Patents

Literature

120 results about "Weight-bearing ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

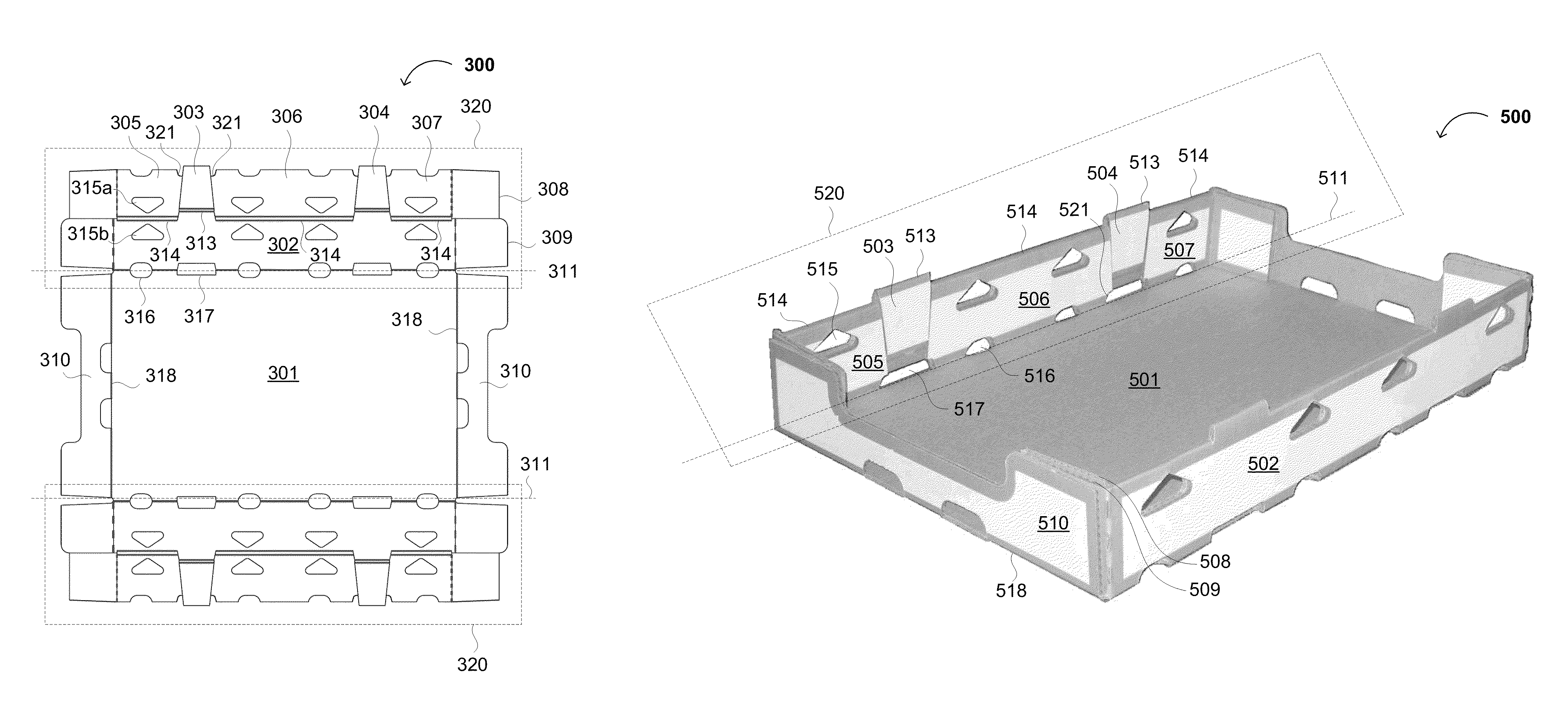

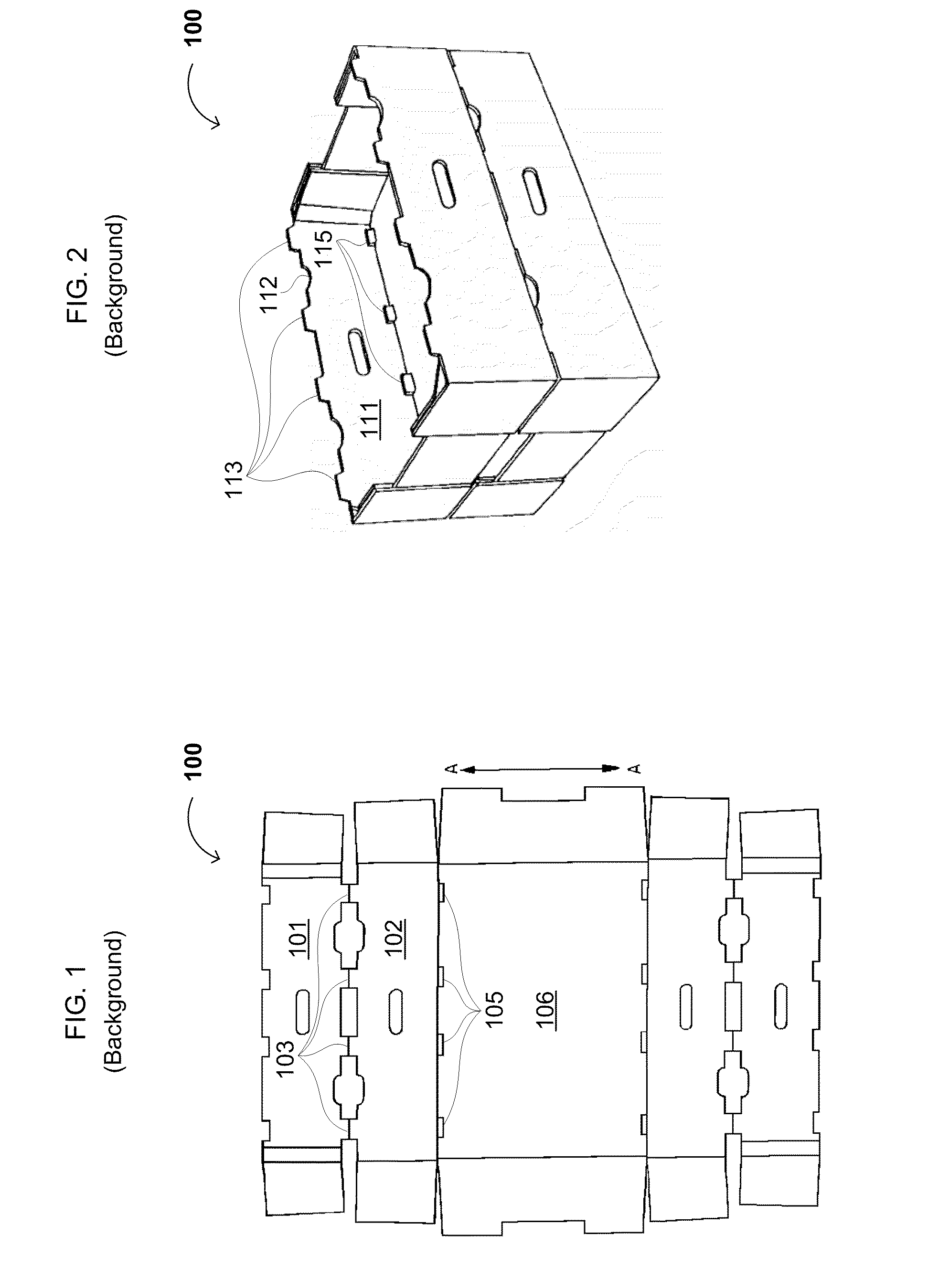

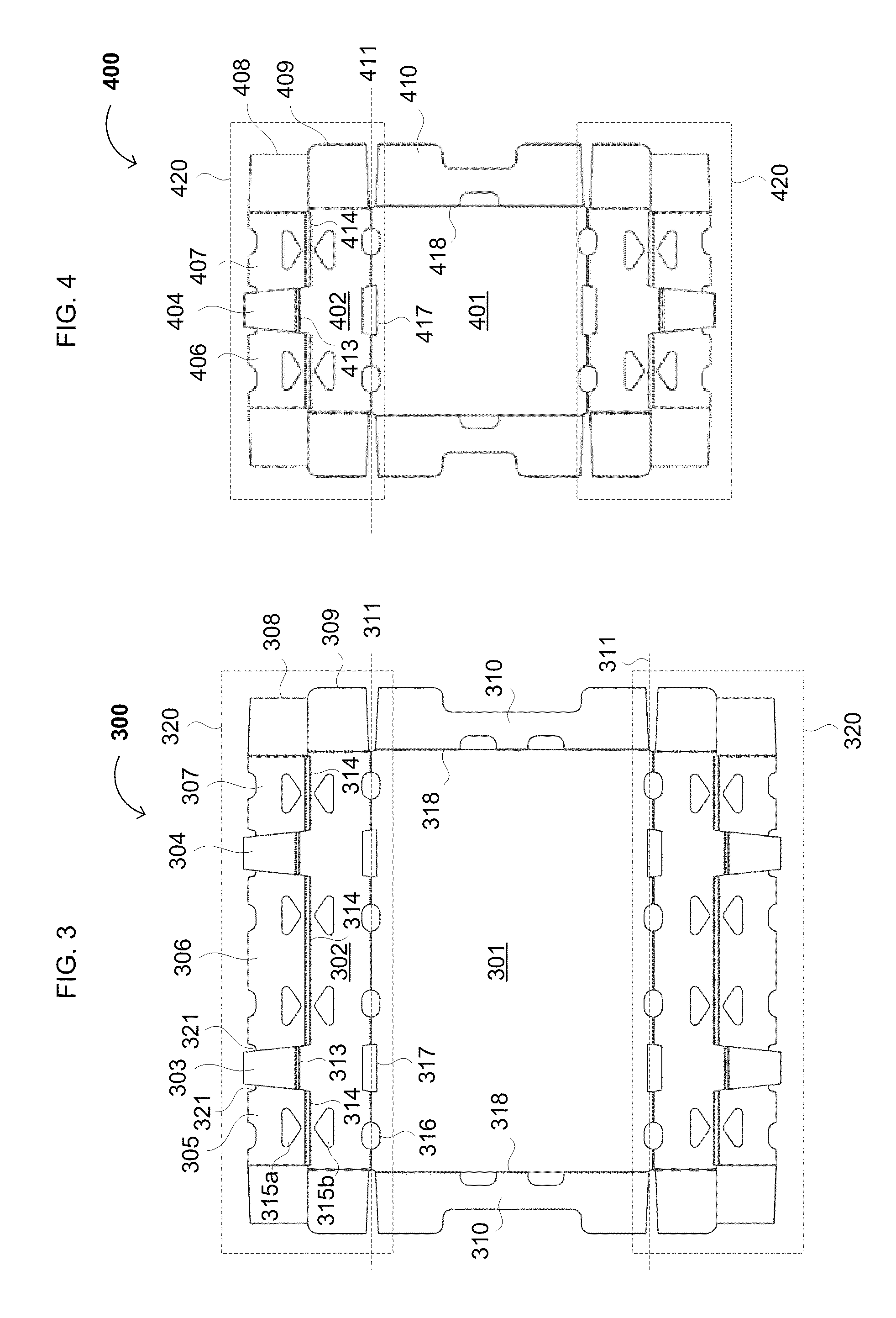

Stackable container and method for making the same

ActiveUS8079474B1Reducing moisture collectionRobust Design MethodPaper/cardboardTray containersWeight-bearing abilityLoad-bearing wall

A stackable container and blanks for forming a stackable container are disclosed. In one embodiment, a stackable container has (a) a base having two pairs of opposed base edges, (b) two first sidewall structures foldably attached to the first base edges at an angle of from about 90 degrees to about 100 degrees, and (c) two second sidewall structures. The second sidewall structures generally each include (i) a wall flap foldably attached to one of the base edges at an angle of from about 90 degrees to about 100 degrees, (ii) an index fold-down flap foldably attached to the wall flap at an angle of about 180 degrees, and (iii) a plurality of inner fold-down flaps foldably attached to the wall flap at an angle of about 180 degrees. Embodiments of the present invention can advantageously provide a reliable design approach for making a stackable container from a blank, whereby the weight-bearing ability and / or stackability of the container is improved, while also covering flutes on the load-bearing wall, thereby reducing moisture collection.

Owner:MAXCO SUPPLY

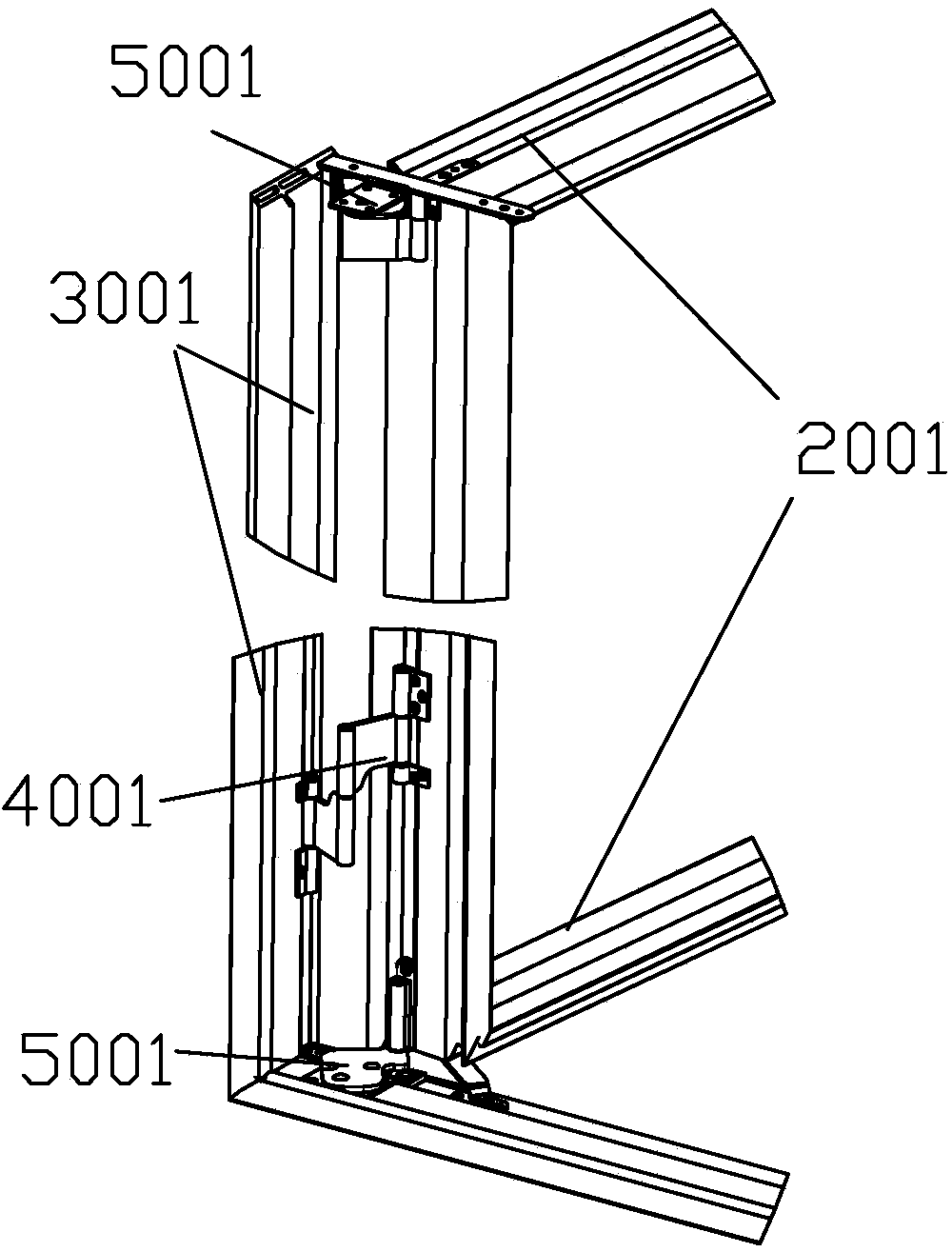

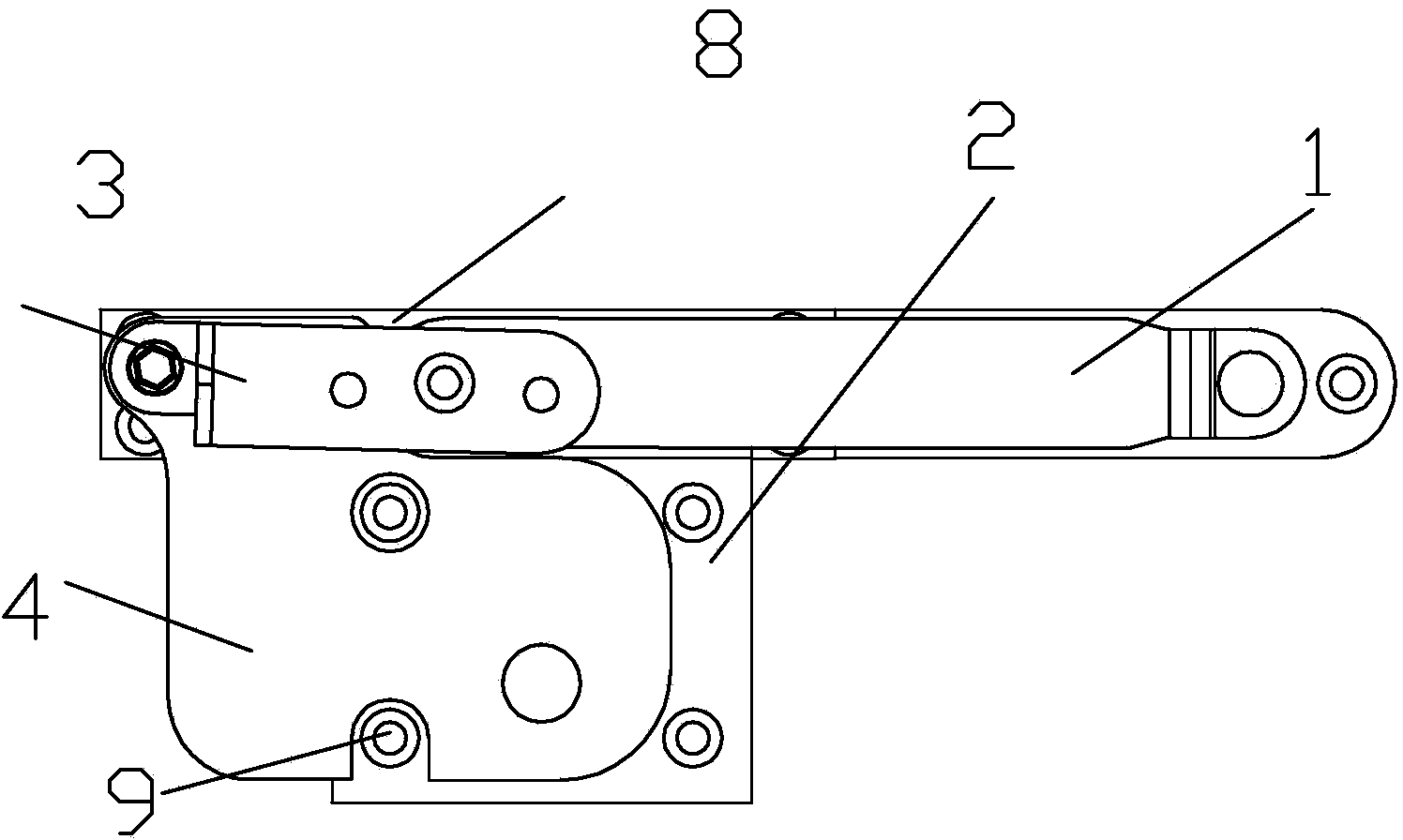

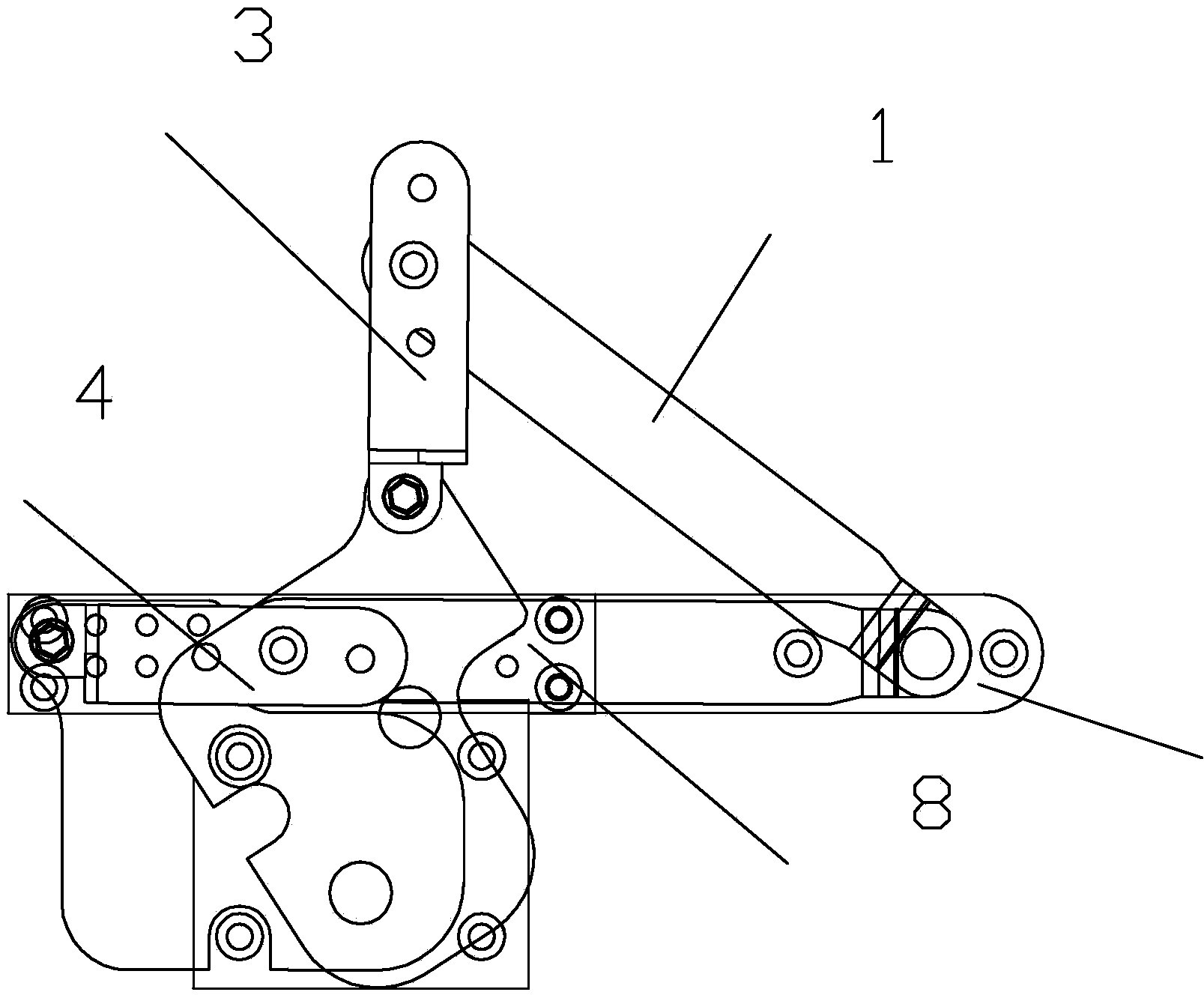

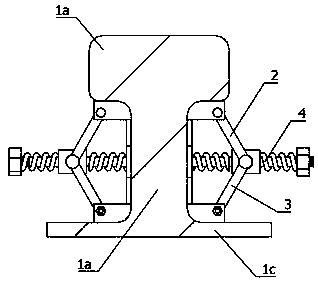

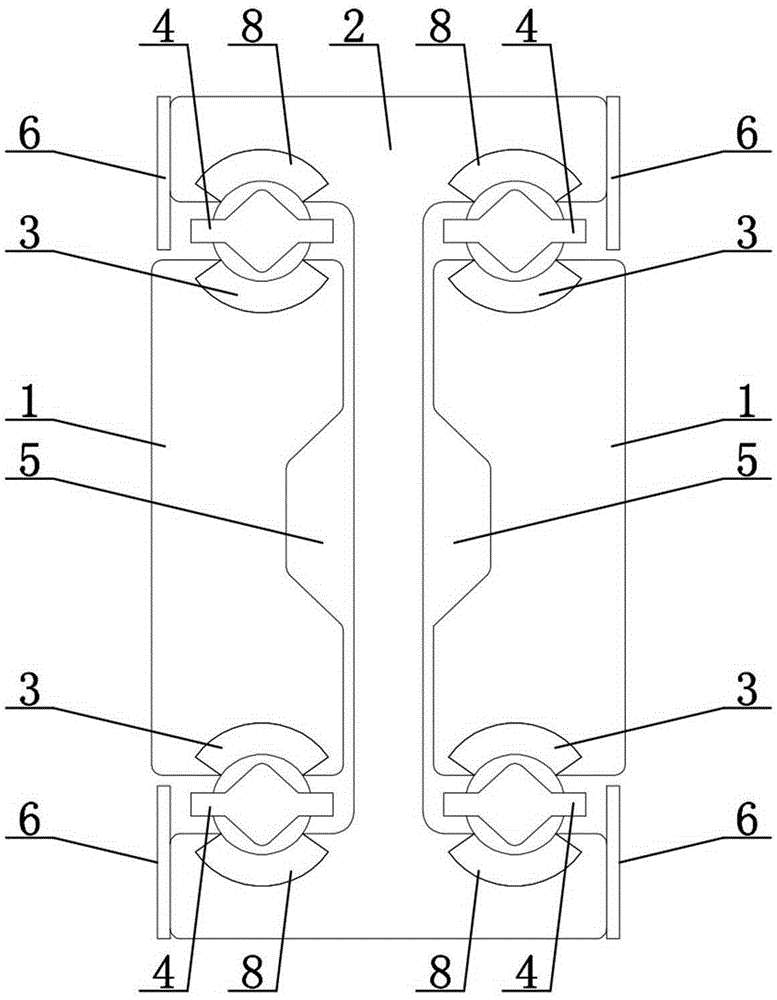

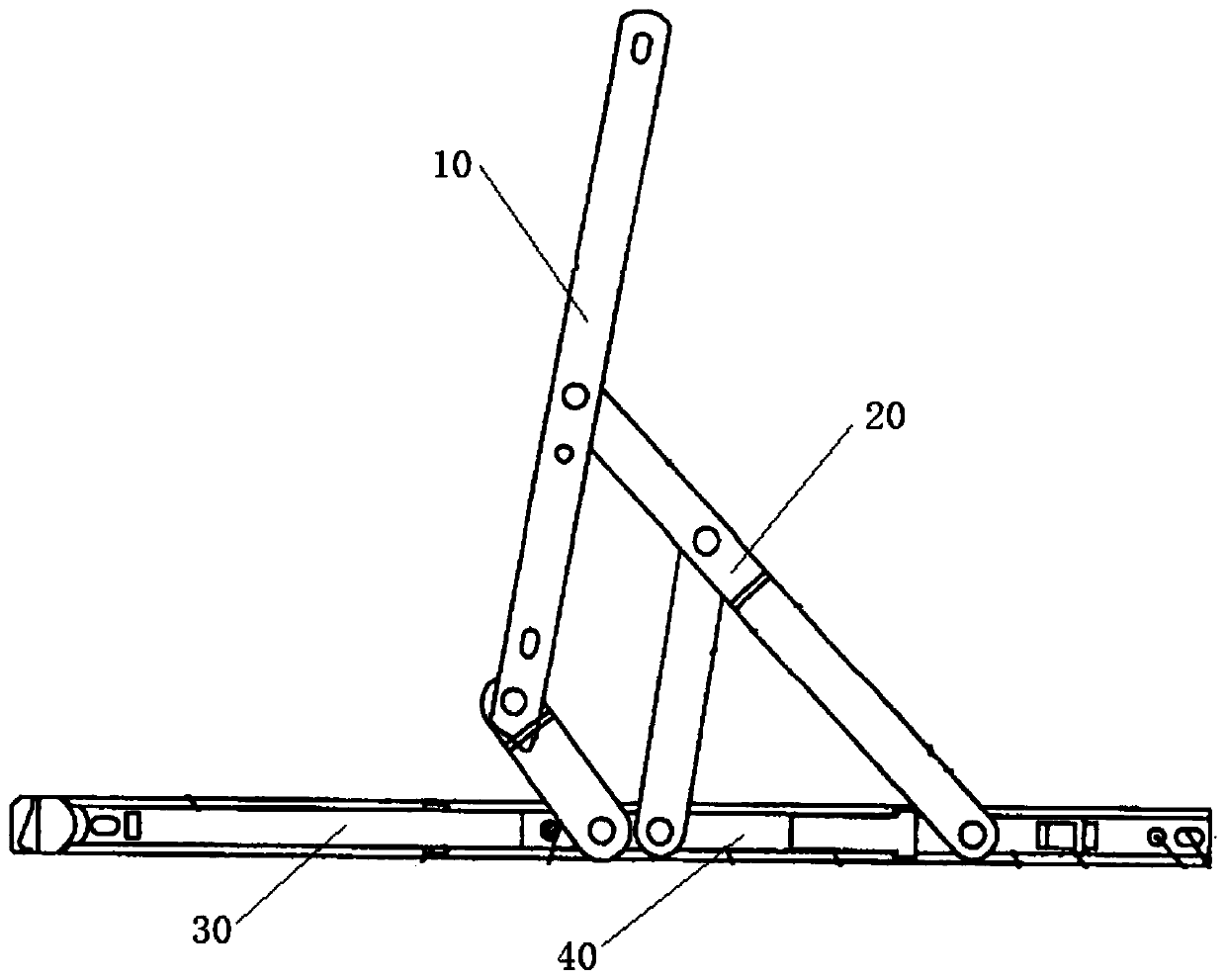

Window with hinge assemblies capable of being hidden

ActiveCN104018761AIncreasing the thicknessReduce wearPin hingesWing arrangementsSash windowWeight-bearing ability

The invention discloses a window with hinge assemblies capable of being hidden. The window with the hinge assemblies capable of being hidden comprises a fixed window frame and a movable window sash connected with the fixed window frame through the upper hinge assembly, the lower hinge assembly and the middle hinge assembly, and the upper hinge assembly and the lower hinge assembly work through a four-connecting-rod mechanism. According to the window with the hinge assemblies capable of being hidden, the upper hinge assembly and the lower hinge assembly work through the four-connecting-rod mechanism and are not overlapped between a movement control rod and a load bearing rod, so that space is provided for improving the thickness of the load bearing rod, and the load bearing capacity of the hinge assemblies is further improved.

