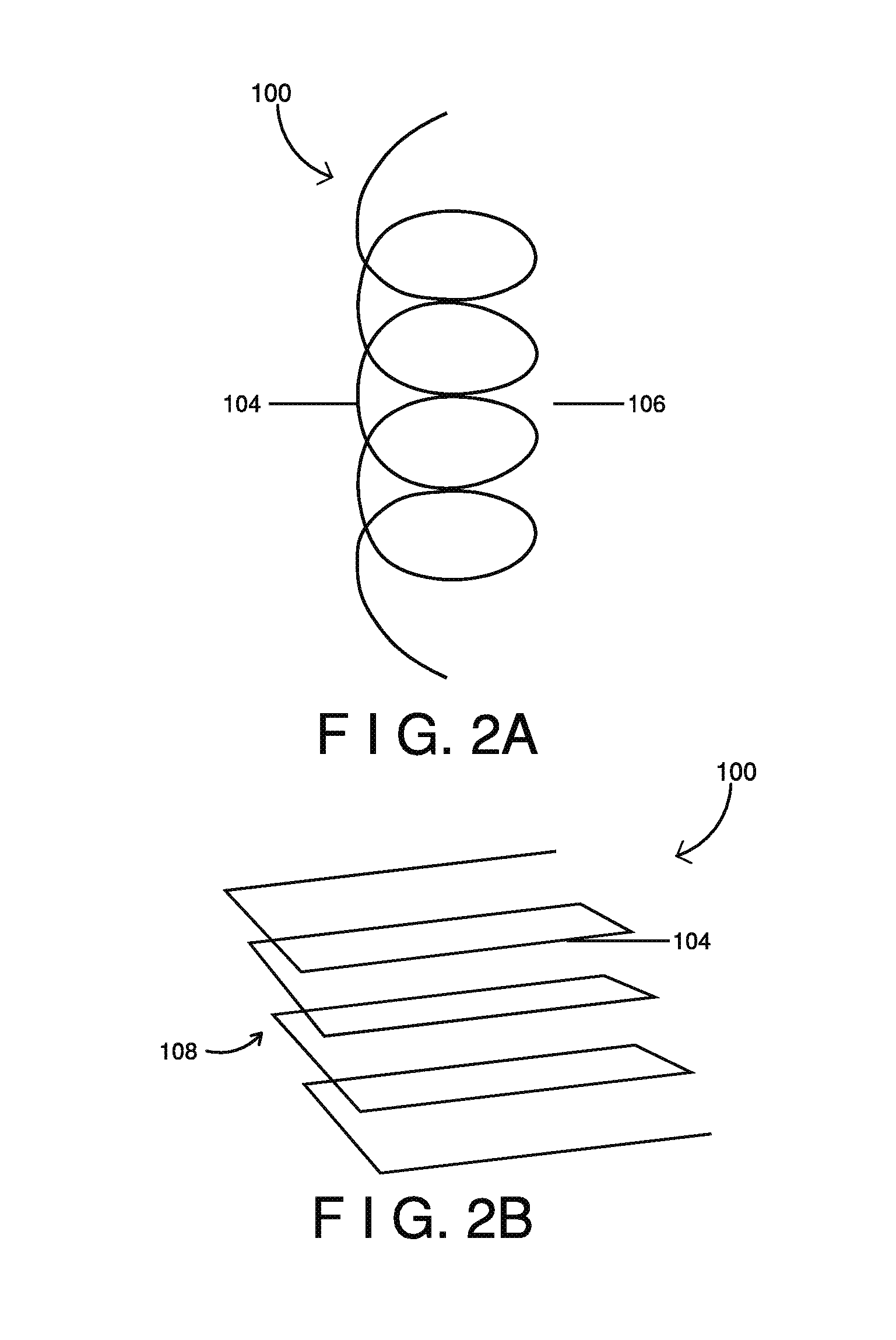

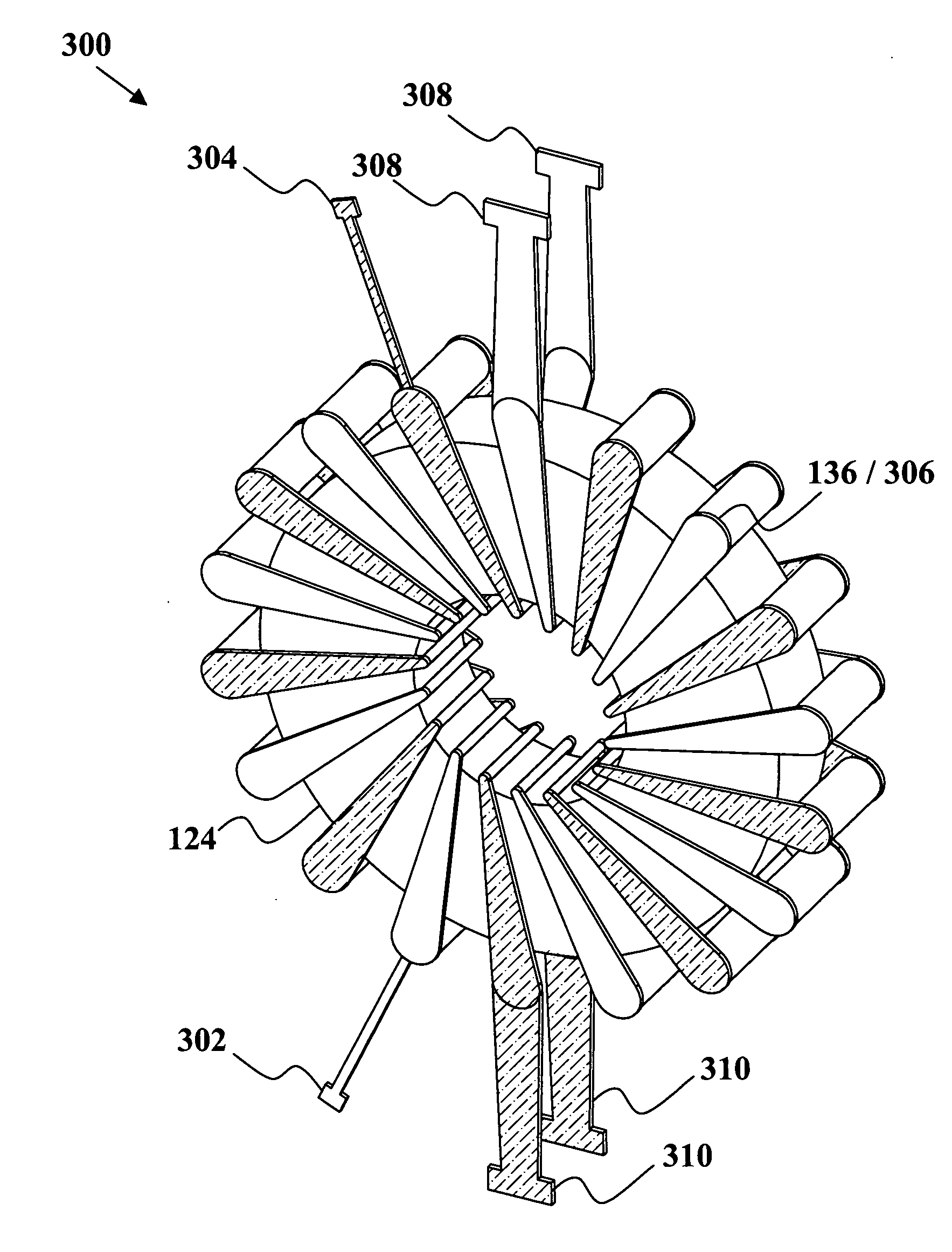

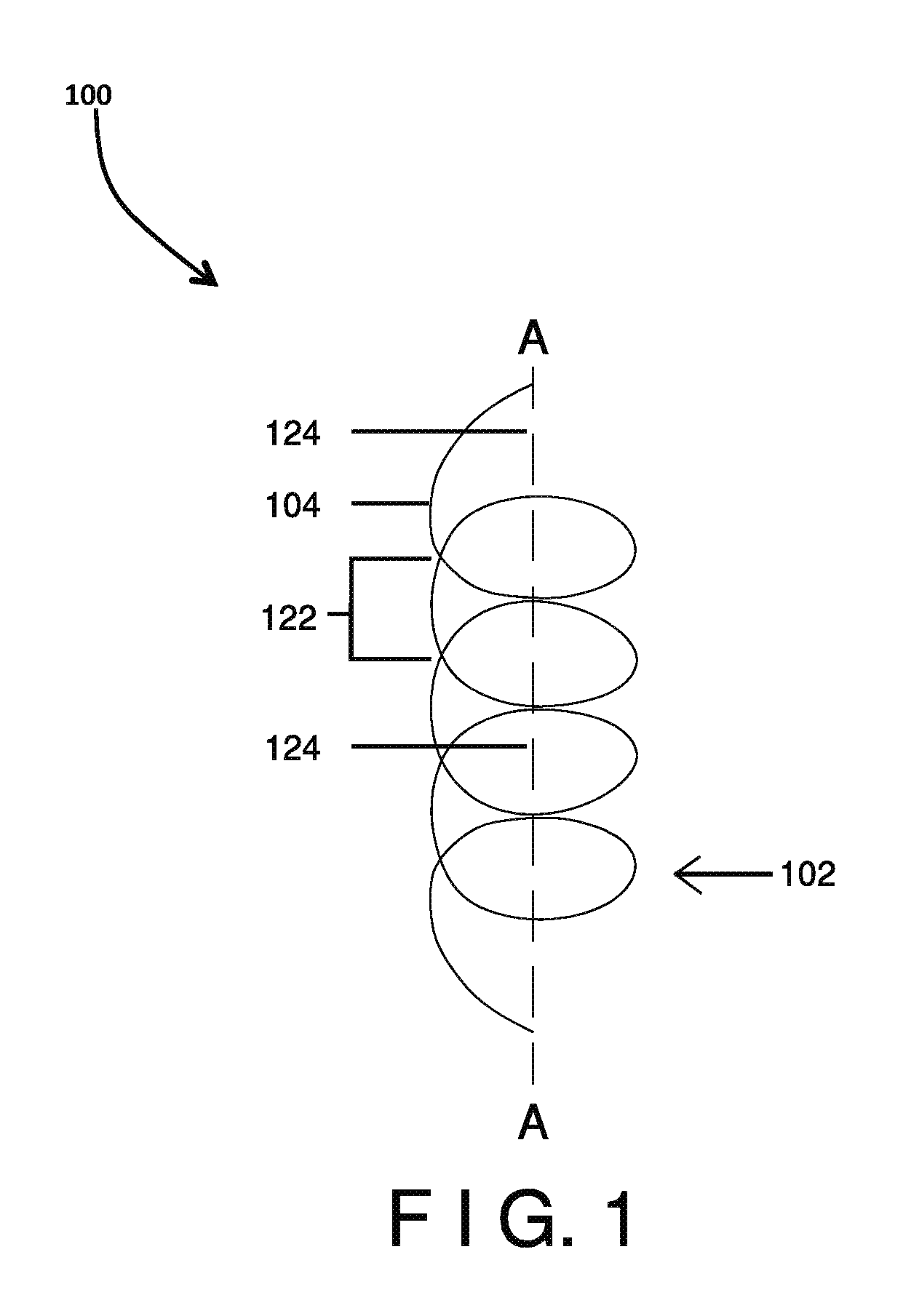

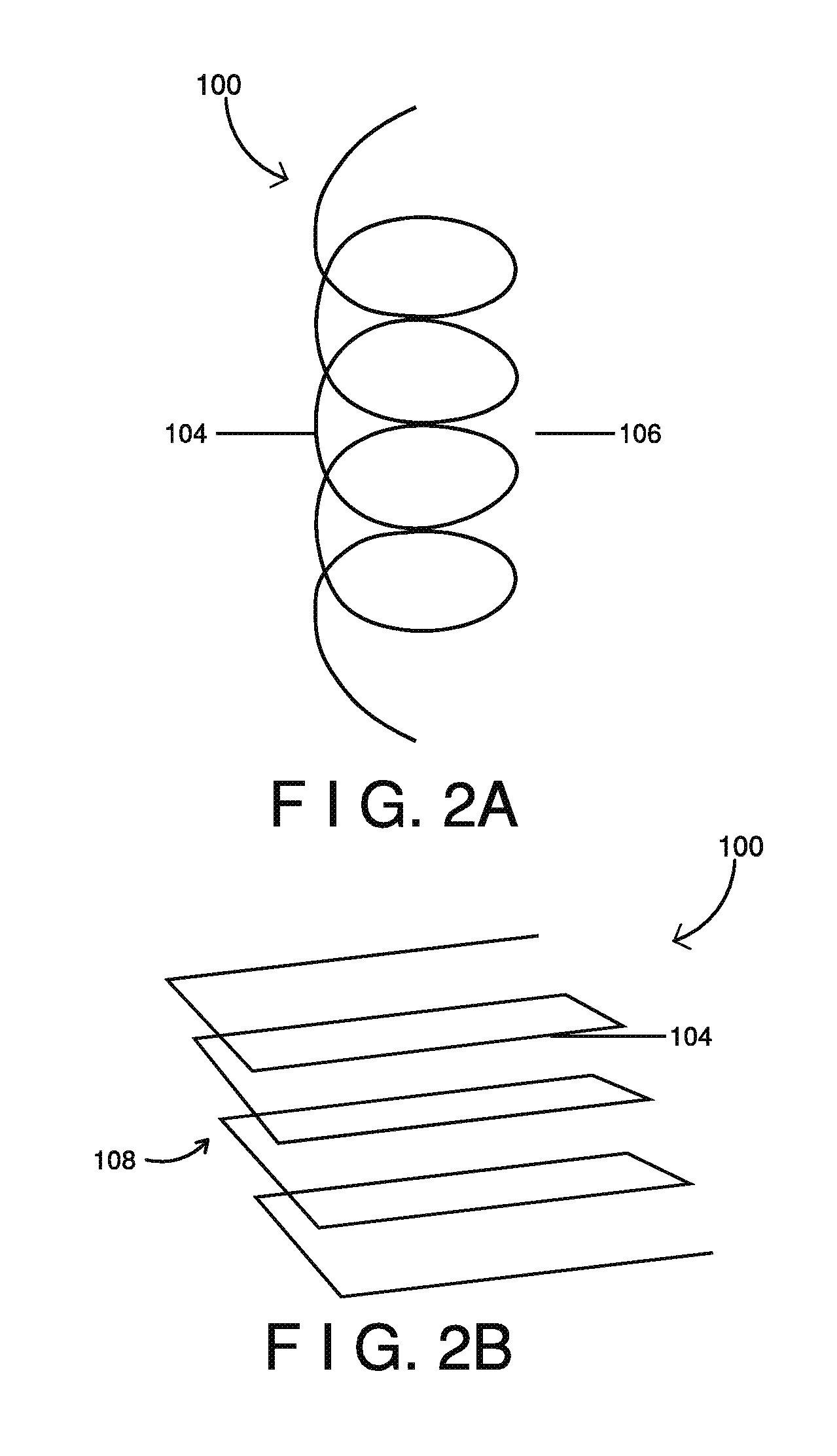

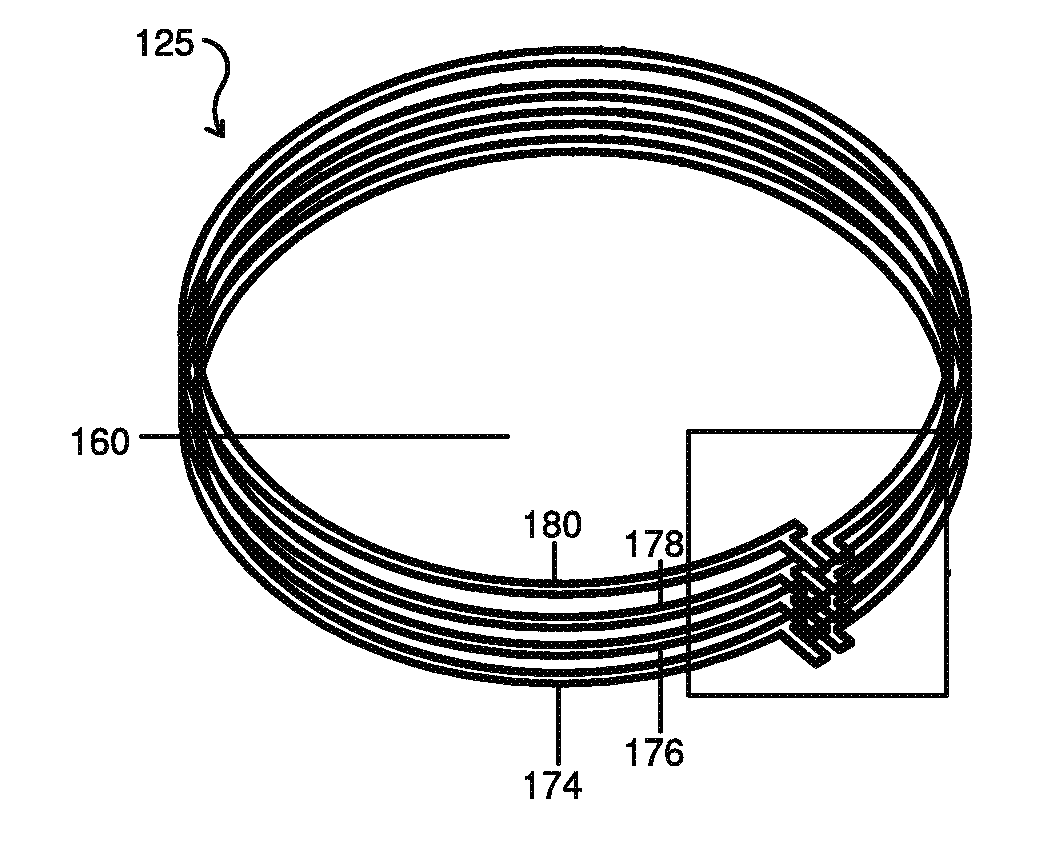

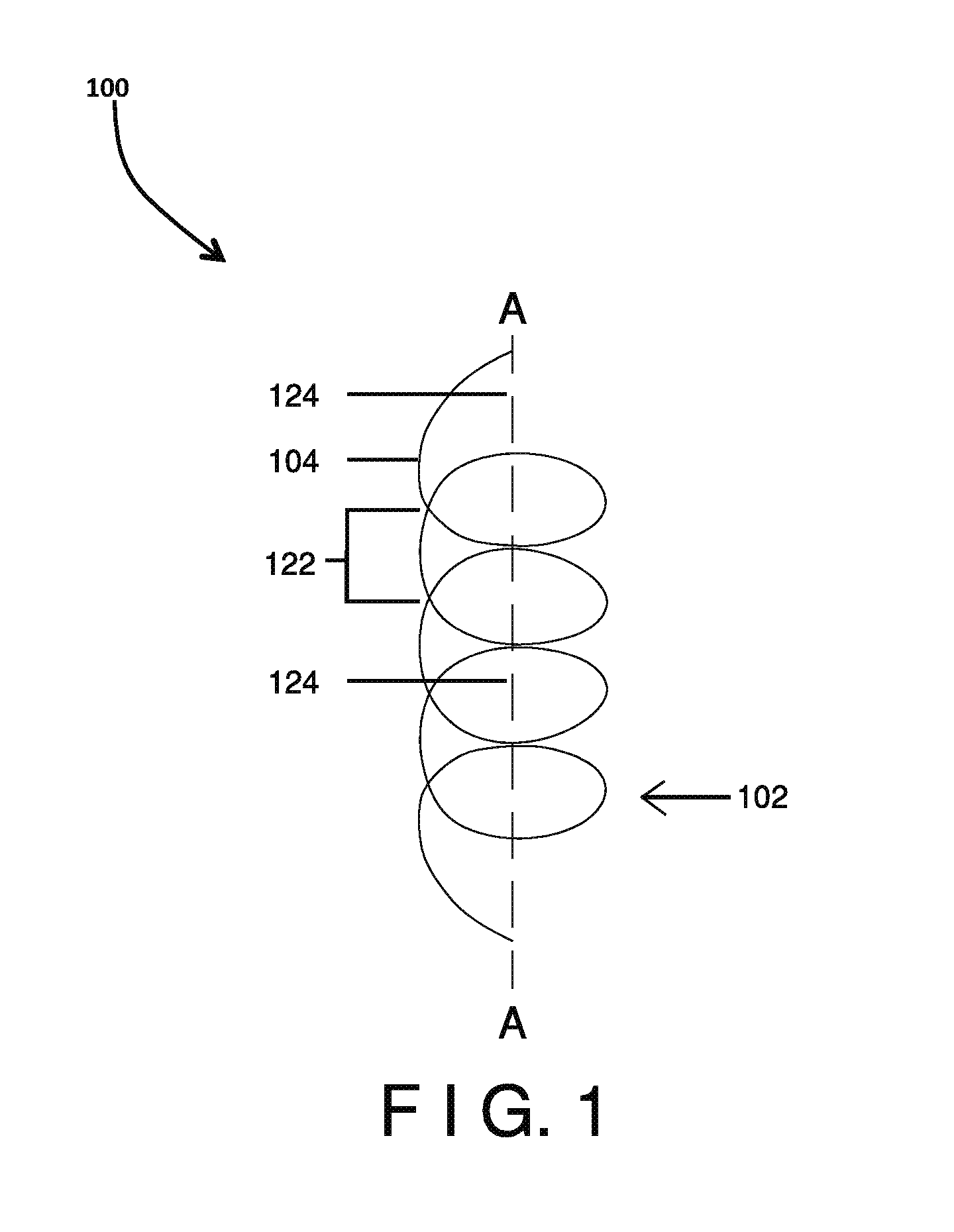

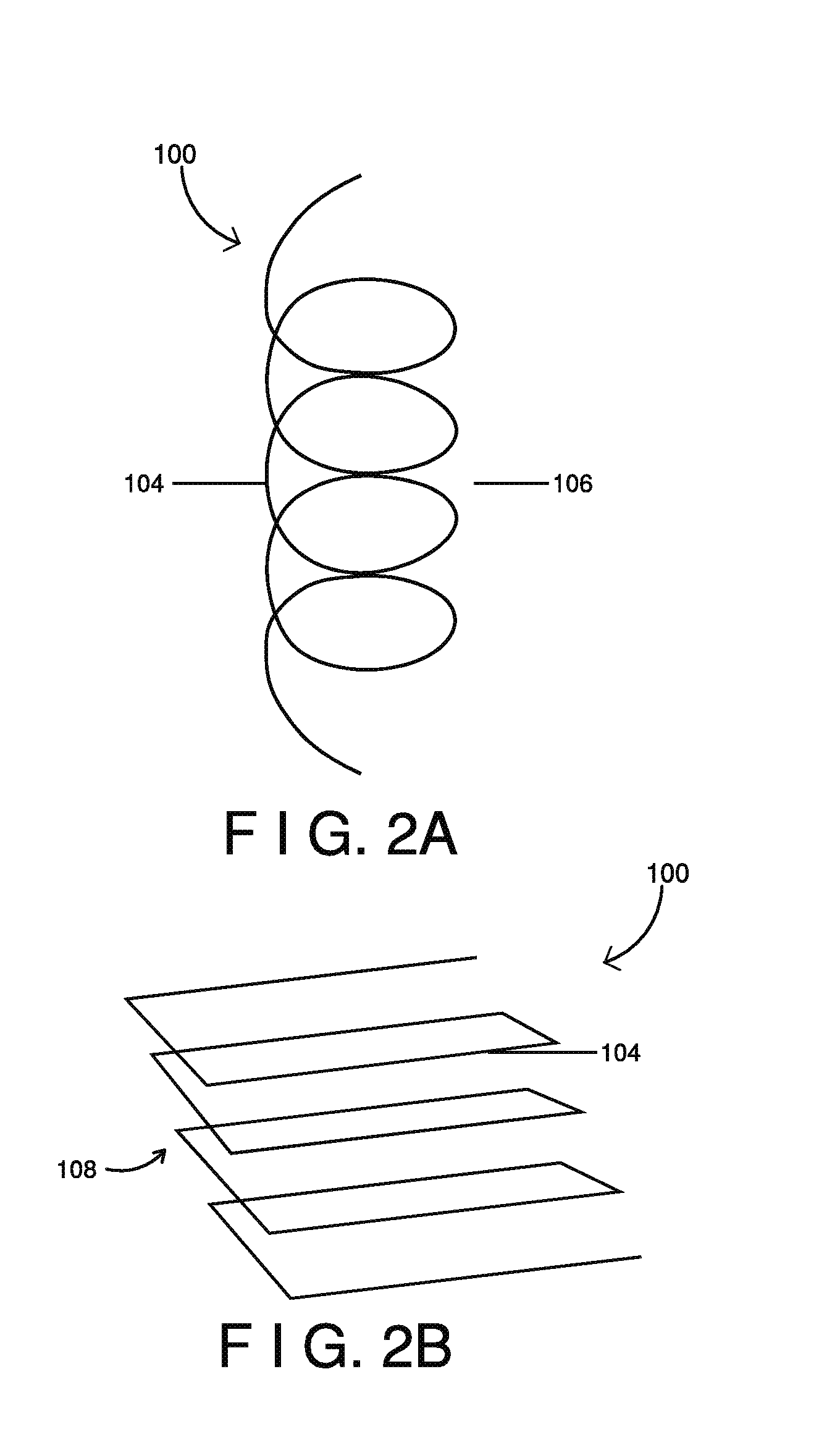

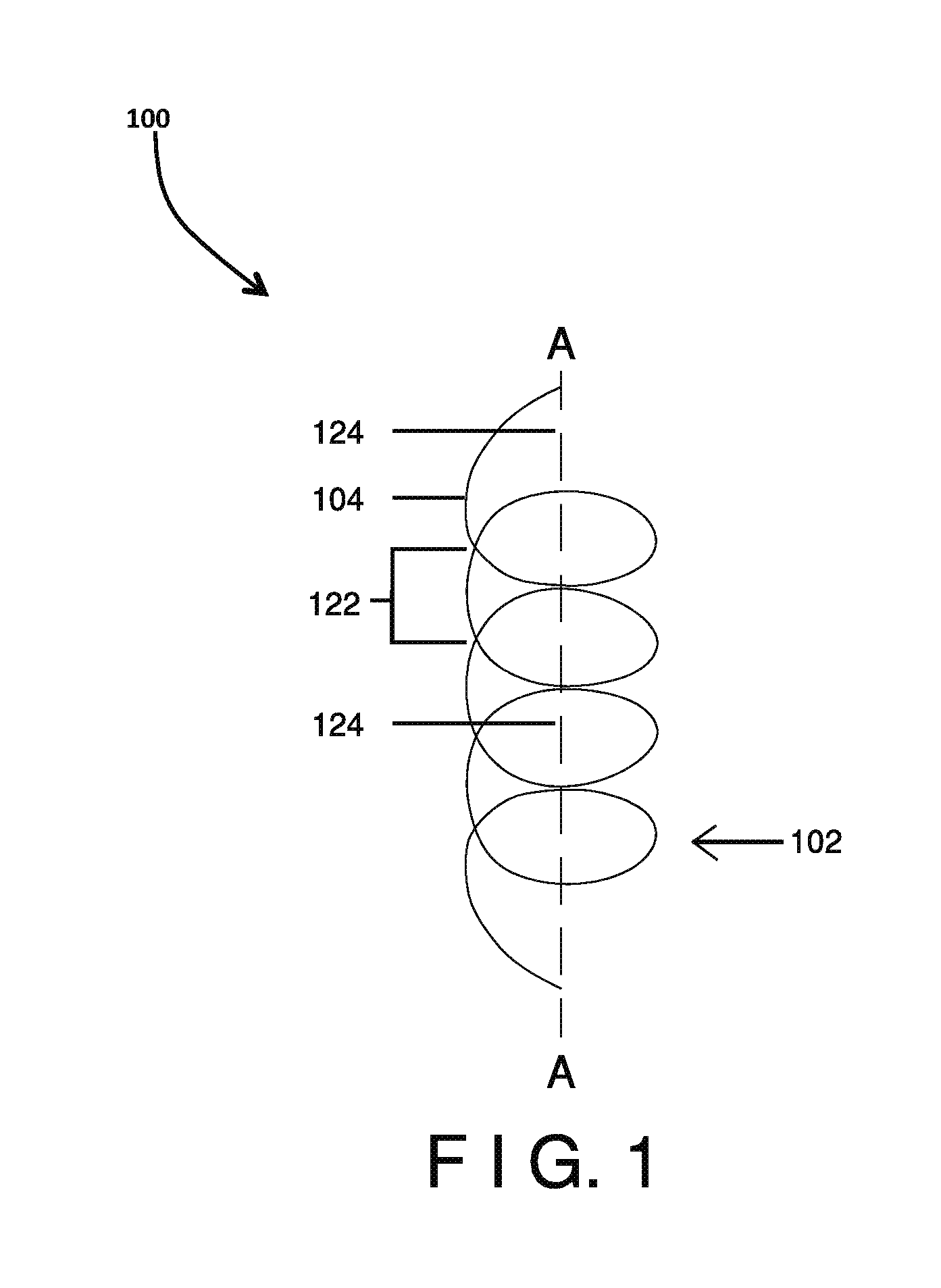

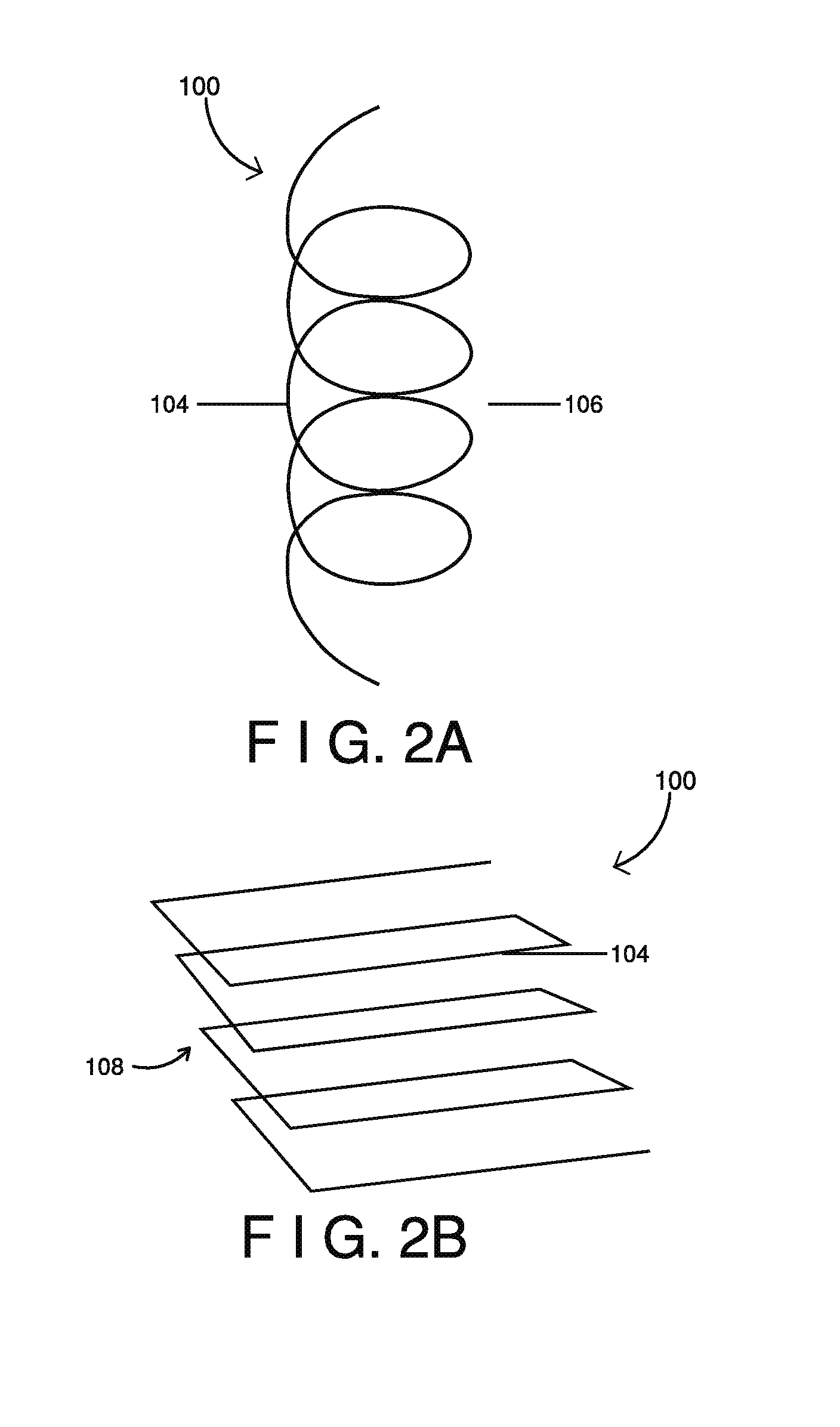

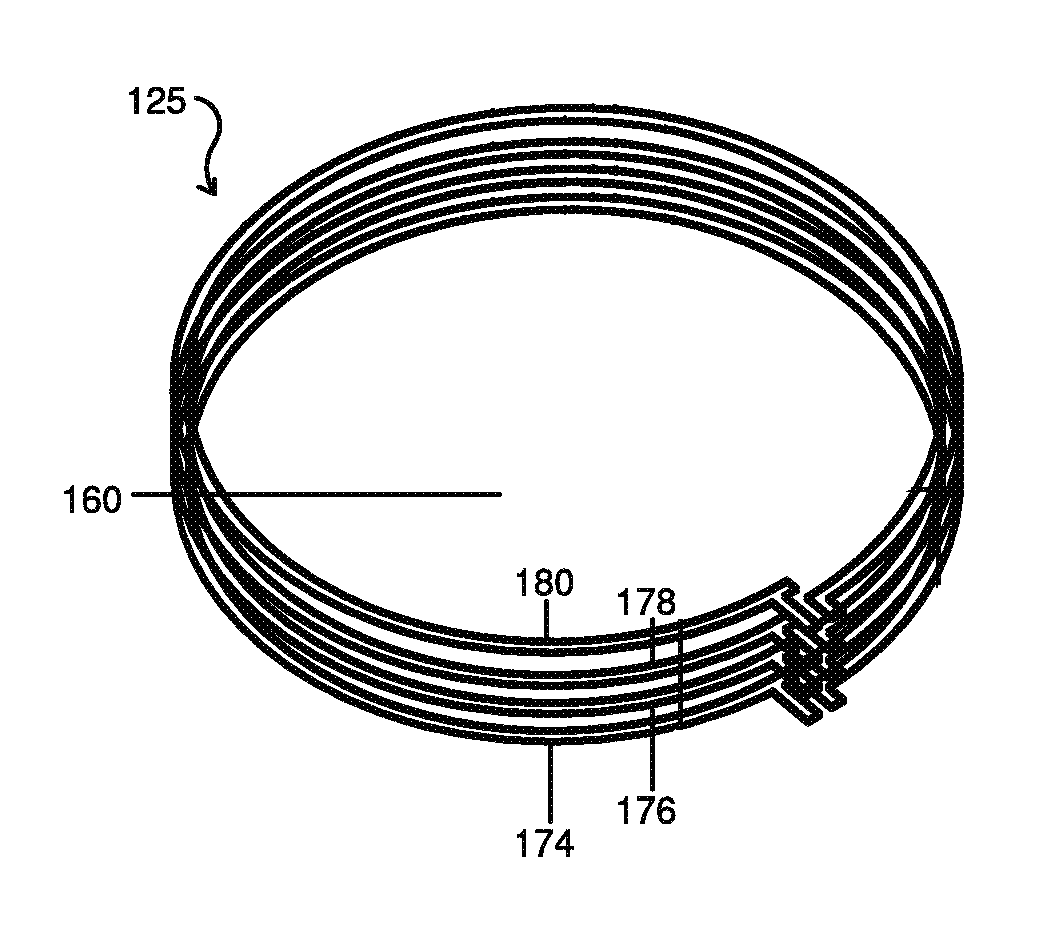

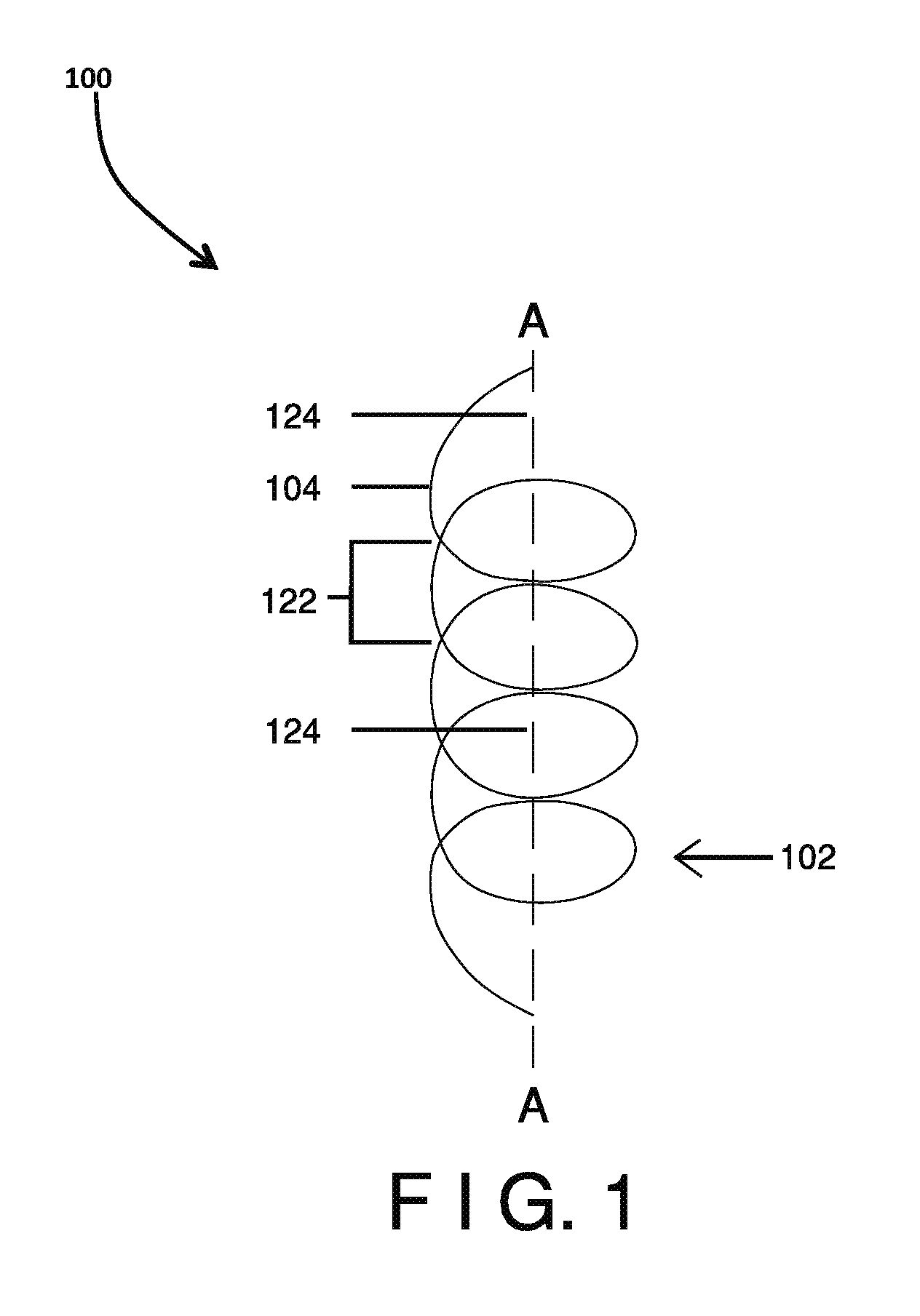

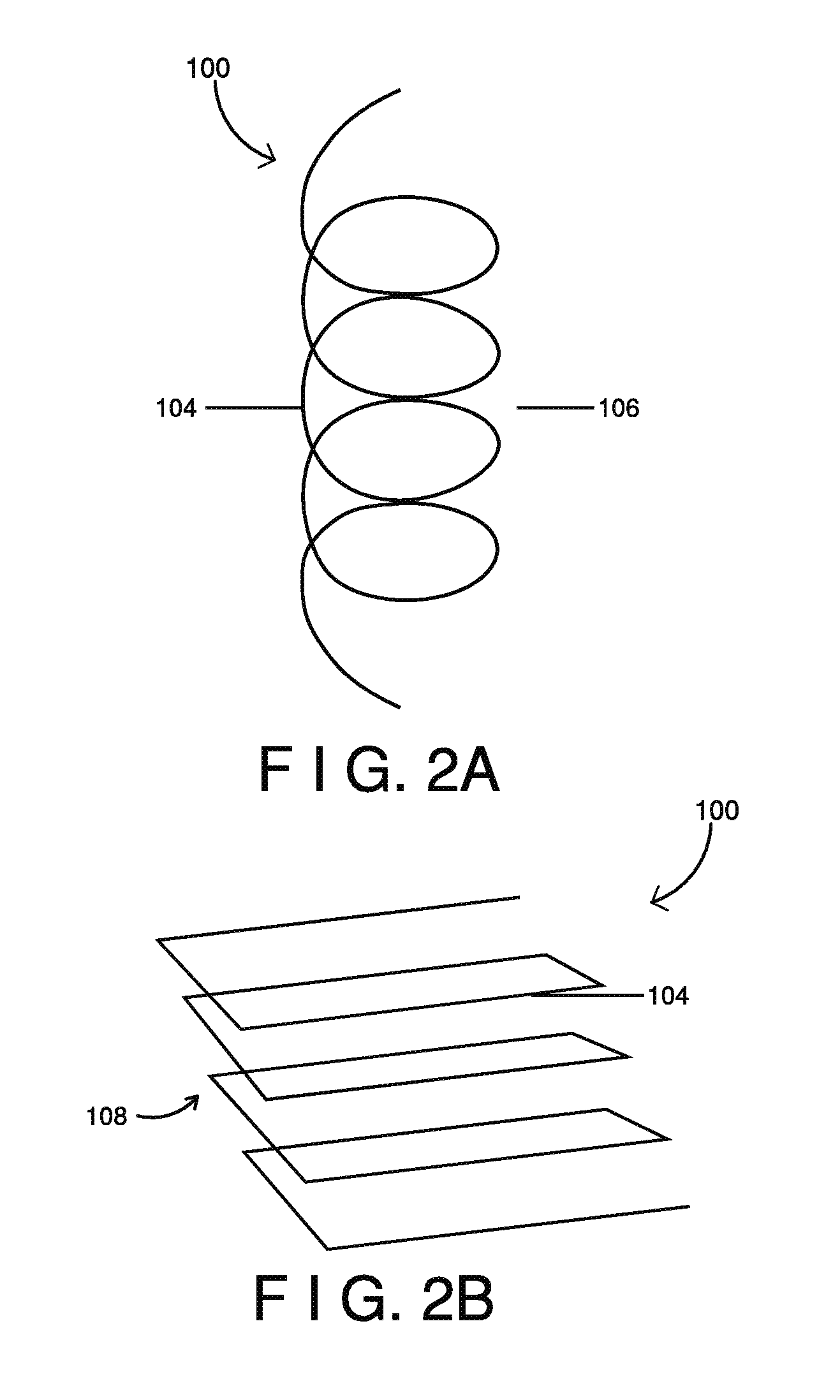

Systems using multi-layer-multi-turn high efficiency inductors

ActiveUS20130208390A1Higher resistive lossIncrease qualify factorTransformers/inductances coils/windings/connectionsInternal electrodesElectrical resistance and conductanceElectricity

Owner:NUCURRENT INC

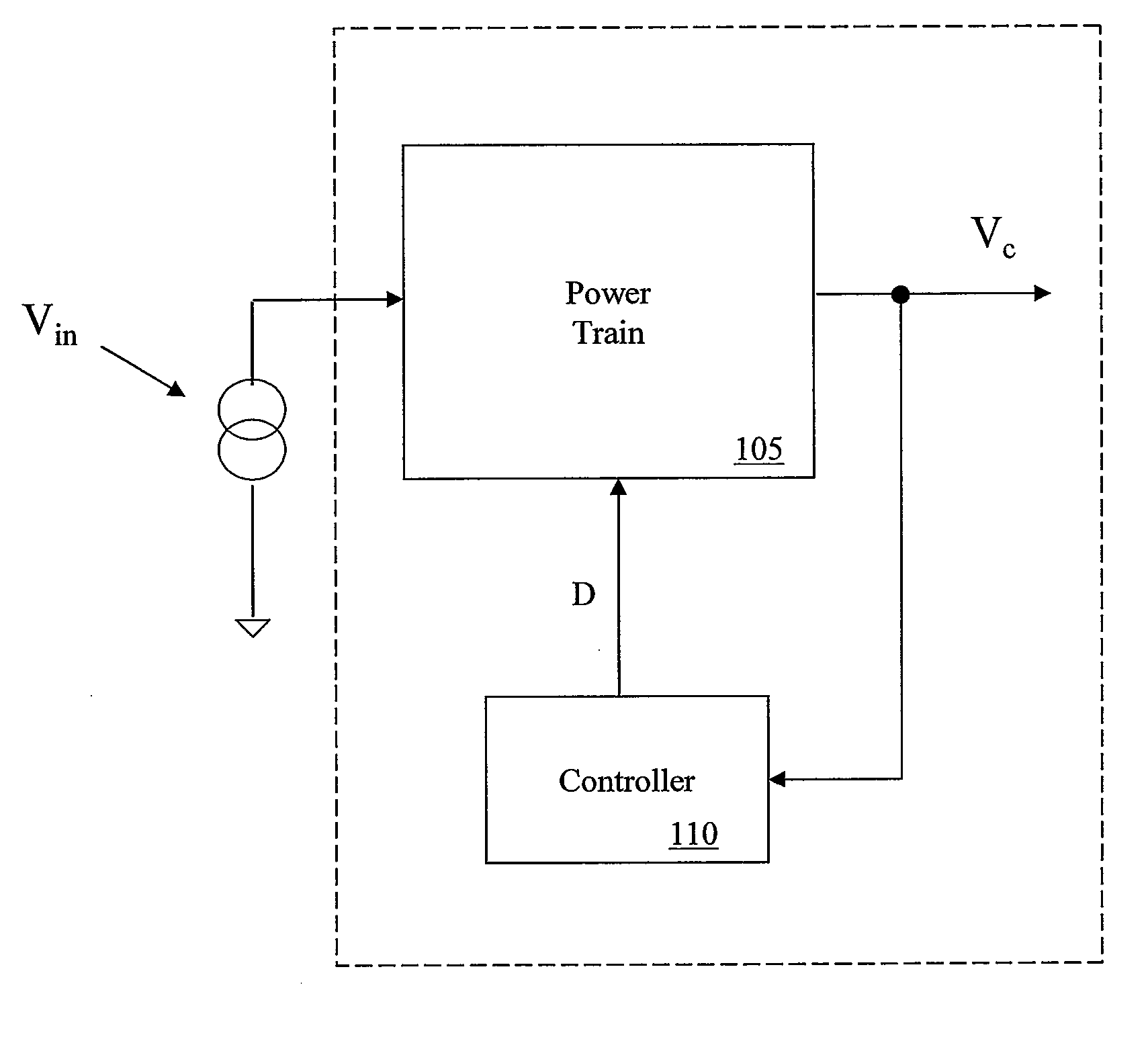

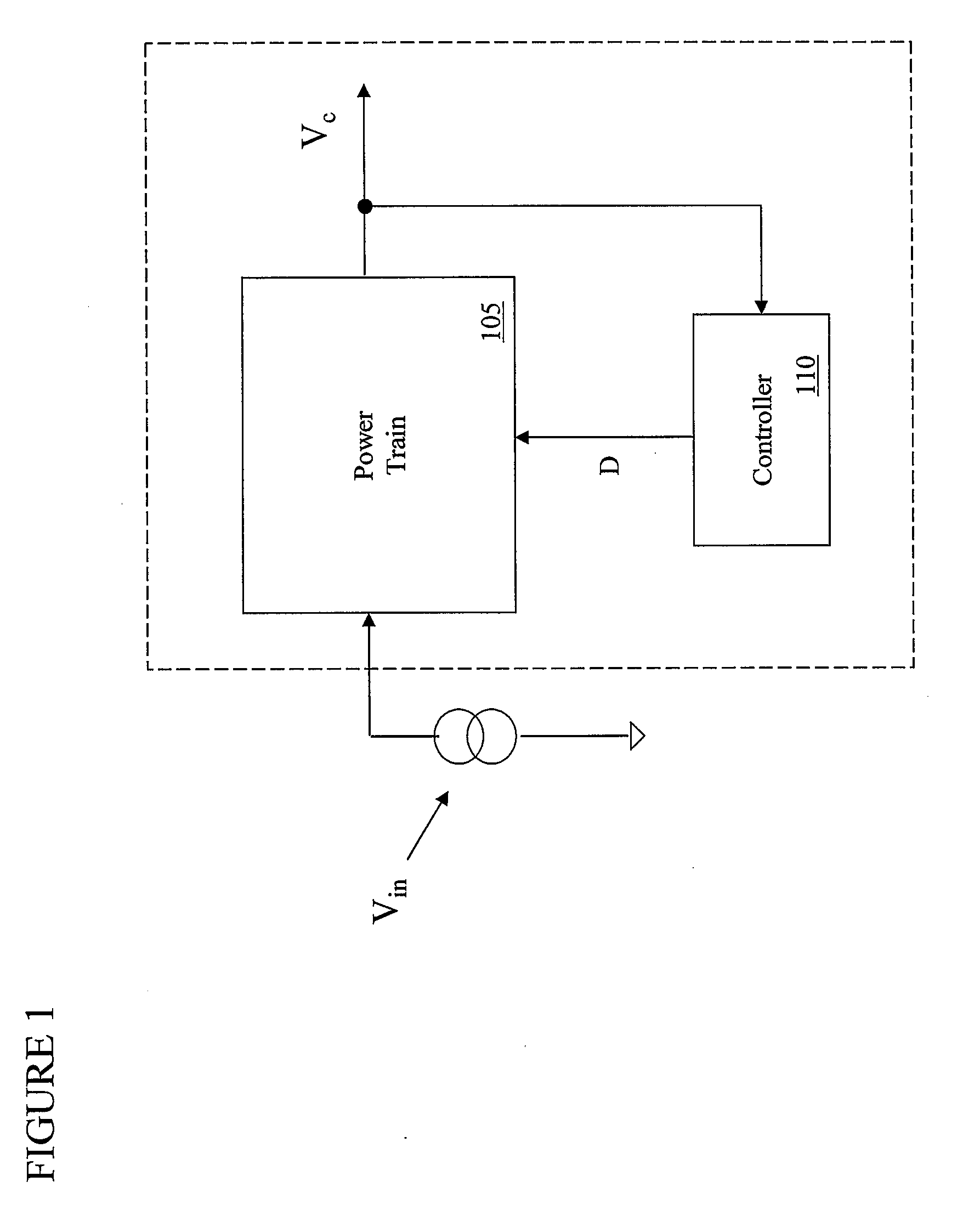

Power Converter Employing Regulators with a Coupled Inductor

A power converter includes a power train with a coupled inductor and a plurality of regulators, and method of forming and operating the same. In one embodiment, the power train includes a coupled inductor including a magnetic core with a common leg, a first leg and a second leg. The coupled inductor also includes a common winding formed around the common leg, and first and second windings. The first winding is formed around the first leg, and is electrically and magnetically coupled to the common winding. The second winding is formed around the second leg, and is electrically and magnetically coupled to the common winding. The power train also includes a first regulator including a first main switch coupled to the first winding and a second regulator including a second main switch coupled to the second winding.

