Patents

Literature

1170 results about "Low smoke zero halogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low smoke zero halogen or low smoke free of halogen (LSZH or LSOH or LS0H or LSFH or OHLS or ZHFR) is a material classification typically used for cable jacketing in the wire and cable industry. LSZH cable jacketing is composed of thermoplastic or thermoset compounds that emit limited smoke and no halogen when exposed to high sources of heat.

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

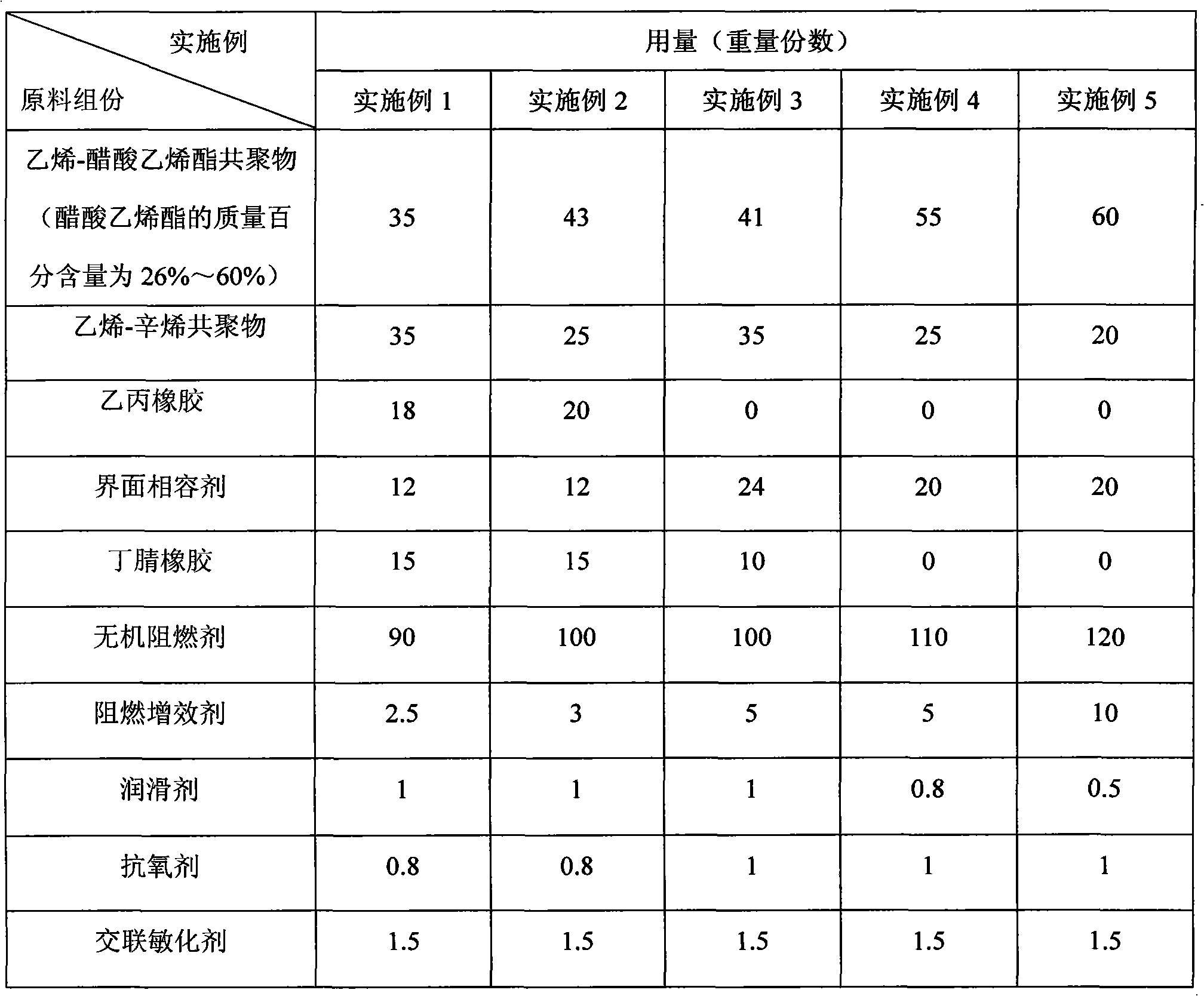

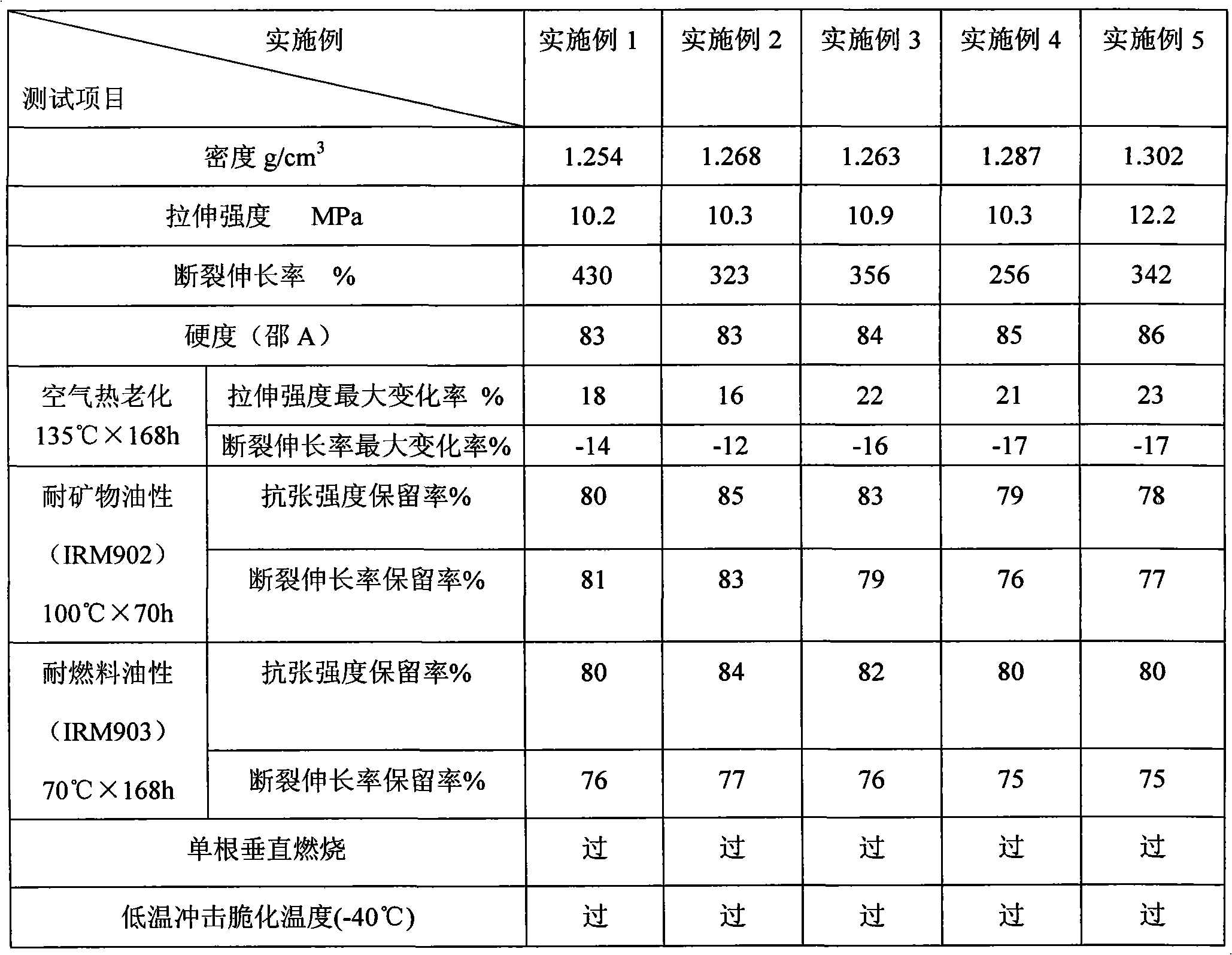

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

ActiveCN102250409AImprove flame retardant performanceImprove uniformityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

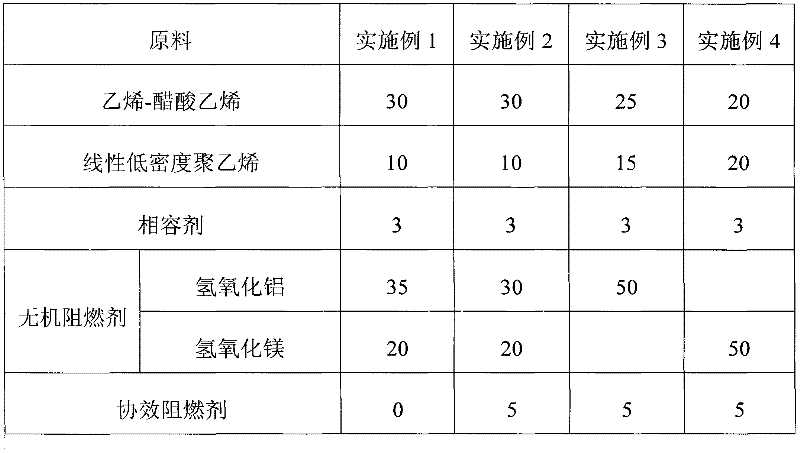

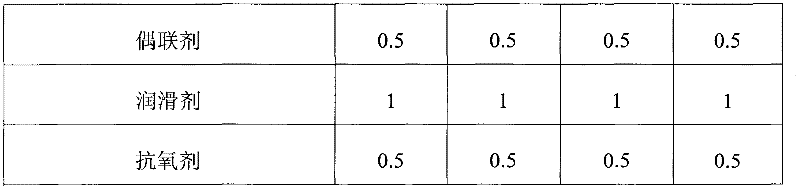

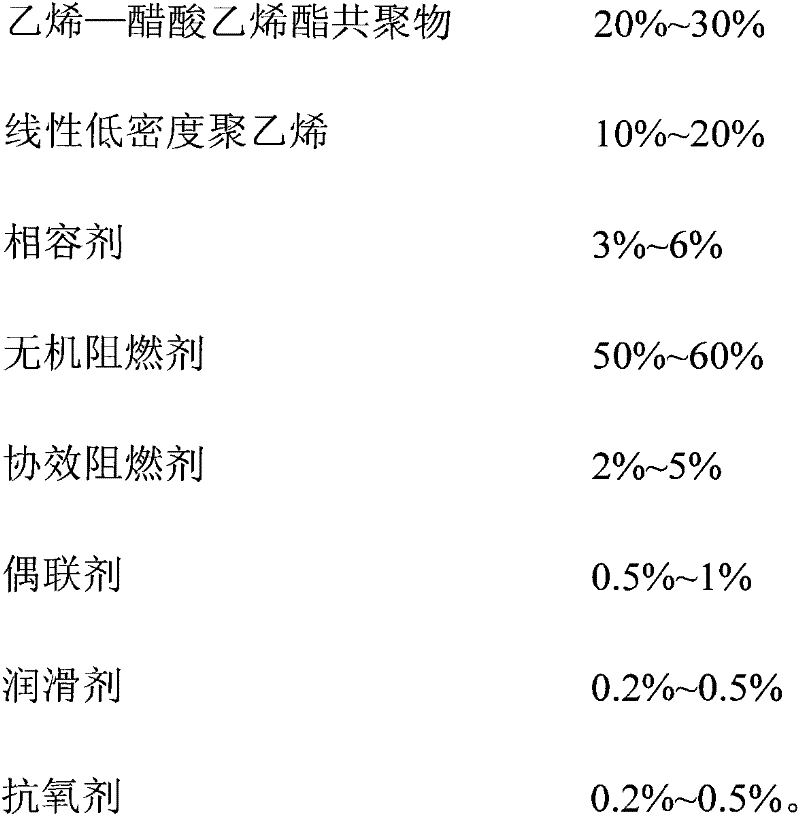

The invention discloses a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The formula of the cable material comprises the following raw materials in percentage by weight: 20-30% of ethylene-vinyl acetate copolymer, 10-20% of linear low-density polyethylene, 3-6% of compatilizer, 50-60% of inorganic flame retardant, 2-5% of synergistic flame retardant, 0.5-1% of coupling agent, 0.2-0.5% of lubricant and 0.2-0.5% of antioxidant. The preparation method of the cable material comprises surface treatment of the inorganic flame retardant, burdening,mixing, milling, extrusion and granulation and other process steps. Compared with the prior art, the cable material disclosed by the invention has the advantages of superior flame retardancy, low smoke, low toxicity, no droplets, good processing performance, good dispersion of the inorganic flame retardant, and better uniformity and surface finish degree.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

Low-smoke halogen-free flame-retardant cable material and preparation method thereof

ActiveCN103172918AEasy to processGood self-extinguishingInsulated cablesInsulated conductorsLow smoke zero halogenAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material which is prepared from the following components in parts by weight: 100 parts of base resin, 80 parts of flame retardant, 0.2-4 parts of coupling agent, 1-4 parts of antioxidant, 5-20 parts of flame-retardant synergist, 2-10 parts of compatiblizing agent and 0.2-4 parts of lubricant. The invention also discloses a preparation method of the low-smoke halogen-free flame-retardant cable material. Due to the adoption of the technical scheme, especially the use of the flame-retardant synergist, the working properties and self-extinguishing property of the low-smoke halogen-free flame-retardant cable material are obviously enhanced. Under the action of the coupling agent and compatiblizing agent, the low-smoke halogen-free flame-retardant cable material has the advantages of favorable working properties, low smoke and favorable flame retardancy.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Low-smoke halide-free fireproof polyolefine material and its preparation method and application

A low-smoke and non-halogen poly-olefine material with radiant graft maleic anhydride vinyl-vinyl acetate multi-polymer as compatilizer is prepared by dissolving maleic anhydride 1-5 proportion into acetone, mixing with vinyl-vinyl acetate multi-polymer 100 proportion, volatilizing for acetone, granulating in double-screw extruder, and electronic-ray or gamma-ray radiating by electronic accelerator with 5-30KGy. The compatilizer graft rate is greater than or equal to 1%, it has better poly-olefine material performance, more white fire retardant and no need for anti-smoke agent. It can be used to make poly-olefine thermal shrinkage pipe with VW-1 vertical burning performance according to UL224 standard.

