Patents

Literature

105results about How to "Meet service life requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather-resistant and high thermal conductive coating, radiating solar rear panel and efficient solar cell panel

InactiveCN102516852AImprove thermal conductivityMeet service life requirementsPolyureas/polyurethane adhesivesPhotovoltaicsWeather resistanceConductive coating

The invention discloses a weather-resistant and high thermal conductive coating, a radiating solar rear panel and an efficient solar cell panel. The weather-resistant and high thermal conductive coating consists of 10 to 50 parts of weather-resistant resin, 5 to 30 parts of curing agent, 0.1 to 5 parts of organic filler, 30 to 80 parts of inorganic filler, and 30 to 100 parts of solvent. The radiating solar rear panel comprises a base layer, and the weather-resistant and high thermal conductive coating is arranged on at least one surface of the base layer or arranged between the base layers. The efficient solar cell panel comprises a solar front panel and the radiating solar rear panel, a solar cell circuit is arranged between the solar front panel and the radiating solar rear panel, and an encapsulation material is arranged on one side or two sides of the solar cell circuit. The weather-resistant and high thermal conductive coating can be directly coated on a base material and has high binding power and an excellent thermal conductive effect, and the weather resistance of the coating meets the requirement of a solar module for the service life of over 25 years.

Owner:ALLSTAE TECH ZHONGSHAN

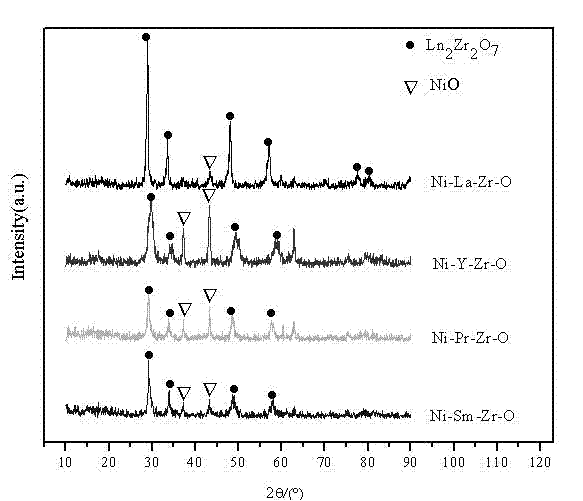

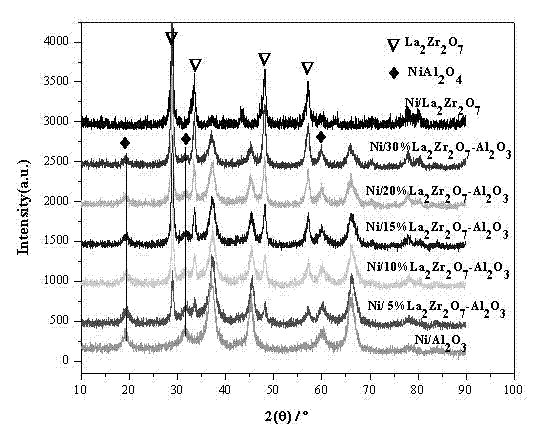

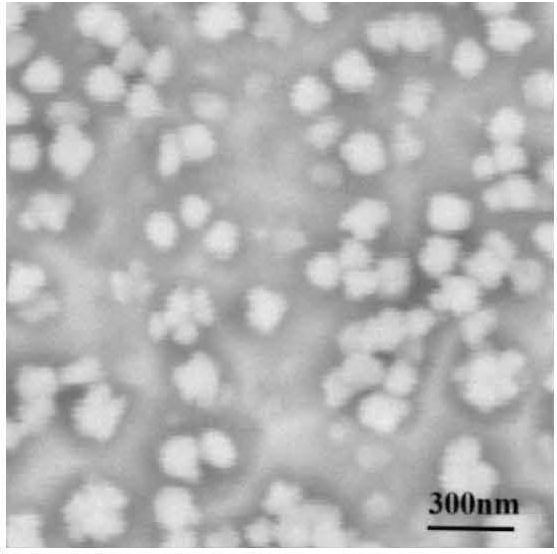

Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

ActiveCN103752319AMeet activityMeet service life requirementsHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

The invention relates to an anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and a preparation method thereof. By taking lanthanum nitrate, praseodymium nitrate, samarium nitrate, yttrium nitrate, zirconium nitrate, zirconium carbonate, zirconium oxychloride, and the like as precursors and taking ammonia as a precipitant, a pyrochlore composite oxide is prepared through using a coprecipitation method; and then the pyrochlore composite oxide is mixed with alumina by using a mechanical mixing method so as to obtain a pyrochlore alumina composite carrier. Nickel nitrate, nickel chloride, nickel sulfate, nickel oxalate and the like serving as nickel sources are loaded on the pyrochlore alumina composite carrier through direct immersion. The loading capacity of nickel in the catalyst accounts for 5-30% of the weight of the catalyst, the pyrochlore content of the catalyst is 5-50%, and the alumina content of the catalyst is 20-90%. By taking the pyrochlore alumina composite oxide as a carrier, the reaction activity and anti-carbon-deposition performance of the catalyst can be greatly increased; the preparation method of the catalyst is simple; and the catalyst has excellent catalytic activity and stability to methane steam reforming in a stationary bed.

Owner:NANCHANG UNIV +1

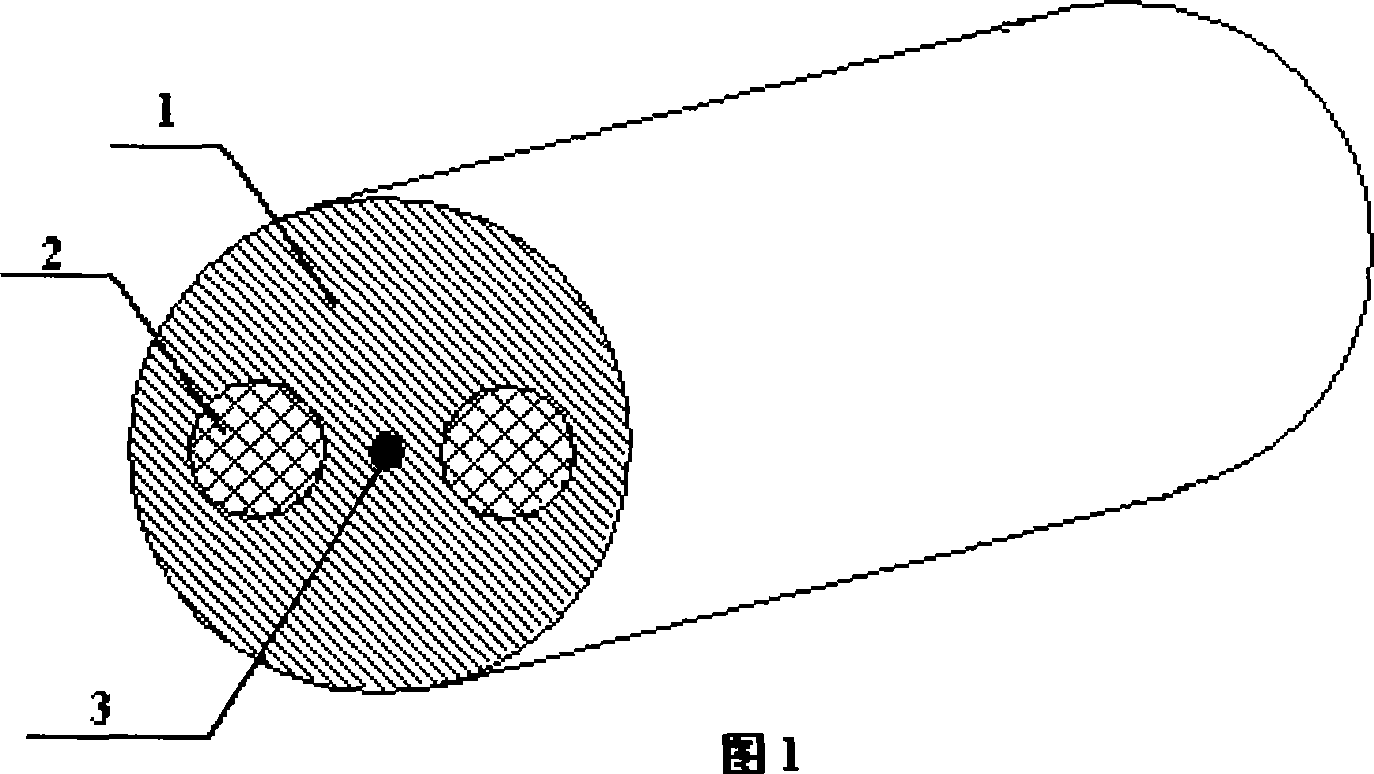

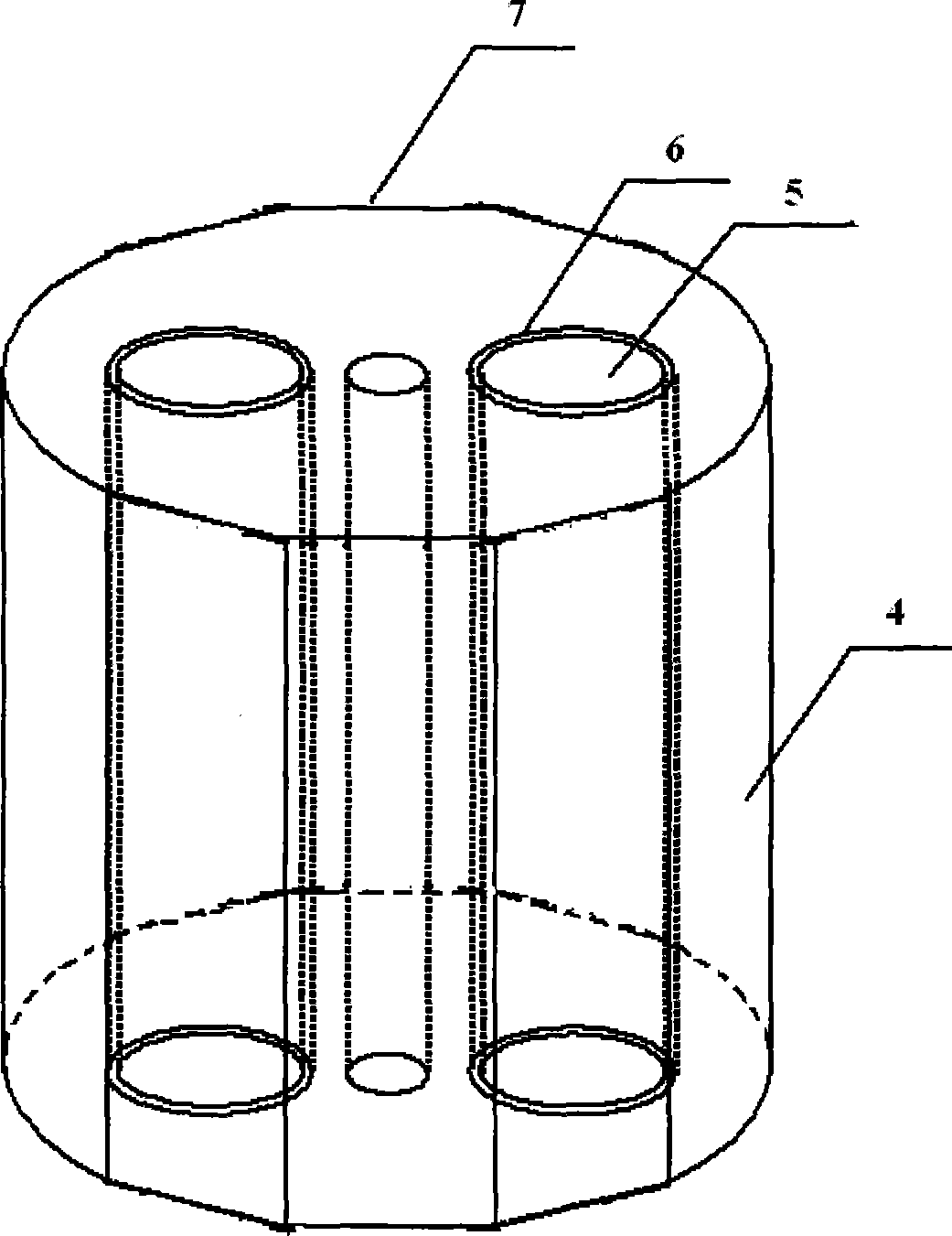

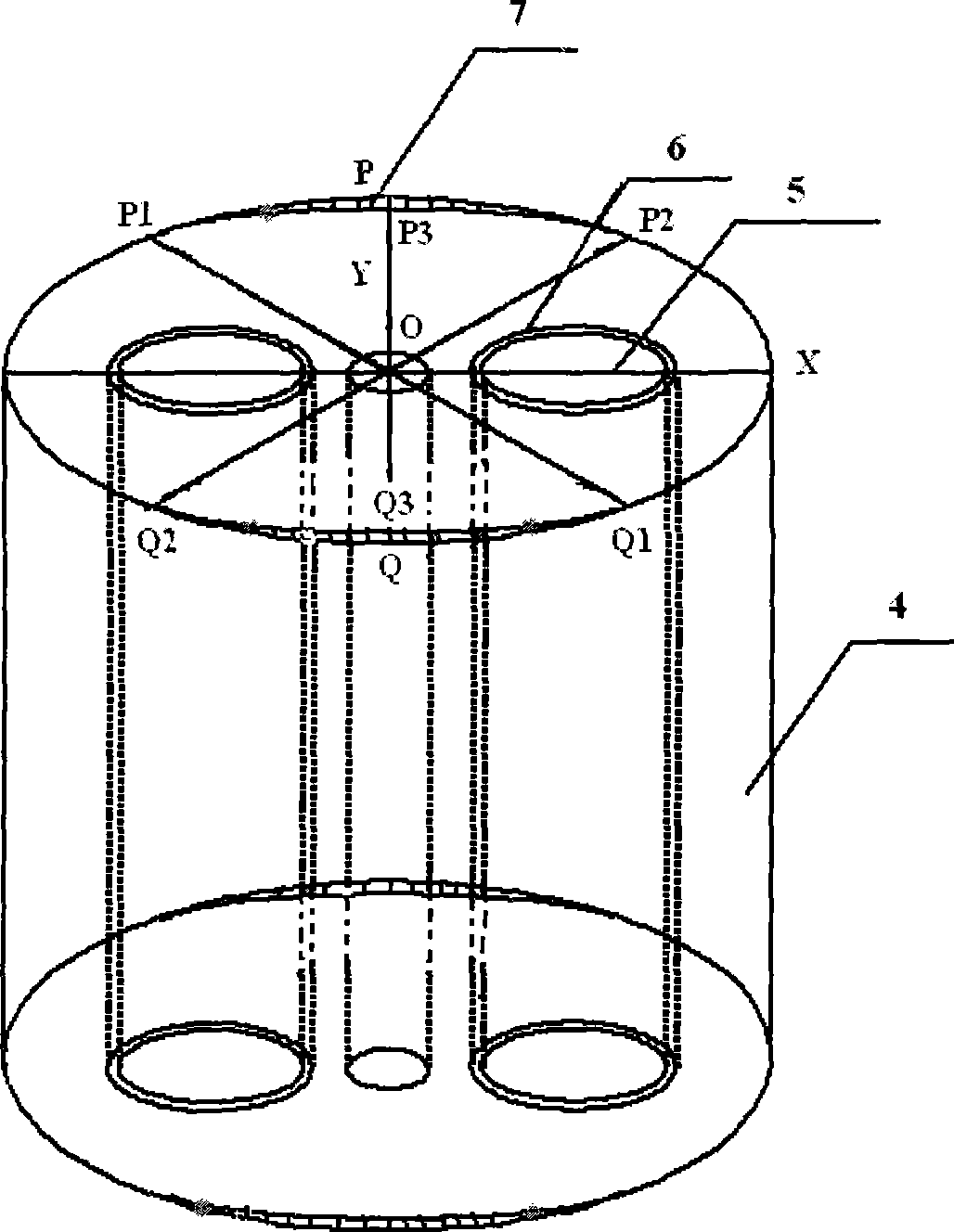

Method of manufacturing polarization maintaining optical fiber

ActiveCN101387720AQuantized geometryHigh mechanical strengthGlass making apparatusCladded optical fibreEllipsePolarization-maintaining optical fiber

The invention relates to a production method for polarization maintaining fibers, comprising an optical fiber perform rod with a fiber core and a clad, wherein the clad at two sides of the fiber core of the optical fiber perform rod are symmetrically processed with two longitudinal penetration holes parallel with the fiber core; two stress rods are respectively inserted into the two holes on the optical fiber perform rod to form a combination optical fiber perform rod; performing the combination optical fiber on an optical fiber drawing tower to draw the fiber to obtain a panda-type polarization maintaining fiber. The production method is characterized in that the upper and the lower circumferences of parallel to the center connecting line of the two holes of the optical fiber perform rod and the insertion stress rod are removed with part of the clad in a transition curve type, to make the radial section of the optical fiber perform rod in an oval or ellipse form. The invention quantifies the correction area and size of the perform rod, therefore, under the surface tension force, the combination perform rod can be instantly fused and reduced into a polarization maintaining fiber with good surface circularity to confirm the clad non circularity of produced polarization maintaining fibers under 0.5%.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

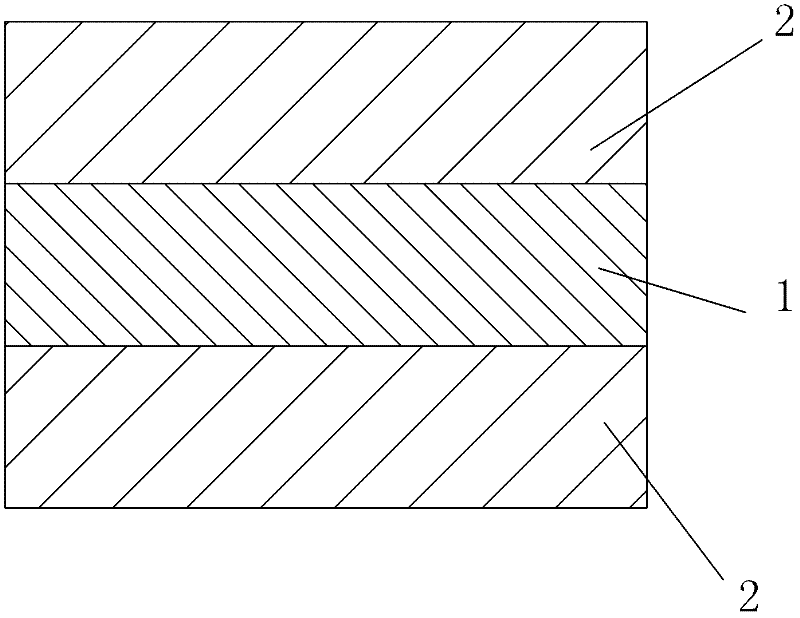

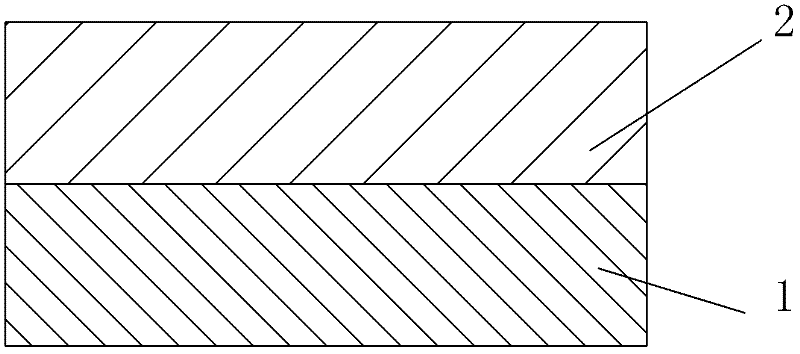

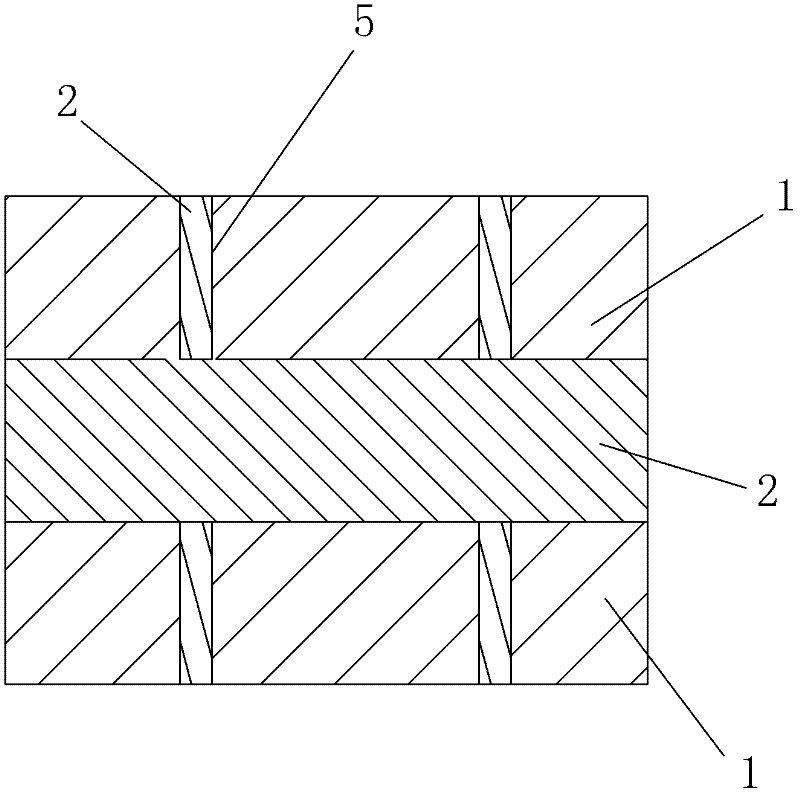

Composite material of wear-resisting rod piece and preparation method thereof

The invention relates to a composite material of a wear-resisting rod piece and a preparation method thereof. The composite material of the wear-resisting rod piece is low in cost, convenient in processing and good in wear resistance, can be used for manufacturing sieve plates of various working conditions and can be used for other fields. The composite material of the wear-resisting rod piece ismainly composed of a metal rod piece as a core part and a surrounding wear-resisting alloy layer arranged along the length direction of the rod piece, and the metal rod piece and the surrounding wear-resisting alloy layer are in metallurgical bonding; and the thickness of the wear-resisting alloy layer is 1-10 mm.