Owner:MYPAQ HLDG LTD

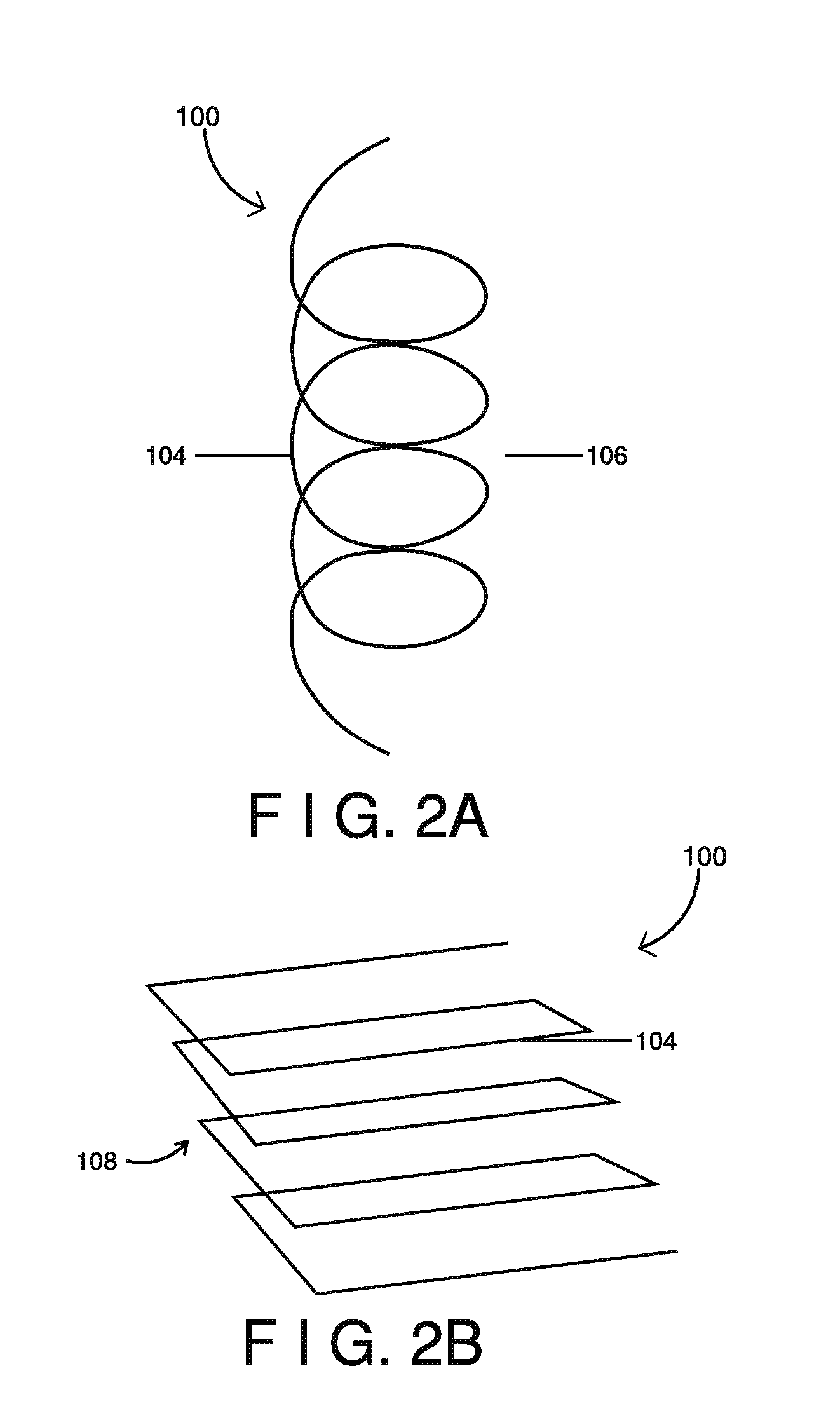

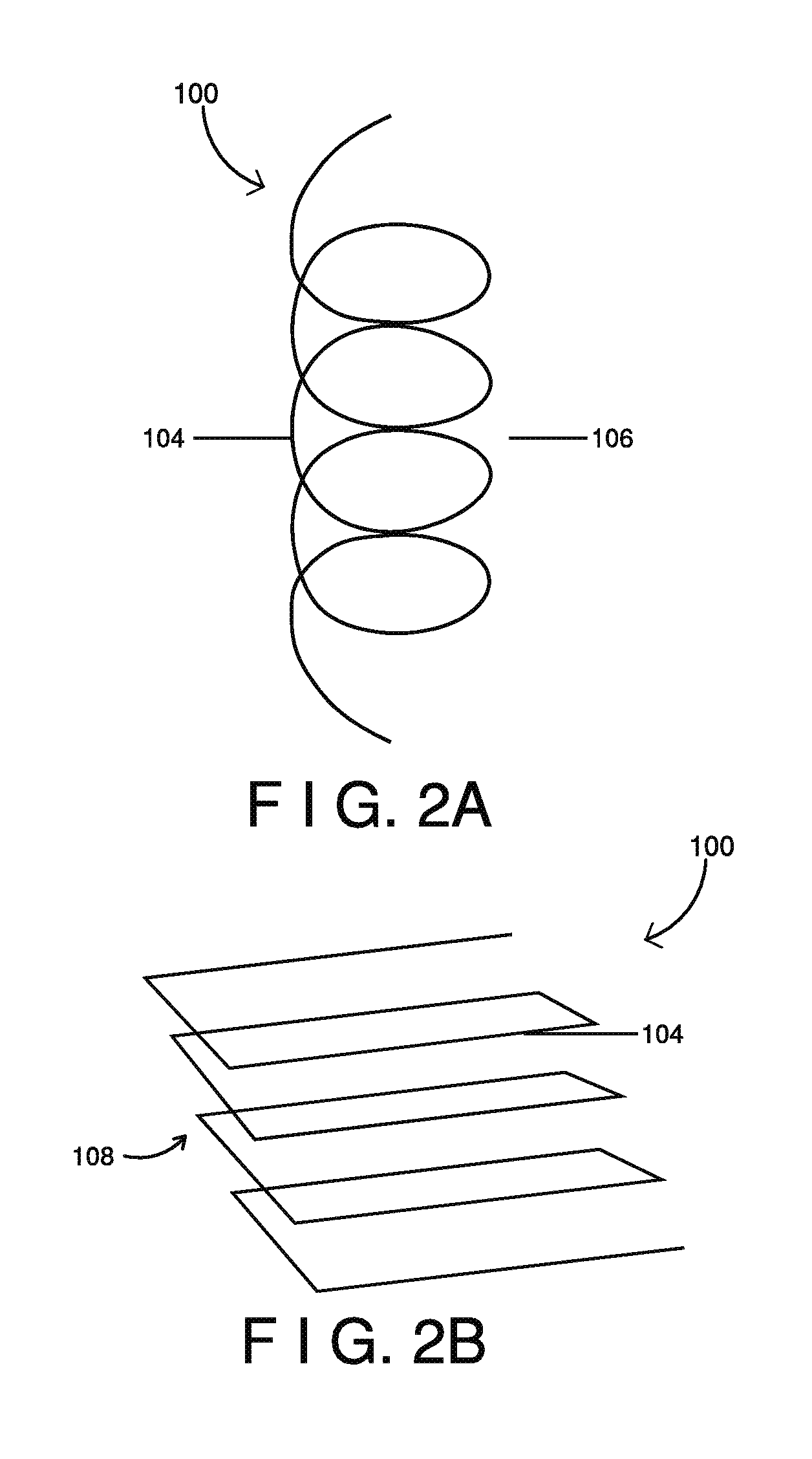

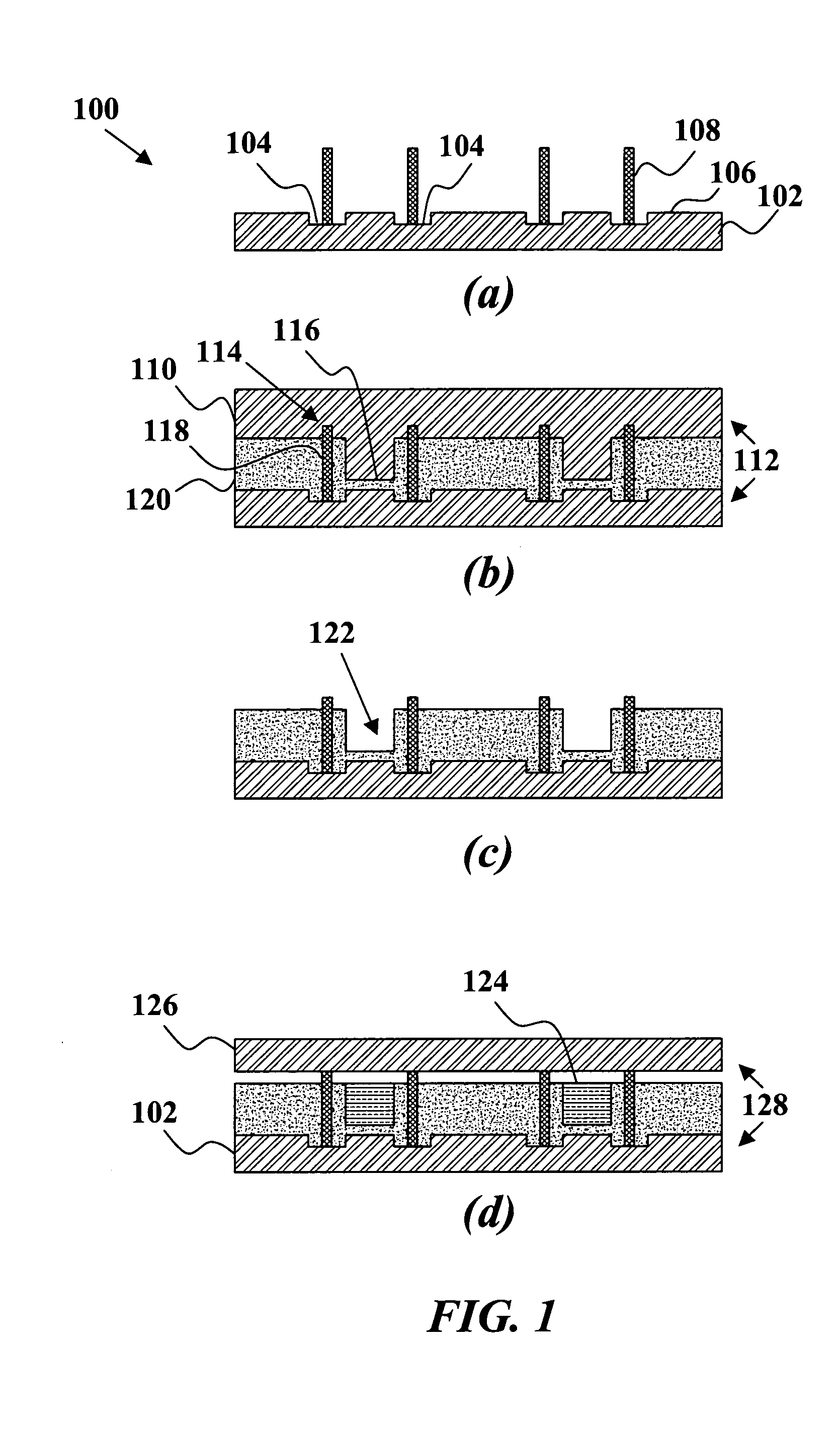

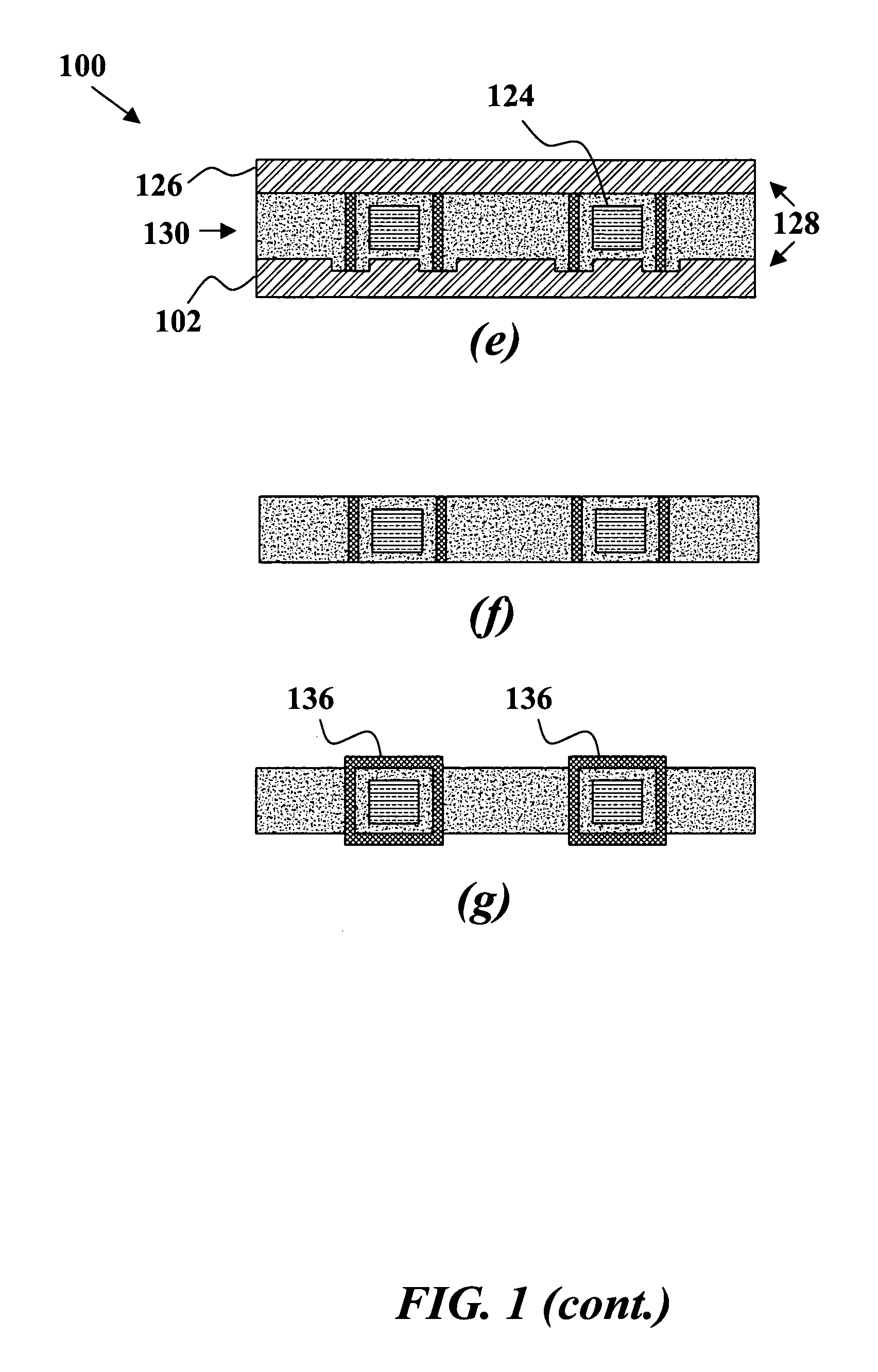

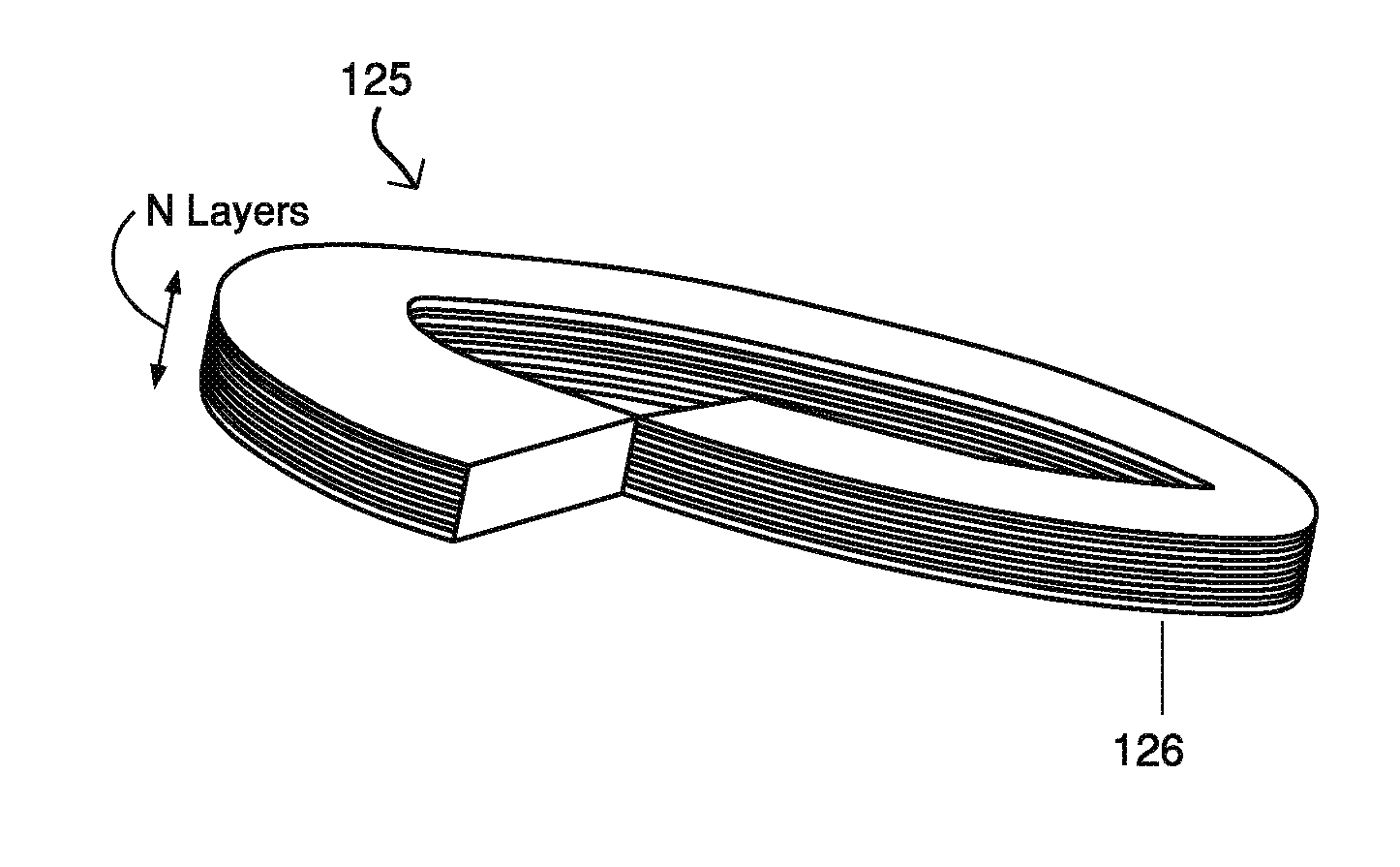

Method for manufacture of multi-layer-multi-turn high efficiency inductors with cavity

ActiveUS20130205582A1Higher resistive lossIncrease qualify factorMultiple-port networksInternal electrodesElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Current source with indirect load current signal extraction

A switching circuit for supplying current to a load has a switching element, an inductive element coupled to the switching element, and a load current extraction circuit responsive to current in the inductive element for producing a load current signal as a simulated current approximating current in the load.

Owner:ANALOG DEVICES INT UNLTD

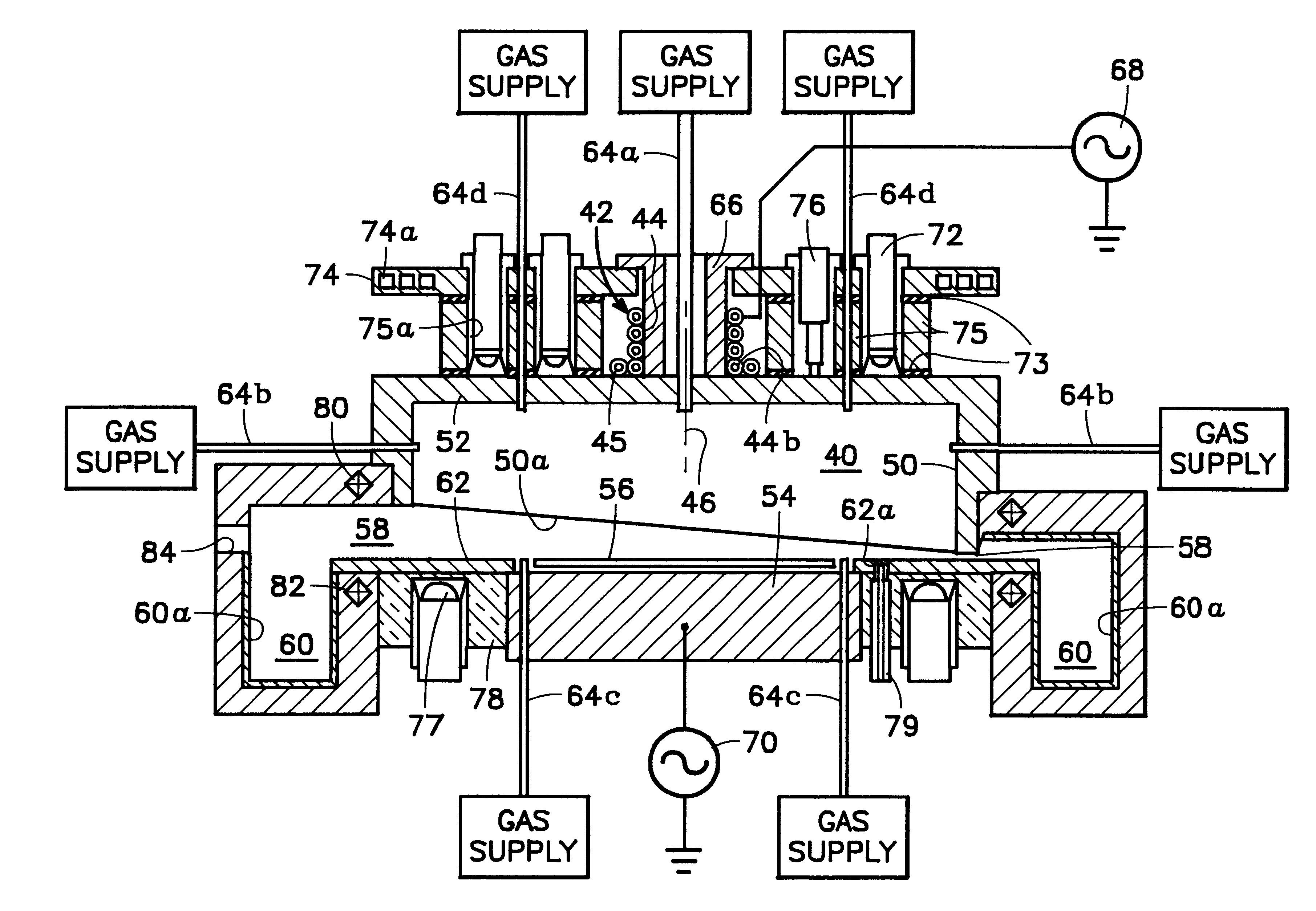

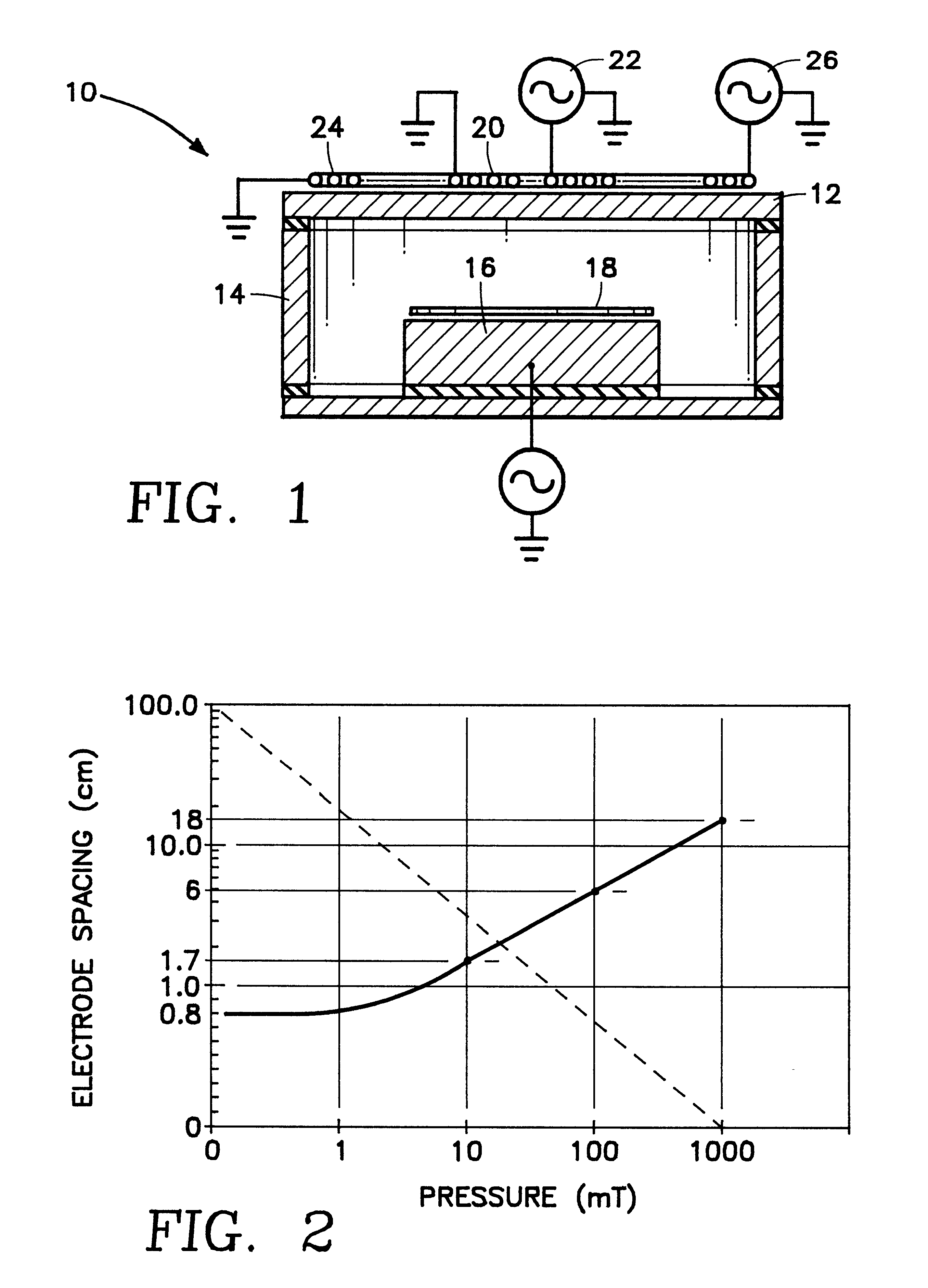

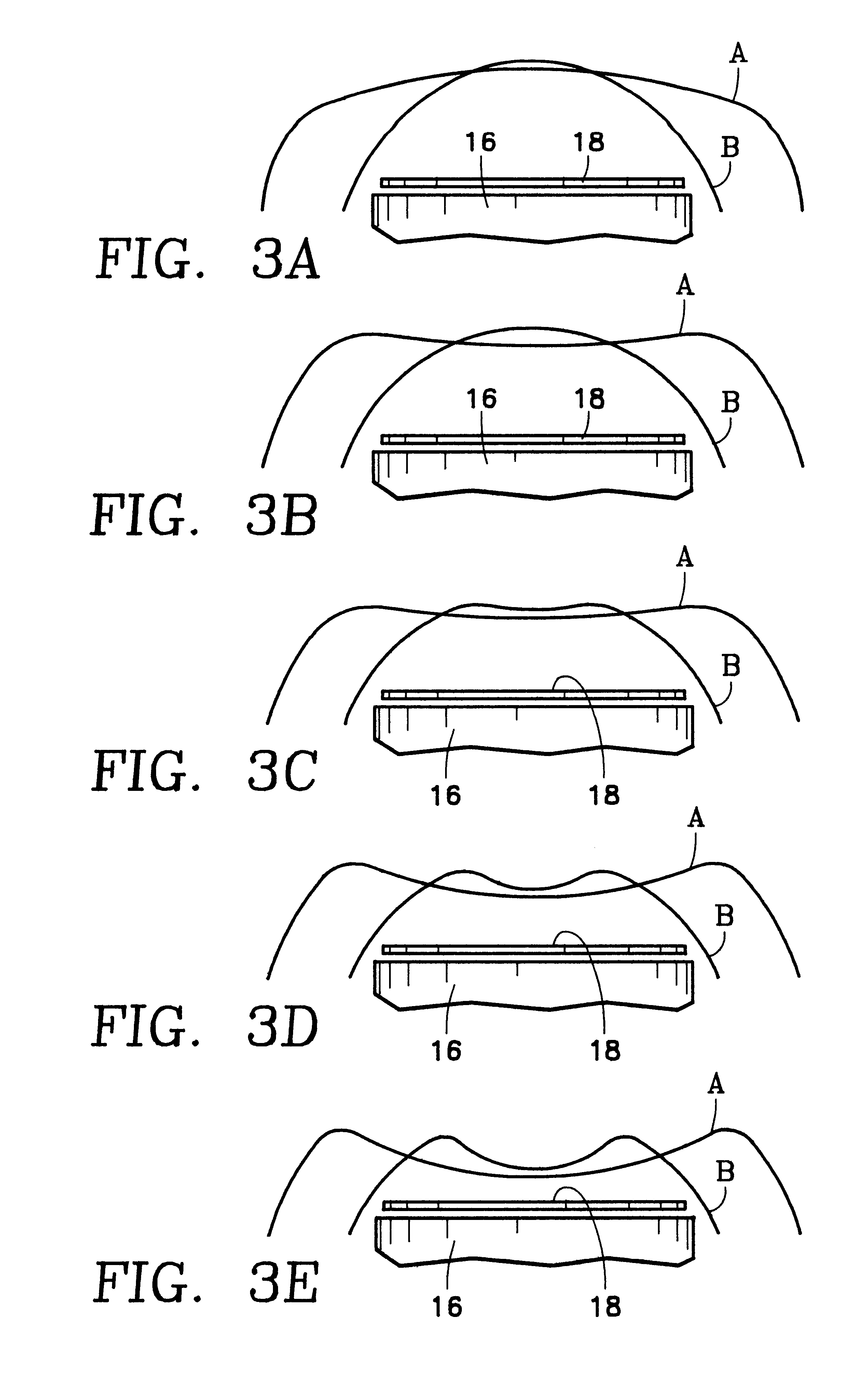

High pressure high non-reactive diluent gas content high plasma ion density plasma oxide etch process

InactiveUS6238588B1Increase pressureHigh strengthElectric discharge tubesDecorative surface effectsHigh plasmaOxygen

The invention is embodied in a method of processing a semiconductor workpiece in a plasma reactor chamber, including supplying a polymer and etchant precursor gas containing at least carbon and fluorine into the chamber at a first flow rate sufficient of itself to maintain a gas pressure in the chamber in a low pressure range below about 20 mT, supplying a relatively non-reactive gas into the chamber at second flow rate sufficient about one half or more of the total gas flow rate into the chamber, in combination with the first flow rate of the precursor gas, to maintain the gas pressure in the chamber in a high pressure range above 20 mT, and applying plasma source power into the chamber to form a high ion density plasma having an ion density in excess of 1010 ions per cubic centimeter. In one application of the invention, the workpiece includes an oxygen-containing overlayer to be etched by the process and a non-oxygen-containing underlayer to be protected from etching, the precursor gas dissociating in the plasma into fluorine-containing etchant species which etch the oxygen-containing layer and carbon-containing polymer species which accumulate on the non-oxygen-containing underlayer. Alternatively, the high pressure range may be defined as a pressure at which the skin depth of the inductive field exceeds {fraction (1 / 10)} of the gap between the inductive antenna and the workpiece.

