Patents

Literature

296results about How to "Solve assembly problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

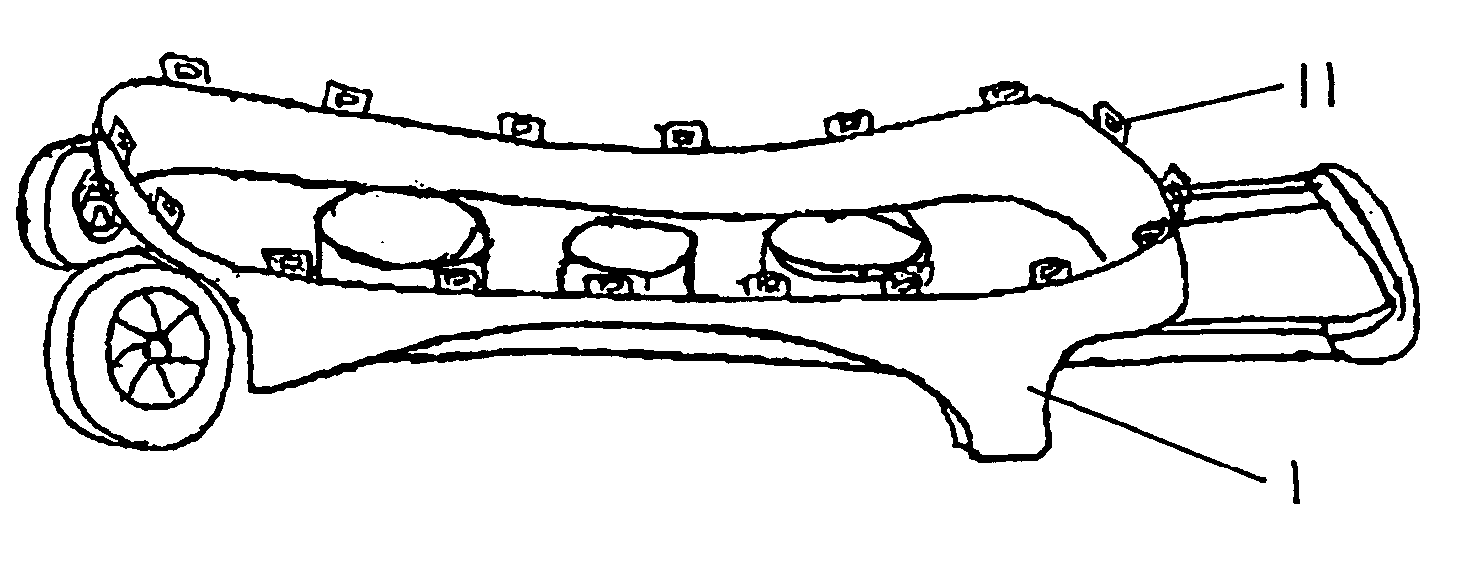

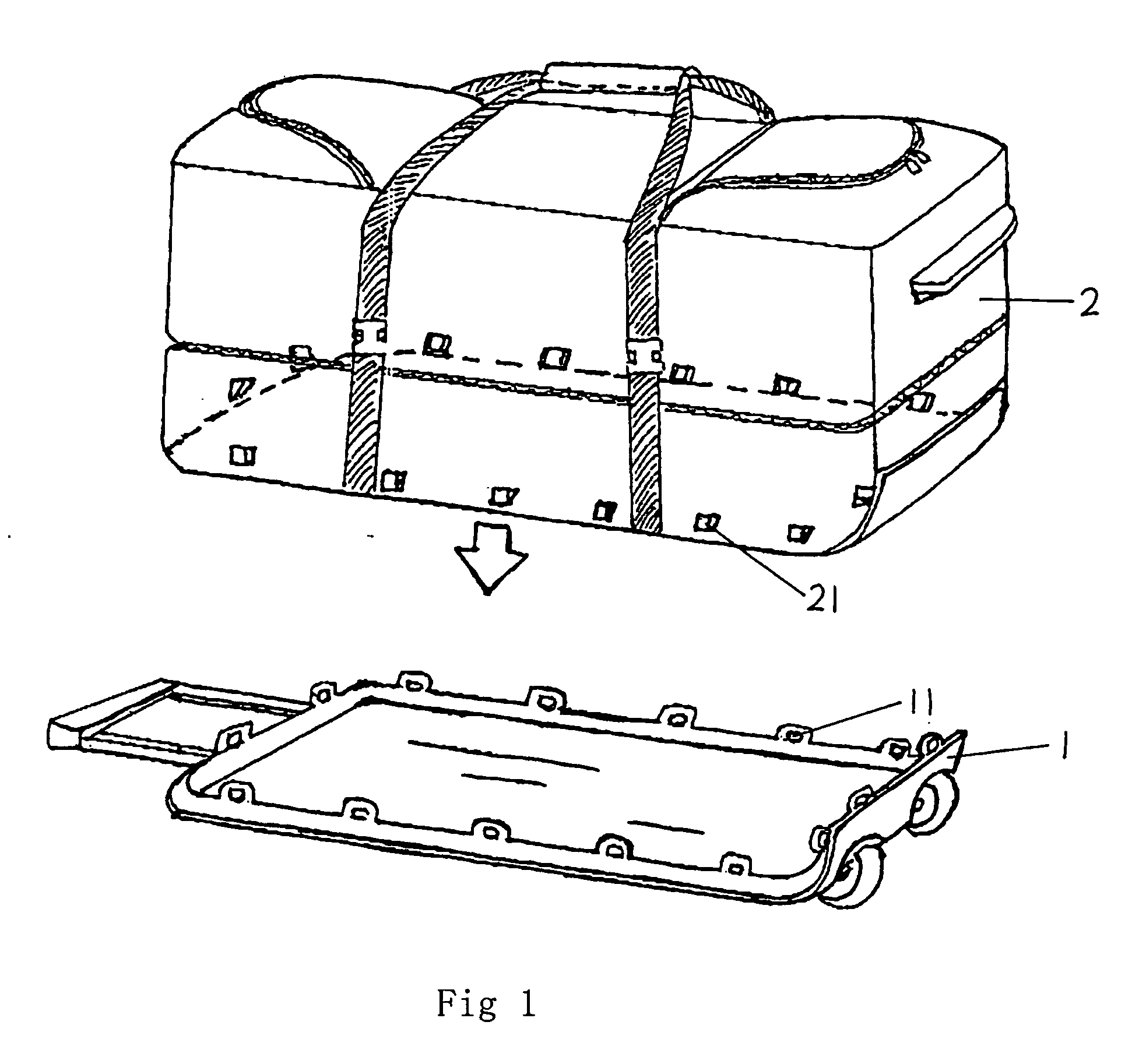

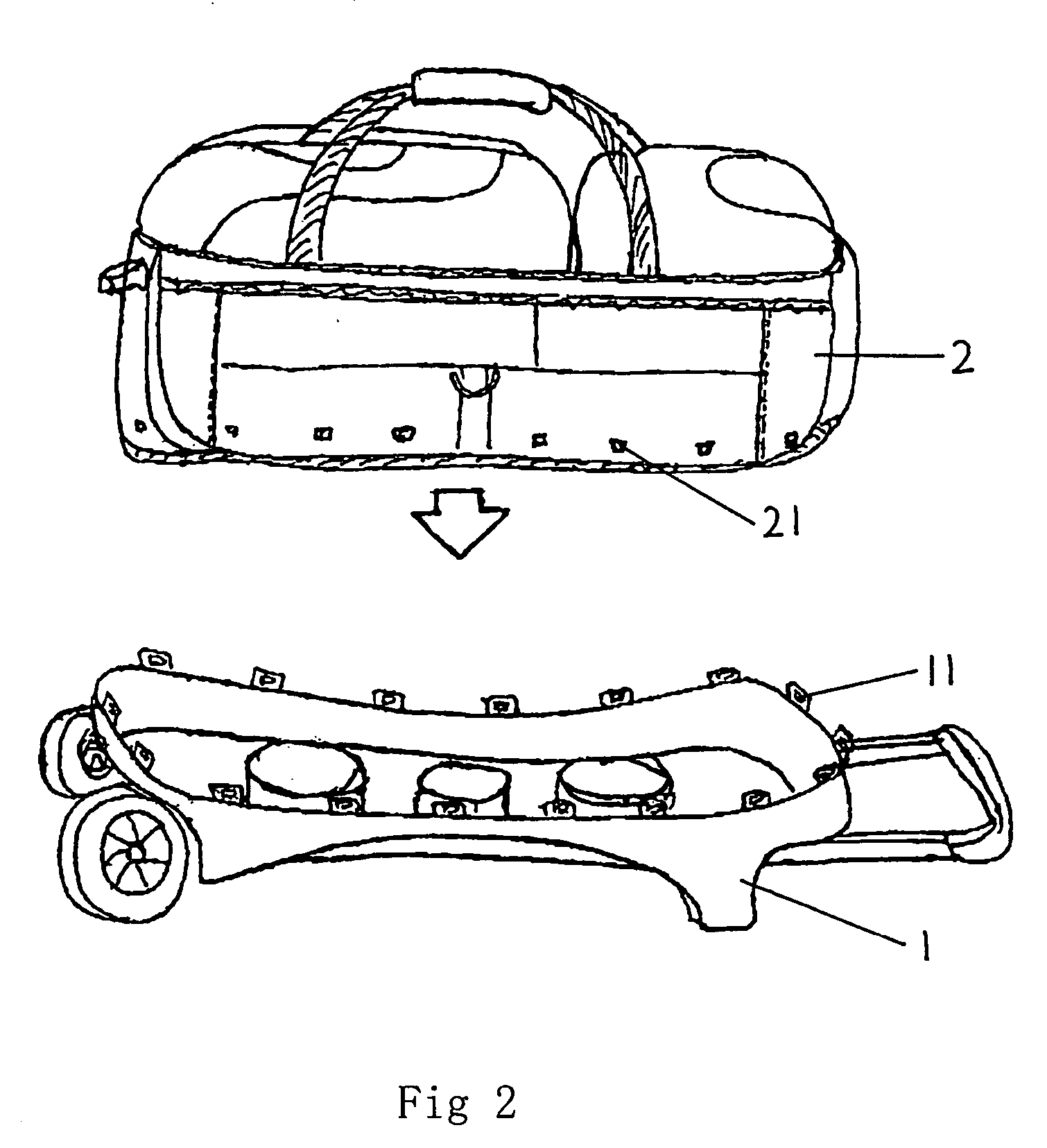

Easily assembled and transported cases and bags with wheels

InactiveUS20070068757A1Low costConveniently manufacturedCarriage/perambulator with single axisLuggageEngineering

Owner:TAN FU HSING

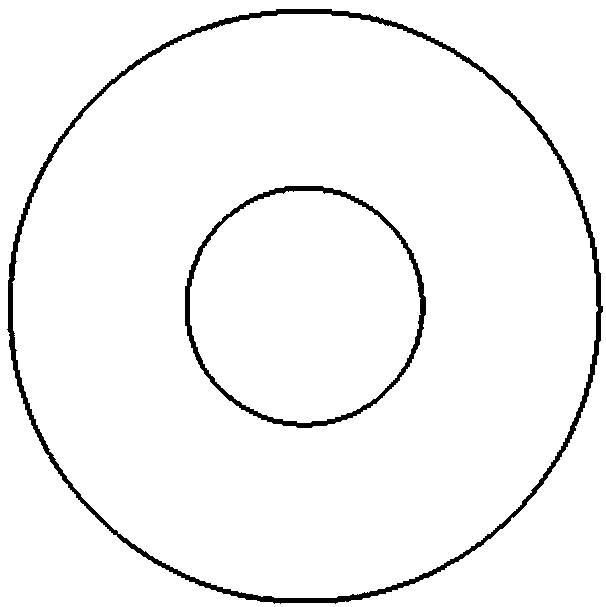

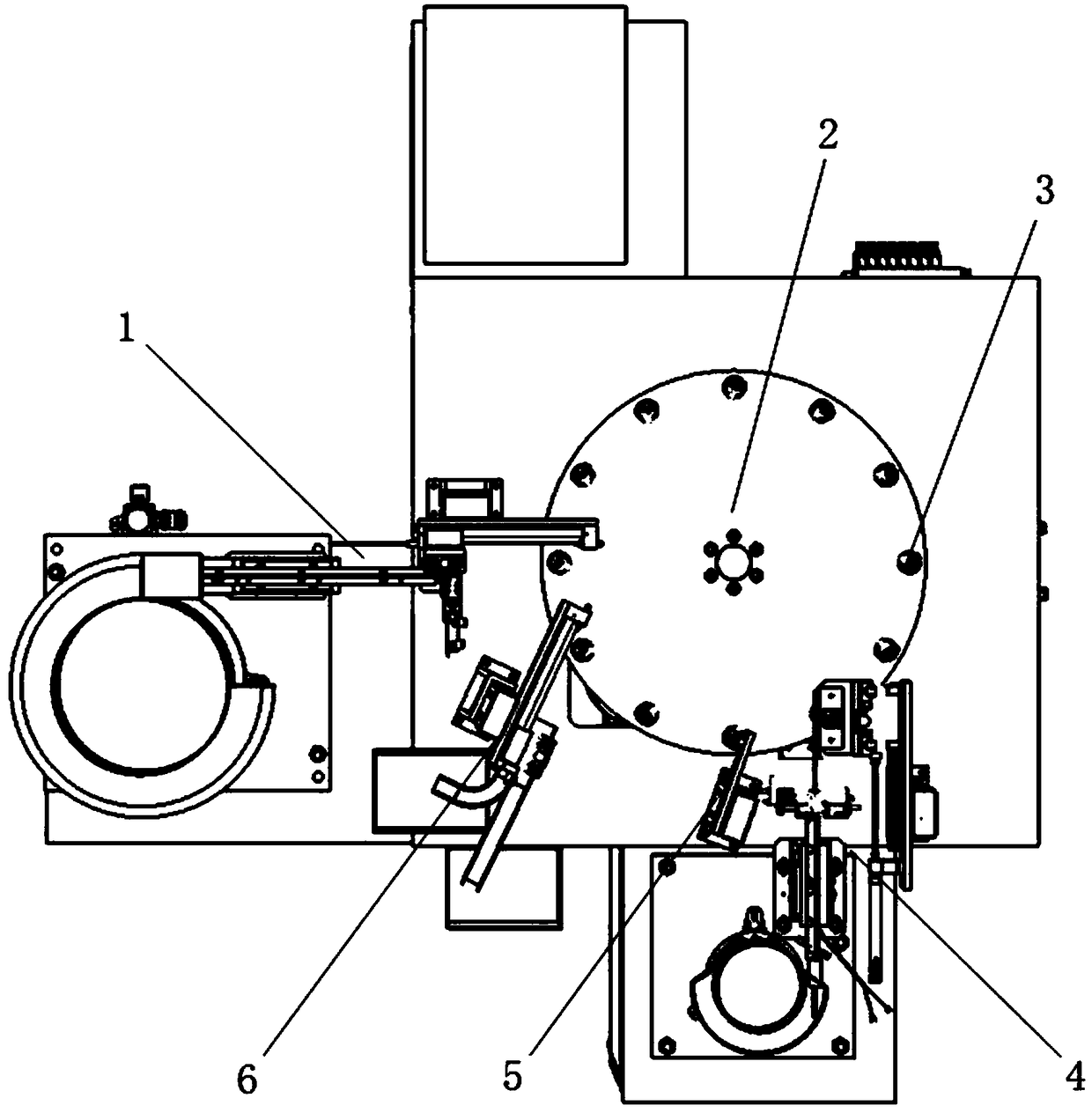

O-shaped sealing ring automatic assembly device and method

InactiveCN108655689AAssembly precisionAccurate assembly tasksMetal working apparatusEngineeringMechanical engineering

The invention discloses an O-shaped sealing ring automatic assembly device and method. The device comprises a sleeve automatic loading module, an O-shaped sealing ring automatic loading module, an automatic detecting module, a finished product sorting module, all of which are arranged on the outer side of a revolving worktable module in the peripheral direction in sequence; the sleeve automatic loading module and the O-shaped sealing ring automatic loading module are in supply connection with the revolving worktable module; the automatic detecting module detects the assembly effect of O-shapedrings on the revolving worktable module in real time; and the finished product sorting module is used for realizing sorting of qualified and unqualified products through chutes according to the detecting result of the automatic detecting module. The device is simple in structure and convenient to use; and through motions of three arc plates on clamping jaws of a three-jaw cylinder and pressing plates with the same apertures as the diameters of sleeves, the clamping and assembly of the O-shaped sealing rings are achieved, the automatic assembly task of the O-shaped sealing rings can be finished with high quality, a lot of manpower and costs are saved, the assembly efficiency is quickly accelerated, and the production demands are met.

Owner:NANJING KANGNI NEW ENERGY AUTO PARTS CO LTD +1

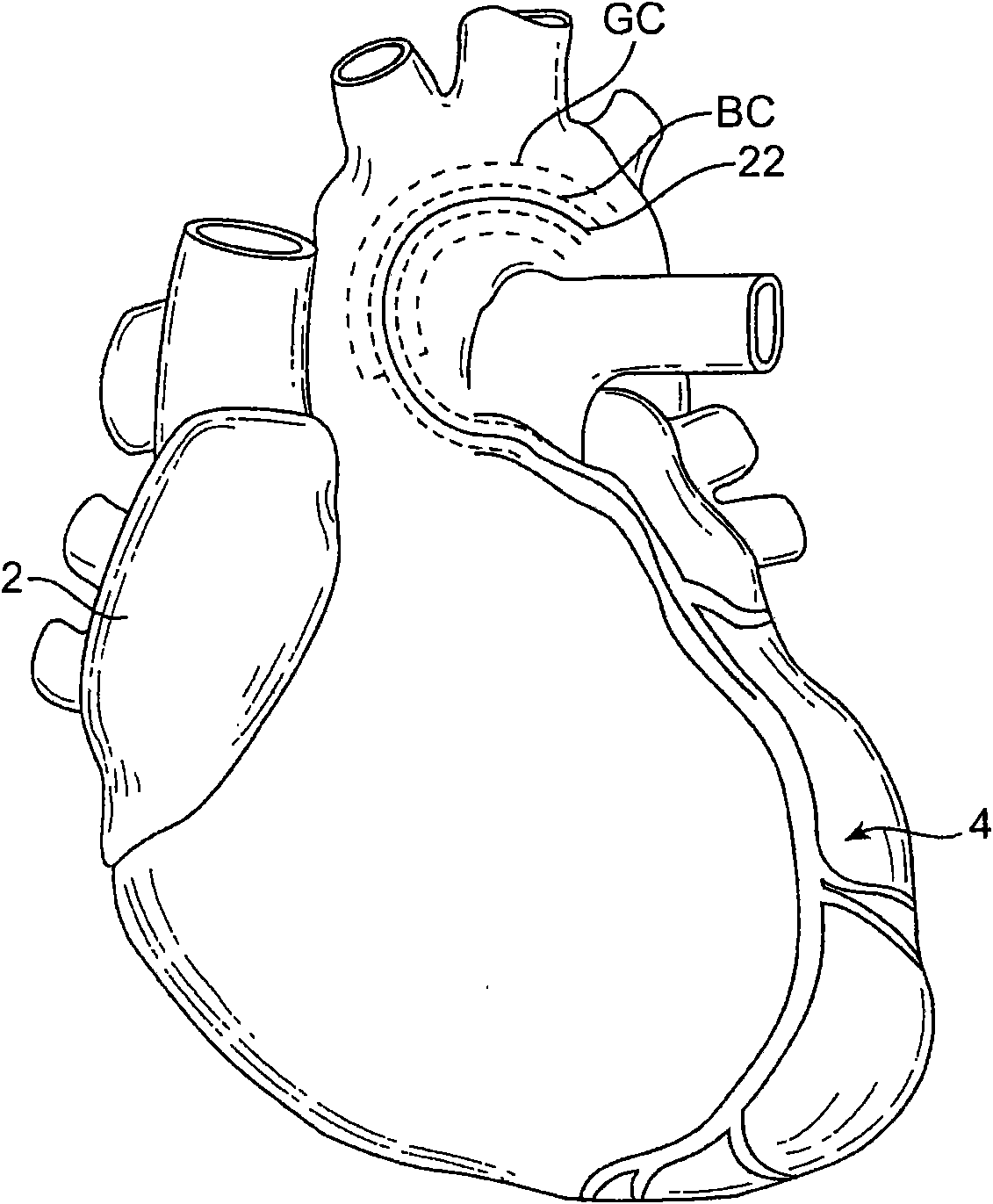

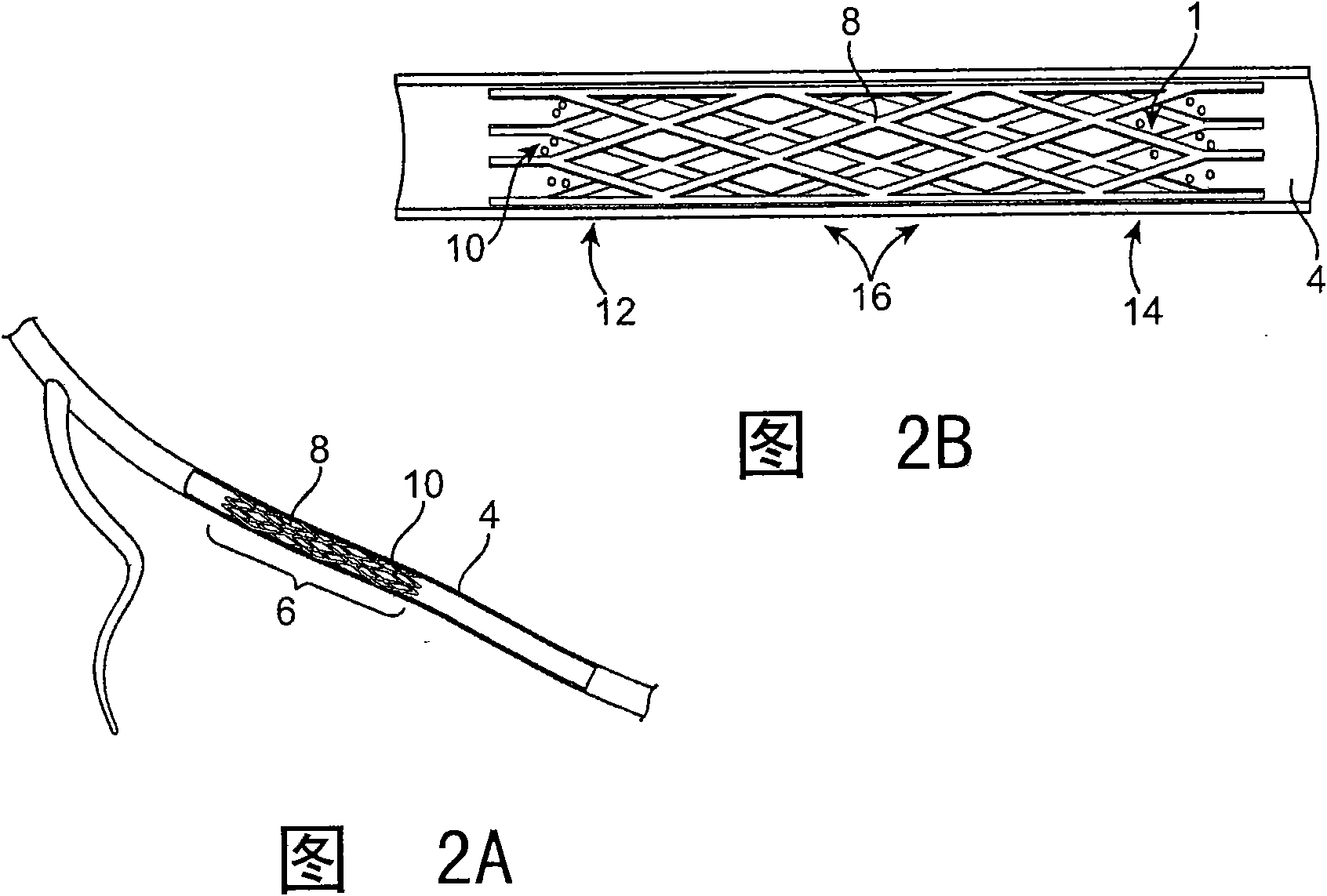

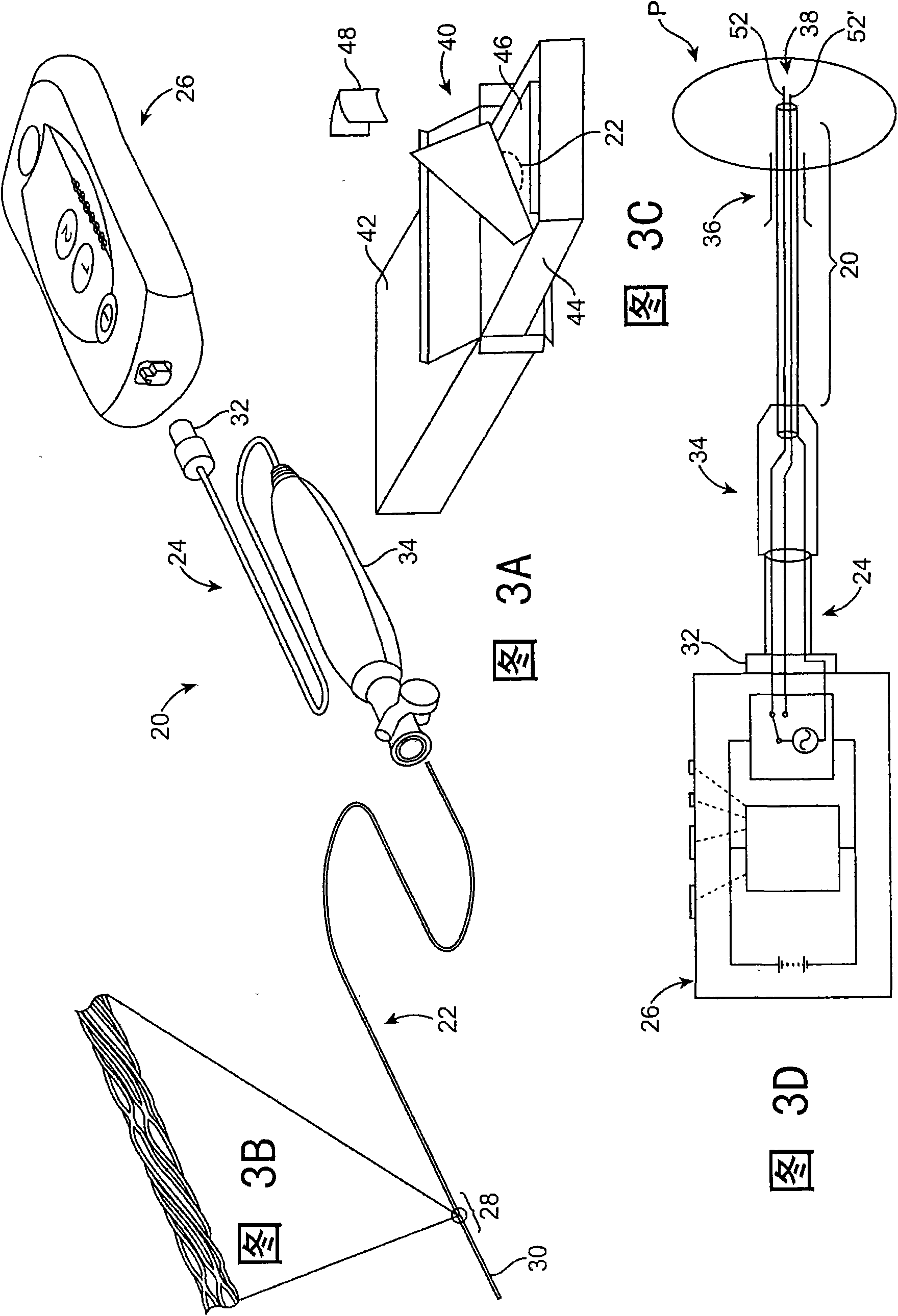

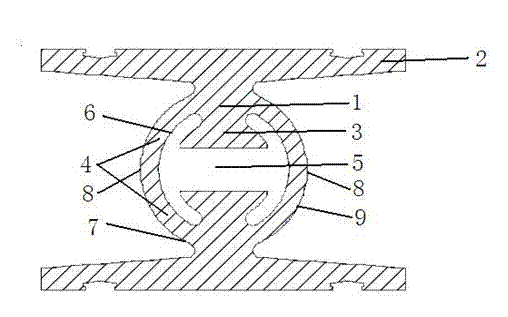

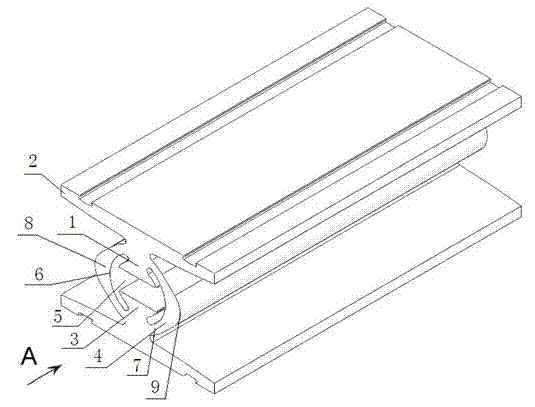

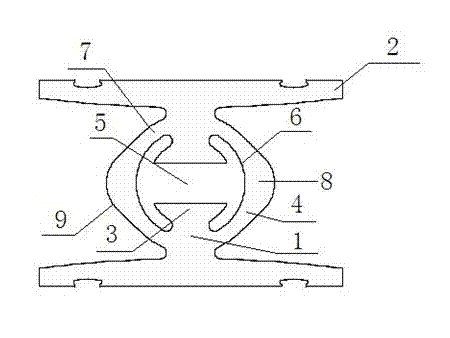

Stent systems

InactiveCN101605509ASolve operational problemsSolve assembly problemsStentsBlood vesselsBody organsStent implantation

Medical devices and methods for delivery or implantation of prostheses within hollow body organs and vessels or other luminal anatomy are disclosed. The subject technologies can be used in the treatment of atherosclerosis in stenting procedures or be used in variety of other procedures. The systems can employ a self expanding stent restrained by one or more members released by an electrolytically erodable latch.