Owner:SHANDONG UNIV

Special weather-resisting functional mulching film capable of being used for two years

ActiveCN102660074AMeet service life requirementsInhibits water evaporationPlant protective coveringsLow-density polyethyleneLinear low-density polyethylene

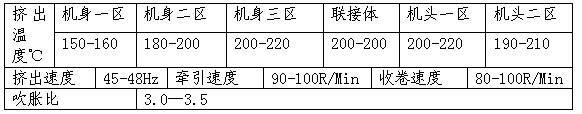

The invention provides a special weather-resisting functional mulching film capable of being used for two years. The special weather-resisting functional mulching film is prepared from the following raw materials in percentage by weight: 60-80% of LLDPE (Linear Low Density Polyethylene), 5-15% of LDPE (Low-Density Polyethylene), 3-8% of HDPE (High-Density Polyethylene), 5-15% of mPE (Metallocene Polyethylene) and 2-6% of anti-ageing master batch. The anti-ageing master batch is prepared from the following raw materials in percentage by weight: 35-45% of LLDPE powder, 25-35% of the LDPE, 6-15% of the HDPE, 5-12% of the mPE, 2-7% of a hindered amine light stabilizing agent, 0.5-3.5% of an antioxidant, 0.5-3.5% of an ultraviolet absorber and 1..5-5.0% of dispersing agent white oil. The special weather-resisting functional mulching film can meet the requirements of 'one film with two-year service life' of the weather-resisting functional mulching film and can be used for 12-18 months; and compared with the common mulching film, the culture under-glass increased production reaches to 30-40%, so that the stable agriculture is realized and the good supply is guaranteed.

Owner:GANSU TIANBAO PLASTIC CO LTD

Porous medium burner material and preparation method thereof

InactiveCN101962299AImprove thermal shock resistanceImprove high temperature resistanceCeramicwarePorous mediumMullite

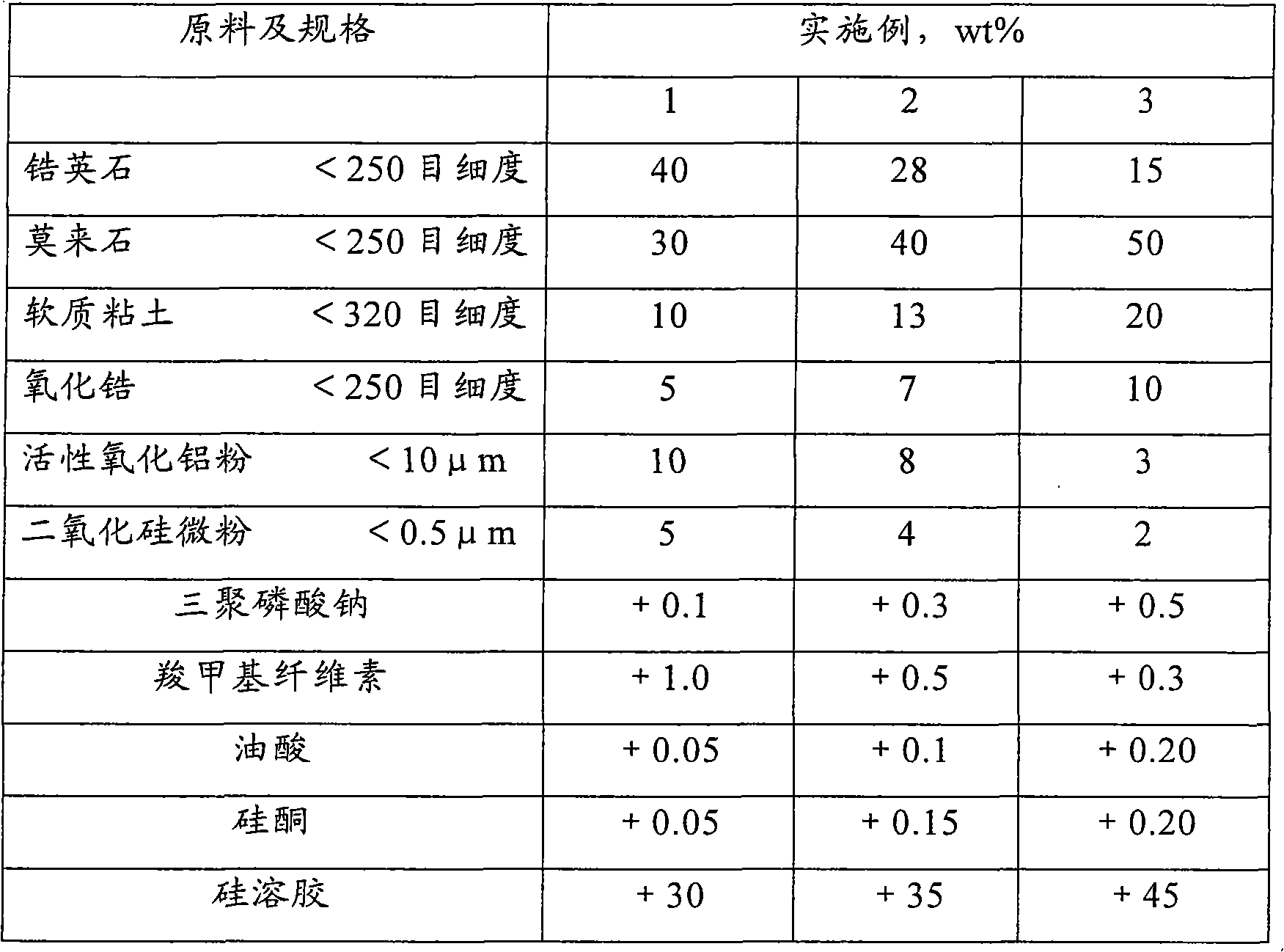

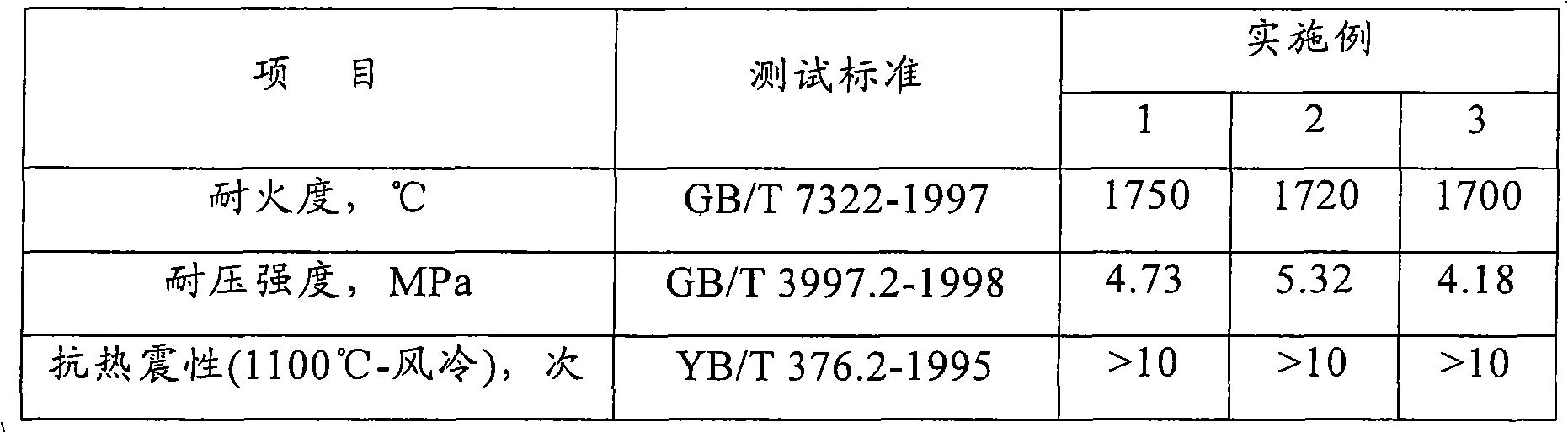

The invention discloses a porous medium burner material. The porous medium burner material comprises ceramic powder, a binding agent, a dispersing agent and a suspending agent, wherein the ceramic powder consists of the following components in percentage by weight: 15 to 40 percent of zirconite powder, 30 to 50 percent of fine mullite powder, 5 to 10 percent of fine zirconium oxide powder, 10 to 20 percent of soft clay, 5 to 10 percent of active aluminum oxide powder and 1 to 5 percent of silicon dioxide micro powder; the binding agent is 30 to 45 percent based on the total weight of the ceramic powder; the dispersing agent is 0.1 to 0.5 percent based on the total weight of the ceramic powder; the suspending agent is 0.2 to 1.0 percent based on the total weight of the ceramic powder; and the particle size of the fine powder is not greater than 250 meshes. The preparation method of the porous medium burner material comprises the following steps of: preprocessing organic foamed plastic; performing ball-milling on the ceramic powder, the additional binding agent, an additive and a proper amount of water; adding an antifoaming agent into the mixture, performing ball milling to obtain uniform paste, and controlling the viscosity to be 1 to 5Pa.s; soaking the preprocessed organic foamed plastic in the paste; repeating the processes for several times until the required density is achieved; removing the excessive paste to obtain the porous biscuit; naturally drying the porous biscuit at the room temperature; drying the biscuit in a drying box of over 90 DEG C to control the moisture to be less than or equal to 1.0 weight percent; and firing the biscuit in a kiln to obtain the porous medium.

Owner:BAOSHAN IRON & STEEL CO LTD +1

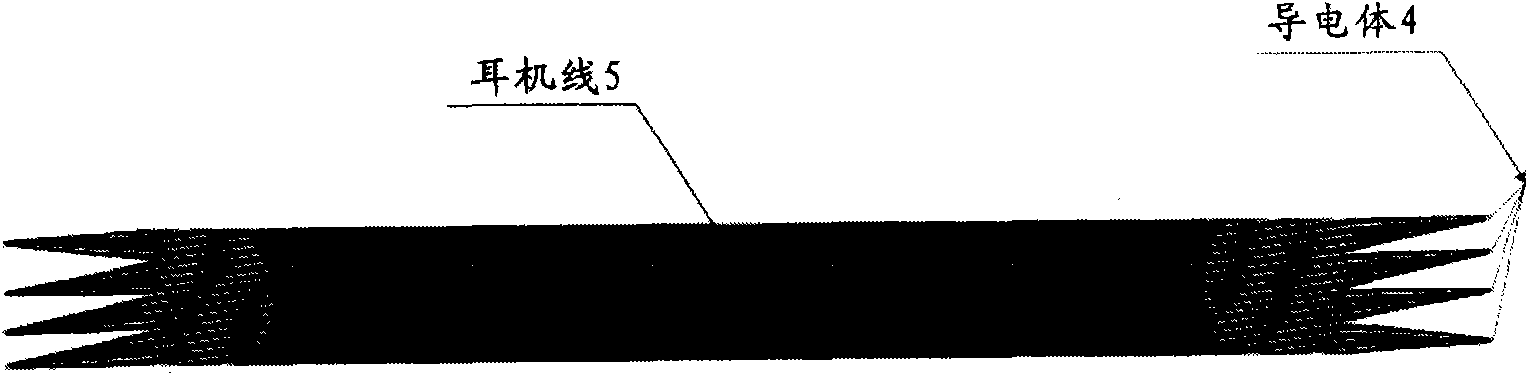

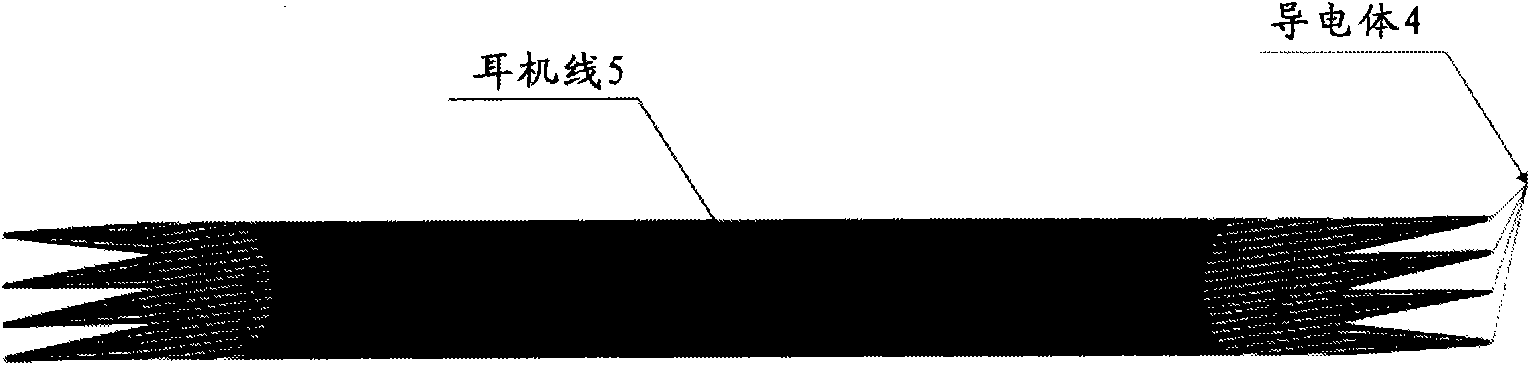

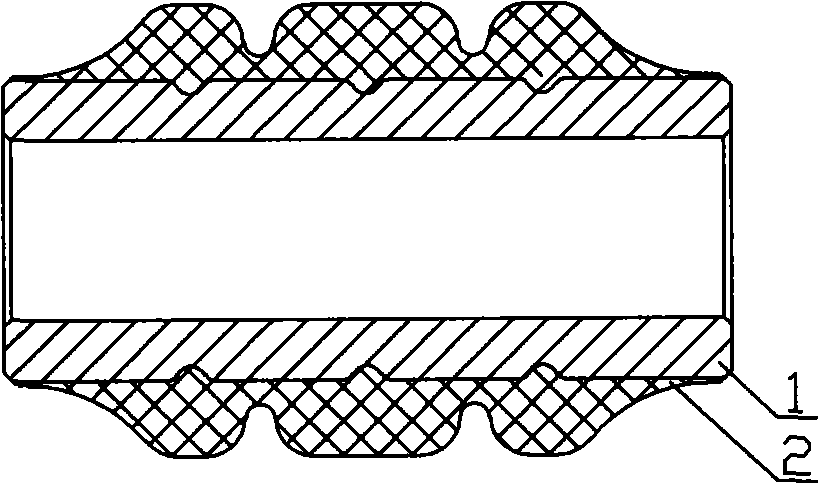

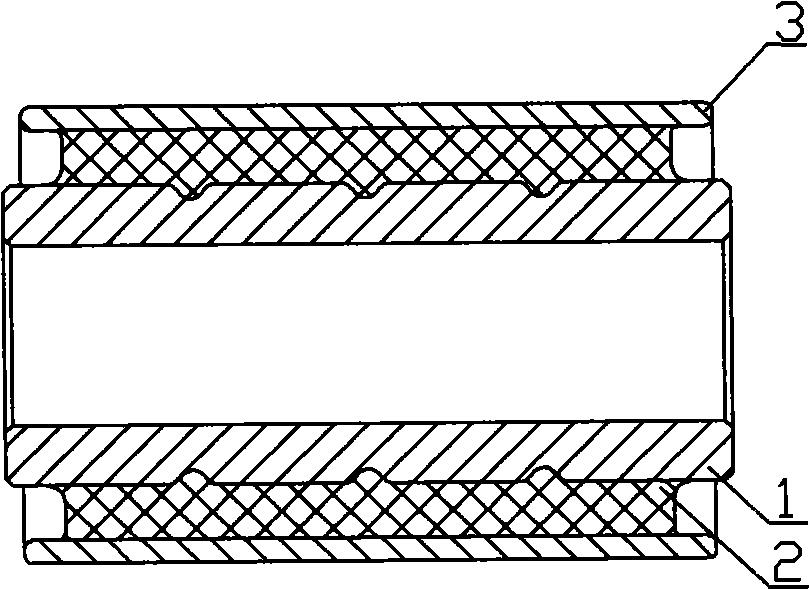

Earphone cord

ActiveCN102074291AMeet service life requirementsEasy to useExtensible conductorsExtensible conductor cablesHeadphones

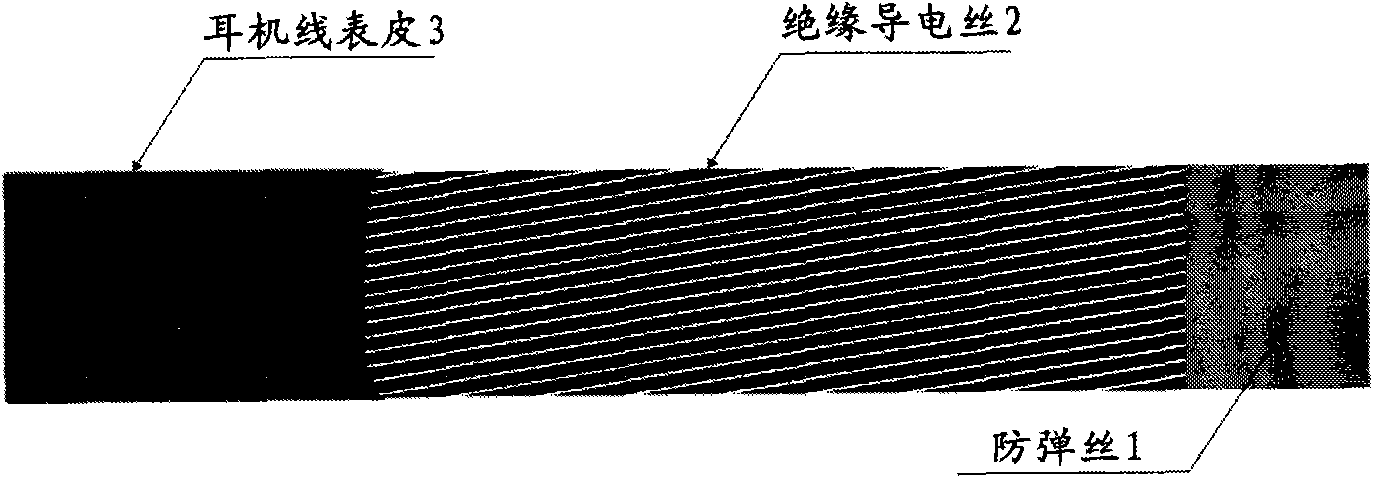

The invention provides an earphone cord comprising an anti-elastic wire, an insulating conducting wire and an earphone cord skin. The earphone cord is characterized by also comprising conductive bodies, the insulating conducting wire is spirally wound on the anti-elastic wire; the earphone cord skin is adhered to and wraps on the surface of the insulating conducting wire to form an ultrathin, flexible and abrasion-resistant skin; and the conductive bodies are positioned on both end parts of the earphone cord and respectively connected with output and input terminals of electronic products and earphones. The invention also provides a method for manufacturing the novel earphone cord. Compared with the traditional earphone cord which is bulky and rigid and is easy to break when bent hundreds of times, the novel earphone cord is very fine and flexible, can not be broken when bent for tens of thousands of times and completely meet the requirements for the service life of built-in telescopic earphones.

