Patents

Literature

36results about How to "Realization error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

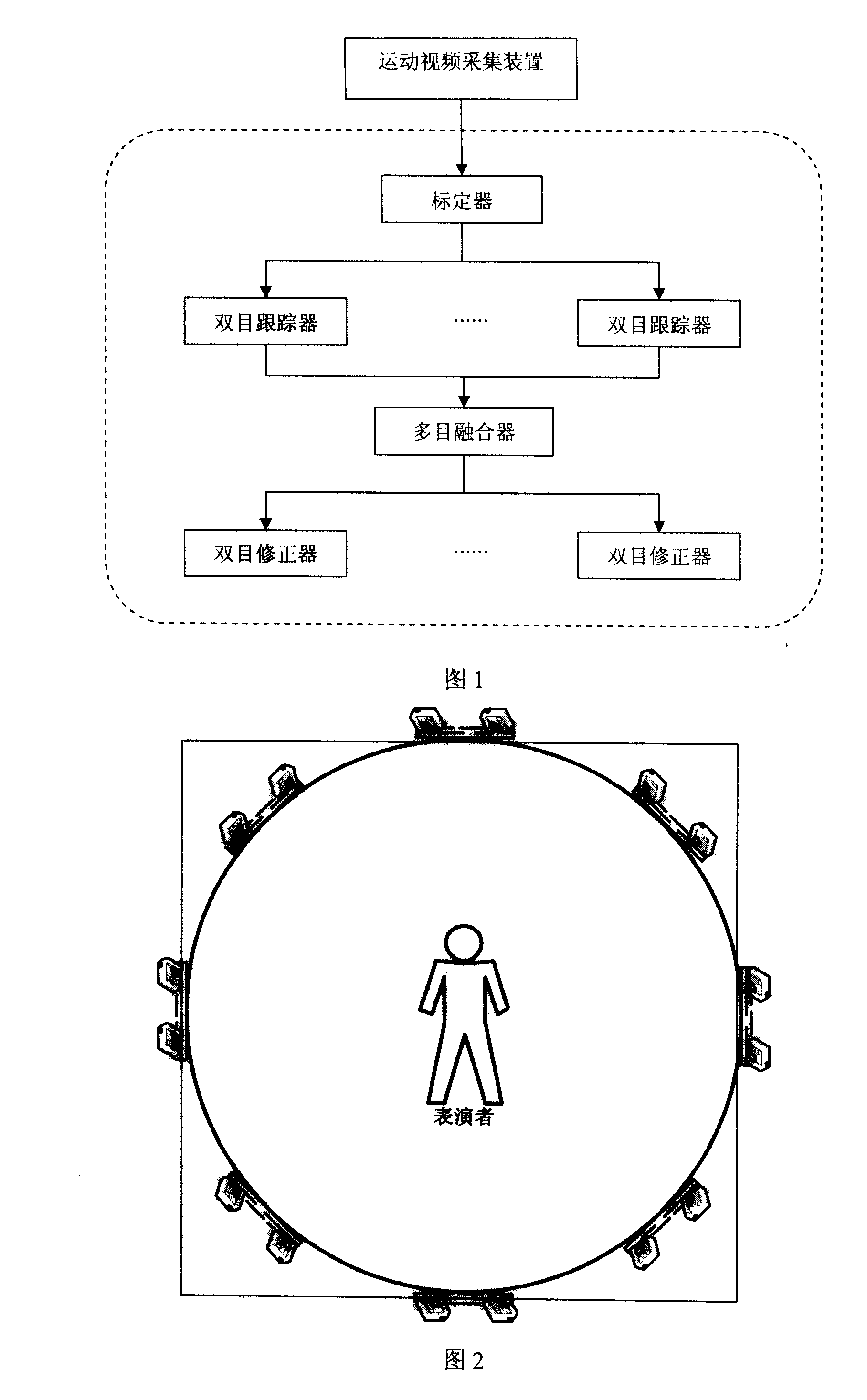

Method for capturing movement based on multiple binocular stereovision

The invention discloses a movement capturing method based on multiple binocular stereo vision. A movement video collecting device is constructed, and human movement video sequences from different orientations are collected by the movement video collecting device. Multiocular movement video sequences shot by a plurality of cameras are calibrated. Marked points matching and tracking of each binocular tracker is finished. Data fusion of three-dimensional tracking result of multiple binocular trackers is completed. The three-dimensional movement information of the marked points acquired by a multiocular fusion device is fed back to the binocular tracker to consummate binocular tracking. On the basis of binocular three-dimensional tracking realized by binocular vision, the invention fuses multiple groups of binocular three-dimensional movement data, resolves parameter acquiring problem of three-dimensional position, tracking, track fusion and the like for a plurality of marked points, increases number of traceable market points and enables the tracking effect to be comparable with three-dimensional movement acquiring device employing multi-infrared cameras for collecting.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