Owner:广东省永续力五金有限公司

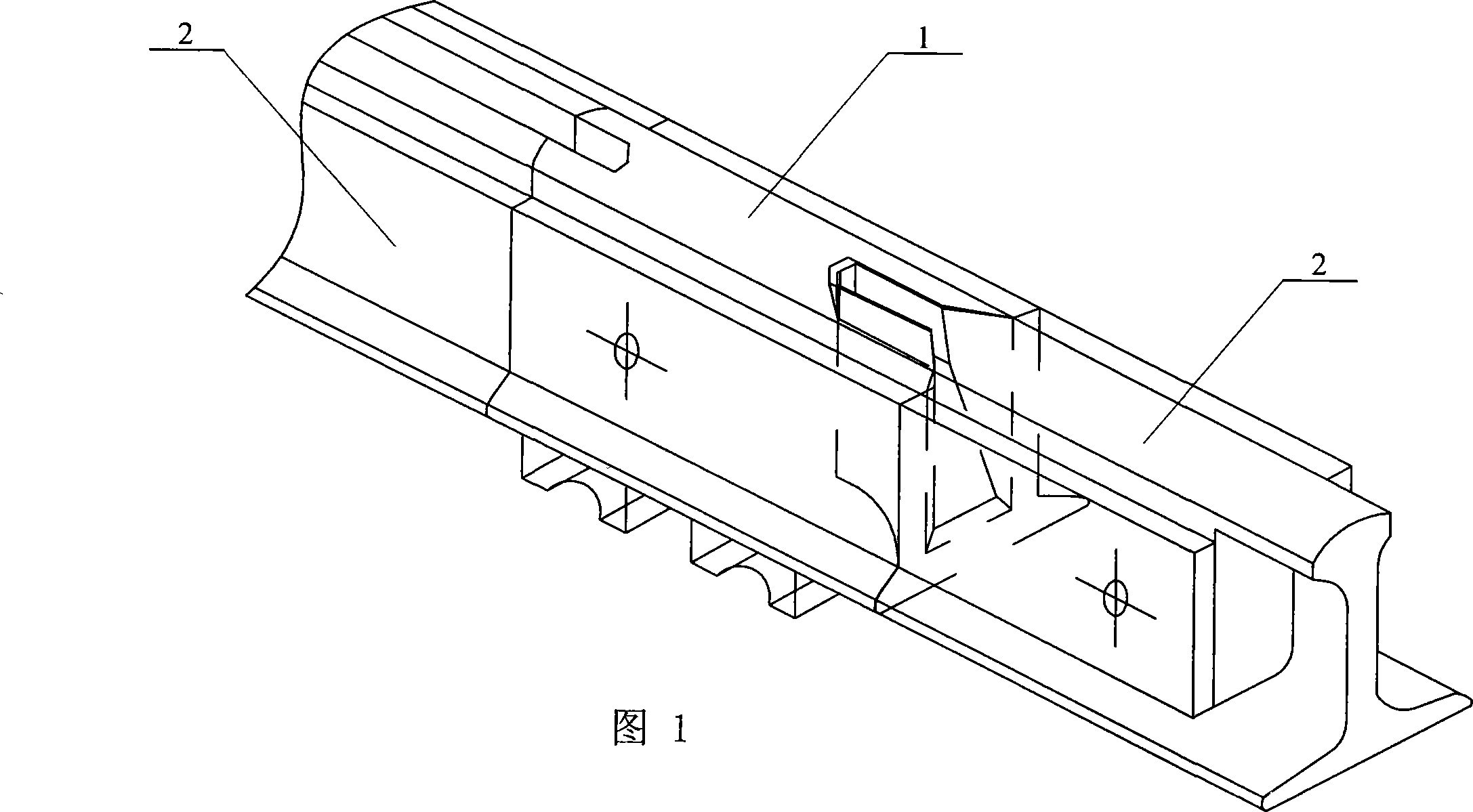

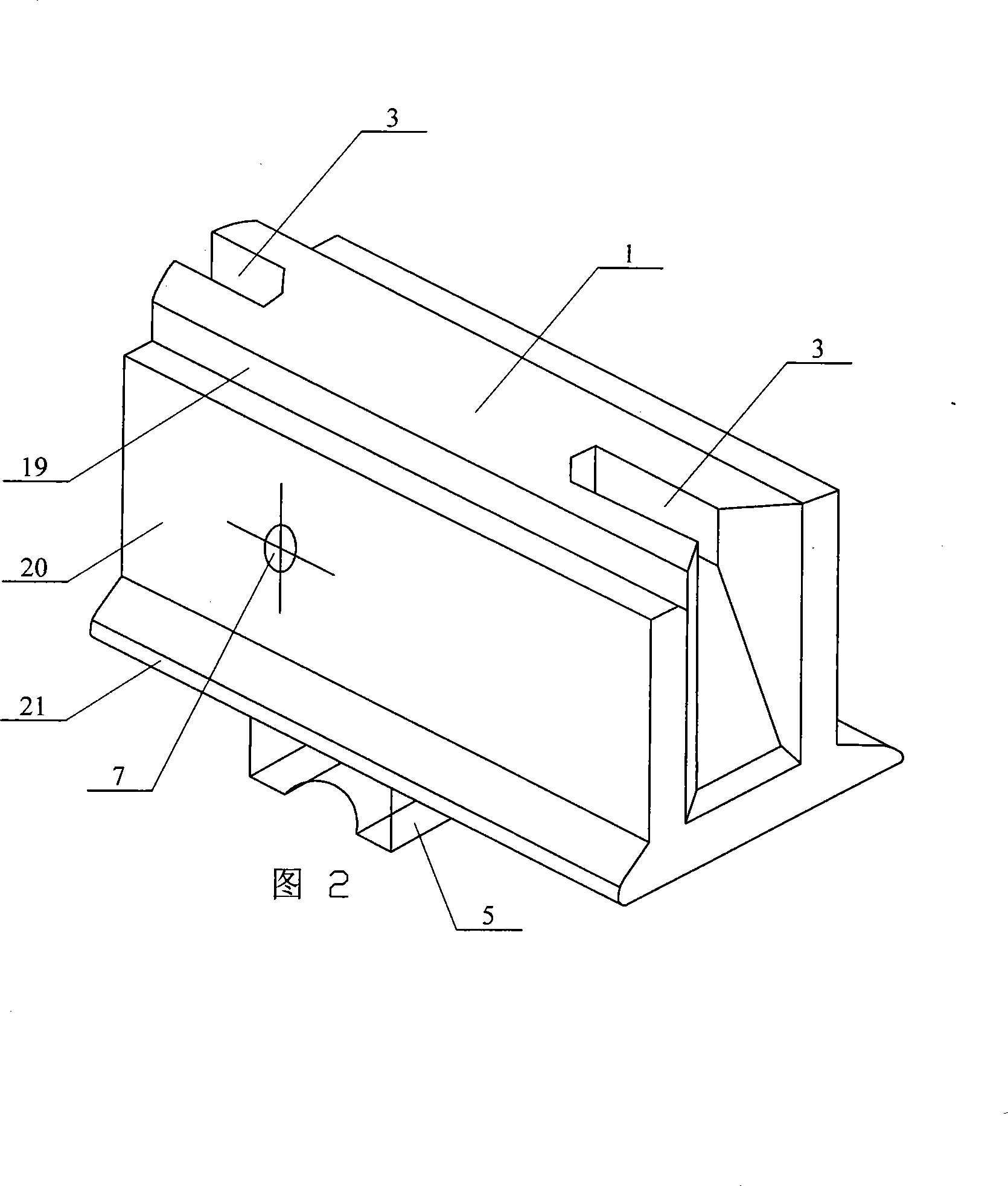

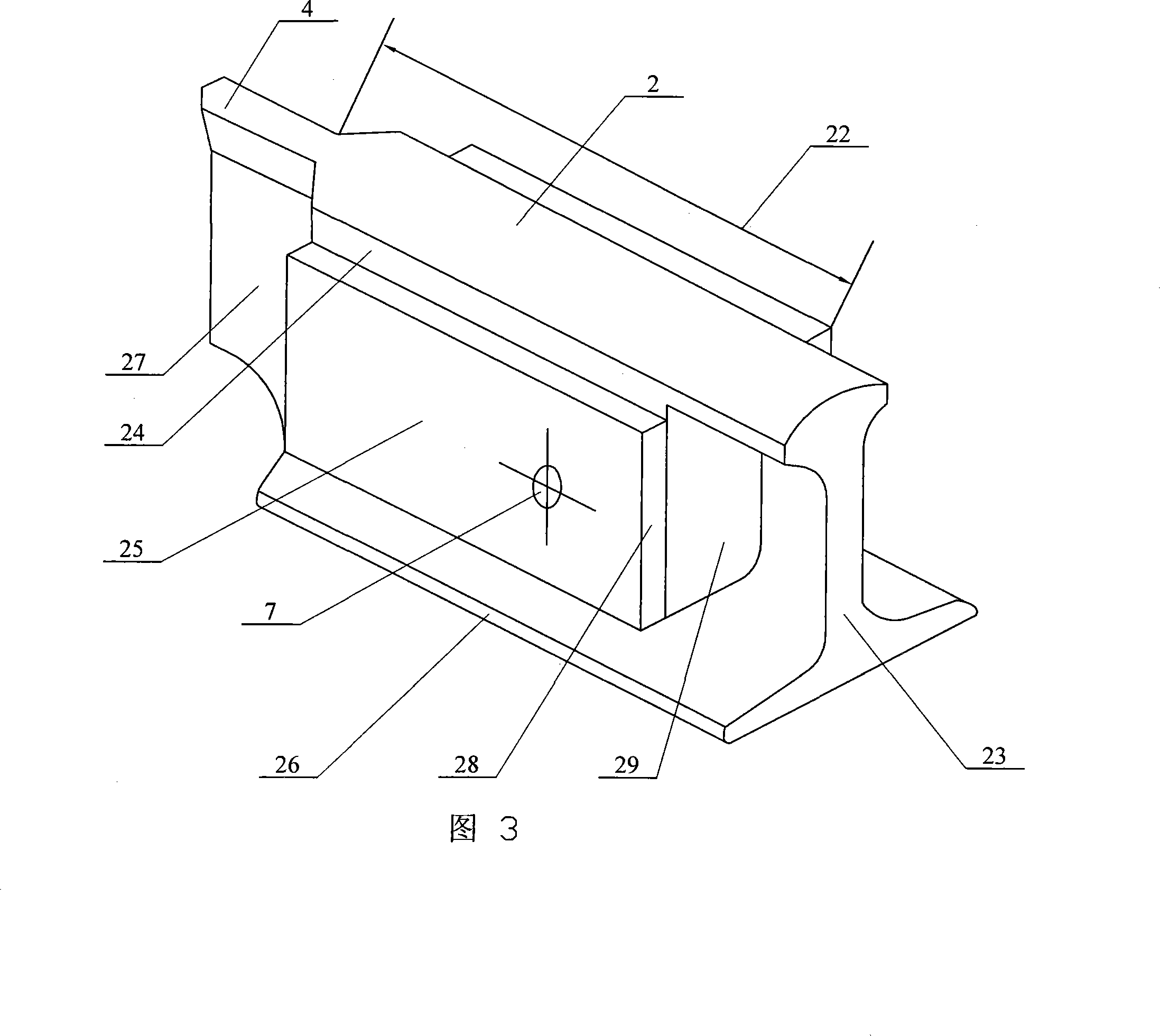

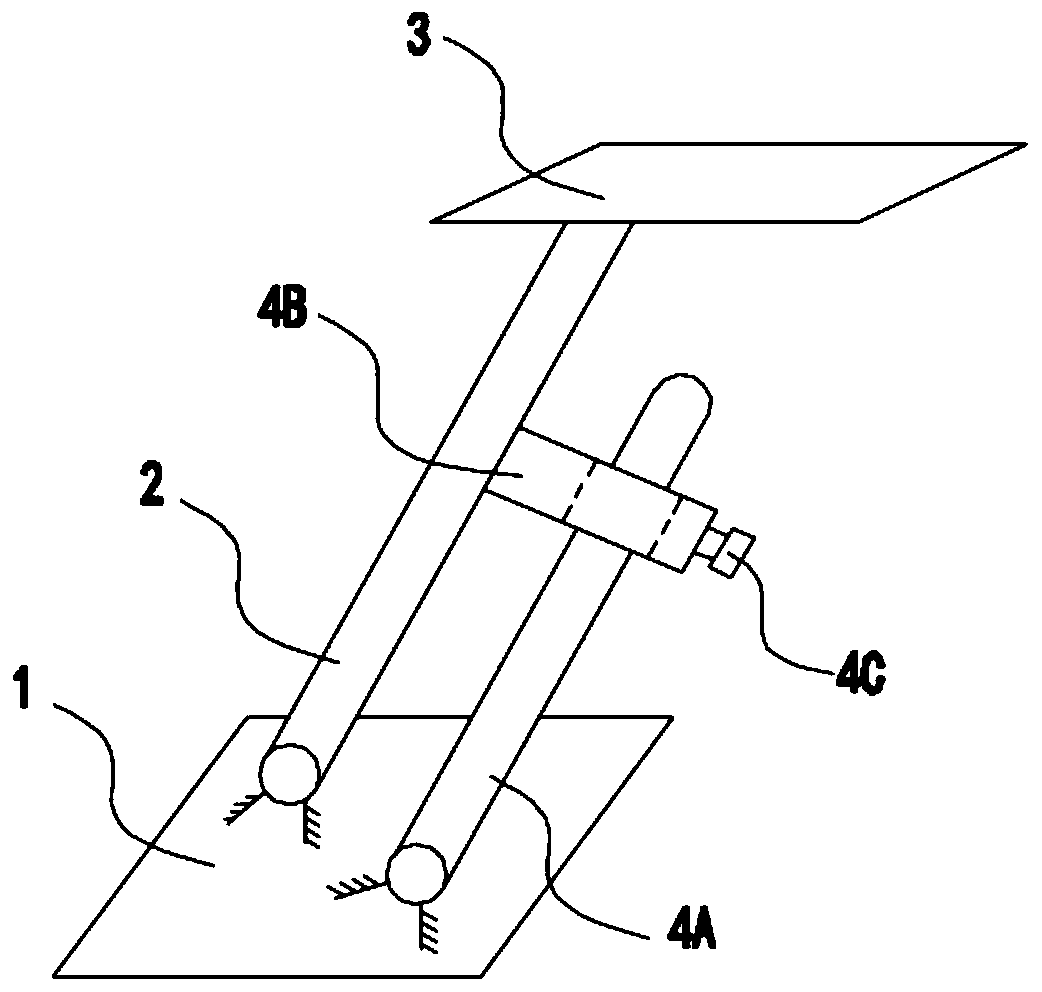

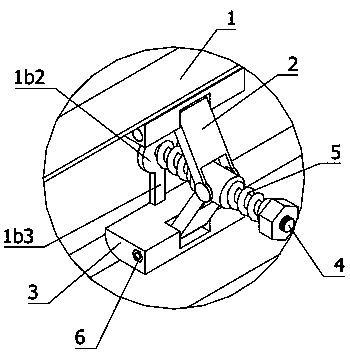

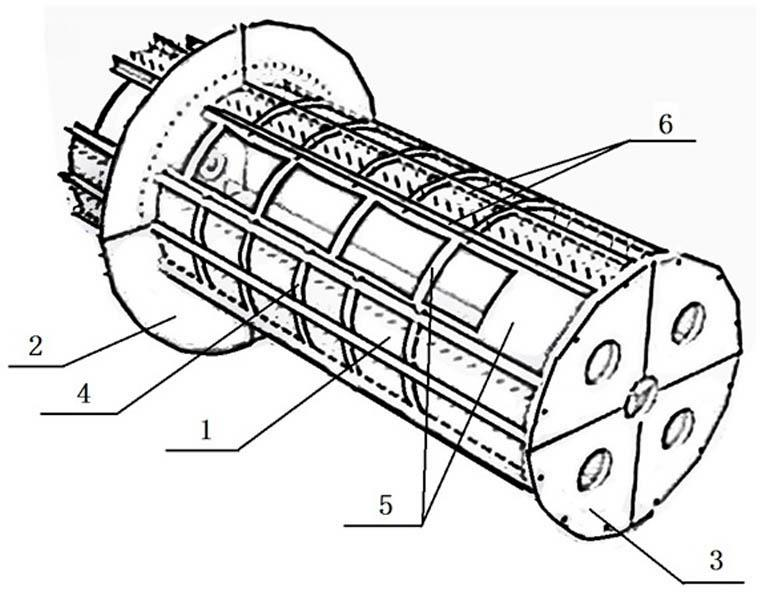

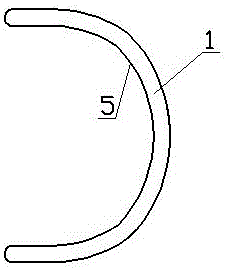

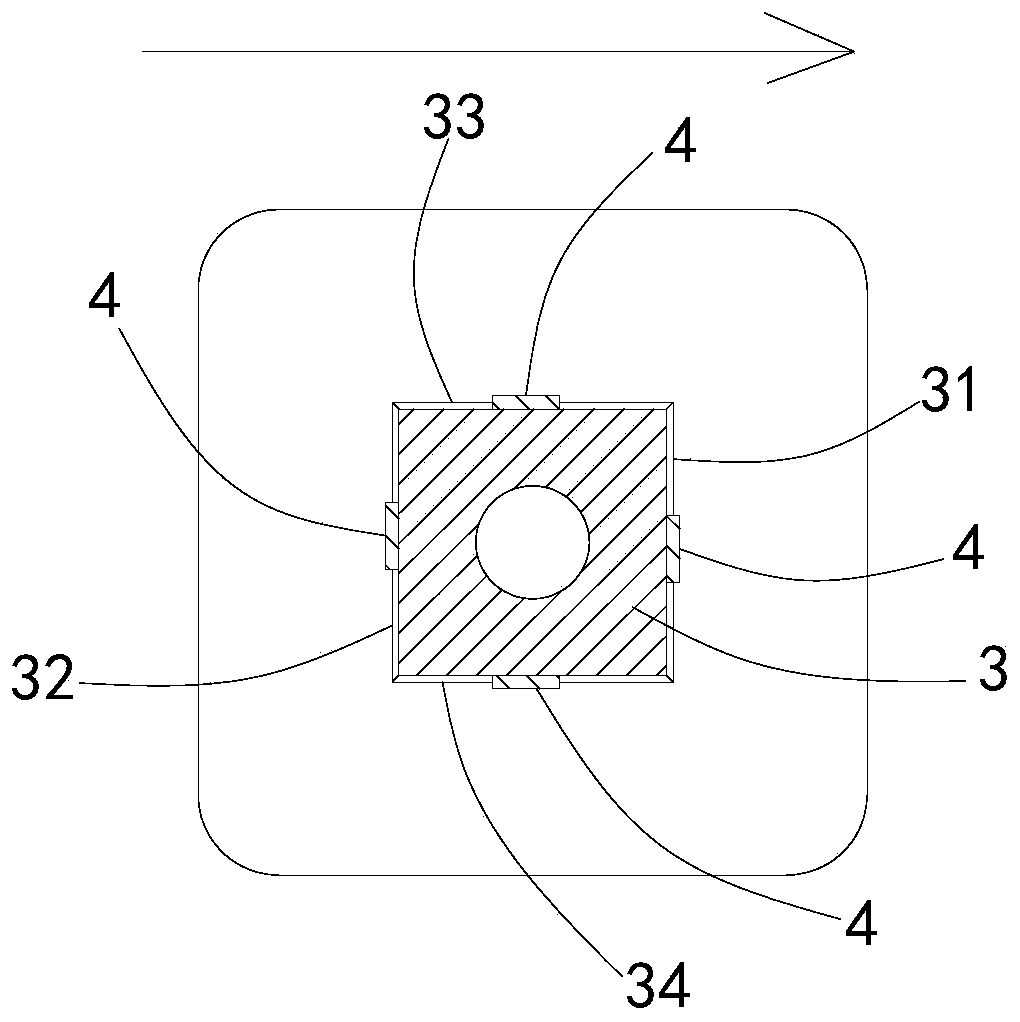

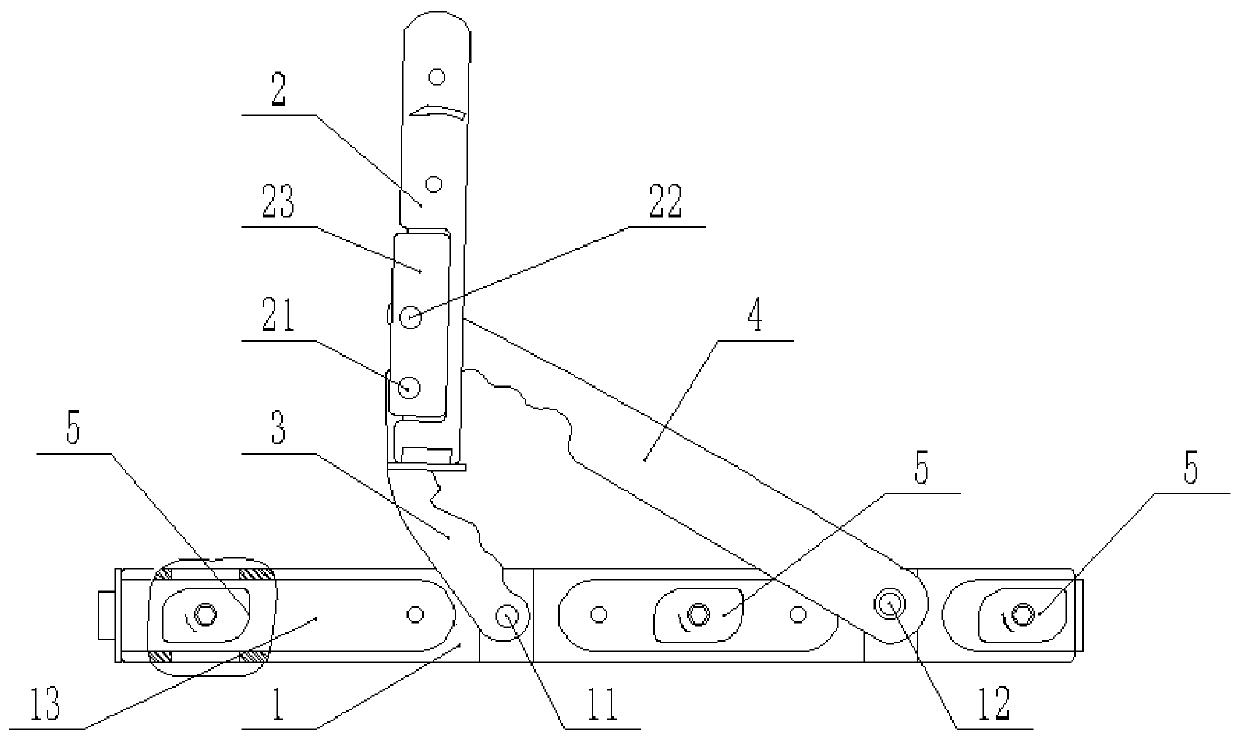

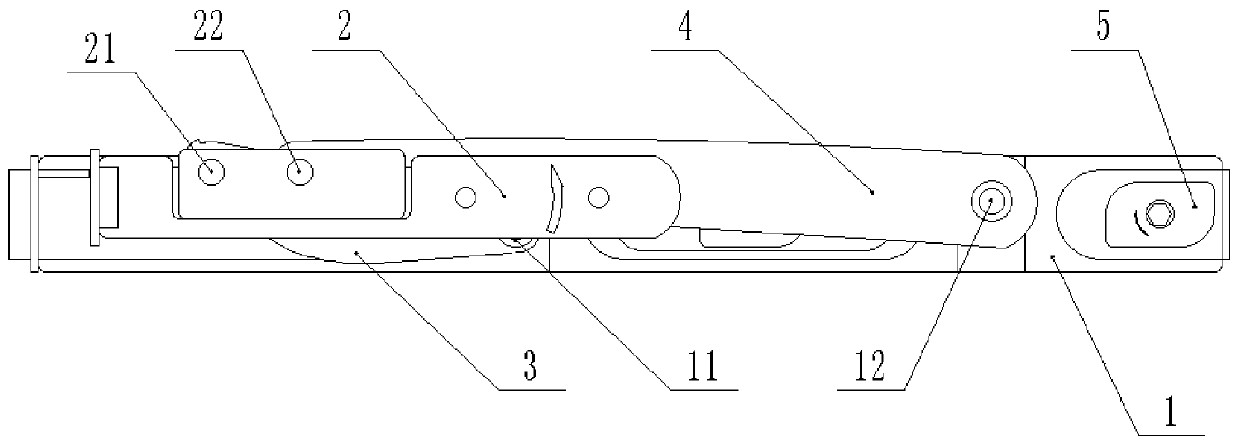

Inserting type fishplate-free rail joint connector

A plug-in steel rail joint connector with no buttcover plate of the invention relates to a steel rail joint connector, which aims at the problems of the buttcover plate connection type that the buttcover plate steel rail bolt holes can be easily cracked, the steel rail joint can be easily worn out, damaged, overlapped, collapsed and peeled off; and aims at the problems of large assembly work volume, bad weight-bearing and deformation ability of the joints of the vibration damping clampboard connection type and the symmetric inclined plane or inclined trapezohedron connection type with steel rail joint clampboards. Both ends of a static rail (1) of the invention are symmetrically provided with plug-in grooves (3), one end of a moving rail (2) is provided with a plug-in rod (4), the shape of the other end of the moving rail is same with the section shape of a rail 60, plug-in grooves of two ends of the static rail (1) is internally provided with the plug-in rod (4) which is movably fit with the plug-in groove in transition, the lower end surface of the static rail (1) is provided with a base (5), and the relative positions of the static and moving rails are provided with conduction wires connection holes (7). The connector of the invention has strong weight-bearing ability, small work volume of adjusting and maintaining and good vibration damping ability, and is most suitable for high-speed railways, urban rails, subways, tunnels, bridges and cargo-passenger stations.