Owner:上海世龙科技有限公司

High temperature resistant soft low-smoke no-halogen flame-proof polyolefine cable material

ActiveCN101397380AGood flexibilityHigh limiting oxygen indexLiquid organic insulatorsInsulated cablesPolyolefinCarvacryl acetate

The invention discloses a high temperature resistant flexible low-smoke zero-halogen flame-retardant polyolefin compound. The material formula thereof consists of the following materials: an ethylene-vinyl acetate copolymer, a propylene-ethylene copolymer, an interfacial compatilizer, a flame retardant, an antioxidant silane coupling agent and a lubricant, wherein, the Shore A hardness of the ethylene-vinyl acetate copolymer is less than 75, the weight content of the vinyl acetate in the raw material monomer is 30 percent to 70 percent, the Shore A hardness of the propylene-ethylene copolymer is less than 90, and the Shore A hardness of the interfacial compatilizer is less than 80. The invention can meet the high temperature resistant conditions of an aging test (135 DEG C 168h), and has the advantage of low cost.

Owner:中广核三角洲(江苏)塑化有限公司

Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

ActiveCN104893088AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

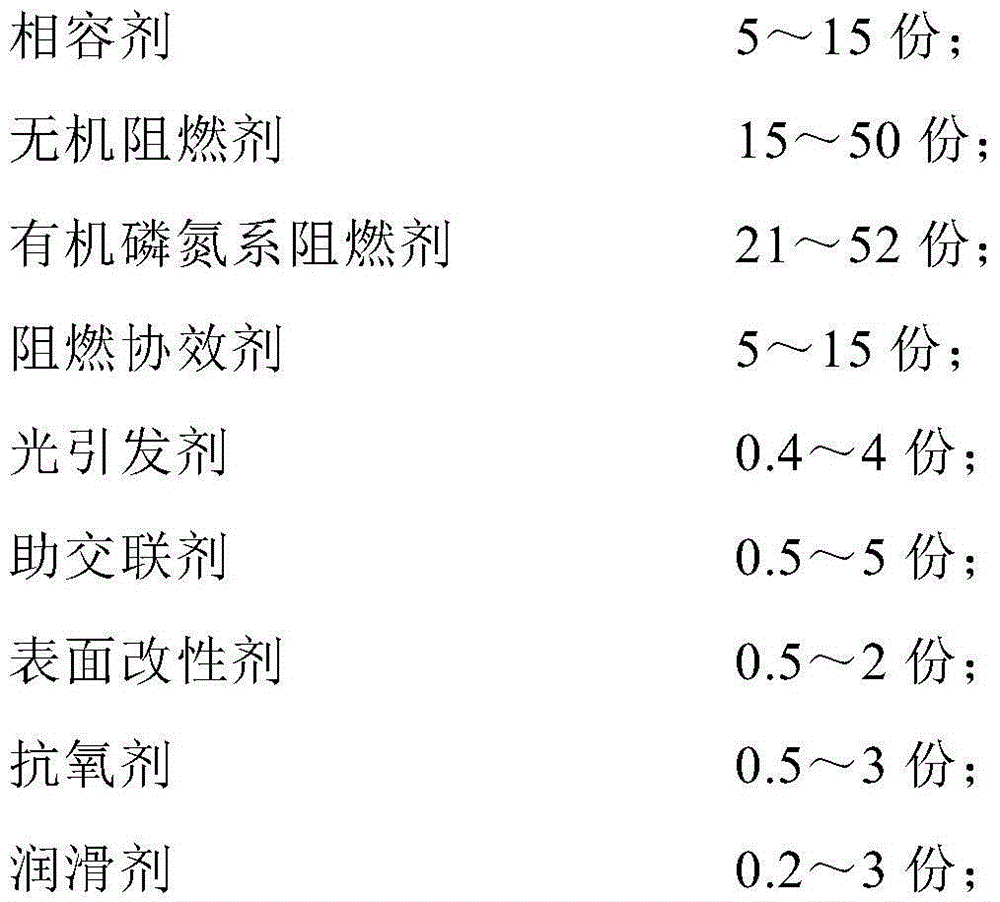

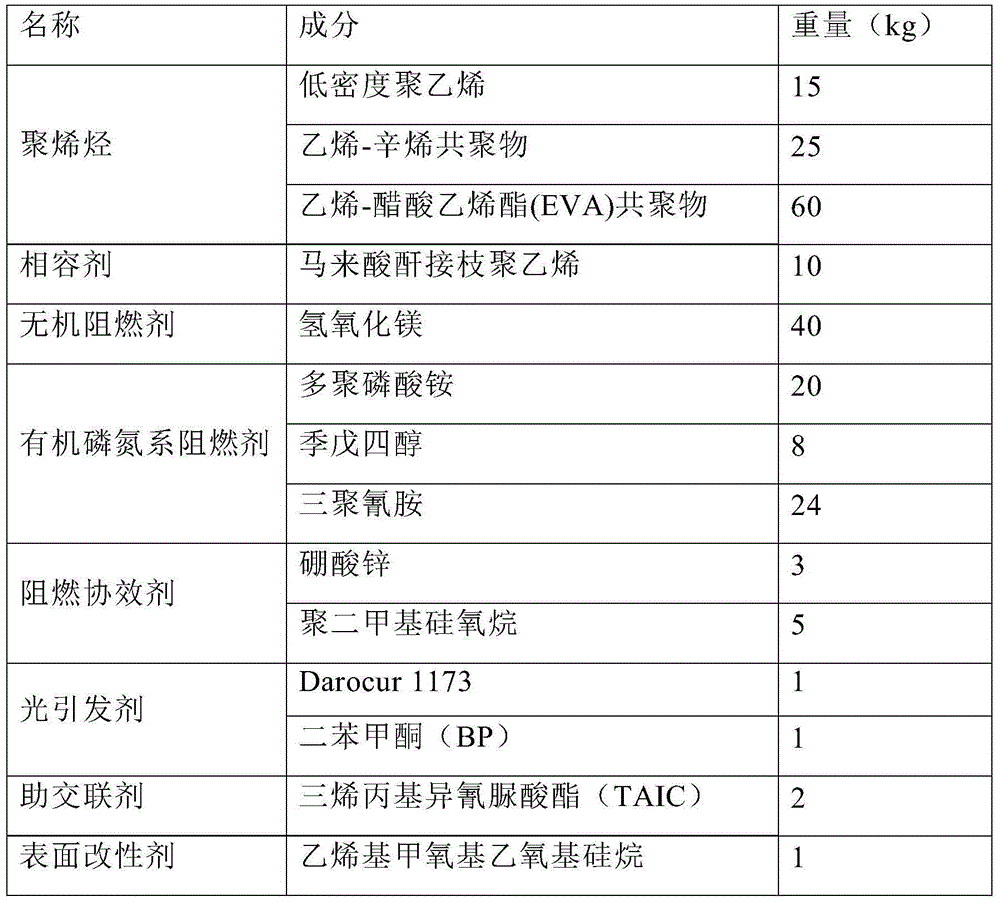

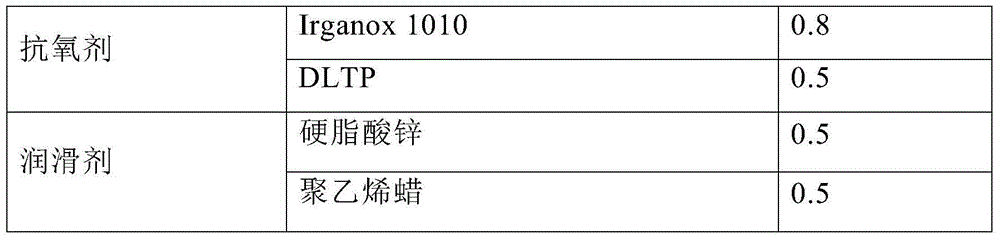

The invention provides an ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material. The cable material comprises polyolefin, a compatilizer, an inorganic flame retardant, an organic phosphorus-nitrogen-containing flame retardant, a flame-retardant synergist, a photoinitiator, an assistant crosslinker, a surfactant, an antioxidant and a lubricant, wherein polyolefin contains low-density polyethylene, an ethylene-octylene copolymer and an ethylene-vinyl acetate copolymer in the weight proportion being (10-25):(20-35):(55-65); the compatilizer is polyethylene for grafting of maleic anhydride; the inorganic flame retardant is selected from magnesium hydroxide and aluminum hydroxide; the organic phosphorus-nitrogen-containing flame retardant contains polyphosphoric acid, pentaerythritol and melamine in the weight proportion being (10-20): (4-8): (15-30); the flame-retardant synergist contains zinc borate and / or polydimethylsiloxane. The cable material has good thermal resistance and anti-aging performance, can be used at the temperature of 125 DEG C for a long time and is excellent in comprehensive mechanical performance and better in flame retardance.

Owner:上海至正新材料有限公司

Ethylene propylene rubber insulation material for longitudinal high-voltage watertight cable of ships and warships and production method thereof

InactiveCN101831115AMeet the needs of useGuaranteed flexibilityRubber insulatorsParaffin waxPolymer science

The invention discloses an ethylene propylene rubber insulation material for longitudinal high-voltage watertight cables of ships and warships and a production method thereof. The method comprises the following steps: adding the ethylen e-propylene-diene mischpolymere, age resister and fire retardant into a banbury for banburying for 3.5min; adding argil, white carbon black and paraffin wax for continued banburying for 2min; adding active agent, and discharging after banburying for 1.5min; filtering the rubber compound with a three-layer filter screen (namely a 60 mesh filter screen, a 60 mesh filter screen and a 80 mesh filter screen) on a rubber filter; and beating into cornucopla on a double-roller mill, adding vulcanizer and co-crosslinker, then beating into cornucopla for 7 times, grinding and slicing after finishing the steps, and then cooling, wherein the materials are as follows in parts by weight: 100 parts of ethylen e-propylene-diene mischpolymere, 1-5 parts of vulcanizer, 1-4 parts of age resister, 15-70 parts of fire retardant, 0.5-10 parts of active agent, 10-20 parts of argil and 2-4 parts of paraffin. The prepared insulation material has the characteristics of low smoke, no halogen, fire resistance, high machinery strengthen, and high insulation resistance, good flexibility, elasticity and viscosity, and can be used for the ships and warships.

