Patents

Literature

387results about How to "Crack resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

Electric welding rod for hand welding X80 grade steel oil, gas transmission pipe

ActiveCN101362257AHas tensile strengthHas a shock valueWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to an electric welding rod used for manual welding. The electric welding rod comprises core welding-wires containing the following chemical compositions (wt%): 0.020-0.100 of C, 0.350-0.550 of Mn, 0.015-0.030 of Si, 0.005-0.015 of P, 0.002-0.005 of S, 0.01-0.20 of Cr, 0.01-0.30 of Ni, 0.01-0.20 of Cu, 98.675-99.47 of Fe, and the residue of impurity; the electrode coating comprises the following compositions: 28-38 of marble powder, 16-28 of fluorite powder, 2-8 of feldspar powder, 2-7 of white titanium pigment, 4-8 of electrolytic manganese, 3-7 of ferrosilicon powder, 6-9 of ferrotitanium powder, 0.5-2 of ferromolybdenum powder, 3-8 of nickel powder, 10-25 of iron power and 5-8 of other elements. The chemical compositions, the performance and the structure of the welding seam of a grade X80 steel pipe welded by using the electric welding rod are closer to the pipe body, and without heat treatment, the welding seam can meet the requirements on technical indicators such as high strength, high toughness, low hardness and the like of the grade X80 steel pipe used for oil and natural gas transferring; the electric welding rod overcomes the defaults in the prior art that the welding seam is required to be heat-treated after welding, the quality is poor, and engineering accidents are easy to happen when in use and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

