Patents

Literature

1232results about How to "High rotation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

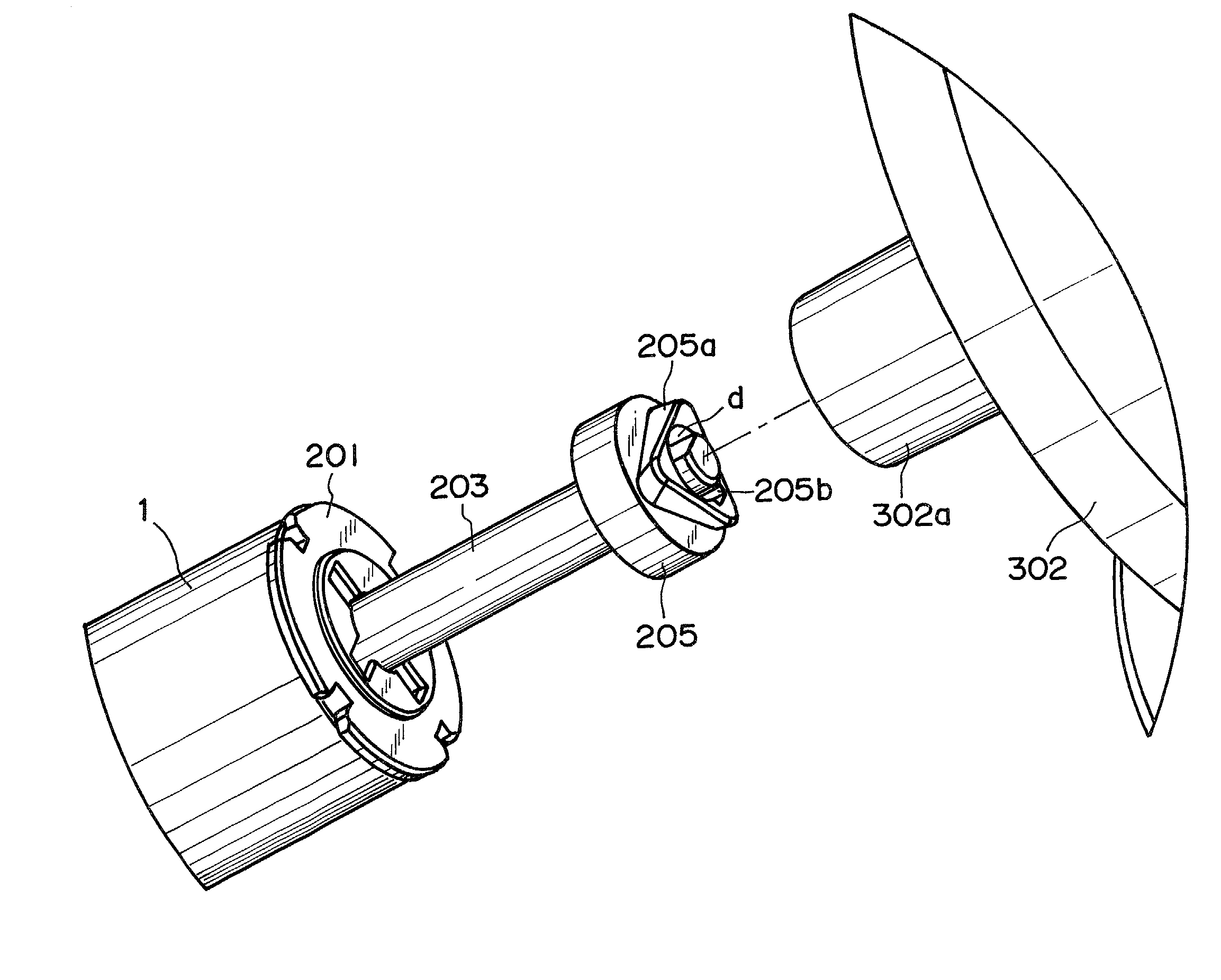

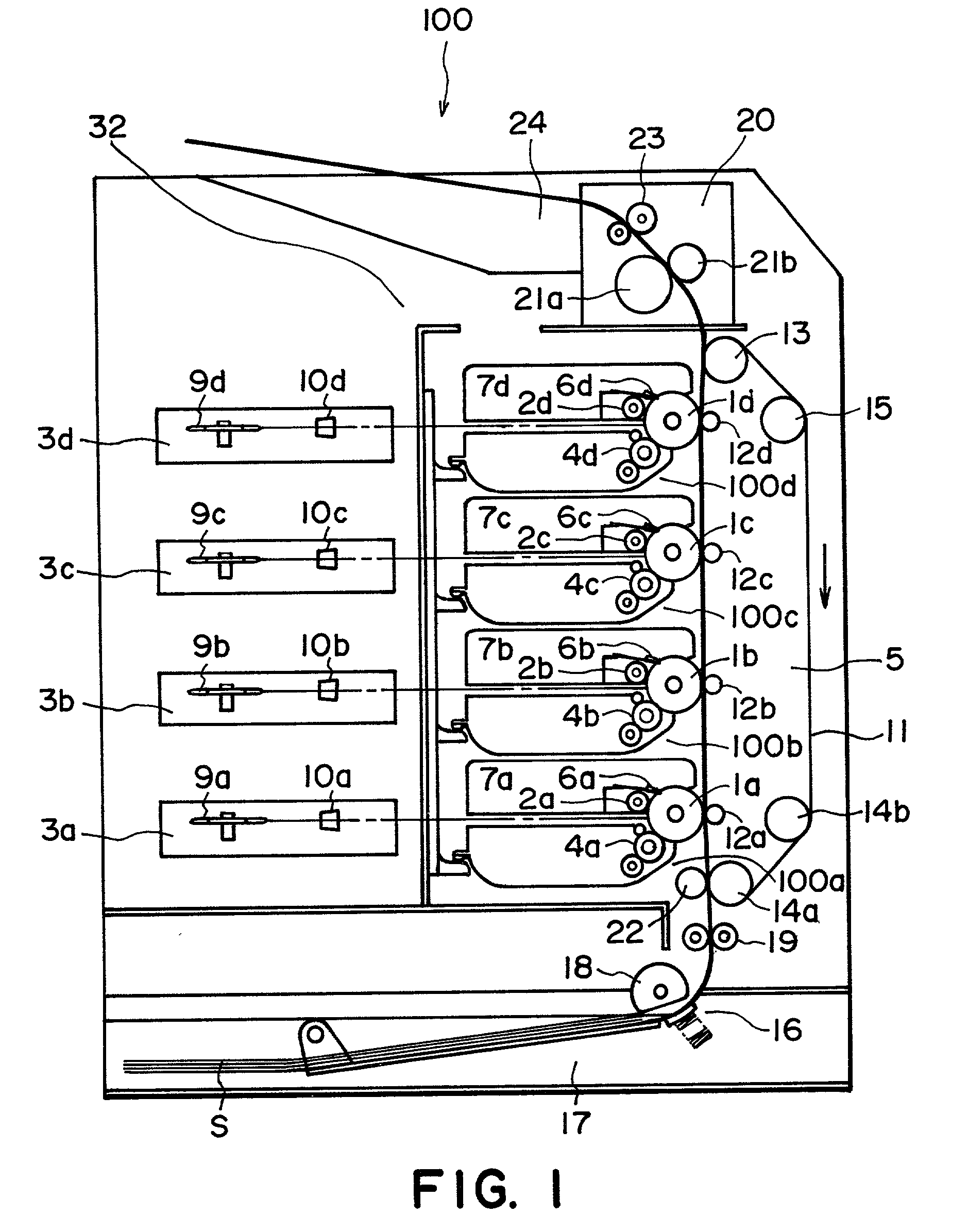

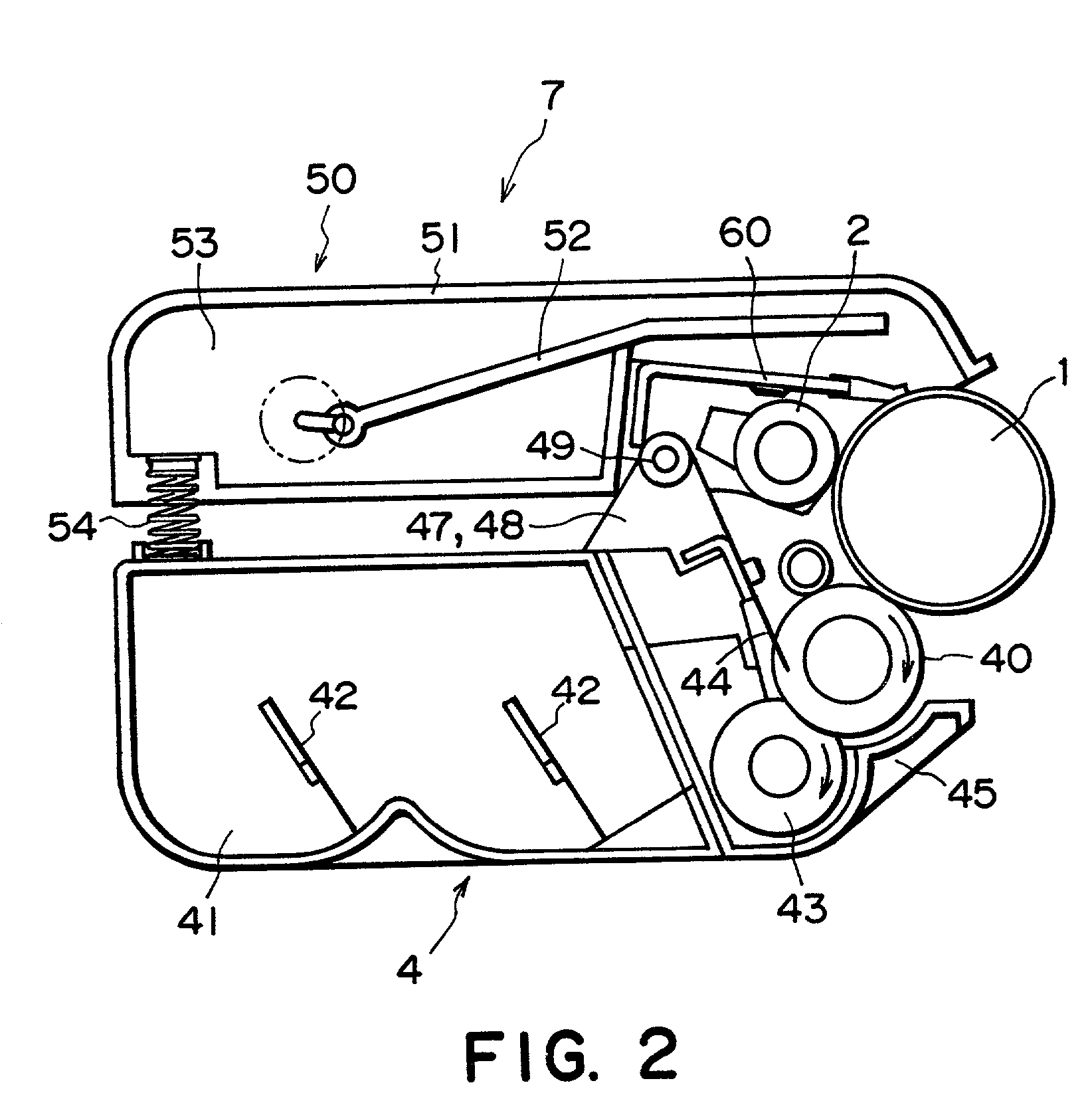

Process cartridge, electrophotographic photosensitive drum, electrophotographic image forming apparatus and color electrophotographic image forming apparatus

InactiveUS20020110388A1High rotation accuracyImprove accuracyCouplings for rigid shaftsElectrographic process apparatusImaging equipmentMechanical engineering

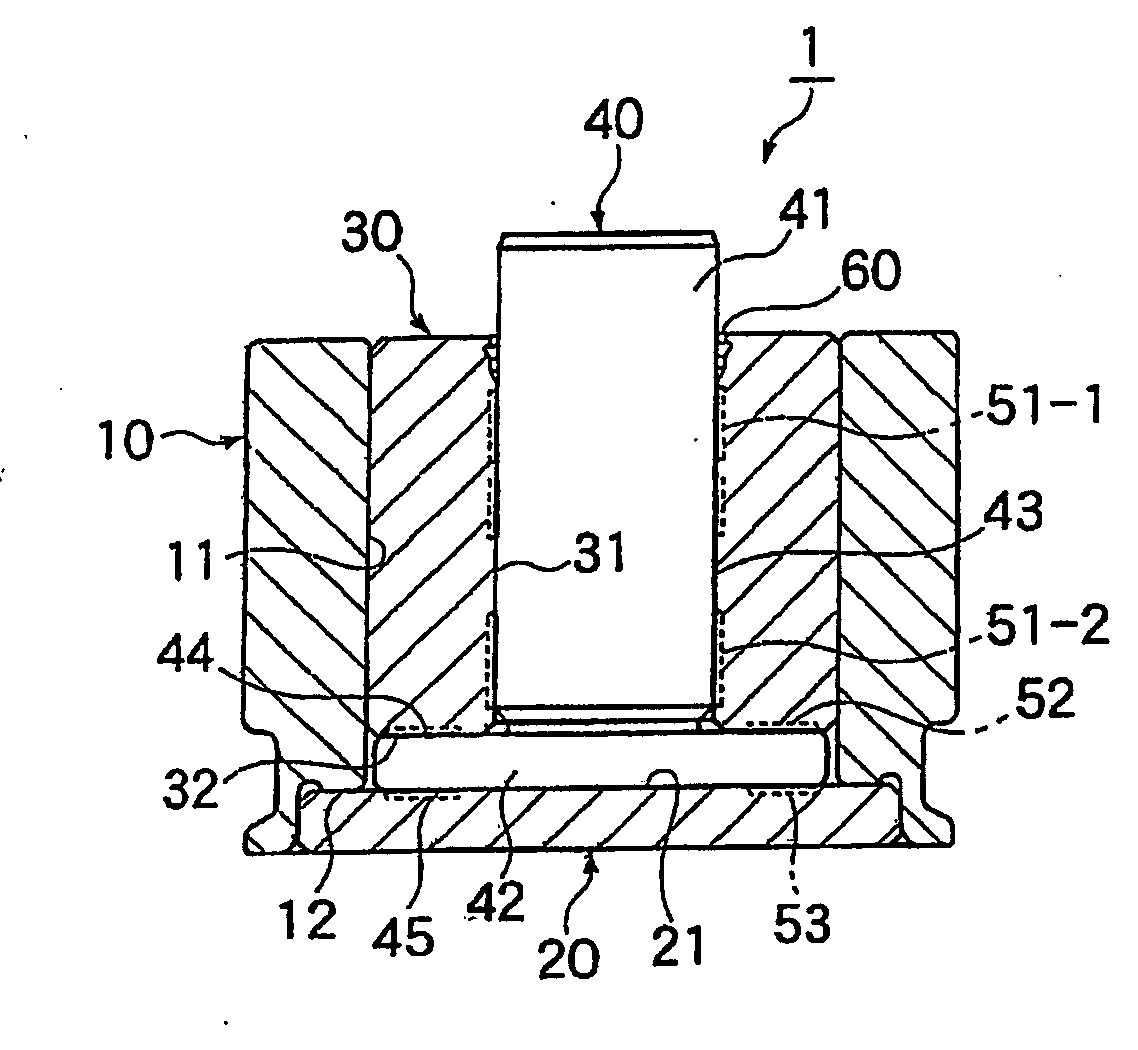

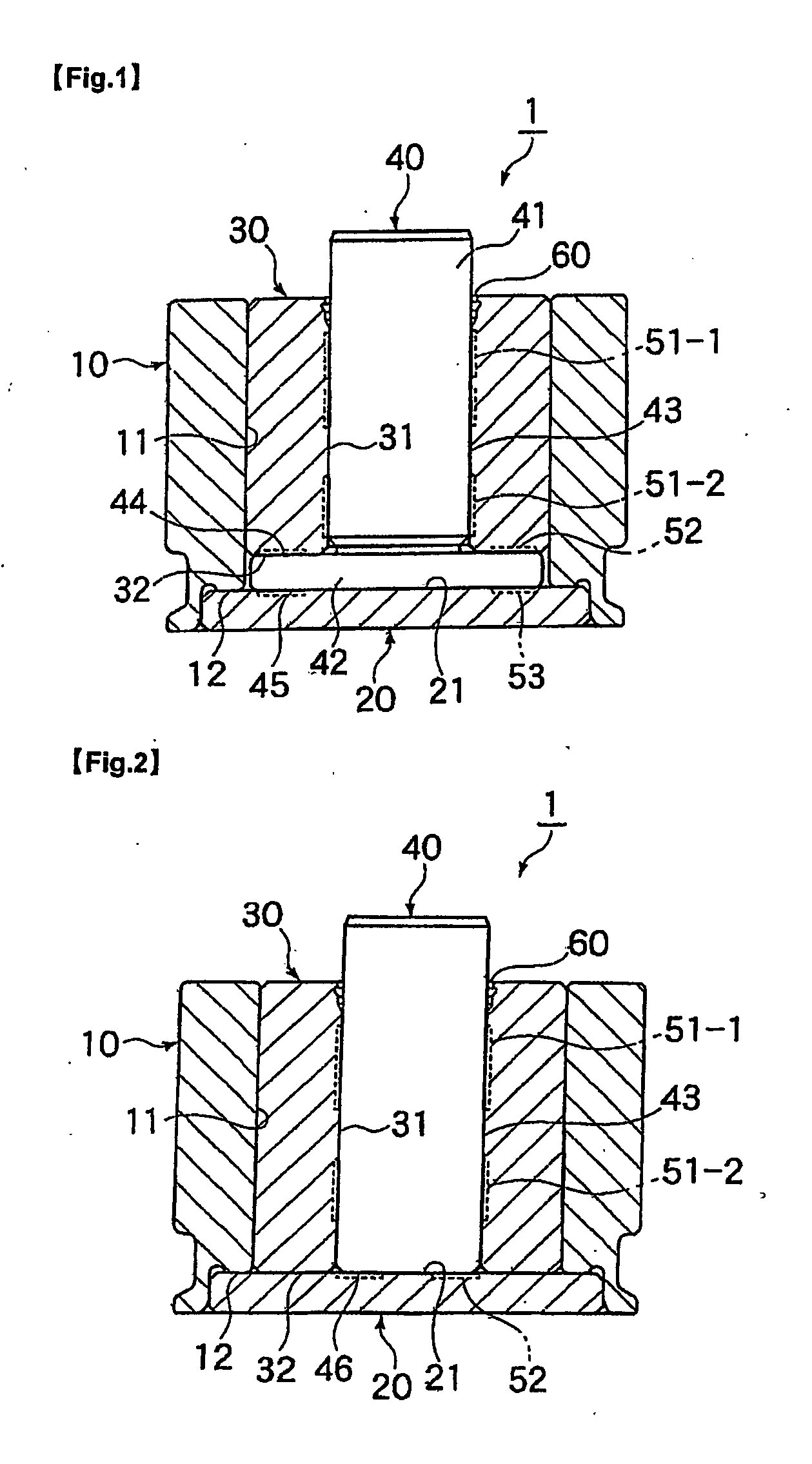

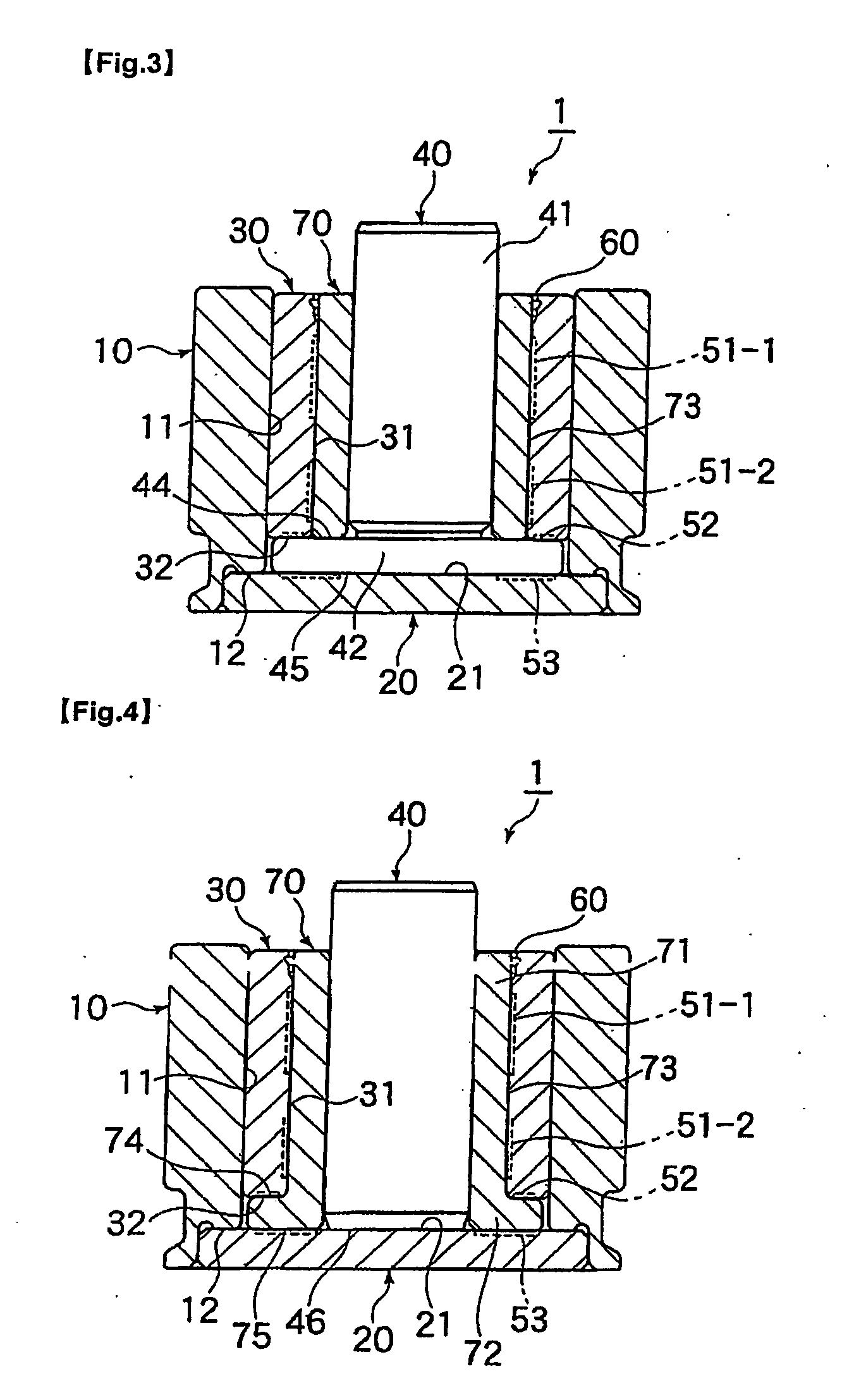

A process cartridge detachably mountable to a main assembly of an electrophotographic image forming apparatus for forming an image on a recording material, the apparatus including a motor, a driving rotatable member for transmitting a driving force from the motor, and a twisted recess provided at a central portion of the driving rotatable member and having a non-circular cross-section with a plurality of corners, the recess being rotatable integrally with the driving rotatable member, the process cartridge includes an electrophotographic photosensitive drum; process means actable on the drum; a twisted projection having a non-circular cross-section with a plurality of corners, the twisted projection being provided at one longitudinal end of the electrophotographic photosensitive drum and being engageable with the recess; a permitting portion for permitting engagement between the twisted protection and the recess only at a predetermined relative rotational position therebetween to establish the engagement therebetween with the predetermined relative to rotational position; wherein when the process cartridge is mounted to the main assembly of the apparatus, the rotating force is transmitted from the driving rotatable member to the electrophotographic photosensitive drum by rotation of the driving rotatable member with the twisted projection being in engagement with the recess.

