Patents

Literature

657 results about "Load-bearing wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A load-bearing wall or bearing wall is a wall that is an active structural element of a building, that is, it bears the weight of the elements above wall, resting upon it by conducting its weight to a foundation structure. The materials most often used to construct load-bearing walls in large buildings are concrete, block, or brick.

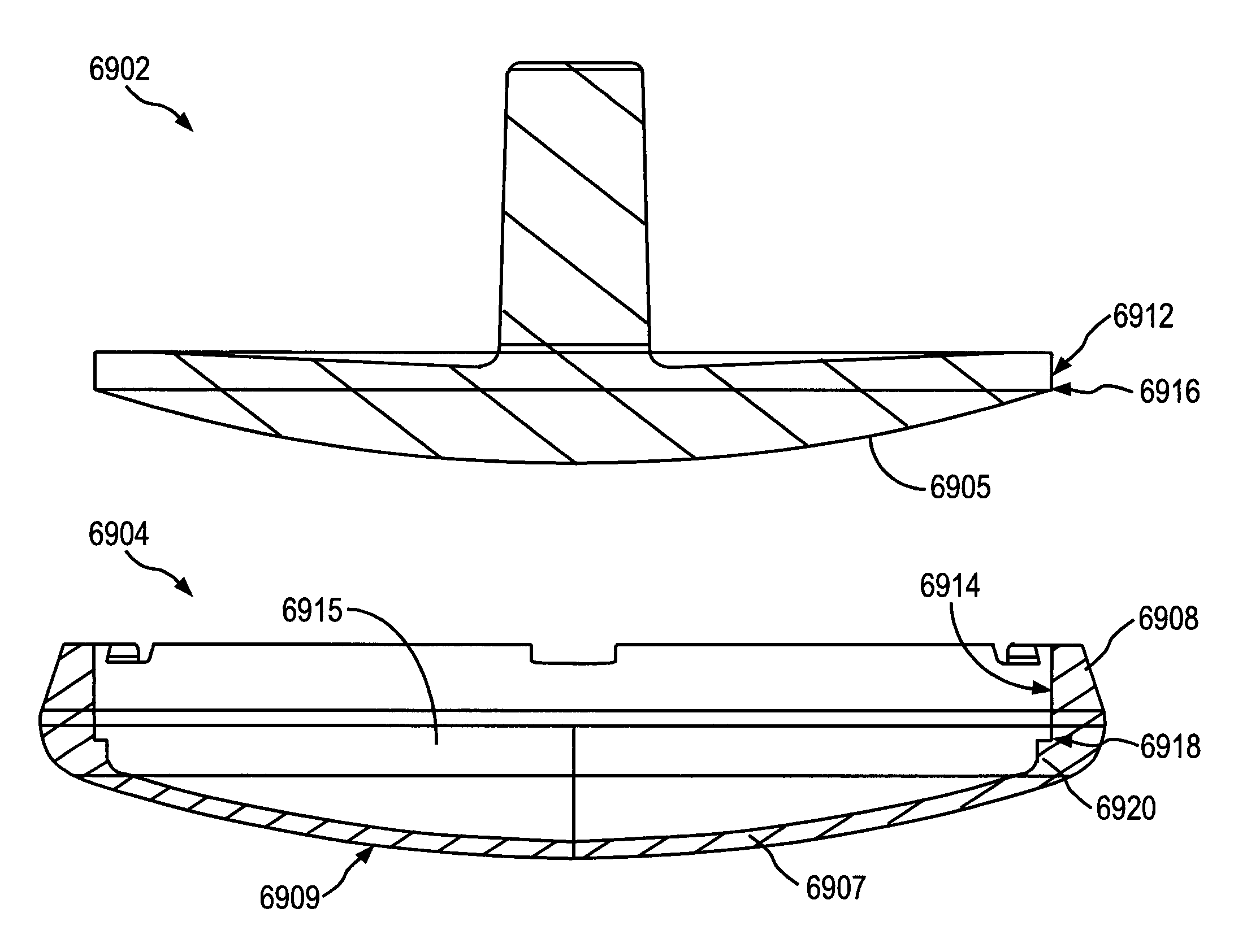

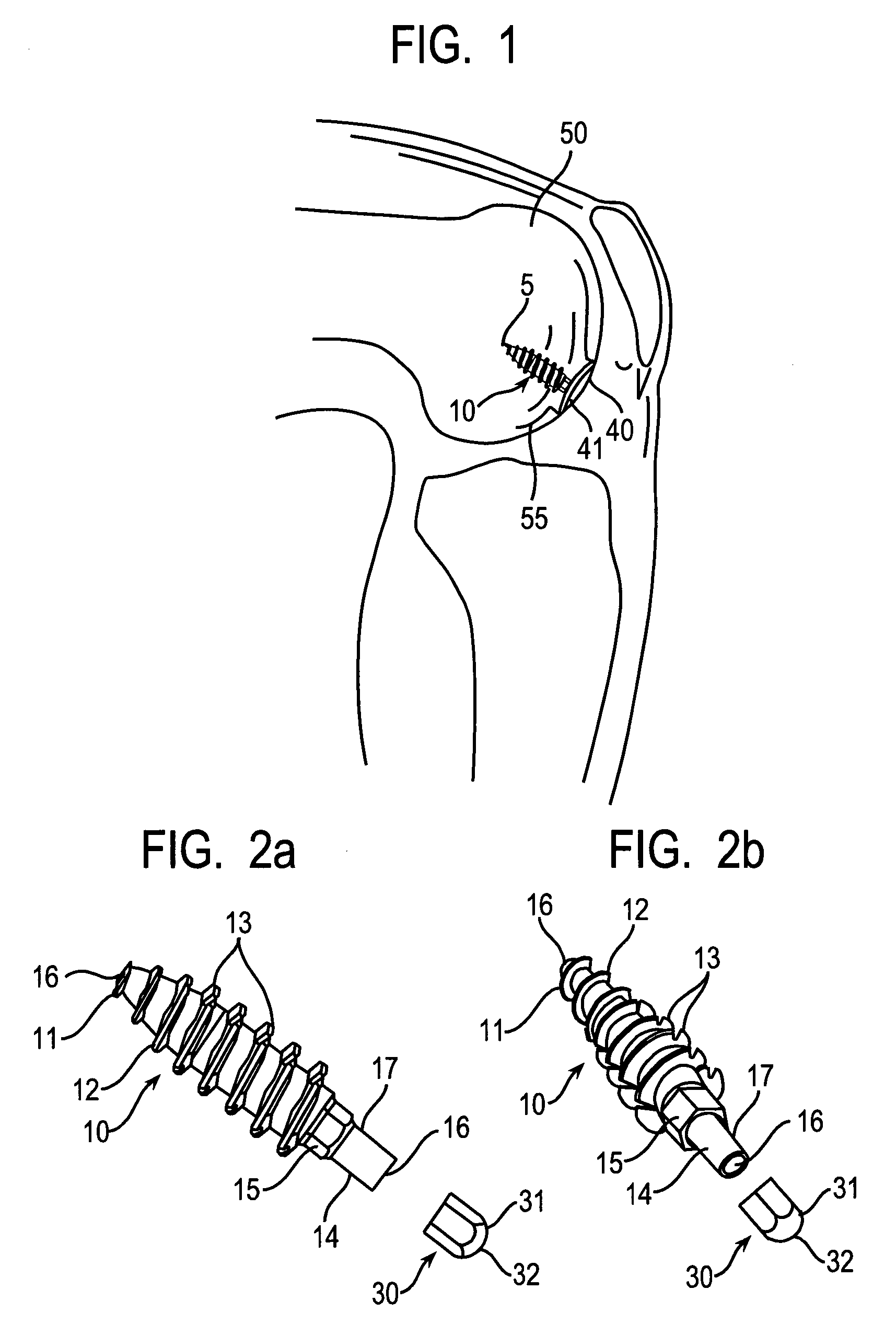

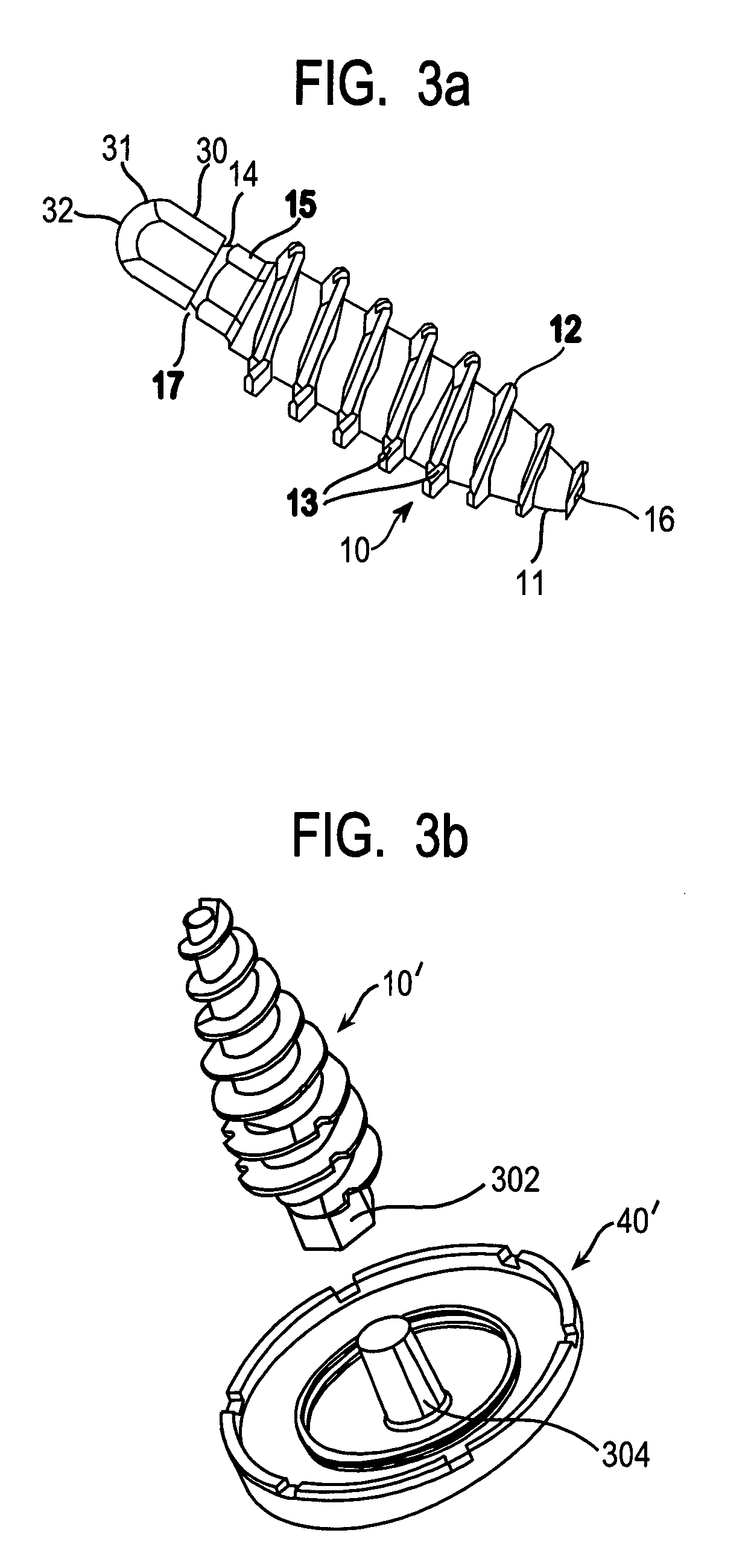

System and method for joint resurface repair

An implant for installation into a portion of an articular surface includes an implant shell component having a proximal load bearing wall with an outer proximal load bearing surface. A peripheral rim extending distally relative to the load bearing wall may provide a bone-facing distal pocket on the shell component. An inner implant component may be received in the bone-facing distal pocket of the implant such that a proximal surface of the inner component is spaced apart from a distal surface of the load bearing wall. The contour of the load bearing surface may be based on an original surface contour of an articular surface, and the load bearing wall of the shell component may be a deflectable wall, so that the load bearing surface can deflect under an applied load. The space between the load bearing wall and the inner implant may include a compressible fluid such as elastomeric gels.

Owner:ARTHROSURFACE

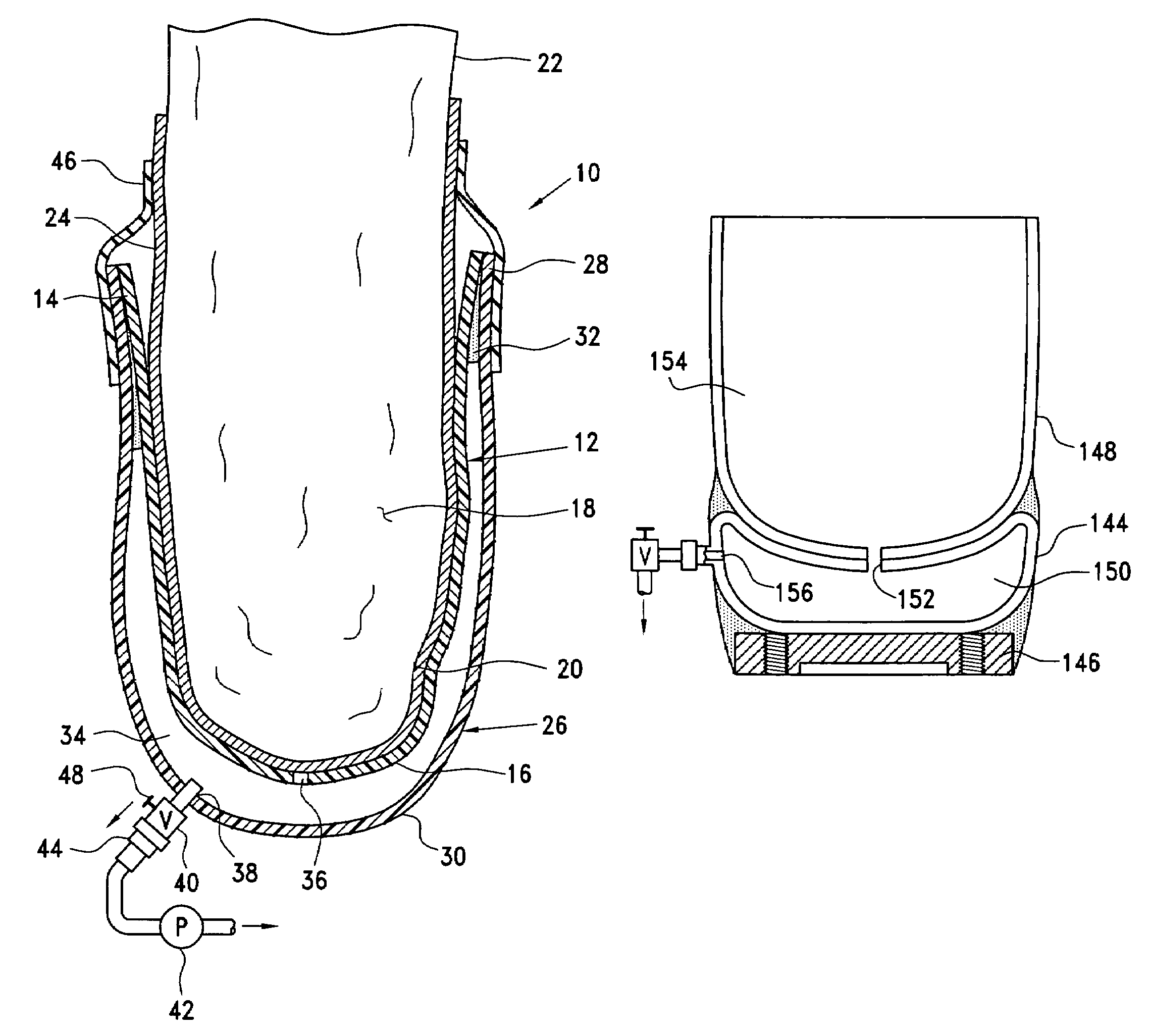

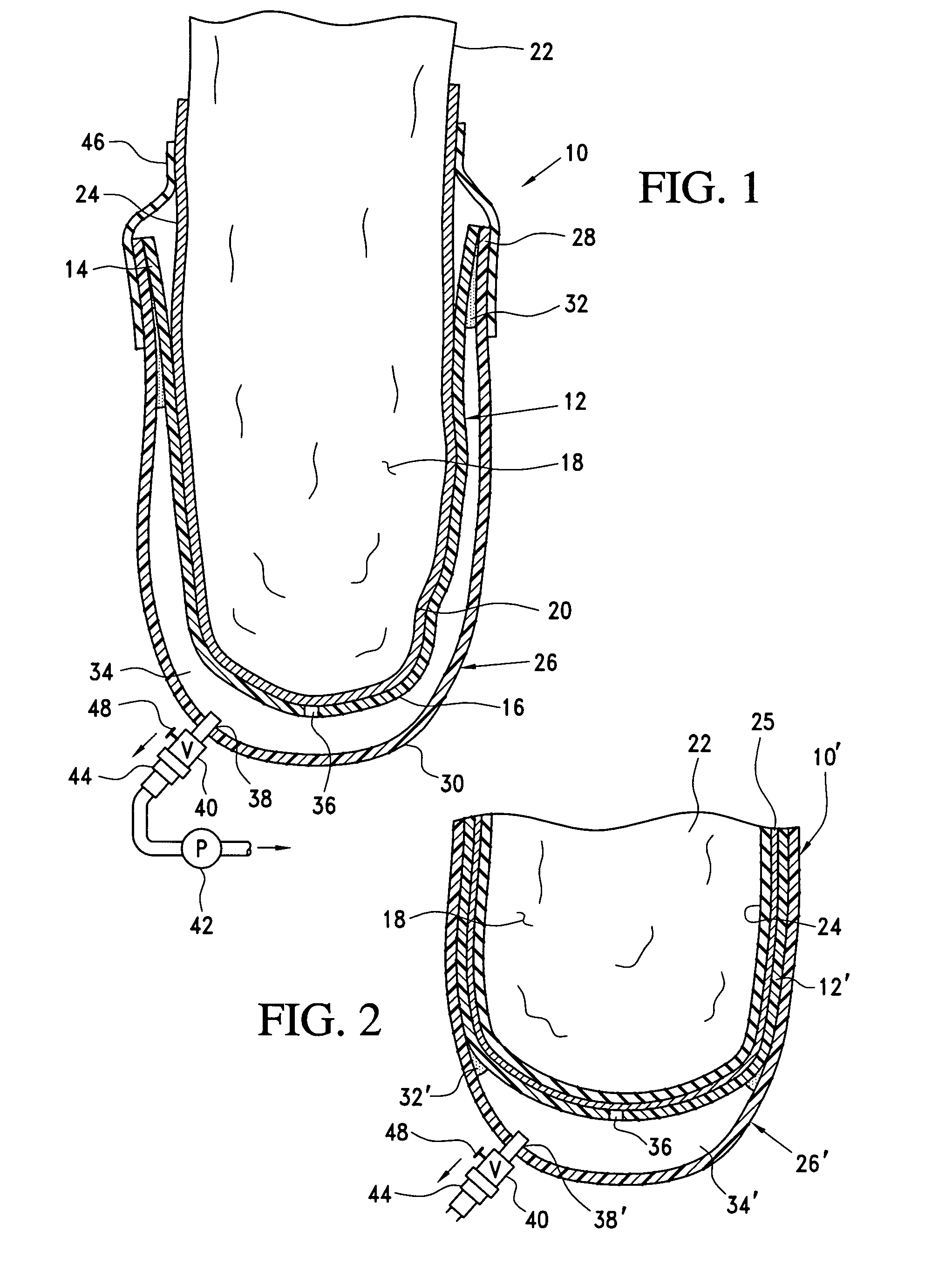

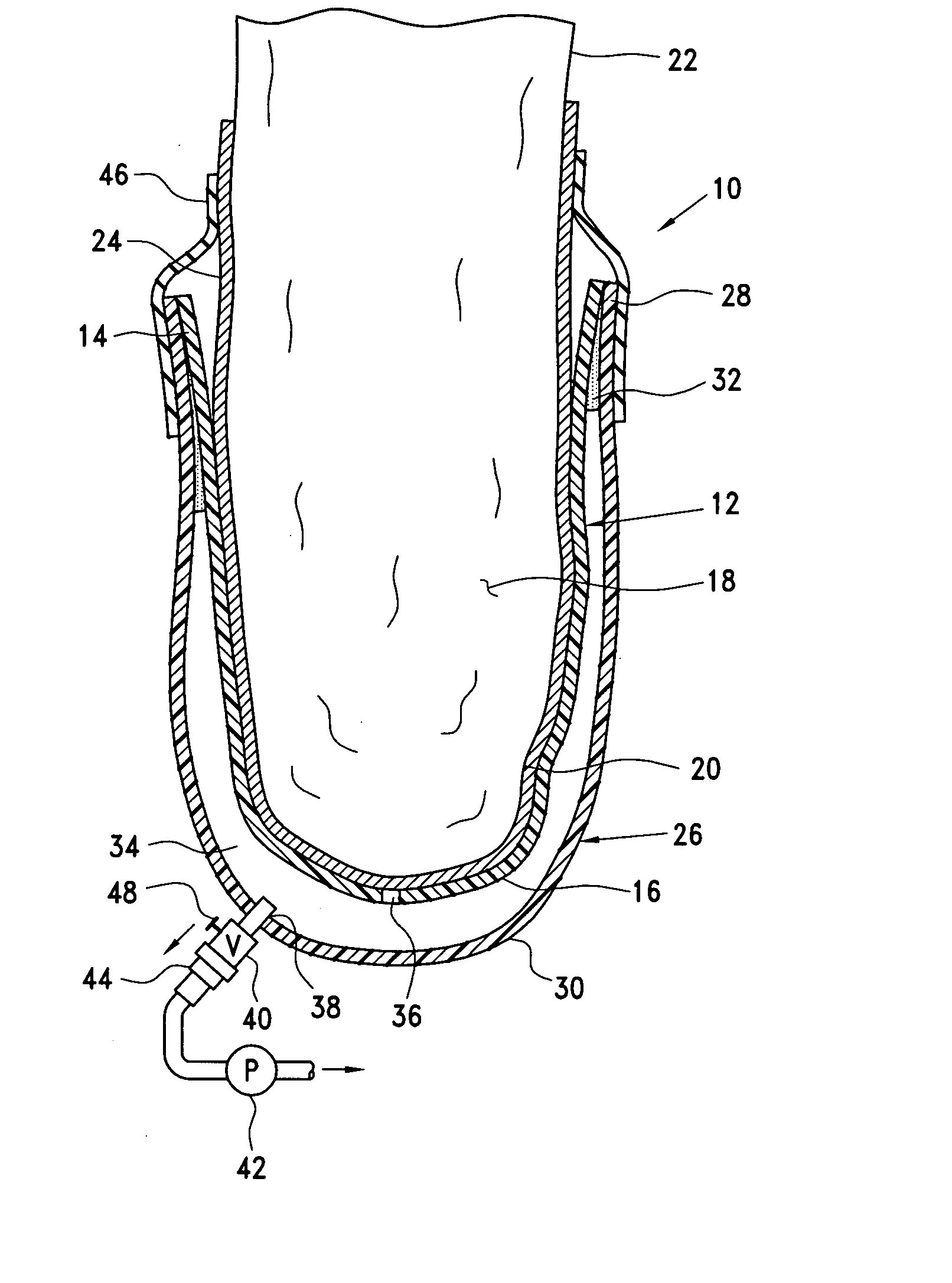

Prosthetic socket with self-contained vacuum reservoir

ActiveUS7427297B2Avoid substantial deflectionDomestic articlesProsthesisEngineeringLoad-bearing wall

Owner:OSSUR HF

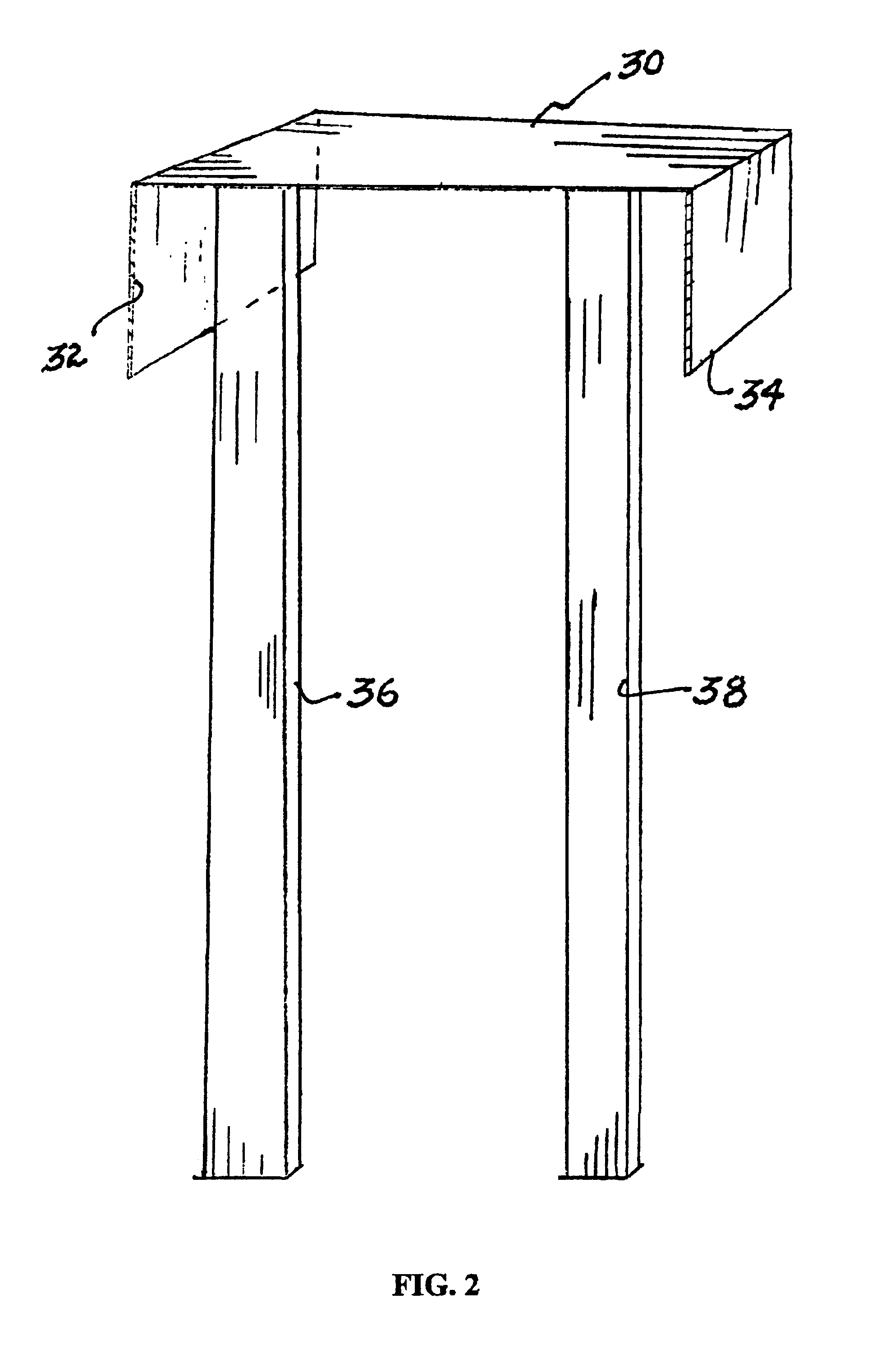

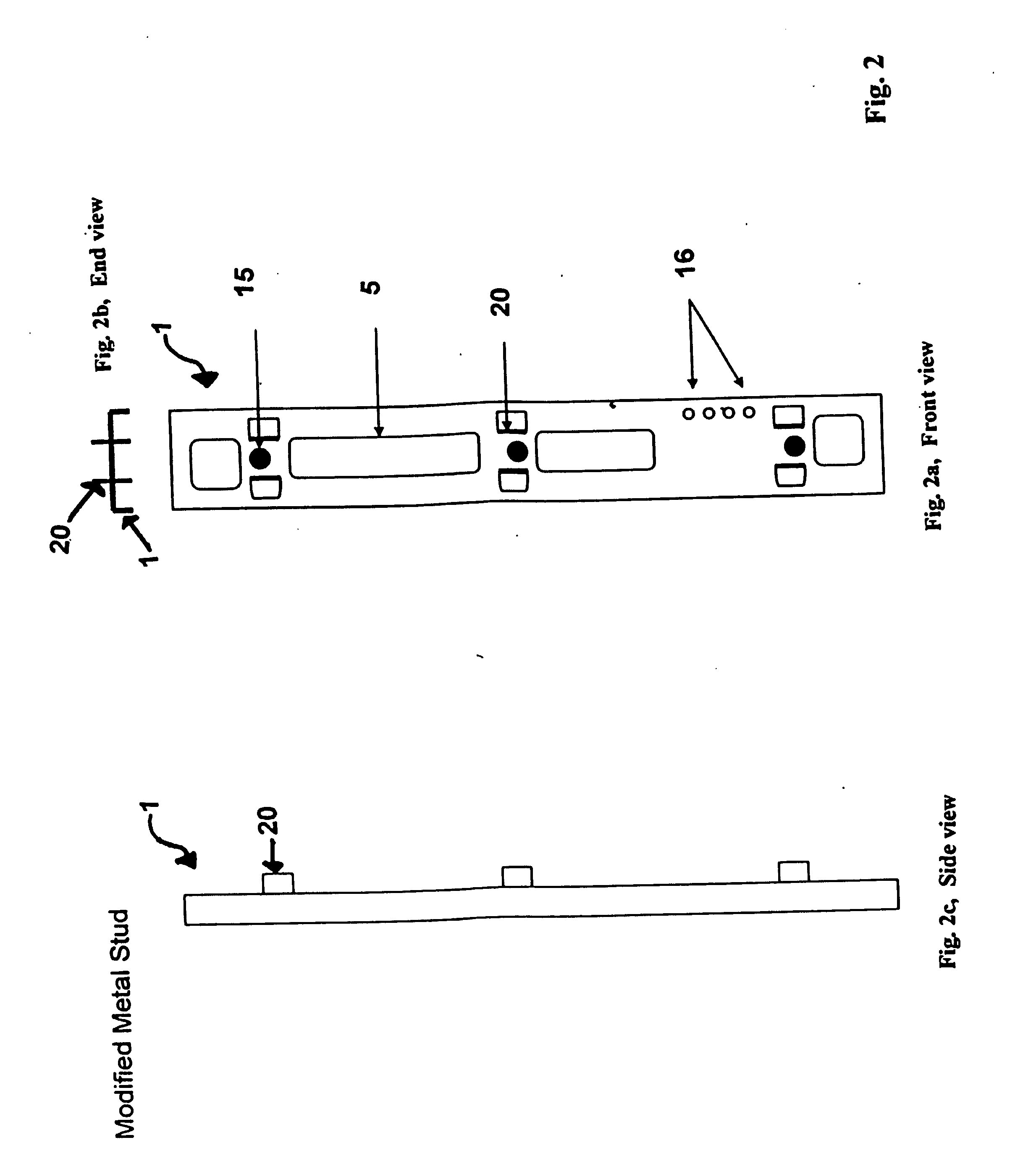

Metal stud building system and method

A metal stud and clip assembly is designed for use in a non-load-bearing wall to allow a horizontal ceiling to vertically float thereon. This is accomplished by an elongated receiving channel on the stud spaced inwardly from its edges. A clip member has an elongated stabilizing bar slidably inserted into the channel, and the stabilizing bar itself then is secured to a horizontal ceiling or a track system mounted to the ceiling. Thus, relative movement of the ceiling with respect to the wall allows the stabilizing bar to move up and down in the receiving channel on the stud member.