Owner:BIOSENSORS INT GROUP

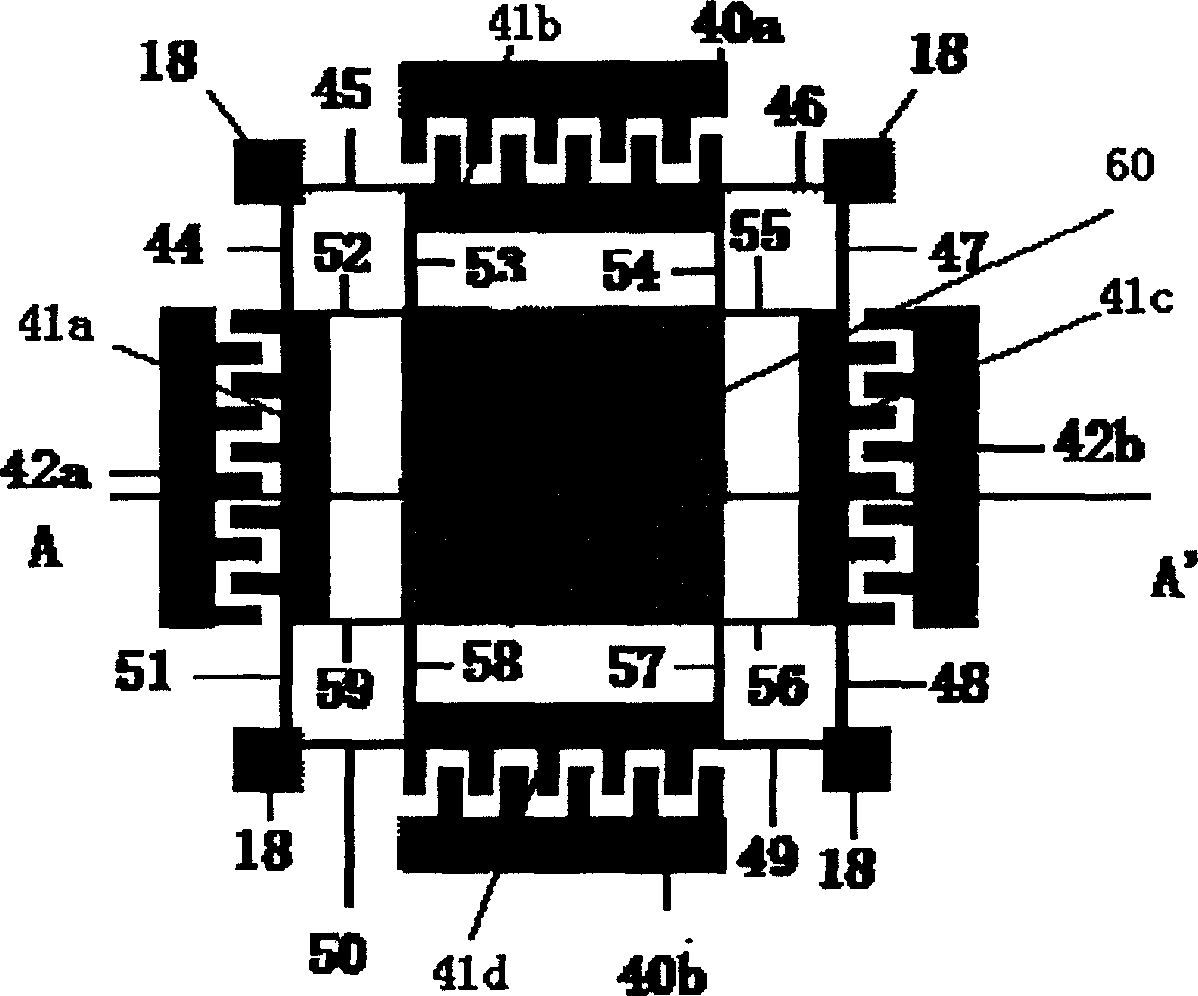

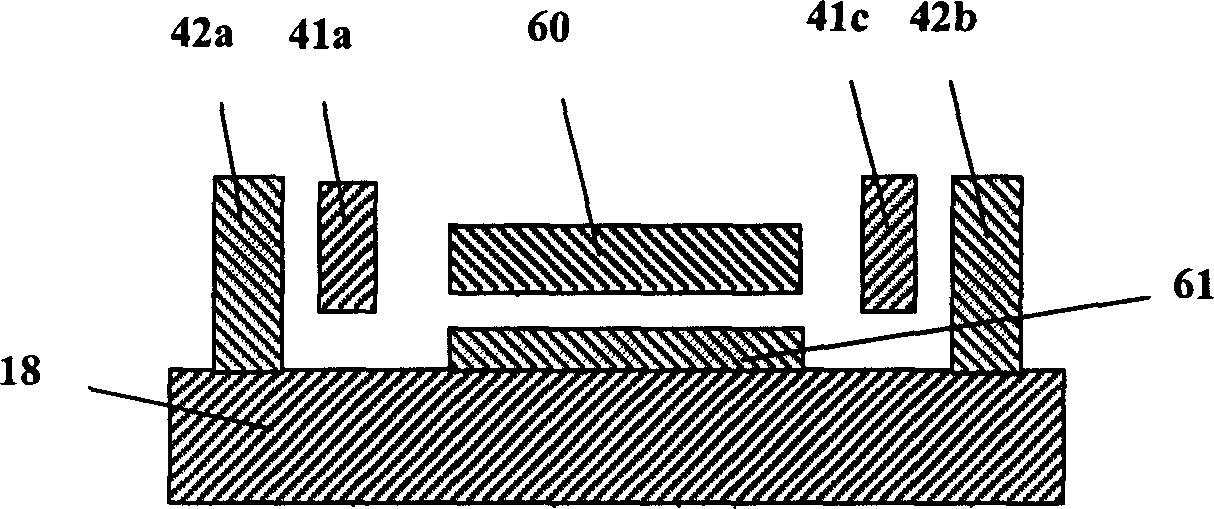

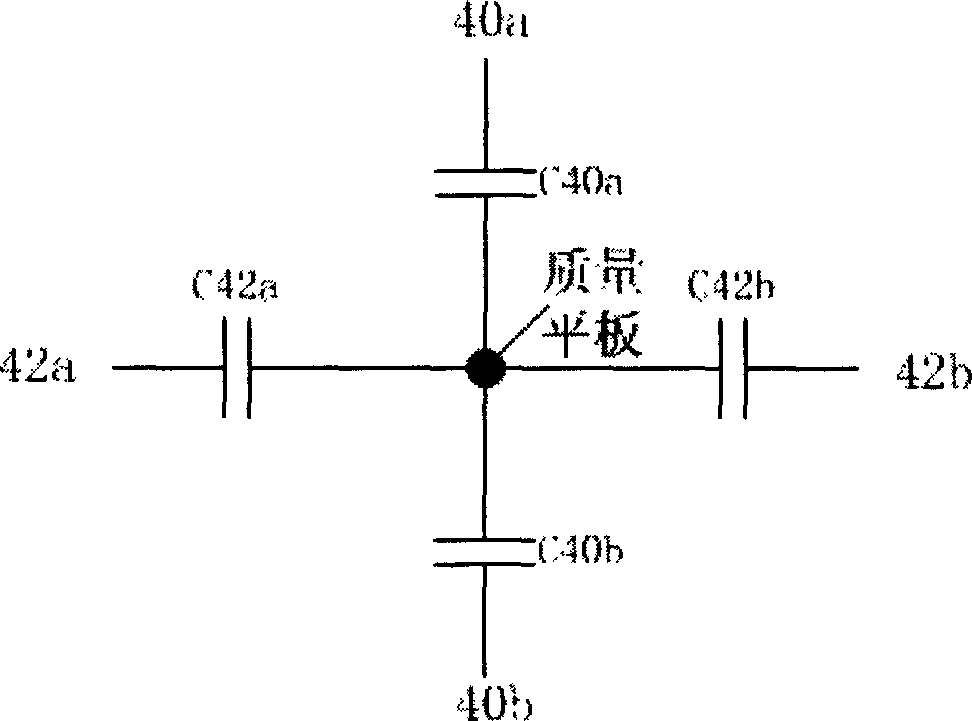

Single mass plate triaxial micro-mechanical accelerometer

The invention discloses a simple mass flat triaxiality tiny machine accelerometer, the mass flat is supported on the fundus by four groups of inner girder and four groups of outer girder, and four groups of comb is protruded on four directions, which cross to four groups of terminal comb on the fundusby to produce four couples of comb capacitor---capacitor C40a, capacitor C40b, capacitor C42a, and capacitor C42b, capacitor C42b and the capacitor C42b is equal to capacitor Cx which is along X direction, the capacitor C40a and the capacitor C40b are equal to capacitor Cy which is along to direction Y, its character is: it also includes a junior board which is under the mass flat, and composes a clinograph capacitor Cz with the mass flat, and the Cz, the Cx and the Cy compose the triaxiality accelerometer. The four groups of comb on the mass flat and the four groups of comb on the funduusby and the junior board are machining on one chip. The excellence of the invention is a mass flat can get linear acceleration on three directions X, Y, Z, and its size is tiny, its weight is light.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

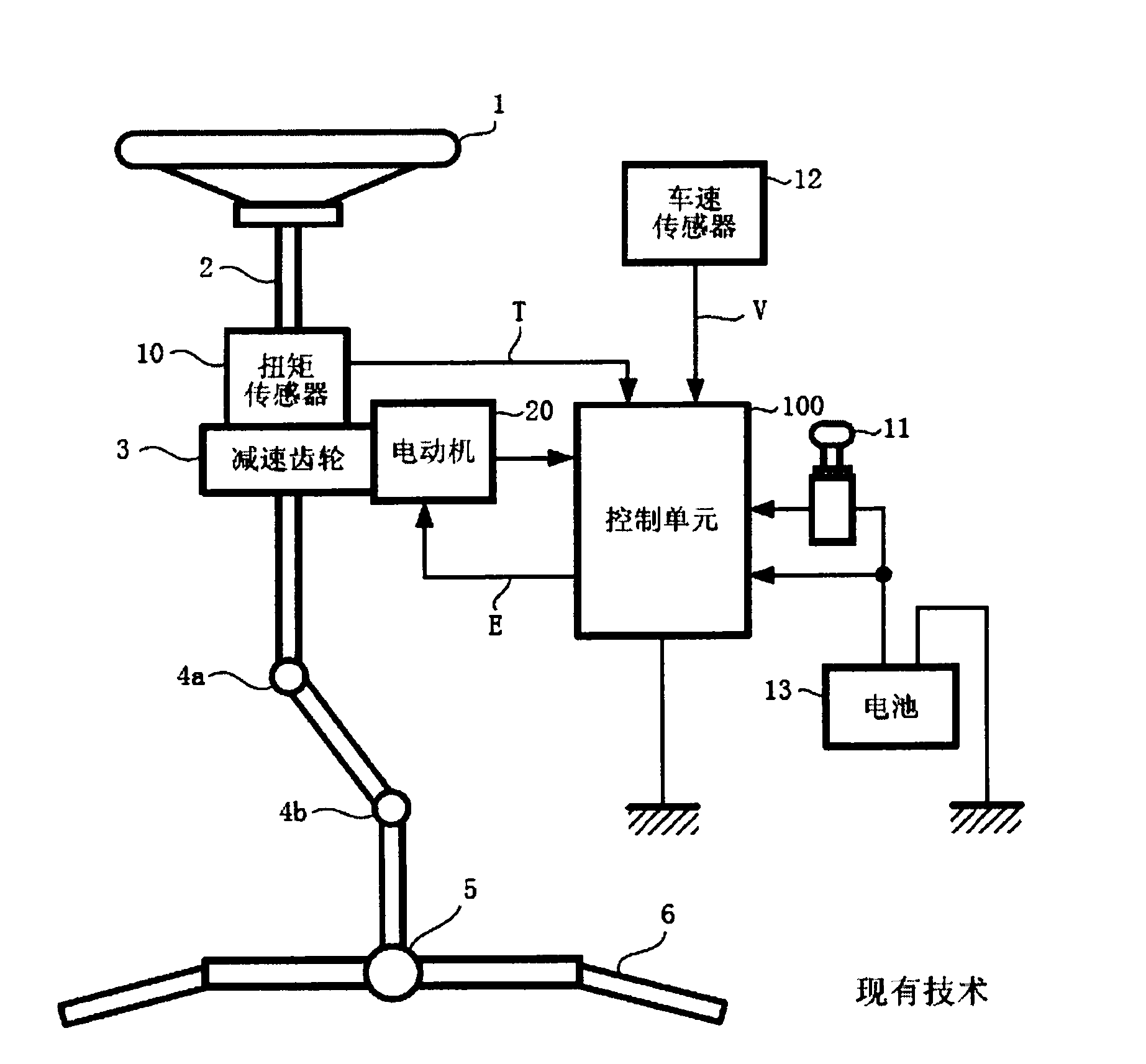

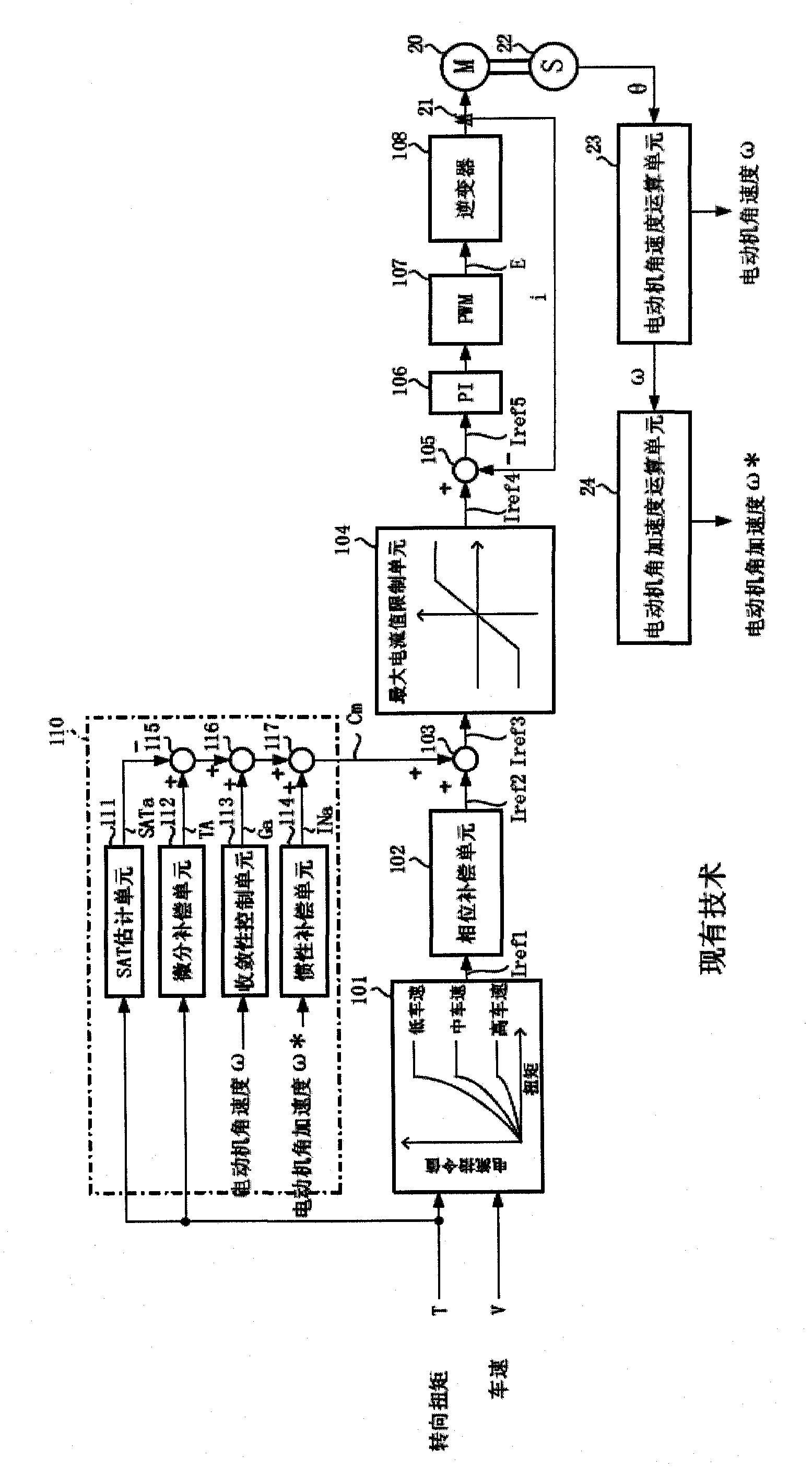

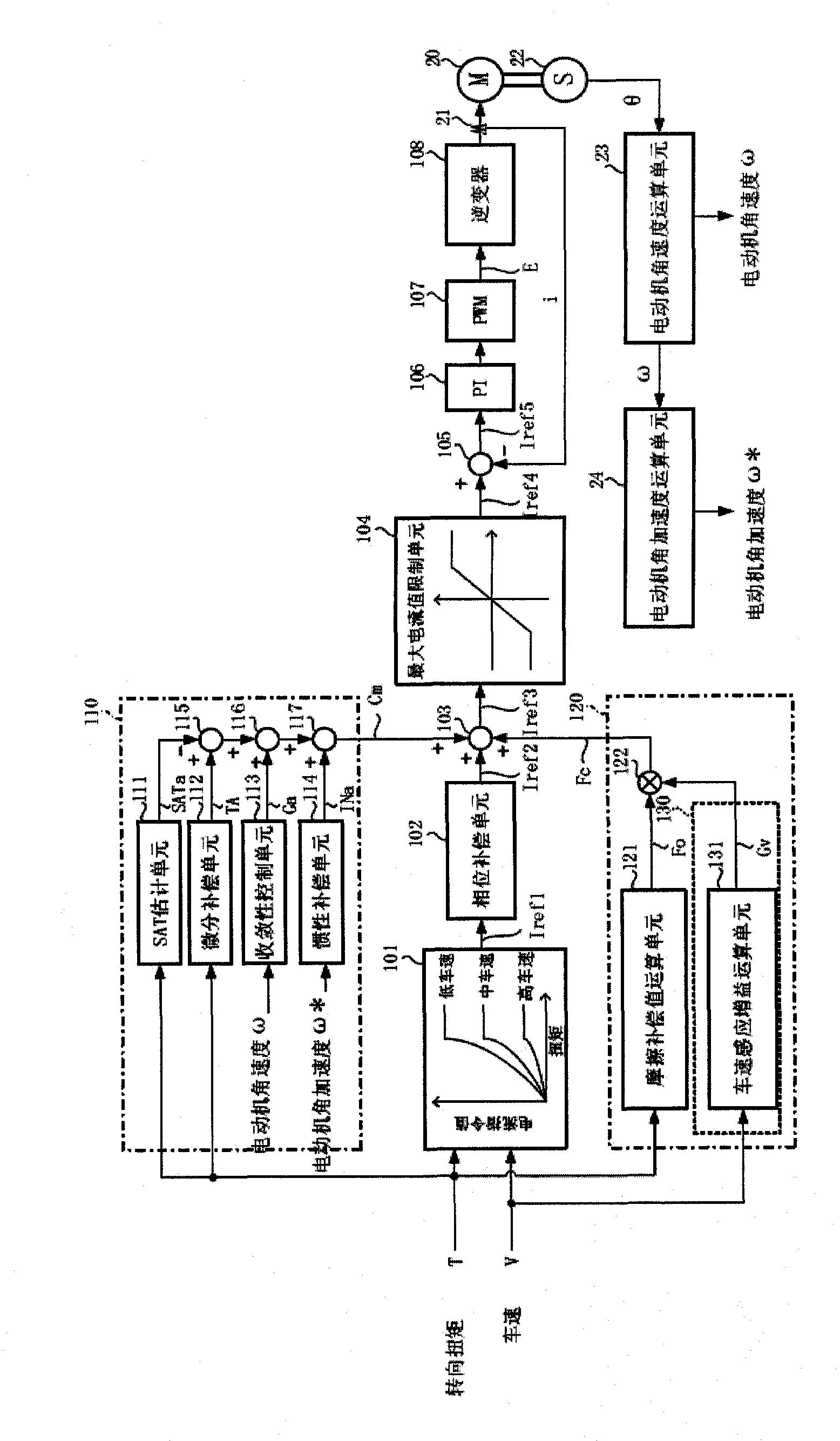

Electric power steering device

ActiveCN102105341ANatural and comfortable steering feelImprove stabilitySteering linkagesAutomatic steering controlElectric power steeringStatic friction

Provided is an electric power steering device that compensates for both the static friction and dynamic friction of the electric power steering device, and that switches smoothly between compensation for the static friction and compensation for the dynamic friction without causing any uncomfortable sensation in order to achieve a natural, comfortable steering feel. In an electric power steering device in which a current instruction value is computed based at least on steering torque, and a motor which applies a steering assist force to a steering mechanism is controlled according to a currentcontrol value computed based on the current instruction value, a friction compensation unit is provided to compute a friction compensation value to provide friction compensation for the steering mechanism based on the steering torque, and the current instruction value is corrected using the friction compensation value.

Owner:NSK LTD

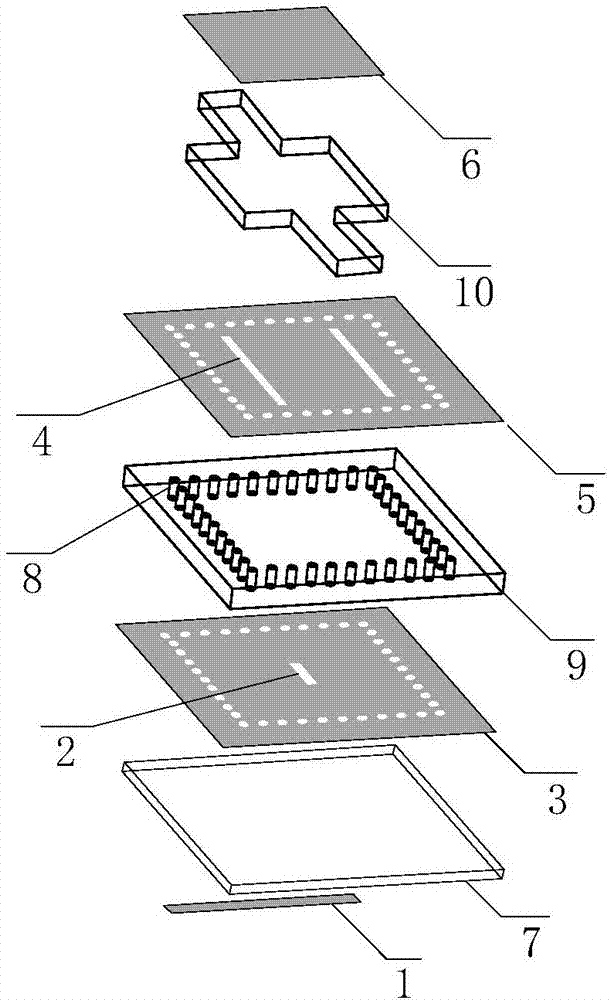

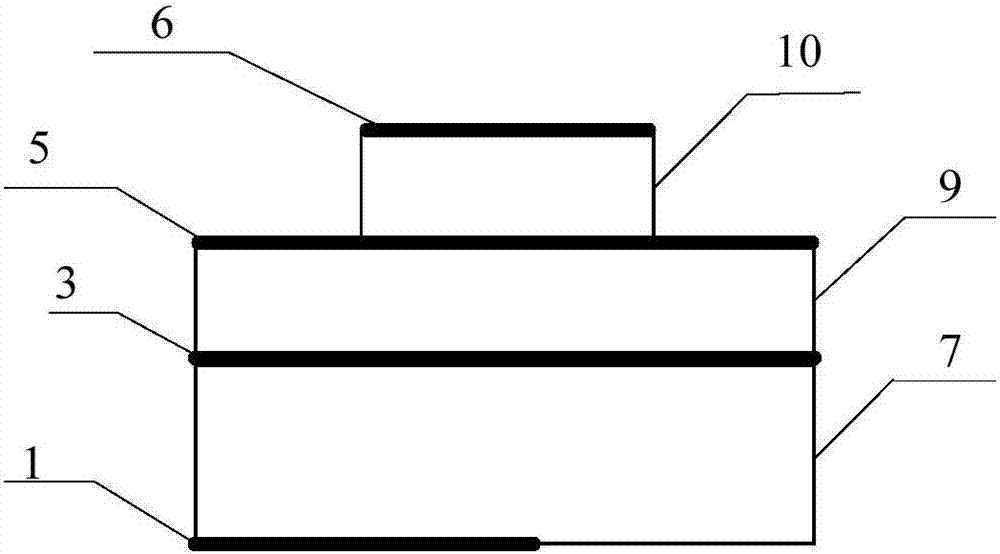

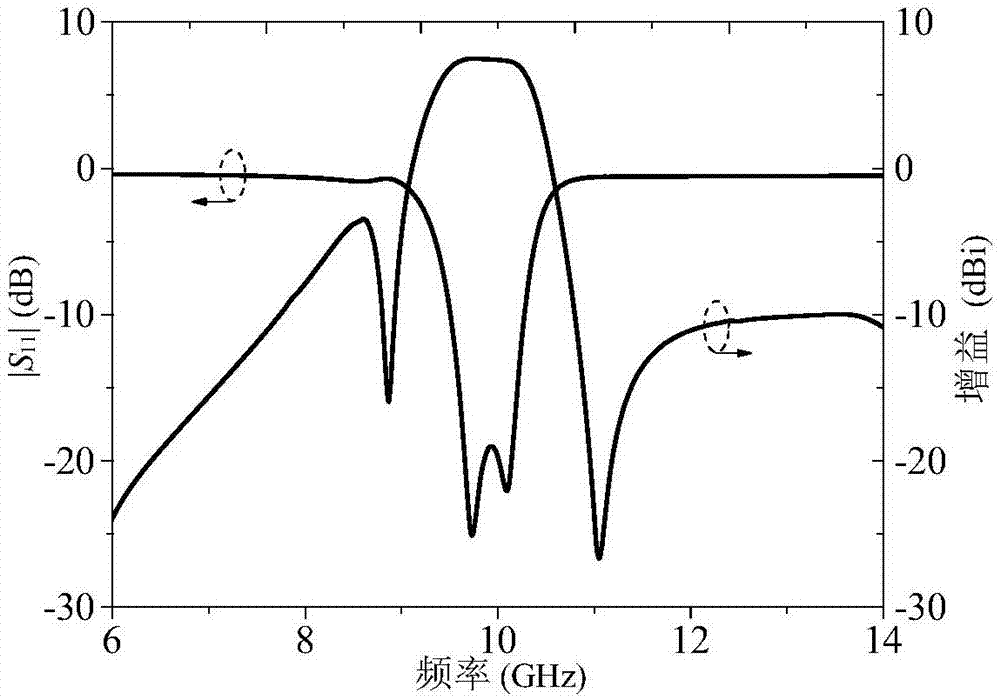

Multilayer structure filtering antenna and microwave communication system

ActiveCN107104275AImprove frequency selectivitySolve assembly problemsRadiating elements structural formsSlot antennasResonant cavityCommunications system

The present invention provides a multilayer structure filtering antenna and a microwave communication system. The multilayer structure filtering antenna comprises a first dielectric substrate, a second dielectric substrate and a third dielectric substrate which are overlapped from down to up; the lower surface of the first dielectric substrate is provided with a microstrip feeder; the lower surface and the supper surface of the second dielectric substrate are respectively provided with a first metal layer and a second metal layer, an entirety formed by the first metal, the second dielectric substrate and the second metal layer is provided with a plurality of metallization through holes in rectangular arrangement mode, the first metal layer, the second metal layer and a plurality of metallization through holes commonly form a rectangular resonant cavity, the first metal layer is provided with a coupling slot, and the second metal layer is provided with two opposite radiation slots; and the third dielectric substrate comprises a rectangular main body portion and two extension bodies, and the main body portion is provided with a radiation metal layer. The multilayer structure filtering antenna and the microwave communication system realize high-frequency selectivity, high gain and bandwidth improvement effects, solve the problem that the whole gain of the antenna id decreased caused by a non-radiation resonator, and realize assembling of a filtering antenna through the antenna itself.

