Patents

Literature

50results about How to "Reduce parallelism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

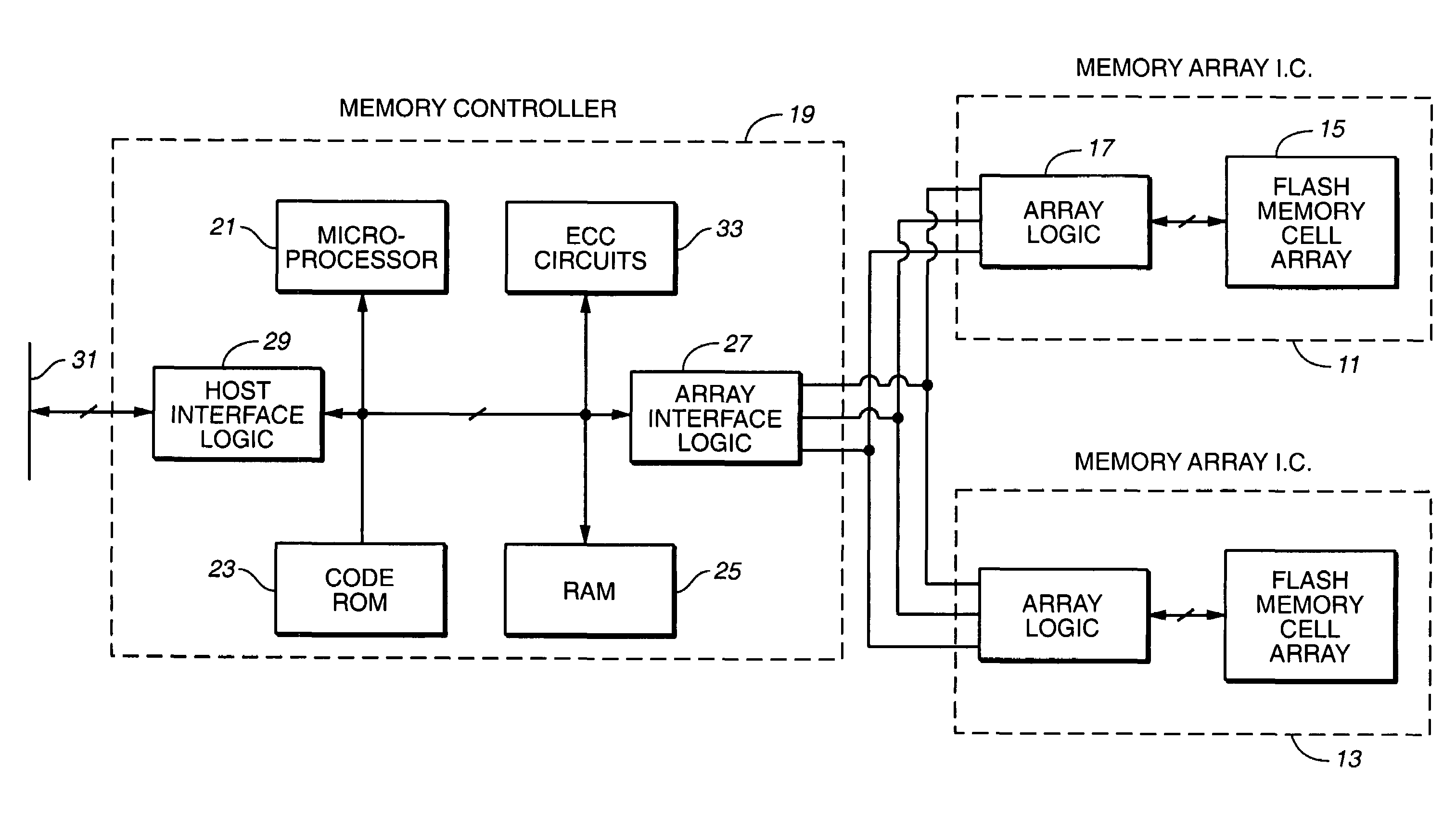

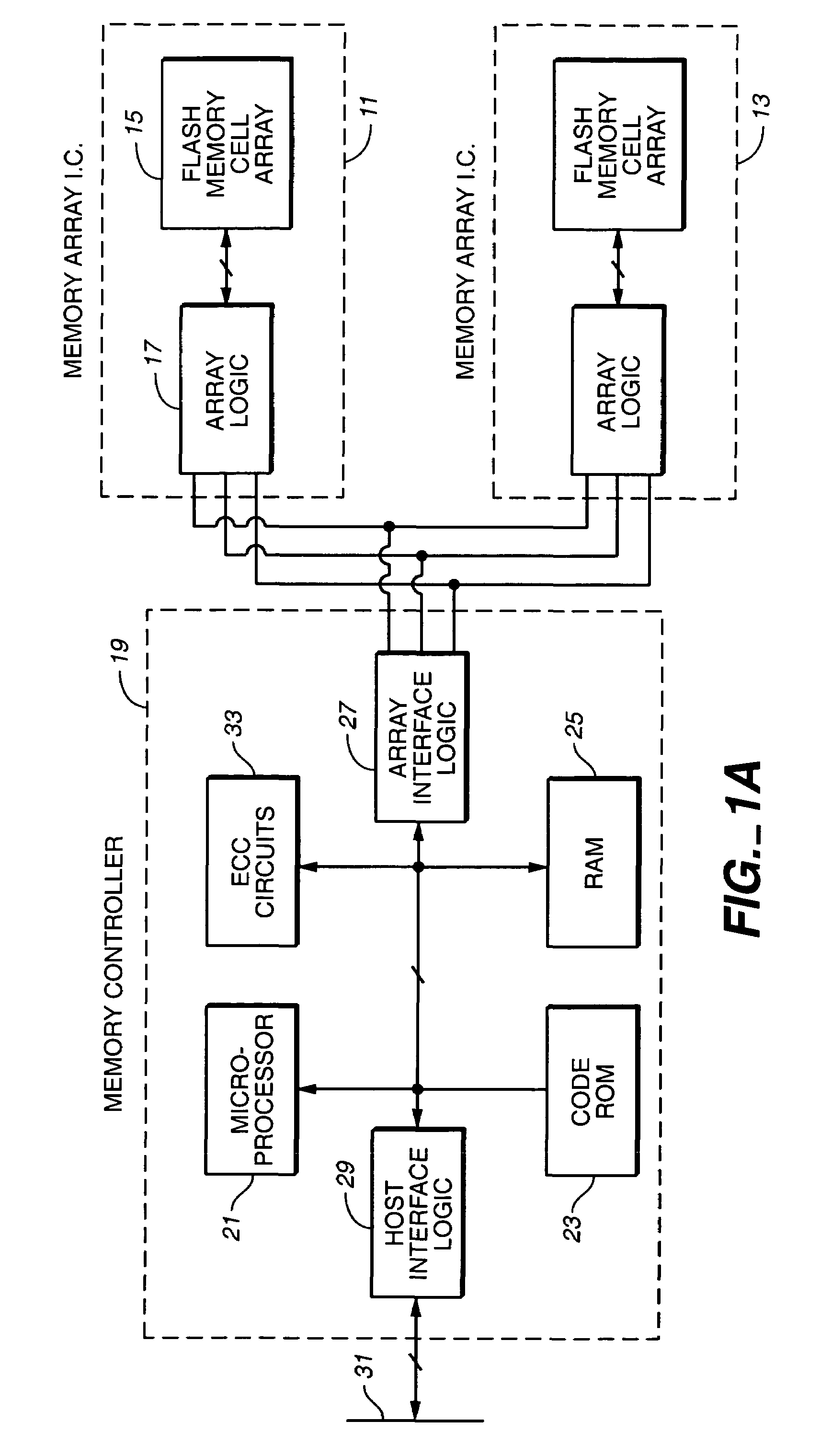

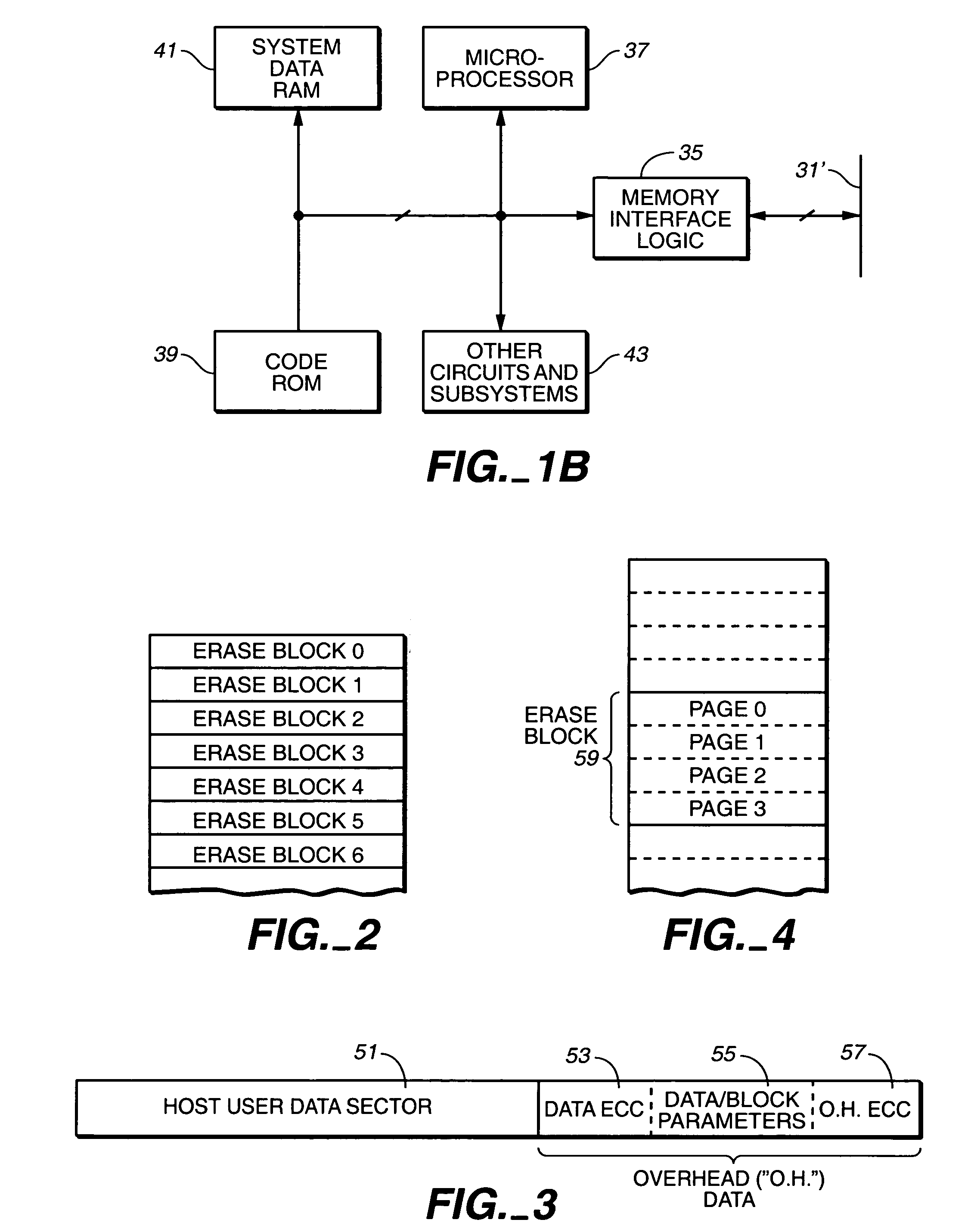

Scratch pad block

ActiveUS7315916B2Improve performanceWrite efficientlyMemory architecture accessing/allocationRead-only memoriesHigh densityHigh velocity

In a memory array having a minimum unit of erase of a block, a scratch pad block is used to store data that is later written to another block. The data may be written to the scratch pad block with a low degree of parallelism and later written to another location with a high degree of parallelism so that it is stored with high density. Data may be temporarily stored in the scratch pad block until it can be more efficiently stored elsewhere. This may be when some other data is received. Unrelated data may be stored in the same page of a scratch pad block.

Owner:SANDISK TECH LLC

Integrated, closely spaced, high isolation, printed dipoles

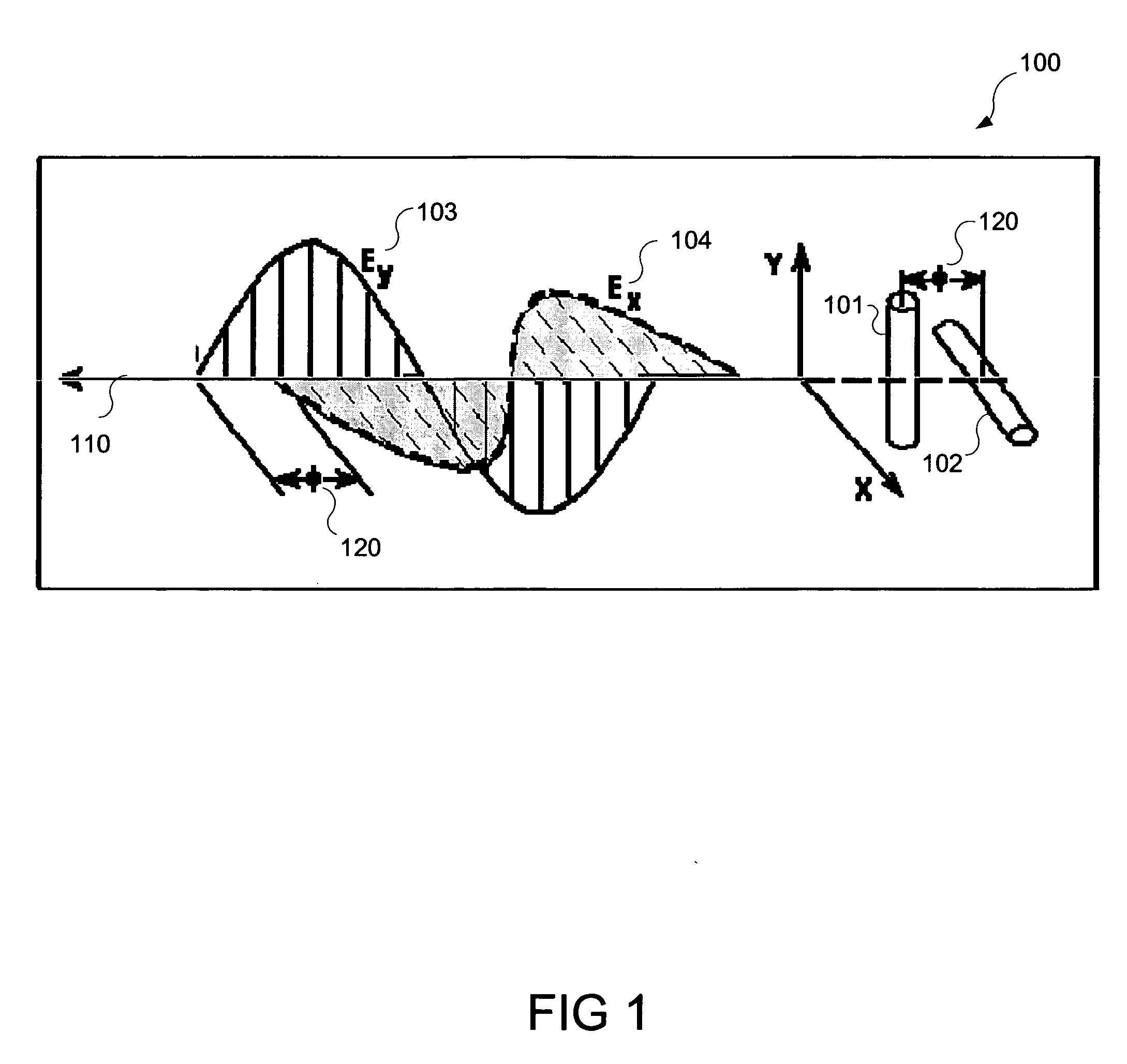

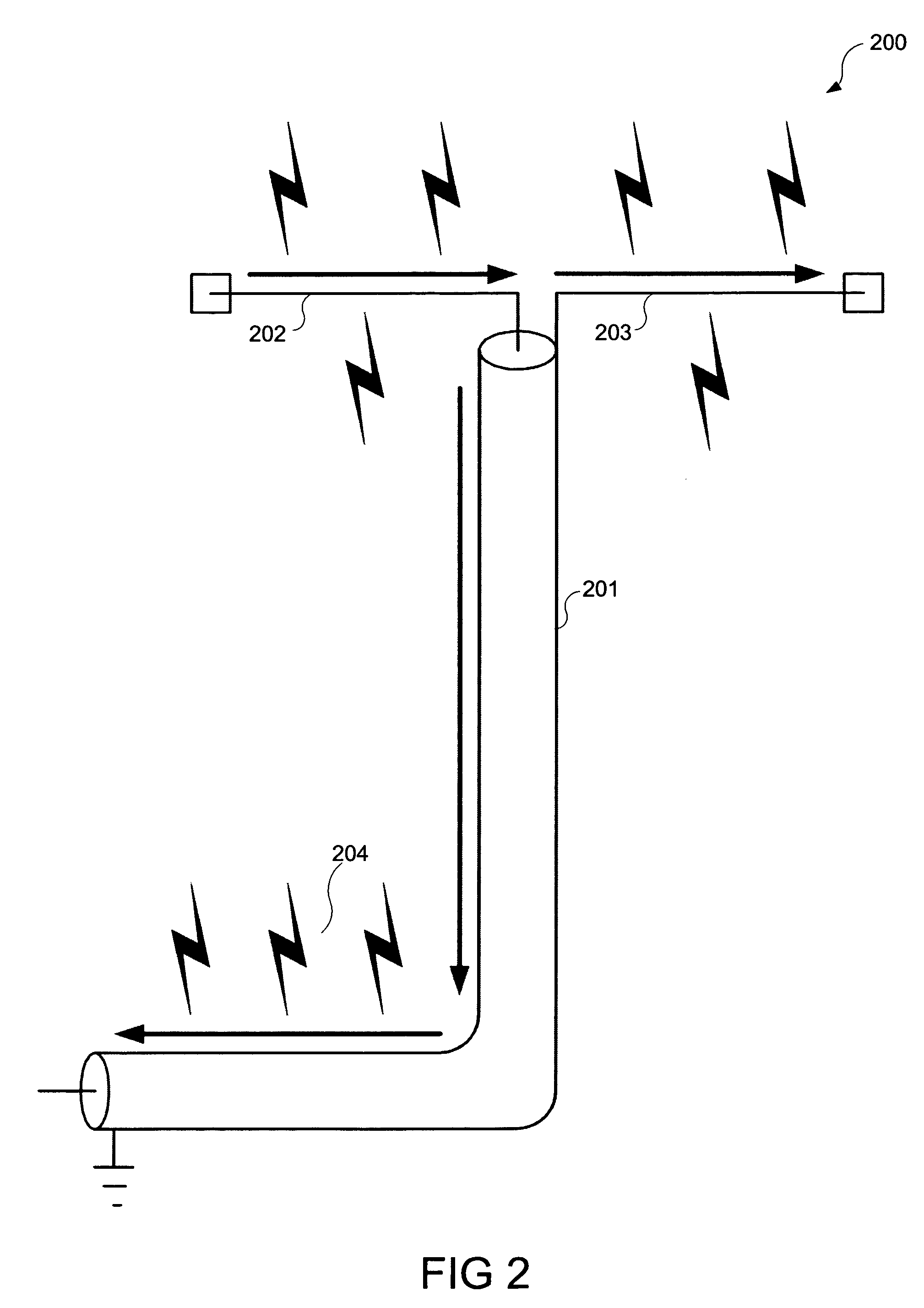

ActiveUS20060262026A1Improve antenna isolationReduce electromagnetic couplingSimultaneous aerial operationsRadiating elements structural formsTransceiverNon symmetric

An antenna configuration includes two closely spaced antennas each positioned so as to be orthogonally polarized with respect to the other. The antenna configuration increases antenna isolation and reduces electromagnetic coupling between donor side antenna and repeat side antenna. The antennas include printed dipoles connected to respective transceivers through respective baluns to balance the non-symmetrical portions of the antenna feed paths to reduce unwanted radiation therein. Printed features such as chokes and non-symmetrical and non-parallel structures are preferably included in the ground plane of a multi-layer circuit board to reduce or eliminate circulating ground currents.

Owner:QUALCOMM INC

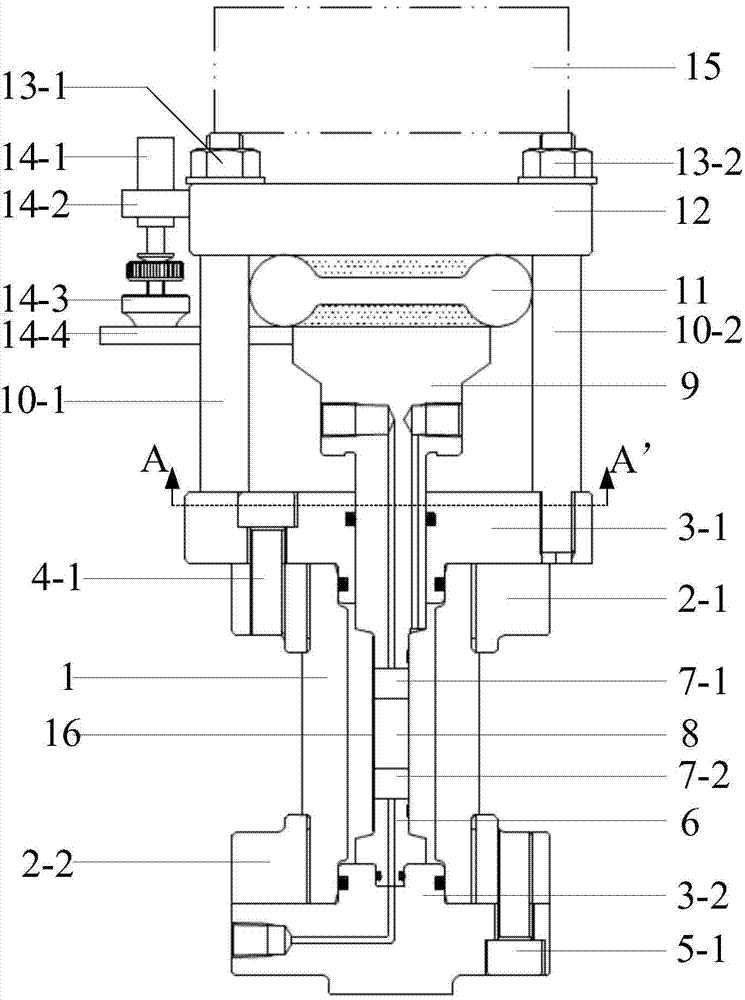

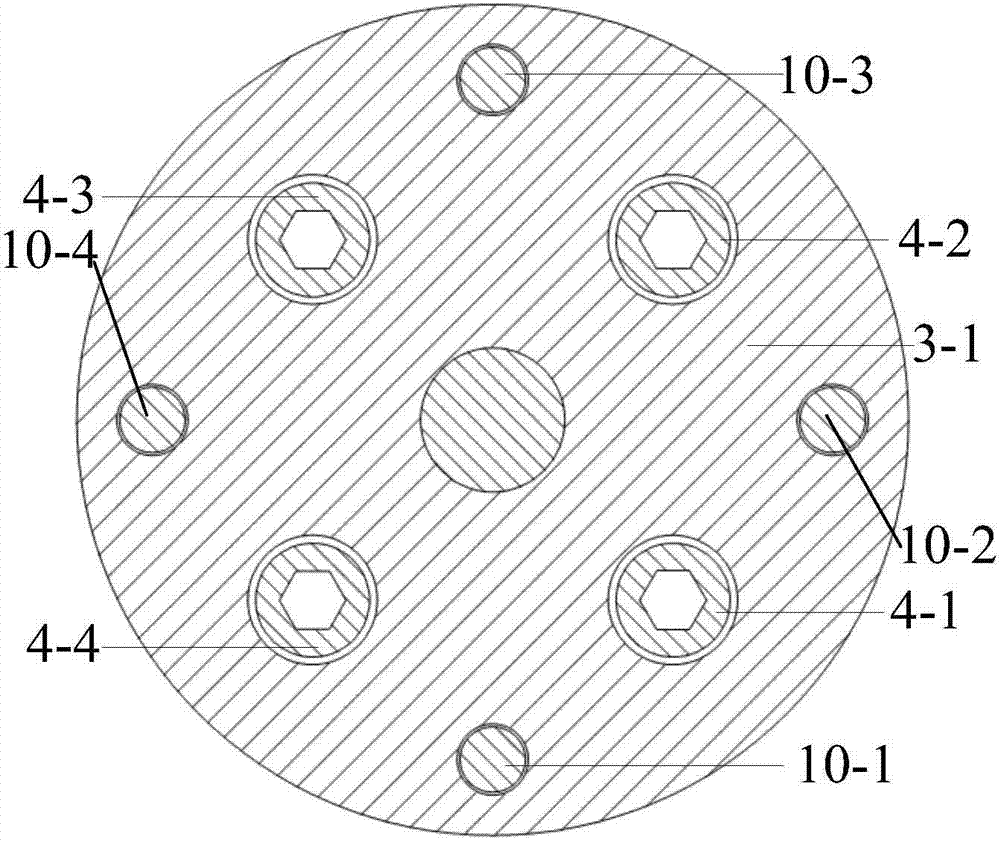

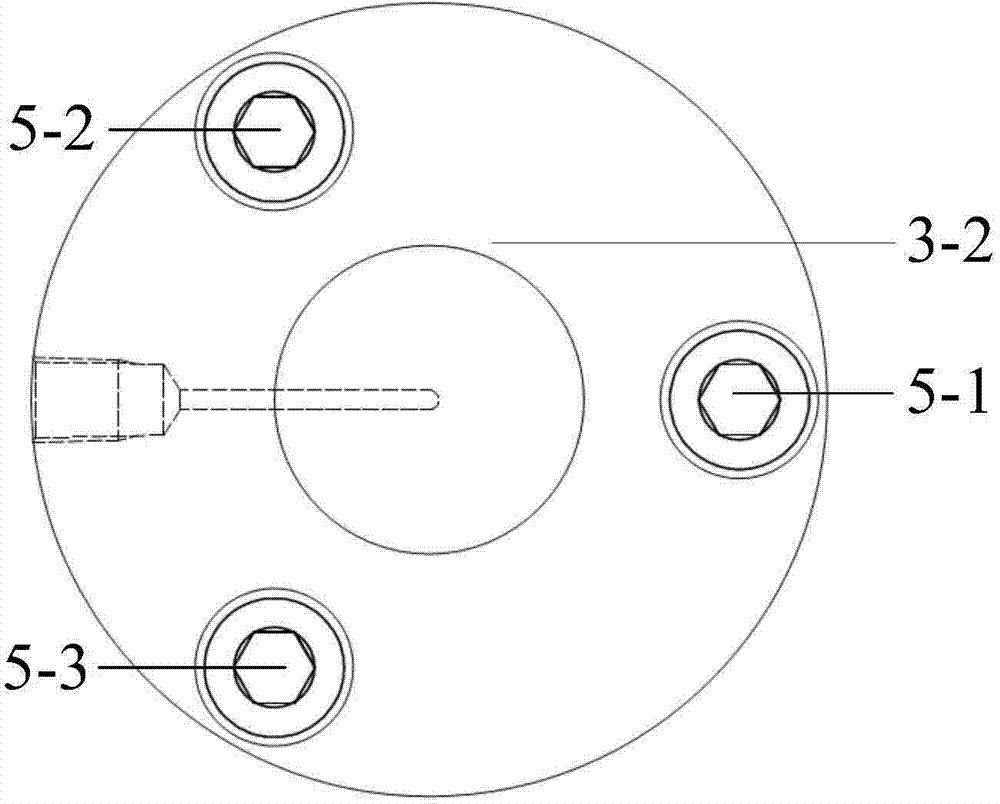

Pressure chamber for CT triaxial test

InactiveCN103487319ASimple structureReduce parallelismStrength propertiesRotary stageComputed tomography

The invention discloses a pressure chamber for a CT triaxial test. A pressure chamber cylinder, a pressure chamber upper fixing flange and a pressure chamber lower fixing flange are cemented and are sealed by a pressure chamber top cover and a pressure chamber pedestal, a loading piston is arranged on the pressure chamber top cover, a sample pedestal is arranged on the pressure chamber pedestal, a lower pressing head, a sample and an upper pressing head are arranged between the loading piston and the sample pedestal in the pressure chamber, and a reaction frame comprises a reaction column fixed on the pressure chamber top cover through a reaction column locking nut. The pressure chamber for the CT triaxial test provides axial loading for the sample by arranging a flat jack between the loading piston and the reaction frame. The pressure chamber has a simple structure, is portable, solves a problem of the influence of the rotation precision of a rotary stage by the overweight of the pressure chamber, and can acquire the confining pressure, the axial load and the sample deformation during CT scanning.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