Owner:STOVER DONIE

Prosthetic socket with self-contained vacuum reservoir

ActiveUS20040260403A1Avoid substantial deflectionDomestic articlesProsthesisEngineeringLoad-bearing wall

A prosthetic socket having a self-contained vacuum reservoir chamber includes a rigid, load-bearing inner socket member for receiving a residual limb and an outer, rigid, load-bearing wall section attached to the inner wall section in a manner providing a vacuum reservoir chamber between the inner wall and the outer wall section. The vacuum reservoir chamber communicates with the inner volume of the inner wall through a vacuum transfer port and the vacuum reservoir chamber may be evacuated via an evacuation port having an appropriate one-way check valve permitting withdrawal of air from the vacuum reservoir chamber while preventing ingress of air into the chamber. A method for making the prosthetic socket is disclosed.

Owner:OSSUR HF

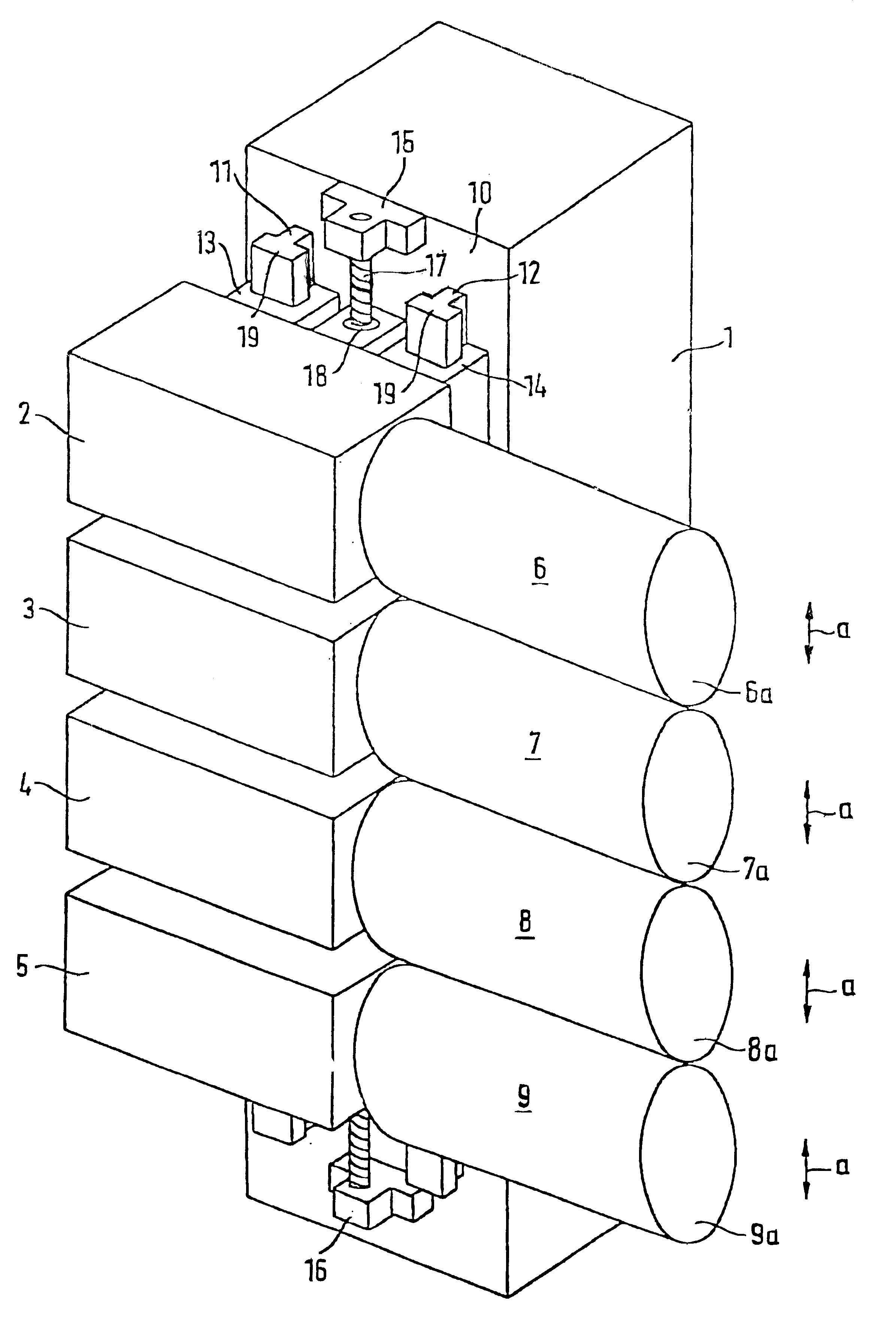

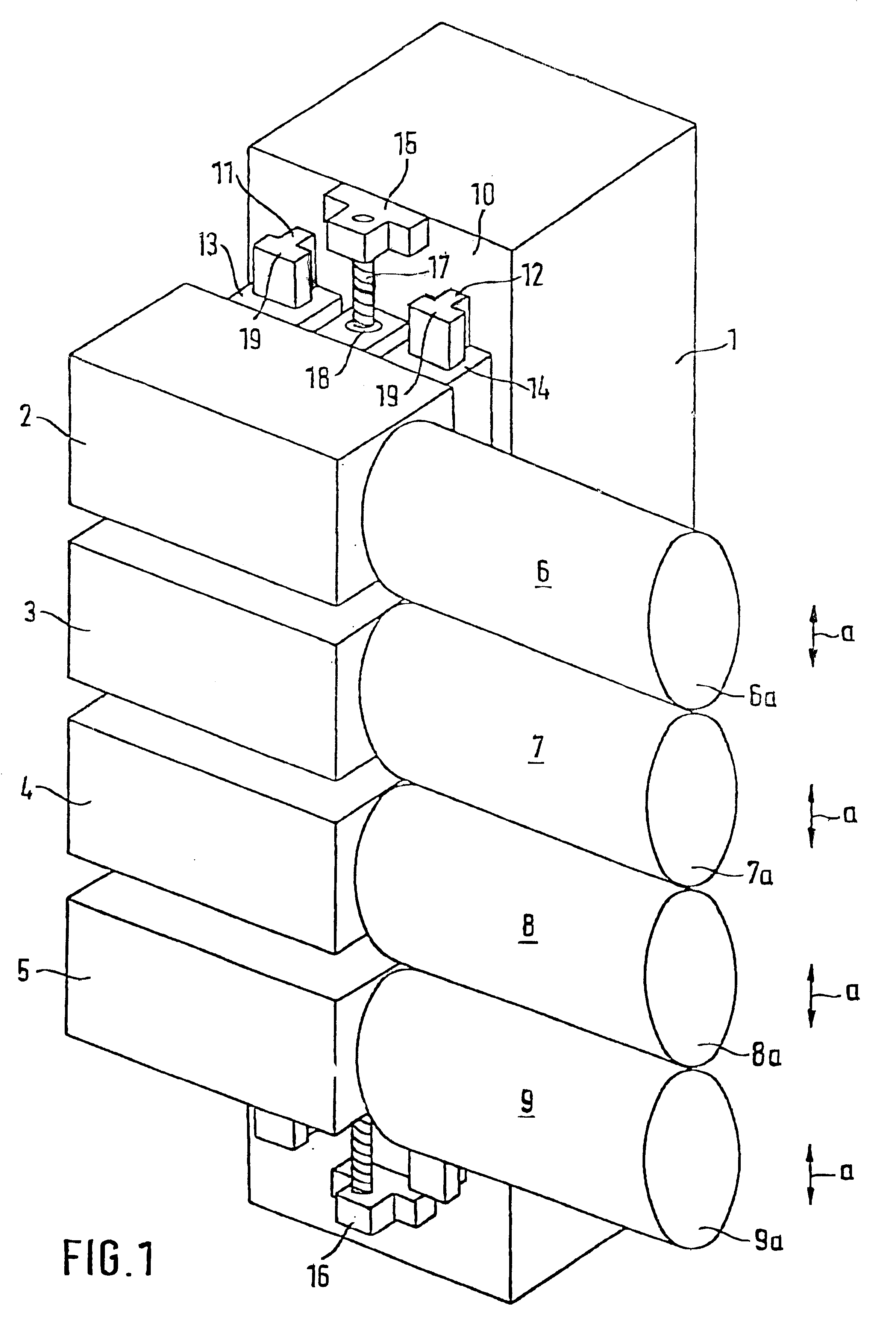

Printing unit

A printing unit is provided for a web fed printing machine having at least two cylinders where at least one of the cylinders is adjustable with respect to another of the cylinders; a machine frame having at least one load bearing wall arranged laterally beside an end of the cylinders; a drive motor corresponding to each cylinder; at least one guide element operably attached to the load bearing wall at a surface of the load bearing wall that runs perpendicular to a plane through the end faces of the cylinders; and a plurality of carriages attached to the guide element. At least one of the cylinders is connected to the carriages so that a distance from another of the cylinders can be adjusted.

Owner:MANROLAND WEB SYST

Continuous structural wall system

InactiveUS6854230B2Protection from damageProvide structural rigidityWallsPublic buildingsLoad-bearing wallWall plate

A composite wall panel having continuous upper and lower hollow horizontal chases and spaced hollow vertical chases formed throughout the panel to permit passage of electrical wiring and the like. The chases have protective barriers to protect the wiring from penetration and damage due to mechanical fasteners used to manufacture the panel and to construct load bearing walls using a plurality of manufactured panels. Further, the panel has a continuous header to provide structural rigidity and to permit rapid manufacturing of the panel without the need to frame openings, such as doors and windows, at the time of manufacture. Openings are cut in the panels and finished after the walls are constructed.

Owner:STARKE CHARLES

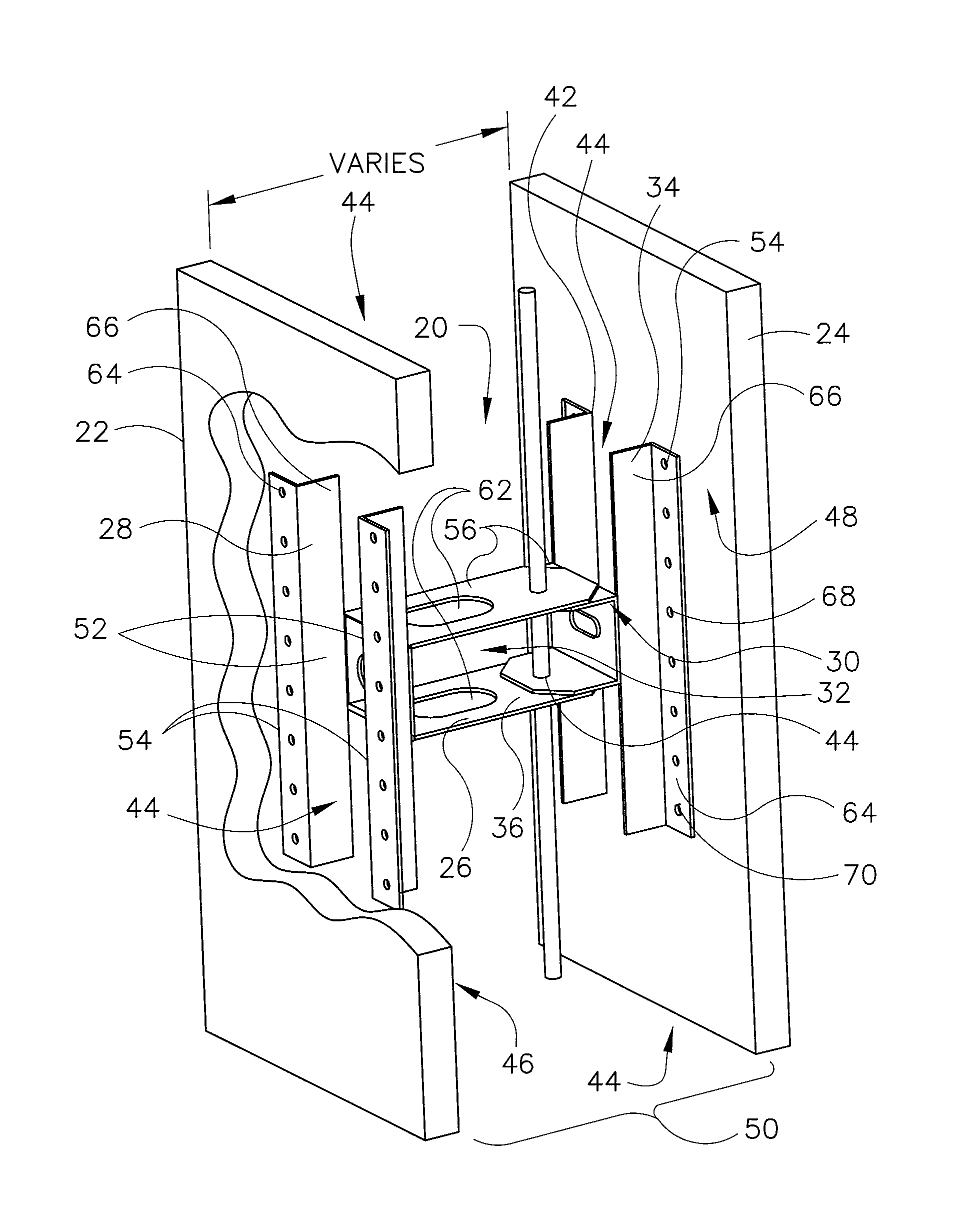

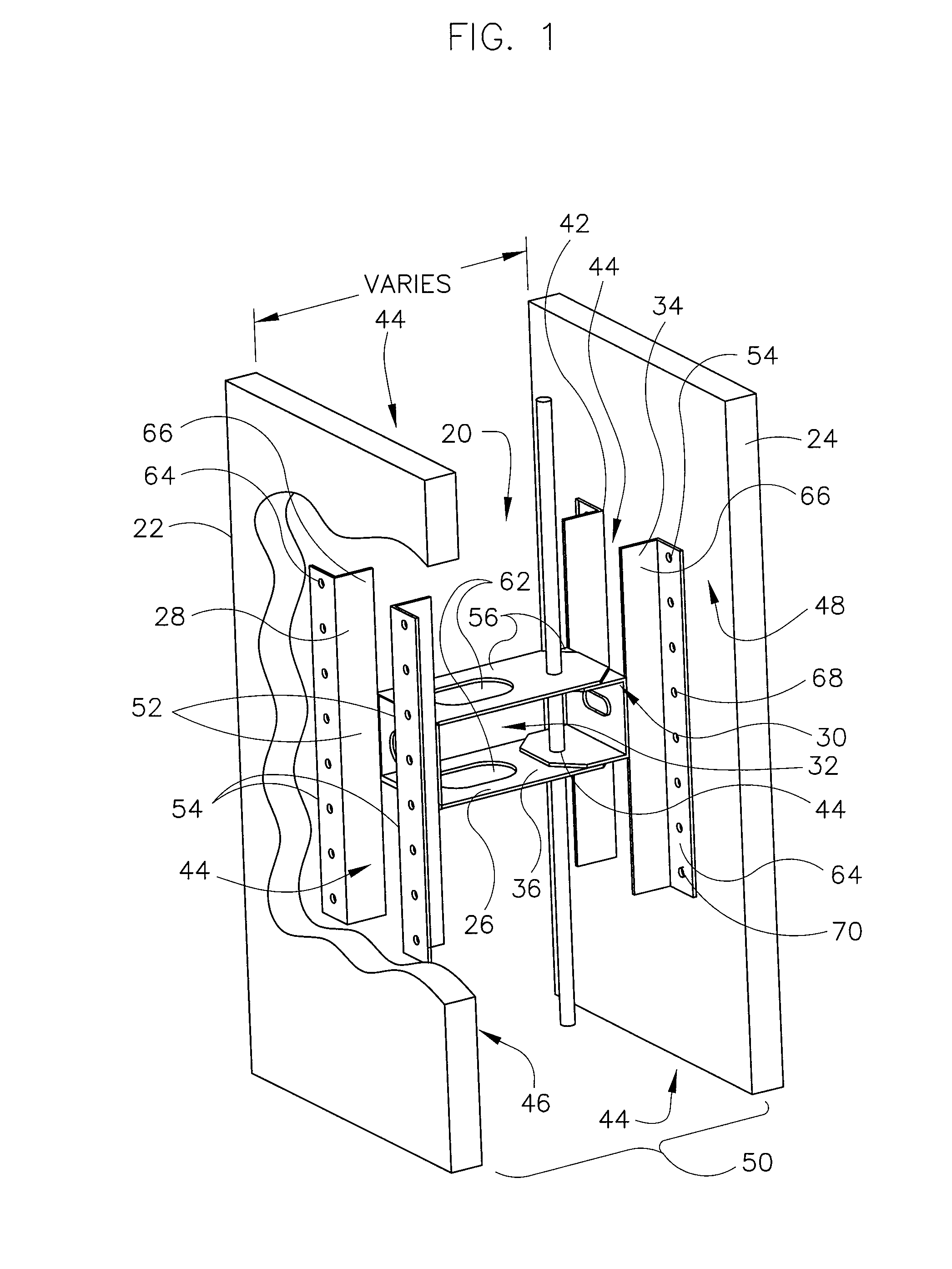

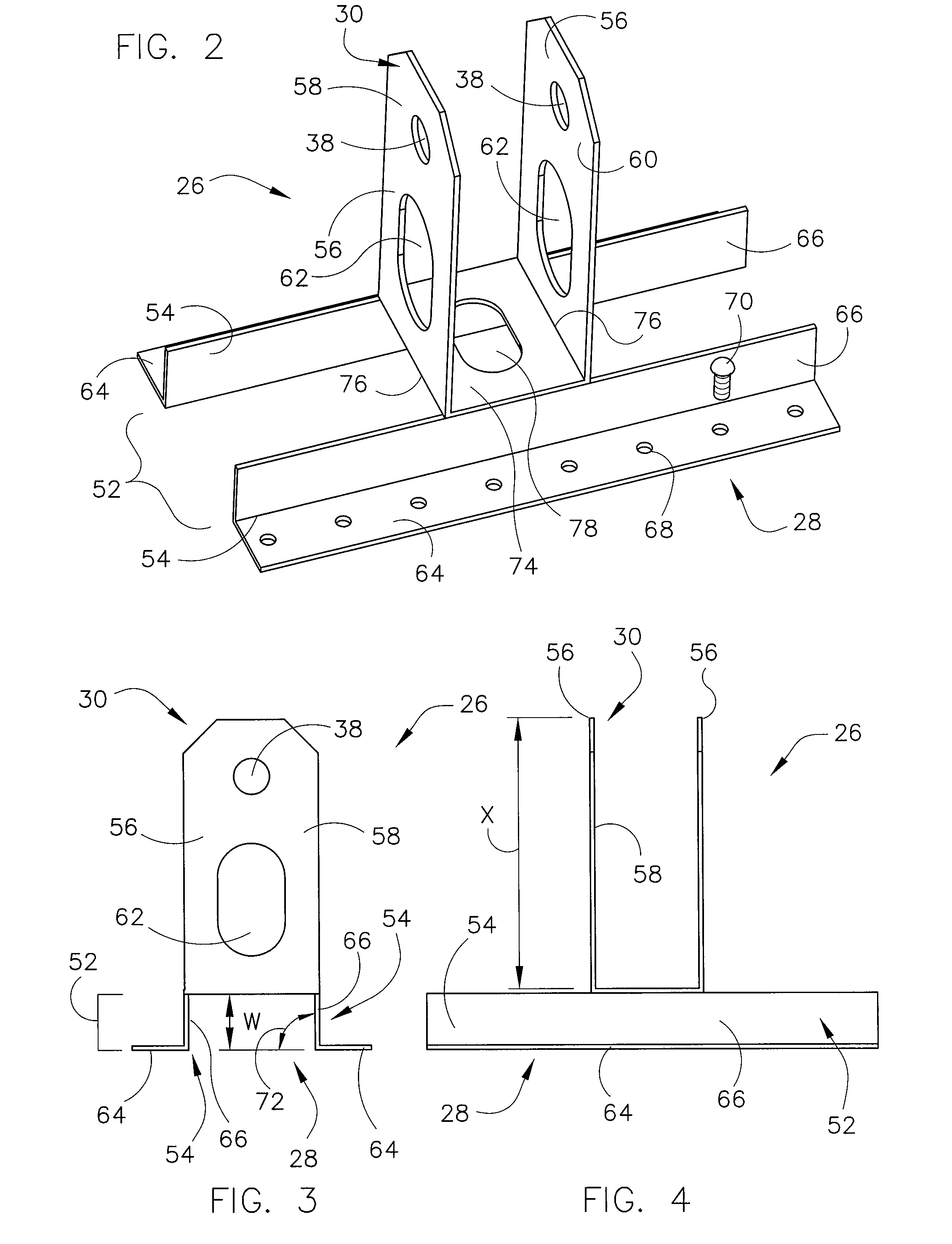

Express framing building construction system

A light steel framing construction technique for light gauge load bearing wall type buildings uses specialized brackets to suspend poured slab floors. Multiple stories of the building can be erected without waiting for individual concrete slab floors to be poured and set at each story. During construction, a building is protected from torsional warping, such as may be occur under wind loads, by a series of lateral and diagonal bracing structures at each level affixed in a plane perpendicular to the load bearing elements. Multiple concrete floor slabs can be poured sequentially or simultaneously, as desired, during the construction process.