Owner:NANTONG RES INST FOR ADVANCED COMM TECH CO LTD

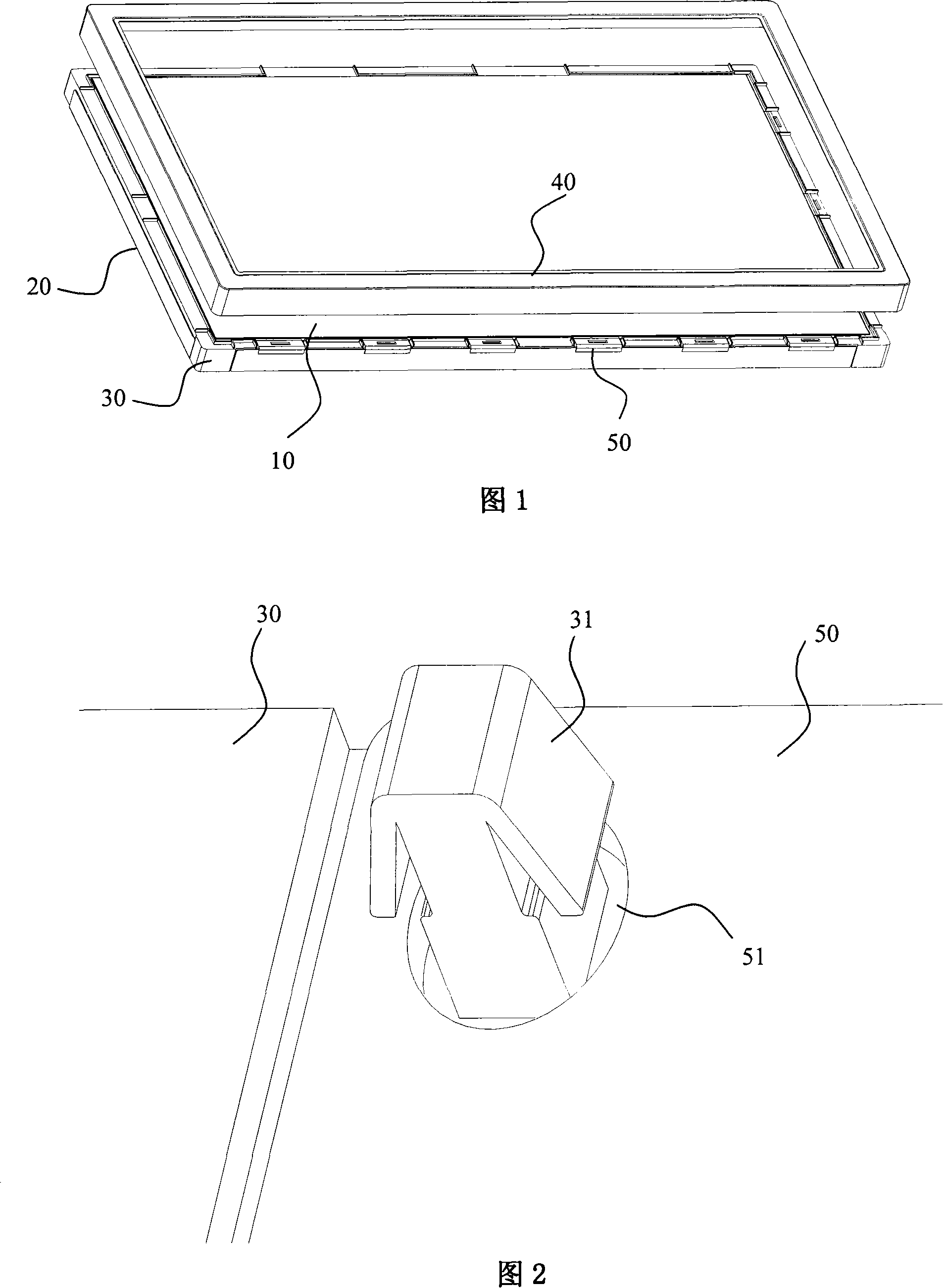

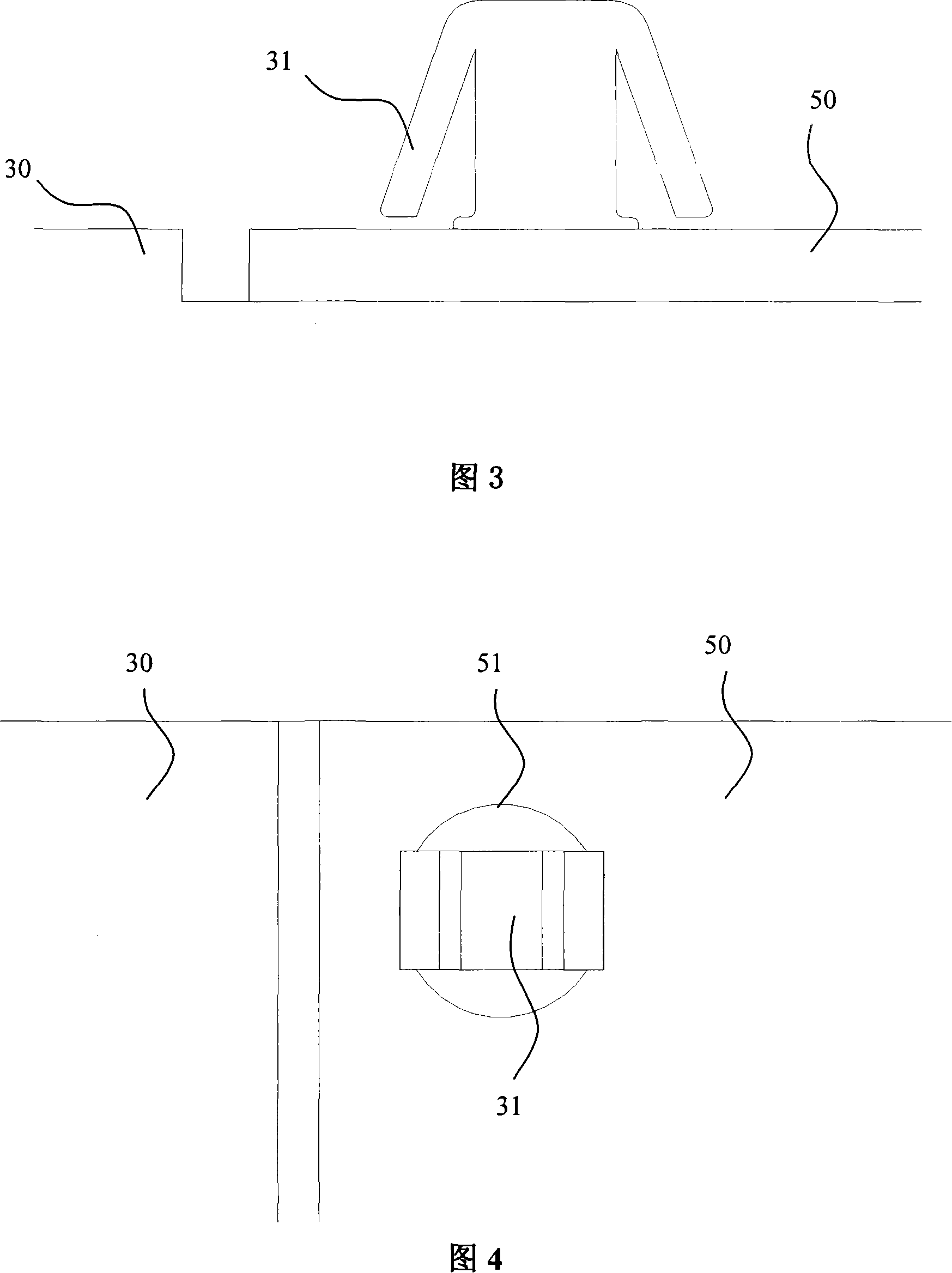

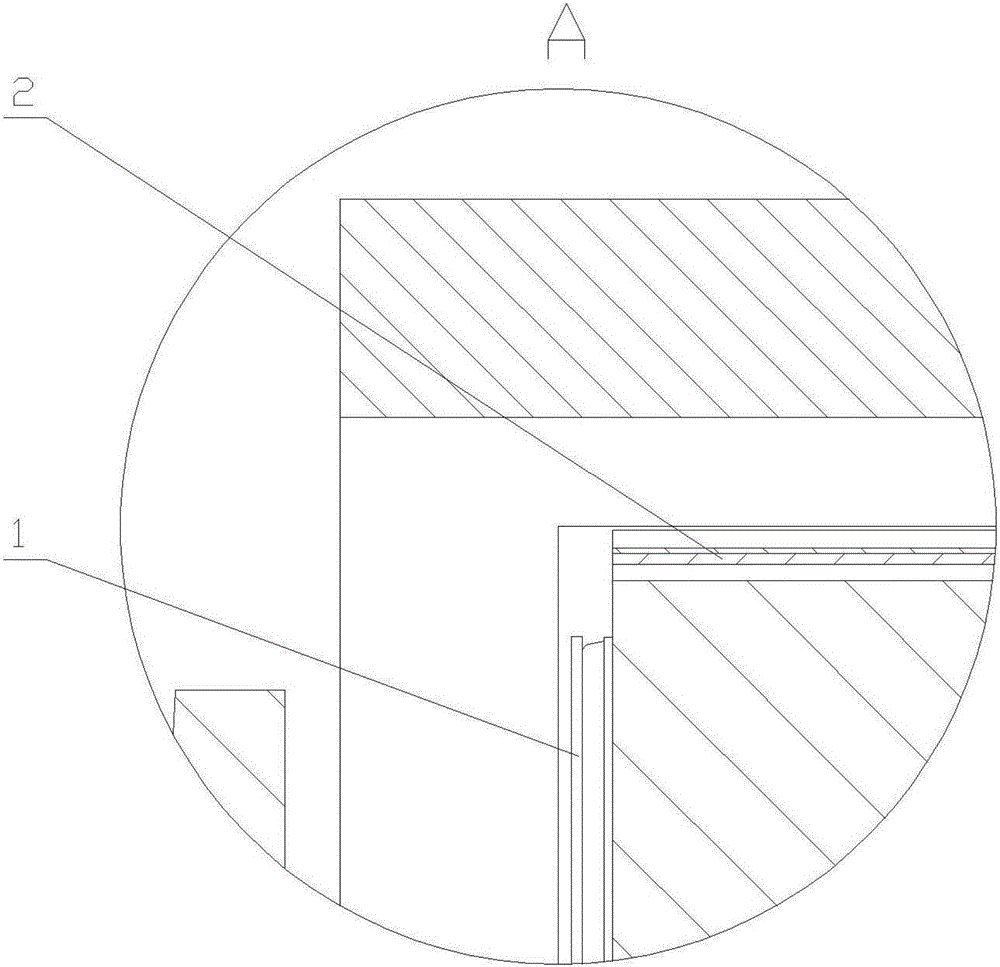

LCD display module

InactiveCN101149495ASolve assembly problemsEasy to assemblePrinted circuit detailsStatic indicating devicesLiquid-crystal displayEngineering

This invention discloses a sort of liquid crystal display die set. It consists of a backboard, a first framing which is laid in this backboard, a second framing which is covered in the first framing, a liquid crystal display panel which is laid in the first framing, a PCB plate which is fixed in the first framing. This first framing has the grab, and this PCB plate has the clip core which corresponds to the grab. This invention adopts the grab orientation configuration to fix the PCB plate, it solves the assemblage problem and the resolving problem of the PCB plate effectively, it predigests the assemblage, and it saves the production time and the manpower cost.

Owner:上海广电光电子有限公司

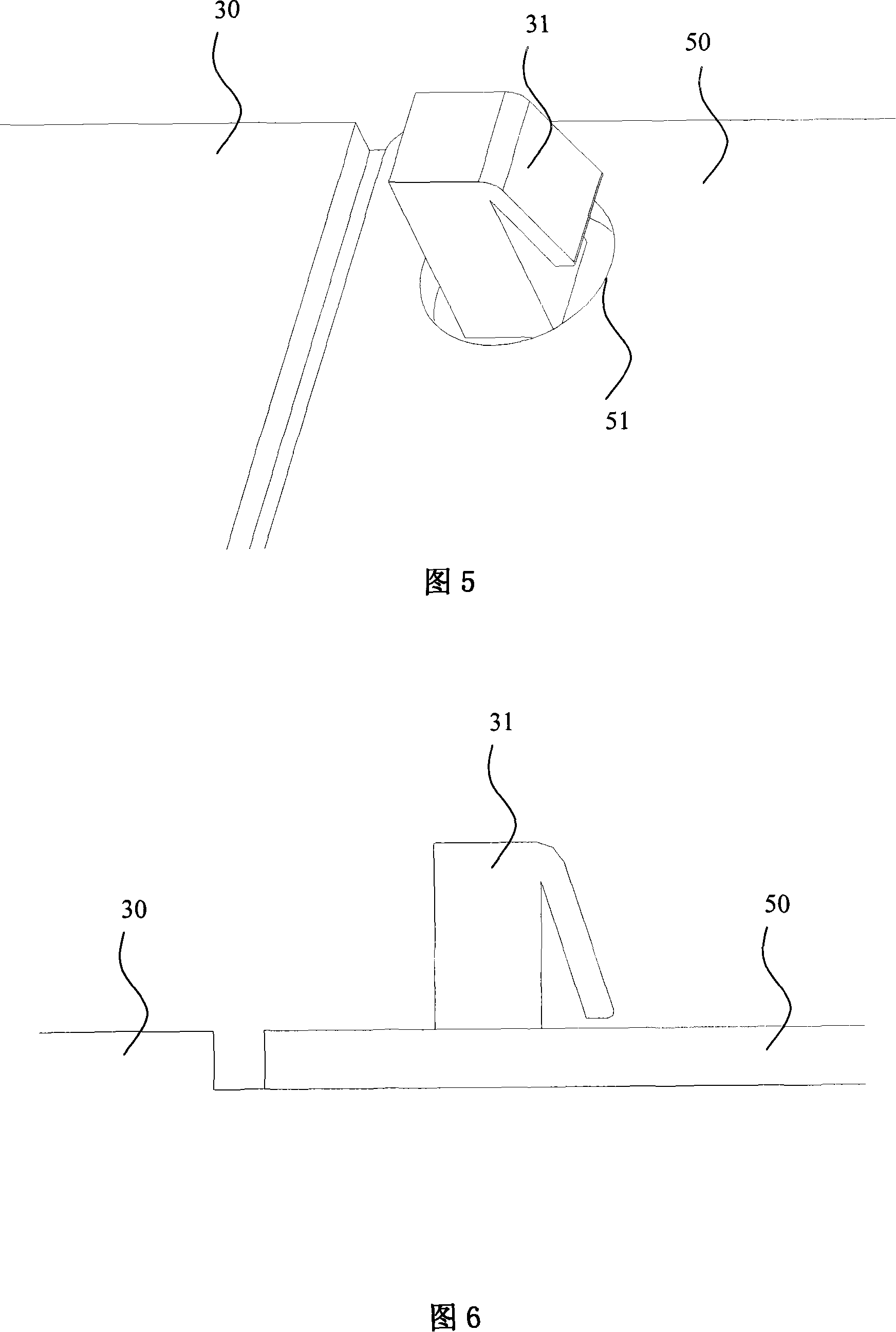

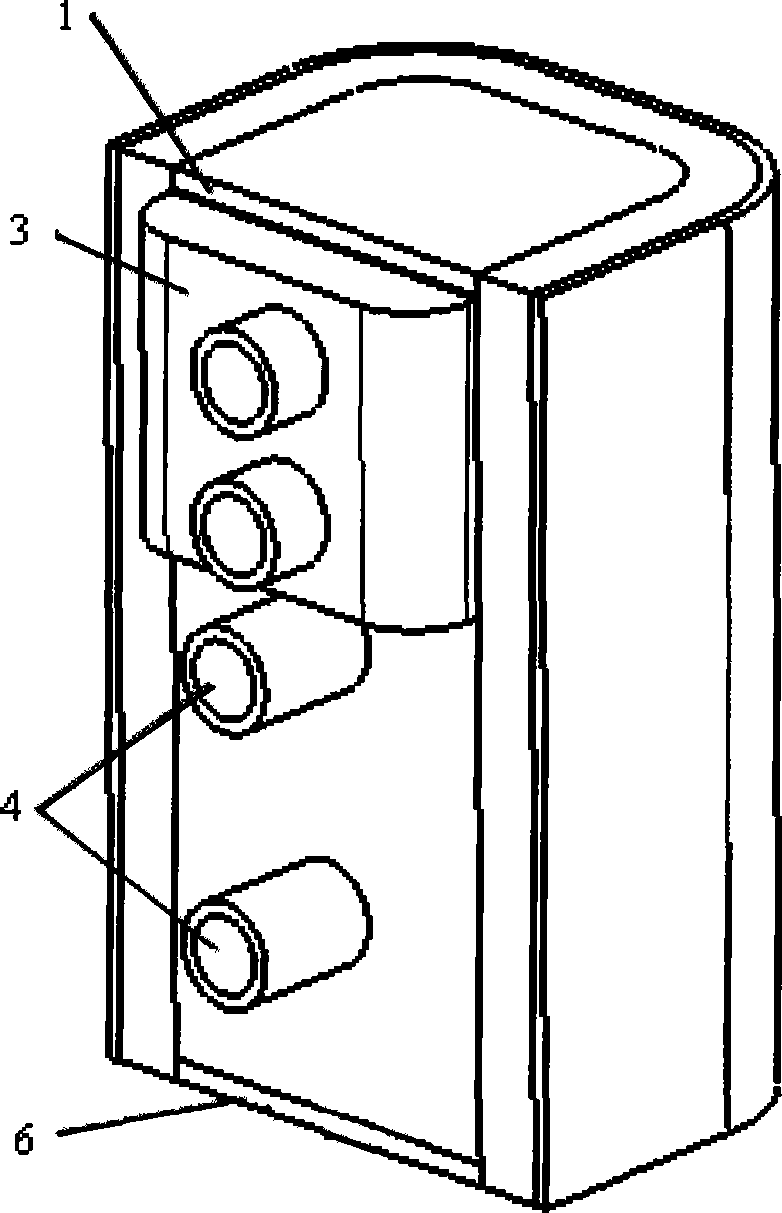

Stationary fixture used for axial compression stability test of columnar bent plate

The invention discloses a stationary fixture used for an axial compression stability test of a columnar bent plate. The stationary fixture comprises a down press plate, two L-shaped upright posts and multiple pairs of collets, wherein horizontal surfaces of the two L-shaped upright posts are respectively fixed on the down press plate and are located at the straight sides of two ends of a to-be-tested bent plate, and the multiple pairs of collets are fixed on the vertical surfaces in a segmental manner respectively along the straight sides of the two ends of the to-be-tested bent plate, so that the straight sides of the two end parts of the to-be-tested bent plate are clamped between the collets at two sides. The stationary fixture used for the axial compression stability test of the columnar bent plate, disclosed by the invention, has a simple structure and is suitable for testing bent plates with multiple curvatures as the clamping positions of the L-shaped upright posts and the collets are adjustable.

Owner:SHANGHAI JIAO TONG UNIV

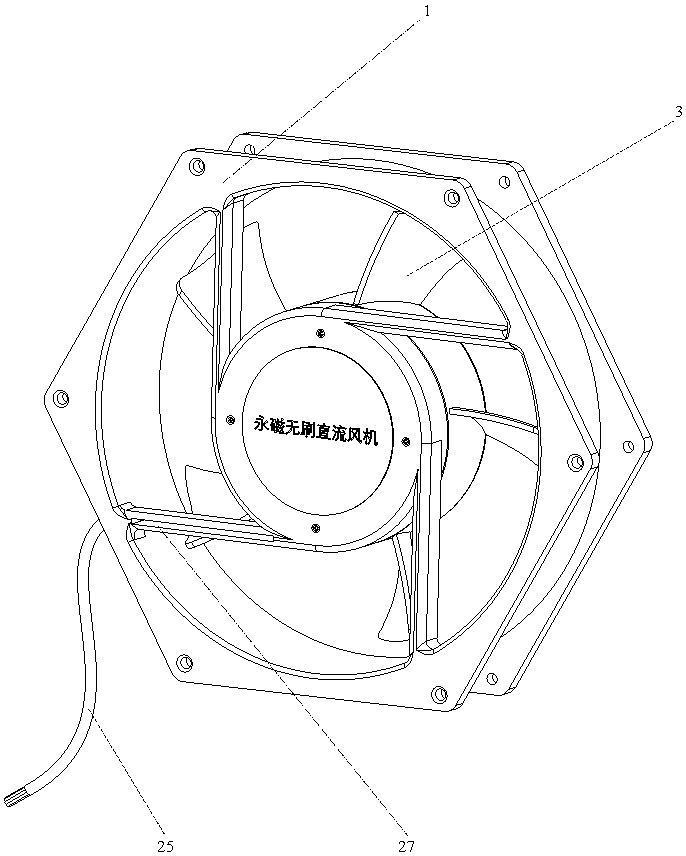

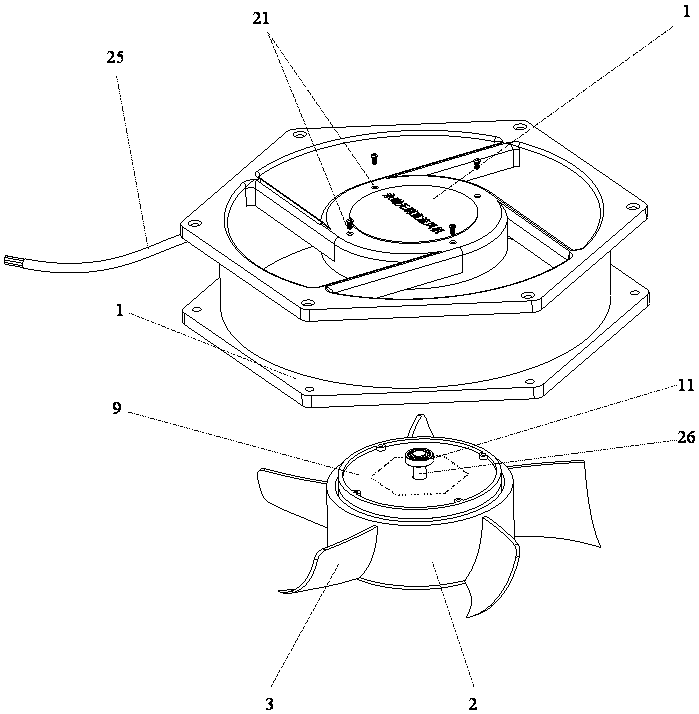

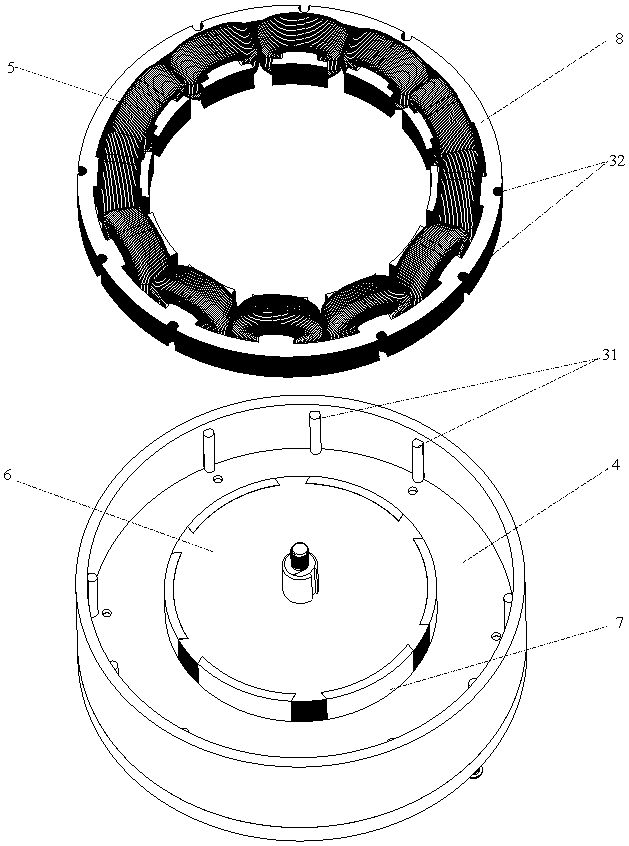

Permanent magnet brushless direct current frequency conversion axial flow fan

ActiveCN106224268AEasy to useEasy to installMagnetic circuit rotating partsPump componentsImpellerDual core

The invention provides a permanent magnet brushless direct current frequency conversion axial flow fan. The permanent magnet brushless direct current frequency conversion axial flow fan comprises a fan frame, an impeller, a cover disk, a coil, a rotor iron core body, permanent magnets, a stator iron core body, a PCB and a heat dissipation frame. The permanent magnet brushless direct current frequency conversion axial flow fan is characterized in that the heat dissipation frame is made of an aluminum alloy material; the PCB is a round printed board of which the center is provided with a hole; a dual-core single chip microcomputer, a front driving chip and a VMOS power pipe are welded to the PCB, and the heat dissipation surface of the PCB is fixed to a hexagonal frame at the center of the heat dissipation frame through screws in a horizontal installation mode; the cover disk is a hollow cylinder of which the middle is provided with an isolation plate; the center of the isolation plate is provided with a bearing B installation step; and the isolation plate divides the cover disk into two parts. The fan and motor integrated permanent magnet brushless direct current frequency conversion axial flow fan scheme provided by the invention represents the development direction of permanent magnet brushless direct current frequency conversion axial flow fans and is quite broad in application prospect.