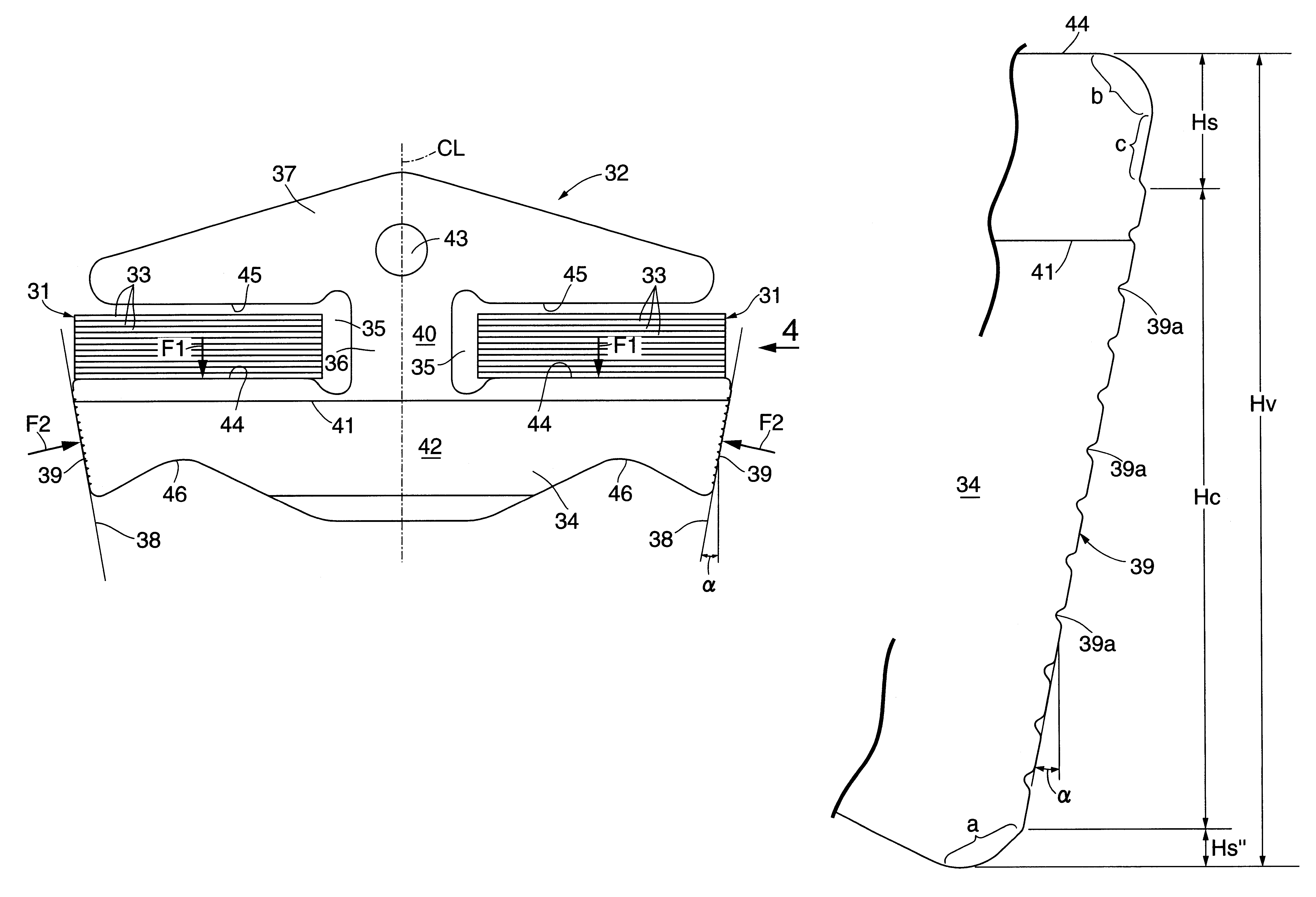

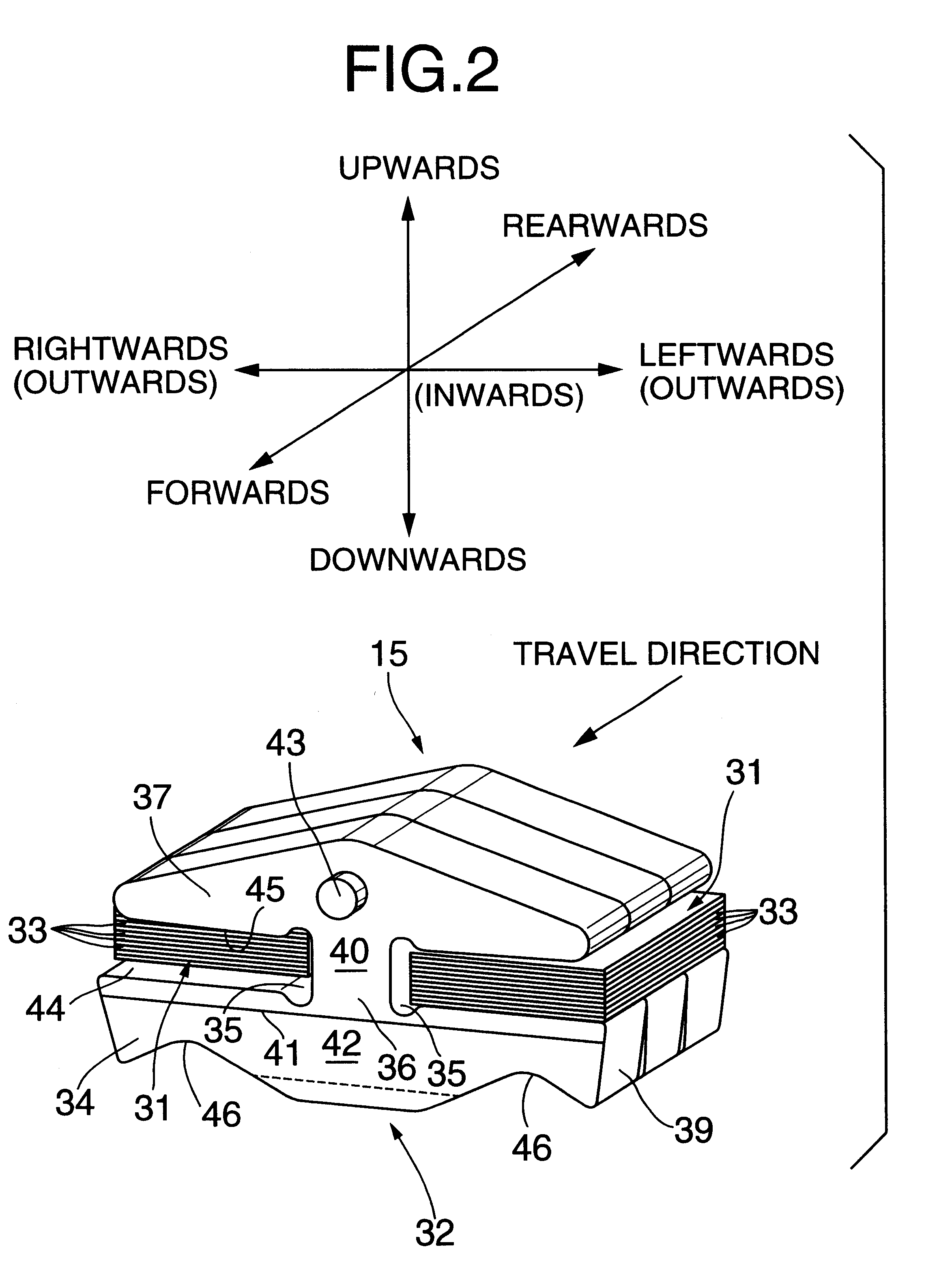

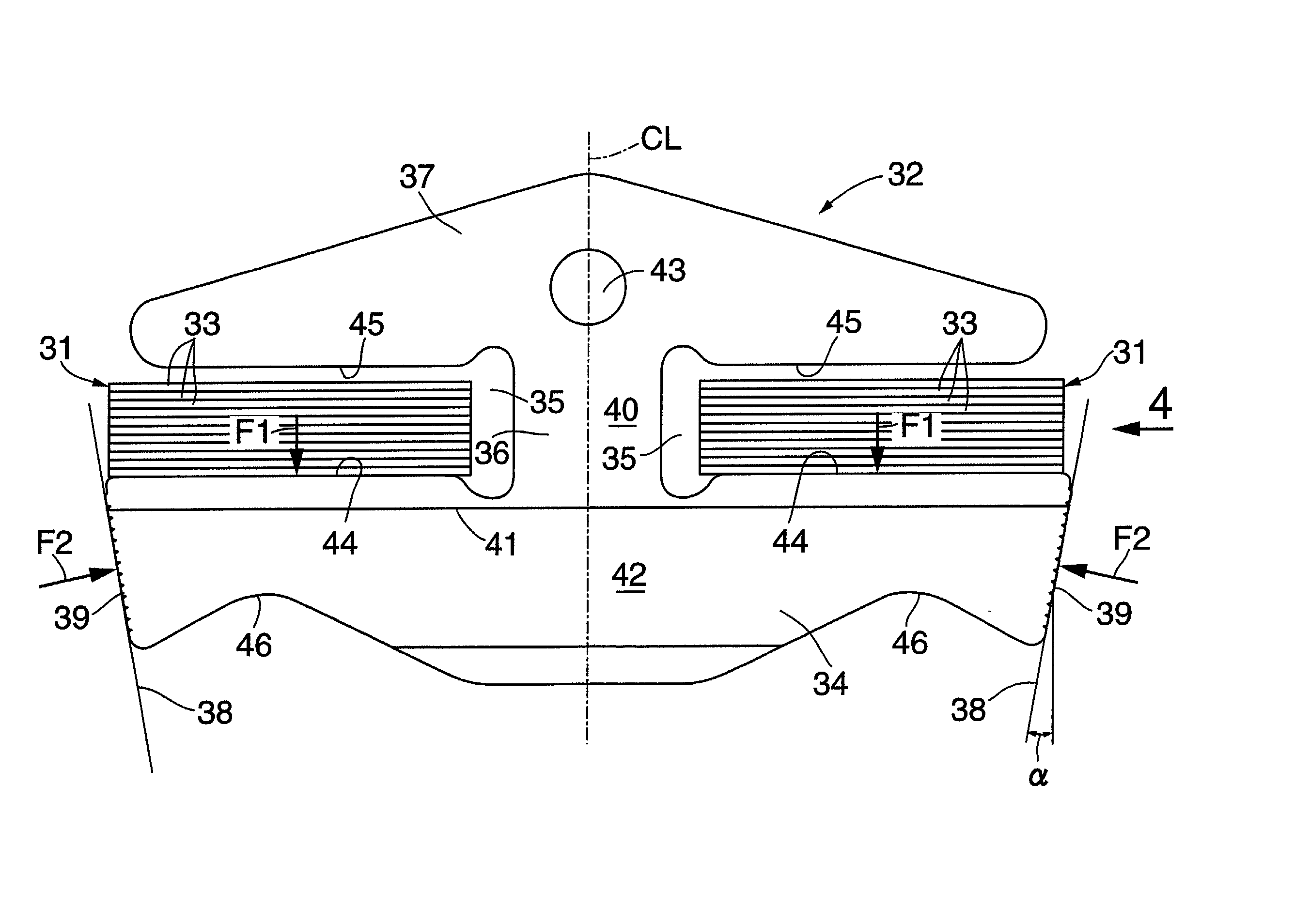

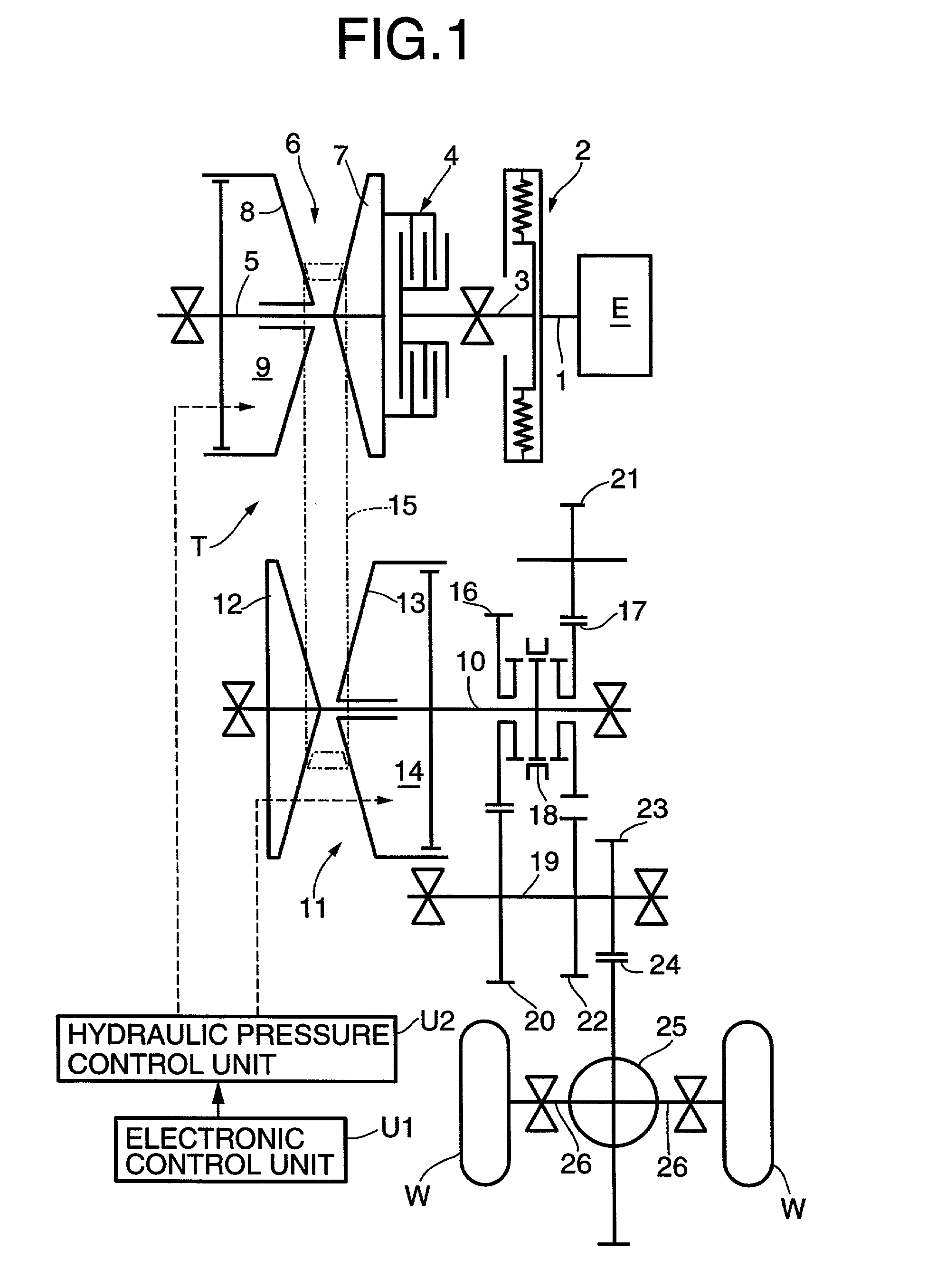

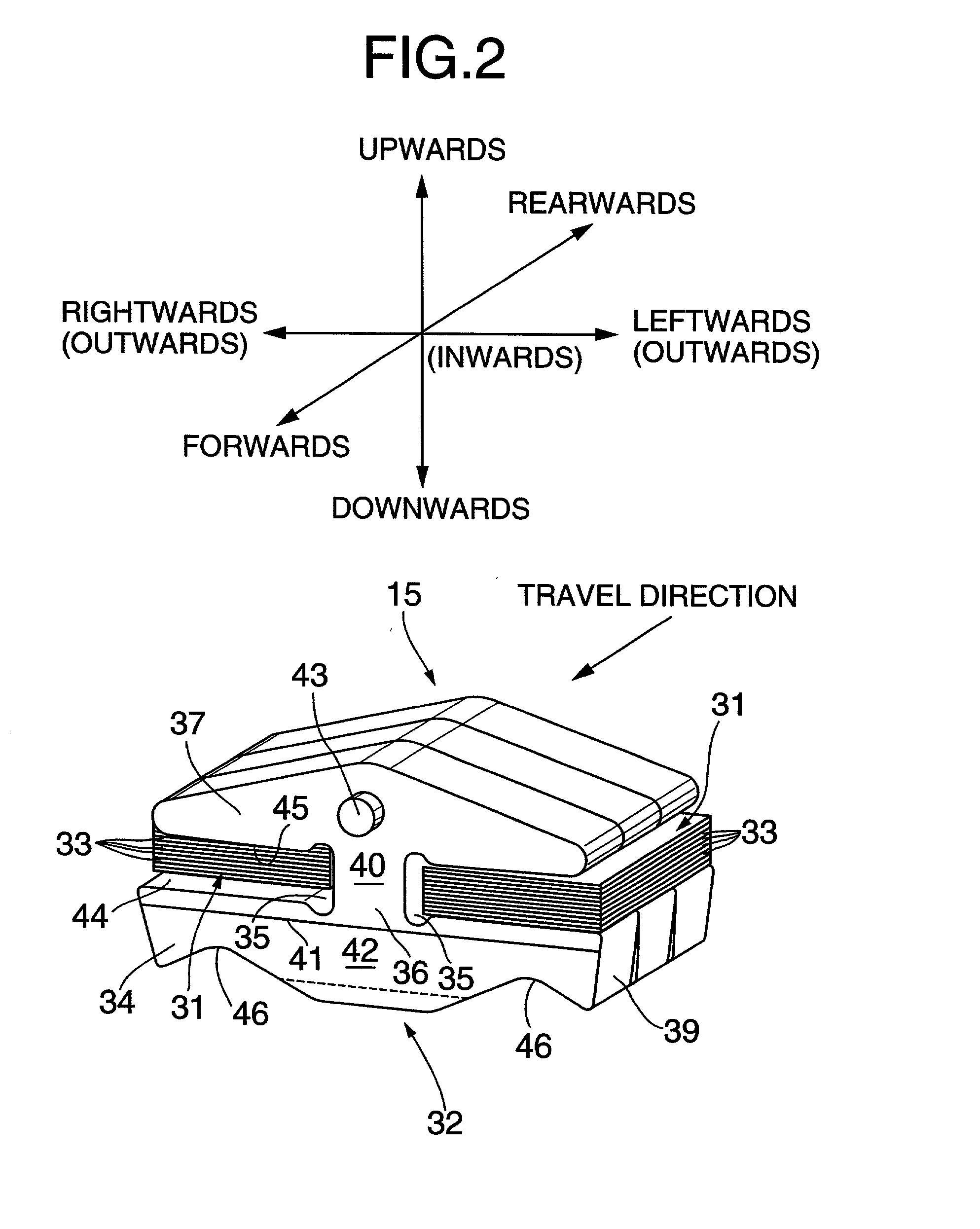

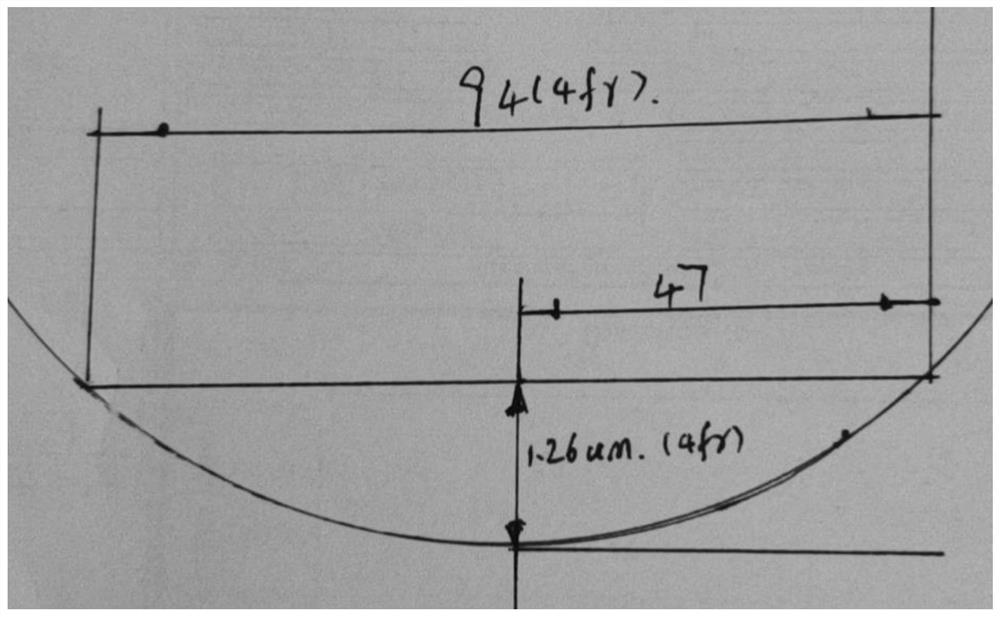

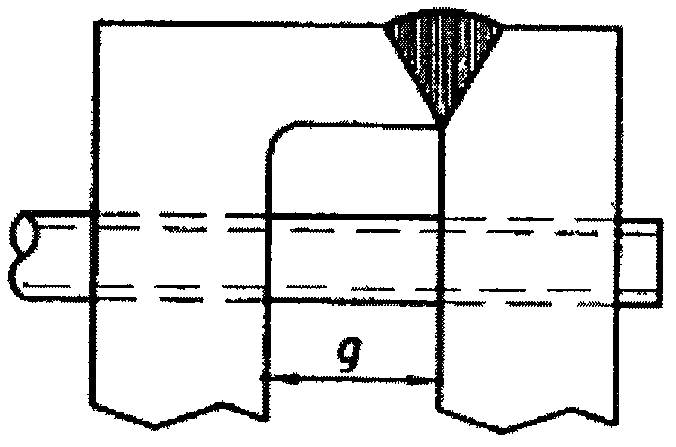

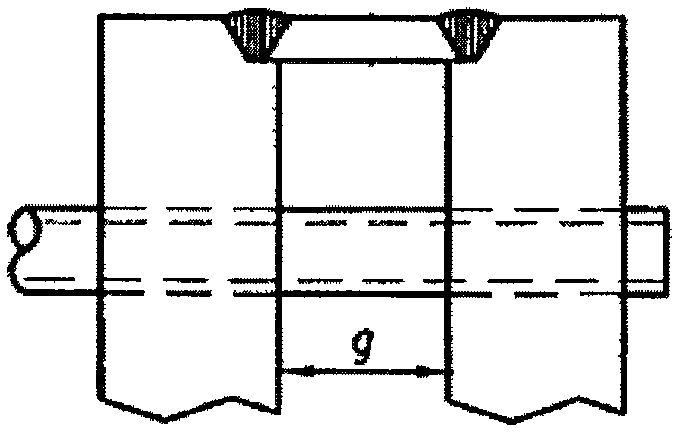

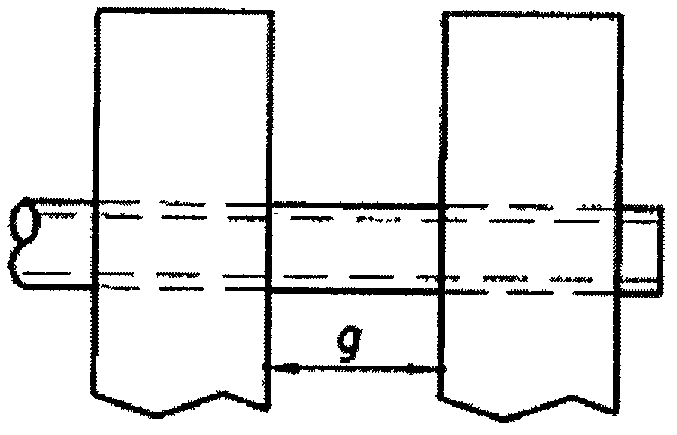

Belt for continuously variable transmission

InactiveUS6599212B2Decreasing V-face heightInhibits uneven wearV-beltsDriving beltsEngineeringPulley

A V-face of a metal element is prevented from being inclined due to a load from a pulley by increasing the height Hs of an upper non-contact portion of the V-face of the metal element. For example, when the height of the V-face is represented by Hv (mm), and the height of the upper non-contact portion of the V-face is represented by Hs (mm), the height Hv of the V-face and the height Hs of the upper non-contact portion are set so that a relationshipis established.

Owner:HONDA MOTOR CO LTD

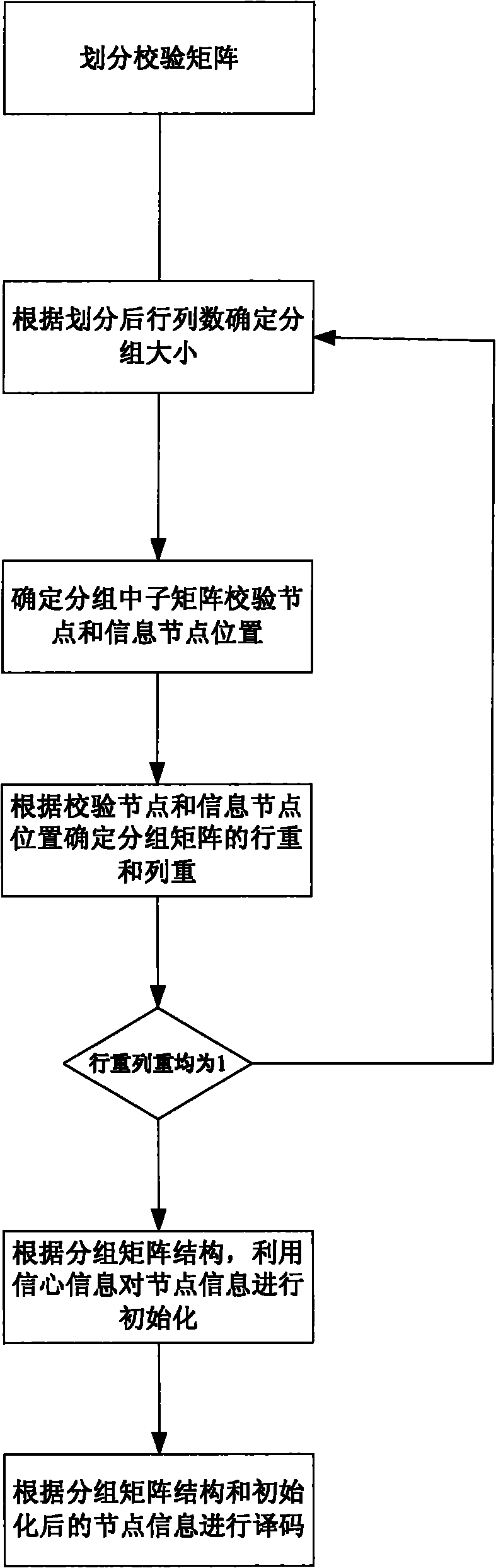

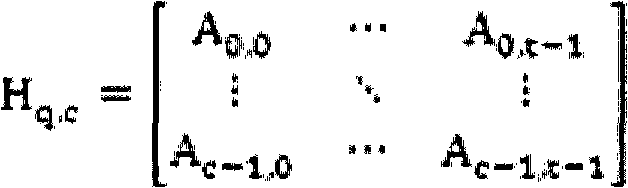

LDPC (low-density parity-check) decoding method

InactiveCN102075197AReduce parallelismSmall scaleError correction/detection using multiple parity bitsDecoding methodsResource consumption

The invention discloses an LDPC (low-density parity-check) decoding method which comprises the following steps: dividing a quasi-cyclic check matrix; grouping the divided check matrix; determining the positions of a check node and an information node in each submatrix group; determining a grouping matrix according to the positions of the check node and the information node; initializing the node information according to the structure of the grouping matrix; and decoding according to the structure of the grouping matrix. The invention solves the problems of single parallel mode and high FPGA (Field Programmable Gate Array) resource consumption for realizing the decoding algorithms in part of existing parallel structure LDPC decoding algorithms.

