Patents

Literature

3067 results about "Conductive coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive Coatings. Conductive coatings are frequently used to shield sensitive electronic components from electromagnetic and radio frequency interference (EMI/RFI) from both the device itself and from surrounding interference.

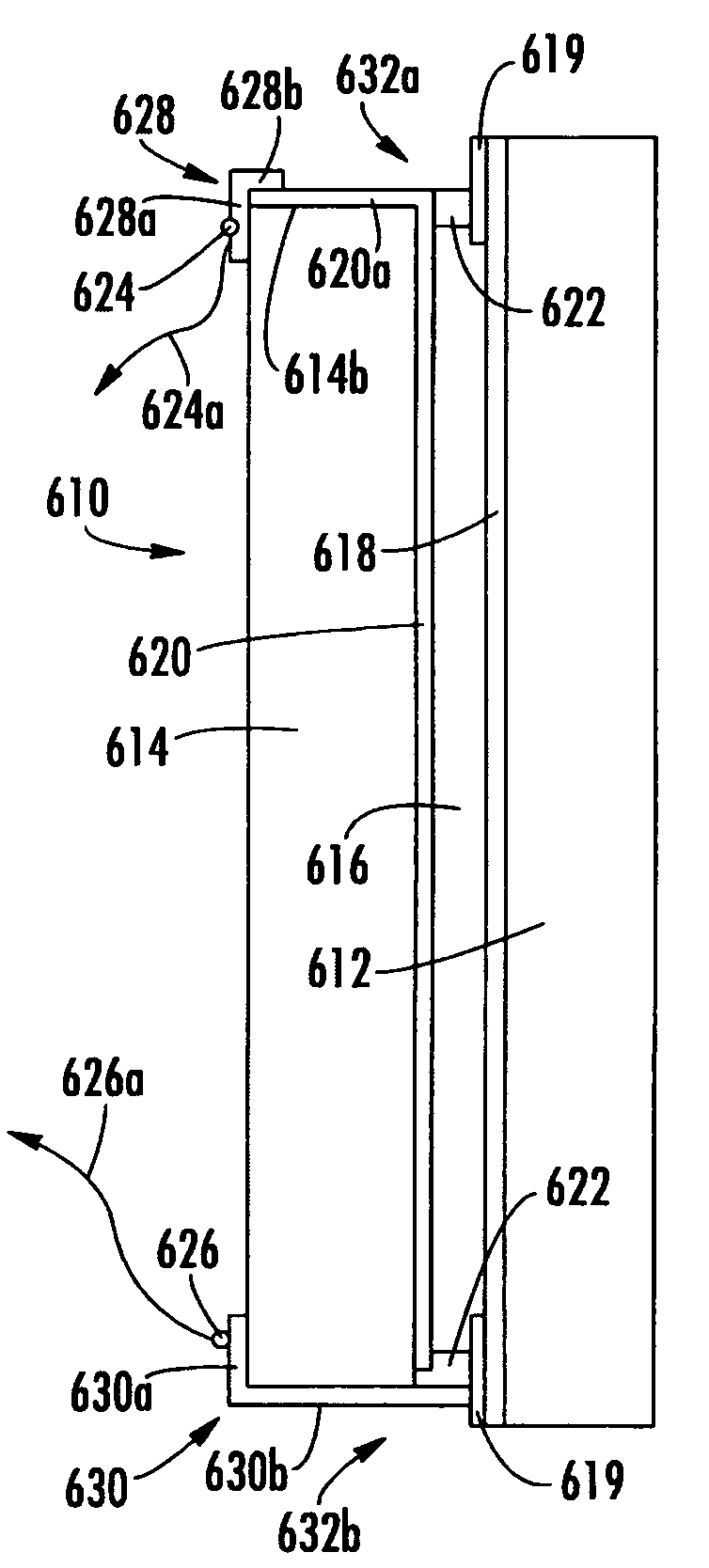

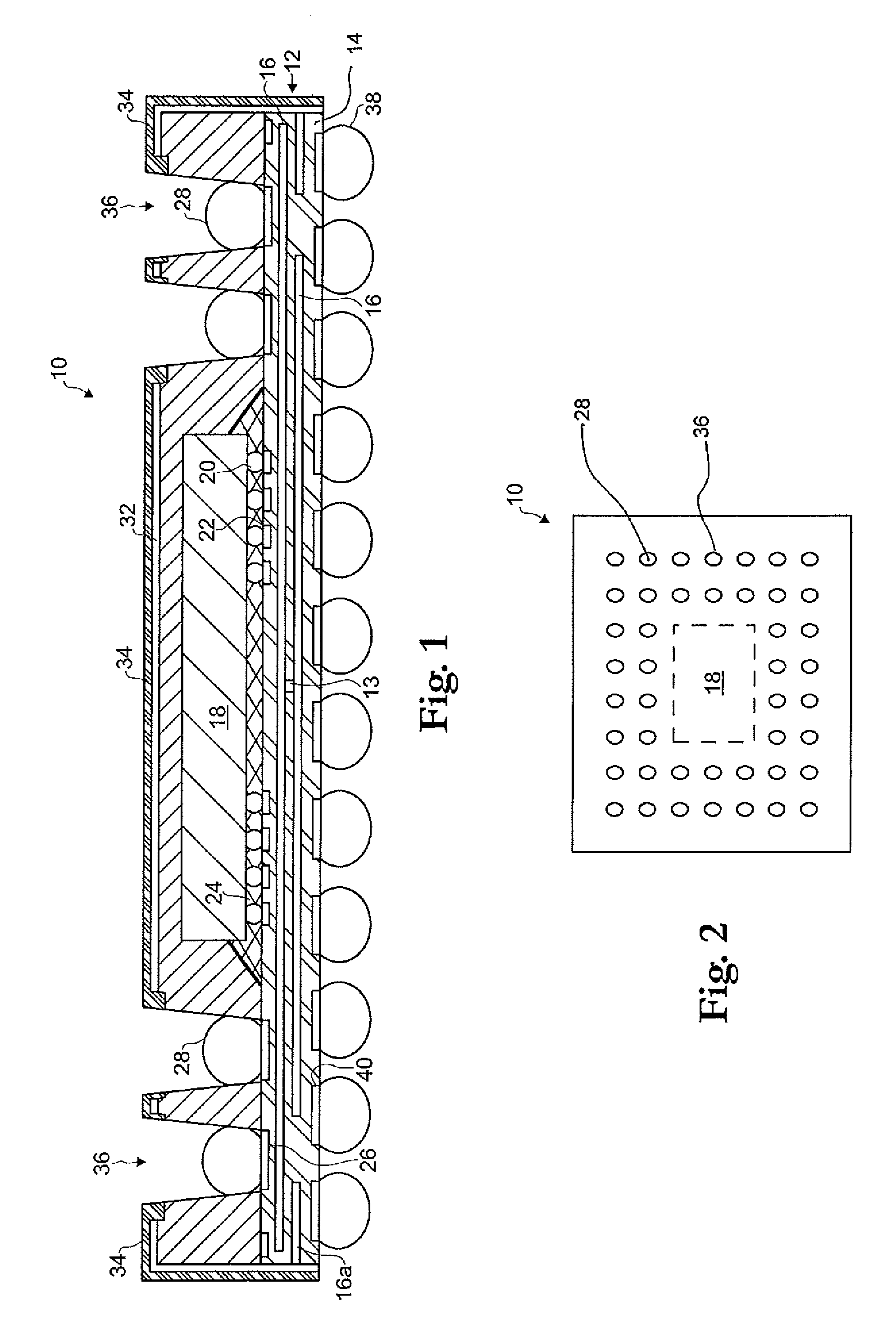

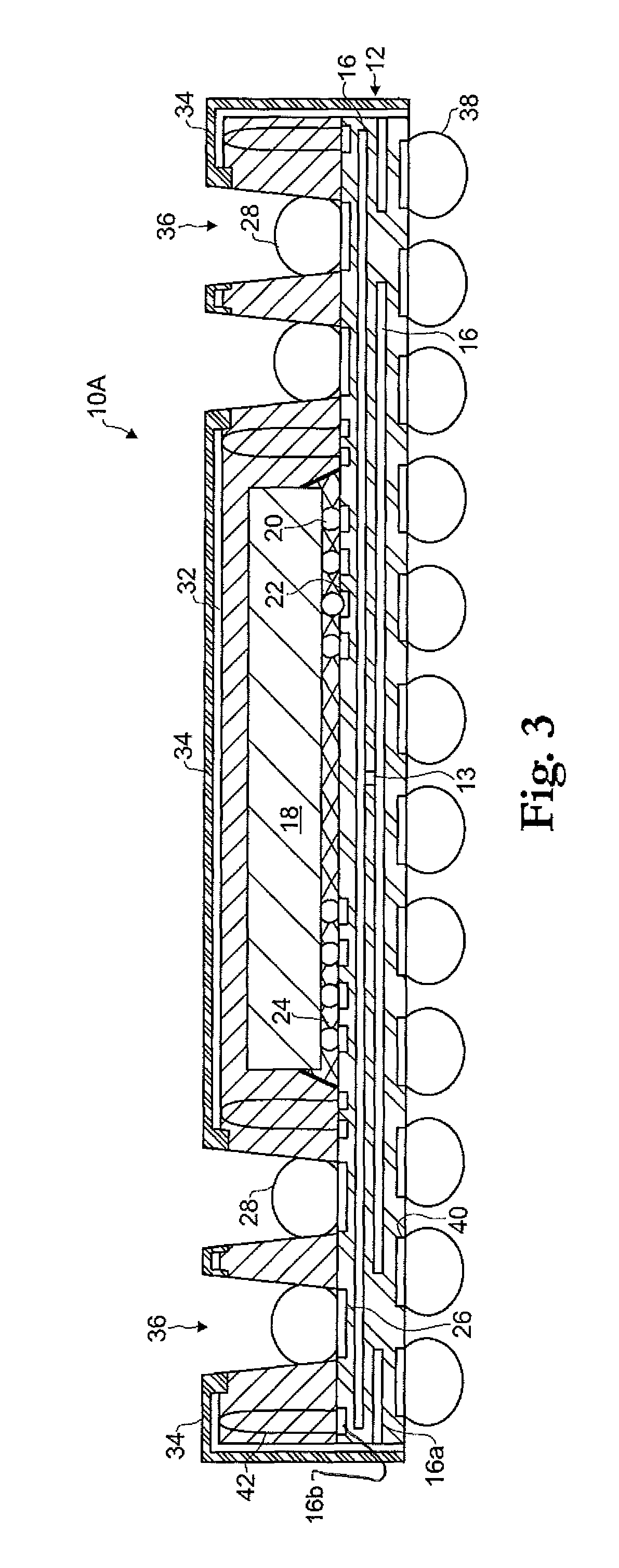

Electro-optic mirror cell

ActiveUS7255451B2Limit and substantially precludes touching and harmingSimple preparation processMirrorsThin material handlingElectricityConductive coating

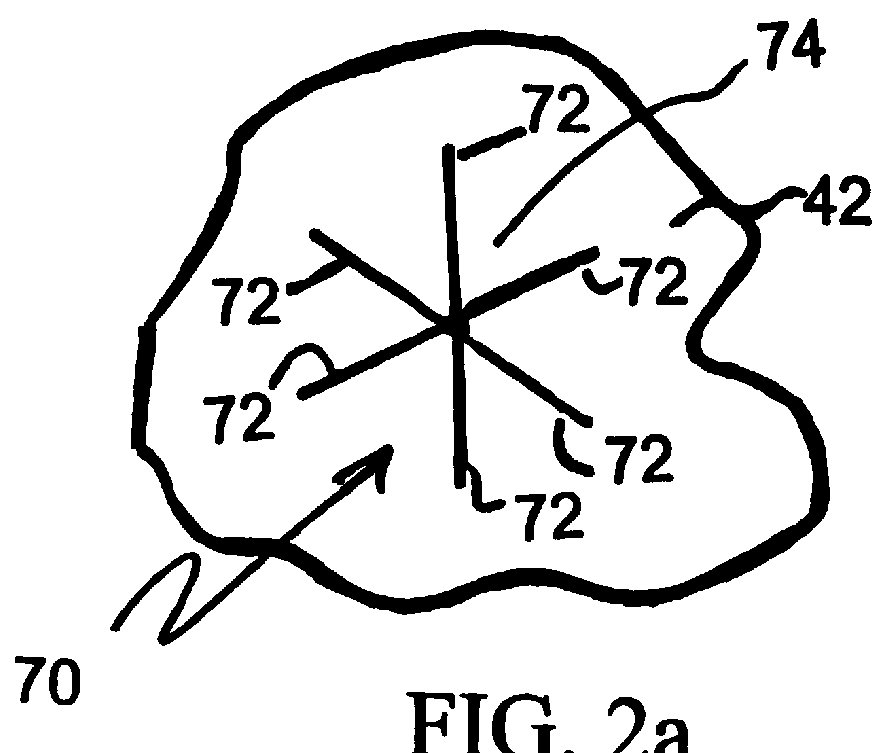

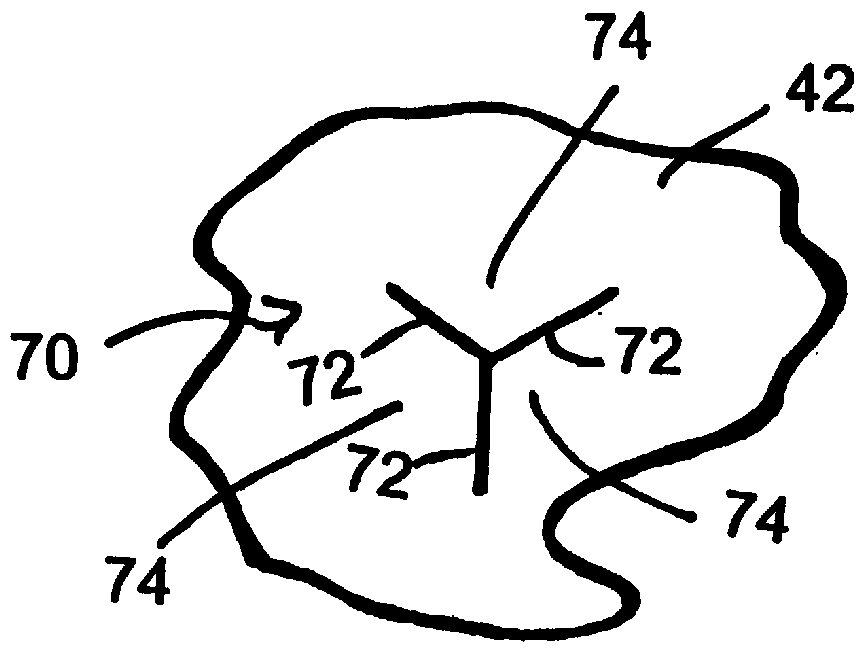

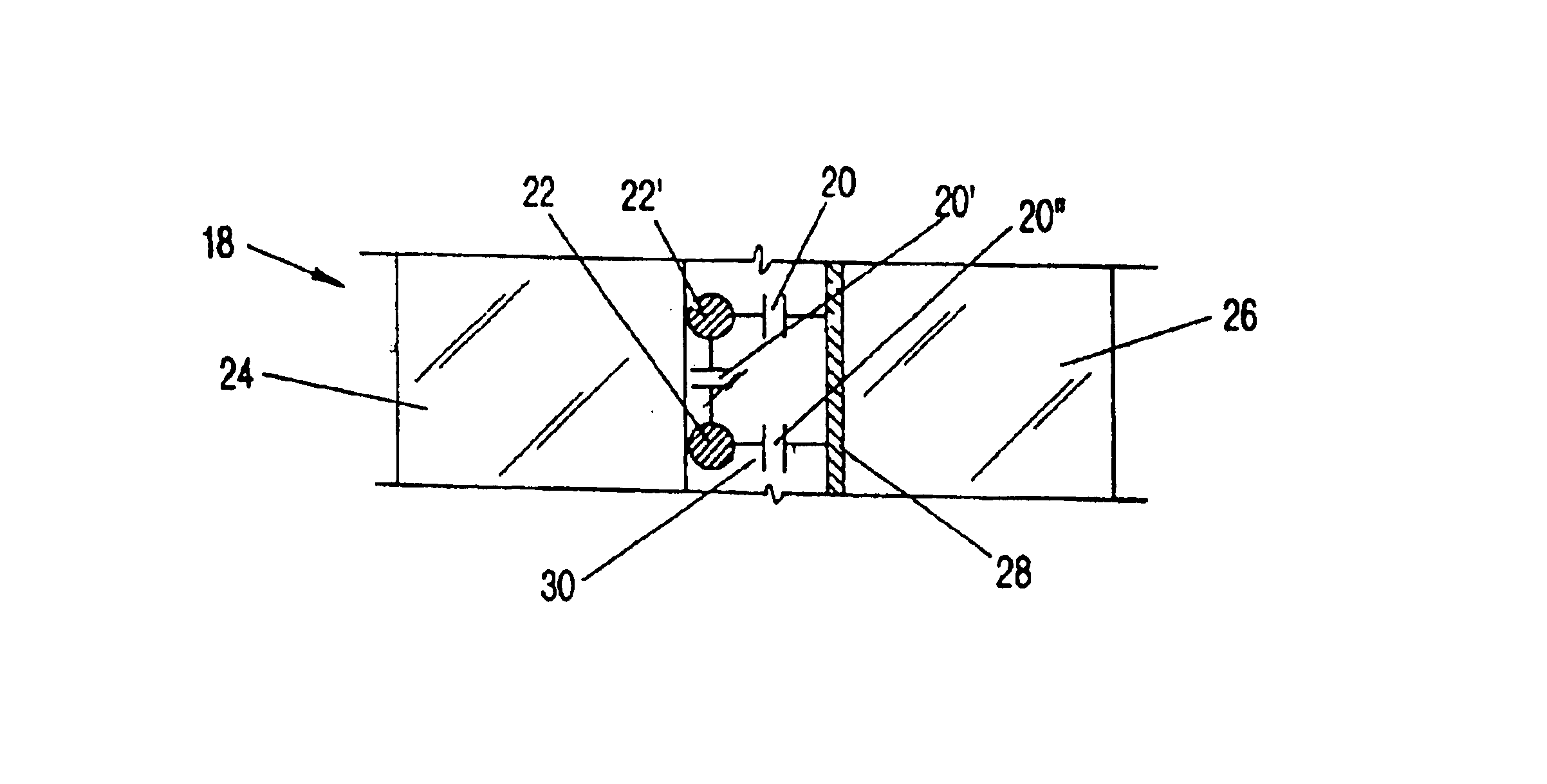

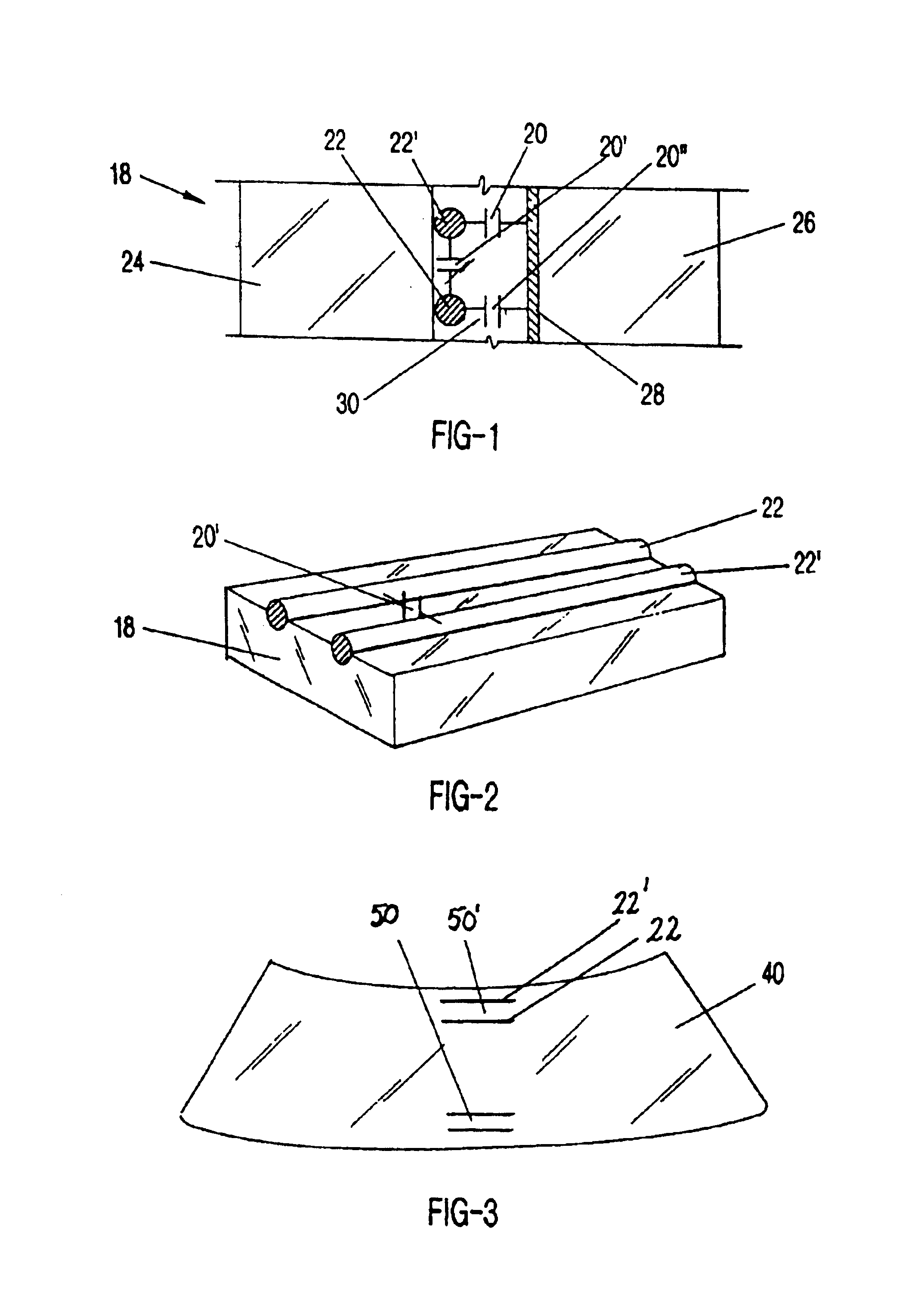

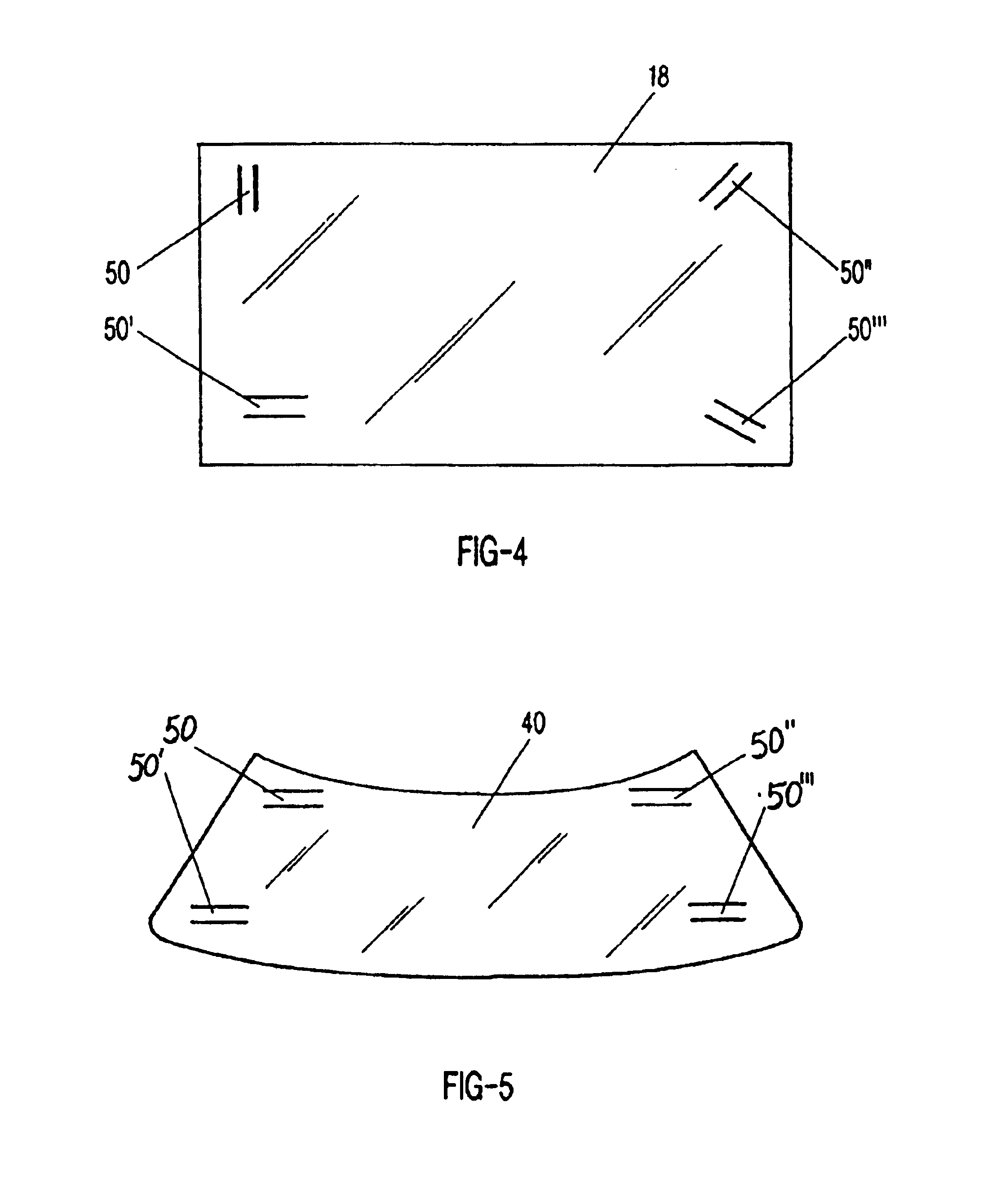

A reflective element assembly for a variable reflectance vehicular mirror includes a front substrate having a transparent conductive coating disposed on a second surface, and a rear substrate having a third surface conductive coating disposed on its third surface and preferably, a fourth surface conductive coating disposed on its fourth surface. At least a portion of the third surface conductive coating may wrap around an edge portion of the rear substrate and at least a portion of the fourth surface conductive coating may wrap around at least a second portion of the perimeter edge so as to establish electrical continuity between the fourth surface conductive coating on the fourth surface and the third surface conductive coating on the third surface. The rear substrate may have a smaller dimension than the front substrate so as to provide an overhang region, preferably at the wraparound region.

Owner:DONNELLY CORP

Ampoule with a thermally conductive coating

ActiveUS20080149031A1Improve temperature uniformityChemical vapor deposition coatingConductive coatingCompound (substance)

Embodiments of the invention provide an apparatus and a process for generating a chemical precursor used in a vapor deposition processing system. The apparatus includes a canister (e.g., ampoule) having a sidewall, a top, and a bottom encompassing an interior volume therein, inlet and outlet ports in fluid communication with the interior volume, and a thermally conductive coating disposed on or over the outside surface of the canister. The thermally conductive coating is more thermally conductive than the outside surface of the canister. The thermally conductive coating may contain aluminum, aluminum nitride, copper, brass, silver, titanium, silicon nitride, or alloys thereof. In some embodiments, an adhesion layer (e.g., titanium or tantalum) may be disposed between the outside surface of the canister and the thermally conductive coating. In other embodiments, the canister may contain a plurality of baffles or solid heat-transfer particles to help evenly heat a solid precursor therein.

Owner:APPLIED MATERIALS INC

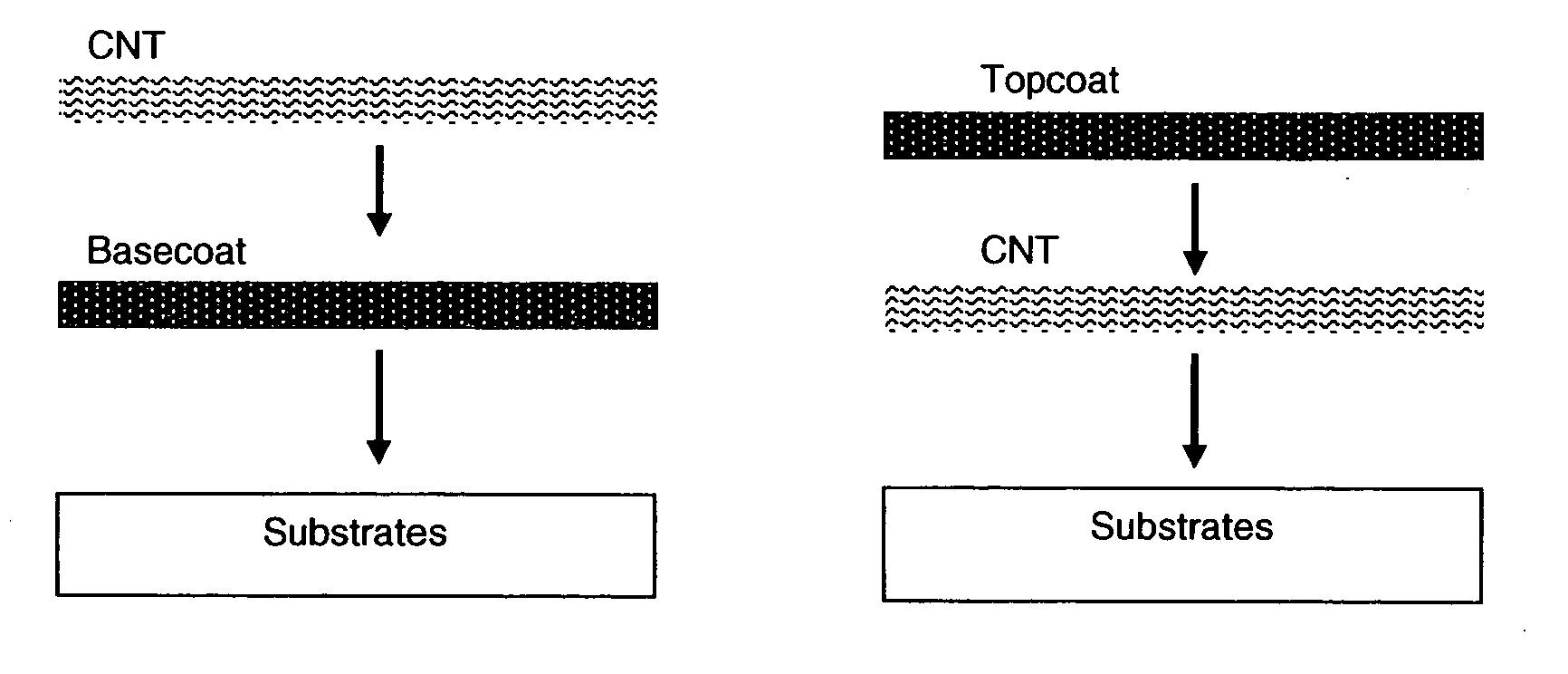

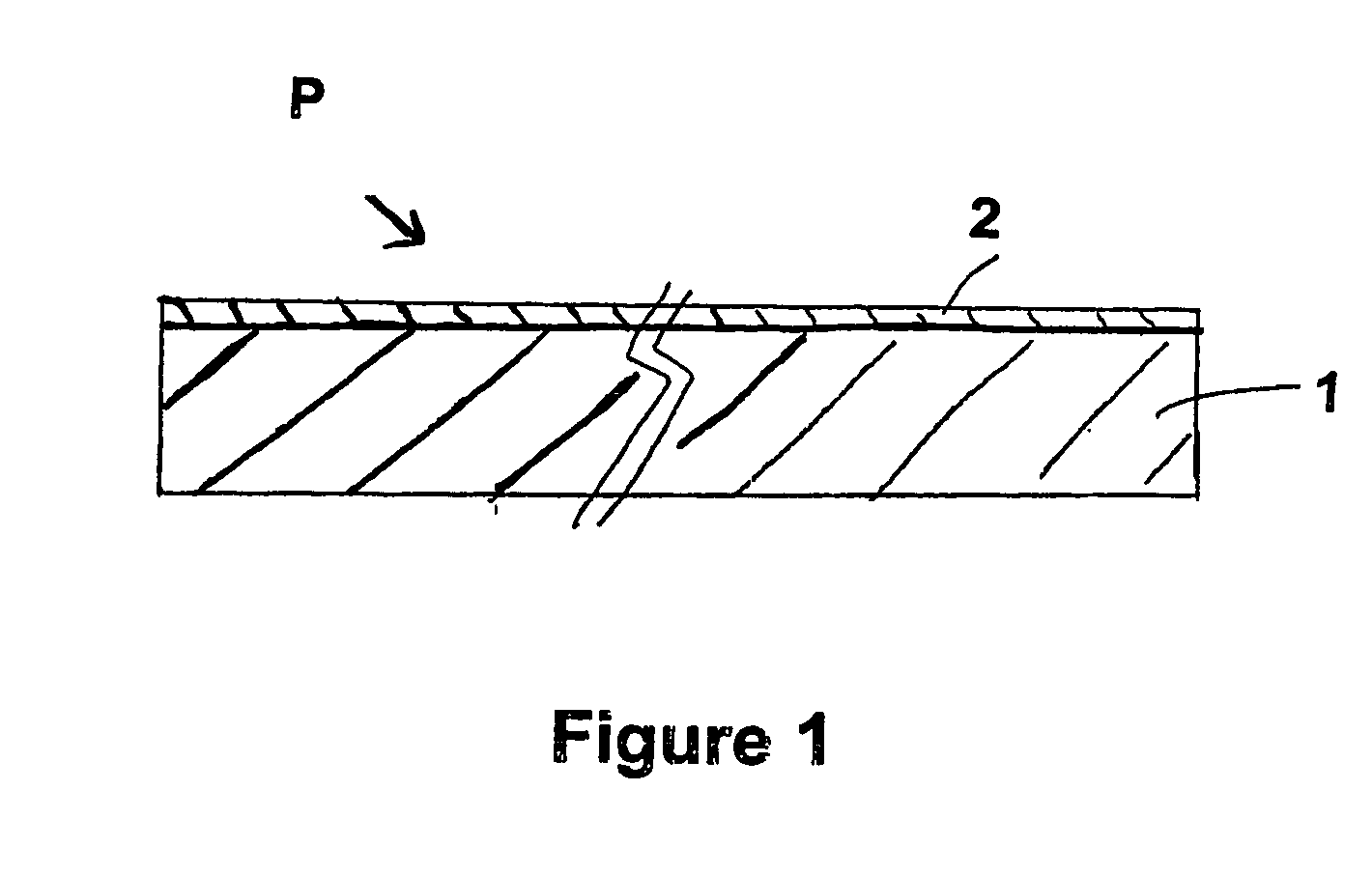

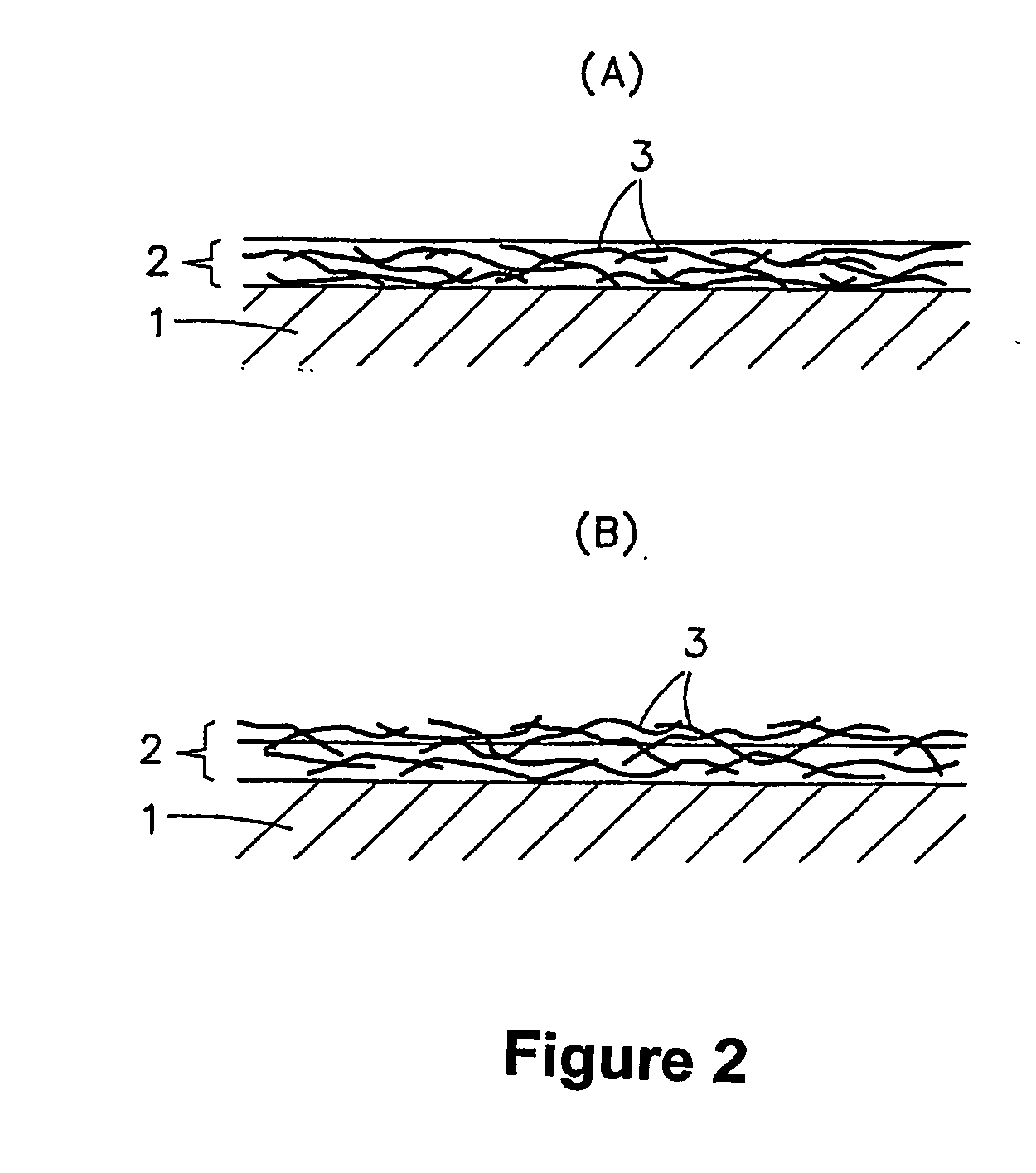

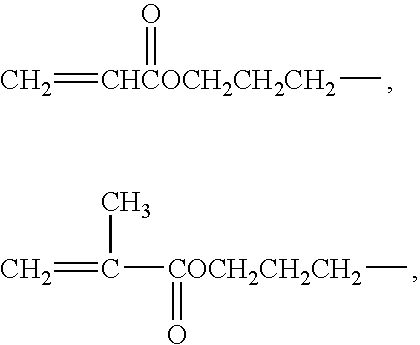

Polymer binders for flexible and transparent conductive coatings containing carbon nanotubes

InactiveUS20050209392A1Decrease in optical transparencyDecrease in surface conductivityMaterial nanotechnologySpecial tyresThermoplasticCarbon nanotube