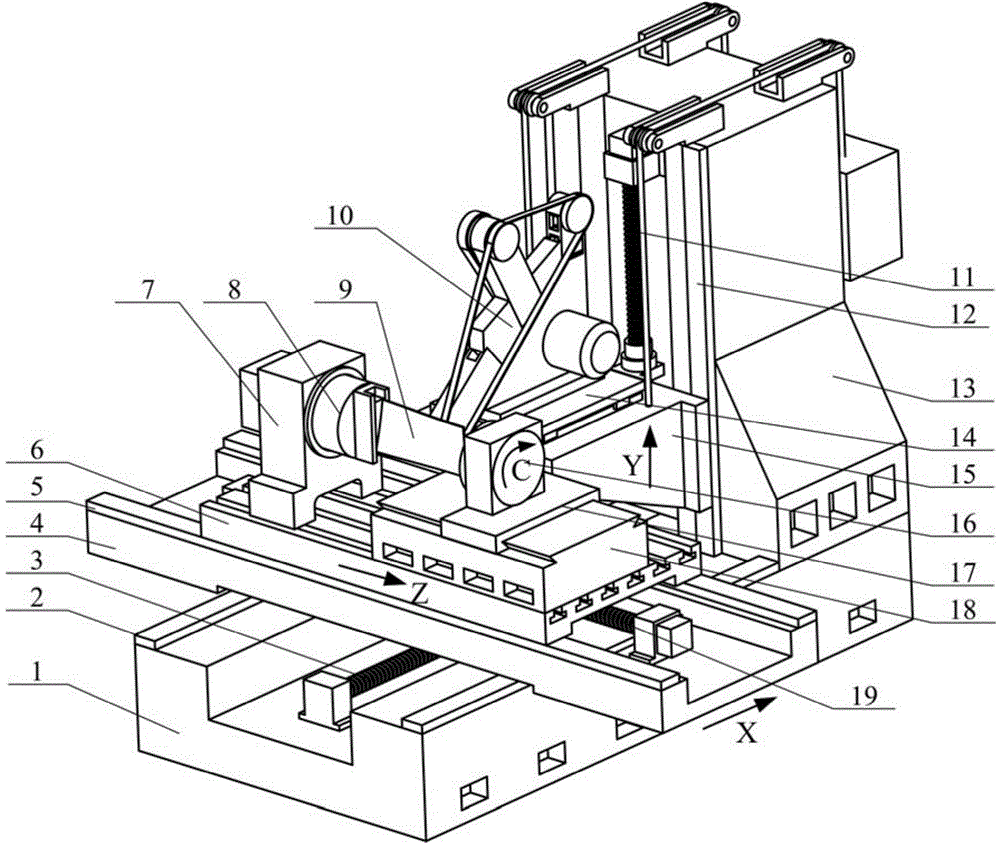

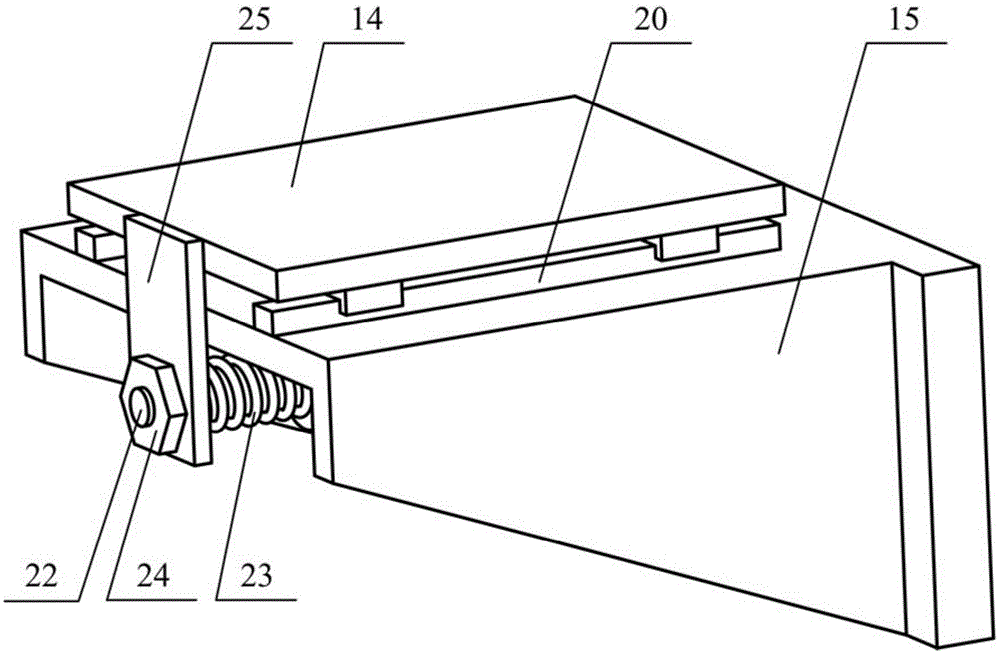

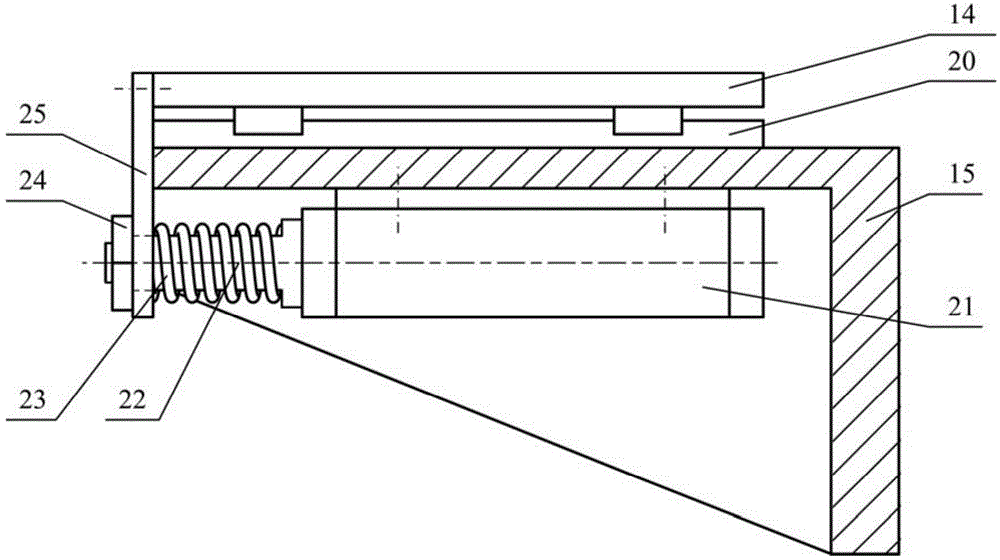

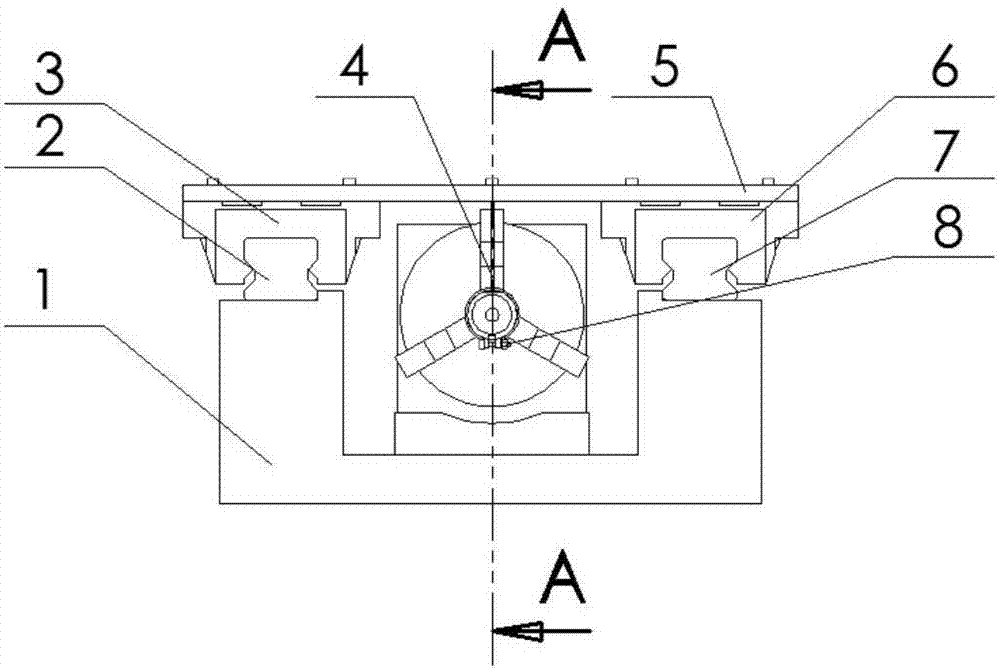

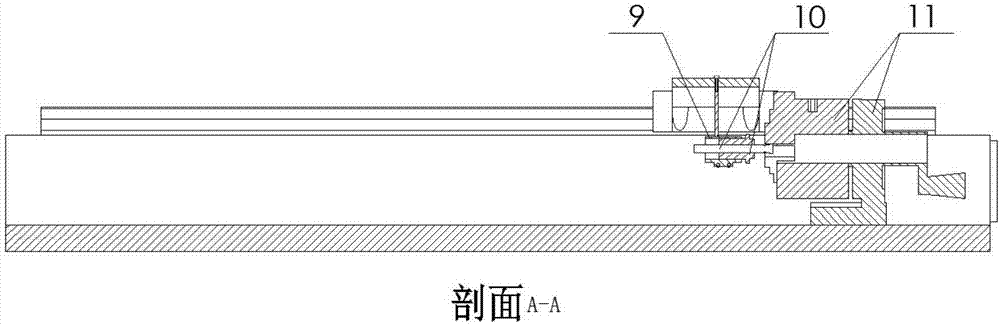

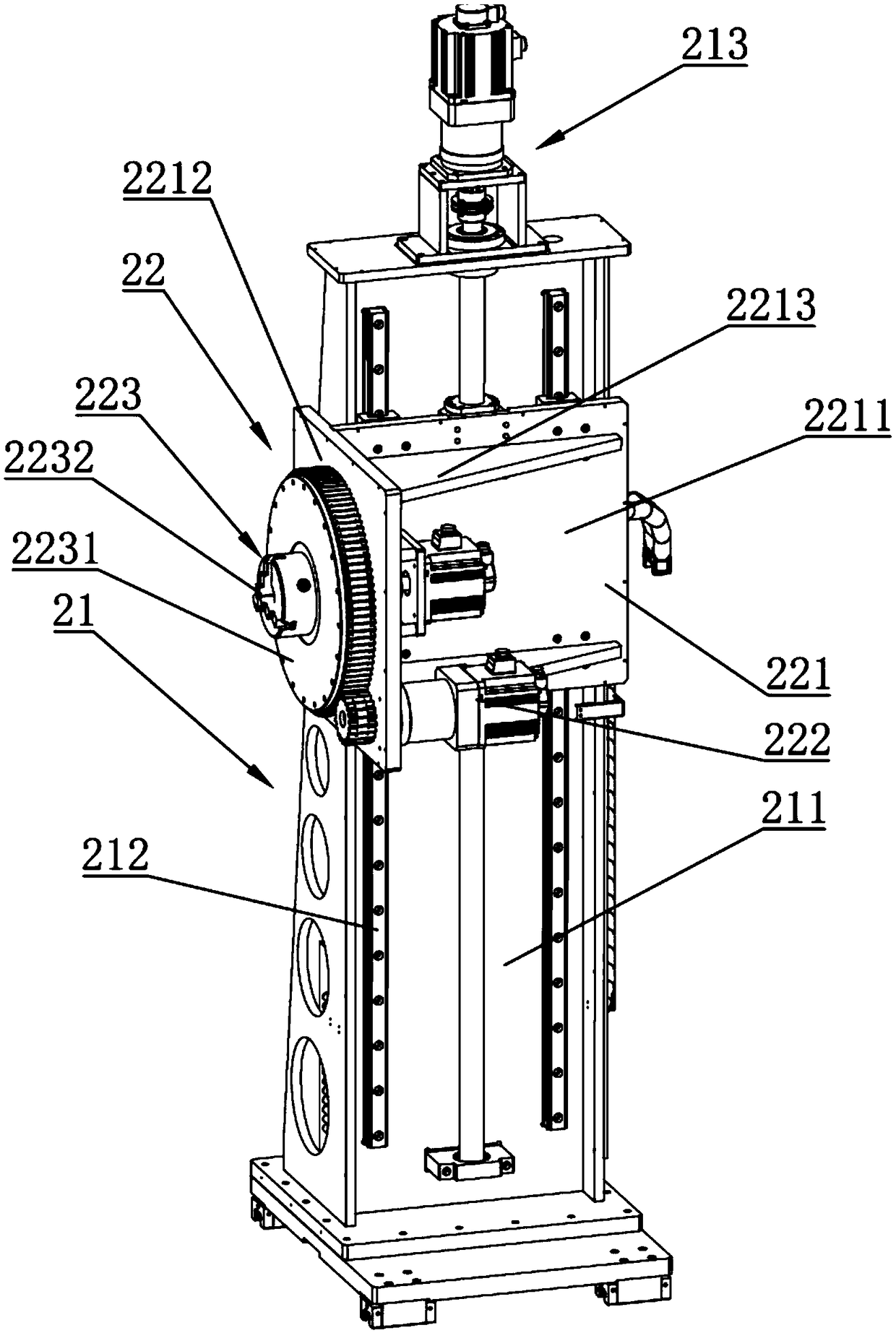

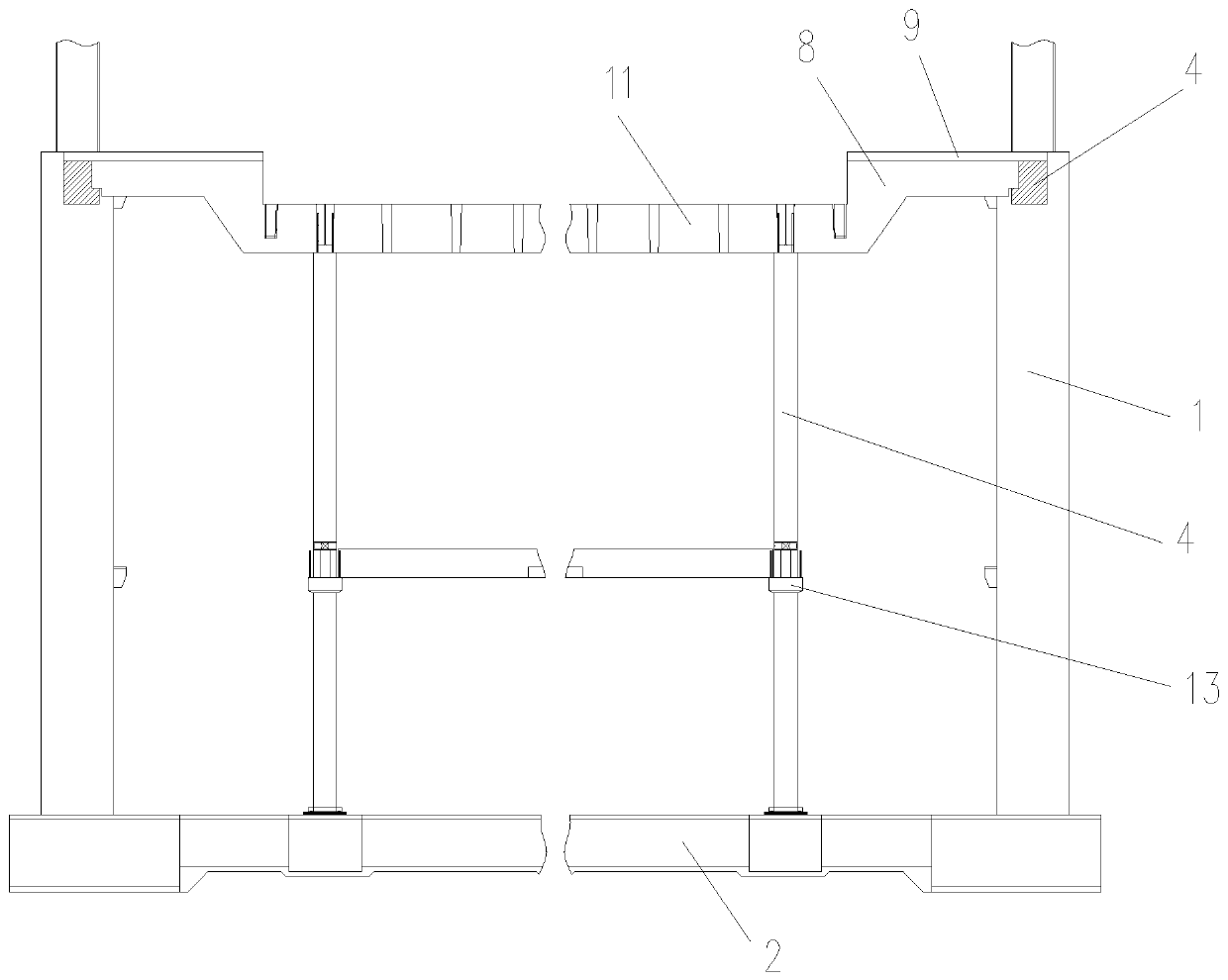

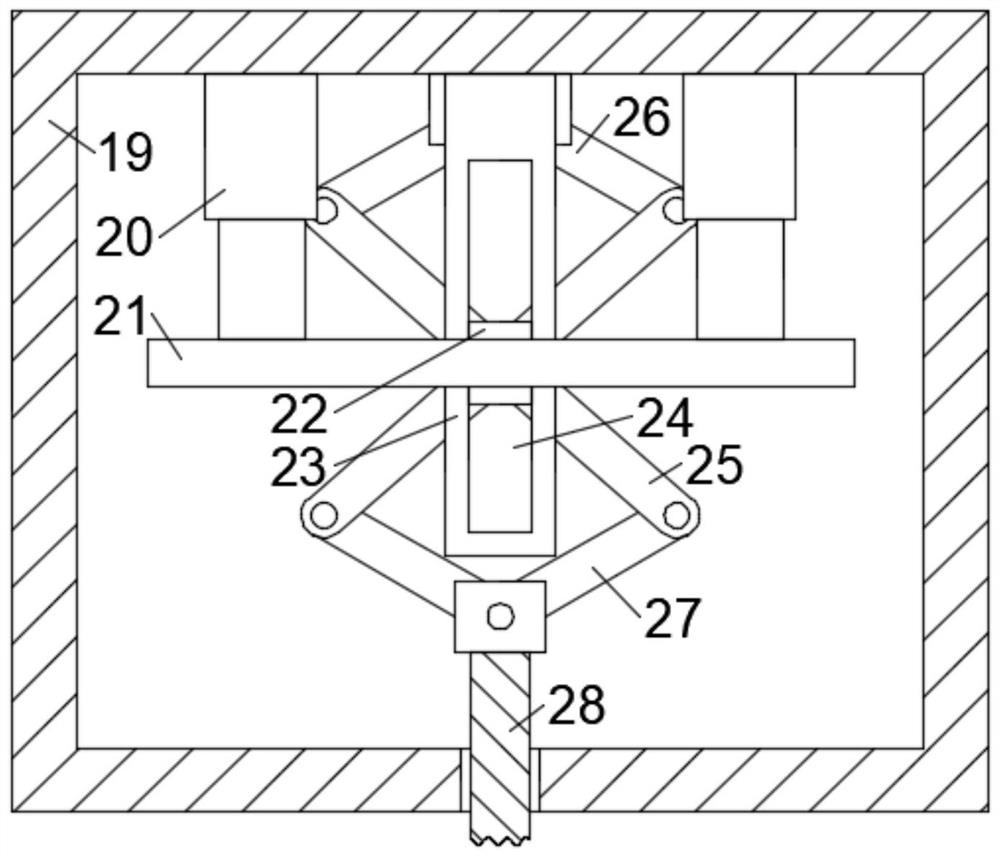

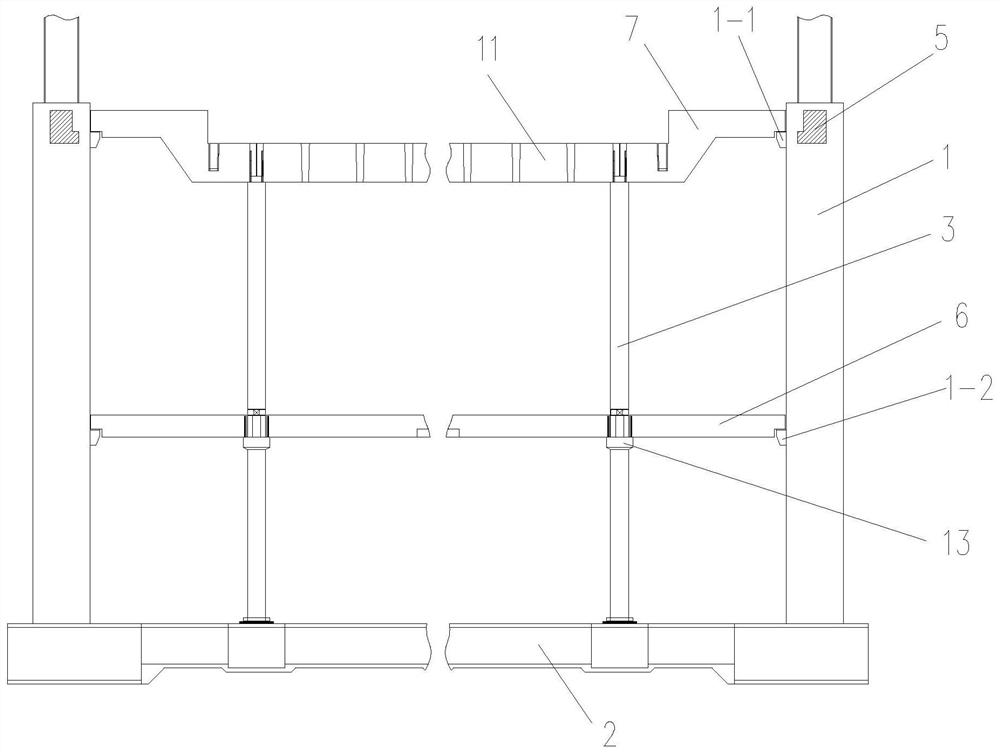

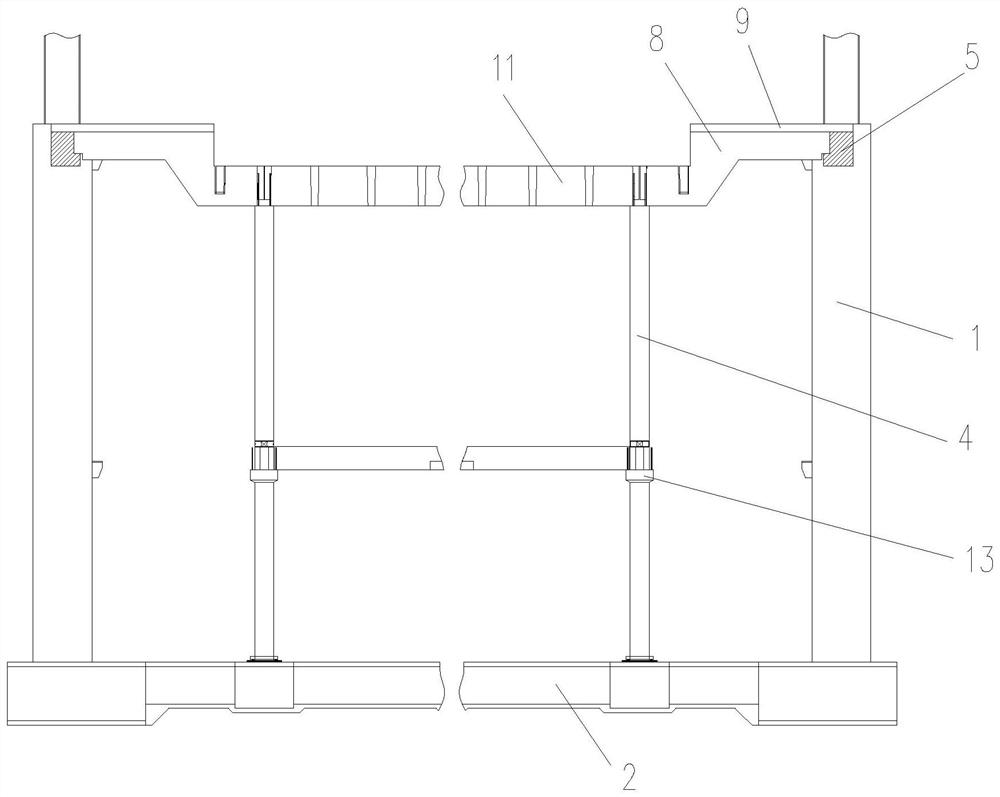

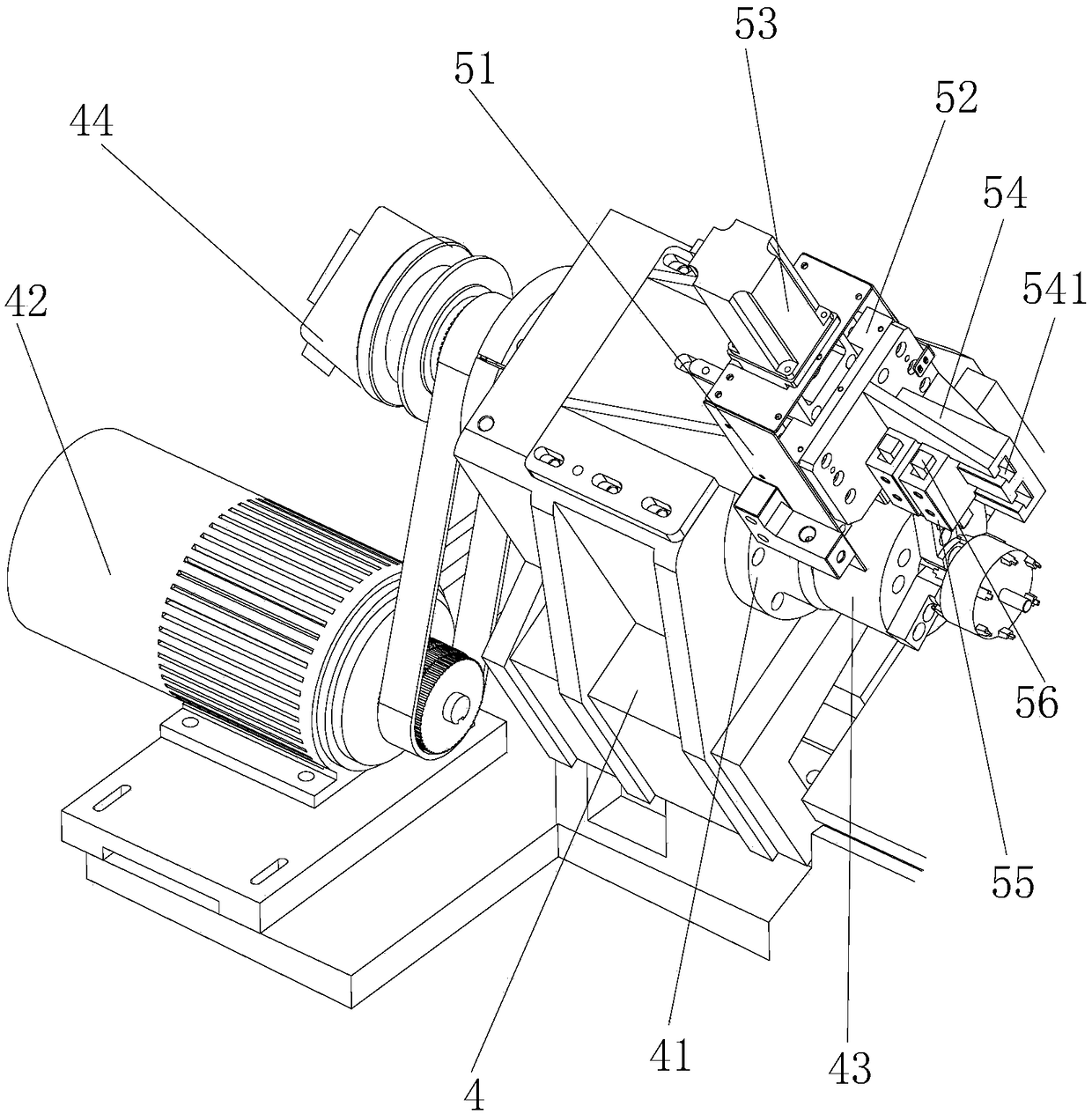

Self-adaption profile modification blade abrasive belt polishing machine tool

ActiveCN104440474ARealize the effect of polishing contact pressure compensationReduce performance pressureGrinding drivesBelt grinding machinesContact pressureCompensation effect

The invention discloses a self-adaption profile modification blade abrasive belt polishing machine tool, comprising a machine tool body, an X-axis carriage, an X-axis carriage, a C-axis rotary table, a Y-axis sliding block, an abrasive belt polishing head component, an air cylinder, and the like, wherein a pressure compensation element is in series connection between the abrasive belt polishing head component and the air cylinder to cooperate with the air cylinder to form a polishing contact pressure. During machining, the polishing machine tool performs interpolation feed according to an ideal polishing track; due to the existence of a blade profile error (or waveness), the polishing contact point deviates from the ideal polishing track in a pressure shaft direction, and the acting pressure of the pressure compensation element changes along with the deviation, so as to realize the polishing contact pressure compensation; the pressure compensation element can utilize a constant-pressure type gas bearing with oppositely arranged air cushions, and realizes the polishing contact pressure compensation effect by utilizing a pressure balance function to the oppositely arranged air cushions. The self-adaption profile modification blade abrasive belt polishing machine tool has the advantages that the response speed of pressure compensation is increased, the self-adaption modification on the profile error (or waveness) during blade polishing machining is realized, and the profile precision is improved.