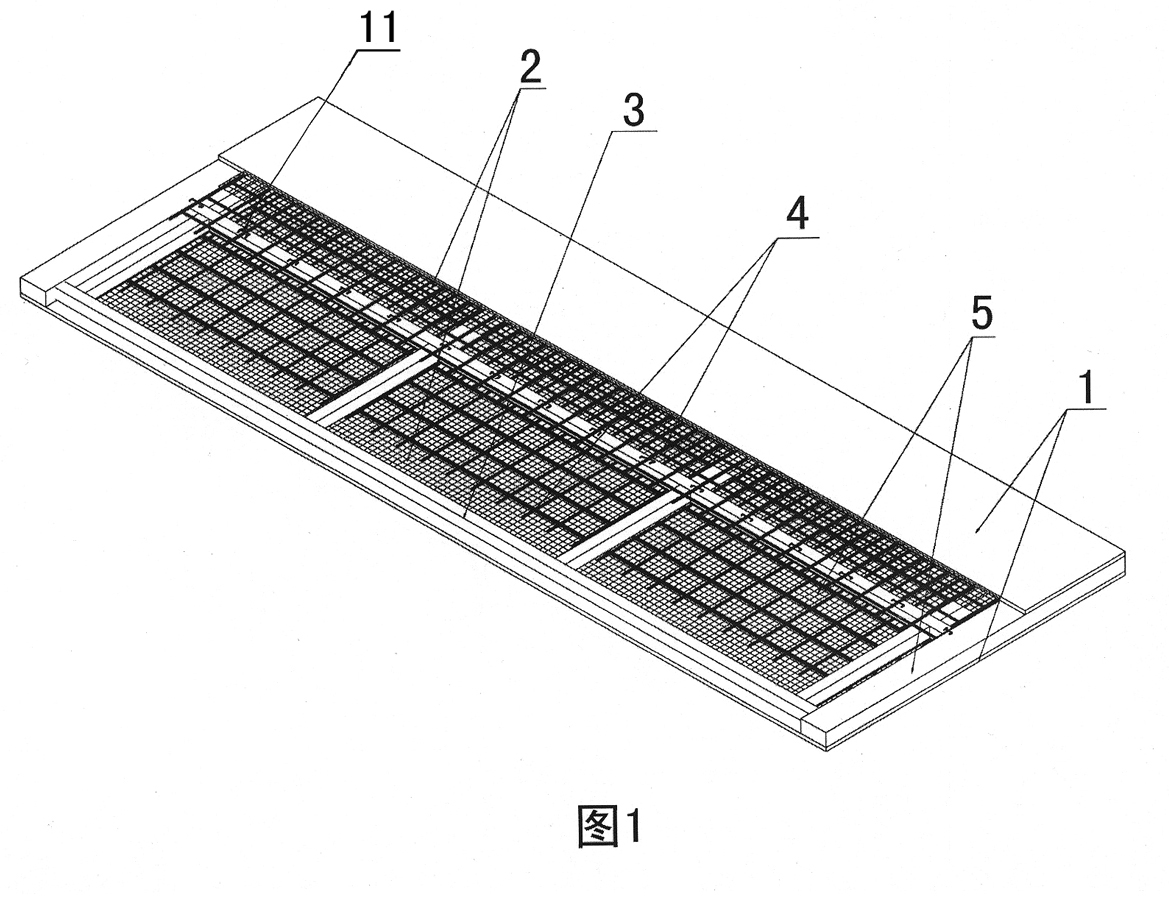

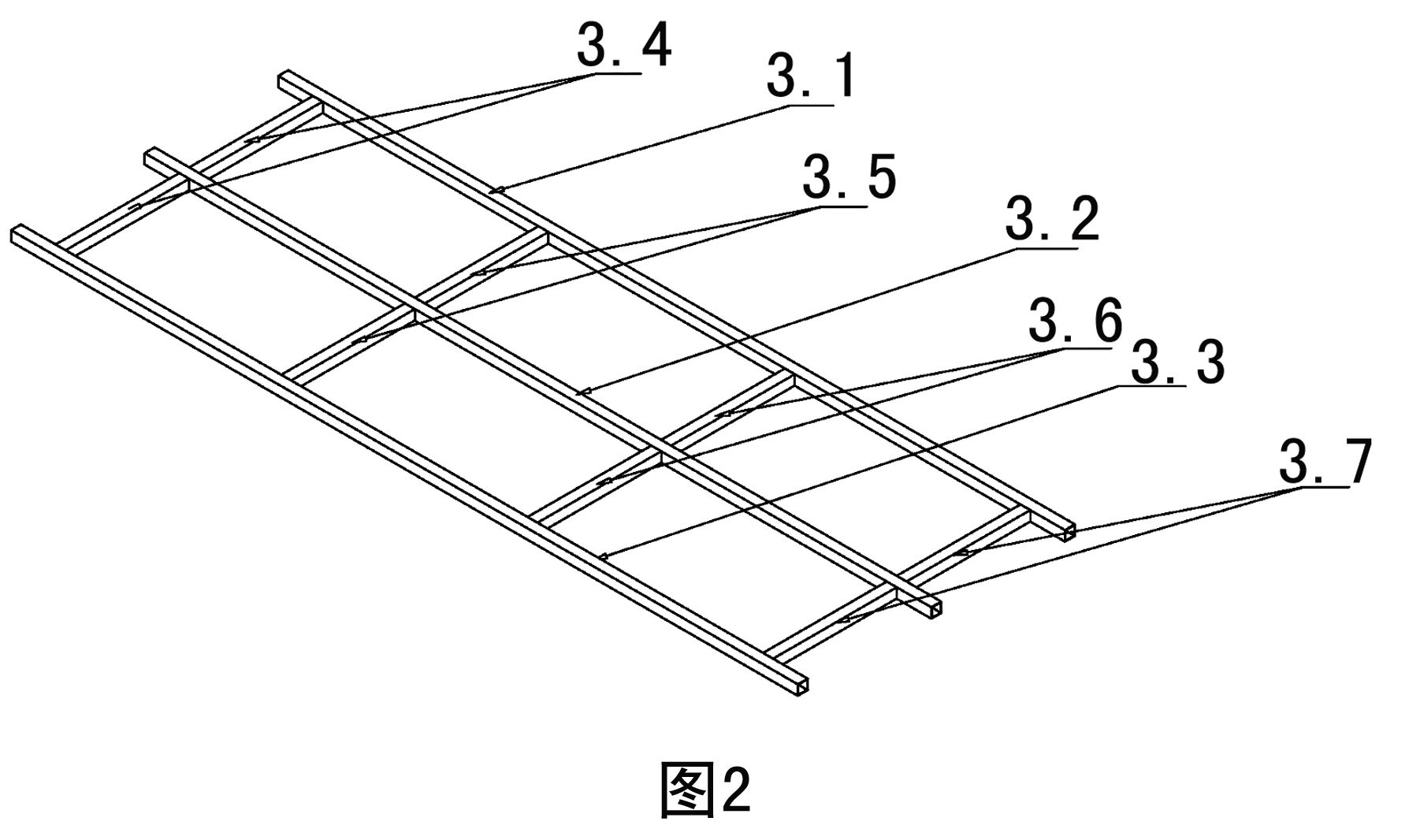

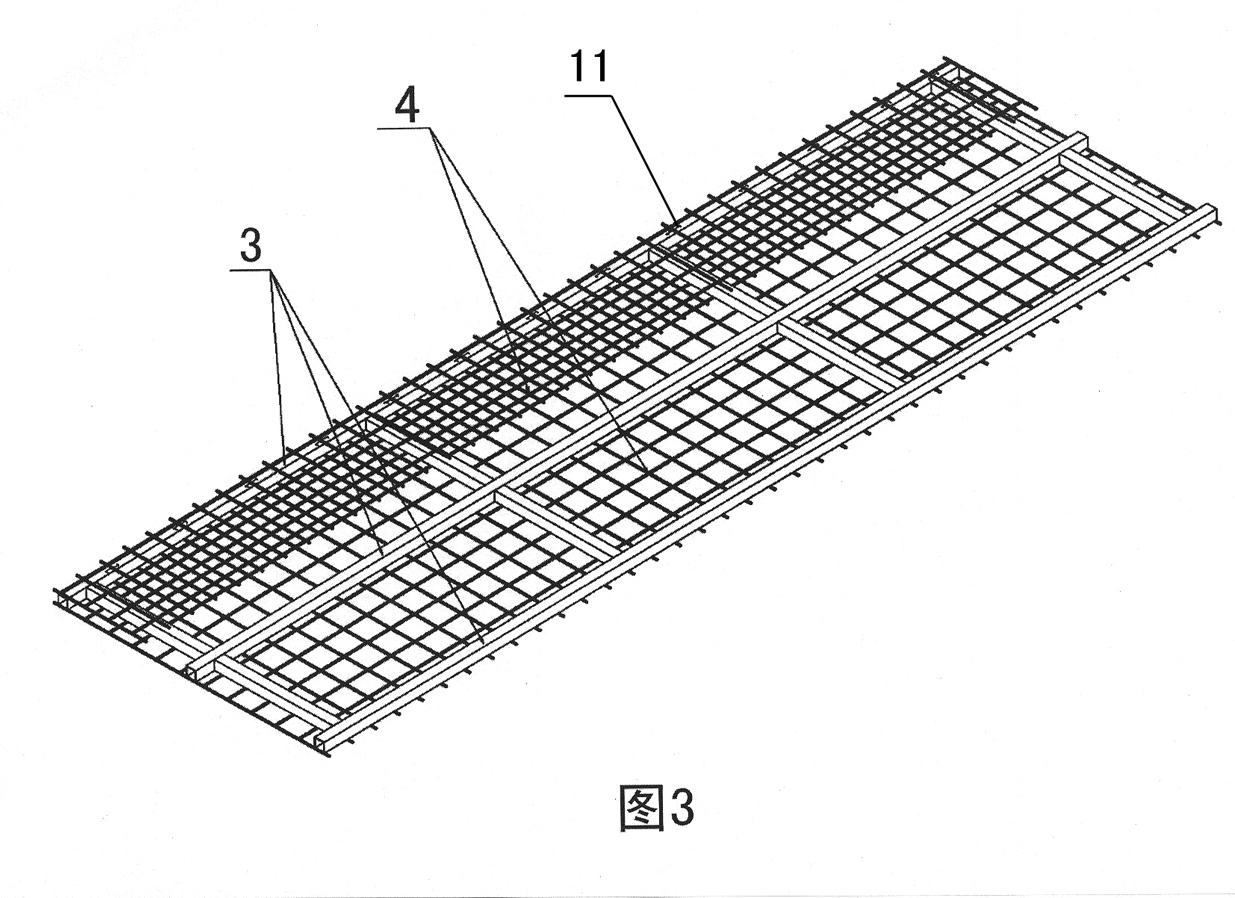

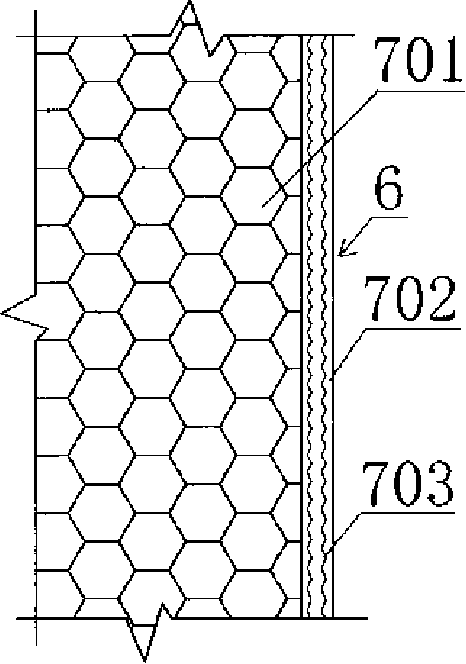

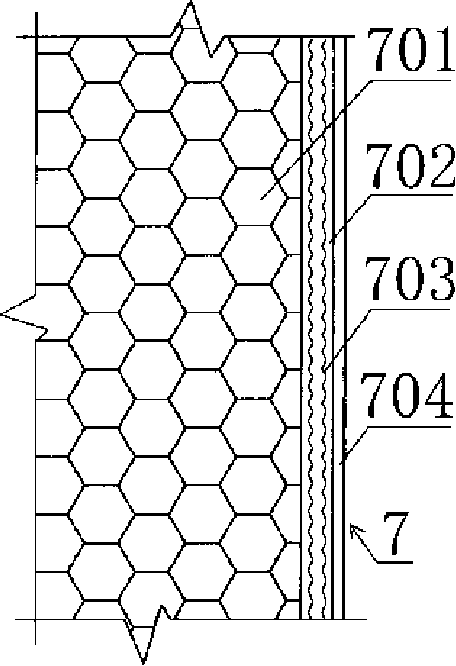

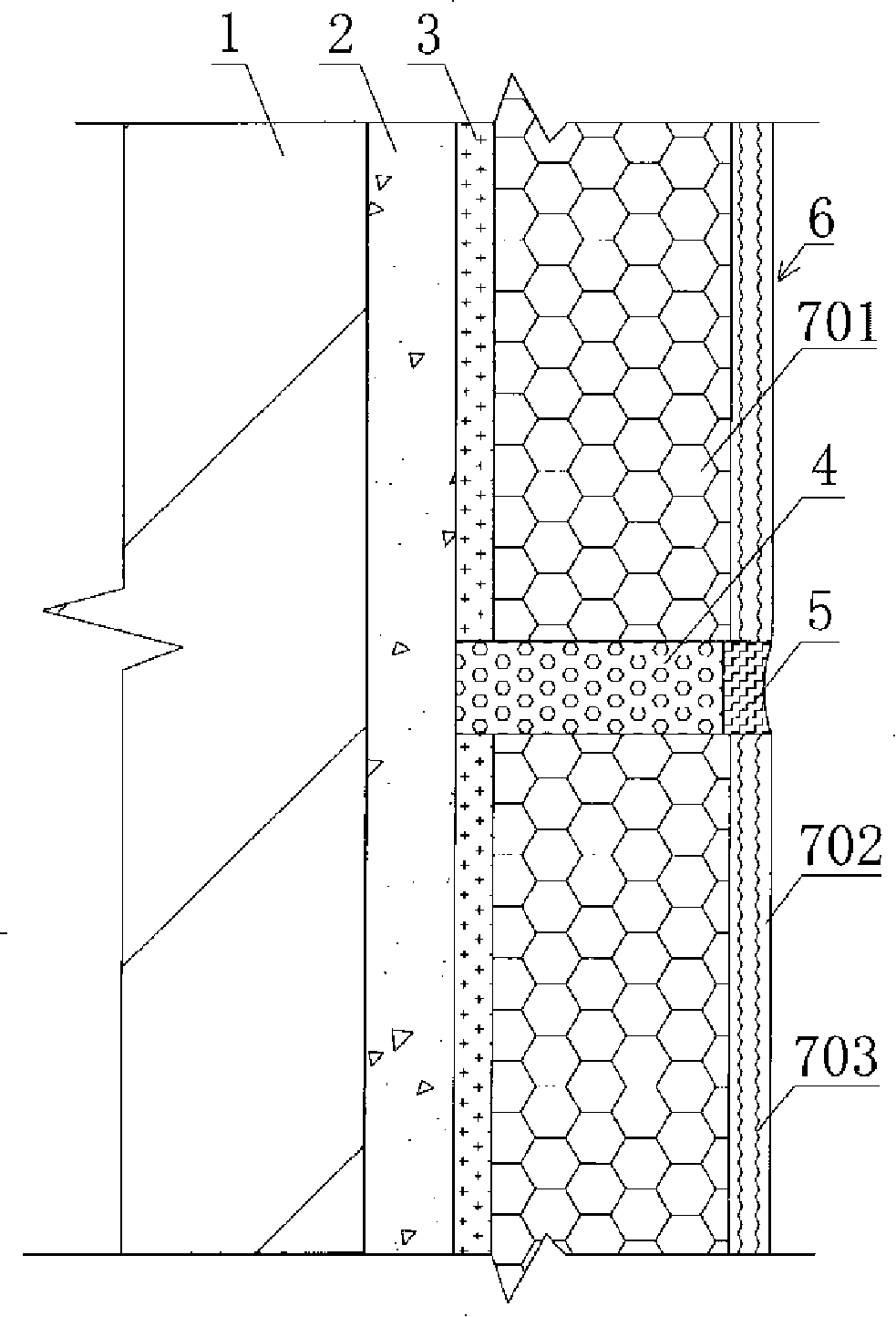

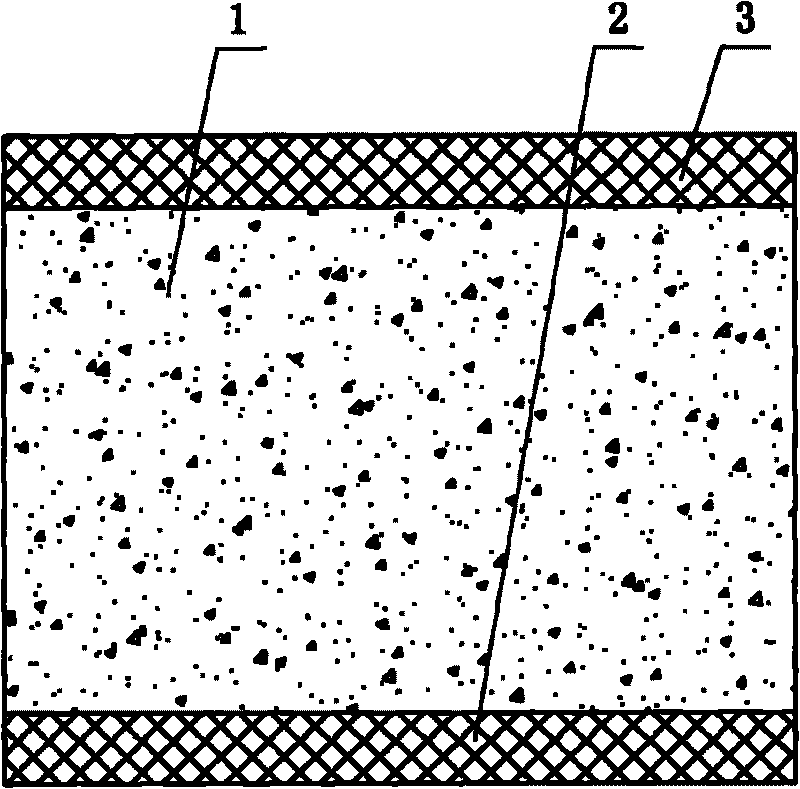

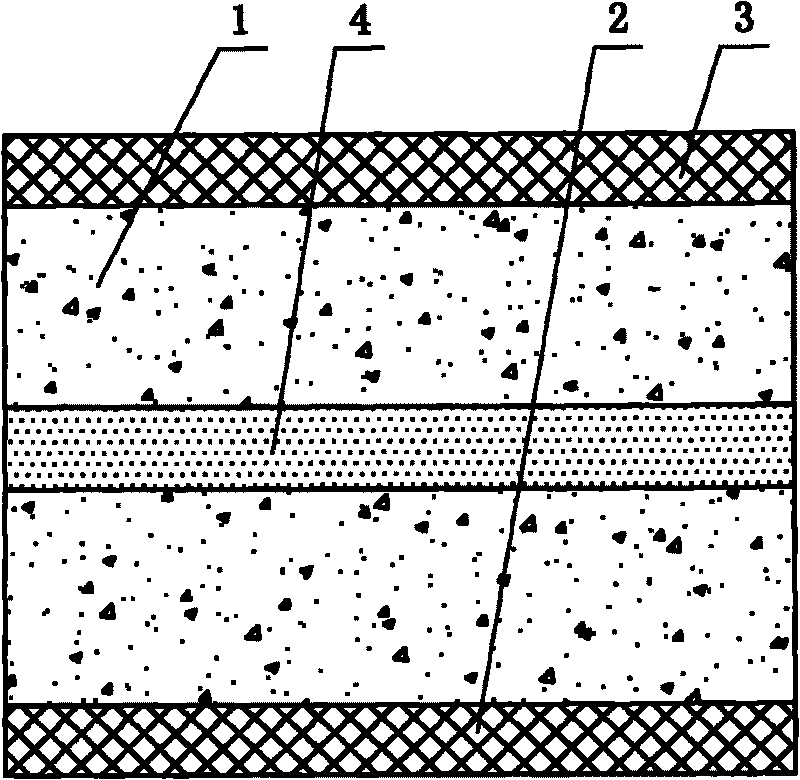

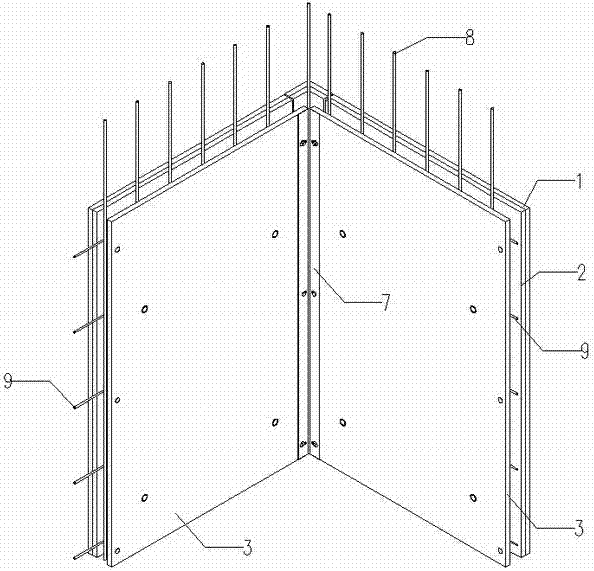

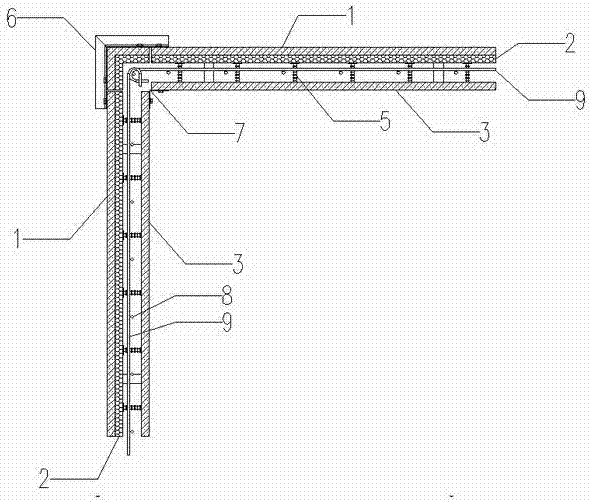

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

Direct-compress EPS inorganic clad plate and exterior outer-insulating system and construction method thereof

InactiveCN101158213AAvoid field workRapid productionCovering/liningsSolid waste managementComposite plateWeather proofing

The invention discloses an external insulation system and a construction method of a straight compressing EPS inorganic composite plate. The external wall firstly pre-produces the straight compressing EPS inorganic composite plate or a straight compressing EPS inorganic composite decorative board in a factory and compresses an inorganic composite enhancement layer onto a single-side of an expanded EPS plate by using a mechanical method; the outer surfaces of a base course wall of a building all adopt the EPS inorganic composite plate which adheres to a leveling blanket through bonding sands; the slab joint is pointed by jointing material and the outside of the jointing material is sealed again by weather proofing sealant; and a finish is arranged at the lateral of the system. The invention is characterized by the anti-crack, the good durability, the reliability and safety, the low cost and the fast construction.

Owner:余景春

Radiation vulcanizing method for environment-friendly type medical rubber products

InactiveCN101104700ANo precipitationSimple recipePharmaceutical containersMedical packagingCross-linkPolymer science

The invention relates to a process method of radiation vulcanization which applies the high energy radiation technology in medical rubber products, in particular to a vulcanization method of the environment protecting medical rubber products that can improve the safety and not-pollution property of the medical rubber products. Green rubber compound, reactive environment protecting cross-linking coagent, filler and compounding agent are mixed in a regulated weight ratio, and then are mixed in a mixing facility, so that non cross-linked rubber profiles are formed preliminarily. The non cross-linked rubber profiles are treated in radiation vulcanization for once or a plurality of times and then become the medical rubber products. The invention has the advantages of good safety, high chemical stability, air tightness and cleanness, no residue precipitation with irritability, volatility and anaphylaxis, ozonation resistance, crack resistance, heat resistance and fine mechanical property, and also has the advantages that the time of the radiation vulcanization is reduces, the energy is saved, fast radiation disinfection proposal method can be accepted.