Owner:SUN REALTY SERVICES

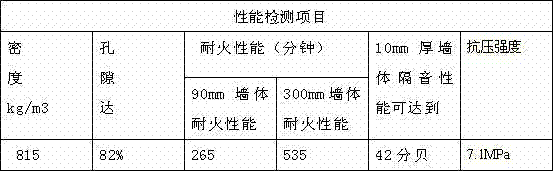

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

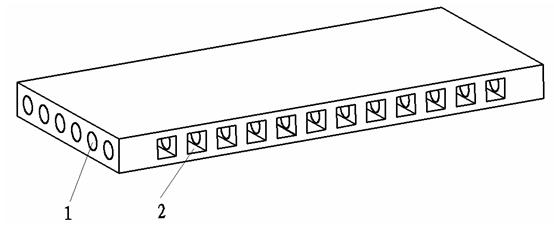

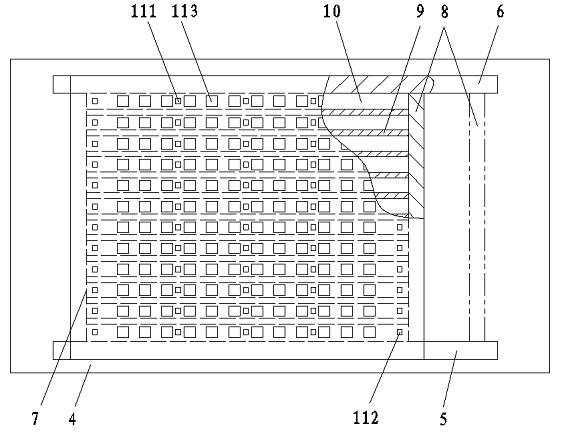

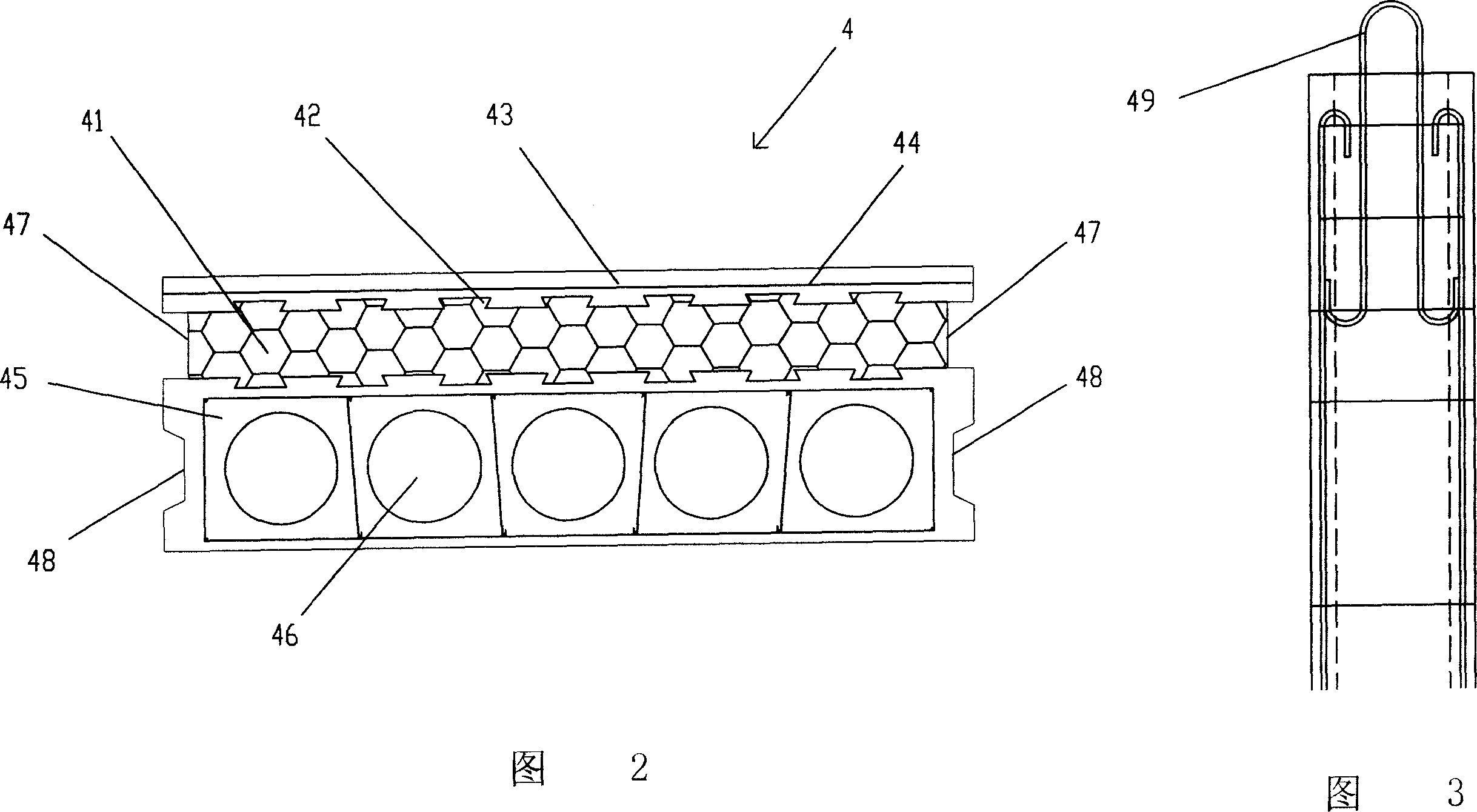

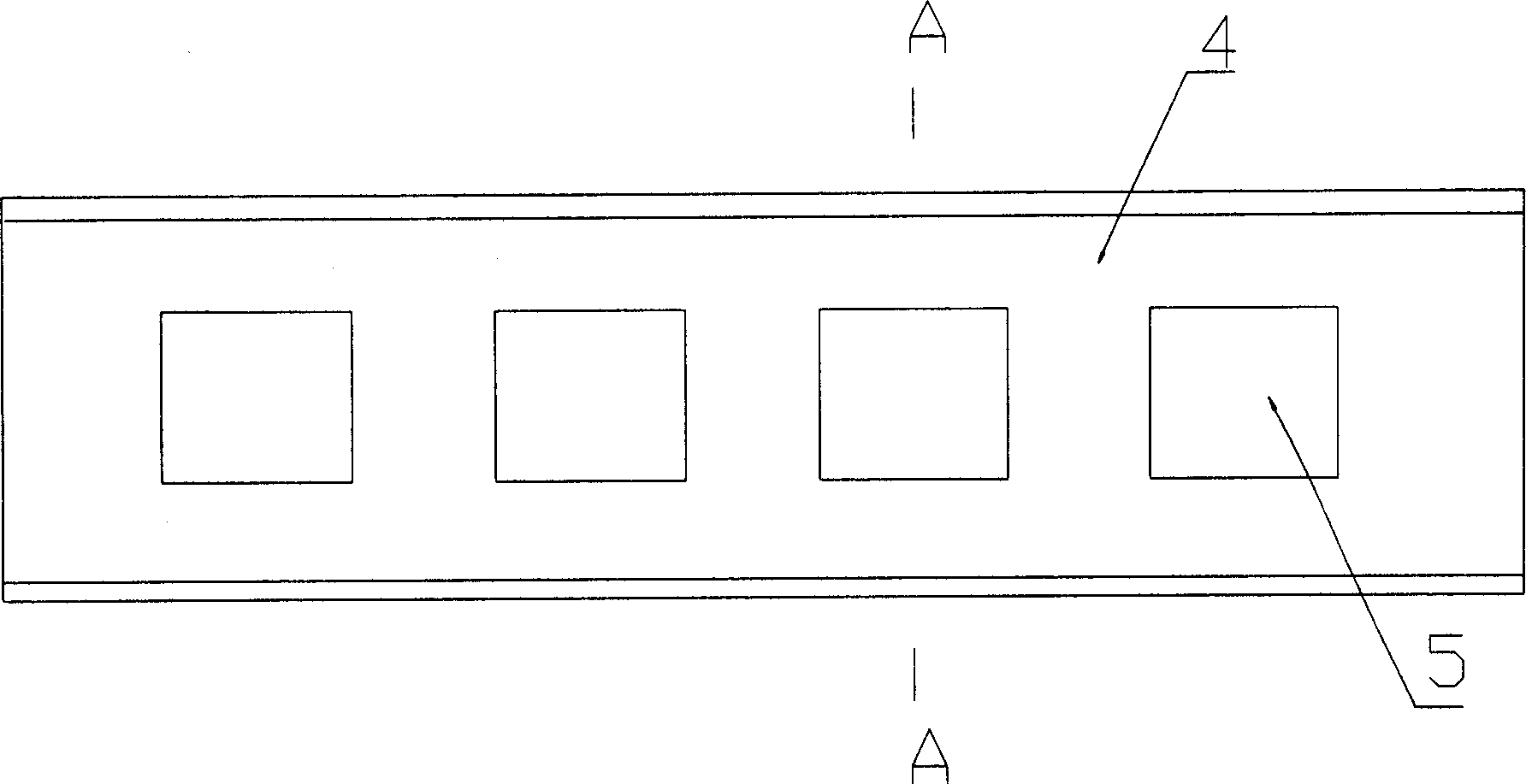

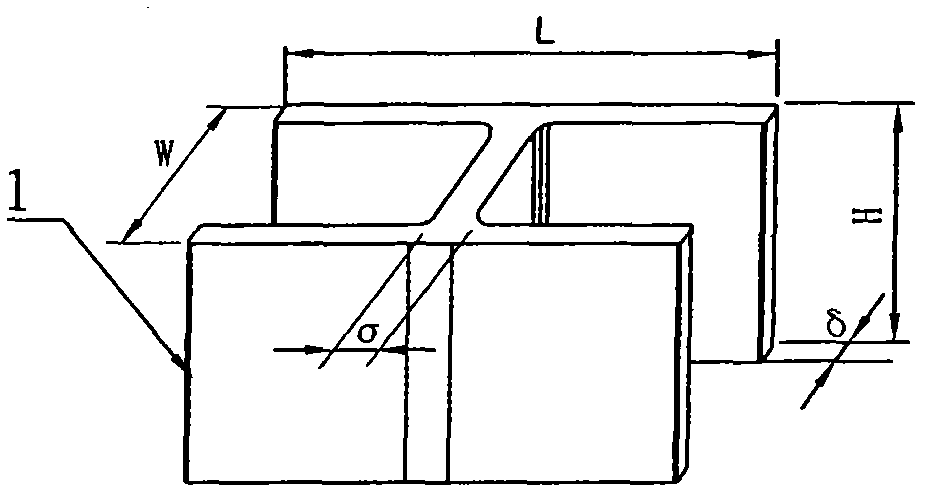

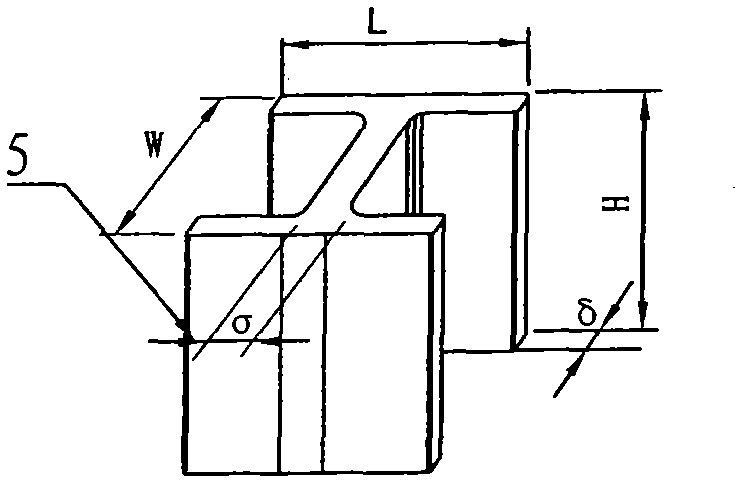

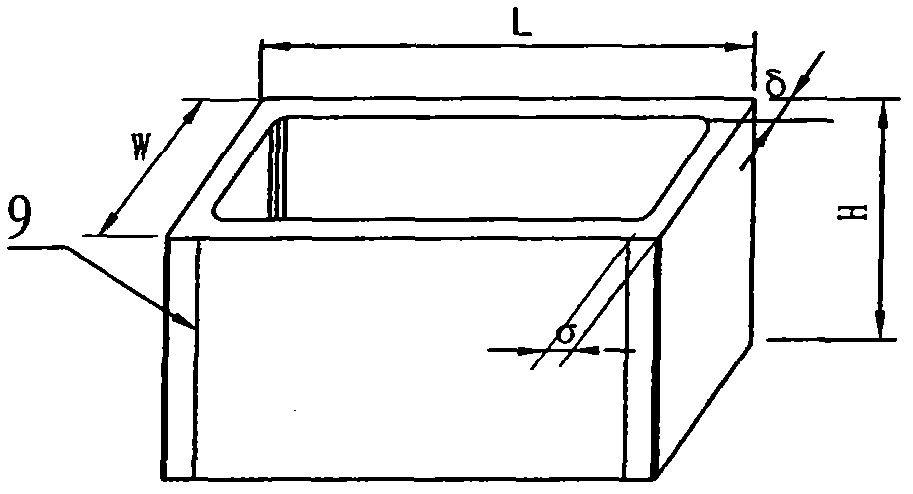

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

Composite fiber reinforced foam concrete and preparation method thereof

InactiveCN102199044APrevent shrinkage crackingImprove flexural strengthSolid waste managementCeramicwareFoam concreteFoaming agent

The invention relates to composite fiber reinforced foam concrete and a preparation method thereof. The foam concrete comprises the following components in parts by weight: 0-400 parts of fly ash, 100-900 parts of cement, 500-1000 parts of sands, 300-600 parts of water, 0.4-1 part of organic fiber, 1-3 parts of plant fiber, 0.2-15 parts of early strength agent, 3-20 parts of foaming agent, 0.5-4 parts of water reducing agent and 0.5-2 parts of water retention agent. The preparation method of the foam concrete comprises the following steps of: generating foams by using the foaming agent, adding the foams to fully stirred cement mortar containing composite fibers and the like and keeping stirring so that the foams are dispersed in the mortar uniformly, measuring the volume weight and carrying out casting forming or coating forming and carrying out standard curing for 28 days. In the invention, industrial and agricultural wastes, such as fly ash, plant fiber and the like, are used, shrinkage crack of the foam concrete is inhibited obviously, and the composite fiber reinforced foam concrete has low price; and the foam concrete has simple formula, good workability, long foam stabilizing time, light weight and low coefficient of thermal conductivity and is suitable for exterior wall thermal insulation, roof thermal insulation and non-load-bearing wall manufacturing.

Owner:TONGJI UNIV

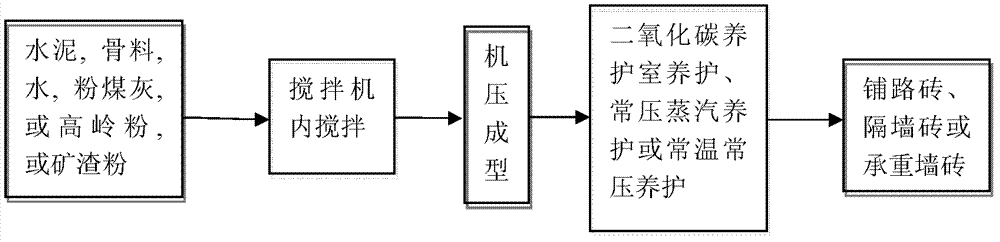

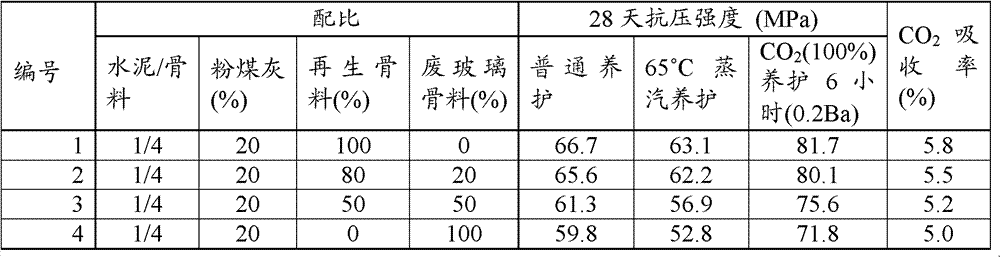

Method for preparing concrete brick

The present invention relates to a method for preparing concrete bricks. The concrete bricks are produced by using cement, aggregate, and fly ash or slag powder, kaolin powder or slag powder, blending through a blender and then pressing by a molding machine. The bricks are then fed into a carbon dioxide curing room for maintenance or are maintained at ambient pressure and room temperature or atmospheric pressure steam. The used aggregate includes recycled aggregates and cullet aggregates, and also may include sand or pebbles. The concrete bricks provided by the present inventions can be made into paving bricks, partition wall bricks and load bearing wall bricks due to different proportions. The performance of the concrete bricks fully meets the standard requirements. The concrete bricks have a good function of absorbing carbon dioxide.

Owner:THE HONG KONG POLYTECHNIC UNIV

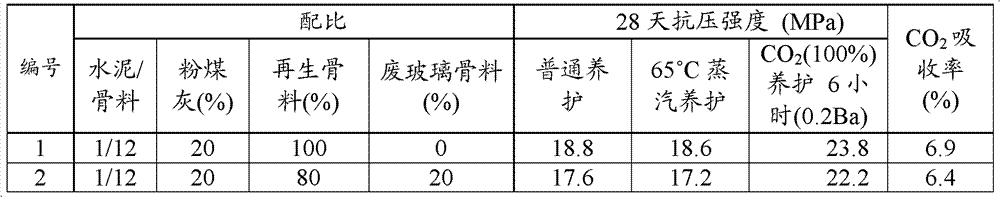

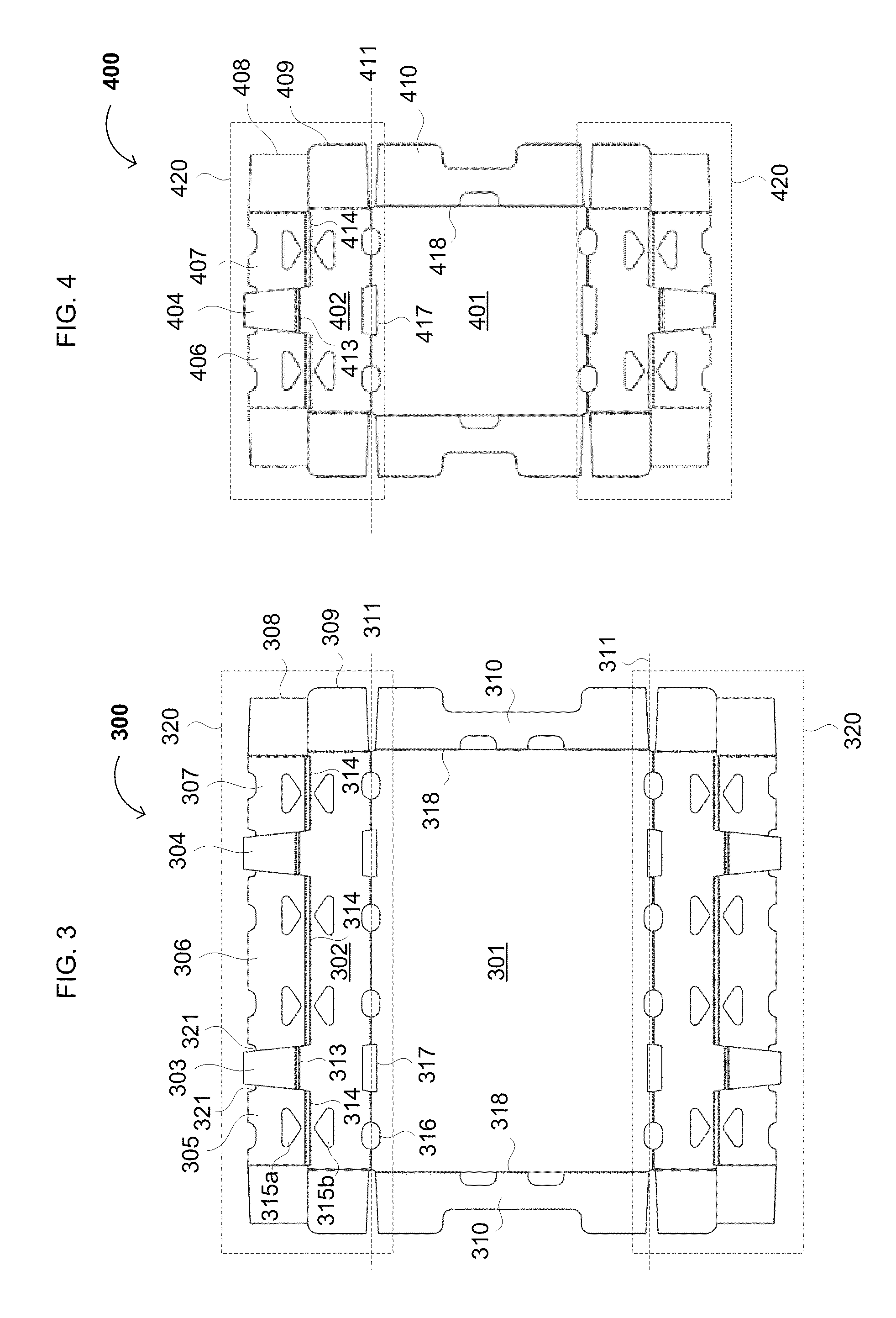

Composite steel joist/composite beam floor system and steel stud wall systems

This invention reveals new metal stud perimeter wall and load-bearing wall systems that support, without eccentricity, concrete-topped floors on open-web-steel-joists, deep-profiled composite metal decks and channel-shaped joists and allow upper floor framing to complete before floor concreting; a new composite steel beam for open-web-steel-joist support; a new shear-connection-ready open-web-steel joist; and a new perimeter metal stud wall system that incorporates an in-wall wheel-stopper. The new wall systems incorporate web-perforated studs, and / or web-perforated tracks doubling as concrete closures, and other concrete closure devices. The composite beam incorporates shear connectors protruding through a special web-perforated track fitted with a load-bearing block and cutouts in the legs for open-web-steel-joist support. Unlike composite open-web-steel joists supporting simple-span metal decks, the new shear-connection-ready joist incorporates a flat-topped chord to allow continuous steel deck layout and field-installed shear connectors. The new joists are best used with medium-depth wide-fluted composite floor deck for maximum system efficiency.

Owner:SIU WILFRED WING CHOW

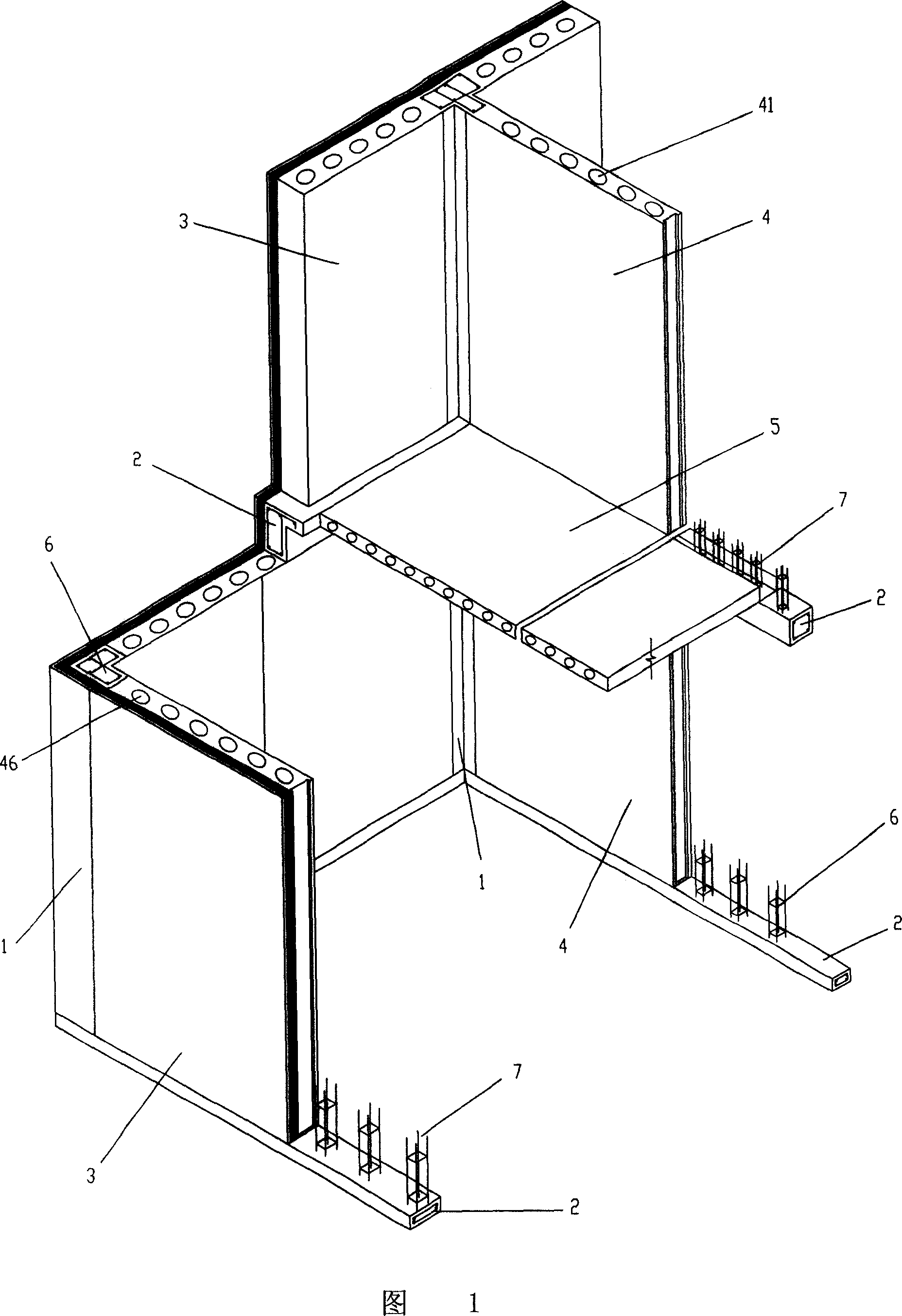

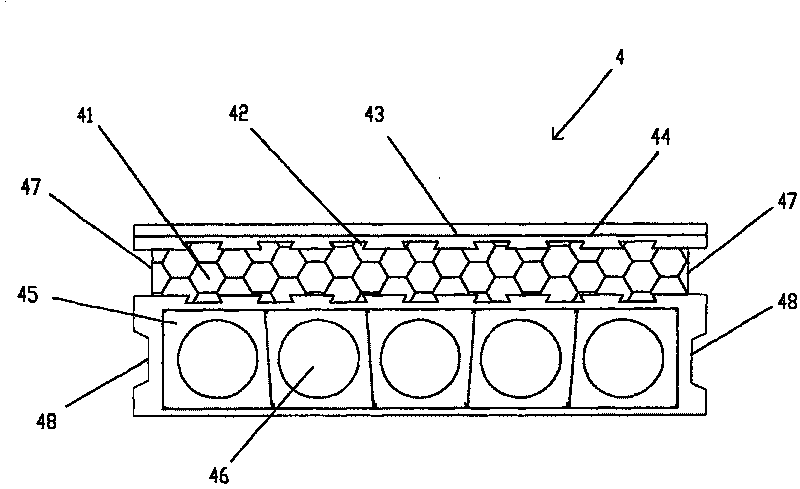

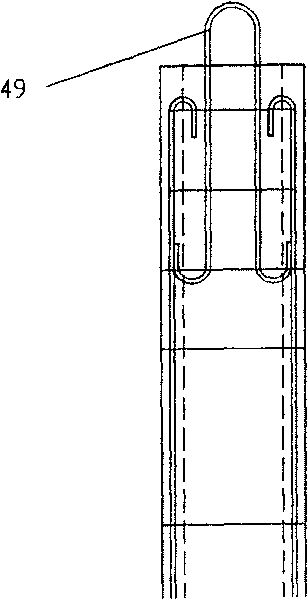

Architectural structure system of preformed hollow load-bearing wall panel and construction method

The invention relates to an architecture systematism and a construction method for a precast hollow load-bearing wall panel comprising a column and a collar beam of cast-in-situ armored concrete, a precast interior or external wall panel and a floor slab equipped in between the column and the collar beam, and a roof slab equipped on the most top, characterized in that the external wall panel is a bearing plate with heat-retaining function, and the interior wall panel is a bearing plate of lightweight armored concrete, while the inside of the interior and external wall panel is equipped with hollow holes whose upper and lower ends are inserted and casting fixed with anchor concrete bars preformed on the collar beam concrete bars. The first hollow hole on the side adjacent the column of the interior and external wall panel is vertical interval inserted the anchor concrete bars on the column concrete bars, and fully pours the concrete. The invention can build a high-rise building with 6 floors and 18 meter height in an anti-seismic prevention region with 8 degrees, or a high-rise building with 7 floors and 21 meter height in an anti-seismic prevention region with 7 degrees, or a high-rise building with 8 floors and 24 meter height in an anti-seismic prevention region with 6 degrees.

Owner:冯葆纯 +1

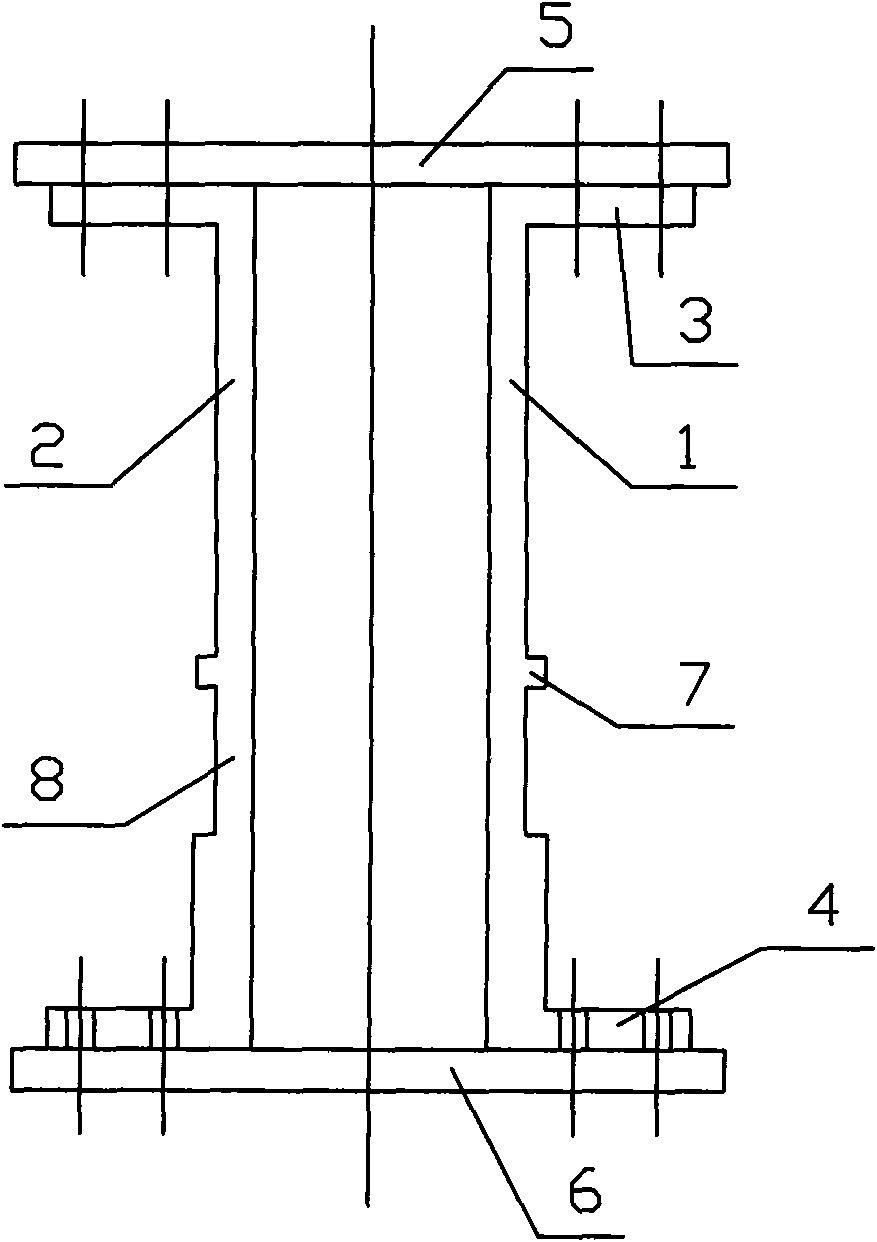

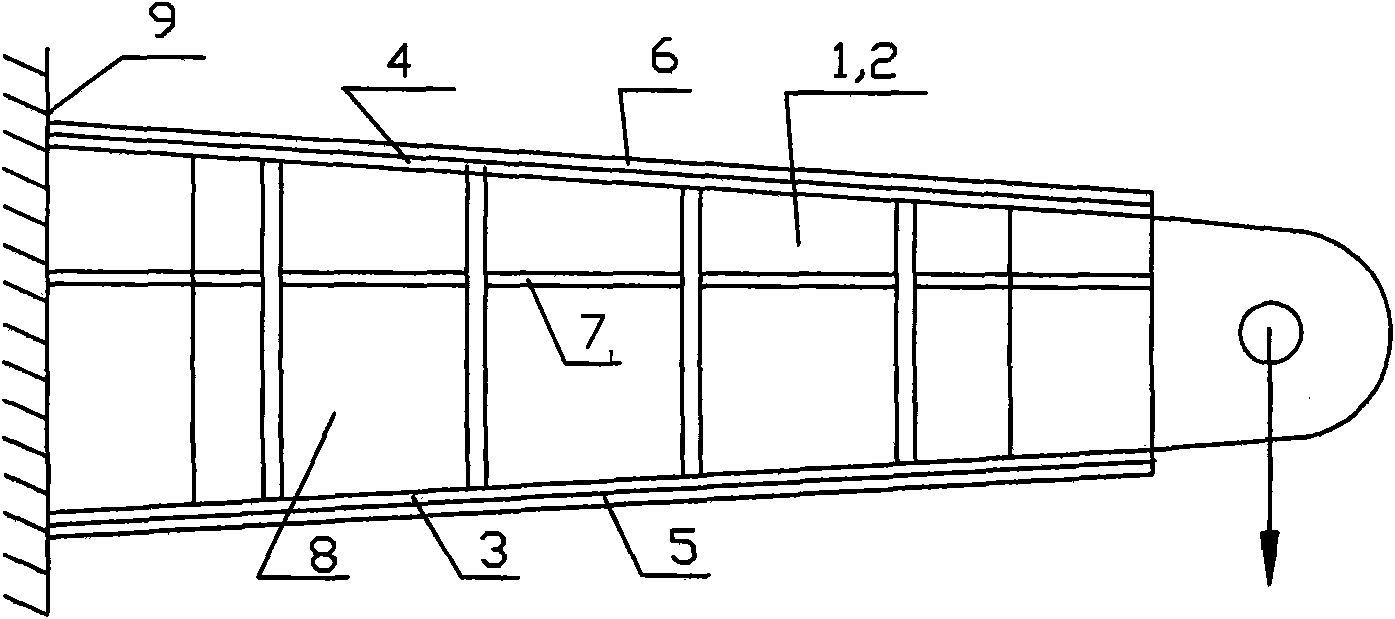

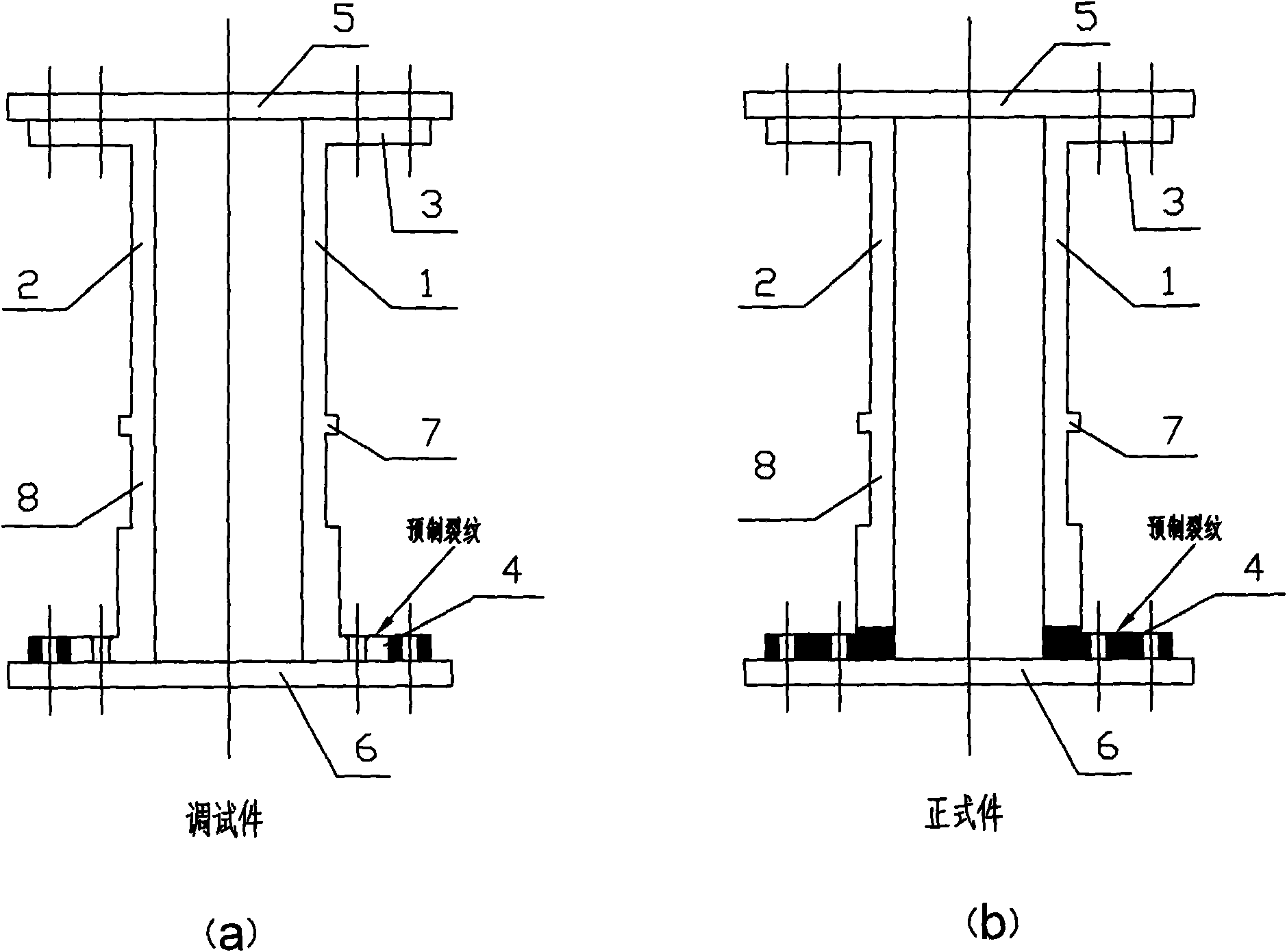

Damage-tolerance testing method for whole wing spar of airplane

InactiveCN101561365ASolve scalabilitySolve the strength problemStructural/machines measurementJet aeroplaneResidual strength