Owner:XINJIANG TIANDI GROUP

Hydrogen production catalyst with high-temperature methyl alcohol water vapour and preparation method thereof

ActiveCN101632929AHigh reactivityImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsCarrying capacityAlcohol

The invention discloses a catalyst and a preparation method thereof, in particular to a hydrogen production catalyst with high-temperature methyl alcohol water vapour and a preparation method thereof. The catalyst comprises active components of VIII group metal and auxiliary agent and also comprises modified Al2O3 spherules serving as a carrier, wherein, the sharing carrying capacity of the active components occupies 2.6-10wt% of the carrier, and the ratio of the active components to the auxiliary agent ZnO is 0.24-0.38:1. The catalyst has high reaction activity, high stability and simple manufacturing method, can lower cost and adopts the method of cocurrent flow dipping and ultrasonic dispersion, so that noble metal has small use amount and little waste, which can satisfy the requirement of the activity and service life of catalyst by industrialization. The catalyst of the invention can be applied in the fuel battery hydrogen supplying field on a large scale.

Owner:HANERGY TECH

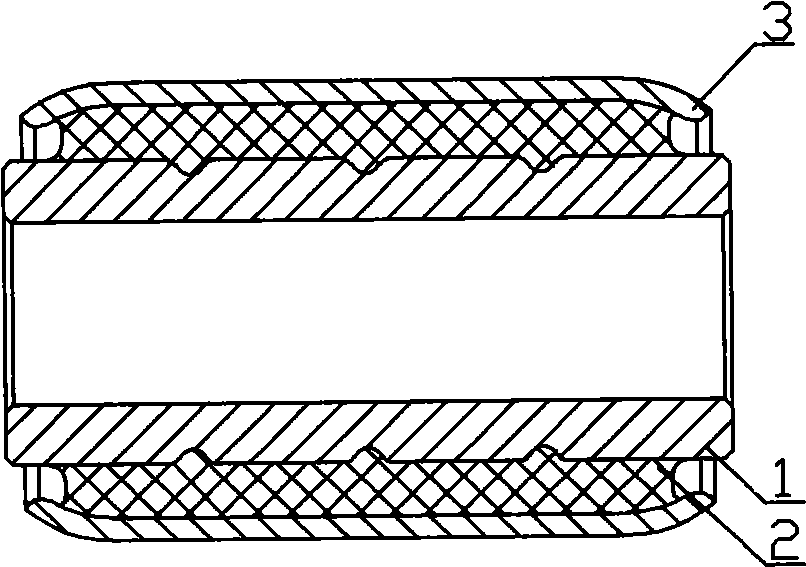

Spring bushing assembly for automobile front steel plates, and production process thereof

InactiveCN101520075AMeet service life requirementsHigh strengthRubber-like material springsEngineeringUltimate tensile strength

The invention discloses a spring bushing assembly for automobile front steel plates, and a production process thereof. The production process comprises the steps of fixing rubber on an inner bushing to form a rubber assembly, squeezing the rubber assembly into an outer bushing so as to reduce the diameter of the rubber assembly, reducing the diameter of the assembly outer bushing (including the rubber assembly), turning the assembly around, reducing the diameter again, finishing and processing the length of the outer bushing, shaping bound circular-arc shape mouths at two ends of the assembly, and the like. The spring bushing assembly can completely meet the requirement of automobiles on life span, and has the advantages of high strength, excellent vibration reducing effects and fatigue resistance.

Owner:赵丰

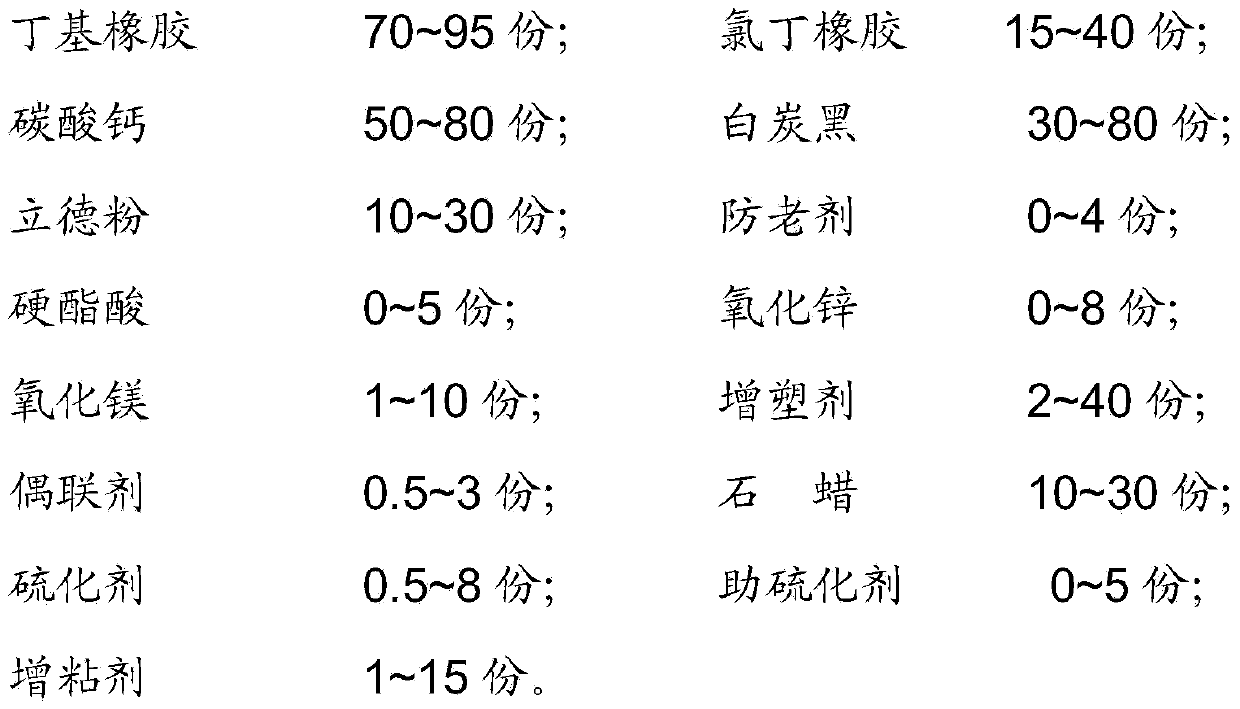

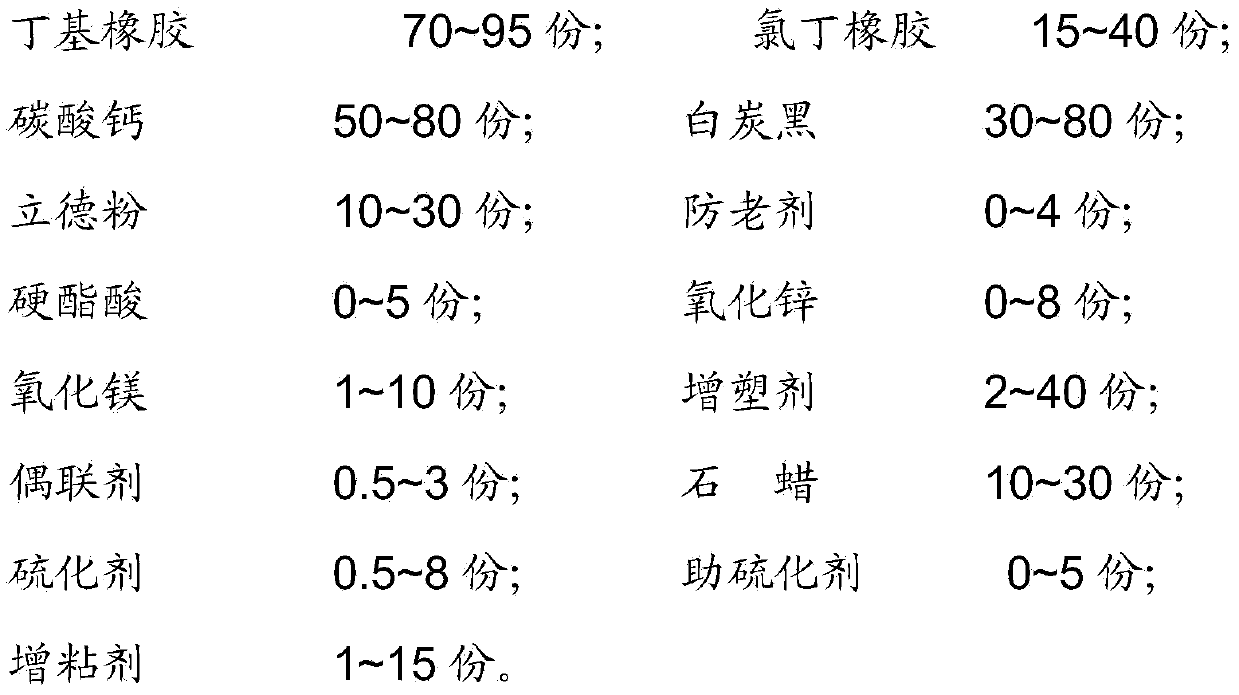

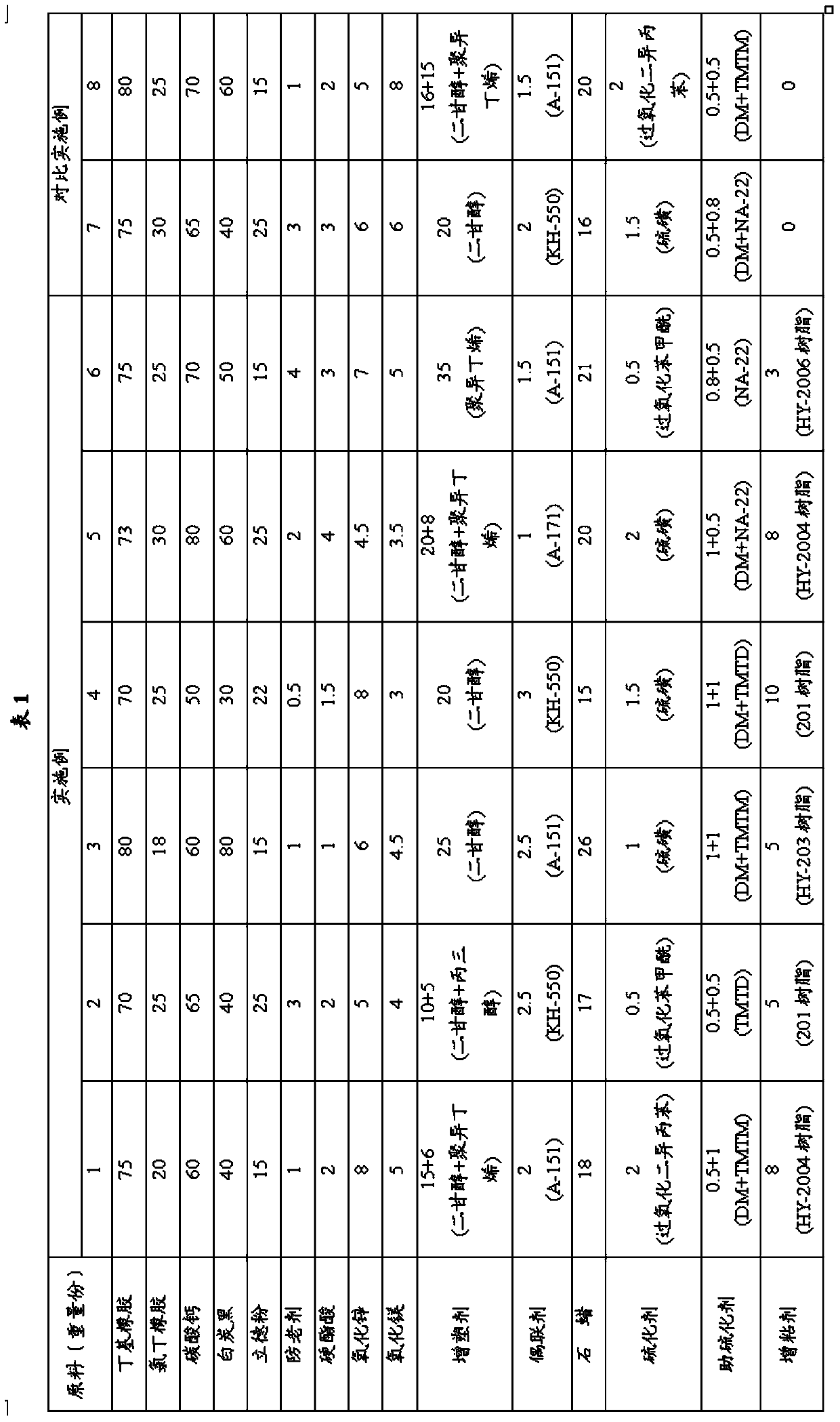

Butyl rubber composition, preparation method and method for preparing pressure hose

ActiveCN104086906AImprove air tightnessImprove low temperature resistanceFlexible pipesPolymer scienceStearic acid

The invention relates to a butyl rubber composition, a preparation method and a method for preparing a pressure hose. The preparation method comprises: (1) putting butyl rubber and chloroprene rubber on a roller, after the roller is completely coated, adding calcium carbonate, stearic acid and lithopone, performing mixing, then adding white carbon black in batches, performing mixing, then adding magnesium oxide, zinc oxide, an anti-ageing agent and a half amount of a plasticizer, performing mixing, then adding a coupling agent, paraffin and a tackifier, and performing mixing and thin passing; and (2) performing straining on mixed rubber by using a straining machine, putting on a roller again, then adding a vulcanizing agent, an auxiliary vulcanizing agent and the other half amount of the plasticizer, and performing mixing and thin passing. The prepared butyl rubber composition has excellent performance. By employing the butyl rubber composition for preparing a lining rubber pipe, the caking strength between a woven layer and a lining layer of a pressure-resistant airtight foldable hose is substantially improved, and the pressure-resistant performance and the airtightness of the hose are substantially improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

