Nuclear-powered ship cable high-flame-resistance low-smoke halogen-free sheath material, and preparation method thereof

A low-smoke halogen-free sheath, high flame-retardant technology, applied in the field of low-smoke halogen-free flame-retardant cable materials, to achieve excellent high temperature and humidity resistance, and solve technical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the high flame-retardant low-smoke halogen-free sheath material for nuclear power ship cables of the present invention, comprising the following steps:

[0065] Ethylene-acrylate copolymers, polyester elastomers, nylon elastomers, polyethylene, compatibilizers, flame retardants, flame retardant synergists, radiation resistance additives, antioxidants, processing aids and crosslinking aids Agents, etc. are mixed according to the formula, and then banburying is carried out, and the lump material after banburying is extruded and granulated by a twin-screw extrusion granulator to obtain a masterbatch.

[0066] In a specific embodiment, ethylene-acrylate copolymer, polyester elastomer, nylon elastomer, polyethylene, compatibilizer, flame retardant, flame retardant synergist, radiation resistance auxiliary agent, antioxidant , processing aids and cross-linking aids, etc. are proportioned, put into a high-speed mixer, ...

Embodiment 1

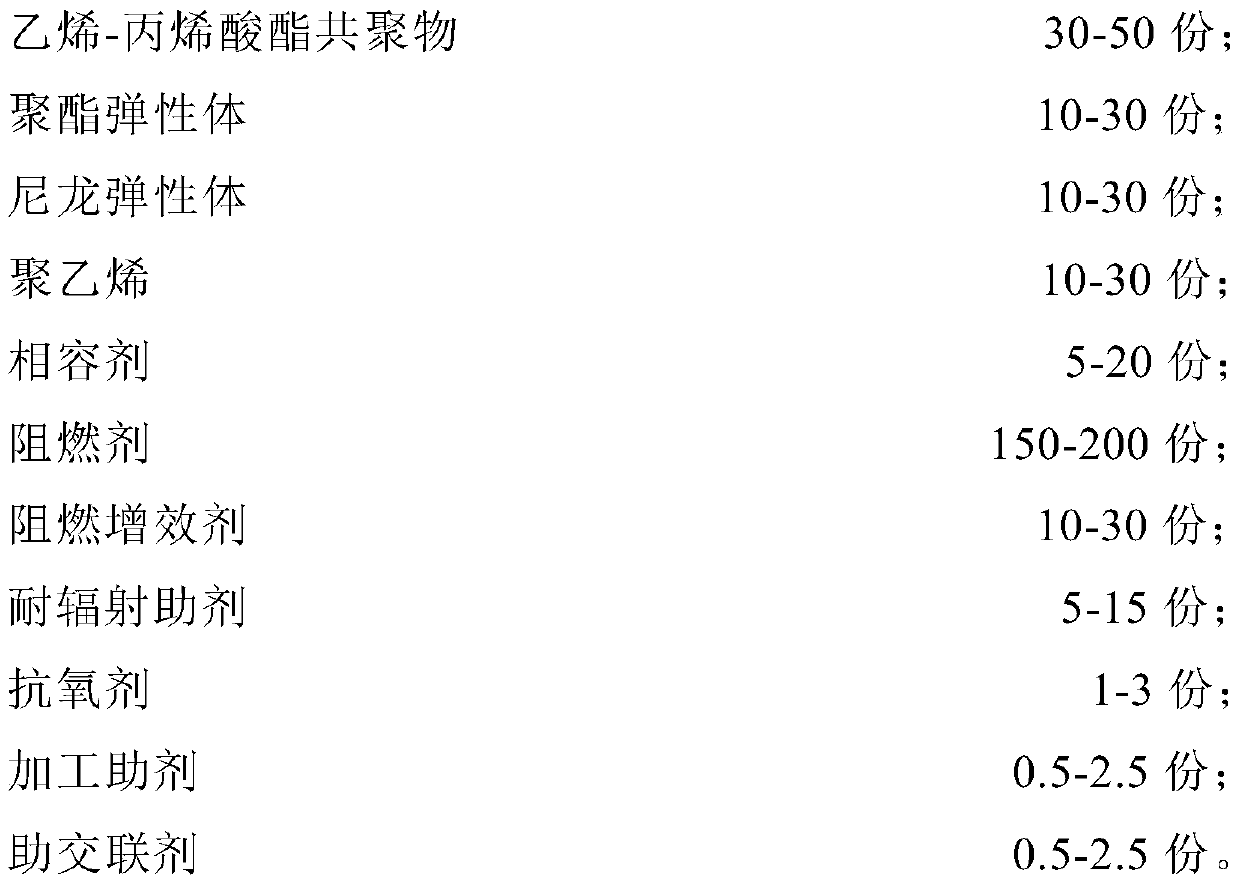

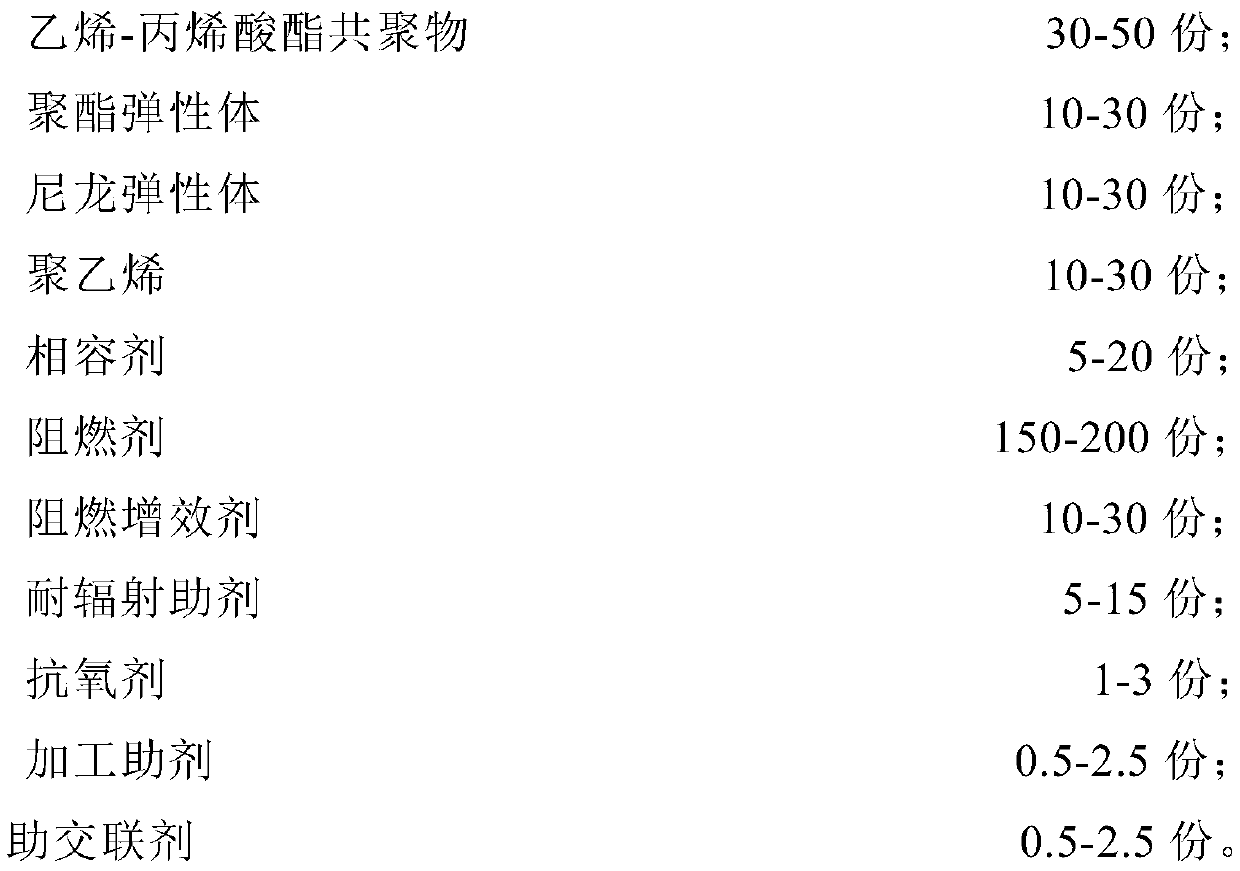

[0098] Each component name and each component parts by weight of formula are as shown in table 1:

[0099] Table 1

[0100] name

weight / kg

name

weight / kg

EBA

30

8

polyester elastomer

20

UV770

2

nylon elastomer

20

Antioxidant 1010

1

LDPE

15

Antioxidant DLTP

1

EBA grafted maleic anhydride

15

Antioxidant 168

0.4

120

PE wax

0.5

25

1.5

Zinc borate

25

TAIC

2

15

[0101] Preparation method: combine ethylene-acrylate copolymer, polyester elastomer, nylon elastomer, polyethylene, compatibilizer, flame retardant, flame retardant synergist, radiation resistance additive, antioxidant, processing aid and After proportioning the auxiliary cross-linking agent, etc., put it into the high-speed mixer, stir at room temperature for ...

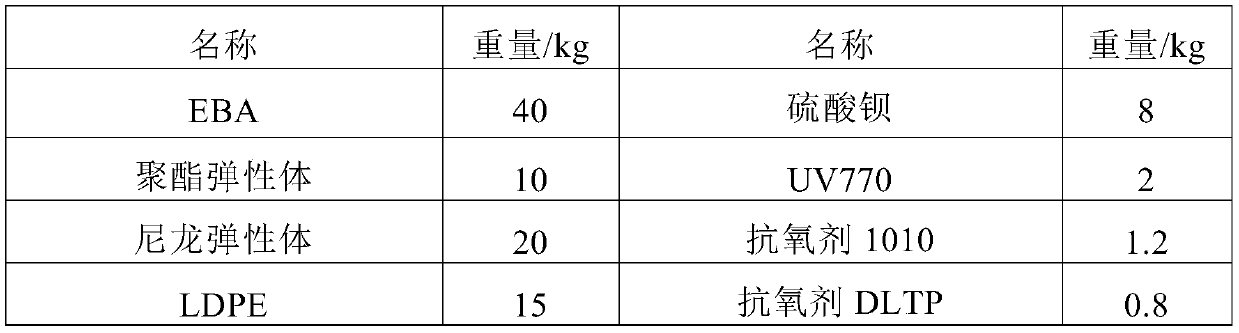

Embodiment 2

[0104] Each component name and each component parts by weight of formula are as shown in table 2:

[0105] Table 2

[0106]

[0107]

[0108] The preparation method is the same as in Example 1.

[0109] The product in Example 2 was obtained by the same method as in Example 2, and a performance detection test was performed, and the performance values are shown in Table 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com