Owner:嘉兴君宏光学有限公司

Low-smoke zero-halogen flame-retardant silane crosslinking polyolefin and preparation method thereof

ActiveCN103205051AEasy to processSolve the contradiction of poor liquidityInsulation layerPolyolefin

The invention belongs to the technical field of high polymer materials and particularly relates to low-smoke zero-halogen flame-retardant silane crosslinking polyolefin and a preparation method thereof. The low-smoke zero-halogen flame-retardant silane crosslinking polyolefin comprises, by weight, 18-40 parts of polyolefin resin, 5-40 parts of thermoplastic elastomer, 25-72 parts of flame retardancy, 0.045-1.35 parts of unsaturated silicone, 0.019-0.45 part of crosslinking initiator and 0.05-1 part of catalyst. Low-smoke zero-halogen flame-retardant silane crosslinking polyolefin cable insulation materials having better processing performance can be obtained and can be disposed for crosslinking in long run at the room temperature, and crosslinking can be accelerated by warm water. Surfaces of insulation layers of obtained cables are flat and smooth, and requirements of GB / T17650.2 and GB / T18380 standard are met.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Low-smoke, halogen-free and flame-retardant irradiation crosslinking polyolefin composite material and preparation method thereof

InactiveCN103450544AImprove flame retardant performanceImprove mechanical propertiesPolyolefinPolymer science

The invention discloses a low-smoke, halogen-free and flame-retardant irradiation crosslinking polyolefin composite material and a preparation method thereof. The preparation method comprises the following steps of adding 0.5-5 parts of flame retardant synergist to 50-60 parts of polyolefin according to the mass ratio; uniformly mixing at 140-200 DEG C, and then adding 40-50 parts of microencapsulated metal hydroxide of a flame-retardant smoke suppressant synergist, 0.5-5 parts of multifunctional crosslinking agent and 0.1-1 part of antioxidant; extruding and cladding the materials on a conductive core of an electric wire or pressing into a board in a forming machine after evenly mixing; and finally carrying out irradiation crosslinking by a high-power electron beam or a cobalt source in a dosage of 80-240 KGy. The low-smoke, halogen-free and flame-retardant polyolefin composite material obtained by the microencapsulated metal hydroxide of the flame-retardant smoke suppressant synergist by irradiation crosslinking has good flame retardant property, excellent smoke suppressing property, and better mechanical property, and can be widely applied to the electric wires in the industries such as power, energy sources, petrochemical industries, electrons, communication, information, locomotives and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE

Thermoplastic crack resistant type low smoke zero halogen flame-retardant polyolefin cable sheath material and preparation method thereof

InactiveCN102020804ACrack resistantImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesThermoplasticPolyolefin

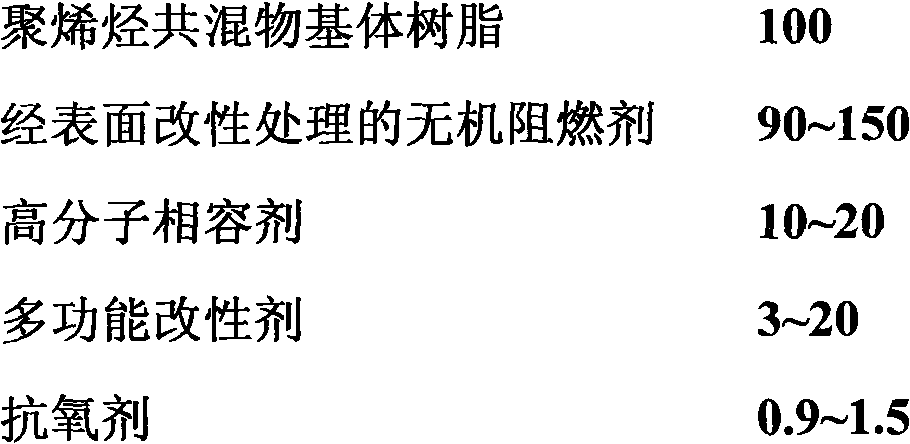

The invention discloses a thermoplastic crack resistant type low smoke zero halogen flame-retardant polyolefin cable sheath material and a preparation method thereof. The cable sheath material comprises the following components in part by weight: 100 parts of polyolefin blend matrix resin, 90 to 150 parts of inorganic flame retardant subjected to surface modification, 10 to 20 parts of high molecular compatilizer, 3 to 20 parts of multifunctional modifier, 1 to 1.5 parts of antioxidant and 1 to 2 parts of processing aid. The preparation method of the cable material comprises the following steps of: blending and extruding polyene resin; performing surface treatment on the inorganic flame retardant; preparing materials; mixing; extruding; granulating and the like. Compared with the prior art, the invention has the advantages that: the cable sheath material has crack resistance, high flame retardancy and high processability, is environmentally friendly, is easy to recycle and the like.

Owner:山东安澜电力科技有限公司 +1

Low smoke zero halogen thermoplastic elastomer flame-retardant cable material and production method thereof

InactiveCN101921437AChange natureImprove naturePlastic/resin/waxes insulatorsInsulated cablesLow smoke zero halogenThermoplastic elastomer

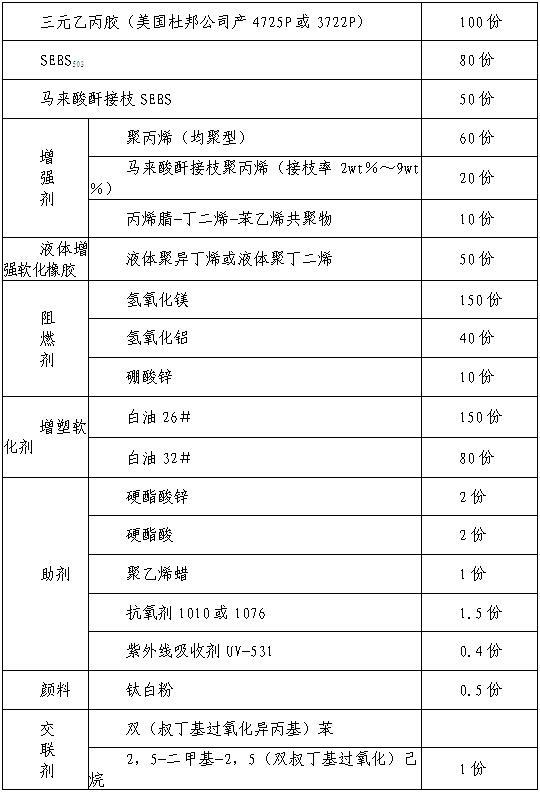

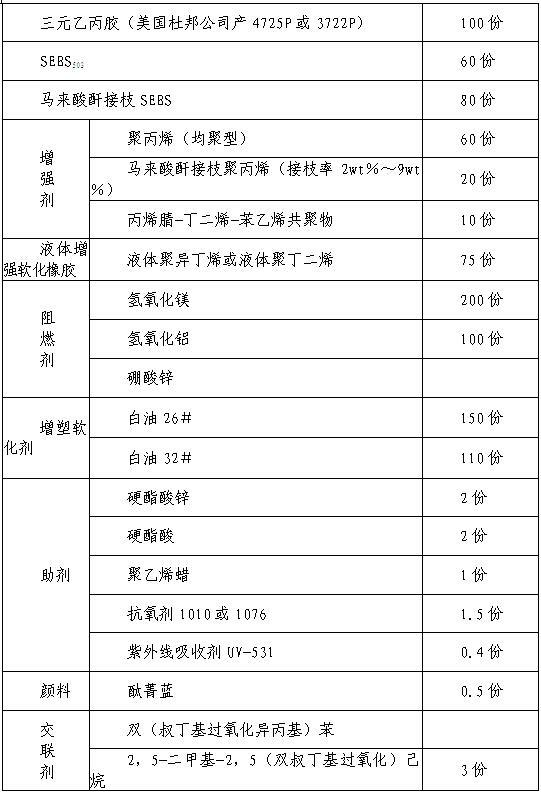

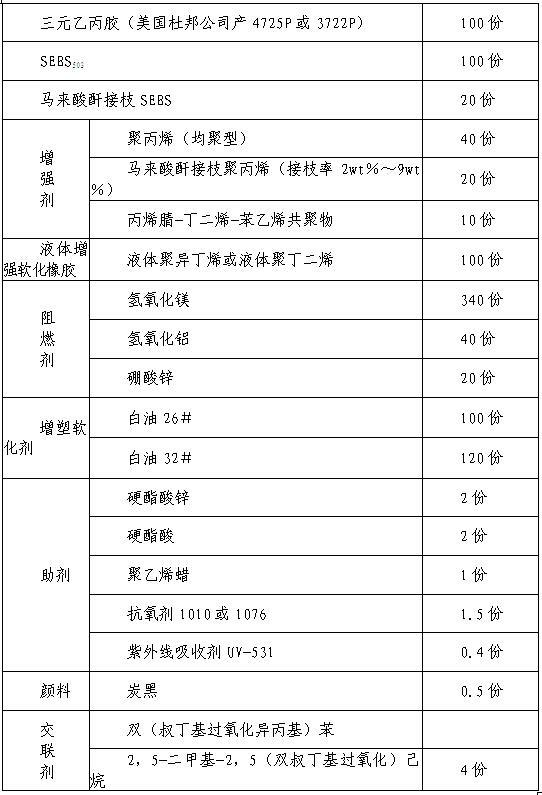

The invention discloses a low smoke zero halogen thermoplastic elastomer flame-retardant cable material which comprises the following components in weight ratio: 100 parts of ethylene-propylene diene monomer rubber, 50-200 parts of SEBS503 and / or maleic anhydride grafted SEBS, 55-100 parts of reinforcing agent, 100-300 parts of plasticizing and softening agent, 0-5 parts of pigment, 8-12 parts of auxiliary agent, 1-4 parts of cross-linking agent, 150-550 parts of flame retardant agent and 40-150 parts of liquid reinforcing and softening rubber. The preparation method of the material comprises the following steps of: firstly, mixing, plasticating, cooling and granulating the SEBS 503 and / or maleic anhydride grafted SEBS, the plasticizing and softening agent, the reinforcing agent, the pigment and the ethylene-propylene diene monomer rubber particles to prepare thermoplastic elastomer master batch; then, mixing the thermoplastic elastomer master batch with the auxiliary agent, the flame retardant agent and the liquid reinforcing and softening rubber, adding into a mixer, and stirring uniformly; and finally, mixing, plasticating, cooling and granulating to obtain a finished product. The product does not contain halogen, has excellent flame retarding efficacy and is not embrittled and hardened under the low temperature condition of subzero 40 DEG C. The preparation method has simple equipment and technology and does not have any three wastes discharge or environmental pollution.

Owner:天龙伟业线缆有限公司 +1

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Polyolefine sheathing compound for coaxial cable and preparation method thereof

ActiveCN102153812AShorten the manufacturing cycleHarm reductionPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

The invention discloses a polyolefine sheathing compound for a coaxial cable and a preparation method thereof. The sheathing compound consists of the following components in parts by weight: 60-90 parts of ethylene-propylene-diene rubber, 5-25 parts of high-density polyethylene, 5-15 parts of functional polyolefin resin, 180-200 parts of flame retardant, 1-3 parts of surface modifier, 0.01-0.05 part of crosslinking agent, 0.5-2 parts of antioxidant and 1.5-9 parts of processing aid. The preparation method comprises the following steps of: putting the flame retardant into a high-speed stirrer for stirring at a high speed at the temperature of not lower than 80 DEG C; adding organosilane and stirring for 3-5 minutes; putting the remaining materials into the high-speed stirrer for continually stirring for 3-5 minutes; adding into a double-screw mixing extruder set by using a feeder for pelletizing; and drying. The sheathing compound has the advantages of flame retardance, low smoke, freeness from halogen, low toxicity, freeness from harmful heavy metals such as lead, cadmium and the like, freeness from phosphorus, difficulty in burning and small smog harm in case of fire, environmental friendliness, high temperature resistance level of 105 DEG C, high extruding performance, excellent electric performance, no need of subsequent crosslinking after stranding, saving in a large amount of manpower and materials and great reduction in the manufacturing period of the cable.

Owner:KINGFA SCI & TECH CO LTD +2

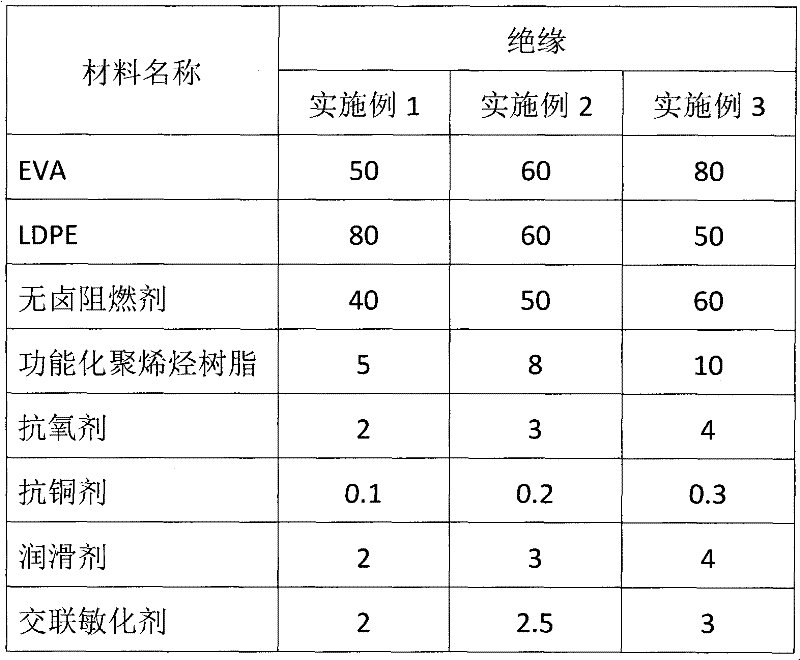

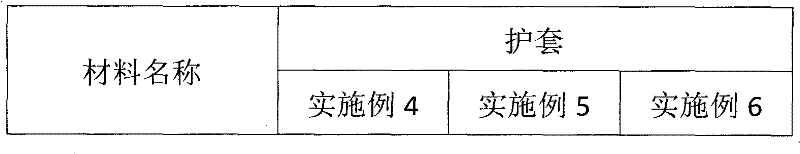

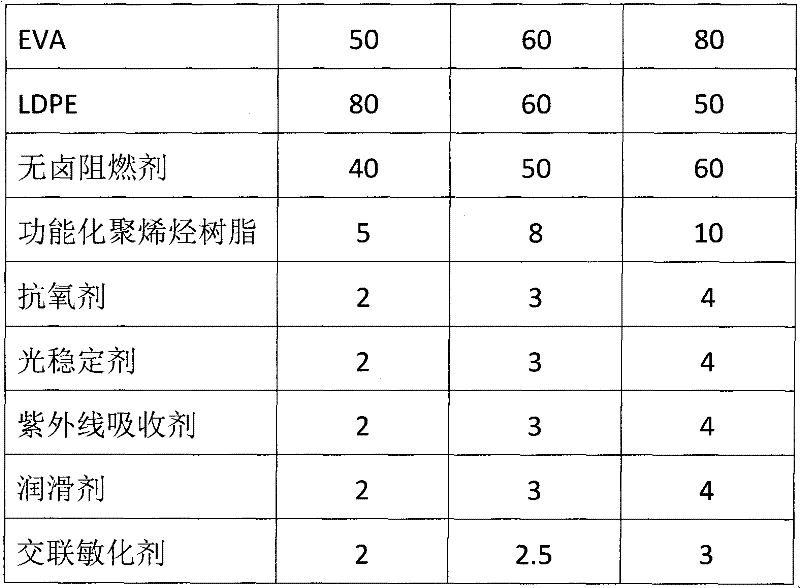

Environmentally-friendly low-smoke halogen-free flame-retardant photovoltaic cable insulation and sheath and preparation method thereof