Owner:陈力求

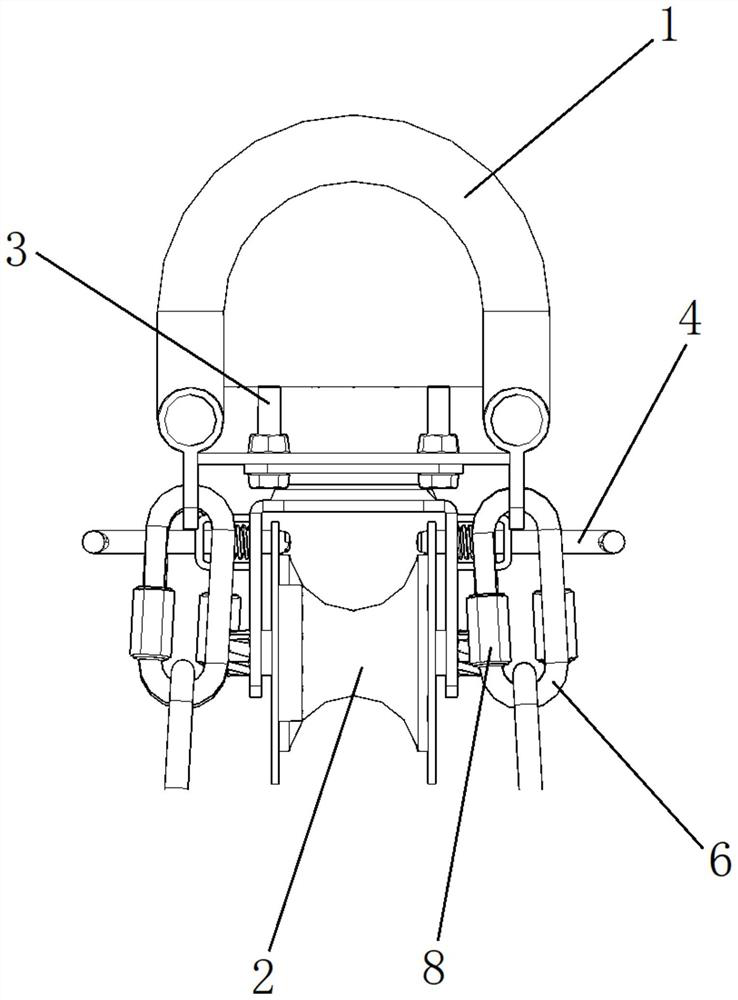

Bearing lock and locking and unlocking method

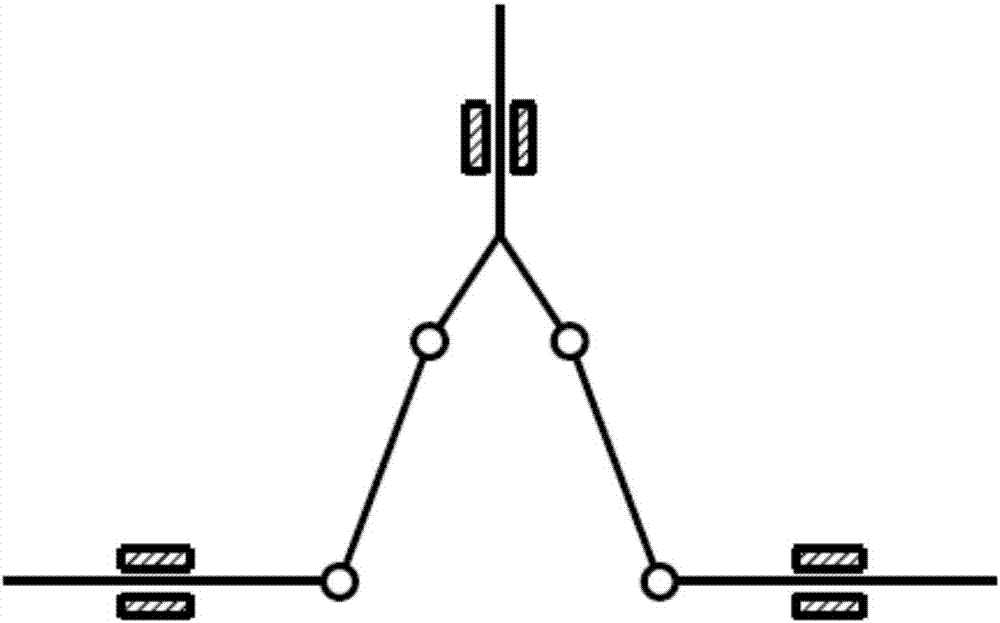

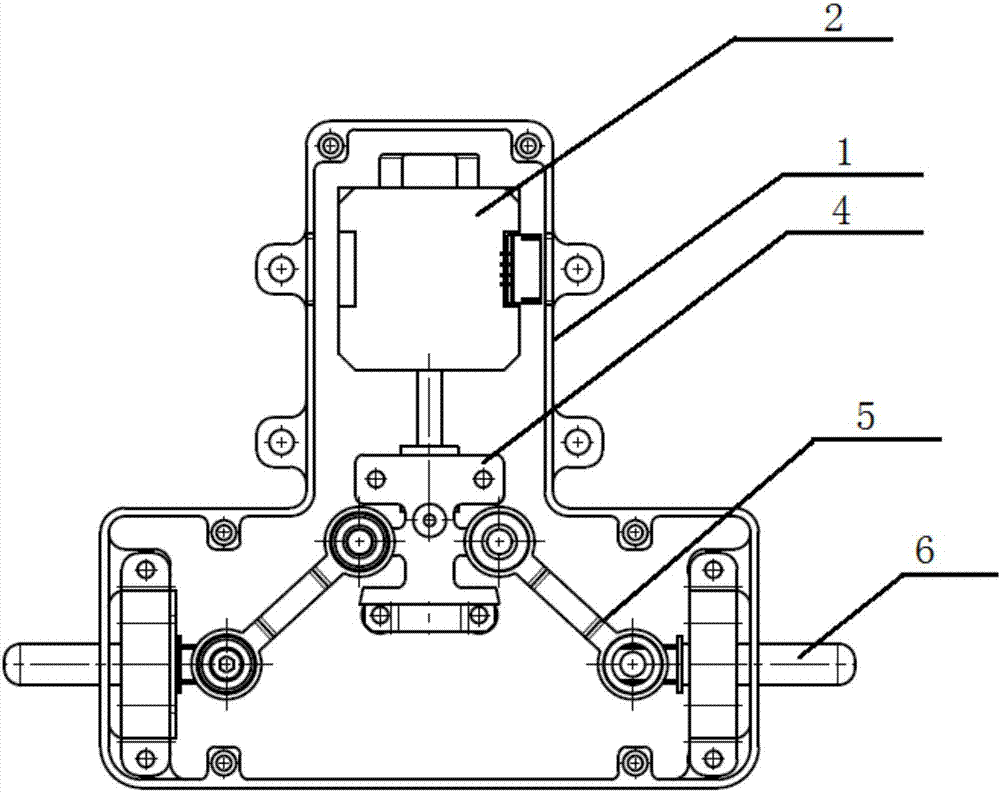

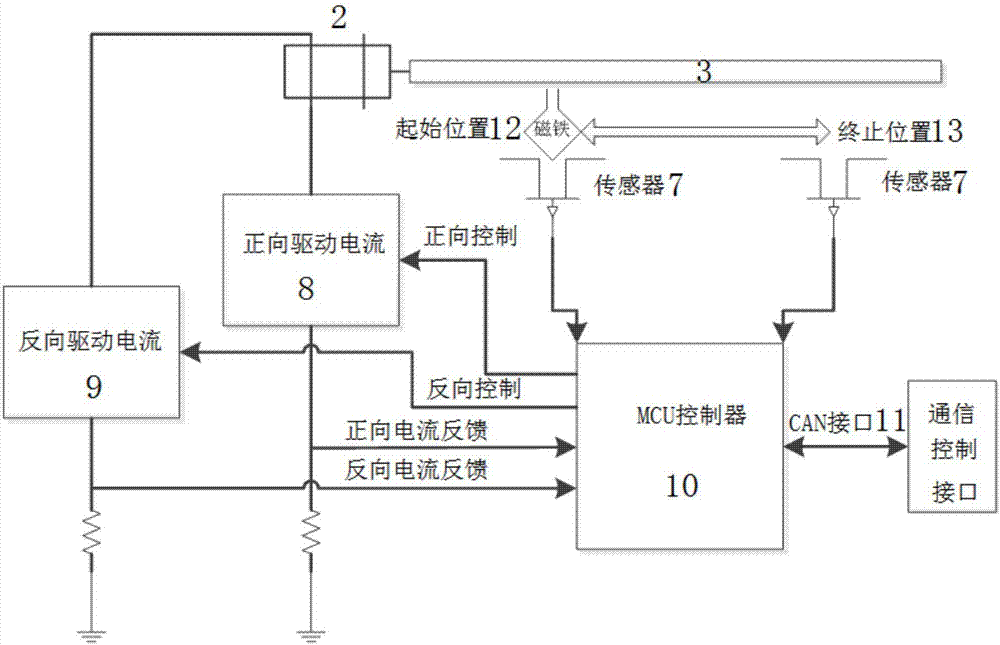

PendingCN107355455AAchieve lockingRealize the unlocking actionSecuring devicesFastening meansReciprocating motionWeight-bearing ability

The invention relates to a bearing lock and a locking and unlocking method. According to the bearing lock, a shell is internally provided with a power mechanism which does straight reciprocating motion, the two sides of the power mechanism are each rotationally connected with a rocker arm, the rocker arms are each rotationally connected with a lockpin, the end portions of the lockpins penetrate out of the shell, and locking and unlocking actions of the bearing lock are achieved. The structure is simple, and the weight is low. The force which is applied by the power mechanism acts on the lockpins through the rocker arms, and the stress directions of the lockpins are perpendicular to the force application direction of the power mechanism. By means of the extending and retracting, relative to the shell, of the lockpins, the power mechanism and the two lockpins form a triangle all the time no matter how the power mechanism moves in the liner direction, the triangle is simple in structure and mostly is high in stability, and then the bearing capacity of the bearing lock is high. While it is guaranteed that the bearing lock can be connected with a warehouse and an unmanned aerial vehicle, the bearing lock can bear the weight of express items in the warehouse and overload, it is further guaranteed that the warehouse cannot move, and the connection strength and rigidity are guaranteed.

Owner:丰翼科技(深圳)有限公司

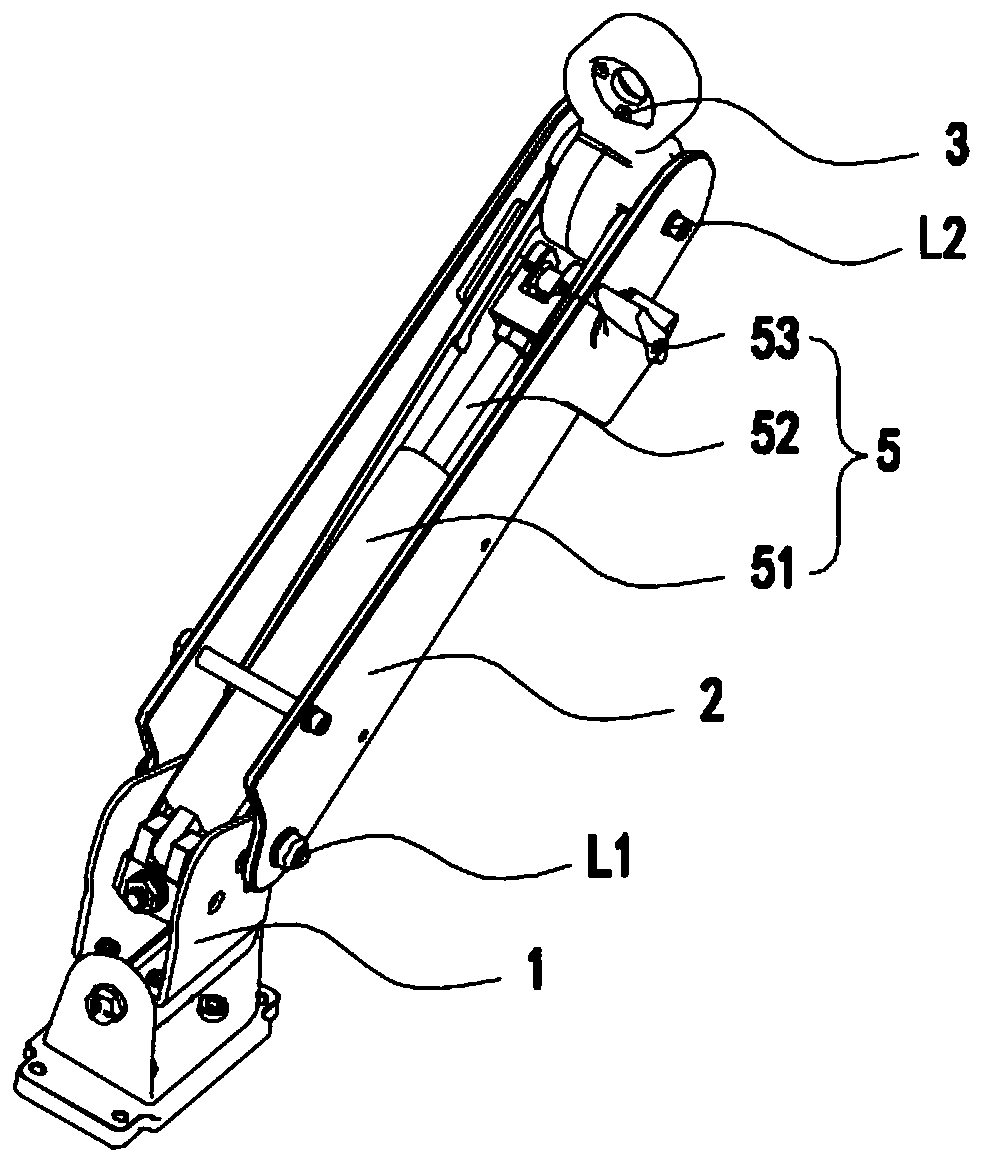

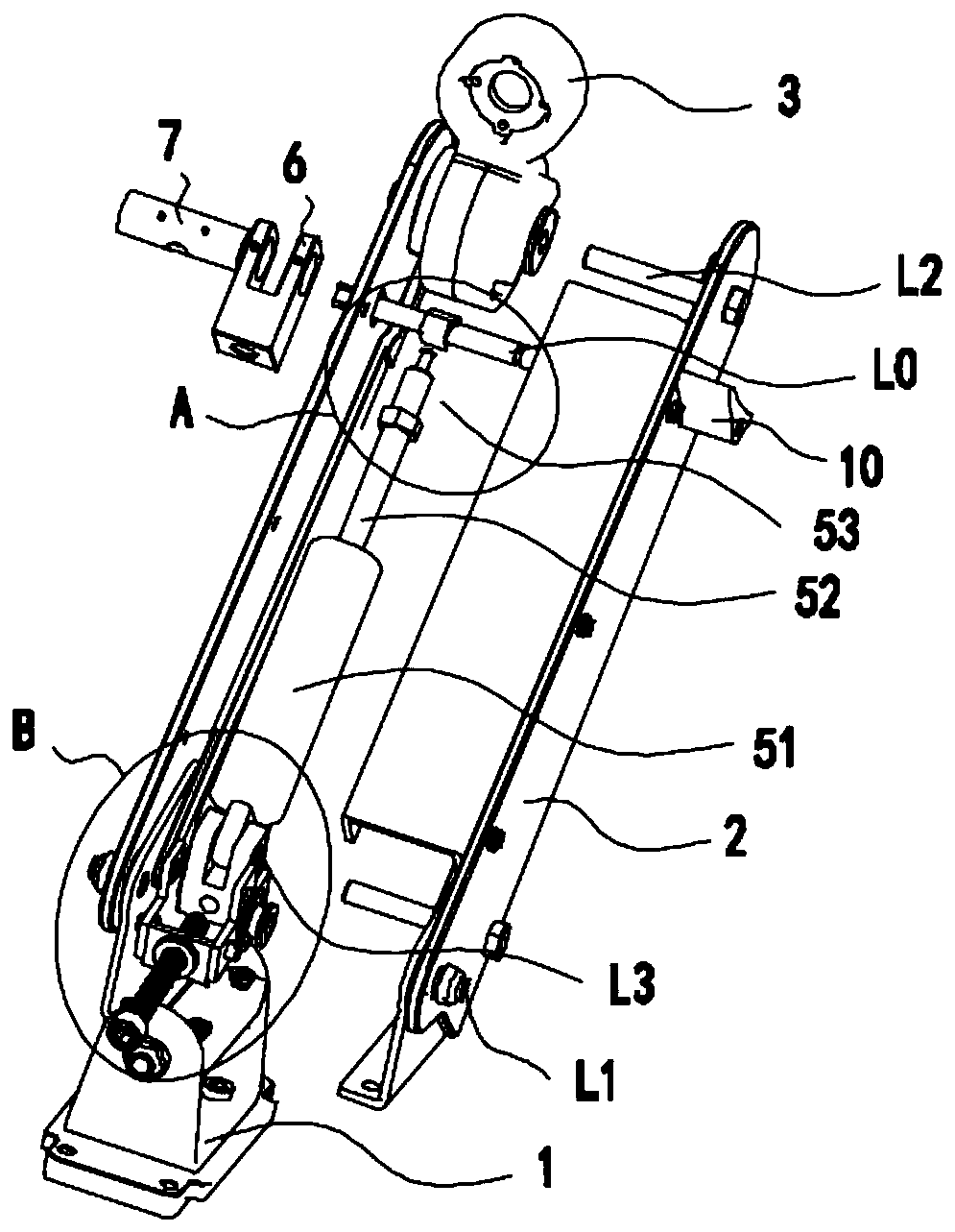

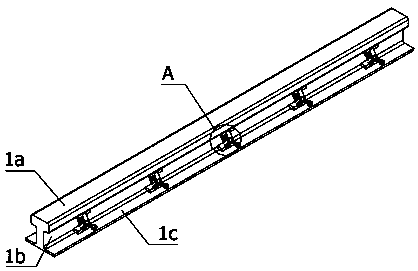

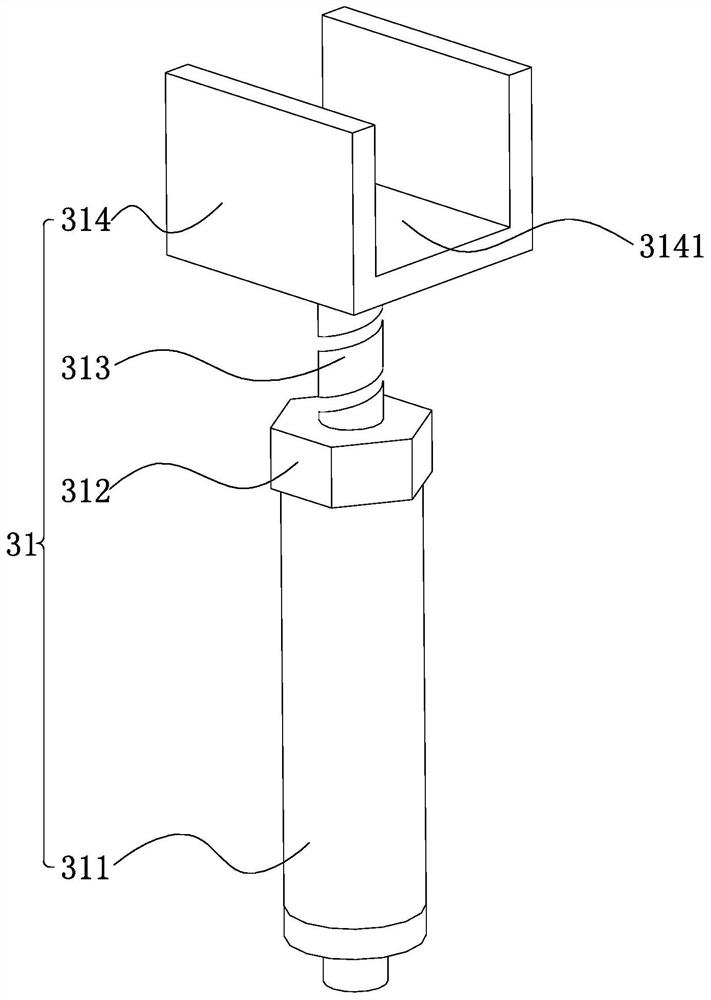

Rocker arm device

ActiveCN110657324AStable supportWeight capacity can be adjustedStands/trestlesPivotal connectionsReciprocating motionAir spring

The invention provides a rocker arm device which comprises a base, a rocker arm and a tray. One end of the rocker arm is hinged to the base through a first installation shaft, and the other end of therocker arm is hinged to the tray through a second installation shaft. The rocker arm device further comprises a reciprocating motion assembly and an air spring. The reciprocating motion assembly is arranged on the side, close to the tray, of the rocker arm through a rotating shaft and conducts reciprocating motion along with rotation of the rotating shaft. The air spring comprises a fixed part, atelescopic part and an ejector pin which are sequentially connected, the fixed part is hinged to the base through a third installation shaft, and the telescopic part supports the rocker arm. The reciprocating motion assembly acts on the ejector pin and is used for locking or unlocking the air spring. A third rotating shaft is located beyond the area which the rocker arm passes when the rocker armrotates to the extreme position, and the position of the third installation shaft is adjustable. Due to locking and unlocking operation of the rocker arm device, accurate control can be achieved by referring to the long distance end and the short distance end of the reciprocating motion assembly, operation is convenient, in addition, the supporting force of the air spring is stable and reliable,the bearing capability can be adjusted, and the application range is wider.

Owner:SHENZHEN COMEN MEDICAL INSTR

Low-noise damping iron rail

ActiveCN110863396ASolve the problem of large vibration and high noiseLow costRailway tracksWeight-bearing abilityMechanical engineering

The invention relates to the technical field of rail traffic, in particular to a low-noise damping iron rail. The low-noise damping iron rail comprises an iron rail, first supporting mechanisms, second supporting mechanisms, a supporting shaft and buffering mechanisms. The work ends of the first supporting mechanisms make contact with a rail head and a rail body. The work ends of the second supporting mechanisms make contact with the rail body and a rail seat. The first supporting mechanisms and the second supporting mechanisms are of the same structure. The buffering mechanisms are arranged on the supporting shaft in a sleeving manner. The ends, hinged to each other, of the first supporting mechanism and the second supporting mechanism are hinged to the buffering mechanisms as well. The supporting shaft penetrates the two ends of the rail body, the length direction of the supporting shaft and the length direction of the rail body are perpendicular to each other in the horizontal plane, and the first supporting mechanisms, the second supporting mechanisms and the buffering mechanisms are arranged at the positions, located at the two ends of the rail body, of the supporting shaft. The low-noise damping iron rail solves the problems that a traditional iron rail is large in vibration amplitude and large in noise when a train passes are solved, and the problems that the manufacturing cost is expensive and the load bearing capability is low in the prior art are improved.