Owner:CANON KK

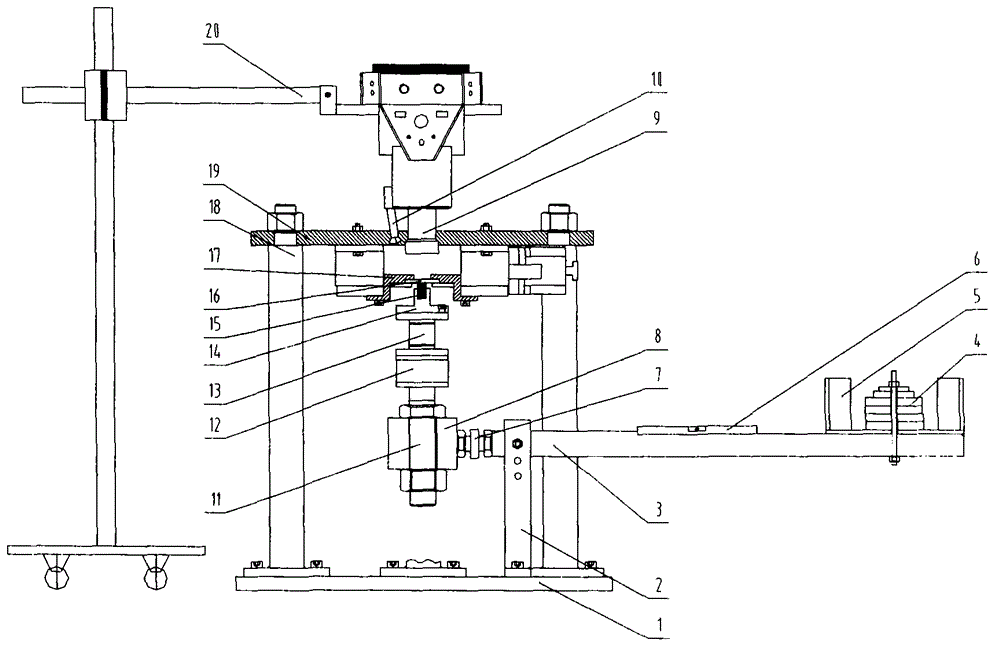

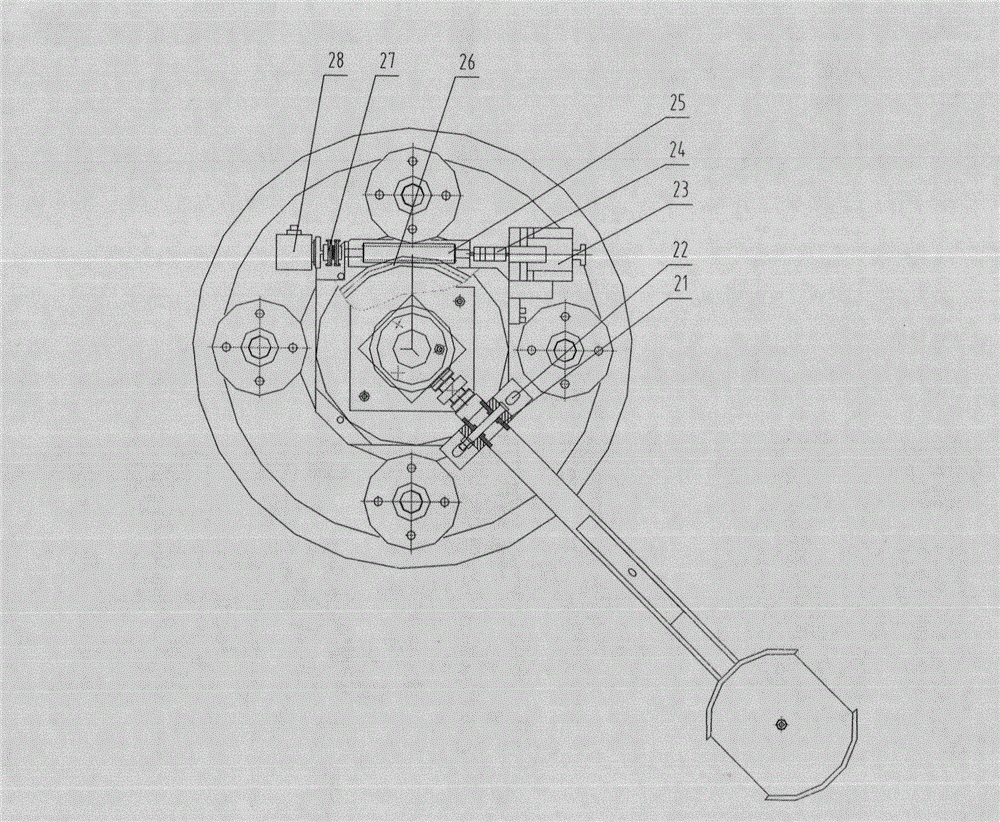

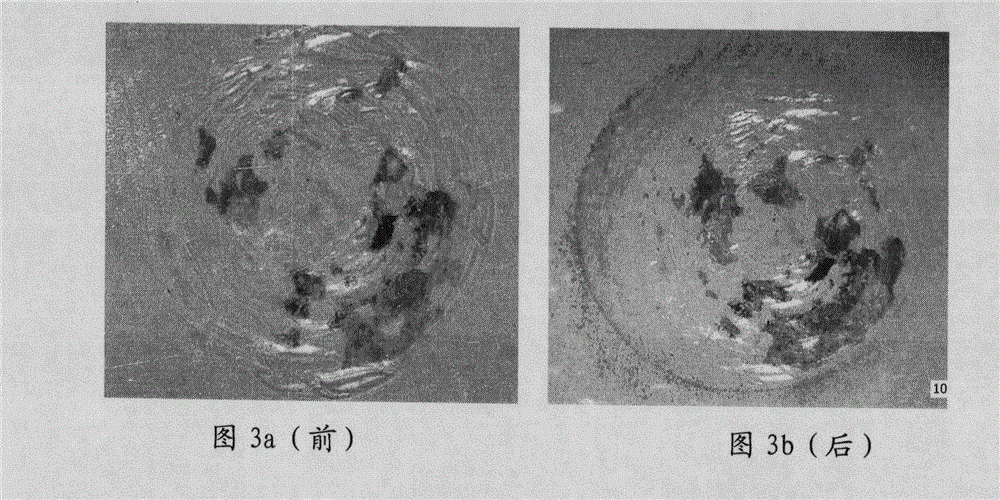

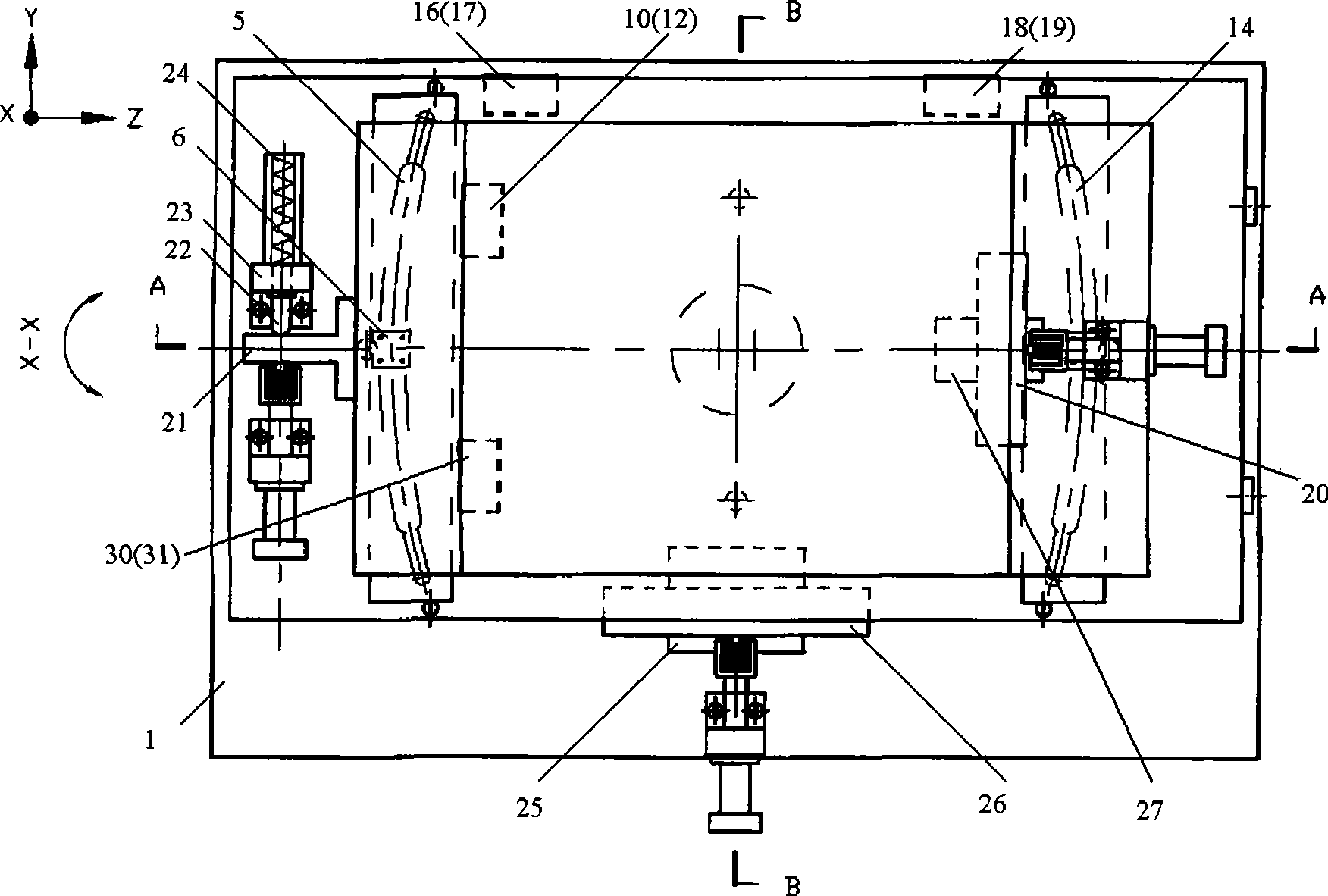

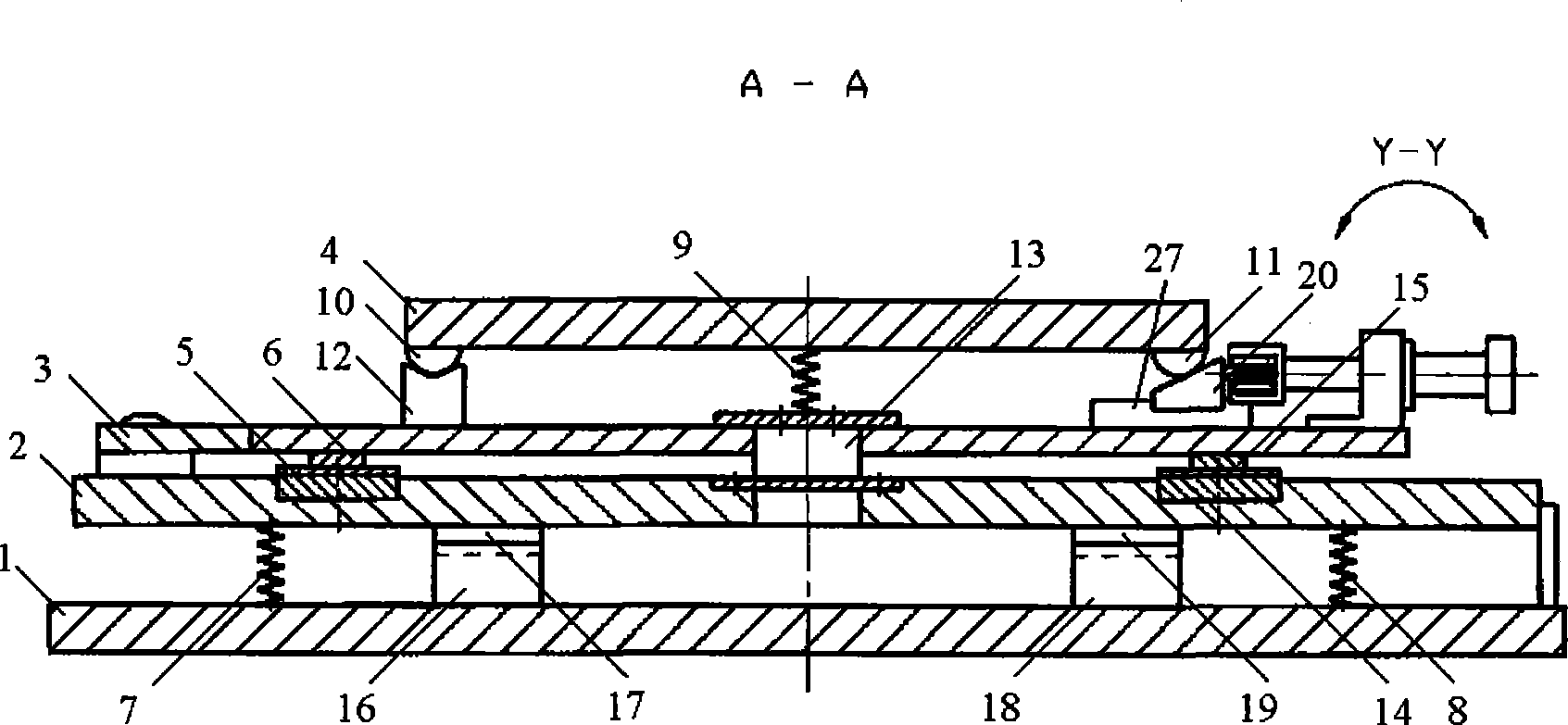

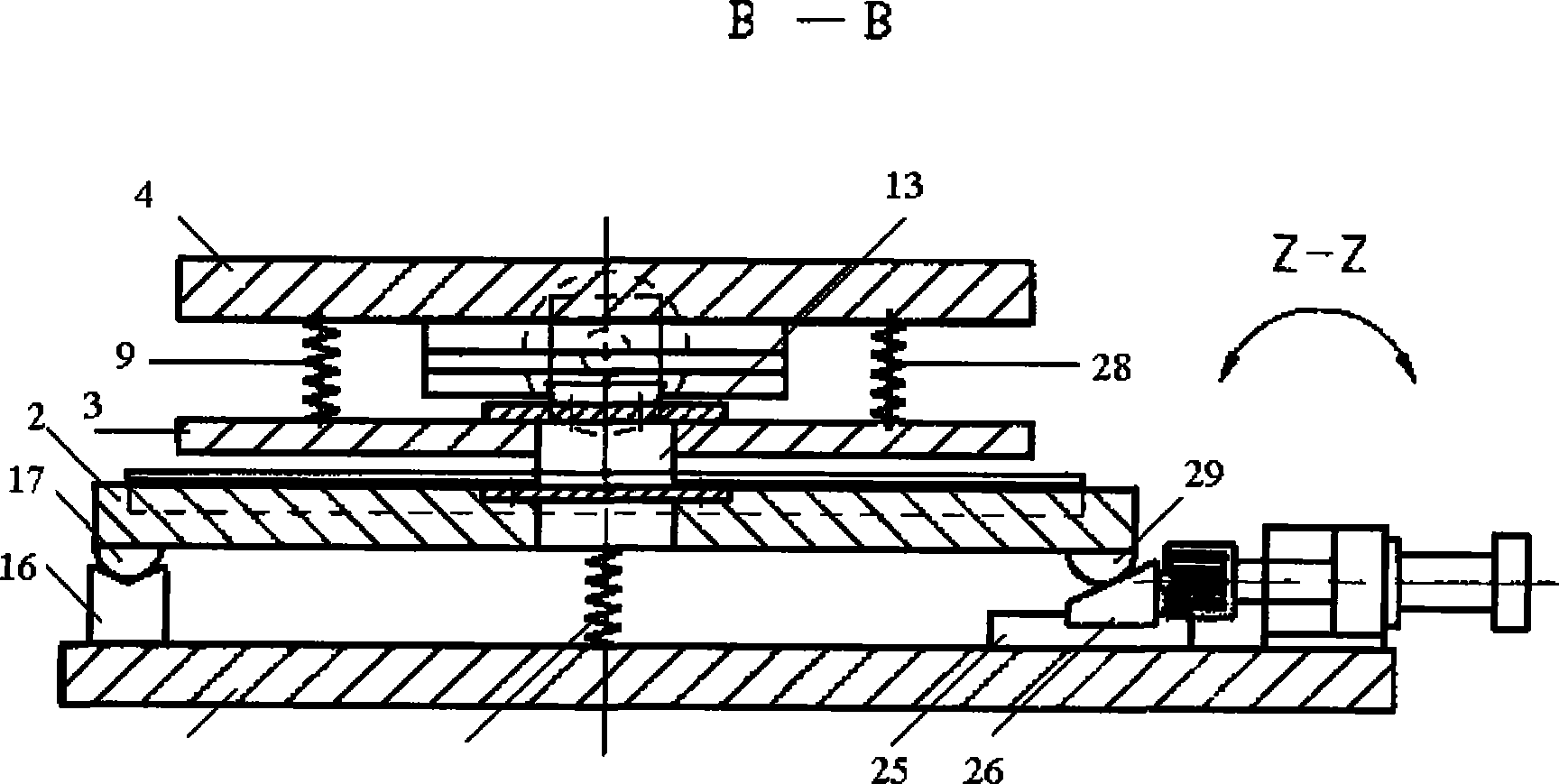

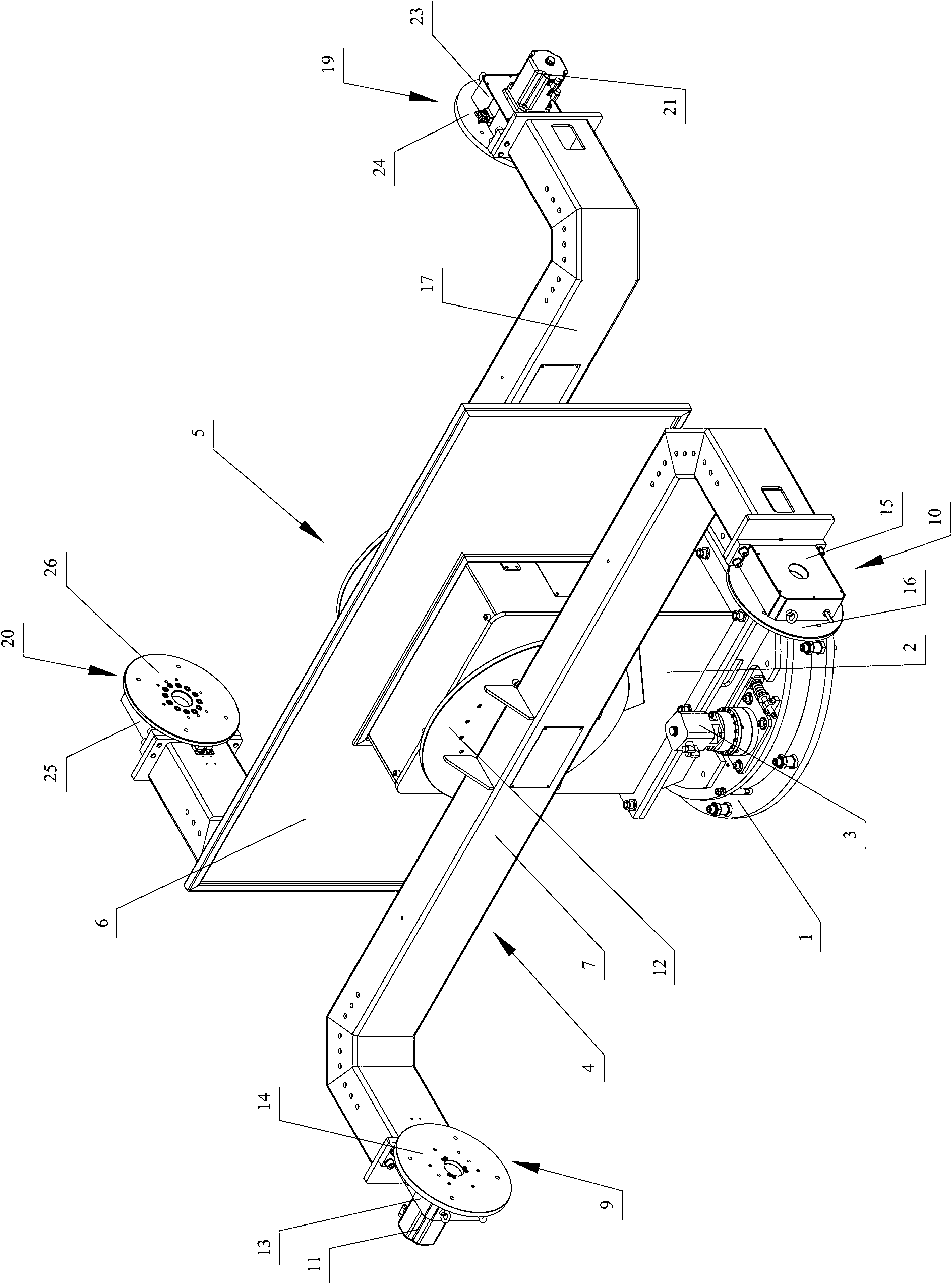

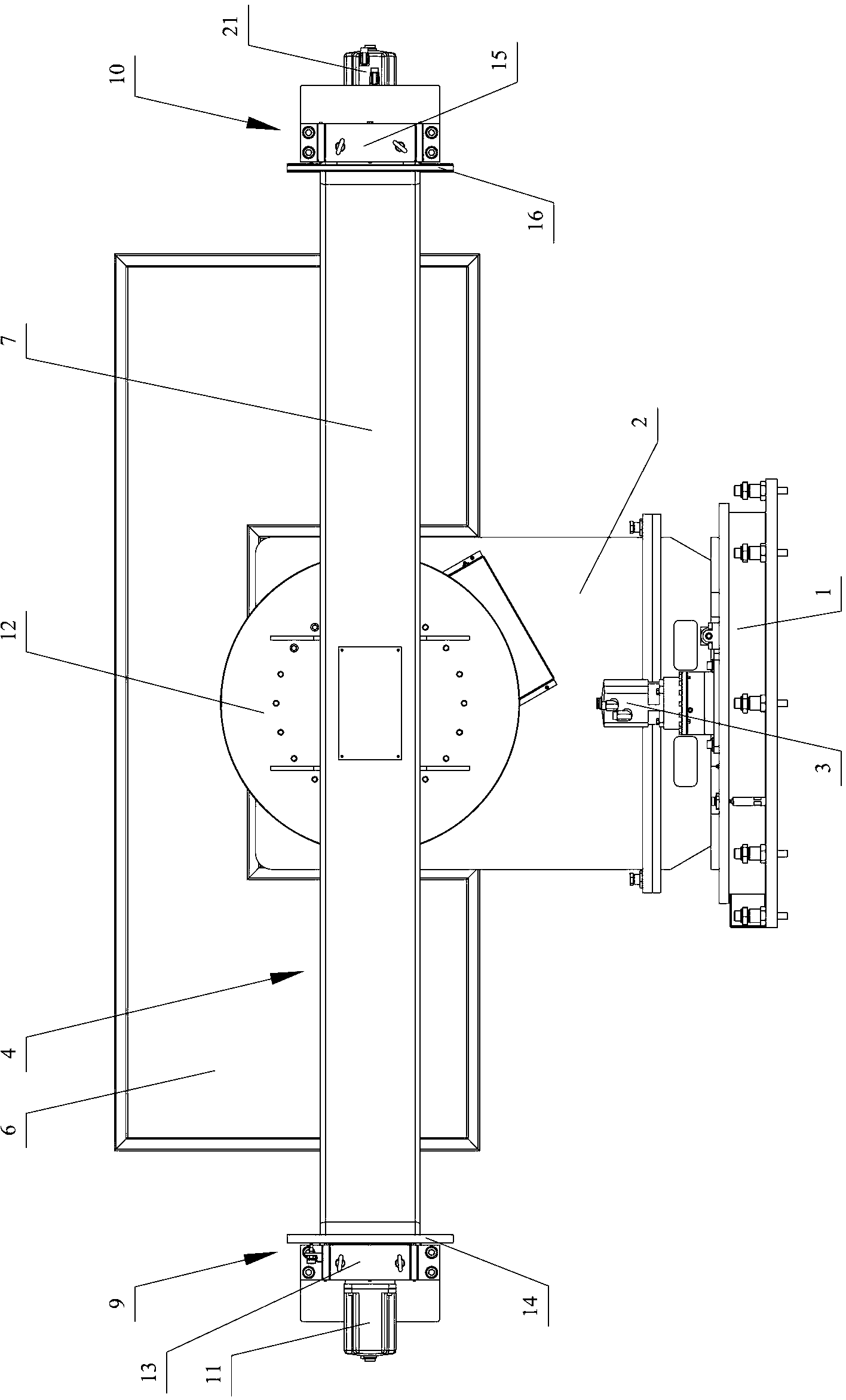

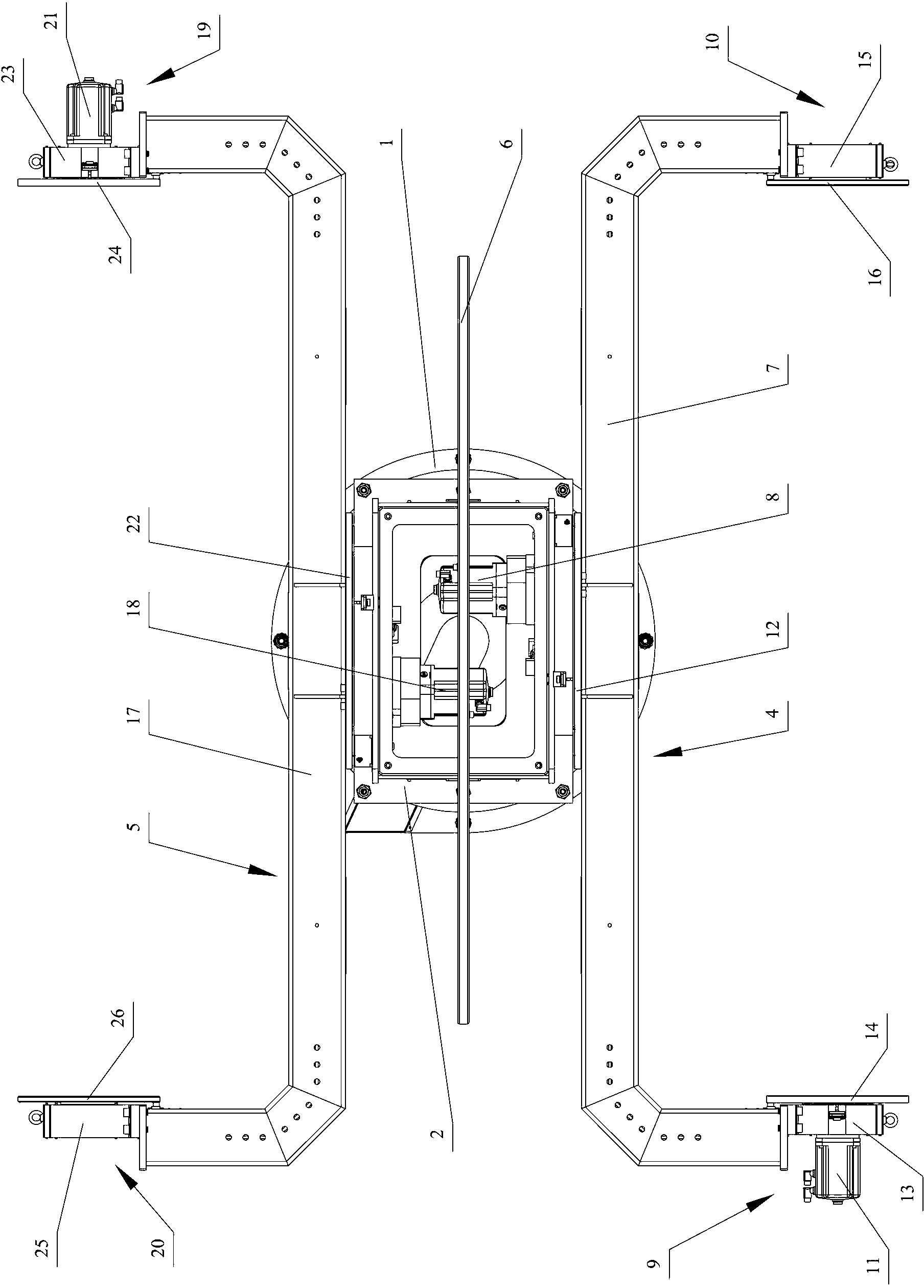

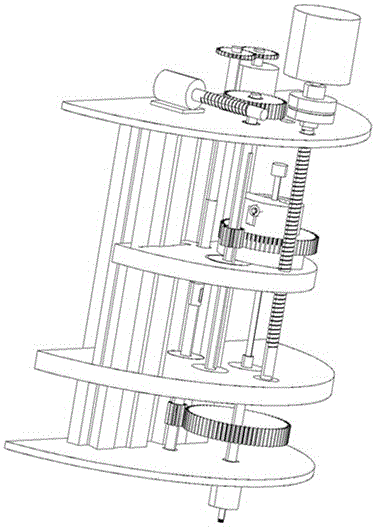

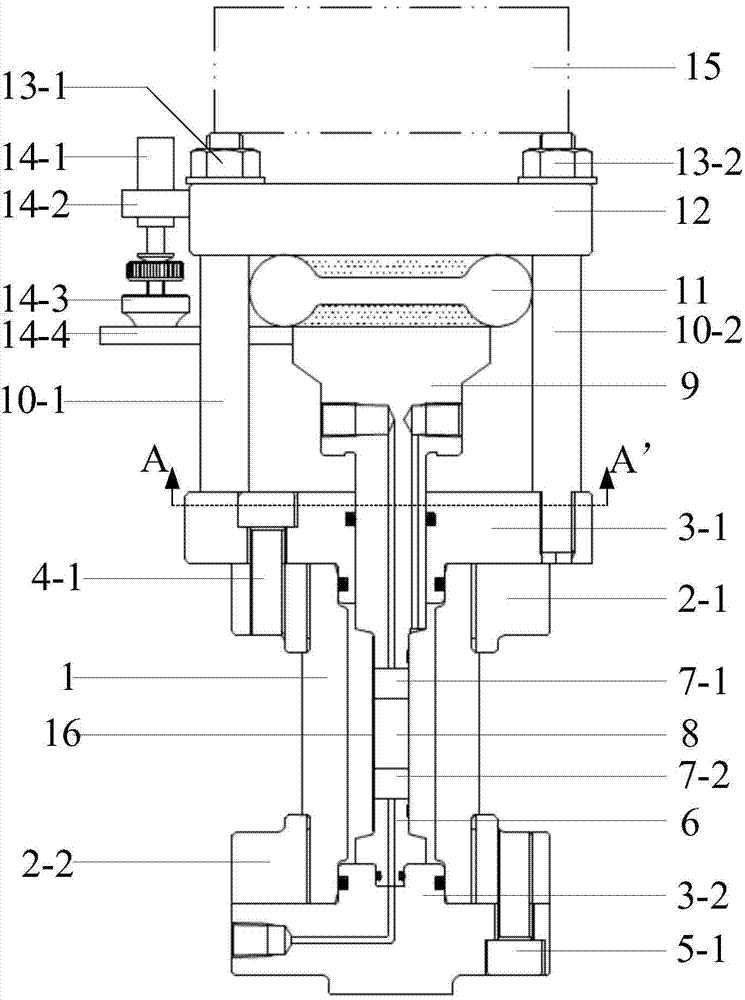

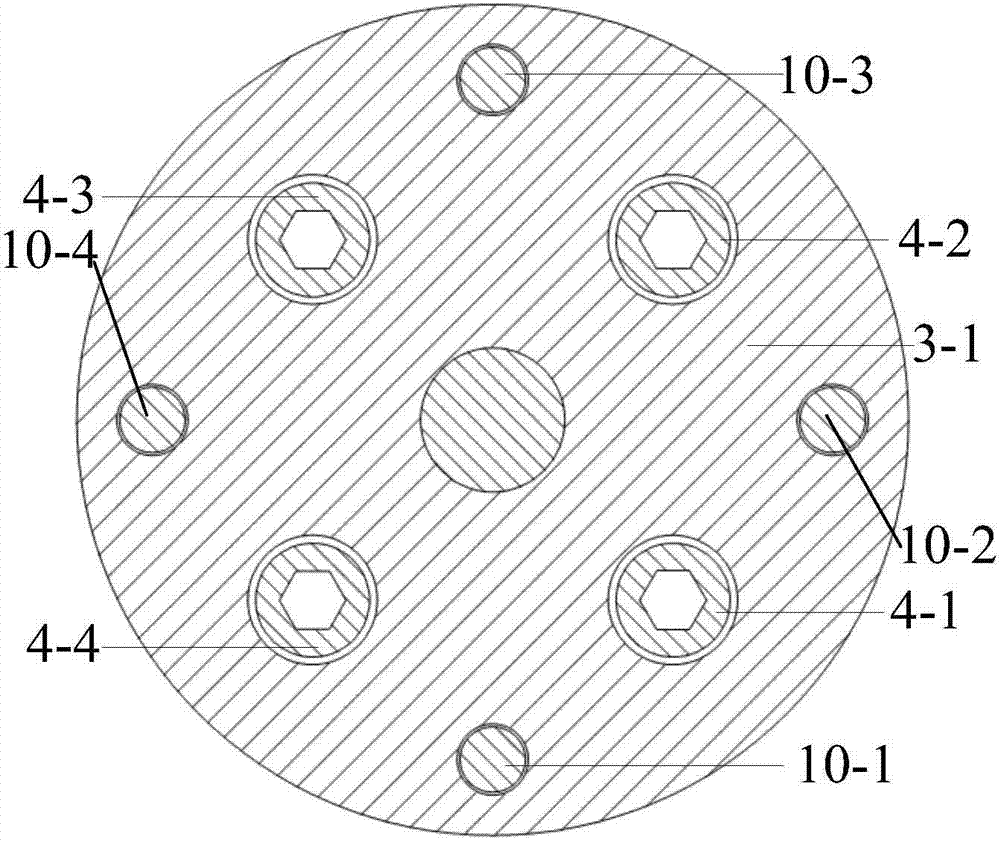

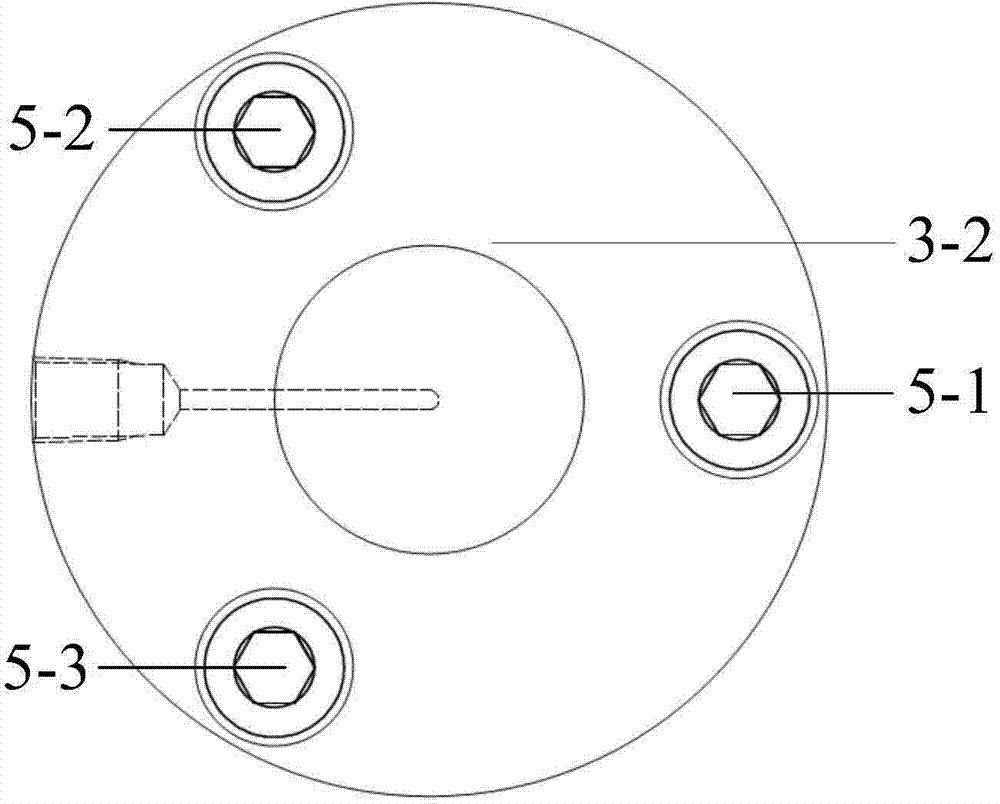

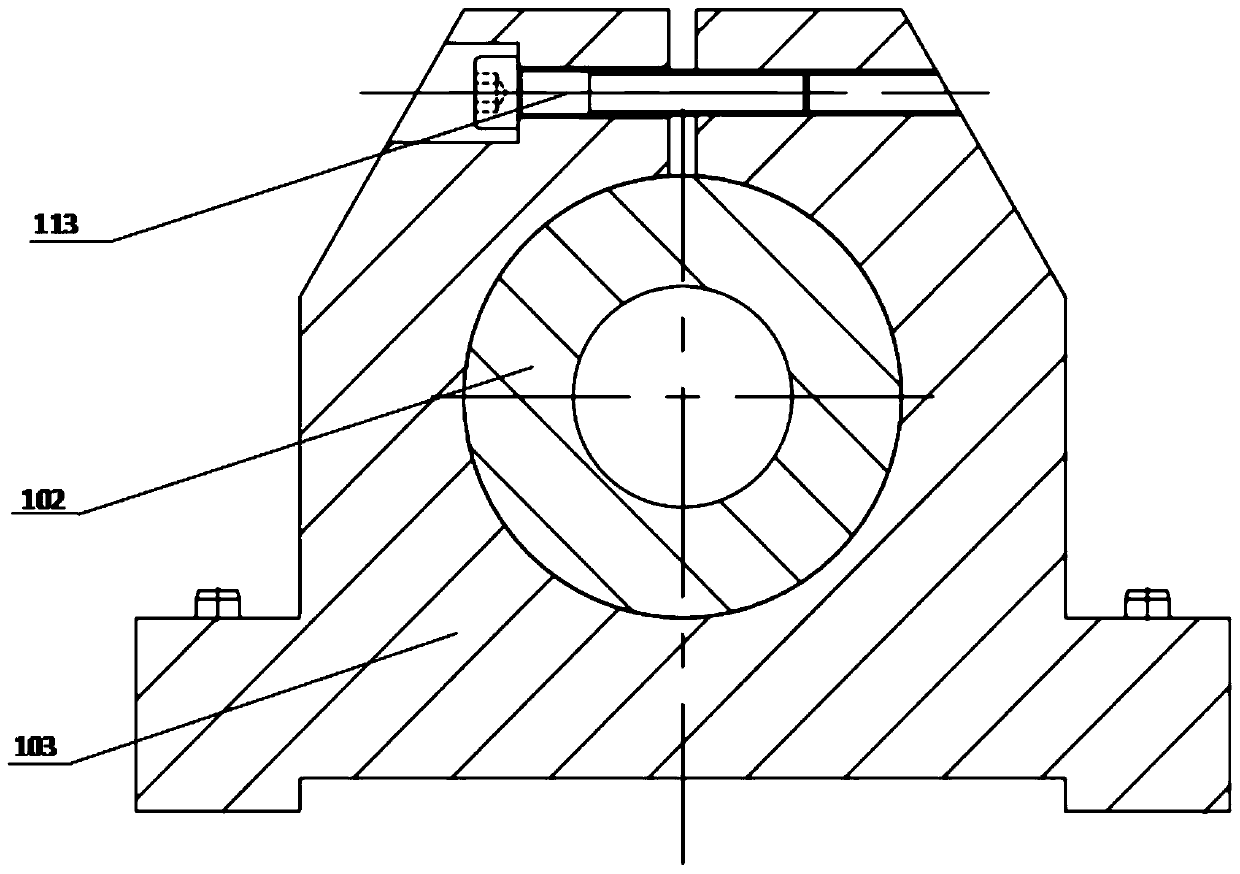

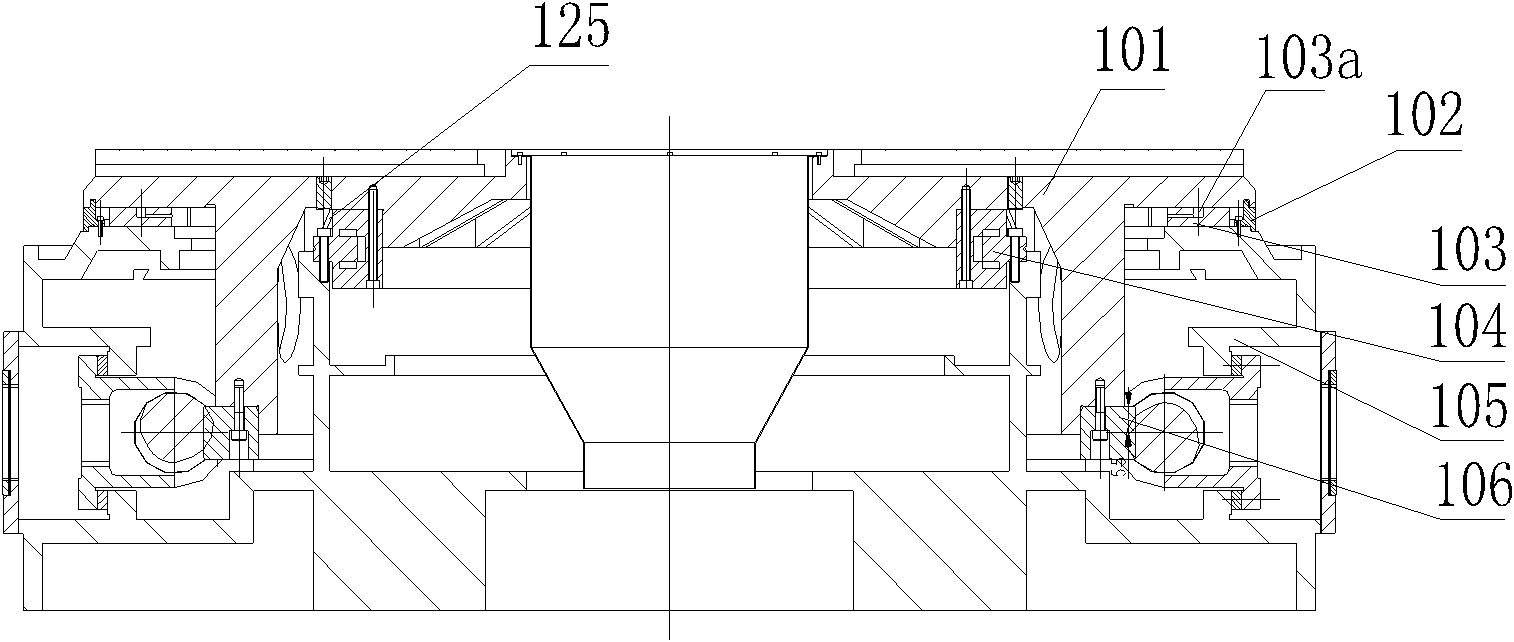

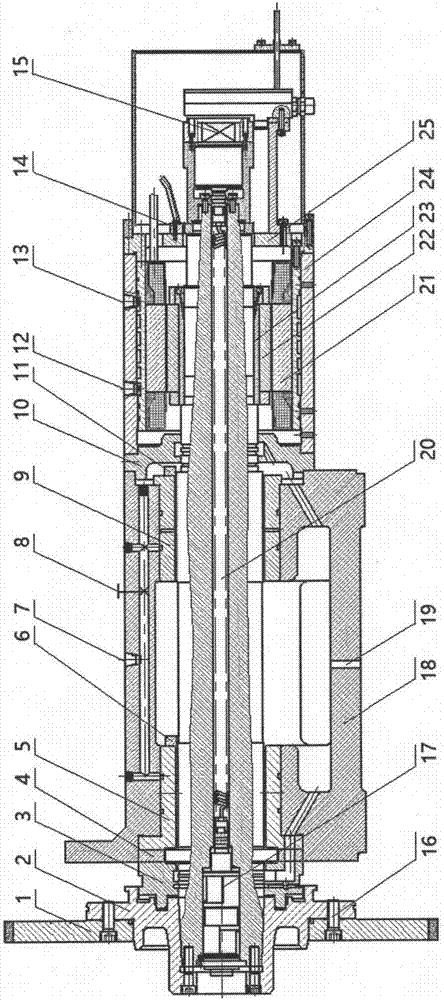

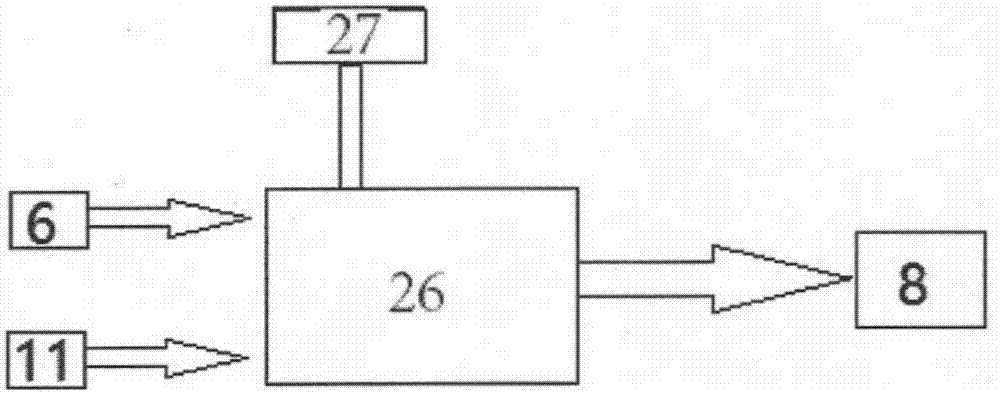

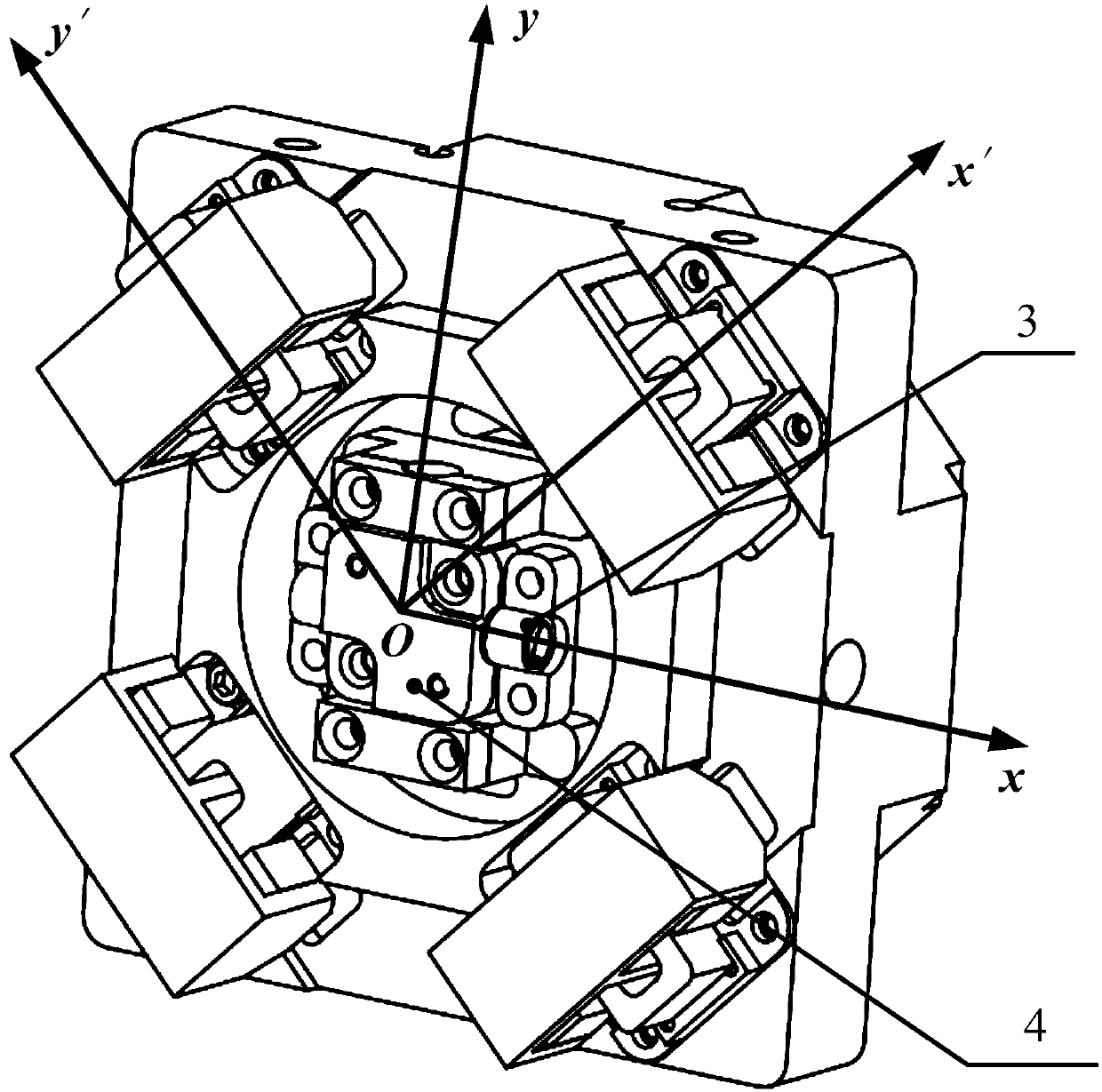

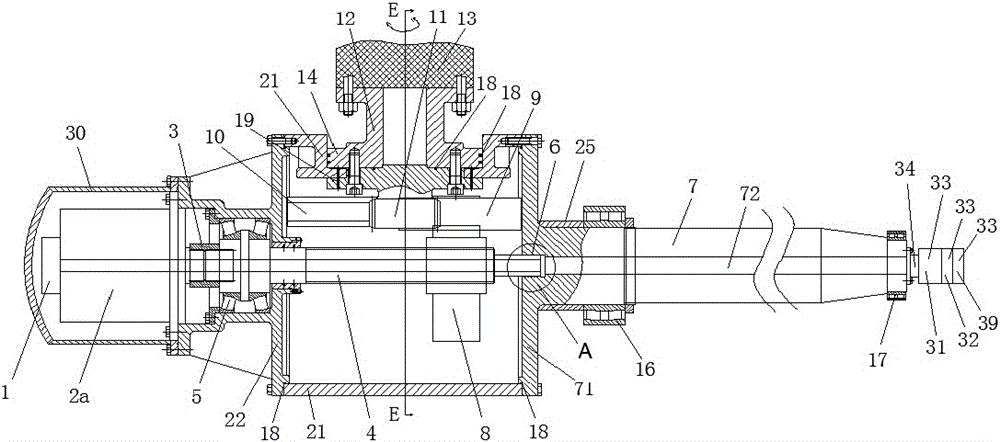

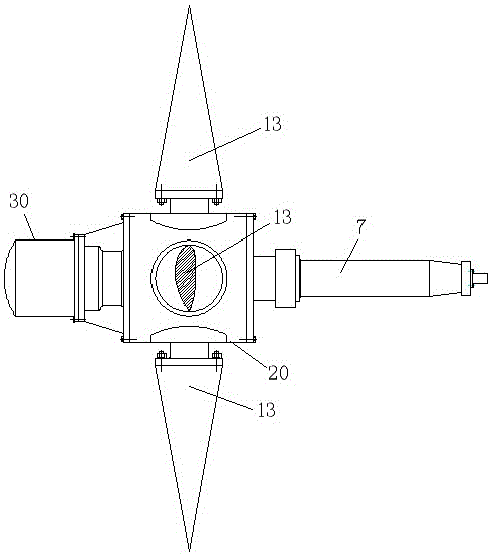

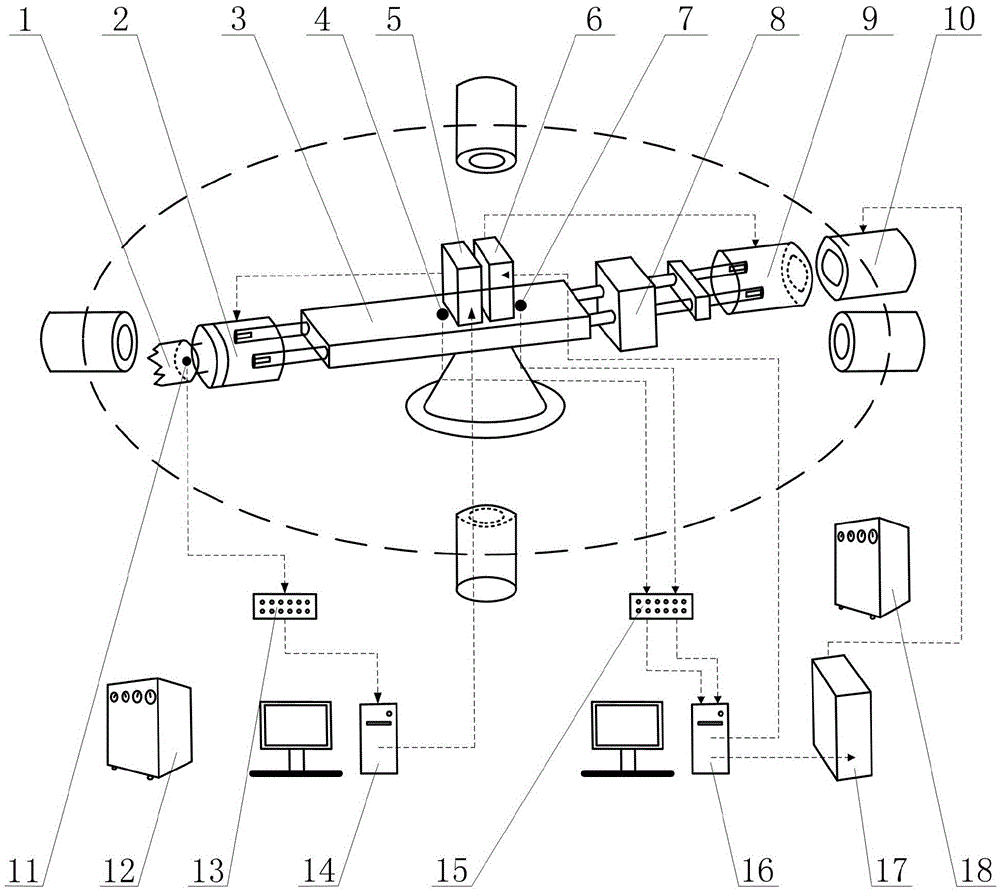

Test machine and test method for real-time and dynamic observation of end surface torsion friction and abrasion of friction interface

ActiveCN102944512AHigh rotation accuracyRun smoothlyUsing mechanical meansMaterial analysisElectric machineryGear transmission

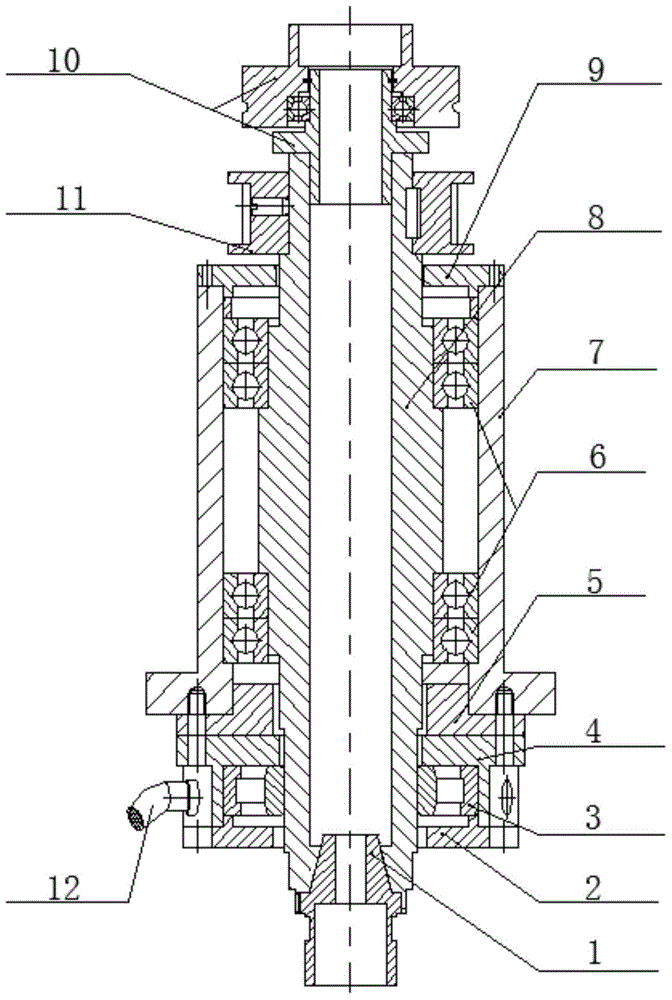

The invention discloses a test machine and a test method for real-time and dynamic observation of end surface torsion friction and abrasion of a friction interface. The test machine comprises a pressure applying device, a rotary platform, a friction interface observing device and an adjusting device, wherein the pressure applying device comprises a lever, a lever bracket and weights, the rotary platform comprises a motor, a shaft encoder and a worm and gear transmission mechanism, the friction interface observing device comprises a high-speed camera, a torque sensor and a pressure sensor, and the adjusting device comprises a level and a vertical adjustable rod element. The axial loading is applied to a lower specimen by the lever and the weights, the rotary platform drives an upper specimen to do reciprocating torsion, the high-speed