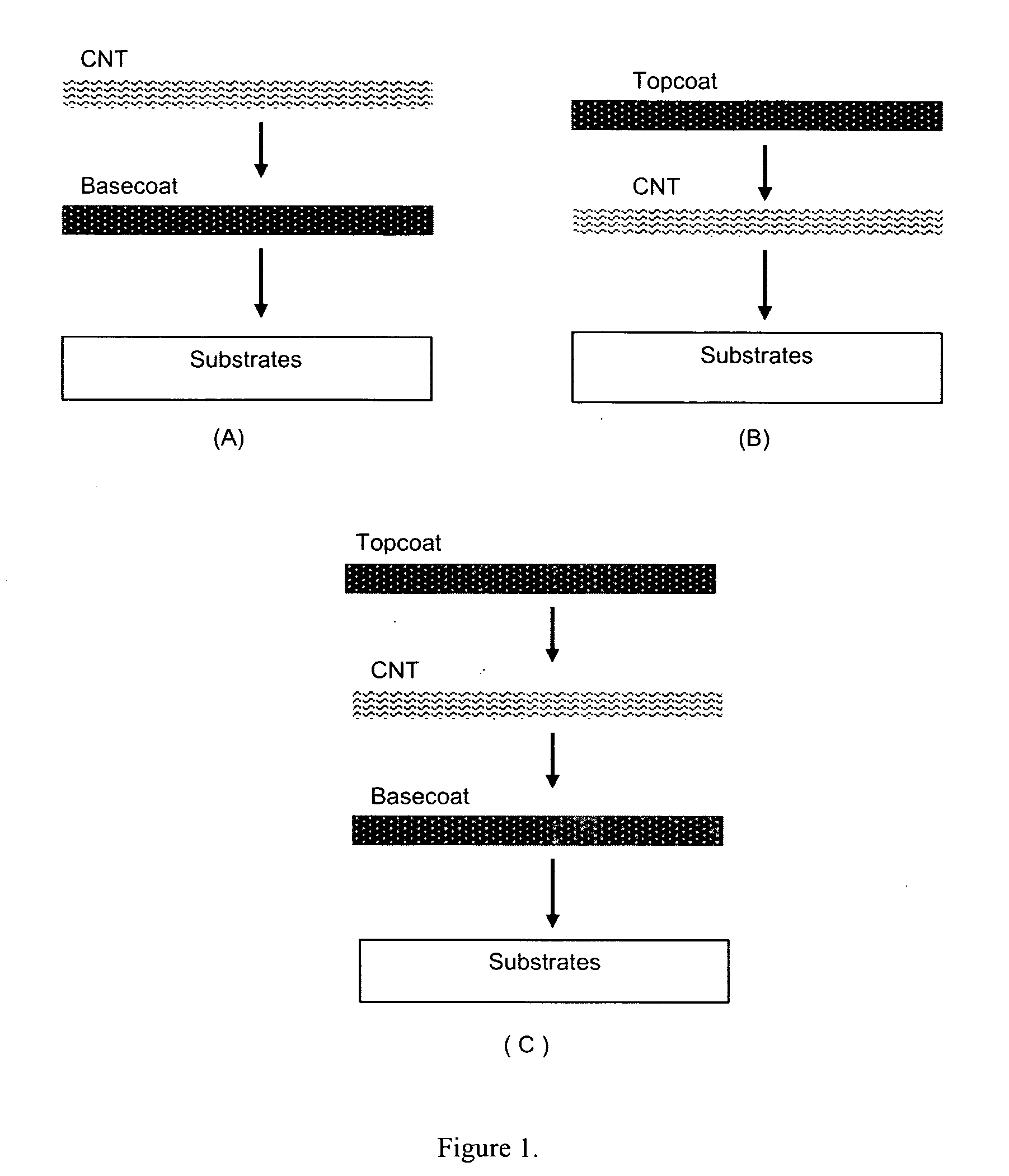

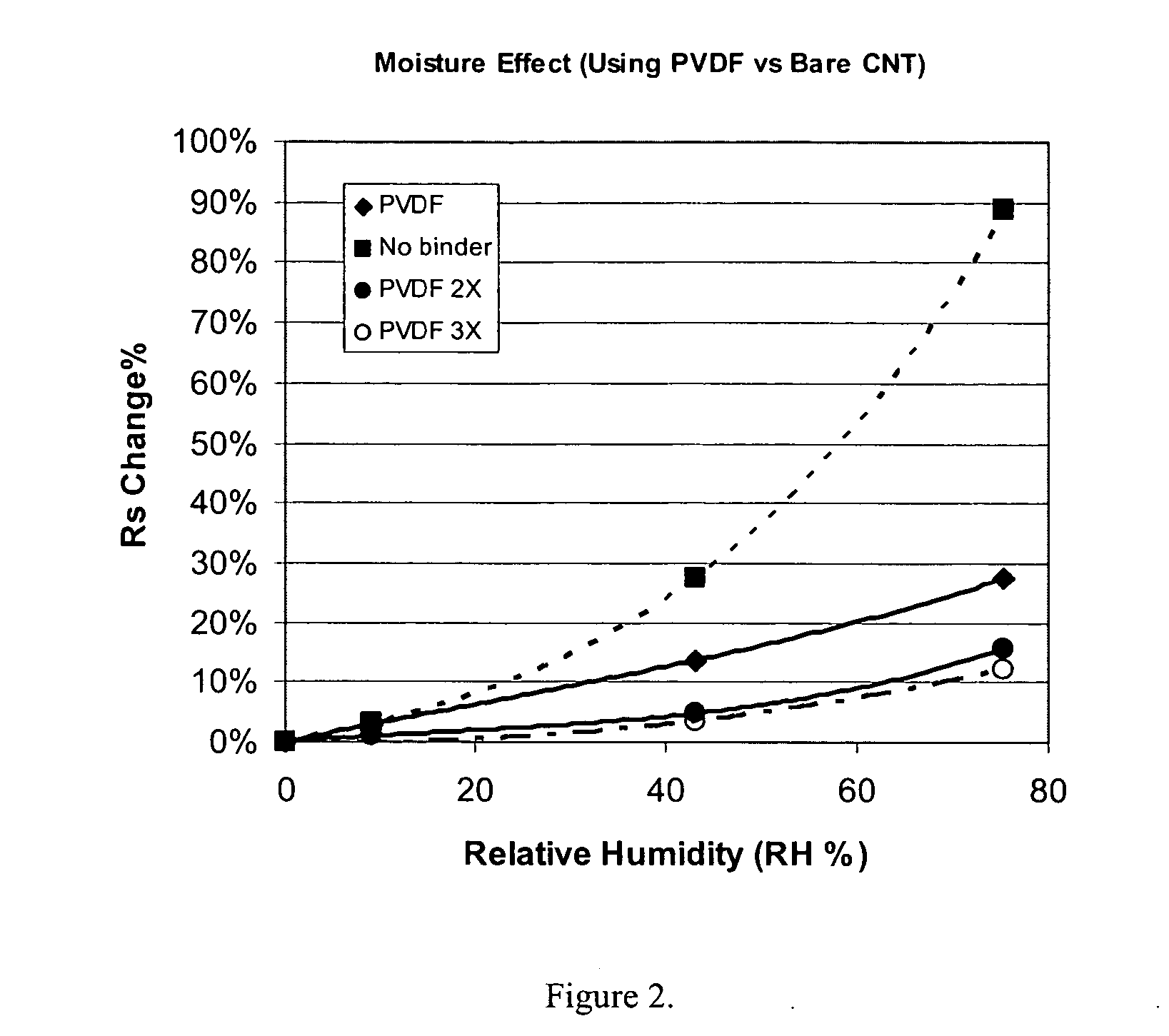

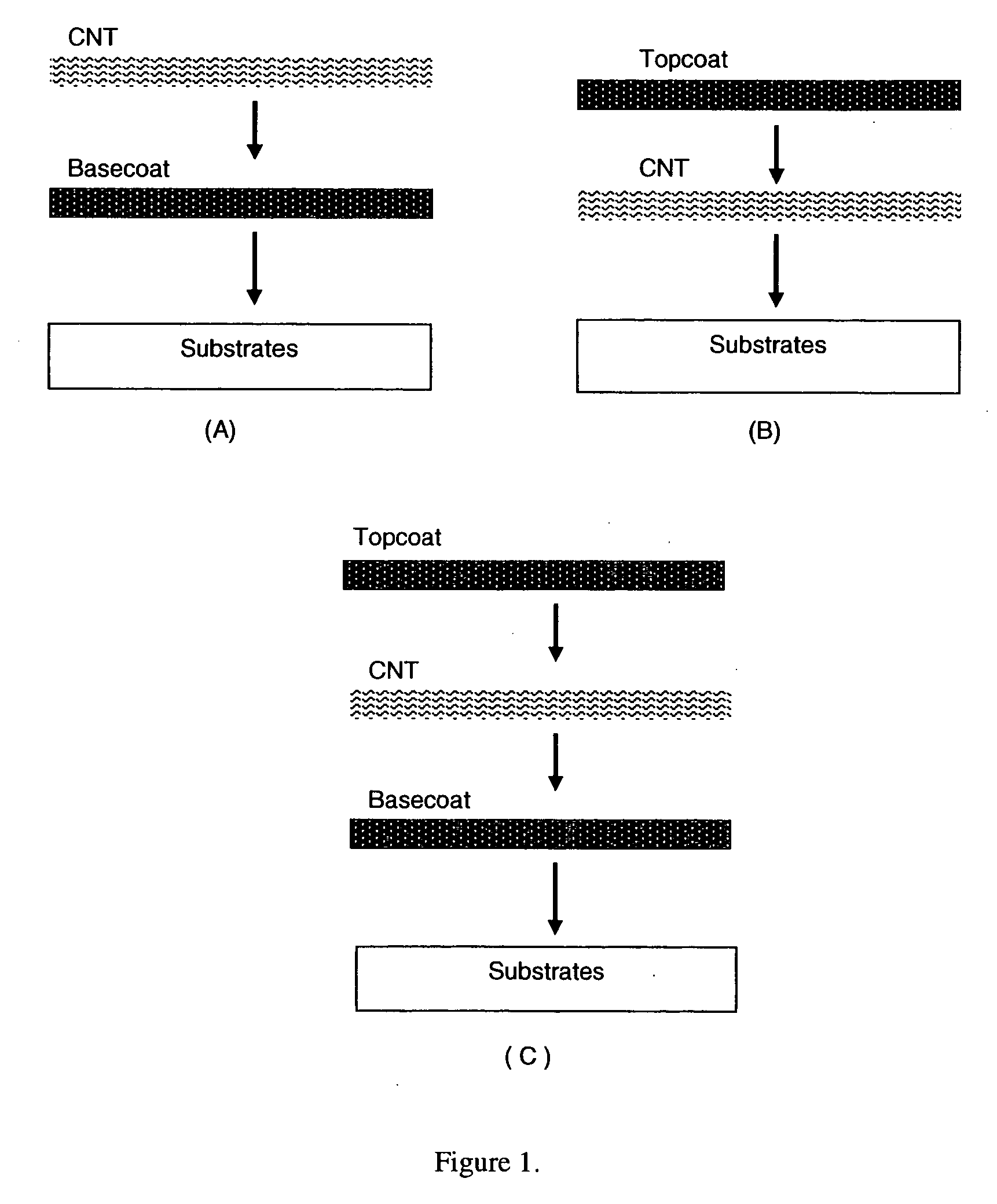

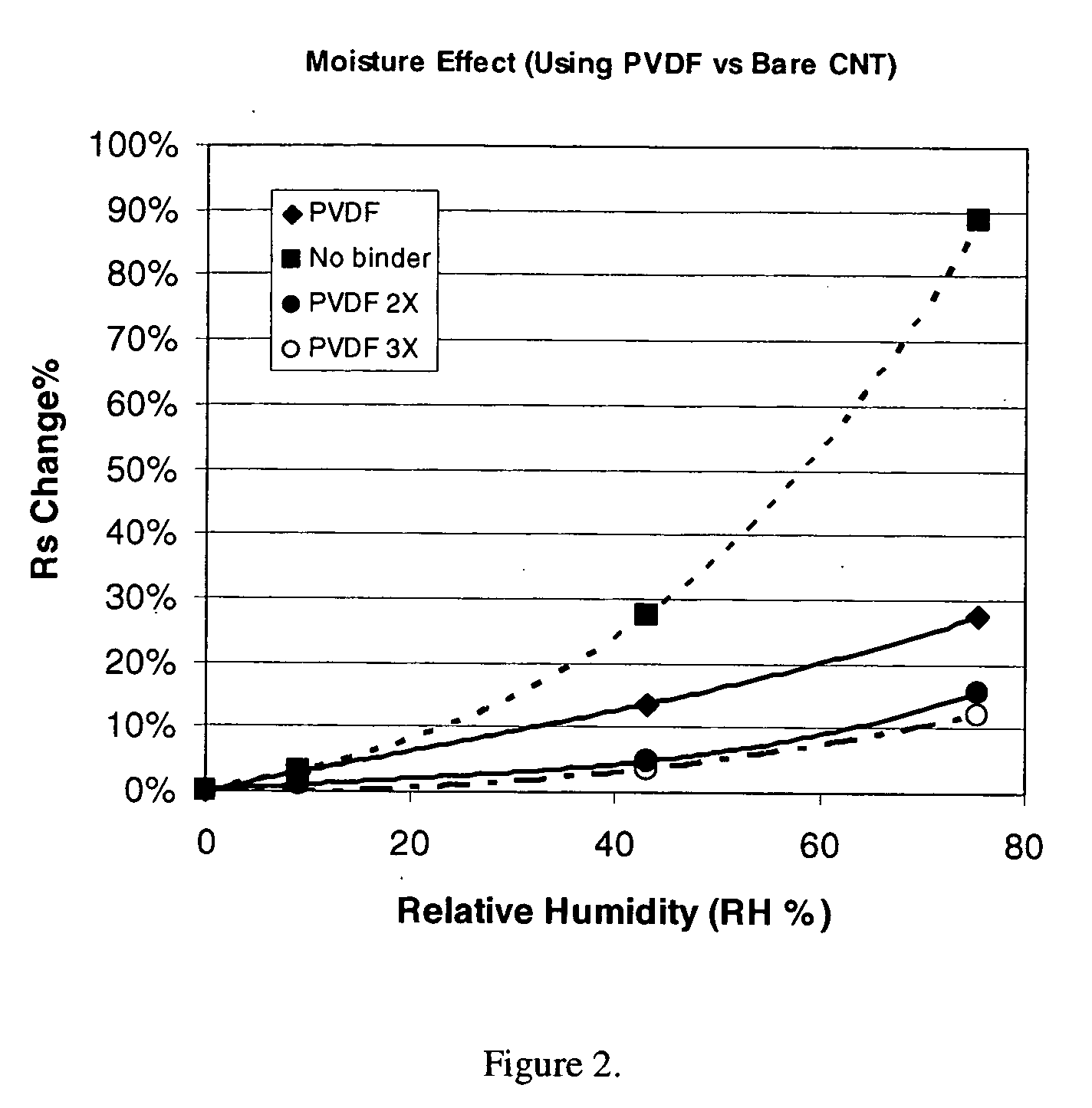

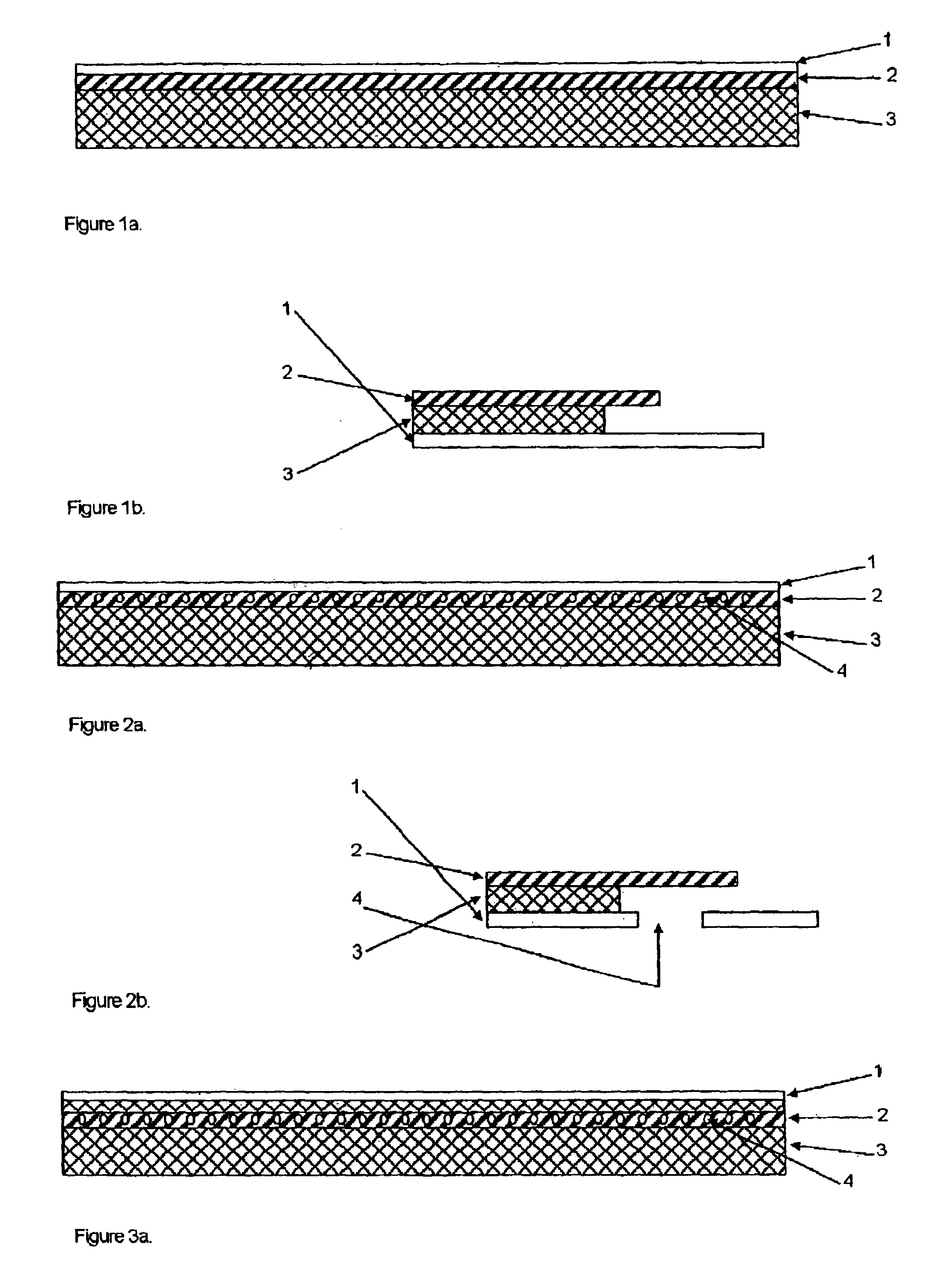

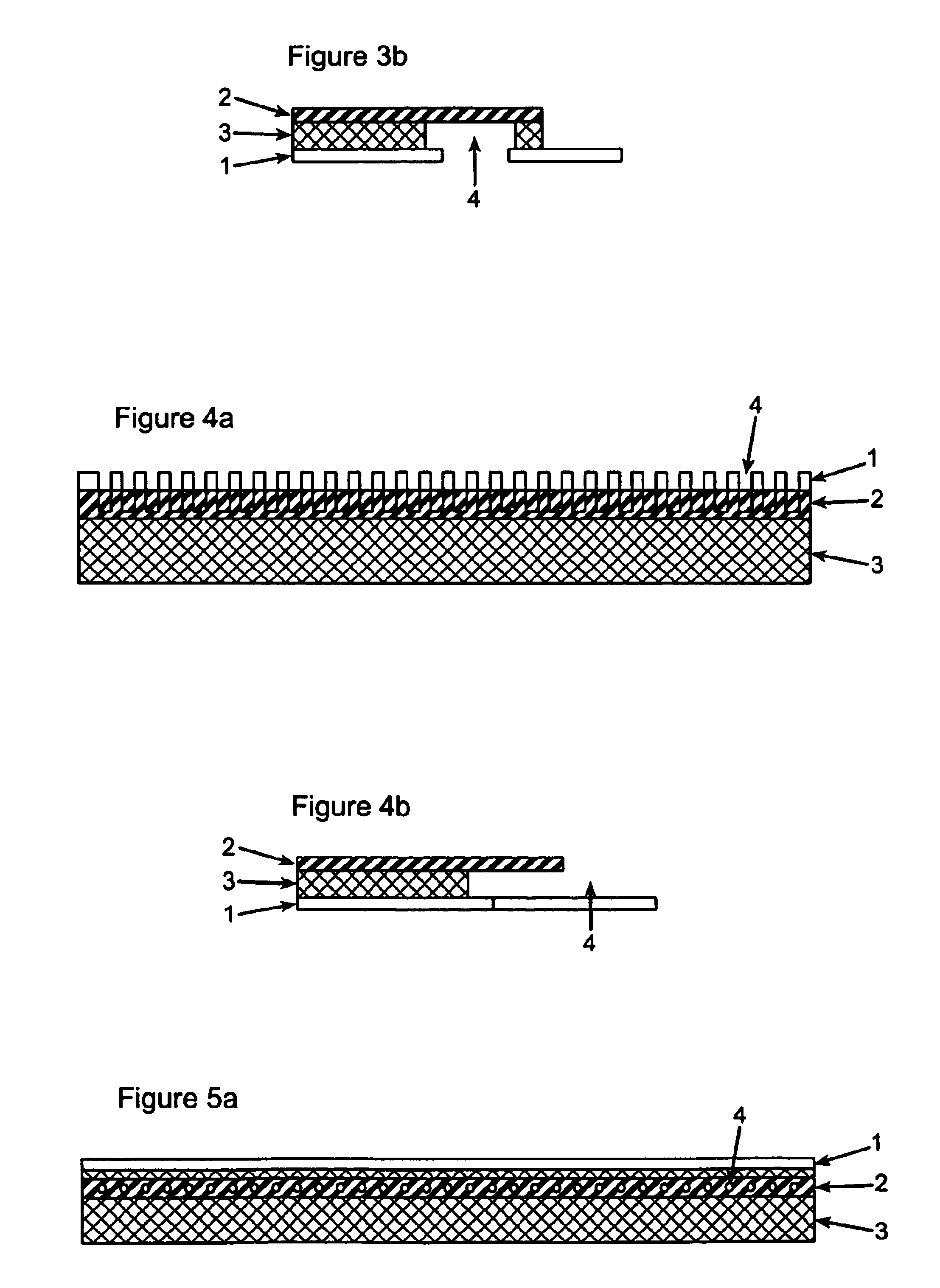

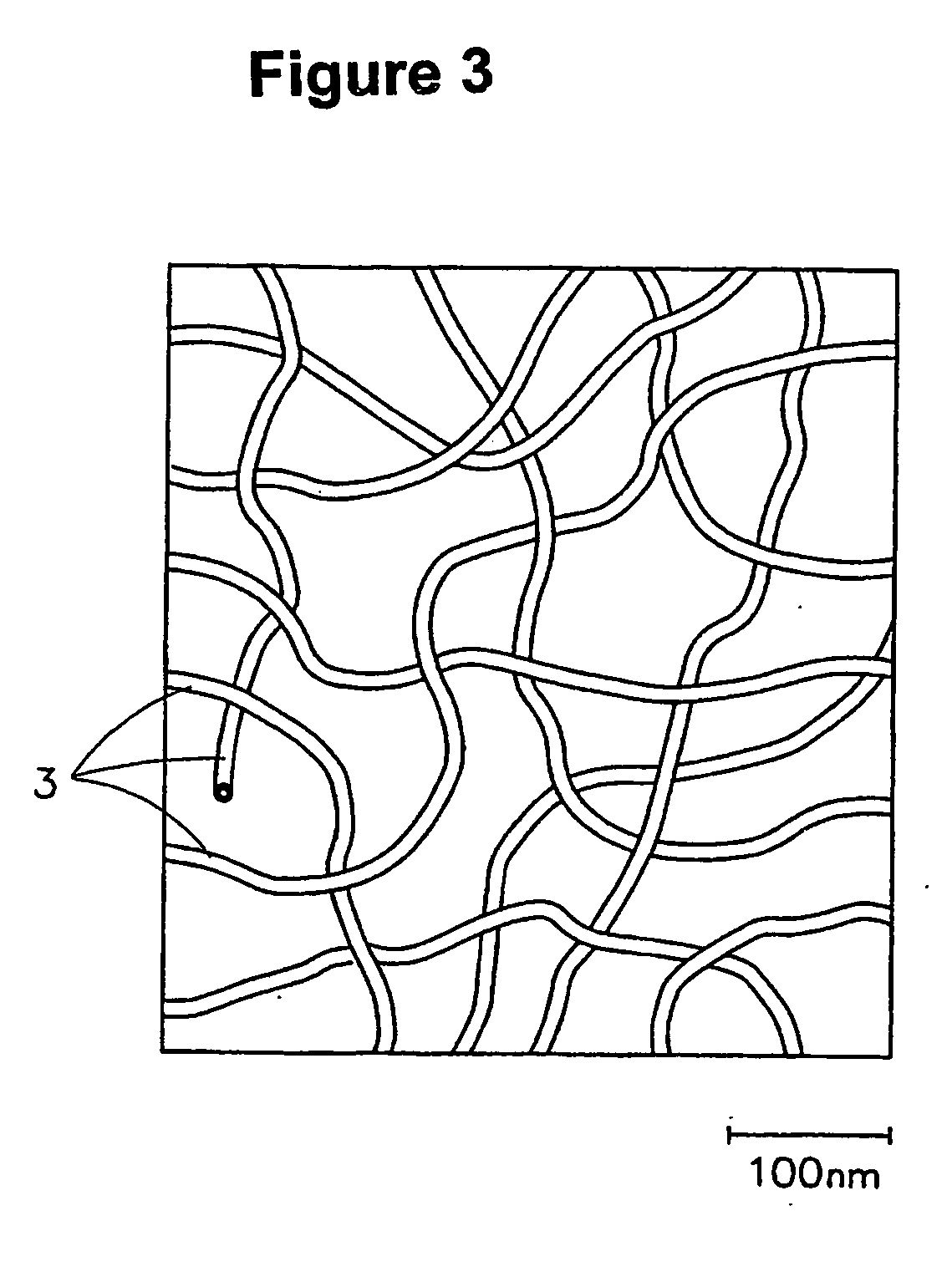

This invention relates to flexible, transparent and conductive coatings and films formed using single wall carbon nanotubes and polymer binders. Preferably, coatings and films are formed from carbon nanotubes (CNT) applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for the enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or any combination of both. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. Resulting films and articles can be used as transparent conductors for flat panel display, touch screen and other electronic devices.

Owner:EIKOS

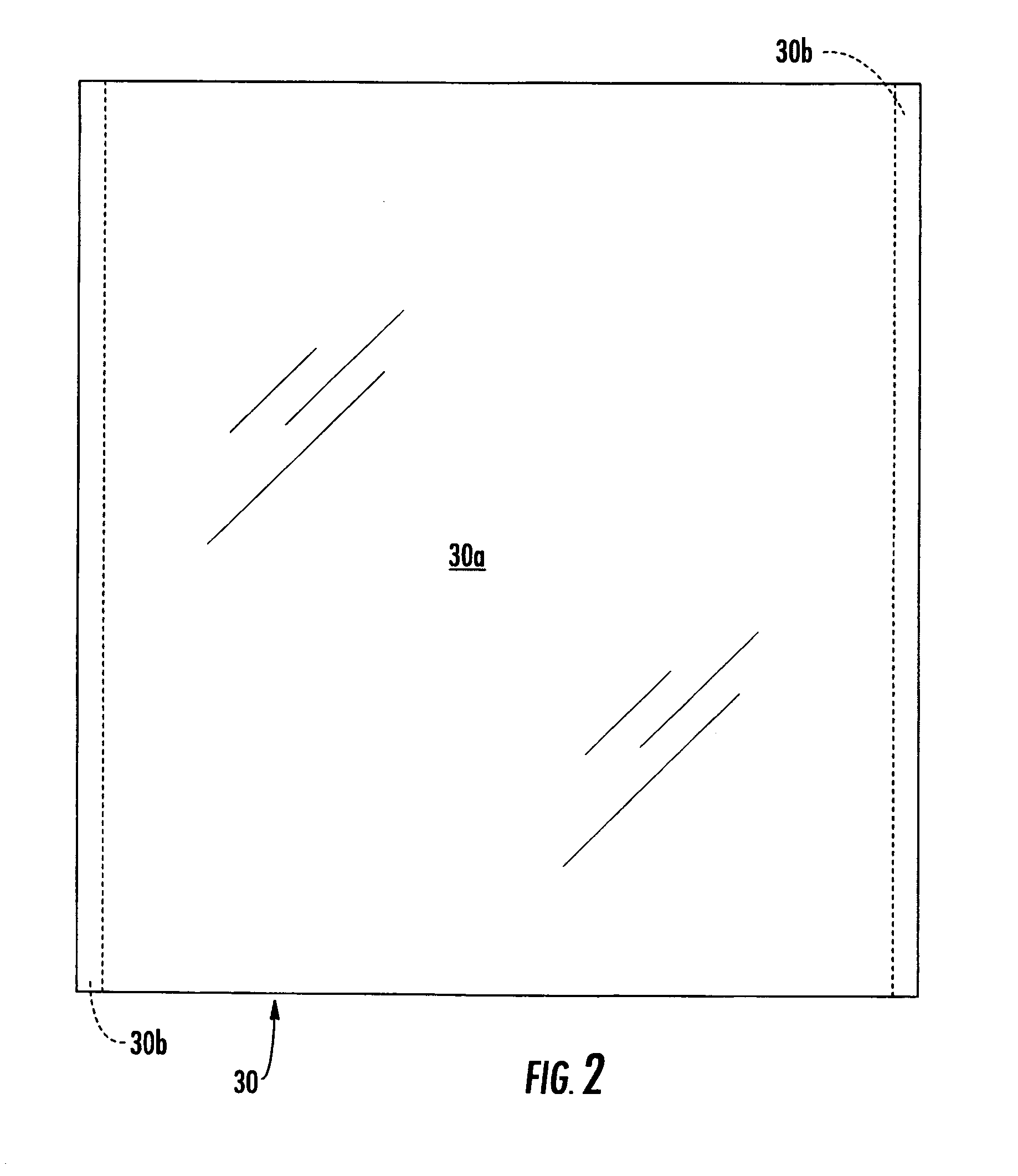

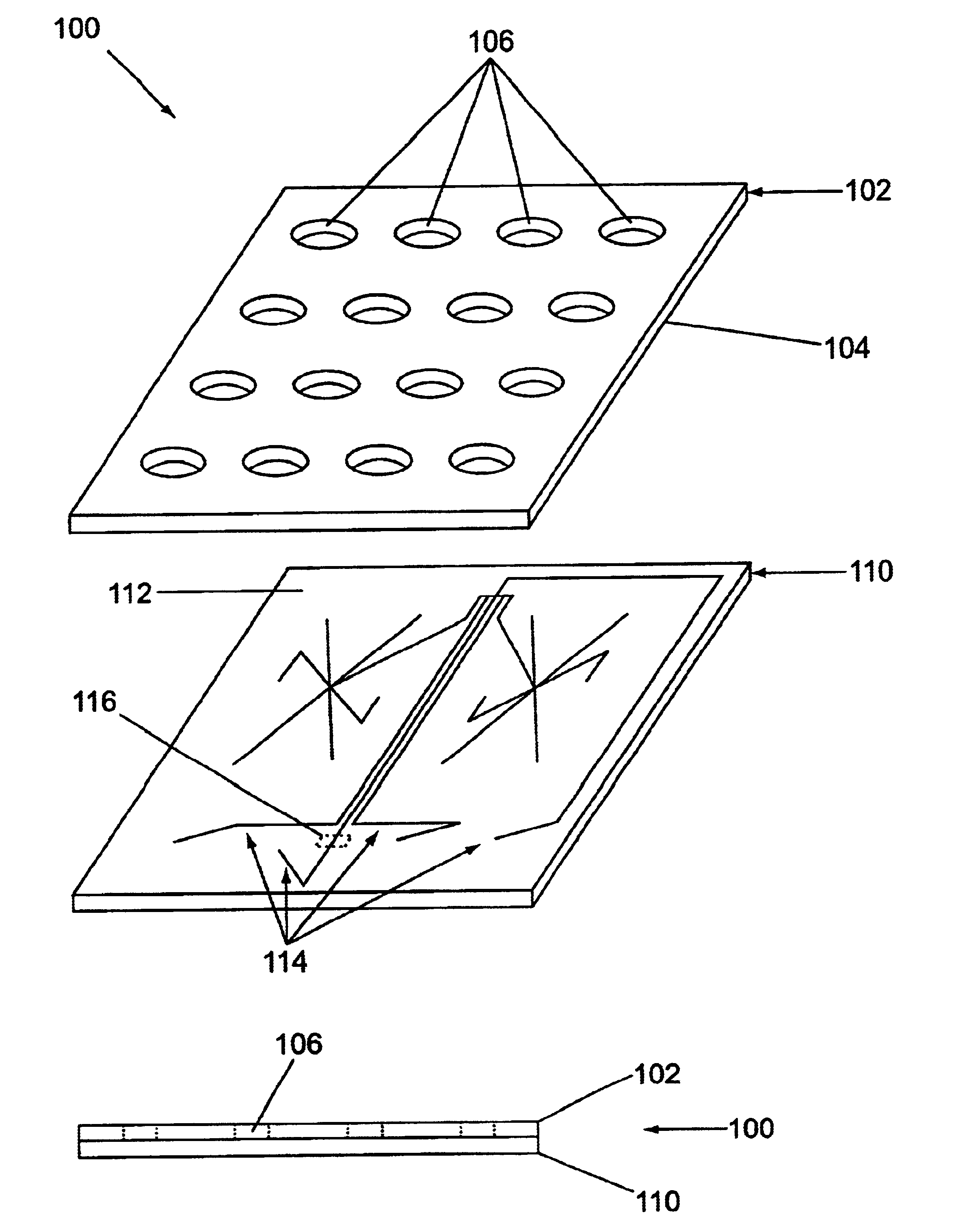

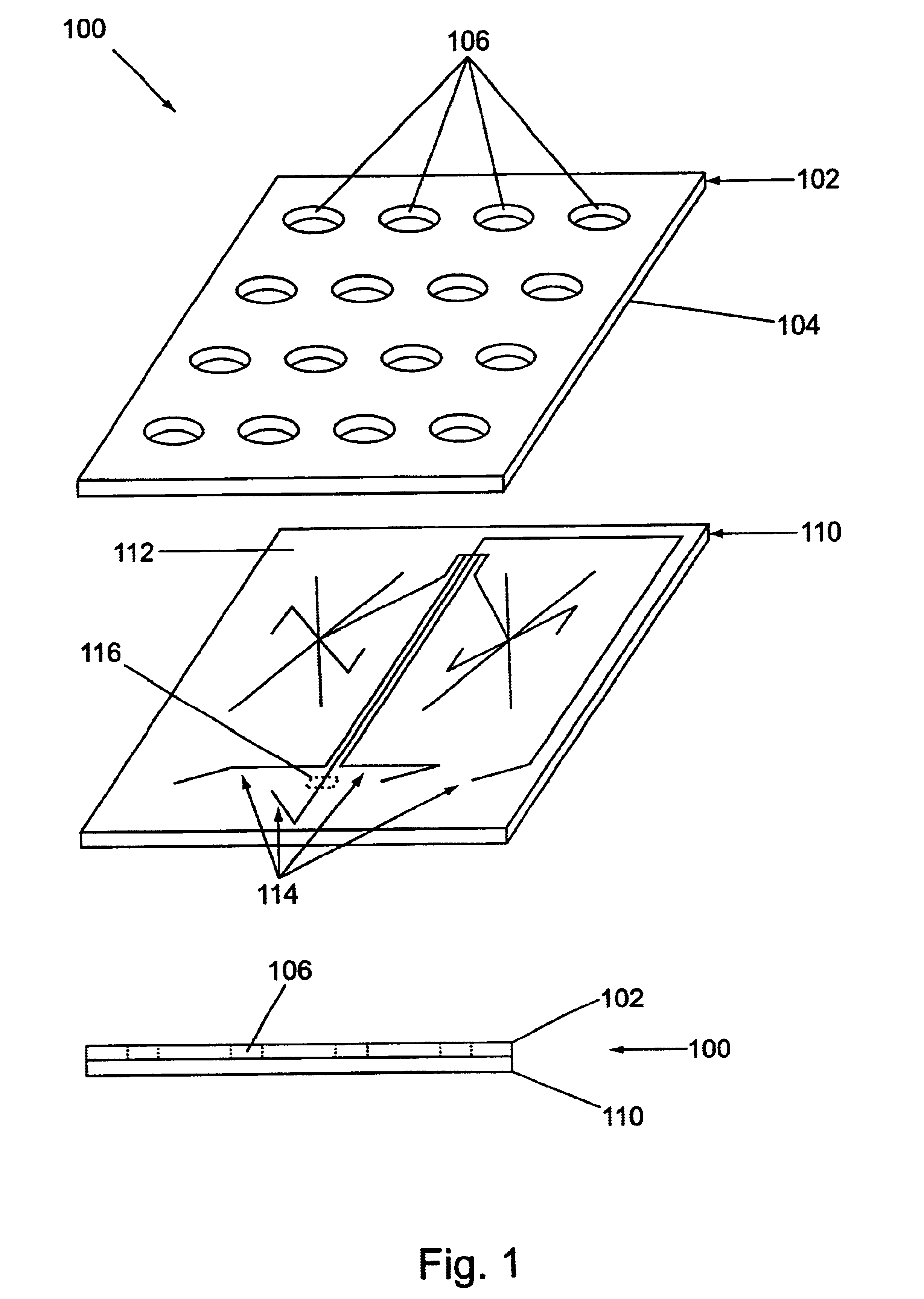

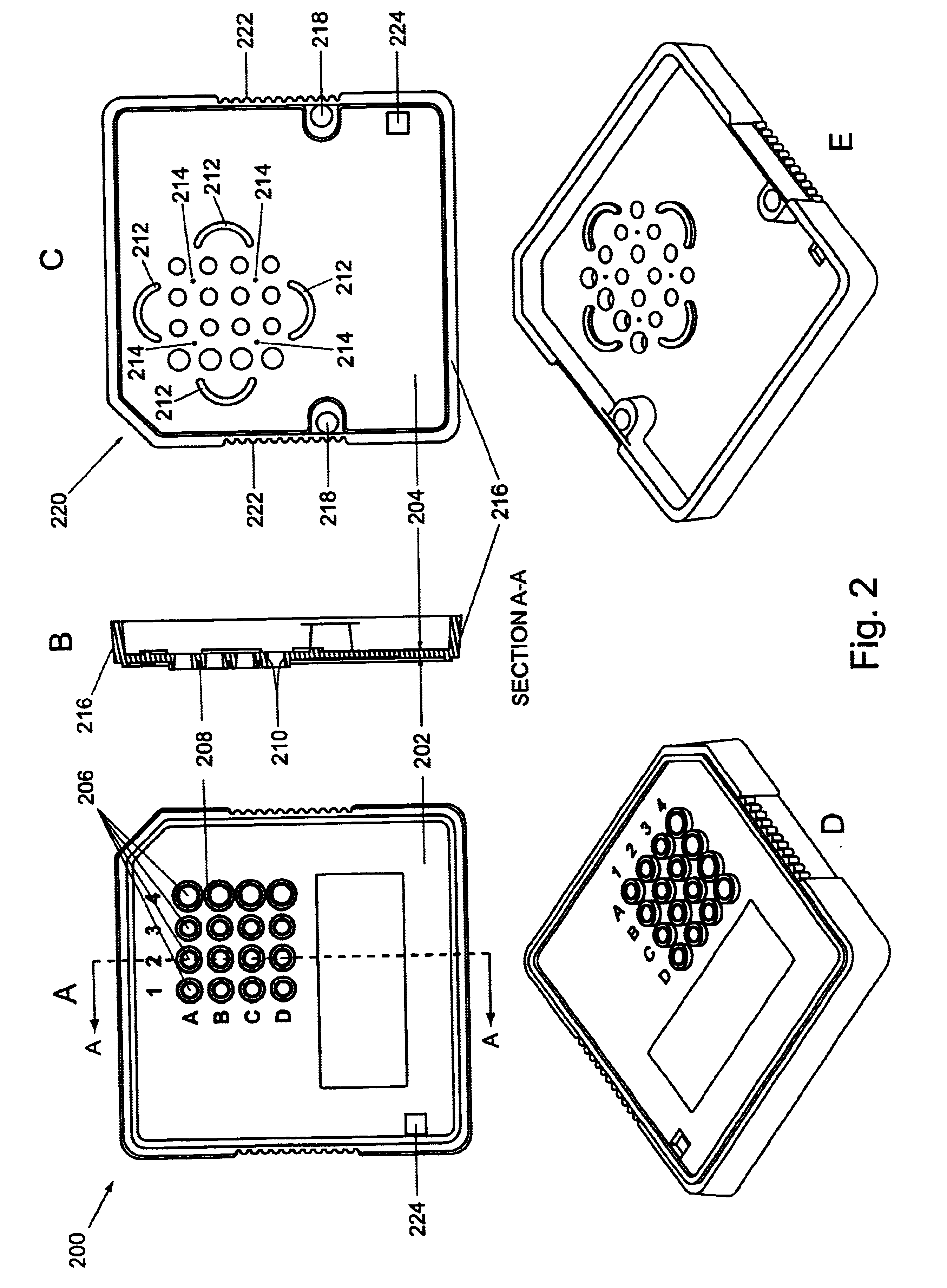

Microfluidic devices and systems incorporating cover layers

InactiveUS6756019B1Improved material handling characteristicReduce manufacturing costWithdrawing sample devicesMaterial analysis by electric/magnetic meansChannel networkConductive coating

The present invention provides microfluidic devices that comprise a body structure comprising at least a first microscale channel network disposed therein. The body structure has a plurality of ports disposed in the body structure, where each port is in fluid communication with one or more channels in the first channel network. The devices also include a cover layer comprising a plurality of apertures disposed through the cover layer. The cover layer is mated with the body structure whereby each of the apertures is aligned with a separate one of the plurality of ports. Rings are optionally disposed between the cover layer and the body structure and circumferentially around pairs of aligned apertures and ports. The devices also optionally include conductive coatings and membranes. The invention additionally provides methods of controlling the delivery of a composition of material into a microfluidic device.