Owner:BEIJING RES INST OF TELEMETRY +1

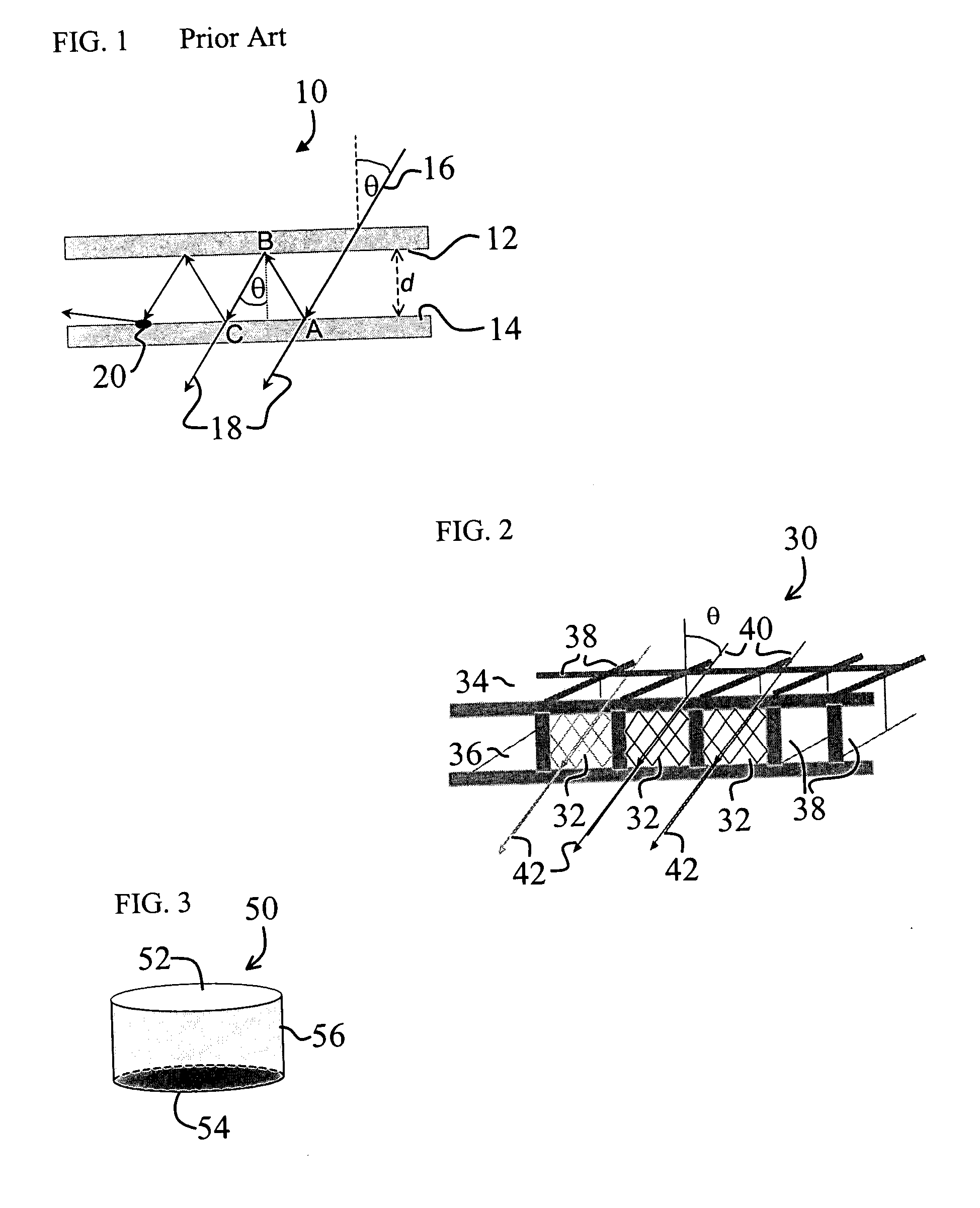

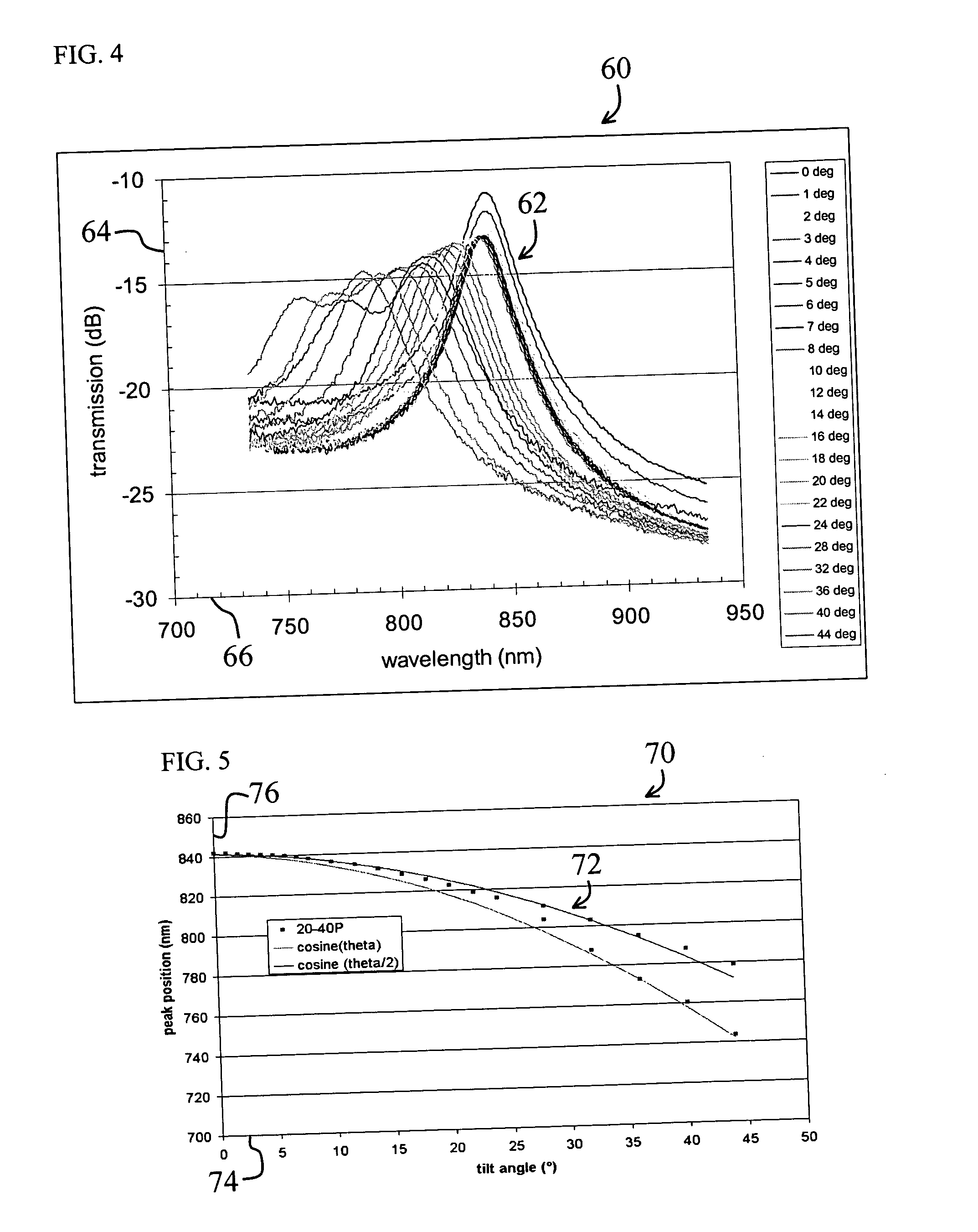

Contained resonant cavity and systems incorporating same

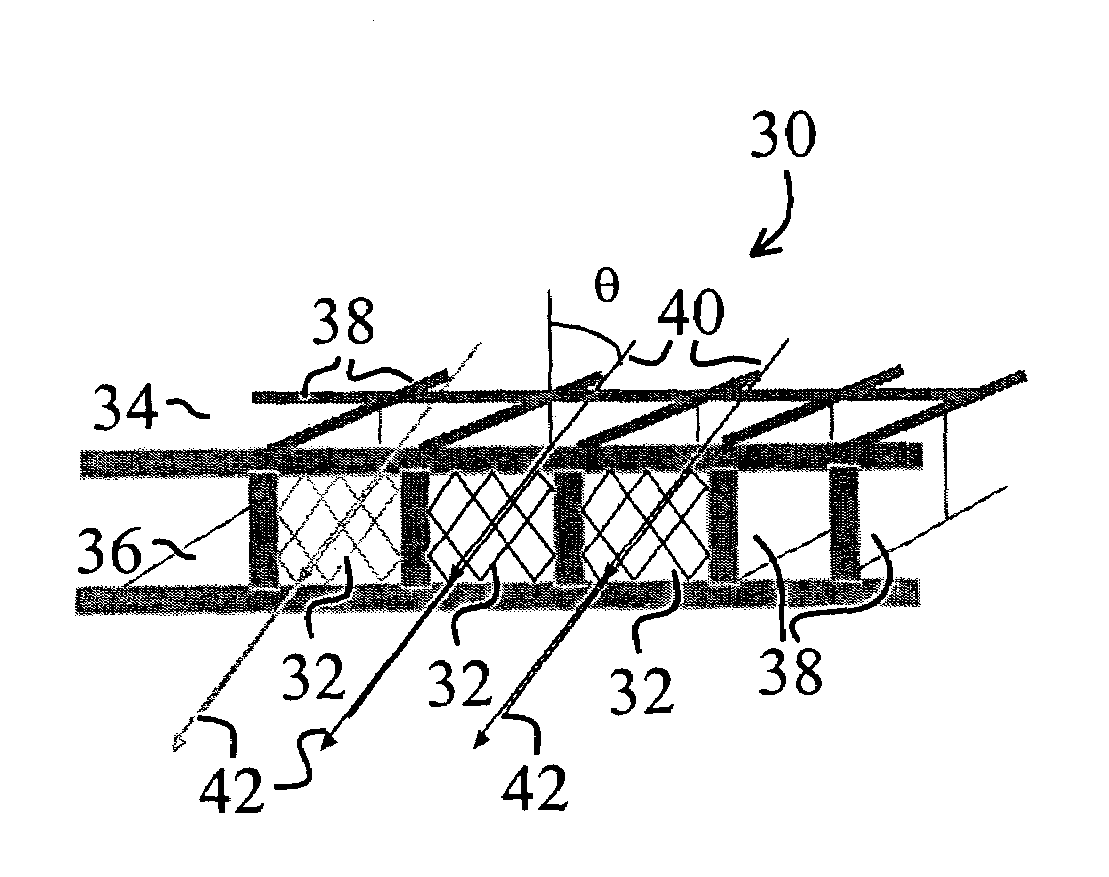

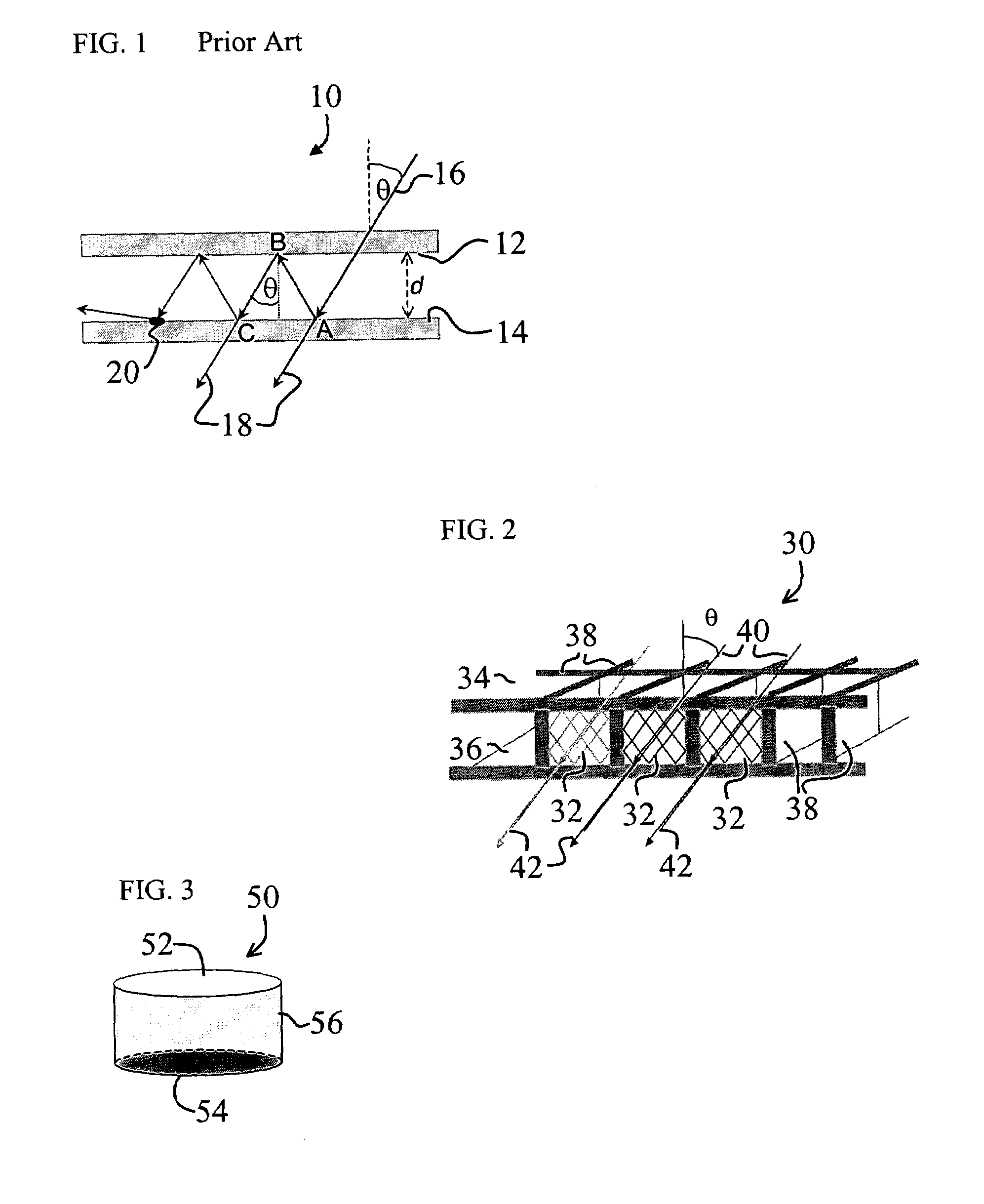

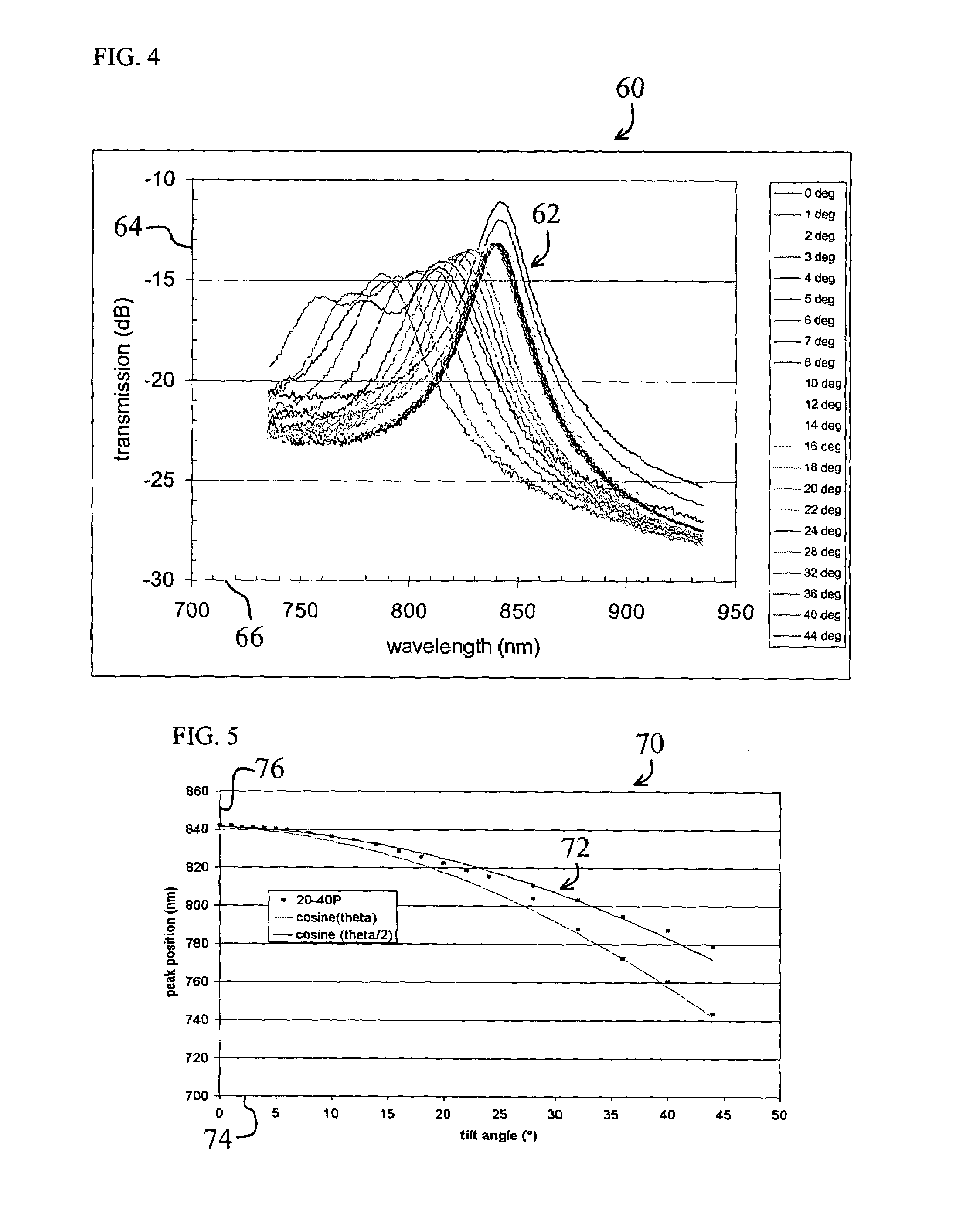

InactiveUS20050073734A1Reduce reflectivityReduce smoothnessUsing optical meansNon-linear opticsResonant cavityPartial reflection

A contained resonant cavity. The contained resonant cavity includes a first surface and a second surface that are partially transmissive and partially reflective. One or more reflective sidewalls are positioned between the first surface and the second surface. In a specific embodiment, the first surface and the second surface are substantially parallel and represent input and output surfaces, respectively, of the contained resonant cavity. The one or more sidewalls are approximately perpendicular to the first surface and the second surface and include a first sidewall having a first substantially reflective planar surface that faces a second substantially reflective planar surface of the second sidewall. A fourth sidewall and a fifth sidewall have fourth and fifth substantially reflective facing sidewalls, respectively. In an illustrative embodiment, the one or more sidewalls include plural reflective sidewalls arranged perpendicularly between the first surface and the second surface to form an array of contained resonant cavities therebetween. The array of contained resonant cavities is readily employed in various applications including unique tunable optical filter arrays, lens-less imaging systems, and multispectral imaging systems.