The invention pertains to airplane fatigue and damage-tolerance testing technologies, and relates to a damage-tolerance testing method for the whole wing spar of an airplane. The method comprises the steps of: (I) choosing a part with large load from the whole wing spar for serving as a testing part examining segment, (II) producing two same testing parts according to the examining segment, (III) reserving an interval of 20 to 30mm between the two back-to-back testing parts which are respectively provided with a coating in the upper part and the lower part (the coating is connected with an upper spar edge strip and a lower spar edge strip to form a case segment), (IV) fixing the root of the testing case segment completing assembly on a load-bearing wall, (V) exerting concentrated load at one end of the testing parts to simulate the bending moment of the spar at the testing segment and the shearing force of a web, without considering the influence of the shearing flow of the coating and (VI) using a finite element method to conduct damage tolerance analysis on the testing parts and comparing testing results. The method solves the difficulty that the crack expansion and remaining strength of the present airplane whole wing spar structure lack theoretical evidence; and the design of the testing parts adopts a method of simultaneously conducting tests to the two back-to-back testing parts, thereby eliminating the distortion of a single spar.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

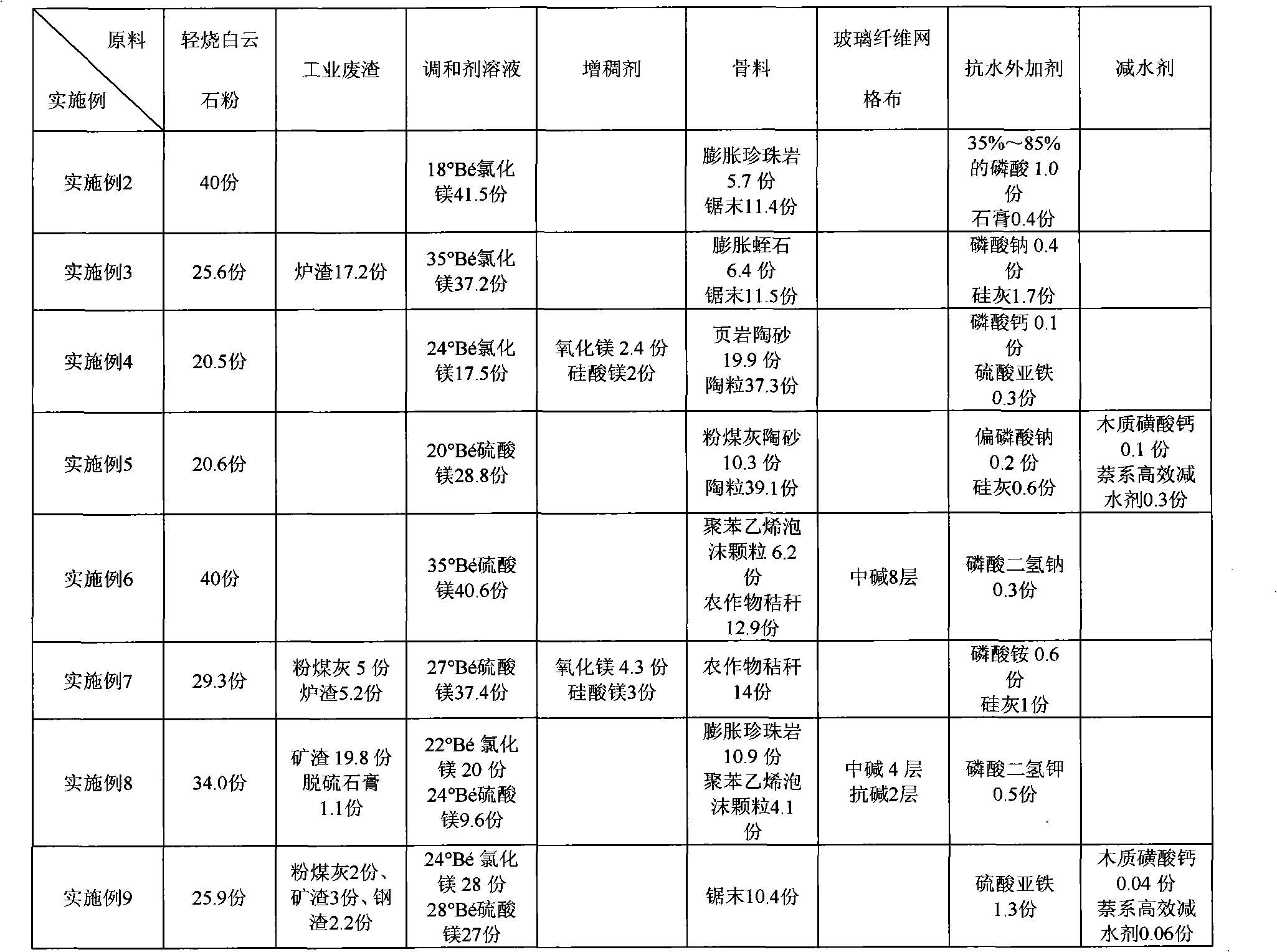

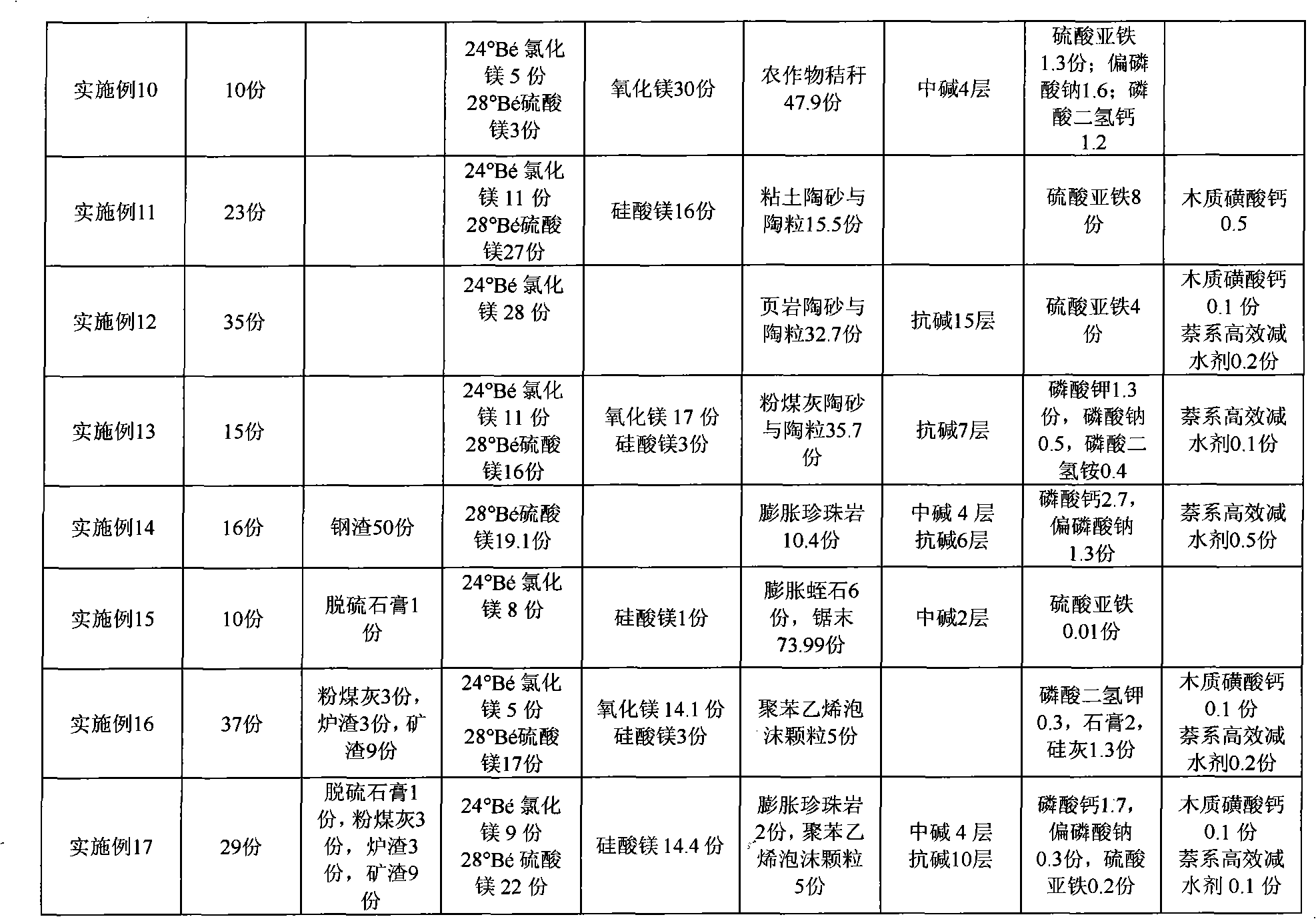

Light-burned dolomite light-weight wall partition board

InactiveCN102079650ACuring reaction at room temperatureHarden fastSolid waste managementMoisture absorptionWater resistant

The invention relates to a light-burned dolomite light-weight wall partition board, comprising the following components in parts by weight: 10 to 40 parts of light-burned dolomite powder, 8 to 55 parts of blender solution, 5 to 85 parts of aggregate, 0.01 to 8 parts of water resistant admixture, 1 to 50 parts of industrial residue, 1 to 30 parts of thickening agent, 1 to 16 layers of glass fiber grid cloth and 0.01 to 0.5 parts of water reducing agent. The light-weight wall partition board of the invention has the advantages of: being free from steam curing or autoclave curing, fast reaction and curing at normal temperature, high strength, good water resistance, no moisture absorption, no halogen accumulation and no scumming, being anti-freezing, soundproofing, heat insulating, heat preserving and flame retardant, massive use of industrial residue and agricultural waste, saving resource and energy, no discharge of the three wastes and the like. The light-burned dolomite light-weight wall partition board has low production cost and great social and economical benefits, and is mainly used for non-load-bearing wall partition.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

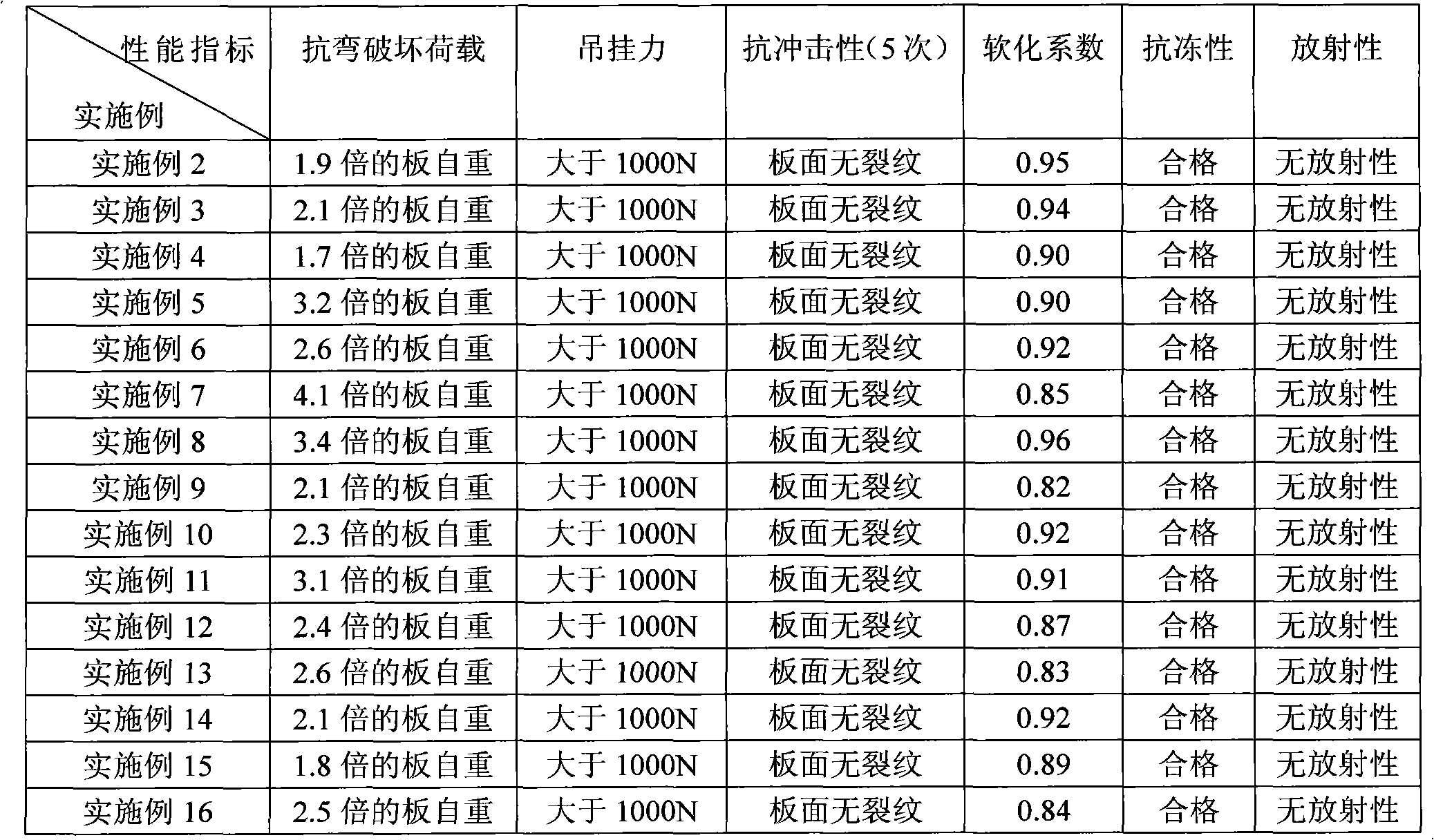

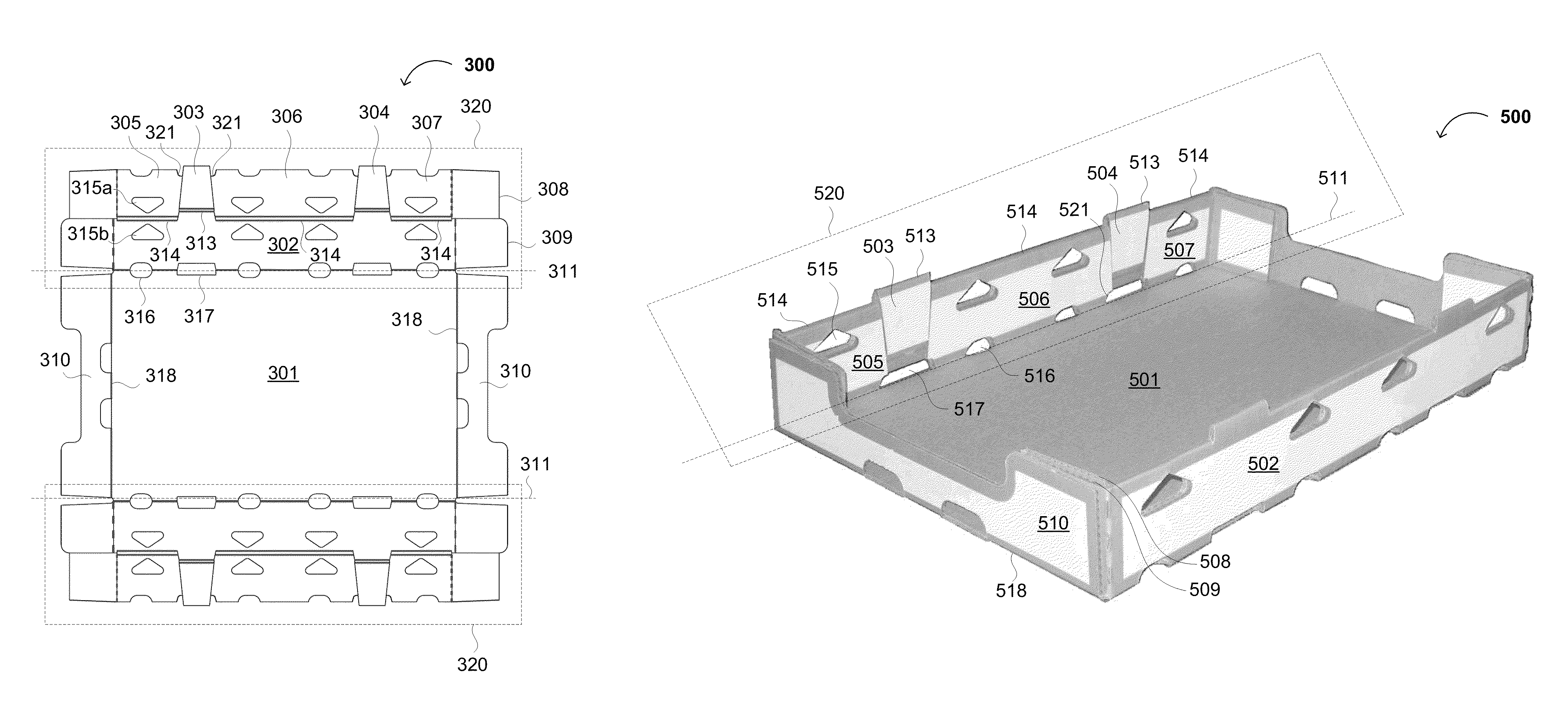

Stackable container and method for making the same

ActiveUS8079474B1Reducing moisture collectionRobust Design MethodPaper/cardboardTray containersWeight-bearing abilityLoad-bearing wall

A stackable container and blanks for forming a stackable container are disclosed. In one embodiment, a stackable container has (a) a base having two pairs of opposed base edges, (b) two first sidewall structures foldably attached to the first base edges at an angle of from about 90 degrees to about 100 degrees, and (c) two second sidewall structures. The second sidewall structures generally each include (i) a wall flap foldably attached to one of the base edges at an angle of from about 90 degrees to about 100 degrees, (ii) an index fold-down flap foldably attached to the wall flap at an angle of about 180 degrees, and (iii) a plurality of inner fold-down flaps foldably attached to the wall flap at an angle of about 180 degrees. Embodiments of the present invention can advantageously provide a reliable design approach for making a stackable container from a blank, whereby the weight-bearing ability and / or stackability of the container is improved, while also covering flutes on the load-bearing wall, thereby reducing moisture collection.

Owner:MAXCO SUPPLY

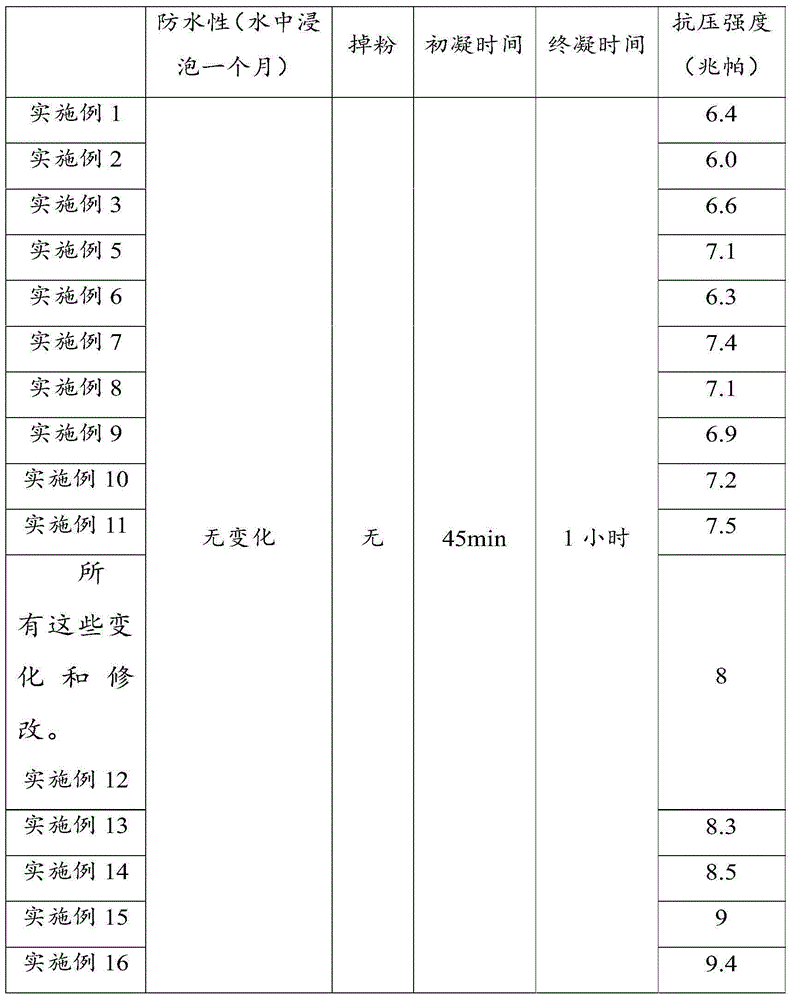

Ardealite premixed dry-mixed mortar capable of being used for 3D printing

The invention provides ardealite premixed dry-mixed mortar capable of being used for 3D printing. The ardealite premixed dry-mixed mortar capable of being used for 3D printing is prepared from, by weight, 500-600 parts of dihydrate gypsum, 400-500 parts of aggregate, 30-50 parts of coal ash, 0.2-0.8 part of redispersible powder, 0.2-0.3 part of foaming agents, 1-1.5 parts of retarder and 0.5-0.7 part of water-retaining agents. The ardealite premixed dry-mixed mortar capable of being used for 3D printing is high in compressive strength, good in hydrolytic performance and capable of being used as an interior wall material as well as an exterior wall material and being applied to a load bearing wall, in particular to the construction in which the 3D printing technology can be adopted.