Owner:APPLIED MATERIALS INC

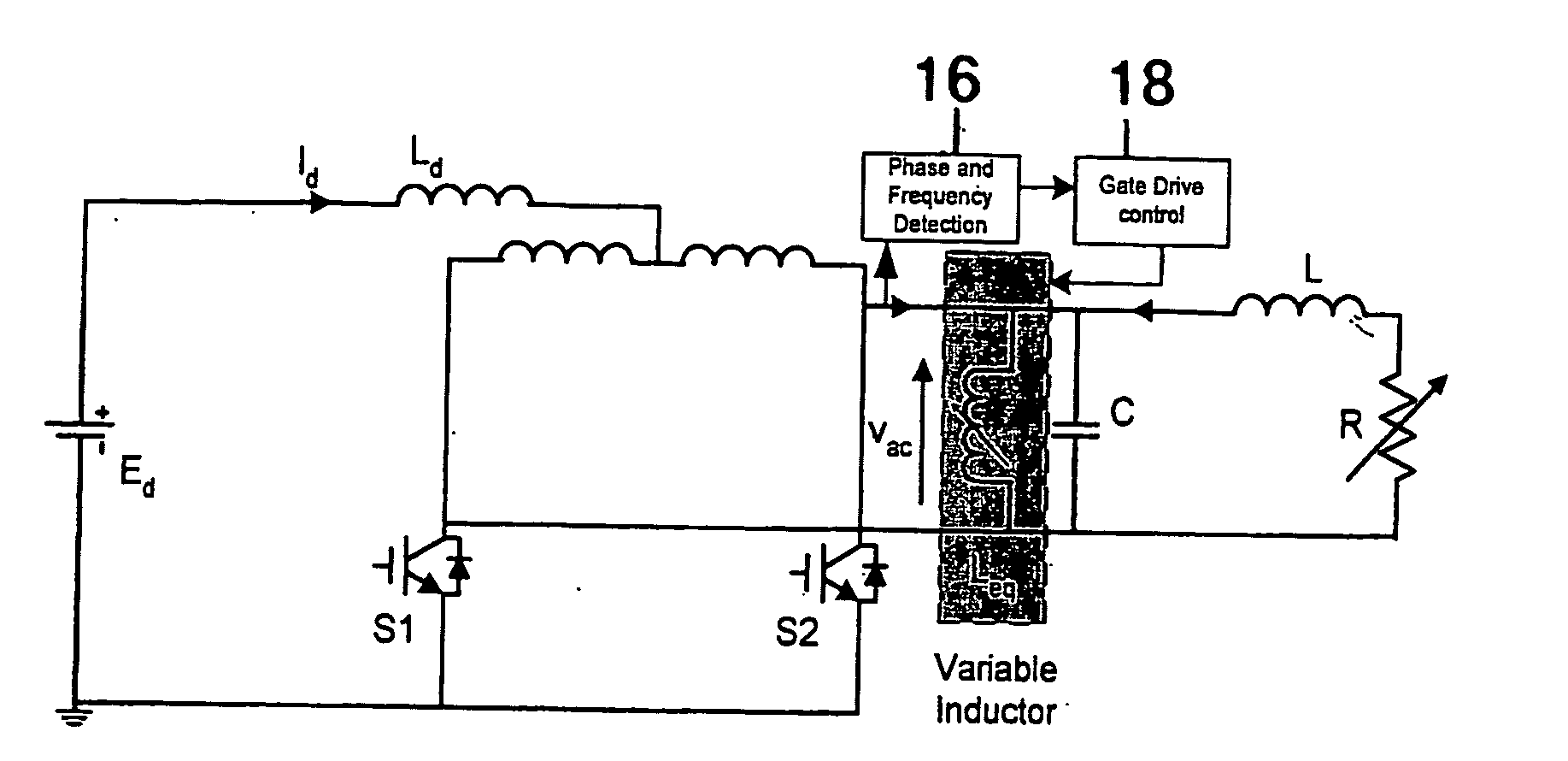

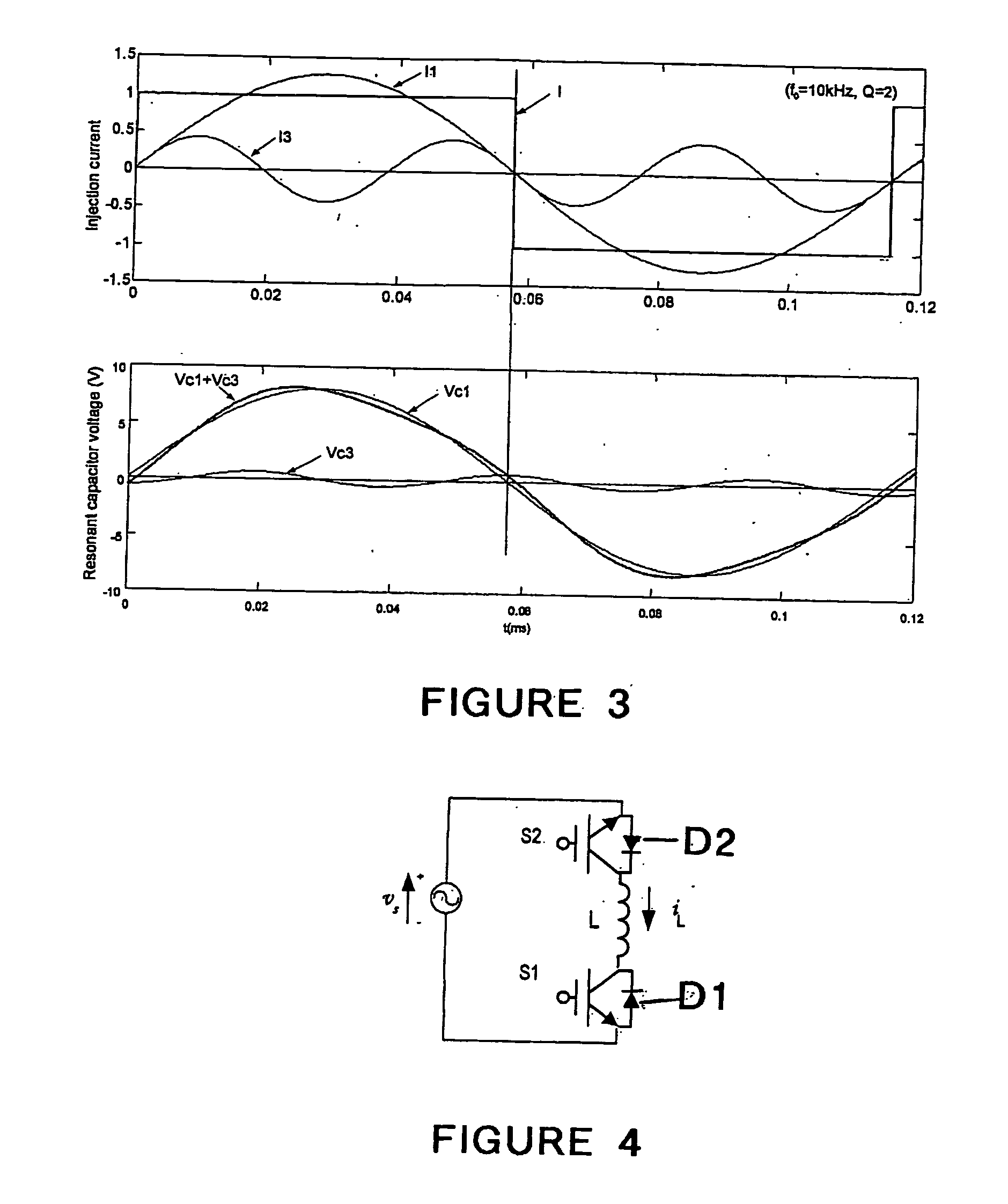

Frequency Controller Resonant Converter

ActiveUS20080211478A1Overcome disadvantagesEfficient power electronics conversionDc-dc conversionElectricityCapacitance

A resonant converter is provided which may be used for supplying power to the primary conductive path of an inductively coupled power transfer (ICPT) system. The converter includes a variable reactive element in the resonant circuit which may be controlled to vary the effective inductance or capacitance of the reactive element. The frequency of the converter is stabilised to a nominal value by sensing the frequency of the converter resonant circuit, comparing the sensed frequency with a nominal frequency and varying the effective inductance or capacitance of the variable reactive element to adjust the converter frequency toward the nominal frequency.

Owner:AUCKLAND UNISERVICES LTD

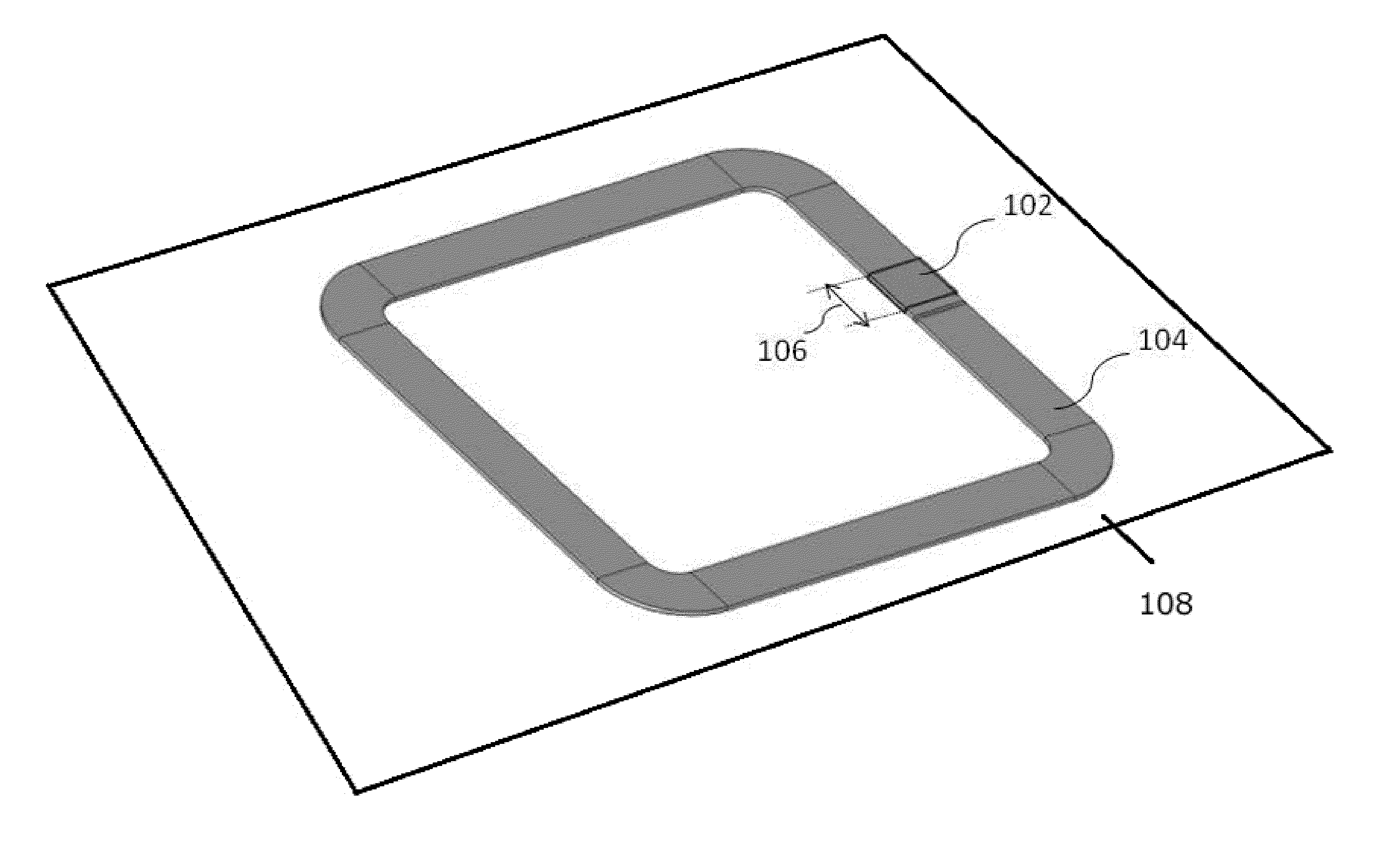

Resonator fine tuning

A tunable resonator assembly includes a resonator coil having an inductance, and a tile residing at a position relative to the resonator coil the position selected to produce a desired change in the inductance of the resonator coil.

Owner:WITRICITY CORP

Multi-layer-multi-turn high efficiency inductors for an induction heating system

ActiveUS20130200070A1Higher resistive lossLower quality factorTransformers/inductances coils/windings/connectionsInternal electrodesElectrical resistance and conductanceElectricity

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

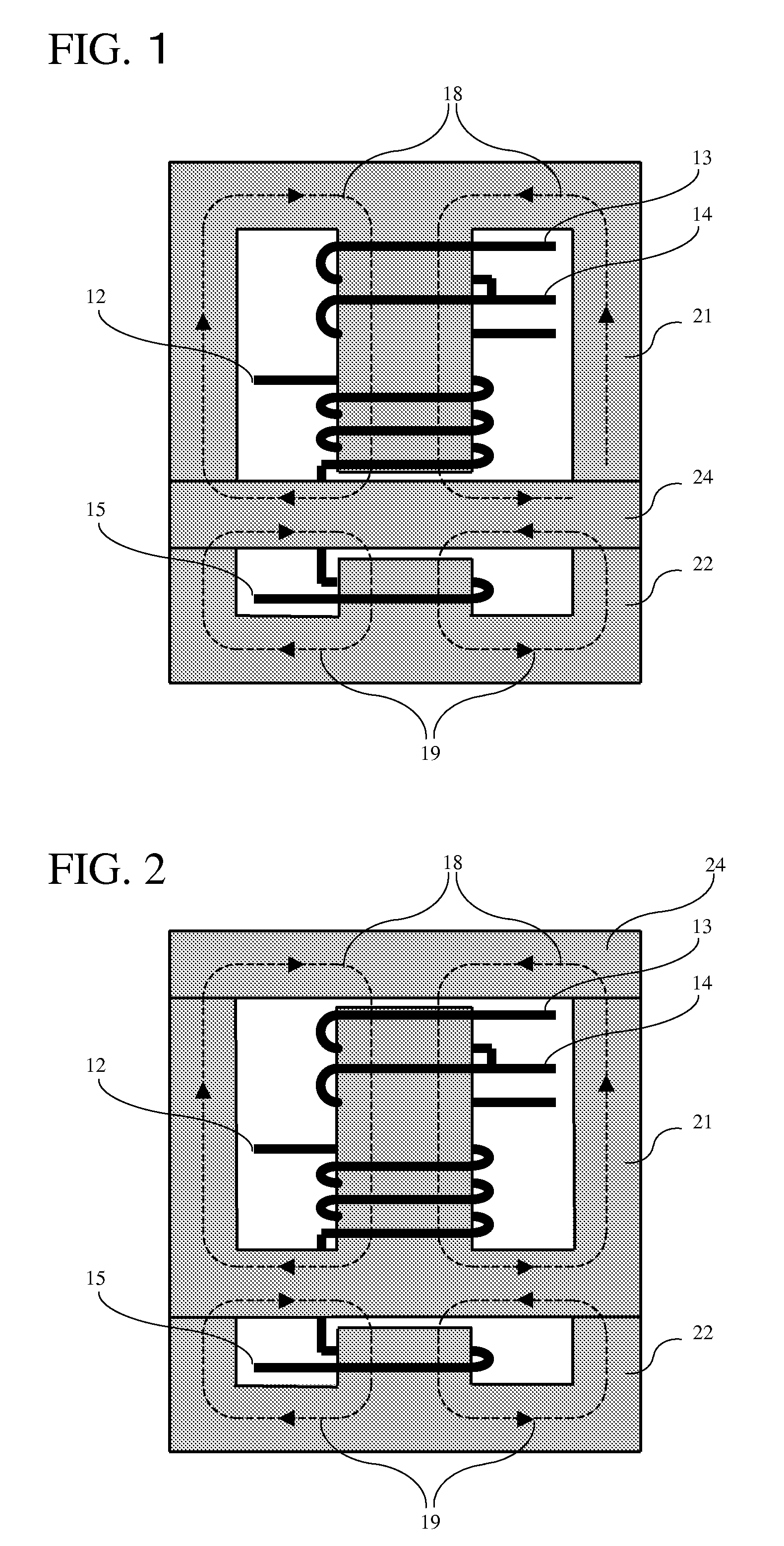

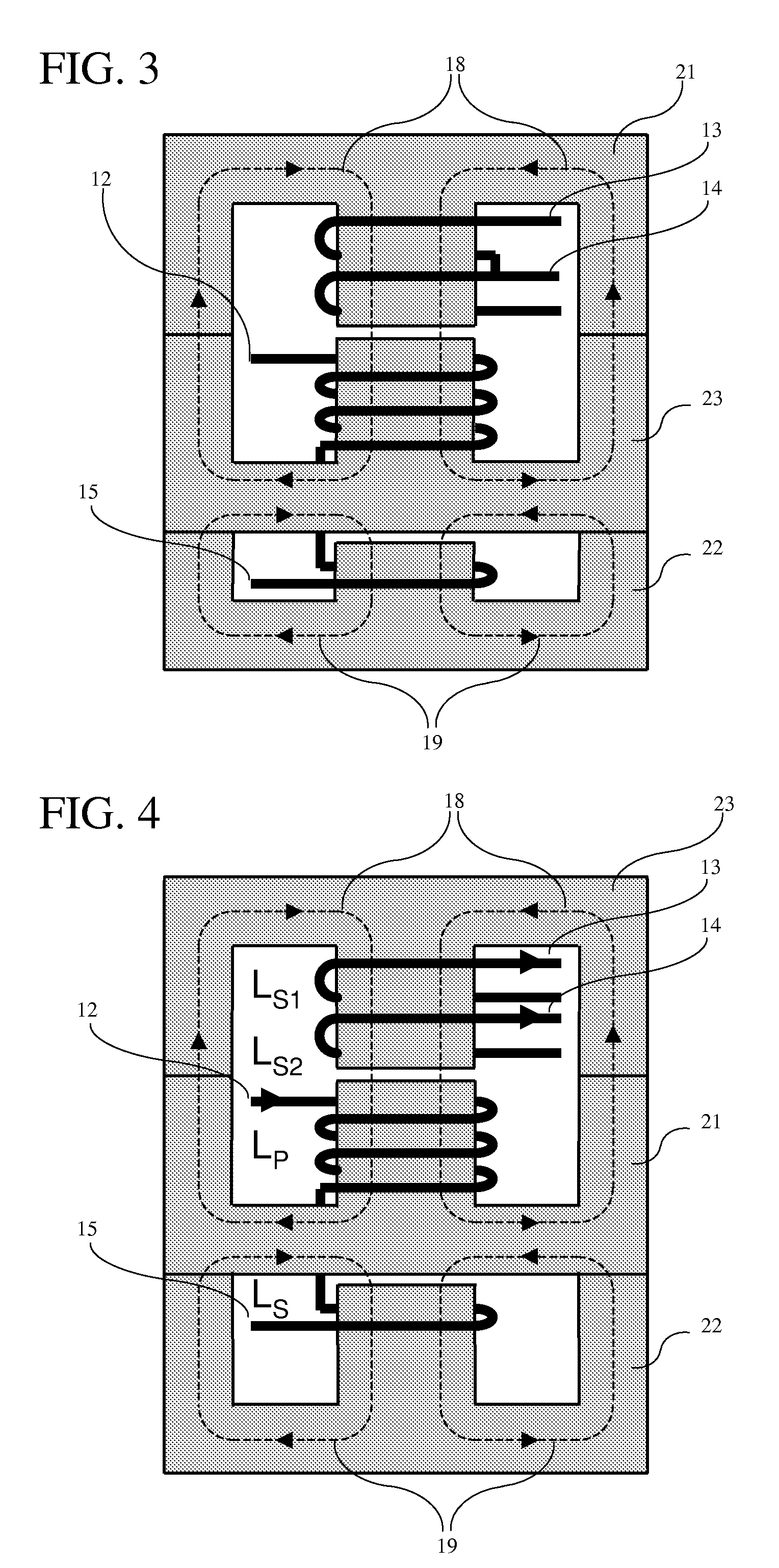

Wideband planar transformer

ActiveUS20090002111A1Minimize reflected energyMinimize total lossTransformers/inductances casingsTransformers/inductances coils/windings/connectionsConductive coatingWide band

A method of arranging and fabricating parallel primary and secondary coils of a wideband planar transformer is provided. The spacing and width of the coils are disposed to extend the bandwidth from DC to GHz and allow for high frequency coupling when the core permeability dramatically drops and achieves low reflected energy and low loss over a wide bandwidth. A bottom mold having a pattern of hole-pairs with conductive elements inserted vertically couples to a top mold such that a middle portion of the conductive elements spans between the top and bottom molds. Dielectric material envelopes the middle portion and a displacement feature of the mold creates a vacancy. A ferrite element is deposited to the vacancy. A second top mold spans the bottom mold and dielectric material is deposited to create a molded assembly. A deposited patterned conductive coating connects the element ends to define the transformer coils.

Owner:PLANARMAG

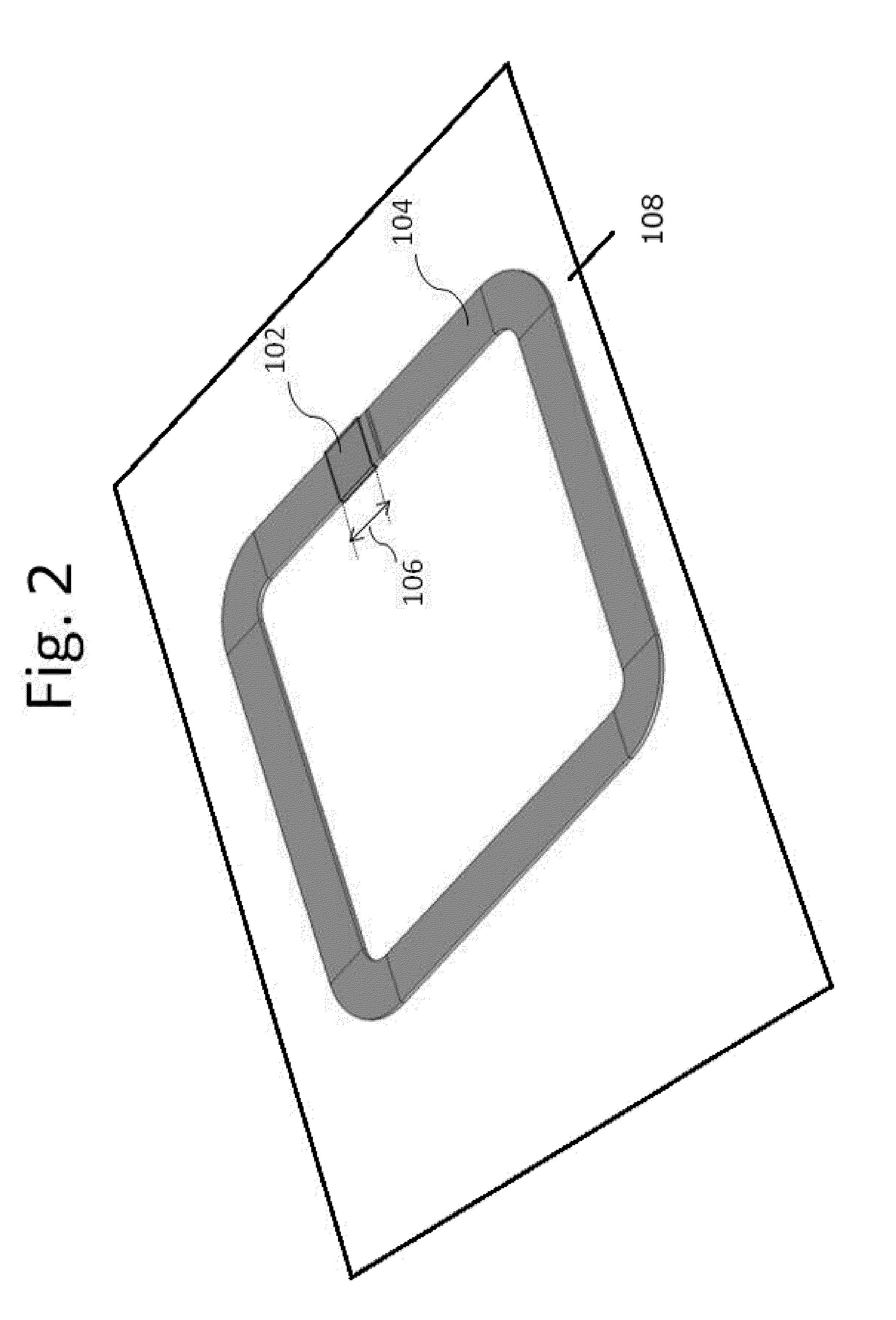

Multi-layer-multi-turn high efficiency inductors with cavity structures

ActiveUS20130200976A1Higher resistive lossLower quality factorInternal electrodesTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Method for operation of multi-layer-multi-turn high efficiency inductors with cavity structure

ActiveUS20130208389A1Higher resistive lossIncrease qualify factorTransformers/inductances coils/windings/connectionsInternal electrodesElectrical resistance and conductanceElectricity