Owner:河北路通铁路器材有限公司

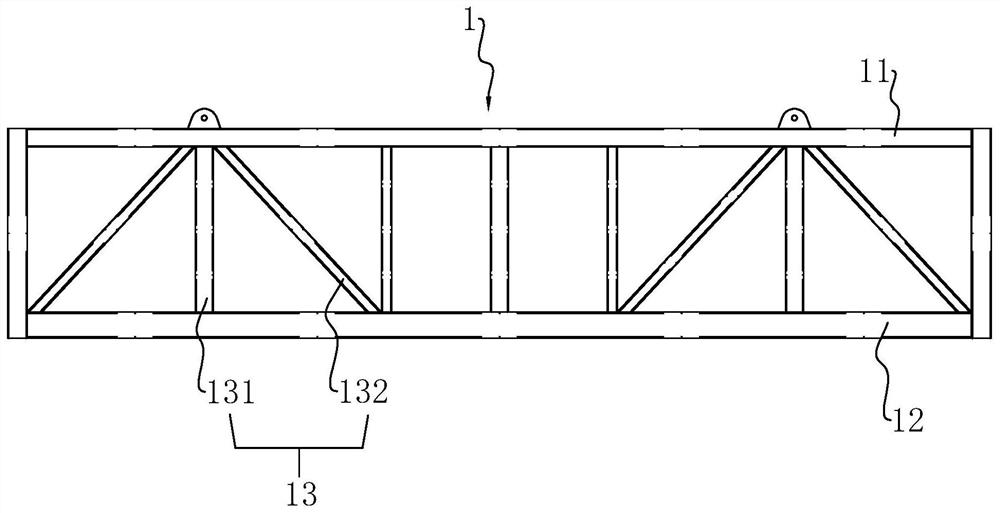

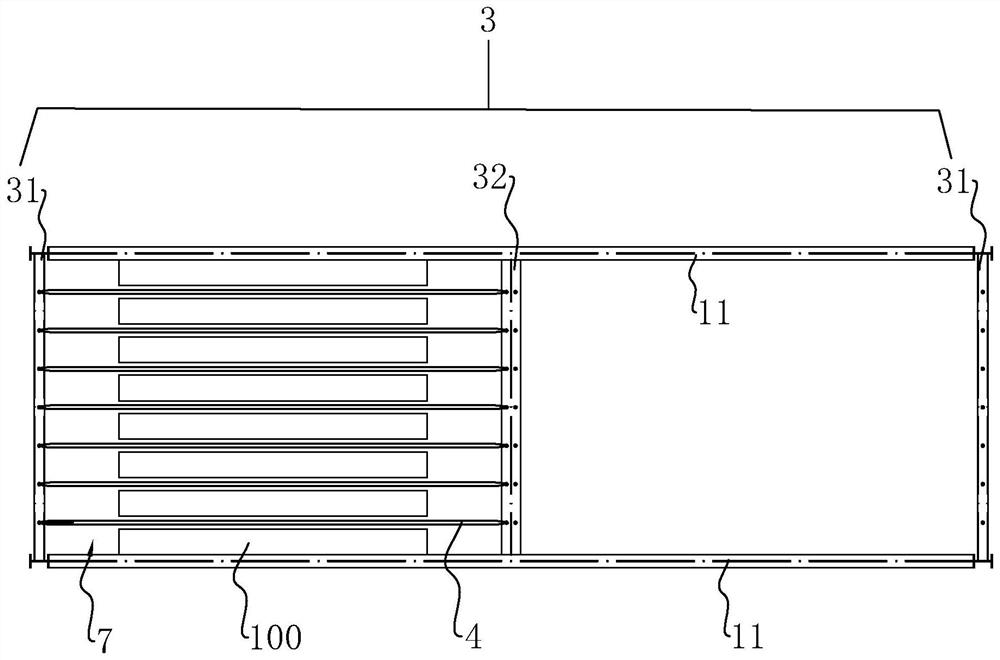

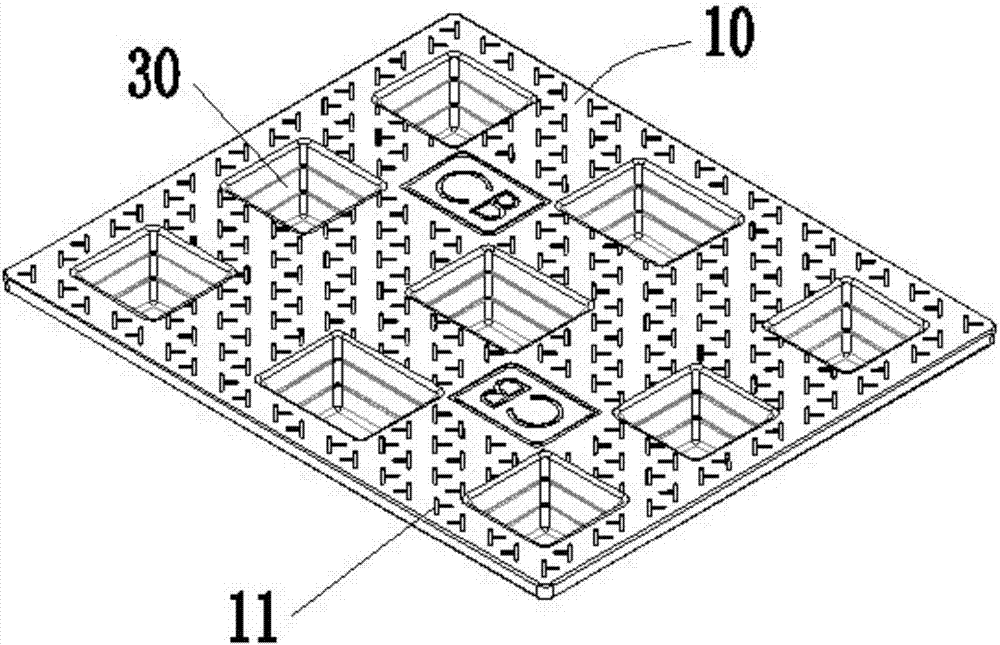

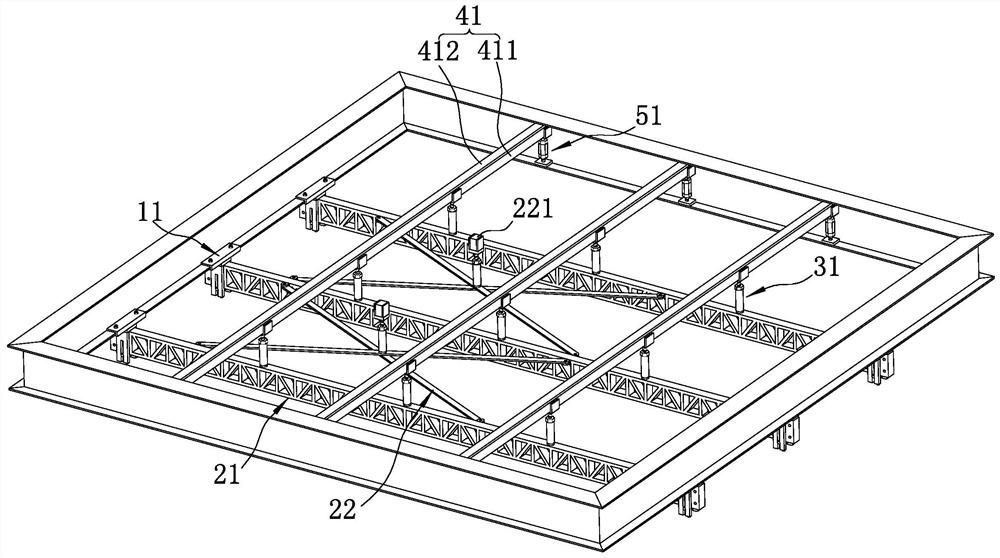

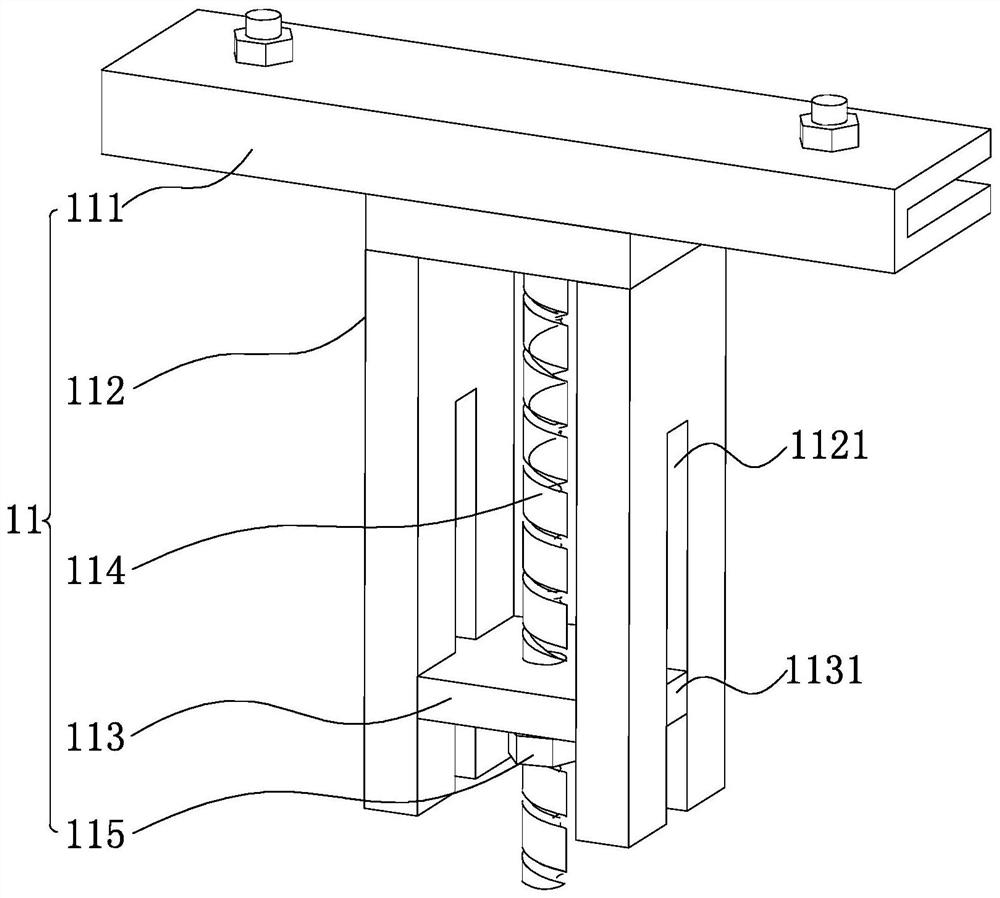

A prefabricated wall panel stacking rack

ActiveCN109230155BGuaranteed structural strengthGuaranteed load capacityConveyorsStorage devicesWeight-bearing abilityClassical mechanics

The invention relates to a stacking device for prefabricated components, and specifically discloses a stacking rack for prefabricated wallboards, which includes two sets of side frames, a bottom support layer horizontally arranged between the two side frames, and an upper beam arranged on the top of the side frames. There are multiple sets of lifting lugs fixed on the top of the side frame; the bottom support layer includes a number of bottom beams arranged in parallel intervals; inserting rods are fixed horizontally between any adjacent two of the upper beams, and any adjacent two of the inserting Sockets are formed between the rods; the ends of the inserted rods are slidingly connected to the adjacent side of the upper beam, and a locking assembly is also provided on the upper beam; the side frame includes an upper chord, a lower chord and a reinforcement Rod group; both sides of the prefabricated wall panel stacking rack are provided with end frames, and the end frames include upright columns and second diagonal braces. The invention provides a prefabricated wallboard stacking frame with stable structure, strong load-bearing capacity, long service life, wide application range, not easy to be damaged, capable of realizing integral hoisting of prefabricated wallboards, and greatly improving the transfer efficiency of prefabricated wallboards.

Owner:上海汉石昀升住宅工业发展有限公司

Round cross-shaped column base and manufacturing method thereof

ActiveCN102155067AIngenious structural designIncreased load-bearing capacityStrutsBuilding material handlingBaseboardWeight-bearing ability

The invention discloses a round cross-shaped column base and a manufacturing method thereof; the round cross-shaped column base comprises a cross body, an external ring plate, a column baseboard, shearing resistant plates, a batten plate and stiffening plates, wherein the external ring plate is fixed on the exterior of the cross body; the column baseboard is fixed at one end of the cross body; the stiffening plate is fixed at the periphery of the cross body and is parallel to the axis of the cross body; the shearing resistant plates are arranged among the stiffening plates and fixed on the cross body; and the stiffening plates are fixed on the cross body. The invention also discloses the manufacturing method of the round cross-shaped column base. The round cross-shaped column base has ingenious structural design and has very strong weight carrying ability; the manufacturing method leads the manufactured round cross-shaped column base to be firm in a reasonable installation mode and realizes the factory production of the round cross-shaped column base and increases the production efficiency.

Owner:JIANGSU HUNING STEEL MECHANISM

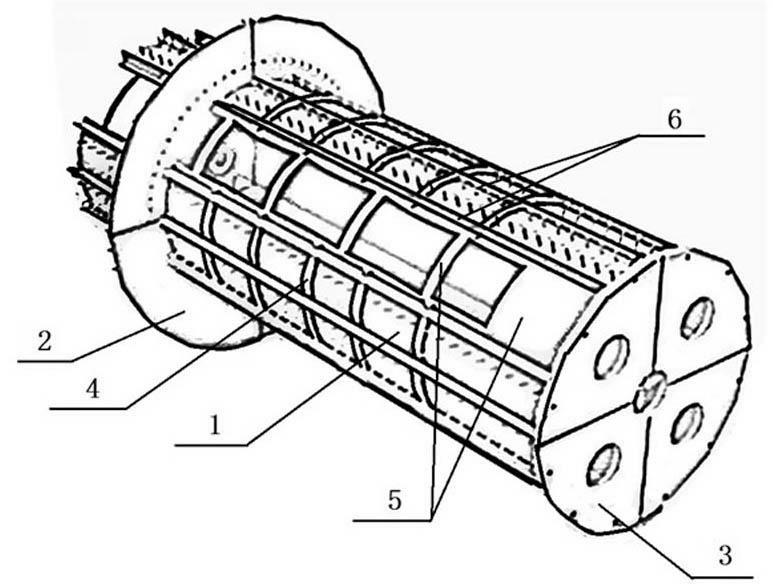

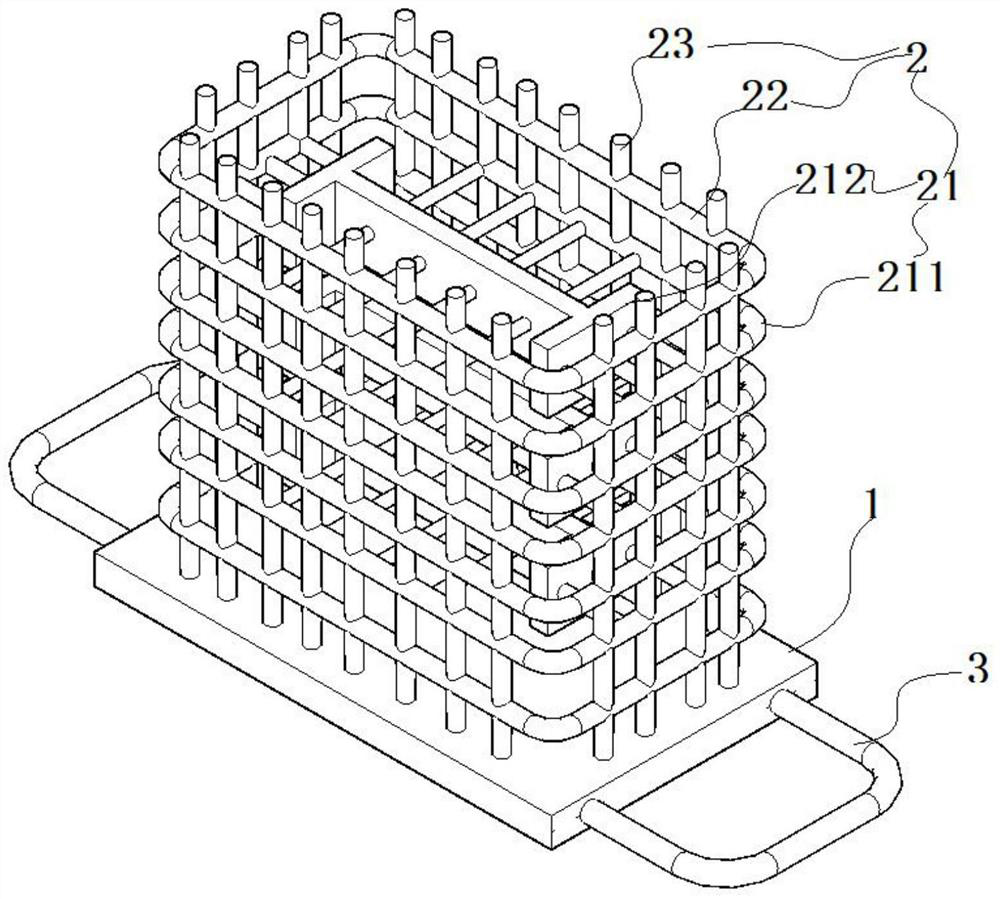

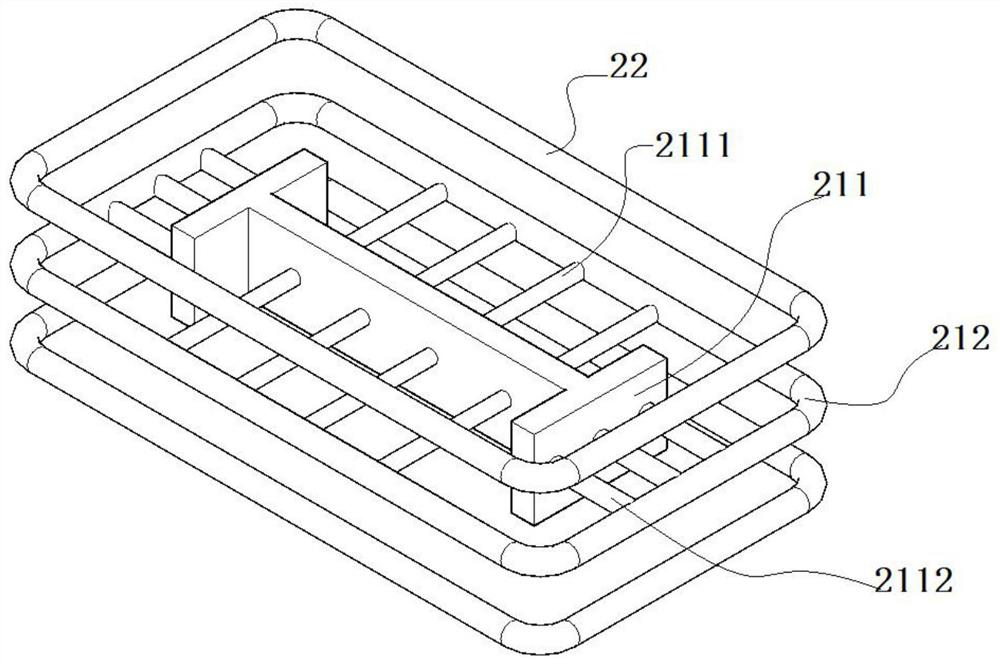

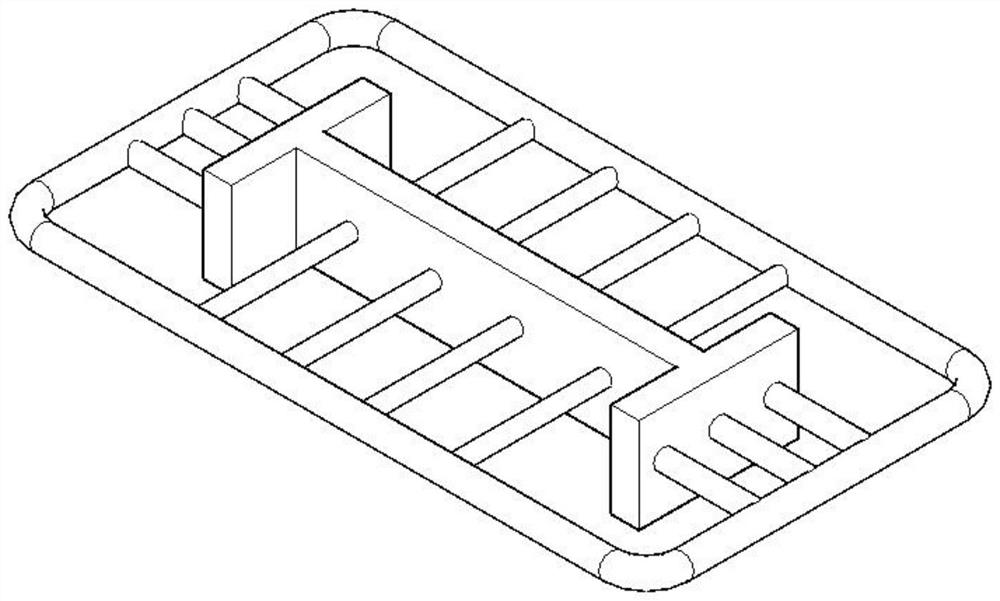

Reinforcement cage device used for house building engineering

InactiveCN111827581AImprove stabilityIncreased load-bearing capacityWallsProtective buildings/sheltersWeight-bearing abilityArchitectural engineering

The invention discloses a reinforcement cage device used for housing building engineering. The reinforcement cage device comprises a reinforcement cage assembly. The reinforcement cage assembly comprises multiple first stirrups which are arranged in a vertically spaced manner, and embedded parts are arranged between the adjacent stirrups. Each embedded part comprises a second stirrup, wherein a middle clearance is formed in the second stirrup, and I-shaped steel is arranged in the middle clearance. Penetrating bars which are arranged in a left-right spaced manner are fixedly connected betweenthe front sides and the rear sides of the second stirrups. The penetrating bars penetrate the I-shaped steel. The reinforcement cage assembly further comprises multiple longitudinal bars penetrating the first stirrups and the second stirrups. The longitudinal bars perpendicularly penetrate the first stirrups and the second stirrups. The reinforcement cage assembly further comprises a bottom steelplate fixedly connected with the multiple longitudinal bars. By the adoption of the above device part design, the bearing capability of a wall body obtained through pouring is improved, meanwhile, theanti-shock capability of the wall body is obviously improved, and the reinforcement cage device is suitable for building construction of areas where earthquakes happen frequently.

Owner:湖北烜豪建筑工程有限公司

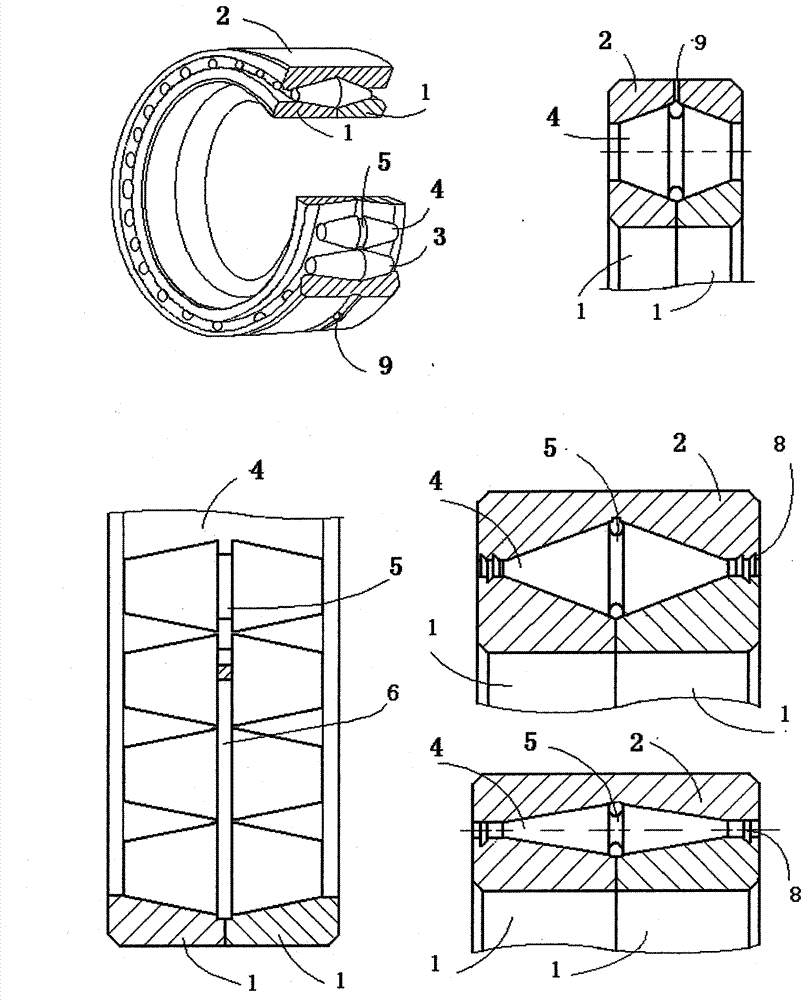

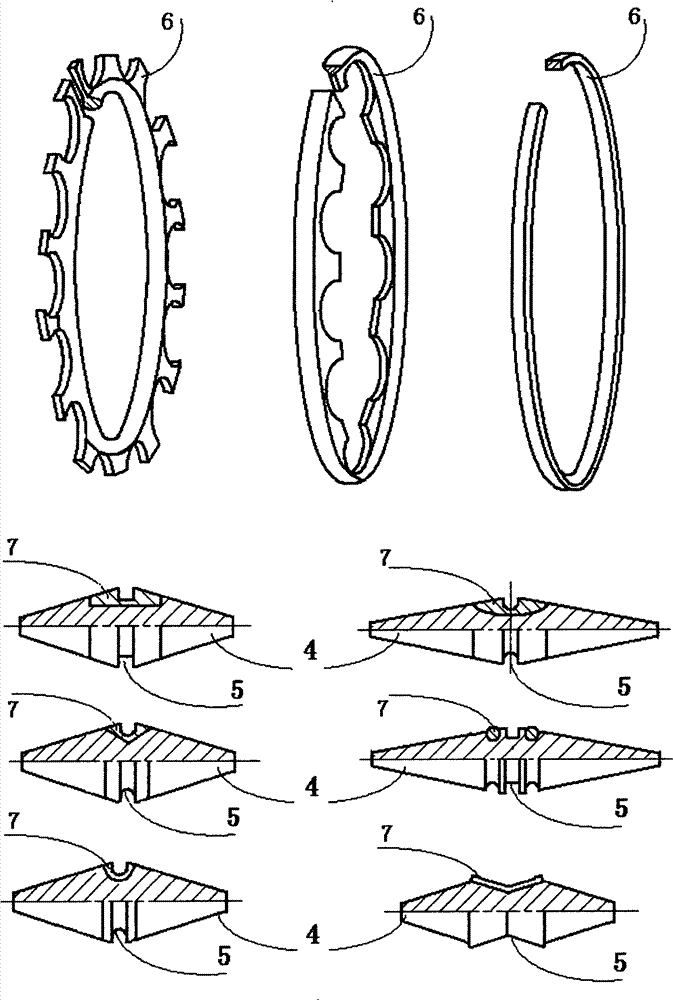

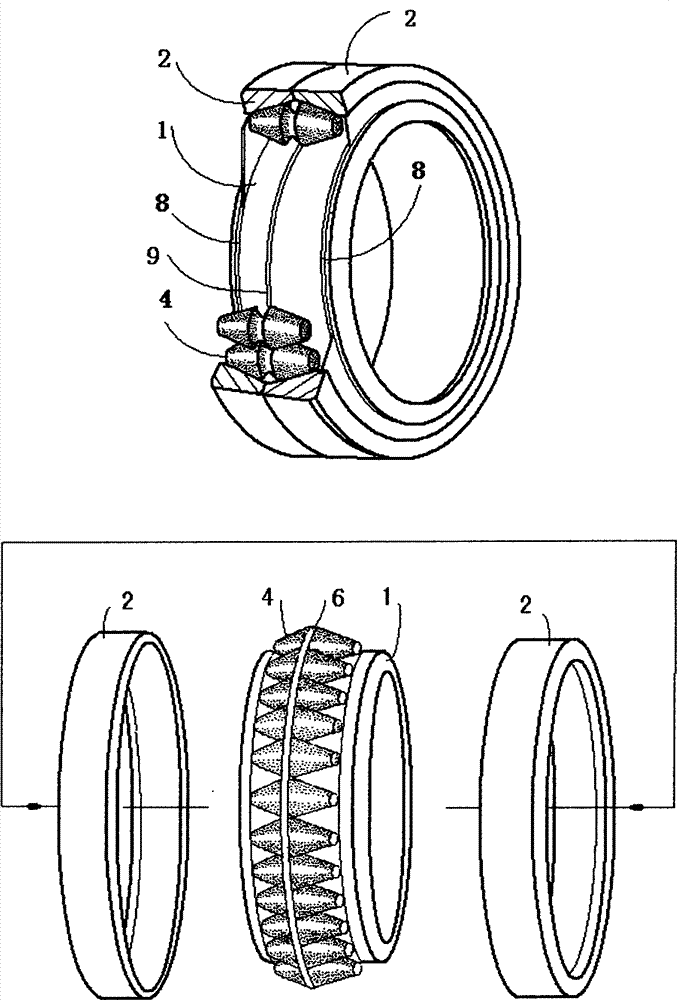

Mute tip cone roller bearing

InactiveCN103047274AReduce frictionReduce radial runout noiseRoller bearingsBearing componentsLeading edgeWeight-bearing ability

The invention relates to a mute tip cone roller bearing. A structure support technology is characterized in that the set of bearing is formed by matching an inner sleeve ring, an outer sleeve ring, a row of single-row tip cone rollers and an invisible retainer. The external dimension standard of the mute tip cone roller bearing is in line with that of an international general roller bearing of international standardization organization (ISO). The invention aims at solving the problem that the third generation leading edge innovative technology bearing is not designed by anyone in the recent 140 years in the world. The mute tip cone roller bearing is characterized in that (1) one bearing can be independently taken as a main hub support; (2) two sealing covers are respectively arranged at the two ends of the bearing; (3) the bearing is high in bearing capacity; (4) the bearing is high in shear impact resistance; (5) the bearing is rapid in rotating speed; (6) the bearing improves the safety factor by 2%; (7) the bearing is good in stability; (8) the bearing is high in two-direction thrust capability; (9) the bearing is low in vibration noise; (10) the bearing is simple in structure and low in cost; (11) the bearing is long in service life; and (12) the bearing is convenient and fast to install and maintain, therefore, the mute tip cone roller bearing is a new generation innovative technology product which is high in economic benefit and environment-friendly.