Owner:CAPLIPER LIFE SCI INC

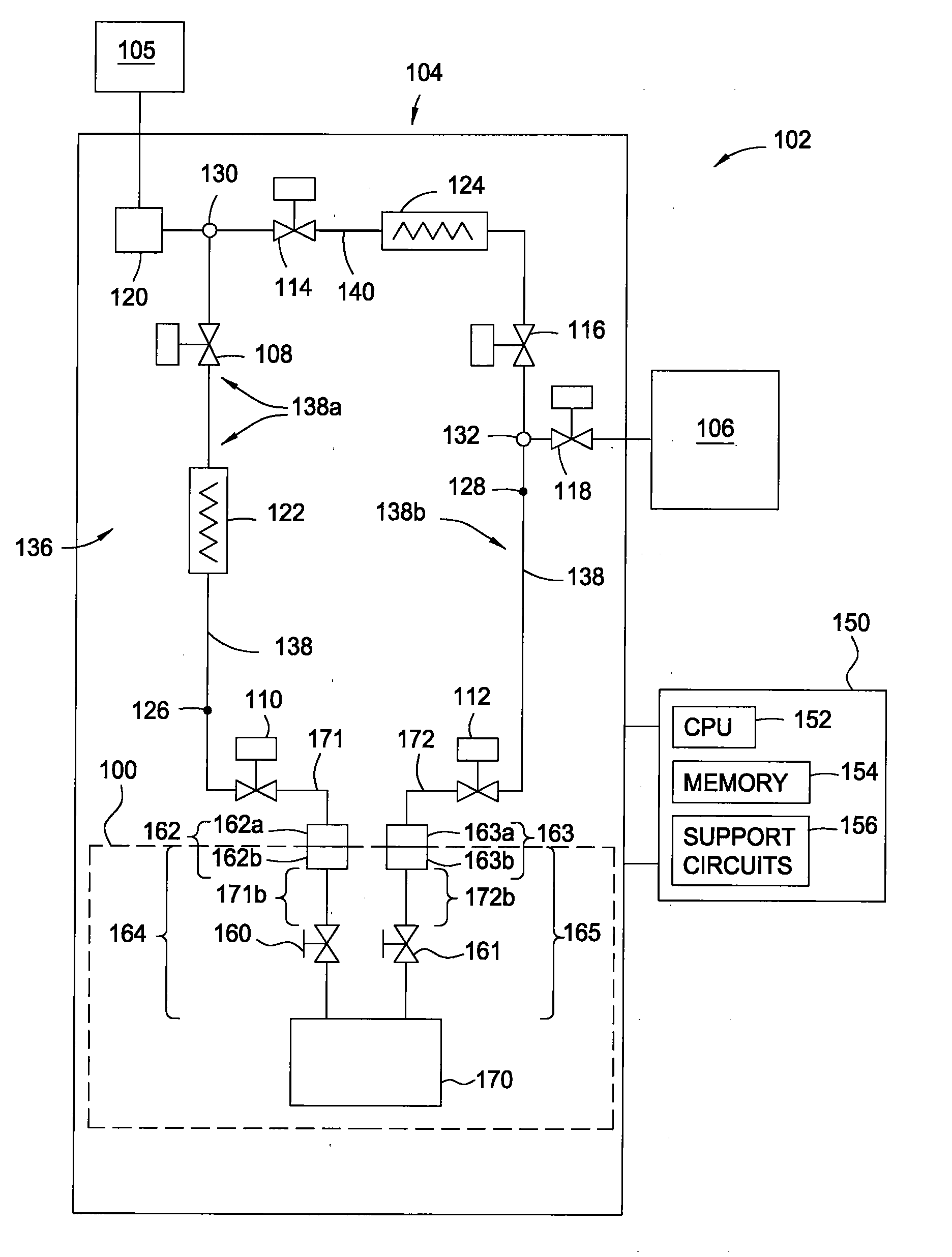

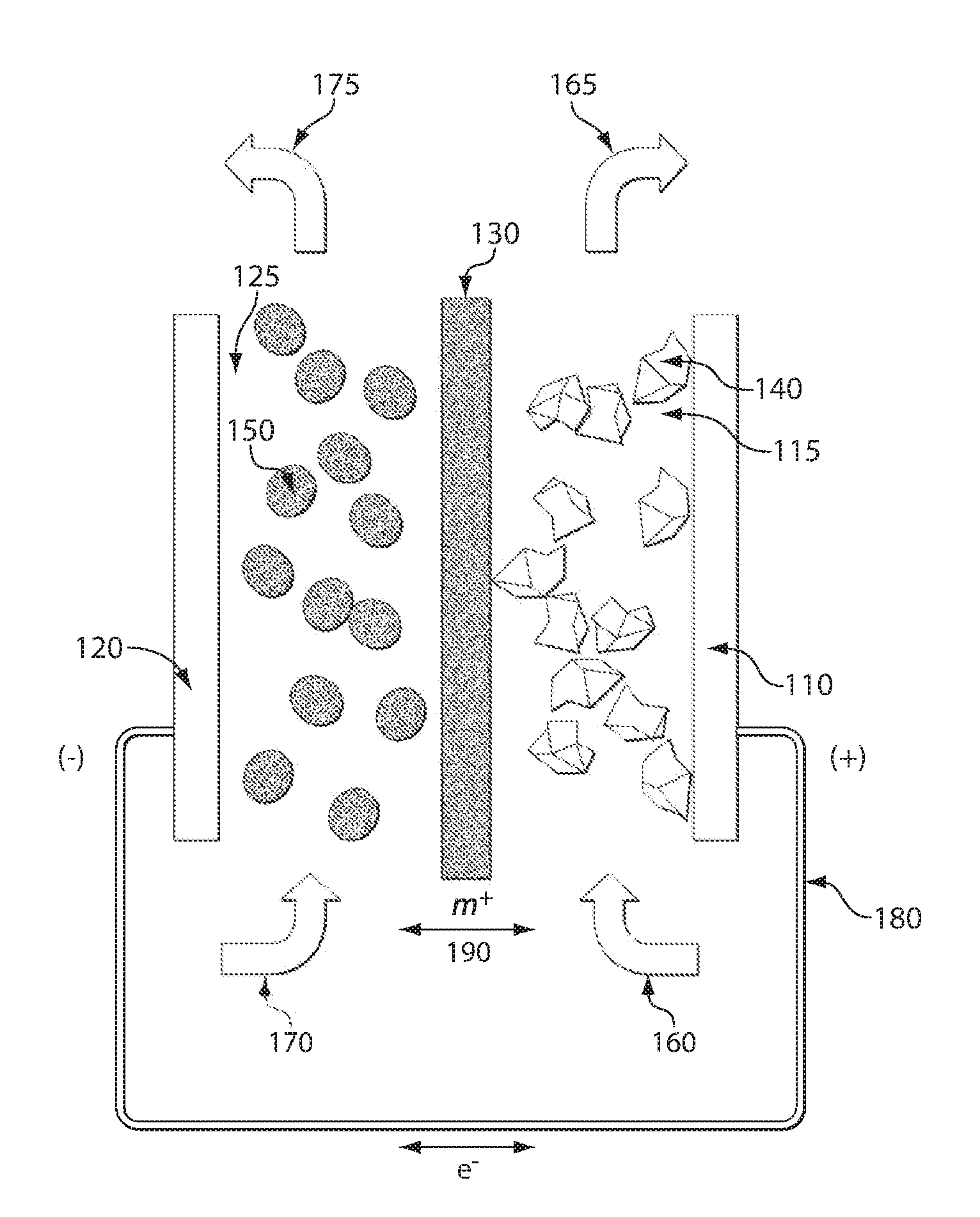

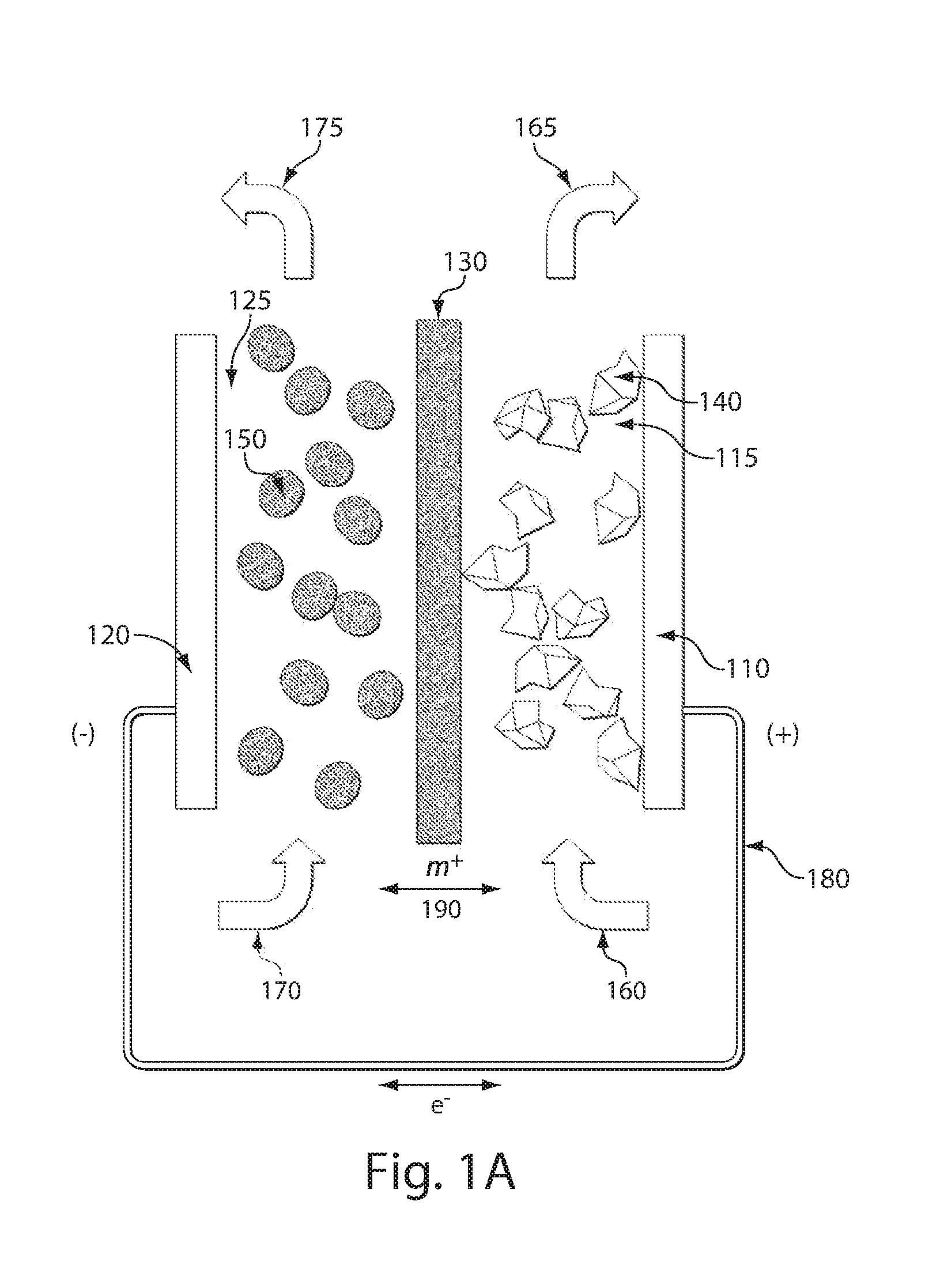

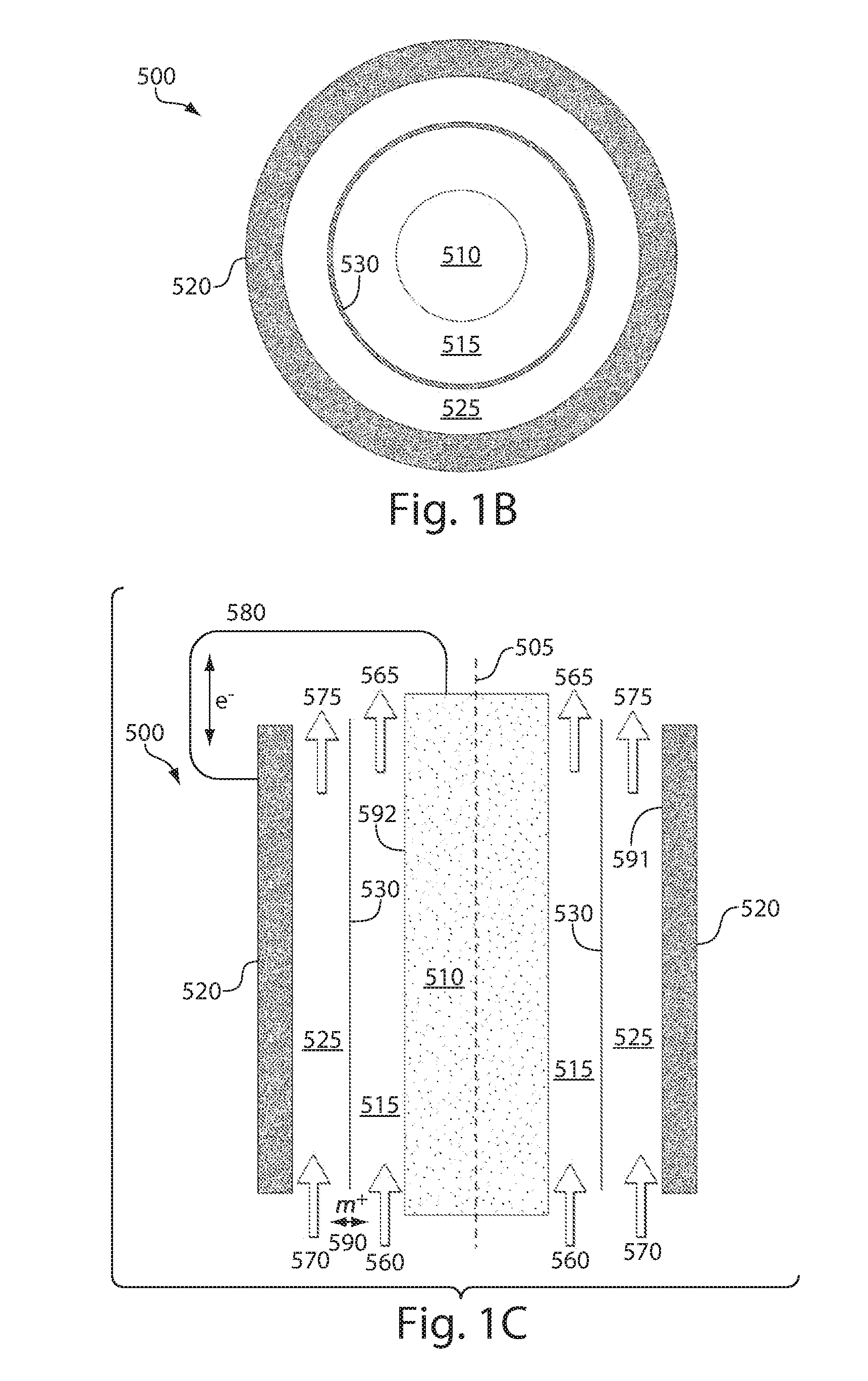

High energy density redox flow device

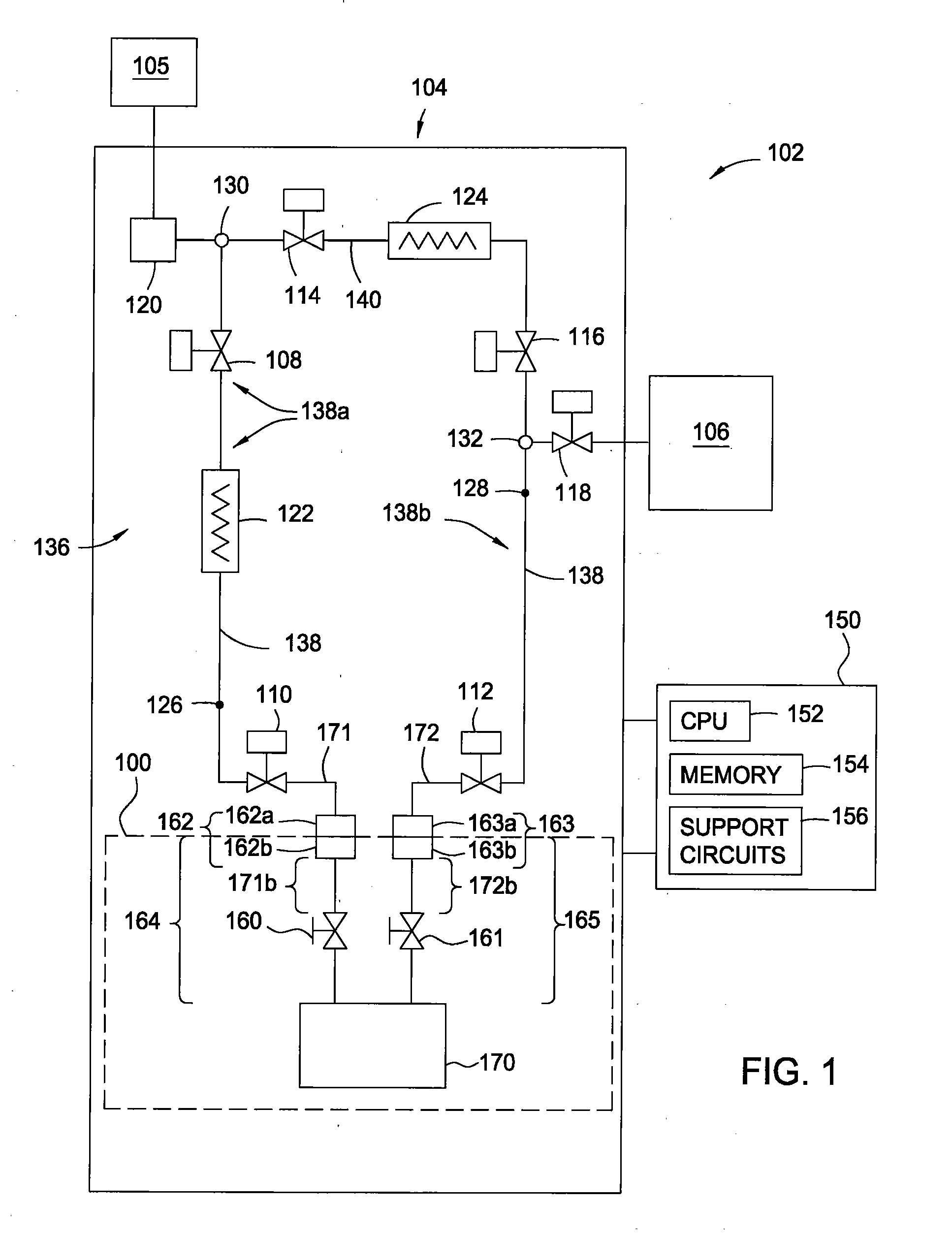

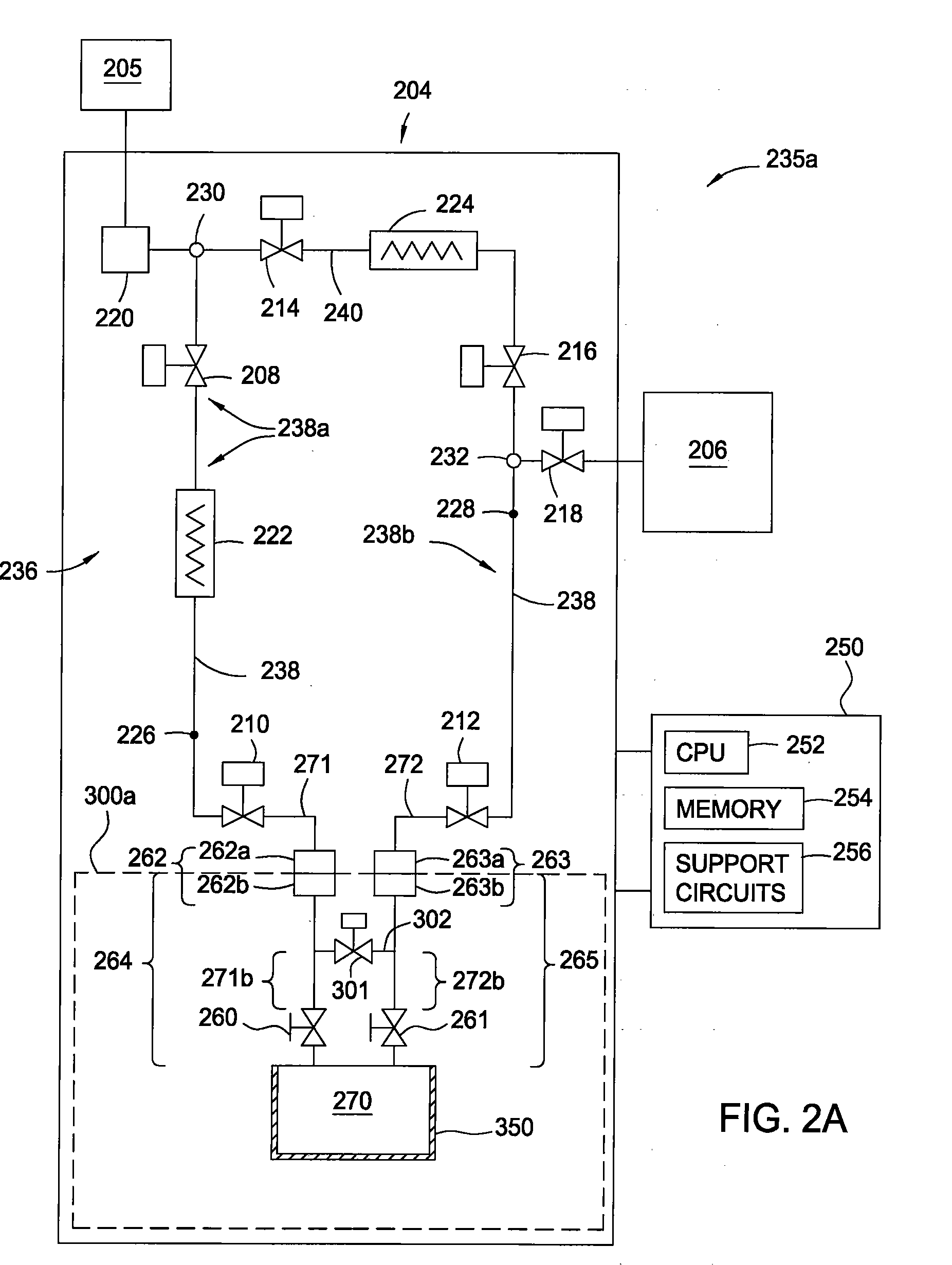

ActiveUS20110200848A1Avoid accumulationHigh enough specific energyOrganic chemistryFlow propertiesElectrochemical responseHigh energy

Redox flow devices are described in which at least one of the positive electrode or negative electrode-active materials is a semi-solid or is a condensed ion-storing electroactive material, and in which at least one of the electrode-active materials is transported to and from an assembly at which the electrochemical reaction occurs, producing electrical energy. The electronic conductivity of the semi-solid is increased by the addition of conductive particles to suspensions and / or via the surface modification of the solid in semi-solids (e.g., by coating the solid with a more electron conductive coating material to increase the power of the device). High energy density and high power redox flow devices are disclosed. The redox flow devices described herein can also include one or more inventive design features. In addition, inventive chemistries for use in redox flow devices are also described.

Owner:MASSACHUSETTS INST OF TECH +2

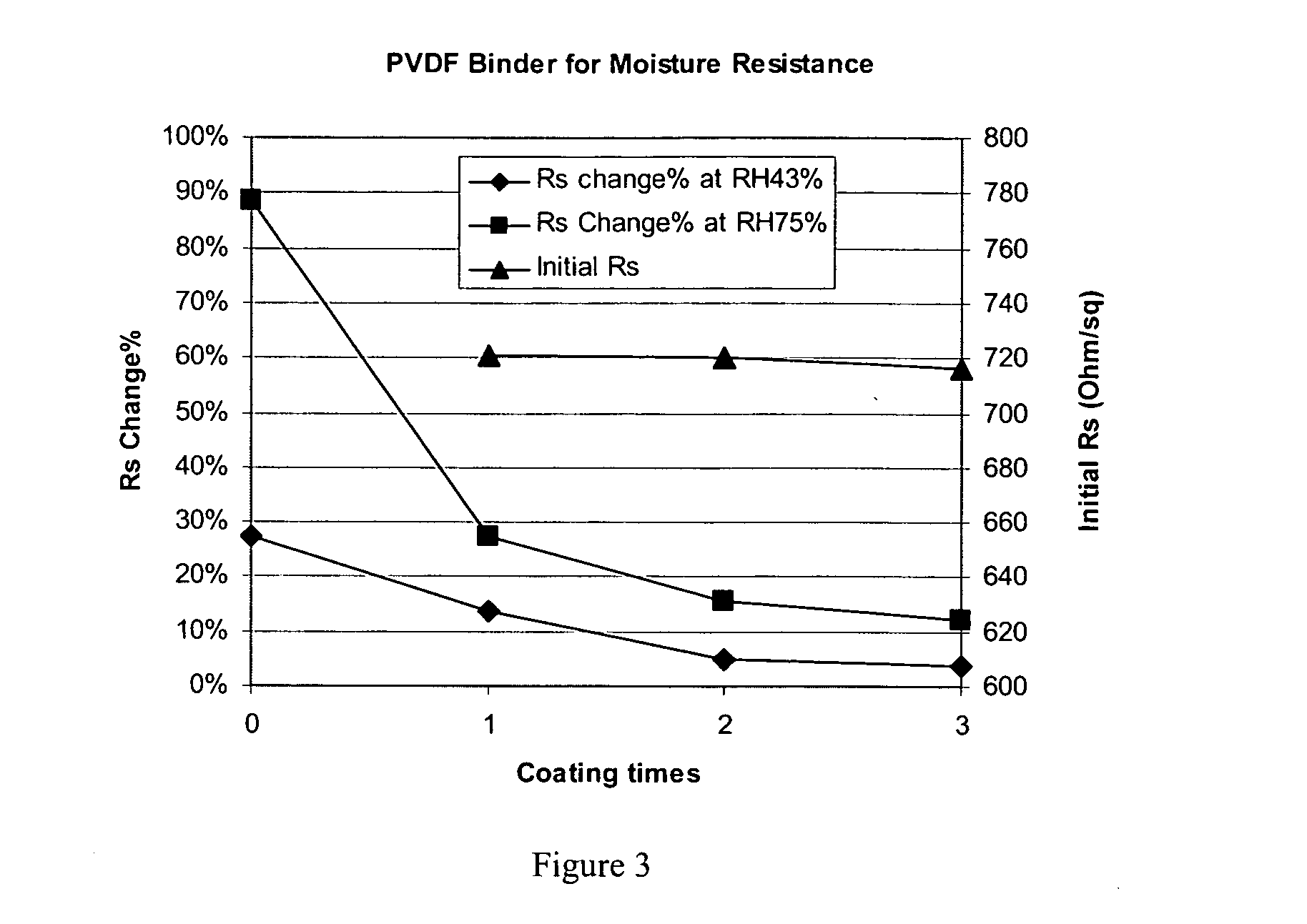

Fluoropolymer binders for carbon nanotube-based transparent conductive coatings

InactiveUS20060113510A1Reduce conductivityFunction increaseNanoinformaticsConductive materialThermoplasticOptical transparency

This invention relates to flexible, transparent and conductive coatings and films formed using carbon nanotubes (CNT) and, in particular, single wall carbon nanotubes, with polymer binders. Preferably, coatings and films are formed from carbon nanotubes applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or a combination thereof. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. A fluoropolymer containing binder, which is a solution of one fluoropolymer or a blend of fluoropolymers, which may be formulated with additives, is applied onto a carbon nanotube-based transparent conductive coating at nanometer level of thickness on a clear substrate such as PET and glass. The fluoropolymers or blend can be either semi-crystalline (with low level of crystallinity) or amorphous, preferably to be amorphous with low refraction index. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. This binder coating significantly improves optical transparency, and also maintain or increases conductivity of the CNT-based coating. With other benefits such as abrasion, thermal and moisture resistance, this binder coating and the resulting products is used for display and electronic applications.

Owner:EIKOS

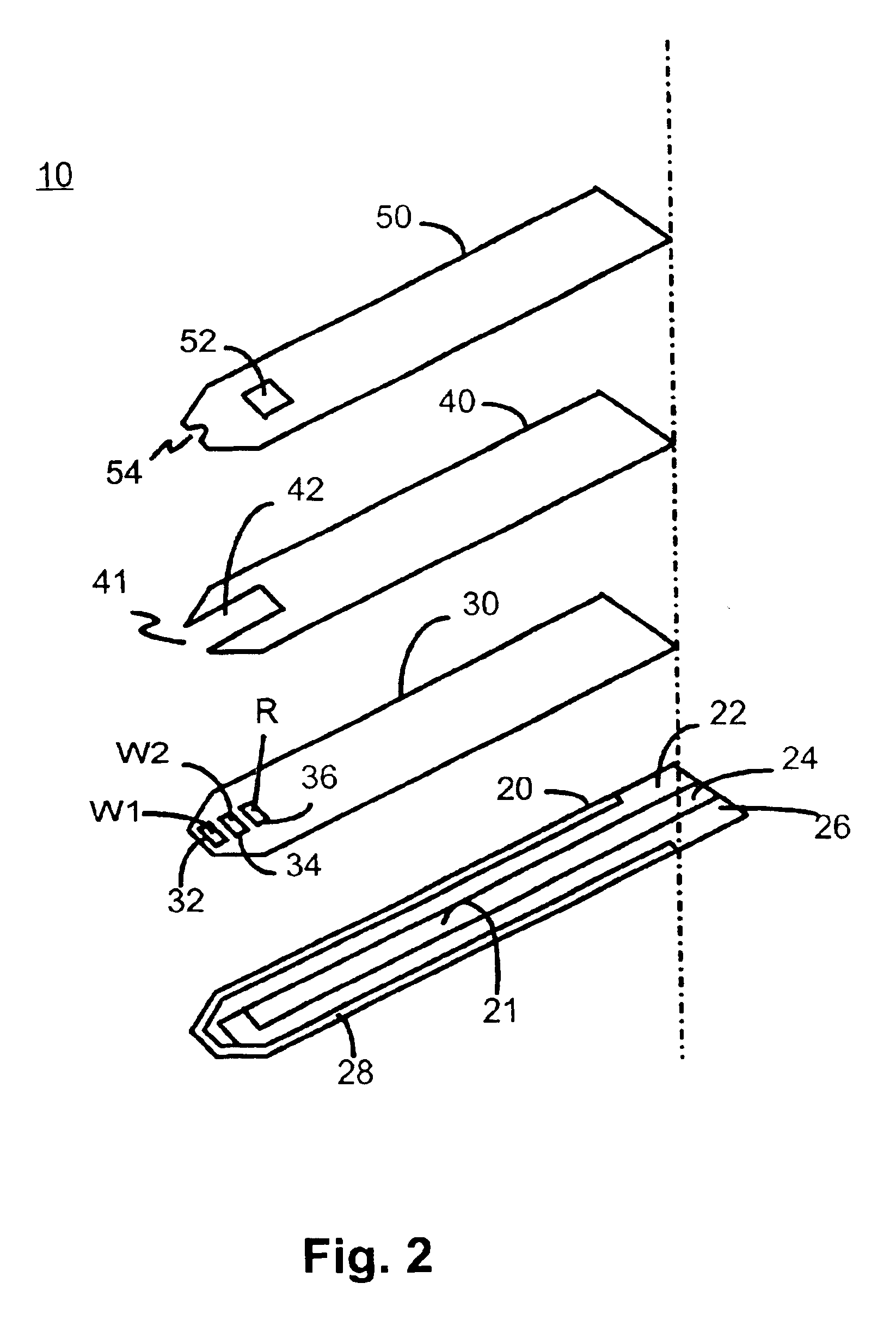

Disposable sensor with enhanced sample port inlet

InactiveUS6837976B2Interference minimizationWide linear measurement rangeImmobilised enzymesBioreactor/fermenter combinationsProximateConductive coating

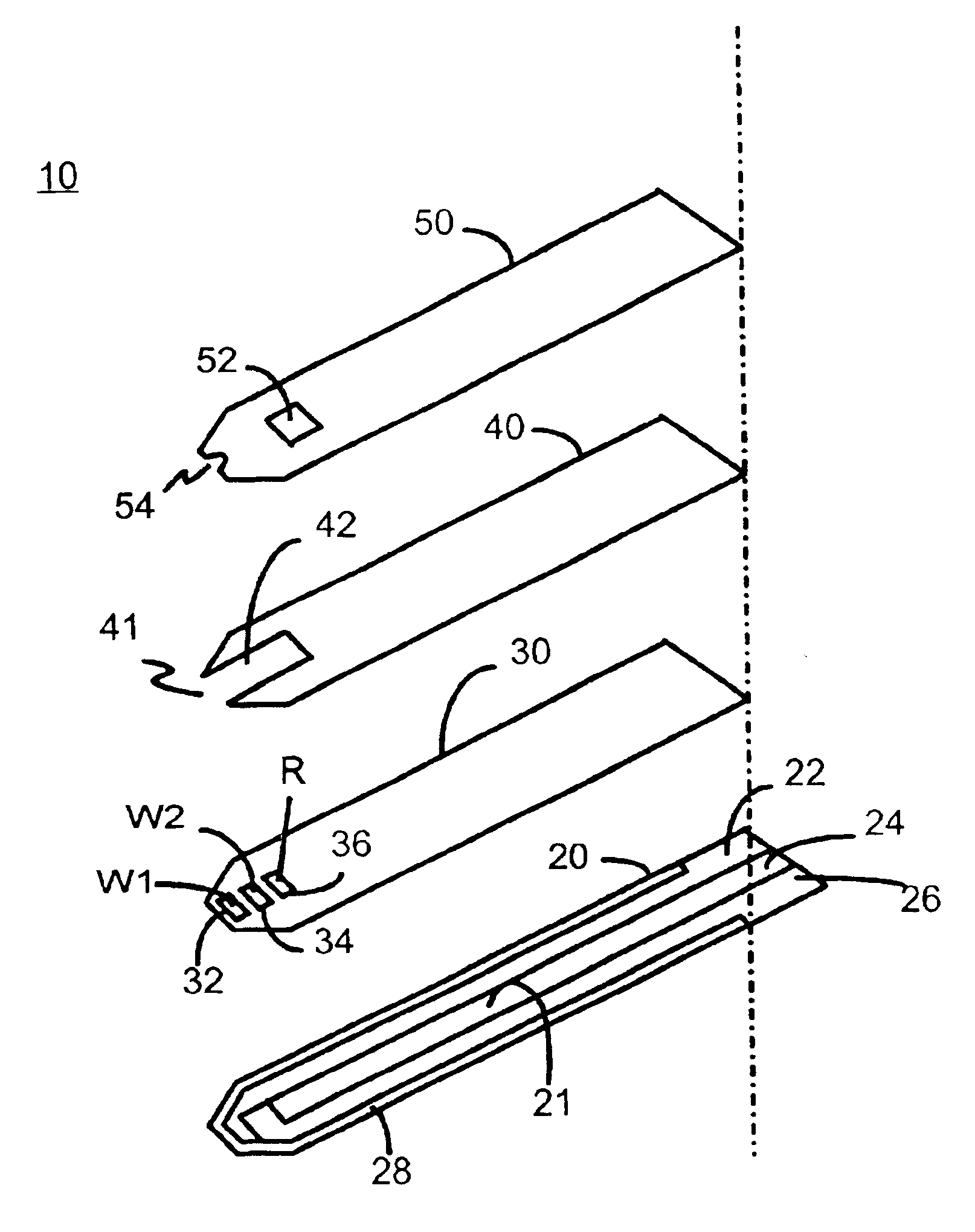

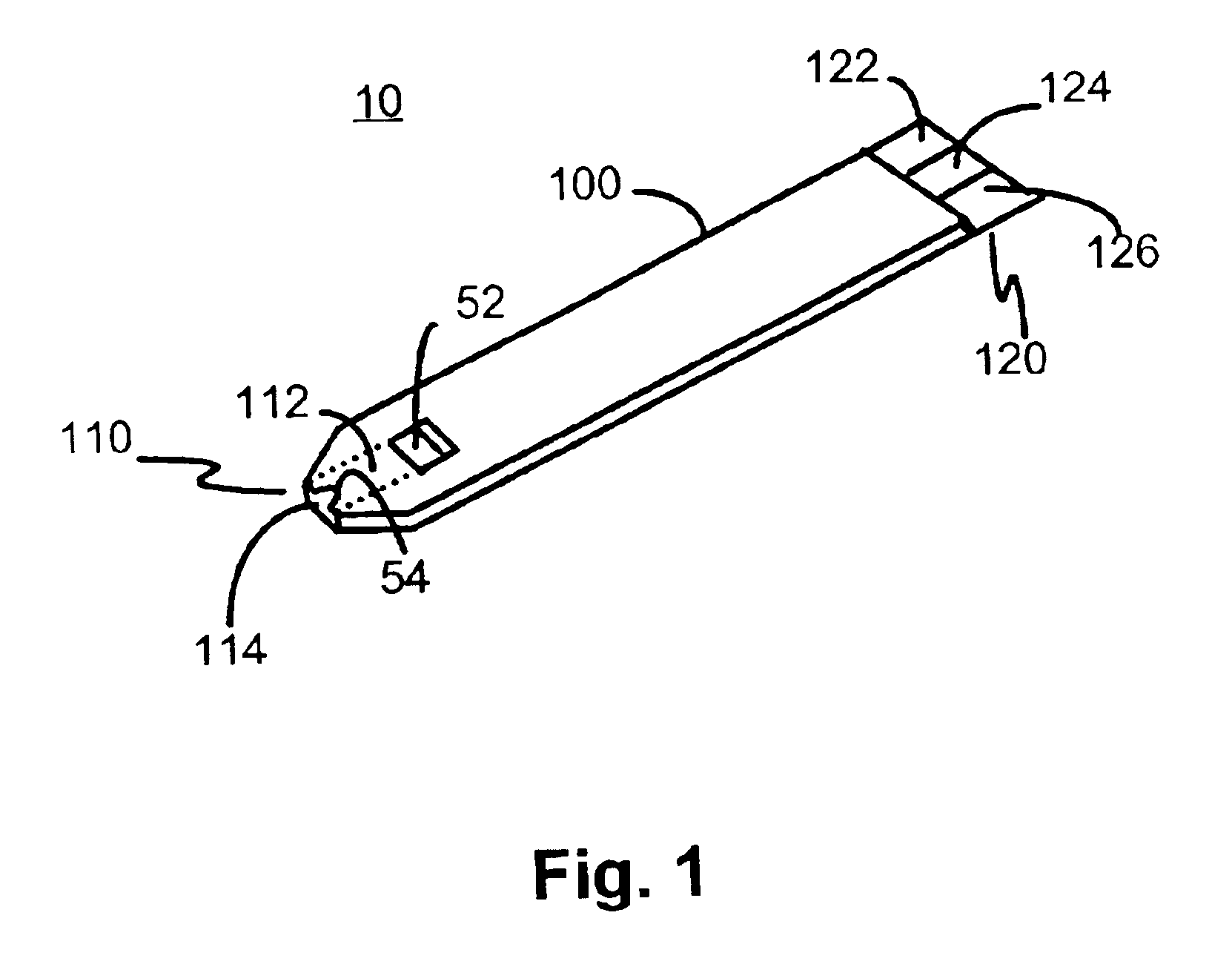

A disposable biosensor for testing a fluid sample including a laminated strip with a first and second end, a reference electrode embedded in the laminated strip proximate to the first end, at least one working electrode embedded in the laminated strip proximate to the first end and the reference electrode, an open path for receiving a fluid sample beginning from the first end and connecting to a vent spaced from the first end, the open path being sufficiently long to expose the reference electrode and the working electrode to the fluid sample, and conductive contacts located at the second end of the laminated strip. The laminated strip has a base layer with a conductive coating, a reagent holding layer, a channel forming layer and a cover having an inlet notch at the first end. The working electrode contains a reagent having an enzyme.