Owner:XI AN JIAOTONG UNIV

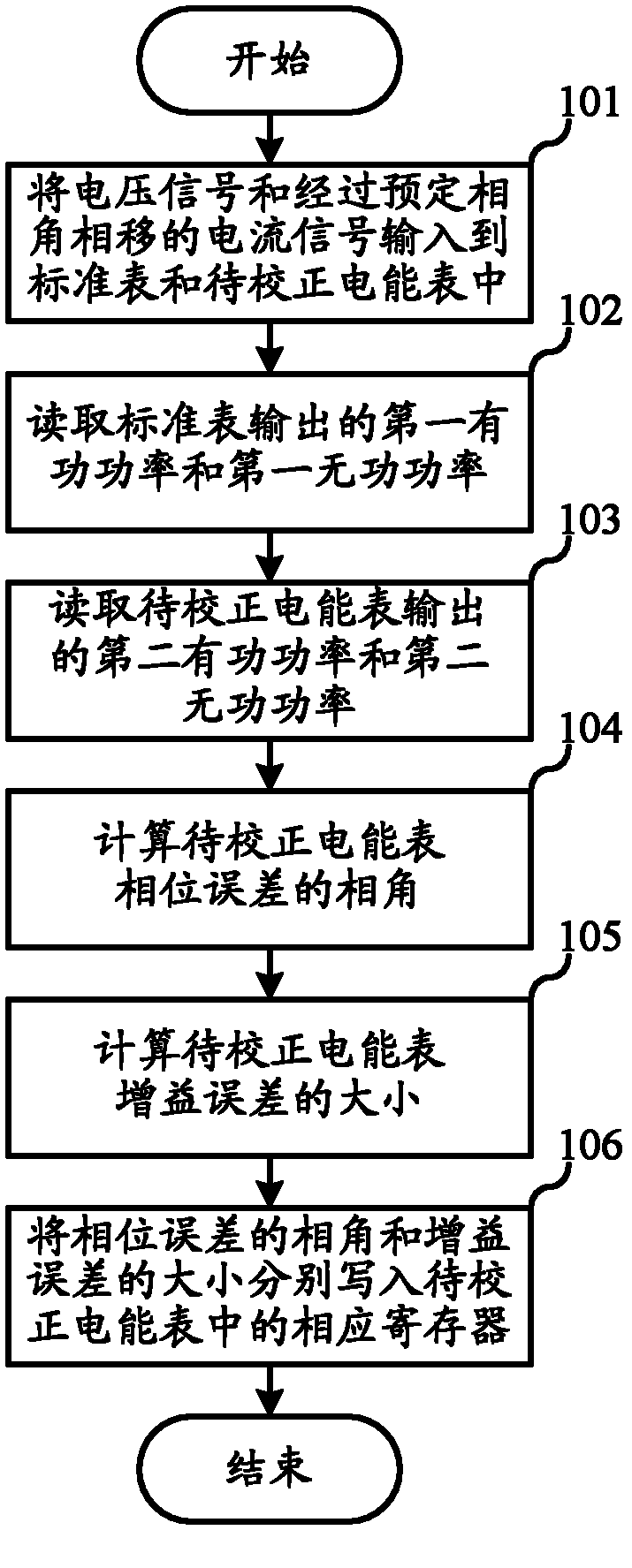

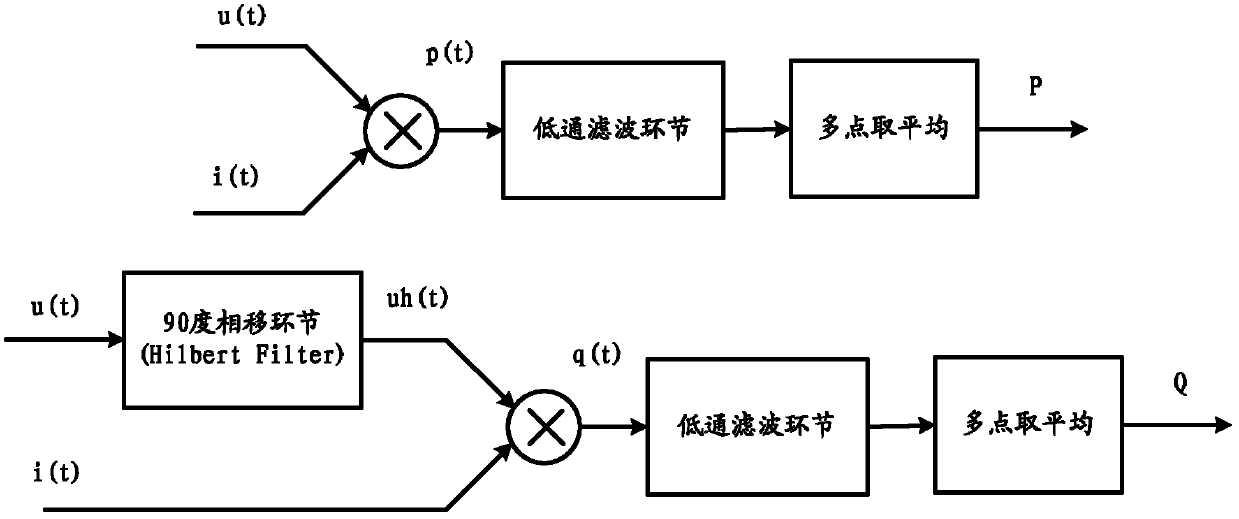

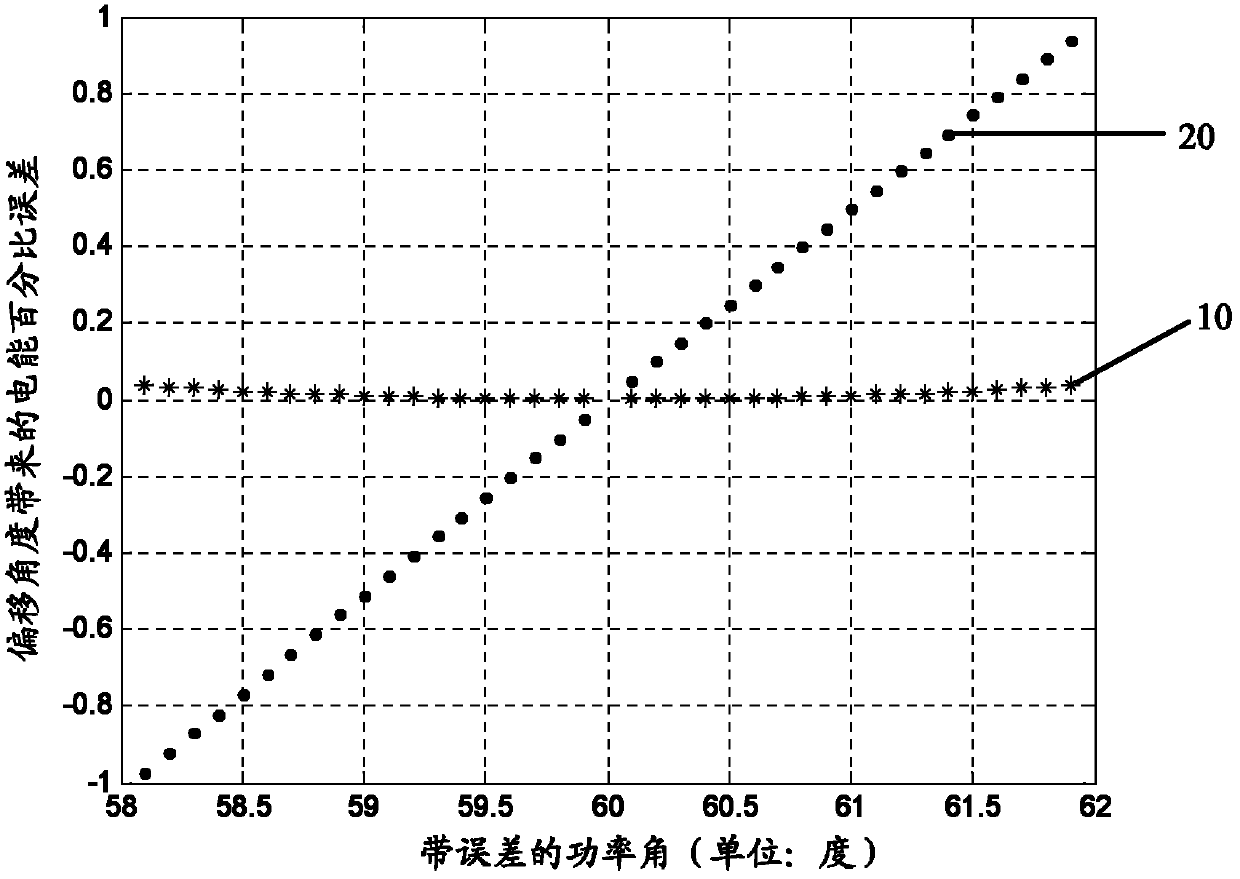

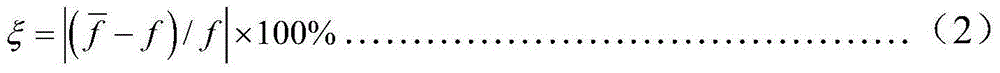

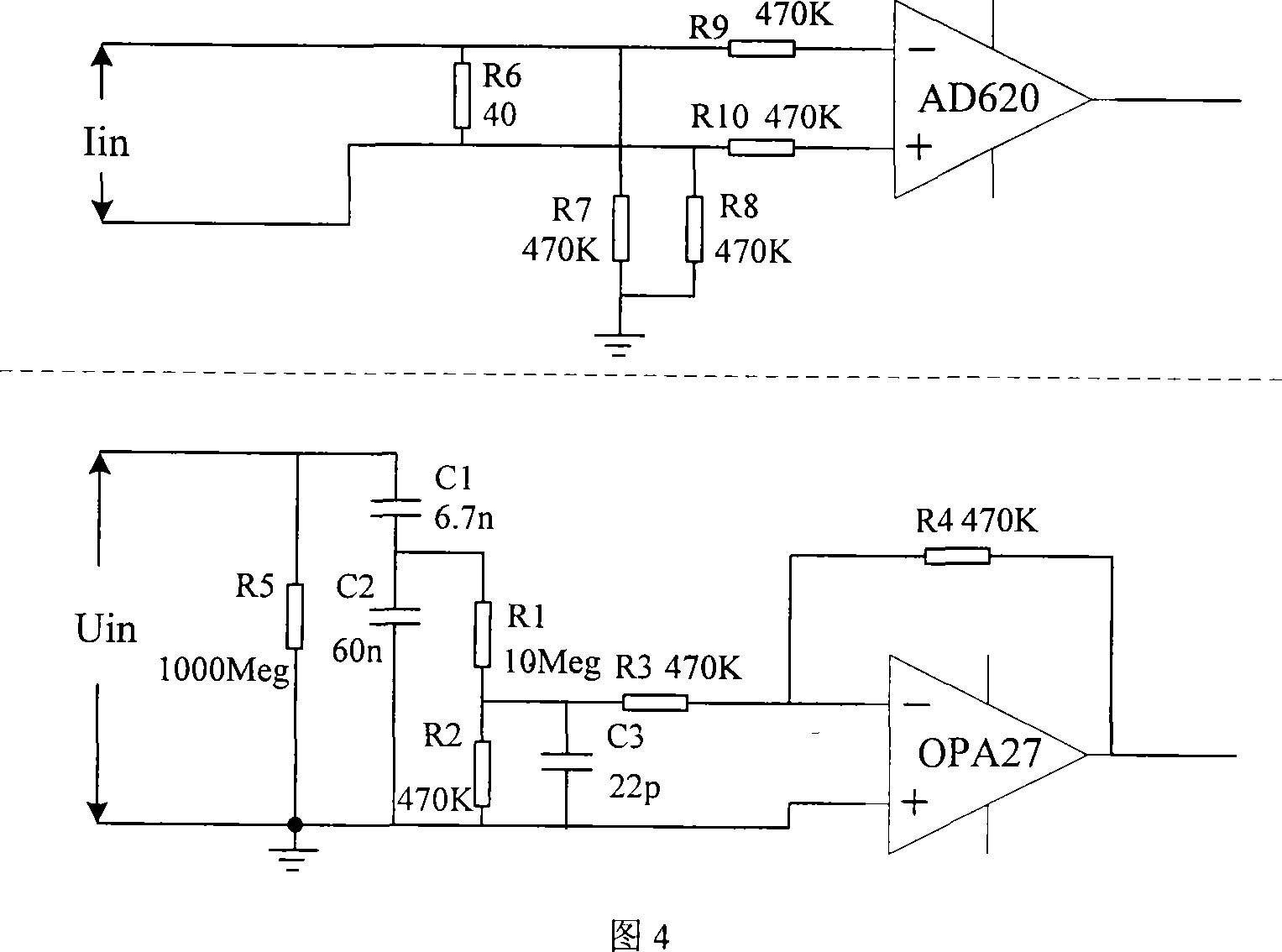

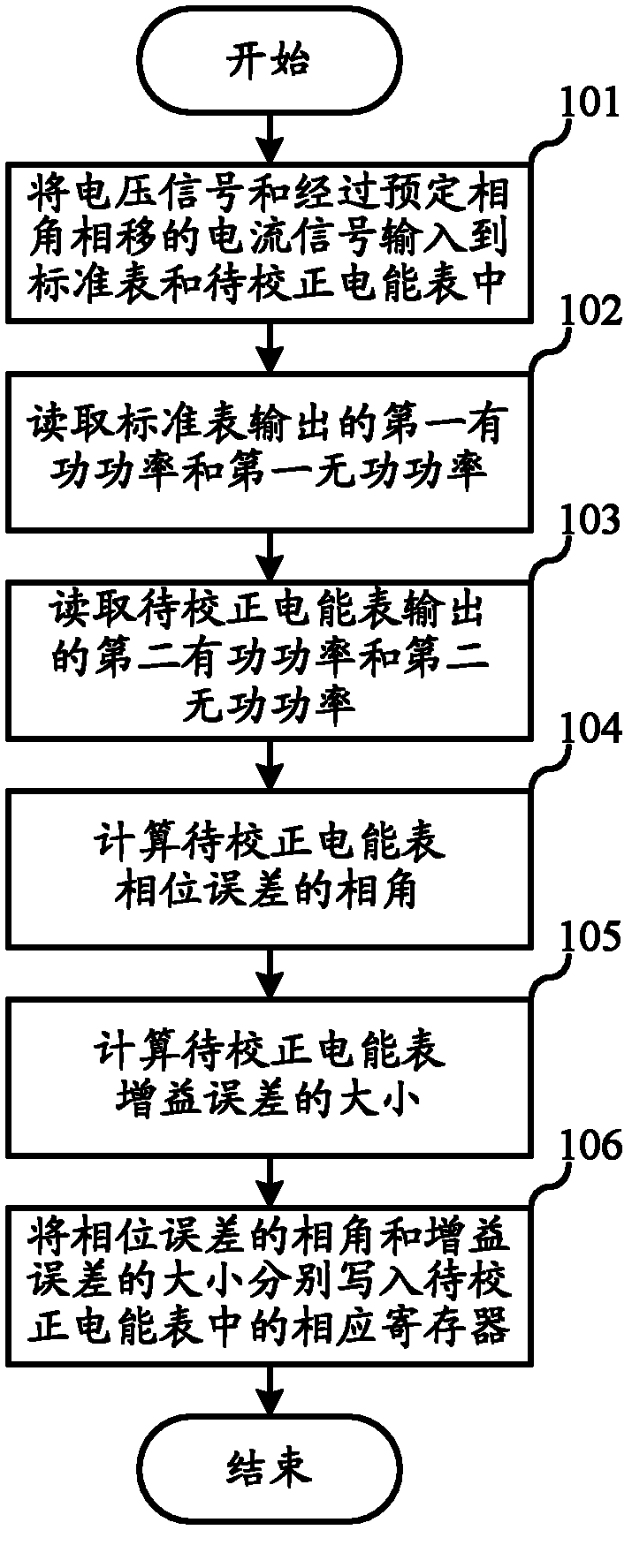

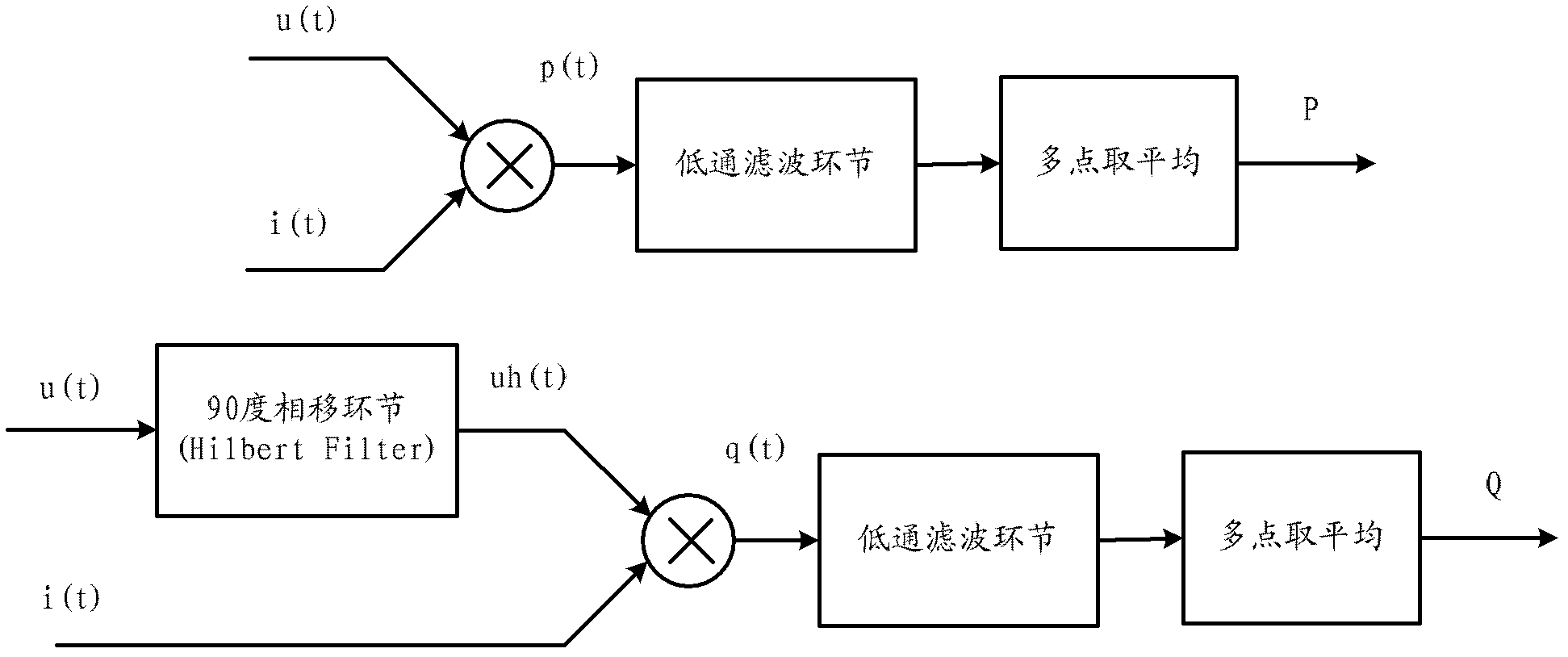

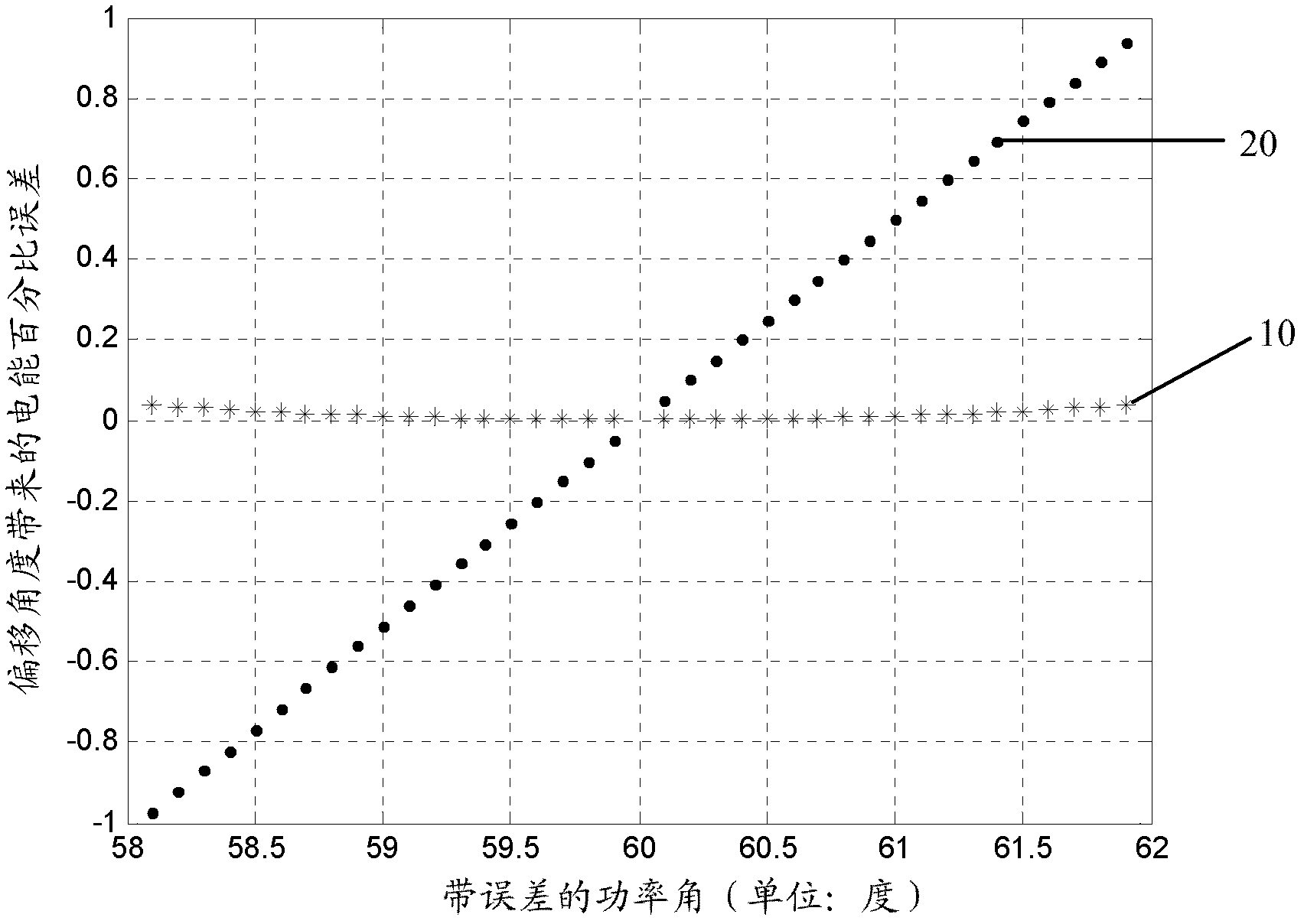

Method for collecting electric energy errors of electric energy meter and device thereof

ActiveCN102608559ARealization errorReduced calibration requirementsElectrical measurementsCollection TimeElectricity meter

The invention relates to the field of electric energy metering, and discloses a method for collecting electric energy errors of an electric energy meter and a device thereof. In the invention, in a reactive load environment, the electric energy meter is collected by using high-accuracy and universal power values; and compared with the traditional pulse correction method, the correction requirements are reduced, the calibration process is simplified, the advantages of quickness, accuracy and convenience are highlighted, and an effect of carrying out single-point correction on the errors of the electric energy meter is achieved. If a phase angle is too big or too small, a situation that the value of a sine or cosine thereof is too big or too small is caused, therefore, the calculation accuracy can not be ensured. Through taking power values as data sources rather than direct and low-accuracy angles or derived parameters (such as power factors and the like) as data sources, a situation that the principle error of correction is low enough can be ensured. Through verification, the accuracy of correction on the electric energy meter can be further ensured. The testing time is only one third of the original testing time, thereby greatly saving the total collection time.

Owner:HI TREND TECH SHANGHAI

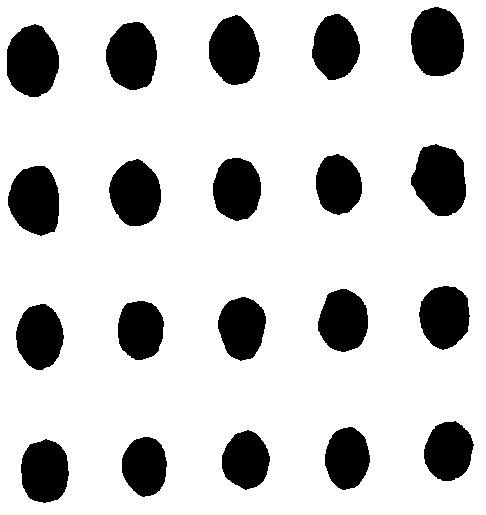

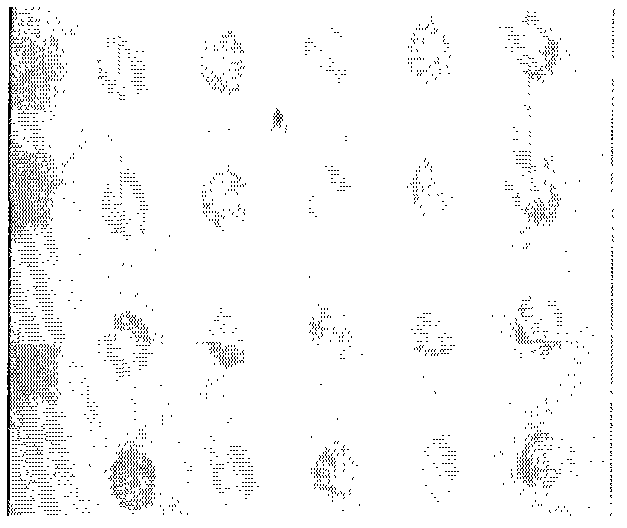

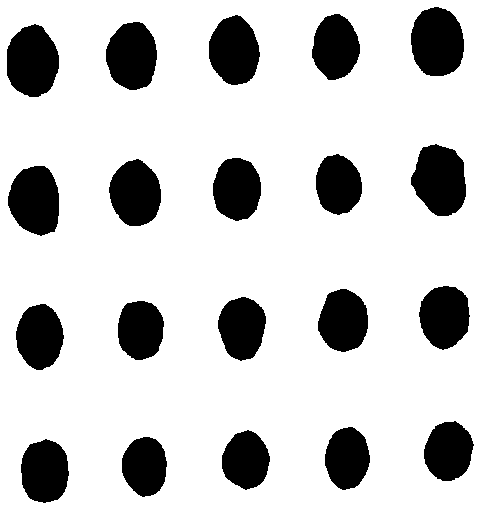

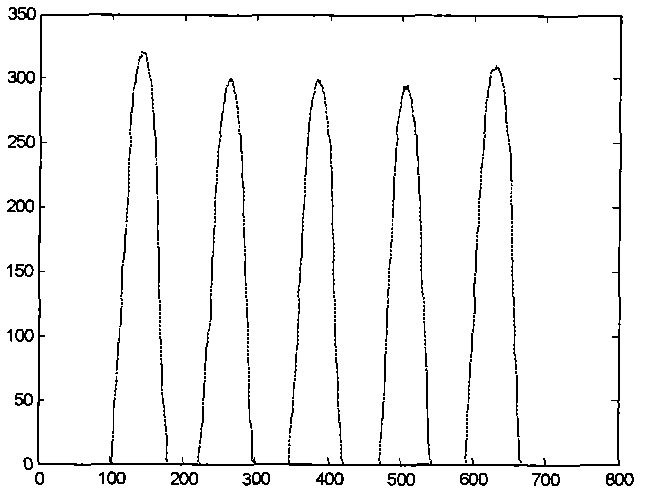

Method for identifying sampling points of biological chip on basis of edge detection

InactiveCN102073876AEasy to operateShort algorithm timeImage enhancementCharacter and pattern recognitionEdge extractionComputer science

The invention discloses a method for identifying sampling points of a biological chip on the basis of the edge detection. The method comprises the following steps of: firstly, determining a real area of the sampling points by edge extraction, edge connection and area filling; then meshing by adopting a scanning method and automatically obtaining the row number, the column number and the total number; and finally corresponding area positions of the sampling points in each determined mesh to an original drawing, carrying out automatic searching to obtain the area and the mean value of gray scale of the sampling points in the original drawing, and comparing the area and the value of gray scale of the sampling points in the original drawing with corresponding parameters of the sampling pointsin the standard chip to obtain an automatic identification result of the sampling points. The method has high positioning accuracy. Software of the method is simpler to implement. The method has short time of an algorithm, is convenient and rapid to operate and makes full automation and intellectualization of information extraction of the biological chip possible.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

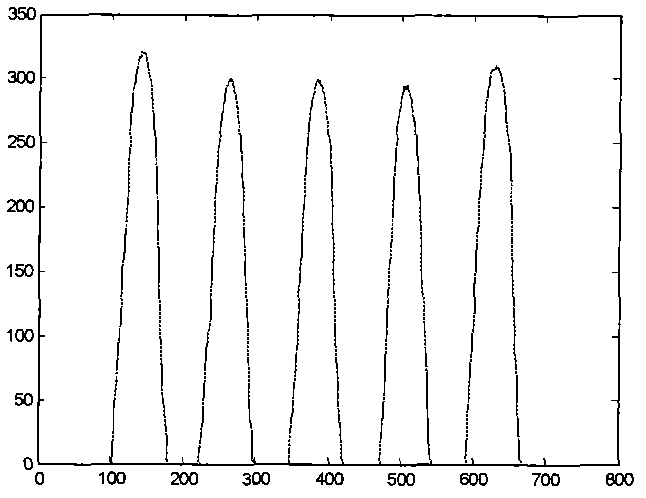

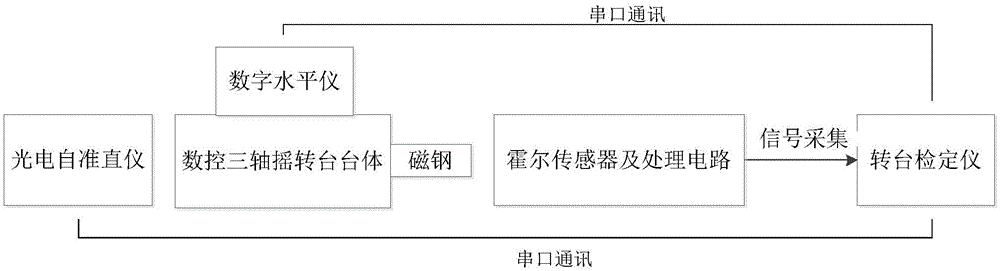

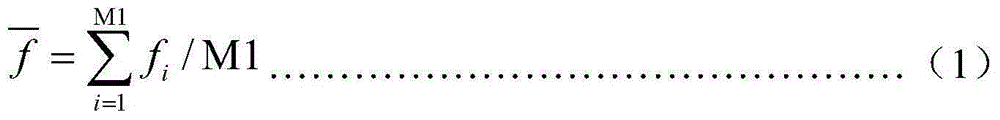

Detection apparatus and method for swing frequency error and swing zeroing error of rotary table

The invention relates to a detection apparatus and method for the swing frequency error and swing zeroing error of a rotary table, belonging to the technical field of testing of inertial devices. According to the invention, magnetic steel is fixedly mounted on a detected rotation frame or side end face of the rotary table; a Hall sensor and a processing circuit are fixedly arranged on an immovable foundation; once the magnetic steel faces an induction surface of the Hall sensor, a TTL level induction signal is generated; a rotary-table calibrating device acquires TTL level induction signals and calculates the cycle length of adjacent TTL level induction signals so as to obtain the error of the swing frequency of the rotary table; a digital level meter is arranged on the reference surface of the detected frame of the rotary table; a photoelectric autocollimator collimates the center of a reflective mirror on the rotary table; and the digital level meter and the photoelectric autocollimator test the states of the rotary table before and after swing test and then data processing is carried out so as to obtain the swing zeroing error. The detection apparatus and method provided by the invention can detect the swing frequency errors and swing zeroing errors of rotary tables of different types, and has the characteristics of good applicability, high accuracy, convenience and rapidness.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

