Mute tip cone roller bearing

A technology of tapered roller bearings and roller bearings, applied in the direction of roller bearings, bearing components, shafts and bearings, etc., which can solve problems such as unsuitable adjustment of clearance, difficulty in structural support, and end of servo life.

Inactive Publication Date: 2013-04-17

王守彬

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cracks on the raceway surface and iron cutting pollute the lubricating oil. This harsh cycle will cause the raceway to enter the fatigue period in advance, and the bearing will soon end the service life of the servo.

Regardless of the type of structure of traditional rolling element bearings, ① it is not suitable to adjust the clearance during work; ② it cannot be used as the overall support of the journal alone; ③ it is not suitable to return the brake and reverse rotation; ④ it cannot stop moving in both directions

Therefore, it is very necessary to invent a silent top tapered roller bearing to solve the technical problems of the previous two generations of traditional bearings and structural support that are difficult to overcome.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

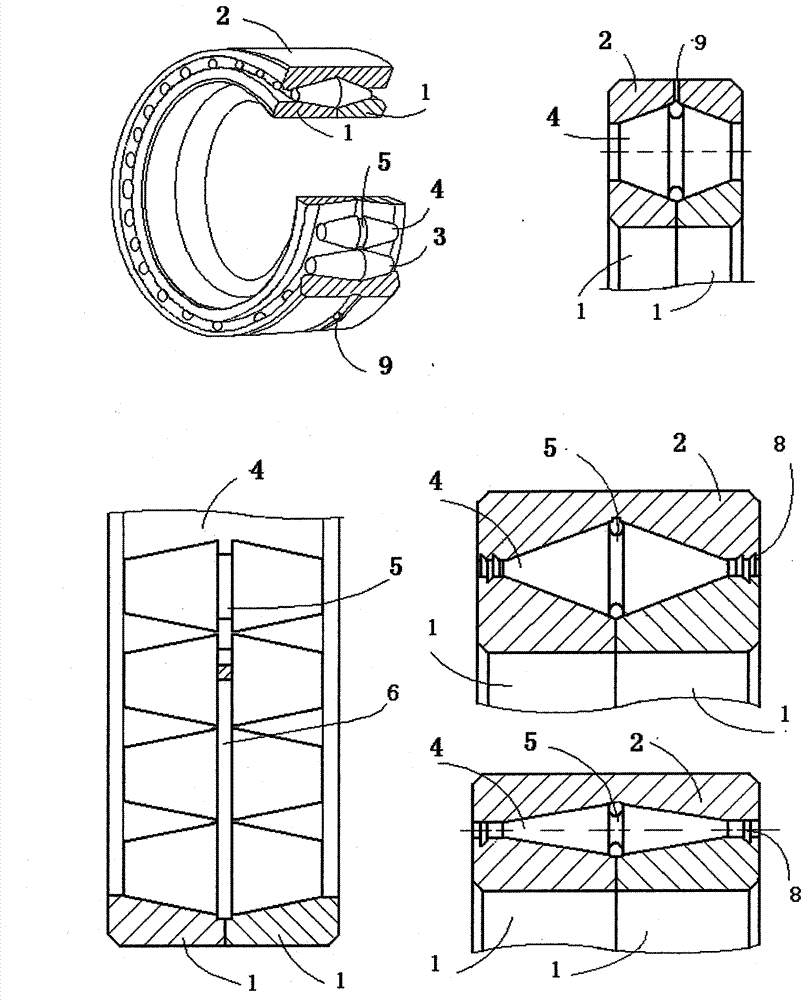

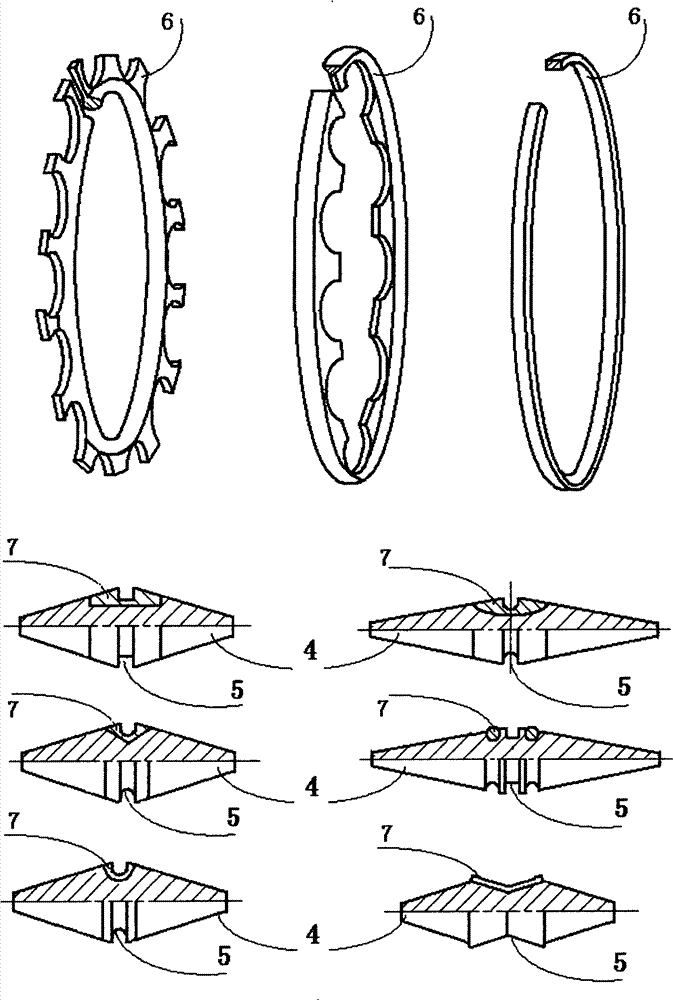

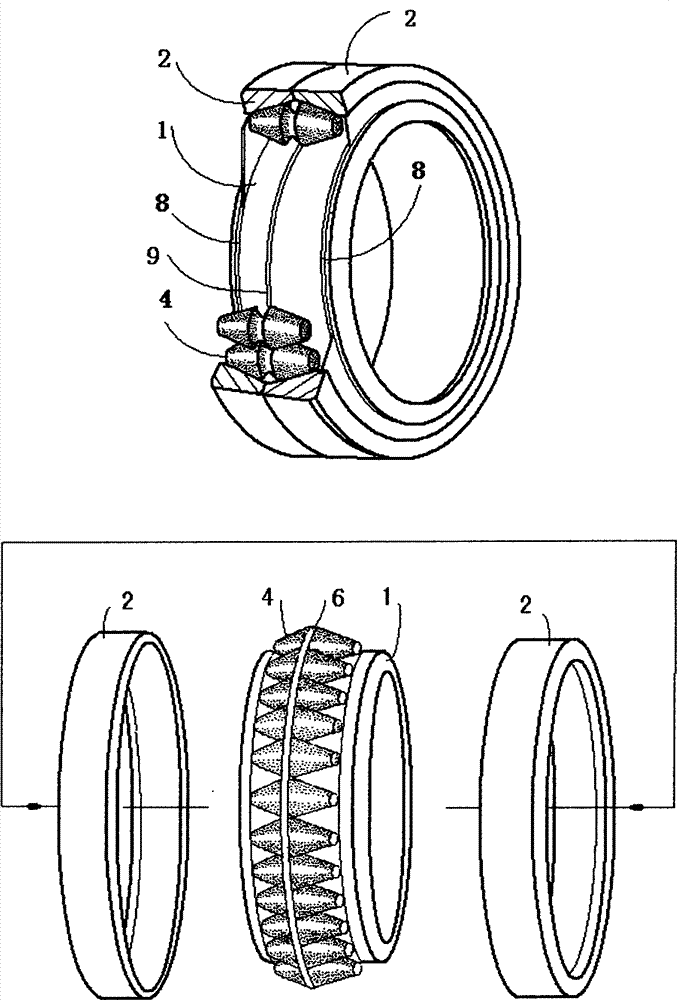

[0012] A specific embodiment of a silent top tapered roller bearing is shown in Figures 3 and 4; a row of top tapered rollers 3 and 4 are inserted in the teeth of the toothed cage 6, and then the two split outer rings 2 Face-to-face fastening on the left and right sides of the top tapered roller; what is realized is a new generation of silent top tapered roller bearings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a mute tip cone roller bearing. A structure support technology is characterized in that the set of bearing is formed by matching an inner sleeve ring, an outer sleeve ring, a row of single-row tip cone rollers and an invisible retainer. The external dimension standard of the mute tip cone roller bearing is in line with that of an international general roller bearing of international standardization organization (ISO). The invention