Owner:QINGDAO UNIV OF SCI & TECH

Polymer fiber reinforced cement-based light thermal insulative roofing plate

InactiveCN1712652AHigh strengthLight weightRoof covering using slabs/sheetsPolymer adhesivePolymer modified

An insulated-room sheet of cement-base fibre polymer is composed of two surfaces and the sandwich layer. The surface is made from the cement, flyash, ceramisite, latex, organic fibre, the water reducing agent, the waterproofing agent, the blister, the excitant and the concrete. The sandwich layer is made from the cement, flyash, EPS, pearlite, ceramisite, latex, interface agent, water reducing agent, the waterproofing agent, the blister, the excitant and the concrete. The sheet has the good insulation, low weight, good fire and water resisting.

Owner:肖力光 +1

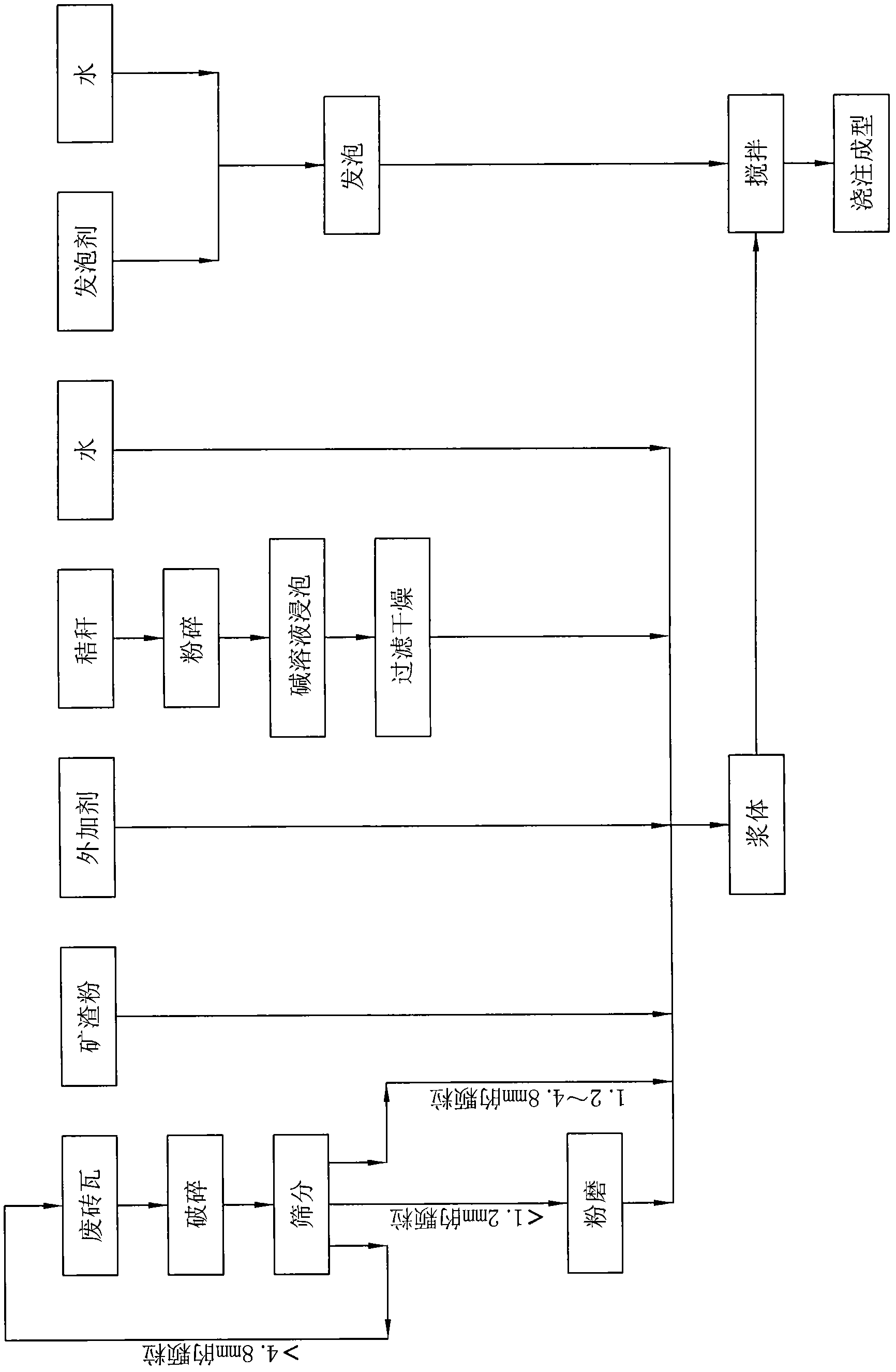

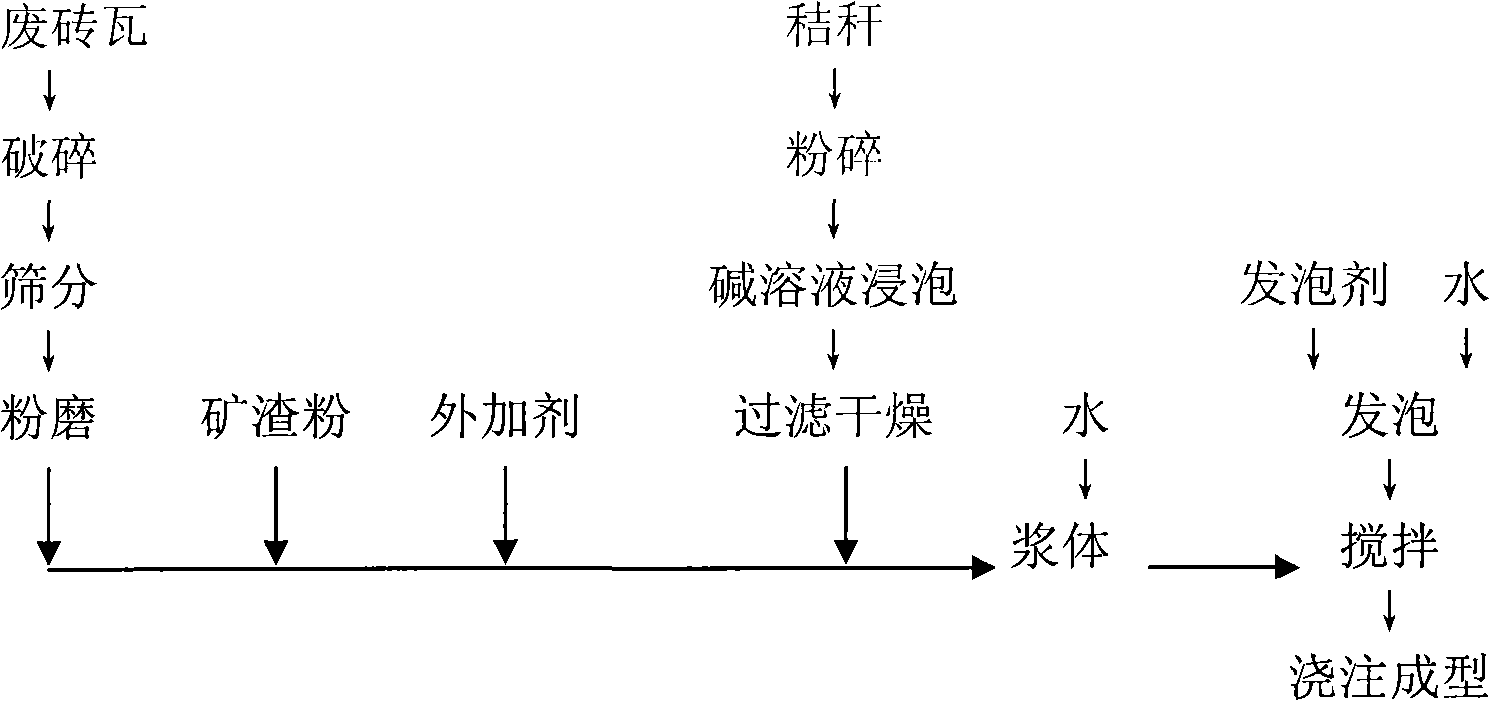

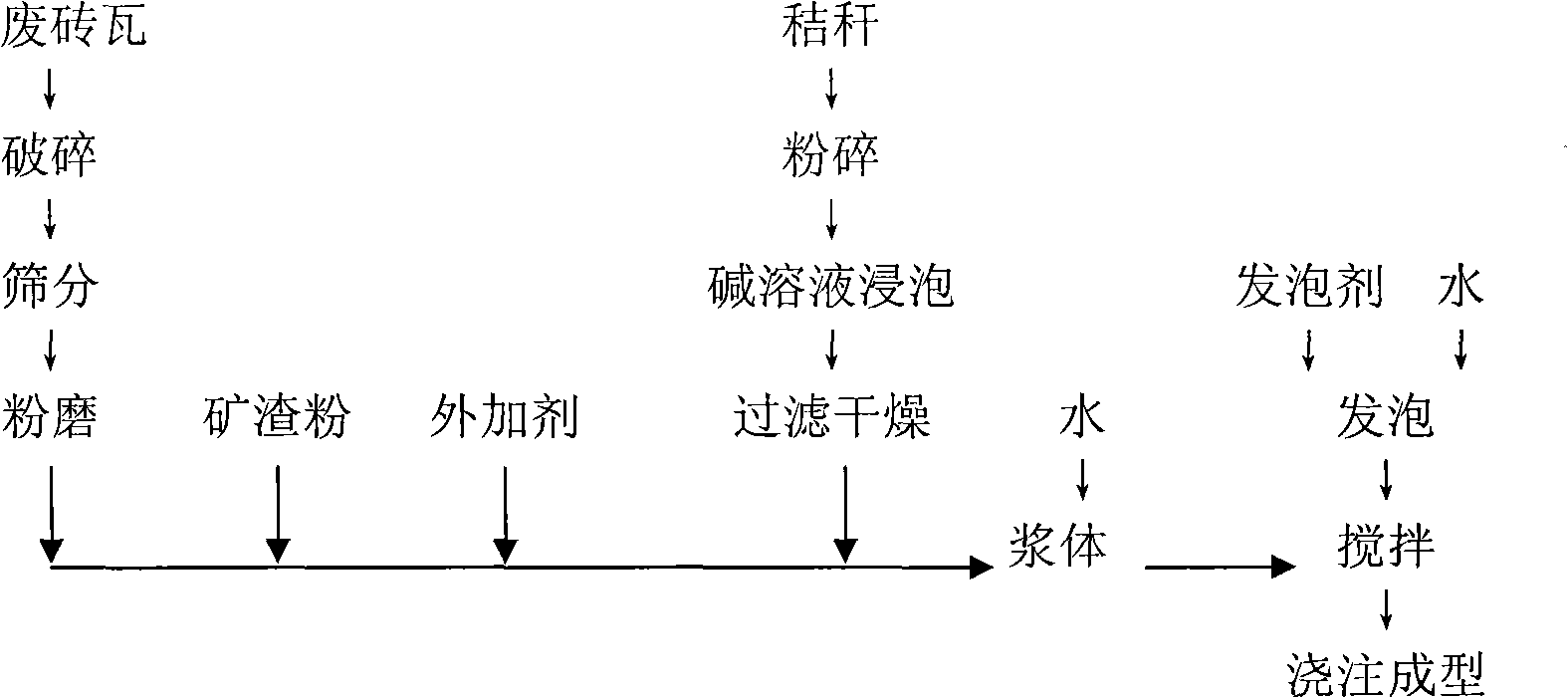

Waste brick tile/straw foam concrete and preparation method thereof

ActiveCN102464497AHigh strengthImprove thermal insulation performanceCeramicwareFoam concreteEcological environment

The invention which provides waste brick tile / straw foam concrete and a preparation method thereof relates to a lightweight building material. The foam concrete is a porous material obtained by mixing more than 90% of a main material comprising industrial and agricultural wastes of waste brick tiles, slag, straws and the like, an additive, a foaming agent and water according to a ratio, stirring,cast-molding and maintaining. The foam concrete which has the functions of light weight, low heat conduction coefficient, heat insulation, sound insulation and fire resistance, water resistance, freezing resistance, cracking resistance, shock resistance and the like and has the advantages of low production cost, simple manufacturing process, realization of onsite casting of prefabricated products, use convenience and safety, changing of wastes into valuables, reaching of energy-saving low-carbon effects, reduction of pollution of the wastes to the environment, ecological environment protection, and nation and civilian benefiting, contributes to the creation of the saving and low carbon society in China.

