Steel truss floor support plate inverted-hanging type supporting system and construction method

A support system and steel truss technology, applied in the field of steel truss floor deck upside-down support system and construction method, can solve the problems of poor support stability, low load-bearing capacity, complicated construction, etc., to improve the support stability and improve the turnover rate. , the effect of high material turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-5 The application is described in further detail.

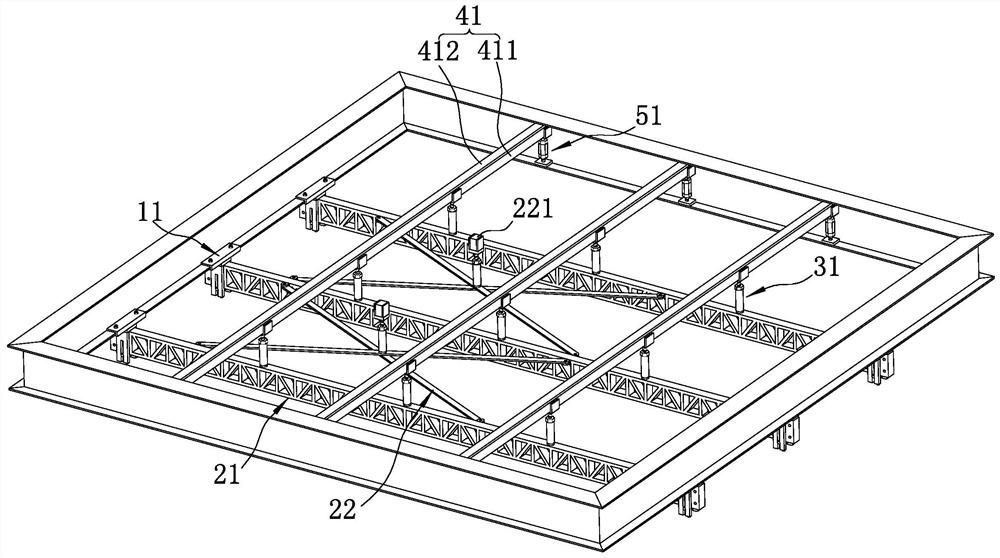

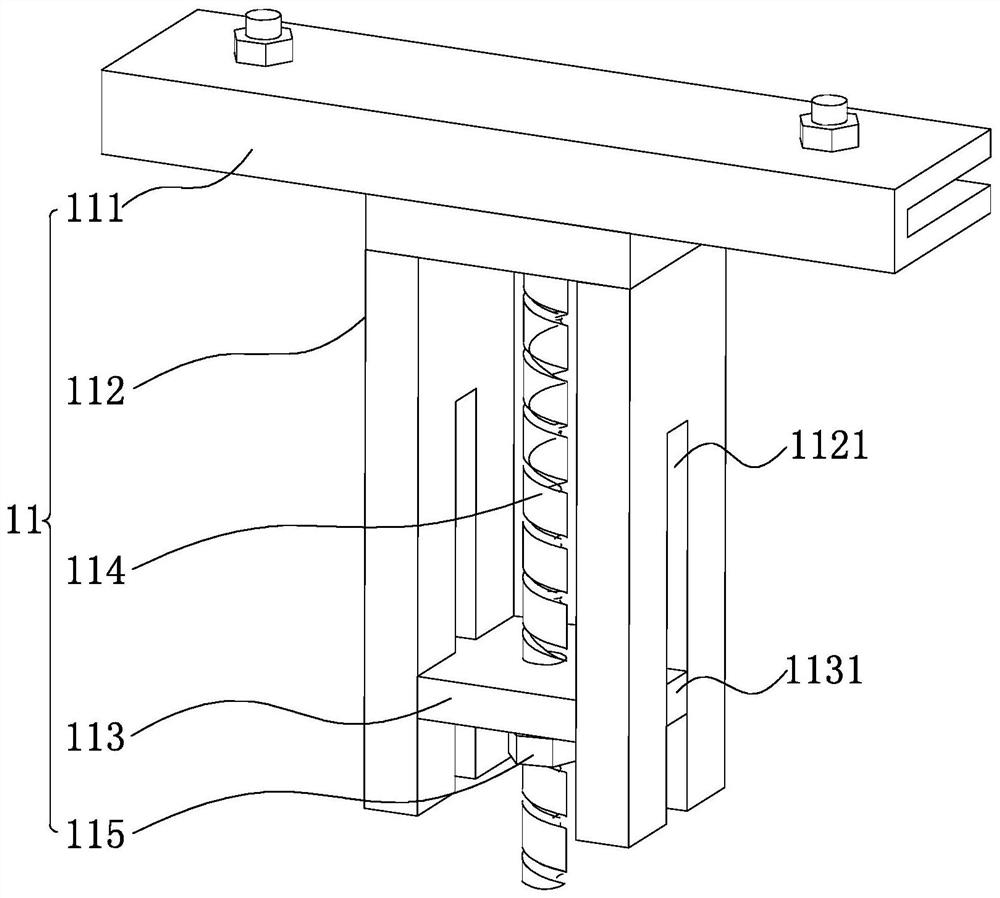

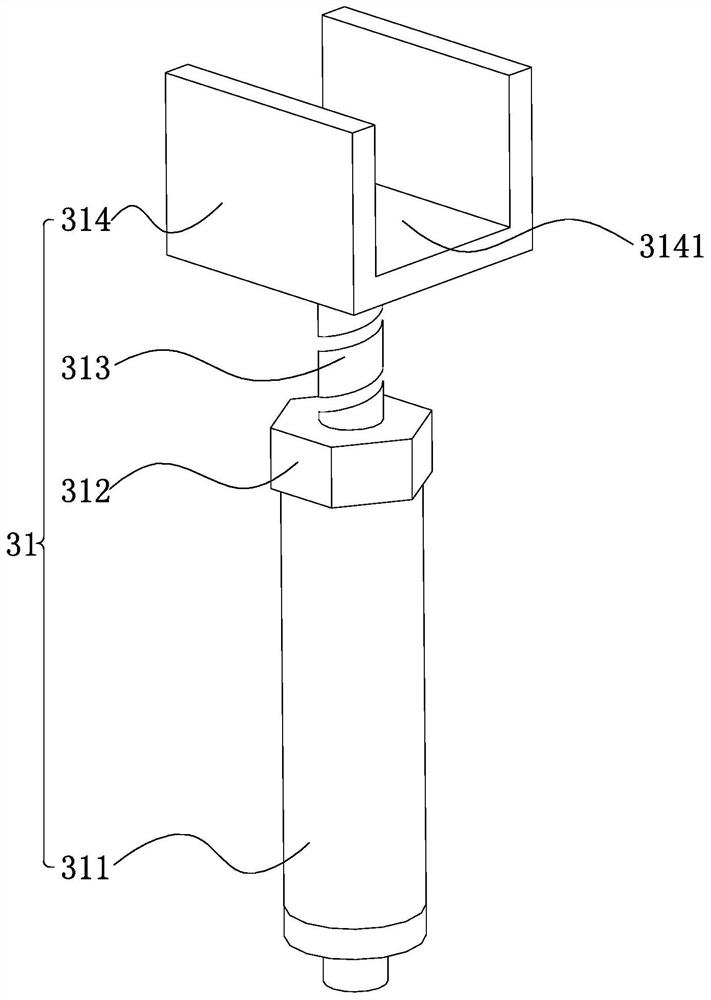

[0046] The embodiment of the present application discloses an upside-down support system for a steel truss floor deck. refer to figure 1 , an upside-down support system for a steel truss floor deck includes an upside-down load-bearing member 11, a steel truss 21, a telescopic support member 31, a formwork reinforcement strip 41 and a telescopic jacking member 51. Among them, the upside-down load-bearing part 11 is detachably connected to the I-beam, the two ends of the steel truss 21 are inserted into two oppositely placed upside-down load-bearing parts 11, and the bottom end of the telescopic support part 31 is detachably connected to the steel truss 21. , the formwork reinforcement strip 41 abuts against the top of the telescopic supporting member 31, and the formwork reinforcement strip 41 abuts against the lower surface of the floor deck to play a supporting role, and the teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com