microscopic camera is used for observing the friction interface, the torsion friction and abrasion tests under different external loads are simulated by the adding and reducing of the weights, the change of the torsion frequency and the like, then the friction coefficient, the abrasion shape and the abrasion chip real-time movement in the friction process are obtained, and the friction and abrasion performances of transparent material in the whole process are evaluated. The test machine has the advantages that the structure is simple, the operation is convenient, and the repetitiveness is high.

Owner:CHINA UNIV OF MINING & TECH

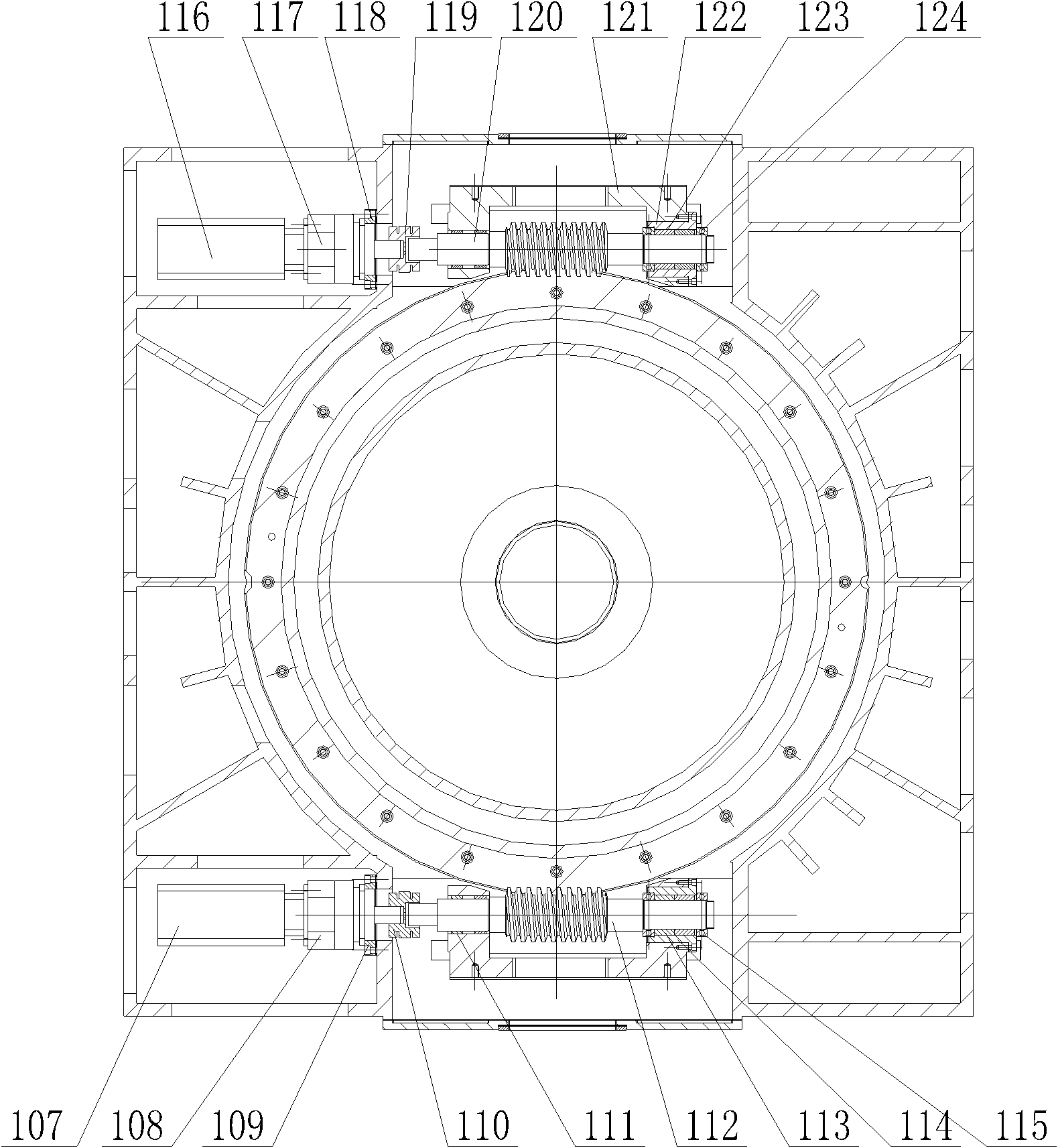

Accurate one-dimensional rotary and two-dimensional tilting table

InactiveCN101436436AImprove carrying capacityHigh adjustment accuracyInstrumental componentsPosition/direction controlEngineeringWork demand

Owner:TONGJI UNIV

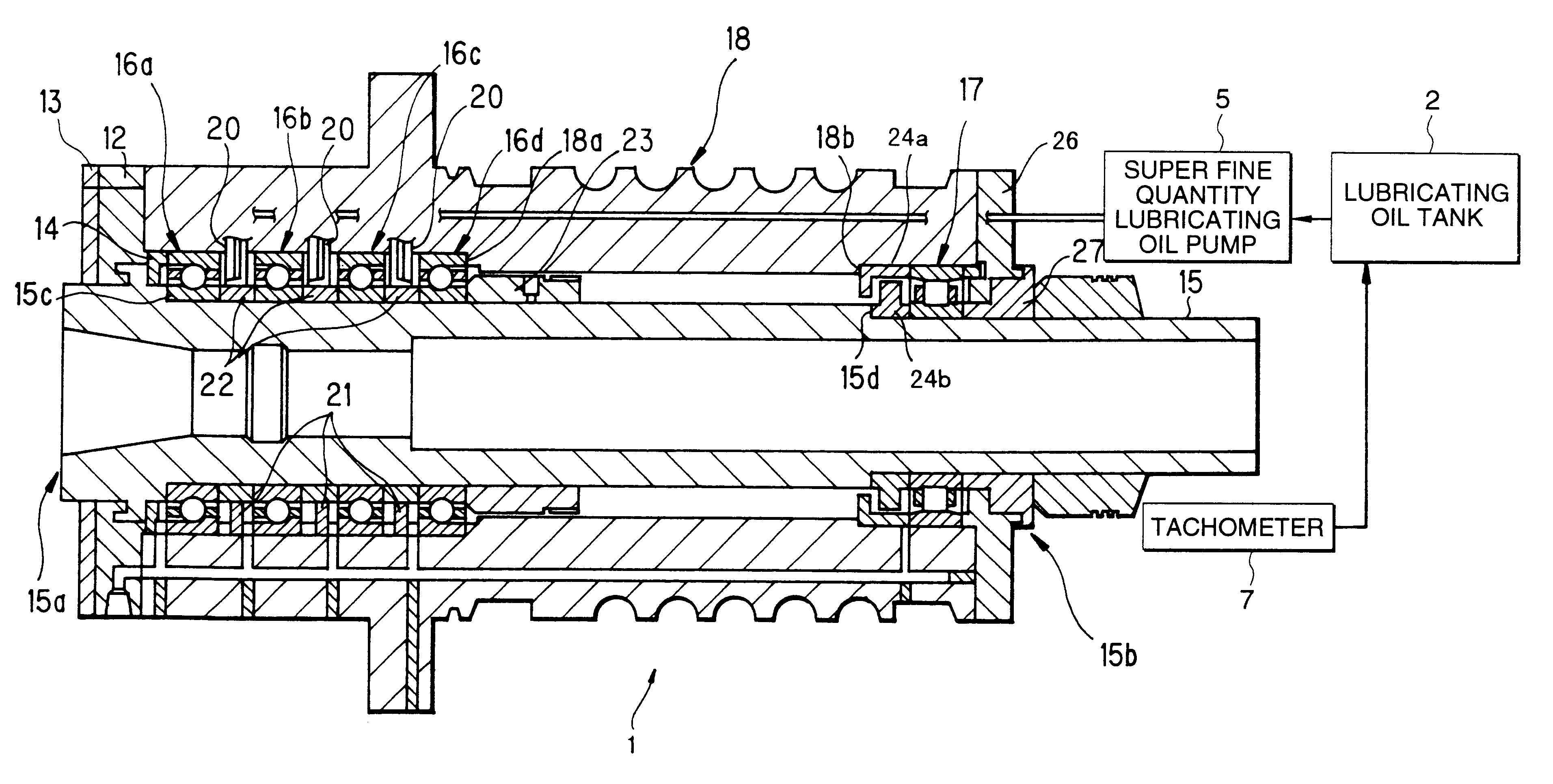

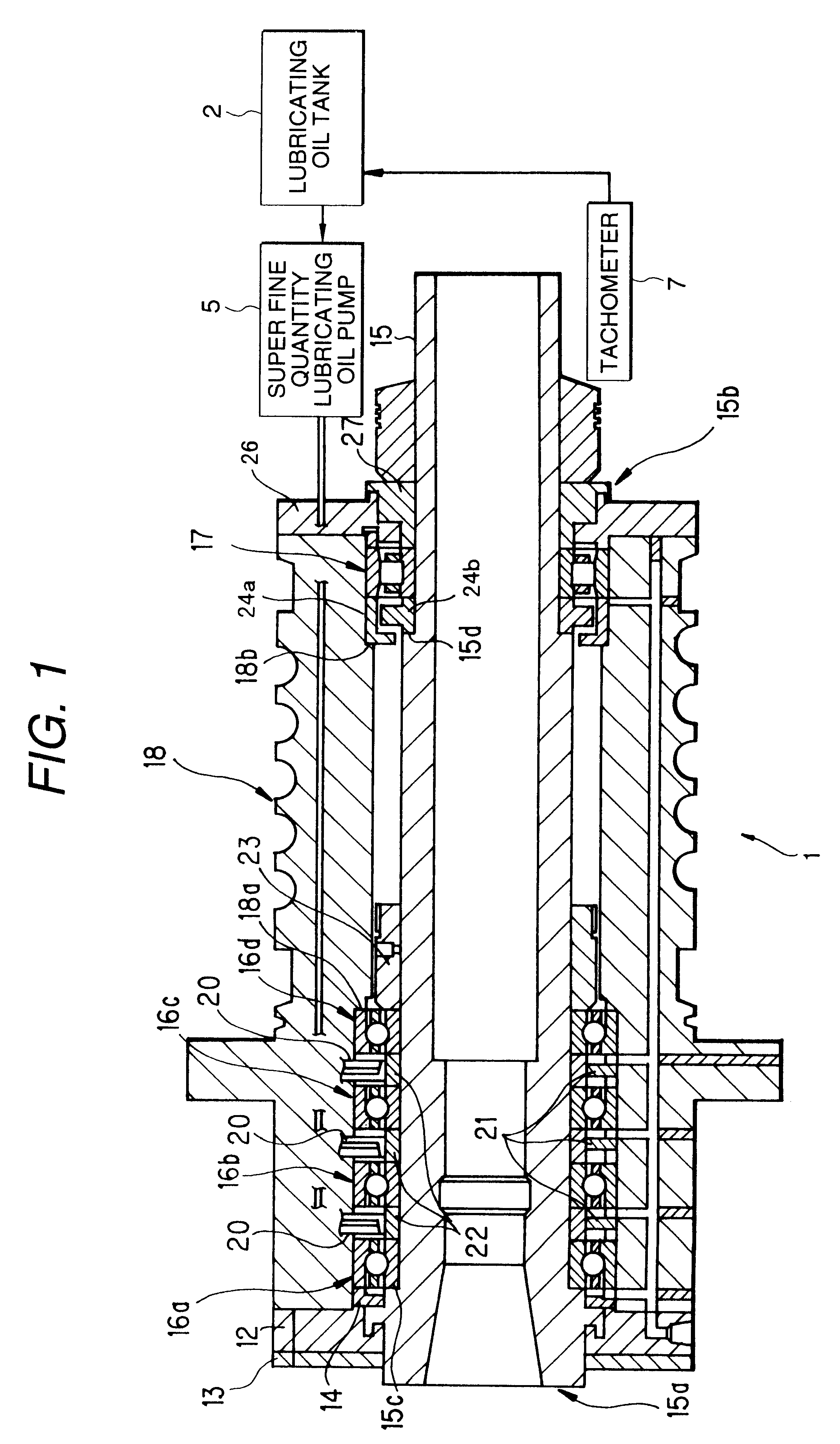

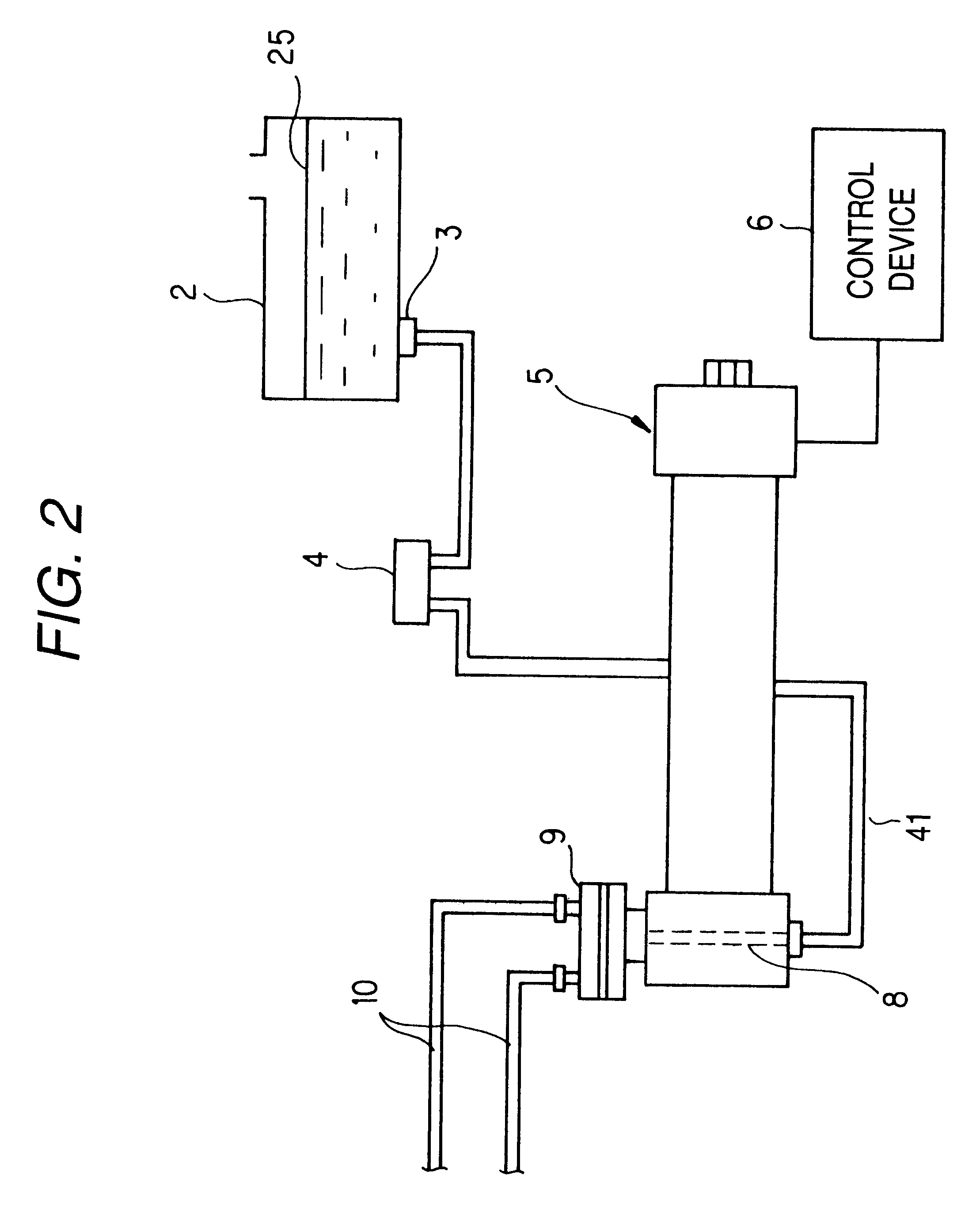

Lubricating device

InactiveUS6398509B1Reduce noiseHigh torque stabilityRolling contact bearingsShaftsPump chamberEngineering

A rod body 30 is formed of magnetostrictive material and includes one end portion 30 fixed, and a piston 35 is fixed to the other end portion 30b of the rod body 30. The piston 35 is slidably disposed within a cylinder 36 in which there is formed a pump chamber 37. A suction port 39 for sucking lubricating oil into the pump chamber 37 is formed in the cylinder 36, while a suction valve 40 for preventing the lubricating oil from flowing out from the suction port 39 is disposed in the suction port 39. In the cylinder 36, there is disposed a nozzle 20 which communicates with the pump chamber 37 and has a sectional area smaller than the lubricating oil passage sectional area of the suction valve 40. There is disposed a coil 43 outside the rod body 30 and, to the coil 43, there is connected a control device 6 for controlling the supply of a current to be supplied to the coil 43.