Owner:DAFENG YINGTAI STRAW STALK TECH DEV CO LTD

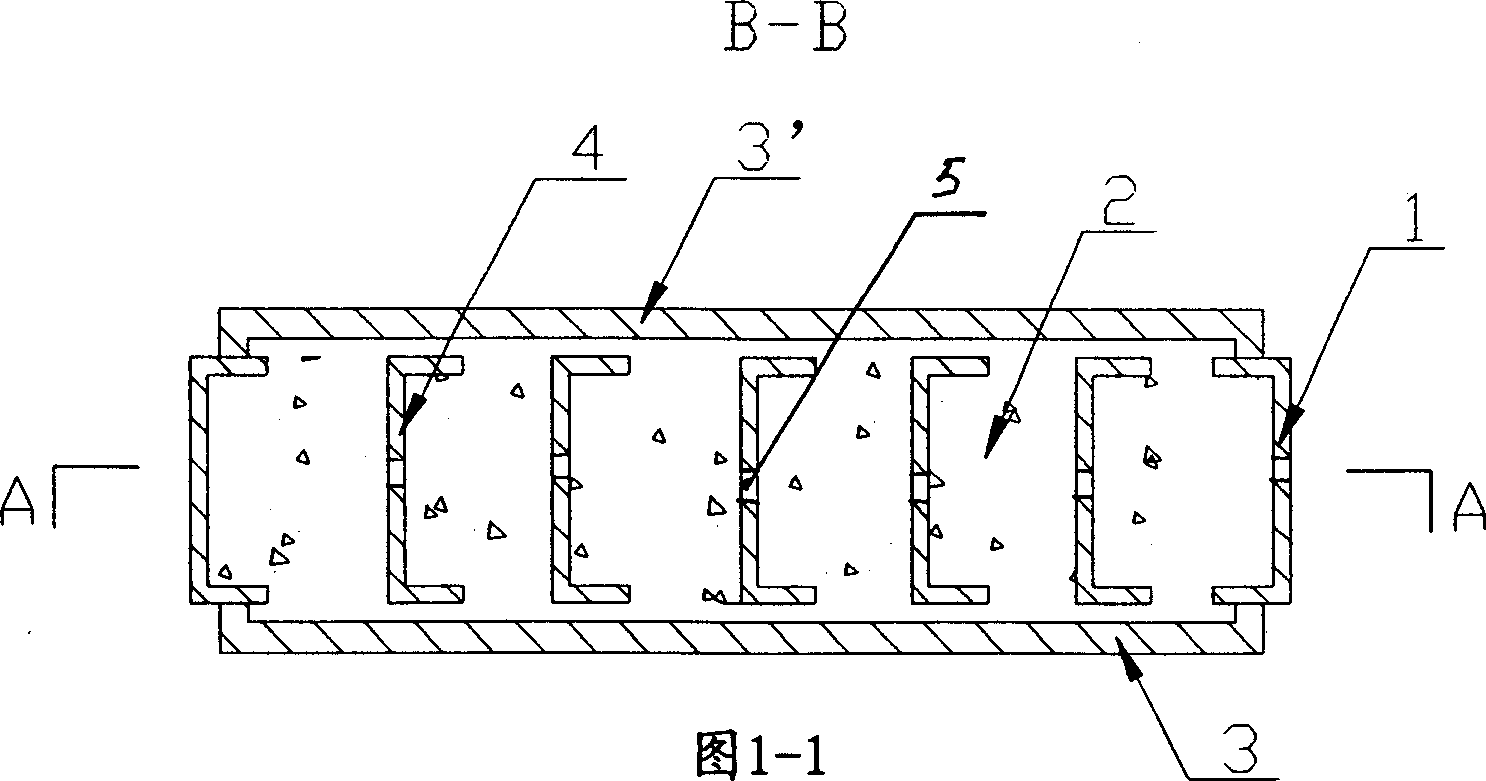

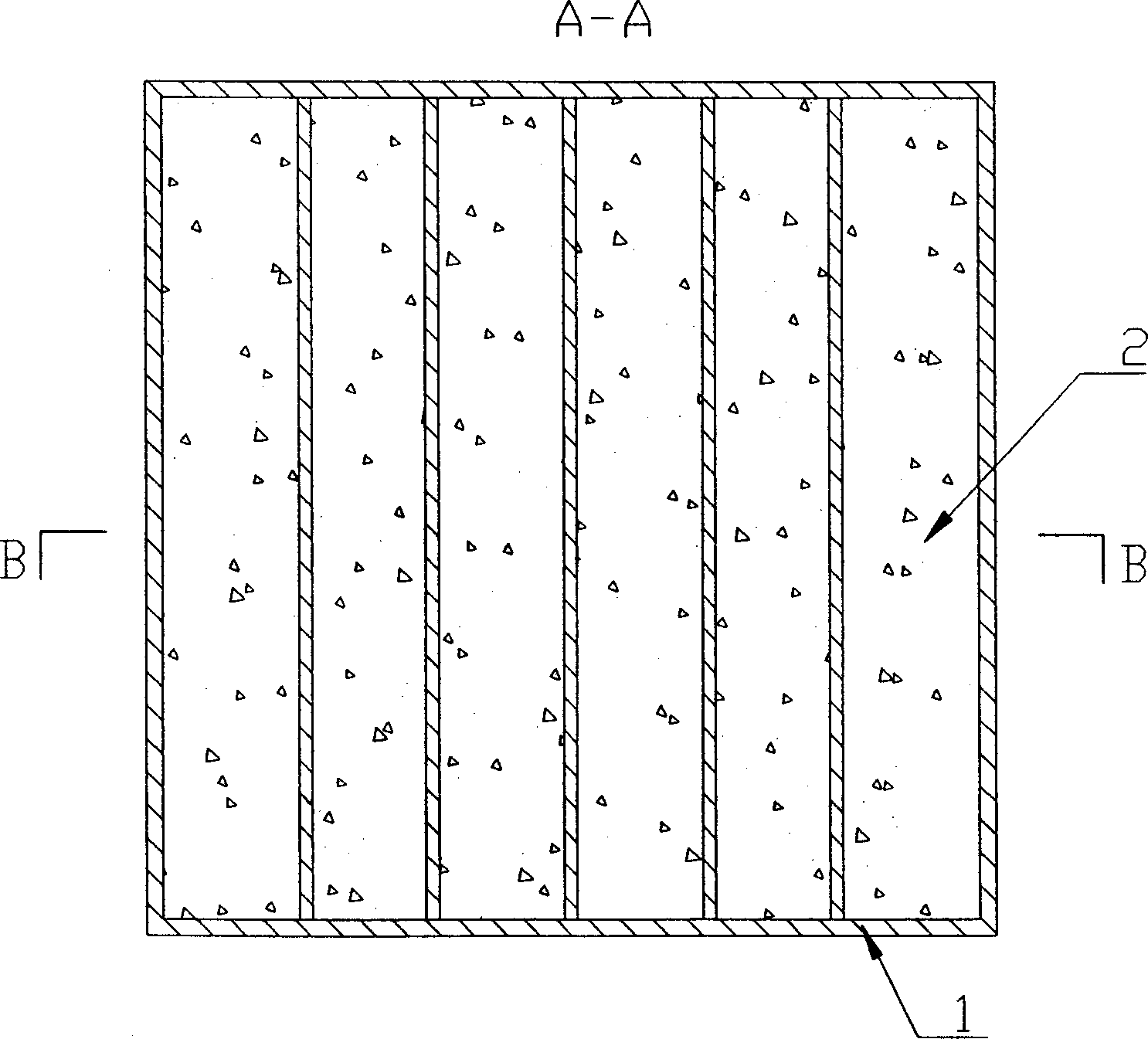

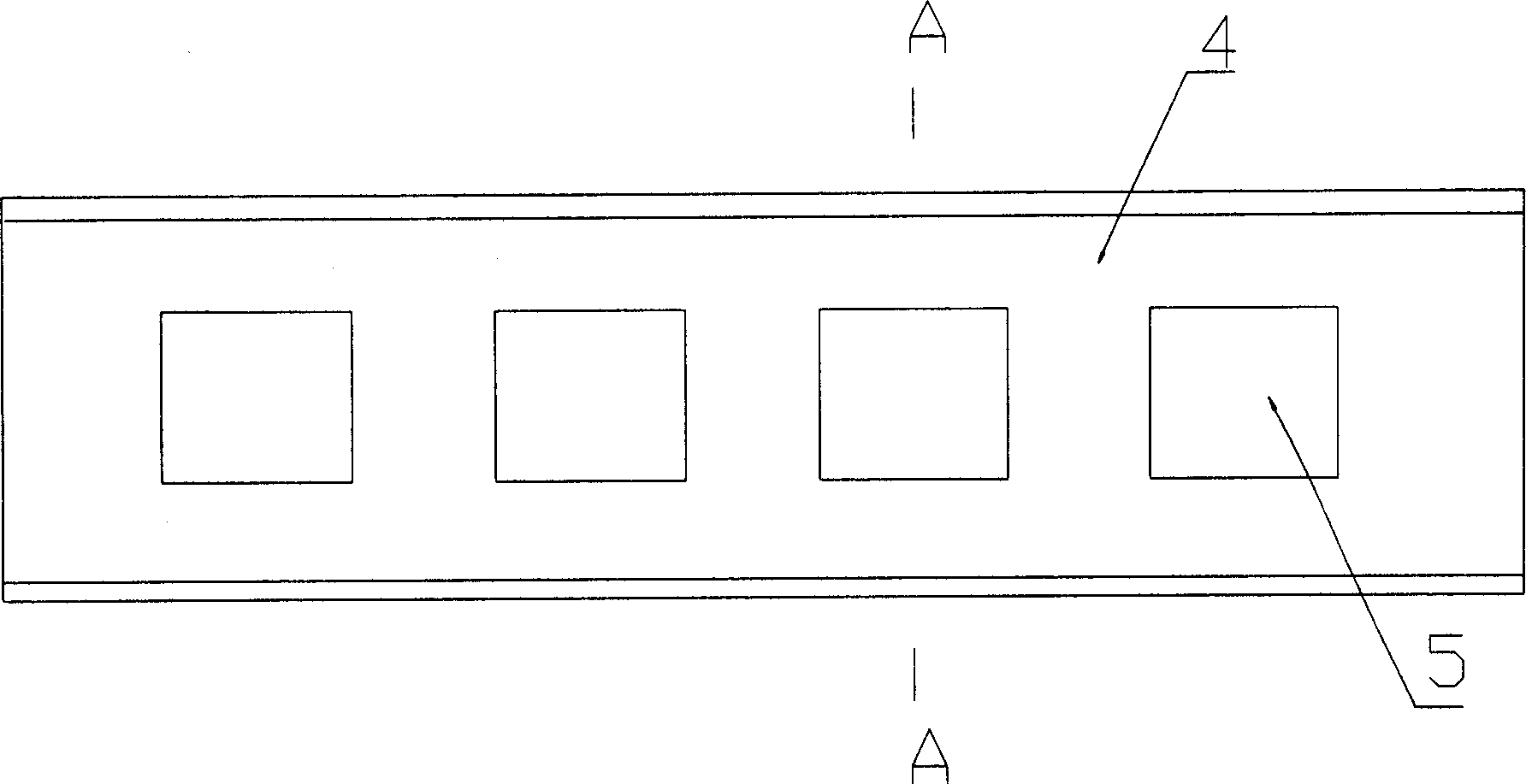

Composite building board material capable of load bearing and its productioin method

InactiveCN1478971AFireproofWith sound insulationMouldsBuilding componentsSteel columnsLoad-bearing wall

A composite building plate able to bear load is composed of the external frame, foamed cement layer filled into the frame, and surfacial layers, and features that several steel columns or beams are unidirectionally arranged in the frame, which have through holes for allowing the foamed cement to penetrate through them. Its advantages are light weight, high weatherability, insulation to heat and sound, and resistance to water, acid and alkali, and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

Environment friendly dry powder emulsion paint and preparation method thereof

The invention provides environment friendly dry powder emulsion paint and a preparation method thereof. The environment friendly dry powder emulsion paint comprises the following substances in percentage by weight: 10-45% of white cement, 0.35-0.65% of cellulose ether, 40-75% of calcium carbonate, 3-25% of ash calcium, 0.1-0.5% of cassava modified starch, 0.1-2% of wood fiber, 0.1-1% of fluorescent whitening agent, 0-25% of redispersible emulsion powder, 0-30% of titanium white and 0-5% of inorganic pigment. The preparation method comprises the following steps: putting the substances in percentage into a blender, evenly mixing and packaging to obtain the finished product; adding water and evenly stirring for using; and realizing one-step forming from bottom to surface. The invention has the advantages of high strength, small possibility of cracking, no drop, no peeling, no hollowing, easy color, bright color, small possibility of color fading, scrubbing resistance, mildew resistance, environmental protection, non-pollution, low cost, simple and easy packaging, convenient transportation, simple construction and the like, and can be widely applied to decoration of interior and exterior walls of the buildings.

