Semi-automatic electrical testing machine testing equipment

A technology for testing equipment and electrical measuring machines, which is applied to parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems affecting the accuracy of test results, low work efficiency, and errors in test results, and achieves simple structure, Improve work efficiency and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

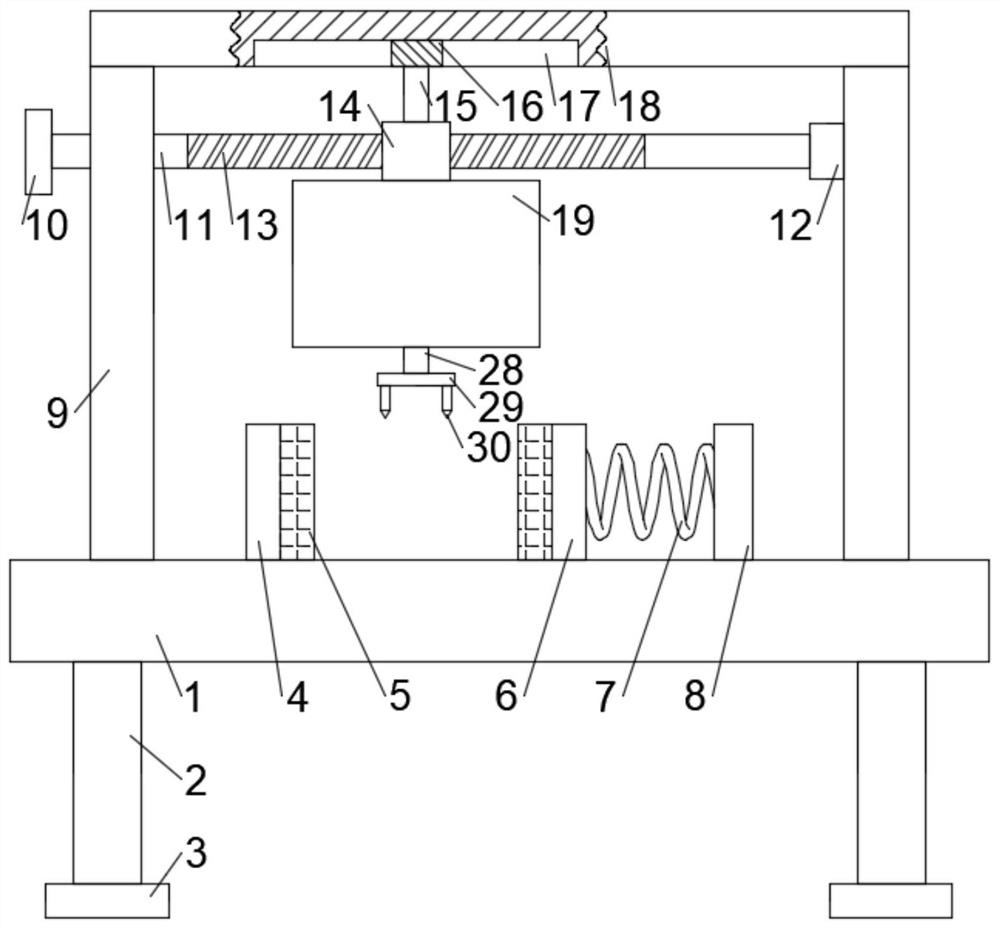

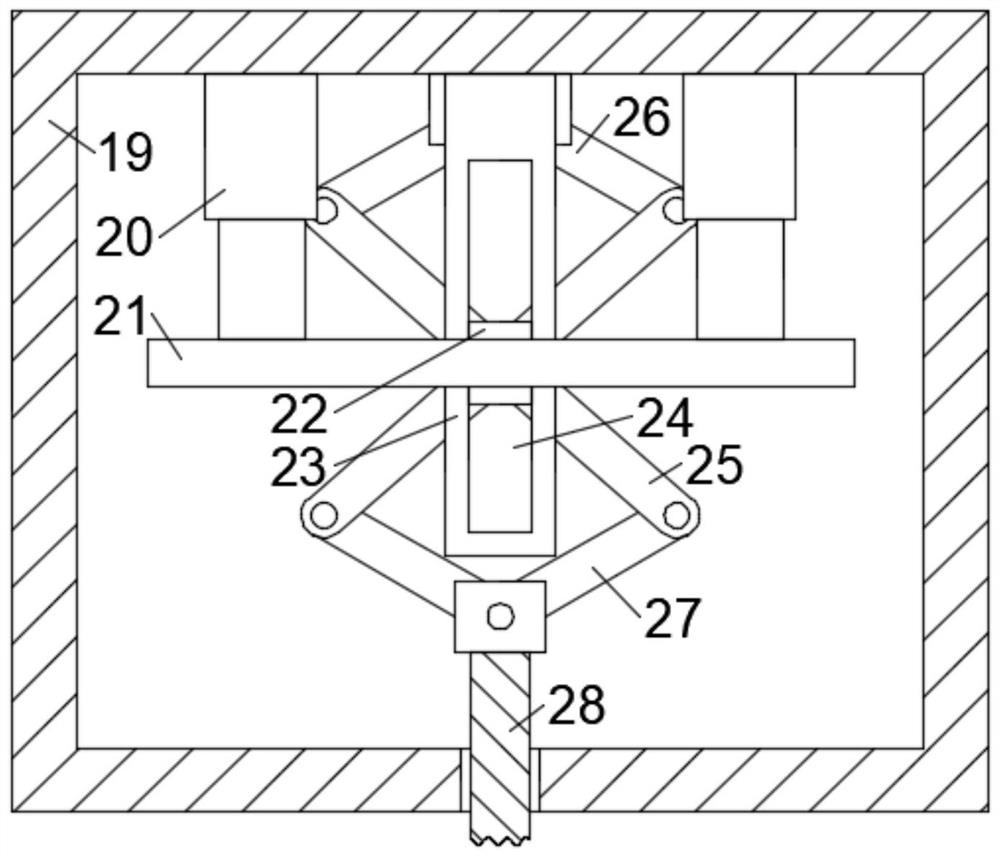

[0018] see Figure 1-2 , in an embodiment of the present invention, a semi-automatic electric measuring machine testing equipment, including a test platform 1, the limit block 4 is fixedly connected to the surface of the test platform 1 on one side, and the surface of the other side of the test platform 1 is fixedly connected to There is a fixed block 8, the side wall of the fixed block 8 and the limit block 4 are fixedly connected with a spring 7, and the other end of the spring 7 is fixedly connected with a moving block 6, and the two sides of the test platform 1 are fixedly connected with spacers. plate 9, the partition plate 9 is connected with a sliding assembly, the sliding assembly is connected with a box body 19, and a lifting assembly is connected inside the box body 19, and the lifting assembly is connected with a movable rod 28, and the movable rod 28 runs through The inner wall of the box body 19 extends to the bottom of the box body 19 , and the end is connected w...

Embodiment 2

[0021] see figure 1 , in an embodiment of the present invention, the four corners of the bottom surface of the test platform 1 are fixedly connected with fixed legs 2 , and the bottom ends of the fixed legs 2 are connected with anti-skid pads 3 .

[0022] In the embodiment of the present invention, fixed legs 2 are provided to fix and support the test platform 1, and anti-slip pads 3 are provided to increase the contact area with the ground and increase the friction with the ground, making the equipment more reliable and stable.

Embodiment 3

[0024] see figure 1 , in an embodiment of the present invention, a buffer pad 5 is connected to the side walls of the limiting block 4 and the moving block 6 facing each other.

[0025] In the embodiment of the present invention, a buffer pad 5 is provided to play the role of buffering and shock absorption, and prevent the limit block 4 and the moving block 6 from causing damage to the surface of the product to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com