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

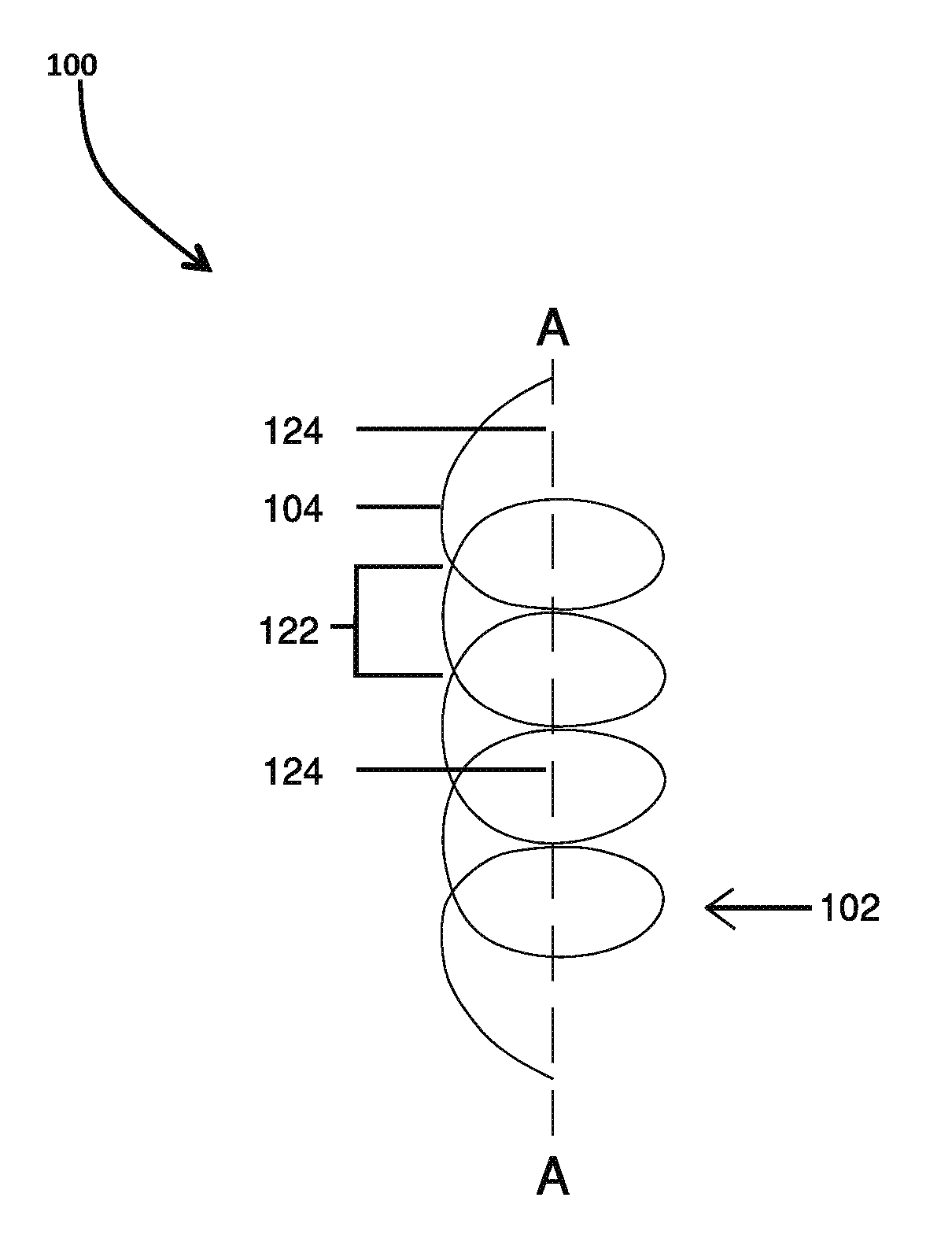

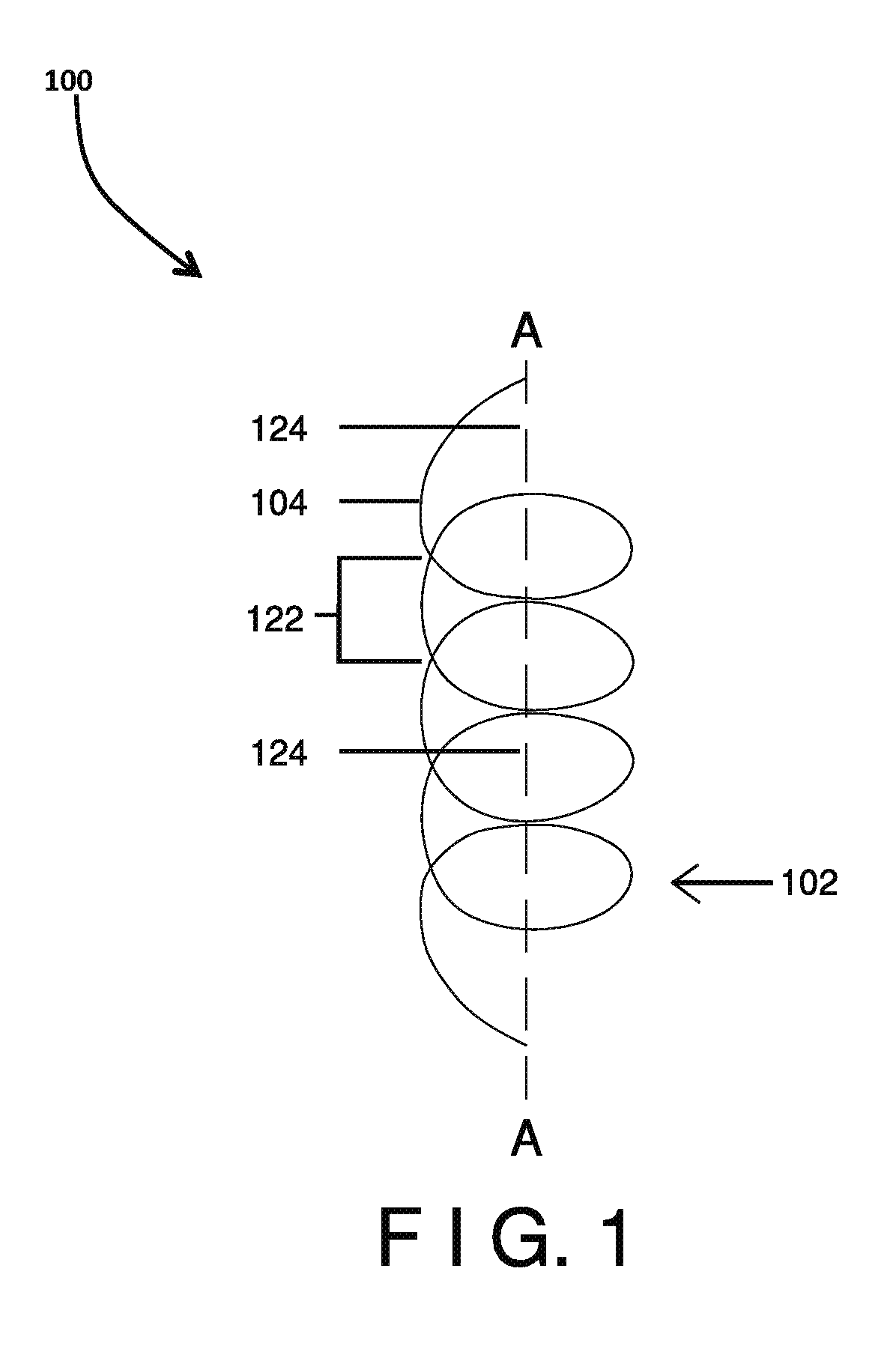

Method for operation of multi-layer-multi-turn high efficiency inductors

ActiveUS20130200722A1Higher resistive lossLower quality factorInternal electrodesTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

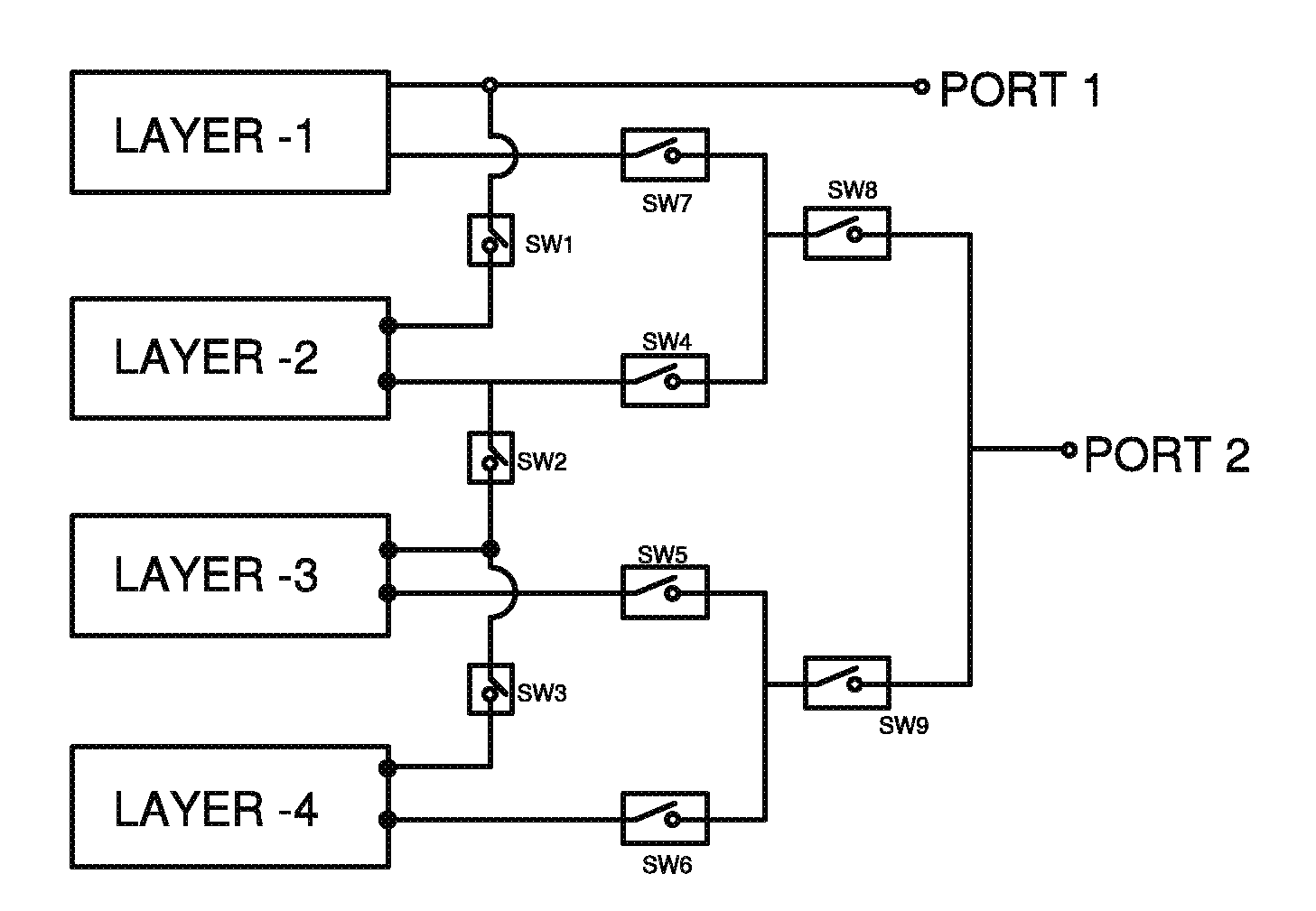

Method for operation of multi-layer-multi-turn high efficiency tunable inductors

ActiveUS20130201589A1Higher resistive lossLower quality factorInternal electrodesTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Magnetic integration structure

InactiveUS20080224809A1Reduced winding spaceReduce partTransformers/inductances coils/windings/connectionsVariable inductancesMagnetic integrationEngineering

Owner:FUJI ELECTRIC CO LTD +1

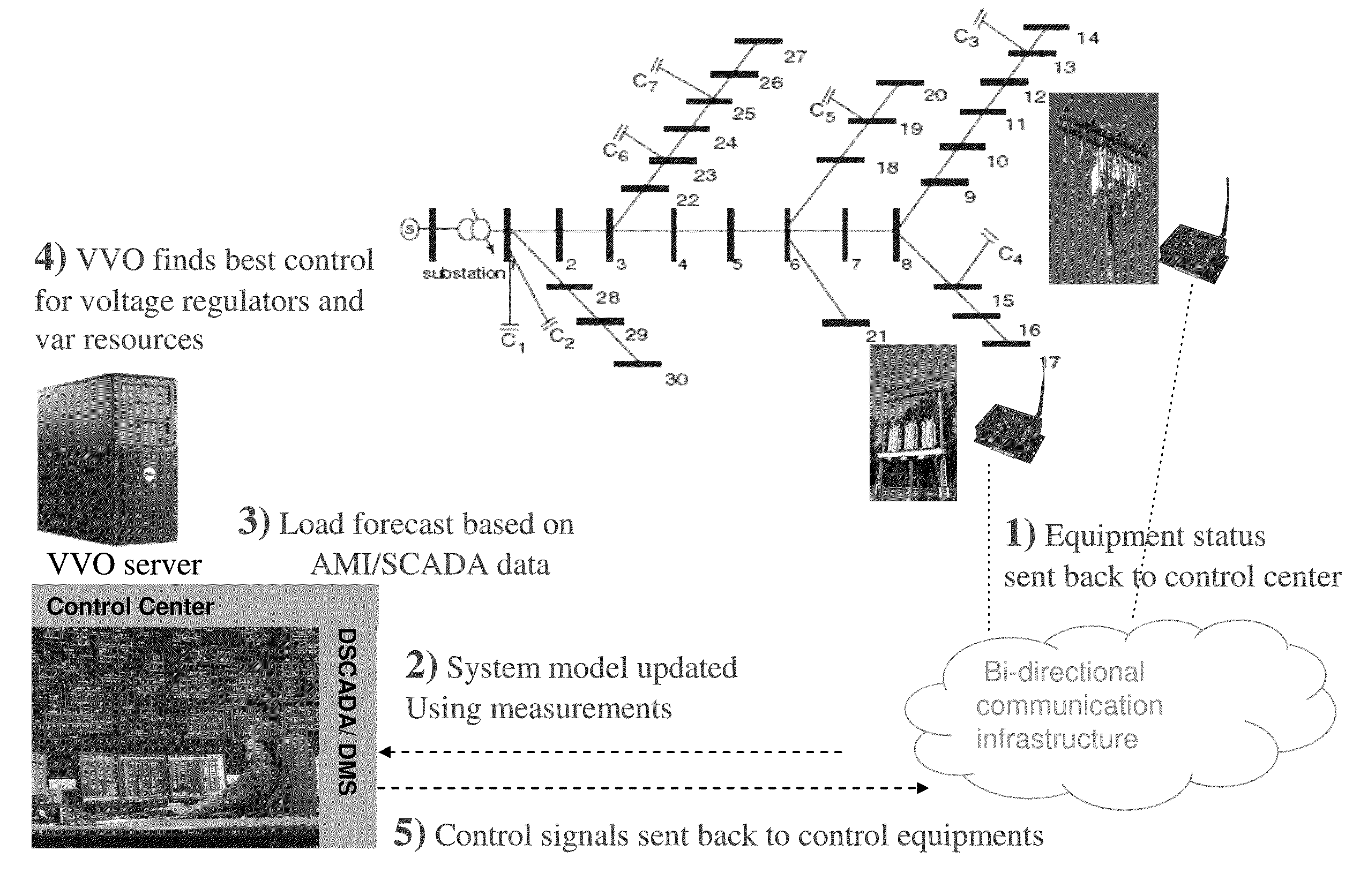

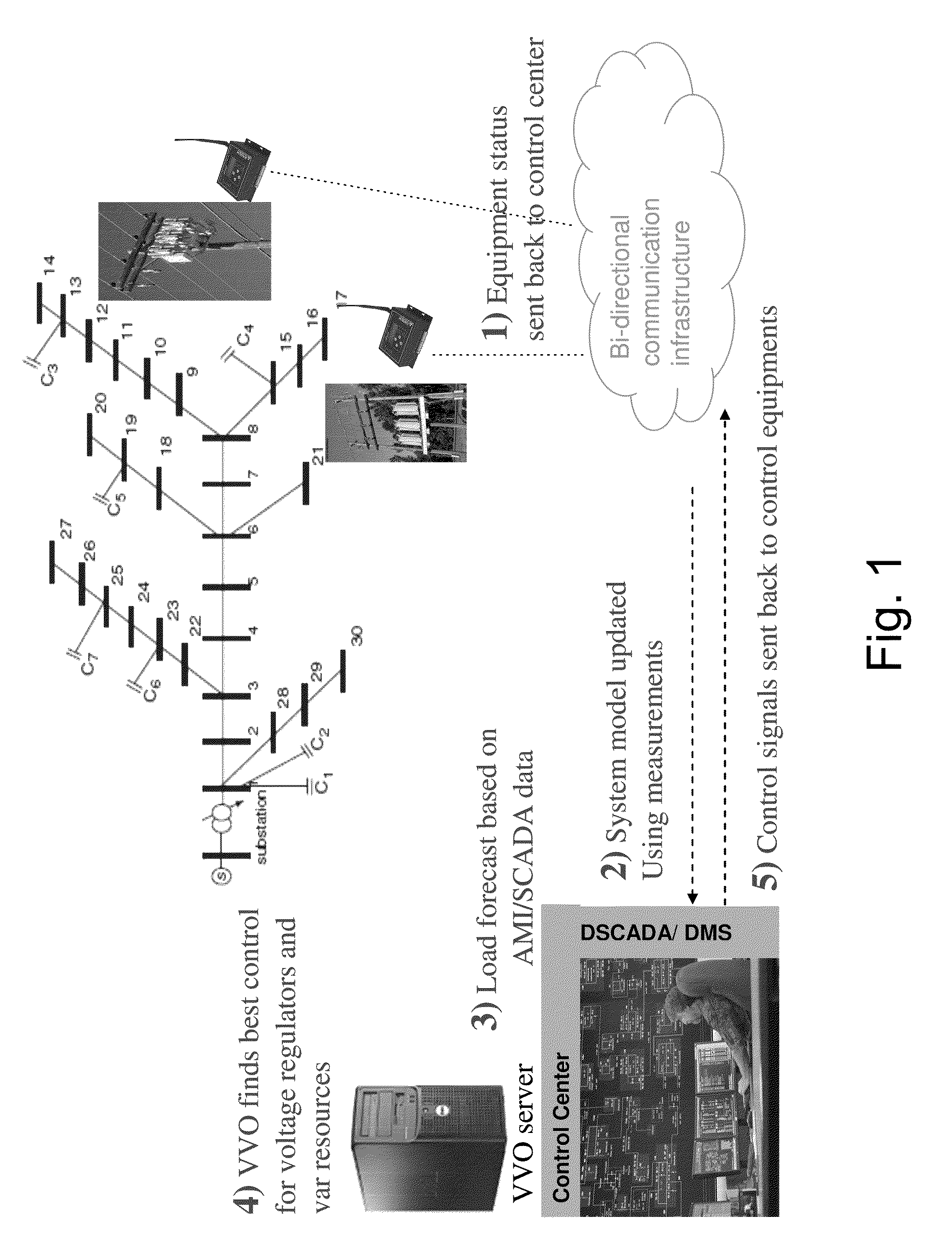

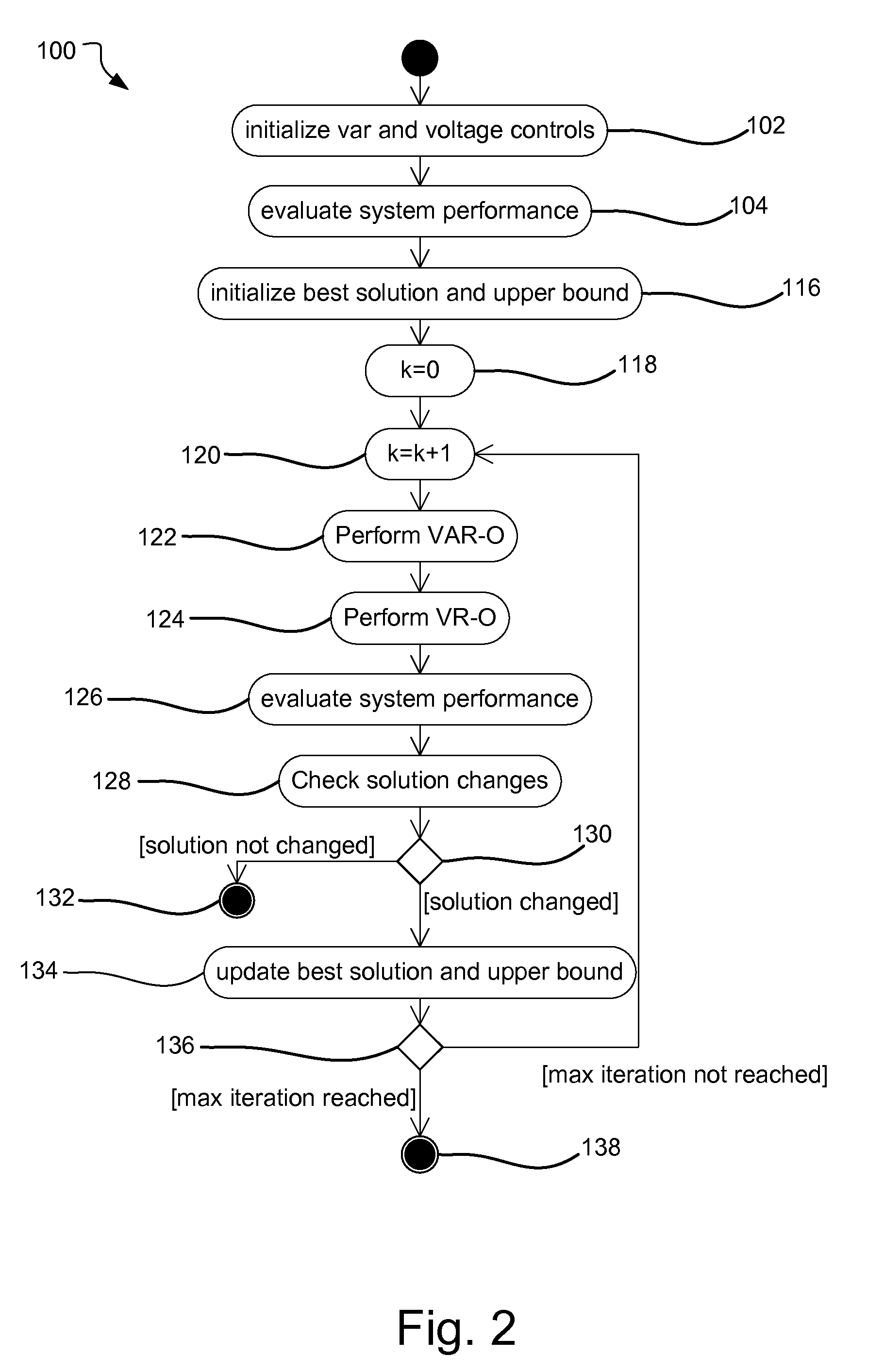

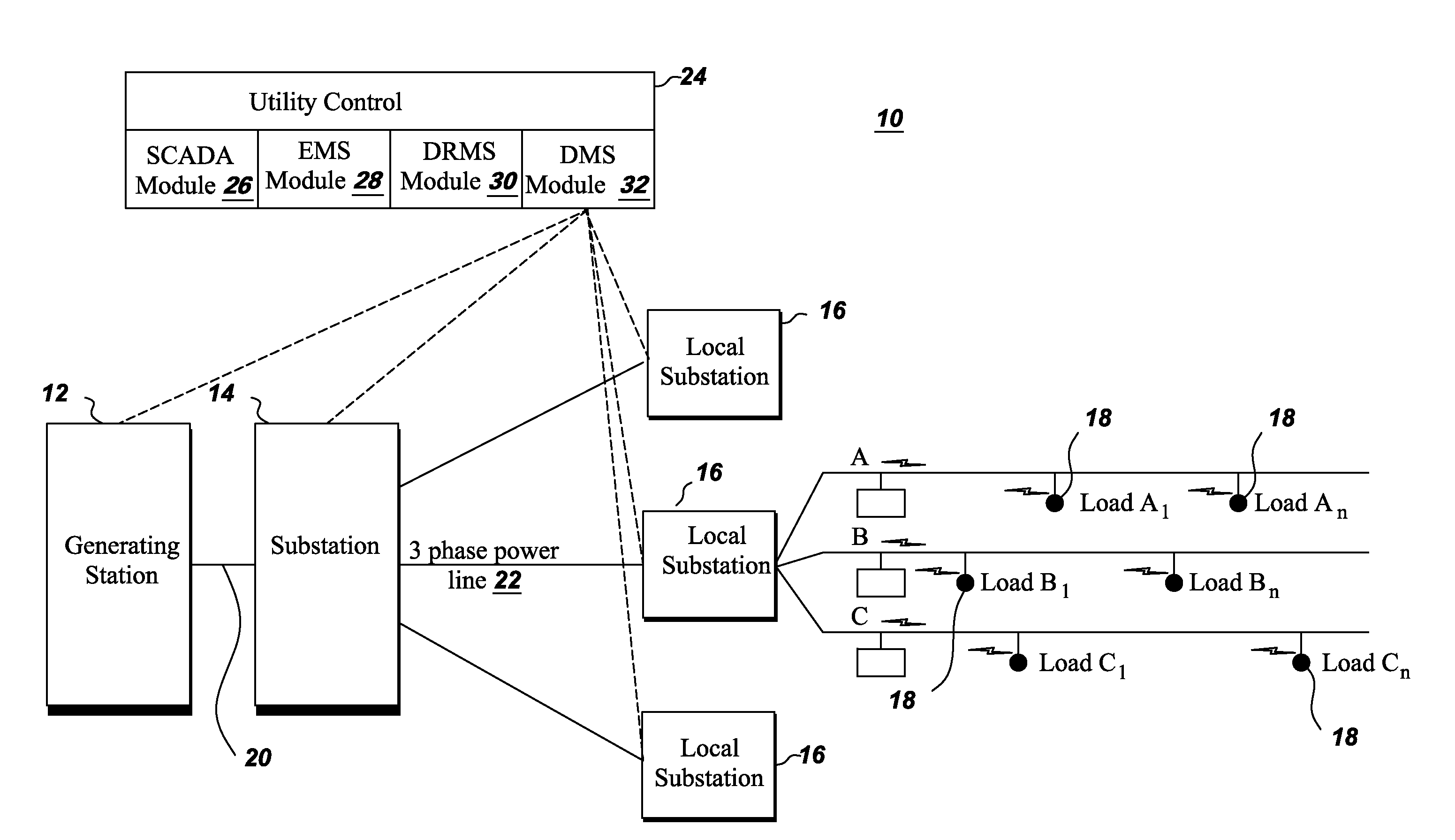

Integrated voltage and var optimization process for a distribution system

The method determines the optimal settings for the controllable taps ut of voltage regulating transformers and the capacitor bank switches uc in a distribution network. Var optimization is calculated with the controllable tap settings ut fixed at an initial value, or the best value found so far, to output an optimized set of control settings uc. Voltage optimization is calculated with the control settings uc fixed at the best solution found so far, to output an optimal set of control settings ut. Using an objective function, system performance is evaluated using the optimal set of control settings ut and uc and repeating the steps until either the control values ut and uc do not change from one iteration to the next, the objective function value does not change or if the new objective function value is greater than the last. The control values ut and uc are then output to a distribution control system.