Owner:GUIZHOU ZHENGHE AERATED CONCRETE CO LTD

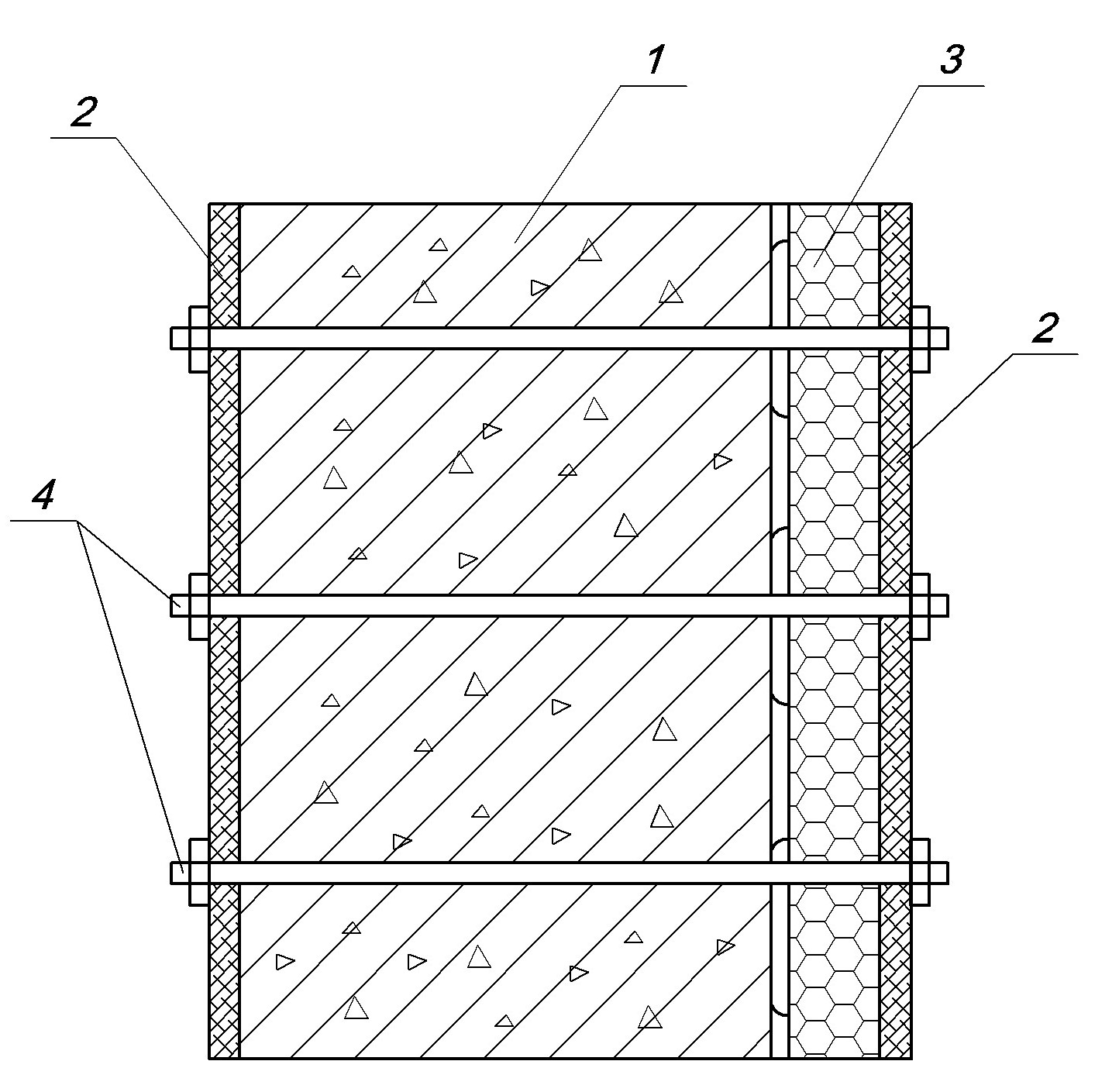

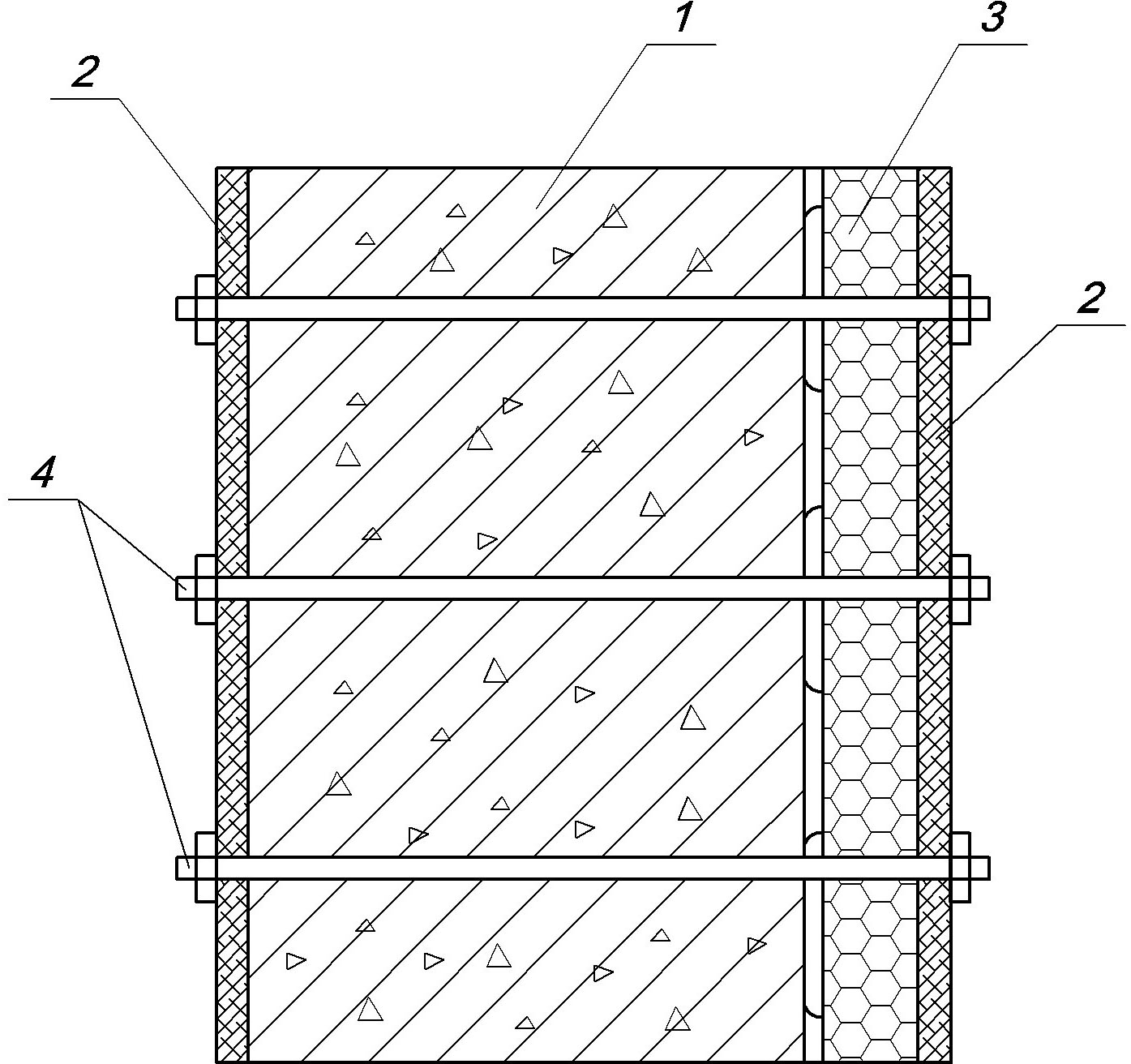

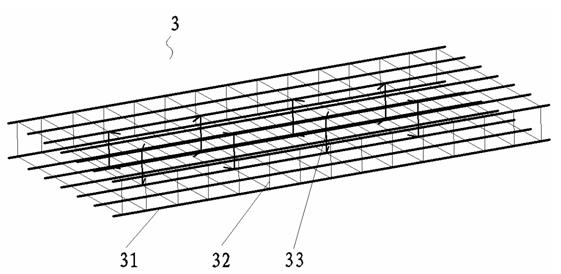

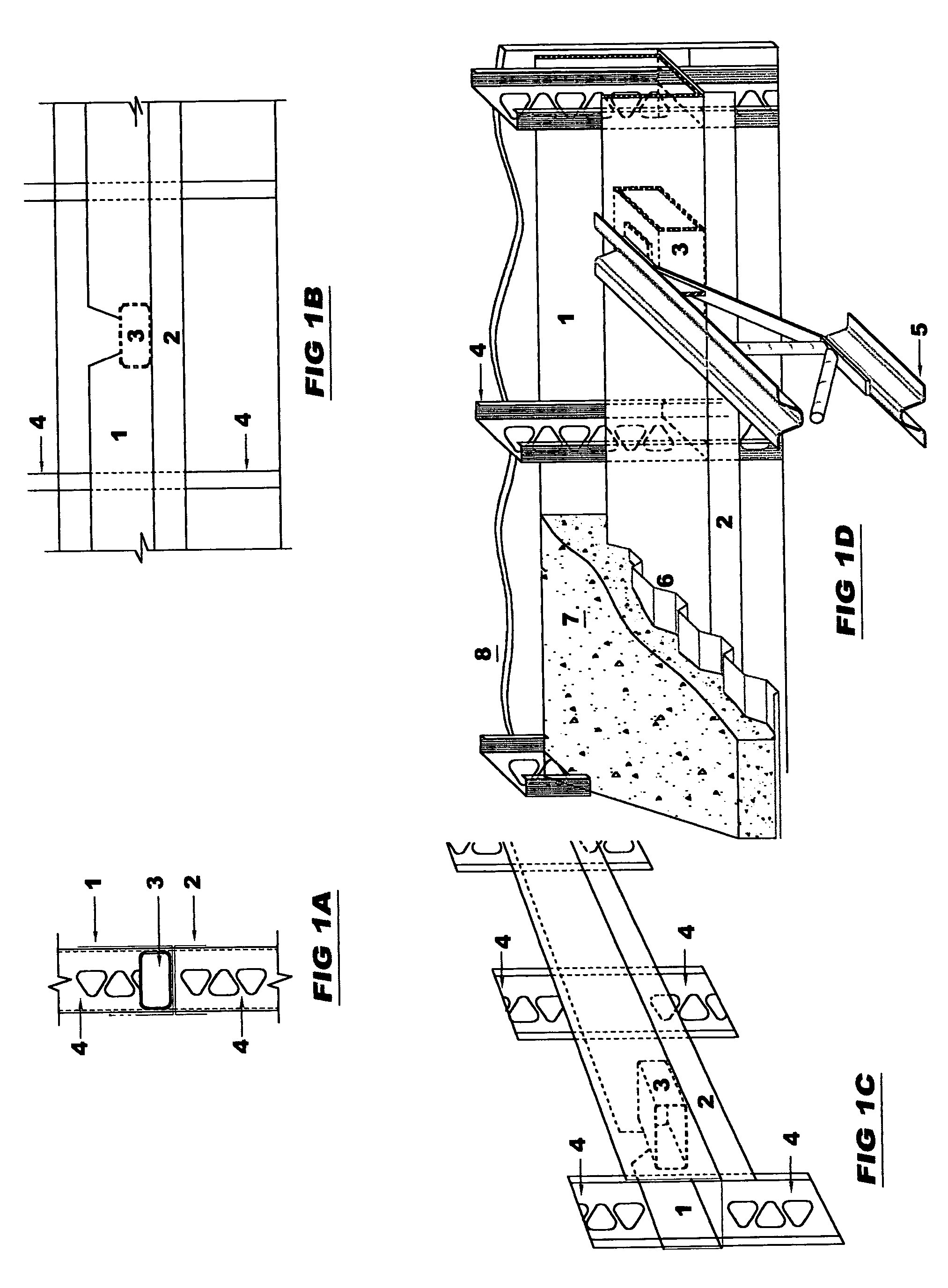

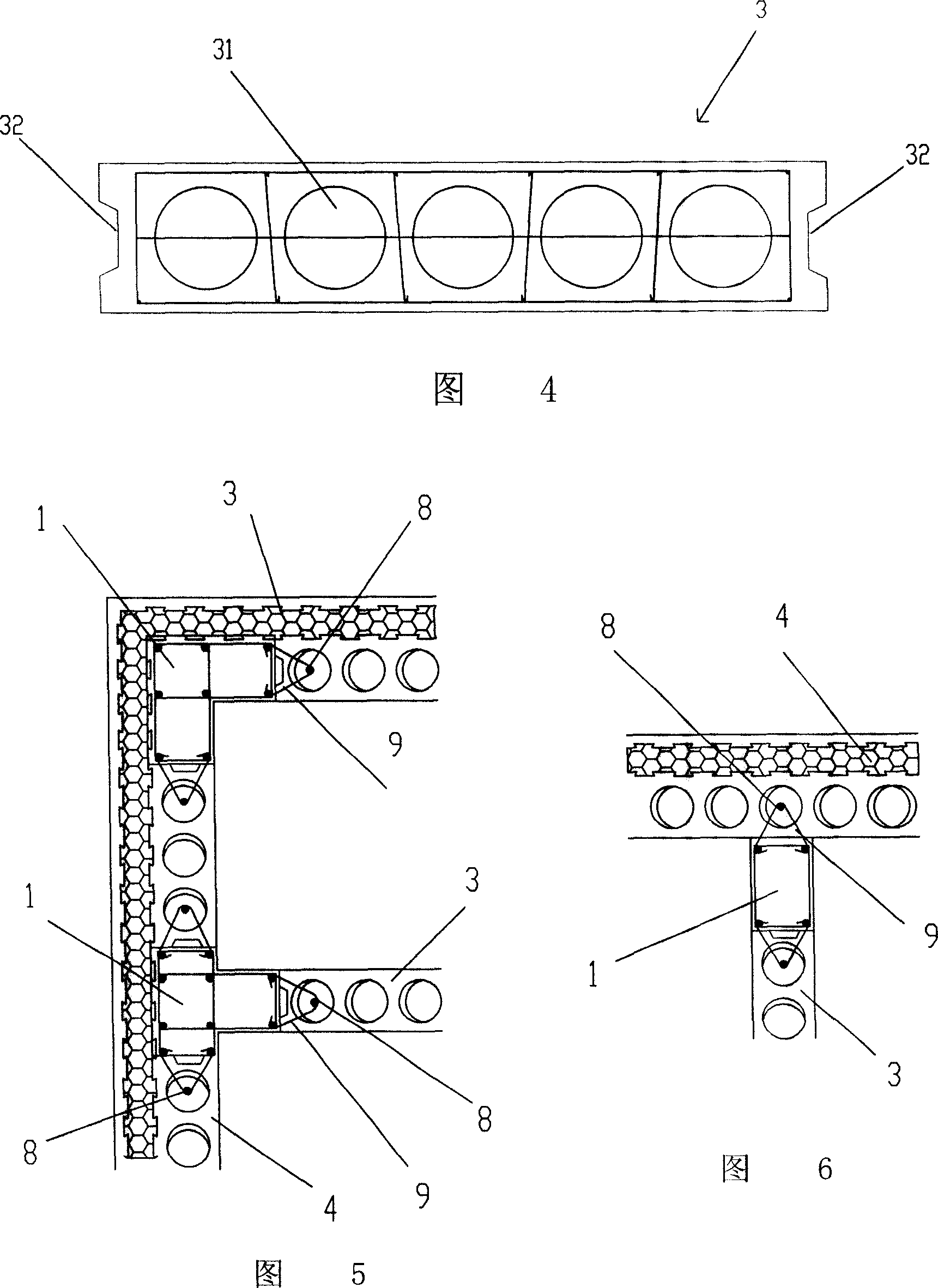

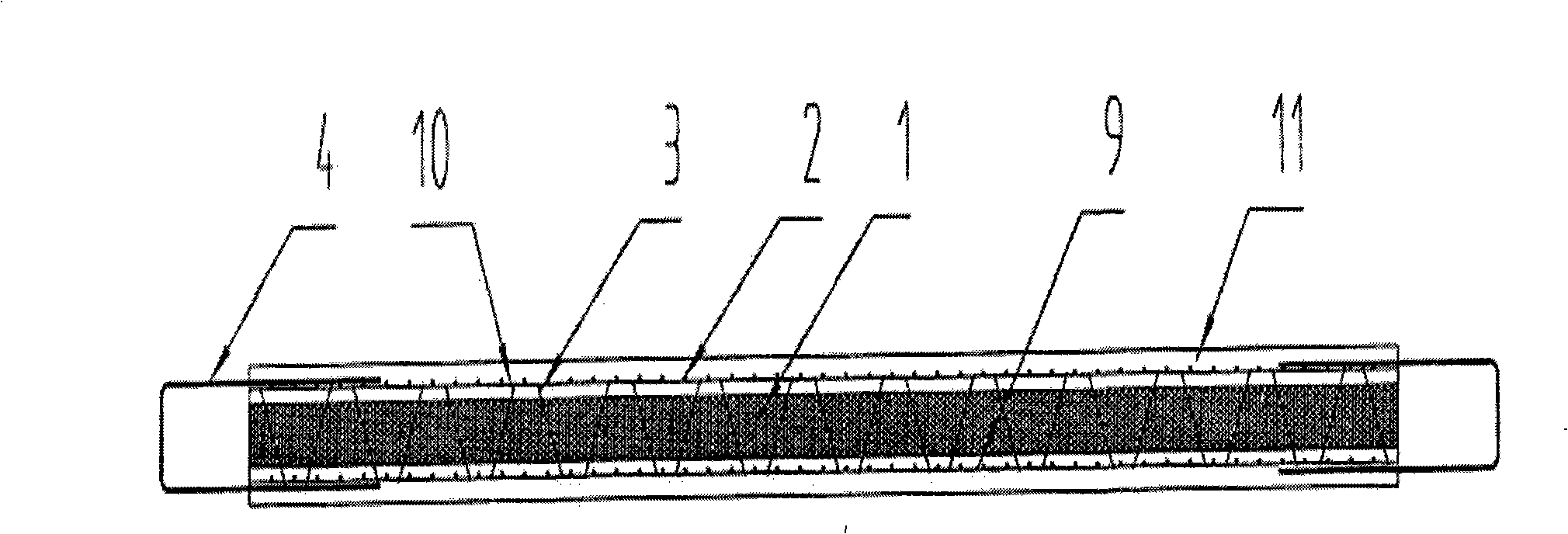

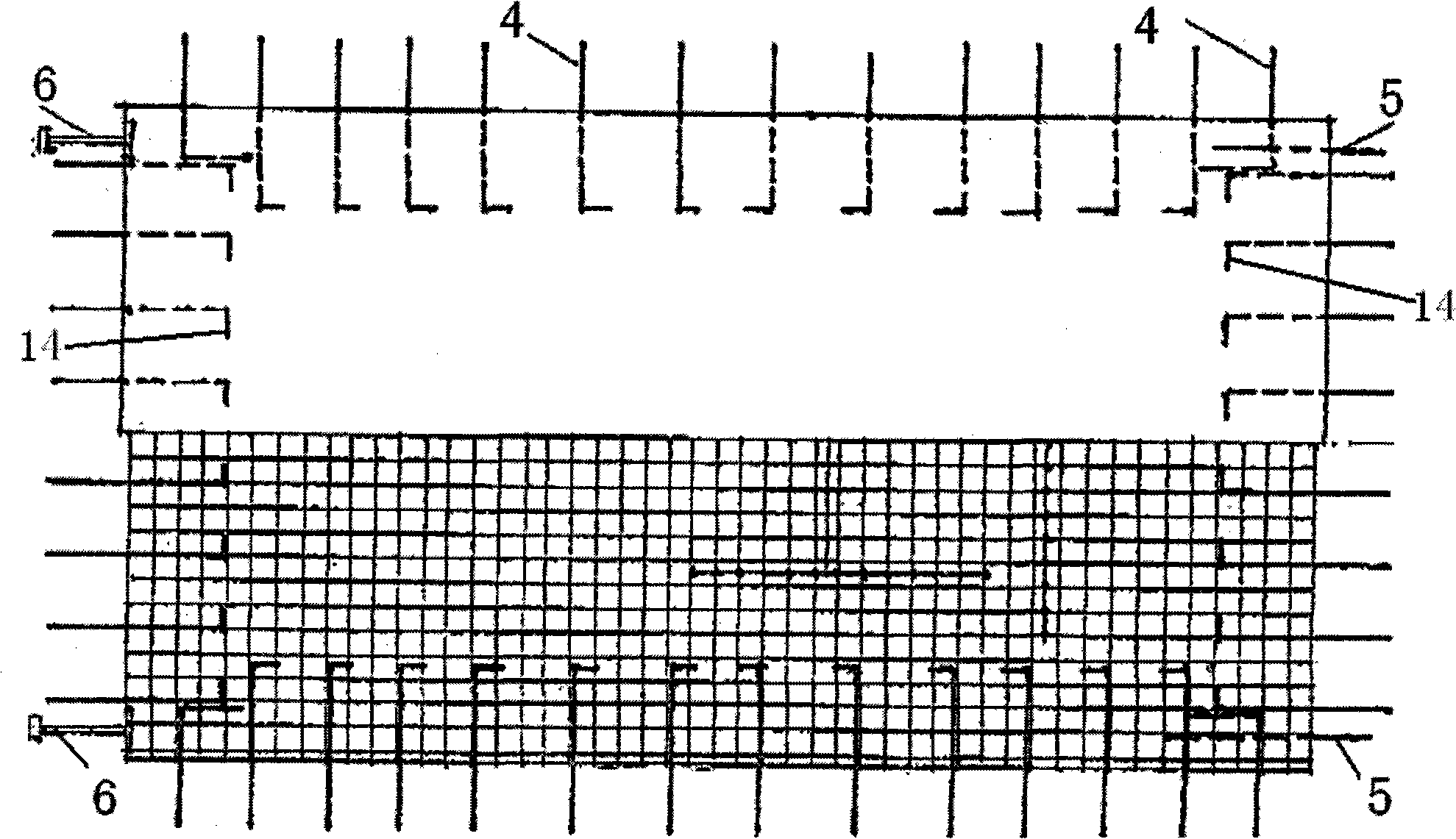

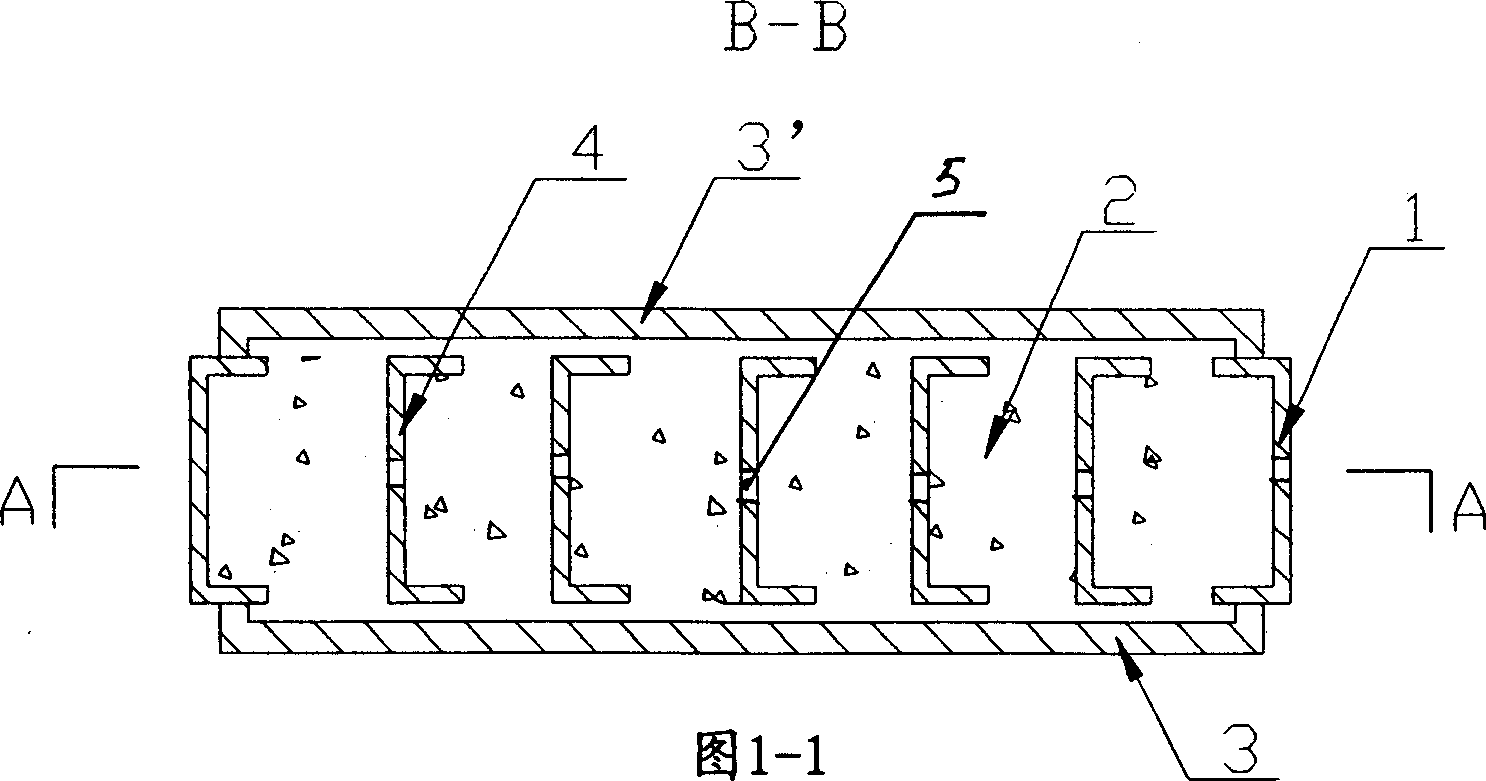

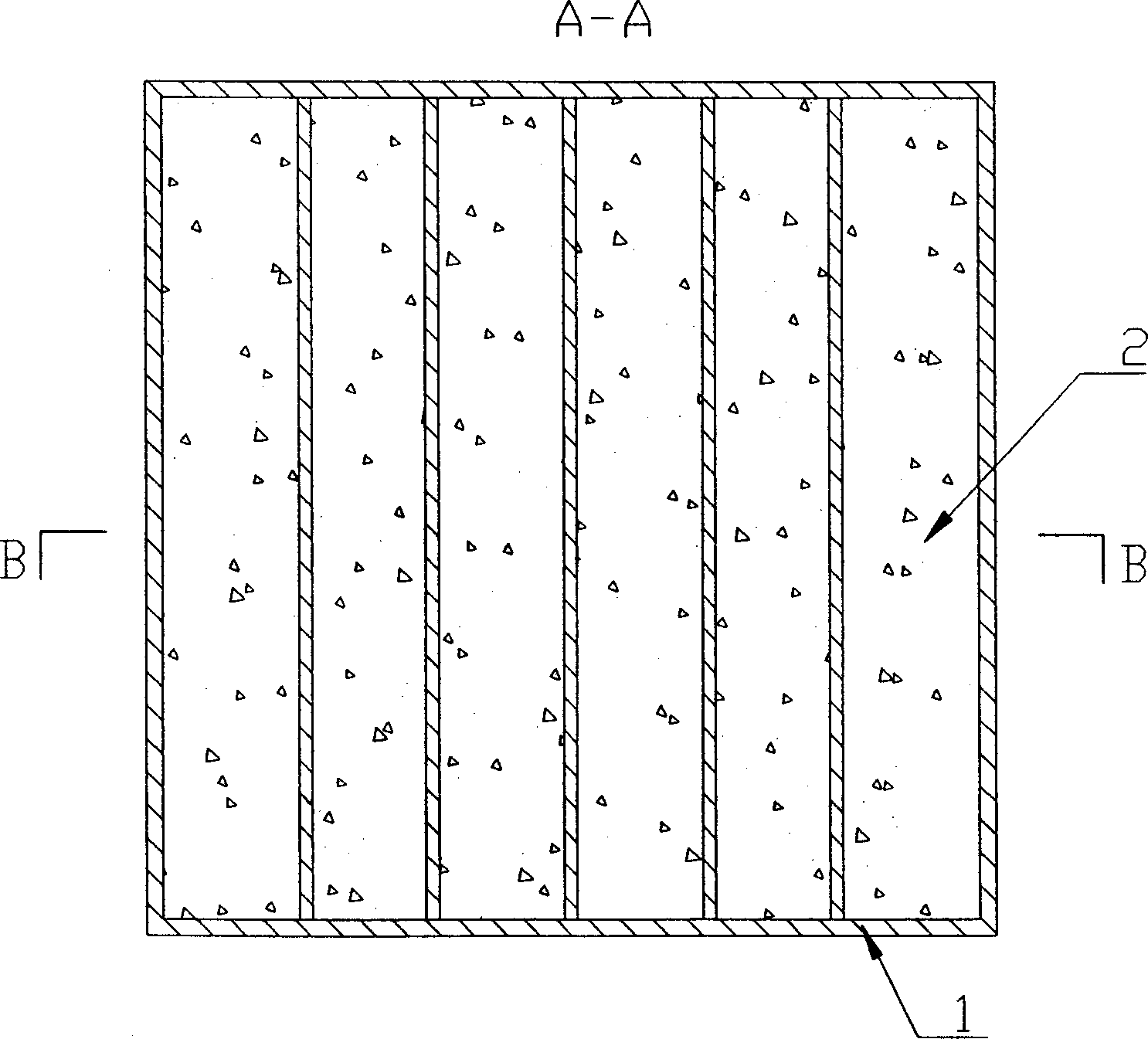

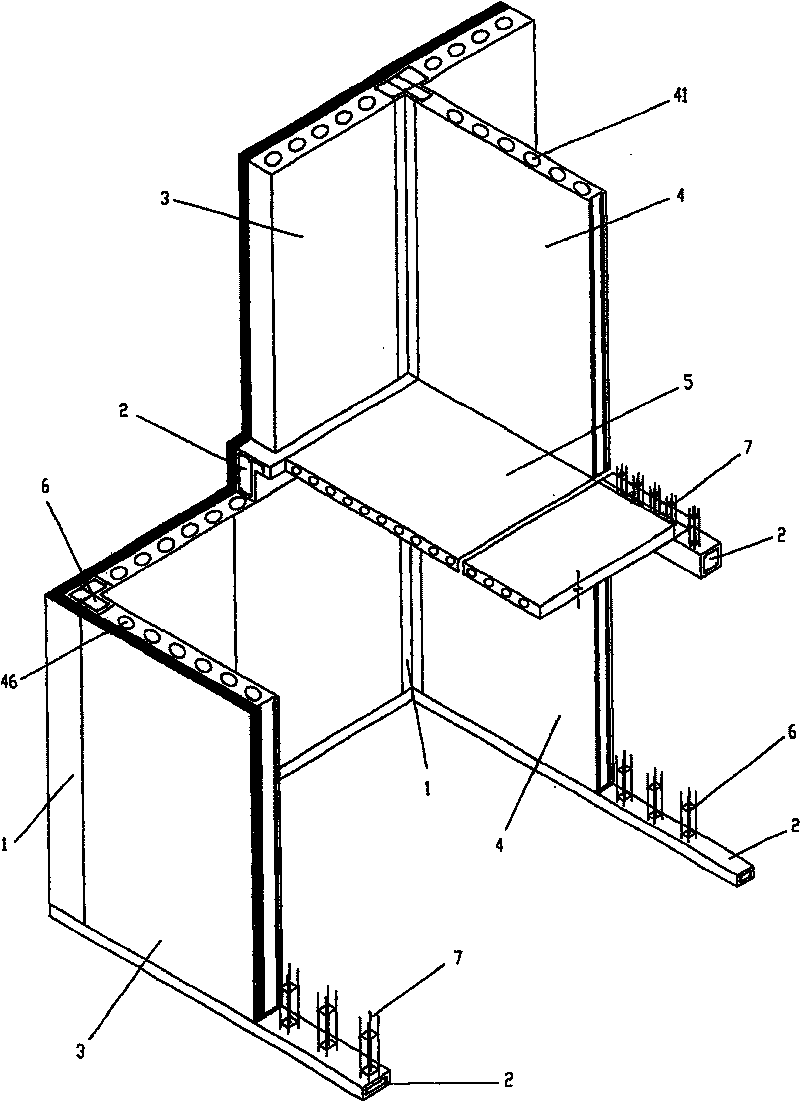

Network frame prefabricated composite board, sandwiched floor and its connection construction method

InactiveCN101260720AReasonable structureImprove bearing capacityConstruction materialWallsThree-dimensional spaceEngineering

The invention relates to a precast net rack sandwich wallboard and a connecting construction method for the same, belonging to the novel building material structure technical field. The precast net rack sandwich wallboard is characterized in that: the precast net rack sandwich wallboard comprises a core plate (1), wherein, a steel wire gauze (2) and a steel wire gauze (9) are respectively arranged on the upper surface and the lower surface of the core plate; the upper steel wire gauze and the lower steel wire gauze are fixedly connected with an inclined dowel bar (3) and an inclined dowel bar (10) which pass through the core plate to form a three-dimensional space net rack structure; U-shaped connecting reinforced rings (4) are arranged on the outsides of the upper steel wire gauze and the lower steel wire gauze along the circumference of the core plate; and a reinforced cement layer (11) in which the steel wire gauzes are coated through placement is formed between the steel wire gauzes and the core plate. The connecting construction method comprises the following steps: firstly, adjacent laminboards are butted on the construction site according to different positions; secondly, reinforcing steel bars (7) are inserted and fixedly connected; and thirdly, a bearing wall is formed by connection of cast-in-situ concrete columns. A parallel walling, an L-shaped walling, a T-shaped walling and a crossed walling are formed by connection and assembly according to different positions. The precast net rack sandwich wallboard and the connecting construction method can realize factory prefabrication and formation of a wall by placing on the construction site, and have light deadweight, large bearing capacity, quick construction, low manufacturing cost and safety and reliability.

Owner:山东龙新建材有限公司

Composite building board material capable of load bearing and its productioin method

InactiveCN1478971AFireproofWith sound insulationMouldsBuilding componentsSteel columnsLoad-bearing wall

A composite building plate able to bear load is composed of the external frame, foamed cement layer filled into the frame, and surfacial layers, and features that several steel columns or beams are unidirectionally arranged in the frame, which have through holes for allowing the foamed cement to penetrate through them. Its advantages are light weight, high weatherability, insulation to heat and sound, and resistance to water, acid and alkali, and low cost.