Owner:广州冠协风机制造有限公司

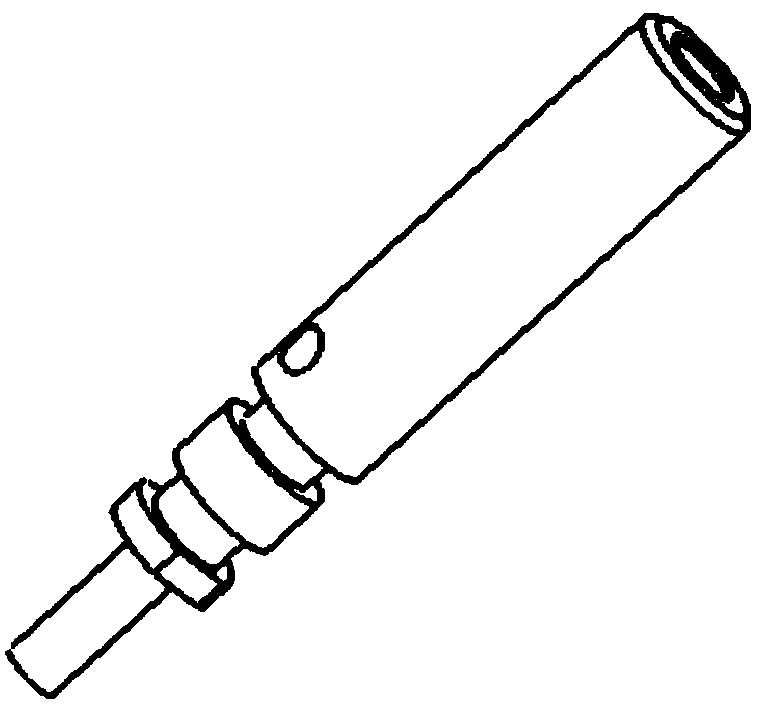

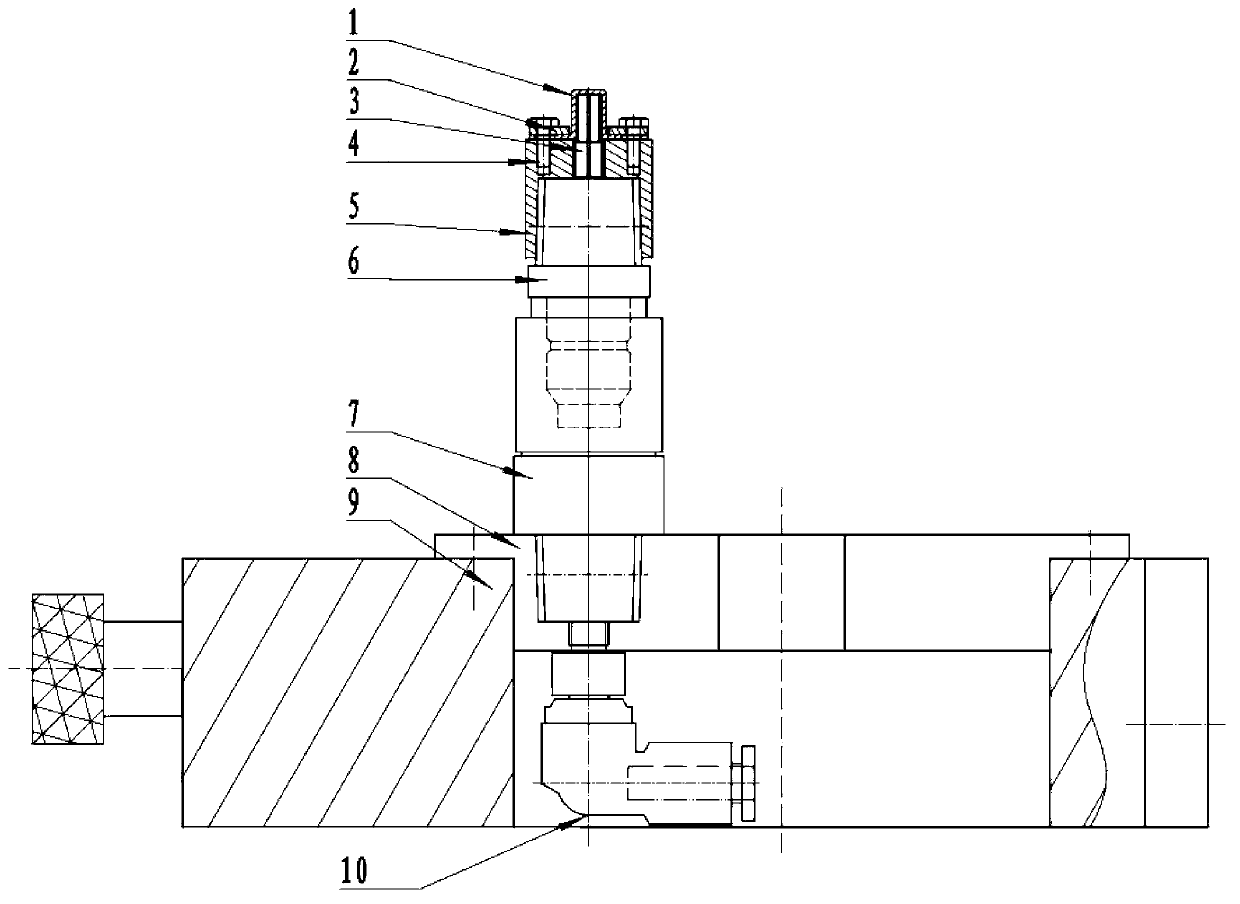

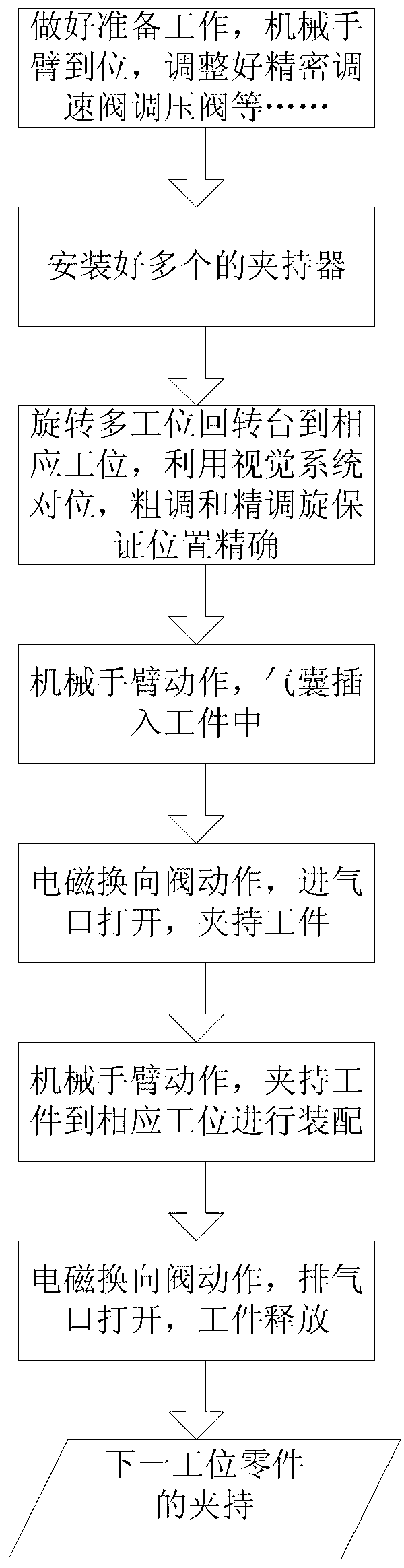

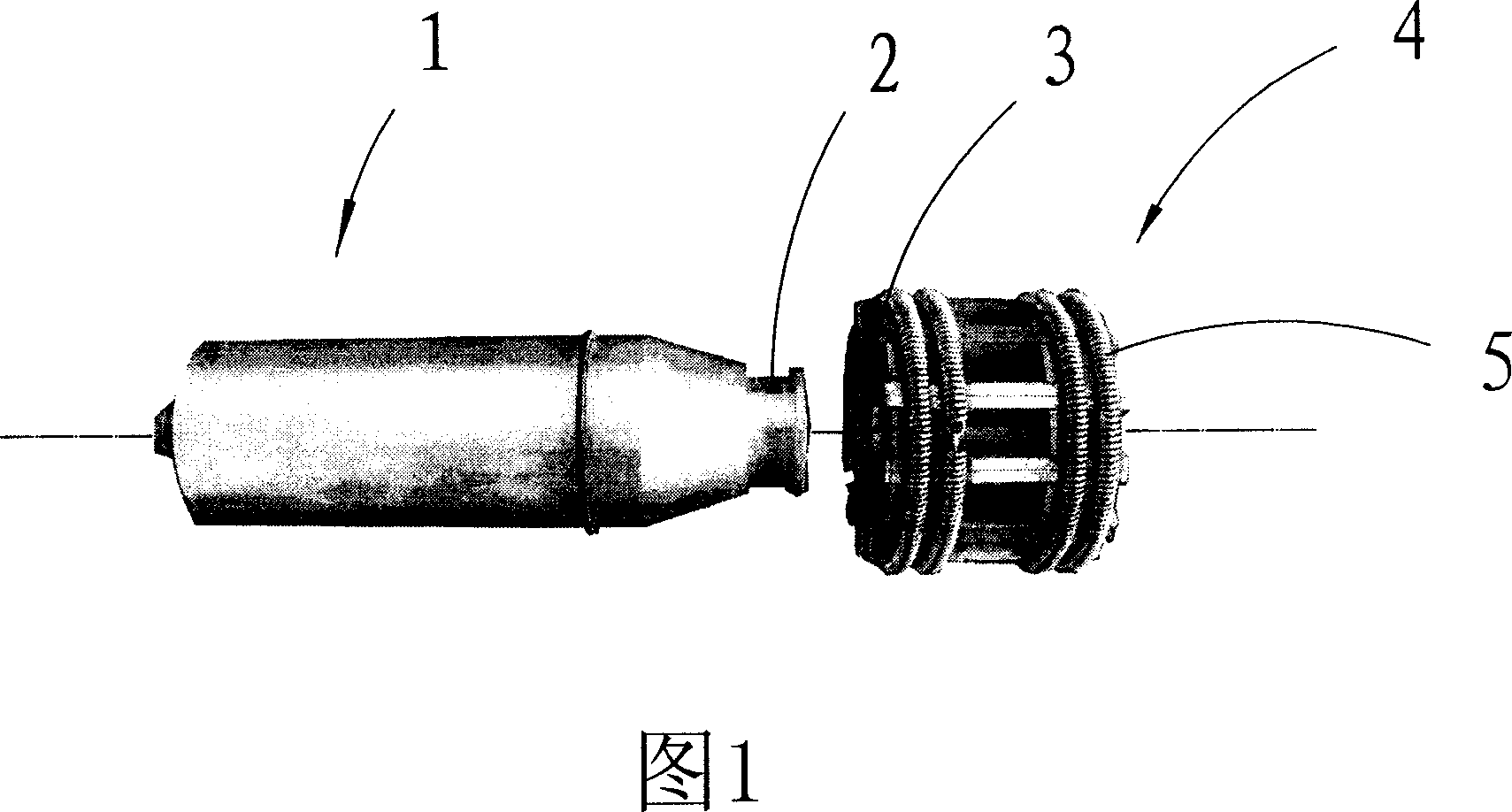

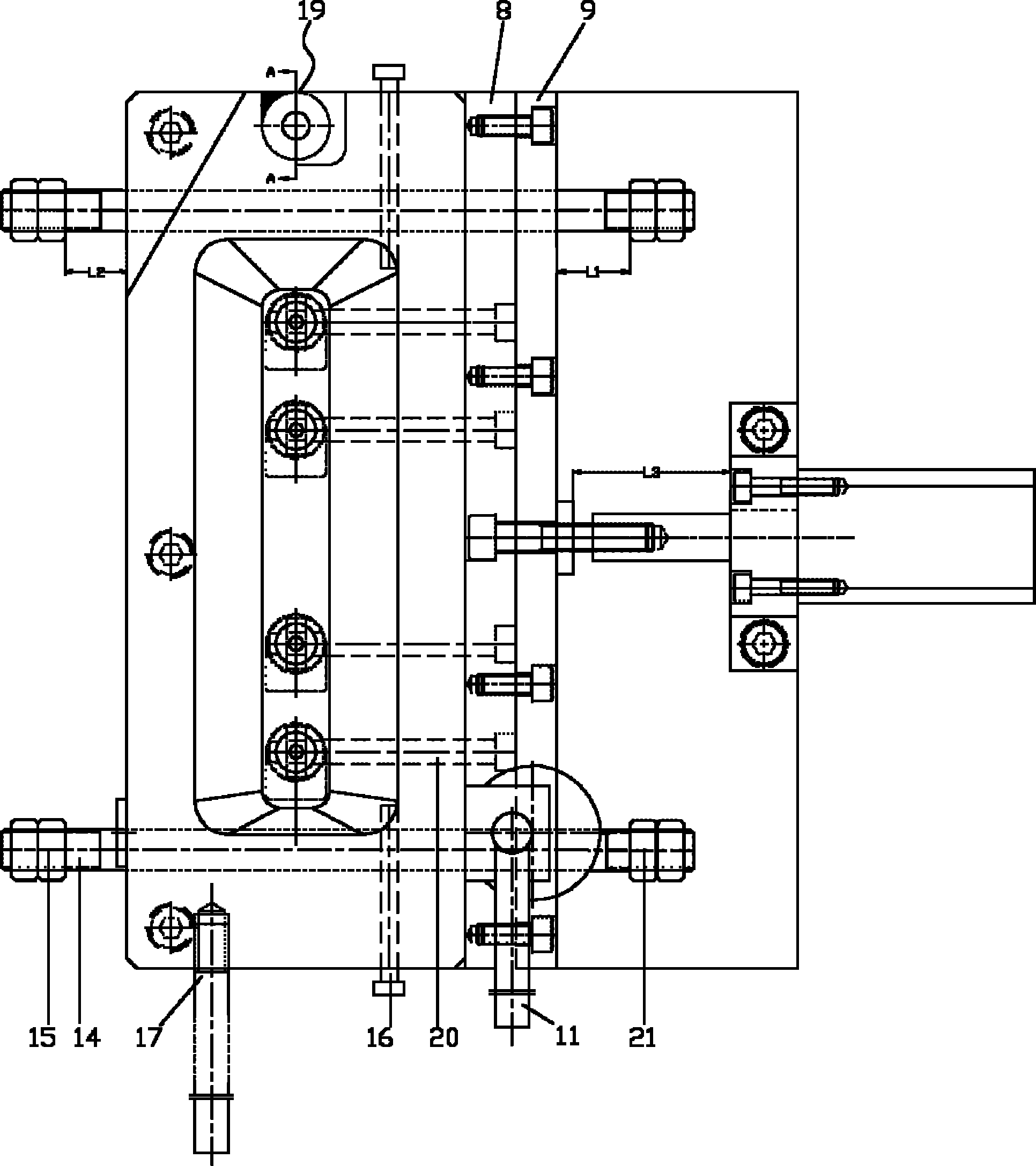

Multi-station silica gel air bag clamping device for clamping ultrathin wall deep cylinder part

ActiveCN103341861ARealize flexible clampingImprove clamping efficiencyGripping headsMetal working apparatusMagnetic exchangeEngineering

The invention relates to a multi-station silica gel air bag clamping device for clamping an ultrathin wall deep cylinder part and belongs to the field of microoperation and the micro electromechanical technology. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part particularly comprises an air bag clamping head, a conical surface quick-insertion connector, a multi-station rotary table and a gas circuit system. The air bag clamping head comprises an air bag, a center retainer, a ring fastening gasket and a connection transition part. The conical surface quick-insertion connector comprises a quick-change connector plug and a quick-change connector socket. The multi-station rotary table comprises a 360-degree manual rotary table and a pinboard. The gas circuit system comprises a gas source, a filter, a pressure regulating valve, a speed controlling valve, a magnetic exchange valve and a gas pipe connector. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part solves the problems that clamping of thin-wall parts is small in strength, poor in intensity, and deformation, invalidation and even damage are prone happening. Use of the quick-change connector and the multi-station rotary table can effectively achieve quick and flexible clamping and assembling of parts of different sizes and the same kind, facilitate operation and improve assembling precision and assembling efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

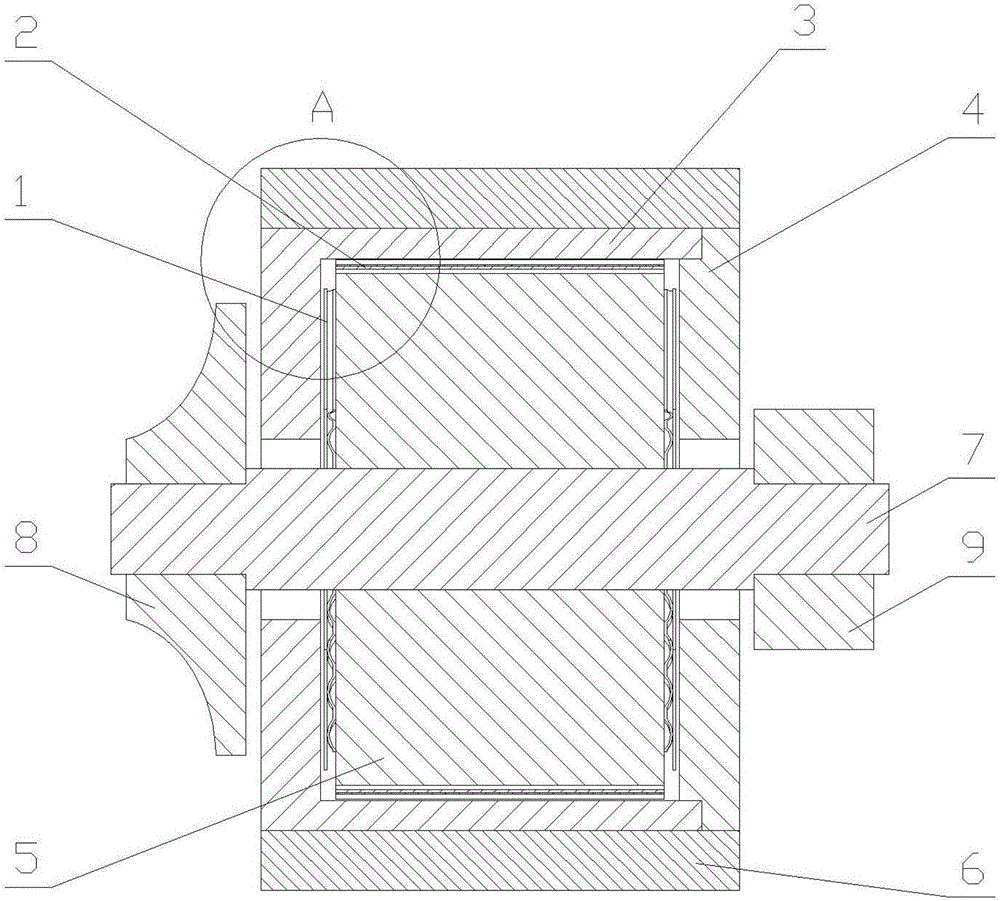

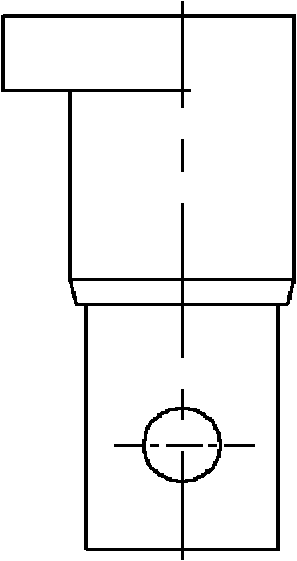

Structural member of sensor

ActiveCN102928005ASolve assembly problemsLarge deformationMeasurement apparatus componentsWeighing apparatus detailsEngineeringFlange

The invention relates to the field of a sensor, specifically to a structural member of a sensor. The structural member of the sensor is in an I-beam structure; the I-beam structurally comprises two parallel flanges, and a web which connects the two flanges, wherein the web is provided with two side walls which are located on left and right sides respectively; a hollow through hole which is parallel to the flanges is arranged in the cross section of the web; the hollow through hole is used for setting the sensor; the inner surfaces of the side walls are cambered surfaces; the curvature radiuses of the cambered surfaces of the inner surfaces of the side walls are the same; the distances between a central point of the hollow through hole and one point and between the central point of the hollow through hole and any other point on the inner surfaces are the same, wherein each side wall of the web is provided with a root part and an end part, wherein the end part is the axle wire position of the web; the end part of each side wall of the web is thicker than the root part; the thicknesses of the two side walls are symmetrical. The structure provided by the invention is characterized in that the web deformation and variation of height of the restorable through hole are increased in multiples, thus the assembly accuracy is improved and the assembly difficulty is reduced.

Owner:SICHUAN XINGDA MINKO ELECTR MECHANICAL ENG

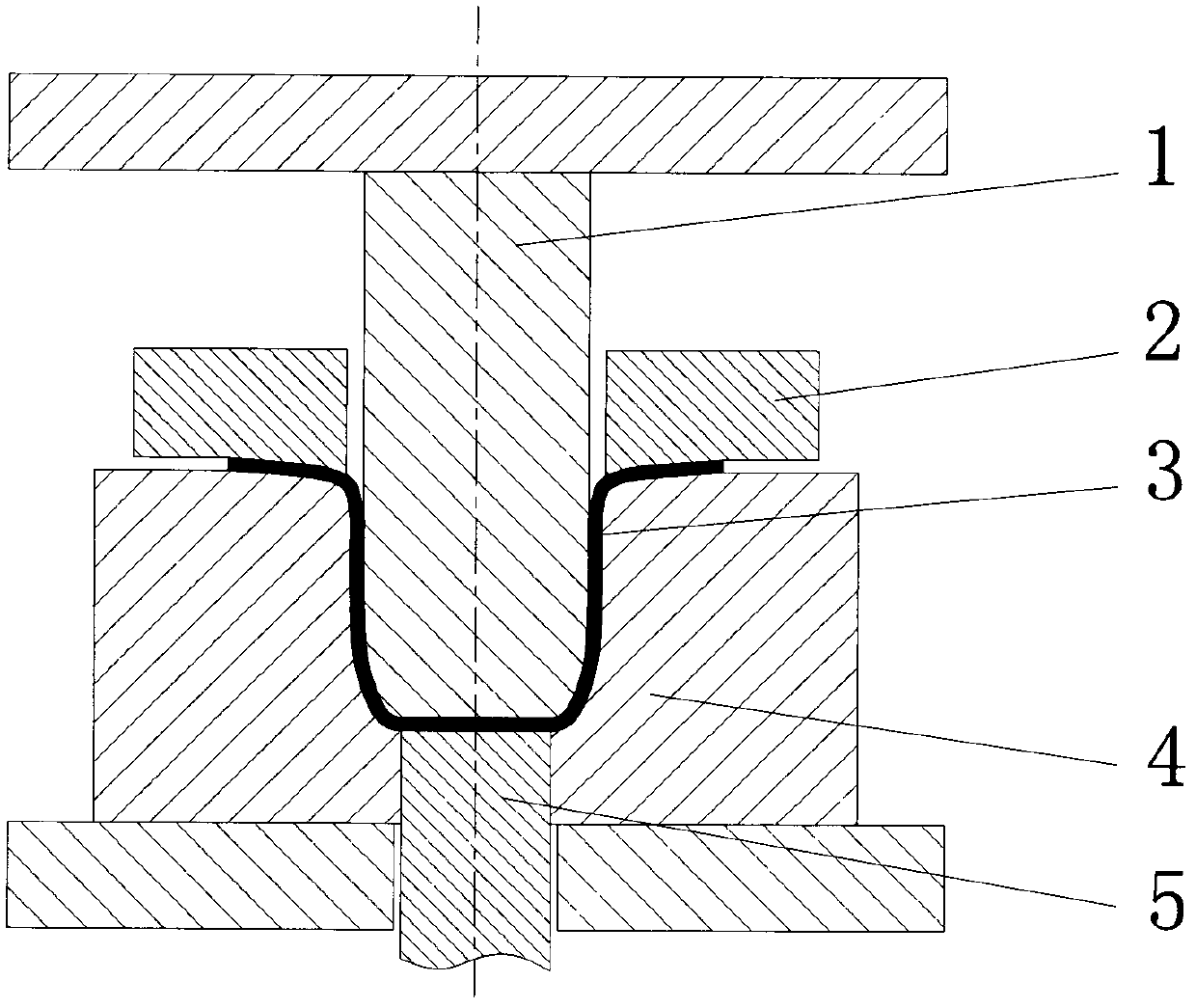

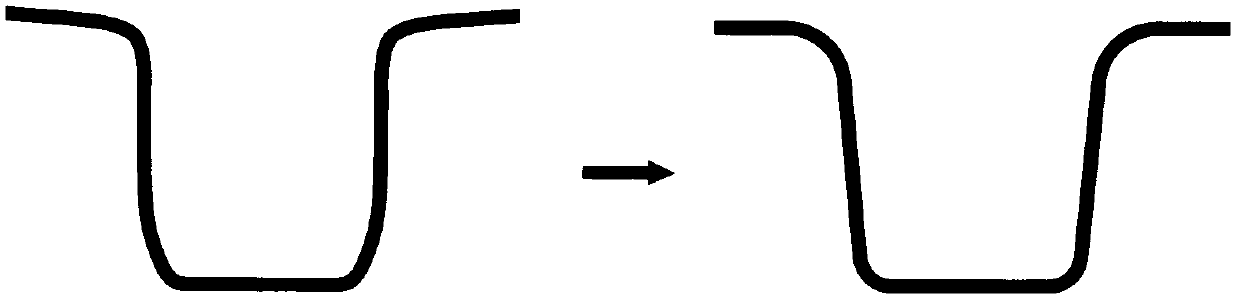

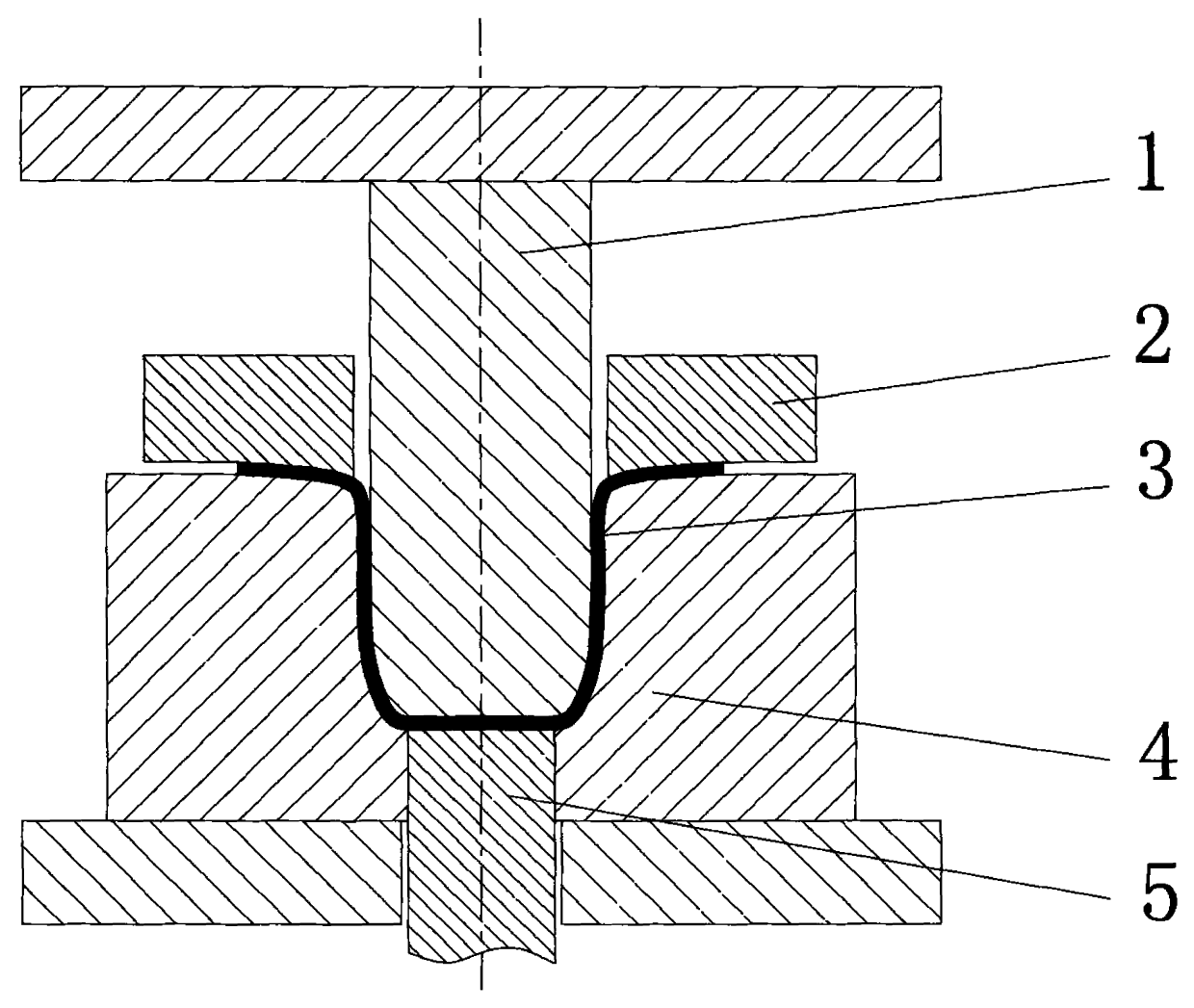

Crimping and rebounding control method of lateral wall of advanced high-strength steel stamping part

InactiveCN102632157AHigh production quality requirementsImprove forming qualityShaping toolsEngineeringHigh intensity

The invention discloses a crimping and rebounding control method of a lateral wall of an advanced high-strength steel stamping part. Lateral wall crimping and flange sinking phenomena easily caused when an advanced high-strength steel plate is stamped and formed are controlled by changing a die structure. The main method disclosed by the invention as follows: processing lateral walls of a convex die and a concave die into arc surfaces as a stamping and rebounding compensation surface; and bending a plate material along with the dies in a forming process to generate reverse deformation stress. Due to high strength, the bent lateral wall rebounds and deforms; reverse deformation stress of previous lateral wall is balanced; crimping of two lateral walls towards the outer side caused by rebounding is avoided when the stamping is finished, and then the die surface of the concave die contacting the edge of a flange is machined into an inclined plane which inclines upwards, and a blank holder is also an inclined plane with the same angle, so that the flange edge of a spare part can compensate sinking amount and the sinking flange edge becomes a horizontal state so as to obtain the spare part with good shape when the lateral wall rebounds. The crimping and rebounding control method disclosed by the invention has important realistic use value to improve forming precision of the advanced high-strength steel.

Owner:JILIN UNIV

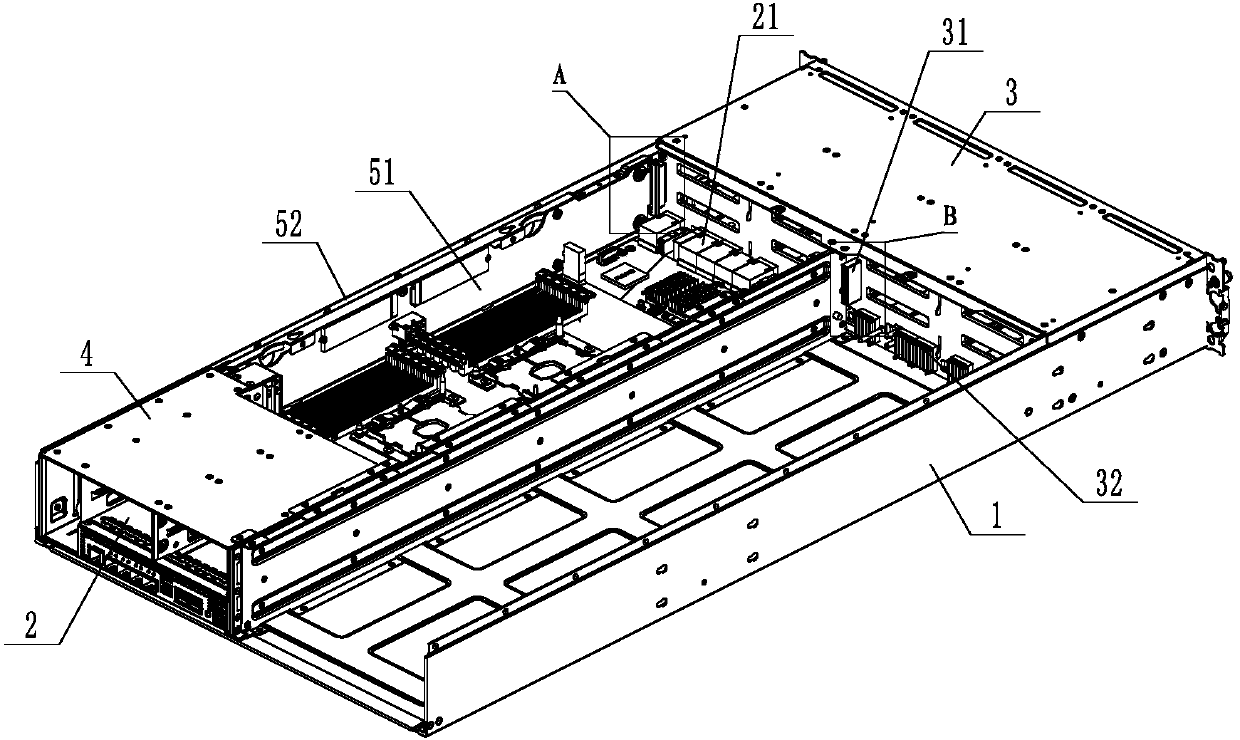

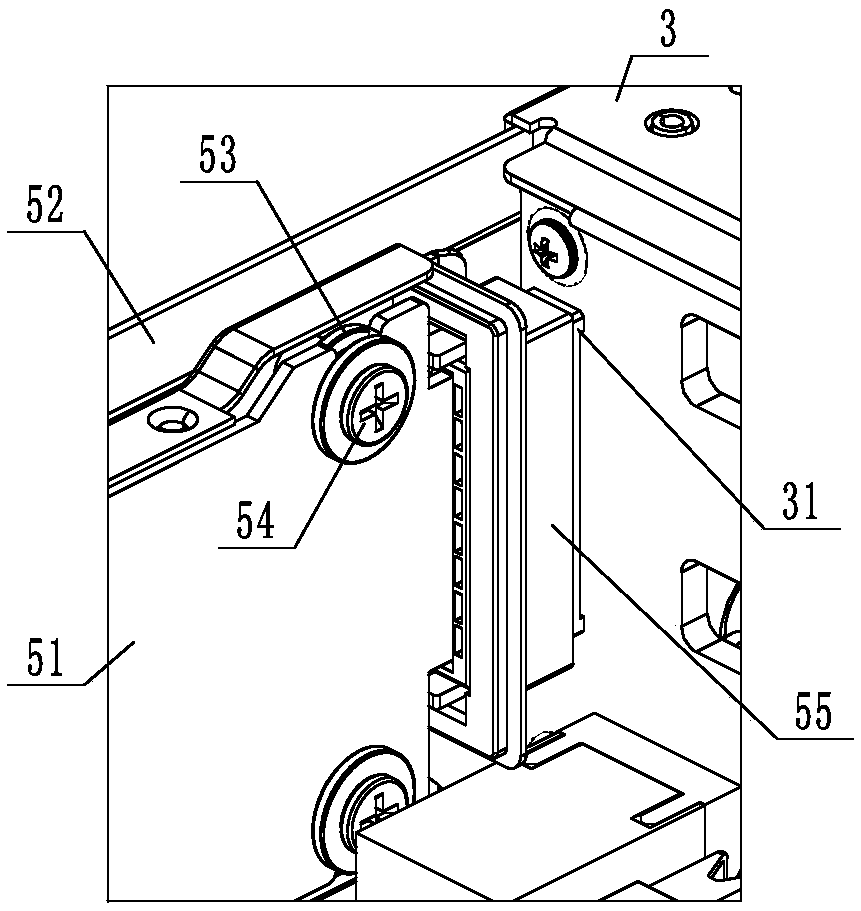

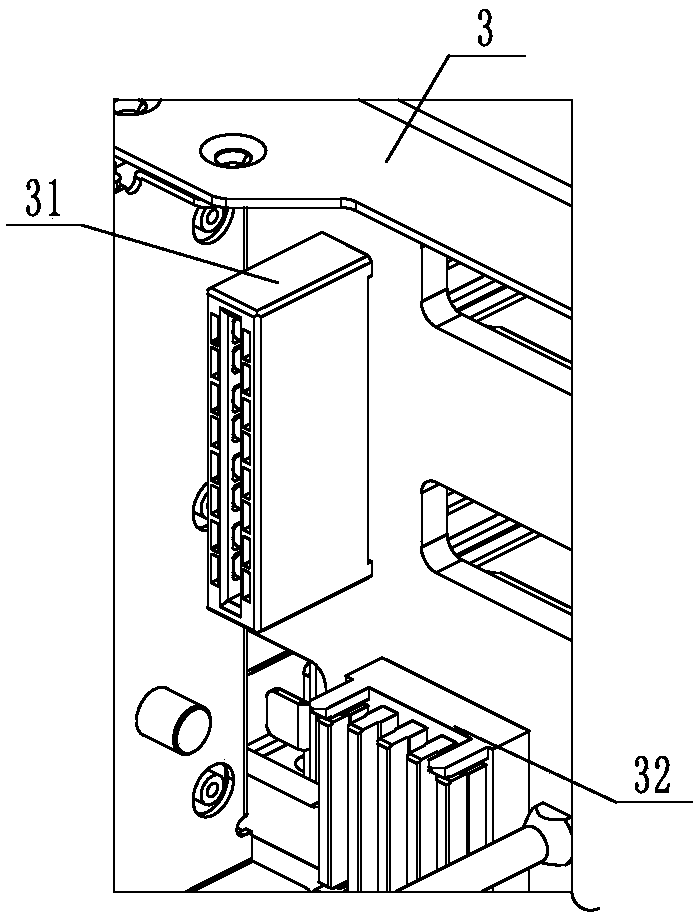

Adapter plate device capable of being mounted in floating way through automatic positioning