Owner:HITACHI ENERGY SWITZERLAND AG

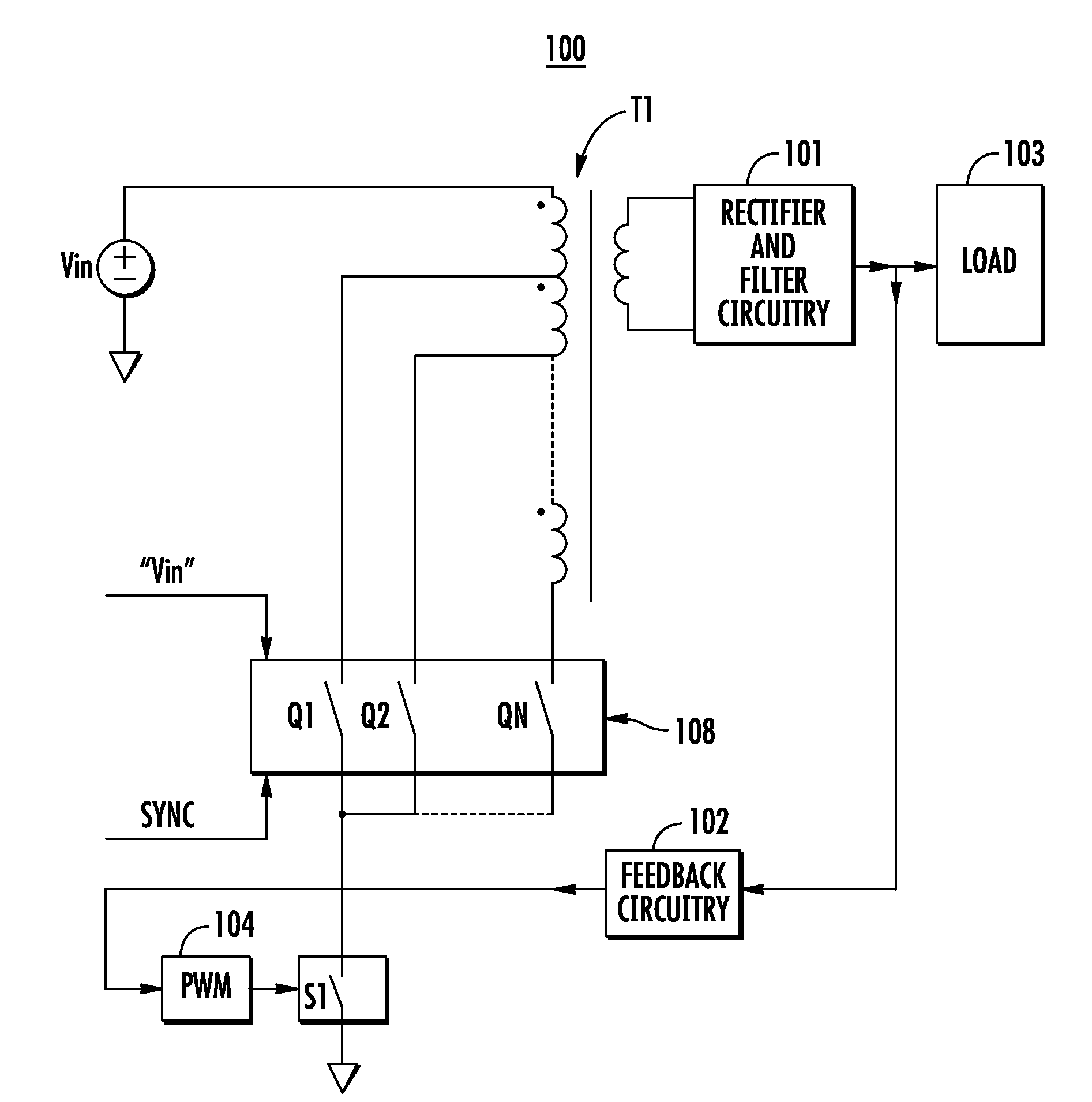

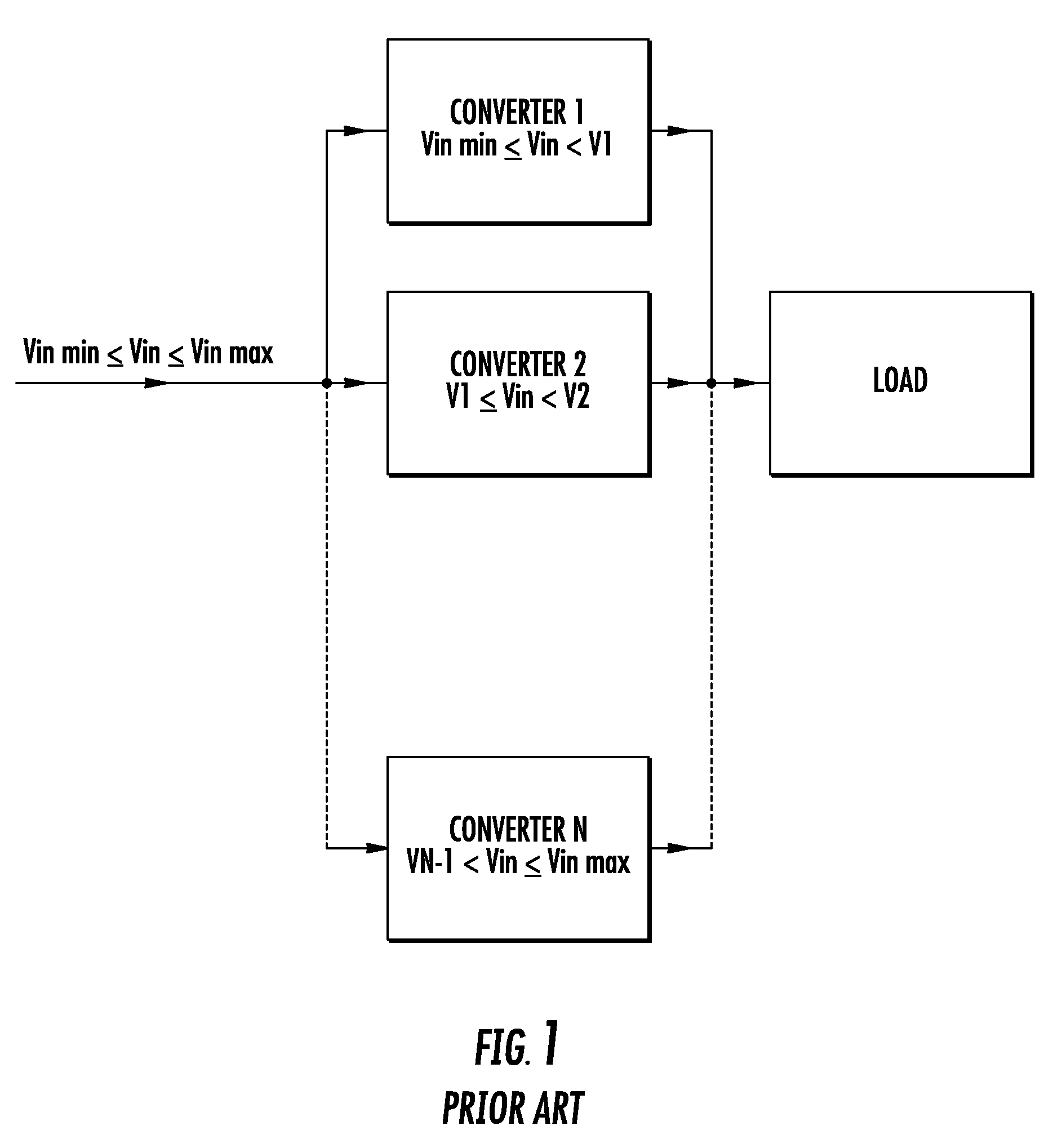

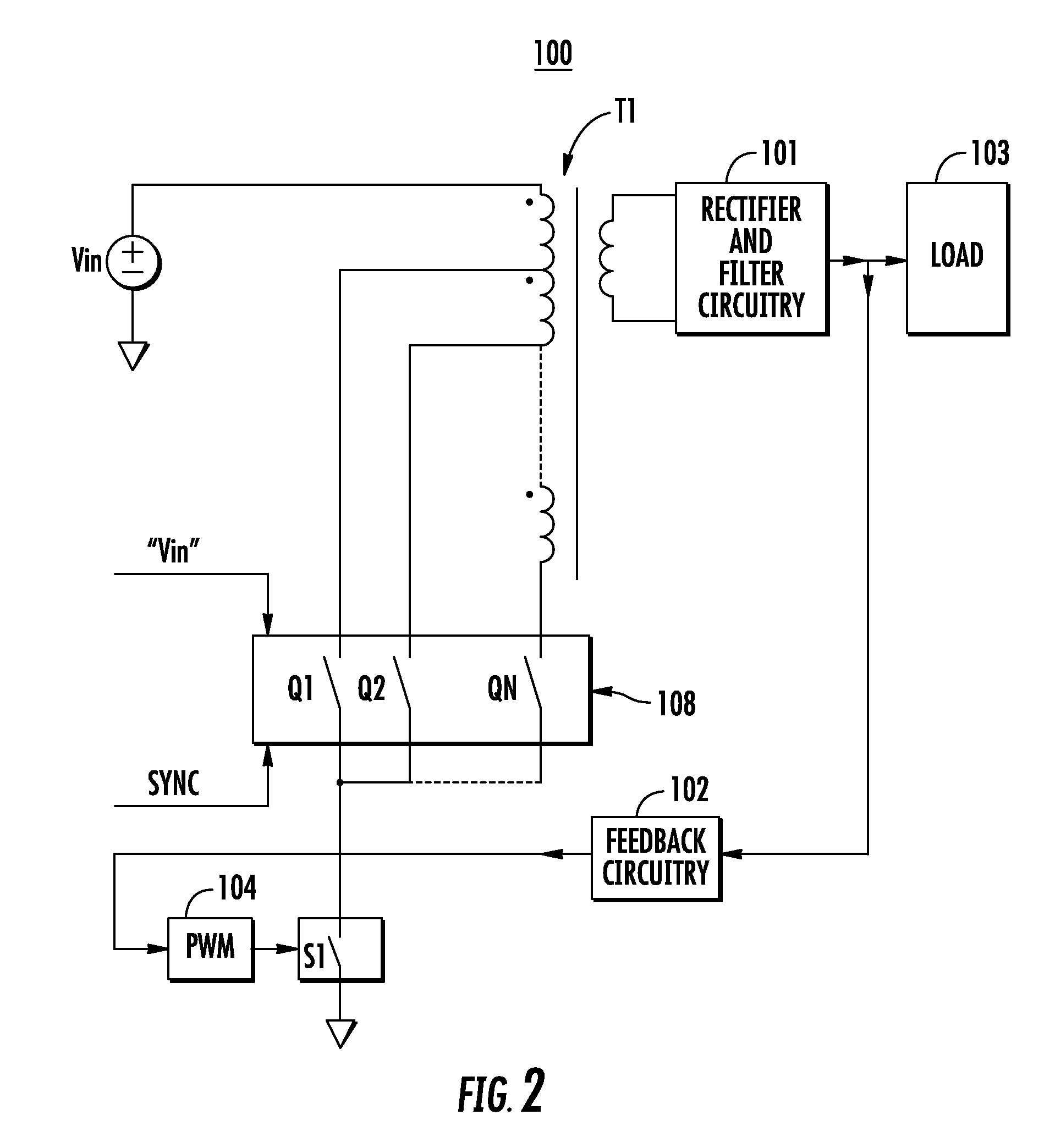

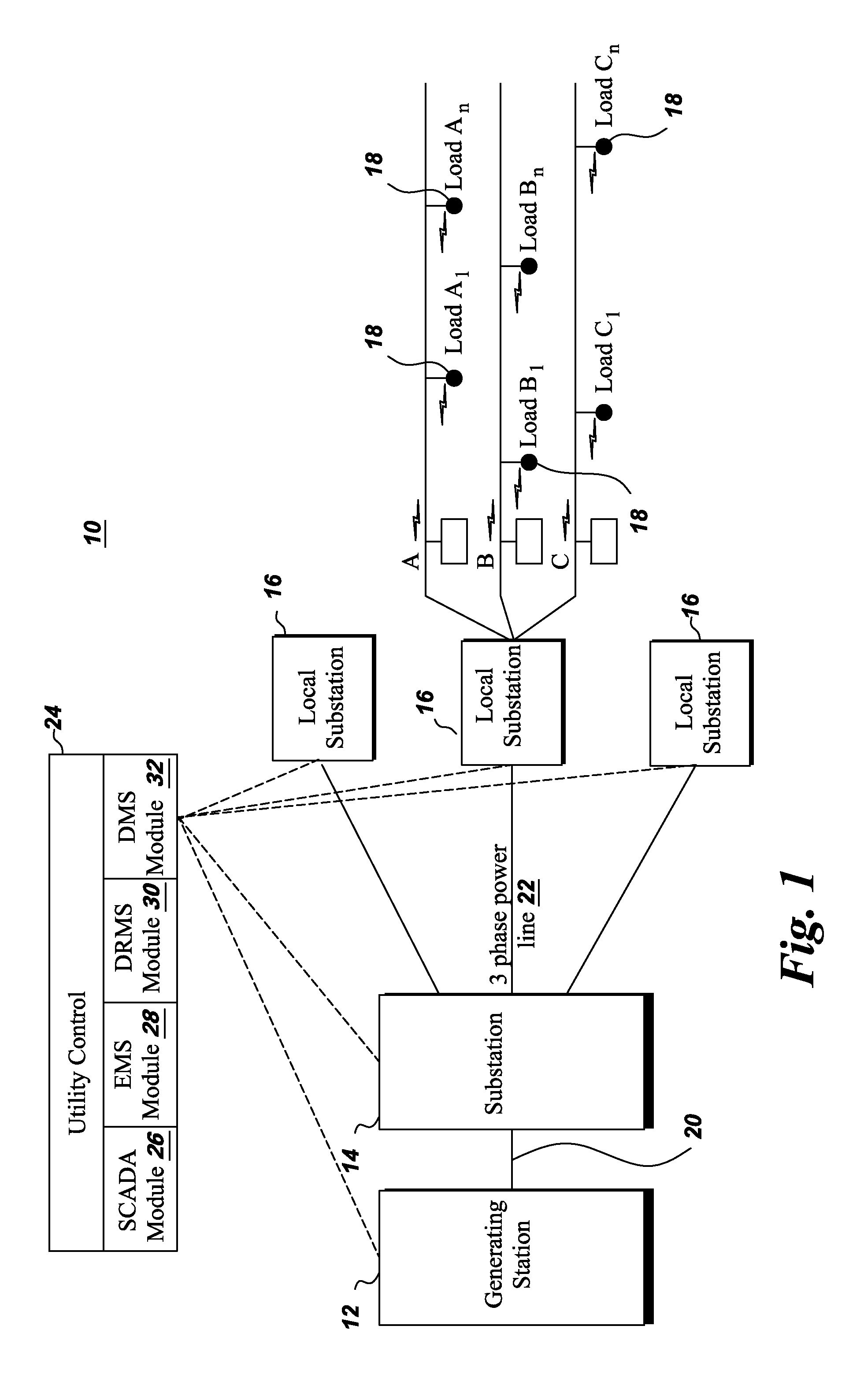

Method and apparatus for power conversion with wide input voltage range

A power conversion system includes an input terminal that is arranged to be connected to a voltage source; a transformer having a first winding connected to the input terminal and a second winding connected to an output terminal of the power conversion system, either the first winding or the second winding is provided with at least three taps that are arranged to divide the first winding or the second winding into at least two sub-windings; at least one tap switch connected to the at least two sub-windings; a control circuit connected to the at least one tap switch; and at least one switch connected to the at least one tap switch. The control circuit is arranged to control the at least one tap switch to control the turn ratio of the transformer.

Owner:MURATA POWER SOLUTIONS

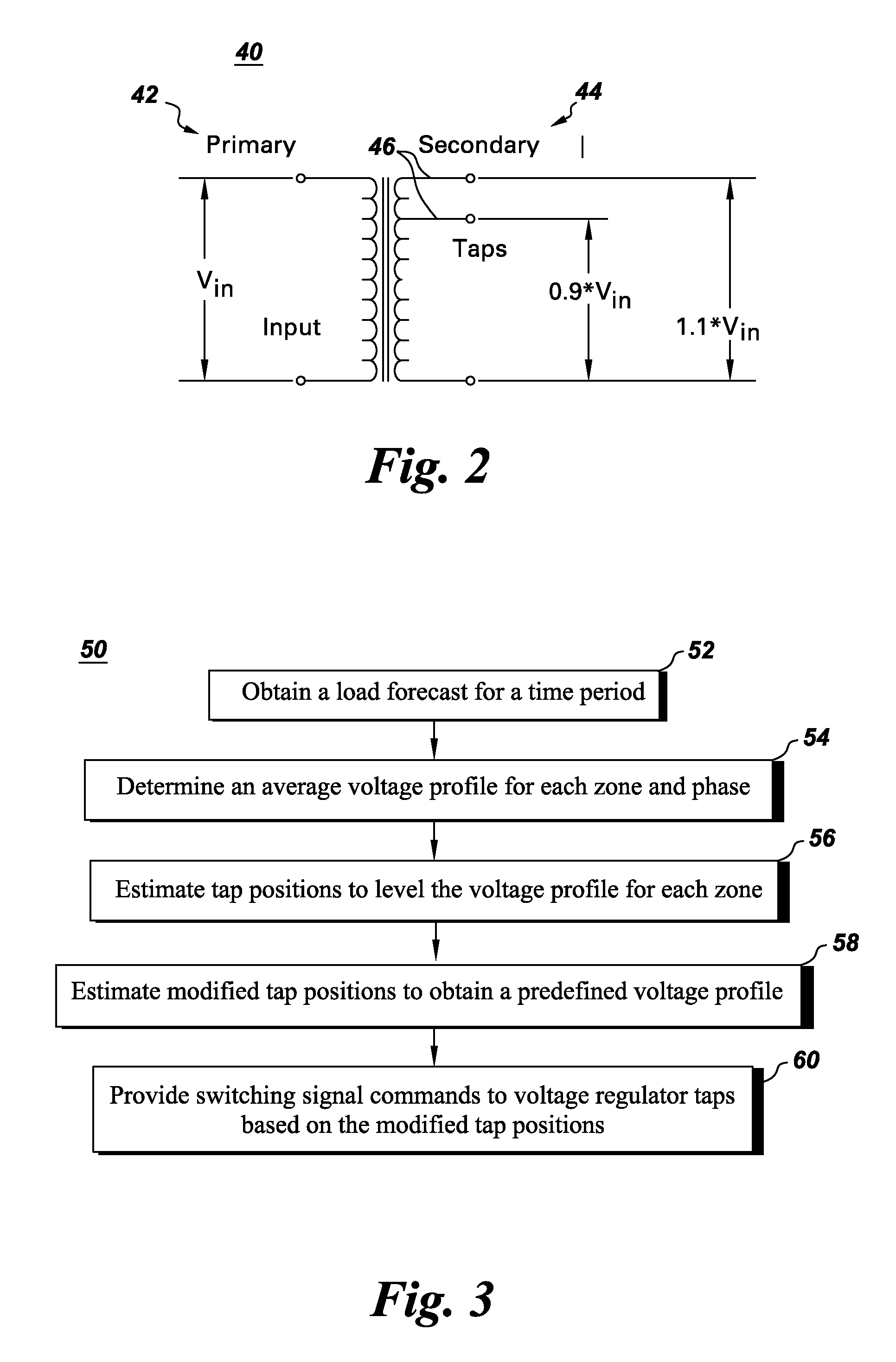

System and method for operating a tap changer

A method of operating a tap changer of a transformer or a voltage regulator in a power grid includes obtaining a load forecast for a time period. An average voltage profile is determined for the time period based on the load forecast. The method further includes estimating tap positions of the tap changer for leveling the average voltage profile during the time period. Switching signal commands are provided to the tap changer based on the estimated tap positions.

Owner:GENERAL ELECTRIC CO

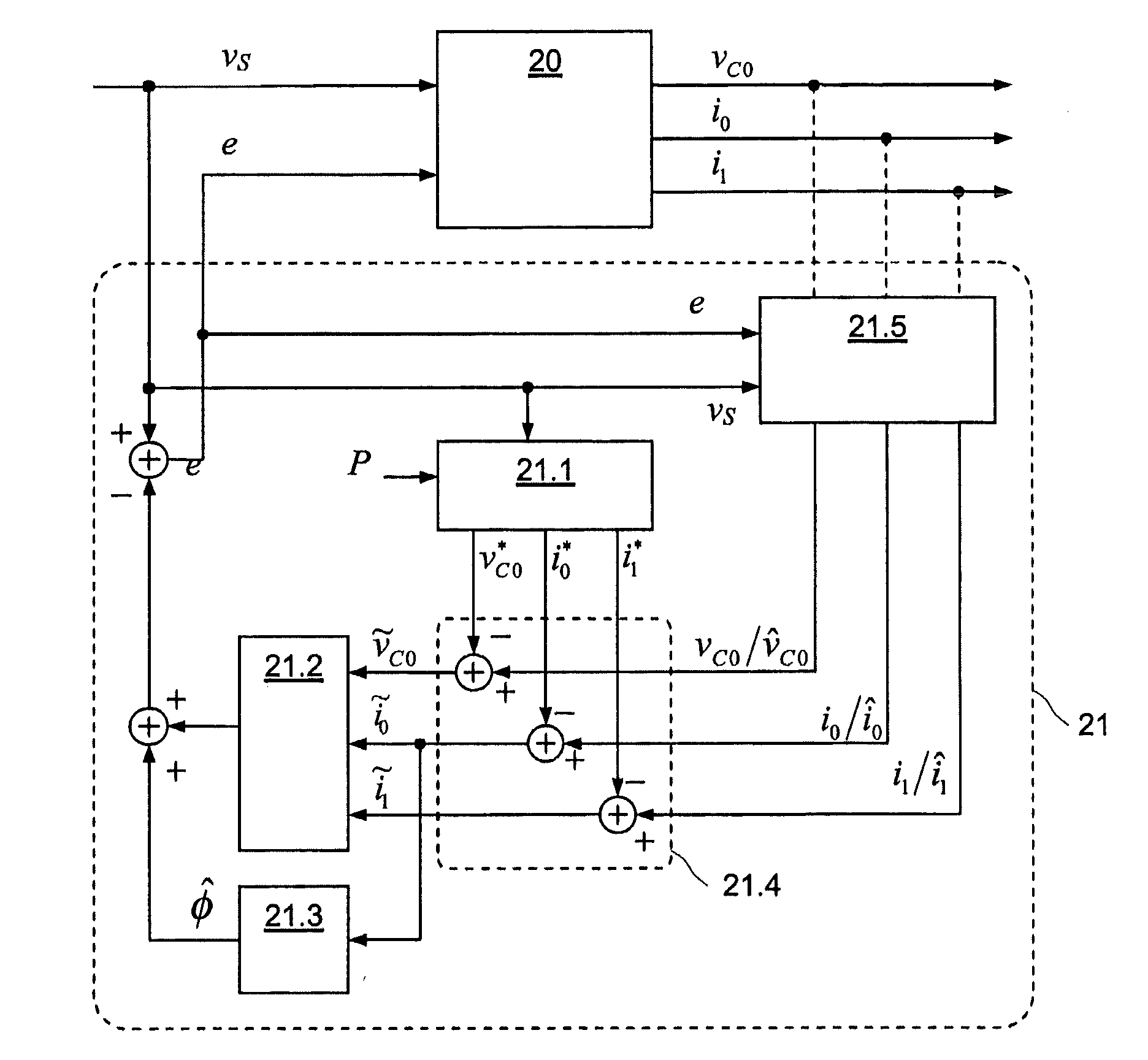

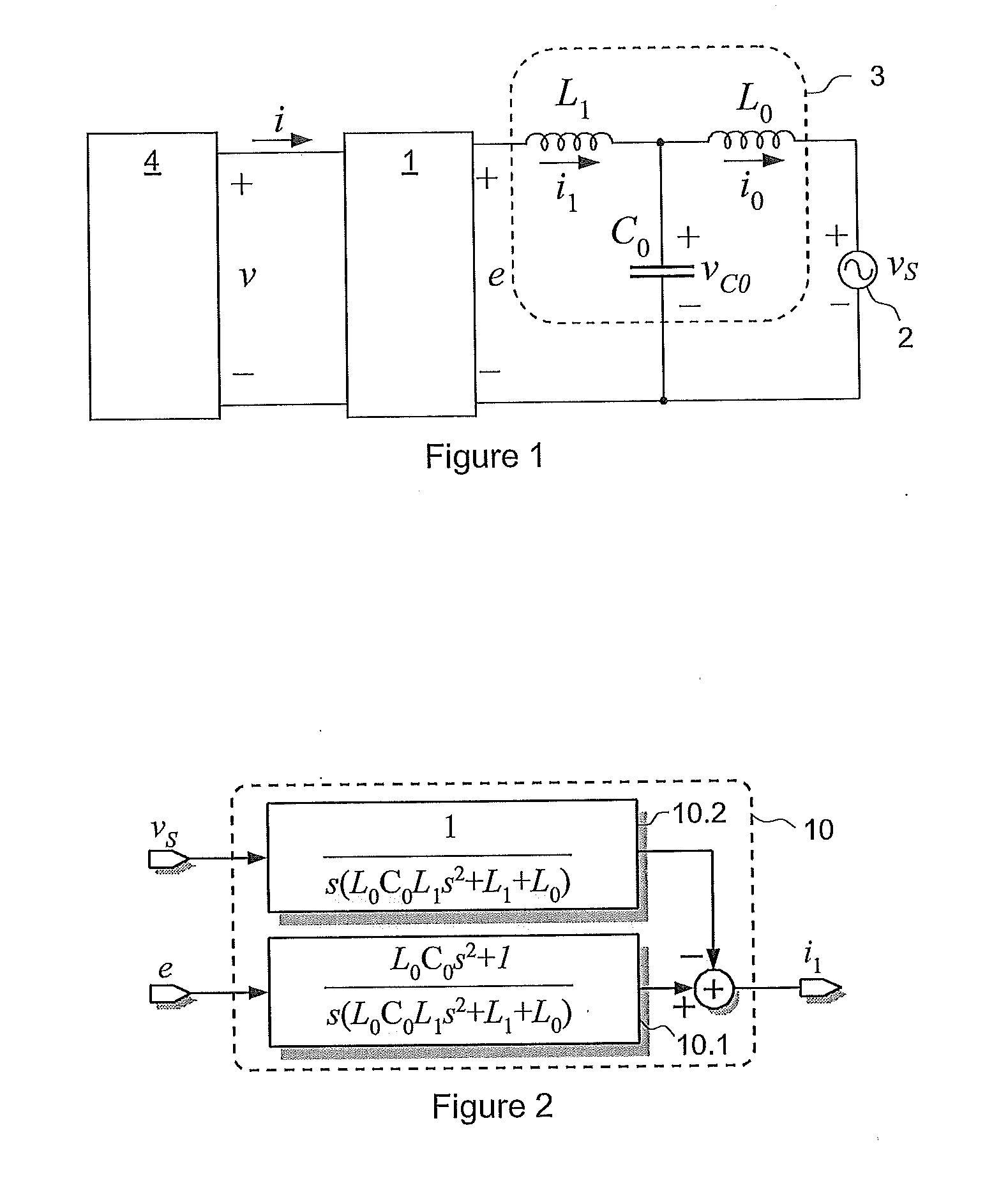

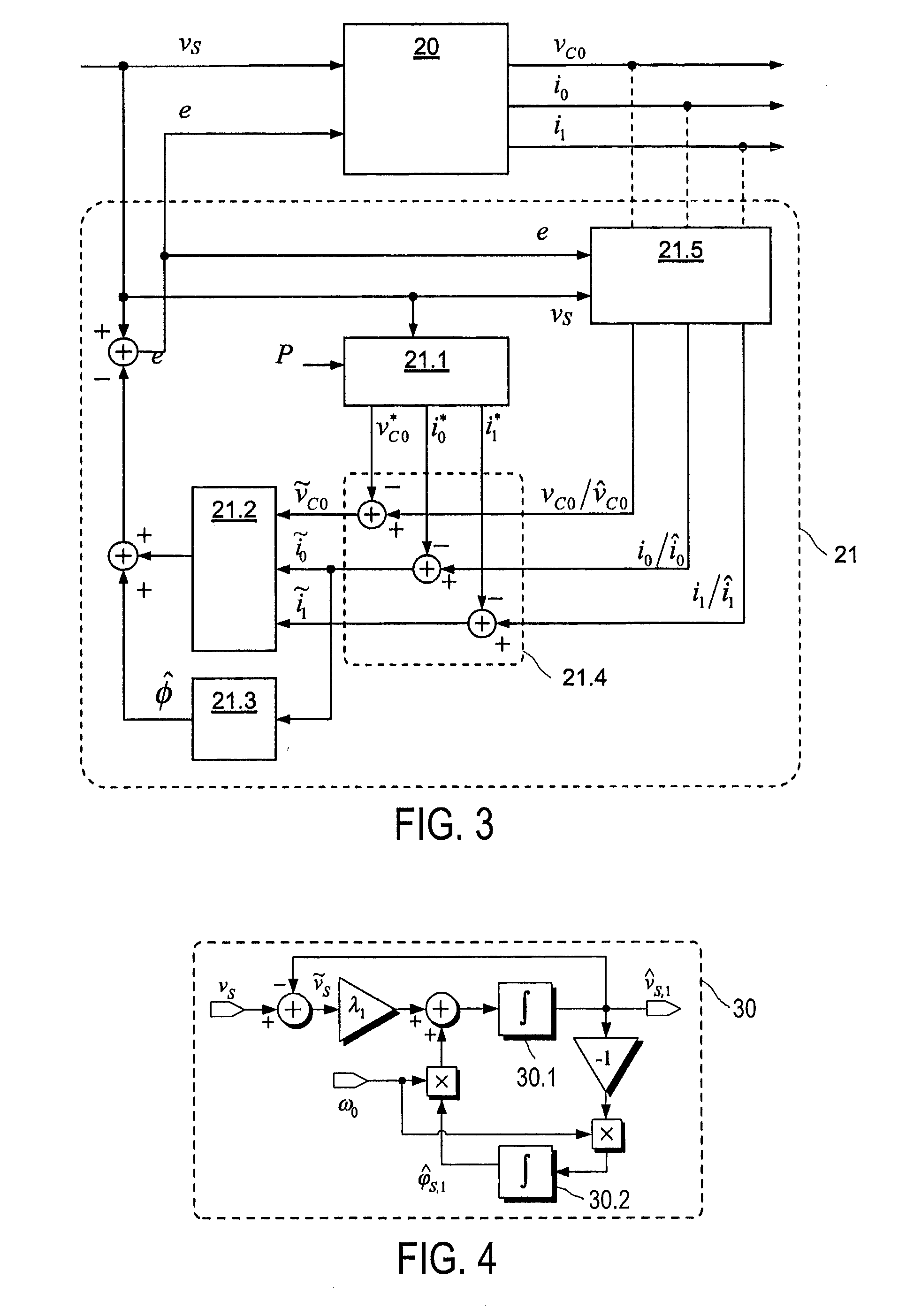

Control method for single-phase grid-connected lcl inverter

ActiveUS20110221420A1Improve performanceReduce resonanceVariable inductancesFixed transformers or mutual inductancesResonanceCapacitor voltage

A method of controlling the grid-side current of a single-phase grid-connected converter having an LCL filter connected between the output of the converter and the grid. The method includes measuring a grid voltage (vS) and at least one signal in a group of signals consisting of a grid-side current (i0), a converter-side current (i1) and a capacitor voltage (vC0). The method includes estimating the fundamental component (vS,1) of the grid voltage (vS), forming a grid-side current reference (i0*), a converter-side current reference (i1*) and a capacitor voltage reference (vC0*) for the grid-side current of the LCL filter using the fundamental component of the grid voltage (vS,1), forming estimates for the non-measured signals in said group of signals, forming a grid-side current difference term (ĩ0), a converter-side current difference term (ĩ1) and a capacitor voltage difference term ({tilde over (v)}C0) from the differences between the references and measured / estimated values of said signals, forming an injection term for damping the resonance of the LCL filter by using an active damping injection mechanism (ADI), in which the grid-side current difference term (ĩ0), the converter-side current difference term (ĩ1) and the capacitor voltage difference term ({tilde over (v)}C0) are used, forming an estimate of harmonic distortion term ({circumflex over (φ)}) using the grid-side current difference term (ĩ0), and controlling the output voltage (e) of the converter on the basis of the grid voltage, formed injection term and formed estimate of the harmonic distortion term ({circumflex over (φ)}) to produce a grid side (i0) current corresponding to the current reference.