Owner:NOVA BIOMEDICAL

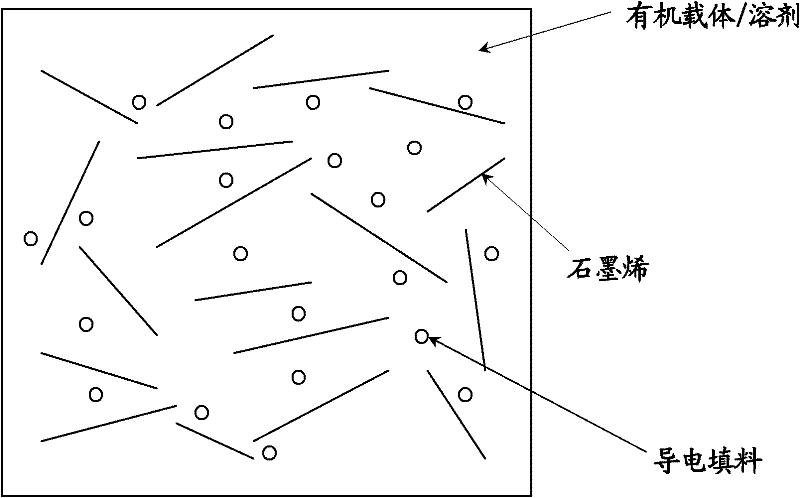

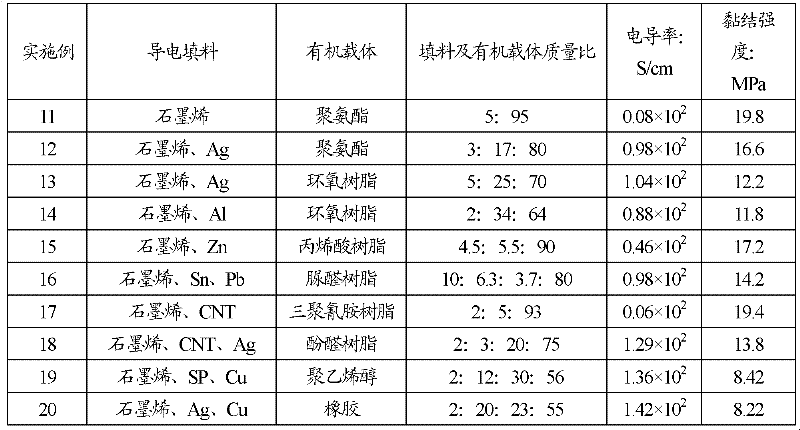

General electronic paste based on graphene filler

ActiveCN102254584AImprove conductivityConductivity regulationNon-conductive material with dispersed conductive materialNano structuringConductive coating

The invention discloses general electronic paste based on graphene filler. The electronic paste contains graphene-containing conductive filler, an organic carrier, a solvent and an auxiliary agent. Because the graphene has good electronic conductivity and a unique two-dimensional laminar nano structure, the graphene forms a conductive network in the organic carrier more easily, and the electric conductivity of the electronic paste is improved by adding the graphene. Further, the conductive filler also contains a conductive material with relatively high electric conductivity, so that the electric conductivity of the electronic paste is further improved. Because the graphene and the conductive material are compounded to form the conductive filler, the electronic paste has good electric conductivity. The electronic paste can obtain a relatively wide electric conductivity range by changing the category of the conductive material mixed with the graphene and adjusting the relative proportion of the graphene to the conductive material of different category. The electric conductivity of the electronic paste is 1*10<-3>S / cm to 1*10<3>S / cm. The paste can be widely applied, and can be particularly used as a conductive coating or adhesive.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Method of manufacturing a female electrical connector in a single layer flexible polymeric dielectric film substrate

InactiveUS6032359APrinted circuit assemblingElectrically conductive connectionsDielectricConductive coating

A method of making a wiping connection between a male connector and a female connector in a single layer of a flexible polymeric dielectric film substrate having a thickness of less than 0.012 inches is disclosed. A laser directs a beam towards the substrate cutting a smooth pattern through the substrate to define a passage extending through the substrate and providing at least one resilient foldable flap normally closing the passage through the substrate. Next an electrically conductive material is coated on the flexible polymeric dielectric film substrate including a circuit trace providing an electrical contact land area surrounding the pattern extending over the foldable flap to form the female connector. The male connector is then inserted into the female connector through the flexible polymeric dielectric film substrate at the pattern, deflecting the foldable flap and conductive coating into wiping electrical and mechanical engagement with the male connector to secure the male connector to the substrate in electrical contact with the trace circuit.

Owner:CRAIG WILSON & CO

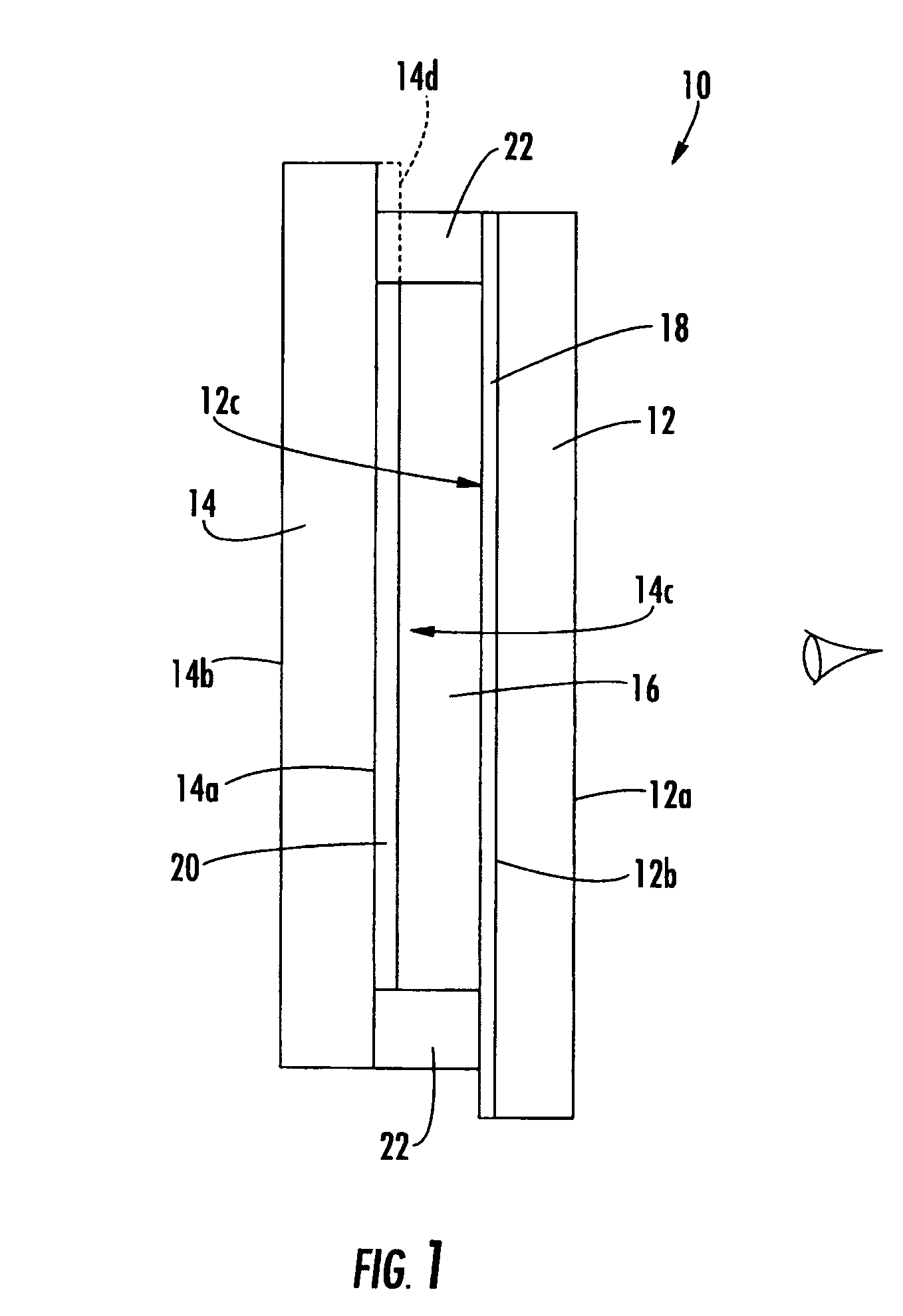

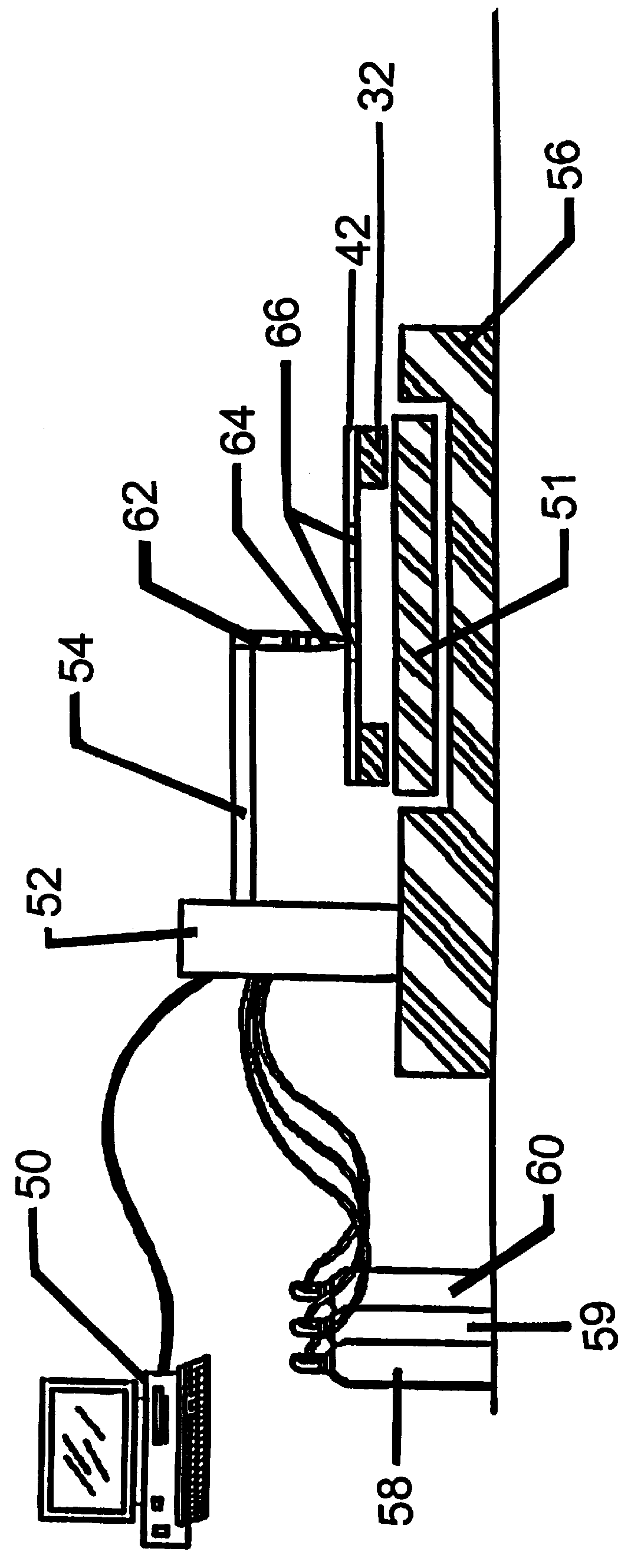

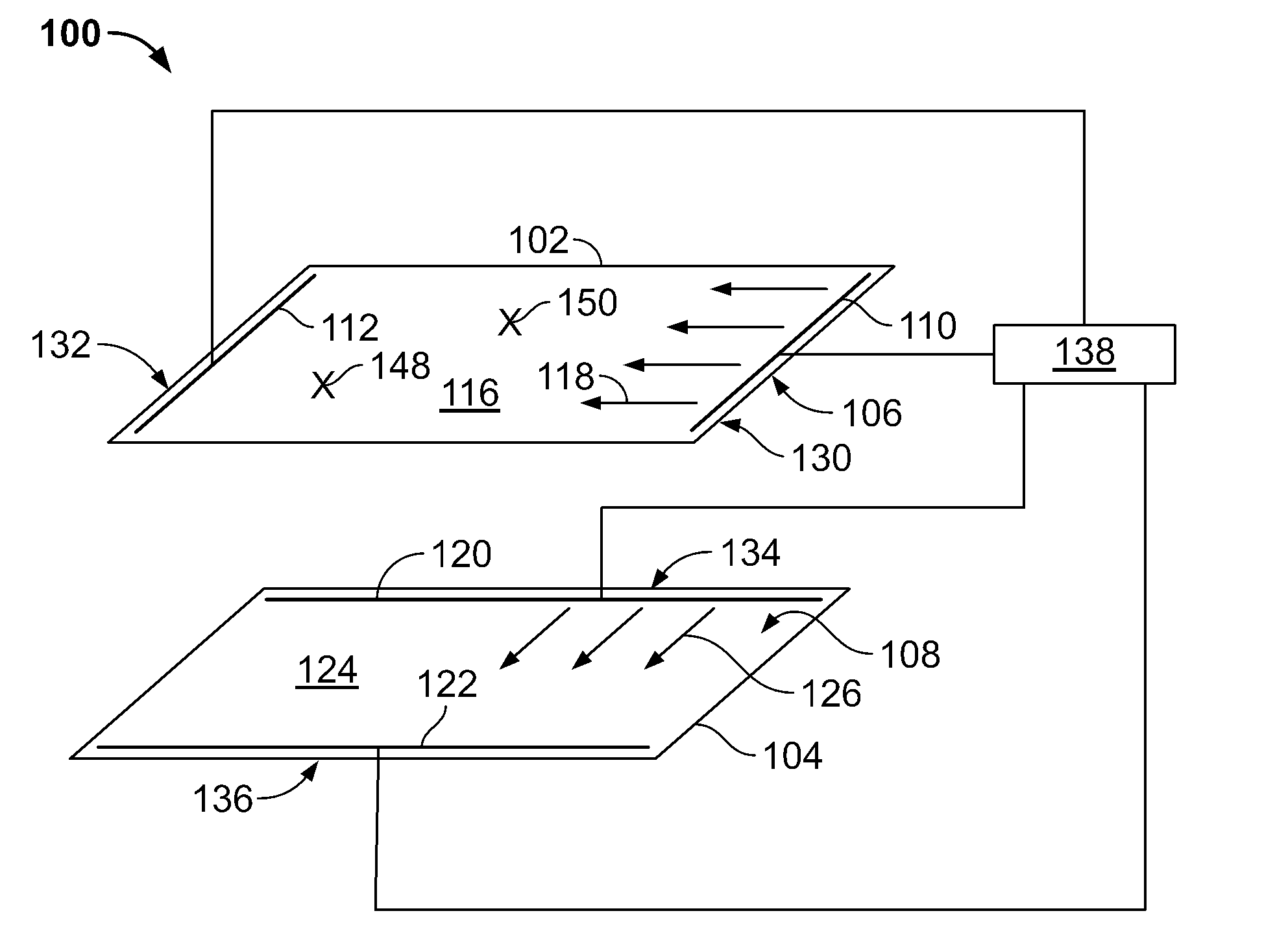

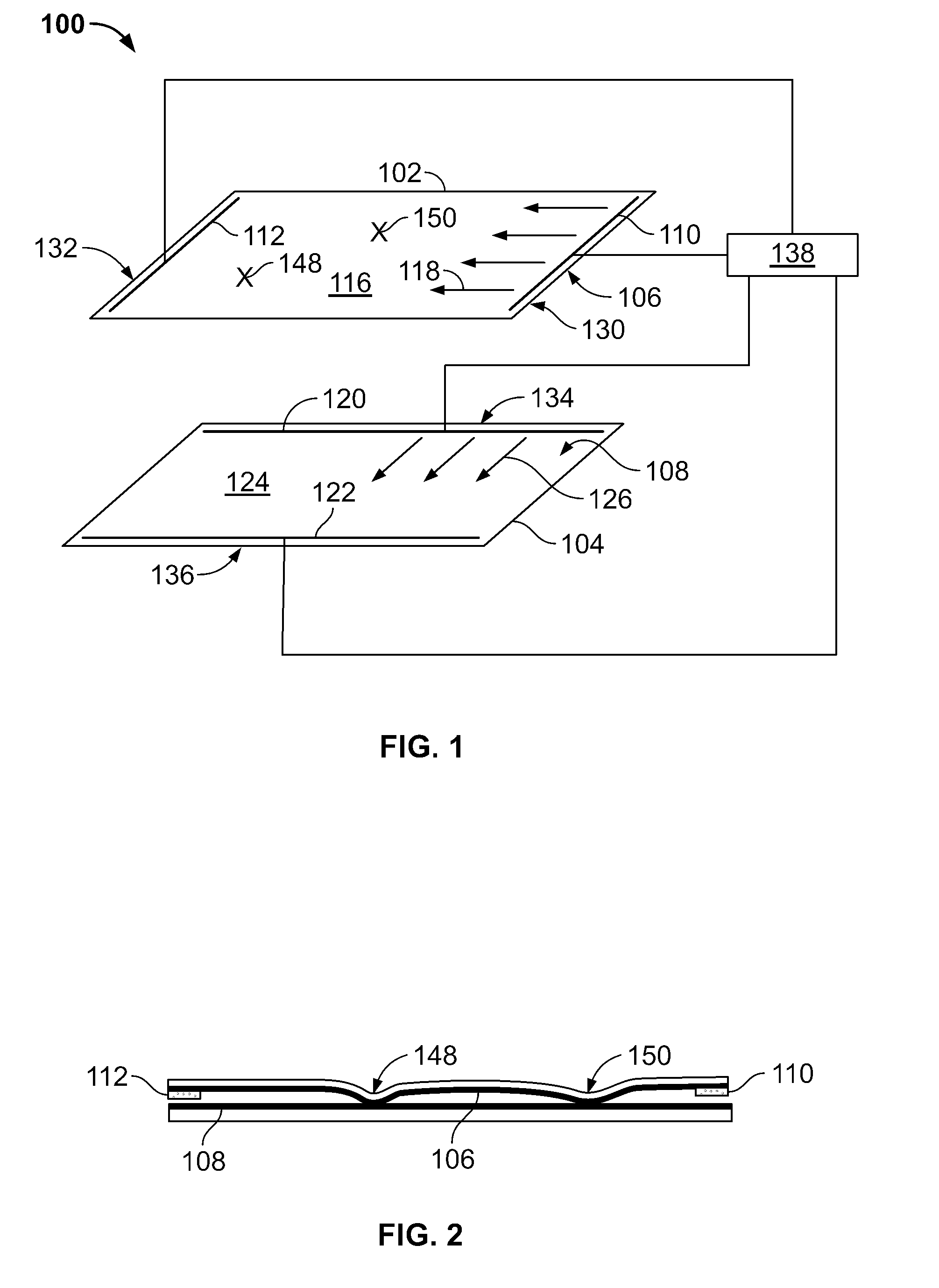

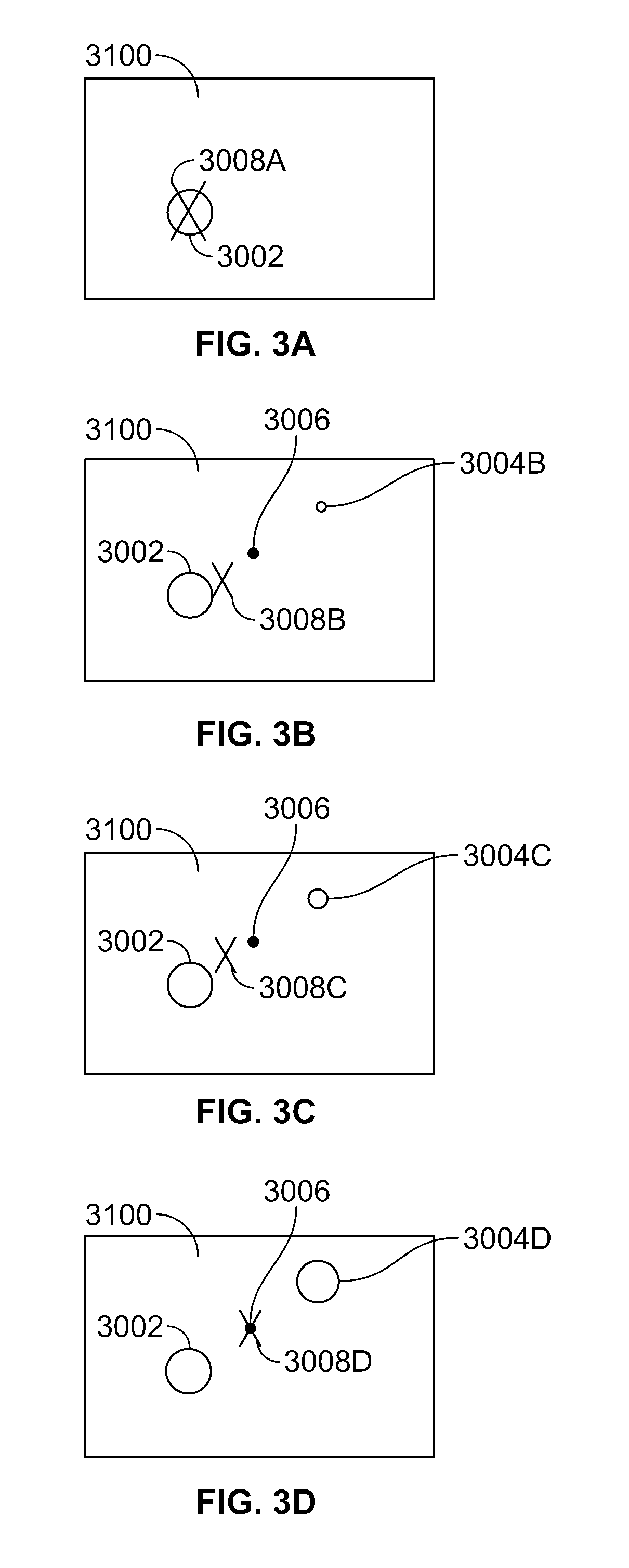

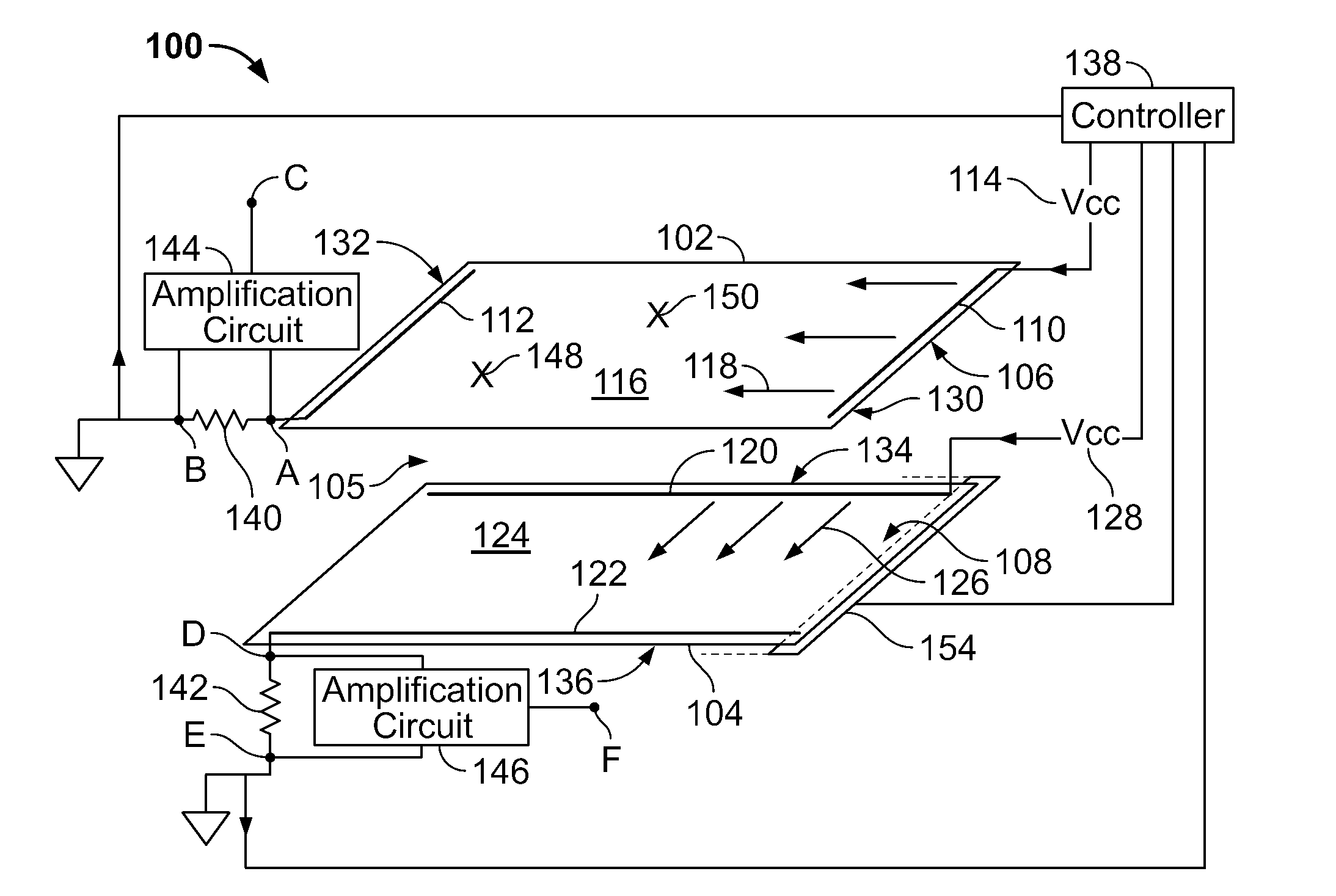

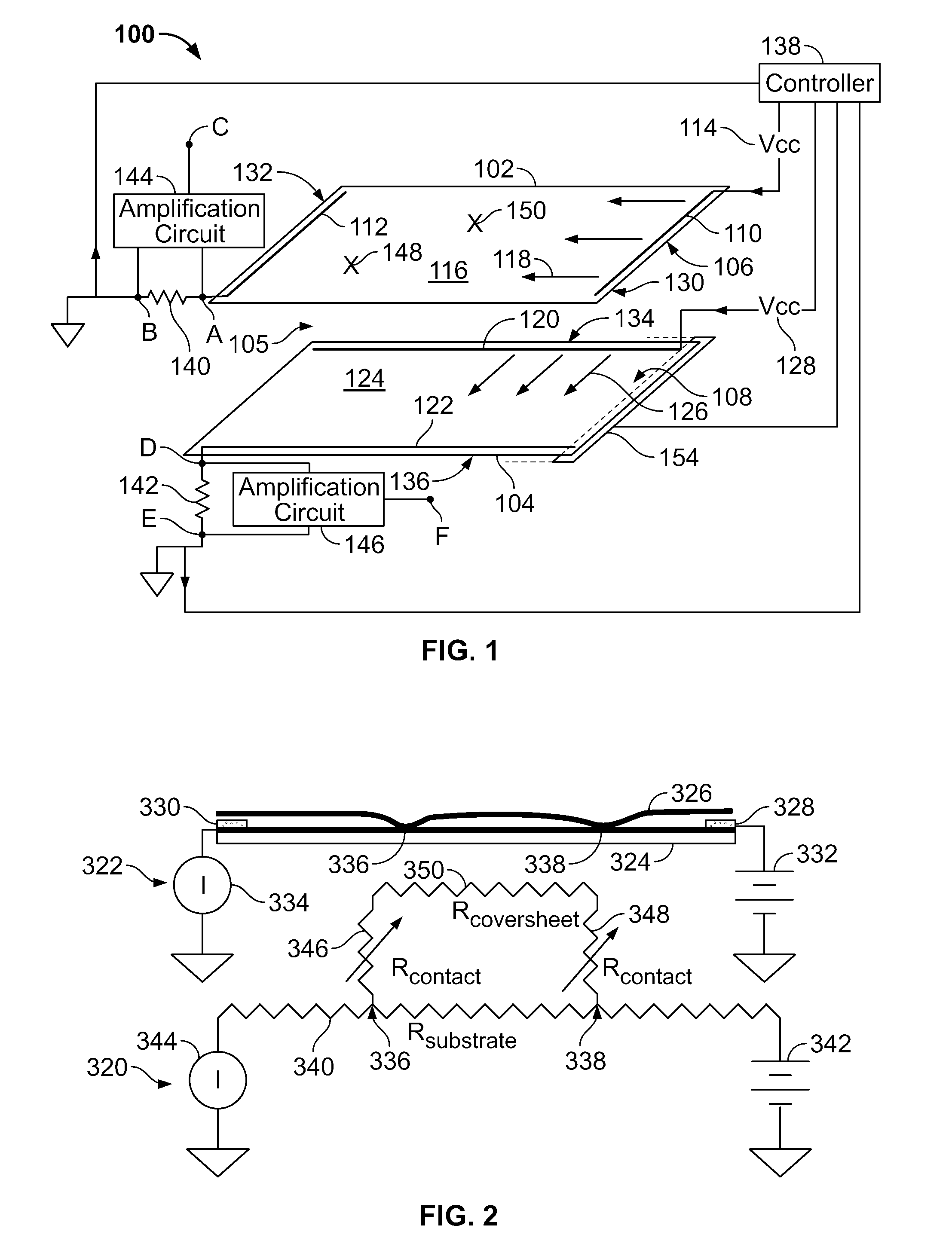

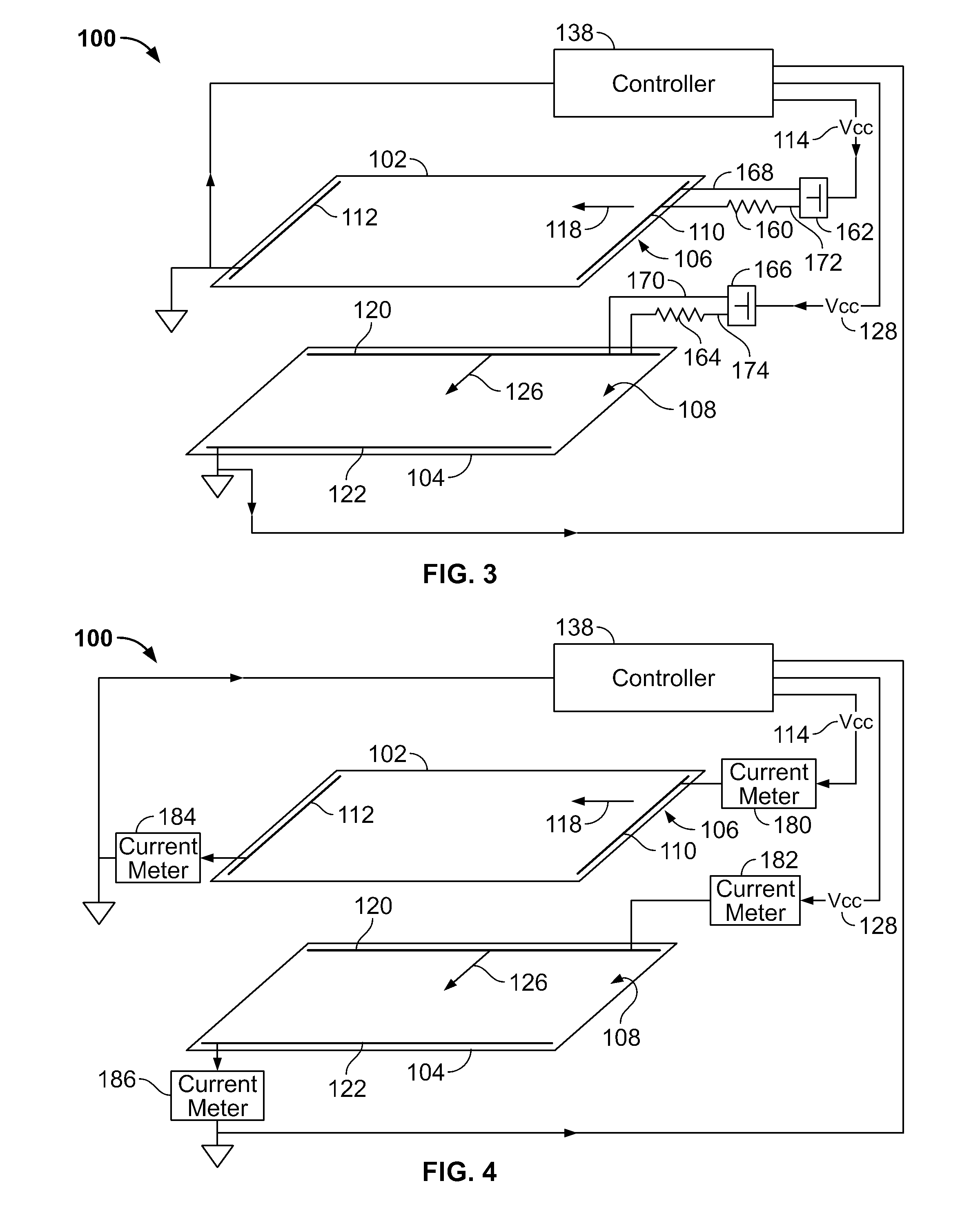

Method and apparatus for detecting two simultaneous touches and gestures on a resistive touchscreen

Resistive touchscreen system has substrate and coversheet with first and second conductive coatings. The substrate and coversheet are positioned proximate each other such that the first conductive coating faces the second conductive coating. The substrate and coversheet are electrically disconnected with respect to each other in the absence of a touch. First set of electrodes is formed on the substrate for establishing voltage gradients in first direction. Second set of electrodes is formed on the coversheet for establishing voltage gradients in second direction wherein the first and second directions are different. Controller biases the first and second sets of electrodes in first and second cycles and senses a bias load resistance associated with at least one of the sets of electrodes. The bias load resistance has a reference value associated with no touch. A decrease in the bias load resistance relative to the reference value indicates two simultaneous touches.

