Installation technology method of rolling steel ball based on metal cold and hot deformation

An installation process and technology of steel balls, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy missing installation, high labor intensity, reduced assembly efficiency, etc., to achieve smooth operation, reduced labor intensity, structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

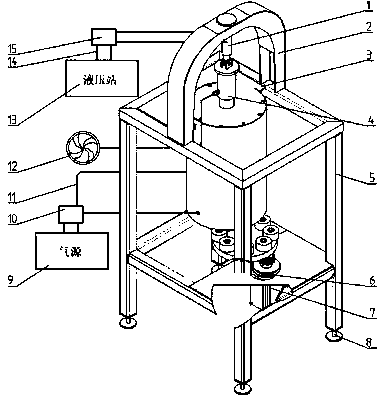

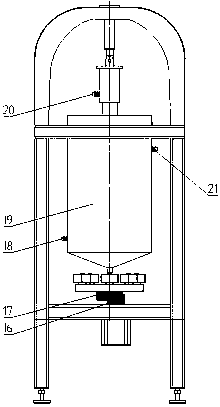

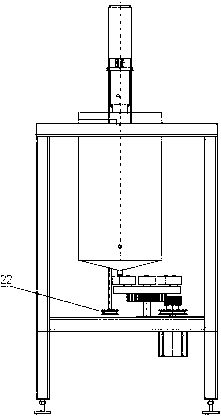

[0036] Such as Figure 1 to Figure 19 , a rolling steel ball installation method based on metal cold and hot deformation of the present invention, comprising: hydraulic cylinder 1, hydraulic cylinder bracket 2, tank body fixing plate 3, rotating negative pressure suction device 4, tank body bracket 5, V Type belt 6, rotary driving motor 7, foot leveling device 8, air source 9, gas distribution valve 10, gas circuit 11, negative pressure fan 12, hydraulic station 13, oil circuit 14, oil distribution valve 15, drive gear assembly 16. Lower plate rotation assembly 17, cooling gas intake joint 8, circulating cooling tank 19, negative pressure suction port joint 20, cooling gas exhaust joint 21, composite gear shaft 22, hanging lug 4-1, axial push rod 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com