ActiveCN107589796ASolve assembly problemsImprove assembly reliabilityDigital processing power distributionPrinted circuit boardMotherboard

The invention discloses an adapter plate device capable of being mounted in a floating way through automatic positioning, and relates to the technical field of servers. The adapter plate device comprises a memory chassis, wherein a back end of the memory chassis is provided with a controller; a front end of the memory chassis is provided with a hard disk backplate; the hard disk backplate is provided with a power connector and a high-speed connector; and a controller chassis is provided with an adapter assembly which is connected with a controller motherboard and the hard disk backplate. An adapter plate is designed with a certain floating amount to absorb an accumulation tolerance. Meanwhile, an auxiliary guide structure is adopted, the adapter plate is guided to a correct assembly positioned before the adapter plate is inserted into a backplate connector, and the backplate connector is inserted correctly through floatation of a PCB (Printed Circuit Board), so that an assembly problemcaused by the accumulation tolerance is solved; the assembly reliability of a product is enhanced; and the overall competitiveness is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

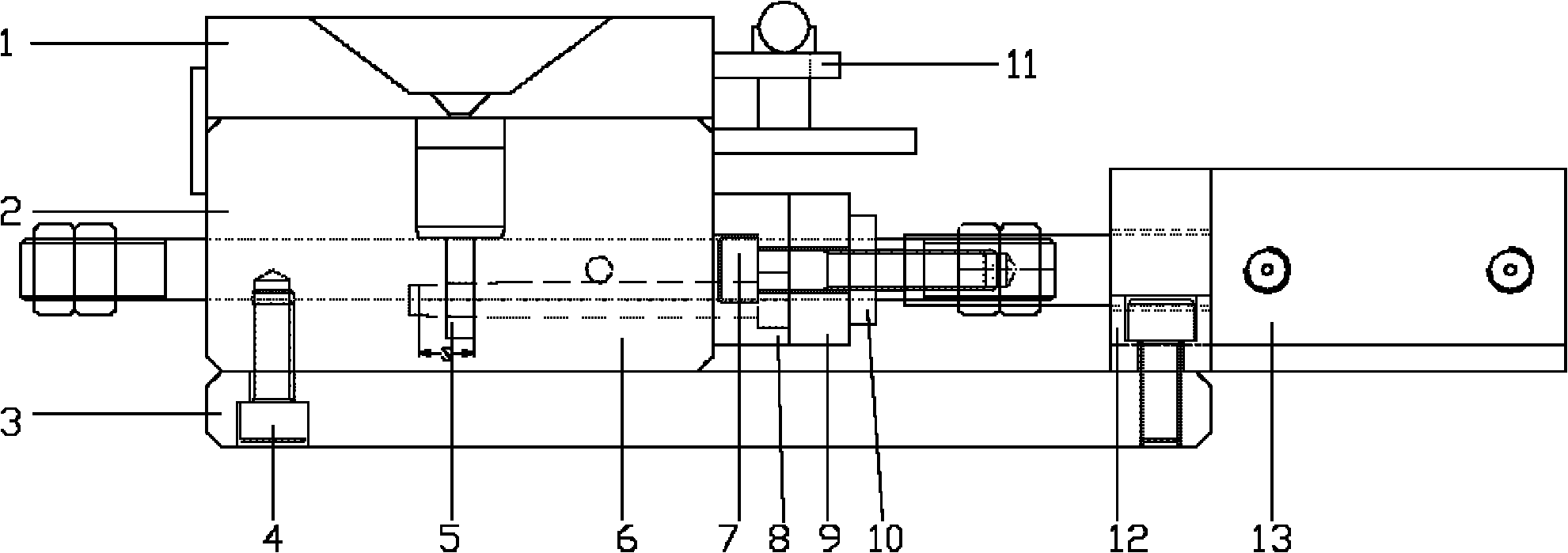

Continuous no-impact automatic uniform-load press-fitting device

ActiveCN104942565ARealize the guidance functionAvoid direct contactMetal working apparatusThrust bearingSteel ball

The invention provides a continuous no-impact automatic uniform-load press-fitting device which comprises a base, a press-fitting gasket, a bearing support sleeve, a sleeve, a gland, a driving screw, a support cylinder, a support gasket and a guide disk. The support cylinder, the gland and the base are positioned through spigots, a hole-cup drawing is arranged in a base positioning boss, the driving screw is screwed into the gland, the guide disk is arranged on the positioning spigot of the support cylinder in a clamped mode, the sleeve is put into a center hole of the guide disk and presses a thrust bearing, and a shaft is arranged in a center hole of the sleeve in a sleeved mode. The screw is rotated to be fed in a slow, no-impact and continuous mode, and press-fitting is achieved. The sleeve and the guide disk are arranged to conduct centering and guiding; the thrust bearing is arranged, so that direct contact between a workpiece and the driving screw is avoided, and the workpiece which is subjected to press-fitting is pressed in through straight line pressure; a steel ball is arranged to eliminate offset loading force. By means of the continuous no-impact automatic uniform-load press-fitting device, the problem of shaft hole interference fitting can be solved, and the situation that incline, misalignment and scuffing of the workpiece happen in the press-fitting process can be avoided. The continuous no-impact automatic uniform-load press-fitting device is simple in structure, reliable in work and capable of achieving the fitting work of shaft hole parts in a large interference magnitude and high accuracy mode.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

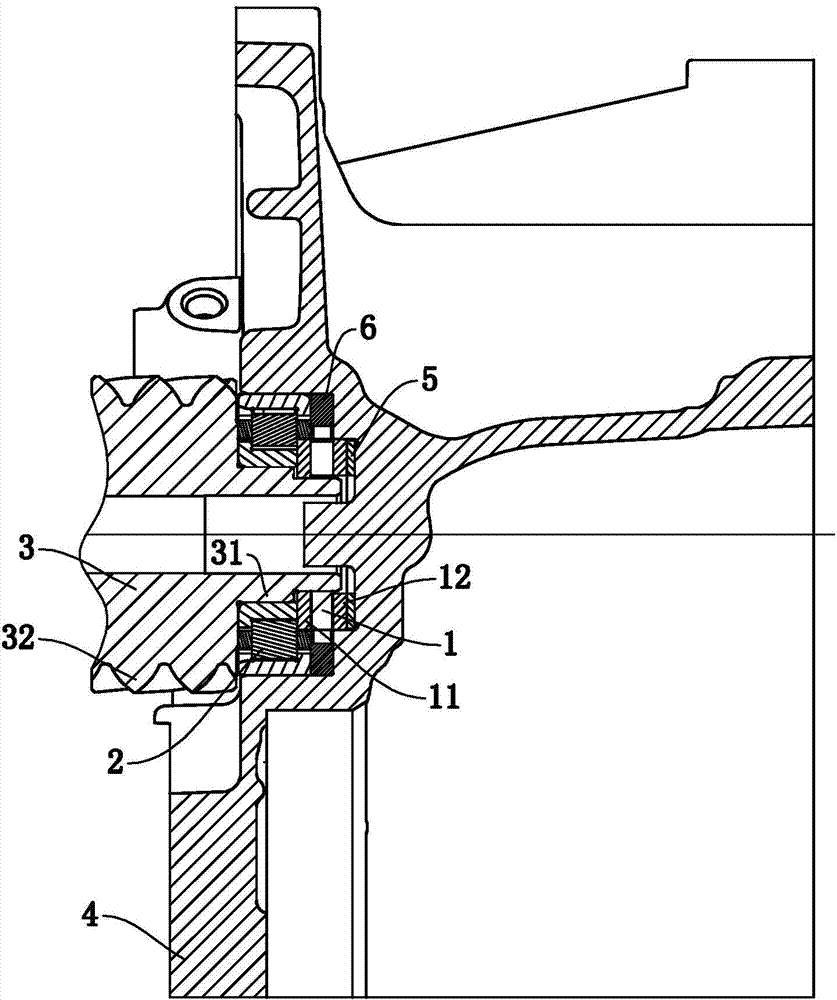

Output shaft support device for automatic gearbox

The invention discloses an output shaft support device for an automatic gearbox, and belongs to the technical field of the automatic gearbox. The output shaft support device for the automatic gearbox comprises an anti-thrust bearing and a radial bearing; an adjusting shim is installed between the ring of the anti-thrust bearing and the shell of the gearbox; the inner ring of the radial bearing is sleeved on the shaft shoulder of the output shaft; the outer side of the inner ring of the radial bearing bears against the output gear of the output shaft, and the inner side of the inner ring bears against the shaft ring of the anti-thrust bearing; the inner side of the outer ring of the radial bearing is provided with a flange; a spacer is installed between the flange and the shell of the gearbox; the outer ring of the radial bearing is fixedly installed with the shell of the gearbox; and the outer side of the outer ring of the radial bearing is provided with an opening. The output shaft support device for the automatic gearbox is capable of, through designing the radial bearing as the separated structure, solving the wearing problem of the gearbox shell, and solving the assembling problem of the radial bearing.

Owner:SHENGRUI TRANSMISSION

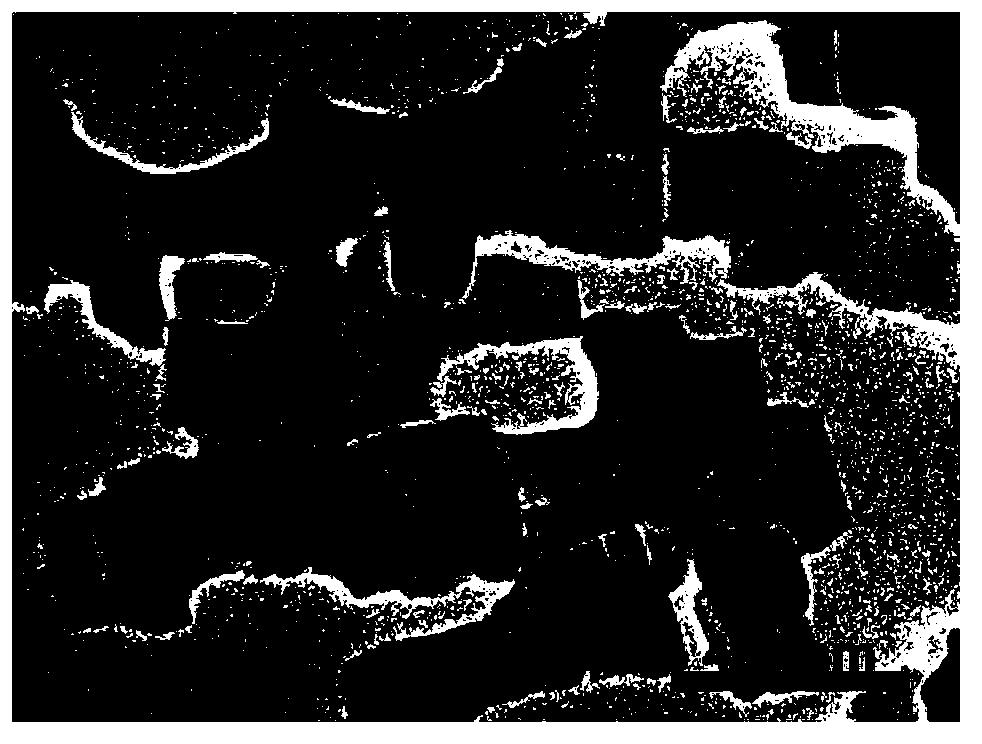

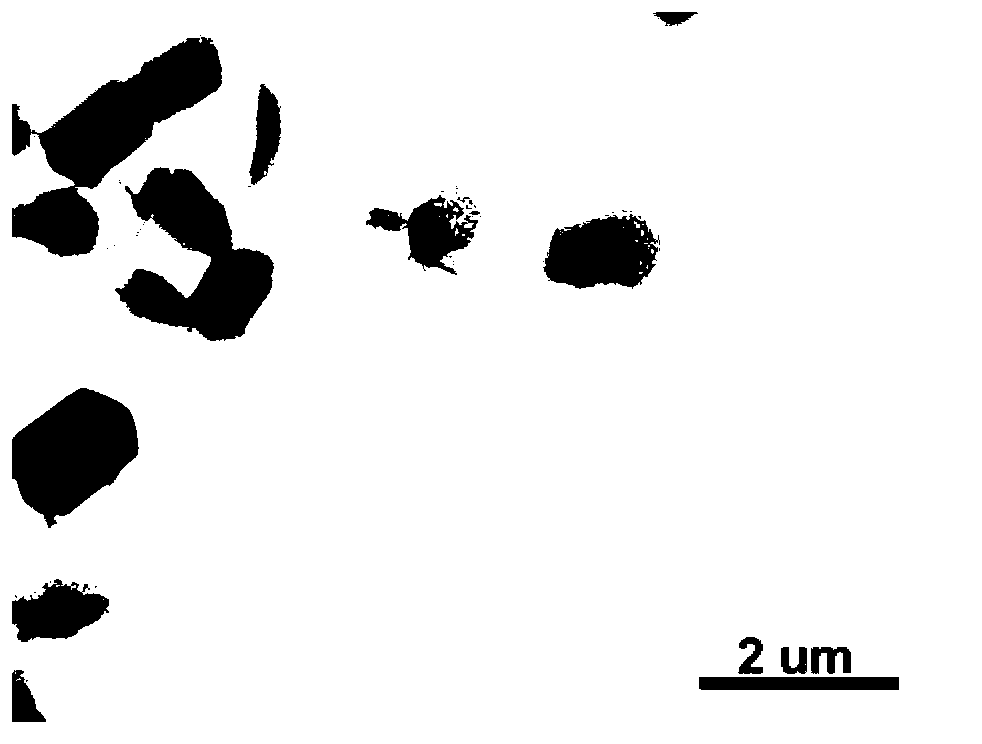

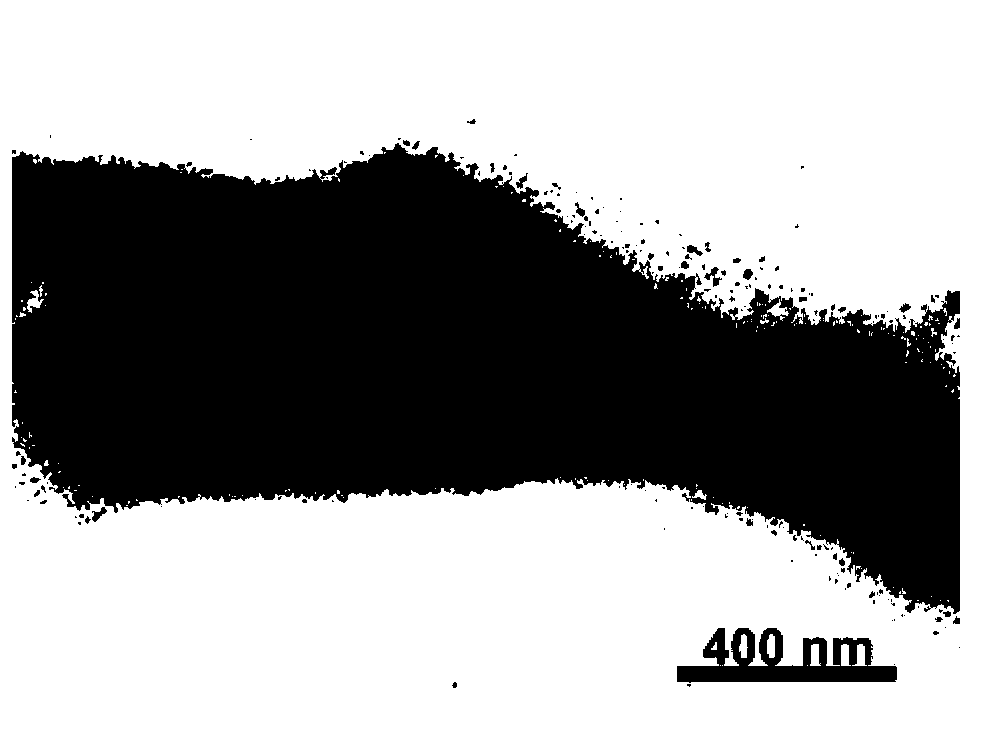

Method for assembling metal nanometer clusters of lamellar structure or structure similar to bipyramidal in high boiling point solvents

The invention relates to a method for assembling metal nanometer clusters to be of a lamellar structure or a structure similar to a bipyramid in high boiling point solvents, and belongs to the technical field of metal nanometer cluster assembly. The metal nanometer clusters which are prepared in advance and have stable alkyl hydrosulfide ligand are placed in two high boiling point solvents, and through simple heating processing, the assembly of the two-dimension lamellar structure or the structure similar to the bipyramid is achieved. In the micro field, the assembly method is of great value to the development of the assembly technology and research on small-size nanometer cluster interfaces. In the assembly process, the method is convenient to operate and small in dangerousness and has good experimental repeatability.

Owner:JILIN UNIV

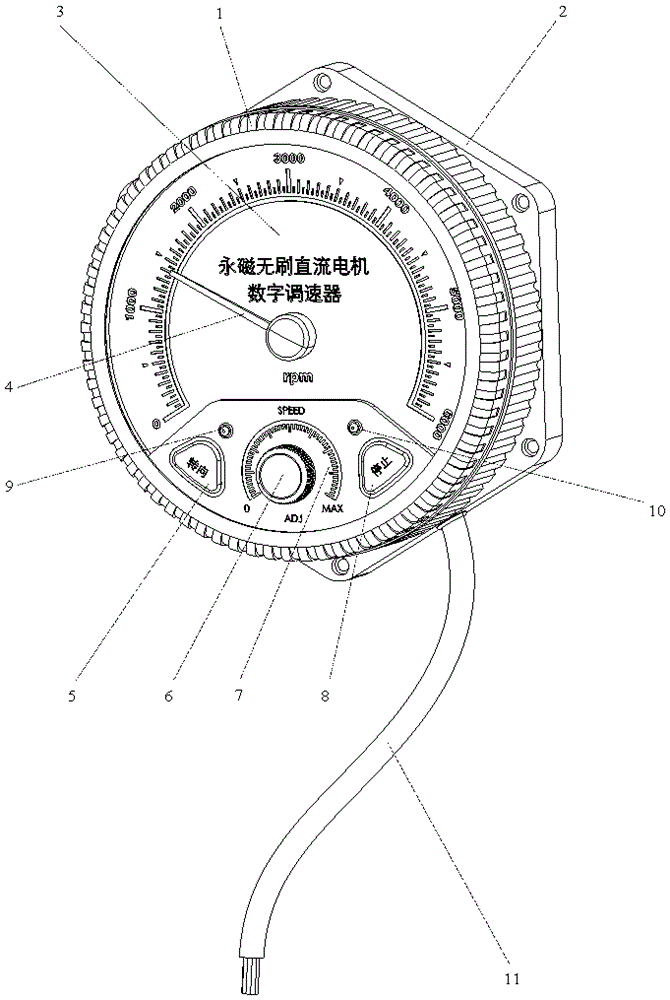

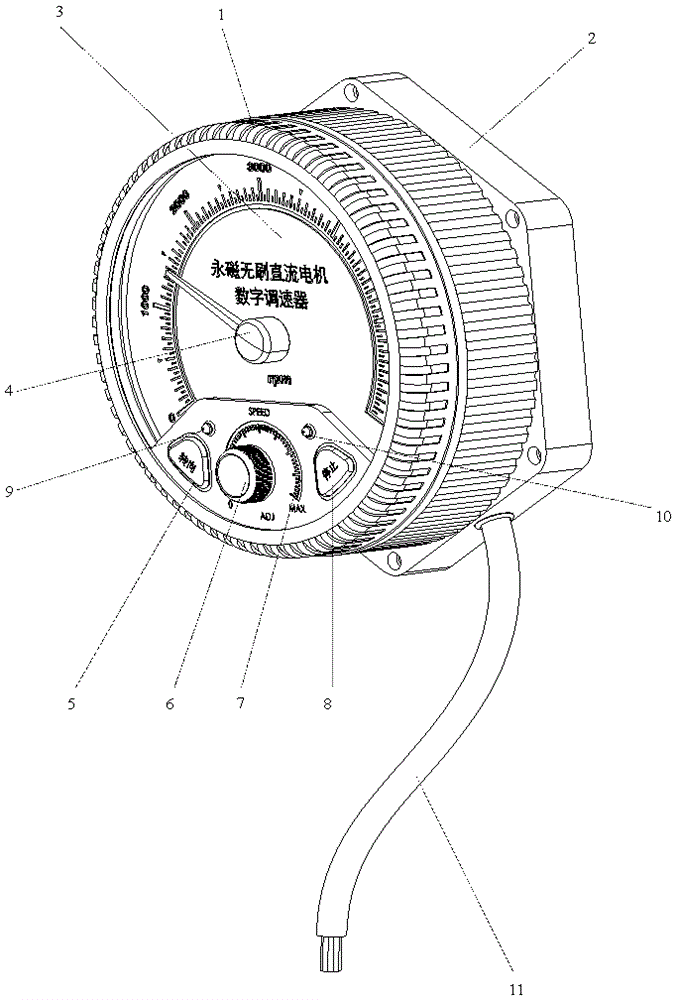

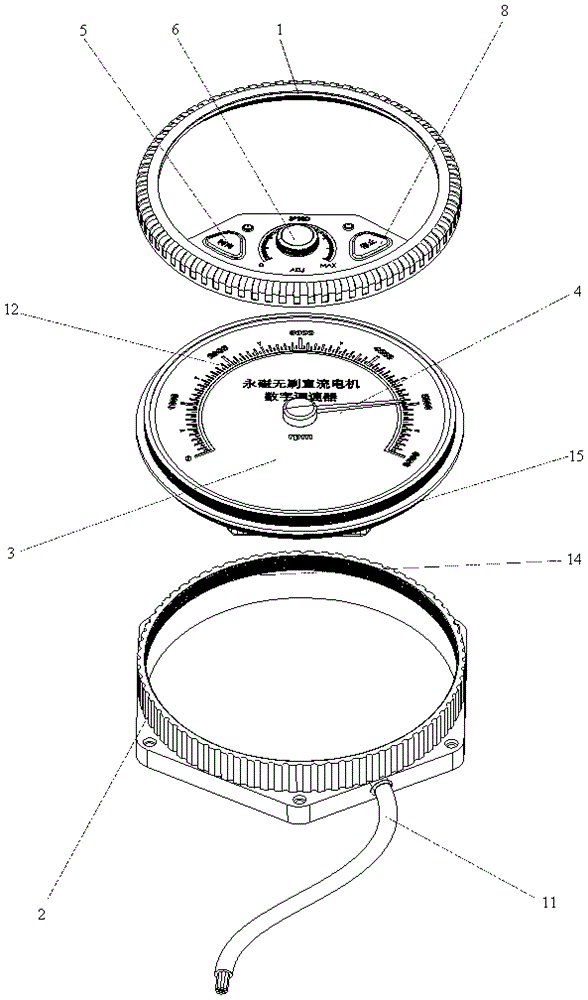

Permanent magnet brushless direct current motor digital speed regulator

ActiveCN106208832AImprove reliabilitySolving Digital GovernorsSingle motor speed/torque controlSignal conditioningVMOS

The invention provides a permanent magnet brushless direct current motor digital speed regulator. The permanent magnet brushless direct current motor digital speed regulator comprises an upper shell end cover, a middle frame, a lower shell end cover, a rotating speed indicating dial plate, a pointer, a PCB, a three-core single-chip microcomputer, a signal conditioning chip, a VMOS transistor drive chip, a VMOS transistor and a micro-stepping motor. The permanent magnet brushless direct current motor digital speed regulator is characterized in that a steering button, a stop button, a steering indicating light-emitting diode, a stopping indicating light-emitting diode, a speed regulating rotary knob and a speed regulating dial are mounted on the upper shell end cover; rotating speed numerical scales are carved in the rotating speed indicating dial plate, the middle frame is made of aluminum alloy and composed of a middle frame hollow cylinder and a middle frame cylinder hexahedron, and the middle frame hollow cylinder and the middle frame cylinder hexahedron are combined through six connecting lugs; the upper shell end cover and the lower shell cover are connected with the middle frame cylinder, a rotary shaft of the micro-stepping motor is externally connected with the pointer, and under control of the three-core single-chip microcomputer, the position, on the rotating speed numerical scales, of the pointer is the current rotating speed of a permanent magnet brushless direct current motor.