Owner:王守彬

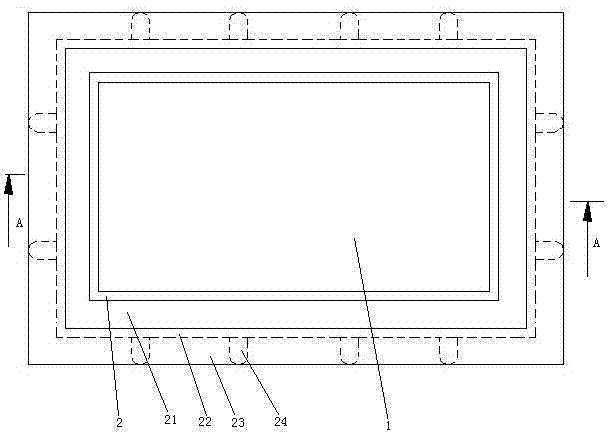

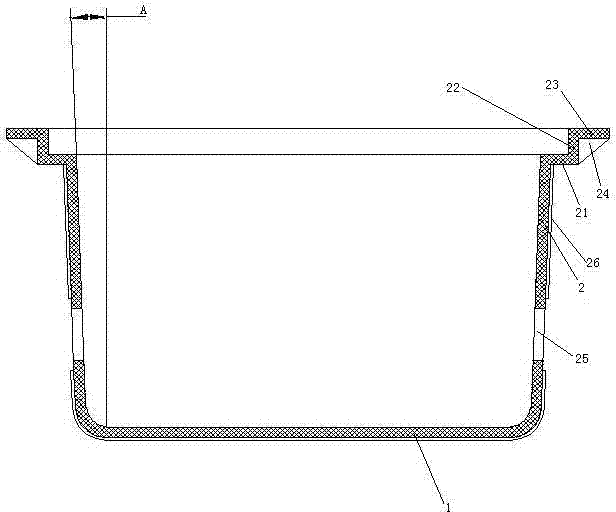

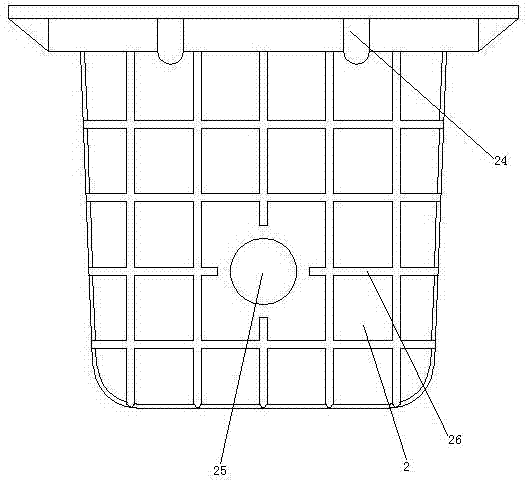

Pre-formed plastic water meter chamber and water meter mounting method

ActiveCN104762994AReduce construction hoursNovel structureArtificial islandsVolume meteringWeight-bearing abilityEngineering

The invention relates to a water meter chamber. A pre-formed plastic water meter chamber comprises a bottom wall, and a tubular sidewall which is connected to the bottom wall, wherein pipe holes are formed in the sidewall; the bottom wall and the sidewall are manufactured from plastic and integrally structured; the sidewall is inclined by a manner that the upper end is outward; the upper end of the sidewall is outwards overturned to form a well lid bearing ring; the outer radial end of the well lid bearing ring is upwards overturned to form a well lid limiting ring; the upper end of the well lid limiting ring is outwards overturned to form an assisting ring. According to the pre-formed plastic water meter chamber and the water meter mounting method, high strength and bearing capacity can be ensured with light weight and small appearance size; the problems of large weight, poor bearing capacity and inconvenient sealing of the existing pre-formed water meter chamber can be solved.

Owner:ZHEJIANG BANGDE PIPE IND

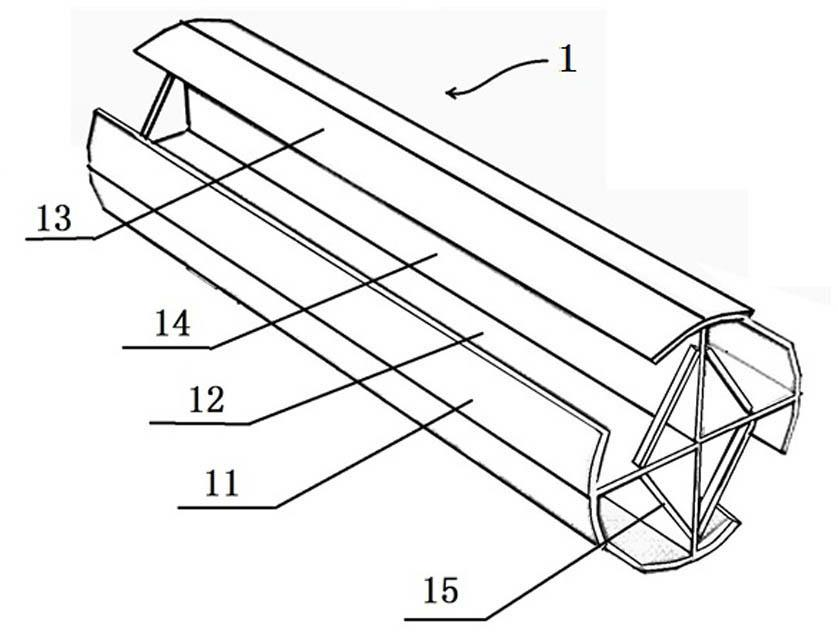

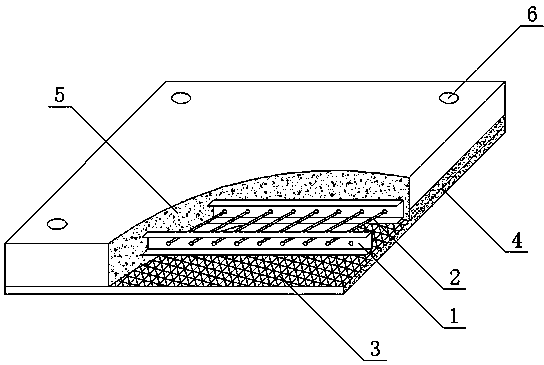

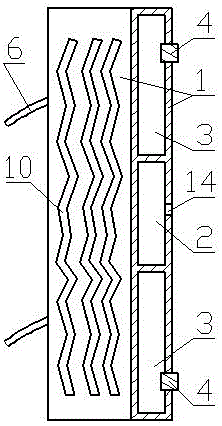

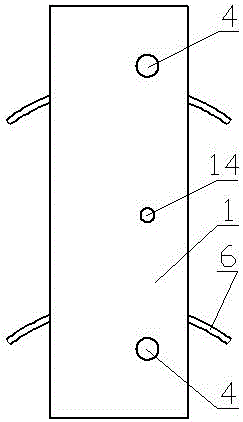

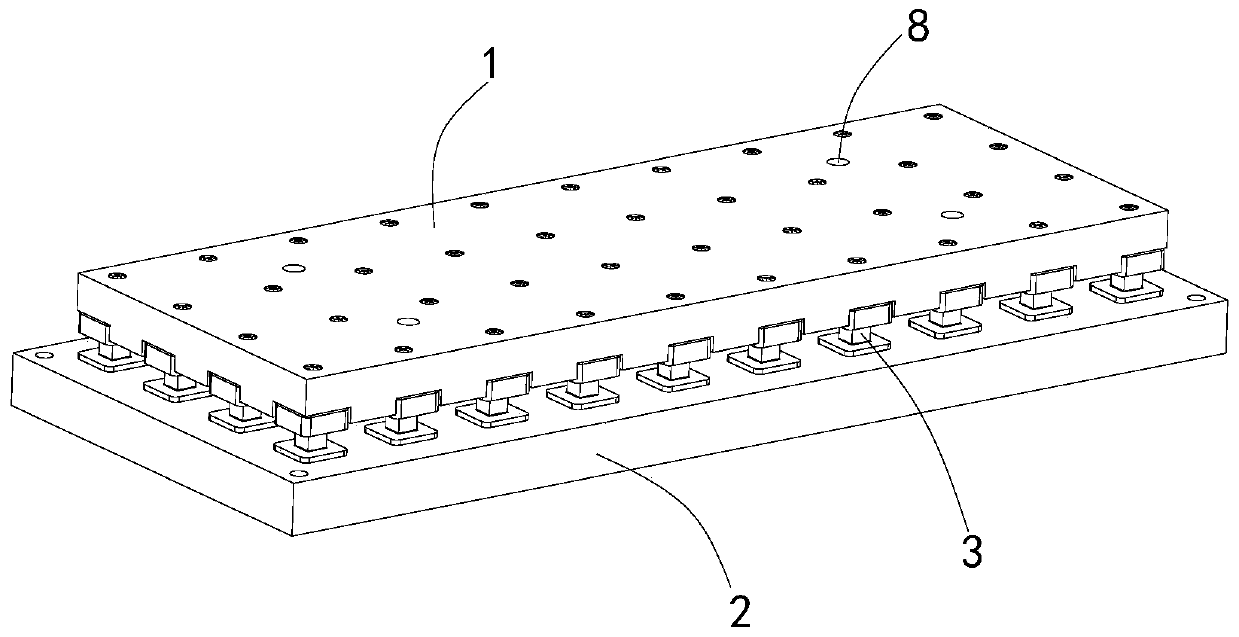

Bearing floor combining steel structure and concrete

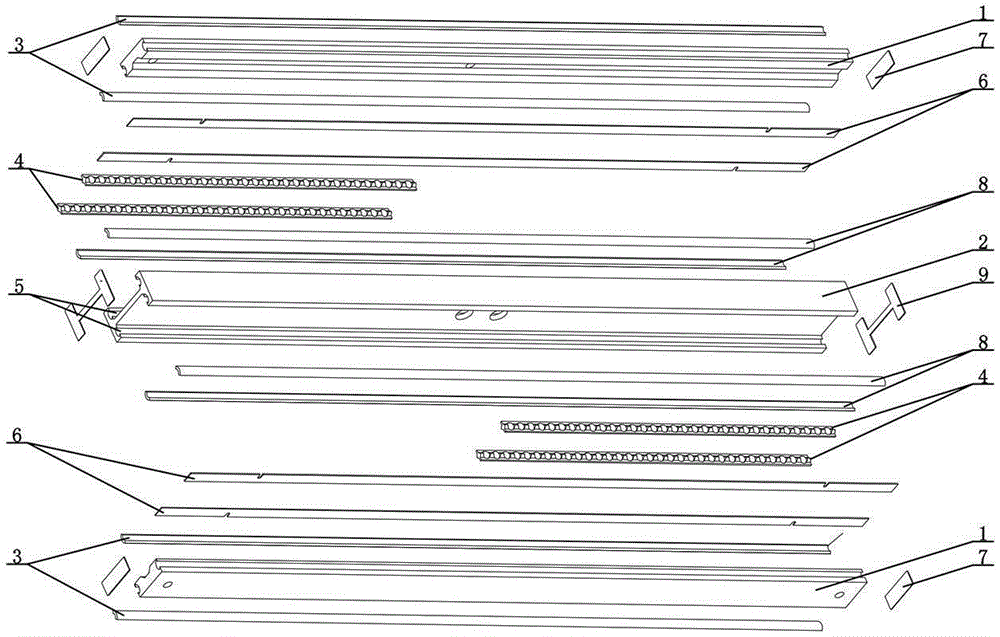

InactiveCN103590522AIncreased load-bearing capacityReasonable structureFloorsFloor slabWeight-bearing ability

A bearing floor combining a steel structure and concrete comprises bearing steel channels (1). The bearing steel channels (1) are placed in parallel at an equal interval, the bearing steel channels (1) are fixedly connected through a plurality of connecting rebars (2), steel wire reinforced nets (3) are arranged on the upper surfaces of the outer sides of the bearing steel channels (1) and the lower surfaces of the outer sides of the bearing steel channels (1) respectively, and a concrete filling body(1) is poured in a framework formed by the bearing steel channels (1), the connecting rebars (2) and the steel wire reinforced nets (3). According to the bearing floor, the bearing steel channels are placed in parallel at the equal interval, the bearing steel channels are fixedly connected through the connecting rebars, the steel wire reinforced nets are arranged on the upper surfaces of the outer sides of the bearing steel channels and the lower surfaces of the outer sides of the bearing steel channels respectively, high bearing capacity can be obtained through mutual connecting and matching of the concrete and the steel beam framework, the bearing capacity which does not exist in an existing common steel beam floor or a common concrete floor is achieved, and the bearing floor is high in deformation resistance.

Owner:HUBEI HONGLU STEEL STRUCTURE

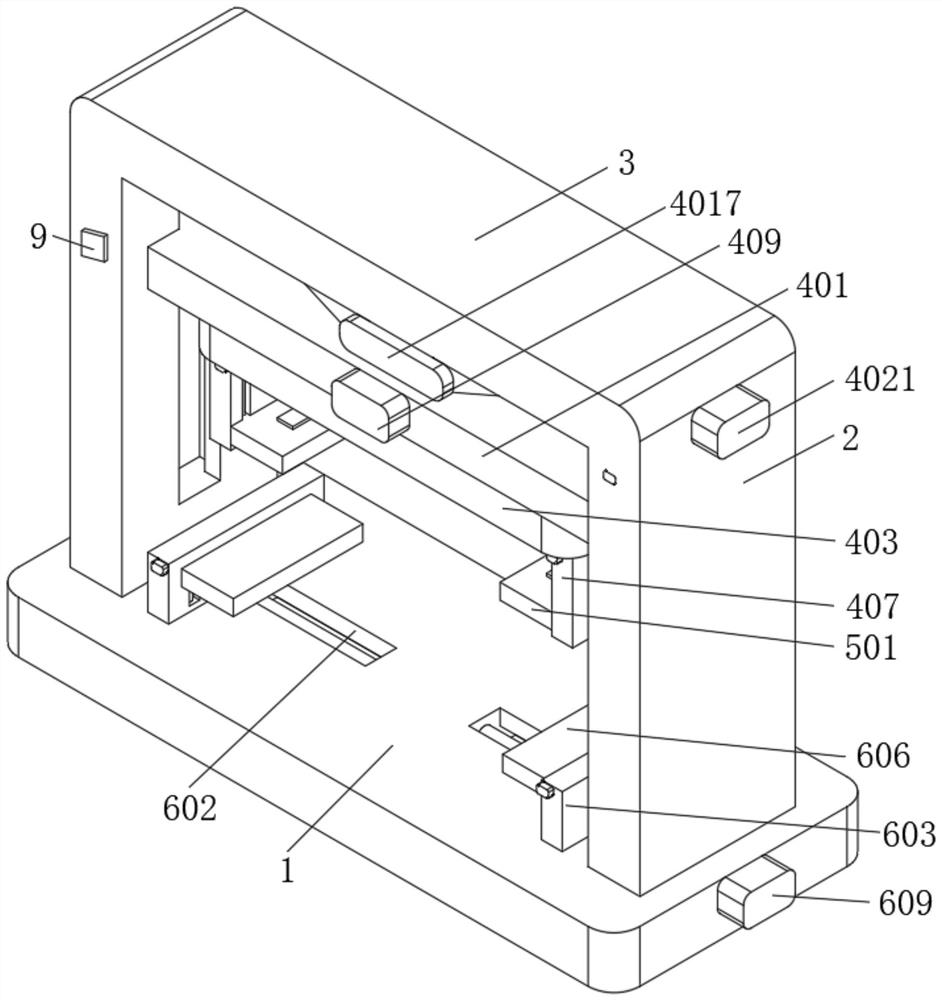

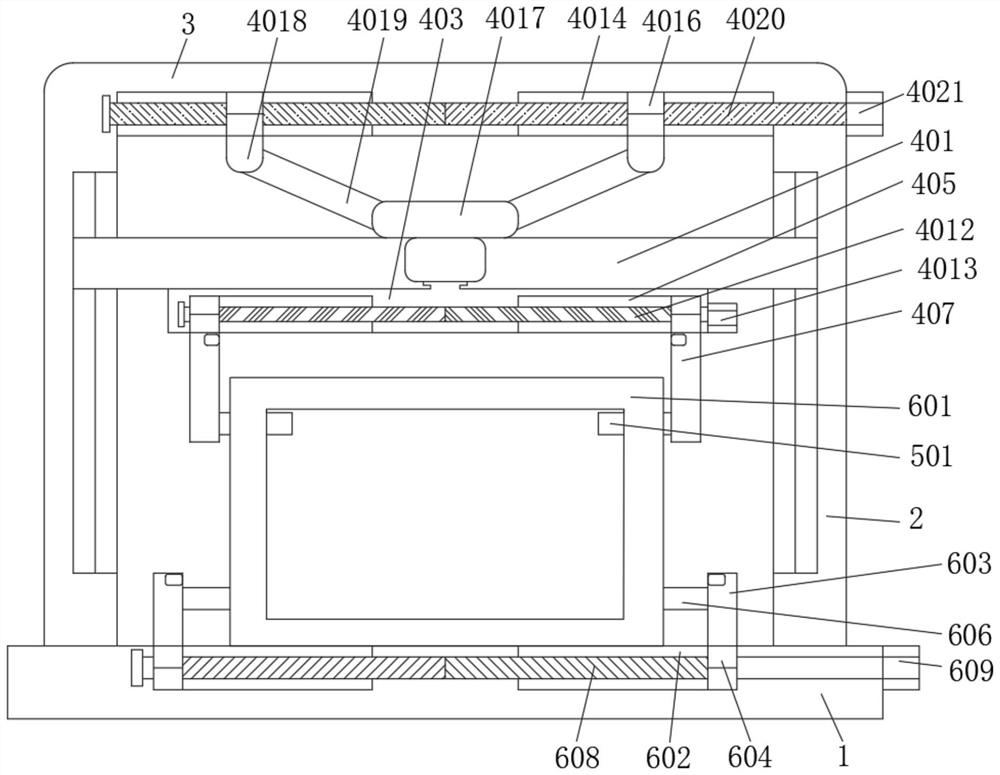

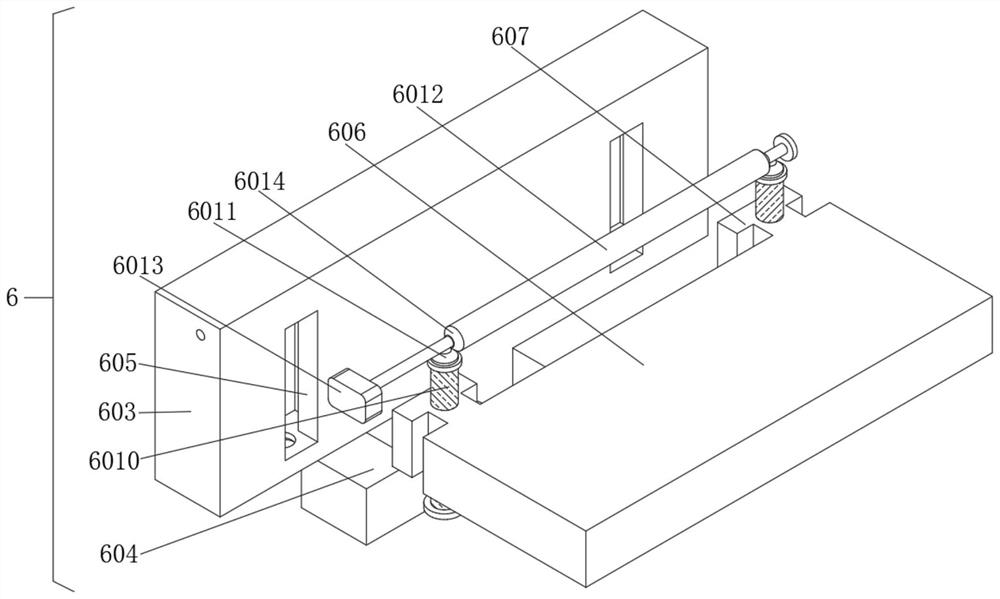

Climbing frame state detection device and method for construction site

ActiveCN114689438ASolve the load-bearing capacityEffective adjustment and fixationMachine part testingMaterial strength using tensile/compressive forcesSingle supportWeight-bearing ability

According to the technical scheme, the climbing frame state detection device for the construction site comprises a base, supporting plates are fixedly connected to the two sides of the top of the base, a top plate is fixedly connected to the tops of the supporting plates, and a detection mechanism is arranged between the top plate and the base; the detection mechanism comprises a first-stage adjusting assembly and a fixing assembly, the first-stage adjusting assembly is arranged at the bottom of the top plate, and the fixing assembly is arranged at the top of the base. According to the climbing frame, multi-directional anti-pressure capability, anti-stretching capability and anti-extrusion capability of the whole climbing frame can be detected at the same time, and the problem that the overall bearing capability of the existing climbing frame is mostly detected by judging whether the bearing of each bracket is standard or not is effectively solved; whether the bearing capacity of a single support is qualified or not cannot represent whether the overall bearing capacity is qualified or not.

Owner:江苏鑫昇腾科技发展股份有限公司

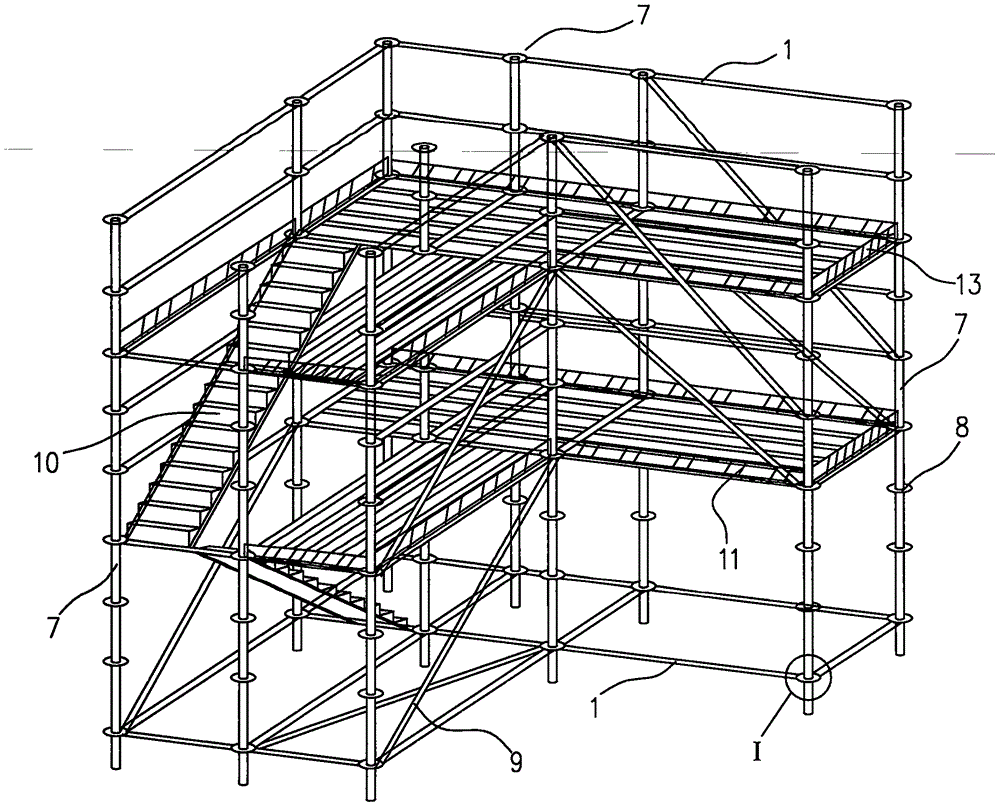

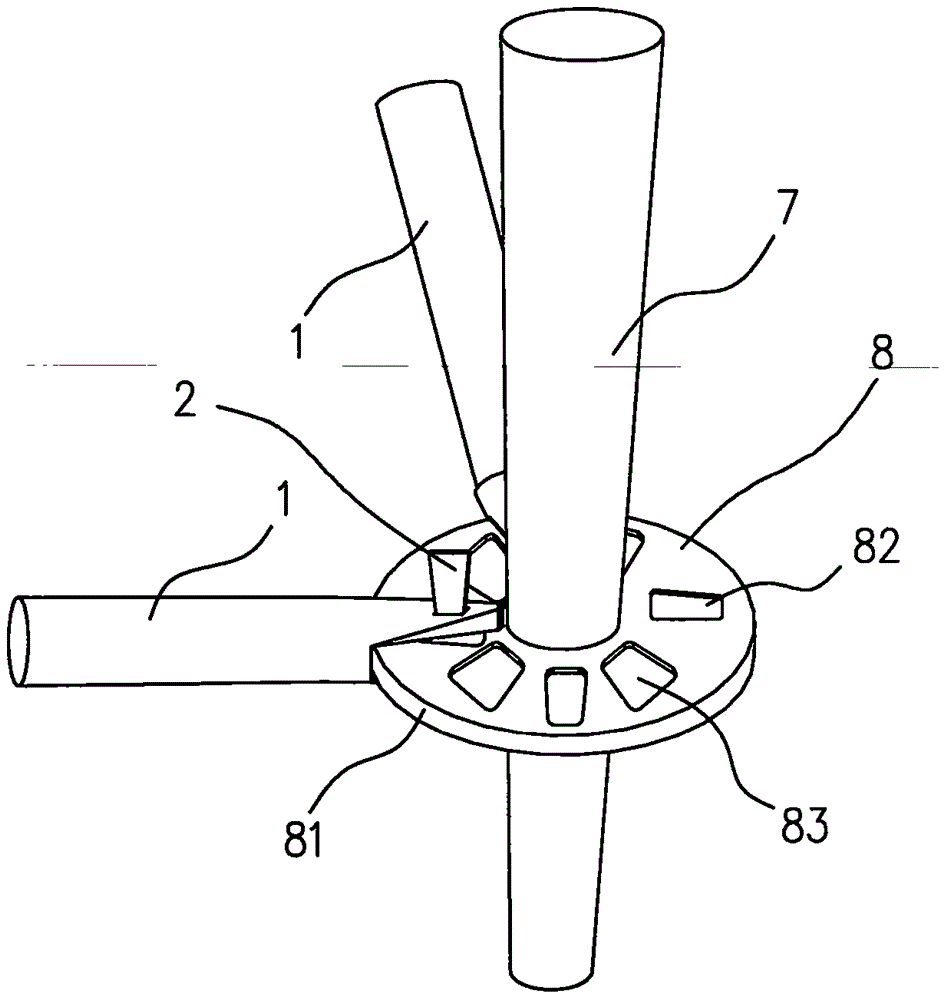

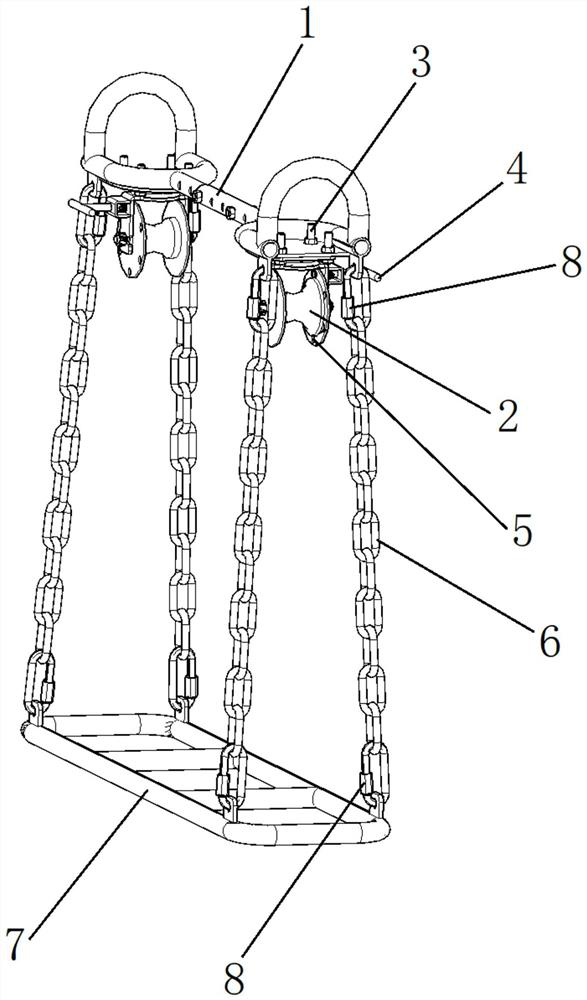

Novel com bined scaffold capable of adjusting position of standing plates and with ultra-safety performance

InactiveCN106193575AFirmly connectedPrevent looseningScaffold connectionsScaffold accessoriesWeight-bearing abilityMetal hook

The invention discloses a novel combined scaffold capable of adjusting position of standing plates and with ultra-safety performance. The scaffold is provided with cross rod connecting pieces, vertical rods and oblique-pulling rods. The cross rod connecting pieces and the vertical rods are combined to be the scaffold with multiple layers, on each layer a standing plate is laid. The standing plate is composed of a cross beam and a metal net. Cross beams are connected in vertical and transverse direction to form a framework. Metal nets are installed on a framework. An outermost cross beam is provided with a metal hook having a semi-circular arc hook and a straight connecting section. Each semi-circular circular hook is used for hooking the upper side of each cross rod connecting part. Each connecting section is welded on each cross beam or inserted into each cross beam. The novel combined scaffold capable of adjusting position of standing plates and with ultra-safety performance has following advantages: by a special connection structure and a connection mode, the standing plates are firmly connected with the cross rods so that the standing plates have higher bearing capabilities; all parts are connected closely and do not loose; and the scaffold is firmly and stably installed so that safety performance is ensured.