Owner:TE CONNECTIVITY CORP

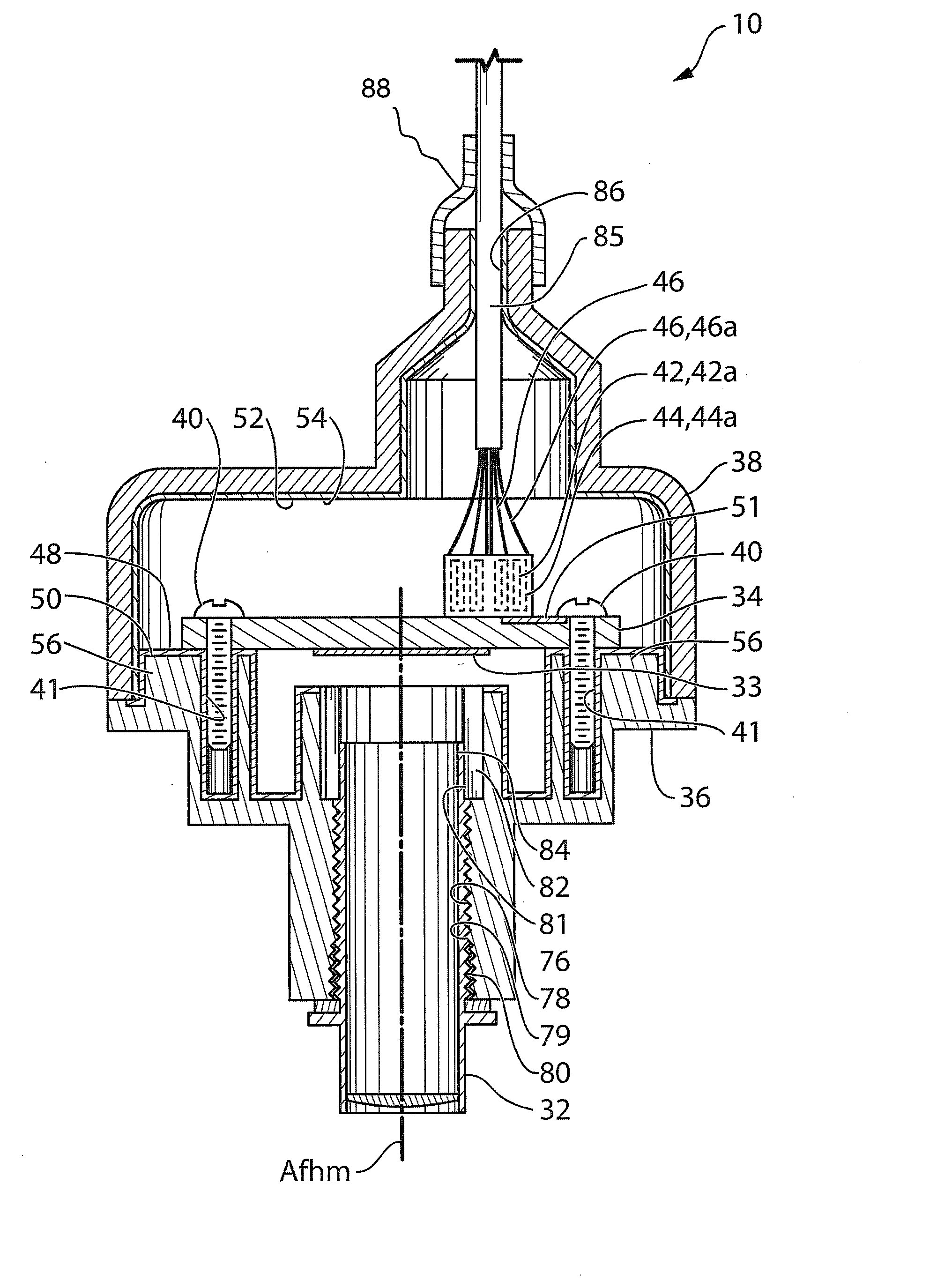

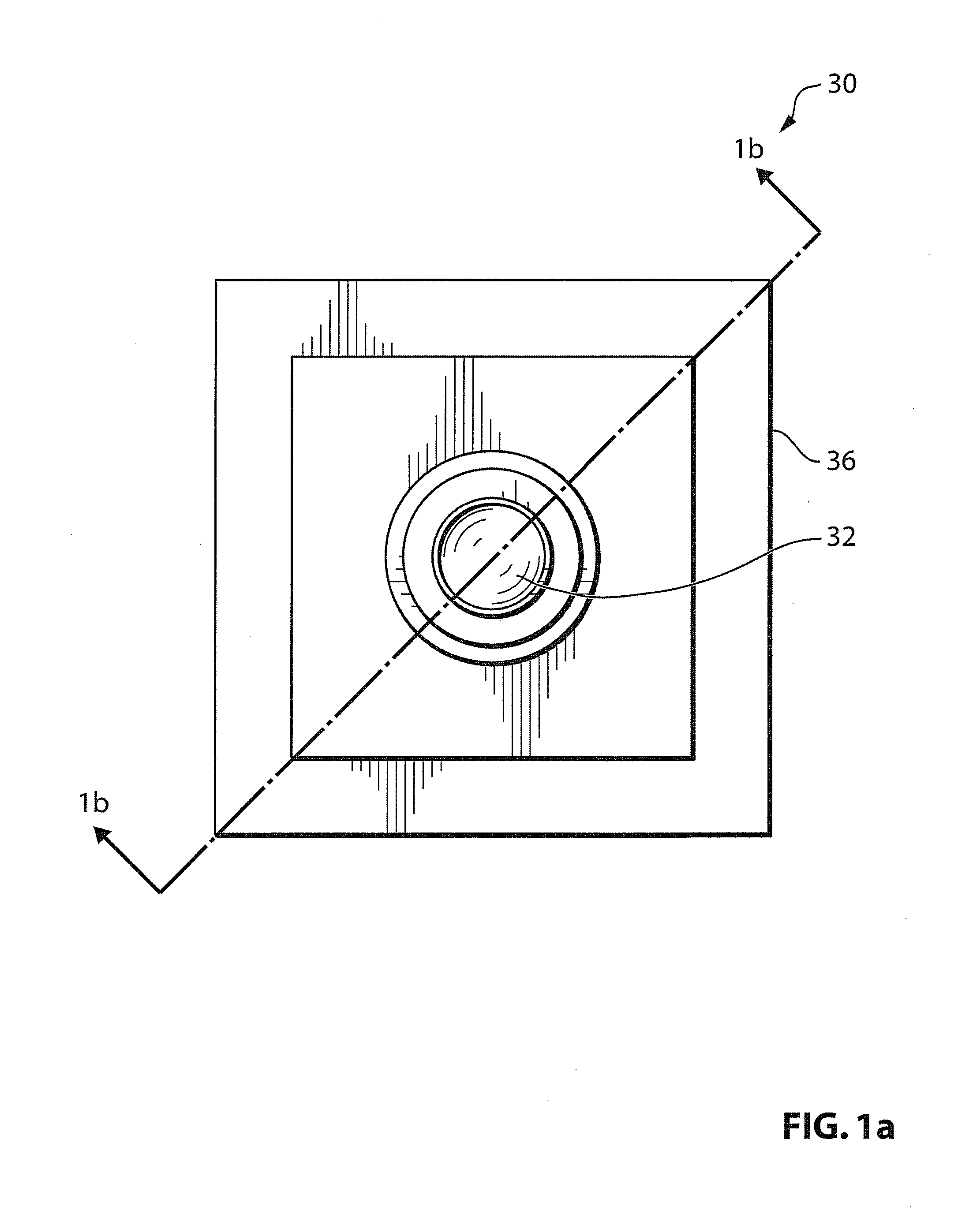

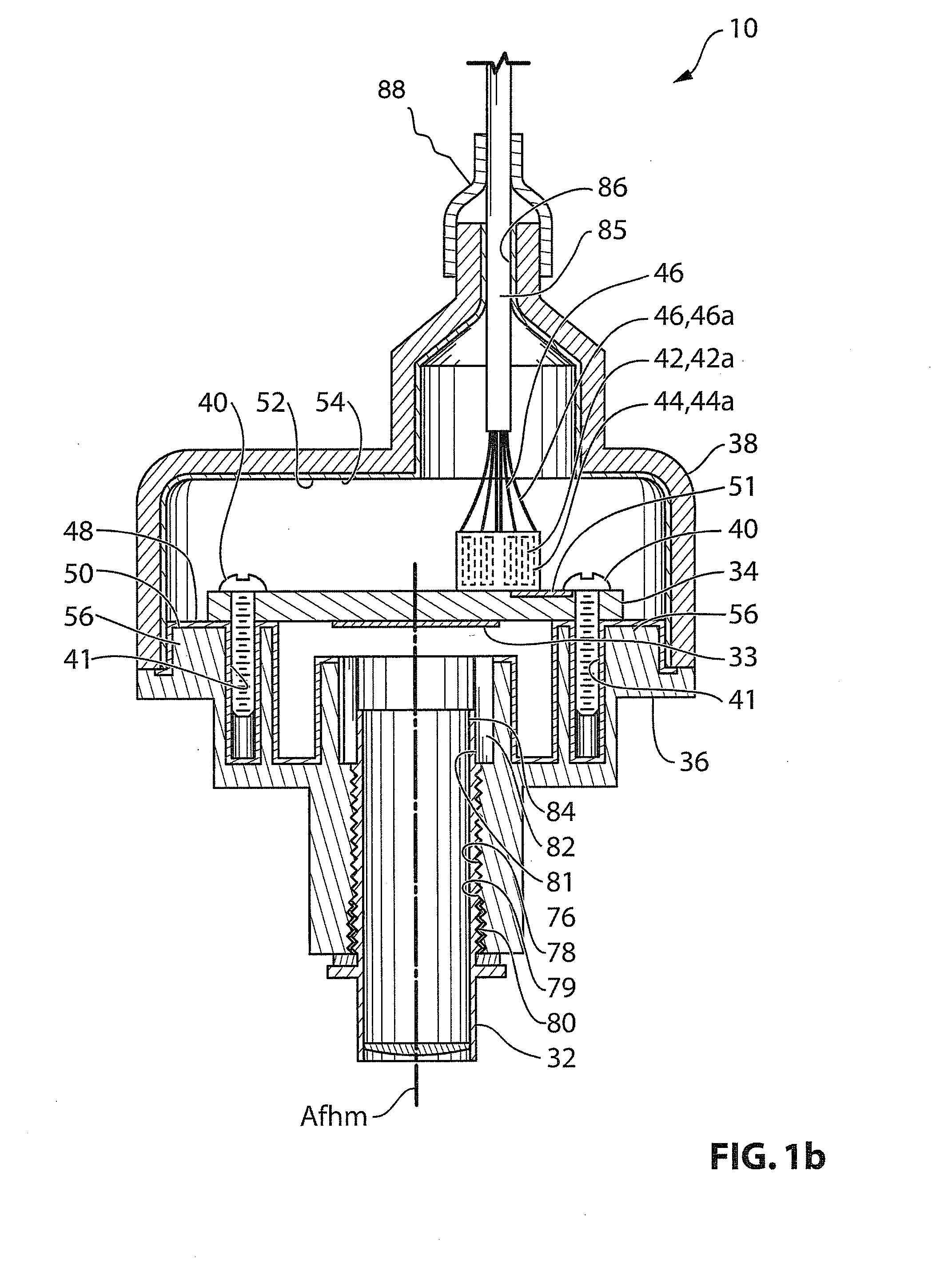

Compact Camera and Cable System for Vehicular Applications

ActiveUS20100097519A1Television system detailsColor television detailsInterference fitConductive coating

In one aspect, the invention is directed to a camera for mounting on a vehicle, wherein the camera housing made up of two housing members, with a conductive coating on the interior of each of the housing members. The two housing members mate together using an interference fit, to provide a greater assurance that they are electrically connected to each other. One of the housing members is connected to ground. In another aspect, the invention provides a camera module that has a housing and a wire harness or wire or lead that is electrically connected to circuitry of the camera and that extends through the camera housing for electrical connection to a vehicle wire harness or the like. The wire or lead extends through a portion of the housing with the housing disposed at the wire prior to connection of the wire to the circuitry of the camera. The electrical connection of the wire to the camera circuitry is made as the housing is assembled. The joint at where the wire extends outward from the housing portion is sealed, such as via shrink wrapping or the like.

Owner:MAGNA ELECTRONICS

Method of forming an electrical connection between an electrochemical cell and a meter

A method of forming an electrical connection between an electrochemical cell and a meter is provided. According to the method, an electrical connection is made between a meter, by means of a wedge-shaped connector with upper and lower conductive surfaces, and an electrochemical cell comprising a first substrate with a first electrically conductive coating and a second substrate with a second electrically conductive coating, the electrically conductive coatings being disposed to face each other in a spaced apart relationship by an insulating spacer. The meter further includes a pivot point for rotating the wedge connector on the pivot point.

Owner:LIFESCAN IP HLDG LLC

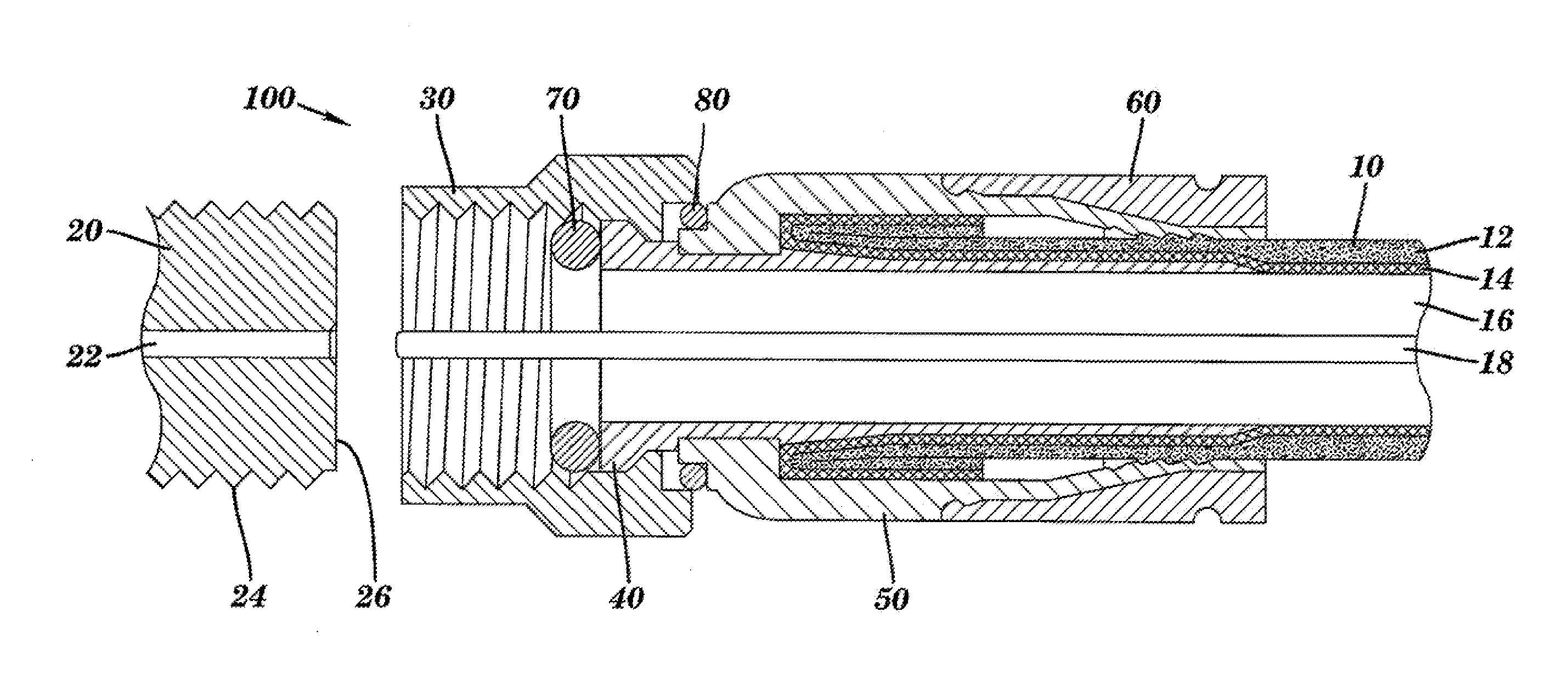

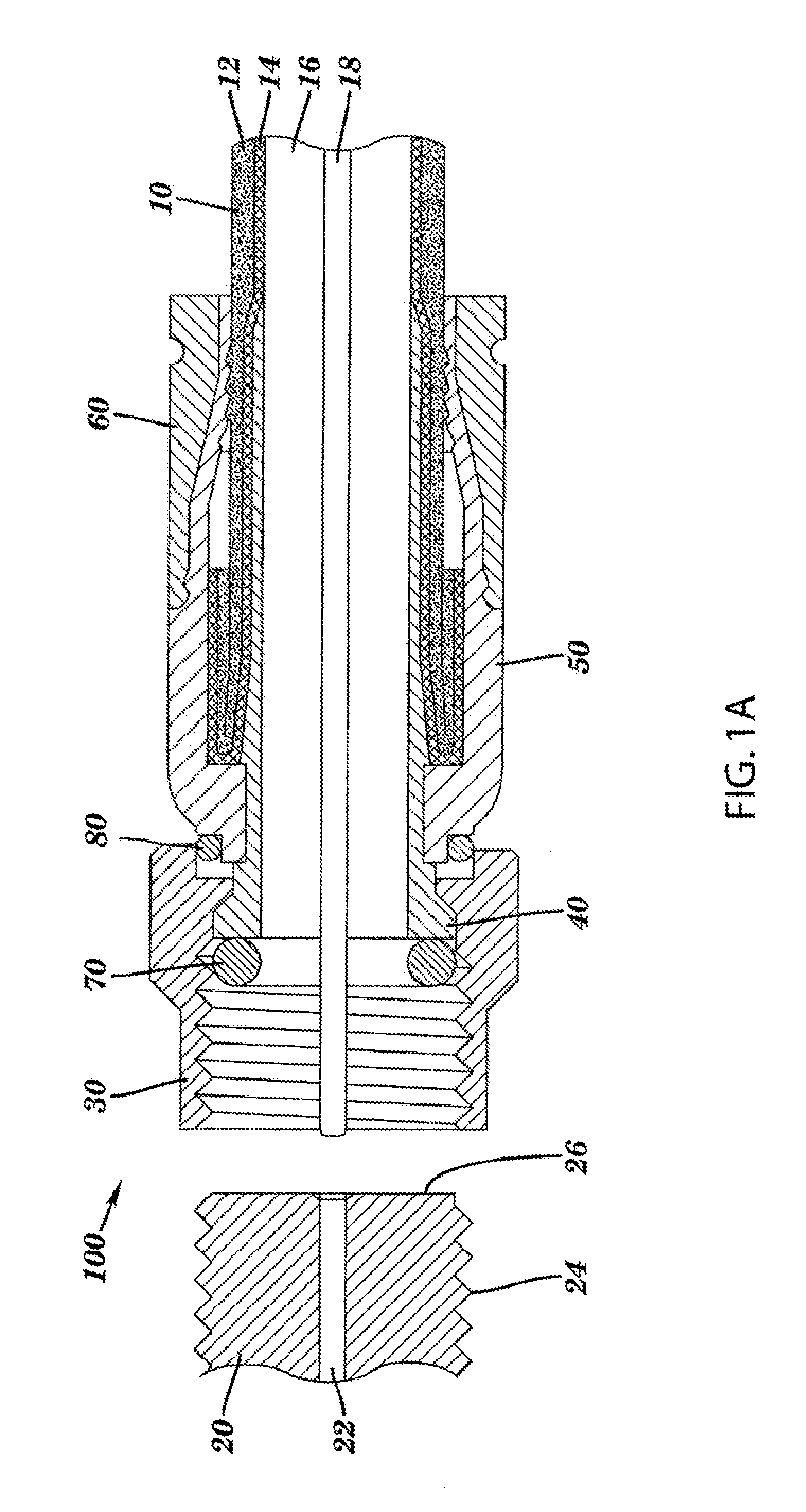

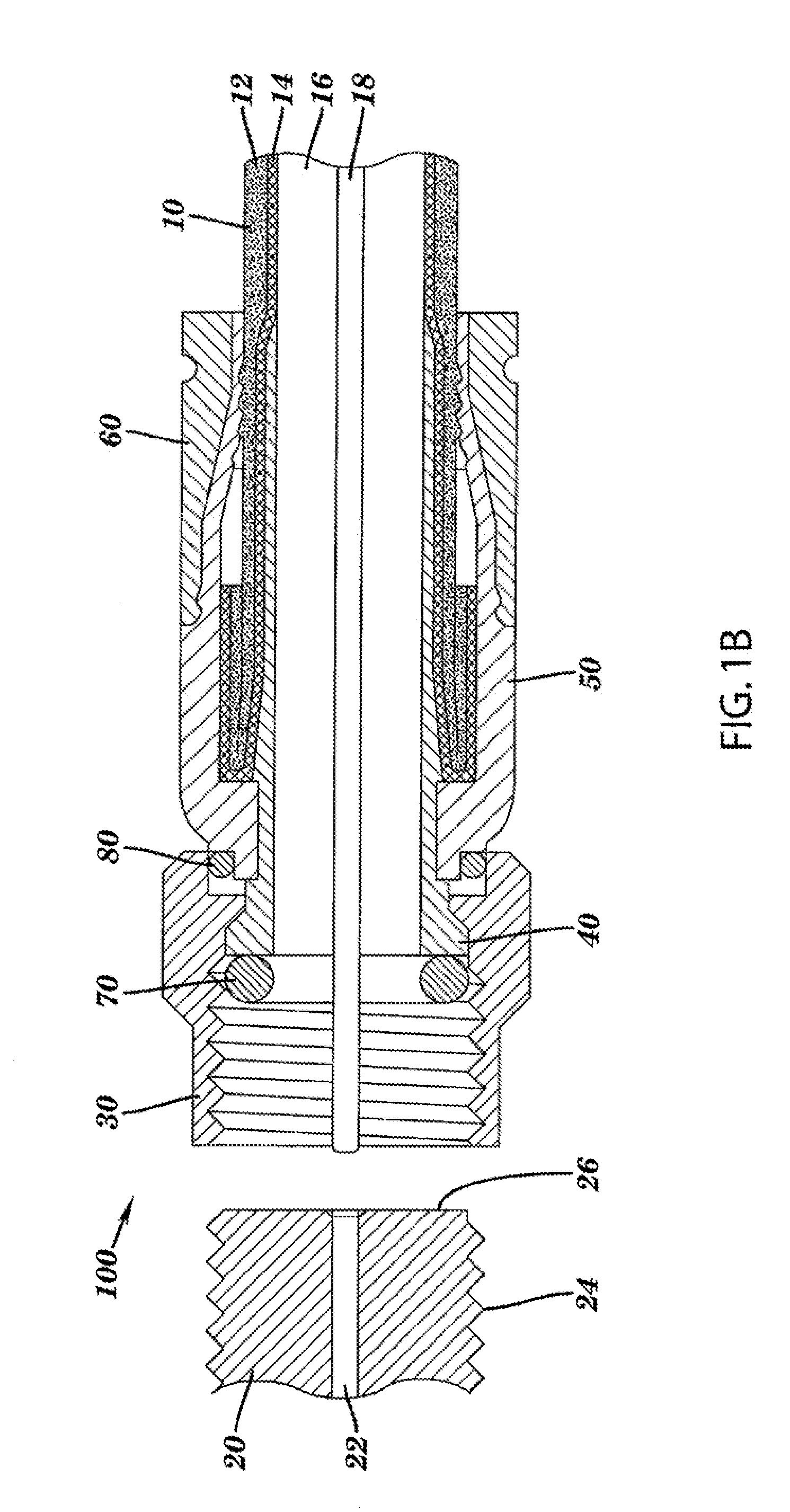

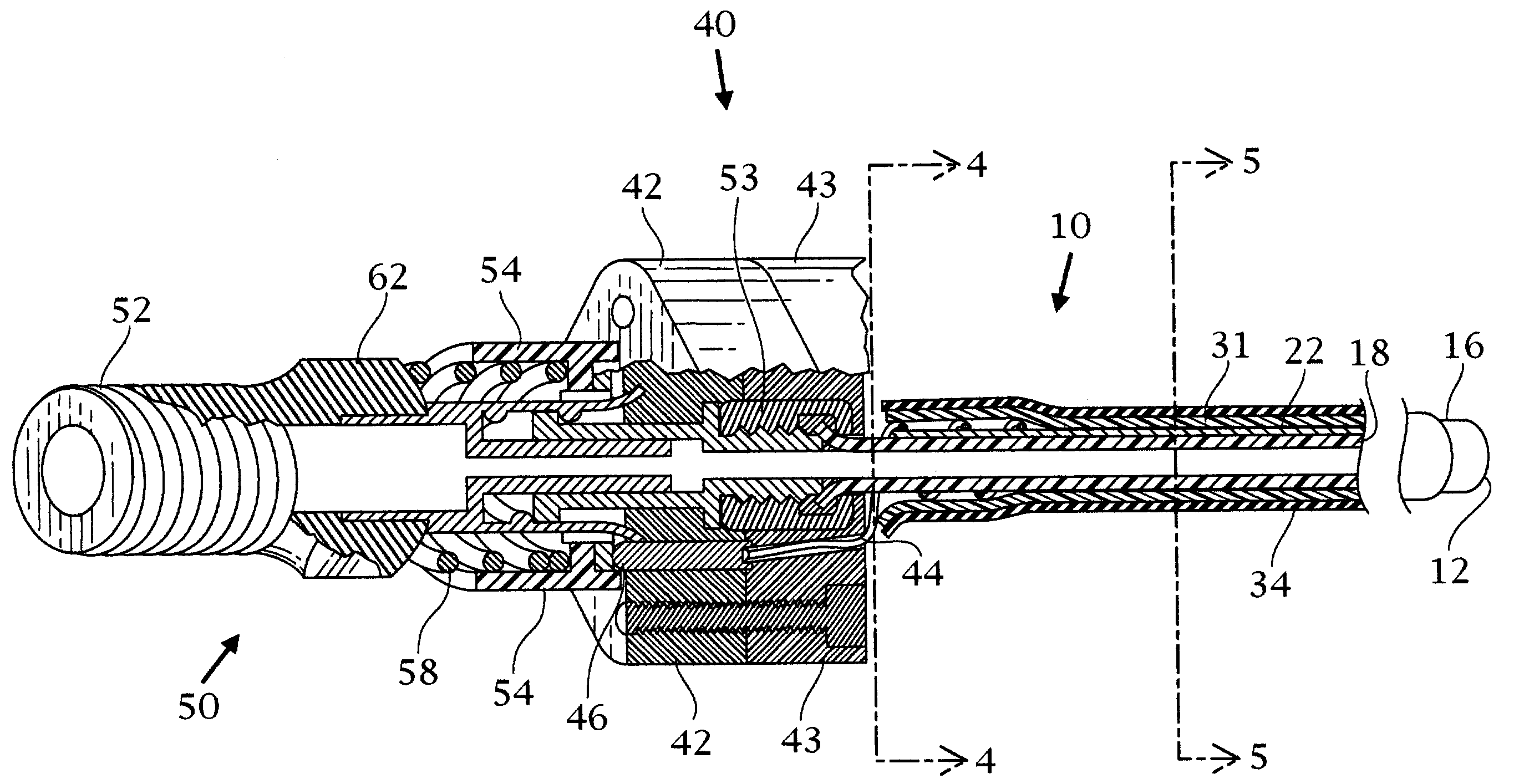

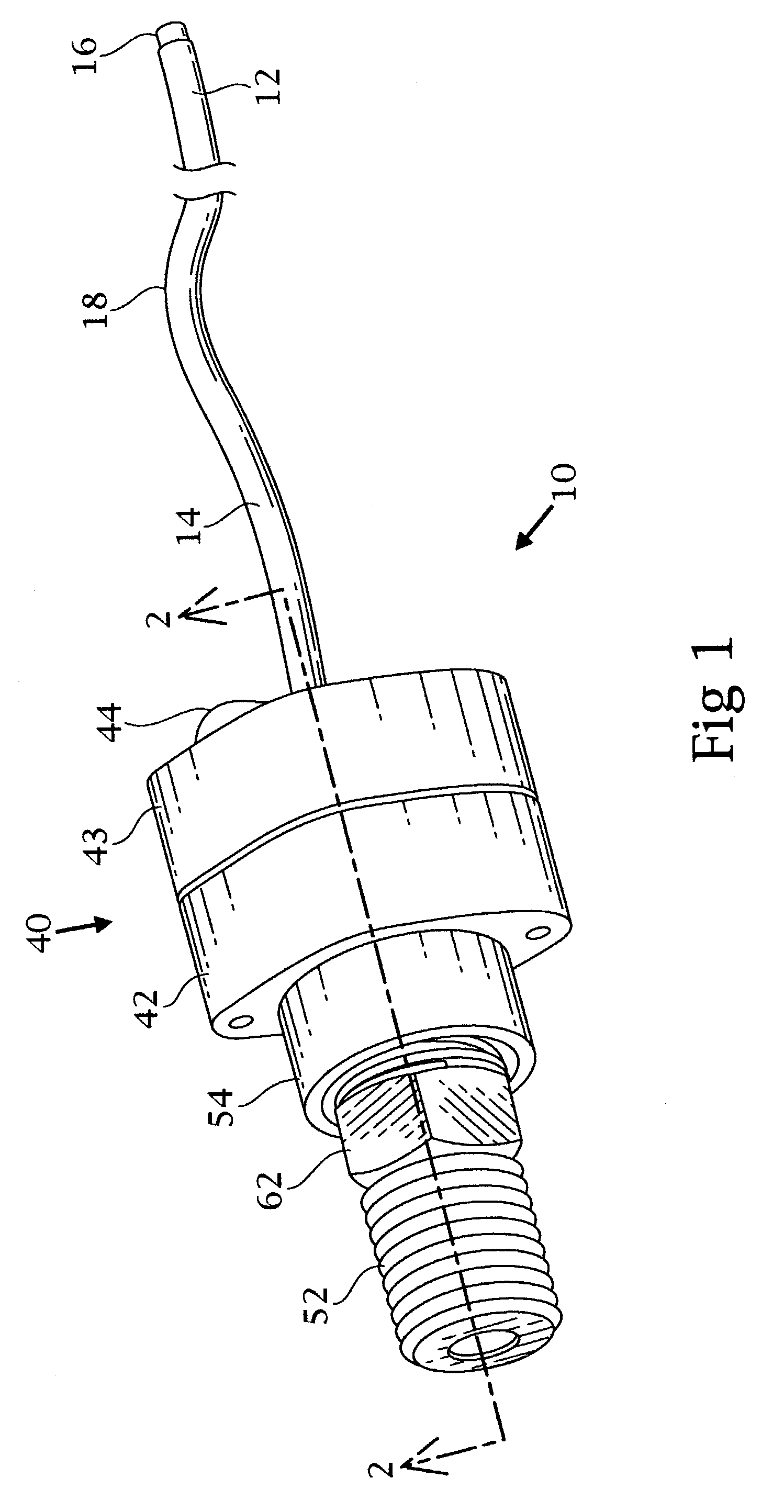

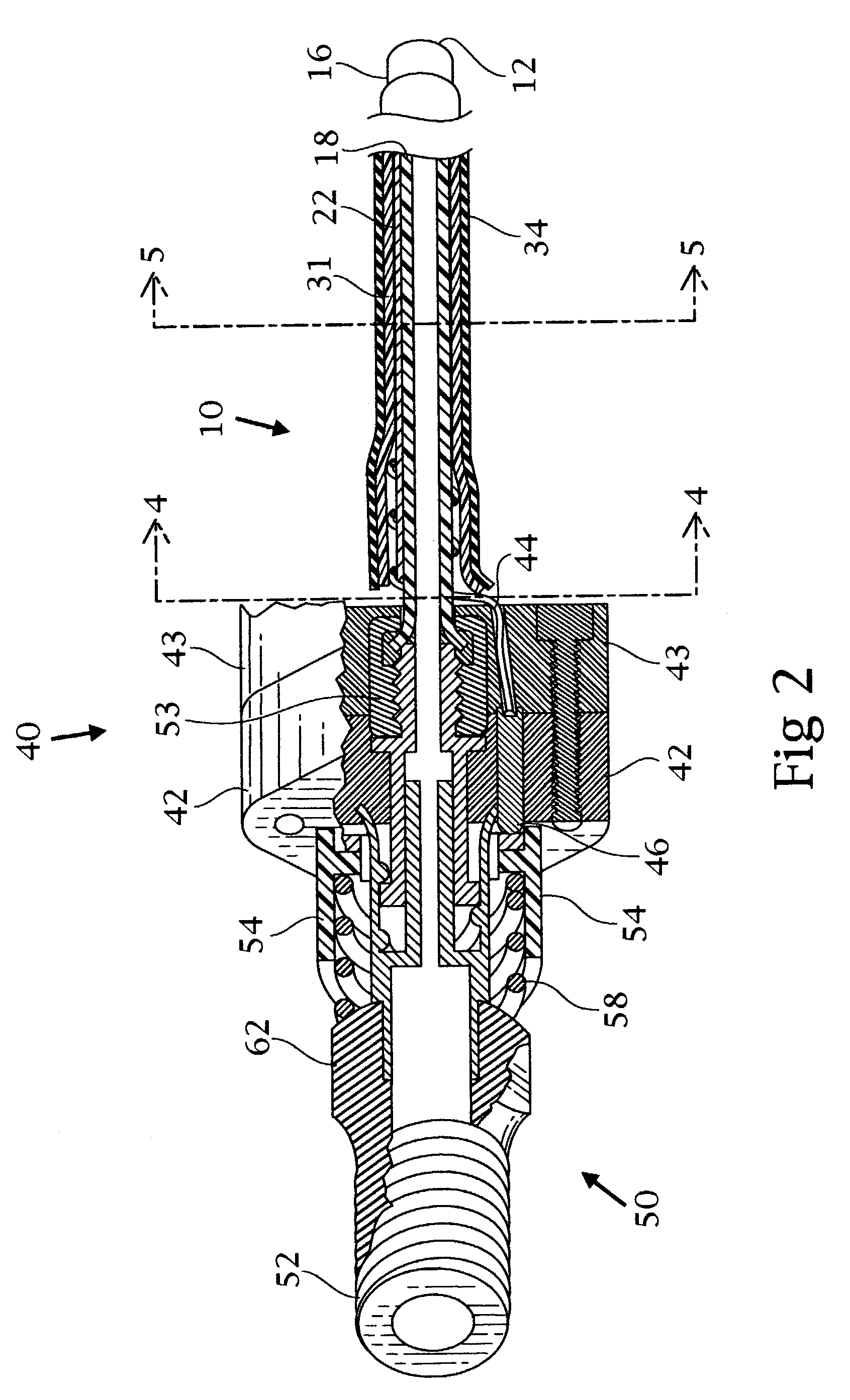

Connector having a conductively coated member and method of use thereof

ActiveUS20110230091A1Improve reliabilityEasy to GrindContact member manufacturingElectrically conductive connectionsEnvironmental noiseCoaxial cable

A connector having a conductively coated member is provided, wherein the connector comprises a connector body capable of sealing and securing a coaxial cable, and further wherein the conductively coated member, such as an O-ring, physically seals the connector, electrically couples the connector and the coaxial cable, facilitates grounding through the connector, and renders an electromagnetic shield preventing ingress of unwanted environmental noise.