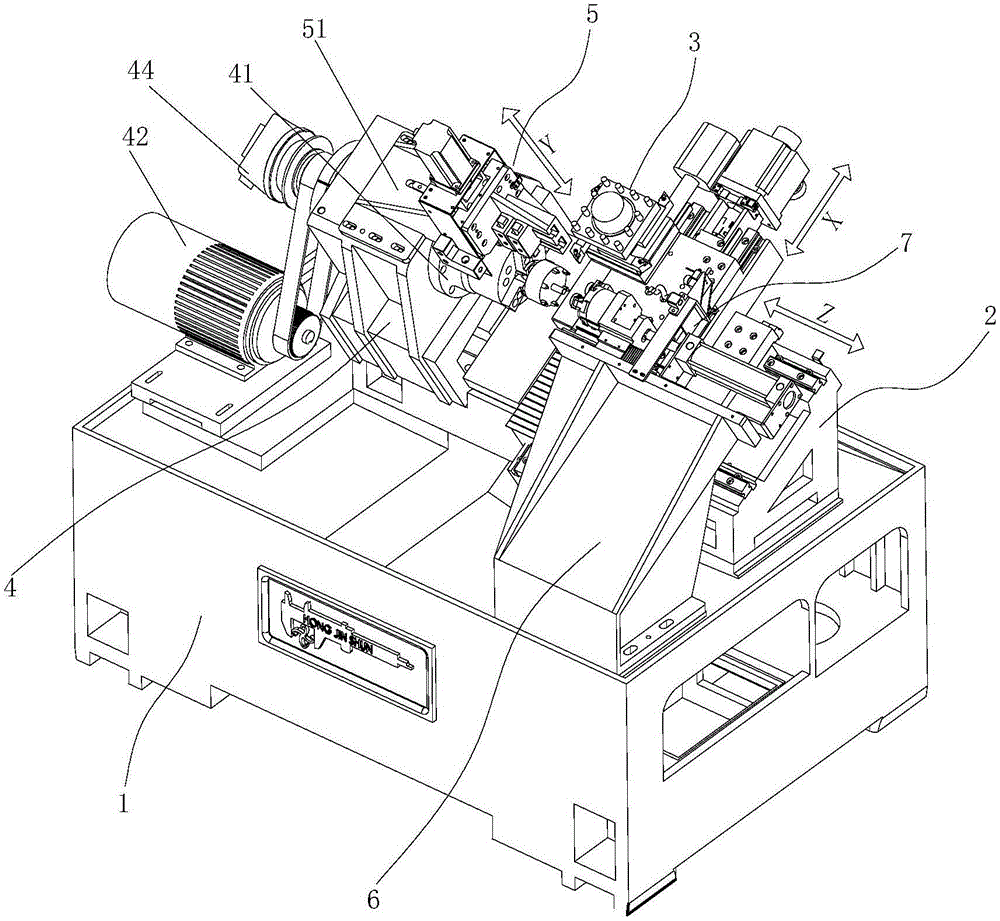

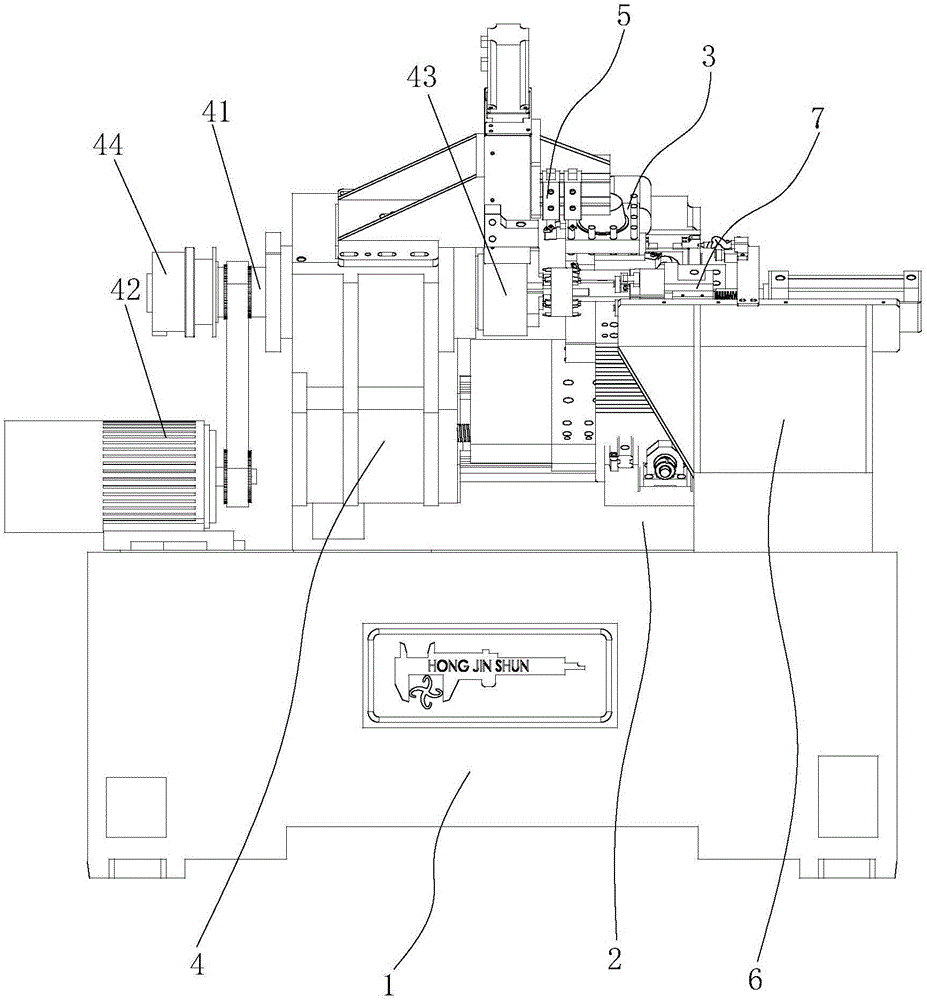

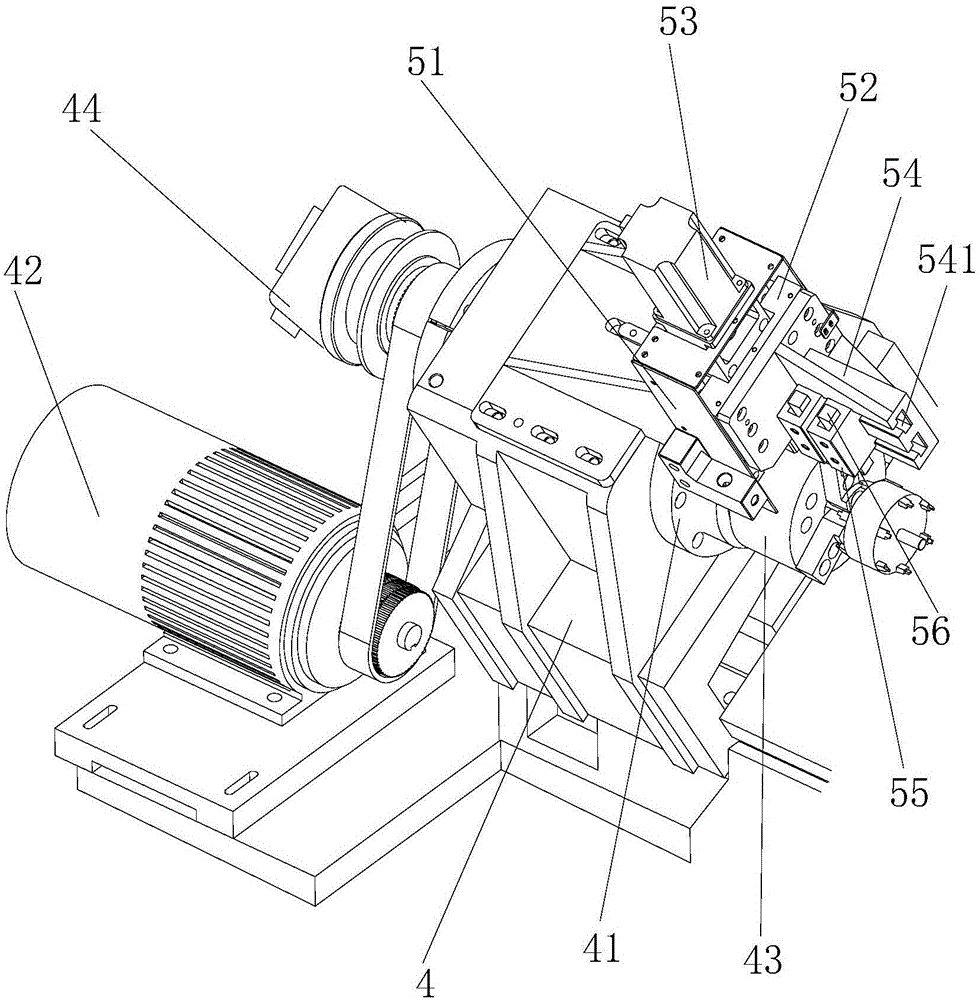

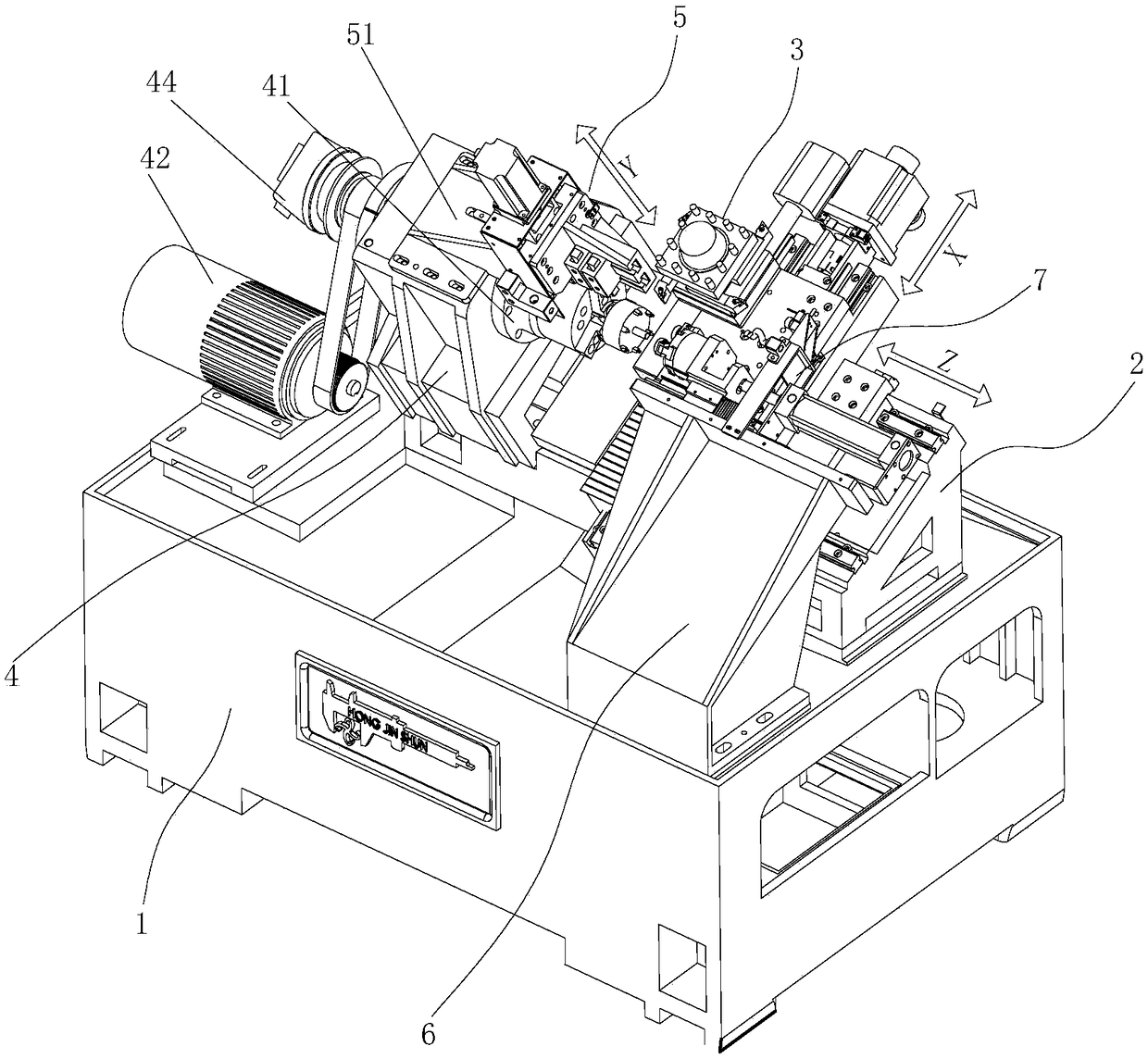

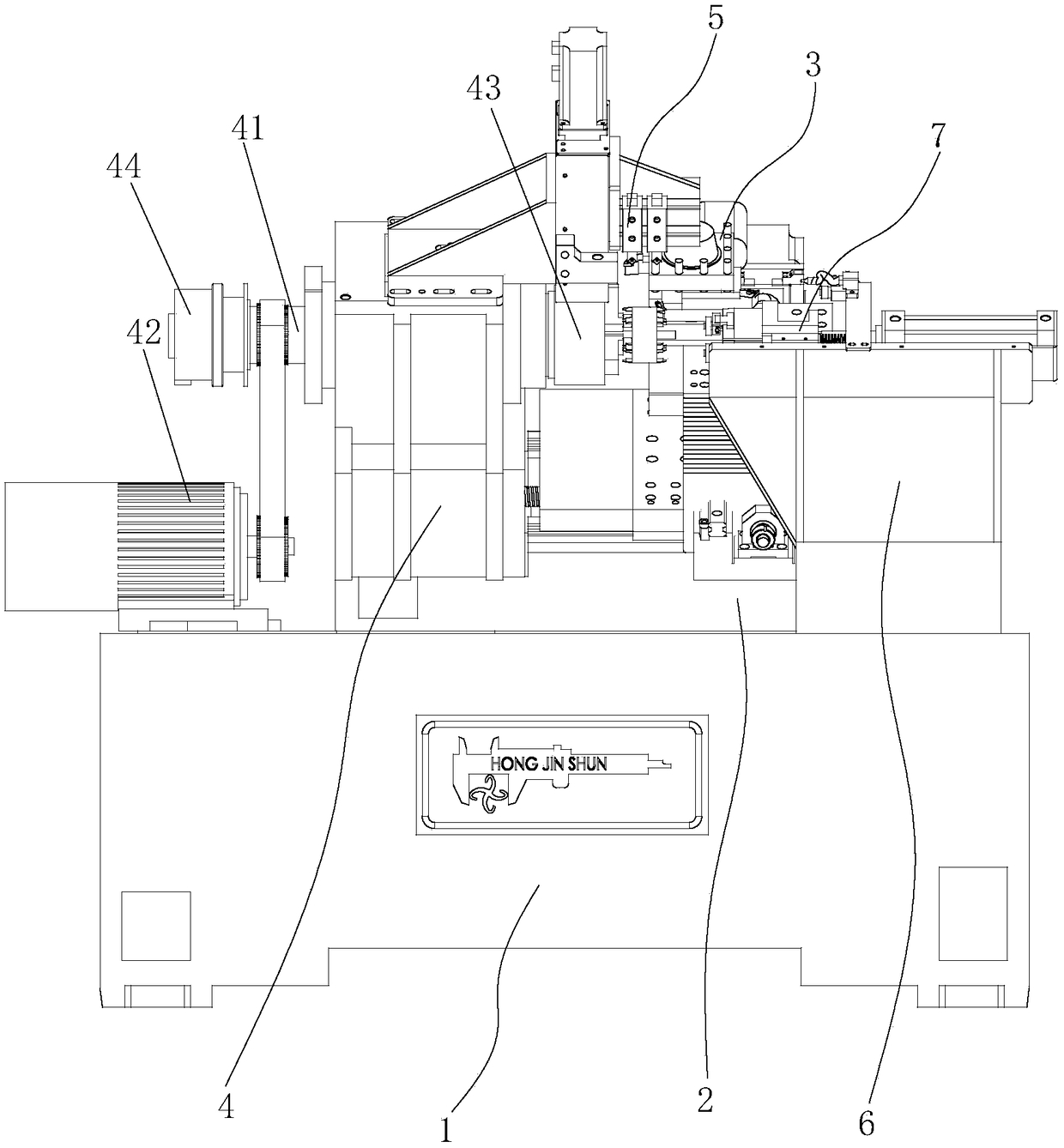

Multi-shaft high-speed numerically controlled lathe

InactiveCN106514260AResolve swingImprove stabilityOther manufacturing equipments/toolsTool holdersCantileverMachining

The invention relates to a multi-shaft high-speed numerically controlled lathe. The multi-shaft high-speed numerically controlled lathe comprises a slant bed lathe body which is provided with a main machine and a slant bed body assembly. A four-station electric tool carrier and a lathe spindle are mounted on the slant bed body assembly, wherein an additional machining shaft system assembly which is arranged perpendicular to the lathe spindle is further mounted on a spindle box; a second fixed seat is arranged on the lateral side of the slant bed body assembly on the main machine; and an auxiliary centering assembly opposite to the lathe spindle is mounted above the second fixed seat. According to the multi-shaft high-speed numerically controlled lathe provided by the invention, a machining shaft is additionally arranged; on the basis of the original machining shaft which machines an excircle, the additionally arranged machining shaft can perform operations such as chamfering and groove milling simultaneously, so that the production efficiency and the machining precision are greatly improved; the auxiliary centering assembly is a three-finger pneumatic finger, and a guide rail and sliding tables are arranged at the bottom of the three-finger pneumatic finger, so that a cantilever of the centering assembly can be prevented from being overlong, and the stability of the centering assembly is greatly improved.

Owner:DONGGUAN HONGJINSHUN MACHINERY MFG

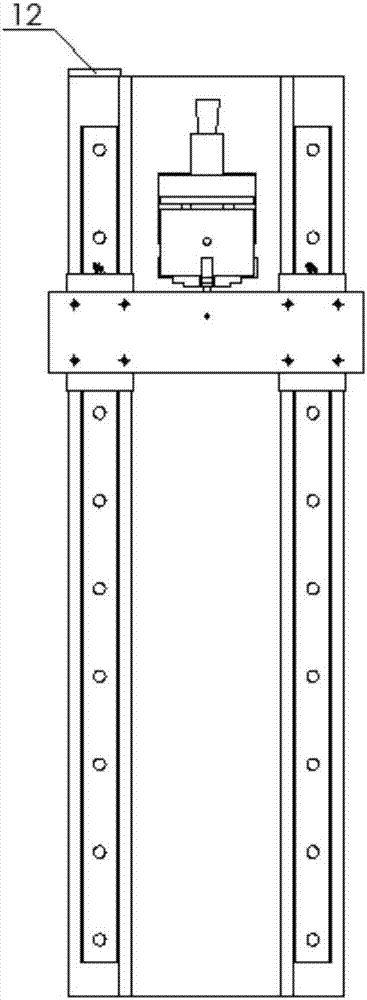

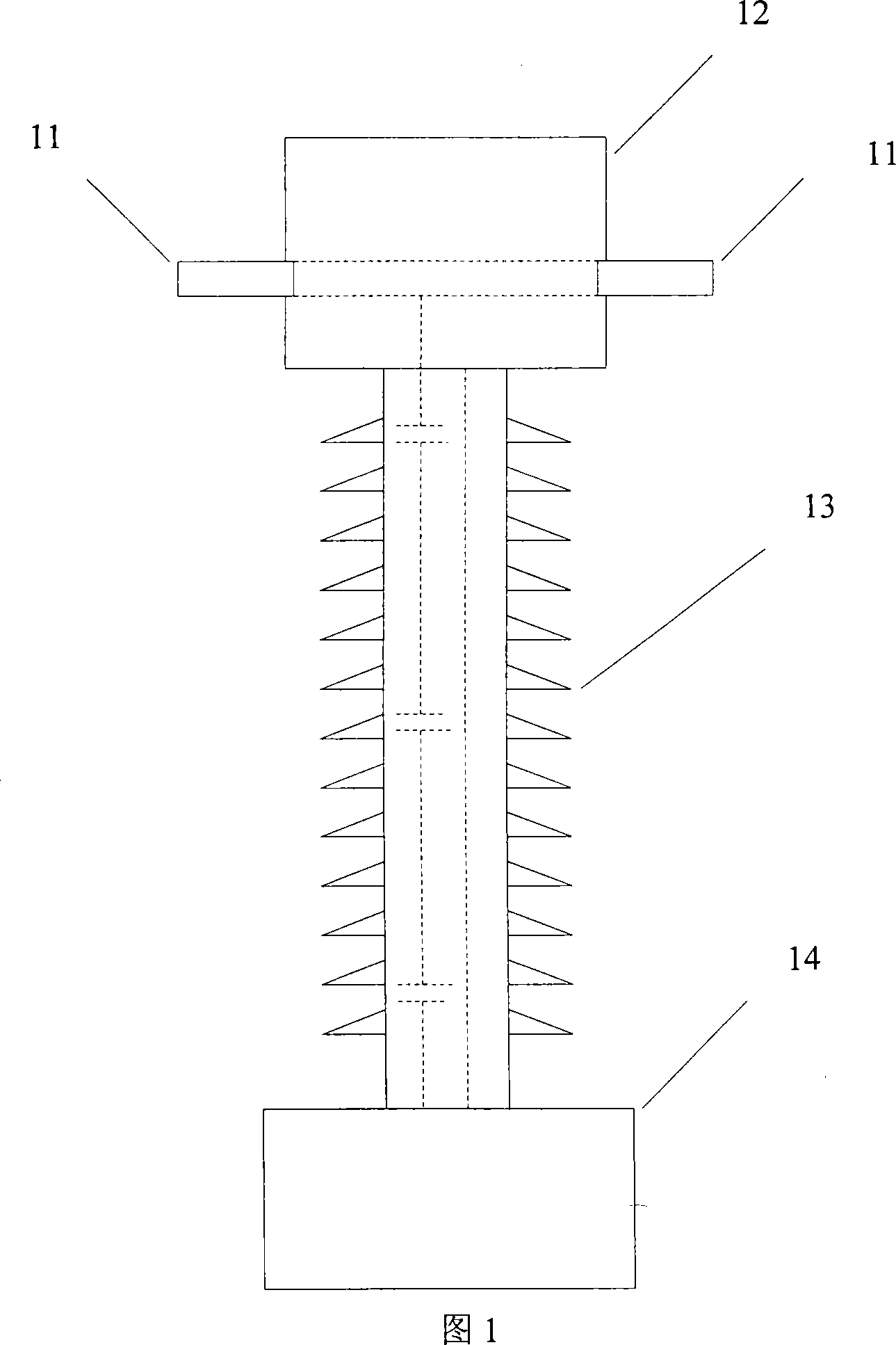

Multi-type high-precision planetary roller lead screw pair precision detection device

InactiveCN106885518ARealization errorAchieve precisionMachine gearing/transmission testingUsing optical meansGratingRoller screw

The invention provides a multi-type high-precision planetary roller lead screw pair precision detection device which comprises a grating ruler, a reading head, a slider, a linear guide rail, a nut sleeve, a punch molding device, a display screen and the like. The two-way positioning handle of the punch molding device is connected with a three-jaw chuck through a rotating shaft, and the three-jaw chuck clamps a lead screw for synchronous rotary motion. One end of a nut sleeve guide rod is fixedly connected with a connection plate, and the other end is fixedly connected with the nut sleeve. Both ends of the connection plate are fixedly connected with the slider and the reading head. The reading head horizontally slides on the grating ruler. The slider slides horizontally on the linear guide rail. The nut position information acquired by the reading head is displayed on the display screen during the straight nut movement. The device provided by the invention can test the return error, the two-way lead precision and the like of a planetary roller lead screw pair, has the advantages of high test precision and simple operation, and is suitable for the test of multiple types of planetary roller lead screw pairs. A reliable method is provided for the precision test of the planetary roller lead screw pair.

Owner:BEIHANG UNIV

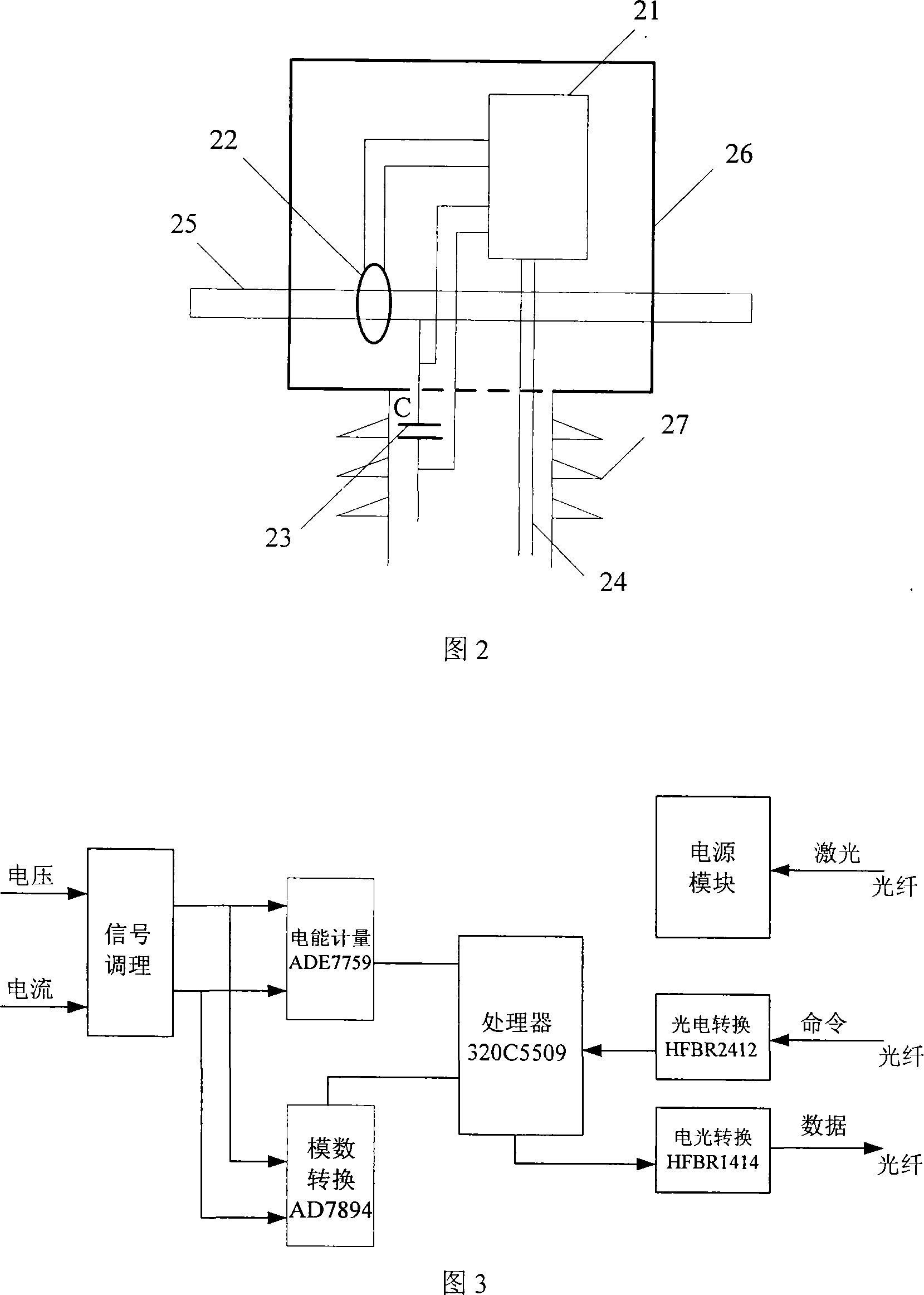

Single-phase electric energy mutual-inductor

InactiveCN101183120AImprove accuracyExcellent insulation designCurrent/voltage measurementTime integral measurementTransformerEngineering

The present invention relates to a single-phase power transformer, which belongs to the technical field of an electric energy measurement and a mutual inductor. The device comprises an once terminal, a high pressure sensing head module, an insulator and a basal seat; wherein, the high pressure sensing head module is connected with a high pressure generatrix through the once terminal; optical fibers are buried in the inductor; the optical fibers in the inductor and the optical fibers in the basal seat are connected with a optical cable through an optical fiber terminal; the high pressure sensing head module is fixed on the top end of the insulator; the output end of the insulator is connected with the optical fiber in the insulator. The present invention can increase the accuracy of an electric energy measuring system to the most extent.

Owner:安徽艺展电气设备有限公司

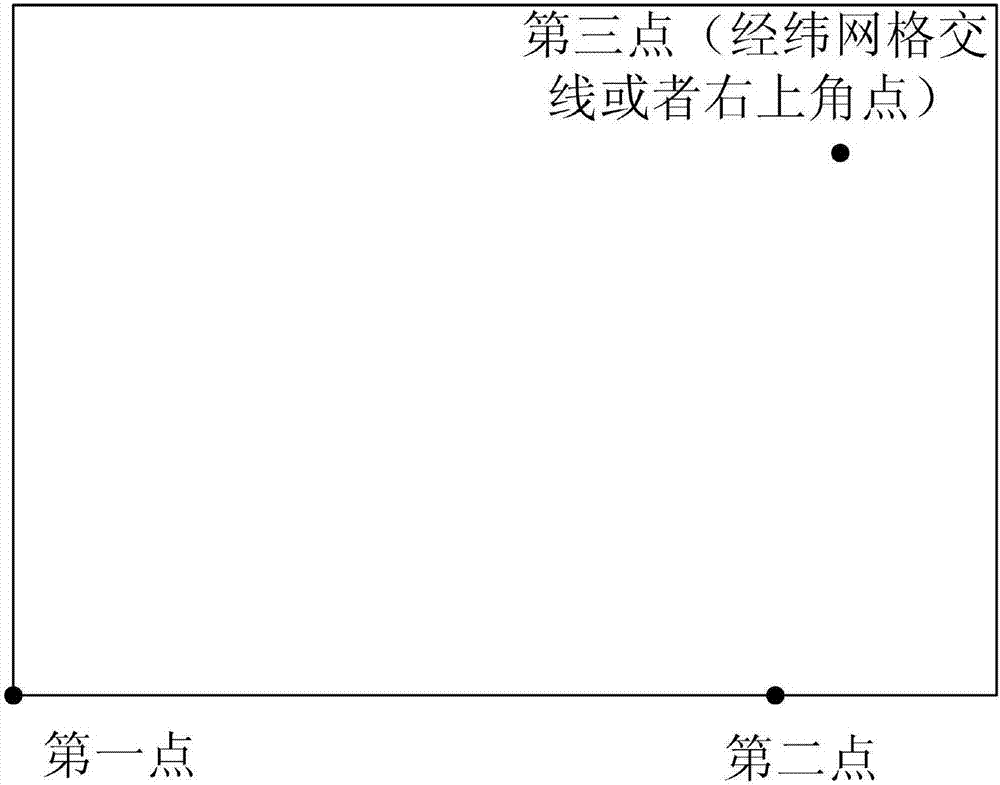

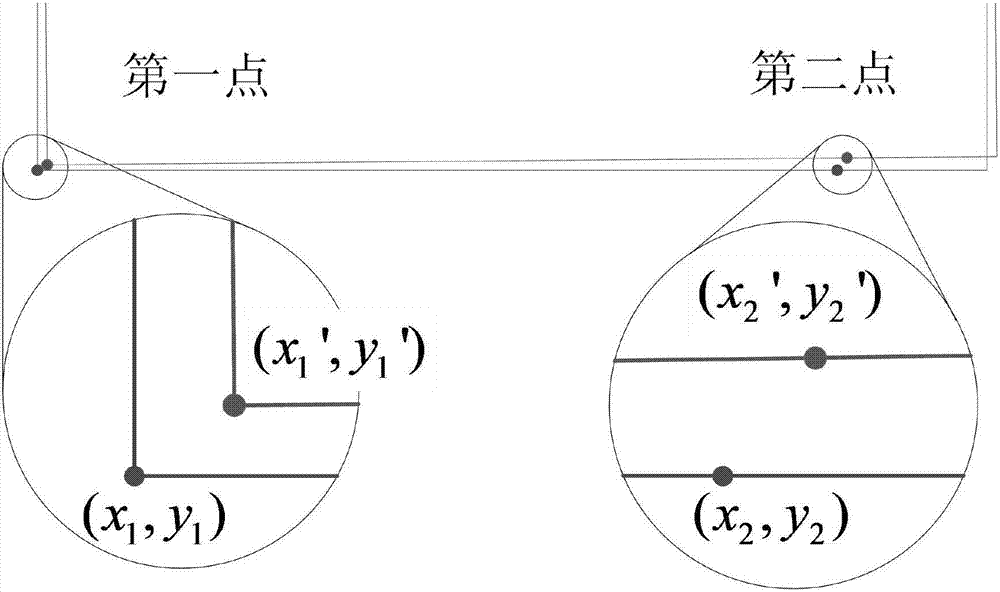

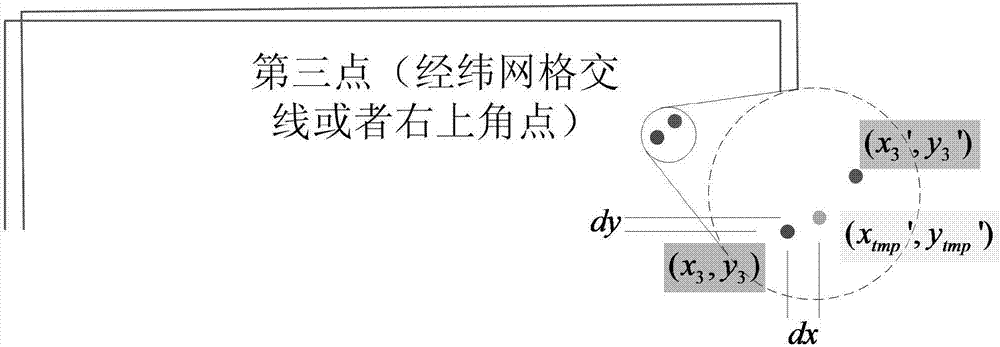

Method used for paper chart correction

ActiveCN107036628AHigh precisionImprove picking accuracyNavigational calculation instrumentsComputer graphics (images)Errors and residuals

The invention relates to a method used for paper chart correction. The method is characterized in that the method comprises the following steps that excursions and rotation errors generated during the placement of a chart are corrected by two calibrated points; deformation errors of the paper chat are corrected by three calibrated points. According to the method, a distortional paper chart coordinate system or a coordinate system out of position in placing can form mapping with a coordinate system of actual placement, and when plotting a position coordinate of a plotting light dot or a paper chart pick point, through mapping transformation, the light dot plotting indication precision and the coordinate pick precision can be improved; through the selection of two position points, two sets of theoretical position coordinates and actual position coordinates are obtained, and the rotation errors and moving errors generated by placing the paper chart are achieved; through the selection of three position points, three sets of theoretical position coordinates and actual position coordinates are obtained, and the rotation errors, the moving errors and the deformation errors of the paper chart are completed.