Owner:CUBIC DIGITAL TECH CO LTD

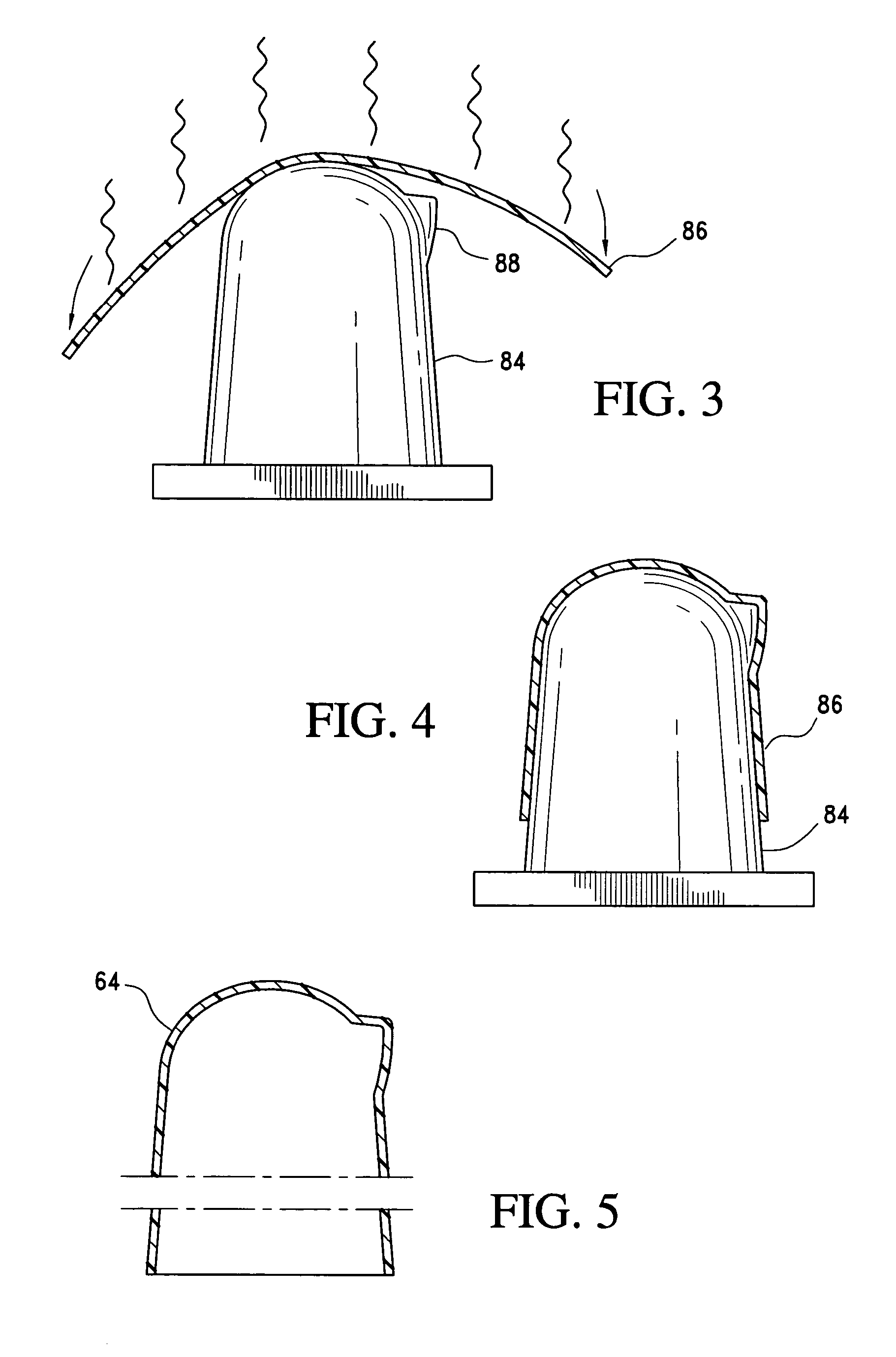

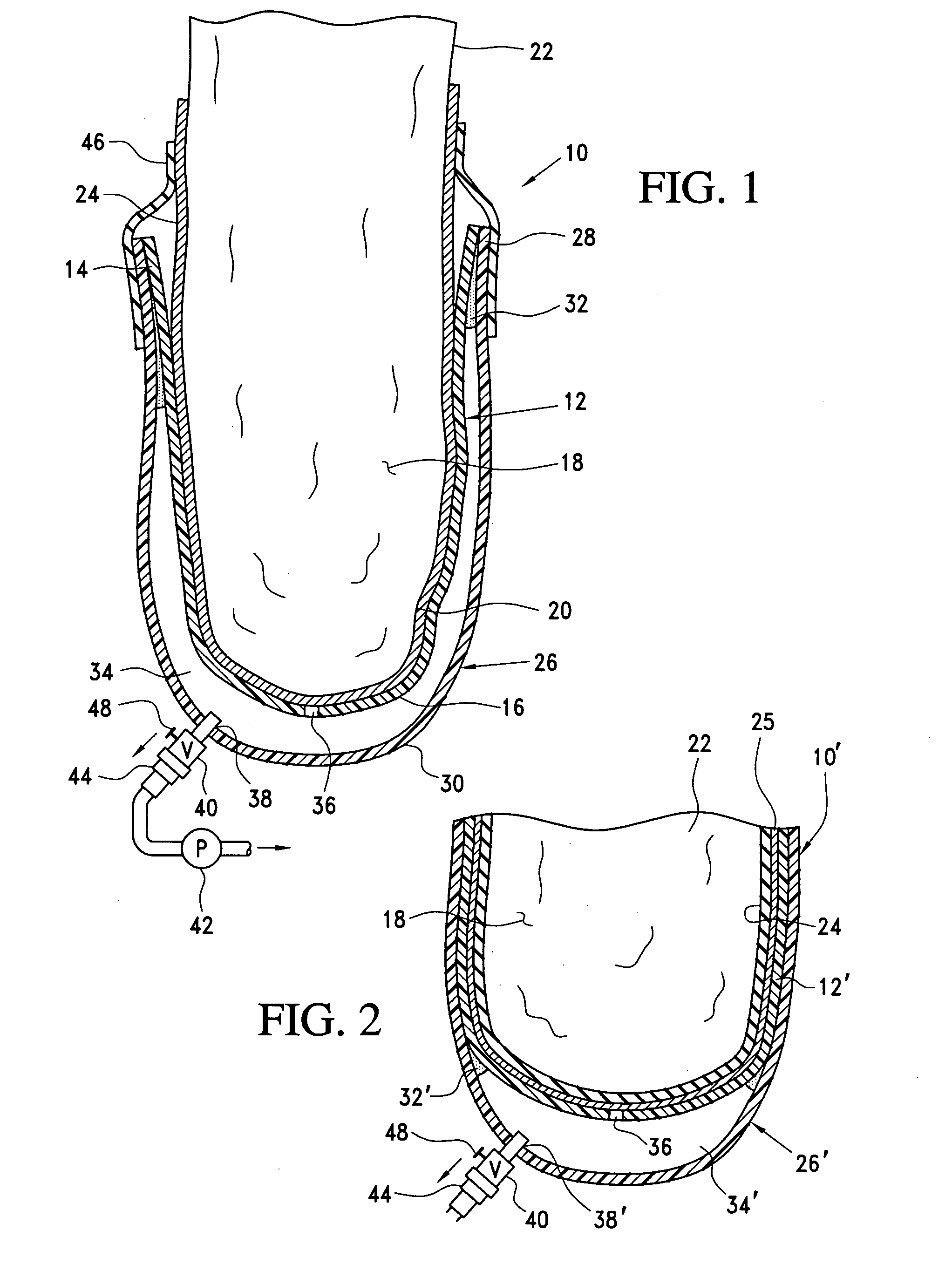

Integral forming technology, a method of constructing steel reinforced concrete structures

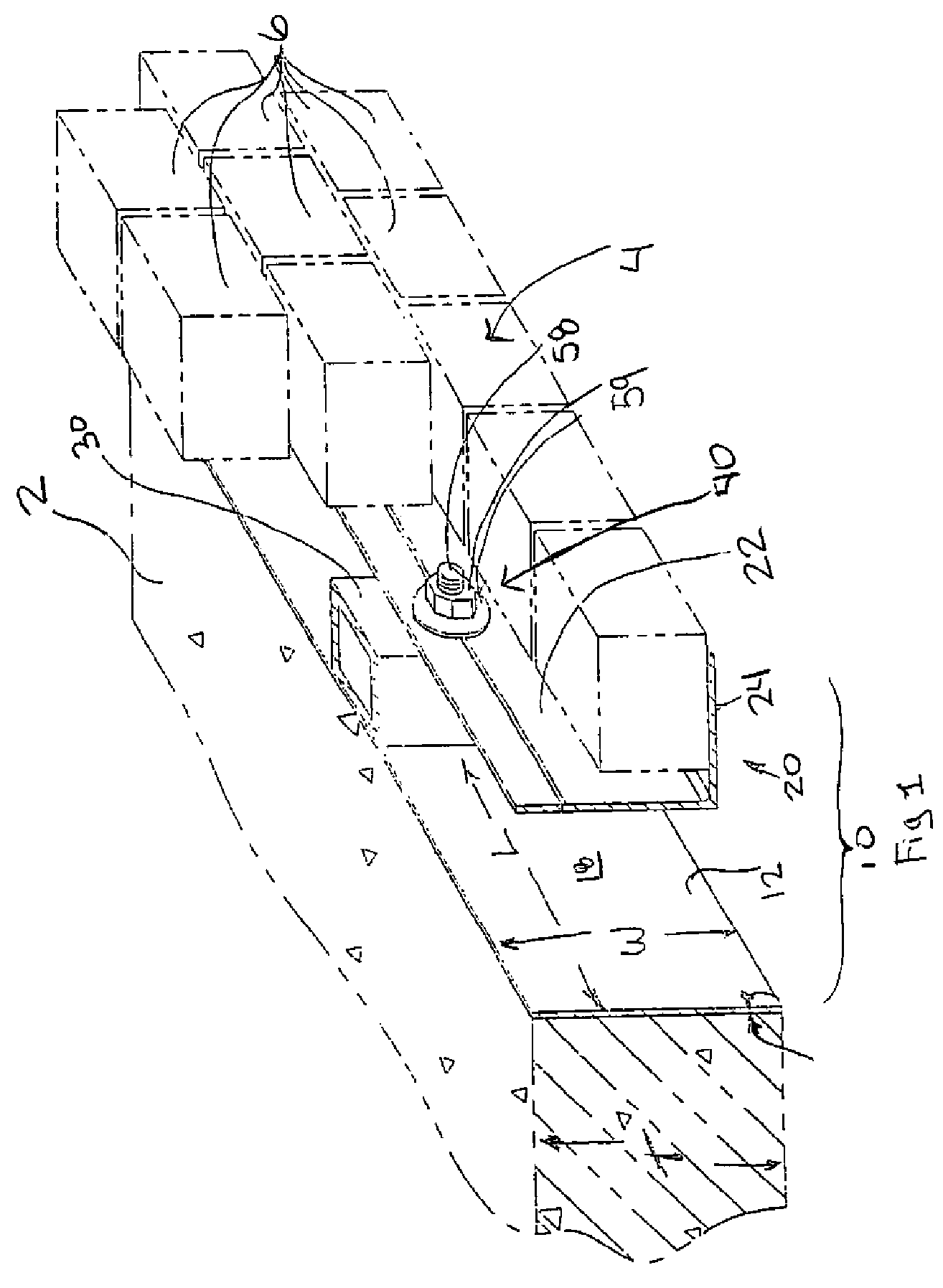

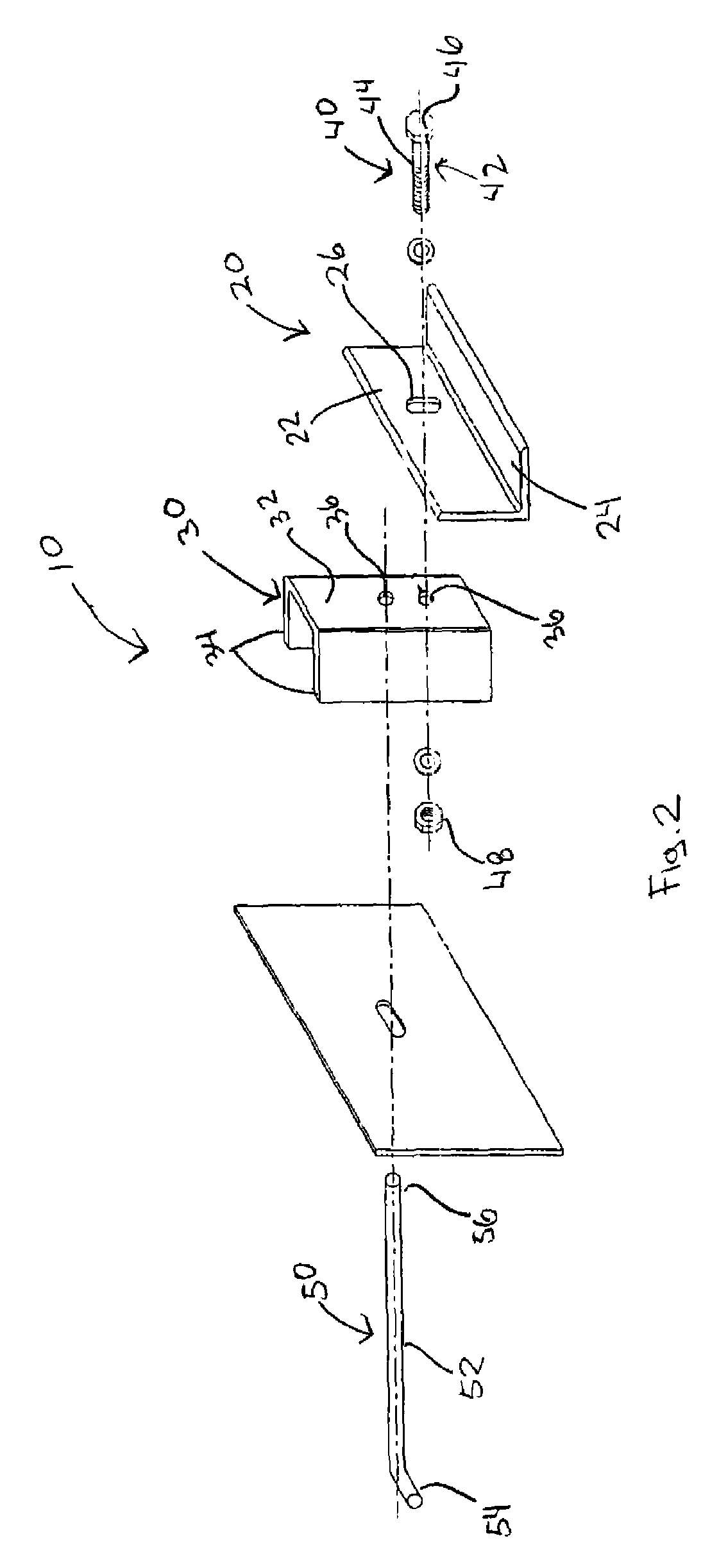

A method for constructing factory prefabricated and finished load bearing wall panels and monolithic ceiling / floor sections and modules comprised of the same for use in a single family or single story building as well as a multi-level and multi-unit building. The integrally formed wall panels are constructed of modified steel studs, rigid insulating material, and metal lathe and are factory finished with plaster or stucco like material. A void is defined by the modified steel studs window casings and door jambs. Upon erection and assembly at the job site, steel rebar is placed in such voids that are then filled with concrete, thereby eliminating the need for any additional concrete form work.