Owner:彭希南

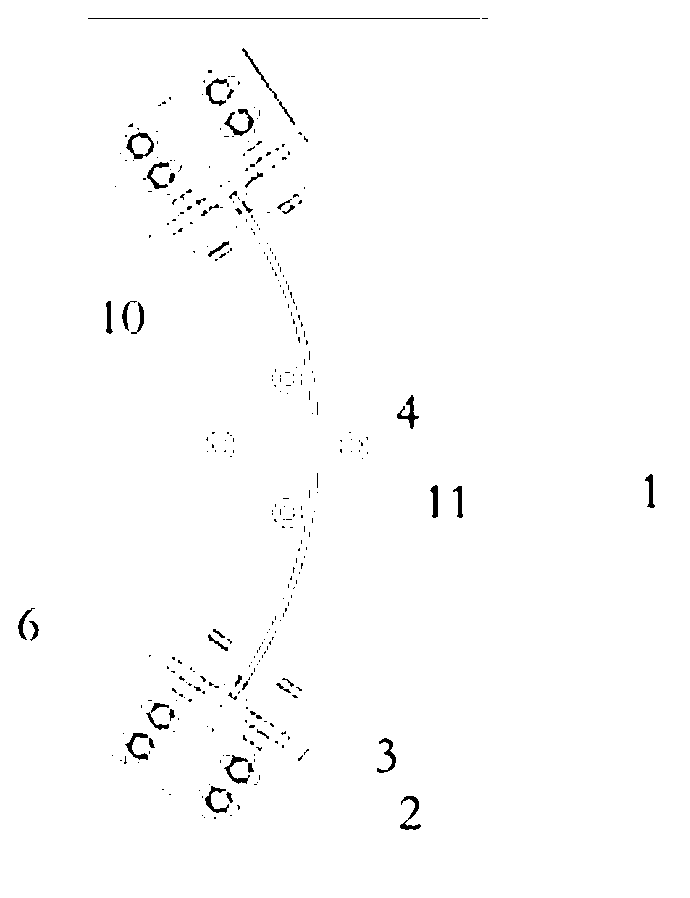

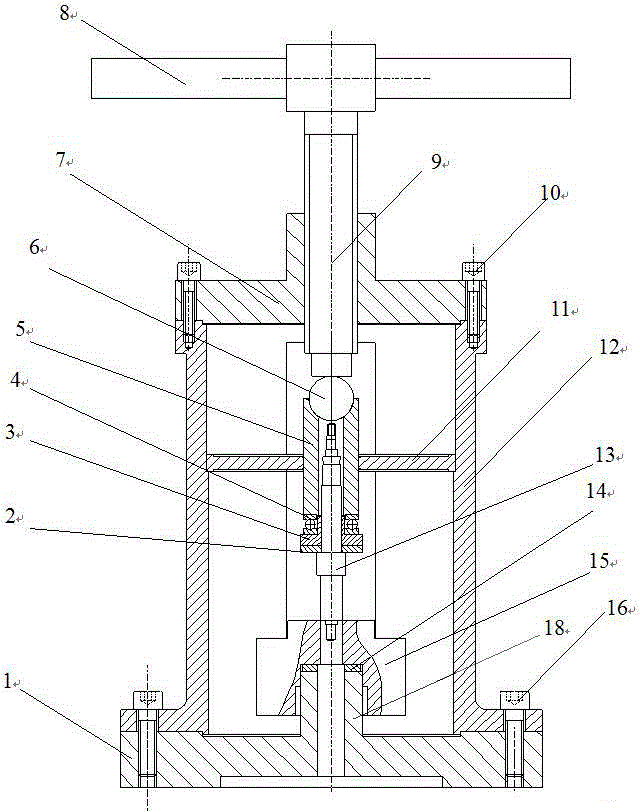

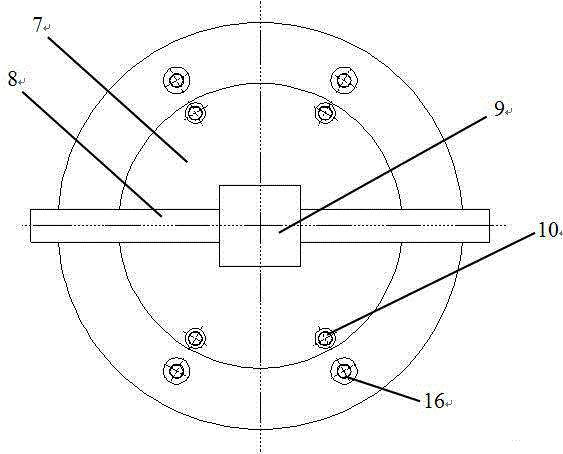

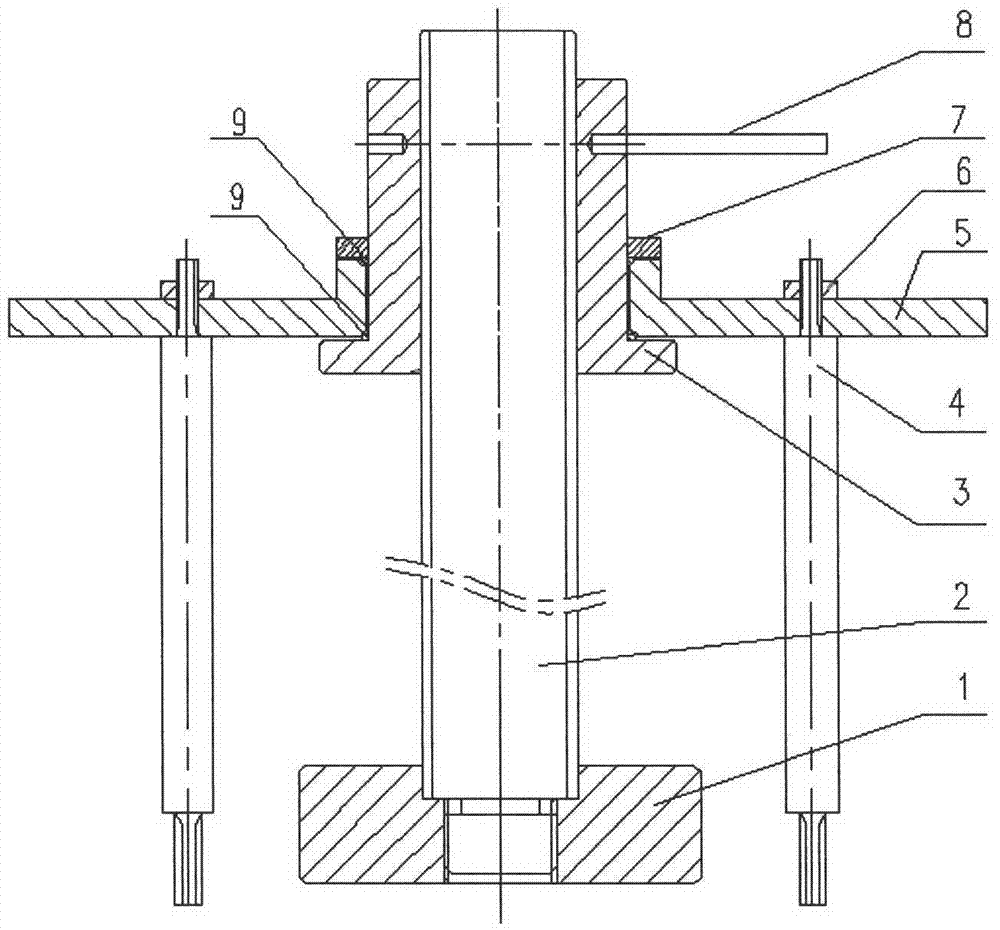

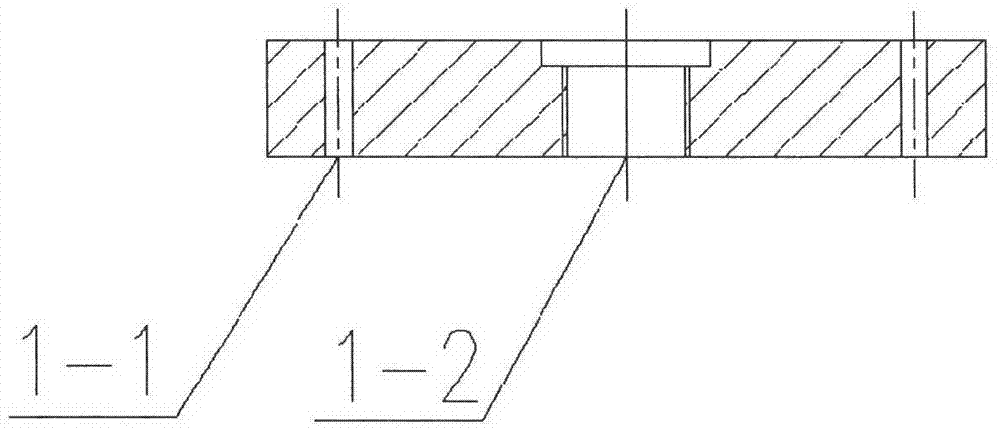

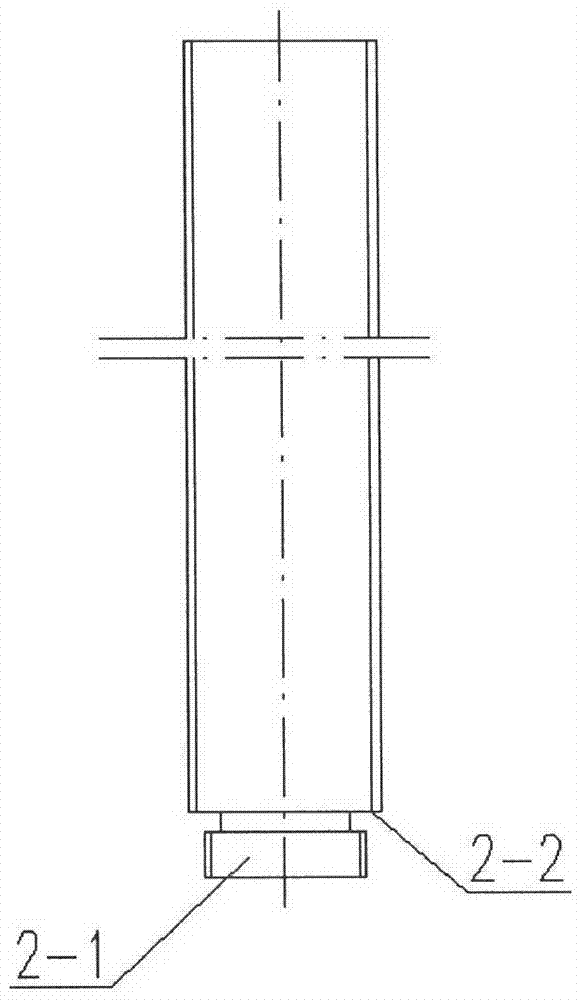

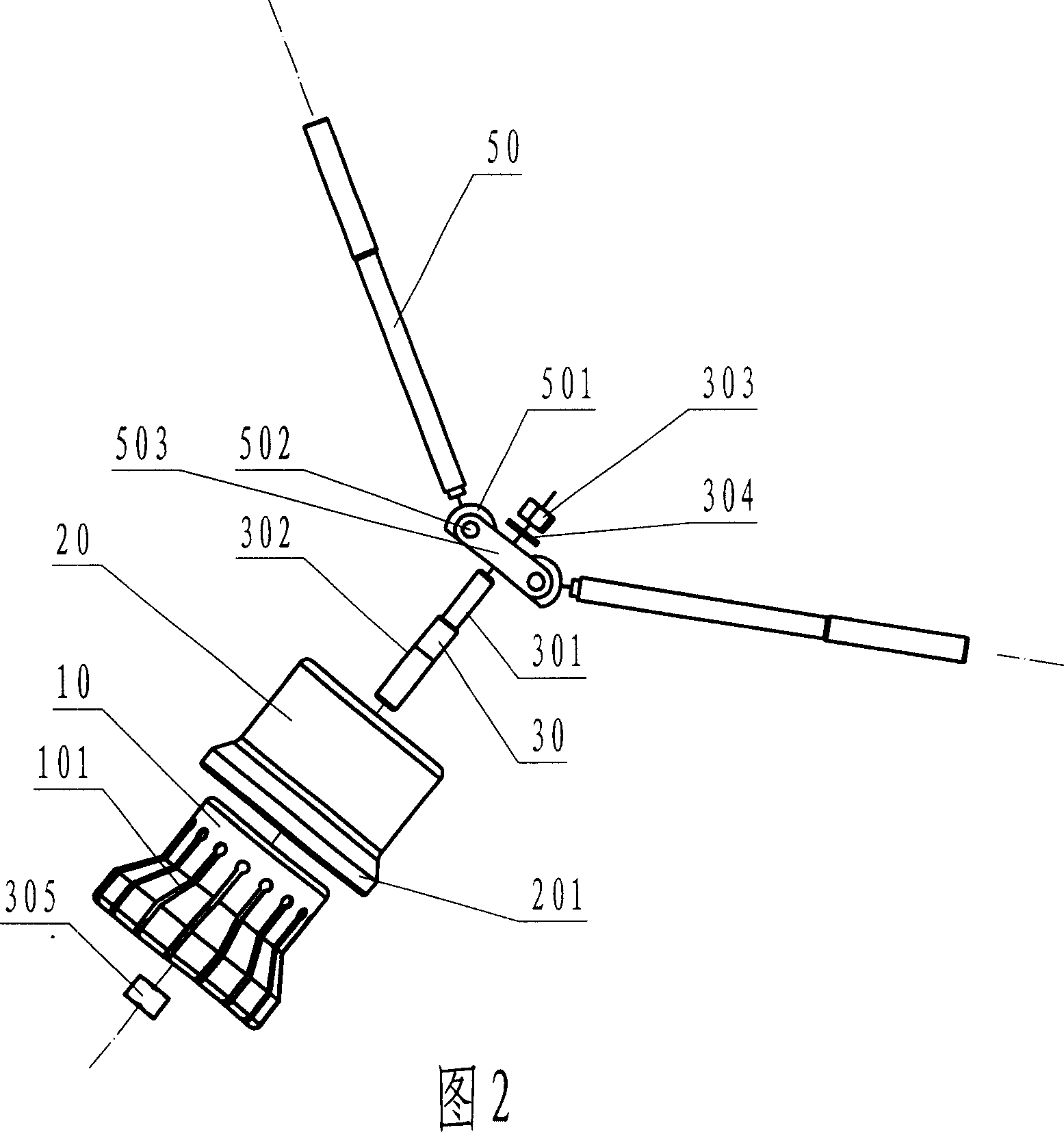

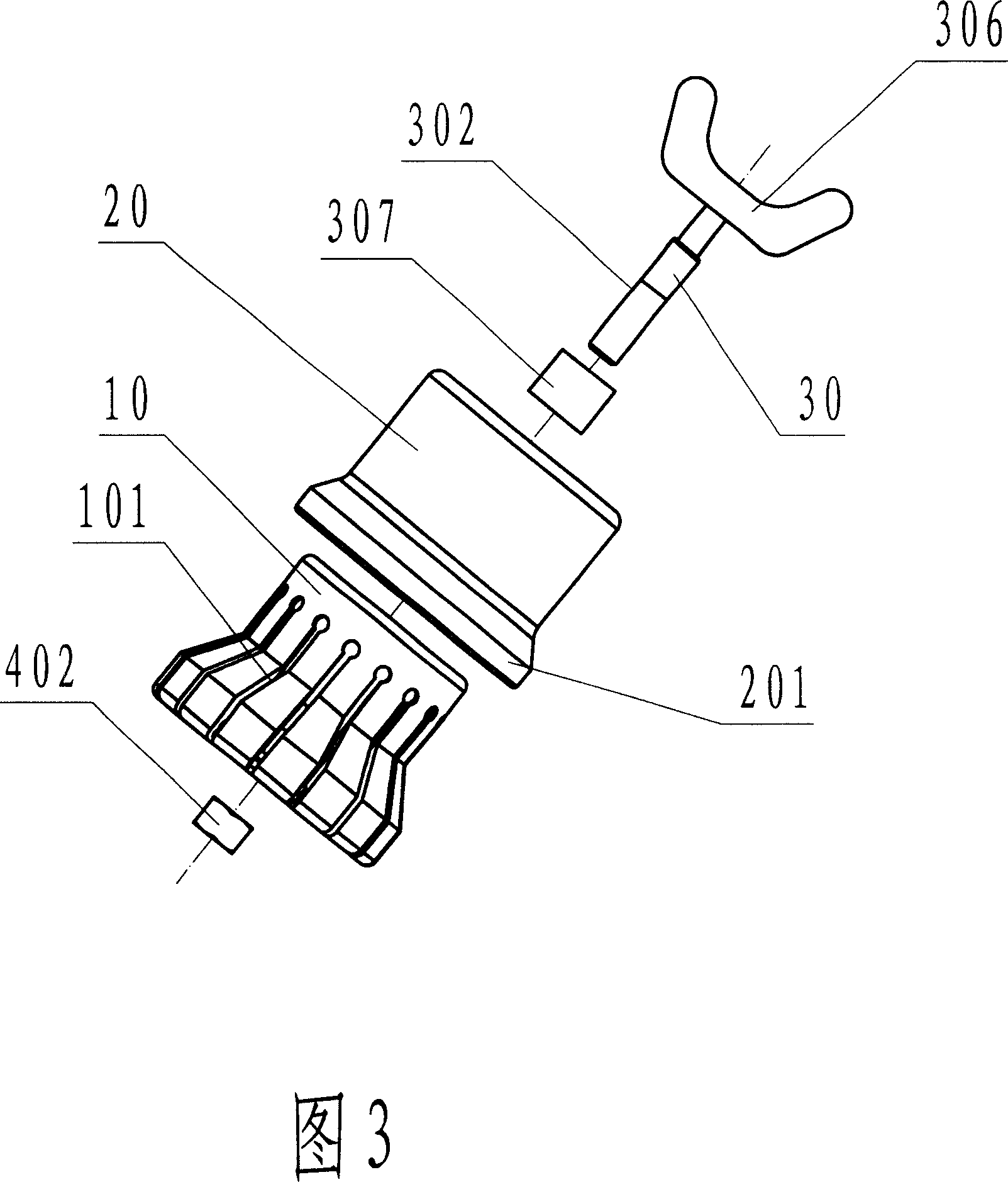

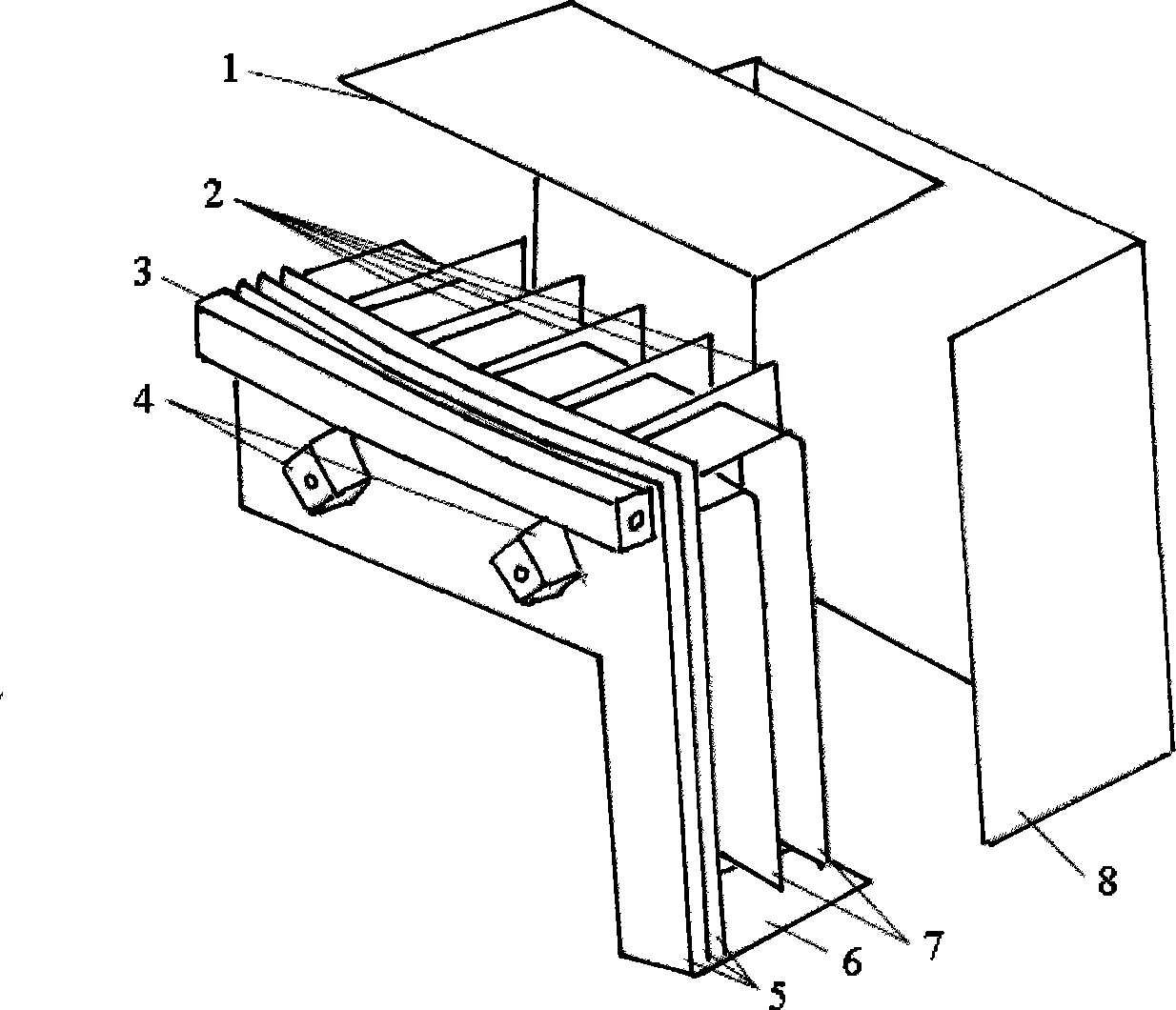

Tool for assembling photoelectric turntable motor

ActiveCN102780326ASolve assembly problemsRest assured to achieveManufacturing dynamo-electric machinesSteel ballEngineering

The invention discloses a tool for assembling a photoelectric turntable motor, which belongs to the technical field of mechanical assembling. The tool is mainly and technically characterized in that a centering mandrel is in matched connection with a dead axle sunken platform of a photoelectric turntable, a lifting lead screw is in matched connection with the centering mandrel, so a reference center is provided for the tool; the two ends of a central hole of a projection cylinder of a cross plate are respectively provided with a conical surface with a circle of steel balls, so the cross plate, the lifting lead screw, a lifting nut and a pressing ring form a rotating shaft system; and one ends of four draw bars are fixedly connected with four narrow plates of the cross plate, the other ends of the four draw bars are fixedly connected with a motor stator, one end of a lever is connected with the lifting nut, and the motor stator can be lifted and descended through pushing the lever to be accurately installed in a dead axle of the photoelectric turntable. The tool is used for solving the problems of conveniently and reliably mounting the photoelectric turntable motor, and has the characteristics of simple structure, convenience in carrying, high working efficiency and the like.

Owner:中国兵器工业第二0五研究所

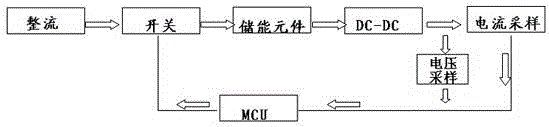

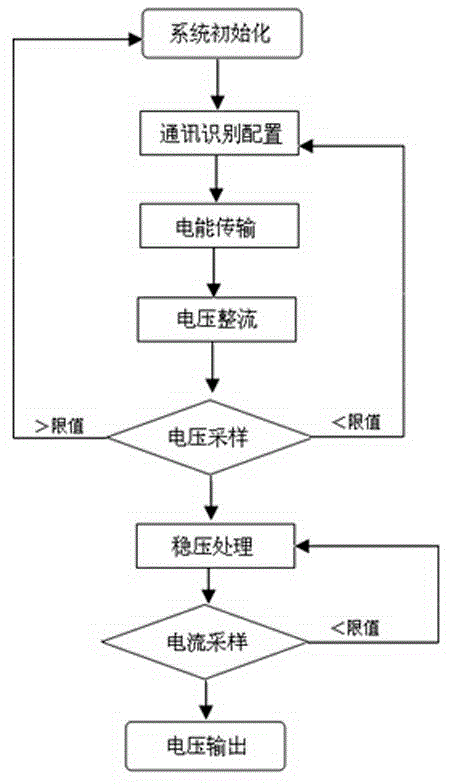

Wireless charging system and method

InactiveCN104868610AAvoid damageSolve assembly problemsBatteries circuit arrangementsElectromagnetic wave systemInductive chargingReal-time computing

The invention discloses a wireless charging system. The system comprises a wireless charging receiving module. The wireless charging receiving module possesses a MCU and a voltage sampling component. The voltage sampling component carries out sampling on a voltage after rectification and voltage stabilization. When a dynamic load is adjusted, voltage abnormity is fed back to the MCU. The MCU controls an output voltage. The invention also discloses a wireless charging method. Two or more Ping phase frequency points are arranged to carry out work by turns. By using the system and the method, problems that a dynamic load response is abnormal and a wireless charging distance is small, which exist in a current wireless charging system, are solved; a damage of the wireless charging system to receiving end circuit component and an assembling problem of office furniture are avoided.

Owner:ZHEJIANG SUNON FURNITURE MFG

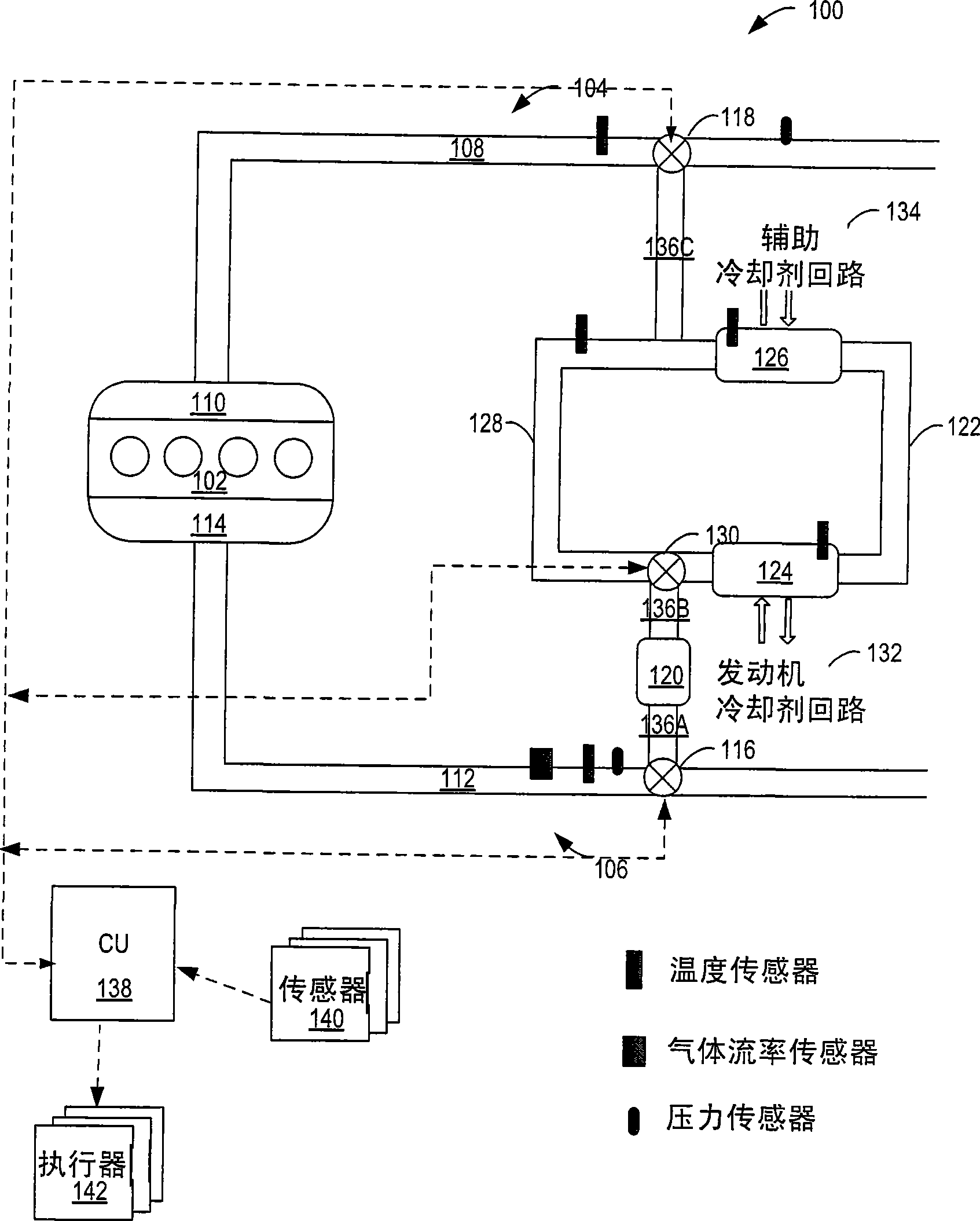

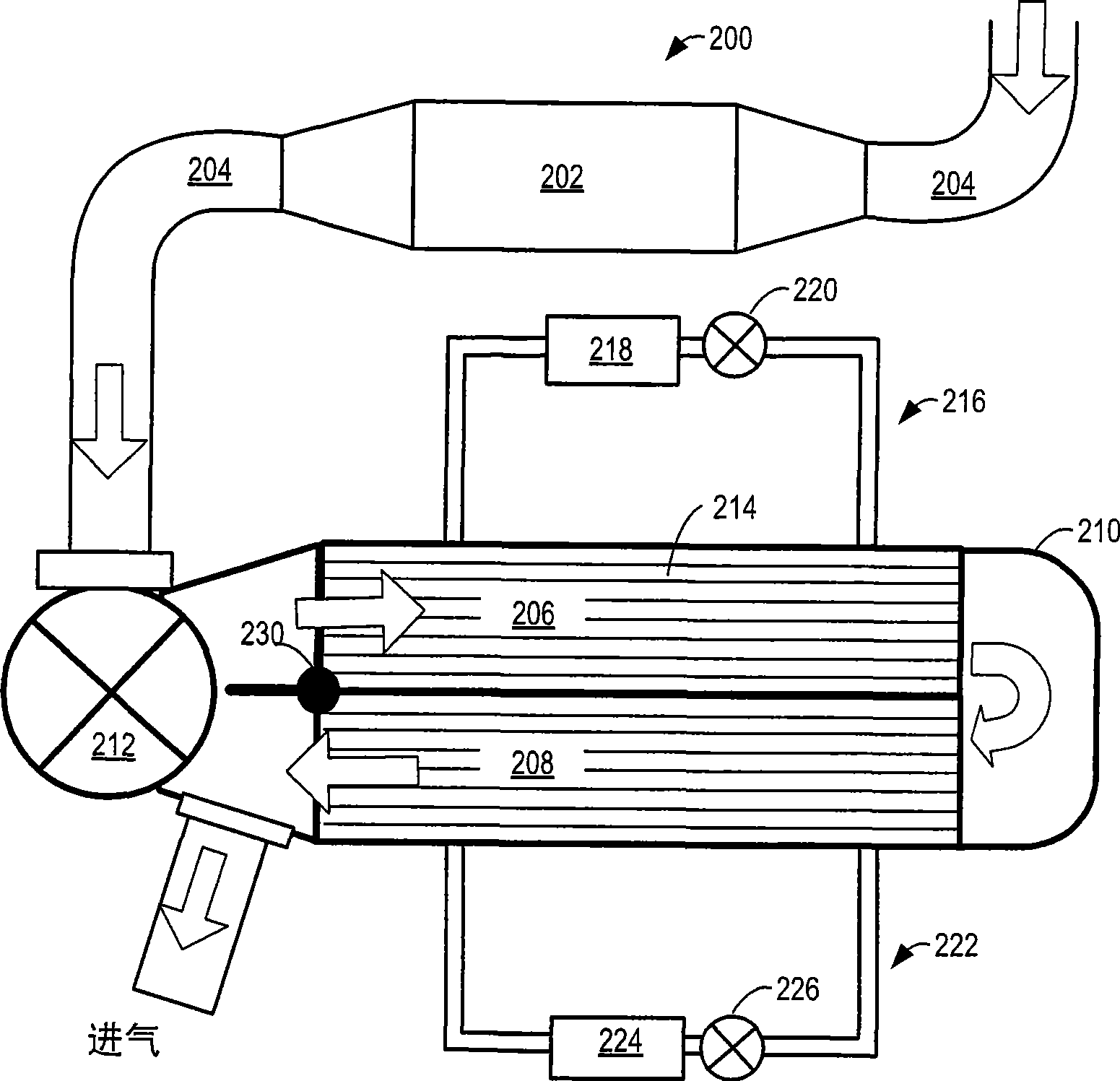

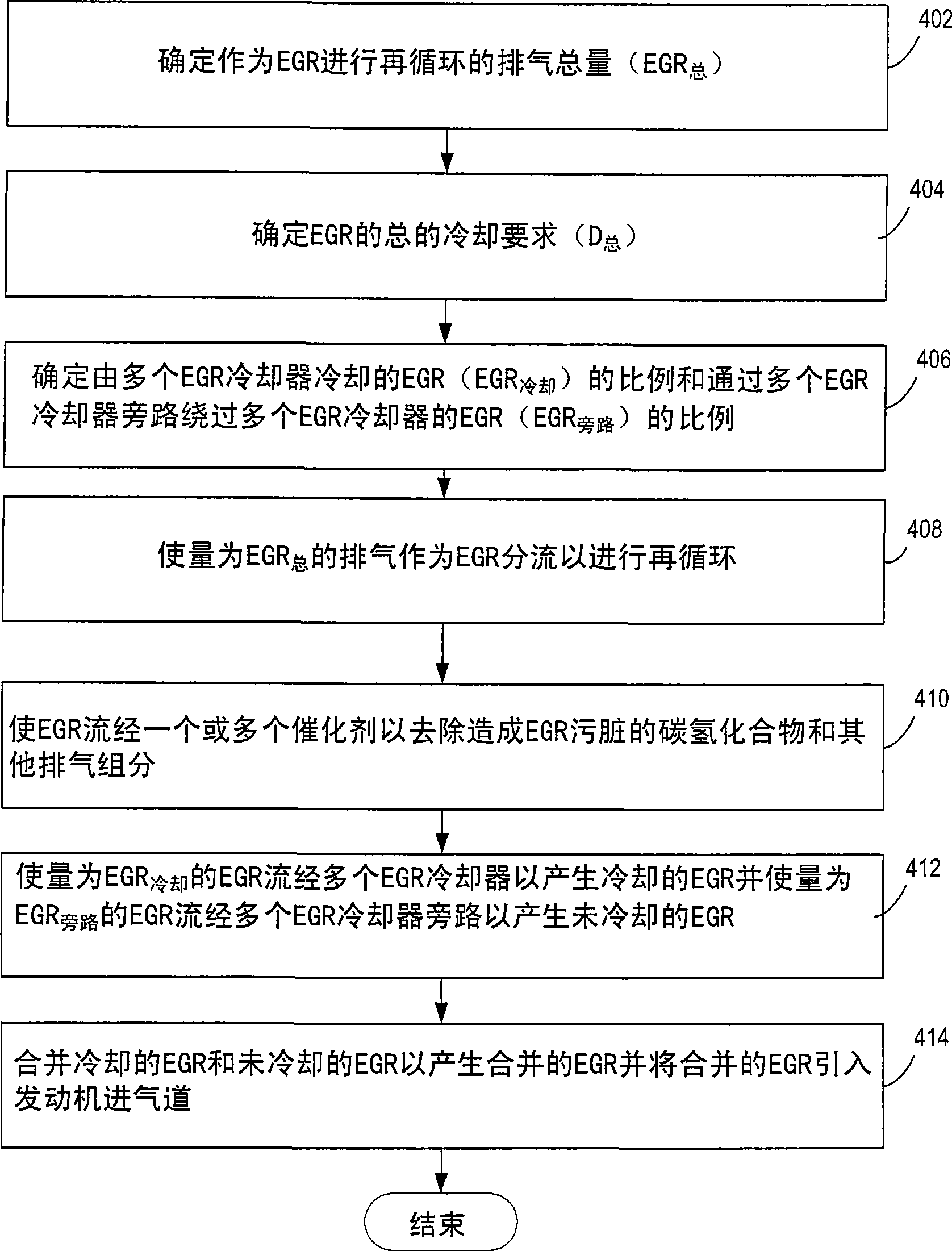

EGR cooling system with multiple EGR coolers

InactiveCN101413466ASolve assembly problemsDoes not increase size significantlyInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringHeat sink

An EGR cooling system is provided. The EGR cooling system comprising a plurality of EGR coolers configured to cool the EGR to a plurality of successively lower temperatures, where at least one of the plurality of EGR coolers includes a finned EGR cooler that comprises a plurality of channels for dissipating heat in the EGR, the plurality of channels increasing heat transfer surface area while having sufficient fin spacing to avoid clogging. The EGR cooling system may further comprise a catalyst configured to remove particle matters and / or hydrocarbons from the EGR, the catalyst positioned upstream of at least one of the plurality of EGR coolers. The inventive EGR cooling system can satisfy the EGR cooling requirement of high load engine without notably incereasing the size of the EGR cooling system and can reduce the dirty of the EGR.