Owner:TIANJIN NAVIGATION INSTR RES INST

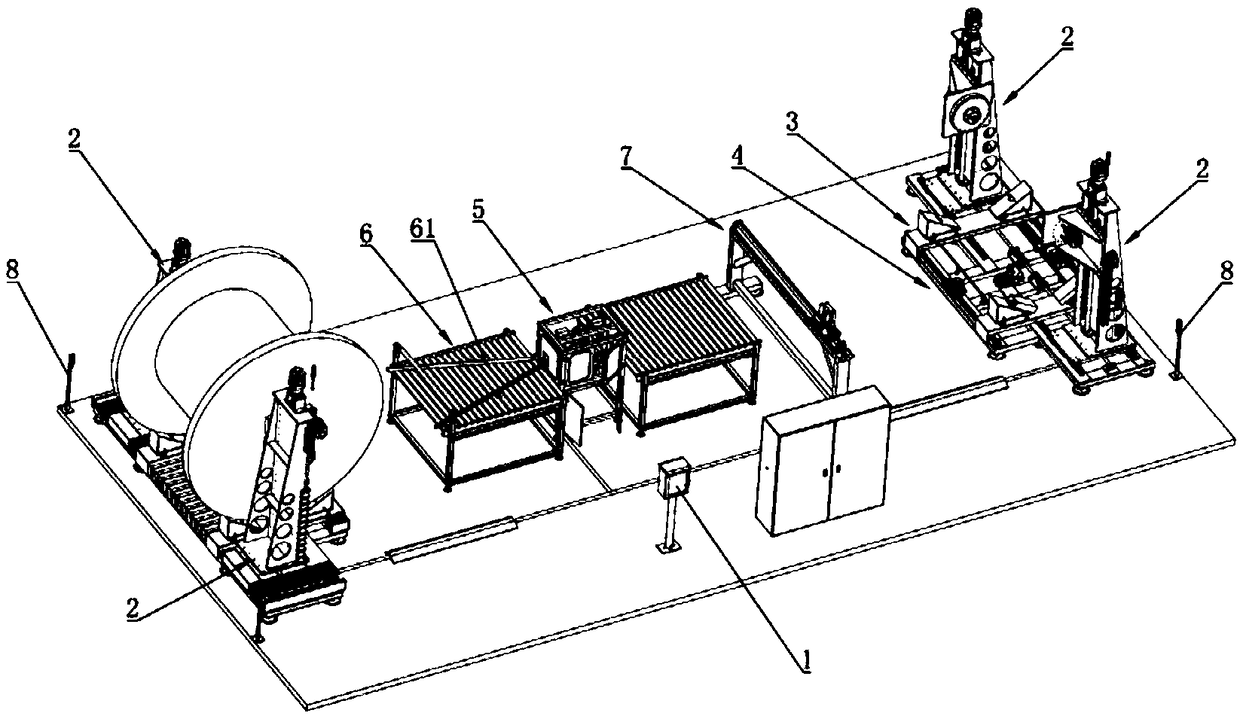

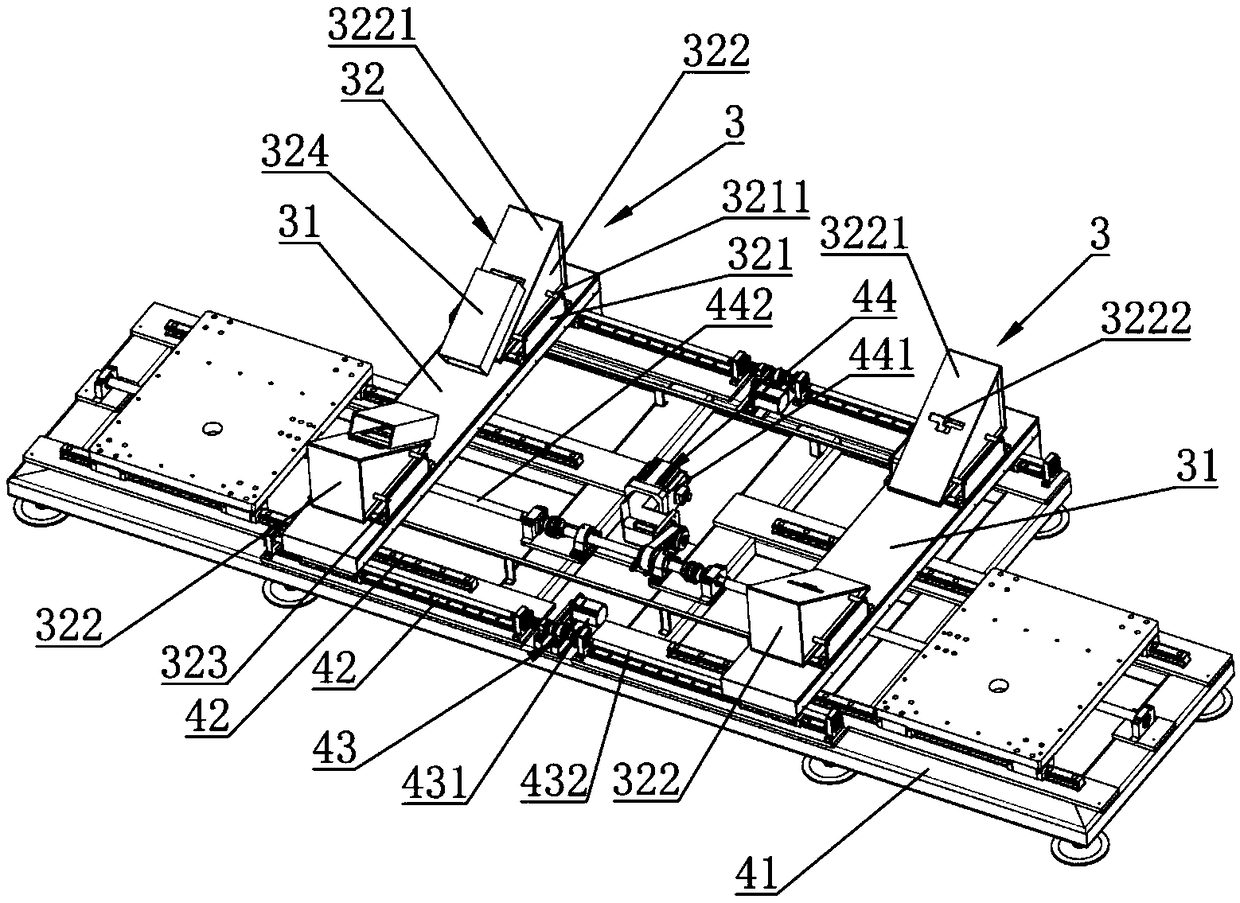

Cable cutting equipment

The invention relates to the technical field of cable cutting, in particular to cable cutting equipment. The equipment comprises a control device, two sets of material reeling devices and a cutting device arranged between the two sets of material reeling devices; the control device is electrically connected with the material reeling devices and the cutting device; each material reeling device comprises a reel receiving and discharging mechanism for rotary discharging or receiving of reeled materials, a reeled material positioning mechanism for placing the reeled materials and facilitating thereel receiving and discharging mechanism, and a Y-axis moving component for driving the reel receiving and discharging mechanism and the reeled material positioning mechanism to move in the Y-axis direction; each reel receiving and discharging mechanism comprises a Z-axis moving component and a reeled material rotating component which can move in the Z-axis direction through the Z-axis moving component; the Z-axis moving components are mounted on the Y-axis moving components and can move in the Y-axis direction; each reeled material positioning mechanism comprises two sets of reel positioningcomponents; and the two sets of reel positioning components are connected with the Y-axis moving components correspondingly. Cables can be cut conveniently through the equipment, and the cutting precision and efficiency are improved.

Owner:广州国机智能电力科技有限公司 +1

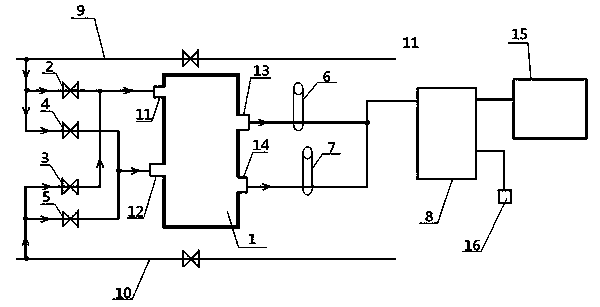

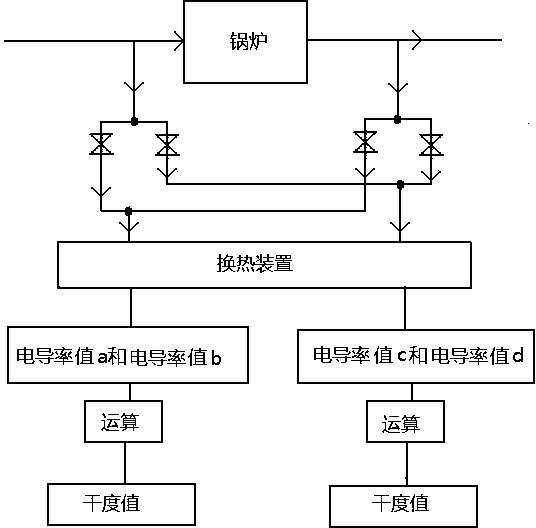

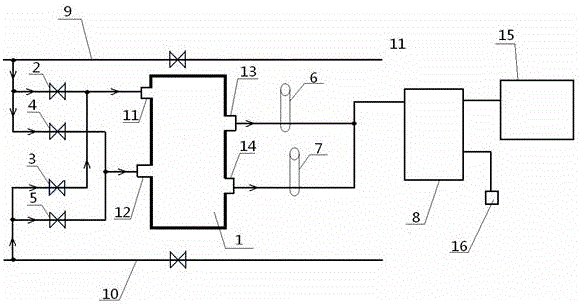

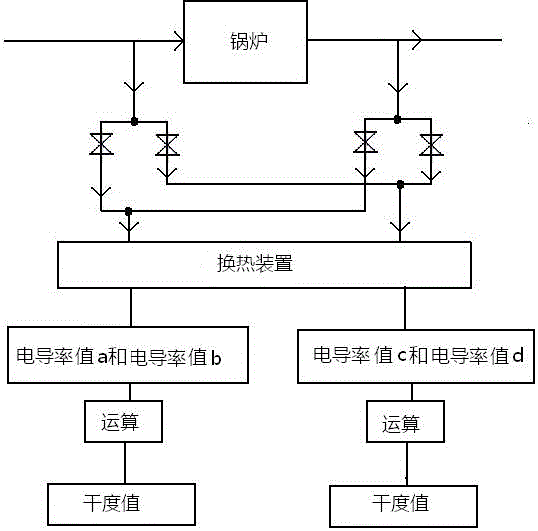

Oil field steam injection boiler steam dryness measurement method and its system

ActiveCN103383370ARealize self-cleaningAvoid measurement errorsMaterial resistanceProgrammable logic controllerEngineering

The invention relates to an oil field steam injection boiler steam dryness measurement method and its system. The measurement method employs a process 1 and a process 2 alternately. The process 1 includes: measuring a conductivity value a by a first conductivity sensor (6), then conducting commutation, measuring a conductivity value b by the first conductivity sensor (6), and calculating a dryness value by a programmable logic controller (8). The process 2 includes: measuring a conductivity value c by a second conductivity sensor (7), then conducting commutation, measuring a conductivity value d by the second conductivity sensor (7), and calculating the dryness value by the programmable logic controller (8). The oil field steam injection boiler steam dryness measurement method and its system provided in the invention improve the accuracy and stability of oil field steam injection boiler steam dryness measurement, and reduce the use cost.

Owner:西安庆晟机电科技有限公司

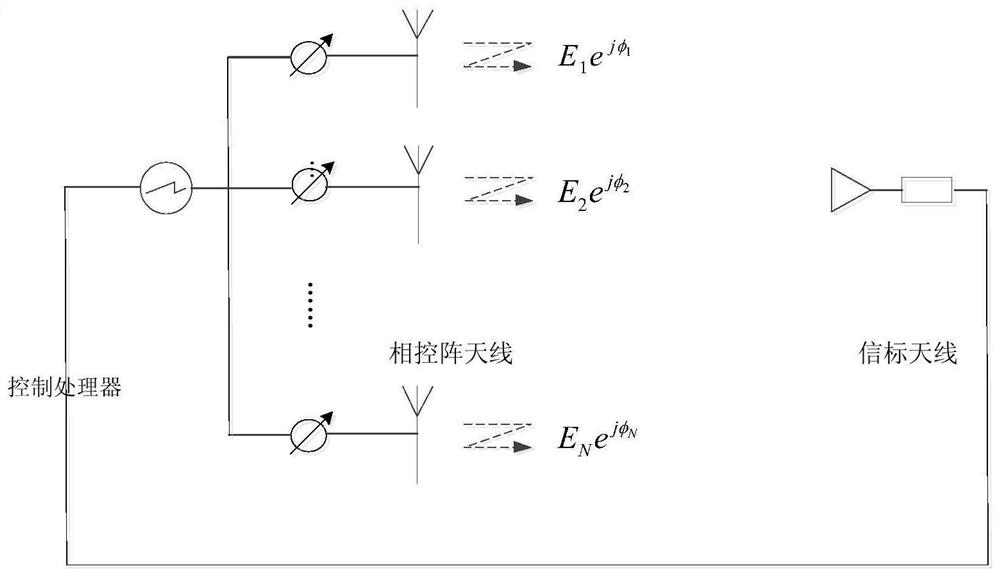

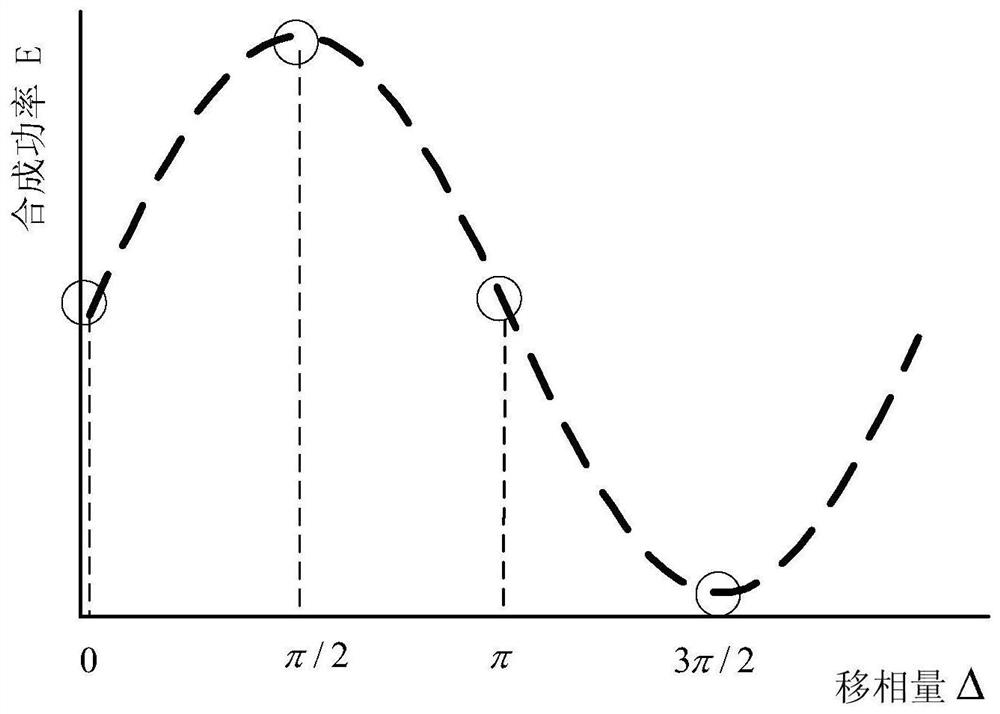

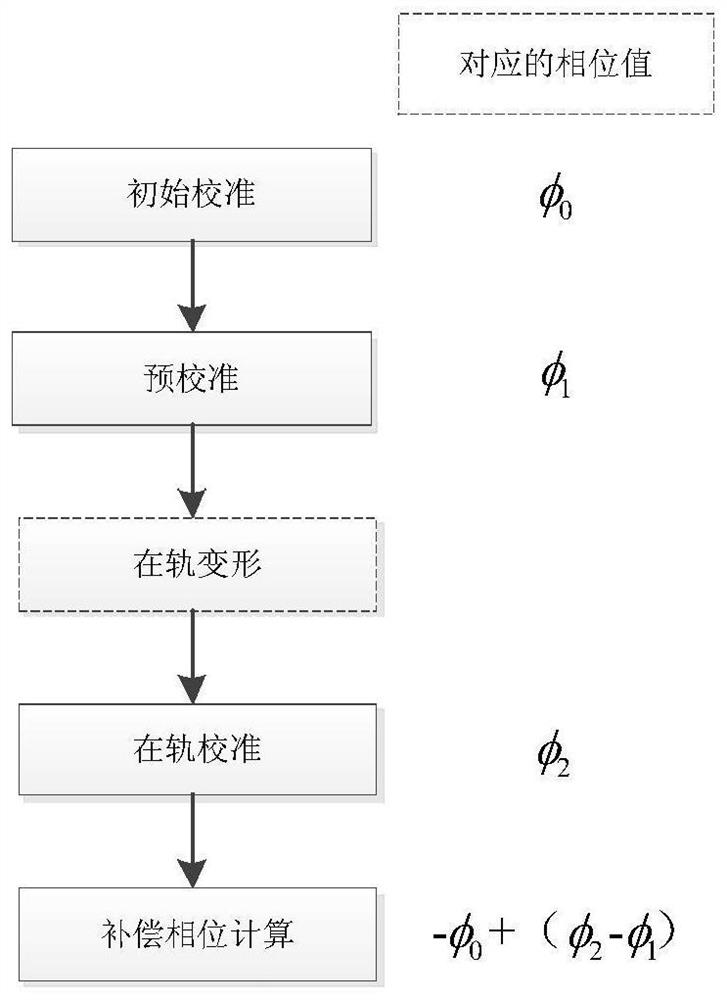

On-orbit correction and deformation evaluation method for phased-array antenna

PendingCN113934965ALoad cost reductionRealize antenna electrical performance correctionGeometric CADDesign optimisation/simulationEngineeringComputational physics

The invention relates to an on-orbit correction and deformation evaluation method for a phased-array antenna. The method comprises the following steps: firstly, carrying out ground structure and amplitude-phase measurement on an integrated link of a beacon, an array plane and a channel of the active phased-array antenna; then obtaining on-orbit compensation phases of all channels through calculation on the basis of ground amplitude-phase measurement data, and on-orbit correction of the electrical performance of the phased-array antenna is completed; secondly, according to the phase change value of each channel, obtaining the physical deformation length from the array antenna beacon to the position of each array plane unit; comparing and calculating with the measured data of the ground structure of the array antenna, and predicting the possible position coordinates of each unit of the array plane after in-orbit deformation; and finally, attributing the array surface deformation on-orbit evaluation to the optimization problem of the array surface unit position, constructing a deformation optimization model and optimization constraint conditions to update the array element position, solving the final array element position coordinate on the basis of multiple iterative optimization, and realizing the on-orbit profile change evaluation.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Method for collecting electric energy errors of electric energy meter and device thereof

ActiveCN102608559BRealization errorReduced calibration requirementsElectrical measurementsPower factorReactive load

The invention relates to the field of electric energy metering, and discloses a method for collecting electric energy errors of an electric energy meter and a device thereof. In the invention, in a reactive load environment, the electric energy meter is collected by using high-accuracy and universal power values; and compared with the traditional pulse correction method, the correction requirements are reduced, the calibration process is simplified, the advantages of quickness, accuracy and convenience are highlighted, and an effect of carrying out single-point correction on the errors of the electric energy meter is achieved. If a phase angle is too big or too small, a situation that the value of a sine or cosine thereof is too big or too small is caused, therefore, the calculation accuracy can not be ensured. Through taking power values as data sources rather than direct and low-accuracy angles or derived parameters (such as power factors and the like) as data sources, a situation that the principle error of correction is low enough can be ensured. Through verification, the accuracy of correction on the electric energy meter can be further ensured. The testing time is only one third of the original testing time, thereby greatly saving the total collection time.

Owner:HI TREND TECH SHANGHAI

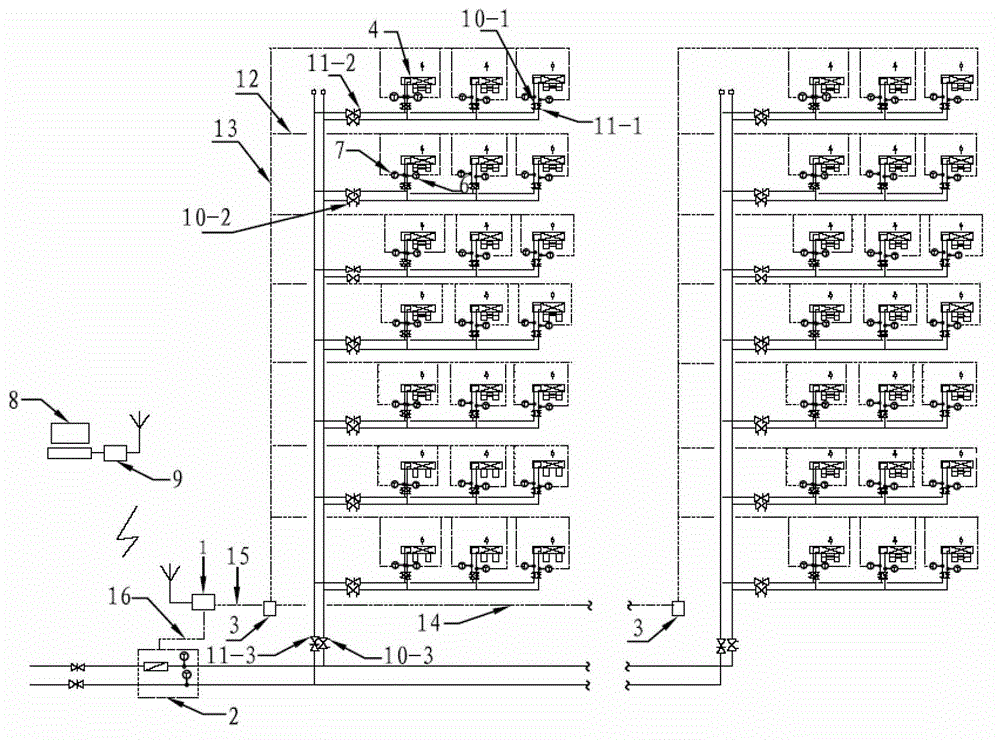

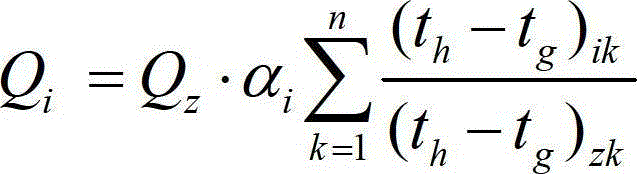

Cold quantity distribution system and method based on flow temperature difference proportion

InactiveCN102914390AEncourage energy-saving behaviorSettle the priceCalorimeterMain branchData center

A cold quantity distribution system and method based on flow temperature difference proportion relates to a cold quantity distribution system and method, solving the defects of a current cold quantity metering method and having advantages of accurate and reliable metering result. The method comprises the following steps: a balance valve with a flow measuring function is arranged at front of each tail-end fan coil unit and is used for system hydraulic power balancing regulation and measuring flow through the fan coil unit; a cold quantity meter is arranged at a cold source outlet or an overall main branch; and supply / return water temperature sensors are respectively arranged on user-tail end inlet / outlet pipes and used for transmitting supply / return water temperature and system overall cold supply quantity to a calculator or a data center in a wired or wireless manner for completing cold quantity calculation and distribution operation. The system and the method, provided by the invention, are suitable for an air-conditioning system capable of regulating tail-end speed through make-and-break regulation, three-gear variable-speed regulation and infinitely variable speed regulation, and also suitable for an air-conditioning system capable of regulating the tail-end wind speed through the combination of make-and-break regulation and stepless speed regulation.

Owner:HARBIN INST OF TECH

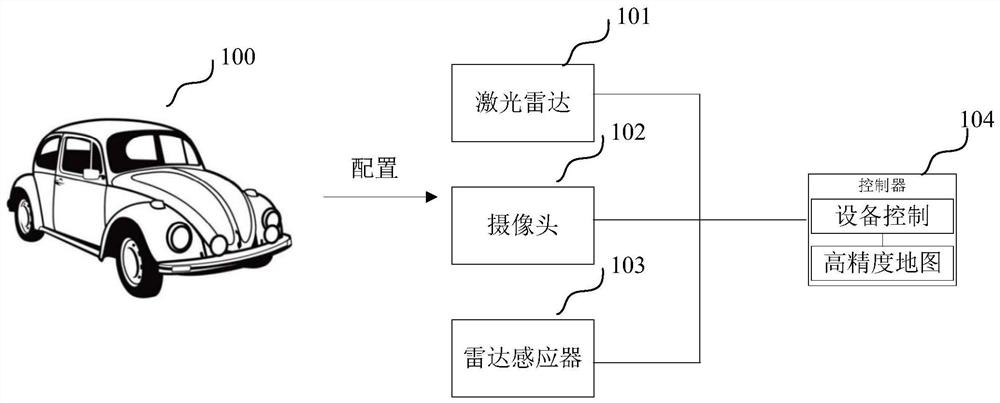

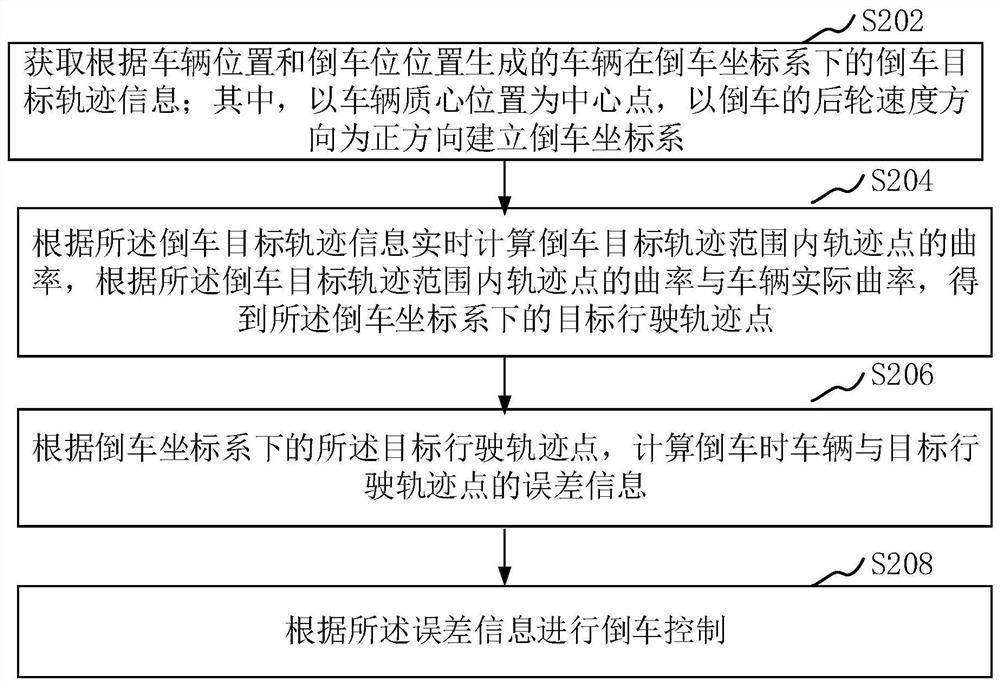

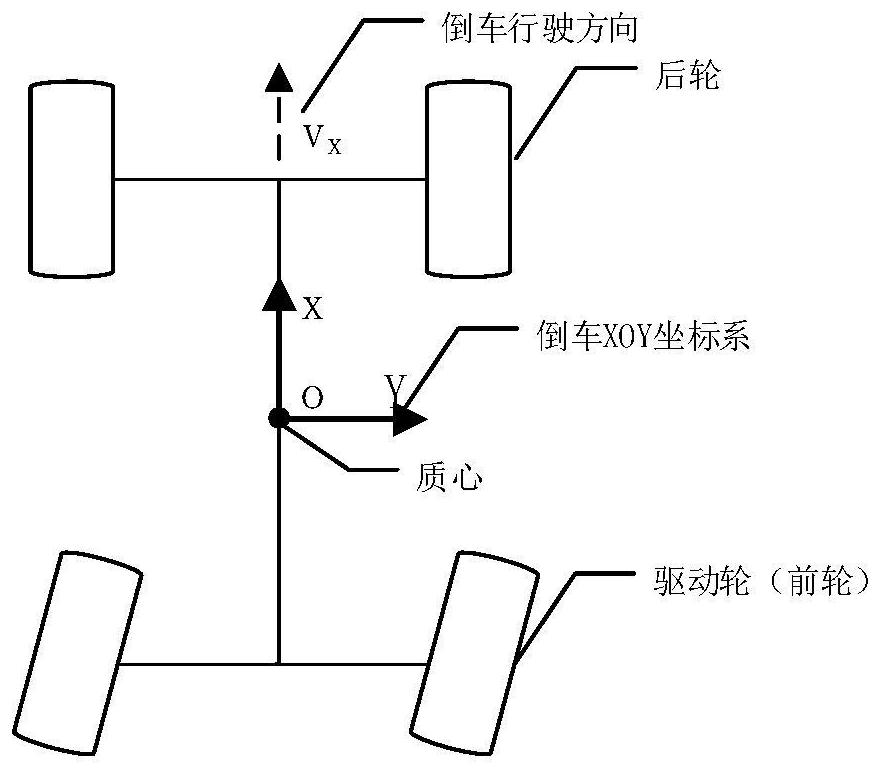

Automatic reversing control method and device, vehicle and storage medium

ActiveCN114435470ARealize advance control functionHigh control precisionSteering partsControl systemControl engineering

The invention relates to an automatic reversing control method and device, a vehicle and a storage medium. According to the method, a back-up coordinate system is established with the back-up rear wheel speed direction as the positive direction, back-up target track information of the vehicle under the back-up coordinate system is obtained, and errors caused by coordinate conversion through back-up drivable area position information can be avoided; the position of the data point with the maximum curvature change within a certain range is calculated in real time according to the backing target driving track, backing control is conducted according to the target position and the error value of the vehicle, the advanced control function of a control system can be achieved, error accumulation caused by system delay and other reasons is made up, and backing, especially parking space control accuracy is improved. According to the method, the accuracy of automatic reversing control is improved.