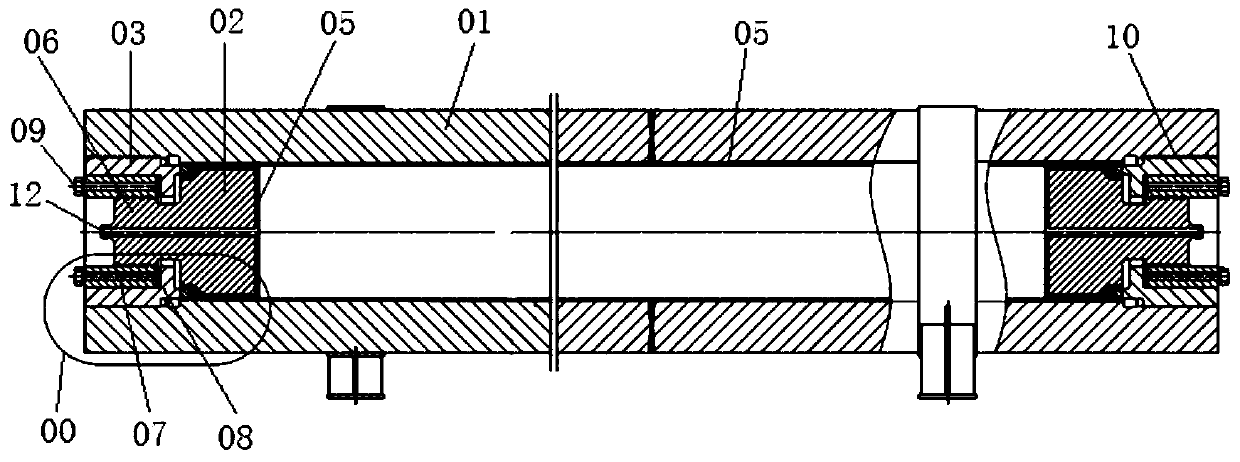

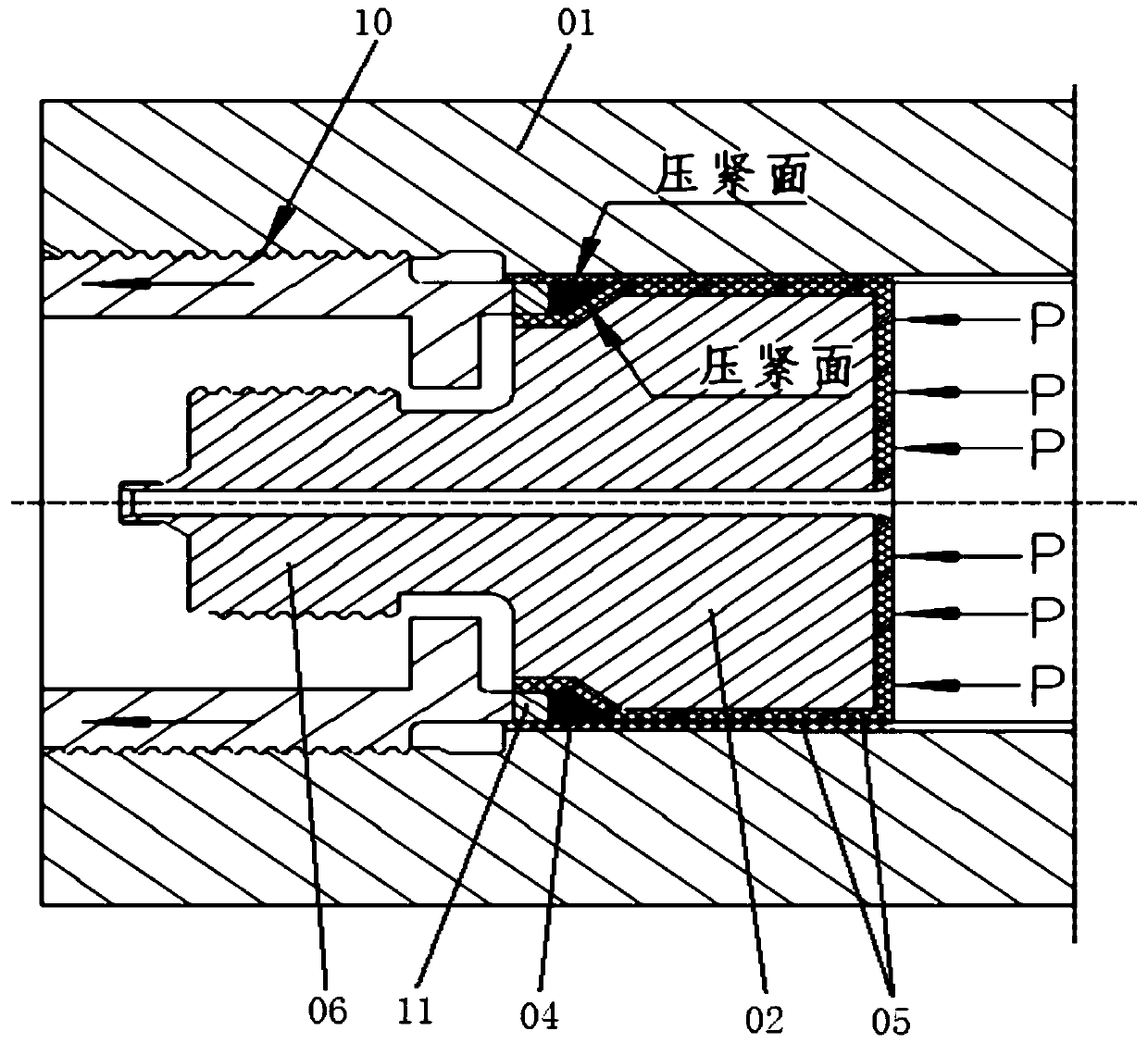

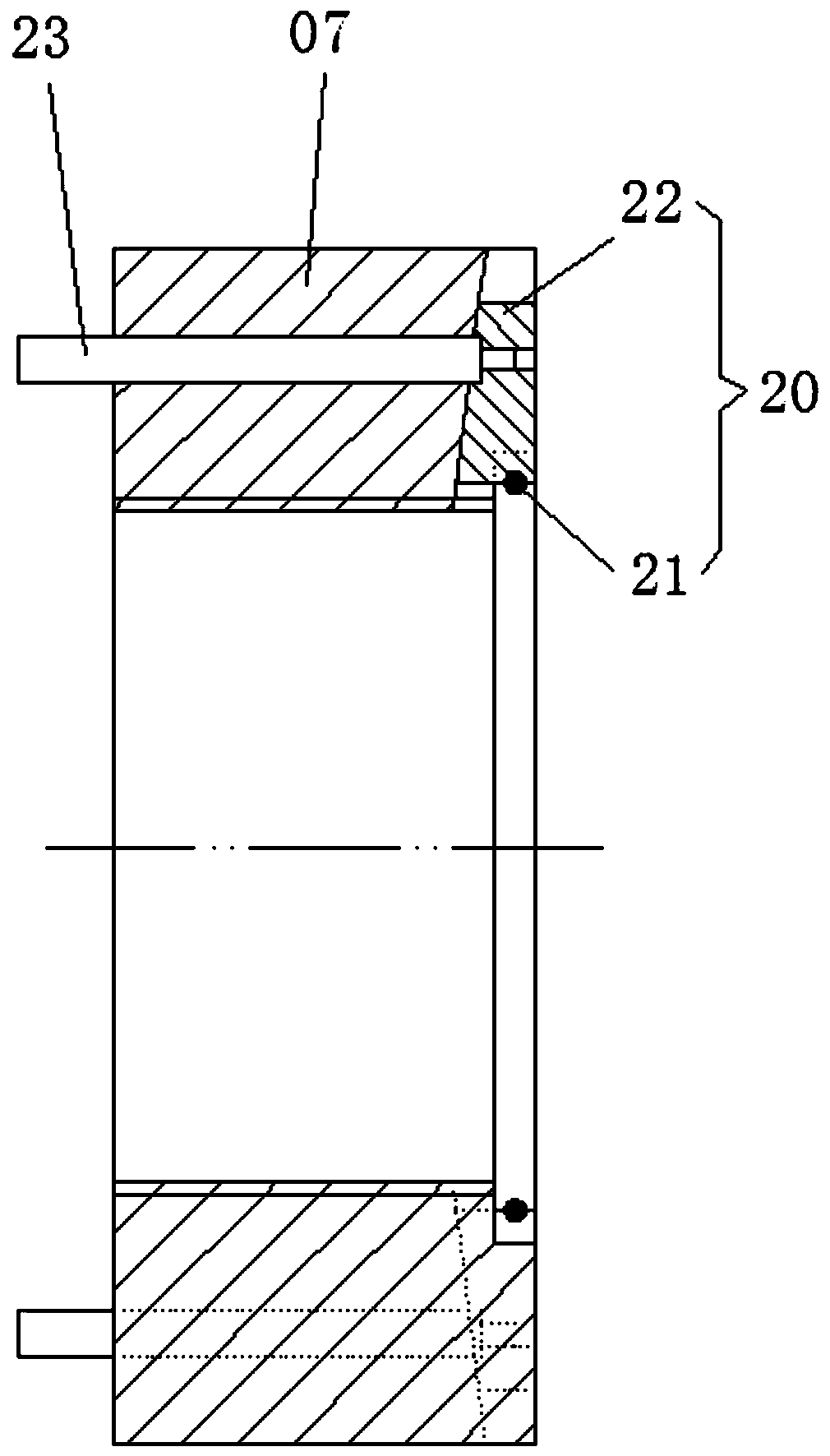

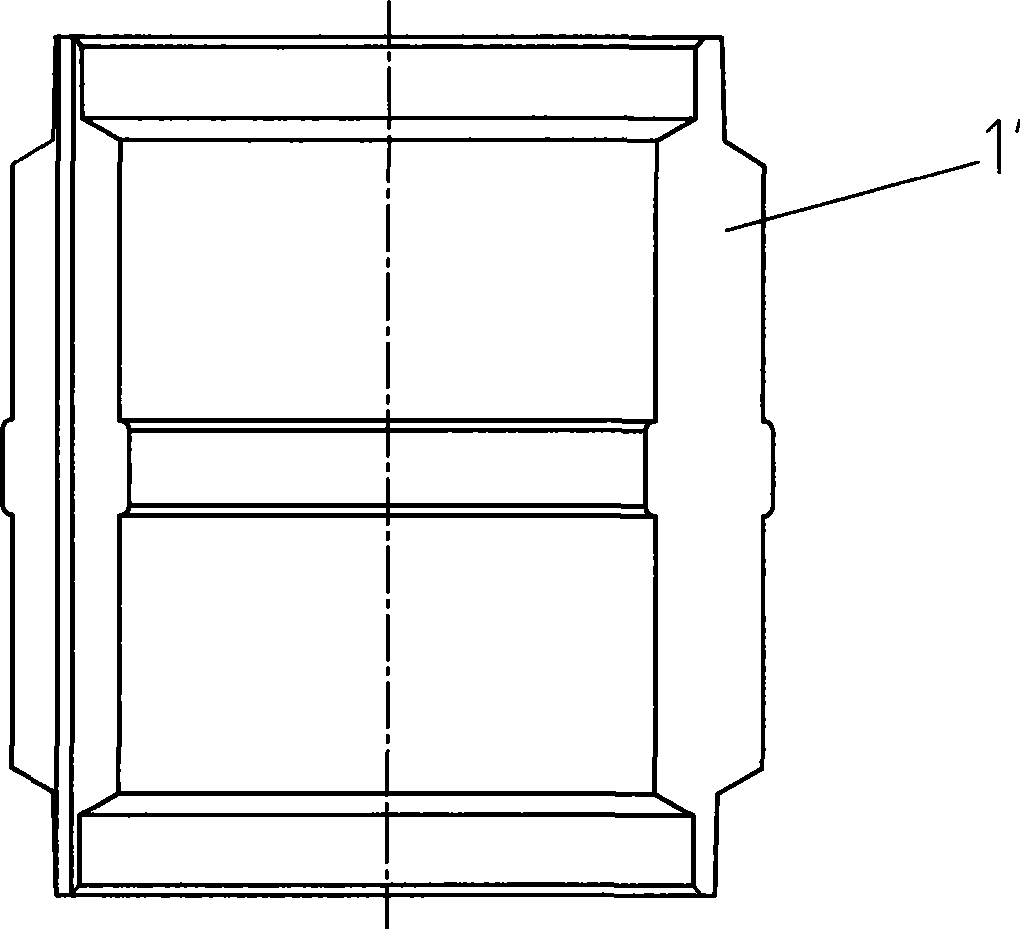

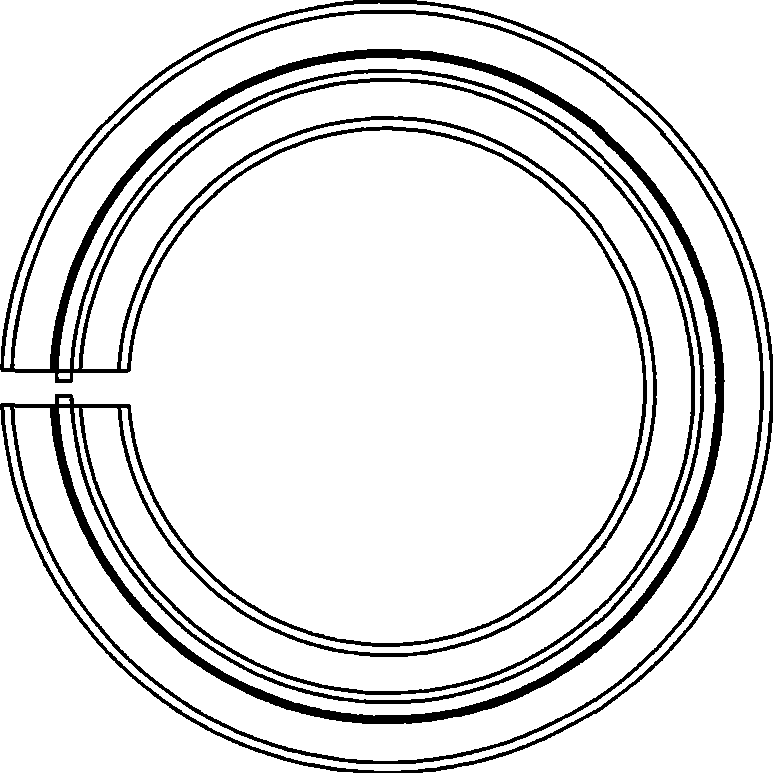

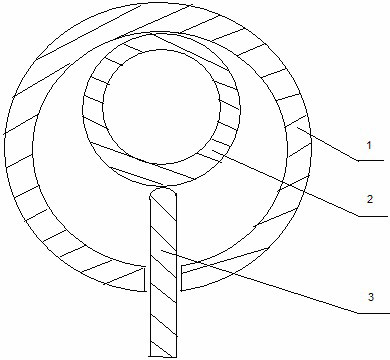

High-pressure hydrogen storage container with sealing structures at two ends

PendingCN110285315AImprove hydrogen embrittlement resistanceImprove fatigue strengthVessel mounting detailsVessel manufacturingHigh pressure hydrogenProcess engineering

The invention relates to the technical field of high-pressure hydrogen storage containers, and discloses a high-pressure hydrogen storage container with sealing structures at two ends. The high-pressure hydrogen storage container comprises a hydrogen storage cylinder, plungers mounted in inner holes at the two ends of the hydrogen storage cylinder, ejecting rings mounted at orifice parts of the two ends of the hydrogen storage cylinder and used for ejecting against the plungers, and tensioning devices for axially tensioning the plungers on the ejecting rings; sealing rings are arranged between the ejecting rings and the plungers; and low-hydrogen-embrittlement stainless steel metal overlaying layers are arranged on the surfaces of the inner holes of the hydrogen storage cylinder and the surfaces of the plungers. The high-pressure hydrogen storage container prolongs the product life period, improves the product reliability, and facilitates the product detection and maintenance after use.

Owner:JIANGYIN FUREN HIGH TECH

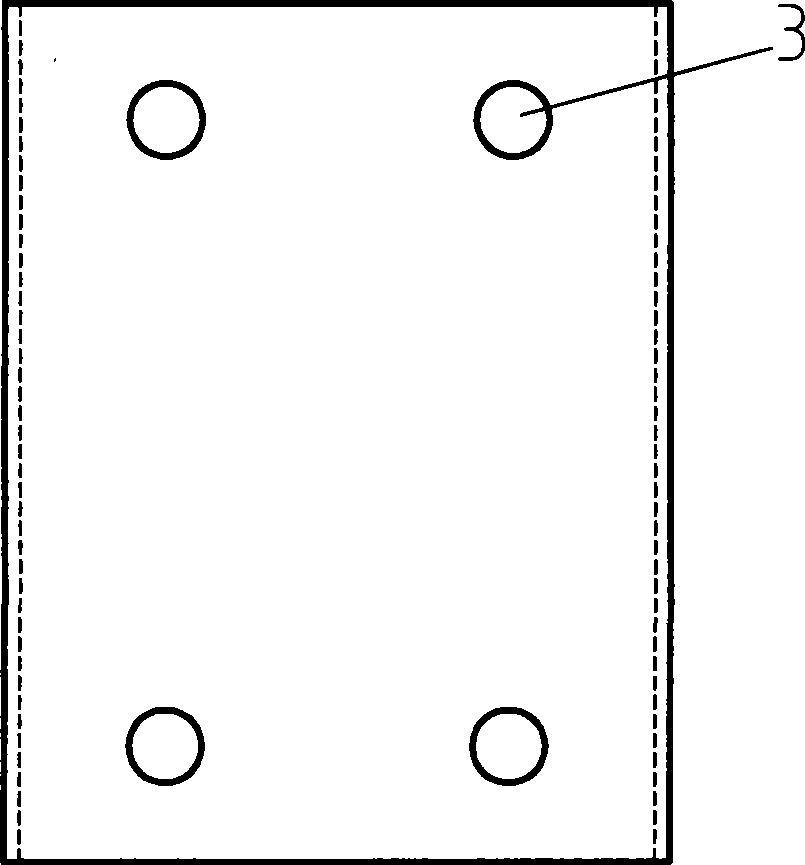

Balance suspension plate spring seat lining assembly

InactiveCN101486305AReduce shockReduce dynamic deformationResilient suspensionsSheet steelEngineering

The invention discloses a lining assembly of a balancing suspension steel plate spring seat for an automobile, which comprises two semicircular steel plates (2) as a framework butted in a tubular shape, two semicircular plates (2) are correspondingly formed with through holes (3), and rubber (1) vulcanized into a regulated shape and integrally adhered to the inner and outer sides of the semicircular plates (2) through the through holes (3) by adopting an injection or oppression method. The lining used for the automobile can effectively reduce impact distortion and dynamic distortion and satisfy rigidity and intensity requirements of different directions, and has superior damping effect and relatively high cohesiveness capability; besides, the better anti-fatigue performance of the lining can satisfy the requirement on service life of products.

Owner:大连安达汽车零部件有限公司

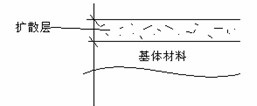

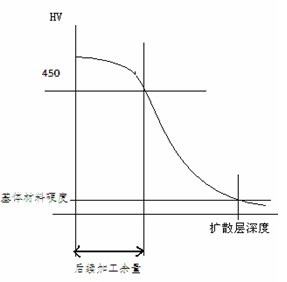

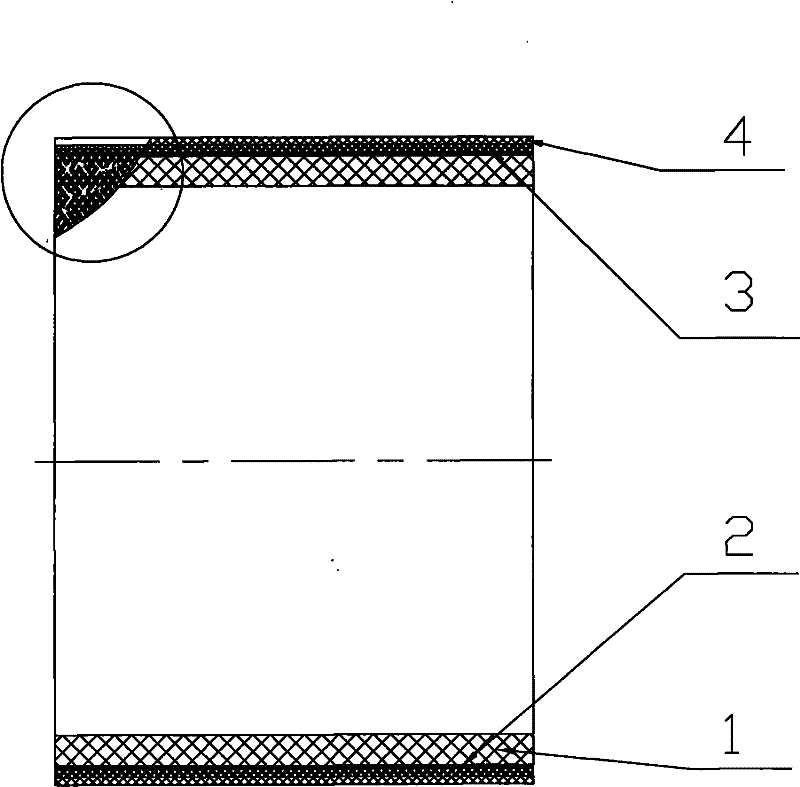

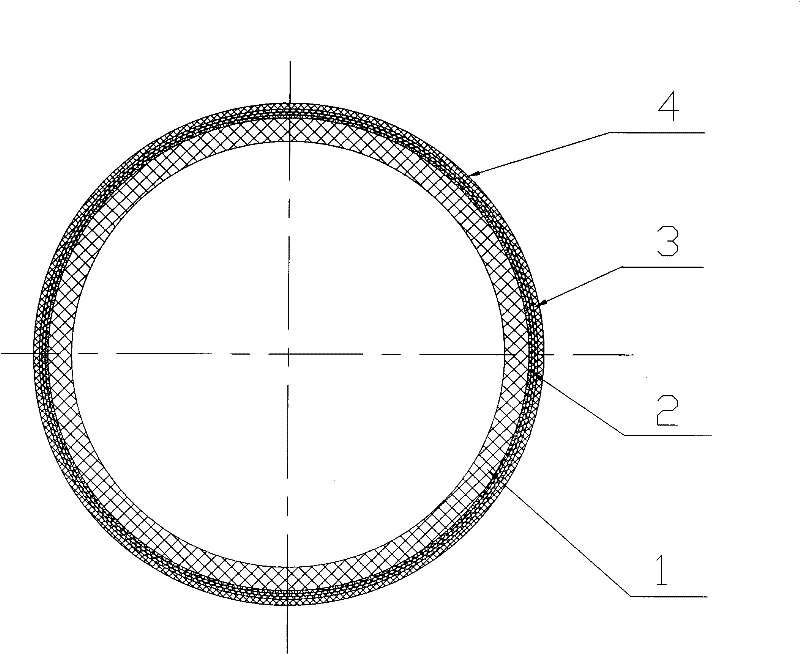

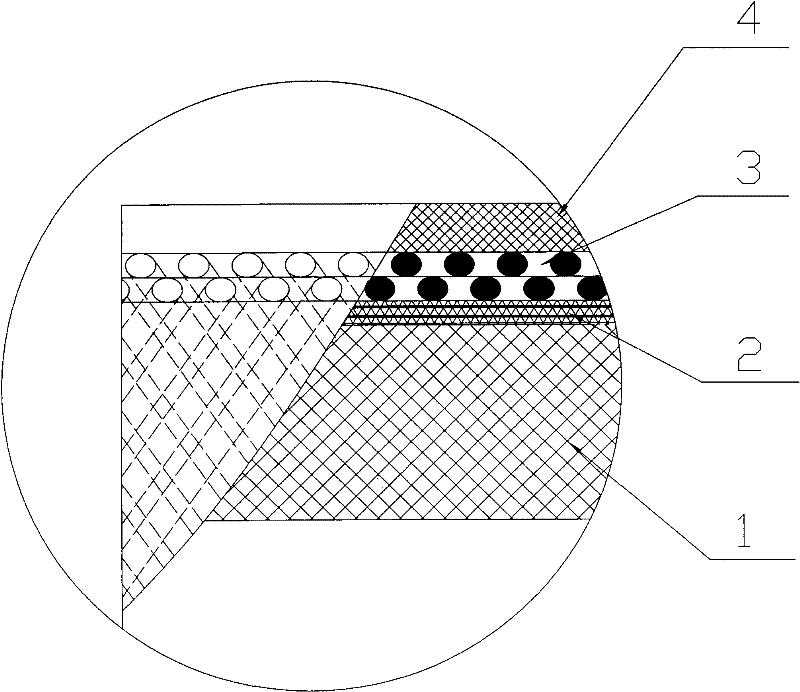

Piston for rotary compressor and manufacturing method of piston

InactiveCN102312838AIncrease coefficient of frictionNo lubricationSolid state diffusion coatingFurnace typesThermal treatmentCarbon steel

The invention relates to a piston for a rotary compressor and a manufacturing method of the piston. A matrix material for manufacturing the piston is piston coarse aggregate made from a 10#-50# carbon steel material or ferrous low alloy steel containing Ni, Cr and Mo. The manufacturing method is characterized by comprising the following steps of: carrying out rough grinding on the piston coarse aggregate first, then carrying out thermostabilization treatment, then carrying out nitriding treatment after the thermostabilization treatment, and finely grinding or polishing the piston subjected to nitriding treatment. According to the invention, materials with low cost in the market are used, which can completely meet the using requirements after being subjected to thermal treatment and nitriding treatment and can successfully substitute Ni-Cr-Mo alloy cast iron which has been used for 30 years, therefore the purposes of energy saving and consumption reduction are achieved.