Owner:安徽三力装饰材料科技有限公司

Aqueous infiltrating crystallization type waterproof agent and preparation method thereof

InactiveCN101619203AImprove permeabilityReduce surface tensionOther chemical processesFiberNuclear chemistry

The invention belongs to the field of construction materials, in particular to an aqueous infiltrating crystallization type waterproof agent and a preparation method thereof. The aqueous infiltrating crystallization type waterproof agent comprises tartaric acid, sodium fluoride, silica sol, silane emulsion and water. The aqueous infiltrating crystallization type waterproof agent is aqueous waterproof admixture comprising a plurality of active chemical components and has high infiltrating ability and lower surface tension. After the aqueous infiltrating crystallization type waterproof agent is applied to the basal plane of concrete, an active compound is infiltrated and diffused in the concrete and reacts with a hydrated product in the concrete in a pore to generate a needle or fiber-shaped crystal so as to block the pore, thereby compacting the concrete and playing the roles of preventing water, ventilating, increasing the compression resistant strength, and the like.

Owner:TONGJI UNIV

Polyurea-polysiloxane organic-inorganic hybridized concrete biological pollution protection material and preparation method thereof

ActiveCN104312398AExcellent imitation biofouling performanceLow Surface Energy PropertiesAntifouling/underwater paintsPaints with biocidesSurface energyBiological growth

The invention discloses a polyurea-polysiloxane organic-inorganic hybridized concrete biological pollution protection material and a preparation method thereof. The pollution protection material is composed of a surface protection material and a base protection material, wherein the surface protection material is composed of the following raw materials in parts by weight: polyaspartic acid ester modified polysiloxane, modified isocyanate, a biological growth inhibitor, a catalyst, a coupling agent, an anti-ageing agent, a filler and pigment; the base protection material is composed of the following raw materials in parts by weight: modified epoxy resin, an epoxy curing agent, an reactive diluent, a coupling agent, an anti-ageing agent and a filler. The pollution protection material is excellent in biological pollution imitation performance, has the characteristic of low surface energy and can prevent biofouling. Special elements in structure interior of the material can inhibit growth of ocean and fresh water creatures, thereby achieving the aim of preventing biological pollution.

Owner:WUHAN CHANGJIANG KECHUANG TECH DEV +1

Water wall paint for external wall

The present invention features that by selecting different sort and amount of emulsion and assistants, four kinds of wall finish paint, including styrene-acrylate wall finish paint, acrylate wall finish paint, organosilicon modified acrylate wall finish paint and high elasticicty wall finish paint, of different performance / cost ratio are proposed. They features the introduction of hydroxyethyl cellulose and non-transparent hollow polymer. Therefore, the outer wall finish paint has excellent alkali resistance, color maintaining property, antifouling property, ultraviolet ray resistance, freeze thawing resistance, waterproof property, etc.

Owner:GUANGDONG BADESE CHEM

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

Water radon-screening emulsion paint

A radon-screening water emulsoid paint used as decorative paint for preventing radon, benzene, xylene and formaldehyde from being educed from wall and adsorbing them contains water, hydroxyethyl cellulose, disperser, defoaming agent, levelling agent, light calcium carbonate, titanium oxide, bentone, talc powder, ethanediol, film forming agent, PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion, and antibacterial mildew-proof agent.

Owner:陈伟常 +1

Efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as preparation method and application method thereof

The invention discloses an efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as a preparation method and an application method thereof. The composition comprises the following components in percentage by weight (100% in total): 1%-5% of a plasticizer, 15%-30% of a thickening agent, 30%-50% of a retarder, 10%-25% of an anti-cracking agent, 1-5% of a water-retaining agent, 5%-10% of an enhancer, and 1%-5% of a binding agent. By utilizing the composition, the workability, water-retaining property, adhesive property and cracking resistance of coating mortar can be remarkably improved, the cracking, hollowing and falling of the mortar are avoided, and various performance indexes such as the strength and permeability resistance of the mortar can be improved; and furthermore, cement can be saved, and the disadvantages of easiness in ash blasting, high shrinkage, low strength and the like of the cement mixed mortar are overcome.

Owner:四川巨星新型材料有限公司

Cement-based decoration material, decoration plate and production method thereof

InactiveCN101693609AImprove general performanceAnti-agingCovering/liningsMixing operation control apparatusCelluloseWeather resistance

The invention relates to a cement-based decoration material which comprises cement flour, emulsion and cellulose in following component relations: when the emulsion is liquid emulsion, the ratio of the cement lour to the emulsion is 100: 40-100, and the ratio of the cement to the cellulose is 100:0.1-0.5; and when the emulsion is dispersible emulsion, the ratio of the cement lour to the emulsion is 100:1.5-2.4, and the ratio of the cement to the cellulose is 100:0.1-0.5. The decoration plate provided by the invention can be directly applied to internal and external walls and floors of buildings, also can be used as waterproof materials of roofs, underground structures, washrooms, or kitchens, can realize the protection against water, fire, damp, crack and falling off, and has good aging resistance and weather resistance and same service life with buildings and is a novel poisonless, tasteless, environment-friendly and energy-saving product with convenient use, low production cost and long service life.

Owner:陈友增

Vibration-damping heat-insulation paint and preparation method thereof

ActiveCN101709188AGood adhesionIncreased durabilityFireproof paintsAnti-corrosive paintsAdhesiveData recording

The invention discloses a vibration-damping heat-insulation paint which comprises the following components by mass percent: 9.5-11.5% of chlorine ether resin, 5-6% of adhesive, 3.5-4.5% of melamine urea copolymerization resin, 18-21% of environment-friendly solvent, 14.5-16.5% of soft filler I, 13-15% of soft filler II, 18-20% of soft filler III, 3.8-5.8% of plasticizer, 1.5-2.3% of titanium pigment and 4-6% of hollow micro-bead. The invention also discloses a preparation method of the vibration-damping heat-insulation paint. The high-efficiency vibration-damping heat-insulation paint can be coated on various substrates, has advantages in various aspects such as heat insulation, heat preservation, fire prevention, water prevention, crack prevention, noise prevention, weather resistance, acid / alkali resistance, salt-fog resistance, corrosion resistance, vibration damping, durability and the like, is suitable for thermal protection and vibration damping at the external surfaces of spaceflight instruments and data recording instruments of aerospacecrafts and can be used for damping the impact friction and the like of containers and the like.

Owner:WUXI HUHUANG PAINT

Resin impregnated cloth veneer and manufacture technology thereof

InactiveCN102049960ADry heat resistantBurn-resistantLamination ancillary operationsSynthetic resin layered productsCrack resistanceManufacturing technology