InactiveCN102336953APlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneCross-link

The invention relates to an environmentally-friendly low-smoke halogen-free flame-retardant photovoltaic cable insulation and sheath and a preparation method thereof. The cable insulation and sheath is characterized by being prepared through blending ethylene-vinyl acetate copolymer (EVA) and low-density polyethylene (LDPE) used as base resin, functional polyolefin resin used as a compatilizer, nanoscale organosilane-treated magnesium hydroxide used as a flame retardant as well as an antioxidant, a light stabilizer (used for sheath), an ultraviolet absorbent (used for sheath), a copper resisting agent (used for insulation), a cross-linking sensitizer and a lubricant. The cable manufactured from the environmentally-friendly low-smoke halogen-free flame-retardant photovoltaic cable insulation and sheath material provided by the invention through radiation cross-linking completely meets the standard requirements of Germany Rheinland TUV 2pfg1169 and UL4703 on the heat resistance, moisture heat resistance, low-temperature resistance, chemical corrosion resistance, weathering resistance, ozone resistance, wearing resistance, direct-current voltage resistance, low smoke, no halogen, flame retardant and other properties, and has the service life of 25 years.

Owner:河北中联塑胶科技发展有限公司

Low-smoke zero-halogen and highly-flame-retardant electric wire and preparation method thereof

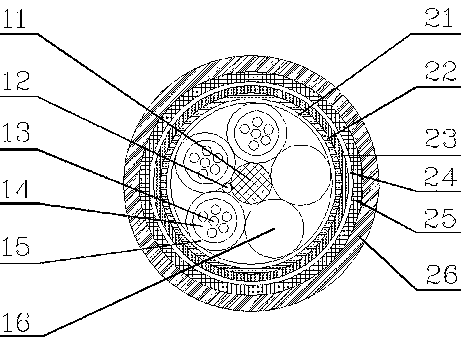

InactiveCN104183306AFlame retardancy exceedsImprove performanceInsulated cablesCable/conductor manufactureLow smoke zero halogenElectrical conductor

The invention provides a low-smoke zero-halogen and highly-flame-retardant electric wire. The wire comprises conductors. Shielding layers are arranged outside the conductors, flame-retardant insulation layers are arranged outside the shielding layers, refractory layers are arranged outside the flame-retardant insulation layers, heat-resisting layers are arranged outside the refractory layers, and rock wool ropes fill the portions among the conductors. A flame-retardant belt is arranged outside the conductors and the rock wool ropes, an inner flame-retardant layer is arranged outside the flame-retardant belt, an armor layer is arranged outside the inner flame-retardant layer, an outer flame-retardant layer is arranged outside the armor layer, an anticorrosive coating is arranged outside the outer flame-retardant layer and coated with an ultraviolet-proof layer, and the ultraviolet-proof layer is coated with a protection wax layer. The invention further provides a preparation method of the electric wire. By arranging the flame-retardant insulation layers, the refractory layers, the rock wool ropes, the inner flame-retardant layer and the outer flame-retardant layer, the flame retardance of the electric wire is much better than that of similar products. Meanwhile, the electric wire and the flame-retardant layers are made of zero-halogen substances, so that the electric wire is low in smoke, free of halogen and highly flame-retardant.

Owner:TAICANG SUSHENG ELECTRICAL TECH

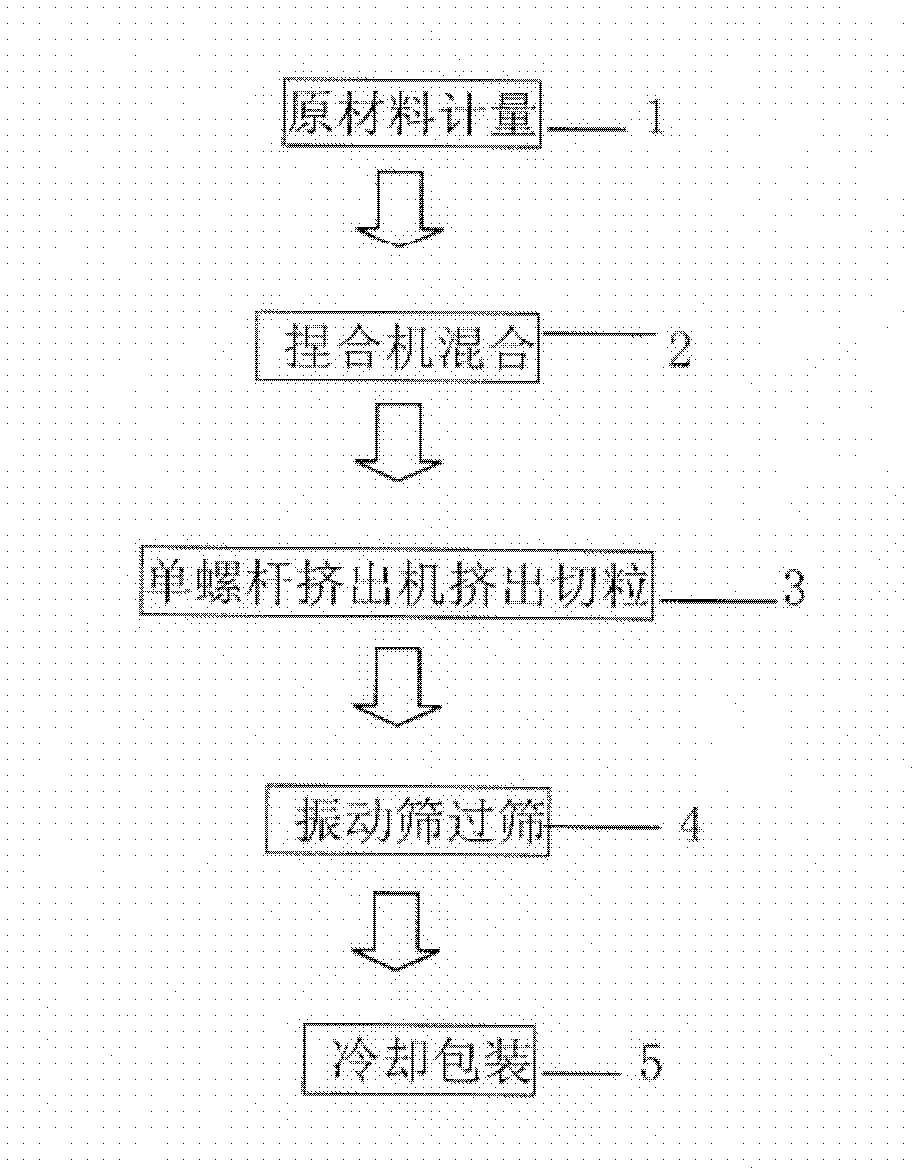

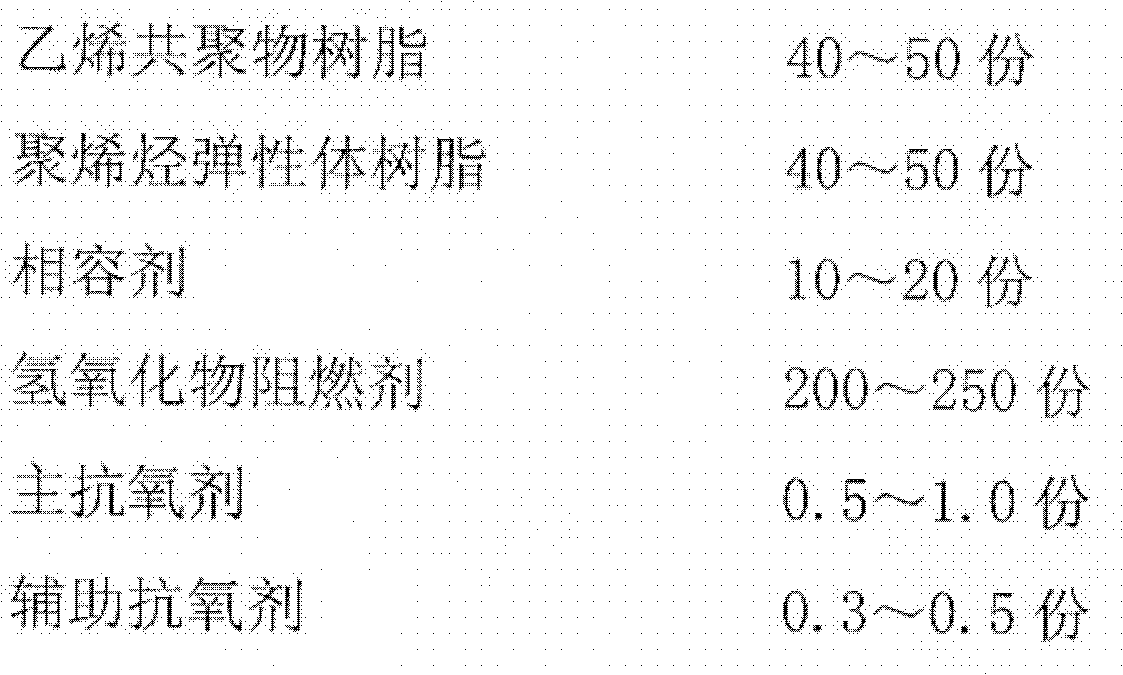

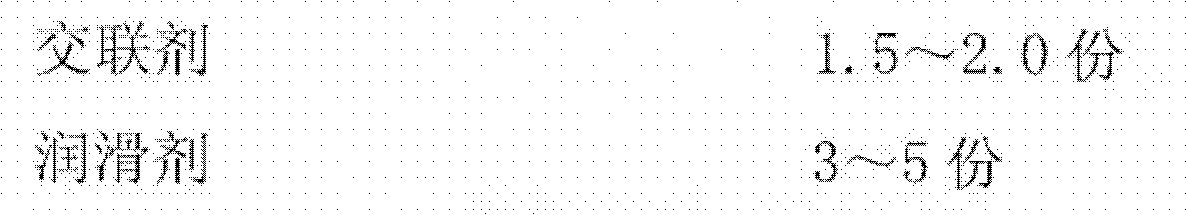

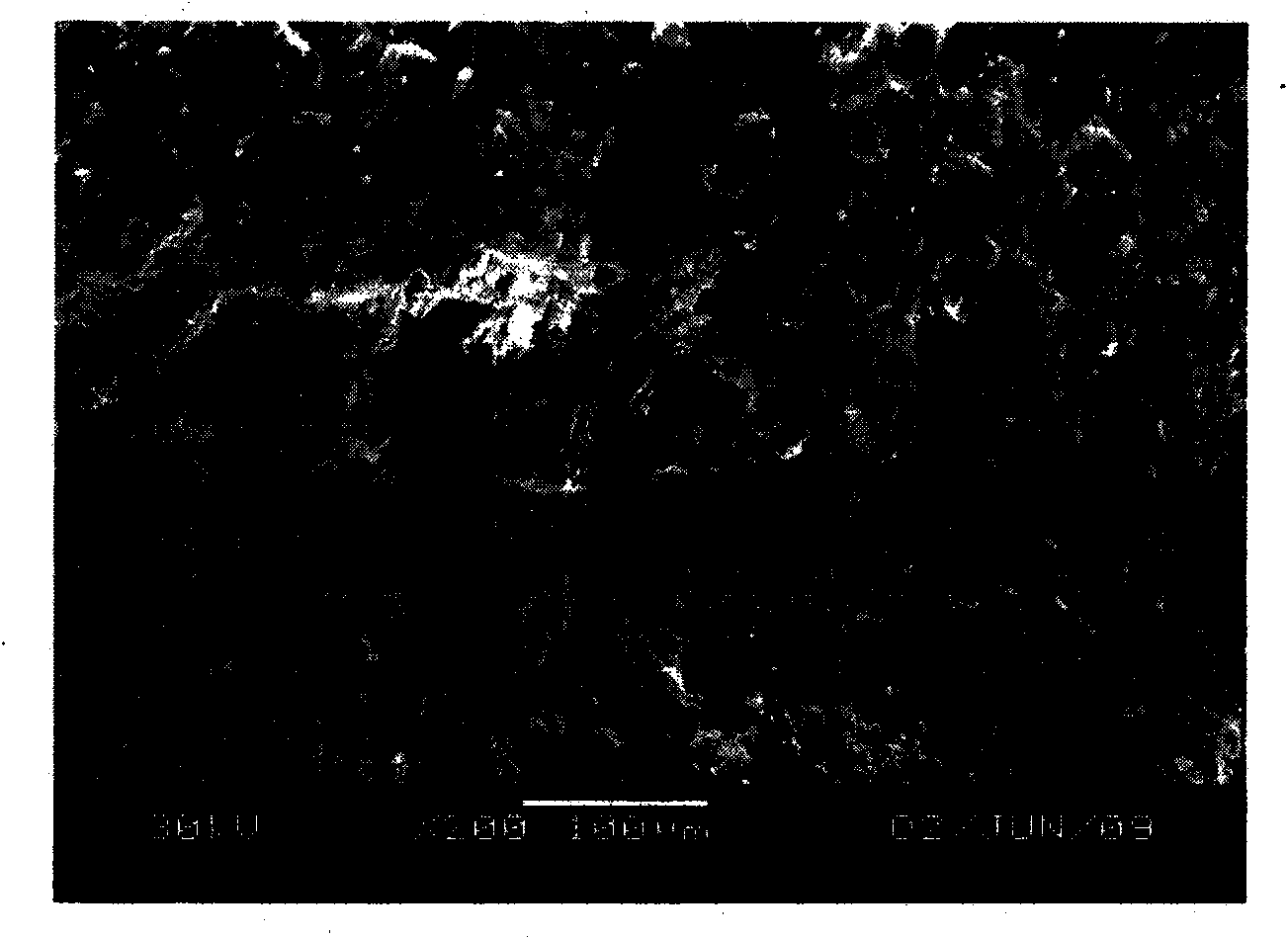

Irradiation cross-linking low-smoke zero-halogen high flame-retarding polyolefin insulation material and preparing method thereof