Owner:浙江百达精工股份有限公司

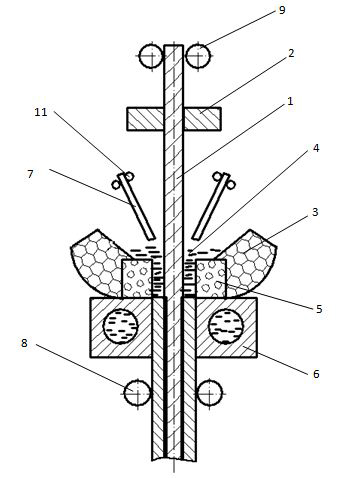

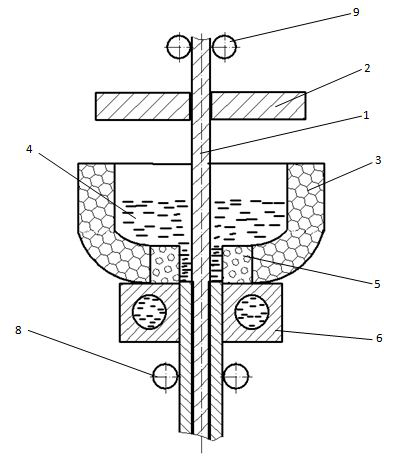

Novel structure for polyethylene reinforced compound pipe

The invention discloses a novel structure for a polyethylene reinforced compound pipe and belongs to the technical field of pipes. The novel structure for the polyethylene reinforced compound pipe comprises a substrate pipe, a metal reinforced layer, a fiber reinforced layer and an outer wall, wherein at least one metal reinforced layer and at least one fiber reinforced layer are arranged; specially used glues are heated and are used for integrally adhering the substrate pipe to the fiber reinforced layer, adhering the fiber reinforced layer to the metal reinforced layer and adhering the metal reinforced layer to the metal reinforced layer; the fiber reinforced layer is arranged at an equidistant interval, in the form of forming an inclined angle of 0-10 degrees between the fiber reinforced layer and the axial line of the pipe; an inclined angle between the metal reinforced layer and the axial line of the pipe is 54-70 degrees; the metal reinforced layer has a steel wire bidirectional crossed wound structure; the steel wire is a spring steel wire; and the diameter of the steel wire is 0.3-2.5 millimeters. The novel structure for the polyethylene reinforced compound pipe has the advantages of reasonable structure design, strong wear-resisting decay resistance and high loading capacity. Compared with a traditional pipe, the novel structure for the polyethylene reinforced compound pipe has the advantages that the loading capacity of the pipe is increased by 2-3 times, a steel pipe in a specific application field can be replaced by the polyethylene reinforced compound pipe, the application range is wide and the service life is long.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

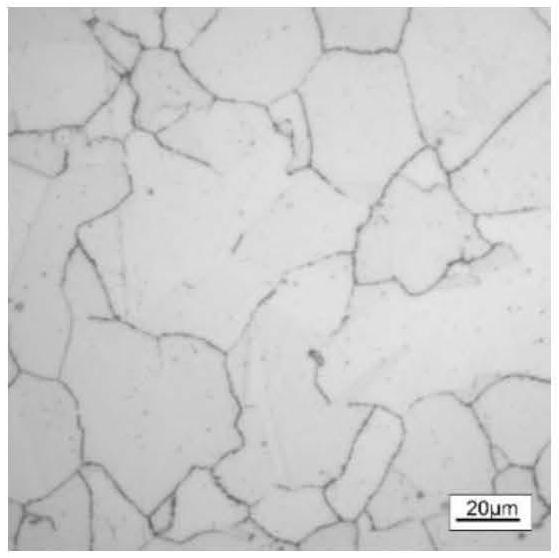

Hot working process of GH4738 nickel-based superalloy

PendingCN113560481AAvoid specimen crackingUniform tissueMetal-working apparatusWheelsVacuum induction meltingCrystallite

The invention discloses a hot working process of a GH4738 nickel-based superalloy. The process comprises the following steps that A, the GH4738 nickel-based superalloy is taken as a raw material, and is smelted by adopting a vacuum induction melting (VIM) process and a vacuum consumable remelting (VAR) process in sequence to obtain a vacuum consumable ingot; B, the vacuum consumable ingot is subjected to homogenization treatment and cogging forging treatment, and a GH4738 alloy bar blank is obtained; C, the GH4738 alloy bar blank is put into a gas furnace to be heated along with the furnace, flat anvil upsetting is conducted through a forging hammer after heat preservation, and a GH4738 alloy disc forge piece is obtained; and D, the GH4738 alloy disc forge piece is sequentially subjected to solution treatment, stabilizing treatment and secondary aging treatment, and the GH4738 nickel-based high-temperature alloy uniform in grain size and excellent in high-temperature erosion performance is obtained. According to the hot working process, the phenomena of mixed crystals, coarse crystals and the like in a GH4738 high-temperature alloy deformation structure can be avoided, the overall hardness and high-temperature erosion performance of a final forge piece are improved, and meanwhile the yield of the forge piece is increased.

Owner:INNER MONGOLIA UNIV OF TECH

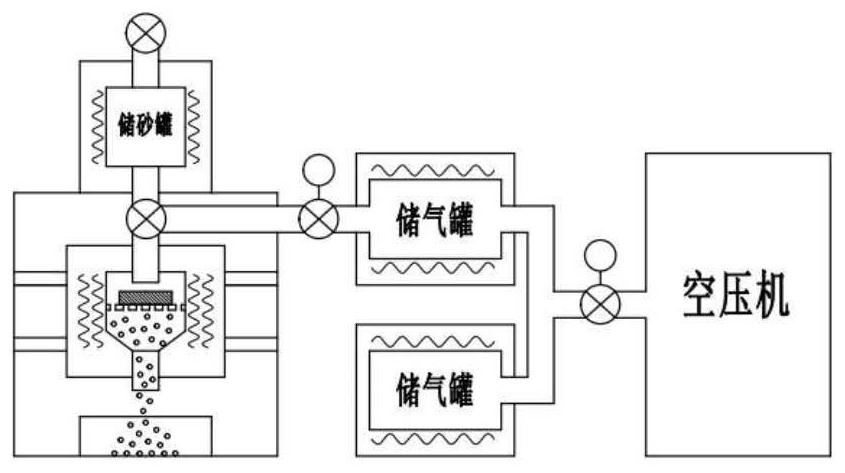

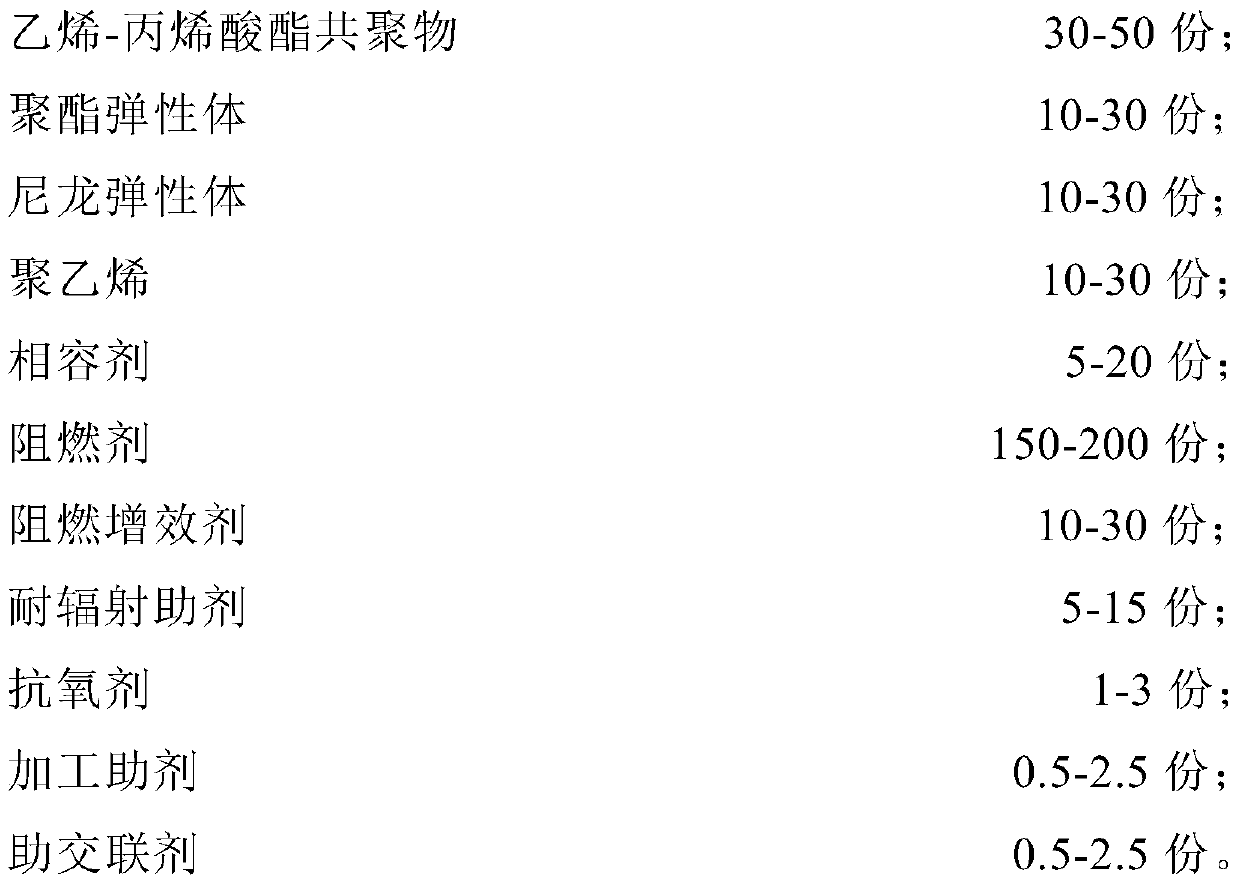

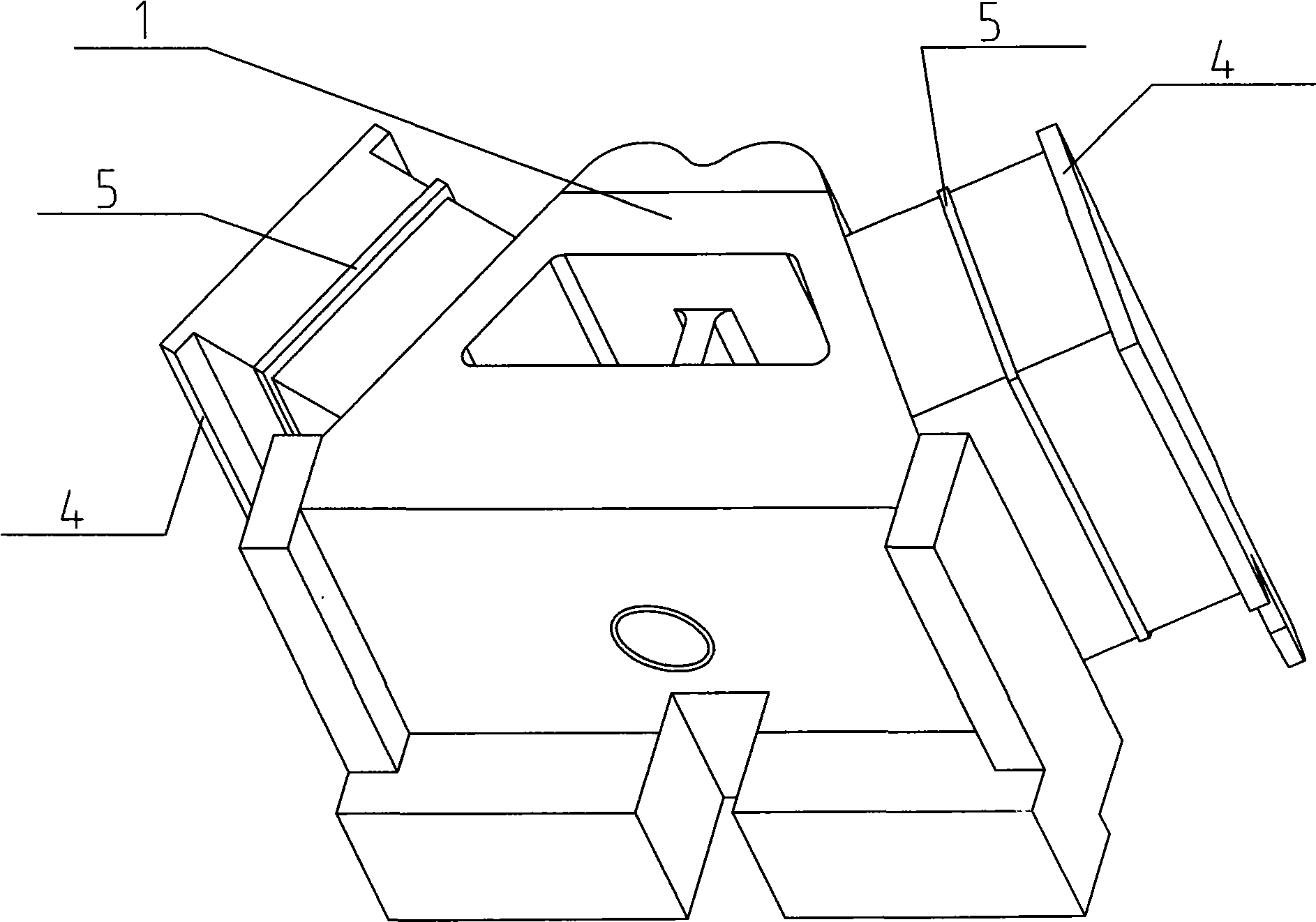

Nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material, and preparation method thereof

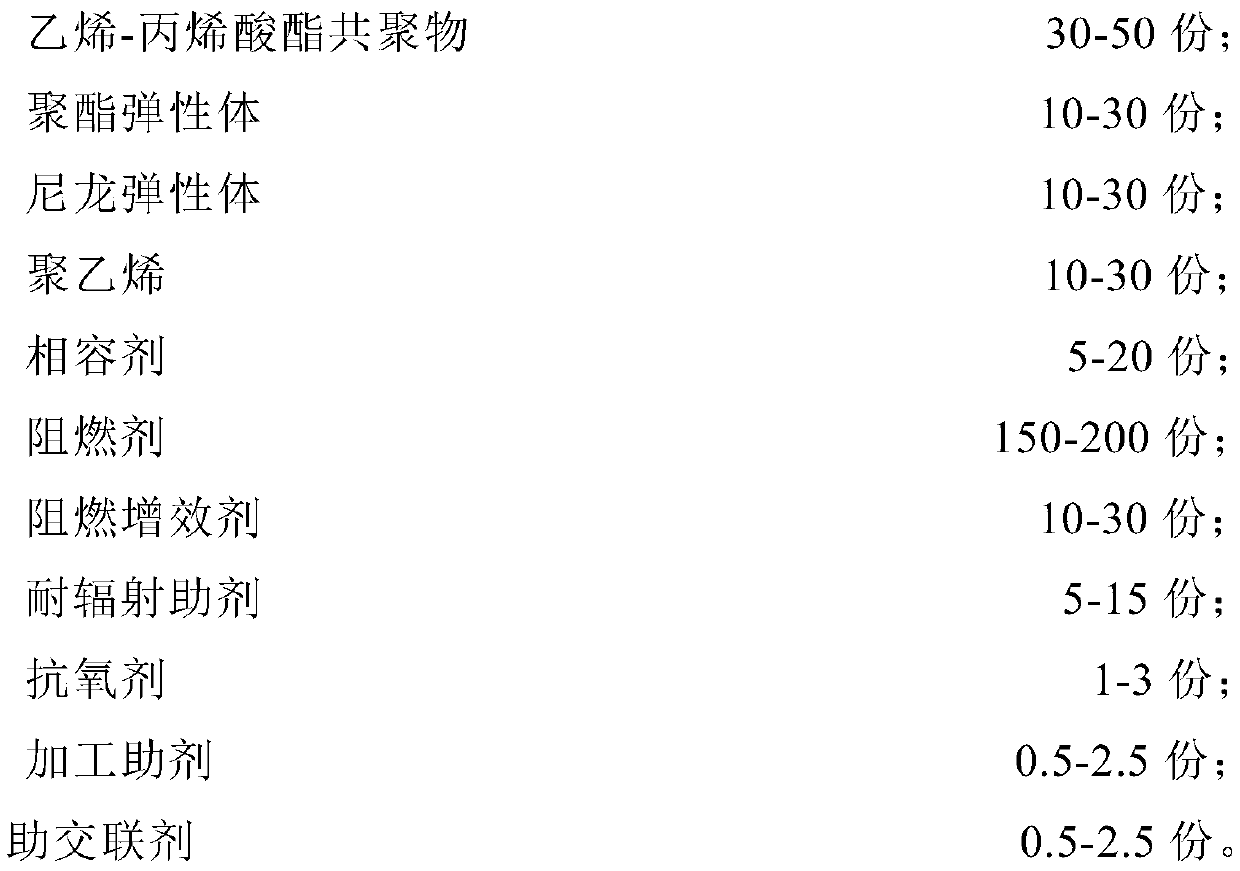

InactiveCN109705449AImprove high temperature and high humidity performanceGood low toxicityElastomerPolyester

The invention discloses a nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material, and a preparation method thereof. The nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material comprises, by weight, 30 to 50 parts of ethylene-acrylate copolymer, 10 to 30 parts of polyester elastomer, 10 to 30 parts of nylon elastomer, 10 to 30 parts of polyethylene, 5 to 20 parts of a compatilizer, 150 to 200 parts of a fire retardant, 10 to 30 parts of a flame retardant synergist, 5 to 15 parts of a radiation resistant auxiliary agent, 1 to 3 parts of an anti-oxidant, 0.5 to 2.5 parts of a processing auxiliary agent, and 0.5 to 2.5 parts of an auxiliary crosslinking agent.