Owner:NSK LTD

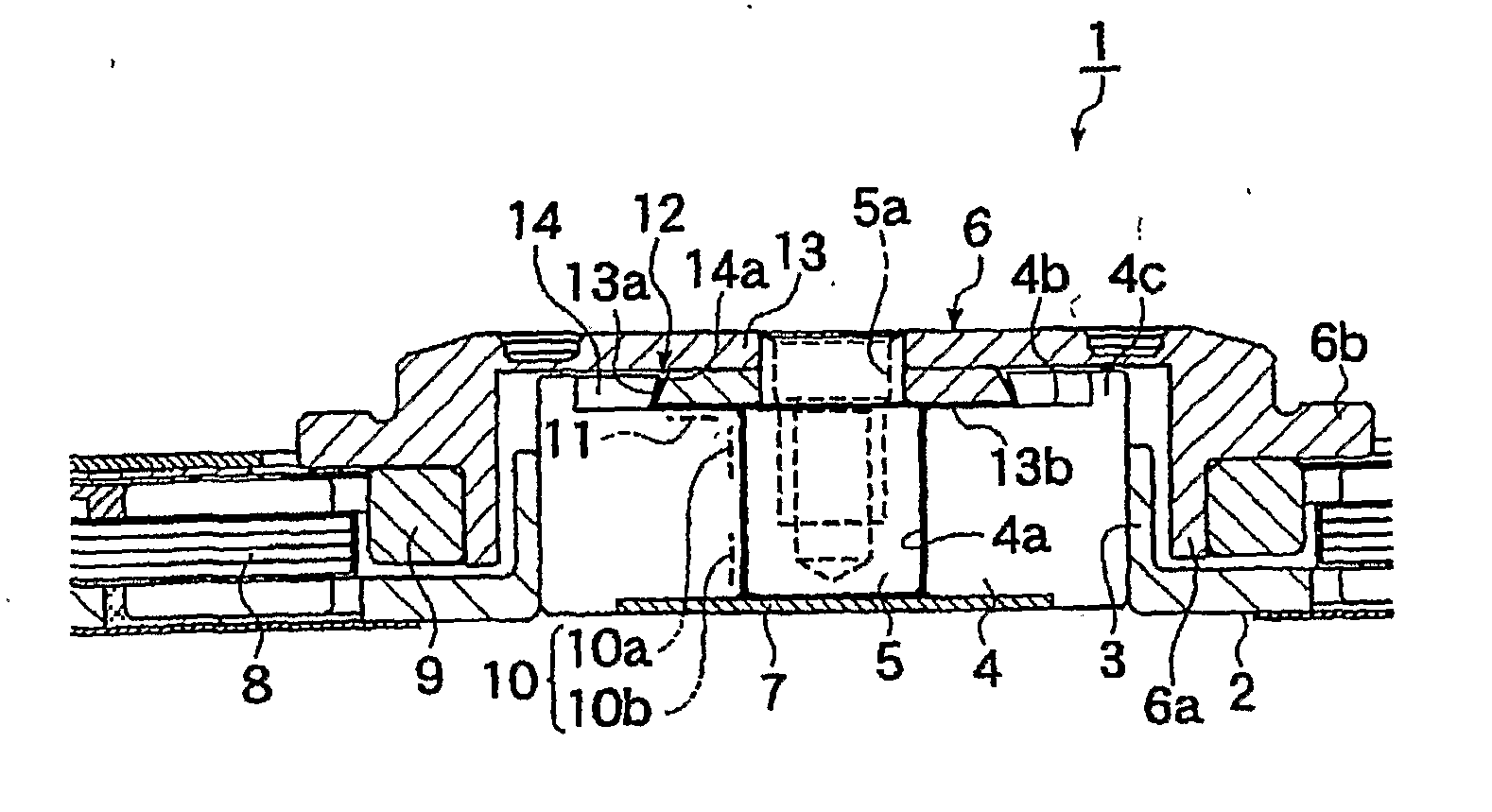

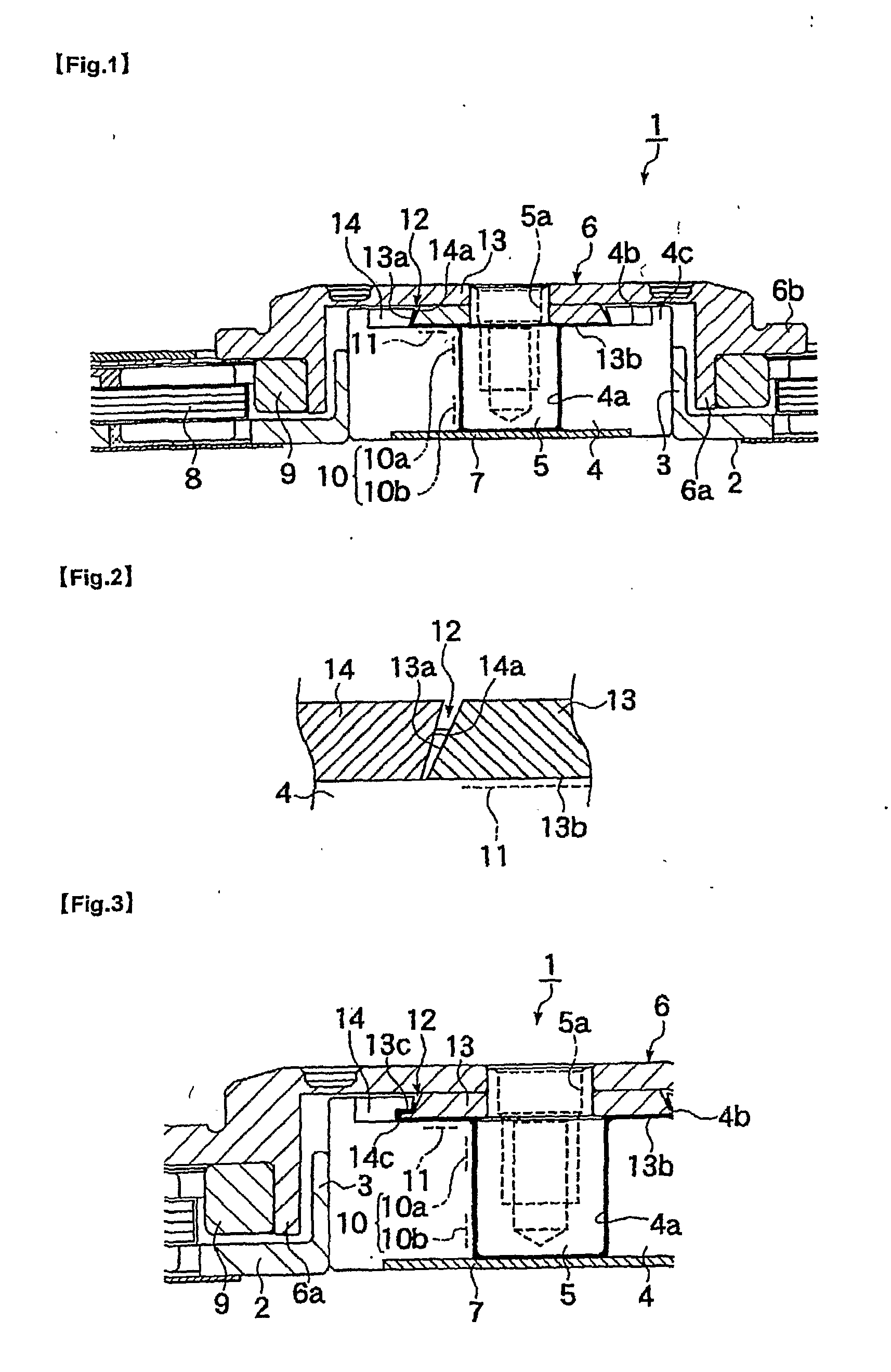

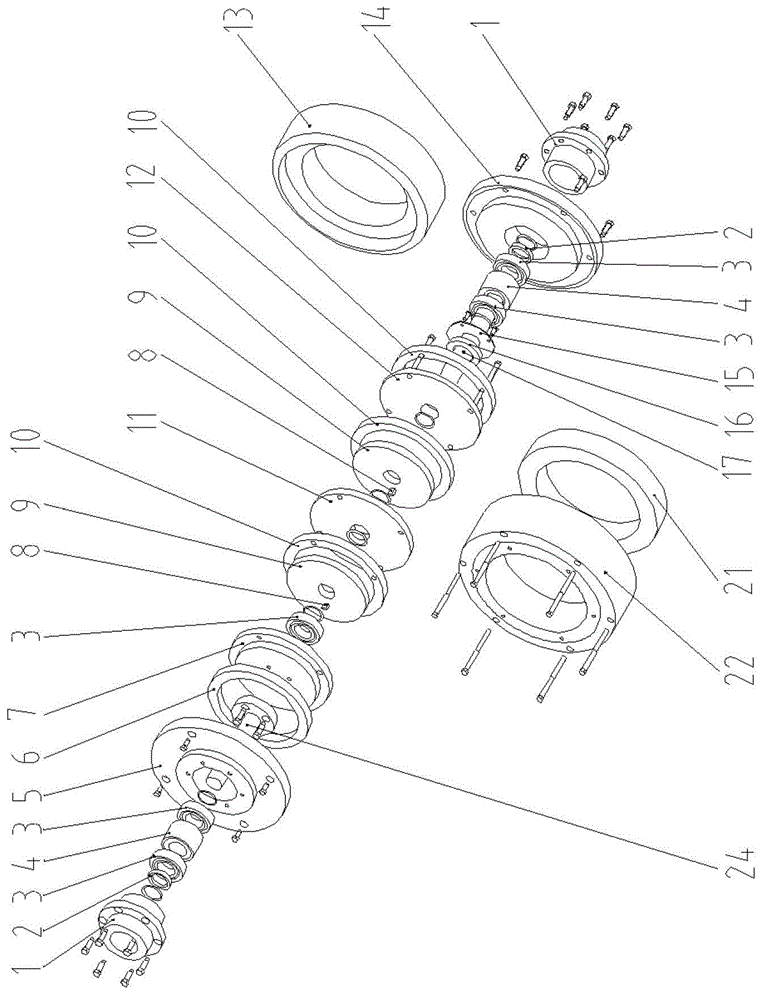

Fluid Dynamic Bearing Mechanism for a Motor

InactiveUS20070211971A1Improve bearing rigidityHigh rotation accuracyShaftsRecord information storageCapillaria obsignataDynamic pressure

A fluid dynamic bearing mechanism for a motor (1) suitable for use in a hard disk drive and having a compact and thin shape, high bearing rigidity, and high rotating accuracy, and which securely keeps the rotor member (6) in place against shocks, and allows the inspection of lubricant supply amount easily. A fluid dynamic bearing mechanism having a capillary seal part (12) on one end of lubricant supply part formed by a minute gap including dynamic pressure grooves (10) formed on a shaft member (5) or a bearing member (4) is provided. An annular member (13) is fitted on the shaft member at the location corresponding to the capillary seal part, another annular member (14) is fitted on the bearing member at the location corresponding to the capillary seal part, a taper or step (13a, 14a) is formed on the outer peripheral surface of the annular member on the shaft member side and the inner peripheral surface of the annular member on the bearing member side. These inner and outer peripheral surfaces are arranged to be close to and facing with each other so that the rotor member is prevented from disengaging from the bearing member, and the capillary seal part can be formed at the same time. An axial dynamic pressure bearing unit (1) is formed between the annular member on the shaft member side and one end of the bearing member.

Owner:MINEBEA CO LTD

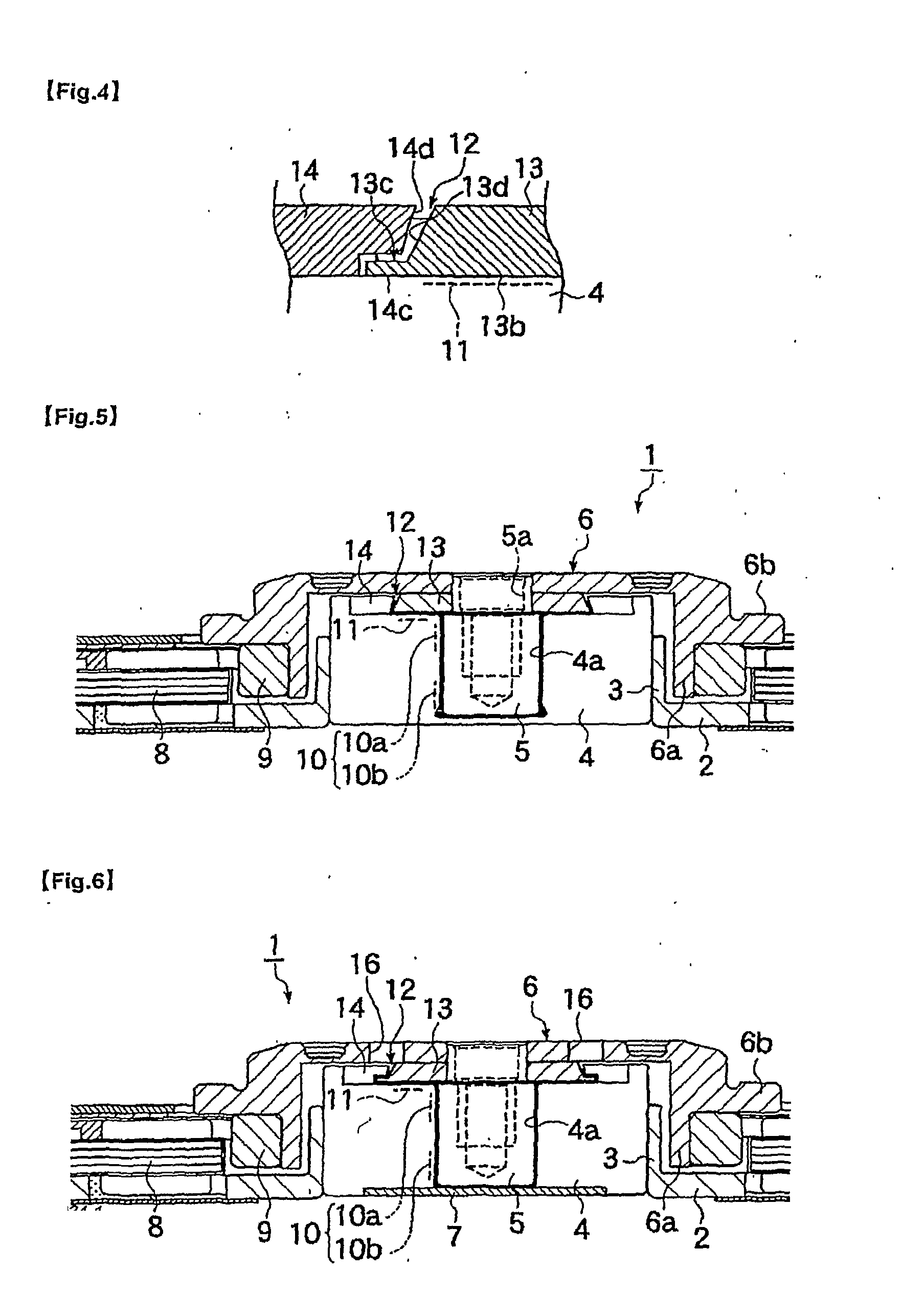

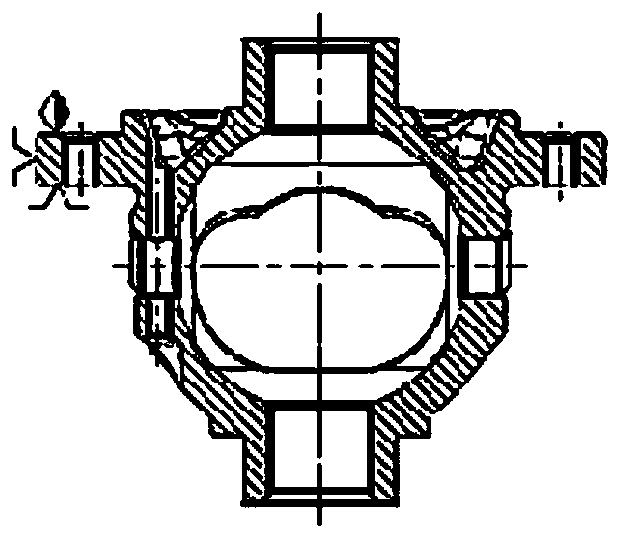

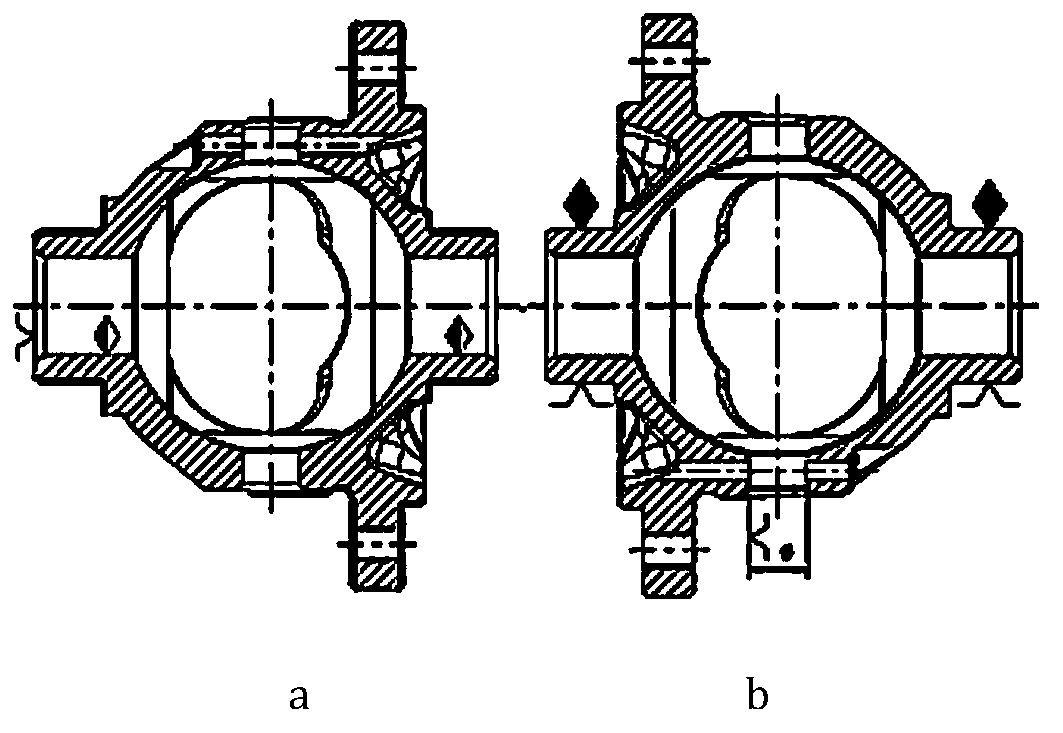

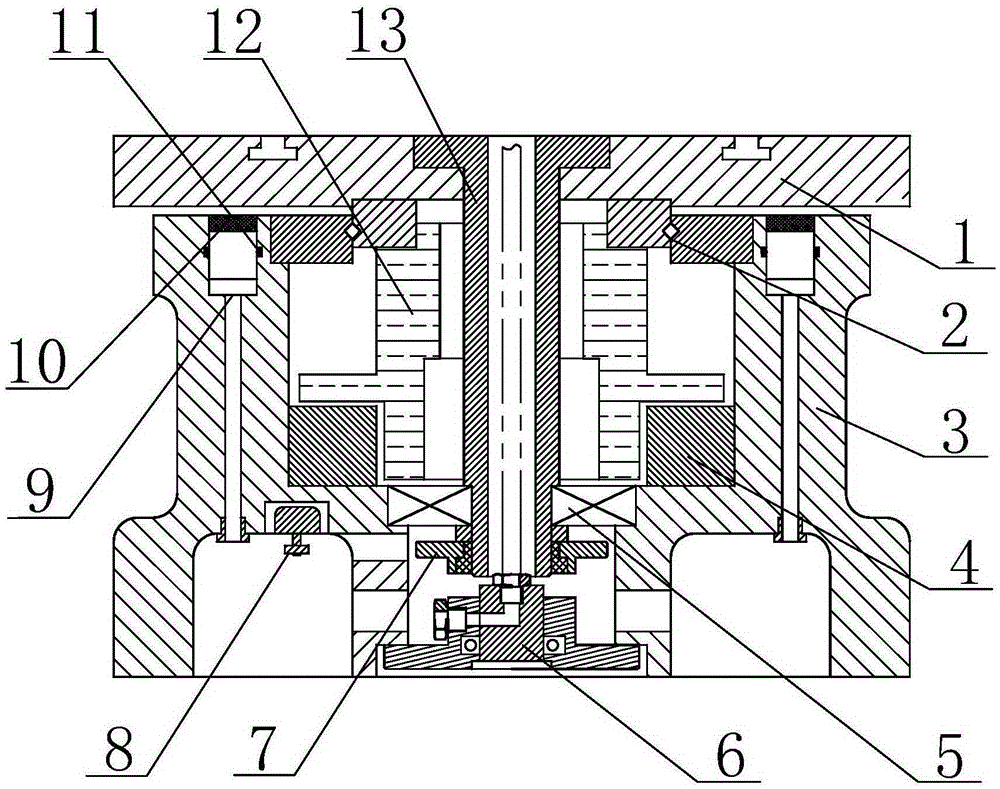

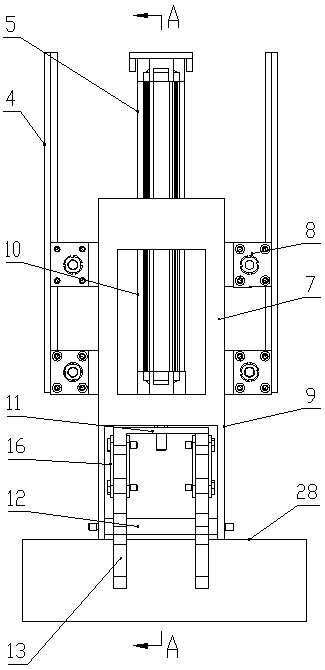

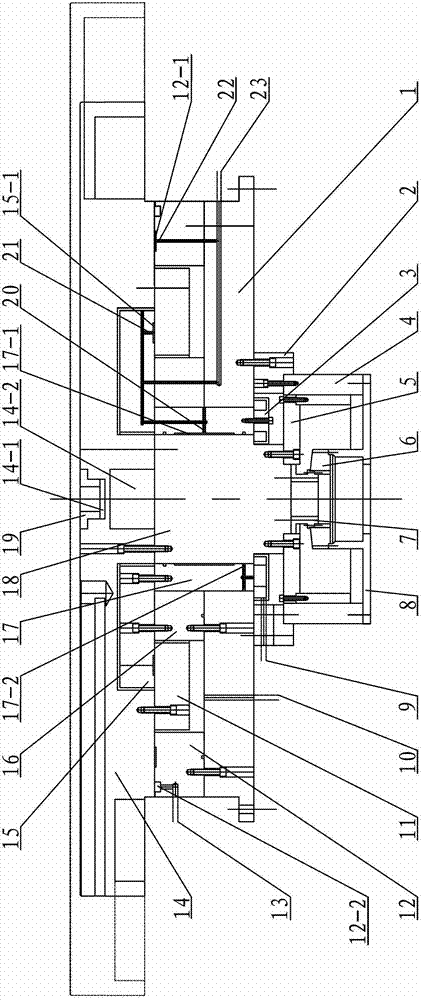

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Three-shaft high-low temperature speed turntable

The invention belongs to a gyro calibrator and discloses a three-shaft high-low temperature speed turntable adaptable to high and low temperature ranges. The turntable comprises a turntable base, an outer frame, a middle frame, an inner frame, driving shafts of the outer frame, the middle frame and the inner frame, and a driving motor, wherein the outer frame has a U-shaped structure, the driving shaft of the outer frame is arranged in the turntable base; the turntable also comprises a temperature box, the outer frame, the middle frame and the inner frame are arranged in the temperature box, and a base plate of the temperature box is provided with a shaft hole which allows the driving shaft of the outer frame to pass through; the middle frame and the inner frame are standard positive circular ring shaped; and the wall of the temperature box is provided with a glass window. The three-shaft high-low temperature speed turntable has the advantages that tests on a gyro in three directions in a high temperature environment and a low temperature environment can be performed simultaneously, and the turntable has low requirement on the motor moment and has high test efficiency.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