Owner:REYNOLDS MILTON

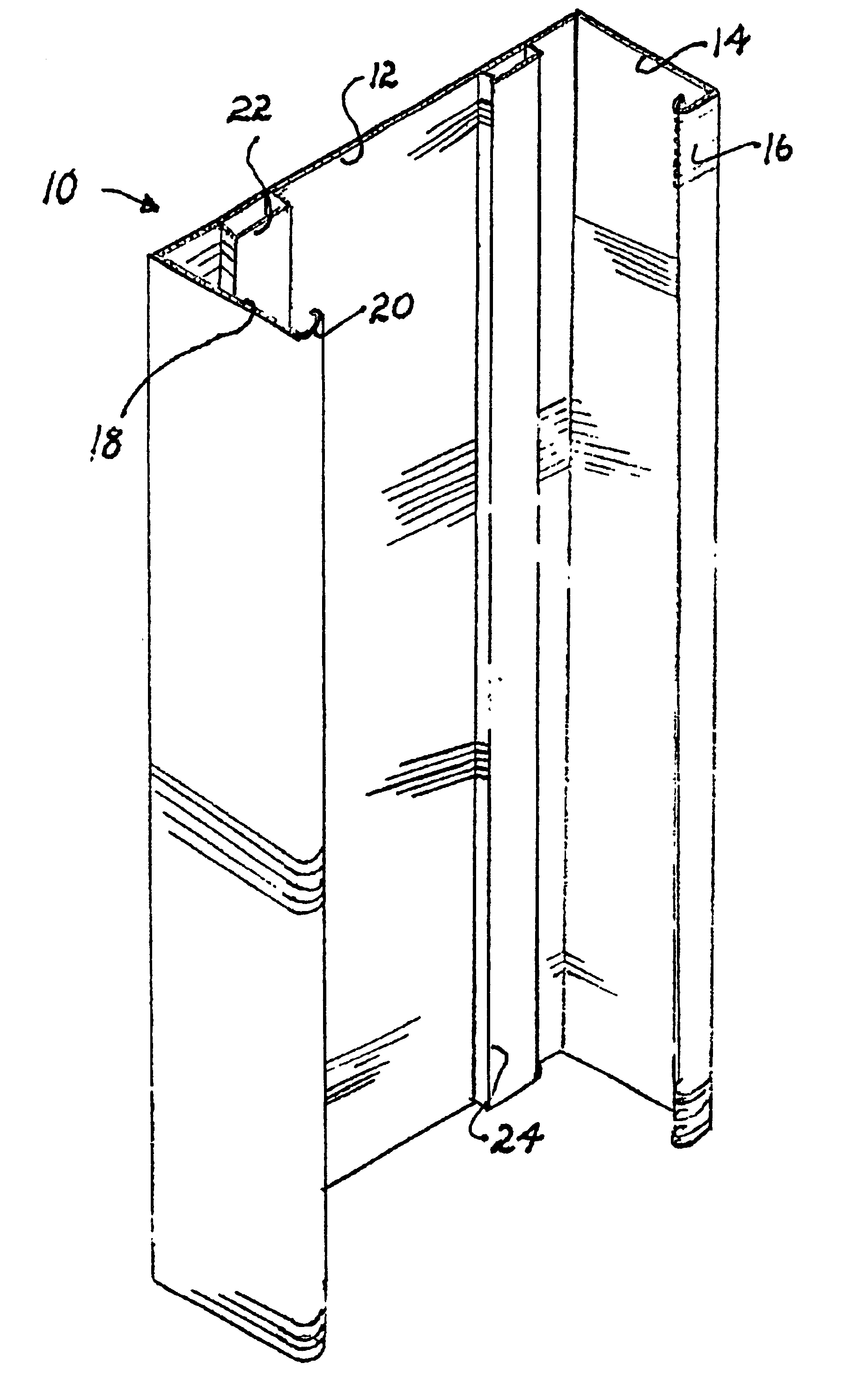

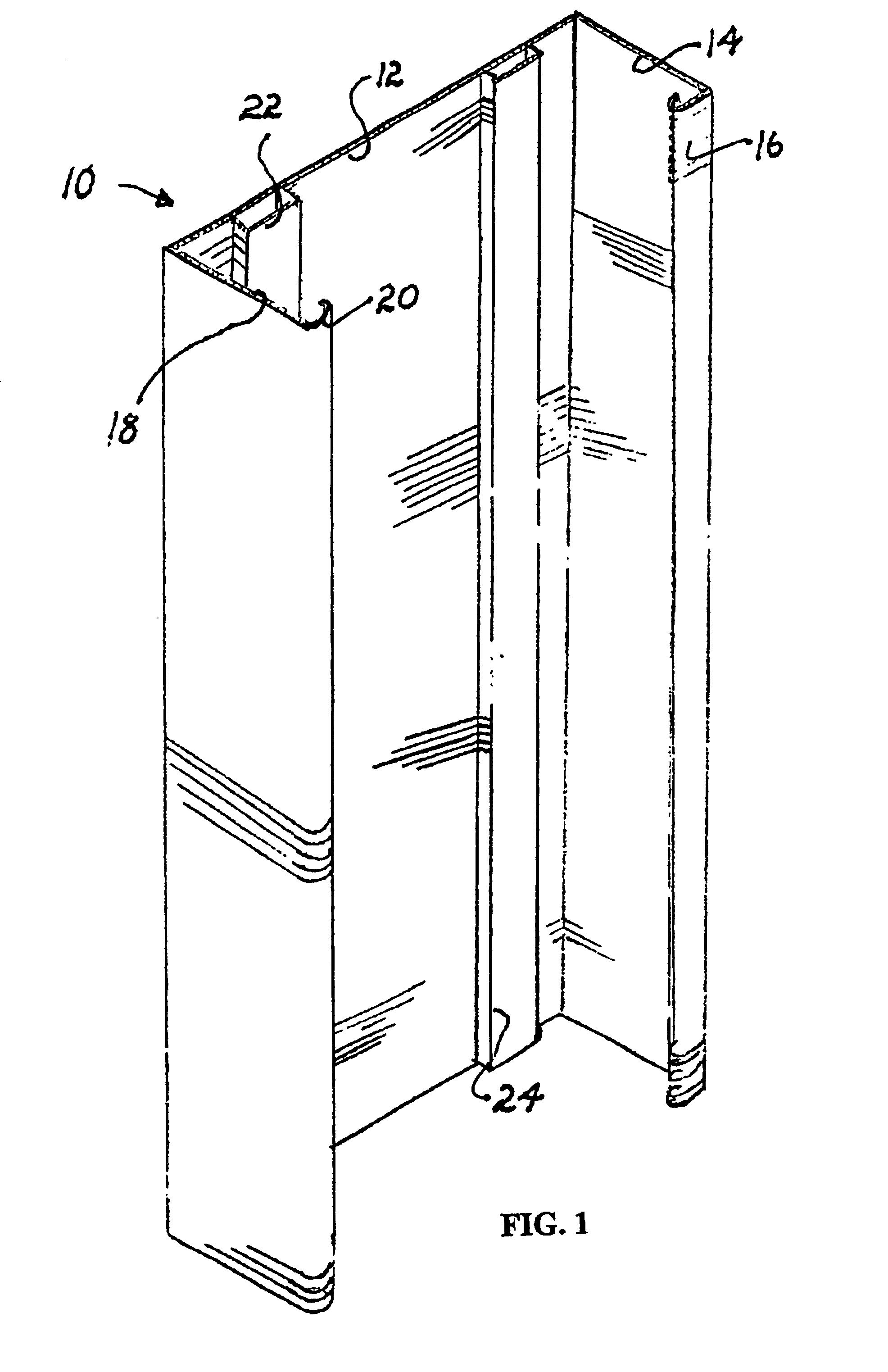

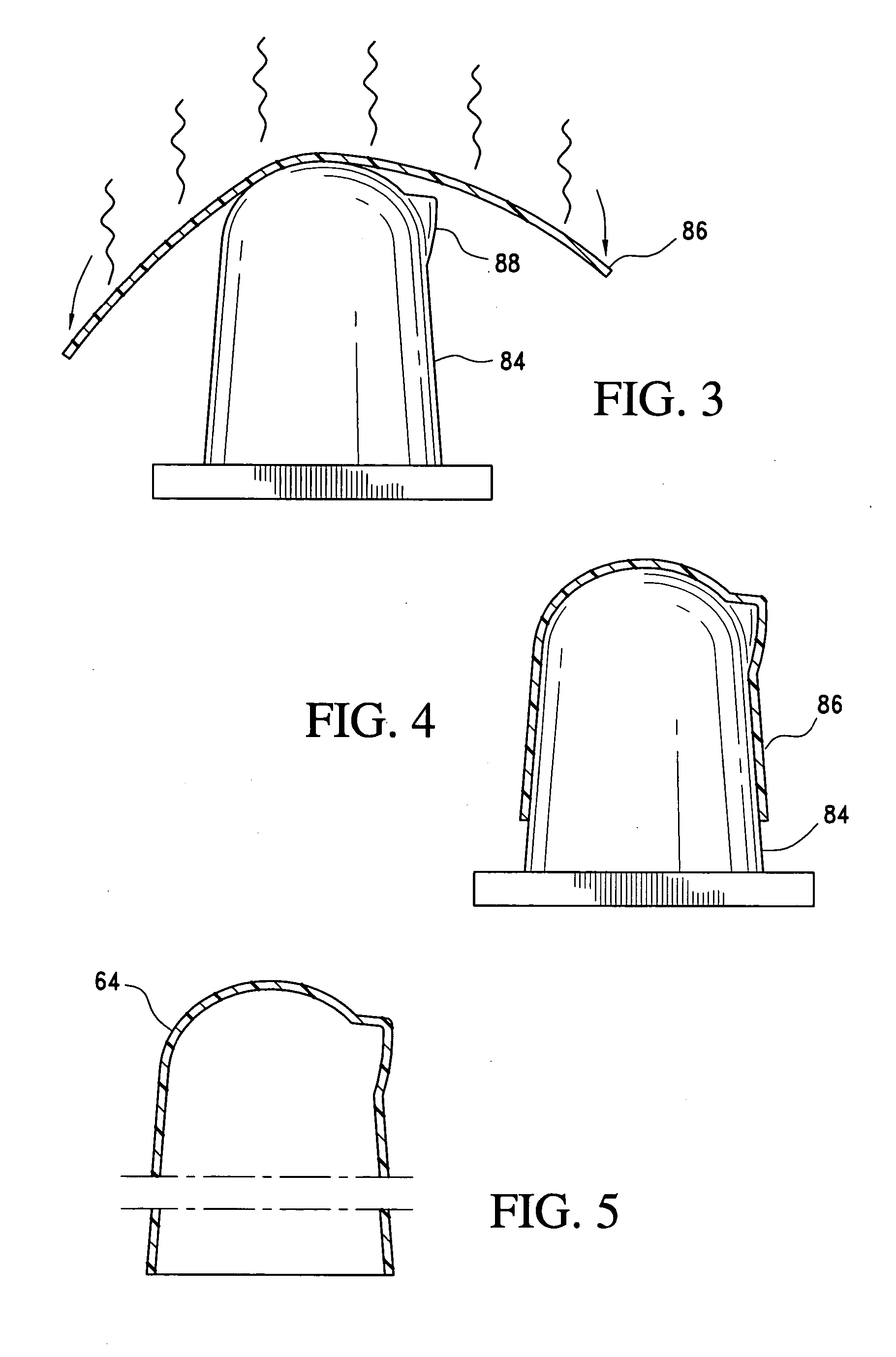

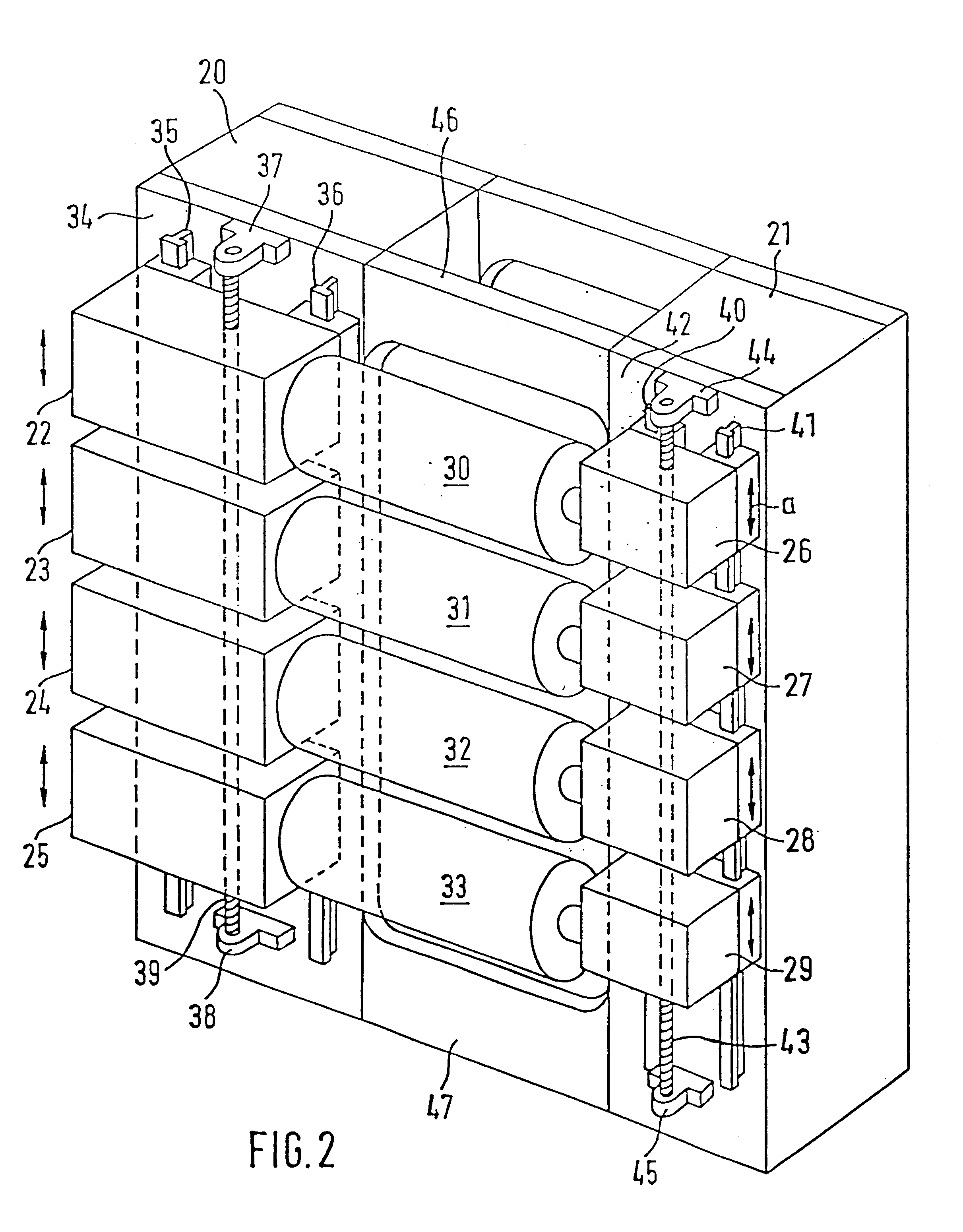

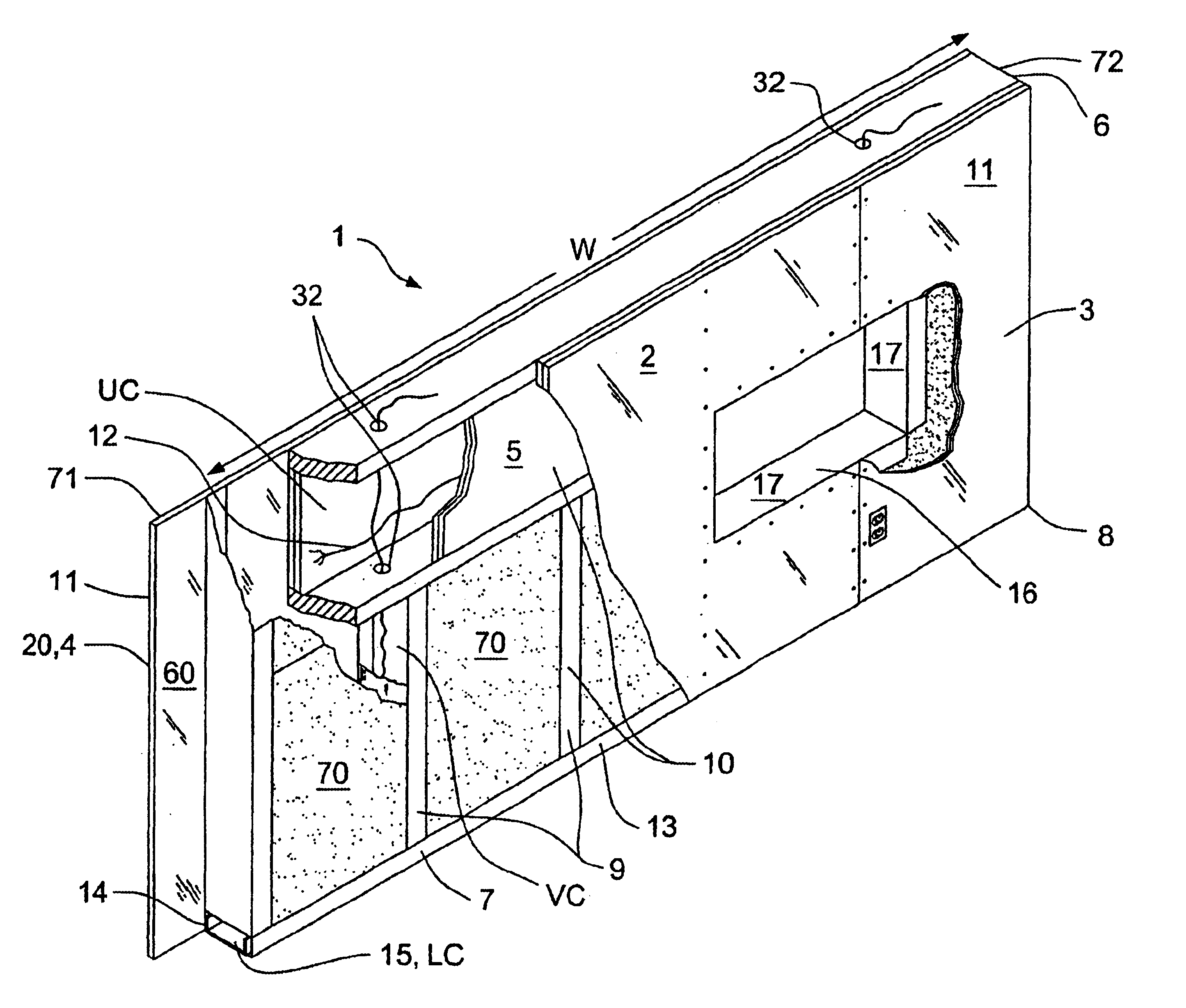

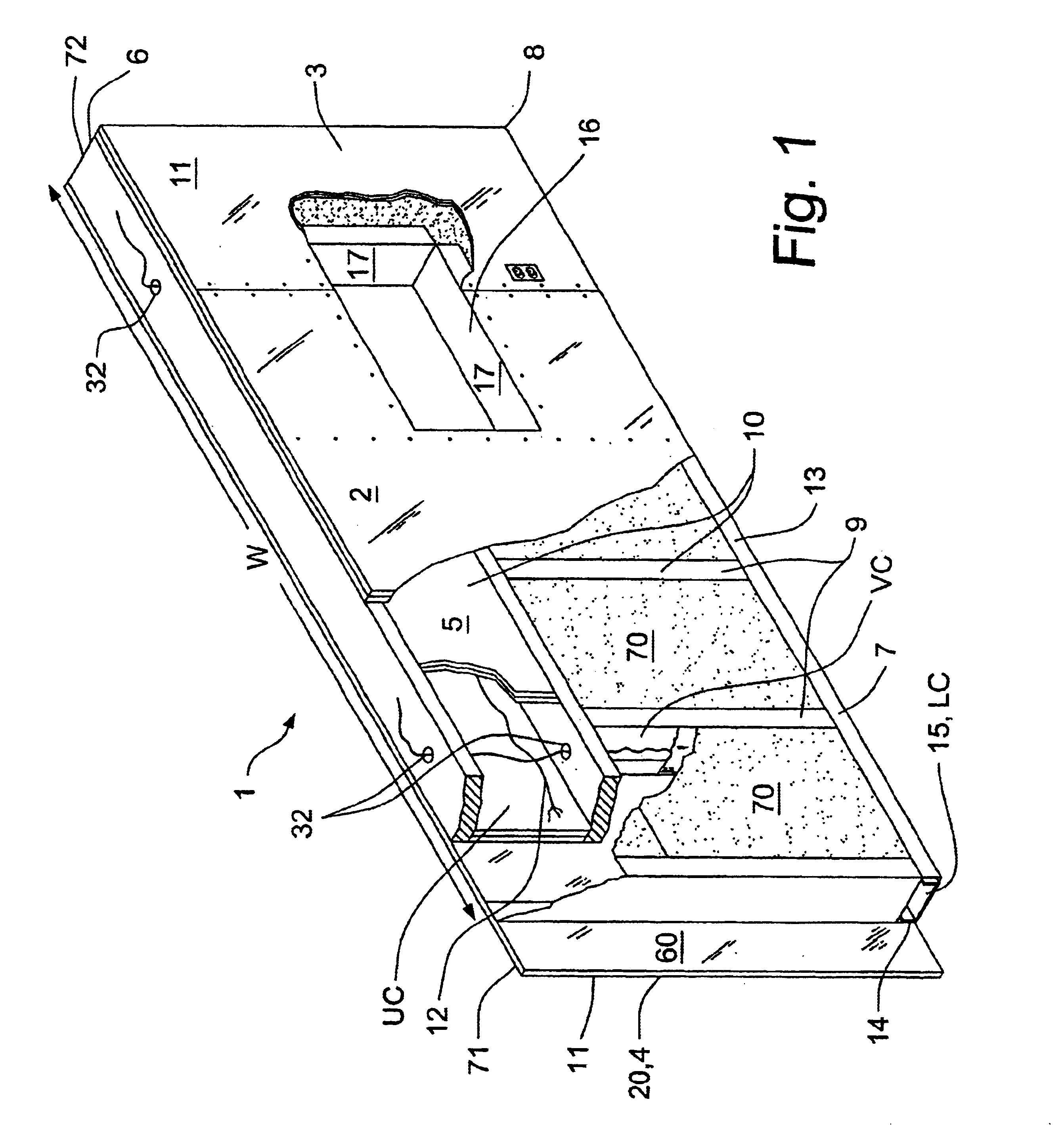

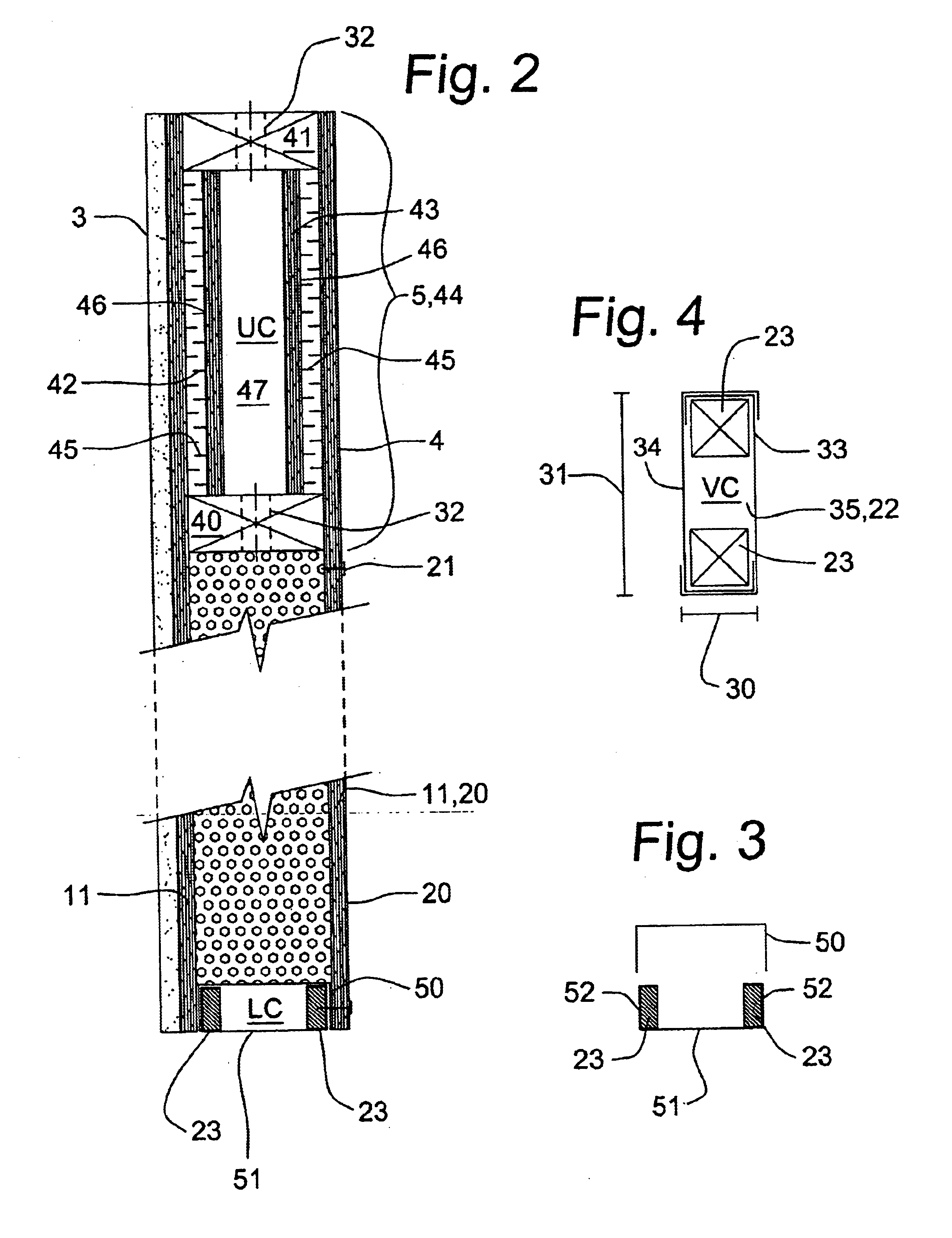

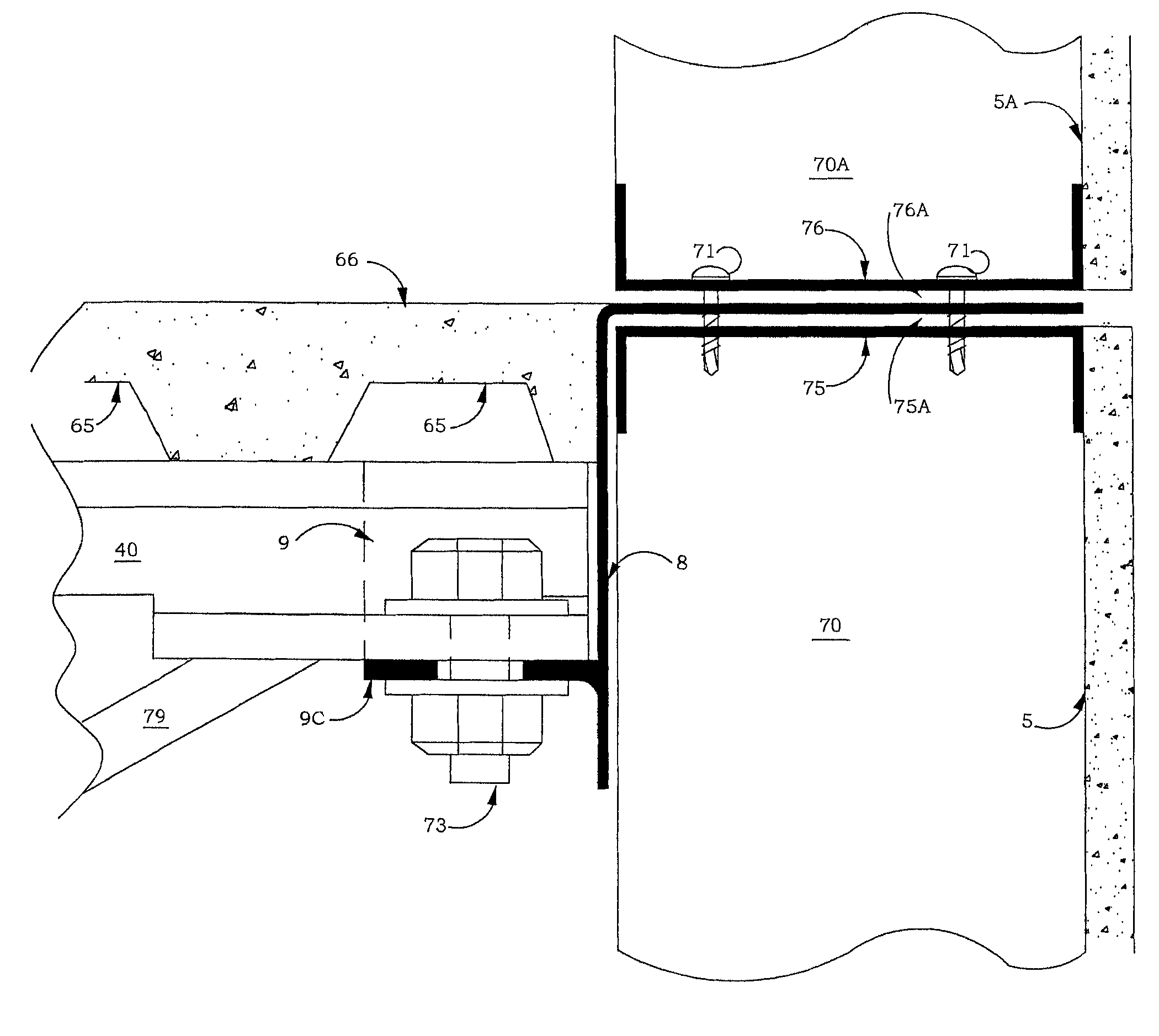

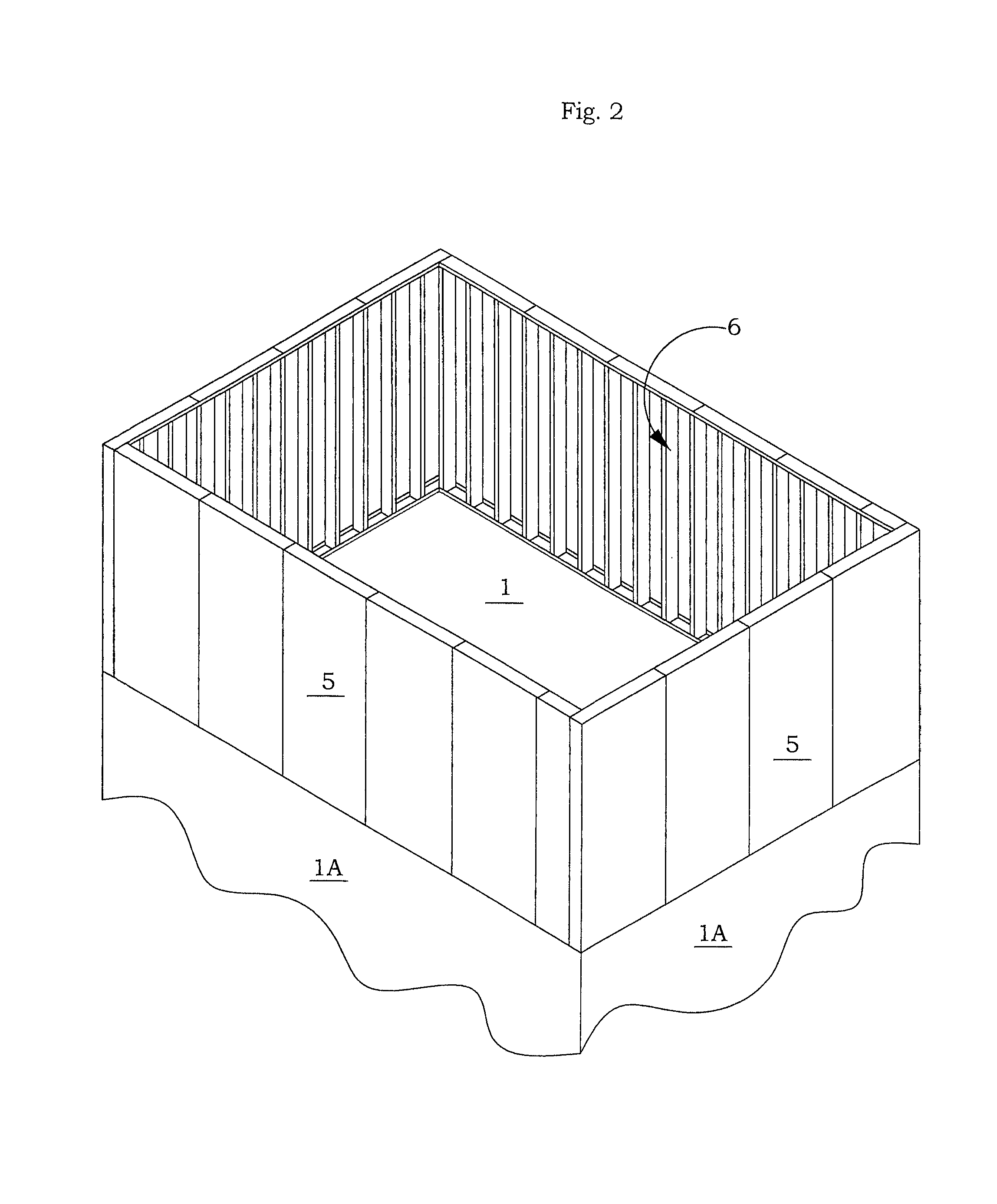

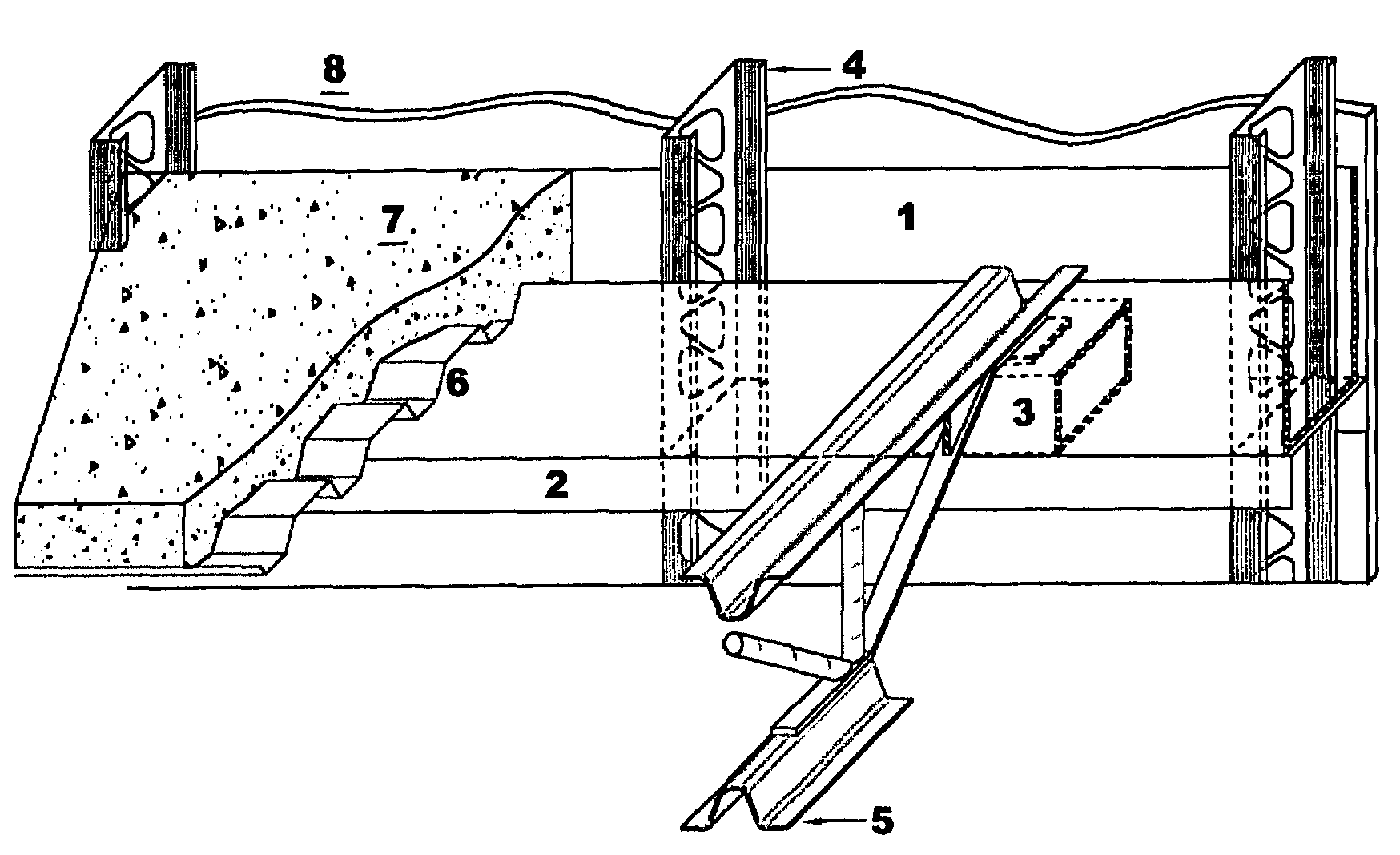

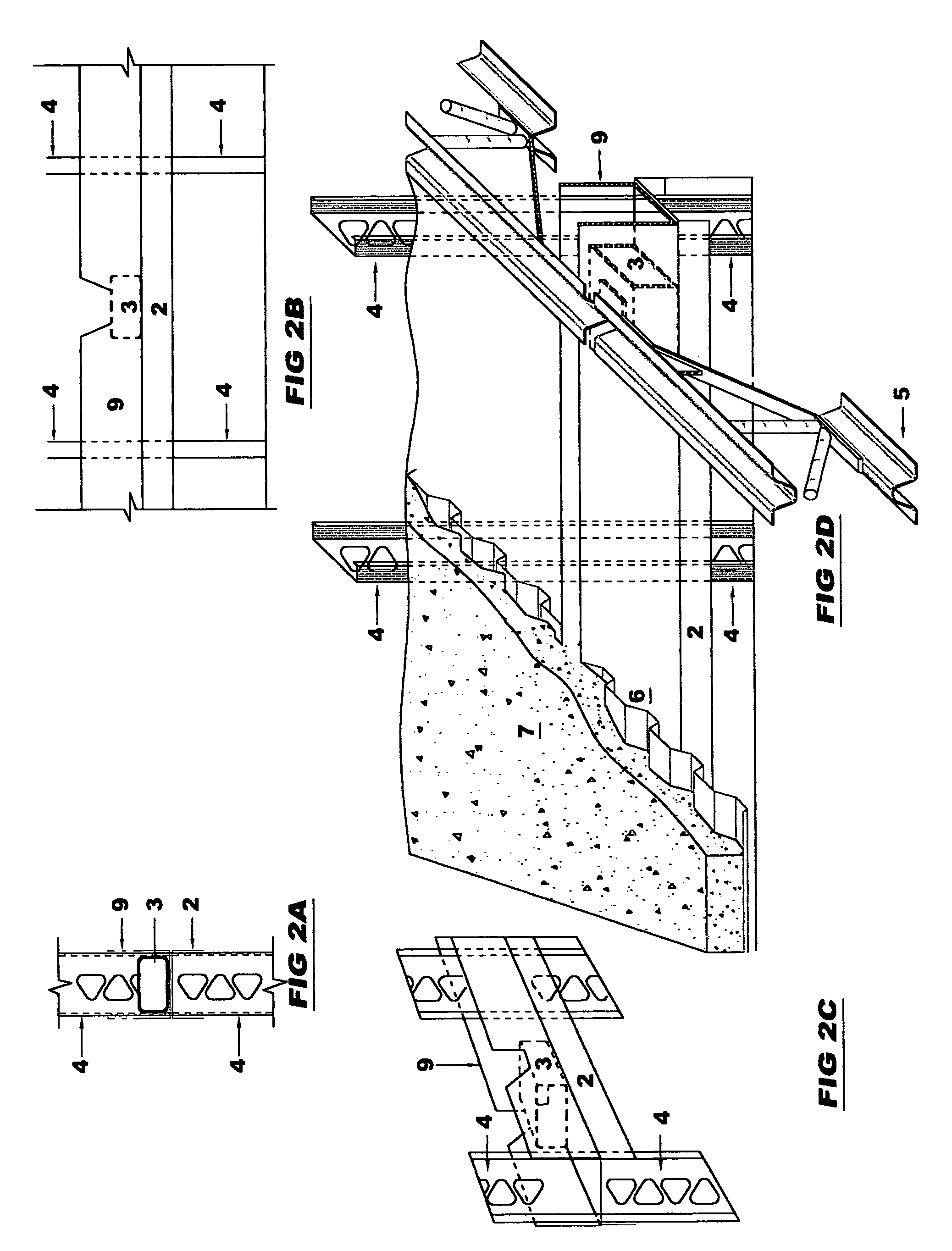

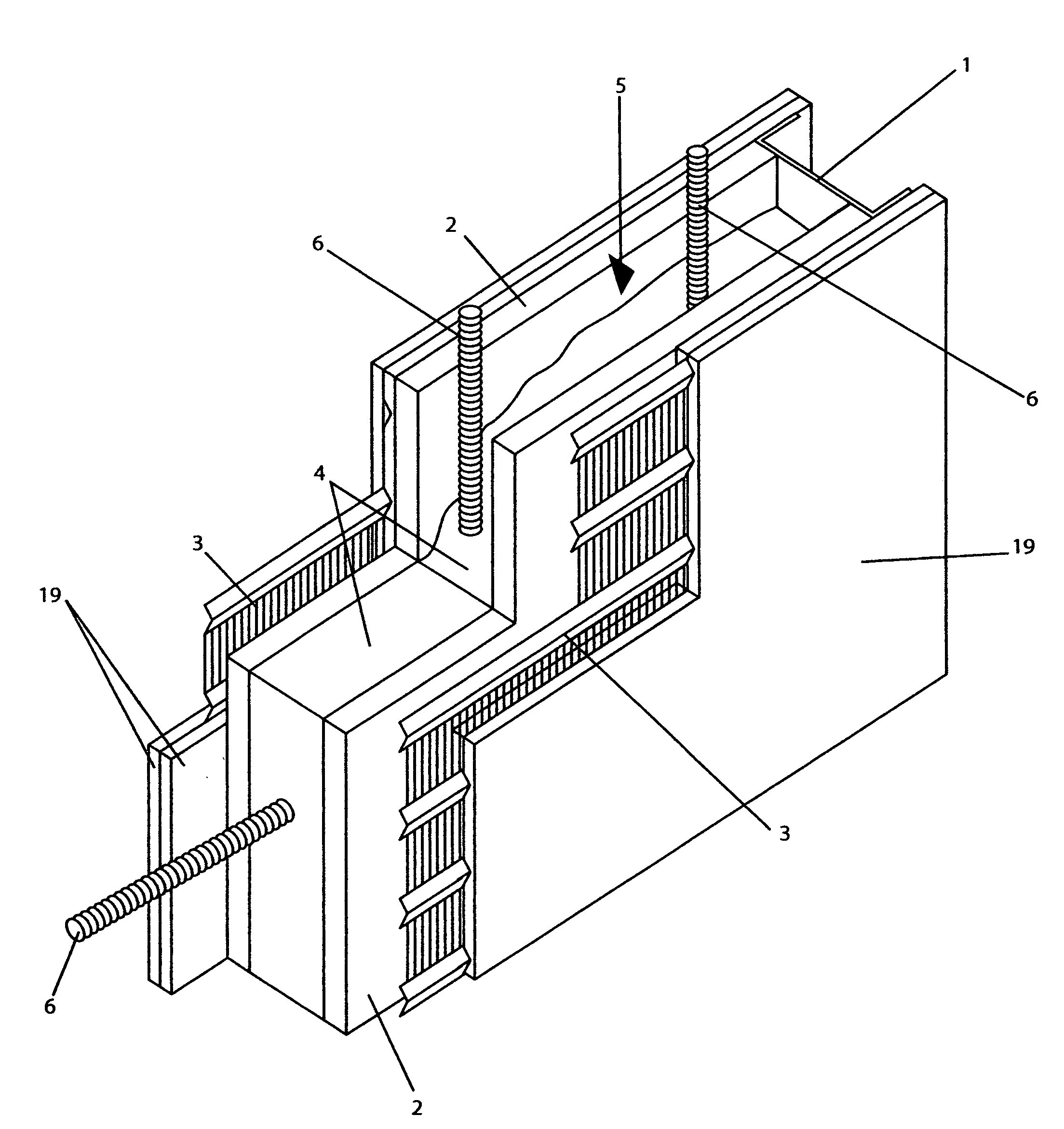

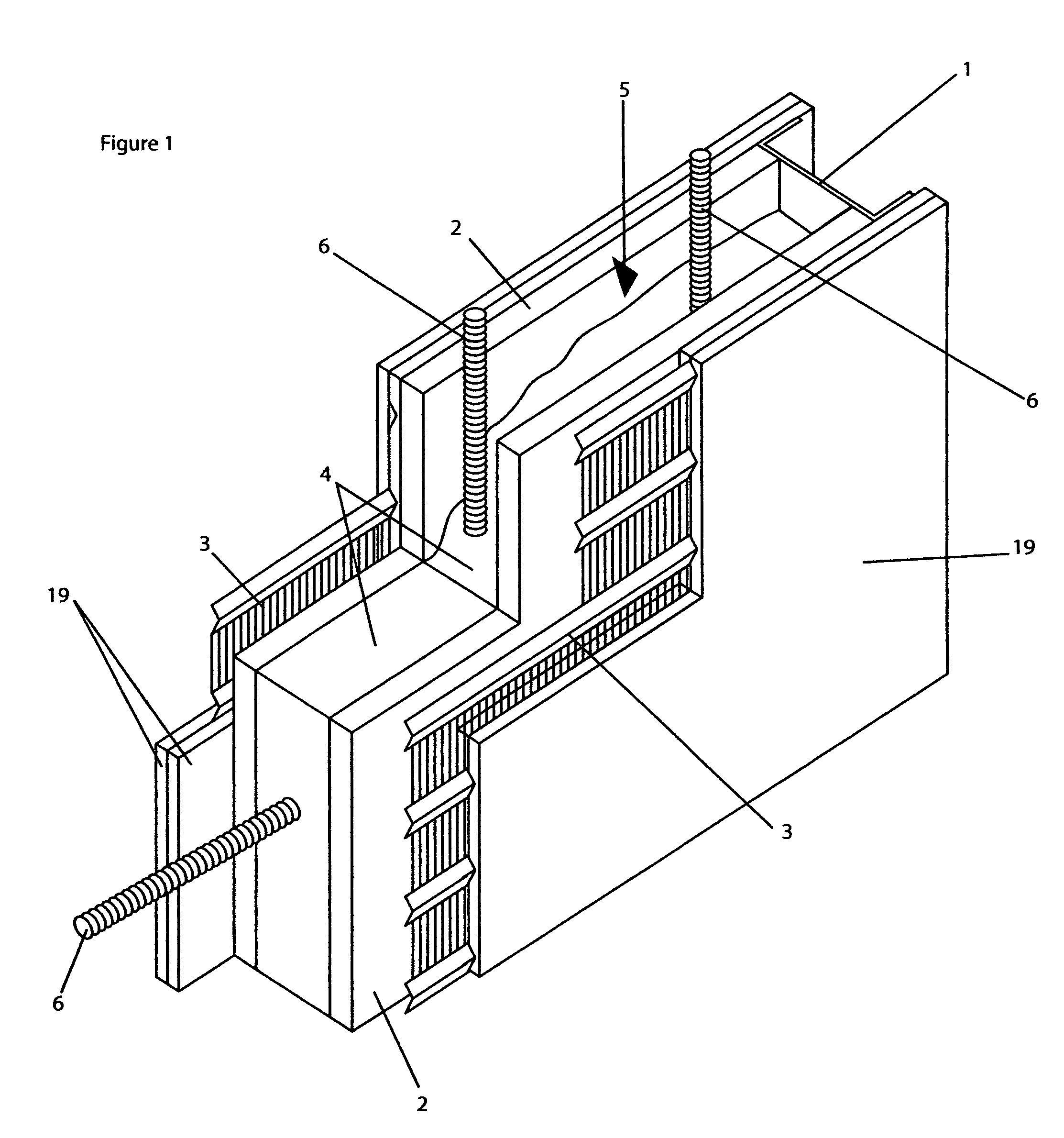

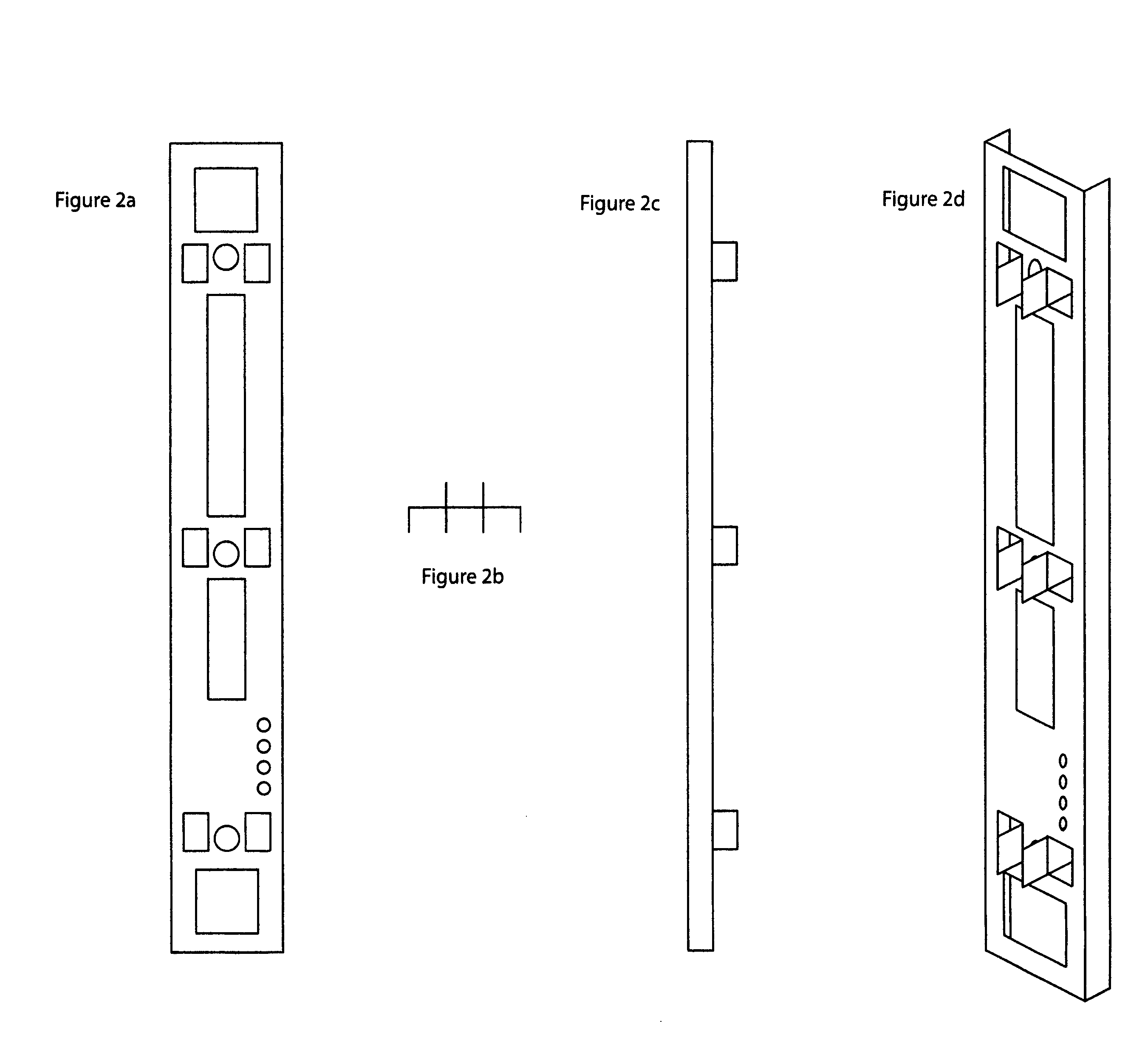

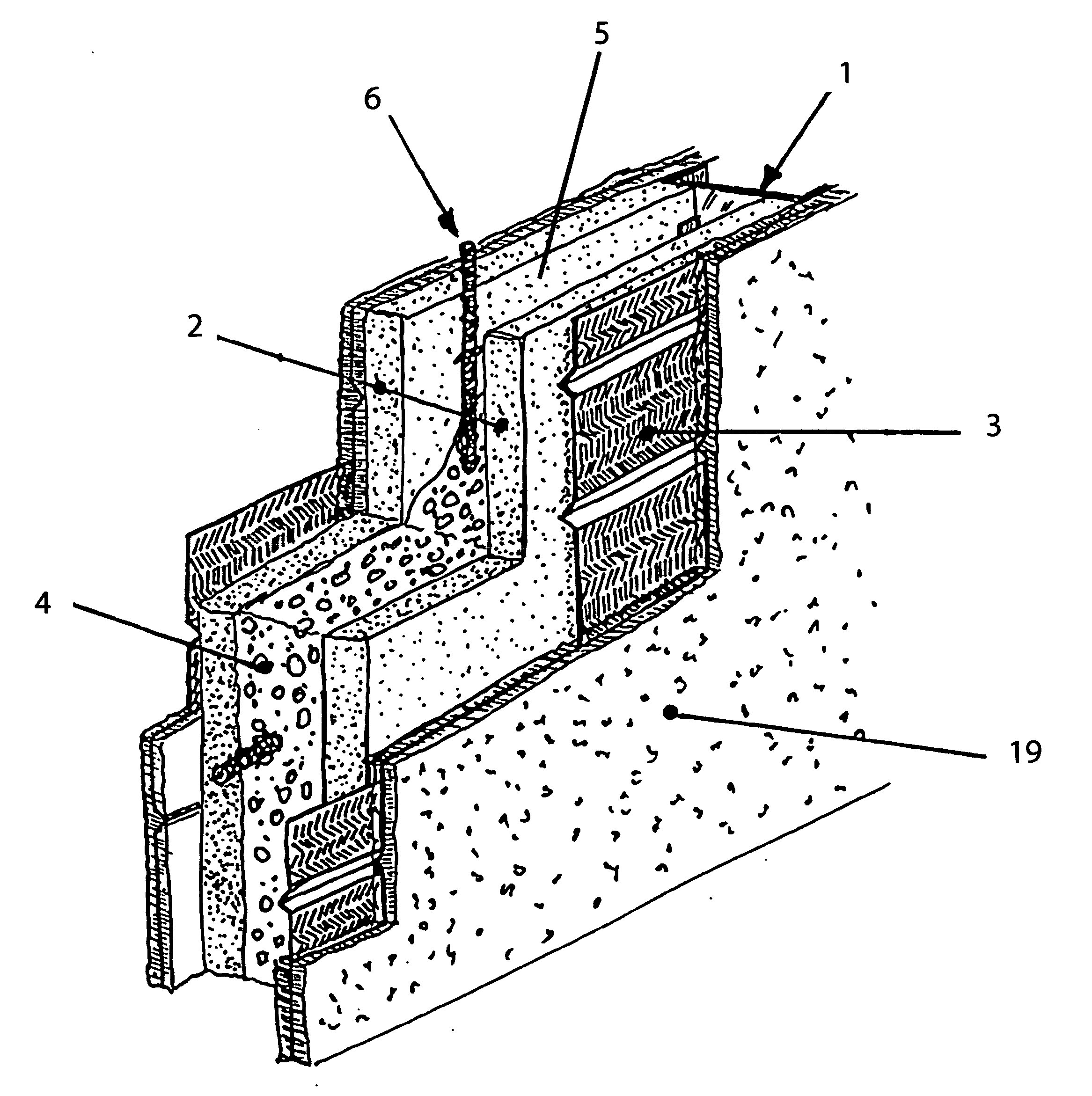

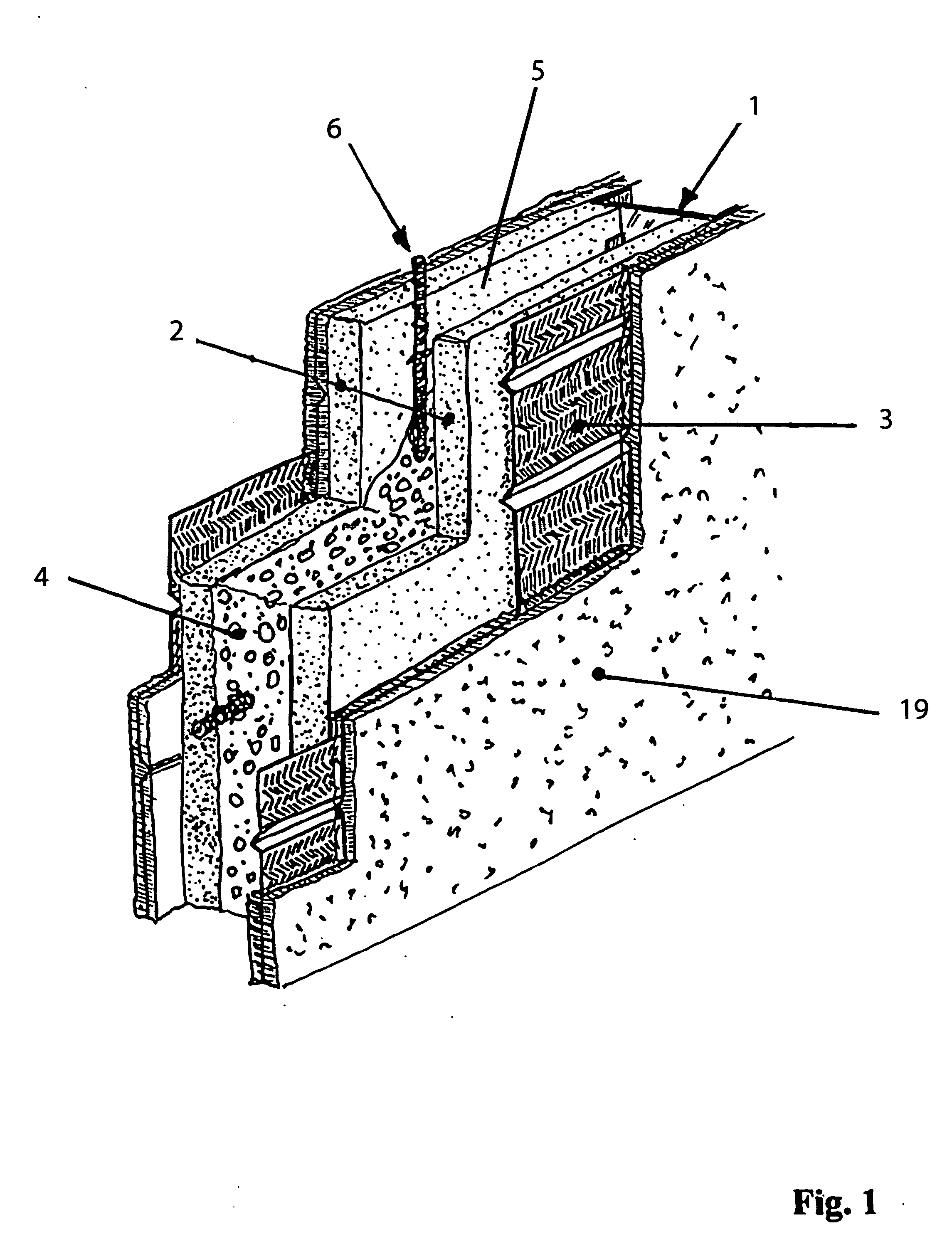

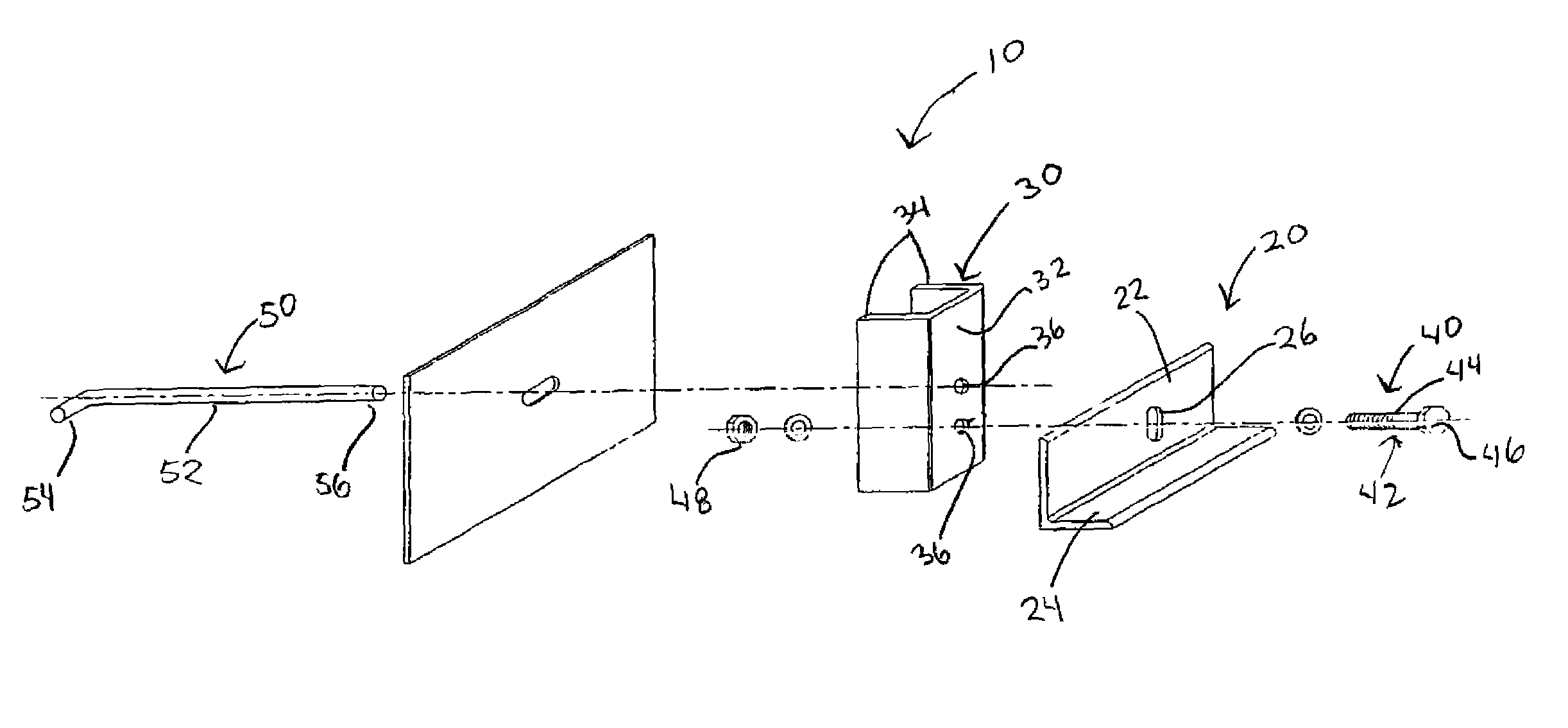

Load bearing wall formwork system and method

InactiveUS20080168734A1Building roofsRoof covering using tiles/slatesLoad-bearing wallMechanical engineering

A load bearing wall formwork system and method are disclosed. The load bearing wall formwork system comprises a unique clip assembly for joining two or more substantially planar structures, such as a wall panel, in a spaced apart manner and providing a space there between for placement of a flowable material. The clip assembly comprises a first clip member having a first side for attachment to the wall panel, a second side and an opening positioned between the first and second sides, as well as a second clip member, engageable with the first clip member, having a first side for attachment to a second wall panel, a second side and an opening positioned between the first and second sides. The openings provided in the first and second clip members are aligned when the clip members are engaged. A connecting member is insertable into the aligned openings of the first and second clip members, connecting the first and second clip members together. A wall formed by the foregoing components and a method of assembling a wall formwork are also disclosed.

Owner:THE PLYCEM

Integral forming technology, a method of constructing steel reinforced concrete structures

A method for constructing factory prefabricated and finished load bearing wall panels and monolithic ceiling / floor sections and modules comprised of the same for use in a single family or single story building as well as a multi-level and multi-unit building. The integrally formed wall panels are constructed of modified steel studs, rigid insulating material, and metal lathe and are factory finished with plaster or stucco like material. A void is defined by the modified steel studs window casings and door jambs. Upon erection and assembly at the job site, steel rebar is placed in such voids that are then filled with concrete, thereby eliminating the need for any additional concrete form work. The integrally formed monolithic ceiling / floor panels are constructed of a U-shaped “gull wing” steel joist, Styrofoam, metal lathe, plaster or stucco like material, and concrete and are factory finished with plaster or stucco type materials. Sections are assembled to create modules. A module is made up of four wall sections and one ceiling / floor section. The ceiling of one module will function as the floor of the module above. The module, which is hauled and erected at the job site, does not have either a bottom or a floor. The ceiling / floor section, serving as the top, provides a work platform for tradesmen in lieu of scaffolding. The gull wing joists can also be installed on a framing table in the upside-down position such that they will function as roof rafters. Rigid insulation is added next and then a pre-finished sheet steel roof membrane is added as a water proofing membrane.

Owner:REYNOLDS MILTON

Structural lintel assembly and building construction method using the same

A prefabricated form assembly for making a concrete floor is disclosed. The form comprises an elongated form plate having a front for forming and retaining a flowable concrete material before it sets, anchor elements extending from the back face of the form plate, and being destined to be embedded into the concrete floor; and an L-shaped lintel having a back wall connected to the front face of the form plate and a bearing wall for supporting a masonry wall. Advantageously the construction of a concrete floor adapted to structurally retain a masonry wall using prefabricated form assemblies according to the invention no more requires the use of different groups of workers from different building trades as in the prior art, only one group of workers is required.

Owner:VIEIRA JOSE

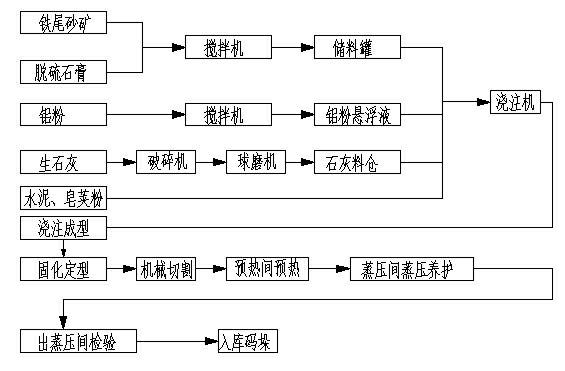

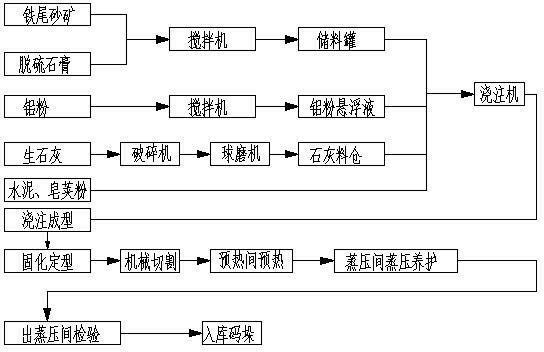

Production method for iron tailing sand aerated concrete building block

InactiveCN102603358AWide variety of sourcesEasy dischargeSolid waste managementCeramicwareThermal insulationWater vapor permeability

The invention discloses a production method for an aerated concrete building block, in particular to a production method for an iron tailing sand aerated concrete building block. The production method for an iron tailing sand aerated concrete building block comprises the following steps of: preparing iron tailing mortar material, wherein the concentration of added desulfurized gypsum is 50-60%; preparing aluminum powder solution of which the concentration is 20-25%; burdening at the following mass ratio: 81.54% of iron tailing mortar, 10.58% of lime powder, 5.88% of cement, 1% of Chinese honey locust powder and 1% of aluminum powder solution; and pouring, procuring, demoulding, cutting for shaping, and steaming for curing. The production method for the iron tailing sand aerated concrete building block has the outstanding characteristics that the abandoned iron tailing sand serves as main raw material for production, and the production method has the advantages of wide raw material resource, high waste use ratio and low production cost and is easy to popularize and apply. Because the product weight is low, the iron tailing sand aerated concrete building block is suitable for the filling wall of a high-rise building and the load bearing wall of a low-rise building; because the iron tailing sand aerated concrete building block has good thermal-insulation performance, the thickness of the wall body can be reduced; because the iron tailing sand aerated concrete building block has good water vapor permeability, moisture on the wall body is easy to discharge; and the iron tailing sand aerated concrete building block has high strength which is equivalent to the compressive strength of No.125 clay bricks and limesand bricks.

Owner:ZUNHUA HAIXIANG NEW BUILDING MATERIAL

Ecological plate made of straws and forestal residues and method for preparing ecological plate

InactiveCN102581918AReduce manufacturing costRealize comprehensive utilizationFlat articlesDomestic articlesFiberEnvironmental resistance