Owner:TANNER RES

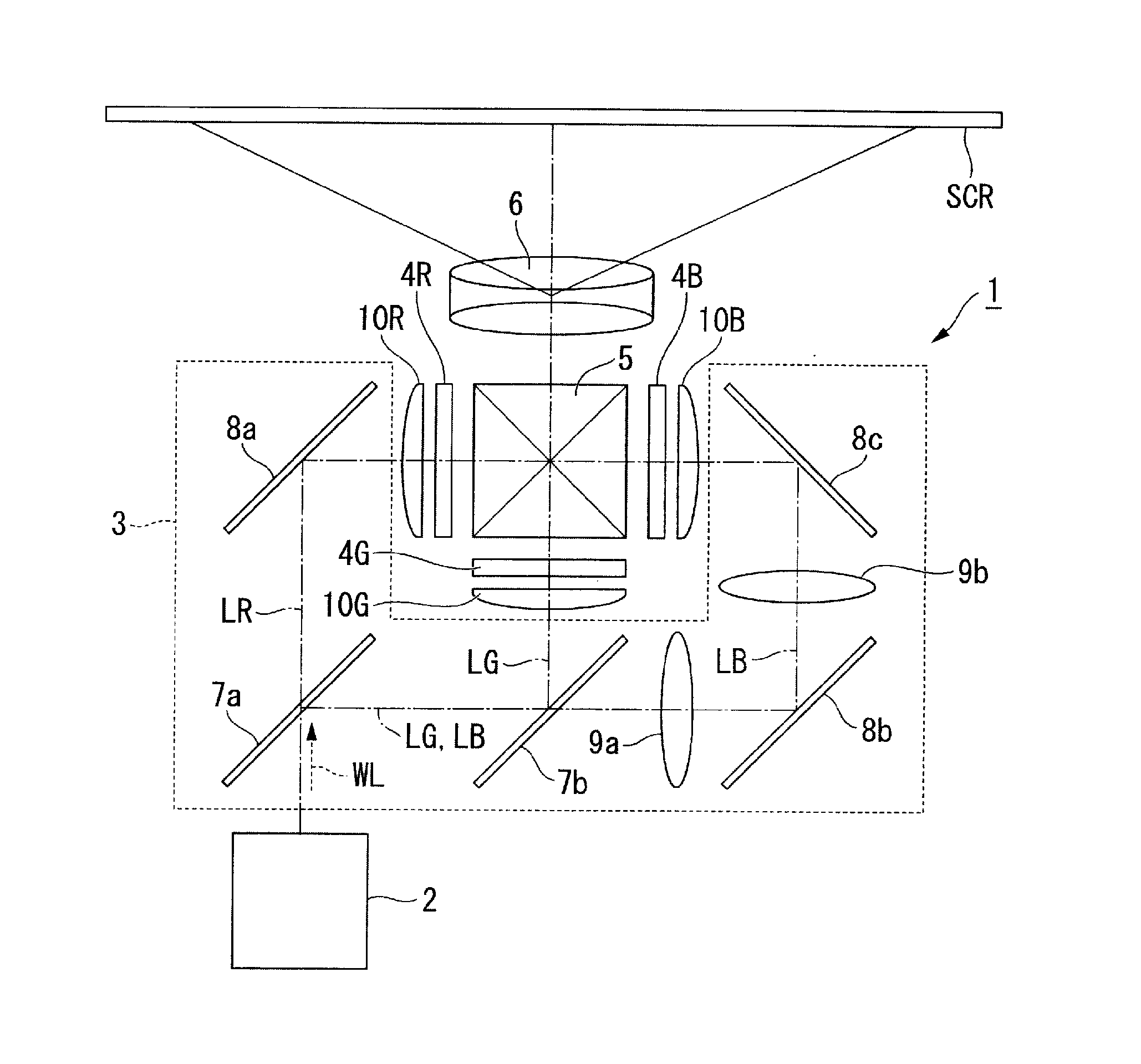

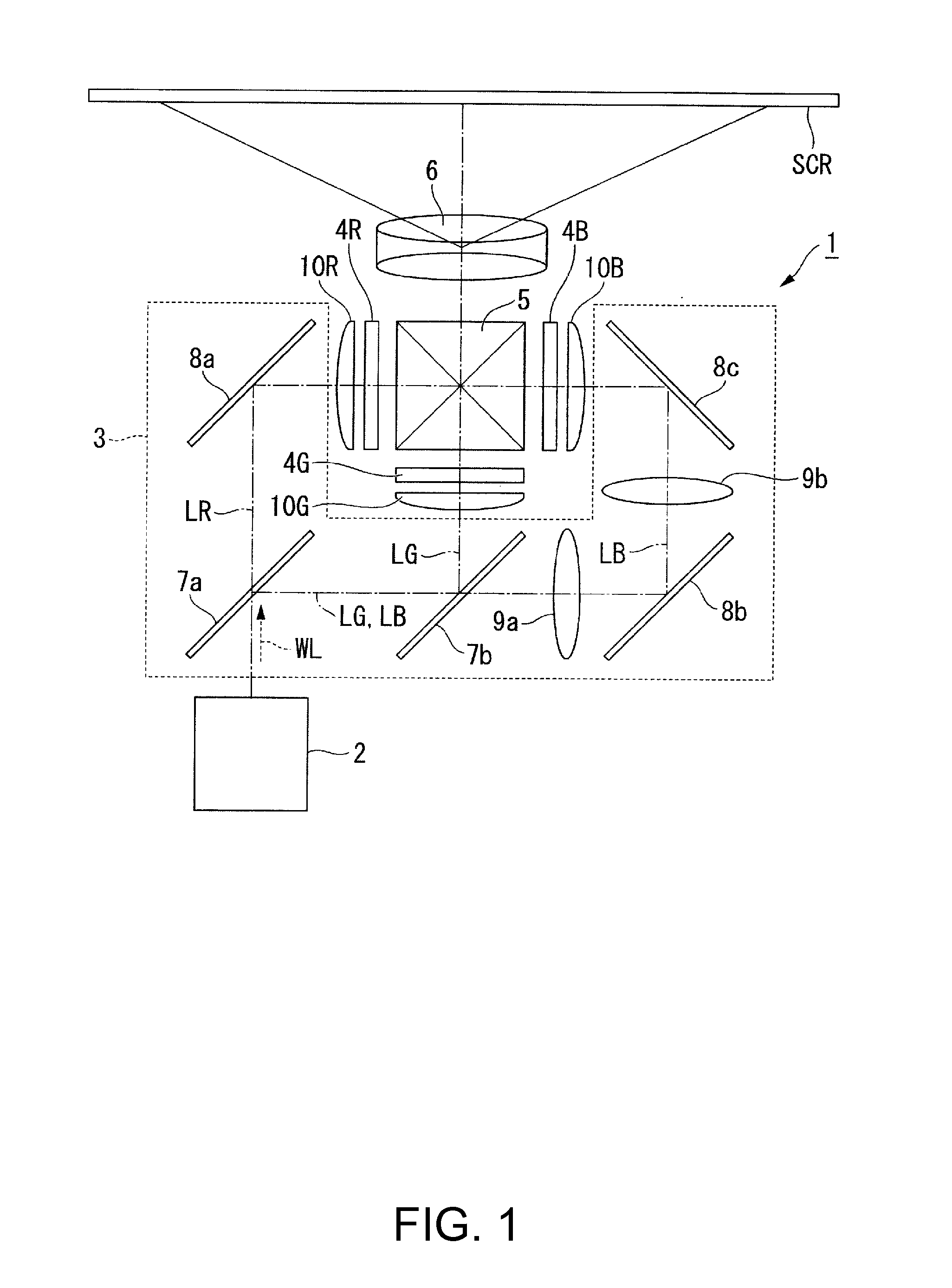

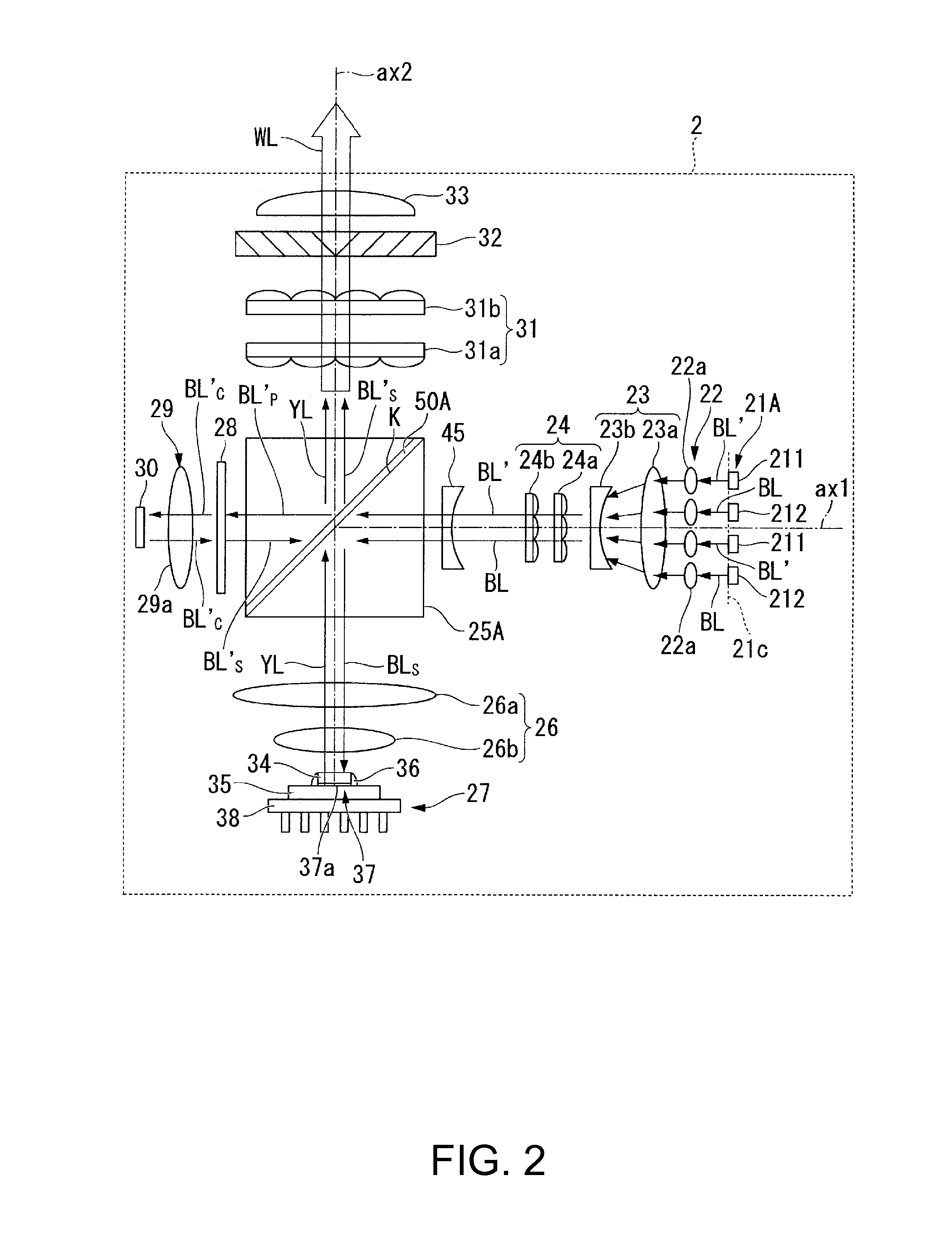

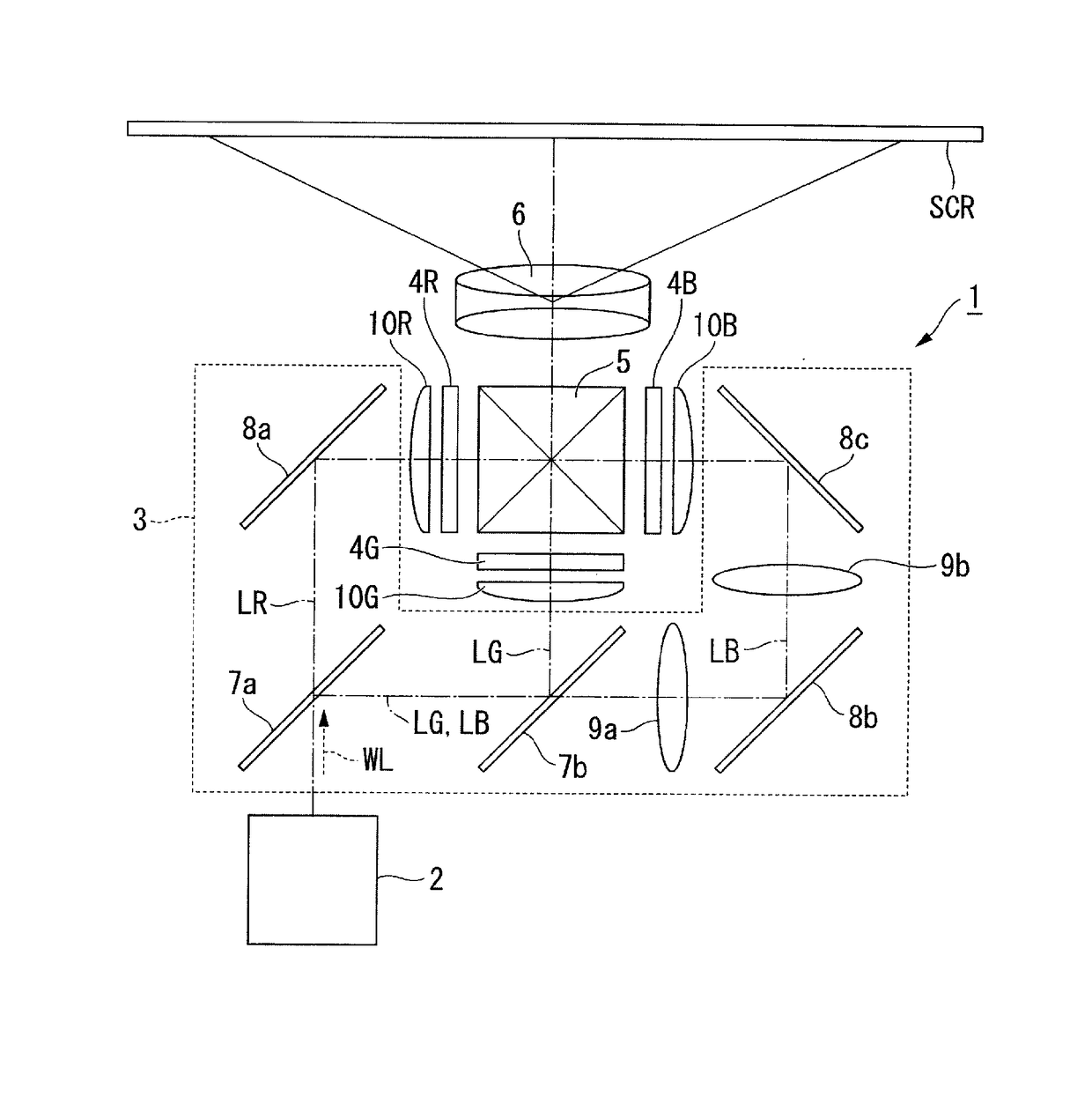

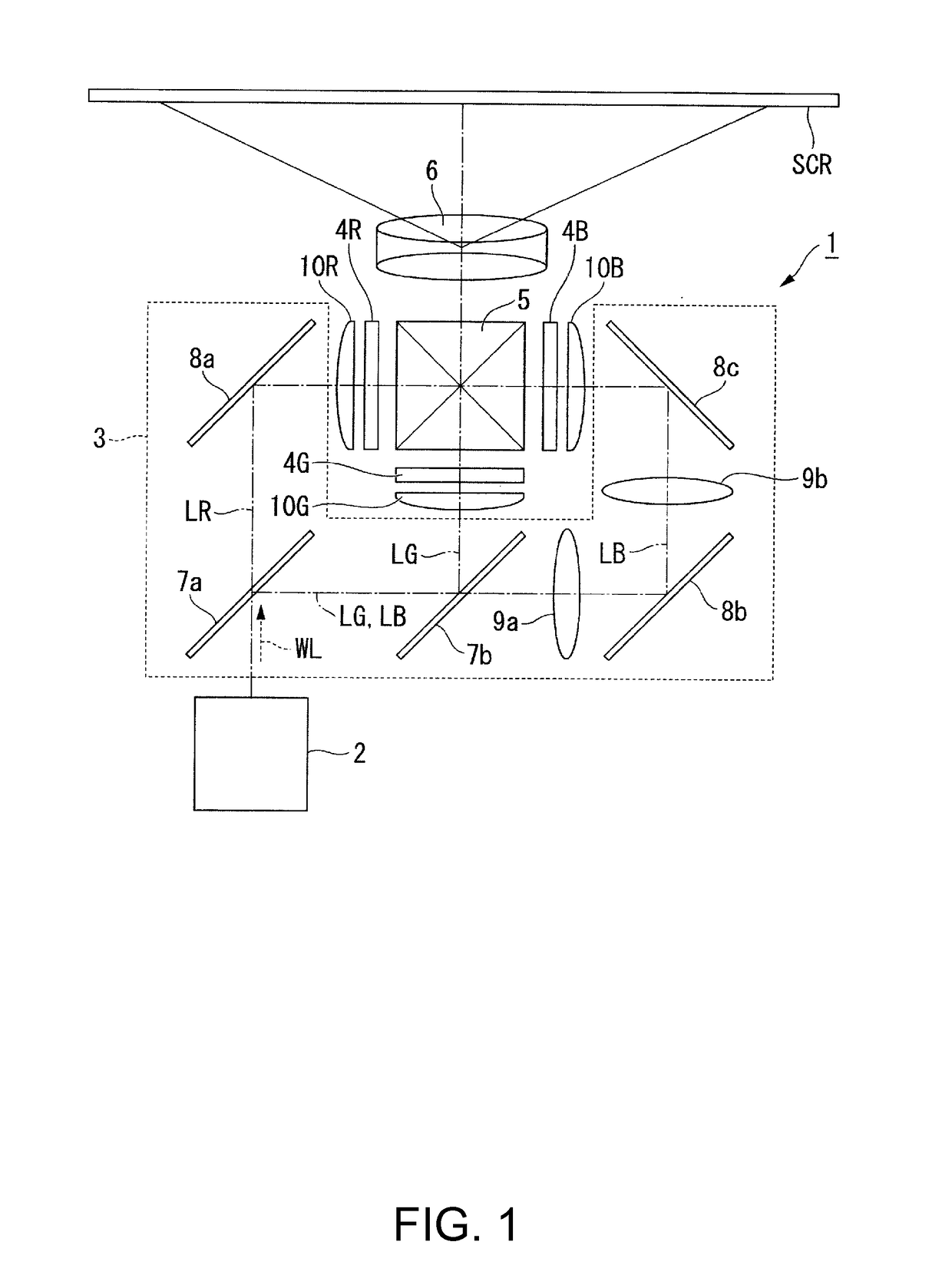

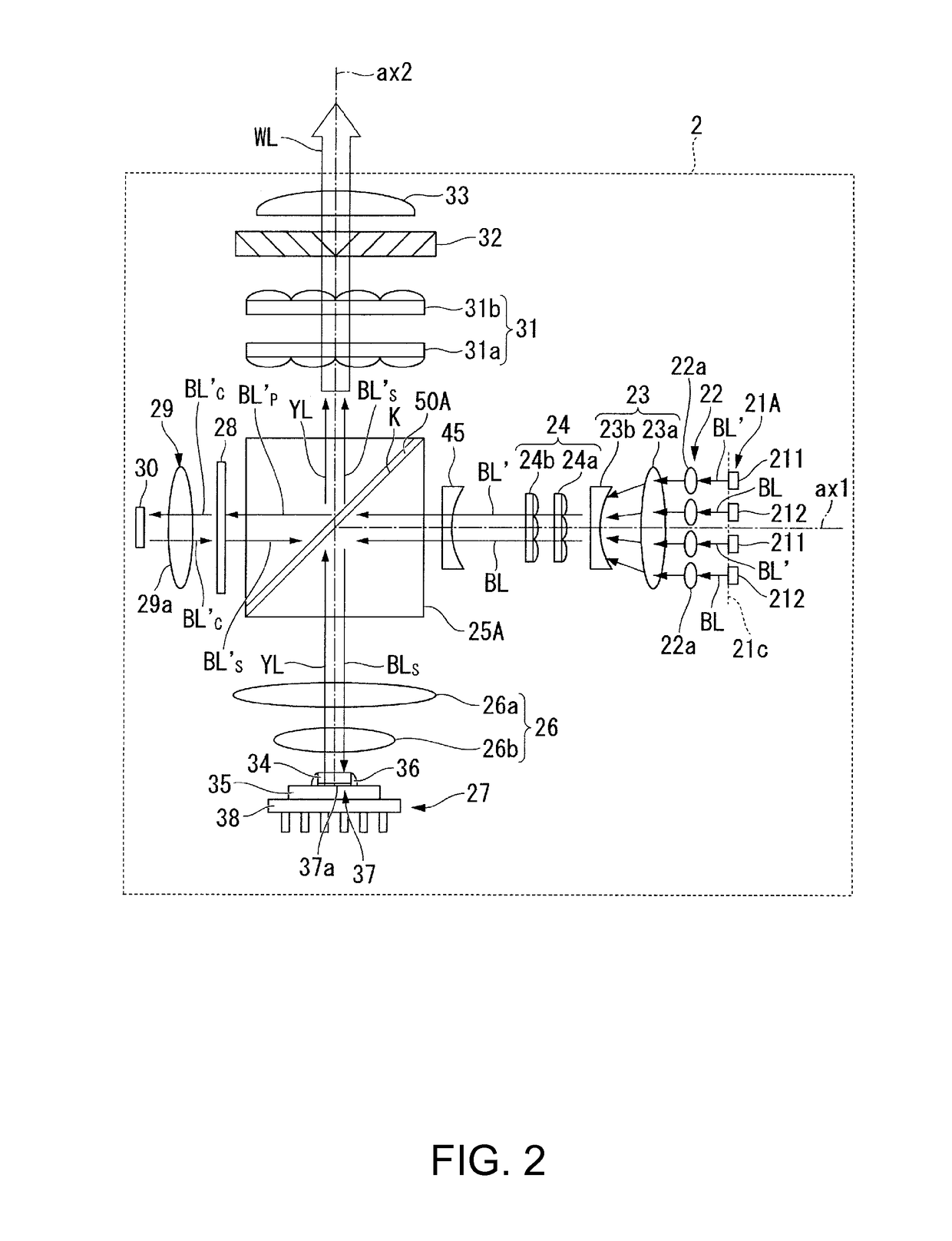

Illumination device and projector

ActiveUS20160011497A1Quality improvementEfficient use ofProjectorsSpectral modifiersIntegratorLength wave

An illumination device includes: a light source that emits first light at a first wavelength; an integrator optical system that the first light enters; a wavelength conversion element that converts the first light transmitting through the integrator optical system into second light at a second wavelength different from the first wavelength; a wavelength separation element provided on an optical path of the first light between the integrator optical system and the wavelength conversion element; a pickup optical system that is provided between the wavelength conversion element and the wavelength separation element and receives the first light and the second light; and a chromatic aberration-correcting optical element provided at least one of between the integrator optical system and the wavelength separation element on the optical path of the first light and at downstream of the wavelength separation element on an optical path of the second light.

Owner:SEIKO EPSON CORP

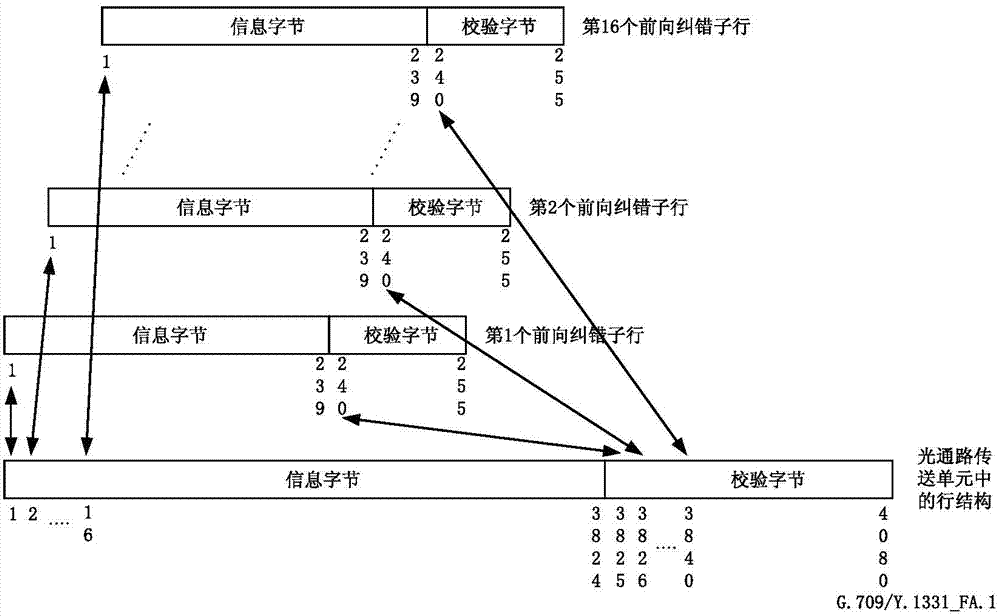

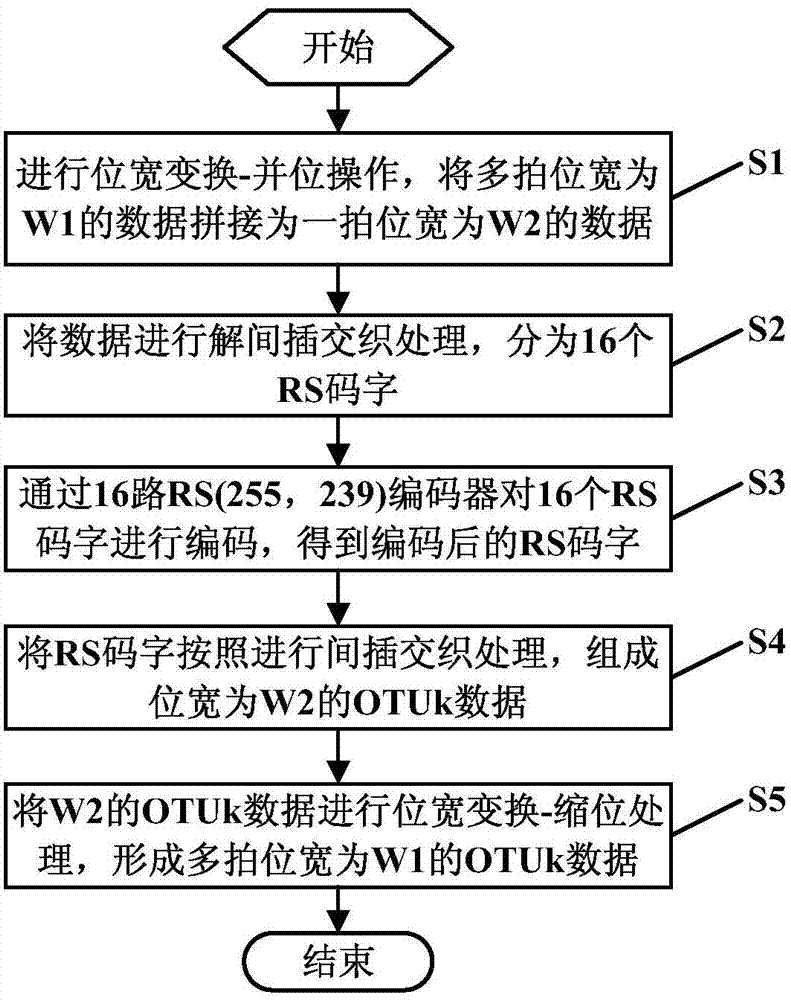

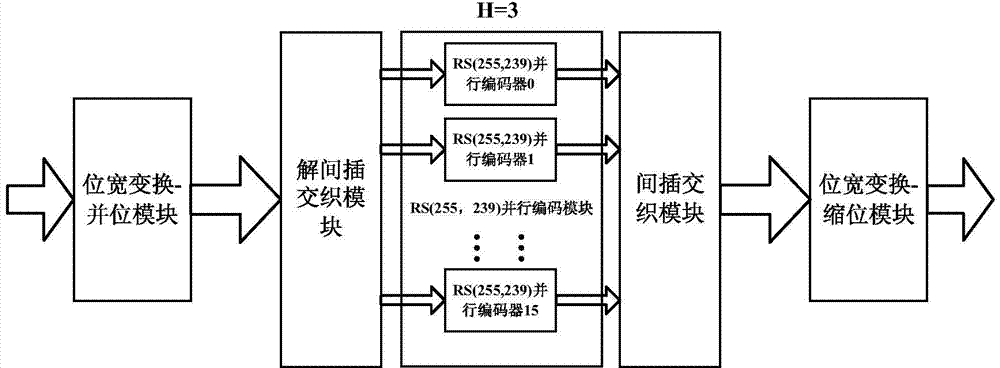

Hardware implementation method and system for FEC in OTN system

ActiveCN104734815ASmall scaleImprove throughputSource coding adaptationFibre transmissionComputer architectureCoded element

The invention discloses a hardware implementation method and system for a high-throughput FEC in an OTN system and relates to the field of optical fiber communication error control. The method includes the following steps that multiple beats of transmitted data with the bit width of W1 are integrated into one beat of integrated data with the bit width of W2; the beat of integrated data is evenly divided into information code elements of 16 RS code words; the information code elements of the 16 RS code words are coded to obtain 16 coded RS code words; the 16 coded RS code words form OTUk data with the bit width of W2; the OTUk data with the bit width of W2 form multiple beats of OTUK data with the bit width of W1. The high throughput of the whole FEC is realized, meanwhile, the degree of parallelism is reduced when an RS (255, 239) coder is implemented, the hardware resources for implementation of the whole FEC are reduced, the implementation scale is small, the data processing capacity of RS (255, 239) parallel cording can be ensured, and the method and system can be utilized by people conveniently.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

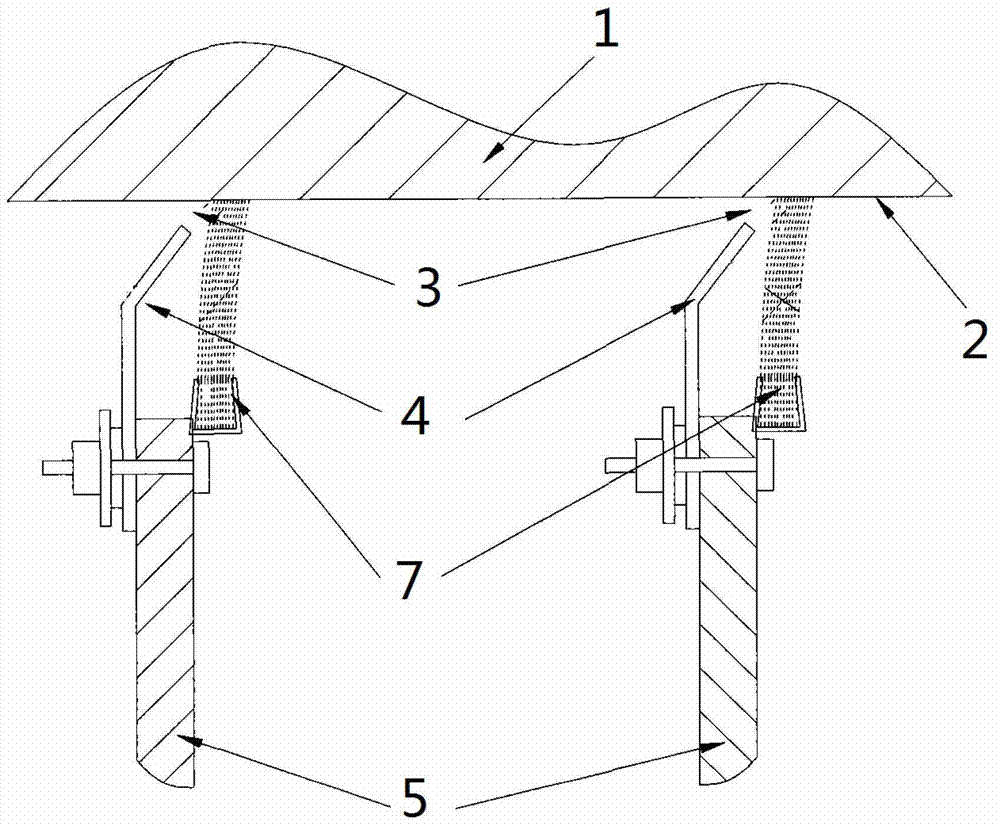

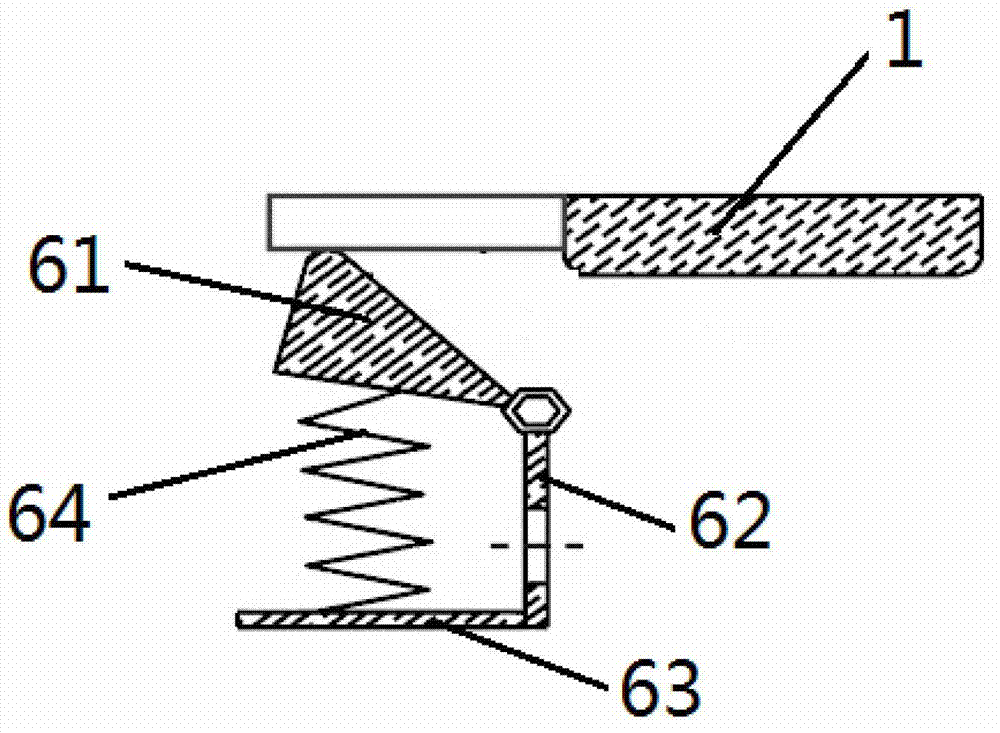

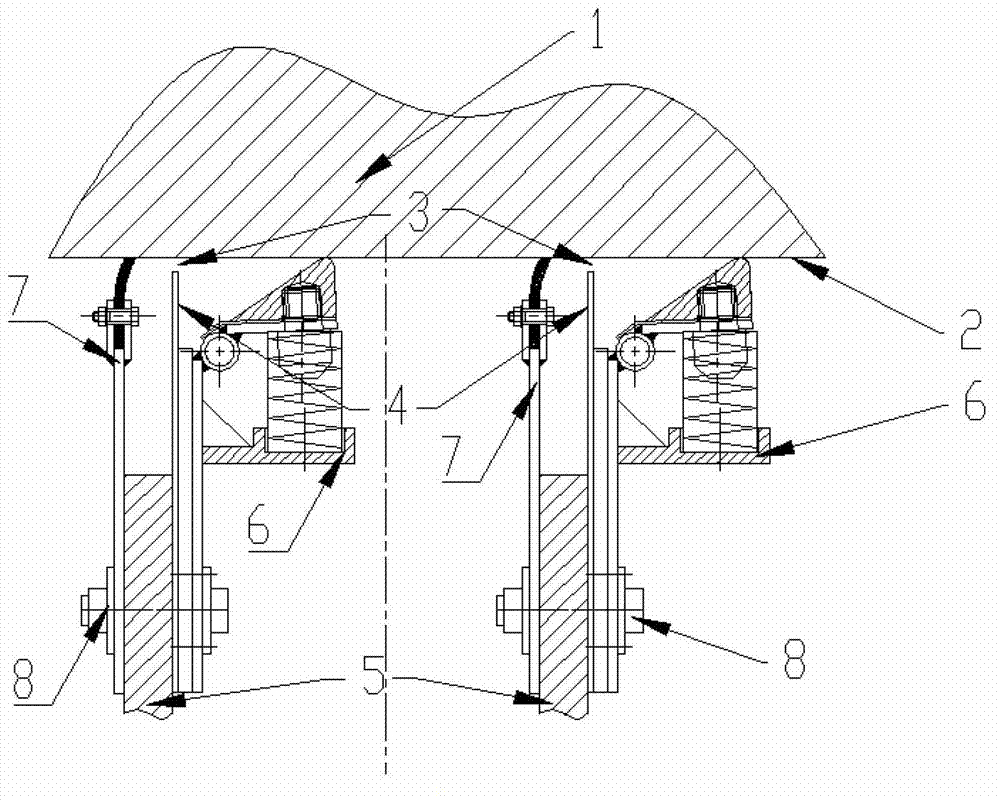

Flexible sealing structure of rotary air pre-heater

ActiveCN102901118AGuarantees a stable sealGood sealing effectEngine sealsCombustion processEngineeringMechanical engineering

The invention discloses a flexible sealing structure of a rotary air pre-heater. The flexible sealing structure is a contact type sealing device and comprises a sealing sliding block, a regulation supporting seat and a supporting fixing plate; the sealing sliding block is rotatablely connected with the supporting fixing plate; the supporting fixing plate is relatively arranged on a radial baffle plate of the air pre-heater fixedly; the regulation supporting seat is fixedly connected with the supporting fixing plate; a compression spring is arranged between the regulation supporting seat and the sealing sliding block; the sealing sliding block is in contact with a fan-shaped plate or an axial arc-shaped plate of the air pre-heater; a reset regulation device is arranged between the sealing sliding block and the regulation supporting seat; two ends of the reset regulation device are respectively connected with the sealing sliding block and the regulation supporting seat; and the reset regulation device is used for regulating the maximal resilience modulus of the compression spring positioned between the sealing sliding block and the regulation supporting seat. By using the flexible sealing structure, through regulating the reset regulation device, the regulation of sealing acting force between a moving component and a stationary component in the air pre-heater is realized; the wear of a sealing surface is decreased; and the service life of a quick-wear part is prolonged.

Owner:南京通用电气装备有限公司

Belt for continuously variable transmission

InactiveUS20020052261A1Suppress uneven wearing of metal elementDecrease heightV-beltsDriving beltsParagraphEngineering

A V-face of a metal element is prevented from being inclined due to a load from a pulley by increasing the height Hs of an upper non-contact portion of the V-face of the metal element. For example, when the height of the V-face is represented by Hv (mm), and the height of the upper non-contact portion of the V-face is represented by Hs (mm), the height Hv of the V-face and the height Hs of the upper non-contact portion are set so that a relationship <paragraph lvl="0"><in-line-formula>-0.5265Hv+2.768<=Hs<=-0.5934Hv+3.524 < / in-line-formula>is established.

Owner:HONDA MOTOR CO LTD

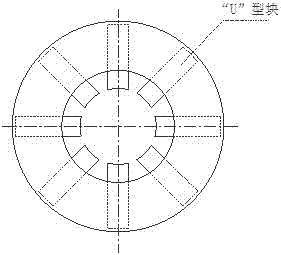

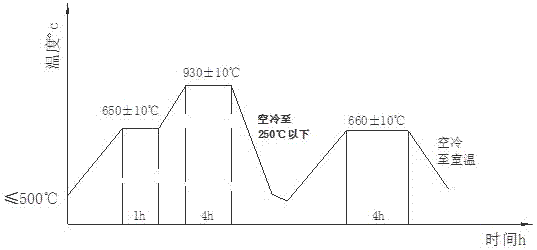

High-speed bullet train brake disc body and casting method and heat treatment method thereof

InactiveCN107354384AImprove mechanical propertiesImprove thermal conductivityBraking discsFoundry mouldsUltimate tensile strengthHeat treated

The invention discloses a high-speed bullet train brake disc body and a casting method and heat treatment method thereof. The brake disc body is obtained through casting and heat treatment, an upper disc surface and a lower disc surface of the disc body are parallel to each other, and the upper disc surface and the lower disc surface of the disc body are connected through a plurality of U-shaped blocks which are uniformly distributed. According to the physical design of the disc body, a good balance degree of the disc body during high-speed rotation is guaranteed, and the amplitude during high-speed braking of the brake disc is greatly reduced; according to the design of the casting technique of the disc body, the quality of the disc body is greatly improved, and a high safety coefficient and a long service life of the disc body in long-time continuous braking are guaranteed; and according to the design of the heat treatment technology, the strength and the impact to be borne by the disc body during high-speed braking under the extremely-cold environment are reduced, and the thermal warping deformation generated in the continuous braking process is also reduced.

Owner:JIANGSU JINSHI CASTING & FORGING

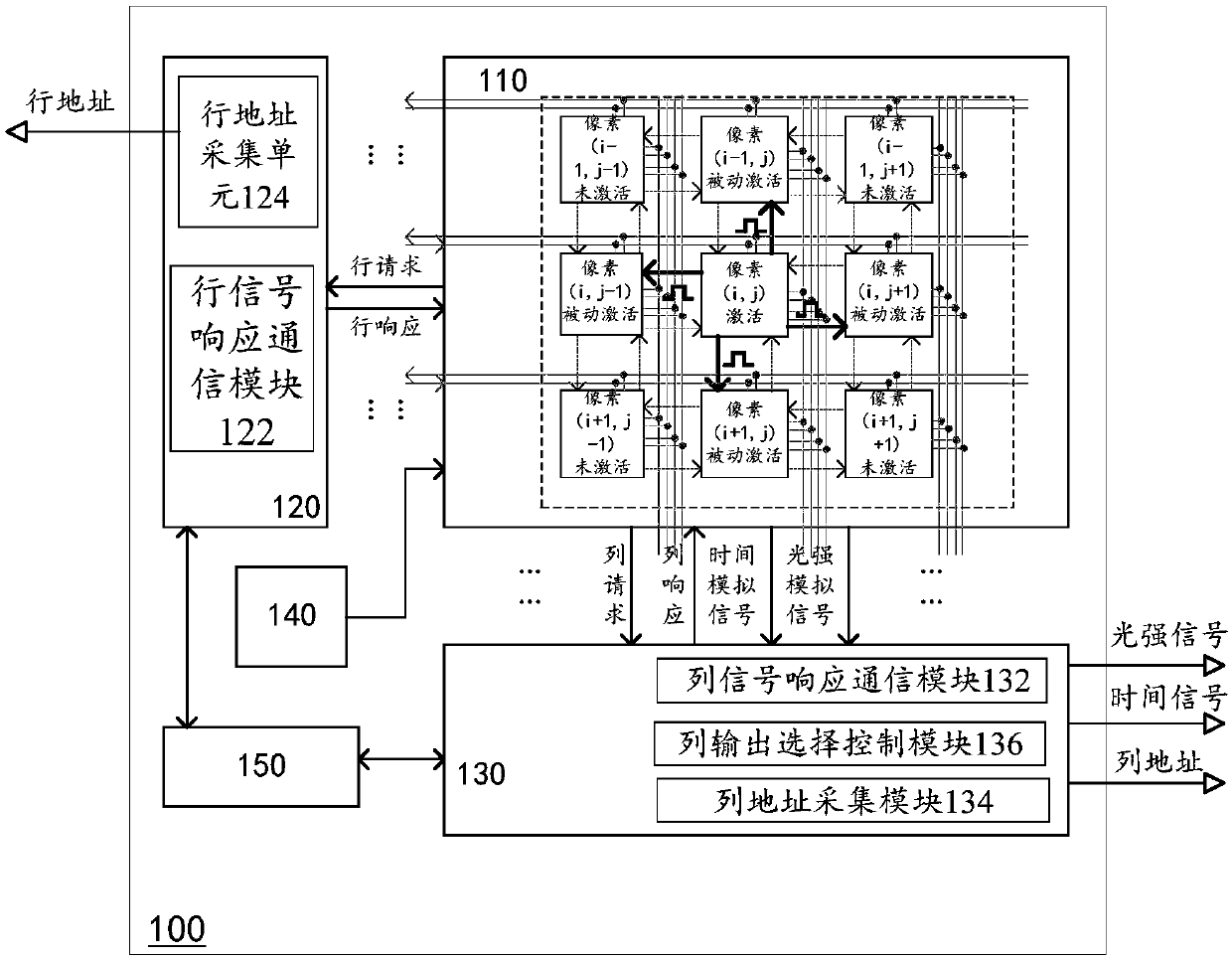

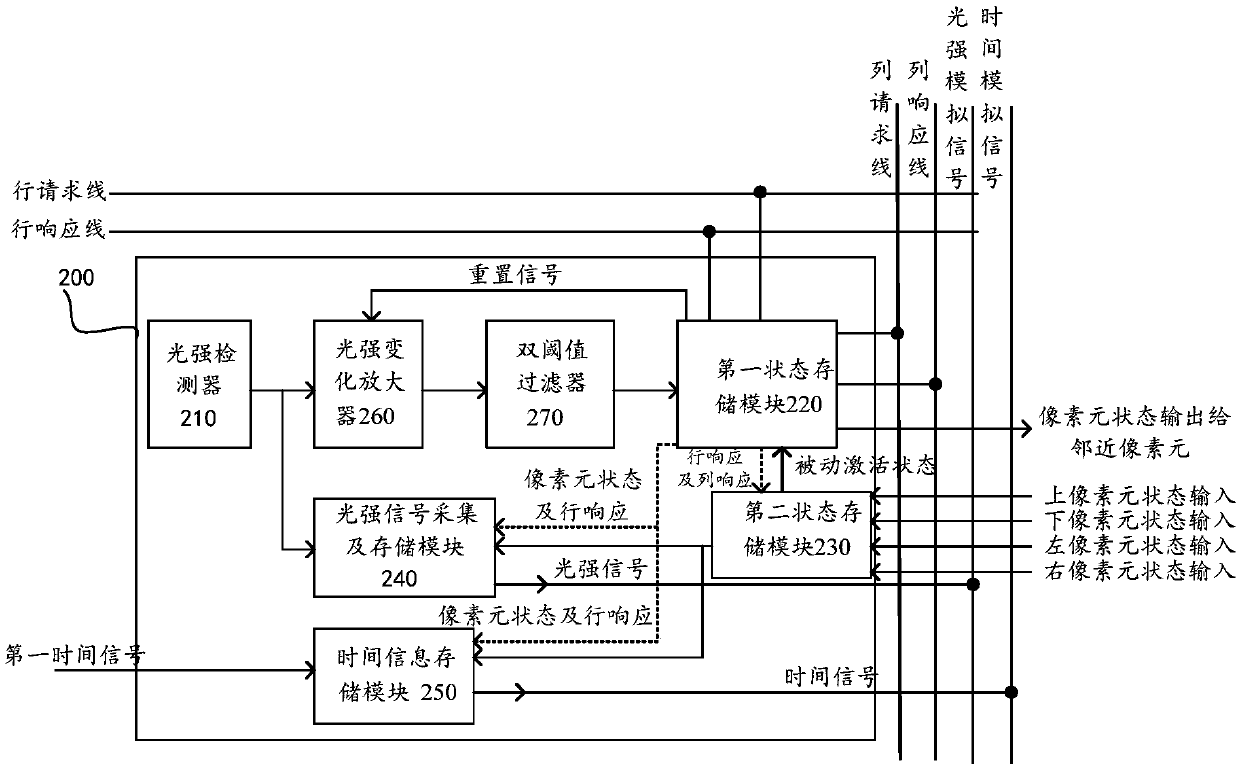

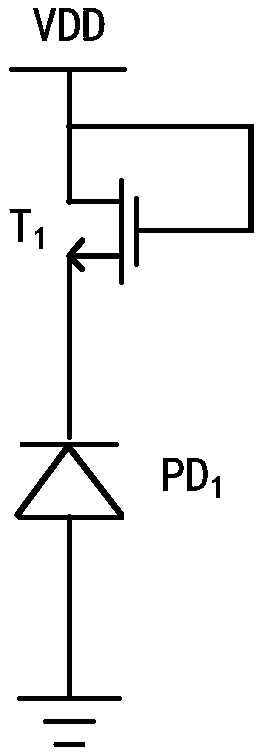

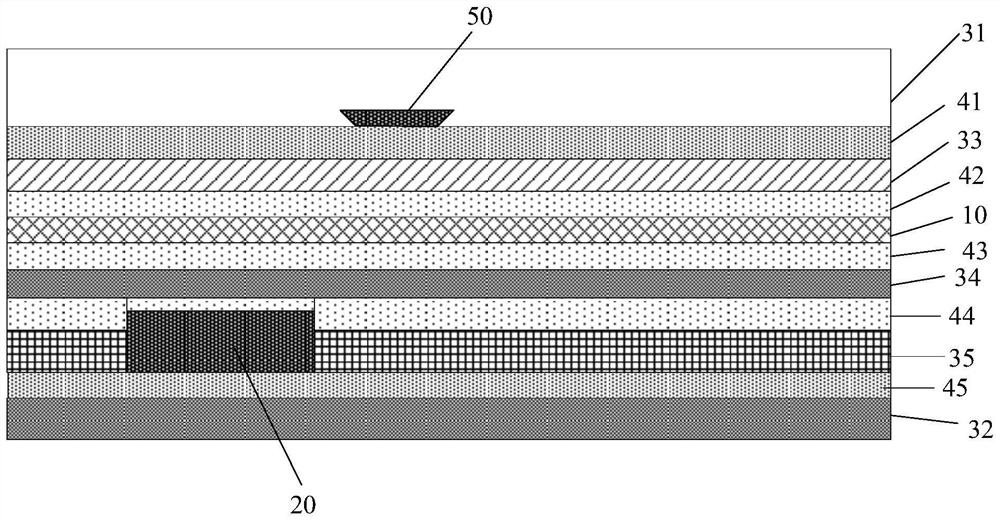

Pixel acquisition circuit and optical flow sensor

ActiveCN108827461AImprove recognition processing speedReduce parallelismPhotometry using reference valueTime informationOptical flow

The invention discloses a pixel acquisition circuit which at least comprises a light intensity detector, a first state storage module, a second state storage module, a light intensity signal acquisition and storage module and a time information storage module. An optical flow sensor including the pixel acquisition circuit is also disclosed.