Owner:PPC BROADBAND INC

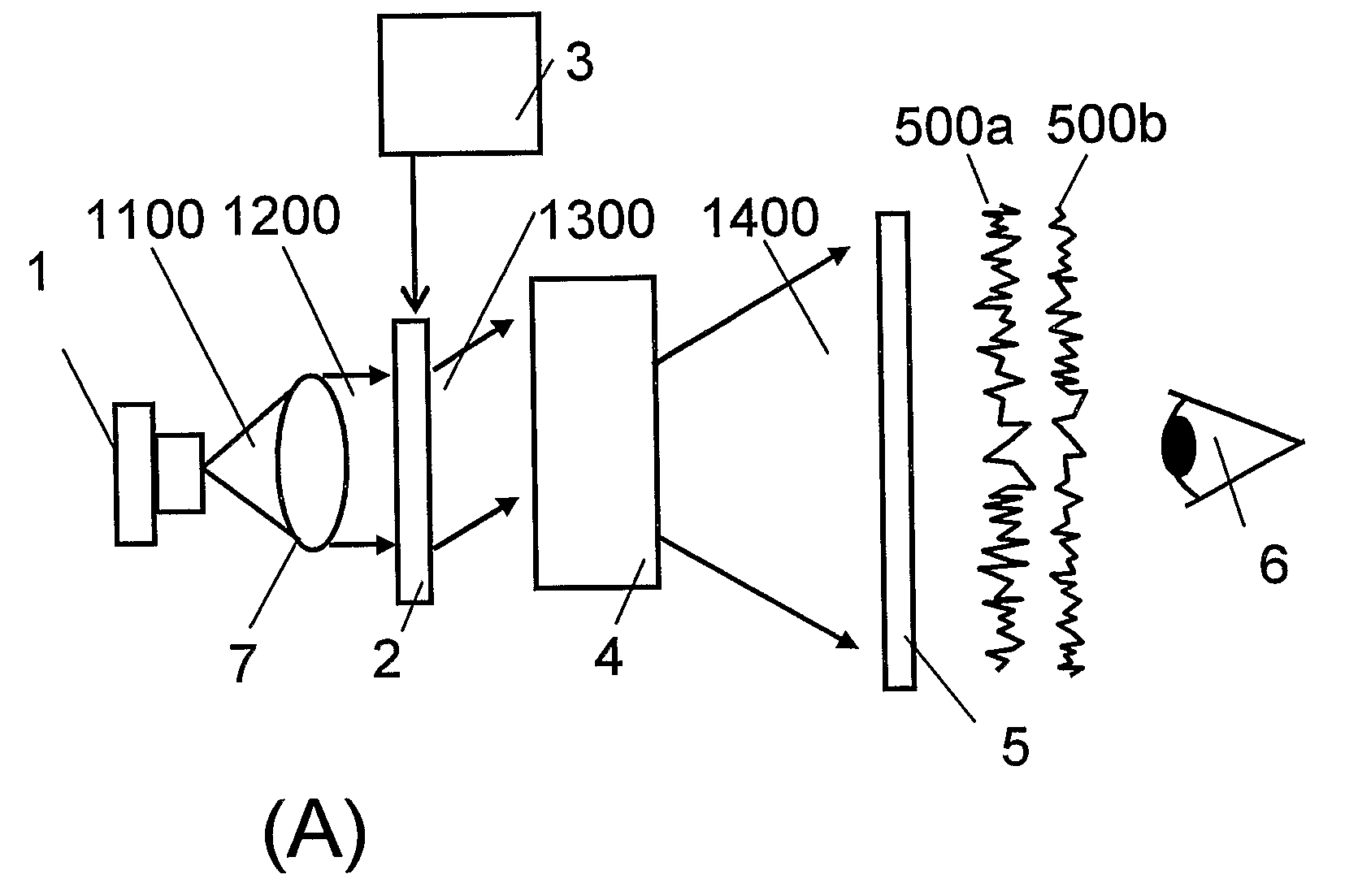

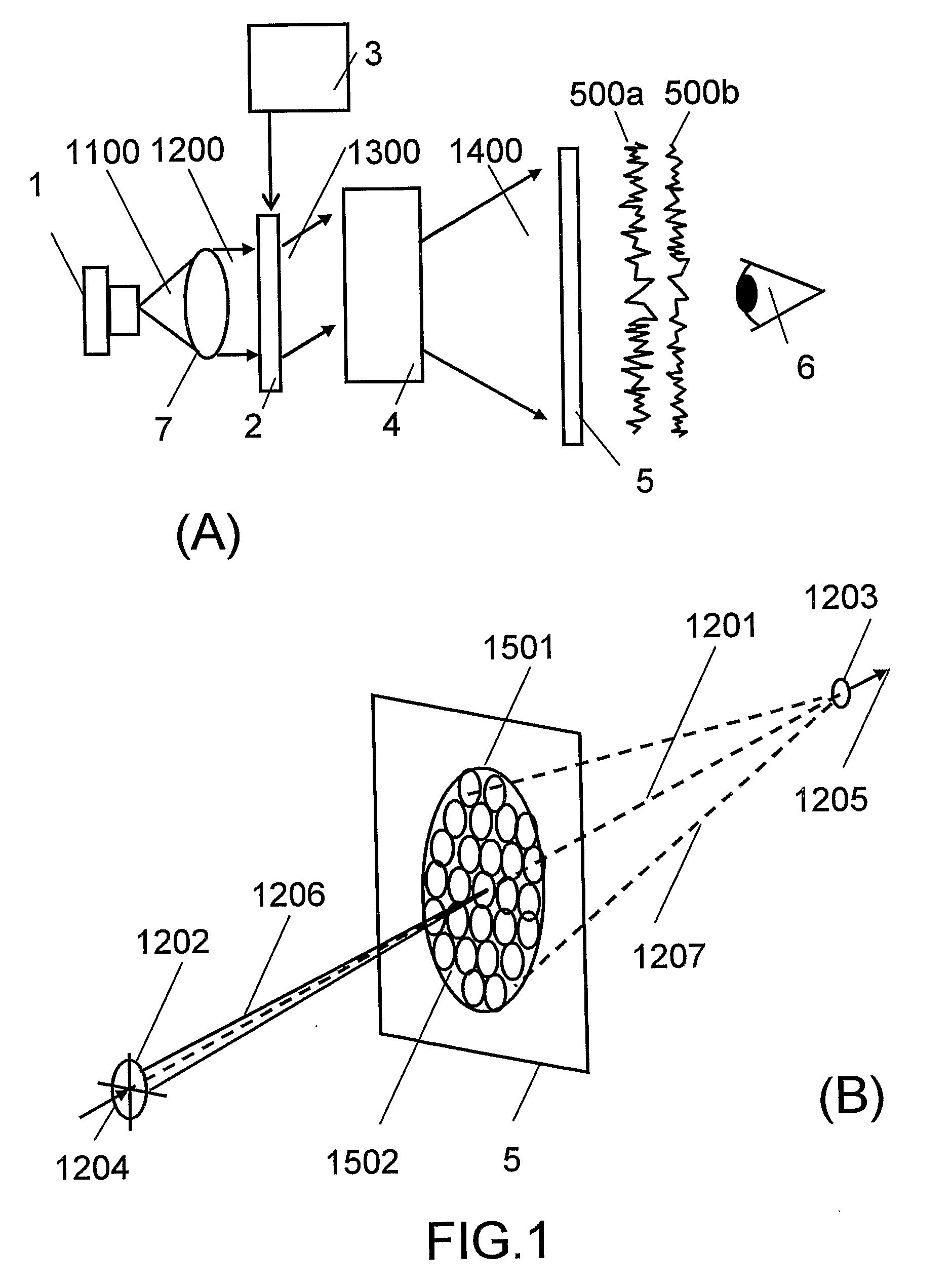

Laser illumination device

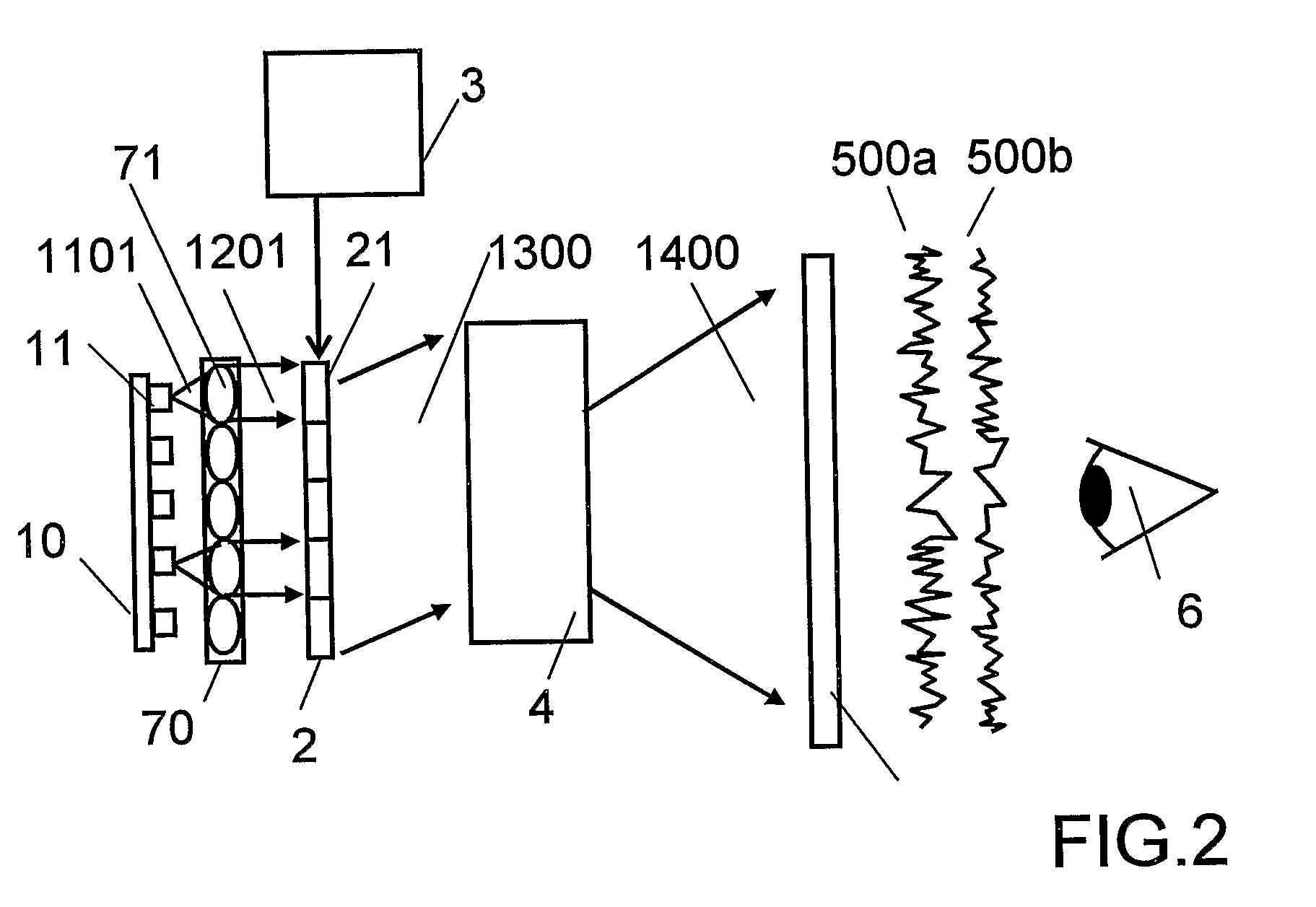

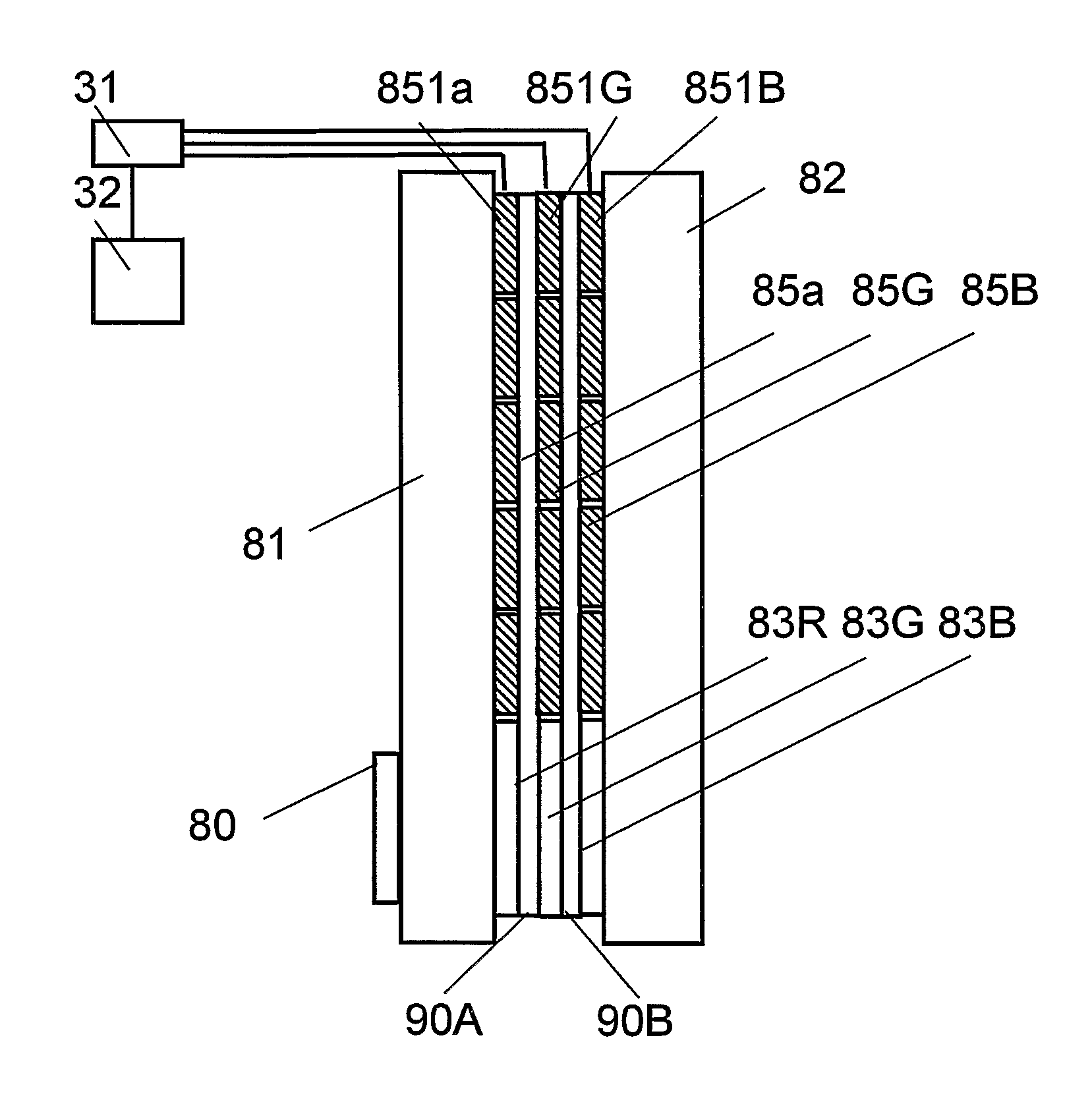

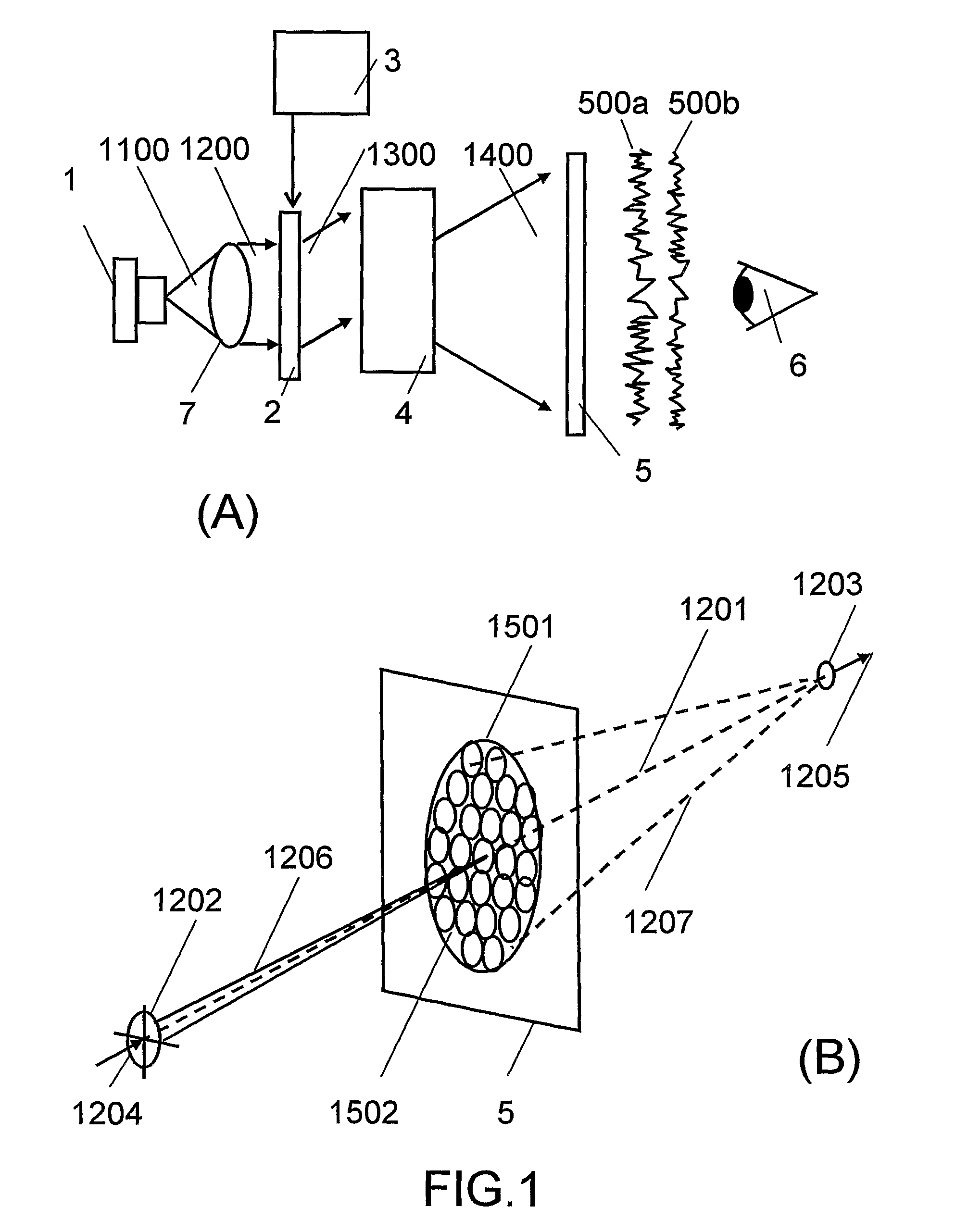

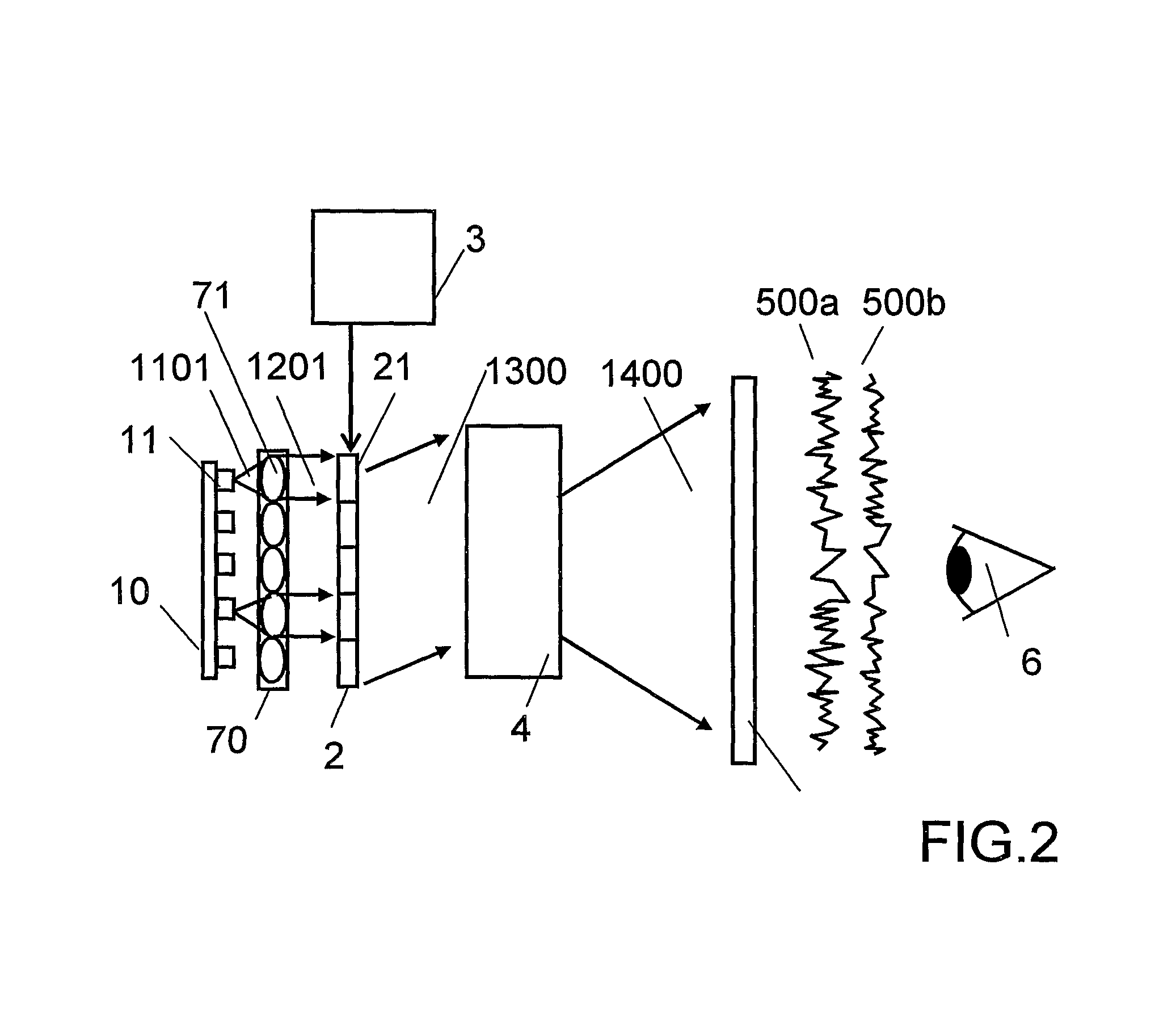

ActiveUS20100202725A1Overcome problemsProjectorsPlanar/plate-like light guidesGratingConductive coating

An Electrically Switchable Bragg Grating (ESBG) despeckler device comprising at least one ESBG element recorded in a hPDLC sandwiched between transparent substrates to which transparent conductive coatings have been applied. At least one of said coatings is patterned to provide a two-dimensional array of independently switchable ESBG pixels. Each ESBG pixel has a first unique speckle state under said first applied voltage and a second unique speckle state under said second applied voltage.

Owner:DIGILENS

Solar cell assembly

InactiveUS20050211291A1PV power plantsSemiconductor/solid-state device manufacturingConductive coatingGallium alloy

A multi-junction solar cell assembly includes a transparent substrate and a transparent conductive coating formed on the transparent substrate. The transparent conductive coating includes gallium nitride. The solar cell assembly also includes a plurality of gallium indium nitride junction layers formed successively on the transparent conductive coating, and a metallization layer formed on the plurality of gallium indium nitride junction layers.

Owner:THE BOEING CO

Laser illumination device

An Electrically Switchable Bragg Grating (ESBG) despeckler device comprising at least one ESBG element recorded in a hPDLC sandwiched between transparent substrates to which transparent conductive coatings have been applied. At least one of said coatings is patterned to provide a two-dimensional array of independently switchable ESBG pixels. Each ESBG pixel has a first unique speckle state under said first applied voltage and a second unique speckle state under said second applied voltage.

Owner:DIGILENS

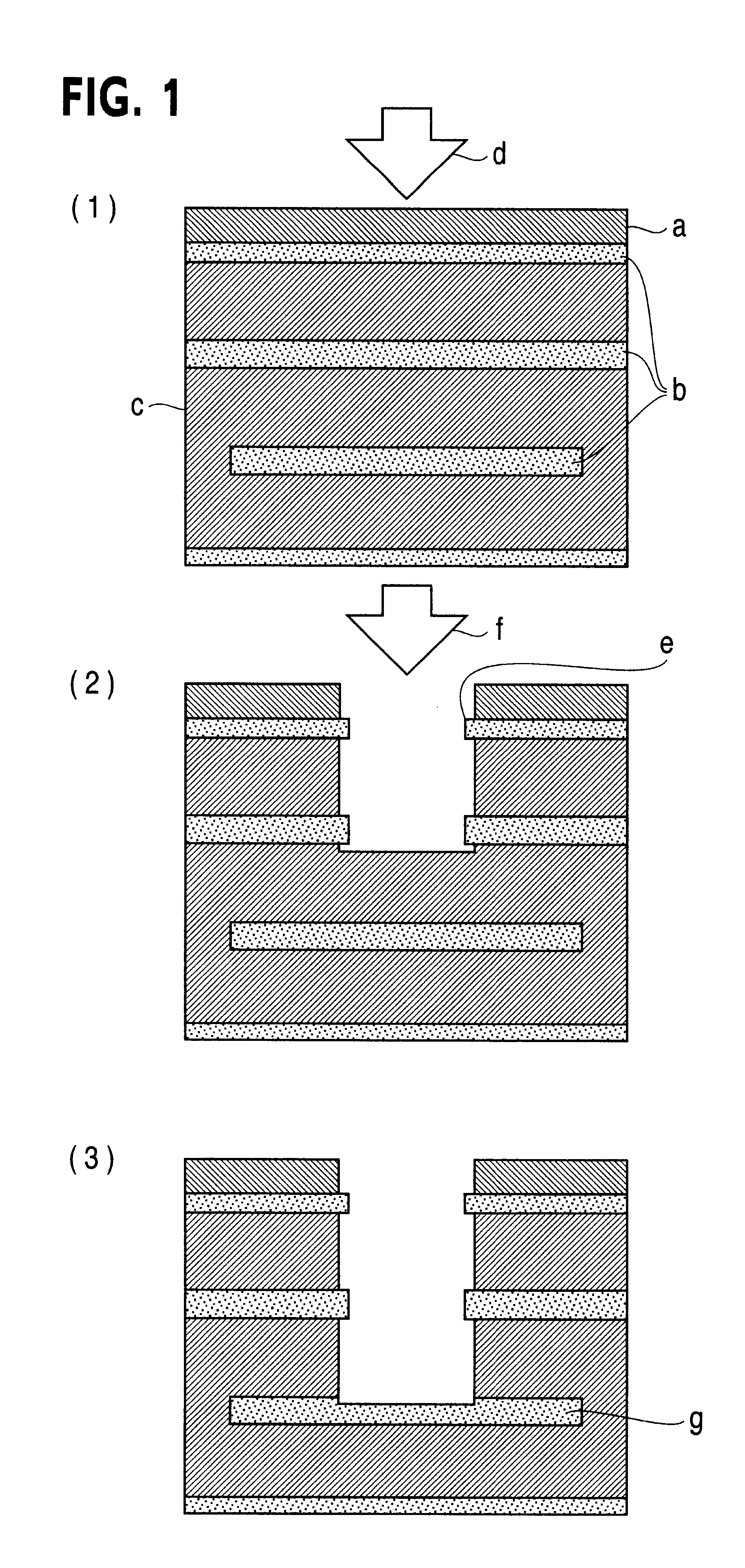

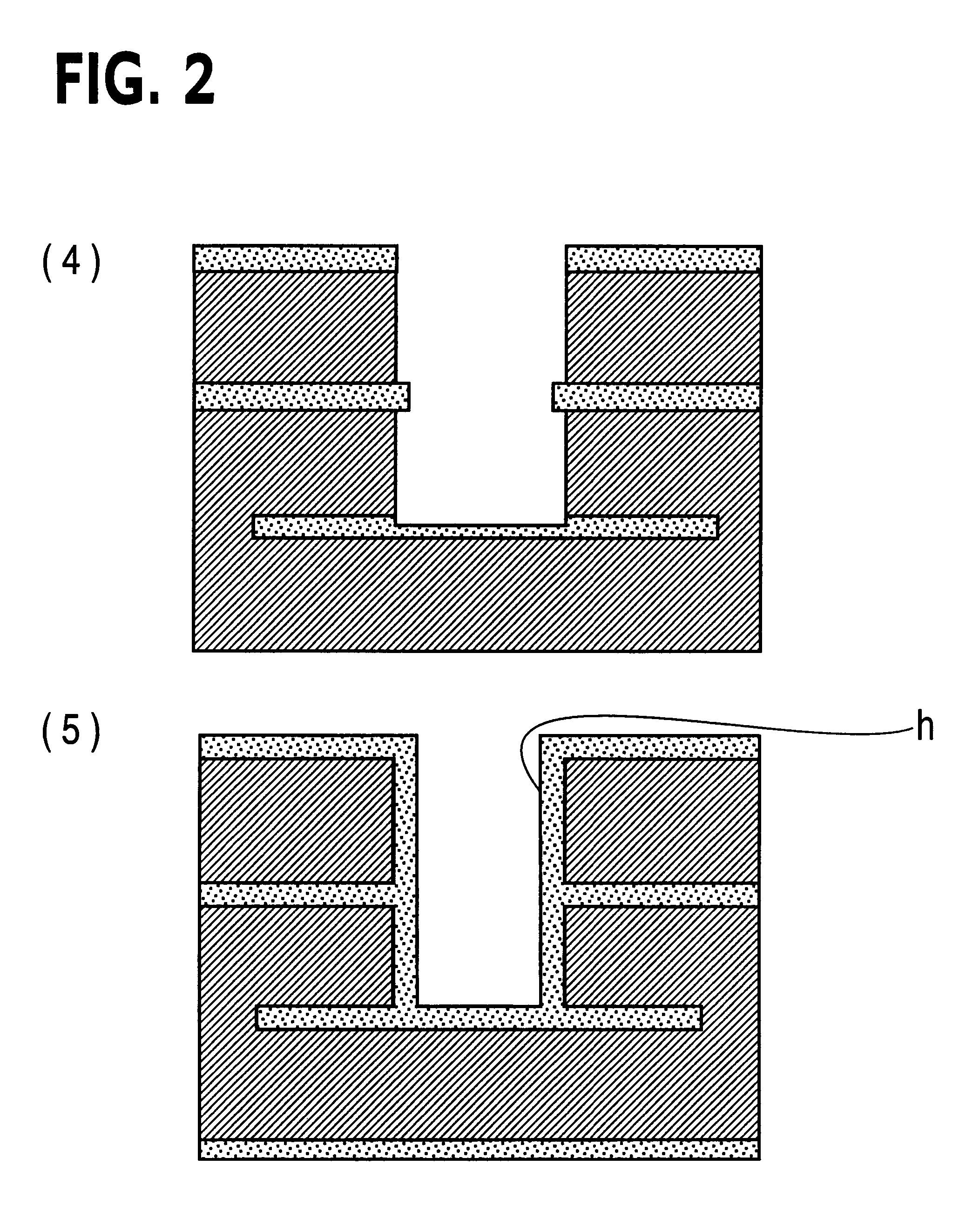

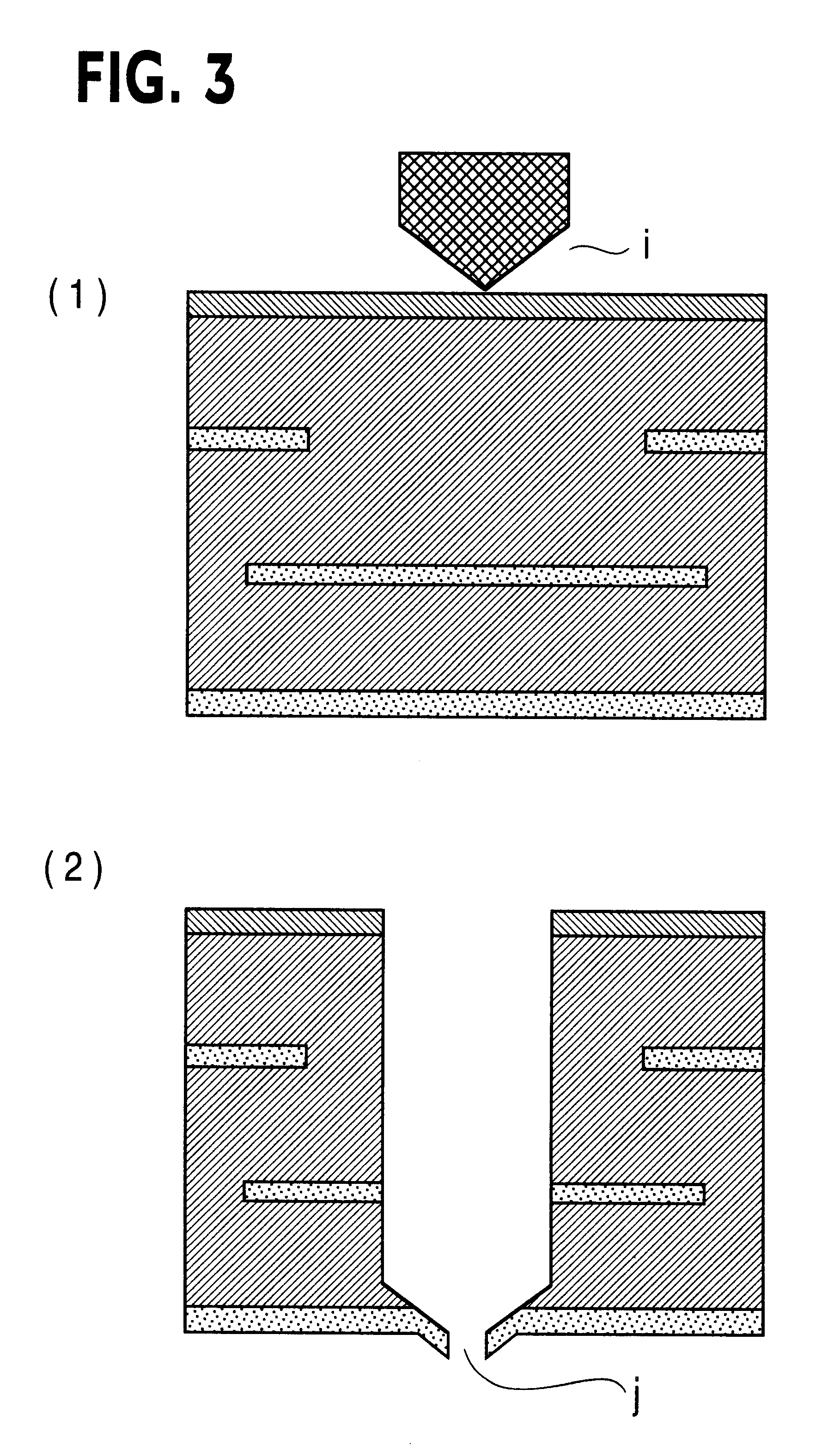

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

Articles with dispersed conductive coatings

InactiveUS20060257638A1Improve conductivityHigh transparencyNon-conductive material with dispersed conductive materialNon-woven fabricsConductive coatingCarbon nanotube

A conductive article includes a substrate made of a thermoplastic resin, and a transparent and conductive layer comprising carbon nanotubes and formed on at least one face of the substrate. The carbon nanotubes are electrical in contact with each other and dispersed so that each of the carbon nanotubes is separated form other carbon nanotubes, or that each of bundles of the carbon nanotubes is separated from other bundles.

Owner:EIKOS

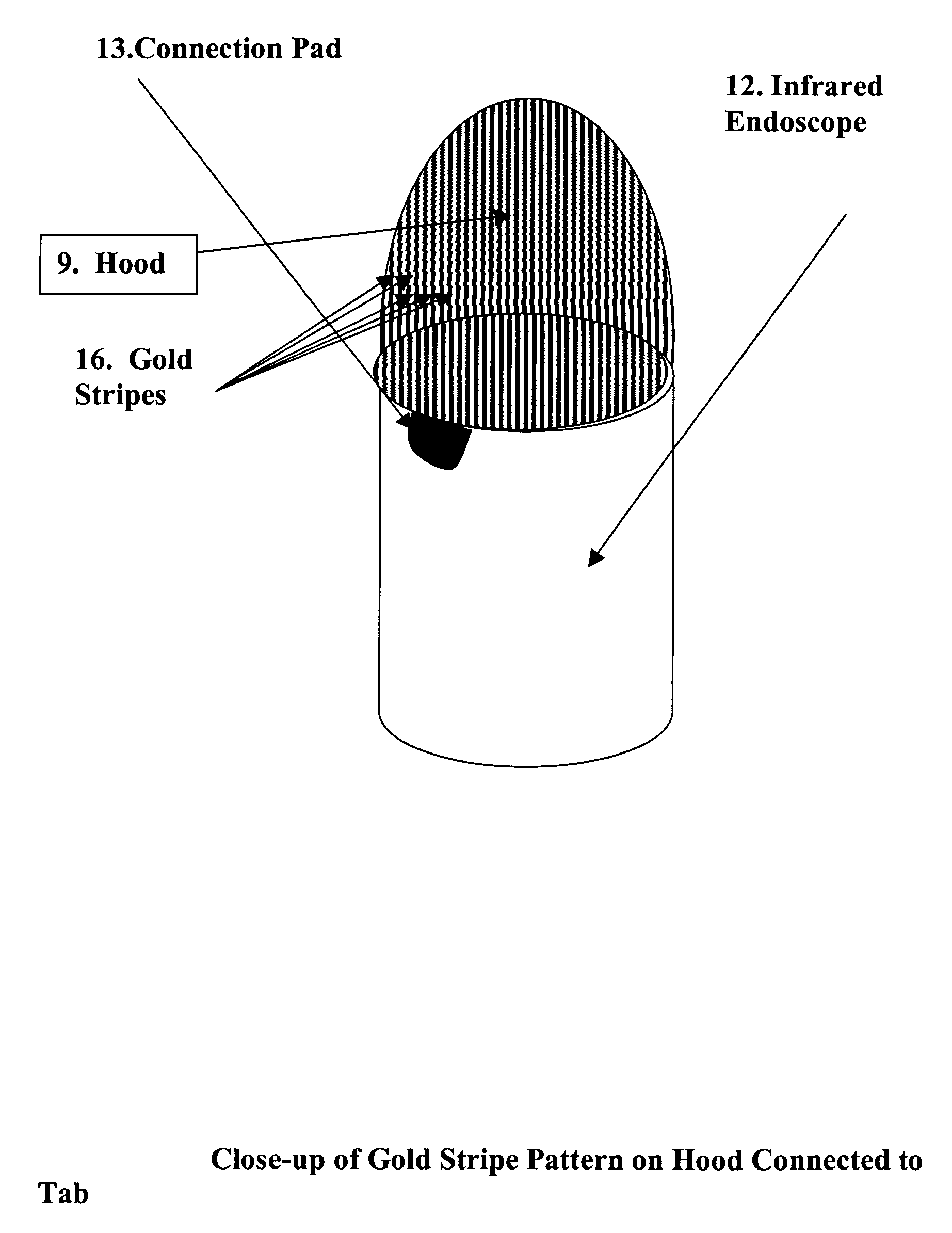

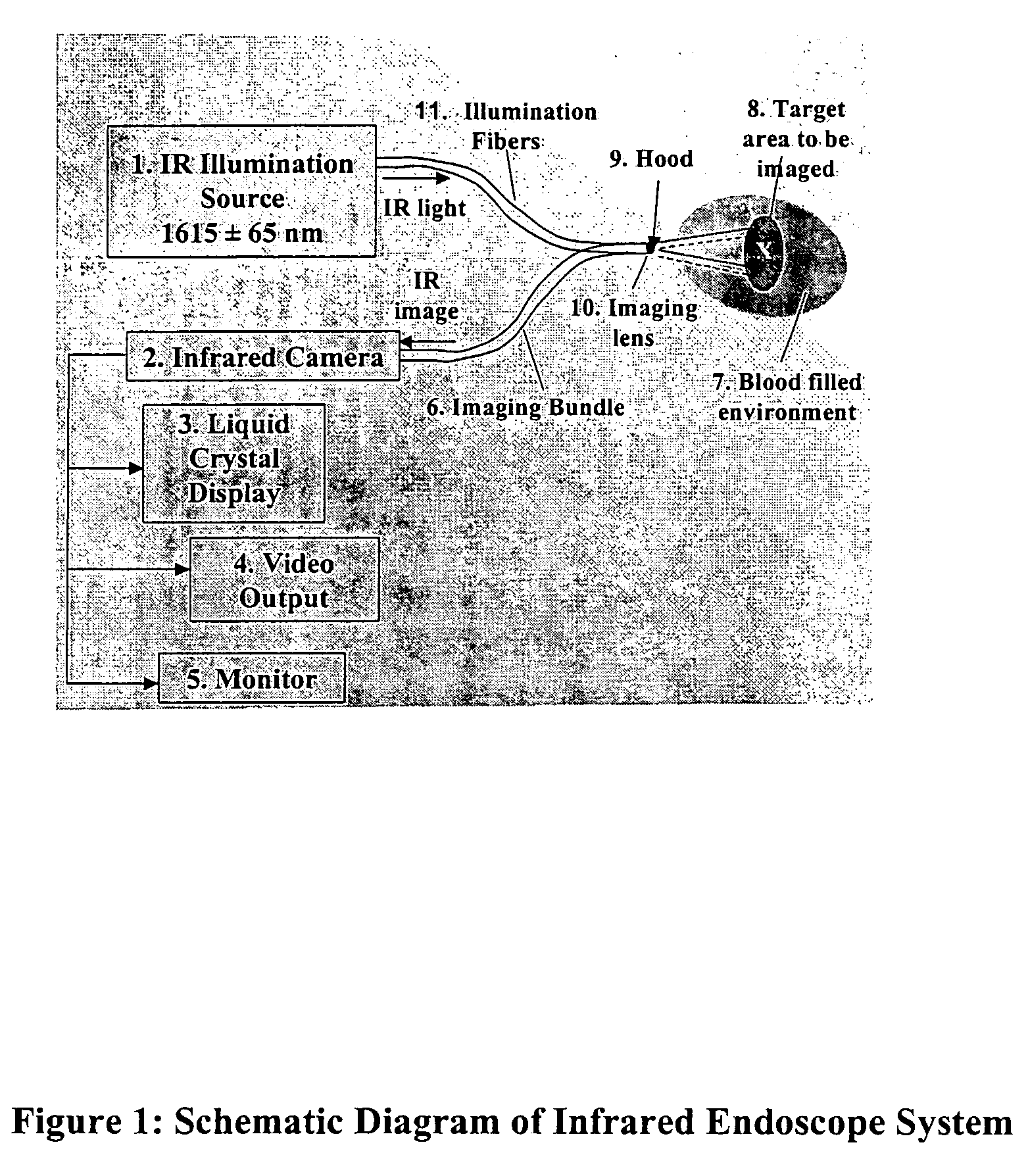

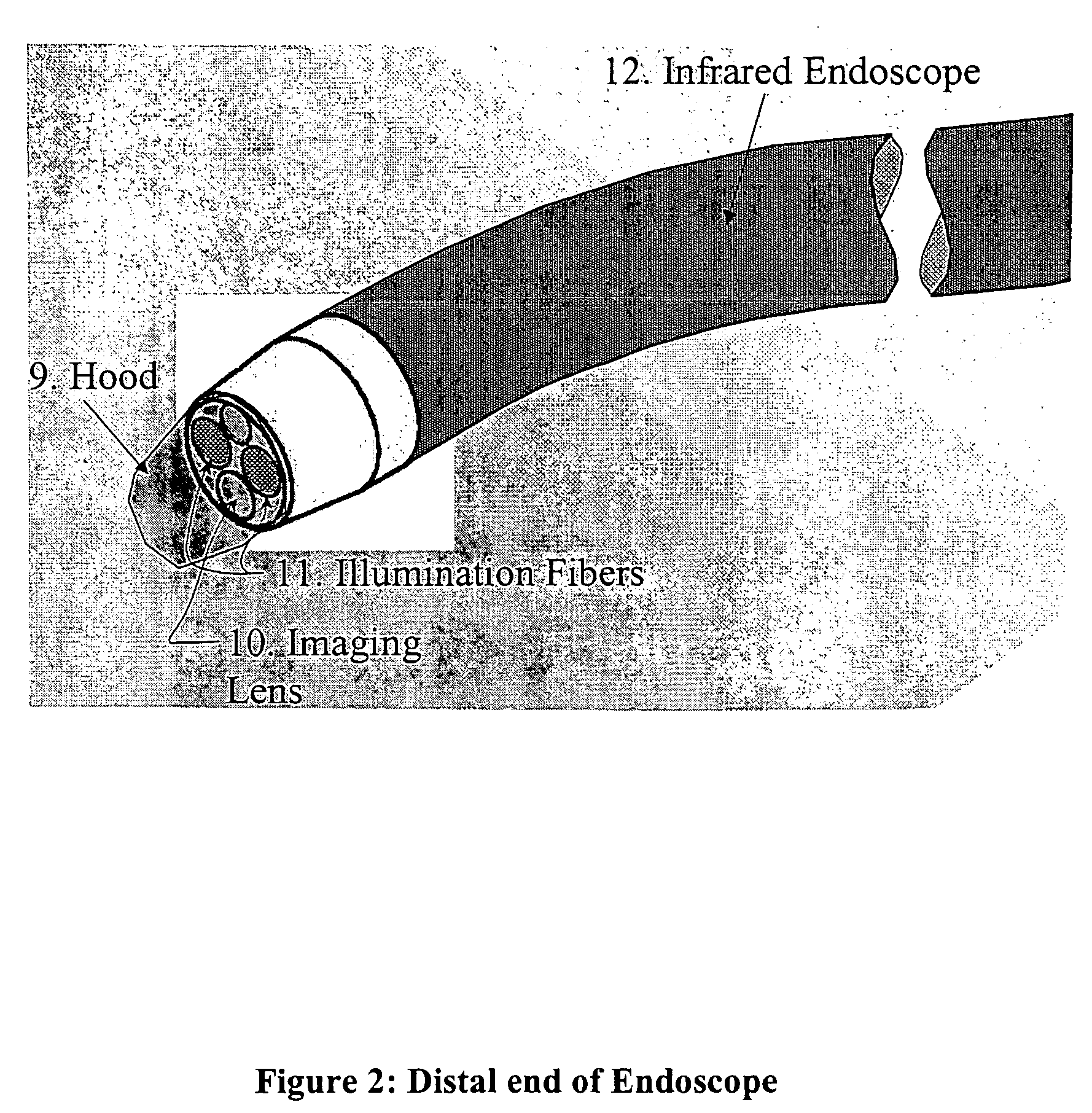

Transparent electrode for the radiofrequency ablation of tissue

ActiveUS7527625B2Efficient use ofNo ionizing radiationSurgical instrument detailsCoatingsPlatinumIntracardiac echocardiography

A novel transparent electrode that uses a conductive coating to allow delivery of current to the heart as well as outward imaging through the electrode is described. The embodiments disclose a catheter incorporating an endoscope, whose imaging tip is coated with a conductive coating that is transparent in the endoscopic image. However, a transparent electrode may be fashioned for any imaging modality, such as intracardiac echocardiography (ICE), that finds the electrode to be transparent to the energy used. This electrode coating may be a thin, optically transparent or translucent coating of platinum or gold or may be a pattern with enough open spaces to see the underlying tissue, such as looking through a screen. A wire is connected to the conductive coating and routed to a radiofrequency generator.