Owner:上海捷超脚手架有限公司

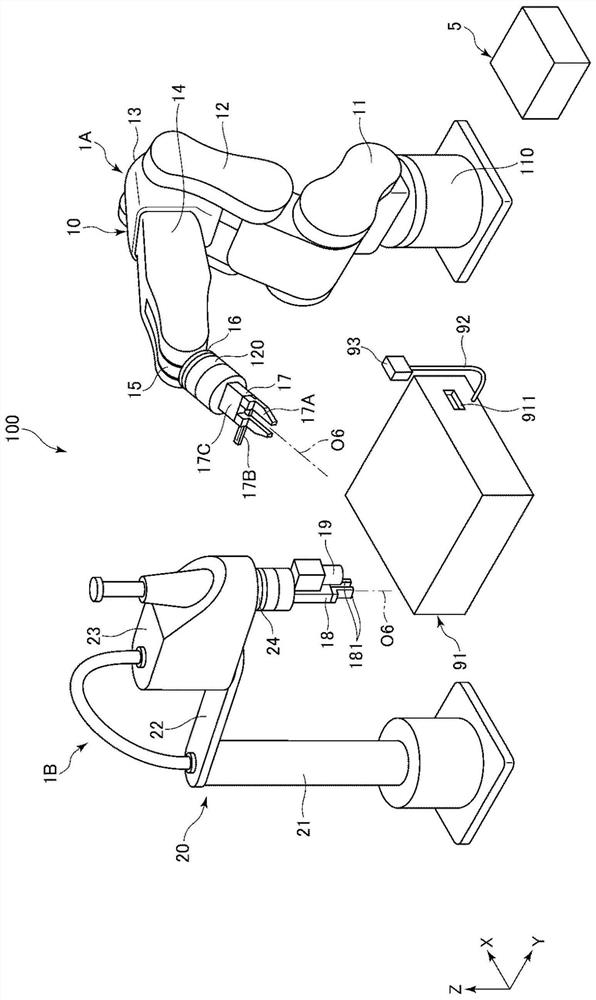

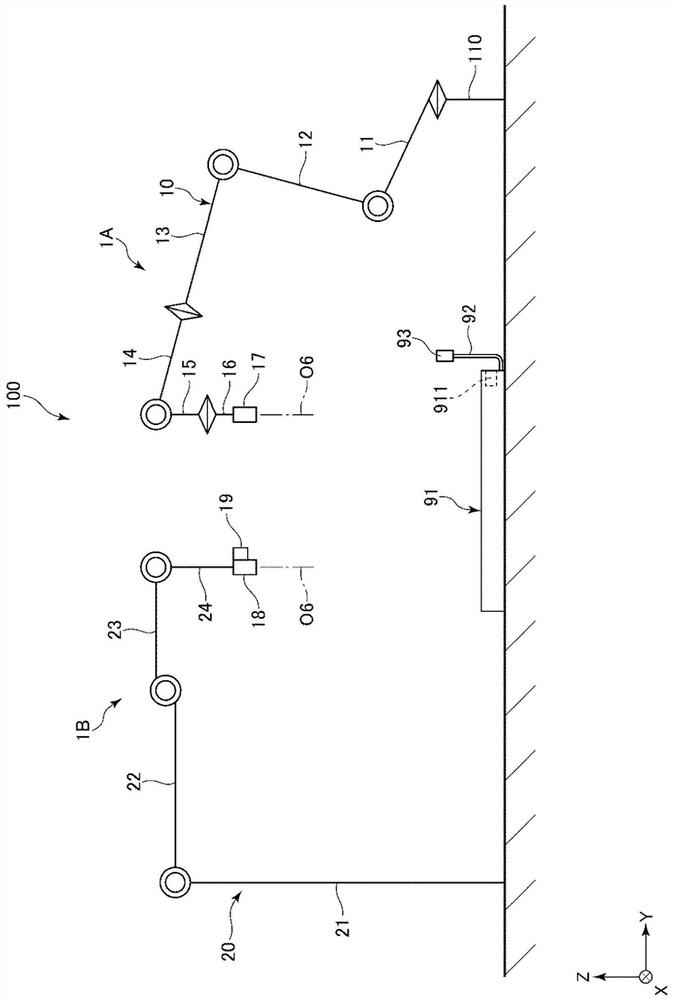

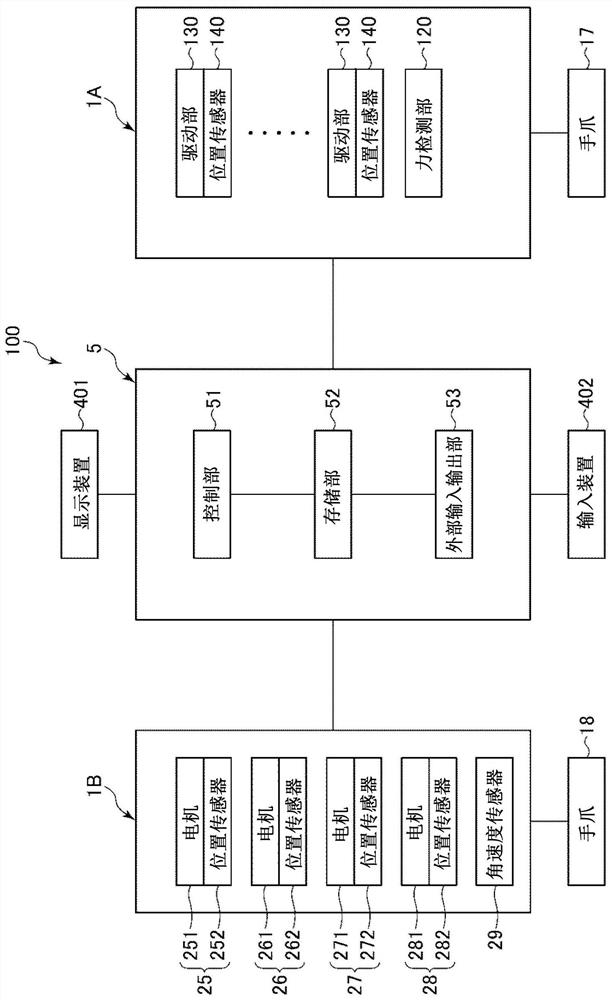

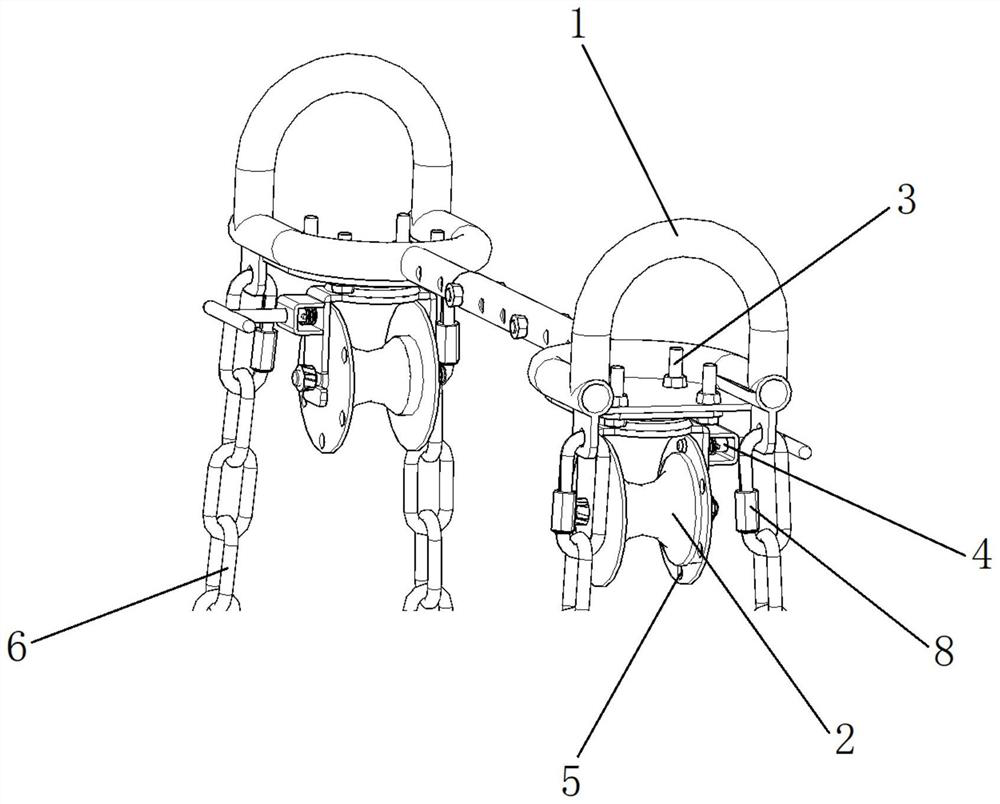

Robot system

ActiveCN111618845AProgramme-controlled manipulatorGripping headsRobotic systemsPhysical medicine and rehabilitation

The invention provides a robot system capable of sufficiently ensuring load-bearing capacity. The robot system is characterized by being provided with: a robot having an arm; and a gripper connected to the arm, the gripper having: a first grip section having a first claw part and a second claw part that approach or separate from each other; a second holding part having a third claw part and a fourth claw part which are close to or separated from each other; and a drive unit for driving the first holding part and the second holding part, wherein the first claw part is connected to the third claw part, the third claw part is separated from the fourth claw part when the drive unit brings the first claw part and the second claw part closer to each other, and the third claw part is brought close to the fourth claw part when the drive unit separates the first claw part and the second claw part.

Owner:SEIKO EPSON CORP

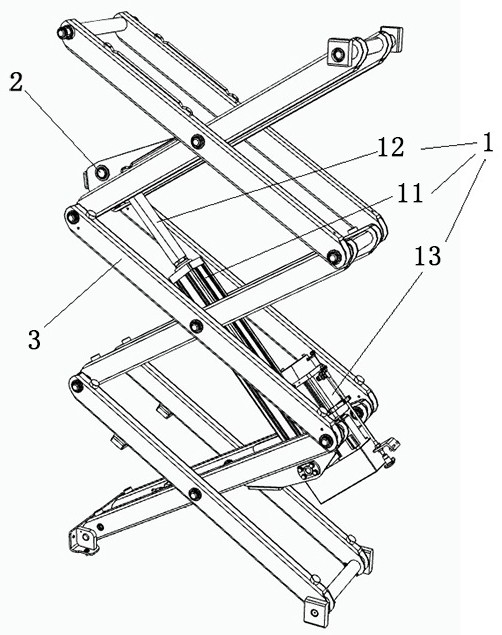

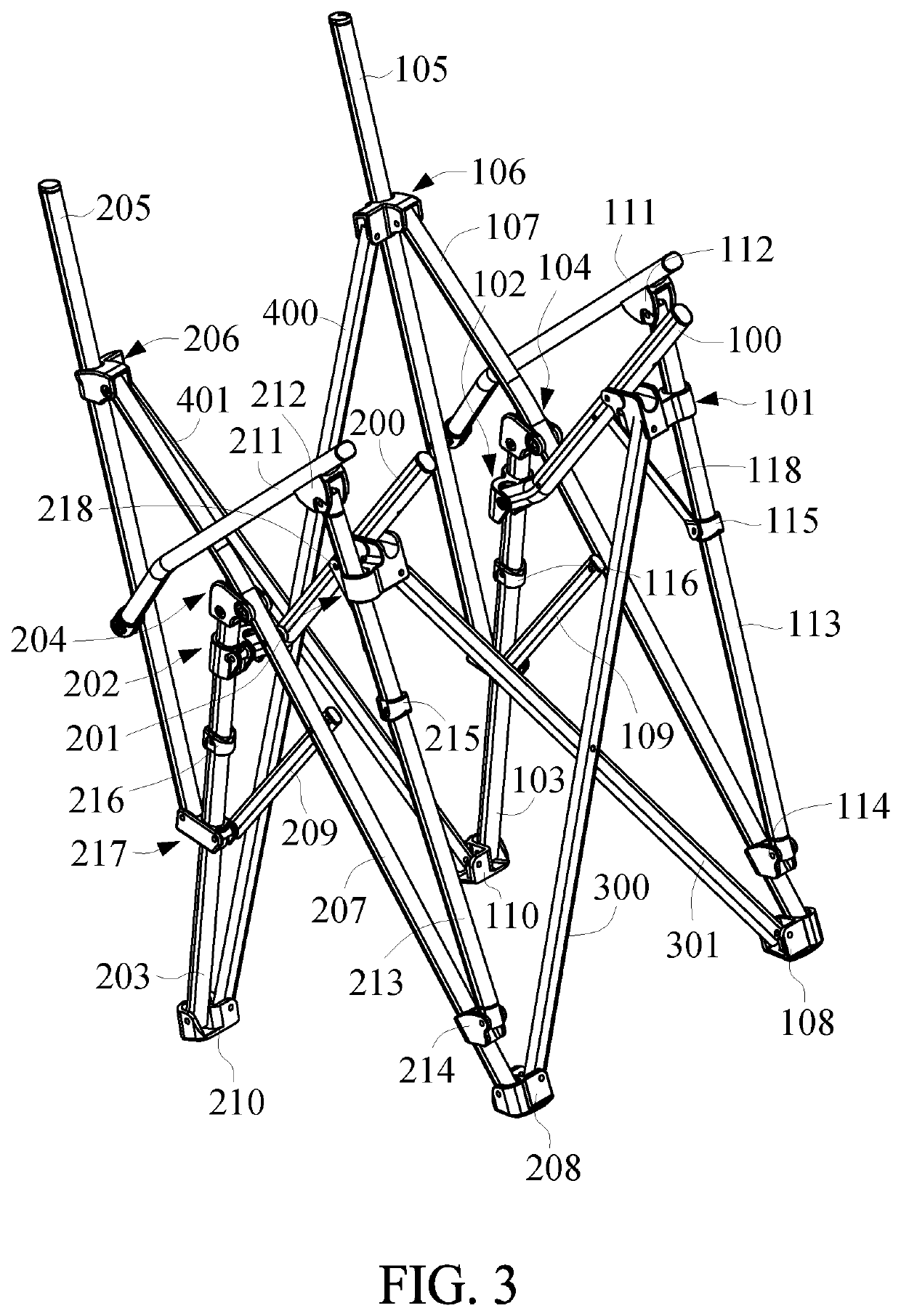

Scissor fork type aerial work platform and scissor fork lifting assembly thereof

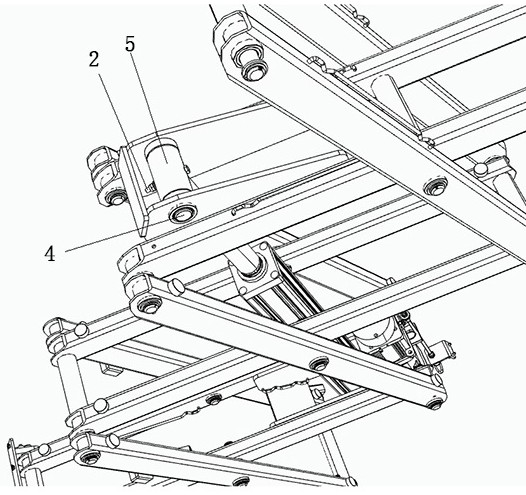

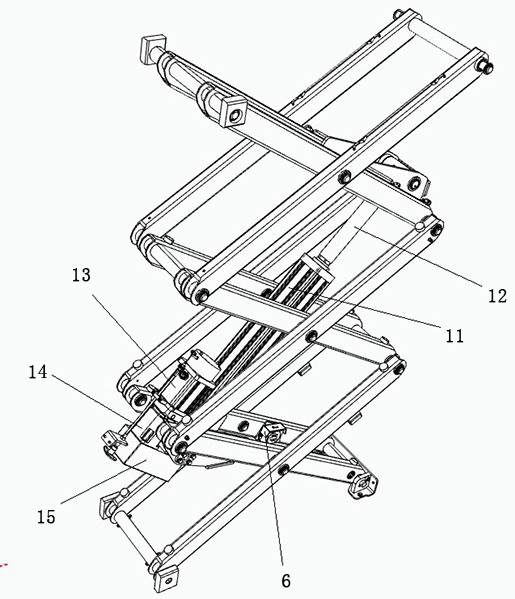

PendingCN114572911AAvoid damageAvoid security issuesSafety devices for lifting equipmentsGearingWeight-bearing abilityClassical mechanics

The invention relates to the technical field of aerial work machinery, in particular to a scissor type aerial work platform and a scissor lifting assembly thereof, the scissor lifting assembly comprises a scissor frame, a lifting mechanism and a weighing mechanism, a rotary connecting rod is transversely arranged on the scissor frame in a penetrating mode, and the rotary connecting rod can rotate around the central axis of the rotary connecting rod; the hoisting mechanism comprises a driving base and a push rod extending out of the driving base; the lower end of the driving base is rotationally connected with the shear fork frame, and a rotary sleeve is fixed to the extending top end of the push rod and fixedly sleeves the periphery of the rotary connecting rod; the weighing mechanism is arranged on the rotary sleeve and the rotary connecting rod and can measure the bearing capacity of the rotary connecting rod. The weighing mechanism can measure the bearing capacity of the rotary connecting rod, a manufacturer determines that the maximum bearing capacity of one rotary connecting rod corresponds to the maximum bearing capacity of the shear fork frame, and the weighing mechanism can enable a user to see whether the actually-measured bearing capacity exceeds the specified maximum bearing capacity or not in a manner of externally connecting a display screen and the like. And safety accidents caused by overload are avoided.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

Steel-aluminum guide rail

InactiveCN105370731AReduce frictionReduce the degree of deformationLinear bearingsBearing componentsWeight-bearing abilityWear resistant

The invention discloses a steel-aluminum guide rail which comprises a movable bearing rail, two groups of slide rails and sliding auxiliary parts, wherein grooves are formed in the two sides of the movable bearing rail respectively; the two groups of slide rails are arranged in the grooves formed in the two sides of the movable bearing rail in a sliding mode through the sliding auxiliary parts respectively; a first wear resistant part is arranged between each sliding auxiliary part and each group of slide rails; a second wear resistant part is arranged between each sliding auxiliary part and the movable bearing rail; the movable bearing rail and the slide rails are all made of aluminum alloy; and the first wear resistant parts and the second wear resistant parts are all made of steel. The steel-aluminum guide rail can greatly promote the bearing capability of the guide rail and prolong the service life, has very excellent performance and is lower in cost compared with the traditional guide rail with the same bearing capability.

Owner:周朝强

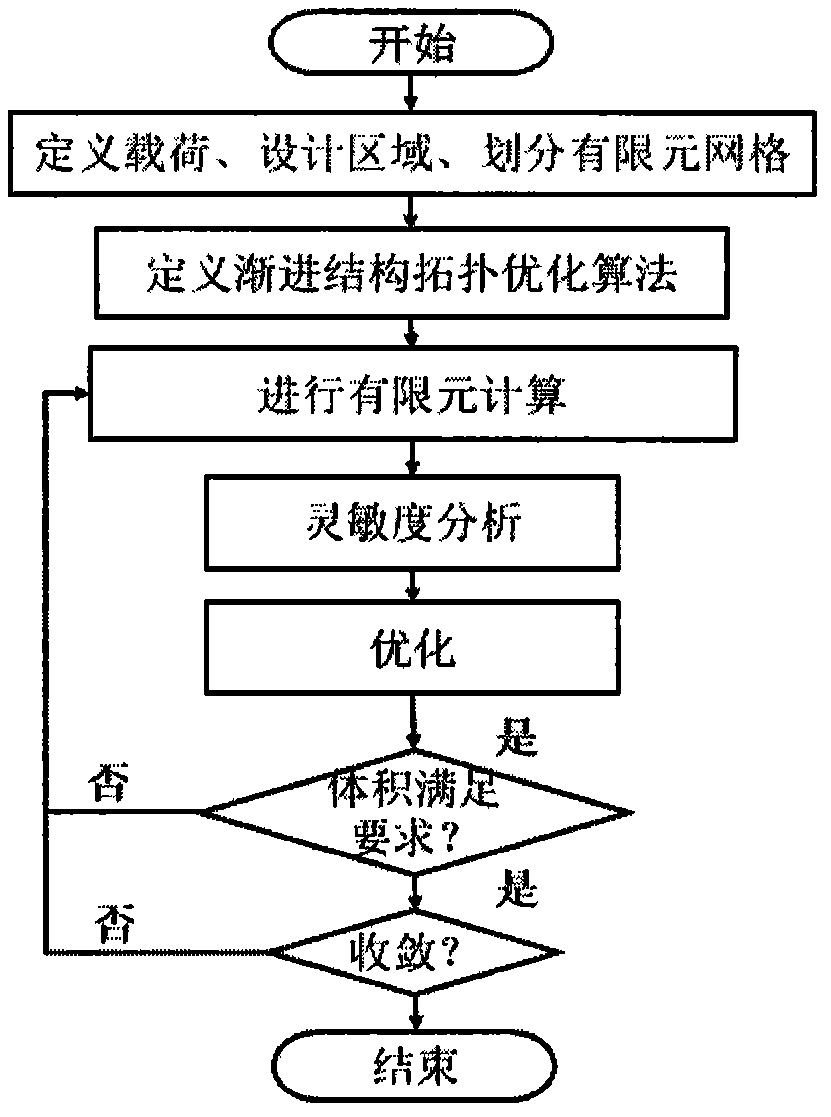

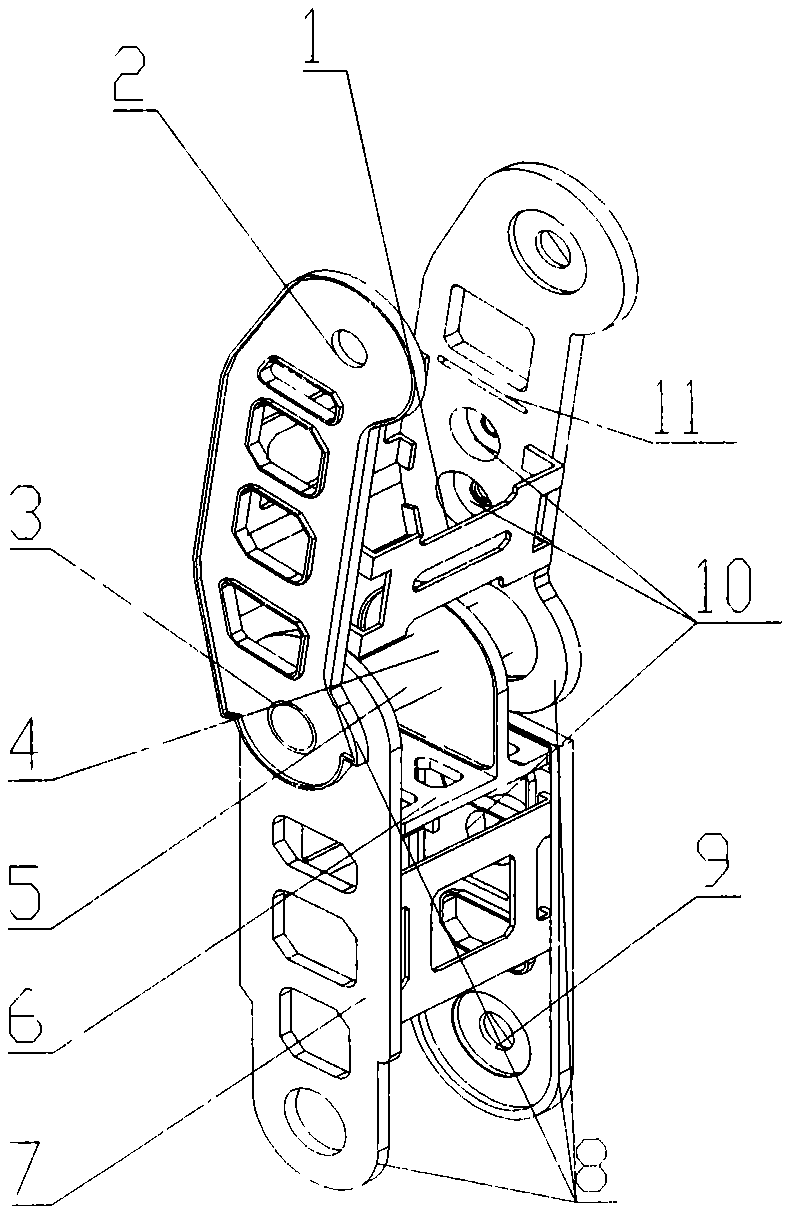

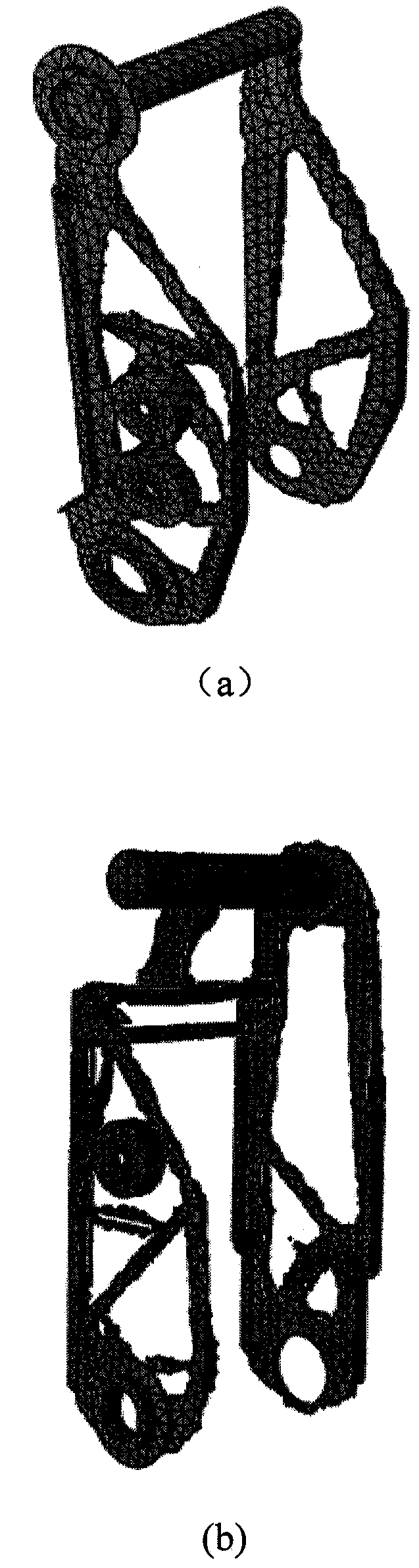

Lightweight design method of leg structure of biped humanoid robot

InactiveCN104318038AEfficient use ofReduced structure profileSpecial data processing applicationsWeight-bearing abilityElement analysis

The invention provides a lightweight design method of a leg structure of a biped humanoid robot. The lightweight design method comprises the following steps: (1) performing evolutionary structural topological optimization based design on the leg structure of the robot according to the weight bearing ability of the leg structure of the robot, and setting two working conditions, namely an upright state in which the included angle of the body and the legs is 180 degrees and an bent state in which the included angle is 150 degrees, for finite element analysis, (2) performing meshing, freezing fixed and part installed components and bolt and sliding groove components with the strain energy of the sum of two load working conditions as a target function and the volume as a constraint condition, adopting withdrawing pattern constraint in the vertical direction of a cover plate and performing topological structural optimization, and (3) designing the legs of the humanoid robot according to the optimization result. The lightweight design method of the leg structure of the biped humanoid robot is capable of realizing the optimal distribution of materials and reducing the outline and the quality of the leg structure of the biped humanoid robot by virtue of the evolutionary structural topological optimization.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