Owner:CHANGSHA INTELLIGENT DRIVING INST CORP LTD

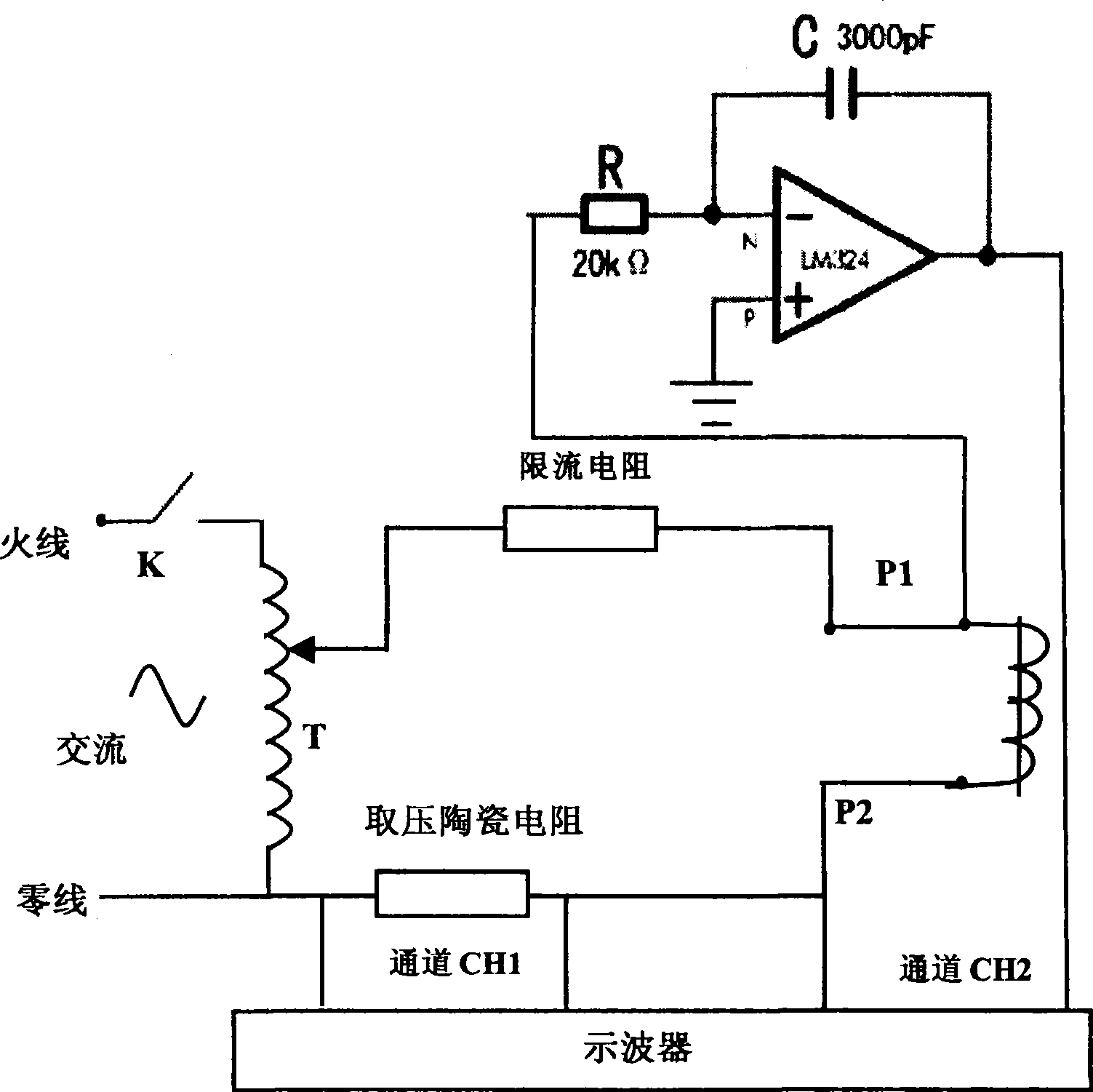

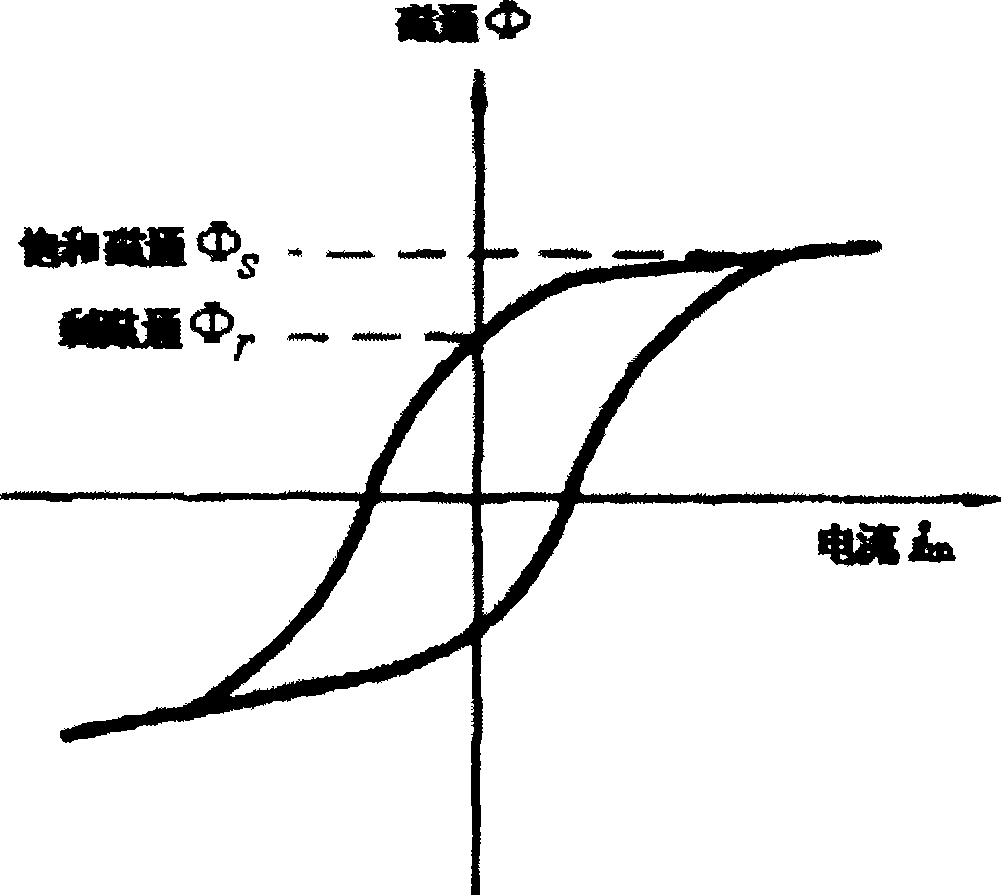

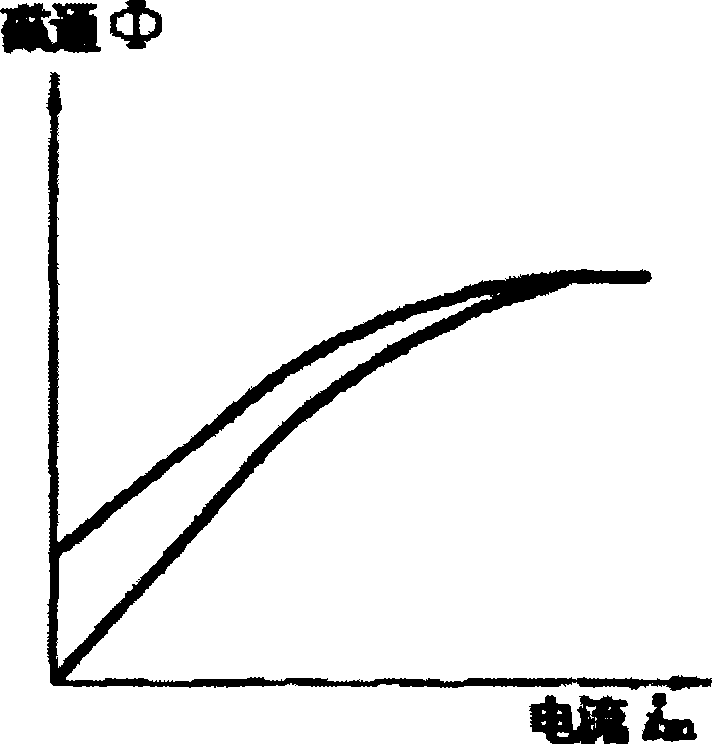

Method for measuring coefficient of residual magnetism based on alternating current method

InactiveCN100495064CReduce accidental errorImprove test accuracyMagnetic property measurementsElectrical measurementsFull waveEngineering

A method for testing residual magnetism based on interchange means includes forming test circuit by connecting oscilloscope, switch, continuous self-coupling transformer, second winding current mutual inductor to be tested, two test probes and integration module; regulating said transformer to record voltage and current waveform on oscilloscope using cursor to calculate full wave average value to confirm residual magnetism; reversing power supply; repeating above said recording and calculating steps to derive out average value according to calculated out residual magnetism value.

Owner:SHANGHAI JIAOTONG UNIV

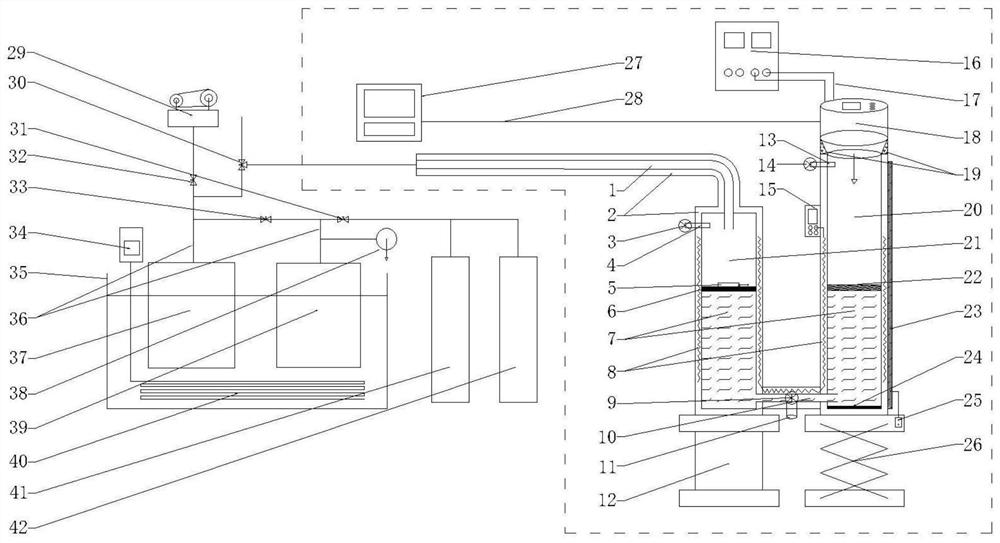

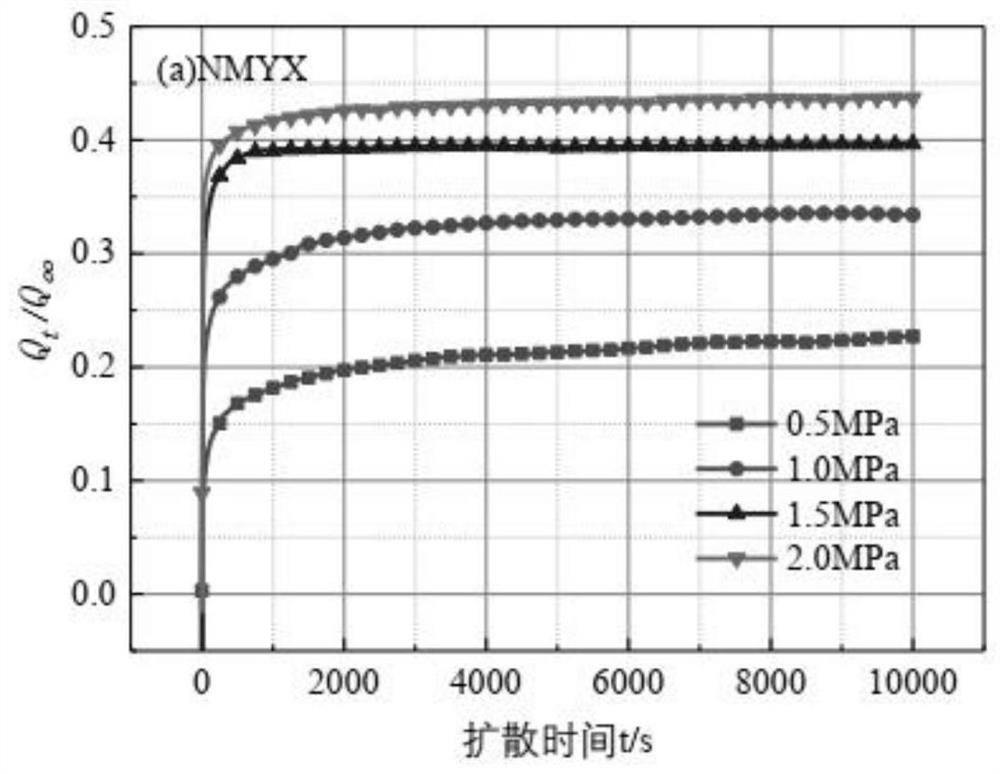

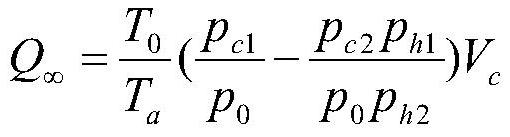

Porous medium adsorption and diffusion dynamic self-test experiment system and method

PendingCN113138151AHigh degree of automationRealize dynamic visualization displayPermeability/surface area analysisWater storageThermodynamics

The invention discloses a porous medium adsorption and diffusion dynamic self-test experiment system and method. The system comprises a diffusion gas constant-temperature storage system, a data high-frequency automatic acquisition system, a pressure difference automatic leveling system and a gas constant-temperature adsorption system. The liquid level of the water storage column and the liquid level of the gas collection column are flush through the differential pressure automatic leveling system, and systematic errors caused by gas pressure changes are avoided; and a diffusion gas constant-temperature storage system and a gas constant-temperature adsorption system are utilized to solve systematic errors caused by gas temperature changes. The data high-frequency automatic acquisition system acquires data information through ultrasonic reflection, and high-frequency and high-accuracy reading can be achieved. And the total volume of gas diffusion and the gas adsorption capacity of the porous medium are calculated through computer programming, and dynamic visual display of experimental data is realized, so that the working efficiency of scientific research is improved. The whole experiment system is high in automation degree, errors caused by manual operation are reduced to a great extent, and meanwhile a large amount of time is saved for researchers.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

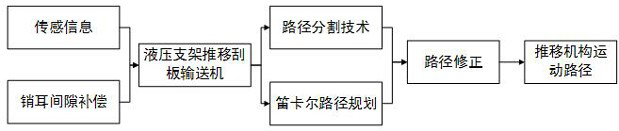

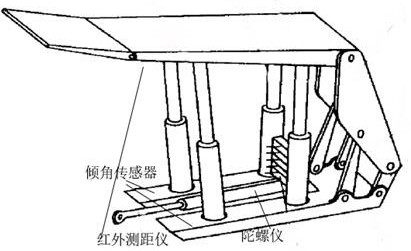

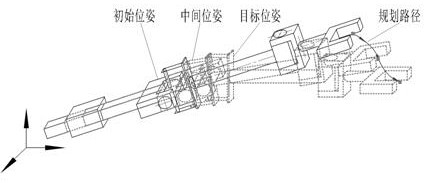

Motion planning method for pushing mechanism of hydraulic support and scraper conveyor

PendingCN113420403ARealization errorRealize virtual-real interactionDesign optimisation/simulationMine roof supportsTime informationService Interface for Real Time Information

The invention provides a motion planning method for a pushing mechanism of a hydraulic support and a scraper conveyor, which comprises the following steps: embedding related sensors in the hydraulic support to obtain real-time information, and after a coal mining machine cuts, planning the motion of each structure of the pushing mechanism by using a Cartesian path planning method after applying a path segmentation technology; obtaining a motion law of the three-dimensional coordinates based on the key points of each structure relative to the time dimension, and carrying out processing by using a Gaussian filtering correction method to obtain a final correction track; and applying the obtained motion rule to a coal seam created by Unity3D and a virtual coal machine equipment joint simulation system, accessing real-time sensing information to a virtual environment through an interface reserved in Unity3D for joint planning, and finally obtaining planned motion of the pushing mechanism. According to the invention, the movement of each structure of the pushing mechanism can be planned, and the mapping relation between the cooperative propulsion of the hydraulic support and the scraper conveyor in the virtual environment and the real underground environment is established.

Owner:TAIYUAN UNIV OF TECH

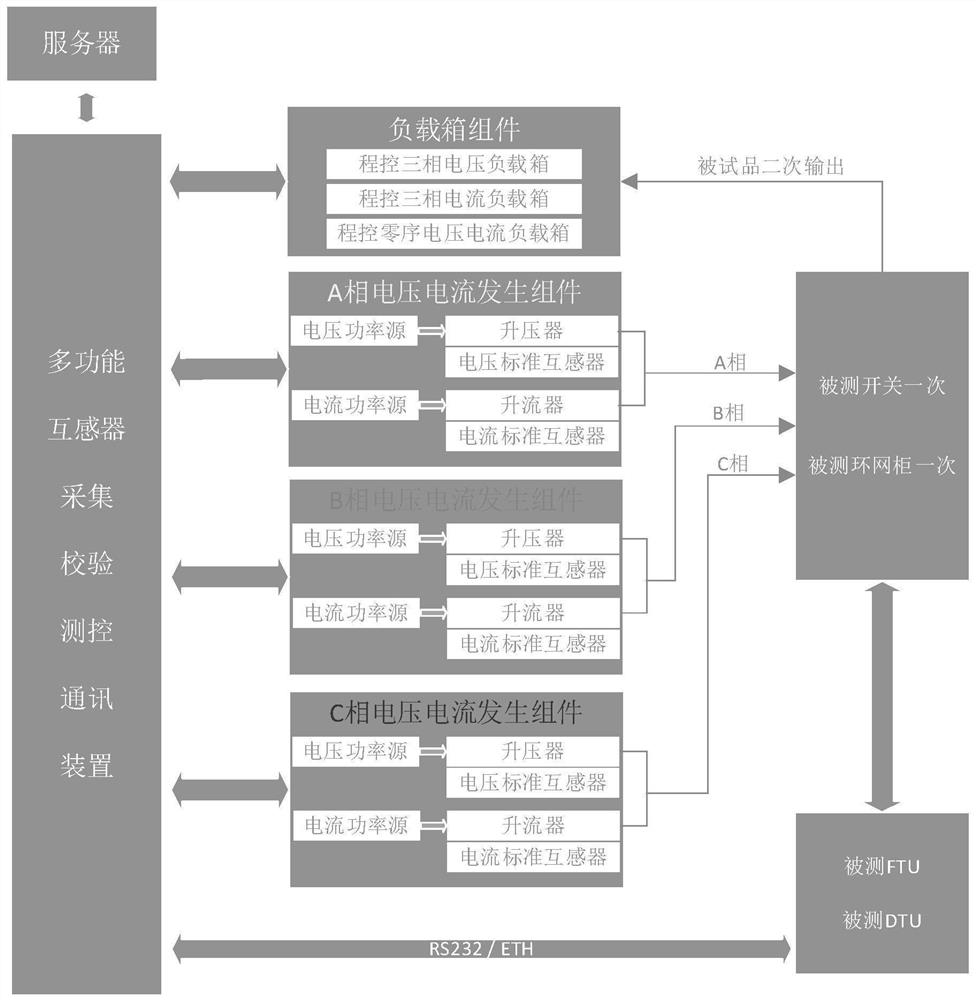

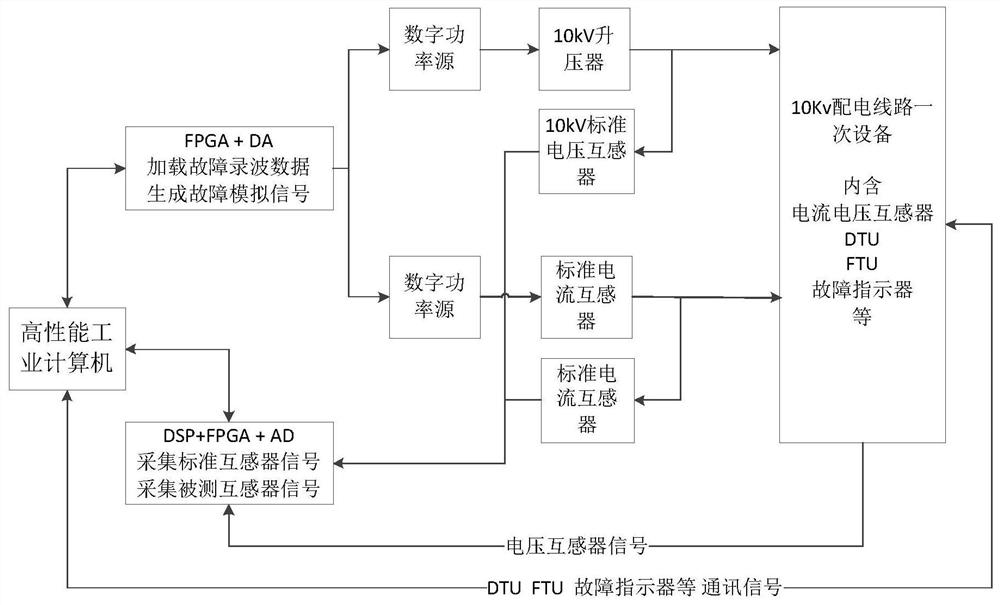

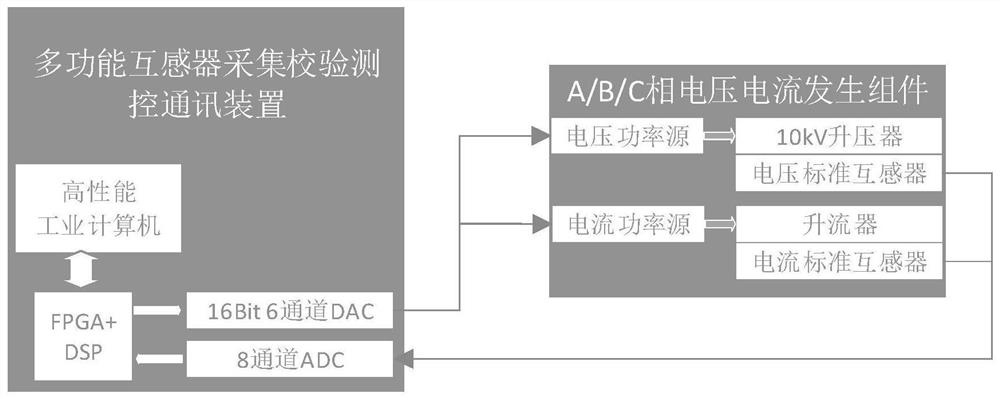

Power distribution line high-frequency transient characteristic signal generating device and control method thereof

PendingCN114019297AMeet functional requirementsMeet the parameter requirementsFault locationCommunication deviceFault recognition

The invention provides a power distribution line high-frequency transient characteristic signal generation device and a control method thereof, and the method comprises the steps: a multifunctional mutual inductor collection verification measurement and control communication device converts a received fault characteristic signal file into a current fault simulation signal and a voltage fault simulation signal; a gear control instruction is sent to the program control load box assembly according to the load requirement of a built-in mutual inductor of the tested equipment; an integrated high-voltage voltage and current generation assembly generates a current primary signal and a voltage primary signal according to the current fault simulation signal and the voltage fault simulation signal; and a program-controlled load box assembly adjusts the working gear of the program-controlled load box assembly according to the gear control instruction, so that the program-controlled load box assembly provides an external load for the secondary output of the tested equipment. The high-frequency transient characteristic signal output by the scheme can meet the requirement of power distribution automation equipment for carrying out a small-current grounding fault identification function test.