Owner:OLYMPUS CORP

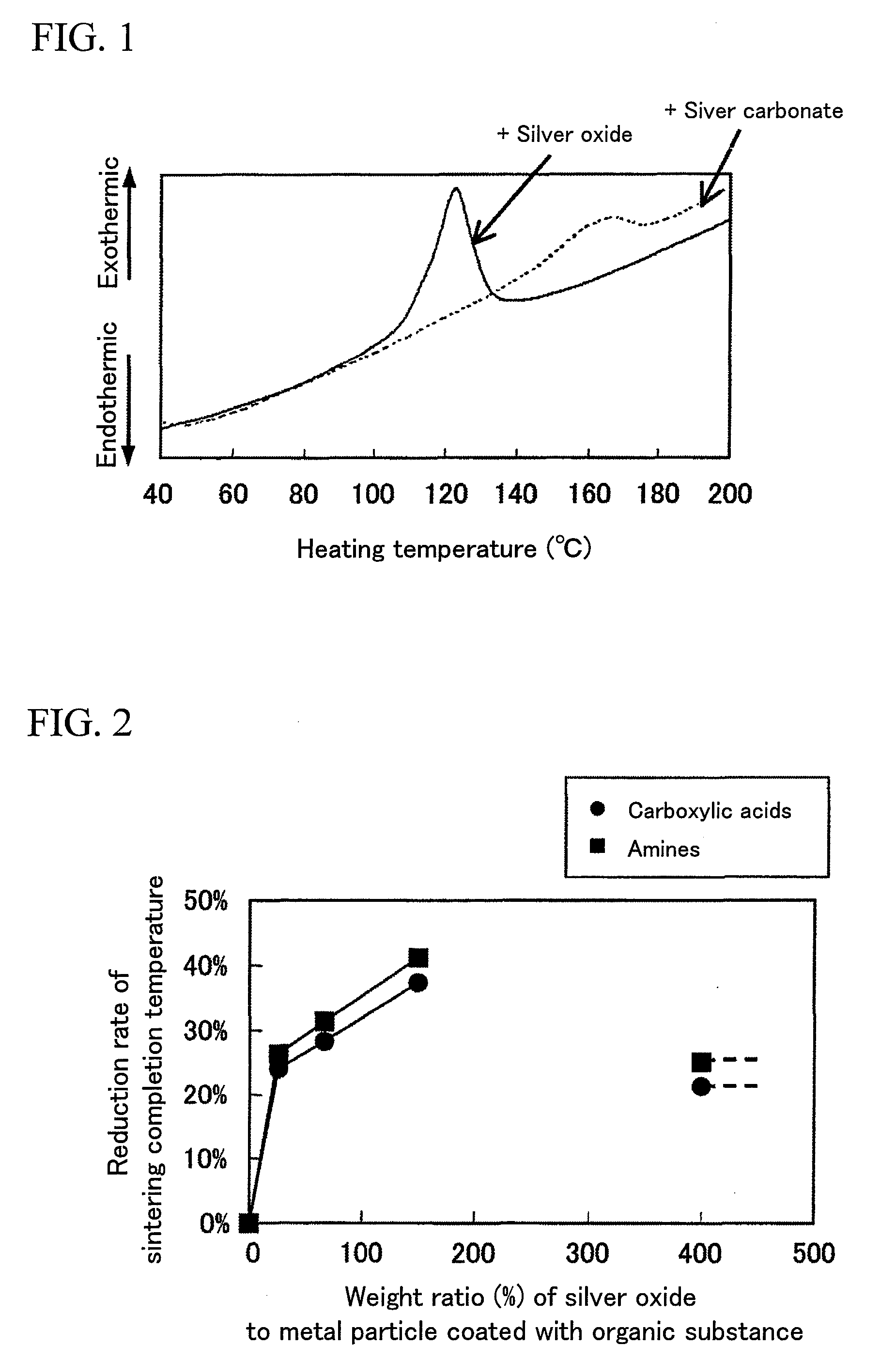

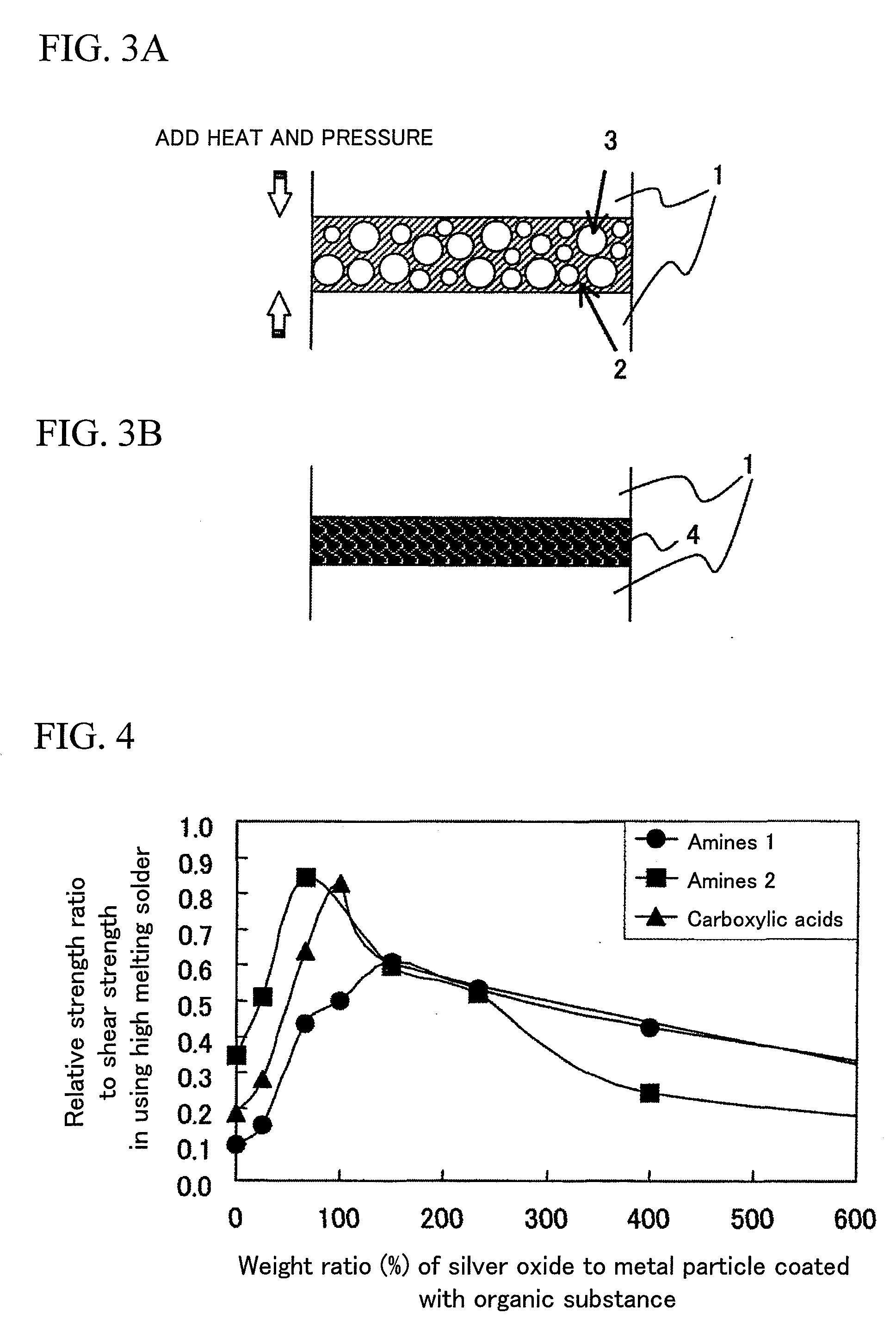

Conductive sintered layer forming composition and conductive coating film forming method and bonding method using the same

InactiveUS20080160183A1Low heating temperatureShorten heating timeSemiconductor/solid-state device detailsConductive materialHeating timeConductive coating

There is provided a conductive sintered layer forming composition and a conductive sintered layer forming method that can lower heating temperature and shorten heating time for a process of accelerating sintering or bonding by sintering of metal nano-particles coated with an organic substance. The conductive sintered layer forming composition may be obtained by utilizing a phenomenon that particles may be sintered at low temperature by mixing silver oxide with metal particles coated with the organic substance and having a grain size of 1 nm to 5 μm as compared to sintering each simple substance. The conductive sintered layer forming composition of the invention is characterized in that it contains the metal particles whose surface is coated with the organic substance and whose grain size is 1 nm to 5 μm and the silver oxide particles.

Owner:HITACHI LTD

Weather-resistant and high thermal conductive coating, radiating solar rear panel and efficient solar cell panel

InactiveCN102516852AImprove thermal conductivityMeet service life requirementsPolyureas/polyurethane adhesivesPhotovoltaicsWeather resistanceConductive coating

The invention discloses a weather-resistant and high thermal conductive coating, a radiating solar rear panel and an efficient solar cell panel. The weather-resistant and high thermal conductive coating consists of 10 to 50 parts of weather-resistant resin, 5 to 30 parts of curing agent, 0.1 to 5 parts of organic filler, 30 to 80 parts of inorganic filler, and 30 to 100 parts of solvent. The radiating solar rear panel comprises a base layer, and the weather-resistant and high thermal conductive coating is arranged on at least one surface of the base layer or arranged between the base layers. The efficient solar cell panel comprises a solar front panel and the radiating solar rear panel, a solar cell circuit is arranged between the solar front panel and the radiating solar rear panel, and an encapsulation material is arranged on one side or two sides of the solar cell circuit. The weather-resistant and high thermal conductive coating can be directly coated on a base material and has high binding power and an excellent thermal conductive effect, and the weather resistance of the coating meets the requirement of a solar module for the service life of over 25 years.

Owner:ALLSTAE TECH ZHONGSHAN

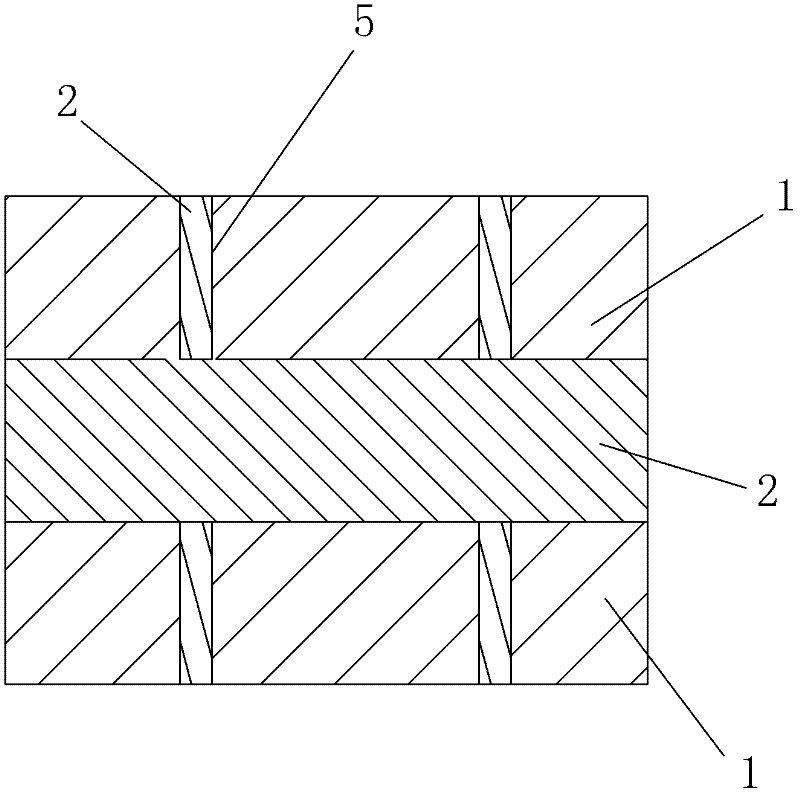

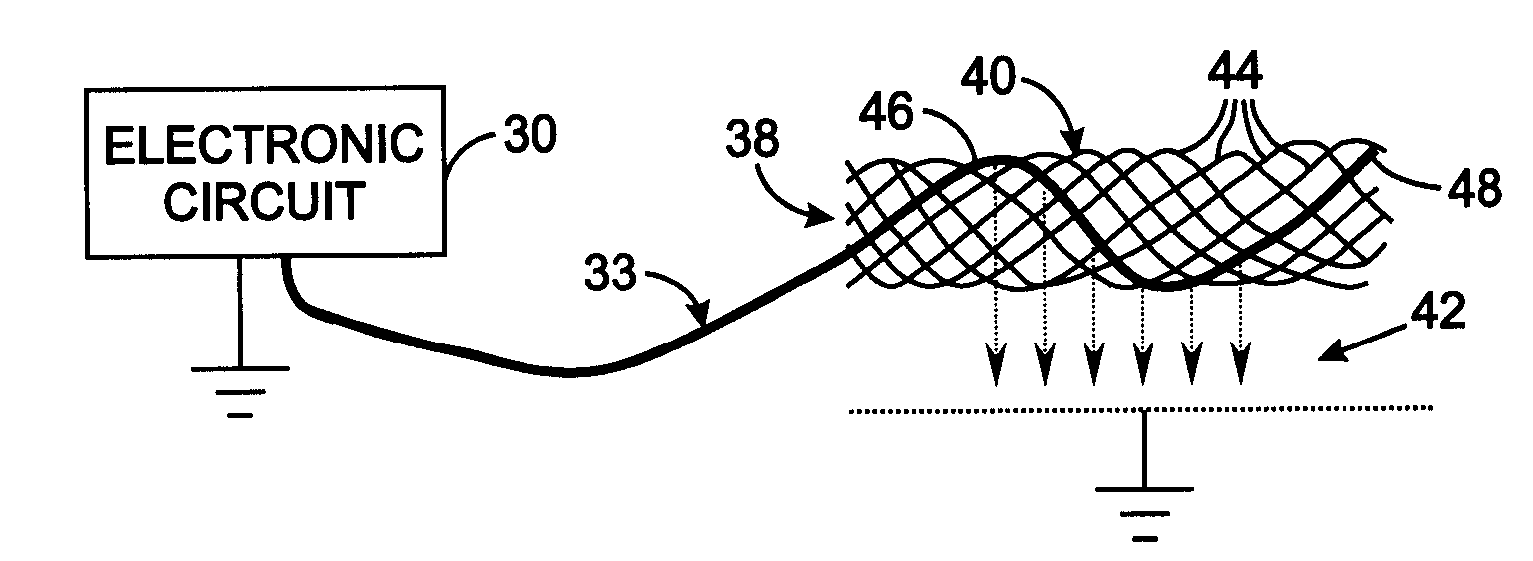

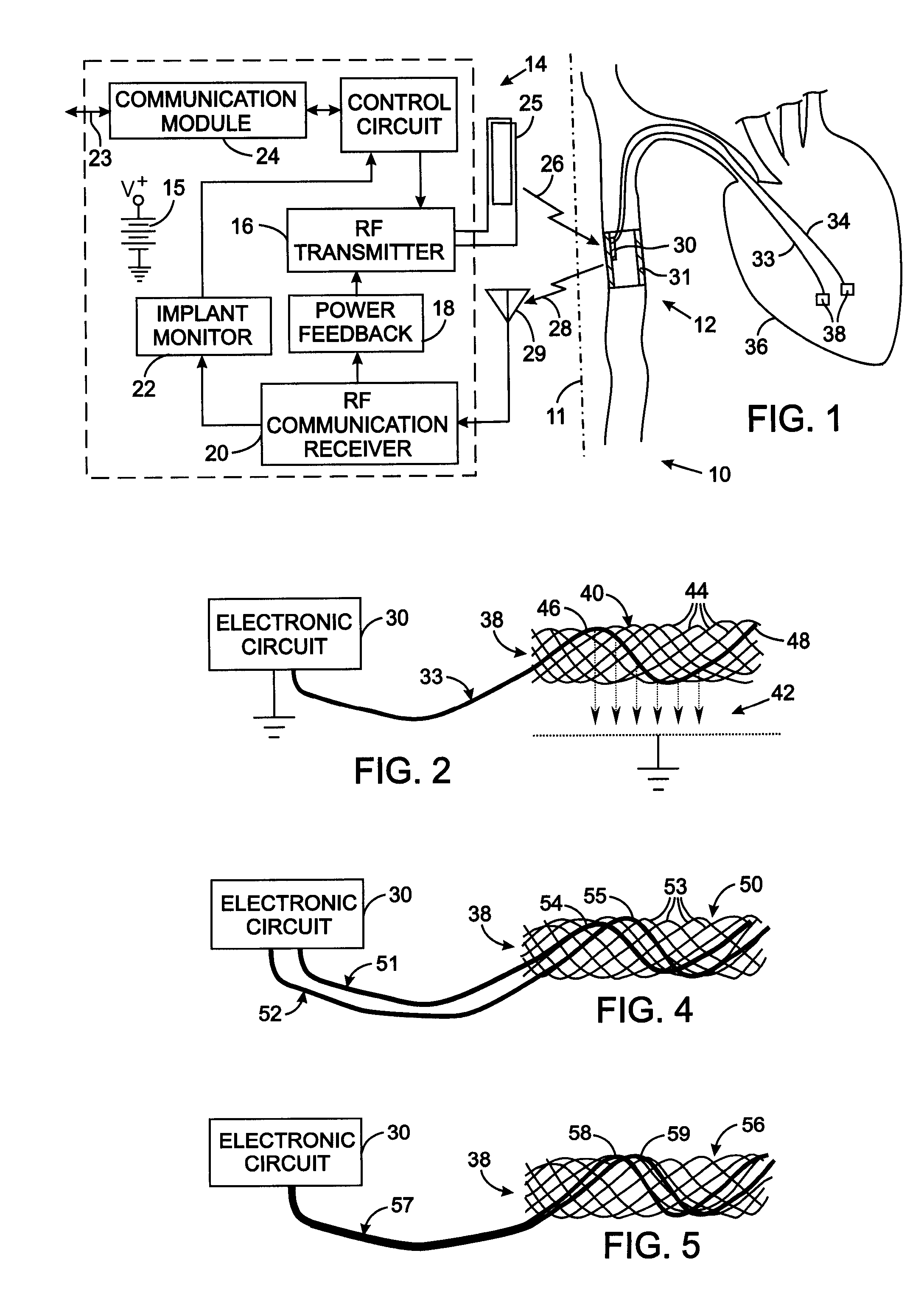

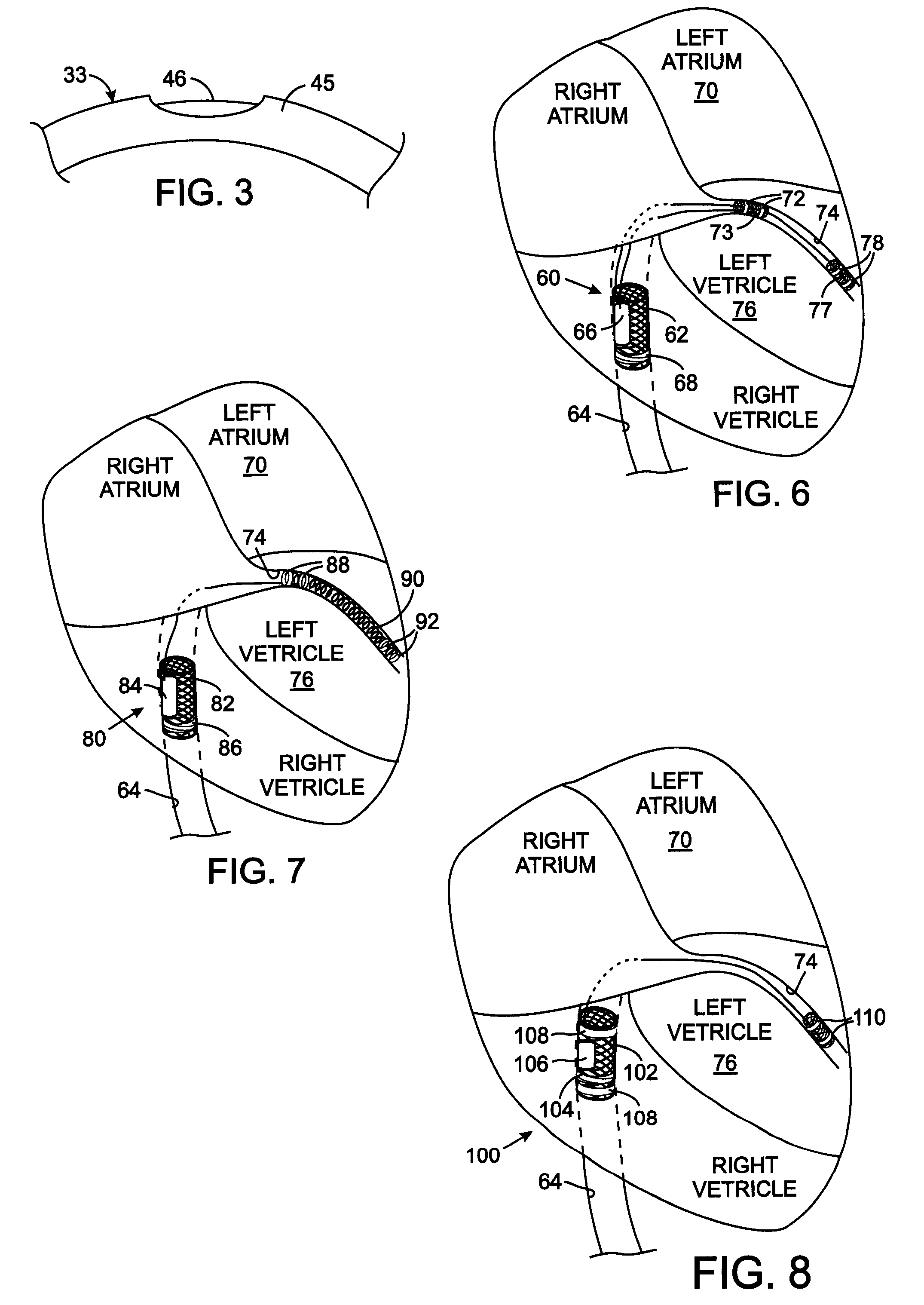

Intravascular Electronics Carrier Electrode for a Transvascular Tissue Stimulation System

An intravascular mesh type electrode carrier eliminates material and mechanical transitions between an electrical lead and an electrode by interweaving the conductor of the lead into the carrier mesh. The mesh material of the electrode carrier can be electrically conductive so that the entire carrier functions as the electrode. Alternatively, the mesh material may either be non-conductive or have an outer non-conductive coating, in which cases only the exposed section of the first conductor acts as an electrode. With a non-conductive mesh material, a second electrode lead can be woven through the mesh of the electrode carrier to provide a second electrode.

Owner:KENERGY INC

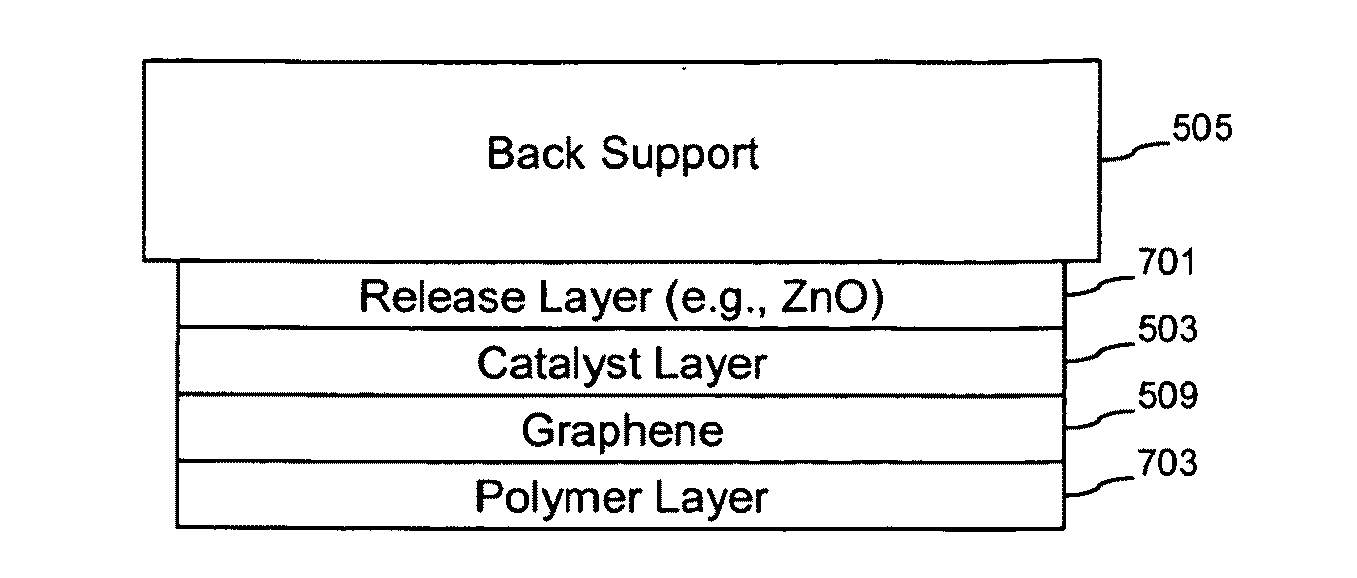

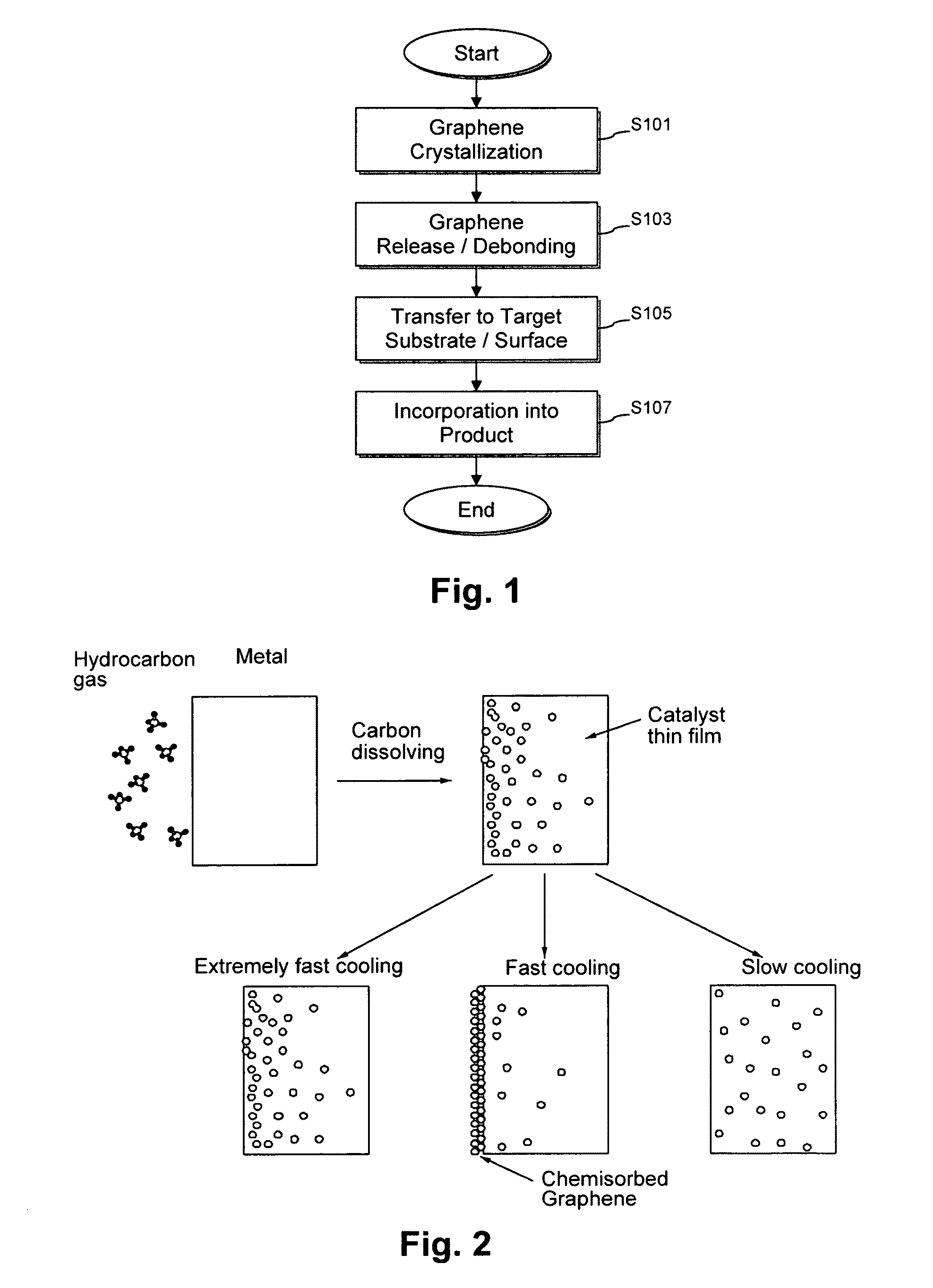

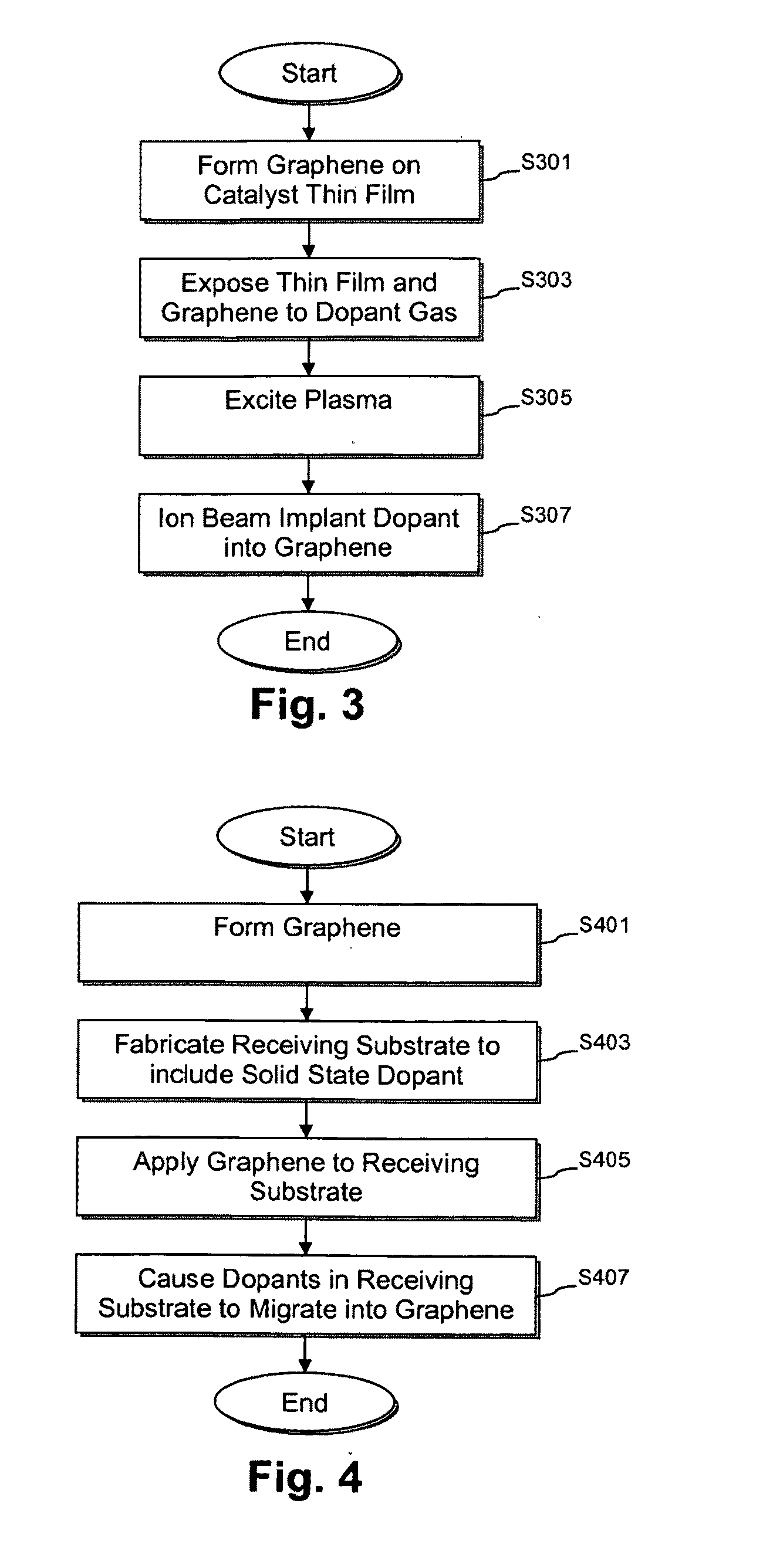

Large area deposition and doping of graphene, and products including the same

InactiveUS20110030991A1Reduced dimensionGood effectMaterial nanotechnologyNon-insulated conductorsConductive coatingTransmittance

Certain example embodiments of this invention relate to the use of graphene as a transparent conductive coating (TCC). In certain example embodiments, graphene thin films grown on large areas hetero-epitaxially, e.g., on a catalyst thin film, from a hydrocarbon gas (such as, for example, C2H2, CH4, or the like). The graphene thin films of certain example embodiments may be doped or undoped. In certain example embodiments, graphene thin films, once formed, may be lifted off of their carrier substrates and transferred to receiving substrates, e.g., for inclusion in an intermediate or final product. Graphene grown, lifted, and transferred in this way may exhibit low sheet resistances (e.g., less than 150 ohms / square and lower when doped) and high transmission values (e.g., at least in the visible and infrared spectra).

Owner:GUARDIAN GLASS LLC

Capacitive sensors in vehicular environments

Capacitive sensors used to detect force upon a transparency product for detecting and discriminating crash characteristics of a vehicle, as well as capacitive sensors used in conjunction with a conductive panel functioning as an airbag cover and ground plane for the capacitive sensors. The capacitive sensors are made up of electrodes, of which one may be a conductive coating. The capacitive sensors can be arranged upon a substrate and can include a reference sensor. Long term effects of temperature upon sensor output are compensated for with an algorithm comparing constant desired sensor output to low frequency drift due to temperature effects. Moisture upon a transparency product is distinguished from a nearby object due to the capacitance sensed. A sleep detection algorithm detects when a vehicle operator is drowsy. A capacitive sensor array having a nested circle sensor and L-shaped sensors, along with a dummy sensor is used in a sunroof-equipped vehicle for sensing occupant head position.