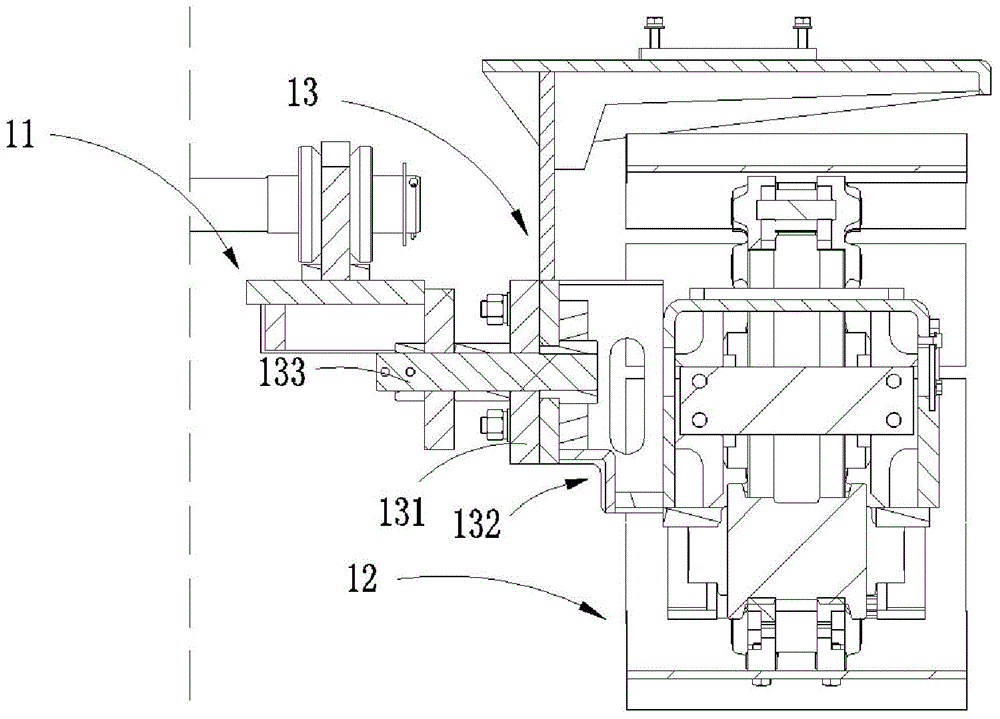

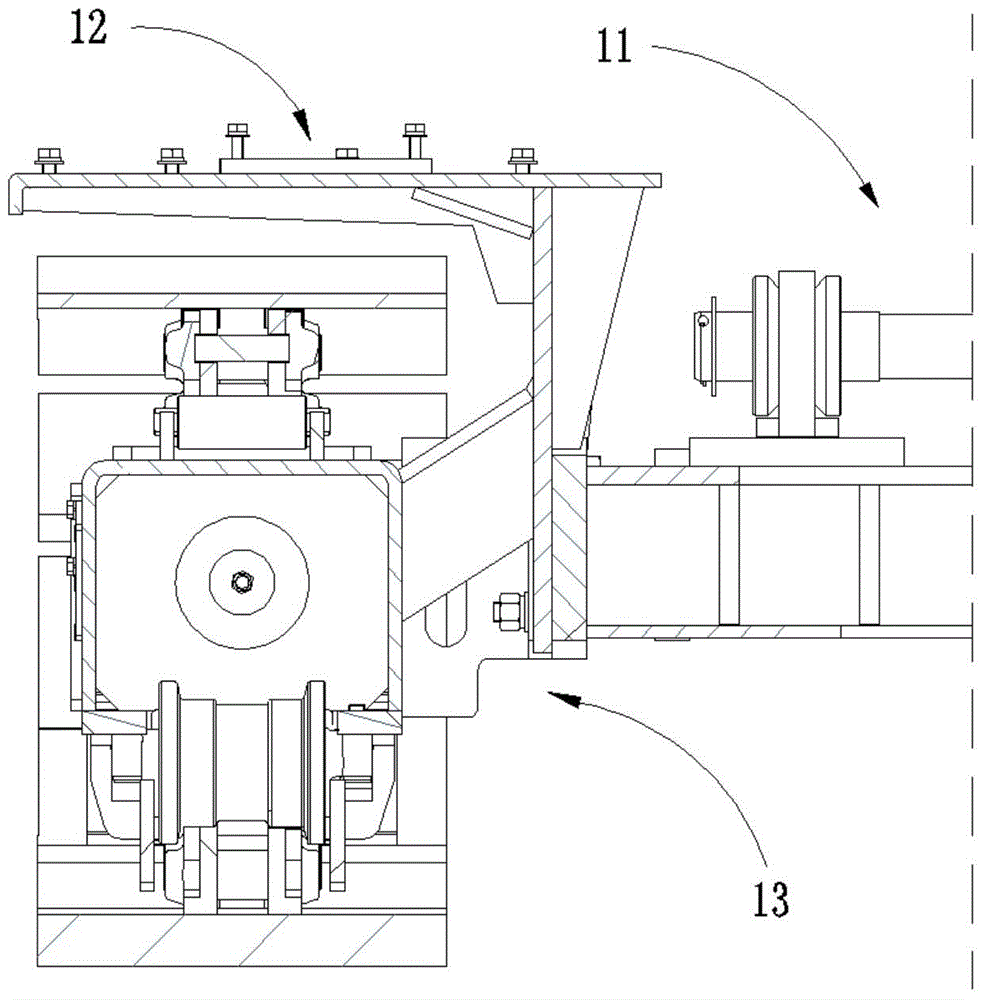

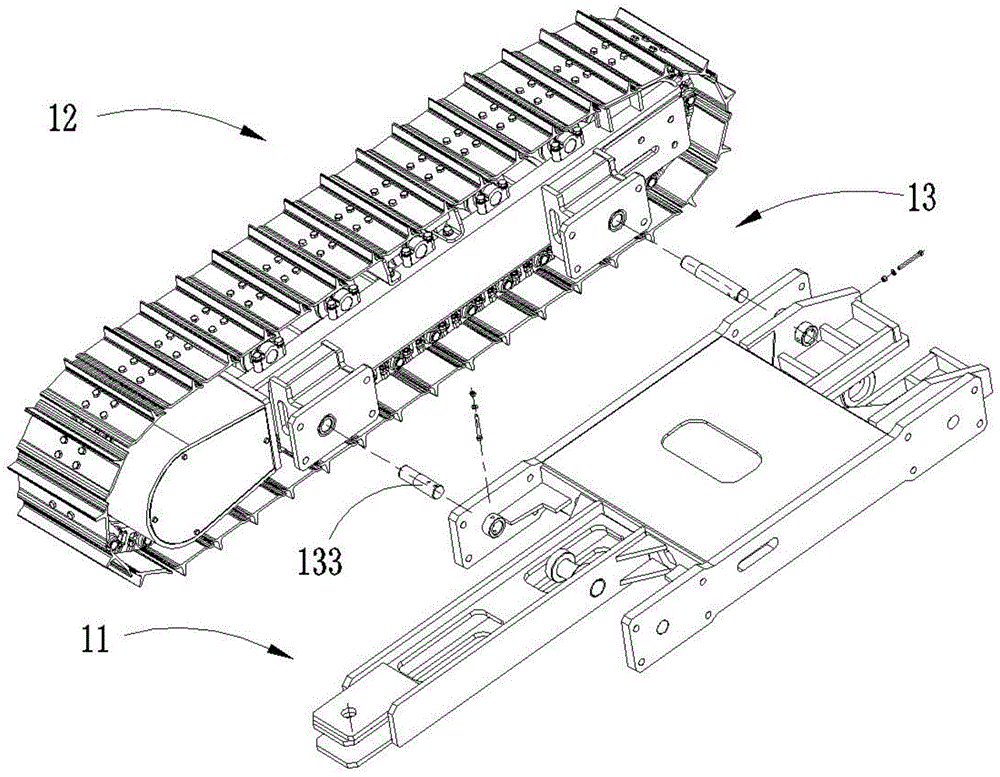

Chassis mechanism used for crawler-type backhoe loader and mounting and demounting of chassis mechanism

ActiveCN104005443AEasy to installEasy disassemblySoil-shifting machines/dredgersEmbedded systemRolling chassis

The invention discloses a chassis mechanism used for a crawler-type backhoe loader and a mounting and demounting of the chassis mechanism. The chassis mechanism comprises a chassis supporting mechanism and two traveling mechanisms, and two sides, along the traveling direction, of the chassis supporting mechanism are movably connected with the traveling mechanisms through two demounting and mounting mechanisms respectively. Compared with the prior art, the chassis mechanism has the advantages that the chassis mechanism is initiatively demounted into three portions under the premise that working capability and safety factors are unchanged, so that size and weight of each portion of the chassis mechanism are reduced, and load-bearing capability of the chassis mechanism is further improved; the chassis mechanism is simple and quick in mounting method, and the objectives of simplicity in demounting and mounting and convenience in transporting by utilizing the demounting and mounting mechanisms are achieved, so that the chassis mechanism is quite wide in application prospect.

Owner:HUNAN NEW TIMEHOPE CONSTR MACHINERY

Clamping plate capable of being stacked and preparing method for shell layer of clamping plate

PendingCN107187696AReduce weightEasy to stackFlat articlesRigid containersWeight-bearing abilityEngineering

Owner:东莞市腾卓美环保新材料科技有限公司

Power assisting device for increasing walking and running speeds

InactiveCN105148492ASimple structureReasonable structureMassage combsMassage beltsWeight-bearing abilityEngineering

The invention discloses a power assisting device for increasing walking and running speeds. The maintaining cavity of an arc air bag of the power assisting device is positioned at the two ends, the pushing cavity of the arc air bag is positioned in the middle and bandages are positioned on two edges, the front surface of the arc air bag is an arc-shaped surface, an inflation valve is fixed on the cavity body of the maintaining cavity, and an oil passing hole in the cavity body of the pushing cavity is communicated with an oil passage hole in a power shoe. One arc air bag is communicated with one power shoe through a hydraulic pipe, and two arc air bags and two power shoes form a pair of power assisting devices for increasing the walking and running speeds. The power assisting device provided by the invention has a simple and compact structure, and the manufacturing and the using are very convenient; a user puts less effect in running and walking, knee pressure in weight-bearing walking and weight-bearing running can be reduced, the weight-bearing ability can be enhanced, the speed is increased, and the use cannot feel tired due to less physical power consumption; and the power assisting device is suitable for being used by army officers and soldiers to increase the walking speed and enhance the weight-bearing ability, and is also suitable for weight-bearing walking and weight-bearing running as well as walking and running.

Owner:CHONGQING BEIJING TECH RES & DEV

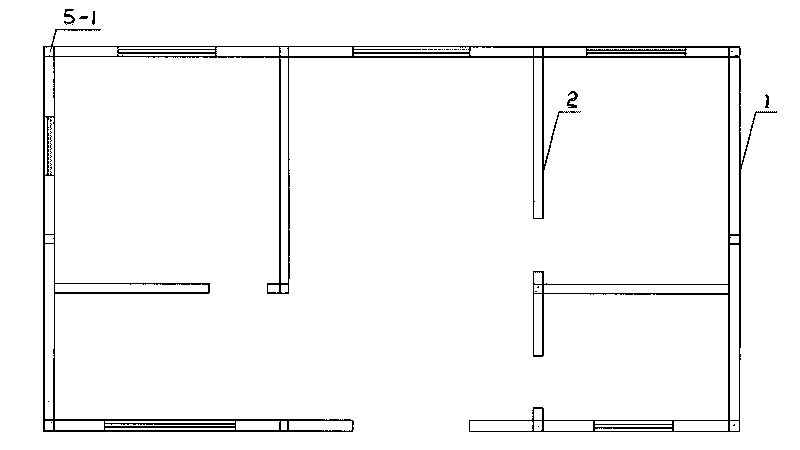

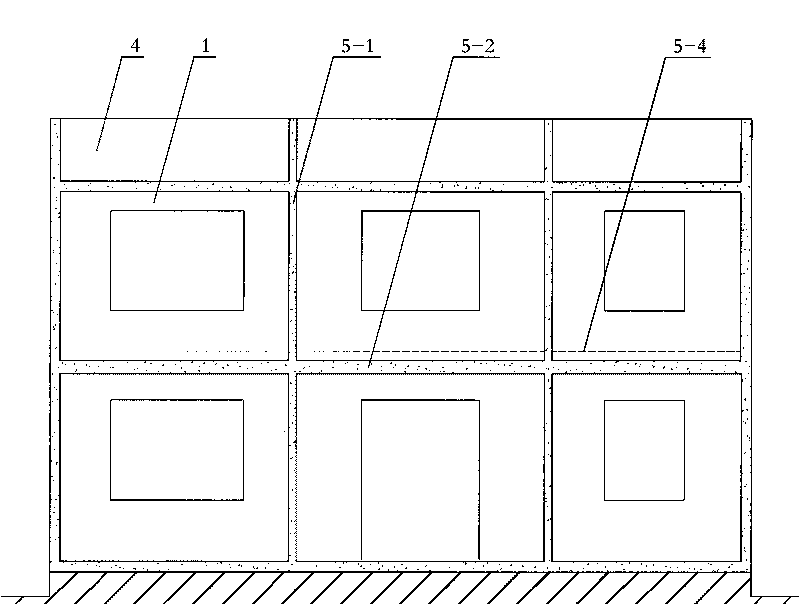

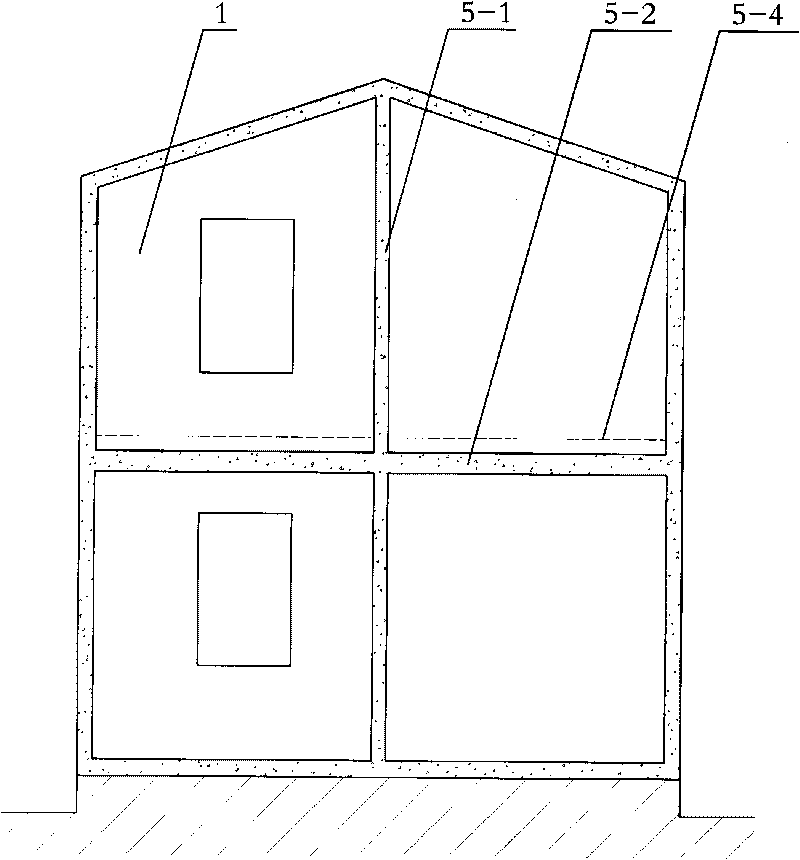

Connecting construction method for assembled-type house building

ActiveCN101718119AMeet different structural force requirementsMeet the structural stress requirementsStrutsPillarsWeight-bearing abilityArchitectural engineering

The invention relates to a connecting construction method for a assembled-type house building. The method comprises the following steps of: keeping a distance between adjacent building panels during mounting the building panels; penetrating main reinforcements through hoop reinforcements arranged around the building panels; pouring concrete in the main reinforcements to form composite concrete construction columns and / or composite concrete construction beams in the relationship of composite stressing with steel structures around the building panels; and by the hoop reinforcements and the main reinforcements around the building panels, firmly and fixedly connecting the concrete with the building panels together, and fixedly connecting the building panels forming a building main body with the base together to bear pressure so as to improve the whole performance and the quake-proof level of the building. The invention has the advantages that the construction is rapid; and by wrapping the exposed steel structures around the building panels, which improves the antisepsis capability of the building panels, the whole performance and the quake-proof level of the building. The invention can be suitable for constructing the assembled-type house building by the building panels with bearing capability or without bearing capability.

Owner:CUBIC DIGITAL TECH CO LTD

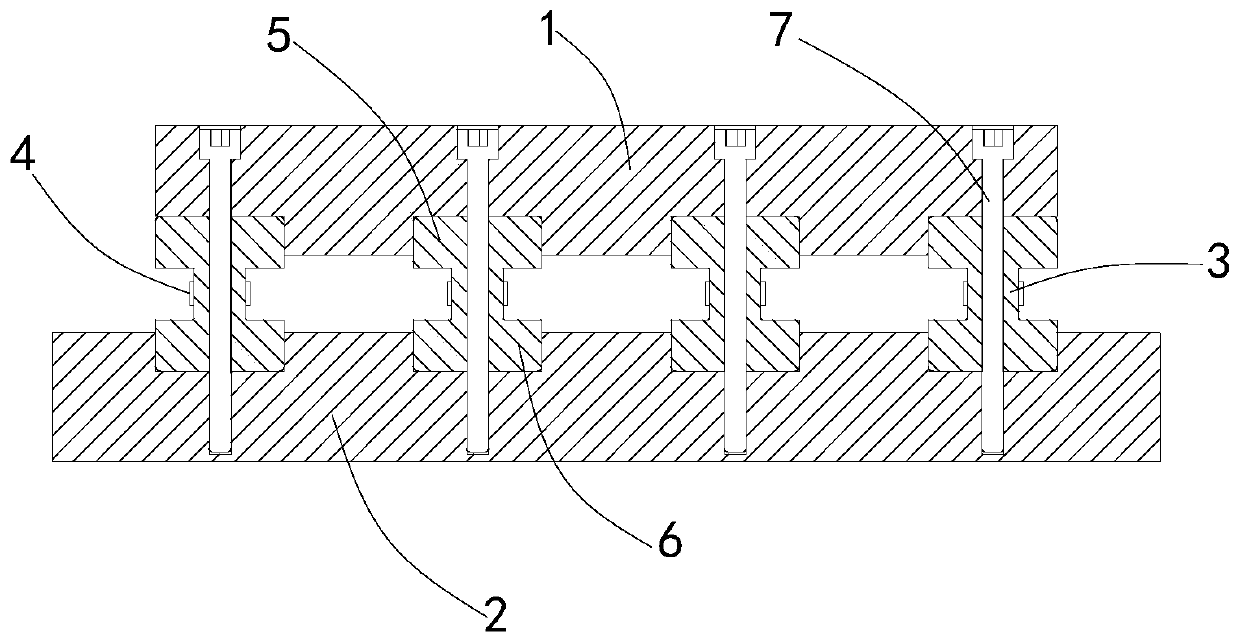

Dynamic weighing sensor and measuring method thereof

InactiveCN111397714AAvoid damageSufficient output amplitudeSpecial purpose weighing apparatusWeight-bearing abilityLoad cell

The invention provides a dynamic weighing sensor. The sensor comprises an upper supporting piece, a lower supporting piece, a sensitive beam and a sensitive element. The sensitive beam is vertically arranged, the upper end of the sensitive beam is installed on the upper supporting piece, and the lower end of the sensitive beam is installed on the lower supporting piece. The sensitive beam is provided with a front side face, a rear side face, a left side face and a right side face. The front side face is parallel to the rear side face, the left side face is parallel to the right side face, andthe front side face is perpendicular to the left side face. Sensitive elements are arranged on the front side face, the rear side face, the left side face and the right side face. The invention further provides a measuring method of the dynamic weighing sensor. The structure is simple, the production and manufacturing difficulty is low, and the production cost is reduced. The output of the four sensitive elements of each sensitive beam is added, so that the influence of brake force, transverse force and the like on output signals can be automatically decoupled, and the measurement accuracy isensured. The sensitive beam is high in bearing capacity, and the sensitive element does not bear load and is prevented from being damaged by pressure.

Owner:李小芳 +1

Adjustable special tool for outgoing line galloping vehicle

PendingCN114069485APlay the role of basic bearingFlexible adjustment and useApparatus for overhead lines/cablesApparatus for laying cablesBrakeWeight-bearing ability

The invention provides an adjustable special tool for an outgoing line galloping vehicle. According to the structure, supports of pulleys are fixed to a fly head fixing support through connecting bolts, a feeding rod is arranged on the supports of the pulleys, a plurality of through holes are formed in wheel discs of the pulleys, the feeding rod is matched with the through holes, an iron cable is connected to the fly head fixing support in a hung mode, a pulley base is connected to the bottom end of the iron cable in a hung mode, and lock catches are respectively arranged on a head-end iron ring and a tail-end iron ring of the iron rope. The two direction-adjustable pulleys are adopted, the distance between the two pulleys can be freely adjusted according to site conditions, and meanwhile the pulleys are provided with brake devices and can be locked when necessary. The use of a flying head can be flexibly adjusted according to the on-site wire arrangement mode; and the bearing capacity of the vehicle body can reach 250 kg, so that an operator can carry out operation after wire outgoing. The tool is suitable for lines which are vertically arranged and horizontally arranged, is stable in structure, is not liable to roll over, is high in bearing capacity, and has outstanding technical advantages.

Owner:ALTAY POWER SUPPLY CO OF STATE GRID XINJIANG ELECTRIC POWER CO +1

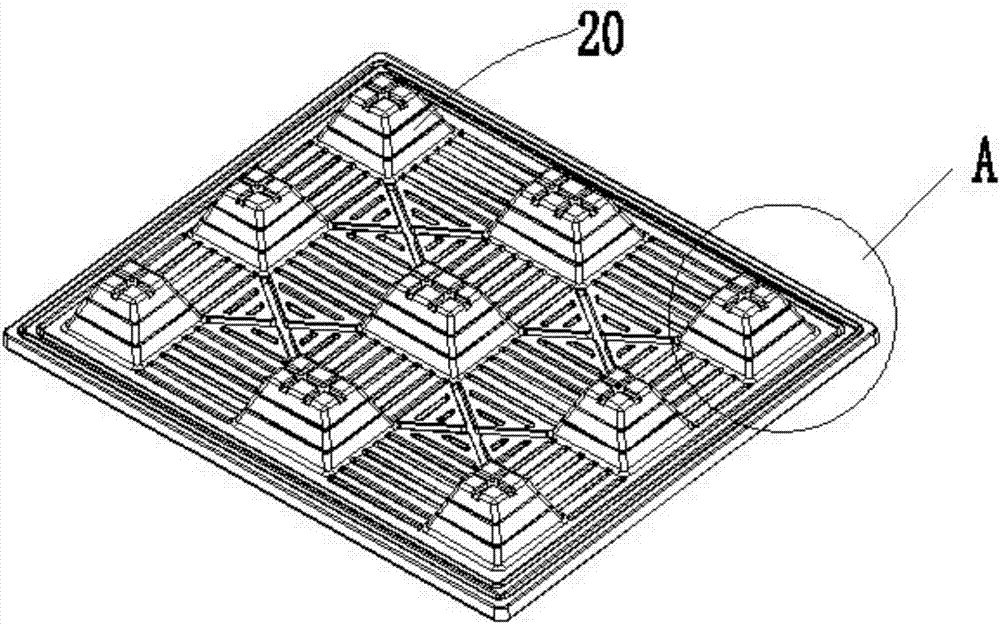

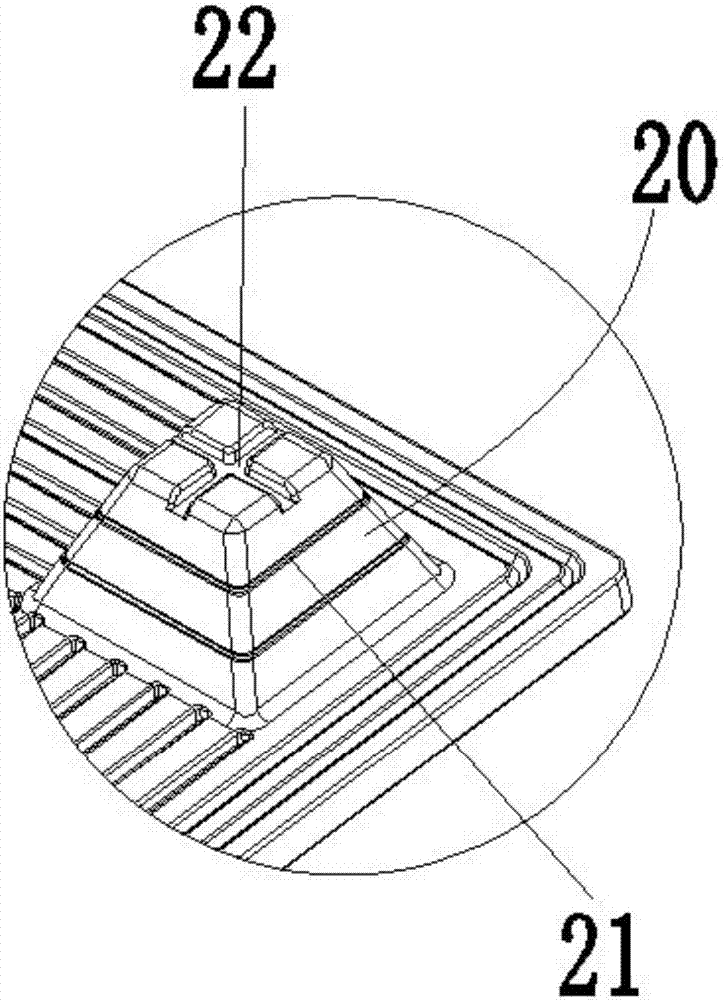

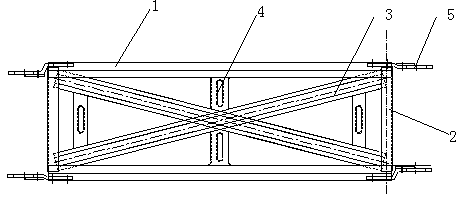

High-bearing-capacity scaffold work platform

InactiveCN104196228AIncreased load-bearing capacityImprove securityScaffold accessoriesWeight-bearing abilityDiagonal

The invention discloses a high-bearing-capacity scaffold work platform comprising side plates, end retainer plates and a bearing structure. The end retainer plates are connected the ends of the side plates. The end retainer plates and the side plates form an outer frame. The support structure is arranged within the outer frame and comprises two oblique bearing plates arranged on diagonals of the outer frame and at least three vertical bearing plates perpendicular to the side plates; a work layer is laid on the oblique bearing plates and the vertical bearing plates. In this way, the high-bearing-capacity scaffold work platform with the triangular structure is higher in bearing capacity, stable in structure and high in safety coefficient.

Owner:WUXI CHENYUAN CONSTR EQUIP

Heavy hinge

PendingCN110821321AImprove fluencyImprove lightweight performanceWing fastenersWeight-bearing abilityMechanical engineering

The invention discloses a heavy hinge, and belongs to the technical field of hardware. The heavy hinge is used for connecting two components needing to be opened and closed. The heavy hinge comprisesa bottom plate, a supporting arm, a short connecting plate and a long connecting plate, the bottom plate is used for being connecting with one of the two components, the supporting arm is connecting with the other component, the short connecting plate and the long connecting plate are used for connecting the supporting arm and the bottom plate, the first end of the short connecting plate is hingedto the supporting arm to form a first supporting arm hinge point, the second end of the short connecting plate is hinged to the bottom plate to form a first bottom plate hinge point, the first end ofthe long connecting plate is hinged to the supporting arm to form a second supporting arm hinge point, the second end of the long connecting plate is hinged to the bottom plate to form a second bottom plate hinge point, a first spacing is arranged between the first supporting arm hinge point and the second supporting arm hinge point, and a second spacing is arranged between the first bottom platehinge point and the second bottom plate hinge point. According to the heavy hinge, opening and closing of the hinge are achieved through a rotating structure; and compared with a sliding support in the prior art, the smoothness, the portability and the workability of a switch are enhanced, and the bearing capacity is improved.