Owner:上海至正新材料有限公司

Chargeable 3V button-type lithium battery

InactiveCN102610848AMeet service life requirementsRealize no replacementCell electrodesLi-accumulatorsFiberComposite film

The invention discloses a chargeable 3V button-type lithium battery with a lithium ferrous phosphate positive electrode. The chargeable 3V button-type lithium battery comprises two half type metal shells, a diaphragm and a filling electrolyte are arranged in each shell, a positive electrode and a negative electrode are respectively arranged on two sides of each diaphragm, each diaphragm is a cellular polypropylene and polyethylene film or a composite film of combined both or a polypropylene felt or a fibrous paper film; the positive electrode is made of a current collector and a positive electrode material, the current collector is a stainless steel wire, and the positive electrode material consists of lithium-lack type lithium ferrous phosphate, an electric conducting agent and an adhesive; and a negative electrode is lithium aluminum alloy, and the electrolyte is prepared by dissolving lithium salt in an organic solution. The chargeable 3V button-type lithium battery disclosed by the invention has the advantages of high capacity, small self discharge, strong deep discharge capability, long service life and the like, and is an ideal substitute product of the 3V button-type chargeable lithium battery with manganese dioxide as the positive electrode.

Owner:天津赫维科技有限公司

Rear suspension bracket cushion assembly

InactiveCN101486310AImprove carrying capacityReduces impact deformation and dynamic deformationNon-rotating vibration suppressionJet propulsion mountingDistortionInternal cavity

The invention discloses a rear suspended bracket cushion assembly, which comprises a bracket assembly (2) and a rear suspended cushion assembly (1) inserted into and jointed with an inner cavity of the bracket assembly. The cushion assembly comprises an upper seat (3) and rubber-made cubic units on two sides, and an intermediate board is arranged between the upper seat of the cushion assembly (1) and a limiting board. The interior of the bracket assembly is V-shaped and two sides of the bracket assembly are provided with rectangular grooves (12) for accommodating the limiting board (4) of the cushion assembly (1). The rear suspended bracket cushion assembly provided for a high power engine of a camion improves the carrying capacity and gives equal consideration to two types of distortion of compression and shear so as to satisfy the requirements on different rigidities and strengths, and effectively reduce impact distortion and dynamic distortion. The assembly has the advantages of higher intensity, better damping effect, better limiting performance and more excellent anti-fatigue performance so as to fully satisfy the requirement of an automobile on the service life of the product.

Owner:大连安达汽车零部件有限公司

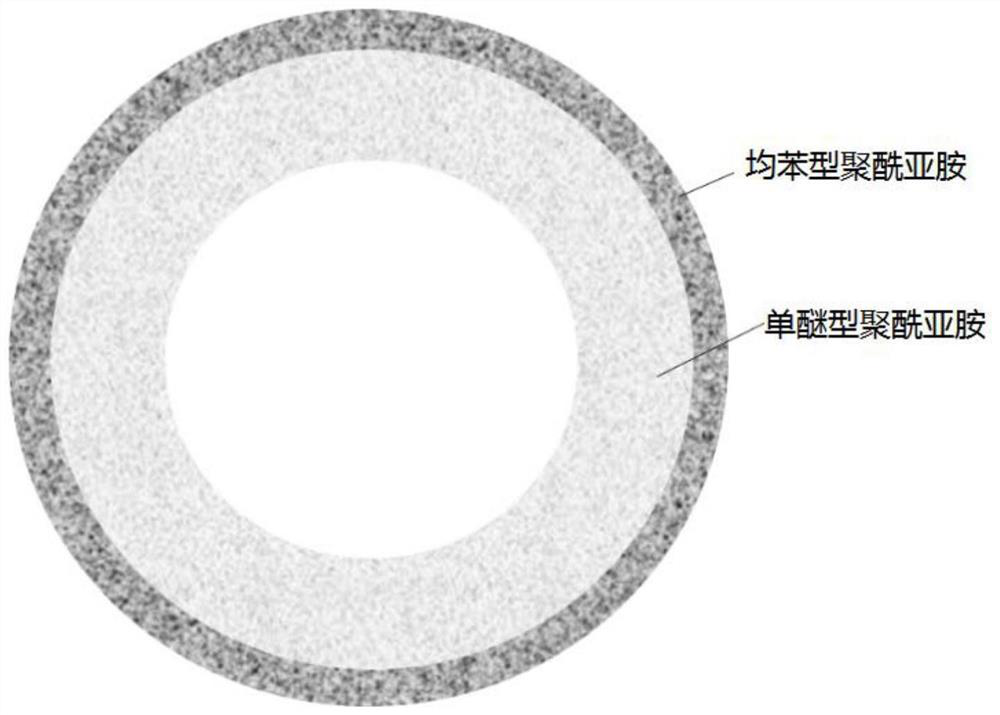

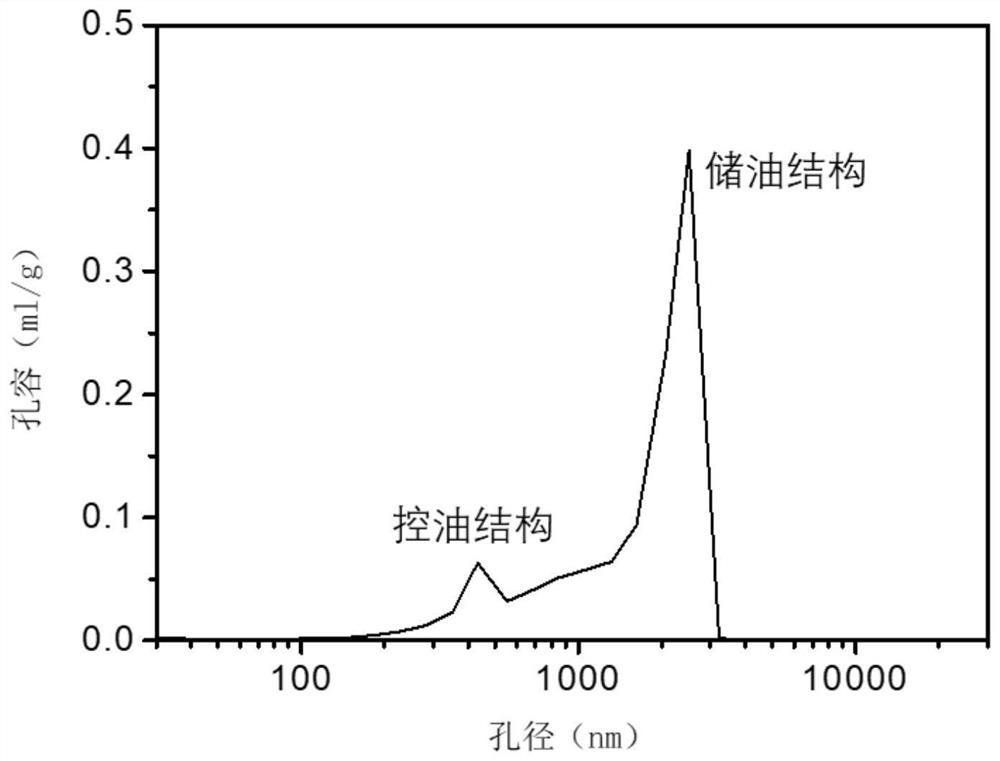

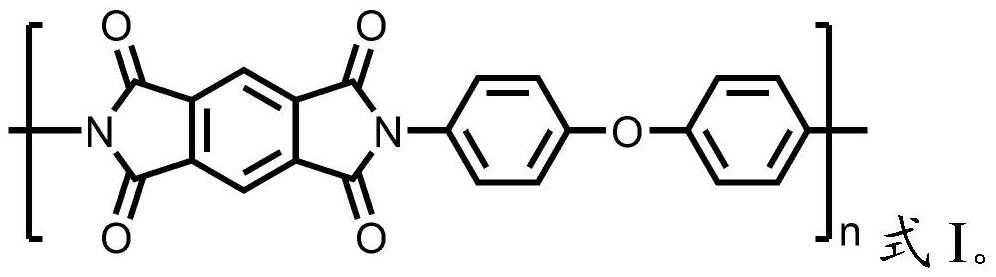

Porous polyimide oil storage and retention structure and preparation method and application thereof

PendingCN113147105AHigh melting pointHigh oil storage rateSynthetic resin layered productsLaminationPore diameterPolyimide

The invention provides a porous polyimide oil storage and retention structure and a preparation method and application thereof, and relates to the technical field of polyimide materials. The porous polyimide oil storage and retention structure comprises an oil storage layer and an oil control layer; the oil storage layer is made of monoether type polyimide, the porosity of the monoether type polyimide is 18-26%, and the aperture of the monoether type polyimide is 1.0-3.0 [mu] m; the oil control layer is made of pyromellitic polyimide, the porosity of the pyromellitic polyimide is 12-18%, and the pore diameter of the pyromellitic polyimide is 0.6-1.0 [mu] m. The pyromellitic polyimide is low in porosity and small in aperture so that the oil release rate of the composite material can be slowed down, and the oil retention rate can be increased; the monoether polyimide is high in porosity and large in aperture, so that the porosity and the oil storage rate of the composite material can be improved; the composite material provided by the invention has high oil storage rate and oil retention rate and good strength and wear resistance, and can meet the requirement of a high-speed and high-precision bearing on the service life.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Bus ribbon welding process for thin film solar cell

InactiveCN102744483AMeet the requirements of long service lifeMeet service life requirementsFinal product manufactureSoldering apparatusEngineeringCopper

The invention discloses a bus ribbon welding process for a thin film solar cell and belongs to the field of semiconductor photoelectricity. The process uses a thin film solar cell with an aluminum back electrode, at least two drainage ribbons, namely the left drainage ribbon and the right drainage ribbon, are arranged on the back electrode of the thin film solar electrode, the left drainage ribbon, the right drainage ribbon and the back electrode are welded by ultrasound, a left bus ribbon and the left drainage ribbon are hot-welded to form a welding point, a right bus ribbon and the right drainage ribbon are hot-welded to form another welding point, the left drainage ribbon and the right drainage ribbon are copper and aluminum composite ribbons, and the left bus ribbon and the right bus ribbon are tinned copper ribbons. Therefore, welding speed and quality can be guaranteed effectively, the bus crosspoint is firm and reliable, and the problems of bussing cost and service life of thin film cells are solved effectively.

Owner:河南新能光伏有限公司

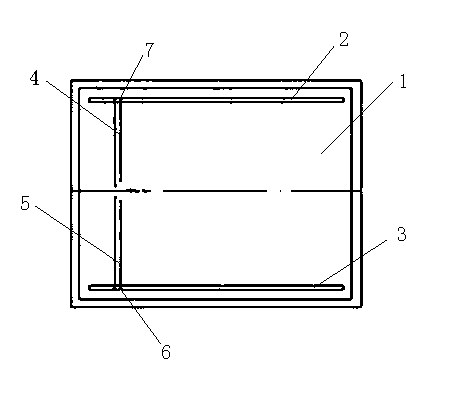

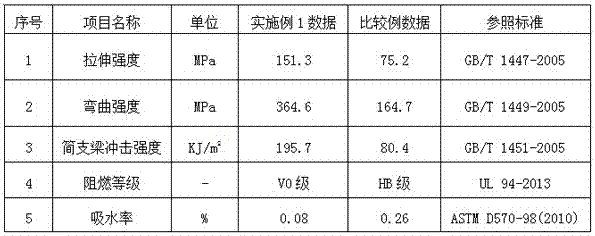

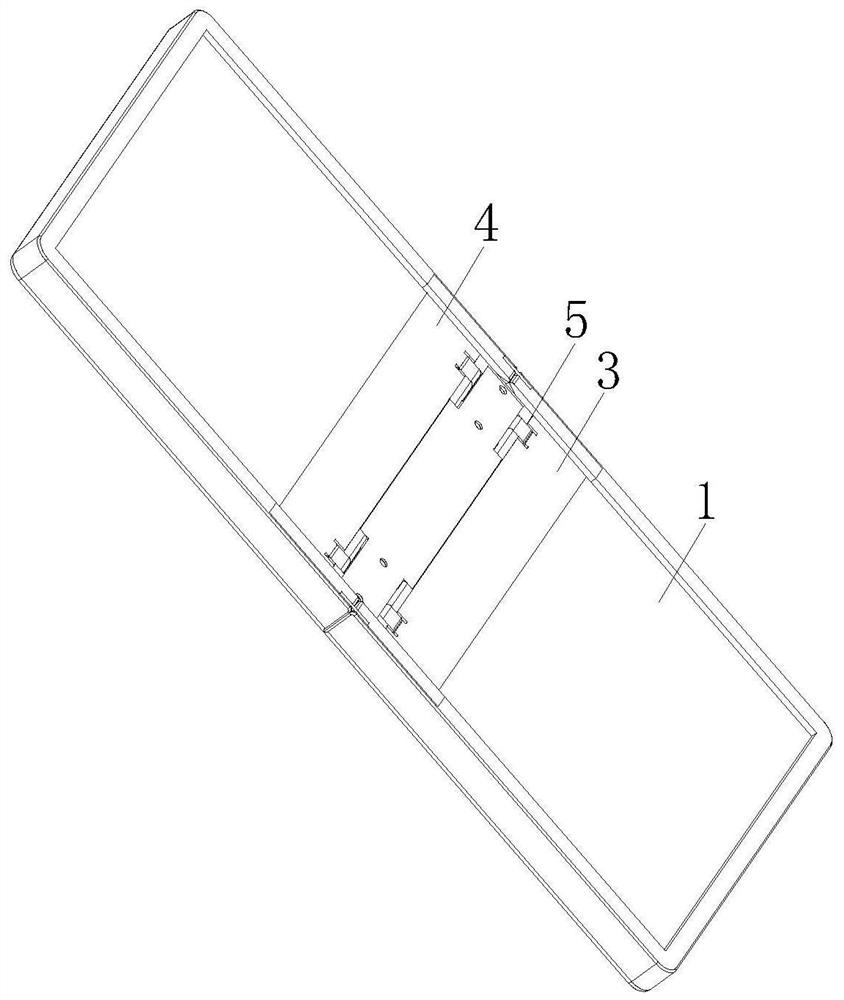

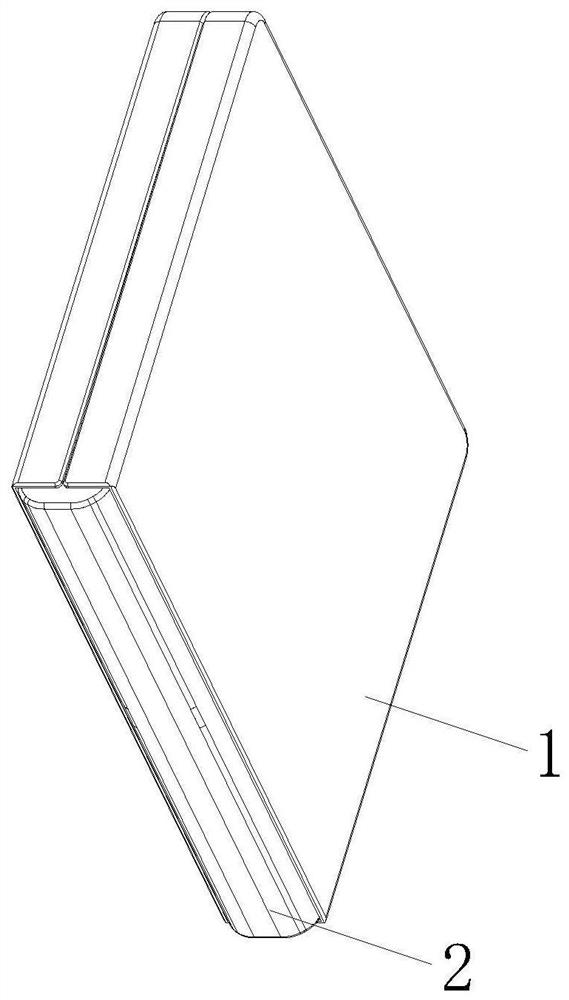

Continuous oriented glass fiber-reinforced high-flame retardance and low-water absorption rate sheet molding compound and preparation method thereof

InactiveCN107474507AImprove mechanical propertiesMeet stability requirementsGlass fiberSheet moulding compound

The invention relates to a continuous oriented glass fiber-reinforced high-flame retardance and low-water absorption rate sheet molding compound and a preparation method thereof and belongs to the field of composite materials. The molding compound comprises the following matters in parts by weight: 60-90 parts of unsaturated polyester resin, 10-40 parts of a low shrinkage agent, 0-10 parts of styrene, 100-200 parts of a filler, 60-120 parts of glass fiber, 0.5-2.0 parts of an initiating agent, 0-0.1 part of a polymerization inhibitor, 0.5-2.0 parts of a thickening agent, 2-6 parts of an internal releasing agent and 0-4 parts of a processing aid. Compared with a conventional full chopped glass fiber reinforced sheet molding compound, the continuous oriented glass fiber-reinforced high-flame retardance and low-water absorption rate sheet molding compound has the benefits that under the situation that the mass fraction of the glass fiber is not improved, chopped glass fiber in the continuous oriented glass fiber matching part is used as a reinforcing material, so that the mechanical properties of the material are significantly improved; the material flame-retardant grade achieves UL-94 VO, and the water absorption rate is less than 0.15 percent; the invention provides the preparation method of the continuous oriented glass fiber-reinforced high-flame retardance and low-water absorption rate sheet molding compound.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