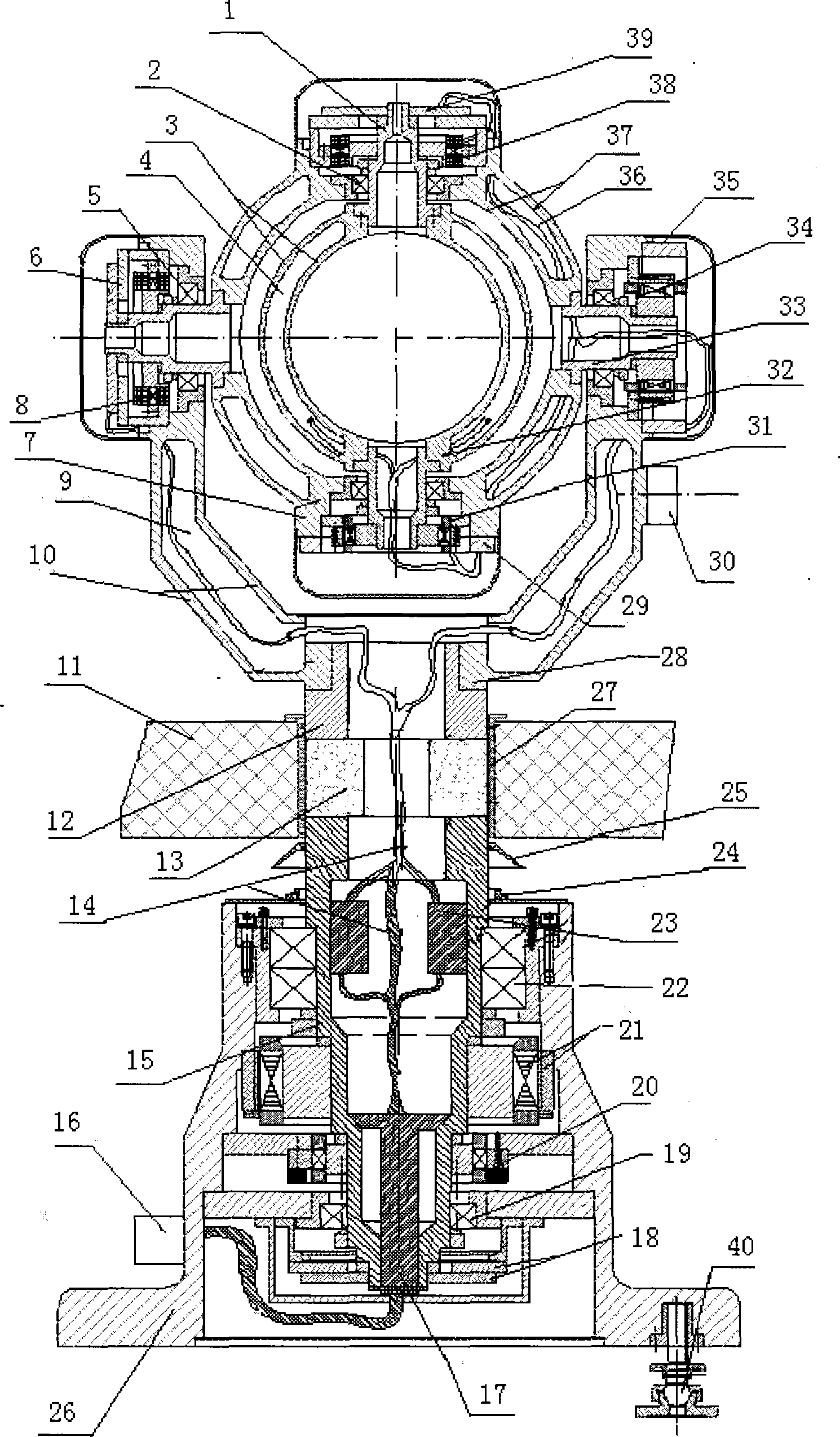

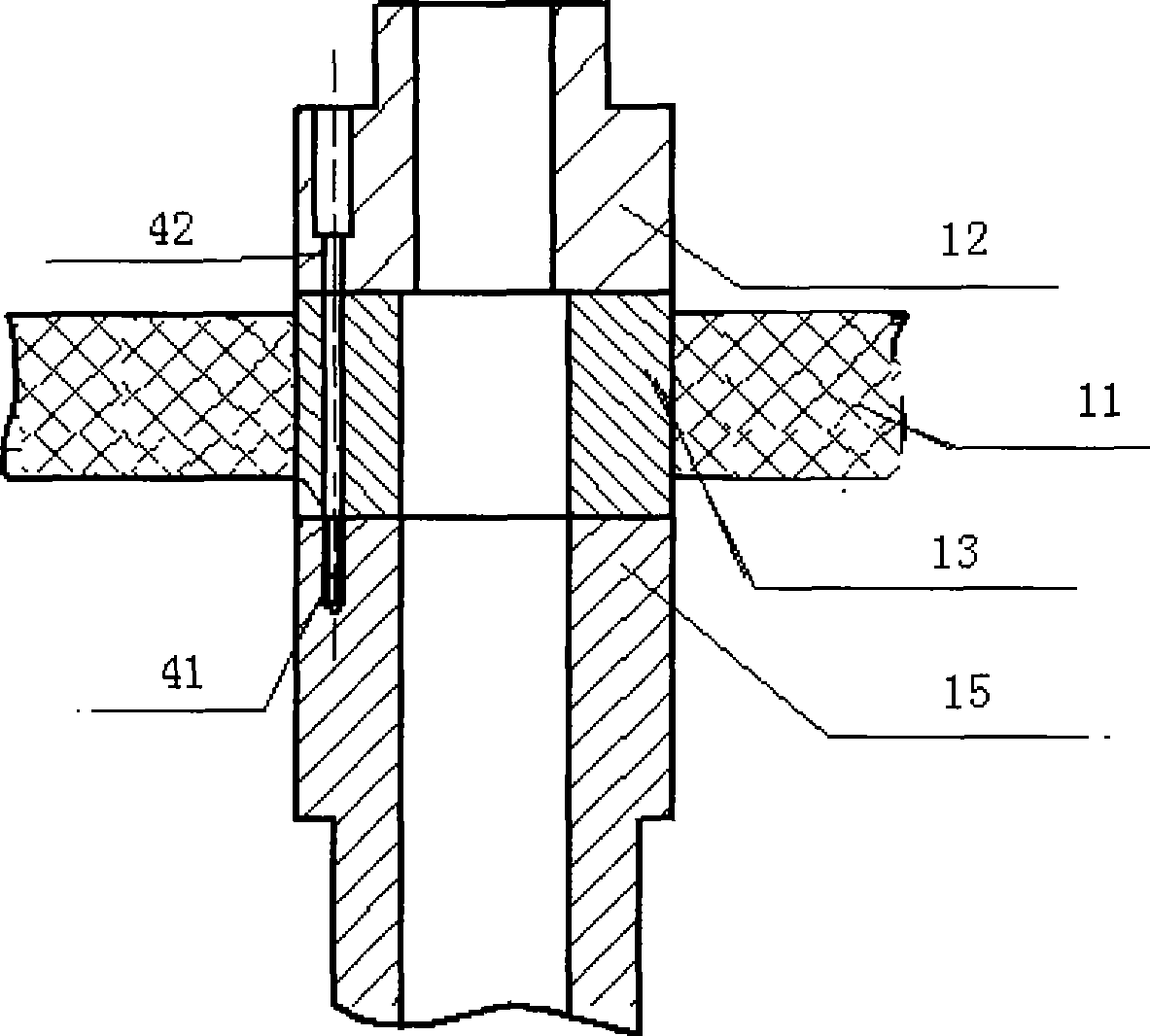

Two-way dynamic-static pressure mixture lubrication thrust bearing

InactiveCN103438097AHigh running precisionImprove running stabilityBearingsGas cushion bearingsThrust bearingEngineering

The invention relates to a two-way dynamic-static pressure mixture lubrication thrust bearing. Aiming to solve the problems of low accuracy and poor operating stability in an existing high-speed and heavy-load extreme working condition, the invention provides the two-way dynamic-static pressure mixture lubrication thrust bearing. The two-way dynamic-static mixture lubrication thrust bearing comprises a dynamic-static pressure oil pad, a circular machine tool base and a rotary workbench, wherein the rotary workbench is arranged right above the dynamic-static pressure oil pad; the circular machine tool base is arranged under the dynamic-static pressure oil pad; wedges are arranged on the dynamic-static pressure oil pad of the two-way dynamic-static pressure mixture lubrication thrust bearing and are arranged in two inner sides of the circumferential direction of an oil sealing edge. The two-way dynamic-static pressure mixture lubrication thrust bearing is applied to the field of high-speed and heavy-load machine tool workbenches.

Owner:HARBIN UNIV OF SCI & TECH

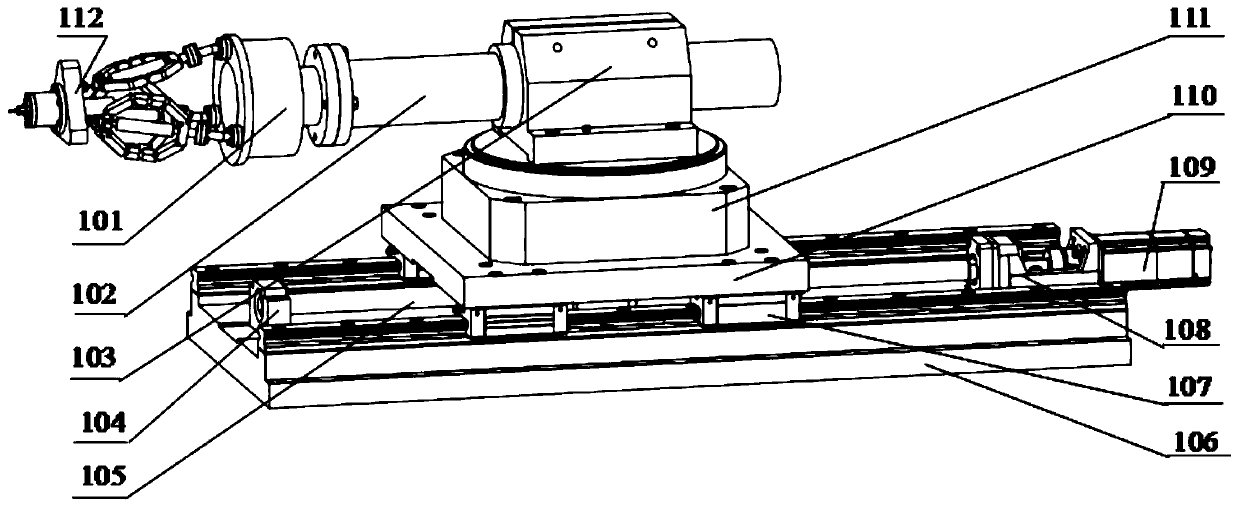

Precision five-axis double-station position changing machine

ActiveCN102699612AReduce production timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesRocker armEngineering

The invention relates to a precision five-axis double-station position changing machine. The machine comprises a rotating base, an upright post box arranged on the rotating base in a horizontal rotating mode, a first servo motor for driving the upright post box to rotate, and a first clamping device and a second clamping device which are respectively arranged on the two sides of the upright post box, wherein the first clamping device comprises a first rocker arm, a second servo motor for connecting the upright post box and the first rocker arm and driving the first rocker arm to vertically rotate, a first headstock and a first tailstock which are arranged on the first rocker arm, and a third servo motor for driving the first headstock to rotate; and the second clamping device comprises a second rocker arm, a fourth servo motor for connecting the upright post box and the second rocker arm and driving the second rocker arm to vertically rotate, a second headstock and a second tailstock which are arranged on the second rocker arm, and a fifth servo motor for driving the second headstock to rotate. Double position-changeable stations are arranged, so that a welding robot can continuously work, time consumption during production is reduced, production efficiency is improved, and rotating accuracy and repositioning accuracy are high.

Owner:XUZHOU HUAHENG ROBOT SYST

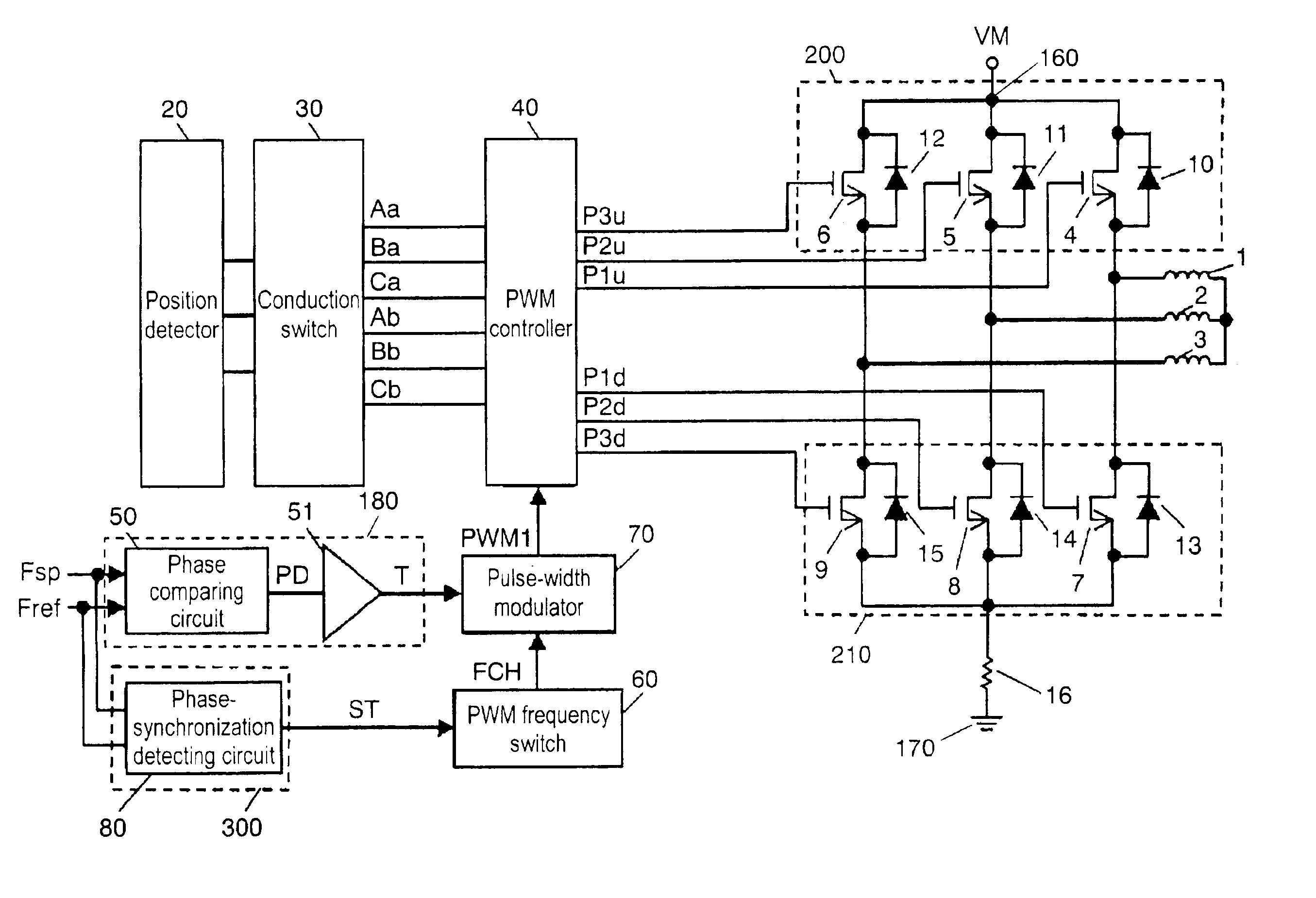

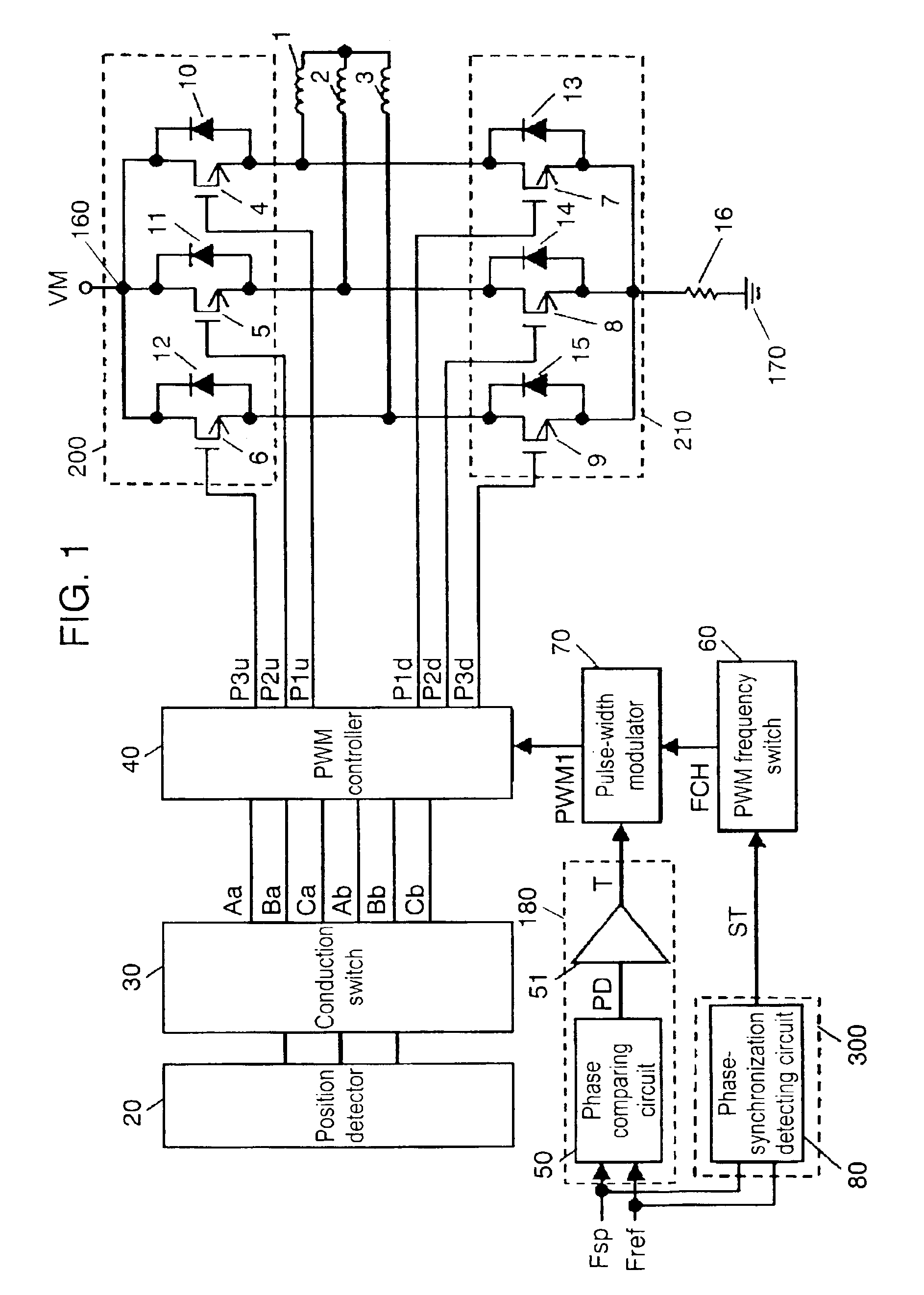

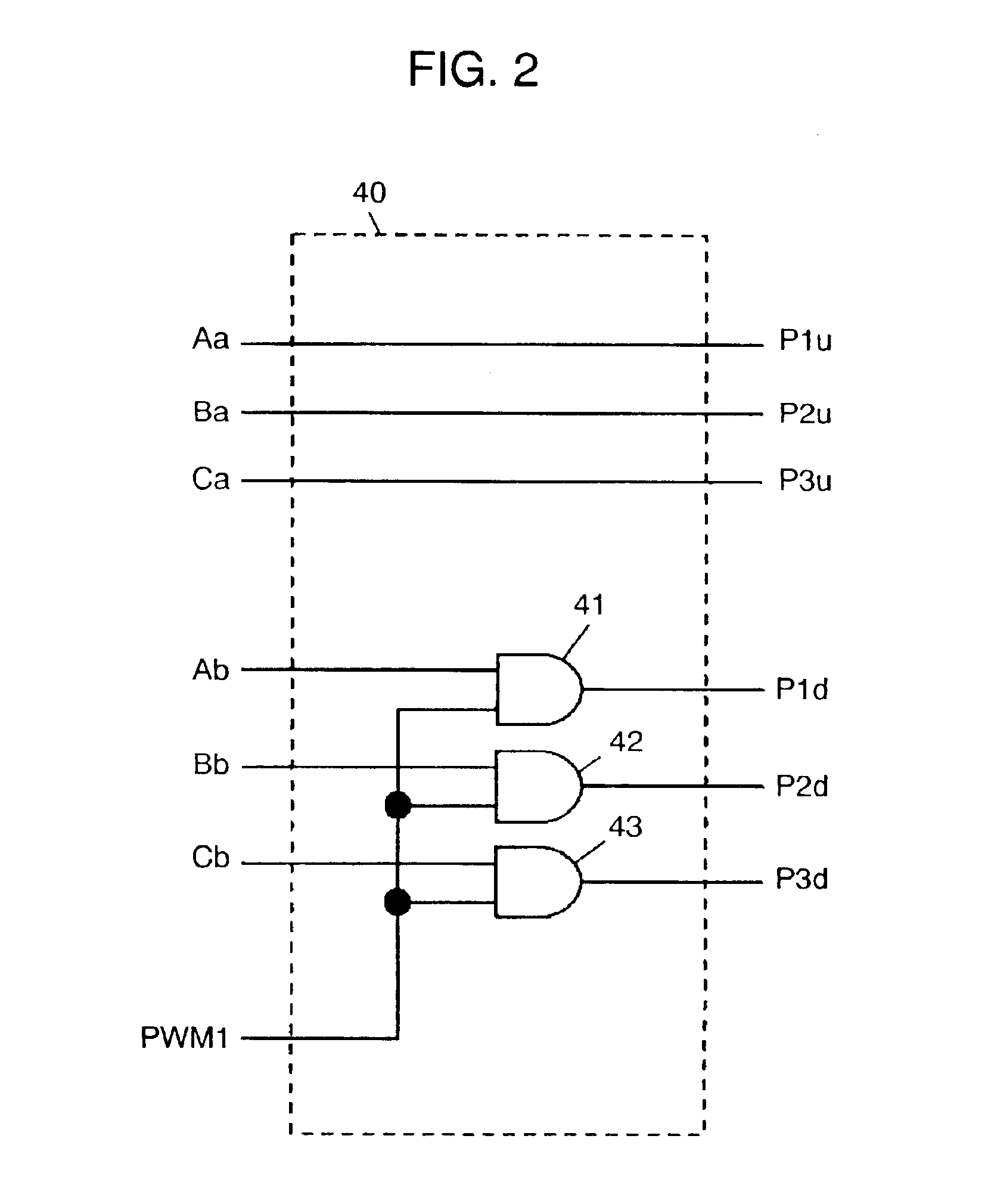

Motor driving apparatus and motor using the same

InactiveUS6873125B2Reduce power lossHigh rotation accuracyMotor/generator/converter stoppersSynchronous motors startersMotor driveElectric machine

A motor driving apparatus includes a pulse-width modulator and a PWM frequency switch for switching a carrier frequency of the modulator. The PWM frequency switch changes a carrier frequency in a start-up period of the motor to another frequency when the motor enters into a regular rotation. The carrier frequency in the start-up period is set at a lower level than that in the regular rotation period, so that the driving apparatus can reduce power-loss generated in the start-up period by switching actions of respective driving elements forming a first and a second drivers. In the regular rotation period, the driving apparatus performs PWM-driving with a high enough carrier frequency, so that the motor driven by this driving apparatus can realize accurate rotation.

Owner:MINEBEA MOTOR MFG

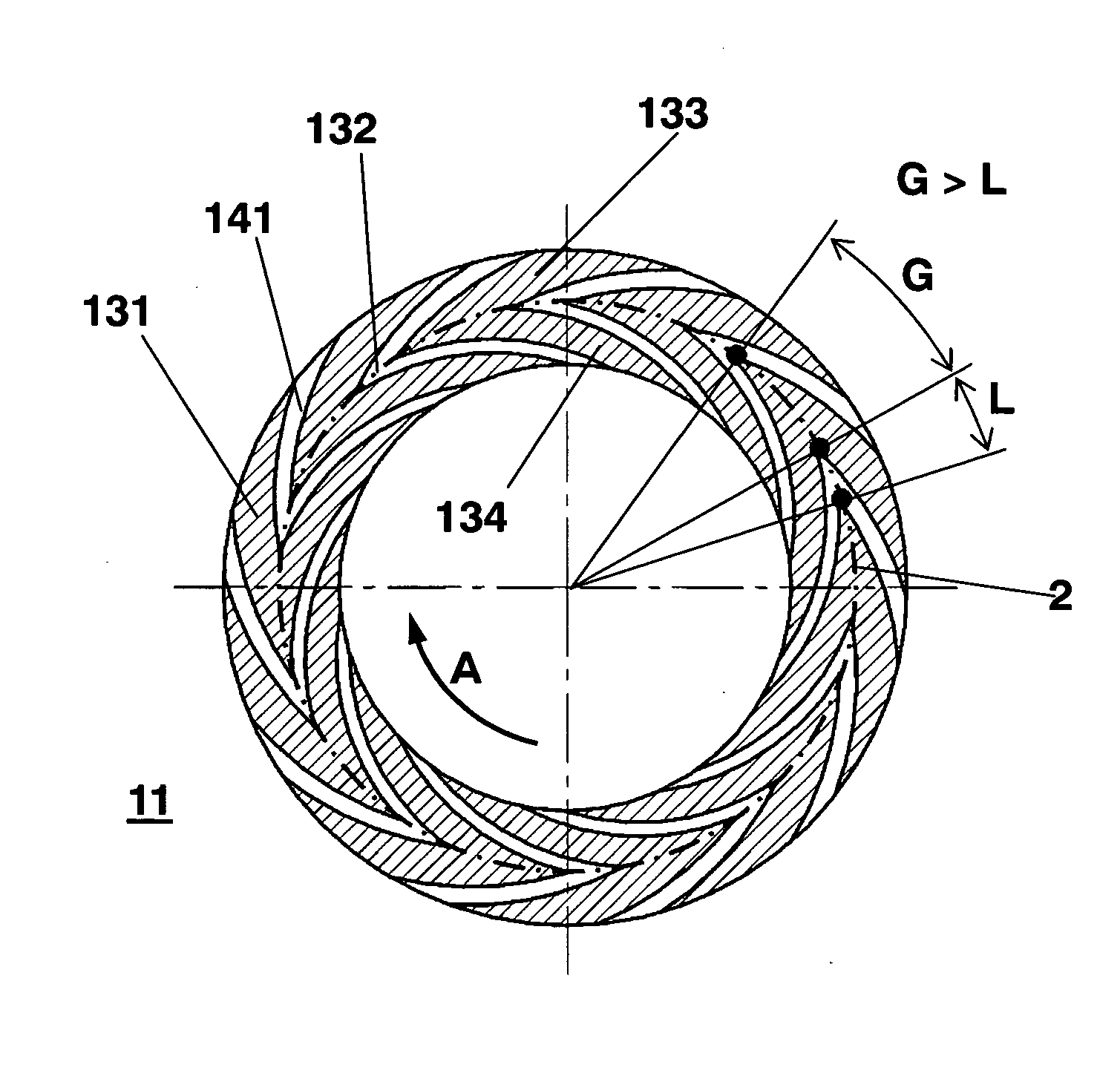

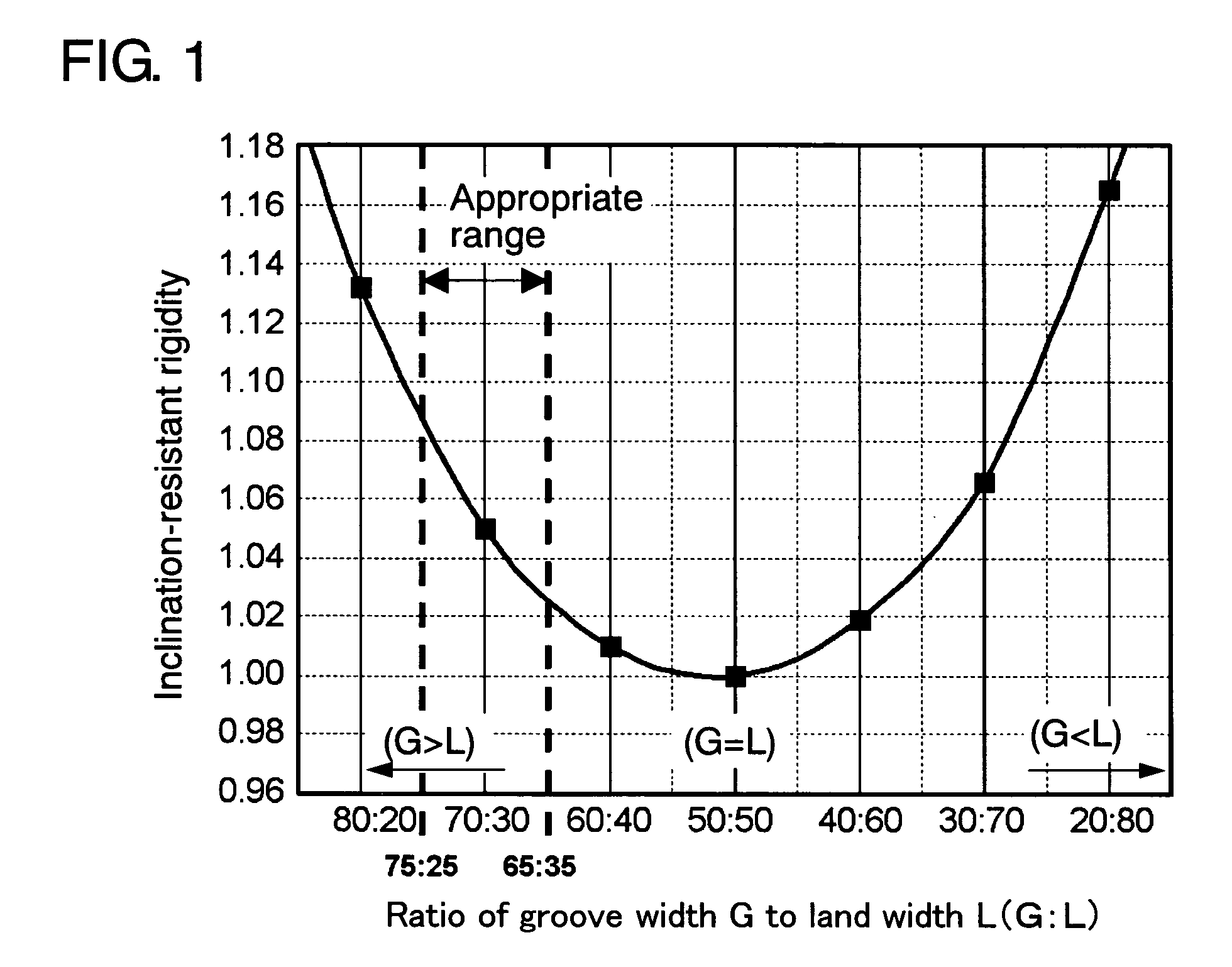

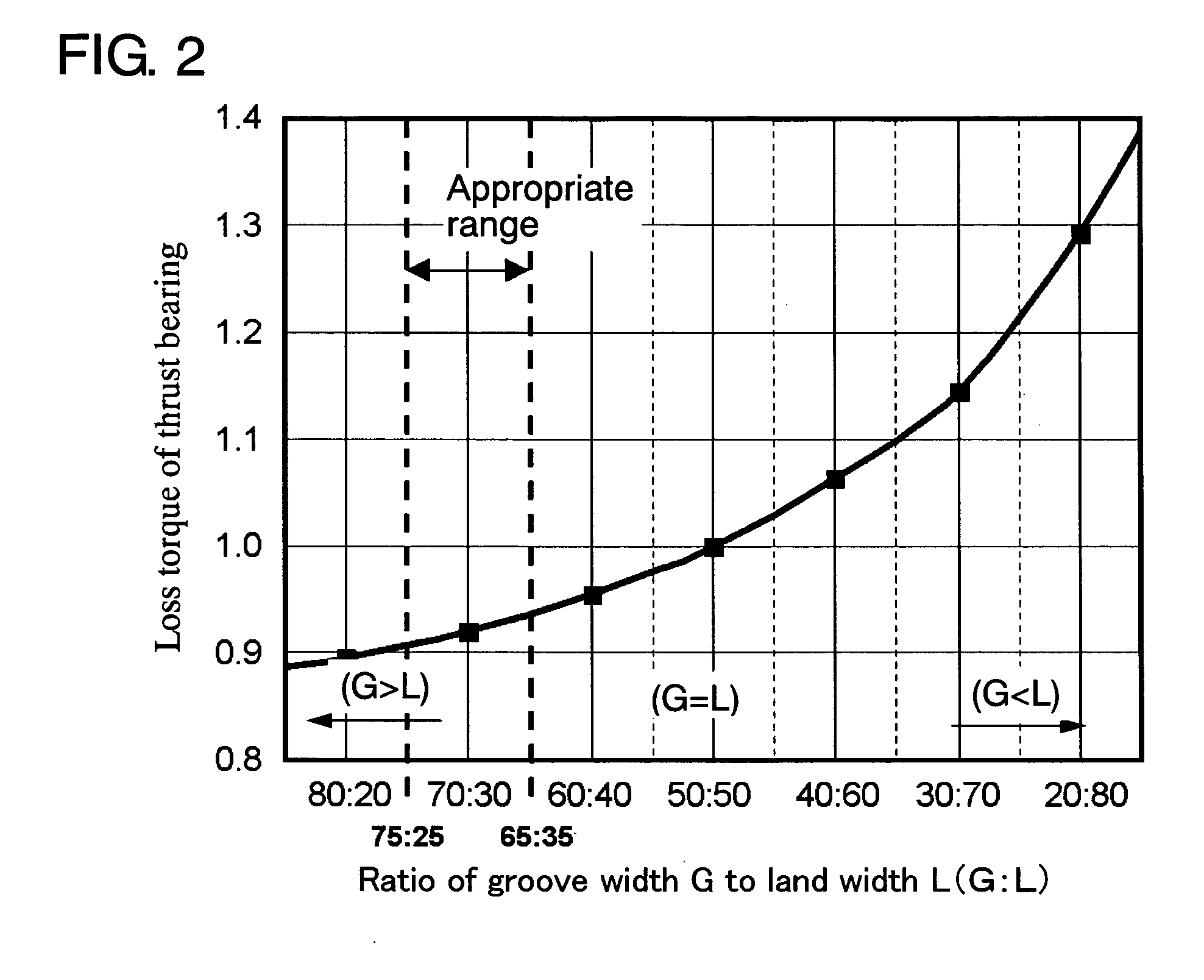

Thrust dynamic pressure bearing, spindle motor using thereof, and information recording/reproducing device using the spindle motor

ActiveUS20070189648A1High inclination-resistant rigidityBearing loss torqueShaftsRecord information storageGroove widthControl theory

A thrust dynamic pressure bearing with high inclination-resistant rigidity against axis runout and additionally low bearing loss torque is implemented. Herringbone grooves (131) having intermediate bends (132) are provided on rotating-side bearing surface (11) provided on the rotating-side bearing member. When rotating-side bearing surface (11) rotates in direction A (clockwise), lubricating oil generates dynamic pressure in an area centering on intermediate bend (132) along radially outer part (133) and radially inner part (134) of herringbone groove (131). As a result that groove width (G) of a dynamic pressure generating groove and width (L) of a land adjacent to the dynamic pressure generating groove holds G>L at an arbitrary radius (2) position, a thrust dynamic pressure bearing with high inclination-resistant rigidity and additionally low bearing loss torque is provided.