Owner:吴朋辉

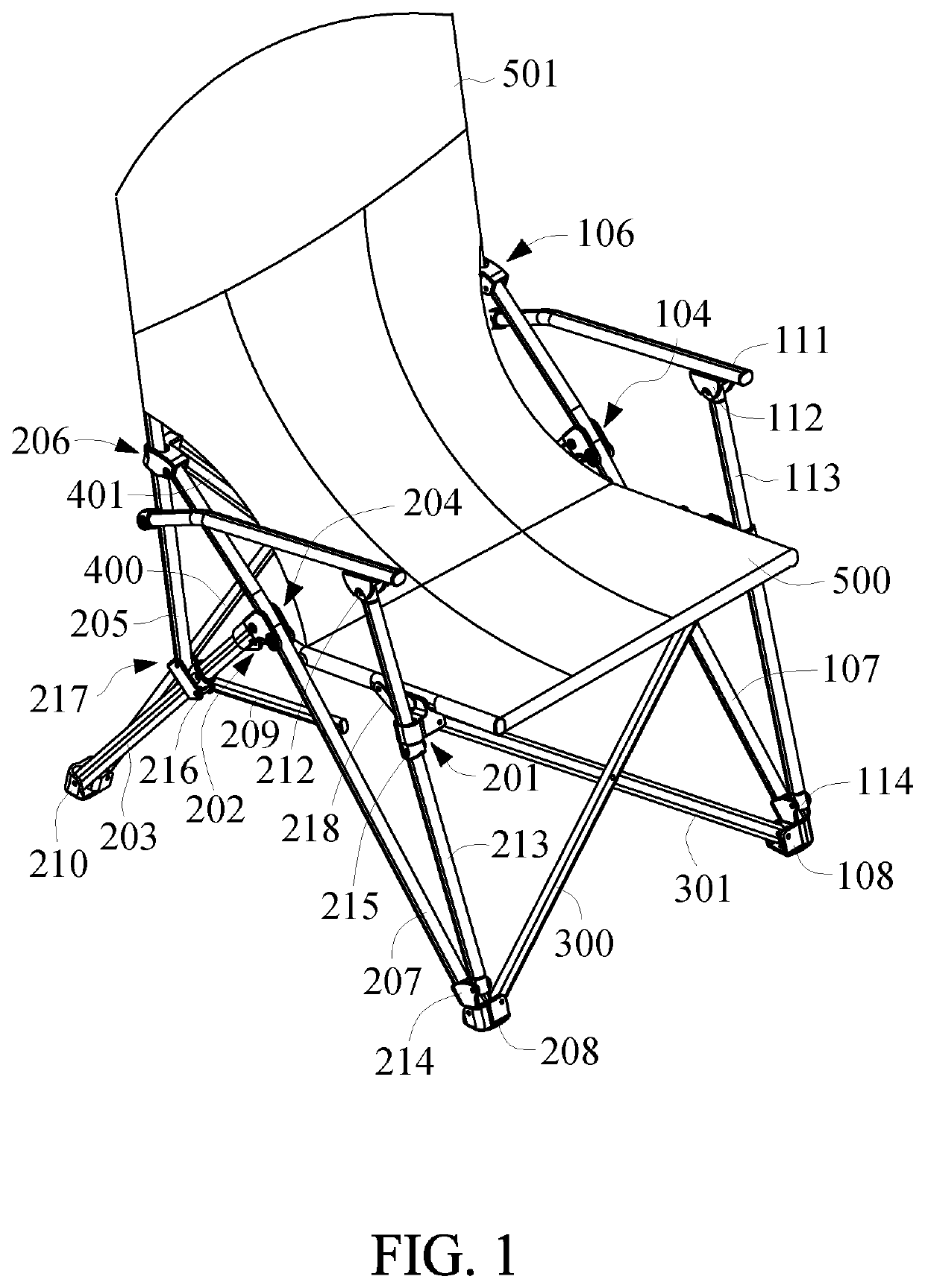

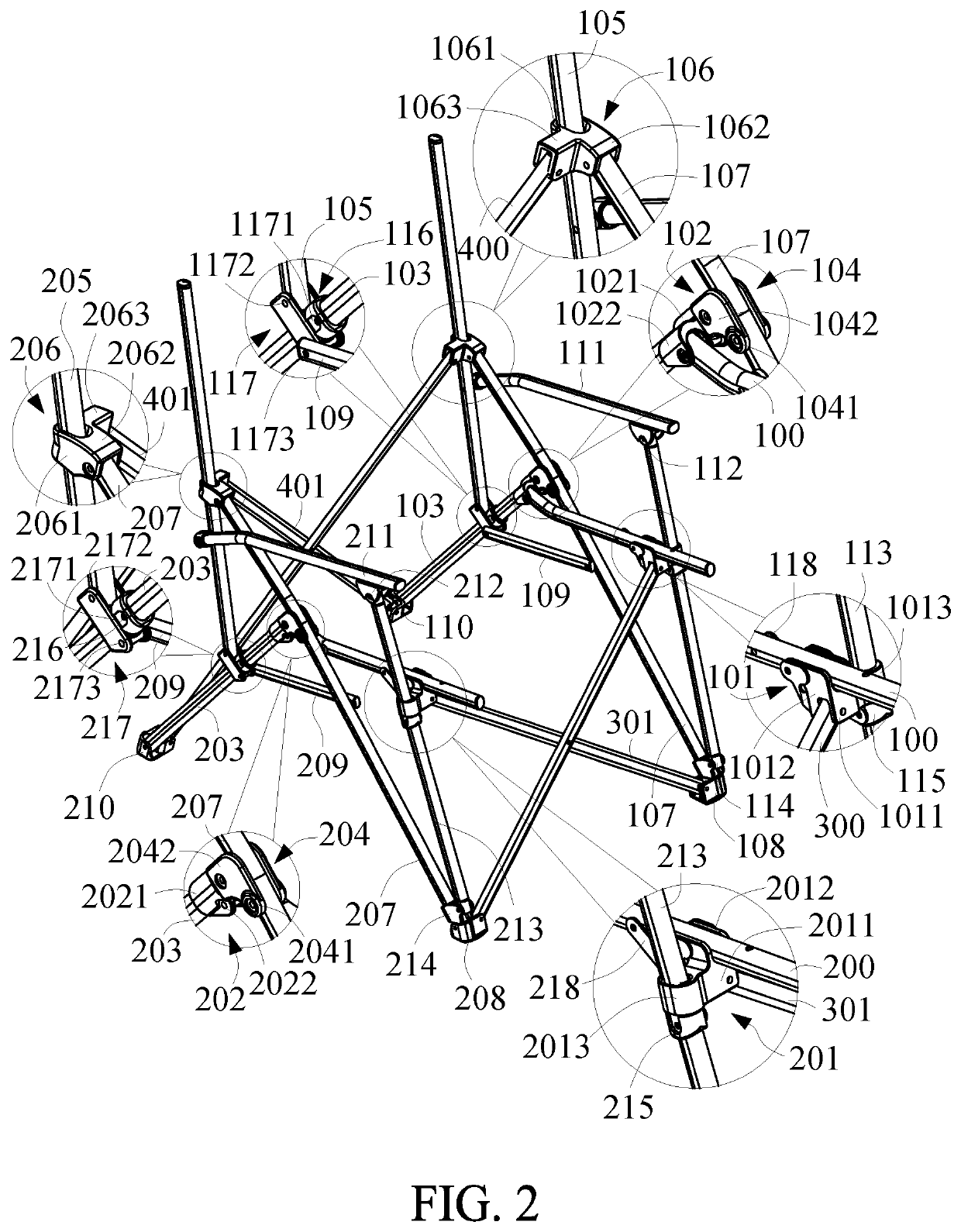

Folding chair

ActiveUS20200288870A1Space minimizationImprove stabilityDismountable chairsFoldable chairsPhysical medicine and rehabilitationWeight-bearing ability

A folding chair includes left and right frame rods, left and right frame rotating elements, left and right rear leg sliding elements, left and right rear leg rods, left and right rear leg fixing elements, left and right back rest rods, left and right back rest rod sliding elements, left and right front leg rods, leg terminals, left and right connecting rods, left and right handrail rods, left and right handrail fixing elements, left and right handrail supporting rods, left and right supporting rod sliding elements, limiting elements, left and right sliding elements, supporting rods, pad portion and back rest portion. The folding chair is compact and portable when folded and demonstrates high stability and high load-bearing capability when unfolded.

Owner:SPORT DIVERSIONS INC

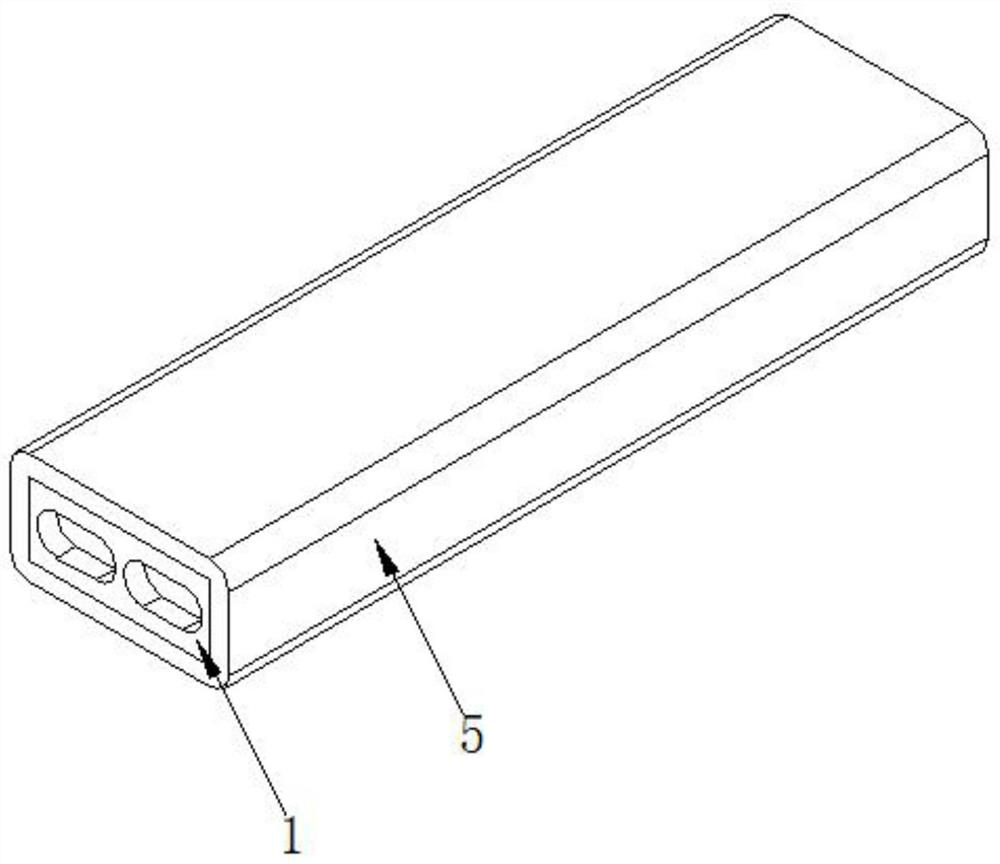

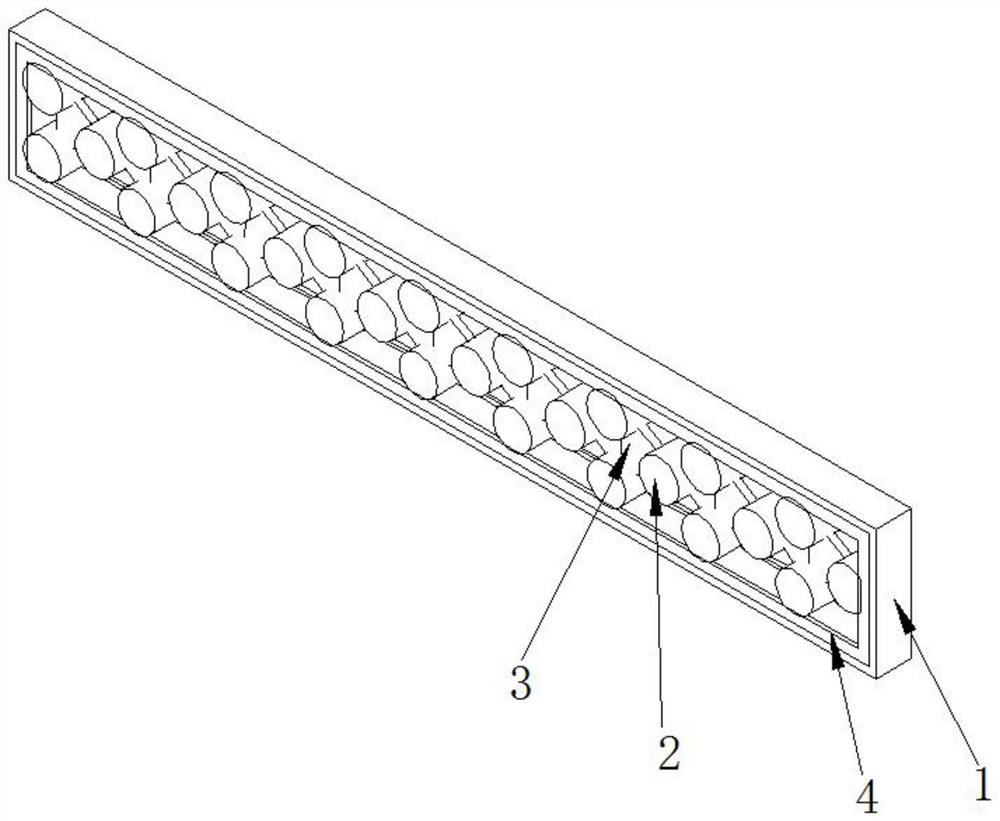

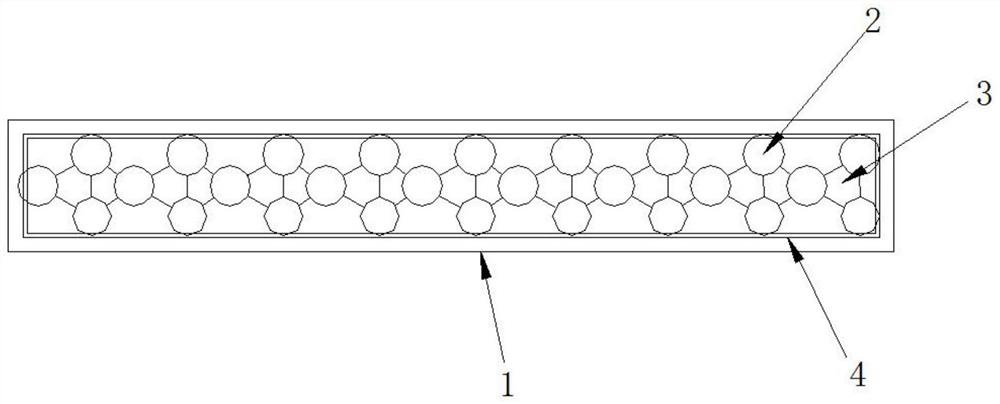

Loading-bearing filler strip and production method thereof

InactiveCN113639043AGuaranteed extrusion load bearingGuaranteed load capacityEngine sealsNon-rotating vibration suppressionWeight-bearing abilityMechanical engineering

The invention discloses a load-bearing filler strip and a production method thereof. The load-bearing filler strip comprises an inner core, damping columns and a load-bearing supporting plate, the load-bearing supporting plate is of a regular triangle structure, and the load-bearing supporting plate is located among the three damping columns. The production method of the load-bearing filler strip comprises the following steps that S1, the inner core is prepared, the inner core 1 is composed of an upper single part and a lower single part which are symmetrical, the single parts are integrally formed through a mold in a pouring mode, the four stages of filling, pressure maintaining, cooling and demolding are conducted, the single bodies are reserved for use after being formed, and lapping grooves are reserved in the inner edges of the two ends of the inner core 1. The loading-bearing filler strip is of an elastic frame structure made of polyurethane, an inner support single part is formed by connecting three waist-drum-shaped support main bodies and triangular plate bodies, extrusion load bearing in the longitudinal direction and the radial direction can be guaranteed, the load bearing effect is guaranteed through multi-point component force, and the overall load bearing capacity is improved.

Owner:肇庆市众成橡胶制品销售有限公司

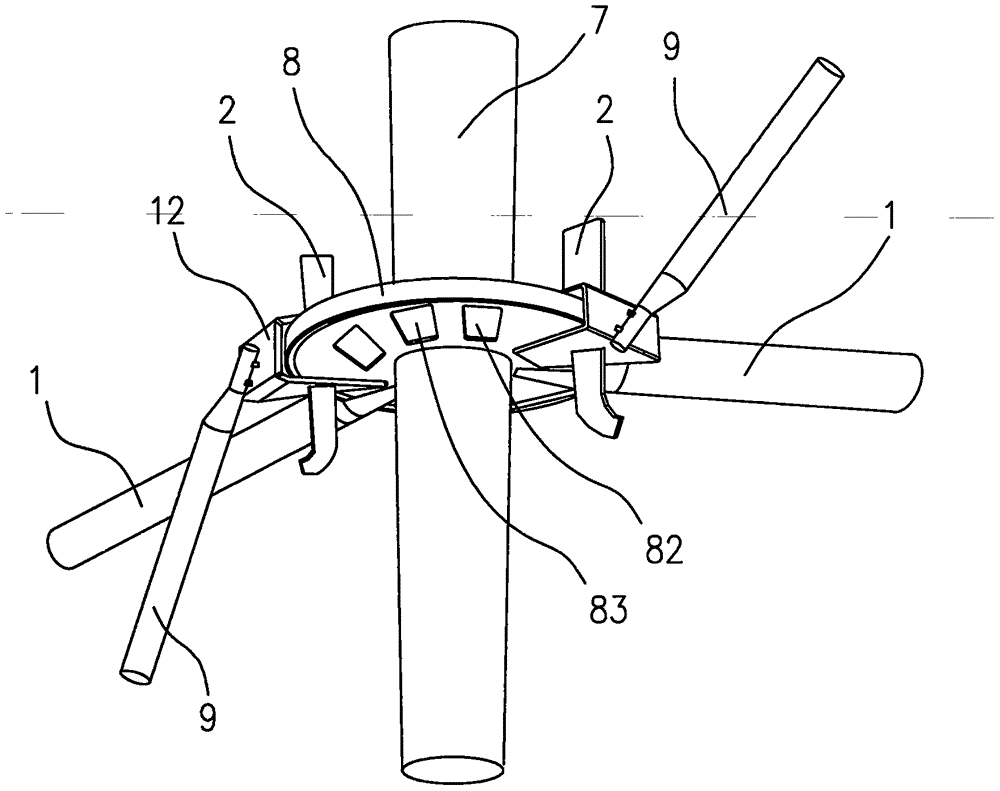

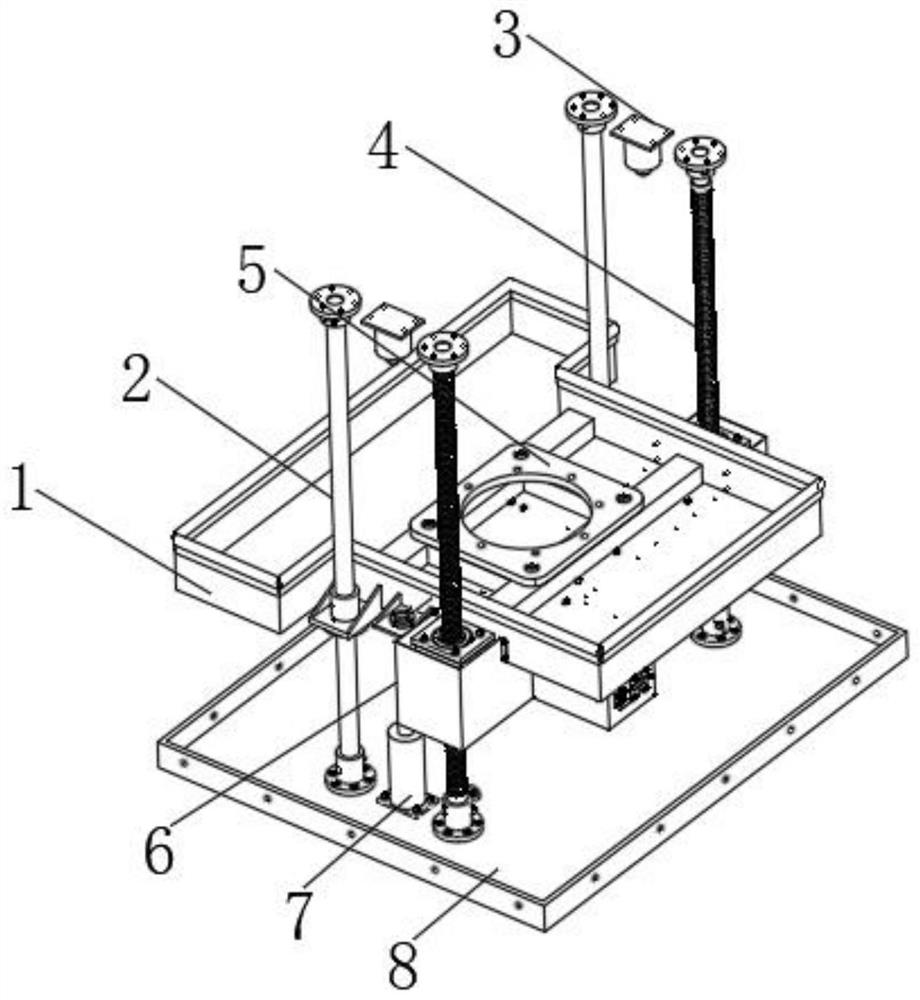

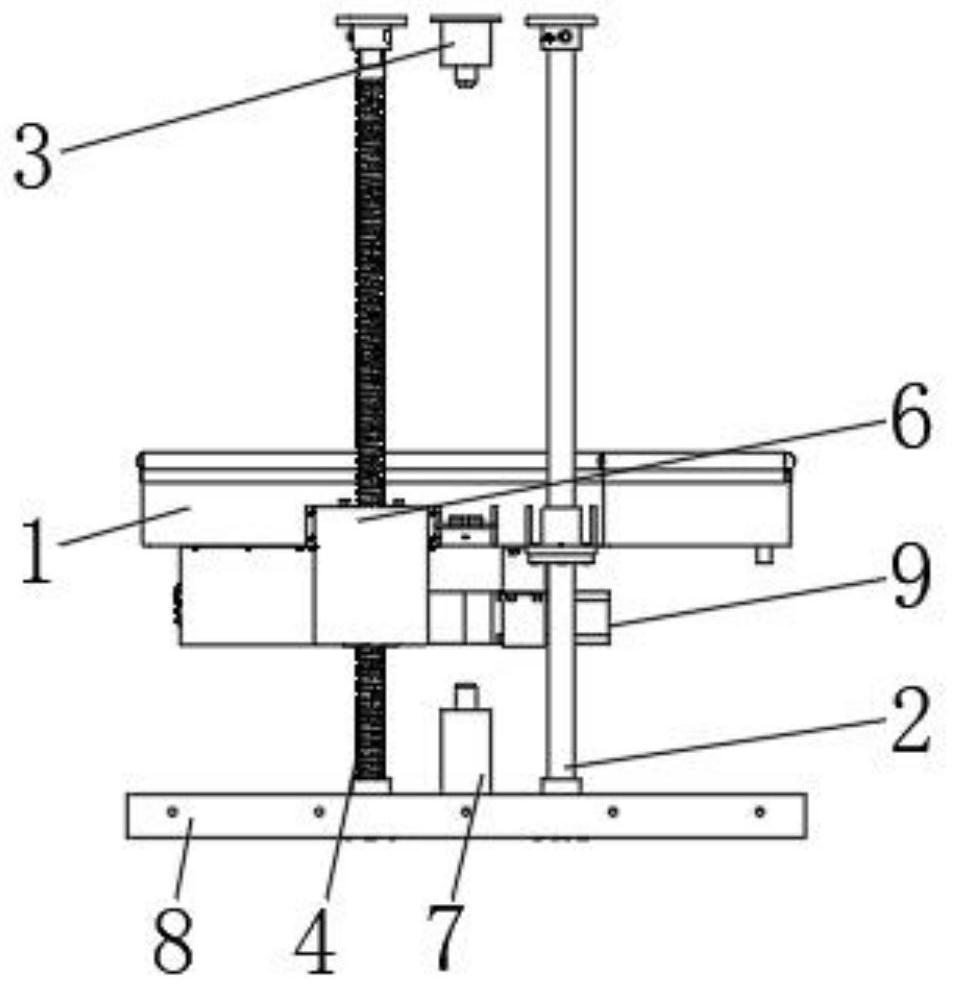

Shelter link lifting platform

The invention discloses a shelter link lifting platform. The shelter link lifting platform comprises a mounting base; sensing pins are fixedly connected to the centers of the front side and the rear side of the top surface of the mounting base correspondingly; ball guide rail modules are fixedly connected to the right sides of the centers of the front side and the rear side of the top surface of the mounting base; and the surfaces of the two ball guide rail modules are longitudinally sleeved with gear transmission boxes. According to the shelter link lifting platform, through cooperative use of a tray, a guide rod, a positioning shaft pin, the ball guide rail modules, a loading disc, the gear transmission boxes, the sensing pins, the mounting base and a servo motor, the lifting platform has high bearing capacity, can be automatically started, and has adjustable starting speed and a manual lifting function, so that the lifting effect of the lifting platform is better; and the problems that in the using process of the lifting platform, due to the fact that the bearing capacity of the lifting platform is limited, the lifting platform cannot be automatically opened, the lifting platform can only be manually opened, meanwhile, a heavy unmanned aerial vehicle cannot be borne, and the bearing platform is low in automation efficiency and poor in universality are solved.

Owner:西安天成益邦电子科技有限公司

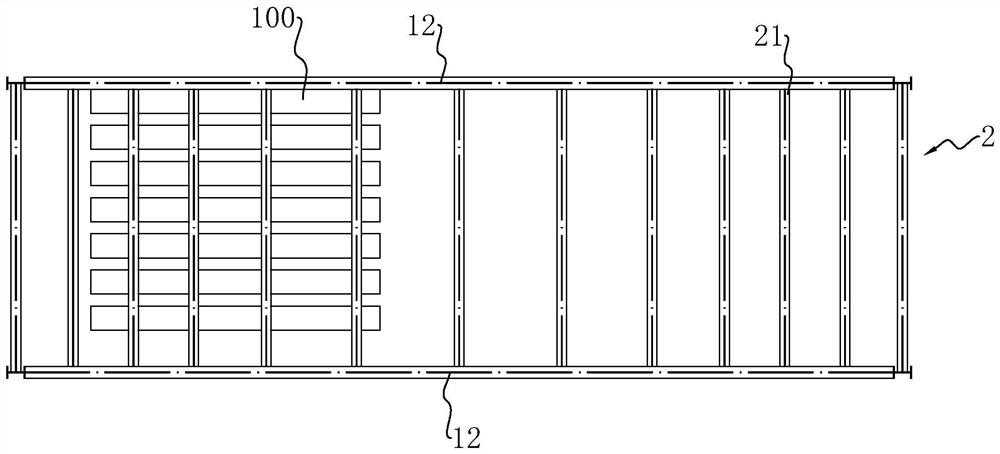

Steel truss floor support plate inverted-hanging type supporting system and construction method

InactiveCN112854746AImprove turnover rateGuaranteed camber valueForms/shuttering/falseworksSupporting systemWeight-bearing ability

The invention belongs to the technical field of building construction, and particularly relates to a steel truss floor support plate inverted-hanging type supporting system and a construction method. The steel truss floor support plate inverted-hanging type supporting system comprises inverted-hanging bearing pieces detachably connected with an I-shaped steel beam, a steel truss with the two ends penetrating through the inverted-hanging bearing pieces which are oppositely arranged, a telescopic supporting piece with the bottom end detachably connected with the steel truss, a formwork reinforcing strip abutting against the top end of the telescopic supporting piece and a plurality of telescopic jacking pieces arranged on the inner side of the I-shaped steel beam, wherein the formwork reinforcing strip abuts against the lower surface of a floor support plate. The steel truss floor support plate inverted-hanging type supporting system has the advantages that construction is convenient, the bearing capacity is improved, the turnover rate is increased, and the supporting stability is improved.

Owner:北京拓翌建筑工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com