InactiveCN102617923AImprove flexibilityImprove liquidityPlastic/resin/waxes insulatorsInsulated cablesCross-linkElastomer

Provided are an irradiation cross-linking low-smoke zero-halogen high flame-retarding polyolefin insulation material and a preparing method thereof. The insulation material is mainly composed of the following components by weight: 40-50 parts of ethylene copolymer resin, 40-50 parts of polyolefin elastomer resin, 10-20 parts of compatilizers, 200-250 parts of hydroxide fire retardants, 0.5-1.0 part of main antioxidants, 0.3-0.5 part of auxiliary antioxidants, 1.5-2.0 parts of cross-linking agents and 3-5 parts of lubricants. The preparing method includes: metering all the raw materials in the raw material formula according to weight parts, sending all the raw materials into a kneading machine to be mixed even, sending the even materials into a single screw extruder for extrusion granulation, sieving the materials in a vibration screen and finally cooling and packing the materials. The irradiation cross-linking low-smoke zero-halogen high flame-retarding polyolefin insulation material and the preparing method thereof completely meet requirements of the standard. The ethylene copolymer resin is adopted as the basic raw material, the polyolefin elastomer resin, the compatilizers, the hydroxide fire retardants and the cross-linking agents are added for blending, and therefore the irradiation cross-linking low-smoke zero-halogen high flame-retarding polyolefin insulation material is prepared.

Owner:天津市普立泰高分子科技有限公司

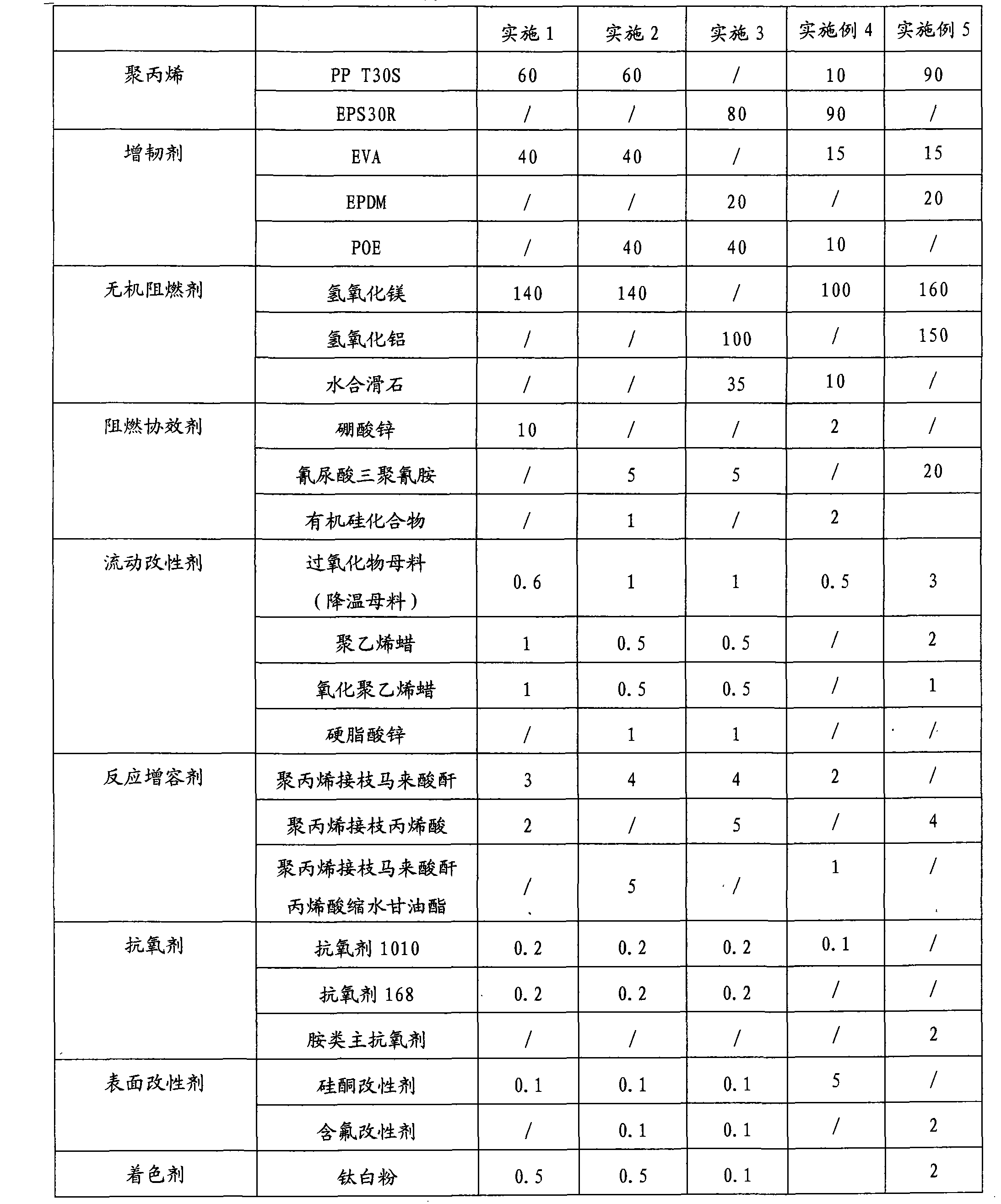

High tenacity low smoke zero halogen flame retardant polypropylene and preparation method thereof

The invention discloses a high tenacity low smoke zero halogen flame retardant polypropylene and a preparation method thereof and the polypropylene comprises the following components according to the parts by weight; 10-90 parts of polypropylene, 10-90 parts of flexibilizer, 100-160 parts of inorganic flame retardant, 2-20 parts of flame-retardant synergist, 2-5 parts of reactive compatibilizer, 0.1-2 parts of antioxidant, 0.5-5 parts of flow modifier, 0.1-5 parts of surface modifier and a defined amount of coloring agent. The low smoke zero halogen flame retardant polypropylene has the advantage of good mechanical properties, good flame resistance (the vertical flame test of the polypropylene passes UL94V-0 level), low smoke density which is not more than 20%, good aging resistance and low cost, and can meet the processing demands for injection and extrusion molding.

Owner:内蒙古睿达鑫科技有限责任公司

Novel low-smoke zero-halogen flame-retardant cable sheath material

InactiveCN102532649AReduce dosageDosage reachedInsulated cablesInsulated conductorsLow-density polyethyleneHigh carbon

The invention relates to a novel low-smoke zero-halogen flame-retardant cable sheath material, which comprises the following components in percentage by weight: 15-35 percent of low-density polyethylene, 15-35 percent of ethylene-vinylacetate copolymer, 8-30 percent of modified nano magnesium hydroxide, 2-6 percent of microencapsulated red phosphorus, 8-19 percent of thermoplastic phenolic resin, 1.8-3 percent of dicumyl peroxide as a crosslinking agent, 0.1-0.25 percent of antioxidant 1010, 1-3.5 percent of lead sulfate tribasic as a lead compound and 0.1-1 percent of N-salicyl aminophthalimide as a copper inhibitor. According to the novel low-smoke zero-halogen flame-retardant cable sheath material, the consumption of the modified nano magnesium hydroxide is reduced by adding the thermoplastic phenolic resin and the microencapsulated red phosphorus on the basis of ensuring the performance of mechanical energy, and the purpose of synergically retarding flame is achieved. When the cable sheath material burns, the microencapsulated red phosphorus absorbs a great deal of water decomposed and released when the modified nano magnesium hydroxide burns, to generate phosphoric acid, metaphosphoric acid, polymetaphosphoric acid and the like which cover the surface of the thermoplastic phenolic resin with higher carbon content, so that the surface of the thermoplastic phenolic resin can be dehydrated and carbonized in an accelerating way to form a thick liquid film layer for isolating oxygen and heat from the inside sheath material, and thus burning can be weakened or interrupted, and the flame-retardant effect of the cable sheath material is enhanced; meanwhile, the novel low-smoke zero-halogen flame-retardant cable sheath material disclosed by the invention has the advantages of zero halogen, low smoke formation amount during burning and little pollution to environment.

Owner:JIANGSU HENGTONG POWER CABLE

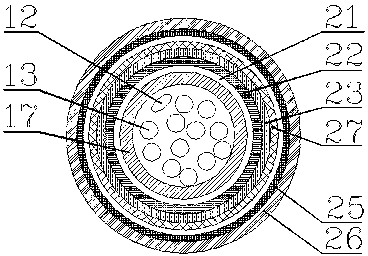

Flame-retardant and fire-resistant optical cable

ActiveCN103064163AImprove fire resistanceStrong luminosityFibre mechanical structuresVulcanizationEngineering

The invention relates to a frame-retardant and fire-resistant optical cable which comprises a cable core and is characterized in that an inner water-resistant layer and an inner fire-resistant layer are coated on the cable core, and an outer fire-resistant layer is arranged outside the inner fire-resistant layer. A steel-plastic composite belt armor layer and a low-smoke zero-halogen outer protection sleeve are respectively coated the outermost layer of a cable. The frame-retardant and fire-resistant optical cable has high frame-retardant and fire-resistant performance, maintenance of good light transmission performance of the optical cable in high-temperature burning and cooling periods is ensured, and the high-grade frame-retardant, fire-resistant and low-smoke zero-halogen protection sleeve enables the optical cable to be high in oxygen index, good in flame retardant efficiency, low in fuming, high in light transmittance, and strong in nucleating after being burnt. Combustion residues are a hard outline layer, a ceramic vulcanization silicon rubber fire-resistant layer is capable of resisting fire within the temperature of 1200 DEG C and 1500 DEG C. A steel belt enables the optical cable to maintain quite high intensity and rigidity. The two points effectively reduce affection of internal stress of different components after the optical cable is burnt, light transmittance of the optical cable is further ensured, the burning from outside to inside of the optical cable is blocked and retarded, and frame-retardant and fire-resistant performance of the optical cable is further enhanced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