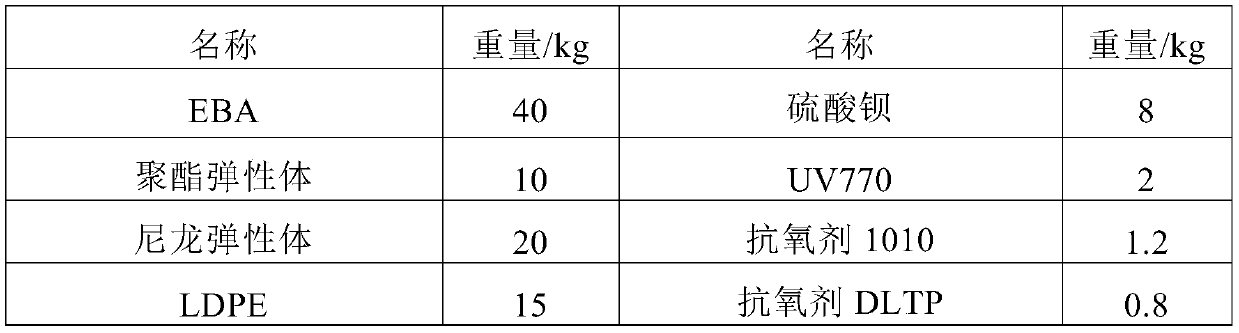

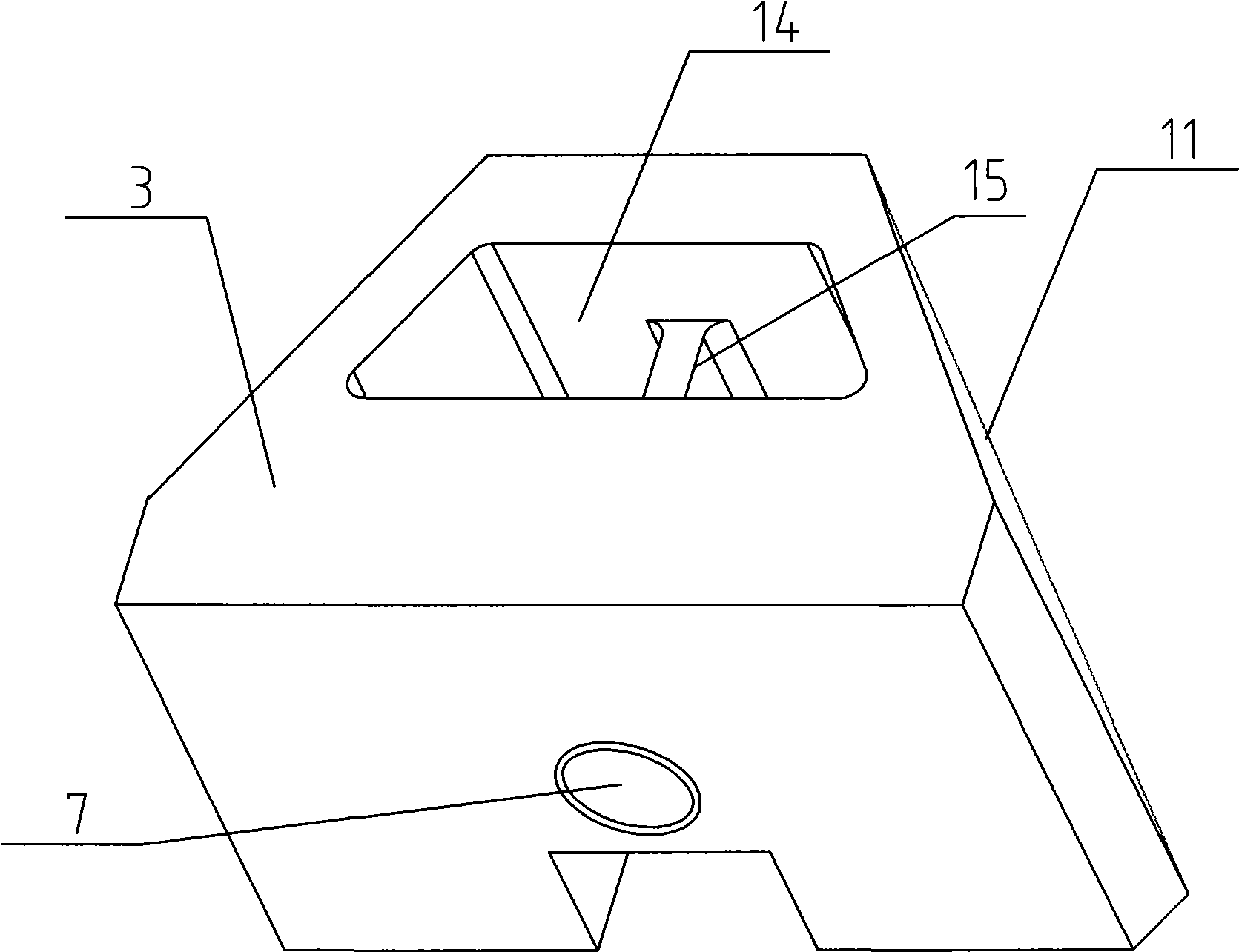

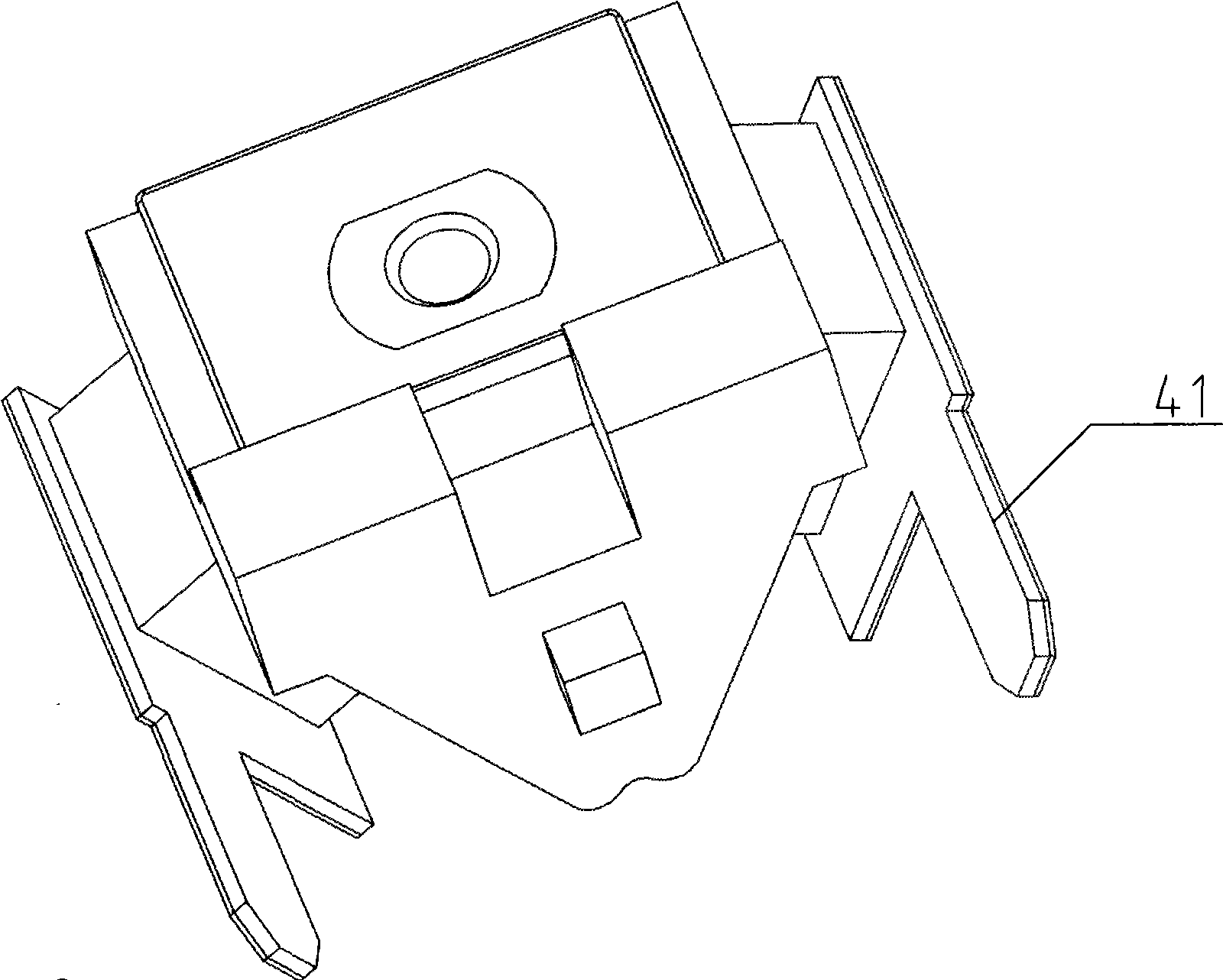

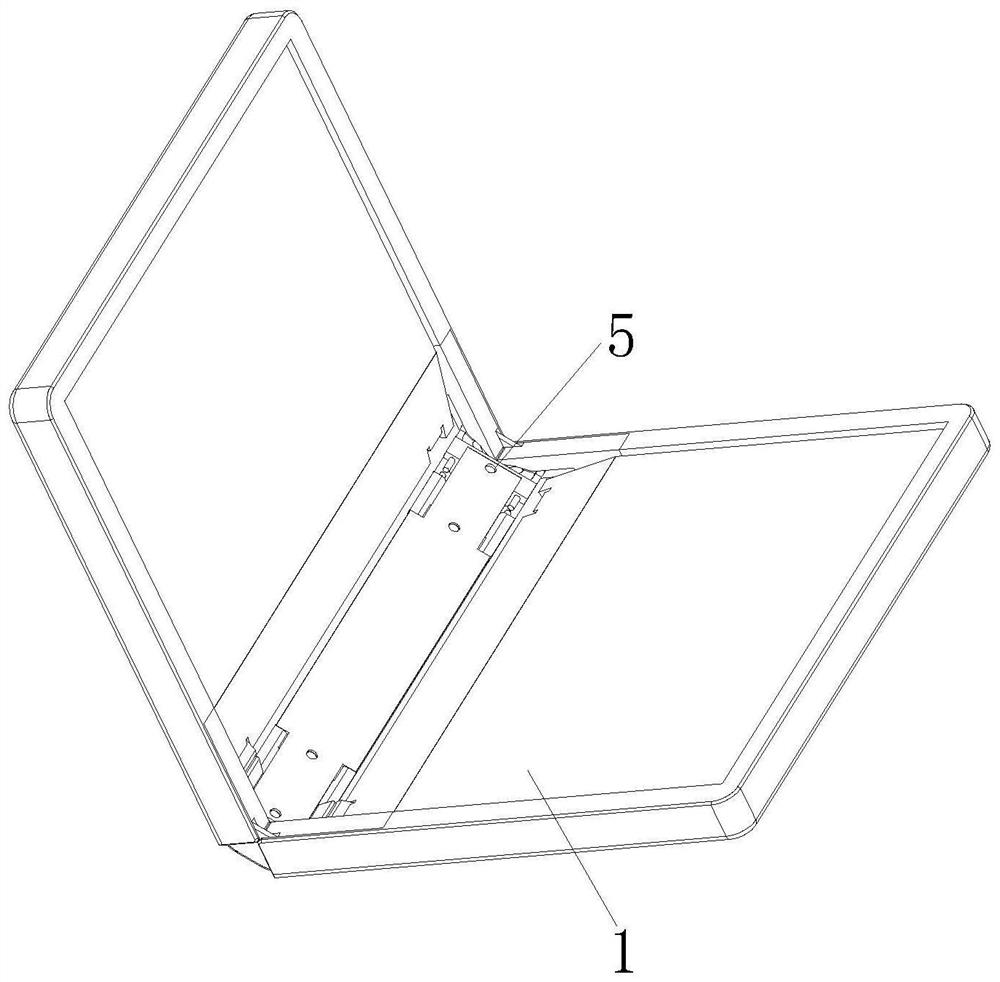

Multi-mode opening and closing drop-shaped inwardly-folding rotating mechanism

PendingCN111810522ASatisfy rotation needsReduce processing difficultyPivotal connectionsTelephone set constructionsGear wheelCam

Owner:DONGGUAN JINFENG ELECTRONICS

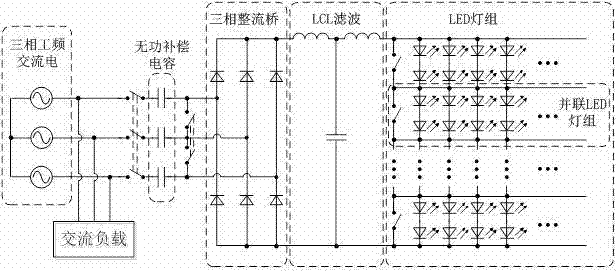

Reactive compensation equipment with LED (light emitting diode) constant-current driver

ActiveCN104753073AReduce electromagnetic interferenceWide load rangeElectric circuit arrangementsElectric light circuit arrangementLed driverInductive load

The invention provides reactive compensation equipment with an LED (light emitting diode) constant-current driver. The reactive-load compensation equipment with the LED constant-current driver comprises a three-phase power frequency alternating-current power supply, reactive compensation capacitors, a three-phase rectifier bridge, an LCL (lower control limit) filter and an LED lamp bank which are sequentially connected to one another; each phase of the three-phase power frequency alternating-current power supply is connected with one end of the corresponding reactive compensation capacitor through a corresponding switch; the other ends of the reactive compensation capacitors are connected to midpoints, which correspond to a bridge arm, of three-phase inputting sides of the three-phase rectifier bridge; two switches are arranged on one side, which is close to the rectifier bridge, of each reactive compensation capacitor; and when the two switches of each reactive compensation capacitor are switched on simultaneously, the three reactive compensation capacitors are connected to one another in a star-shaped manner. By the reactive compensation equipment, reactive compensation can be realized, the latter LED driver does not need an electrolytic capacitor, the service life is long, a complex controller is not required, and the reactive compensation equipment with the LED constant-current driver is maintained and repaired conveniently in the later period, has important using value for places needing reactive compensation, is suitable for workshops at which a large number of inductive loads are used, and is also suitable for places needing reactive compensation and illumination such as a power distribution room with a transformer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Transformer coil bending-shaped oil guide system

ActiveCN103123857AMeet service life requirementsGuaranteed cooling effectTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerCooling effect

The invention relates to a transformer coil bending-shaped oil guide system. A longitudinal oil channel-bending-shaped oil guide structure is arranged in a coil. The transformer coil bending-shaped oil guide system is characterized by comprising a coil wire, a transverse oil channel, a coil inner diameter side longitudinal oil channel, a coil outer diameter side longitudinal oil channel, a coil middle longitudinal oil channel, an inner oil stopping ring and an outer oil stopping ring. Each coil pie in the coil is divided into three equal portions. According to the odd number coil pies, the longitudinal oil channels are only arranged between a first portion coil pie and a second portion coil pie. According to the even number coil pies, the longitudinal oil channels are only arranged between a second portion coil pie and a third portion coil pie, a result is calculated according to the height of the coil, the number of the coil pies and distribution of oil flow and an inner oil stopping clapboard and an outer oil stopping clapboard are arranged along the height direction of the coil. The transformer coil bending-shaped oil guide system is high in filling coefficient, good in cooling effect, excellent in performance parameters and capable of effectively guaranteeing coil heat dissipation effect, reducing coil temperature rise and satisfying the requirement for transformer service life of a user.

Owner:SHANDONG DACHI ELECTRIC

Novel composite insulator material and preparation method thereof

InactiveCN107141664AMeet the electrical characteristicsFulfil requirementsComposite insulatorsStearic acid

The invention discloses a novel composite insulator material. The novel composite insulator material is prepared from the following raw materials in parts by weight: 25-35 parts of fluororubber raw rubber, 18-27 parts of methyl vinyl silicone rubber, 15-26 parts of EPDM (ethylene-propylene-diene monomer) rubber, 7-13 parts of polyimide, 10-20 parts of silica powder, 12-25 parts of aluminum hydroxide, 6-13 parts of polypropylene, 2-5 parts of stearic acid, 3-7 parts of fumed silica, 1-3 parts of a plasticizer, 2.3-4.7 parts of a colorant, 1-2 parts of a treatment agent and 1.5-2.3 parts of an anti-aging heat-resistant additive. The novel composite insulator material of the invention can meet electrical characteristic and mechanical performance requirements of an insulator, also has anti-fouling and self-cleaning functions, cannot hinder safe operation of a line, is energy-saving and environmentally friendly and has relatively good marketing value.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

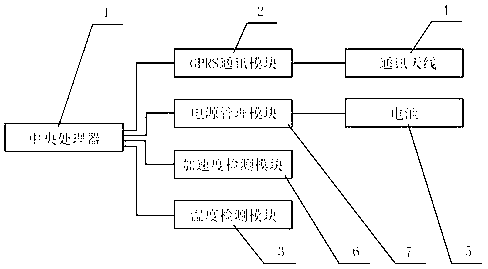

Maintenance-free active position tracer for container positioning

InactiveCN102937712ADown to consumptionReduce operating frequencyEnergy efficient ICTTransmission systemsGeneral Packet Radio ServiceElectrical battery

The invention provides a maintenance-free active position tracer for container positioning, which is low in power consumption and long in service life. The maintenance-free active position tracer comprises a central processor, a GPRS (General Packet Radio Service) communication module, an acceleration detection module, a communication antenna and a battery, wherein the central processor is respectively connected with the GPRS communication module and the acceleration detection module, and the GPRS communication module is connected with the communication antenna. The maintenance-free active position tracer is characterized by also comprising a power management module and a temperature detection module, wherein the central processor is respectively connected with the power management module and the temperature detection module, the power management module is connected with the battery, the central processor is used for controlling working frequencies and working modes, and the battery is high in resistance. The energy consumption of the battery is reduced by optimizing the working frequency and selecting a technical scheme and components with low power consumption. By carrying out optimization management on the battery and improving the driving capability of the battery, the position tracer meets the requirement on a service life of ten years.

Owner:天津孚感科技有限公司

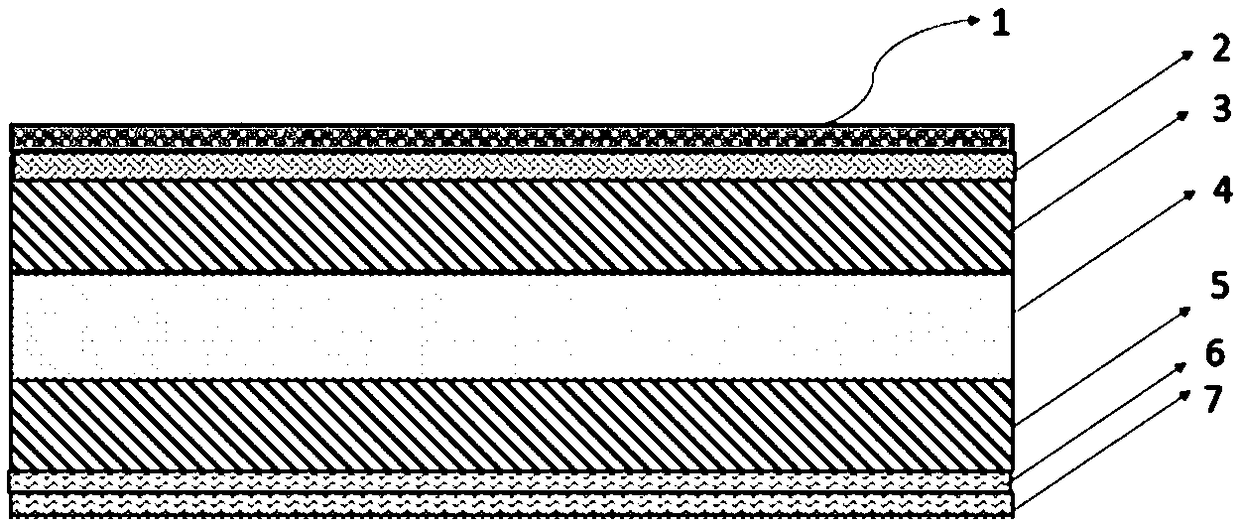

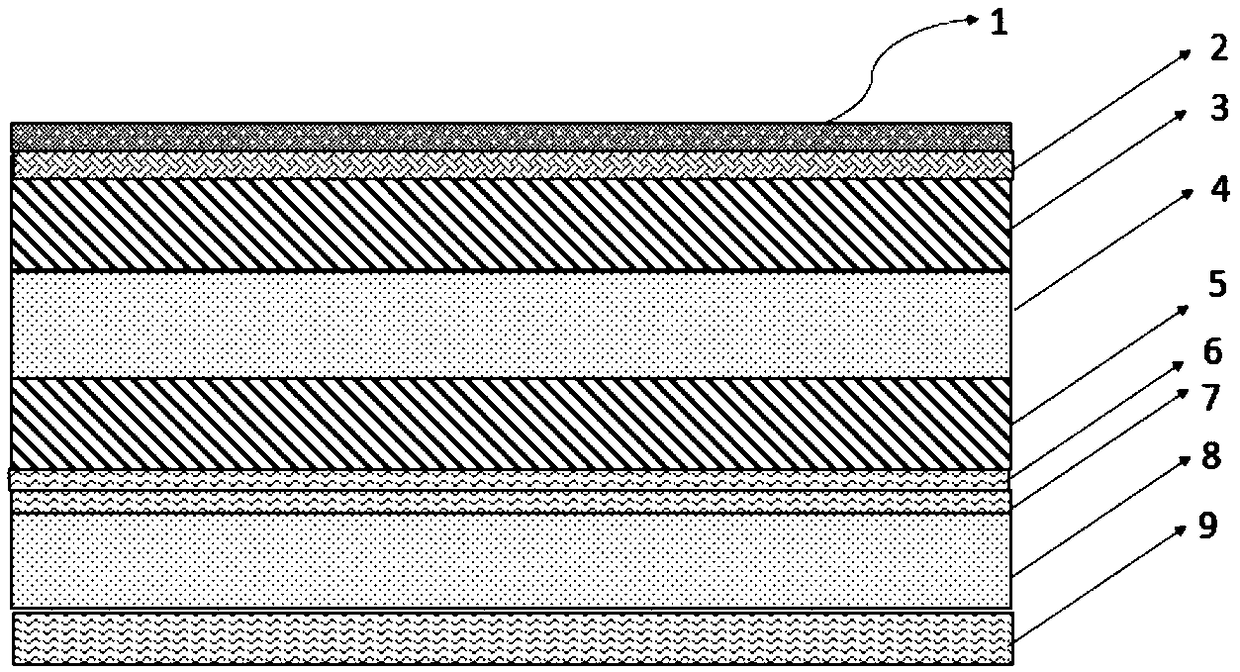

A packaging front panel and a preparation process thereof

PendingCN109087963AImprove scratch resistanceImprove aging resistancePhotovoltaic energy generationSemiconductor devicesComposite filmWater vapor

The invention provides an packaging front panel and a preparation process thereof, wherein the packaging front panel is a composite film bonded on the upper surface of a solar cell module, and the composite film comprises an anti-adhesion coating, an abrasive anti-aging layer, a first thin film base material layer, a first adhesive film layer, a second thin film base material layer, a modified undercoat layer and a water vapor barrier layer from top to bottom. The packaging front panel of the invention can meet the requirements of lower water vapor transmission rate and lower service life of mobile energy sources (less than 5 years), meanwhile, the surface of the flexible front panel is anti-fingerprint and anti-scratch, the packaging process is simple and efficient, and the material and process cost are low.