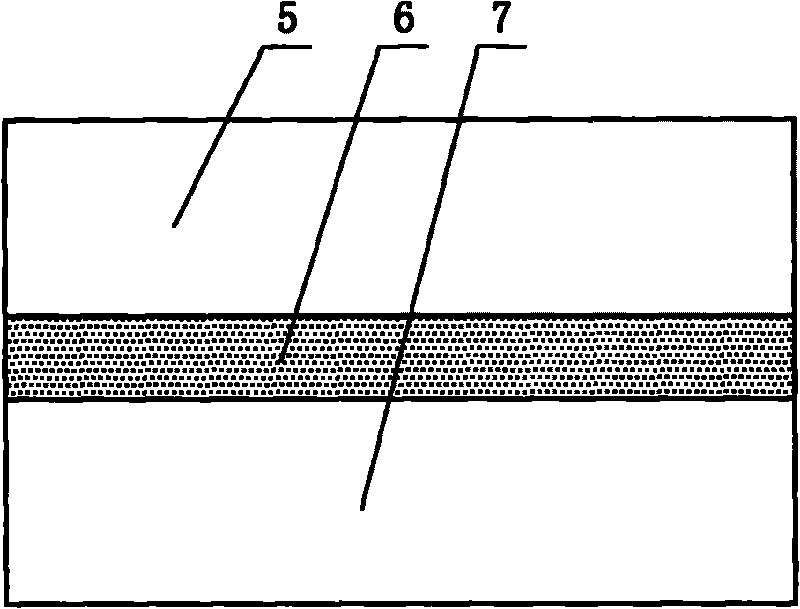

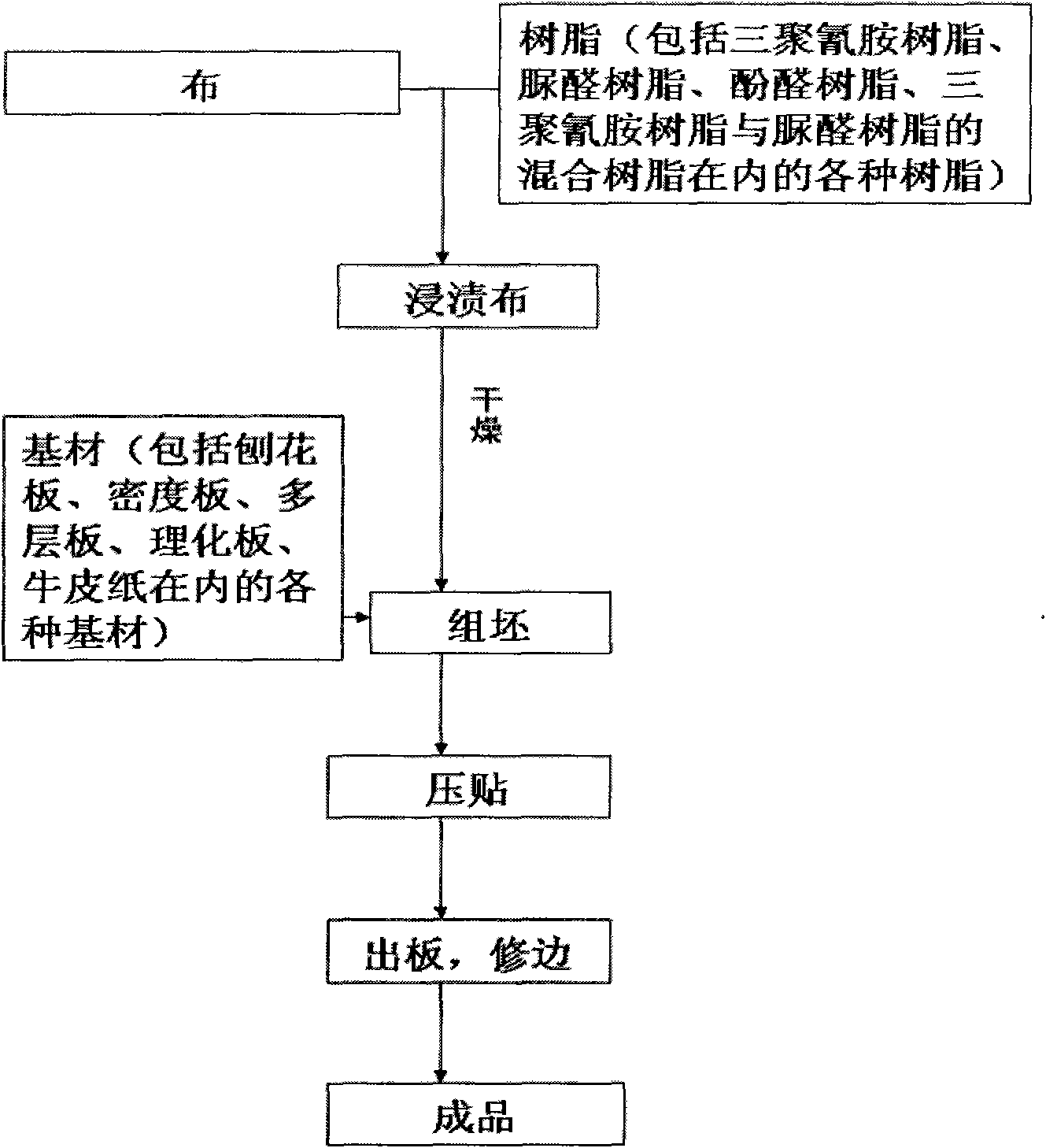

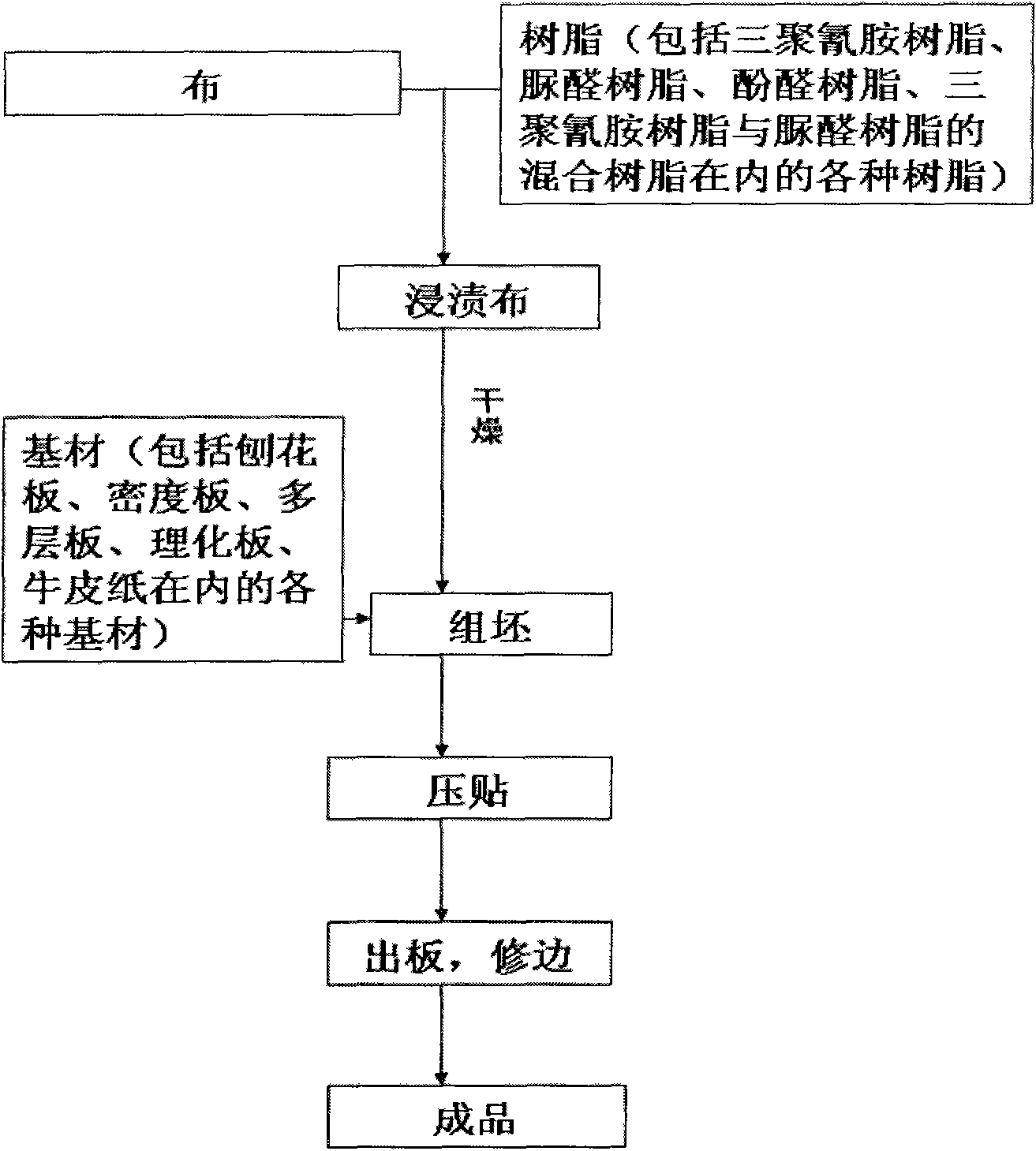

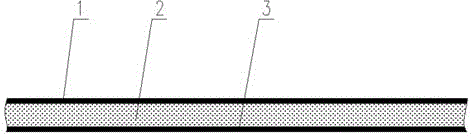

The invention relates to a resin impregnated cloth veneer and a manufacture technology thereof, wherein the resin impregnated cloth veneer comprises a base material and a cloth; the cloth is pressed on the surface of the base material; the resin impregnated cloth veneer is characterized in that the cloth is a resin impregnated cloth; the surface of the cloth is impregnated with resin which is melamine resin or urea resin or phenolic resin, or the mixed resin of the melamine resin and the urea resin. During manufacture, a proper cloth is selected; and the cloth is impregnated and cemented in various manners, so as to obtain the impregnated cloth. And then, the impregnated cloth is covered on the base material and fed into a multilayer laminating machine, wherein the laminating time is 10 seconds to 60 minutes; the hot pressing temperature is 100 to 200 DEG C; and the loaded weight is 300-20000 tons. Finally the resin impregnated cloth veneer is obtained. Therefore the surface of the veneer has the characteristics of dry heat resistance, burning resistance, crack resistance, light fastness, corrosion resistance and the like.

Owner:吴根水

Reactive type modified bituminous waterproof sheet material with gold foil surface

ActiveCN102975419AGood weather resistanceAdvantages of weather resistanceWater-setting substance layered productReaction layerBituminous waterproofing

The invention relates to a reactive type modified bituminous waterproof sheet material with a gold foil surface. The reactive type modified bituminous waterproof sheet material with the gold foil surface is characterized by comprising a gold foil sheet layer, a modified bituminous binding layer, and an isolating membrane protection layer, wherein the modified bituminous binding layer is arranged in the middle, the gold foil sheet layer is arranged at the upper layer and the isolating membrane protection layer is arranged at the lower layer; and the three layers of waterproof sheet materials are bound together by hot melting in the production process. The waterproof sheet material is a high-grade sheet material used for exposed walls or interior walls needing water resistance, the reactive type modified bituminous layer can creep and permeate into cement gel and concrete pores in the solidification process of cement and concrete, the chemical cross-linking reaction can be produced at a contact interface so as to form a basal plane reaction layer with high binding force, inreversible binding, both severe and soft binding and relatively durable binding, a close, firm and inreversible binding effect can be achieved, and the reactive type modified bituminous waterproof sheet material can be applied to columns, inner walls, outer walls and basements of important places needing the water resistance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