Owner:OMNIVISION SENSOR SOLUTION (SHANGHAI) CO LTD

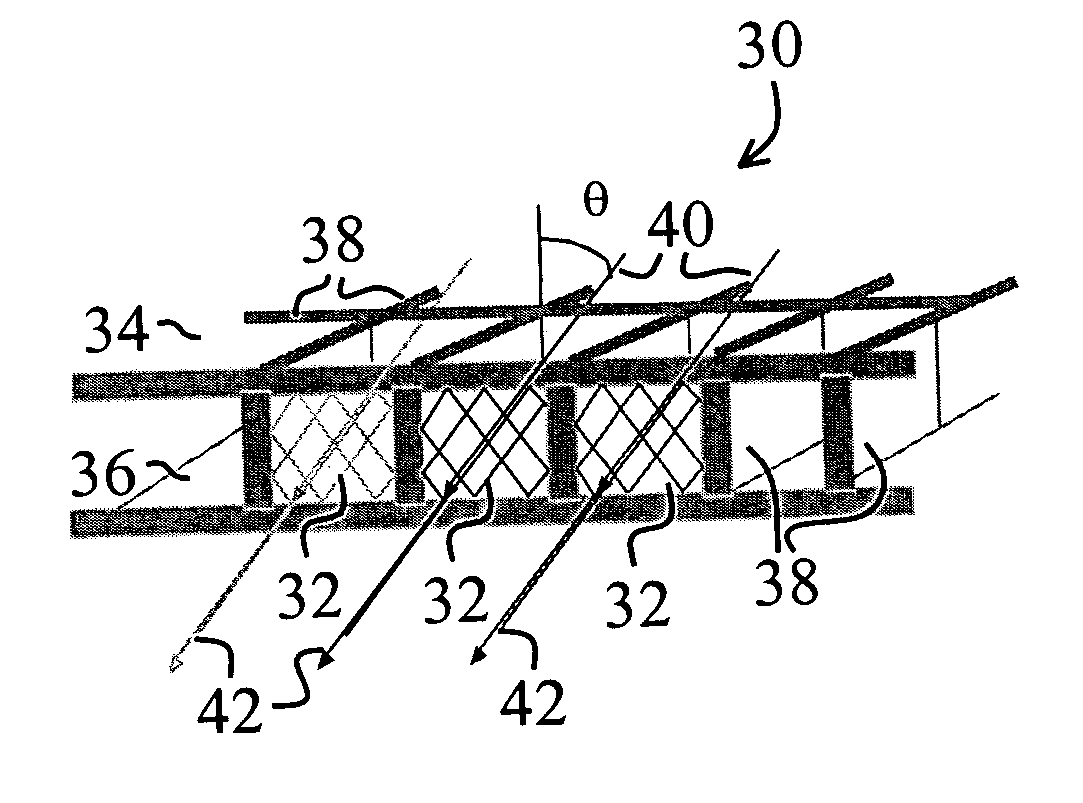

Contained resonant cavity and systems incorporating same

InactiveUS7292383B2Reduce reflectivityReduce smoothnessUsing optical meansNon-linear opticsResonant cavityPartial reflection

A contained resonant cavity. The contained resonant cavity includes a first surface and a second surface that are partially transmissive and partially reflective, One or more reflective sidewall, are positioned between the first surface and the second surface. In a specific embodiment, the first surface and the second surface are substantially parallel and represent input and output surfaces, respectively, of the contained resonant cavity. The one or more sidewalls are approximately perpendicular to the first surface and the second surface and include a first sidewall having a first substantially reflective planar surface that faces a second substantially reflective planar surface of the second sidewall. A third sidewall and a fourth sidewall have fourth and fifth substantially reflective Lacing sidewalls, respectively. In an illustrative embodiment, the one or more sidewalls include plural reflective sidewall, arranged perpendicularly between the first surface and the second surface to form an array of contained resonant cavities therebetween. The ray of contained resonant cavities is readily employed in various applications including unique tunable optical filter rays, lens-less imaging systems, and multispectral imaging systems.

Owner:TANNER RES

Illumination device and projector

ActiveUS9632321B2Efficient use ofHighly uniform intensity distributionProjectorsOptical elementsIntegratorLength wave

An illumination device includes: a light source that emits first light at a first wavelength; an integrator optical system that the first light enters; a wavelength conversion element that converts the first light transmitting through the integrator optical system into second light at a second wavelength different from the first wavelength; a wavelength separation element provided on an optical path of the first light between the integrator optical system and the wavelength conversion element; a pickup optical system that is provided between the wavelength conversion element and the wavelength separation element and receives the first light and the second light; and a chromatic aberration-correcting optical element provided at least one of between the integrator optical system and the wavelength separation element on the optical path of the first light and at downstream of the wavelength separation element on an optical path of the second light.

Owner:SEIKO EPSON CORP

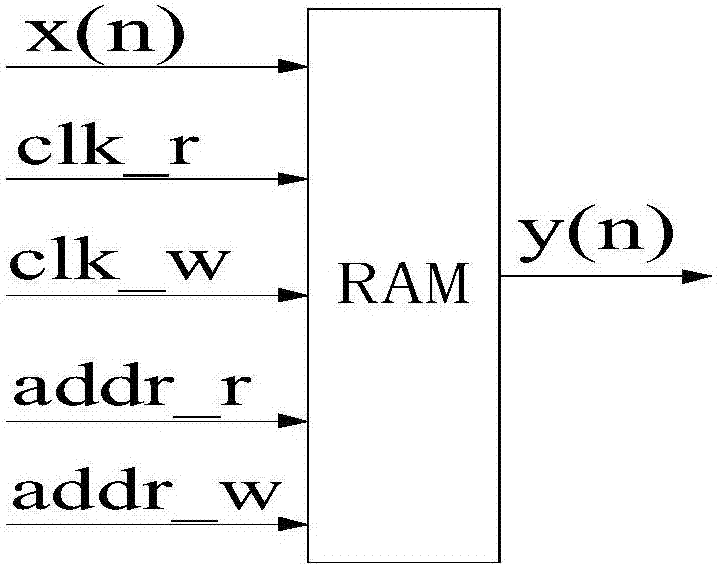

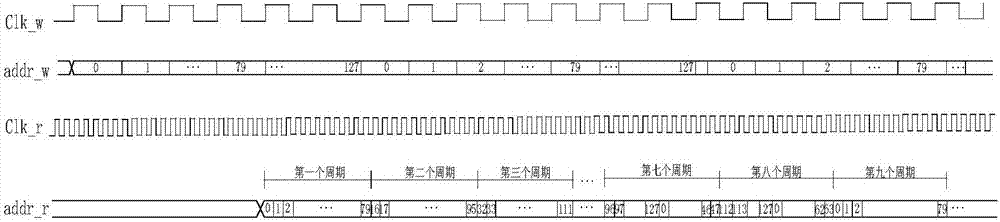

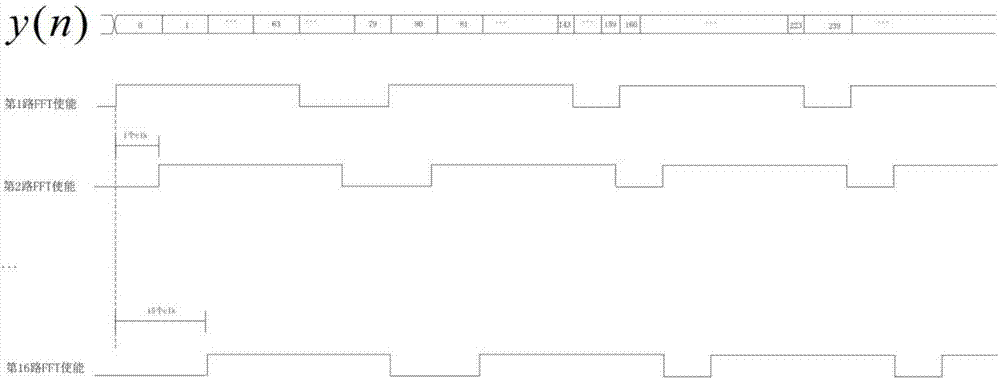

High-throughput FFT/IFFT-based FPGA signal processing method

ActiveCN107451096AReduce consumptionReduce parallelismMemory adressing/allocation/relocationComplex mathematical operationsData streamHigh rate

The invention discloses a high-throughput FFT / IFFT-based FPGA signal processing method and relates to an FPGA technology. The method comprises the following steps of 1) reading data of a low-frequency signal; 2) writing contents of the data of the low-frequency signal into a first storage region and other storage regions of an RAM in sequence; 3) under the control of a high-frequency read clock, reading the data contents written into the storage regions in sequence through a sliding window, and outputting the data contents in the sliding window in sequence to form data flow; and 4) from a starting moment of the data flow, enabling an Nth FPGA to enter a data processing stage after (N-1) waiting cycles to read the data flow, performing FFT calculation, and outputting a calculation result. Through the RAM, low-rate data is converted into high-rate data, so that subsequent modules can work at a relatively high frequency, the purpose of reducing degree of parallelism is achieved, and finally the hardware consumption is reduced. The method is simple in algorithm and easy for engineering realization.

Owner:电信科学技术第五研究所有限公司

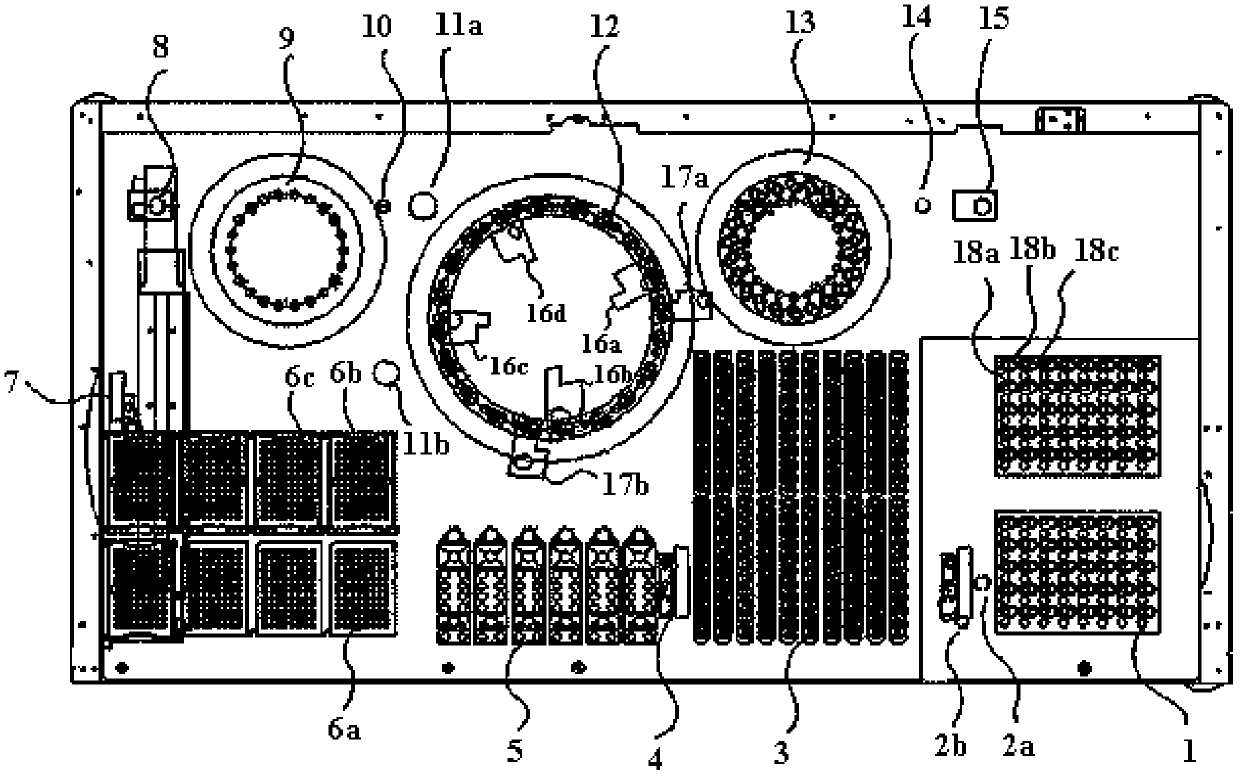

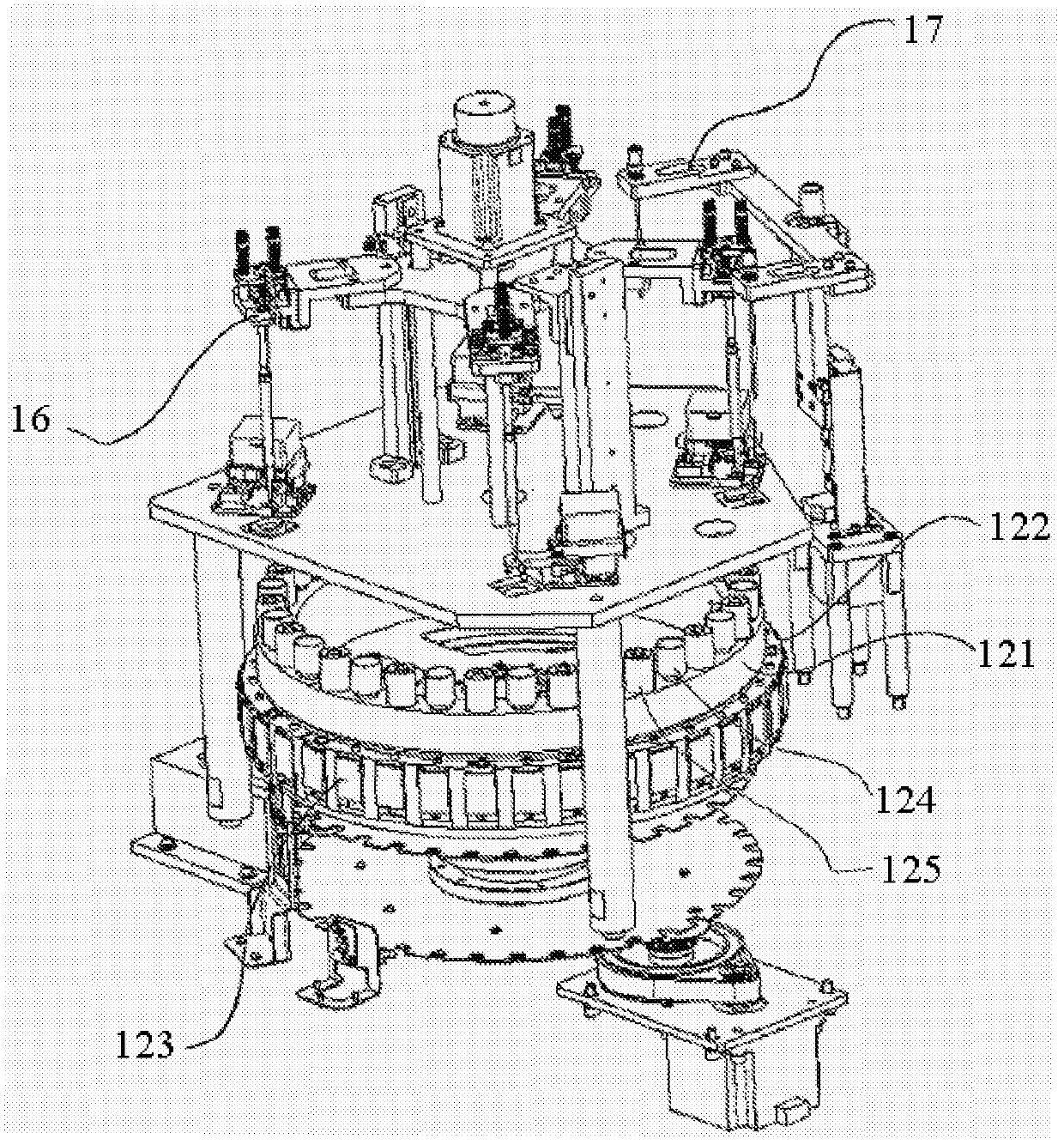

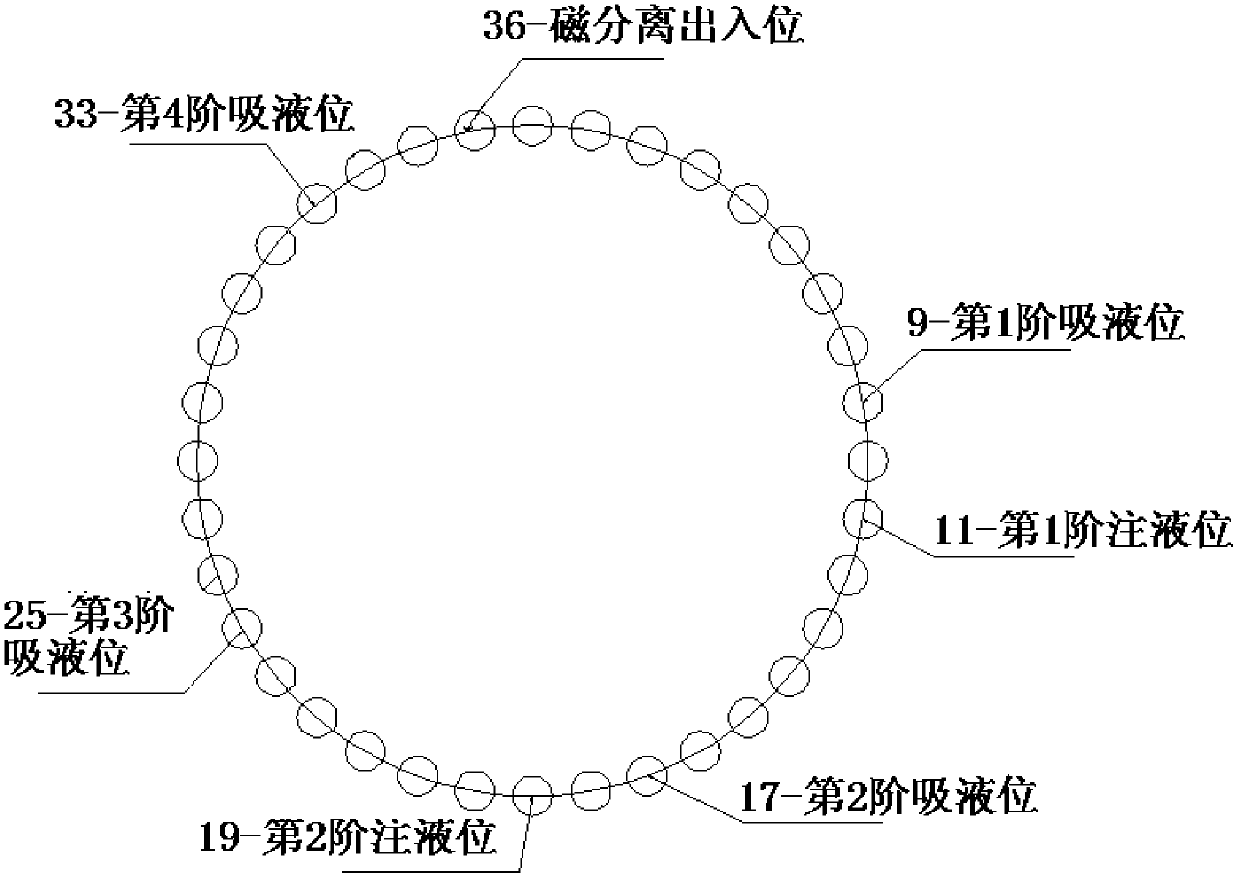

Nucleic acid extraction device and working method thereof

ActiveCN105940094BSolve cross-contaminationReduce parallelismBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

Provided are nucleic acid extraction apparatuses and operation methods thereof. The apparatus may include at least one cyclically moveable annular structure, at least one pipetting mechanism, at least one injection mechanism and a driving mechanism. The annular structure may be provided with a plurality of cuvette positions and a plurality of operation positions. The pipetting mechanism and the injection operation may be arranged along the annular structure. The driving mechanism may drive the annular structure to move cyclically.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

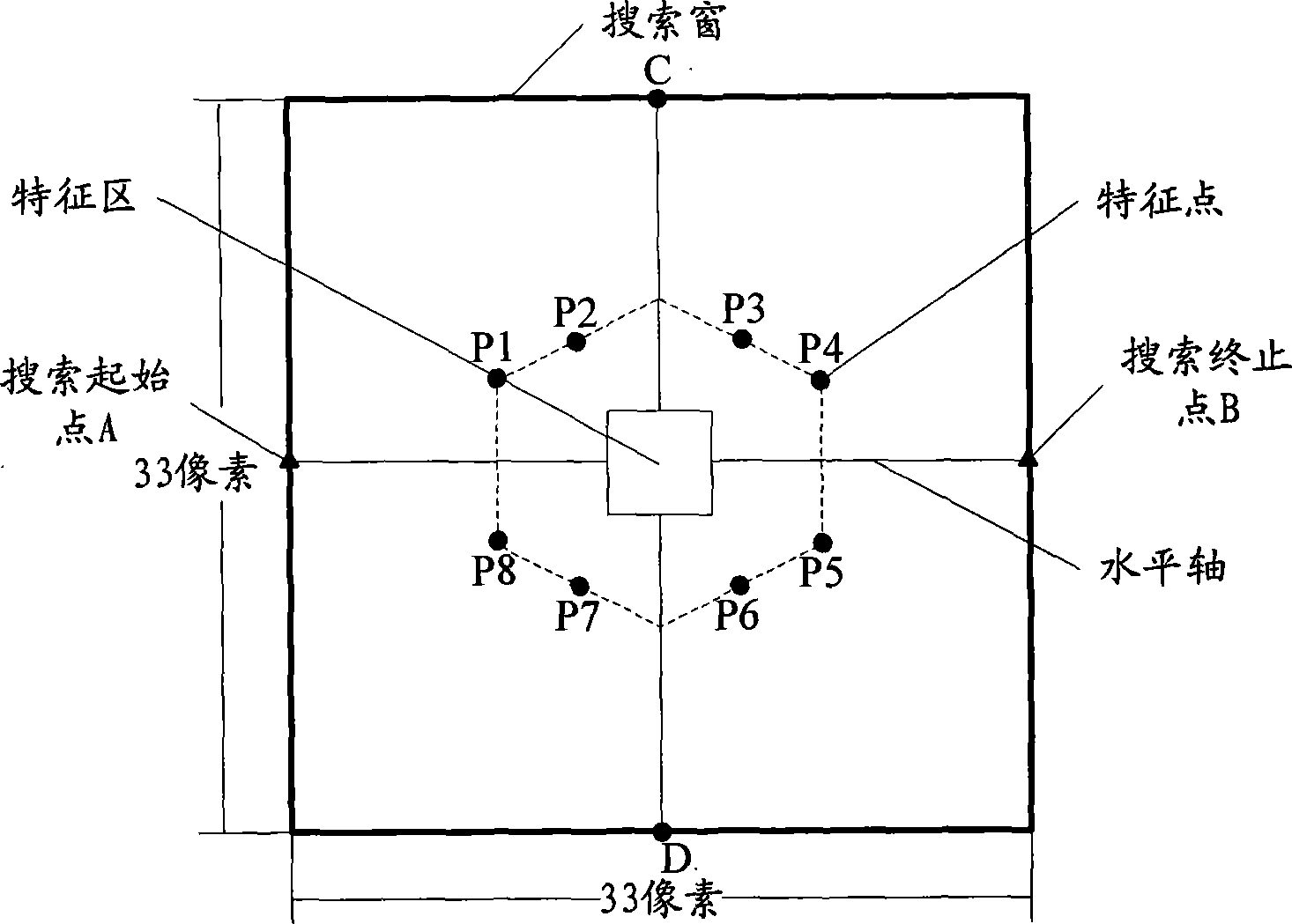

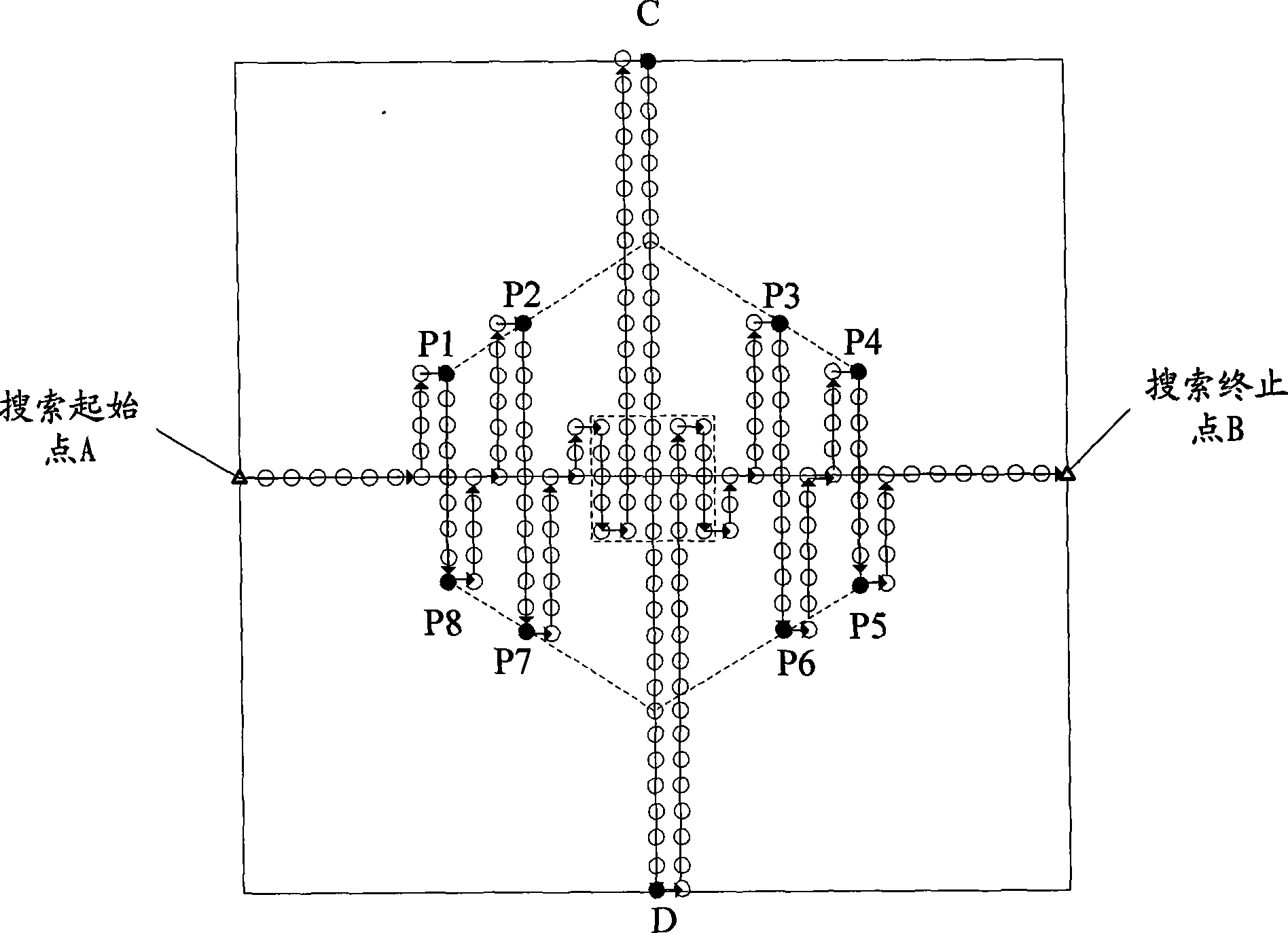

Motion estimation method by non-uniform zigzag searching

InactiveCN101489132AReduce parallelismRealize multiplexingTelevision systemsDigital video signal modificationOptimal matchingMotion estimation

The present invention provides a nonuniform saw tooth search motion estimation method which combines a statistical feature of the motion estimation and sets a feature point and a feature zone in a certain search zone, and sets a nonuniform saw tooth search path. Thus on one hand the invention guarantees a certain search range and enables the best matching point to avoid the local excellent selection defect; on the other hand, a point to point movement and non-repeated path effectively reduce the search point number, implement the reuse of the data, thereby reducing a motion estimation implemented parallel number and better conforming a demand for implementing coding.