Owner:DONGJUN NEW ENERGY CO LTD

Production process of new energy solar power generation panel

InactiveCN112349808AHigh light conversion efficiencyImprove convenienceFinal product manufacturePhotovoltaicsTest batteryElectrical battery

The invention discloses a production process of a new energy solar power generation panel. The production process comprises the steps: putting produced battery pieces into a battery testing machine for testing output parameters of the batteries and classifying the battery pieces, connecting the solar batteries in series in an infrared spot welding manner to form a solar battery string, and puttingthe batteries into the grooves in the corresponding mold plates through a mechanical arm. By adopting the process product produced and molded by the invention, the production efficiency is greatly improved by adopting a full-automatic production mode, and the positive terminal and the negative terminal can be further formed on the back surface of the base material through the electric soldering iron and the soldering tin wire, so that the convenience of the whole solar cell panel in use is greatly improved; the heat conduction coating is excellent in binding power, weather resistance meets the requirement for the service life of 25 years or longer of the solar module, the heat conduction effect is excellent, the light conversion efficiency of the solar backboard is greatly improved, and the process of the product better meets the market requirement.

Owner:曹景

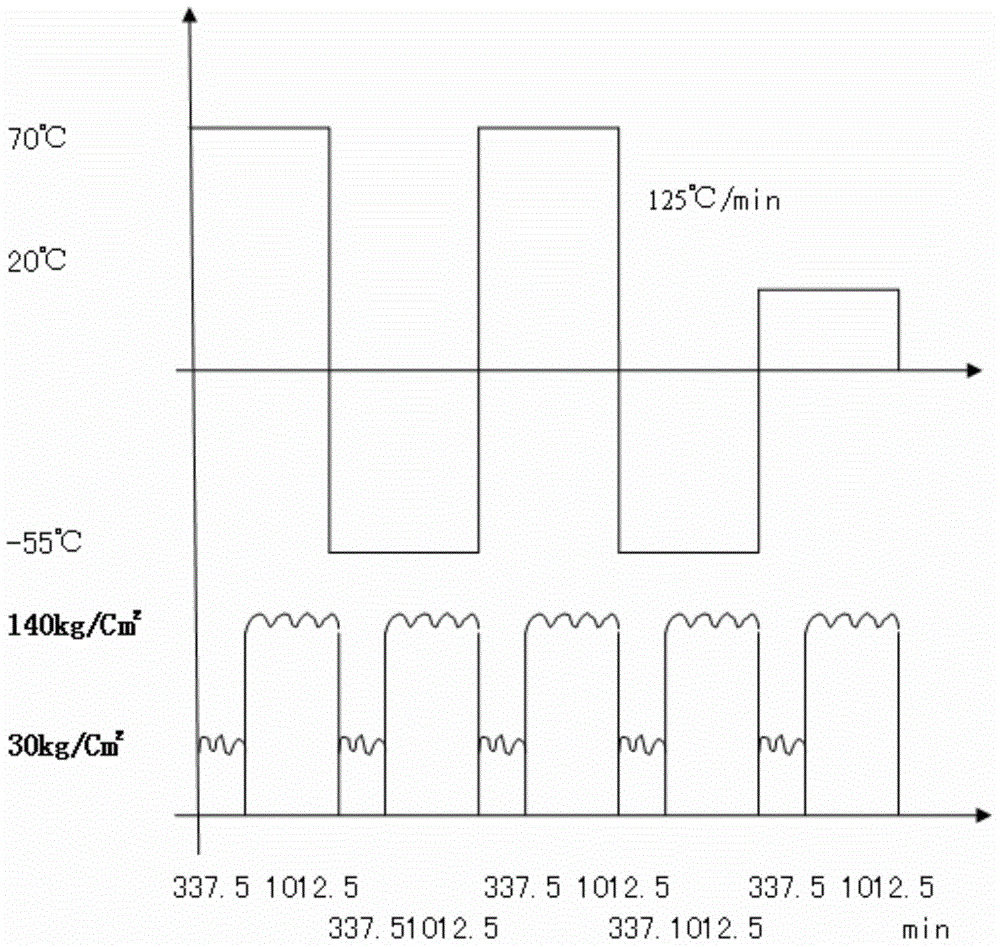

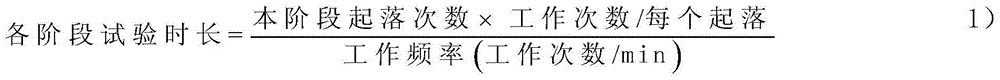

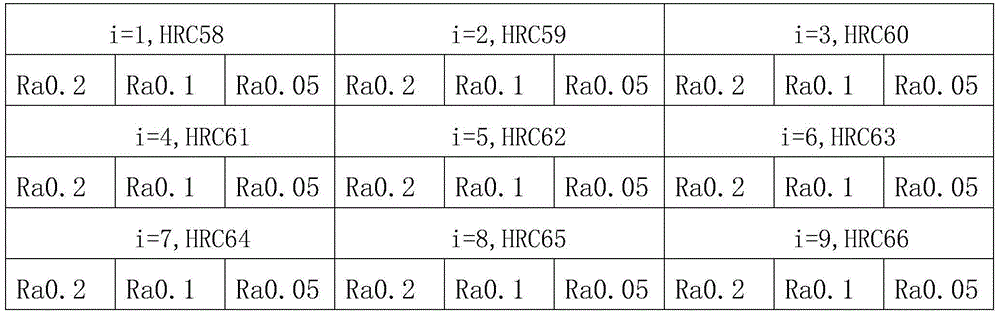

Method for verifying internal leakage fault of aircraft brake valve

InactiveCN104819836AReduce manufacturing overheadElimination of internal leak failure modesMachine part testingFluid-tightness measurementValidation methodsEngineering

A method for verifying an internal leakage fault of an aircraft brake valve comprises the steps of determining a life test scheme of a brake valve according to the operating condition, performing life test according to the life test scheme, determining the specific scope of roughness and the specific scope of hardness of the fitting surface between a valve core and a valve sleeve according to life test data, and adding manufacturing parameters minimizing the cost to a design drawing. By adopting the method of the invention, the wear life of a slide valve in the using process can be prolonged, so that the internal leakage fault of the brake valve is eliminated, the brake valve can meet the regulated service life requirement, and the brake valve has a stopping brake function under the condition of neither adding a chock nor using a large pressure accumulator. The demand of leakage control is made on the brake valve. Through internal leakage control, the brake valve can achieve a stopping brake function under the condition of using neither a chock nor a large pressure accumulator. The specific requirements of internal leakage control are stipulated in a development contract of the brake valve.

Owner:XIAN AVIATION BRAKE TECH

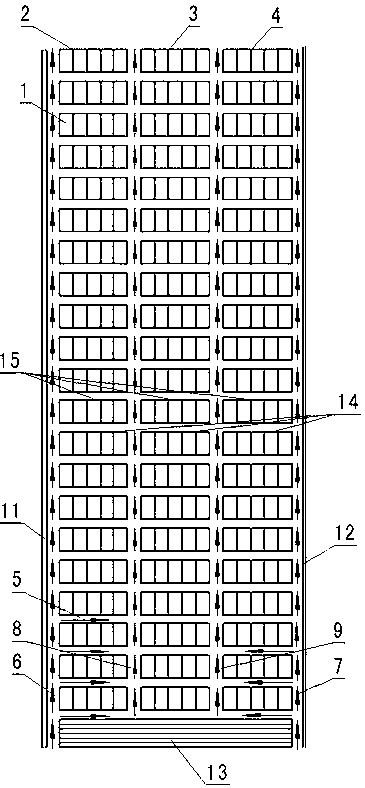

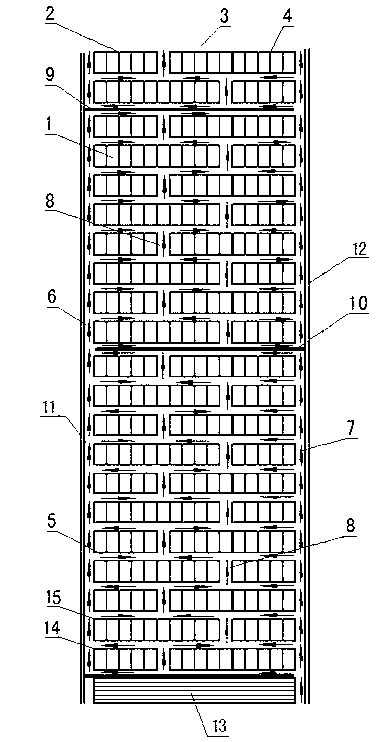

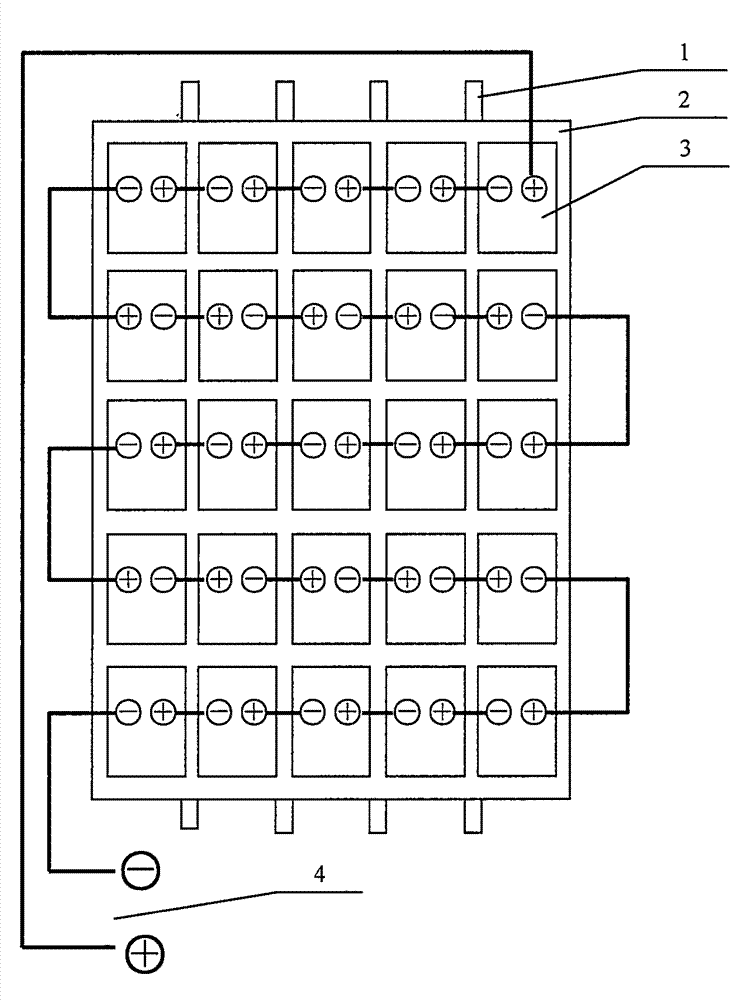

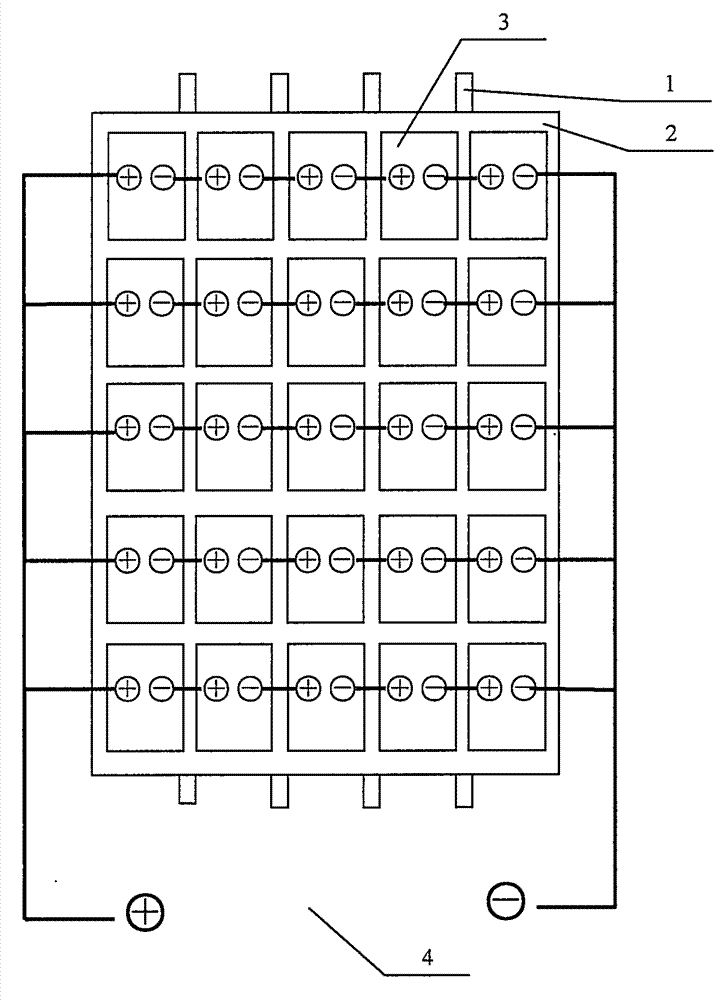

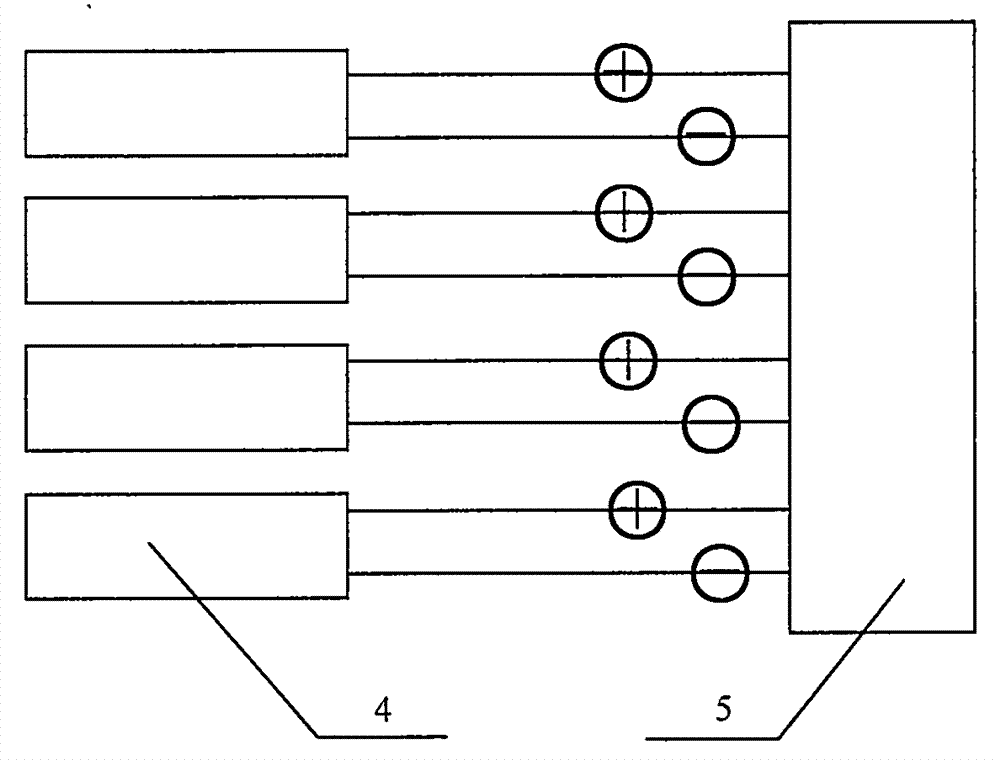

External building vertical surface film-based organic photovoltaic system and installation method

ActiveCN104852671ATaking into account the integrationImprove adaptabilityPhotovoltaic supportsRoof covering using slabs/sheetsOrganic solar cellBuilding integration

The invention relates to an external building vertical surface film-based organic photovoltaic system and an installation method. Photovoltaic junction boxes (11) are fixedly arranged on the back surface of an organic solar film (3), and a junction box embedding groove (10) is formed in a corresponding position on an external building vertical surface carrying structure and used for installing the photovoltaic junction box (11); outgoing wires of the adjacent photovoltaic junction boxes (11) are connected with one another to form an organic photovoltaic unit (4) which is accessed to a photovoltaic convergence box (5) and a photovoltaic inverter (6) device, and the organic photovoltaic unit (4) can be further connected to an energy storage system (7) or a 220V power grid (8). The organic photovoltaic film is ingeniously combined with a external building vertical surface, so that the conversion efficiency is higher than 12 percent under the condition of low light and high temperature, the conversion efficiency of the organic solar film (3) with light transmittance of 40 percent reaches 7.2 percent, the building characteristics can be completely maintained, a decorative function, a waterproof function, a heat preserving function and a photovoltaic power generation function are integrated, the heat radiation problem in the solar battery power generation process also can be solved, and the integration of a photovoltaic building can be realized.

Owner:上海鼎中新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com