Owner:MARICI HLDG THE NETHERLANDS BV

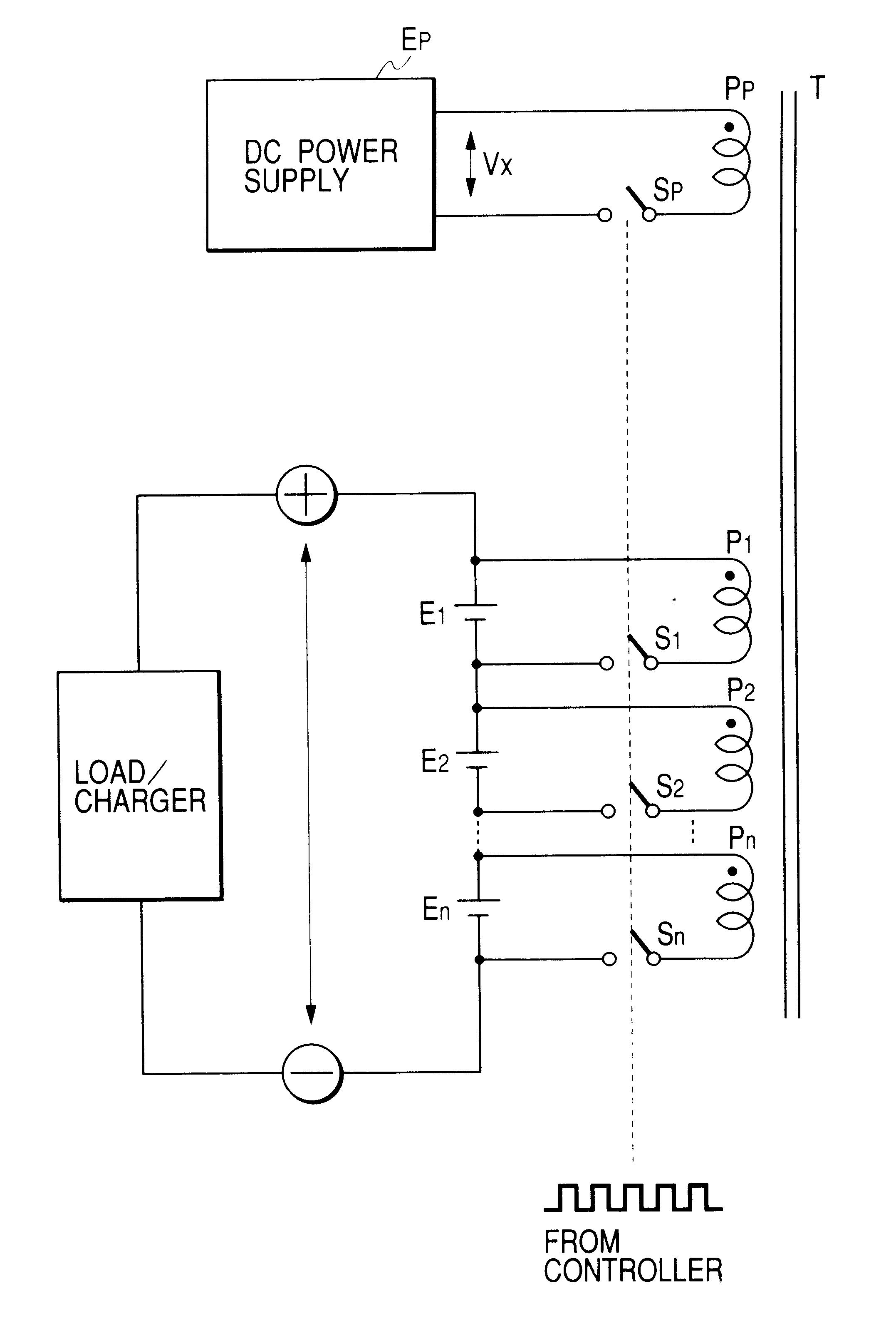

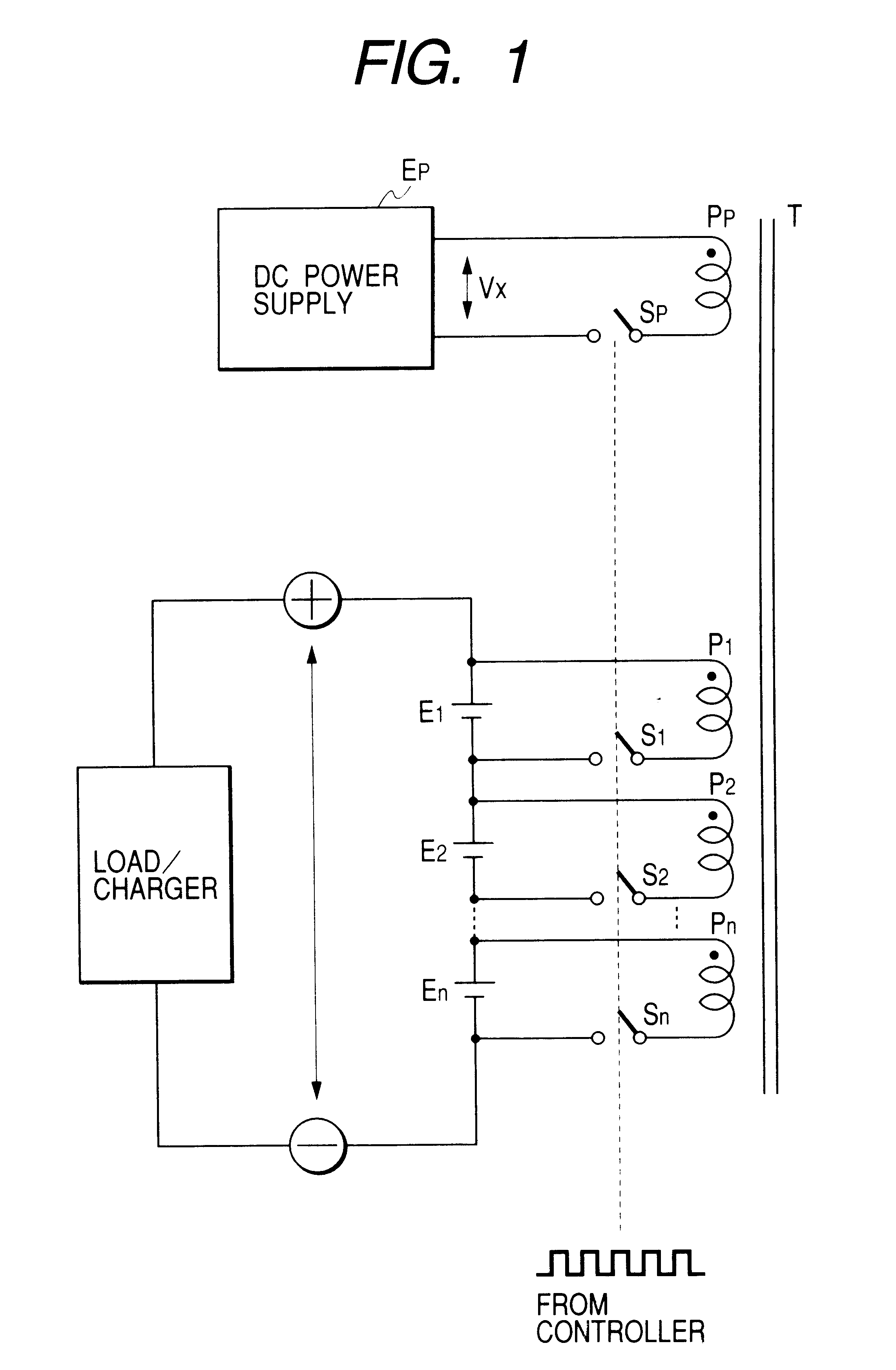

Voltage equalizer apparatus and method thereof

InactiveUS6586910B2Dc network circuit arrangementsCharge equalisation circuitElectromagnetic couplingConductor Coil

In such a voltage equalizer circuit in which each of plural windings P1 to Pn electromagnetically coupled to each other, each of plural storage elements E1 to En series-connected to each other, and each of plural first switching elements S1 to Sn are connected to each other in a series connecting manner so as to constitute a plurality of closed circuits, this voltage equalizer apparatus is featured by that a reference voltage winding Pp electromagnetically coupled to the plurality of windings is provided; both a DC power supply Ep and a second switching element Sp are series-connected to the second winding; and all of the plural first switching elements and the second switching element are turned ON / OFF in a synchronous manner.

Owner:SUBARU CORP +1

Transformer with voltage regulating means

InactiveUS6995646B1Reduce extra spaceCompact designWindingsPlastic/resin/waxes insulatorsElectrical conductorTransformer

A power or regulating transformer with voltage regulator includes regulating windings made of a flexible conductor having an electric field containing mechanism that forces the electric field due to the current in the winding to be contained within the flexible conductor. Since virtually no electric field is to be found outside the flexible conductor of the regulating winding, the regulating winding may be formed without having to consider the electric field distribution, thus providing for a transformer with a favorable regulating winding design.

Owner:ABB (SCHWEIZ) AG

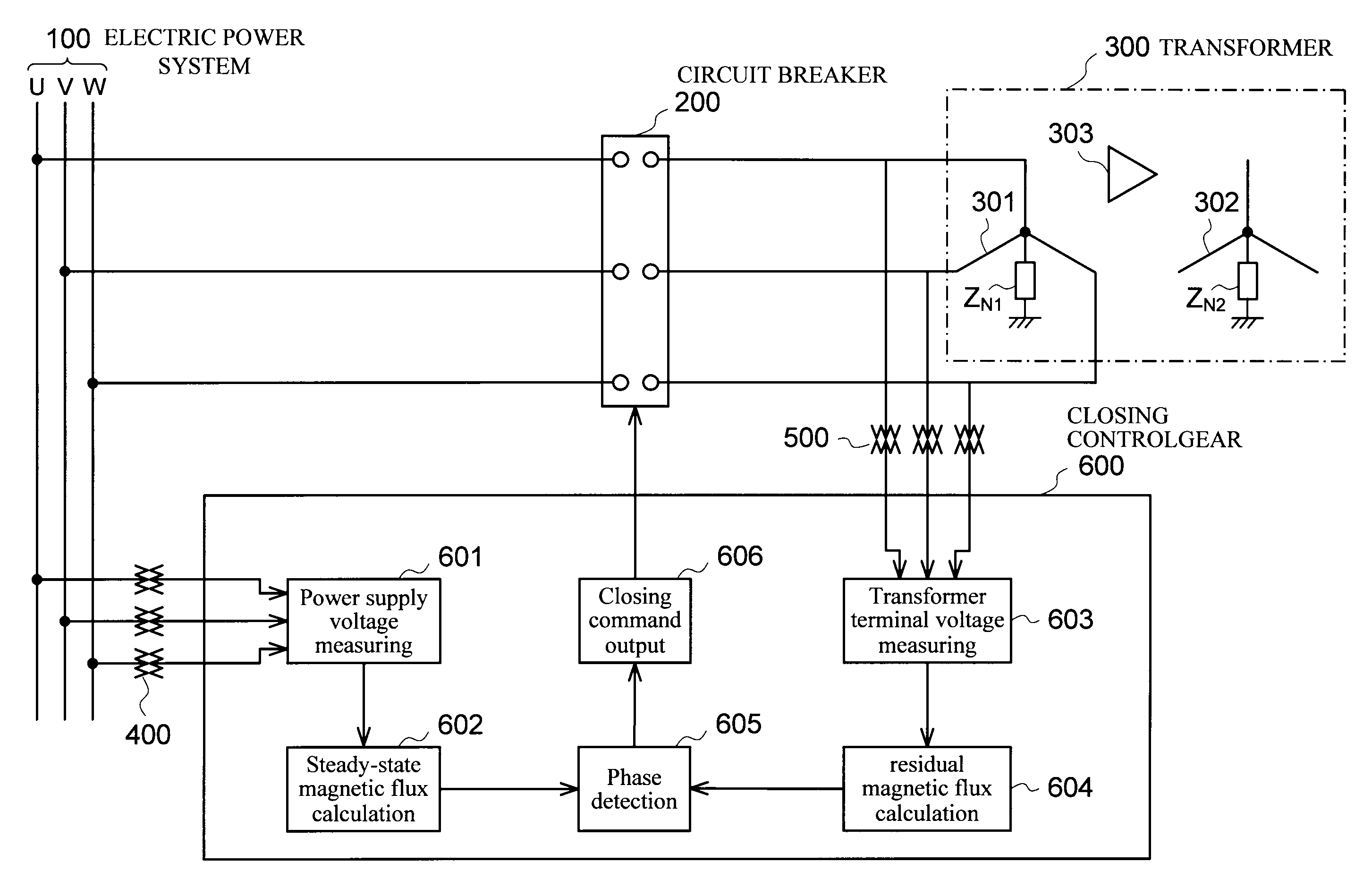

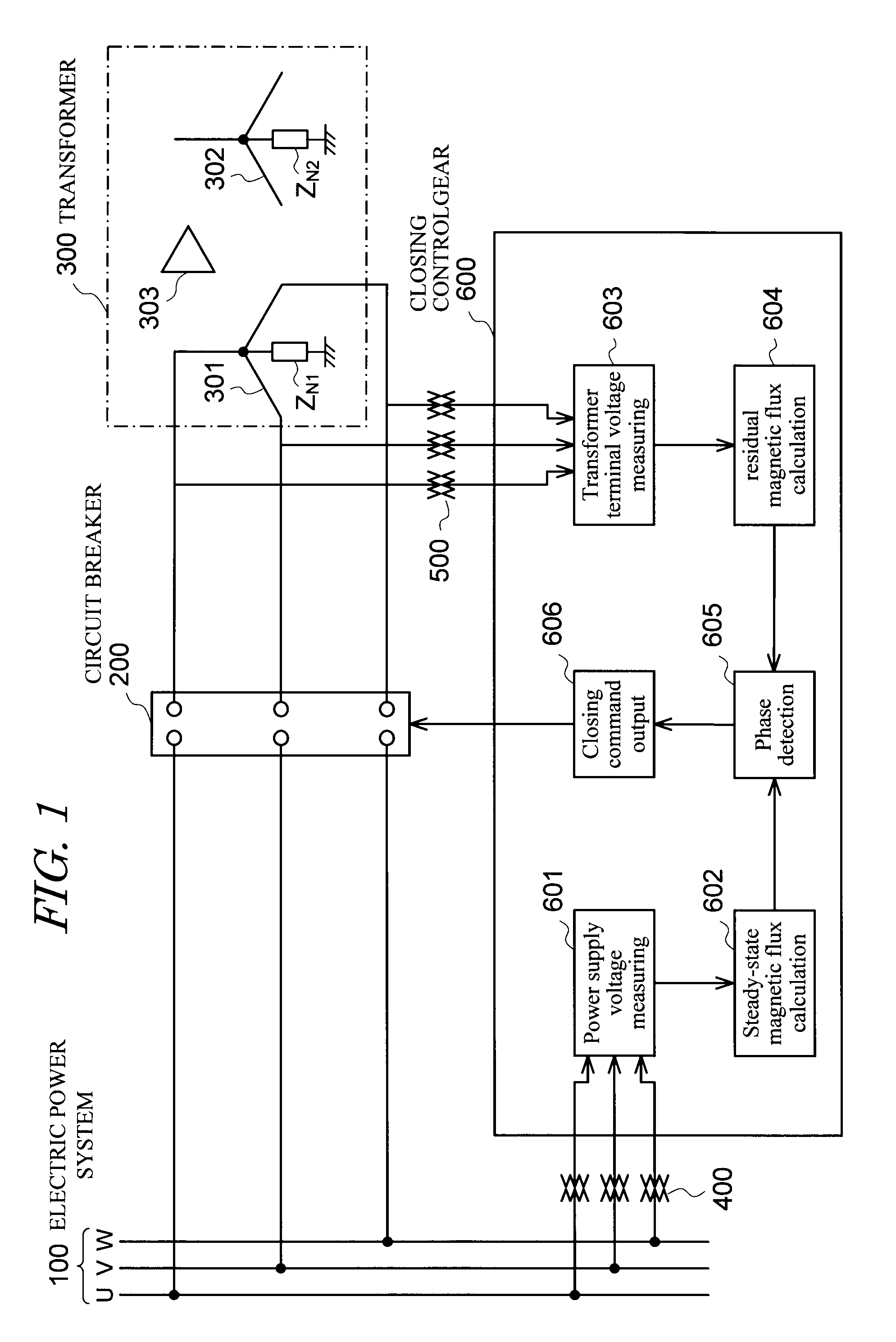

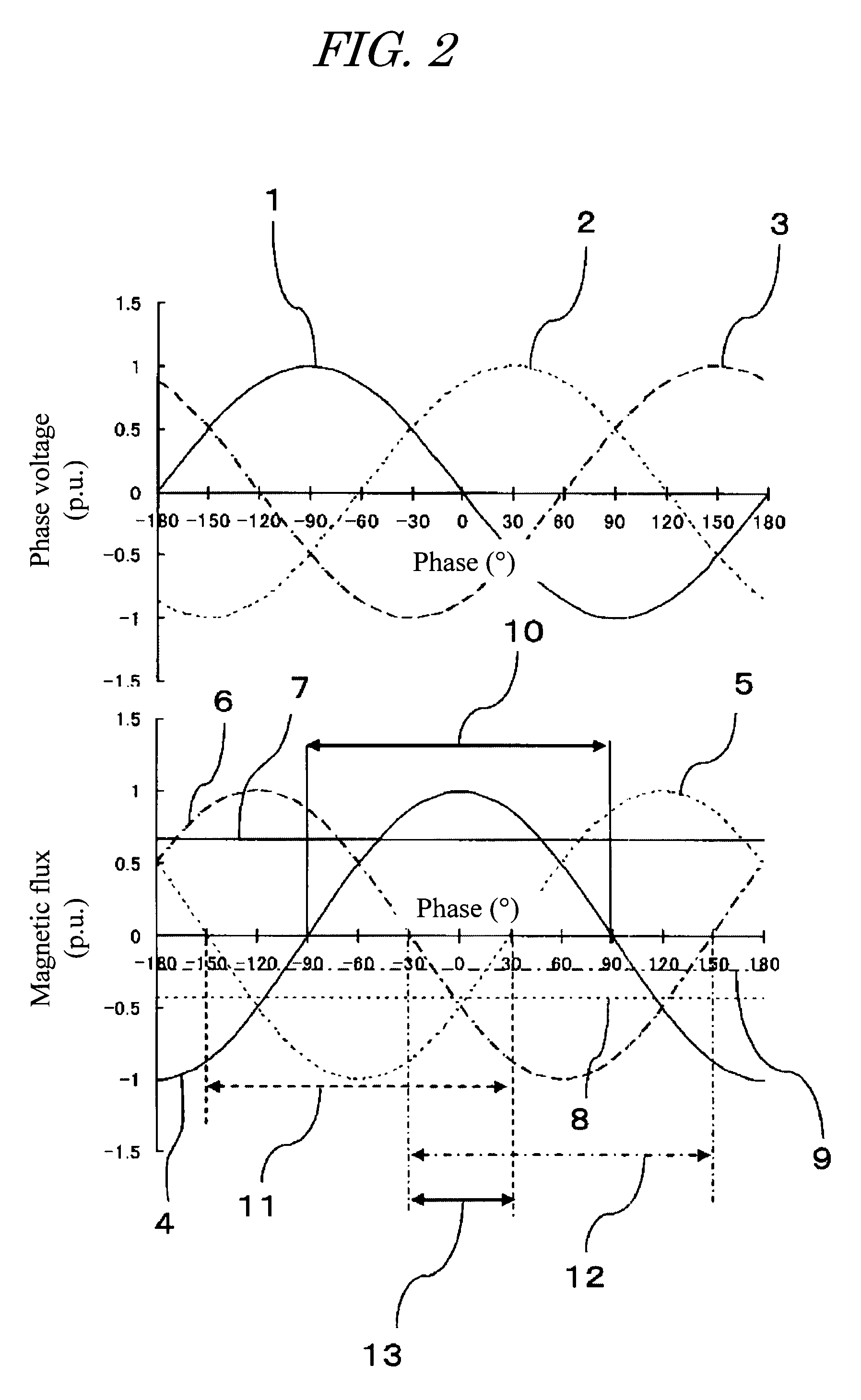

Magnetizing inrush current suppression device and method for transformer

ActiveUS20100141235A1Accurate calculationBatteries circuit arrangementsVariable inductances/transformersEngineeringInrush current

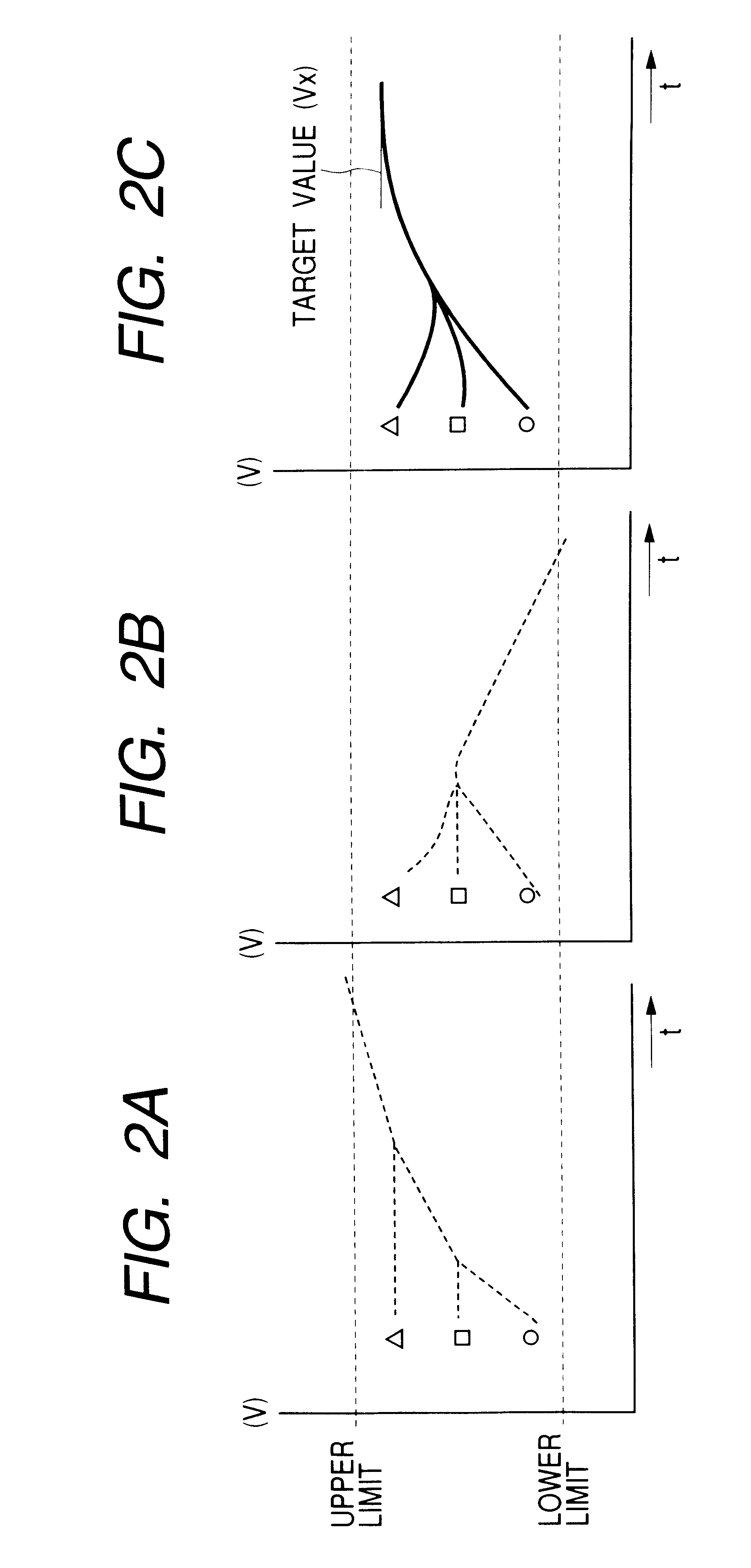

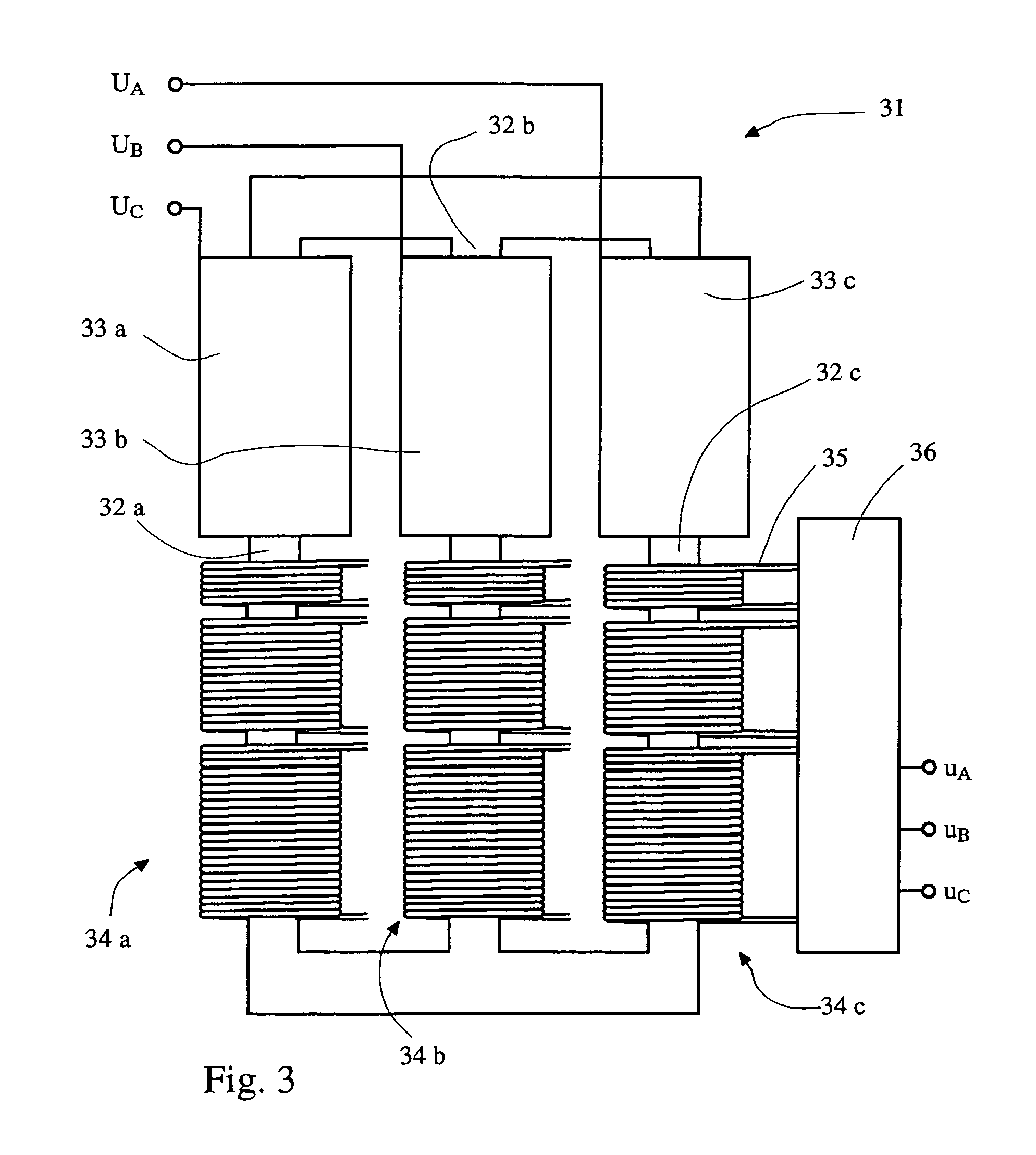

To suppress the magnetizing inrush current occurring when supplying power of three phases of the transformer are performed simultaneously using three single-phase circuit breakers or a non-phase segregated operation-type circuit breaker, without providing a circuit breaker with a resistor or other equipment. A magnetizing inrush current suppression method for transformer suppresses a magnetizing inrush current occurring at the start of energizing of a three-phase transformer 300, when a three-phase power supply 100 is input to a terminal of each phase by means of a three-phase circuit breaker 200. In the method, by integrating phase voltages or line-to-line voltages on the primary side or the secondary side or the tertiary side when three-phase AC voltages are applied in a steady state to the transformer 300, steady-state magnetic flux 4, 5, 6 for each phase of the transformer is calculated, and the polarity and magnitude of the residual magnetic flux 7, 8, 9 of each phase of the transformer after the circuit breaker 200 shuts off the transformer are calculated, and the three-phase circuit breaker is caused to close simultaneously in a region 13 in which three phases overlap, each of the three phases having the polarity of the steady-state magnetic flux 4, 5, 6 equal to the polarity of the residual magnetic flux 7, 8, 9 for each phase of the transformer.