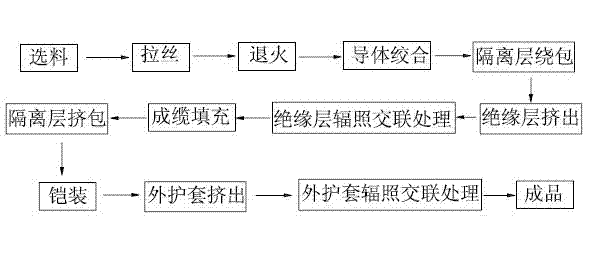

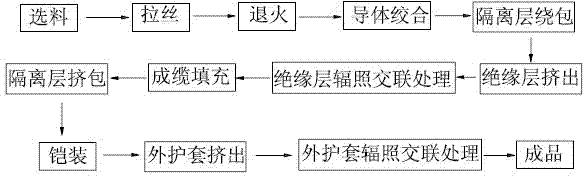

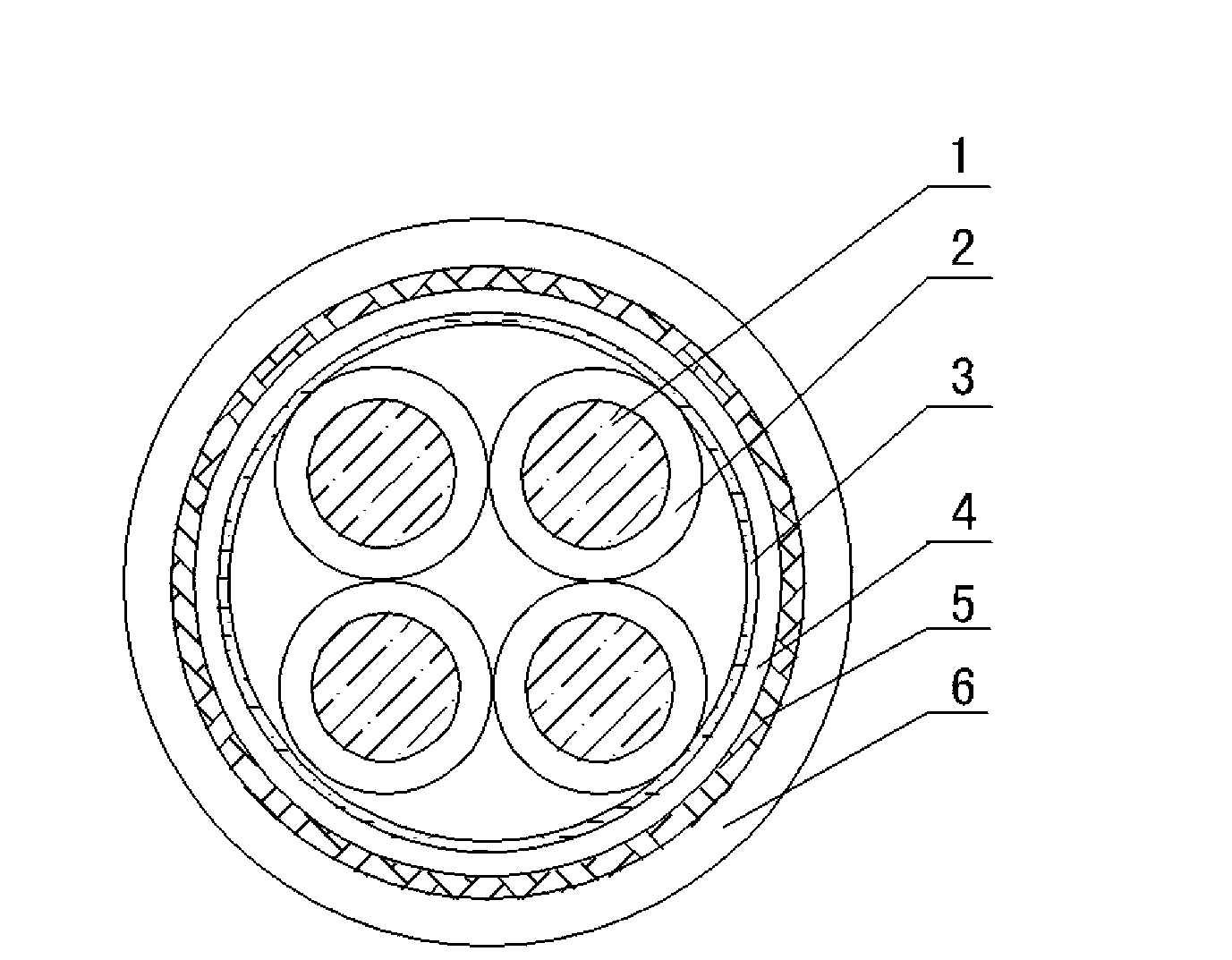

Manufacture method for low-voltage electric power cable used for nuclear power station

ActiveCN102347109AImprove insulation performanceImprove flame retardant performanceCoatingsInsulating conductors/cablesNuclear powerLow voltage

The invention discloses a manufacture method for a low-voltage electric power cable used for a nuclear power station, which comprises the following steps: sorting; drawing wires; annealing; twisting a conductor; lapping an isolation layer; extruding the isolation layer; carrying out irradiation crosslinking processing to the isolation layer; cabling and filling; sheathing the isolation layer; armoring; extruding an outer sheath; carrying out irradiation crosslinking processing to the outer sheath; and obtaining a finished product. The manufacture method is characterized in that the step of extruding the isolation layer adopts double-layer coextrusion, wherein an inner layer adopts a polyethylene (PE) screw, and an outer layer adopts a semi-extruded die; the step of extruding the outer sheath adopts the semi-extruded die; the screw with the compression ratio of 1.25:1-2.0:1 sheathes low-smoke halogen-free thermosetting polymer on the isolation layer subjected to irradiation crosslinking processing to form the outer sheath; and machining temperature is controlled to 105-175 DEG C. The cable manufactured with the manufacture method disclosed by the invention has the advantages of high insulativity and high fire resistance, and the use requirement of a nuclear power station cable can be satisfied.

Owner:SICHUAN MINGXING CABLE

High-temperature fire-resistant insulated cable for ships and warships

InactiveCN102842376ASimple structureReduce weightInsulated cablesInsulatorsPolyolefinElectrical conductor

Owner:海南宏海电缆有限公司

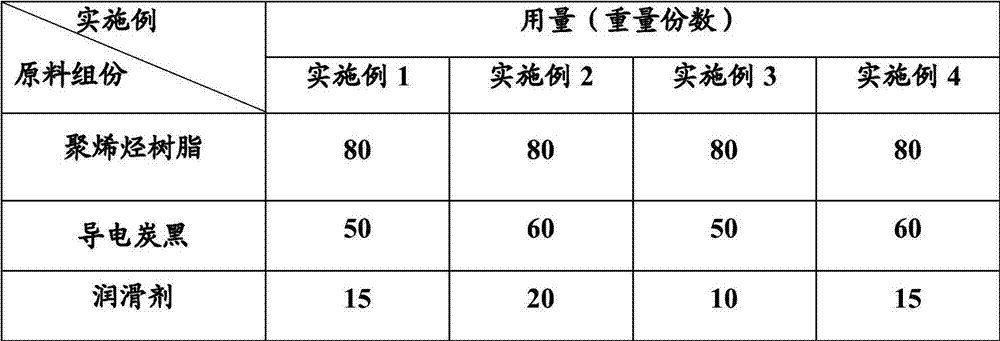

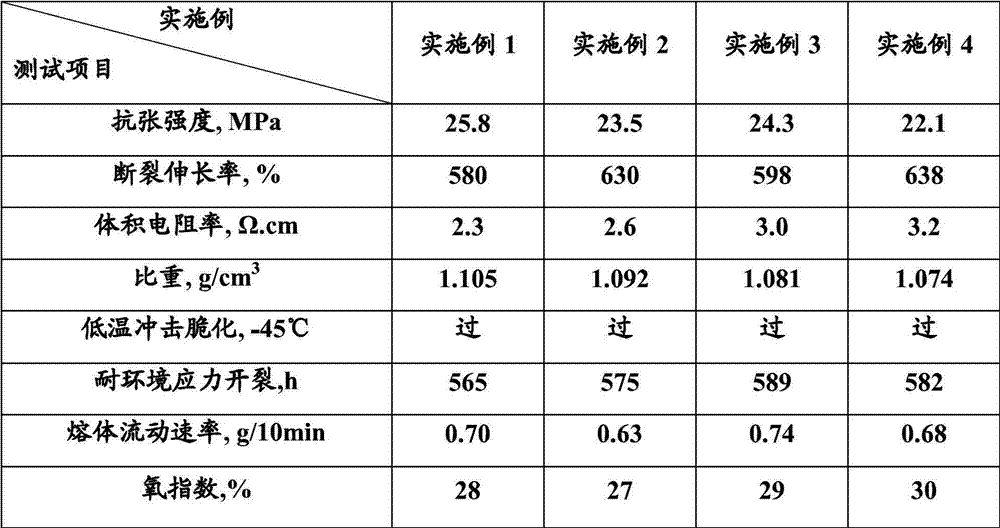

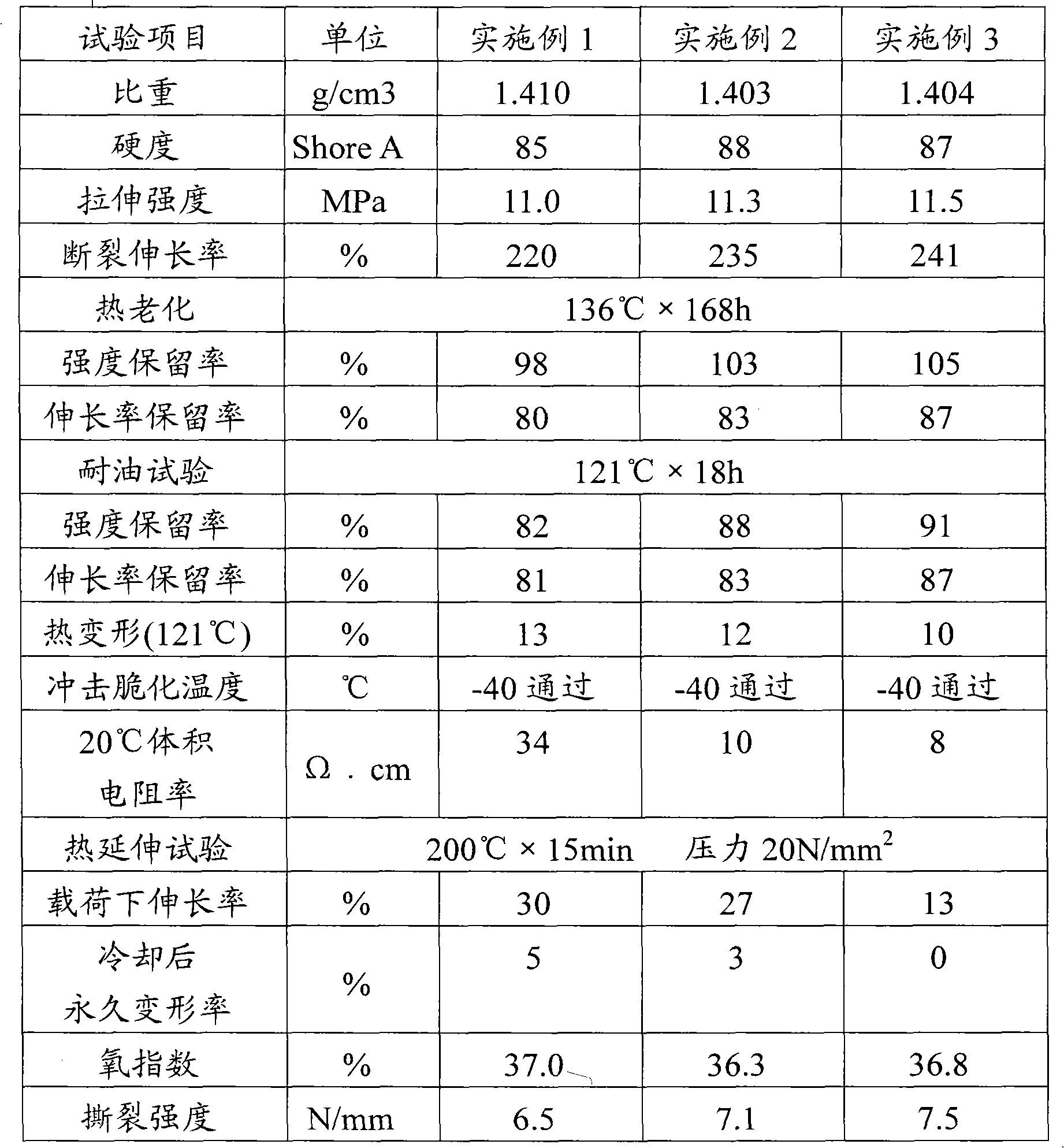

Semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material and preparation method thereof

ActiveCN102863686ADoes not affect mechanical and physical propertiesGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesPolyolefinPolymer science

The invention relates to a semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material and a preparation method thereof. The semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material is made of, by weight, 60-100 parts of polyolefin resin, 40-80 parts of conductive carbon black, 20-40 parts of flame retardant, 1-5 parts of dispersing agent, 0.1-3 parts of stearate, 0.1-3 parts of silane coupling agent, 5-20 parts of lubricant, 2-8 parts of wetting agent, 3-10 parts of antioxidant and 0-3 parts of uvioresistant agent, wherein the dispersing agent is composed of oleamide, erucyl amide or mixture of the oleamide and the erucyl amide. The improved semiconductive low-smoke zero-halogen flame-retardant polyolefin sheath material special for ultrahigh-voltage cables is advantageous in comprehensive performances, especially in electricity conductivity, flame retardation performance, low cost and the like.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