Owner:CENT ACADEME OF SVA GROUP

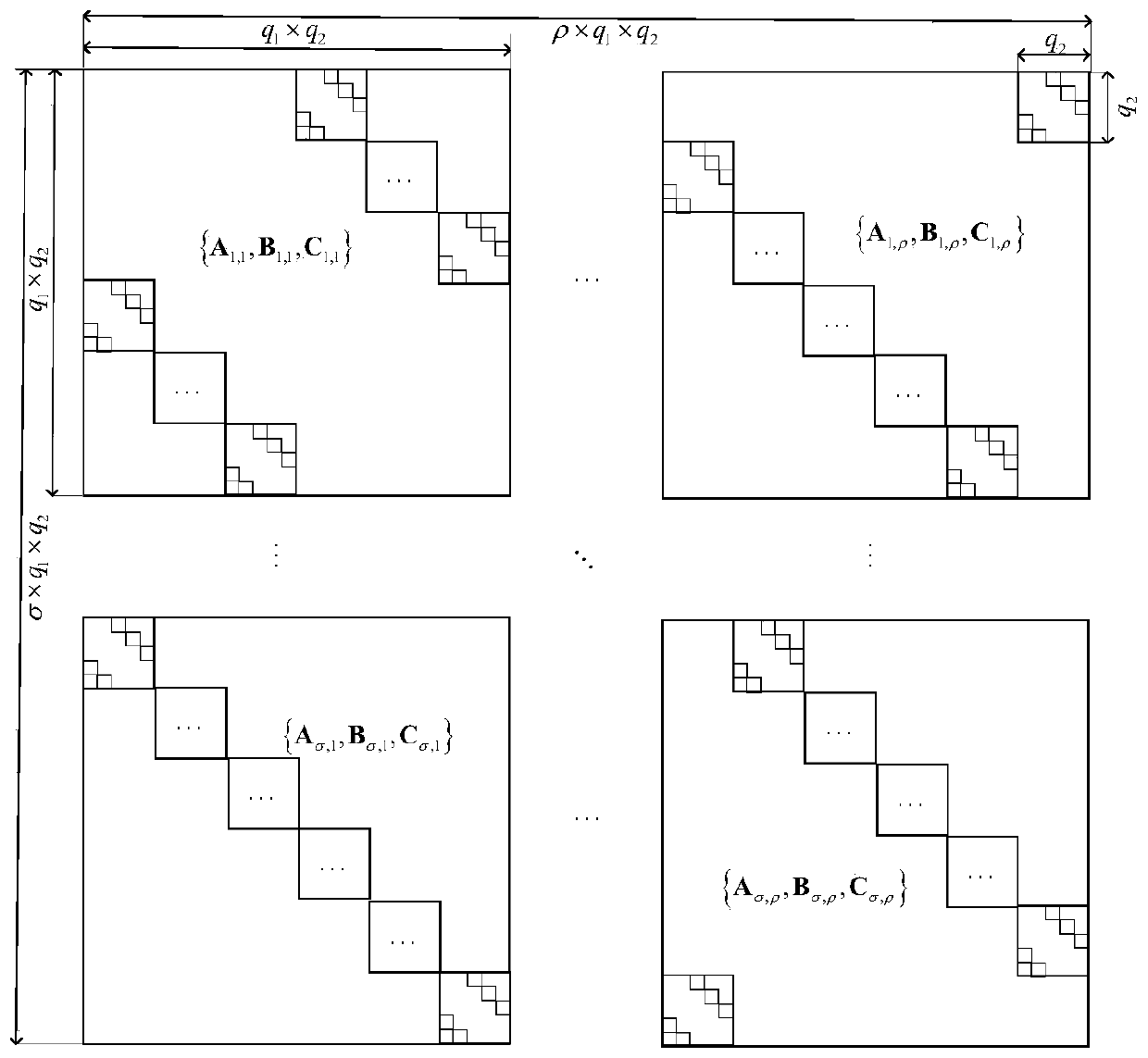

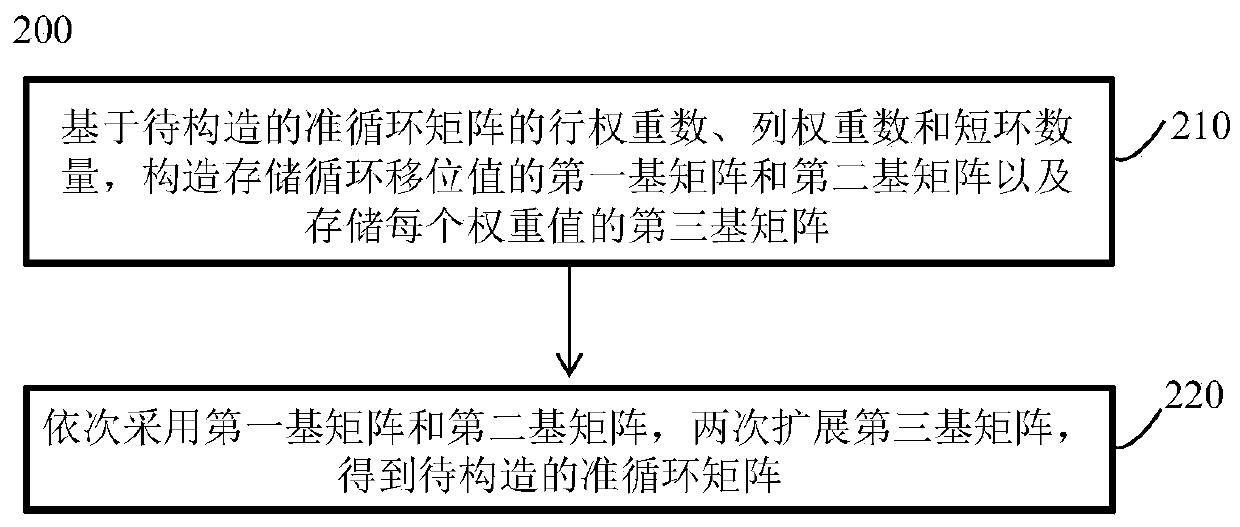

Quasi-cyclic matrix and construction method thereof

ActiveCN110224703ASmall sizeFlexible size adjustmentError correction/detection using multiple parity bitsCode conversionComputer scienceCyclic shift

The invention discloses a quasi-cyclic matrix and a construction method thereof applied to channel coding in wireless communication.The quasi-cyclic matrix comprises a plurality of first-level sub-matrixes and a plurality of second-level sub-matrixes located in each first-level sub-matrix, each first-level sub-matrix is obtained through weighted cyclic shift expansion based on the base matrix, andeach second-level sub-matrix is obtained through weighted cyclic shift expansion based on the first-level sub-matrix where the second-level sub-matrix is located. The quasi-cyclic matrix is composedof two stages of sub-matrixes, and each secondary sub-matrix is obtained through secondary expansion according to a primary expansion mode based on the primary sub-matrix where the secondary sub-matrix is located, so that the parallelism degree of the decoder can be greatly reduced by reducing the size of the secondary sub-matrix, and different node parallelism degree requirements of the decoder are met; besides, the number of short rings in the quasi-cyclic matrix can be effectively reduced by selecting appropriate shift values of the first-level sub-matrix and the second-level sub-matrix, and compared with a traditional quasi-cyclic matrix, the quasi-cyclic matrix is wide in application range.

Owner:HUAZHONG UNIV OF SCI & TECH

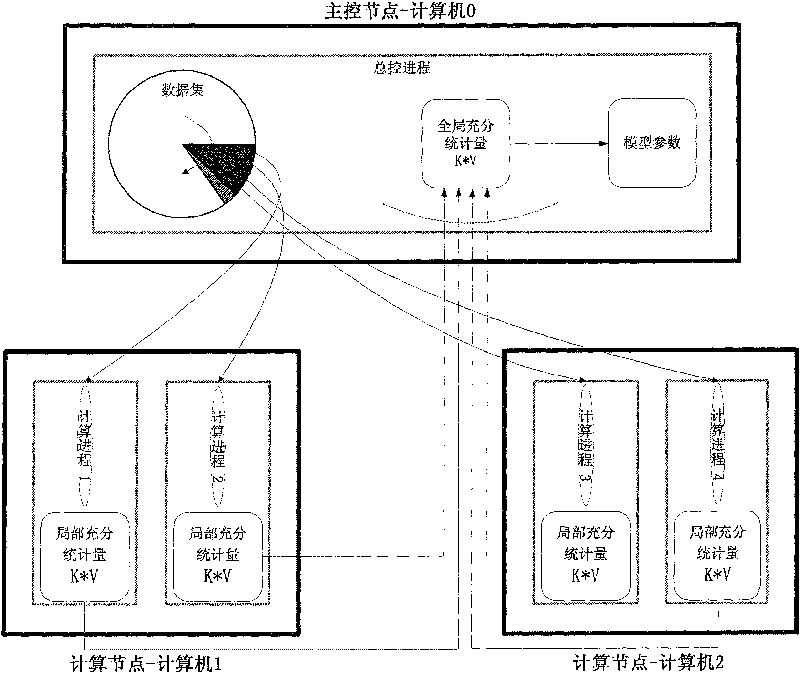

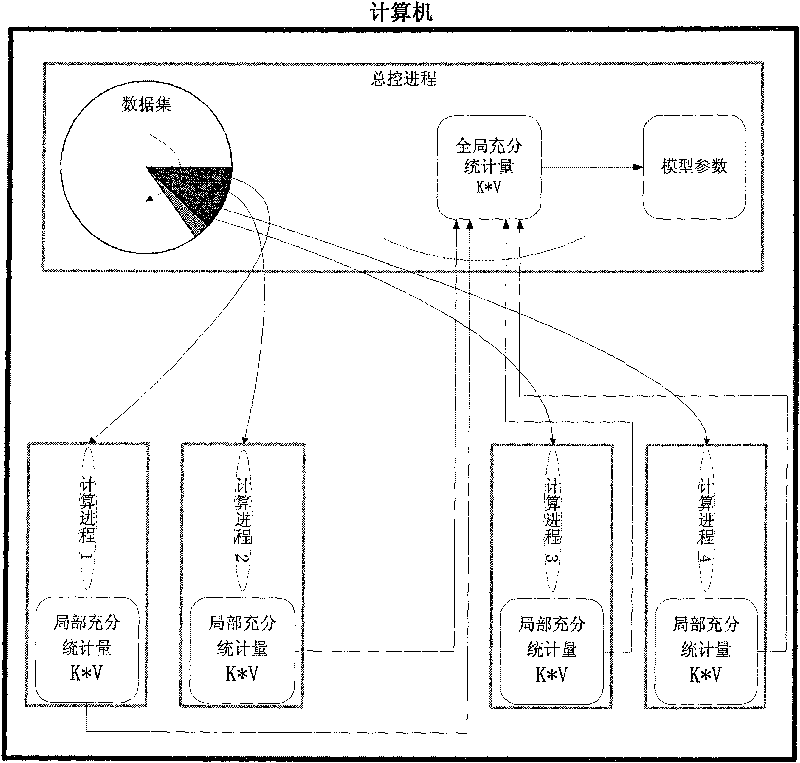

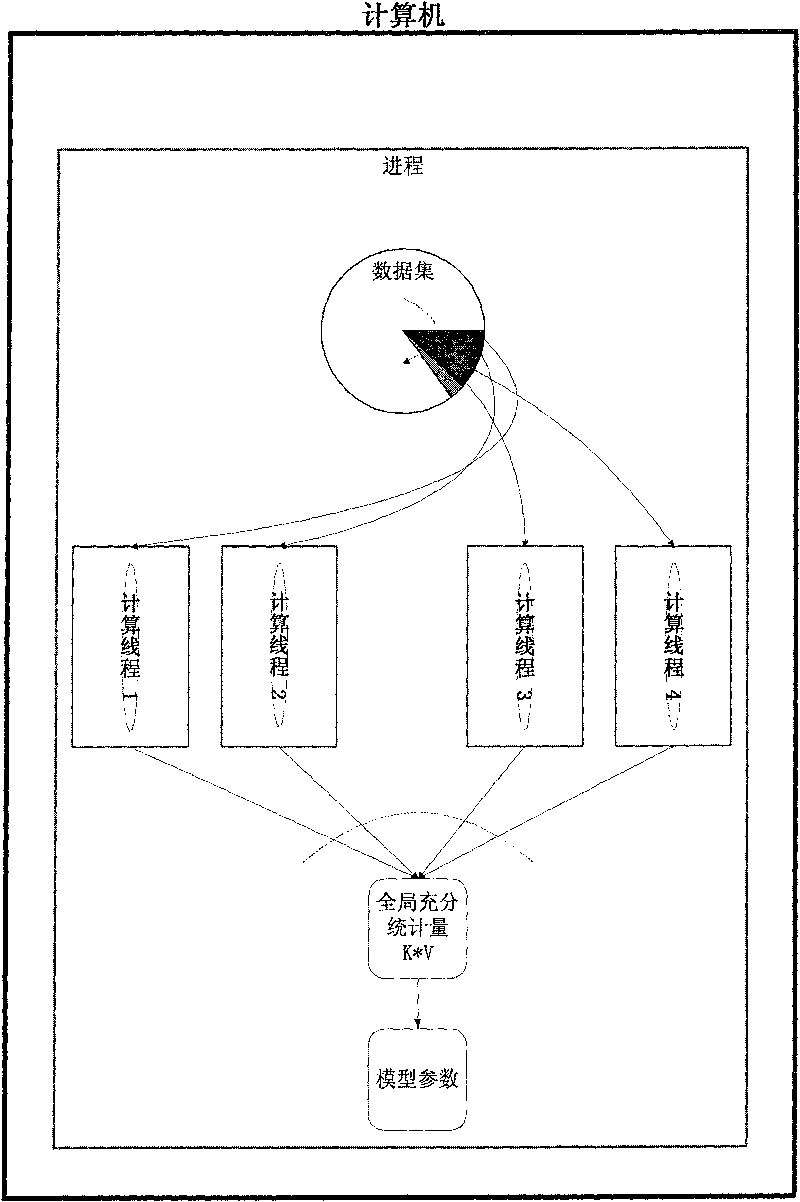

Parallel data processing method based on latent dirichlet allocation model

InactiveCN101359333BReduce parallelismHigh speed processingSpecial data processing applicationsData segmentLatent Dirichlet allocation

The invention discloses a parallel data processing method based on the hidden Dirichlet distribution model, which belongs to the data mining field. The method includes three solutions, including the multi-process parallel processing, the multi-thread parallel processing and the composite multi-process multi-thread processing; the data DM for being processed is divided into data segments in equal or unequal length in the three solutions; each data segment is provided with an index; each computer process / thread processes the corresponding data segment through applying the index, so as to obtainthe subject information of each data item and generate the local sufficient statistic; when the whole DM is processed, the global sufficient statistic is obtained through the merge of the local sufficient statistics so that the current Mi model is obtained through the estimation until the model becomes convergence. The parallel data processing method can utilize the multi-kernel parallel frame ofa single computer and the cluster large-scale parallel capability of multi-computer to realize the high-speed processing of the large-scale text sets and effectively reduce the memory usage during theparallel processing process.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

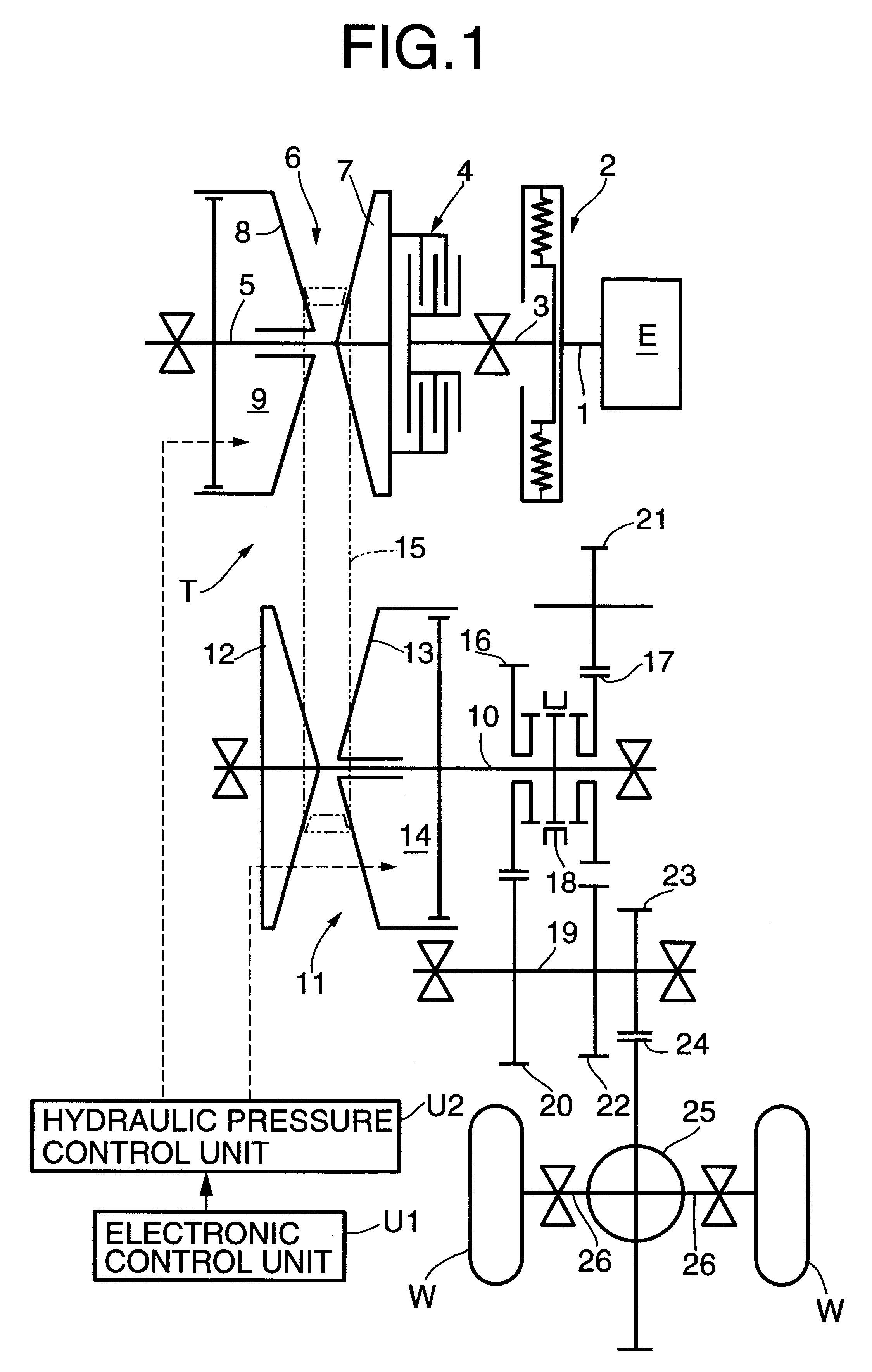

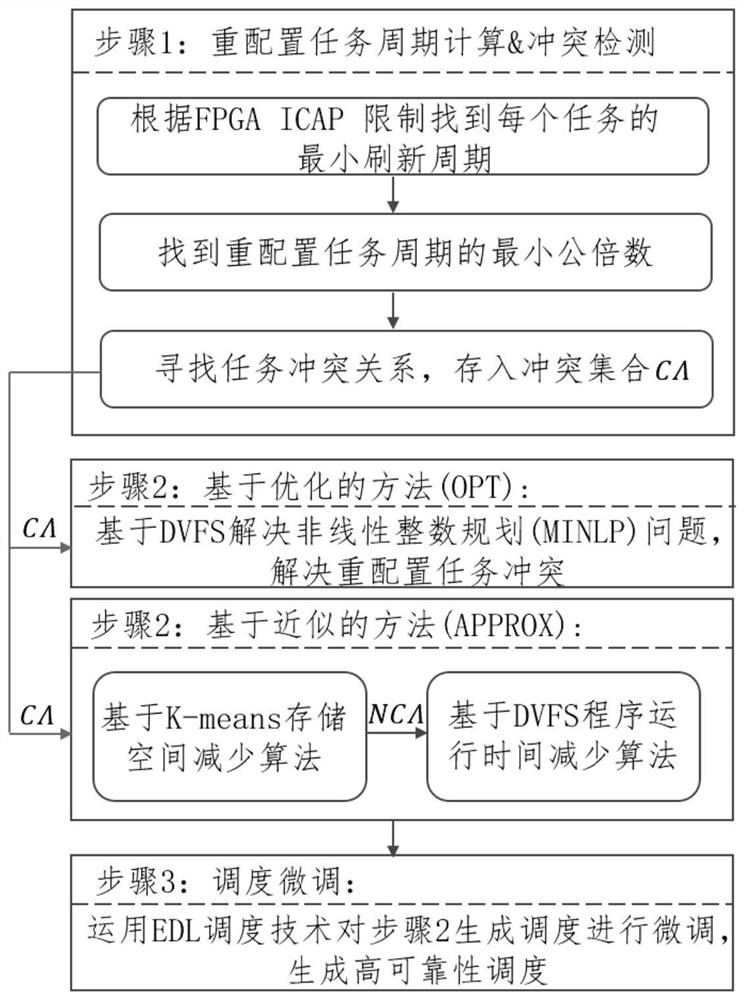

DVFS-based optimal reconfiguration algorithm

PendingCN111858463AReduce potential conflictReduce parallelismCharacter and pattern recognitionCAD circuit designTerm memoryDependability

The invention provides a DVFS-based optimal reconfiguration algorithm, and the main contribution of the method provided by the invention is as follows: the DVFS-based reconfiguration method can schedule user tasks according to the degree of parallelism of the user tasks so as to allow reconfiguration of more parallel user tasks, thereby achieving higher reliability. According to the heuristic approximation algorithm based on K-Means, the delay of a reconfiguration scheduling algorithm based on DVFS can be reduced to the maximum extent. The invention discloses a method based on K-Means. According to the method, the memory overhead caused by application of DVFS-based reconfiguration scheduling can be reduced. According to the method provided by the invention, the reliability of the FPGA system is improved, and the expenditure of the hardware circuit area is reduced to the maximum extent.

Owner:SHANGHAI TECH UNIV

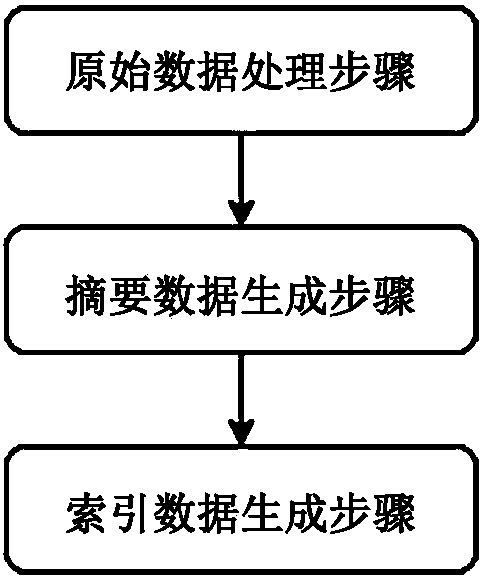

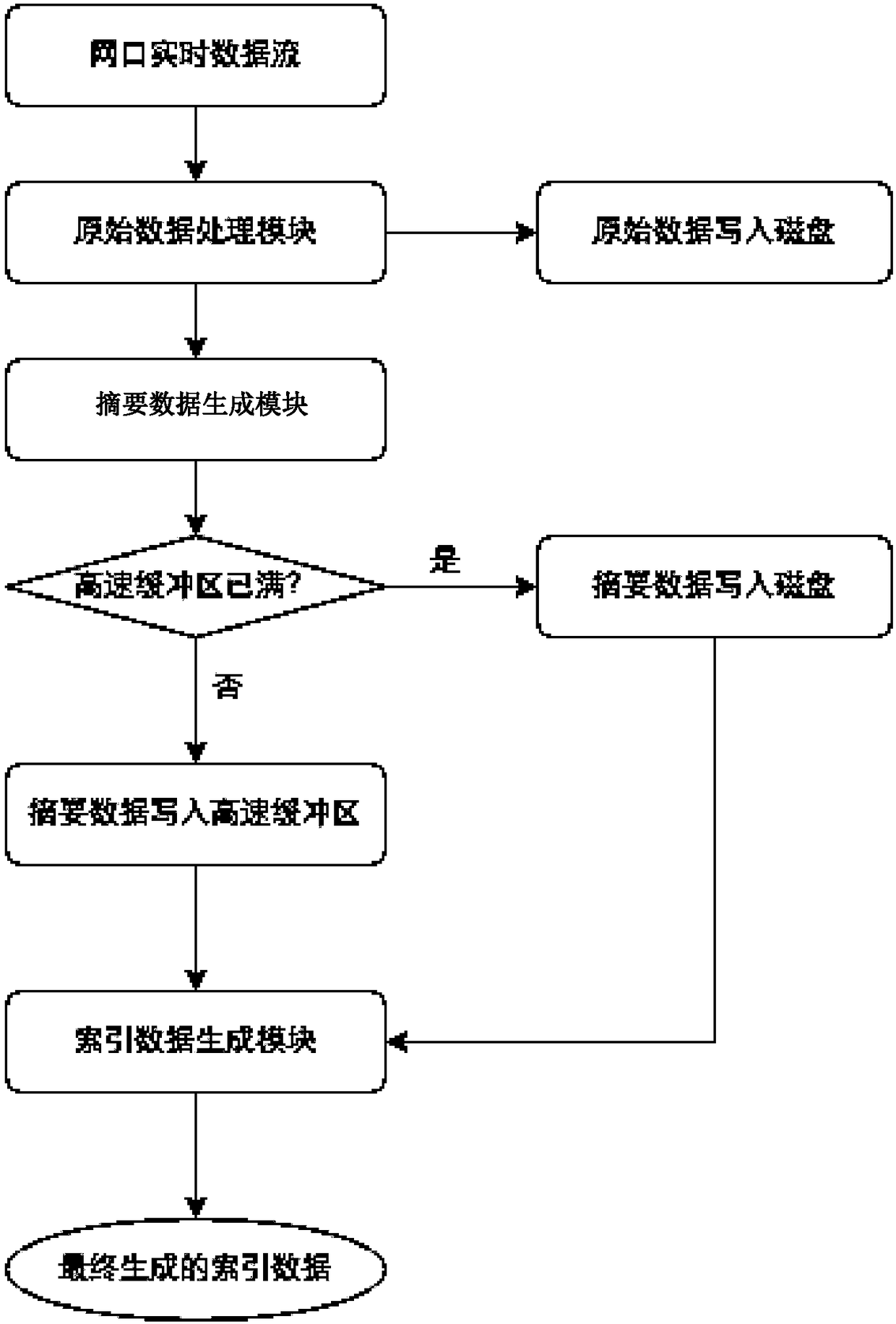

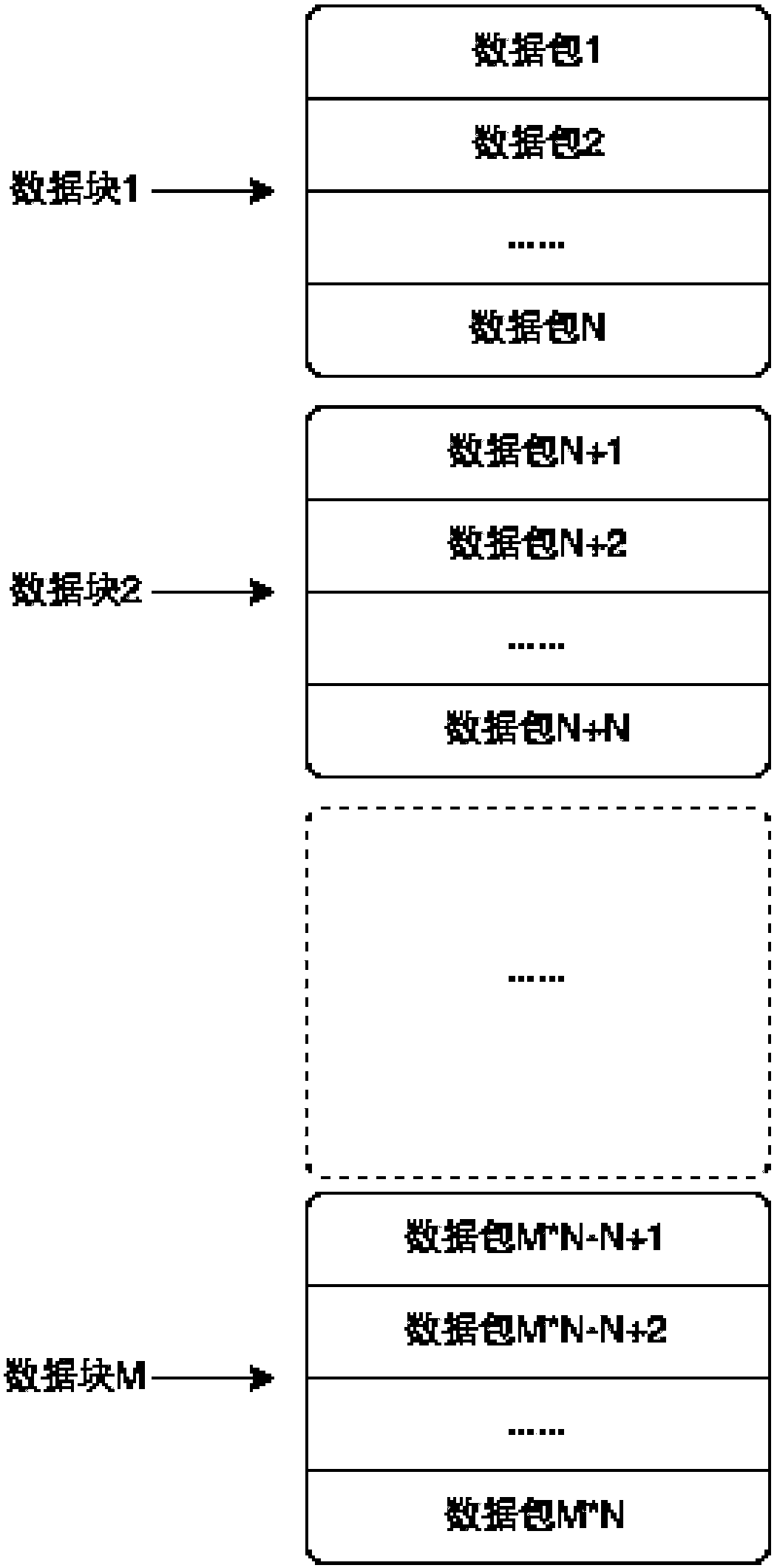

Network abstract data-based index creation method and system

InactiveCN108446076ASolve the lossReduce IO conflictsInput/output to record carriersSpecial data processing applicationsTraffic capacityReal-time data

The invention provides a network abstract data-based index creation method and system. The method comprises the following steps of: generating a data block according to a real-time data flow capturedfrom an internet access; generating abstract data according to a key field in the data block; and generating index data according to the abstract data. According to the method and system, the problemof data loss caused by the reason that original data cannot be written into disks in time can be solved; the disk IO conflicts in index creation processes are reduced, the system throughput is improved, and real-time data can be written into the disks under big data flows; the problem that the data index creation is not timely is solved, only a small amount of abstract data needs to be read, and the disk overhead and CPU overhead during the index creation are reduced; the flexibility is good, and when the system load is low, index creation can be carried out by utilizing a plurality of CPUs; when the load is high, the degree of parallelism is reduced and resources are turned over to other modules; and data captured from internet accesses in real time can be stored into disks, and corresponding inverted index data can be generated in real time.