Owner:KK TOSHIBA

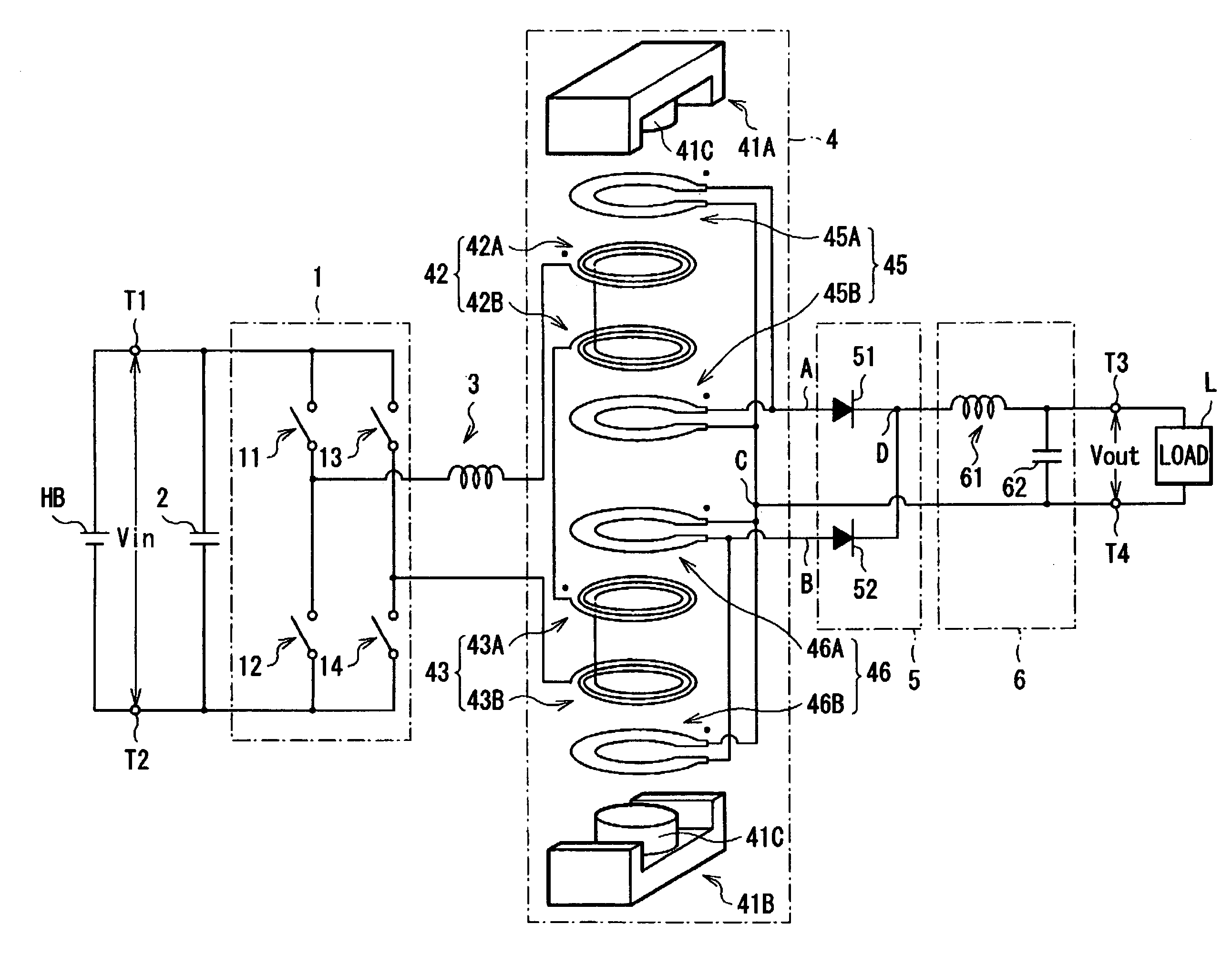

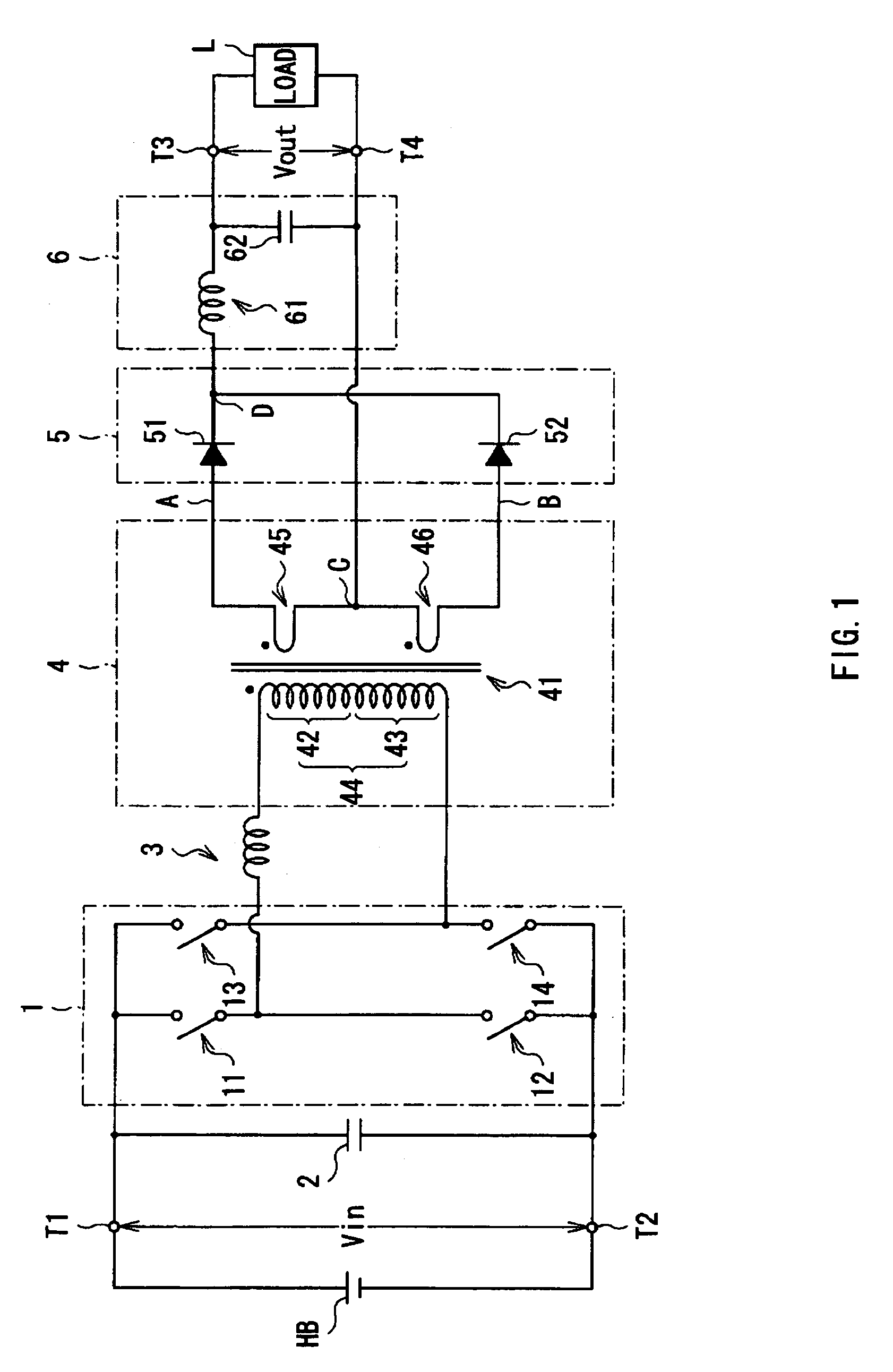

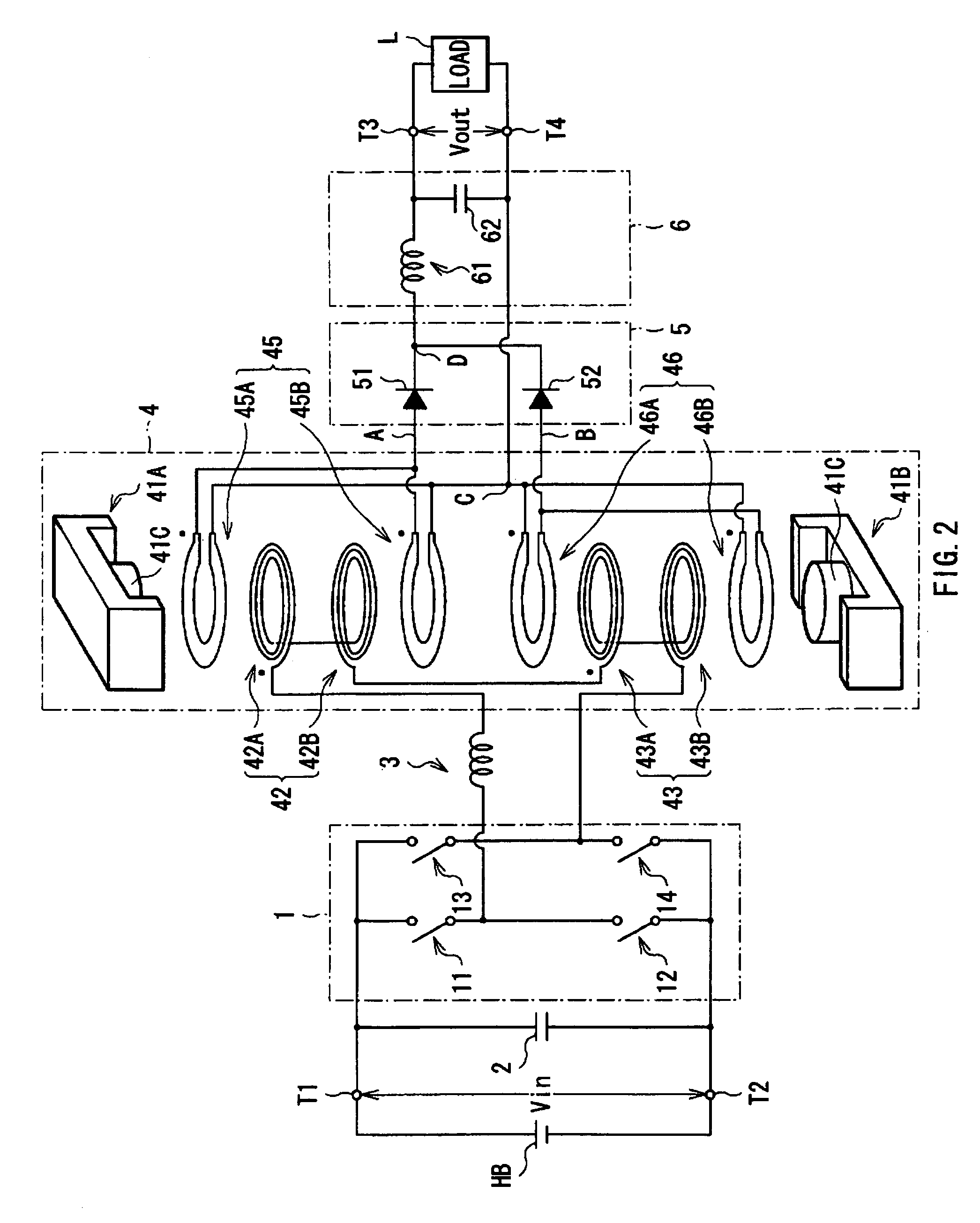

Switching power supply unit

ActiveUS7199569B1Line capacitanceLow efficiencyConversion constructional detailsTransformers/inductances coils/windings/connectionsPower inverterEngineering

A switching power supply unit is provided, in which core loss in a transformer or a level of heating due to AC resistance of the transformer can be reduced. A switching power supply unit has a transformer, an inverter circuit and a rectifier circuit. In a secondary side of the transformer, secondary wirings are connected to each other. In a primary side of the transformer, primary wirings are connected in series to each other, and connected to the inverter circuit to allow them to be driven in a time-divisional manner in phases opposite to each other in response to operation of the inverter circuit. The rectifier circuit has diodes connected to the secondary wirings to allow the secondary wirings to be driven in a time-divisional manner in phases opposite to each other in response to operation of the inverter circuit.

Owner:TDK CORPARATION

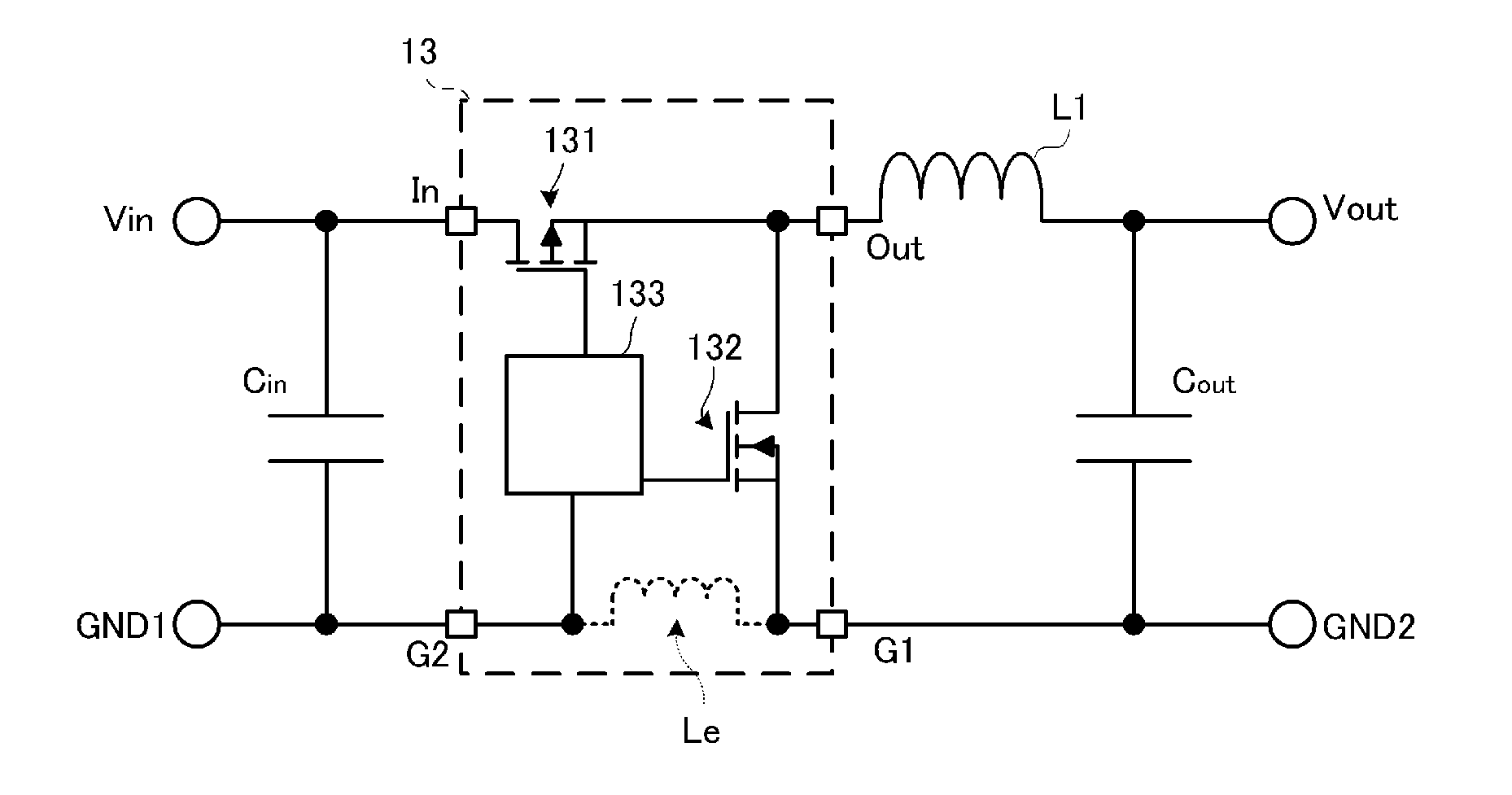

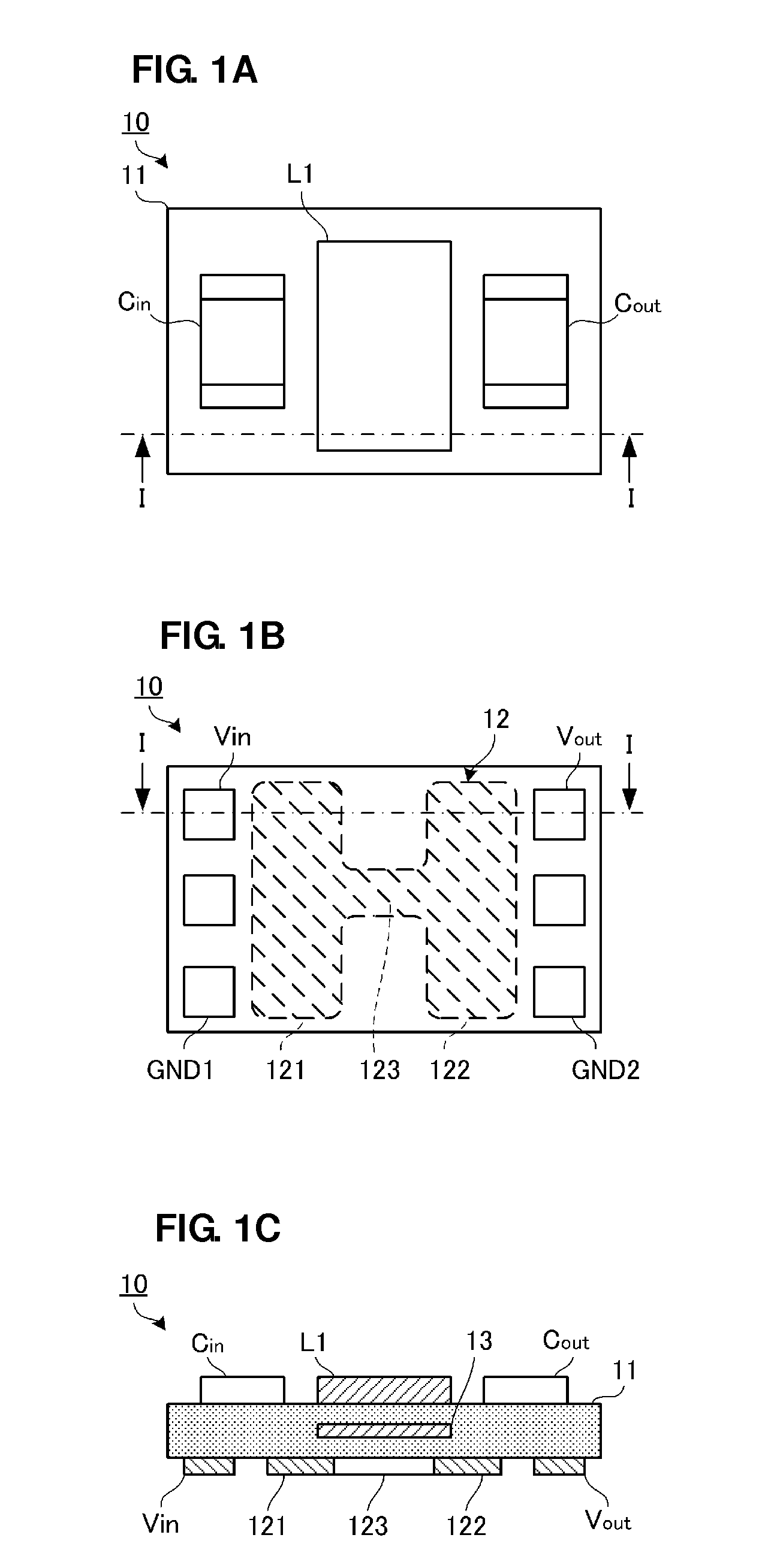

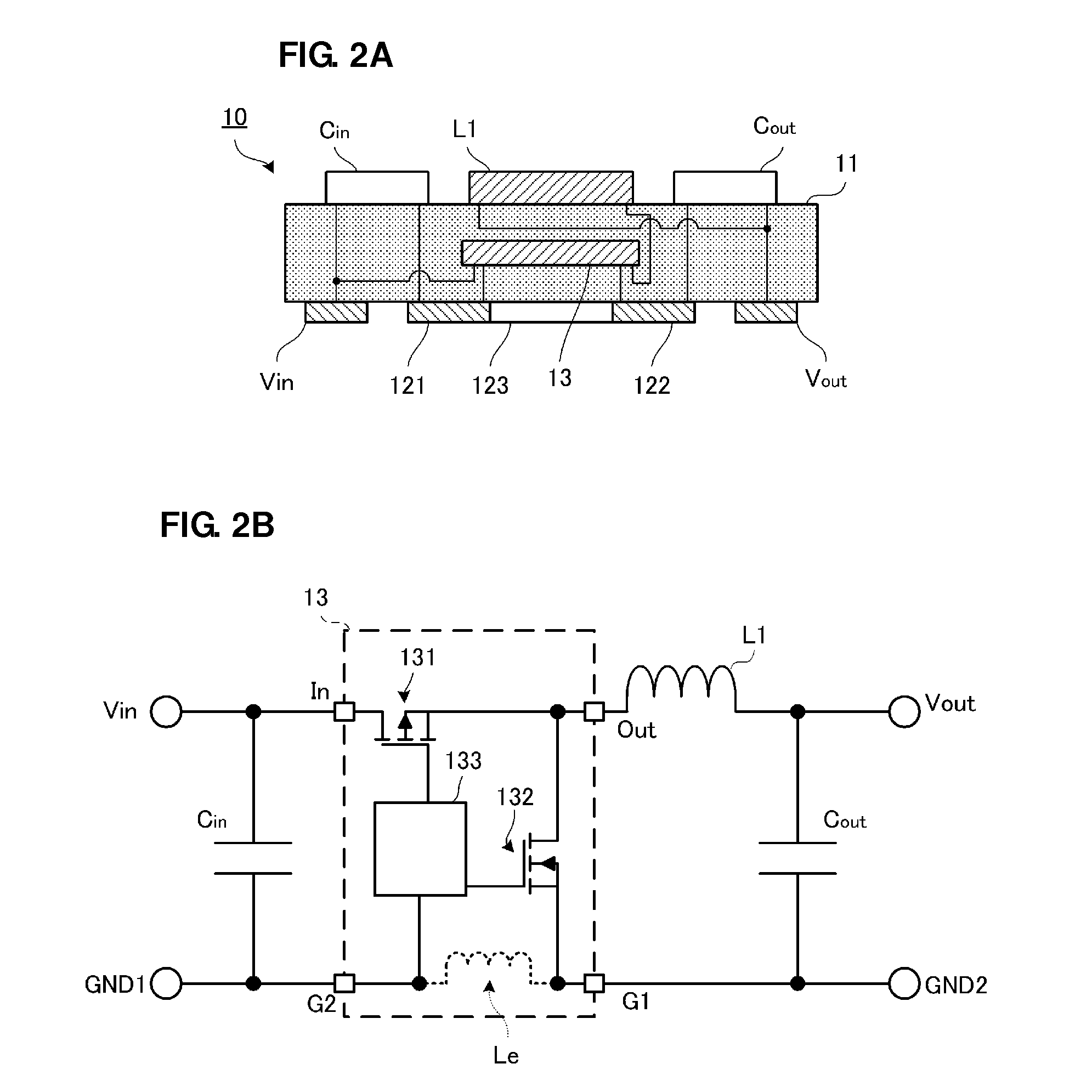

Dc-dc converter

ActiveUS20130049730A1Avoid switchingNoise current is significantly reduced and preventedEfficient power electronics conversionSemiconductor/solid-state device detailsDc dc converterBridge pattern

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com