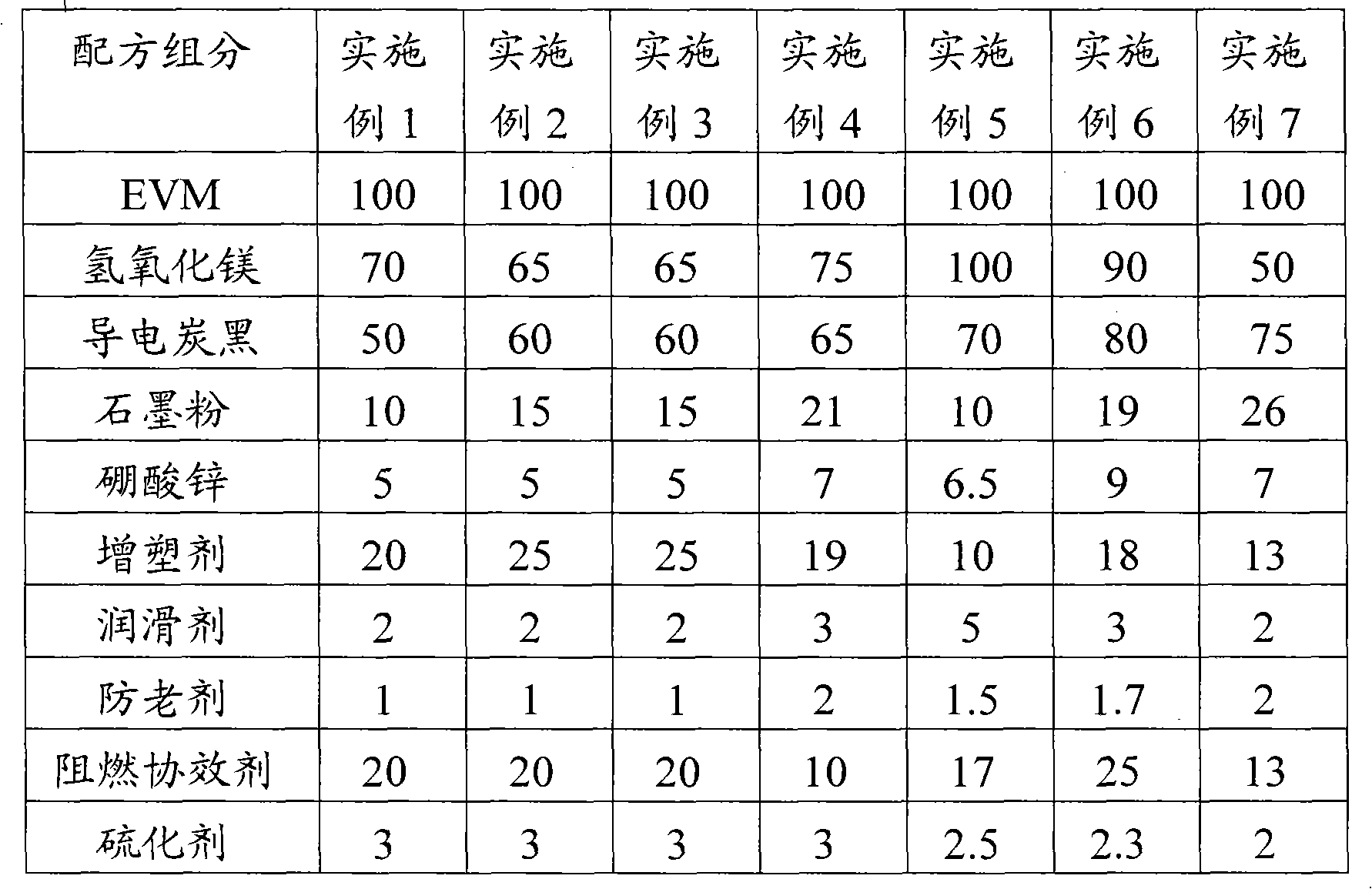

Conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and preparation method thereof

ActiveCN101942144AGood oil resistanceLow crystallization plasticizing temperatureInsulated cablesNon-conductive material with dispersed conductive materialVulcanizationHazardous substance

The invention relates to a conductive screening material, in particular to a conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and a preparation method thereof. The conductive screening material comprises the following basic components: 100 parts of ethylene-vinyl acetate rubber, 50-100 parts of magnesium hydroxide, 50-80 parts of conductive black, 10-30 parts of graphite powder, 5-10 parts of zinc borate, 10-25 parts of plasticizer, 2-5 parts of lubricant, 1-2 parts of antiager, 10-30 parts of flame retarding synergist, 2-3 parts of vulcanizer and 1-2 parts of vulcanization assistant. The preparation method comprises the four steps of material preparation, mixing, extrusion and tabletting. The conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material has the advantages of high conductivity, good oil resistivity, excellent flame retarding effect, no peculiar smell, easy stripping and high heat resistance level, and can pass the environment protection authentication of RoHS (Restriction of the use of certain Hazardous Substances Registration), REACH (Evaluation, Authorization and Restriction of Chemicals) and the like.

Owner:中广核三角洲(江苏)塑化有限公司

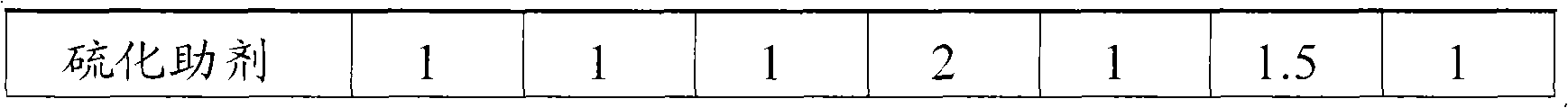

Low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material, preparation method thereof and cable

ActiveCN103627074AGood cold and oil resistanceImprove mechanical propertiesRubber insulatorsInsulated cablesAntioxidantCarvacryl acetate

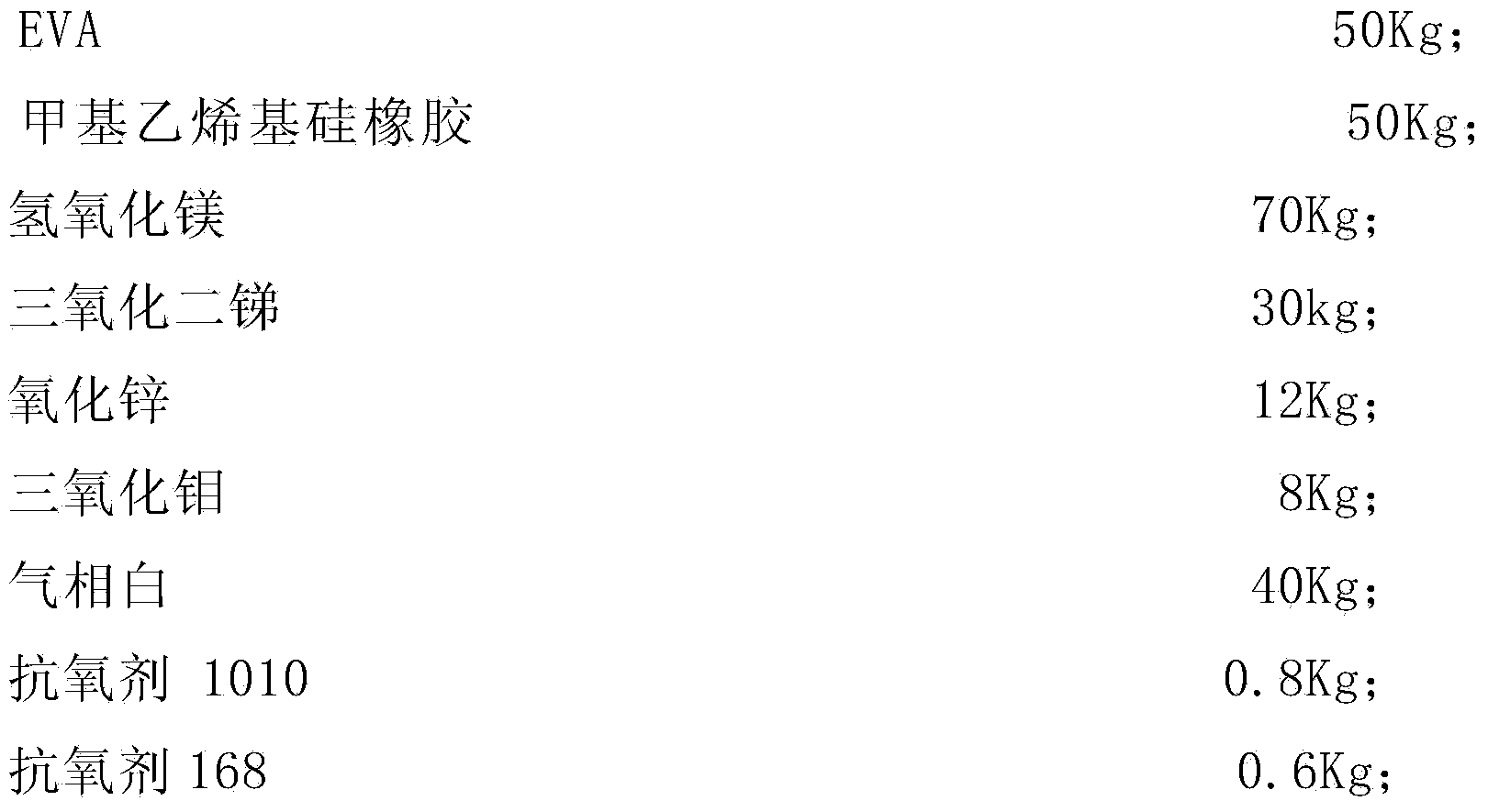

The invention provides a low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material and a preparation method thereof. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material comprises the following components in parts by weight: 100 parts of basic material, 80-100 parts of flame retardant A, 10-20 parts of flame retardant B, 0.8-2 parts of antioxidant, 0.4-2 parts of lubricant, 0.8-3 parts of coupling agent, 25-40 parts of reinforcing agent and 0.4-0.6 parts of vulcanizing agent, wherein the basic material is a combination of ethylene-vinyl acetate (EVA) and methyl vinyl silicone rubber; the flame retardant A is a combination of magnesium hydroxide and antimony trioxide; the flame retardant B is a combination of zinc oxide and molybdenum trioxide; the antioxidant is a combination of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate), (antioxidant 1010) and tri(2,4-di-tert-butylphenyl) phosphite (antioxidant 168); and the reinforcing agent is fumed silica. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material has the following characteristics of high abrasion resistance, high flame retardance, good oil resistance and chemical corrosion resistance, low temperature resistance, aging resistance, and excellent mechanical properties and the like. The invention further provides the preparation method of the low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material.

Owner:上海至正新材料有限公司

Low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and preparation method thereof

ActiveCN102093625AReliable Extrusion PerformanceReliable degree of cross-linkingInsulated cablesInsulated conductorsMasterbatchLow smoke zero halogen

The invention relates to a low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and the cable material contains the raw materials of flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent. The preparation method comprises the following steps: mixing flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent in a sealed mixer for absorption, discharging after 3-5 hours, and packaging to obtain the low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material finished product. Compared with the common low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material, the temperature resistant grade and mechanical properties of the product of the invention can be increased and the problem that the common low smoke non-halogen polyolefin cable material is easy to crack can be eliminated.

Owner:中广核三角洲(江苏)塑化有限公司

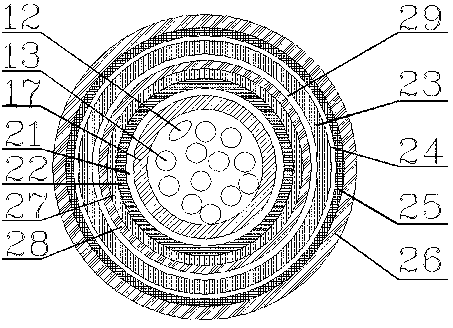

Expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and method thereof

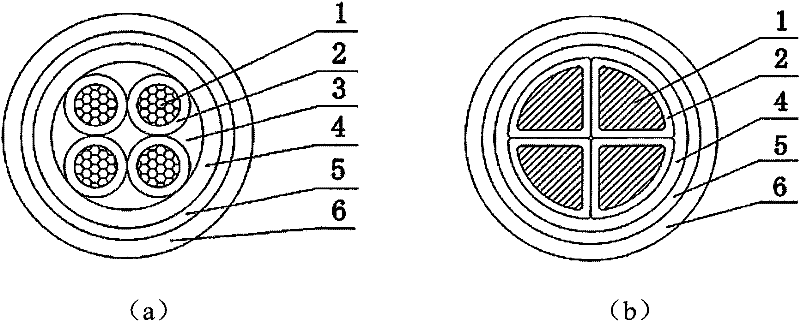

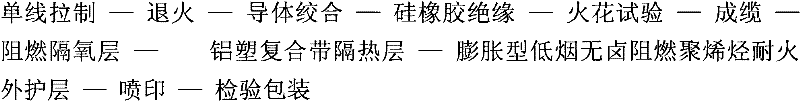

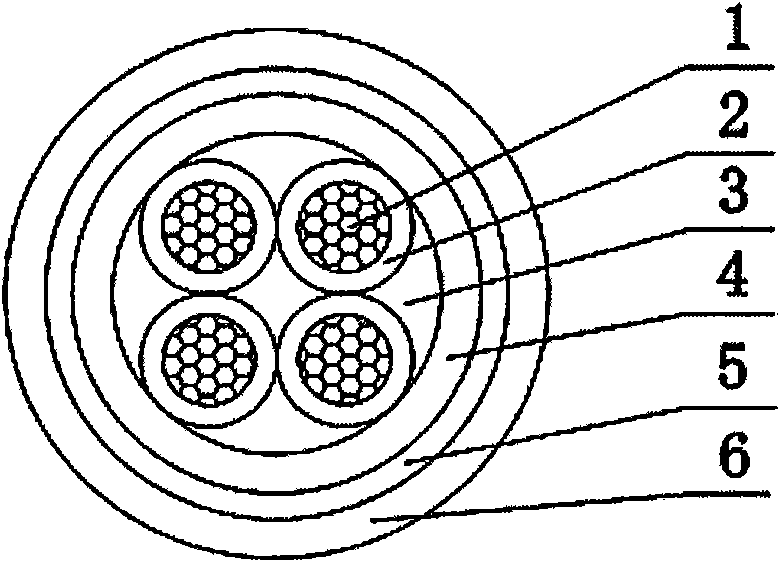

InactiveCN102306513AEasy to processImprove mechanical propertiesFlexible cablesCable/conductor manufactureEnvironmental resistanceInsulation layer

The invention relates to an expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and a method thereof. The cable is characterized in that: each core sequentially consists of conductors, a silicon rubber insulating layer, a filler, a flame retardant oxygen separation layer, an aluminum-plastic composite tape insulation layer and an expansion type fire-resistant outer protective layer made of low-smoke halogen-free flame retardant polyolefin from inside to outside, and adopts a fire-resistant cable structure formed by combining the expansion type fire-resistant outer protective layer made of the low-smoke halogen-free flame retardant polyolefin, the aluminum-plastic composite tape insulation layer and the silicon rubber insulating layer; and a flame retardant oxygen separation layer structure is formed by a halogen-free high-flame retardant material coated with metal hydrates. The preparation method comprises the following steps of: drawing single lines, performing annealing, twisting the conductors, insulating silicon rubber, cabling, and preparing the flame retardant oxygen separation layer, the aluminum-plastic composite tape insulation layer and the expansion type refractory outer protective layer made of the low-smoke halogen-free flame retardant polyolefin. The cable provided by the invention is easy to process, the external diameter of the cable is smaller than that of the traditional cable by 2 to 4 millimeters, and the structure can be obviously lightened.