Owner:SHANGHAI NETIS TECH

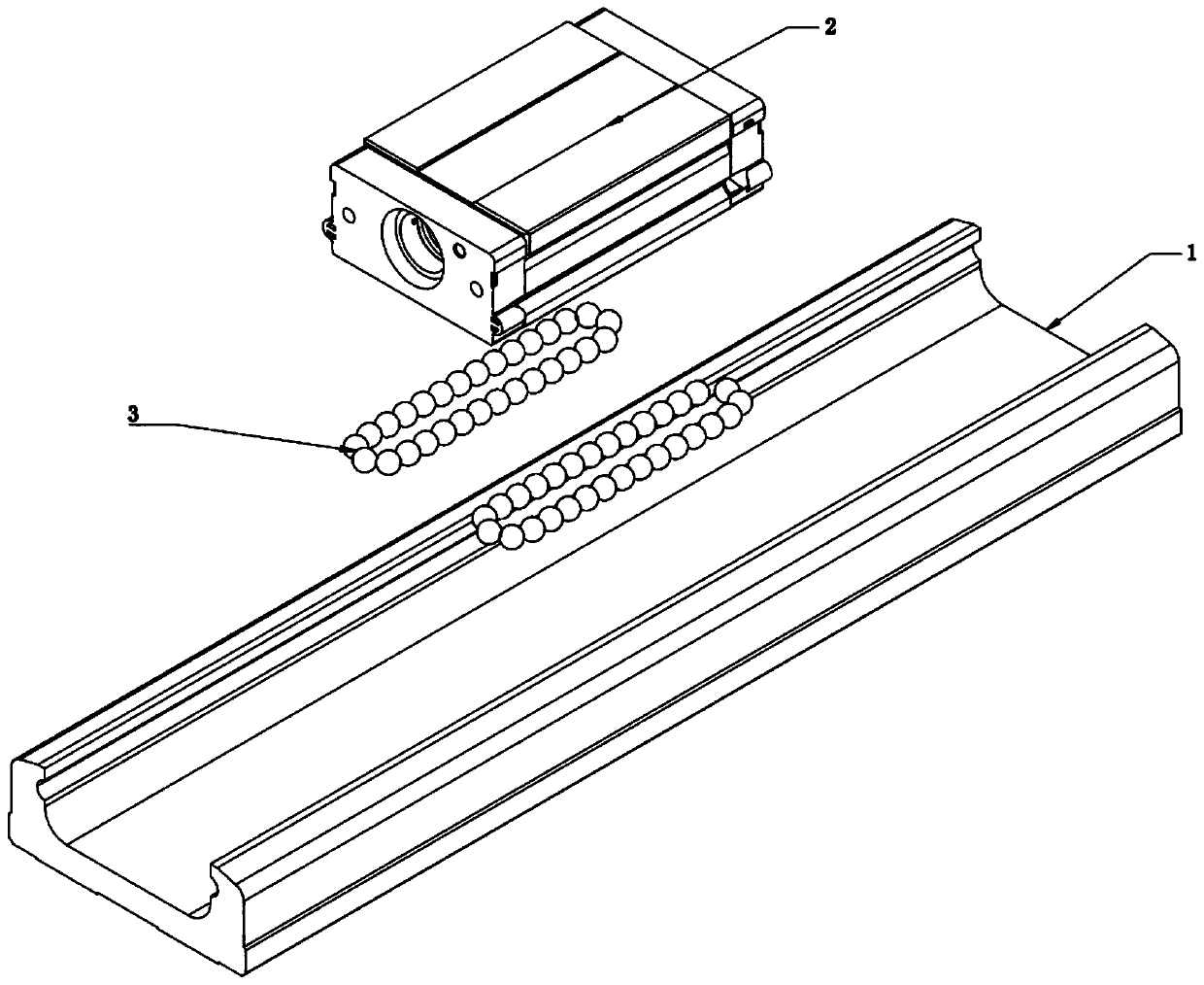

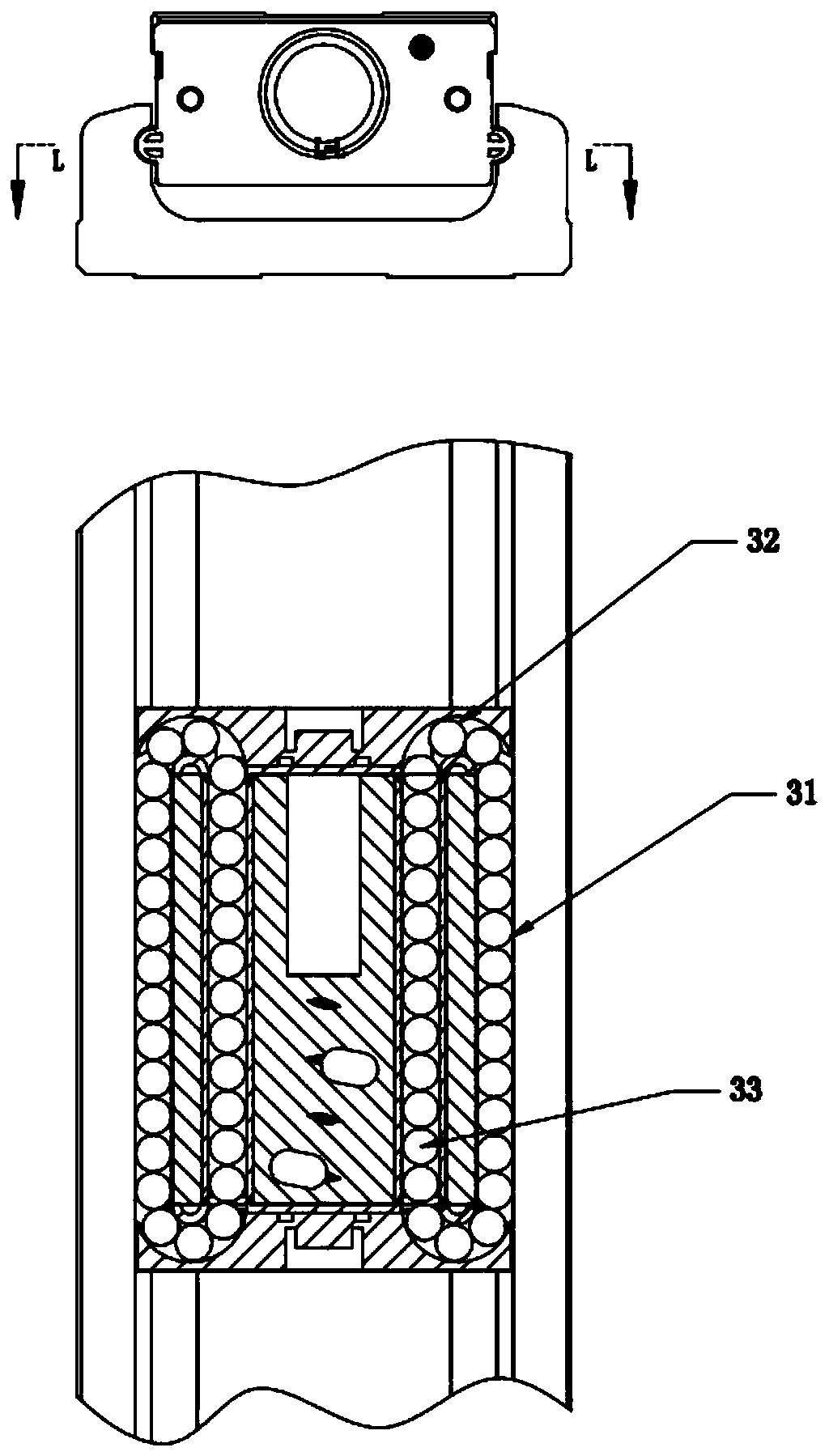

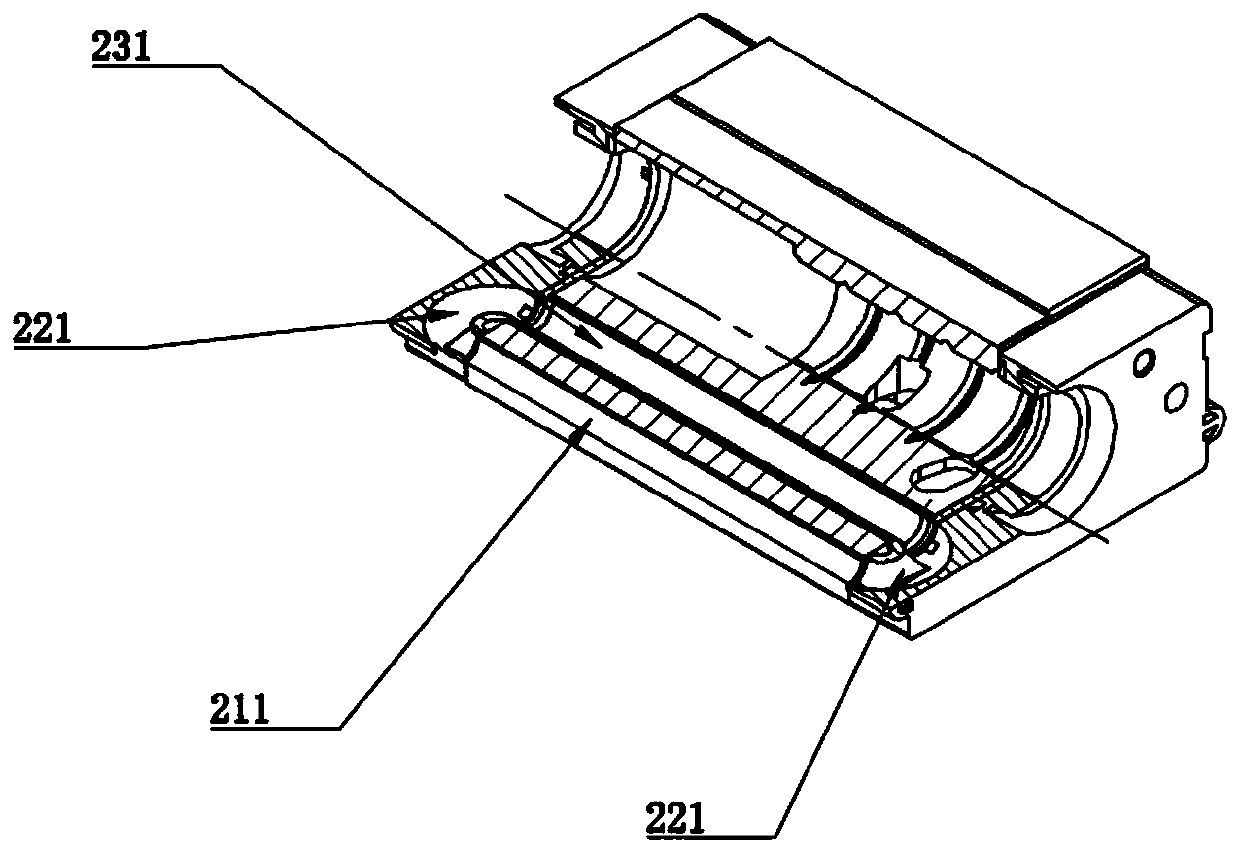

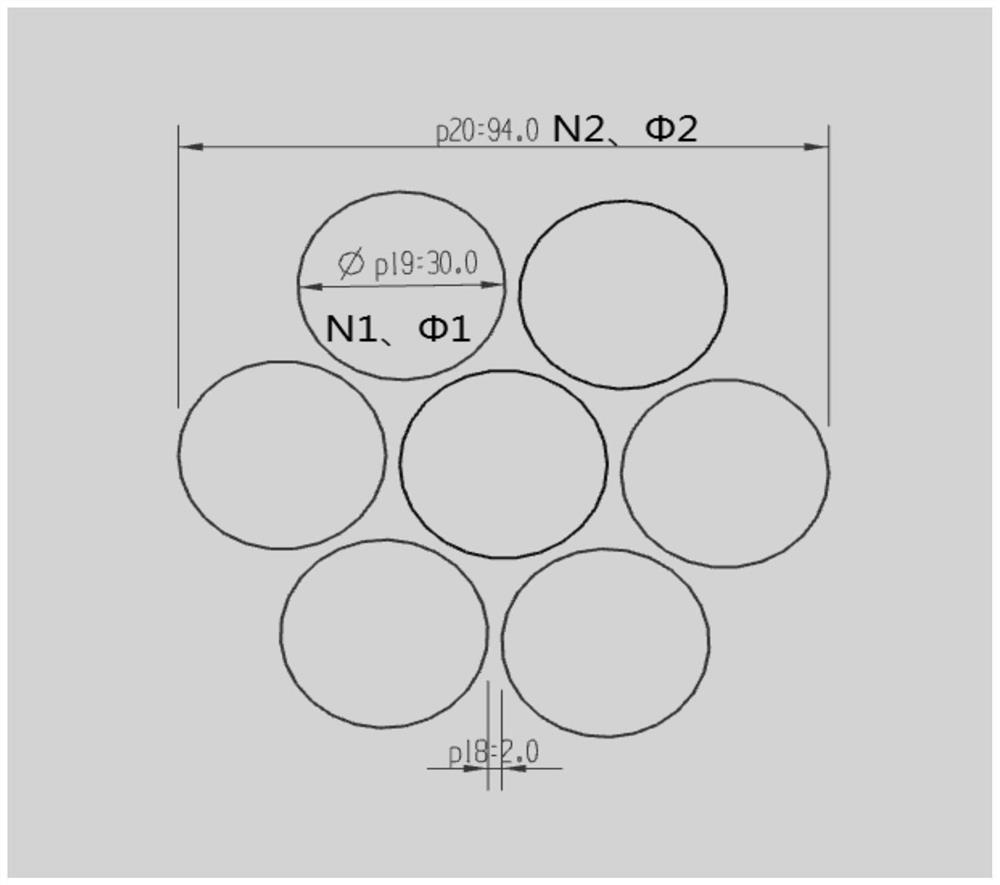

Circular rolling mechanism for steel ball

PendingCN110594293AThe interface axial clearance is reducedReduce parallelismLinear bearingsMetallurgySteel ball

The invention discloses a circular rolling mechanism for a steel ball. The circular rolling mechanism comprises a fixed part, a moving part and a plurality of rolling steel balls. The rolling steel balls are divided into loading steel balls, reverse steel balls and returning steel balls according to different positions. The fixed part is a U-shaped groove structure in shape, and fixed loading rollaway nests are arranged on two sides of the inner wall of the U-shaped structure of the fixed part; the moving assembly comprises a slide block, a reverser and a ball returning pipe. The circular rolling mechanism has the advantages that the processing demands on mechanical products such as a linear rolling guide rail, a sliding table and a module employing the mechanism can be reduced, and the assembling efficiency is improved, so that the manufacturing cost of the product is reduced; and meanwhile, the colliding noise between the steel balls and the walls of the ball returning hoes can be reduced.

Owner:SHENZHEN JINWANGDA ELECTRICAL & MECHANICAL CO LTD

Device and method for simultaneously processing multiple planar optical parts

PendingCN112658882AImprove surface accuracyImprove parallelismOptical surface grinding machinesGrinding work supportsSquare MillimeterAdhesive

The invention belongs to the technical field of optical part preparation, and particularly discloses a device and a method for simultaneously processing multiple planar optical parts.The device comprises a polishing machine, a base die and a bonding die, the base die and the bonding die are connected to the polishing machine, a fixing column is arranged on the edge of the base die, and a positioning area of the bonding die is determined on the base die; and the manufactured parts containing the adhesives are evenly distributed on the base die in the positioning area, the distance between the parts ranges from 1 mm to 2 mm, the bonding die is heated to 100 DEG C, hot pressing is conducted on the parts through positioning of fixing columns, and when the temperature of the bonding die is reduced to 70 DEG C, 100 g of pressure per square millimeter of the parts is applied till the parts are cooled and machined at the normal temperature. The device realizes simultaneous machining of multiple planar parts, higher surface precision and parallelism can be easily obtained, according to the size of the mirror disc of a polishing machine, compared with single optical part machining, the machining efficiency is improved by 5-30 times, and machining of ultra-small-diameter parts is simplified.