Owner:PHC HLDG CORP

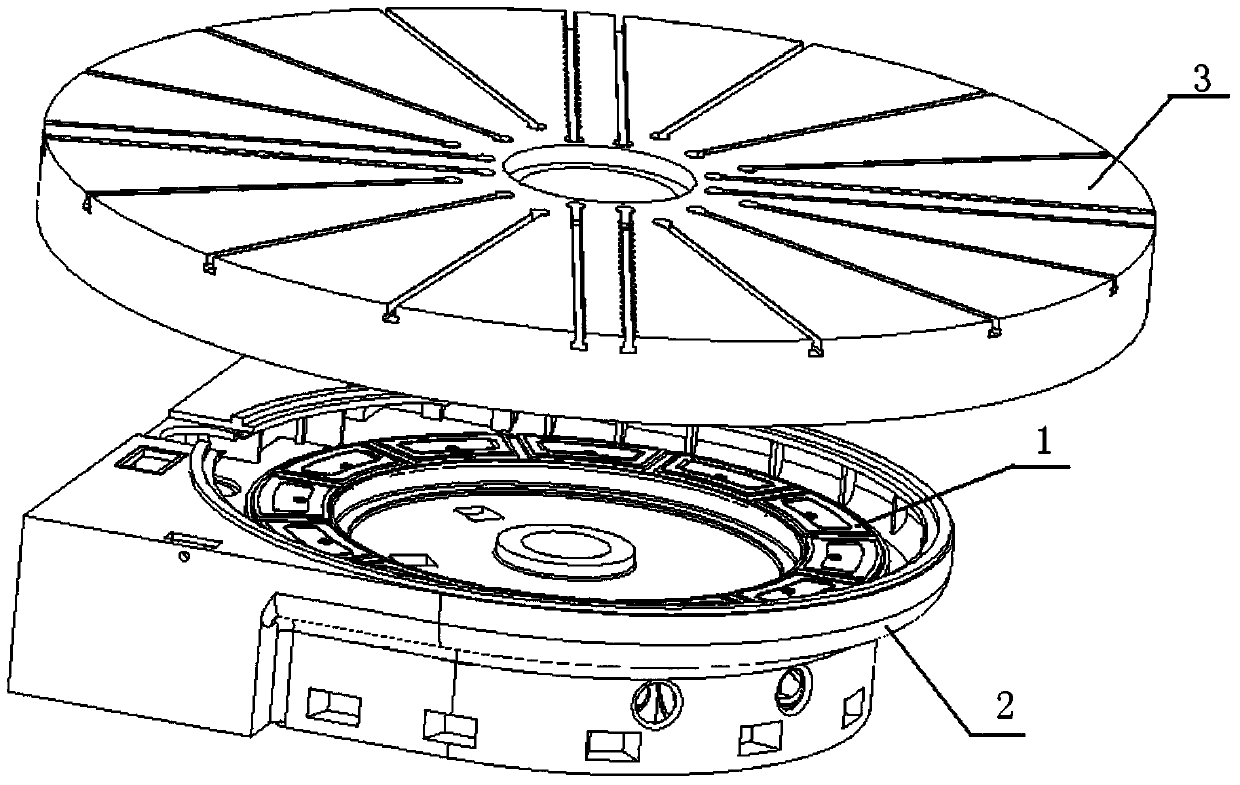

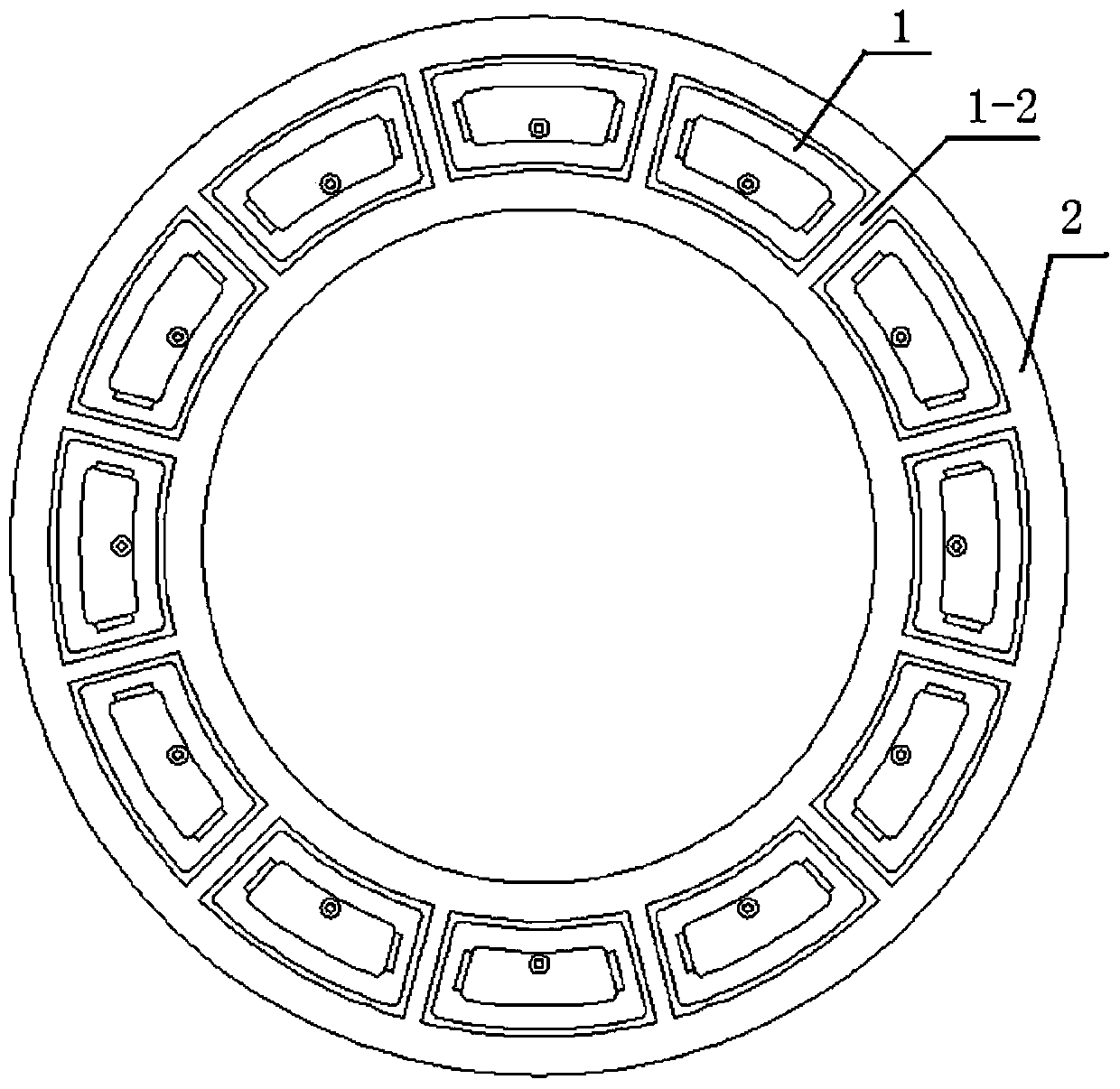

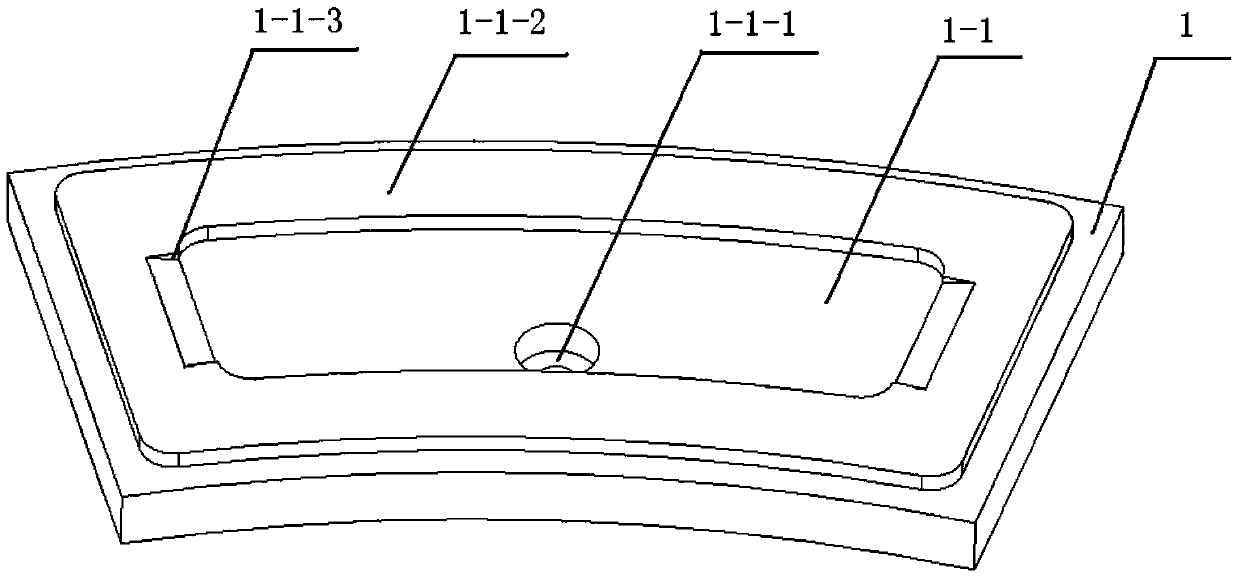

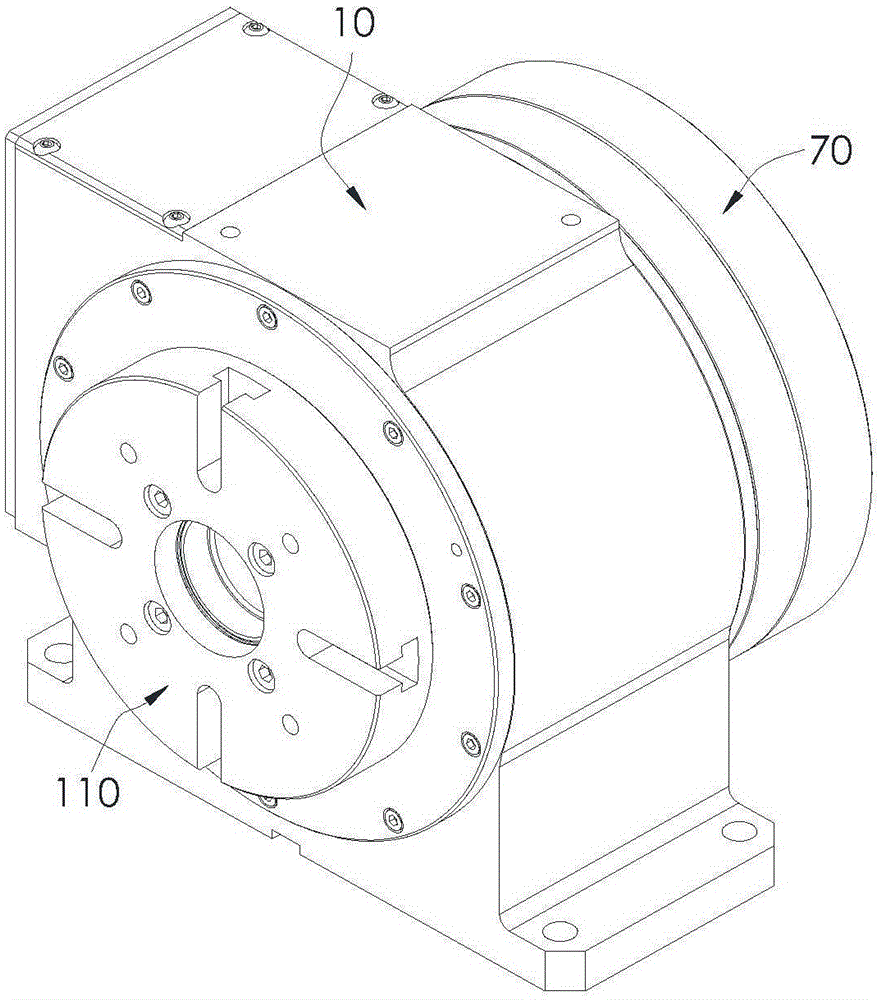

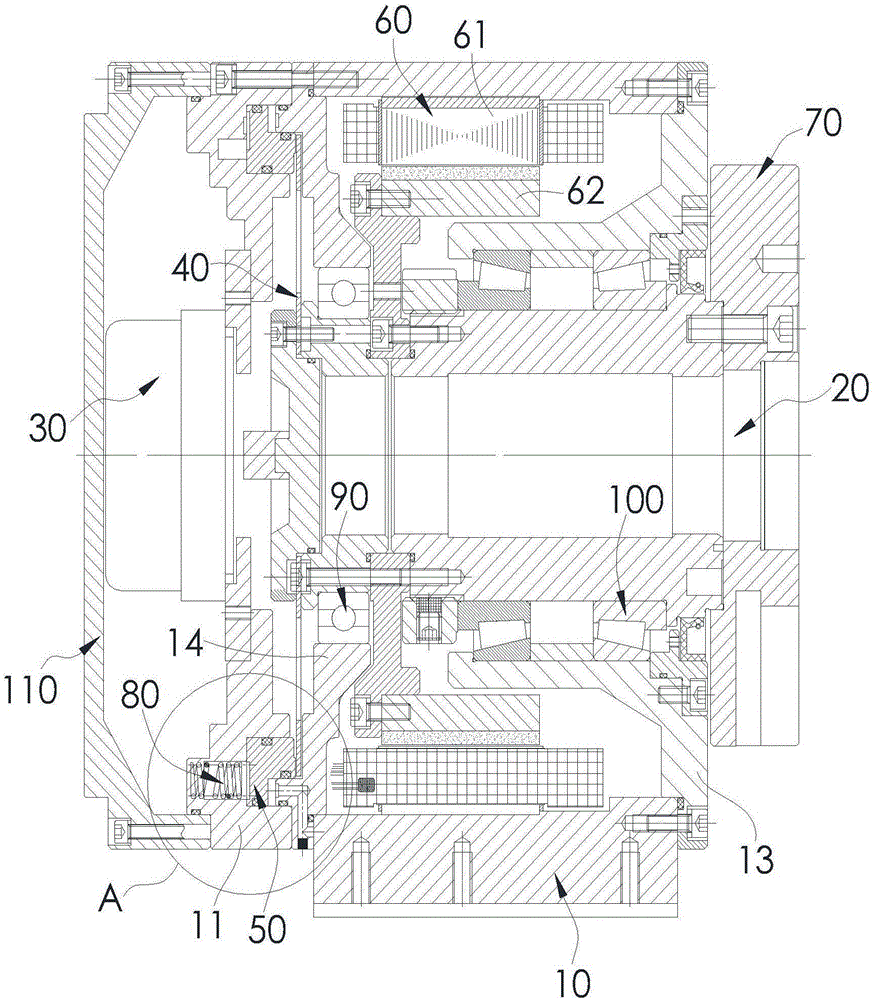

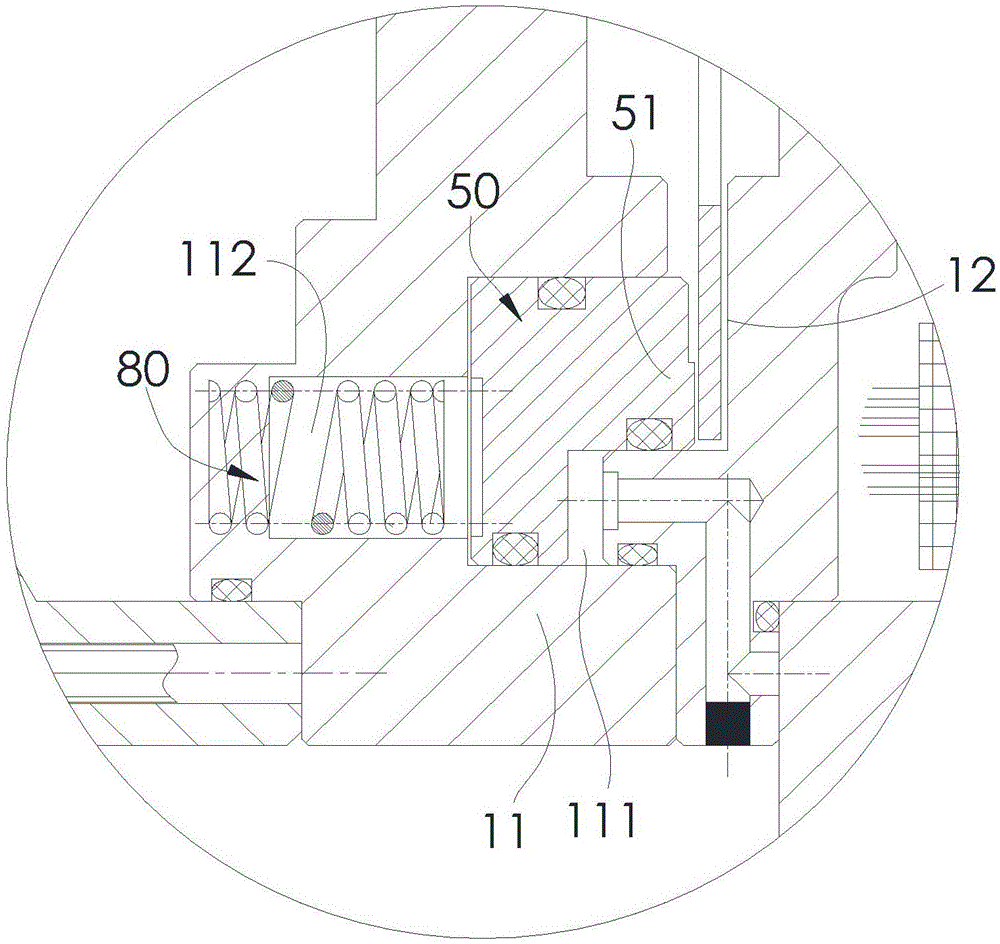

Rotary working table

InactiveCN105345491ACompact structureHigh rotation accuracyLarge fixed membersElectric machineryStator

The invention relates to a rotary working table. The rotary working table comprises a working surface, a motor stator, a rotor, a crossed roller swing bearing, a deep groove ball bearing and a table base, wherein a spigot shaft is fixed in the center of the working surface; the rotor is fixed in the middle of the outer wall of the spigot shaft; the crossed roller swing bearing is arranged among the working surface, the rotor and the table base; the motor stator is fixed in the middle of the inner wall of the table base; the outer ring of the deep groove ball bearing is fixed with the lower part of the inner wall of the table base; the inner ring of the deep groove ball bearing is fixed with the lower part of the spigot shaft; a synchronous pulley is further fixed in the position, below the inner ring of the deep groove ball bearing, of the spigot shaft; an encoder feedback detection device is fixed in the position, corresponding to the synchronous pulley, of the lower part of the table base; cylinder locking levers are arranged in the side wall of the table base, and a friction brake pad is fixed at the top of each cylinder locking lever. The rotary working table is high in support precision and high in rigidity, realizes mechanical and electrical integration and avoids mechanical transmission errors.

Owner:浙江博雷重型机床制造有限公司

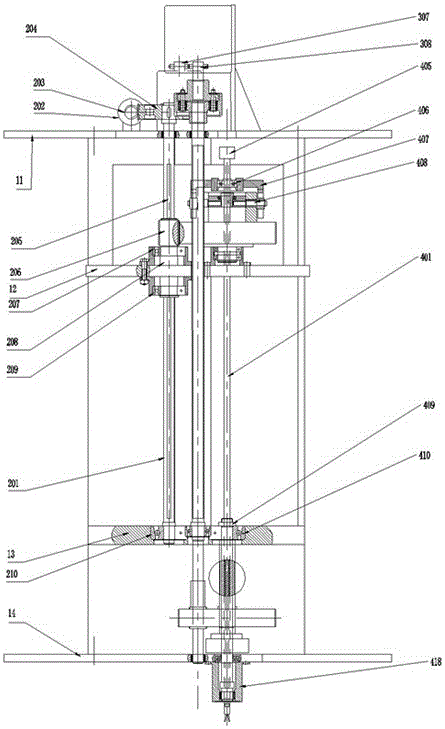

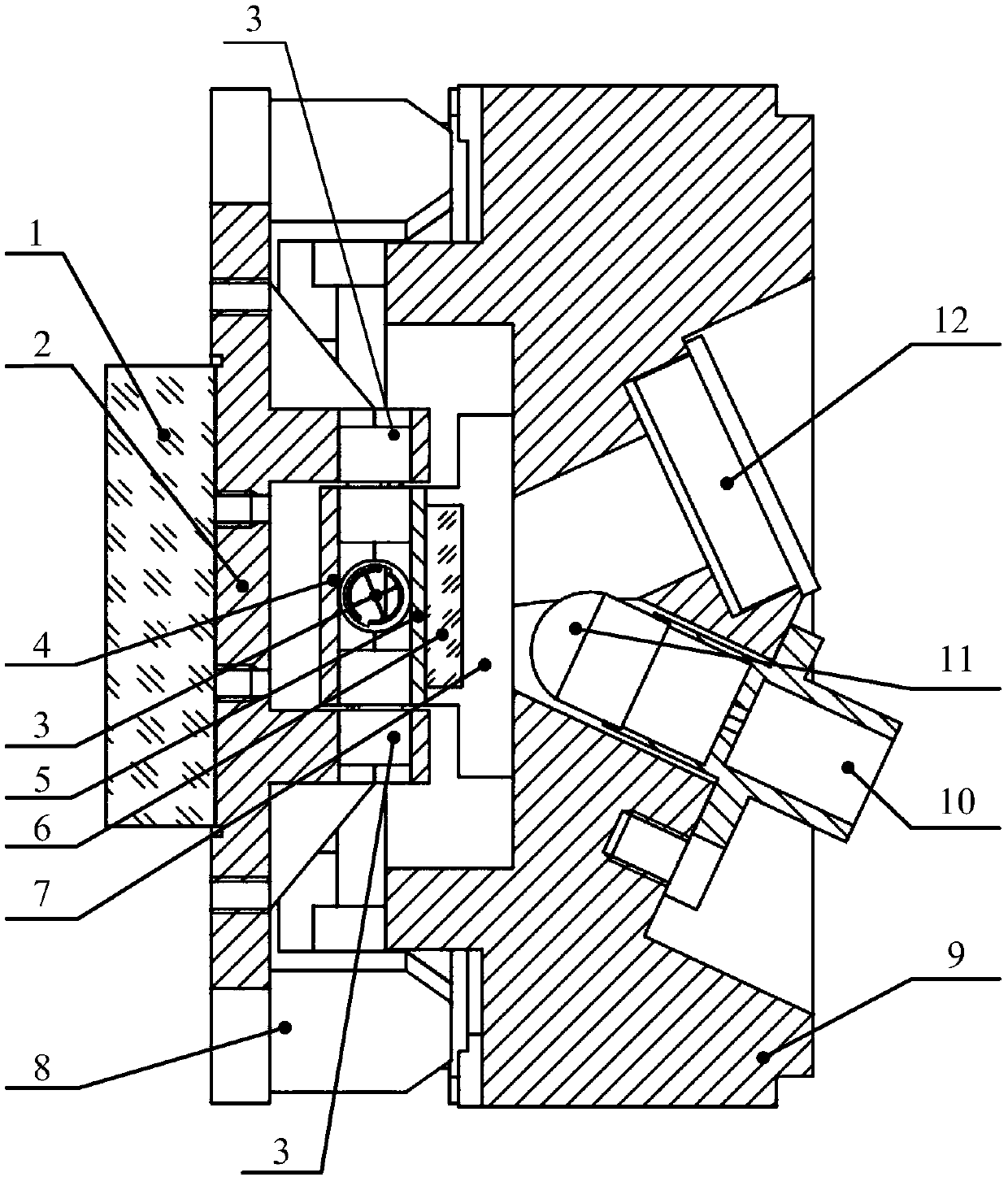

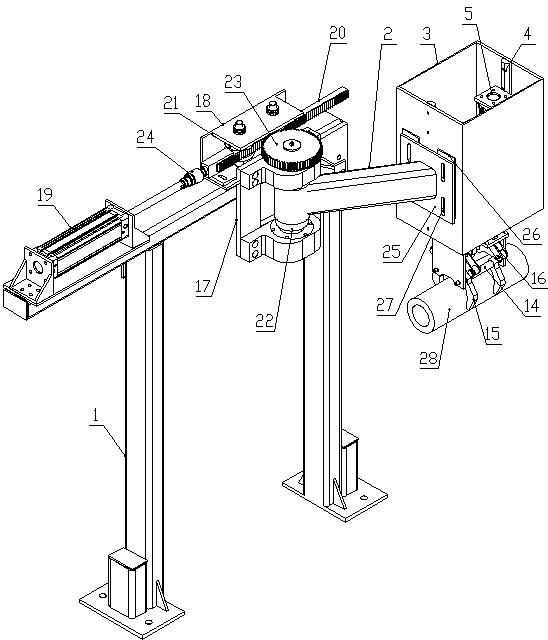

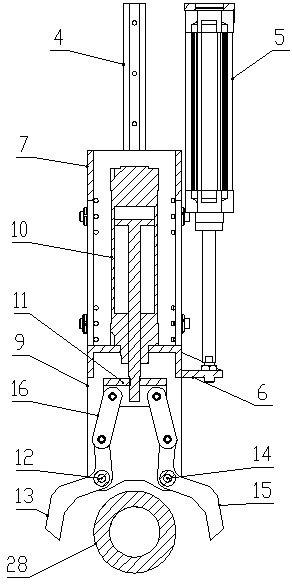

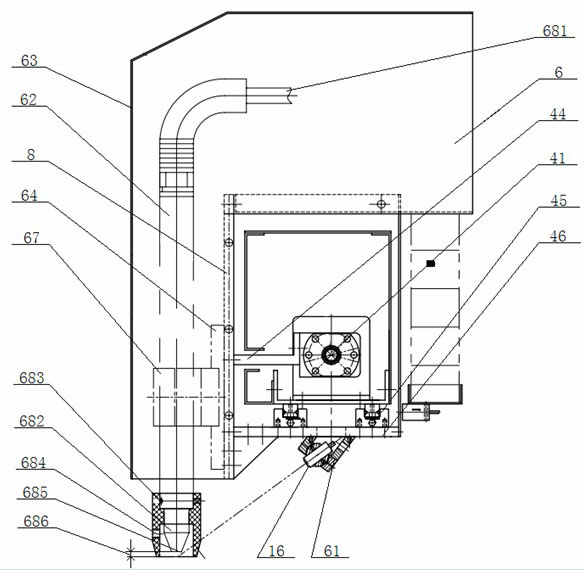

Minimally-invasive surgery assistant robot

InactiveCN105919670ACompact structureIncrease stiffnessProgramme-controlled manipulatorSurgical robotsLess invasive surgeryBall screw

The invention provides a minimally-invasive surgery assistant robot, relates to the field of surgery robots, particularly relates to a minimally-invasive surgery assistant robot and aims to solve the problem that an existing robot hardly opens high-quality and high-accuracy wounds in minimally-invasive surgery. The robot comprises a main shaft lifting mechanism, a main shaft rotating mechanism and a main shaft tail end opening and closing mechanism, wherein the main shaft lifting mechanism is used for driving a ball screw-nut pair via a coupler by using a motor, so that a movable plate exerts the lifting function on a guide rail pair; the main shaft rotating mechanism is used for transmitting torque to a long sleeve by driving two pairs of gears via the motor, then transmitting the torque to a main shaft and enabling the main shaft to rotate; the main shaft tail end opening and closing mechanism is used for transmitting the torque via a worm and gear and a pair of gears by using the motor, lifting a turntable and stretching an inner rod so as to close a tail end surgical instrument.