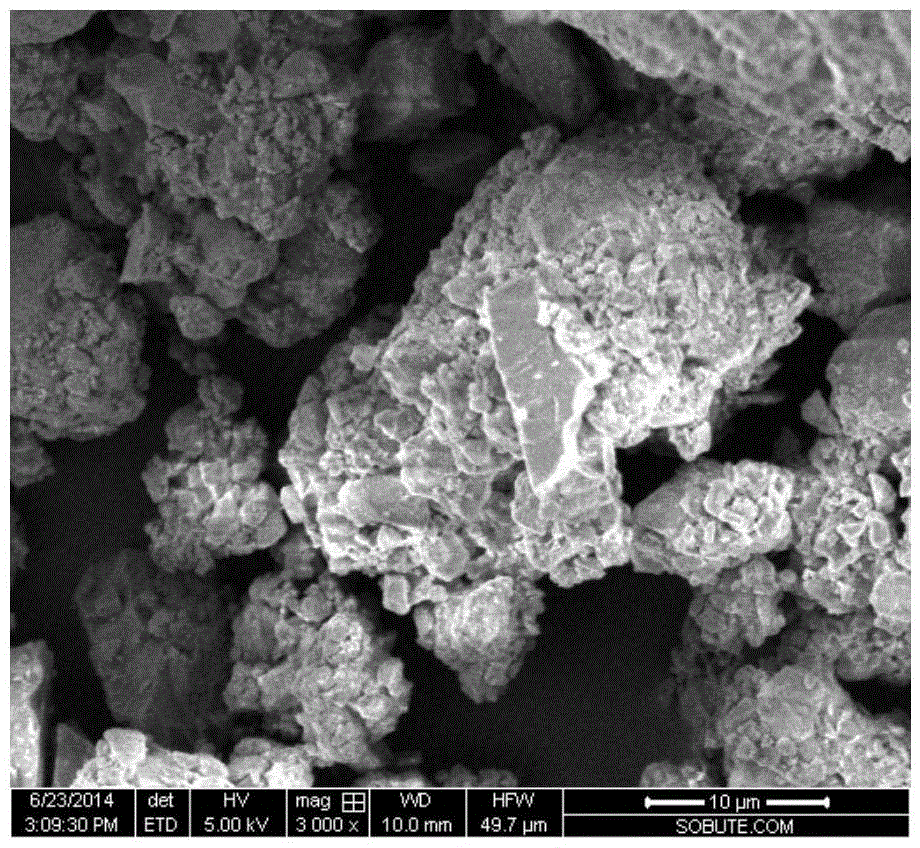

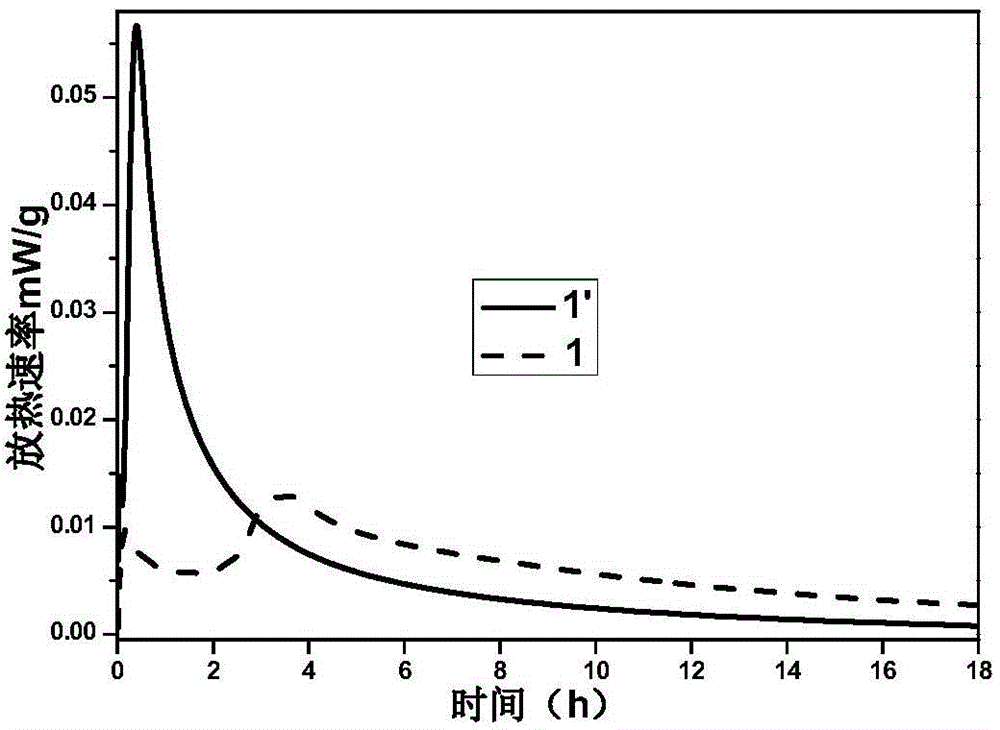

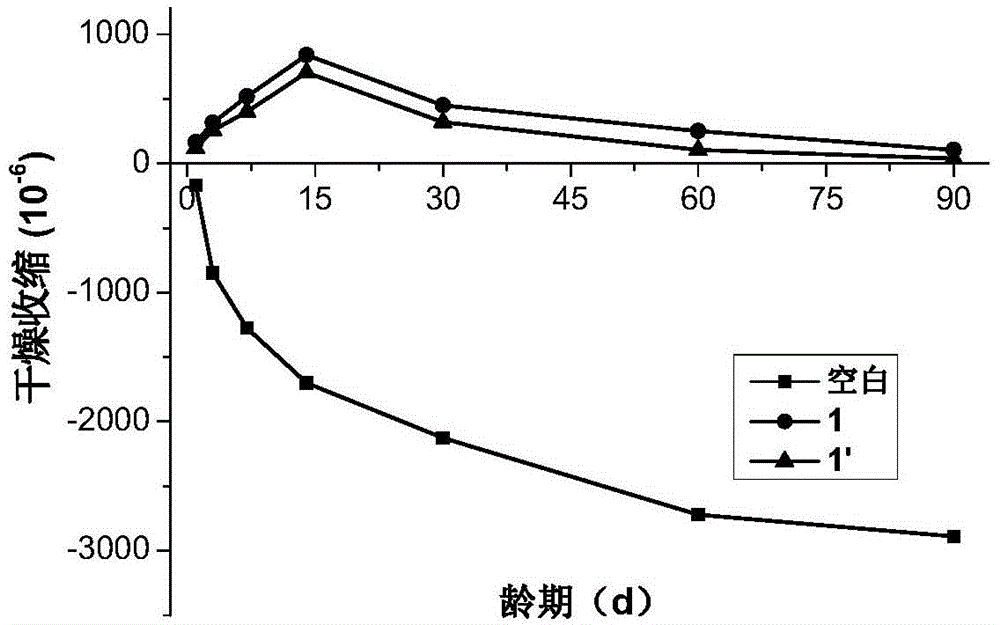

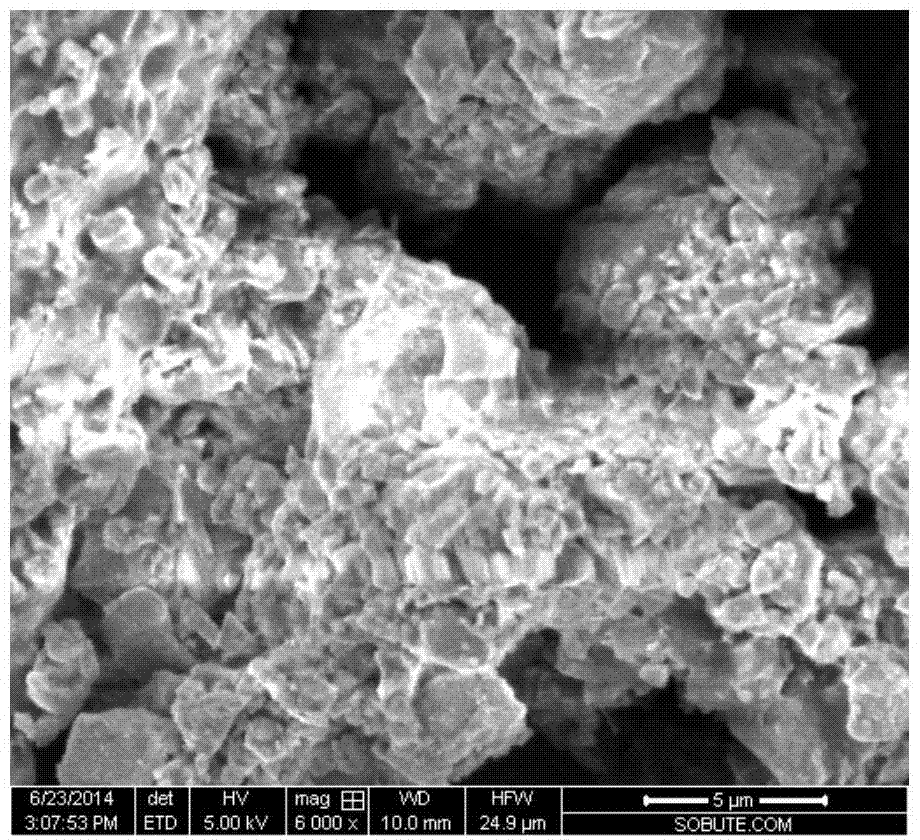

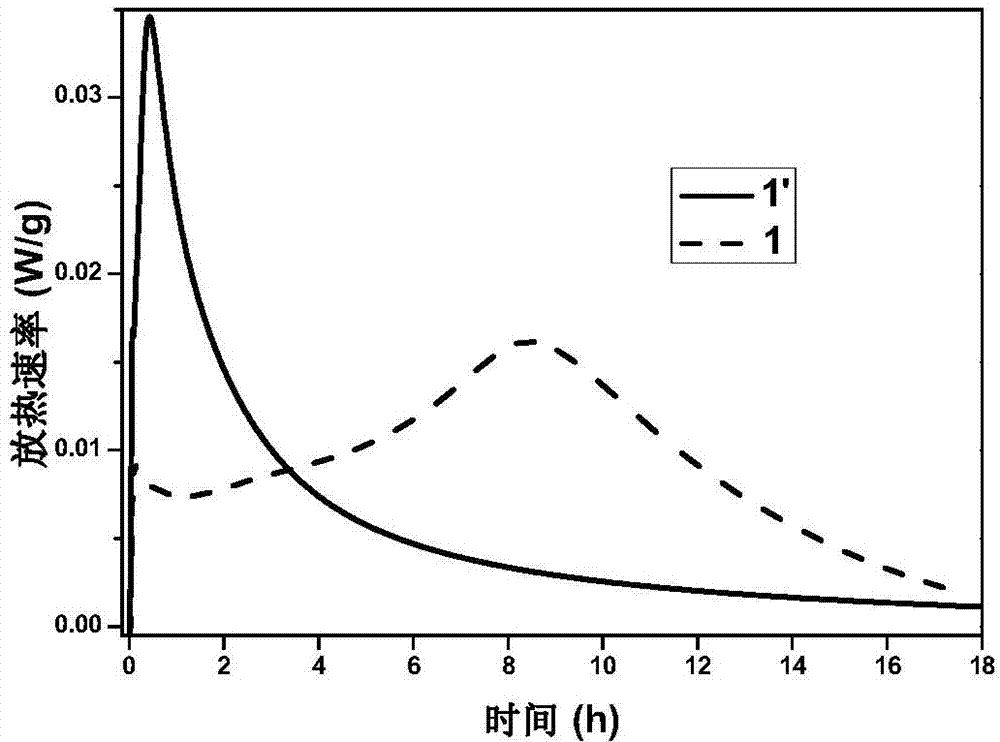

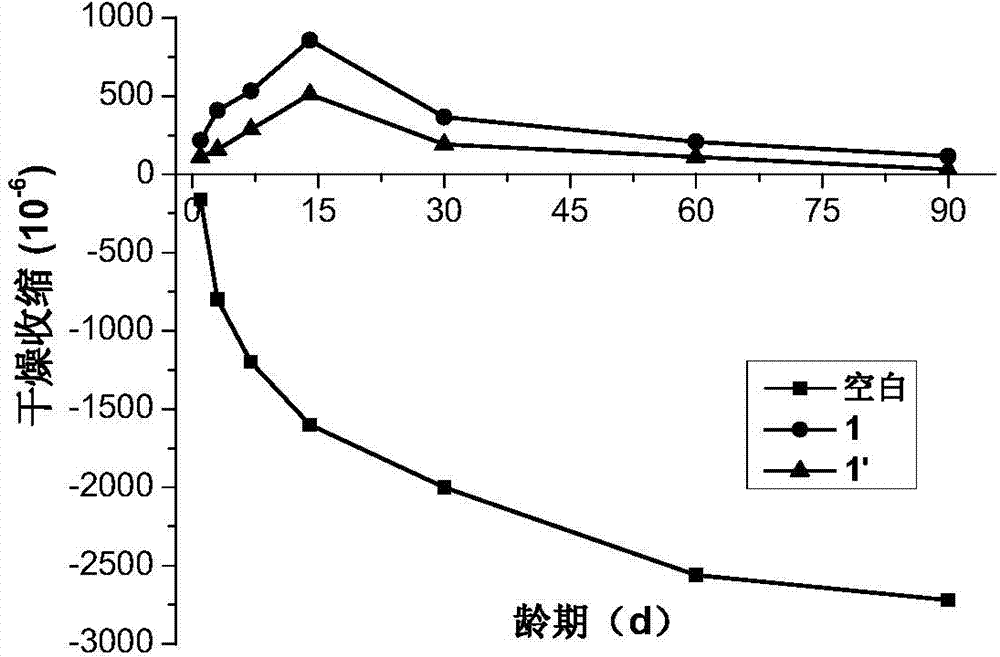

Modified calcium oxide expansion agent for cement concrete and preparation method of modified calcium oxide expansion agent

The invention provides a modified calcium oxide expansion agent for cement concrete. The modified calcium oxide expansion agent for the cement concrete has the specific surface area of 100-600m<2> / kg and is prepared from a degradable high polymer and calcium oxide expansion clinker. According to the modified calcium oxide expansion agent for the cement concrete, provided by the invention, the invalid hydration of calcium oxide at a plastic stage of concrete is reduced, the hardened expansion quantity is increased, and the shelf life of the product can be further prolonged; the expansion agent can be applied to the crack resisting and seepage prevention of a concrete structure and can be used for greatly improving the durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

Aqueous stone-like paint and preparation method thereof

InactiveCN102807792AImprove the decorative effectColor pattern controllableCoatingsDispersed mediaThermal insulation

The present invention discloses an aqueous stone-like paint and a preparation method thereof. During preparation, a dispersing phase and a dispersing medium are respectively prepared; and then the dispersing phase with a single color is added to the dispersing medium to uniformly stir to obtain a one-component aqueous stone-like paint. The aqueous stone-like paint of the present invention has strong decoration, wherein a texture effect created by the aqueous stone-like paint with one spray coating is the same as a texture effect of the original stone, imitation degree exceeds 90%, and a color and patterns can be controlled. In addition, the aqueous stone-like paint of the present invention is widely used for cement base wall surfaces, coating materials, stucco, stone paints and other various foundation walls, and is especially suitable for external thermal insulation systems.

Owner:TIANJIN TIANTU HAOBANG COATING

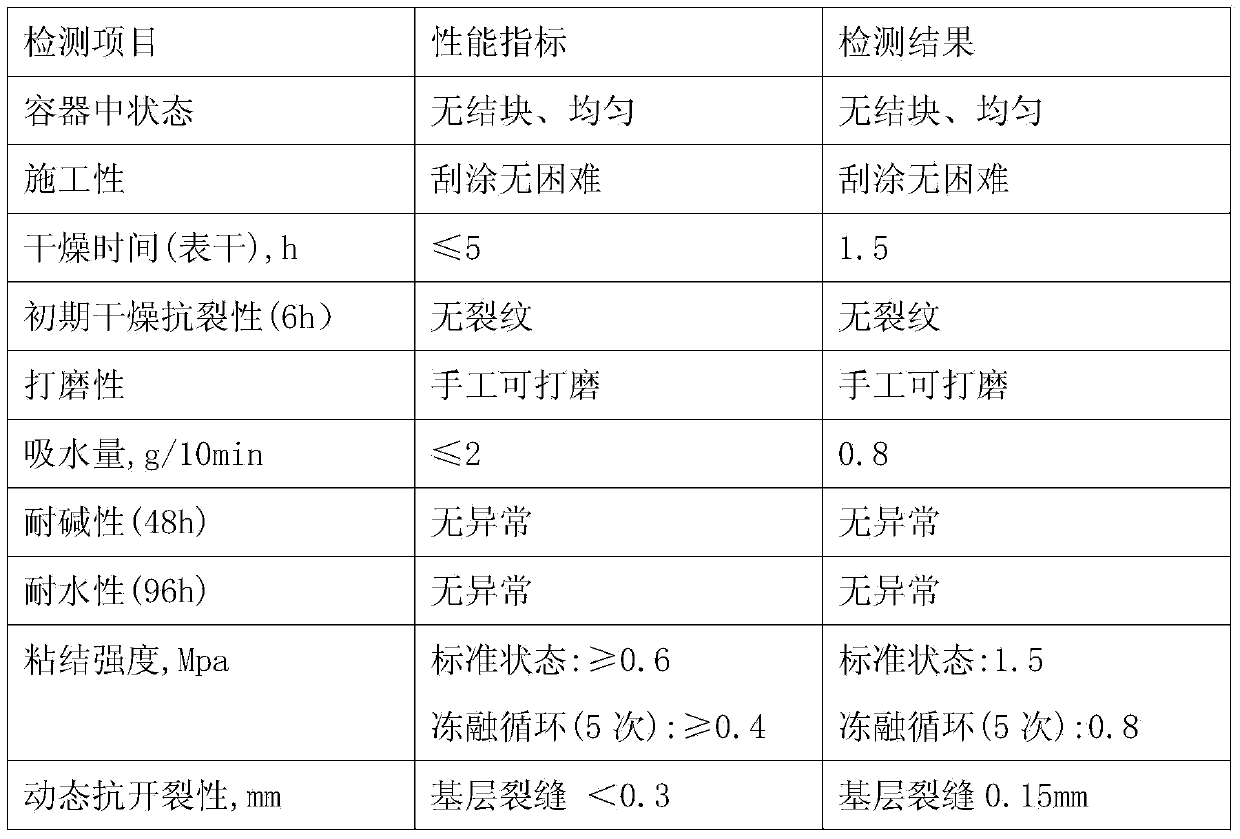

Exterior wall crack resistant elastic putty powder

The invention discloses exterior wall crack resistant elastic putty powder comprising the following raw materials: by weight, 20-30 parts of ash calcium powder, 10-15 parts of white cement powder, 10-20 parts of calcium carbonate powder, 10-15 parts of quartz powder, 40-50 parts of modified talcum powder, 1-1.5 parts of carboxymethyl cellulose, 2-3 parts of carboxymethyl starch ether, 3-4 parts of redispersible latex powder, 2-3 parts of polypropylene staple fiber, 1-2 parts of aluminum silicate fiber and 0.5-1 part of NSJF-2 latex powder. The powder putty has crack resistance, frost resistance, heat resistance, alkali resistance, water resistance and other functions, can greatly improve the bonding strength of a wall body paint substrate, improves the service life of a wall body paint, overcomes the defects of easy falling, peeling and cracking of traditional putty powder, is completely environmentally friendly, may not pollute the environment, is harmless to human body, easy to use, simple to construct, durable and reliable, and has obvious social benefits and environmental benefits.