Owner:CHINA ELECTRIC POWER RES INST

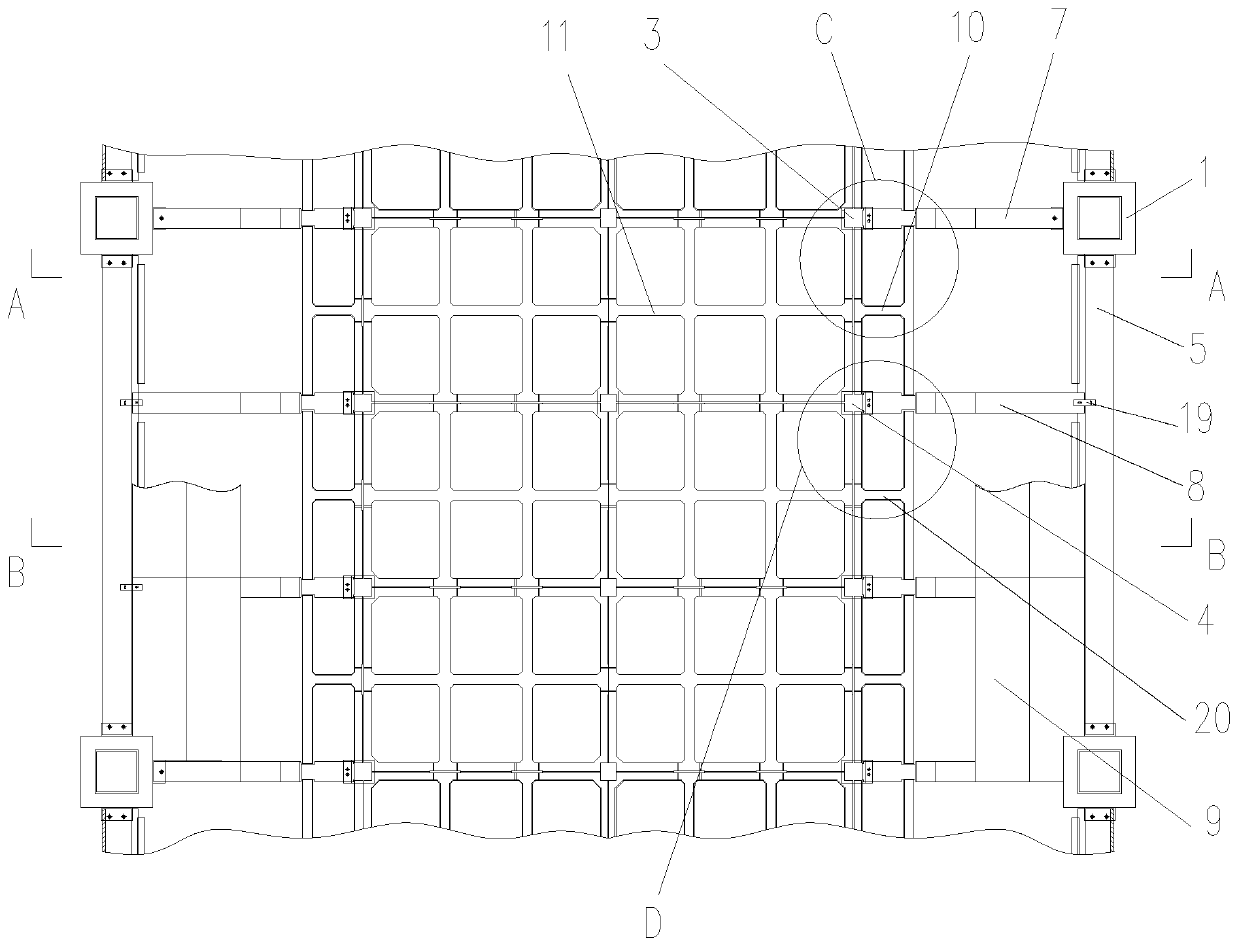

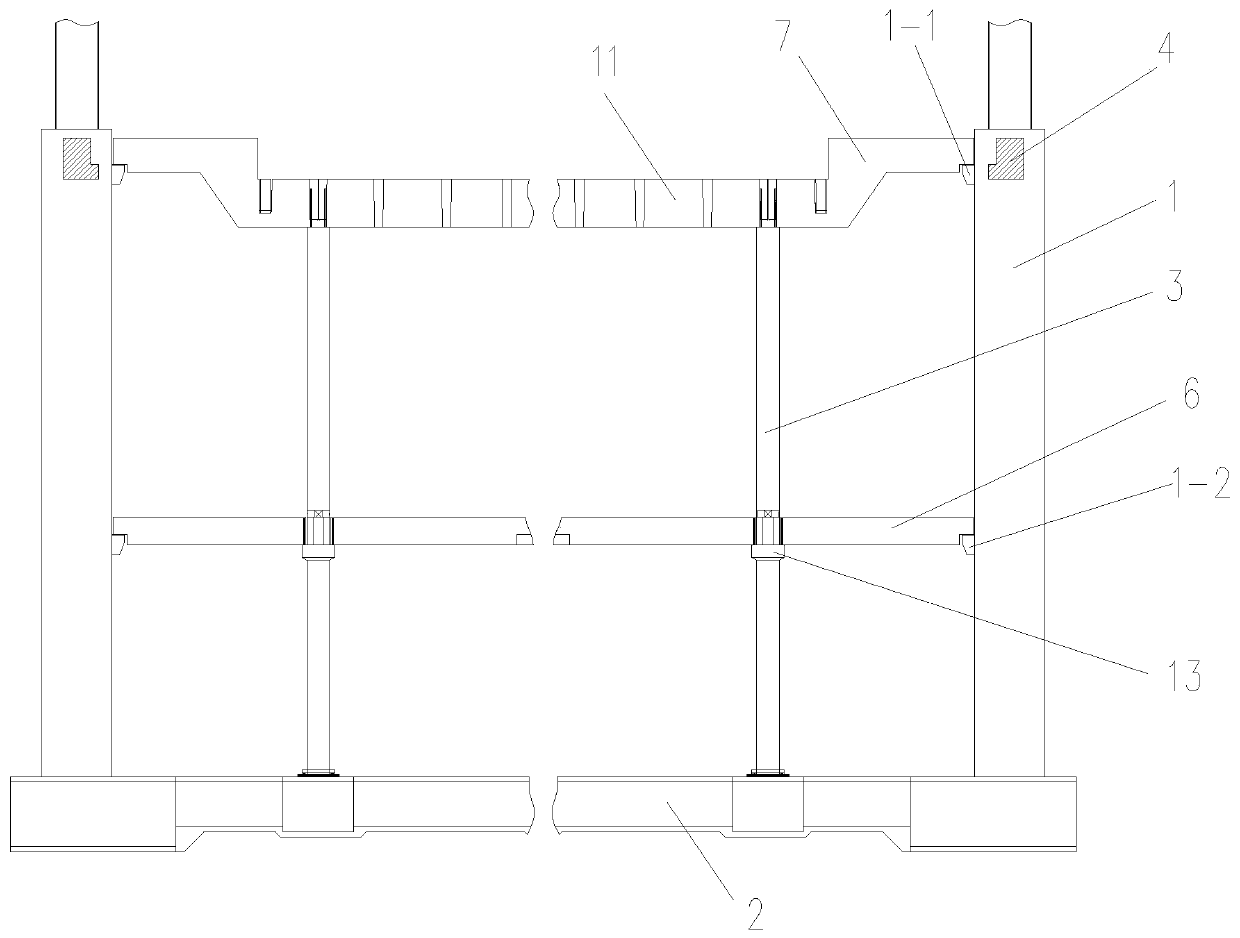

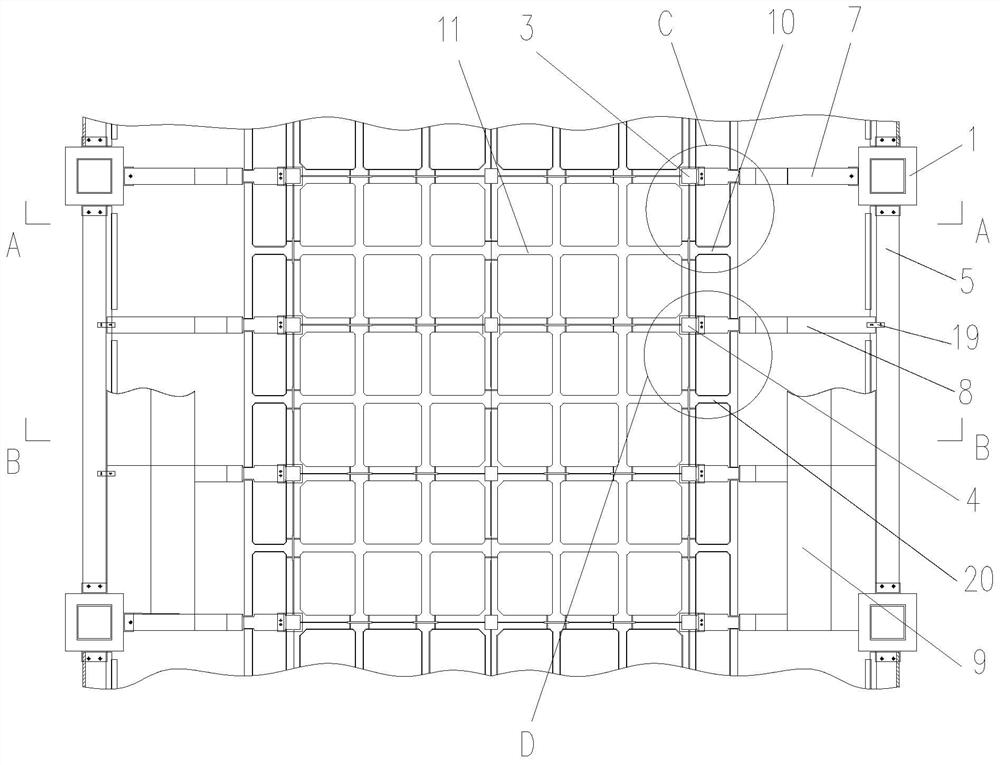

Fabricated electronic plant side span structure and construction method thereof

ActiveCN110206347AReduce investmentHigh speedFloorsBuilding material handlingH shapedBuilding construction

The invention discloses a fabricated electronic plant side span structure and a construction method thereof. The fabricated electronic plant side span structure comprises a plurality of first prefabricated PC columns, a plurality of second prefabricated PC columns, longitudinal prefabricated rectangular PC beams, transverse prefabricated rectangular PC beams, first prefabricated Z-shaped PC beamsand second prefabricated Z-shaped PC beams. The construction method comprises the steps that first, the longitudinal prefabricated rectangular PC beams are hoisted; second, the first prefabricated PCcolumns and the second prefabricated PC columns are hoisted; third, the transverse prefabricated rectangular PC beams are hoisted; fourth, the first prefabricated Z-shaped PC beams and the second prefabricated Z-shaped PC beams are hoisted; fifth, prefabricated laminated boards are laid; sixth, first prefabricated H-shaped PC beams and second prefabricated H-shaped PC beams are hoisted; seventh, prefabricated lattice beams are hoisted; and eighth, first connection joints and second connection joints are constructed. According to the construction method, the stability of the fabricated electronic plant side span structure is improved, the construction quality of the fabricated electronic plant side span structure is ensured, and the plant construction speed of a fabricated electronic plantis increased.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

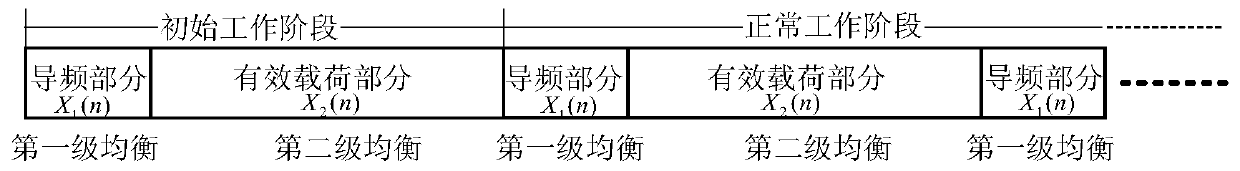

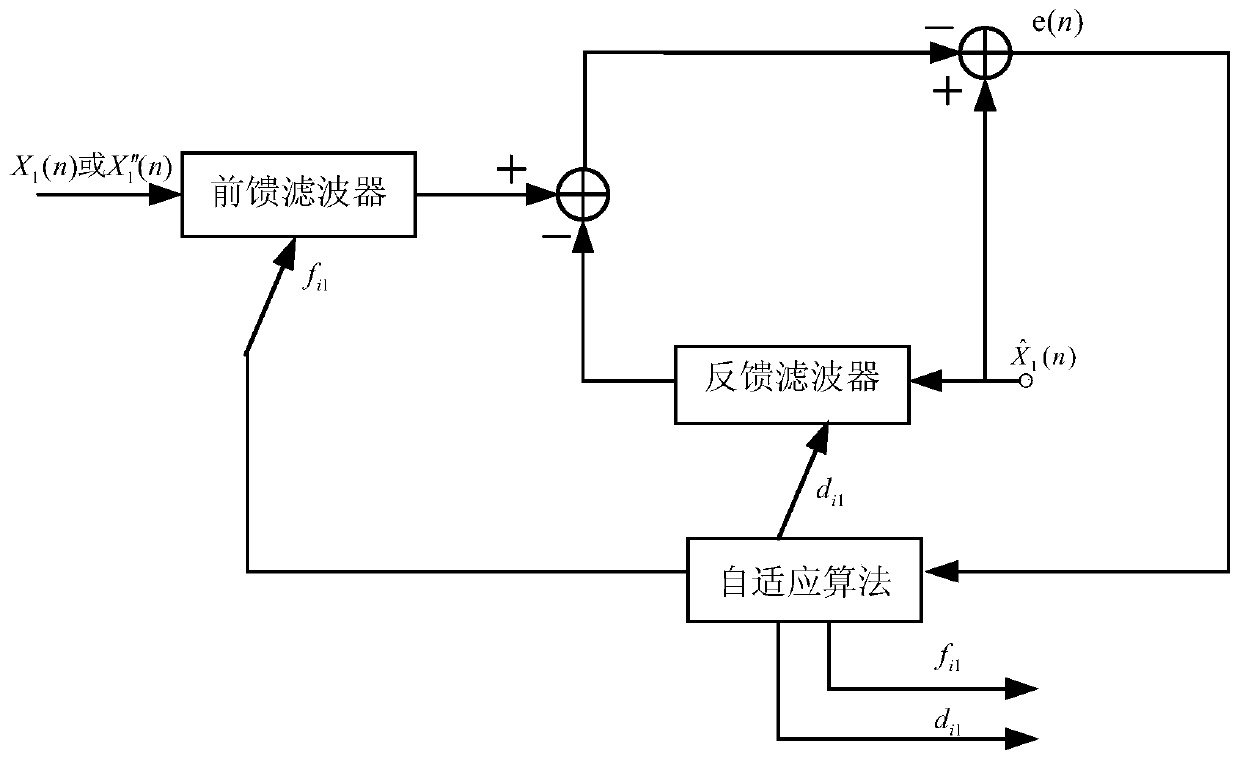

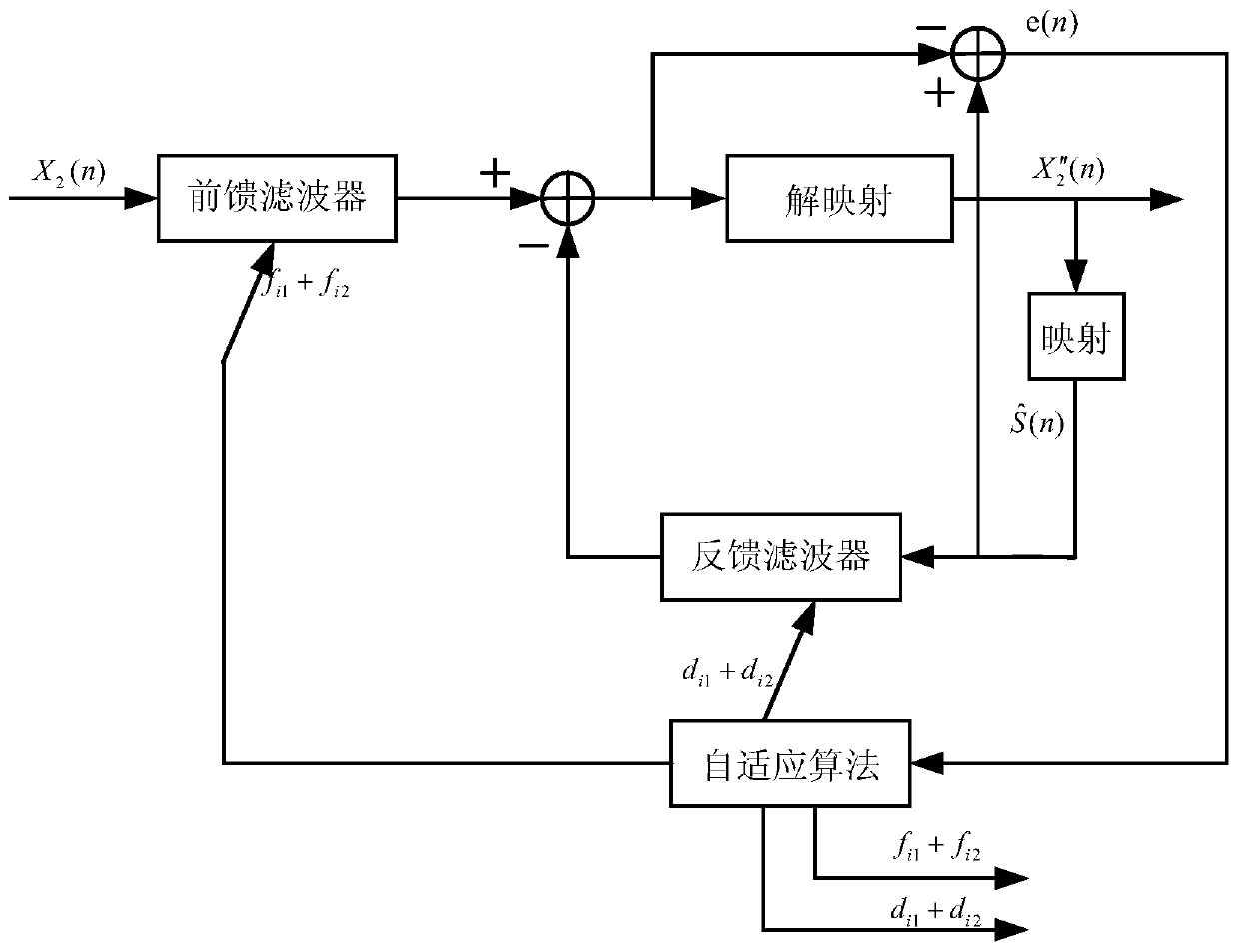

Self-adaptive transmission link intelligent joint equalization device

ActiveCN110784424AAchieve captureRealization errorTransmitter/receiver shaping networksSoftware engineeringEqualization

The invention discloses a self-adaptive transmission link intelligent joint equalization device, and belongs to the technical field of self-adaptive code modulation, transmission link equalization andthe like. The system comprises a demodulation module, a first-stage intelligent equalization module and a second-stage intelligent equalization module, each of the first-stage intelligent equalization module and the second-stage intelligent equalization module comprises a feedforward filter and a feedback filter, wherein the demodulation module is used for carrying out clock and carrier recoveryon a high-order modulation signal inserted with a prior pilot frequency; the first-stage intelligent equalization module and the second-stage intelligent equalization module adaptively update tap coefficients of the feed-forward filter and the feedback filter in the modules respectively; and finally, the second-stage intelligent equalization module filters the demodulated data frame output by thedemodulation module according to the equalized tap coefficient to obtain filtered payload part data. According to the invention, the tap coefficient of the filter can be adaptively adjusted, and rapidand effective equalization of data is realized.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

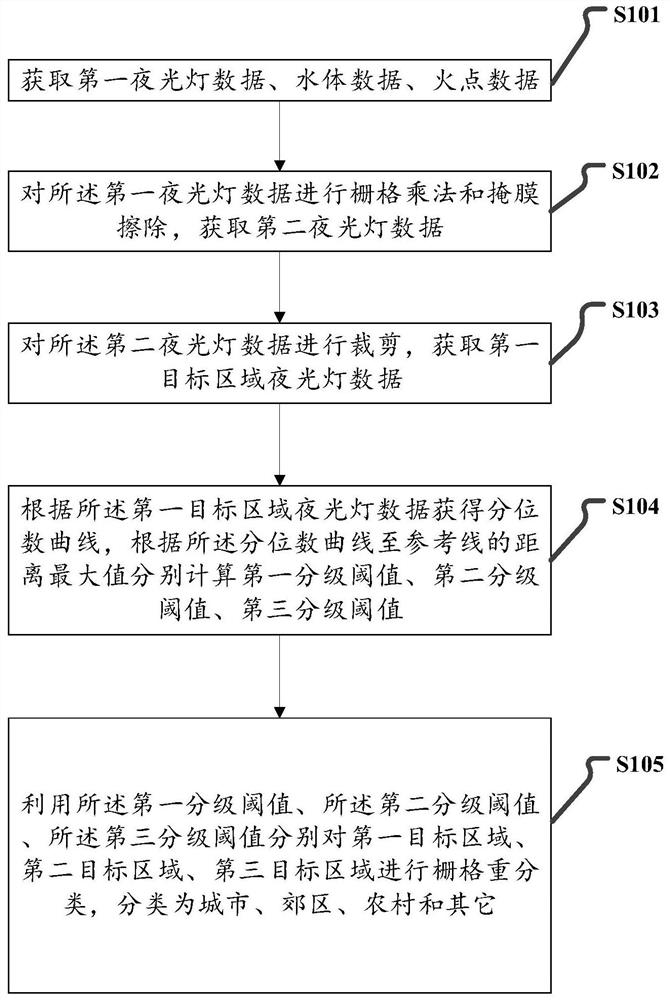

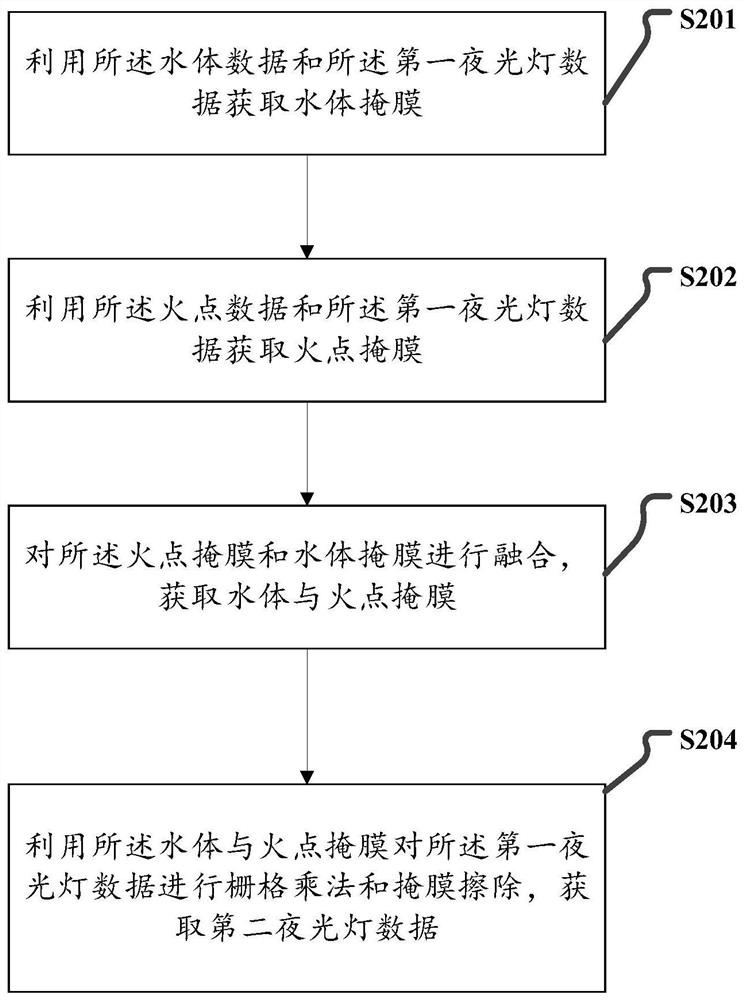

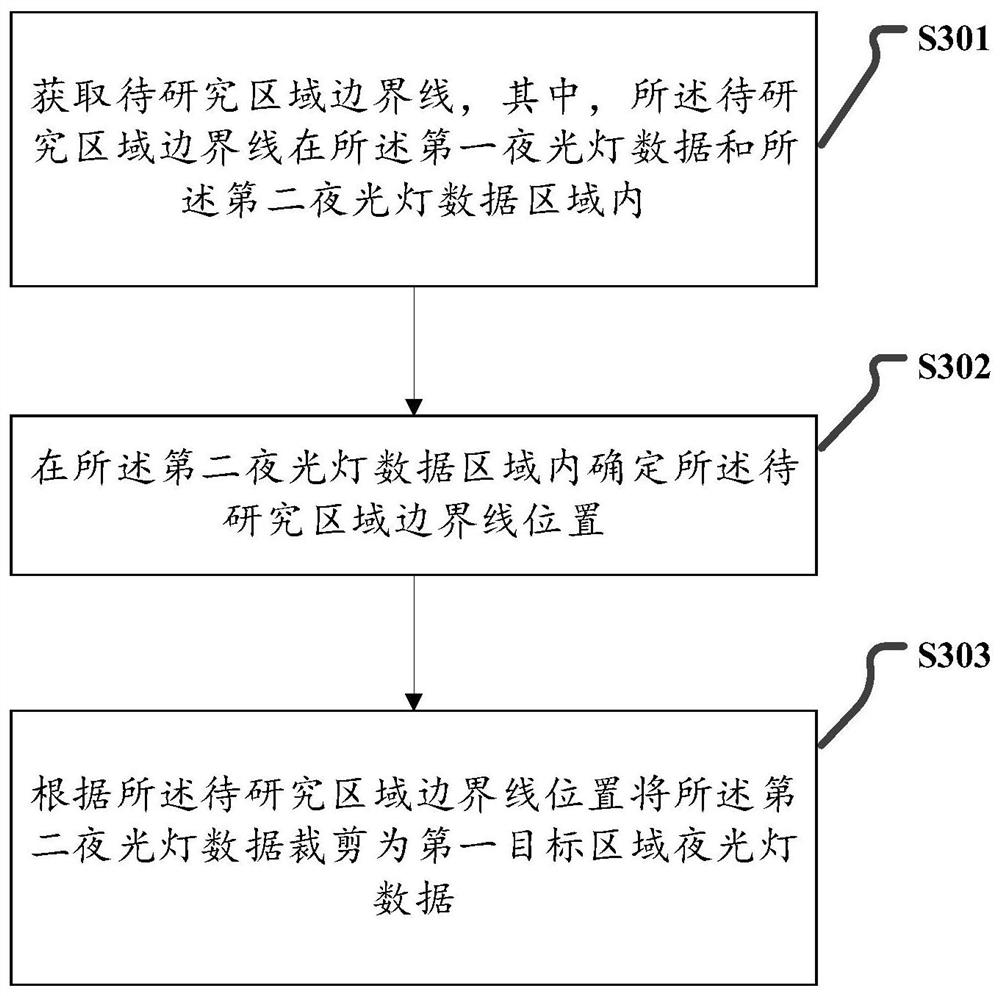

Automatic suburb village ternary structure extraction method based on DMSP night light image

ActiveCN112561942AAvoid errorsRealize automatic calculationImage enhancementImage analysisAlgorithmStructure extraction