Owner:FORD GLOBAL TECH LLC

Circuit-breaker bundling type moveable contact special mounting tool

InactiveCN1937134AGood assembly qualityGuaranteed accuracyElectric switchesEmergency protective device manufactureContactorEngineering

The dedicated installation tool is composed of spring clamp, extrusion cup and handle. The spring clamp is in shape of lamp cover. Shape of cavity of the clamp is matched to external shape of contactors of the moving contact. Scaling clearance grooves towards to opening on top of the cover are setup on wall of the cover. The extrusion cup is sheathed on periphery of the clamp. There is gap between base of the spring clamp and base of the extrusion cup. A pull rod connects with the clamp and the extrusion cup in series, the other end is connected to handle. Changing position of the handle makes the clamp stretch along axial direction inside cavity. Using the pull rod to control retraction of the spring clamp, the invention simulates hand to hold contacts. Thus, the contact arms can be assembled into breaker in advance to check and adjust distance and gap between contactors, and afterward to install contactors. The invention installs moving contactor and guarantees size of breaker.

Owner:纪元电气集团有限公司

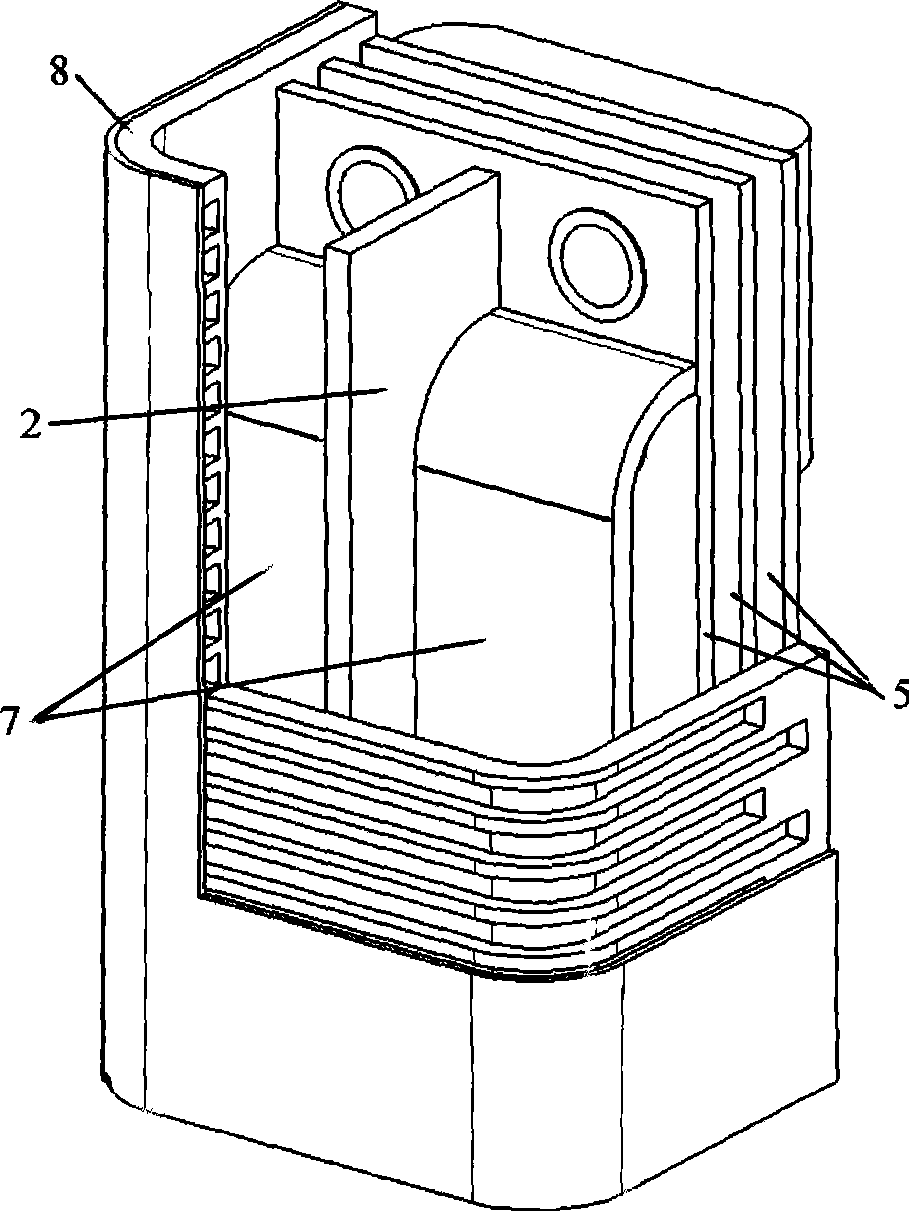

Welding method of thermonuclear reactor experiment cladding modular unit assembly

InactiveCN101380697ASolve assembly problemsSimple processElectron beam welding apparatusLaser beam welding apparatusModular unitEngineering

The invention discloses a welding method for assembling the parts of a fusion reactor test blanket module and aims at solving the assembling and manufacturing problems for the parts of the test blanket module. The invention is characterized in that the welding steps comprise in sequence: a, a radical pole clapboard is welded on a first wall; b, an annular pole clapboard is welded in an area formed by the radical pole clapboard and the first wall; c, an upper cover plate and a lower cover plate are welded on the first wall; d, back plates and pipe branches are welded in sequence from the inside to the outside; e, finally, a dividing / receiving box is welded on the back plate at the outermost layer. The welding method has the advantages of simple technique, small welding deformation, programming manufacture process, and the like. The welding method is suitable for manufacturing the test blanket modules with various structural forms.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

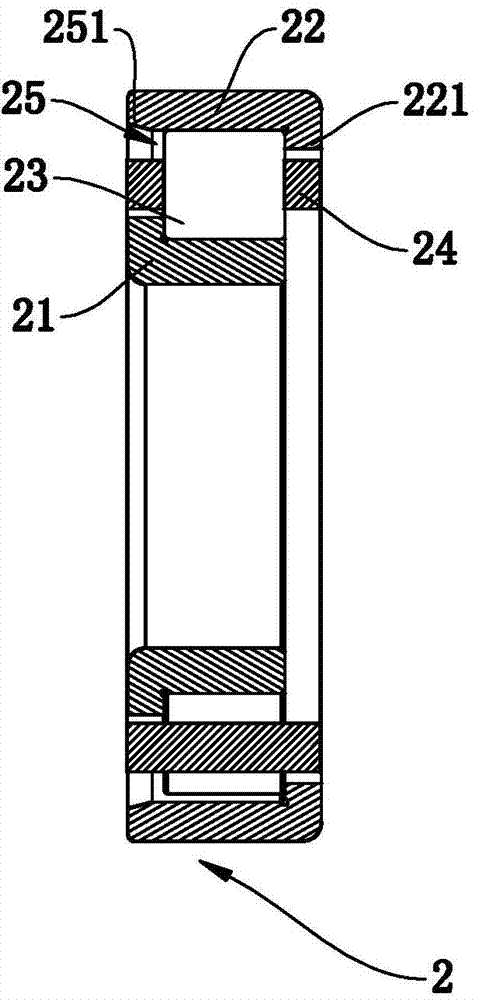

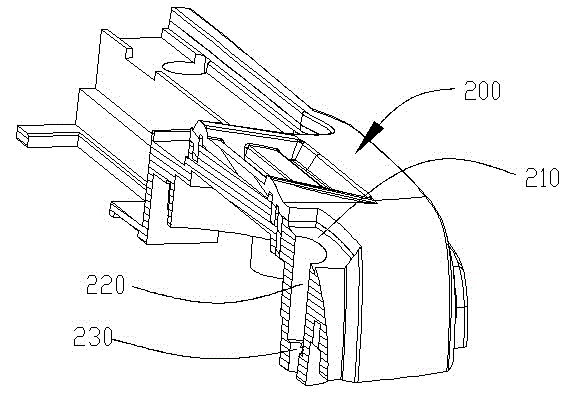

Automobile purifying pump module supported by foil self-acting air bearings

ActiveCN106089791AIncrease speedHigh rotation accuracyNon-fuel substance addition to fuelPump componentsAir bearingRolling-element bearing

The invention relates to an automobile purifying pump module supported by foil self-acting air bearings. The thrust foil self-acting air bearings, the radial foil self-acting air bearing, a bearing pedestal and a shaft sleeve are made into an integral module with the modularization design thought. The thrust foil self-acting air bearings are arranged on the outer sides of the two end faces of the shaft sleeve respectively, and the radial foil self-acting air bearing is arranged on the outer side of the outer-diameter cylindrical face of the shaft sleeve. By means of the modularization design, installation is convenient, and mass production is promoted. The foil self-acting air bearings are used for replacing traditional rolling bearings or oil bearings to serve as the supporting component of an automobile purifying pump, and thus the automobile purifying pump module supported by the foil self-acting air bearings has the advantages of traditional air journal bearings which are high in rotating speed and revolving precision, small in power consumption, free of pollution, long in service life, capable of working in harsh working environments and the like, and also has the advantages of being high in adaptability, low in manufacturing and assembling precision requirement, good in shock resistance, high in stability, free of a special lubrication system, low in maintaining cost and the like.

Owner:SHIJIAZHUANG KINGSTON BEARING TECH

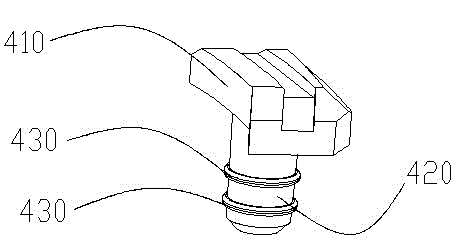

Waterproof connecting piece structure and waterproof mobile phone of waterproof connecting piece structure

ActiveCN104580597AUniform pressureSolve assembly problemsHermetically-sealed casingsTelephone set constructionsElectrical and Electronics engineeringMobile phone

The invention relates to a waterproof connecting piece structure. The waterproof connecting piece structure comprises a first shell, a second shell, a waterproof plug and a connecting piece, a first connecting hole is formed in the first shell, a second connecting hole is formed in the second shell, the waterproof connecting piece penetrates through the first connecting hole and the second connecting hole for mutual locking so that the first shell can be connected with the second shell, a shell space is formed between the first shell and the second shell, the waterproof plug is located on the side, close to the outer surface of the first shell, in the first connecting hole, an exhaust channel is further formed in the first connecting hole, gas in the first connecting hole can enter the shell space through the exhaust channel, the waterproof plug is at least provided with an annular protrusion, and the protrusion is in extrusion interference with the sidewall of the first connecting hole. Thus, effective waterproofness is achieved between the connecting piece and an external space, and the problem that the waterproof plug is not convenient to assemble is solved.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

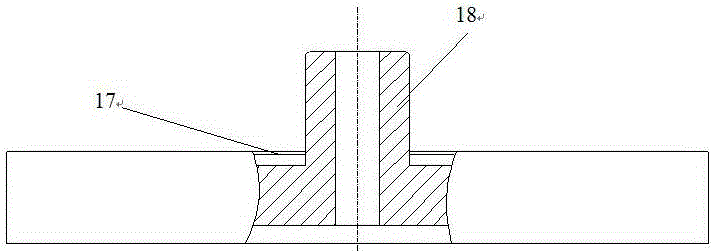

Polar pole die

InactiveCN102179503AIncrease the mold opening distanceEnough opening distanceTransmitted powerUltimate tensile strength

The invention discloses a polar pole die and relates to improvement of the structure of the polar pole die. A horizontal driving mechanism is mainly used for providing power, a die opening limiting mechanism plays the roles of limiting, guiding and transmitting power and is used for controlling core-pulling and operation of taking a product out of the die during the whole die opening and closing process; by setting the horizontal driving mechanism, semi-automation of the die is realized, the working intensity of operation staff is reduced, the die opening limiting mechanism can ensure the sufficient die opening distance and prevent the assembly problem caused by excessive die opening. In general, compared with manual core-pulling, the structure is simple to operate, manpower can be effectively saved, the production cycle can be reduced and the efficiency can be improved.

Owner:ZHAOQING LEOCH BATTERY TECH

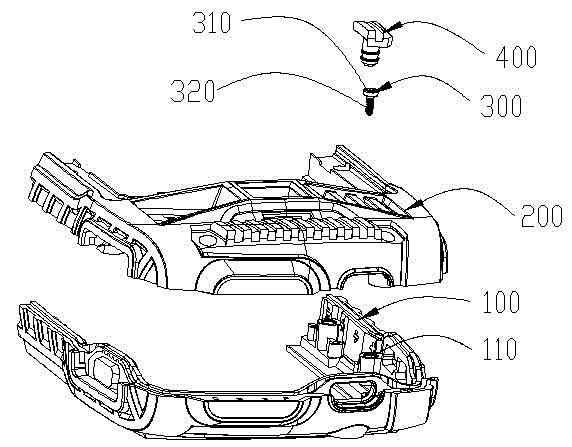

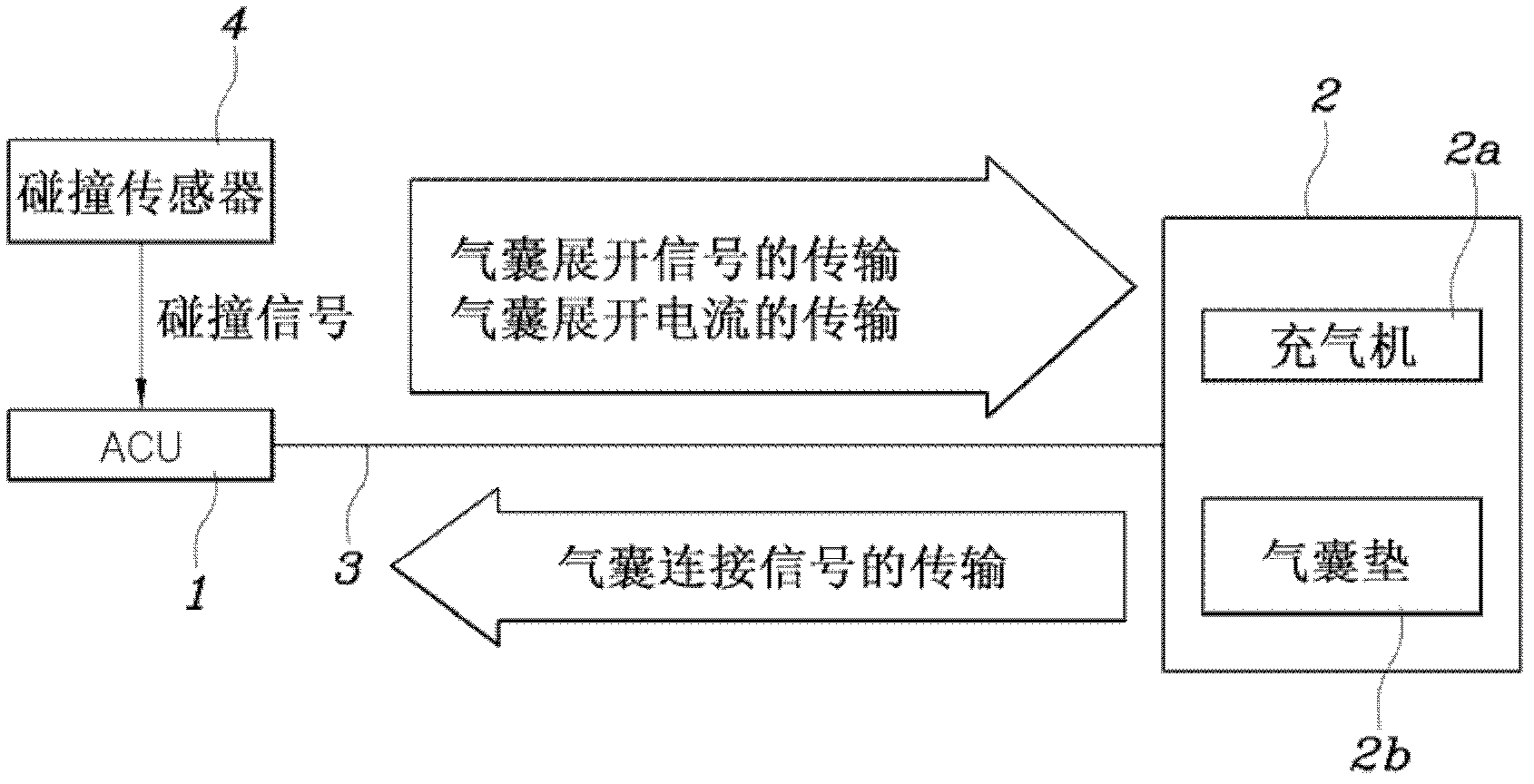

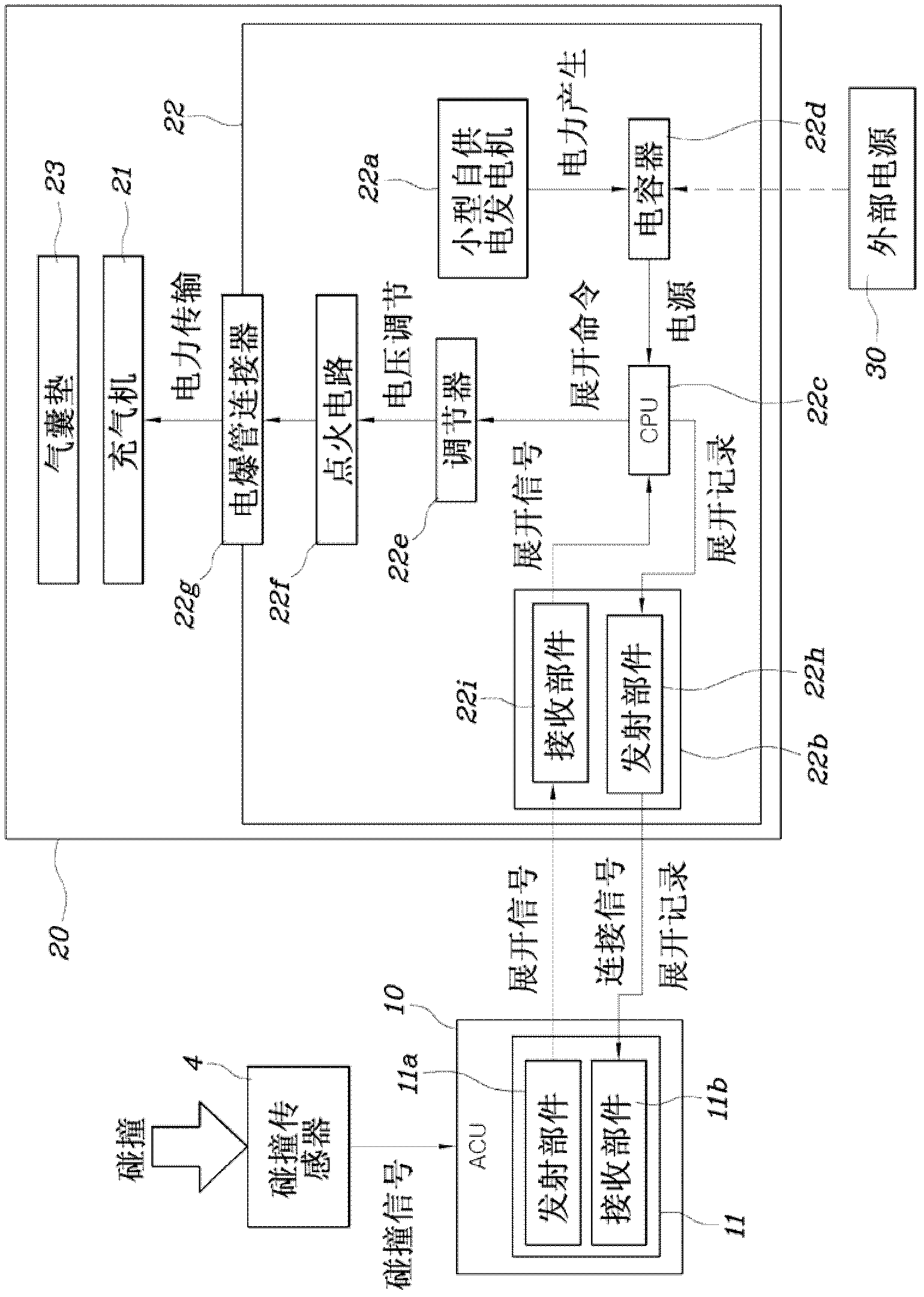

Wireless airbag apparatus

InactiveCN102923084AAvoid failureAvoid going outPedestrian/occupant safety arrangementCommunication unitEngineering

A wireless airbag apparatus may include an airbag control unit (ACU) receiving a sensing signal from a collision sensor and having a first wireless communication unit, and an airbag module having a second wireless communication unit and a power supply circuit to transceive a signal with the wireless communication unit of the ACU, wherein the power supply circuit supplies operating power to an inflator in accordance with a deployment signal of the airbag module.

Owner:HYUNDAI MOTOR CO LTD

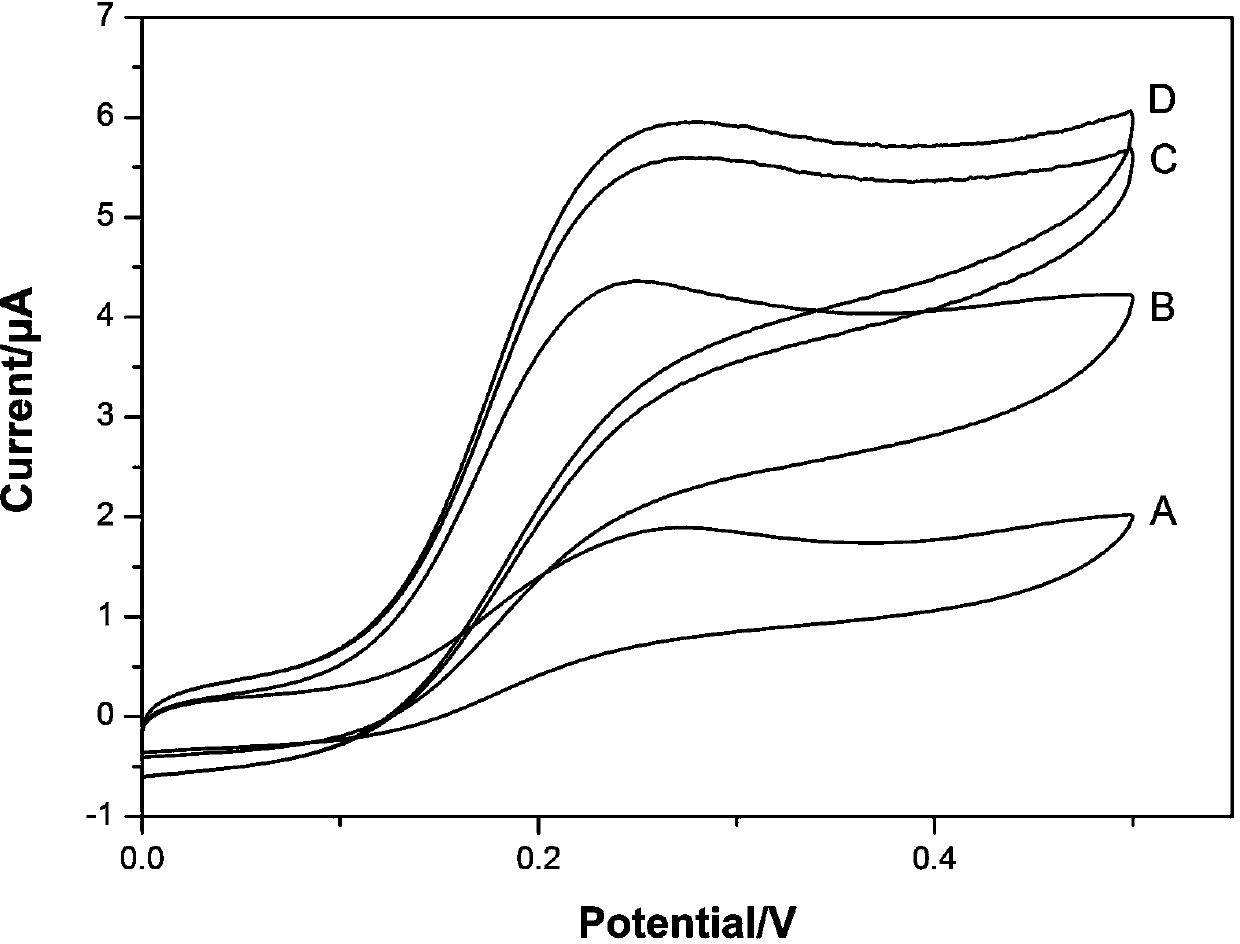

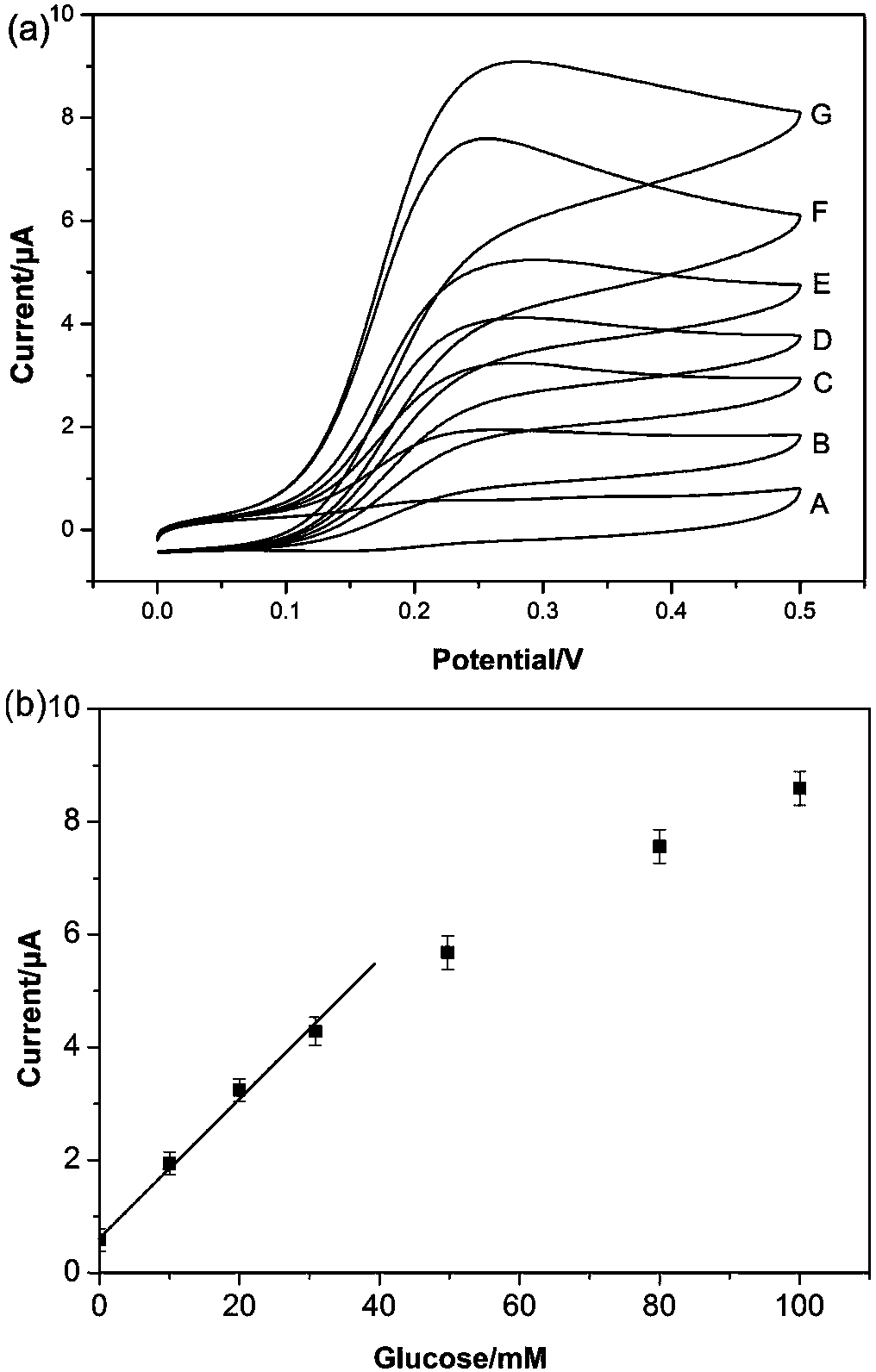

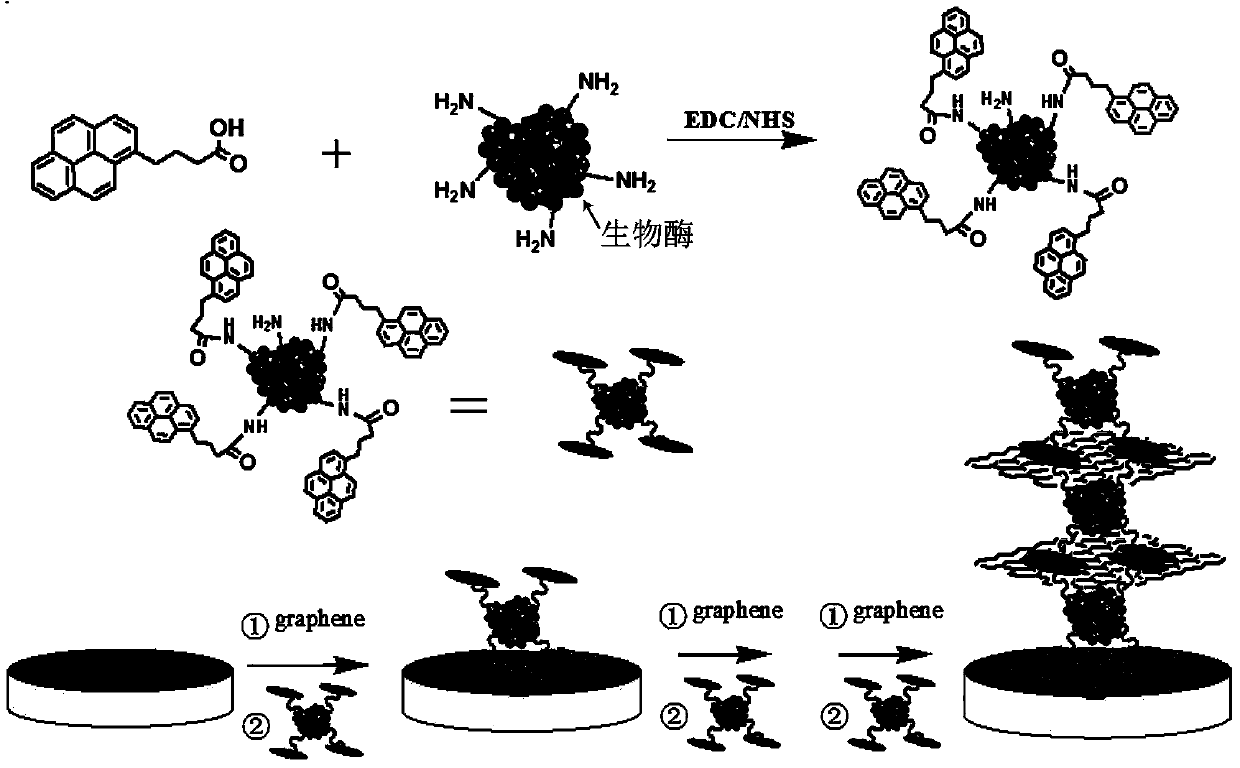

Novel method for assembling multi-layer biological enzyme sensor to improve detection performance by using graphene

InactiveCN103743797AThe number of layers is controllableHigh sensitivityMaterial electrochemical variablesEngineeringGraphene

The invention aims at providing a novel method for assembling a multi-layer biological enzyme sensor to improve detection performance by using graphene. In order to utilize and transform a reagent pyrene butyric acid with a large phi-ring terminal group by amidation reaction with an amino group on the surface of biological enzyme (for example, glucose oxidase), so as to obtain the glucose oxidase with the large phi-ring terminal group on the surface, the transformed glucose oxidase is fixed on the surface of an electrode by using graphene in a layer-by-layer assembly manner, so as to prepare the biological enzyme sensor with controllable layer quantity and high sensitivity. The modified enzyme and the graphene are assembled layer by layer by phi-phi superposition. Thus, the assembly problem of the biological sensor with controllable layer quantity, ordered structure and stable performance is solved, and the detection sensitivity and the detection range of the biological enzyme sensor can be greatly improved.

