Tube side type heat exchanger with composite double-tube plate structure

A technology of heat exchanger and tube program, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low application ratio of double tube sheets, difficult processing, and reduced heat exchange area, etc., to achieve Reduce processing difficulty and manufacturing cost, simplify structure and manufacturing procedures, and increase the effect of effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

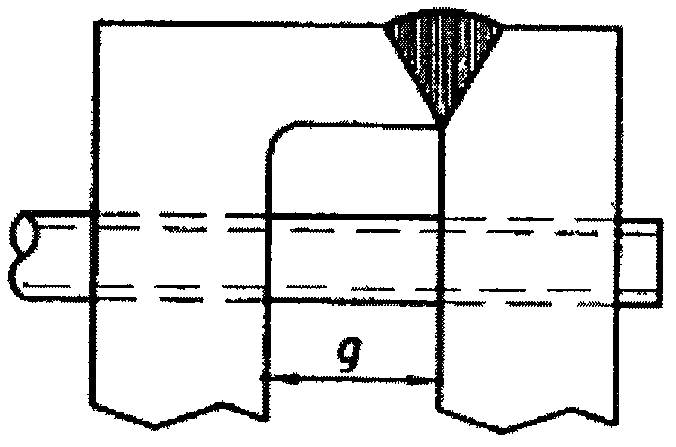

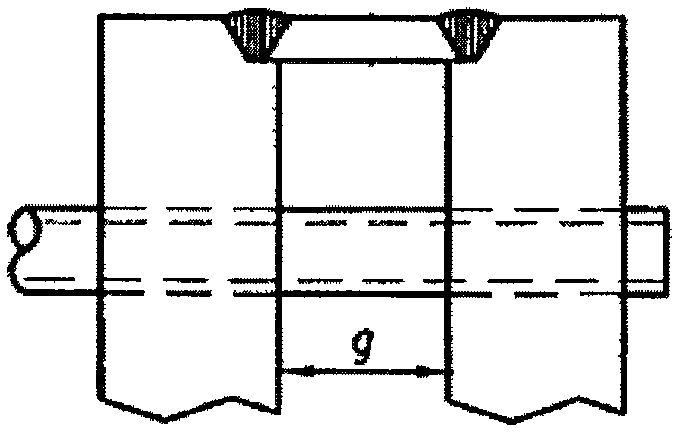

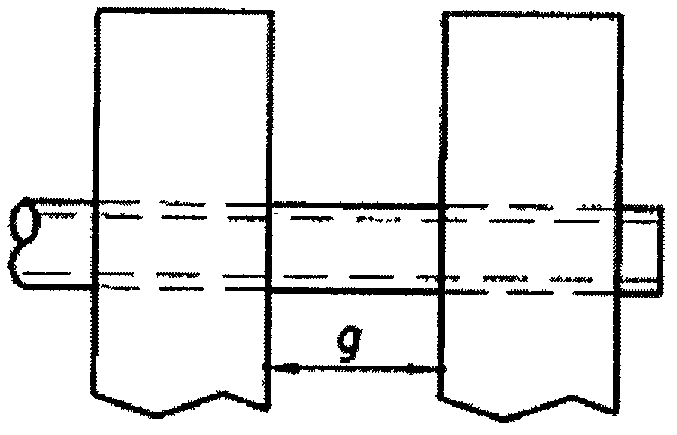

[0051] As shown in Figure 2~5:

[0052] The tube heat exchanger with composite double tube plate structure includes:

[0053] Shell side cylinder 5, heat exchange tube 4 and heat exchange tube plate,

[0054] The heat exchange tube sheet is an integrated structure composed of a base tube sheet 2 and a cladding tube sheet 1 with a peripheral seal and a cavity in the middle. The cavity is the tube layout area of the base tube sheet 2 recessed along the axis of the heat exchanger Cavity with a depression of 2mm,

[0055] The upper part of the base tube sheet 2 is provided with a venting nozzle 3 that is inserted into the base tube sheet 2 in a direction perpendicular to the heat exchange tube, and communicates with the outside and the inner cavity;

[0056] The lower part of the base tube sheet 2 is provided with a drain nozzle 6 which is inserted into the base tube sheet 2 in a direction perpendicular to the heat exchange tube, communicates with the outside world, and communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com