aims at solving the problem that the third generation leading edge innovative technology bearing is not designed by anyone in the recent 140 years in the world. The mute tip cone roller bearing is characterized in that (1) one bearing can be independently taken as a main hub support; (2) two sealing covers are respectively arranged at the two ends of the bearing; (3) the bearing is high in bearing capacity; (4) the bearing is high in shear impact resistance; (5) the bearing is rapid in rotating speed; (6) the bearing improves the safety factor by 2%; (7) the bearing is good in stability; (8) the bearing is high in two-direction thrust capability; (9) the bearing is low in vibration noise; (10) the bearing is simple in structure and low in cost; (11) the bearing is long in service life; and (12) the bearing is convenient and fast to install and maintain, therefore, the mute tip cone roller bearing is a new generation innovative technology product which is high in economic benefit and environment-friendly.

Description

technical field [0001] A silent top tapered roller bearing, which is the only one among the three types of tapered rollers in the world that can be installed with a dust cover; a single piece can independently serve as a new generation of innovative technology bearings for the shaft diameter. It is used in the same field of optoelectronic integration as the first generation of sliding shoe bearings and the second generation of rolling element bearings; its application range is wider than that of the previous two generations of traditional bearings. Background technique [0002] In the 21st century with the rapid development of global industrial technology, the industry generally adopts the first generation of traditional sliding shoe bearings and the second generation of rolling element bearings. The first generation of sliding shoe bearings; it has been used for more than five thousand years. The structural support technology of this traditional sliding shoe bearing is cha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16C19/36F16C33/36F16C33/58F16C33/66F16C33/78

Inventor 王守彬

Owner 王守彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com