Owner:HARBIN UNIV OF SCI & TECH

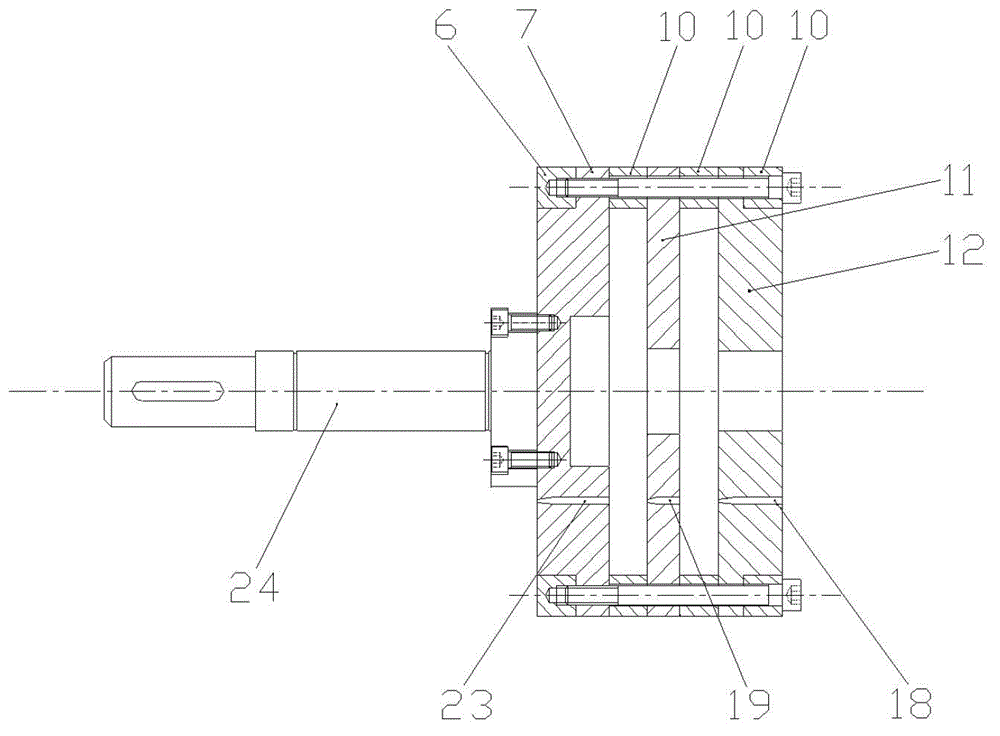

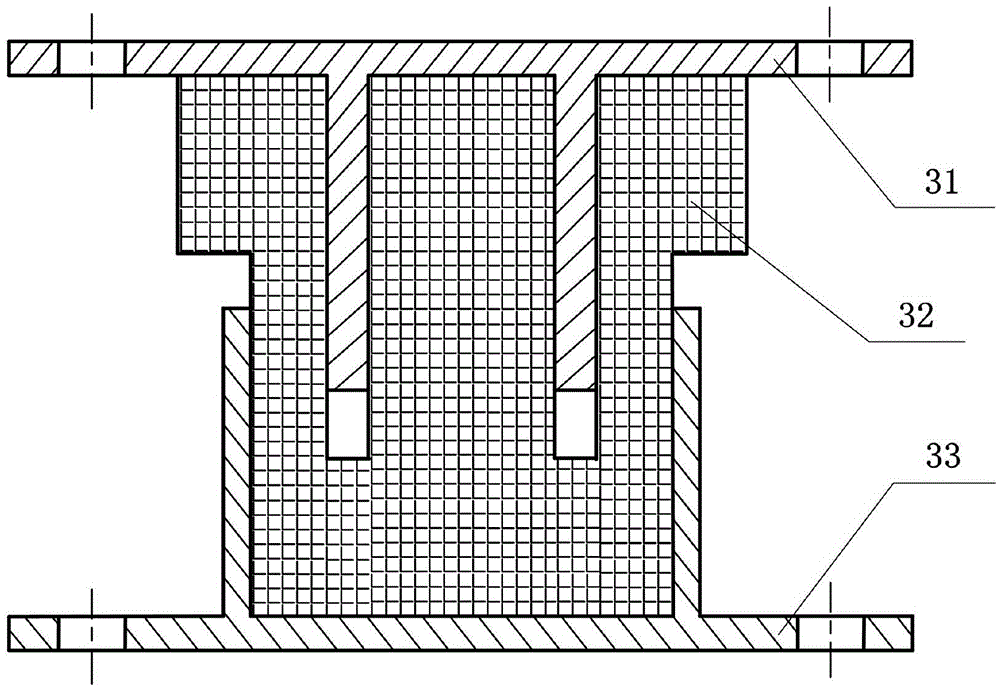

Pressure chamber for CT triaxial test

InactiveCN103487319ASimple structureReduce parallelismStrength propertiesRotary stageComputed tomography

The invention discloses a pressure chamber for a CT triaxial test. A pressure chamber cylinder, a pressure chamber upper fixing flange and a pressure chamber lower fixing flange are cemented and are sealed by a pressure chamber top cover and a pressure chamber pedestal, a loading piston is arranged on the pressure chamber top cover, a sample pedestal is arranged on the pressure chamber pedestal, a lower pressing head, a sample and an upper pressing head are arranged between the loading piston and the sample pedestal in the pressure chamber, and a reaction frame comprises a reaction column fixed on the pressure chamber top cover through a reaction column locking nut. The pressure chamber for the CT triaxial test provides axial loading for the sample by arranging a flat jack between the loading piston and the reaction frame. The pressure chamber has a simple structure, is portable, solves a problem of the influence of the rotation precision of a rotary stage by the overweight of the pressure chamber, and can acquire the confining pressure, the axial load and the sample deformation during CT scanning.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Induction type ultrasound electric principal shaft

InactiveCN101369757ASmooth vibrationIncrease speedPiezoelectric/electrostriction/magnetostriction machinesAsynchronous induction clutches/brakesTransducerContact type

The present invention discloses a induction type ultrasound electric principal shaft, which is composed of two parts: the rear part being an electric principal shaft and the front part being a ultrasound vibration system, electromagnetic field interference between the two parts being insulated by a shield ring, the motor making the principal shaft to rotate in high speed; the ultrasound vibration system is composed of an ultrasound transducer, a amplitude-variation lever and a tool head, and generates an axial ultrasound vibration of the principal shaft; an ultrasound driving signal is transmitted between a ultrasonic transmitter and a ultrasonic receiver with induction mode, wherein the non-contact type transmission signal being capable of omitting electrical brush, avoiding brush wear, reducing heating and improving greatly the rotary speed of the principal shaft; the principal shaft is supporting by a fore bearing, a middle bearing and a rear bearing, therefore the stiffness and rotating accuracy of the principal shaft can be improved, and the fore bearing is supported on the wave node point of the ultrasound vibration system, thus the vibration can be reduced; water-sealing covers are packed outside the motor and the ultrasound signal transmission system, and the cooled water ensures the principal shaft to be used in normal temperature all the time.

Owner:GUANGDONG UNIV OF TECH

Fluid dynamic bearing unit

InactiveUS20070110348A1High rotation accuracyExceptional accuracyShaftsRecord information storageHard disc driveEngineering

A fluid dynamic bearing unit comprised of a plurality of modularized elements that are combined is provided with a case element 10, an end plate element 20, a first outer ring element 30, a second outer ring element 80, a flangeattached shaft element 40, and a spacer element 100. On the inner circumferential surface of the first outer ring element 30 and the inner circumferential surface of the second outer ring element 80, a first dynamic pressure groove 91 and a second dynamic pressure groove 92 are formed to generate dynamic pressure that supports a load in the radial direction. On the upper end surface of the second outer ring element 80 and on the upper surface of an end plate element 20, a third dynamic pressure groove 93 and a fourth dynamic pressure groove 94 are formed to generate dynamic pressure that supports a load in the axial direction. Lubricating oil is filled into the minute gaps corresponding to each of these dynamic pressure grooves. The elements on which the dynamic pressure grooves are formed are made from steel, or stainless steel, which can be hardened. The fluid dynamic bearing units being suitable for use in a hard disk drive such a HDD or DVD.

Owner:MINEBEA CO LTD

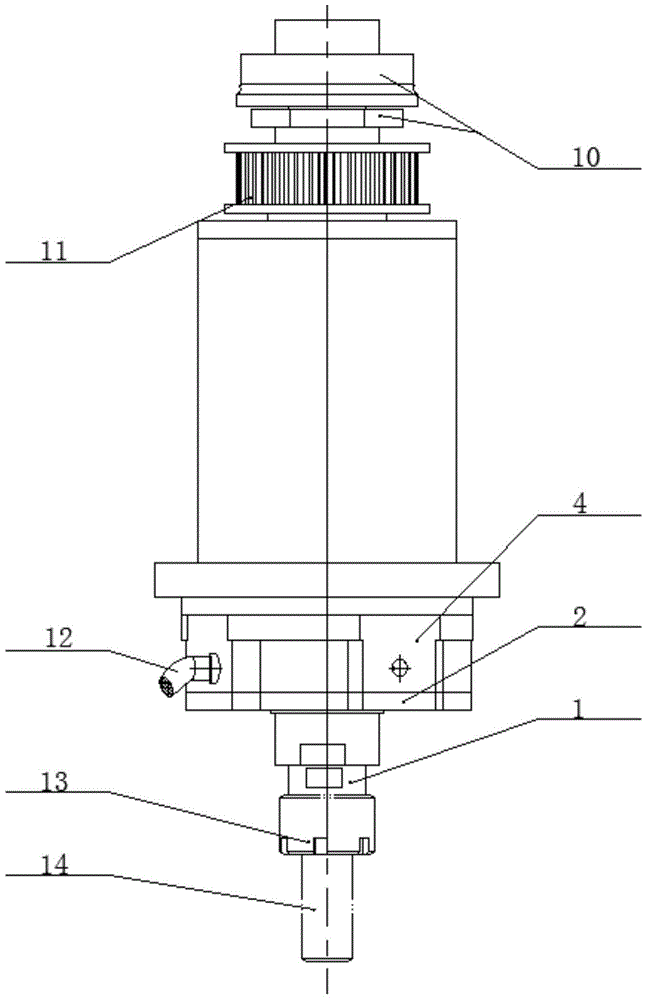

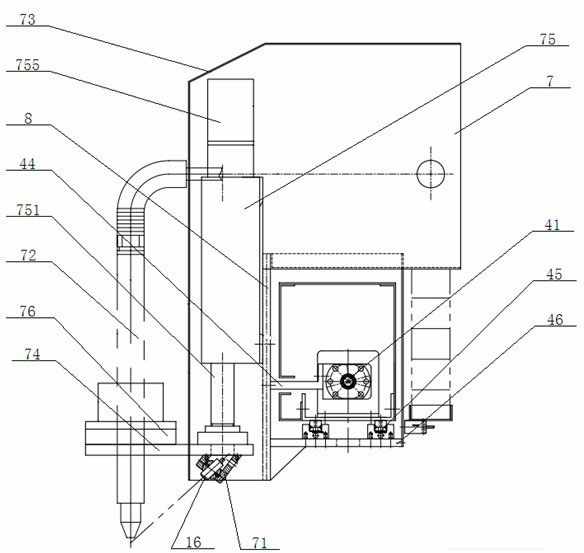

High-speed arc discharge, flushing and rotating main shaft device

ActiveCN104607729AOptimized conductive contact surfaceReduce the difficulty of rotating conductionElectrical-based machining electrodesElectrical-based auxillary apparatusCorrosionElectric arc

The invention discloses a high-speed arc discharge, flushing and rotating main shaft device which comprises a mandrel, a shell, a conductive bearing, a conductive disc, an insulating bearing, an insulating flange, a belt wheel, a rotating connector and the like. A main shaft structure capable of rotating, discharging and flushing is given to achieve the purposes of circulating and supply of high-pressure fluid, rotating and conducting, and the problems of discharge corrosion and the like are solved. According to the high-speed arc discharge, flushing and rotating main shaft device, the light-weight design that the insulating bearing is matched with the mandrel in a supporting mode is adopted, the rotating speed of a main shaft is increased, the accuracy of the main shaft is improved, and the insulating reliability of the main shaft is enhanced; the hollow mandrel structure is combined with the rotating connector to achieve the purposes of high-pressure fluid supply and sealing; the rotating conducting defect that overcurrent capacity of an electric brush is limited, or the rotating speed of a conductive sliding ring is low, or a structure is enormous and complex is overcome; the rotating conducting difficulty is lowered to the maximum degree, and the cost is lowered to the maximum degree. The high-speed arc discharge, flushing and rotating main shaft device is simple in structure, convenient to maintain, low in maintaining cost and capable of being effectively used for various discharging milling including electric arc machining.

Owner:SHANGHAI JIAO TONG UNIV

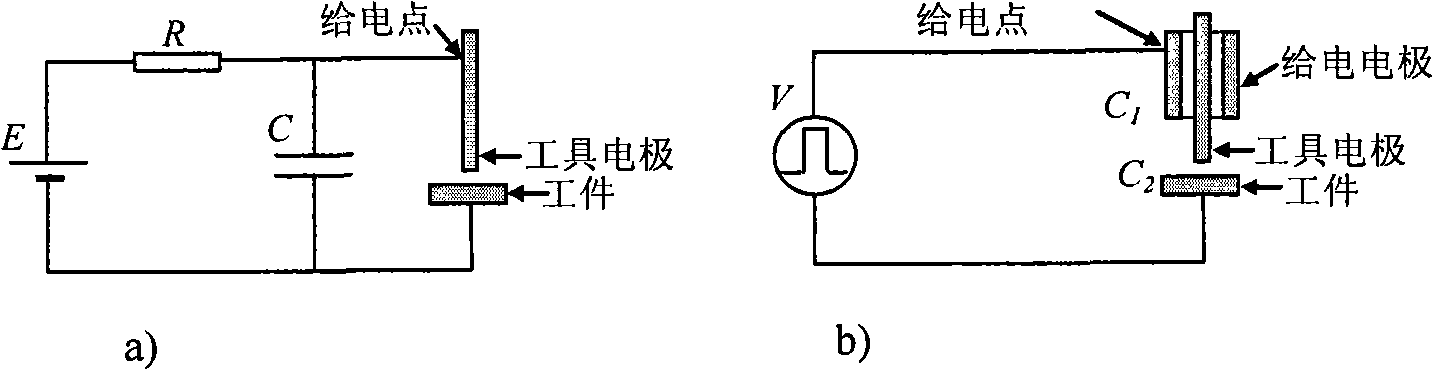

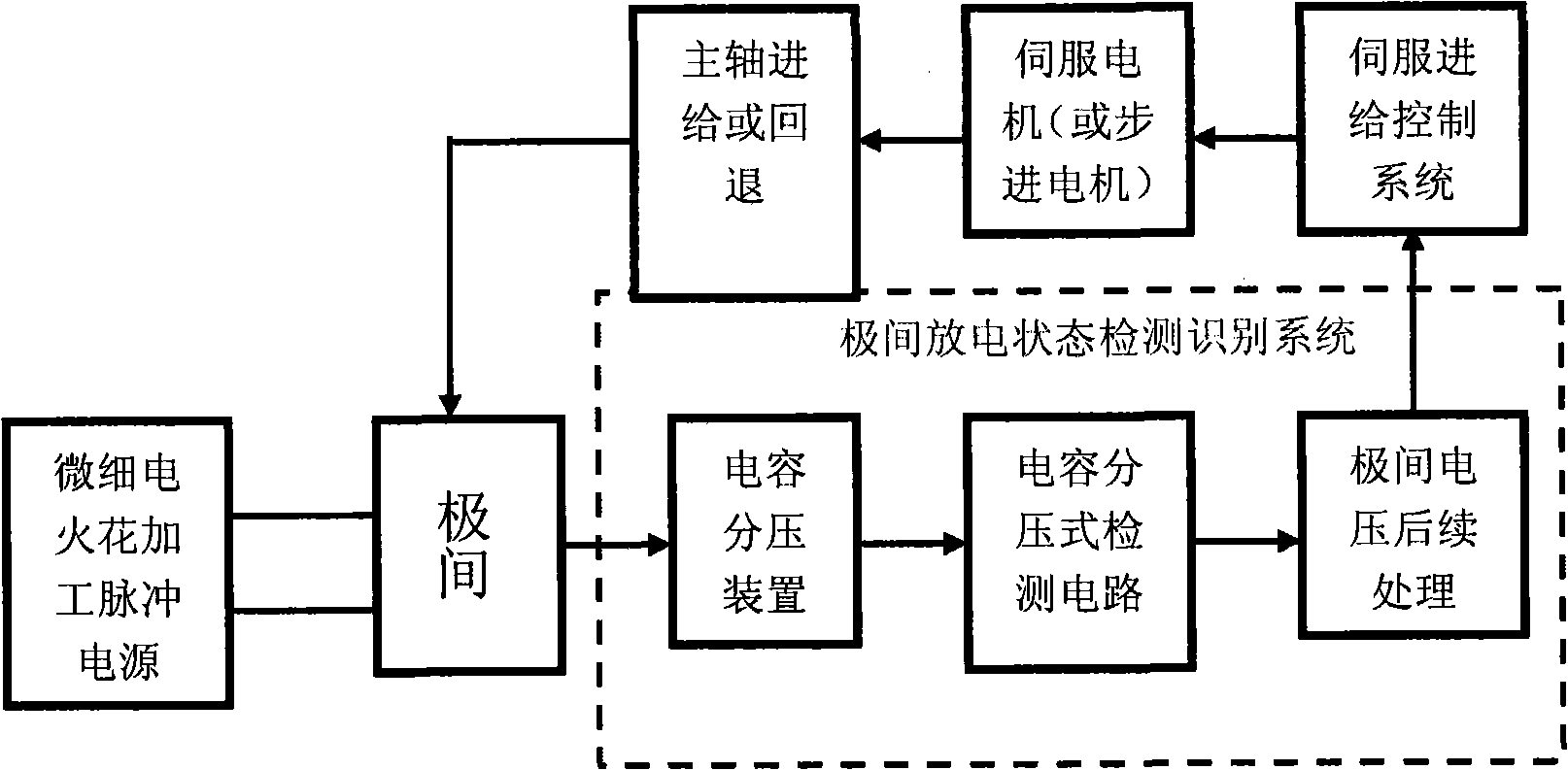

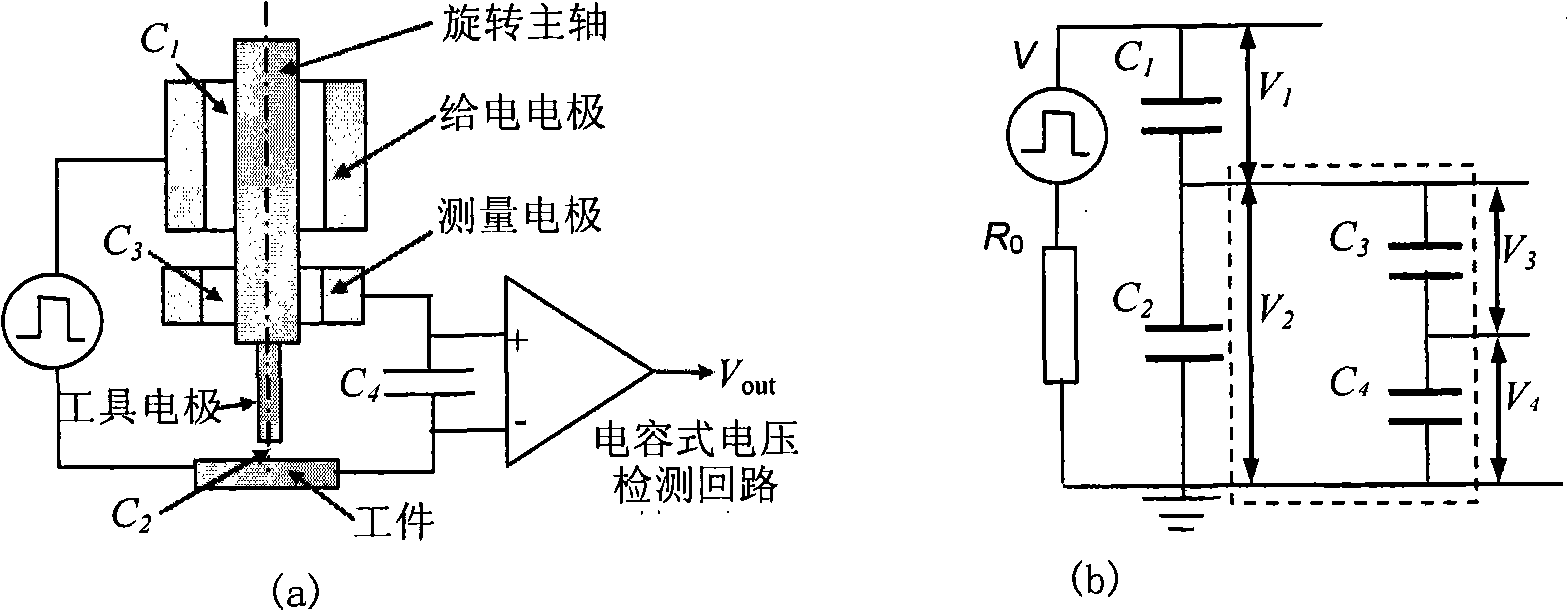

Voltage detection method between non-contact poles for electrostatic induction micro electro discharge machining and circuit design thereof

InactiveCN101791728ASolve the measurement problem of inter-electrode voltageHigh rotation accuracyUsing electrical meansElectric circuitsCapacitanceCapacitor

The invention provides a voltage detection method between non-contact poles for electrostatic induction micro electro discharge machining and a circuit design thereof. By using the electrostatic induction principle, a metal ring is sleeved on a rotating main shaft (or a tool electrode) and is arranged opposite to the tool electrode in a non-contact mode. The metal ring is used as a non-contact voltage measurement probe. A capacitor formed between the probe and the tool electrode is serially connected with a matching capacitor connected in a detection loop; the two capacitors in serial connection are connected in parallel with the poles; and the voltage distributed on the matching capacitor is in a direct proportion to the voltage between the poles. The voltage on the matching capacitor is measured by adopting the capacitive voltage dividing type inter-polar voltage detection loop, so the aim of measuring the voltage between the poles can be fulfilled.

Owner:HARBIN INST OF TECH

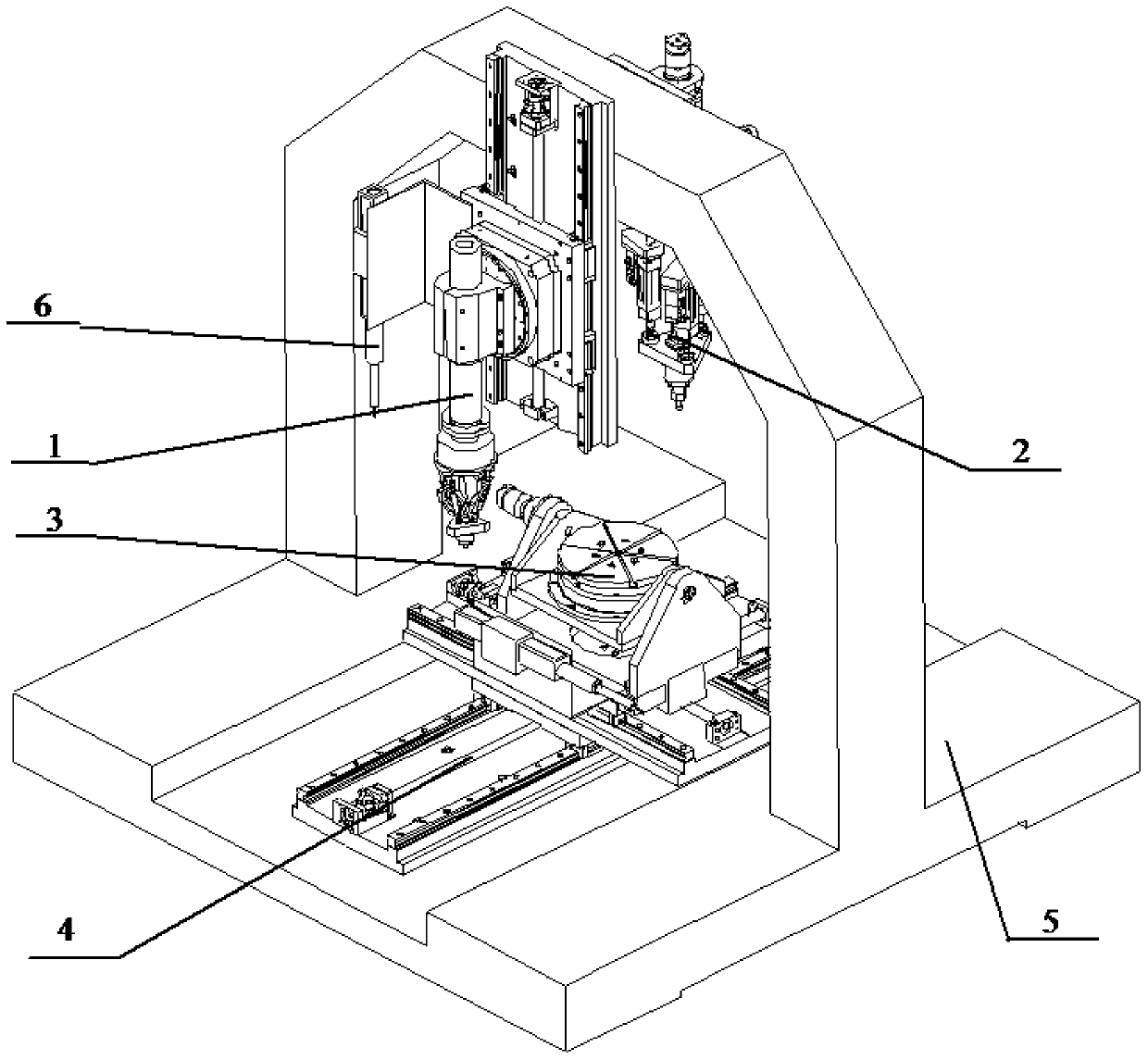

Gantry type rough and finish composite five-axis precision machine tool and processing method thereof

PendingCN110548908AQuick removalEnsure complete removalMilling machinesFeeding apparatusMilling cutterEngineering

The invention relates to a gantry type rough and finish composite five-axis precision machine tool and a processing method thereof and belongs to the field of precision machine tools. A rack is horizontally arranged; an X-Y feeding component is installed on the rack; a two-axis turntable component is installed on the X-Y feeding component through a Y-direction sliding plate; a sharp knife processing component and a fast removing component are installed on the two sides of a middle cross beam in a gantry shape through a guide rail seat and a vertical plate respectively; and a detector is installed on a sliding plate of the sharp knife processing component. The gantry type rough and finish composite five-axis precision machine tool has the characteristics of high processing efficiency and processing precision and can meet the processing precision requirement for rough milling semi-finish milling; by adopting a five-axis linkage processing method, multi-angle flexible processing can be realized, and the processing process from a blank to a finished product can be completed at one time; as a two-axis turntable is compact in structure, high in rotation precision and good in rapid response characteristic, the gantry type rough and finish composite five-axis precision machine tool has better use reliability; and with three-direction rotation and one sharp knife feeding system moving in a longitudinal feeding direction, multi-dimensional adjustment of a milling cutter processing angle is realized.

Owner:JILIN UNIV

Full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting

ActiveCN102059402AIncrease cutting forceImprove accuracyGear-cutting machinesGear teethHydraulic cylinderCoupling

The invention relates to a full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting, comprising a rotary table, a shaper body assembly, an intermediate shaper body assembly, a stand column, a cutter relieving mechanism, a cutter rest mechanism, a numerical control system, a hydraulic system, a lubricating system and a cooling chip removing system. Serve motors are arranged on both sides of the rotary table and are connected with a worm gear motion pair through a shaft coupler to form a dual-driving mechanism of the rotary table; a cutter shaft of the cutter rest mechanism is driven by a hydraulic cylinder to do reciprocating motion; a motor base of the cutter rest mechanism is provided with a servo motor; and the cutter relieving mechanism is provided with camshafts of a conjugate dual cams to connect and drive the servo motor. The invention has the advantages that the gear shaper adopts the servo hydraulic cylinder to drive to provide reciprocating motion of the cutter shaft, adopts a torque motor to provide the rotary motion of the cutter shaft and adopts the servo motor to drive the cutter relieving mechanism to meet the processing requirement of large-scale precise gears; the rotary table bears heavy load and has high operation stability; the processing range, the stroke length and the cutting force are enlarged; the processing precision is high; and the processing flexibility adaptability is strong.

Owner:通用技术集团天津第一机床有限公司

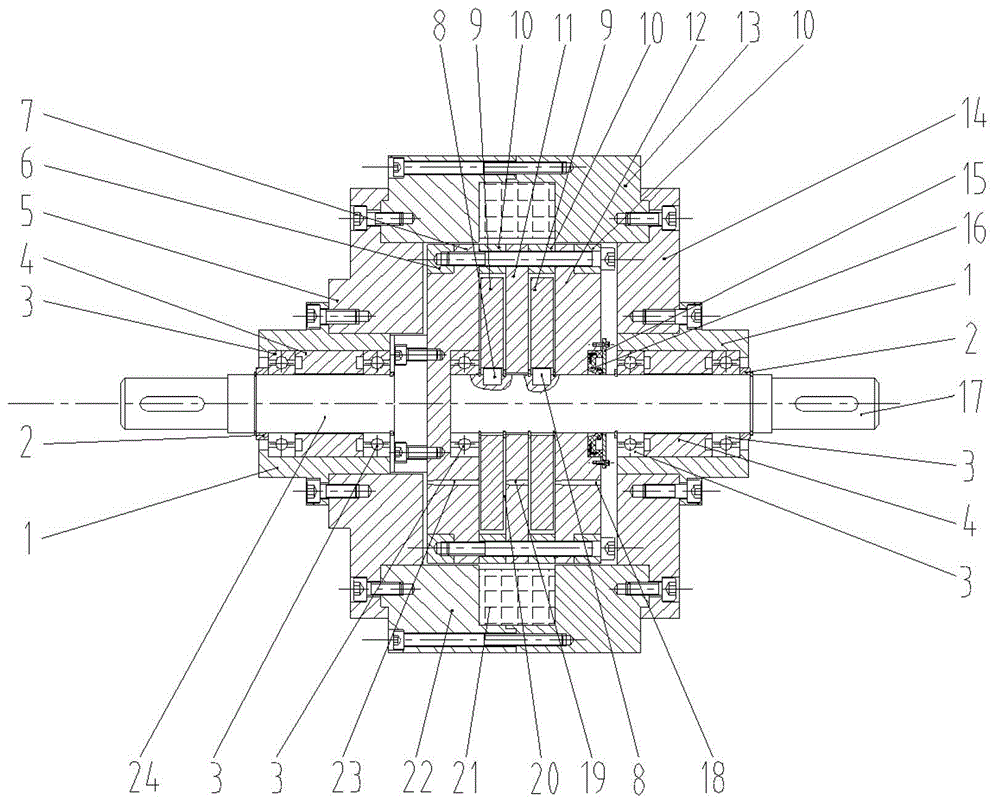

Multiple-piece magneto-rheological fluid torque transferring device

InactiveCN102878225AIncrease contact areaIncreased torque transmission (output) rangeFluid clutchesDrive shaftNon magnetic

The invention relates to a multiple-piece magneto-rheological fluid torque transferring device. The device has a multiple-piece layered structure, so that transferred torque is increased exponentially; the torque transferred by the device can be adjustable within a wide range by changing the current of a magnet exciting coil in the device; and under the condition that a driven shaft is fixed, the device can output adjustable and flexible torque which can be used as protecting links in a damper, a torsion applying device or a transmitting system. The device consists of a fixed supporting part, a driving rotor part, a driven rotor part, the magnet exciting coil, magneto-rheological fluid, a seal part and the like. The fixed supporting part consists of a left bearing end cap, a right bearing end cap, a shell left end cap, a shell right end cap, a left magnet yoke and a right magnet yoke. The driving rotor part and the driven rotor part consist of a driving shaft, driving discs, non-magnetic aluminum sleeves, a driven shaft and driven discs. The seal part comprises a dynamic seal ring, a seal ring baffle plate and a rubber oil seal. The multiple-piece magneto-rheological fluid torque transferring device has the characteristics of low energy consumption, wide torque adjustable range, sensitive response, excellent performance and the like.