Owner:QINGDAO UNIV

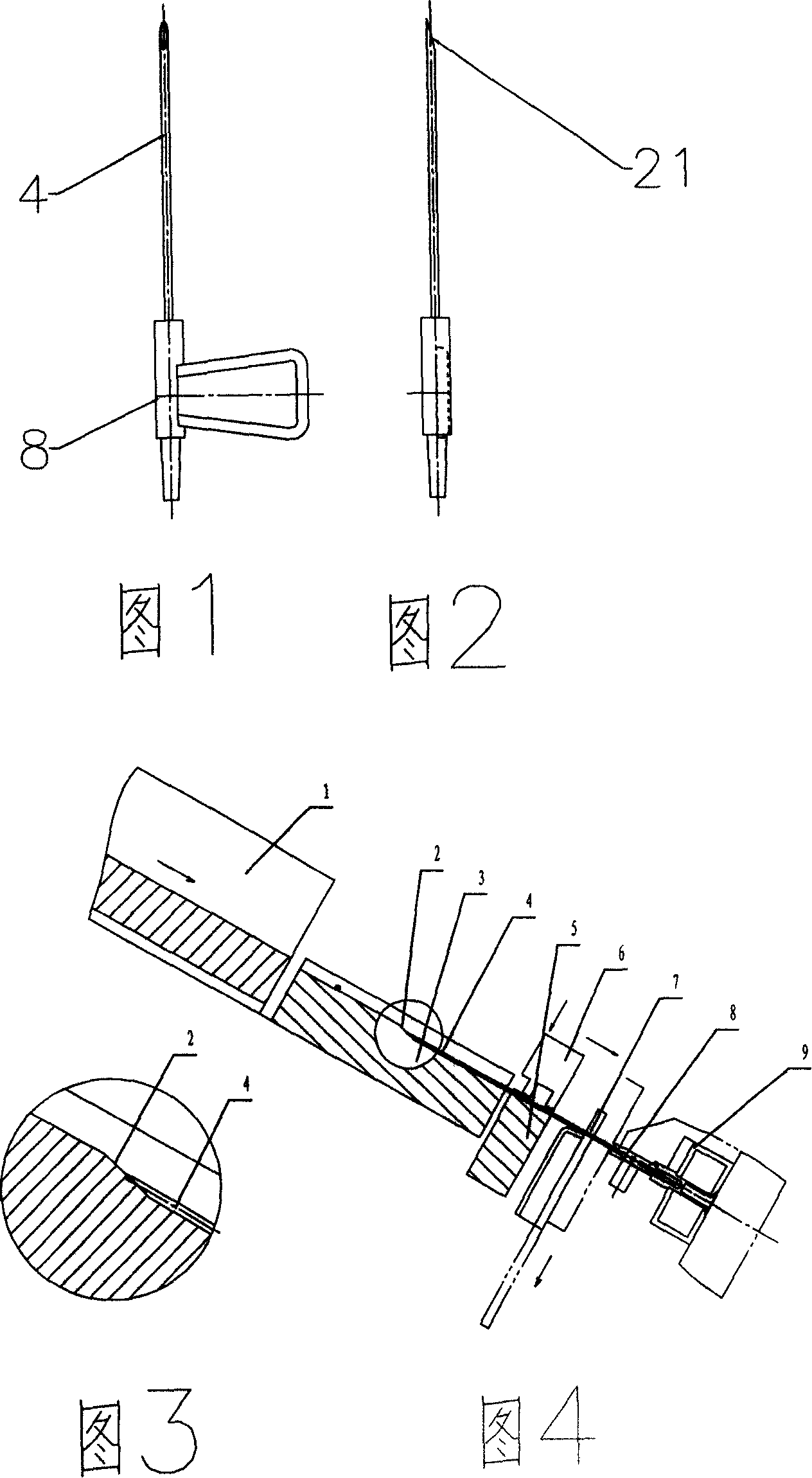

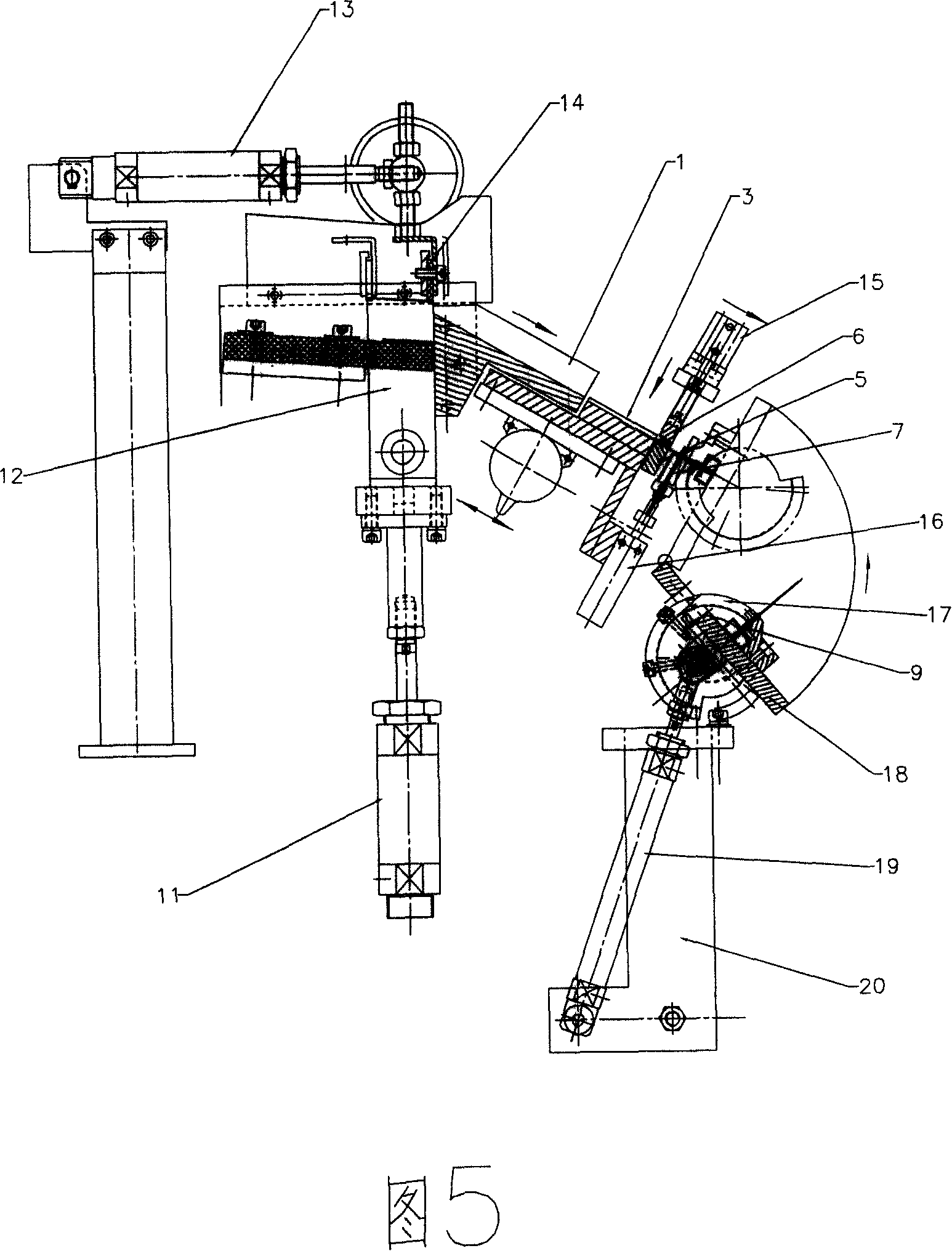

Transfusion needle mechanical needle tube mounting technique and device thereof

The invention provides a method of mechanical assembly of infusion needle, which comprises setting a predetermined inclined surface in the needle convey route to allow an inclined plane produced by grinding the needle tube tip substantially parallel to the plane of the needle base wing; conveying the needle tube to a preset position; vibrating to make the needle tube rotate; and positioning the needle tube by stopping rotation until the needle tip inclined plane engages with the predetermined inclined surface. The invention solves the problems of needle tube positioning and assembly, and integrates the processes of needle grinding, needle positioning, needle clamping, and needle insertion, thereby increasing the work efficiency greatly.

Owner:HANGHOU ACAD OF MACHINERY SCI & TECHCO

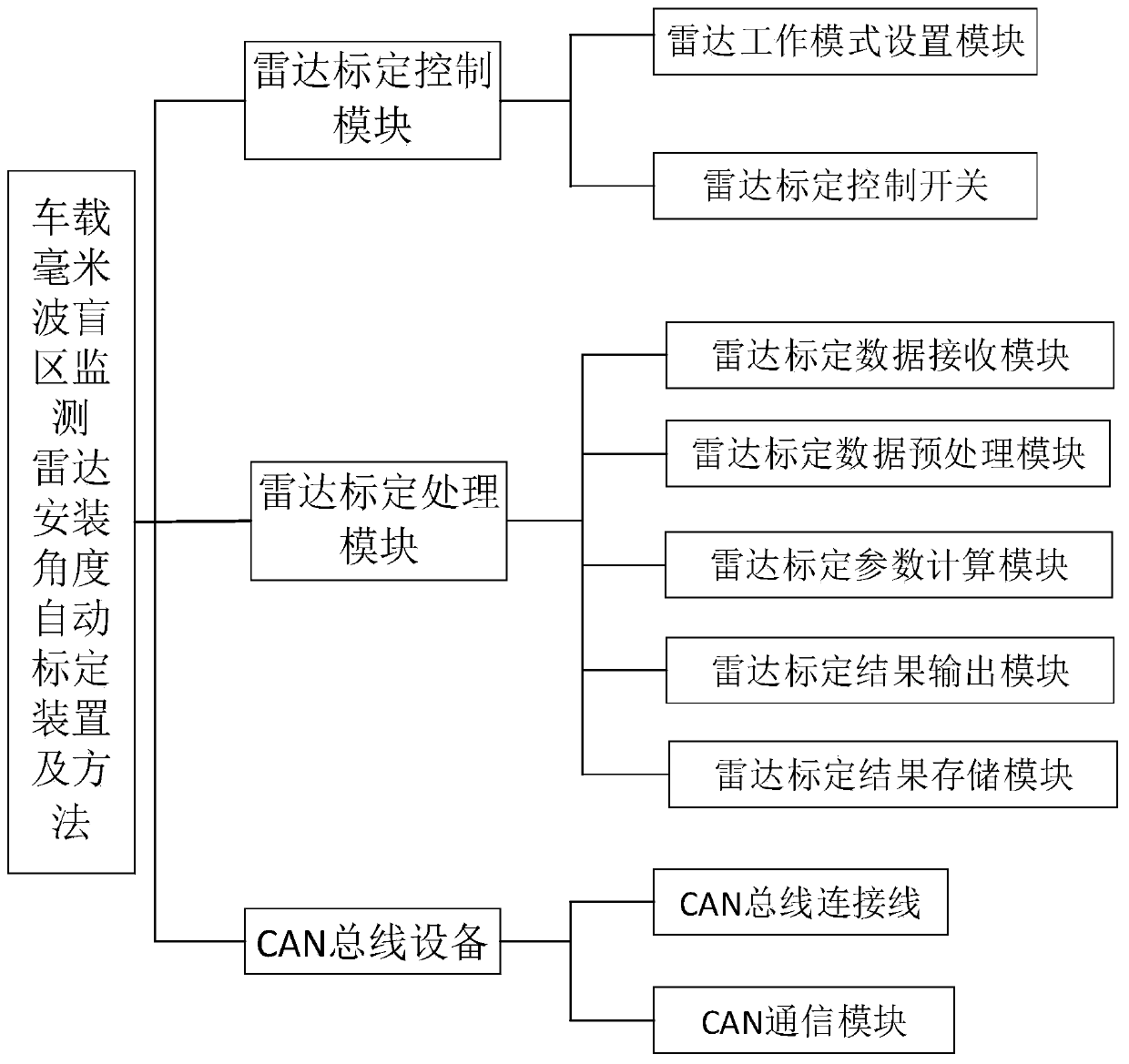

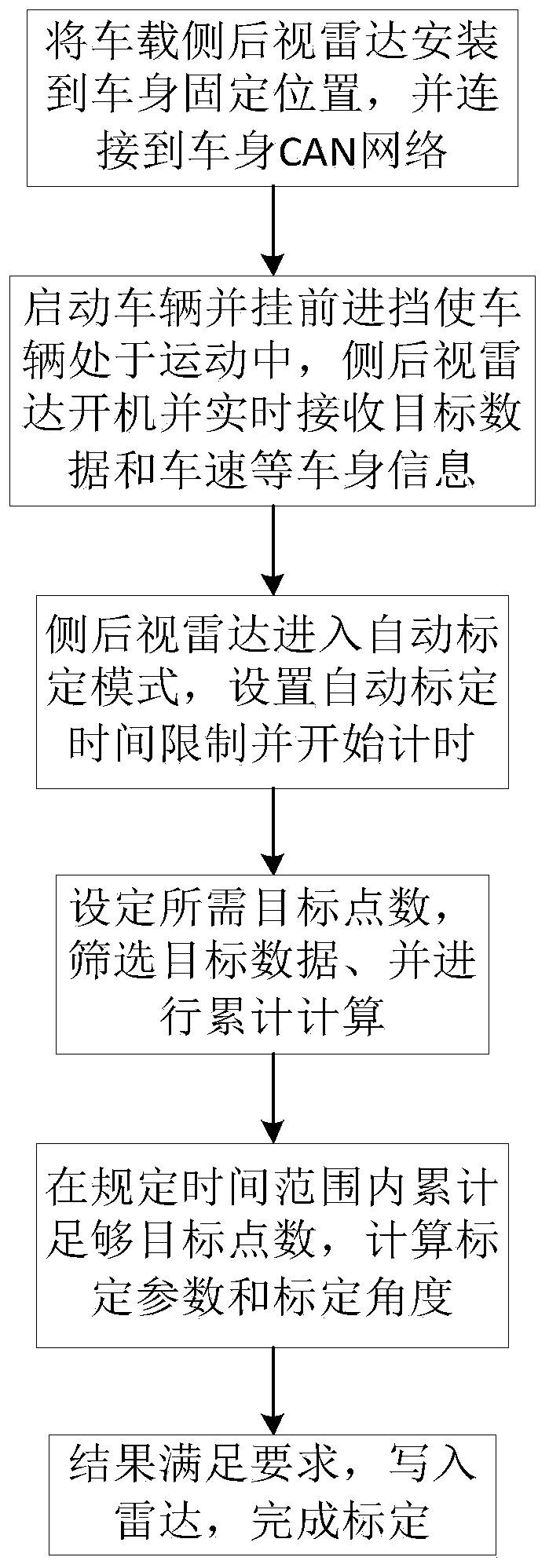

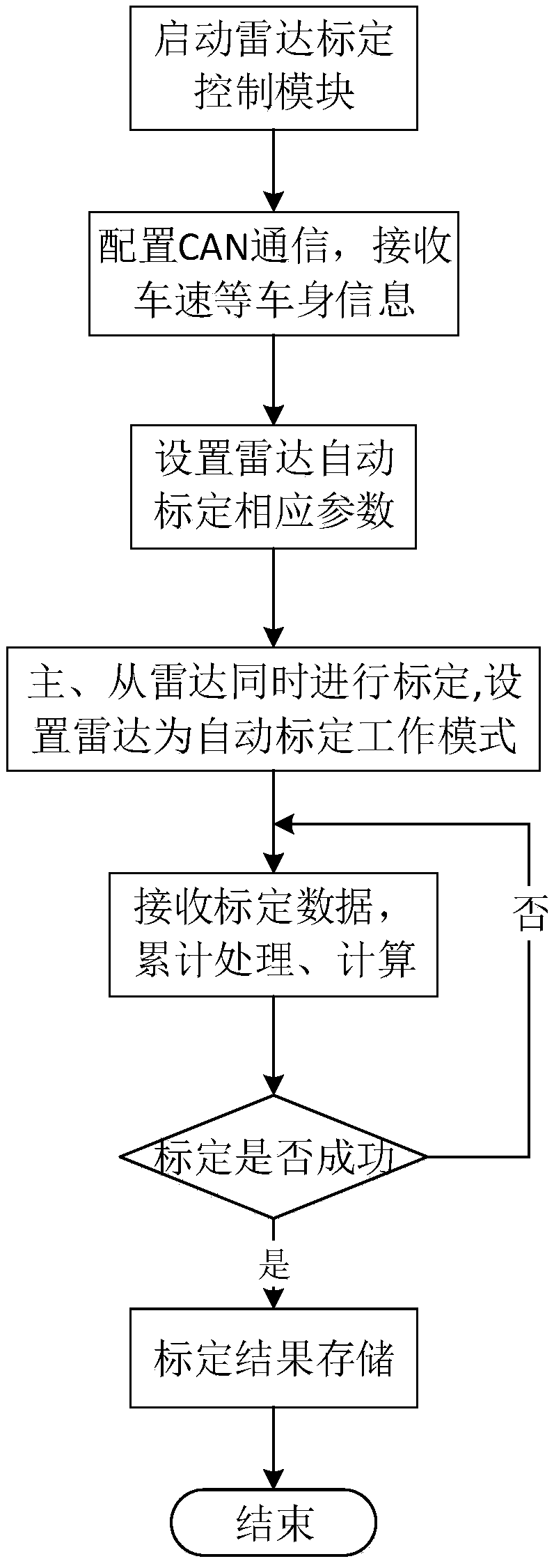

Automatic calibration device and method for mounting angle of vehicle-mounted millimeter wave blind zone monitoring radar

InactiveCN110109071AMeet the needs of useSolve assembly problemsWave based measurement systemsBlind zoneElectronics

The invention, which belongs to the technical field of automobile electronics, discloses an automatic calibration device and method for the mounting angle of a vehicle-mounted millimeter wave blind zone monitoring radar. The automatic calibration device comprises a radar calibration control module, a radar calibration processing module and a CAN bus device. The radar calibration control module isused for setting a radar working mode and calibration parameters. The radar calibration processing module is configured to complete the processing work of radar calibration parameters and data. The CAN bus device is used for completing communication connection work between the calibration device and the radar. The radar calibration control module and the radar calibration processing module are electrically connected to the CAN bus device. According to the invention, installation requirements of the a vehicle-mounted millimeter wave radar blind zone monitoring system by different vehicle manufacturers and different vehicle models can be met in a self-adaptive manner; and the relevant calibration parameters are adjusted by the automatic calibration device; a radar installation angle calibration problem after mass-produced vehicle type radars of the whole-vehicle-factory production line is solved effectively; and the usage demand of the radar by the user is satisfied.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

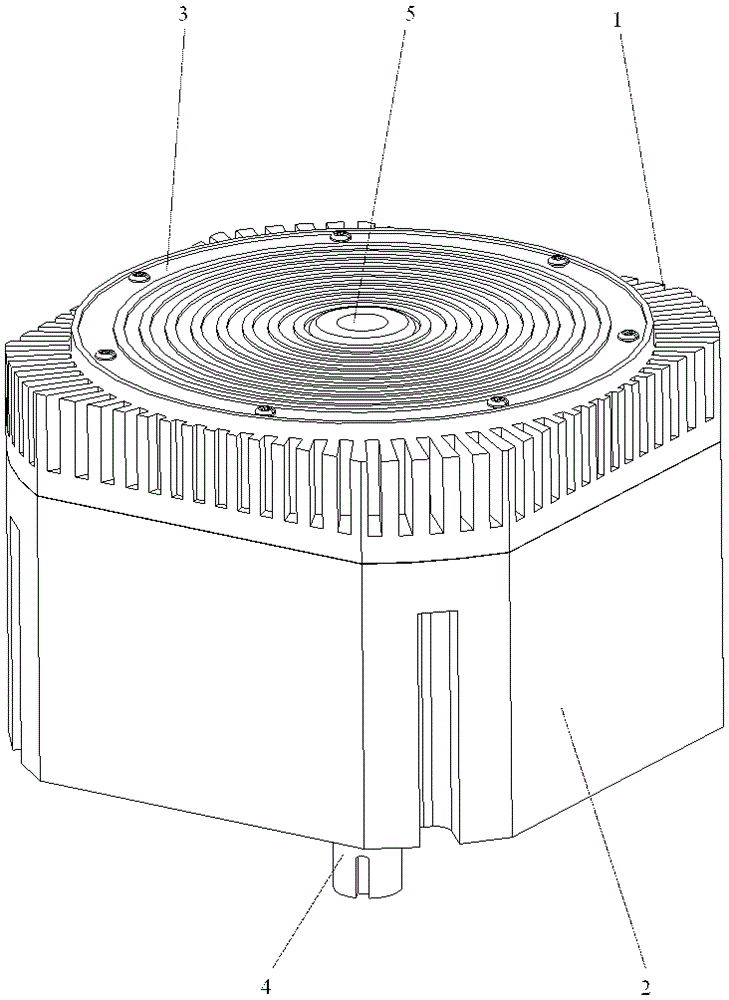

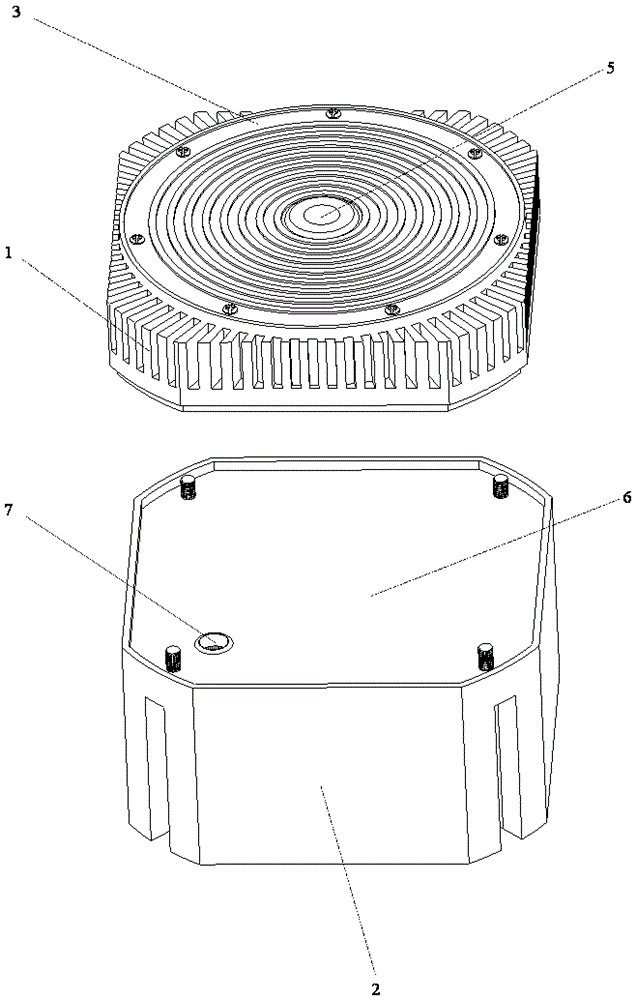

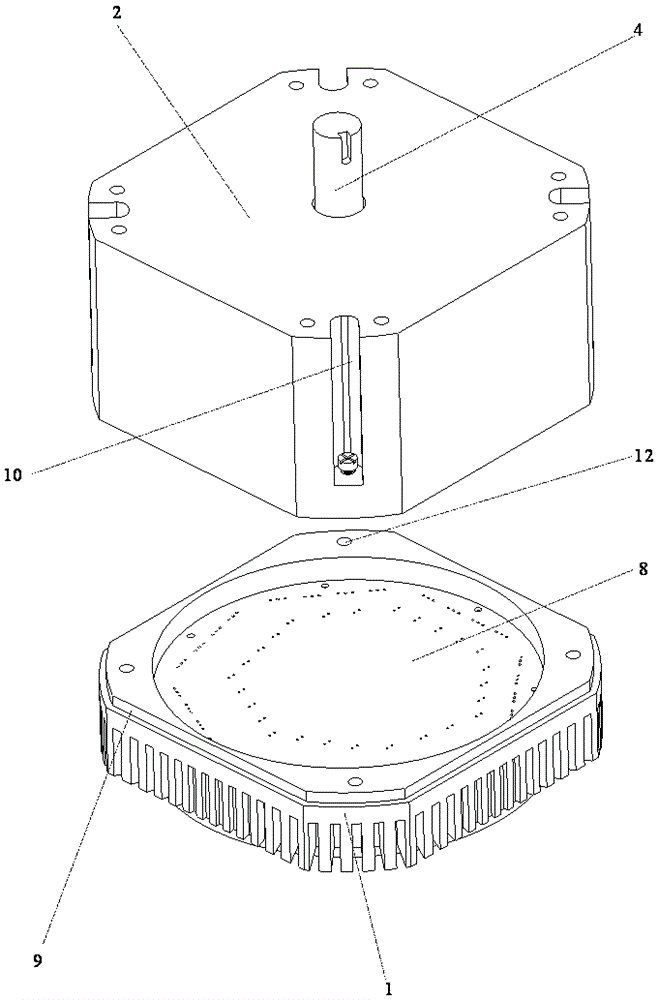

Module type permanent magnet brushless direct-current motor

ActiveCN106169851AImprove reliabilityImprove efficiencyElectronic commutation motor controlAssociation with control/drive circuitsDual coreVMOS

The invention discloses a module type permanent magnet brushless direct-current motor. The module type permanent magnet brushless direct-current motor consists of a motor module and a controller module, and has the following key points: a motor shell (2) is a circular column which is externally octagonal and internally hollow; through combining the motor shell (2) with a separation plate, components such as a rotation shaft, a wire bag, a stator core body, a rotor core body, a bracket and a neodymium-iron-boron permanent magnet required by the permanent magnet brushless direct-current motor are packaged; a controller shell is combined with an end cover to package components such as a PCB board, a VMOS power tube, a dual-core single chip and a driving chip required by a controller; and the motor shell and the controller shell are integrally connected through a fastening bolt. The invention provides a module solution which is low in cost and is capable of carrying out large-scale production and realizing integration of the permanent magnet brushless direct-current motor and the controller, and the module solution is broad in market prospect.

Owner:彭希南

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com