The invention provides an automatic suburb village ternary structure extraction method based on a DMSP night light image. The method comprises the following steps: acquiring first noctilucent lamp data, water body data and fire point data; performing grid multiplication and mask erasing on the first noctilucent lamp data to obtain second noctilucent lamp data; cutting the second noctilucent lamp data to obtain first target area noctilucent lamp data; obtaining a quantile curve according to the first target area noctilucent lamp data, and respectively calculating first, second and third gradingthresholds according to the maximum value of the distance from the quantile curve to the reference line; and respectively carrying out grid re-classification on the first, second and third target areas by utilizing the first, second and third grading thresholds to classify the first, second and third target areas into cities, suburbs, villages and others. According to the method, automatic quantile curve analysis is carried out on the basis of the DMSP night light image, extraction of a suburb village ternary internal fine structure can be achieved, the threshold value is automatically selected from DMSP night light brightness distribution, and errors caused by introduction of auxiliary data and subjective factors are avoided.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

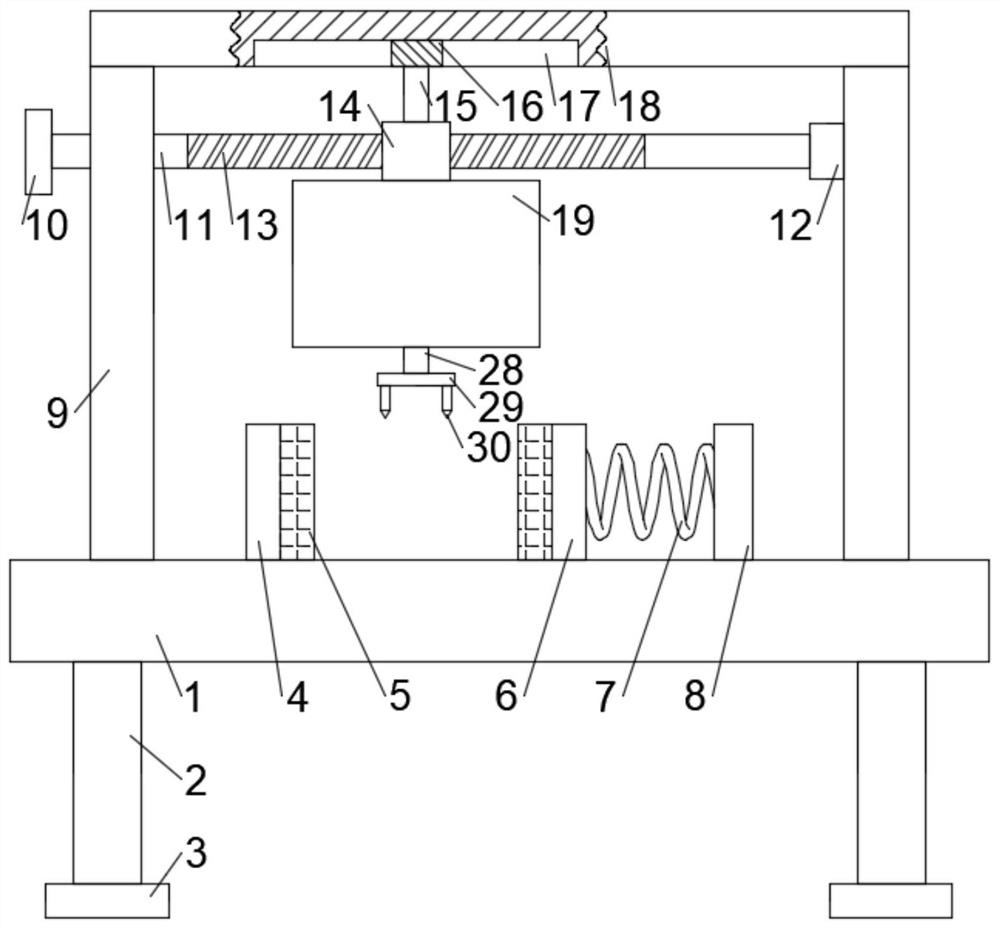

Semi-automatic electrical testing machine testing equipment

PendingCN113640550AReasonable structural designSimple structureElectrical testingMeasurement instrument housingElectrical testingEngineering

The invention relates to the technical field of testing equipment, in particular to semi-automatic electrical testing machine testing equipment which comprises a testing platform, a limiting block is fixedly connected to the surface of one side of the testing platform, a fixing block is fixedly connected to the surface of the other side of the testing platform, and springs are fixedly connected to the side walls, in the same direction, of the fixing block and the limiting block. the other end of the spring is fixedly connected with a moving block, two sides of the test platform are fixedly connected with partition plates, the partition plates are connected with a sliding assembly, and the sliding assembly is connected with a box body. The semi-automatic electrical testing machine testing equipment solves the problems that the existing testing equipment of the electric testing machine is long in testing time, low in working efficiency, causes frequent errors of testing results, and thenthe accuracy of a test result is influenced. According to the invention, the semi-automatic electrical testing machine testing equipment is reasonable in structural design, is simple in structure, is convenient to use, achieves the automatic testing, improves the working efficiency, reduces the errors during the testing, improves the accuracy of the testing result, and is very good in practicality.

Owner:深圳市合力泰光电有限公司

Method and system for measuring steam dryness of oilfield steam injection boiler

ActiveCN103383370BRealize self-cleaningAvoid measurement errorsMaterial resistanceProgrammable logic controllerEngineering

Owner:西安庆晟机电科技有限公司

Method for detecting flatness of 3D printed powder laying surface

ActiveCN111791495AAvoid wastingAchieve precision printingAdditive manufacturing apparatusManufacturing data aquisition/processing3d printData acquisition

The invention discloses a method for detecting the flatness of a 3D printed powder laying surface, and belongs to the technical field of 3D printing. The method is used for solving the problems that initial precision of the flatness of the powder laying surface of 3D printing equipment is low in adjusting efficiency and inaccurate. The method comprises the steps of selecting a to-be-printed product, setting a printing path, setting a data acquisition point path, collecting data, processing the data, judging the flatness of the powder laying surface and the like. Through the method, the production preparation time is greatly shortened; the adjusting precision of the powder laying flatness can be controlled within the range of 0.05 mm, and the precision is improved by dozens of times compared with manual adjustment, so that precise printing of the product and high precision of the equipment are achieved; and the production efficiency is improved, and the production cost is reduced.

Owner:NINGXIA KOCEL MOLD

A side-span structure of a prefabricated electronic factory building and its construction method

ActiveCN110206347BReduce investmentHigh speedFloorsBuilding material handlingStructural engineeringMechanical engineering

The invention discloses a fabricated electronic plant side span structure and a construction method thereof. The fabricated electronic plant side span structure comprises a plurality of first prefabricated PC columns, a plurality of second prefabricated PC columns, longitudinal prefabricated rectangular PC beams, transverse prefabricated rectangular PC beams, first prefabricated Z-shaped PC beamsand second prefabricated Z-shaped PC beams. The construction method comprises the steps that first, the longitudinal prefabricated rectangular PC beams are hoisted; second, the first prefabricated PCcolumns and the second prefabricated PC columns are hoisted; third, the transverse prefabricated rectangular PC beams are hoisted; fourth, the first prefabricated Z-shaped PC beams and the second prefabricated Z-shaped PC beams are hoisted; fifth, prefabricated laminated boards are laid; sixth, first prefabricated H-shaped PC beams and second prefabricated H-shaped PC beams are hoisted; seventh, prefabricated lattice beams are hoisted; and eighth, first connection joints and second connection joints are constructed. According to the construction method, the stability of the fabricated electronic plant side span structure is improved, the construction quality of the fabricated electronic plant side span structure is ensured, and the plant construction speed of a fabricated electronic plantis increased.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Method for identifying sampling points of biological chip on basis of edge detection

InactiveCN102073876BEasy to operateShort algorithm timeImage enhancementCharacter and pattern recognitionEdge extractionEdge based

The invention discloses a method for identifying sampling points of a biological chip on the basis of the edge detection. The method comprises the following steps of: firstly, determining a real area of the sampling points by edge extraction, edge connection and area filling; then meshing by adopting a scanning method and automatically obtaining the row number, the column number and the total number; and finally corresponding area positions of the sampling points in each determined mesh to an original drawing, carrying out automatic searching to obtain the area and the mean value of gray scale of the sampling points in the original drawing, and comparing the area and the value of gray scale of the sampling points in the original drawing with corresponding parameters of the sampling points in the standard chip to obtain an automatic identification result of the sampling points. The method has high positioning accuracy. Software of the method is simpler to implement. The method has short time of an algorithm, is convenient and rapid to operate and makes full automation and intellectualization of information extraction of the biological chip possible.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

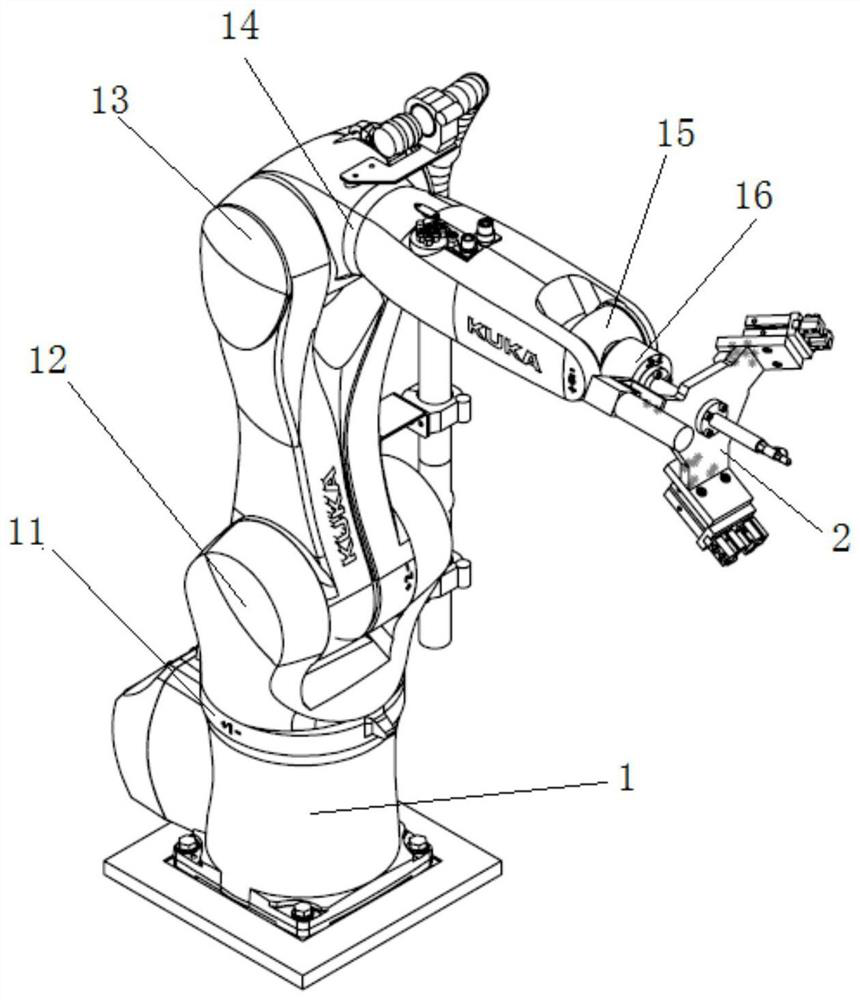

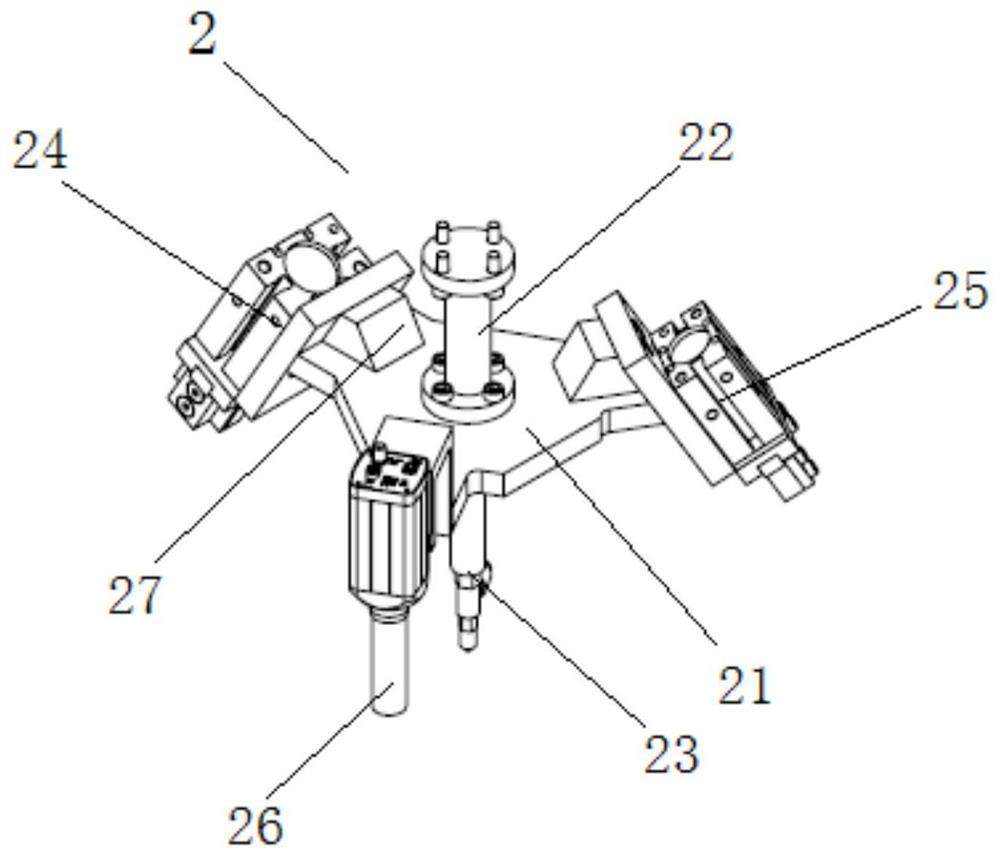

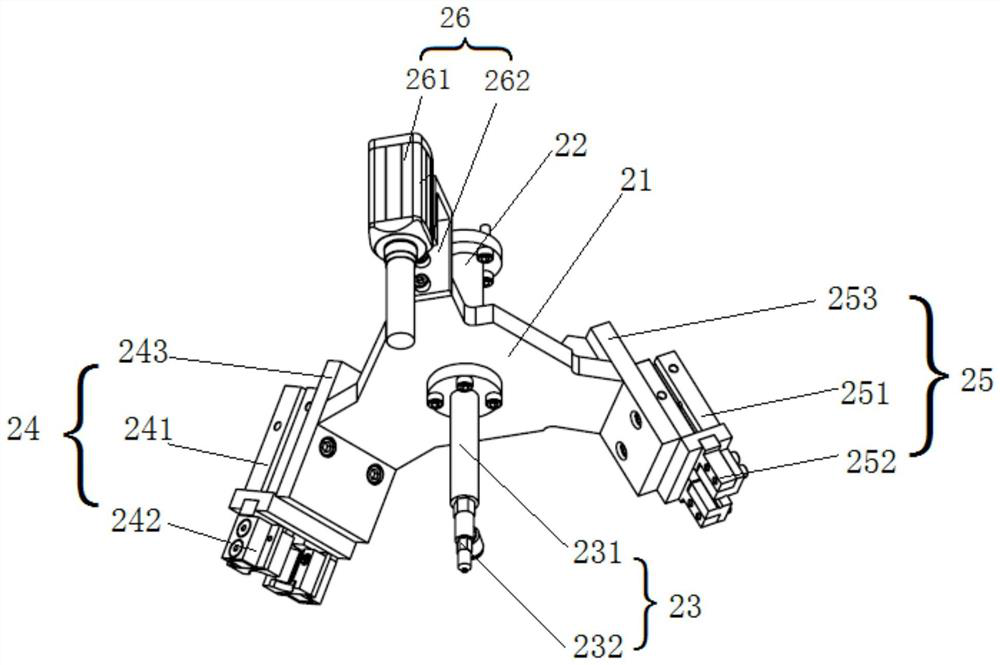

Welding manipulator based on six-axis robot for pole needle and bridge belt welding

ActiveCN111922577BSmooth rotationAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesRobot handEngineering

The invention provides a welding manipulator based on a six-axis robot for a pole needle and a bridge strip of a sealing body, which solves the problems of misjudgment of the qualification of the bridge strip during the welding process of the existing pole needle and the bridge strip, and the quality cannot be guaranteed after welding. The manipulator includes a six-axis robot, a welding jig connecting plate, a bridge belt suction jig connected to the connecting plate, a sealing body grasping jig, a welding pin grasping jig and a vision system. The welding jig connecting plate is connected by The flange is connected with the output shaft of the six-axis robot; the bridge belt suction jig includes a jig shaft arranged in the middle of the lower surface of the welding jig connecting plate and a suction cup arranged at the lower end of the jig shaft; the sealing body grabbing jig includes a set The sealing body cylinder and 2 sealing body chucks on the welding jig connecting plate and whose lower end is inclined outward; the welding pin grabbing jig includes a welding pin cylinder which is arranged on the welding jig connecting plate and whose lower end is inclined outward and 2 welding pin chucks; the vision system includes a camera on the connecting board of the welding jig, and the axis of the camera is parallel to the axis of the jig shaft.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Multi-axis high-speed CNC lathe

InactiveCN106514260BResolve swingImprove stabilityOther manufacturing equipments/toolsTool holdersMulti axisCantilever

The invention relates to a multi-shaft high-speed numerically controlled lathe. The multi-shaft high-speed numerically controlled lathe comprises a slant bed lathe body which is provided with a main machine and a slant bed body assembly. A four-station electric tool carrier and a lathe spindle are mounted on the slant bed body assembly, wherein an additional machining shaft system assembly which is arranged perpendicular to the lathe spindle is further mounted on a spindle box; a second fixed seat is arranged on the lateral side of the slant bed body assembly on the main machine; and an auxiliary centering assembly opposite to the lathe spindle is mounted above the second fixed seat. According to the multi-shaft high-speed numerically controlled lathe provided by the invention, a machining shaft is additionally arranged; on the basis of the original machining shaft which machines an excircle, the additionally arranged machining shaft can perform operations such as chamfering and groove milling simultaneously, so that the production efficiency and the machining precision are greatly improved; the auxiliary centering assembly is a three-finger pneumatic finger, and a guide rail and sliding tables are arranged at the bottom of the three-finger pneumatic finger, so that a cantilever of the centering assembly can be prevented from being overlong, and the stability of the centering assembly is greatly improved.

Owner:DONGGUAN HONGJINSHUN MACHINERY MFG

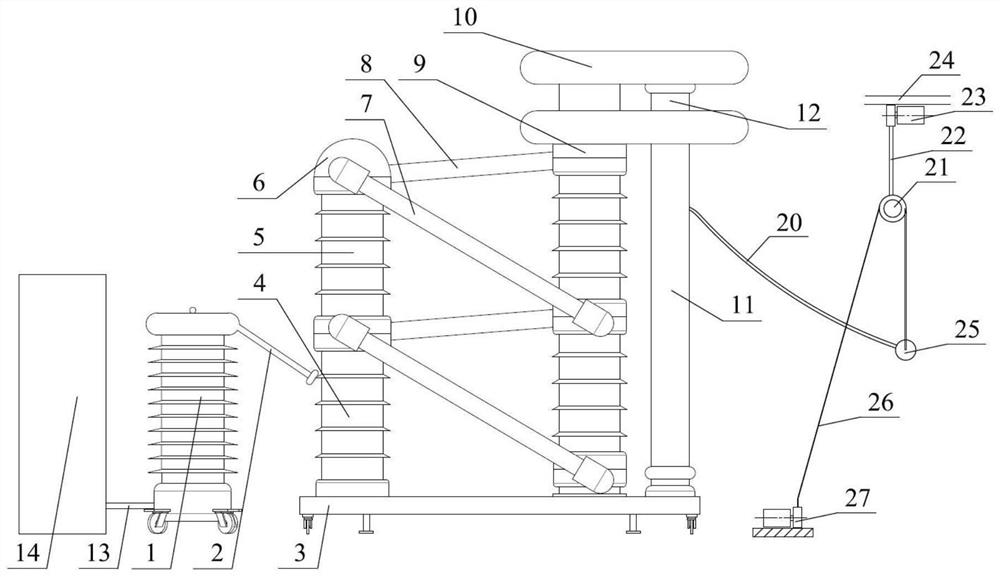

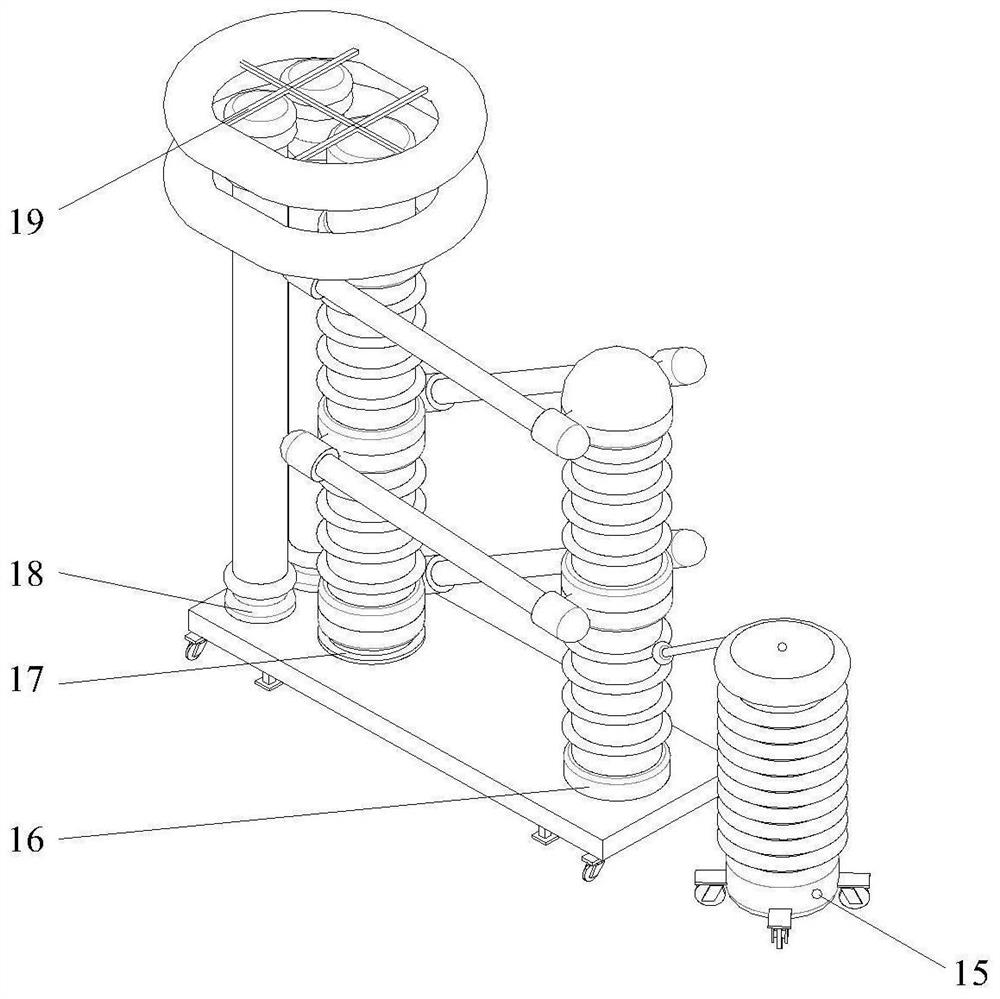

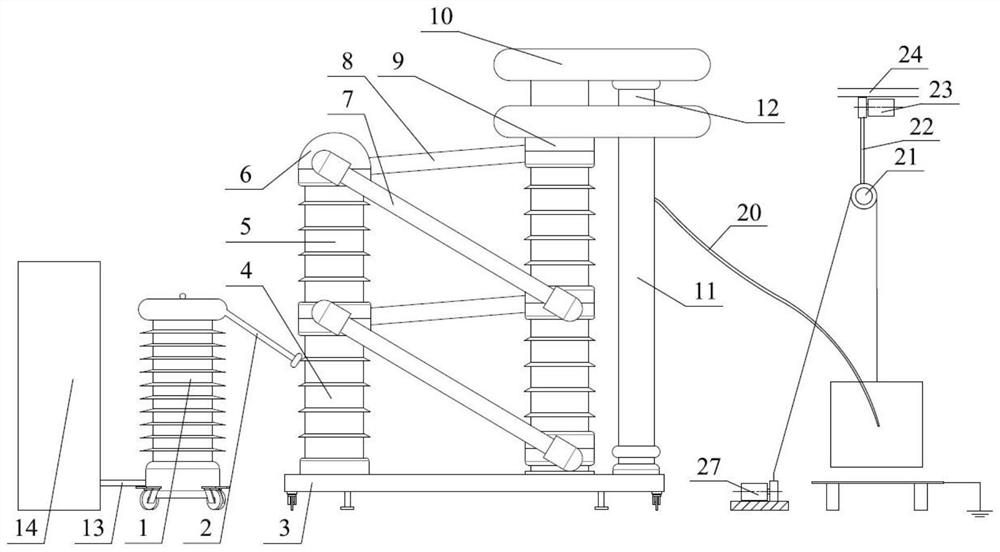

Experimental Application of a DC Electrostatic High Voltage Generator

ActiveCN112379137BStable outputImprove overload capacityTesting dielectric strengthElectrical measurement instrument detailsCapacitanceAircraft fuel system

The invention discloses a DC electrostatic high-voltage generator and its test application. The generator includes: a transformer, a transformer connection line, a body base, a voltage doubler capacitor, a filter capacitor, a voltage equalizing cap, a long silicon stack, a short silicon stack, a protection Resistors, shielding covers, grounding switches, discharge switches, voltage dividers, transmission lines, power supply units, power input terminals, capacitor columns, resistance columns, switch columns, support frames, high-voltage transmission lines, fixed pulleys, lifting ropes, top motors, Guide rail, discharge electrode, pull rope, bottom electrode, can be used for electrostatic discharge test of aircraft fuel system and electrostatic withstand voltage test of composite materials. The invention can provide a test method with small footprint, stable performance and controllable process, thereby saving maintenance cost, reducing the physical work of test personnel, reducing the influence of human factors on the test process, thereby ensuring the test quality, shortening the test period, and saving energy. test cost.

Owner:HEFEI HANGTAI ELECTROPHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com