Owner:JILIN UNIV

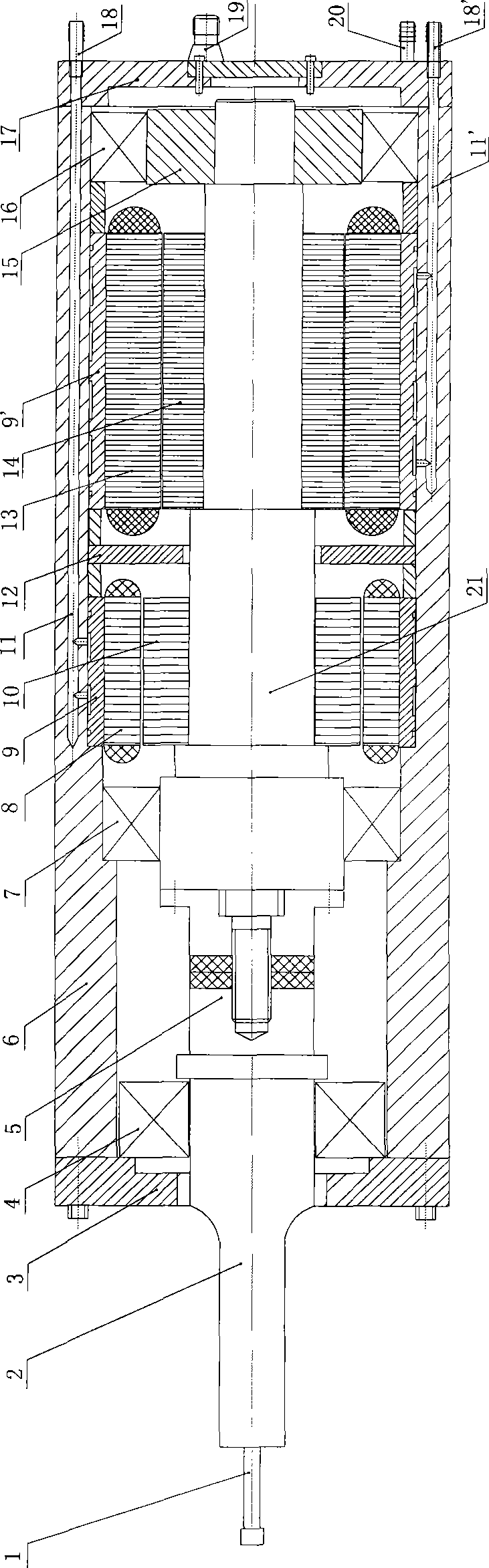

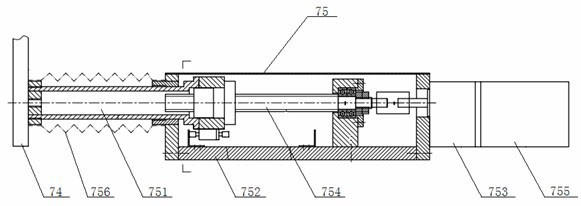

High-speed high-precision built-in dynamic and static piezoelectric main shaft

ActiveCN106984836ASmall amount of thermal deformationImprove output accuracyLarge fixed membersMaintainance and safety accessoriesNumerical controlElectricity

The invention relates to a high-speed high-precision built-in dynamic and static piezoelectric main shaft. The high-speed high-precision built-in dynamic and static piezoelectric main shaft is characterized in that the main shaft comprises a box body, a front bearing and a rear bearing are arranged in the box body through a front bearing end cover and a rear bearing end cover correspondingly, and the front bearing and the rear bearing jointly bear a main shaft body internally provided with an online dynamic balancing head; the box body is provided with an oil inlet and an oil outlet, the oil inlet communicates with the oil outlet through an oil way, the oil way is divided into two parts, and one part enters the front bearing and the rear bearing through the oil inlet to suspend the main shaft body in a gap between the front bearing and the rear bearing to form pure liquid lubrication; and the other part is fed to the front bearing and the front bearing end cover to make the main shaft body achieve axial positioning, and a grinding wheel is arranged on the front bearing end cover through a flange disc. The high-speed high precision built-in dynamic and static piezoelectric main shaft is simple in structure, good in dynamic performance, large in rotation number of the main shaft, high in rotation precision and small in heat deformation and can be widely applied to grinding wheel electric main shafts of precise grinding machines, main shafts of numerical control machining centers and precise lathes and the like.

Owner:DONGHUA UNIV

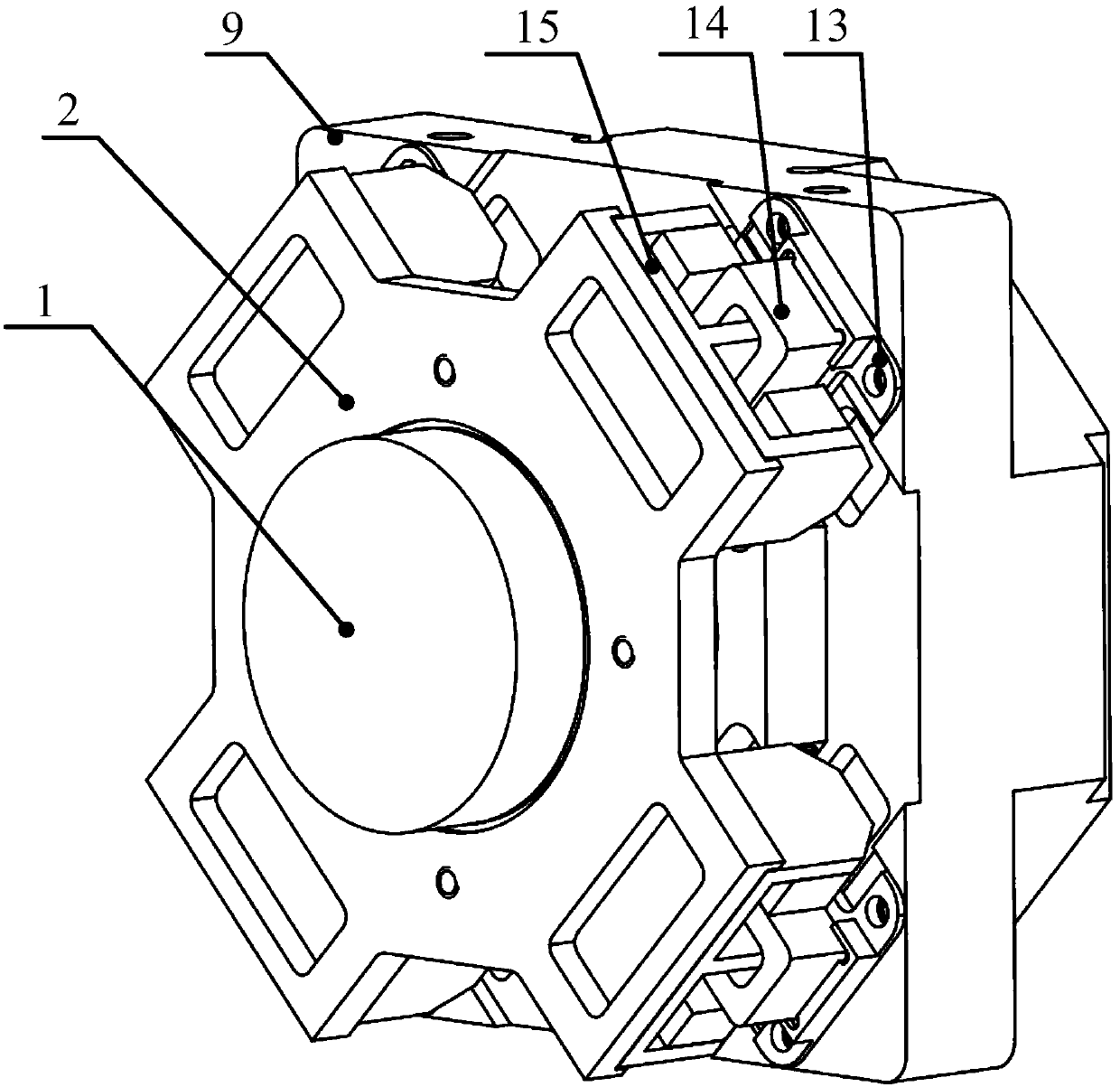

Fast reflection mirror

InactiveCN107942473ALarge deflection rangeHigh rotation accuracyMountingsMedical equipmentMeasuring instrument

The invention discloses a fast reflection mirror, comprising a base, a working mirror body, cross spring bearings and a driver; the working mirror body is assembled on a reflection mirror seat; two cross spring bearings constitute one group, there are totally two groups, wherein the axes of the two cross spring bearings in the first group of cross spring bearings coincide with a first straight line, and the axes of the two cross spring bearings in the second group of cross spring bearings coincide with a second straight line; the first straight line and the second straight line are perpendicular to each other and intersected at an origin; each cross spring bearing is connected to the reflection mirror seat and the base respectively; and the driver is used for driving the reflection mirrorseat to rotate within a preset angle range around the first straight line and / or the second straight line. According to the fast reflection mirror, the cross spring bearings support the reflection mirror seat, the cross spring bearings have the advantages of large deflection range and high rotating precision, and when the cross spring bearings are used with the driver, the deflection angle and therotating precision of the working mirror body can be improved, so that the fast reflection mirror is applicable in the fields of precision machinery, precision measuring instruments, medical equipment and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Cylinder sleeve workblank transfer device

ActiveCN104192567AReduce power consumptionHigh rotation accuracyConveyor partsEngineeringManipulator

A cylinder sleeve workblank transfer device comprises a rack, wherein a horizontal linear driving mechanism is arranged on the rack, and the horizontal driving mechanism is connected with a vertical grabbing manipulator through a horizontal rotation arm. The cylinder sleeve workblank transfer device is reasonable in design and compact in structure, workblanks can be grabbed rapidly and accurately, labor intensity of workers is reduced, the cylinder sleeve workblanks can be automatically transferred to a conveying rail after being discharged from a furnace, and the cylinder sleeve workblank transfer device is high in automation degree and positioning accuracy and meets the requirement for reducing cost in foundry practice.

Owner:ZYNP GRP

Numerical control rotation working table

InactiveCN105014480AImprove machining accuracyAvoid loss of precisionPrecision positioning equipmentNumerical controlTorque motor

A numerical control rotation working table comprises a machine body, a rotation shaft, a rotating encoder, a braking ring piece, a piston, a torque motor and a working rotating plate used for installing a workpiece. A cylinder is formed in the machine body. The rotation shaft is connected to the machine body in a pivoted mode. The rotating encoder is arranged on the machine body. The piston is movably arranged in the cylinder. The end, located on the outer side of the cylinder, of the piston forms an ejection end. The ejection rod is used for ejecting the braking ring piece and pressing the braking ring piece to the side wall of the machine body. According to the numerical control rotation working table, very high rotation accuracy and positioning accuracy can be output through direct drive of the torque motor and the cooperation with the high-precision encoder; in addition, linked machining and angle-fixed indexing machining can be achieved according to different machining requirements; in the linked machining process, stable machining can be conducted in the rotating process of the working rotating plate; and in the angle-fixed indexing machining process, by pressing the braking ring piece through the position and by means of the keeping torque of the torque motor, extremely high braking keeping torque can be generated so that the machining stability can be ensured.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

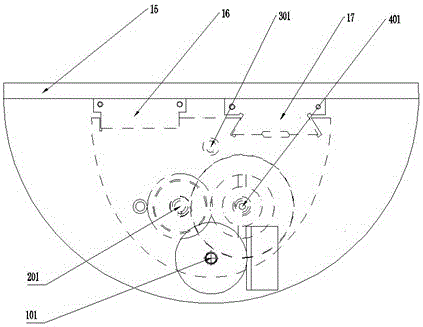

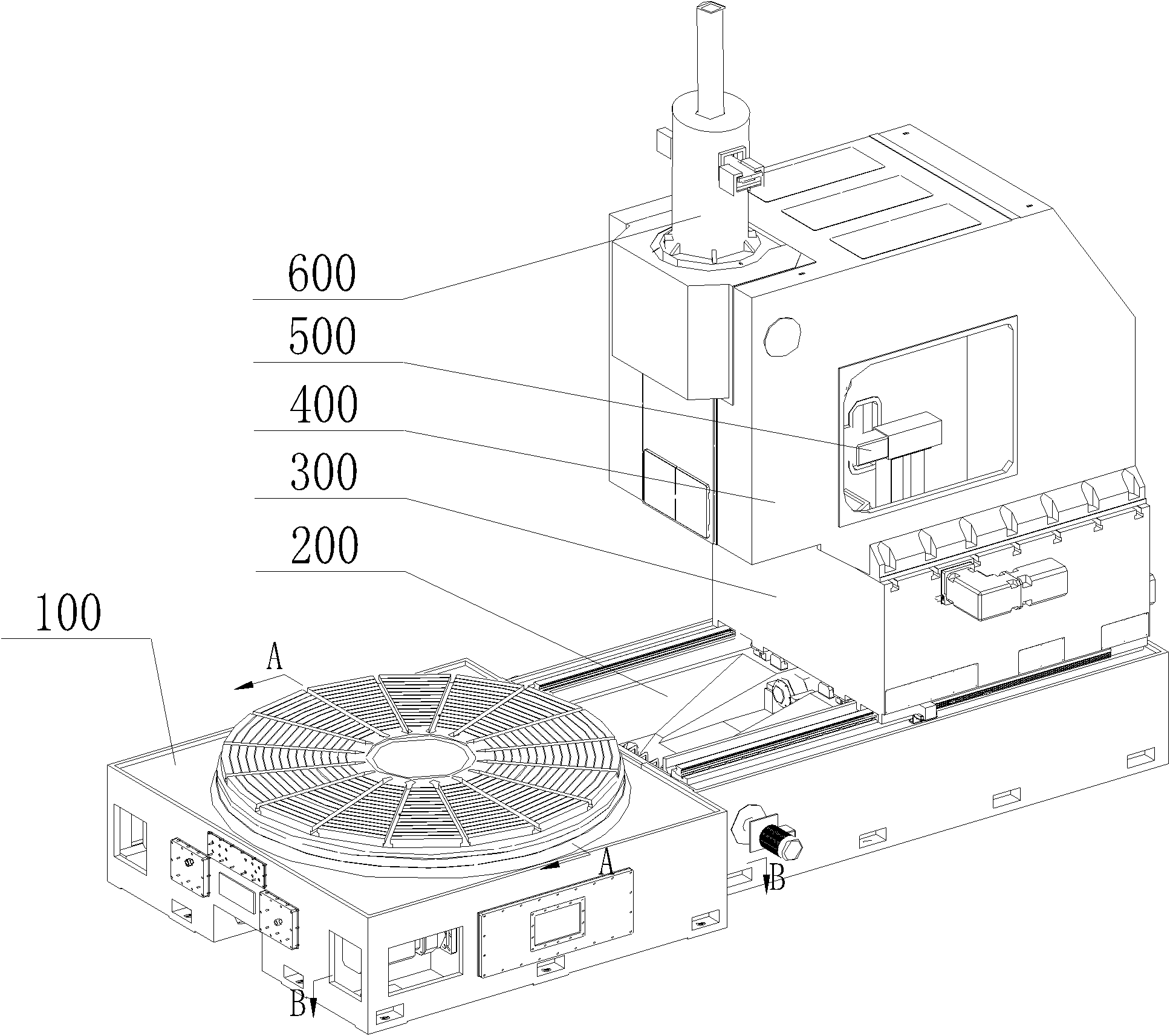

Large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table

ActiveCN103111855AImprove machining accuracyHigh axial accuracy and high rotational accuracyShaftsRotary machine partsEngineeringLarge aperture

The invention discloses a large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table, belongs to the technical field of ultra-precision manufacturing equipment, and meets the requirements of a large-size ultra-precision lathe used for machining high-precision large-aperture non-spherical optical parts. An upper floating throttler and a lower floating throttler are respectively installed on an upper floating thrust plate and a lower floating thrust plate, the upper floating thrust plate is fixedly connected with a base seat of the rotary table, the lower floating thrust plate is fixedly connected with the base seat of the rotary table through an inner isolation ring and is arranged in an annular groove of the upper floating thrust plate, a radial bearing bush is fixedly connected with the base seat of the rotary table through the lower floating thrust plate and the inner isolation ring, a main shaft is fixedly connected with an upper floating plate, and hydraulic oil is throttled through the throttlers and forms an upper floating liquid hydrostatic pressure thrust oil film between the upper floating plate and the upper floating thrust plate, a lower floating liquid hydrostatic pressure thrust oil film between a lower floating plate and the lower floating thrust plate, and a radial hydrostatic pressure support oil film between the radial bearing bush and the main shaft, so that an axial sealed-type liquid hydrostatic pressure plane round ring thrust bearing and a radial liquid hydrostatic pressure cylindrical bearing are formed. The large-diameter-height-ratio ultra-precision hydrostatic pressure rotary table is applied to the large-size ultra-precision lathe used for machining the high-precision large-aperture non-spherical optical parts.

Owner:HARBIN INST OF TECH

Multifunction high-precision numerical control plasma machining device

The invention relates to a multifunction high-precision numerical control plasma machining device comprising a base and a machining platform with a nail bed structure. A Y-axis transmission mechanism and an X-axis transmission device are respectively arranged above and below the machining platform, wherein the Y-axis transmission mechanism is connected with a sheet cutting torch unit and a medium plate cutting torch unit which can be alternately used and are provided with infrared locating real-time tracking devices; a cutting torch formed by extending a Y-axis cross beam is provided with a pipe cutting torch unit matched with a pipe rotating mechanism; the X-axis transmission device and the Y-axis transmission mechanism respectively comprise a ball screw and a servo motor; the sheet cutting torch unit comprises a sheet cutting torch with a water spray cover; the medium plate cutting torch unit comprises an automatic arc voltage boosting Z-axis actuating mechanism and an arc voltage boosting anticollision clamp; and the pipe rotating mechanism comprises a lifting open and close roller wheel followup device and a big-power bearing block servo motor. The invention not only has stronger comprehensiveness, lower production cost, higher cutting precision, low noise, small vibration, high stability and higher cutting quality but also facilitates fine blowdown.

Owner:武汉薪火智能切割机器有限公司

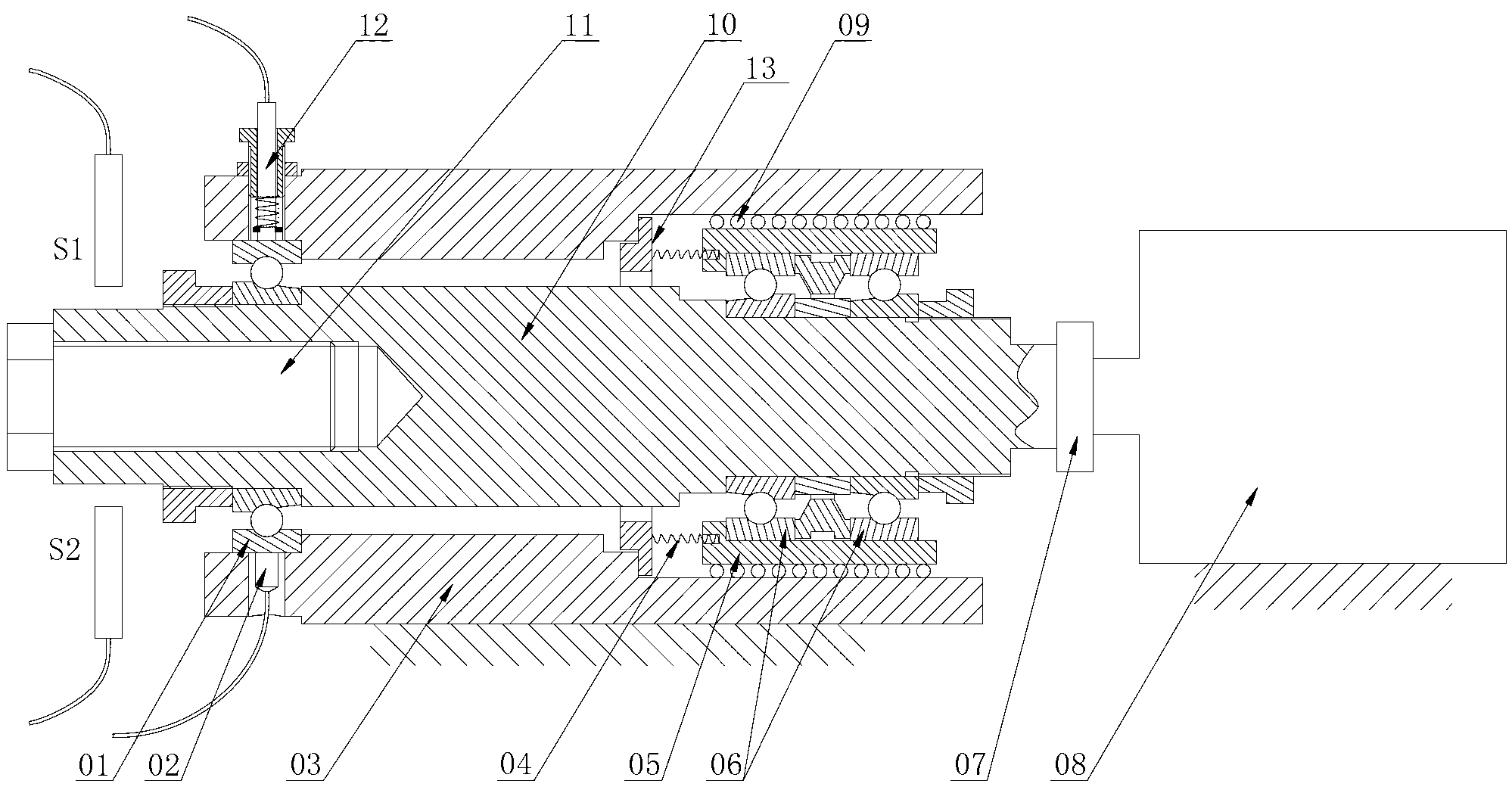

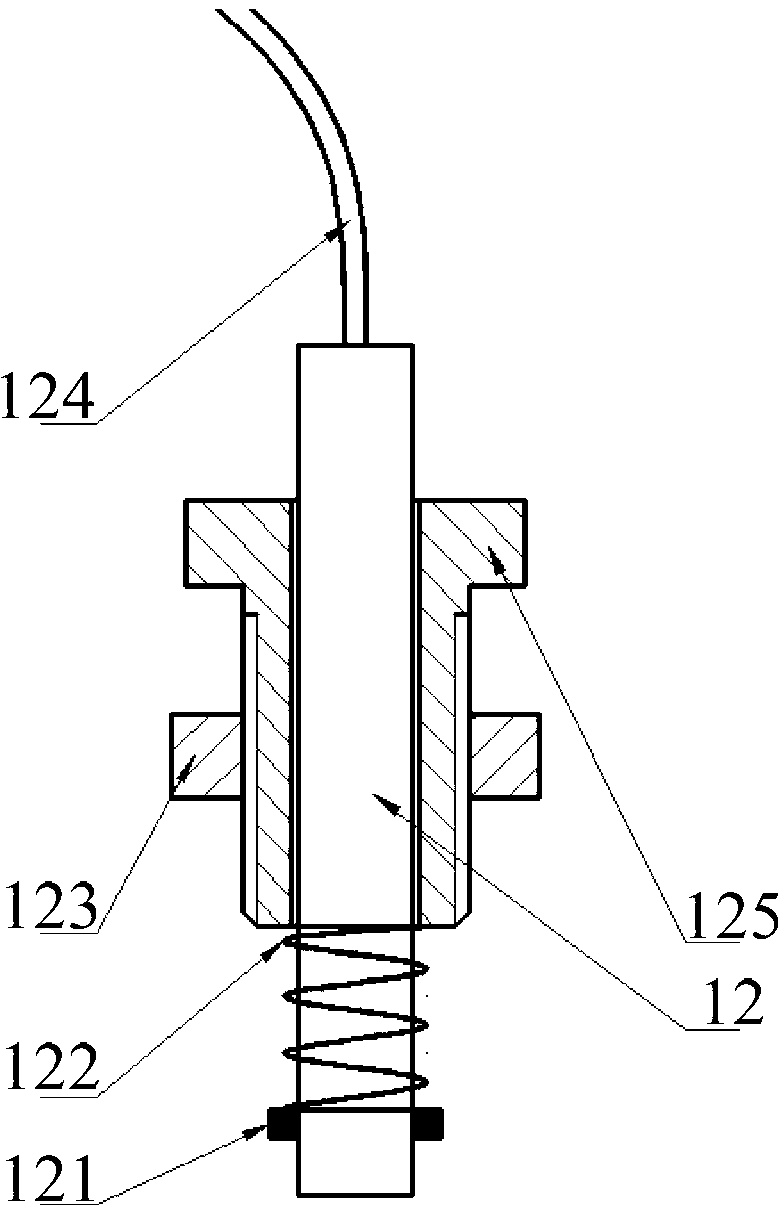

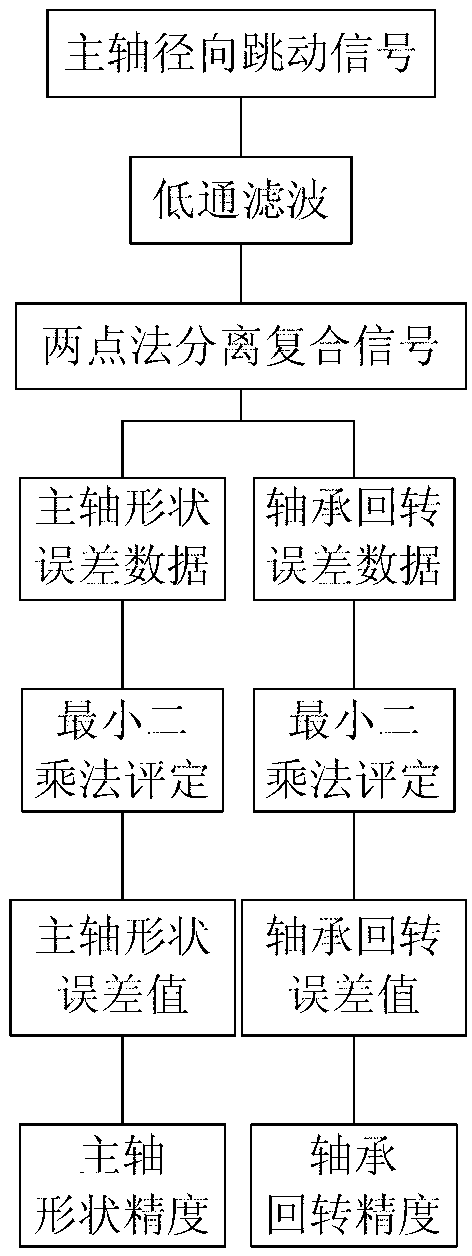

Device and method for testing bearing precision performance and method for determining bearing precision initial failure part

InactiveCN103323244AReduce the impactGuaranteed reliabilityMachine bearings testingBall bearingControl theory

The invention discloses a device and method for testing bearing precision performance and a method for determining a bearing precision initial failure part. The device comprises a main shaft and a servo motor which are mounted on two machine frames respectively, wherein a main shaft shell is sleeved outside the main shaft, the main shaft is fixed on one machine frame through the main shaft shell, the rear end of the main shaft is fixedly connected with an output shaft of the servo motor, radial through holes for an acceleration sensor and a temperature sensor to be mounted in are formed in a face, matched with a tested bearing, of the main shaft shell, and a part, stretching out of the main shaft shell, of the front end of the main shaft is provided with a displacement sensor used for measuring the radial jump of the front end of the main shaft. The main shaft and the servo motor are mounted on the two machine frames respectively, the influence of vibration of the servo motor on the main shaft is reduced, a pair of precise angular contact ball bearings is arranged at the rear end of the main shaft for supporting, and the rotating precision and rigidity of the main shaft are improved. A constant-pressure pre-tightening device is mounted, the types and the number of springs can be changed according to requirements of a test, so that constant-pressure pre-tightening of the tested bearing is achieved.

Owner:XI AN JIAOTONG UNIV

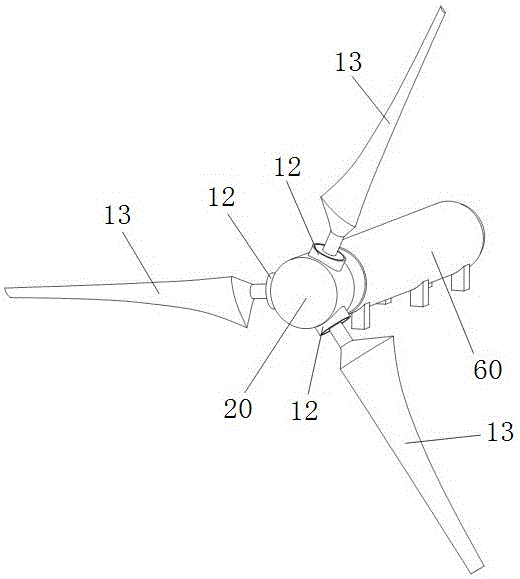

Horizontal axis ocean current energy electric generator variable-pitch device and horizontal axis ocean current energy electric generator

ActiveCN105840411AEasy to captureHigh transmission powerHydro energy generationReaction enginesGear wheelHorizontal axis

The invention discloses a horizontal axis ocean current energy electric generator variable-pitch device and a horizontal axis ocean current energy electric generator. The variable-pitch device comprises a driving part which is a motor or a hydraulic motor, a screw rod which is fixedly connected with an output shaft of the driving part through a coupler and a push plate which is arranged on the screw rod in a sleeving mode and is in threaded connection with the screw rod. The left end of the screw rod is supported through a pair of centripetal thrust bearings. The right end of the screw rod extends into the left end of a central hole of a spindle flange and a spindle. A first sliding bearing is formed between the screw rod and the left end of the central hole of the spindle flange and the spindle. Electric slip rings or a hydraulic slip ring are / is mounted at the right end of the spindle. One gear rack is fixed to each side surface of the push plate, each gear rack is engaged with a gear wheel, all the gear wheels are fixedly connected with the roots of corresponding blades through variable-pitch flanges, and second sliding bearings are formed between the variable-pitch flanges and the wheel hub wall. An angle transducer is installed at the left end of the driving part. By means of the horizontal axis ocean current energy electric generator variable-pitch device and the horizontal axis ocean current energy electric generator, the variable-pitch angle larger than 180 degrees can be achieved, therefore, double-way electricity generation is achieved, unified pitch variation can be achieved, and operation is stable.

Owner:ZHEJIANG UNIV

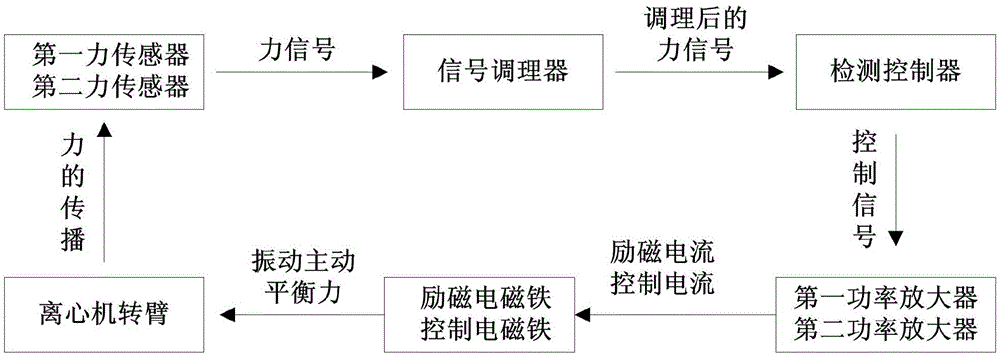

Vibration reaction force active balancing device for vibration-acceleration test device

ActiveCN105547628ASignificant force balancing effectHigh rotation accuracyVibration testingVibration accelerationAudio power amplifier

The present invention discloses a vibration reaction force active balancing device for a vibration-acceleration test device. The vibration-acceleration test device comprises a centrifuge, a vibration table and a balancing weight; the vibration table and a balancing weight are respectively installed at two ends of the pivoted arm of the centrifuge; in the vibration reaction force active balancing device, an excitation electromagnet is fixedly installed at one end of the pivoted arm of the centrifuge and is located at the outer side of the balancing weight; a plurality of control electromagnets is installed at the position having the same height as the excitation electromagnet and is distributed around the rotation virtual circle of the excitation electromagnet; two force sensors are installed on the pivoted arm, signal output ends of the two force sensors are connected with a signal conditioner, a detection controller two power amplifiers in order, and the signal output ends of the two power amplifiers are respectively connected with the excitation electromagnet and the control electromagnets. The vibration reaction force active balancing device for vibration-acceleration test device performs active balance of vibration reacting force generated by a vibration table so as to realize a remarkable force balance effect and achieve the purpose of reducing the vibration of the main shaft of a centrifuge.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com