Cold quantity distribution system and method based on flow temperature difference proportion

A cooling capacity distribution and temperature difference technology, applied in the field of cooling capacity distribution system, can solve the problems of unmeasured cooling capacity of variable air volume system, difficult measurement and calibration of humidity and air volume, heavy maintenance workload, etc., to achieve initial investment and later stage Low maintenance and management costs, accurate results, and the effect of achieving hydraulic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

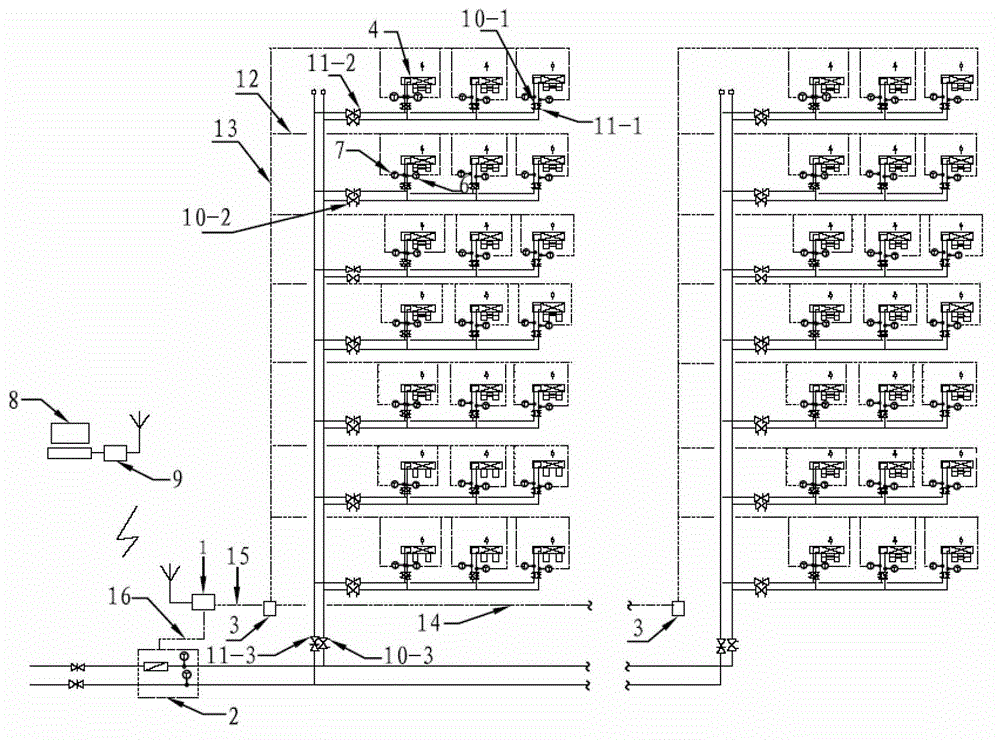

specific Embodiment approach 1

[0046] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, flow temperature difference ratio cooling capacity distribution system, it comprises wireless signal transmitting equipment 1, total cooling capacity meter 2, A data collection display 3, computer 8, wireless signal receiving equipment 9, the 3rd communication line 14, N groups of fan coil units 4, N water supply temperature sensors 6, N return water temperature sensors 7, N single point balancing valves 10-1, N single point gate valves 11-1, M branch balancing valves 10-2 , M branch gate valves 11-2, Z group of total balance valves 10-3 and Z total gate valves 11-3; said N groups of fan coil units 4 are divided into A group, A, N, M and Z are all positive integers ;

[0047] The water supply pipes of each group of fan coil units 4 communicate with a water supply branch through a single-point gate valve 11-1, and each water supply branch communicates with a water supply main circuit...

specific Embodiment approach 2

[0057] Embodiment 2. The difference between this embodiment and the flow-temperature-difference proportional cooling capacity distribution system described in Embodiment 1 is that it also includes a fifth communication line 16, the output terminal of the cooling capacity signal of the total cooling capacity meter 2 The fifth communication line 16 is connected to the cooling signal input end of the wireless signal transmitting circuit 1 .

specific Embodiment approach 3

[0058] Embodiment 3. The difference between this embodiment and the flow-temperature-difference proportional cooling capacity distribution system described in Embodiment 1 is that it also includes A second communication lines 13 and N / A water supply temperature sensors 6. The signal output end is connected to a second communication line 13; the return water temperature signal output ends of the N / A return water temperature sensors 7 are also connected to the second communication line 13; A data acquisition displays 3 are respectively connected to A The second communication line 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com