The invention discloses an ecological plate made of straws and forestal residues and a method for preparing the ecological plate, which relate to the technical field of building decoration materials. The ecological plate consists of components, by weight, including from 45 to 48 parts of fine straw fibers, from 45 to 48 parts of fine forestal residue fibers, from 2 to 4 parts of adhesive, from 1 to 3 parts of flame retardant and from 1 to 3 parts of water repellent, and the ecological plate is processed by the aid of working procedures including chopping and crushing, preparing the fibers, beaching, adding the additives (the flame retardant, the water repellent and the adhesive), mixing and stirring, drying, briquetting and forming, adhering a decorative plate, forming a commercial plate and the like. The ecological plate has various advantages of low production cost, ecological property, environmental protection, high density and strength, wide material source, waterproofing, fireproofing and the like, is a medium and high-density composite fiber plate, can be widely applied to non-load bearing wall materials in frame structure and steel structure engineering, wall partitions for indoor decoration, wall partitions of factories, shopping malls and enclosing walls of plant areas, walls of trailer coaches and farm houses and the like, and is an environment-friendly product which is widely popularized according to wall modification policy of the country.

Owner:HUNAN ZHONGKE AGRI

Foam concrete composite heat preservation wall body with concrete blocks and construction method thereof

InactiveCN102691363AWidely used valueCause secondary pollutionWallsHeat proofingFoam concreteBuilding energy

The invention provides a foam concrete composite heat preservation wall body with concrete blocks, belonging to the field of building energy conservation. The foam concrete composite heat preservation wall body is used for buildings, such as dwellings, workshops, hotels and the like, and is particularly suitable for new rural reconstruction. The wall body provided by the invention is prepared by constructing different combinations of five concrete precast blocks with different shapes with cement mortar. According to a quantity of floors, the wall body is reinforced, and a wall post and a ring beam can be borne by using wall body reinforcing ribs with different quantities, different manners and different specifications. Ordinary concrete is cast at positions of posts and beams in the hollow wall body, and foam concrete with a concentration of 200-400 kg / m<3> is cast at the other positions, so as to form the heat preservation and sound insulation wall body, and carry out mortar plastering and decoration. When the wall body provided by the invention is more than or equal to 250 mm thick, an average volume weight of the wall body is less than or equal to 600 kg / m<3>, a heat conduction coefficient is less than or equal to 0.4 W / (m2.K), and a pressure-resistant strength of a wall surface is more than or equal to 20 MPa. The wall body provided by the invention has the advantages of convenience and rapidness of construction. Furthermore, the wall body is firm, durable, mild, environment-friendly and safe.

Owner:洛阳原生建筑工程技术有限公司

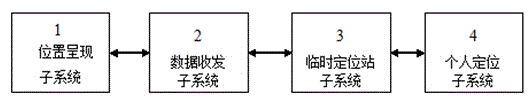

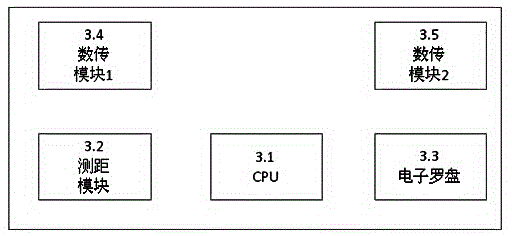

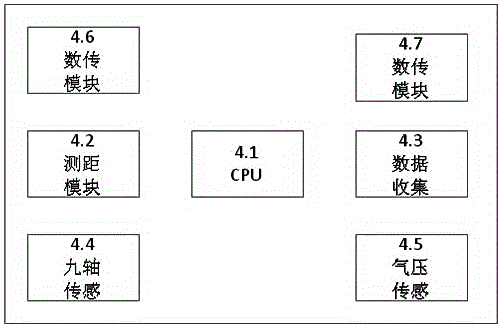

Emergency rescue personnel location system and emergency rescue personnel location method

ActiveCN104457750AEffective penetrationRealization of wireless distance measurementNavigation by speed/acceleration measurementsEmergency rescueEngineering

The invention discloses an emergency rescue personnel location system and an emergency rescue personnel location method. The emergency rescue personnel location system comprises a position presenting subsystem, a data receiving-transmitting subsystem, a temporary location station subsystem and a personal location subsystem, wherein the temporary location station subsystem comprises a plurality of temporary location stations; the personal location subsystem comprises a plurality of personal location modules, the data receiving-transmitting subsystem is respectively connected with the position presenting subsystem and the temporary location stations, and the temporary location stations are connected with the personal location modules. The ranging distance in an open space can reach 1km, and the ranging precision is less than or equal to 3cm under 99% situation. The emergency rescue personnel location system can effectively penetrate through a load-bearing wall with the thickness of 30cm inside a room; even in a large-sized building, the effective transmission of the data also can be guaranteed. Under the outdoor situation, the transmission distance in the open space can reach 2 km, the transmission distance is more than 300m when an obstacle exists, and in order to guarantee sufficient diffraction performance, on the aspect of the wireless data transmission, a Mesh network working at 433Mhz is adopted.

Owner:NANJING WOXU COMM TECH

Boron slag aerated brick and preparation method thereof

The invention provides a boron slag aerated brick. The boron slag aerated brick is prepared from the raw materials: 20 to 30 weight parts of boron slag, 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 4 to 6 weight parts of modified sepiolite powder, 5 to 10 weight parts of powdered carbon, 5 to 10 weight parts of ceramics factory waste, 5 to 10 weight parts of calcium carbonate powder, 10 to 15 weight parts of lime, 0.1 to 0.3 weight percent of triethanolamine lime, 4 to 5 weight parts of gypsum, 0.02 to 0.08 weight part of aluminum powder, nekal which is 3 to 5 percent based on the weight of the aluminum powder, 0.01 to 0.02 weight part of calcium bicarbonate, 2 to 3 weight parts of volcanic rock, 1 to 2 parts of lignocellulose, 0.3 to 0.5 weight part of soda ash, 1 to2 weight parts of white emulsion, 1 to 2 weight parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 weight parts of chitosan. Boron slag is added into the raw materials of the aerated brick, other conventional aids and modified aids are added, and the aerated brick processed by an appropriate process is low in cost, high in performance, achieves a cyclic economy effect of changing waste into wealth, and reduces pollution; and the processed aerated brick has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high intensity, and can be used for a non-load bearing wall body or a load bearing wall body.

Owner:任羚羊

Architectural structure system of preformed hollow load-bearing wall panel and construction method

The invention relates to an architecture systematism and a construction method for a precast hollow load-bearing wall panel comprising a column and a collar beam of cast-in-situ armored concrete, a precast interior or external wall panel and a floor slab equipped in between the column and the collar beam, and a roof slab equipped on the most top, characterized in that the external wall panel is abearing plate with heat-retaining function, and the interior wall panel is a bearing plate of lightweight armored concrete, while the inside of the interior and external wall panel is equipped with hollow holes whose upper and lower ends are inserted and casting fixed with anchor concrete bars preformed on the collar beam concrete bars. The first hollow hole on the side adjacent the column of theinterior and external wall panel is vertical interval inserted the anchor concrete bars on the column concrete bars, and fully pours the concrete. The invention can build a high-rise building with 6 floors and 18 meter height in an anti-seismic prevention region with 8 degrees, or a high-rise building with 7 floors and 21 meter height in an anti-seismic prevention region with 7 degrees, or a high-rise building with 8 floors and 24 meter height in an anti-seismic prevention region with 6 degrees.

Owner:冯葆纯 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com