Owner:METHODE ELETRONICS INC

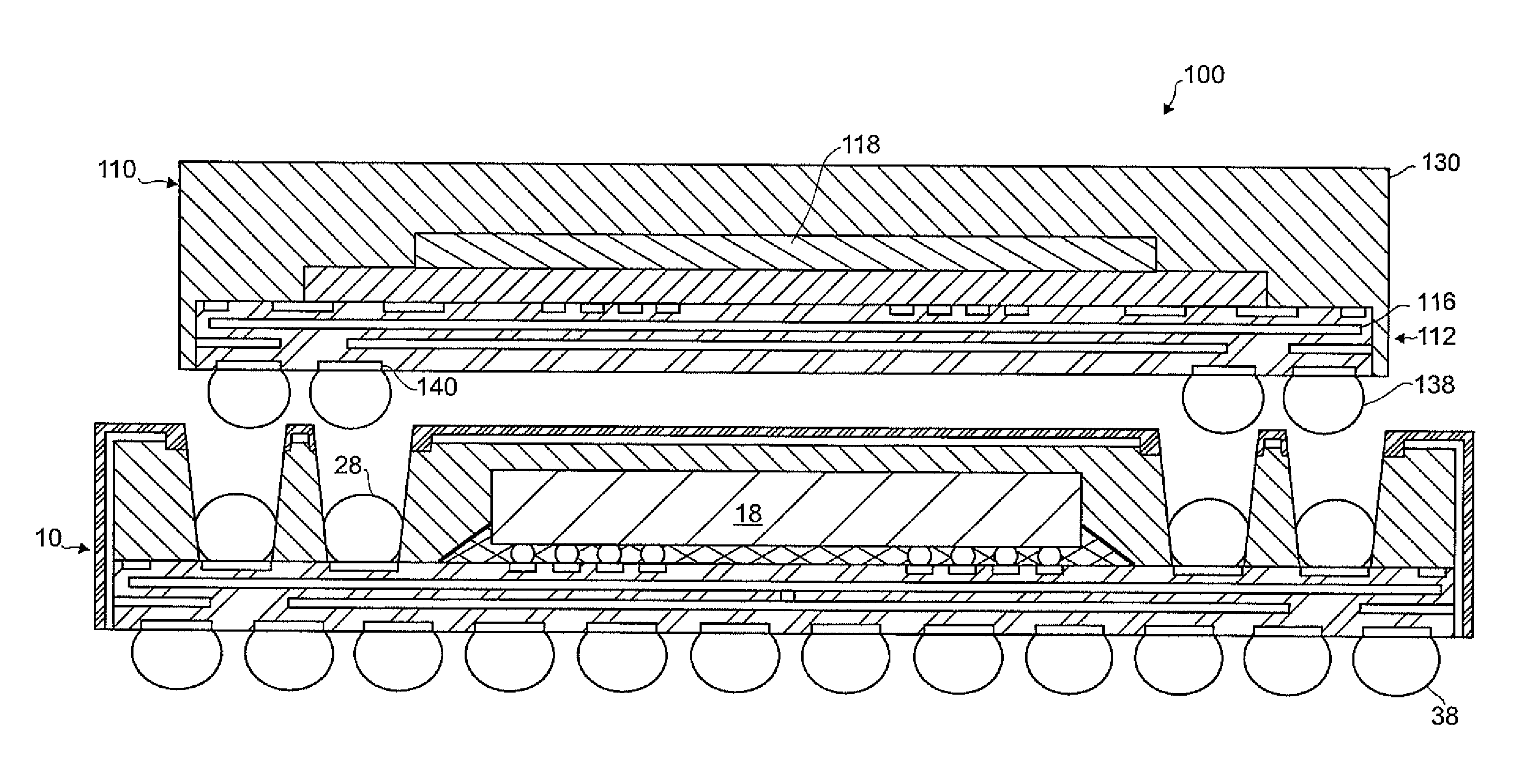

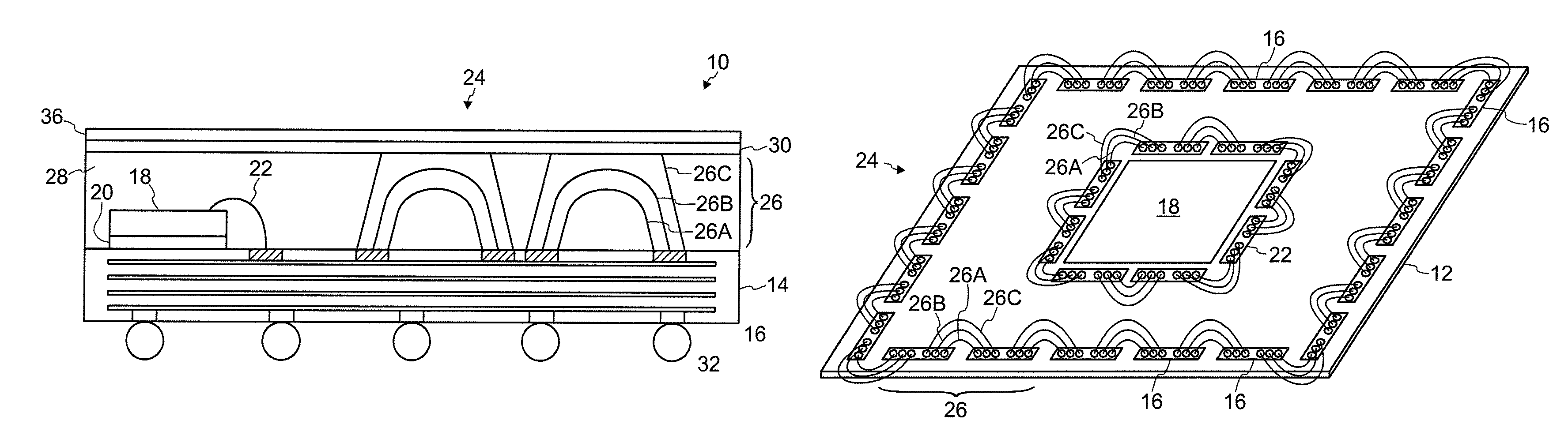

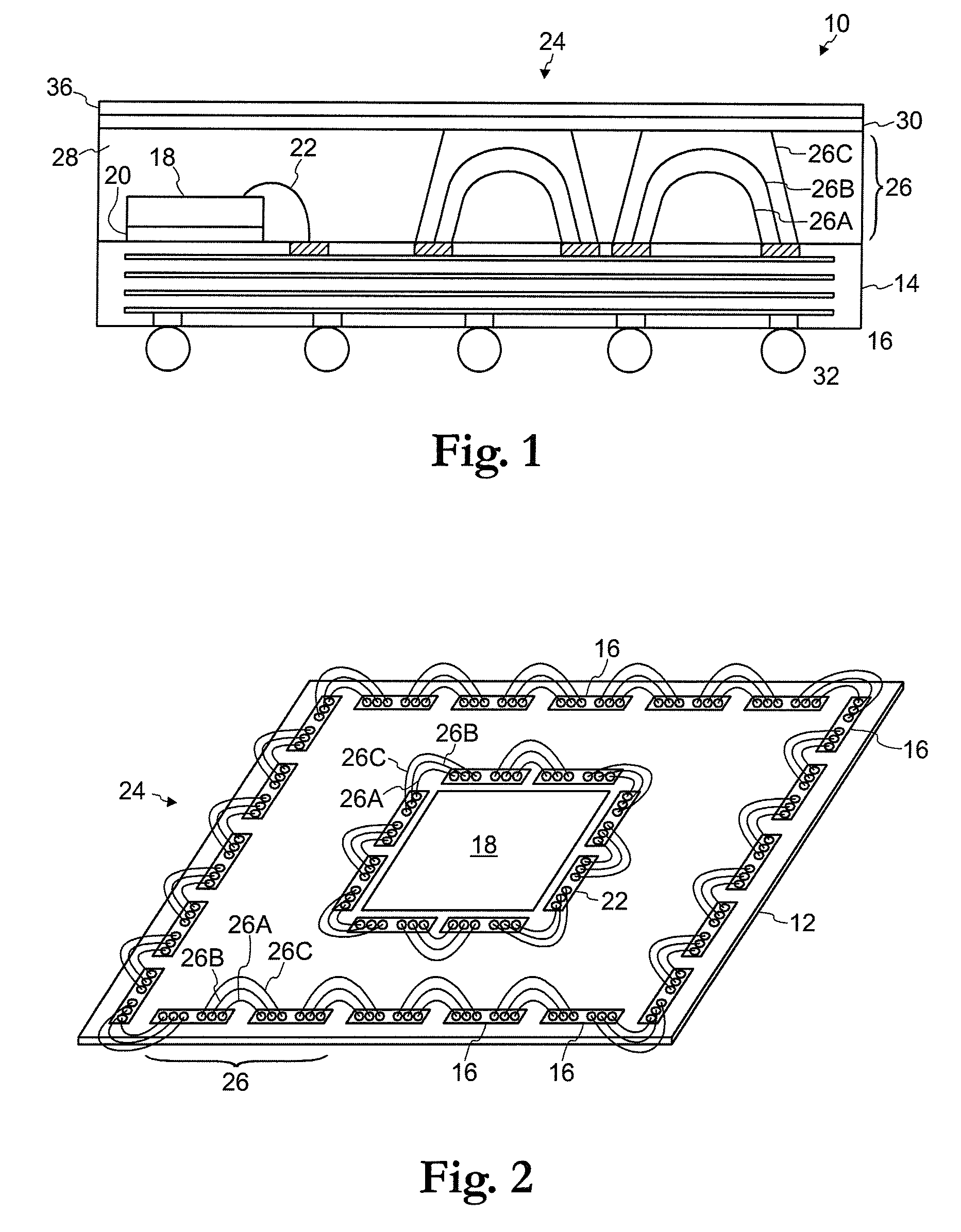

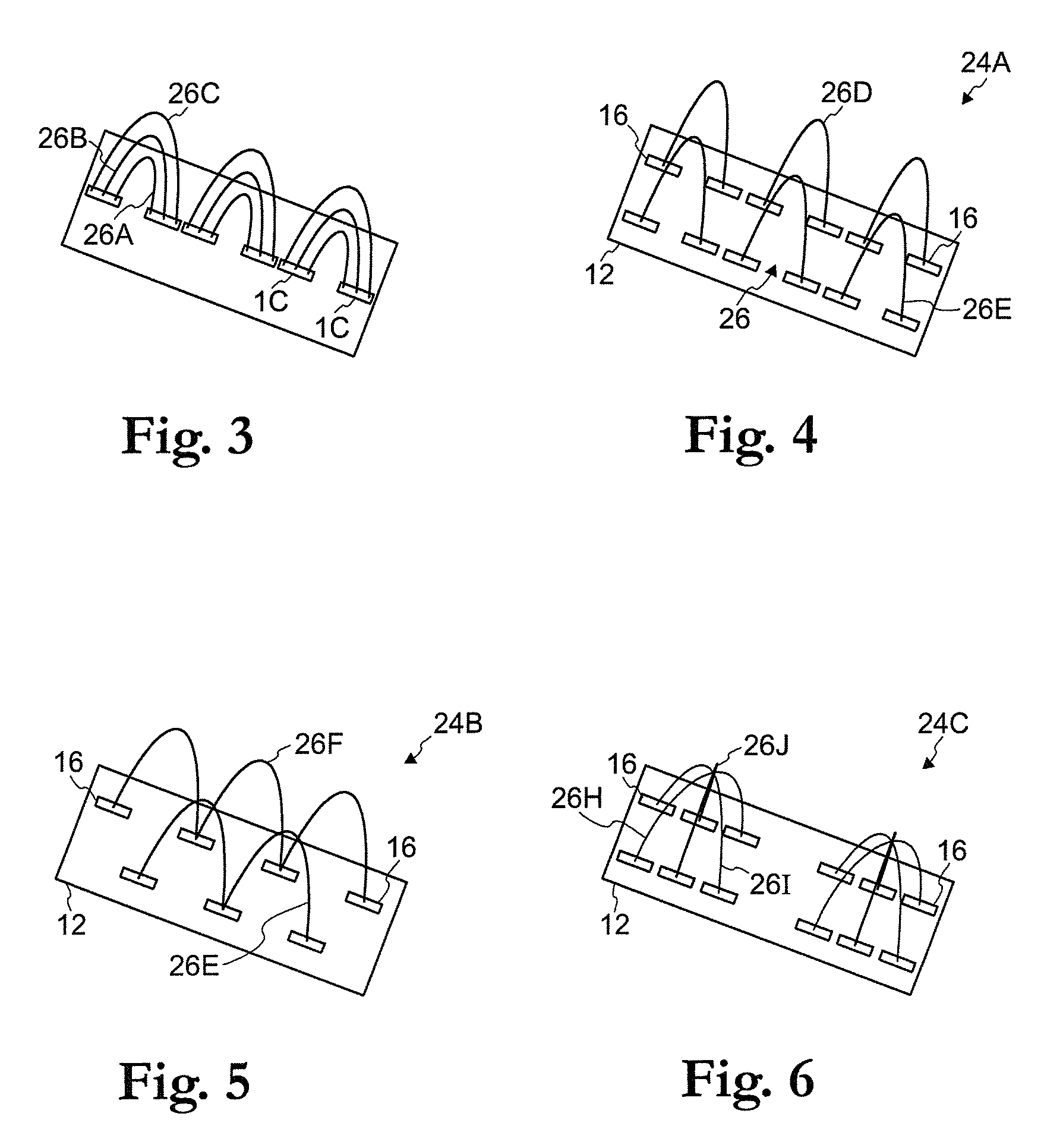

System and method for shielding of package on package (PoP) assemblies

ActiveUS7851894B1Semiconductor/solid-state device detailsSolid-state devicesConductive coatingSemiconductor package

A semiconductor package has a first substrate having a plurality of metal traces. At least one die is electrically coupled to the first surface of the first substrate. A plurality of land pads is formed on the first surface of the first substrate. A mold compound encapsulates portions of the die and portions of the first surface of the first substrate. A conductive coating is applied to the mold compound and electrically coupled to at least one metal trace. A non-conductive coating is formed over the conductive coating and portions of the mold compound. A plurality of vias is formed through the non-conductive coating and the mold compound to expose the land pads.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

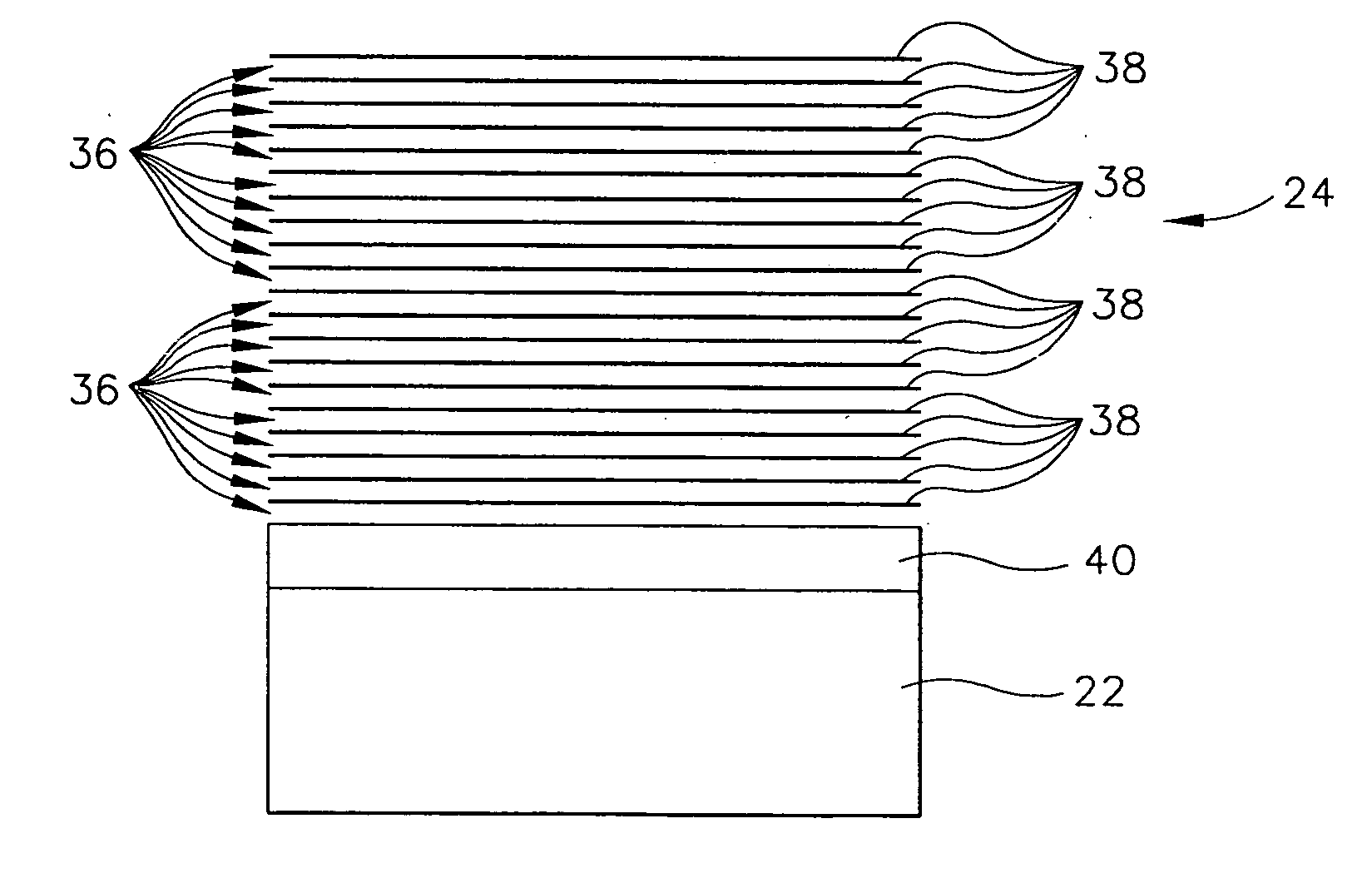

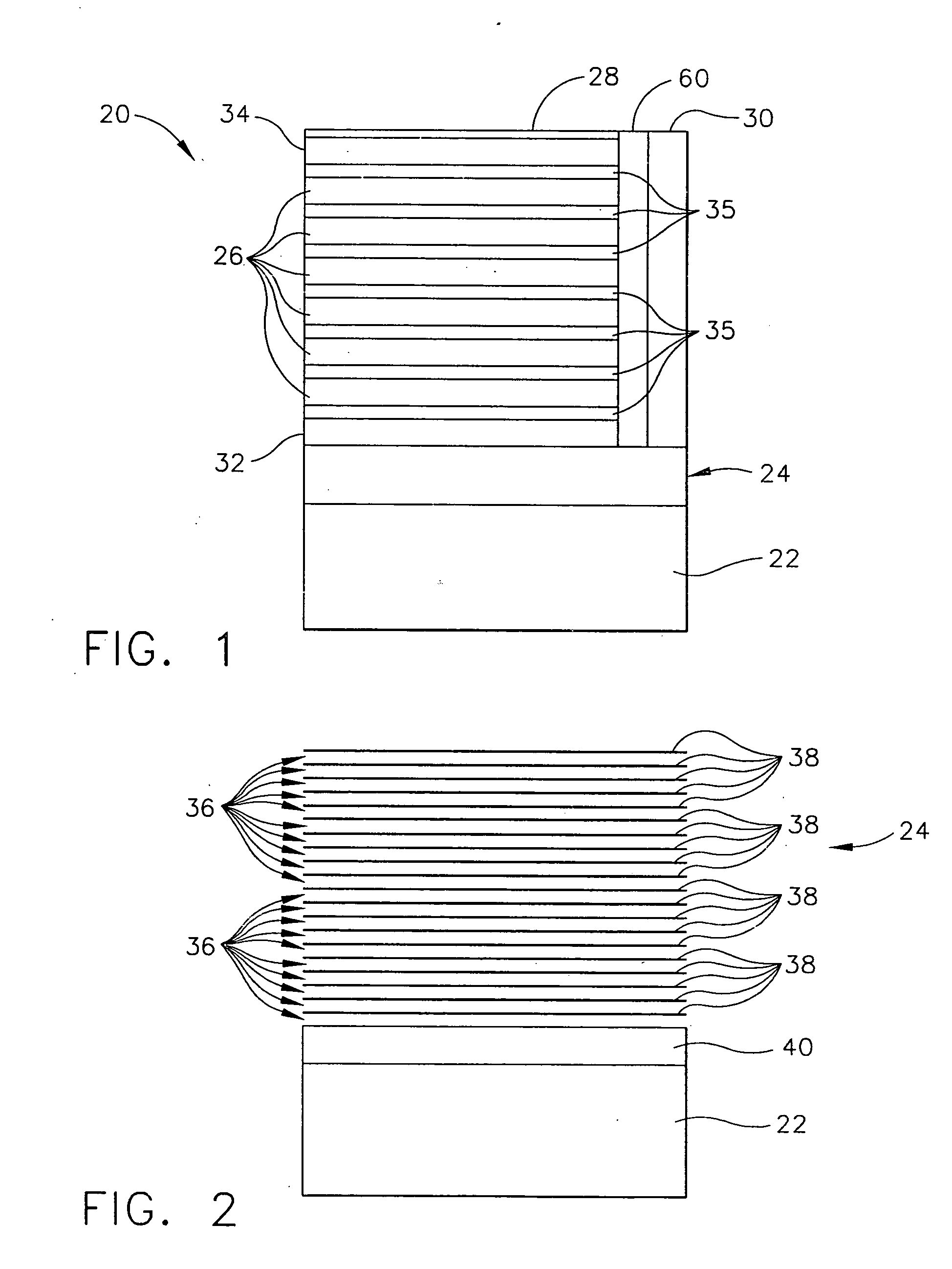

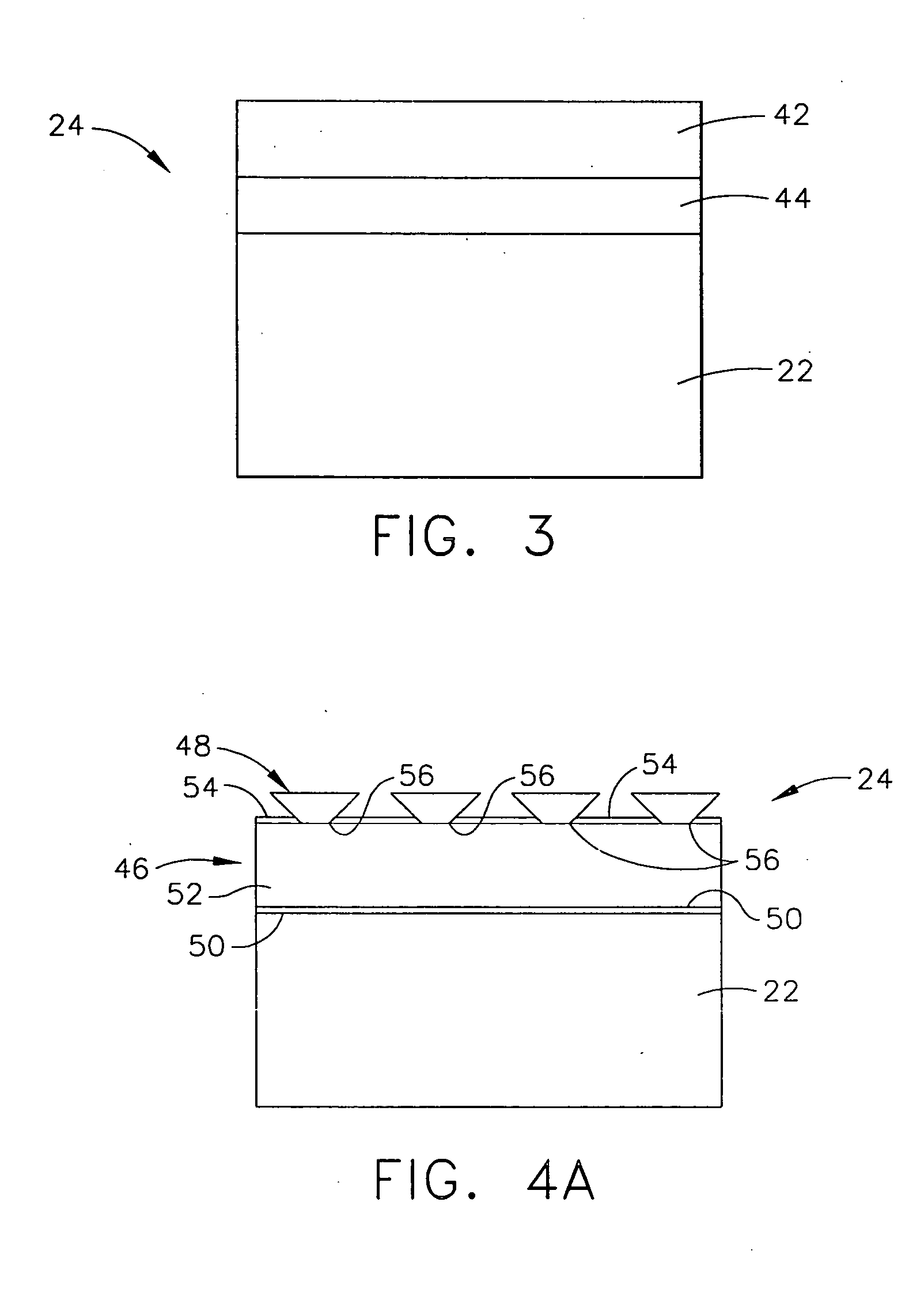

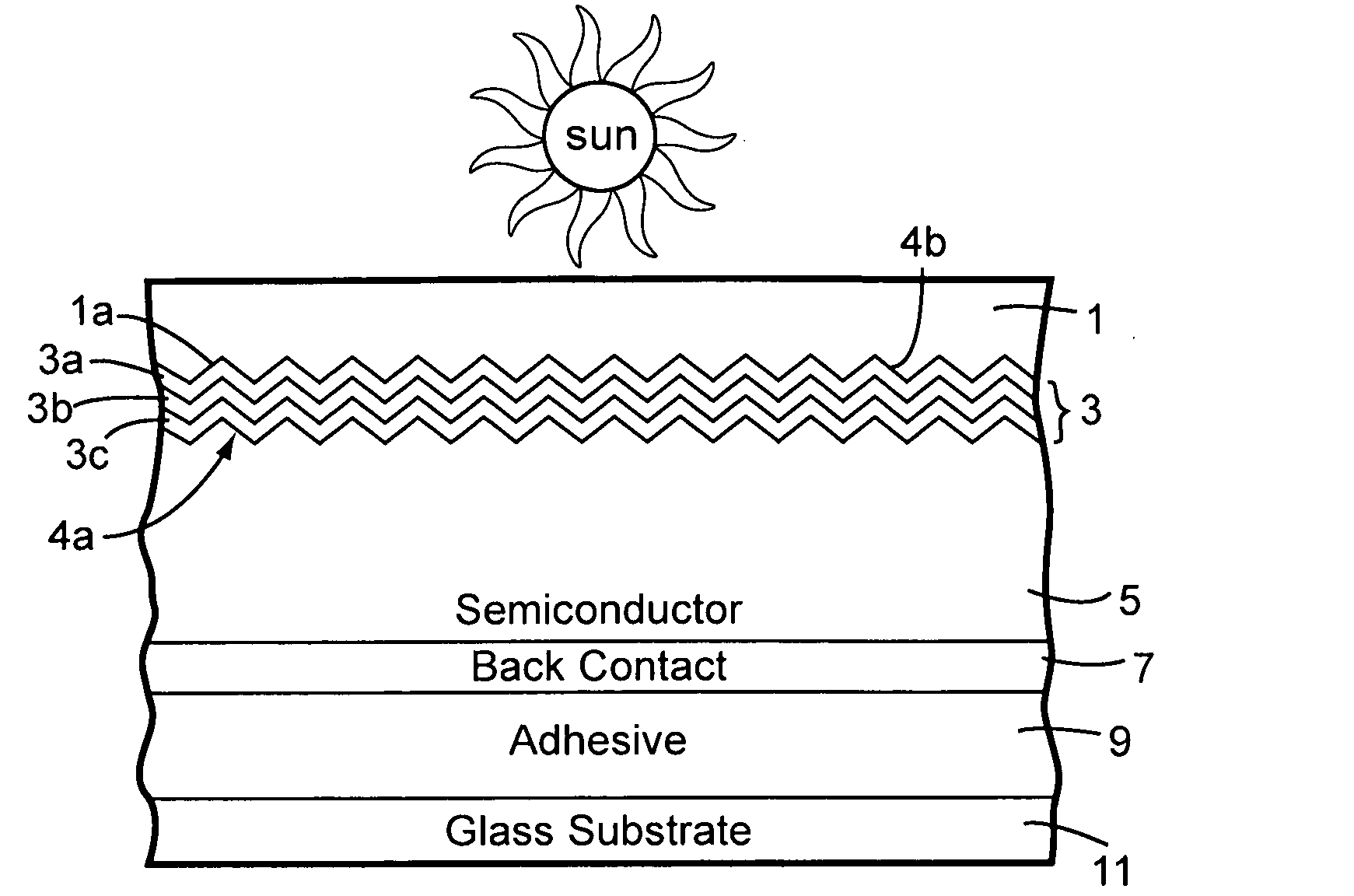

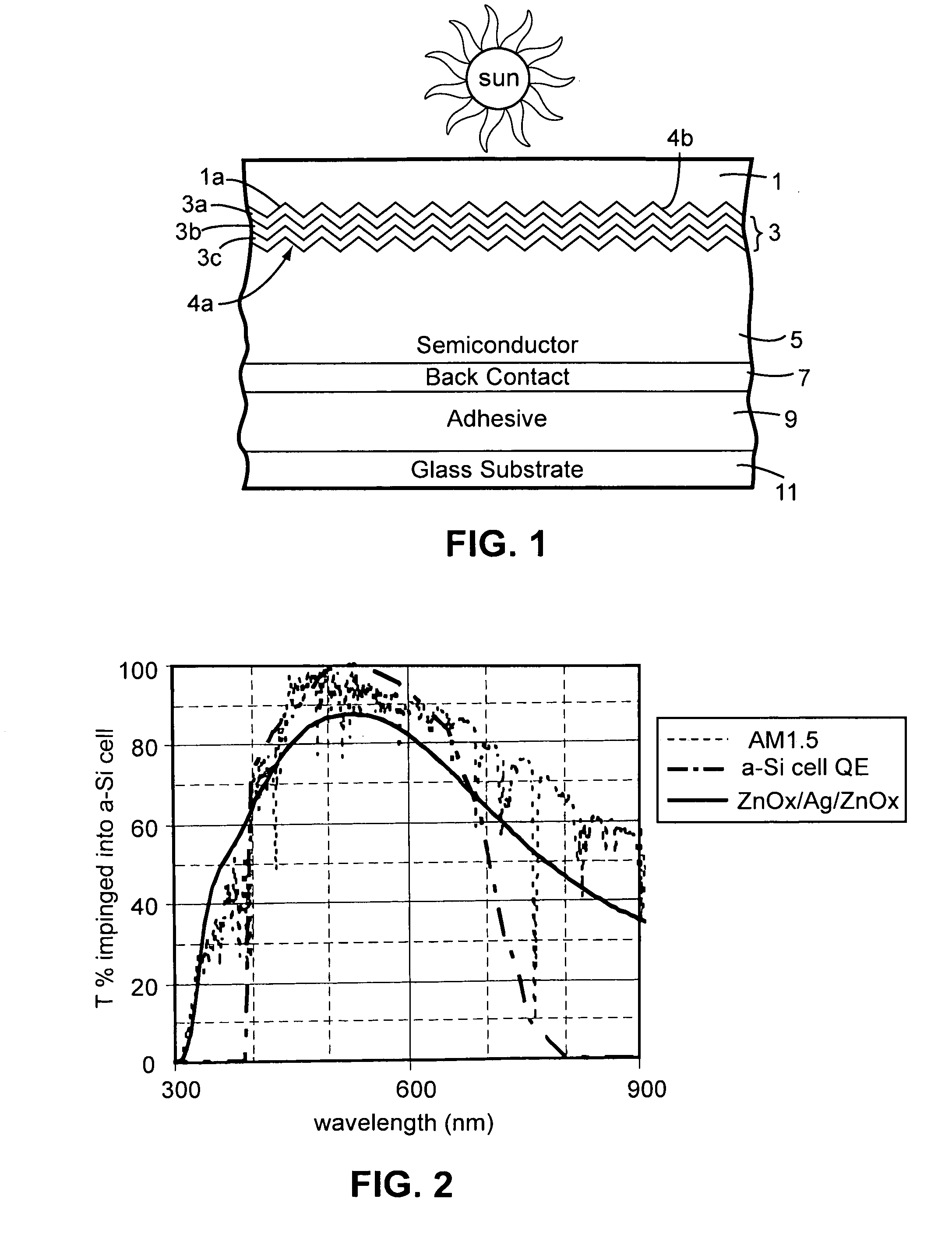

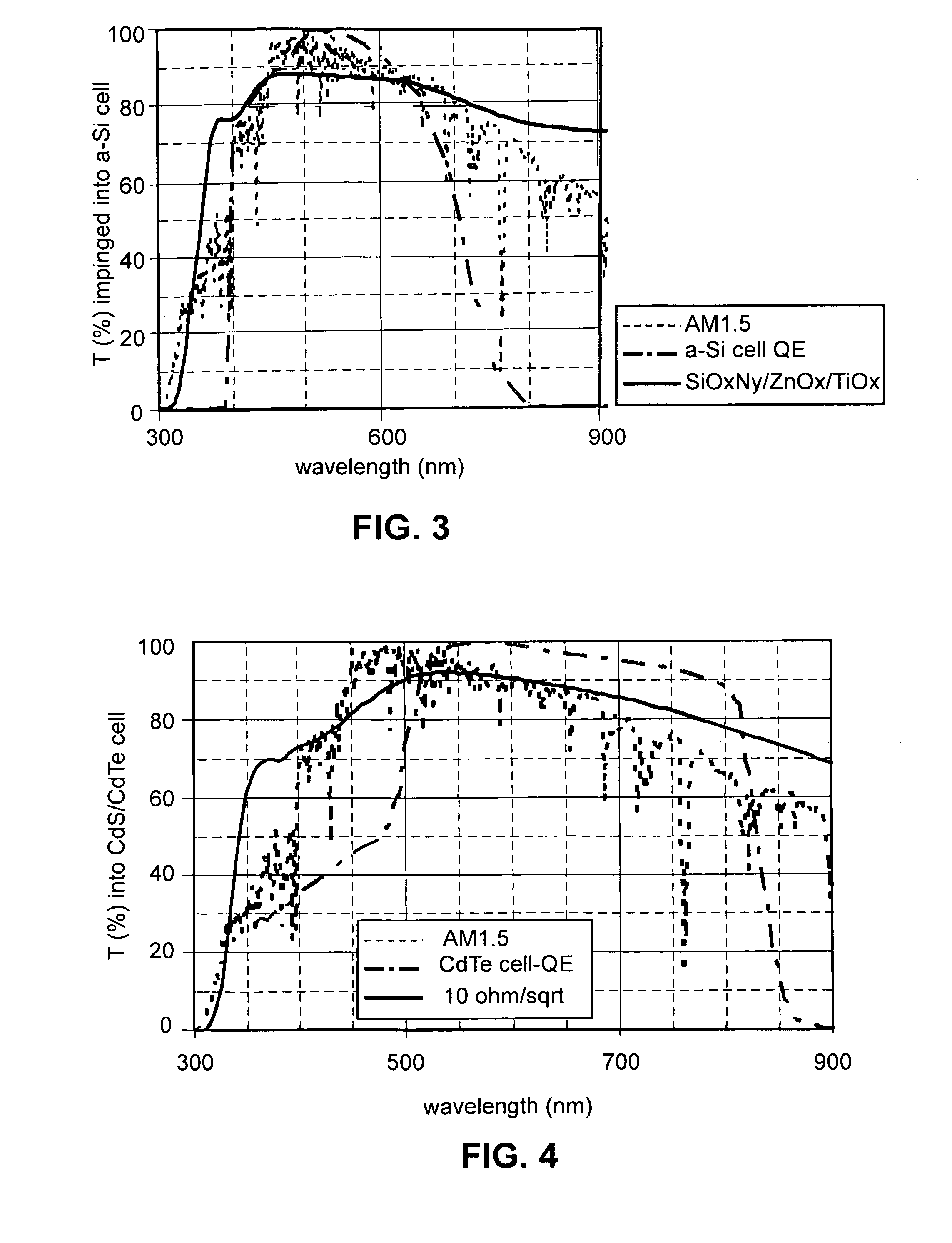

Front electrode including transparent conductive coating on patterned glass substrate for use in photovoltaic device and method of making same

InactiveUS20080178932A1Reduced visible light reflectionImprove conductivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationPeak valuePeak area

This invention relates to a photovoltaic device including an electrode such as a front electrode / contact. In certain example embodiments, the front electrode of the photovoltaic device includes a multi-layered transparent conductive coating which is sputter-deposited on a textured surface of a patterned glass substrate. In certain example embodiments, a maximum transmission area of the substantially transparent conductive front electrode is located under a peak area of a quantum efficiency (QE) and / or QEx (photon flux of solar radiation) curve of the photovoltaic device and a light source spectrum used to power the photovoltaic device. In certain example embodiments, the front electrode includes a transparent conductive layer of or including one or more of (i) titanium zinc oxide doped with aluminum and / or niobium, and / or (ii) titanium niobium oxide.

Owner:GUARDIAN GLASS LLC

Heated catheter used in cryotherapy

InactiveUS7255693B1Constant visualizationEasy to viewCatheterSurgical instruments for heatingConductive coatingElectrical connection

Disclosed is a cryosurgical catheter which is heated in order to prevent its freezing within the lumen of an endoscope. The catheter is to be used with an endoscope to perform cryoablation on an internal tissue; e.g., the esophagus. Electric conductivity to produce heat employs an electrical conductive coating on the catheter. Also, disclosed is a fitting for use with a catheter comprising both a connection for receiving gas and an electrical connection.

Owner:CSA MEDICAL

Method and apparatus for detecting two simultaneous touches and gestures on a resistive touchscreen

InactiveUS20090322701A1Input/output processes for data processingElectrical resistance and conductanceConductive coating

Resistive touchscreen system has a substrate with a first conductive coating having a first resistance and a coversheet with a second conductive coating having a second resistance. The substrate and coversheet are positioned proximate each other such that the first conductive coating faces the second conductive coating. The substrate and coversheet are electrically disconnected with respect to each other in the absence of a touch. First and second sets of electrodes for establishing voltage gradients in first and second directions are formed on the substrate and the coversheet, respectively. A controller biases the first and second sets of electrodes in two different cycles. The controller senses a bias current associated with at least one of the first and second resistances. The bias current has a reference value associated with no touch. An increase in the bias current relative to the reference value indicates two simultaneous touches.

Owner:ELO TOUCH SOLUTIONS INC

Non-aqueous electrolyte secondary battery negative electrode material, making method, and lithium ion secondary battery

ActiveUS20040106040A1Large capacityImprove cycle performanceNon-aqueous electrolyte accumulatorsNegative electrodesConductive coatingMaterials science

A non-aqueous electrolyte secondary battery negative electrode material is provided wherein a negative electrode active material containing a lithium ion-occluding and releasing material which has been treated with an organosilicon base surface treating agent is surface coated with a conductive coating. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

Semiconductor device having EMI shielding and method therefor

ActiveUS8012868B1Semiconductor/solid-state device detailsSolid-state devicesConductive coatingEngineering

A semiconductor device has a substrate having a plurality of metal layers. A die coupled to the substrate. A first wire fence structure is formed on the substrate. A second wire fence structure is formed on the substrate. A mold compound is used for encapsulating the die, a first surface of the substrate, the first wire fence structure, and the second wire fence structure, wherein a top portion of at least one of the first wire fence structure or the second wire fence structure is exposed. A conductive coating is applied to the mold compound and to the portion of the at least one of the first wire fence structure or the second wire fence structure is exposed.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com