Owner:岑其挺

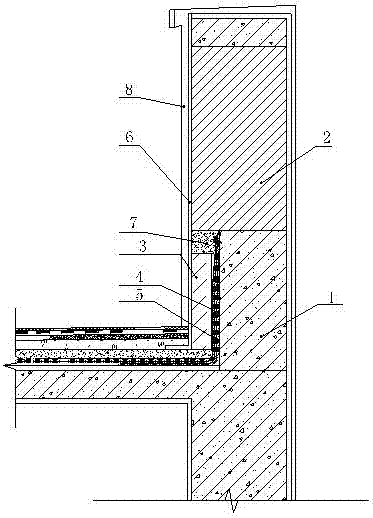

Building roof parapet wall flashing construction process

ActiveCN106906962ALow costEconomical cost, convenient operation and economicalSnow trapsBrickReinforced concrete

The invention relates to a flashing structure construction process, in particular to a building roof parapet wall flashing construction process. The building roof parapet wall flashing construction process comprises the following steps that step one, a flashing wall body of a reinforced concrete structure is poured on a building roof; step two, a waterproof roll is paved and pasted on the inner facades of the roof and the flashing wall body to form a waterproof layer, and the upper end of the waterproof roll is subjected to head retraction treatment; step three, a protective brick wall is laid on the outer facade of the waterproof layer through solid bricks, the inner facade of the protective brick wall is tightly attached to the waterproof roll, and the waterproof roll is tightly pressed on the flashing wall body, wherein the protective brick wall is no larger than the flashing wall body; and step four, a parapet wall is laid on the flashing wall body through solid bricks on the basis of the top of the flashing wall body, wherein the thickness of the wall body of the parapet wall is equal to the distance between the outer facade of the flashing wall body and the outer facade of the protective brick wall. A flashing structure built through the building roof parapet wall flashing construction process has the advantages of being resistant to cracking and falling-off and long in guarantee period and is convenient to construct and low in cost, and materials are convenient to obtain.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Modified calcium oxide cement concrete expansion agent and preparation method thereof

ActiveCN104710121ASmall water absorptionStrong resistance to moisture absorptionCrack resistanceAcrylic resin

The invention provides a modified calcium oxide cement concrete expansion agent and a preparation method thereof. The modified calcium oxide cement concrete expansion agent consists of acrylic resin and a calcium oxide expansion clinker, wherein the surface of the calcium oxide expansion clinker is wrapped with the acrylic resin; the mass of the acrylic resin accounts for 0.01 to 10 percent of the total mass of the modified calcium oxide cement concrete expansion agent; the specific surface area of the modified calcium oxide cement concrete expansion agent is 100 to 600m<2> / kg. According to the modified calcium oxide cement concrete expansion agent, a hydration process of the calcium oxide expansion clinker can be regulated, ineffective hydration in the plastic stage of concrete can be reduced, expansion after hardening can be increased, and the shelf life of the expansion agent product can be prolonged; the modified calcium oxide cement concrete expansion agent can be used for the crack resistance and seepage resistance of a concrete structure, and the durability of the concrete can be greatly improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

SAPs microcapsules and cement-based self-repairing material

InactiveCN110734243AEasy to prepareHigh mechanical strengthMicroballoon preparationMicrocapsule preparationPolymer scienceCrack resistance

The invention relates to SAPs microcapsules and a cement-based self-repairing material. The SAPs microcapsules are prepared by coating a hydrophobic adhesive with a water-absorbing polymer (SAPs), andthe particle size of the SAPs microcapsules ranges from 0.2 mm to 2.0 mm; the content of the core material of the microcapsule is 20-80wt%. The cement-based self-repairing material comprises the following basic components: cement, sandstone, the SAPs microcapsules and water. The SAPs microcapsules are prepared by adopting a sharp hole forming coagulating bath method, the process is easy for large-scale production, the mechanical properties meet the concrete mixing requirements, the matrix shrinkage can be reduced, the freeze thawing resistance and the cracking resistance can be improved, andthe strength of a set cement matrix can be improved; the cement-based self-repairing material has multiple crack self-repairing mechanisms, efficient self-repairing of the cement-based material can beachieved, durability is improved, and the service life is prolonged.

Owner:BEIJING UNIV OF TECH

Water-based varnish

The invention relates to a material for construction and decoration and in particular relates to water-based varnish. The formula of the water-based varnish is as follows: 15 to 30 parts of water, 10 to 20 parts of acrylic polymers, 12 to 20 parts of titanium dioxide, 3 to 5 parts of barite powders, 5 to 15 parts of ground calcium carbonate, 3 to 5 parts of kaolin, 3 to 5 parts of mica powders, 0.4 to 0.8 parts of wetting and dispersing agents, 0.3 to 0.4 parts of a defoaming agent, 0.3 to 0.6 parts of a leveling agent, 0.5 to 2 parts of a thickener, 0.2 parts of a multifunctional auxiliary agent, 0.8 to 1 part of a film-forming agent, and 0.8 to 2 parts of a disinfectant and anti-mildew agent. The water-based varnish is made from high-quality acrylic polymers, natural mineral powders and multiple auxiliary agents and refined by the advanced production process. The water-based varnish has the characteristics of environmental friendliness, no toxicity, alkali resistance, mildew resistance, primer-coat property, crack resistance, energy saving, flame retardancy, sound insulation, moisture protection, leakage resistance, strong adhesion, high hardness and dry friction resistance.

Owner:深圳市名雕丹迪设计有限公司

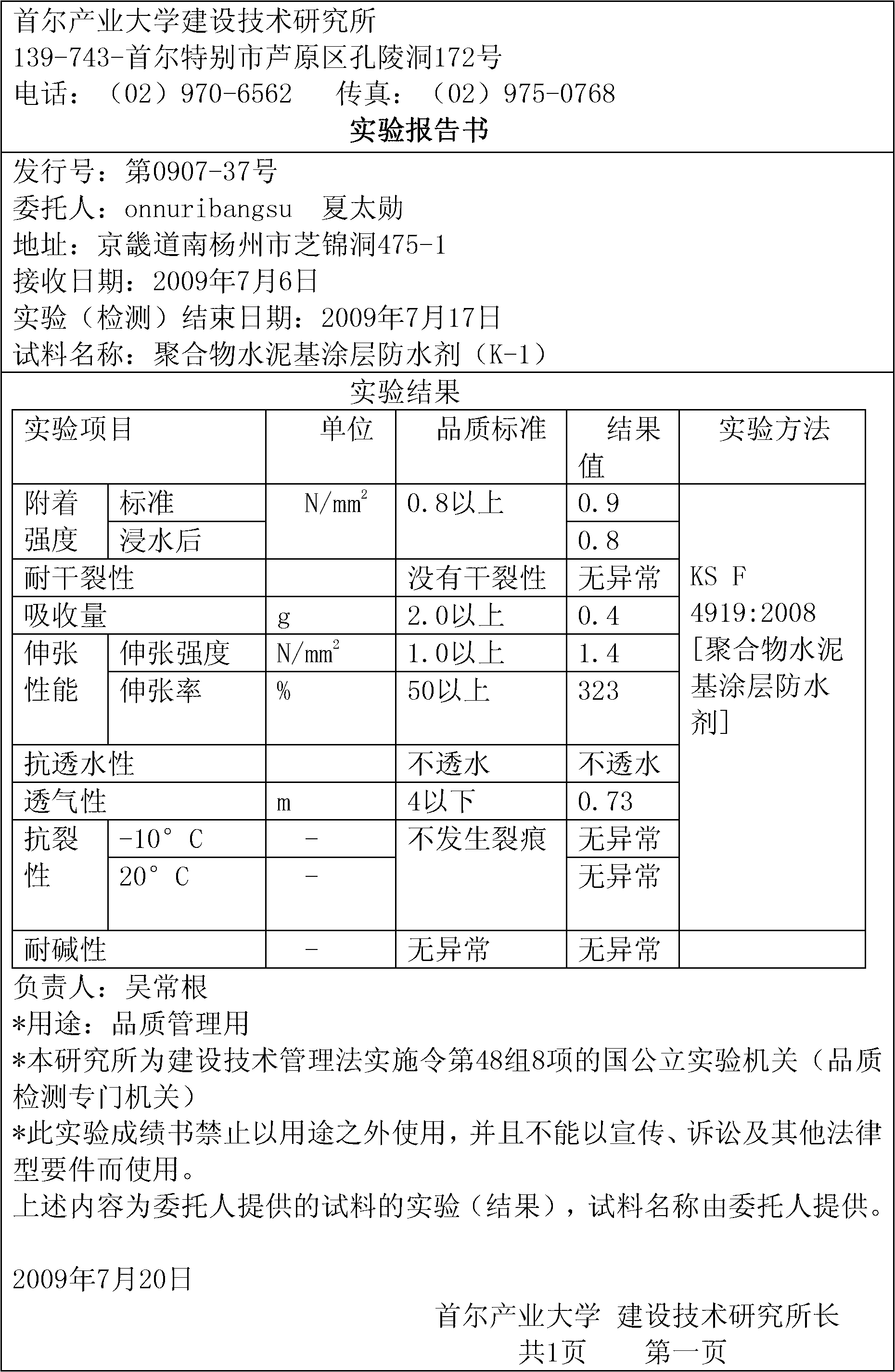

Polymer-based film waterproofing agent mixed with cement, and preparation method thereof

InactiveCN102762678AHigh tensile strengthChemical resistantBuild-up roofsProtective foundationCrack resistanceWater leakage

The present invention relates to a polymer-based film waterproofing agent mixed with cement which is coated on a structure requiring waterproofing and water leakage prevention so as to show excellent chemical resistance, weather resistance, crack resistance and impact resistance and high tensile strength in addition to waterproofness by preventing penetration of water into the structure, and a preparation method thereof. The polymer-based film waterproofing agent mixed with cement of the present invention comprises: 65-75 wt% of an acrylic emulsion; 12-20 wt% of micro-cement; 10-18 wt% of quicklime; 0.02-0.2 wt% of a superplasticizer; 0.02-0.2 wt% of an antifoaming agent; and 0.02-0.2 wt% of an expansion agent. The preparation method comprises: the first step of preparing 65-75 wt% of an acrylic emulsion in a liquid state in a first circular container; the second step of preparing 12-20 wt% of micro-cement in a powder state, 10-18 wt% of quicklime, 0.02-0.2 wt% of a superplasticizer, 0.02-0.2 wt% of an antifoaming agent, and 0.02-0.2 wt% of an expansion agent in a second circular container; and the third step of pouring the contents prepared in the second circular container into the first circular container to dilute the same with an electric mixer.

Owner:河泰薰

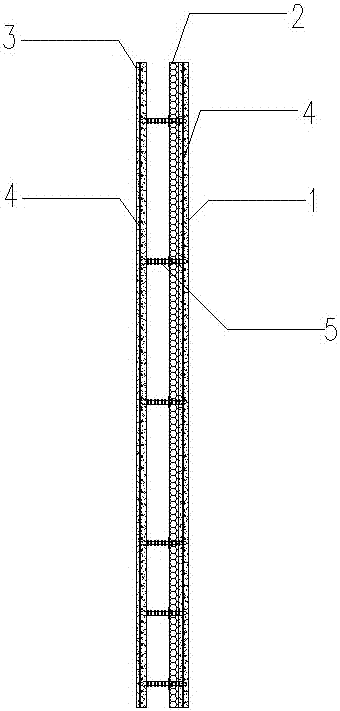

Assembly type non-dismantling concrete formwork and manufacturing method thereof

The invention relates to an assembly type non-dismantling concrete formwork and a manufacturing method thereof, and belongs to the technical field of building construction. The assembly type non-dismantling concrete formwork comprises a straight section formwork body and a corner section formwork body; the straight section formwork body comprises an outer side concrete protection layer, a heat insulation board and an inner side concrete protection layer from outside to inside, or comprises the outer side concrete protection layer and the inner side concrete protection layer from outside to inside; the corner section formwork body comprises an L-type concrete protection layer and an L-type heat insulation board attached to the inner side of the L-type concrete protection layer from outside to inside, or is only provided with the L-type concrete protection layer; the outer side concrete protection layer, the heat insulation board and the inner side concrete protection layer are connected into a whole through pull rods evenly distributed in an inner cavity, or the outer side concrete protection layer and the inner side concrete protection layer are connected into a whole through the pull rods evenly distributed in the inner cavity; and the outer side concrete protection layer, the inner side concrete protection layer and the L-type concrete protection layer are all internally provided with wire flat screens.

Owner:张勰 +1

Adhesive mortar for ceramic tile

The invention relates to a mortar and provides an adhesive mortar for a ceramic tile. The adhesive mortar for the ceramic tile contains tailings, is high in tensile adhesive strength and low in cost, does not pollute the environment, and has a heat preservation effect. The adhesive mortar for the ceramic tile comprises the following materials in parts by weight: 30-35 parts of ecological cement, 0.5-0.6 part of polyving akohol, 30-50 parts of tailings, 5-10 parts of polypropylene monofilament, 1.3-2.8 parts of a defoamer, 12-17 parts of a water reducer, 17-19 parts of coal ash, 7-9 parts of glass bead, 21-32 parts of ceramic sand, 1.5-2.5 parts of cellulose ether, 4-8 parts of redispersible powder and 70-90 parts of water, wherein the ceramic sand comprises sand grains with the grain diameters of 0.10-2.0 mm and with a plurality of pores not communicated in the surfaces.

Owner:荣达新型建材(福建)集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com