Owner:KUNMING YUNZHE HIGH TECH

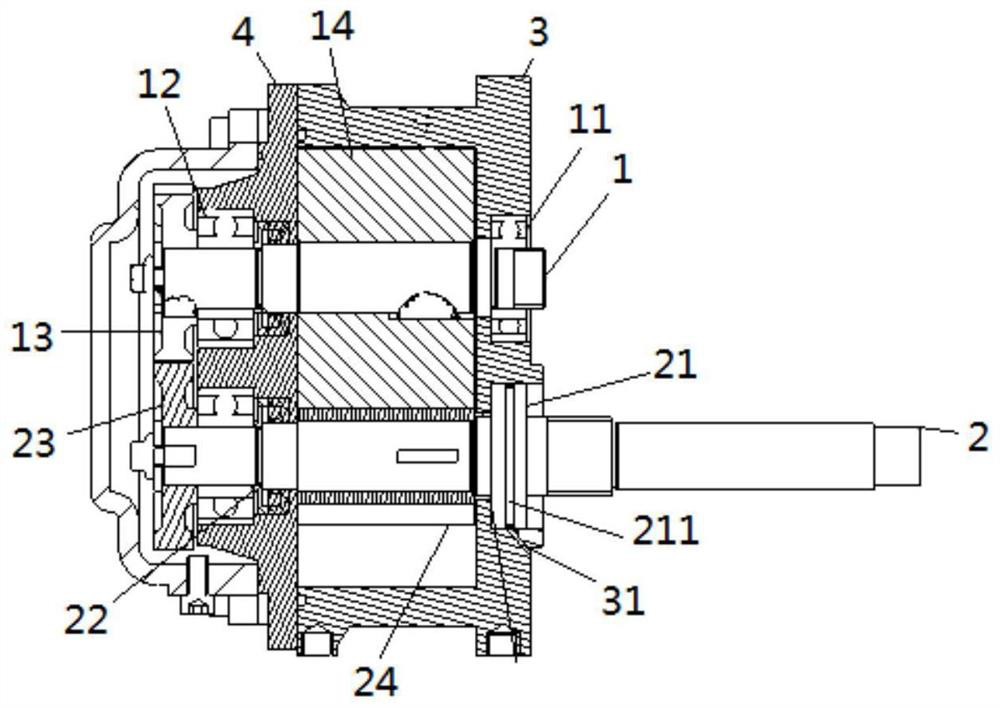

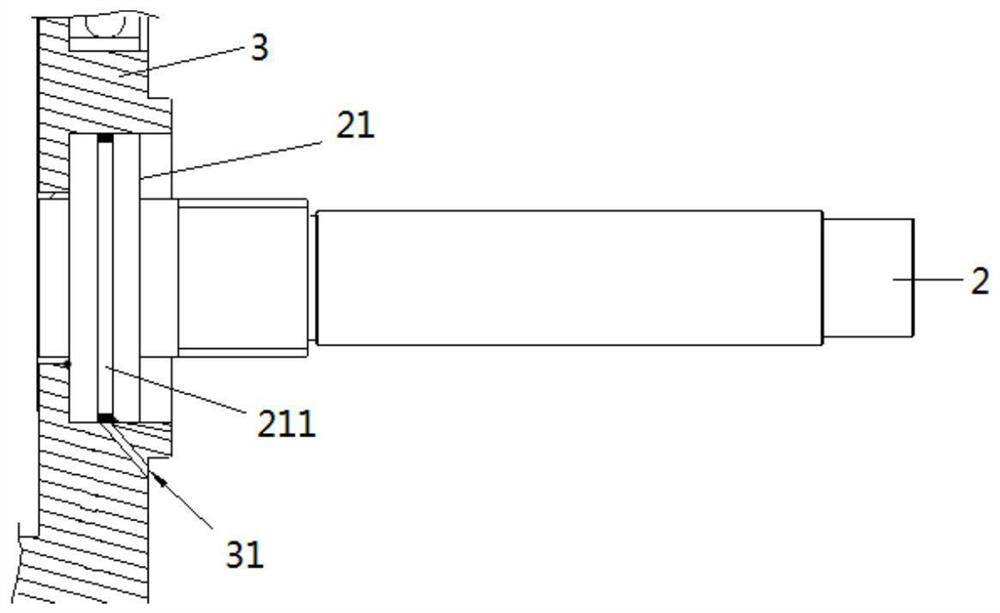

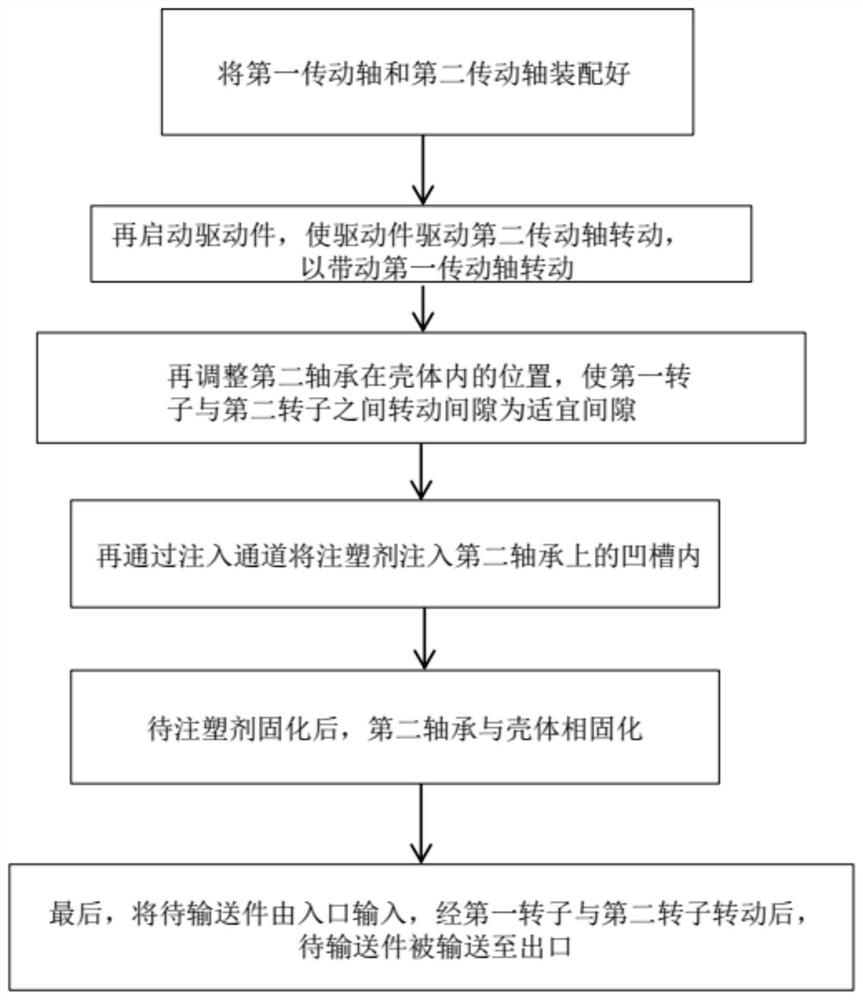

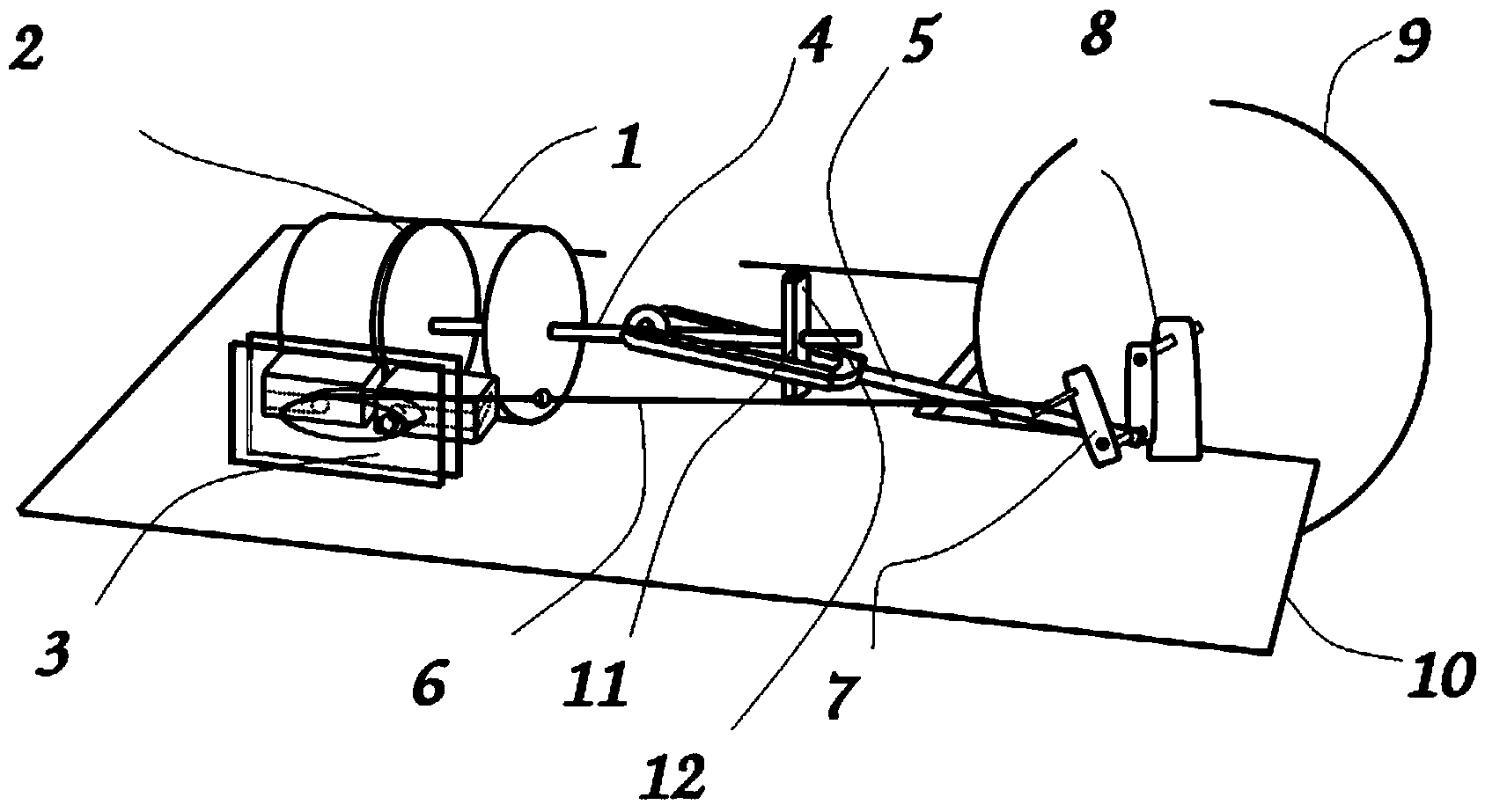

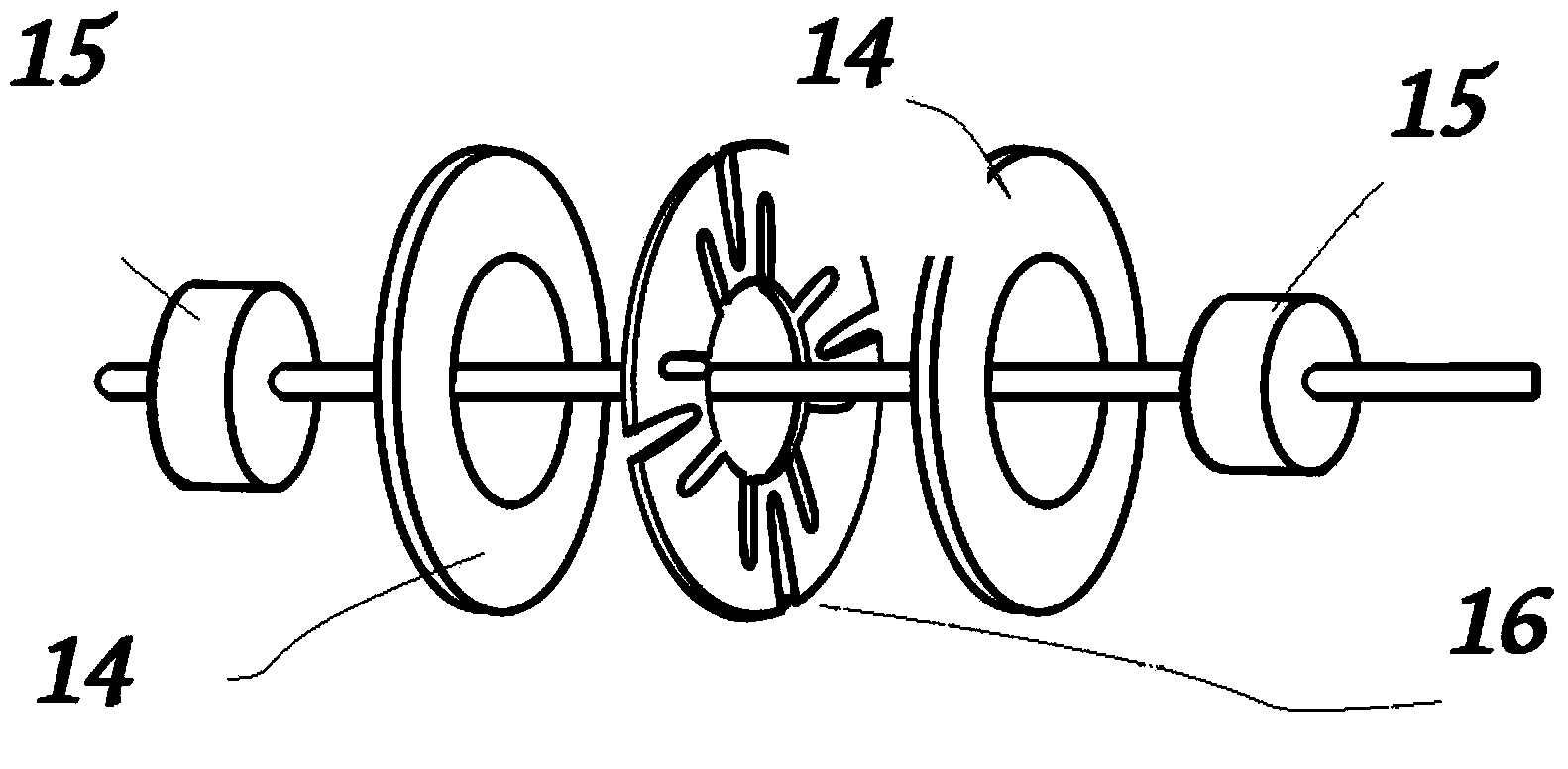

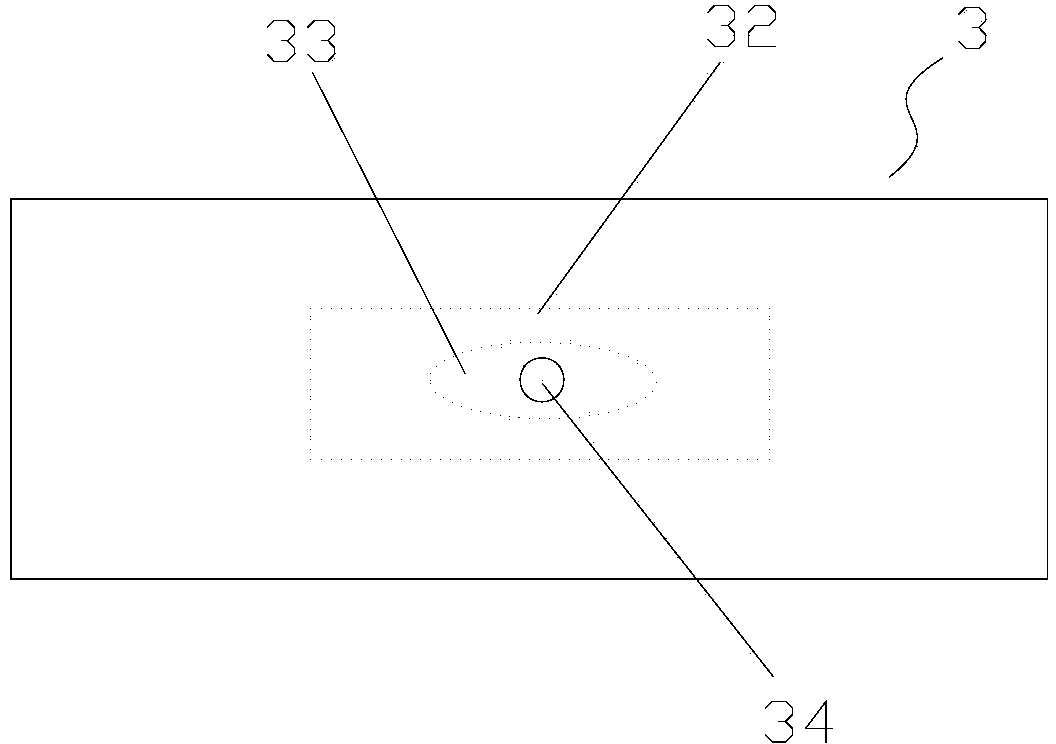

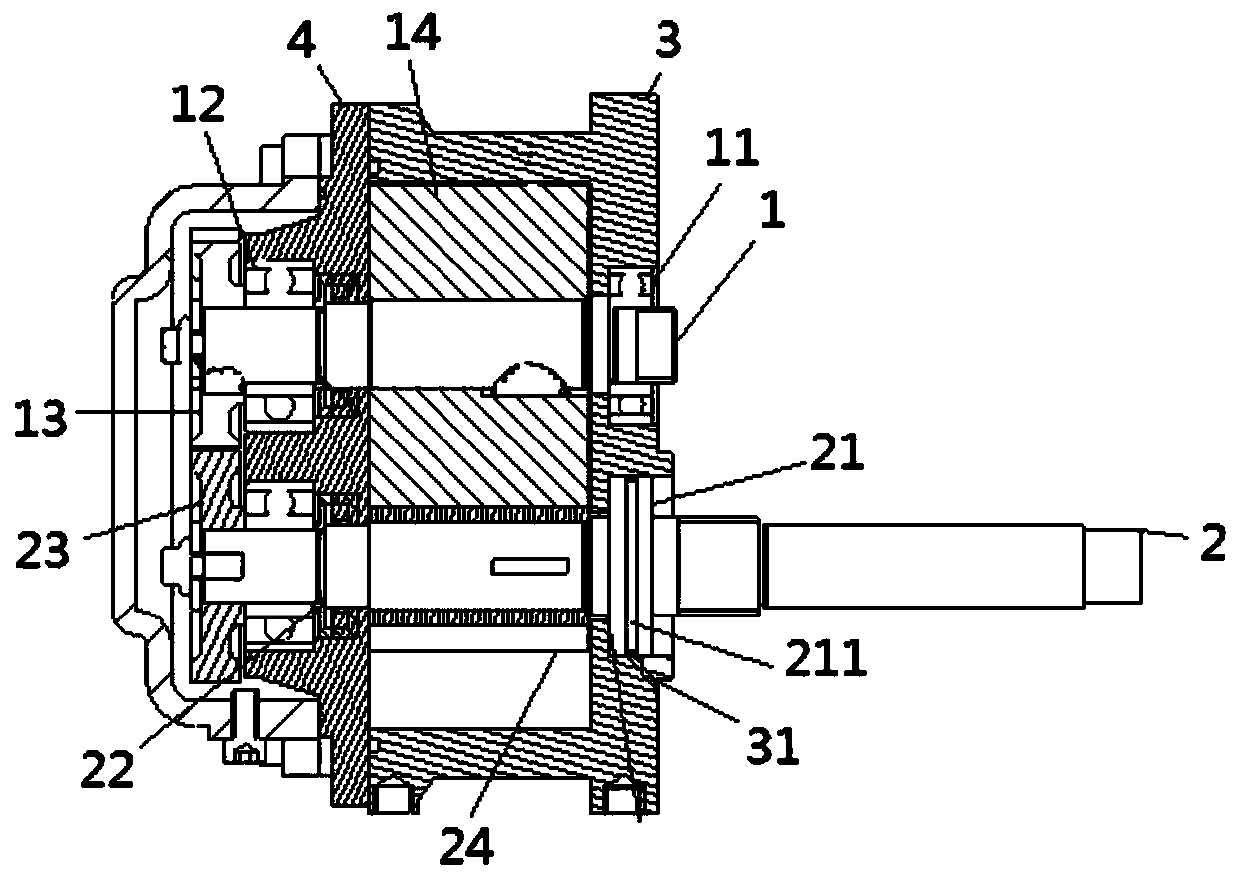

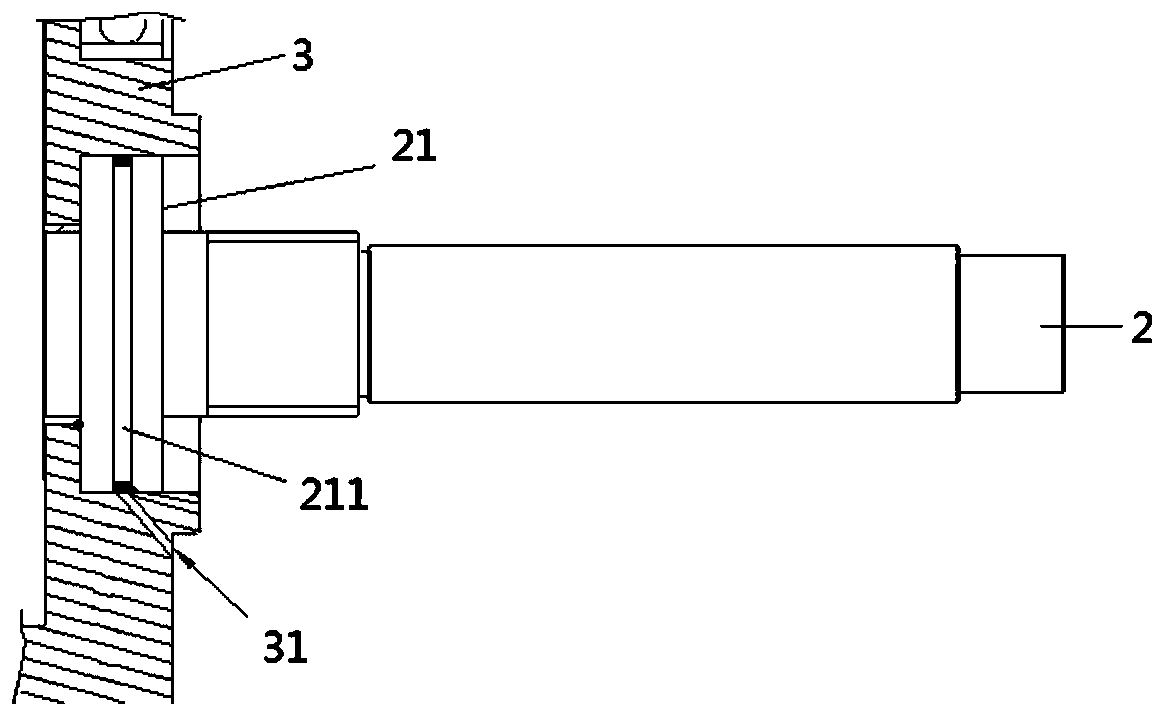

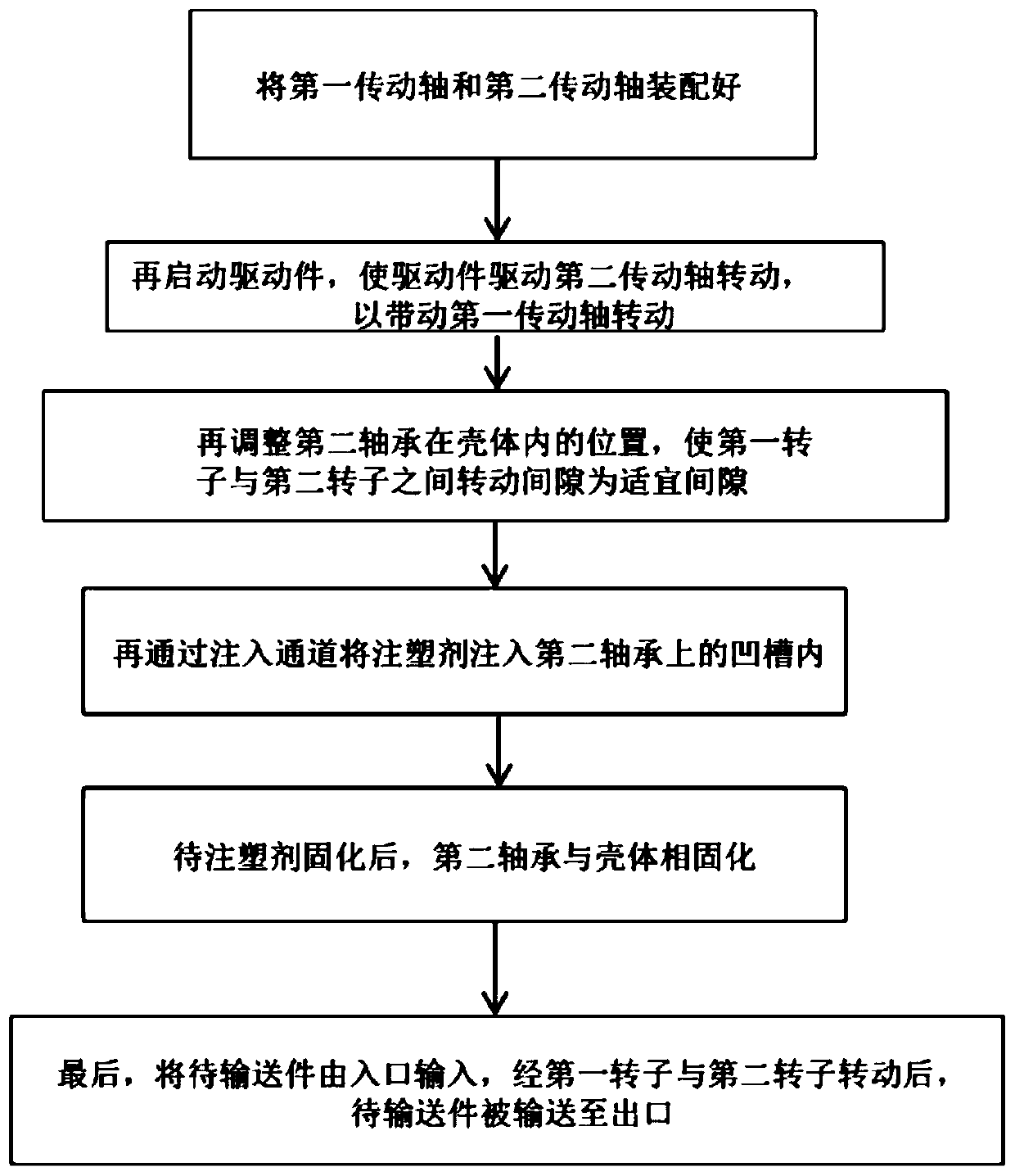

Rotor pump and assembly method thereof

ActiveCN111306057BAvoid crashes and jamsLarge rotation clearanceRotary piston pumpsRotary piston liquid enginesDrive shaftClassical mechanics

The invention discloses a rotor pump and an assembly method thereof, belonging to the technical field of rotor pumps. The rotor pump includes a casing; a first transmission shaft, one end of which is provided with a first bearing, and the first bearing is arranged in a first bearing seat on the casing, and the first transmission shaft is provided with a first Rotor; second transmission shaft, which is parallel to the first transmission shaft, the second transmission shaft is provided with a second rotor, one end of the second transmission shaft is provided with a second bearing, and the second bearing In the second bearing seat provided on the housing, injection molding grooves are provided on the outer peripheral wall of the second bearing and / or on the upper ring of the inner peripheral wall of the second bearing seat for injection molding and containing injection molding agent. Its advantage is that it can adjust the rotation gap between the first rotor and the second rotor without disassembly, and at the same time keep the rotation gap between the first rotor and the second rotor unchanged during the rotation process .

Owner:FAW JIEFANG AUTOMOTIVE CO

Transparent and simulated teaching steam engine

The invention relates to a transparent and simulated teaching steam engine comprising a pedestal, an air cylinder, a piston. The piston is connected to one end of a power connecting rod; and the other end passes through the air cylinder and a penetrating hole of a penetrating hole support. A fork portion of a fork connecting rod is movably connected with the power connecting rod; and the other end is connected with a simulated crank. The simulated crack is arranged at one end of a rotating shaft and the other end of the rotating shaft is provided with a flywheel; and the rotating shaft is arranged at a support. Two vent holes are arranged in the side wall of the air cylinder and are used for air suction and exhausting; a flow dividing air valve is arranged at the outer side of the air cylinder; two openings, approaching the air cylinder, of the flow dividing air valve are respectively communicated with the two vent holes of the air cylinder; and an air inlet, far away from the other side of the air cylinder, of the flow dividing air valve is connected with an airflow source. A sliding block, which is arranged in the flow dividing air valve and is connected with a dividing connecting rod and the simulated crank, moves back and forth at the axial direction of the air cylinder under the driving of the simulated crank, so that the air flow is guided to enter the air cylinder through one opening of the flow dividing air valve and one vent hole of the air cylinder and thus the piston is pushed to make motion.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

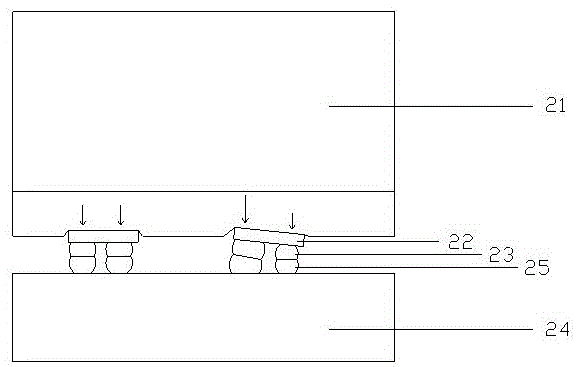

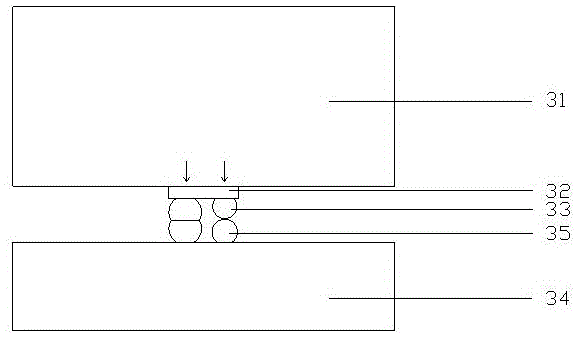

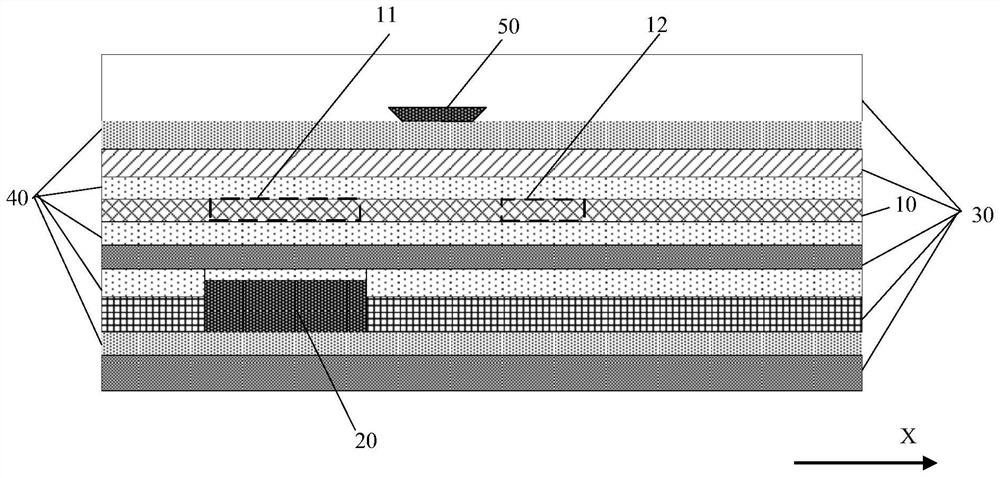

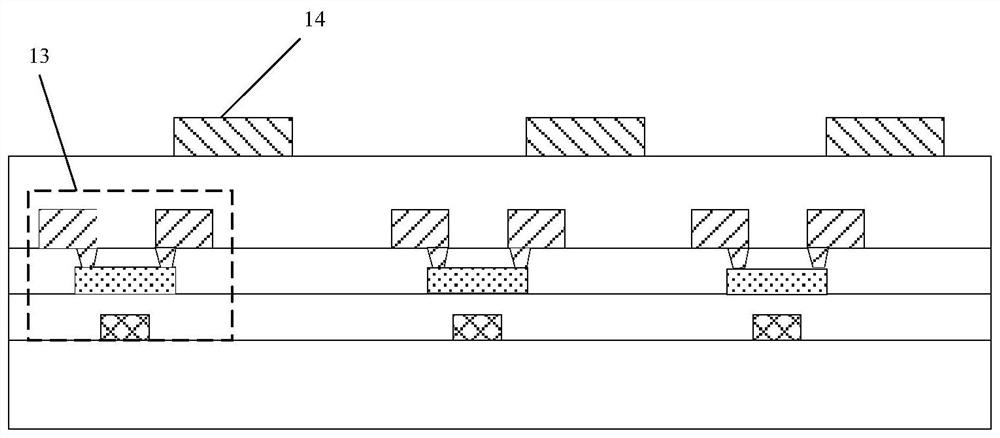

Automatic-regulating type hot-pressing head structure suitable for flip chip die bonding

InactiveCN106356309AOvercoming demandsOvercoming YieldSolid-state devicesSemiconductor/solid-state device manufacturingElectricitySurface mounting

The invention provides an automatic-regulating type hot-pressing head structure suitable for flip chip die bonding. The automatic-regulating type hot-pressing head structure comprises a hot-pressing head arranged on a laminating machine and is characterized in that an elastic film produced by high-elasticity alloy materials coats the surface of the hot-pressing head, the elasticity modulus E of the elastic film is lower than 200GPa, the compressive strength of the elastic film is higher than 0.2GPa, and the thickness of the elastic film ranges from 100 micrometers to 10cm. The invention further discloses flip chip laminating machine integrating electricity, machinery, light and image and using the hot-pressing head. The automatic-regulating type hot-pressing head structure has the advantages that the defects that an existing hot-pressing head is high in parallelism requirement and poor in yield during chip surface mounting are overcome, high-precision hot-pressing head manufacturing under a common machining precision condition is achieved, the surface of the elastic film of the hot-pressure head can always attach to the surface of a workpiece during use, the position of the workpiece can be adjusted according to the flatness of the workpiece, product quality is guaranteed, and the automatic-regulating type hot-pressing head structure is suitable for batch production due to the fact that the parallelism requirements are lowered.

Owner:GUANGDONG DELI PHOTOELECTRIC

Display device

PendingCN113392802AReduce parallelismReduce damage rateCharacter and pattern recognitionIdentification meansDisplay deviceEngineering

The embodiment of the invention discloses a display device. The display device comprises a display functional layer, a fingerprint identification module, at least one functional layer and at least one adhesive layer, wherein the display function layer comprises a first area and a bending area which are arranged in the first direction, and the first area comprises a first sub-area; at least one functional layer comprises at least one first functional layer, at least one adhesive layer comprises at least one first adhesive layer, the first functional layer is in contact with the first adhesive layer, and one side, facing the first adhesive layer, of the first functional layer is provided with at least one first groove; the orthographic projection of the first groove on the plane where the display function layer is located is located between the first sub-area and the bending area, so that the probability that the parallel relation between the first sub-area of the display function layer and the binding face of the fingerprint recognition module is damaged in the repeated bending process of the display device is reduced, and the fingerprint identification precision of the fingerprint identification module based on the received light or sound wave characteristics is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Tube side type heat exchanger with composite double-tube plate structure

ActiveCN102564203BGuaranteed expansion effectReduce concentricityHeat exchanger casingsPlate heat exchangerDouble tube

Owner:CHINA PETROCHEMICAL CORP +1

Rotor pump and assembly method thereof

ActiveCN111306057AAvoid crashes and jamsLarge rotation clearanceRotary piston pumpsRotary piston liquid enginesDrive shaftClassical mechanics

The invention discloses a rotor pump and an assembly method thereof, and belong to the technical field of rotor pumps. The rotor pump comprises a shell body, a first transmission shaft and a second transmission shaft, wherein a first bearing is arranged at one end of the first transmission shaft and in a first bearing seat on the shell body; a first rotor is arranged on the first transmission shaft; the second transmission shaft is in parallel transmission with the first transmission shaft; a second rotor is arranged on the second transmission shaft; a second bearing is arranged at one end ofthe second transmission shaft and in a second bearing seat on the shell body; and an injection molding groove is formed in the outer circumferential wall of the second bearing and / or the inner circumferential wall of the second bearing seat, and used for the injection molding and the accommodation of an injection molding agent. The rotor pump has the advantages that the a relatively good rotatinggap can be formed between the first rotor and the second rotor through adjustment without disassembly; and meanwhile, the rotating gap between the first rotor and the second rotor can be kept unchanged during the rotating process.

Owner:FAW JIEFANG AUTOMOTIVE CO

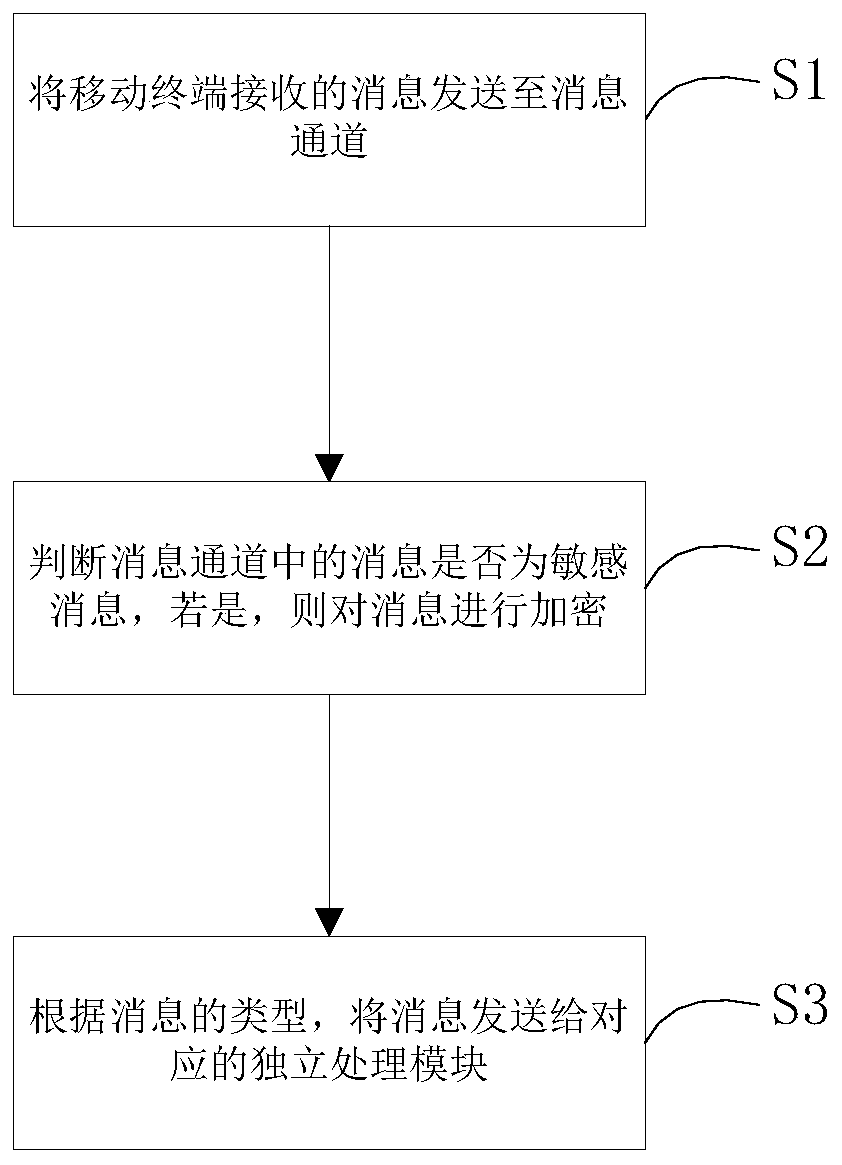

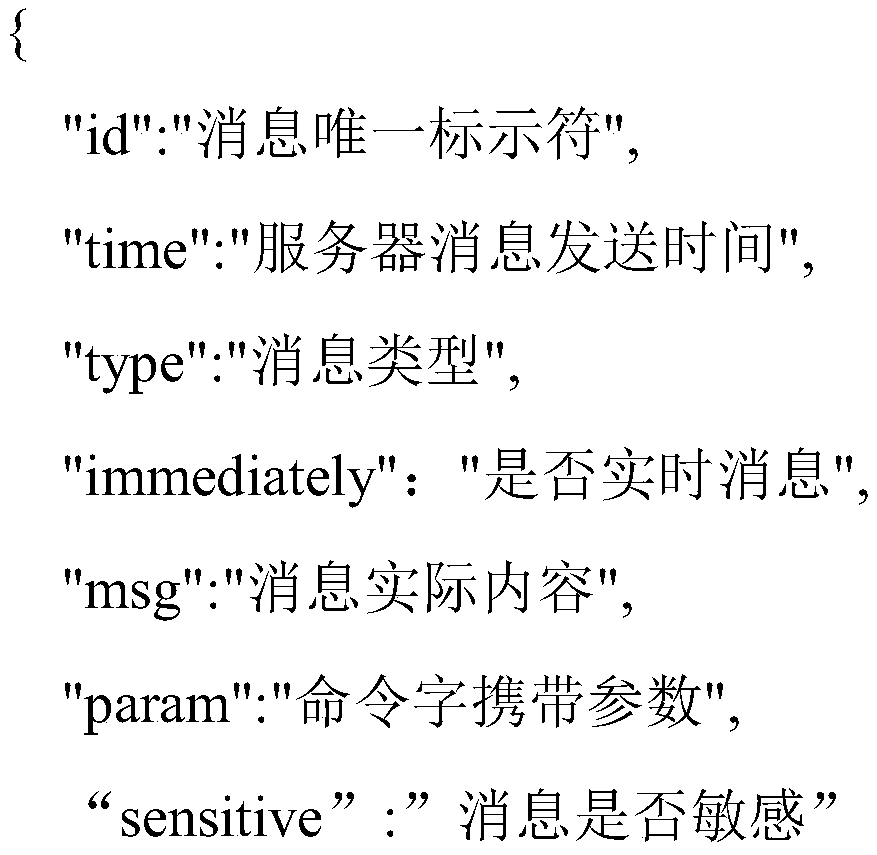

A method and system for classifying and distributing messages on a mobile terminal

ActiveCN106454770BReduce energy consumptionReduce parallelismMessaging/mailboxes/announcementsData switching networksEngineeringNetwork communication

The invention relates to the technical field of network communication, and discloses a method for classifying and distributing messages on a mobile terminal, including step S1: sending the message received by the mobile terminal to a message channel; and step S2: judging whether the message in the message channel is a sensitive message , if it is a sensitive message, encrypt the message; step S3: according to the type of the message, send the message to the corresponding independent processing module for processing and then push it to the user. There are multiple independent processing modules, and each independent processing module Responsible for processing one type of message. The invention also discloses a system for classifying and distributing messages on the mobile terminal. The invention can quickly and efficiently classify, distribute and process the messages received by the mobile terminal.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com