Module type permanent magnet brushless direct-current motor

A DC motor, permanent magnet brushless technology, applied in the direction of electronically commutated motor control, electric components, electrical components, etc., to achieve overall optimization, reduce iron loss, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

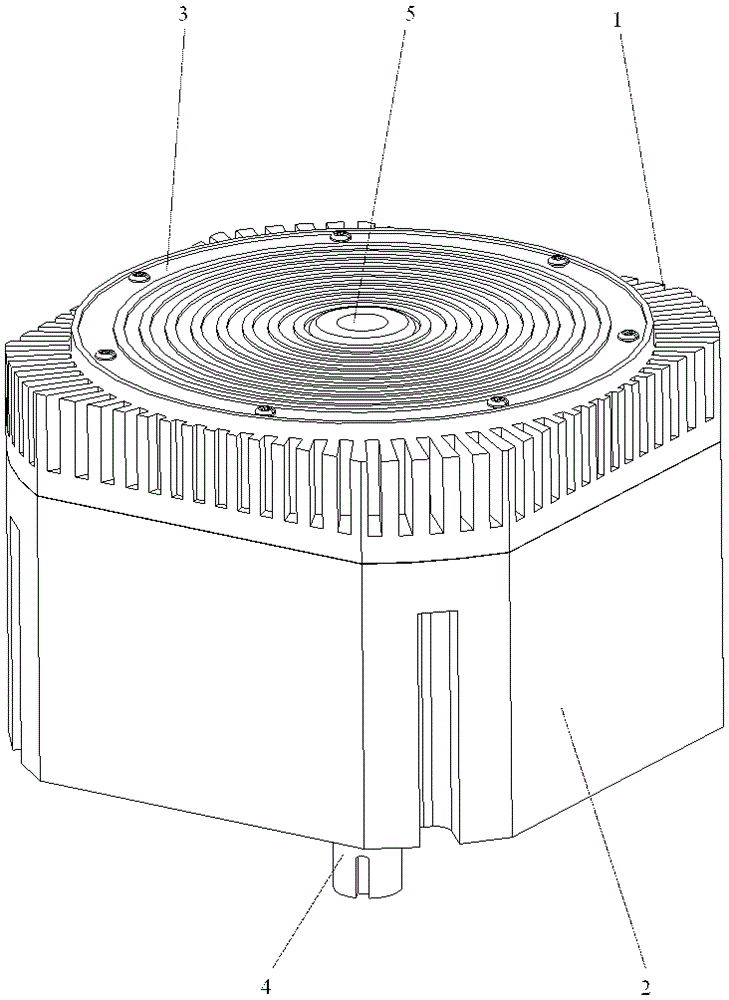

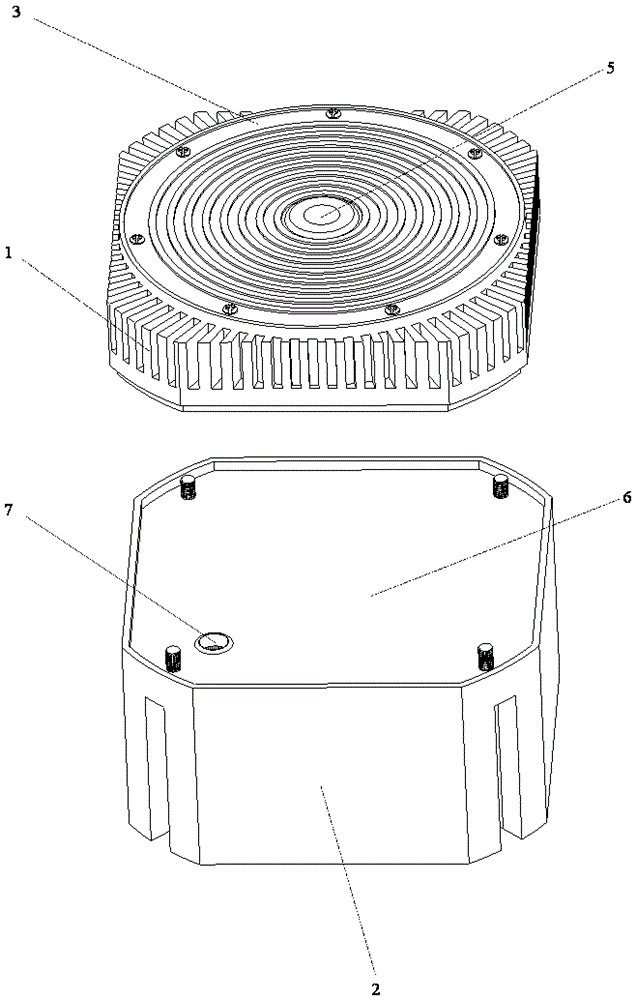

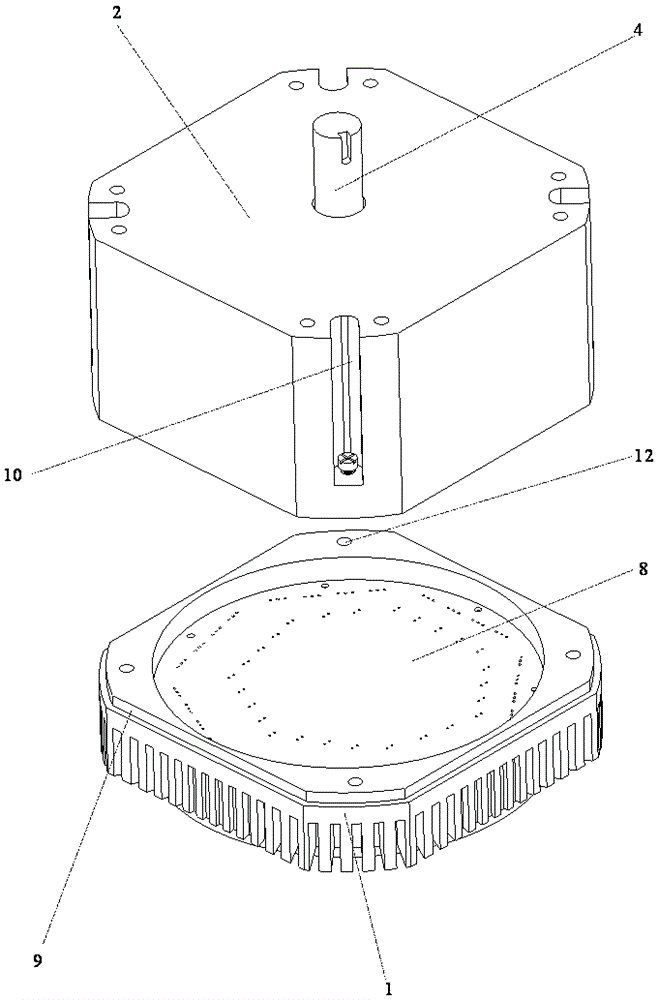

[0055] The present invention as Figure 1 to Figure 13 shown.

[0056] The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

[0057] The modular permanent magnet brushless DC motor consists of two parts, the motor module and the controller module. The motor module part includes: the motor housing (2), the separator (6), the rotating shaft (4), and the wire package (16) , stator core body (26), rotor core body (27), bracket (28), NdFeB permanent magnet block (30), the controller module part includes: controller housing (1), end cover (3), PCB board (8), VMOS power tube (18), dual-core microcontroller (19), driver chip (20), characterized in that:

[0058] The motor casing (2) is a circular cylinder with an octagonal outside and a hollowed out interior. One end of the circular cylinder is open and the other end is closed, but there is a lower bearing in the center of the closed end. The supporting circular step (31) h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com