Owner:南洋电缆集团有限公司

Weatherproof low-smoke zero-halogen polyolefin sheath material for extra-high-tension cable and preparation method of weatherproof low-smoke zero-halogen polyolefin sheath material

InactiveCN106366425AIncrease temperatureImprove wear resistanceClimate change adaptationInsulated cablesLow smoke zero halogenPolymer science

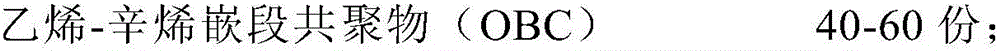

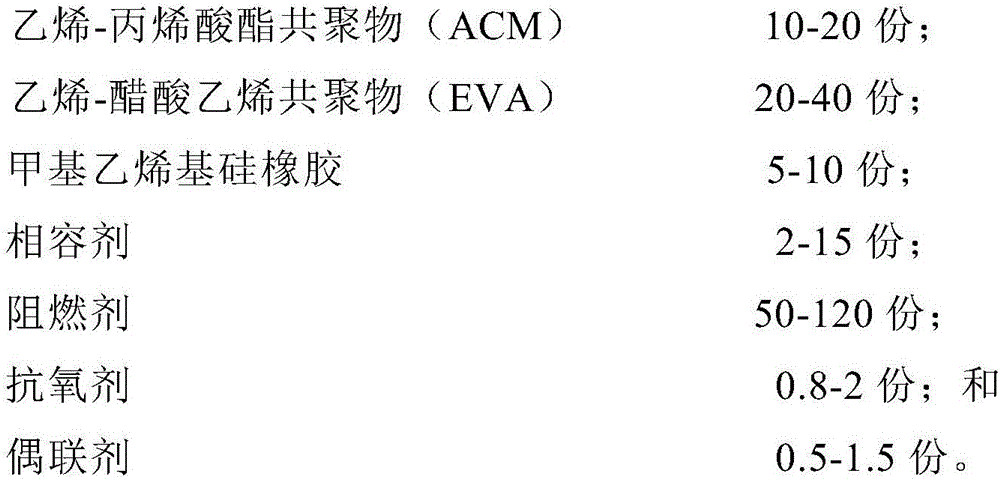

The invention relates to a weatherproof low-smoke zero-halogen polyolefin sheath material for an extra-high-tension cable. The weatherproof low-smoke zero-halogen polyolefin sheath material is prepared from, by weight, 40-60 parts of ethylene-octene block copolymer (OBC), 10-20 parts of ethylene-acrylate copolymer (ACM), 20-40 parts of ethylene-vinyl acetate copolymer (EVA), 5-10 parts of methyl vinyl silicone rubber, 2-15 parts of compatilizer, 50-120 parts of fire retardant, 0.8-2 parts of antioxygen and 0.5-1.5 parts of coupling agent.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

EVA/MLLDPE (ethylene-vinyl acetate/metallocene linear low-density polyethylene) component-type low-smoke halogen-free irradiation-crosslinked wire cable material, and preparation method and application thereof

InactiveCN104231409AImprove flame retardant performanceWith low smoke and non-toxicInsulated cablesInsulatorsLow-density polyethylenePolymer science

The invention discloses an EVA / MLLDPE (ethylene-vinyl acetate / metallocene linear low-density polyethylene) component-type low-smoke halogen-free irradiation-crosslinked wire cable material which is prepared from the following raw materials in parts by weight: 100 parts of EVA, 10-25 parts of MLLDPE, 80-130 parts of halogen-free flame retardant, 1.5-5.5 parts of coupling agent, 1.0-2.5 parts of crosslinking agent, 0.8-1.5 parts of antioxidant, 0.8-1.5 parts of ultraviolet absorbent, 5-10 parts of maleic anhydride graft compatilizer and 1.5-4.5 parts of lubricant. The invention also discloses a preparation method of the wire cable material and a low-smoke halogen-free irradiation-crosslinked wire cable prepared from the wire cable material. The low-smoke halogen-free irradiation-crosslinked wire cable material and wire cable are free of halogen elements, and have the characteristics of high flame retardancy, and low smoke and no toxicity during combustion. The MLLDPE and EVA are compounded to enhance the compatibility between the base and inorganic filler, and thus, the wire cable material has excellent mechanical properties. The wire cable material has the characteristics of high temperature resistance, aging resistance and the like. The preparation method of the wire cable material and wire cable is simple and easy to implement, and is suitable for industrial production.

Owner:GUANGDONG HUASHENG ELECTRICAL APPLIANCES CO LTD

Easily-processed low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation and application thereof

ActiveCN102585322AMeet the requirements of green environmental protectionImprove surface smoothnessTubular articlesProcedure AgentsPolyolefin

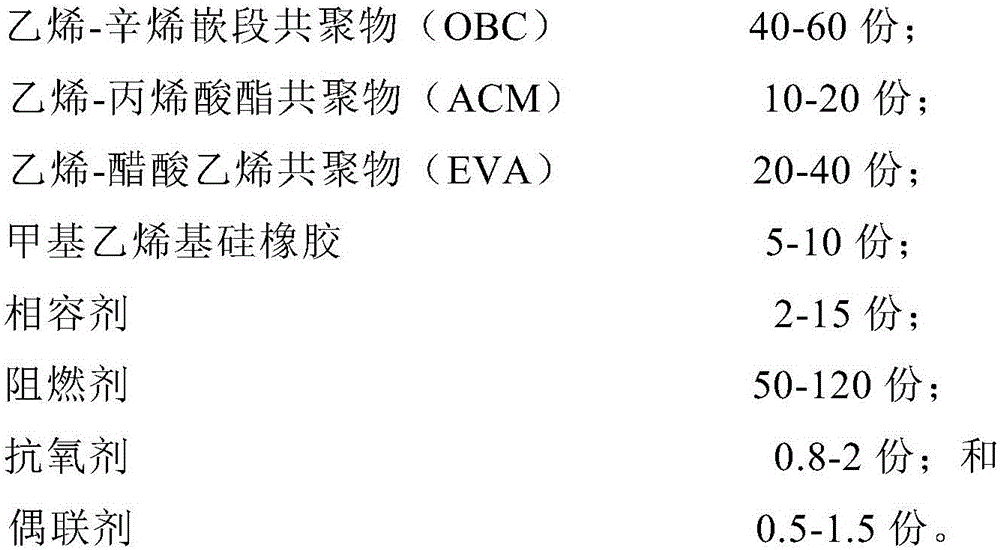

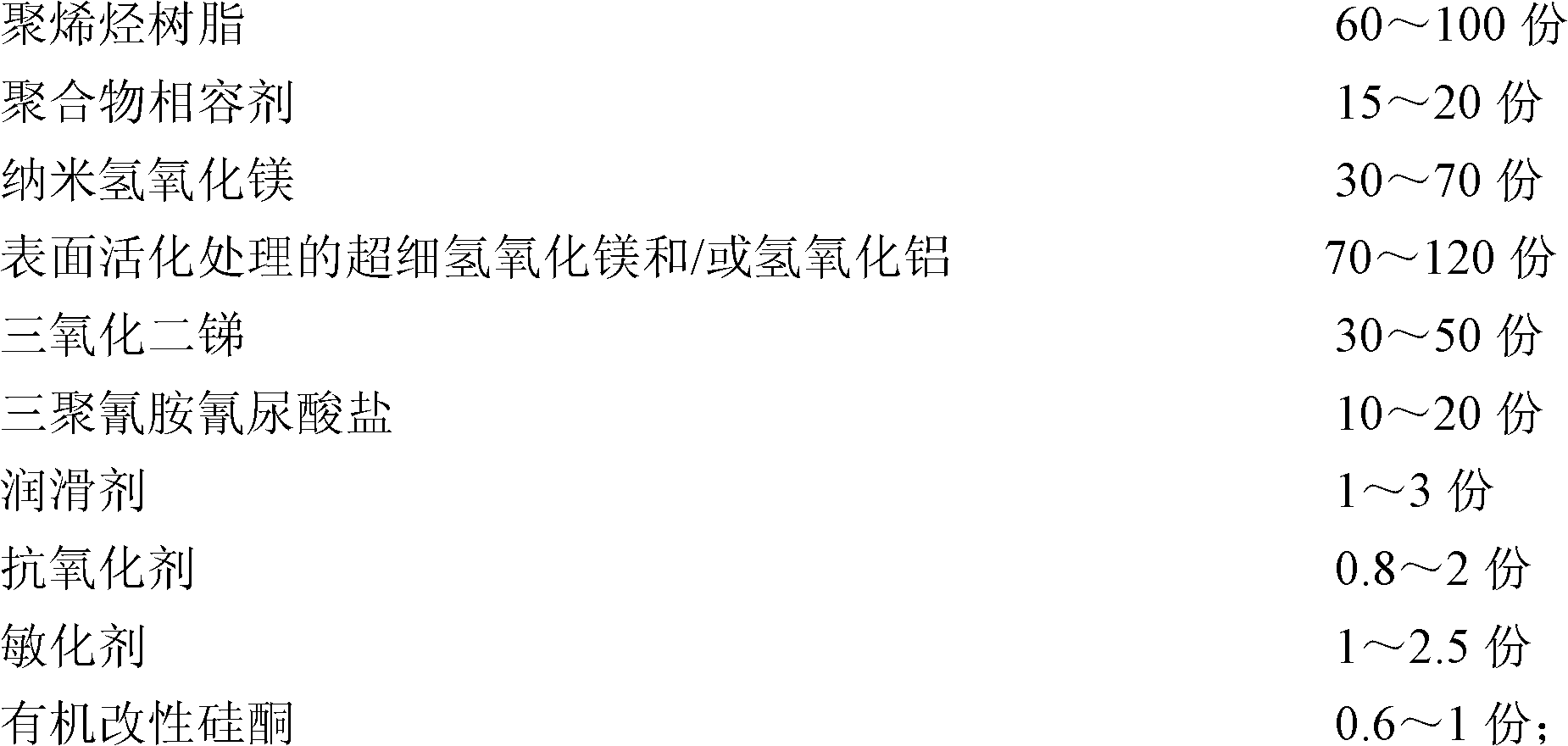

The invention discloses an easily-processed low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as a preparation method and application thereof. The identification sleeve consists of the following components in parts by weight: 60 to 100 parts of polyolefin resin, 5 to 20 parts of polymer compatilizer, 30 to 70 parts of nano magnesium hydroxide, 70 to 120 parts of surface activated superfine magnesium hydroxide or aluminum hydroxide, 30 to 50 parts of antimony trioxide, 10 to 20 parts of melamine cyanurate, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant, 1 to 2.5 parts of sensitizer and 0.6 to 1 part of processing aid. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould; radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance, produces little smoke, permanently preserves the label, and has good mechanical property and processing performance. The sleeve can be applied to facilities with high environment-friendly requirement.

Owner:广州凯恒科塑有限公司

Halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material and preparation method thereof

ActiveCN104479339ALess smokeImprove flame retardant performanceLow smoke zero halogenPolymer science

The invention belongs to the technical filed of thermoplastic polyurethane elastomer materials, and particularly relates to a halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material which comprises the following components in percentage by weight: 70-85% of thermoplastic polyurethane elastomer, 10-28% of halogen-free nitrogen and phosphorus flame retardant, 1-5% of smoke suppressor, 0.1-1% of antioxidant and 0.1-1% of lubricant. The halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material prepared by the invention produces a small amount of smoke in the combustion process, has excellent flame retardancy and excellent mechanical property, and can be used as a low-smoke halogen-free flame-retardant cable coating material. Besides, the invention also discloses a preparation method of the halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material.

Owner:ANGREEN DONGGUAN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com